Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

344 results about "Quay crane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

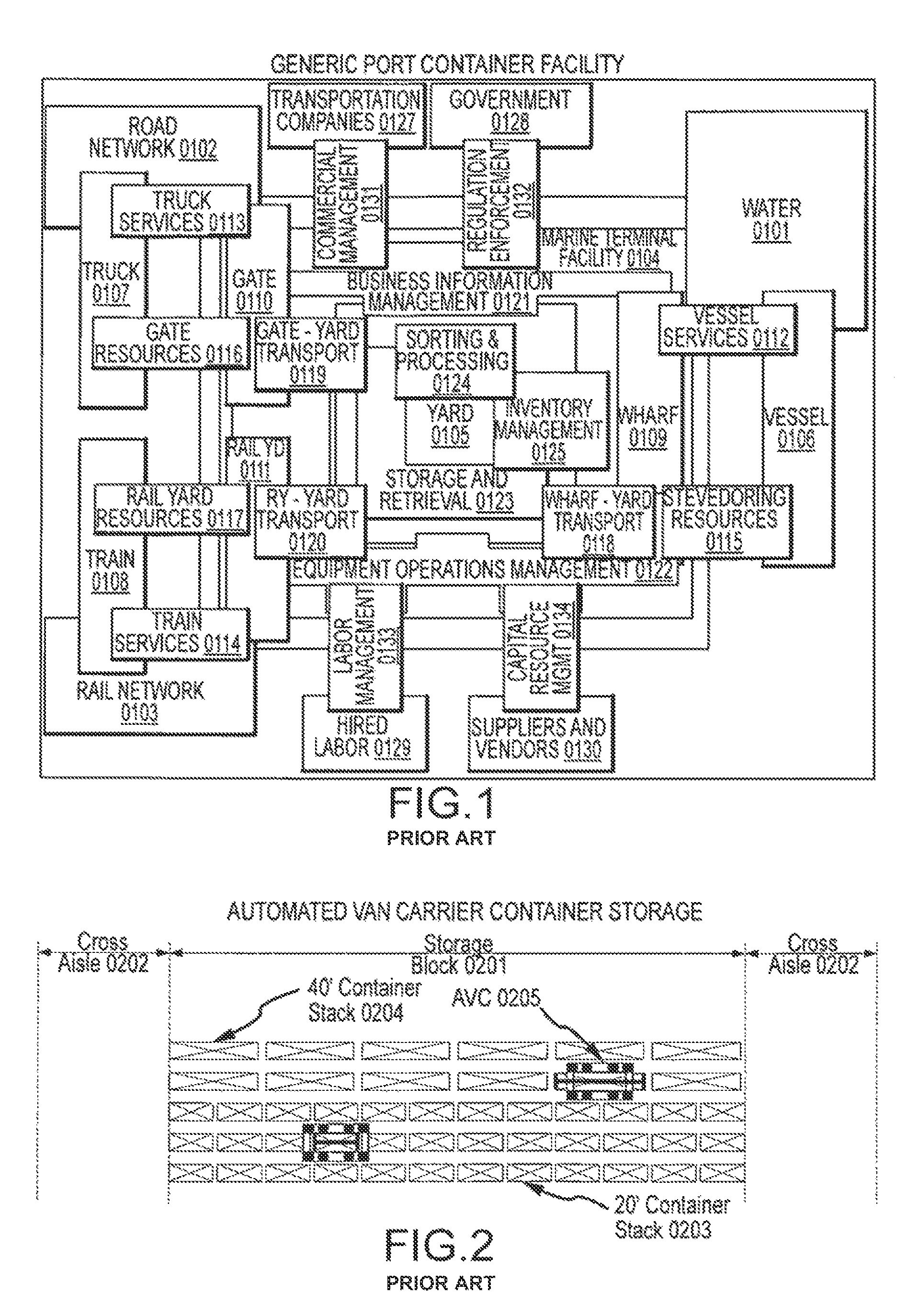

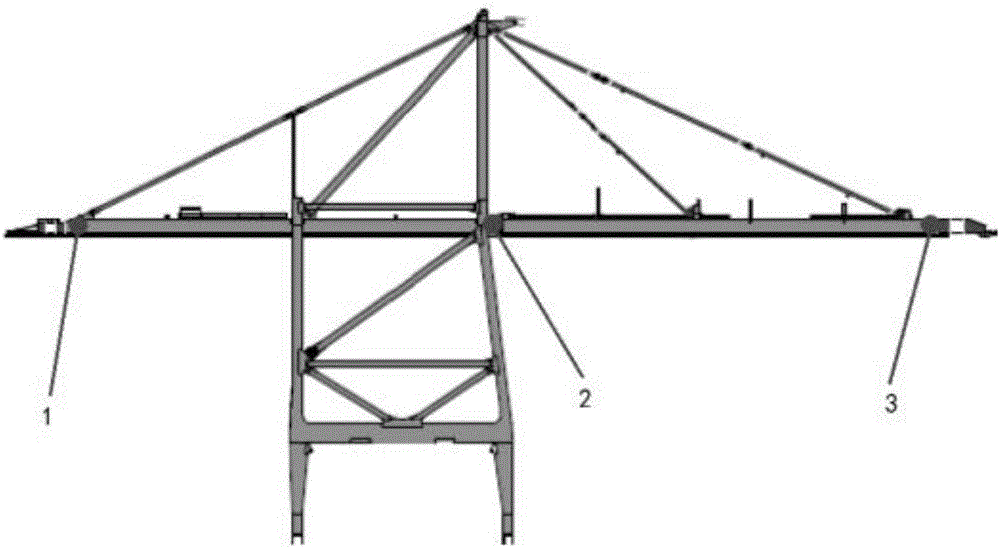

Quay gantry crane is used to deal with a variety of cargo and container at dockside and port.

