Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about "Testing semiconductor materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

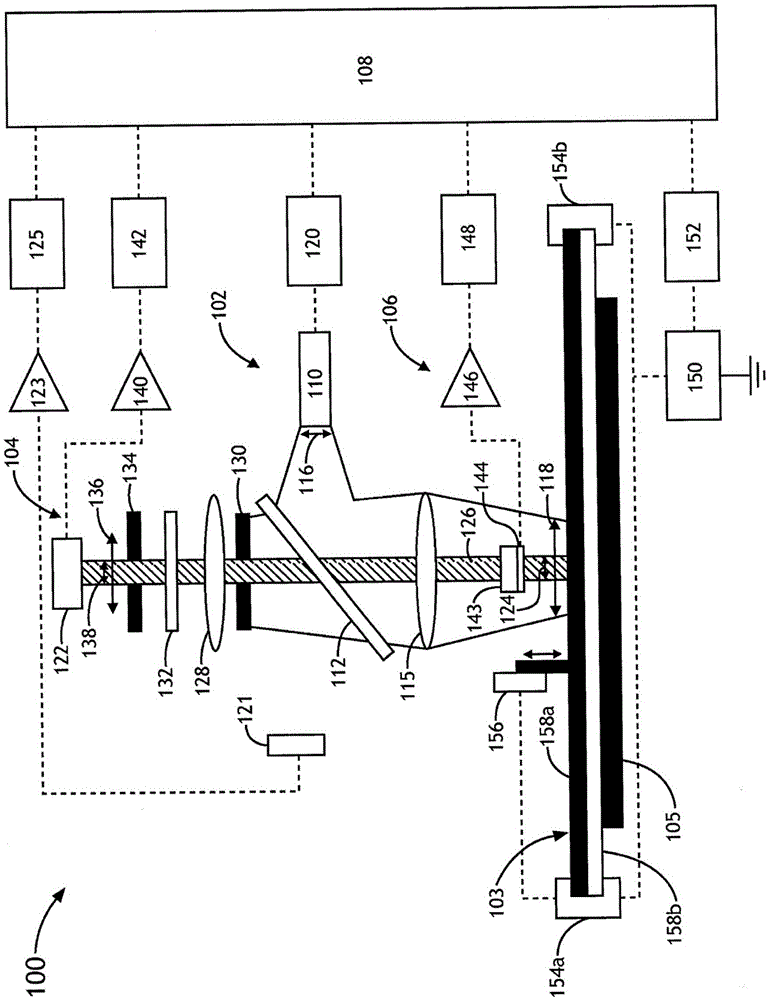

Small-angle scattering x-ray metrology systems and methods

ActiveUS20150110249A1Material analysis using wave/particle radiationTesting semiconductor materialsSoft x rayMetrology

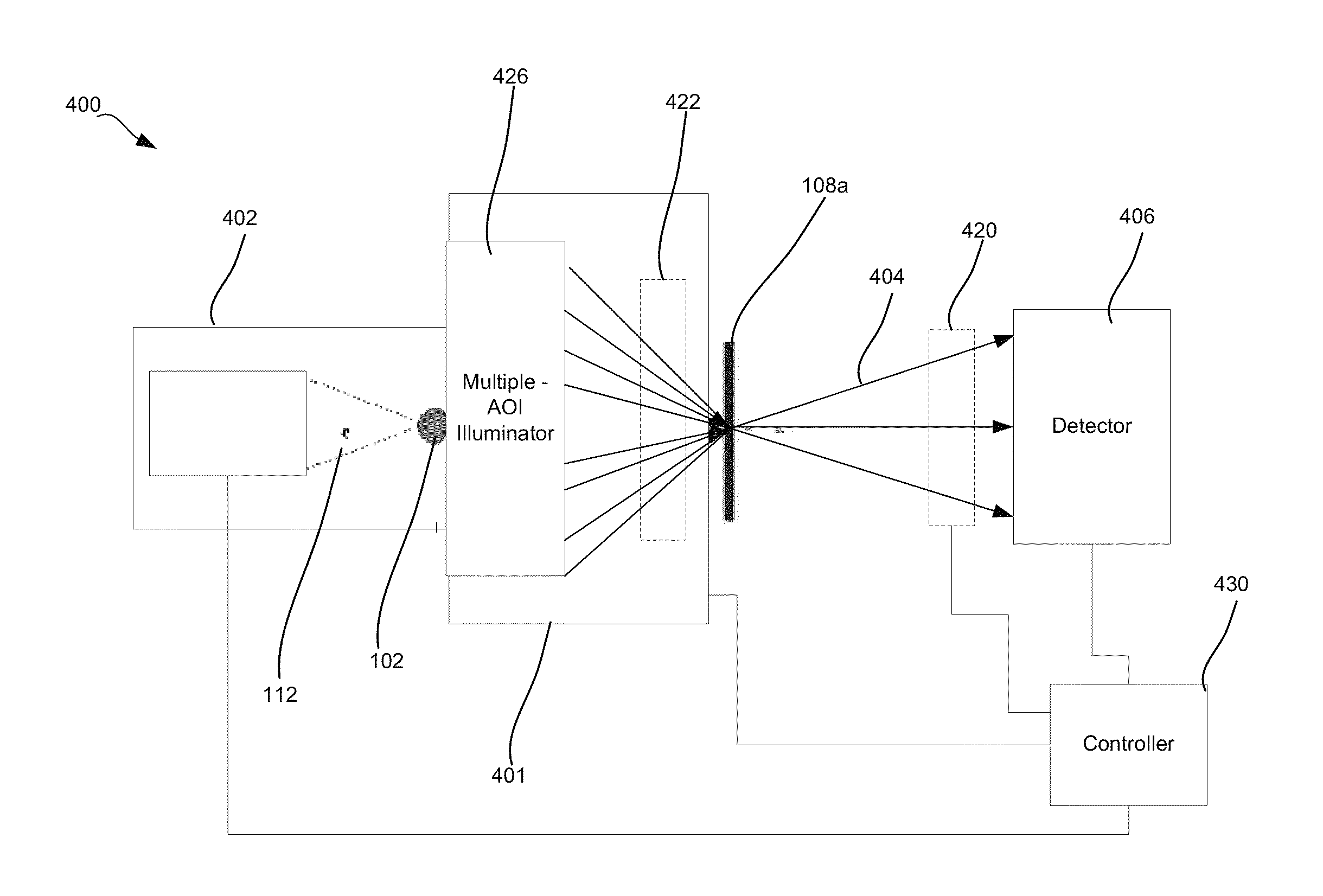

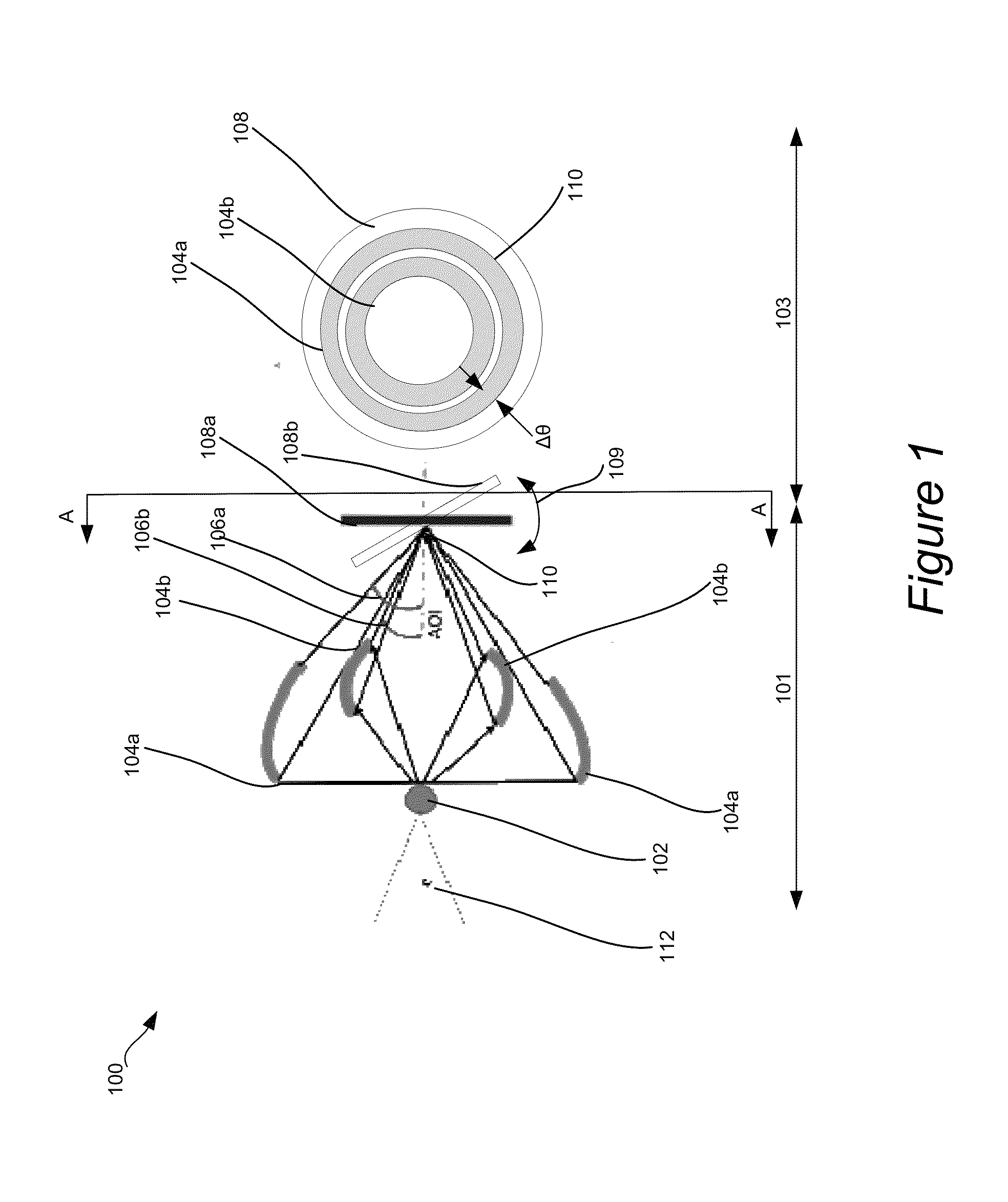

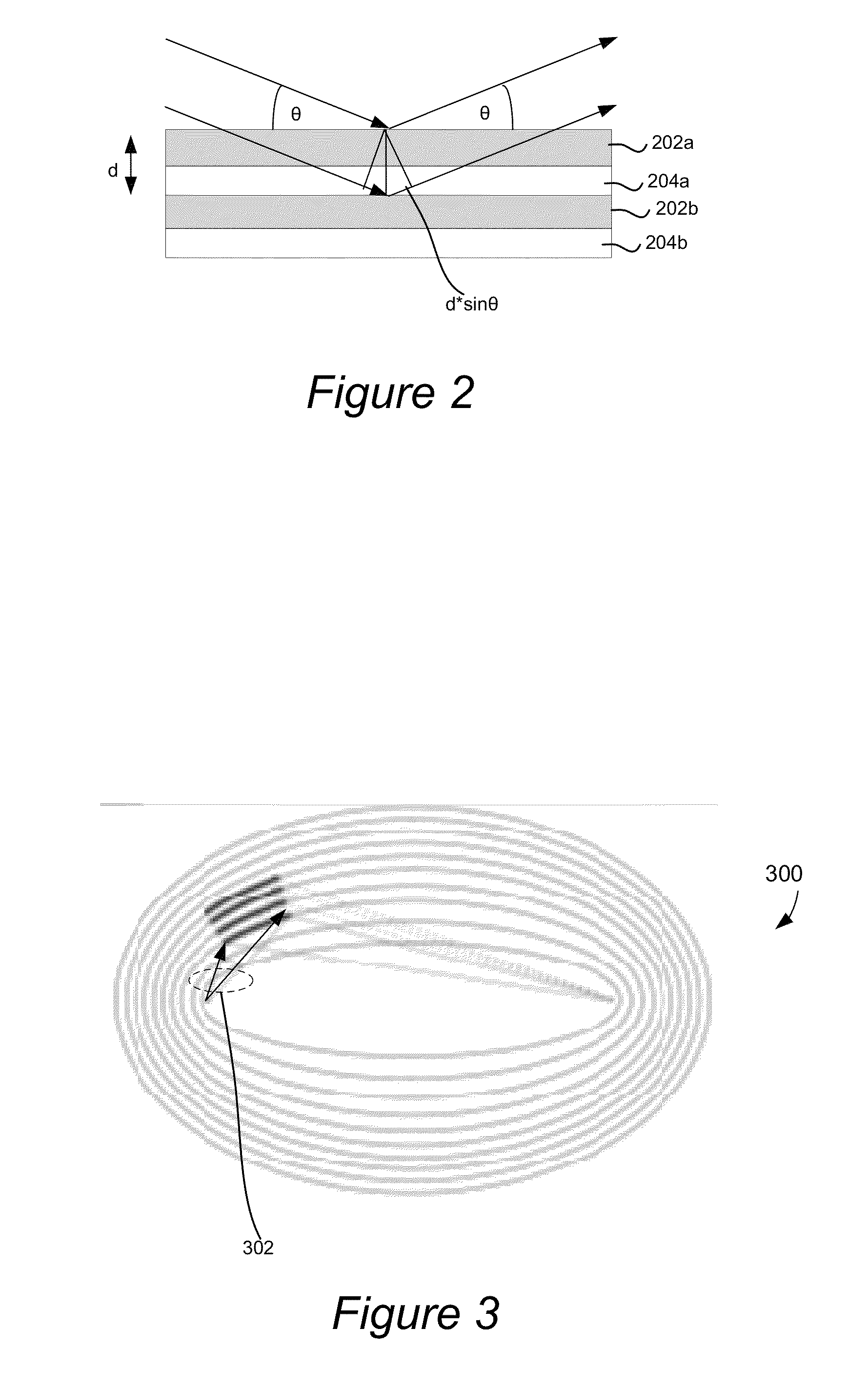

Disclosed are apparatus and methods for performing small angle x-ray scattering metrology. This system includes an x-ray source for generating x-rays and illumination optics for collecting and reflecting or refracting a portion of the generated x-rays towards a particular focus point on a semiconductor sample in the form of a plurality of incident beams at a plurality of different angles of incidence (AOIs). The system further includes a sensor for collecting output x-ray beams that are scattered from the sample in response to the incident beams on the sample at the different AOIs and a controller configured for controlling operation of the x-ray source and illumination optics and receiving the output x-rays beams and generating an image from such output x-rays.

Owner:KLA CORP

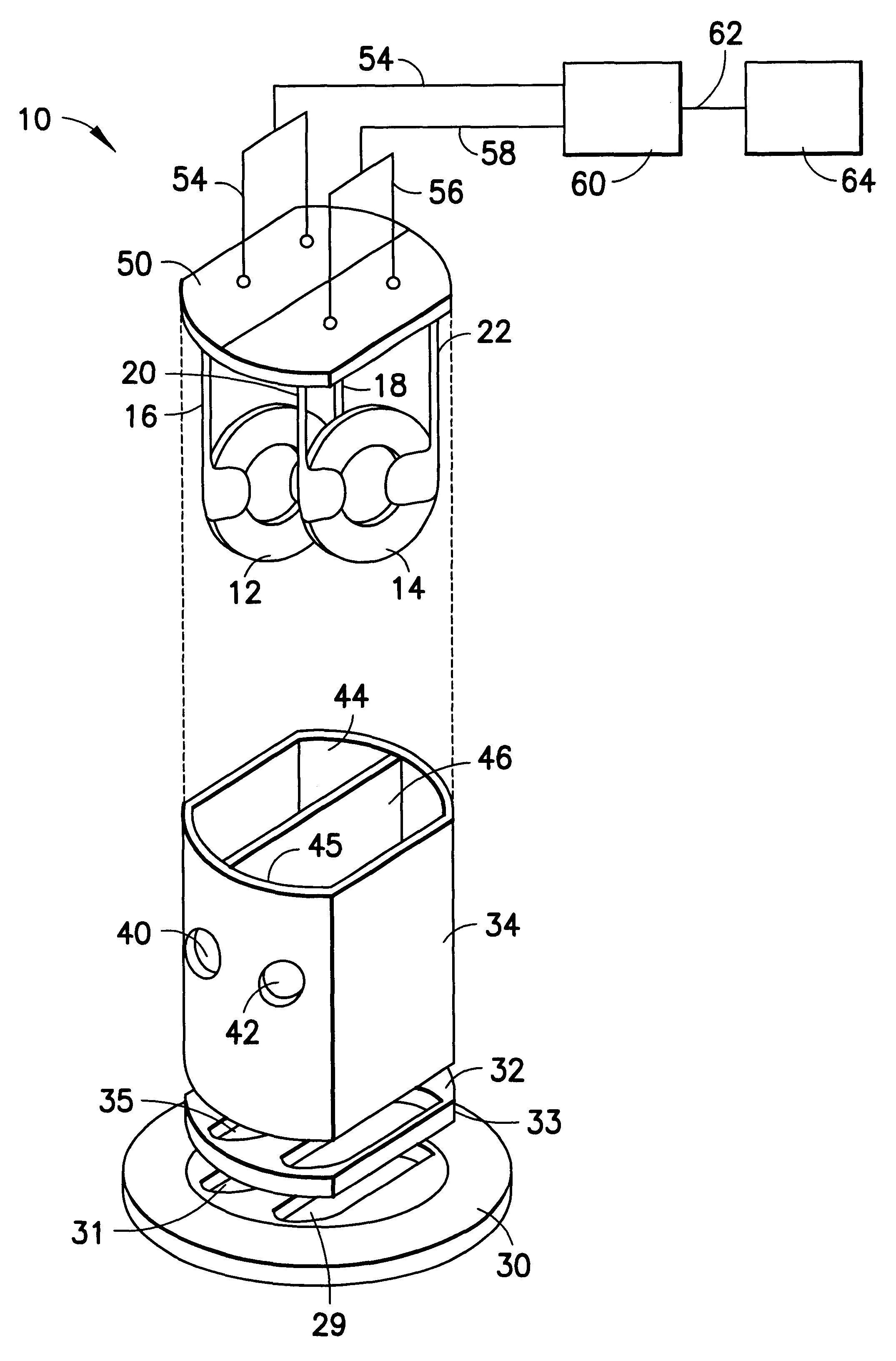

Quartz crystal microbalance sensors and semiconductor manufacturing process systems comprising same

InactiveUS6295861B1Analysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansProcess systemsQuartz crystal microbalance

A sensor device for detecting the presence of a gas species in a gas environment susceptible to the presence of same. The sensor device may include a piezoelectric crystal coated with a sensor material having adsorptive affinity for the gas species, with an electric oscillator arranged for applying an oscillating electric field to the piezoelectric crystal to generate an output frequency therefrom indicative of the presence of the gas species when present in the gas environment, when the gas environment is exposed to the piezoelectric crystal. Another aspect of the invention involves a porous polymeric material that may be employed as a sensor material on a piezoelectric crystal sensor device, as well as a quartz microbalance holder that enables reactor gas monitoring. The sensor device alternatively may comprise an optical sensor arranged in a non-contaminating fashion in relation to the gas environment being monitored.

Owner:LIFE SAFETY GERMANY

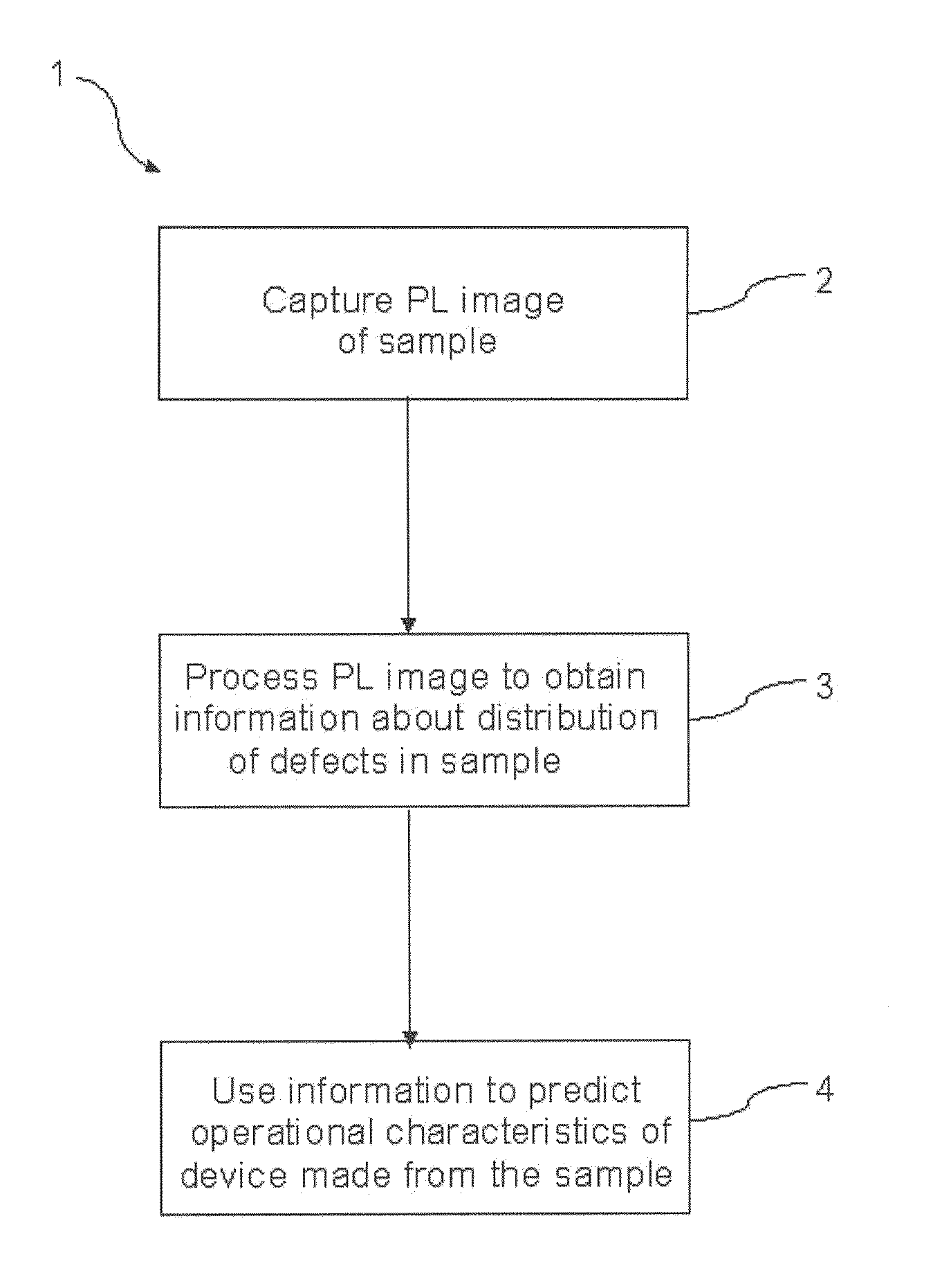

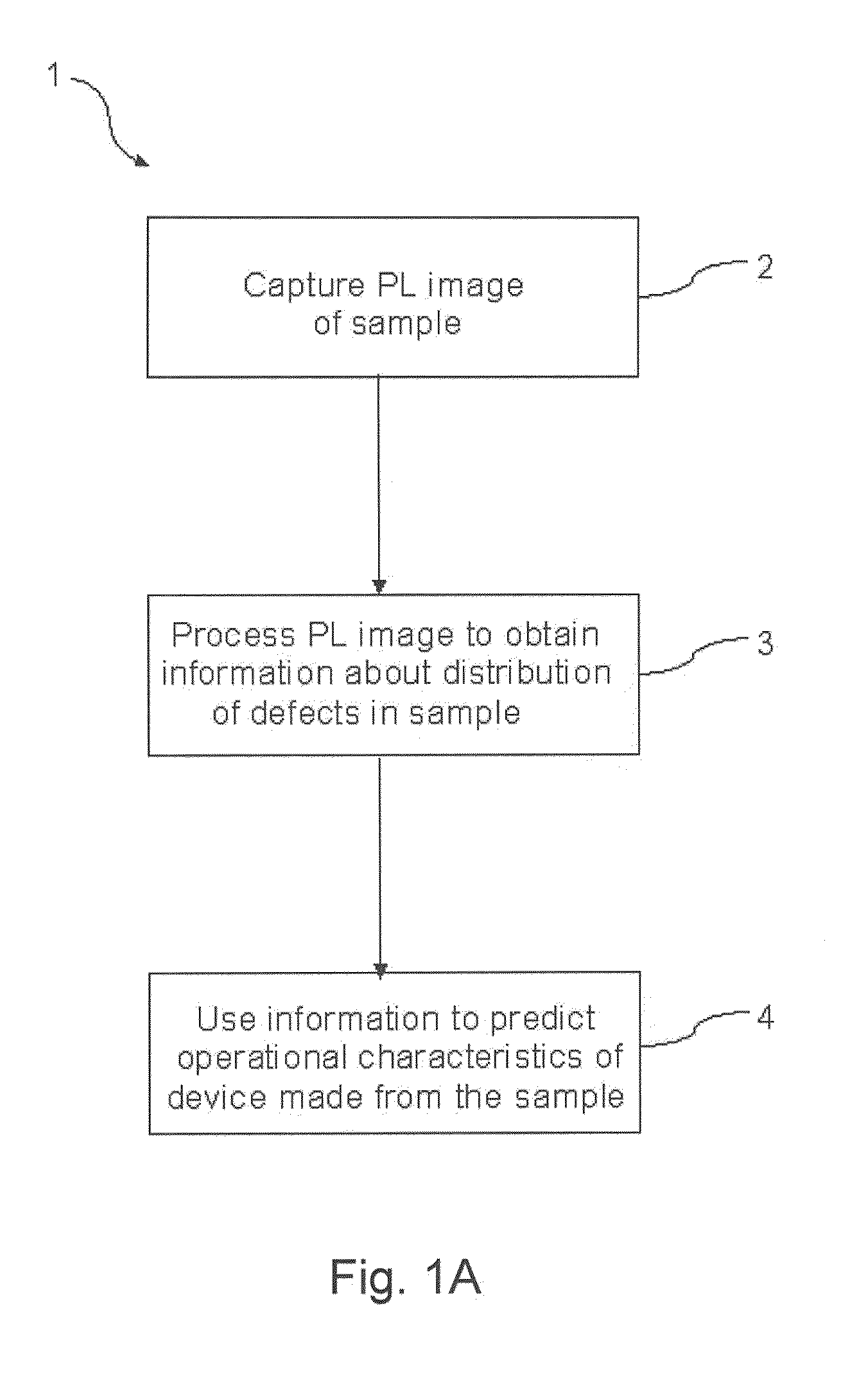

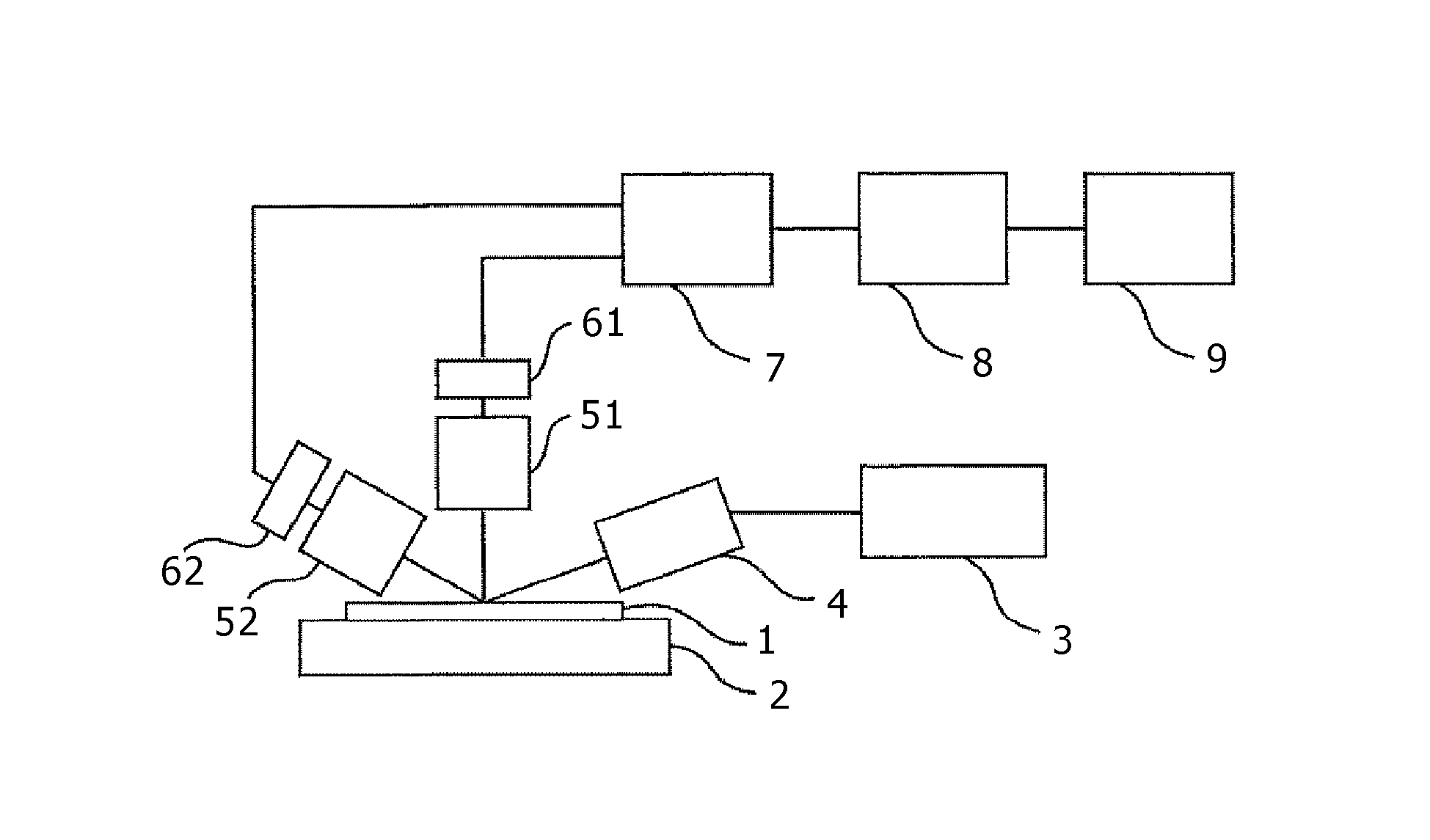

Wafer imaging and processing method and apparatus

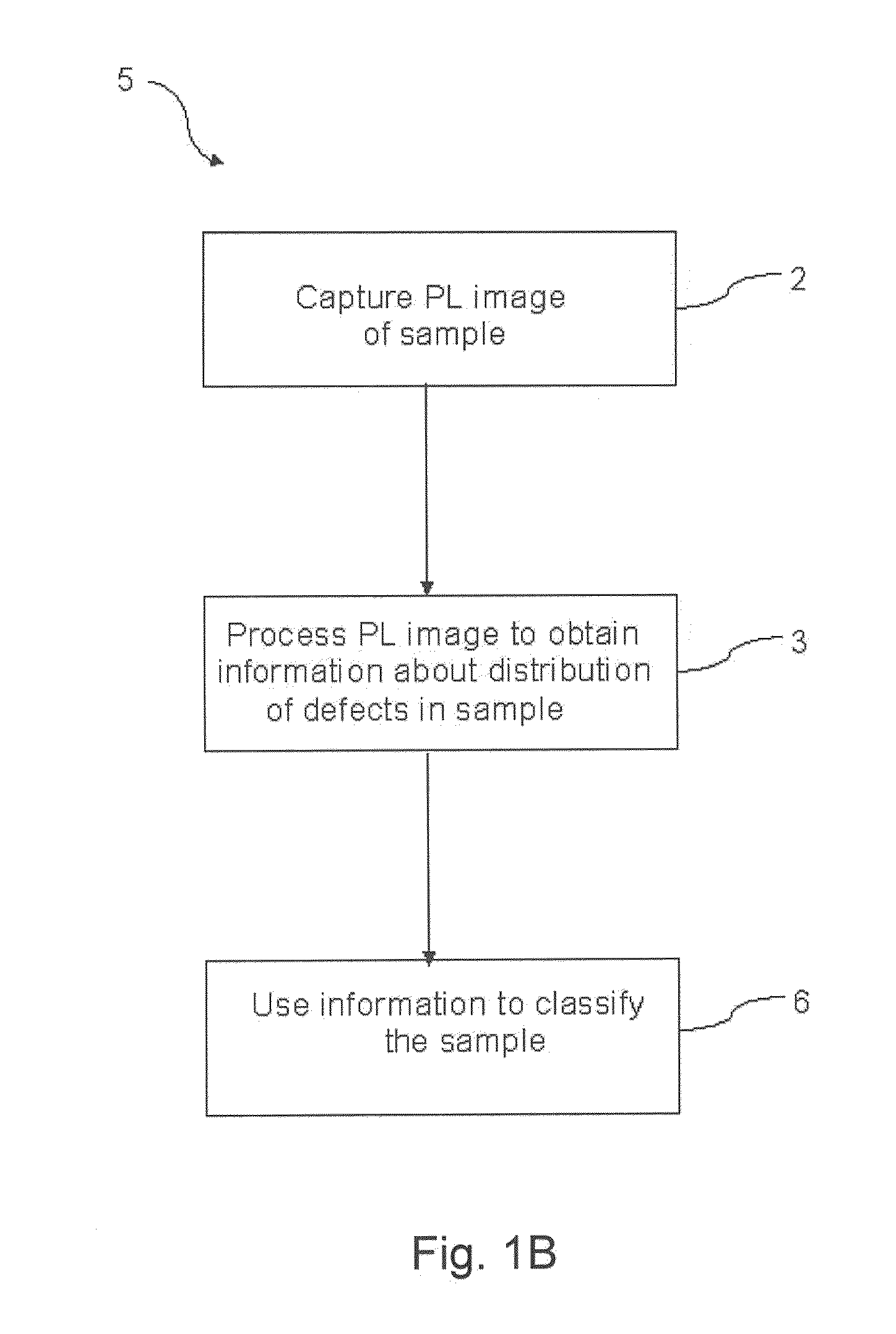

A method (1) is disclosed whereby luminescence images are captured (2) from as-cut or partially processed bandgap materials such as multicrystalline silicon wafers. These images are then processed (3) to provide information about defects such as dislocations within the bandgap material. The resultant information is then utilised (4) to predict various key parameters of a solar cell manufactured from the bandgap material, such as open circuit voltage and short circuit current. The information may also be utilised to apply a classification to the bandgap material. The methods can also be used to adjust or assess the effect of additional processing steps, such as annealing, intended to reduce the density of defects in the bandgap materials.

