Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

354results about "Integrated arm assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

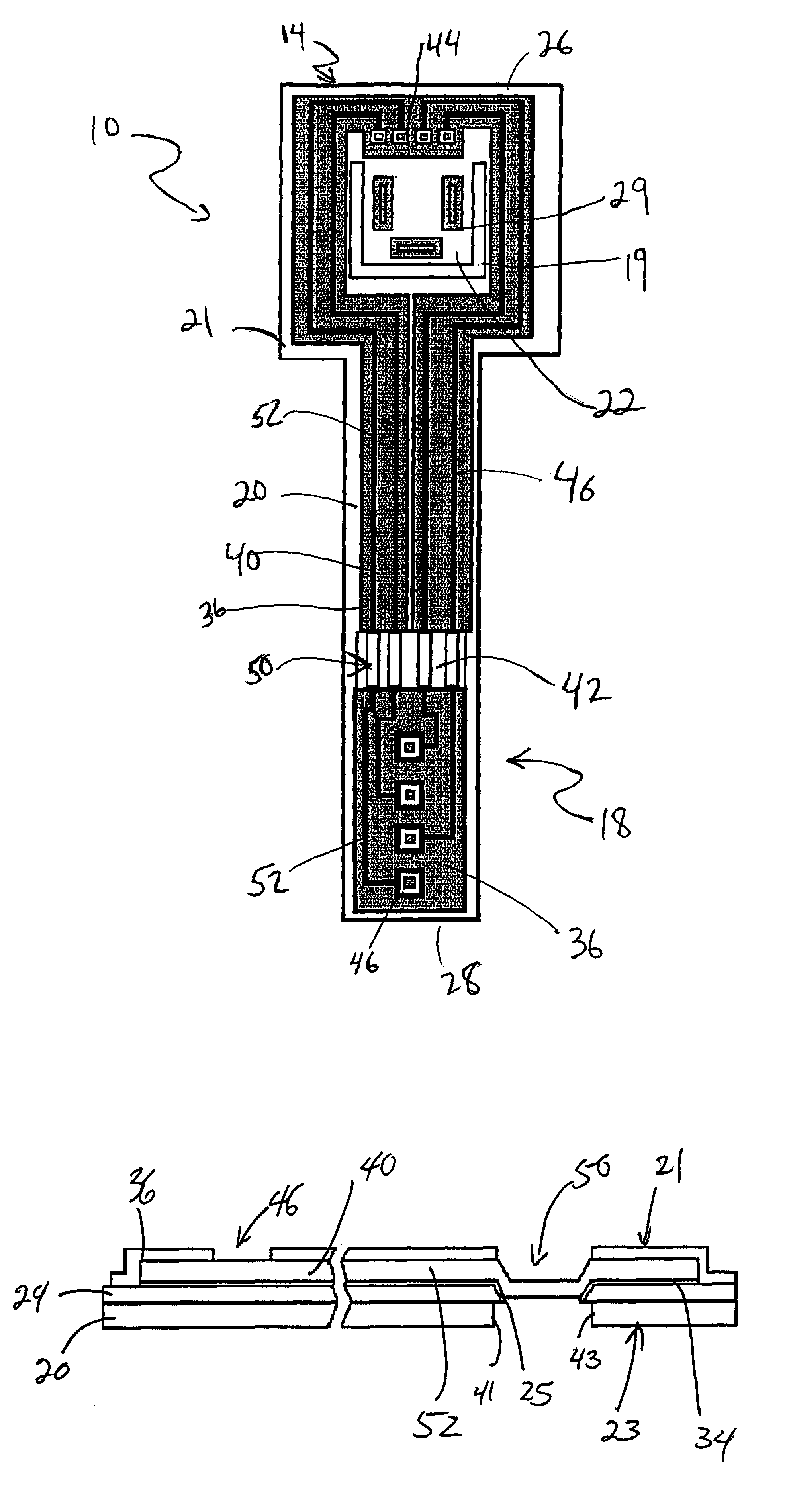

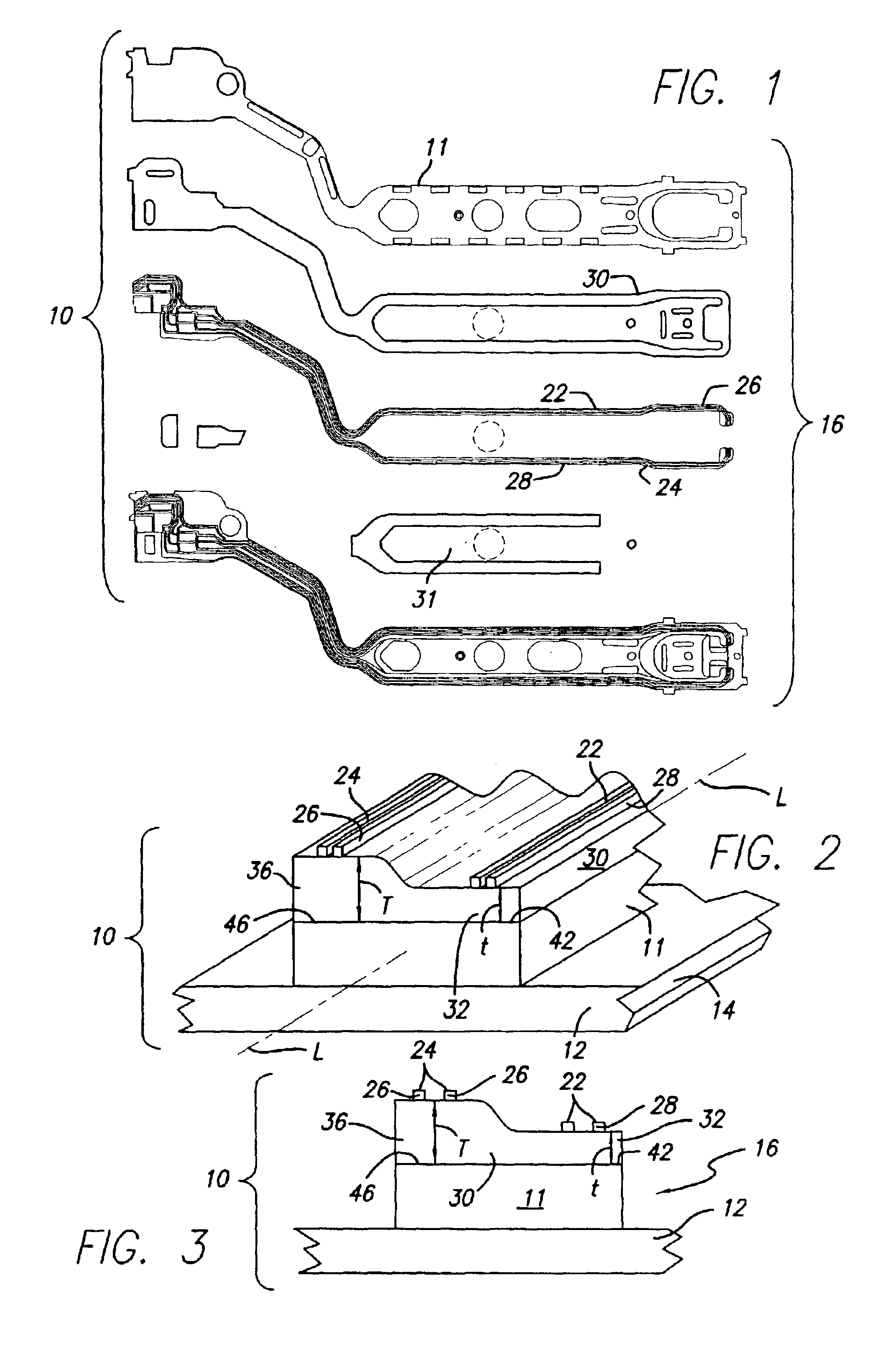

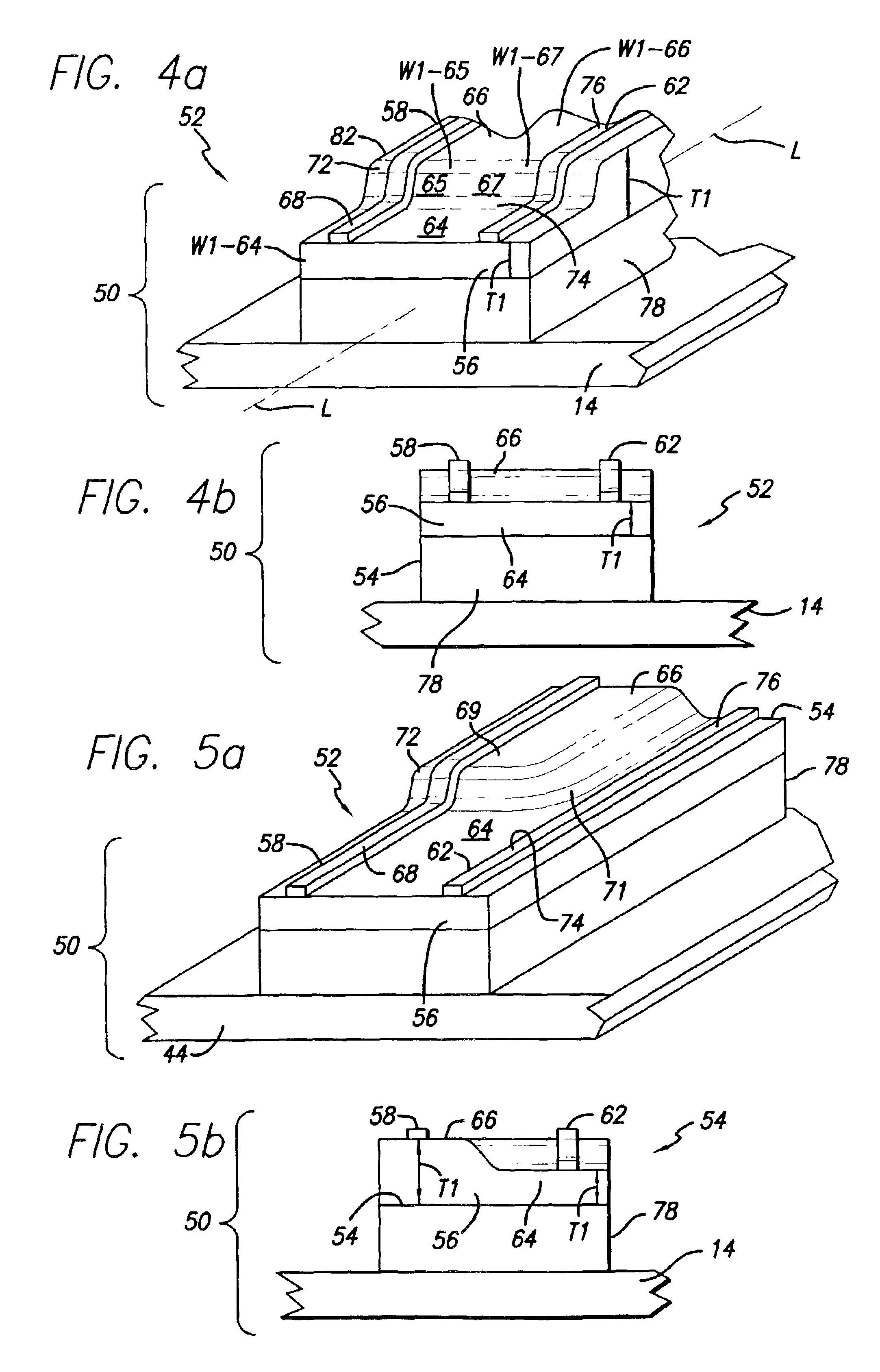

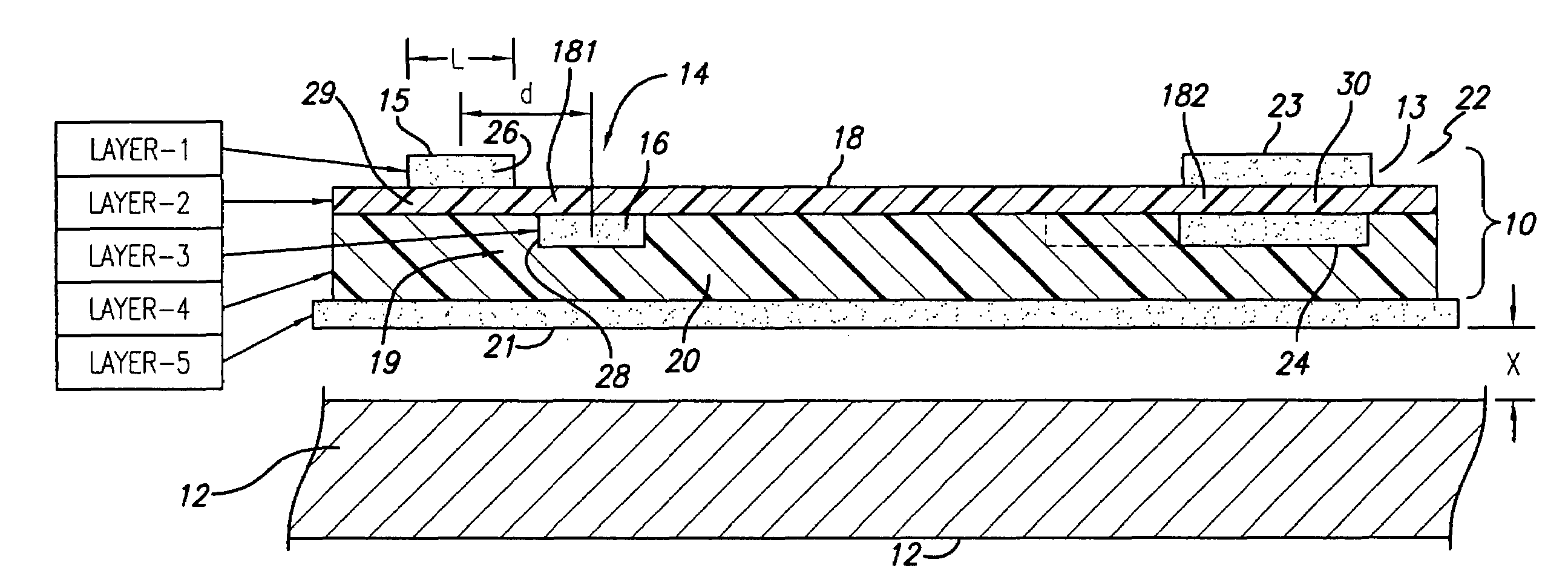

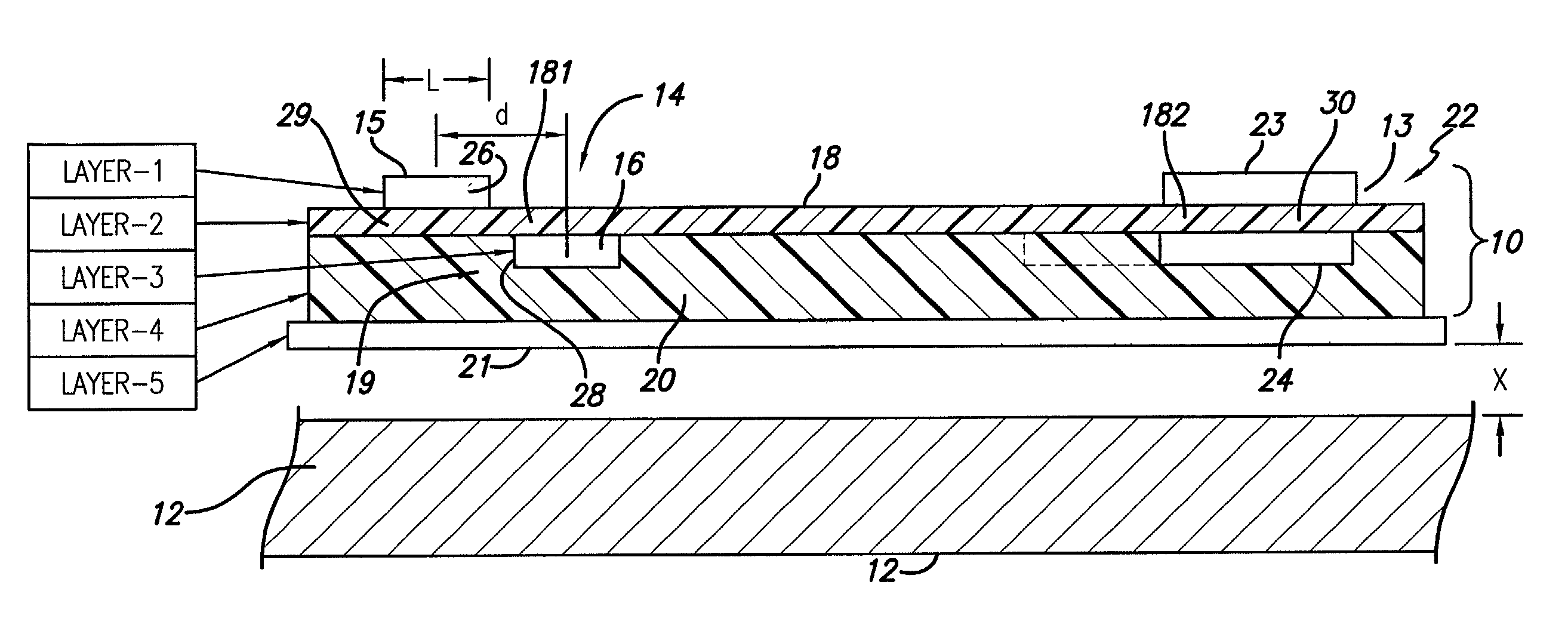

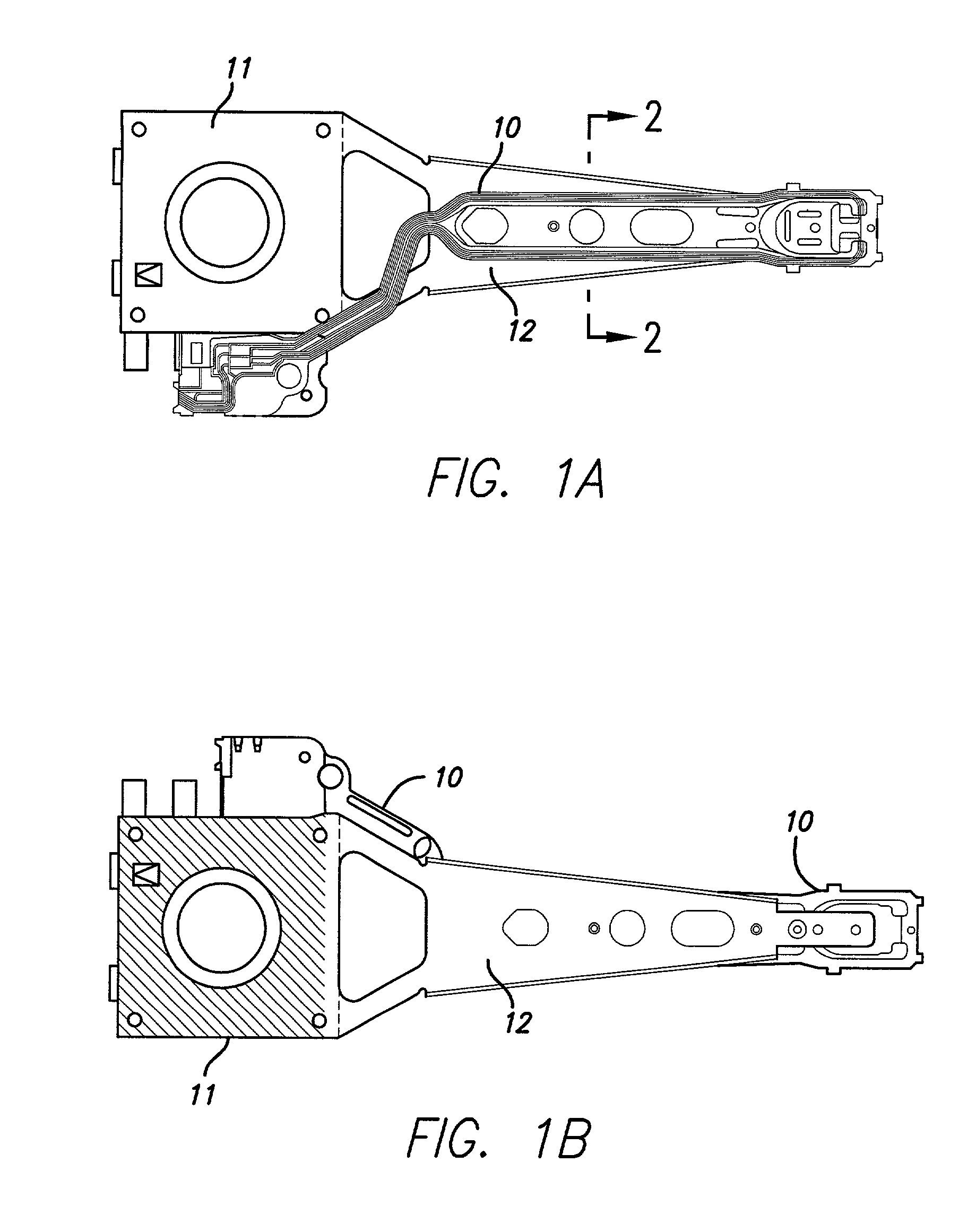

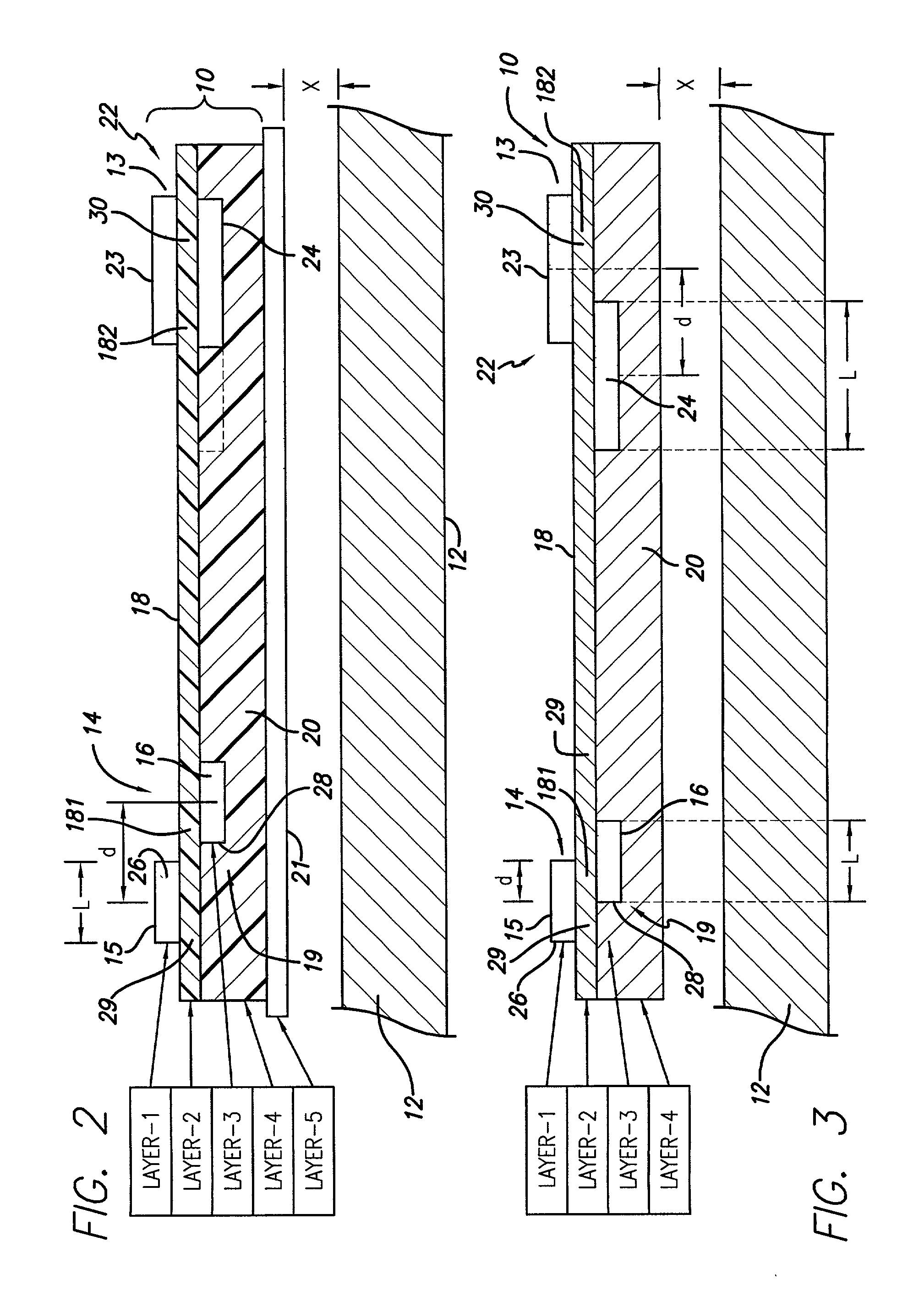

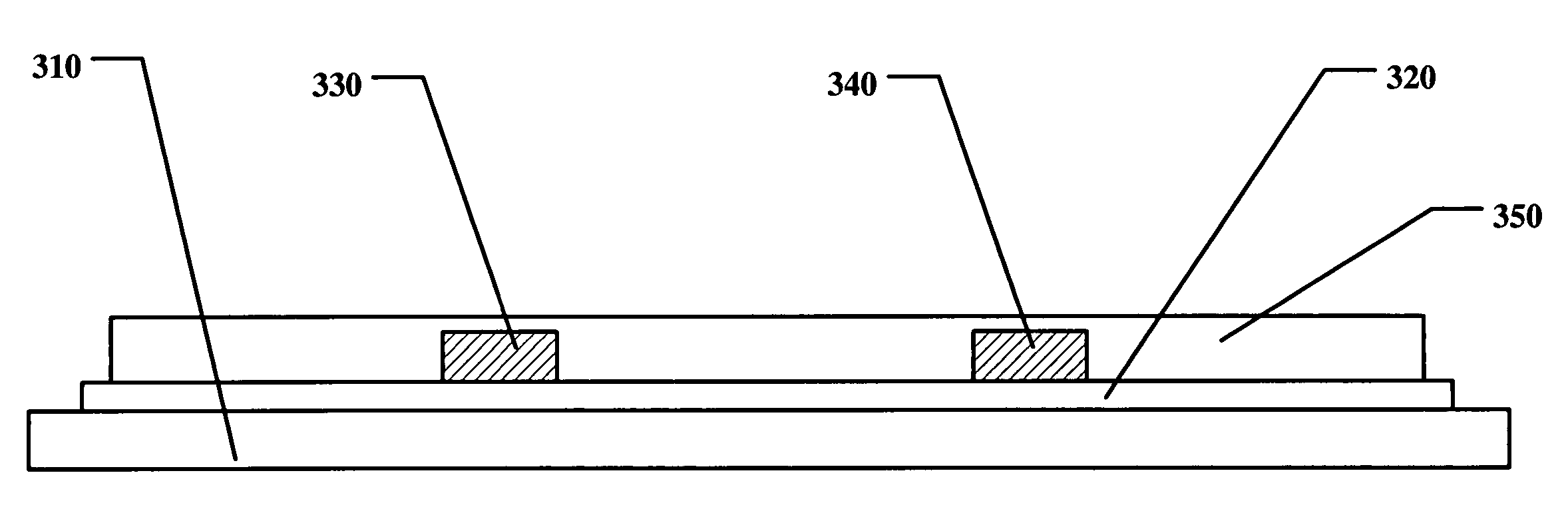

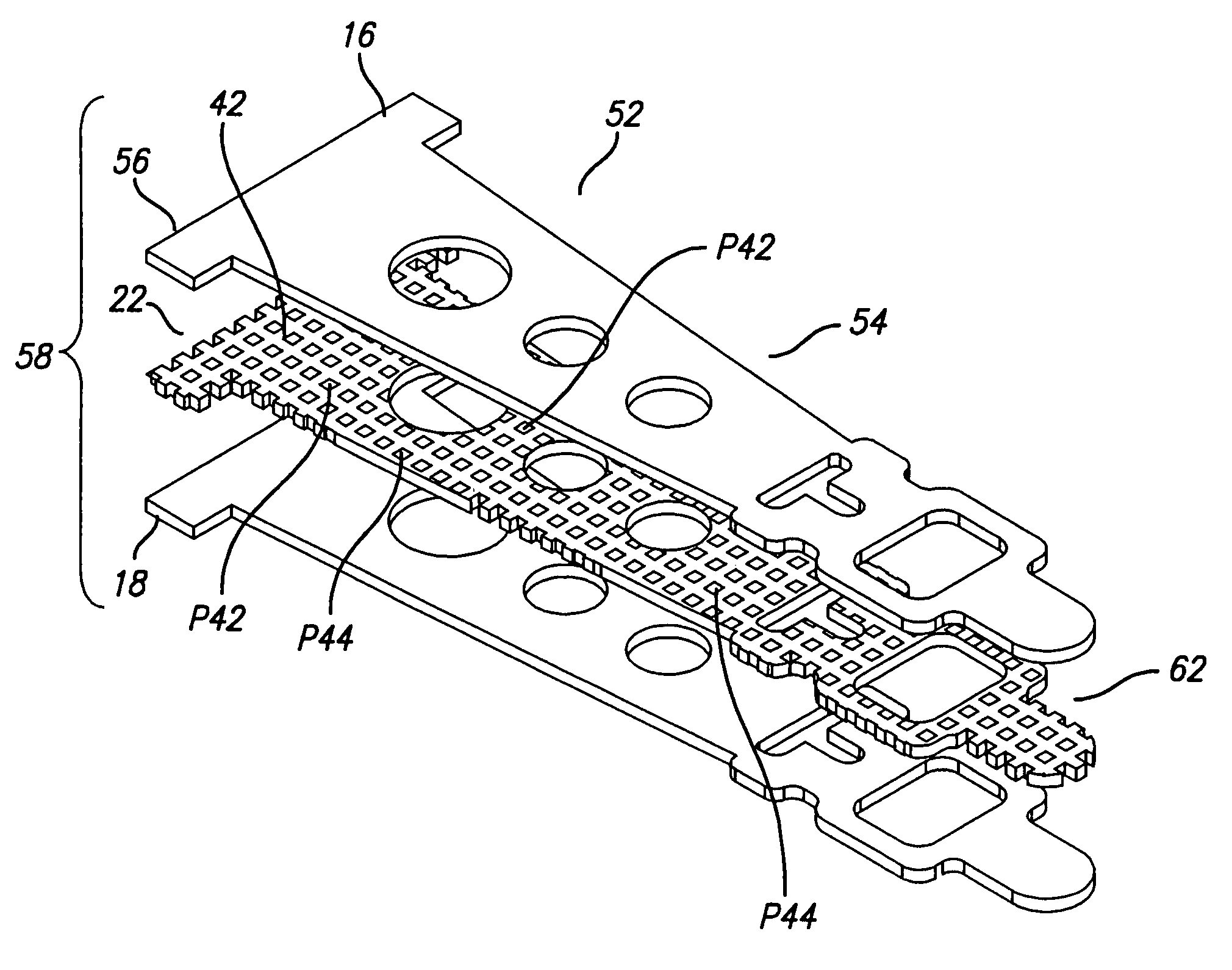

Multi-layer ground plane structures for integrated lead suspensions

ActiveUS7929252B1Additive manufacturing apparatusHigh frequency circuit adaptationsStructure of the EarthGround plane

Multi-layer ground plane structures and methods of manufacture for integrated lead suspension flexures. A flexure in accordance with one embodiment of the invention includes an insulating layer, a plurality of traces on the insulating layer and a stainless steel base layer on the side of the insulating layer opposite the traces. The stainless steel base layer includes one or more void portions with voids in the base layer opposite the insulating layer from the traces and one or more backed portions with the base layer backing the traces. A plurality of patterned and transversely-spaced first conductive ground planes are located opposite the insulating layer from the traces at the void portions and backed portions of the stainless steel base layer. A continuous gold second conductive ground plane is located opposite the insulating layer and the first ground planes from the side of the insulating layer adjacent to the traces at the void portions and backed portions of the stainless steel base layer. The gold ground plane can be used as an etch stop during formation of the voids in the base layer.

