Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Calcium/strontium/barium sulfites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

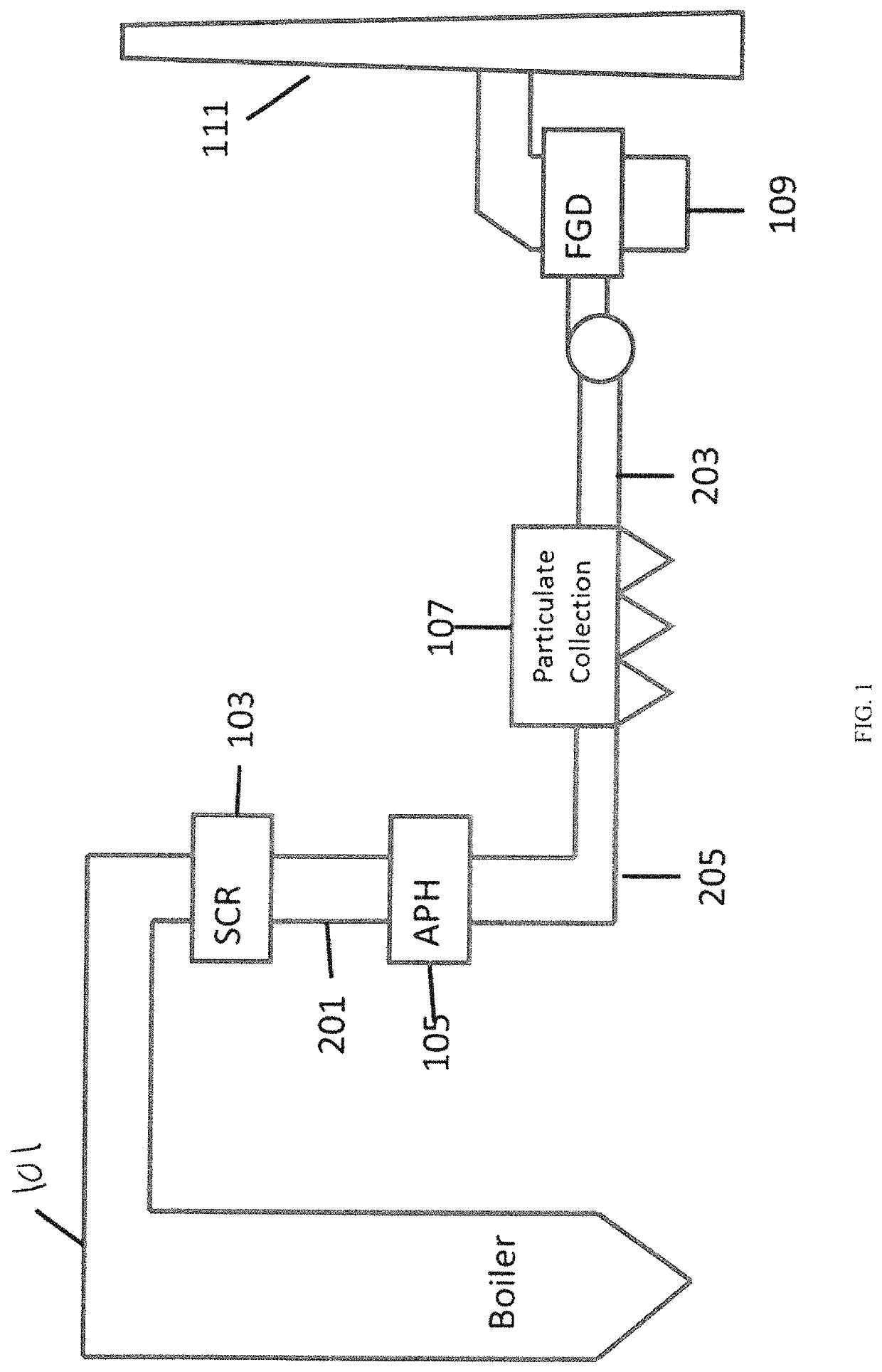

Sorbents for removal of mercury from flue gas cross reference to related applications

InactiveUS7771700B2Solid waste managementUsing liquid separation agentParticulatesAlkaline earth metal

Owner:CHEM PROD CORP

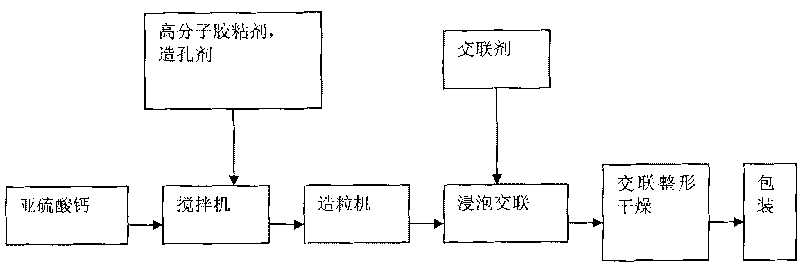

Calcium sulfite particles and preparation method

InactiveCN101712484ASolve the problem of graininessUniform shapeCalcium/strontium/barium sulfitesCalcium sulfiteAqueous solution

The invention provides calcium sulfite particles. The calcium sulfite particles are in a cylindrical structure, the surfaces of the calcium sulfite particles are provided with pores, and the content of the component of calcium sulfite is more than 90%. The invention also provides a method for preparing the calcium sulfite particles, which comprises the following steps: weighing each substance; preparing a water solution; mixing and stirring evenly; granulating; crosslinking; pre-crosslinking, baking and shaping; and finally, drying and packaging. The invention overcomes the limitation of the prior art and also solves the problem of granulation of the calcium sulfite well. Short cylindrical calcium sulfite the surface of which is in a micropore structure is prepared. Because a plurality of micropores are distributed at the surfaces of the particles, the special structure enables water molecules to fully contact with the calcium sulfite directly and enhances the dechlorination effect greatly.