Owner:BT IMAGING PTY LTD

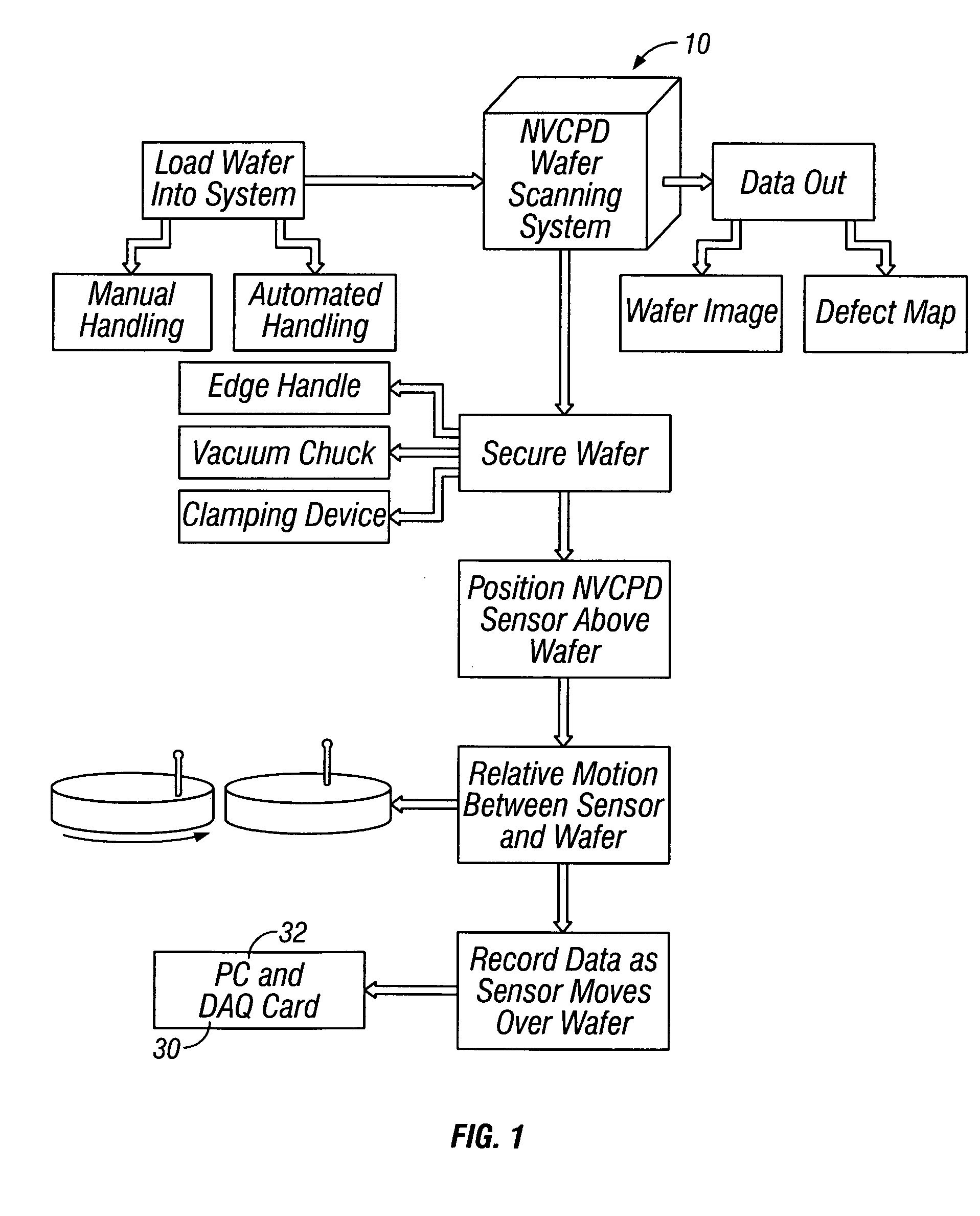

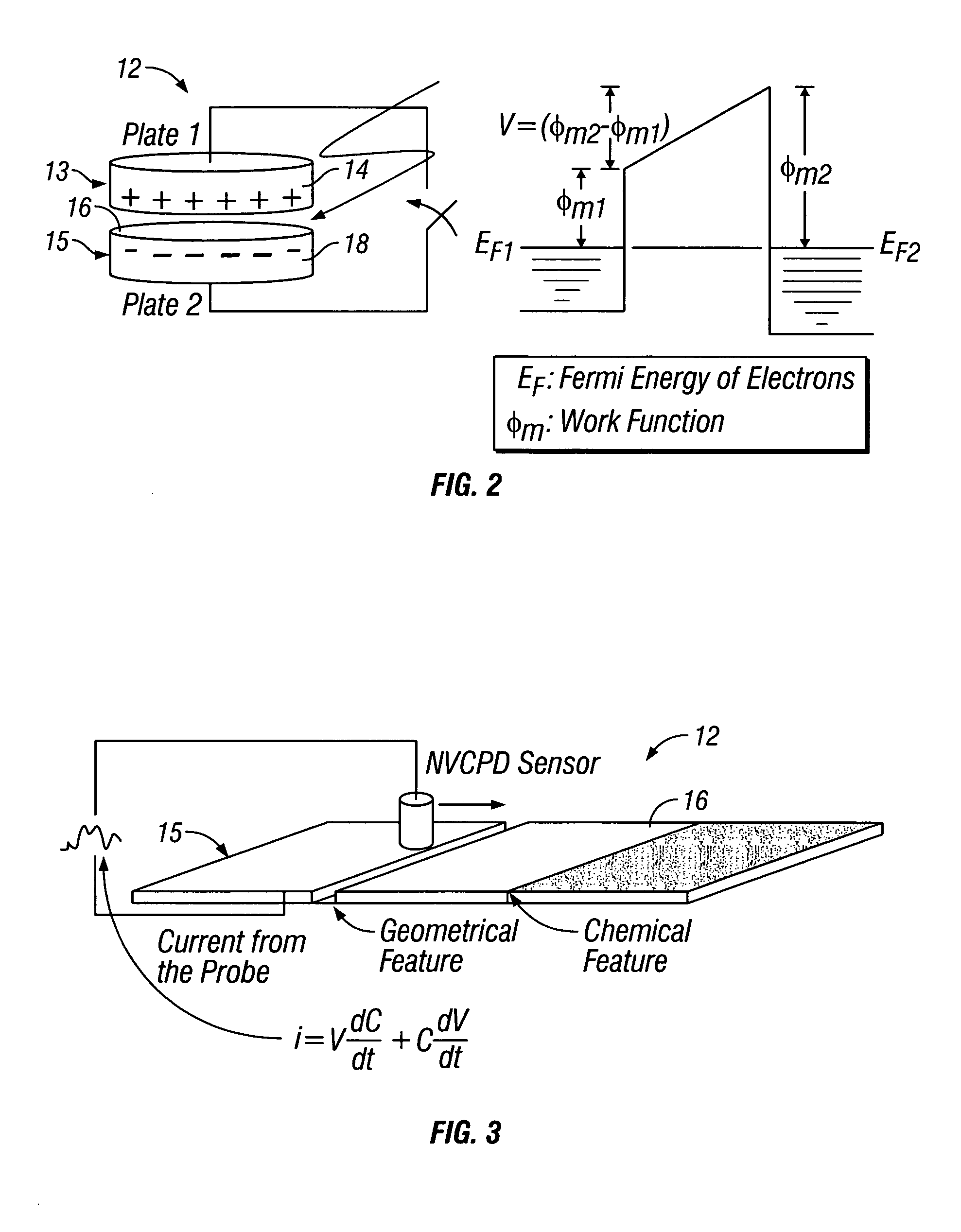

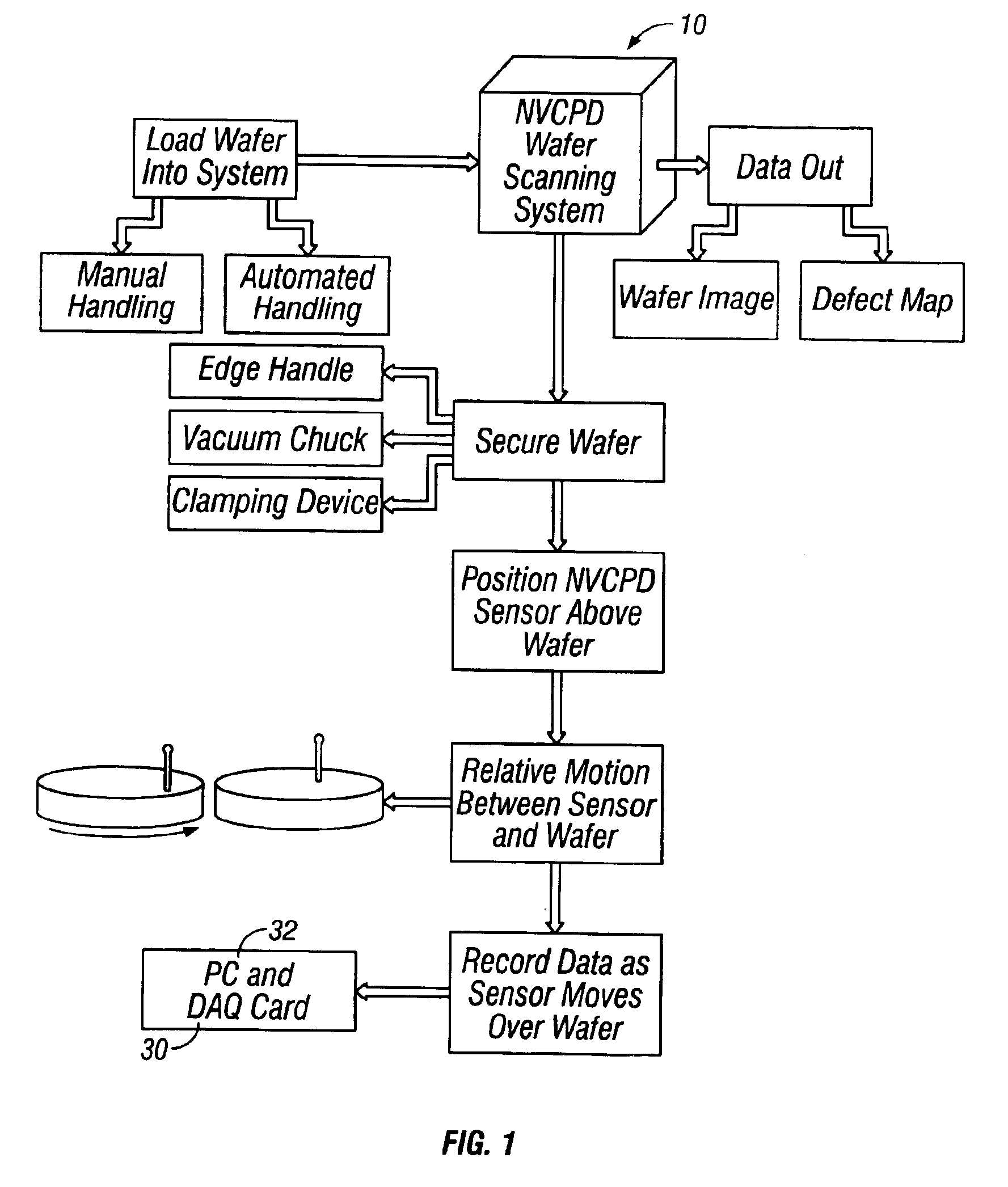

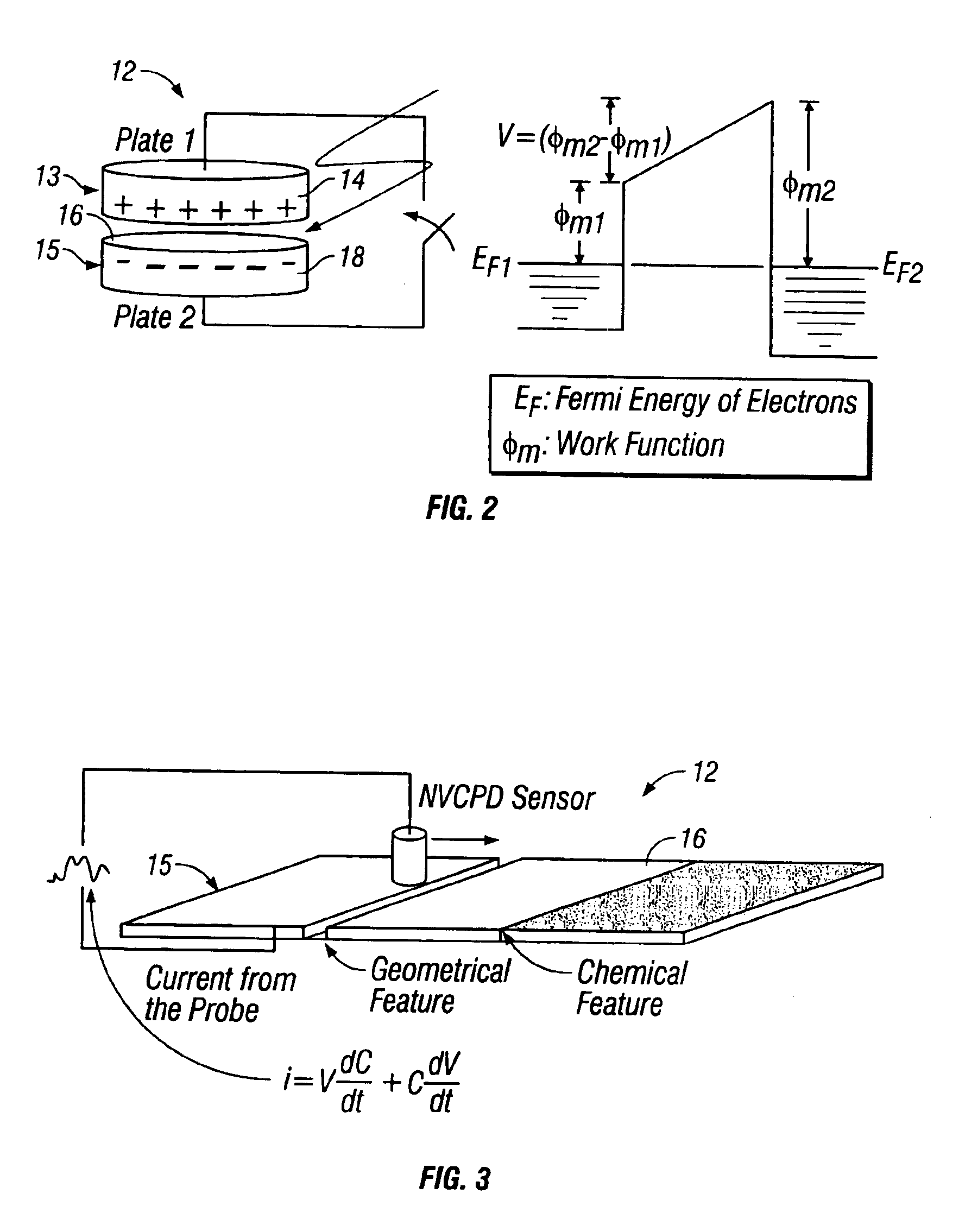

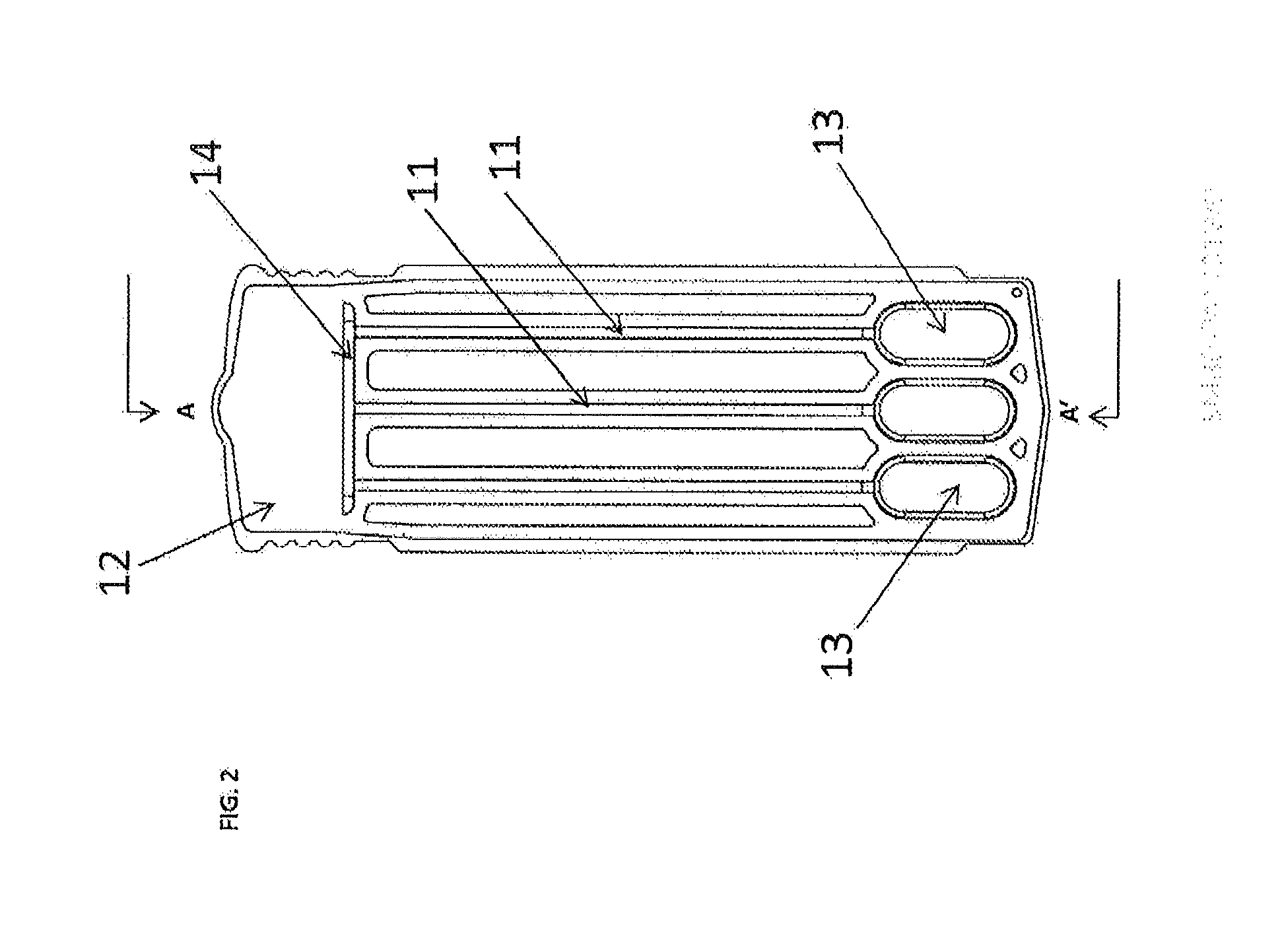

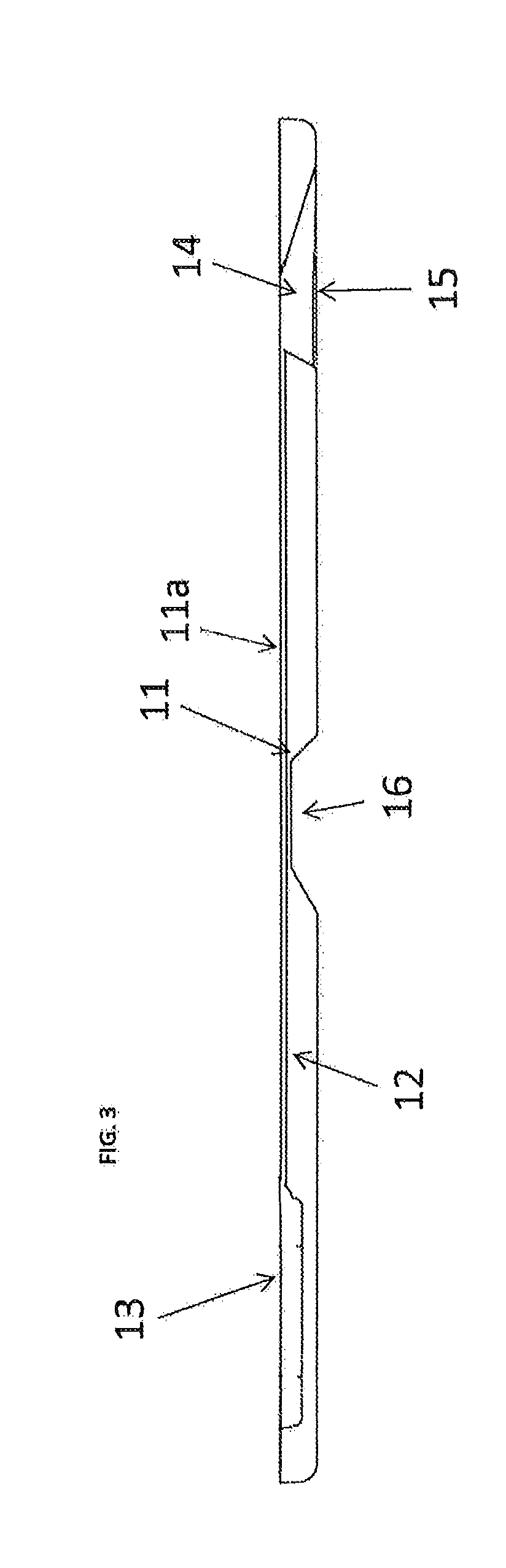

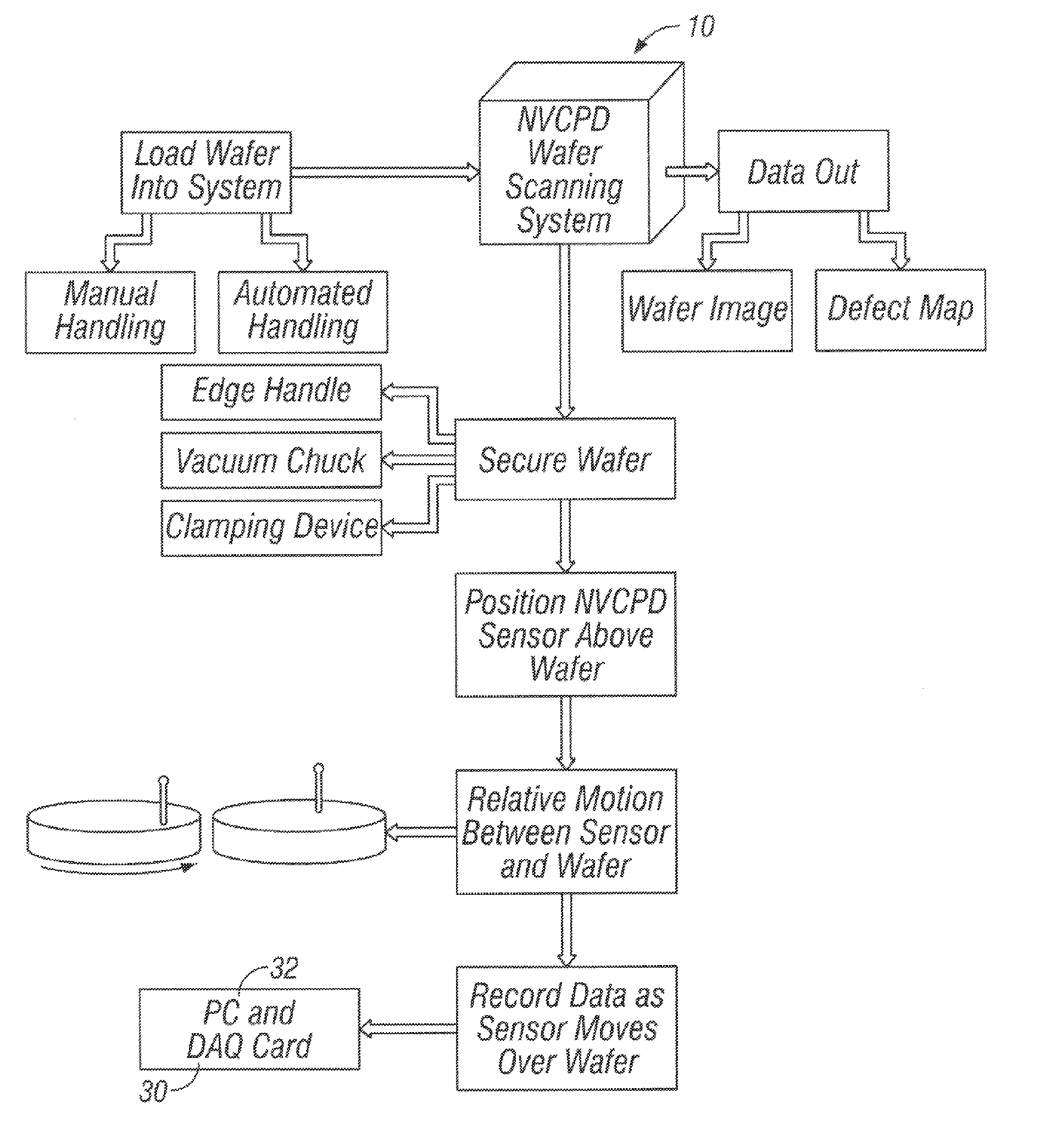

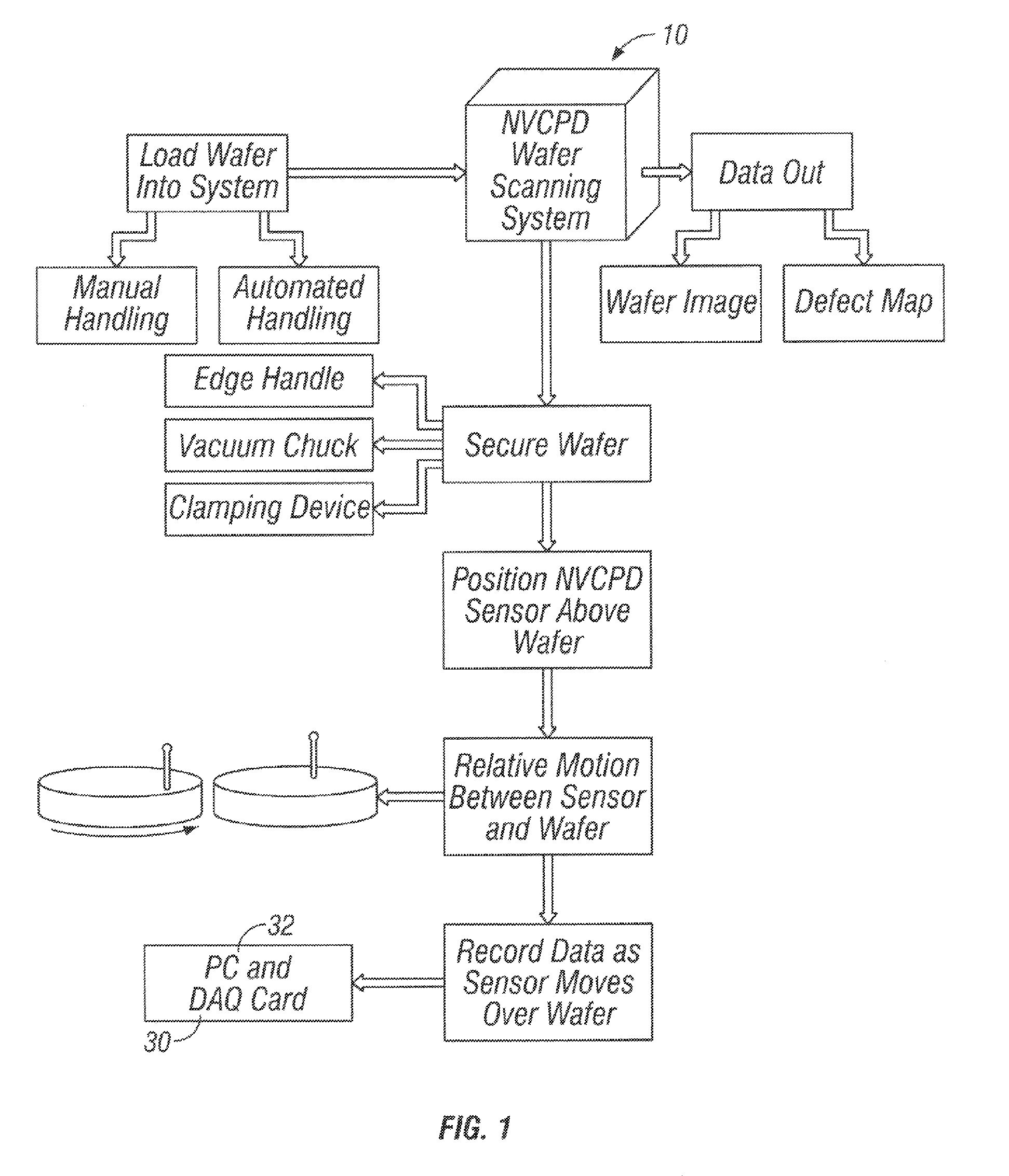

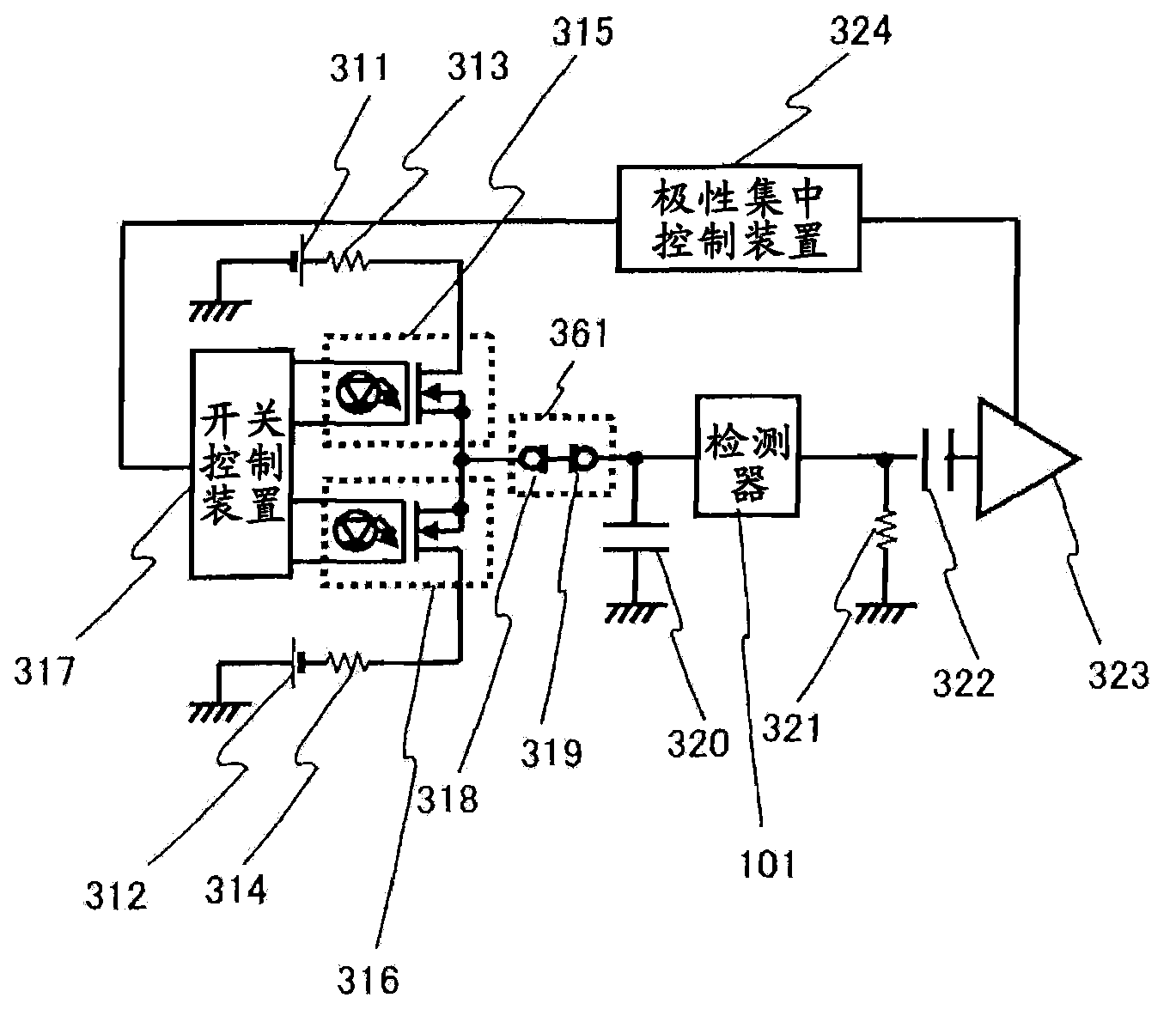

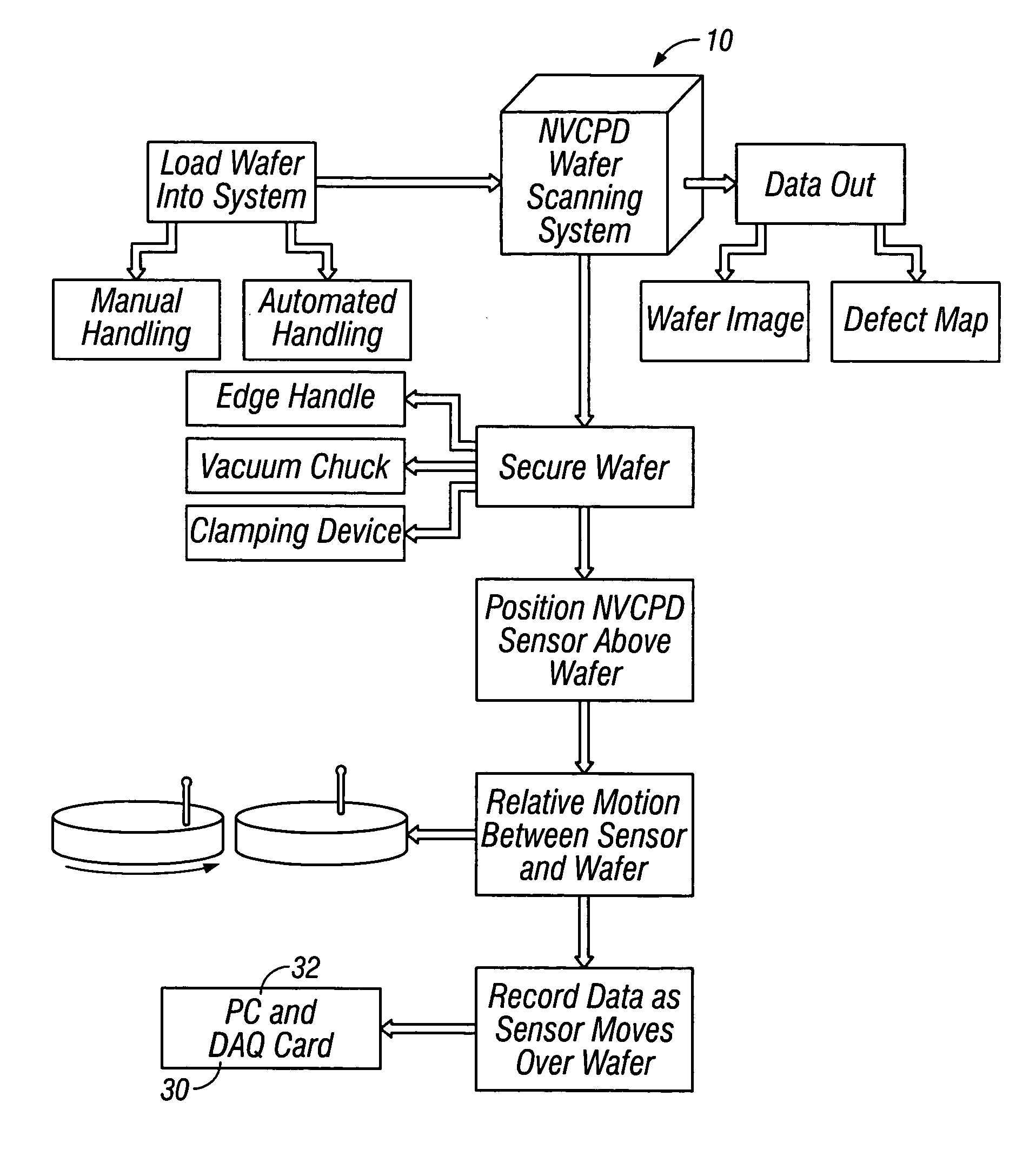

Inspection system and apparatus

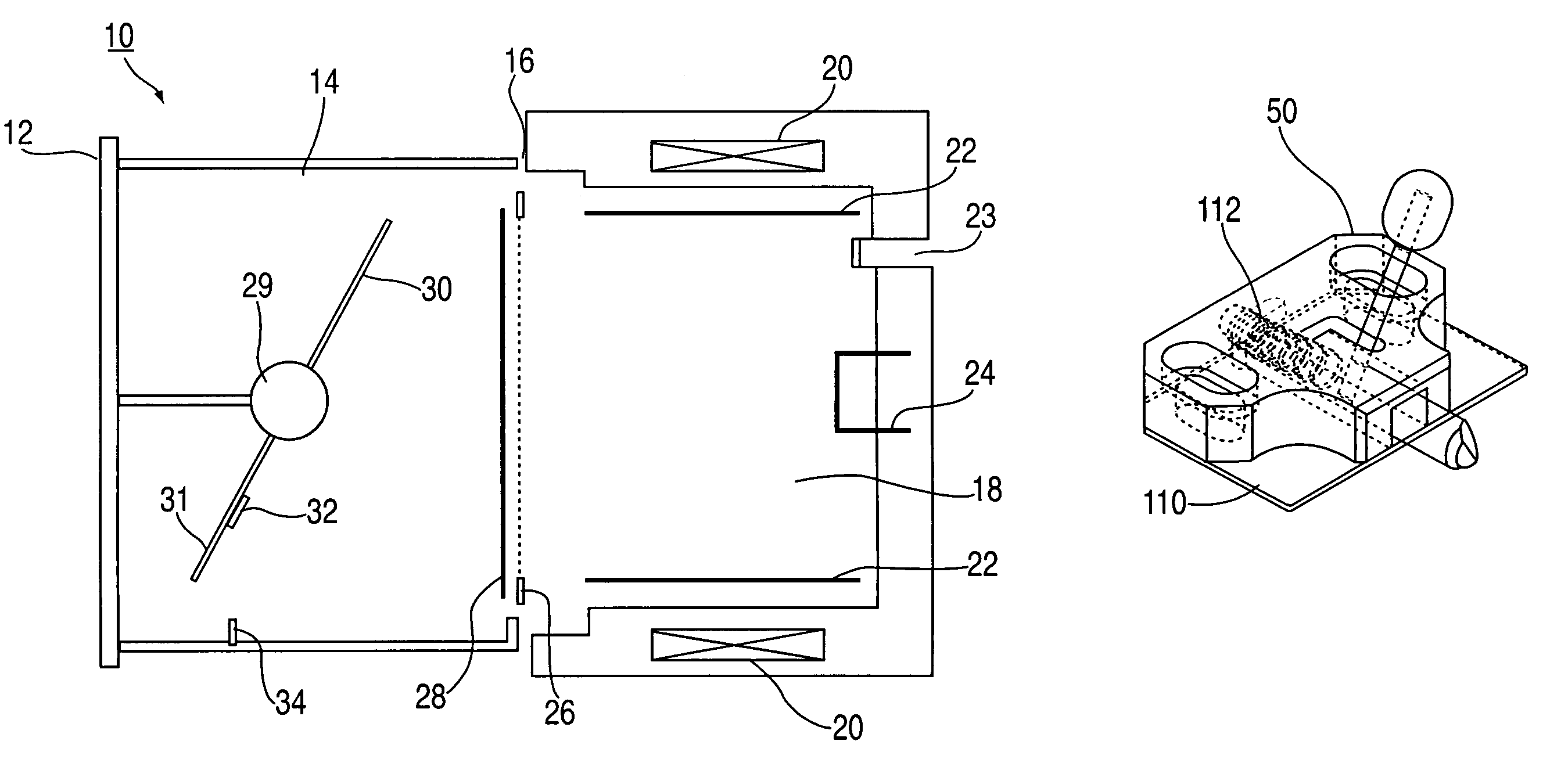

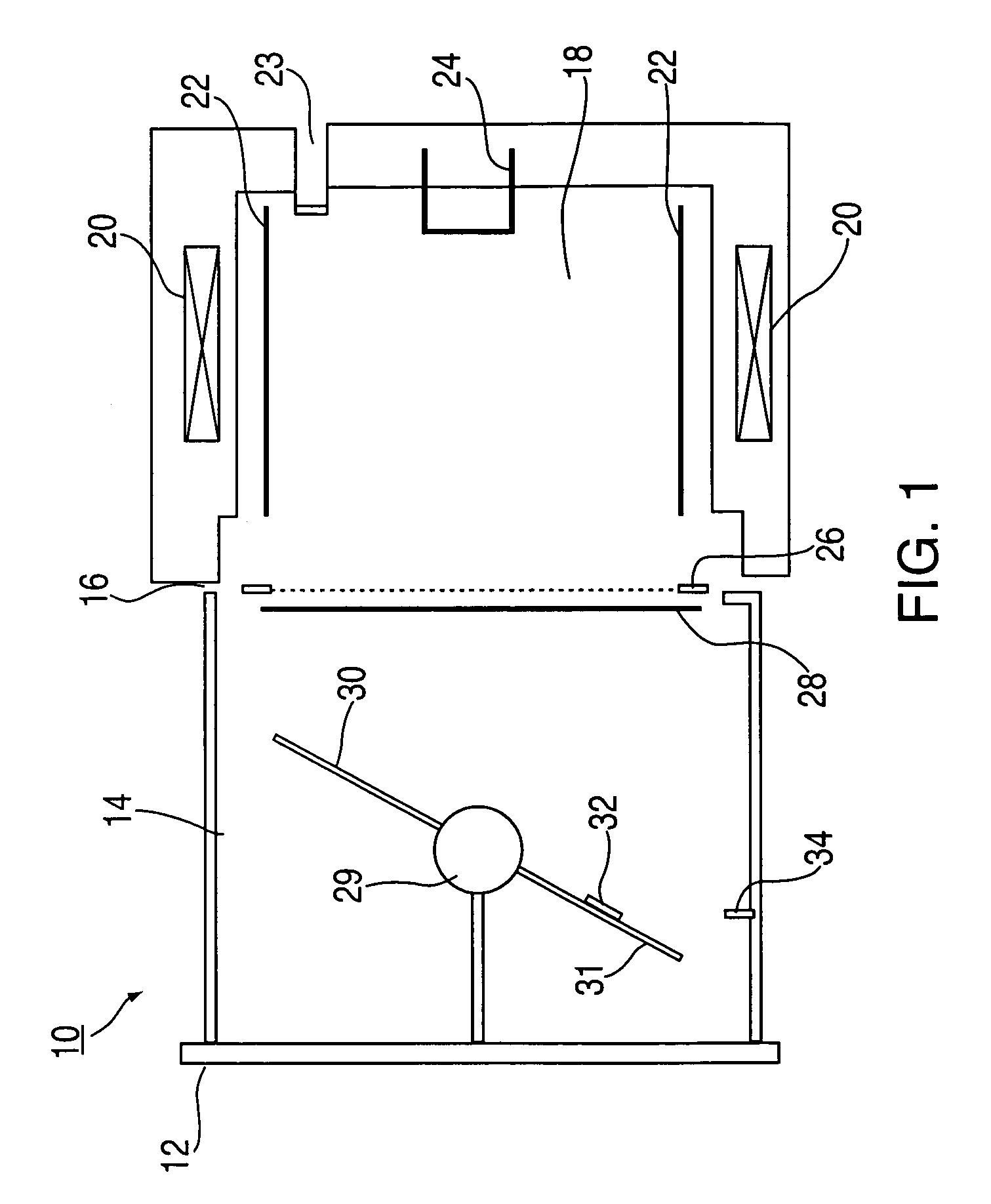

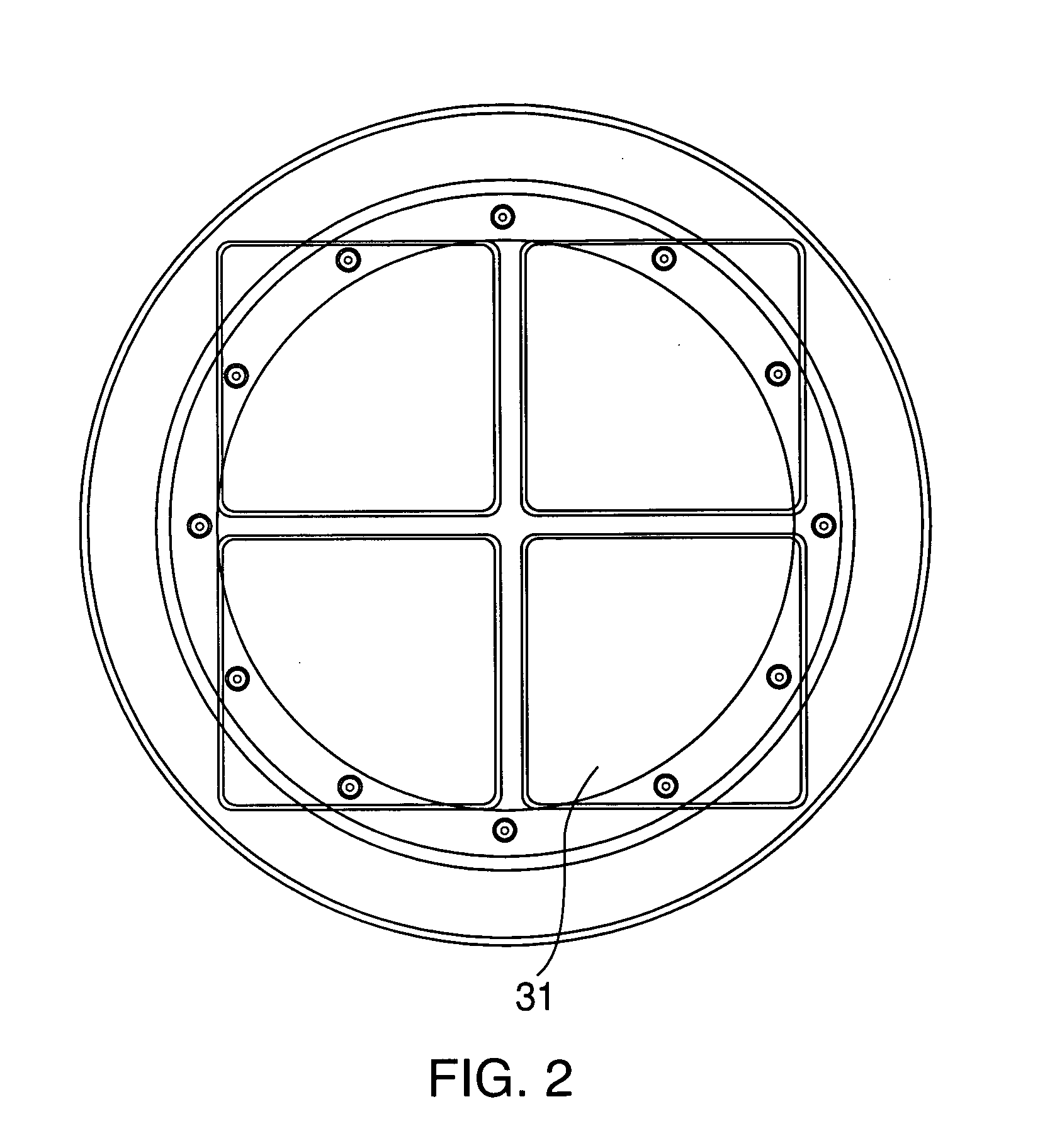

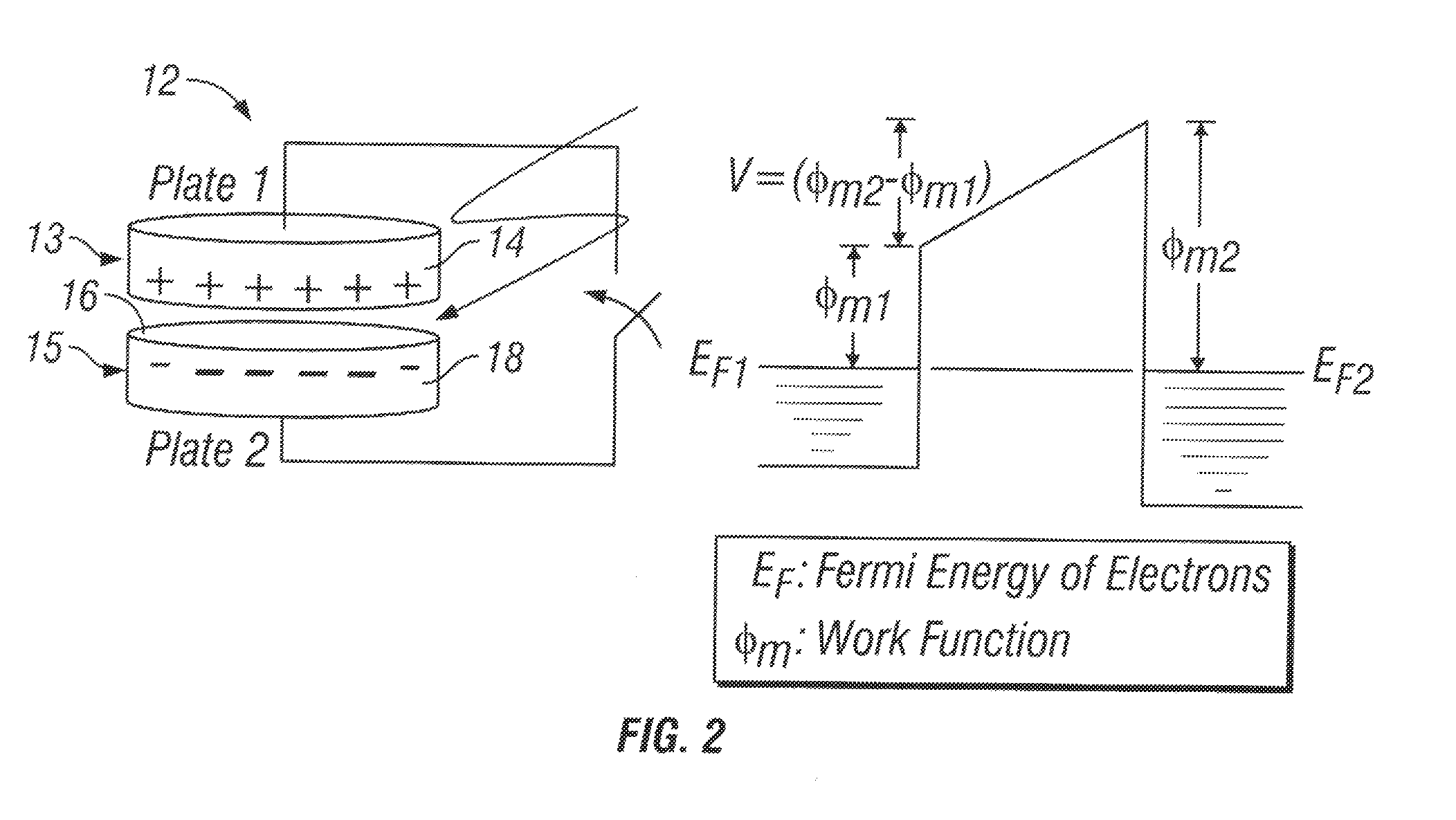

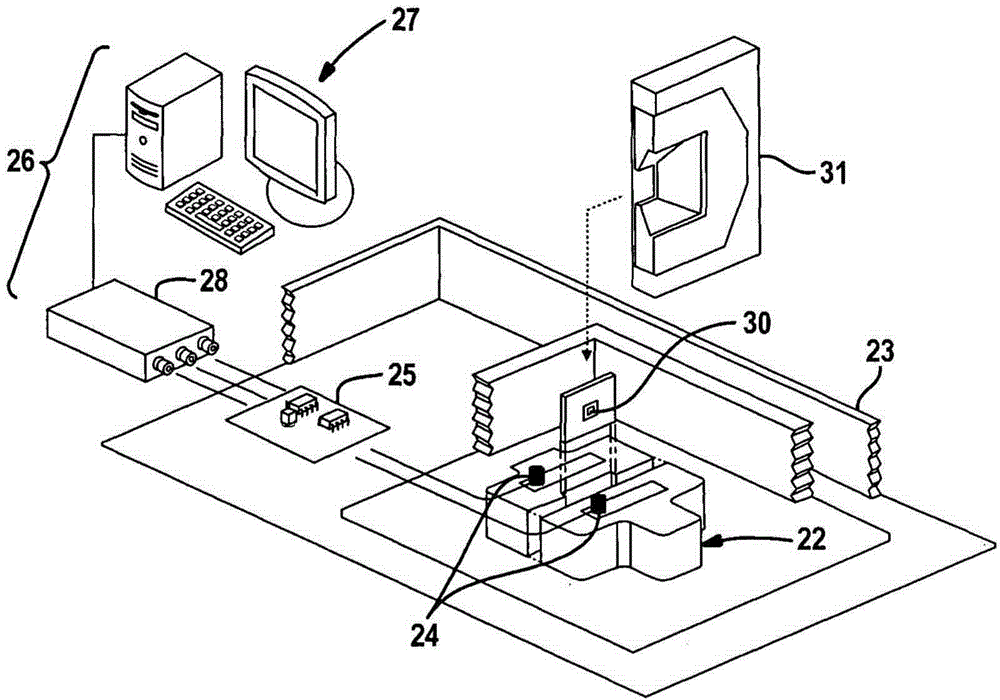

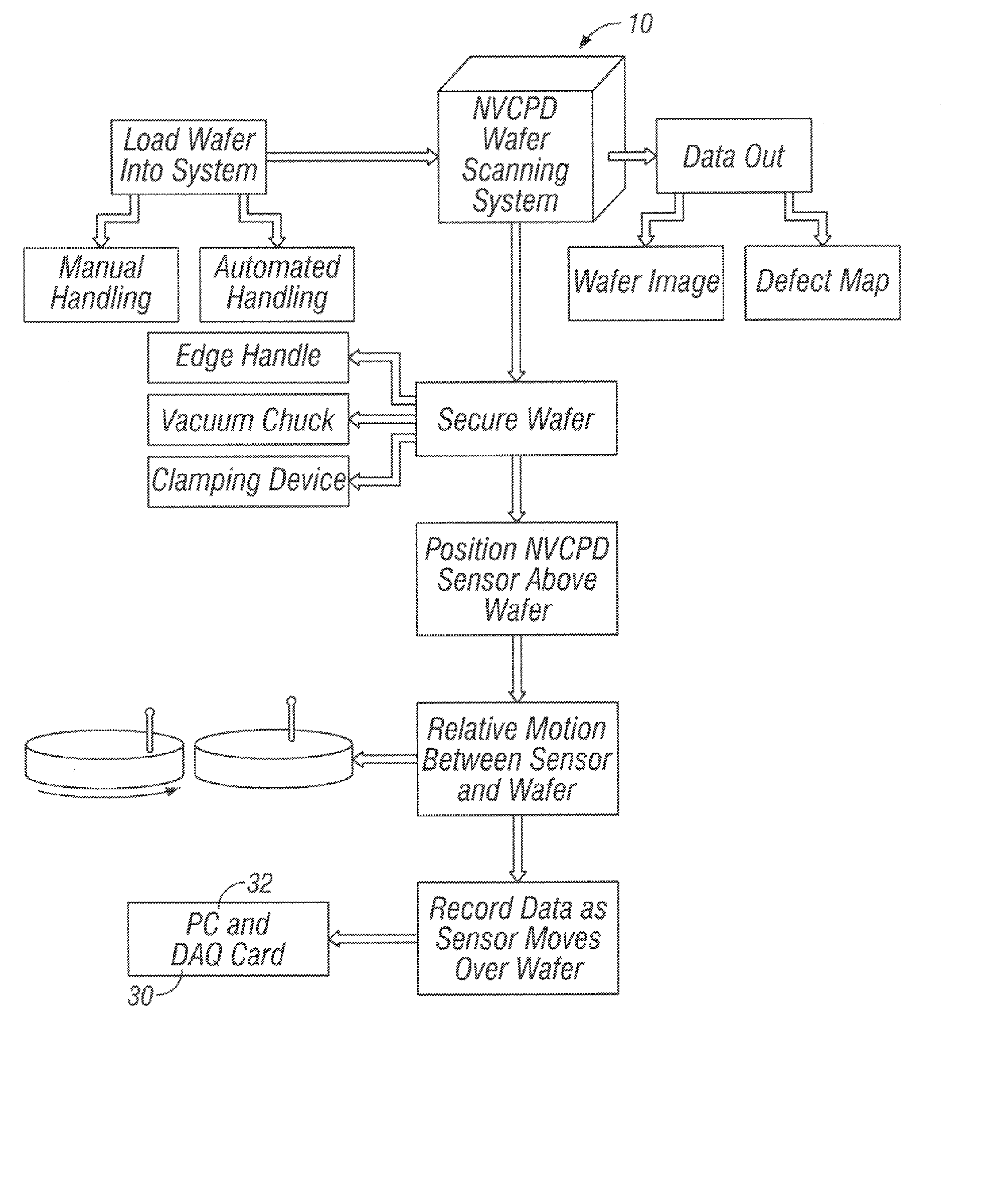

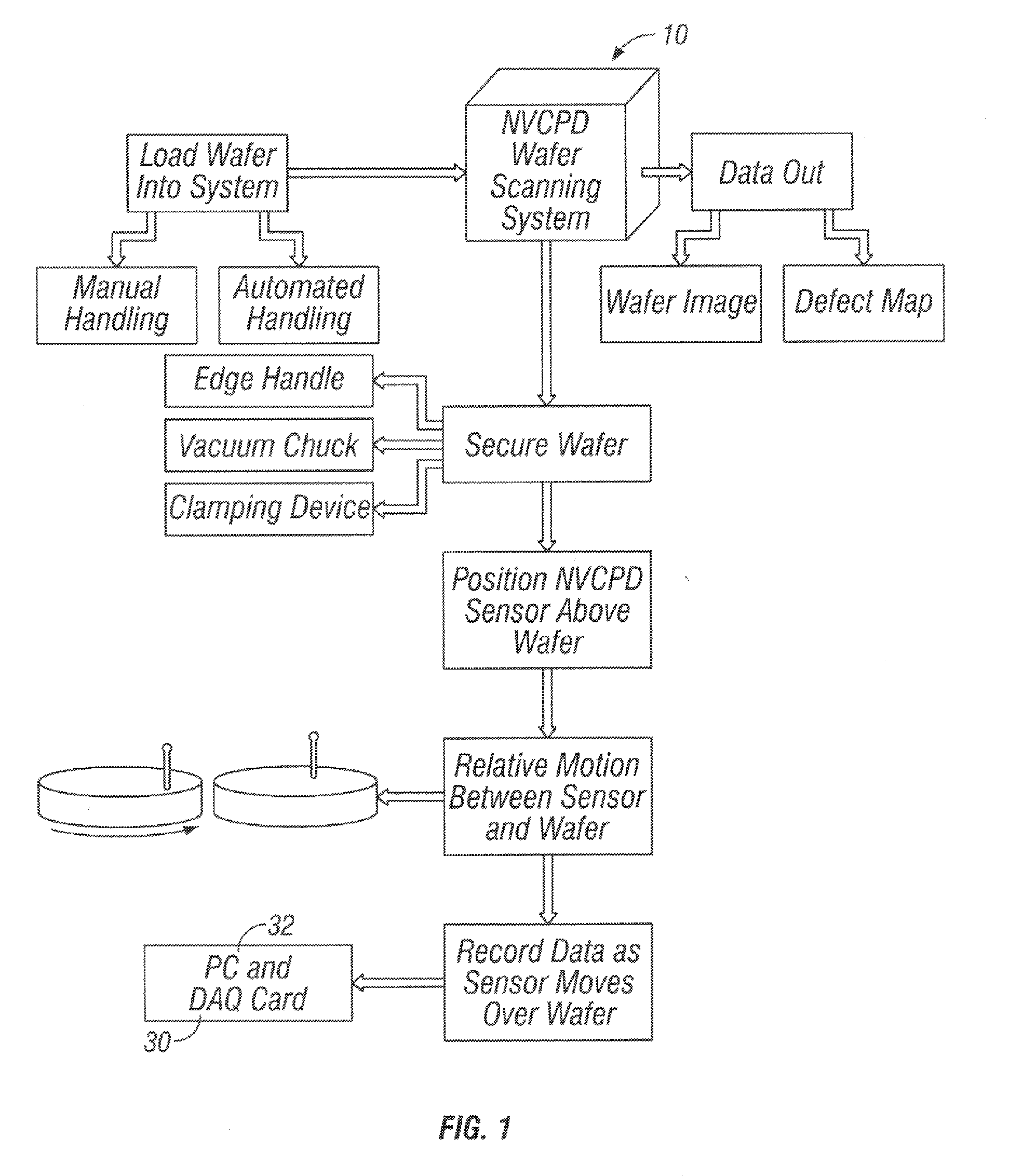

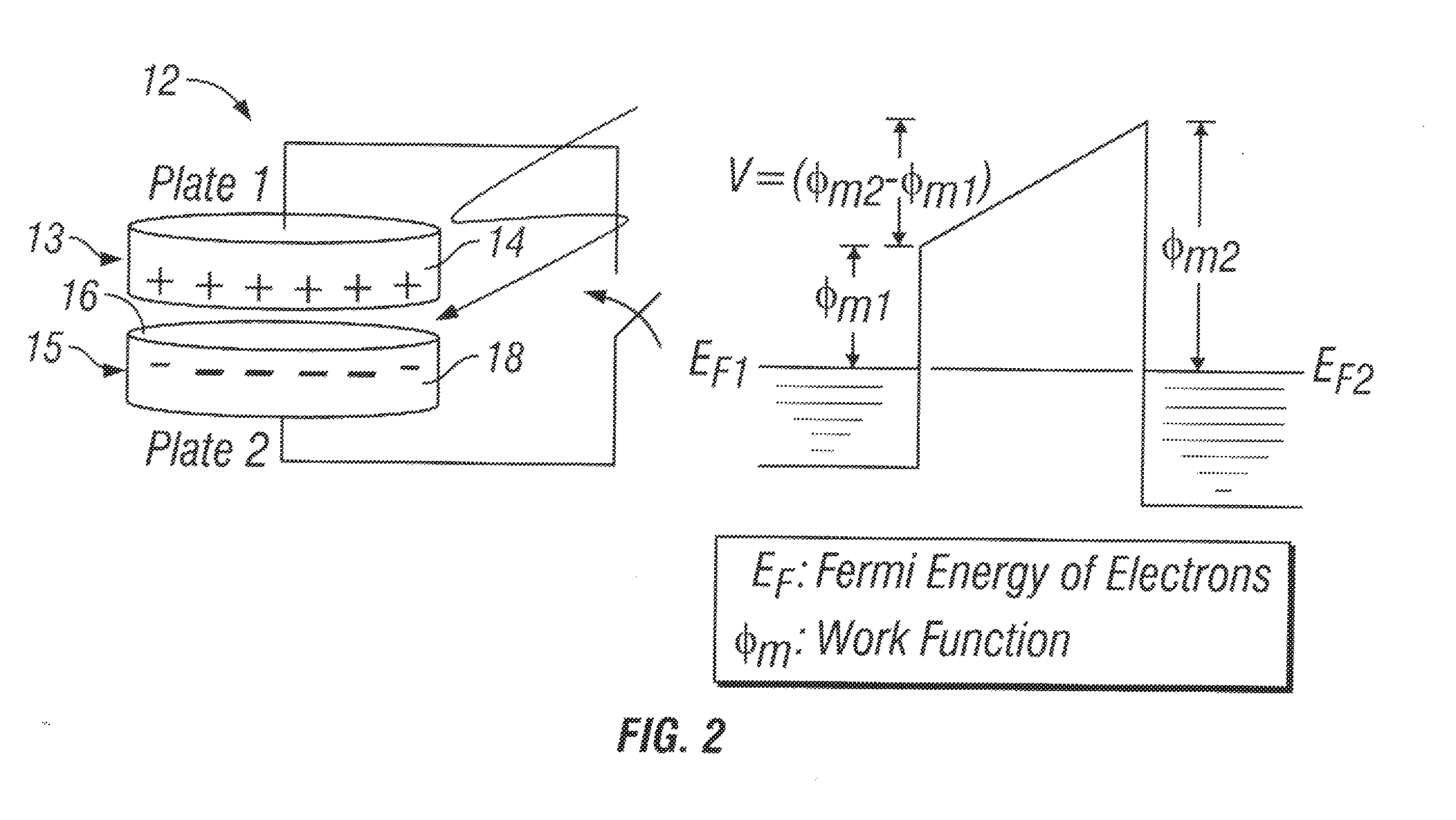

InactiveUS20050162178A1Minimize complexitySimple signal processingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingRapid imagingPotential difference

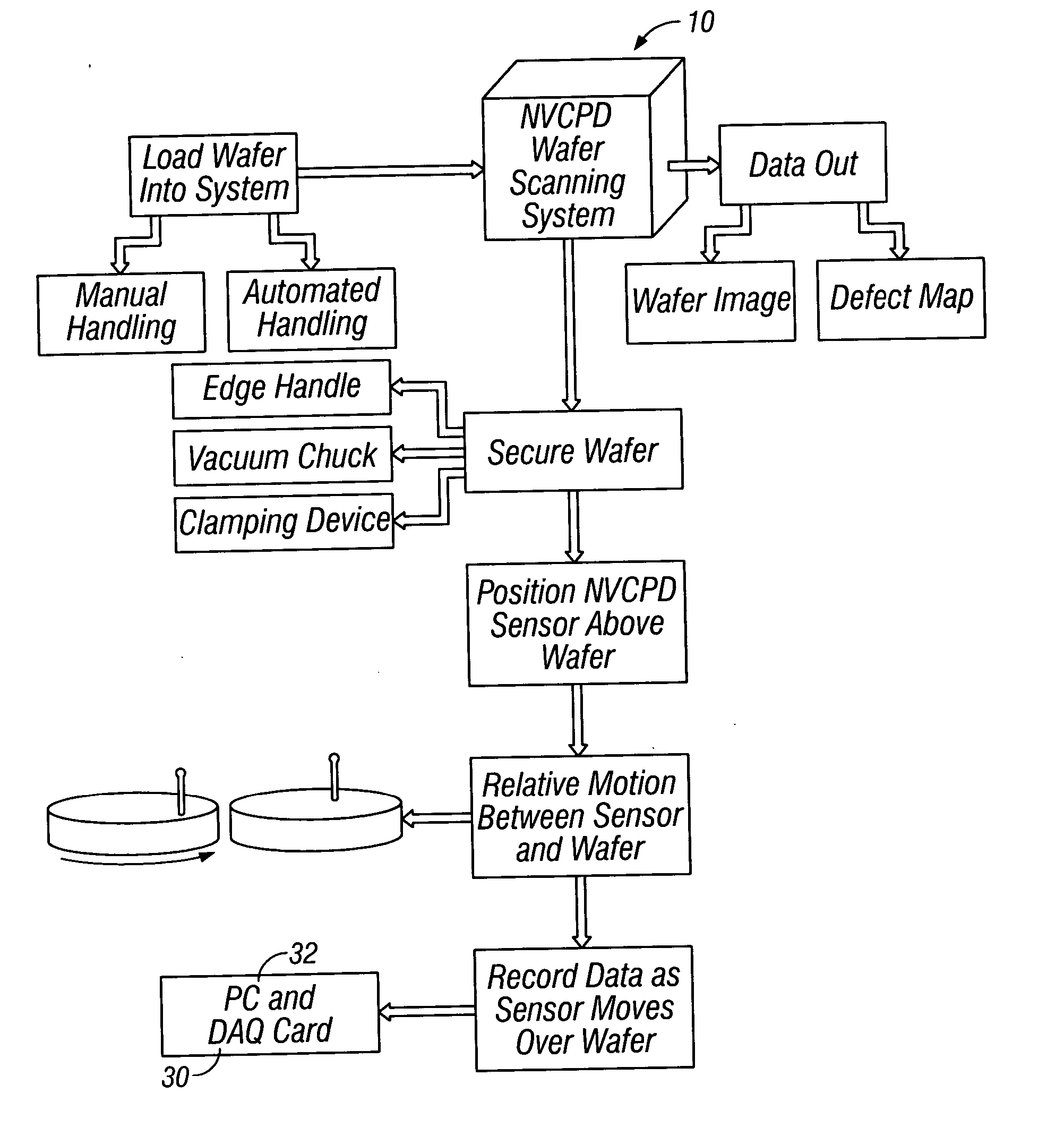

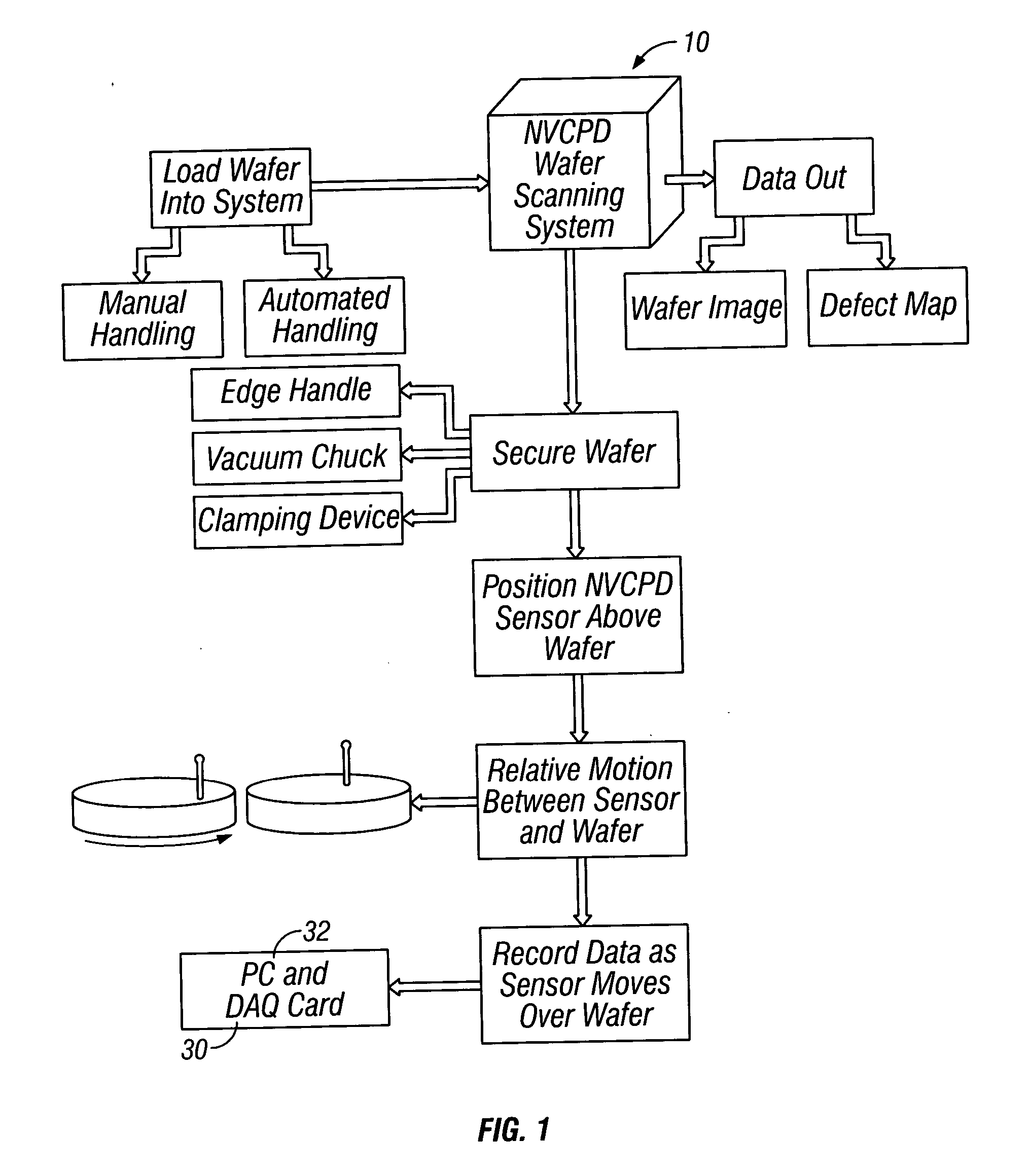

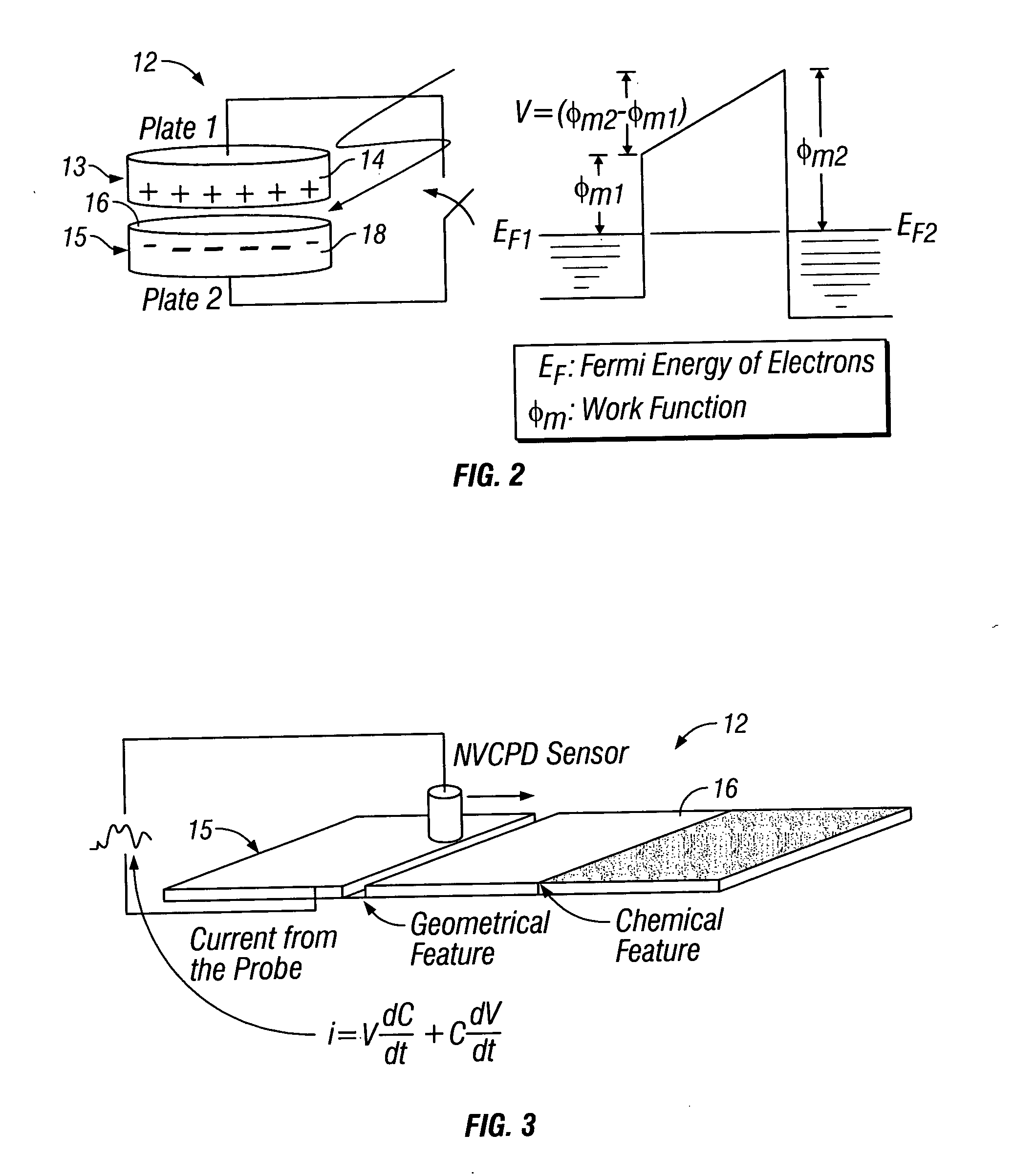

A method and system for identifying a defect or contamination on a surface of a sample. The system operates by detecting changes in work function across a surface via both vCPD and nvCPD. It utilizes a non-vibrating contact potential difference (nvCPD) sensor for imaging work function variations over an entire sample. The data is differential in that it represents changes in the work function (or geometry or surface voltage) across the surface of a sample. A vCPD probe is used to determine absolute CPD data for specific points on the surface of the sample. The combination of vibrating and non-vibrating CPD measurement modes allows the rapid imaging of whole-sample uniformity, and the ability to detect the absolute work function at one or more points.

Owner:QCEPT INVESTMENTS LLC

In-situ wear indicator for non-selective material removal systems

InactiveUS6957622B2Analysis using chemical indicatorsMeasurement apparatus componentsMaterial removalEngineering

An in-situ wear indicator for detecting wear to at least one selected part in a semiconductor manufacturing environment. The indicator is manufactured in a selected material with a selected thickness so that the indicator degrades upon exposure to the semiconductor manufacturing process at a fixed rate relative to the wear of the selected part. The indicator displays a visual indication of wear which is discernible by an automated detection device.