Owner:HUTCHINSON TECH

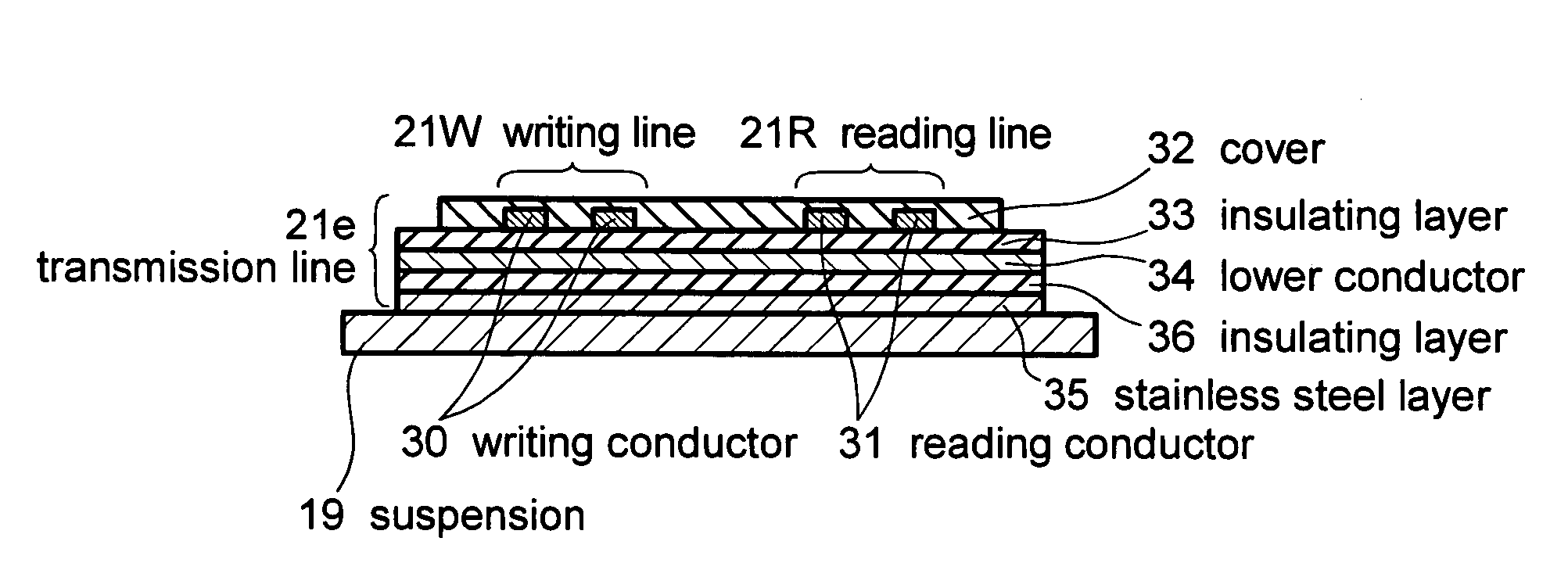

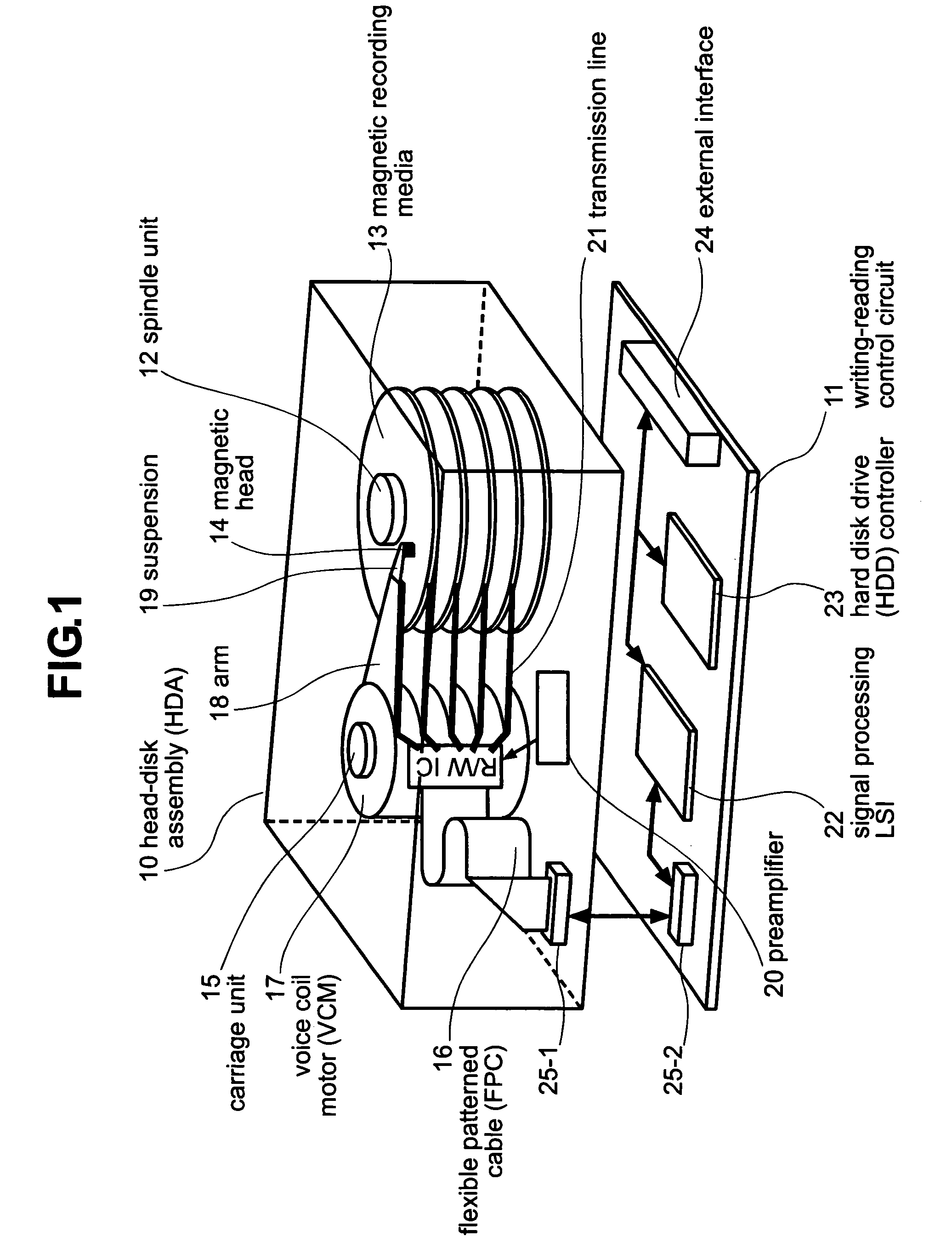

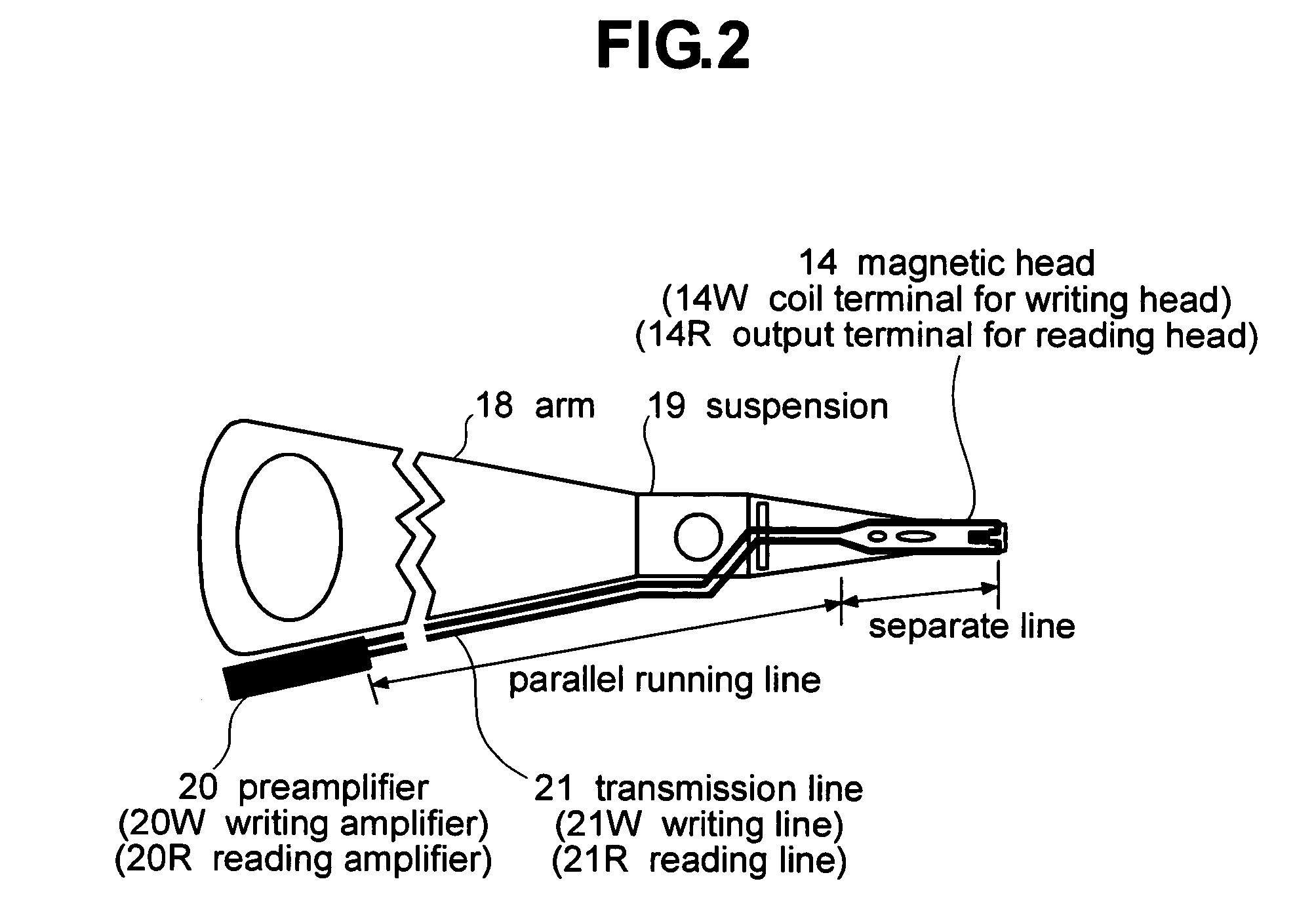

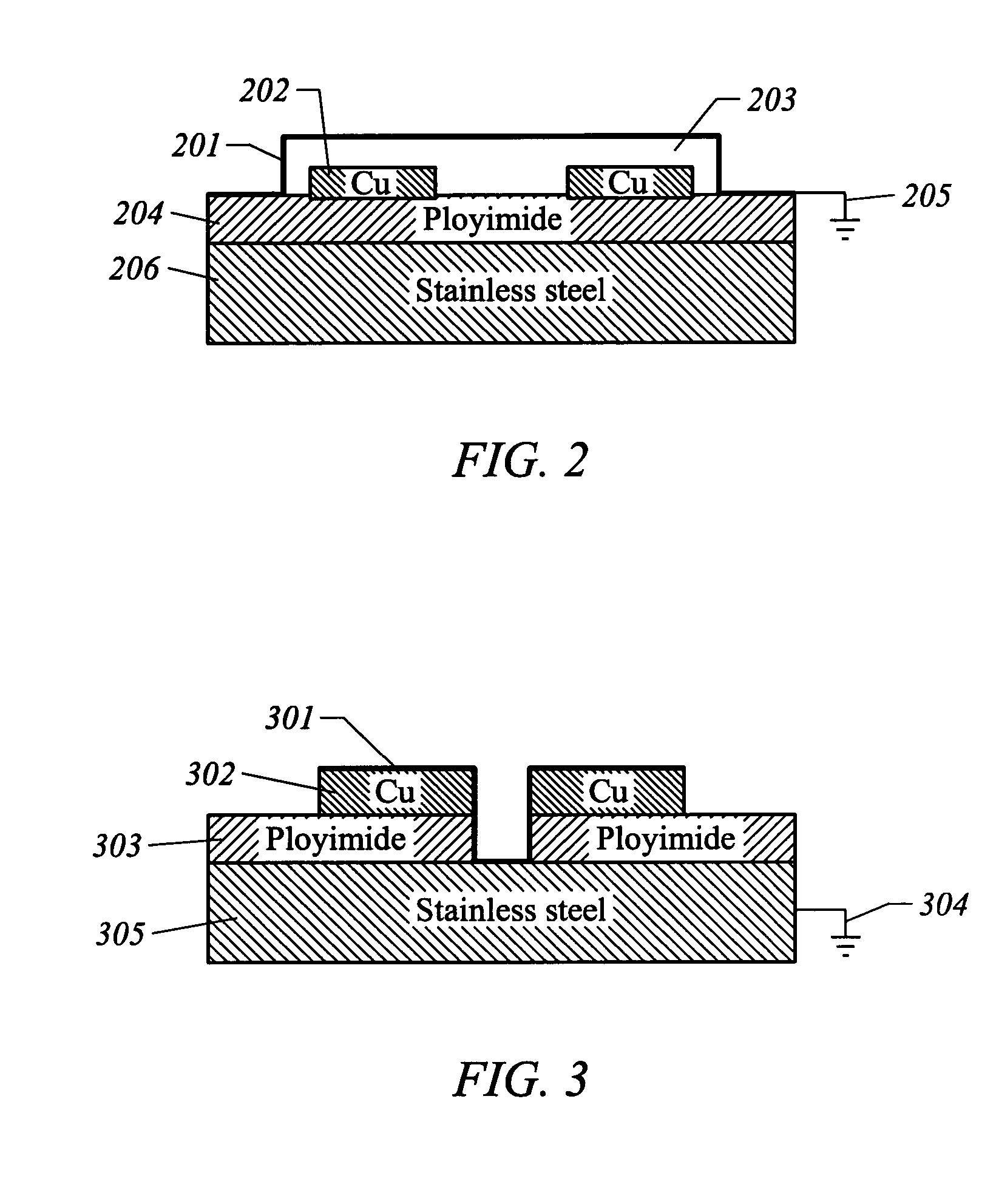

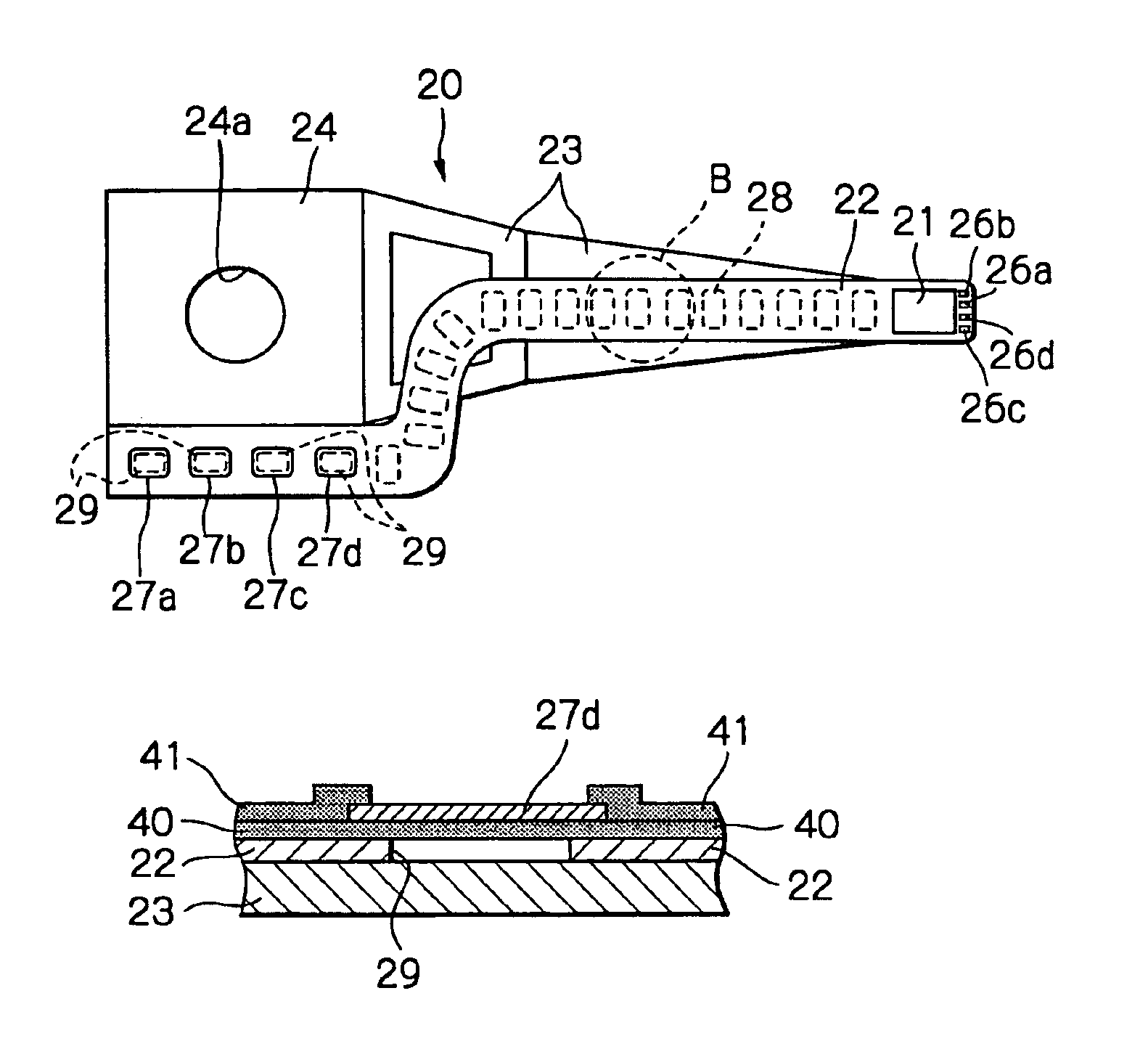

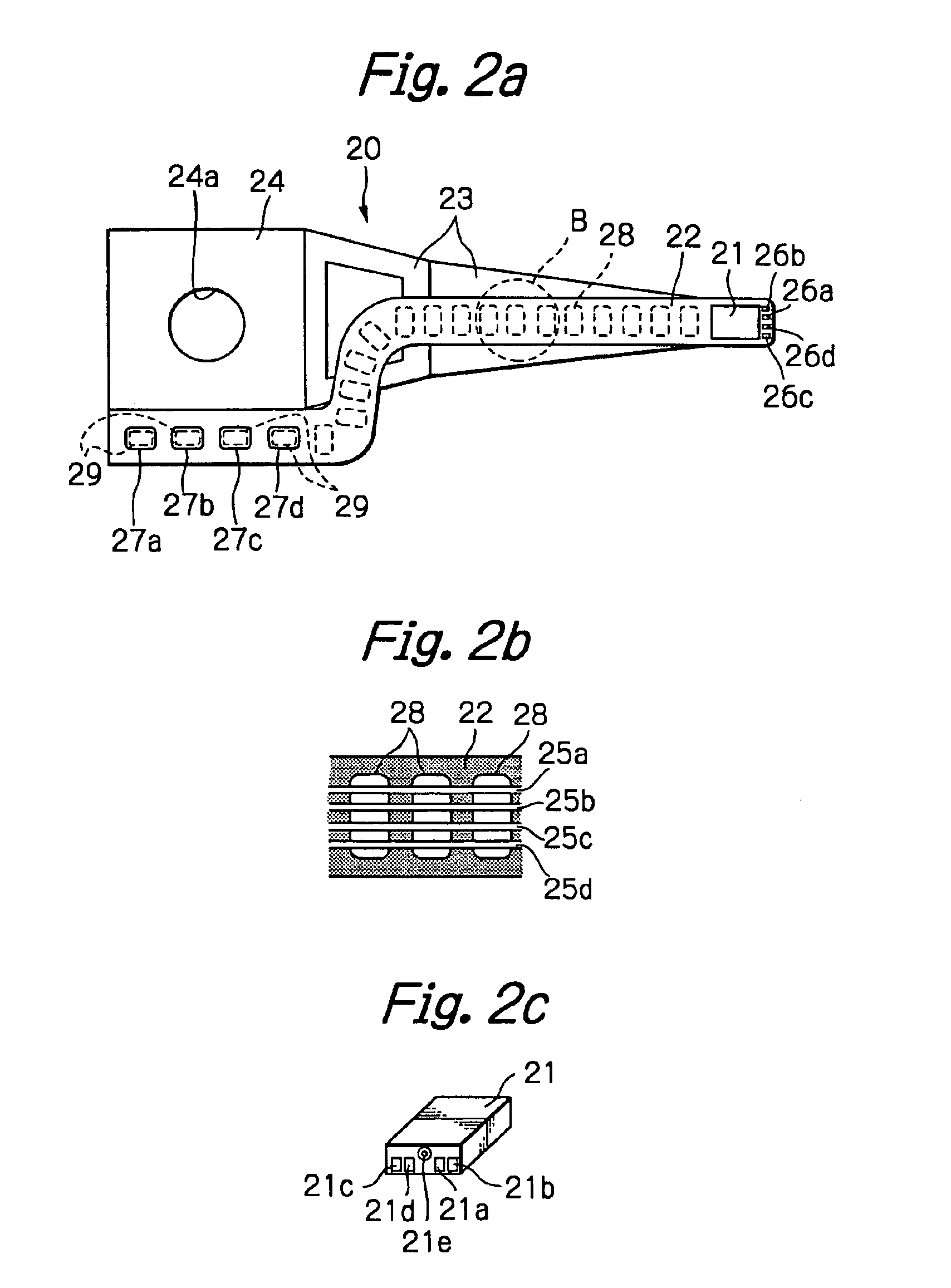

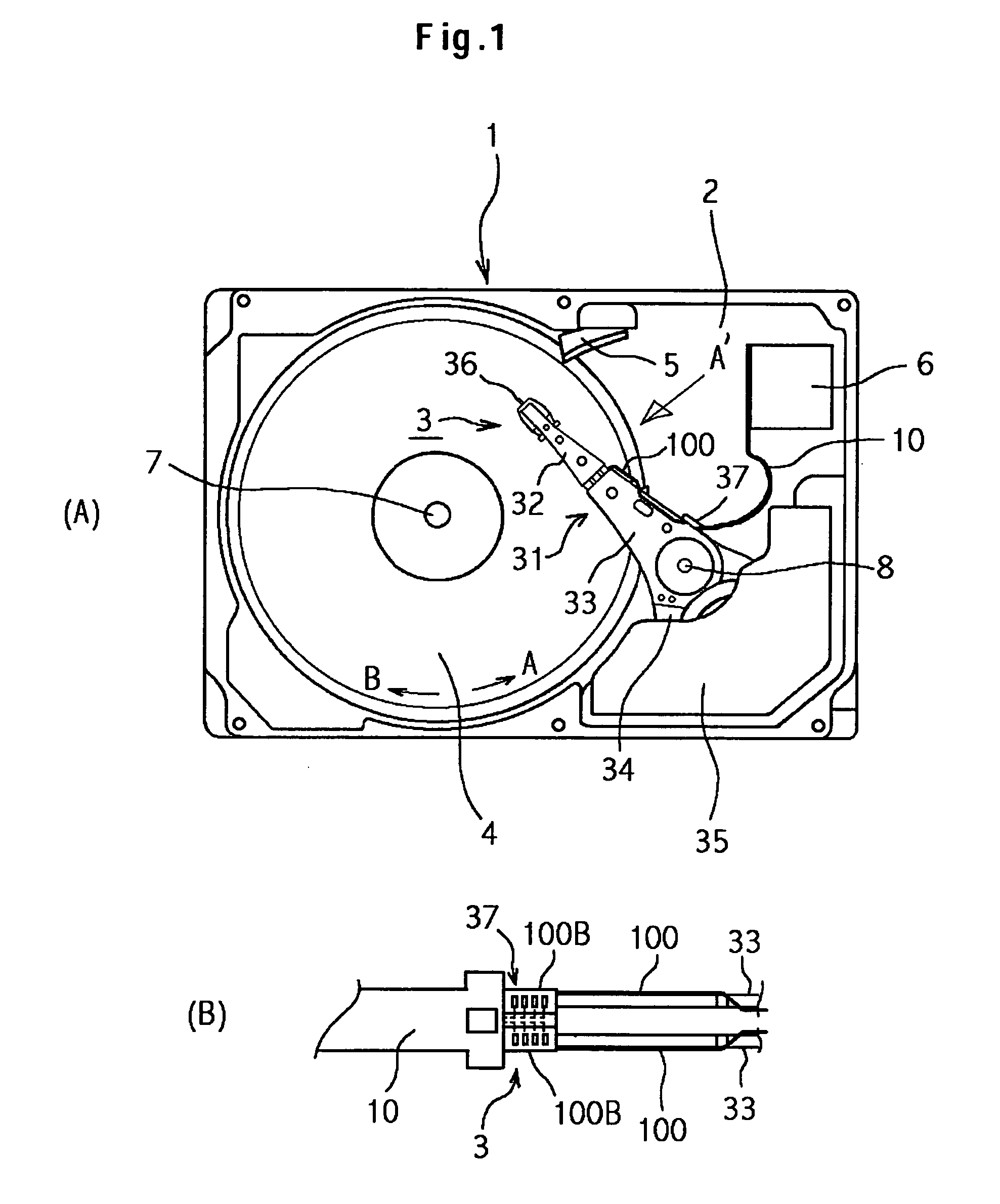

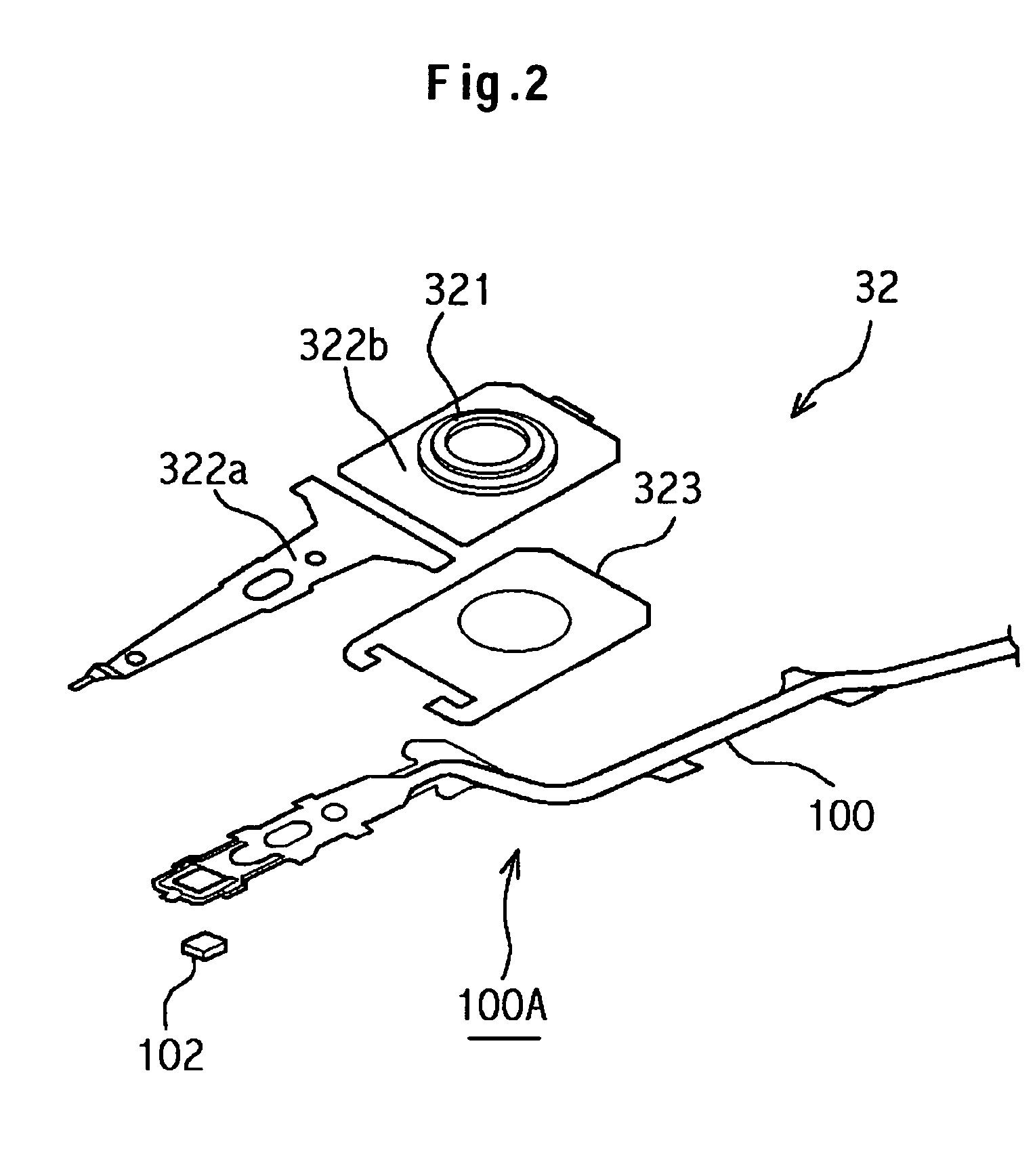

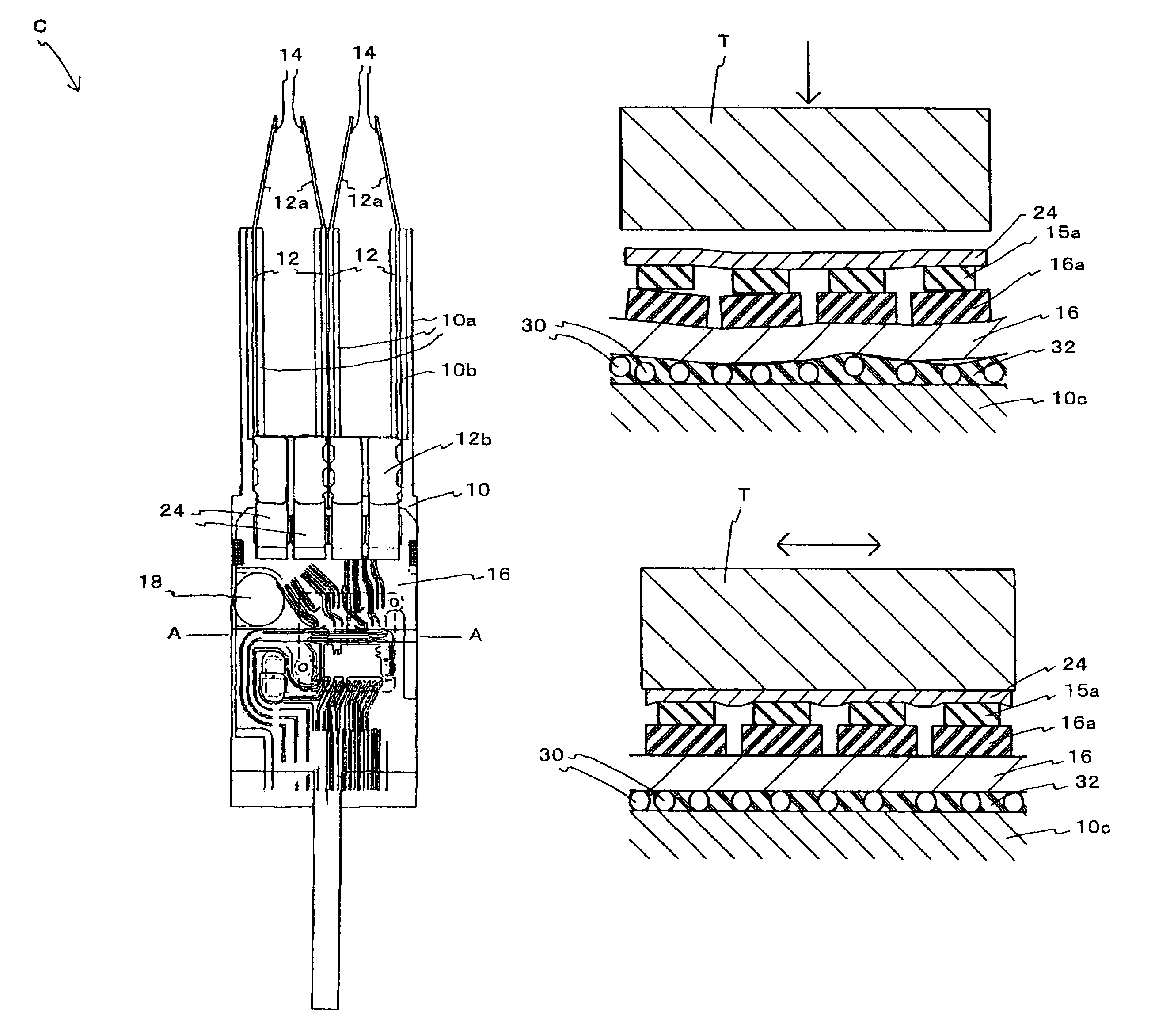

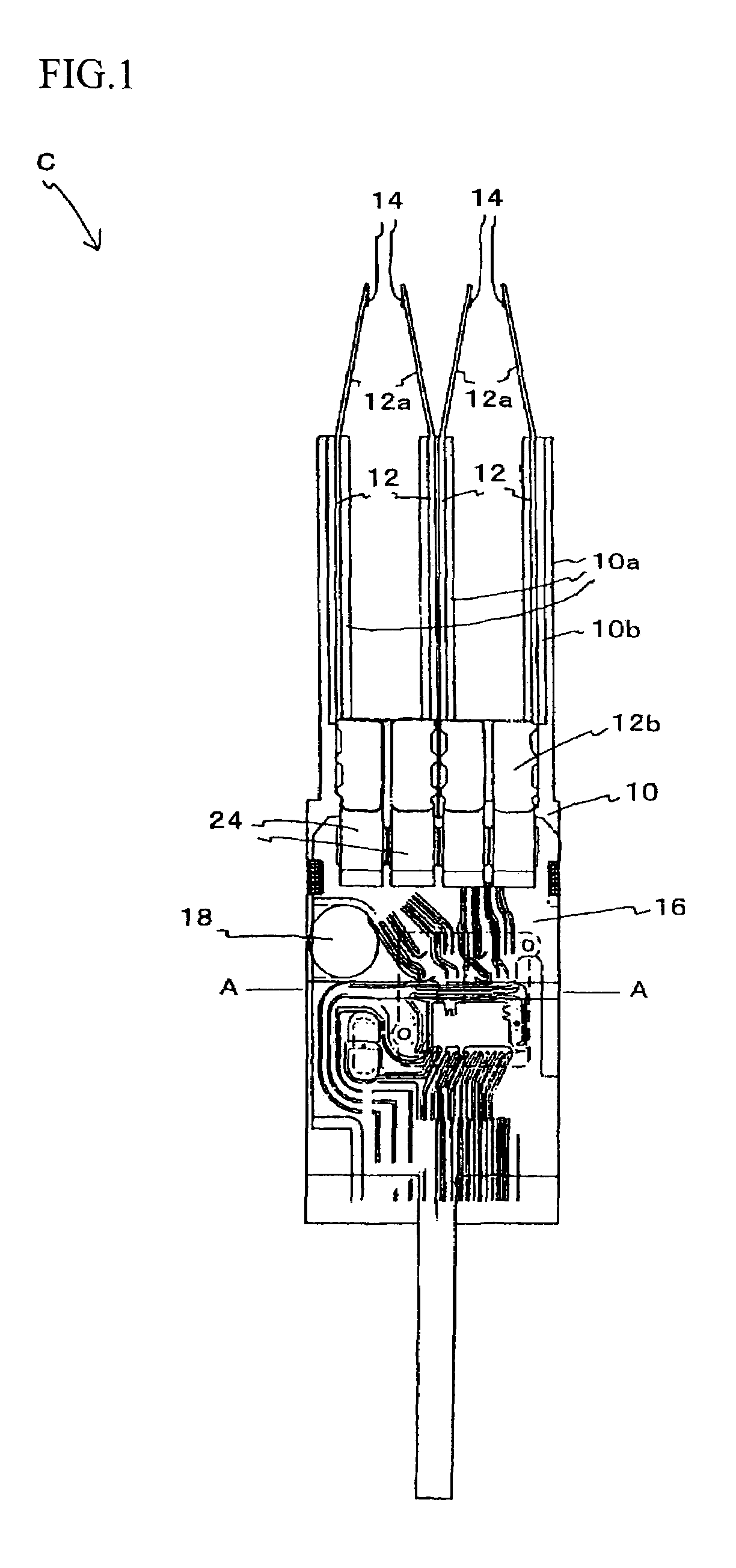

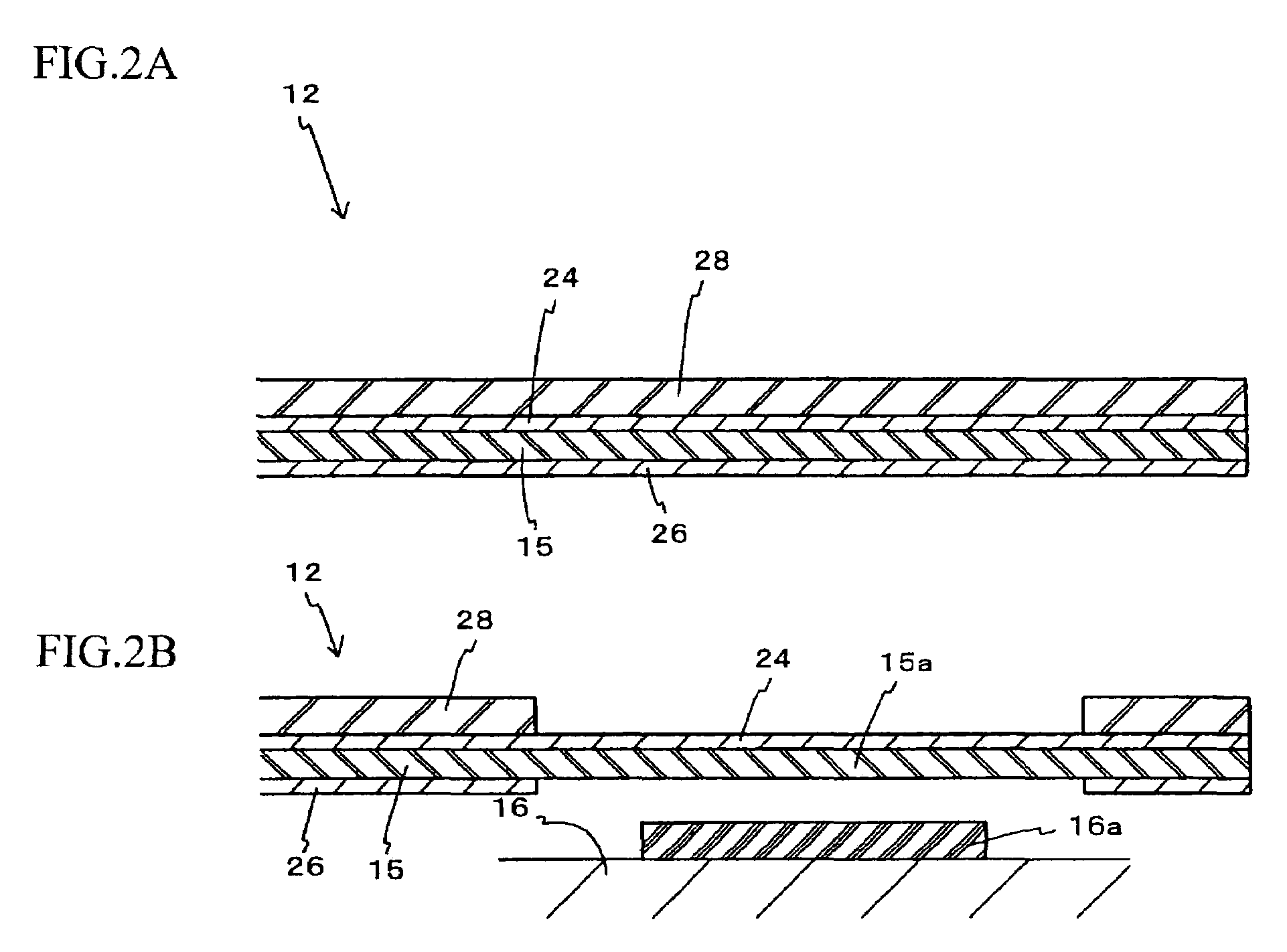

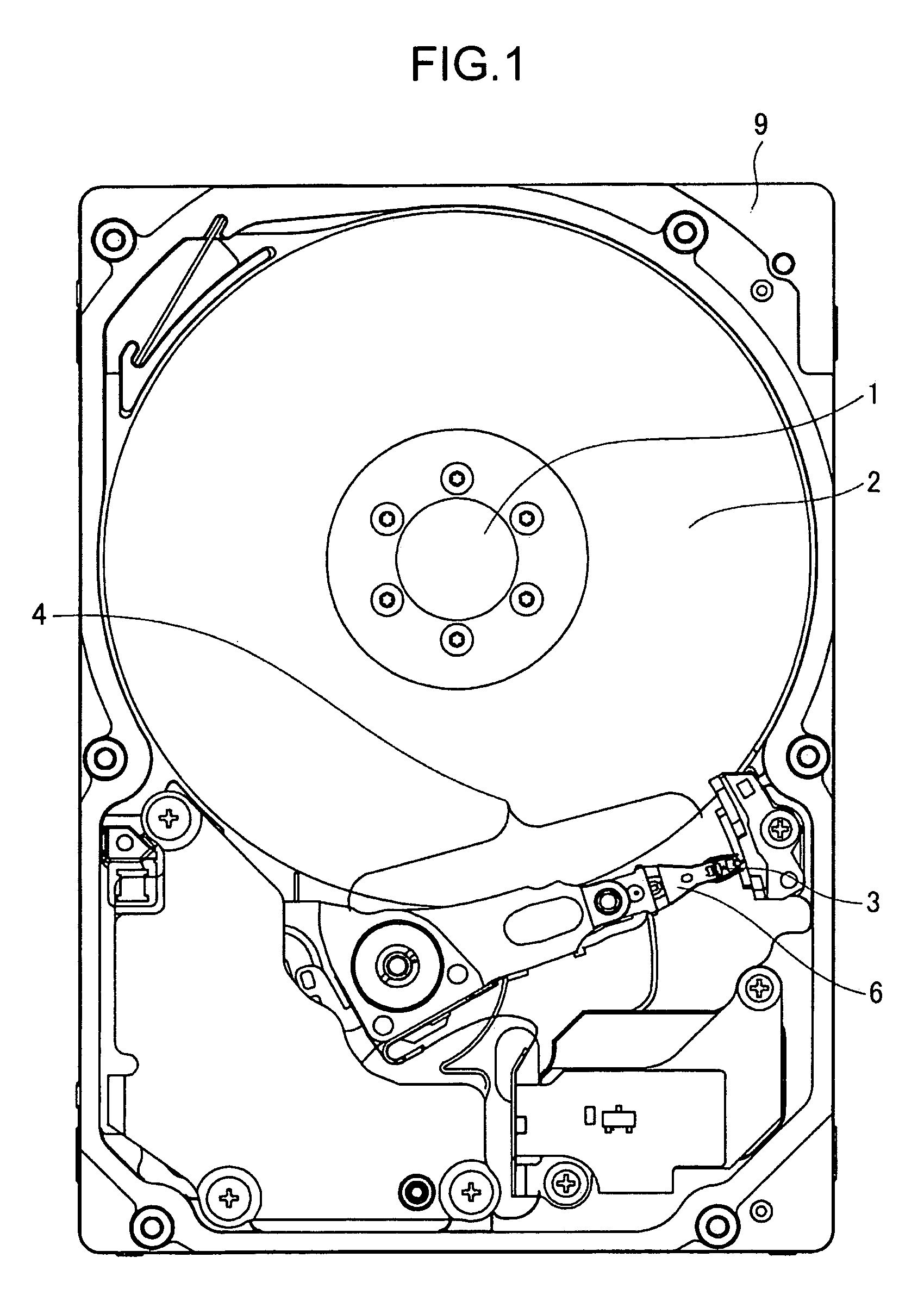

Magnetic disk drive having a suspension mounted transmission line including read and write conductors and a lower conductor

InactiveUS7319573B2Improve electrical performanceReduce transmission lossElectrotherapyMagnetotherapy using coils/electromagnetsElectrical conductorAlloy

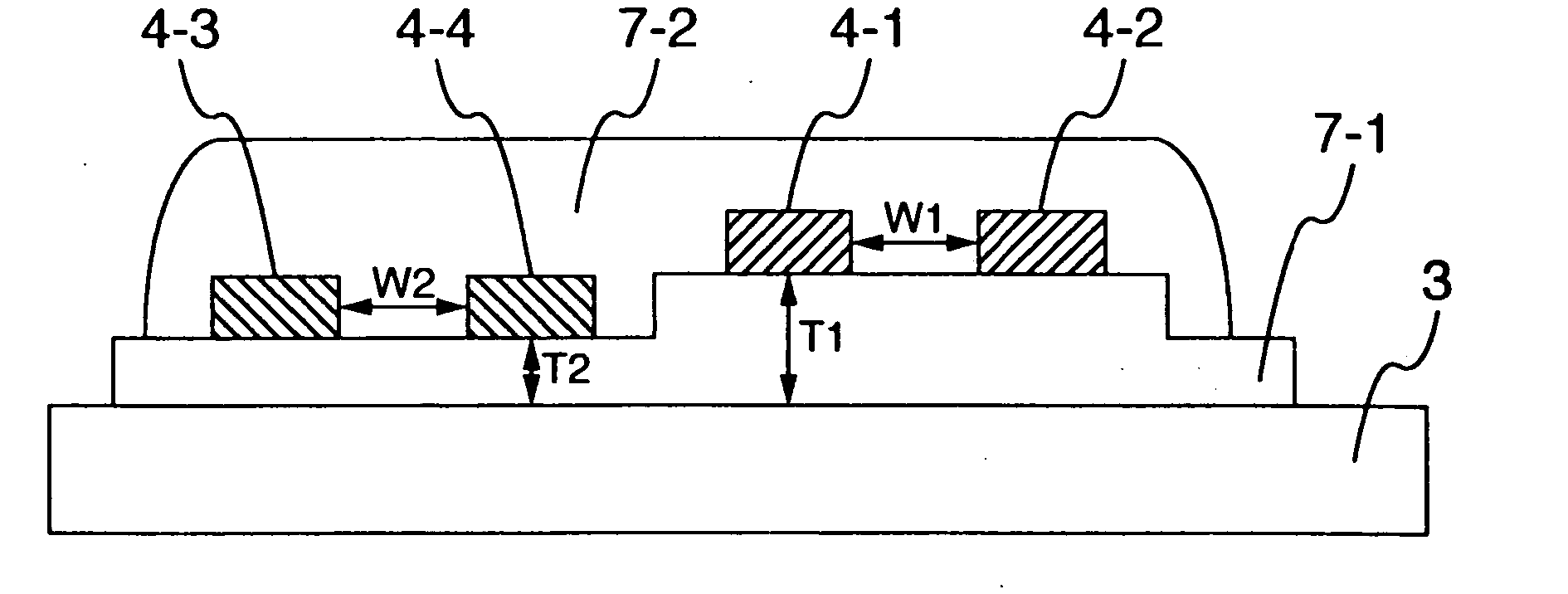

Embodiments of the invention provide a magnetic disk drive which has improved electrical properties owing to a reduction in the loss of transmission line, improved vibration properties owing to a reduction in the stiffness of wiring around the head, and a flat impedance in the transmission line. In one embodiment, a magnetic disk drive comprises a suspension; a magnetic head coupled with the suspension and configured to write and read information to and from a magnetic recording medium; and a transmission line disposed on the suspension to transmit writing and reading information to and from the magnetic head. The transmission line includes a writing line and a reading line, a lower conductor disposed underneath the writing line and the reading line, and an insulating layer interposed between the lower conductor and the writing and reading lines. The lower conductor comprises copper or copper-based alloy and has a thickness of substantially less than 25 μm, desirably about 2-12 μm, and more desirably about 5 μm.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

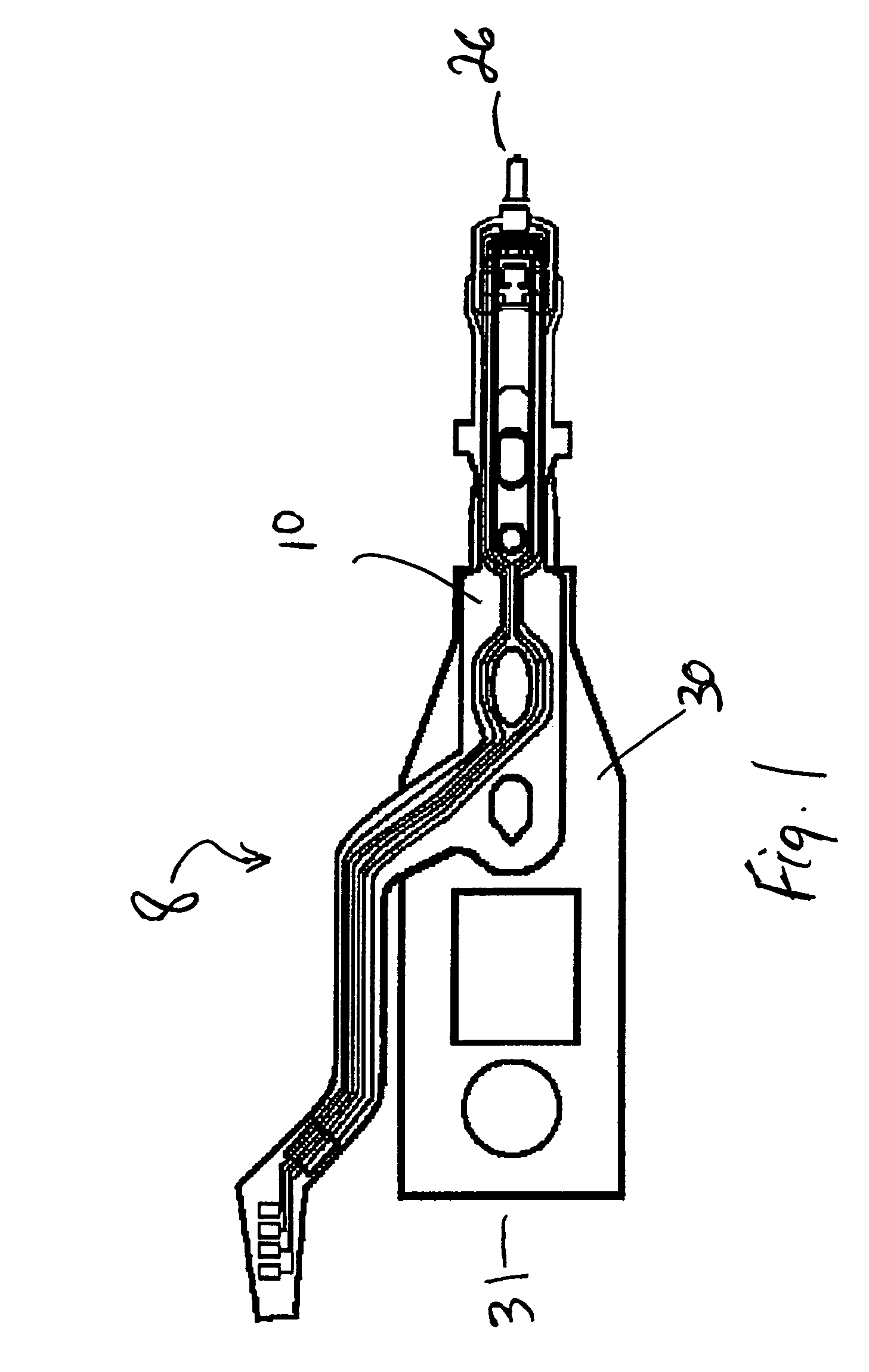

Method for making noble metal conductive leads for suspension assemblies

A method of manufacturing an integrated lead head suspension flexure of the type having conductors on a spring metal layer capable of being etched by a first etching process. The method includes forming a patterned layer having gaps one or more flying lead regions of dielectric material on a major surface of the spring metal layer and forming one or more conductive leads on the flexure, including onto the dielectric material and over exposed spring metal at the gap at each flying lead region. At least the flying lead portion of the conductive lead is formed from conductive material resistant to the first etching process. The method also includes etching a flying lead region of the spring metal layer to remove a portion of the spring metal layer in the flying lead region and expose the flying lead portions of the conductive lead.

