Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Avoid long waits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

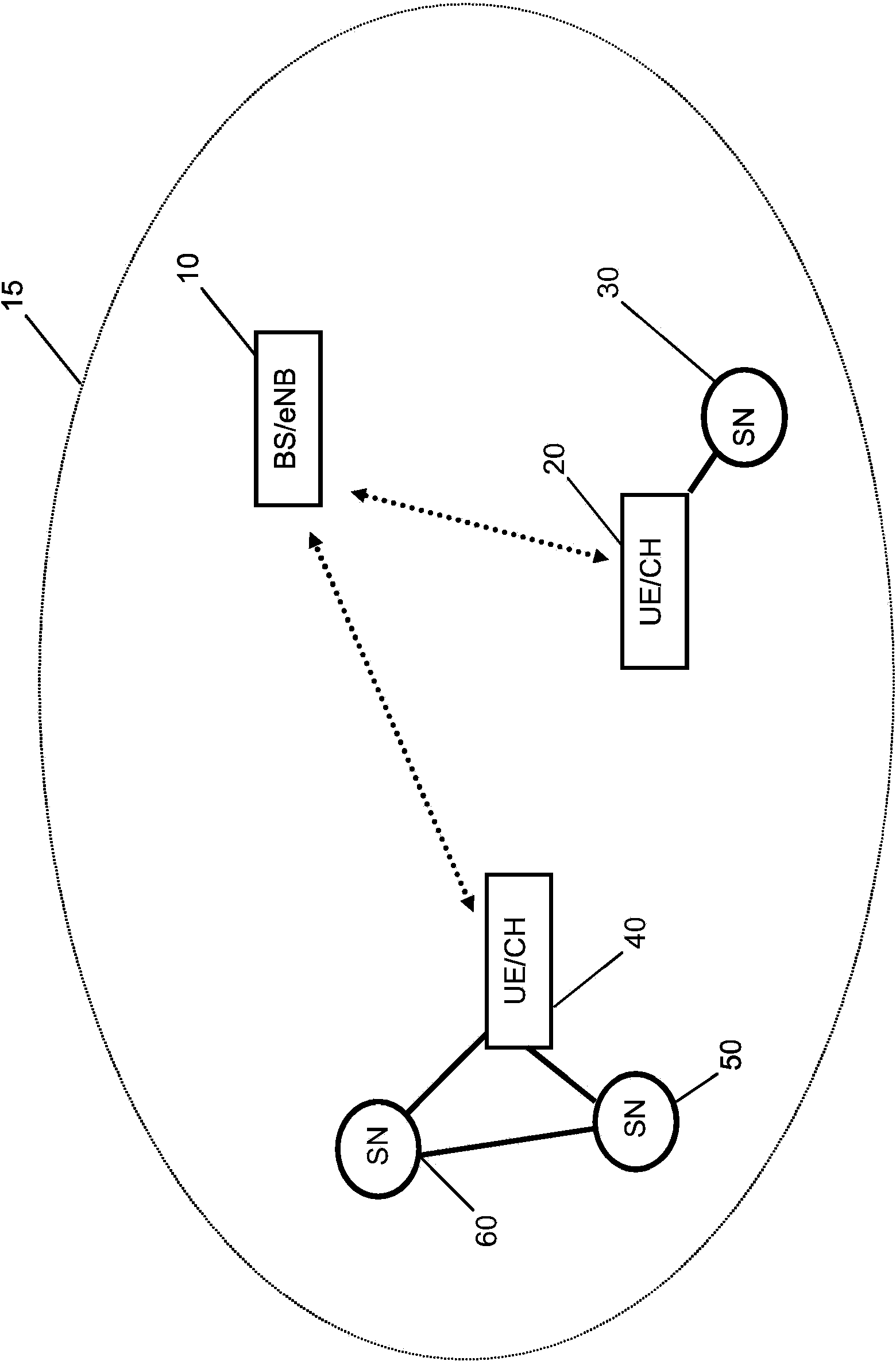

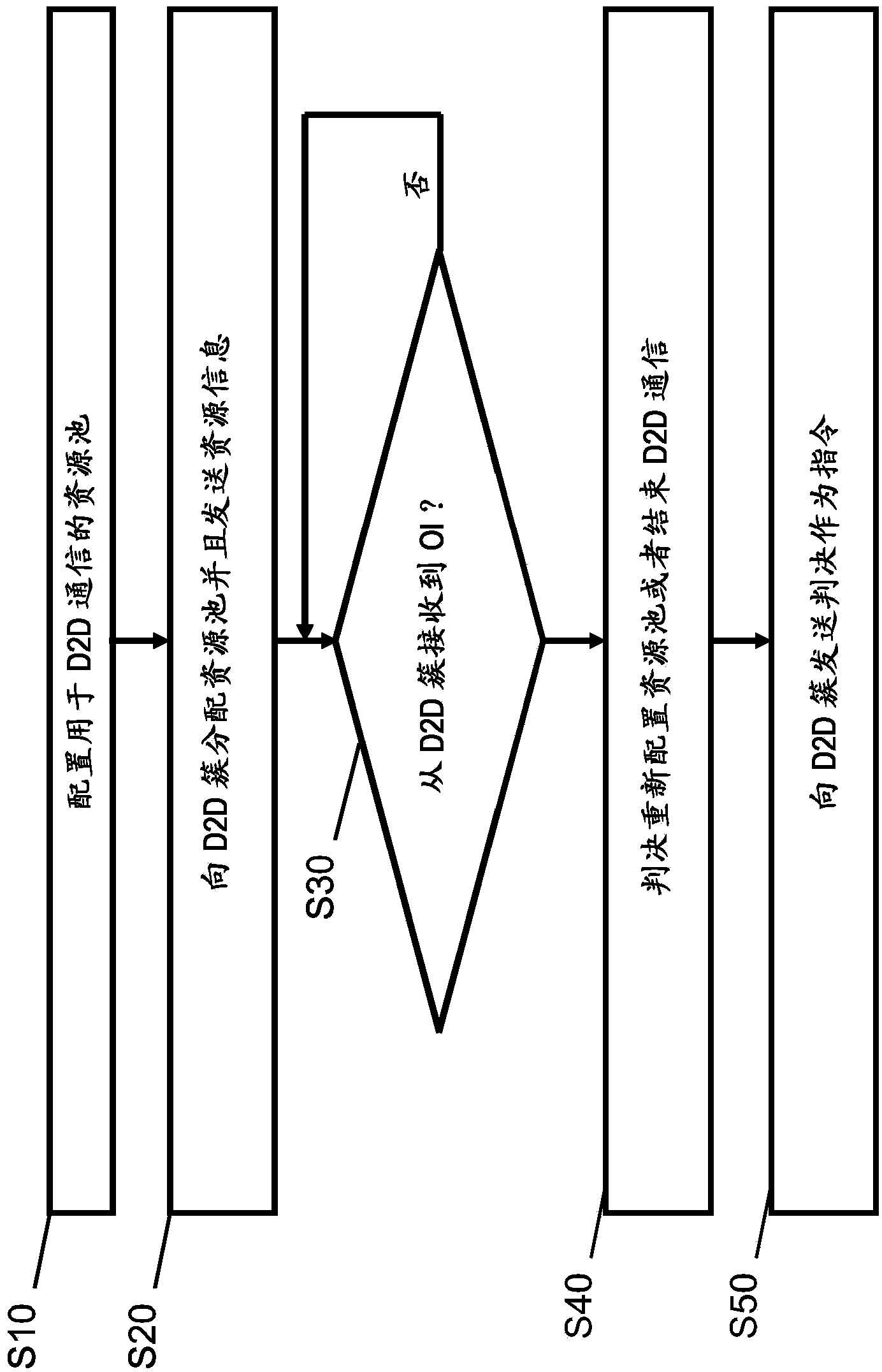

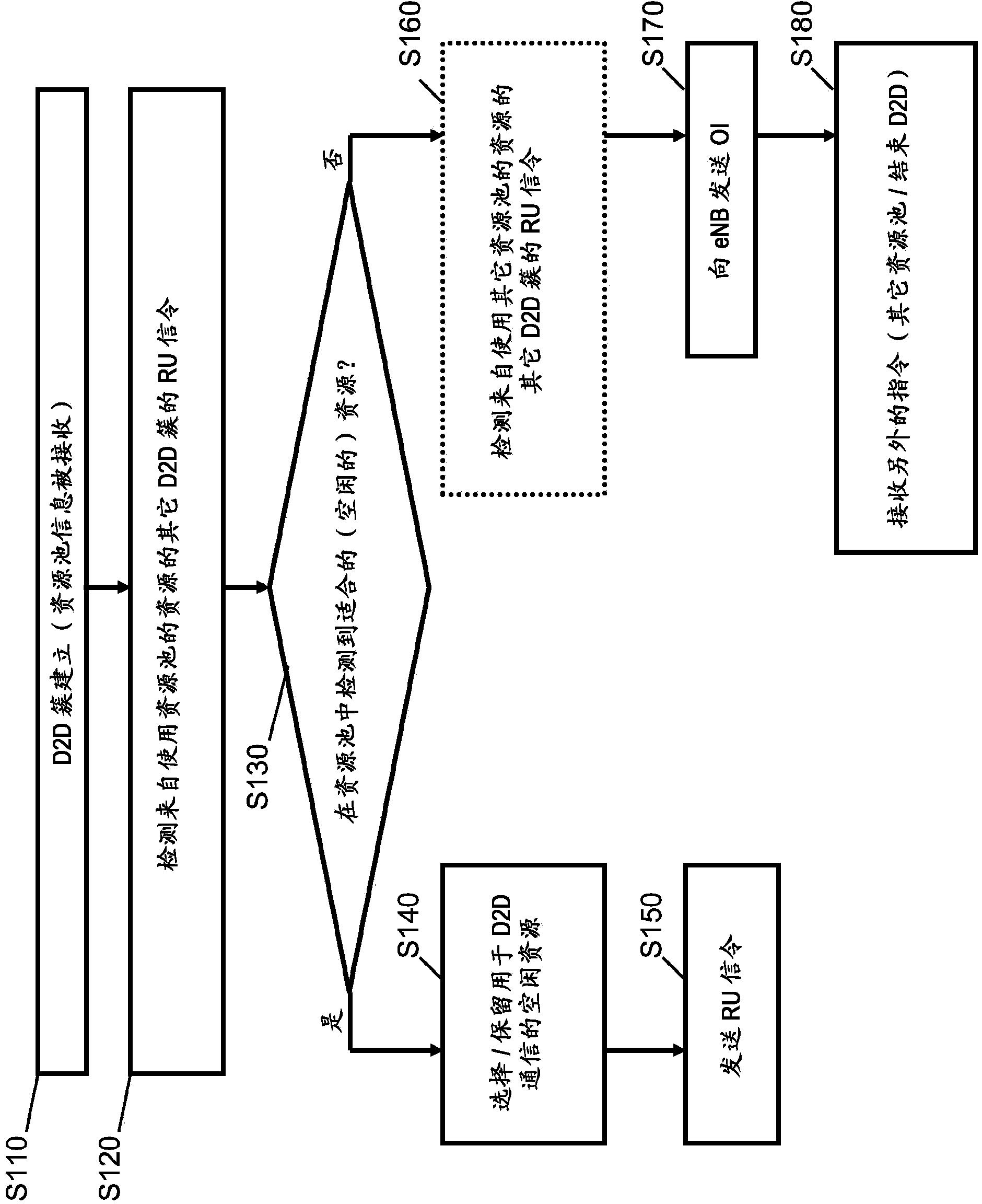

Resource allocation for D2D communication

InactiveCN103843444AReduce signaling overheadReduce control signalingConnection managementResource poolResource utilization

There is provided a mechanism for allocating communication resources of a cellular communication network to a D2D communication. After an eNB has configured a number of resource pools indicating a set of resources usable in the D2D communication, D2D clusters which share a same resource pool are enabled to obtain resources for their respective D2D communication. By detecting the current resource utilization state in the allocated resource pool by measurement on the UE side, it is decided whether suitable resources are available or not. An overload situation is signalled to the eNB if no suitable resource can be detected.

Owner:BROADCOM CORP

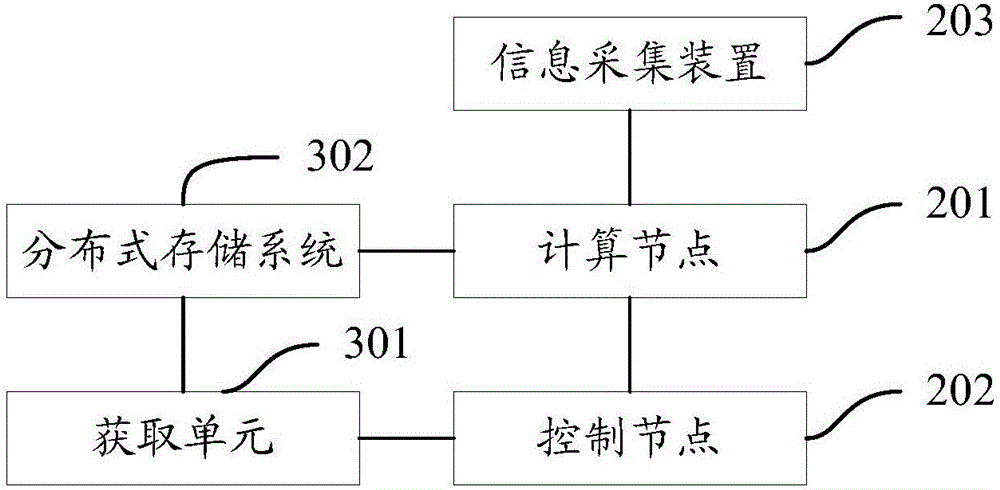

Task scheduling method, device and system

The invention discloses a task scheduling method, a device and a system. The method comprises steps: during a predetermined scheduling cycle, the number K of unexecuted tasks in a task buffer pool is determined; whether the number K of the unexecuted tasks is zero is judged; if the number K of the unexecuted tasks is not zero, the first M unexecuted tasks with the highest priority are selected in the task buffer pool, wherein priorities of the unexecuted tasks are updated according to the predetermined scheduling cycle, and M is associated with the number of automated guided vehicles (AGV) currently in the idle state; and the selected M unexecuted tasks are issued to an AGV control system so as to enable the AGV control system to process the received tasks. According to the method, the device and the system provided by the invention, priorities of the AGV tasks can be flexibly controlled, the AGV control system executes tasks according to priorities of the AGV tasks specified by a WCS (Warehouse Control System), and AGV tasks of each service can be ensured to be executed at the right time.

