Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Reduce on-site commissioning time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

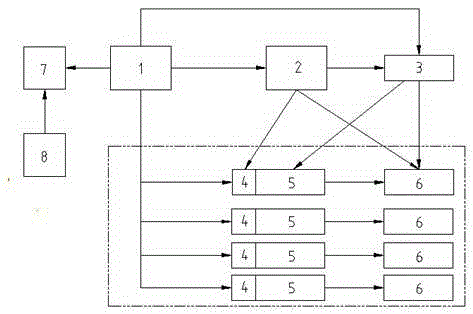

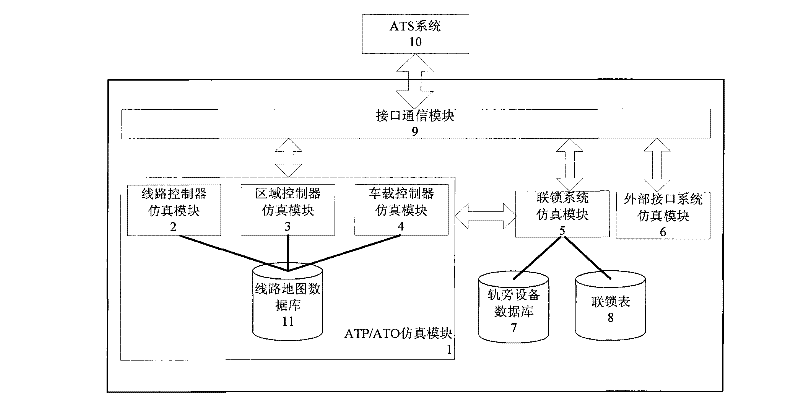

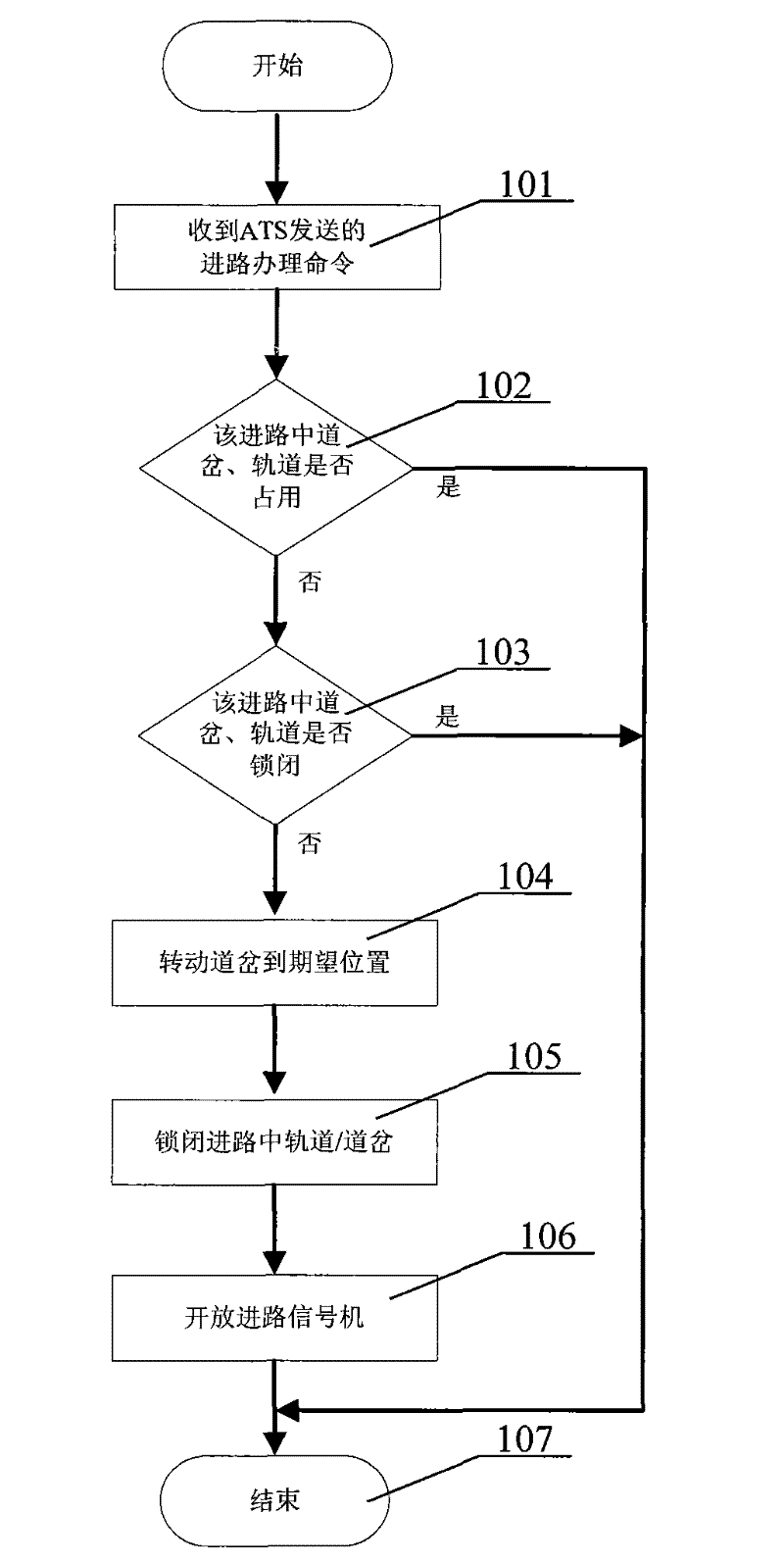

Simulator suitable for testing and training of ATS system

ActiveCN101719189AImprove stabilityReduce on-site commissioning timeCosmonautic condition simulationsSpecial data processing applicationsSystems simulationExternal interface

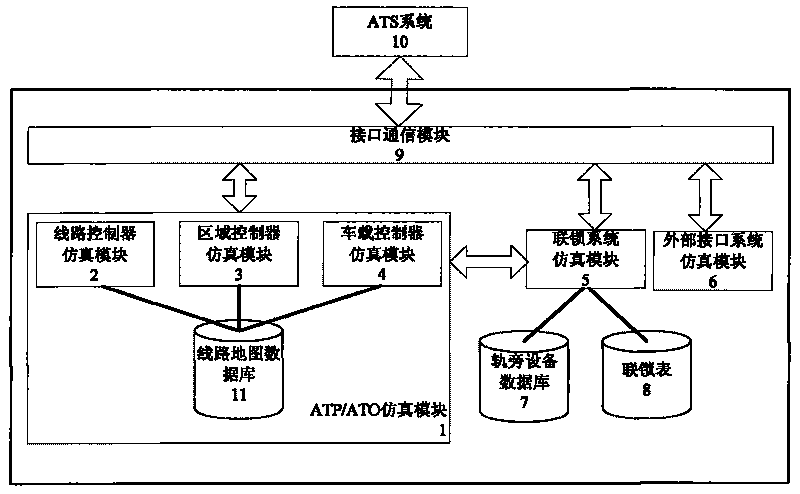

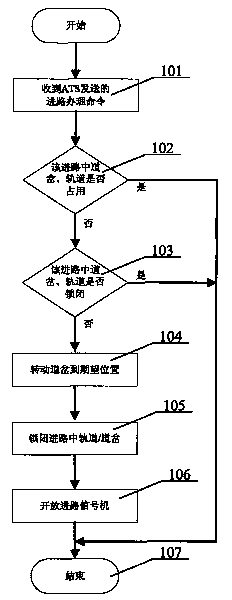

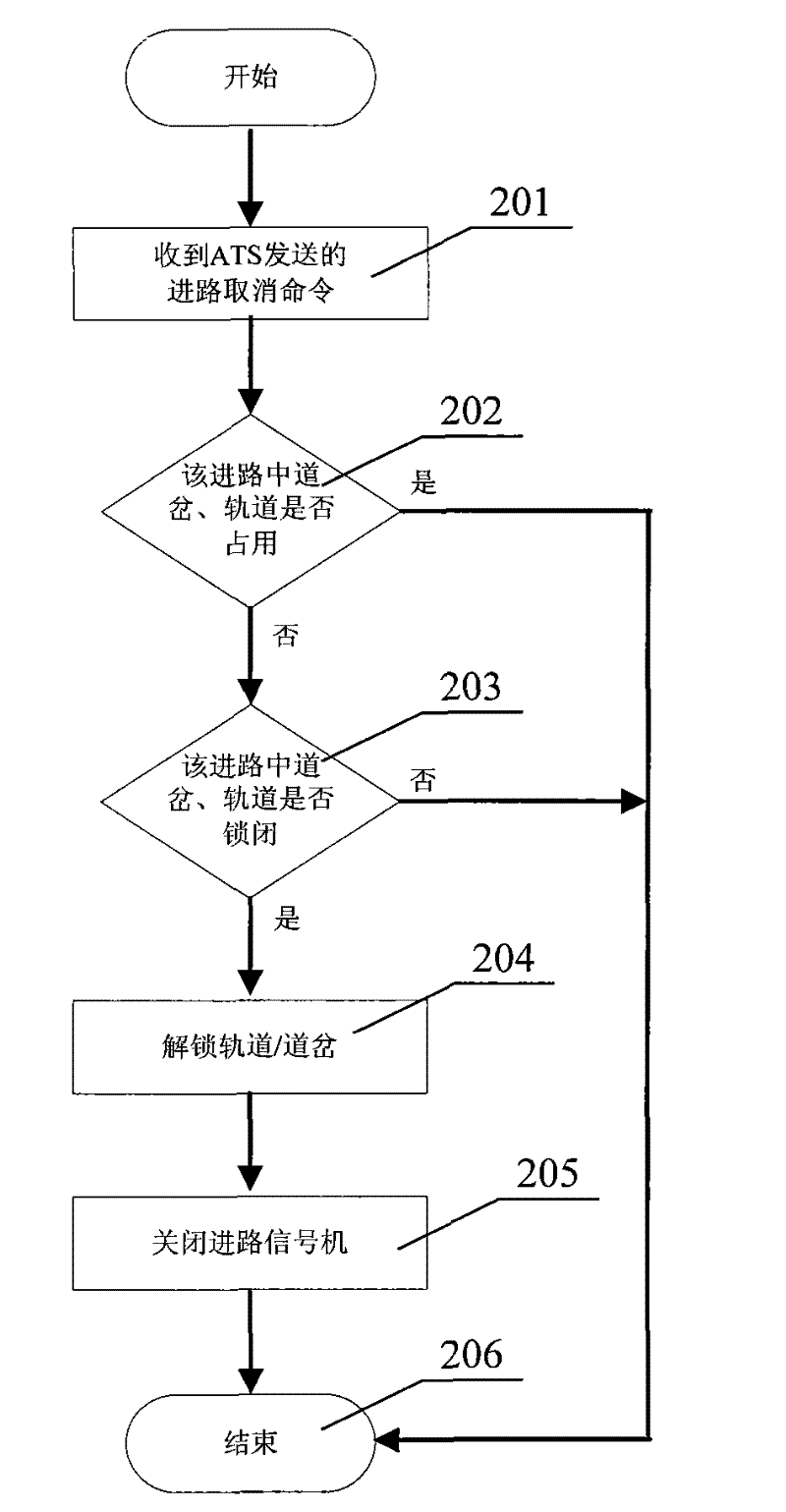

The invention relates to a simulator suitable for the testing and the training of an ATS system, comprising an ATP / ATO simulation module, an interlocking system simulation module, an ATS external interface system simulation module, an interface communication module, a trackside equipment database and an interlocking table, wherein the ATP / ATO simulation module comprises a circuit controller simulation module, an area controller simulation module, a vehicle-mounted controller simulation module and a circuit map database; the ATP / ATO simulation module, the interlocking system simulation module and the ATS external interface system simulation module are respectively connected with the interface communication module; the interlocking system simulation module is respectively connected with the trackside equipment database and the interlocking table; and the circuit controller simulation module, the area controller simulation module and the vehicle-mounted controller simulation module are respectively connected with the circuit map database. Compared with the prior art, the invention enhances the stability and the like of the ATS system through ATS functional test.

Owner:CASCO SIGNAL

Ground automatic neutral-section passing device and control method thereof

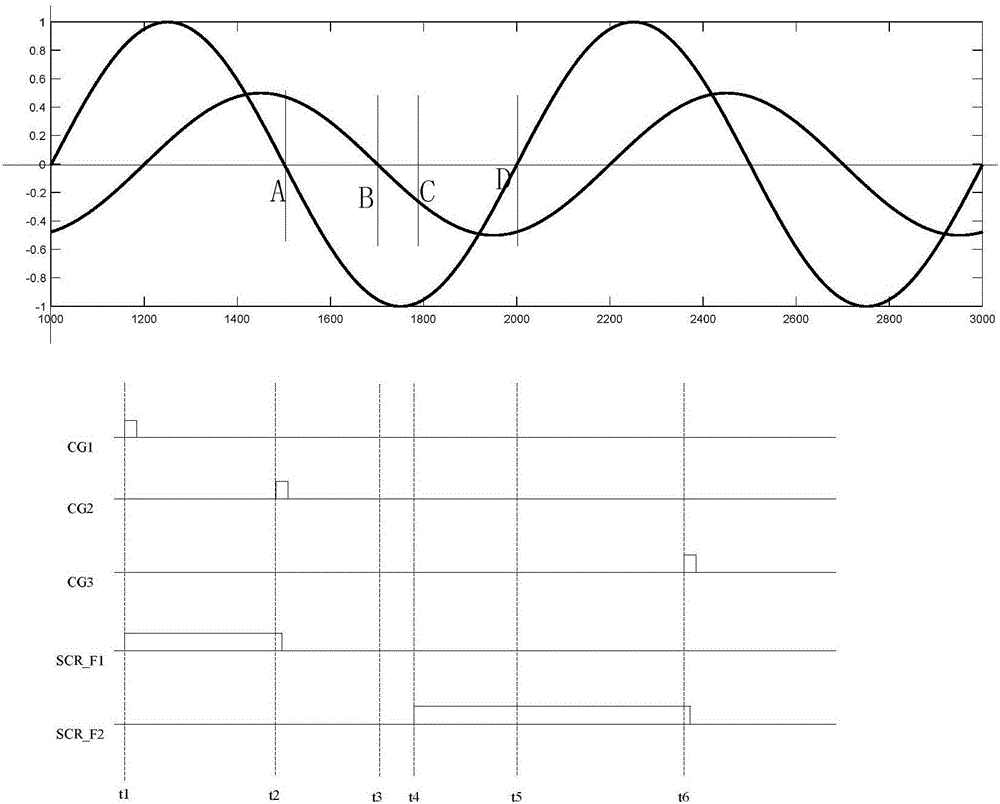

ActiveCN106394318AComplete protection functionsImprove reliabilityPower supply linesThyratronEngineering

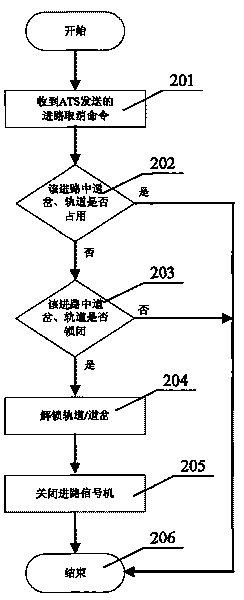

The invention discloses a ground automatic neutral-section passing device and a control method thereof. The ground automatic neutral-section passing device comprises a train identification unit, a logic control system, a valve control unit, a thyristor valve block unit consisting of two thyristor valve blocks connected in series, and a current detection unit for detecting the current of the thyristor valve blocks, which are connected successively, wherein the thyristor valve block unit is connected with a two-phase power supply arm and a neutral zone of a catenary respectively; the logic control system is connected to one of the thyristor valve blocks according to an identified train travelling position and direction control to supply power for the neutral zone; and when phase change is needed, the logic control system is connected to the other thyristor valve block according to the state switching of thyristor current. According to the control method, neutral-section passing is realized through controlling the two thyristor valve blocks, and when the phase change is performed, if the current of one of the thyristor valve blocks achieves a cross-zero state through detection and judgment, the other thyristor valve block is opened immediately. The ground automatic neutral-section passing device and the control method disclosed by the invention have the advantages of being capable of realizing automatic neutral-section passing of a train under a condition that the power is not cut off, high in reliability, stable in operation, extremely small in power-off dead zone of the neutral zone, and the like.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