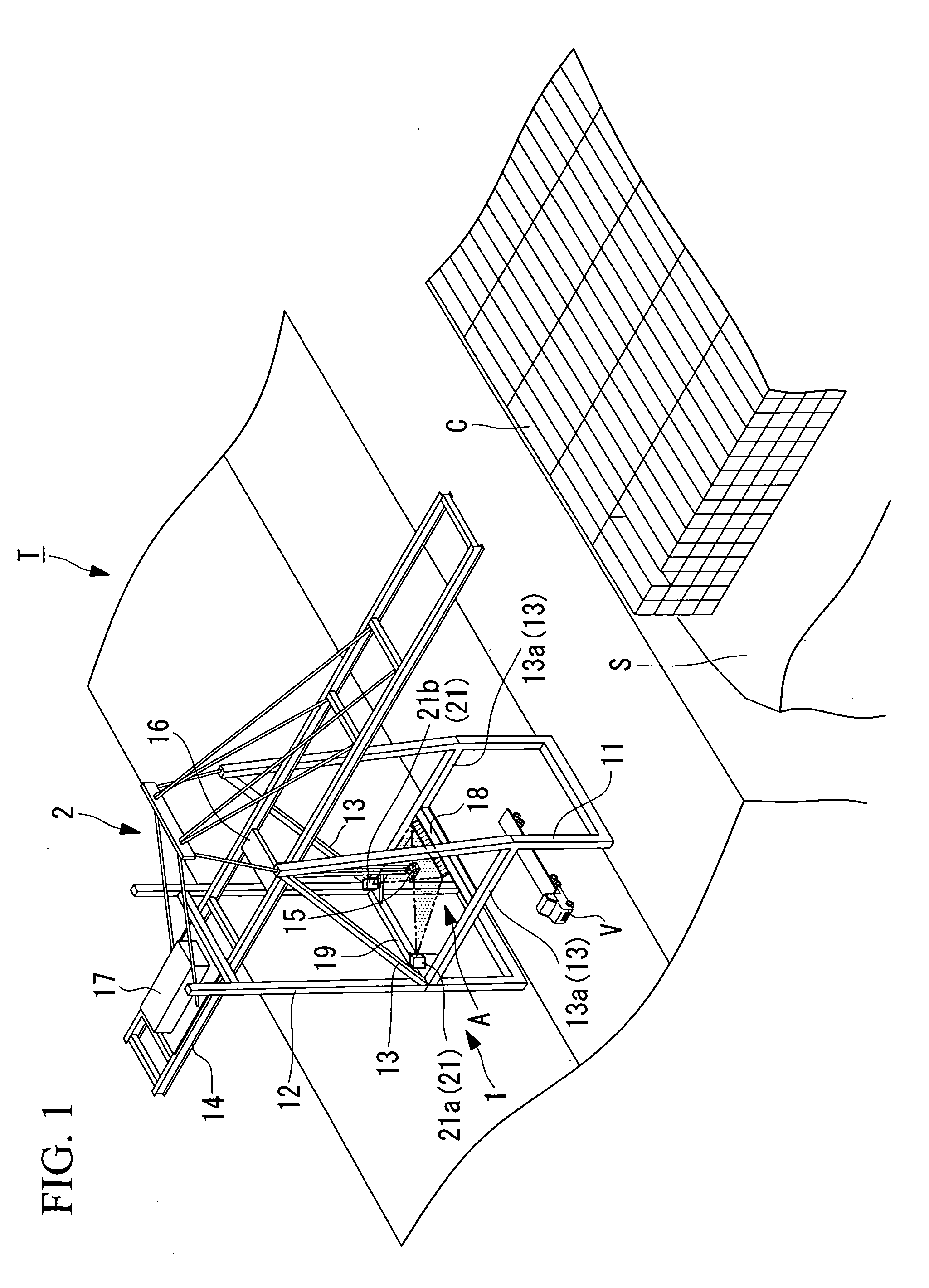

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

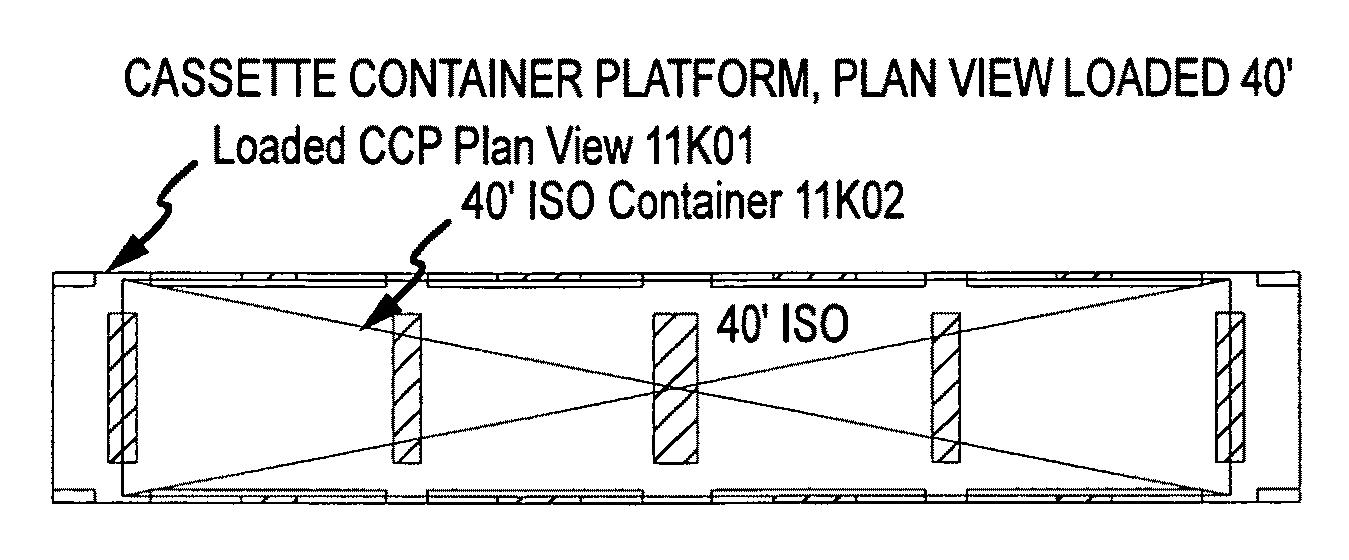

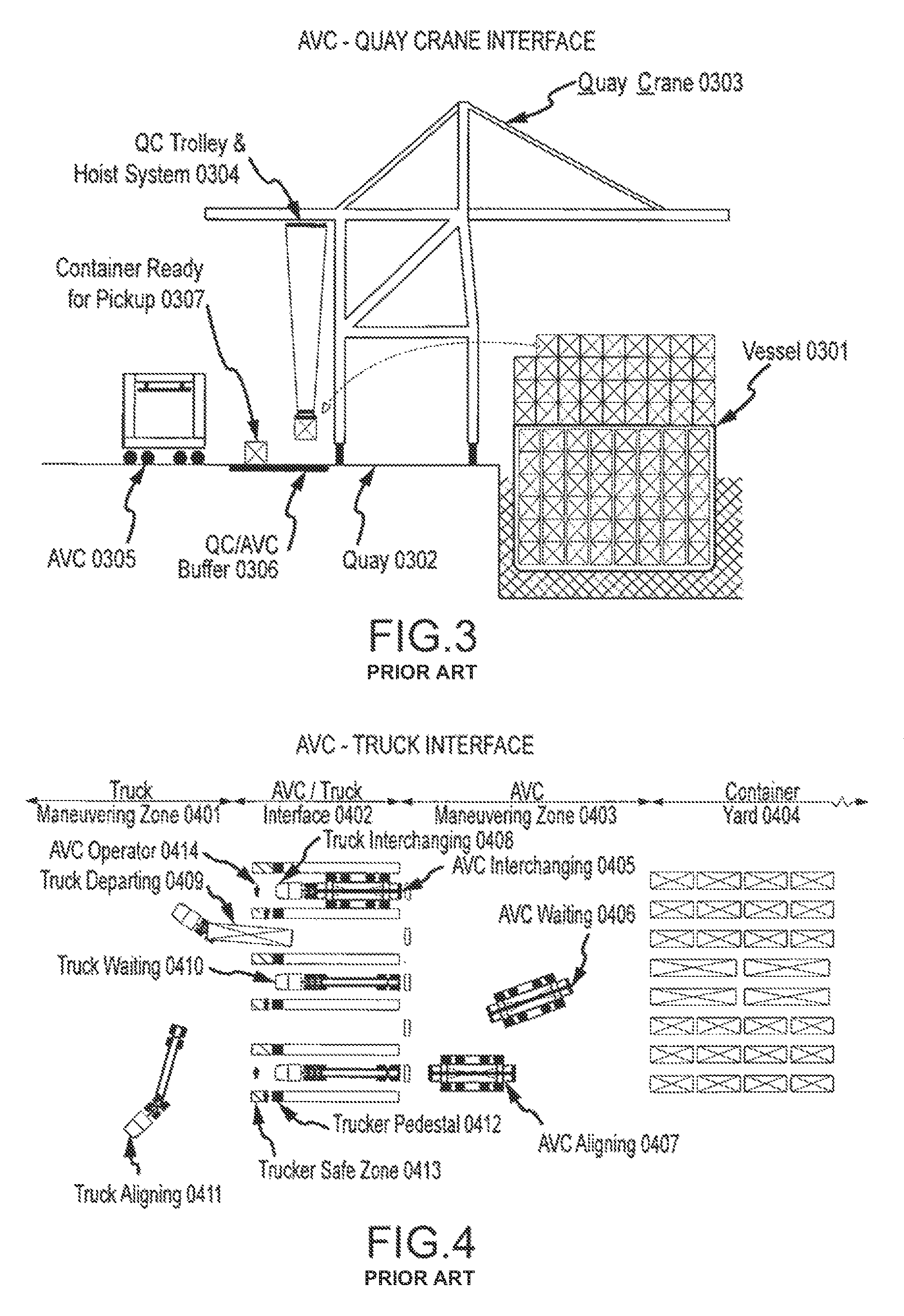

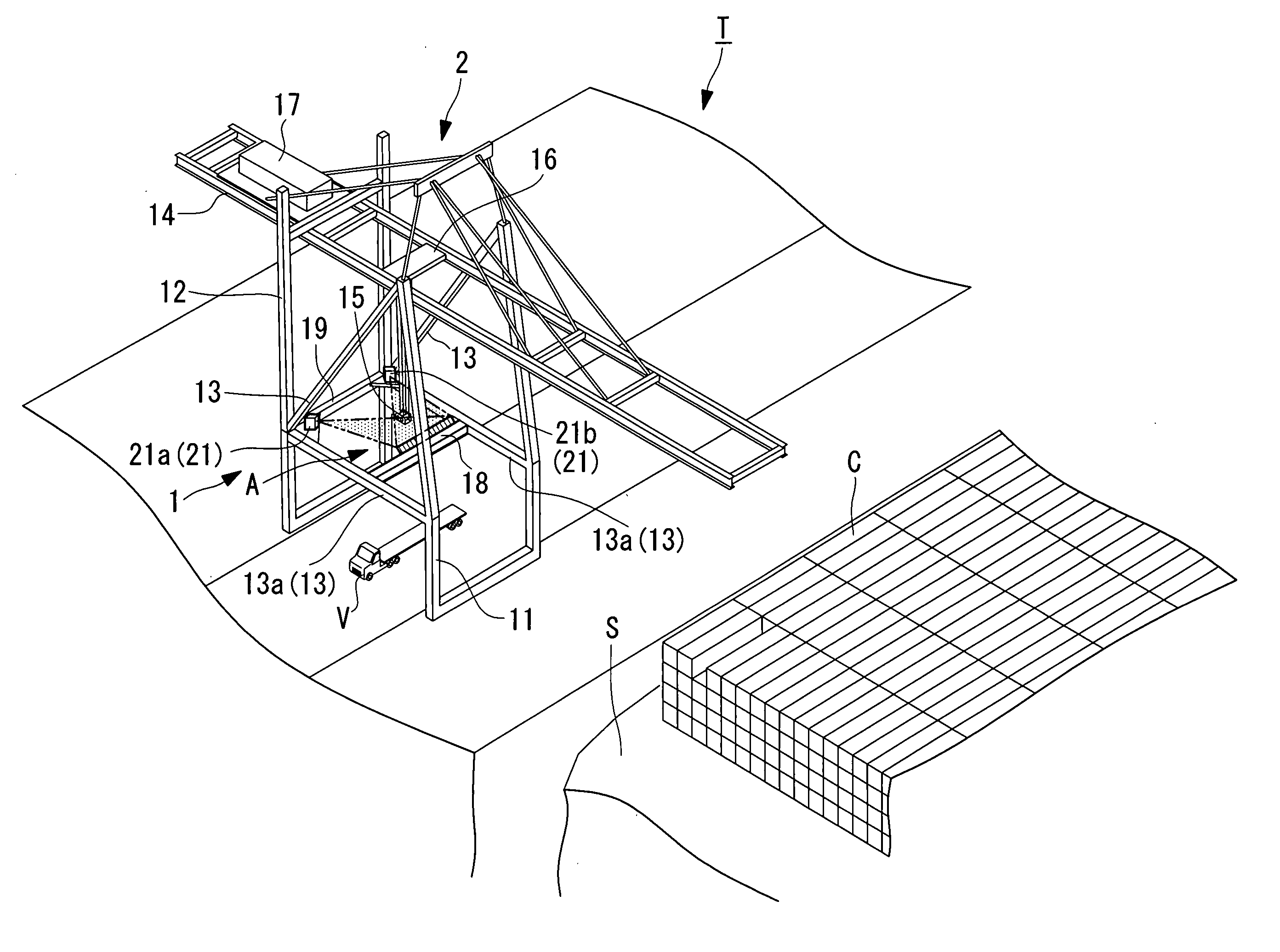

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

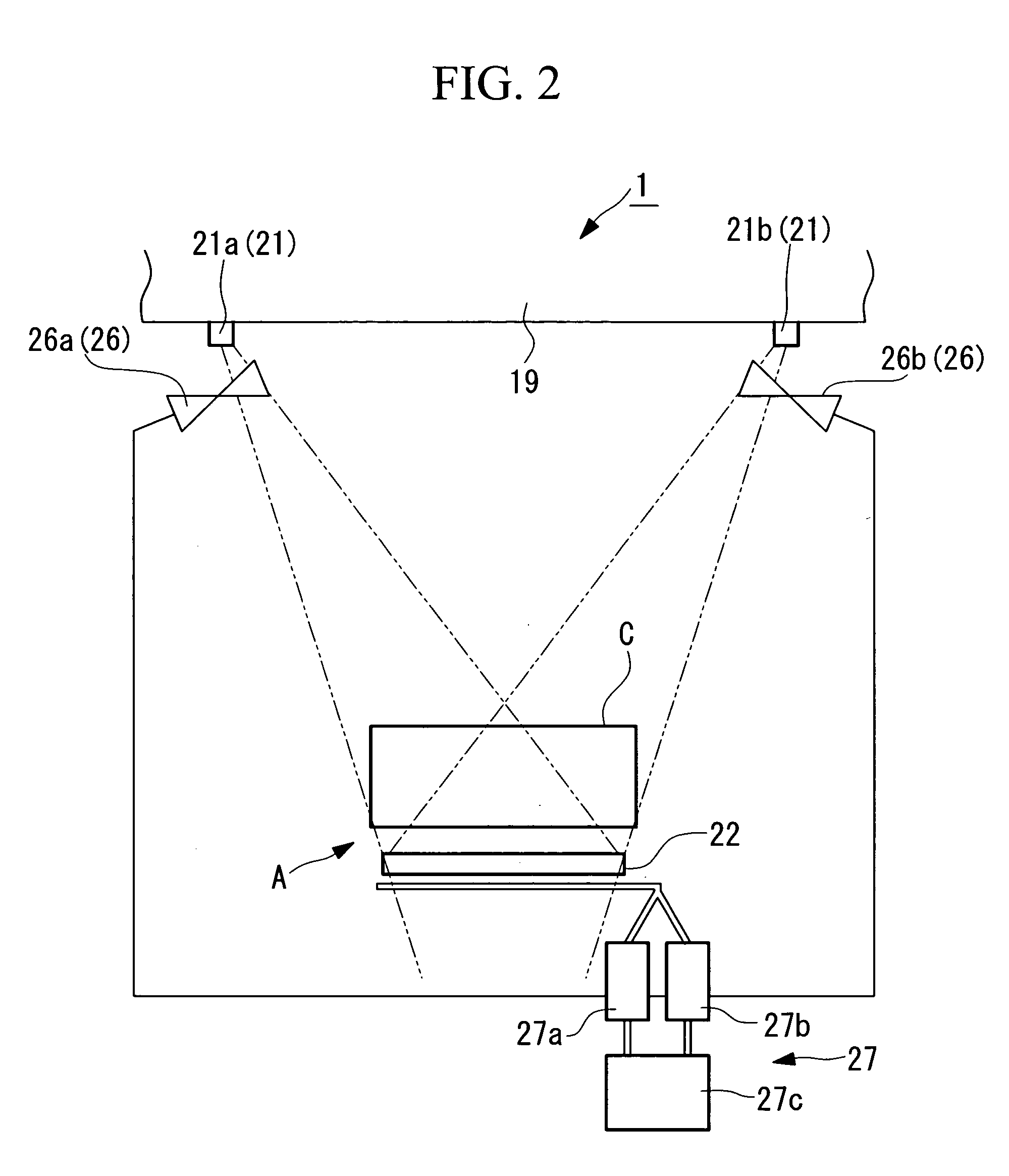

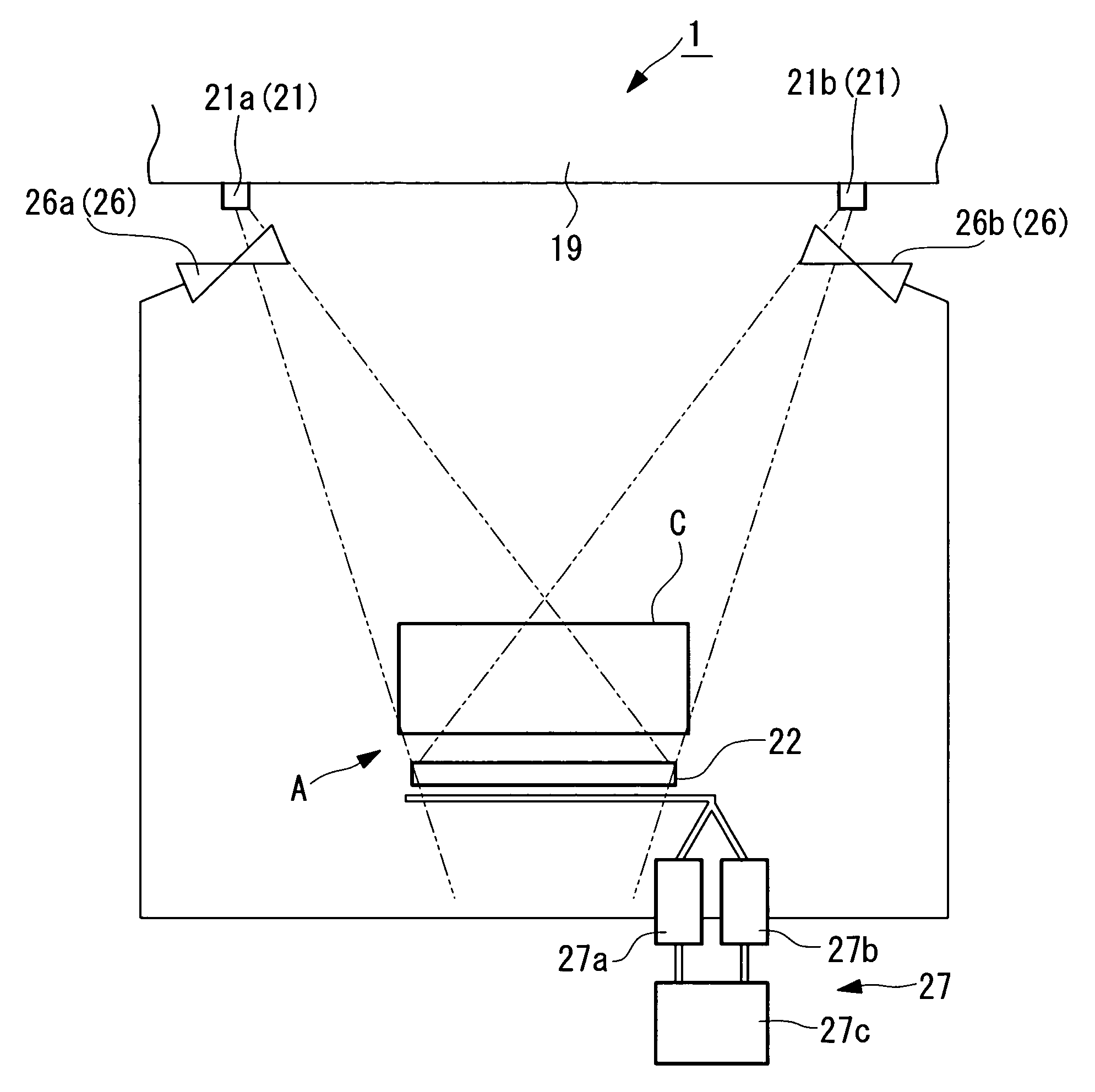

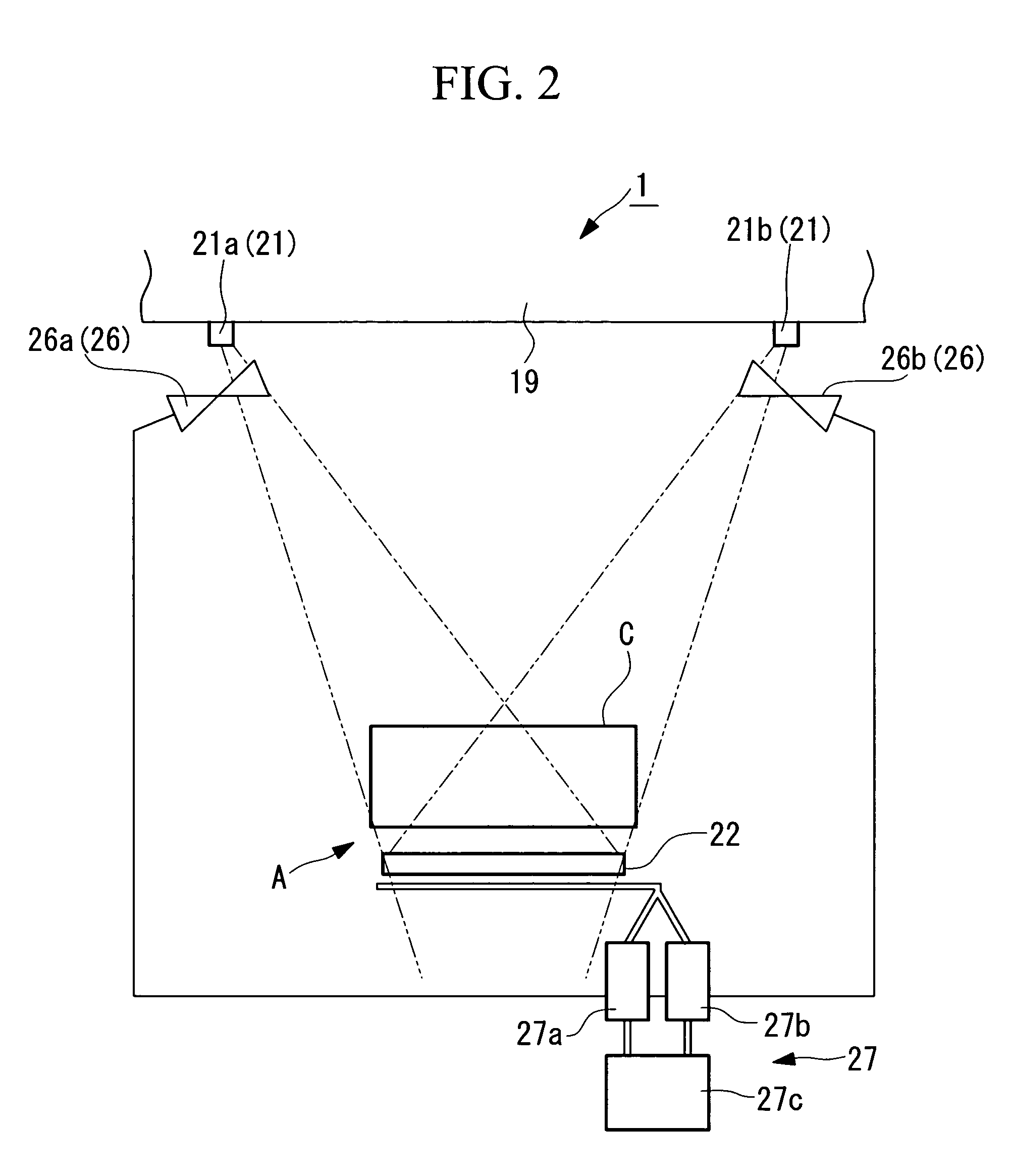

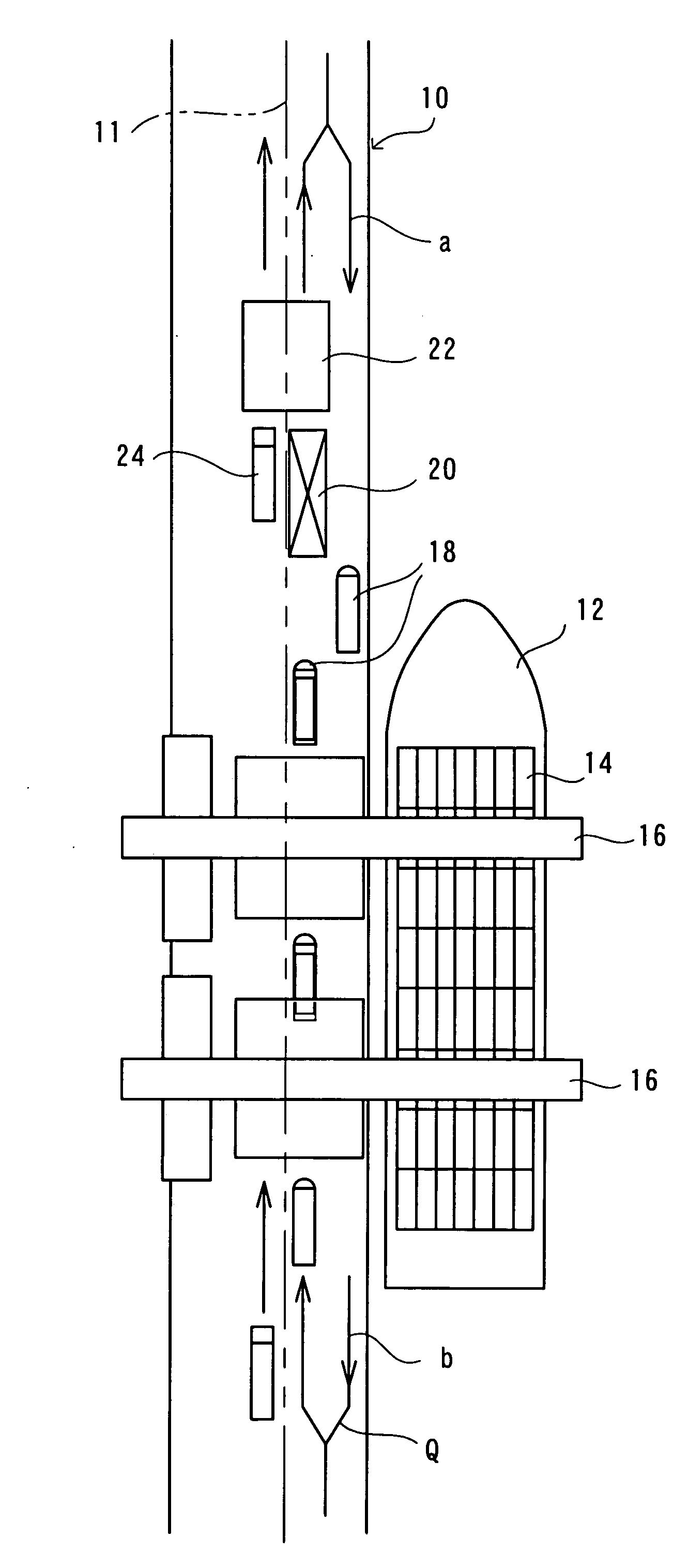

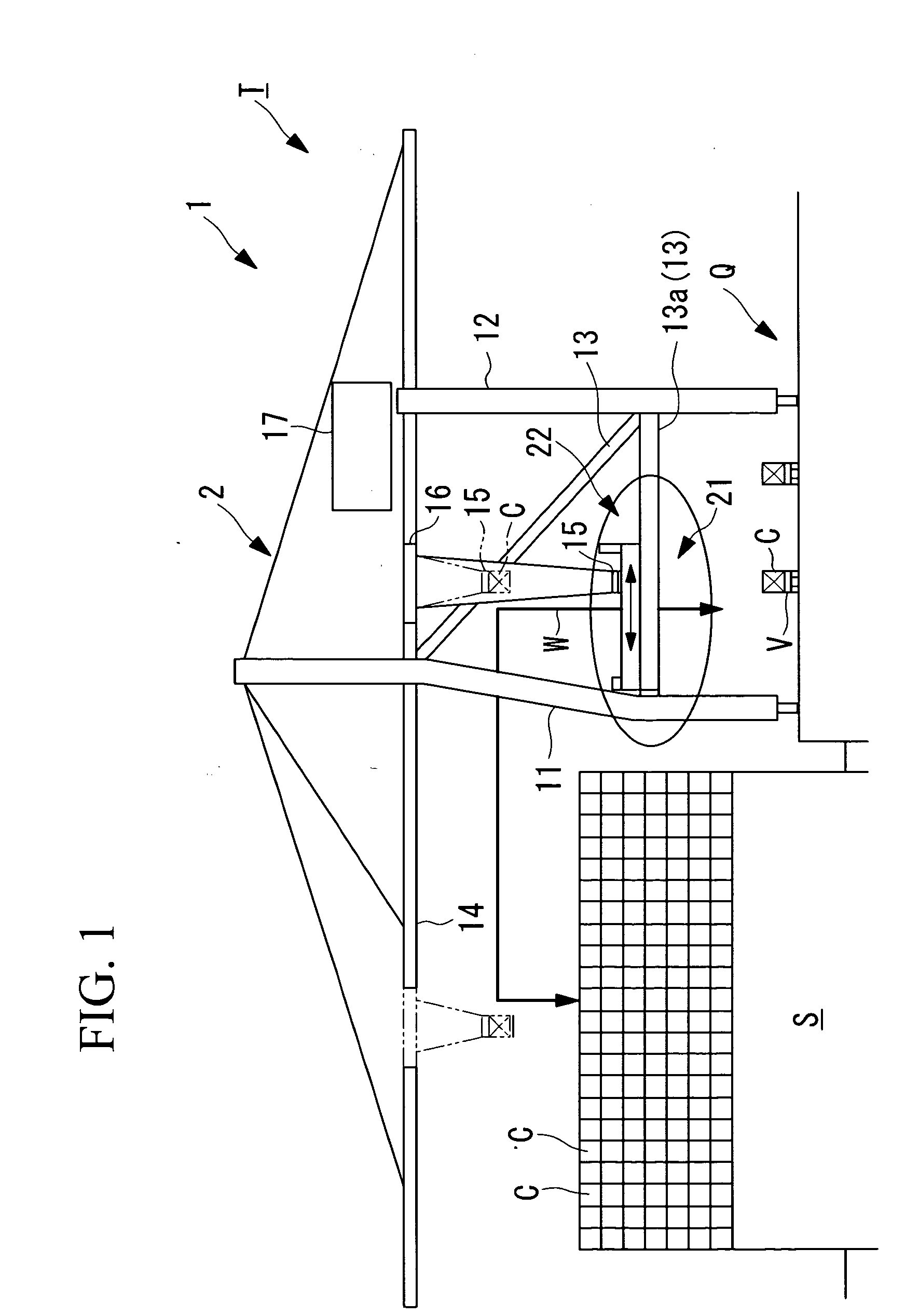

Nondestructive inspection device and crane equipped with nondestructive inspection device

InactiveUS20060027751A1Low equipment costMaterial analysis by optical meansMachines/enginesNon destructiveFluence

An object is to provide a nondestructive inspection device of a low equipment cost, and a crane equipped with the nondestructive inspection device. The nondestructive inspection device is provided for a quay crane, on a transporting route of the container. The nondestructive inspection device irradiates radiation from radiation sources to a container which has entered into an inspection area, and detects radiation that has transmitted through the container using the same detector, and nondestructively inspects the entire inside of the container based on information of intensity of the radiation and information of detection position of the radiation. The nondestructive inspection device is provided with; a modulation device which assigns different modulations to each radiation emitted from each of the radiation sources, and an identification device that distinguishes the modulation assigned to the radiation incident on the detector based on the output of the detector, and identifies which one of the radiation sources this radiation has been emitted from.

Owner:MITSUBISHI HEAVY IND LTD

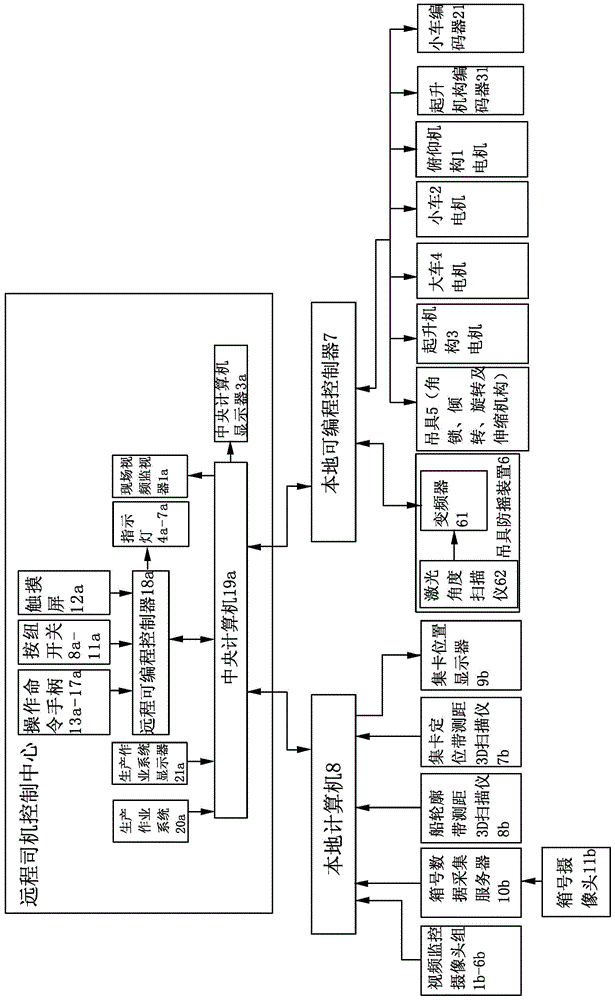

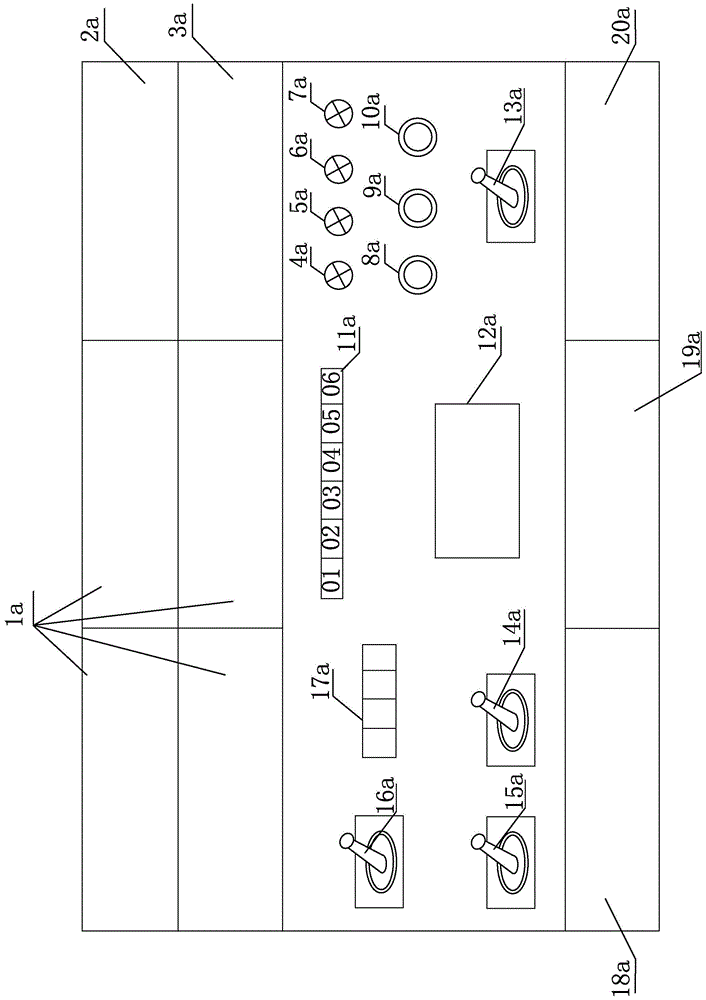

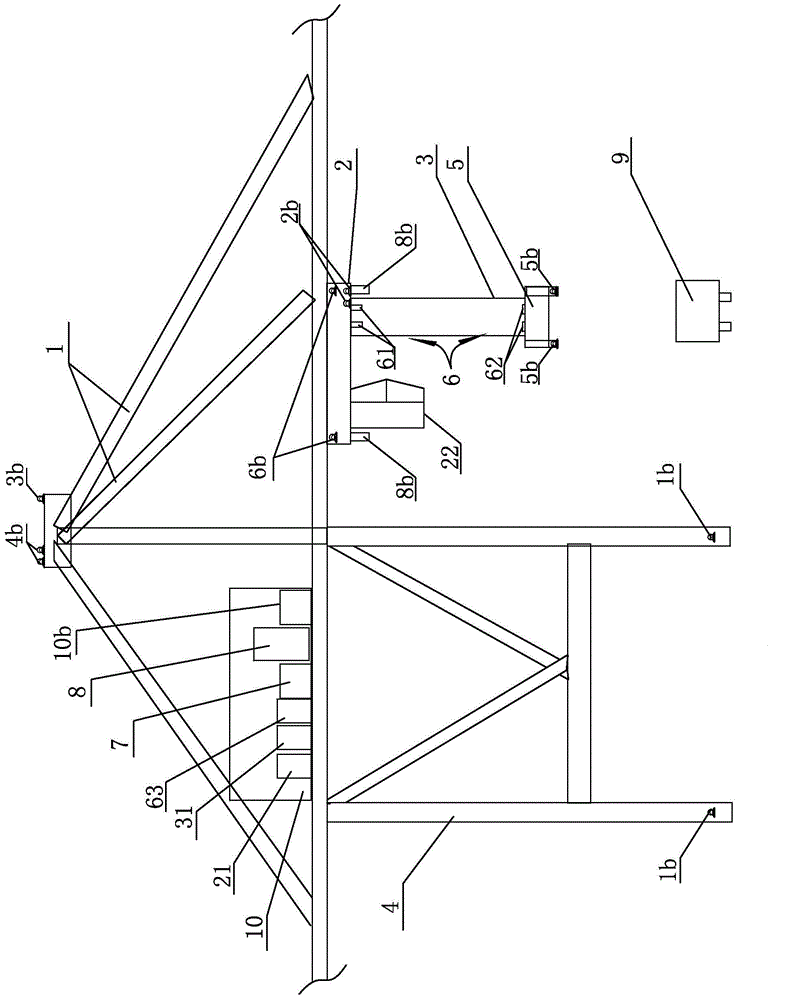

Quay crane loading and unloading operation remote-control operation system and operation method thereof

ActiveCN104649146AImprove working comfortReduce labor intensityTravelling cranesLoad-engaging elementsVideo monitoringRemote control

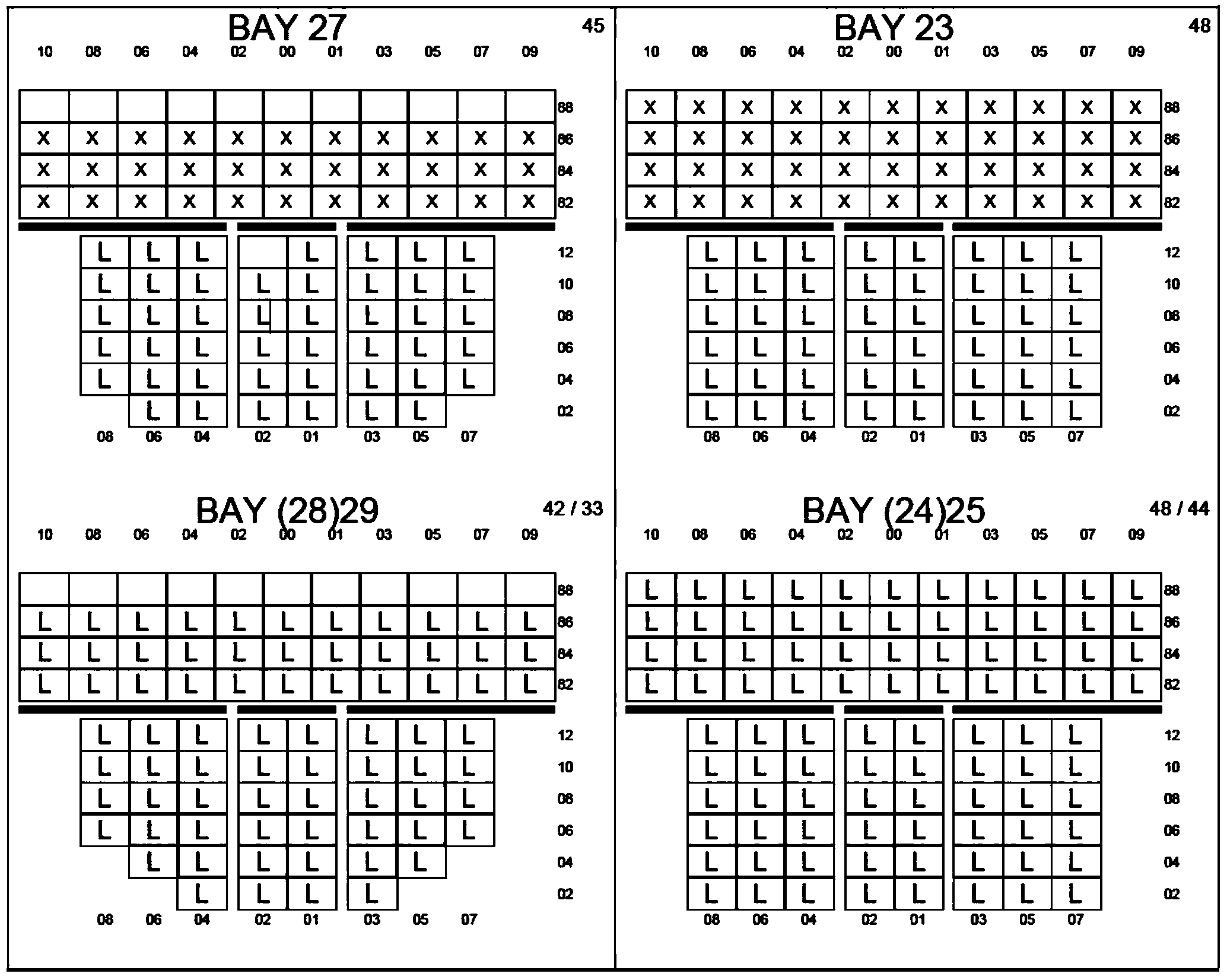

The invention relates to a quay crane loading and unloading operation remote-control operation system and operation method thereof. The operation system is characterized in that a remote driver controlling center is provided. The remote driver controlling center is provided internally with a central computer, a remote programmable controller, a central computer displayer, an operation command handle, a button switch and an on-site video monitor. The central computer is connected to the central computer displayer, a production and operation system, a production and operation displayer and the on-site video monitor and is also remotely connected to the local programmable controller and a local computer. The local computer is connected to a video monitoring camera, a container number data collector, a ship outline distance measuring 3D scanning instrument, a container truck positioning distance measuring 3D scanning instrument, and a container truck position displayer. The operation method includes following steps: (1) receiving a production operation system command, moving a cart to a bay position, flattening a pitching mechanism and scanning the outline of a ship by a trolley, (2) shipment: regulating the position of the trolley by a container truck driver, determining the container number, aligning and leveling a hoisting device, and performing shipment according to a best loading path; and (3) ship unloading: performing anti-shaking adjustment of the hoisting device, aligning and leveling the hoisting device and unloading the ship according to a best unloading path.

Owner:天津港太平洋国际集装箱码头有限公司

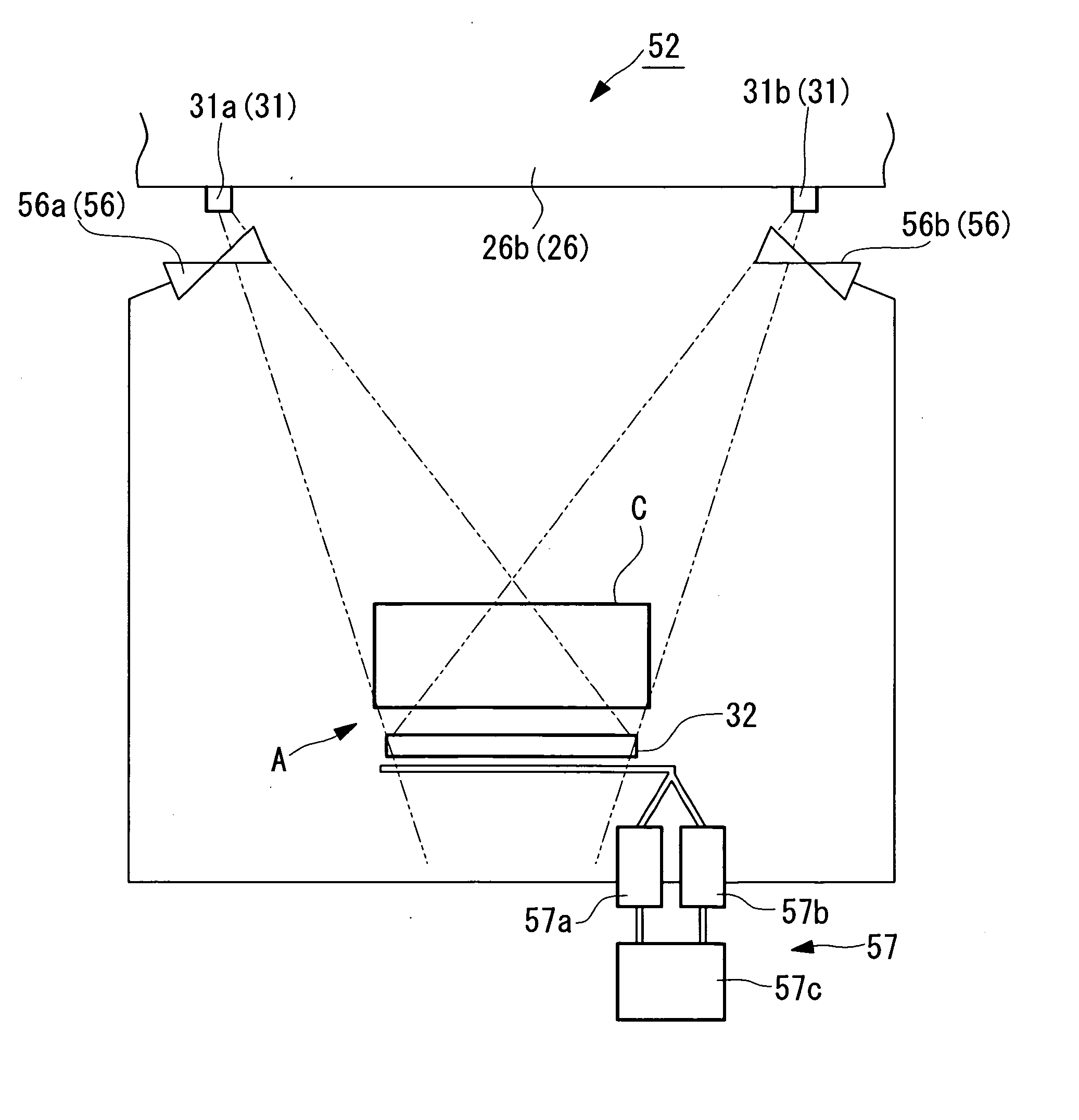

Nondestructive inspection device and crane equipped with nondestructive inspection device

InactiveUS7420174B2Low equipment costMaterial analysis by optical meansMachines/enginesNon destructiveIdentification device

An object is to provide a nondestructive inspection device of a low equipment cost, and a crane equipped with the nondestructive inspection device. The nondestructive inspection device is provided for a quay crane, on a transporting route of the container. The nondestructive inspection device irradiates radiation from radiation sources to a container which has entered into an inspection area, and detects radiation that has transmitted through the container using the same detector, and nondestructively inspects the entire inside of the container based on information of intensity of the radiation and information of detection position of the radiation. The nondestructive inspection device is provided with; a modulation device which assigns different modulations to each radiation emitted from each of the radiation sources, and an identification device that distinguishes the modulation assigned to the radiation incident on the detector based on the output of the detector, and identifies which one of the radiation sources this radiation has been emitted from.

Owner:MITSUBISHI HEAVY IND LTD

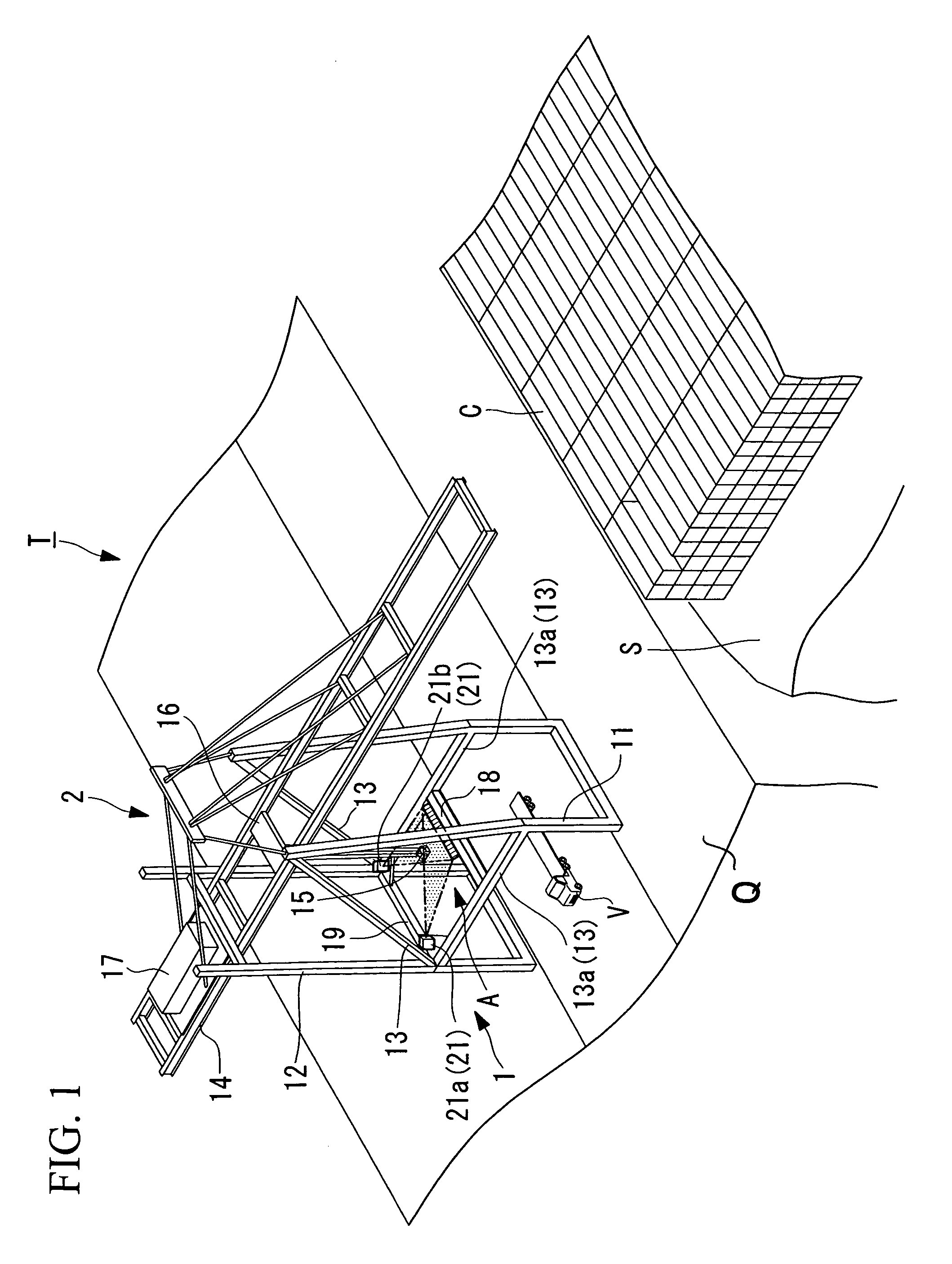

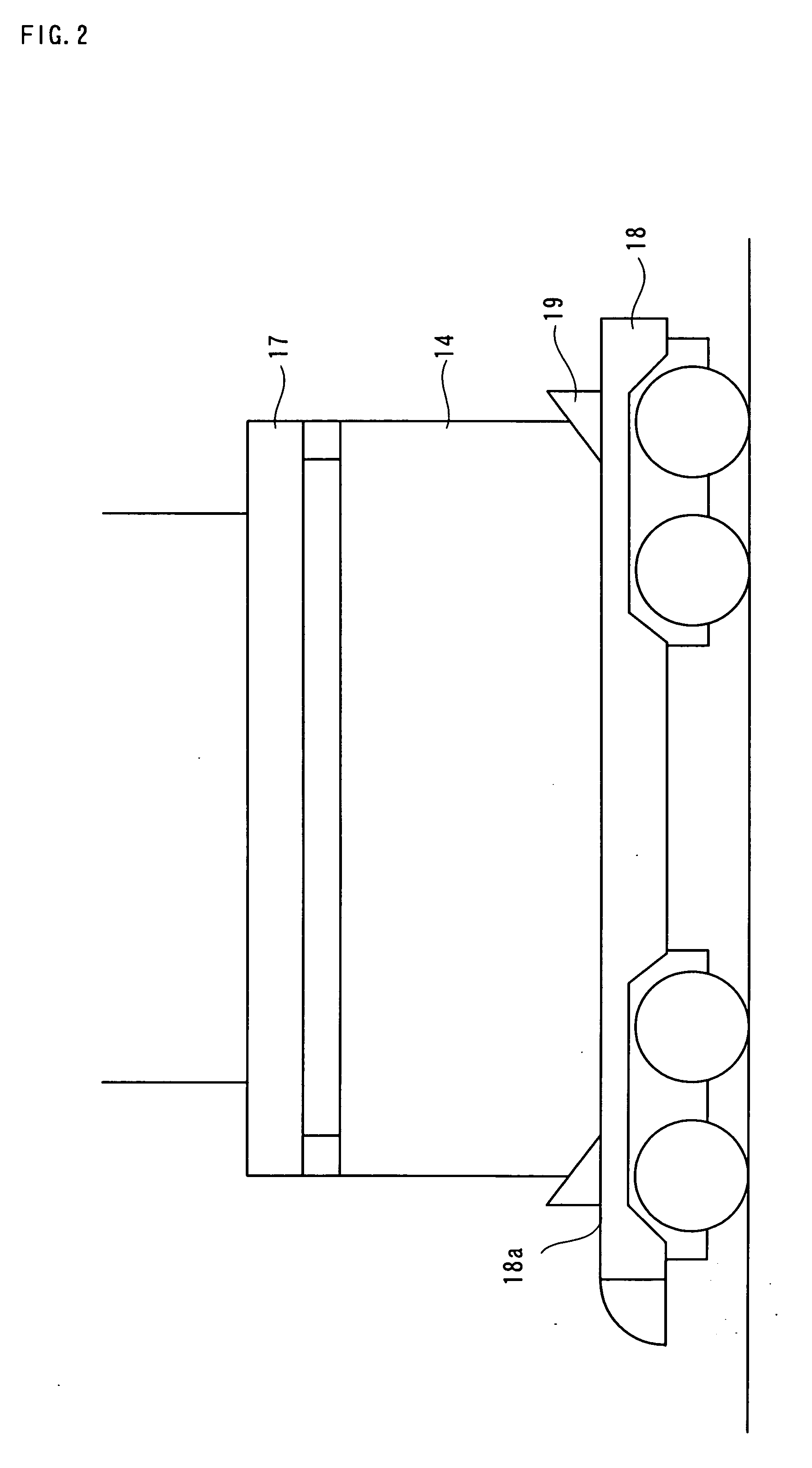

Container Inspection/Cargo-Handling Method and Container Inspection/Cargo-Handling System

InactiveUS20080025825A1Efficient container cargo inspectionEliminate wasteCargo handling apparatusPassenger handling apparatusAutomated guided vehicleHandling system

To provide a container inspection / cargo-handling system capable of efficiently inspecting import / export containers.In order to solve the aforesaid problem, a container inspection / cargo-handling system of the present invention includes an automated guided vehicle (AGV) 18 that travels in circulation in a quay area. Further, on a circulation travel line of the AGV 18, provided are a quay crane 16 loading / unloading a container 14 to / from the AGV 18, a radiation inspection device 20 inspecting a cargo in the container 14 loaded on the AGV 18, and a container transfer means 22 for transferring the container 14 between the AGV 18 and a manned transport vehicle (container transport vehicle) 24.