Owner:LONGYAN CIGARETTE FACTORY

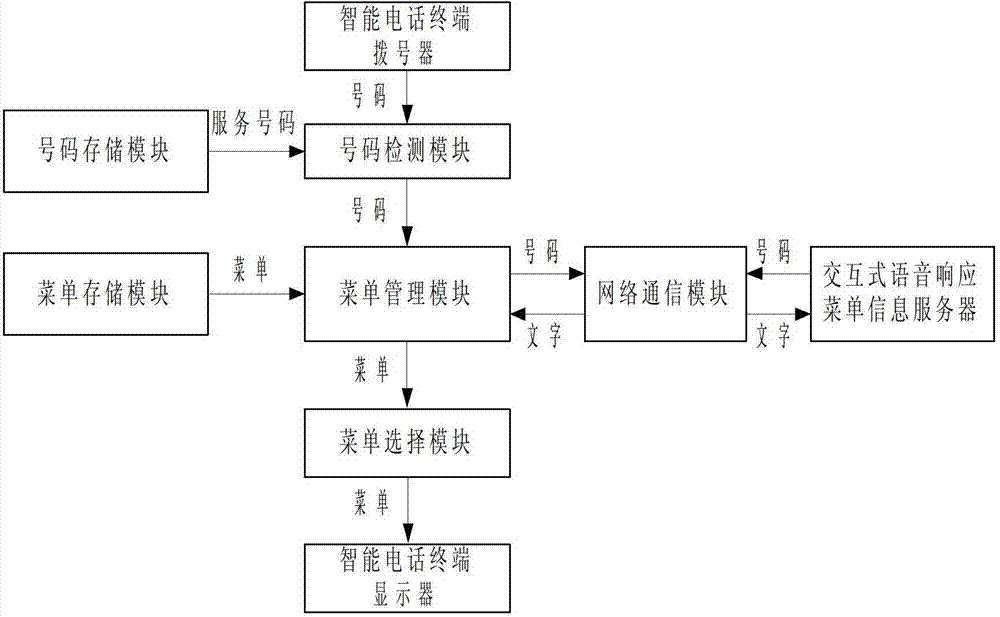

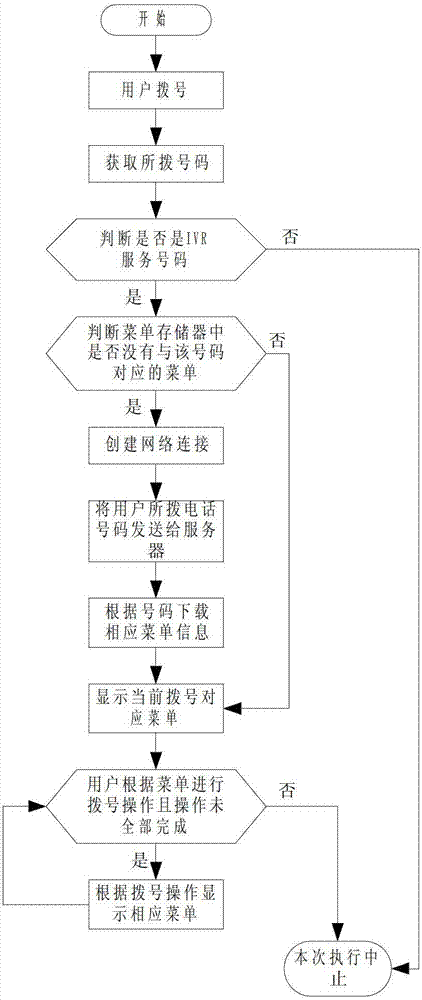

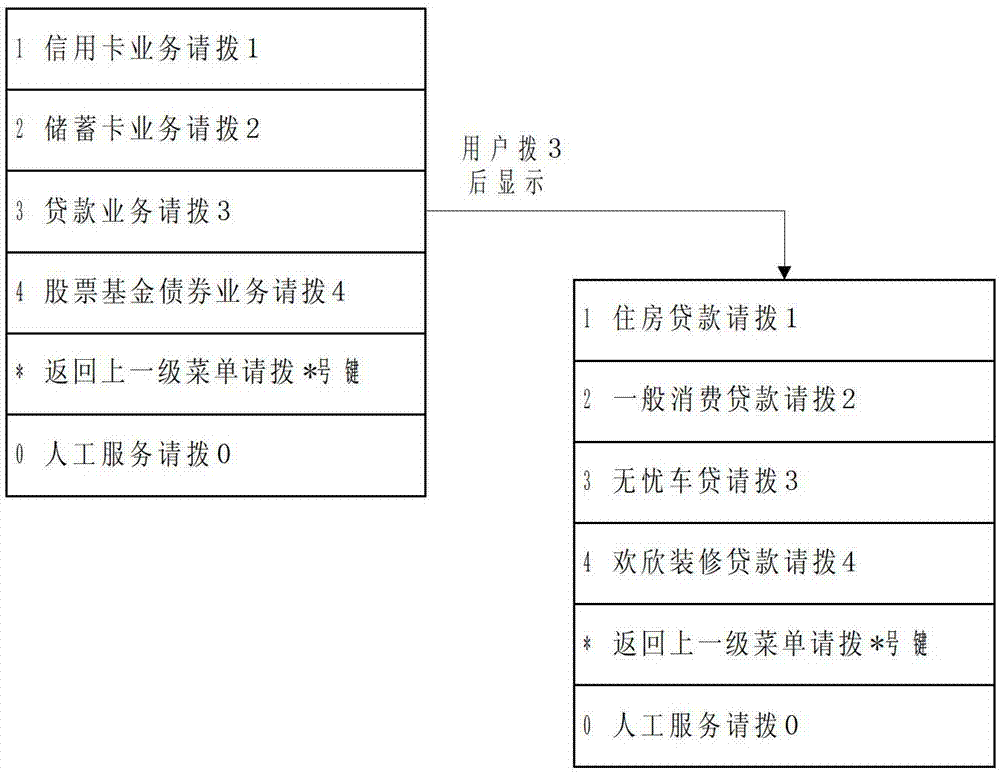

System and method for displaying menus based on network generated interactive voice response information

ActiveCN103118206AFind quicklyImprove experienceAutomatic exchangesTelephone sets with user guidance/featuresComputer networkNetwork generation

The invention discloses a system and a method for displaying menus based on network generated interactive voice response information. The system comprises a number detection module, a menu management module, a menu selection module, a number storage model, a menu storage module and an interactive voice response menu information server. After a user dials a number, the number detection module judges whether the number is an interactive voice response service number or not according to information stored in the number storage module and sends the number to the menu management module if yes, the menu management module acquires a corresponding menu from the menu storage module or the interactive voice response menu information server and displays the menu on a display, and the menu selection module judges services are ended or not according to user dialing operation or selects a menu corresponding to a user dialed number to display on the display. By the system and the method, interactive voice response service efficiency is improved, user experience is improved, application range is widened, and voice prompt services of original interactive voice response navigation are unaffected.

Owner:西安电子科技大学工程技术研究院有限公司

Control method and device of helmet display

InactiveCN105955470AAvoid misuseAvoid long waitsInput/output for user-computer interactionGraph readingHelmet-mounted displayDisplay device

Embodiments of the present invention provide a control method and device for a head-mounted display, which relate to the field of computer technology, and the main purpose is to perform fast and accurate control operations simply by using a VR helmet, so as to improve the user's operating experience. The technical solution adopted in the embodiment of the present invention is: judging whether the position of the control cursor in the head-mounted display falls on the operable target in the virtual interface; when the control cursor falls on the operable target, an operation control window pops up , the operation control window displays a helmet operation action graphic for confirming that the operable target is selected; it is judged whether the operation action of the control cursor is consistent with the helmet operation action in the operation control window, and if they are consistent, it is confirmed that the selected target is selected actionable goals. The invention is mainly used for the interface operation control of the VR helmet.

Owner:LETV HLDG BEIJING CO LTD +1

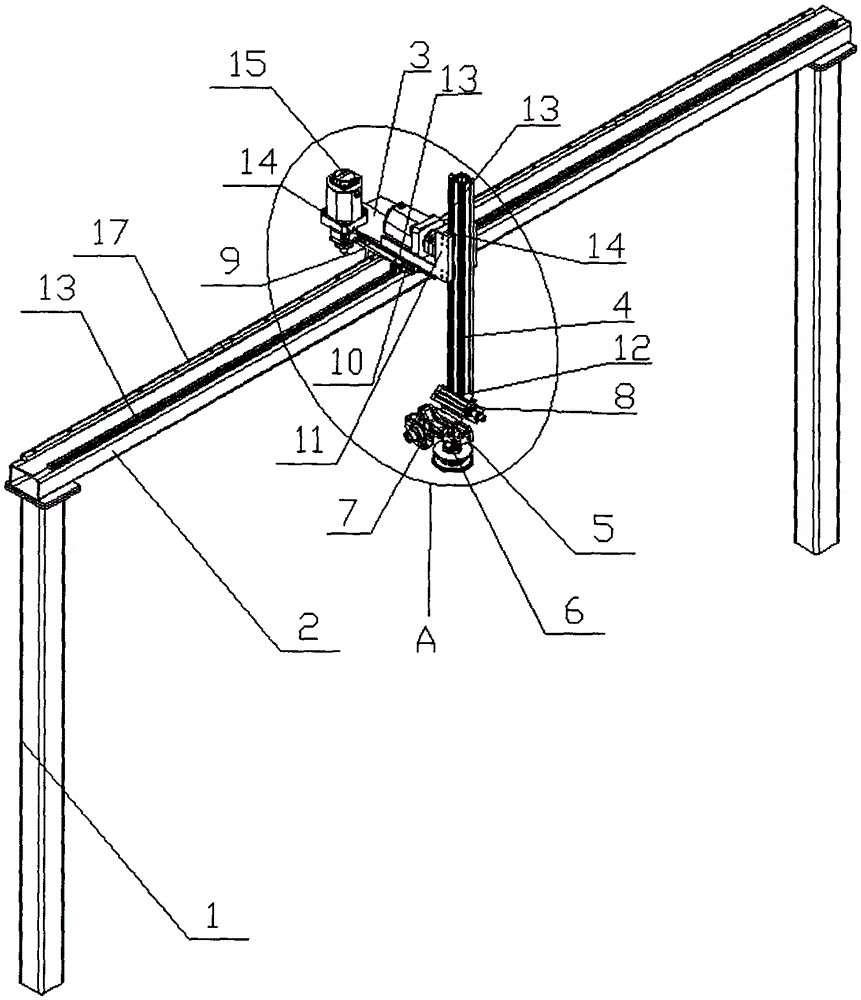

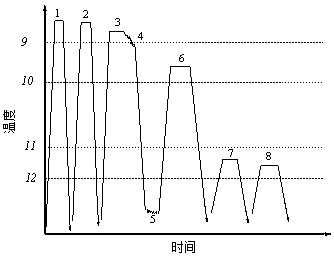

High-speed truss manipulator

InactiveCN105522573ASmall footprintHigh guiding precisionProgramme-controlled manipulatorVibration amplitudeEngineering

The invention discloses a high-speed truss manipulator. A first sliding block is arranged on an X-direction track on a supporting frame in a sliding mode; a Y-direction track is arranged on a second sliding block fixed to the first sliding block in a linearly reciprocated sliding mode; a Z-direction track is arranged on a third sliding block fixed to the Y-direction track in a longitudinally and linearly reciprocated sliding mode; a mechanical clamping jaw installation support is rotationally positioned at the lower end of the Z-direction track; an included angle of 135 degrees is formed between the axial direction of a rotary shaft of the mechanical clamping jaw installation support and the Z direction; first and second mechanical clamping jaws are symmetrically distributed on the two sides of the rotary shaft of the mechanical clamping jaw installation support; an included angle of 90 degrees is formed between the axial directions of the first and second mechanical clamping jaws; first, second and third drive devices are used for driving the first sliding block, the Y-direction track and the Z-direction track to move respectively; a rotary drive device is used for driving the mechanical clamping jaw installation support to rotate. The manipulator can operate stably at high speed, the vibration amplitude is small after movement is finished, the speed is high as two manipulators operate alternately, and the occupied space is small.