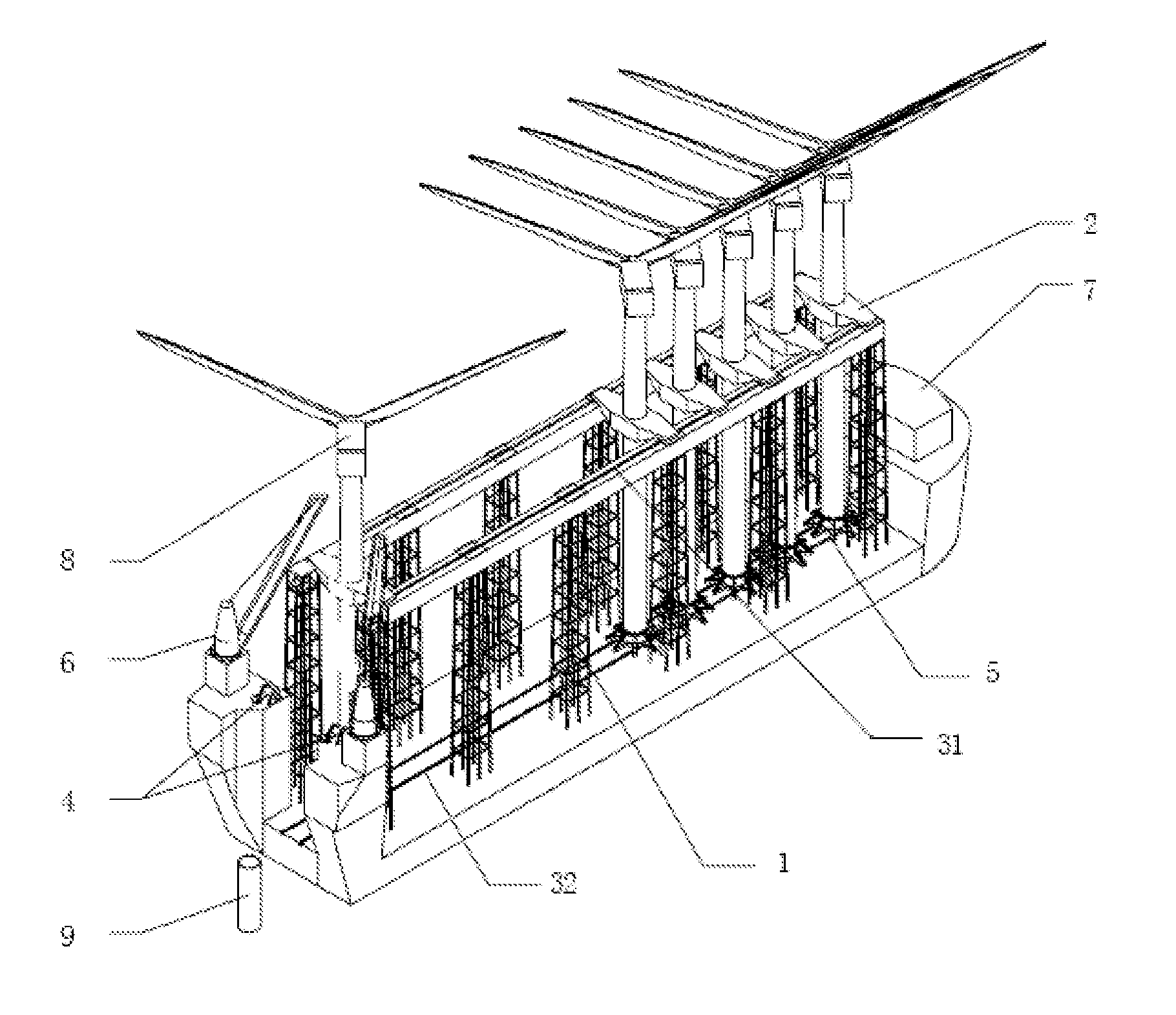

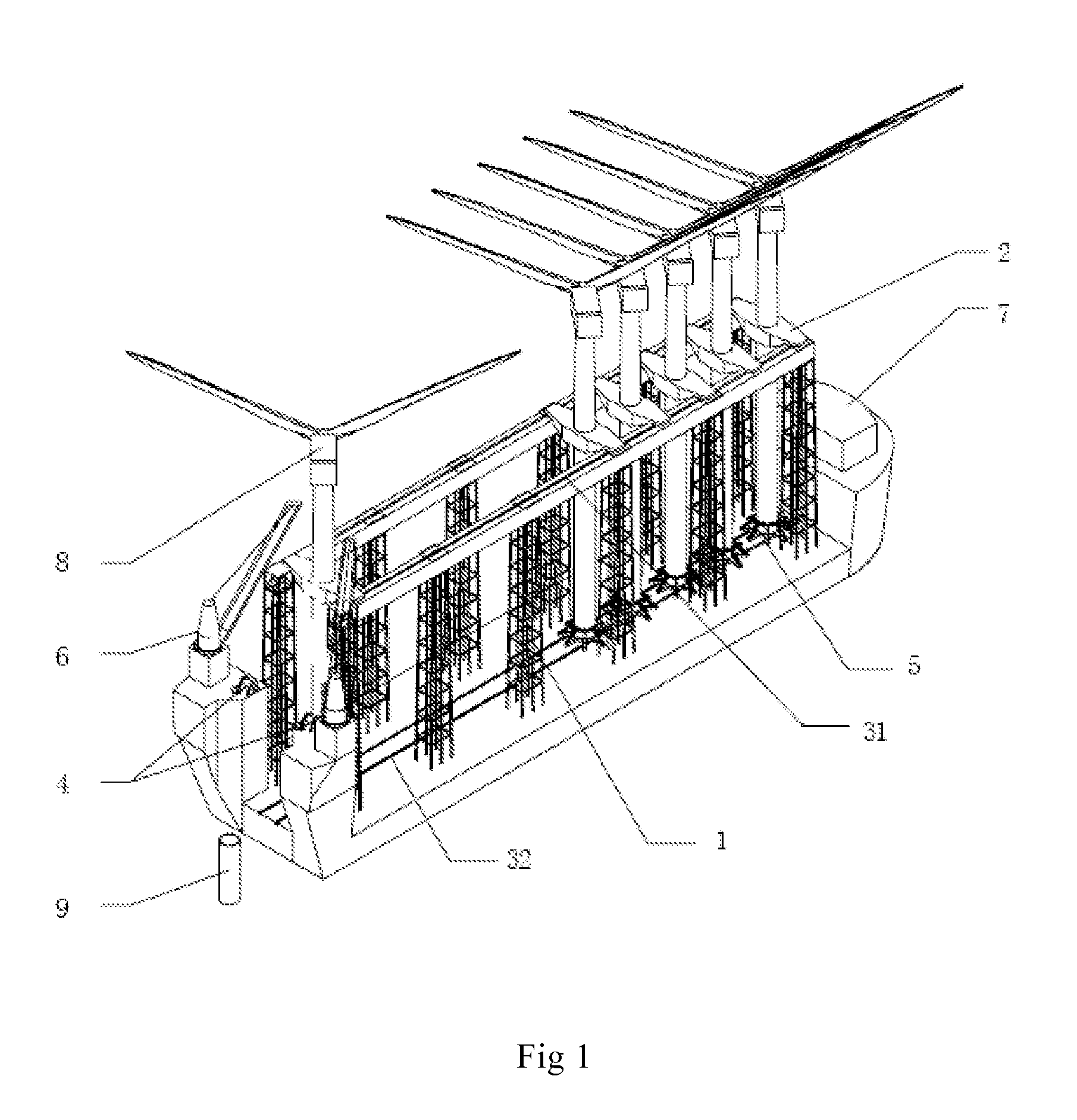

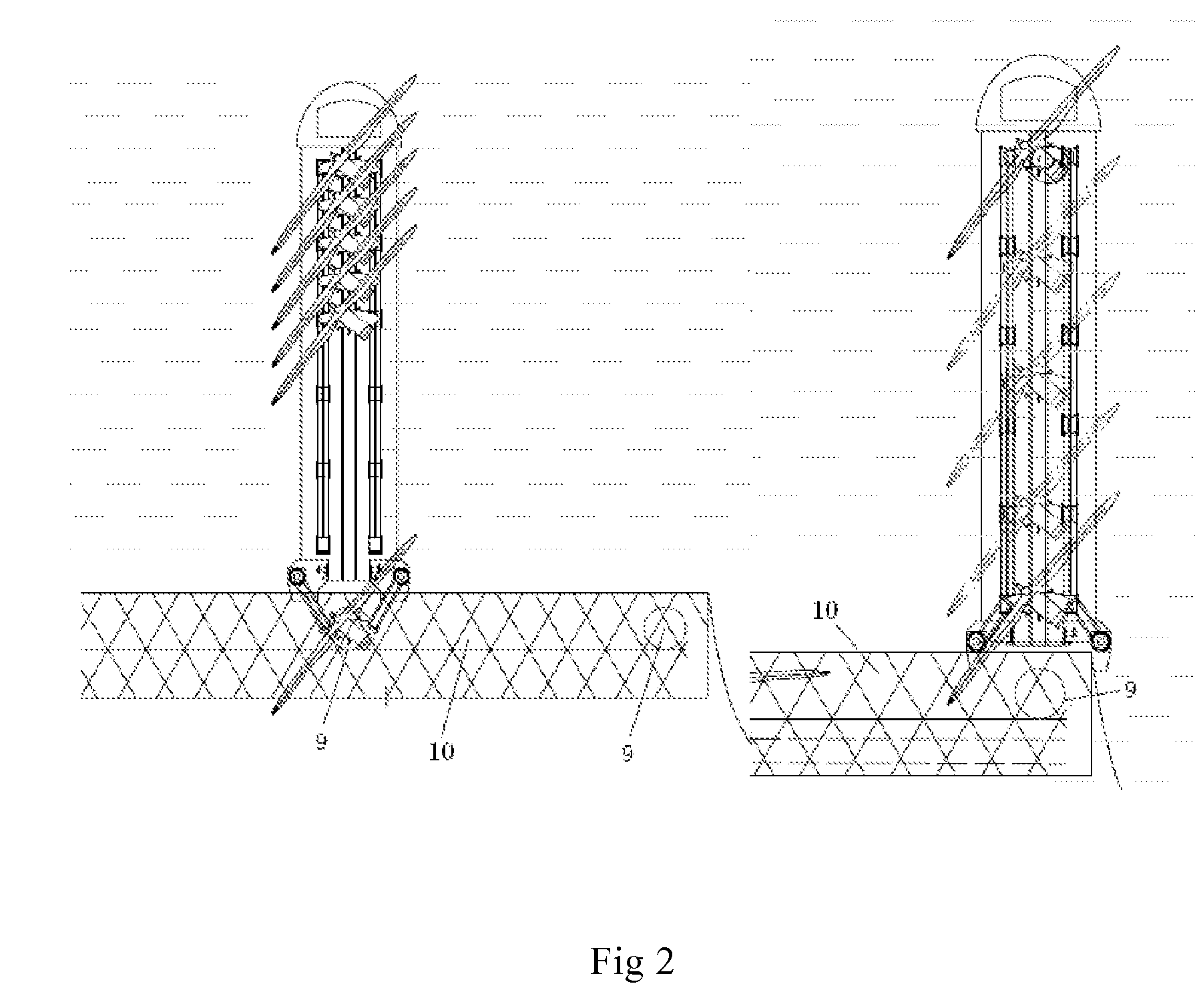

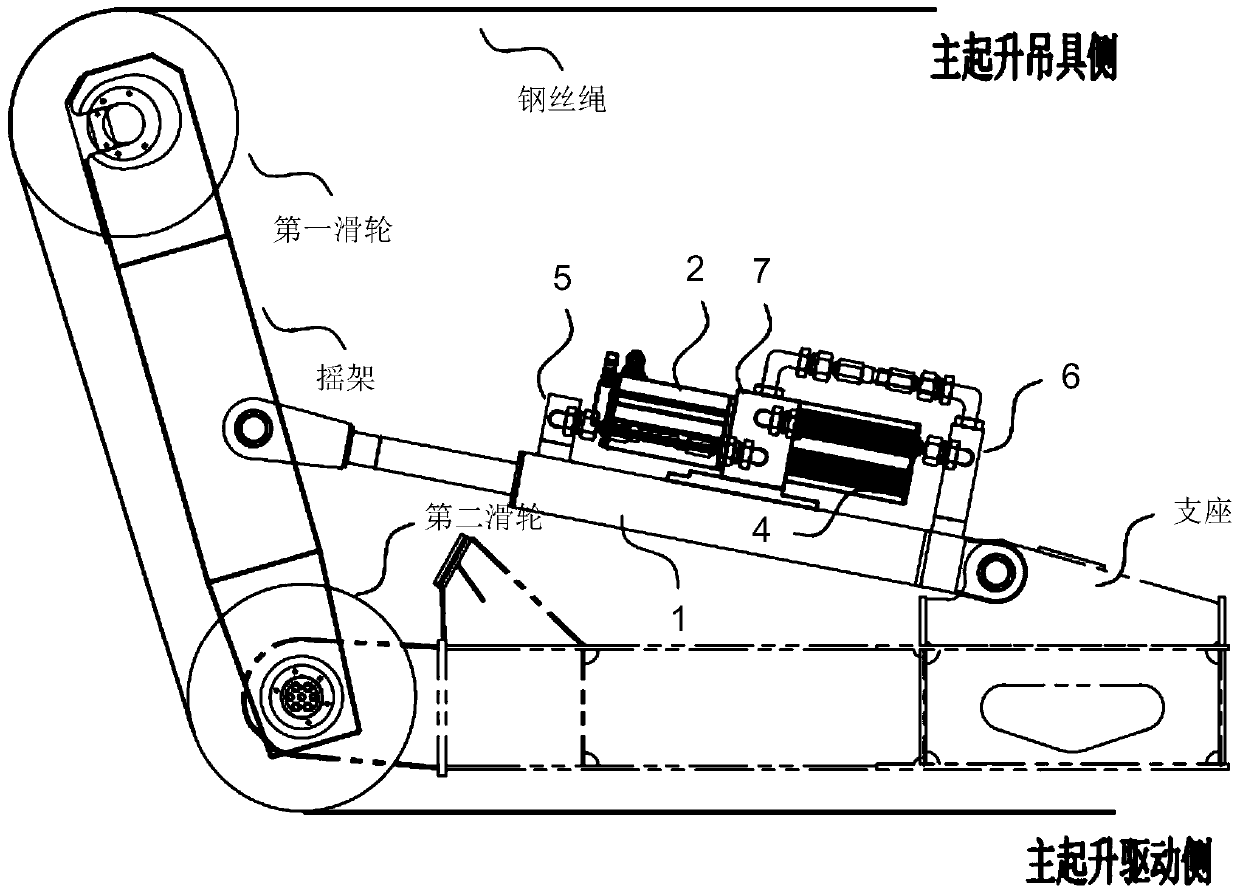

Vessel and method for transporting and hoisting the offshore wind turbine generator system

InactiveUS20120219364A1Reduce deliveryReduce on-site commissioning timeCargo handling apparatusPassenger handling apparatusSternWinch

A vessel for transporting and hoisting offshore wind turbine includes a hull, fixing brackets, first sliding rails, second sliding rails, a buffer device, rotary cranes and winch devices. A U-shaped opening is provided at the stern of the hull for a wind turbine to pass through. The fixing brackets are arranged in two rows in parallel, and their bottoms are fixed onto the deck in the hull. The second sliding rails are in parallel with the first sliding rails. A hanging beam slidably matched with the first sliding rails is installed on the body of the wind turbine. The buffer device is fixed to the bottom of the wind turbine. The rotary cranes are fixed on the top of two sides of the U-shaped opening. The winch devices are installed on the stern of the hull. An offshore wind turbine transporting and hoisting method using the vessel is also disclosed.

Owner:SINOVEL WIND GRP

Deep integration and interconnection method for track traffic system

InactiveCN101492062AEnhance system functionsRealize network resource sharingRailway traffic control systemsRail trafficLinkage concept

The invention relates to a deep integration and interconnection method for a rail traffic system. The method combines the characteristics of an automatic comprehensive monitoring system of an urban rail traffic system in China, and adopts a deep integration and interconnection mode suitable for subways and light rails to contribute to real-time centralized monitoring for electromechanical devices and coordinating linkage among various systems. The method is characterized in that a station level local network of the comprehensive monitoring system is established, and a plurality of control layer devices positioned in upper and lower computer structures directly access the station level local network of the comprehensive monitoring system; therefore, inter-station communication function and remote access, downloading and maintenance functions between the control layer devices can be realized through the station level local network of the comprehensive monitoring system, which cannot be realized in the prior top end information integration mode.