Owner:上海亚弘过滤器材股份有限公司

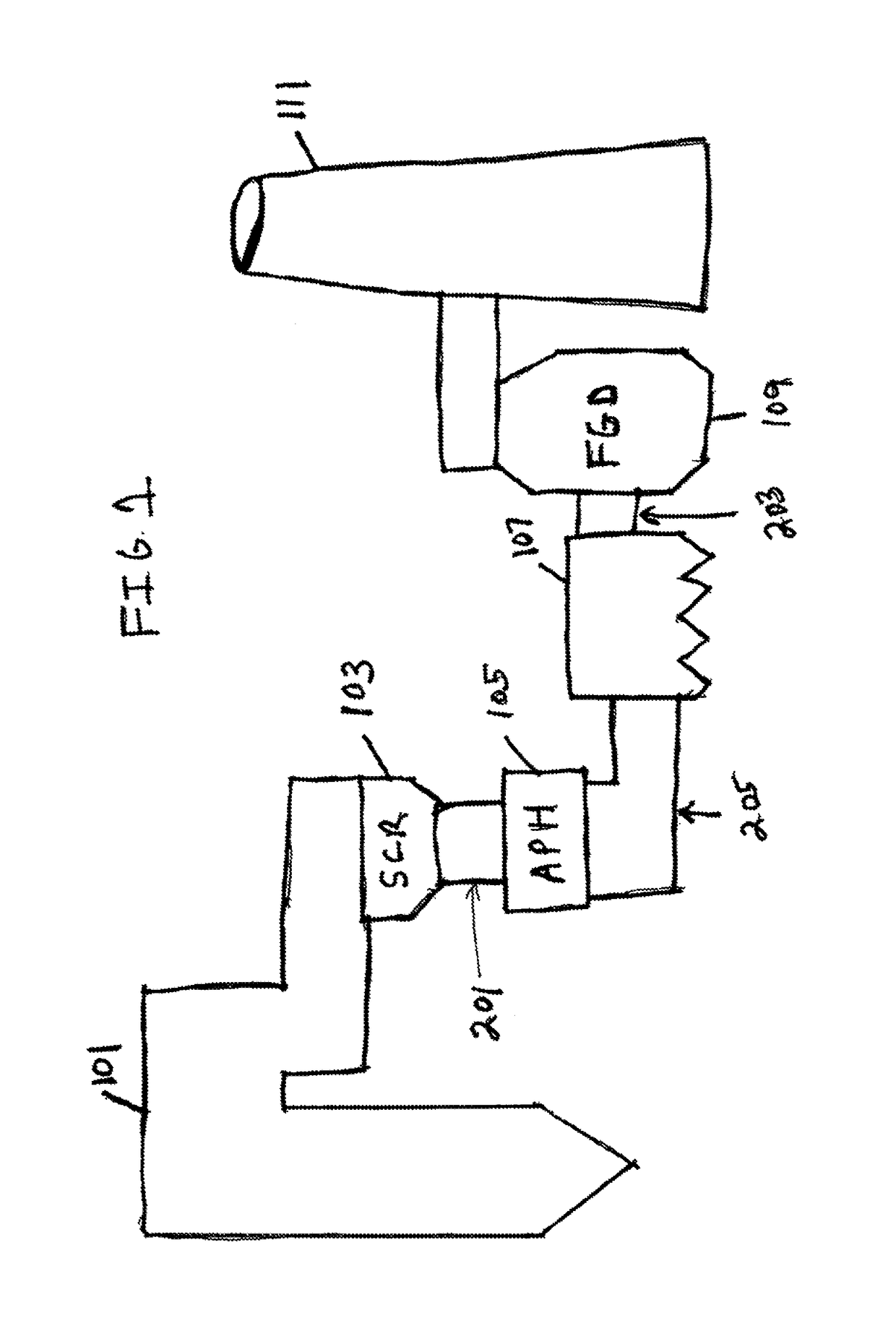

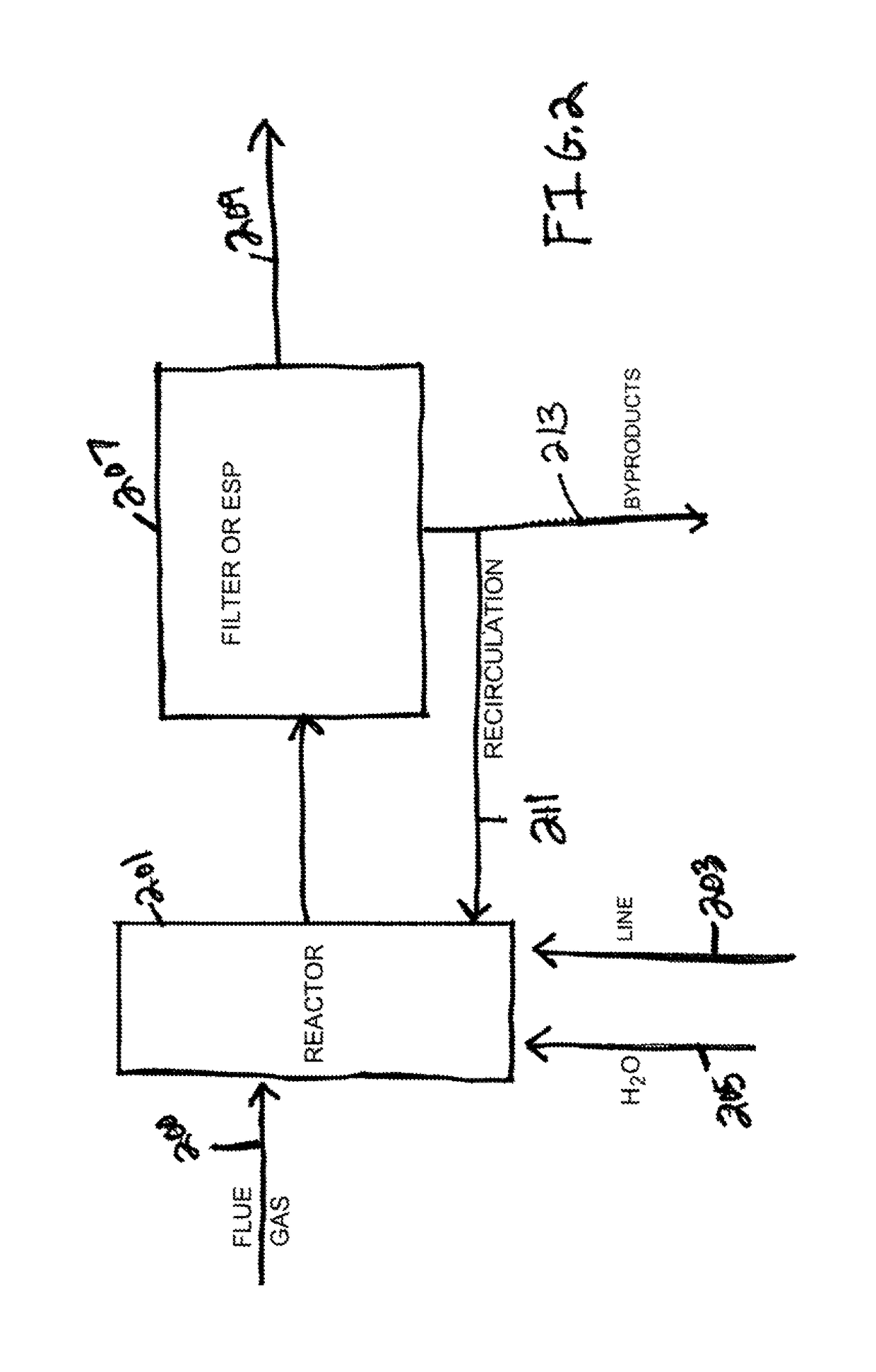

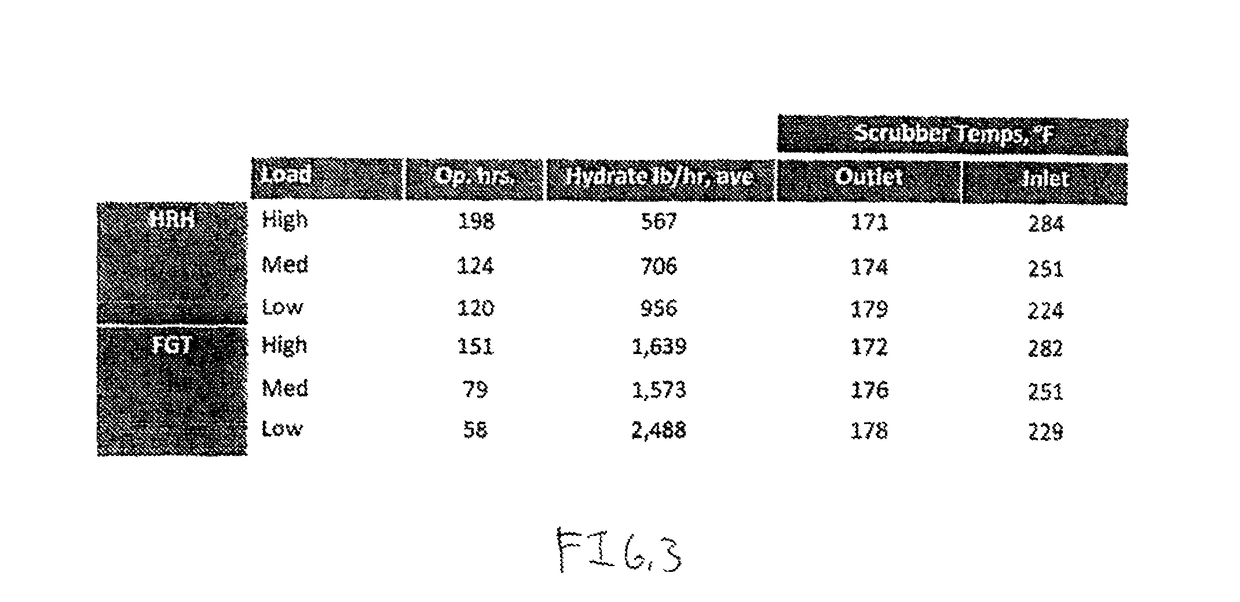

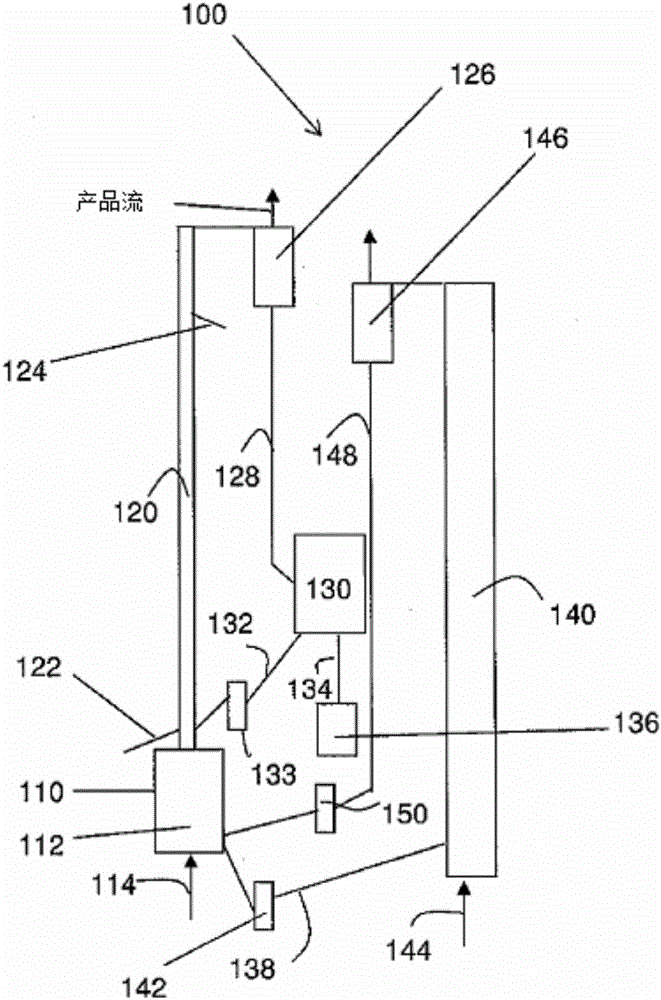

