Box sealing machine

A technology of box sealing machine and machine base, applied in packaging and other directions, can solve problems such as operator injury, damage to equipment below, death, etc., and achieve the effect of eliminating the risk of smashing the operator, preventing the loss of working hours, and having a high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

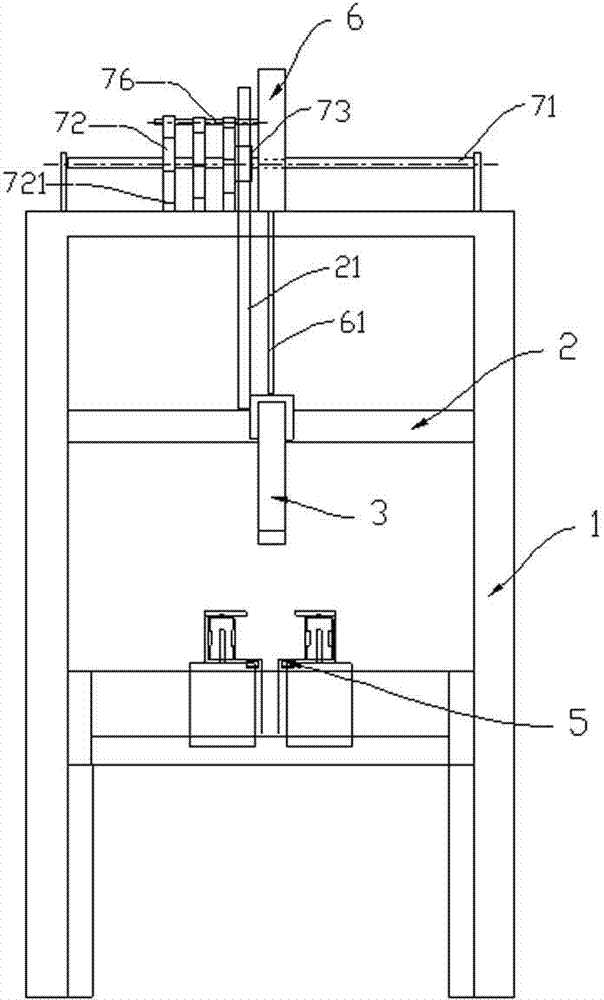

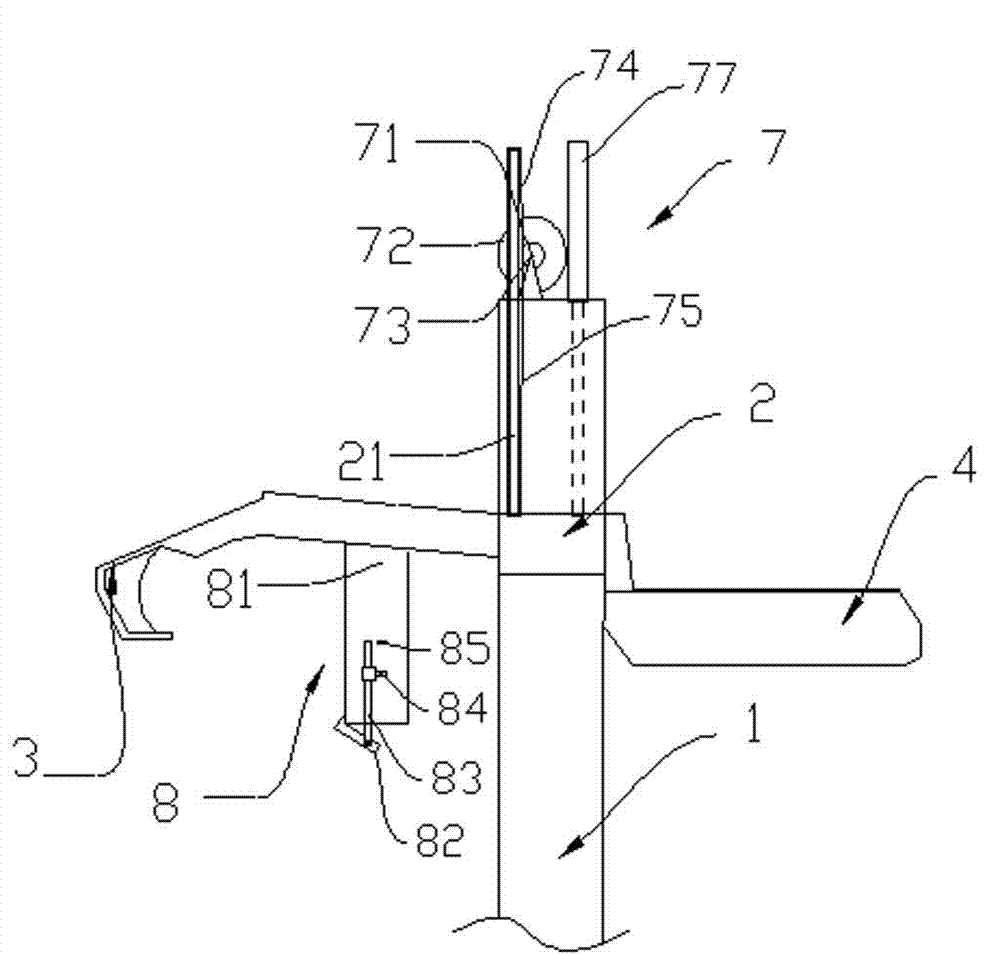

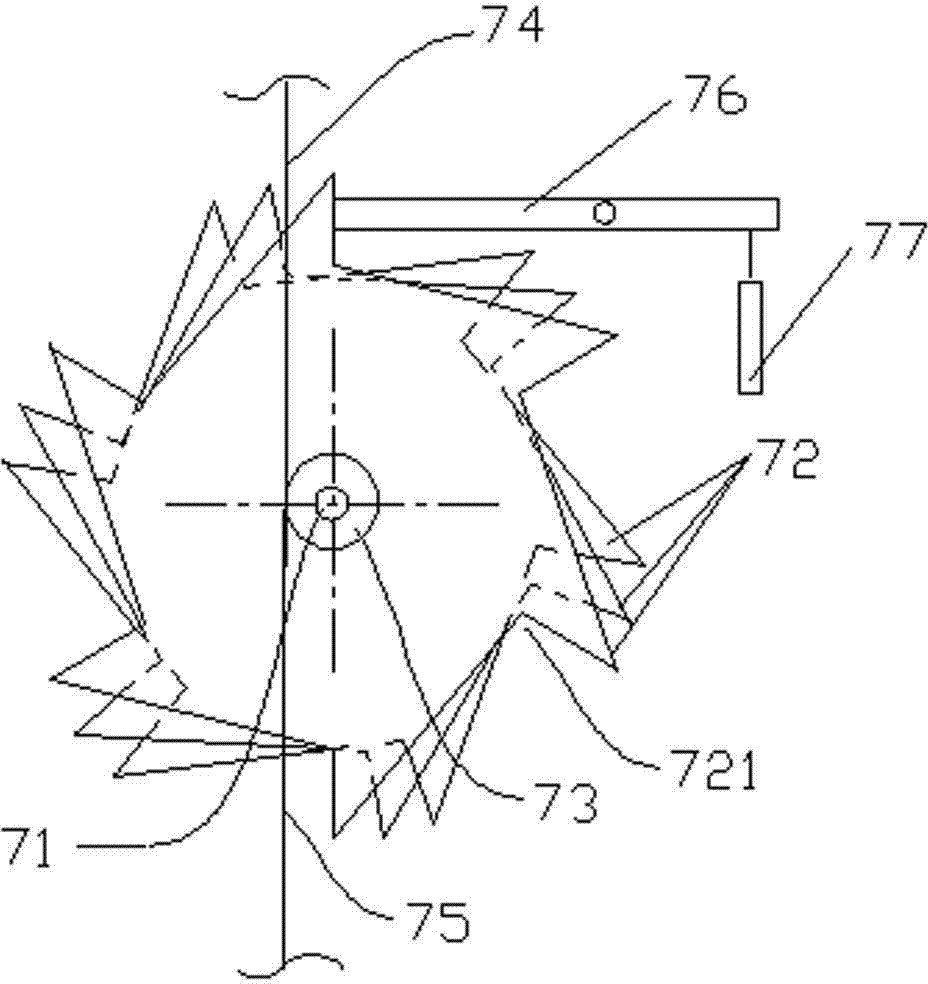

[0033] Refer to attached Figure 1-2 As shown, a box sealing machine includes a machine base 1, a machine head 2 arranged on the machine base 1 that can move up and down along the machine base 1, and a machine head 2 arranged on the machine head 2 for folding the upper cover of the carton. Cover folding mechanism 3 and the upper core 4 for sealing the carton upper cover, the conveying track 5 for conveying the carton provided on the machine base 1, the machine head 2 adjusts the folding by moving up and down relative to the machine base 1 The distance between the cover mechanism 3 and the upper core 4 and the conveying track 5 also includes:

[0034] The first cylinder 6, which is installed on the support 1 and is positioned above the nose 2, the piston rod 61 of the first cylinder 6 is fixedly connected with the nose 2, the first cylinder 6 has a first air inlet and The second air inlet, the aperture of the first air inlet is larger than the aperture of the second air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com