Owner:TRANSCEND COMM BEIJING

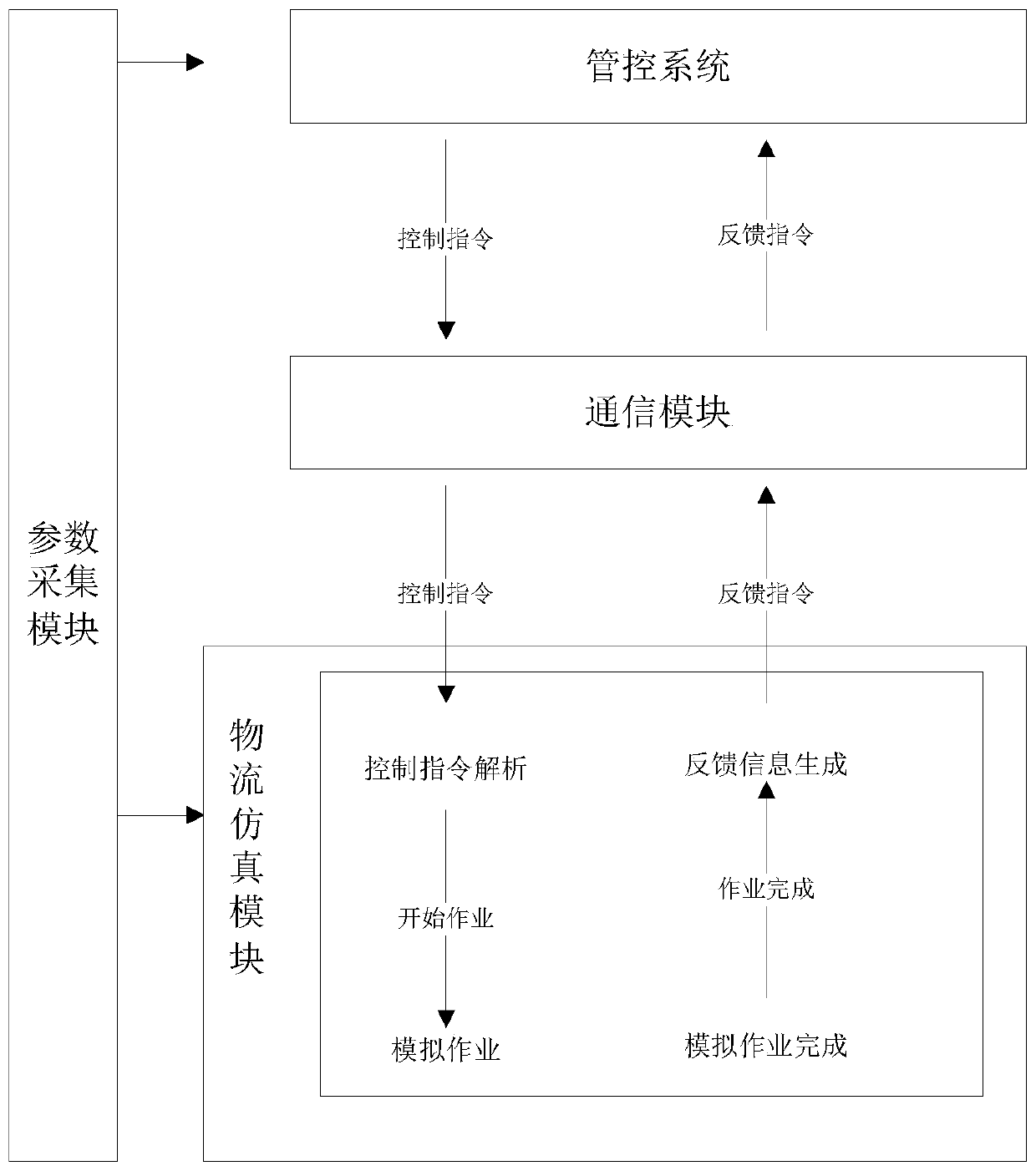

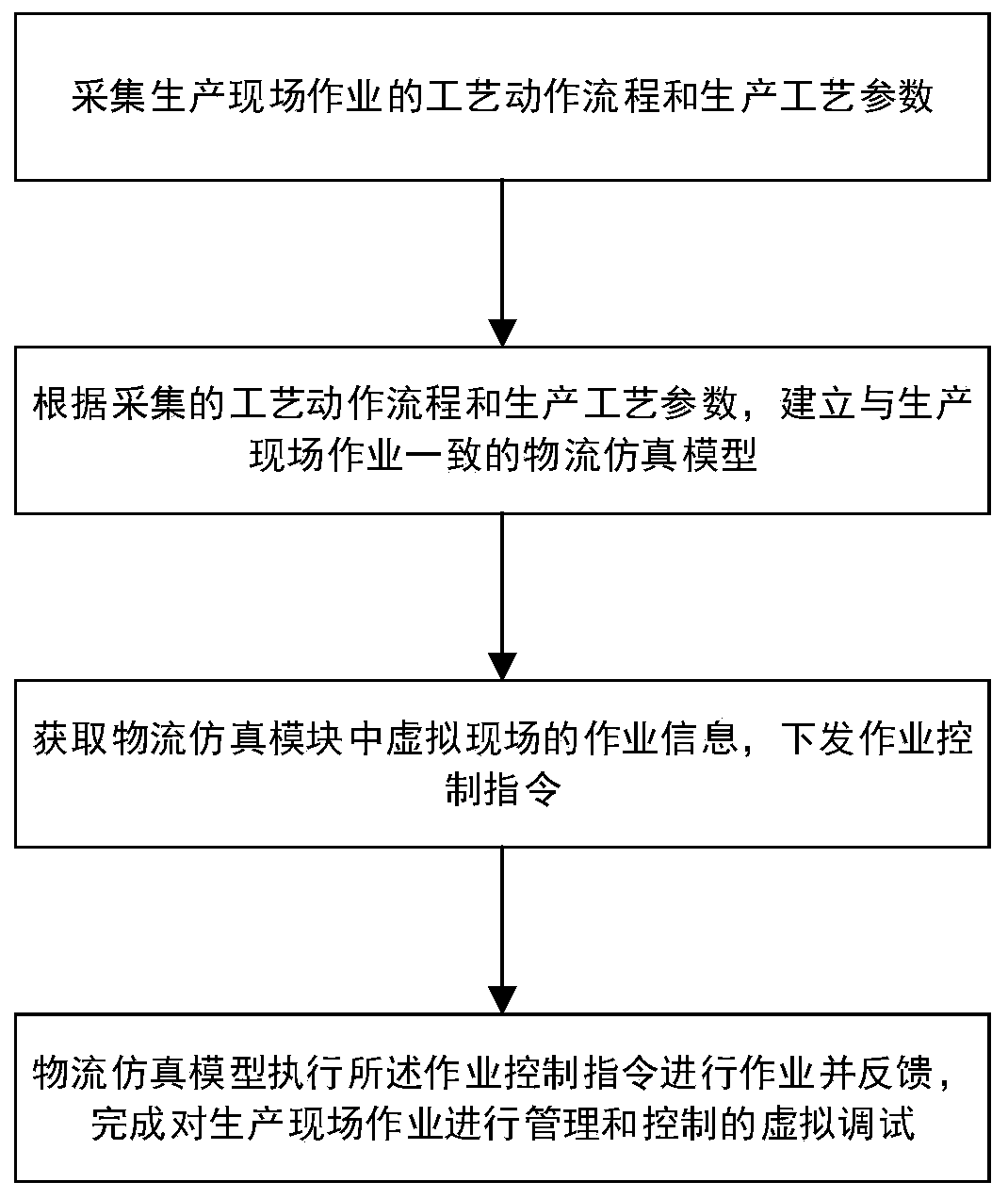

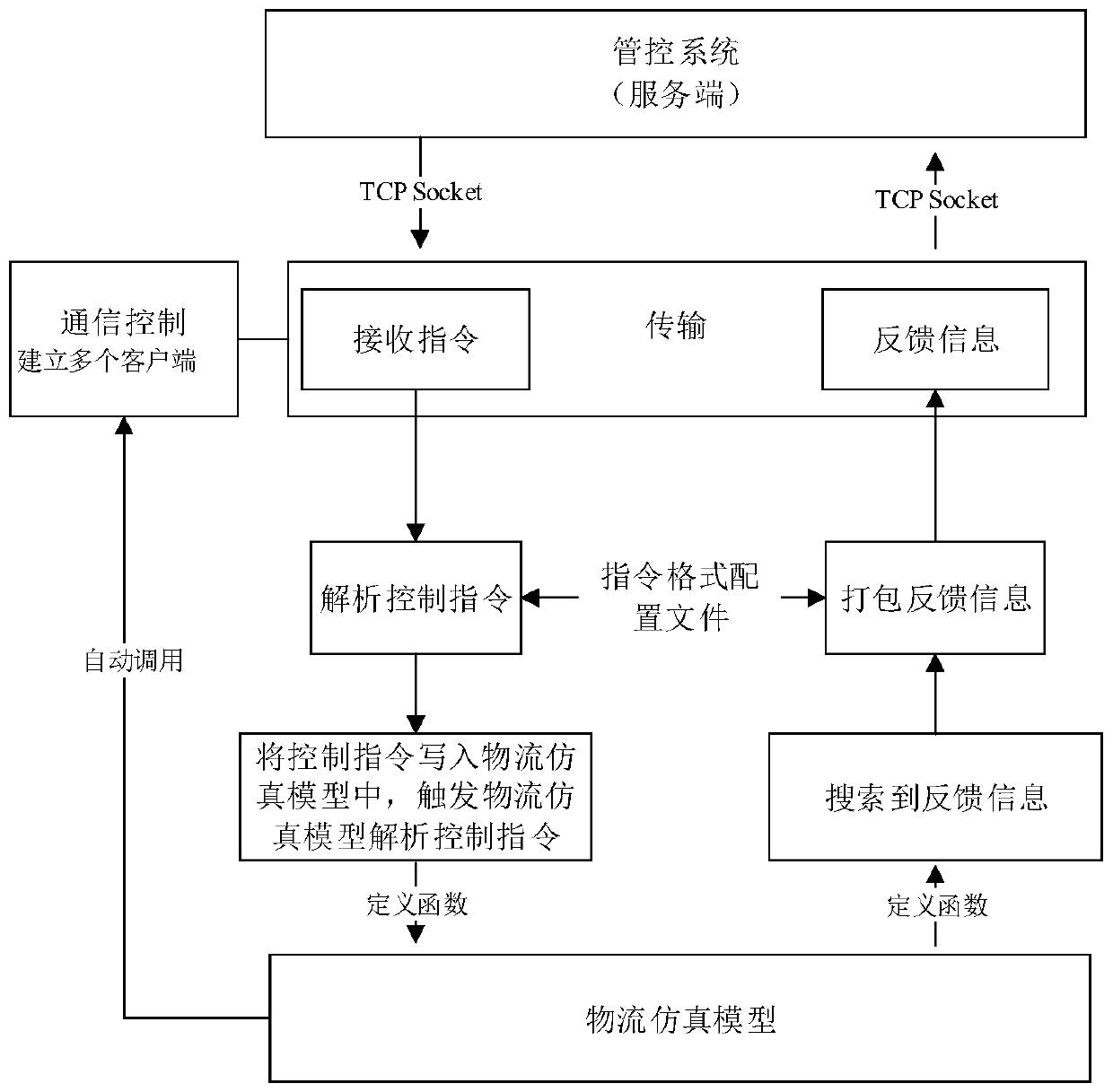

Virtual debugging system and method for automatic management and control system based on logistics simulation

PendingCN110175803ASimple processReasonable resource schedulingResourcesLogisticsLogistics managementControl system

The invention provides a virtual debugging system and method for an automatic management and control system based on logistics simulation, and the system comprises a parameter collection module whichis used for obtaining a process action flow and the production process parameters of an unbuilt production field operation according to a preset design scheme, a management and control system which isused for carrying out production scheduling management and control on the production field operation, a logistics simulation module which is used for establishing a logistics simulation model consistent with the production field operation according to the collected process action flow and the production process parameters, a communication module which is used for data communication between the logistics simulation module and the automatic management and control system. According to the present invention, the automatic management and control system can be virtually debugged under the conditionthat an actual operation scene is not built or the on-site debugging is limited, so that the on-site debugging time is greatly shortened; after the automatic management and control system is put intooperation, the on-site operation can be virtually displayed in real time through the simulation model, an operation index result is outputted in the simulation model in real time, the on-site operation conditions are counted and analyzed, and the operation completion conditions and indexes are predicted.

Owner:CISDI INFORMATION TECH CO LTD

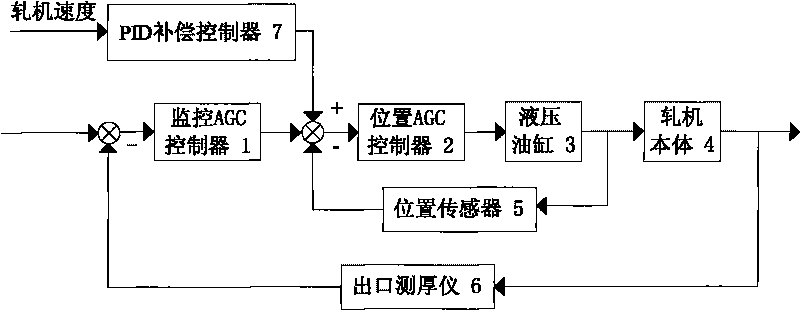

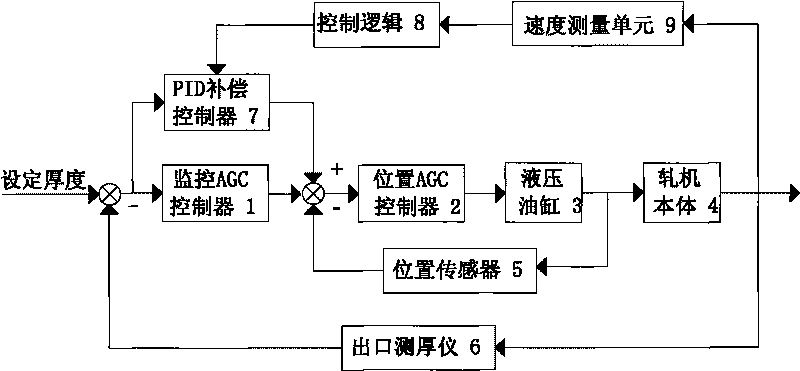

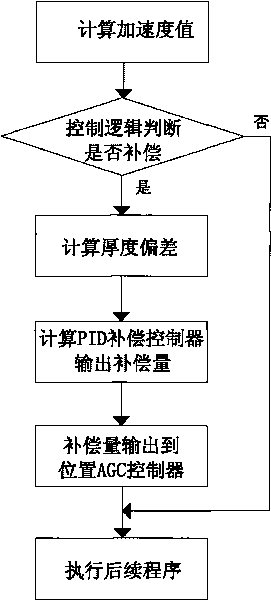

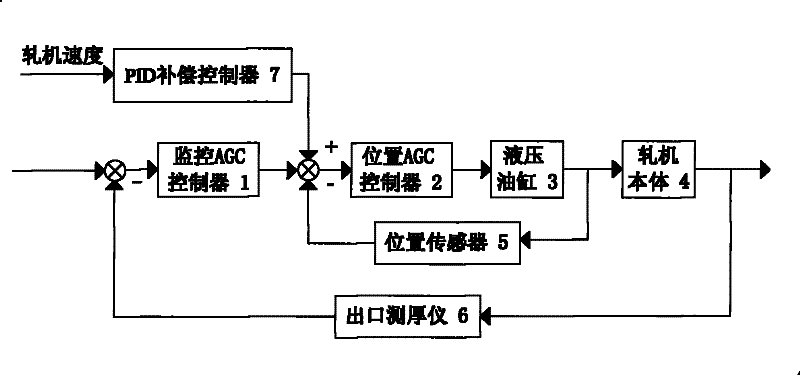

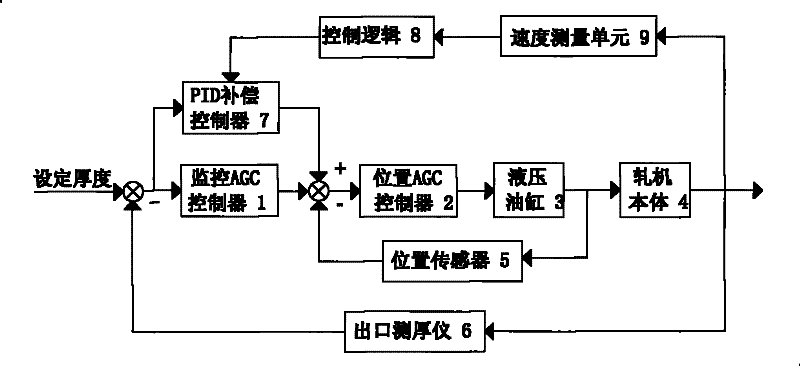

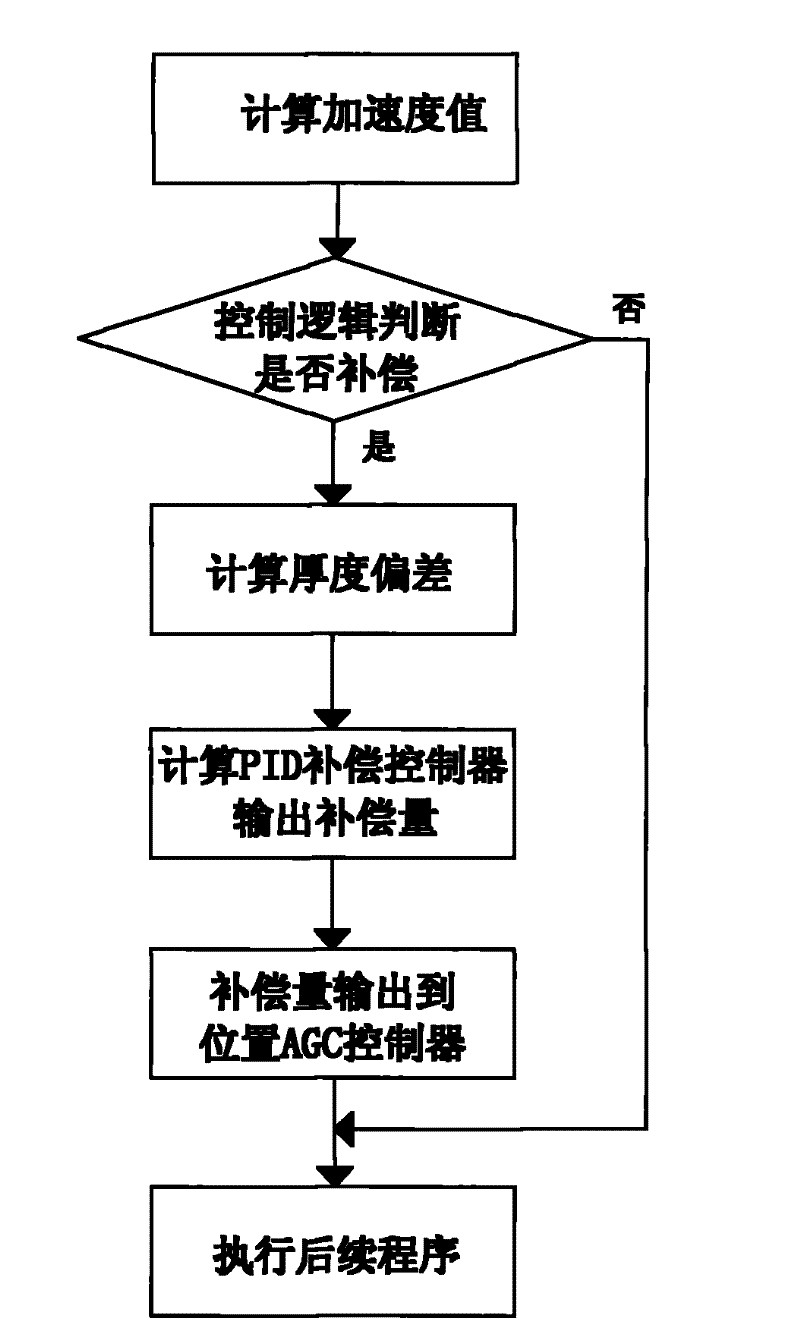

Closed loop speed compensation method for thickness control system of aluminum cold rolling mill

ActiveCN101745541AImprove performanceImprove efficiencyRoll mill control devicesMetal rolling arrangementsControl systemClosed loop

The invention relates to a closed loop speed compensation method for a thickness control system of an aluminum cold rolling mill. The method comprises the following steps: data is obtained according to a speed measuring unit for calculating the value of acceleration, then control logic judgment is carried out, the thickness deviation is taken as an input signal of a closed loop PID compensation controller, the compensation amount is calculated and then output to a position AGC controller, and the computing process of closed loop speed compensation for one time is further finished. The stability of the system can be obviously improved by converting the open-loop compensation into a closed-loop compensation control algorithm, and the method can be better automatically adapted for the change conditions of the rolling process; and furthermore, by adjusting the parameter of the closed loop PID compensation controller, the field debugging time of the speed compensation controller can be reduced, the production cost can be reduced, and the performance of dynamic process of the thickness control system can be enhanced, therefore, the method is worthy of wide application in the industry.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

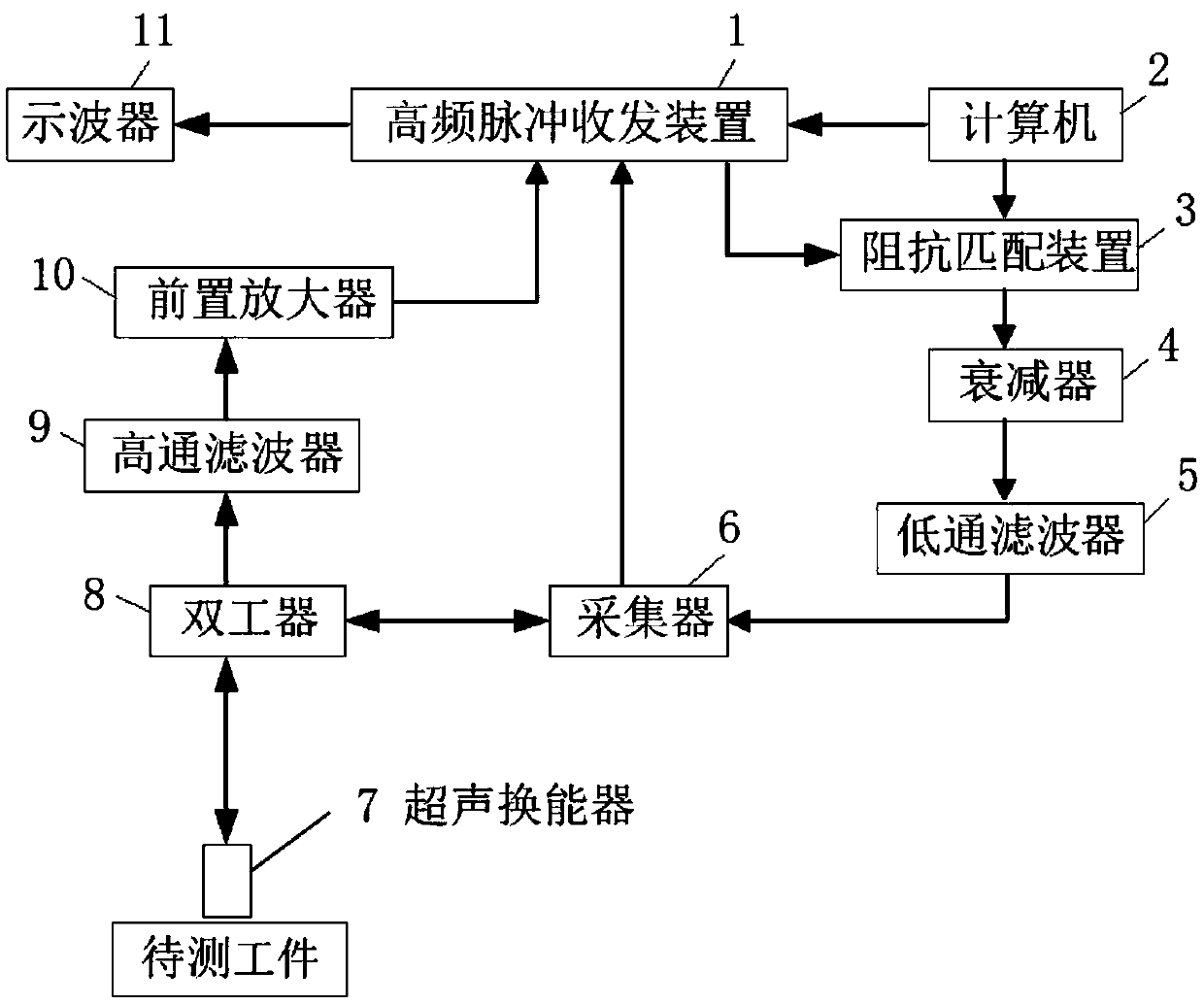

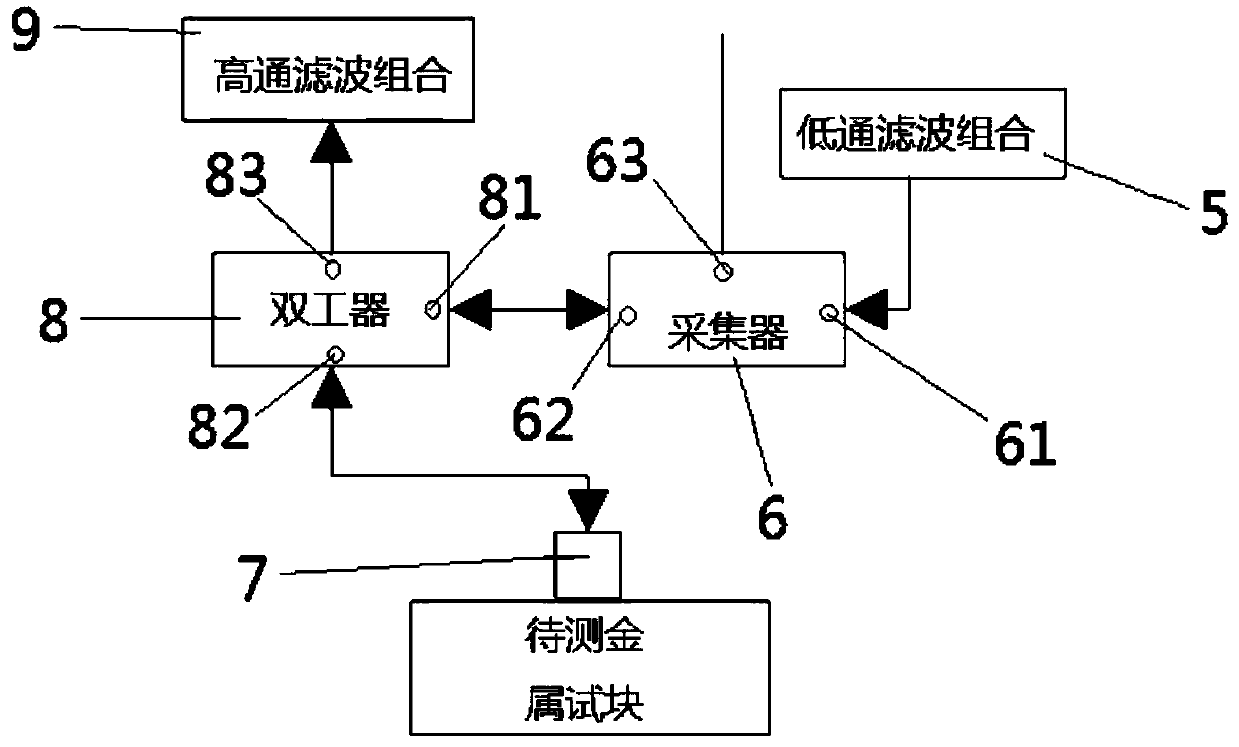

Nonlinear ultrasonic detection system and detection method for reflective metal creep performance