Owner:INT BUSINESS MASCH CORP

Inspection system and apparatus

InactiveUS7107158B2Minimize complexityFast and inexpensive and effective meanSemiconductor/solid-state device testing/measurementElectrostatic cleaningRapid imagingPotential difference

Owner:QCEPT INVESTMENTS LLC

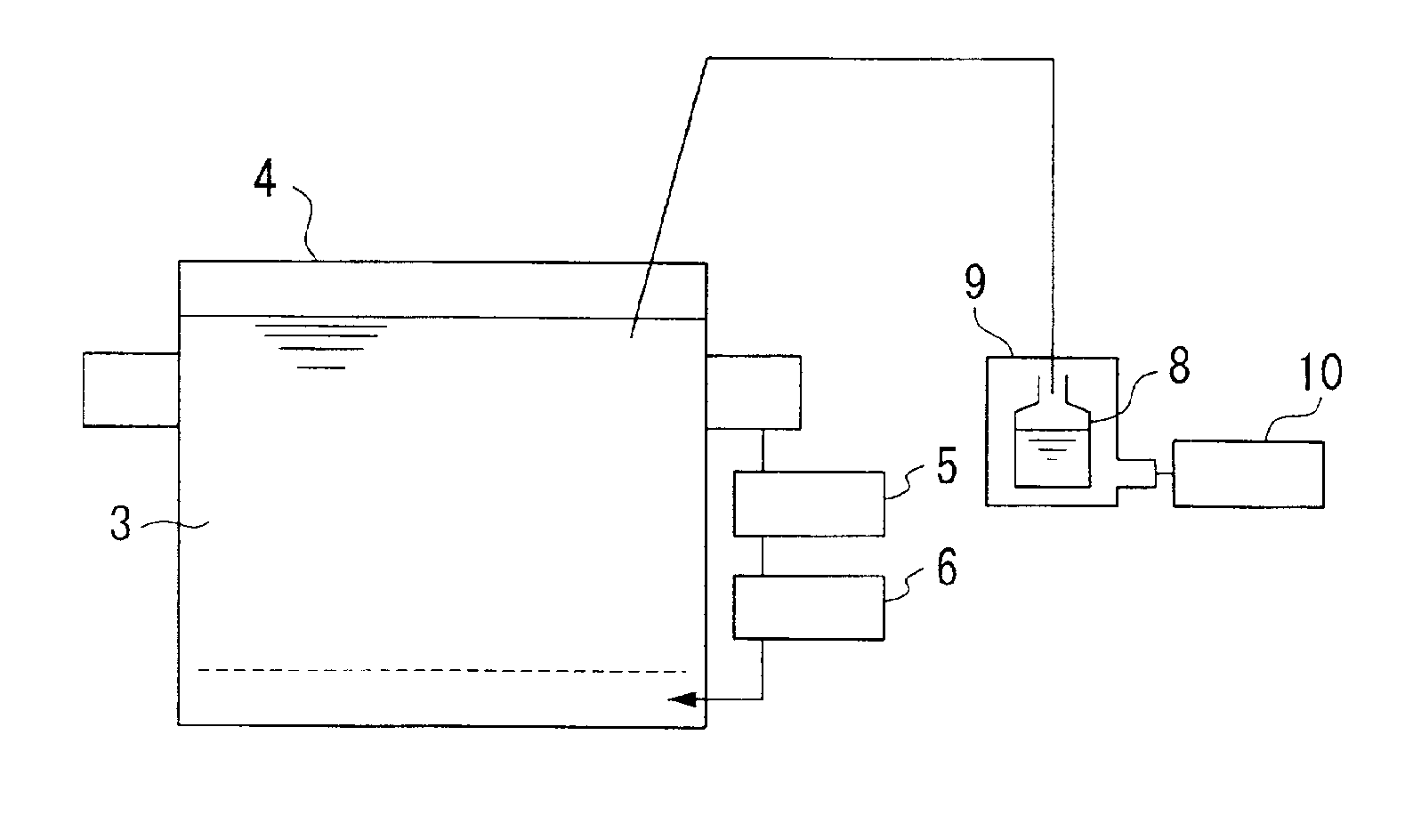

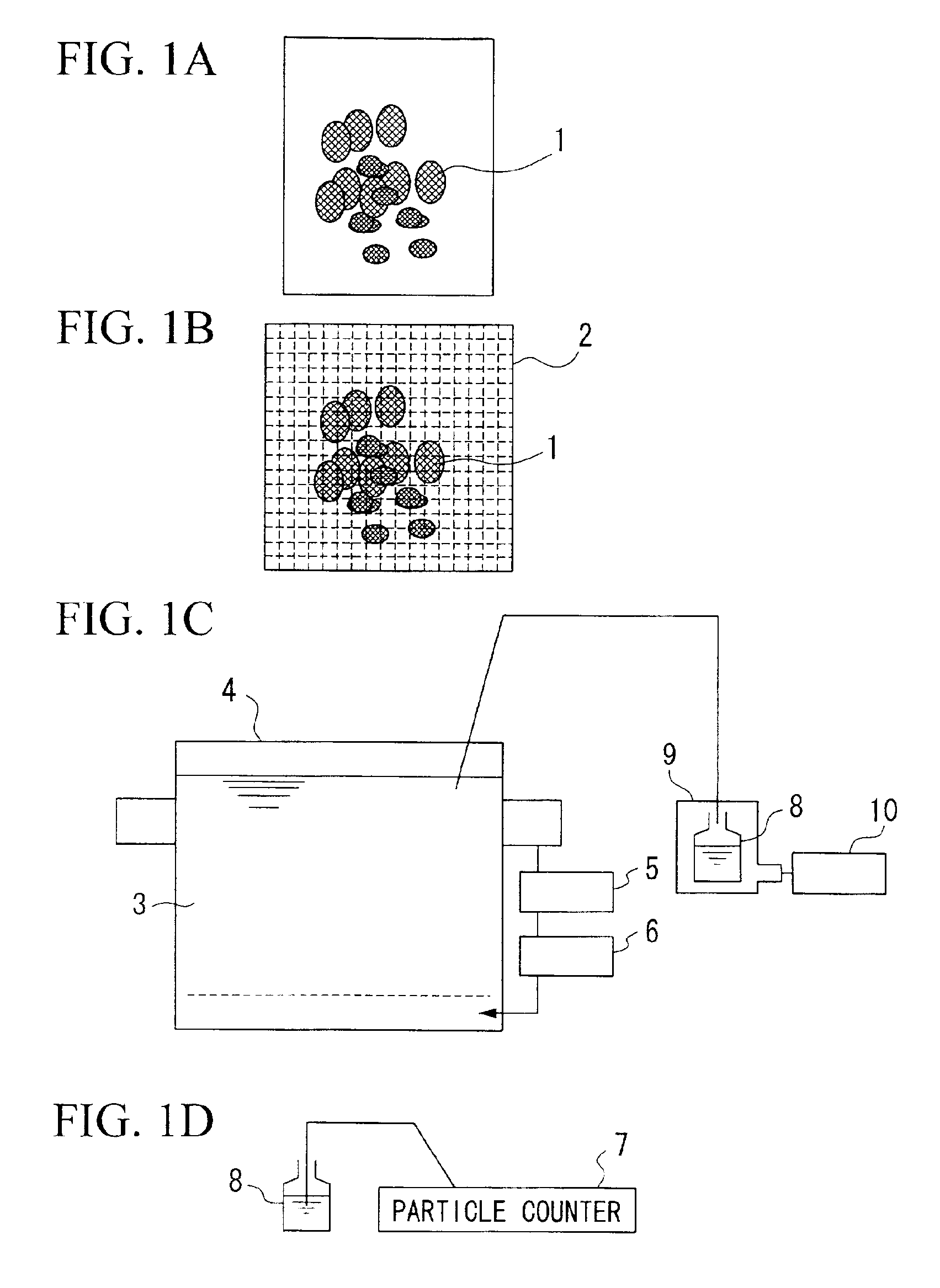

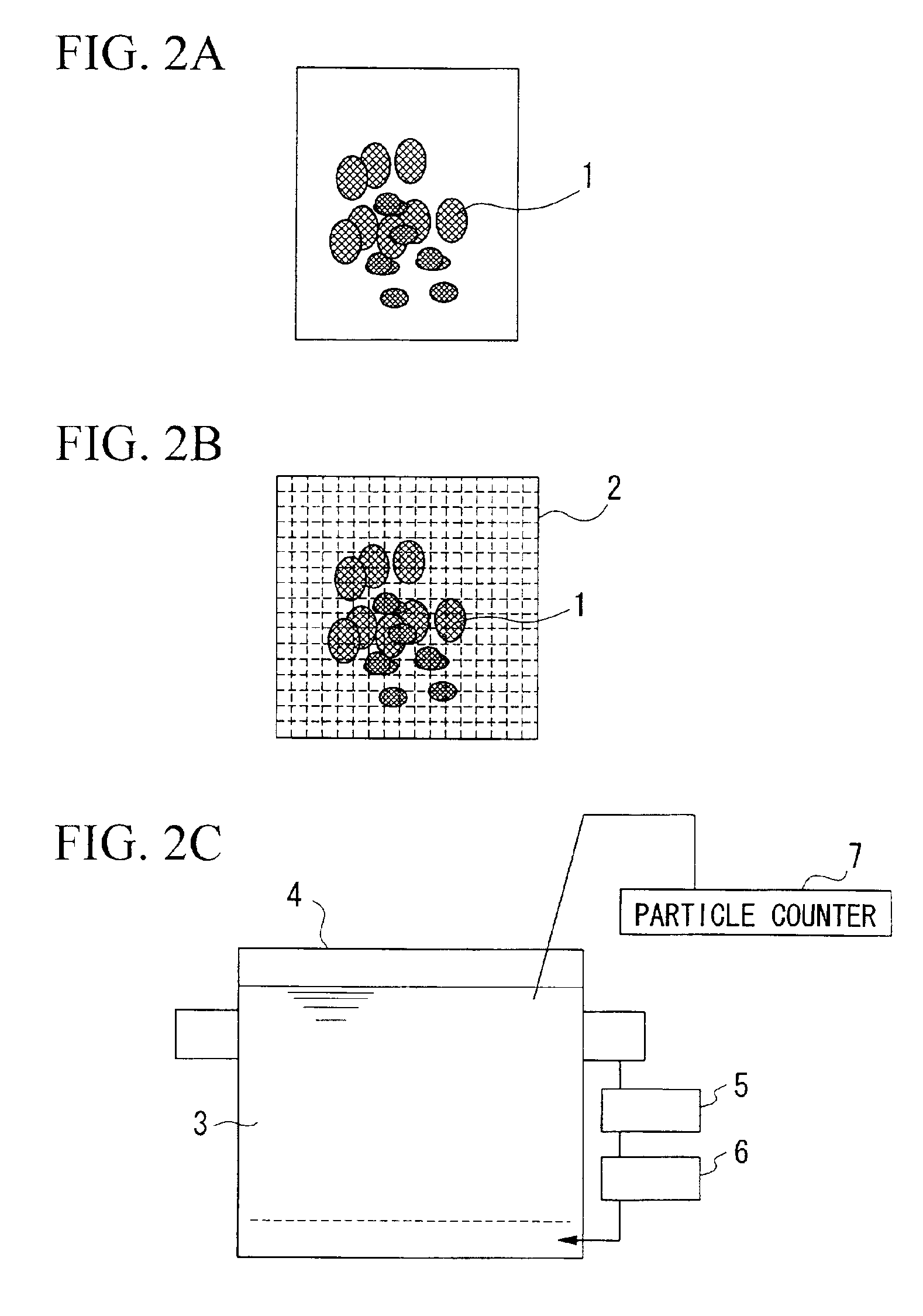

Evaluation method for polycrystalline silicon

InactiveUS6916657B2Accurate countRapidly used in practiceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetallurgyPolycrystalline silicon

An evaluation method for polycrystalline silicon including the steps of immersing the polycrystalline silicon in an agent which is capable of dissolving the polycrystalline silicon, and counting the number of foreign particles in the agent. The polycrystalline silicon thus evaluated may be used as a material for pulling single crystal silicon. The evaluation method may further include a step of analyzing the composition of the foreign particles. In yet another aspect, the evaluation method may further include a step of subjecting the agent to a circulation filtering process prior to the immersion of the polycrystalline silicon in the agent.

Owner:MITSUBISHI MATERIALS CORP

Semiconductor wafer inspection system

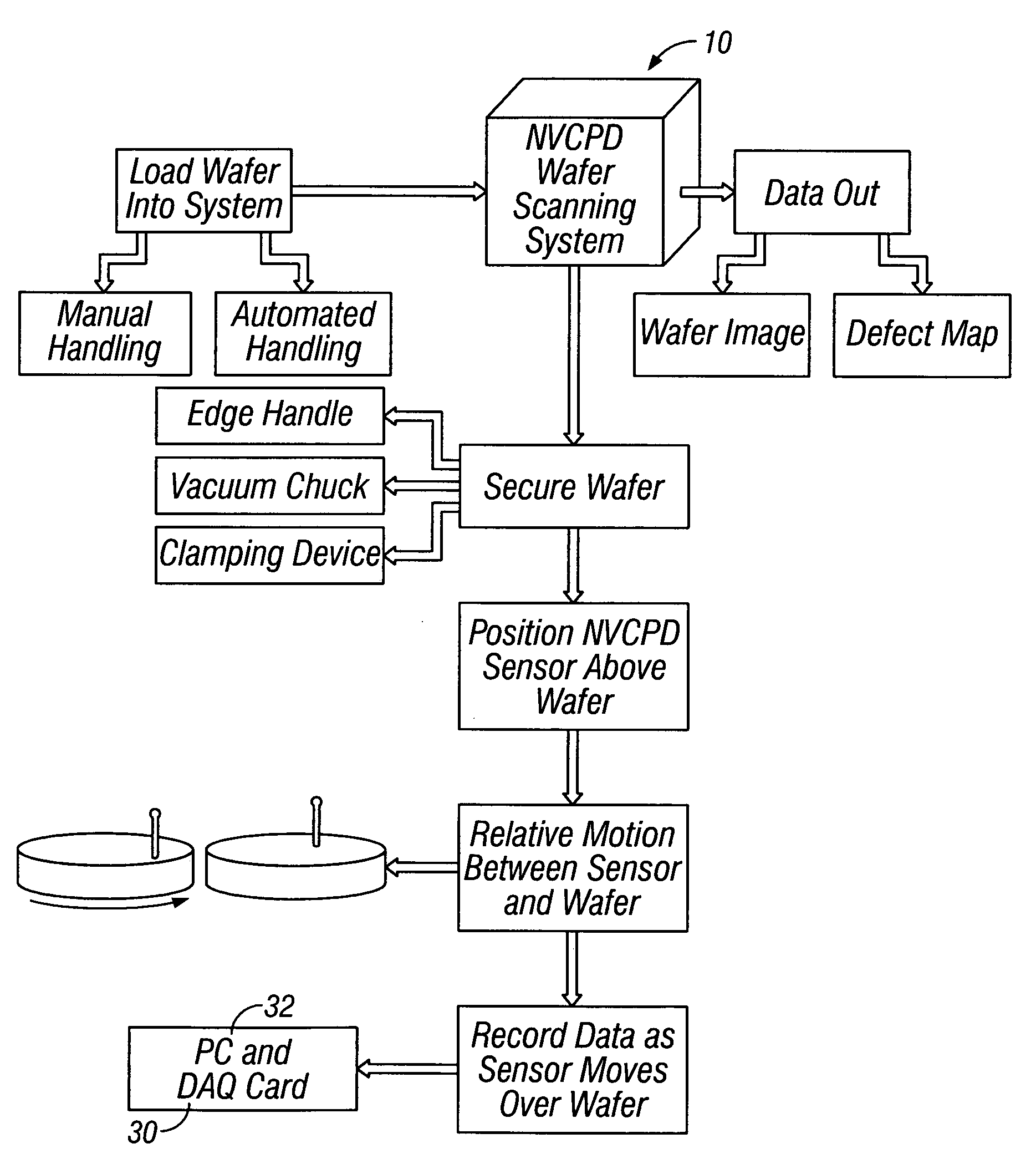

InactiveUS6957154B2Avoid timeAvoid expensesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPotential differenceBiomedical engineering

A method and system for identifying a defect or contamination on a surface of a material. The method and system involves providing a material, such as a semiconductor wafer, using a non-vibrating contact potential difference sensor to scan the wafer, generate contact potential difference data and processing that data to identify a pattern characteristic of the defect or contamination.

Owner:QCEPT INVESTMENTS LLC

Method and a system for quantitative or qualitative determination of a target component

ActiveUS20150247845A1The process is simple and fastLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFluorophoreQualitative property

A method and a system for quantitative or qualitative determination of a target component in a liquid sample includes i) providing a plurality of magnetic particles including one or more capture sites for the target component on their respective surfaces; ii) providing a plurality of fluorophores configured to bind to the capture sites of the magnetic particles; iii) bringing the liquid sample into contact with the fluorophores and the magnetic particles in a flow channel of a micro fluidic device including a transparent window; and iv) at least temporally immobilizing the magnetic particles adjacent to the transparent window using a magnet, emitting exciting electromagnetic beam towards the immobilized magnetic particles, reading signals emitted from fluorophores captured by the immobilized magnetic particles and performing a quantitative or qualitative determination of the target component based on the read signal.

Owner:ZOETIS DENMARK APS

Inspection system and apparatus

InactiveUS7103482B2Minimize complexityFast and inexpensive and effective meanSemiconductor/solid-state device testing/measurementElectrostatic cleaningPotential differenceContamination

A method and system for identifying a defect or contamination on a surface of a material. The method and system involves providing a material, such as a semiconductor wafer, using a non-vibrating contact potential difference sensor to scan the wafer, generate contact potential difference data and processing that data to identify a pattern characteristic of the defect or contamination.

Owner:QCEPT INVESTMENTS LLC

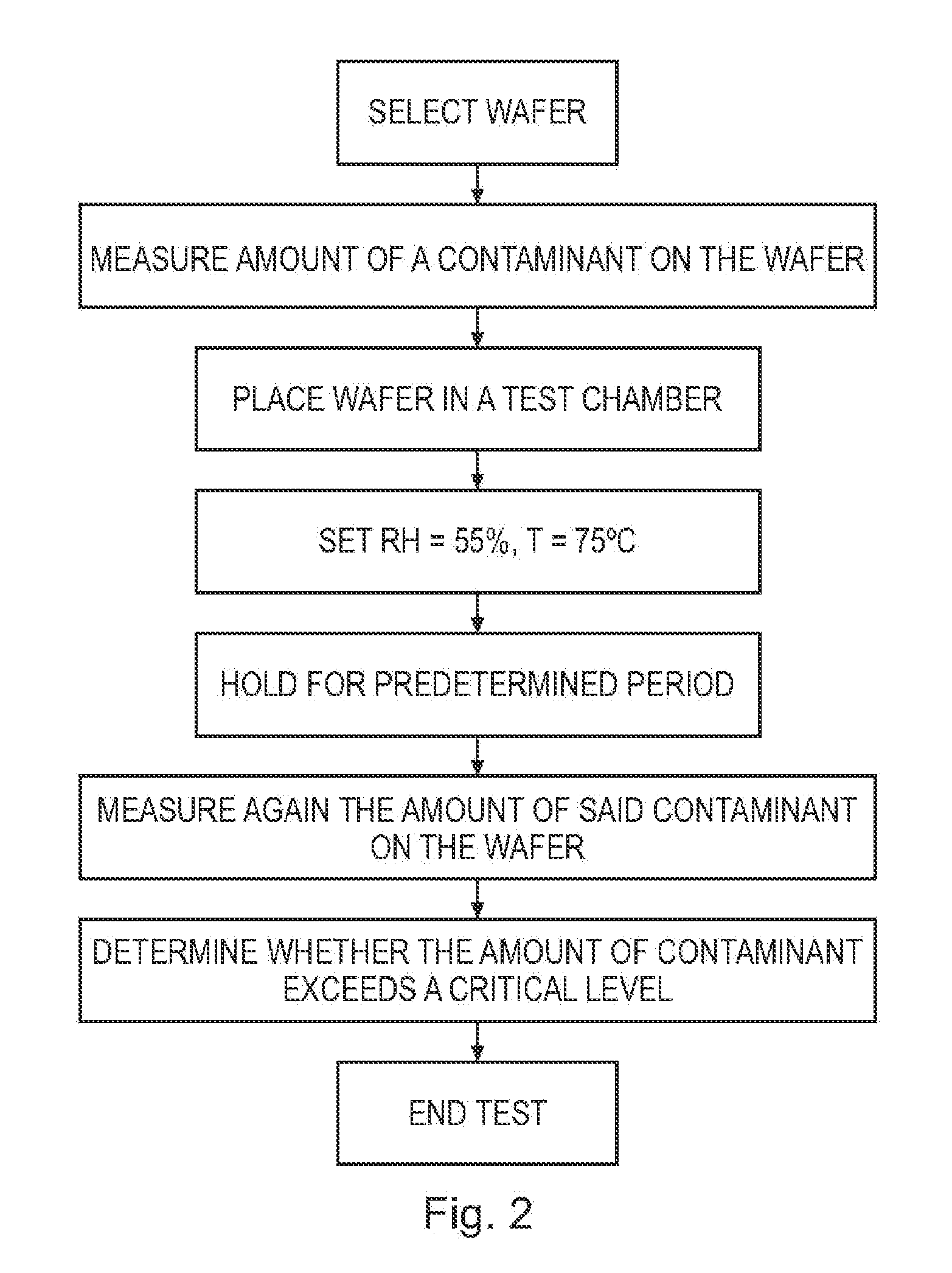

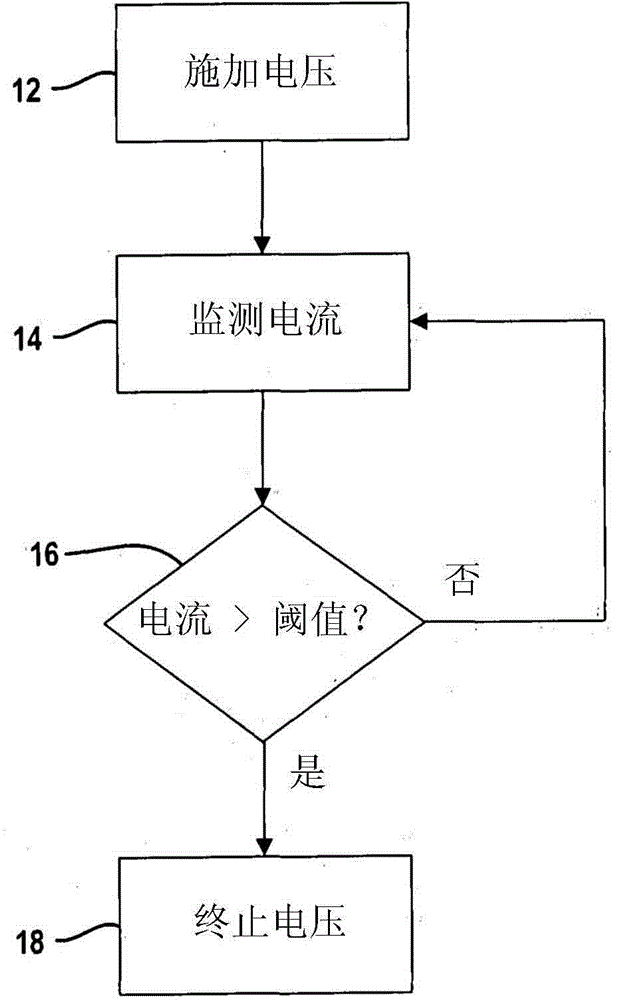

Method for performing a shelf lifetime acceleration test

InactiveUS20090277287A1Avoid introducingPrevent surfaceSemiconductor/solid-state device testing/measurementWeather/light/corrosion resistanceEngineeringContamination

Embodiments of the invention provide a method of determining a storage lifetime of a wafer in a storage environment, the storage environment corresponding to an environment having a first value of temperature and a first value of relative humidity, the wafer having a pre-test value of a first contamination parameter, including the steps of: subjecting the wafer to a test environment for a test period, the test environment includes an environment having a second value of temperature and a second value of relative humidity; subsequently, inspecting the wafer thereby to determine a post-test value of a second contamination parameter, wherein the second value of relative humidity is greater than 30% and the second value of wafer temperature is greater than 30° C.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING +1

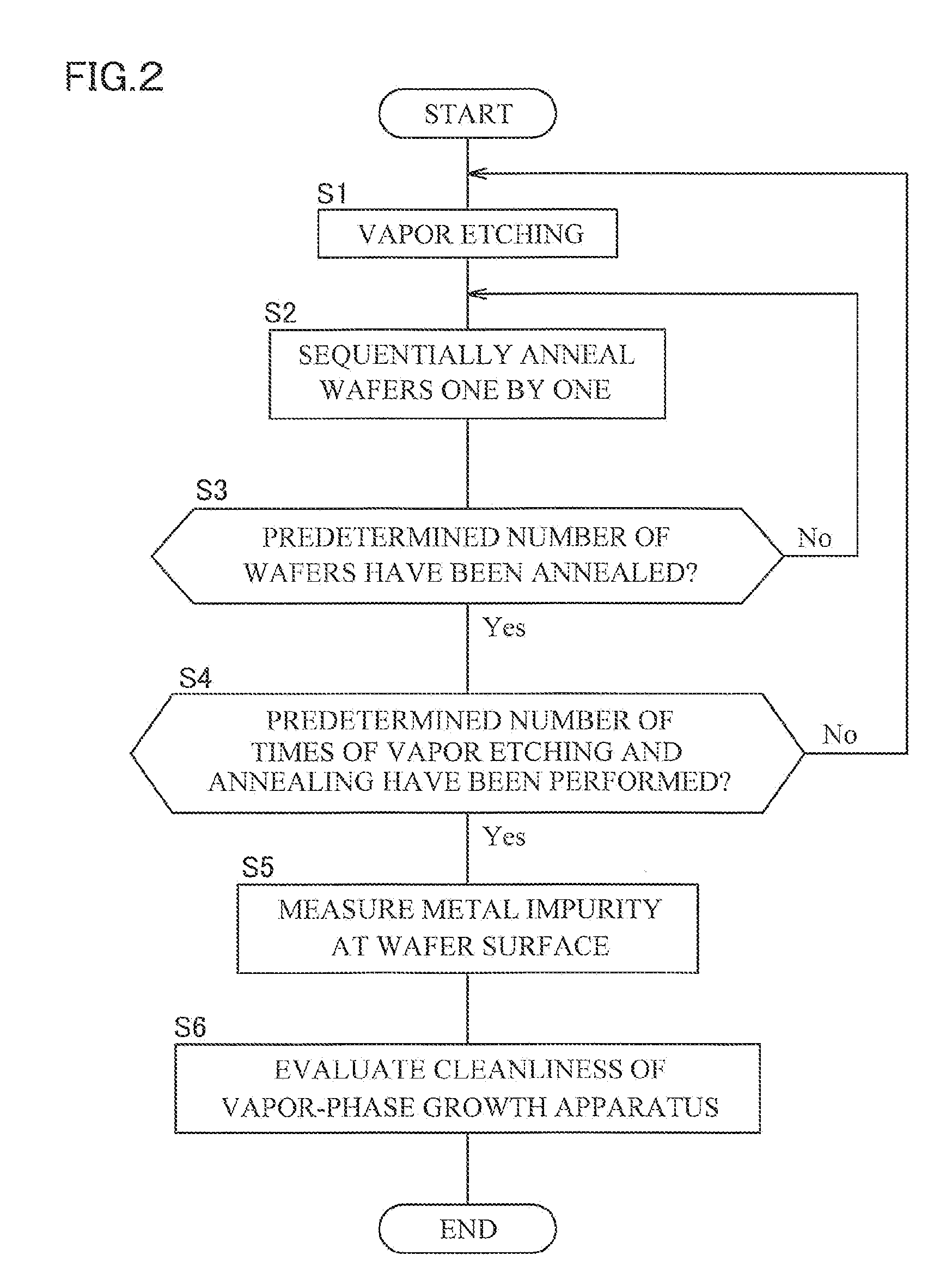

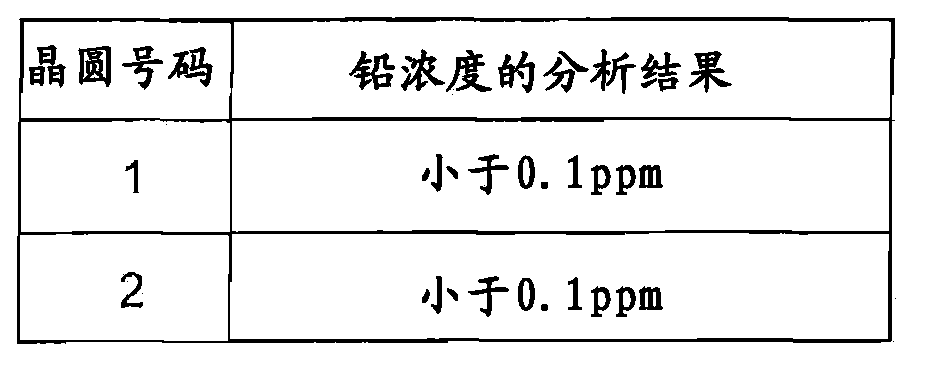

Method of measuring contamination amount of vapor phase growth apparatus, and method of manufacturing epitaxial wafer

ActiveUS20150243566A1High sensitivityReduce pollutionPolycrystalline material growthSemiconductor/solid-state device testing/measurementGas phaseVapor phase

Carry out a vapor etching step of cleaning an inside of a chamber of a vapor phase growth apparatus by vapor etching using HCl gas (S1). Carry out an annealing step of sequentially annealing a predetermined number of silicon wafers, one by one, in a non-oxidizing atmosphere (S2, S3). Repeat the vapor etching step and the annealing step a prescribed number of times. After having carried out the vapor etching step and the annealing step the prescribed number of times (S4: Yes), collect contaminants on the surface of each of the wafers, and measure the Mo concentration using ICP-MS (S5). Evaluate the cleanliness of the vapor phase growth apparatus on the basis of each Mo concentration value and the relationship between the Mo concentrations (S6). Thus, provided is a method with which it is possible to measure, with high sensitivity, the contamination amount of a vapor phase growth apparatus.