Owner:HUTCHINSON TECH

Trace flexure suspension with differential insulator and trace structures for locally tailoring impedance

InactiveUS6900967B1Easy to controlUniform impedanceRecord information storageRecording/reproducing/erasing methodsCapacitanceElectrical conductor

A novel flexure or interconnect for a disk drive suspension having a locally different thickness and / or width of insulative layer and a locally different thickness, width and / or relative spacing in its trace conductors to vary capacitance and circuit impedance values accordingly to locally desirable different and optimum values for the type of circuit and the suspension features.

Owner:MAGNECOMP

Method to form electrostatic discharge protection on flexible circuits

ActiveUS20050117257A1Avoid noisePreventing ESD damageSubstation/switching arrangement detailsRecord information storageFlexible circuitsIon deposition

Techniques for preventing electrostatic discharge (ESD) and circuit noise are provided. More particularly, the present invention provides a method to prevent ESD damage during the assembly of computer disk commonly called a hard disk for memory applications. The coating mainly involves a ion-deposition process. Merely by way of example, the present invention is implemented by using filtered cathodic vacuum arc (FCVA) with a dissipative crystalline and / or amorphous carbon base thin film coating on a flexible circuit to drain the potential electrostatic charges during circuit assembly and interconnect processes, yet it would be recognized that the invention has a much broader range of applicability on any electronic apparatus that is susceptible to electrostatic damage and static noise.

Owner:MAGNECOMP

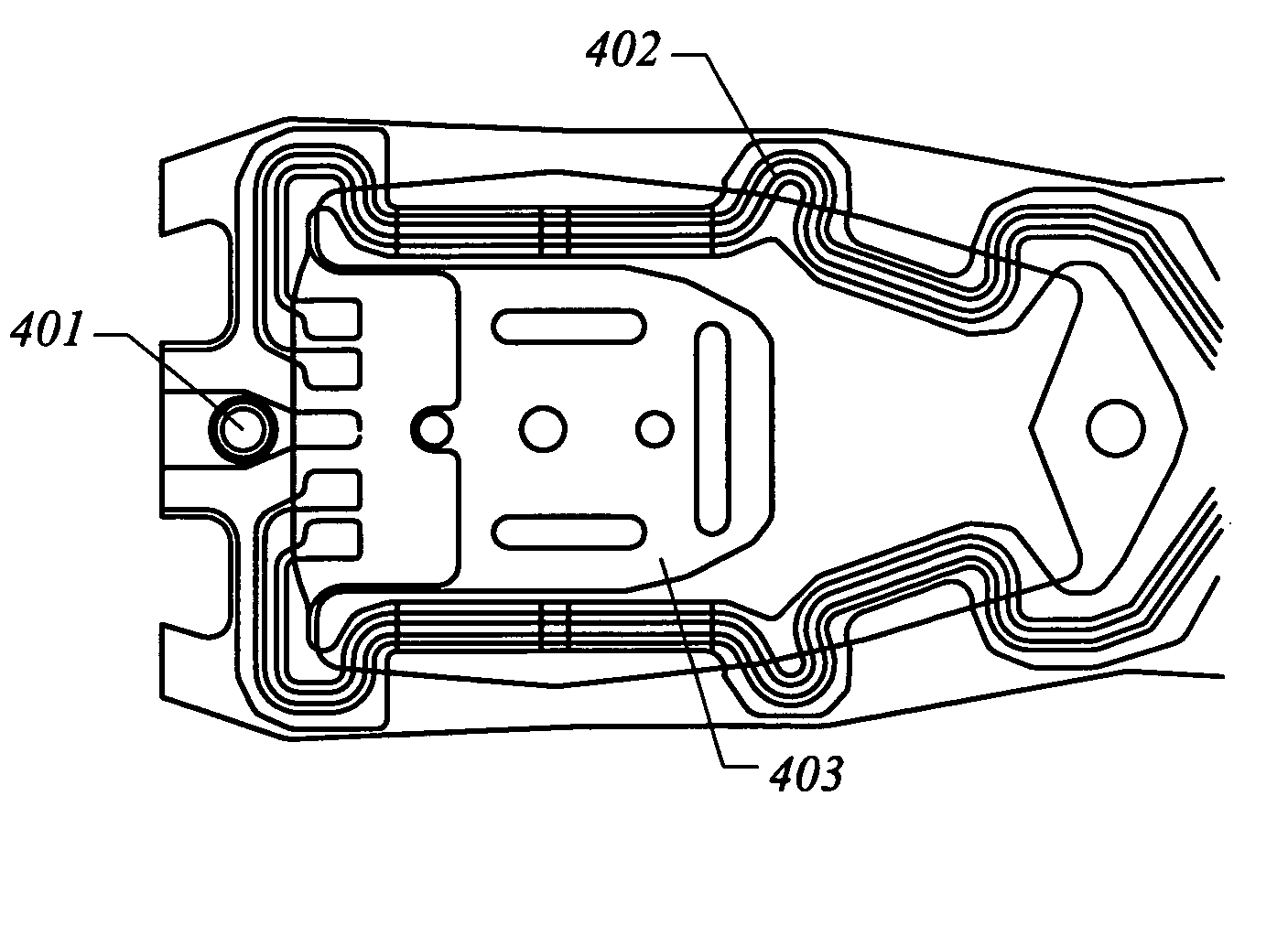

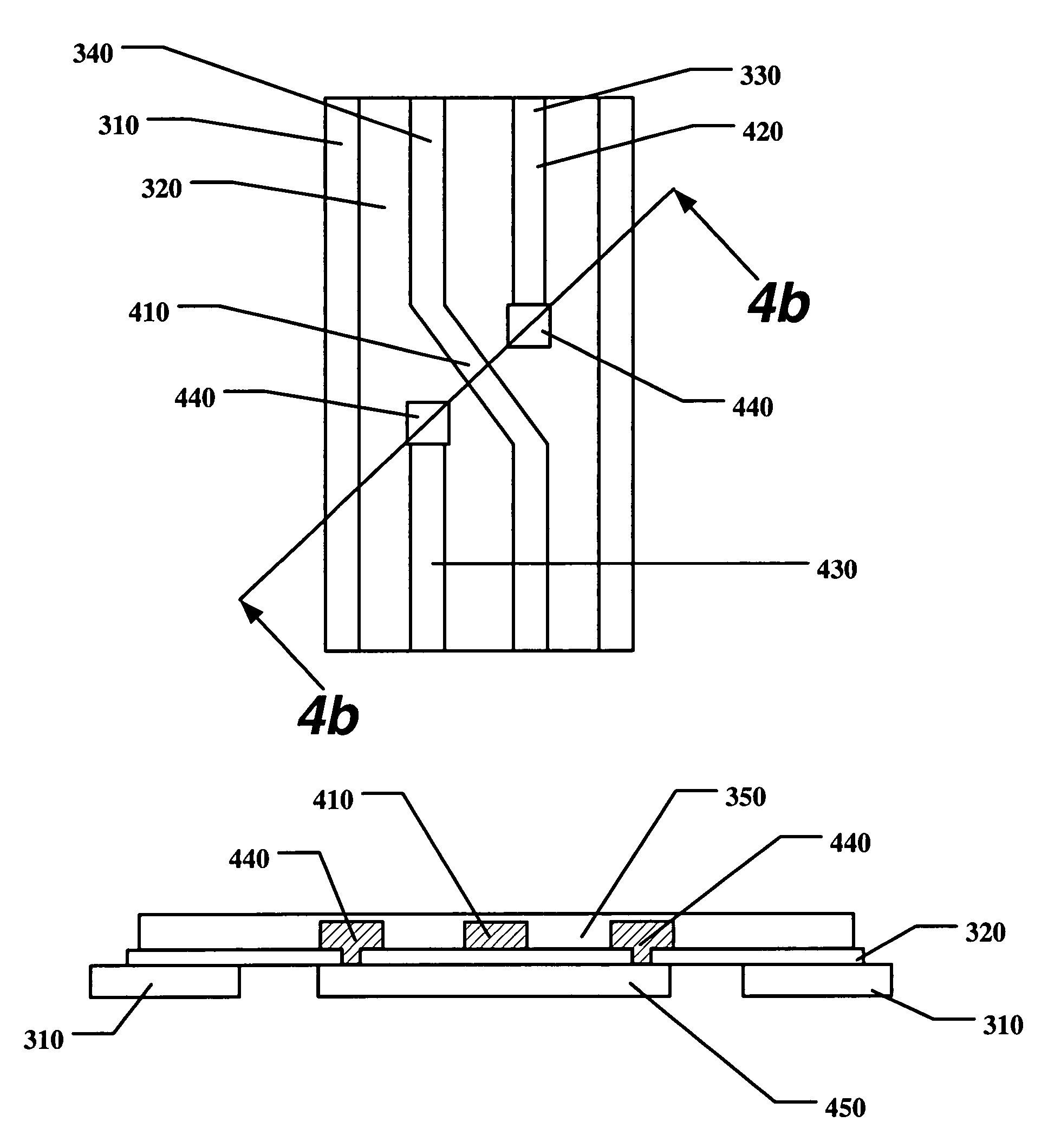

Additive-process suspension interconnect with controlled noise

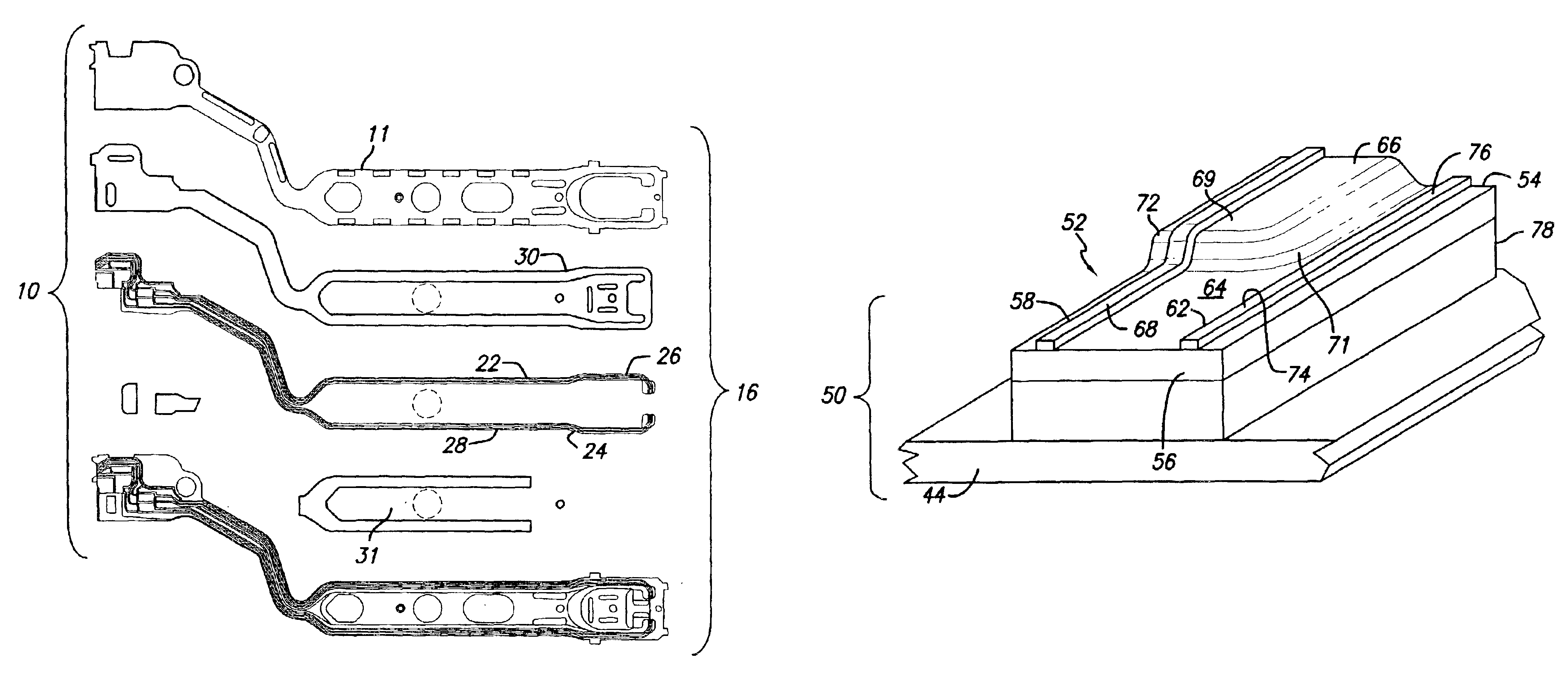

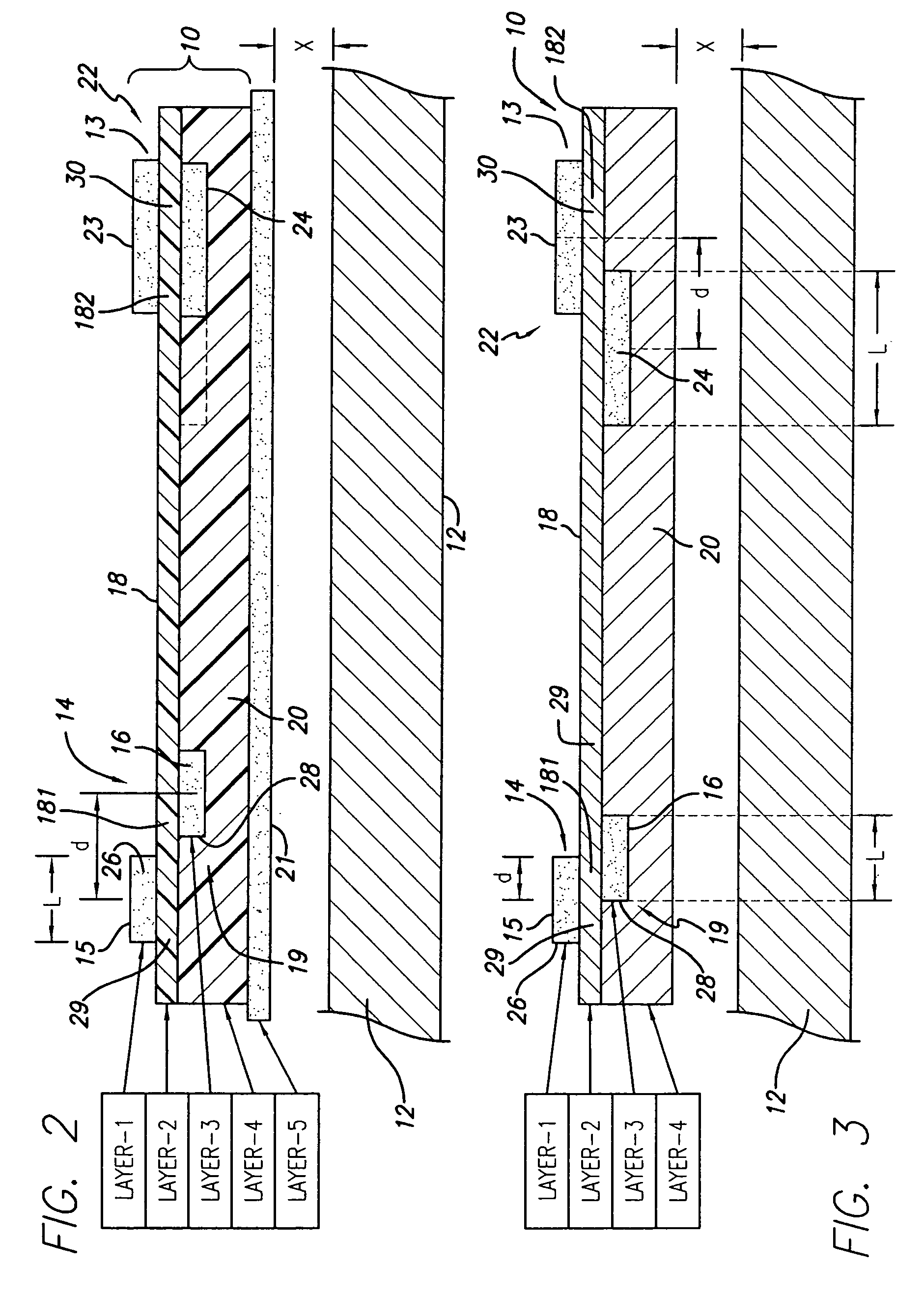

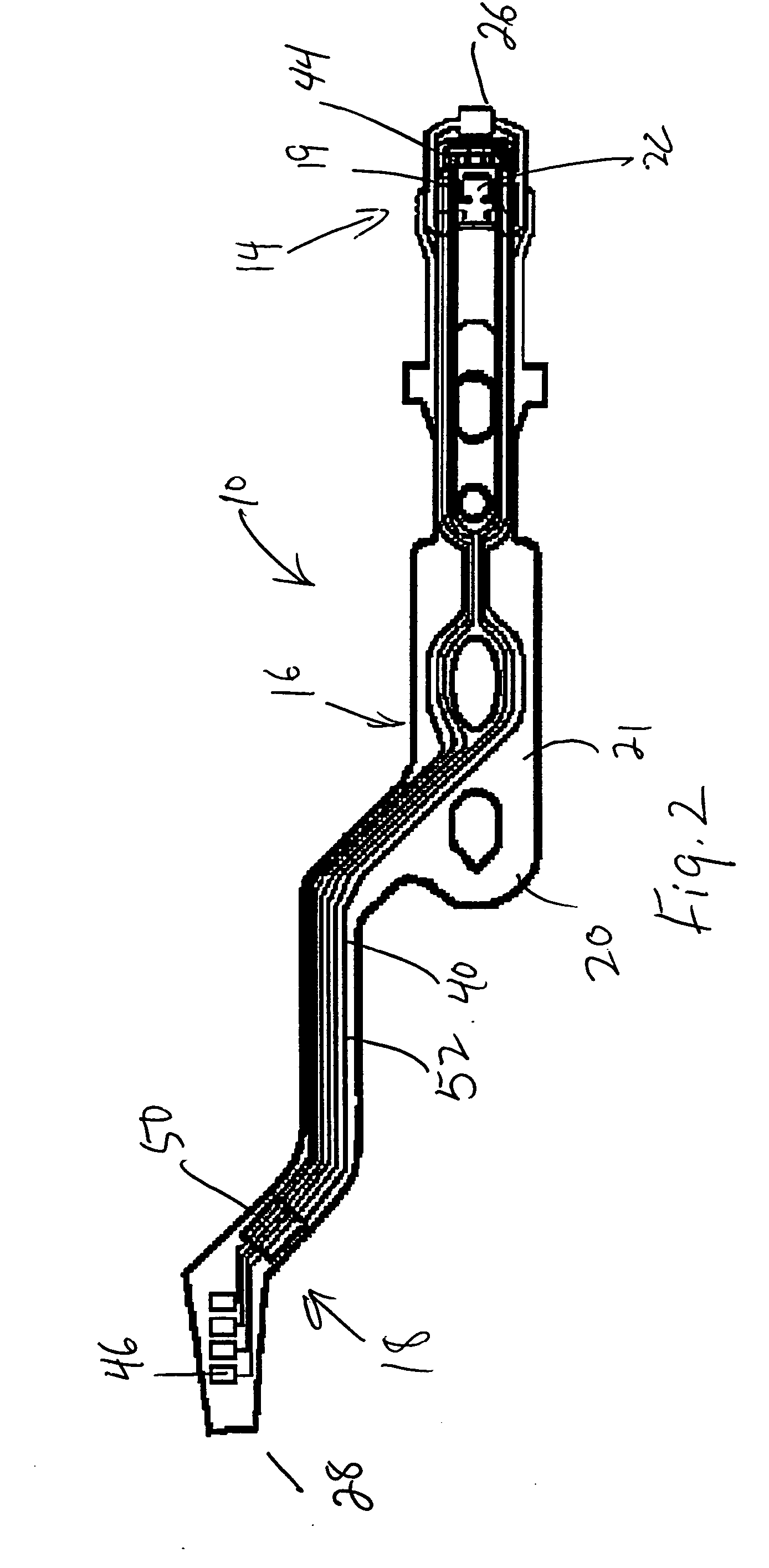

InactiveUS7079357B1Increase electrical couplingLess sensitiveRecord information storageStructure of arm assemblyAdditive processElectrical interconnect

A disk drive electrical interconnect assembly and additive method therefor. The interconnect assembly has a supporting or fifth layer of metal, a fourth layer of a polyimide precursor or a polyimide with a first face directed away from the fifth layer, a third layer directly attached to the first face and defining a first subset of one or more conductive trace pair members, a second layer on the third and fourth layers of a polyimide precursor or a polyimide with a second face directed away from the third layer, and a first layer directly attached to the second layer and defining a second subset of one or more conductive trace pair members in spaced, paired and laterally offset relation respectively with one or more of the first subset pair members.

Owner:MAGNECOMP

Method for making noble metal conductive leads for suspension assemblies

ActiveUS20050254175A1Printed circuit aspectsRecord information storageConductive materialsMetallic Lead

A method of manufacturing an integrated lead head suspension flexure of the type having conductors on a spring metal layer capable of being etched by a first etching process. The method includes forming a patterned layer having gaps one or more flying lead regions of dielectric material on a major surface of the spring metal layer and forming one or more conductive leads on the flexure, including onto the dielectric material and over exposed spring metal at the gap at each flying lead region. At least the flying lead portion of the conductive lead is formed from conductive material resistant to the first etching process. The method also includes etching a flying lead region of the spring metal layer to remove a portion of the spring metal layer in the flying lead region and expose the flying lead portions of the conductive lead.

Owner:HUTCHINSON TECH

Suspension interconnect with controlled noise

InactiveUS6975488B1Improved disk drive suspensionIncrease electrical couplingCross-talk/noise/interference reductionPrinted circuit aspectsEngineeringMetal

A disk drive suspension and method has a metal load beam and an electrical interconnect assembly. The interconnect assembly has an insulative layer, a read pair of forward and return path conductive traces, a write pair of forward and return path conductive traces that are supported by the insulative layer, preferably in offset relation across the insulative layer, and a metal layer for grounding and mounted on the insulative plastic layer in fixed spaced relation to the conductive traces to be between the interconnect assembly and the load beam. The metal layer shields the conductive traces from variations in impedance occasioned by varying distances between said electrical interconnect and said load beam.

Owner:MAGNECOMP

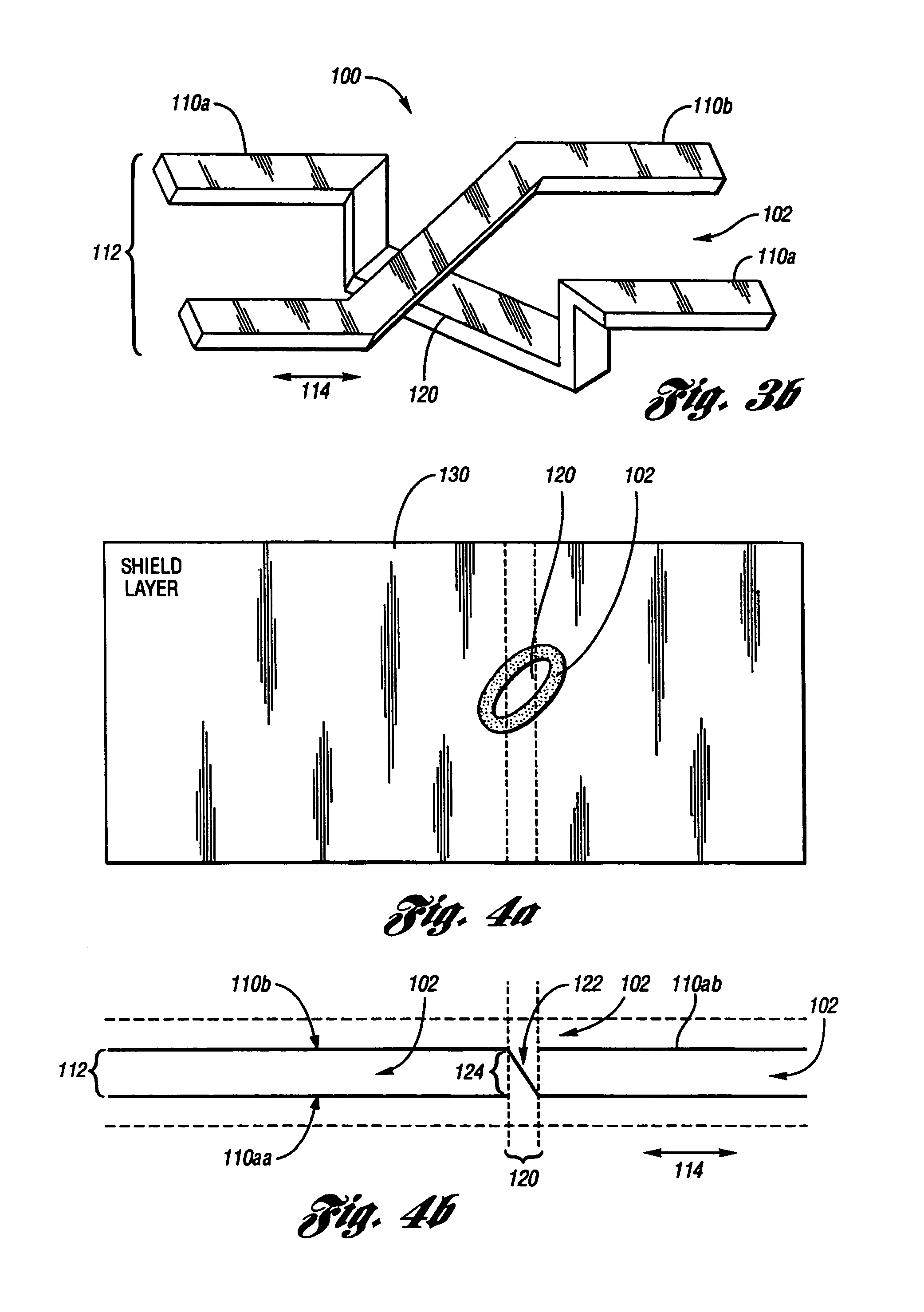

Method for providing electrical crossover in laminated structure

An externally wireless laminated suspension for a hard disk drive are disclosed. In one embodiment, the externally wireless laminated suspension has an insulating layer to electrically isolate a first and second electrical trace from a conductive support layer. The second electrical trace crosses over the first electrical trace. The first electrical trace may be made of a first part on one side of the second electrical trace and a second part on the opposite side of the electrical trace. A conductive island area may be patterned into the support layer. The conductive island area may electrically couple the first part of the first electrical trace to the second part. The number of crossover points that the first electrical trace has may equal the number of crossover points that the second electrical trace has.

Owner:HUTCHINSON TECH

Head gimbal assembly

InactiveUS6891700B2More frequencyReduce parasitic capacitanceFluid-dynamic spacing of headsRecord information storageElectrical conductorSignal trace

An HGA includes a magnetic head slider with at least one thin-film magnetic head element, a metal suspension for supporting the magnetic head slider, signal trace conductors formed via an insulation material layer on the metal suspension, for transmitting signals of the at least one thin-film magnetic head element, and external signal connection pads formed via an insulation material layer on the metal suspension and electrically connected to the signal trace conductors. At least part of the metal suspension under the external signal connection pads is removed.