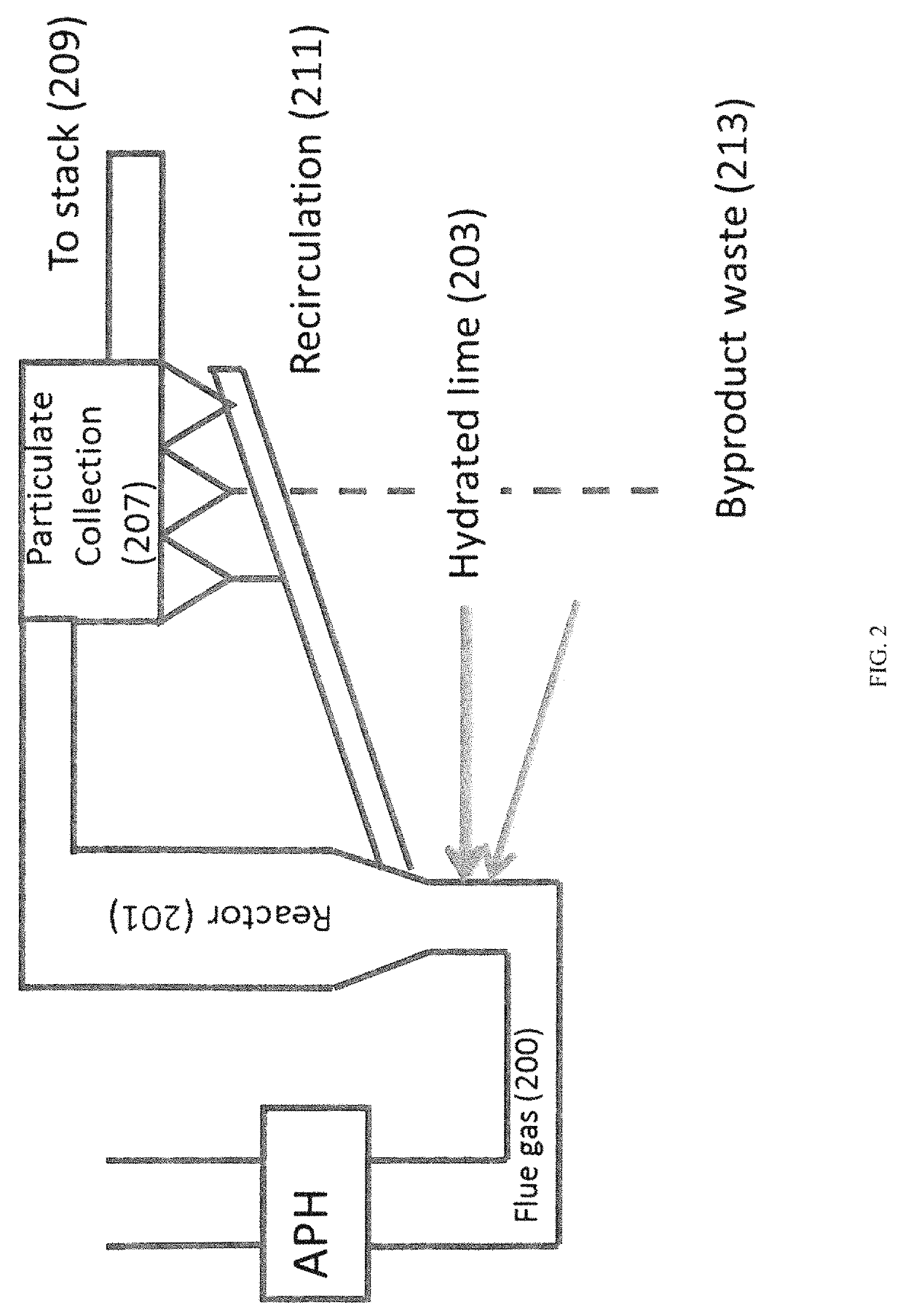

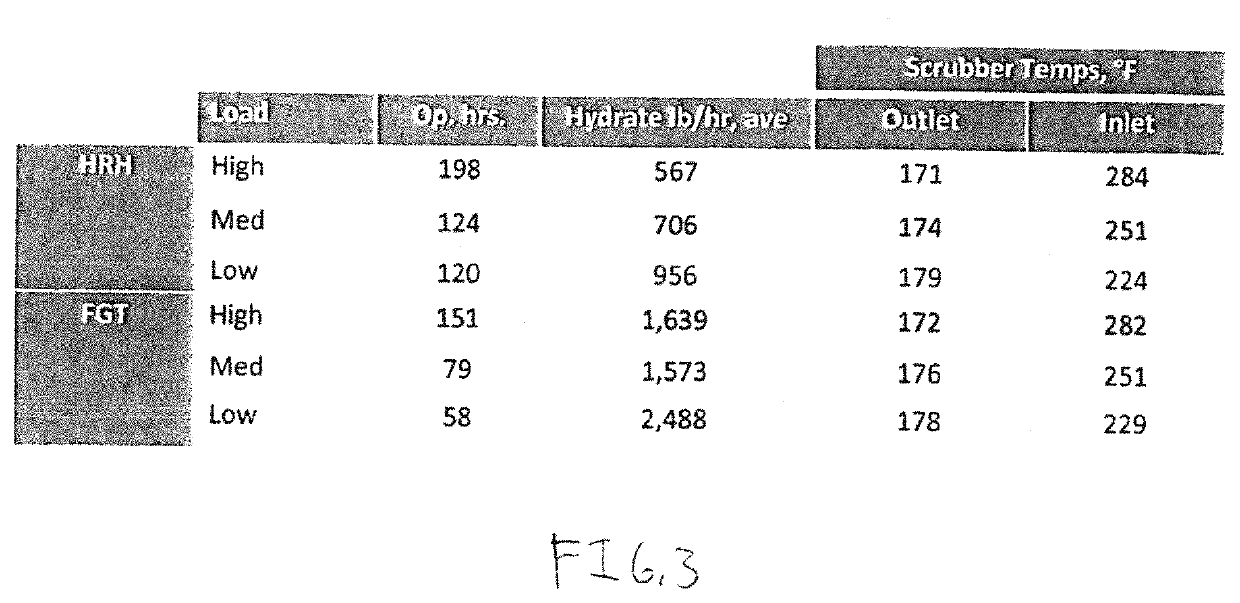

Systems and method for removal of acid gas in a circulating dry scrubber

Owner:MISSISSIPPI LIME CO