Owner:SHIN-ETSU HANDOTAI CO LTD

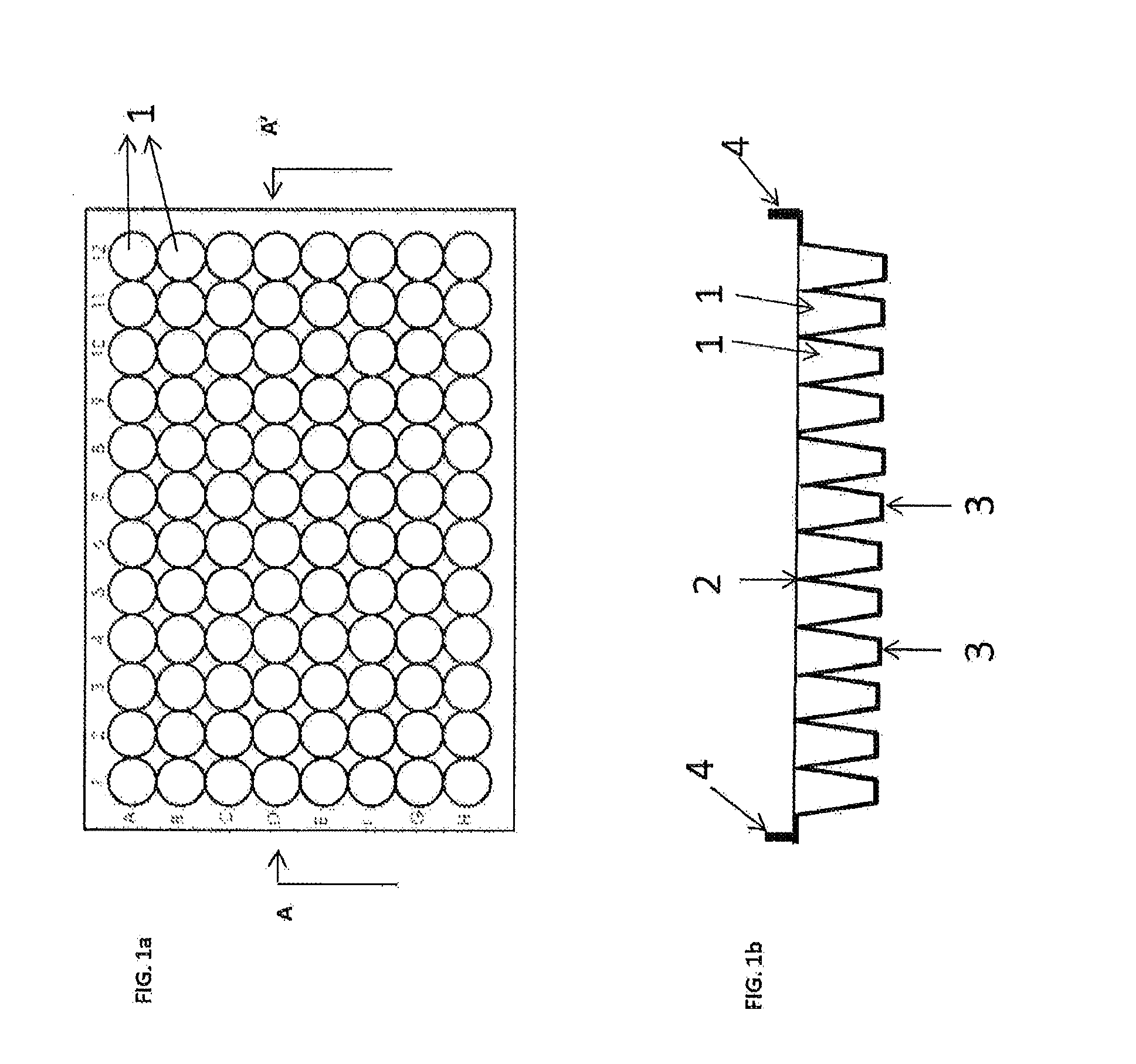

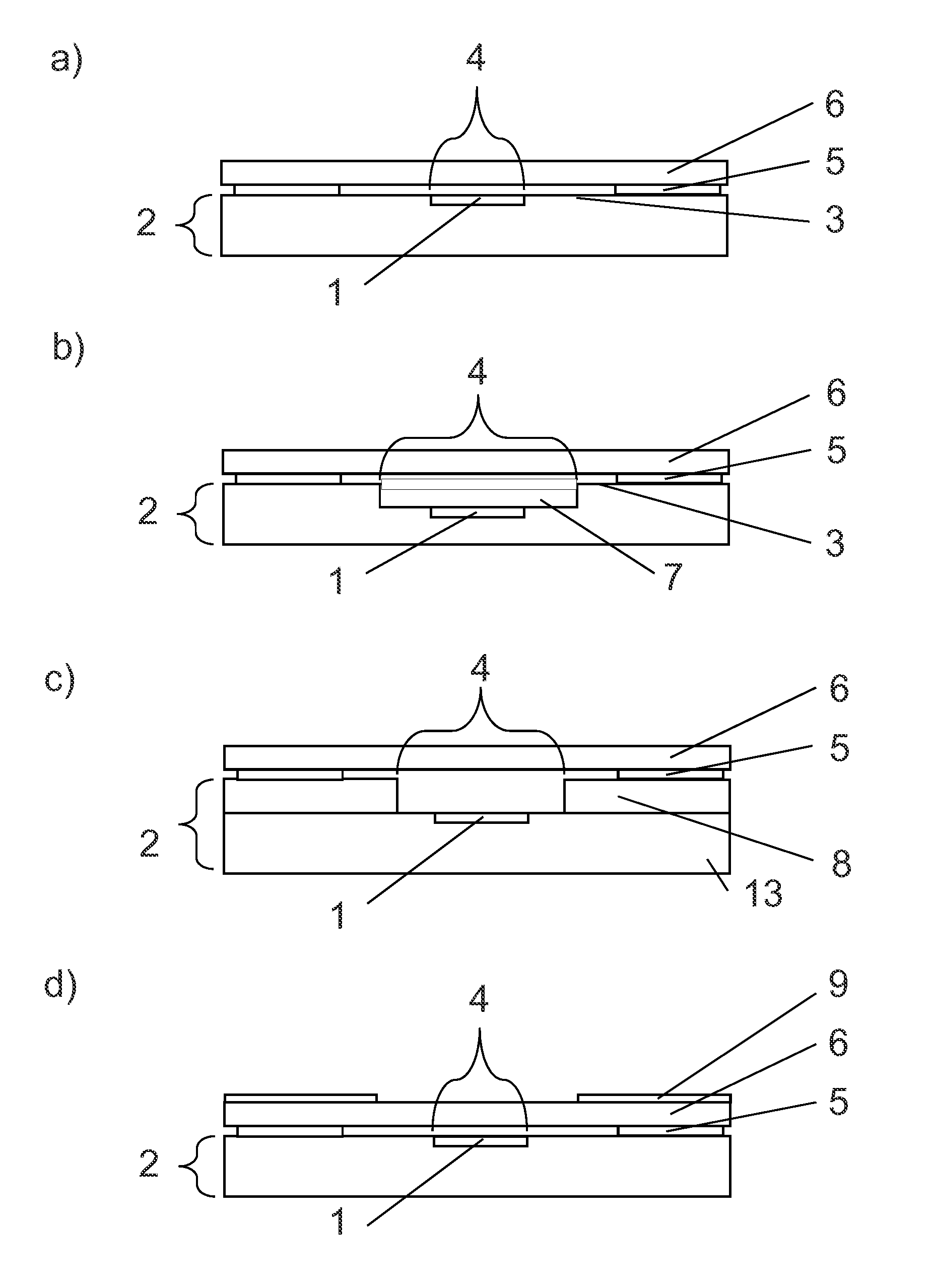

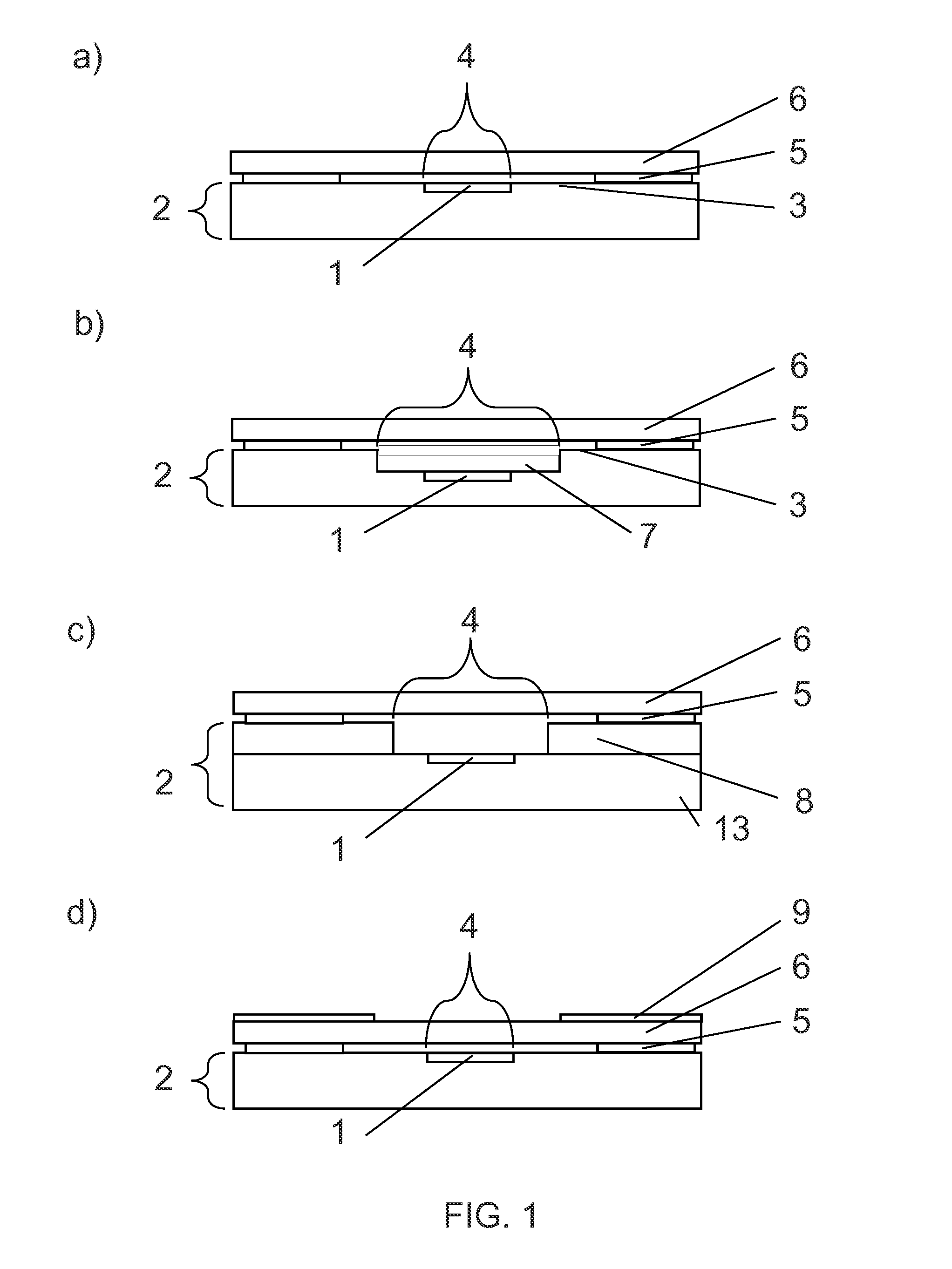

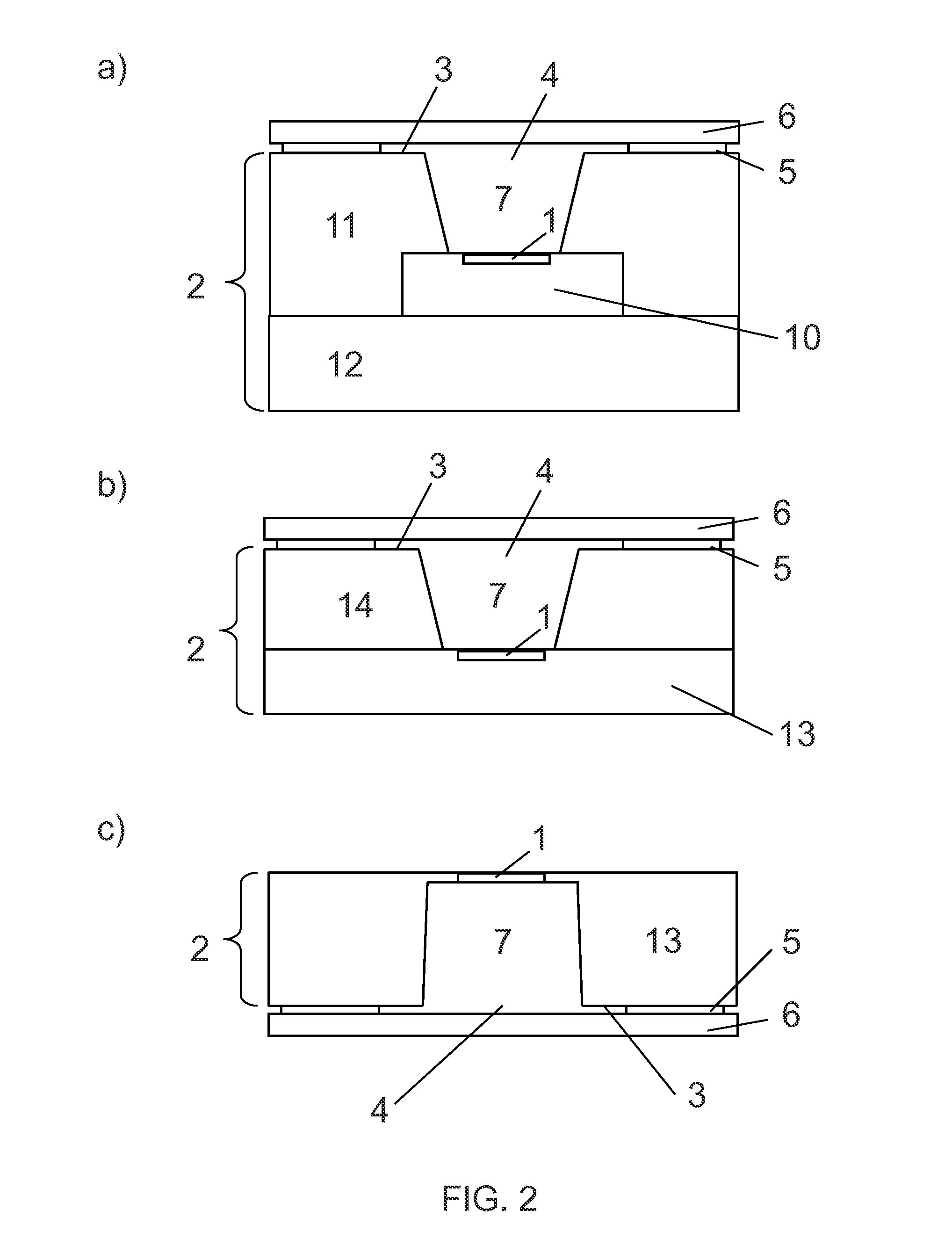

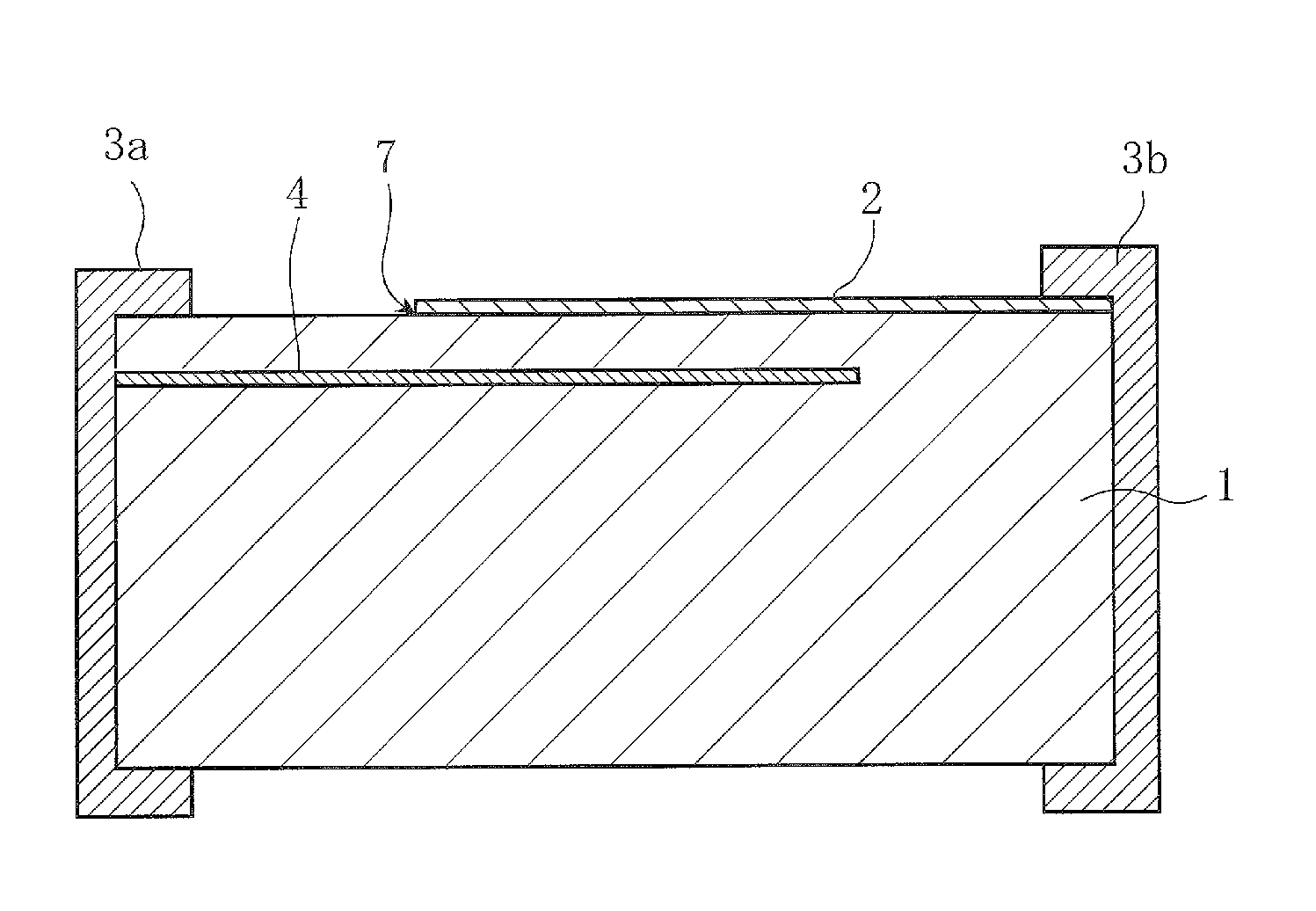

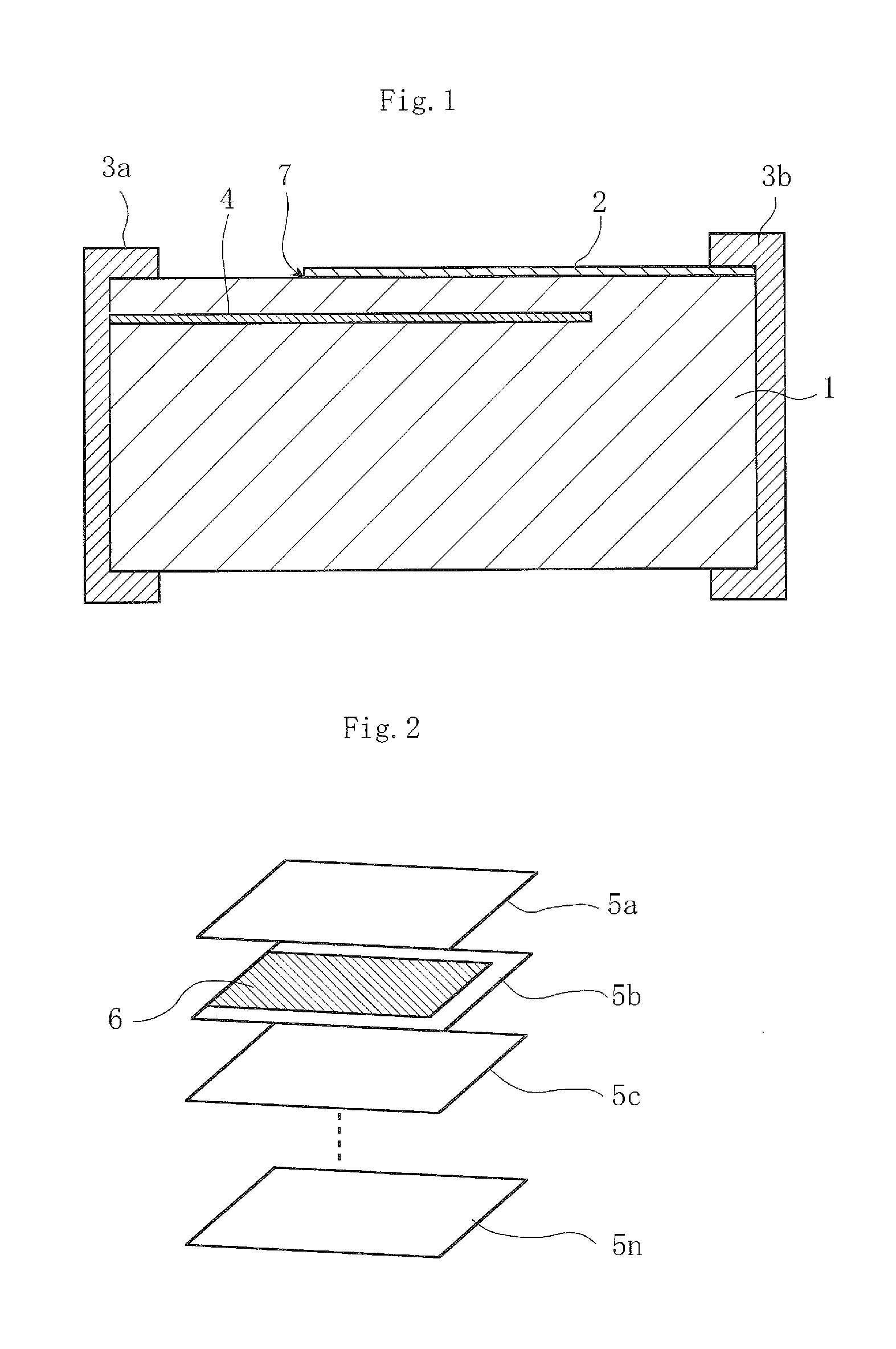

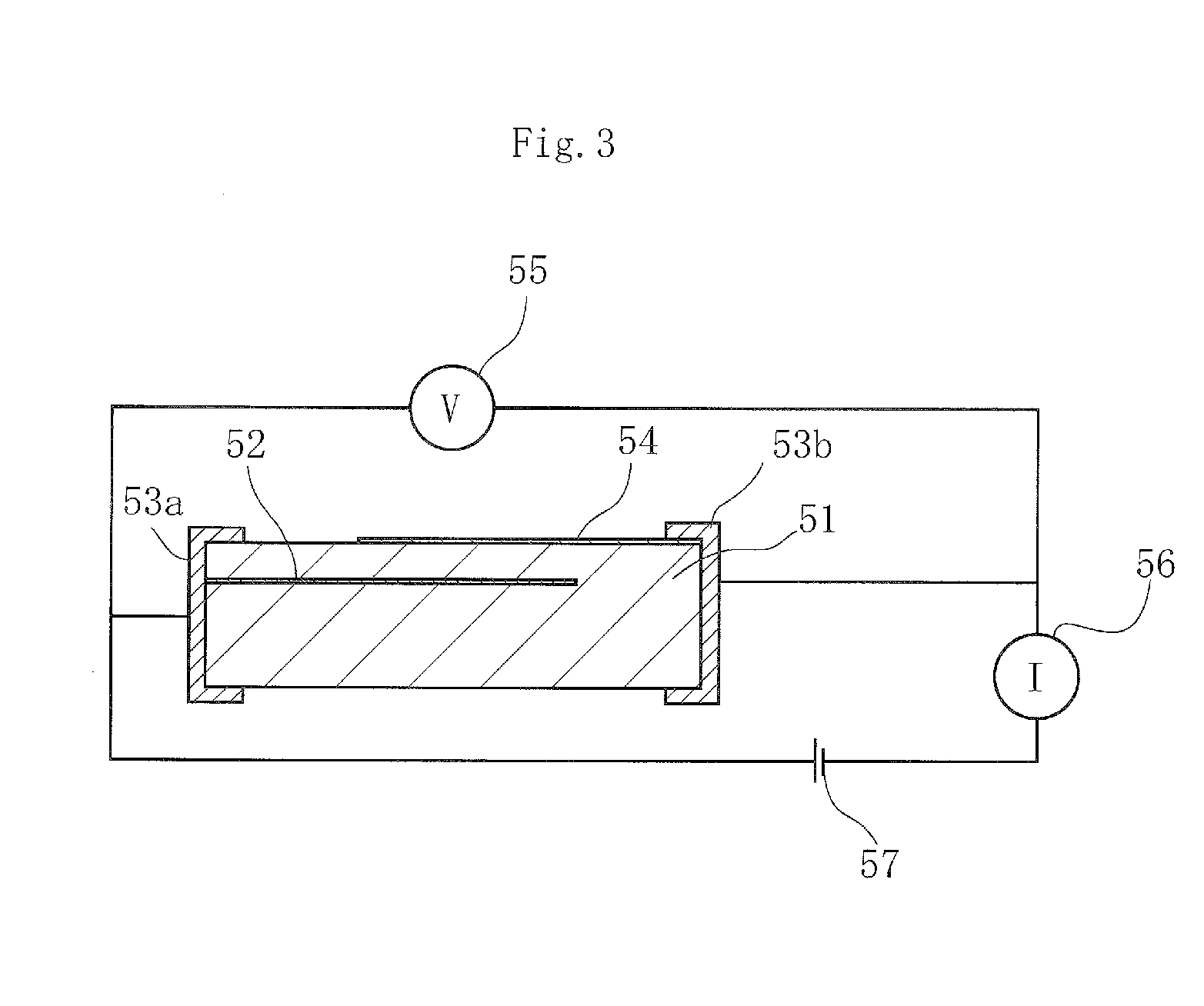

Sensor device

ActiveUS20150143874A1Ease sensor device singulationLamination ancillary operationsDecorative surface effectsAdhesive materialsBiomedical engineering

A sensor device comprises a sensitive element (1) and a support (2) for the sensitive element, the support having a surface (3) with an access opening (4) to the sensitive element (1). A layer of adhesive material (5) covers at least parts of the surface (3). A venting medium (6) extends over the entire surface (3) of the support (2) and the access opening (4) and is attached to the support (2) by the layer of adhesive material (5).

Owner:SENSIRION AG

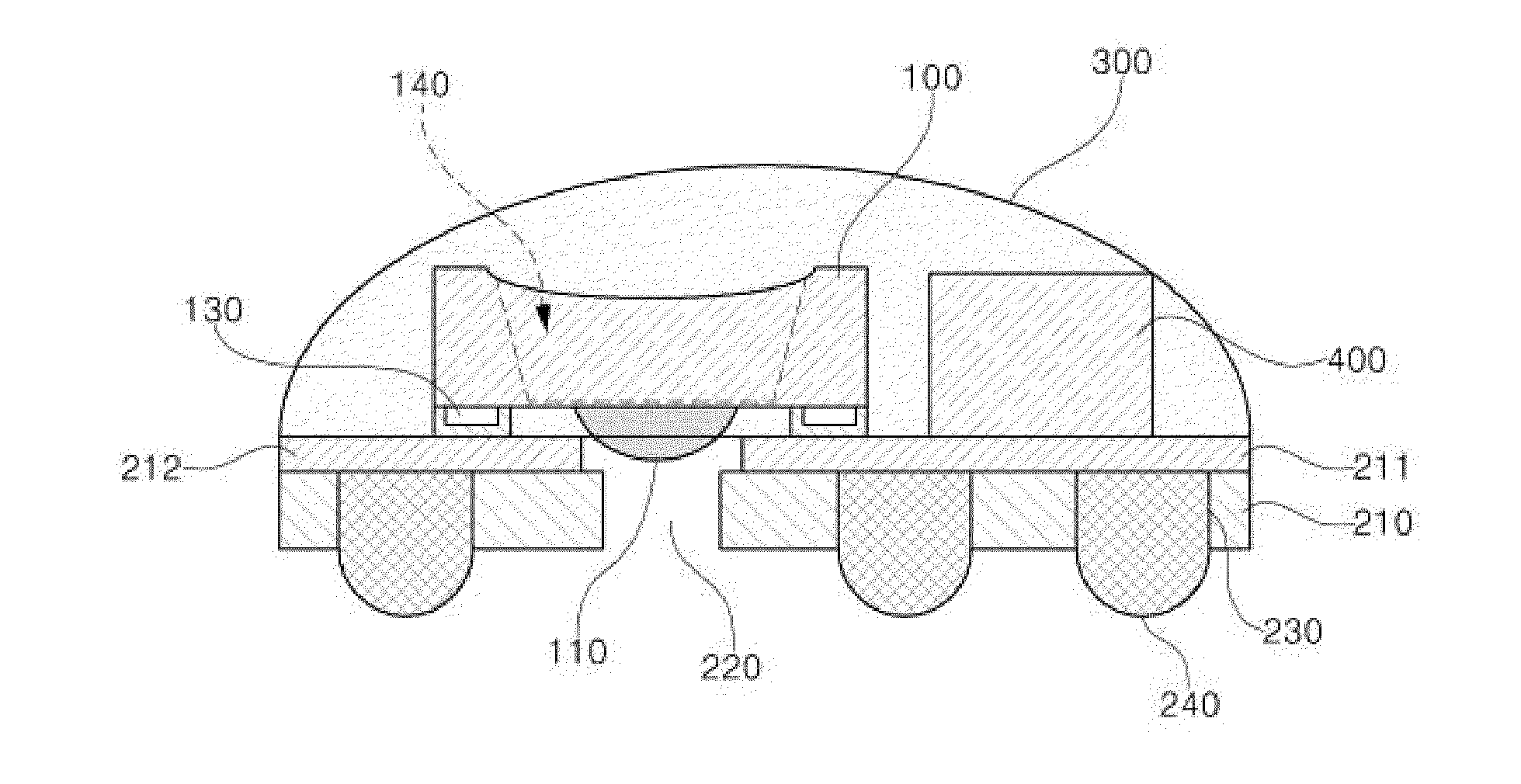

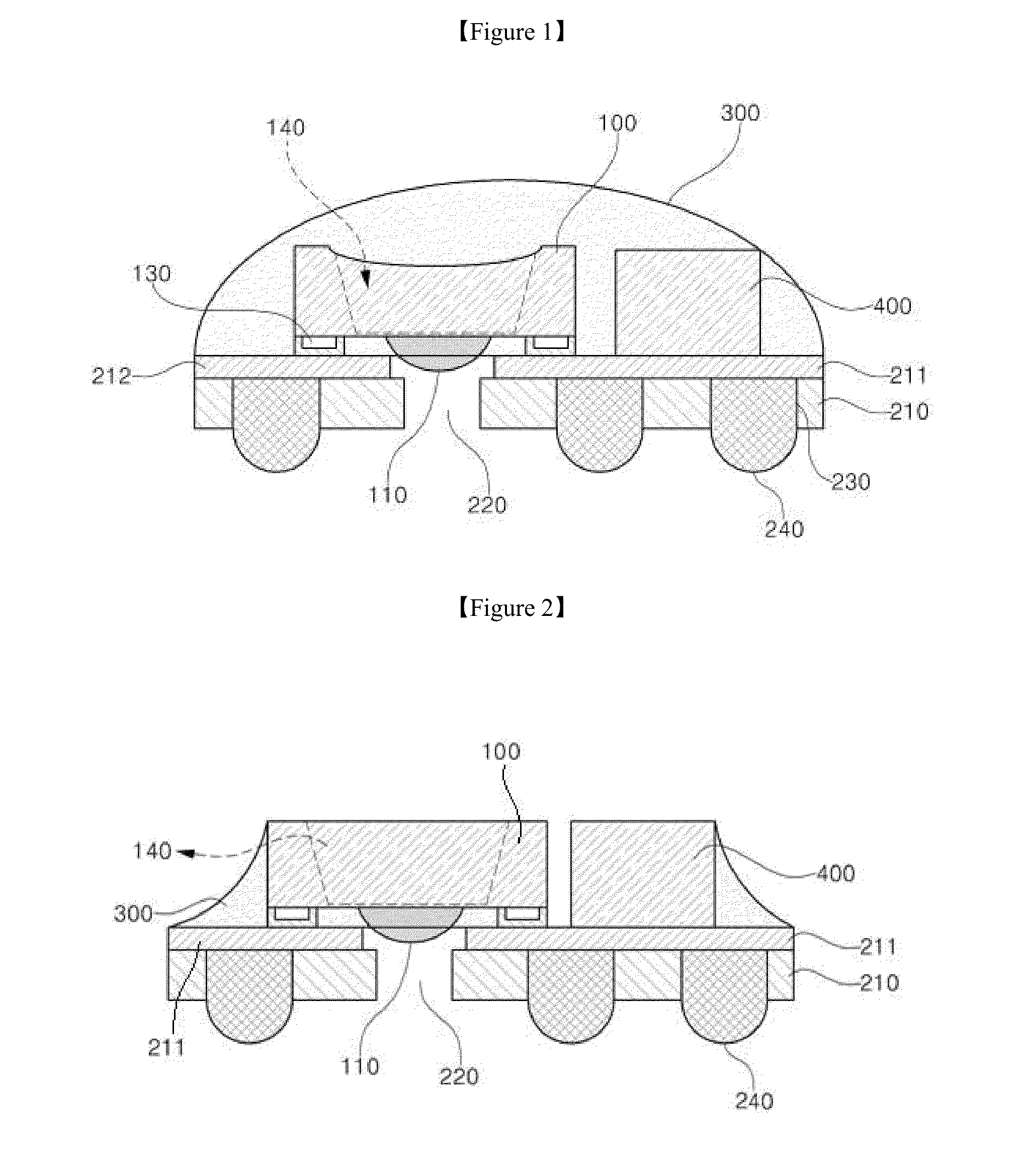

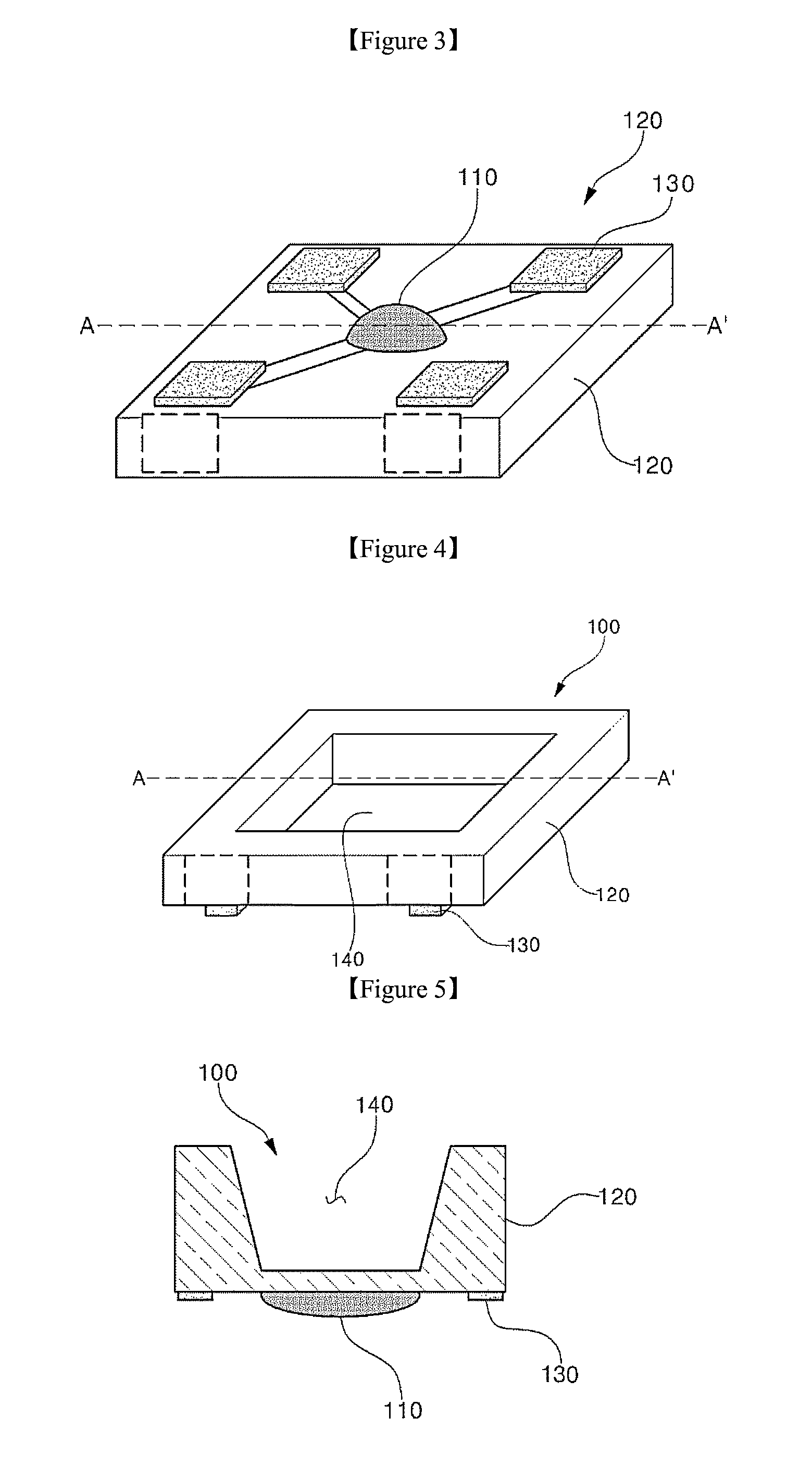

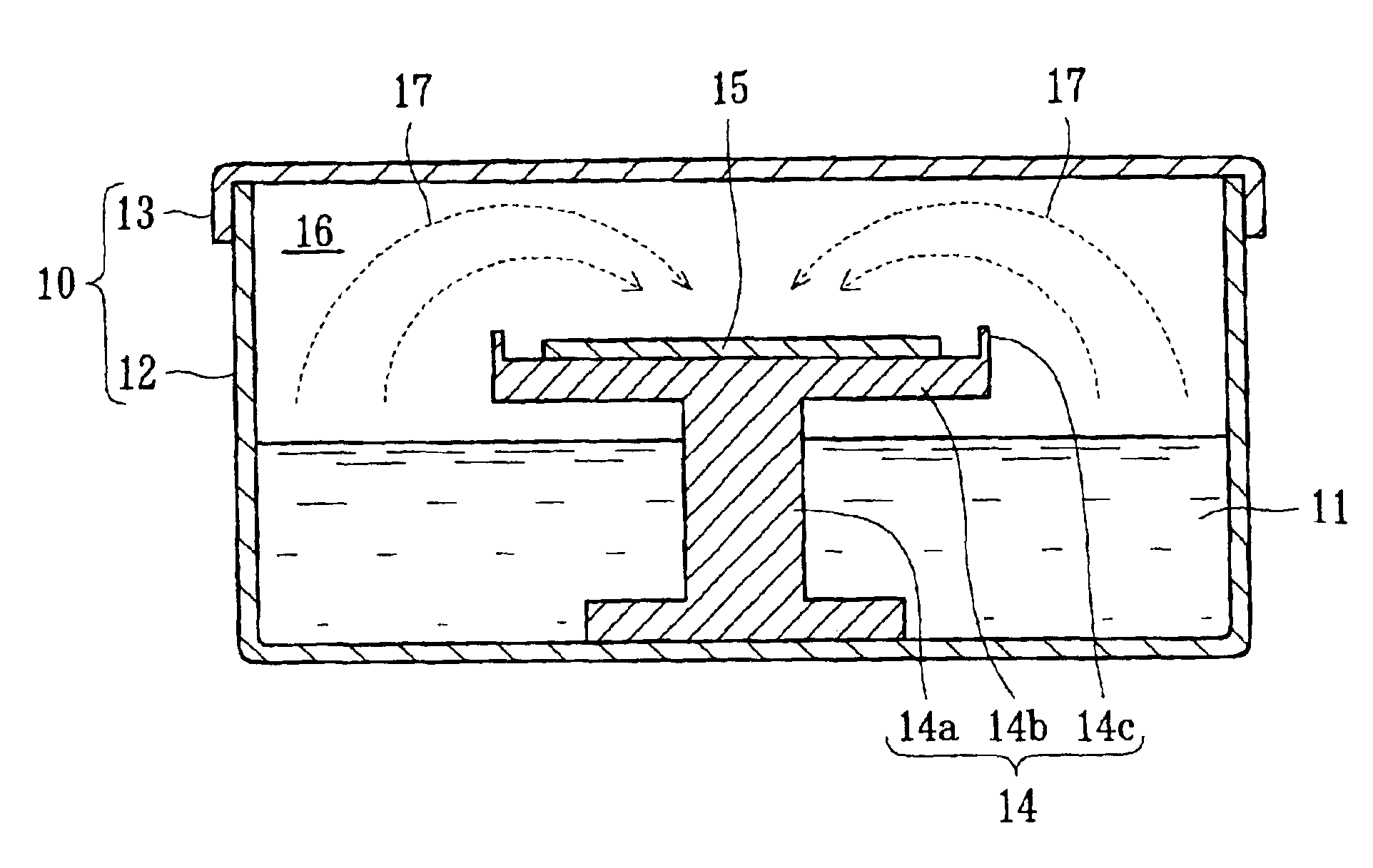

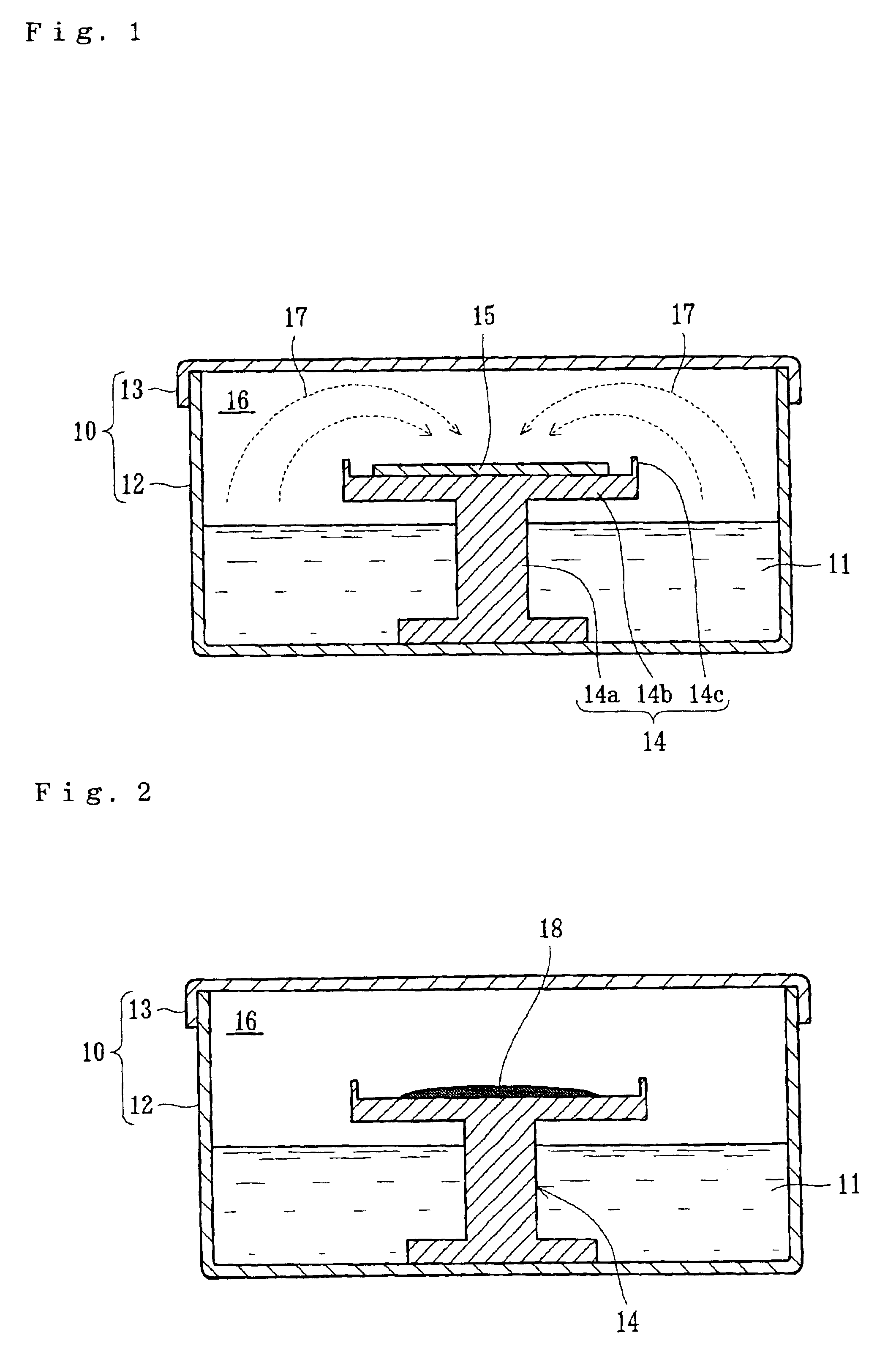

Gas sensor package

ActiveUS20150090002A1Solid-state devicesMaterial analysis by electric/magnetic meansProcess engineering

Provided is a gas sensor package, including: a first substrate including a gas inflow hole; and a gas sensing element mounted to the first substrate and including a gas sensing portion disposed to correspond to the gas inflow hole.