Owner:MITSUI E&S MACHINERY CO LTD

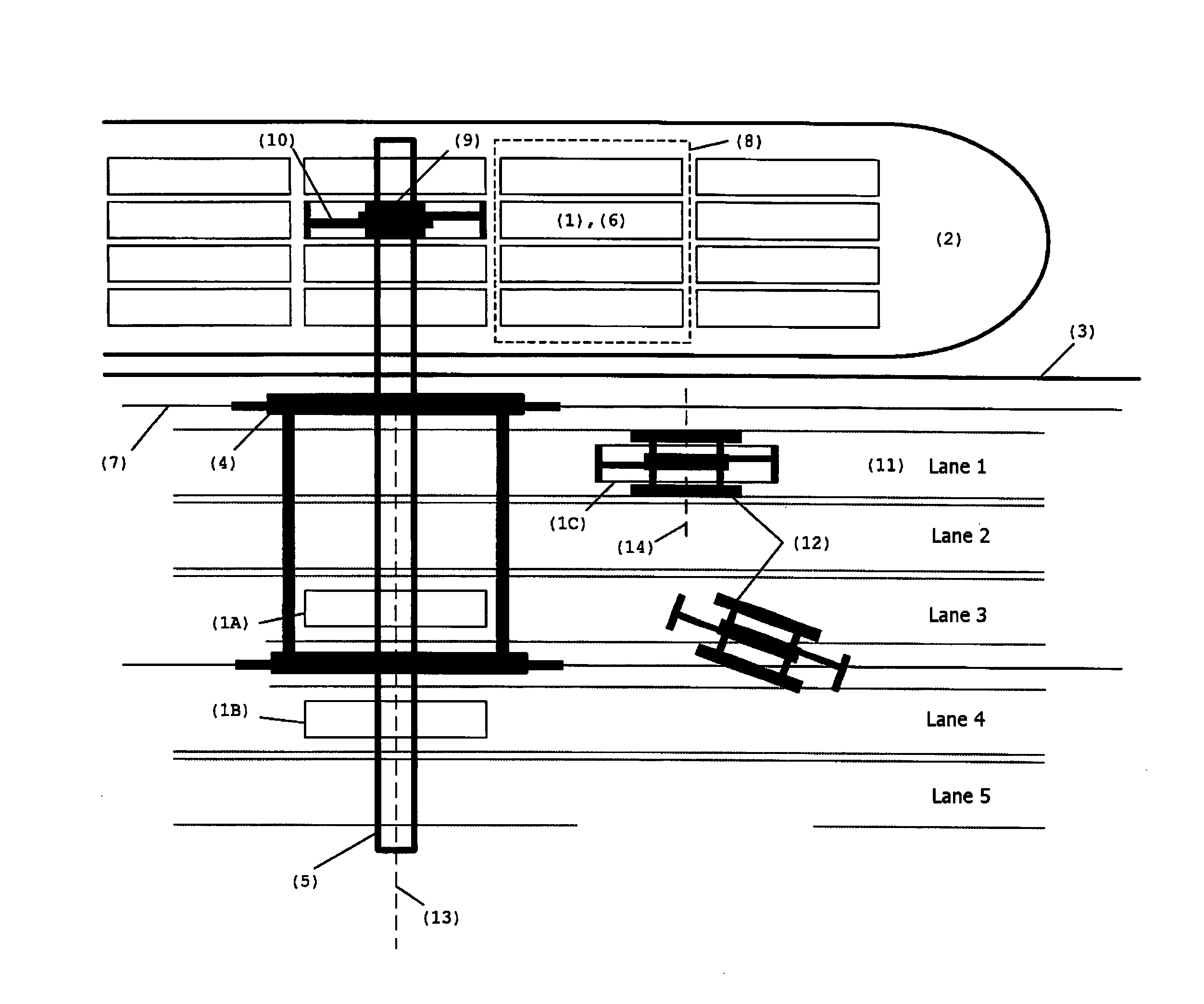

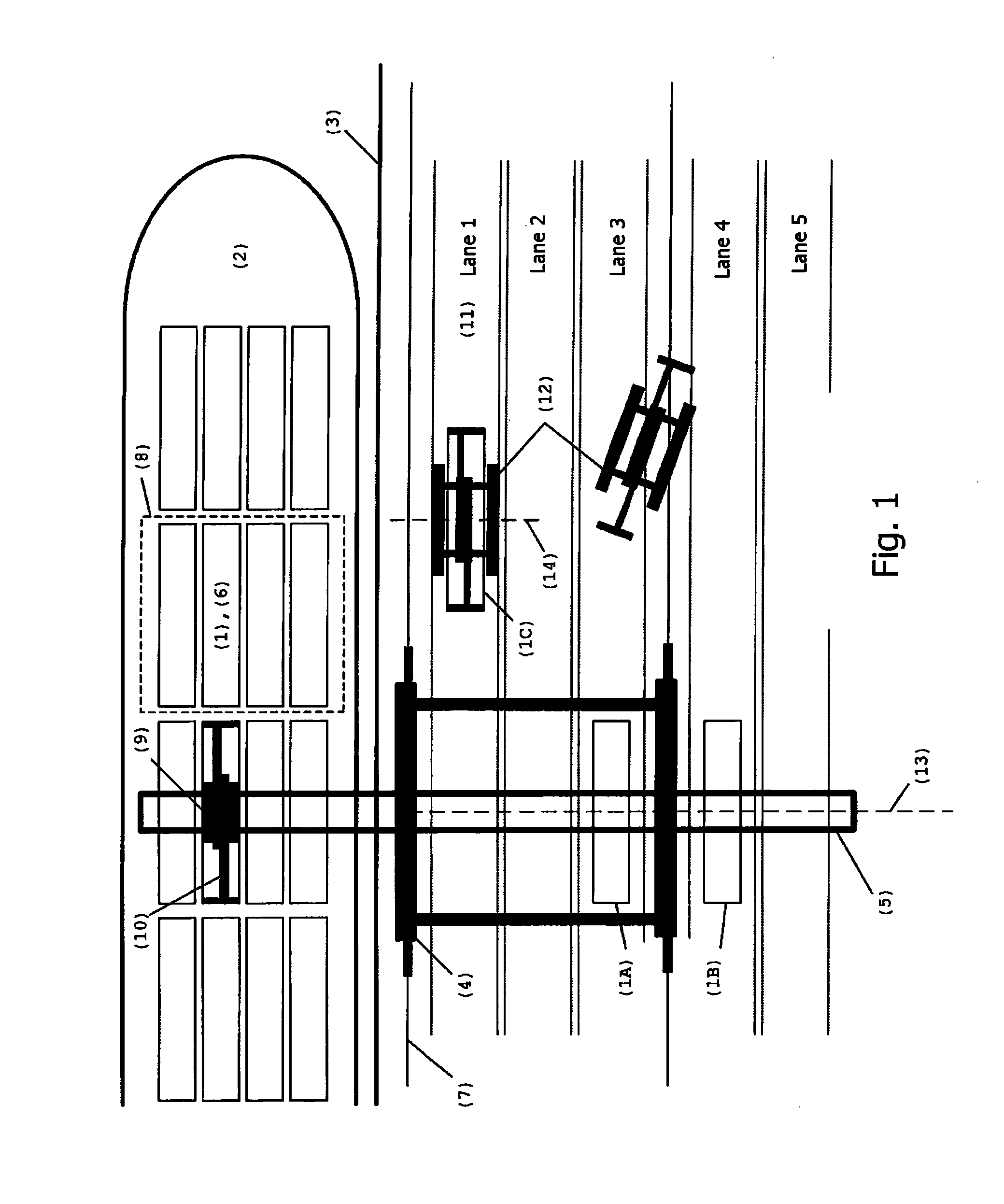

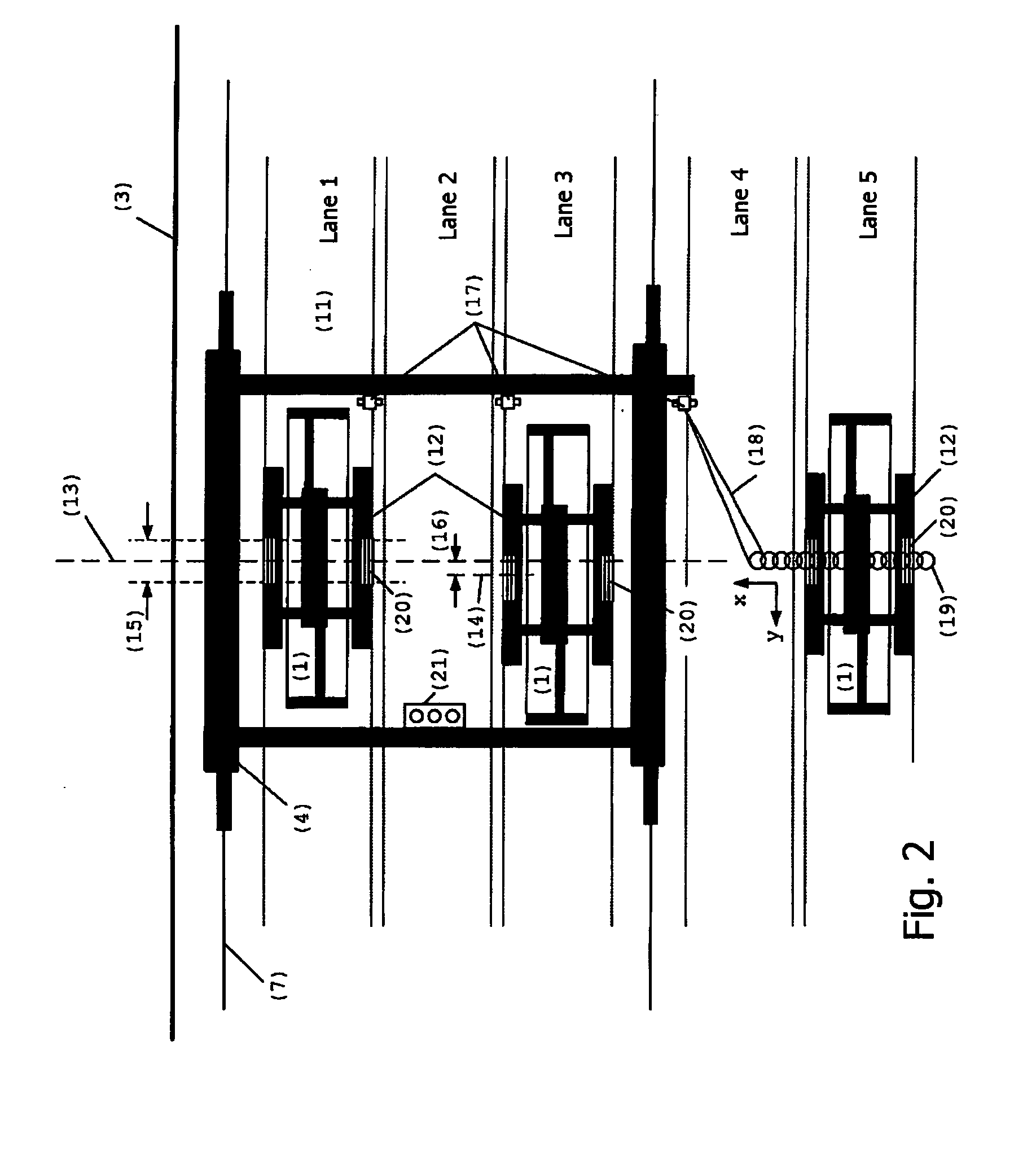

System for the identification and/or location determination of a container handling machine

ActiveUS20120092643A1Improve automationEasy to handleOptical rangefindersElectromagnetic wave reradiationDistance sensorsMechanical engineering

The invention relates to a system capable of determining in which lane a container handling machine is present below a quay crane or the like crane and / or capable of determining the correct location of a container handling machine in its driving direction (y) with respect to a quay crane or the like crane as containers are delivered to the crane or containers are retrieved from the crane by the container handling machine. The crane is fitted with at least one scanning laser distance sensor or the like range finder, and the container handling machines are fitted with one or more reflectors whose height profile is used for the determination of a correct location and / or for the identification of a container handling machine and for the distinction thereof from other container handling machines.

Owner:KONECRANES GLOBAL

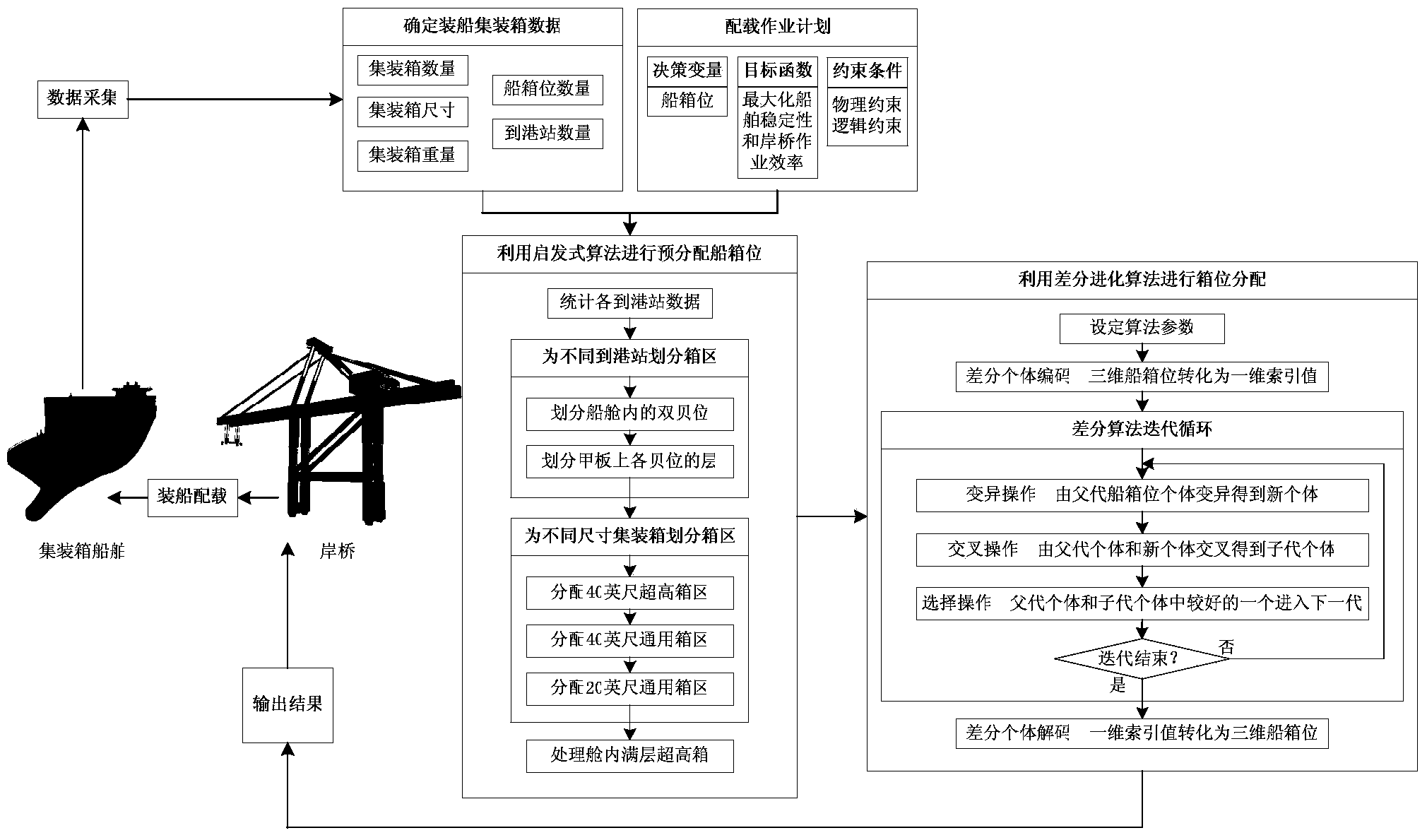

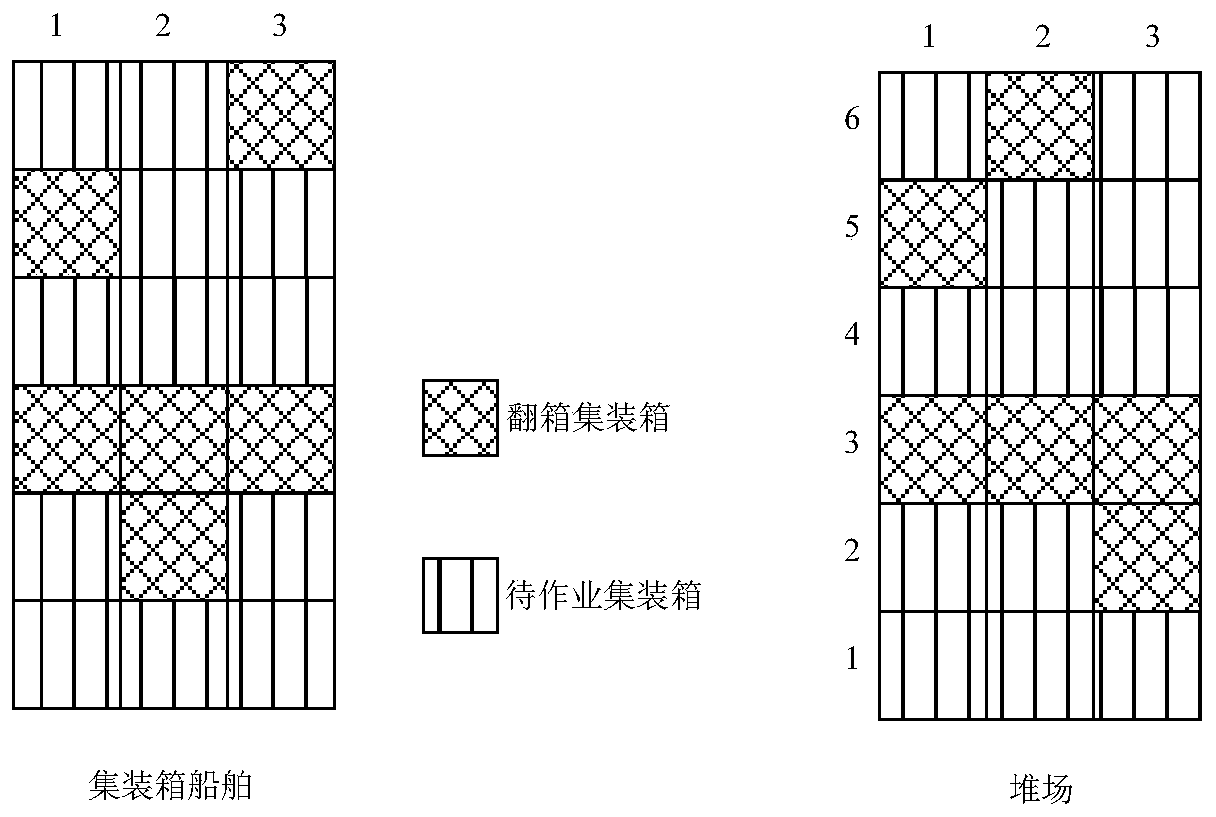

Cargo allocation method for improving quay crane operation efficiency and vessel stability of containers

The invention provides a cargo allocation method for improving quay crane operation efficiency and ship stability for containers. First, the quantity, size and weight of containers for shipment and departure, the quantity of the ship container positions and the destination port of the containers are determined; then, the decision variable of the ship container position for stacking each container is determined; an objective function of the ship stability and the constraint condition of the quay crane operation efficiency and the ship stability are established; the ship container positions are distributed in advance by utilizing a heuristic algorithm; the ship container position specifically for stacking each container is further determined, and the containers are loaded on a ship and allocated. The cargo allocation method is provided for solving the problems that the optimal stability and the least container loading and unloading frequency are difficult to be both considered according to an allocation schedule and long time is consumed in the making process, the constraint conditions needing to be met by making the cargo allocation schedule are fully considered, wherein the constraint conditions include ship performance, a ship structure, container types and sizes, port operation and the like. A container position distribution result is obtained with the aim of minimizing the ship stability deviation and the loading and unloading operation frequency in the ship unloading operation process.

Owner:NORTHEASTERN UNIV

Intelligent dispatching system and intelligent dispatching method of container trucks

ActiveCN103164782AImprove work efficiencyReduce operating costsCo-operative working arrangementsLogisticsComputer terminalTruck

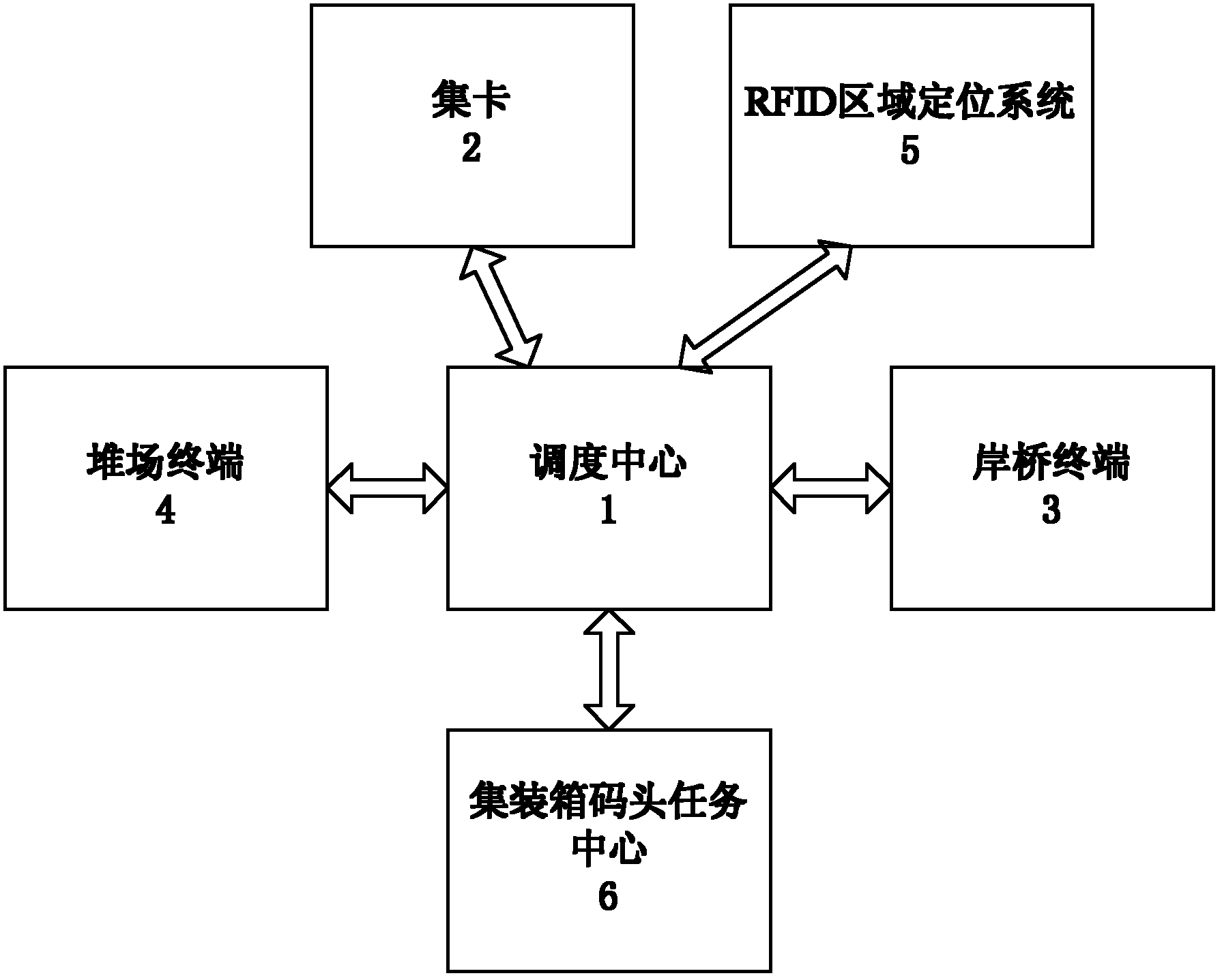

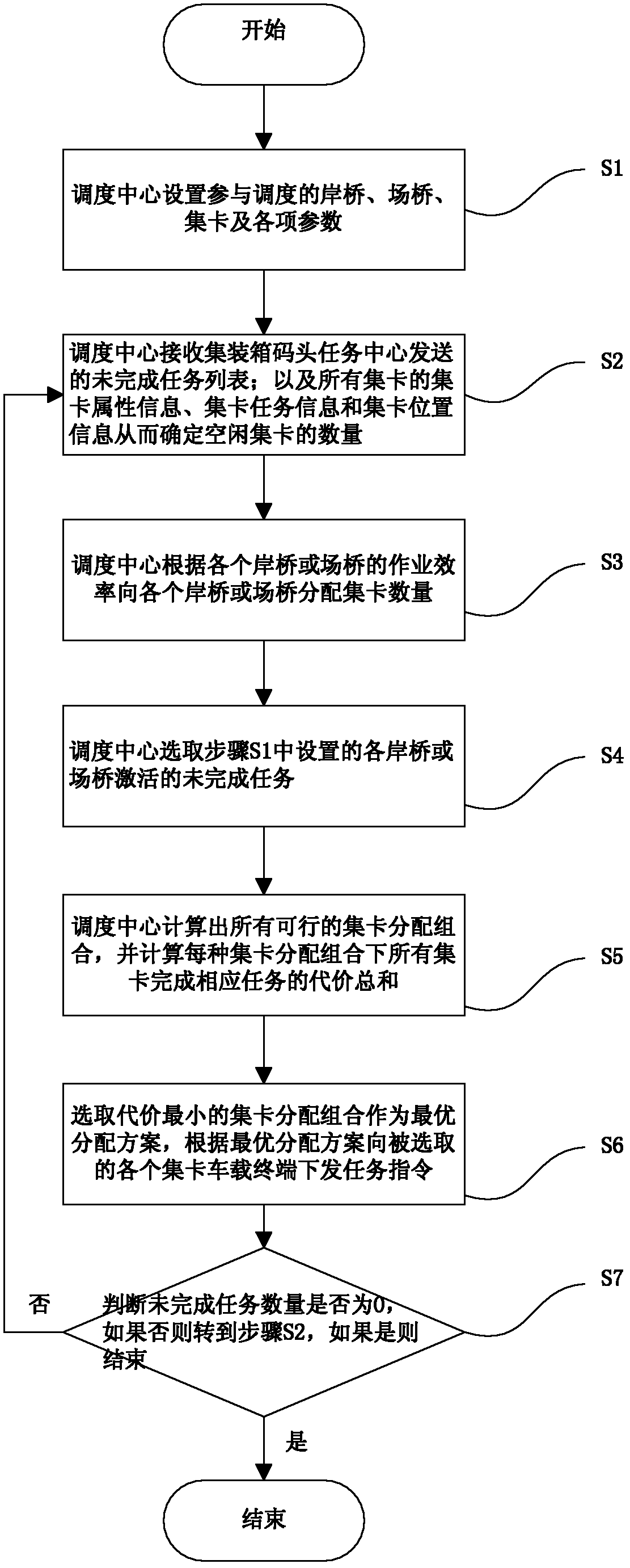

The invention relates to the dispatching field of container tucks and discloses an intelligent dispatching system and an intelligent dispatching method of the container trucks. The dispatching system comprises a dispatching center (1), a container wharf task center (6) communicated with the dispatching center (1), the container trucks (2), a quay crane terminal (3), a field crane terminal (4), a radio frequency identification device (RFID) regional positioning system (5) composed of a plurality of RFID readers distributed in places of a wharf. The dispatching center (1) acquires properties and position information of all container trucks and information of tasks to be finished uploaded by the container wharf task center (6). The container trucks (2) is distributed in number according to operation efficiency of all quay cranes and all field cranes, then, the total cost, of the tasks to be finished, of all feasible distribution schemes is calculated, and finally a scheme with smallest cost is chosen to be executed. The intelligent dispatching system and the intelligent dispatching method of the container trucks can improve wharf operation efficiency, reduce wharf operation cost, improve the utilization rate of equipment, reduce inefficient waiting-around of operation equipment, and reduce no-load ratio and energy consumption of the container trucks.