Owner:SUZHOU KAILINJIE ROBOT CO LTD

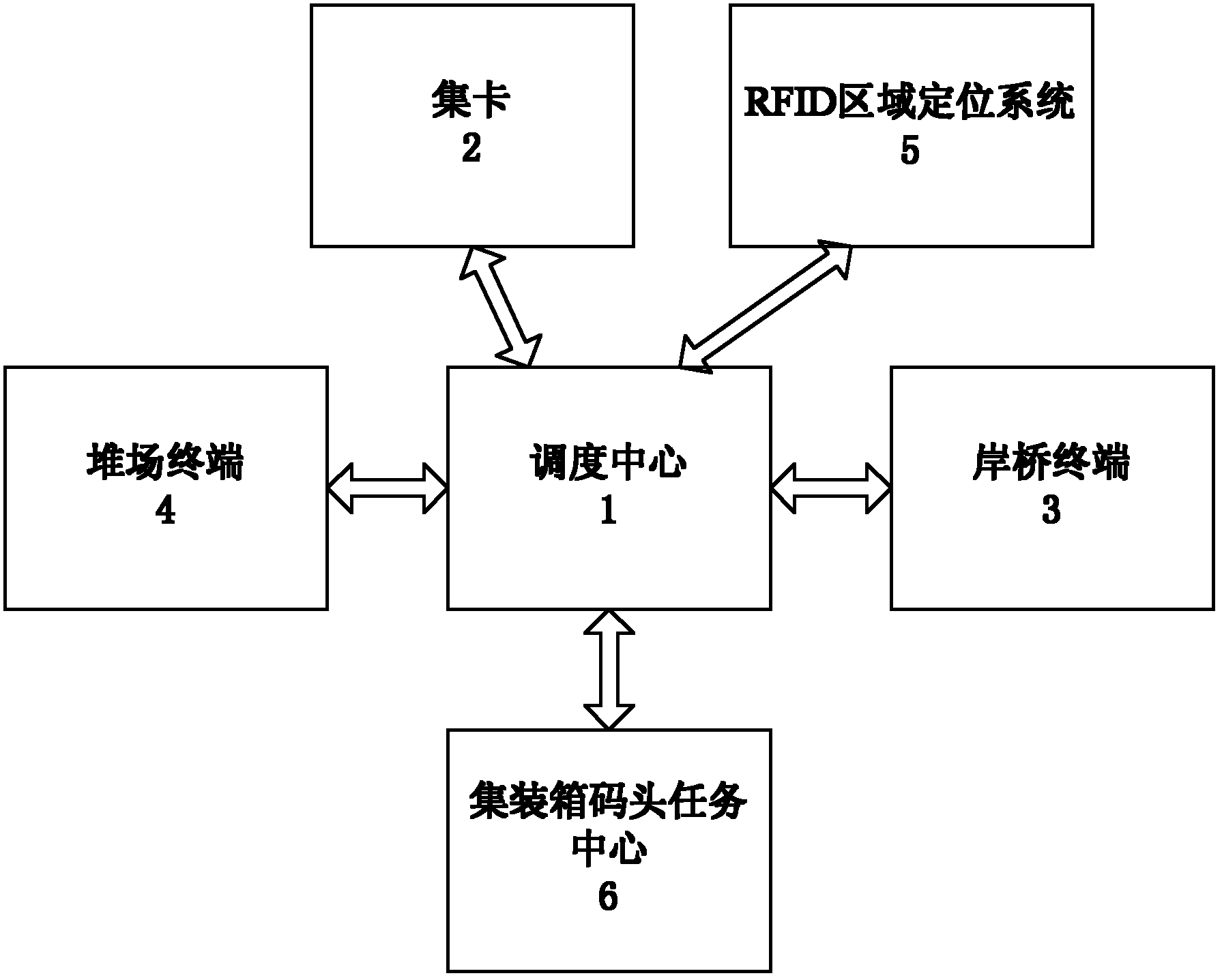

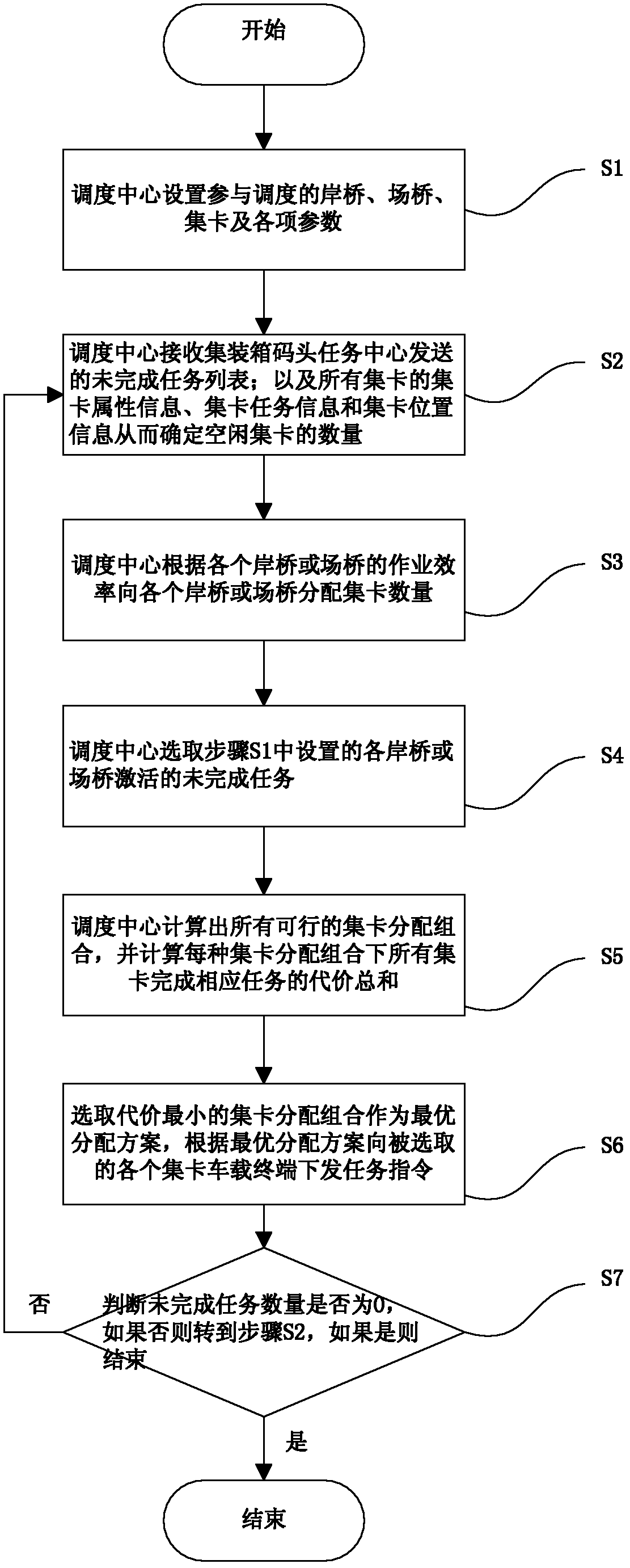

Intelligent dispatching system and intelligent dispatching method of container trucks

ActiveCN103164782AImprove work efficiencyReduce operating costsCo-operative working arrangementsLogisticsComputer terminalTruck

The invention relates to the dispatching field of container tucks and discloses an intelligent dispatching system and an intelligent dispatching method of the container trucks. The dispatching system comprises a dispatching center (1), a container wharf task center (6) communicated with the dispatching center (1), the container trucks (2), a quay crane terminal (3), a field crane terminal (4), a radio frequency identification device (RFID) regional positioning system (5) composed of a plurality of RFID readers distributed in places of a wharf. The dispatching center (1) acquires properties and position information of all container trucks and information of tasks to be finished uploaded by the container wharf task center (6). The container trucks (2) is distributed in number according to operation efficiency of all quay cranes and all field cranes, then, the total cost, of the tasks to be finished, of all feasible distribution schemes is calculated, and finally a scheme with smallest cost is chosen to be executed. The intelligent dispatching system and the intelligent dispatching method of the container trucks can improve wharf operation efficiency, reduce wharf operation cost, improve the utilization rate of equipment, reduce inefficient waiting-around of operation equipment, and reduce no-load ratio and energy consumption of the container trucks.

Owner:CHINA MERCHANTS HLDG INT INFORMATION TECH COMPANY

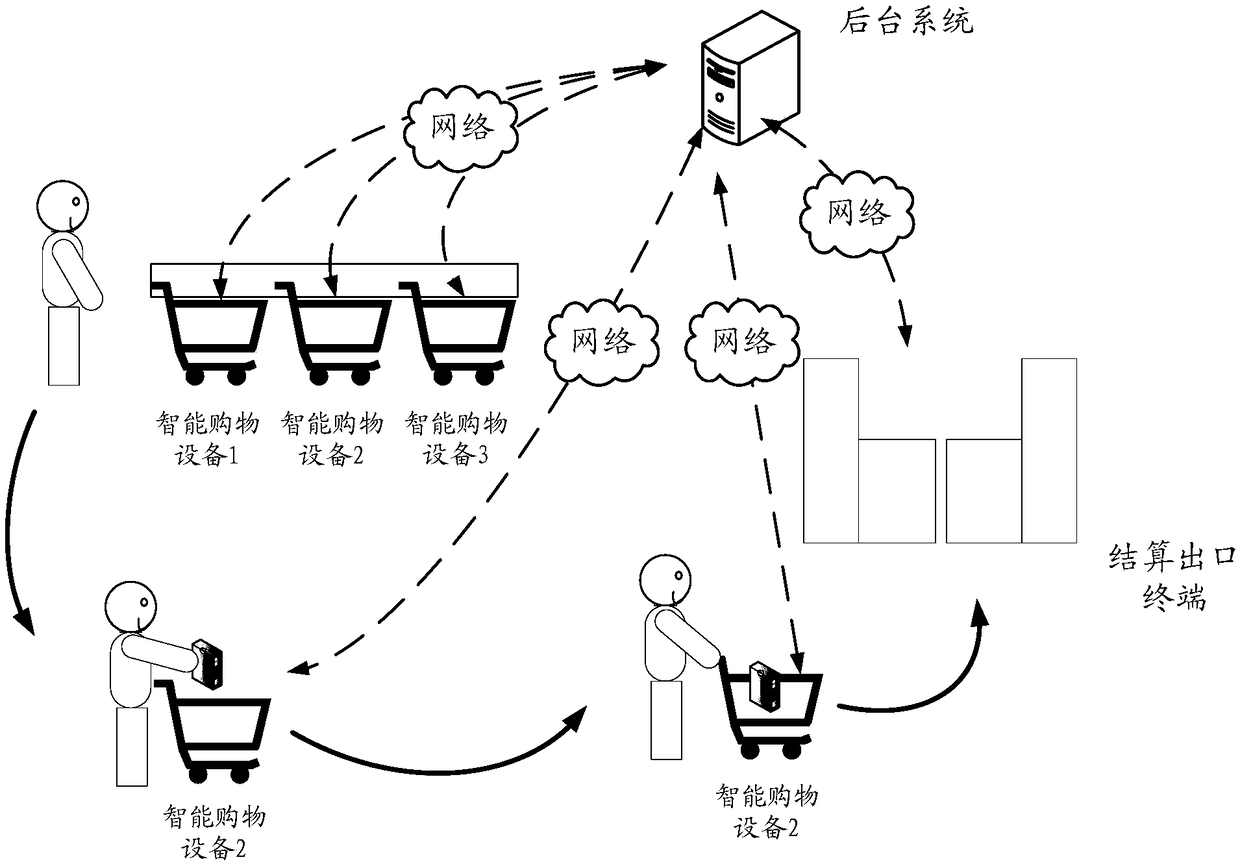

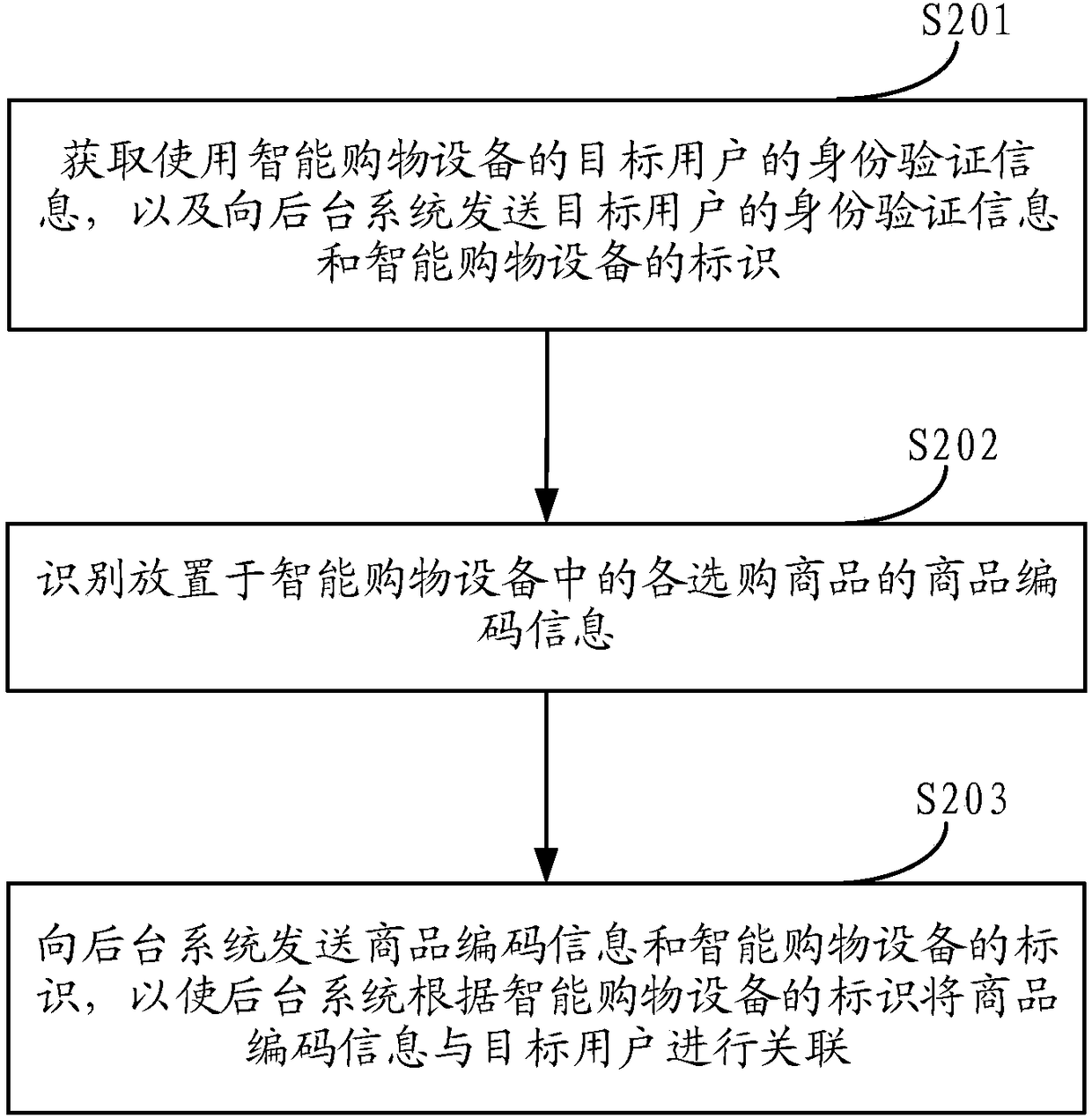

Self-service shopping method, intelligent shopping device, background system and self-service shopping system

InactiveCN108399692AImprove shopping experienceAvoid long waitsCash registersPayment architectureSelf-serviceComputer science

The invention provides a self-service shopping method, an intelligent shopping device, a background system and a self-service shopping system. The method comprises the following steps: acquiring identity verification information of a target user using the intelligent shopping device, and sending the identity verification information and the identification of the intelligent shopping device to thebackground system; identifying the commodity coding information of each selected commodity placed in the intelligent shopping device; sending the commodity coding information and the identification ofthe intelligent shopping device to the background system to enable the background system to associate the commodity coding information with the target user according to the identification of the intelligent shopping device. In the embodiment of the invention, self-service shopping and self-service settlement are realized, and the situation that a consumer waits for a long time in a settlement channel is avoided, the shopping experience of the user is improved, and meanwhile, a large number of cashier persons do not need to be hired, and the labor cost required by commercial supermarket operation is reduced.

