Wind shield transportation support for paint spraying

A windshield and frame technology, applied in the field of transport brackets, can solve problems such as affecting work, achieve the effects of easy operation, avoiding work delays, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

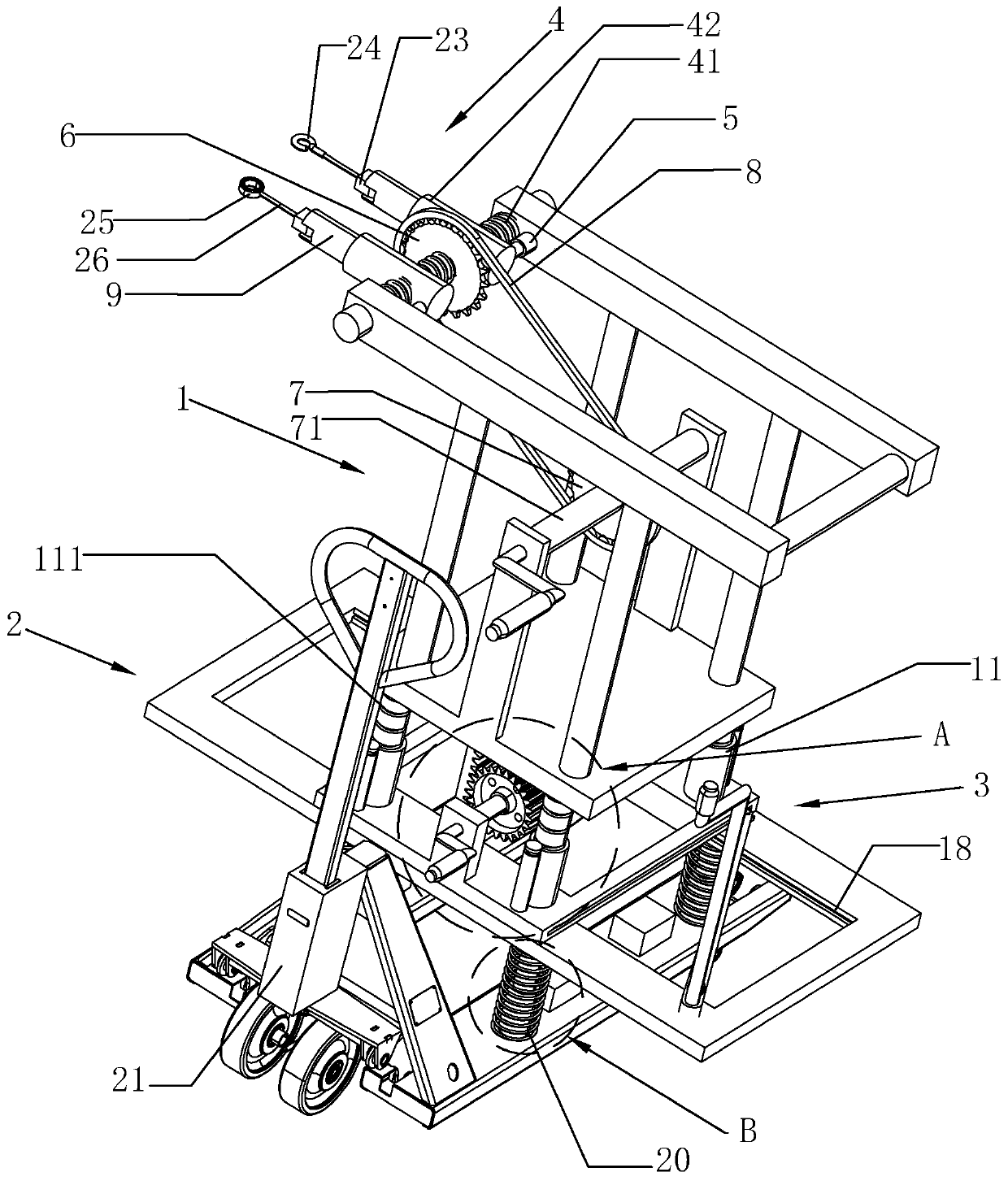

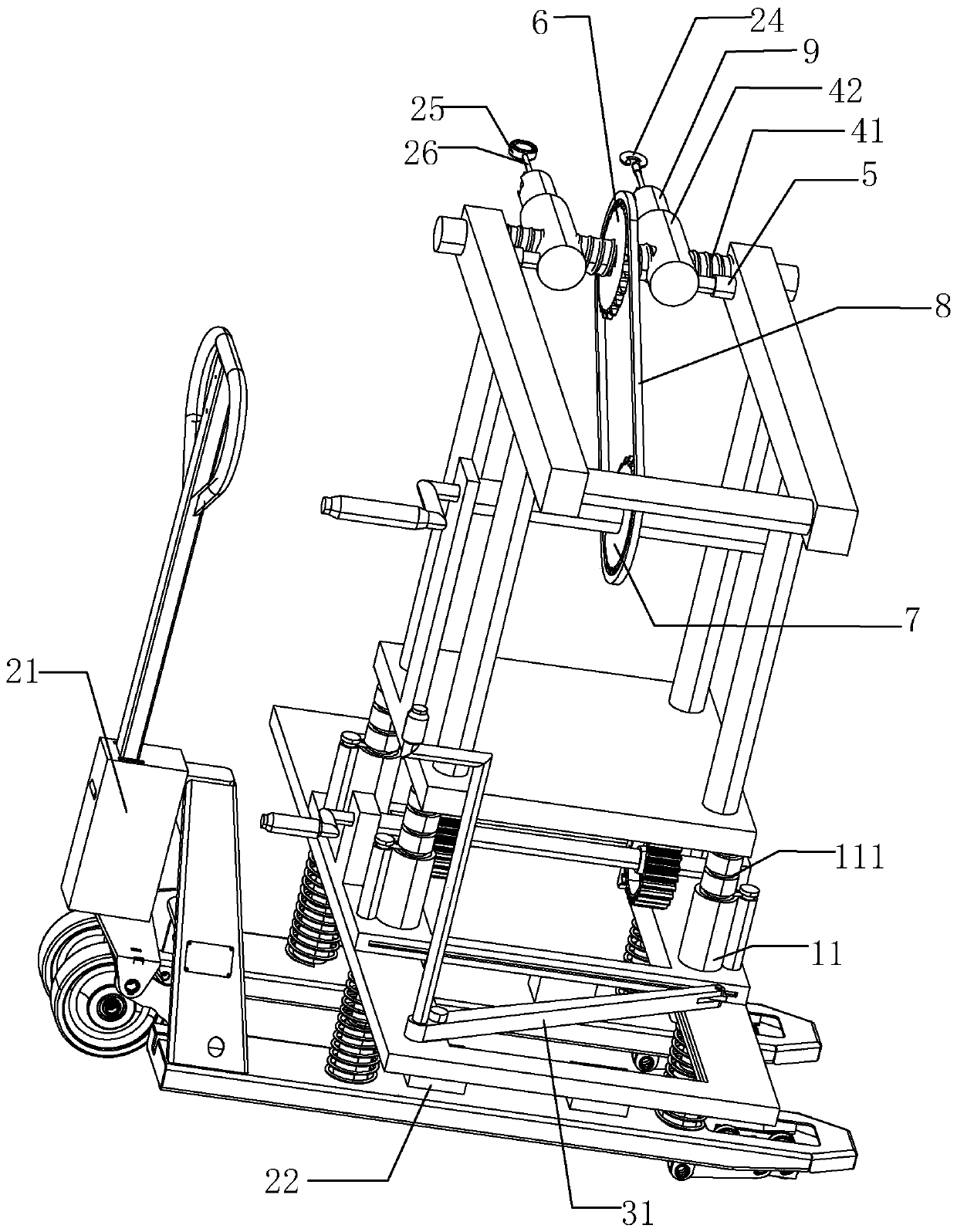

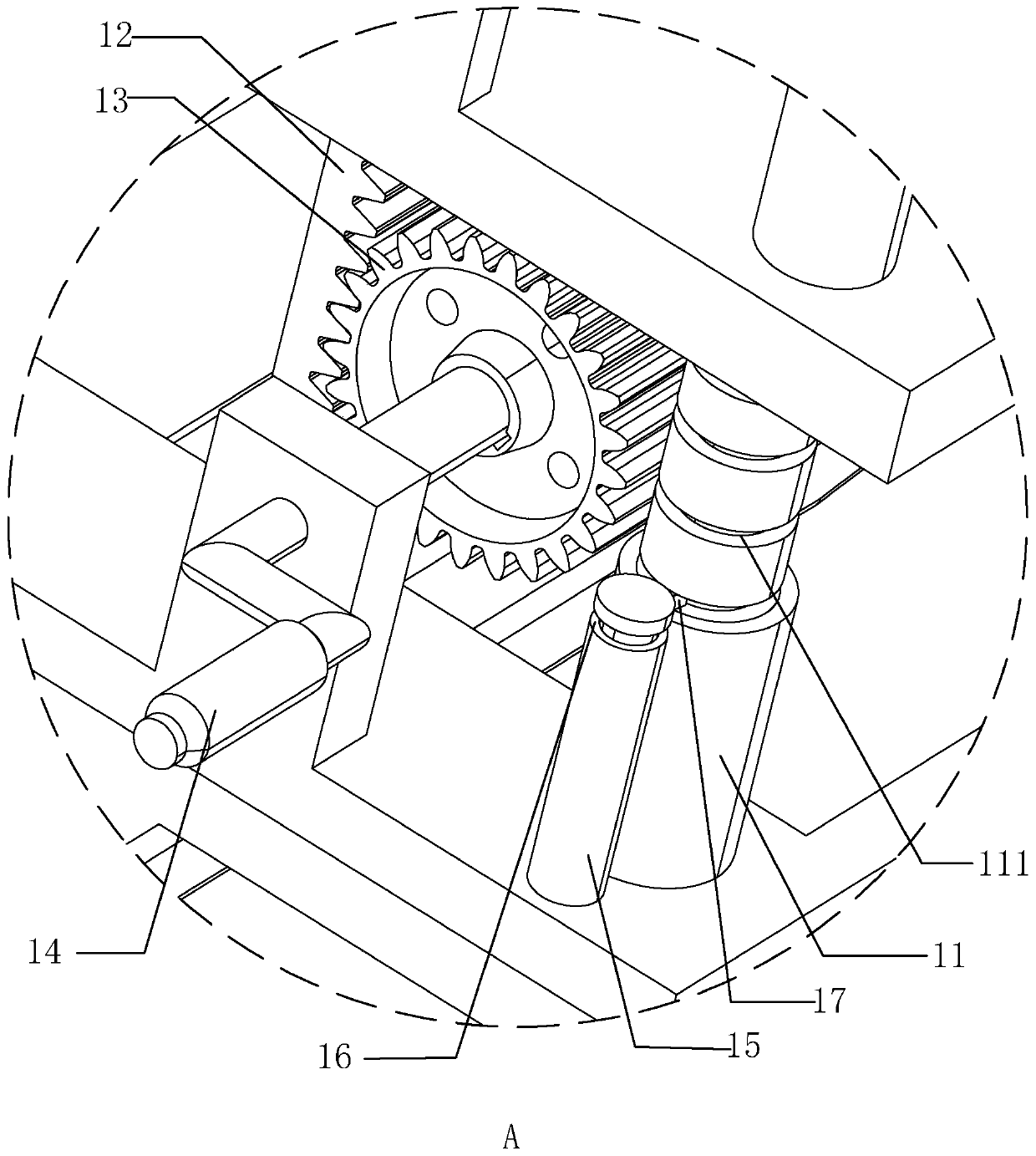

[0034] Such as figure 1 and figure 2As shown, it is a windshield transportation bracket for painting disclosed by the present invention, including a sliding frame 1 and a lower frame 2, the sliding frame 1 is located on the upper side of the lower frame 2, and the sliding frame 1 and the lower frame 2 pass through the sliding mechanism 3 connection, the lower side of the lower frame 2 is provided with a sliding device, the lower frame 2 is fixedly connected with the sliding device, the upper side of the sliding frame 1 is provided with a plugging device 4, and the plugging device 4 includes a stud bolt plugged into the sliding frame 1 41. The two ends of the stud bolt 41 are not threaded and are rotatably connected to the sliding frame 1. The stud bolt 41 is symmetrically provided with two plug joints 42 along the midpoint of its own length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com