Owner:TDK CORPARATION +1

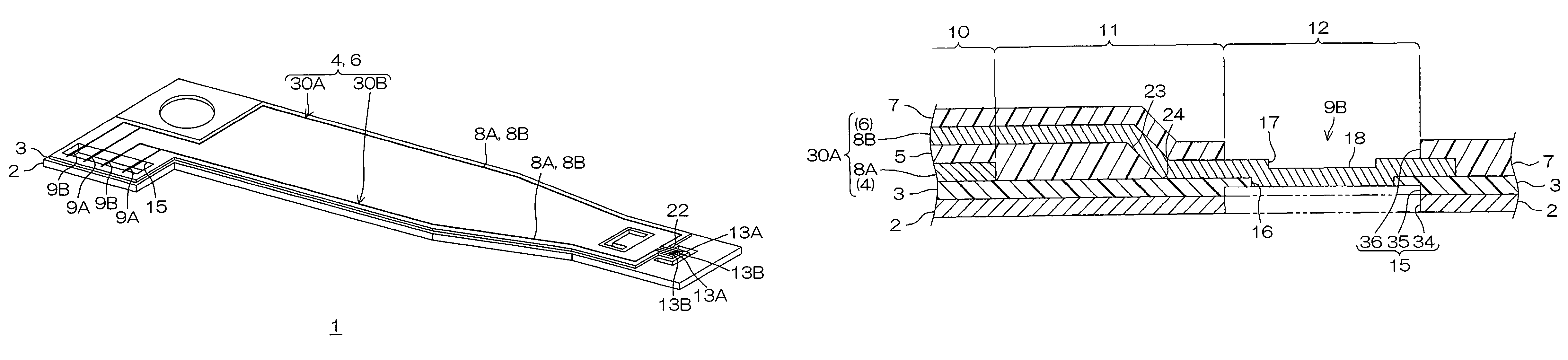

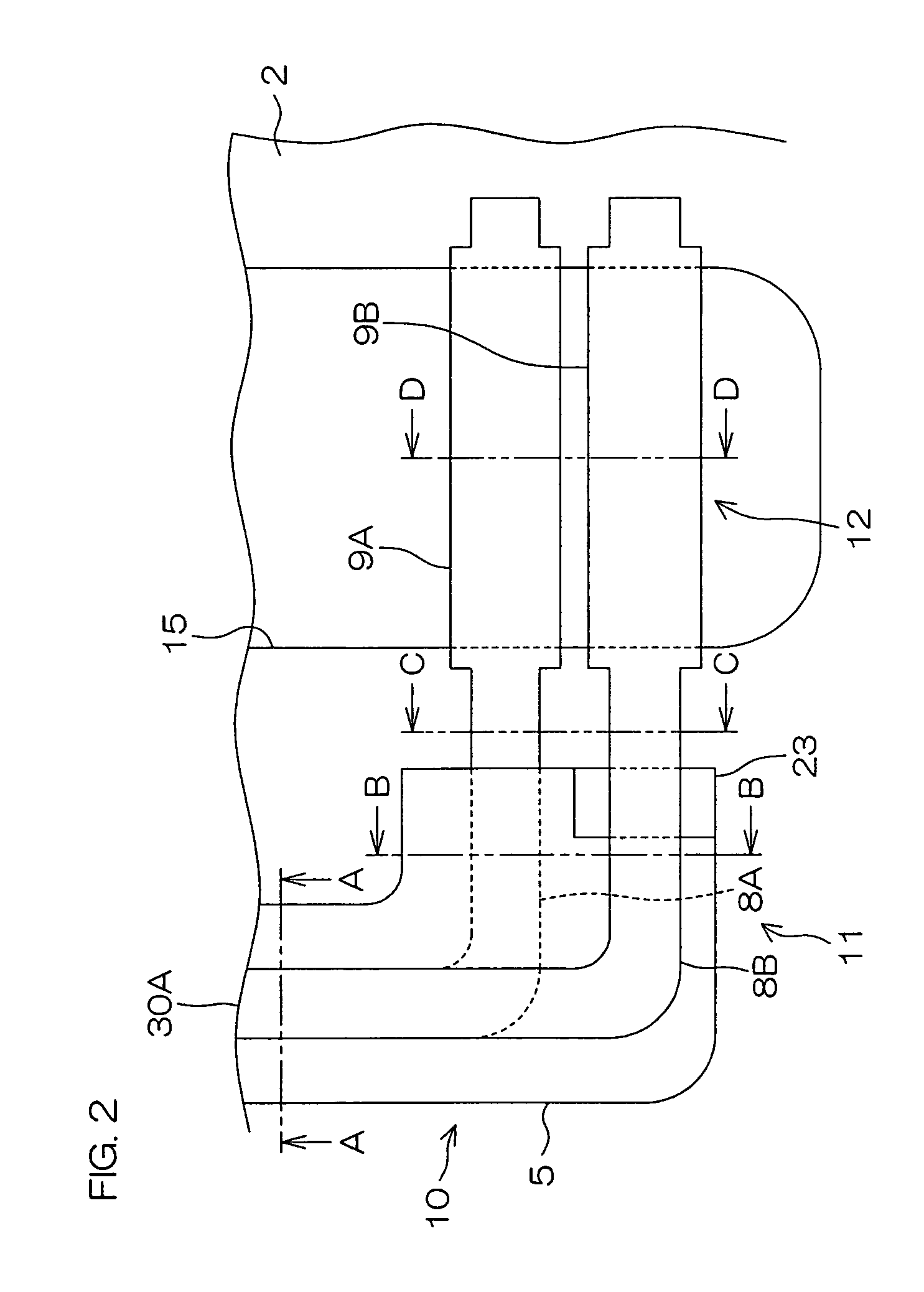

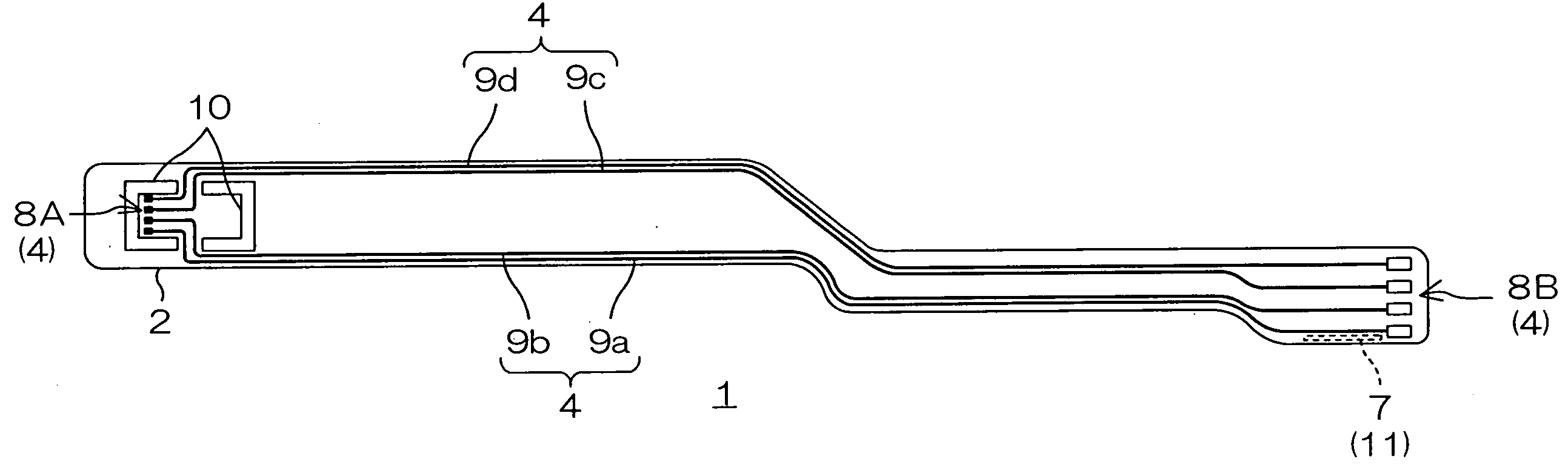

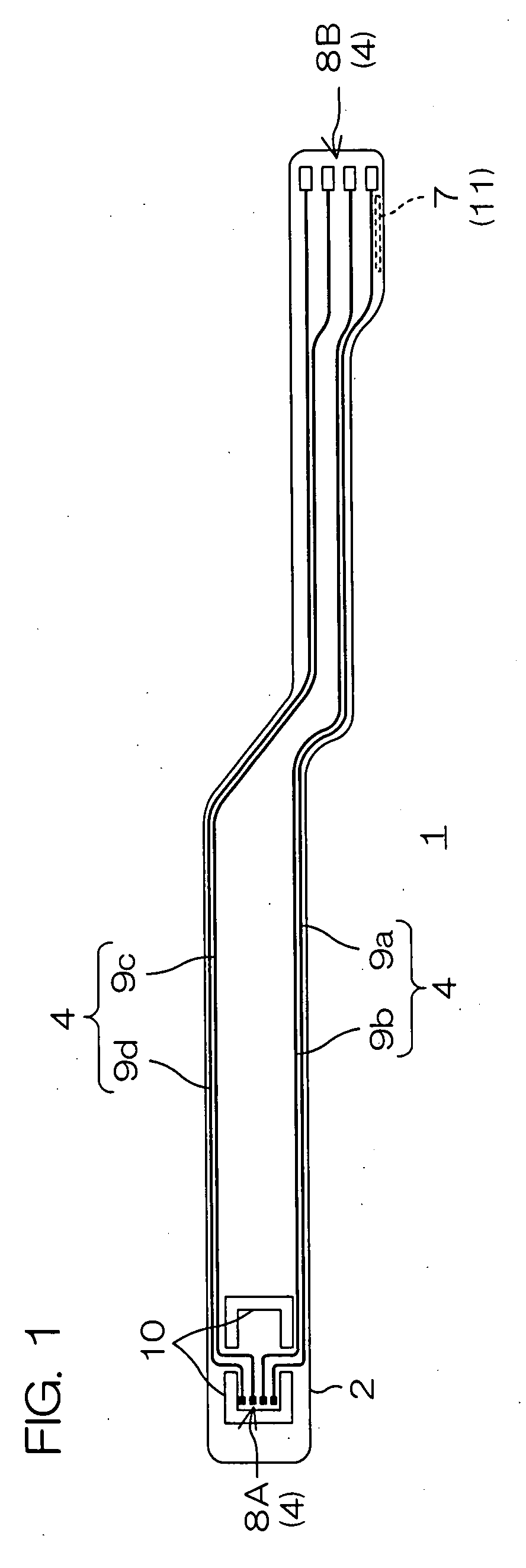

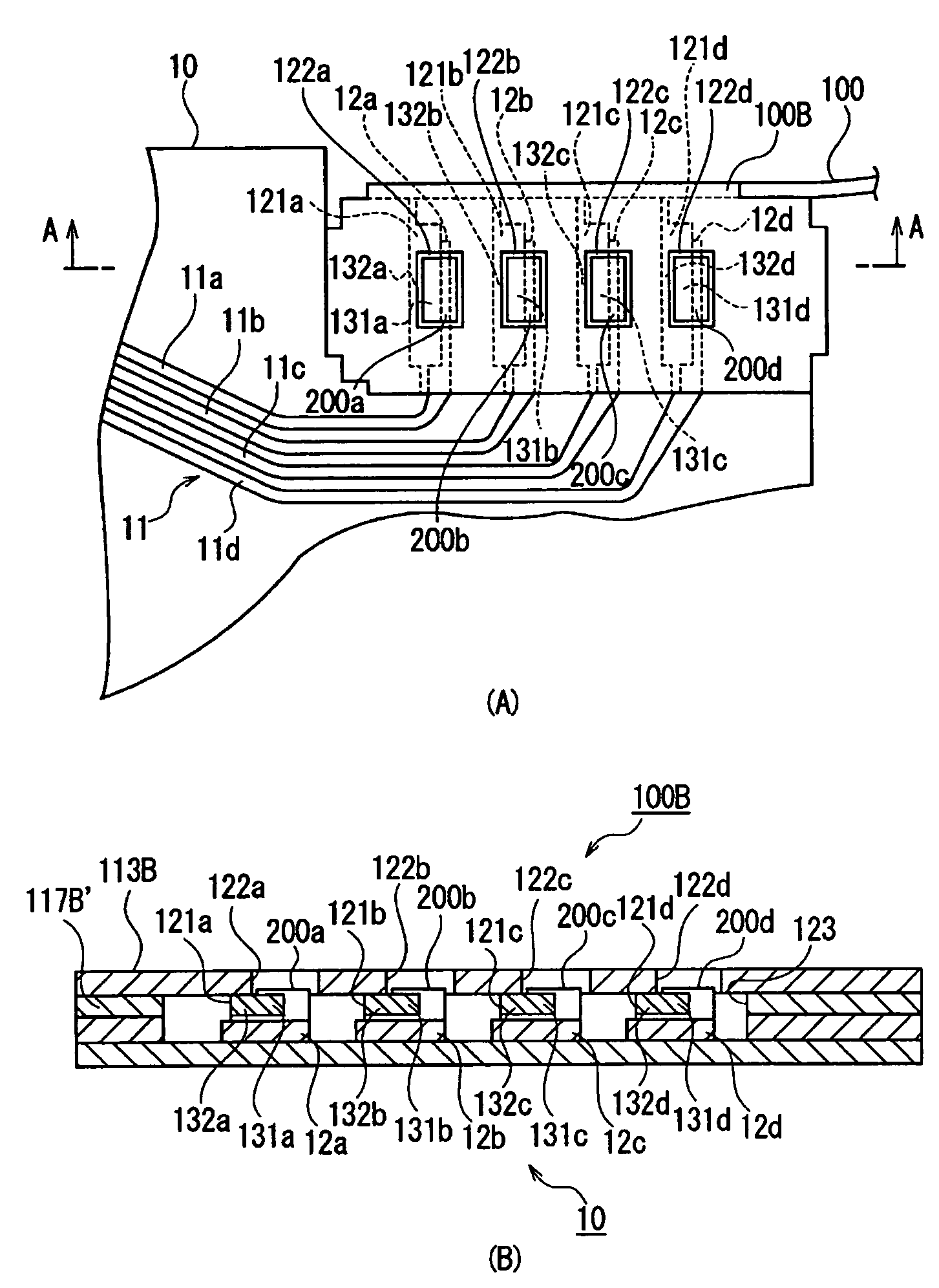

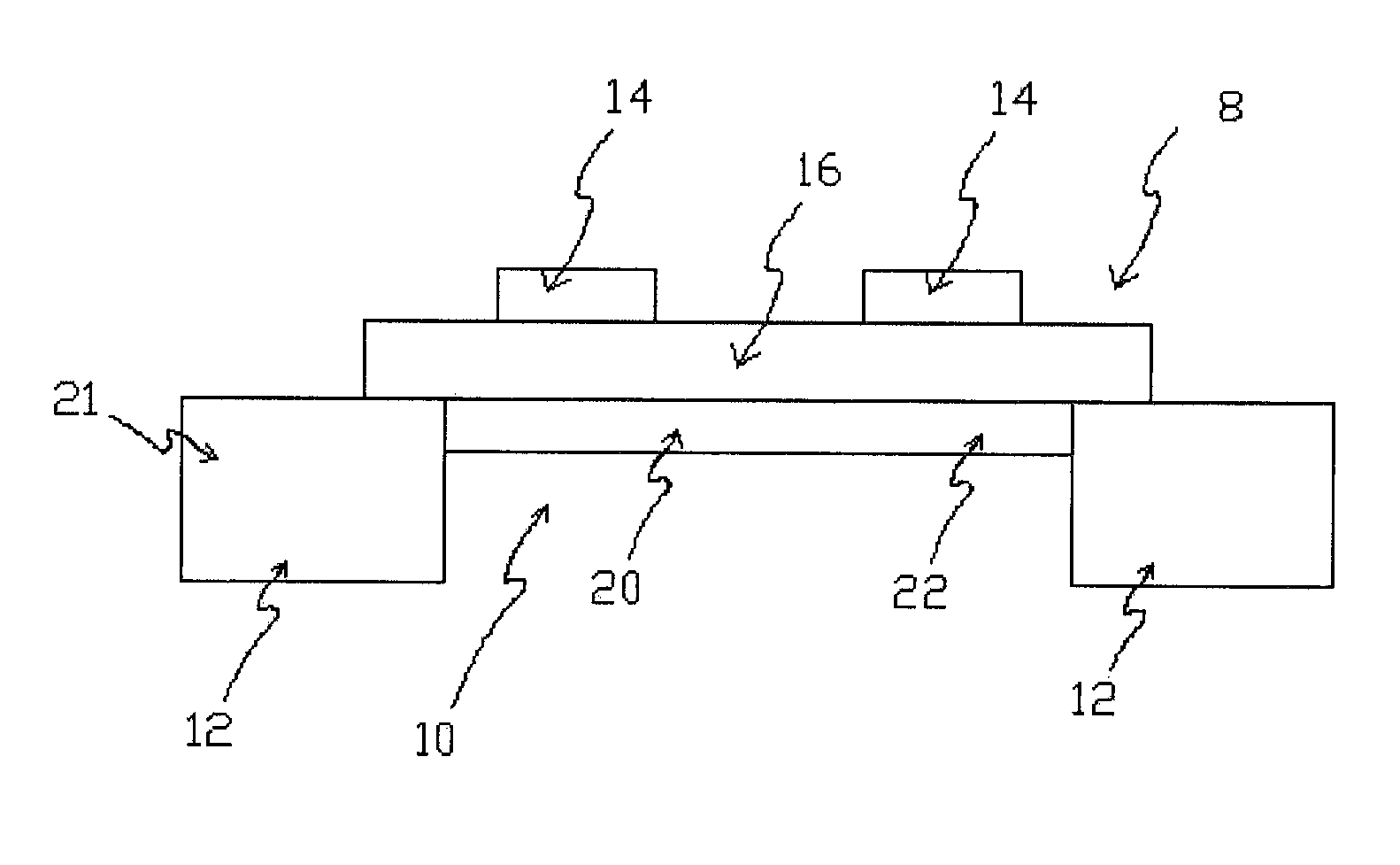

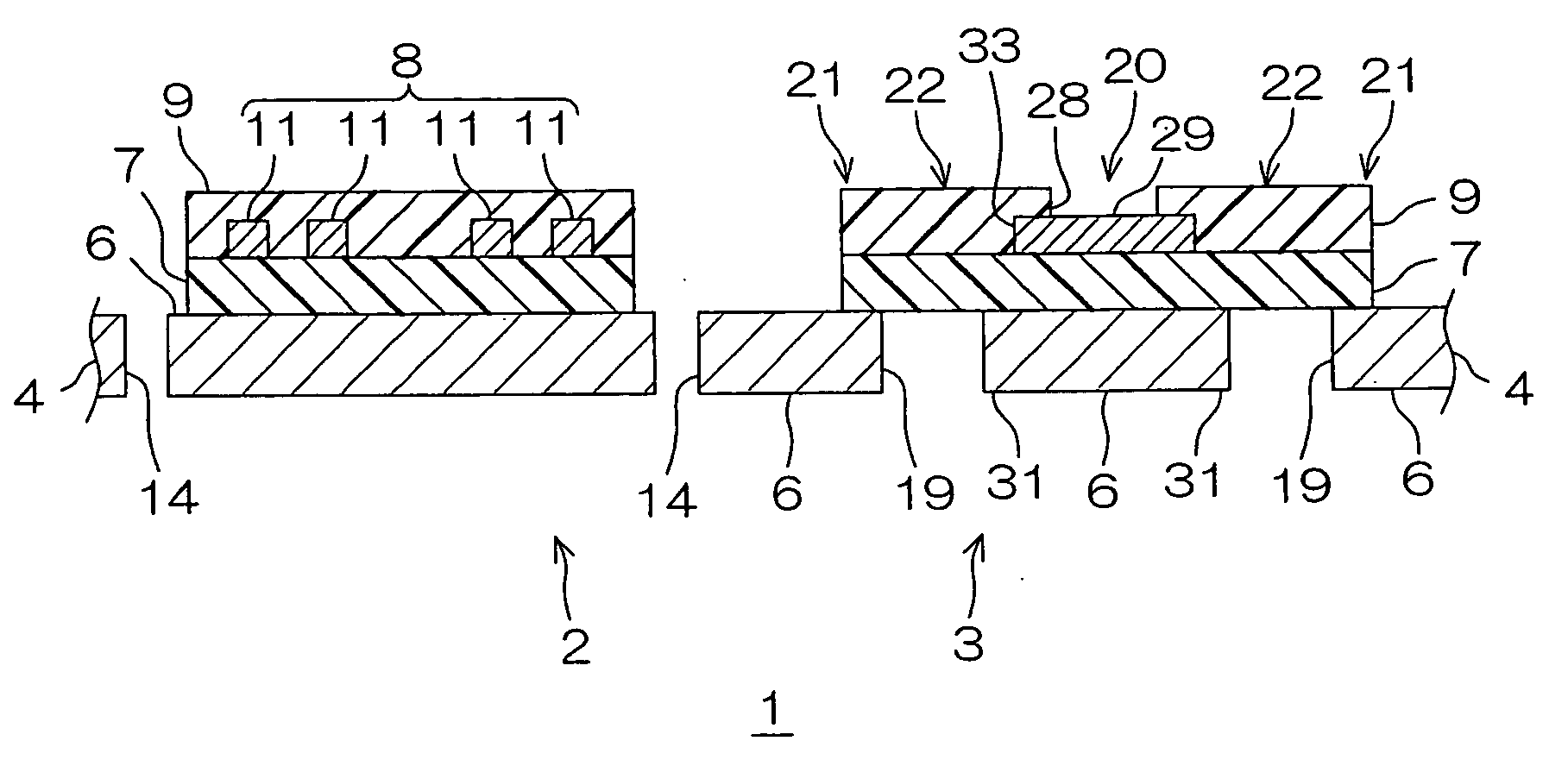

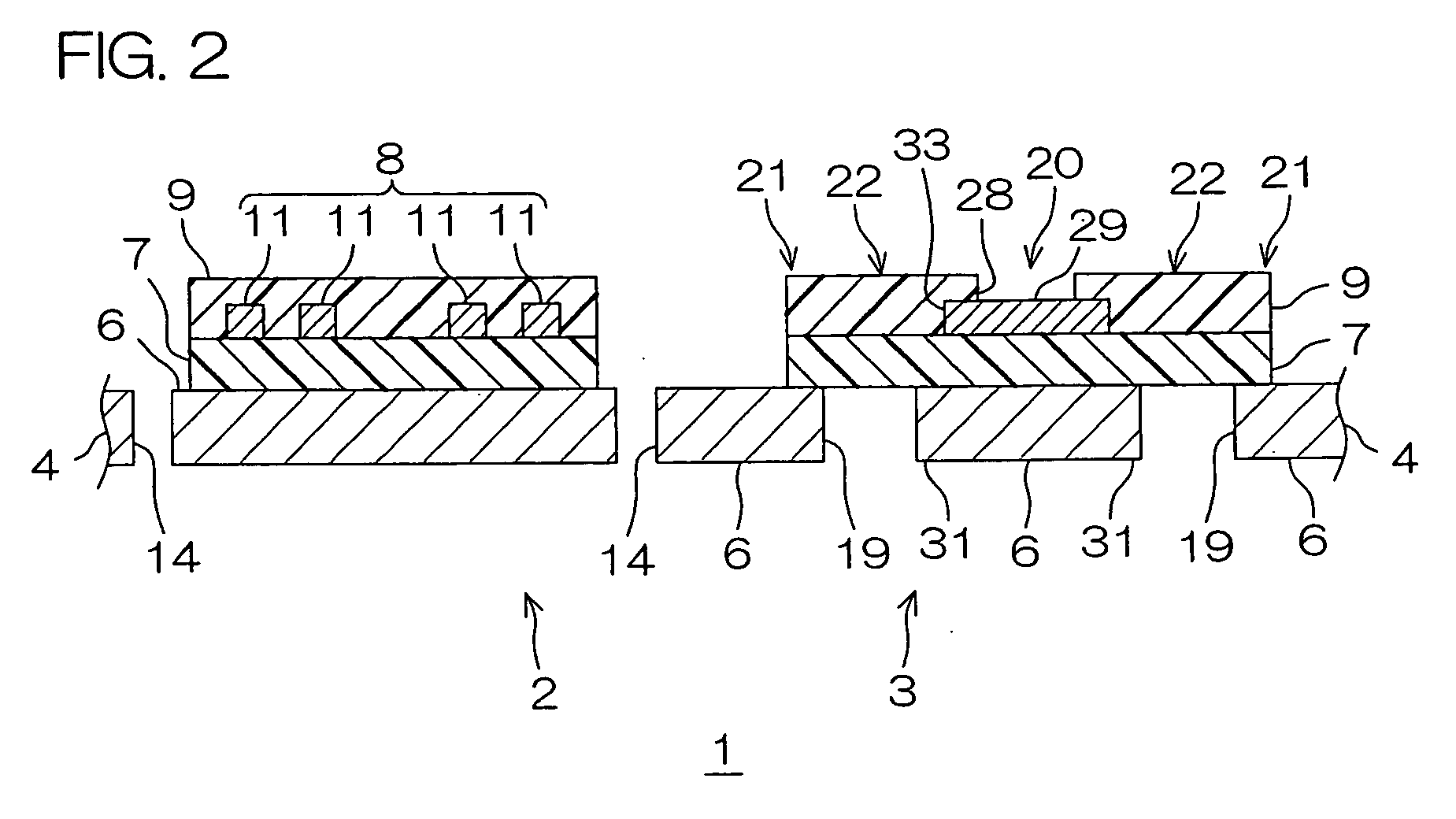

Wired circuit board

InactiveUS20090151994A1Firmly connectedImpedance stabilityElectrically conductive connectionsPrinted circuit aspectsPrinted circuit board

A wired circuit board includes a wiring formation portion, a terminal formation portion, and a middle portion formed therebetween. The wiring formation portion includes a first conductive layer formed on a first insulating layer, and a second conductive layer formed on a second insulating layer so as to overlap the first conductive layer in a thickness direction. The terminal formation portion includes the first and second conductive layers formed in parallel in the same plane. The middle portion includes the first conductive layer formed on the first insulating layer, and the second conductive layer formed on a portion of the second insulating layer extending from the wiring formation portion to a mid-point between the wiring formation portion and the terminal formation portion, and formed on a portion of the first insulating layer extending from the mid-point to the terminal formation portion.

Owner:NITTO DENKO CORP

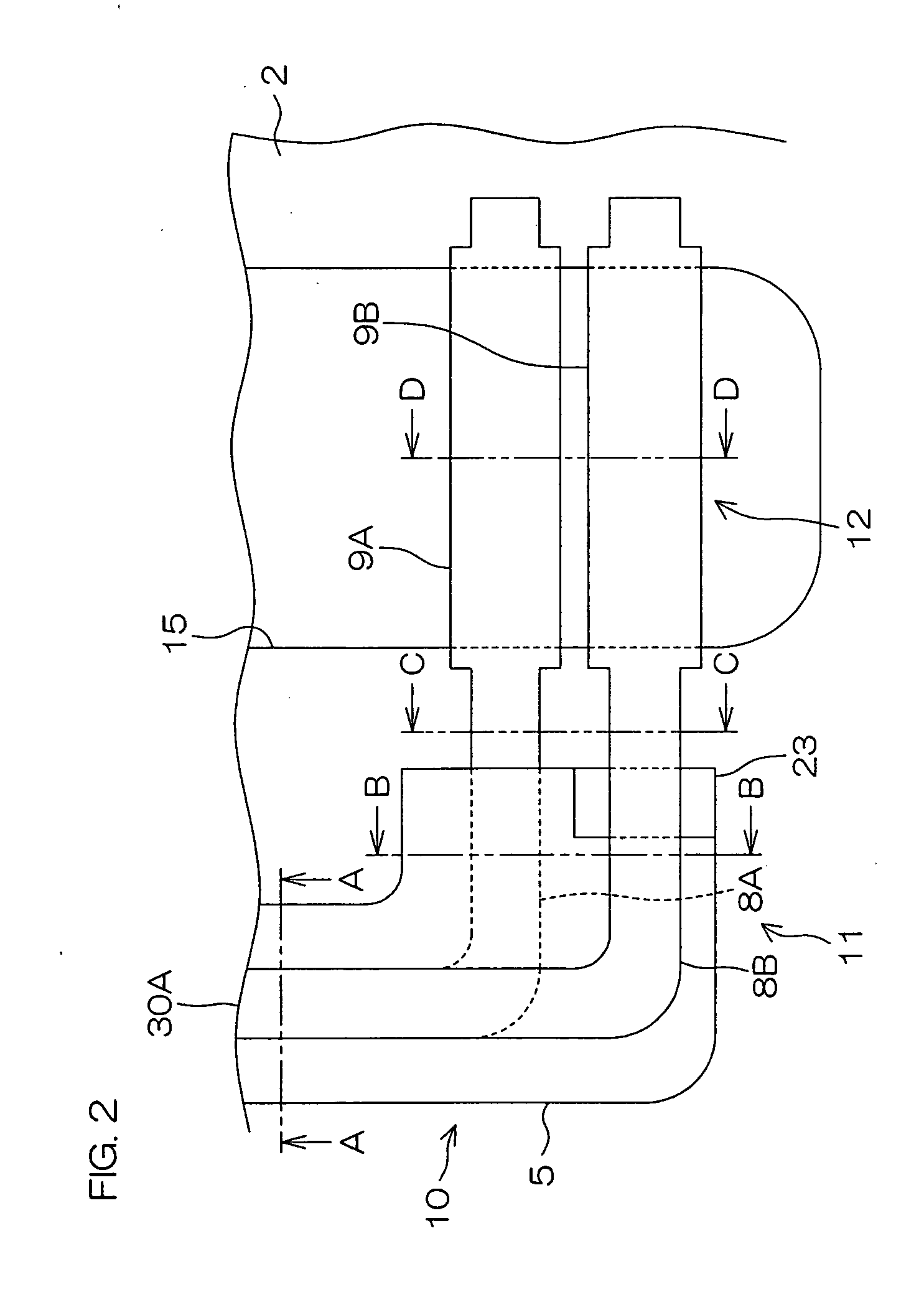

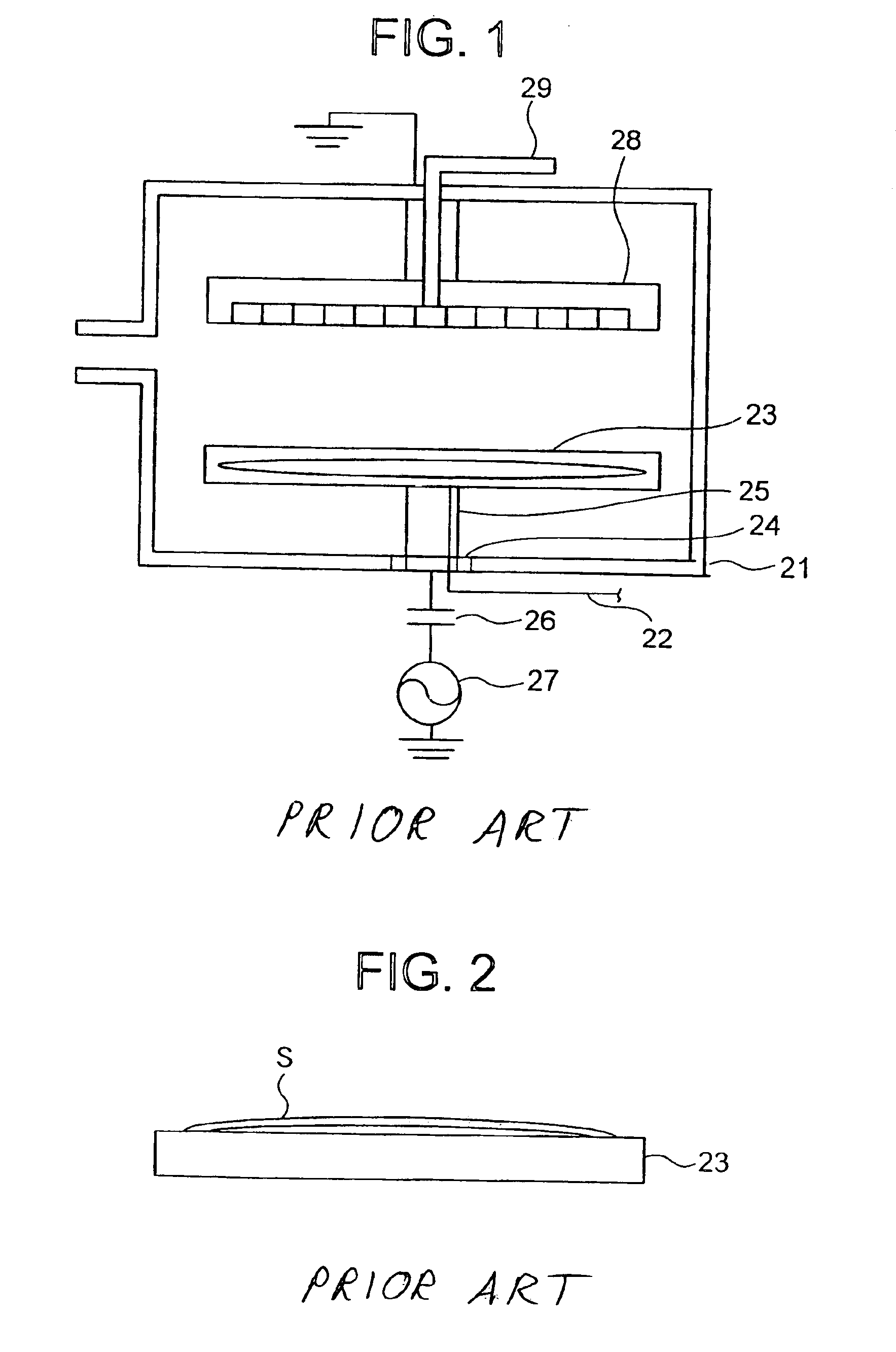

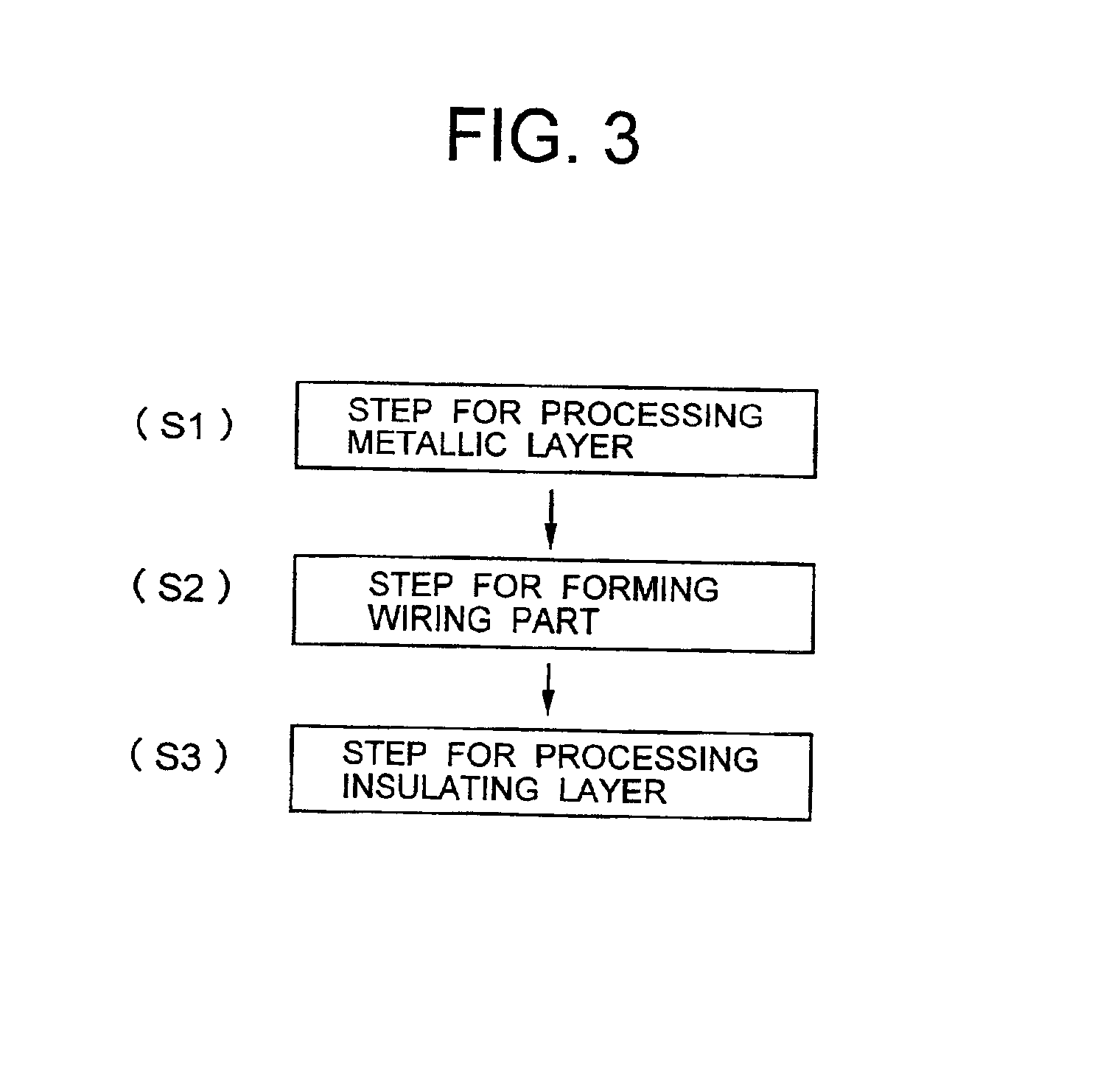

Method of manufacturing wireless suspension blank

InactiveUS6942817B2Decorative surface effectsSemiconductor/solid-state device manufacturingDry etchingMaterials science

A wireless suspension blank is made using a two-layer laminate composed of a metallic layer with the spring property and an electrically insulating layer. The first method includes a first step for working the metallic layer by the photo etching method, a second step for forming a wiring part on the insulating layer by the semi-additive method and a third step for working the insulating layer by the wet-etching method. The second method includes a first step for working the metallic layer by the photo etching method, a second step for forming a wiring part on the insulating layer by the semi-additive method and a third step for working the insulating layer by the plasma etching method. The third method includes a first step for forming a wiring part on the metallic layer by the semi-additive method, a second step for working the metallic layer by the wet-etching method and a third step for working the insulating layer by the dry-etching method or the wet-etching method. The use of a two-layer laminate makes possible a low cost production. Further, the forming of a wiring part by the semi-additive method makes possible to working very accurately a fine wiring part.

Owner:DAI NIPPON PRINTING CO LTD

Integrated head for heat assisted magnetic recording

ActiveUS20080170319A1Record information storageRecording/reproducing/erasing methodsHeat-assisted magnetic recordingMagnetic media

Owner:SEAGATE TECH LLC

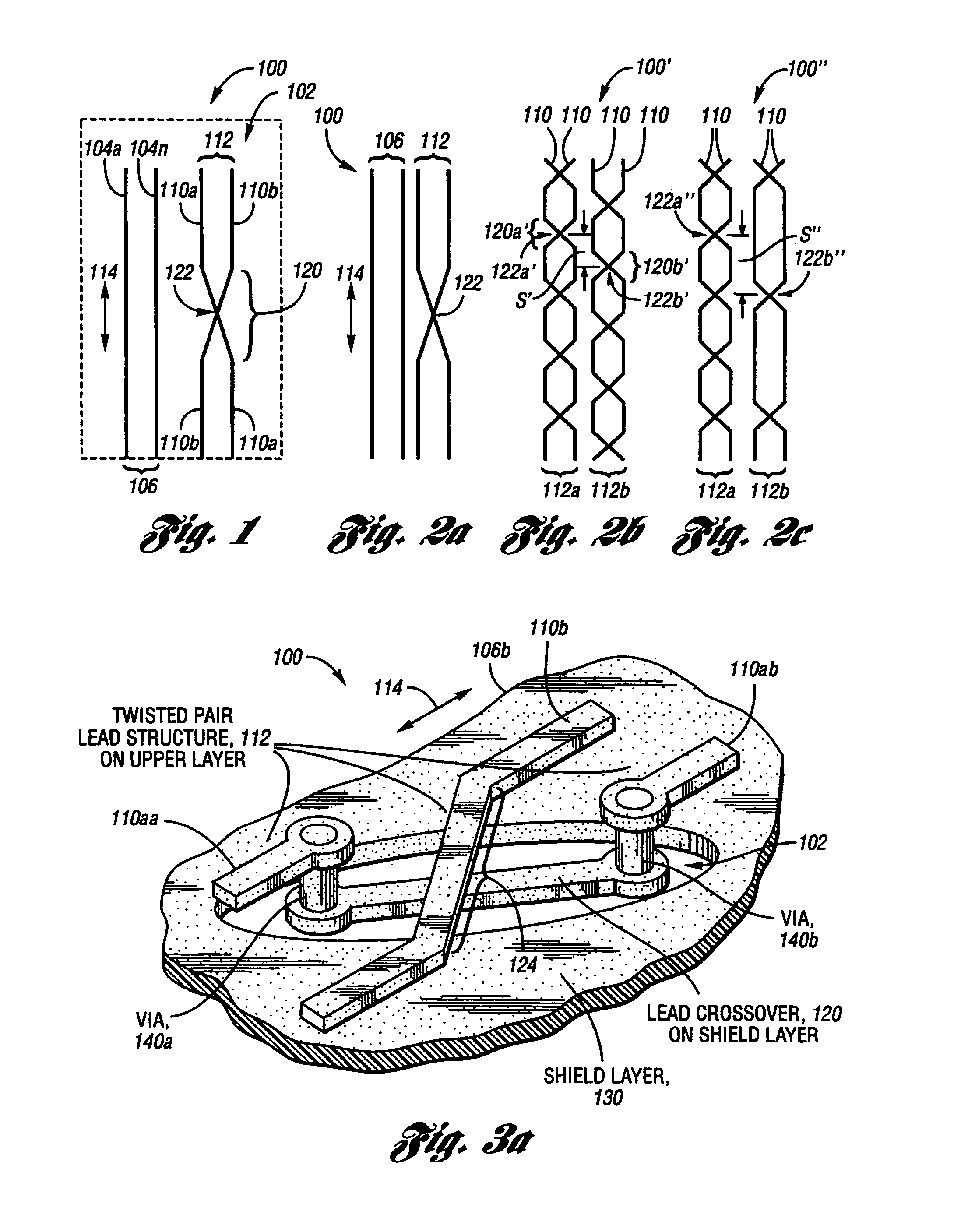

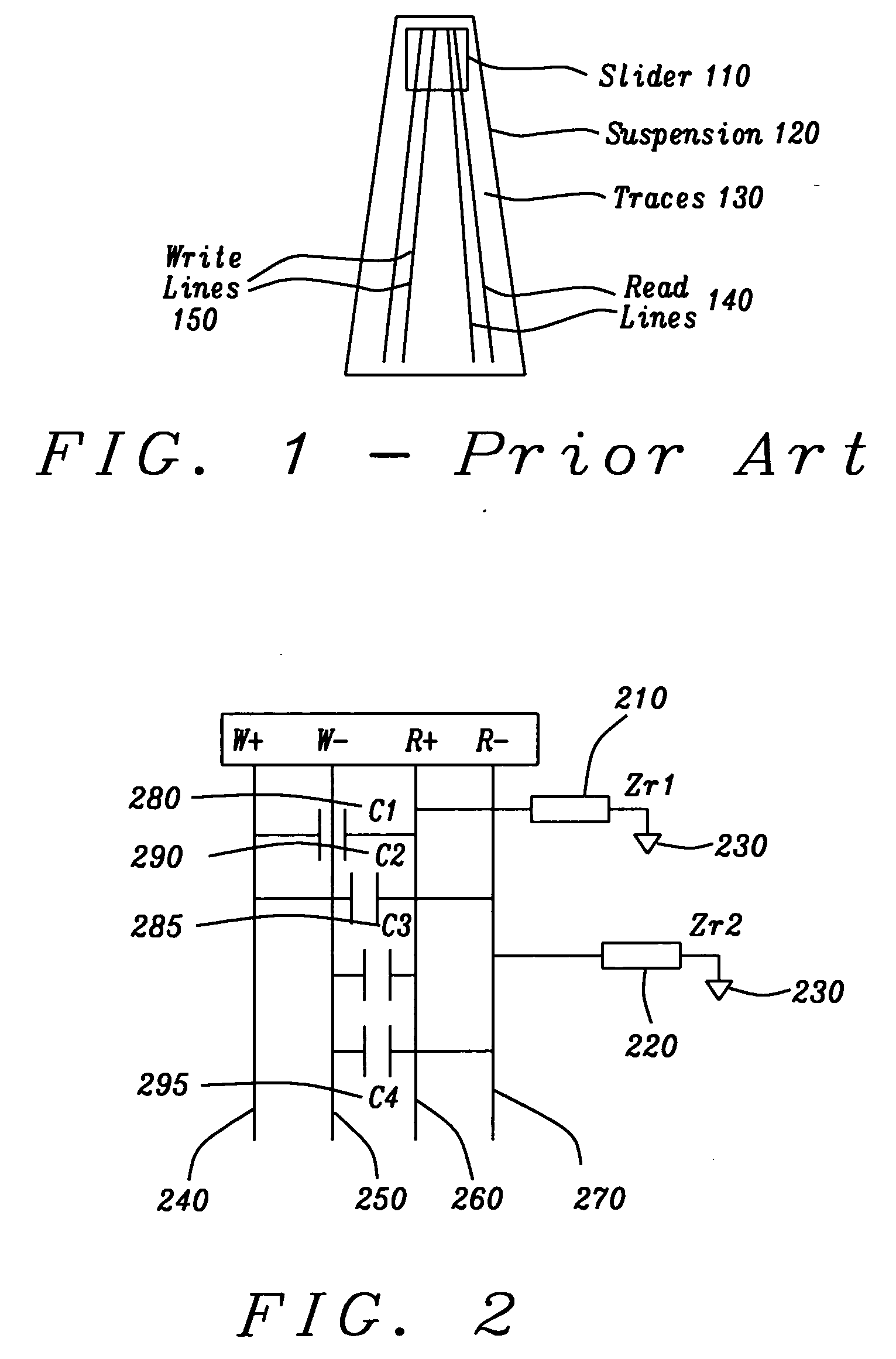

System and method for crosstalk reduction in a flexible trace interconnect array

ActiveUS7271985B1Reduce signal crosstalkPrinted circuit aspectsRecord information storageElectrical conductorEngineering

A system for reducing signal crosstalk in a flexible trace interconnect array includes a flexible dielectric material base, and a plurality of conductors longitudinally arranged as pairs in a signal layer array on the base. At least one of the pairs of conductors comprises a twisted pair.