Owner:LG INNOTEK CO LTD

Semiconductor radiation detector using it, and nuclear medicine diagnosis apparatus

Owner:HITACHI LTD

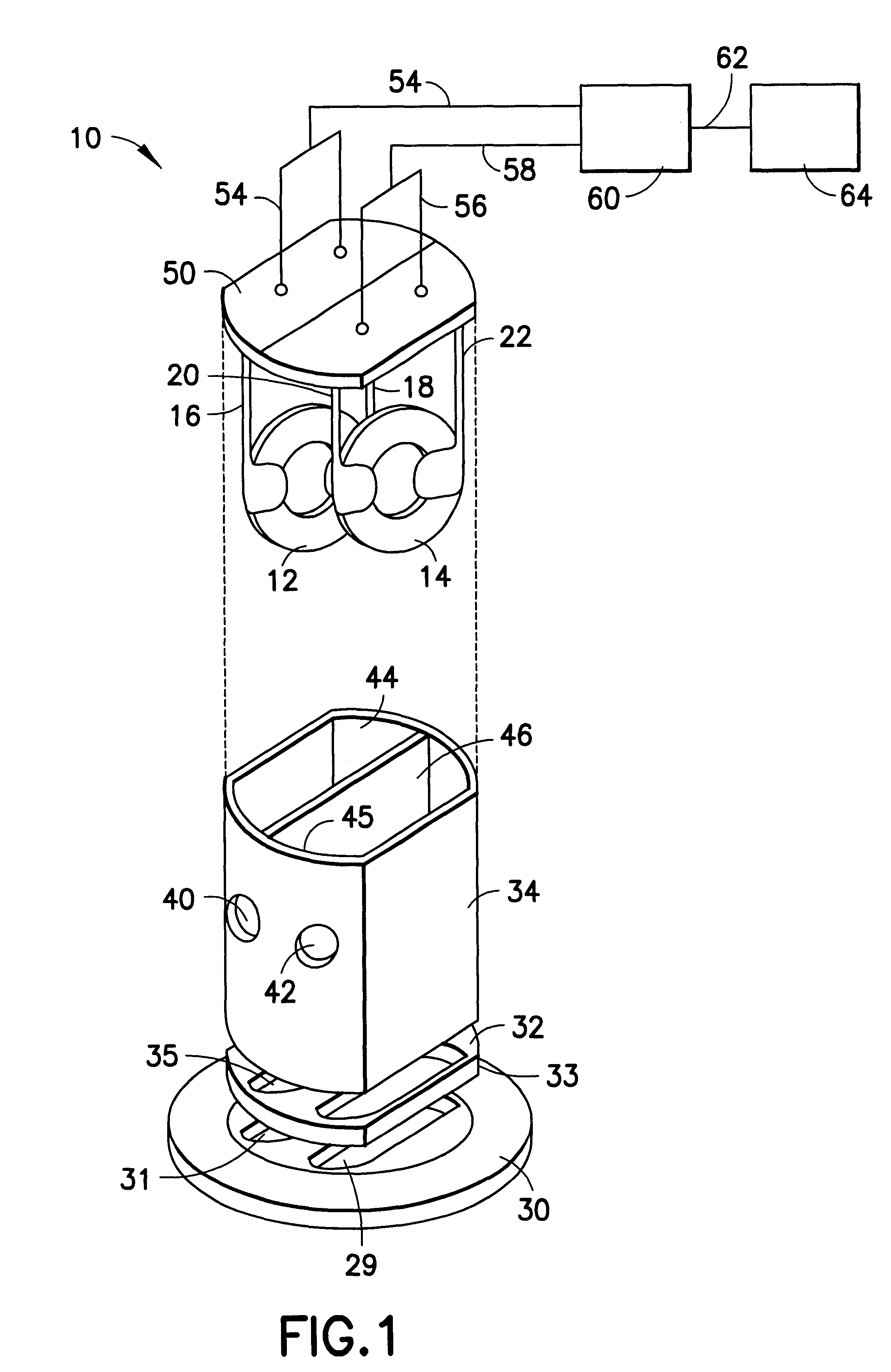

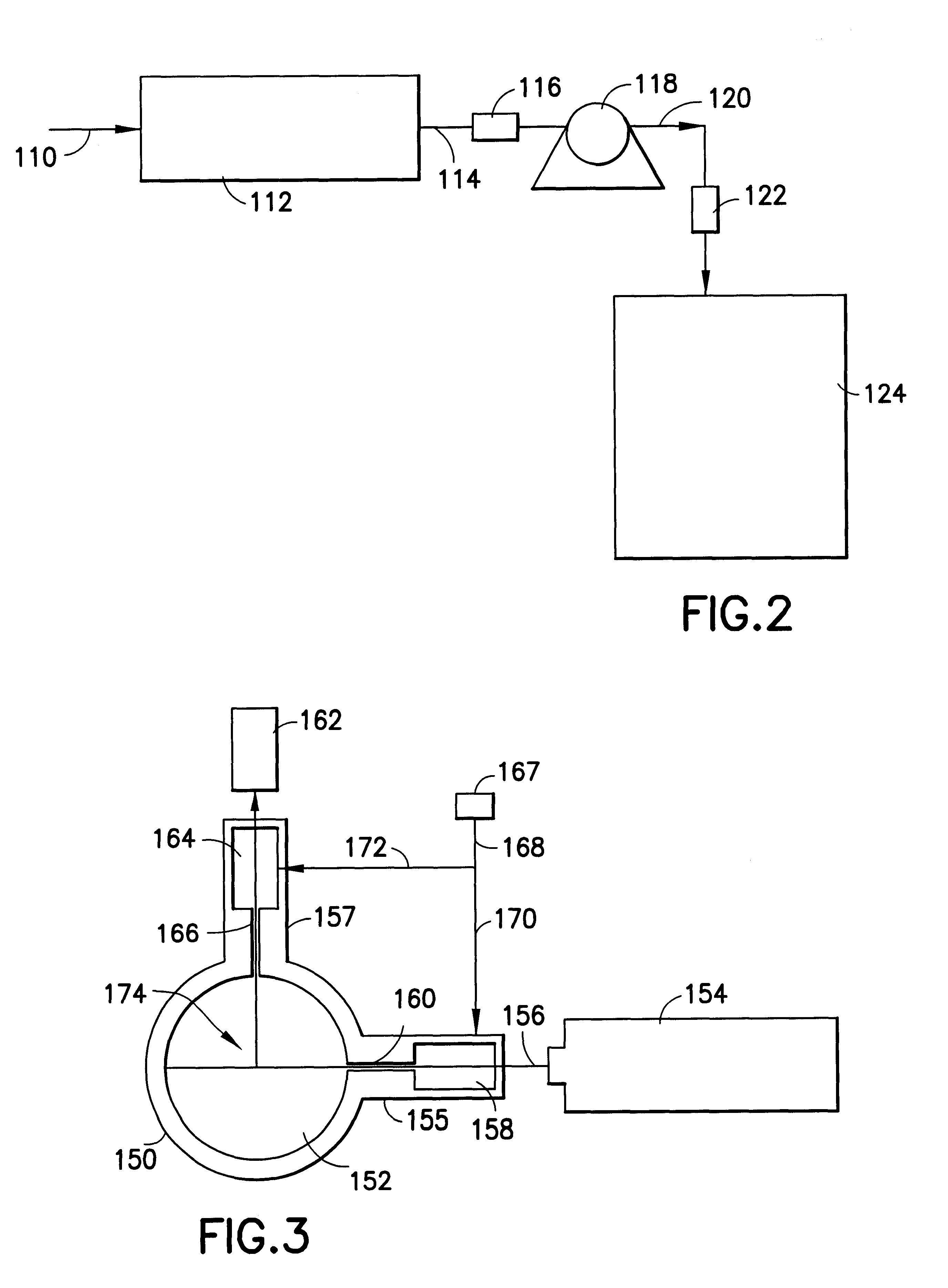

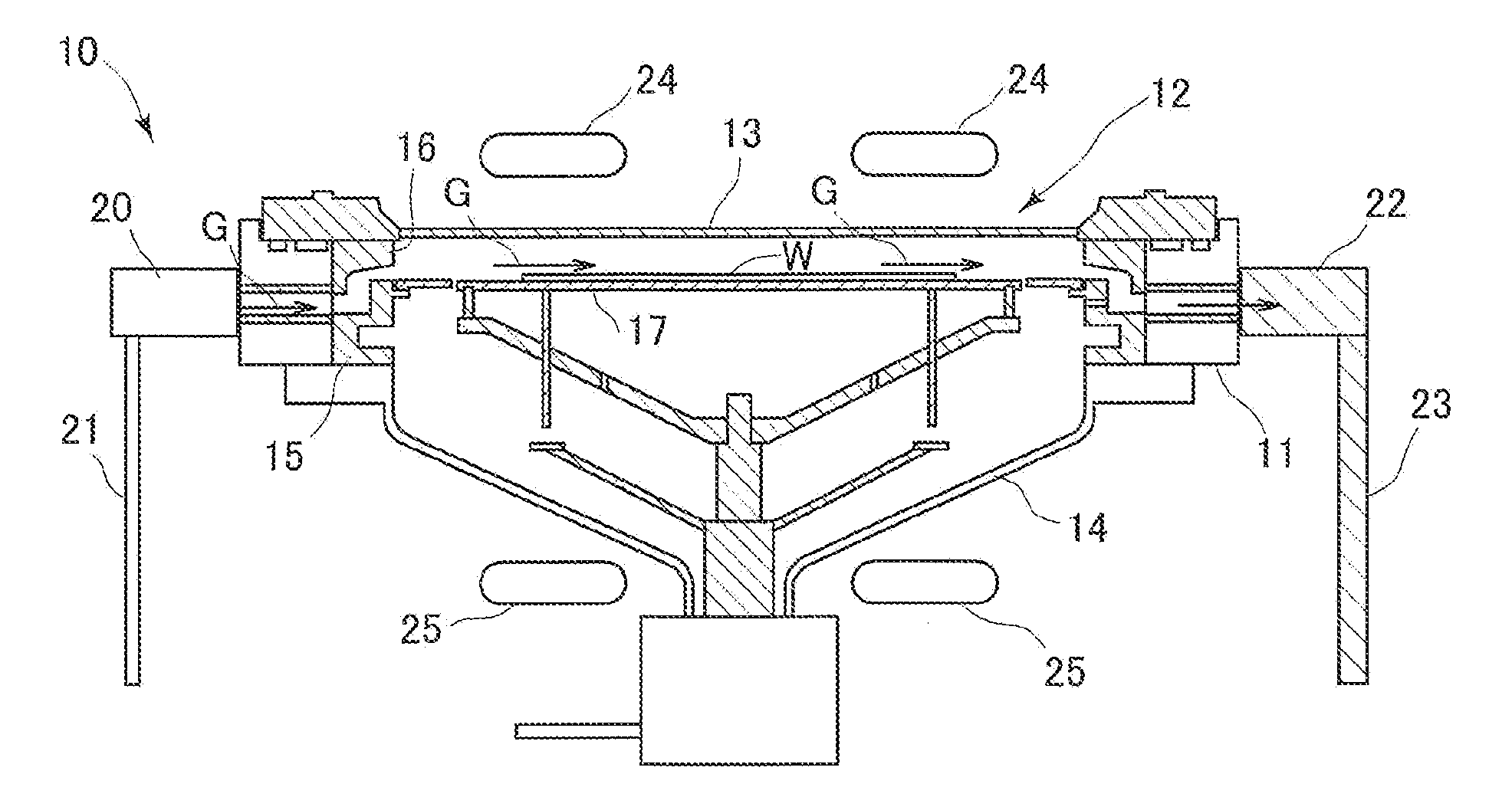

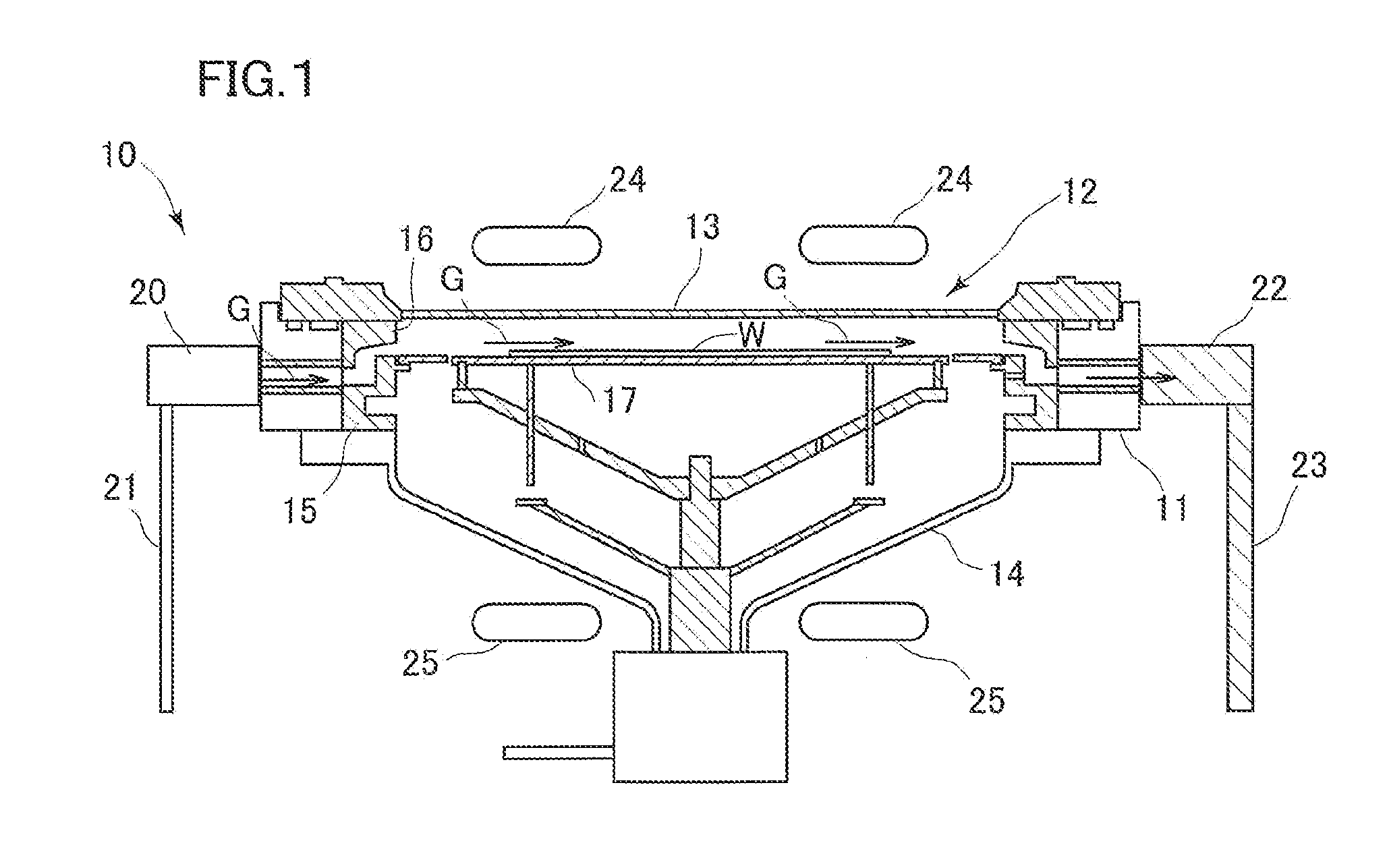

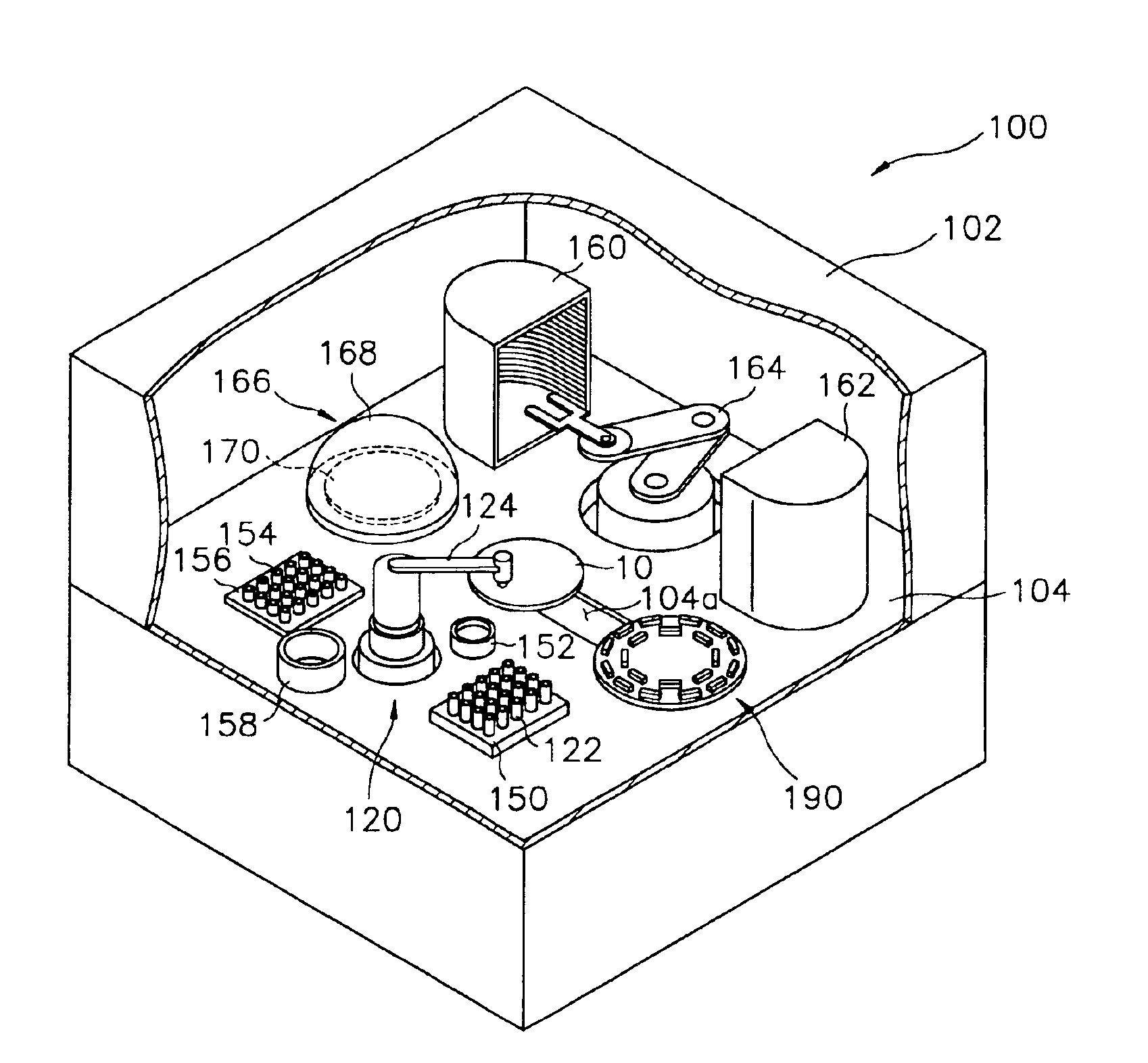

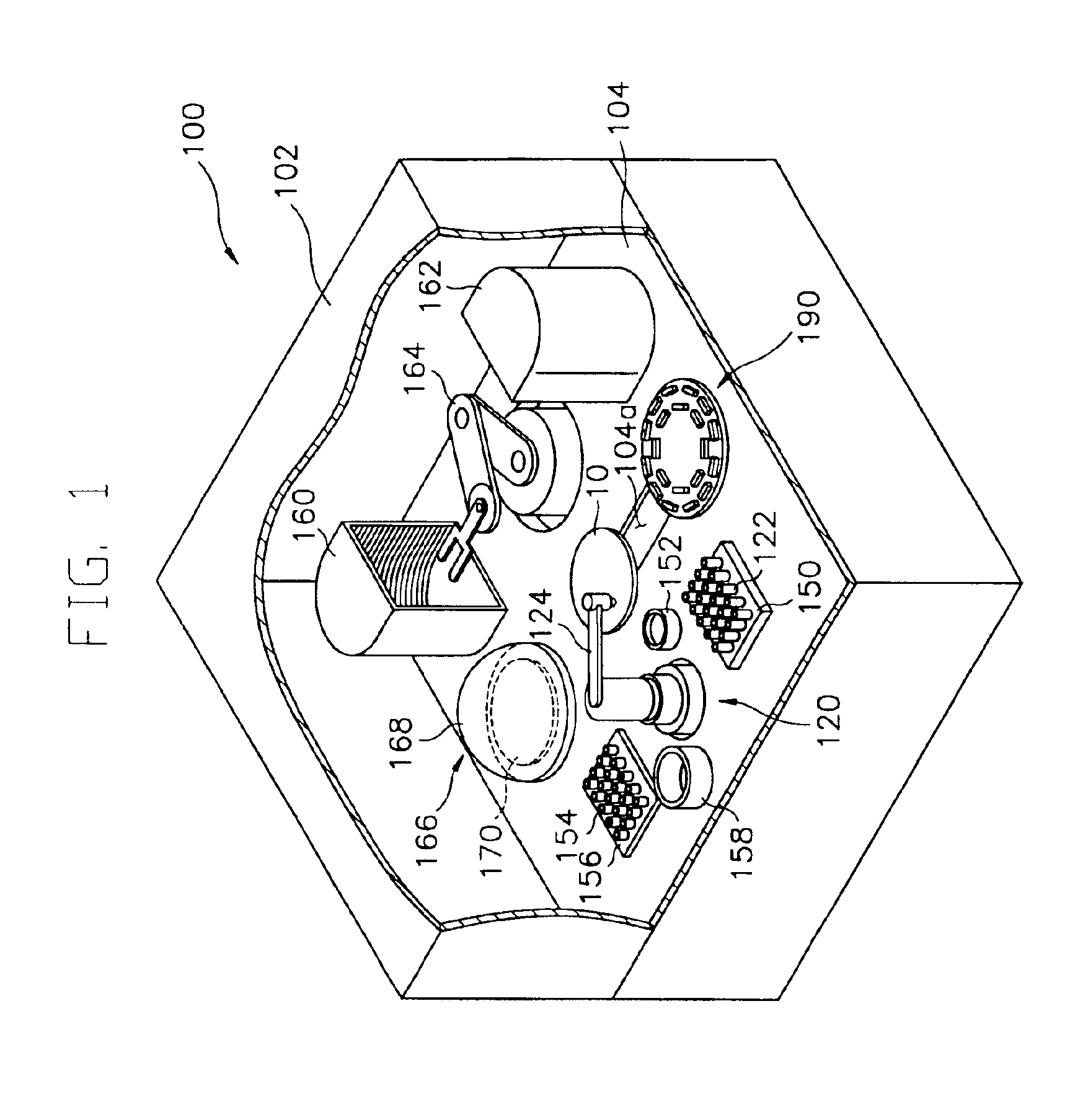

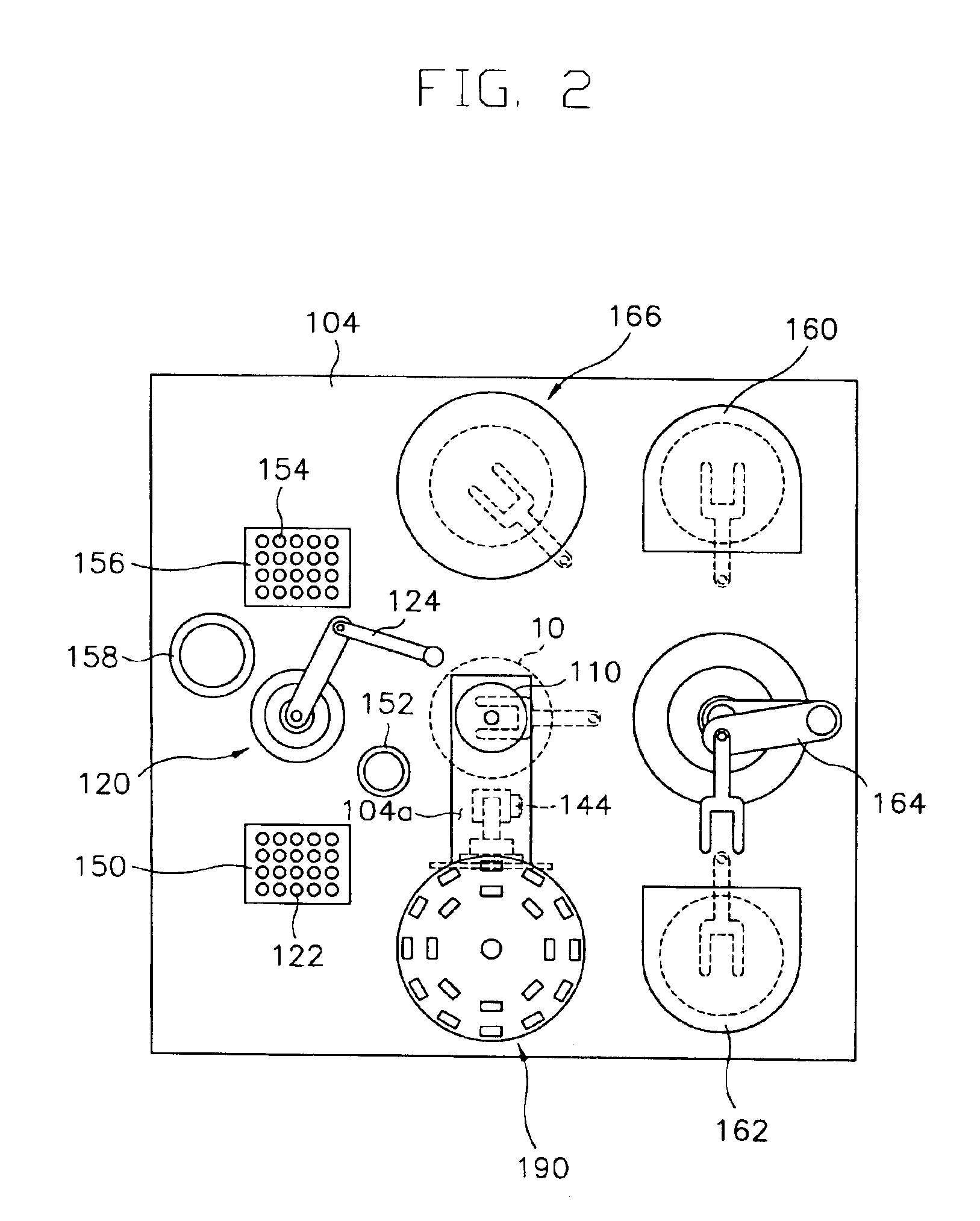

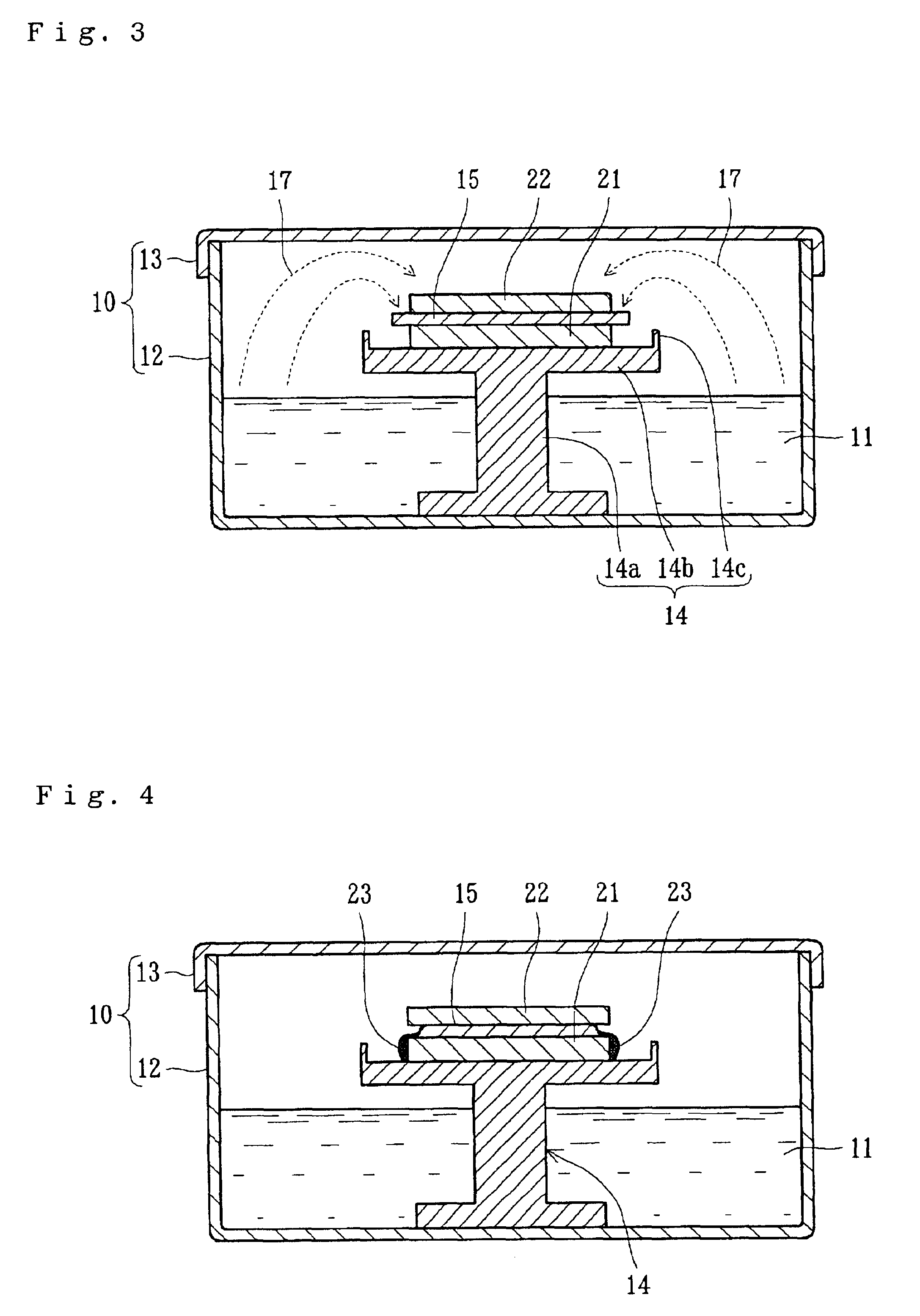

Apparatus and method for collecting impurities on a semiconductor wafer

An apparatus for collecting impurities on a semiconductor wafer includes an airtight process chamber, a rotary chuck disposed in the process chamber for rotating and horizontally supporting the semiconductor wafer, a first scanning unit for forming a droplet of a first scanning solution and for scanning an upper surface of the semiconductor wafer rotated by the rotary chuck with the droplet to collect first impurities, a driving unit for tilting the rotary chuck and the semiconductor wafer supported on the rotary chuck, and a second scanning unit for receiving a second scanning solution for collecting second impurities from an edge portion of the semiconductor wafer, the second scanning solution being in contact with the edge portion of the semiconductor wafer tilted by the driving unit and rotated by the rotary chuck so that the second scanning solution scans the edge portion of the semiconductor wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

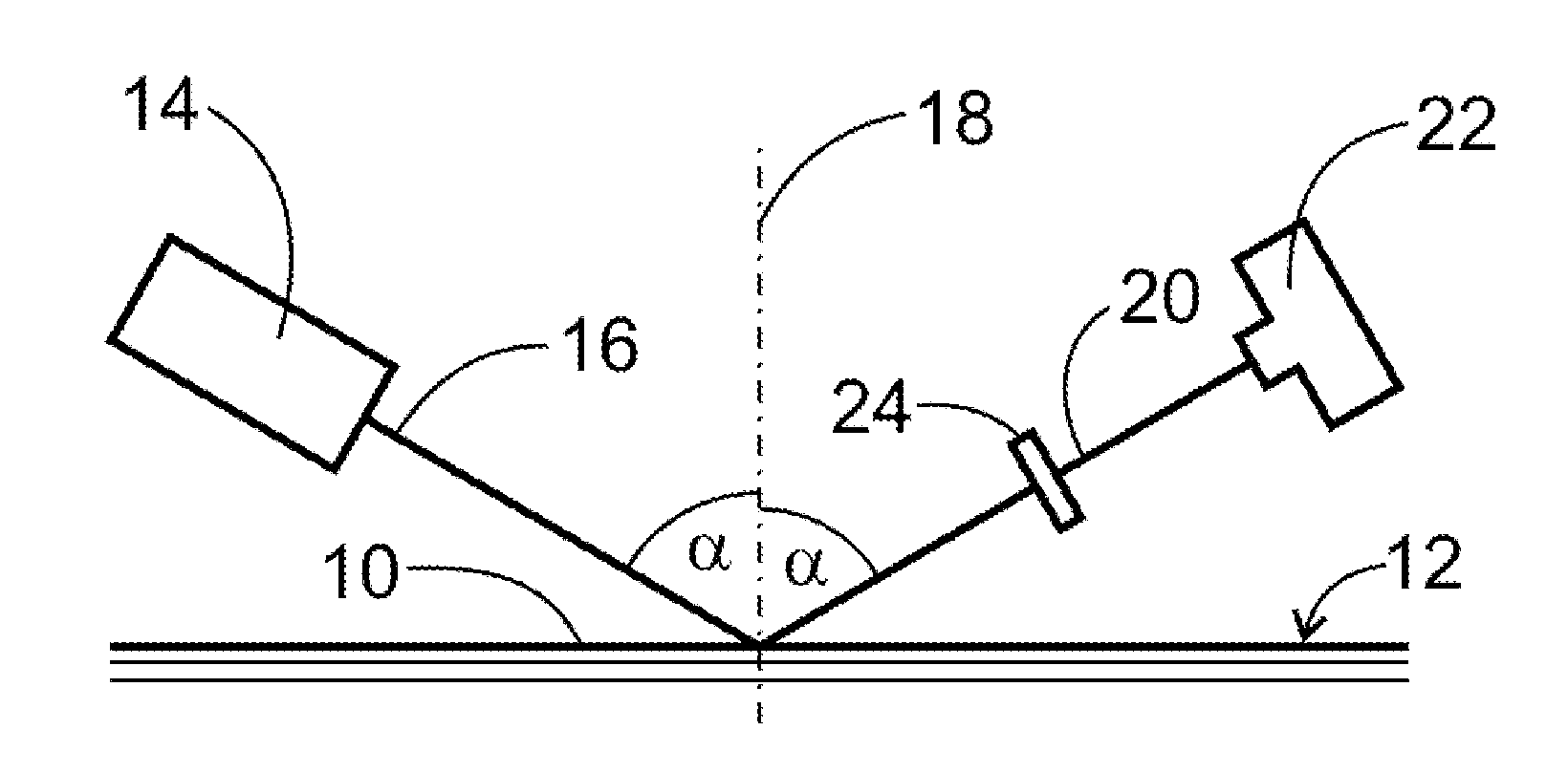

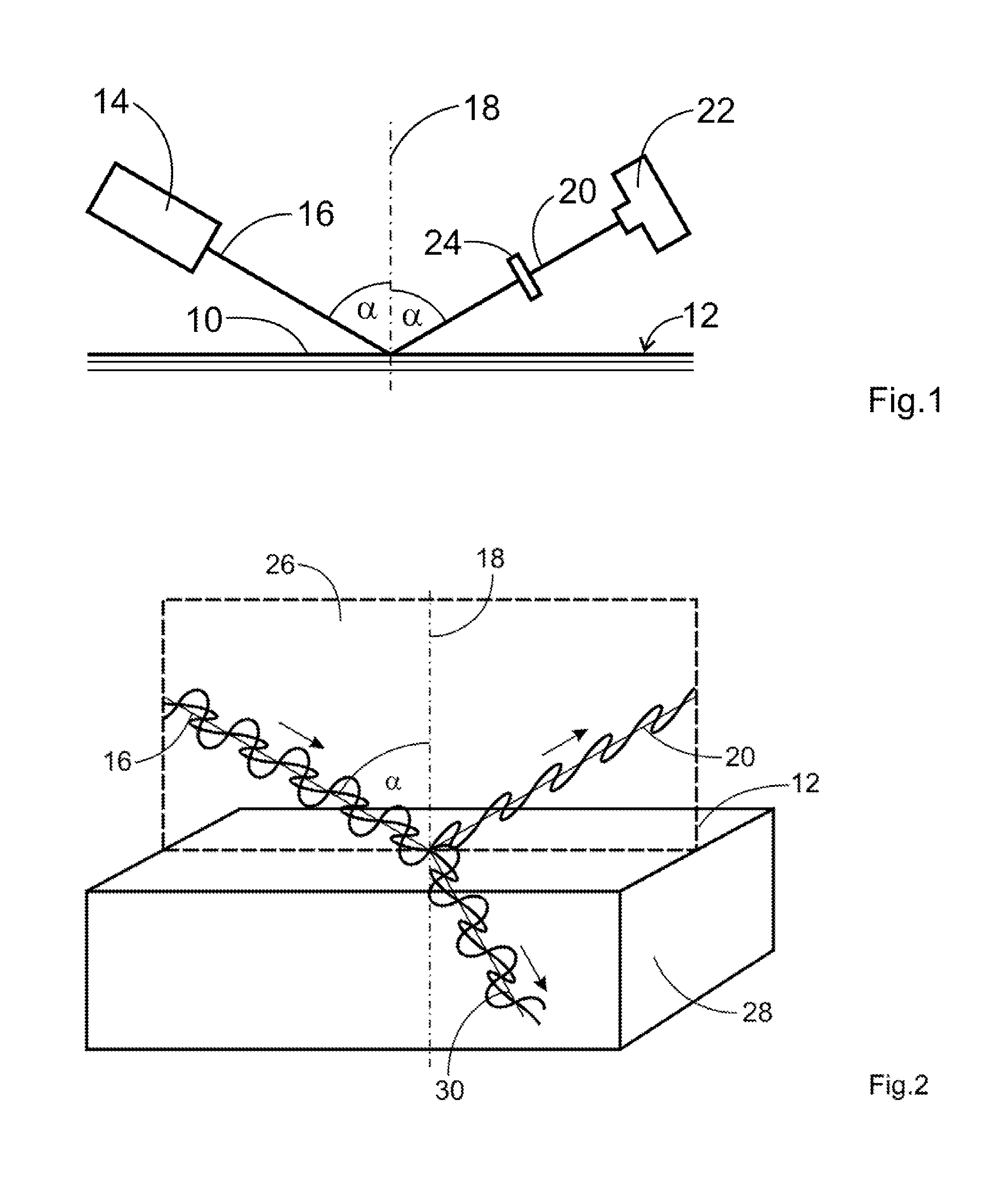

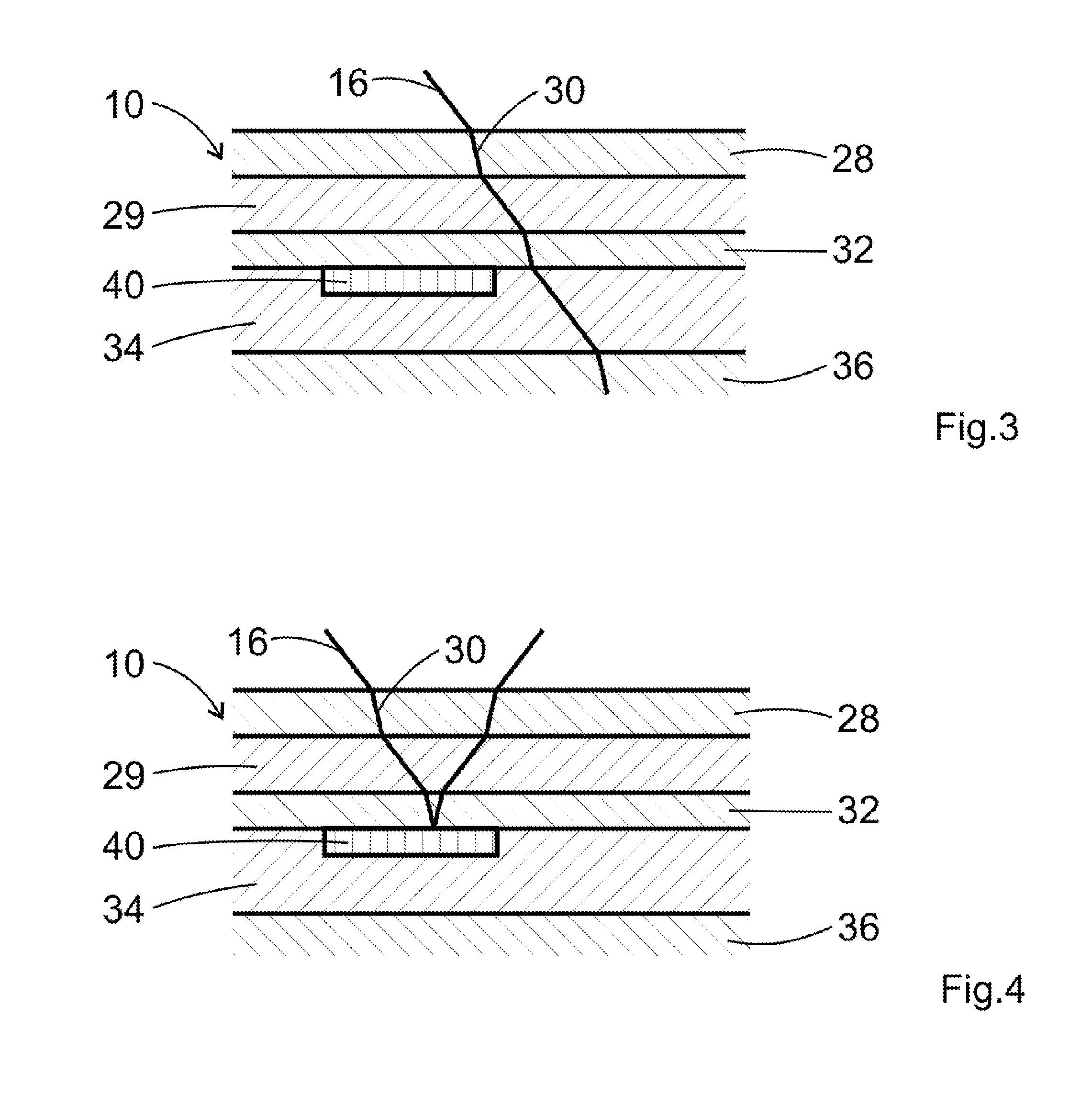

Method For Detecting Buried Layers

InactiveUS20150014542A1Increase speedLow costRadiation pyrometryScattering properties measurementsLight beamPlane of incidence

An arrangement for optically detecting buried layers of flat objects having a plurality of layers, in particular wafers, containing a radiation source for illuminating the surface of the object at an angle; a polarization filter arranged in the beam path; and a detector for detecting radiation reflected by the surface of the object or transmitted by the object; is characterized in that that layer of the object which is closest to the radiation source at least partially transmits the radiation from the radiation source; the polarization filter transmits only radiation which is polarized parallel to the plane of incidence; and the surface of the object is illuminated at the Brewster angle. The surface of the object is preferably illuminated with unpolarized radiation and the polarization filter is arranged in the beam path between the surface of the object and the detector.