Owner:CHINA MERCHANTS HLDG INT INFORMATION TECH COMPANY

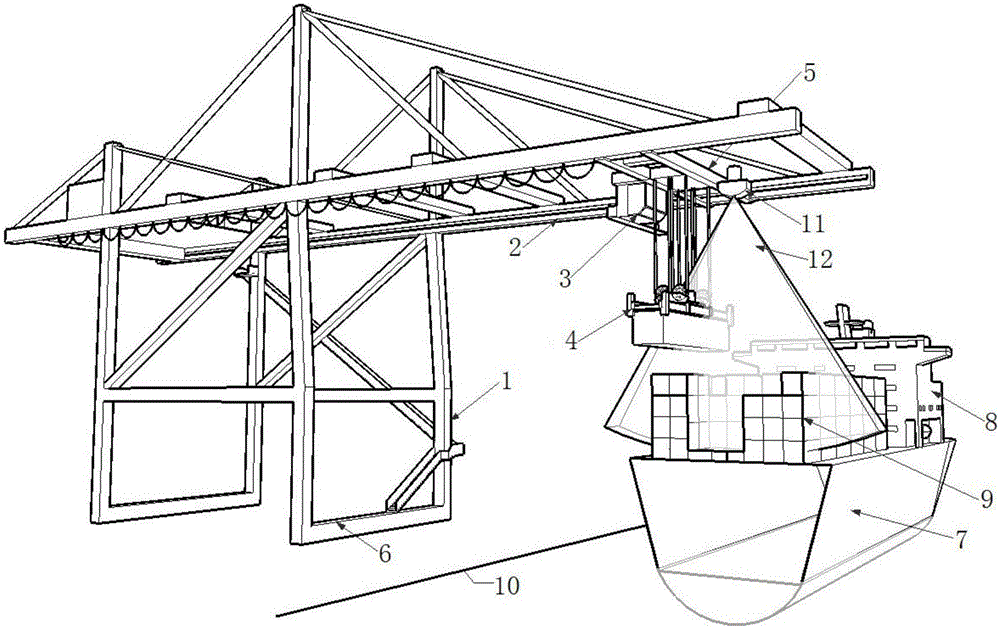

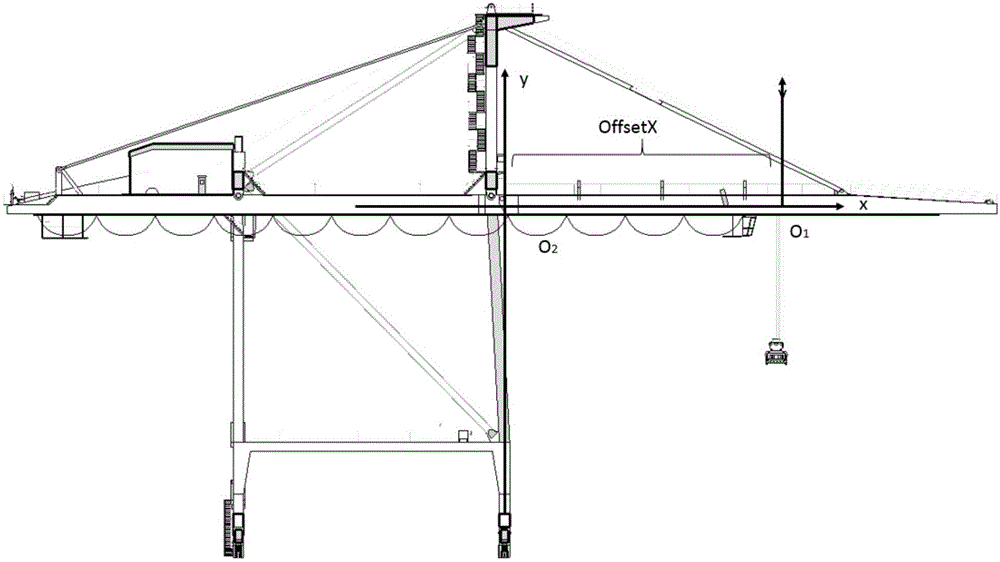

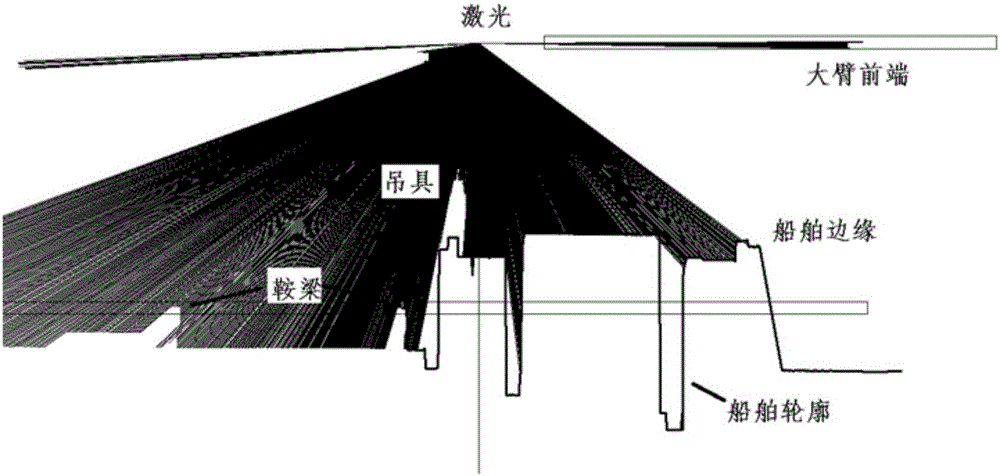

System for profile identification of ship under container terminal quay crane and anti-collision of lifting sling and method for profile identification of ship under container terminal quay crane

The invention discloses a system for profile identification of a ship under a container terminal quay crane and anti-collision of a lifting sling and a method for profile identification of the ship under the container terminal quay crane. The system comprises a controller, and a quay crane PLC control system, a laser scanner and a display or a warning device which are connected with the controller. Compared with the prior art, the system has the positive effects that a conventional ship profile scanning system is improved, a ship profile is integrally scanned through adopting the laser scanner, and the shipment location error caused by human error of a director or a driver is prevented through recognizing positions of rows and the lifting sling on the ship; the dangerous conditions that the ship shakes and is away from a wharf can be monitored and alarmed; and the cost is reduced through adopting a newest laser scanner product.

Owner:CATHAY NEBULA SCI & TECH CO LTD

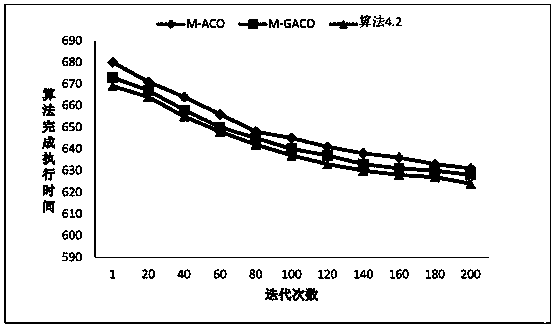

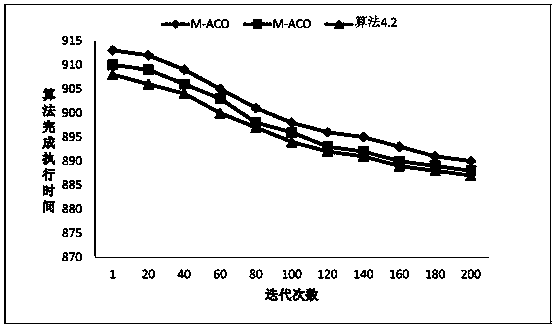

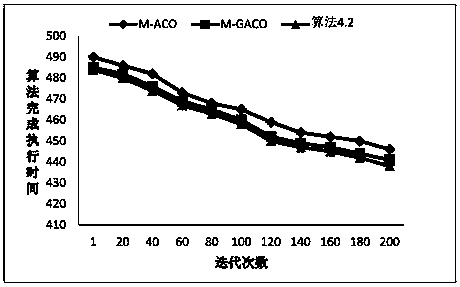

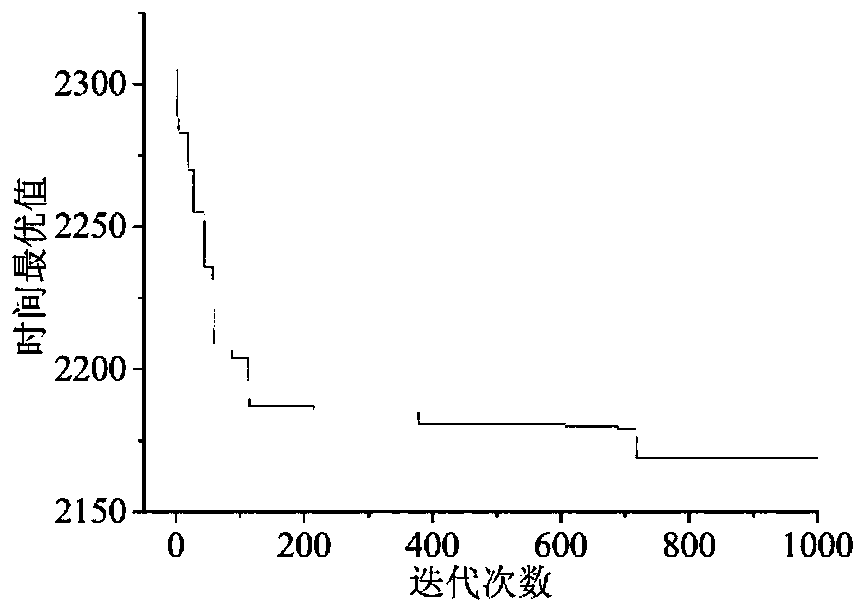

Multi-object quay crane-berth scheduling optimization method based on ant colony algorithm

InactiveCN107330561AFacilitate communicationSolveForecastingArtificial lifeParallel computingPareto optimal

The invention discloses a multi-object quay crane-berth scheduling optimization method based on the ant colony algorithm, and belongs to the port scheduling field. For a multi-object quay crane-berth scheduling model brought forward in the application, two algorithms for solving the model are brought forward on the basis of the ant colony algorithm. Scheduling optimization for containers and ships arriving at a port can be performed through the algorithms, and then algorithm execution efficiency is improved, so a Pareto optimal solution needed by us can be got in a short time, port operation efficiency is improved then, port operation cost can be saved, and the method is of great significance to prompting regional and national economic development; and, finally, the algorithms brought forward in the application are verified through simulation experiments, the algorithms and other algorithm are compared on two aspects of convergence and algorithm execution time in the experiments, and superiority of the algorithms of the application is verified in the experiments.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

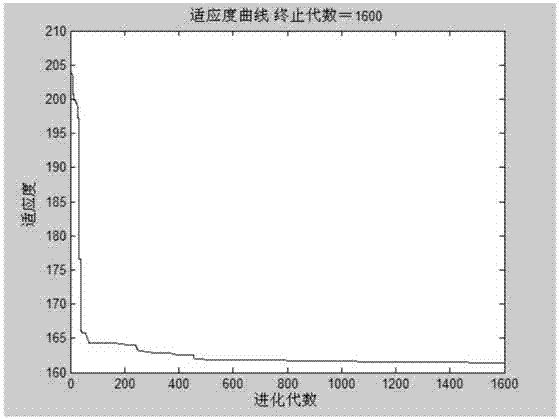

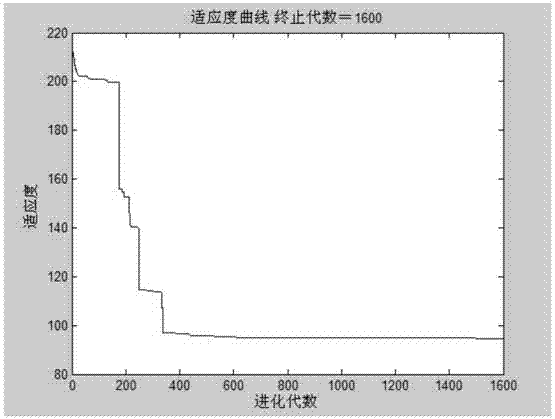

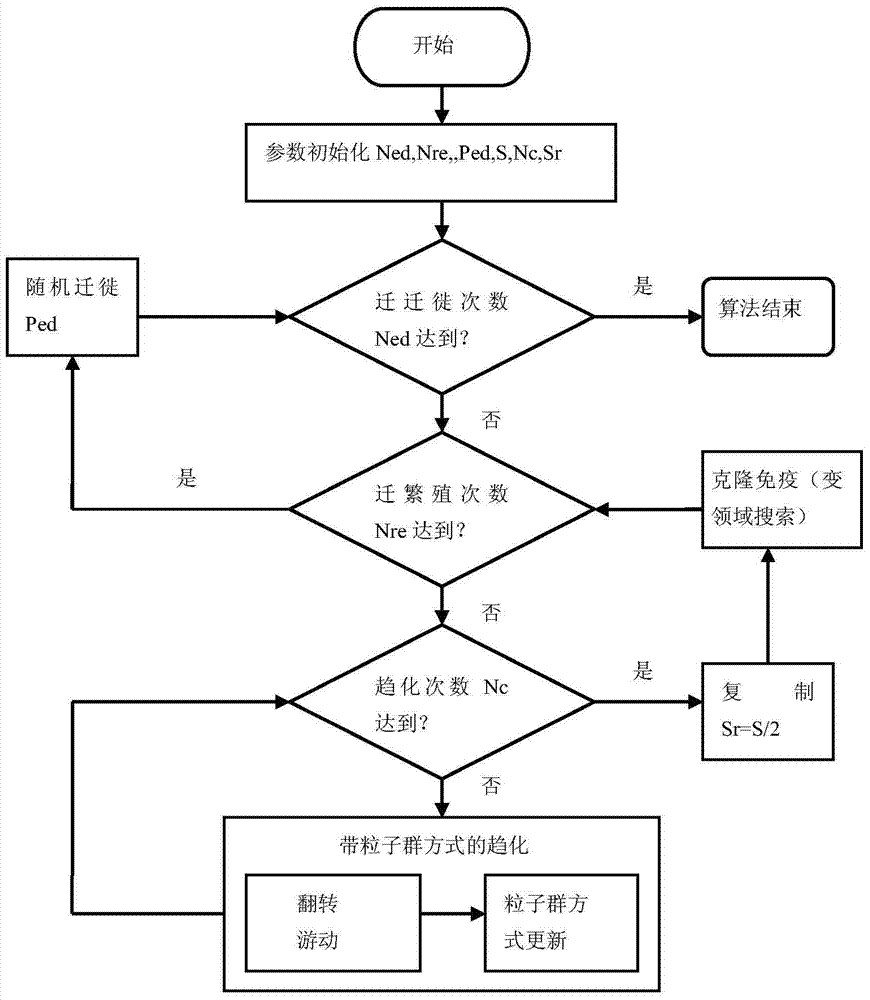

Container quay berth and quay crane distribution method based on bacterial foraging optimization method

InactiveCN103530709AImprove efficiencyShorten the timeGenetic modelsForecastingBacteria foraging algorithmParticle swarm algorithm

The invention discloses a container quay berth and quay crane distribution method based on a bacterial foraging optimization method. The method comprises the following steps: initializing and defining a solution space; defining a fitness function; randomly initializing the position and the speed of bacteria and selecting out the local and global optimal positions; allowing the bacteria to move in the solution space and performing chemotaxis circulation; after the chemotaxis times reach the set times, reproducing a certain proportion of individuals with high adaptive value to replace individuals with low adaptive value; performing cloning immunization on the individuals after reproduction; after the reproduction times reach the set times, performing individual migration; circulating. The invention has the benefits that the method is different from other single methods, is a new mixed algorithm combining a bacterial foraging algorithm, a particle swarm optimization, a cloning immunization algorithm and a variable field searching method, and has the advantages of the four algorithms. Through the adoption of the method, the efficiency of a wharf can be improved, resources are distributed reasonably, the congestion phenomenon is avoided, the information transfer time is shortened and the error rate of operation is reduced.

Owner:SHANGHAI MARITIME UNIVERSITY

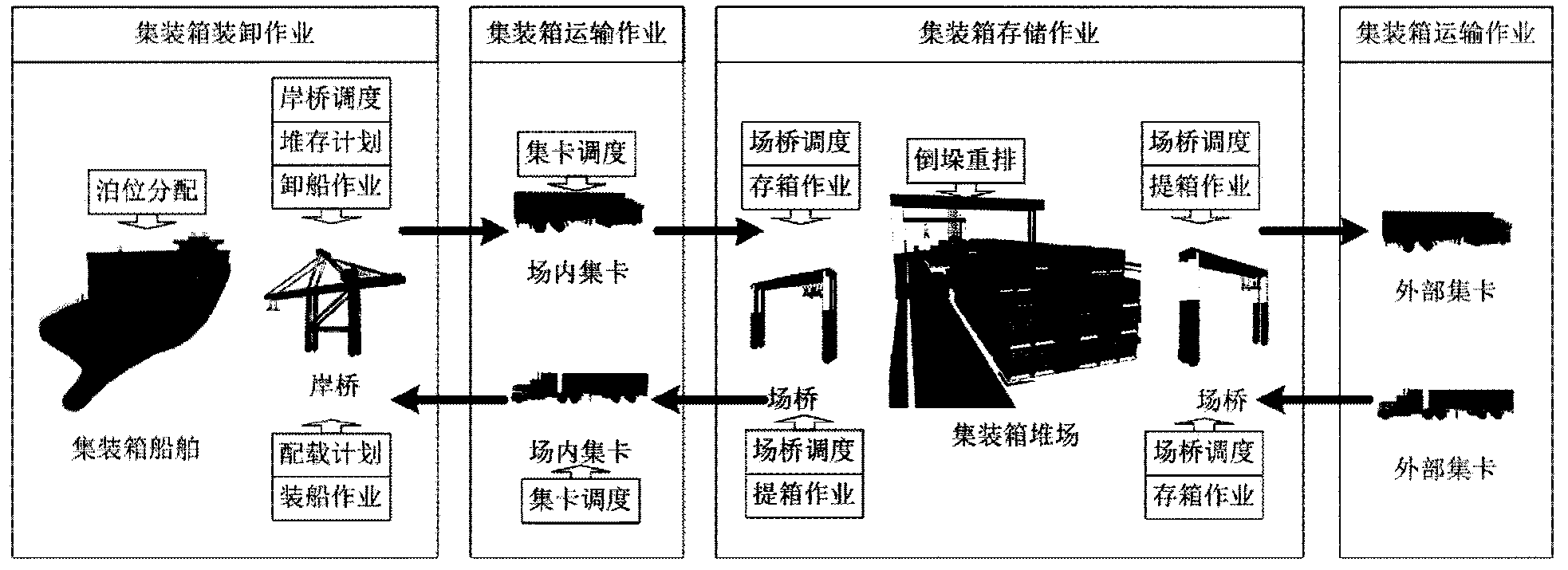

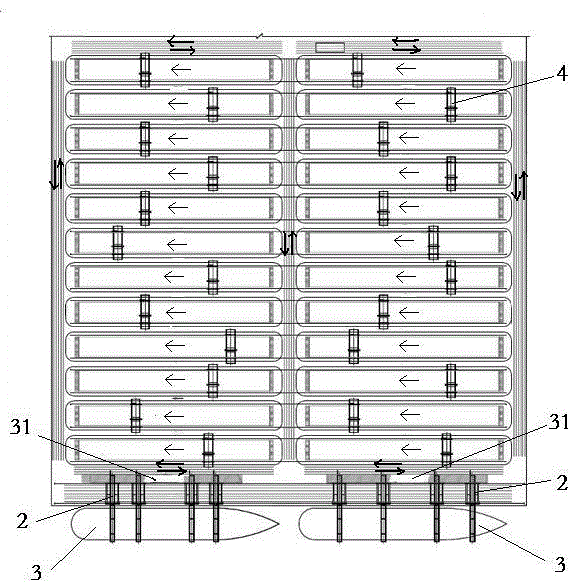

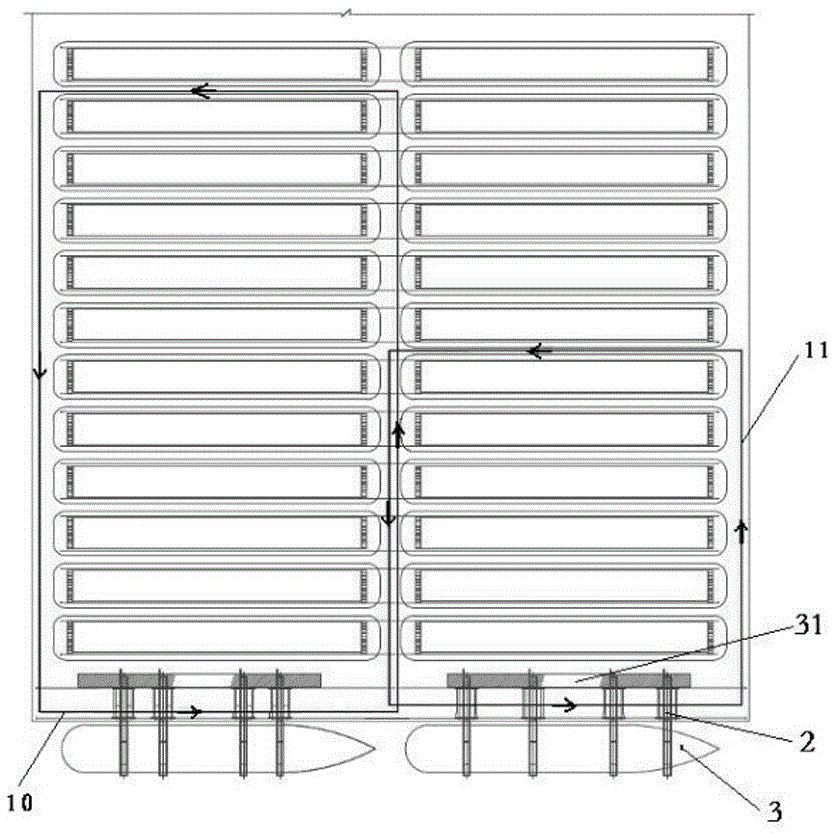

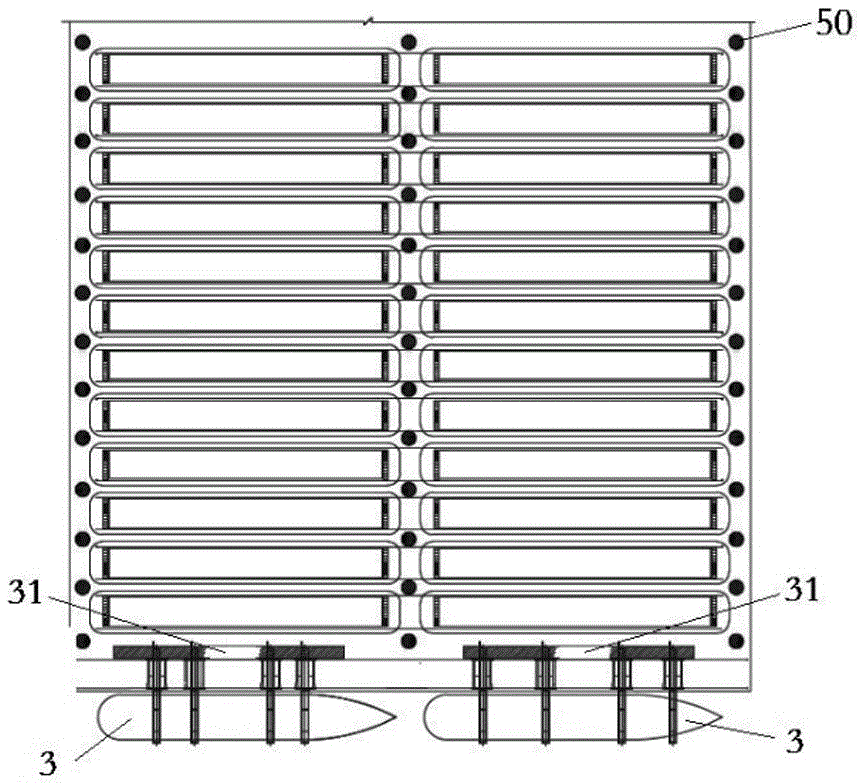

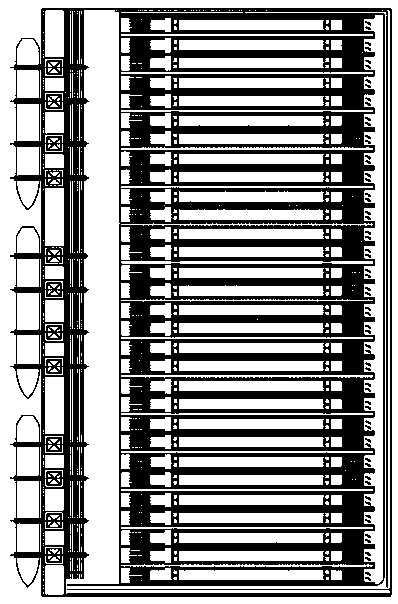

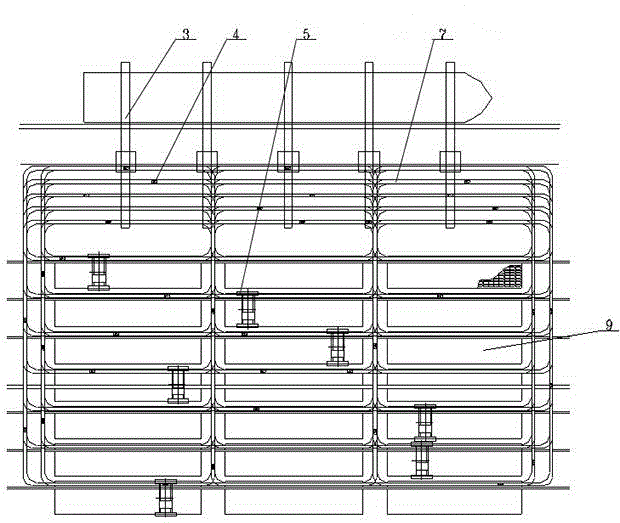

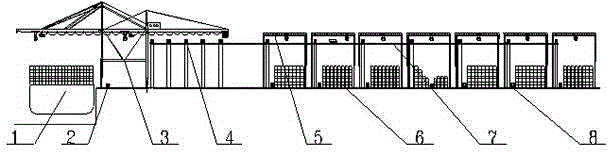

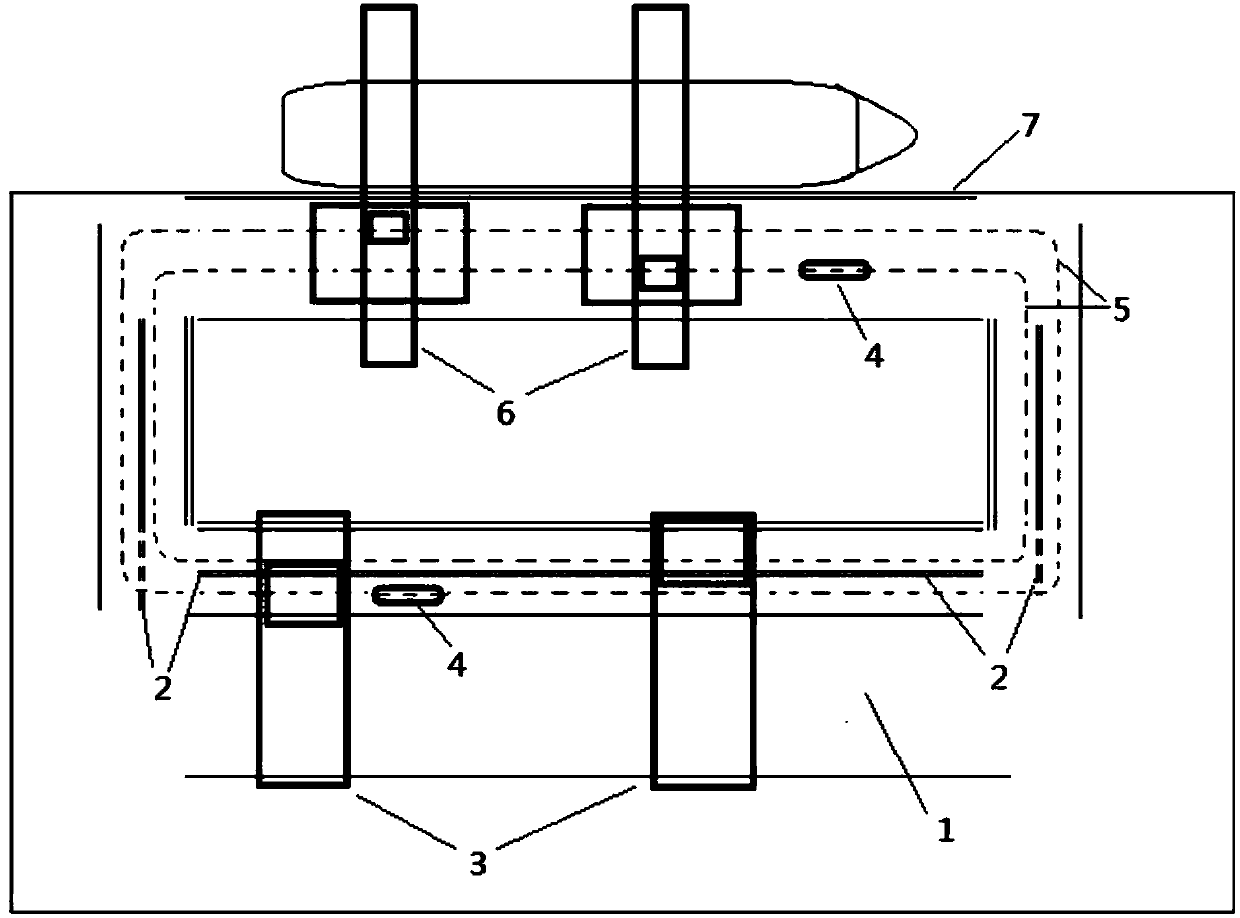

Automatic container wharf loading and unloading system and method for yard

InactiveCN105621122AIncreased tank capacityImprove service levelLoading/unloadingEngineeringFront edge

The invention discloses an automatic container wharf loading and unloading system for a yard. The automatic container wharf loading and unloading system comprises quay cranes, trucks and yard single-cantilever rail-mounted gantry cranes, wherein the yard single-cantilever rail-mounted gantry cranes are automatically controlled. The quay cranes are used for perpendicularly and horizontally transporting containers from a container ship to a shore side operation area. The quay cranes are arranged on the front edge of a berth, and rails of the quay cranes are parallel to the direction of a berth shoreline. A hatchway cover of the container ship is unloaded into the rails of the quay cranes from a deck of the container ship. Truck loading and unloading lanes used for conducting ship loading and unloading operation are arranged behind quay crane landside rails. The trucks are used for horizontally transporting the containers in a harbor. The single-cantilever rail-mounted gantry cranes are used for perpendicularly or horizontally transporting the containers from the quay cranes to the yard. The invention further discloses an automatic container wharf loading and unloading method for the yard. The container capacity of the container yard in the harbor is increased to a certain degree, the road service level in the harbor is effectively improved, the truck transporting distance used for the ship loading and unloading operation is effectively shortened, and the loading and unloading efficiency and the energy-saving level of the whole system are improved.