Owner:ADVANCED NEW TECH CO LTD

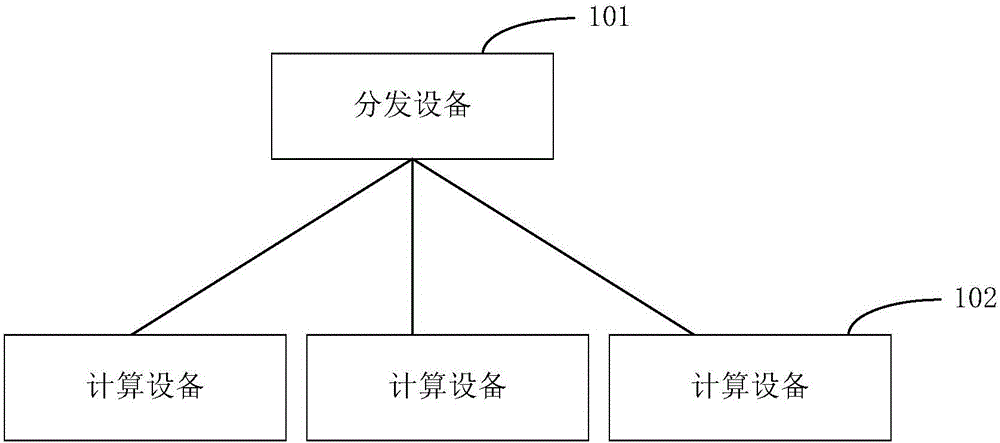

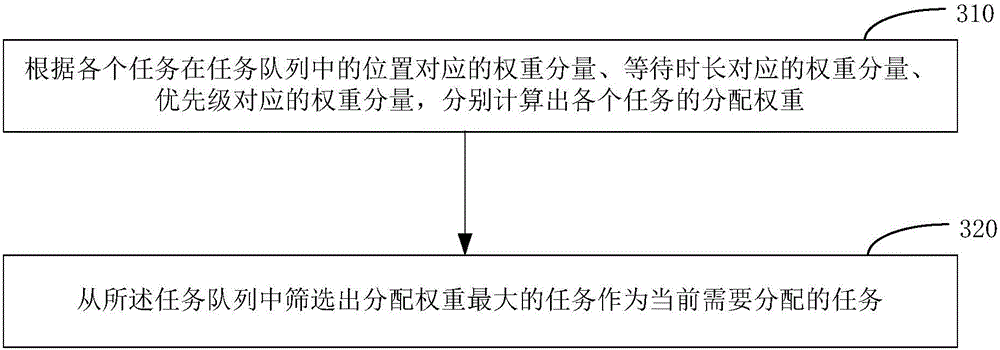

Task scheduling method and apparatus

ActiveCN106095545AAvoid long waitsAvoid cloggingProgram initiation/switchingDistributed computingLower priority

The invention discloses a task scheduling method and apparatus. The method comprises the steps of calculating an allocation weight of each task according to the position, waiting duration and priority of each task in a task queue; and screening out a task required to be allocated currently according to the allocation weight of each task in the task queue. The task allocation is influenced by the priority as well as the position and waiting duration of the task in the queue, so that the situation that the task with the low priority has to be executed after the task with the high priority is processed can be prevented, long-term waiting of the task with the low priority is avoided, and the congestion of the task with the low priority is prevented from being formed.

Owner:NEUSOFT CORP

Preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel

The invention relates to a preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel. The steel is prepared from 0.15-0.22% of C, 0.60-1.70% of Si, 1.10-2.40% of Mn, 0.1-0.5% ofMo, 0.1-0.5% of Al, 0.05-0.11% of V, 0.01-0.05% of Y, 0.02-0.04% of P, 0.005% or below of S, 0.040-0.0700% of Nb, 0.0060% or below of N, 0.001-0.006% of B and the balance Fe and unavoidable impurities. After batching, the raw materials are smelt by a converter and refined and continuously cast by a vacuum furnace to obtain a cast blank, then trace alloy powder is added into an arc-melting furnace, a secondary cast blank is obtained, and heating and hot rolling are conducted in sequence; cold rolling is conducted after acid pickling; then the blank is heated to a two-phase region for heat preservation; carbon partitioning and tempering are conducted to obtain the final steel. According to the preparation method, through the addition of an appropriate quantity of various beneficial alloy elements, the contents of C, Si, Mn and other elements in traditional steel species are reduced, the weldability and corrosion resistance are improved, crystal grains are refined, produced steel plateshave good comprehensive mechanical properties, and lightweight, energy conservation and emission reduction of vehicles are facilitated.

Owner:SHANDONG JIANZHU UNIV

Network access server accessing method and network access server

ActiveCN102130818AAvoid long waitsAvoid occupyingNetworks interconnectionNetwork access serverComputer network

The invention provides a layer 2 tunnel protocol (L2TP) network server (LNS) accessing method and an LNS. The method comprises that: after receiving a L2TP connection establishment request from an L2TP access concentrator (LAC), the LNS checks whether the current resource service conditions of the LNS meet preset L2TP access conditions or not, starts an L2TP progress for L2TP connection negotiation if the current resource service conditions of the LNS meet the preset L2TP access conditions, otherwise, transmits an L2TP connection failure message to the LAC to indicate the LAC to transmit the L2TP connection establishment request to another LNS. By the method and the LNS, a user can be prevented from waiting for an excessively long time in an LNS accessing process, and the normal running of other important service progresses is ensured as much as possible.

Owner:NEW H3C TECH CO LTD

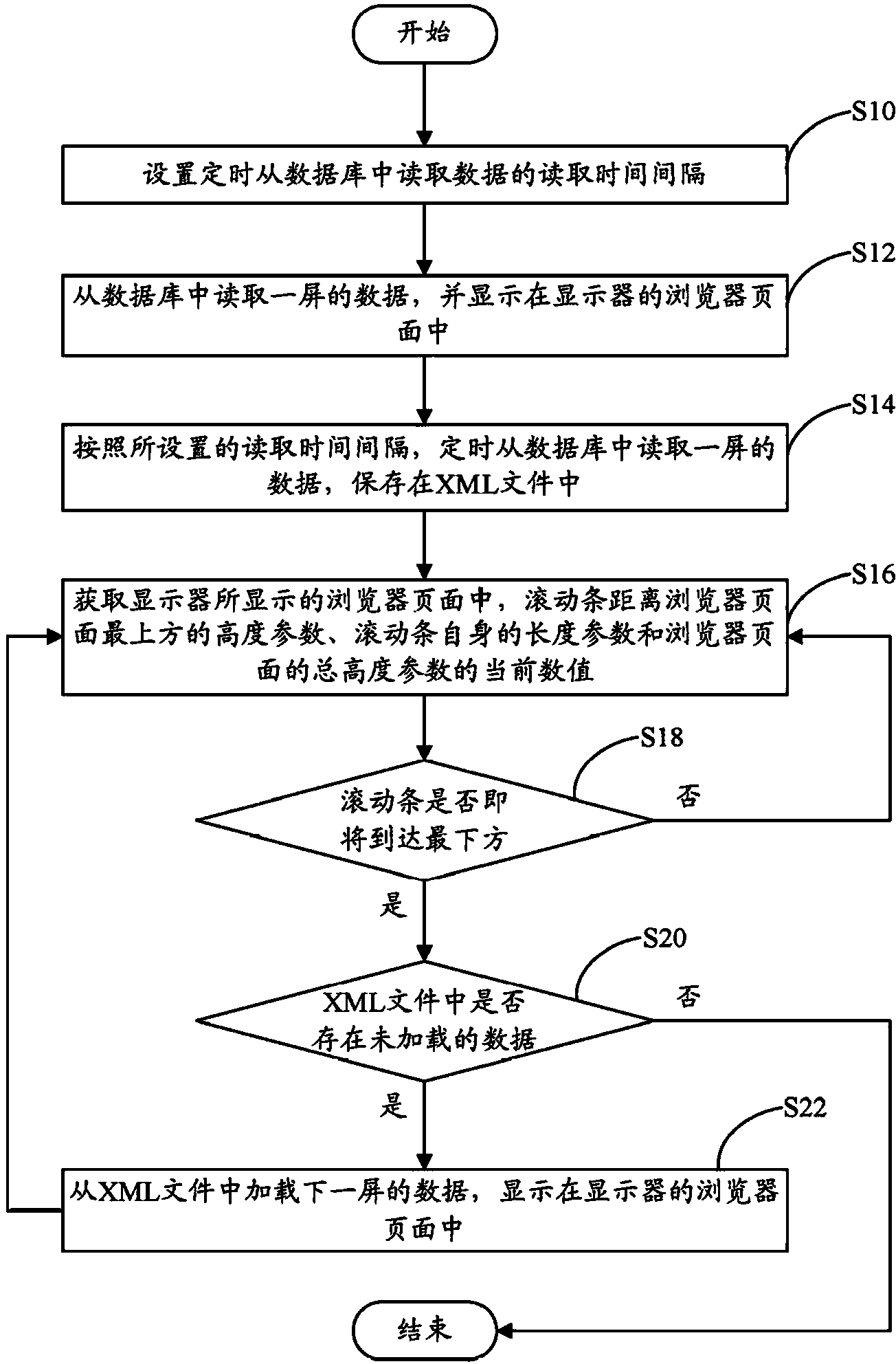

Page loading management method and page loading management system

InactiveCN103885965AAvoid long waitsReduce waiting timeDigital data information retrievalTransmissionDisplay deviceExtensible markup

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Microgrid inverter grid disconnection/connection seamless switching control method based on phase angle estimation

ActiveCN105762829AReduced phase angle tracking speedAvoid long waitsEnergy industrySingle network parallel feeding arrangementsVoltage amplitudeIslanding

The invention relates to a microgrid inverter grid disconnection / connection seamless switching control method based on phase angle estimation. An energy storage system serves as a main power supply, and comprises an energy storage battery, a current transformer, and a PCS mode controller. In a grid connection mode, PQ control is employed; in an island mode, V / F control is employed. During the switching from the grid connection mode to the island mode, a voltage amplitude reference value is given by a phase voltage peak value of a power grid before grid disconnection, and is calculated through a mean value of angular frequency of the power grid before grid disconnection and an instant phase angle at the moment of grid disconnection. During the switching from the island mode to a grid connection mode, a phase angle reference value of the inverter in the V / F mode is modified through a phase angle estimation algorithm based on an instant voltage value of the power grid, the phase angle of the power grid is tracked quickly, and a precise voltage phase angle is employed for replacing an estimation value after the stable phase locking of PLL. Through the superposing of frequency interference quantities, the method judges whether the grid connection of a microgrid is completed or not. The method changes the corresponding control modes, and achieves the seamless switching.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for quickly starting application of Android system

The invention provides a method for quickly starting an application of an Android system. The method comprises the following steps: customizing scanning to enable Package Manager Service of the Android system to scan an installation package of the application so as to obtain a UID allocated by the Package Manager Service, and replacing Owner ID and Group ID satisfying a UID format in all to-be-loaded files with the obtained UID during the operation of the application. According to the method, as long as all to-be-loaded files are stored in a specified catalogue of the application during the operation of the application, the application can be directly started, no file loading, or patch downloading and other operations is executed. The quick startup of the application avoids the long time wait of users, and thus the user experience of the Android system is greatly improved.