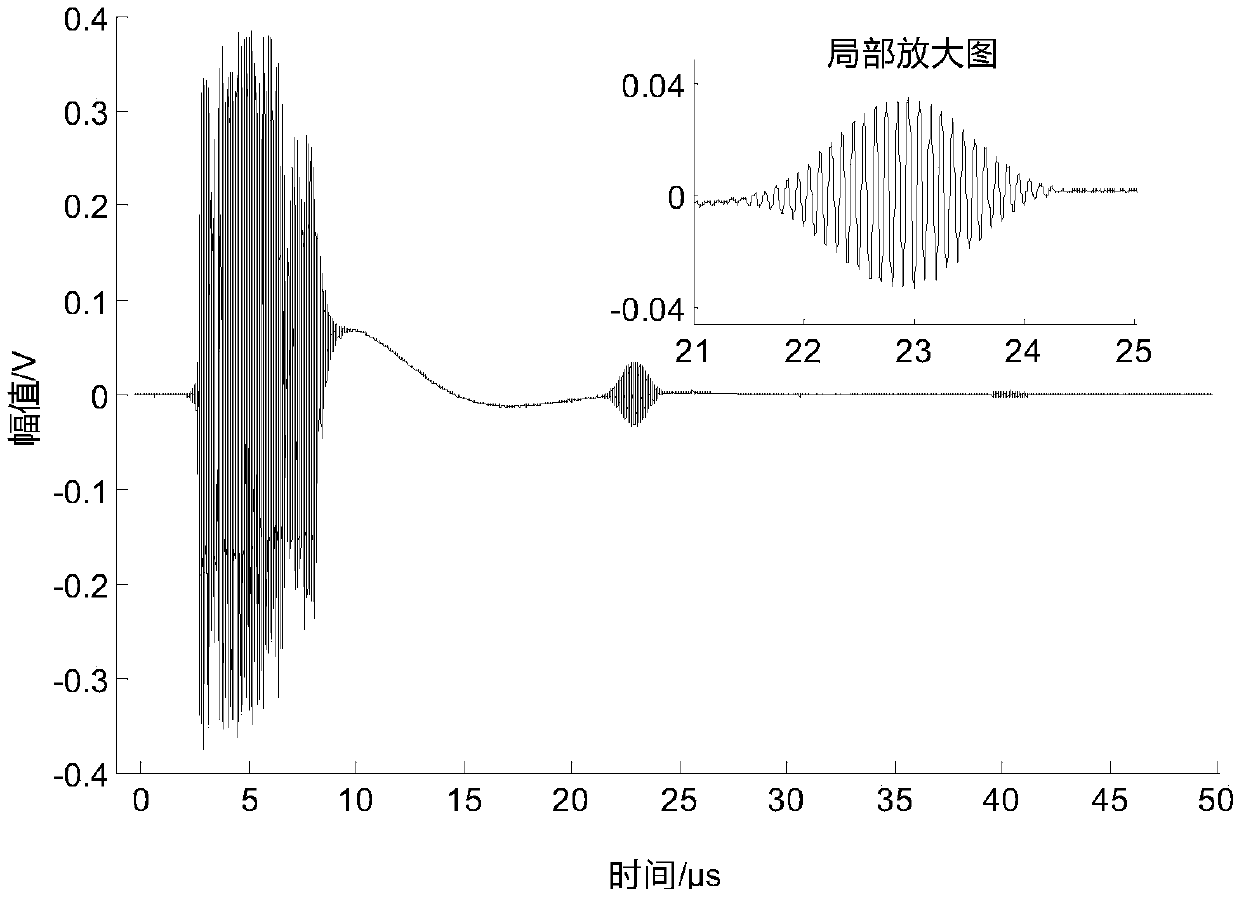

InactiveCN109541026AReduce on-site commissioning timeEasy on-site applicationAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicHigher order harmonics

The invention relates to a nonlinear ultrasonic detection system and a detection method for a reflective metal creep performance. The nonlinear ultrasonic detection system for the metal creep propertytransmits and receives ultrasonic detection signals through an ultrasonic transducer, and extracts high-order harmonic signals and fundamental wave signals separately by separating the received detection signals, so as to obtain the nonlinear ultrasonic parameters for evaluating the metal creep property. Since the detection system uses only one ultrasonic transducer, the problem that two ultrasonic transducers are difficult to be located in a coaxial position due to the use of two ultrasonic transducers for the detection is avoided in practical applications. The nonlinear ultrasonic detectionmethod based on the detection system has high accuracy and good applicability in the field application of the metal creep.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

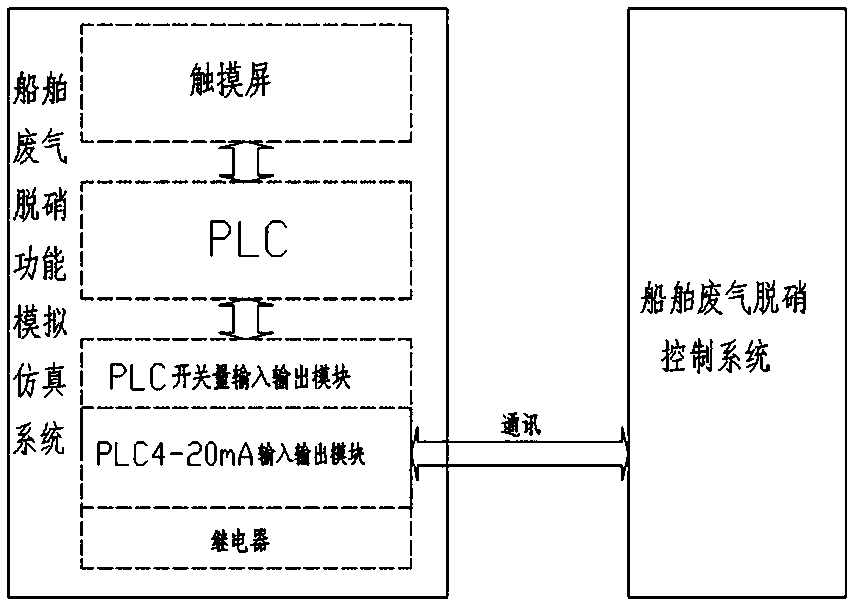

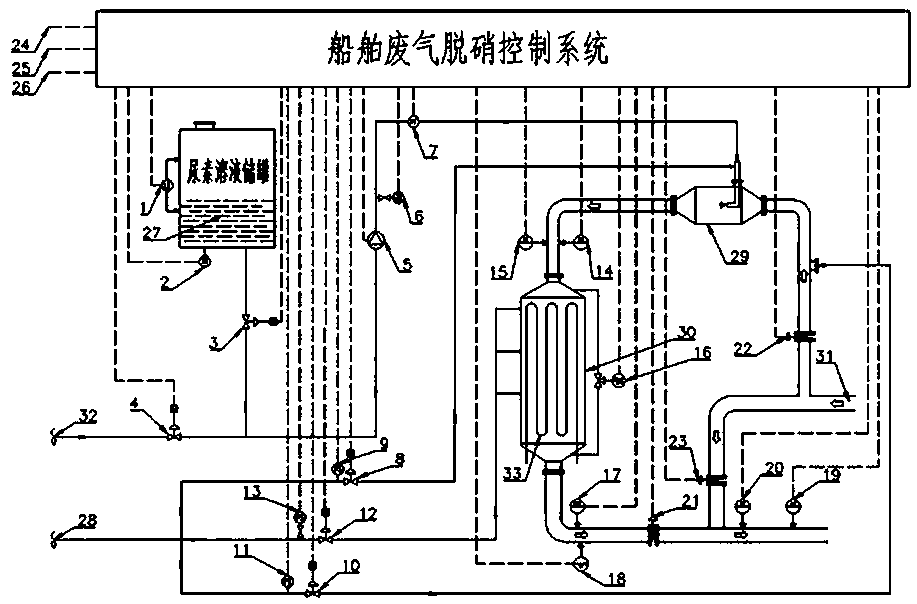

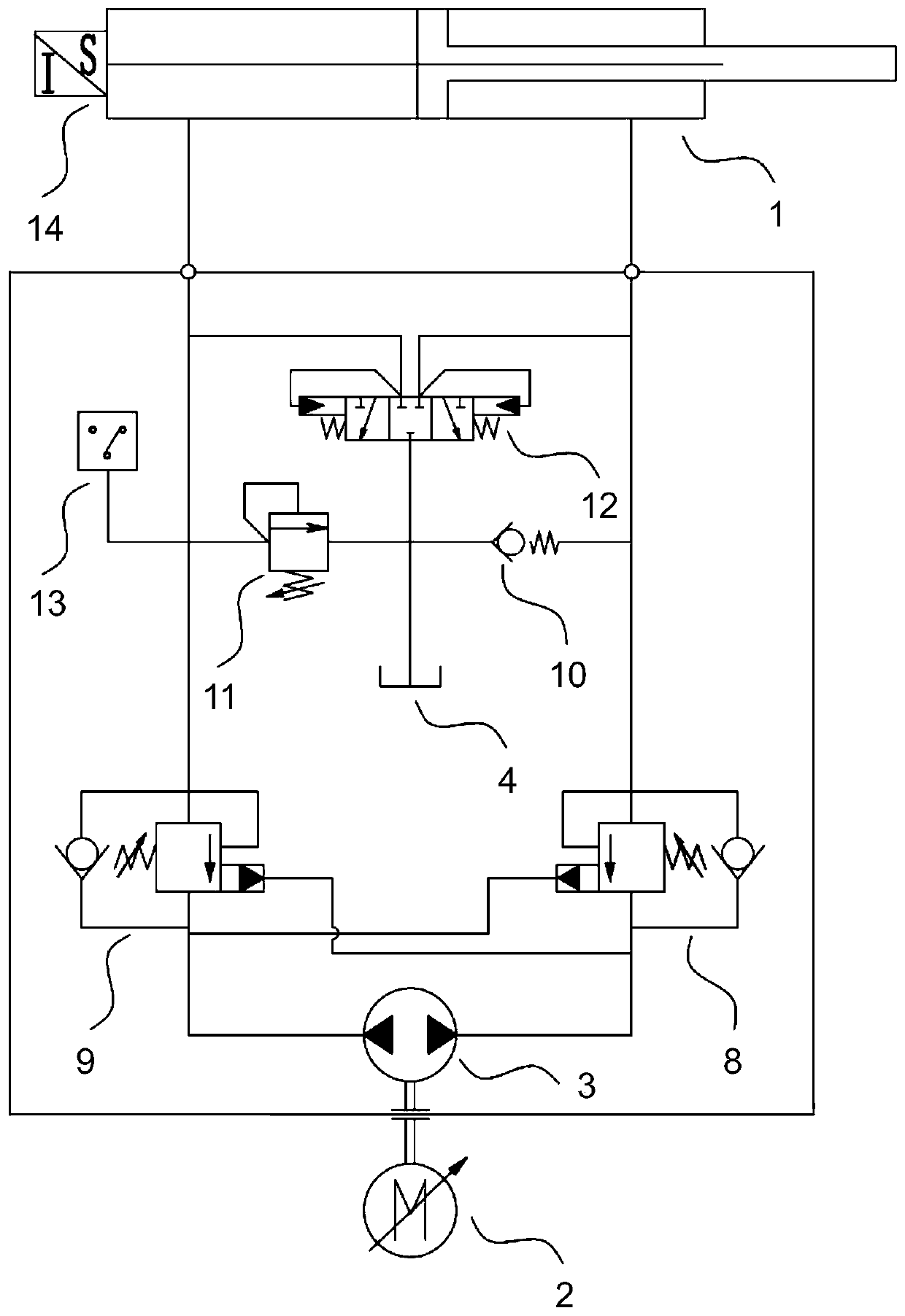

Ship exhaust gas denitration function simulation system

ActiveCN108415265AReduce on-site commissioning timeRealize working condition simulationSimulator controlControl systemExhaust fumes

The invention discloses a ship exhaust gas denitration function simulation system. The system comprises a touch screen, a PLC, a relay, a button switch and an indication lamp. The hardware signals ofship exhaust gas denitration equipment are simulated by using the switching value input and output module of the PLC, the relay, the 4-20mA input and output module of the PLC, and the software programming of the PLC is used to realize a logic relation among the various hardware signals. For the different ship exhaust gas denitration equipment, corresponding simulation control output signals are designed to realize the working condition simulation of the whole process of ship exhaust gas denitration. Through modifying simulation parameters, a ship exhaust gas denitration control system is debugged, whether the response of the ship exhaust gas denitration control system is correct is confirmed and the on-site debugging time of the ship exhaust gas denitration control system is reduced. The system can be used for the training and learning of a beginner, disadvantages that traditional training work is difficult and is time-consuming and labor-consuming and so on are overcome, and the training cost of the ship exhaust gas denitration control system is reduced.

Owner:SUNRUI MARINE ENVIRONMENT ENG

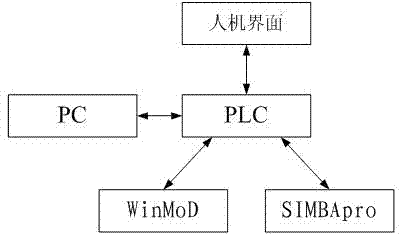

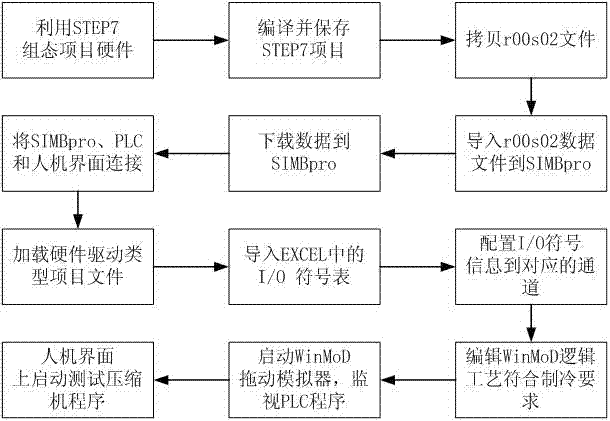

Simulation test system for industrial refrigerating unit and testing method applied to system

InactiveCN104765279AImprove stability and reliabilityAvoid variable errorsSimulator controlTest efficiencyHuman–machine interface

The invention provides a simulation test system for an industrial refrigerating unit, and a testing method applied to the system. The system comprises a simulation system for the industrial refrigerating unit, and a main control system for the industrial refrigerating unit, wherein the main control system is connected with the simulation system. The simulation system comprises a PLC, a WinMoD simulation unit, and an SIMBApro simulation unit, wherein the WinMoD simulation unit and the SIMBApro simulation unit are connected with the PLC. The main control system comprises the PLC and a man-machine interface. The WinMoD simulation unit is used for simulating I / O channels of all devices in the industrial refrigerating unit, and the SIMBApro simulation unit is used for simulating the I / O channels and the function of terminal equipment through a bus DP / PA. The system provided by the invention can completely simulate the condition of on-site equipment and an on-site bus, can achieve the simulation tests of all devices, avoids variable errors or dot mark leakage during on-site debugging, saves a large amount of time for on-site debugging, achieves the real seamless joint of a PLC program with simulation software, and employs a PC to debug the PLC program. When the system is used for debugging the PLC program, the testing efficiency is high, and the on-site debugging time is saved. Moreover, the energy is saved, and the stability of a program is good.

Owner:基伊埃工程设备技术(苏州)有限公司

DCS engineering configuration verification method based on nuclear power simulation technology

PendingCN111665816AReduce on-site commissioning timeDependency implementationProgramme controlElectric testing/monitoringProcess engineeringVerification procedure

The invention relates to the technical field of nuclear power DCS engineering, and particularly discloses a DCS engineering configuration verification method based on a nuclear power simulation technology. The method comprises the following steps: designing an input file according to DCS configuration, and constructing a verification procedure; building a verification platform, and creating a verification scene; verifying the verification procedure by utilizing the verification platform and the verification scene, and forming a verification procedure record; and performing DCS engineering configuration modification according to the verification procedure record, performing regression test on the modified verification procedure, and further performing verification procedure until no inconformity item exists in the verification procedure record. According to the method, parallel testing can be carried out on the whole system of a running unit, DCS configuration is verified and correctedin an early stage, the number of DCS configuration problems on site is reduced, DCS on-site debugging time can be shortened, the overall debugging progress of the unit is guaranteed, and large economic benefits are obtained.

Owner:CHINA NUCLEAR POWER OPERATION TECH

Remote automatic monitoring system for generating set

InactiveCN105259864AComprehensive dynamic display of status parametersDynamically display status parametersProgramme control in sequence/logic controllersFiberMonitoring system

The invention provides a remote automatic monitoring system for a generating set. The remote automatic monitoring system for a generating set comprises an engine electric control module, a generating set controller, a PLC and a touch screen, wherein the PLC is connected with the touch screen through a fiber accessory; the touch screen is electrically with storage equipment; the PLC is connected with the generating set controller and a relay through a signal line; the generating set controller is connected with the engine, the engine electric control module, a generator and the relay through a signal line; and the relay is connected with the engine and the generator through a signal line. For solving the problem for on-site manual control and monitoring of a current gas generating set, the remote automatic monitoring system for a generating set establishes communication between a programmable controller and the generating set controller and transmits signals in the fiber mode, and at the same time realizes the function for sudden stop of the set on the hardware so as to realize monitoring and control of the on-line state of the generating set.

Owner:成都安美科燃气技术股份有限公司

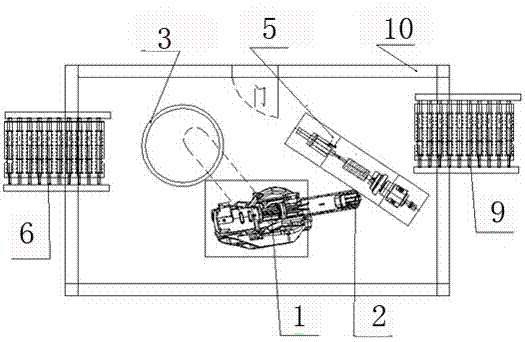

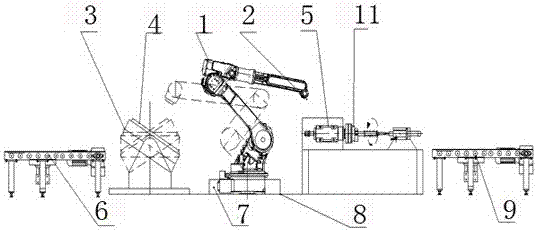

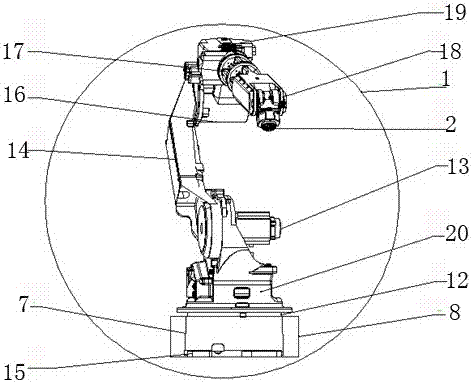

Novel and intelligent dedicated equipment of thermal spraying wear-resistant workpiece

InactiveCN107138308AThe equipment is easy to operateExpand the scope of workLiquid spraying apparatusWear resistantThermal spraying

The invention provides novel and intelligent dedicated equipment of a thermal spraying wear-resistant workpiece. The novel and intelligent dedicated equipment comprises an intelligent six-shaft robot and a PLC automatic control system, wherein a rotary table clamp tool is arranged at the front-left part of the intelligent six-shaft robot; a rotary bed clamp tool is arranged at the front-right part of the intelligent six-shaft robot; a preheating caterpillar track transmission device is arranged on the left side of the rotary table clamp tool; a cooling caterpillar track transmission device is arranged on the right side of the rotary bed clamp tool; a pneumatic clamp is arranged on the rotary table clamp tool; another pneumatic clamp is arranged on the rotary bed clamp tool; a spray gun is arranged on the intelligent six-shaft robot; and an alloy powder storage barrel is arranged below the intelligent six-shaft robot and is connected with a high-pressure gas storage tank. Compared with manual operation, the coating thickness is precisely calculated and easy to control, consumption of alloy powder is small and the cost is reduced; and the intelligent six-shaft robot is adopted for operation, a high-grade servo control system is adopted to control operation at the best speed, so that the working time is shortened, and the cost is reduced.

Owner:烟台市三立工业有限公司

Active microorganism carrier for use in biological treatment

InactiveCN1206173CWide range of raw materialsLow priceSustainable biological treatmentBiological water/sewage treatmentSludgeWastewater

An active microbe carrier in the form of particle, short tube, plate or block, band, etc for the biologic treatment of sewage contains rubber powder, specific weight regulator, adhesive and active filler chosen from dried microbe powder and dried active mud powder.