Owner:CCCC THIRD HARBOR CONSULTANTS

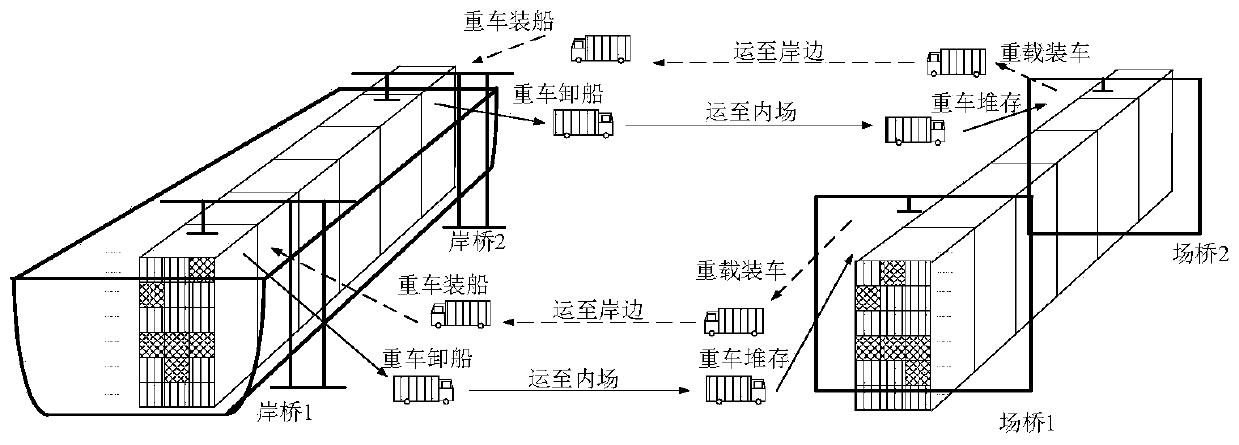

Wharf shore bridge and field bridge collaborative optimization scheduling method

ActiveCN109784547AHigh utilization rate of loading and unloading operationsReduce operating costsGenetic modelsForecastingMathematical modelMinimum time

The invention discloses a wharf shore bridge and field bridge collaborative optimization scheduling method. The method comprises the following steps: carrying out pretreatment; defining the shore bridge and the field bridge as scheduling objects; a container stack is used as a minimum loading and unloading unit; combining the ship date table and the position of the container in the ship and the storage yard; the minimum time spent on loading and unloading of all containers on a ship and the short moving distance between a quay crane and a field bridge are taken as targets for scheduling of thequay crane and the field bridge, a mathematical model of synchronous loading and unloading operation of the import and export containers is constructed, and an optimal quay crane and field bridge scheduling scheme under a given import and export container loading and unloading task is obtained. According to the wharf quay crane and field bridge optimization scheduling method, the entropy evaluation system is designed, the improved genetic algorithm based on the entropy matching principle is designed, the solving capability of the algorithm is greatly improved, and the cooperative scheduling capability of the quay crane and the field bridge is improved.

Owner:ZHEJIANG UNIV OF TECH

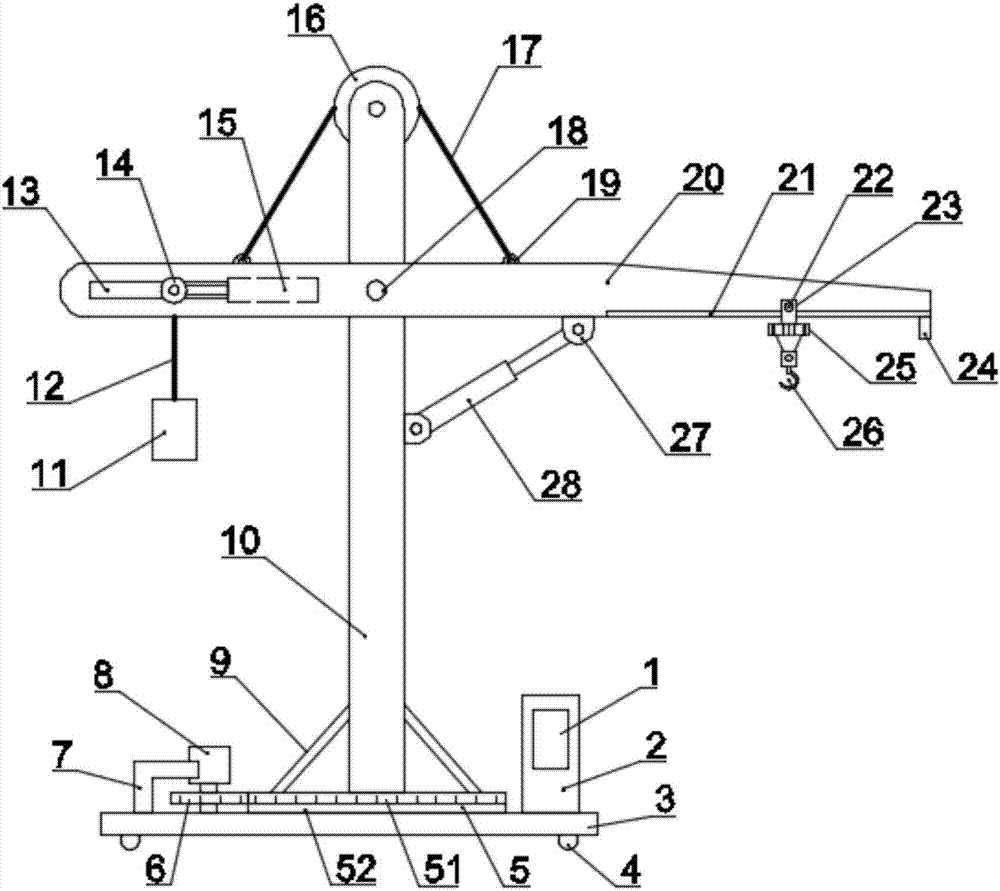

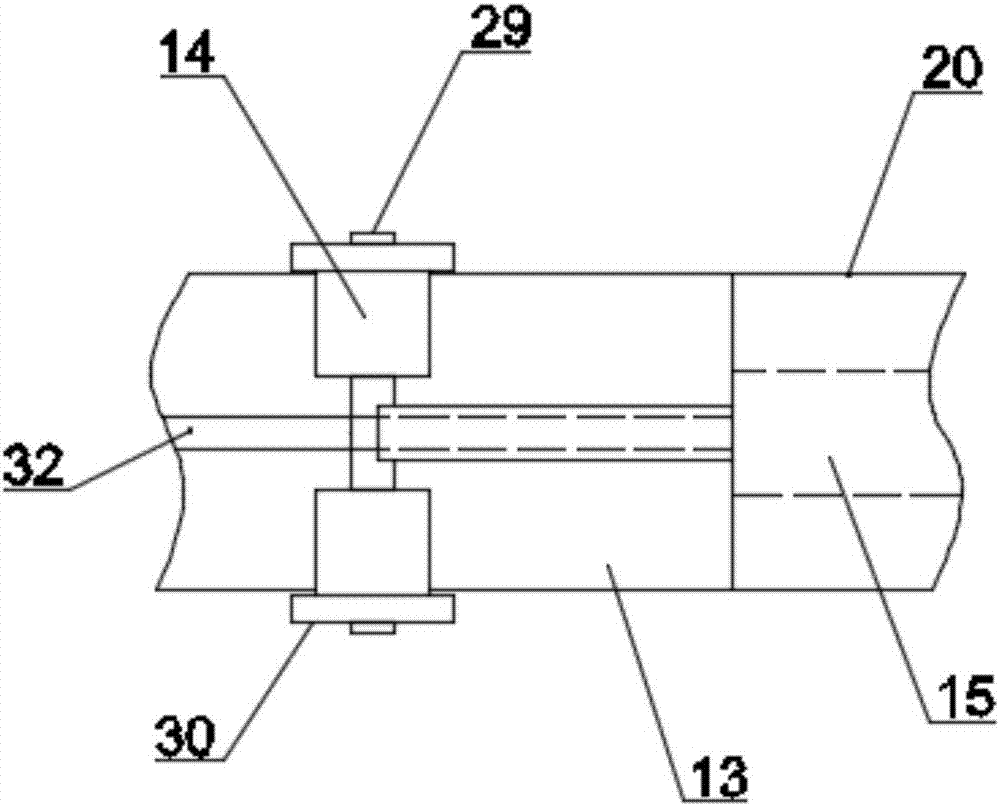

Balance-weight-adjustable cantilever type rotary crane

InactiveCN107010550AEasy to adjust the angleLose weightCranesHydraulic cylinderAgricultural engineering

The invention discloses a cantilever type rotating crane with adjustable counterweight, which comprises a base, a rotating mechanism, a column, a counterweight and a main beam. The column is connected to the base through a rotating mechanism, and the upper part of the column is rotated by a rotating shaft to be provided with a main beam. , the left side of the column is provided with an adjustment groove on the main beam, and a roller shaft is arranged in the adjustment groove, and rollers are installed on the front and rear ends of the roller shaft. The groove is located on the lower side of the main beam and there is a rope moving groove. The right side of the adjustment groove is installed in the main beam with the first hydraulic cylinder connected with the roller shaft. The lower right side of the main beam is provided with a driving device and a guide rail. An electric hoist is installed at the lower end of the driving device, the lower part of the electric hoist is connected with a hook, and the upper right side of the column is also provided with a second hydraulic cylinder for adjusting the angle of the main beam. The invention can lift objects in all directions, is stable and reliable, is convenient to adjust, and has improved service life.

Owner:李瑞平

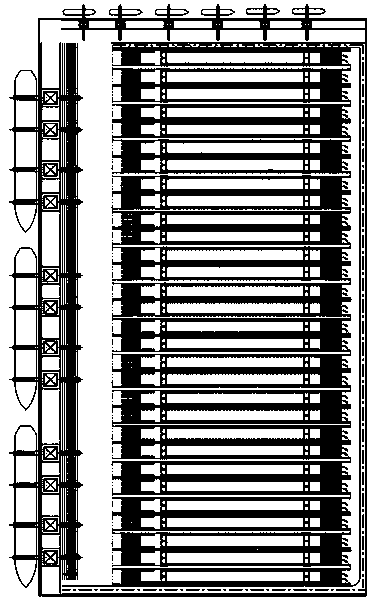

Three-dimensional general arrangement, loading and unloading process and system of automatic container wharf

PendingCN108750694AConducive to unmanned operationEasy to reachLoading/unloadingStorage devicesTransit systemControl system

The invention discloses three-dimensional general arrangement, loading and unloading process and system of an automatic container wharf. The container wharf comprises six parts: a seagoing vessel wharf, a lighter berth, a seagoing vessel wharf front edge working area, a lighter berth front edge working area, a container yard and a landside interaction area. The loading and unloading system is formed by a quay crane, a lighter loading and unloading ship overhead crane, a seagoing vessel wharf front edge three-dimensional track horizontal transportation system, a lighter berth front edge three-dimensional track horizontal transportation system and a three-dimensional automatic container yard loading and unloading system. The loading and unloading process comprises the steps of unloading a ship; loading and unloading a ship at the lighter berth; carrying out cargo concentration in a port and evacuation of cargoes from the port for a container, and loading and unloading the container; andrehandling, loading and unloading a container yard. The various function areas in general arrangement are compact in arrangement, high in land area utilization rate, short in horizontal load distance,free of interference, and low in energy consumption. The whole loading and unloading system and the process technology are mature and reliable, the control system is simple, and the cost is low.

Owner:CCCC FHDI ENG

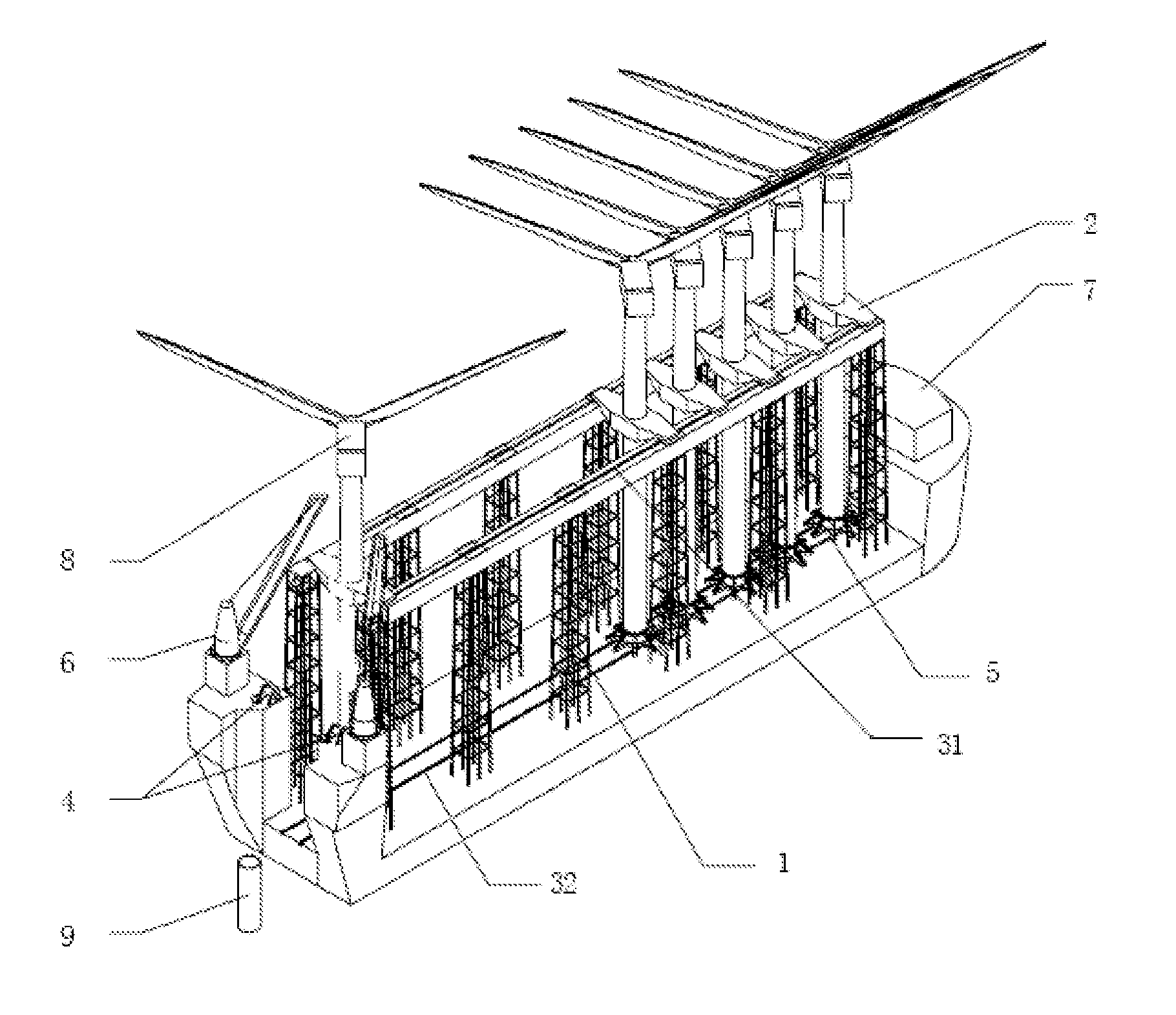

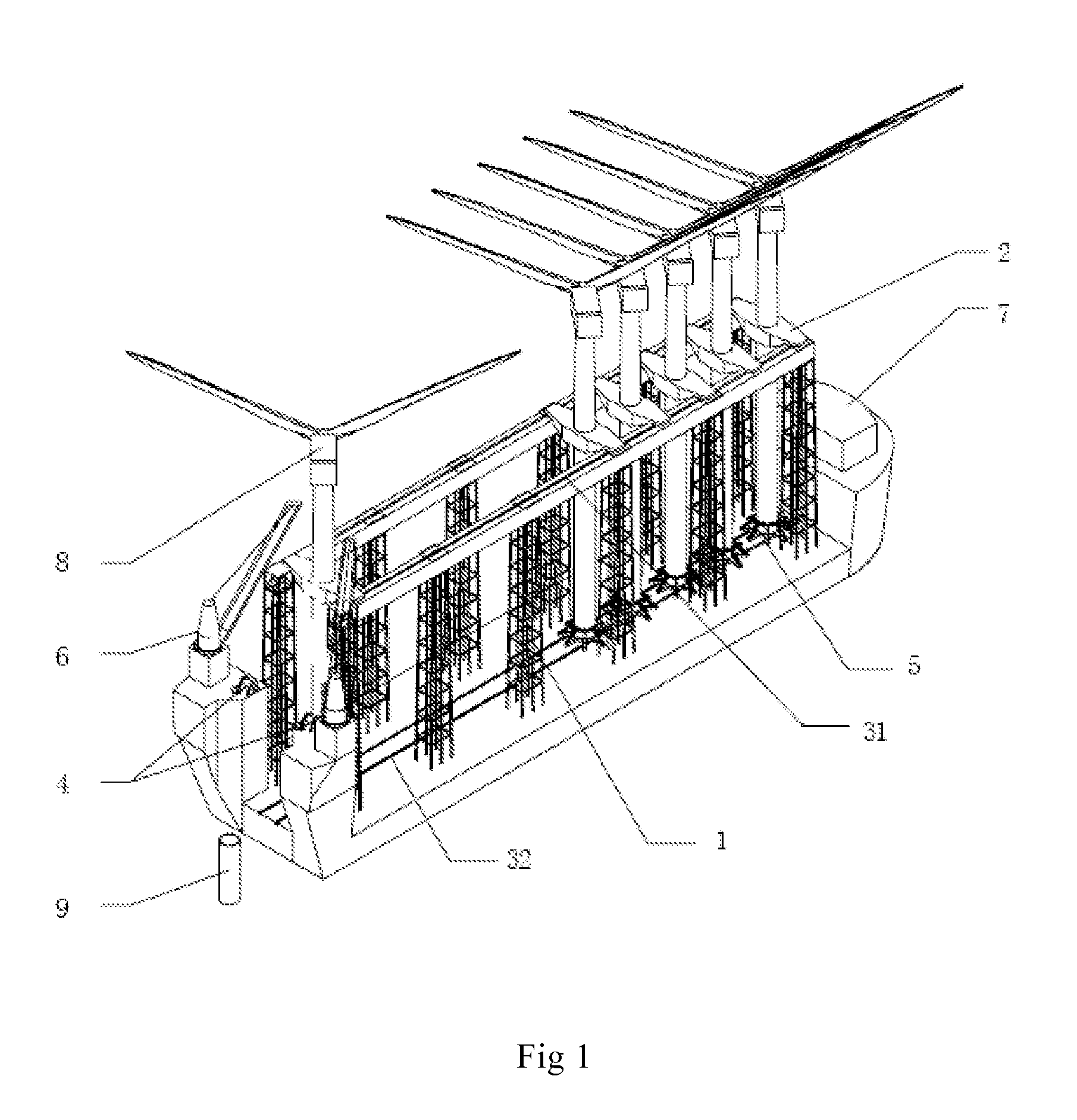

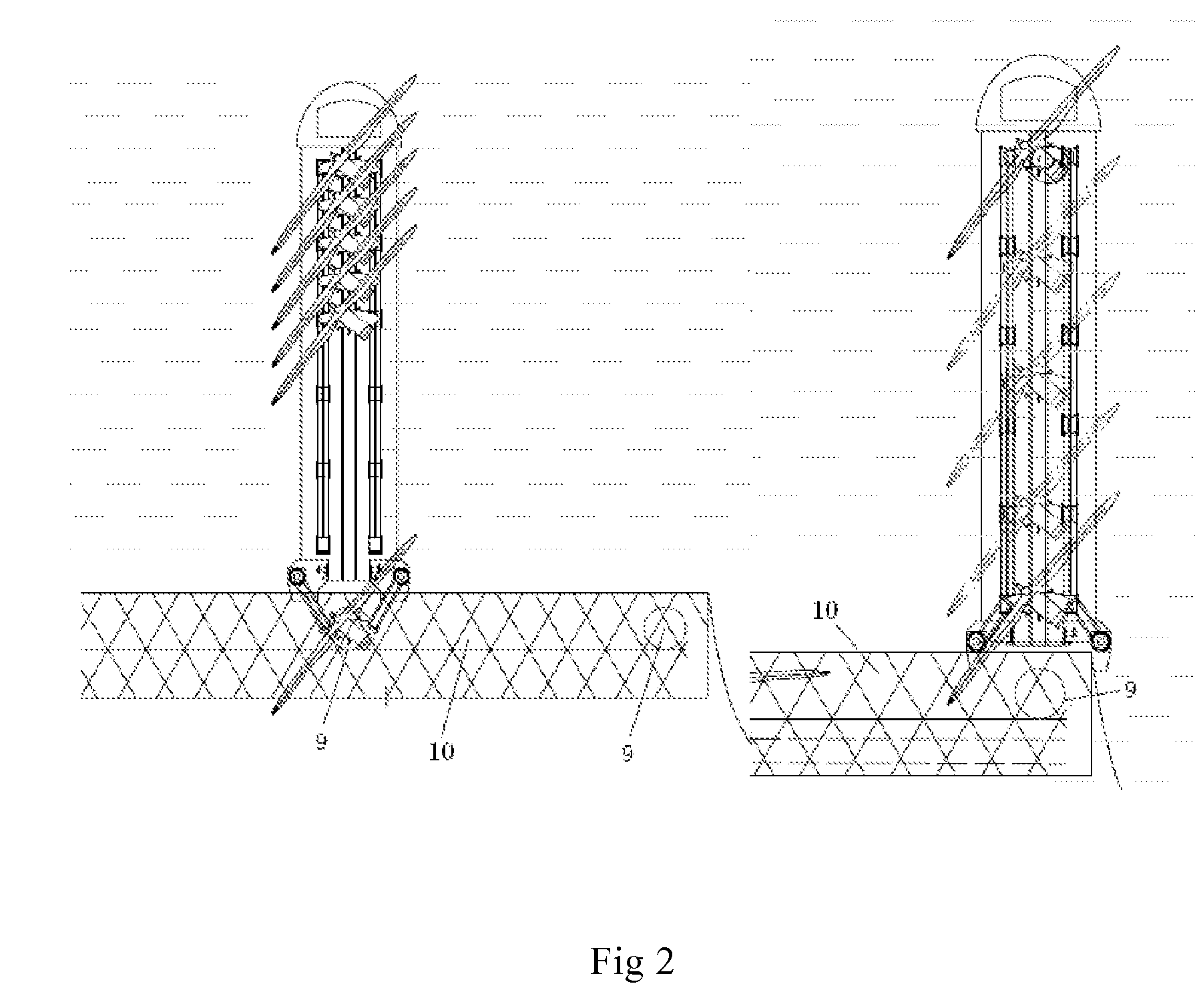

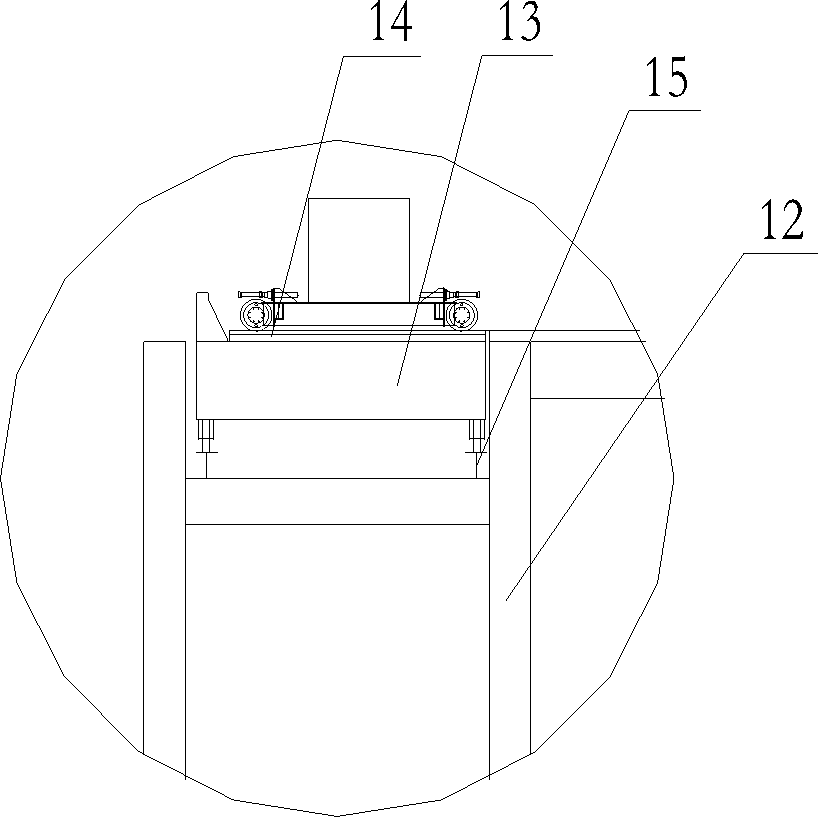

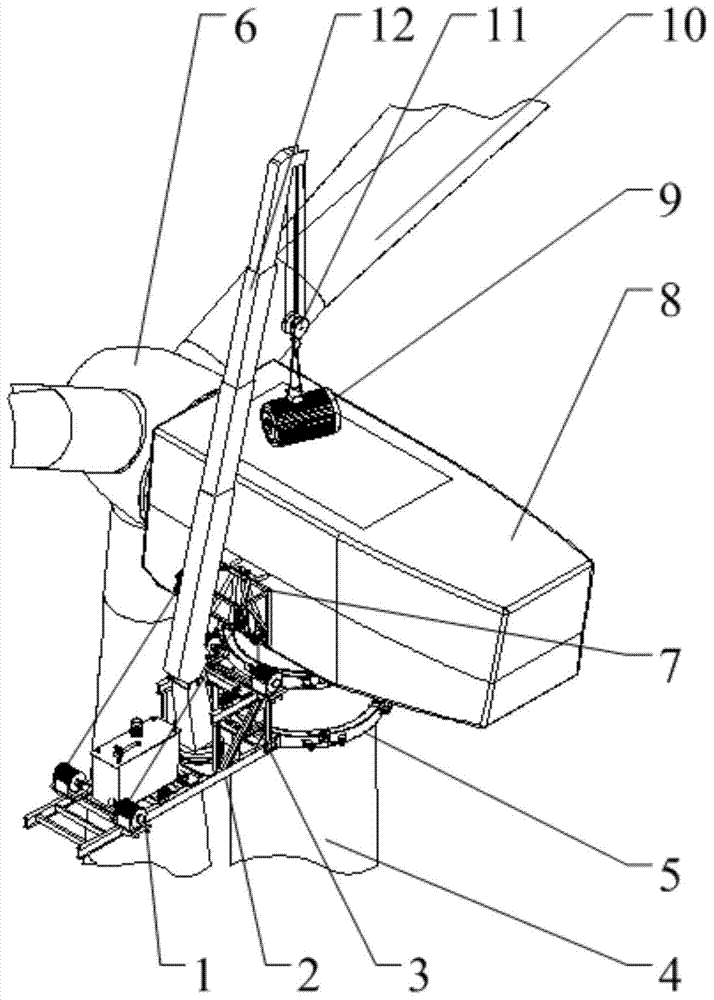

Vessel and method for transporting and hoisting the offshore wind turbine generator system

InactiveUS20120219364A1Reduce deliveryReduce on-site commissioning timeCargo handling apparatusPassenger handling apparatusSternWinch

A vessel for transporting and hoisting offshore wind turbine includes a hull, fixing brackets, first sliding rails, second sliding rails, a buffer device, rotary cranes and winch devices. A U-shaped opening is provided at the stern of the hull for a wind turbine to pass through. The fixing brackets are arranged in two rows in parallel, and their bottoms are fixed onto the deck in the hull. The second sliding rails are in parallel with the first sliding rails. A hanging beam slidably matched with the first sliding rails is installed on the body of the wind turbine. The buffer device is fixed to the bottom of the wind turbine. The rotary cranes are fixed on the top of two sides of the U-shaped opening. The winch devices are installed on the stern of the hull. An offshore wind turbine transporting and hoisting method using the vessel is also disclosed.

Owner:SINOVEL WIND GRP

Efficient quayside container transfer method and system

ActiveCN103818734AEasy loading and unloadingImprove efficiencyTrolley cranesStorage devicesTruckTransfer system

The invention discloses an efficient quayside container transfer method and system. The transfer method includes unshipping, evacuation of cargoes from a port, transition, entrance and shipping. The transfer system comprises more than one quay crane, a ferry crane and a stereoscopic transtainer, the quay cranes are arranged on a quayside rail a, the ferry crane is arranged below one sides, away from the shore line, of the quay cranes, and the stereoscopic transtainer is arranged on one side, away from the shore line, of the ferry crane. Compared with the prior art, the method and the system have the advantages that through the container transfer method, container loading, unloading and transition efficiency can be effectively improved, and production, manufacture and use cost of the container transfer system is lowered; the process of quick evacuation of the cargos from the port and port entrance of the containers can be realized through a quick channel; longitudinal transfer of the containers can be realized through automatic rail cars; besides, usage quantity of container trucks is reduced, and the problem that the container trucks easily jam on a container yard road is solved.