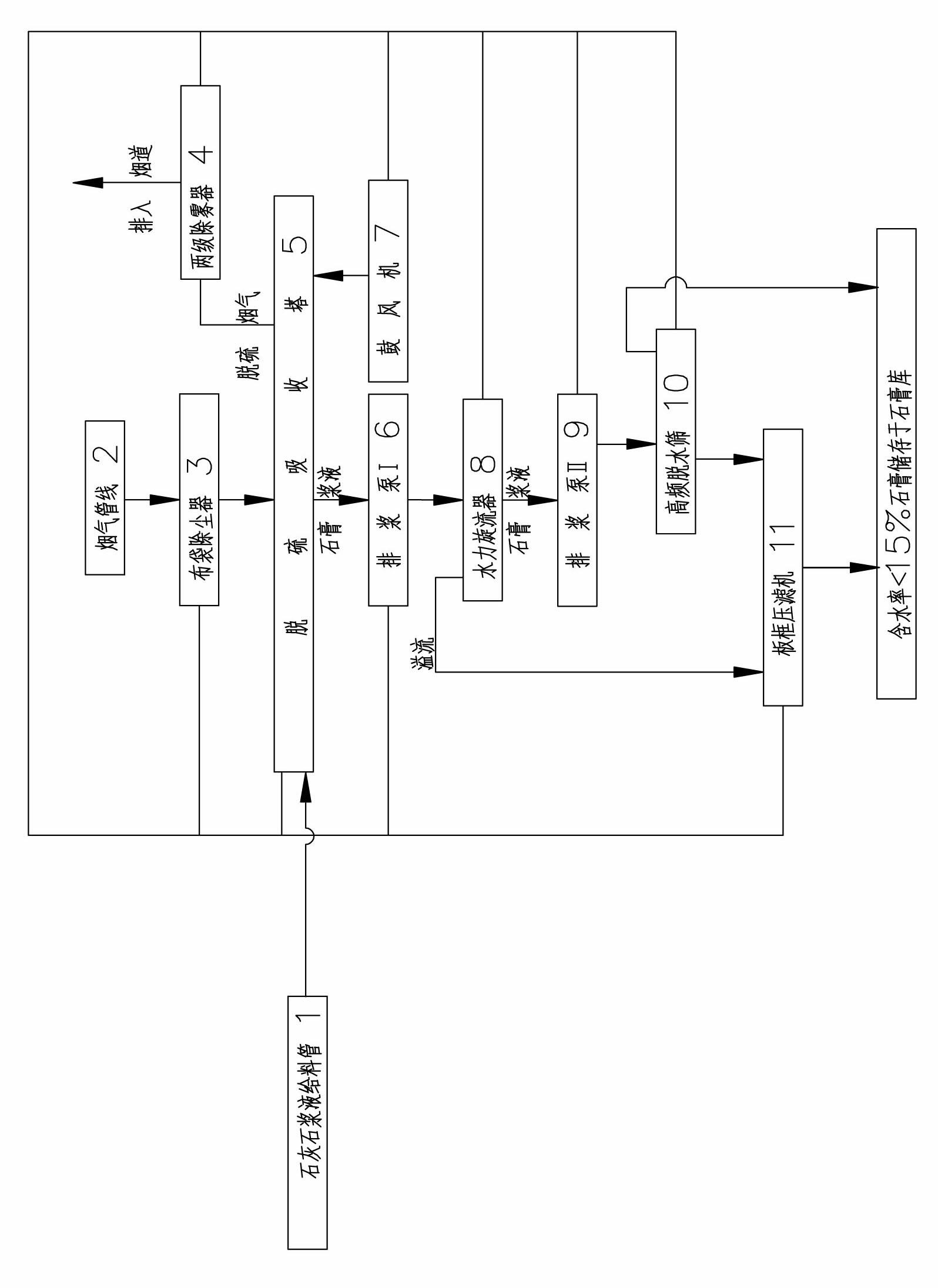

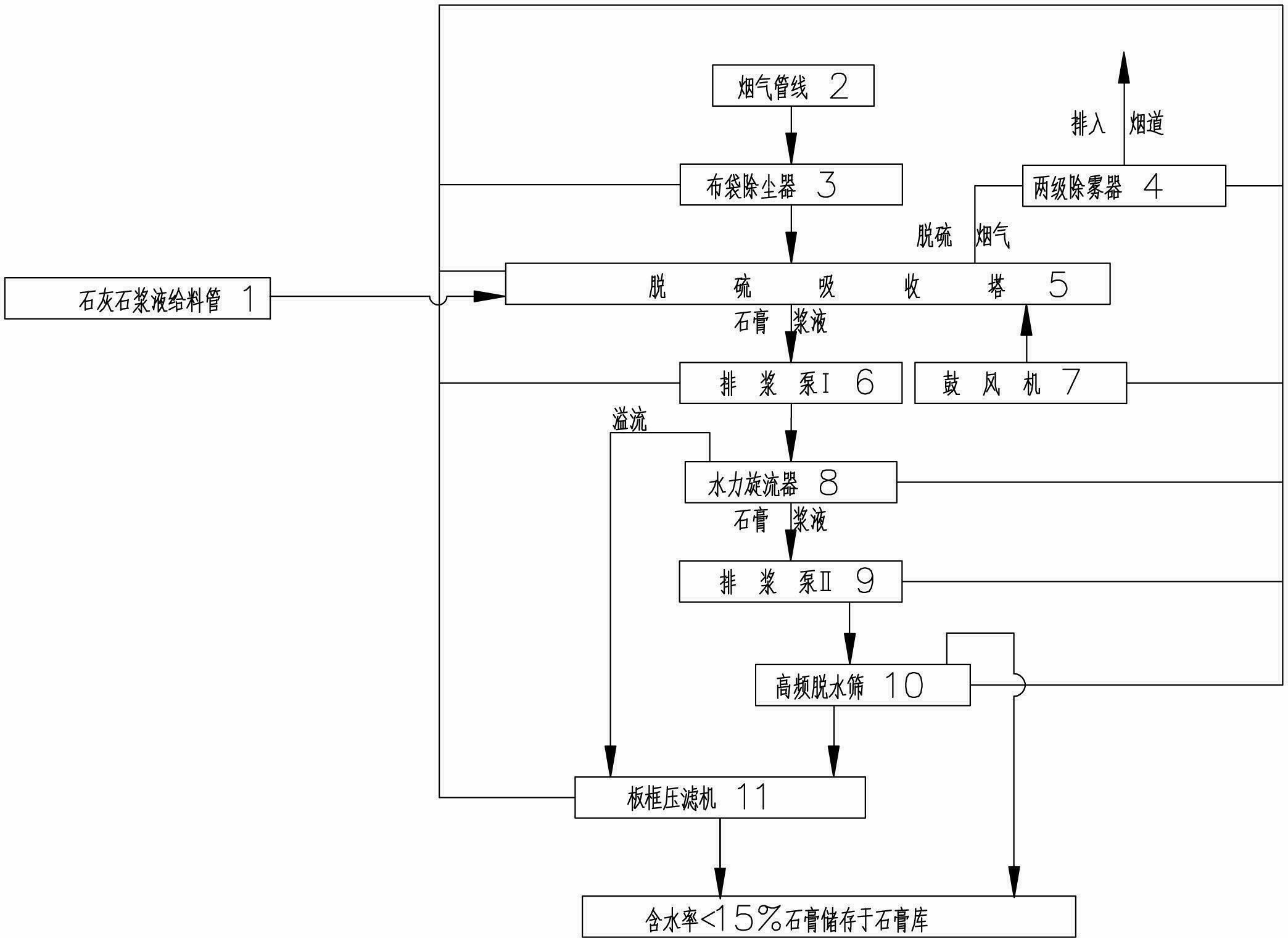

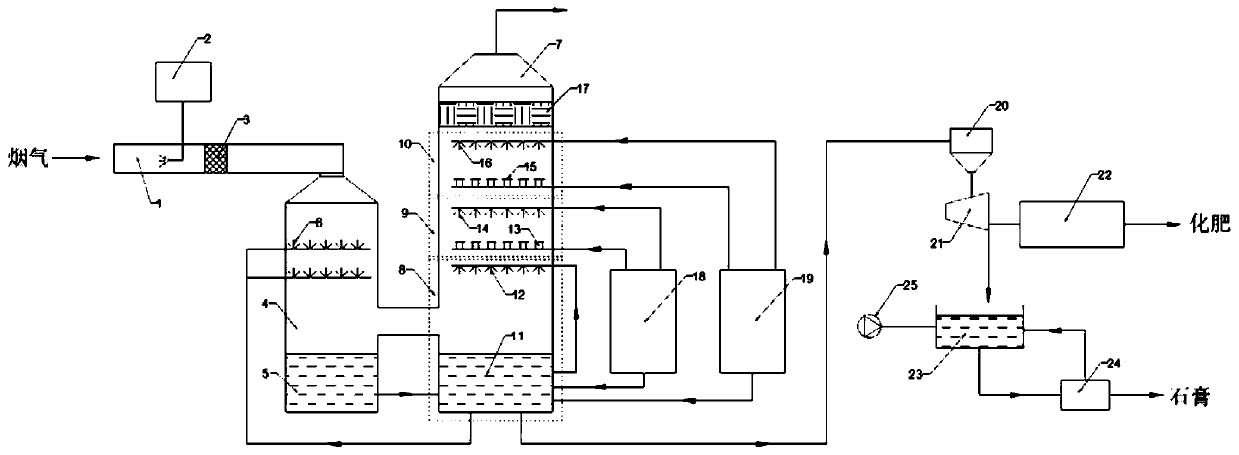

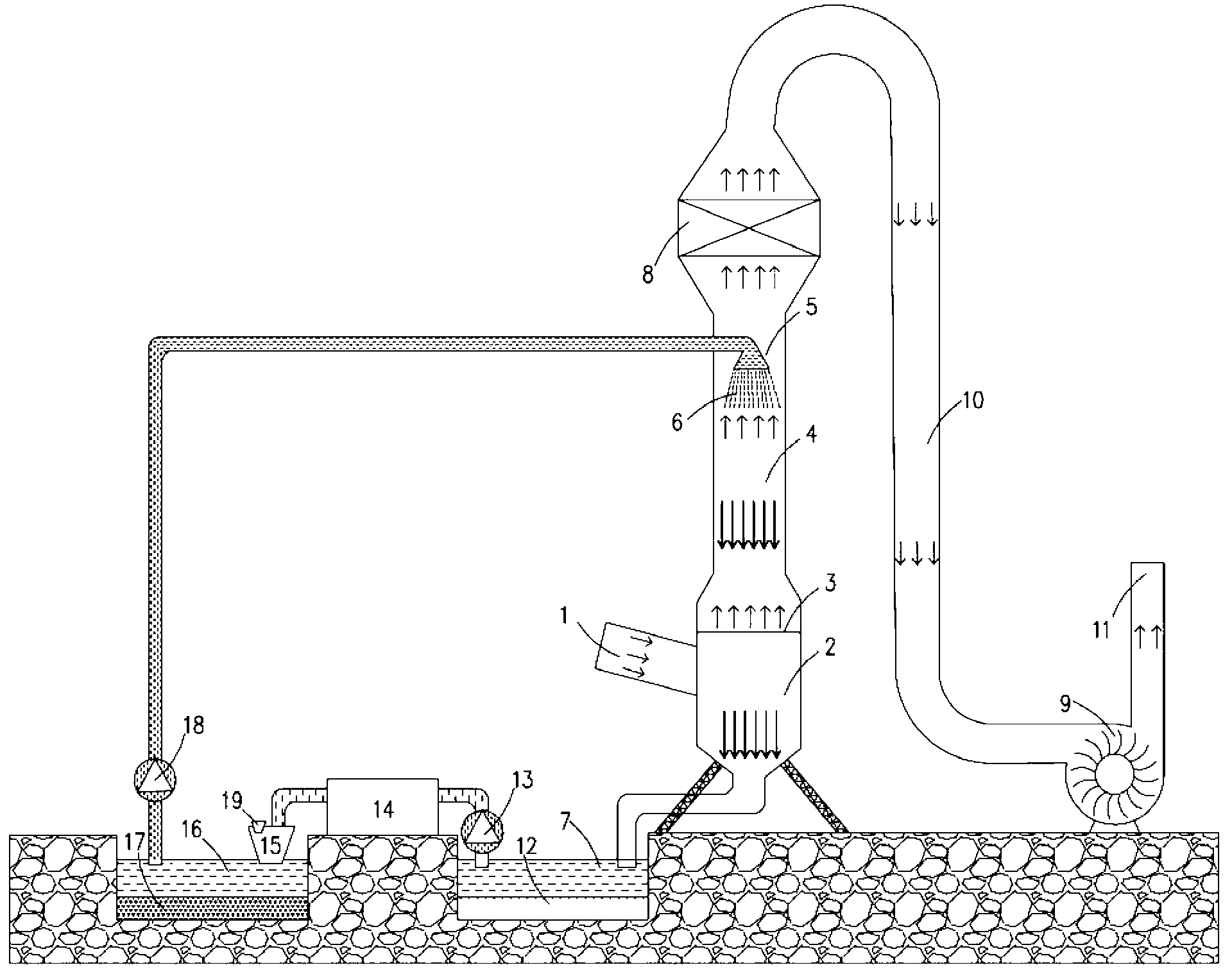

Flue-gas desulphurization system and flue-gas desulphurization method

InactiveCN102489143ASolving Dehydration ProblemsIncrease added valueDispersed particle separationCalcium/strontium/barium sulfitesCycloneEngineering