Owner:HSEB DRESDEN

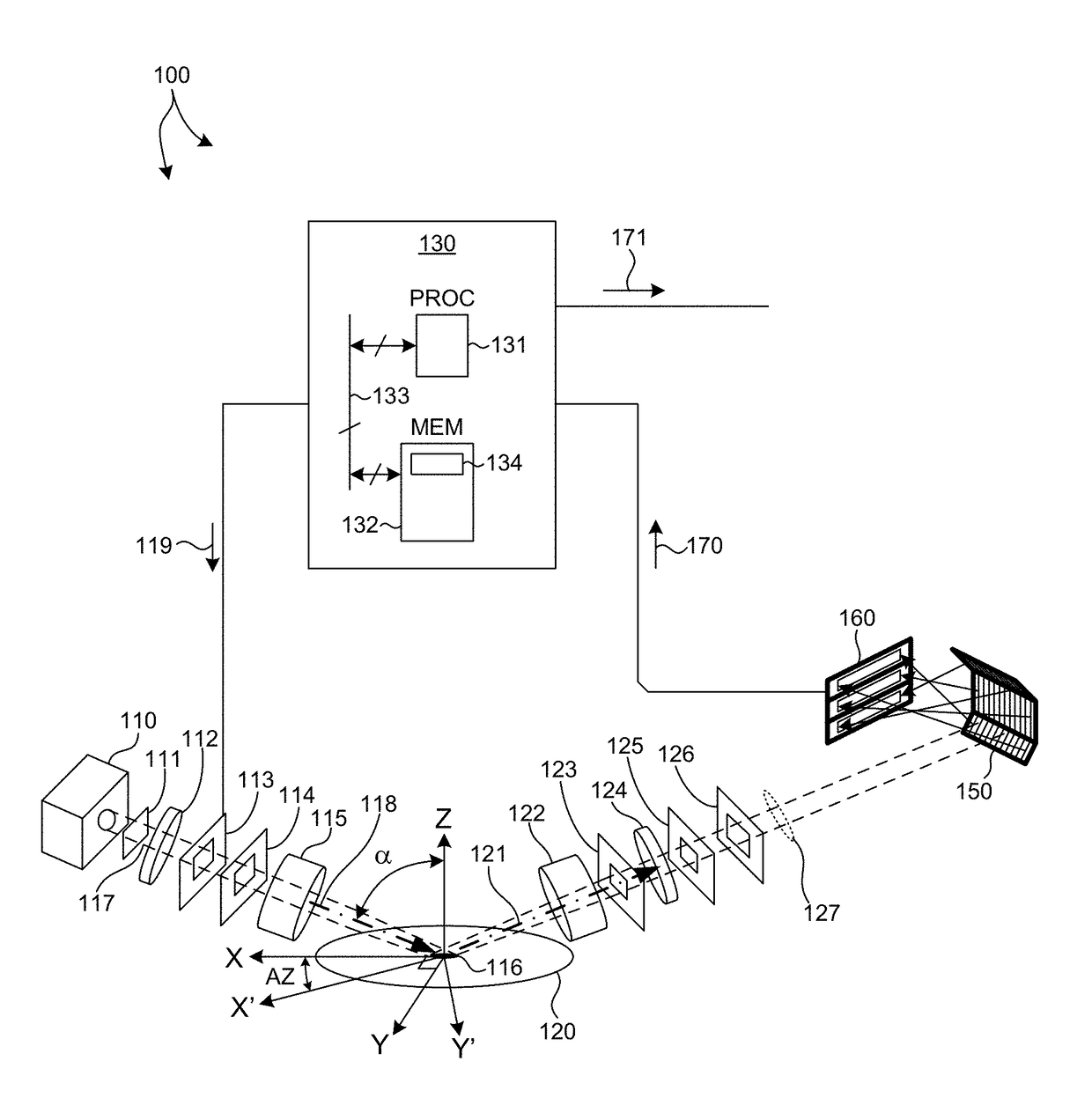

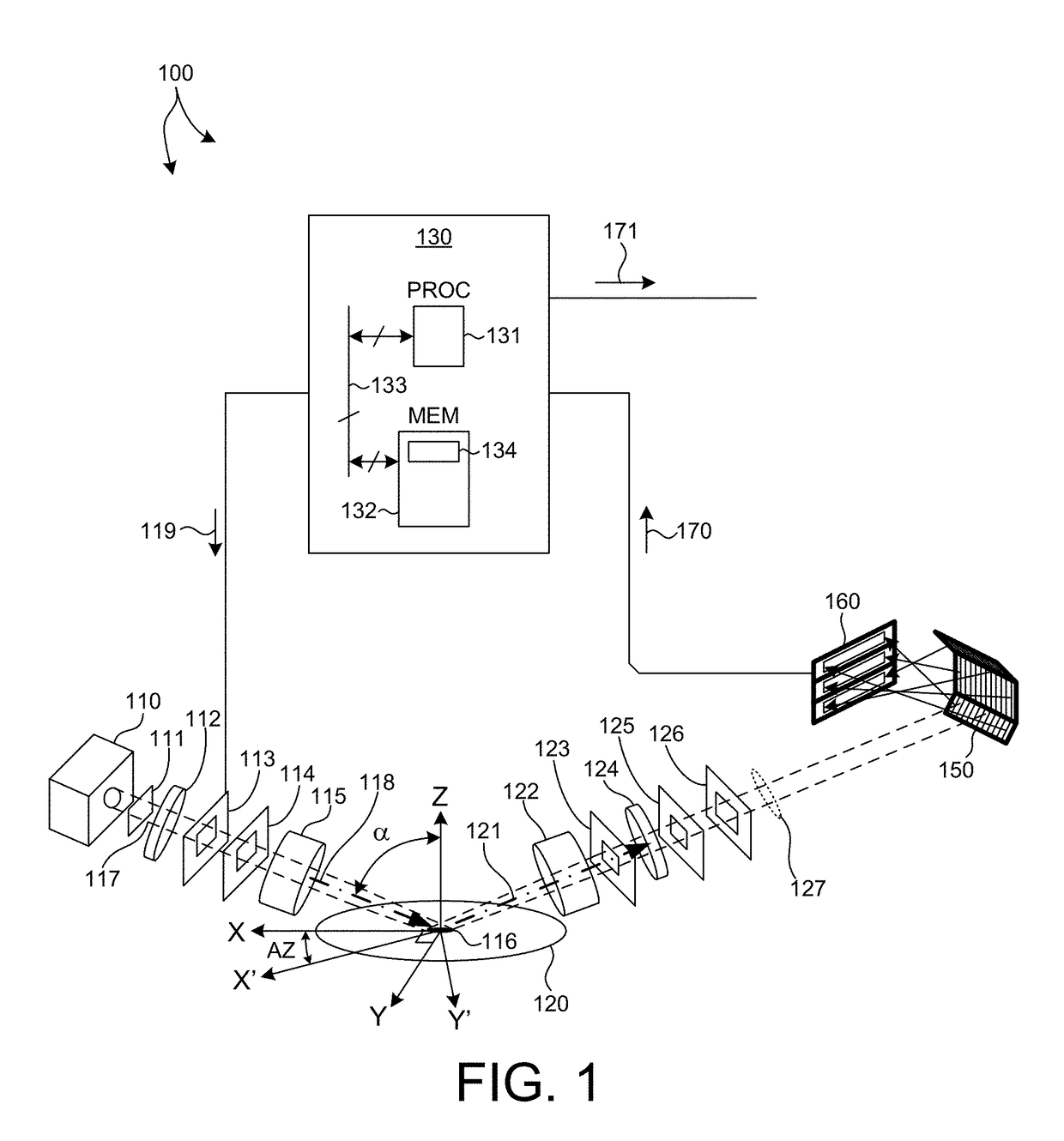

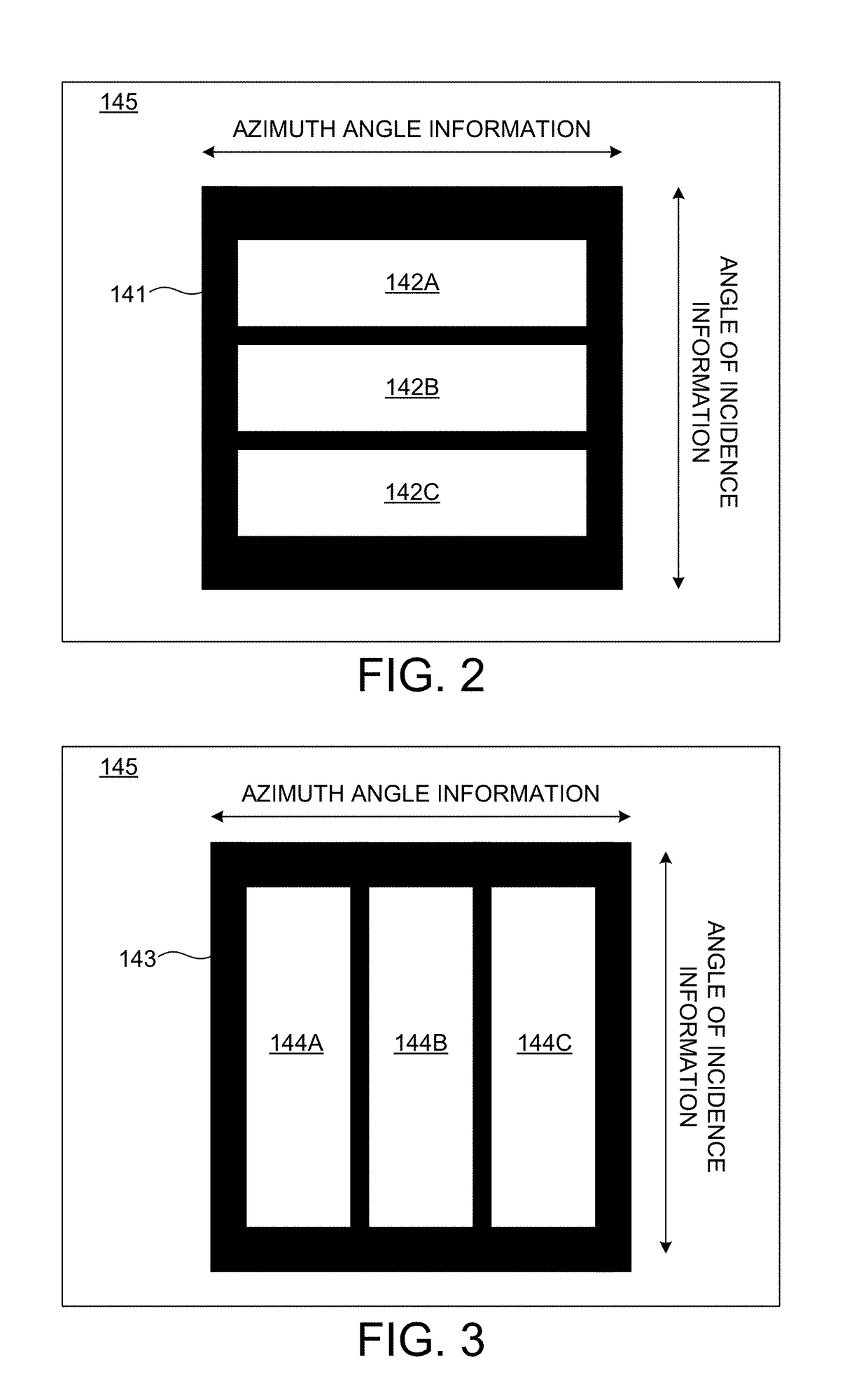

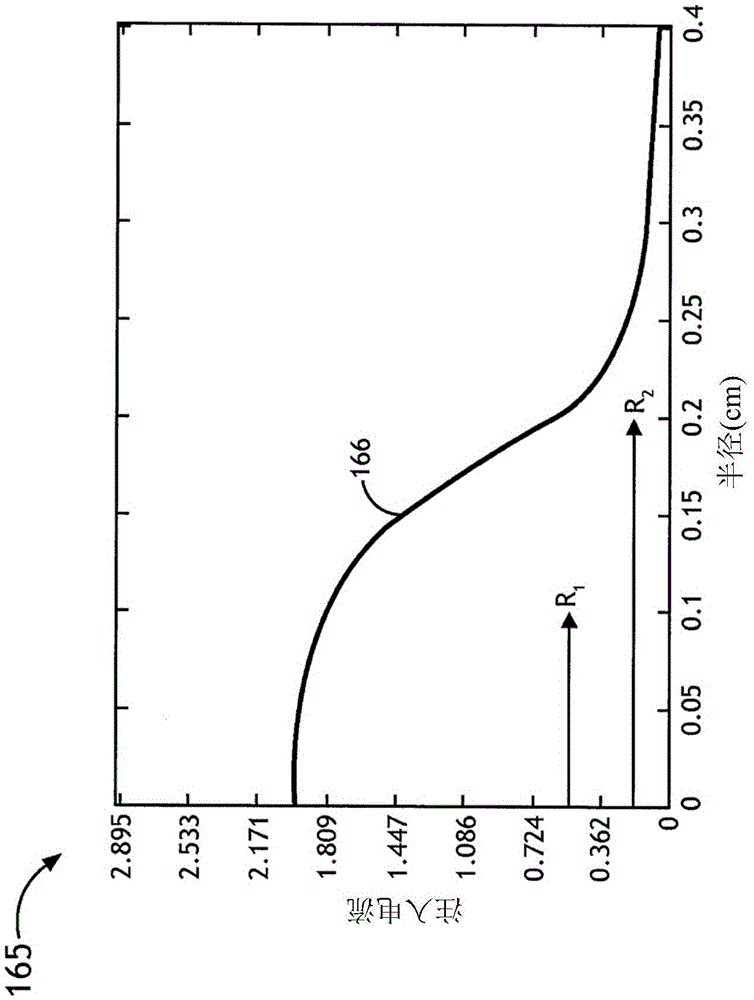

Simultaneous Multi-Angle Spectroscopy

ActiveUS20170356800A1High throughput measurementImprove signal-to-noise ratioRadiation pyrometrySemiconductor/solid-state device testing/measurementAngle of incidenceSignal-to-noise ratio (imaging)

Methods and systems for performing simultaneous spectroscopic measurements of semiconductor structures over a broad range of angles of incidence (AOI), azimuth angles, or both, are presented herein. Spectra including two or more sub-ranges of angles of incidence, azimuth angles, or both, are simultaneously measured over different sensor areas at high throughput. Collected light is linearly dispersed across different photosensitive areas of one or more detectors according to wavelength for each subrange of AOIs, azimuth angles, or both. Each different photosensitive area is arranged on the one or more detectors to perform a separate spectroscopic measurement for each different range of AOIs, azimuth angles, or both. In this manner, a broad range of AOIs, azimuth angles, or both, are detected with high signal to noise ratio, simultaneously. This approach enables high throughput measurements of high aspect ratio structures with high throughput, precision, and accuracy.

Owner:KLA TENCOR TECH CORP

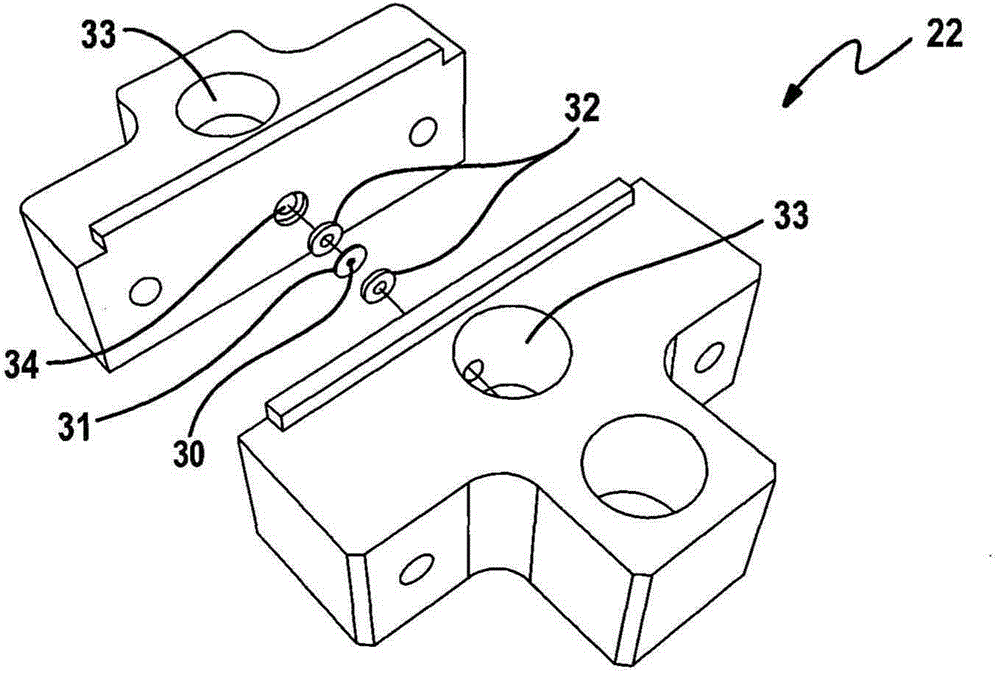

Wafer inspection system

InactiveUS7308367B2Minimize complexityFast and inexpensive and effective meanSemiconductor/solid-state device testing/measurementInstrumental componentsPotential differenceContamination

A method and system for identifying a defect or contamination on a surface of a material. The method and system involves providing a material, such as a semiconductor wafer, using a non-vibrating contact potential difference sensor to scan the wafer, generate contact potential difference data and processing that data to identify a pattern characteristic of the defect or contamination.

Owner:QCEPT INVESTMENTS LLC

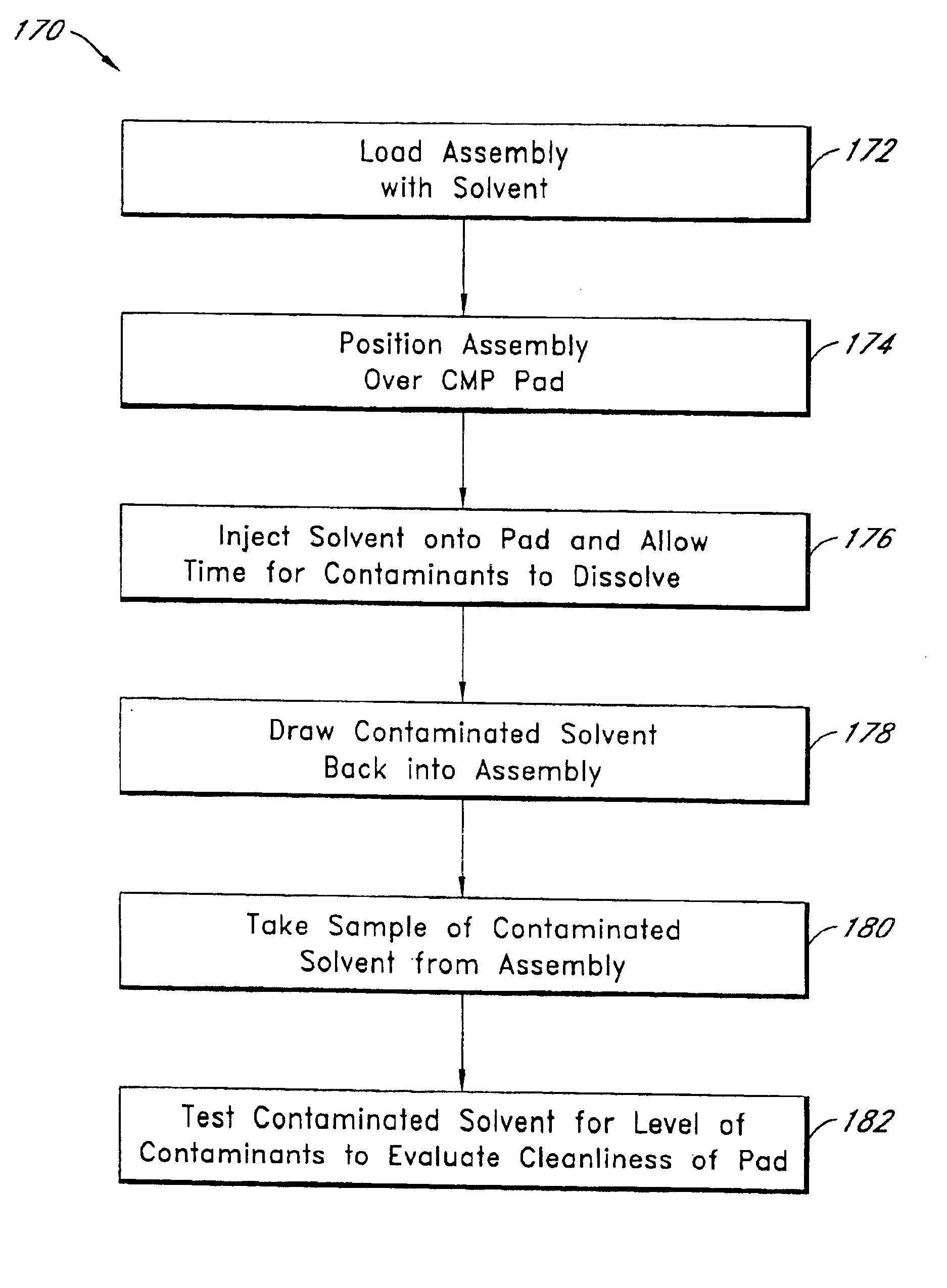

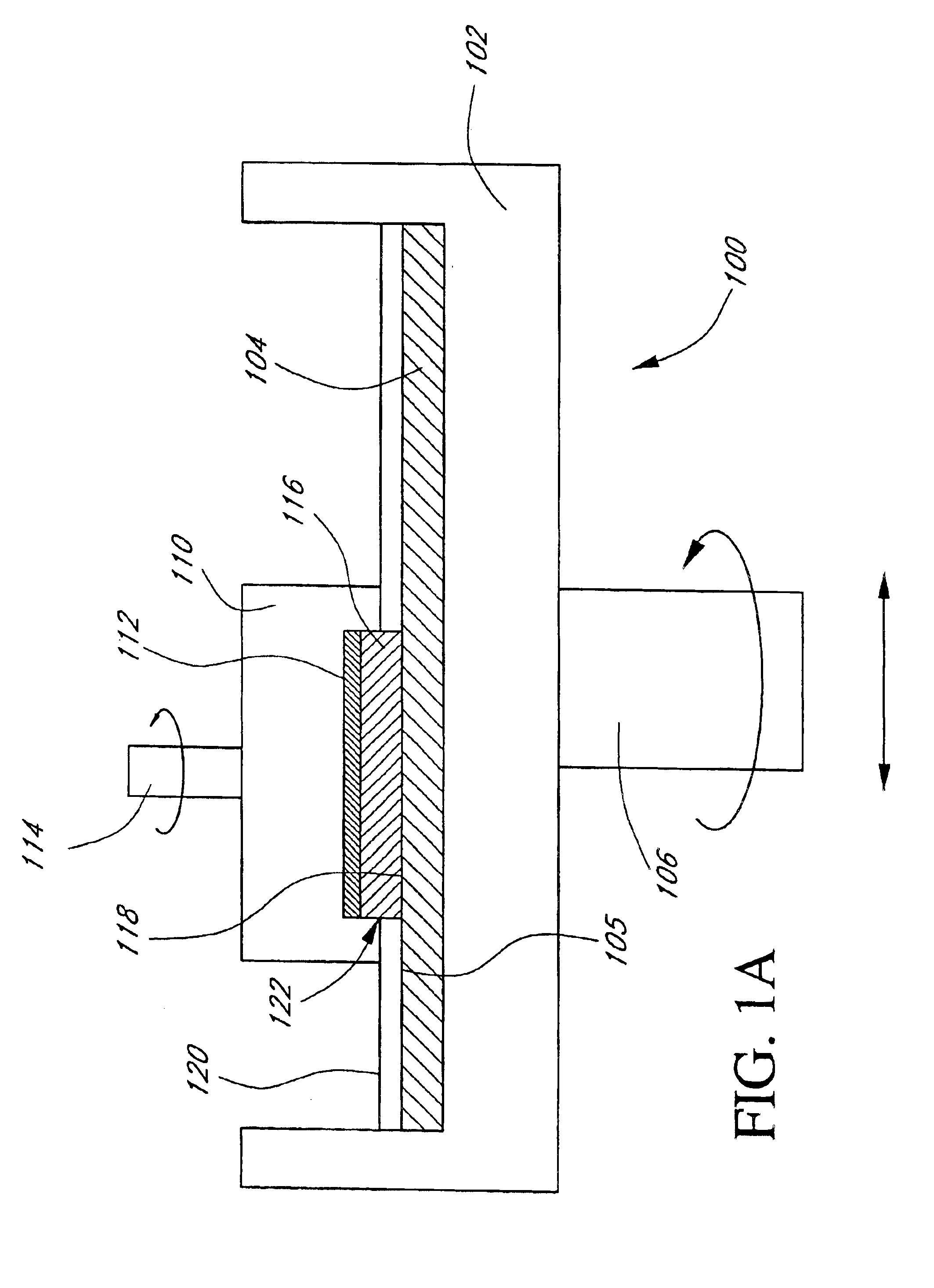

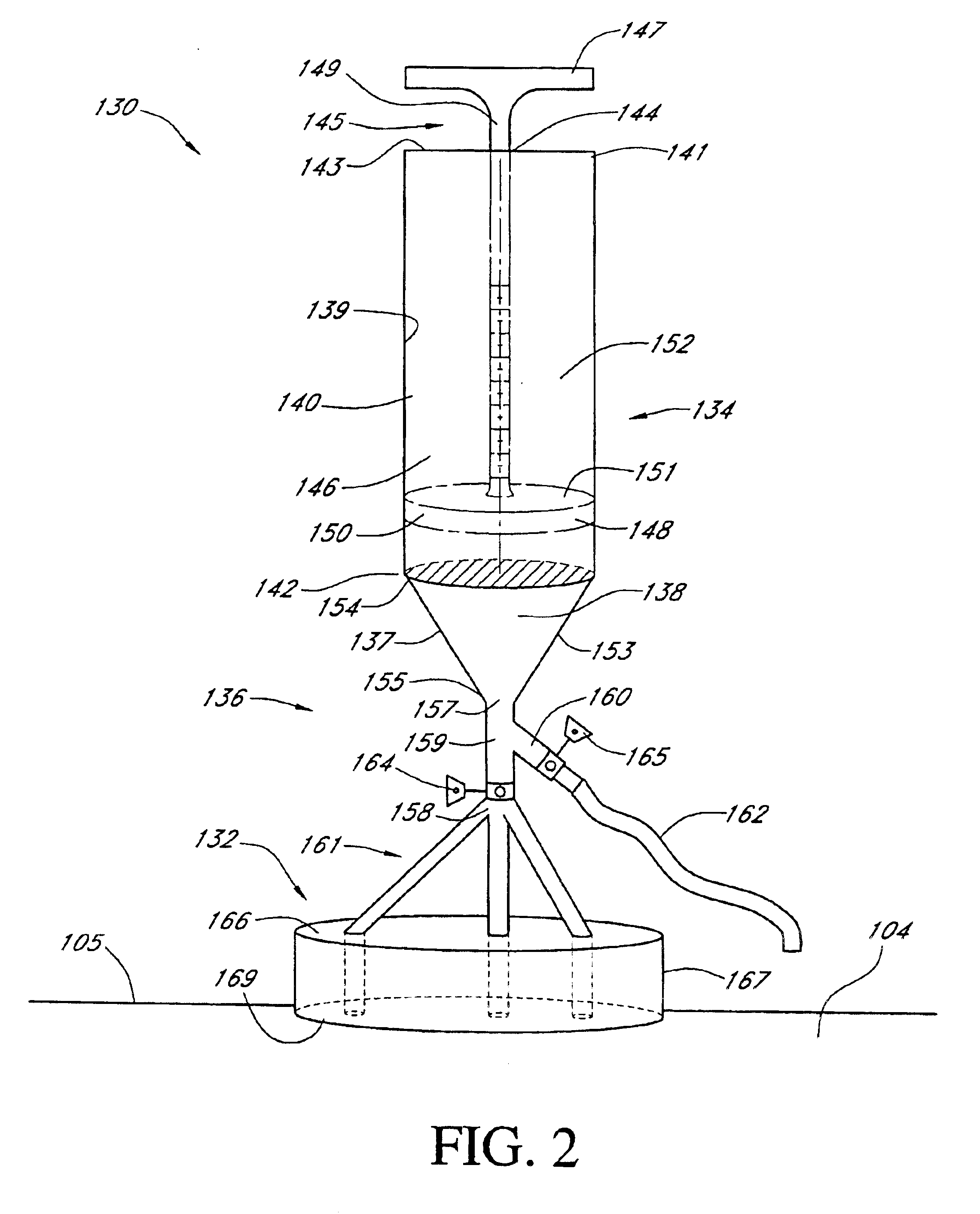

Device and method for collecting and measuring chemical samples on pad surface in CMP

InactiveUS6837942B2Easy and accurate and more controlled samplingEasy to collectWithdrawing sample devicesPreparing sample for investigationSolventSemiconductor wafer fabrication

A chemical collection assembly and a method for using the assembly such that a chemical-mechanical polishing (CMP) pad used in the manufacture of semiconductor wafers can be assessed for cleanliness. The method involves delivering solvent from the assembly's reservoir to an enclosed volume over the CMP pad. The solvent then brings contaminants imbedded on the CMP pad into solution. This solution is then drawn back up from the enclosed volume wherefrom a sample of the solution can be taken. That sample is then analyzed for the level of contaminants present therein, and the analysis is compared to a pre-determined level of cleanliness to determine whether the CMP pad should or should not continue to be used for semiconductor wafer manufacturing.

Owner:MICRON TECH INC

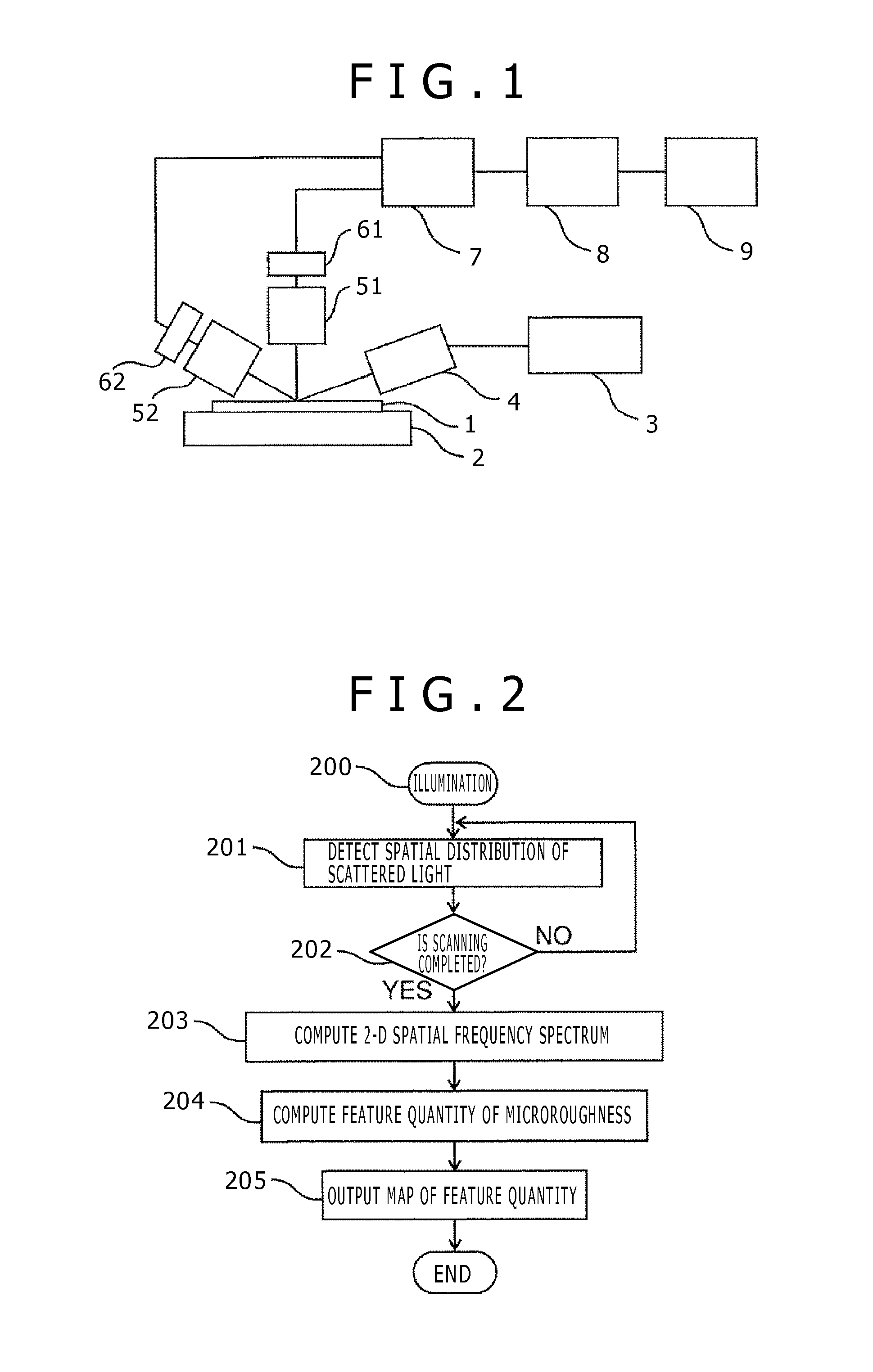

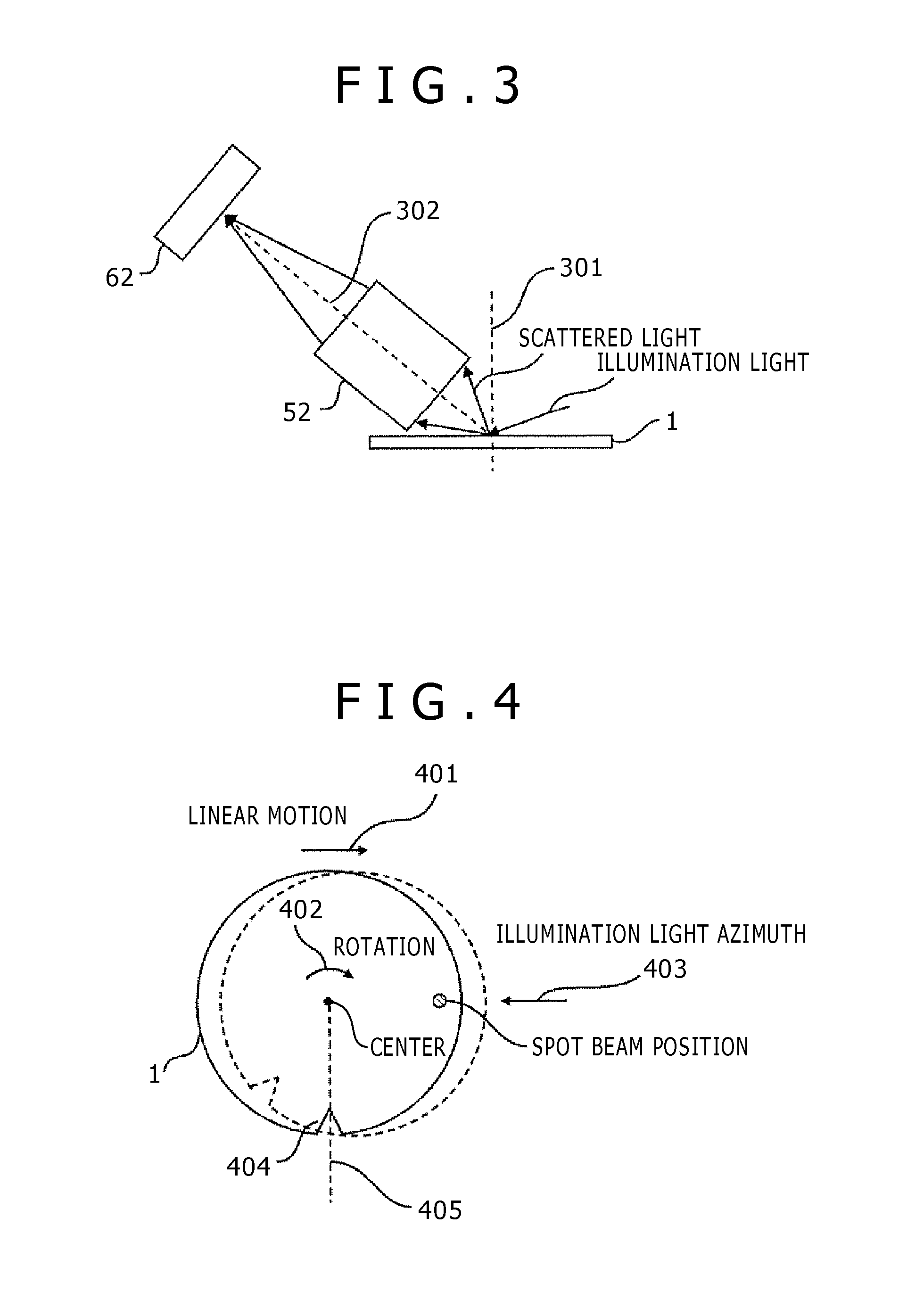

Surface measurement device

ActiveUS20140375988A1Accurate measurementSemiconductor/solid-state device testing/measurementScattering properties measurementsImage resolutionSurface measurement

In conventional technologies in surface measurement and defect inspection, considerations are not made for the following points: (1) coarseness of resolution of spatial frequency; (2) variation of detection signal resulting from anisotropy of microroughness; and (3) variation of background signal resulting from anisotropy of microroughness. The present invention is characterized by acquiring a feature quantity about the anisotropy of the microroughness of the substrate surface. Further, the present invention is characterized by acquiring a surface state in consideration of the anisotropy of the microroughness of the substrate surface. Further the present invention is characterized by detecting a defect over the substrate in consideration of the anisotropy of the microroughness of the substrate surface.

