High-speed truss manipulator

A technology of manipulators and trusses, applied in the field of truss manipulators, can solve the problems of large vibration, low alternating operation speed, and low guiding precision, so as to achieve high-efficiency work, avoid long-term waiting, and improve rigidity and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

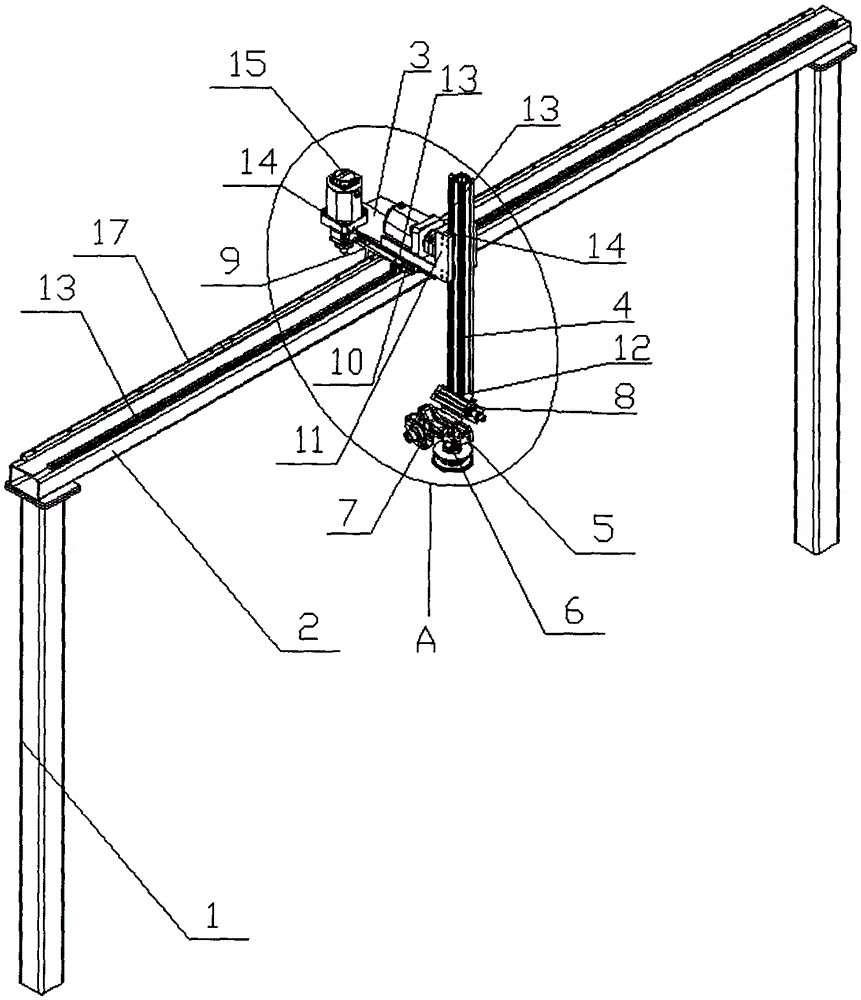

[0022] Embodiment: A high-speed truss manipulator, set three mutually perpendicular directions as X direction, Y direction and Z direction respectively, wherein Z direction is the vertical direction, including support frame 1, X direction track 2, Y direction track 3, Z-direction track 4, mechanical gripper mounting bracket 5, first and second mechanical grippers 6, 7, first, second and third drive devices, rotary drive device 8 and first, second and third sliders 9, 10 and 11 , the X-direction rail 2 is horizontally installed on the upper end of the support frame 1, the first slider 9 can slide and be positioned on the X-direction rail 2 along the extension direction of the X-direction rail 2, and the second slider 10 is fixedly installed on the first slider 9 Above, the Y-direction track 3 can be reciprocally slid along the Y direction and positioned on the second slider 10, the third slider 11 is fixedly installed on the Y-direction track 3, and the Z-direction track 4 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com