Owner:华电蓝科科技股份有限公司

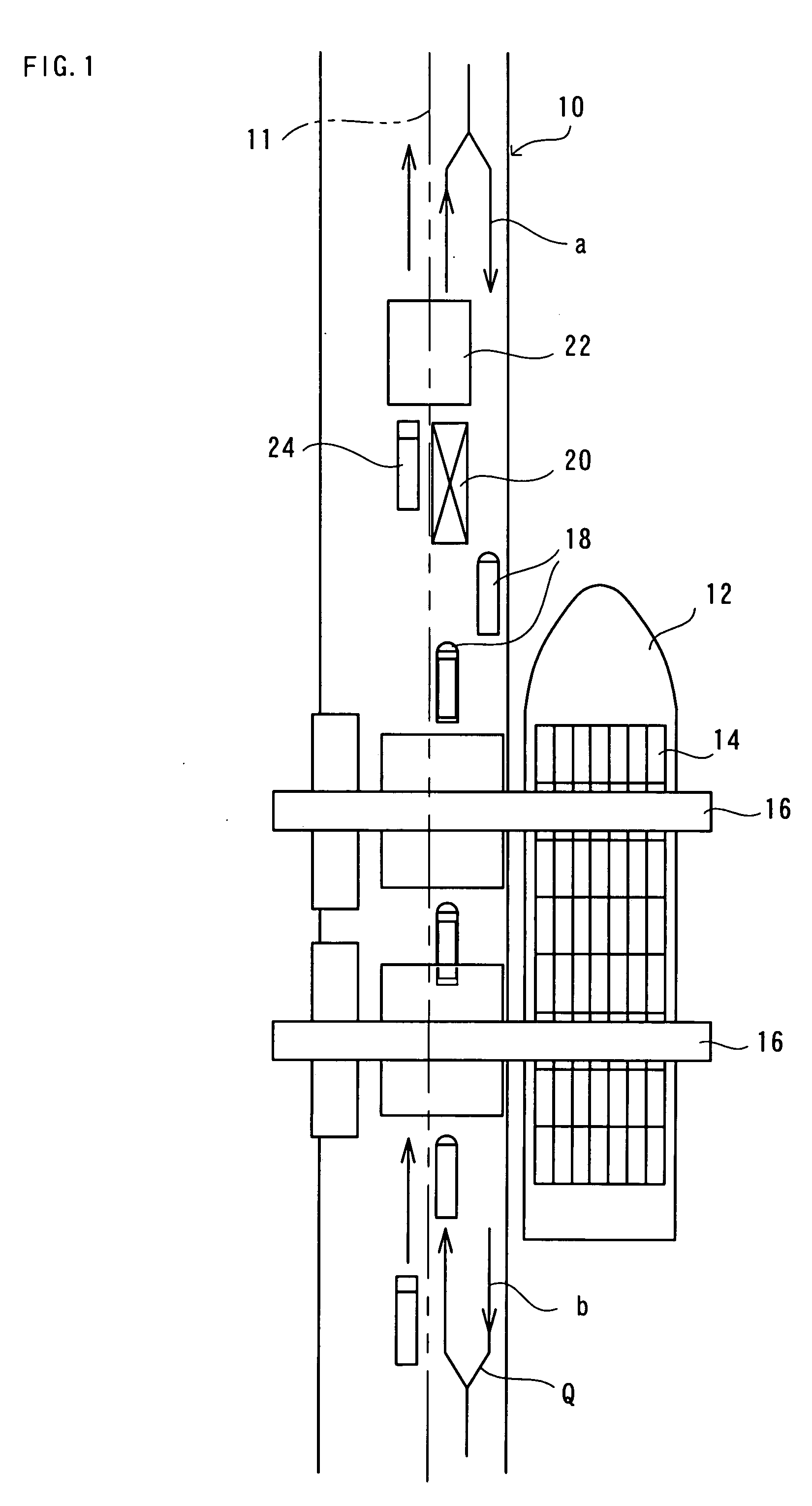

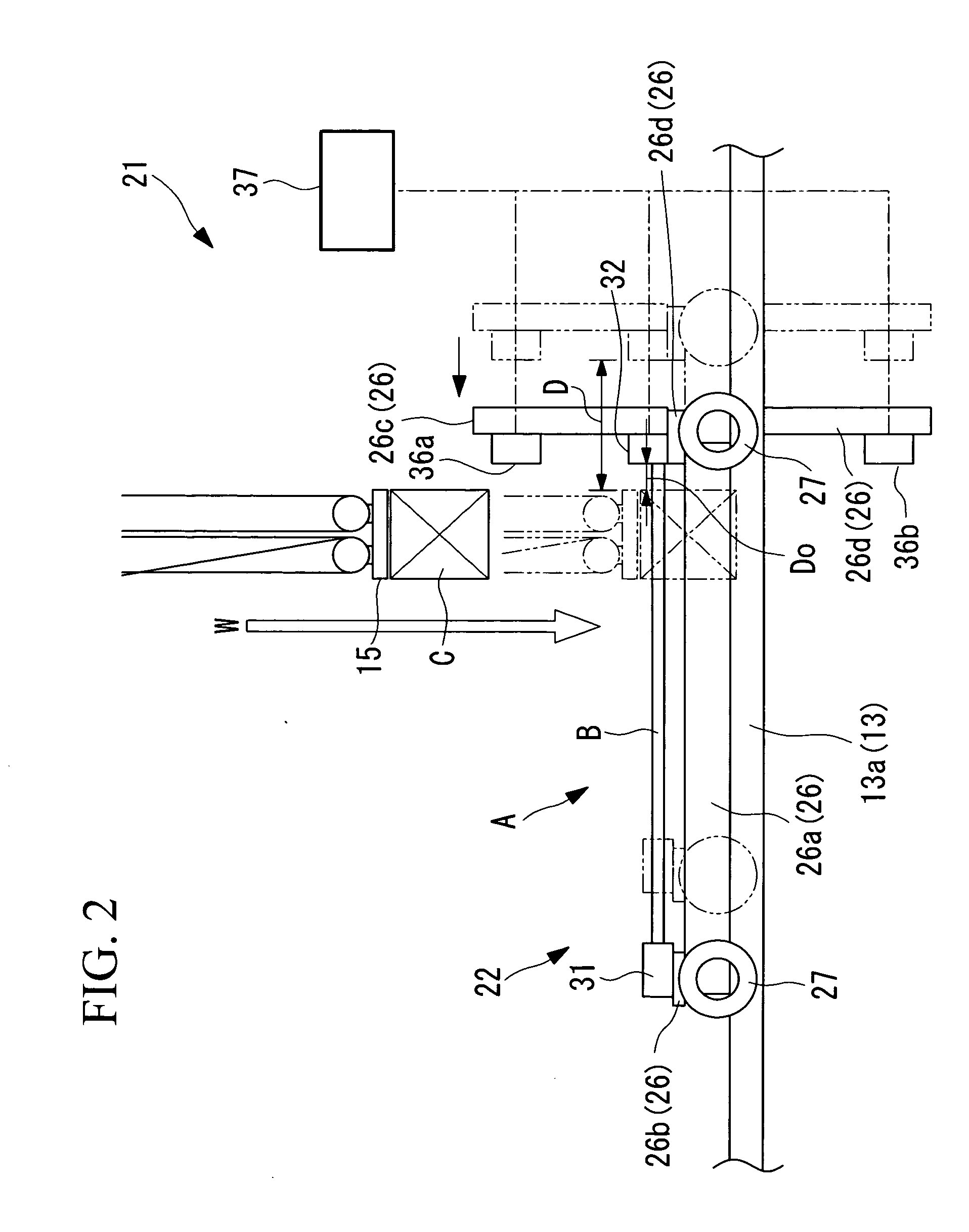

Crane equipped with inspection device

InactiveUS20060042397A1Optimal inspecting conditionDecreasing cargo transporting efficiencyVolume/mass flow measurementForce measurement by measuring optical property variationEngineeringTruck

The invention aims at providing a crane equipped with an inspection device that can maintain excellent inspection conditions without decreasing cargo transporting efficiency. On a container transporting route of a quay crane, a truck (position adjustment device), is provided moveably in a direction across this transporting route. An inspection device, which inspects the container, is provided on this truck. An upper part frame, which projects above the inspection device, and a lower part frame, which projects under the inspection device, are provided on the truck. An upside position detector, which detects the relative position of the container and the inspection device in the direction of movement of the truck, is provided in a position higher than that of the inspection device of the upper frame. A control device is provided, which controls operation of the position adjustment device based on detection results of the upside position detector so that the inspection device and the container are positioned appropriately for inspection.

Owner:MITSUBISHI HEAVY IND LTD

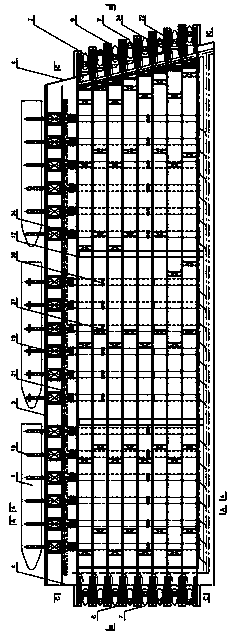

Overhead rail transit type container port loading and unloading system

The invention provides an overhead rail transit type container port loading and unloading system. The overhead rail transit type container port loading and unloading system comprises ships, container trucks used for horizontally conveying special containers, quay cranes, rail mounted gantry cranes (RMGs), containers and a storage yard, and is characterized in that the quay cranes are communicated with the RMGs and the storage yard through annular overhead rail systems; one rail in each overhead rail system corresponds to one quay crane; the container trucks used for horizontally conveying special containers are arranged below the spans of the quay cranes; the overhead rail systems are provided with horizontal self-running conveying carts used for horizontally conveying standard containers. Collecting and evacuating transportation vehicles run along the appointed path on the ground and are used for collecting and evacuating the containers. The storage yard is arranged at the back of the front of a port and used for temporarily storing the containers. According to overhead rail transit type container port loading and unloading system, the problems of interference of ship loading and unloading activities and collecting and evacuating transportation activities and intrinsic stochasticity of the loading and unloading system are solved, and meanwhile the overhead rail transit type container port loading and unloading system is high in automation degree, small in energy consumption, safe and environmentally friendly.

Owner:WUHAN UNIV OF TECH

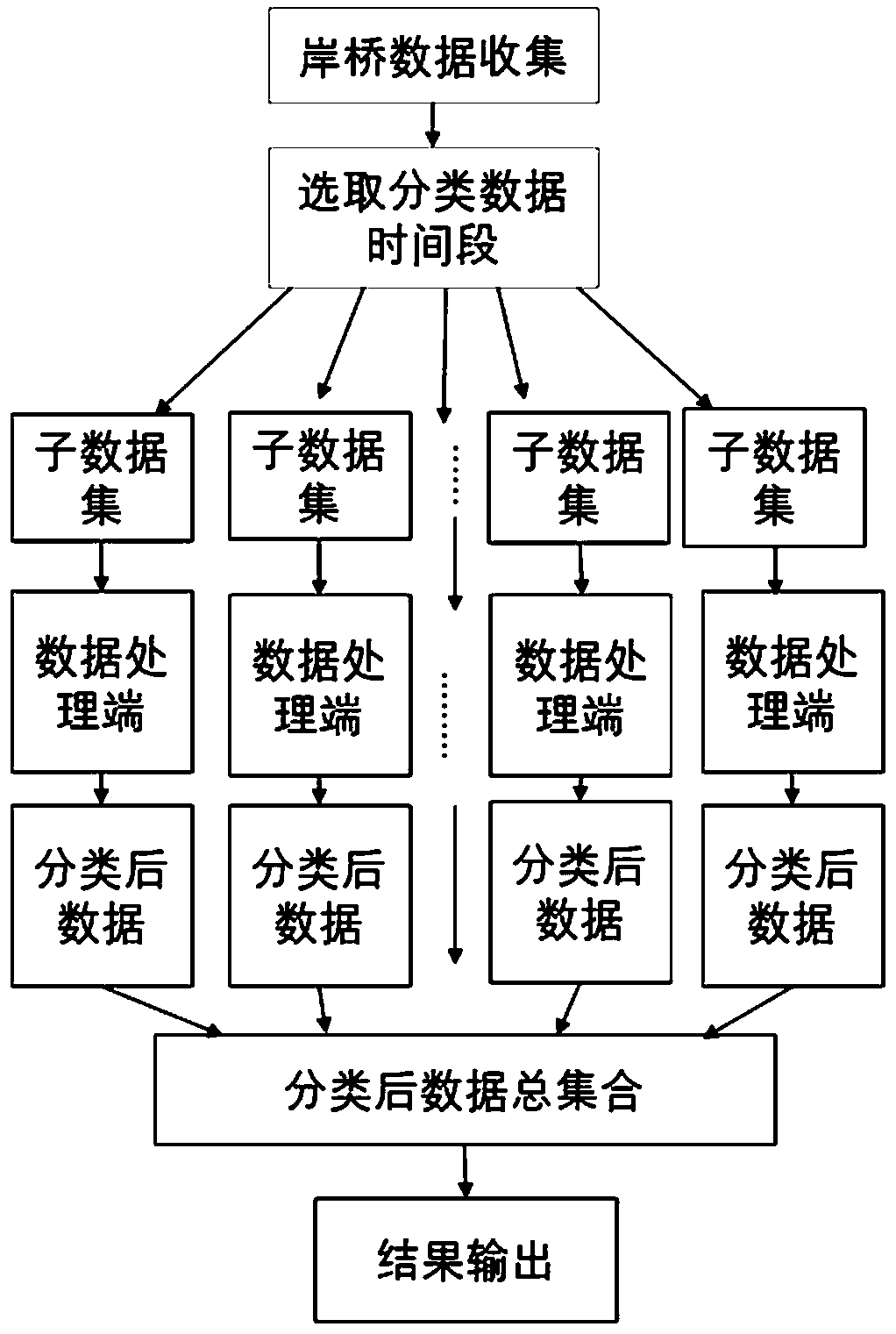

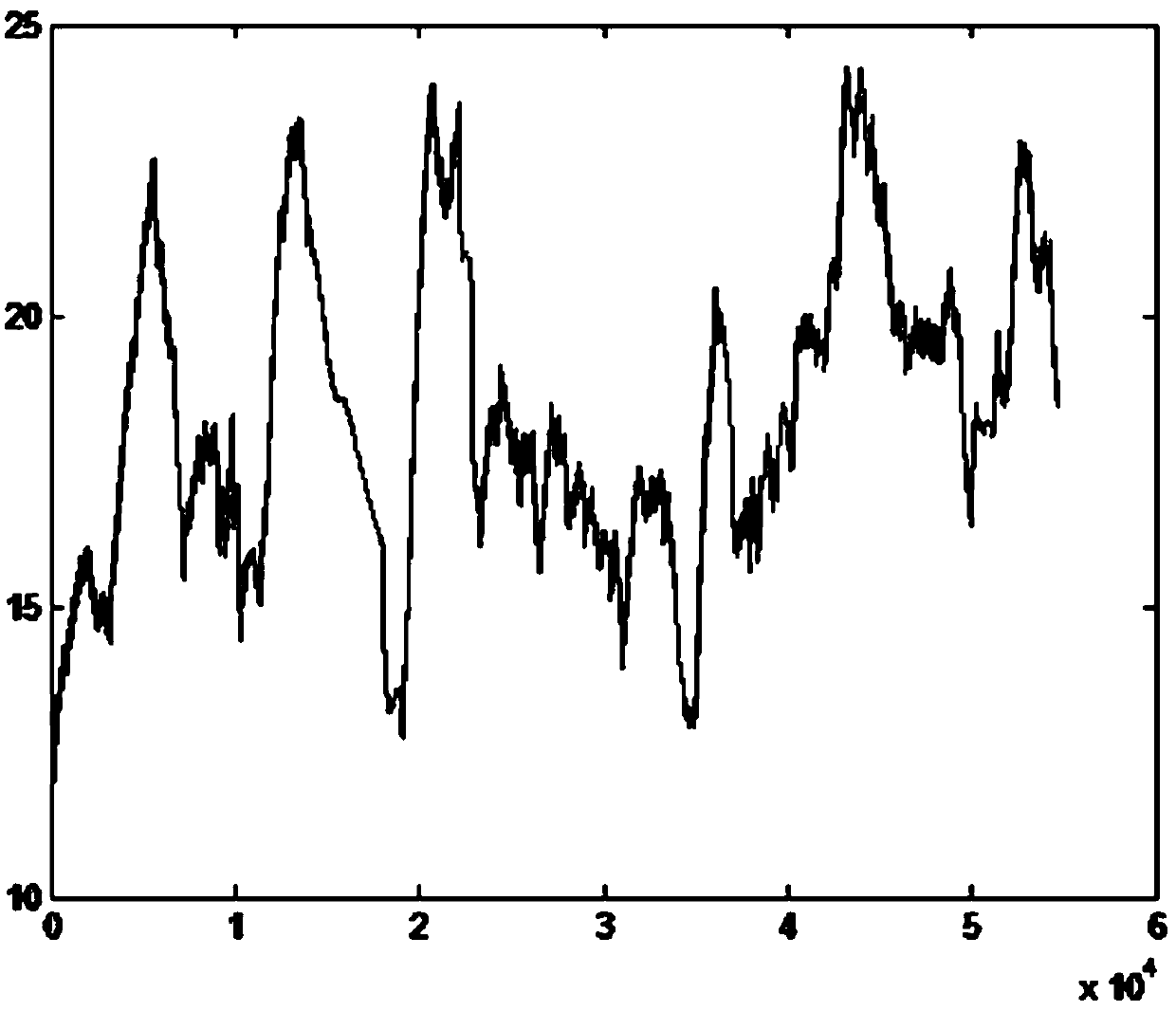

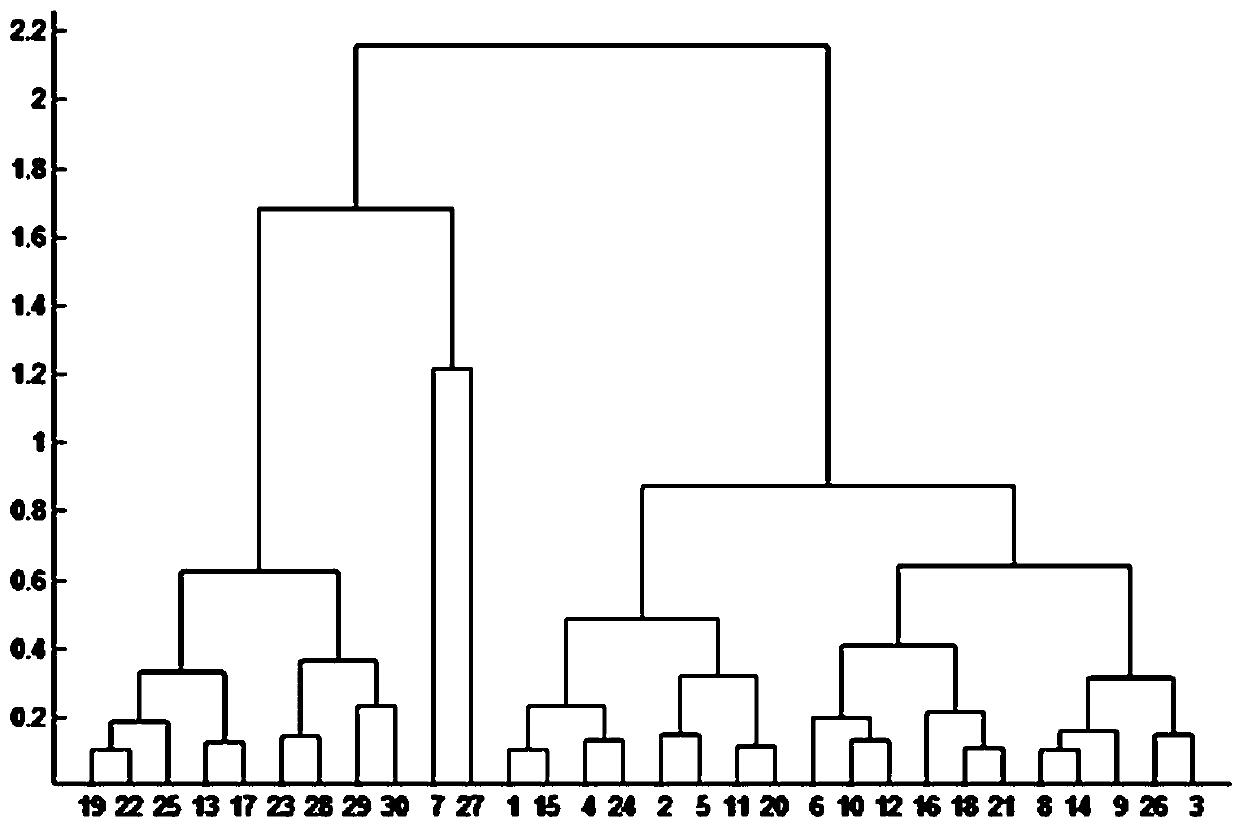

Mechanical working state fault classification method for port quay crane based on decision tree algorithm

InactiveCN109522957AImprove use valueImprove work efficiencyCharacter and pattern recognitionAlgorithmClassification methods

The invention discloses a mechanical working state fault classification method for port quay crane based on decision tree algorithm, which comprises the following steps: step 1, acquiring acquired data through a sensor installed on a quay crane, and storing the acquired data in a database; 2, obtaining standard fault sample data by analyzing various historical monitoring quantities of the quay crane equipment, and then carrying out classification analysis on the fault sample data by adopting a decision tree generation algorithm to obtain a fault decision tree; And step 3, classifying the acquired real-time monitoring data by using the decision tree obtained in the step 2 as a classification model of the fault mode, thereby determining the fault type. The method does not need manual data recording, data processing is directly carried out through the data collected by the sensor, the error-tolerant rate of the data is reduced, and a more accurate result is obtained. According to the method, large-scale monitoring data of the quay crane can be efficiently processed without other algorithms, and the method has universality and operability.

Owner:SHANGHAI MARITIME UNIVERSITY

Port container all-directional pattern recognition and tally information monitoring system and corresponding monitoring method

ActiveCN104683772ARealize automatic collectionRealize "informatizationCharacter and pattern recognitionClosed circuit television systemsInformatizationGraphics

The invention discloses a port container all-directional pattern recognition and tally information monitoring system which comprises a wharf quay crane, an image acquisition device and background terminal equipment, wherein a connection beam of the wharf quay crane is provided with the image acquisition device used for obtaining a container surface image; an image signal acquired by the image acquisition device is transmitted to the background terminal equipment for displaying. The invention further discloses a tally information monitoring method. The port container all-directional pattern recognition and tally information monitoring system and method enable tally personnel not to work at the site and solve problems of high risk, low efficiency, long consumed time and the like of manual damage checking. The image acquisition device is used for automatically acquiring a state of the container in a loading or unloading process and transmitting acquired image information to the background terminal equipment, and the background terminal equipment is used for monitoring and recognizing the state of the container and accurately and effectively authenticating original damage and stevedore damage, so that the tally quality and the service quality are improved, tally service informatization is realized, commercial disputes are avoided, and interests of both entrusting parties are maintained.