Owner:王文兵

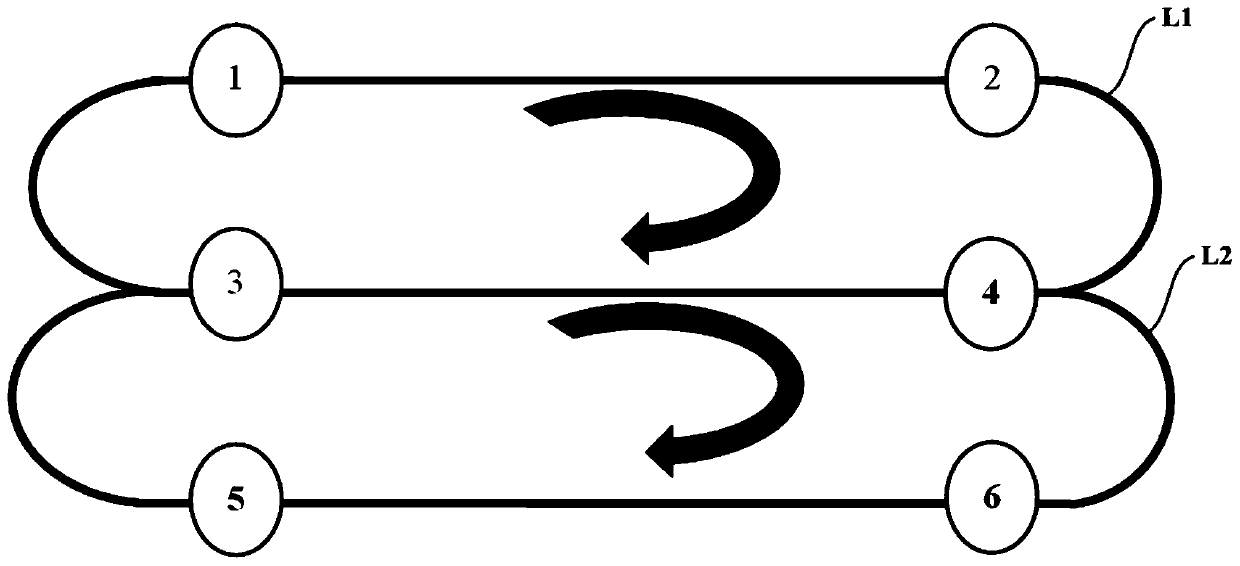

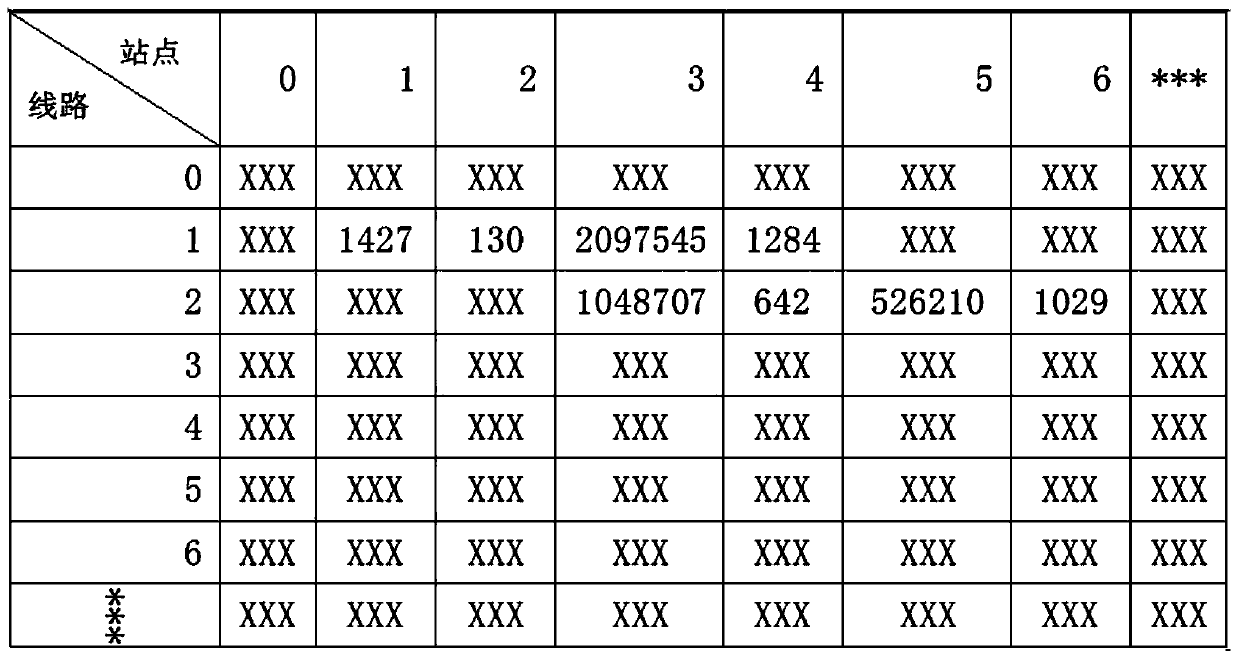

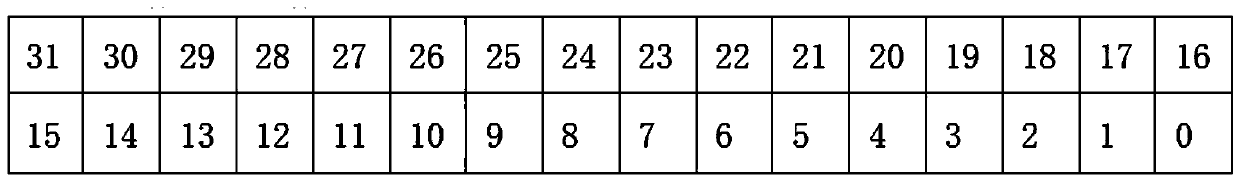

Path planning method of magnetic navigation AGV

InactiveCN111323019AReduce on-site commissioning timeTroubleshoot issues that require source code changesAutonomous decision making processNavigational calculation instrumentsNumeric ValueReal-time computing

The invention discloses a path planning method of a magnetic navigation AGV. A two-dimensional array is included, a row of the two-dimensional array corresponds to a set line number in a field environment; a column of the two-dimensional array corresponds to a set station number in the field environment, and a value corresponding to each station number is a preset numerical value; and when the AGVpasses through the station number, the AGV reads the numerical value, functional analysis is performed on the numerical value through decompilation, and the value is sent to an execution mechanism soas to achieve a purpose of controlling a driving route of the AGV. According to the method, a problem that source codes need to be changed when lines and stations are changed is solved, and comparedwith an existing path planning method of the magnetic navigation AGV, by using the method of the invention, on the basis that the source codes are not changed, a running environment line function is planned rapidly, and therefore field debugging time is greatly shortened.