Owner:HITACHI HIGH-TECH CORP

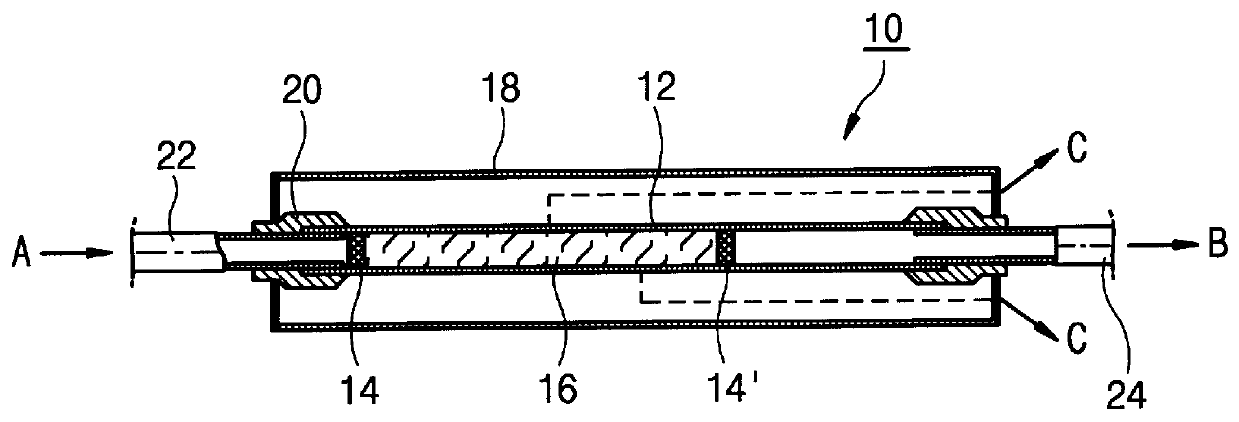

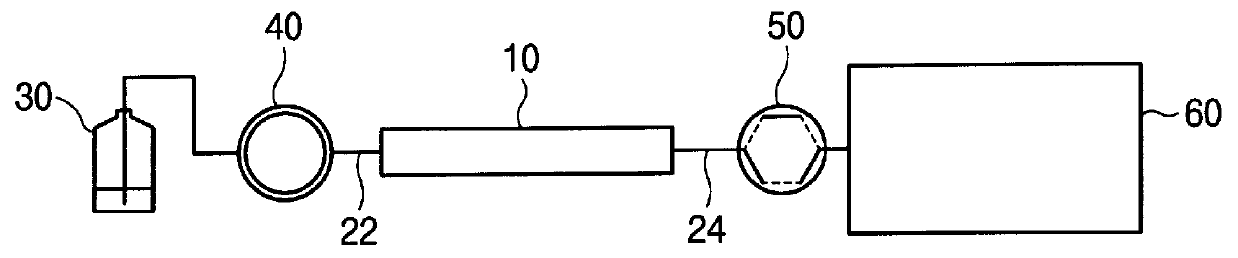

Apparatus and method for on-line decomposition of hydrogen peroxide solution in fabrication of semiconductor device

InactiveUS6146898AIncrease supplyEasy exitSemiconductor/solid-state device testing/measurementTesting waterDevice materialCoupling

An apparatus and method for on-line decomposition of a hydrogen peroxide solution, for use in fabricating a semiconductor device, includes a membrane tube having a porous plug inserted in each end, with the porous plugs defining a space where a platinum catalyst is disposed. A first coupling tube is inserted into one end of the membrane tube to supply a hydrogen peroxide sample to the membrane tube. The hydrogen peroxide contained in hydrogen peroxide sample is decomposed into water and oxygen gas according to an action of the platinum catalyst. A second coupling tube is inserted into a second end of the membrane tube to discharge a diluted hydrogen peroxide solution to an analytical instrument, where the decomposed hydrogen peroxide solution is analyzed on-line.

Owner:SAMSUNG ELECTRONICS CO LTD

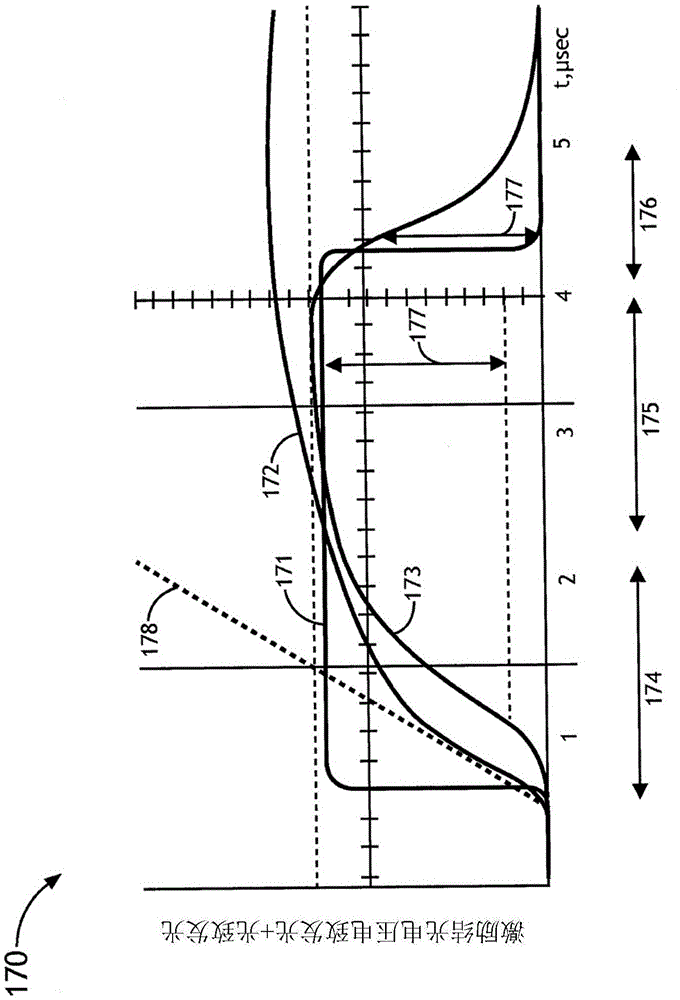

Method and apparatus for non-contact measurement of internal quantum efficiency in light emitting diode structures

Non-contact measurement of one or more electrical response characteristics of a LED structure includes illuminating an illumination area of a surface of a light emitting diode structure with one or more light pulses, measuring a transient of a luminescence signal from a luminescence area within the illumination area of the light emitting diode structure with a luminescence sensor, determining a first luminescence intensity at a first time of the measured transient of the luminescence signal from the light emitting diode structure, determining a second luminescence intensity at a second time different from the first time of the measured transient of the luminescence signal from the light emitting diode structure and determining an intensity of the electroluminescence component of the luminescence signal from the light emitting diode structure based on the first luminescence signal and the second luminescence signal.

Owner:KLA TENCOR TECH CORP

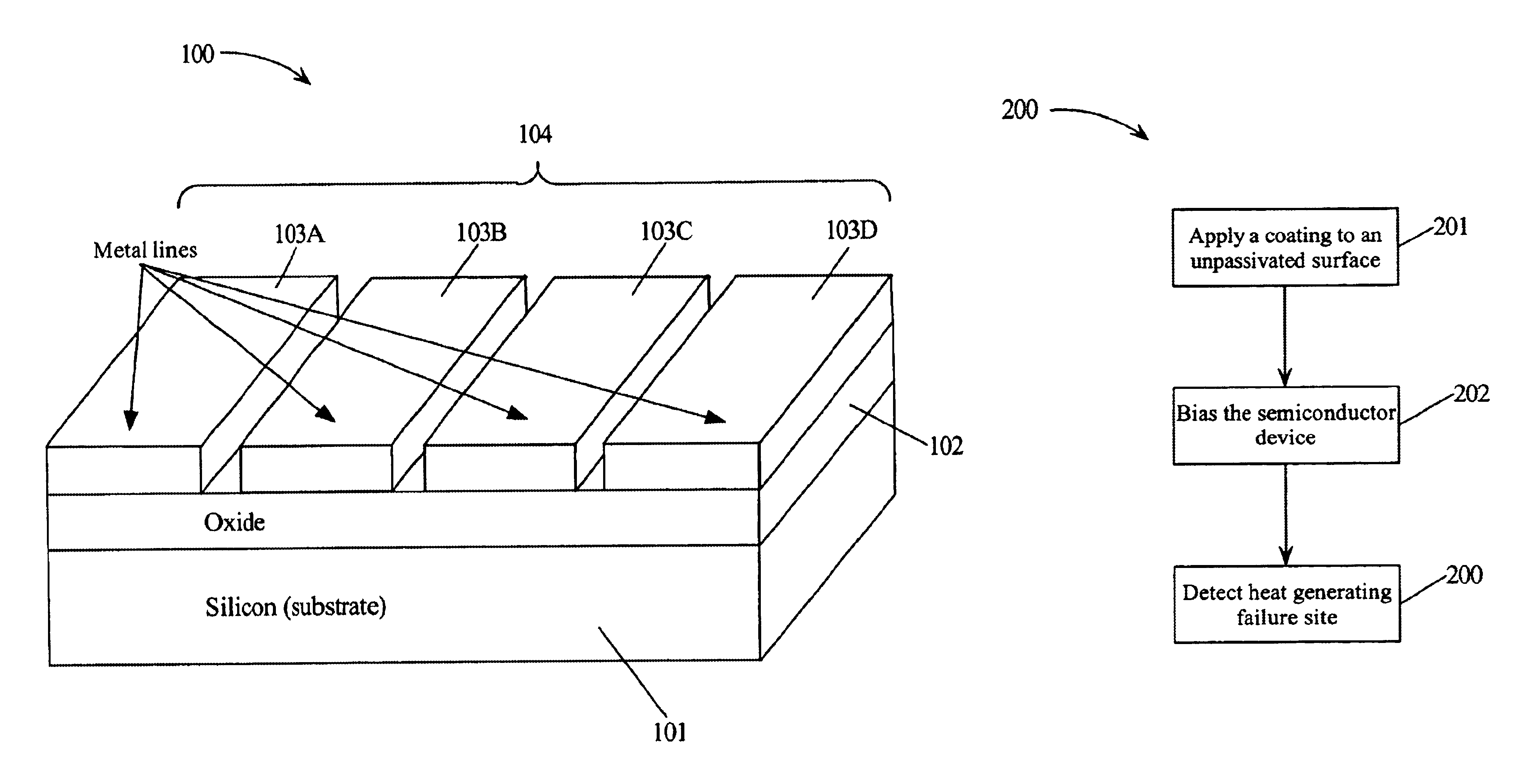

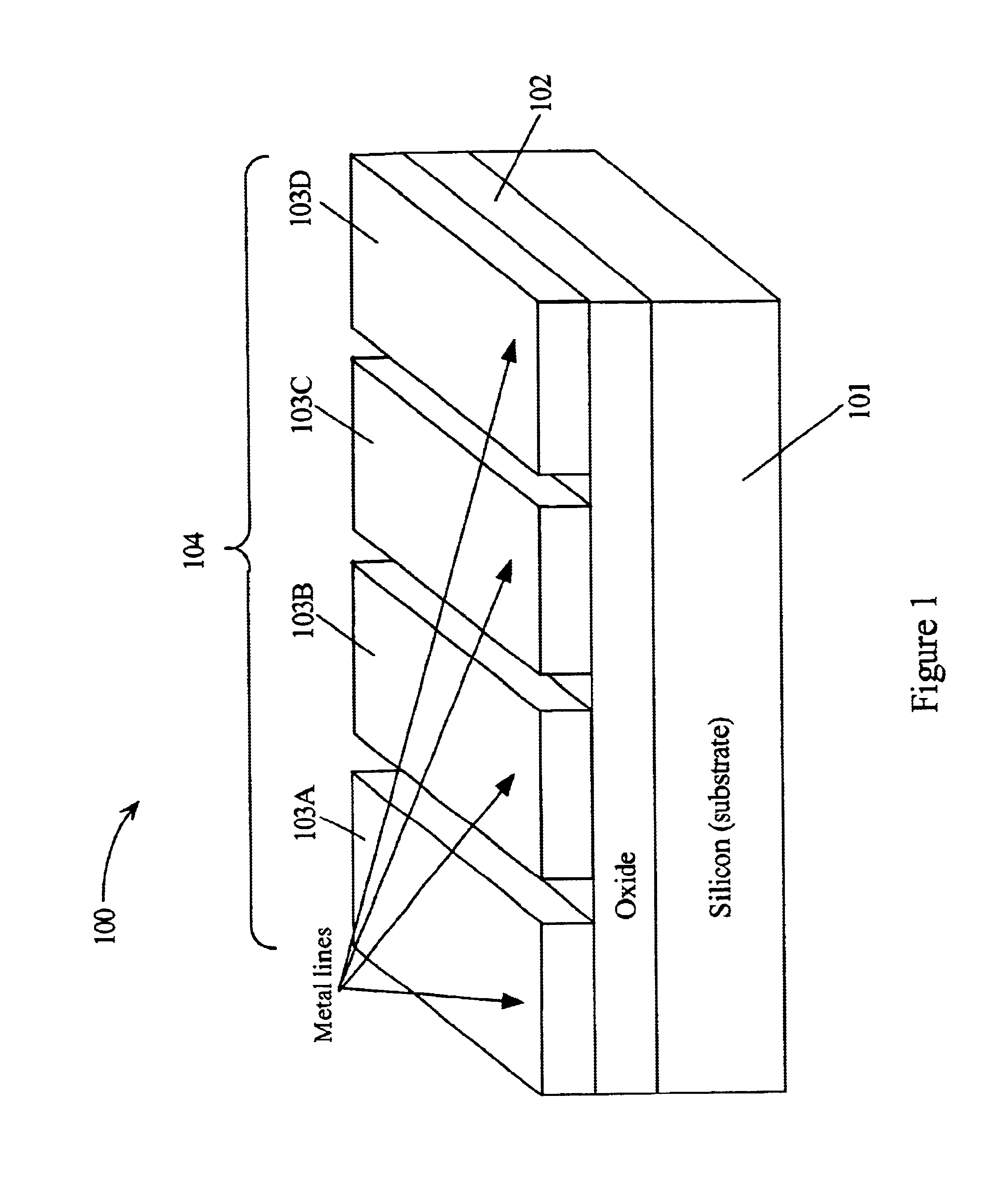

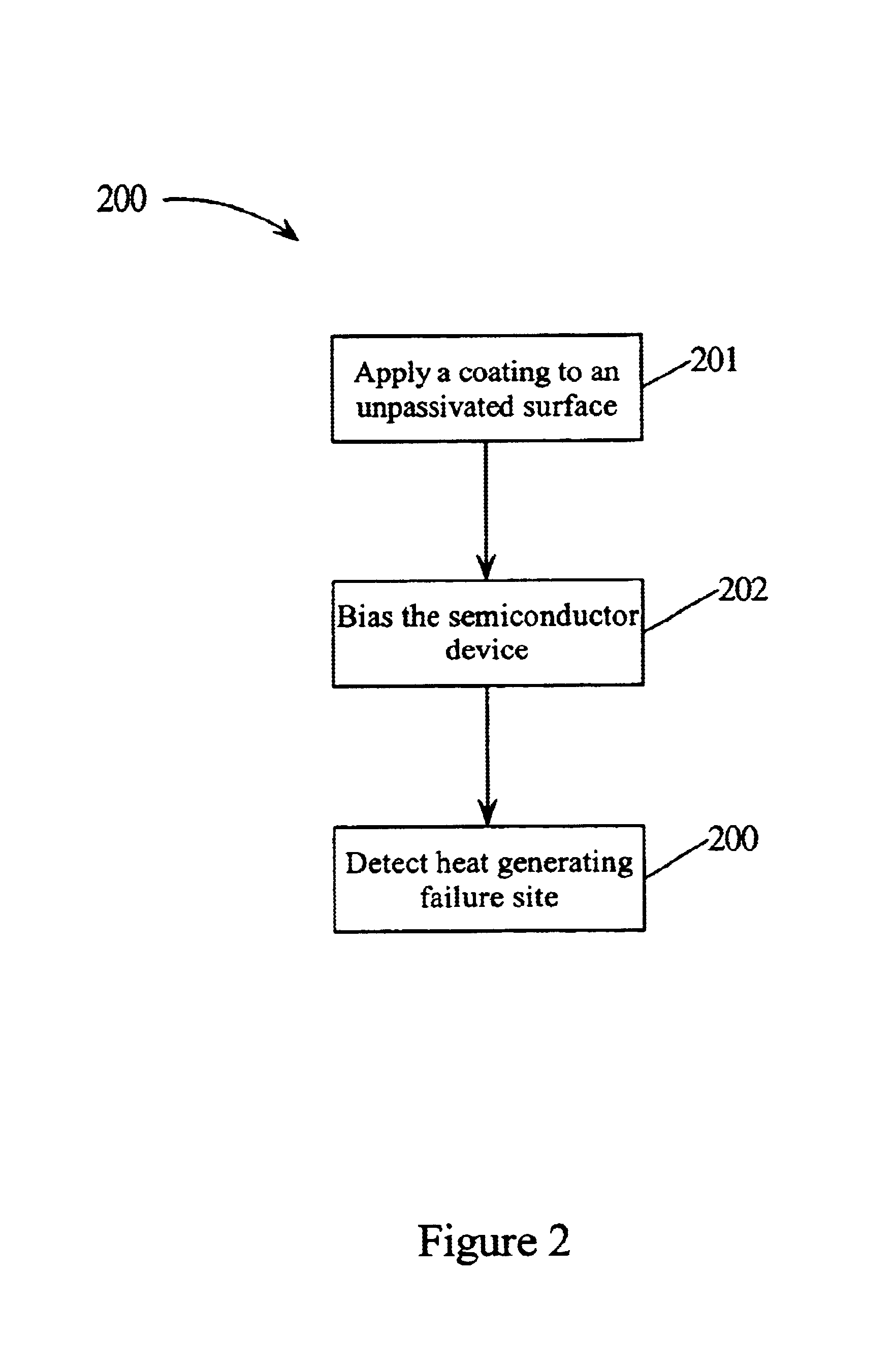

Detecting heat generating failures in unpassivated semiconductor devices

InactiveUS6866416B1Localized heatingWeather/light/corrosion resistanceMaterial flaws investigationEngineeringSemiconductor

A method and semiconductor device for detecting a heat generating failure in an unpassivated semiconductor device. The semiconductor device has an unpassivated surface and a heat generating failure, e.g., short circuit. A coating may be applied to the unpassivated surface of the semiconductor device. The coating may be non-electrically conducting and capable of localizing heat generated by the failure in a particular area. The semiconductor device may be biased. The failure may then be detected by detecting a location of the heat generated by the failure in the coating.

Owner:ADVANCED MICRO DEVICES INC

Method for analyzing impurities in a silicon substrate and apparatus for decomposing a silicon substrate through vapor-phase reaction

ActiveUS6995834B2Highly precisely analyzingShort timeSemiconductor/solid-state device testing/measurementPreparing sample for investigationHydrofluoric acidGas phase

A method for analyzing impurities present in a silicon substrate. The method includes the steps of accommodating a silicon substrate resting on a support, and a solution for decomposing a silicon substrate which comprises a mixture of hydrofluoric acid, nitric acid and sulfuric acid, in an air-tight reaction vessel, in such a way as to keep the silicon substrate from directly contacting with the decomposing solution; allowing the decomposing solution to vaporize, thereby causing the substrate to decompose through vapor-phase reaction for sublimation, without heating or pressurizing the reaction vessel; and recovering the residue left by the decomposed substrate, to analyze the impurities contained in the substrate. This method makes it possible to determine the content of impurities that are present in a silicon substrate extremely precisely in a comparatively short time by decomposing the substrate through vapor-phase reaction without resorting to heating or pressurization.

Owner:MITSUBISHI MATERIALS SILICON CORP

Fabrication of nanopores using high electric fields

Owner:UNIVERSITY OF OTTAWA

Inspection system and apparatus

InactiveUS20050059174A1Minimize complexitySimple signal processingSemiconductor/solid-state device testing/measurementElectrostatic cleaningPotential differenceEngineering

A method and system for identifying a defect or contamination on a surface of a material. The method and system involves providing a material, such as a semiconductor wafer, using a non-vibrating contact potential difference sensor to scan the wafer, generate contact potential difference data and processing that data to identify a pattern characteristic of the defect or contamination.

Owner:QCEPT INVESTMENTS LLC

Gas sensor, method for manufacturing gas sensor, and method for detecting gas concentration

InactiveUS20160161443A1Easily interfaceExcellent characteristicsWeather/light/corrosion resistanceVolume/mass flow measurementSputteringSolid solution

A humidity sensor that includes a p-type semiconductor layer and an n-type semiconductor layer on the p-type semiconductor layer. The p-type semiconductor layer is a sintered body made mainly of a solid solution of NiO and ZnO, and the n-type semiconductor layer is made mainly of at least one of ZnO and TiO2. The p-type semiconductor layer has a molar ratio of Ni to Zn, or Ni / Zn, of 6 / 4 or more and 8 / 2 or less. The n-type semiconductor layer is produced using sputtering or through the firing of a multilayer structure composed of a green multilayer body to be made into the p-type semiconductor layer and a green sheet thereon to be made into the n-type semiconductor layer.

Owner:MURATA MFG CO LTD

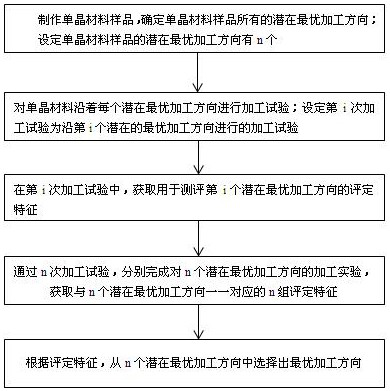

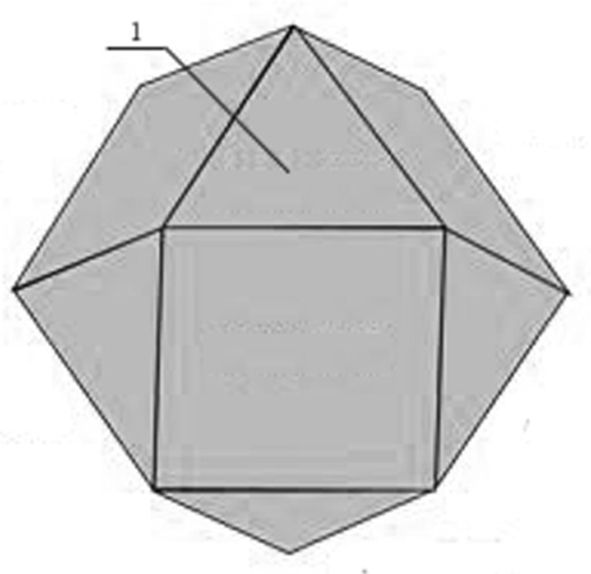

Method for determining optimal processing direction of single crystal material

ActiveCN111638305AReduce processing forceReduce depthUsing mechanical meansUsing optical meansEngineeringSingle crystal

The invention discloses a method for determining an optimal processing direction of a single crystal material. The method comprises the following steps: manufacturing a single crystal material sample,determining all potential optimal processing directions of the single crystal material sample, and processing the single crystal material along each potential optimal processing direction; obtainingevaluation characteristics used for evaluating the potential optimal machining direction in each time of machining, wherein the evaluation characteristics comprise the machining force in the machiningprocess and surface topography characteristics and the sub-surface damage layer depth after machining is completed, and the machining force comprises a tangential force and a normal force; selectingthe optimal machining direction according to the evaluation characteristics so as to improve machining efficiency and machining quality.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

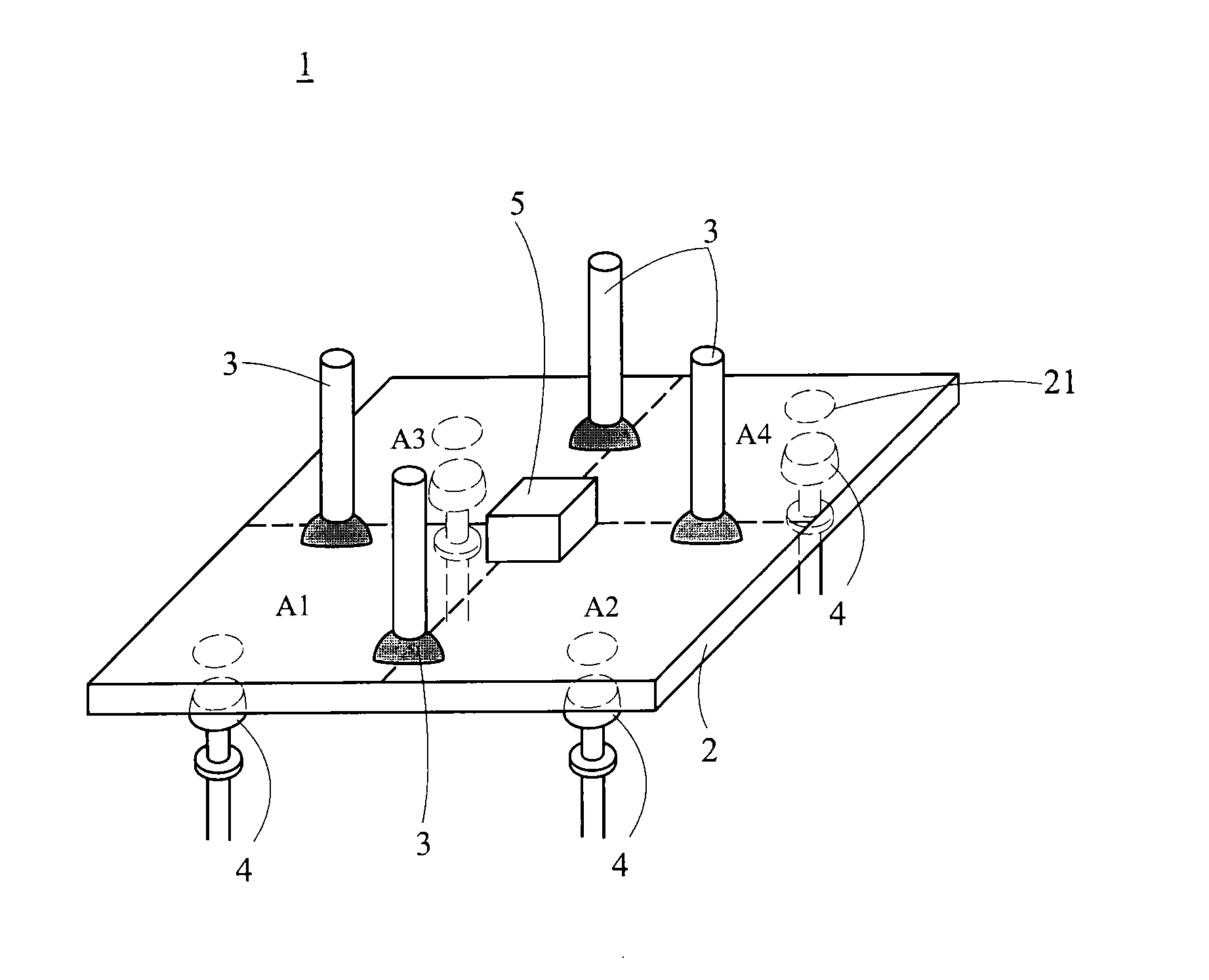

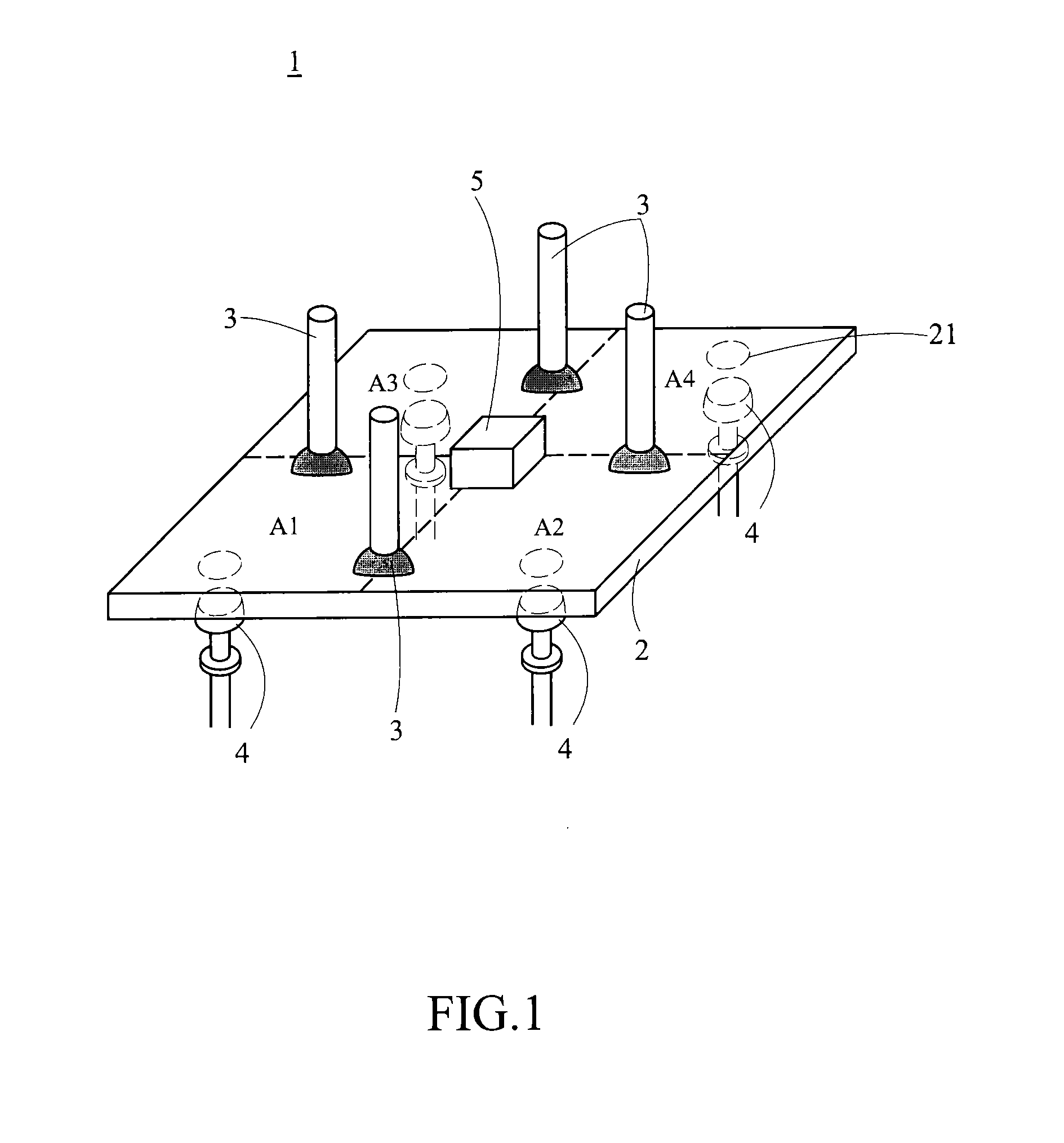

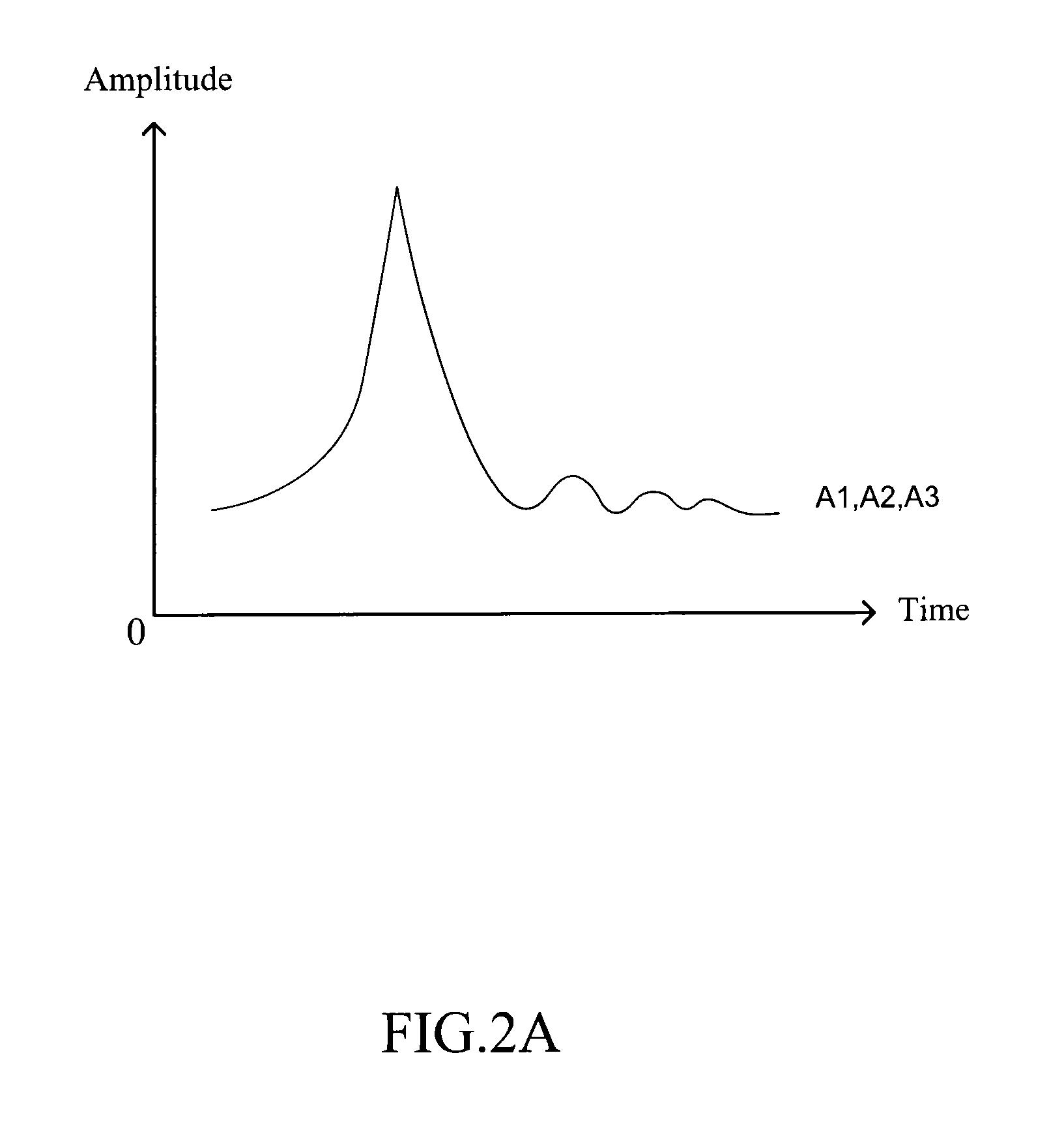

Apparatus and Method for Testing Solar Panel

InactiveUS20130014557A1Quick testImprove test efficiencyAcceleration measurementTesting semiconductor materialsEngineeringSolar cell

A testing apparatus for testing a solar panel is provided. The testing apparatus includes at least one sensor, at least one impact hammer and at least one adsorbing element. The testing apparatus adsorbs the solar panel with the at least one adsorbing element and the at least one sensor is disposed on the solar panel. At least one vibration is produced when the at least one impact hammer hits the solar panel. The at least one vibration is received and transformed into at least one digital signal by the at least one sensor. The at least one digital signal is then compared with a database to determine the yield of the solar panel.

Owner:LEE KUN TA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com