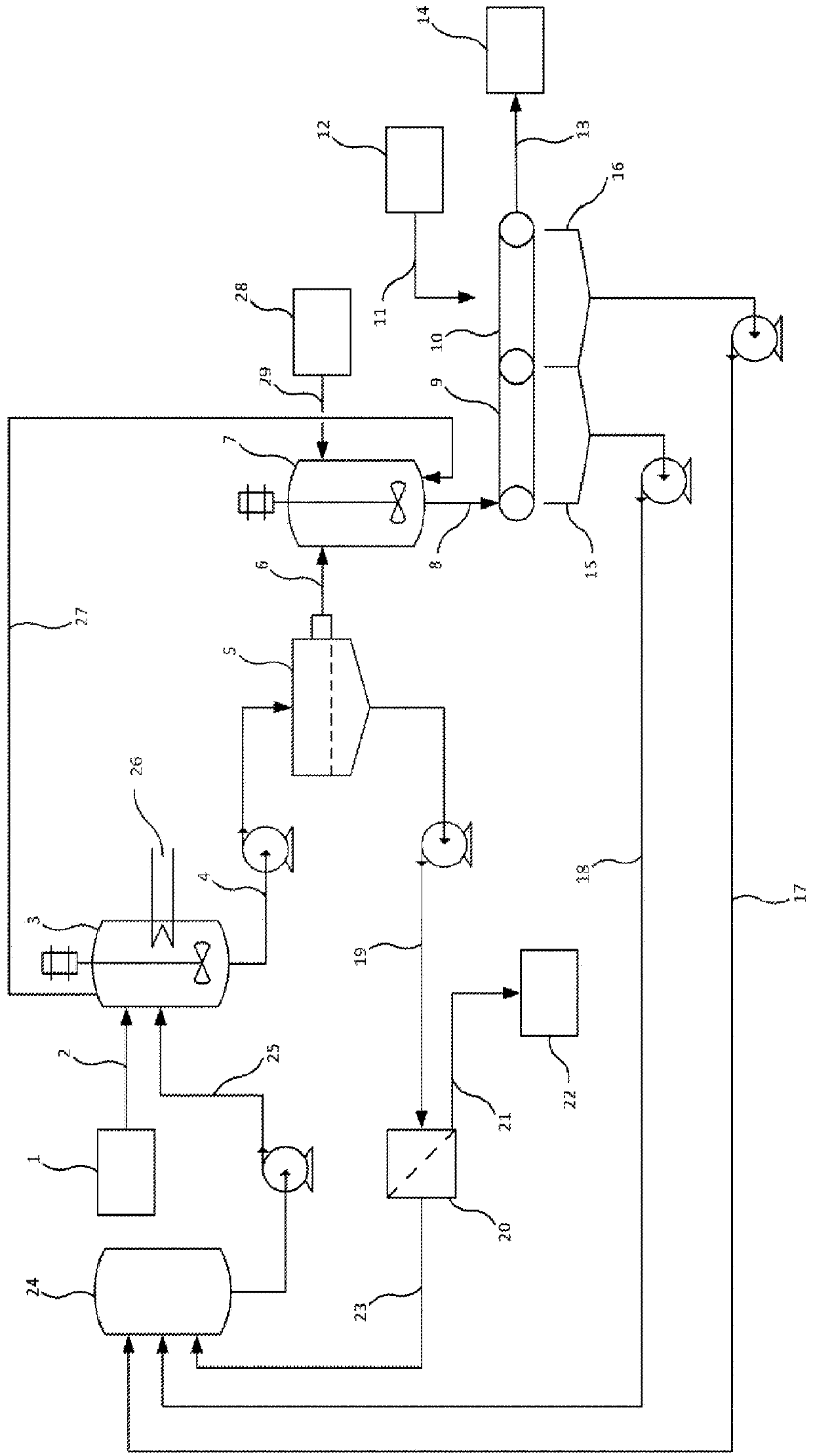

The invention relates to a flue-gas desulphurization system and a flue-gas desulphurization method. The flue-gas desulphurization system comprises a desulphurization absorbing tower connected with a limestone slurry feeding pipe, a flue-gas pipeline, a cloth-bag dust remover, a two-stage mist remover, a blower, a slurry discharging pump I and a hydraulic cyclone connected with the slurry discharging pump I, and is characterized in that the hydraulic cyclone is also connected with a slurry discharging pump II and a filtering machine; and the slurry discharging pump II is also connected with a dewatering screen which is also respectively connected with the filtering machine and a gypsum stockpile. The flue-gas desulphurization method comprises the following steps that: flue gas is dissolved in limestone slurry and then oxidized and crystallized to form gypsum slurry; and the gypsum slurry is concentrated by the hydraulic cyclone, the underflow of the hydraulic cyclone is pumped into the dewatering screen for dewatering by the slurry discharging pump II, and the overflow of the hydraulic cyclone is fed into the filtering machine for filtering. According to the flue-gas desulphurization system and the flue-gas desulphurization method, since the filtering machine and the dewatering screen are additionally arranged behind the hydraulic cyclone of the flue-gas desulphurization system and the dewatering screen is adopted for dewatering, so that the problem of difficult dewatering of the gypsum is effectively solved and the additional value of a gypsum product is high.