Owner:江苏亿控智能装备有限公司

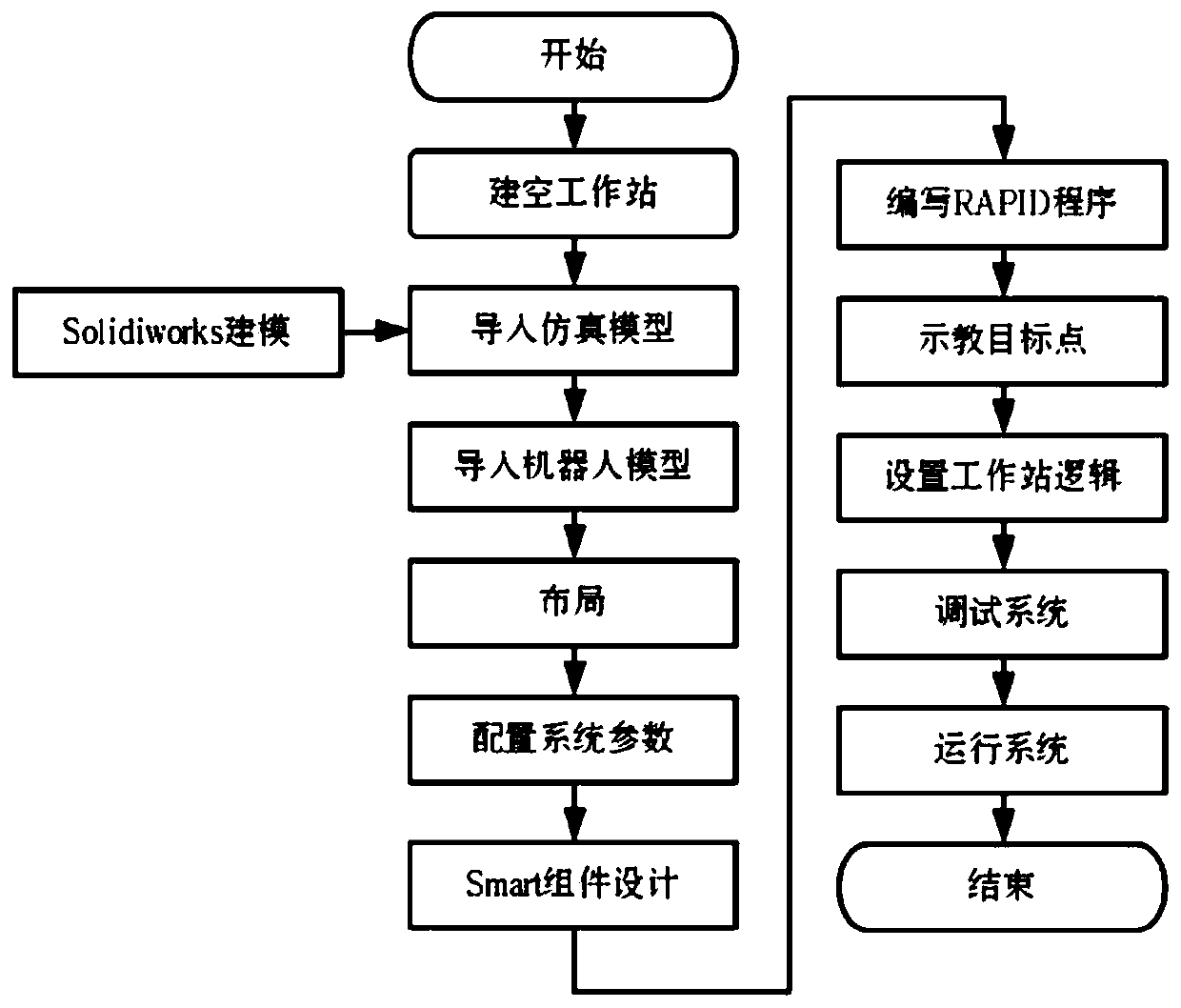

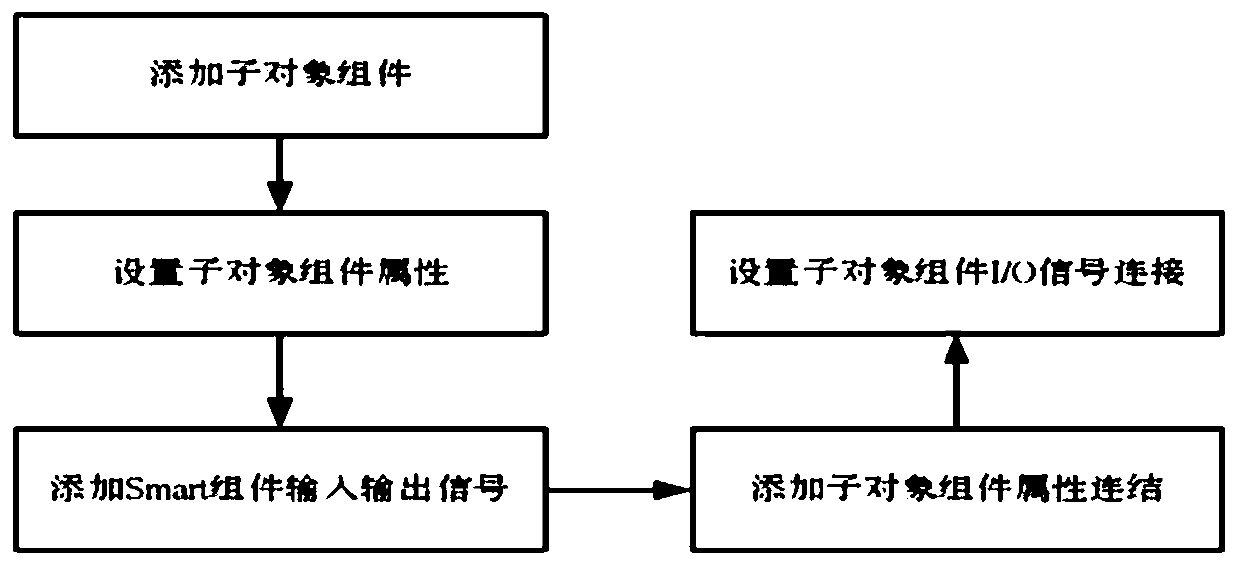

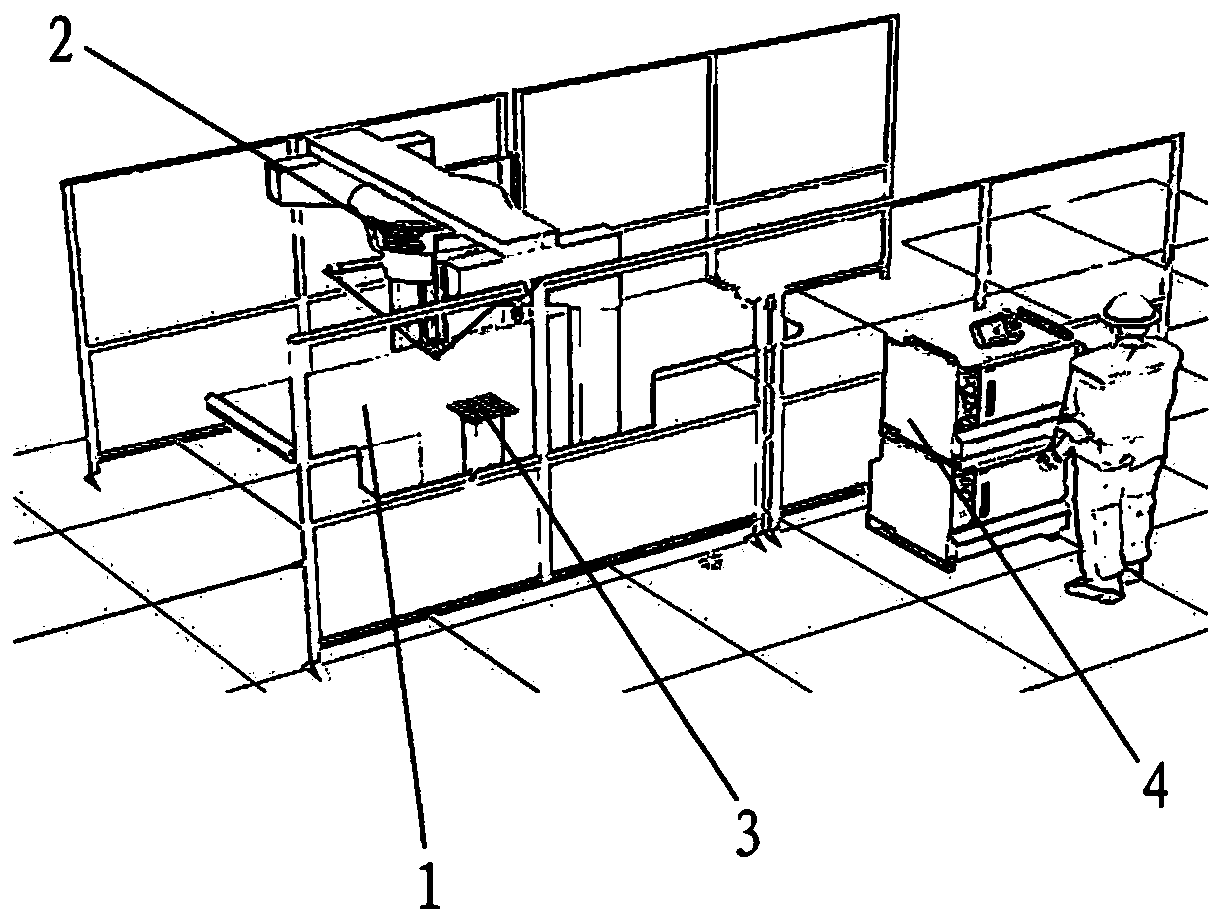

Simulation design method based on industrial robot sorting workstation

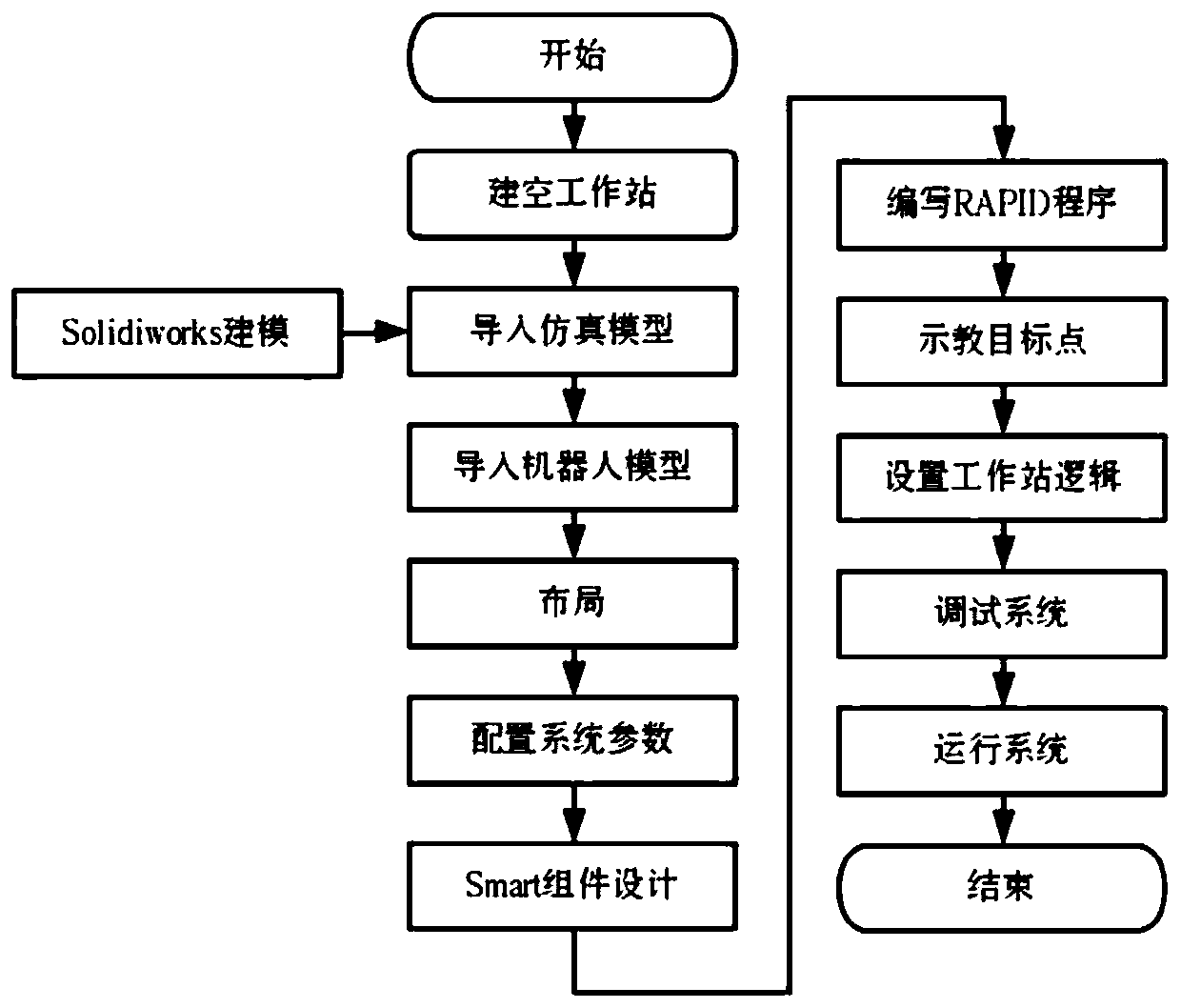

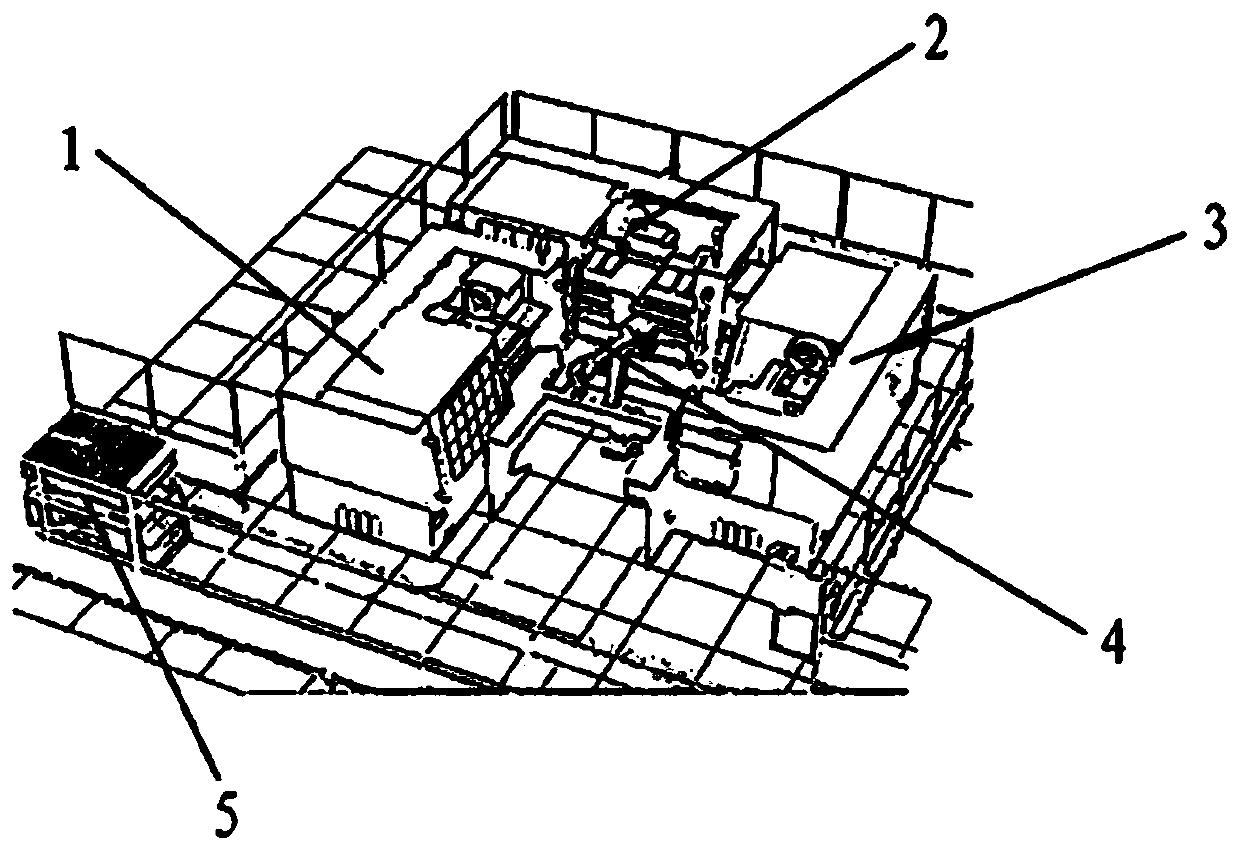

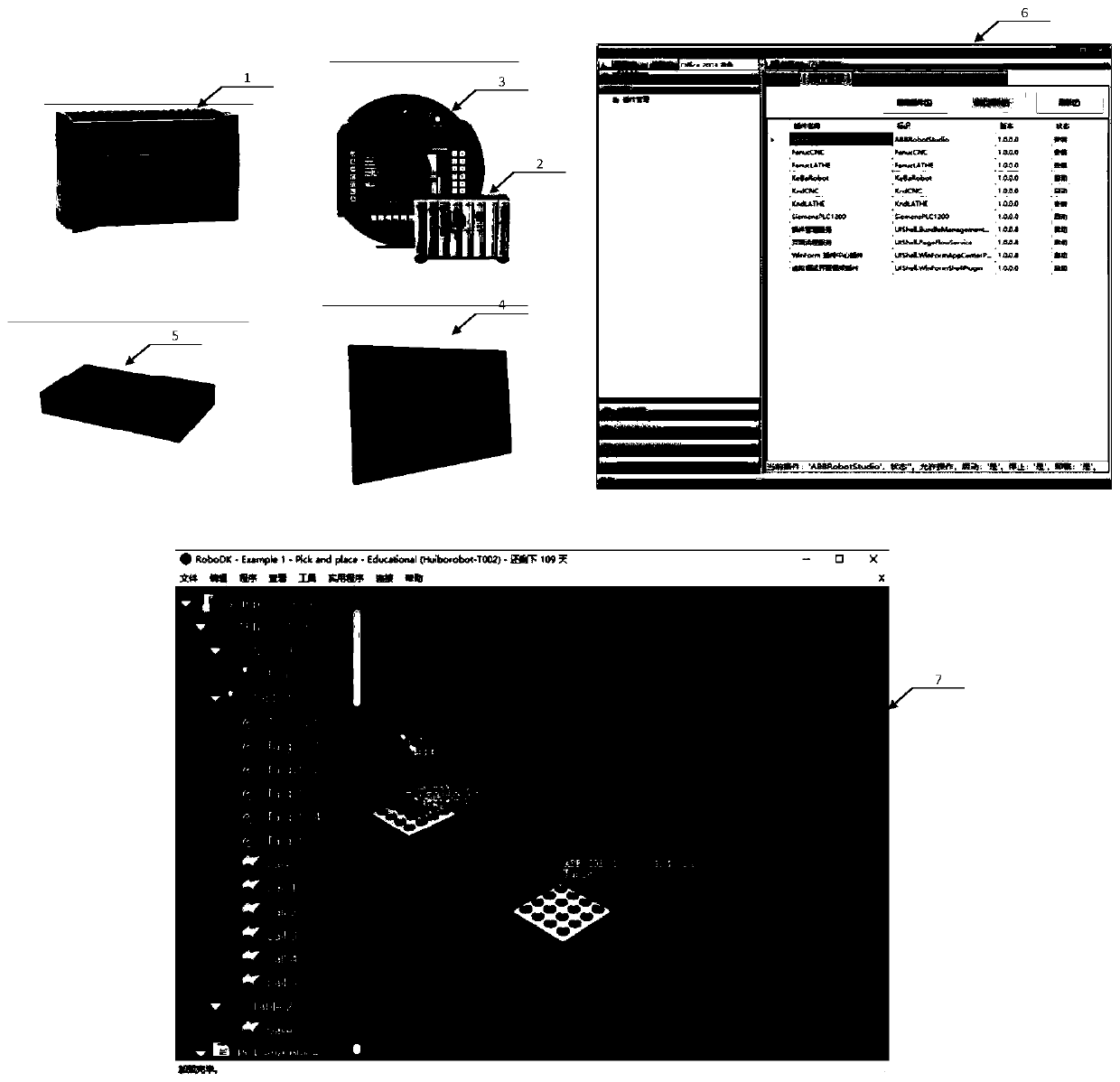

InactiveCN110737205AImprove debugging work efficiencyImprove reliabilitySimulator controlWorkstation designWorkstation

The invention relates to a simulation design method based on an industrial robot sorting workstation. The simulation design method comprises the following steps of: S1, establishing a conveying mechanism model, an industrial robot model and an object storage device model by adopting three-dimensional software, and importing a model file into RobotStudio software; S2, determining control parametersbased on the industrial robot model, and determining an industrial robot simulation model according to the control parameters; S3, enabling objects to appear on the conveying mechanism according to arandom distribution function rule, and distributing different features to different types of objects; and S4, designing parameters of a Smart component according to the operation logic of the industrial robot, and performing simulation control on the industrial robot simulation model, wherein the industrial robot recognizes the objects through a feature recognition mechanism and places differentobjects into corresponding storage areas in the object storage device according to the features of the objects. The simulation design method provides a theoretical basis and a test platform for the design of the industrial robot sorting workstation for designers and managers.

Owner:GUANGZHOU PANYU POLYTECHNIC

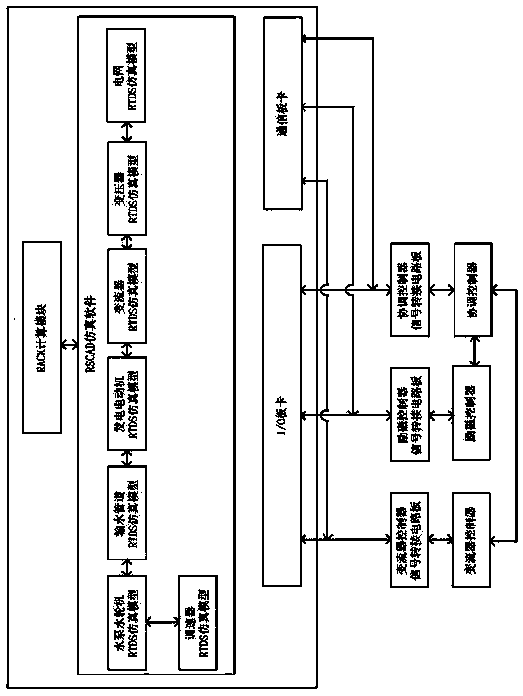

Variable speed constant frequency pump storage group controller hardware-in-loop simulation test platform

InactiveCN109782629AQuality improvementReduce on-site commissioning timeSimulator controlConstant frequencyGroup controller

The invention discloses a variable speed constant frequency pump storage group controller hardware-in-loop simulation test platform and belongs to the pump storage group simulation test technology field. The platform comprises an RACK calculation module, an I / O interface board, a communication board and RSCAD simulation software. The platform is characterized in that the platform also includes anexcitation controller, an excitation controller signal transfer circuit board, a converter controller, a converter controller signal transfer circuit board, a coordination controller, and a coordination controller signal transfer circuit board; the excitation controller signal transfer circuit board is connected with the I / O interface board and the communication board in a communication connectionmode; the converter controller signal transfer circuit board is connected with the I / O interface board and the communication board in the communication connection mode; and the coordination controller signal transfer circuit board is connected to the I / O interface board and the communication board in the communication connection mode. Simulation testing, verification and optimization can be performed on an actual control system, site debugging time is short, cost is low and the platform is good for popularization and application.

Owner:中国东方电气集团有限公司

Shore bridge tilting-snagging integrated electric hydraulic control system and method

PendingCN110240067AReduce the amount of constructionReduce the risk of oil spillsFluid-pressure actuator testingServomotorsHydraulic pumpControl theory

The invention provides a shore bridge tilting-snagging integrated electric hydraulic control system and method. The system comprises a servo driver, an electric hydraulic drive module and a hydraulic cylinder; the electric hydraulic drive module comprises a servo motor, a hydraulic pump, a valve block and an integration oil tank, the servo motor is connected with the servo driver, one end face of the valve block is connected with the face, with a flange, of the servo motor, the other end face of the valve block and the face, with a flange, of the integration oil tank are connected and sealed, the hydraulic pump is arranged inside the integration oil tank, an input shaft of the hydraulic pump is connected with an output shaft of the servo motor through a coupler, and an oil port of the hydraulic pump is connected with the valve block through a hydraulic pipe; input / output hydraulic oil of the hydraulic pump passes through the valve block and then the hydraulic pump is separately connected with a first oil way block and a second oil way block by adopting hydraulic pipes, and the first oil way block and the second oil way block control the hydraulic cylinder. By changing the configuration of an existing system into a distributed integrated servo direct drive pump control hydraulic cylinder system, the defects that an existing system hydraulic pipelines is complex, energy dissipation is high, and fault handling is complex are overcome.

Owner:SHANGHAI ZHENHUA HEAVY IND

Simulator suitable for testing and training of ATS system

ActiveCN101719189BImprove stabilityReduce on-site commissioning timeCosmonautic condition simulationsSpecial data processing applicationsComputer moduleSystems simulation

Owner:CASCO SIGNAL

Simulation design method based on industrial robot loading-unloading workstation

PendingCN110456659AImprove debugging work efficiencyImprove reliabilitySimulator controlSimulationWorkstation design

The invention relates to a simulation design method based on an industrial robot loading-unloading workstation. The simulation design method comprises the following steps: S1, establishing a machine tool and industrial robot model by adopting three-dimensional software, and importing a model file into RobotStudio software; S2, determining control parameters based on the industrial robot model, anddetermining the industrial robot simulation model according to the control parameters; S3, designing parameters of Smart module according to industrial robot running logic, and performing simulationcontrol on the industrial robot simulation model. The simulation design of the industrial robot loading-unloading workstation is realized, the feasible evidence is provided for the design of the industrial robot loading-unloading workstation, the reliability of the design scheme can be improved by utilizing robot simulation technology, the project implementation cycle can be shortened, the field debugging time is reduced, and the debugging working efficiency of the industrial robot is improved. And meanwhile, the theoretic evidence of the workstation design is provided for a designer and a manager, the design and debugging cost of a production line are reduced.

Owner:GUANGZHOU PANYU POLYTECHNIC

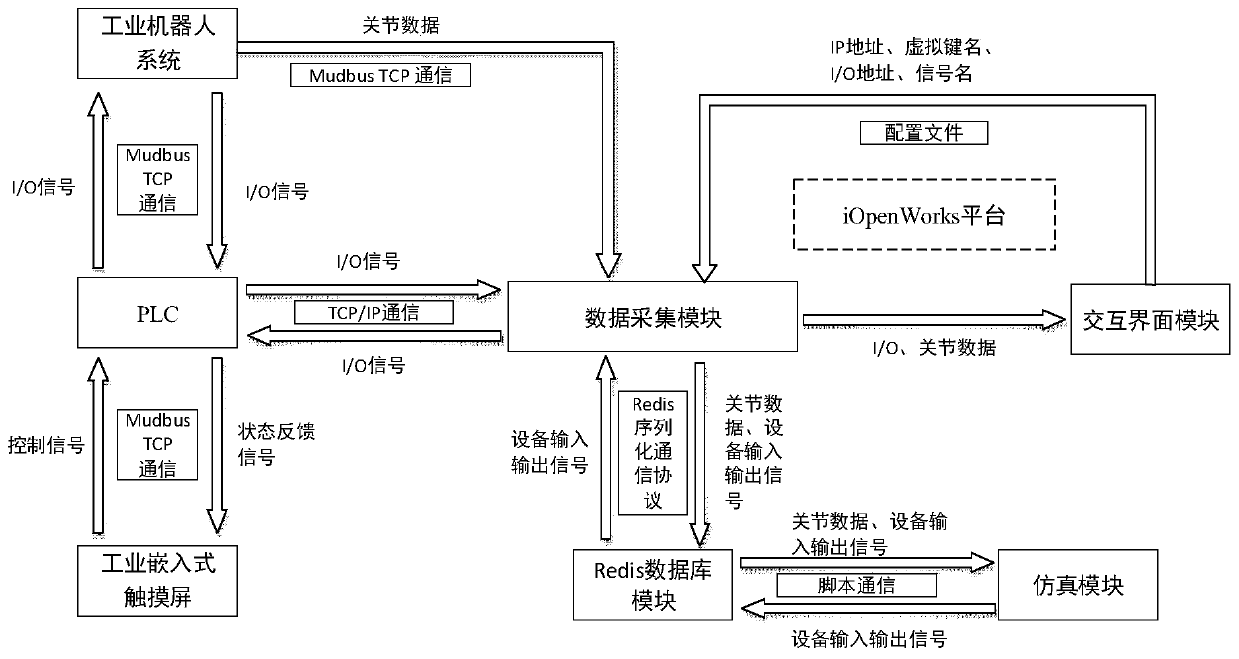

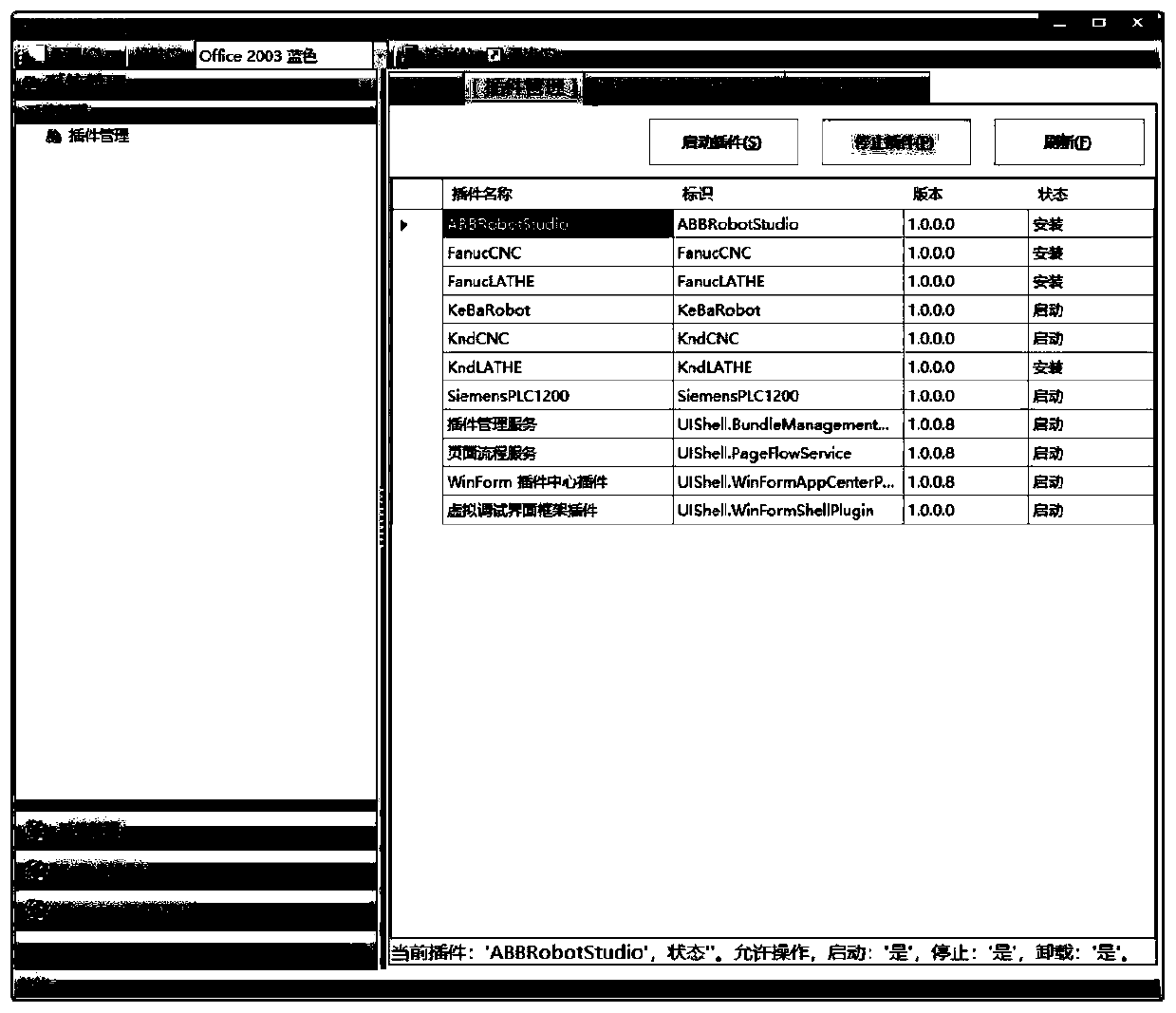

Virtual debugging system based on iopenworks

ActiveCN109814478BReduce complexityImprove accuracyTotal factory controlProgramme control in sequence/logic controllersSoftware engineeringData acquisition

The invention relates to a virtual debugging system based on iOpenWorks, which mainly comprises industrial control equipment, a PC client, a Redis database module and a simulation module, wherein theindustrial control equipment comprises an industrial robot system, a PLC and an industrial embedded touch screen; and the PC client comprises a data acquisition module and an interactive interface module. The PC client is integrated on an iOpenWorks platform, signals and data of industrial control equipment are collected in real time, and the data is stored in the Redis database; the simulation module reads the database data through a Python program to drive a robot model to produce and manufacture; meanwhile, robot state information in the simulation module is also stored in the Redis database; and the PC client reads the robot model state information in the Redis database in real time and writes the robot model state information into the PLC, so that conditions in the PLC are meet and the robot model state information is sent to an industrial robot system to futher execute the robot program, virtual-real interaction is achieved, and the feasibility of industrial program design and products can be verified.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

Closed-loop Speed Compensation Method for Thickness Control System of Aluminum Cold Rolling Mill

ActiveCN101745541BImprove performanceImprove efficiencyRoll mill control devicesMetal rolling arrangementsSpeed control systemBuck converter

The invention provides a closed-loop speed compensation method for the thickness control system of an aluminum cold rolling mill. The acceleration value is calculated according to the data obtained by the speed measurement unit, and the control logic is judged. The thickness deviation is used as the input signal of the closed-loop PID compensation controller, and the calculated compensation amount is output to the The position AGC controller completes the calculation process of a closed-loop speed compensation. By converting the open-loop compensation to the closed-loop compensation control algorithm, the stability of the system can be significantly improved, and the rolling process can be better automatically adapted to the changing conditions. Moreover, by adjusting the parameters of the PID controller, the on-site debugging time of the speed compensation control can be reduced, the production cost can be reduced, and the performance of the dynamic process of the thickness control system can be improved, which is worthy of wide application in the industry.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