Owner:海马云(天津)信息技术有限公司

Time synchronization system and method for network instruments

InactiveCN106961312AReduce Data Transmission InterferenceAvoid long waitsTime-division multiplexData transmissionTree shaped

The invention discloses a time synchronization system and method for network instruments. The system comprises a tree-shaped instrument gateway, a control center, and the network instruments, wherein the control center is connected with a root node of the tree-shaped instrument gateway; the network instruments are connected with leaf nodes of the tree-shaped instrument gateway; the tree-shaped instrument gateway is composed of a main instrument gateway positioned at a root node position of the tree-shaped instrument gateway, and branch instrument gateways connected with the main instrument gateway; the control center communicates with the main instrument gateway via an Ethernet communication module; and the main instrument gateway is connected with a GPS time source used for synchronizing a local clock; and the method comprises the following steps: 1, synchronizing a time of the main instrument gateway; 2, synchronizing a time of an ith layer of the instrument gateways; 3, repeating the step 2 for N times till a time synchronization process of an Nth layer of the instrument gateways is finished; and 4, synchronizing a time of the network instruments. According to the time synchronization system and method disclosed by the invention, the design is original, the data transmission interference among the network instruments is reduced, and the network transmission efficiency and the time synchronization precision are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

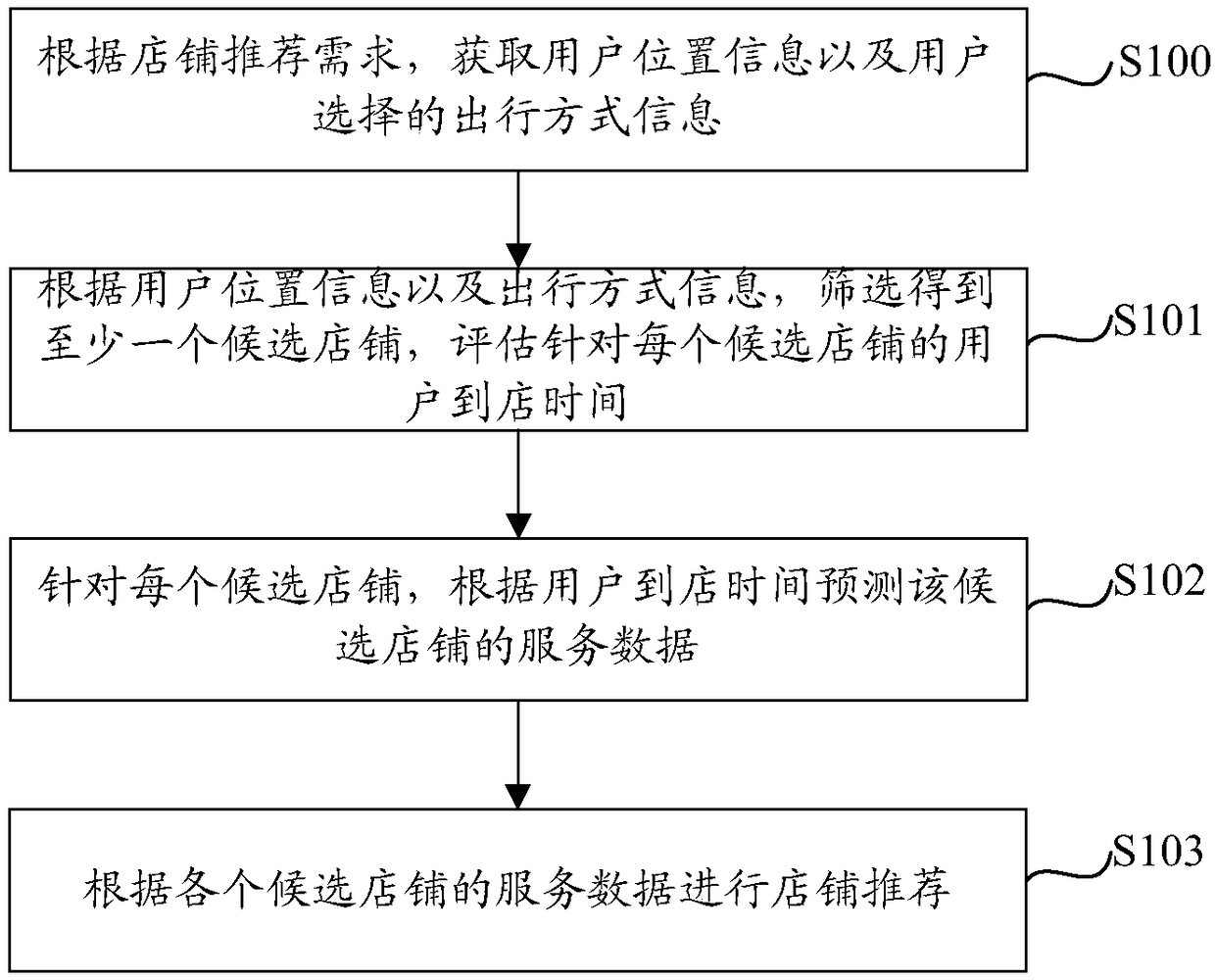

Shop recommendation method and device

InactiveCN109471984ASave dining timeAvoid long waitsDigital data information retrievalSpecial data processing applicationsTravel modeArrival time

The invention discloses a shop recommendation method and a device. The store recommendation method comprises the following steps: obtaining the location information of the user and the travel mode information selected by the user according to the store recommendation demand; At least one candidate store is selected according to user location information and travel mode information, and user arrival time for each candidate store is evaluated; For each candidate store, the service data of the candidate store is predicted according to the arrival time of the user; Store recommendation is performed according to the service data of each candidate store. Based on the scheme provided by the invention, when the user selects the recommended store for dining, the dining time of the user can be shortened, and the user can avoid waiting for a long time, especially for the user with short time, not only the user can dine in a limited time, but also the user time can be avoided to occupy too much, and the user experience is improved.

Owner:ZHEJIANG KOUBEI NETWORK TECH CO LTD

Multi-main-bus arbitration sharing device and arbitration method

InactiveCN102419739AAvoid long waitsAvoid the problem of long waitsElectric digital data processingMotherboardACCESS.bus

The invention relates to a multi-main-bus arbitration sharing device, which comprises a first processor, a second processor, a complex programmable logic device (CPLD), a chip-select-line read-write-line drive device and a motherboard comprising multiple data buses, wherein after receiving a request bus event of the first and the second processors, the CPLD arbitrates the request bus event and returns an arbitration result to the first and the second processors; a processor obtaining an access priority transmits an access bus event to the CPLD; after the CPLD receives the access bus event, the access bus event is transmitted by the chip-select-line write-read-line drive device to the motherboard; after receiving the access bus event, the motherboard executes the write or read operation on the bus; after the access of the processor obtaining the access priority is ended, the bus access ending event is returned by the motherboard to the processor through the CPLD; and the processor obtaining the access priority executes the write or the read operation according to the bus access ending event so as to complete the multi-main-bus arbitration sharing operation.

Owner:宁波联能仪表有限公司

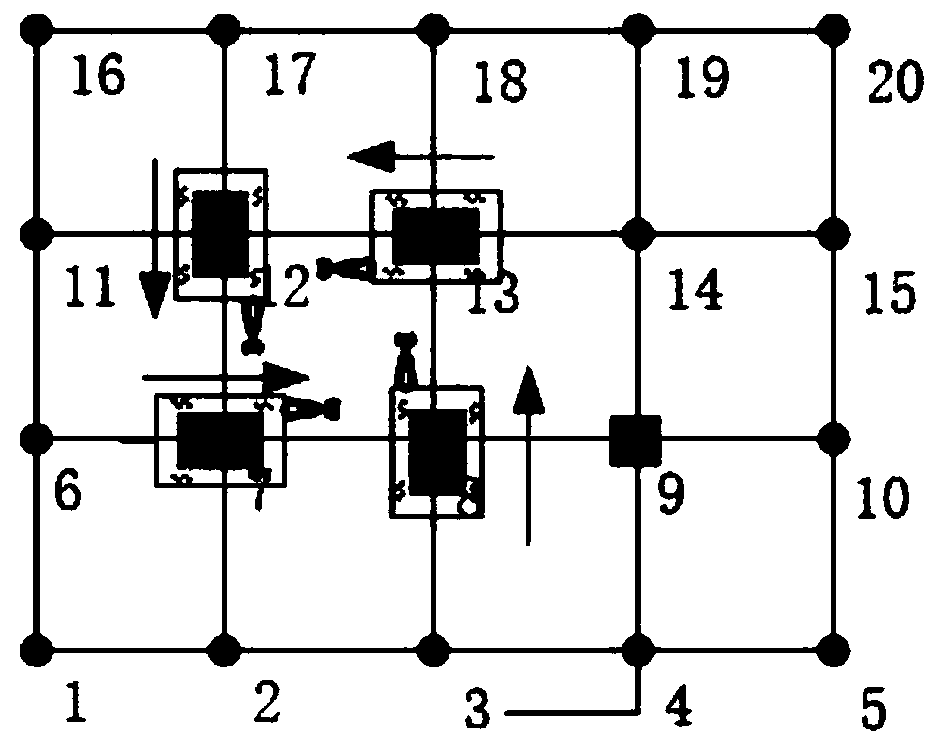

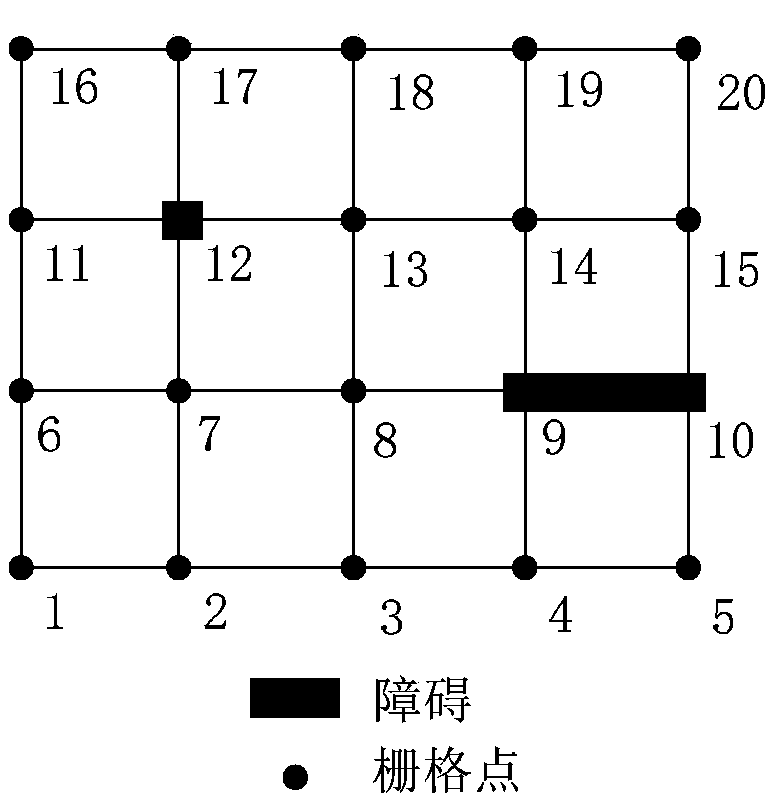

Foresight anti-lock dynamic allocation method for multi-mobile robot system grid points based on grid map

ActiveCN109508010AAvoid deadlockAvoid long waitsPosition/course control in two dimensionsVehiclesBlock graphMultirobot systems

The invention provides a foresight anti-lock dynamic allocation method for multi-mobile robot system grid points based on a grid map. According to the method, when the grid points are allocated, eachgrid point is only allocated to one mobile robot at most, and collision between the robots can be effectively avoided. Each robot only can obtain preset NC grid points per round at most, the phenomenon that a lot of robots in the system wait for a long time is avoided, the aim that the robots share the grid map is achieved, and the overall efficiency of the multi-robot system is effectively improved. In the allocation process, the strategy of foresight one step is adopted, a blocking graph model of the system obtained after foresight one step is built in real time, a corresponding loop lockingdetection and avoiding method is adopted, and the loop locking phenomenon is effectively avoided.