Owner:ORACLE INT CORP

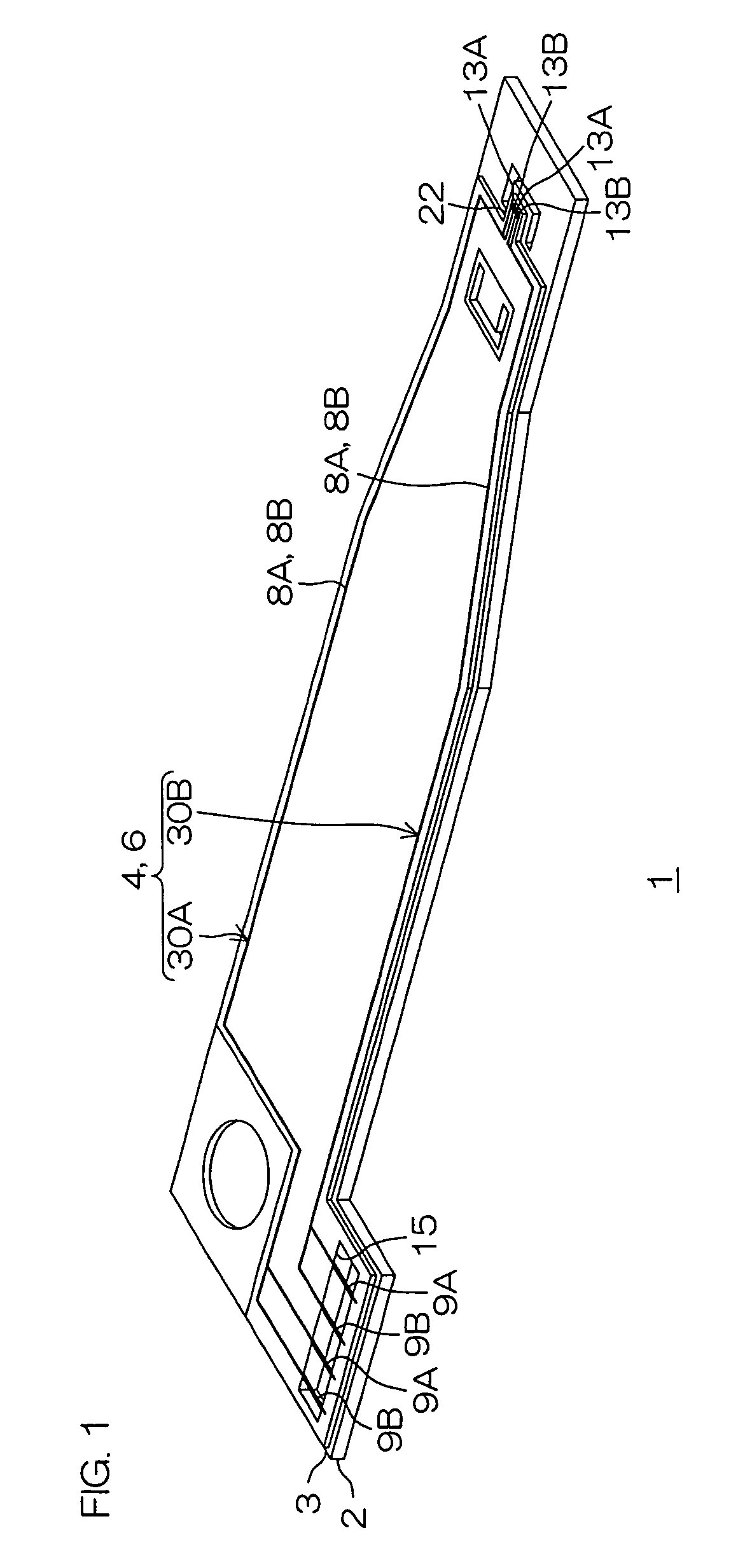

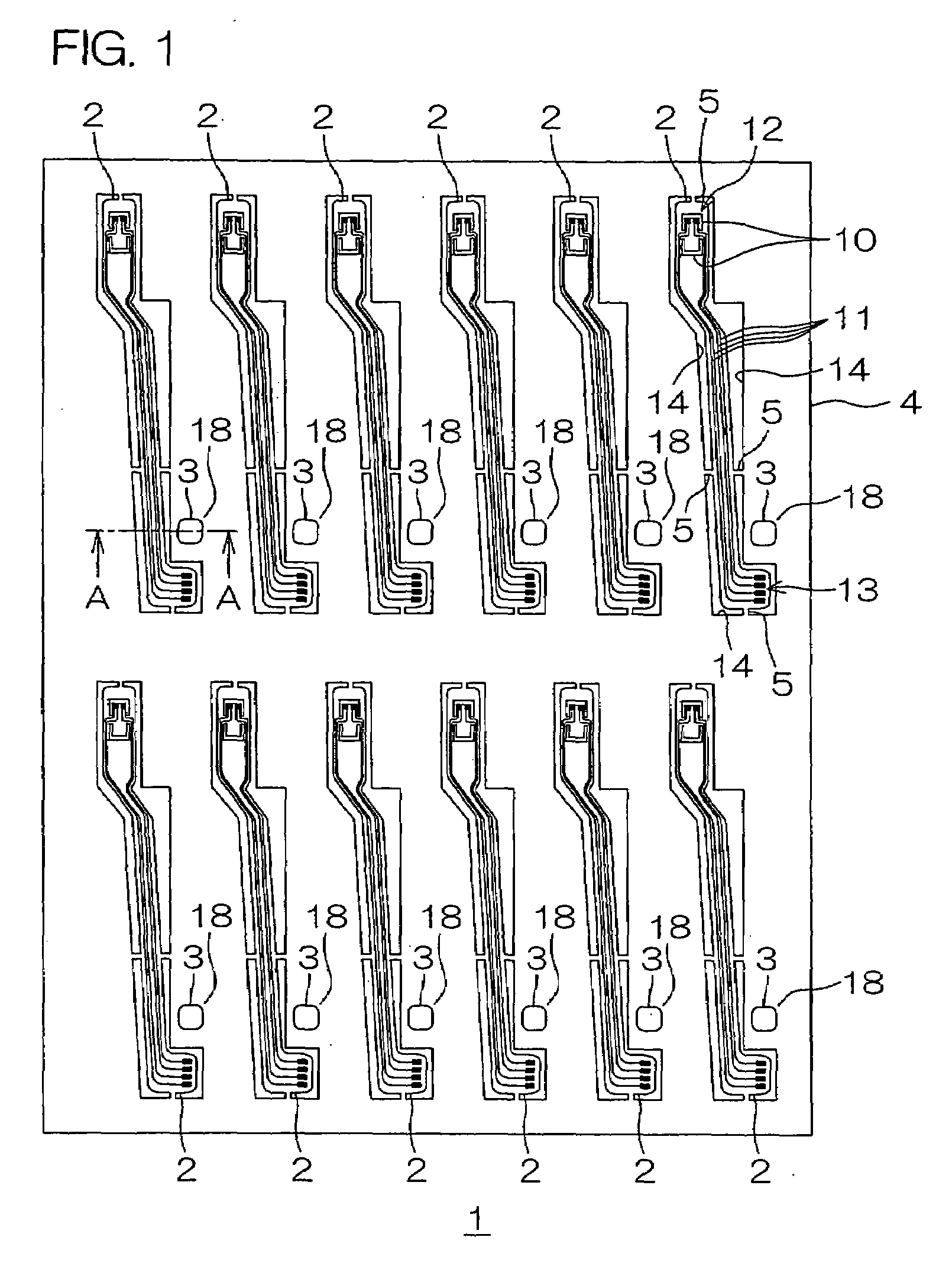

Suspension board with circuit

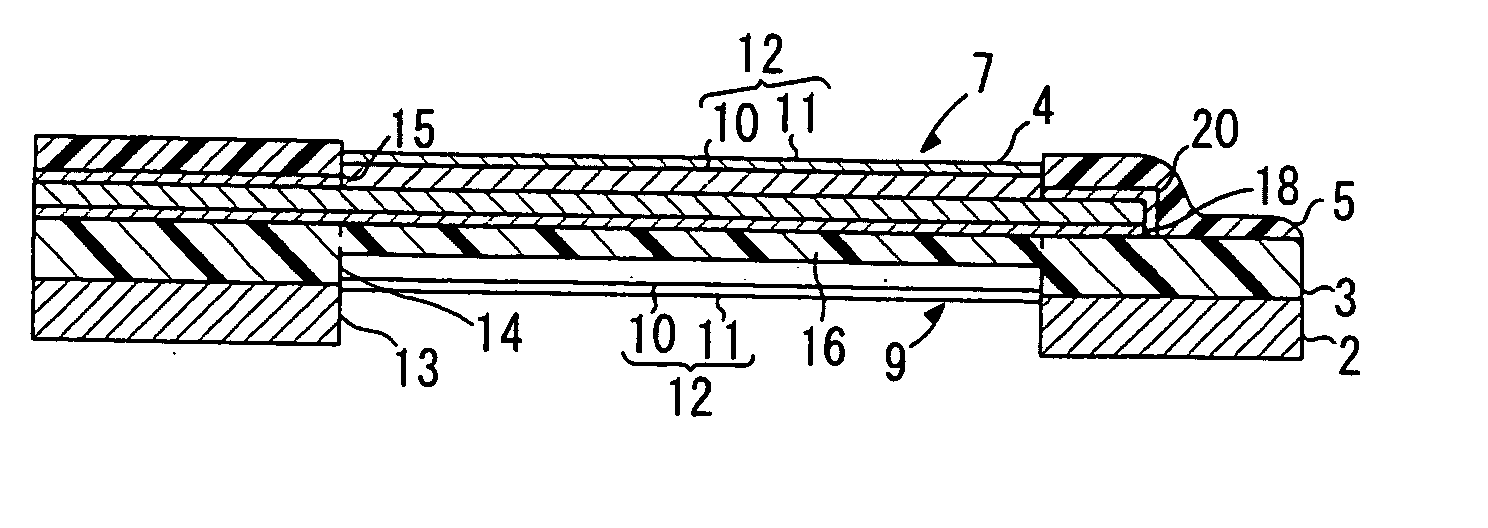

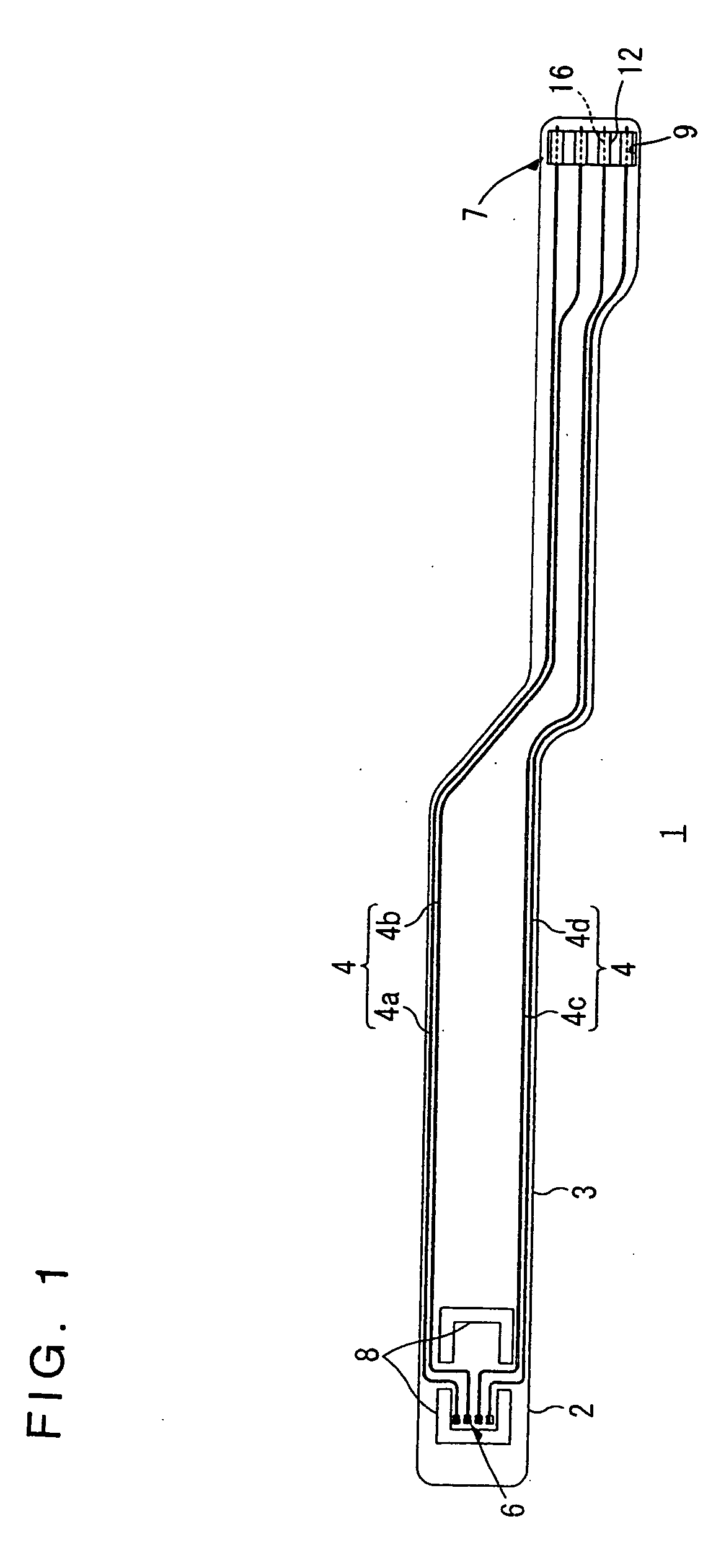

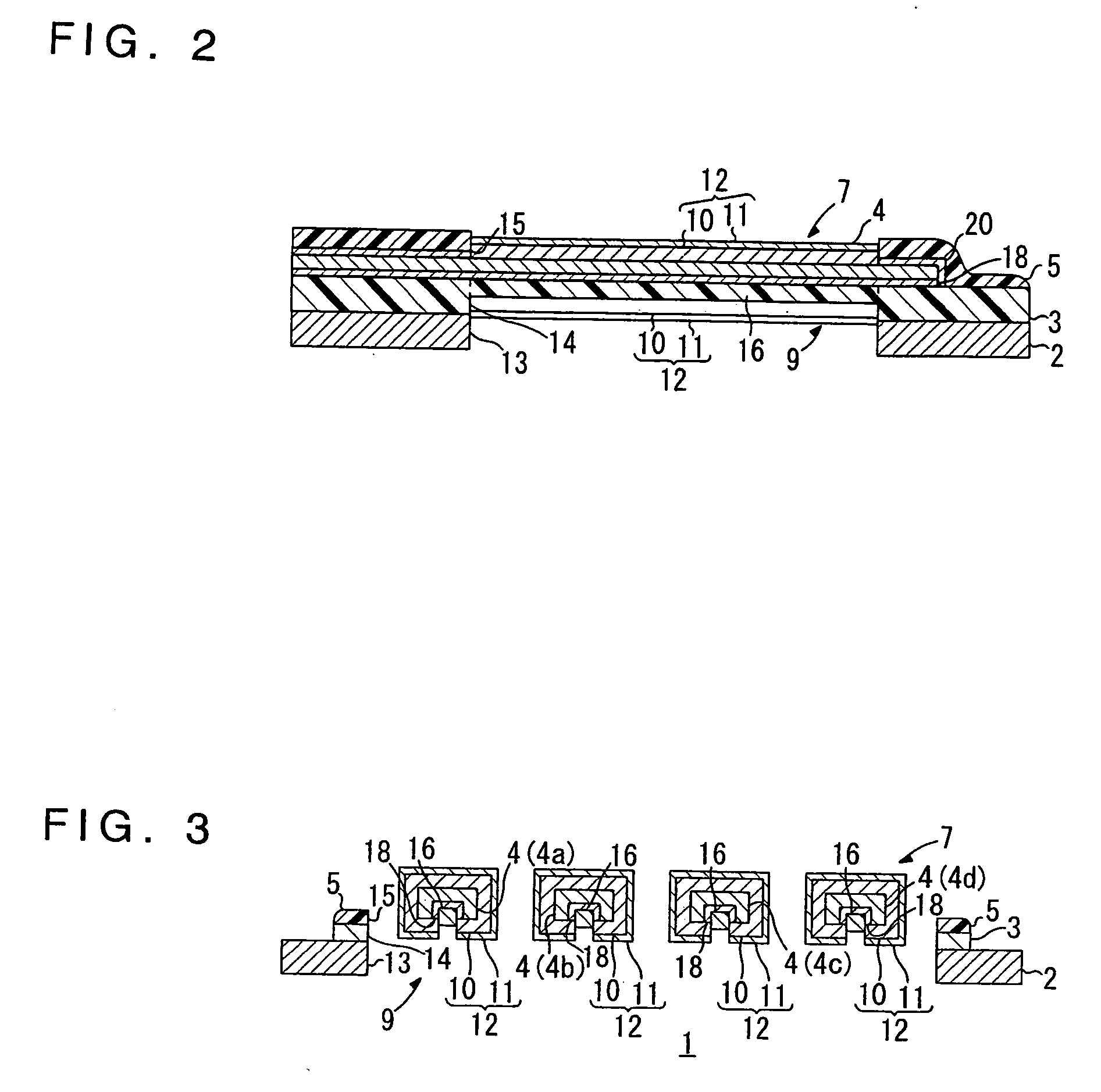

InactiveUS20050122627A1Reduce risk of damageImprove reliabilityDriving/moving recording headsPrinted circuit aspectsElectrical conductorAdditive process

A suspension board with circuit having a conductor layer formed in the form of a fine wiring circuit by an additive process, while providing a reduced risk of damage and breaking of the conductor layer in a flying lead portion. The suspension board with circuit comprises a supporting board 2, an insulating base layer 3 formed on the supporting board 2, a conductor layer 4 formed on the insulating base layer 3, an insulating cover layer 5 formed on the conductor layer 4, and a flying lead portion 9 in which a supporting-board-side opening 13, a base-layer-side opening 14, and a cover-layer-side opening 15 are formed so that both sides of the conductor layer 4 can be exposed therefrom. A reinforcing portion 16 or 23 for reinforcing the conductor layer 4 formed continuously from at least either of the insulating base layer 3 and the insulating cover layer 5 along the longitudinal direction of the conductor layer 4 is included in the flying lead portion 9.