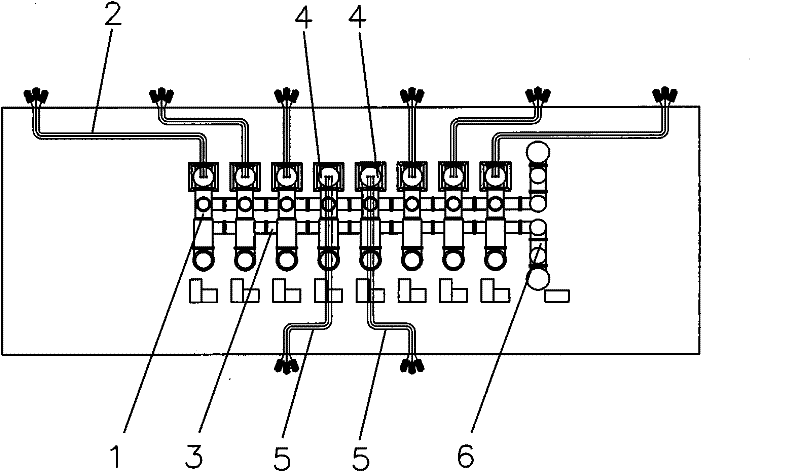

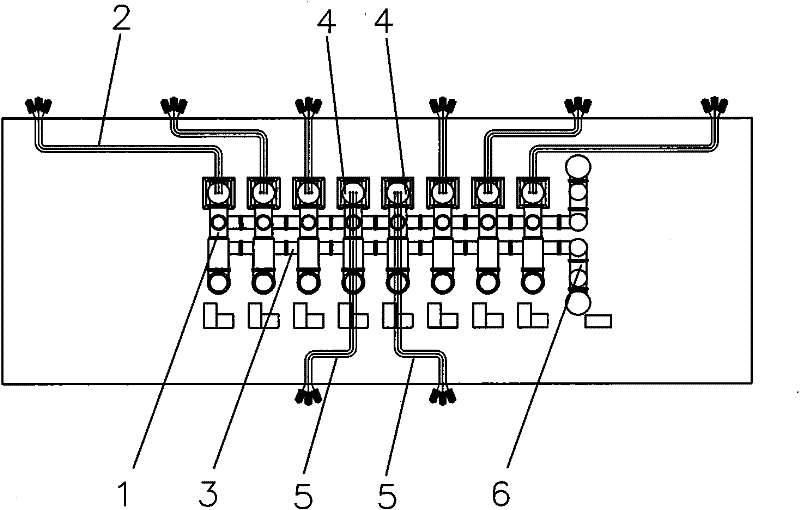

Novel in-parallel compact type distribution scheme of combined electrical apparatuses

InactiveCN102412511ACompact structureReduce on-site commissioning timeBus-bar/wiring layoutsSwitchgear arrangementsModularityCapacitance

The invention discloses a novel in-parallel compact type distribution scheme of combined electrical apparatuses and relates to a distribution scheme of the combined electrical apparatuses used by a power system. The novel in-parallel compact type distribution scheme comprises a plurality of wire incoming gaps, a plurality of wire outgoing gaps, a plurality of wire-incoming capacitance-type insulating buses, a plurality of wire-outgoing capacitance-type insulating buses and an SF6 (sulfur hexafluoride) gas main bus, wherein the wire incoming gaps and the wire outgoing gaps are distributed compactly in parallel, so that the single SF6 gas main bus or double SF6 gas main buses is / are shortened as much as possible; and the SF6 gas main bus is used for connecting the wire incoming gaps and the wire outgoing gaps; and at least one wire incoming gap adopts one wire-incoming capacitance-type insulating bus, or at least one wire outgoing gap adopts one wire-outgoing capacitance-type insulating bus. The novel in-parallel compact type distribution scheme has the beneficial effects that the SF6 gas main bus is furthest shortened, the standard modular design is carried out without considering the site, the production cost and the design cost are reduced, the structure is compact, the design is convenient, the debugging time on site is short and SF6 gas is greatly reduced.

Owner:王日新

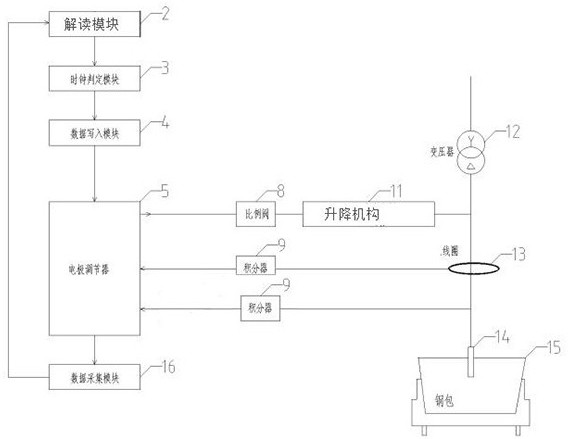

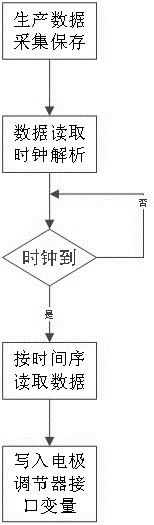

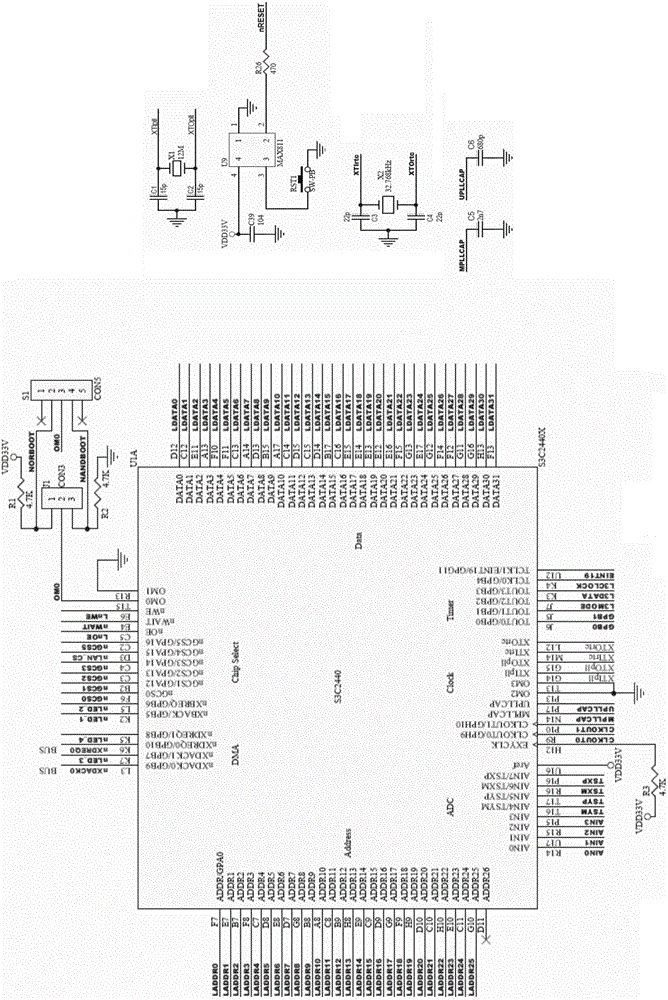

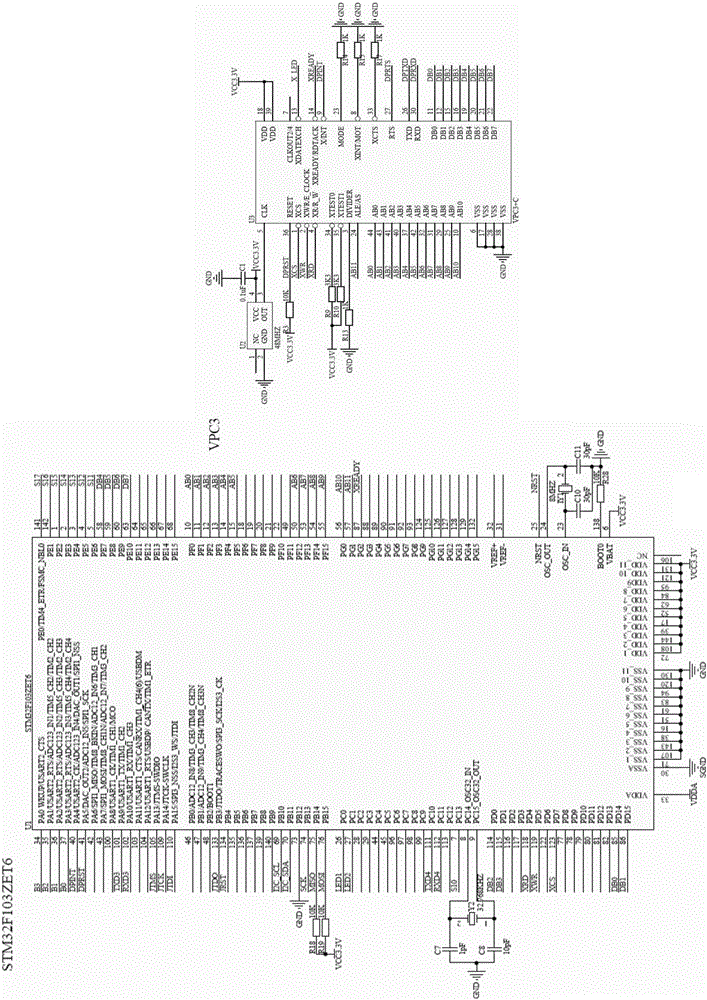

LF furnace electrode test system and test method

ActiveCN113281581AReduce on-site commissioning timeImprove stabilityElectrical testingControl using feedbackElectrical connectionControl theory

The invention discloses an LF furnace electrode test system and a test method. The system comprises an electrode regulator, a lifting mechanism, an electrode, a coil and a controller, wherein the electrode is connected to the lifting mechanism, the electrode passes through the coil, the coil is also electrically connected with a first feedback module, the electrode is also electrically connected with a second feedback module, the first feedback module and the second feedback module are in electric signal connection with the electrode regulator, and the controller is in electric signal connection with the electrode regulator. The non-working LF furnace is driven to work according to the actual working condition through historical data to test the electrode regulator, so that the field debugging time is shortened, the equipment stability is improved, the equipment debugging and maintenance cost is reduced, and the equipment production efficiency is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

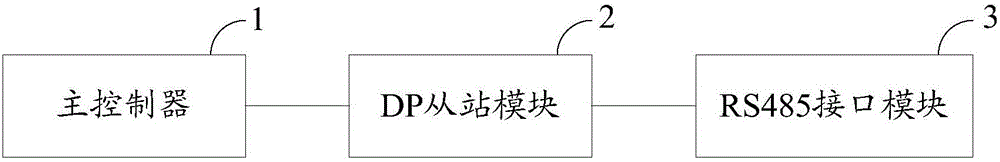

DP intelligent module and PLC control system and method

InactiveCN105988411AFunction increaseReduce on-site commissioning timeProgramme control in sequence/logic controllersEncryptionMaster controller

The invention discloses a DP intelligent module, which is used to solve the technical problems of insufficient encryption protection of PLC algorithm programs and the technical problem that a PLC control module can only apply one control algorithm. The DP intelligent module includes: a main controller and a DP slave station module And the RS485 interface module; the main controller is connected to the DP slave module, the DP slave module is connected to the RS485 interface module, and the RS485 interface module is connected to the Profibus‑DP bus; the main controller is used to receive, store and run the PLC control algorithm; The DP slave module is used to realize the data interaction between the main controller and the RS485 interface module; the RS485 interface module is used to realize the data interaction between the DP slave module and the Profibus‑DP bus. The invention also discloses a PLC control system and method.

Owner:HUADIAN HEAVY IND CO LTD

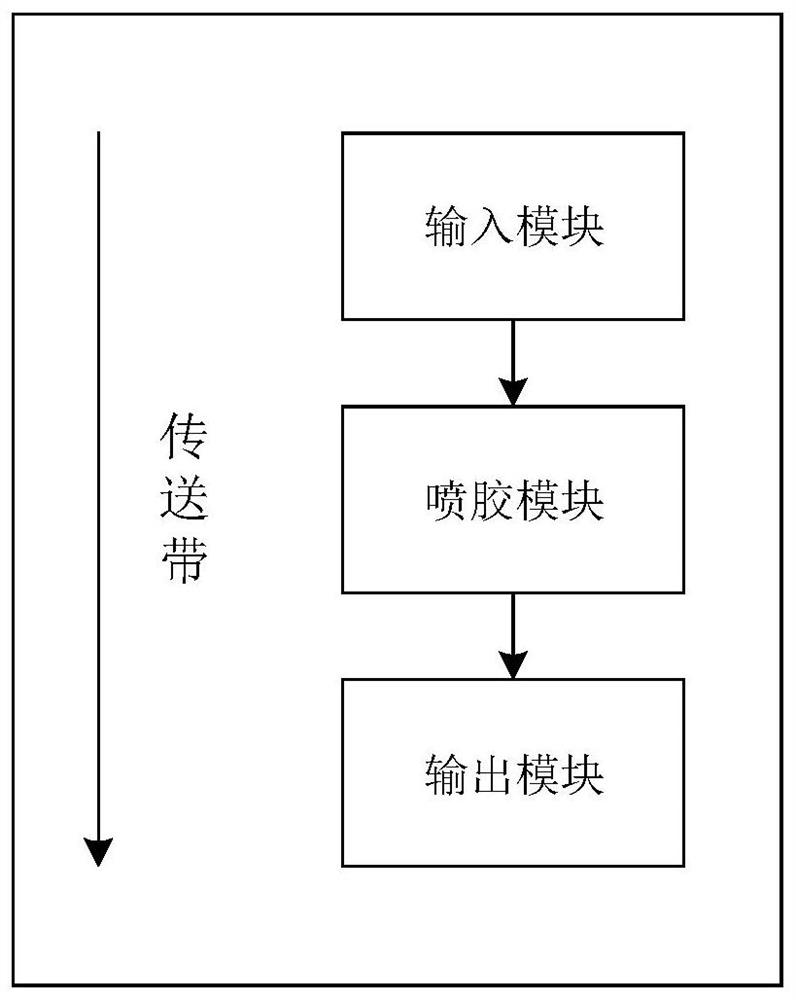

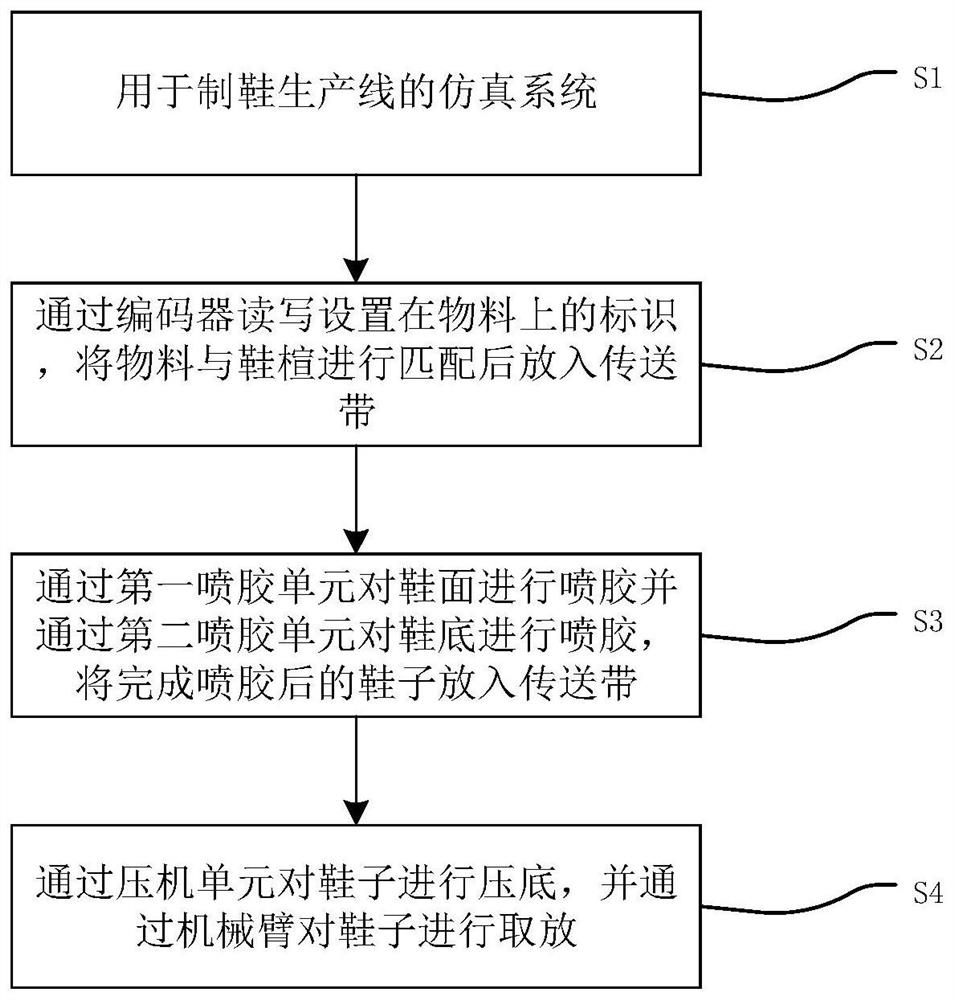

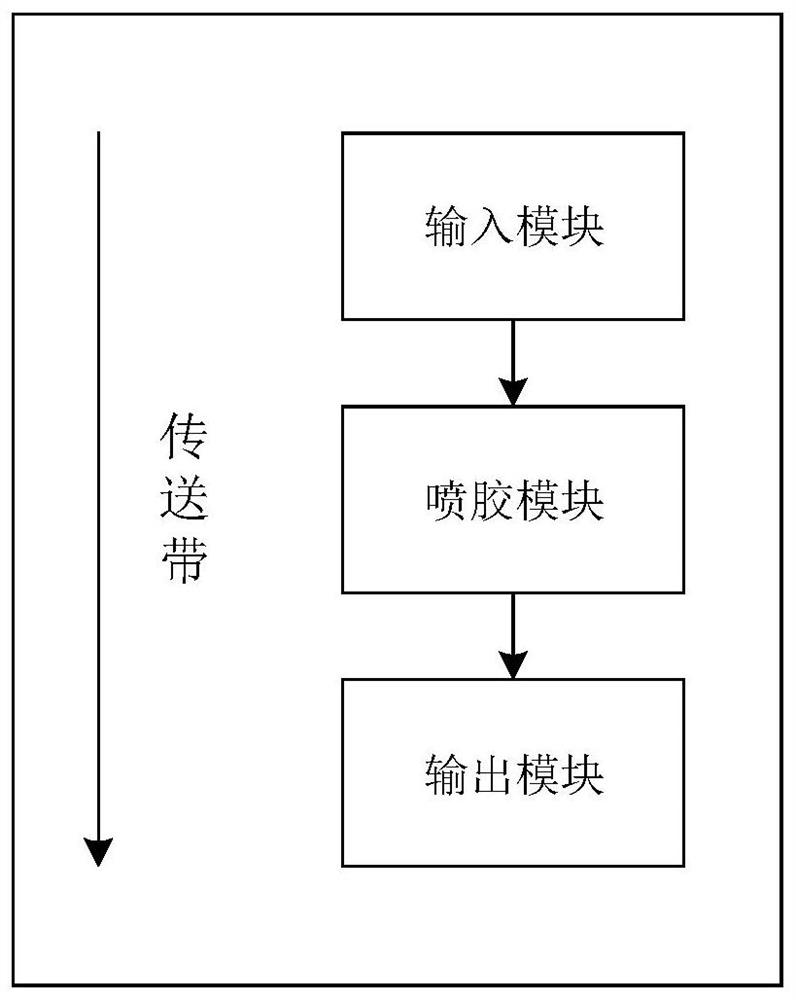

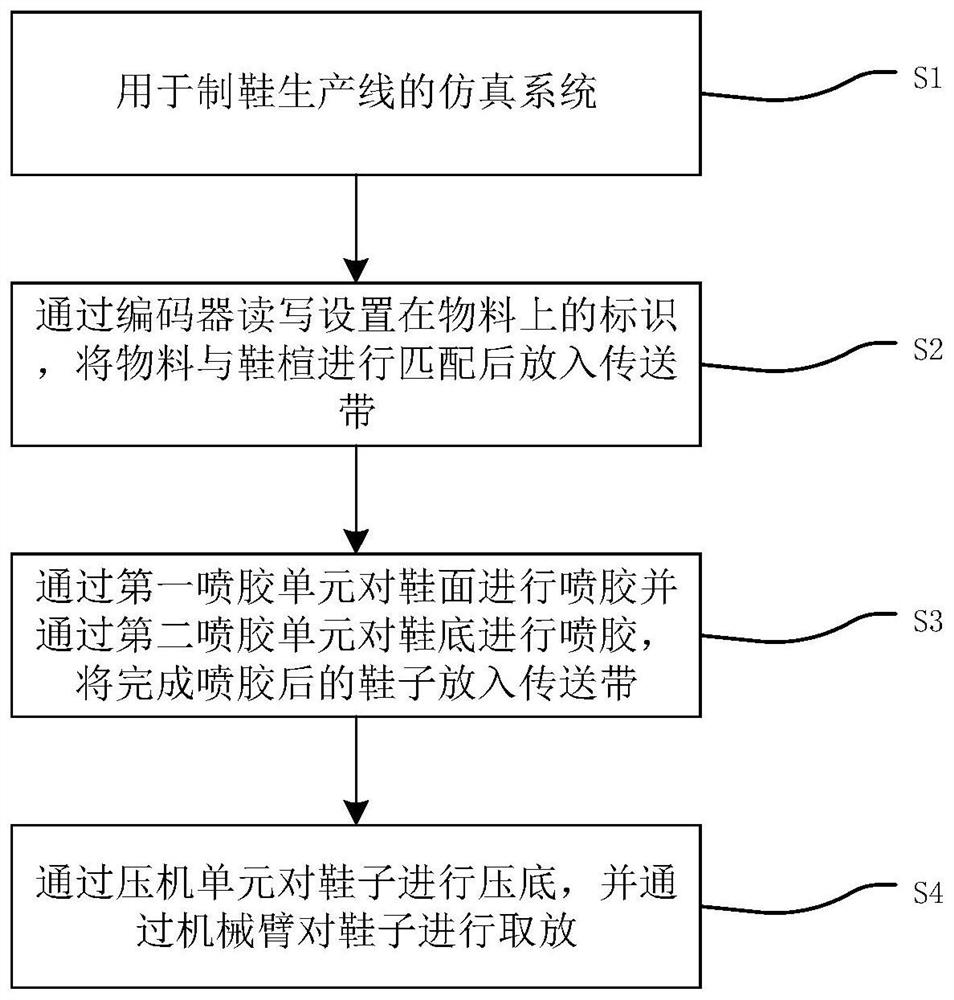

A simulation system and method for shoe-making production line

The invention provides a simulation system and method for a shoe-making production line. The system includes: an input module, the input module includes an encoder for reading and writing a mark set on a material and an encoder for matching the material with the shoe last. a cooperating unit; a glue spraying module, the glue spraying module includes a first glue spraying unit for spraying glue on the upper and a second glue spraying unit for spraying glue on the sole; an output module, the output module includes A mechanical arm for picking and placing shoes and a press unit for making shoes; the input module, the glue spraying module, and the output module are arranged in sequence according to the movement direction of the conveyor belt. The simulation system can be used to simulate or run when the actual operation scene has not been completed or the on-site debugging is limited, and the on-site debugging time can be shortened.