Owner:YANCHENG INST OF TECH

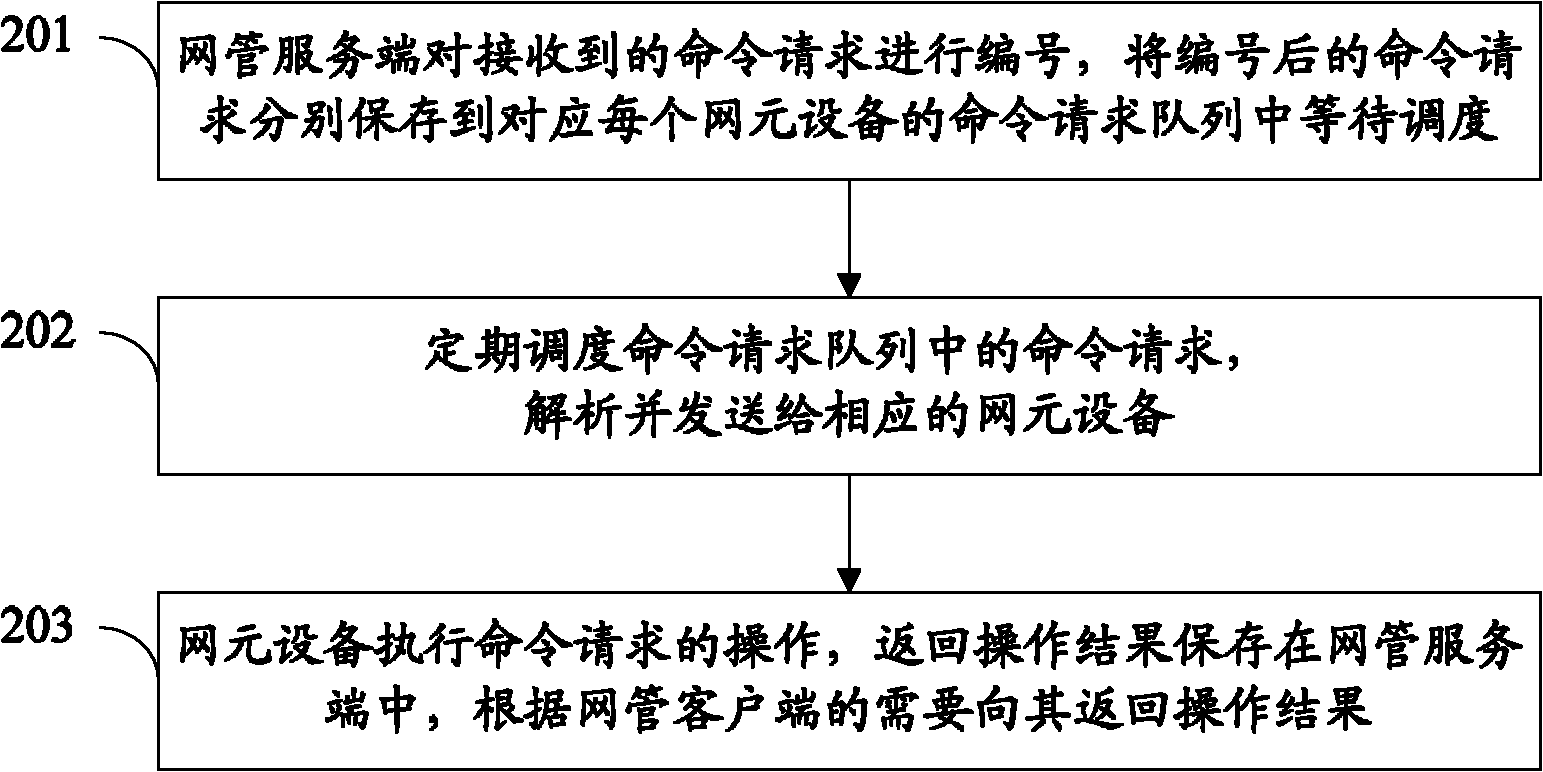

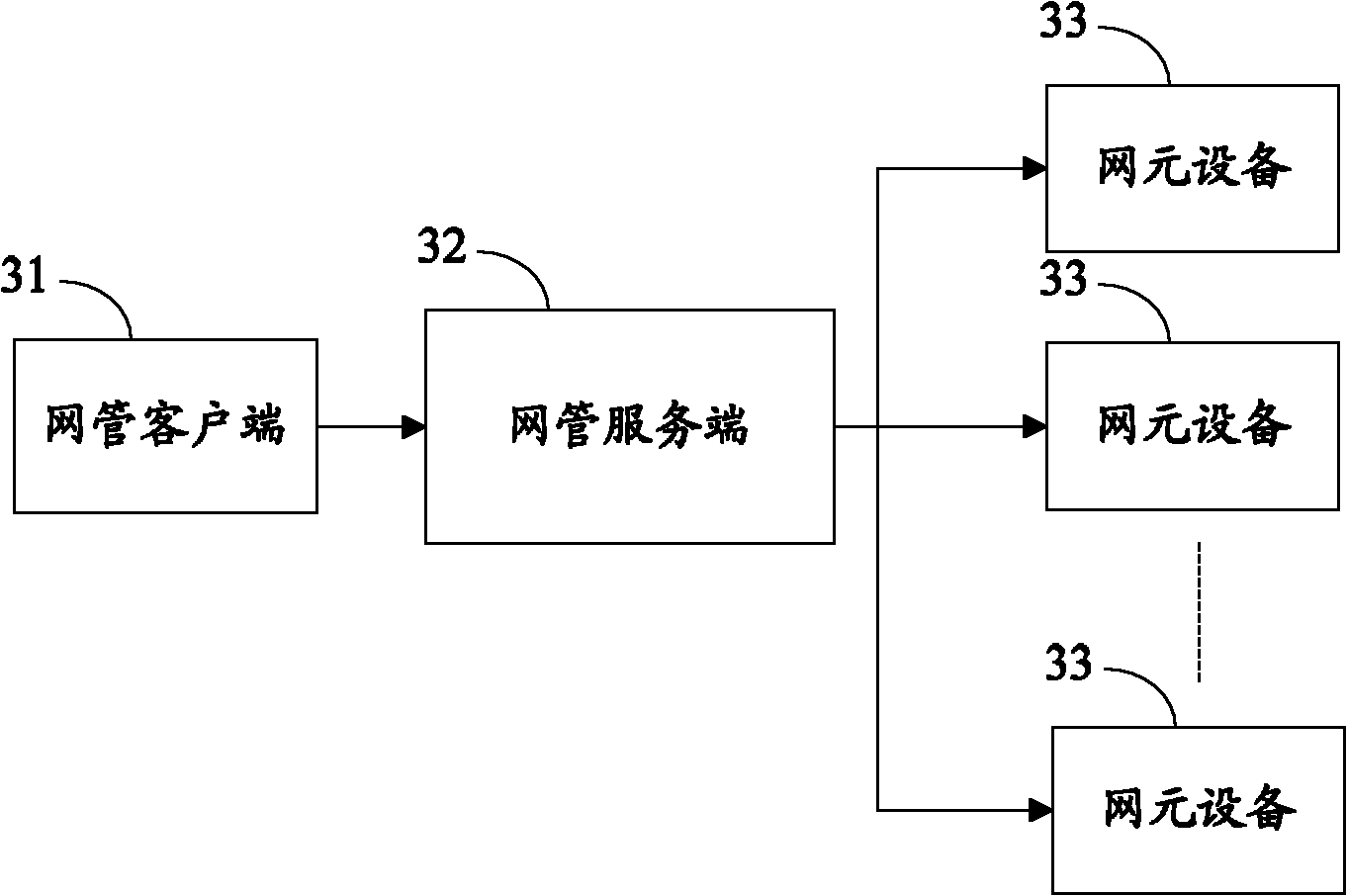

Method and system for managing multiple kinds of network element equipment

ActiveCN102014002AAvoid accumulationAvoid unnecessary waitingData switching networksNetwork managementNetwork element

The invention discloses a method for managing multiple kinds of network element equipment. The method comprises the following steps that: a network management server numbers received command requests, stores the numbered command requests in command request queues corresponding to each piece of network element equipment to wait dispatching respectively; the network management server periodically dispatches the command requests in the command request queues and analyzes and transmits the command requests to the corresponding network element equipment; the network element equipment executes the operation of the command requests, returns an operation result and stores the operation result in the network management server; and the network management server returns an operation result to a network management client according to the demand of the network management client. The invention also discloses a system for managing the multiple kinds of network element equipment. Through the method and the system, the command requests aiming at the network element equipment are automatically dispatched by the network management server in a unified way; and the operation result can be purposely examined.

Owner:ZTE INTELLIGENT IOT TECH

Paging download method and device based on large data

ActiveCN109344197AImprove query efficiencyReduce the number of queriesDatabase distribution/replicationSpecial data processing applicationsPagingData query

The invention relates to a paging downloading method, a device, a computer device and a storage medium based on large data. The method comprises the following steps: receiving a query instruction of auser terminal; Obtaining a query condition parameter transmitted by the user terminal according to the received query instruction; According to the query condition parameters, the database is paged to generate the query data summary table of the paged query; Wherein, when querying the current query page, the primary key ID of the last data of the above query page is the index, the paging data ofthe current query page located after the last data of the previous query page in the database is queried, and the paging data of the current query page queried is written into the query data summary table; Returning a query data summary table to the user terminal. In the method, the primary key ID generated by the last data of the next paging query of the previous paging is an index, so that the previous paging query data need not be queried repeatedly, the number of queries is reduced, and the efficiency of the data query is improved.

Owner:广州帷策智能科技有限公司

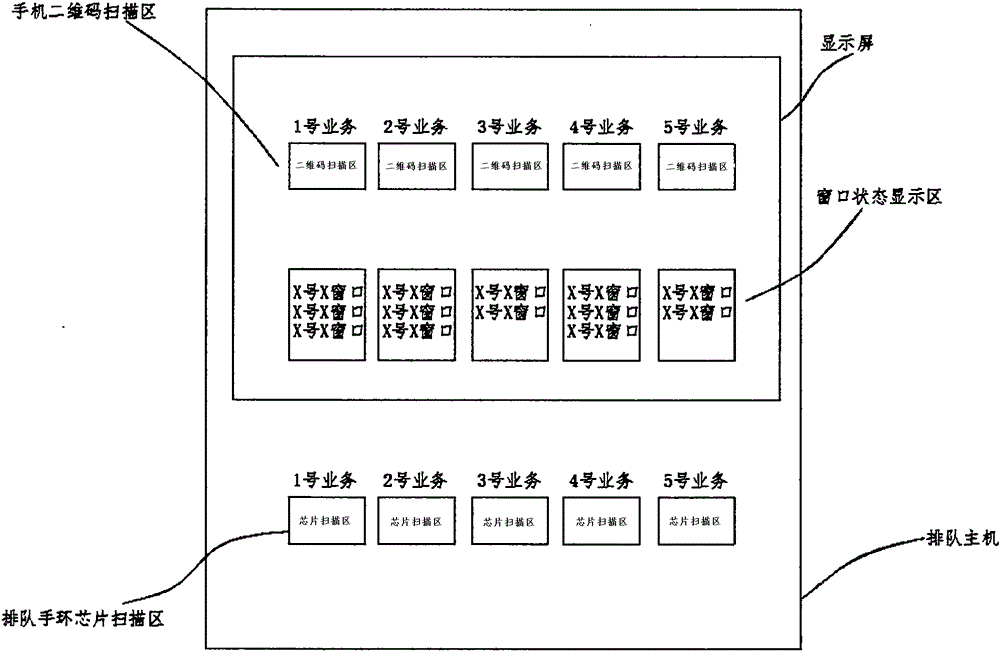

Public place intelligent queuing machine system

ActiveCN106097532AReduce queuing timeReduce the noise decibelChecking apparatusTransmissionPublic placeWireless transmission

A public place intelligent queuing machine system comprises a server, a queuing machine host, two-dimensional code scanners, a mobile phone temporary terminal APP and queuing bracelets, a control signal is transmitted between the queuing machine host and the server in a wireless manner, and the two-dimensional code scanners are arranged at office windows; the server is used for controlling receiving, processing and sending of information of the queuing machine host, the scanners, the mobile phone temporary terminal APP and the queuing bracelets; and the queuing machine host can display various two-dimensional codes to meet transaction requirements for different businesses. When a mobile phone scans the correspond two-dimensional code of the queuing host, the mobile phone automatically downloads the temporary APP, and generates a two-dimensional code in the APP used for being scanned in order to identify client queuing information. The intelligent queuing machine system saves 80% or above of the queuing time of people, saves consumables required by previous paper printing in the business halls of all mechanisms, greatly reduces noises in the business halls, properly reduces the area of the business halls, and saves the cost.