Owner:ANSTEEL GRP MINING CO LTD

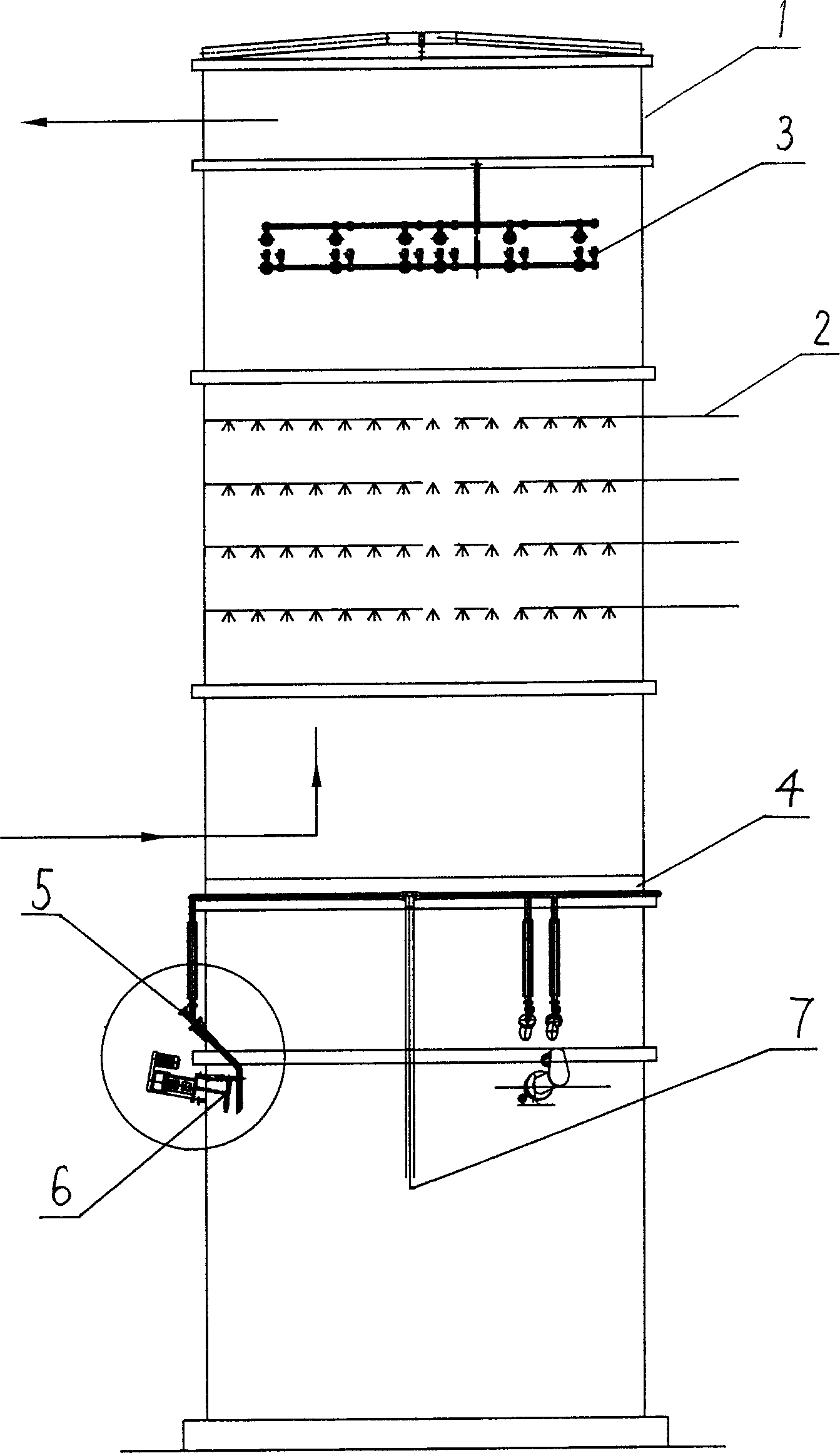

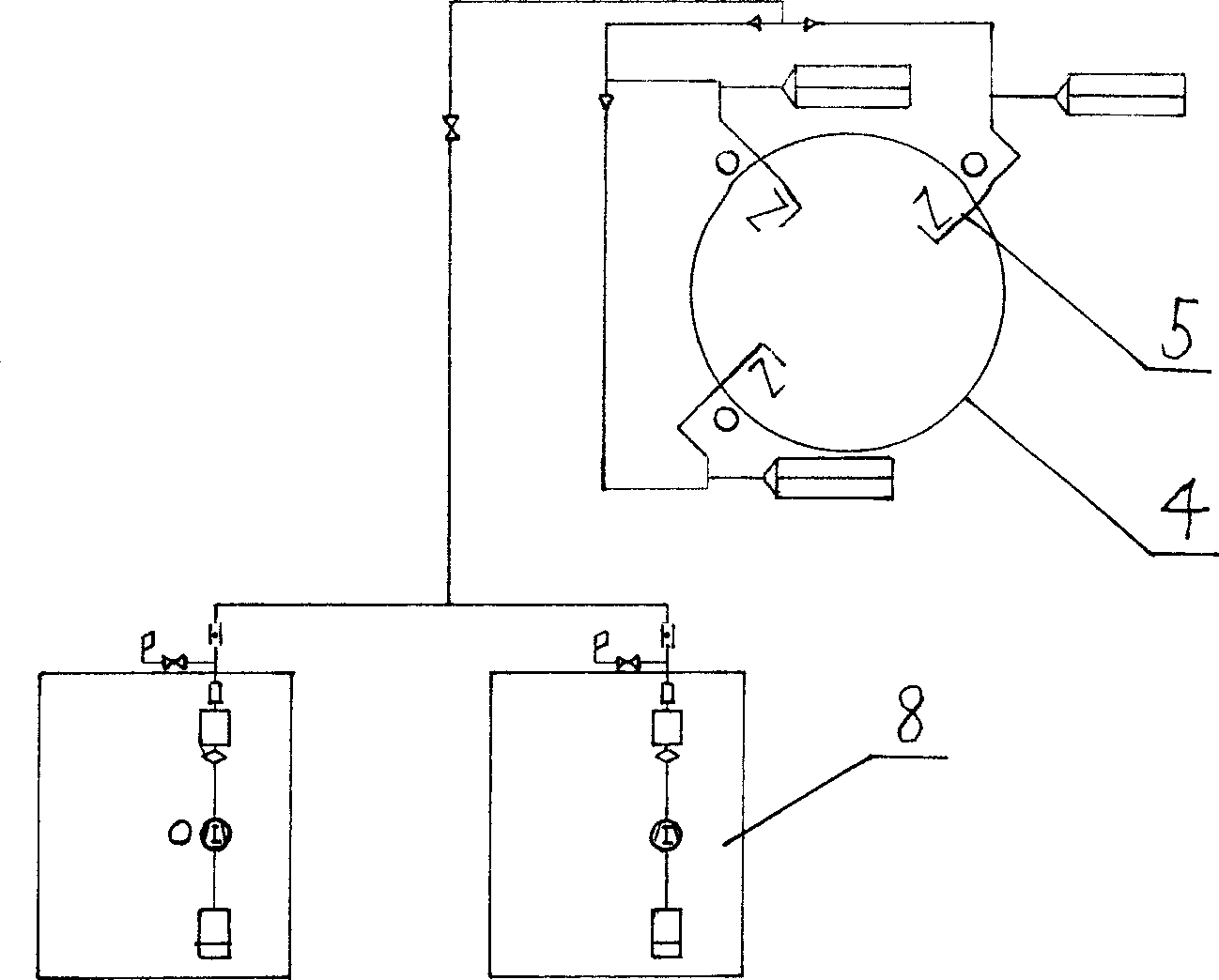

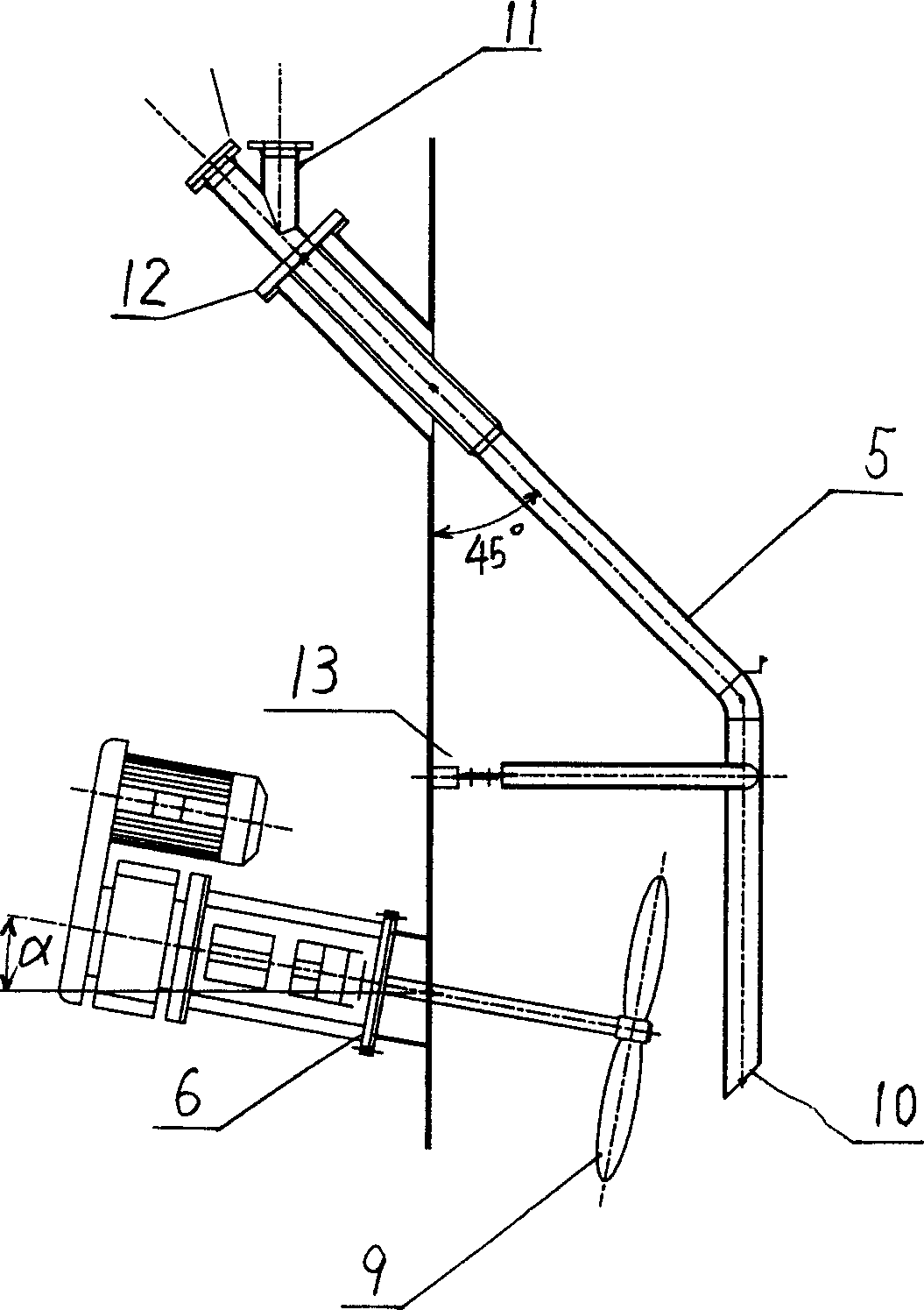

Forced oxidizing method and its device for smoke desulfurizing intermediate product-calcium sulfite

ActiveCN1587057AGuaranteed uptimeGuaranteed qualityCalcium/strontium/barium sulfatesDispersed particle separationEngineeringTower

The present invention provides forced oxidizing method and apparatus for calcium sulfite as the intermediate produce of desulfurizing fume. There are gypsum slurry pond in the bottom of the absorbing tower for desulfurizing reaction and storing slurry, oxidizing air generator outside the slurry pond and connected to two or three air spraying guns around the absorbing tower; air spraying guns inserted obliquely into the gypsum slurry to blow air into the slurry pond, and side stirrers between each of the air spraying gun outlets and the pond wall. The present invention has the advantages of simple and reasonable technological arrangement, low power consumption, full forced oxidation, etc.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Processes for the production of citric acid

ActiveUS11236033B2High operating temperaturePrevent oxidationPreparation from carboxylic acid saltsCarbon compoundsAlkaline earth metalCarboxylic acid anion