Owner:重庆赛宝工业技术研究院有限公司

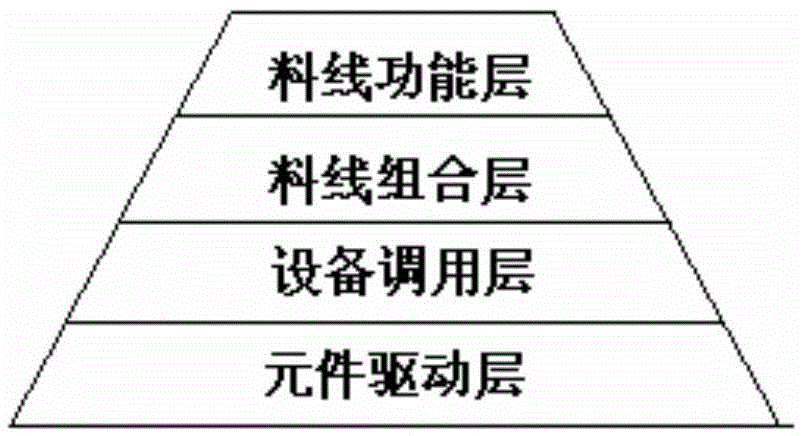

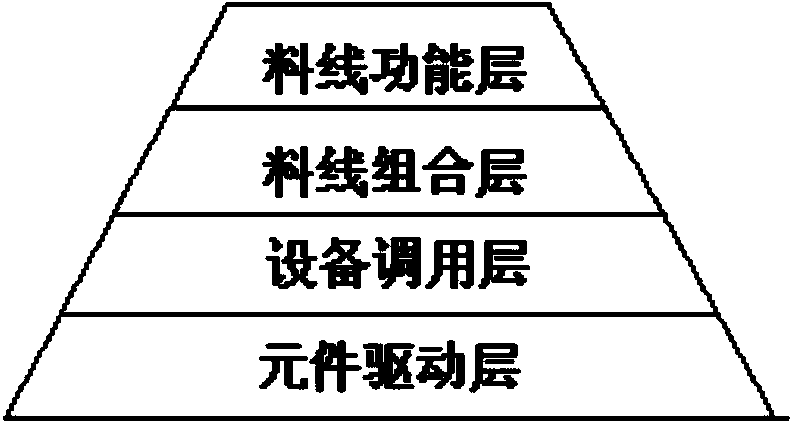

Universal material line control method

InactiveCN104340413BReduce control development timeReduce on-site commissioning timeConveyorsControl devices for conveyorsComputer moduleFeed line

The invention discloses a control method for a general material line. The control method comprises the following steps: firstly, establishing an element driving layer, an equipment calling layer, material line combining layers and a material line functional layer on a general material line control terminal; secondly, according to a field material line structure to be constructed, calling all driving modules of corresponding general material line sub equipment in the field material line structure to be constructed from the element driving layer through the equipment calling layer by the general material line control terminal, and then establishing physical connection between each called driving module and the corresponding general material line sub equipment; thirdly, performing combined connection on all material line combining layers establishing the physical connection relationship with the driving modules by the general material line control terminal; fourthly, performing logic control on material line structures which are formed and required by the field by the material line functional layer. According to the control method disclosed by the invention, the development control time for different material lines and the field debugging time of the system are shortened.

Owner:武钢集团有限公司

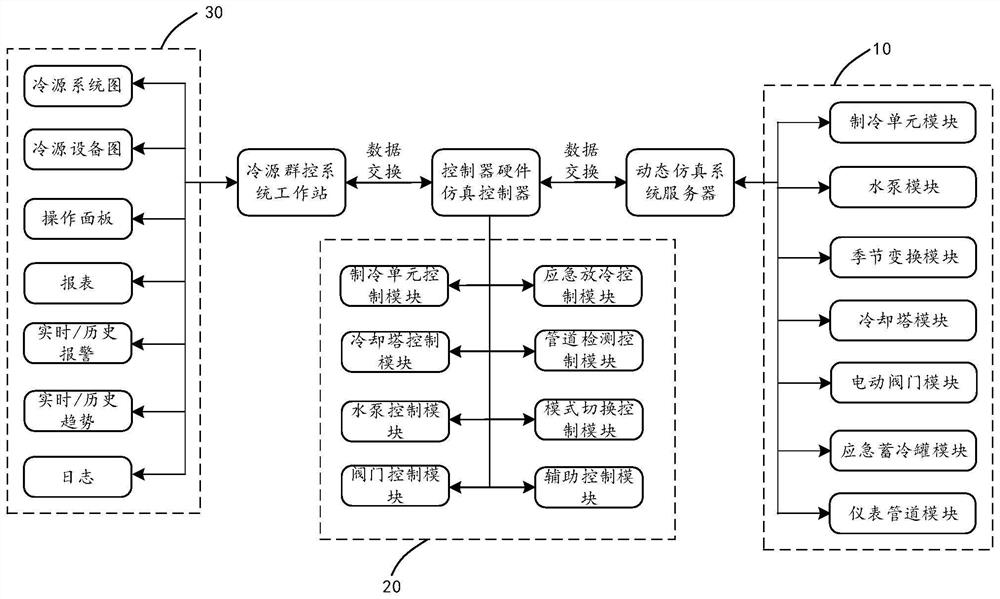

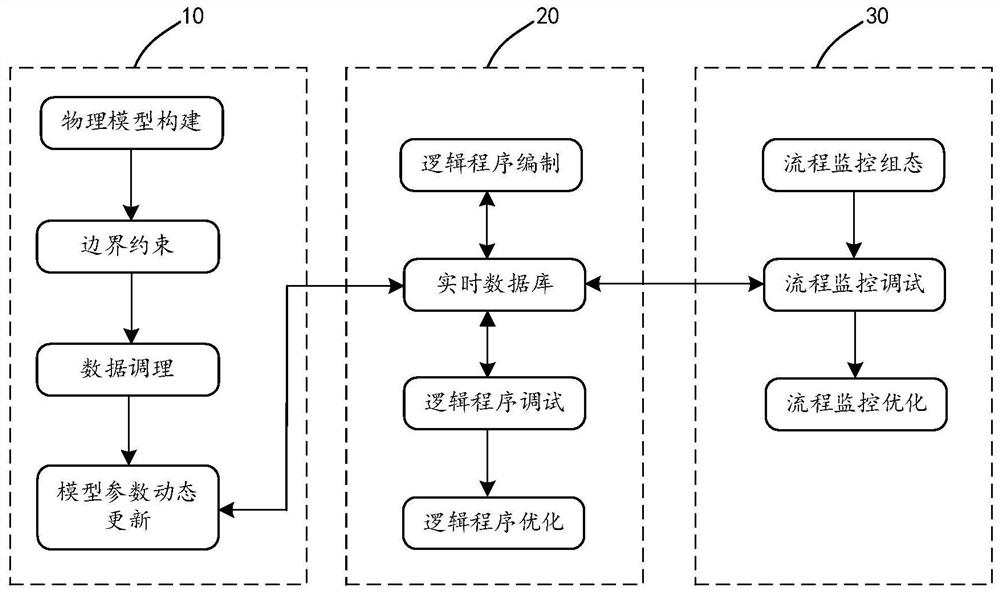

Data center cold source group control virtual debugging system and method

PendingCN114777295AReduce on-site commissioning timeReduced commissioning riskSpace heating and ventilation safety systemsLighting and heating apparatusData centerLogisim

The invention provides a data center cold source group control virtual debugging system. The system comprises a cold source system dynamic simulation module, a logic control module, a real-time database and a process monitoring module. The cold source system dynamic simulation module is used for realizing process flow analogue simulation and reproducing the running process of a real system; the logic control module is connected with the cold source system dynamic simulation module and used for compiling cold source system control logic and logic interlocking between devices. The real-time database exchanges data with the dynamic simulation module of the cold source system, and debugs and optimizes a logic control program of the logic control module based on real behavior feedback provided by the dynamic simulation module of the cold source system; and the process monitoring module is used for realizing graphical display of the cold source system process flow and acquisition, recording and pushing of alarm and trend information. Automatic program logic and system performance debugging verification can be realized in advance, so that the aims of shortening the field debugging time and reducing the debugging risk are fulfilled.

Owner:上海宝信数据中心有限公司

Control method for general material line

InactiveCN104340413AReduce on-site commissioning timeThe modification process is simple and convenientConveyorsControl devices for conveyorsMaterial lineManufacturing engineering

The invention discloses a control method for a general material line. The control method comprises the following steps: firstly, establishing an element driving layer, an equipment calling layer, material line combining layers and a material line functional layer on a general material line control terminal; secondly, according to a field material line structure to be constructed, calling all driving modules of corresponding general material line sub equipment in the field material line structure to be constructed from the element driving layer through the equipment calling layer by the general material line control terminal, and then establishing physical connection between each called driving module and the corresponding general material line sub equipment; thirdly, performing combined connection on all material line combining layers establishing the physical connection relationship with the driving modules by the general material line control terminal; fourthly, performing logic control on material line structures which are formed and required by the field by the material line functional layer. According to the control method disclosed by the invention, the development control time for different material lines and the field debugging time of the system are shortened.

Owner:WUHAN IRON & STEEL (GROUP) CORP

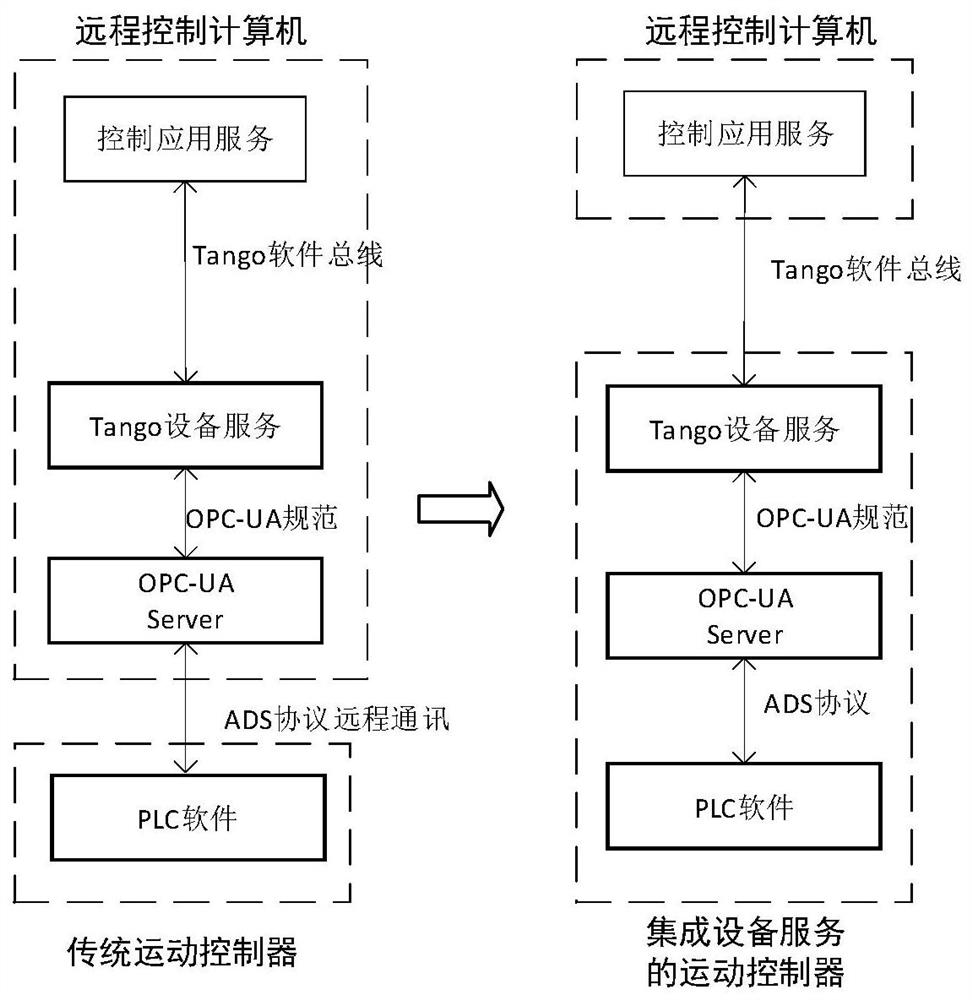

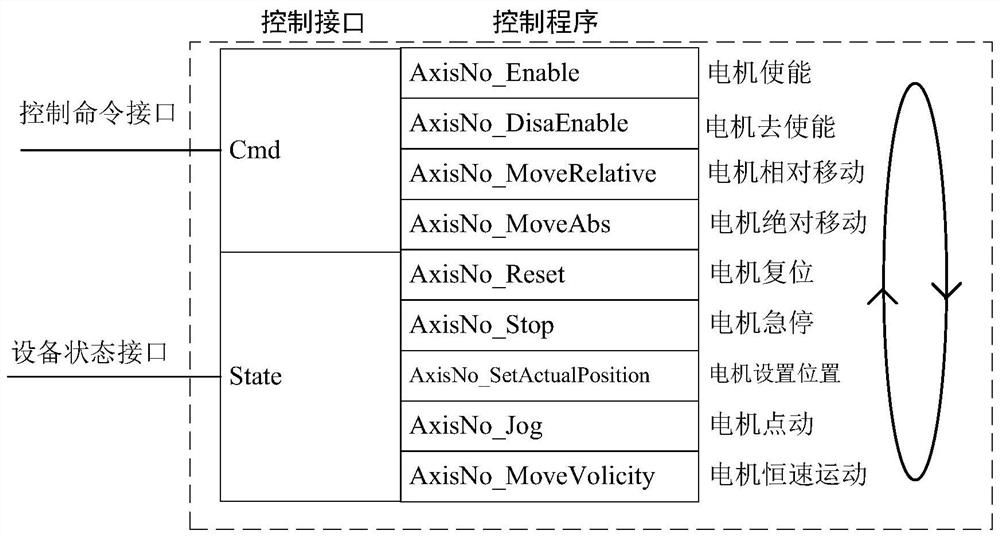

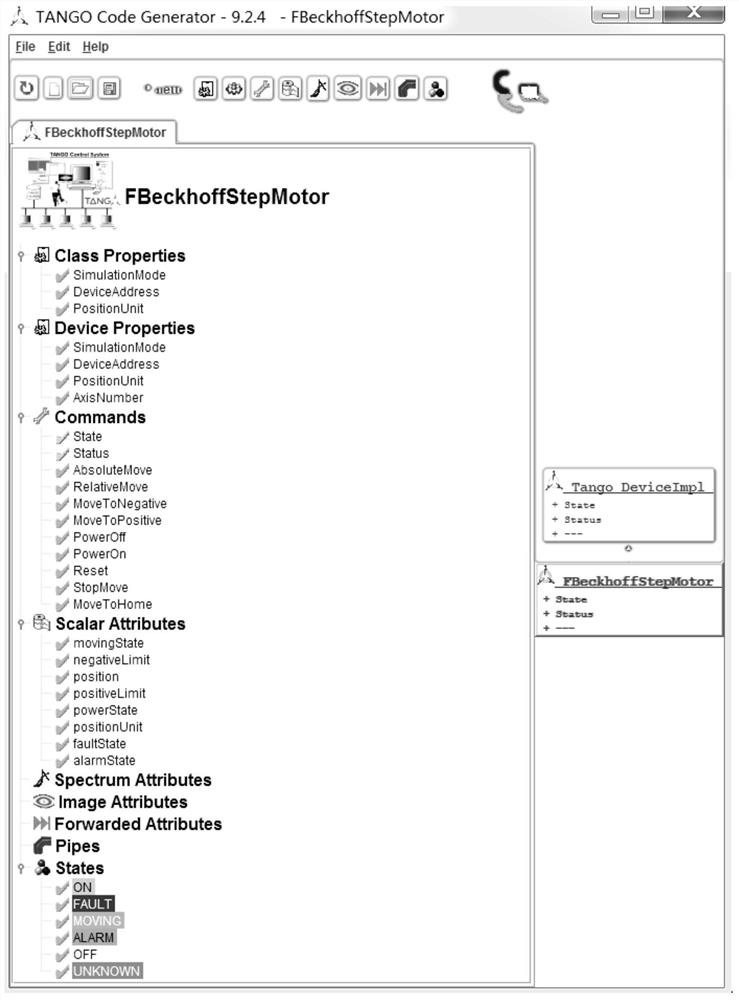

Embedded motion controller with integrated tango device services

ActiveCN112327740BRealize integrated designImplement debuggingElectric motor controlTotal factory controlSoftware busKinematic controller

The invention discloses an embedded motion controller integrating Tango equipment services, which is characterized in that the PC-based motion controller is embedded with PLC control programs, OPC-UA services and Tango equipment services; wherein, the The Tango device service on the motion controller establishes a communication link with the control application service program of the remote control computer through the Tango software bus for data exchange. The invention provides an embedded motion controller integrating Tango equipment services, in which the equipment service of the motor object is designed and deployed, and the integrated design, debugging and deployment of the motor object control program and the equipment service program are realized.

Owner:COMP APPL RES INST CHINA ACAD OF ENG PHYSICS

Simulation system and method for shoemaking production line

The invention provides a simulation system and method for a shoemaking production line. The system comprises an input module which comprises an encoder for reading and writing an identifier disposed on a material, and a matching unit for matching the material with a shoe tree; a glue spraying module which comprises a first glue spraying unit used for spraying glue to a vamp and a second glue spraying unit used for spraying glue to a sole; an output module which comprises a mechanical arm used for taking and placing shoes and a pressing machine unit used for manufacturing the shoes. The input module, the glue spraying module and the output module are sequentially arranged in the moving direction of a conveying belt. Under the condition that an actual operation scene is not built or field debugging is limited, simulation or operation can be conducted through a simulation system, and the field debugging time is shortened.

Owner:重庆赛宝工业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com