Owner:NITTO DENKO CORP

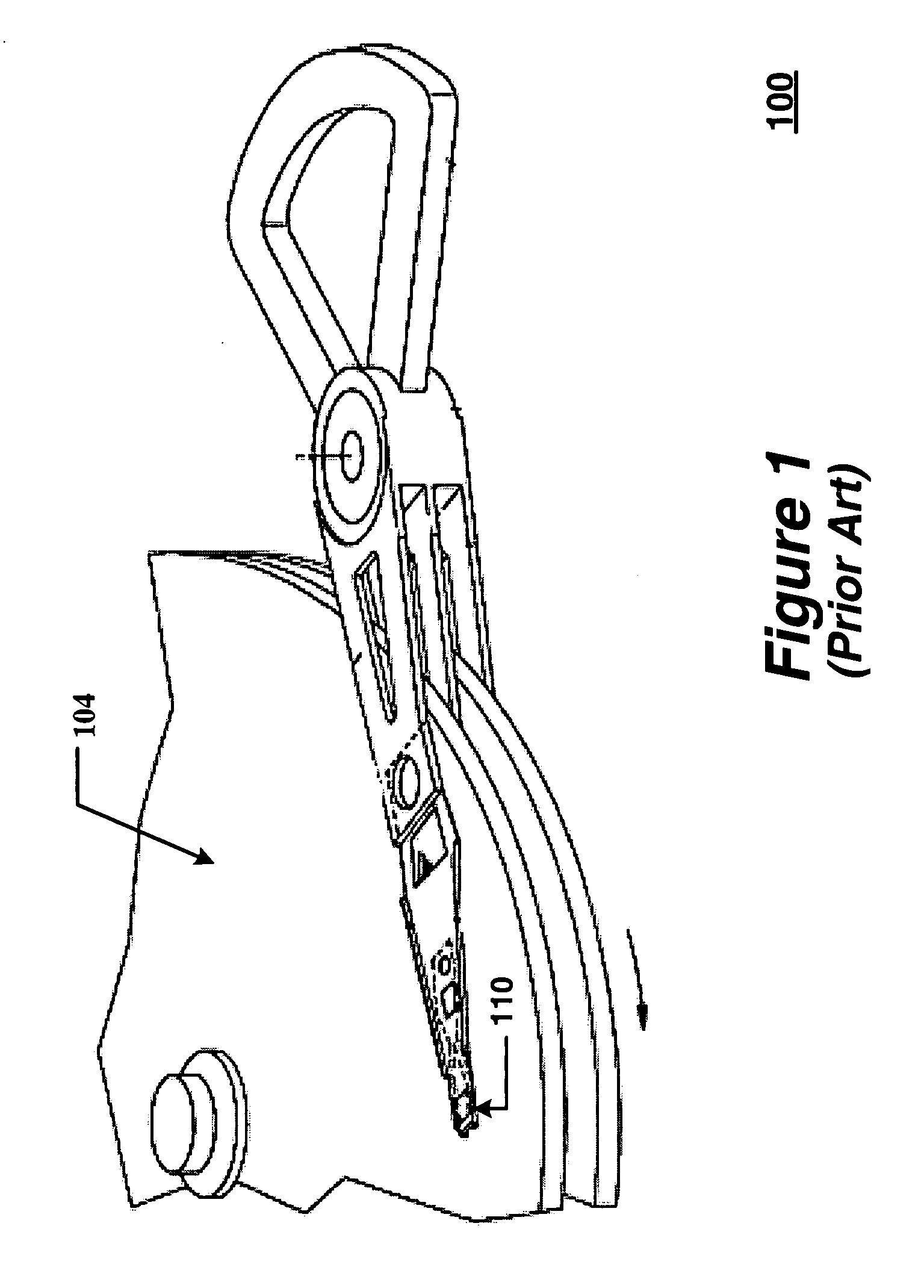

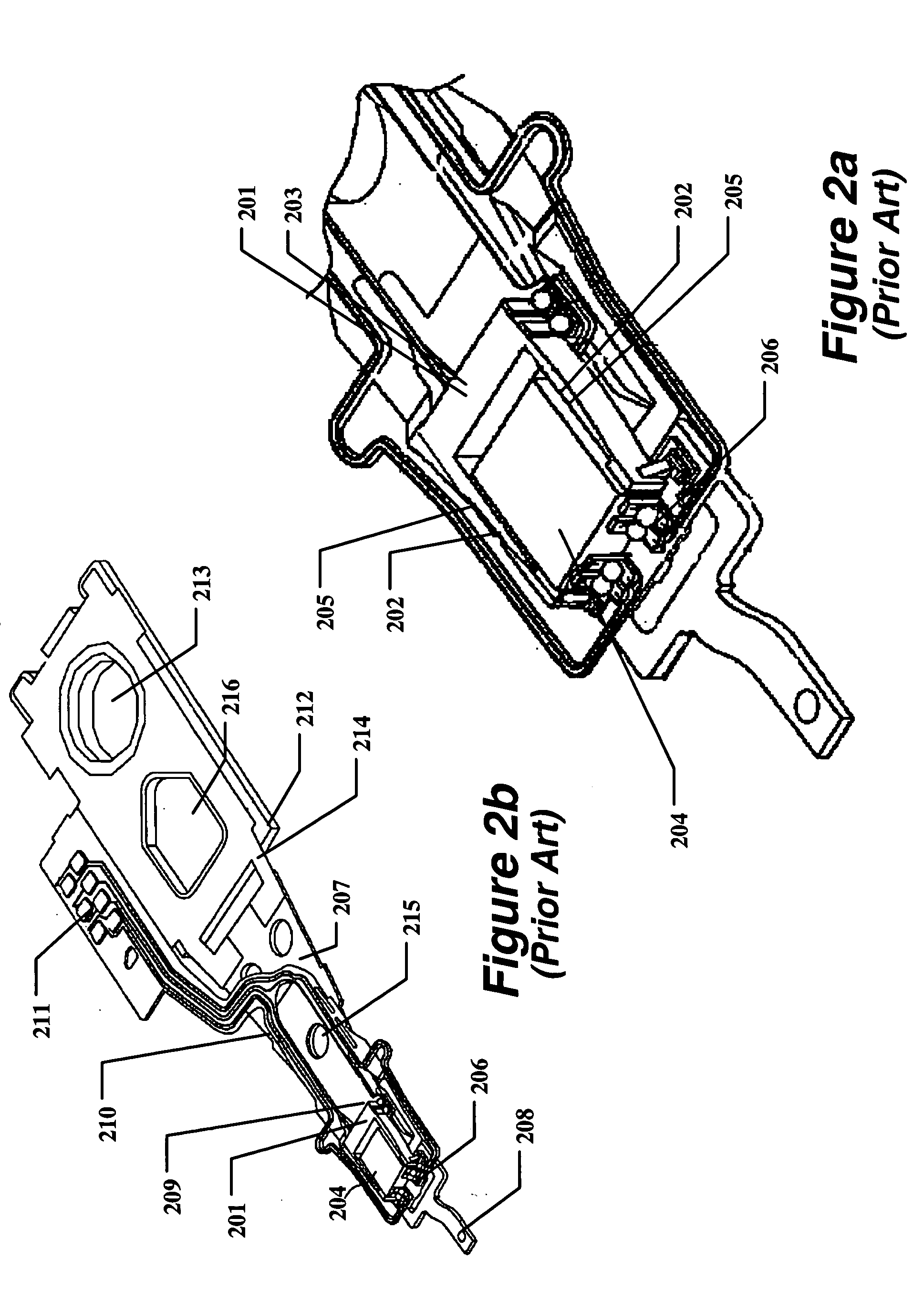

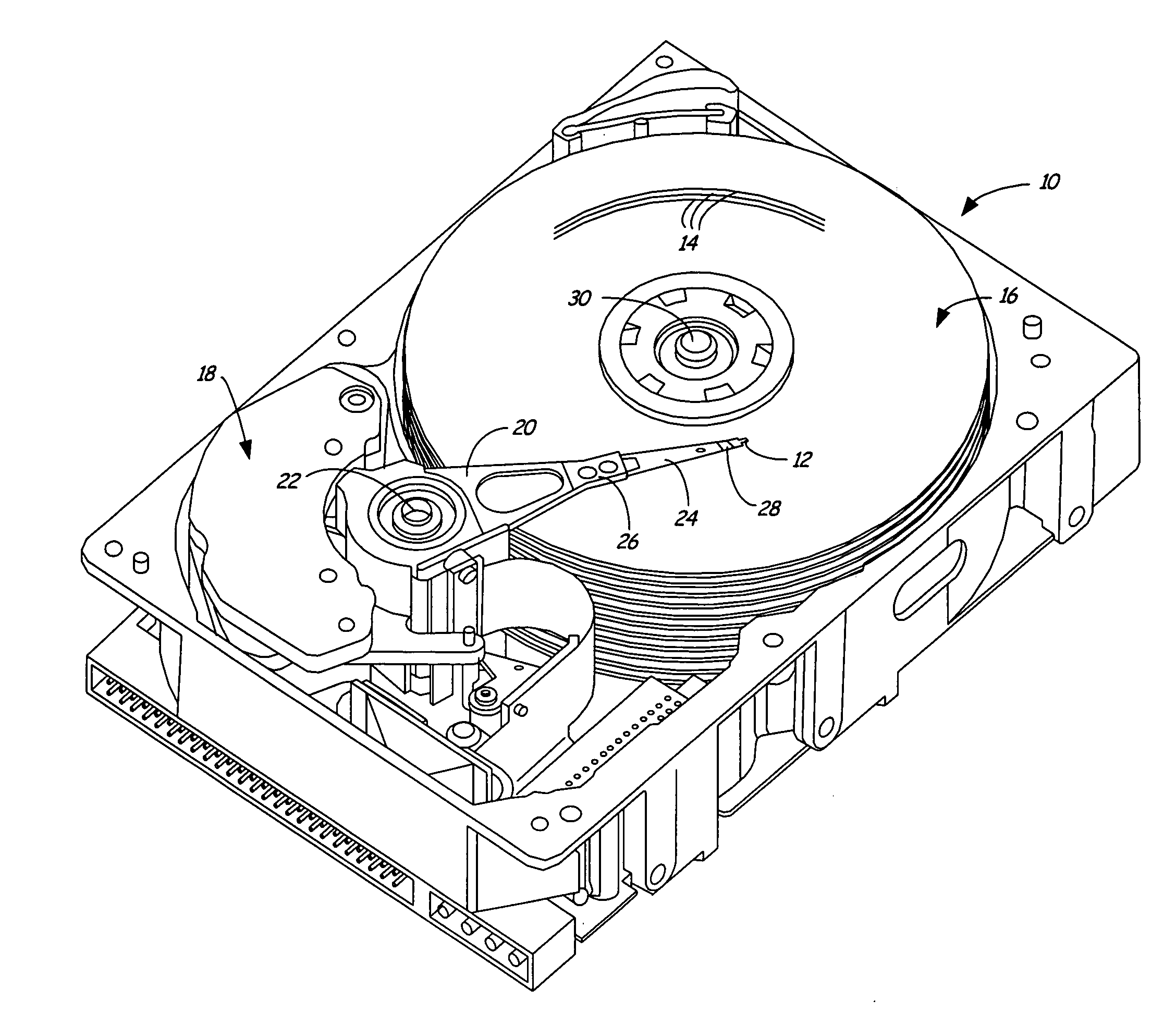

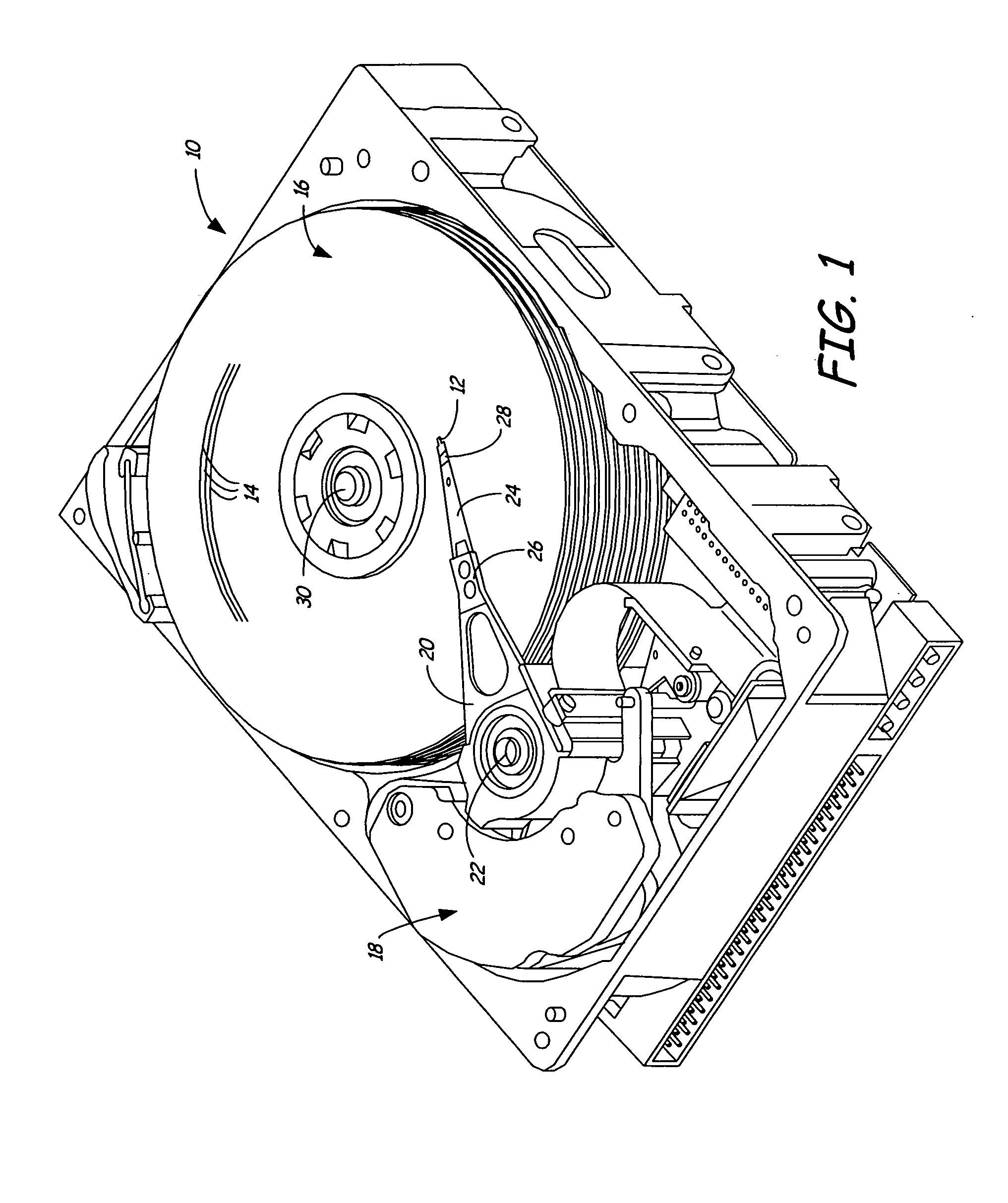

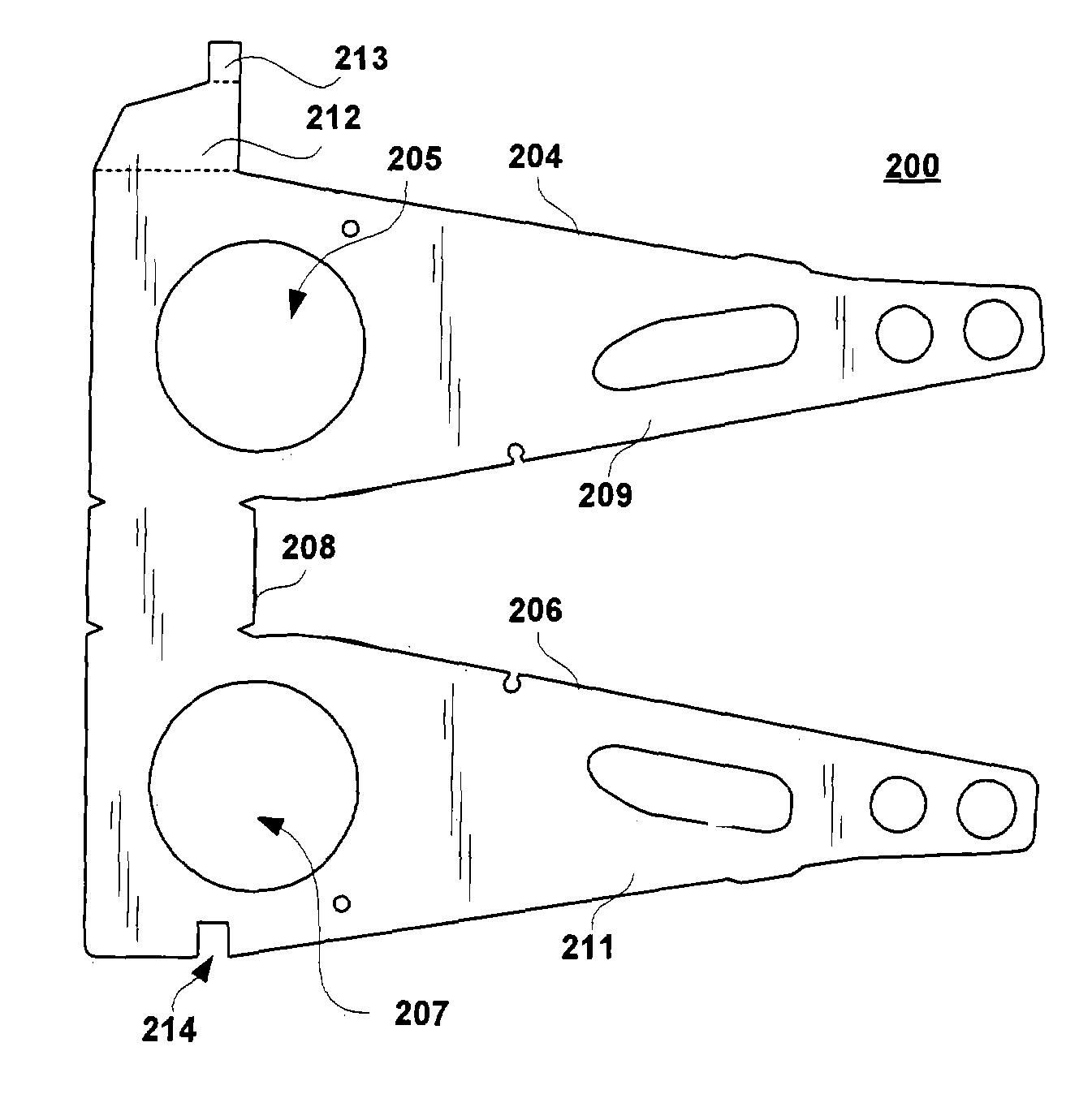

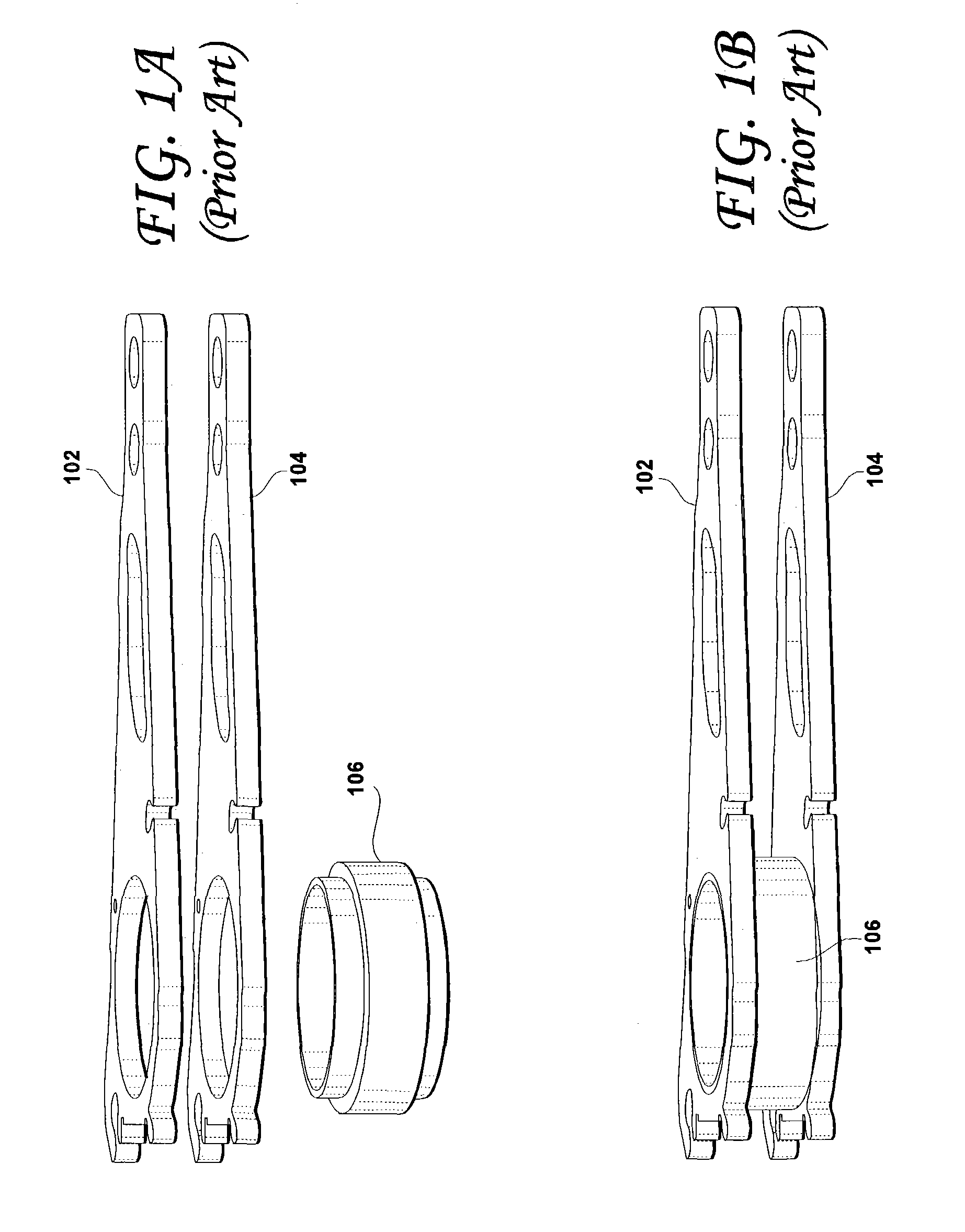

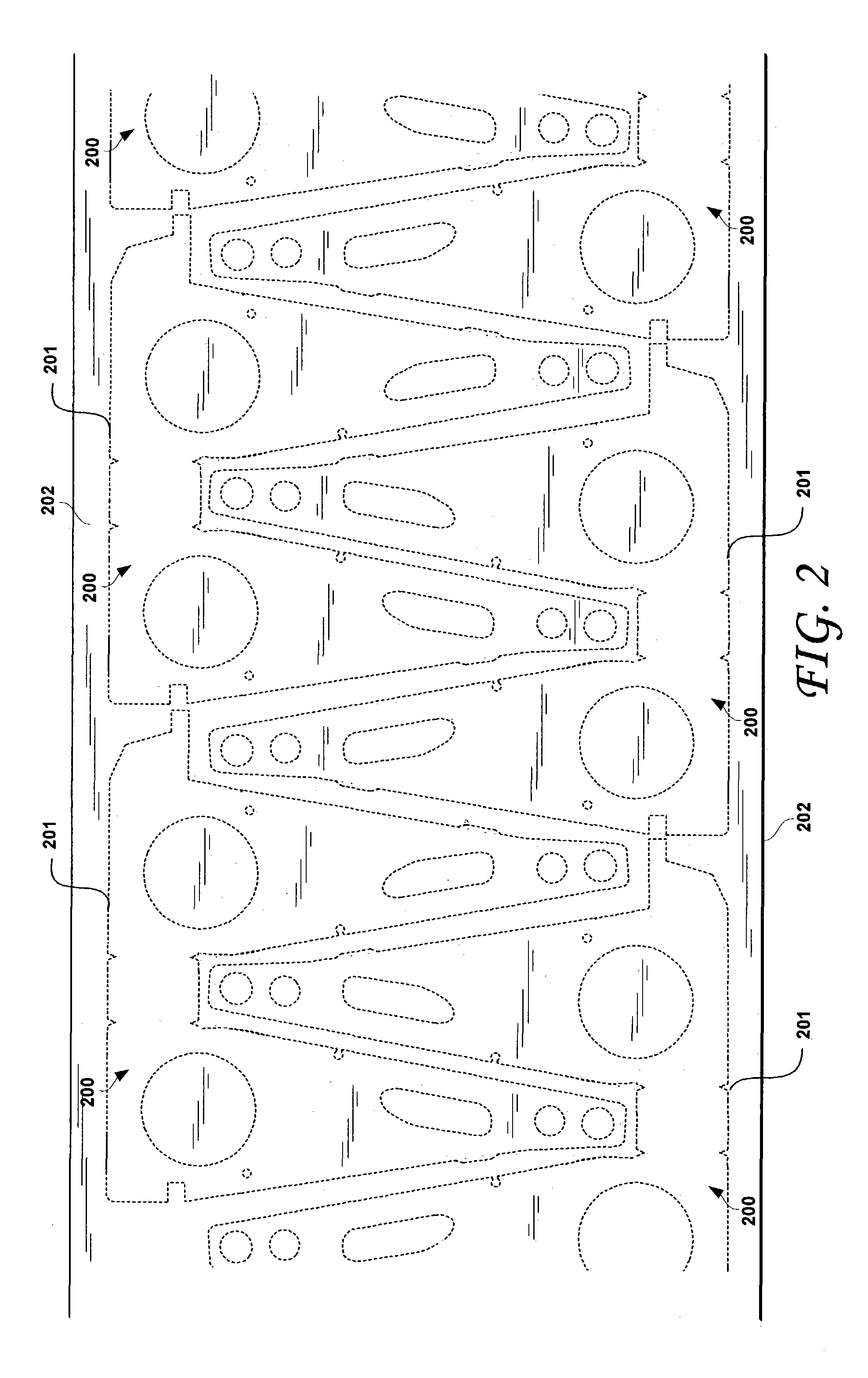

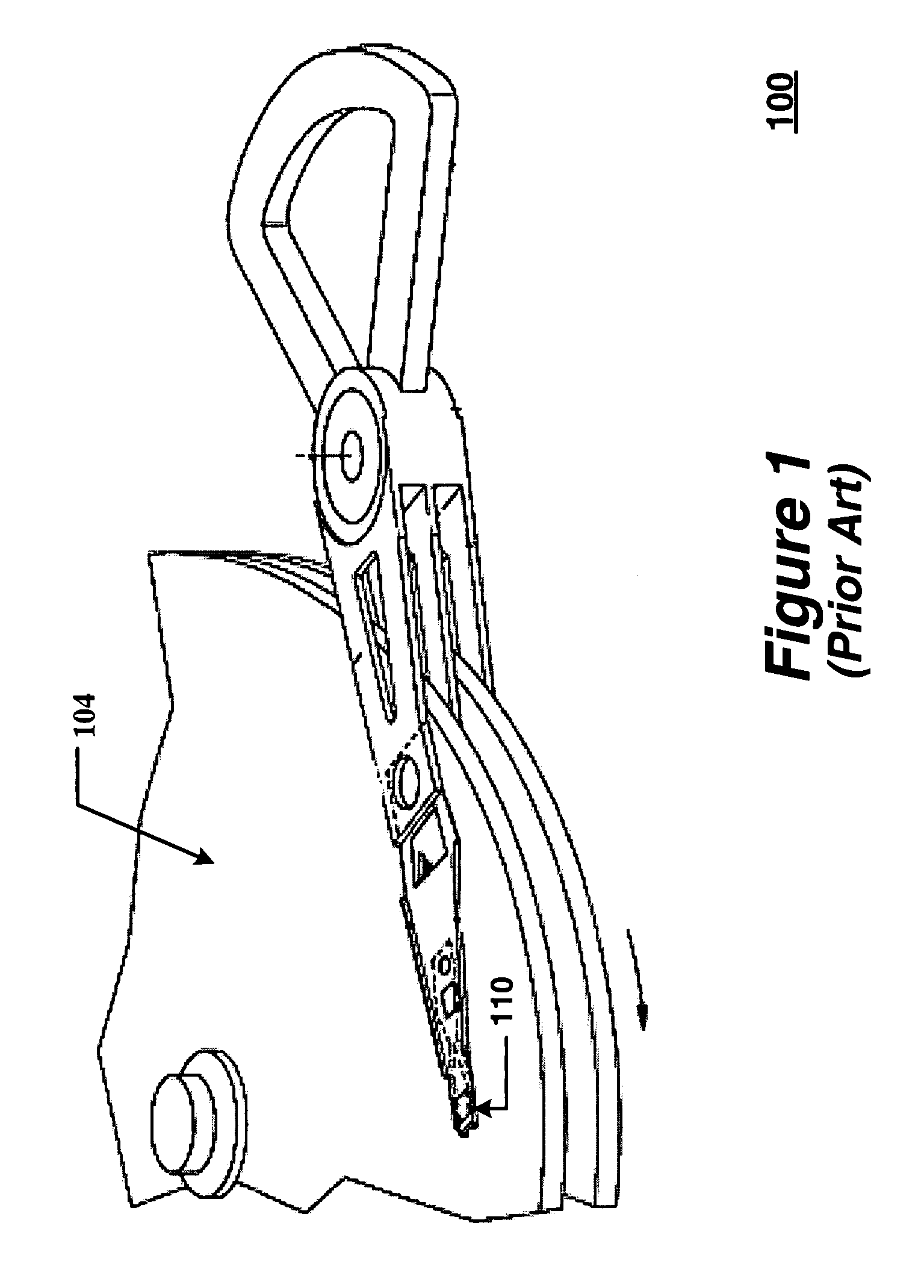

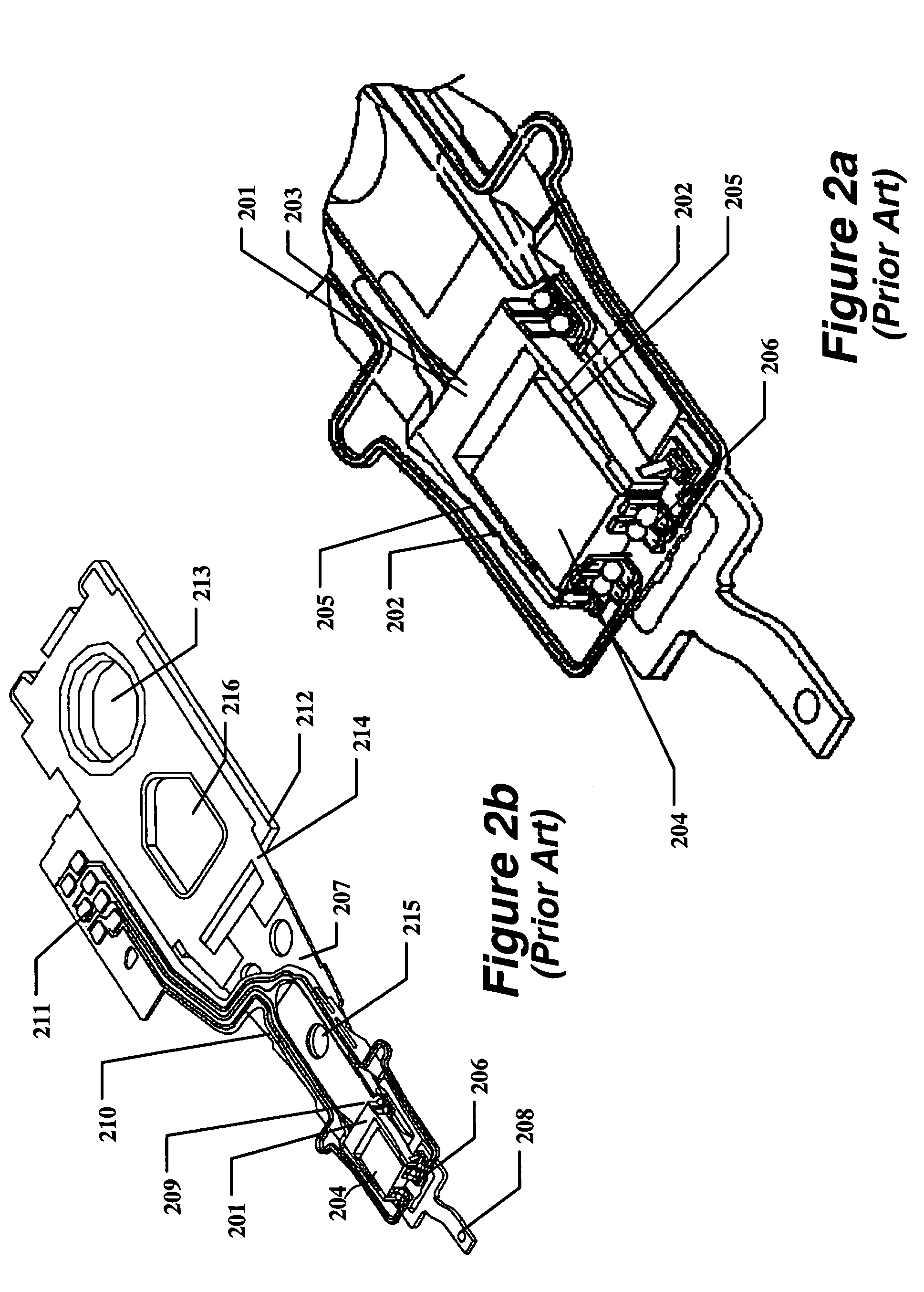

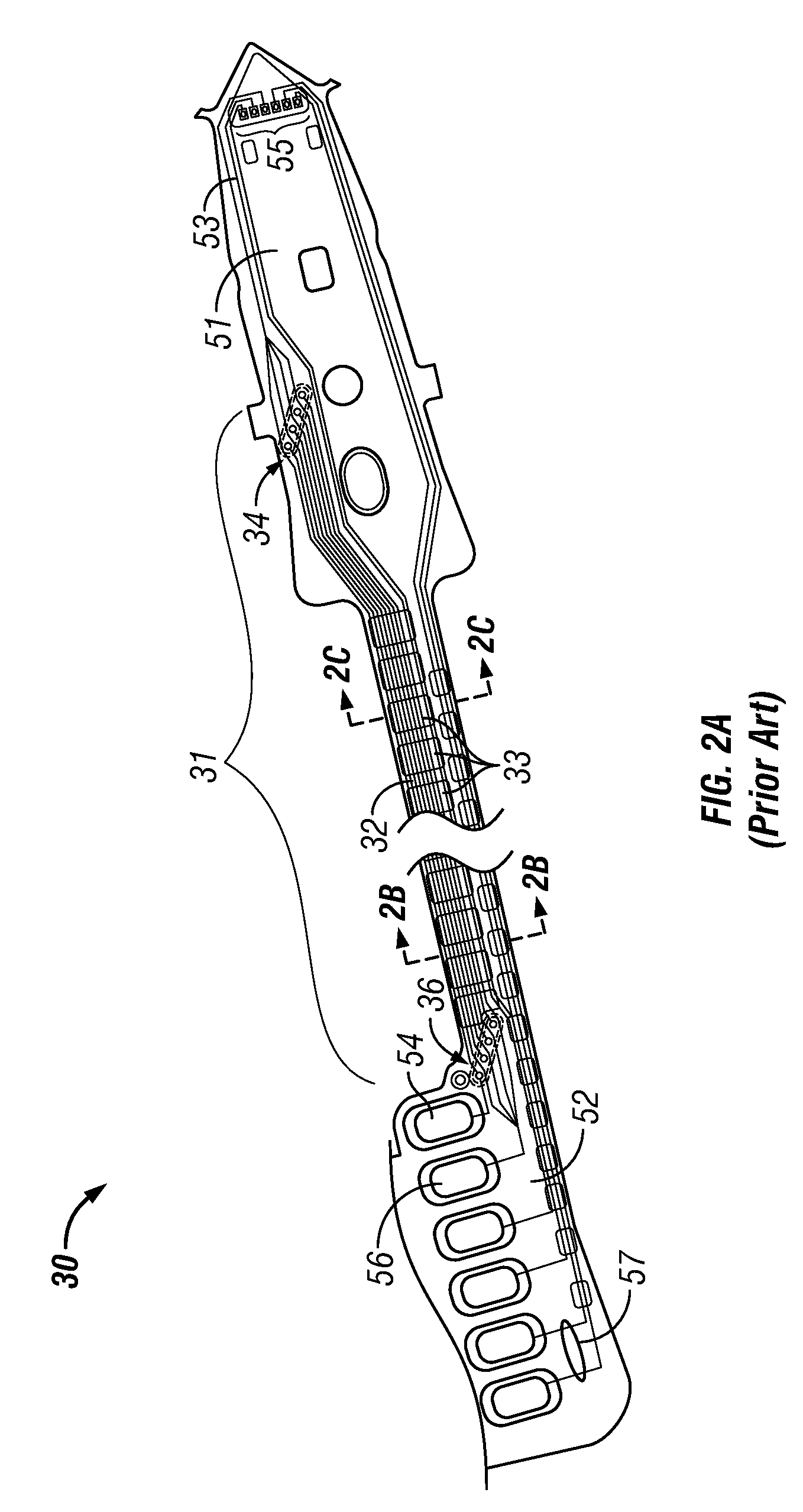

Disk drive including a one-piece stamped actuator arm assembly and method of making same

An actuator arm assembly of a disk drive is stamped from a single flat sheet of material and includes first and second actuator arm portions and one or more bendable portions integrally joining the first and second actuator arm portions. A method of making an actuator arm assembly for a disk drive includes steps of providing a flat sheet of material and stamping an actuator arm assembly from the sheet such that the stamped actuator arm assembly includes first and second actuator arm portions and one or more bendable portions integrally joining the first and second actuator arm portions.

Owner:WESTERN DIGITAL TECH INC

Wired circuit board

InactiveUS7652890B2Firmly connectedImpedance stabilityElectrically conductive connectionsPrinted circuit aspectsEngineeringPrinted circuit board

Owner:NITTO DENKO CORP

Method for providing electrical crossover in a laminated structure

An externally wireless laminated suspension for a hard disk drive are disclosed. In one embodiment, the externally wireless laminated suspension has an insulating layer to electrically isolate a first and second electrical trace from a conductive support layer. The second electrical trace crosses over the first electrical trace. The first electrical trace may be made of a first part on one side of the second electrical trace and a second part on the opposite side of the electrical trace. A conductive island area may be patterned into the support layer. The conductive island area may electrically couple the first part of the first electrical trace to the second part. The number of crossover points that the first electrical trace has may equal the number of crossover points that the second electrical trace has.

Owner:HUTCHINSON TECH

Wired circuit board

InactiveUS20070253176A1Inhibition formationAvoid componentsPrinted circuit aspectsHigh voltage circuit adaptationsPrinted circuit boardSemiconductor

A wired circuit board has a metal supporting board, an insulating base layer formed on the metal supporting board, a conductive pattern formed on the insulating base layer and including at least one pair of wires arranged in mutually spaced-apart and opposed relation having different potentials, a semiconductive layer formed on the insulating base layer to cover the conductive pattern and electrically connected to the metal supporting board on one side outside a region where the pair of wires are opposed, and an insulating cover layer formed on the semiconductive layer.

Owner:NITTO DENKO CORP

Magnetic disk drive, wiring connection structure and terminal structure

InactiveUS7372669B2Avoid crackingEasy to solvePrinted circuit aspectsRecord information storageElectrical conductorFlexible electronics

Terminals of a flexible printed circuit board and terminals of a wiring trace in a head suspension assembly are to be connected with each other by soldering without causing a soldering defect. In an embodiment, a terminal structure of a multi-connector in a wiring trace which includes an insulating layer and a conductor pattern portion formed on a surface of the insulating layer is provided with exposed portions of terminals exposed from apertures formed in part of the insulating layer and is also provided with lining portions adjacent to the exposed portions in a longitudinal direction of the conductor pattern portion and bonded to the insulating layer. Even if terminals of the multi-connector are cracked when soldered, not only conductivity is ensured, but also it is possible to strengthen the terminals, because the lining portions of the terminals are bonded to the insulating layer.

Owner:WESTERN DIGITAL TECH INC

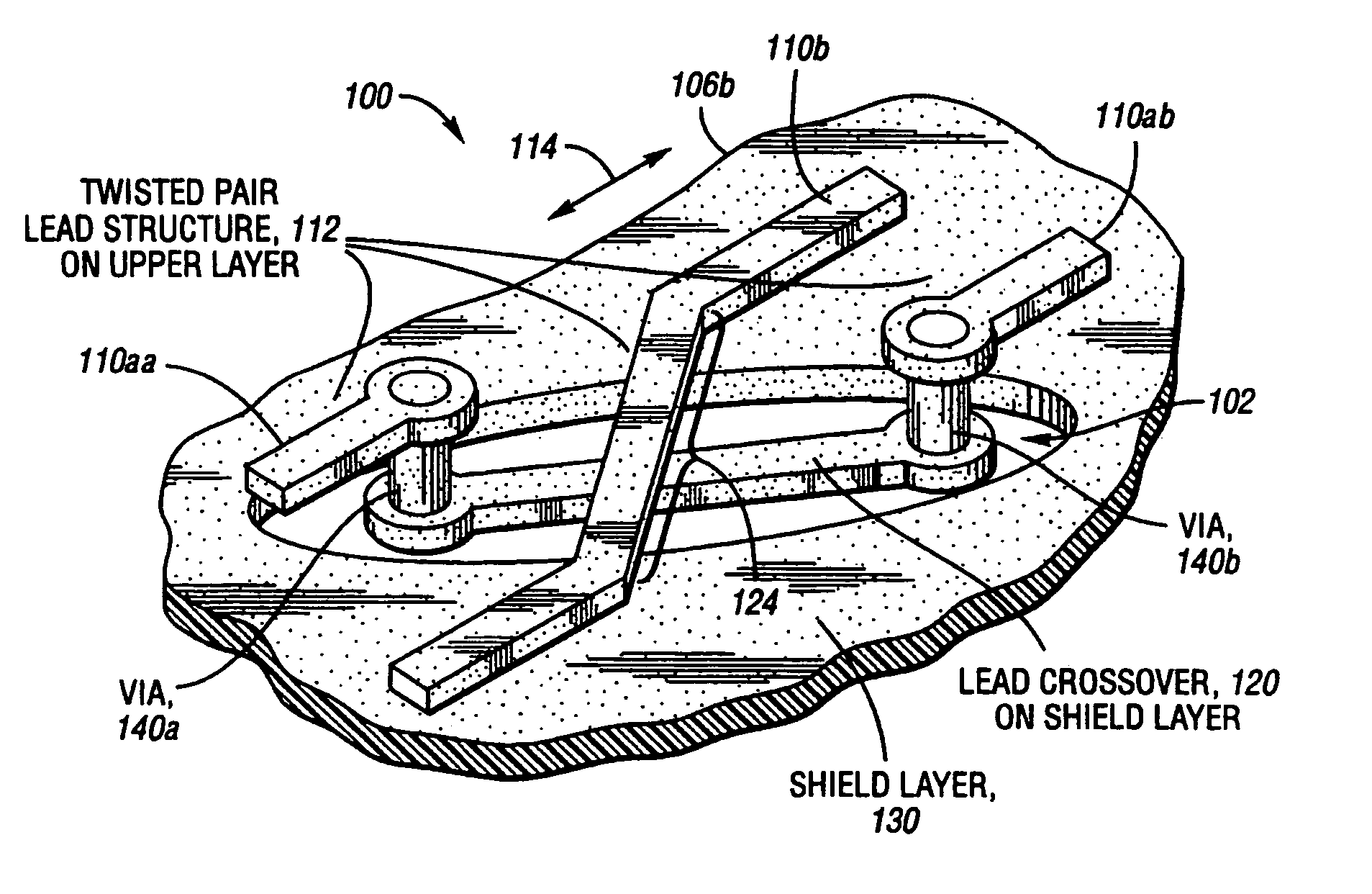

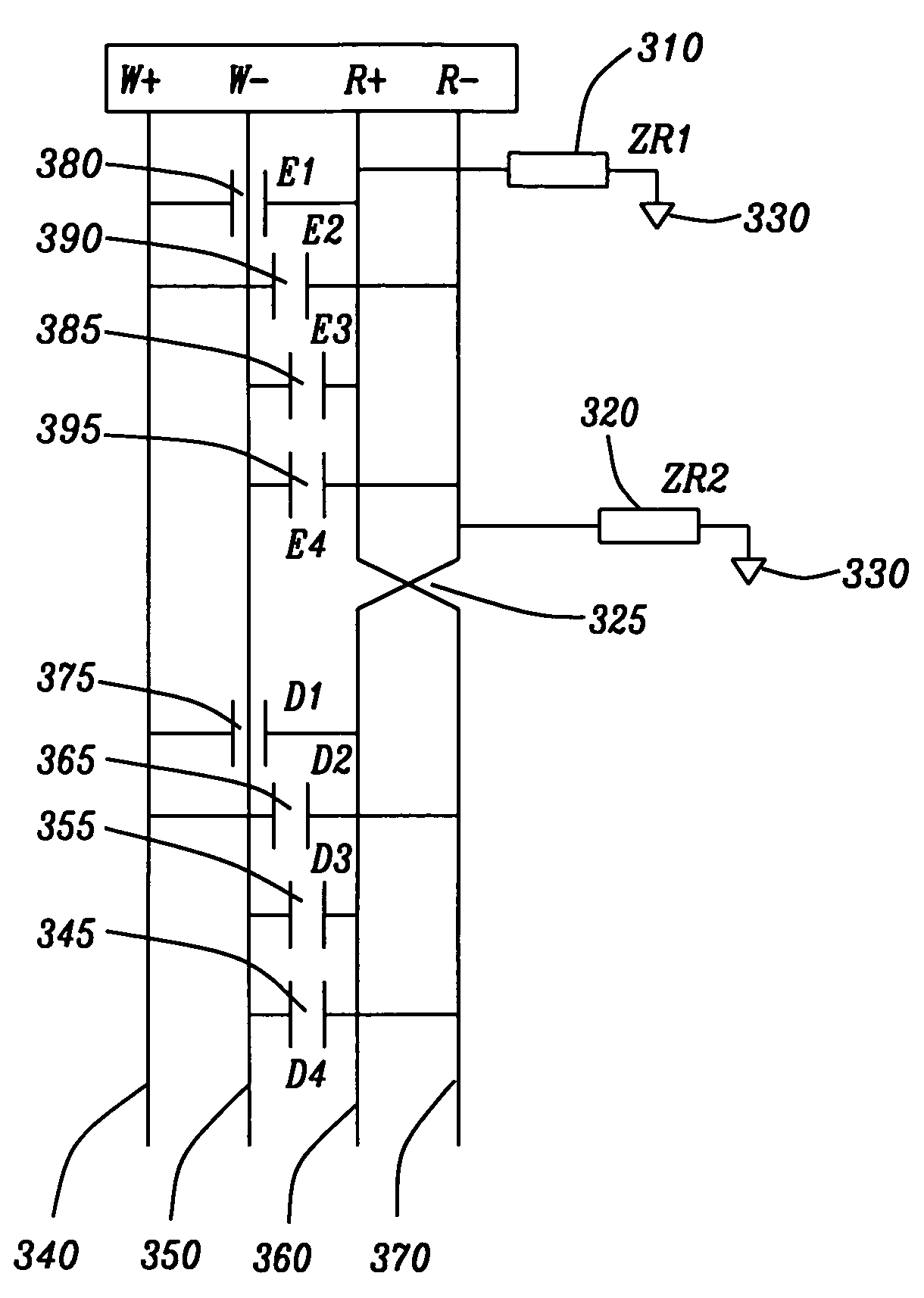

Cross talk and EME minimizing suspension design

InactiveUS20050180053A1Reduce crosstalk interferenceMinimize crosstalkRecord information storageFluid-dynamic spacing of headsParasitic capacitanceEngineering

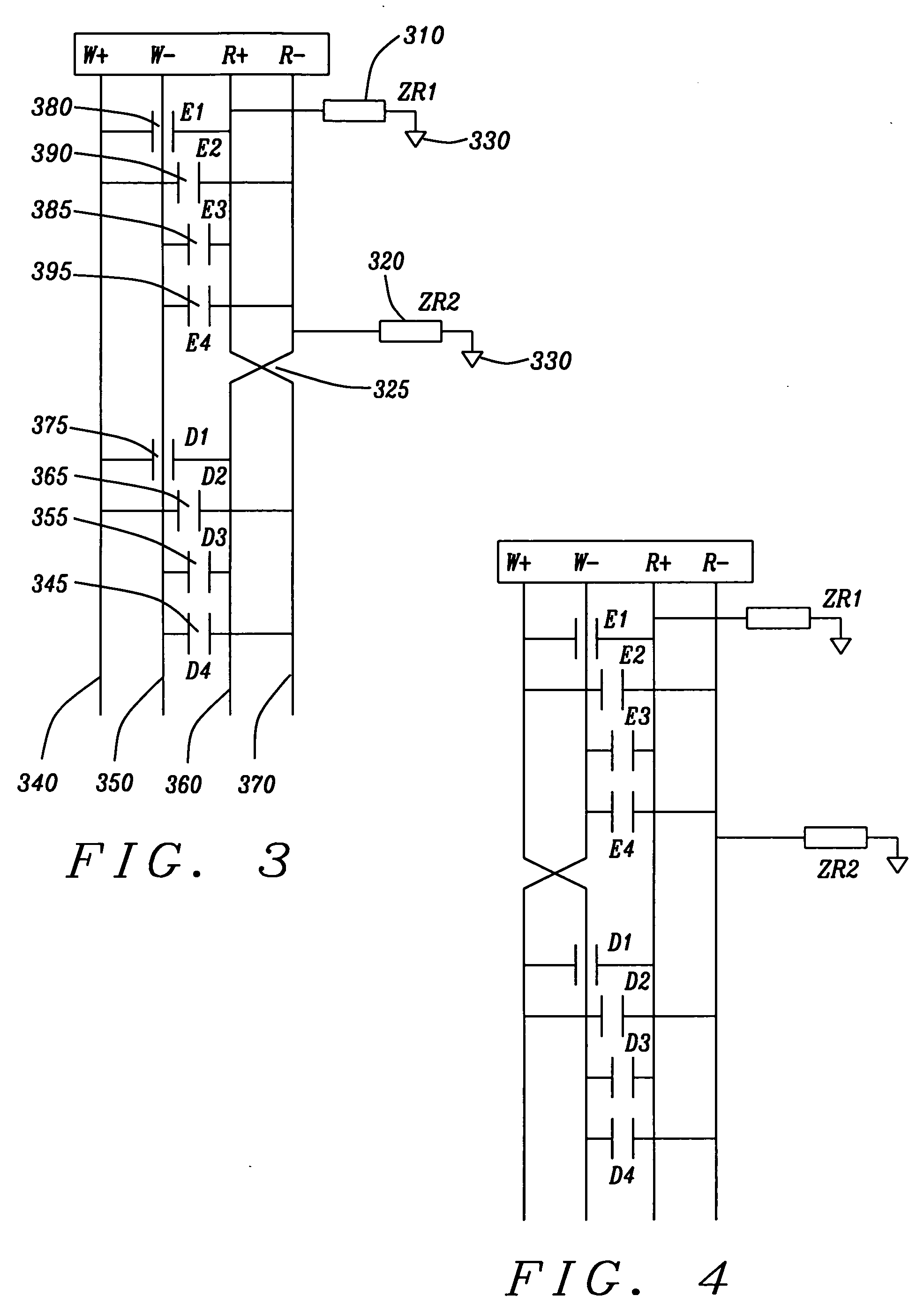

This structure and method for minimizing EME (Electromagnetic Emission) and the crosstalk between the signal lines which are used to write and read the tracks of magnetic disk drives. These signal lines are located on magnetic trace suspension assemblies which move above the magnetic disk drives. The structure and method utilize well-placed single and multiple crossovers on either or both of the lines used to read and write the tracks on magnetic disks. In addition, the structure and method utilize the parasitic capacitances between the write and read lines to couple beneficial voltages which cancel the unwanted crosstalk noise.

Owner:HEADWAY TECH INC

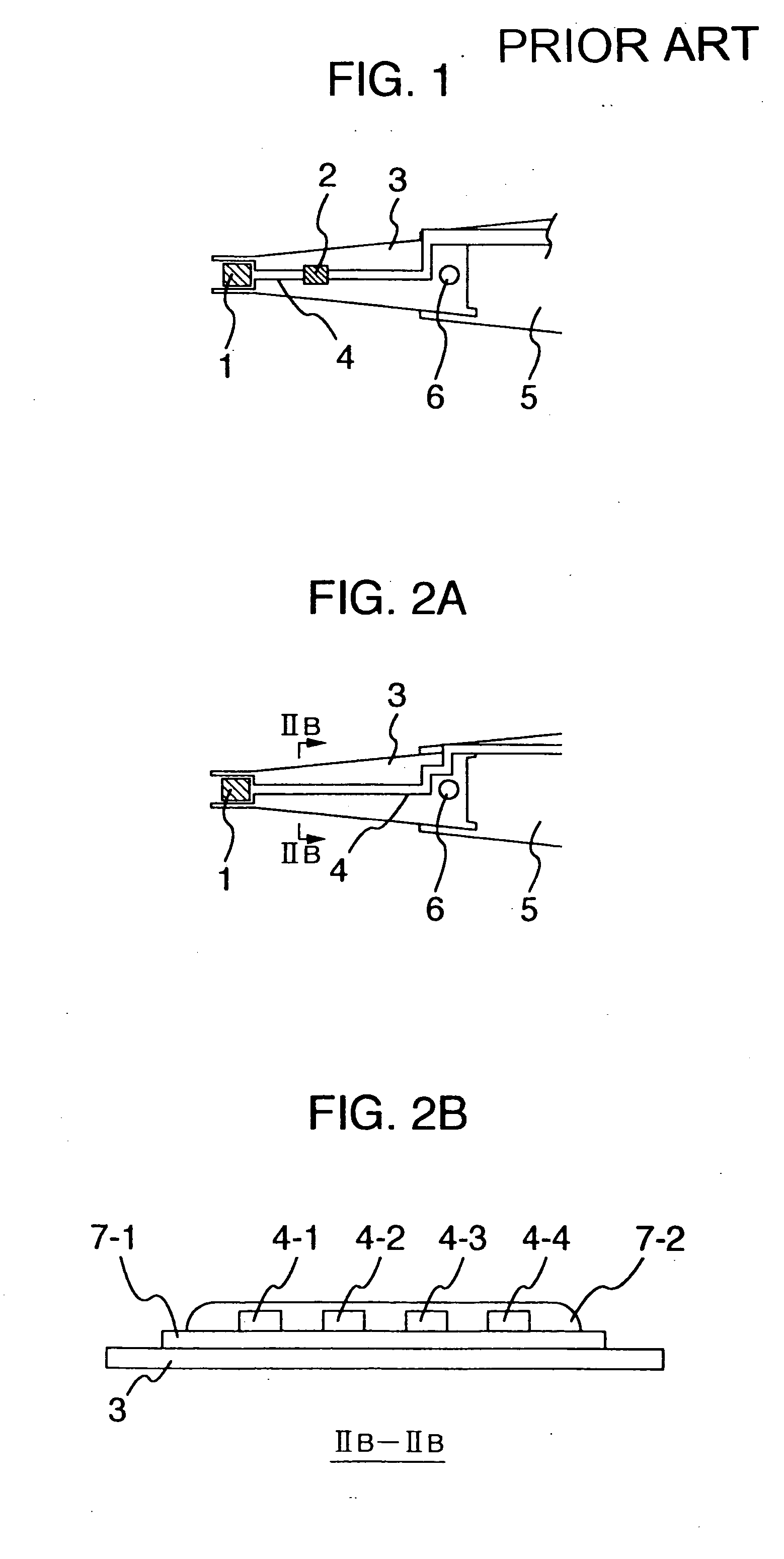

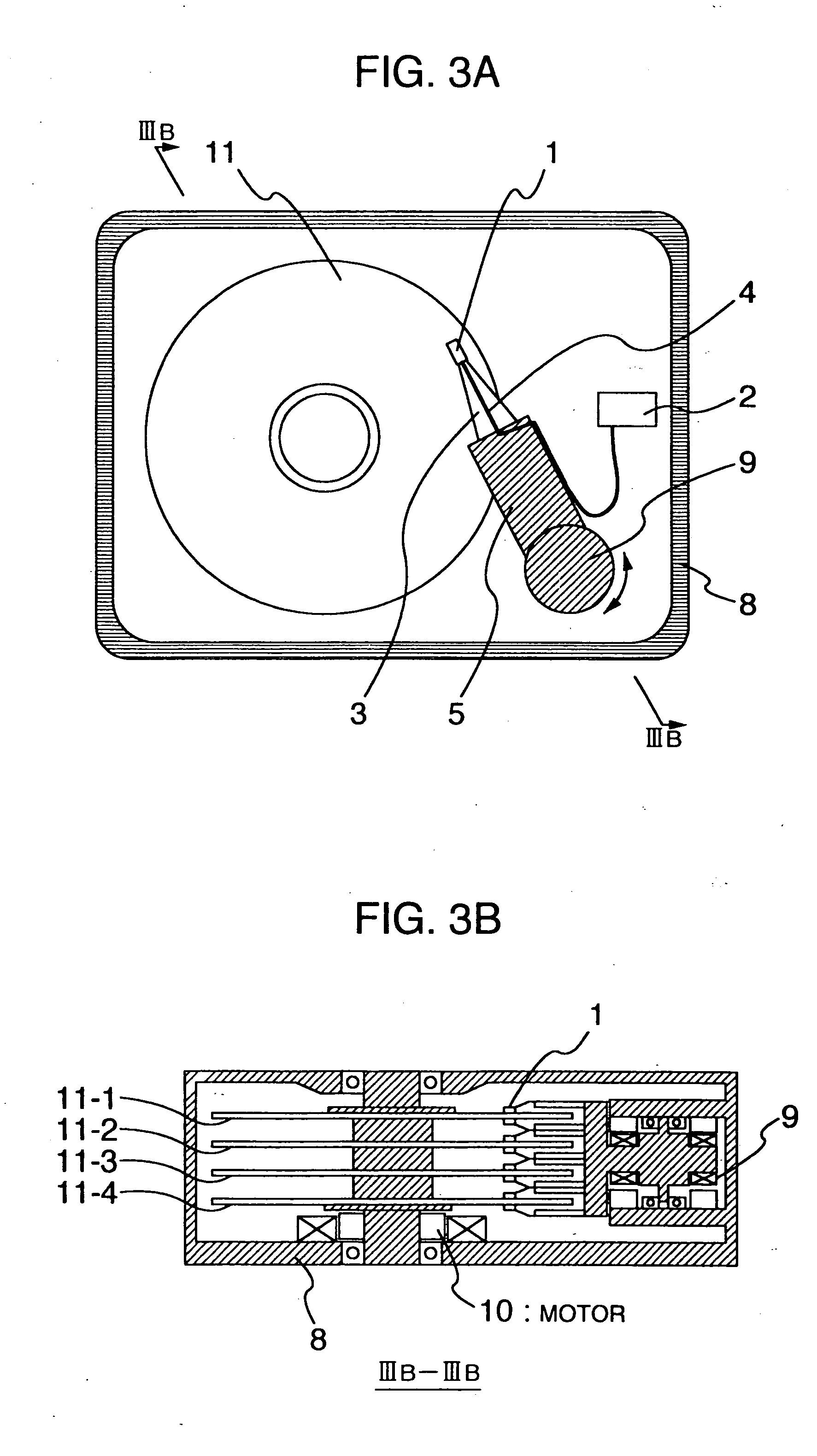

Magnetic disk drive

InactiveUS20050063097A1Without increasing a cost-up aspectHigh frequency recording operation operableFluid-dynamic spacing of headsRecord information storageCharacteristic impedanceElectrical current

Magnetic disk apparatus includes an electric wiring capable of satisfying an electric condition under which high frequency recording higher than or equal to 200 MHz, a magnetic head having at least a recording device to a magnetic recording medium, and also the electric wiring corresponding to a recording current supplying device to this magnetic head are formed on a suspension member for mechanically suspending the magnetic head, the recording current being supplied to a magnetic head recording device by employing such electric wiring, the characteristic impedance of which is higher than a maximum impedance of the magnetic head recording device.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

Disk drive suspension

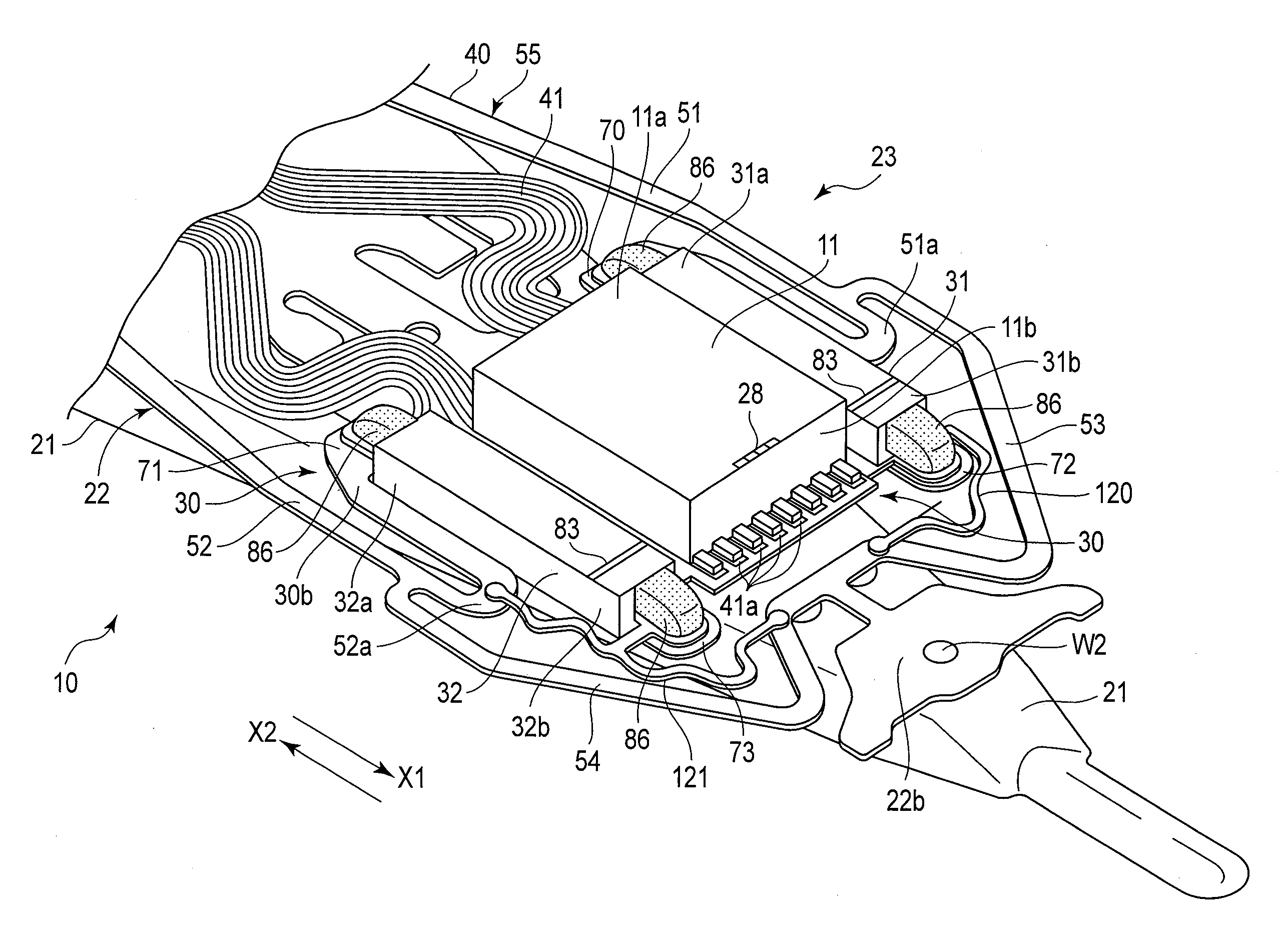

ActiveUS20140085755A1Growth inhibitionShort-circuiting between the conductive paste and conductor can be preventedElectrical connection between head and armArm with actuatorsConductive pasteEngineering

A slider and a microactuator element are disposed on a gimbal portion of a flexure. The gimbal portion comprises a metal base, an electrically insulating resin layer, a conductor disposed on the resin layer, an electrically insulating adhesive block, and an electrically conductive paste. The adhesive block secures an end portion of the microactuator element to the metal base. The conductive paste is provided between the conductor and an electrode of the microactuator element. A first adhesive interface extending along the thickness of the resin layer, a second adhesive interface extending along a surface of the resin layer, and a corner portion are formed between the metal base and the conductive paste.

Owner:NHK SPRING CO LTD

Low density, high rigidity disk drive suspension for high resonance frequency applications

ActiveUS7460337B1Low densityRigidity through layer separationFluid-dynamic spacing of headsRecord information storageInter layerResonance

A disk drive suspension component for carrying a slider at a disk is formed of a laminate of at least three metal layers of like mechanical and chemical formability, including a first outer layer, a second outer layer, and an intermediate layer, at least one of the layers having a void-containing interior and a surface area having an undivided series of local regions distributed across substantially the width and length thereof with each local region equaling less than 10% of the surface area. Each of the local regions have an overall pattern of discontinuities and lands between the discontinuities substantially the same as the overall pattern of discontinuities and lands in laterally and longitudinally adjacent local regions for local attachment of the layers at some and not all of the lands to adjacent layers to form a laminate having common formability properties, high rigidity and light weight.