Owner:汪桂楠

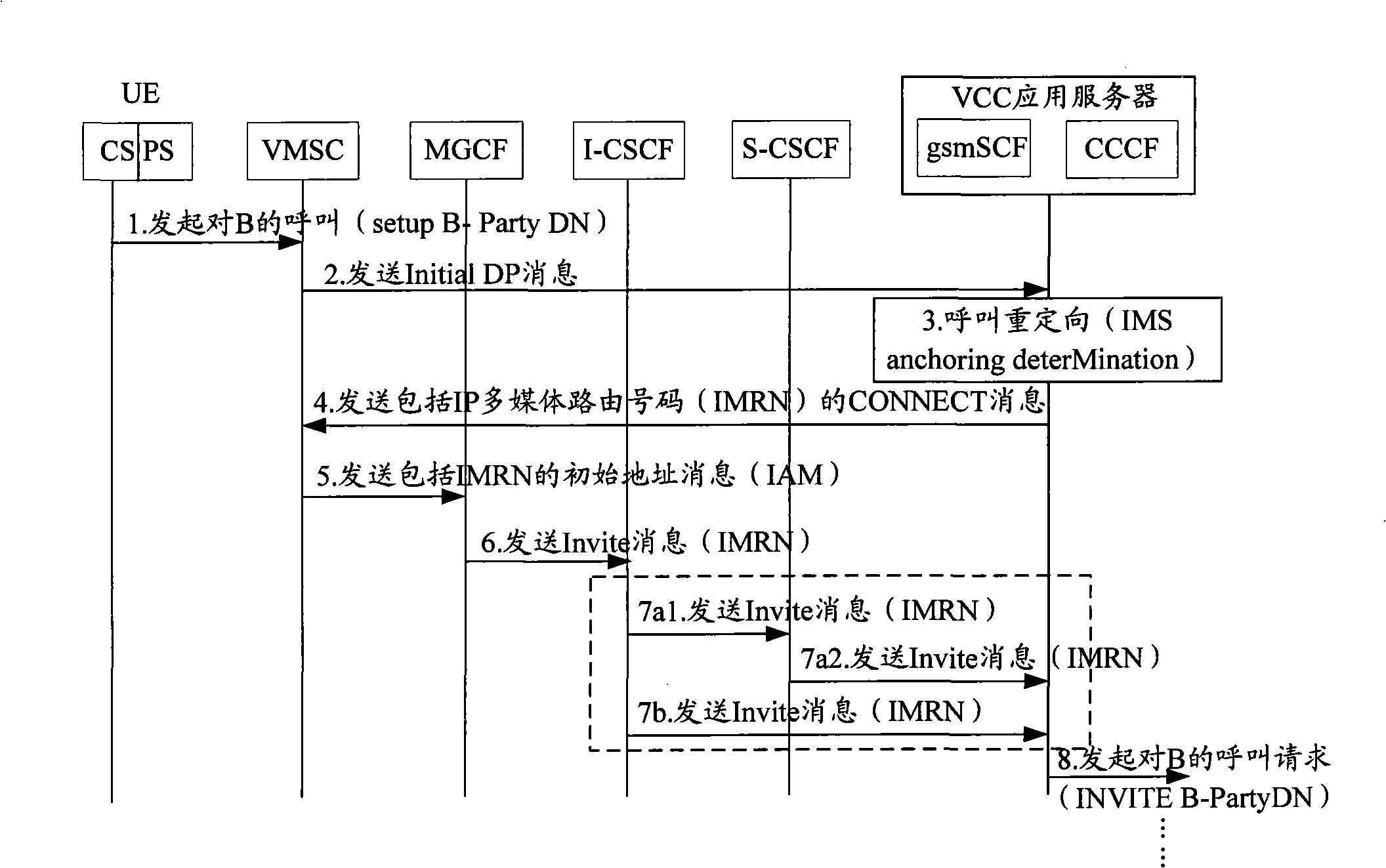

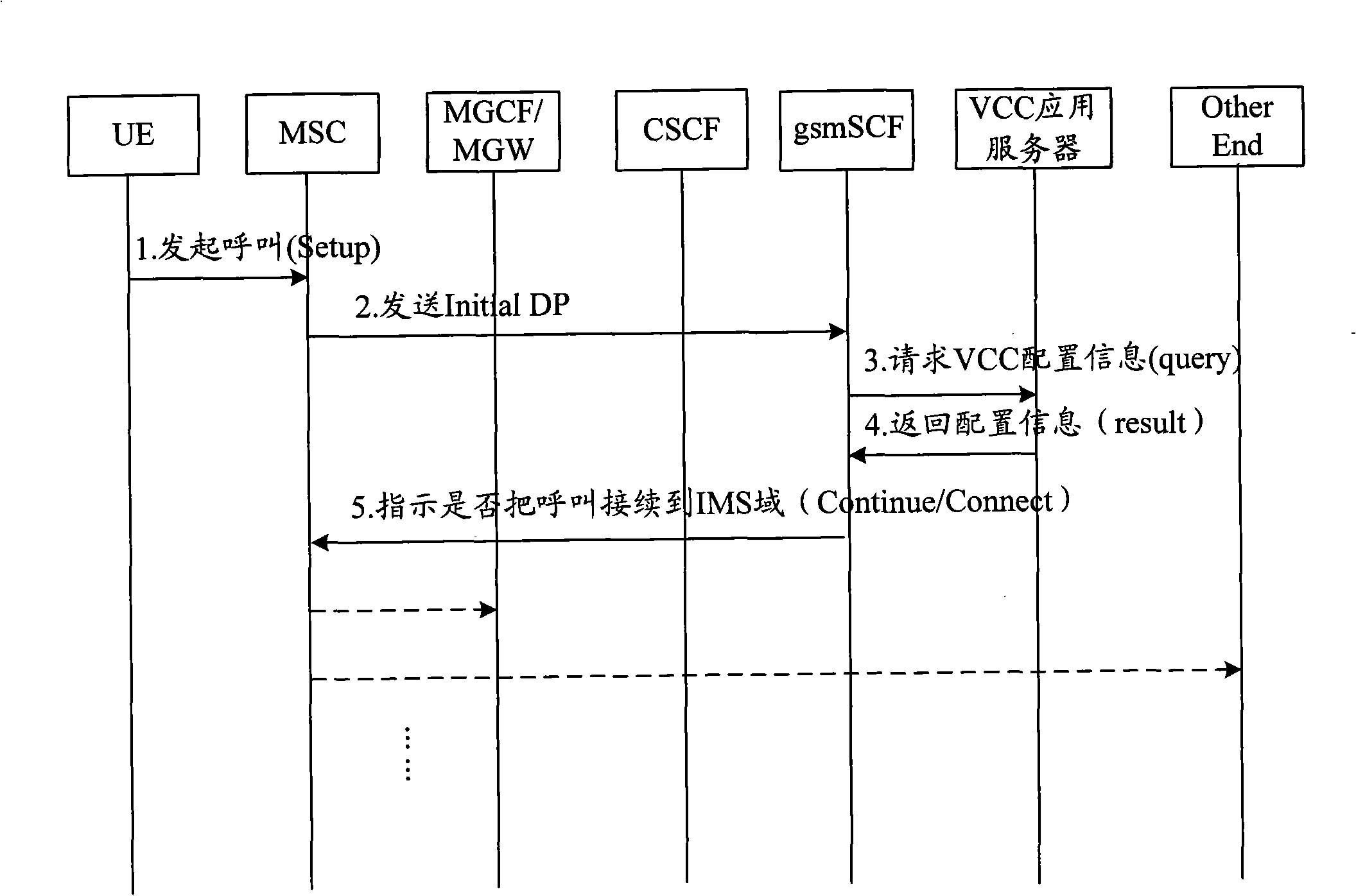

Call processing method and system

InactiveCN101287276AQuick connectionAvoid long waitsInterconnection arrangementsData switching by path configurationTelecommunicationsUser identifier

The invention is applicable to the field of communications and provides a call processing method and a system thereof. The call processing method of the invention comprises the steps that: the voice call continuity configuration information of a subscriber is collected and kept; when a call issued from a first domain by the subscriber is received, the configuration information is read according to a subscriber identifier; the configuration information is taken as a basis to judge whether the call needs to be continued to a second domain and the corresponding continuing is carried out. The embodiment of the invention pre-configures relevant VCC information by a CS domain or an IMS domain so as to ensure that gsmSCF can carry out the corresponding processing to the information in the subsequent call processing, which leads that the subscriber can optionally determine whether a certain calls need to be processed by the VCC and if the calls need not to be processed by the VCC, the faster continuing of the call from the subscriber can be realized, thereby the subscriber needs not to wait for a long time.

Owner:HUAWEI TECH CO LTD

Microblog-based system and method for consultation, requested repair and requested installation of natural gas

InactiveCN103020217AAvoid long waitsImprove service qualityTransmissionSpecial data processing applicationsOperational costsNatural gas

The invention provides a microblog-based system and method for consultation, requested repair and requested installation of natural gas. The method comprises the steps of: receiving information groups sent by bound microblog accounts of users by a microblog account of a natural gas company; classifying and accumulating the information groups according to a preset standard; issuing a microblog message by the natural gas company via the microblog account; replying any one or multiple microblog messages in a first accumulation group by the natural gas company via the microblog account; replying any one or multiple microblog messages in a second accumulation group by the natural gas company via the microblog account; and replying any one or multiple microblog messages in a third accumulation group by the natural gas company via the microblog account. According to the invention, time and manpower are saved, the operating cost of the natural gas company is reduced, and the communication between the natural gas users and the natural gas company is facilitated.

Owner:ZHAOQING XINAO GAS

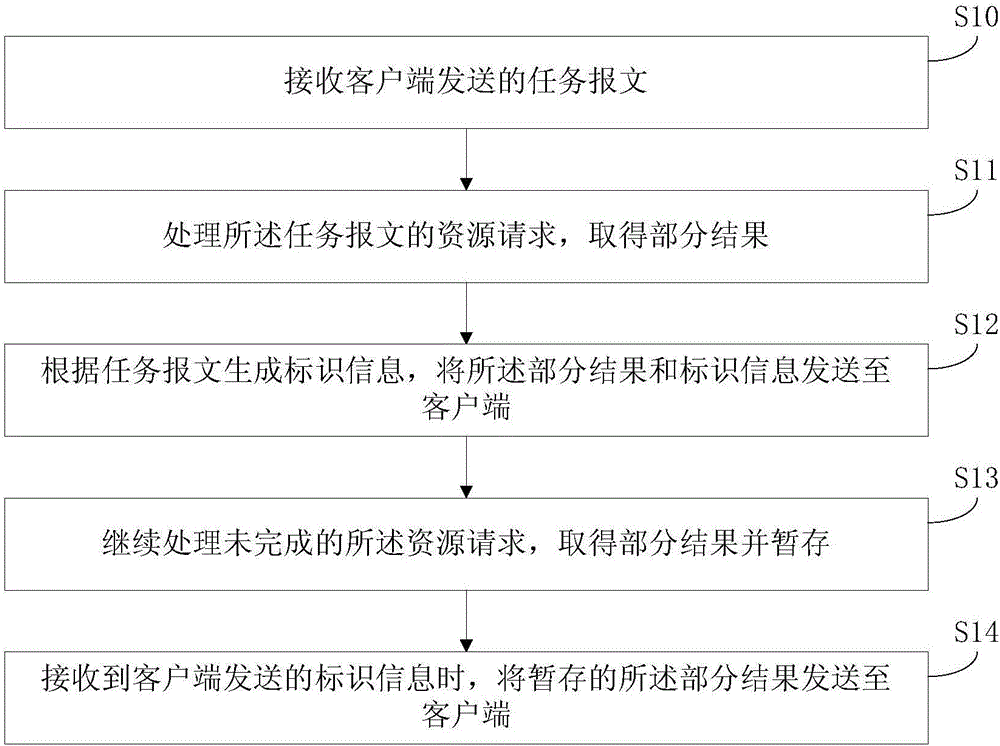

Asynchronous communication method and device

The invention discloses an asynchronous communication method, and the method comprises the steps: receiving a task message sent by a client; processing a resource request for the task message, and obtaining a part of obtained results; generating identification information according to the task message, and enabling the part of obtained results and the identification information to be transmitted to the client; continuously processing unfinished resource request, obtaining the part of obtained results, and temporarily storing the part of obtained results; and transmitting the temporarily stored result to the client when the identification information transmitted by the client is received. According to the invention, through the stepped processing of the resource request for the task message, the method processes the resource requests of all parts through the time difference between two requests, obtains a part of results, and transmits the part of results, divides a complex task with longer time consumption into simple tasks with shorter time consumption, respectively completes the simple tasks through employing occupied threads, effectively reduces the processing pressure, can avoid the long-time waiting of the client, and especially can avoid request failure caused by no response under the high parallel requests.

Owner:LETV HLDG BEIJING CO LTD +1

House resource information processing method and device

ActiveCN112596694AGuaranteed timelinessImprove efficiencySound input/outputPersonalizationResource information

The embodiment of the invention provides a house resource information processing method and device. The method comprises the steps that a terminal responds to an access operation of a user, obtains auser identification corresponding to the terminal, obtains an access state corresponding to the access operation through employing the user identification, and outputs a total audio of a house resource if the access state is that a three-dimensional house space is accessed for the first time in a first preset time period; in the process of outputting the house resource total audio, in response toa selection operation for the functional space, a target functional space and a target house resource sub-audio corresponding to the target functional space are selected, the output of the house resource total audio is paused, a first suspension node of the house resource total audio is recorded, the target house resource sub-audio is outputted, therefore, when the user accesses the three-dimensional house space for the first time, the corresponding house source total audio is output to introduce the target house source, the timeliness of the house source information is ensured, personalized playing and breakpoint continuous playing of the house source audio are provided, the efficiency and comprehensiveness of acquiring the house source information by the user are effectively improved, and the house finding experience of the user is ensured.

Owner:BEIJING CHENGSHI WANGLIN INFORMATION TECH CO LTD

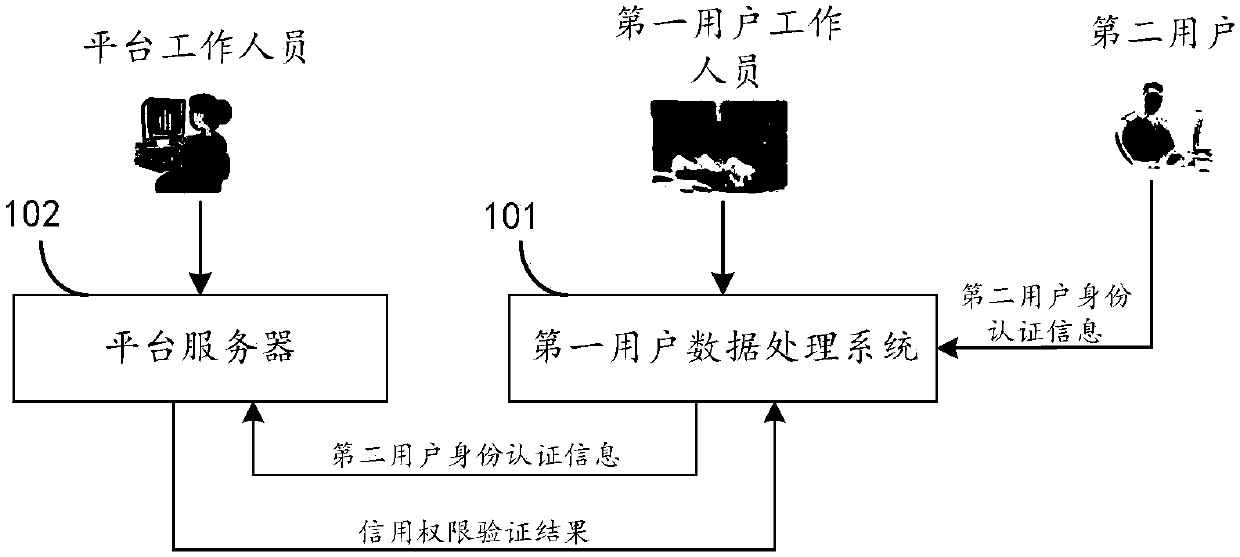

Order information processing method, device and system

InactiveCN107590705AAvoid long waitsImprove efficiencyReservationsPayment architectureInformation processingData processing system

The embodiment of the invention discloses an order information processing method, device and system, and the method comprises the steps: determining the identity recognition information of a second user when a first user data processing system processes a business request of the second user; submitting the identity recognition information of the second user to the server so that the server carriesout the credit authority verification of the second user; generating a business order after a verification success message is received, and submitting the business order to the server; and submittingthe consumption resource information of the business order to the server so that the server ends the business order according to the consumption resource information and the information of a paymentaccount correlated with the second user. According to the embodiment of the invention, the method can achieve the improvement of efficiency, and also can avoid the long-time waiting for the second user who is handling the business.