Owner:广州外轮理货有限公司

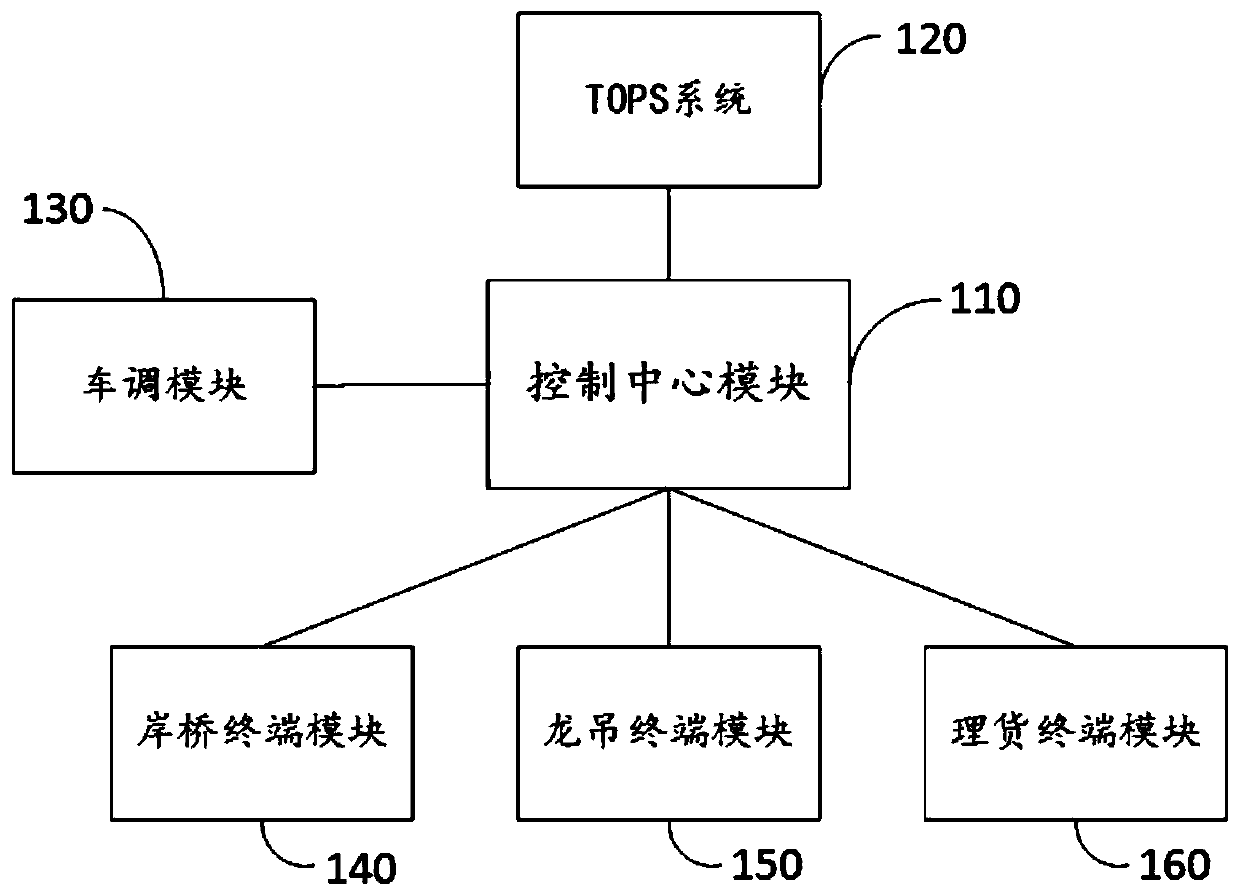

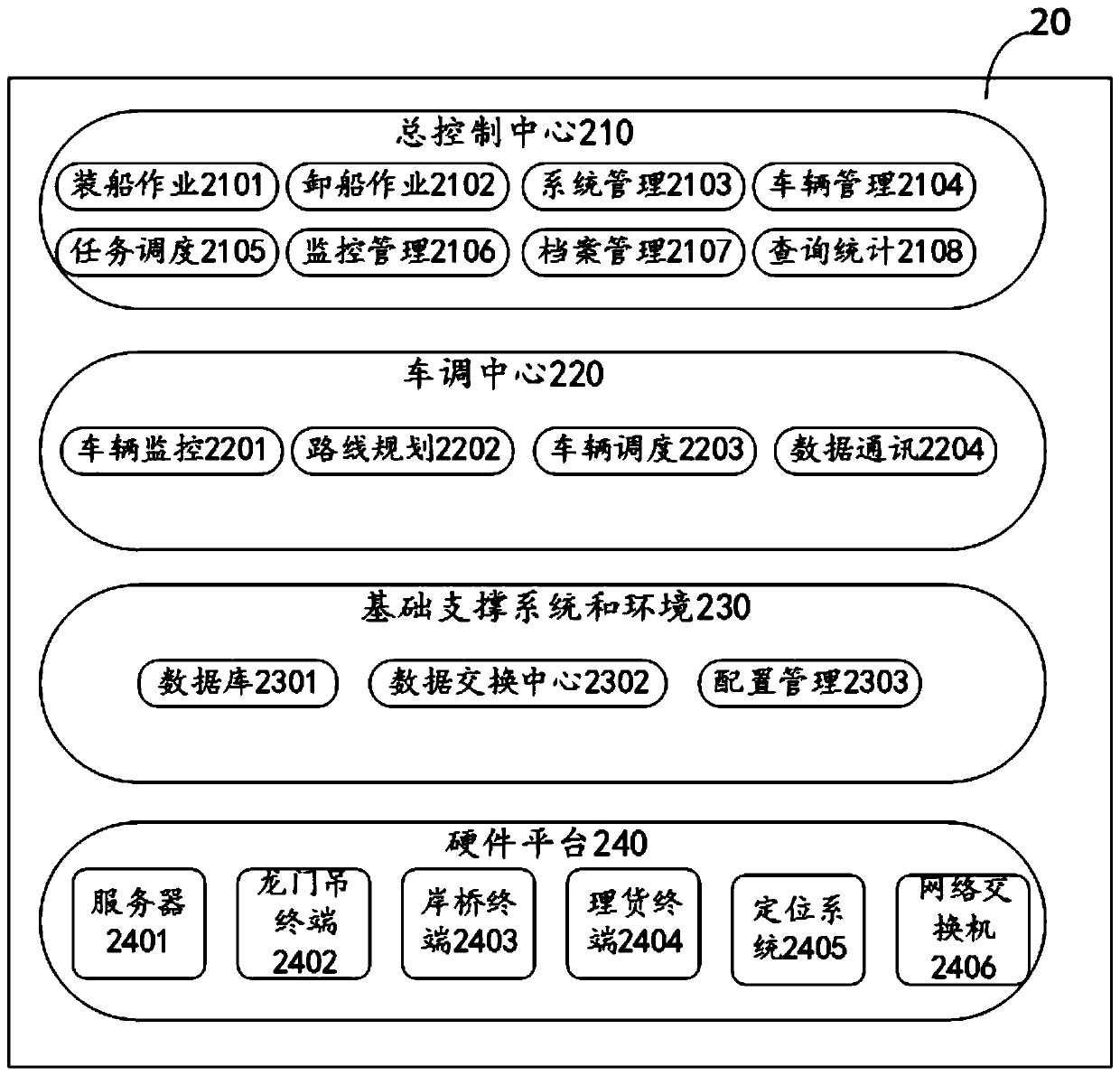

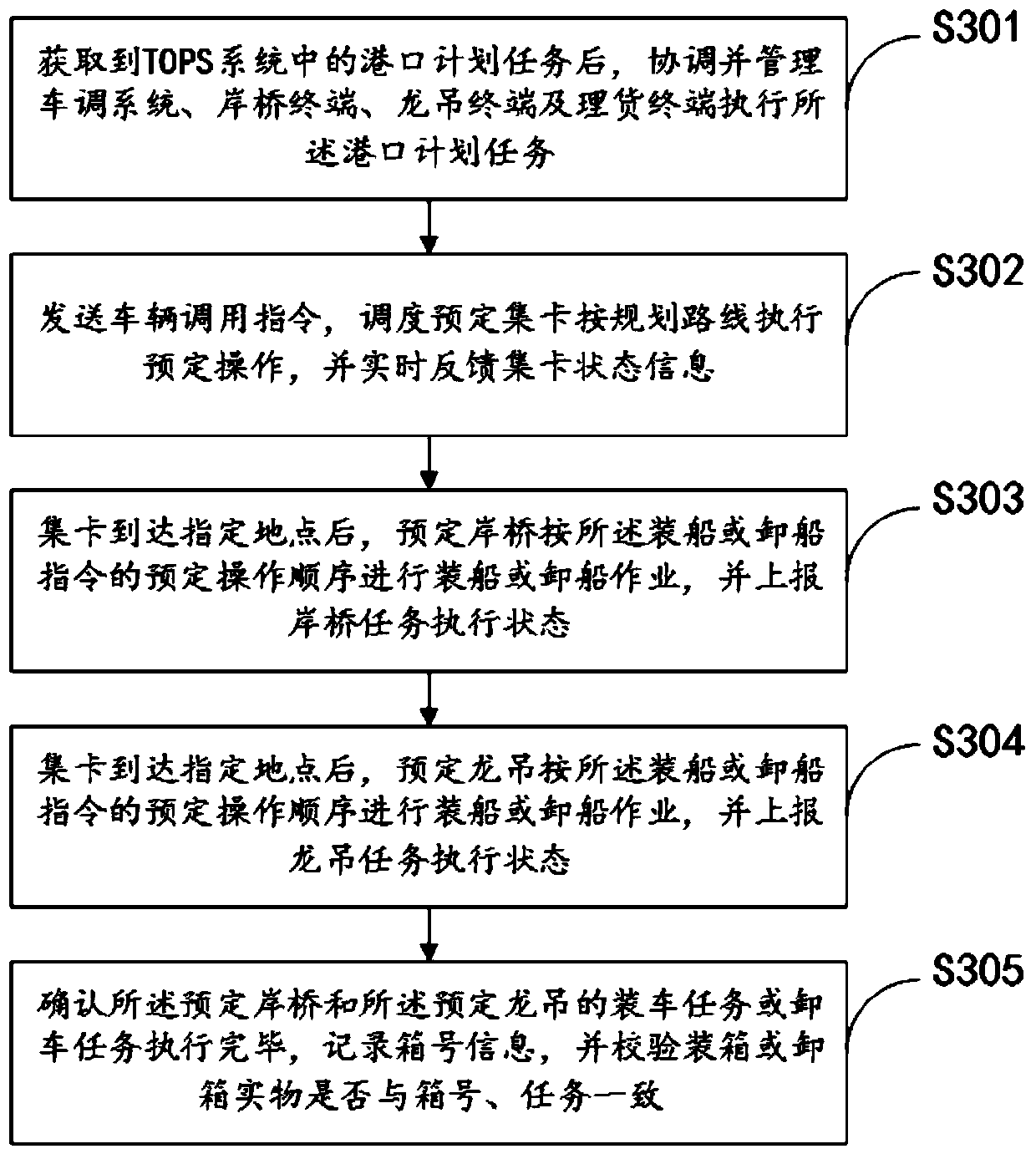

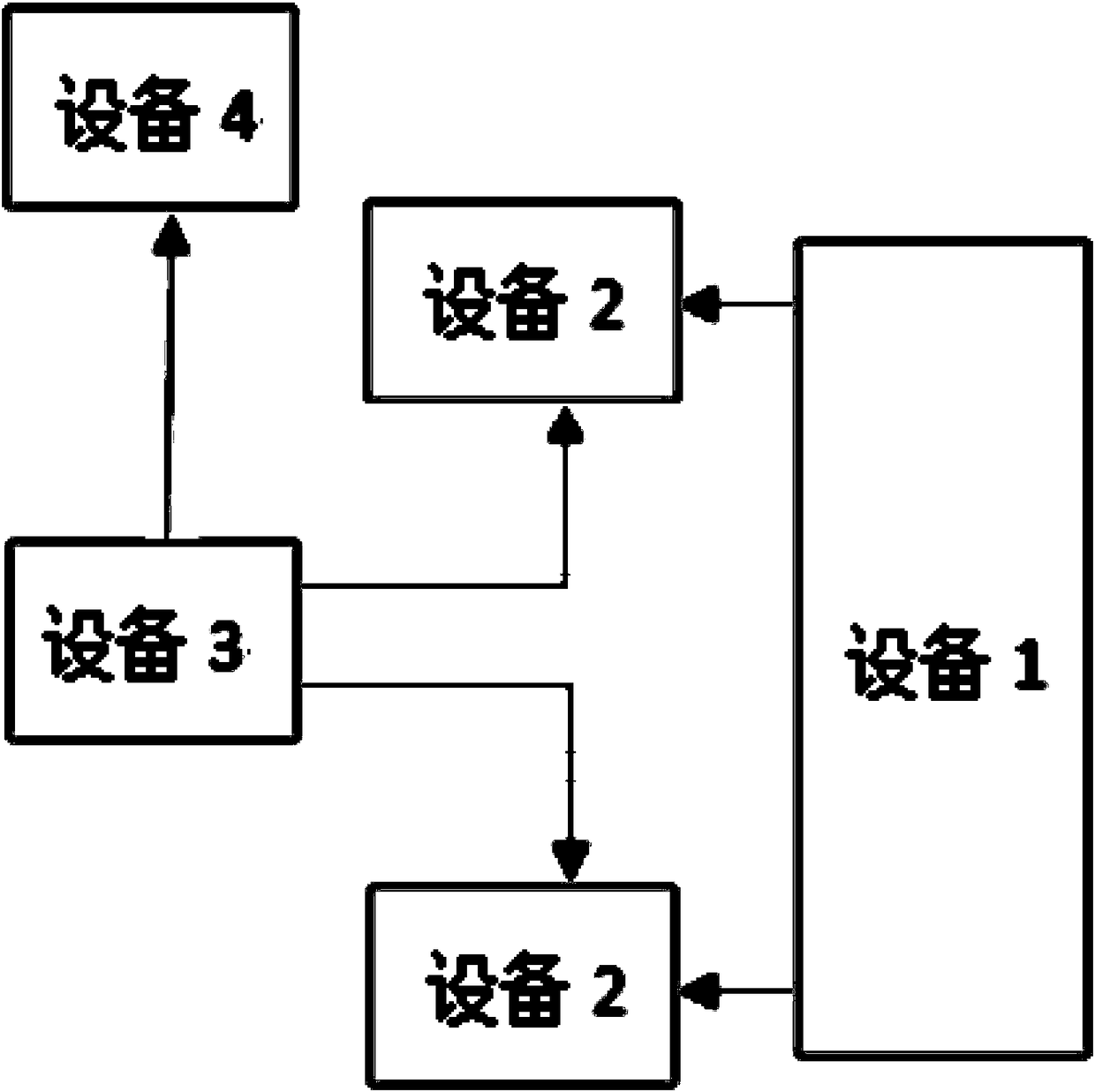

Port scheduling system and method based on unmanned driving

PendingCN110598987AGuarantee reasonable schedulingRealize automatic connectionResourcesLogisticsGantry craneQuay crane

The invention relates to a port scheduling system and method based on automatic driving, and belongs to the field of automatic driving. The port scheduling system comprises a control center module which is used for inputting a planned task, managing and coordinating a vehicle dispatching module, a quay crane terminal module, a gantry crane terminal module and a cargo handling terminal module to execute the planned task, carrying out the information interaction with the vehicle dispatching module, and obtaining the vehicle state information in real time, a vehicle dispatching module which is used for receiving the control management of the control center module, monitoring the state of the vehicle, planning a driving route and controlling the operation of the vehicle, a quay crane terminalmodule and a gantry crane terminal module which are used for receiving the shipment or unshipment instruction, carrying out shipment or unshipment operation according to a preset sequence and feedingback an execution state, and a tallying terminal module which is used for confirming that the container loading task or unloading task is executed, and recording and verifying the container loading orunloading information. Through the port scheduling system, the port operation efficiency can be improved, and the scheduling cost is reduced, and efficient and orderly operation of port operation isensured.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD

Container transfer system arrangement method

The invention provides a container transfer system arrangement method. The system comprises a storage yard, a two-lane, a rail-mounted gantry crane, a container lorry, a quay crane and a frontage, wherein the storage yard is parallel to the frontage; the two-lane is an annular path and connected with a wharf and the storage yard; the rail-mounted gantry crane is arranged on the two-lane of a storage yard area; the quay crane is arrange on the two-lane of the wharf; and the shuttling container lorry is arranged in the two-lane. The storage yard is parallel to the frontage, the two-lane is reserved in the storage yard area without a cantilever rail-mounted gantry crane, and the two lanes are designed as one-way lanes. According to the design, a single-lane delayed unloading phenomenon can beavoided, and the cross operations of two rail-mounted gantry cranes with the same span are avoided, so that the container transfer operating efficiency is effectively improved. The traveling route ofthe container lorry is designed into the annular path, a back-up phenomenon is avoided, the operating time of the container lorry is shortened, and the operating efficiency is improved. The containertransfer system disclosed by the invention has the advantages of simple design, high practicality, high transfer efficiency and the like.

Owner:TANGSHAN PORT GRP +1

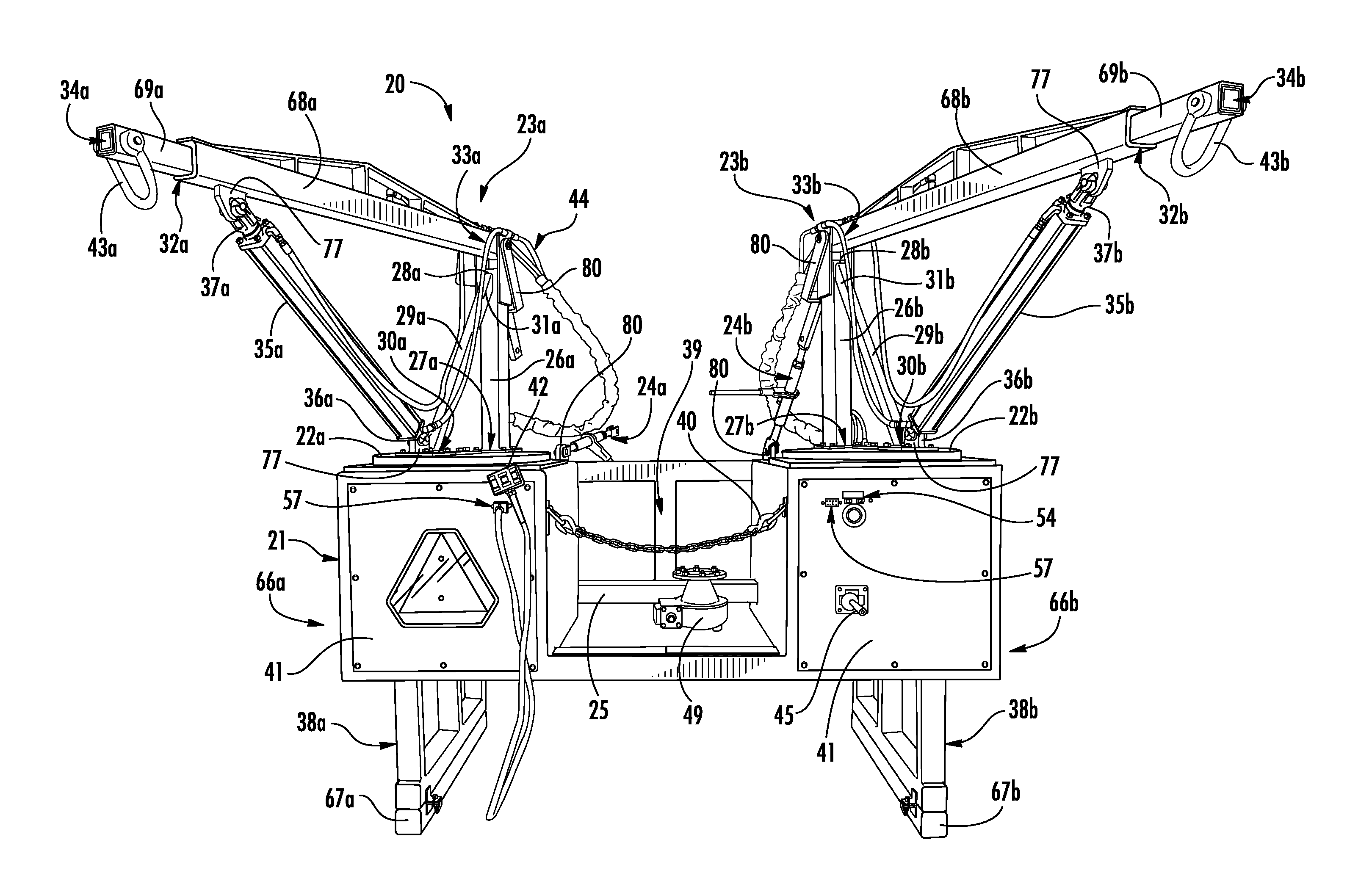

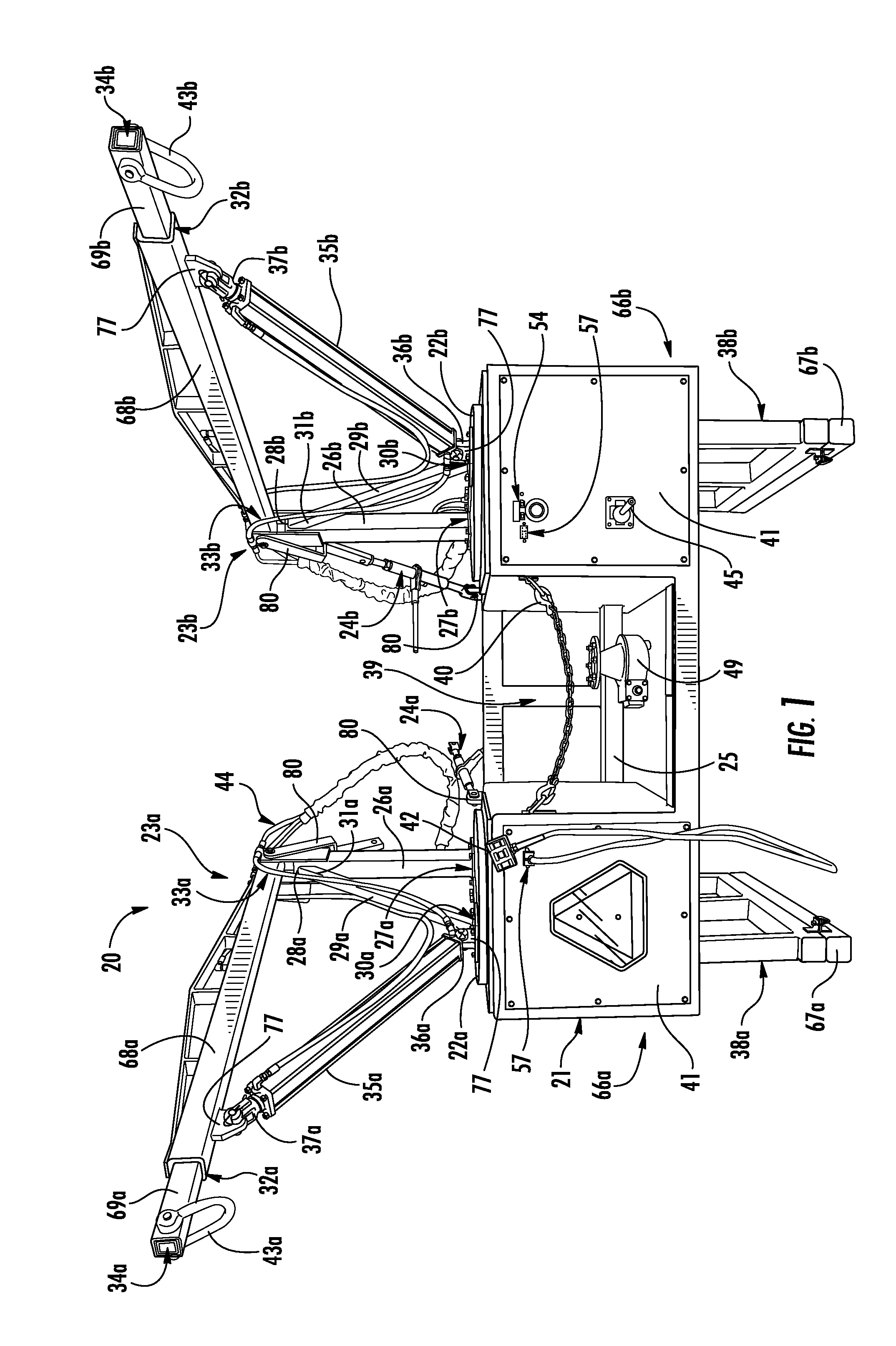

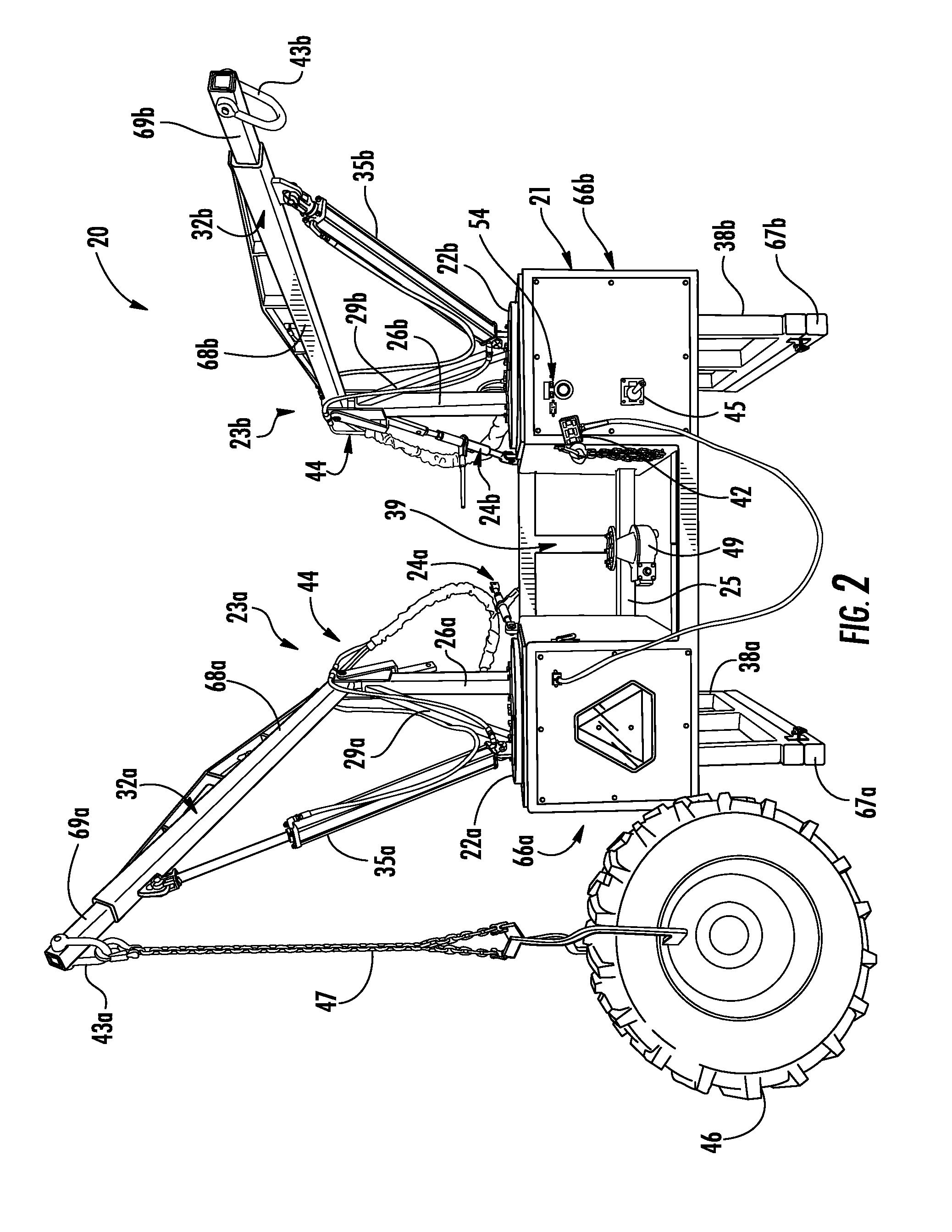

Dual Crane Apparatus and Method of Use

ActiveUS20140150232A1Overcomes drawbackReduces dangerMetal working apparatusCranesEngineeringQuay crane

A dual crane apparatus and a method of use are disclosed herein. The disclosed dual crane apparatus generally comprises a support frame and two rotating crane members mounted to the support frame, wherein the crane members can each independently move up and down in a vertical direction, extend and retract in a horizontal direction, and rotate clockwise and counterclockwise. The disclosed dual crane apparatus can be utilized for servicing mobile irrigation systems.

