Preparation technology of ethylhexyl salicylate emulsion

A technology of isooctyl salicylate and a preparation process, applied in the field of chemical materials, can solve the problems of poor thermal imaging effect, affecting work efficiency, difficult continuous production, etc., and achieves clear coating, low labor intensity, and thermal image. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

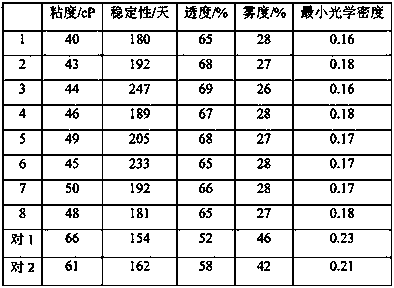

Examples

Embodiment 1

[0023] A kind of preparation technology of isooctyl salicylate emulsion, comprises the following steps:

[0024] (1) Pulverization: use a pulverizer to pulverize the massive solid isooctyl salicylate into small pieces with a particle size of ≤2cm;

[0025] (2) Freezing: cool the small pieces of material crushed in step (1) to below 5°C in a freezer or cold storage, and keep for 30 minutes;

[0026] (3) Grinding: Grinding the material obtained in step (2) into a powder with a particle size of ≤0.5mm by using a pulverizer;

[0027] (4) Grinding: Mix the powder obtained in step (3), an aqueous adhesive solution, a dispersant and water, and grind in a grinder for 4 hours to obtain an isooctyl salicylate emulsion. The isooctyl salicylate emulsion is The weight of particles with a medium particle size ≤ 1 μm accounts for more than 90%.

[0028] The grinding speed of the pulverizer described in step (3) is 55kg / h.

[0029] The weight ratio of powder, adhesive aqueous solution, dis...

Embodiment 2

[0033] A kind of preparation technology of isooctyl salicylate emulsion, comprises the following steps:

[0034] (1) Pulverization: use a pulverizer to pulverize the massive solid isooctyl salicylate into small pieces with a particle size of ≤2cm;

[0035] (2) Freezing: cool the small pieces of material crushed in step (1) to below 5°C in a freezer or cold storage, and keep for 50 minutes;

[0036] (3) Grinding: Grinding the material obtained in step (2) into a powder with a particle size of ≤0.5mm by using a pulverizer;

[0037] (4) Grinding: Mix the powder obtained in step (3), an aqueous adhesive solution, a dispersant and water, and grind in a grinder for 6 hours to obtain an isooctyl salicylate emulsion. The isooctyl salicylate emulsion is The weight of particles with a middle particle size ≤ 1 μm accounts for more than 90%.

[0038] The grinding speed of the pulverizer described in step (3) is 50kg / h.

[0039] The weight ratio of powder, adhesive aqueous solution, dis...

Embodiment 3

[0043] A kind of preparation technology of isooctyl salicylate emulsion, comprises the following steps:

[0044] (1) Pulverization: use a pulverizer to pulverize the massive solid isooctyl salicylate into small pieces with a particle size of ≤2cm;

[0045] (2) Freezing: cool the small pieces of material crushed in step (1) to below 5°C in a freezer or cold storage, and keep for 40 minutes;

[0046] (3) Grinding: Grinding the material obtained in step (2) into a powder with a particle size of ≤0.5mm by using a pulverizer;

[0047] (4) Grinding: Mix the powder obtained in step (3), an aqueous adhesive solution, a dispersant and water, and grind in a grinder for 5 hours to obtain an isooctyl salicylate emulsion, and the isooctyl salicylate emulsion is The weight of particles with a middle particle size ≤ 1 μm accounts for more than 90%.

[0048] The grinding speed of the pulverizer described in step (3) is 50kg / h.

[0049] The weight ratio of powder, adhesive aqueous solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com