Owner:ALIBABA GRP HLDG LTD

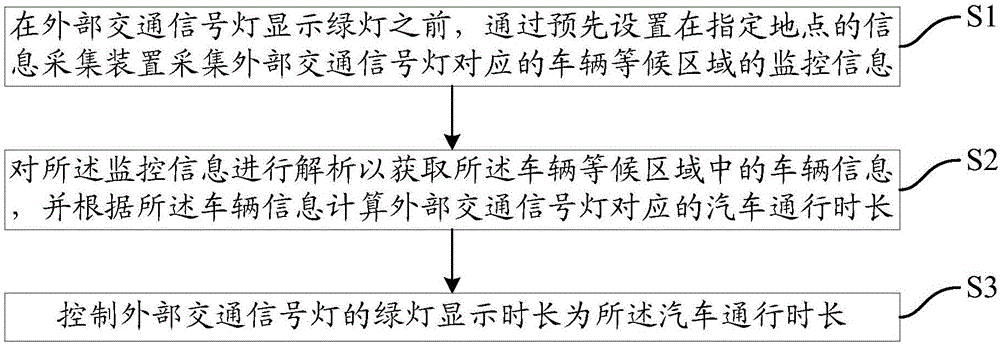

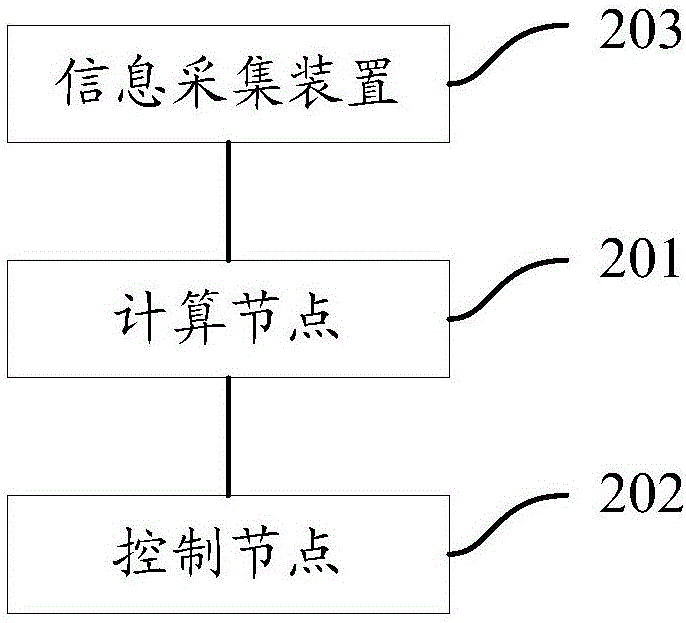

Traffic signal lamp control method, device and system

InactiveCN106056931AAvoid long waitsImprove experienceControlling traffic signalsTraffic signalEngineering

The invention provides a traffic signal lamp control method, device and system. The method comprises that S1) before that an external traffic signal lamp displays a green light, an information collector which is arranged in a specific position in advance is used to collect corresponding monitoring information of a vehicle waiting area of the external traffic signal lamp; S2) the monitoring information is parsed to obtain vehicle information of the vehicle waiting area, and a vehicle passing time length corresponding to the external traffic signal lamp is calculated according to the vehicle information; and S3) a green light display time length of the external traffic signal lamp is controlled as the vehicle passing time length. According to technical schemes of the invention, it is ensured that all vehicles in the corresponding vehicle waiting area of the traffic signal lamp can pass the specific position corresponding to the traffic signal lamp during one green-light area, users are prevented from long-time waiting in the waiting area, and user experience can be improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

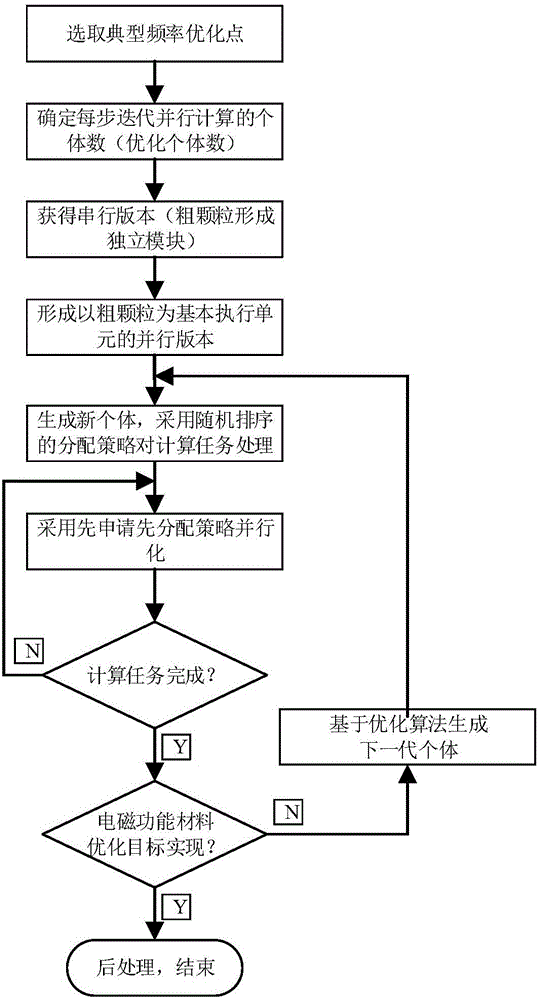

Coarse particle parallel method and system for electromagnetic function material optimization design

ActiveCN106126878AImprove Parallel Computing EfficiencySolve the low efficiency of parallel computingSpecial data processing applicationsInformaticsHigh performance computationMaterial Design

The invention relates to the field of function material design and high-performance calculation, in particular to a coarse particle parallel method and system for electromagnetic function material optimization design. The method comprises the steps of obtaining a serial version by taking a coarse particle as an independent execution module, and obtaining a parallel version by taking the coarse particle as a basic execution unit; further, processing a plurality of calculation tasks by adopting an allocation policy of random sorting, wherein the allocation policy of random sorting can thoroughly disrupt an allocation sequence of all the calculation tasks to obtain a new sequence of the calculation tasks; then, applying for allocating to-be-allocated calculation tasks in the new sequence by each calculation process through adopting a first-application first-allocation policy, and performing calculation until all the calculation tasks are finished; and finally, performing statistics on calculation results, performing targeting processing, comparing a processing result with an expected optimization goal, and judging whether the optimization goal is achieved or not. According to the coarse particle parallel method, the problem of low parallel calculation efficiency in electromagnetic function material optimization design at the present stage is effectively solved.

Owner:北京智芯仿真科技有限公司

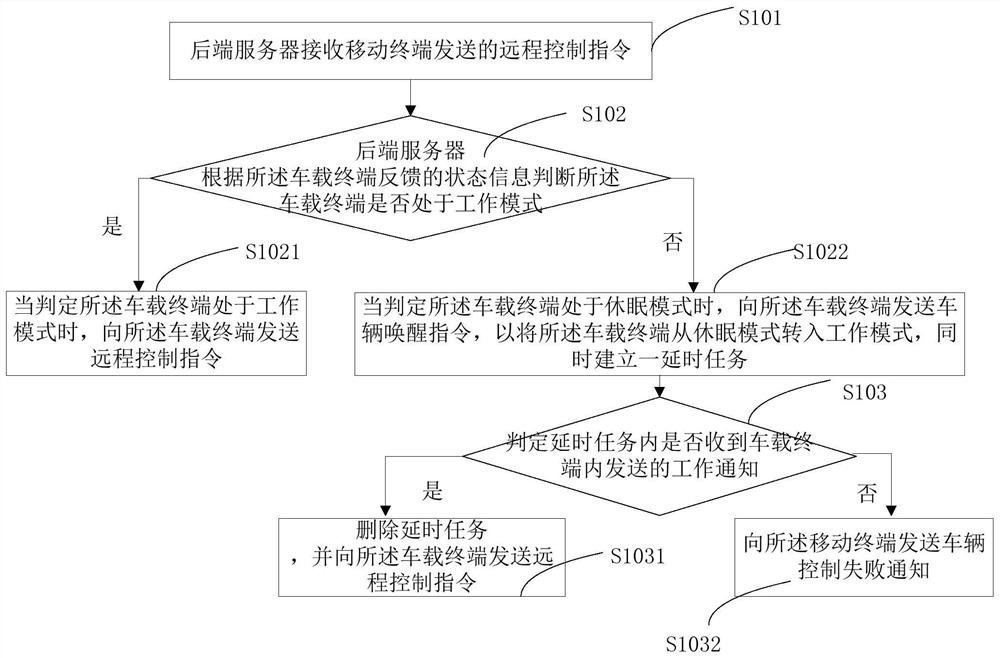

Vehicle remote control method and system, readable storage medium and equipment

InactiveCN111711652AAvoid invalid queriesEasy accessParticular environment based servicesMessaging/mailboxes/announcementsIn vehicleRemote control

The invention relates to the technical field of vehicle remote control, and in particular relates to a vehicle remote control method, device and system, a readable storage medium and equipment. The method comprises the steps of sending a state query request to a vehicle-mounted terminal after receiving a remote control instruction sent by a mobile terminal, and judging whether the vehicle-mountedterminal is in a working mode or not according to state information fed back by the vehicle-mounted terminal; when it is judged that the vehicle-mounted terminal is in the sleep mode, sending a vehicle awakening instruction to the vehicle-mounted terminal so that the vehicle-mounted terminal can be switched into a working mode from the sleep mode, and meanwhile establishing a delay task; when a work notification sent by the vehicle-mounted terminal is received, deleting the delay task, and sending a remote control instruction to the vehicle-mounted terminal; and when the delay task is exceededand the work notification sent by the vehicle-mounted terminal is not received, sending a vehicle control failure notification to the mobile terminal. According to the method, a user can obtain the vehicle state information as soon as possible, long-time waiting of the user is avoided, and the requirements for low time delay and quick response of remote vehicle control are met.

Owner:JIANGXI JIANGLING GRP NEW ENERGY AUTOMOBILE CO LTD

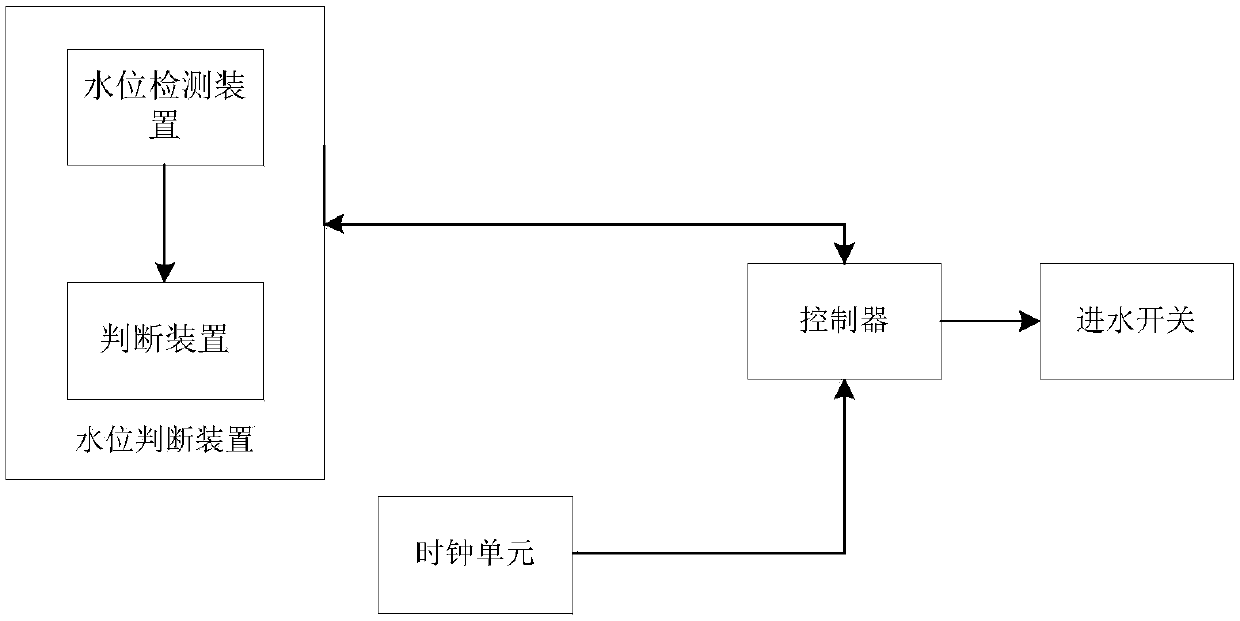

Water inlet control method of dishwasher and dishwasher

ActiveCN110604527AEasy to findEasy to controlTableware washing/rinsing machinesHome appliance efficiency improvementEnvironmental engineeringWaiting time

The invention discloses a water inlet control method of a dishwasher and a dishwasher. The water inlet phase includes a plurality of water inlet cycles executed in sequence until the water inlet phaseends or the water inlet phase is suspended. The dishwasher disclosed by the invention can meet the control of the water inlet time under various water pressure conditions; and the failure of the water inlet device of the dishwasher can be detected as soon as possible; therefore, the unnecessary water inlet waiting time is significantly reduced, the working time of the dishwasher is effectively used, and the work of the dishwasher is more efficient.

Owner:QINGDAO HAIER DISHWASHER

Travel order processing method and device and server

The embodiment of the invention provides a travel order processing method, a travel order processing device and a server. The method is applied to a server, and comprises the steps of receiving a collective travel order sent by a client, and obtaining an order parameter of the collective travel order; determining an alternative vehicle according to the order parameter, and determining the pick-uptime of the alternative vehicle; traversing the alternative vehicles according to the pick-up time, screening the required number of the target vehicles from the alternative vehicles, and respectivelydistributing the travel orders to the target vehicles; wherein after the target vehicles are sorted according to the pick-up time, the pick-up time interval between every two adjacent target vehiclesis smaller than a preset interval threshold value, and the sum of the order refusal times of all the target vehicles is smaller than a preset order refusal threshold value. The embodiment of the invention provides an online car-hailing mode supporting collective travel, and realizes unified scheduling of collective travel vehicles.

Owner:NANJING LINGXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com