Owner:MAGNECOMP

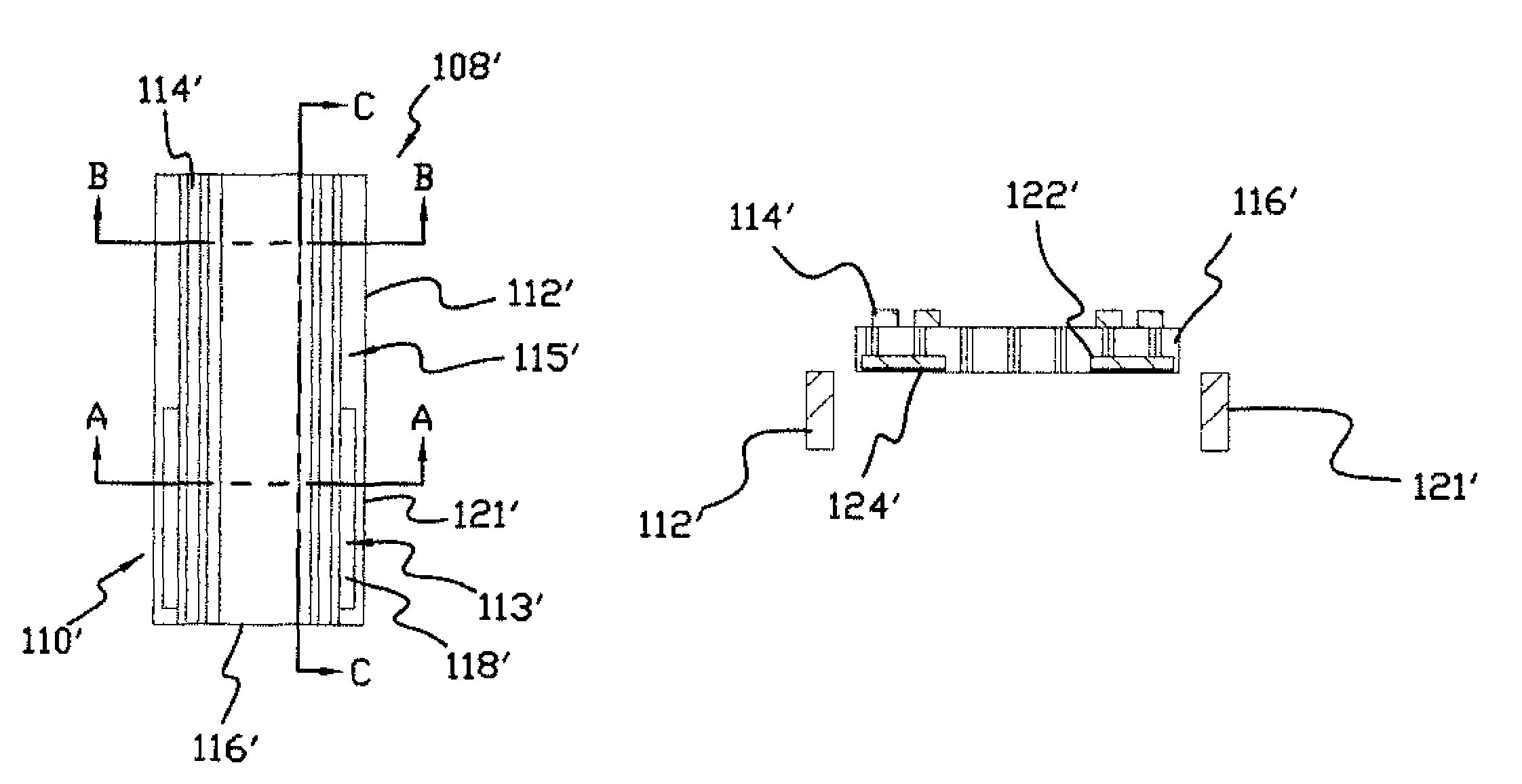

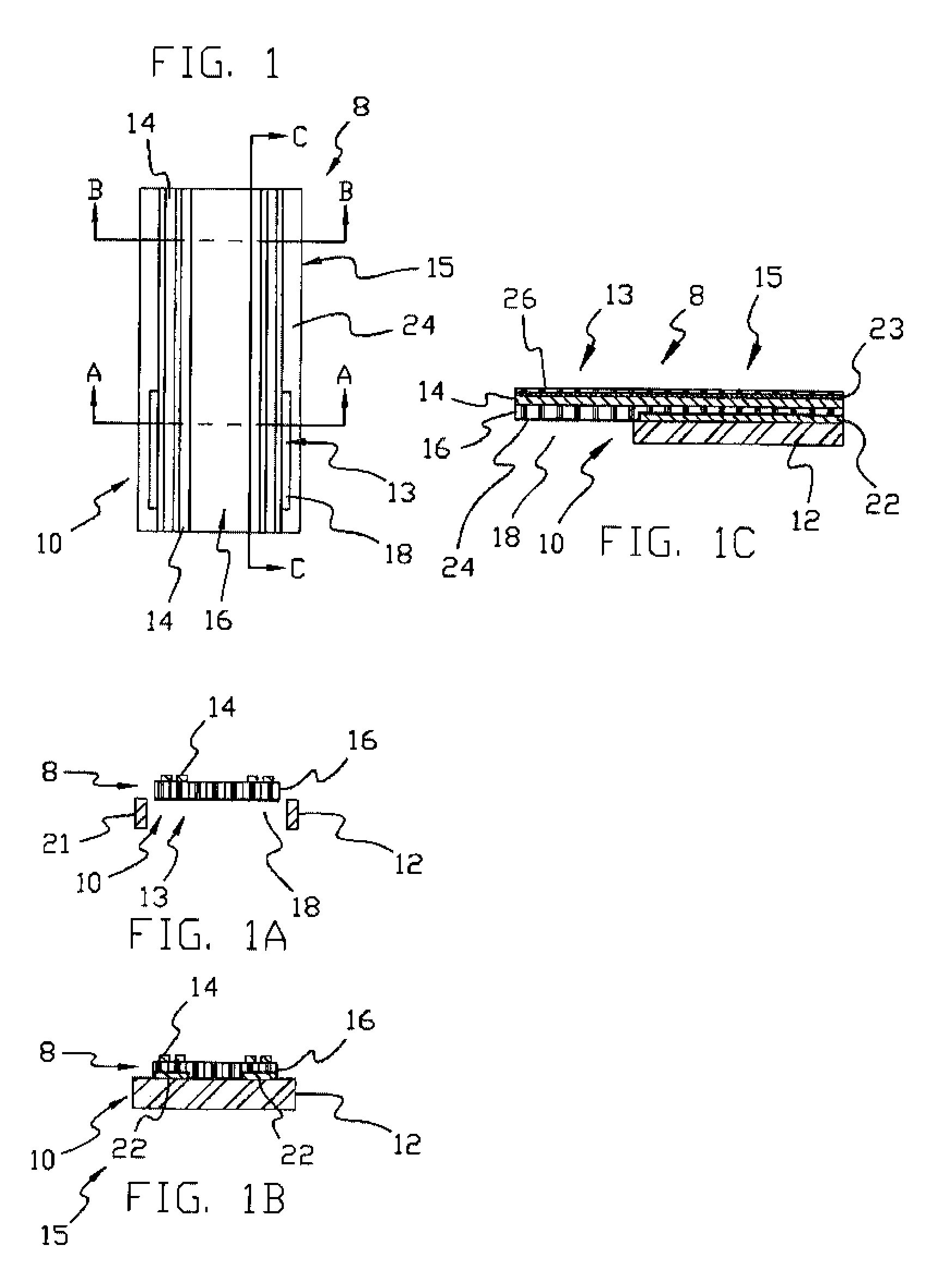

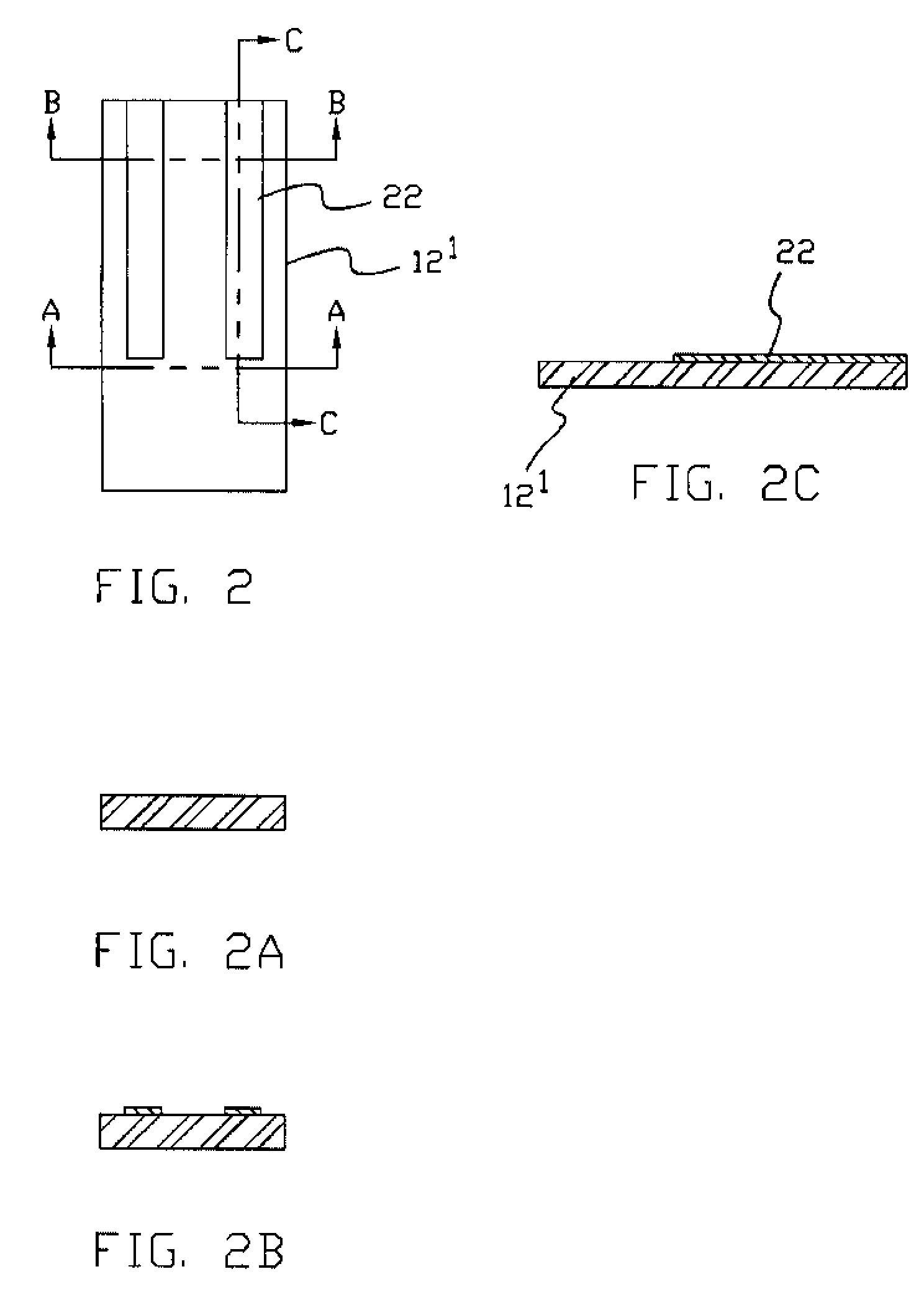

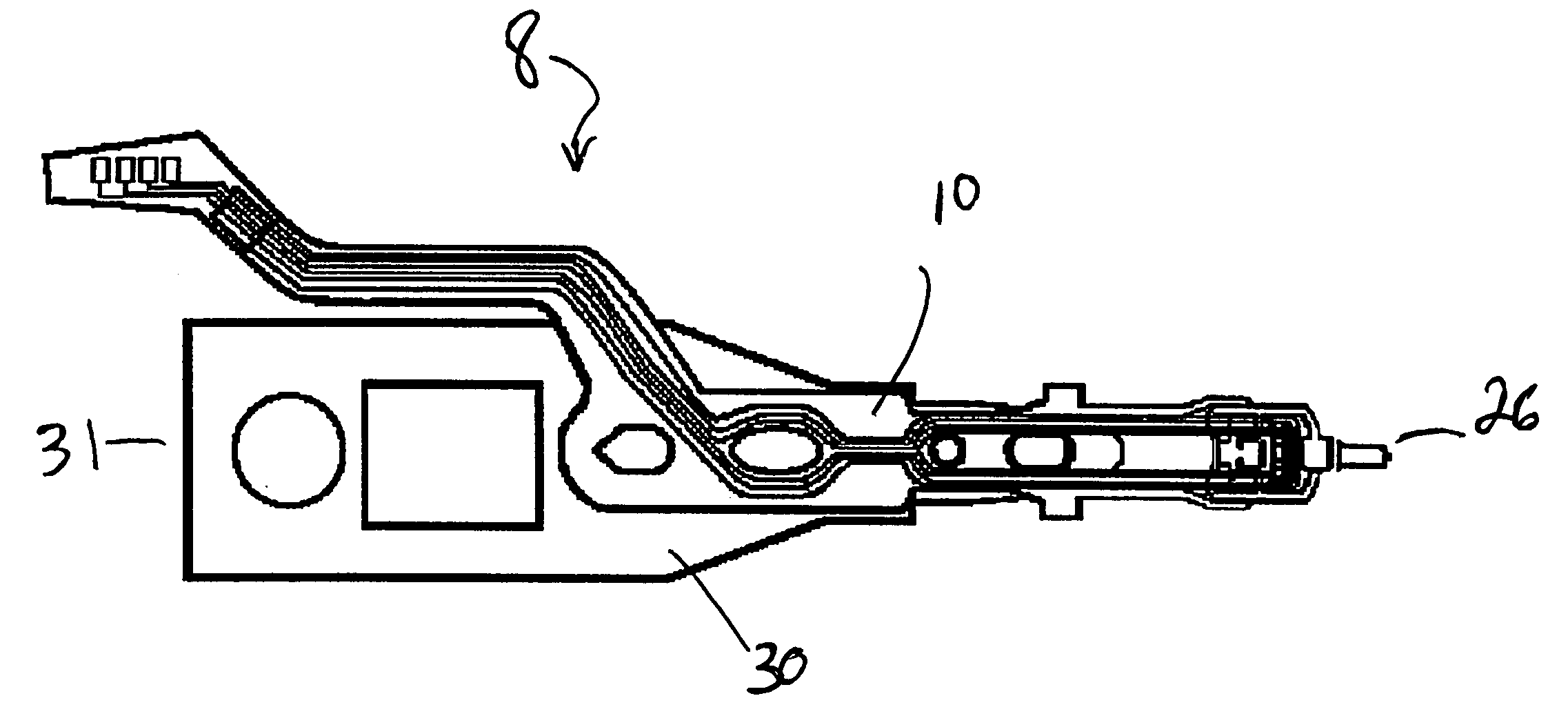

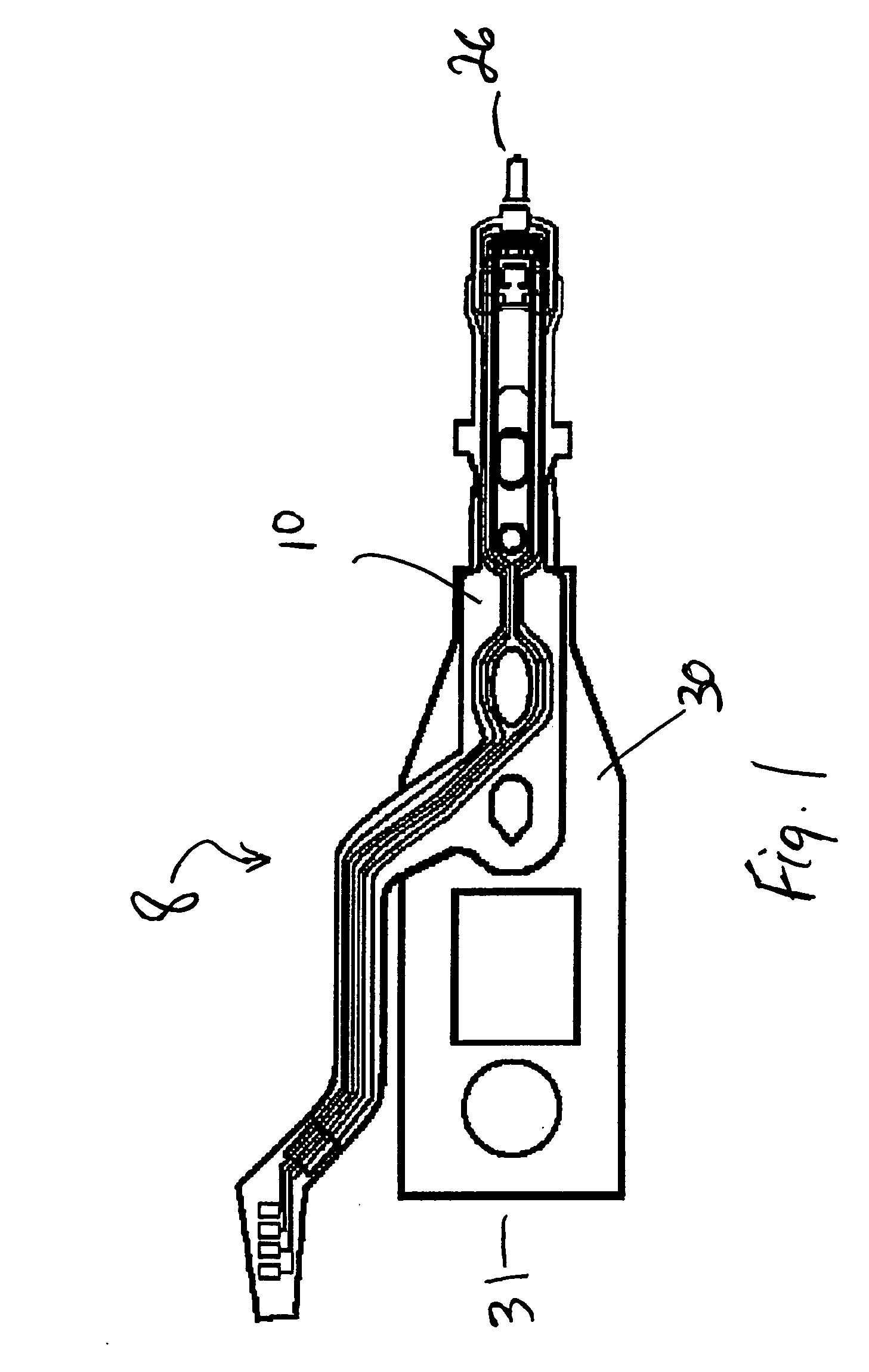

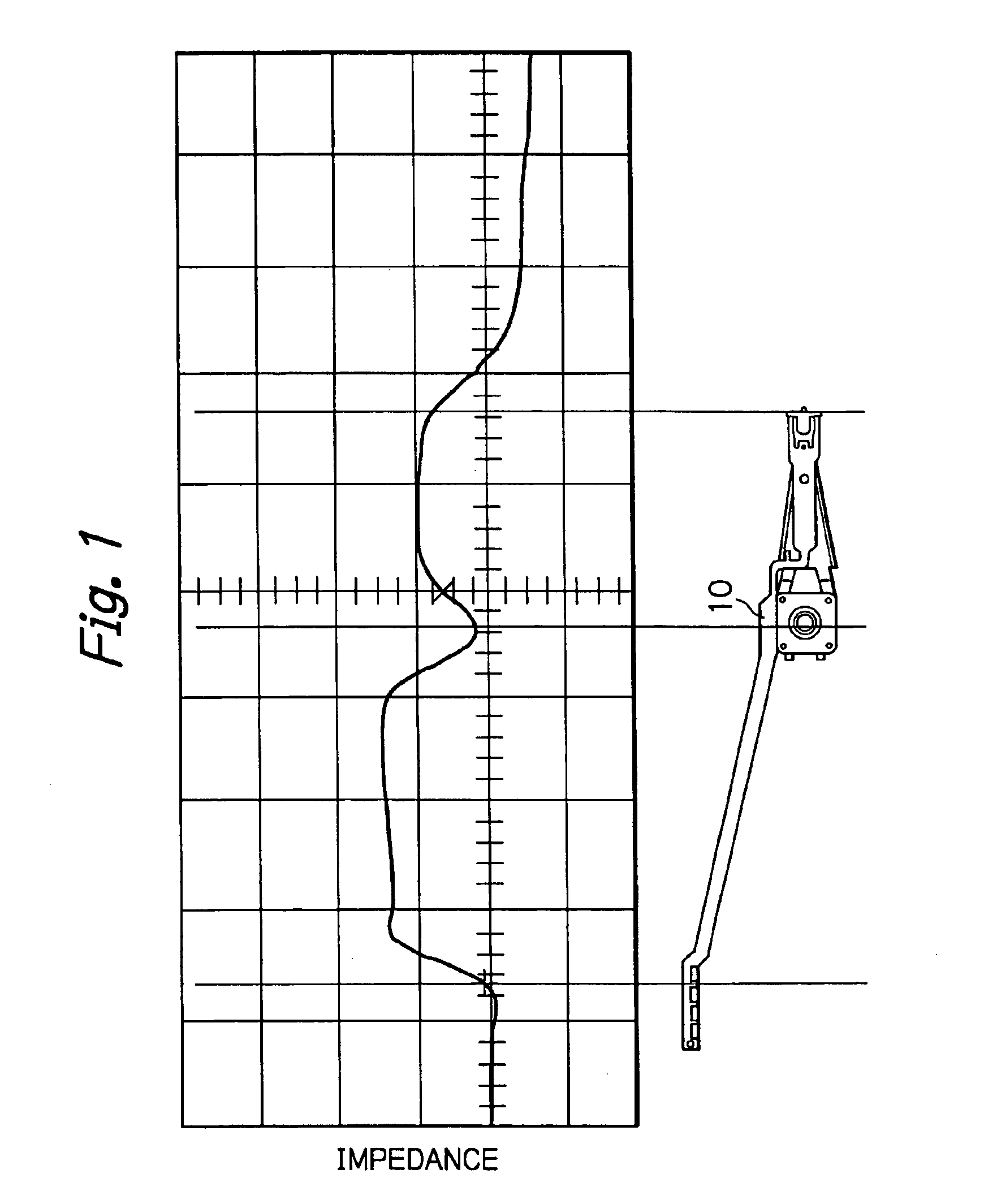

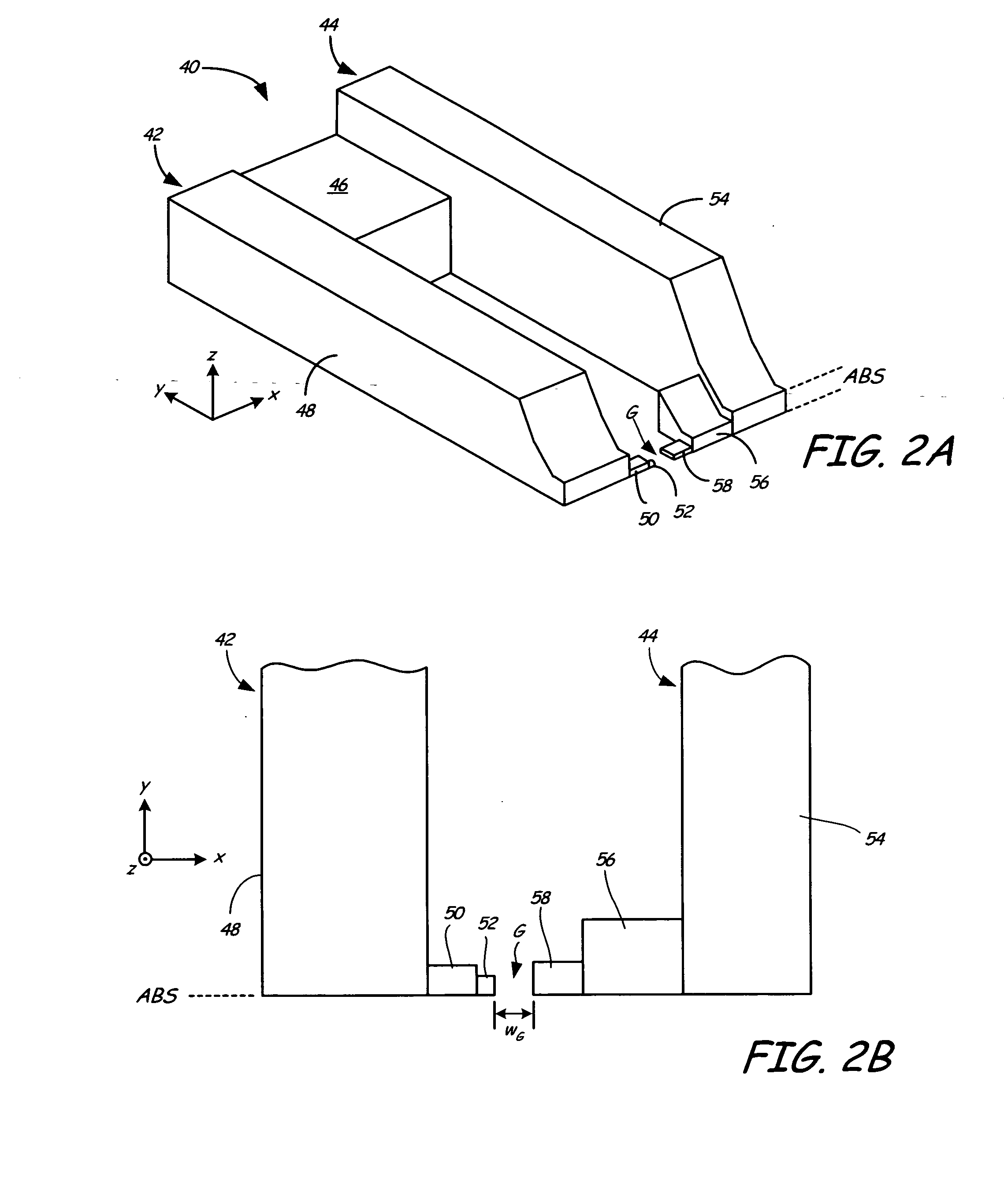

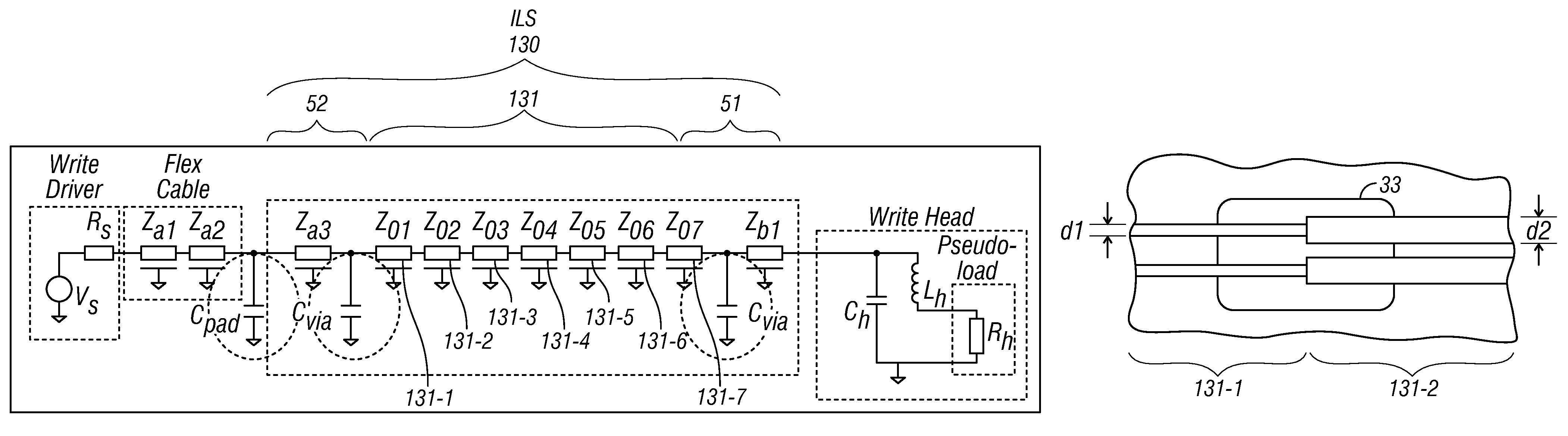

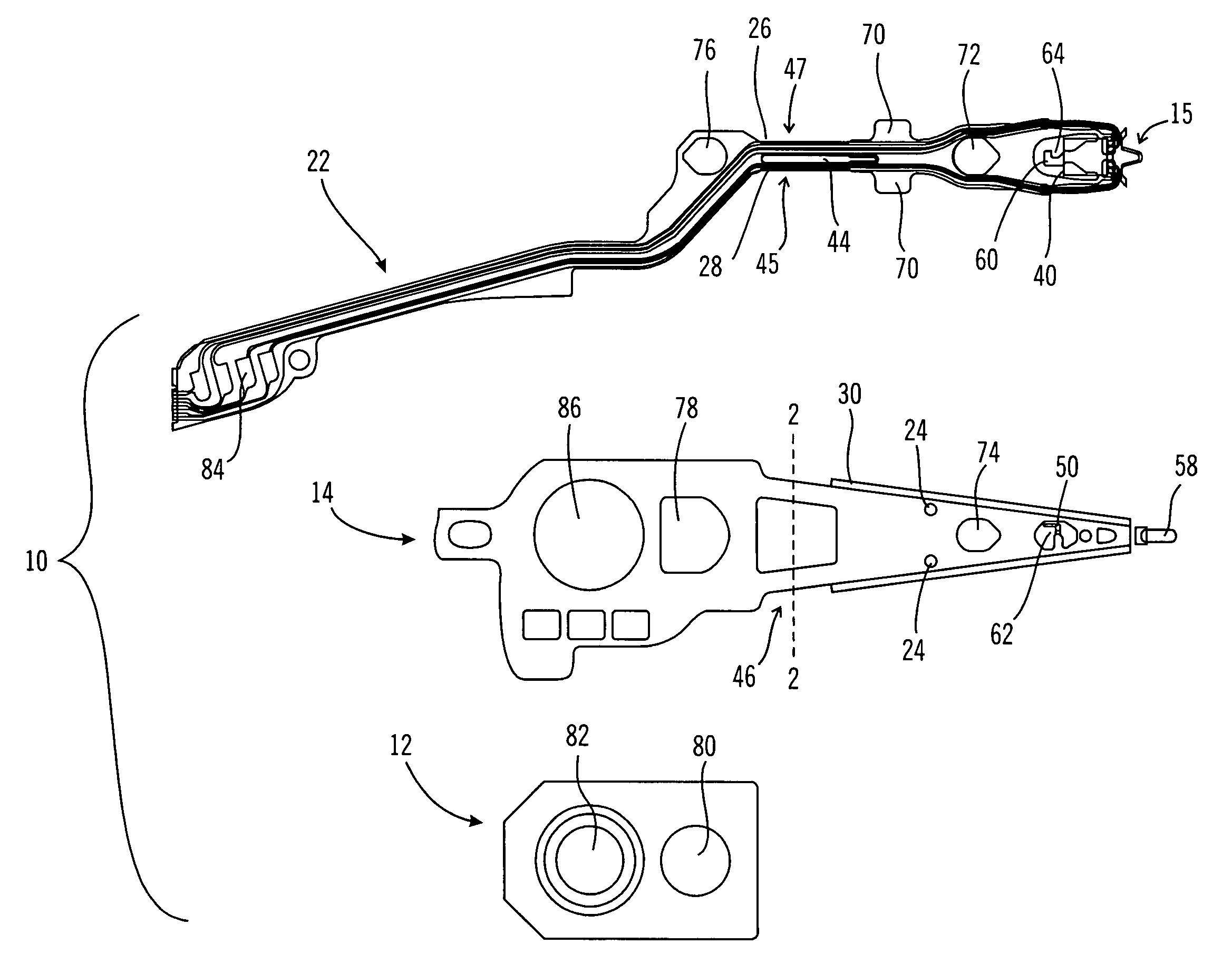

Magnetic recording disk drive with integrated lead suspension having multiple segments for optimal characteristic impedance

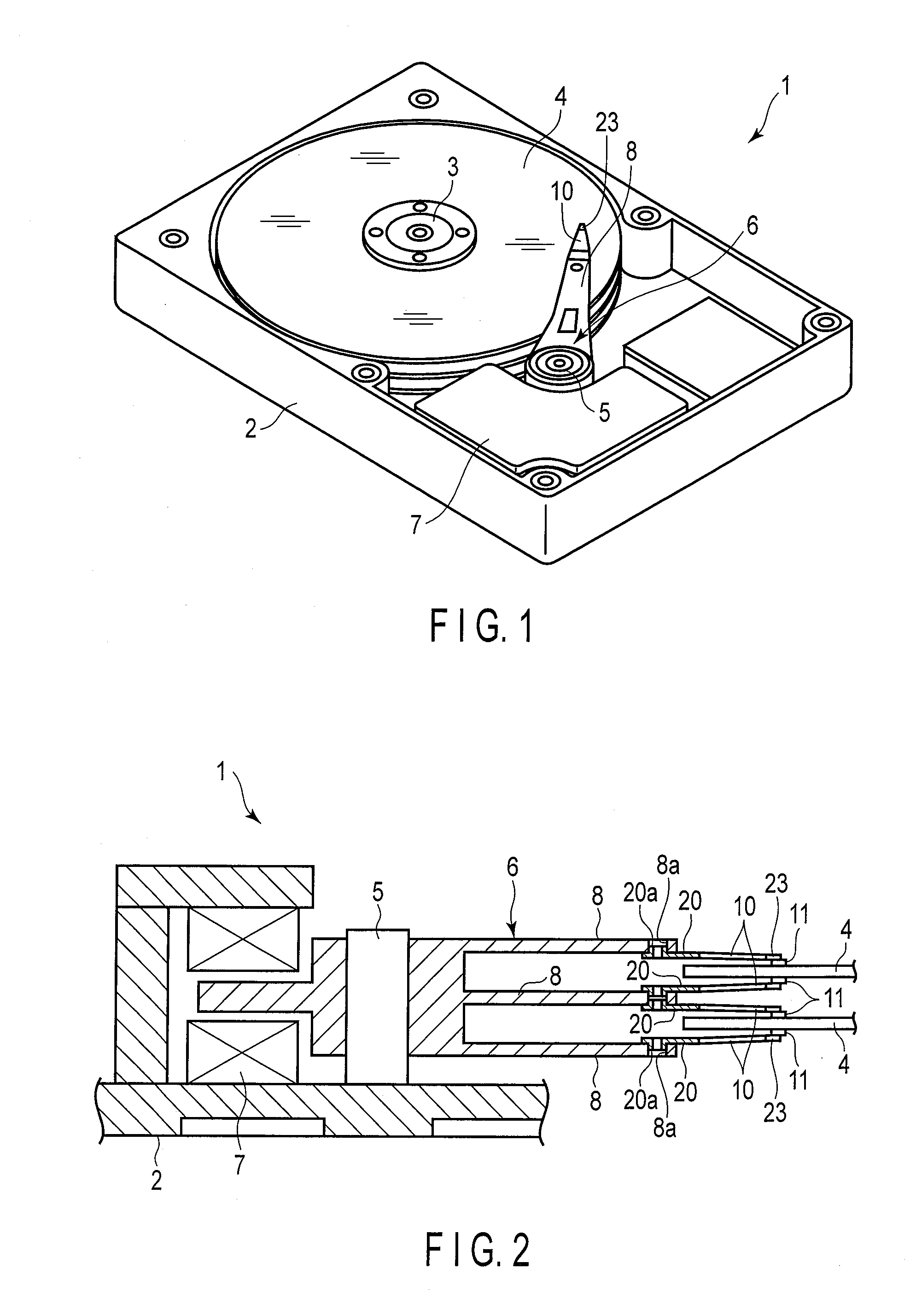

ActiveUS8233240B2Record information storageIntegrated arm assembliesEngineeringCharacteristic impedance

An integrated lead suspension (ILS) in a magnetic recording disk drive has the transmission line portion of the ILS between the flex cable and the gimbal formed of multiple interconnected segments, each with its own characteristic impedance. At the interface between any two segments there is a change in the widths of the electrically conductive traces of the transmission line. The change in impedance of a fixed-length segment is a function of the change in its trace width. The number of segments and their characteristic impedance values are selected to produce the largest frequency bandwidth with a substantially flat group delay from the write driver to the write head.

Owner:WESTERN DIGITAL TECH INC

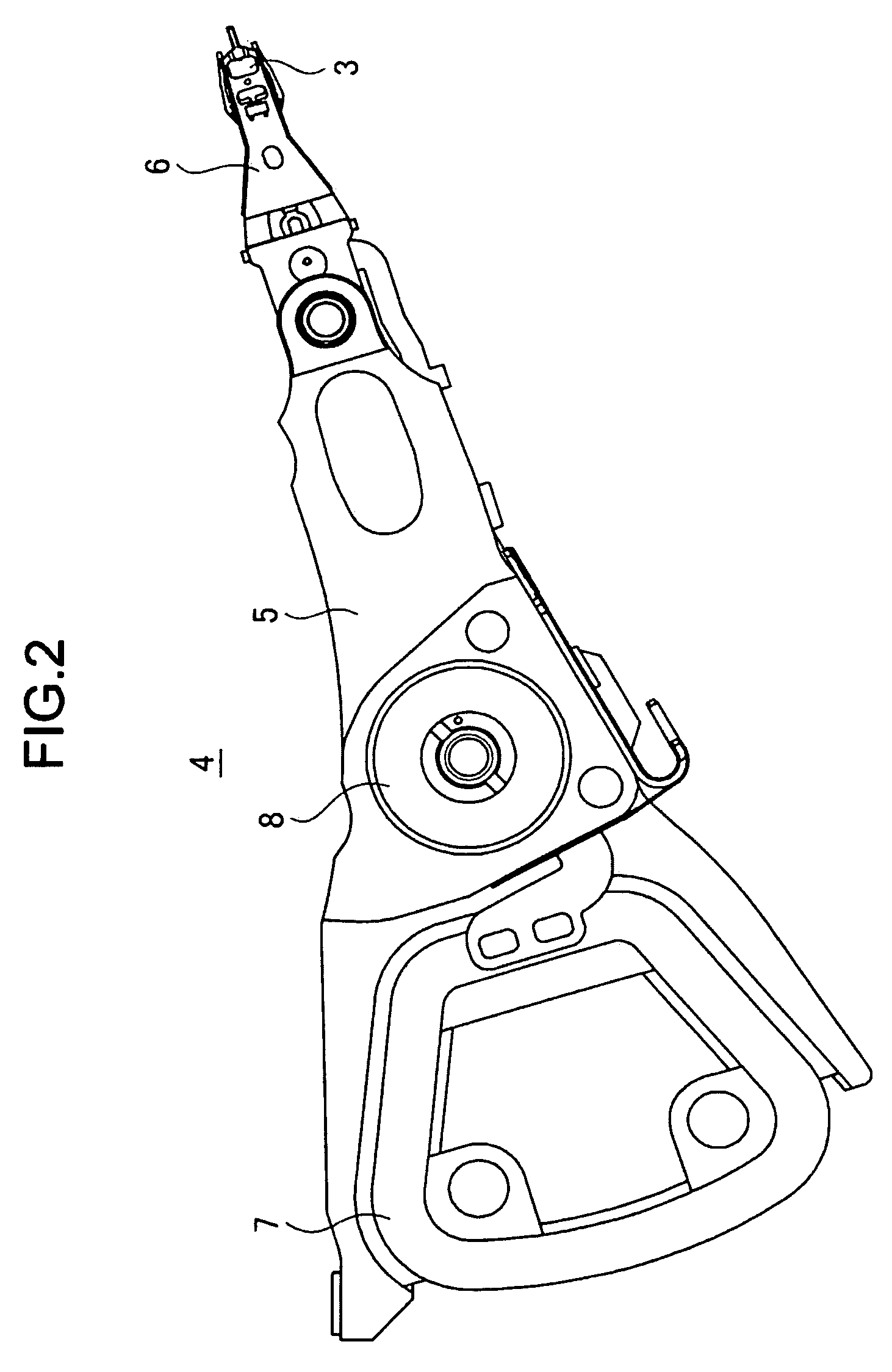

Carriage assembly of a hard disk drive

InactiveUS7385788B2Improve liquidityDeformation of the adhesive layer is facilitatedLaminating printed circuit boardsPrinted circuit aspectsHard disc driveAdhesive

A carriage assembly of a hard disk drive is constructed so that the bonding of flying leads of a long tail suspension circuit board and bonding terminals of a flexible printed circuit board can be carried out uniformly and reliably, and the problem of the flying leads breaking when the flying leads are pulled off the bonding terminals does not occur. The flexible printed circuit board is attached to a reinforced part by an adhesive in which spacers with a substantially equal particle diameter are mixed, and the flying leads and the bonding terminals are bonded together by ultrasonic bonding by applying ultrasonic vibration in a state where the flying leads are pressed onto the bonding terminals. In addition, an insulating film is provided on an opposite surface of the flying leads to the surface bonded to the bonding terminals, and during the ultrasonic bonding, ultrasonic vibration is applied in a state where the flying leads are pressed via the insulating film onto the bonding terminals.

Owner:TOSHIBA STORAGE DEVICE CORP

Suspension equipped with vibration sensor and manufacturing method thereof

InactiveUS20080229842A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersElectricityHard disc drive

A suspension for a hard disk drive has a vibration sensor which is impervious to influence by external noise, to obtain more stable positioning precision of the head on the suspension. The suspension has a load beam, a vibration sensor sandwiched by a first electrode and a second electrode, and a conductive wiring pattern on the load beam for electrically connecting the first electrode and the second electrode to an external detection circuit. The first electrode is sandwiched by the second electrode via the vibration sensor and a shield layer via an insulating layer. The second electrode and the shield layer are at a same potential.