Owner:ARTHUR BRADY PAUL +1

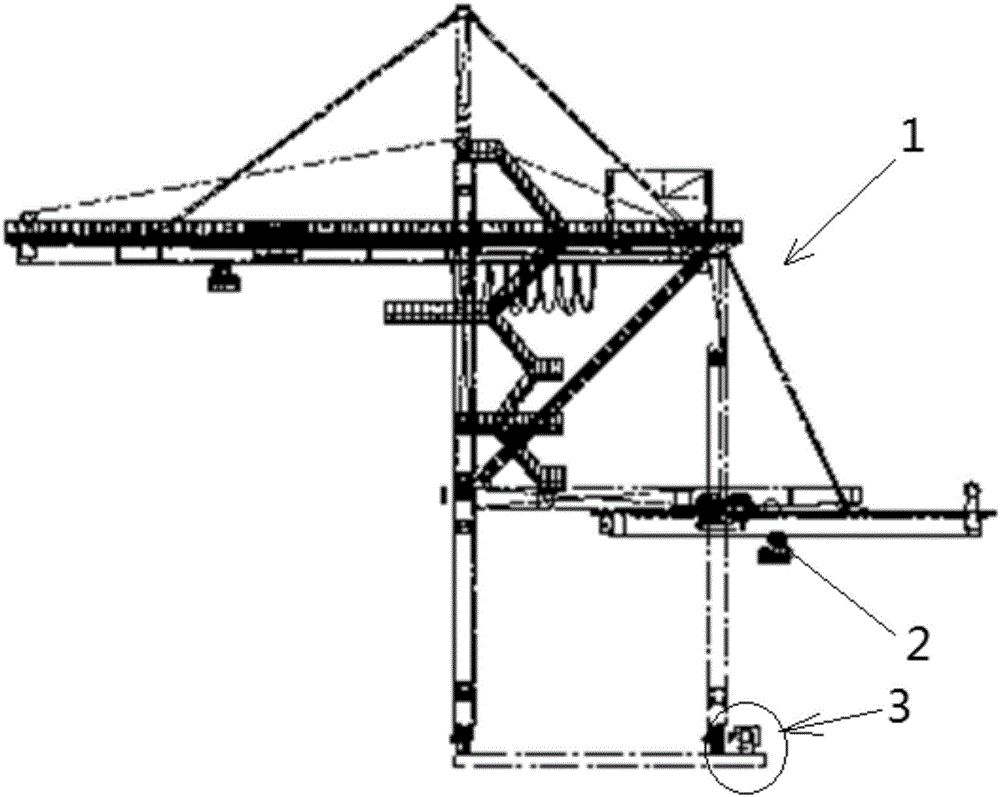

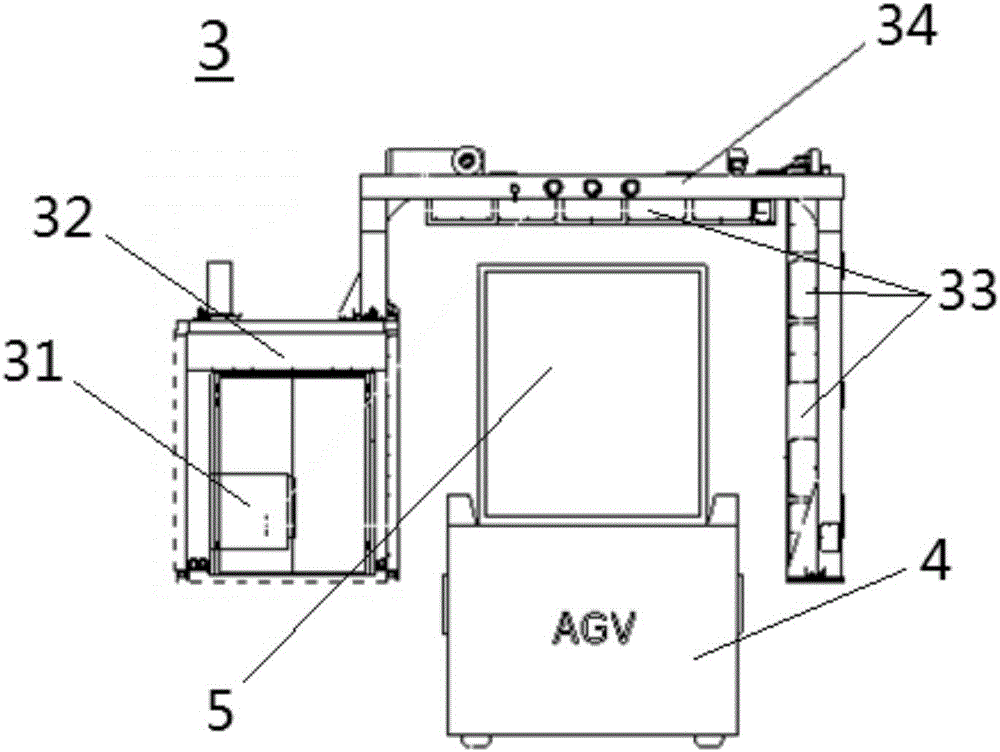

Mobile article check system, method and port

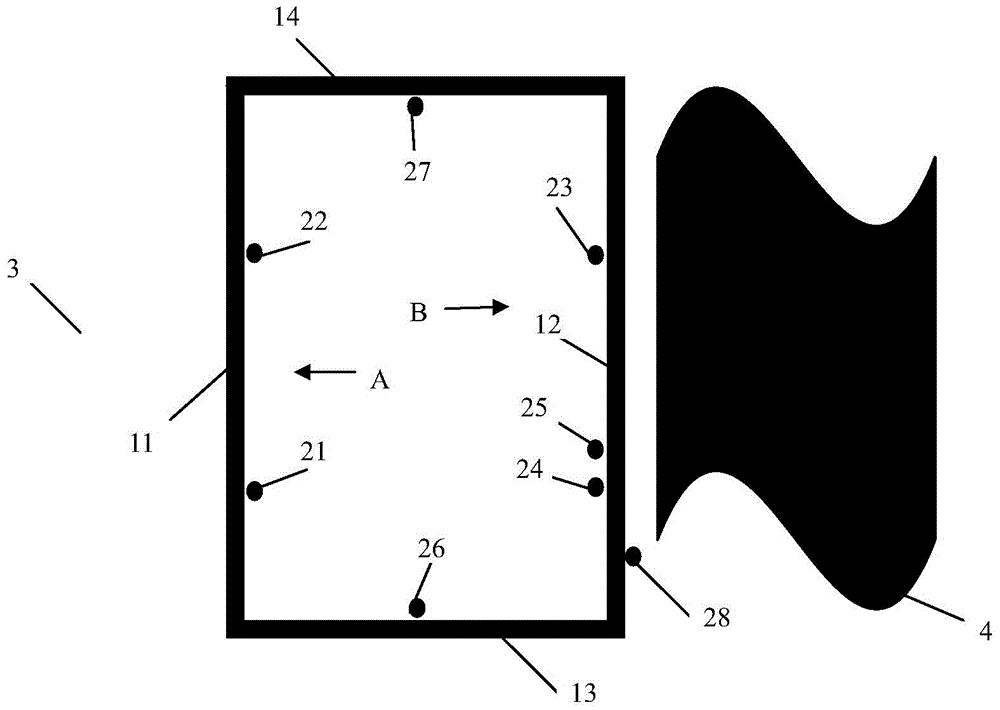

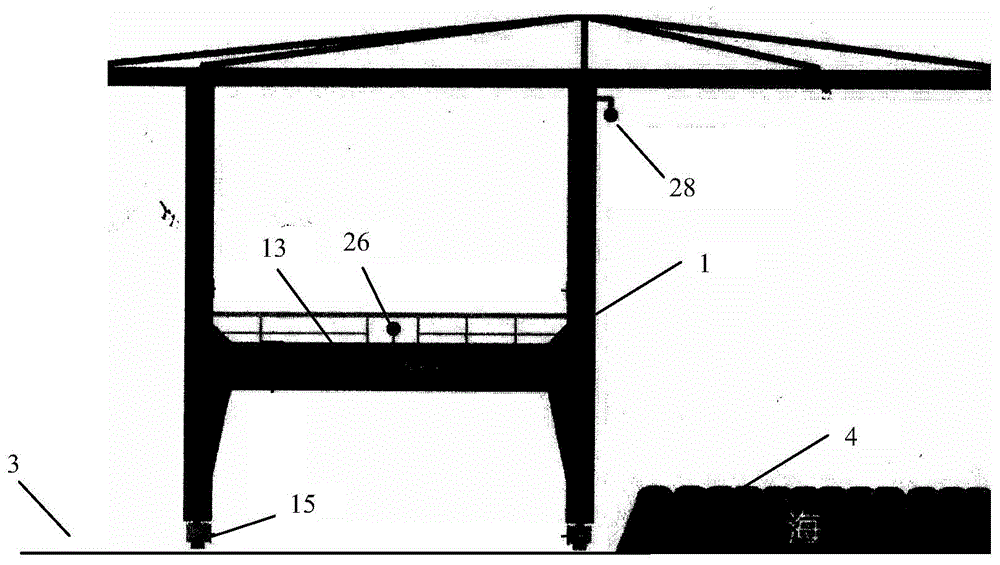

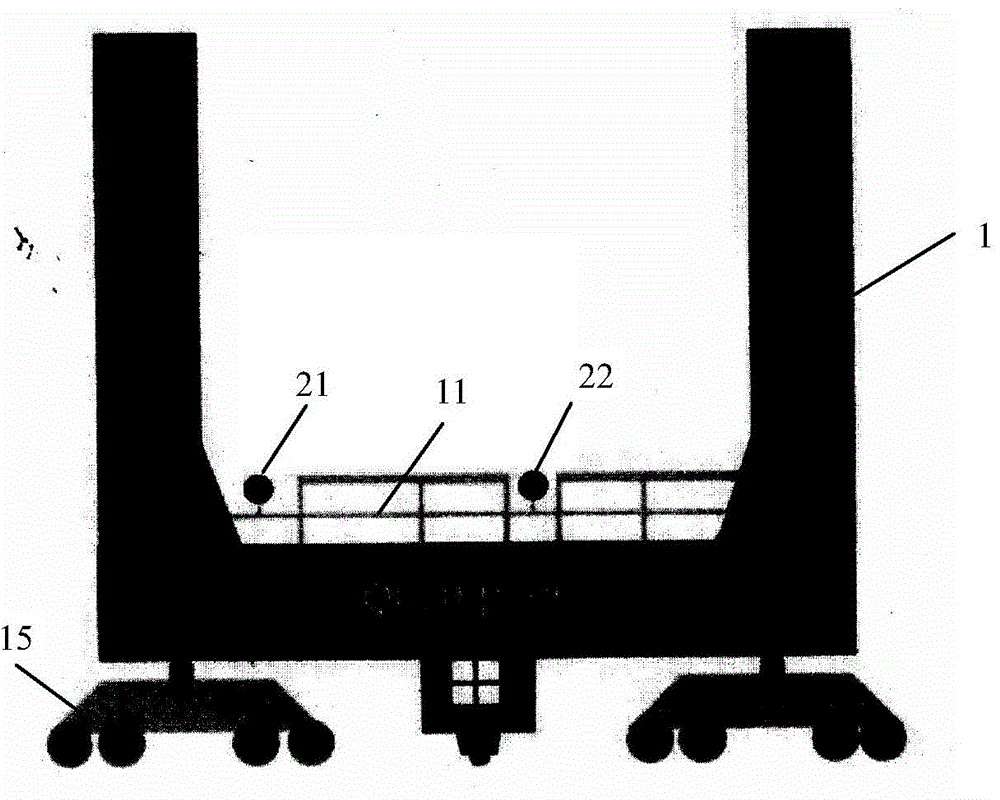

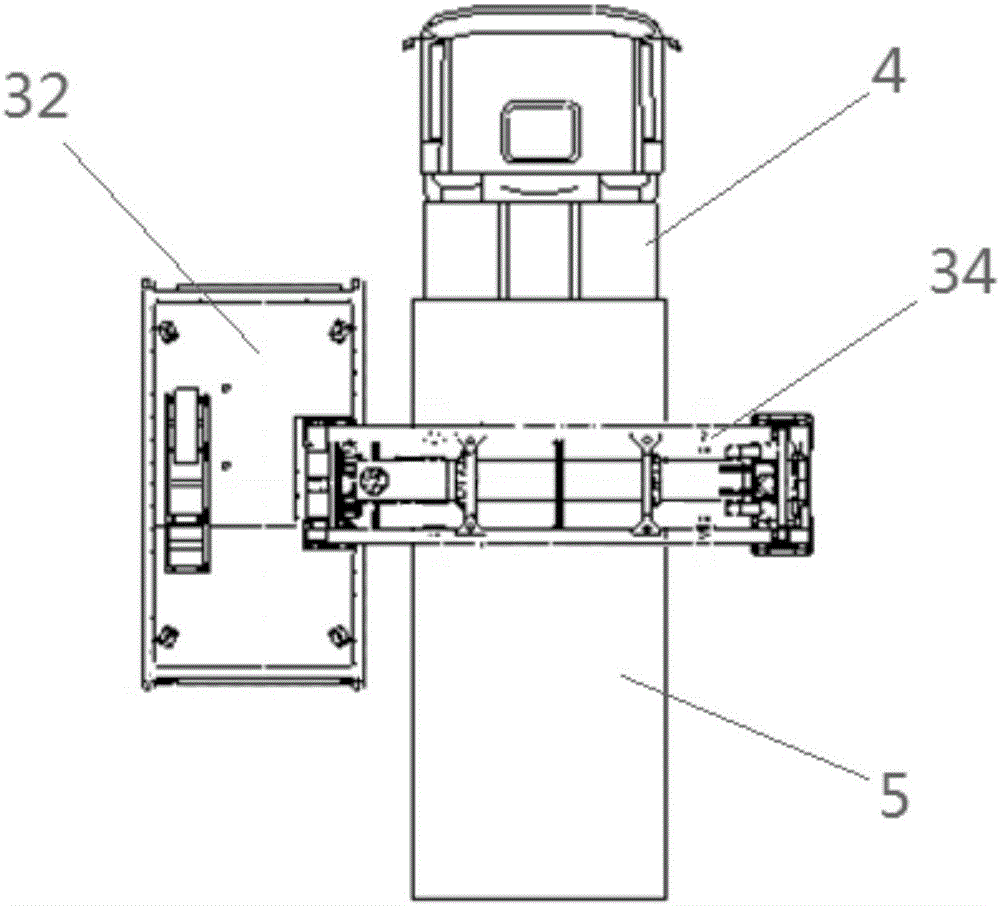

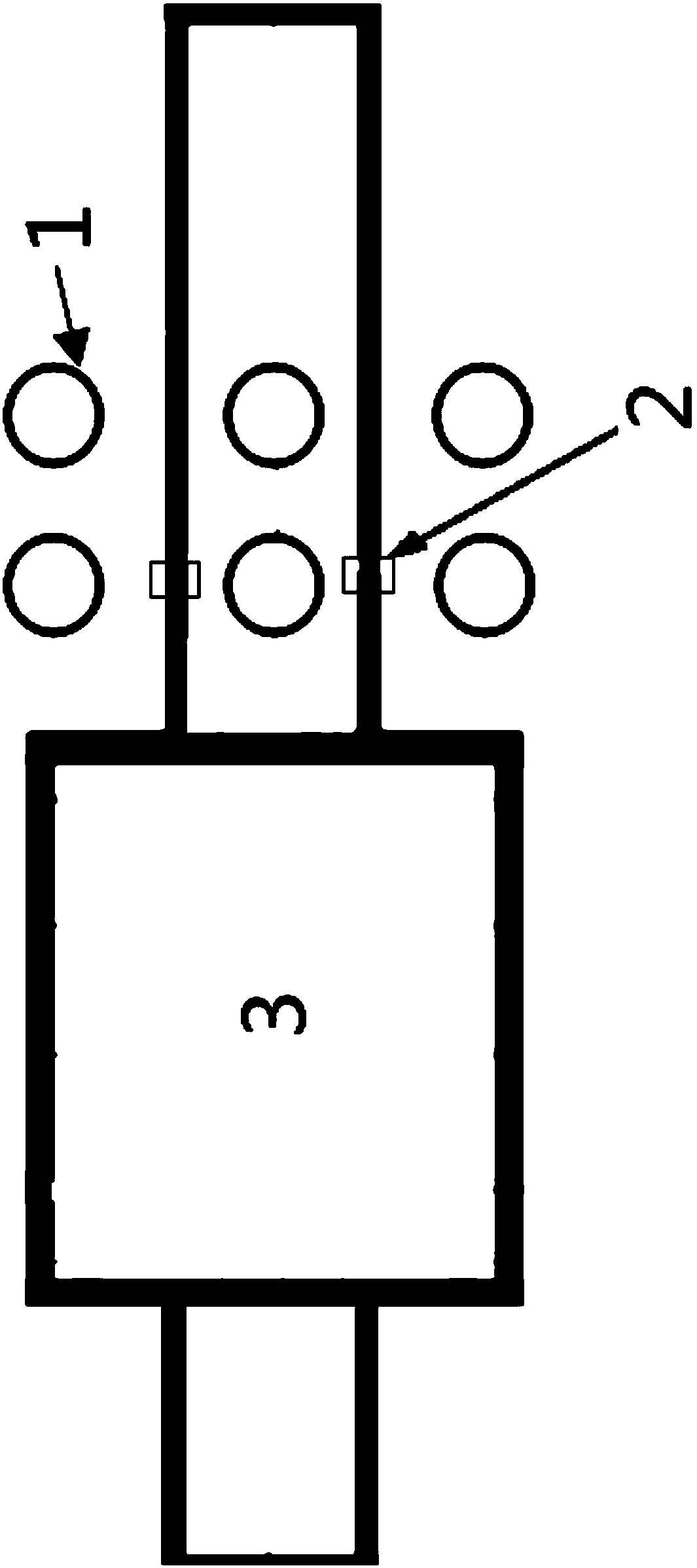

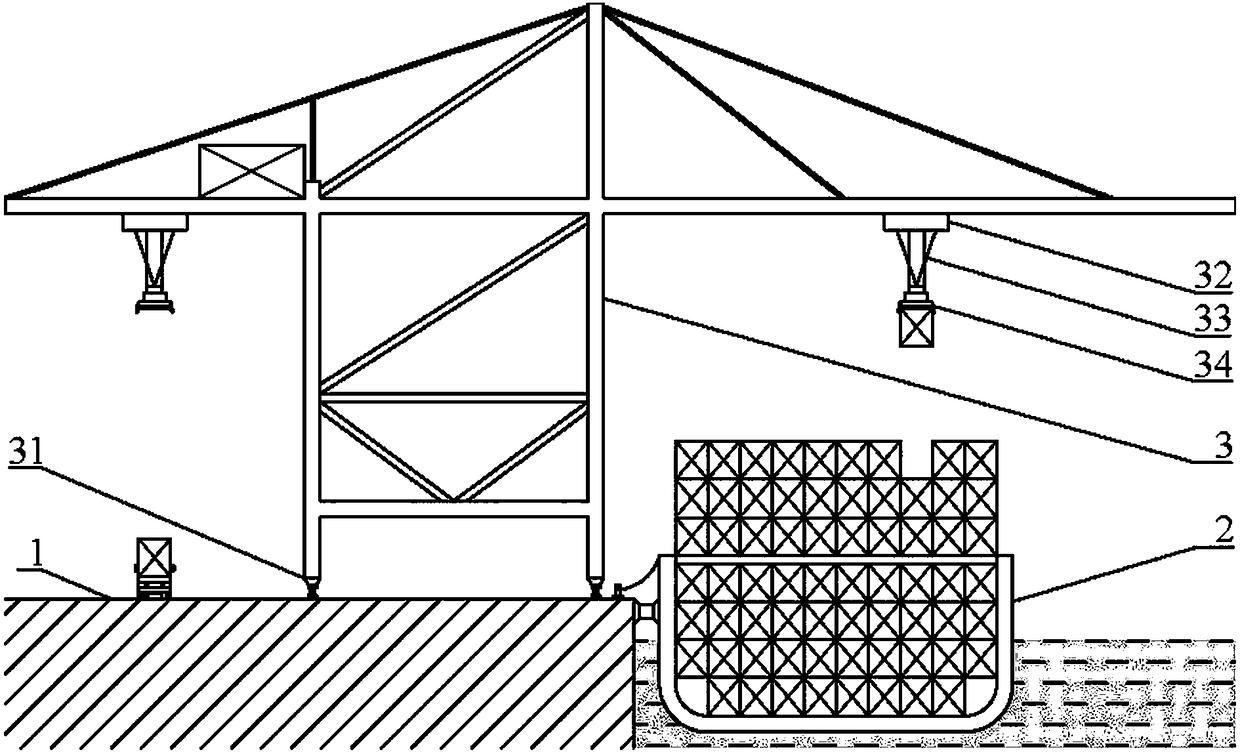

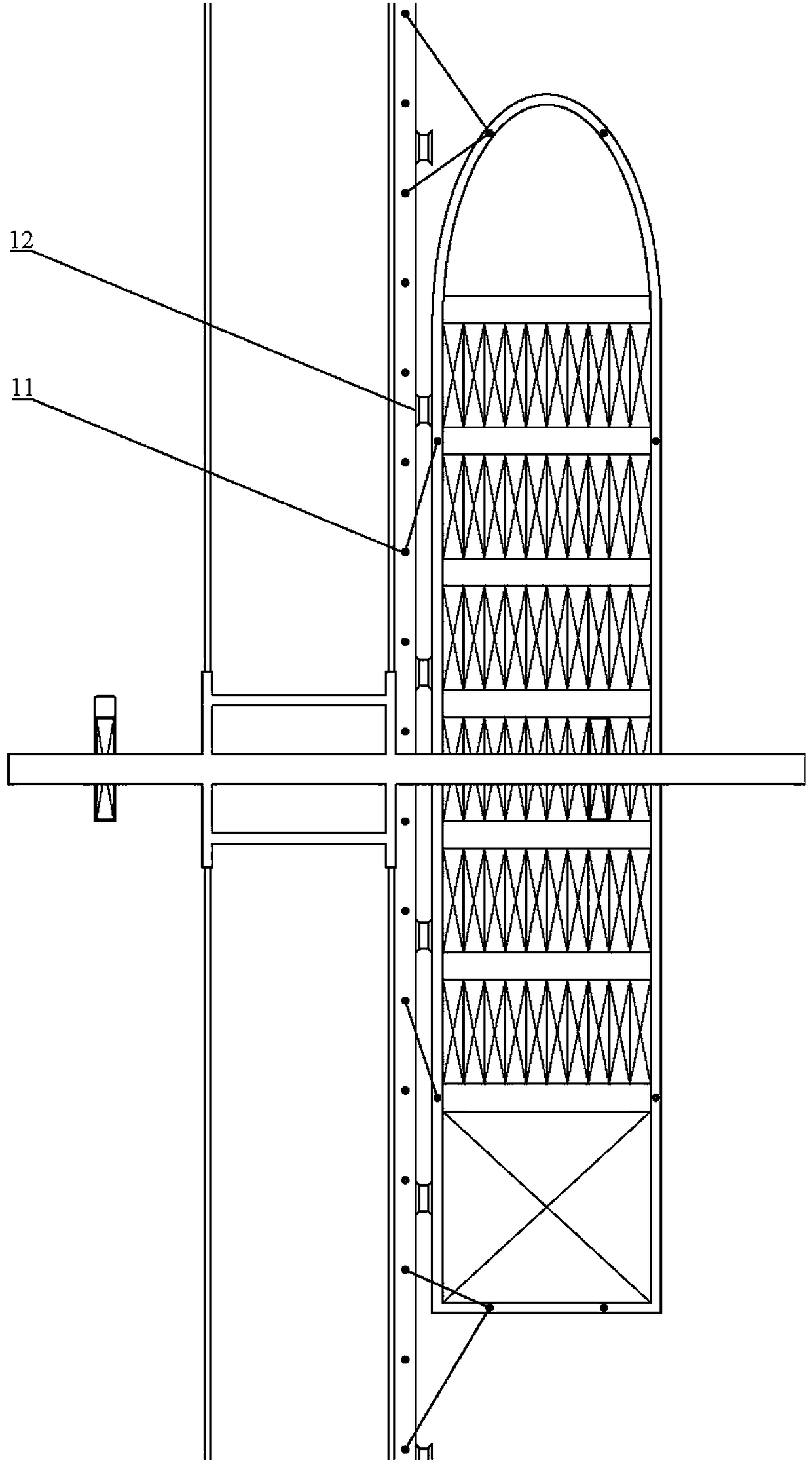

PendingCN106226336AScan check implementationImprove inspection efficiencyTrolley cranesLoad-engaging elementsQuay craneAutomatic guidance

The invention relates to a mobile article check system, a method and a port. The mobile article check system comprises a ray source (31) and a detection mechanism with a detector (33), wherein the ray source (31) and the detection mechanism are mounted on one side of a quay crane and can move to a loading position for an automatic guiding transport cart following the quay crane, so as to complete the scanning check for the automatic guiding transport cart after the articles are loaded. According to the invention, the ray source and the detection mechanism are not specially deployed to enter into the field, the ray source and the detection mechanism can move to the loading position for the automatic guiding transport cart following the quay crane and the automatic guiding transport cart after the articles are loaded can complete the scanning check nearby, so that the scanning check for the mobile articles can be more conveniently realized and the check efficiency can be increased.

Owner:NUCTECH CO LTD

Guiding system and method for quay crane cart based on image recognition

PendingCN108394814AImprove working environmentReduce labor costsLoad-engaging elementsExternal referenceWorking environment

The invention discloses a guiding system and method for a quay crane cart based on image recognition. The guiding system for the quay crane cart based on the image recognition comprises image acquisition devices, a calibration reference object, external reference marks, a cart and processing equipment. The external reference marks are used for calibrating a world coordinate system and an image coordinate system of the image acquisition devices. The two image acquisition devices are separately used for collecting the images of the calibration reference object and transmit the images to the processing equipment. The processing equipment obtains the three-dimensional coordinate information of the calibration reference object. The processing equipment extracts contour information of a container from the collected images to calculate the position data of the container and obtain the coordinate transformation relationship between the image coordinate system and the world coordinate system ofthe container. The processing equipment calculates the real-time position of the container according to the relationship between the two coordinate systems, and controls the cart to carry out bay-position-changing guiding according to the real-time position. According to the guiding system and method for the quay crane cart based on the image recognition, the working environment of a dock driveris improved, the labor cost of the staff is reduced, and the operation efficiency of the port is improved.

Owner:SHANGHAI ZHENHUA HEAVY IND +2

Quay crane structure detection system based on quadrotor unmanned aerial vehicle

InactiveCN106598073ATimely discovery of potential safety hazardsLow costSatellite radio beaconingOptical apparatus testingTransceiverUncrewed vehicle

The present invention discloses a quay crane structure detection system based on a quadrotor unmanned aerial vehicle. The system comprises an unmanned aerial vehicle subsystem, a task pod subsystem and a ground control measurement and control subsystem. The unmanned aerial vehicle subsystem employs a quadrotor unmanned aerial vehicle platform, and comprises a quadrotor unmanned aerial vehicle, and a flight control computer, a flight navigation module, an obstacle avoidance module and a power driving device which are built by the quadrotor unmanned aerial vehicle; the task pod subsystem includes a holder carrying a visual light high-definition camera and a signal transceiver; and the ground control measurement and control subsystem includes a ground controller and a ground computer. The quay crane structure detection system based on the quadrotor unmanned aerial vehicle is simple in structure, convenient to use and is limited by the limitation of the time and the space. The unmanned aerial vehicle can perform near-distance, multi-angle and omnibearing high-definition camera of the quay crane, can be hovered in air for long-term camera of a certain point, can transmit the image to a ground computer to timely and accurately discover the metal structure problem of the crane and solve the potential safety hazard to ensure the safety operation work of the crane.

Owner:WUHAN UNIV OF TECH

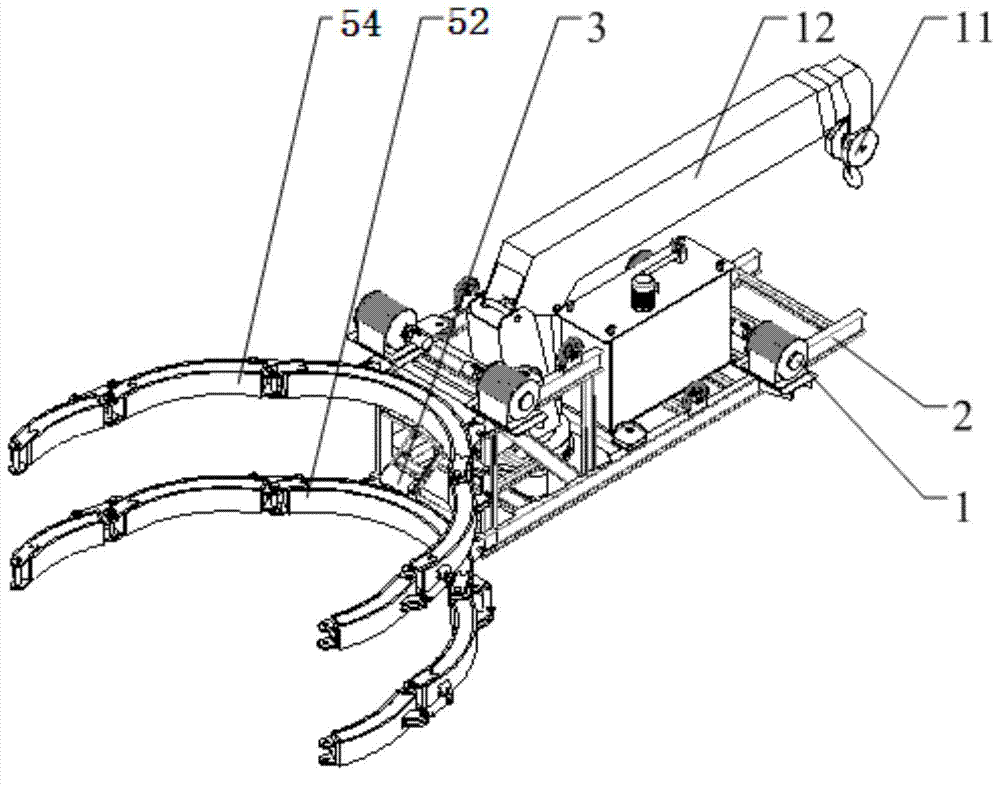

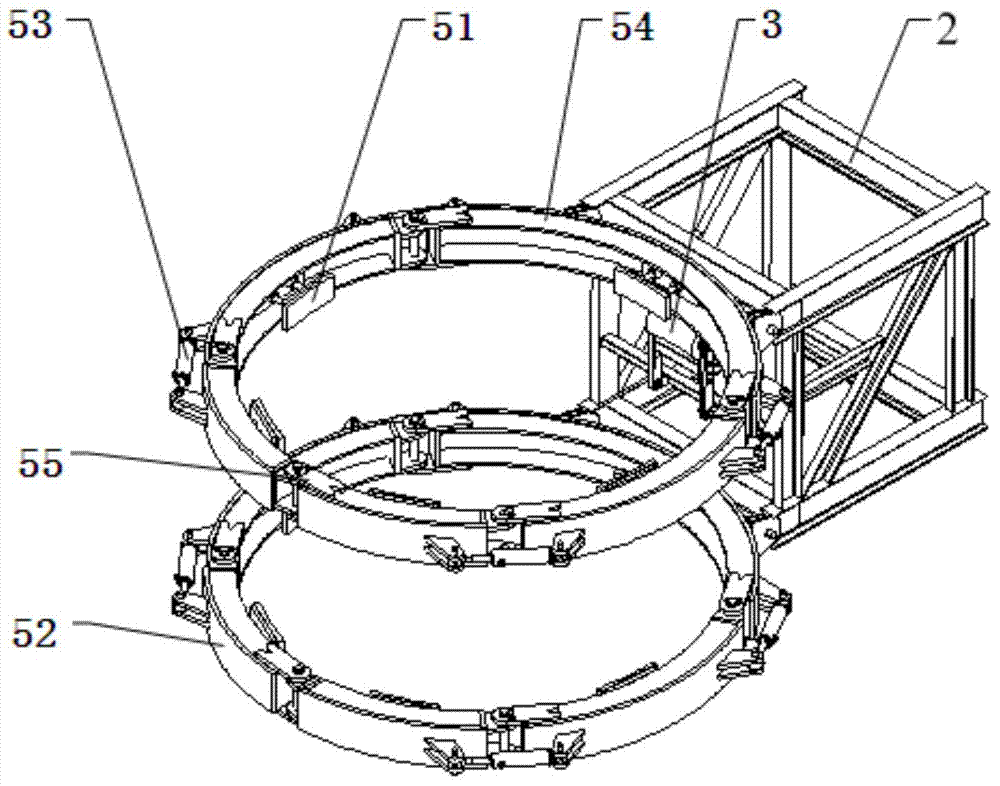

Traction attached type fan maintenance hoisting platform

The invention discloses a traction attached type fan maintenance hoisting platform, belonging to the technical field of fans. The traction attached type fan maintenance hoisting platform comprises a reducing attachment device, a depended wheel mechanism, a pulley block hanging bracket, a working platform and a rotatable hoisting mechanism, wherein one end of the working platform is connected with the reducing attachment mechanism fixedly connected with a tower tube, the working platform is also connected with the retractable depended wheel mechanism used for supporting the tower tube, the pulley block hanging bracket is fixed on a fan cabin, and connected with the working platform through a coiling drum steel wire rope on the working platform so as to realize the lifting and descending of the working platform; the rotatable hoisting mechanism for hanging the parts is fixed on the working platform. The hoisting platform disclosed by the invention can be lifted and can descend, the climbing synchronism and the security are good, the whole machine is stable, the assembling / disassembling and the operation are convenient; the hosting platform is suitable for maintaining and repairing outer vertical faces of various wind driven generator tower drums, cabin outer surfaces and fan blades.

Owner:SHENYANG JIANZHU UNIVERSITY

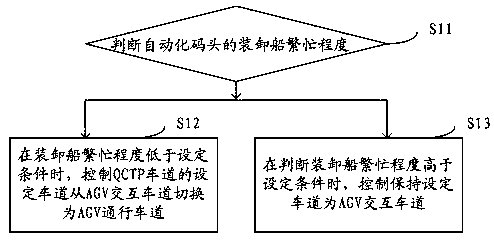

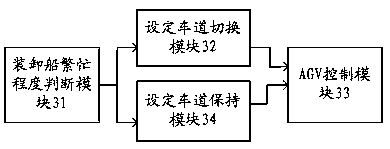

Automated guided vehicle AGV path optimization method and system in automated container terminal quay crane transpoint QCTP operation

InactiveCN109213163AShorten the running distanceImprove work efficiencyPosition/course control in two dimensionsAutomated guided vehicleDegrees of freedom

The invention discloses an automated guided vehicle AGV path optimization method and system in an automated container terminal quay crane transpoint QCTP operation. The busyness degree of loading andunloading a ship of the automated container terminal is judged; when the busyness degree of loading and unloading a ship is lower than a set condition, a set lane of the QCTP lane is controlled to beswitched from an AGV interaction lane to an AGV passing lane so that the AGV can pass on the set lane; when the busyness degree of loading and unloading a ship is higher than a set condition, the setlane is kept as the AGV interaction lane. According to the automated guided vehicle AGV path optimization method and system in an automated container terminal quay crane transpoint QCTP operation in the application, a set lane is set; when the ship loading and unloading operation is busy, the set lane is used as the AGV interaction lane; when the ship loading and unloading operation is not busy, the set lane is used as the AGV interaction lane; when the ship loading and unloading operation is not busy, the set lane is switched into the AGV passing lane for use, thereby reducing the AGV operation path, improving the AGV driving degree of freedom, thereby improving the AGV operation efficiency.

Owner:QINGDAO PORT INT +1

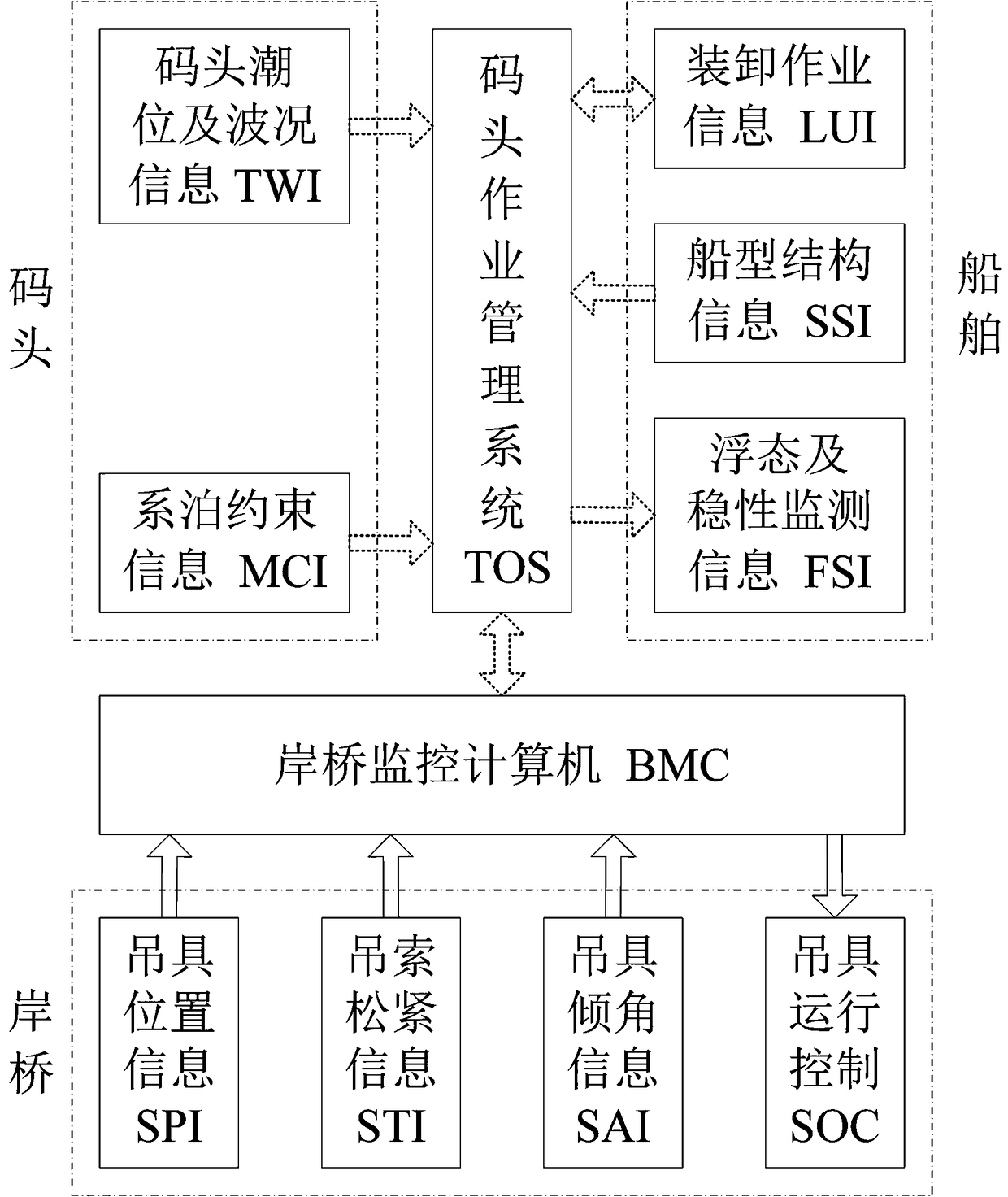

Ship floating state and stability monitoring device and method for container quay crane

ActiveCN109437020AMeet efficiency requirementsReduced measurement timeLoad-engaging elementsVessel typeMonitoring methods

The invention relates to a ship floating state and stability monitoring device and method for a container quay crane. According to information, such as quay tide level and wave conditions, mooring constraints, loading and unloading operation, a ship-type structure, a hanger position, sling tightness, and a hanger inclination angle, obtained through a quay operation management system and a quay crane monitoring computer, a natural period and a steady-state inclination angle are predicted through a ship rolling non-mooring constraint extreme point measurement method, a ship static inclination angle and initial stability safety are calculated and verified, and floating state and stability alarming in the ship loading and unloading processes is conducted; the problems of a small container shipwhich is not equipped with a loader, cannot provide carrying information, and is difficult to accurately verify the initial stability are solved, thus the crew testing work intensity is reduced, andthe ship loading stability safety is ensured; the disadvantage that a rolling period test method needs to remove ship mooring and measures the complete period is overcame, free rolling generated by loading and unloading operation in a quay is effectively used, the measurement time of a hanger loaded on the ship is greatly shortened, and the efficiency requirements of quay crane loading and unloading operation are basically met; and immediate data reference is provided for timely stowage or ballast adjustment of the quay and the ship, and the ship floating state and stability monitoring deviceand method for the container quay crane can be widely applied to various container quay cranes of manual or automated quays.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com