Owner:TOSHIBA STORAGE DEVICE CORP

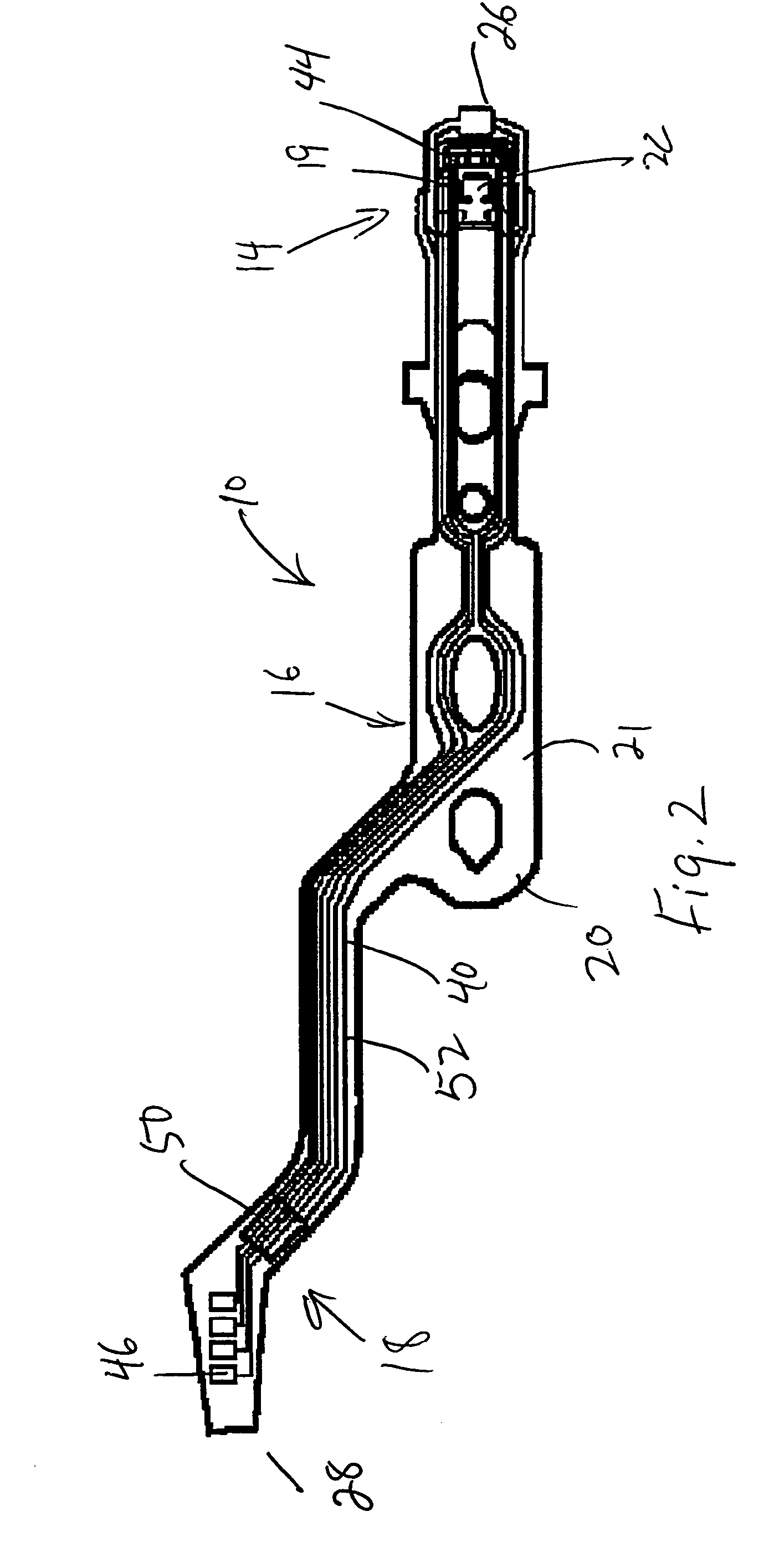

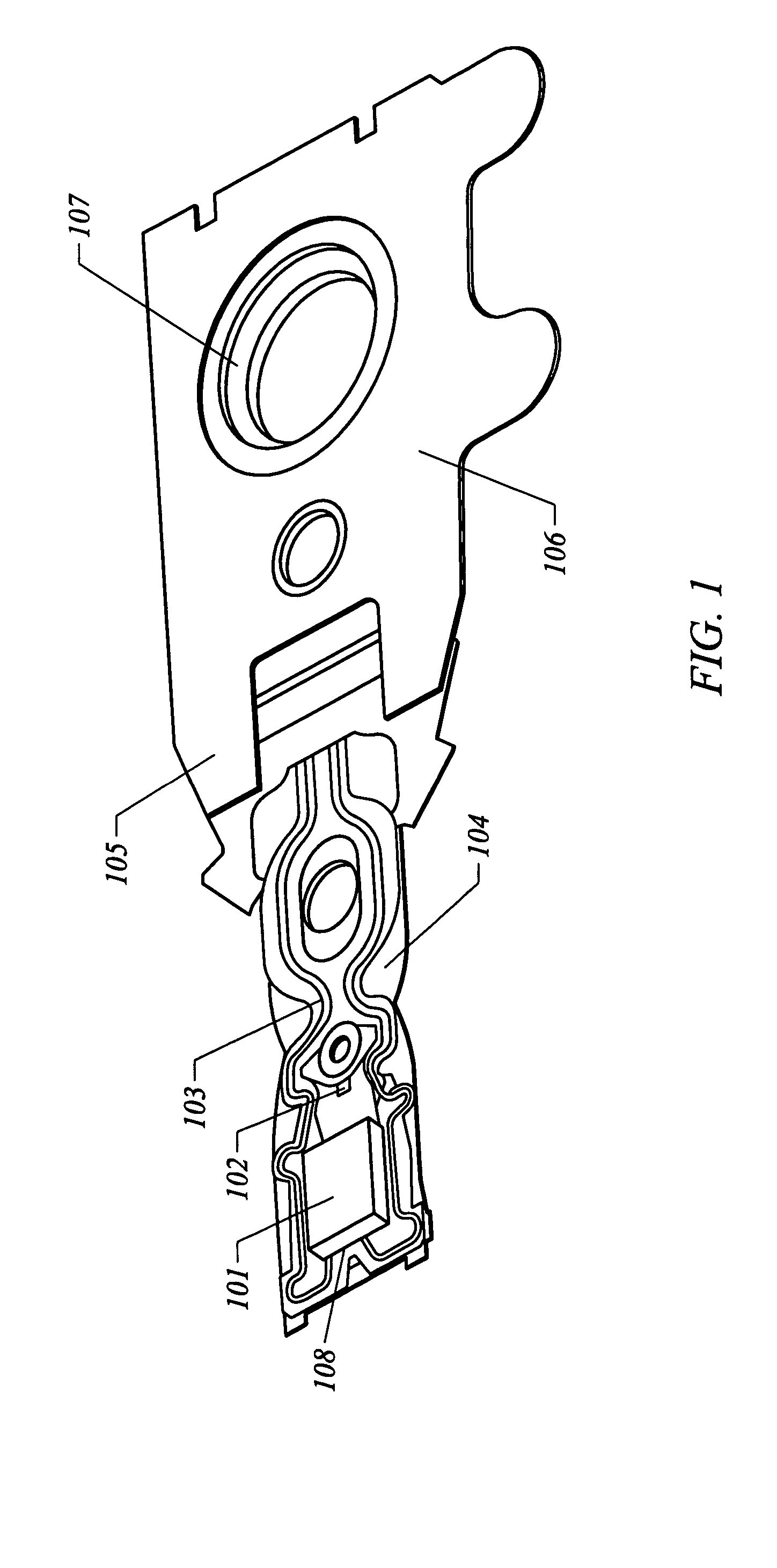

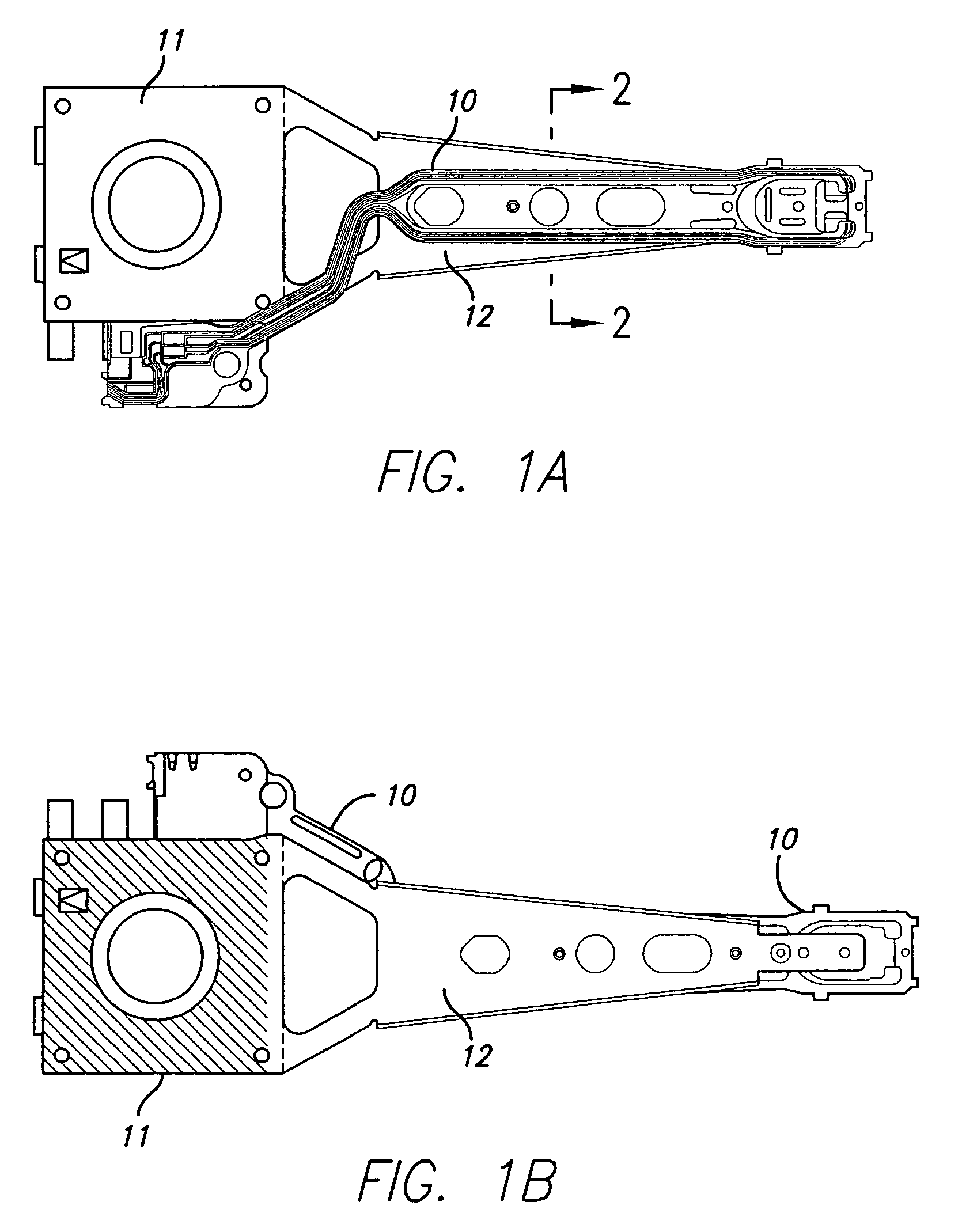

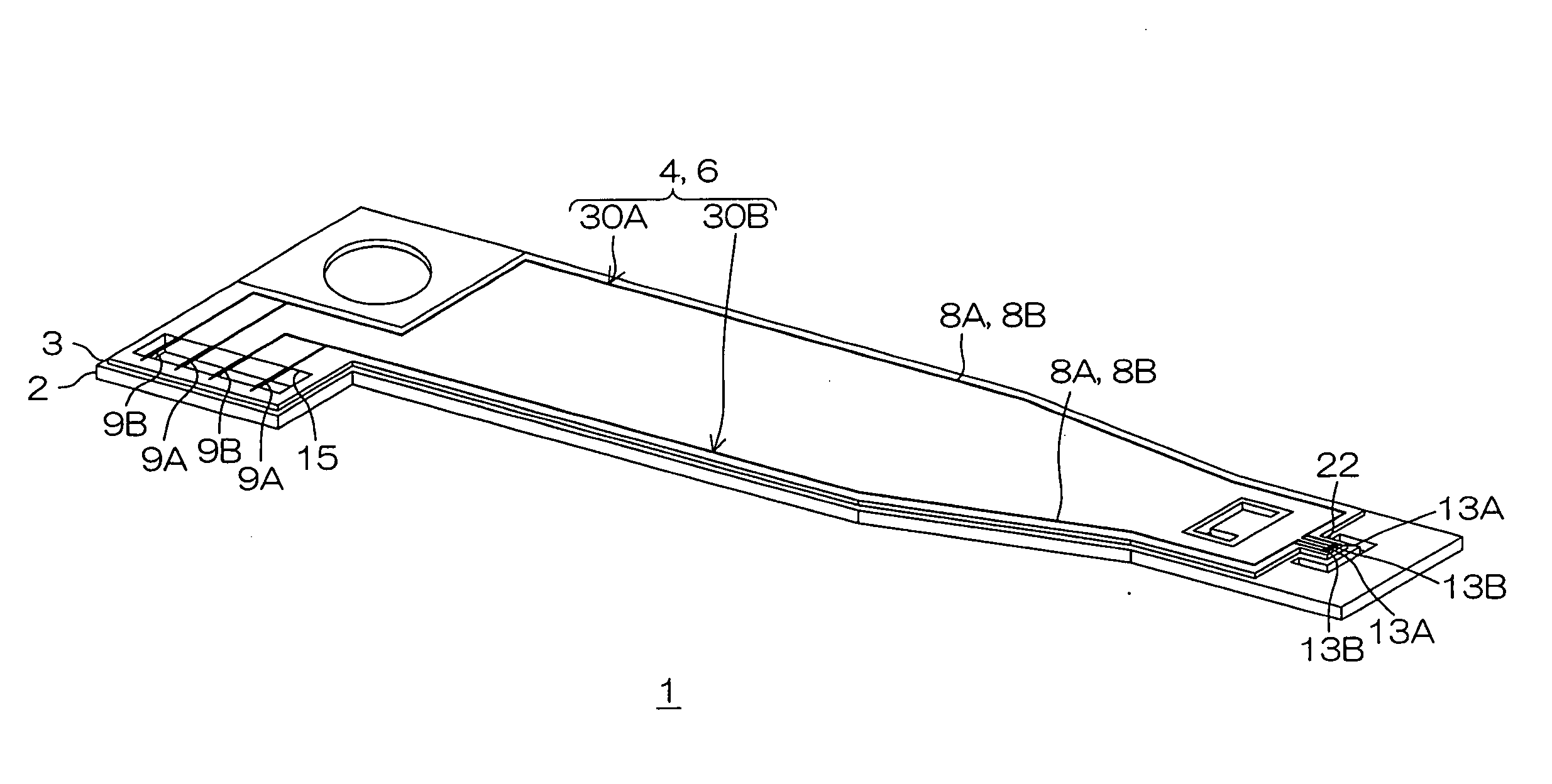

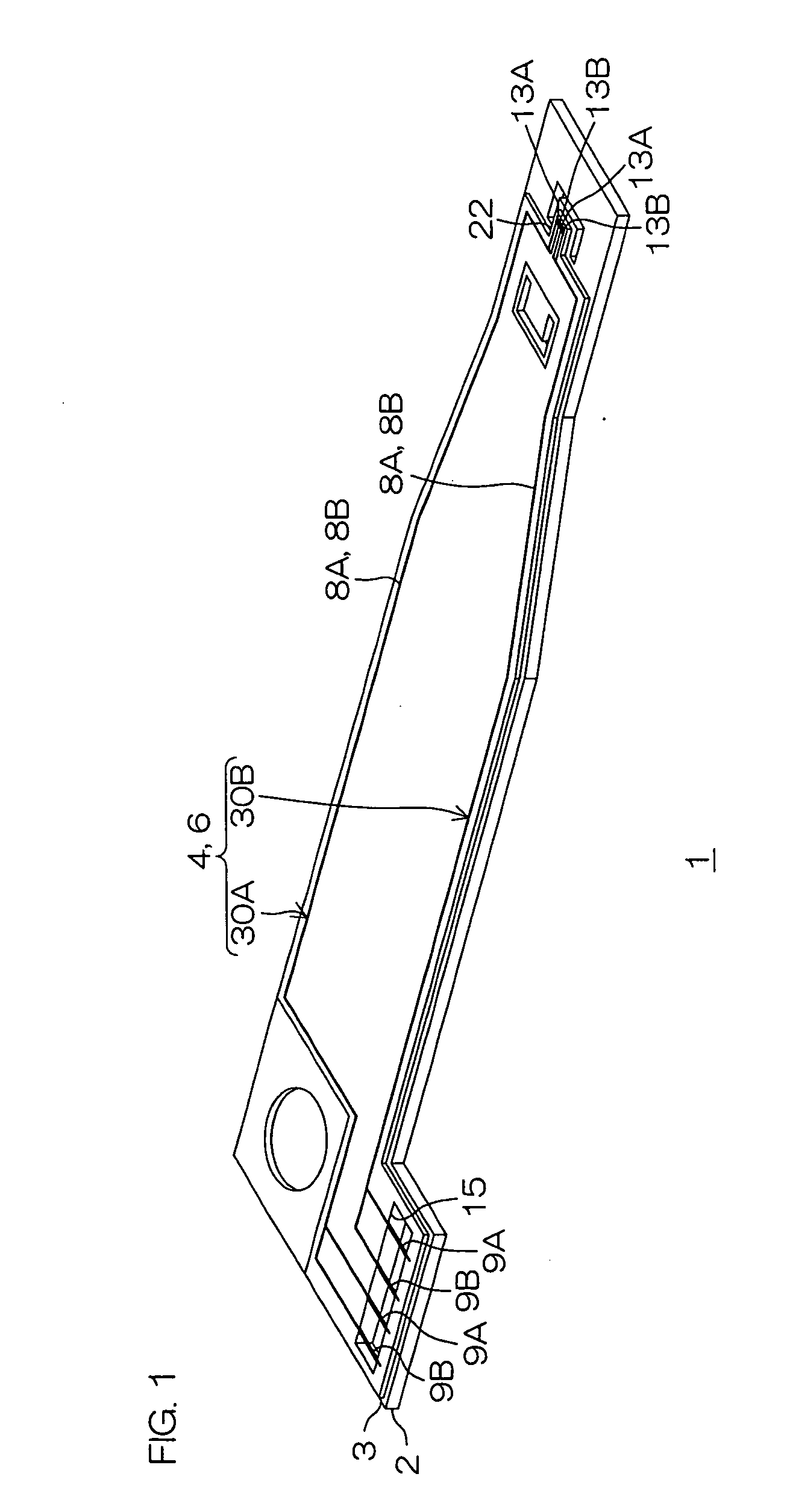

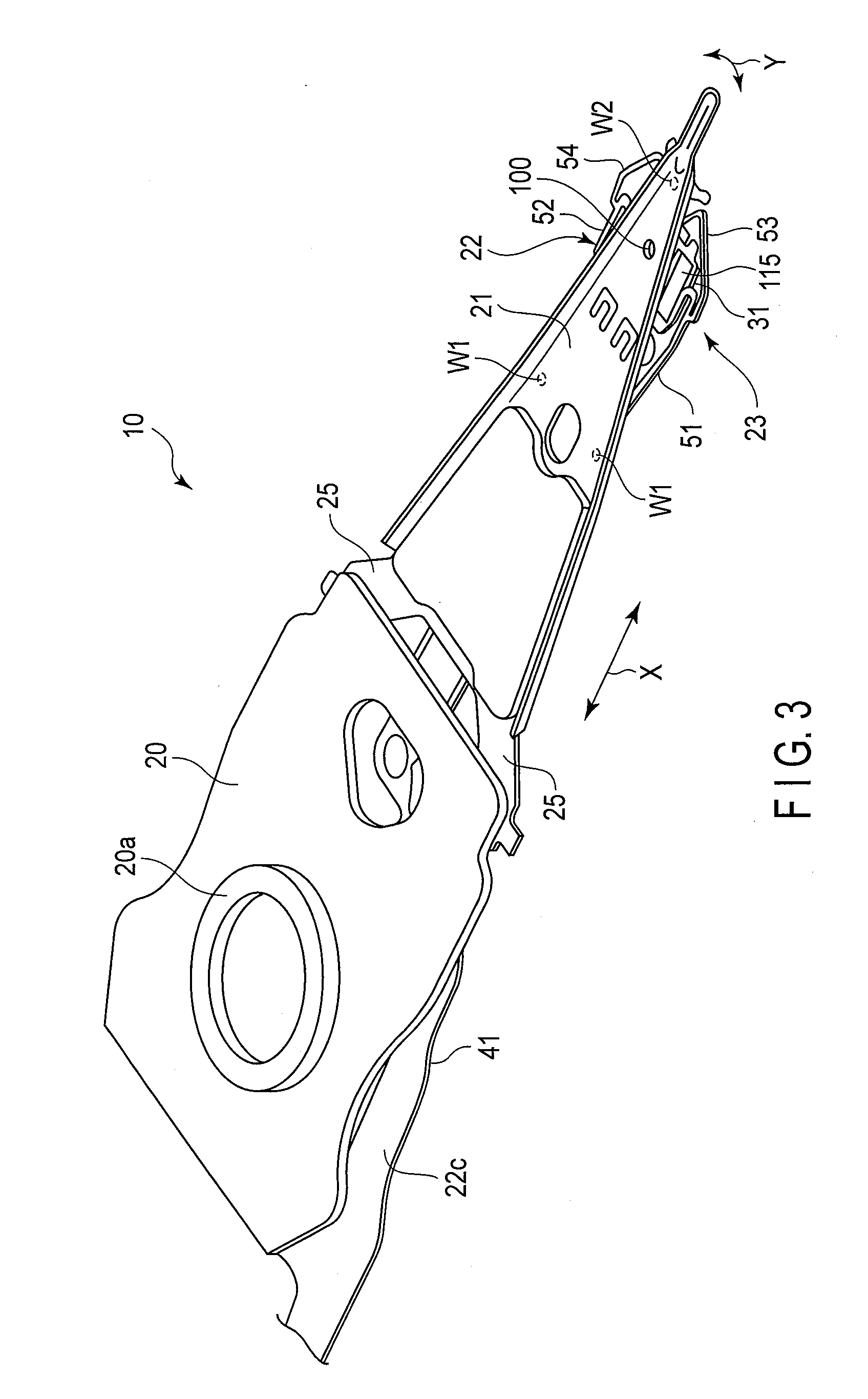

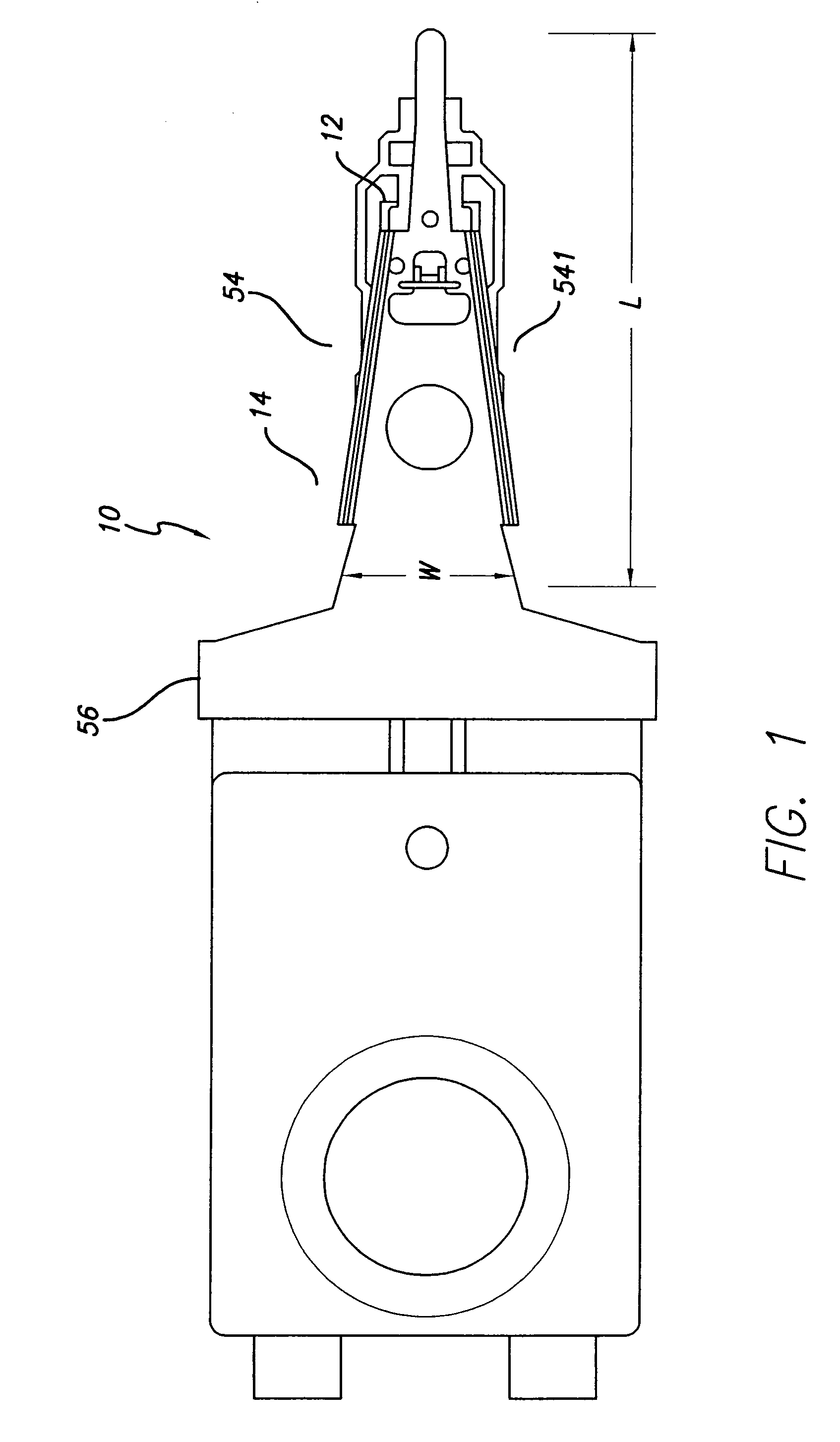

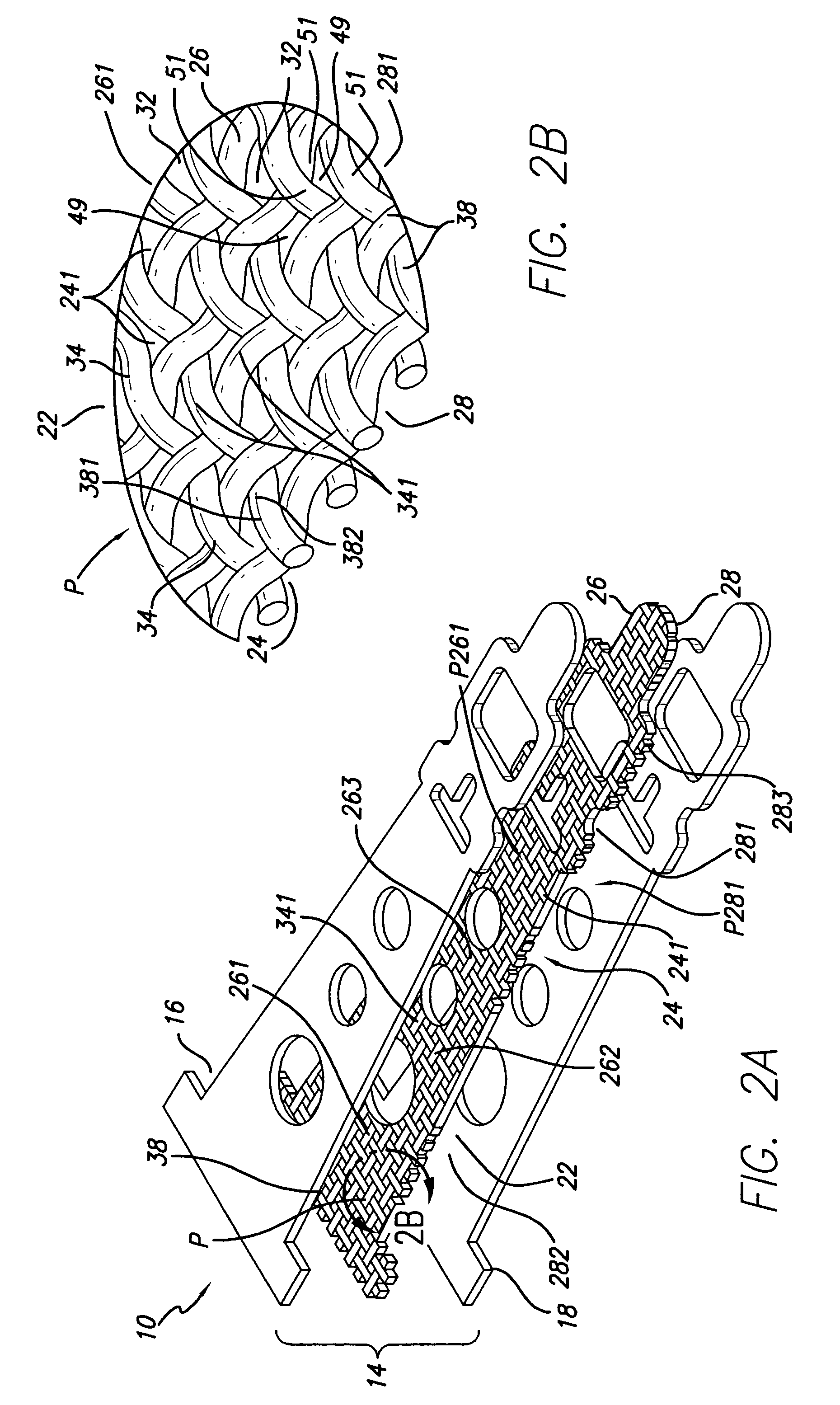

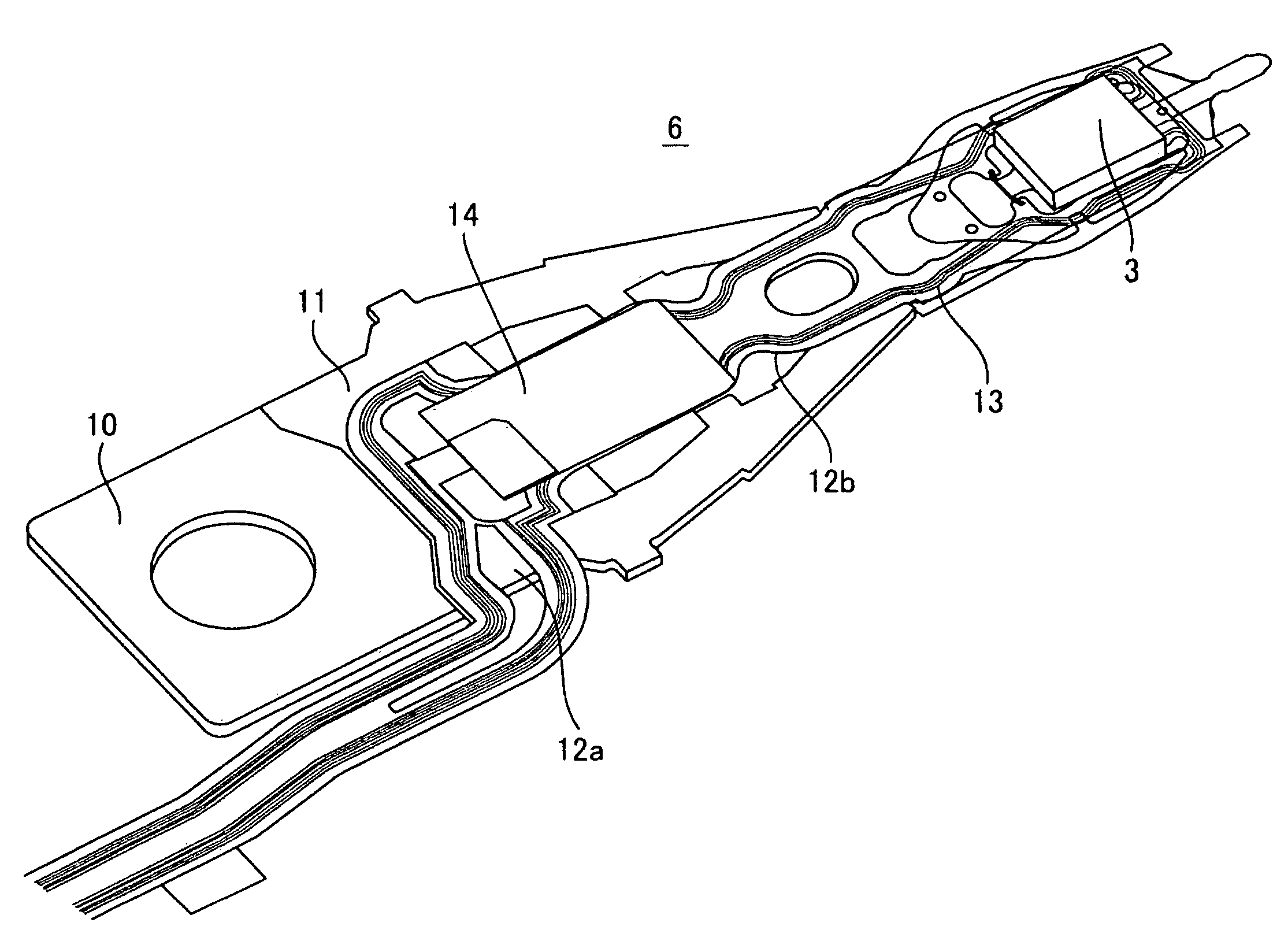

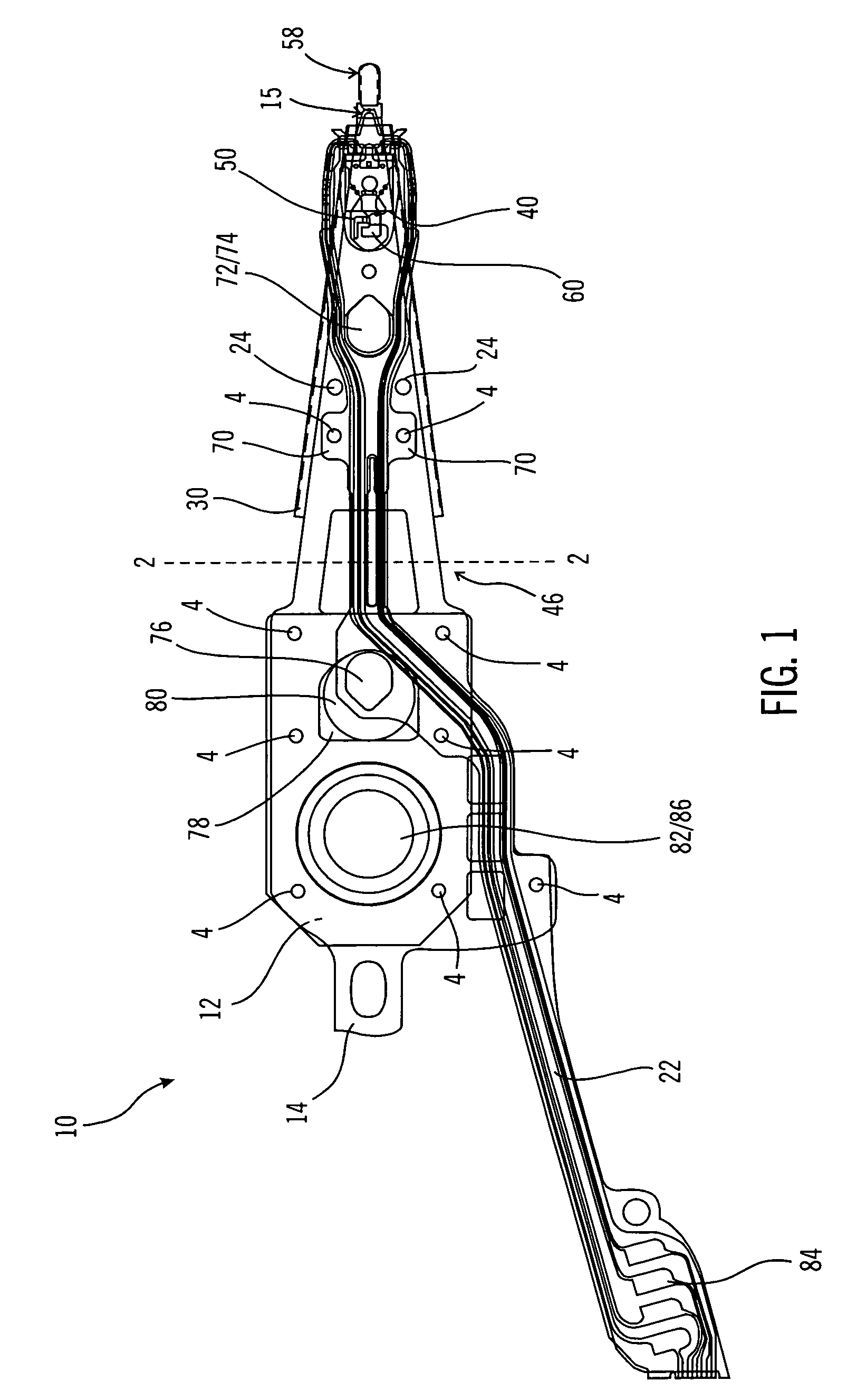

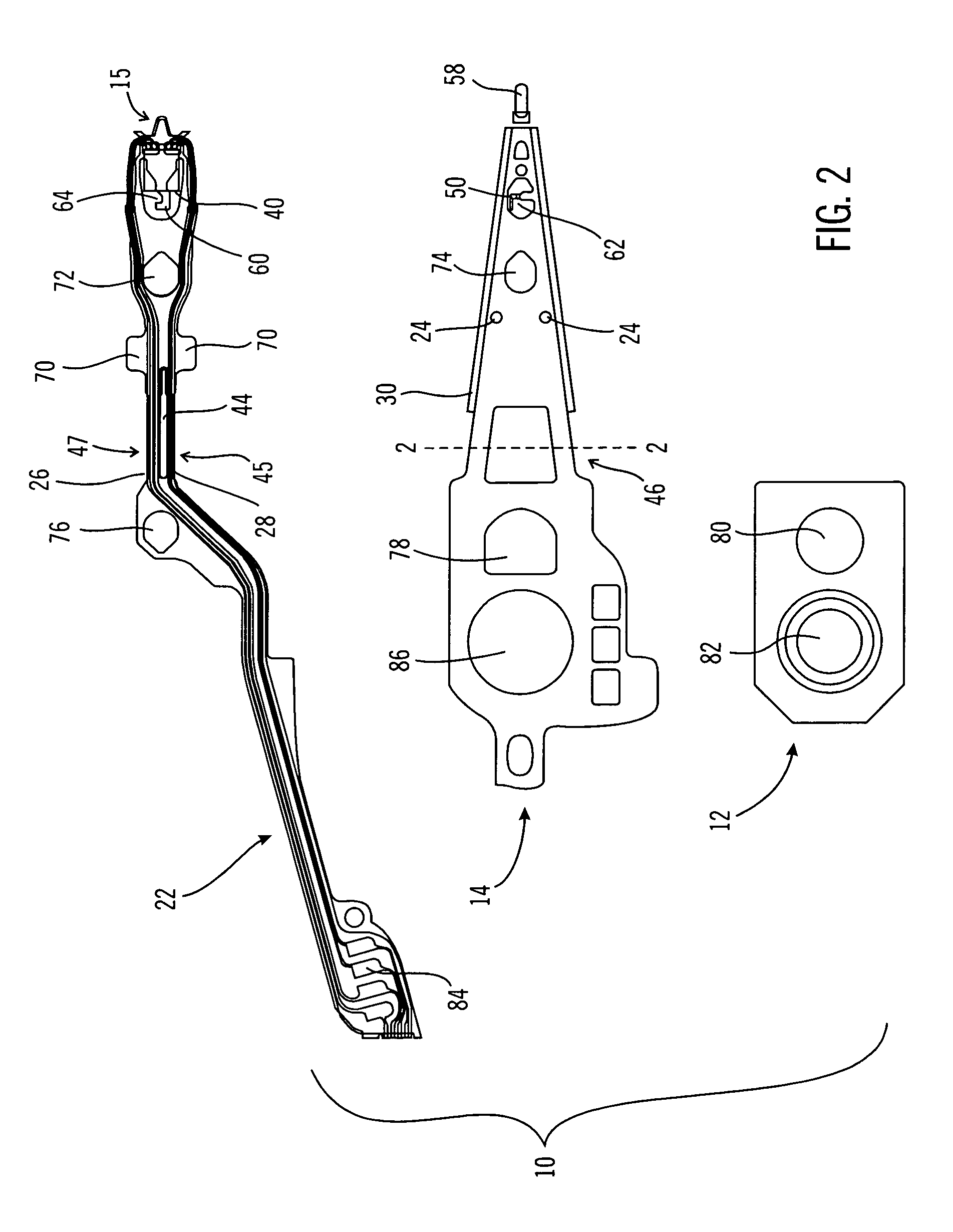

Integrated lead suspension for high density drive

InactiveUS6965501B1Avoid damageImprove dynamic performanceRecord information storageIntegrated arm assembliesLeading edgeInsulation layer

The integrated lead suspension assembly comprises several improvements. An oversized terminating pad for the electrical traces and a smaller adjacent insulation layer on the flexure assembly enable laser solder ball bonding of the pads to the read / write terminal contacts on the slider without clamping operation. Consequently, the tip of the load beam can be made narrow for a structure that provides for head loading and unloading functions, which improves the dynamic performance of the suspension assembly. The flexure assembly is configured such that it requires no permanent bending in its forming process, and any permanent bending required is done to the load beam. The limiter that limits the travel of the flexure assembly is formed on the load beam and it is bent to the functional position only after attachment of the flexure assembly to the load beam. The limiter is configured and positioned at the leading edge side of the slider to optimize the unloading process and to minimize the possibility of disengagement of the limiter and the flexure assembly during high shock environment. Asymmetric backing branches are provided for the read and write traces in the flexure assembly located at the hinge area of the load beam, the widths of which are sized to optimize the dynamic signal performance of the read and write traces without impact on the vertical stiffness of the suspension. Low profile flanges at 30°–60° that bend from the plane of the load beam are provided along the edges of the load beam to optimize bending stiffness and flow induced vibration. Dimples are provided along the load beam to facilitate insertion of a plastic head separation tool.

Owner:WESTERN DIGITAL TECH INC

High conductivity ground planes for integrated lead suspensions

ActiveUS7710687B1Improve conductivityHigh materialElectrical connection between head and armRecord information storageGround planeHigh conductivity

An integrated lead flexure or suspension including an insulating layer, a plurality of traces on the insulating layer and a stainless steel base layer on the side of the insulating layer opposite the traces. The traces are free of a conductive shield layer on the side opposite the insulating layer. One or more voids extend through the stainless steel layer below the traces. The voids are filled with a high conductivity metal layer.

Owner:HUTCHINSON TECH

Wired-circuit-board assembly sheet

InactiveUS20070170911A1Easy to disassembleReduce wearPrinted circuit aspectsRecord information storageEngineeringMetal powder

A wired-circuit-board assembly sheet is provided having removable portions that are easily removable without any generation of metal powder. The wired-circuit-board assembly sheet comprises a plurality of suspension boards with circuits, distinguishing marks for distinguishing defectiveness of the suspension boards with circuits, and a supporting sheet for supporting the suspension boards with circuits and the distinguishing marks, wherein openings are formed in the supporting sheet, and removable portions which are to be removed when the suspension boards with circuits are judged defective are located in the openings and also supported by the supporting sheet via joint portions formed of resin.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com