Owner:INNOVATOR ENERGY LLC

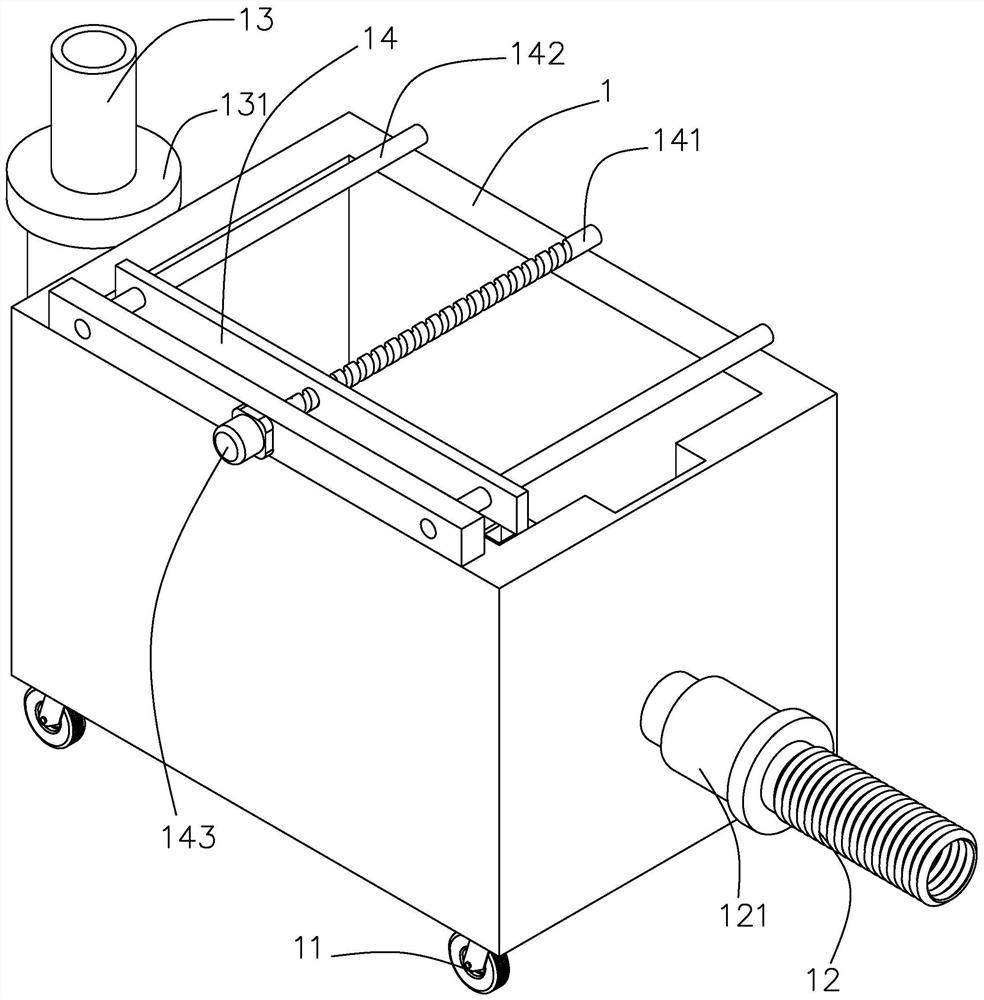

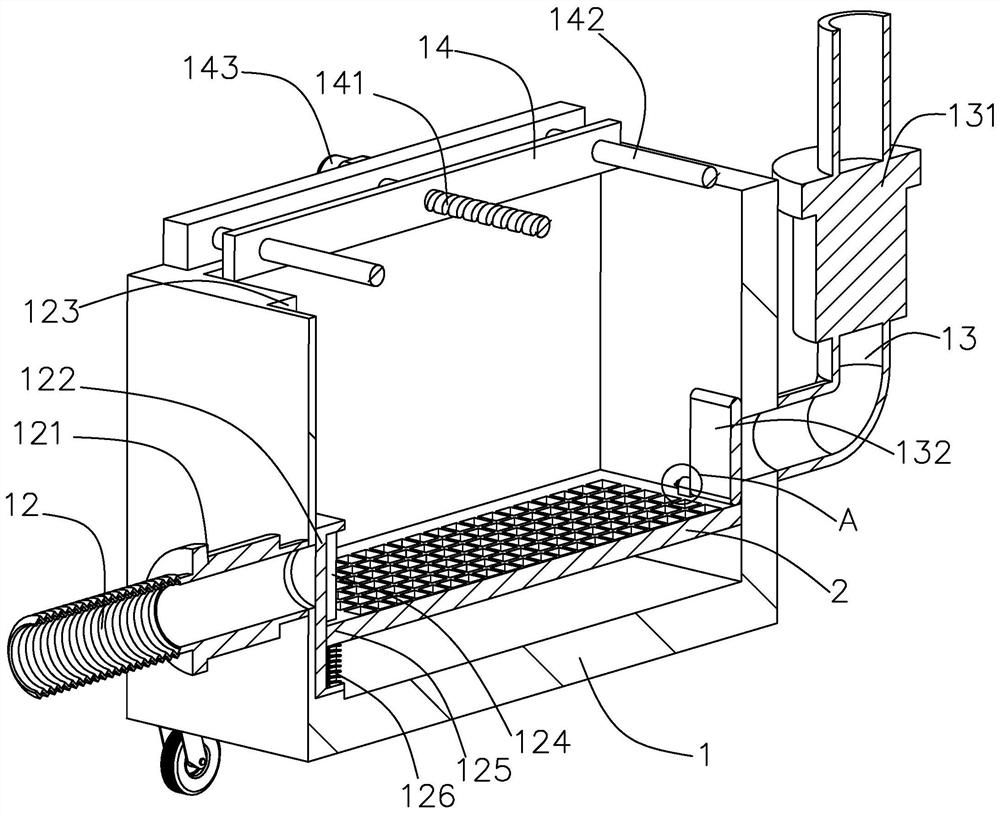

Desulfurization wastewater treatment process and transfer device for same

ActiveCN111635056AConvenient recycling operationEfficient collectionCalcium/strontium/barium sulfatesTreatment involving filtrationProcess engineeringWater treatment

The invention relates to a desulfurization wastewater treatment process. The desulfurization wastewater treatment process comprises the following steps: S1, collecting: collecting desulfurization wastewater; S2, carrying out a forced reaction: introducing sufficient oxygen into the desulfurization wastewater; S3, carrying out evaporation separation: evaporating the desulfurization wastewater to obtain a sulfur-containing solid; and S4, storing: collecting and storing the sulfur-containing solid. The desulfurization wastewater treatment process has the effect of efficiently treating and recycling desulfurization wastewater.

Owner:杭州临江环保热电有限公司

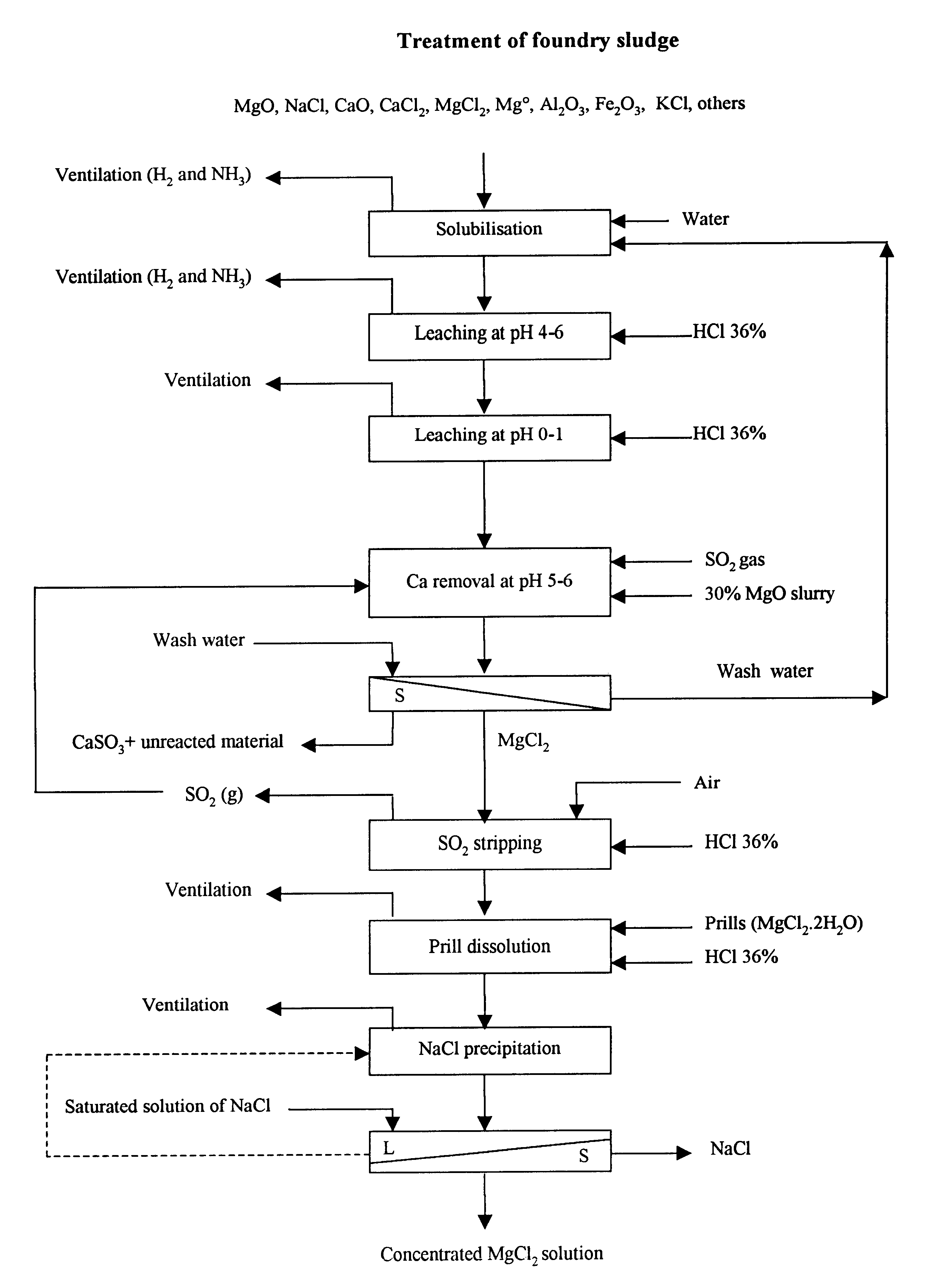

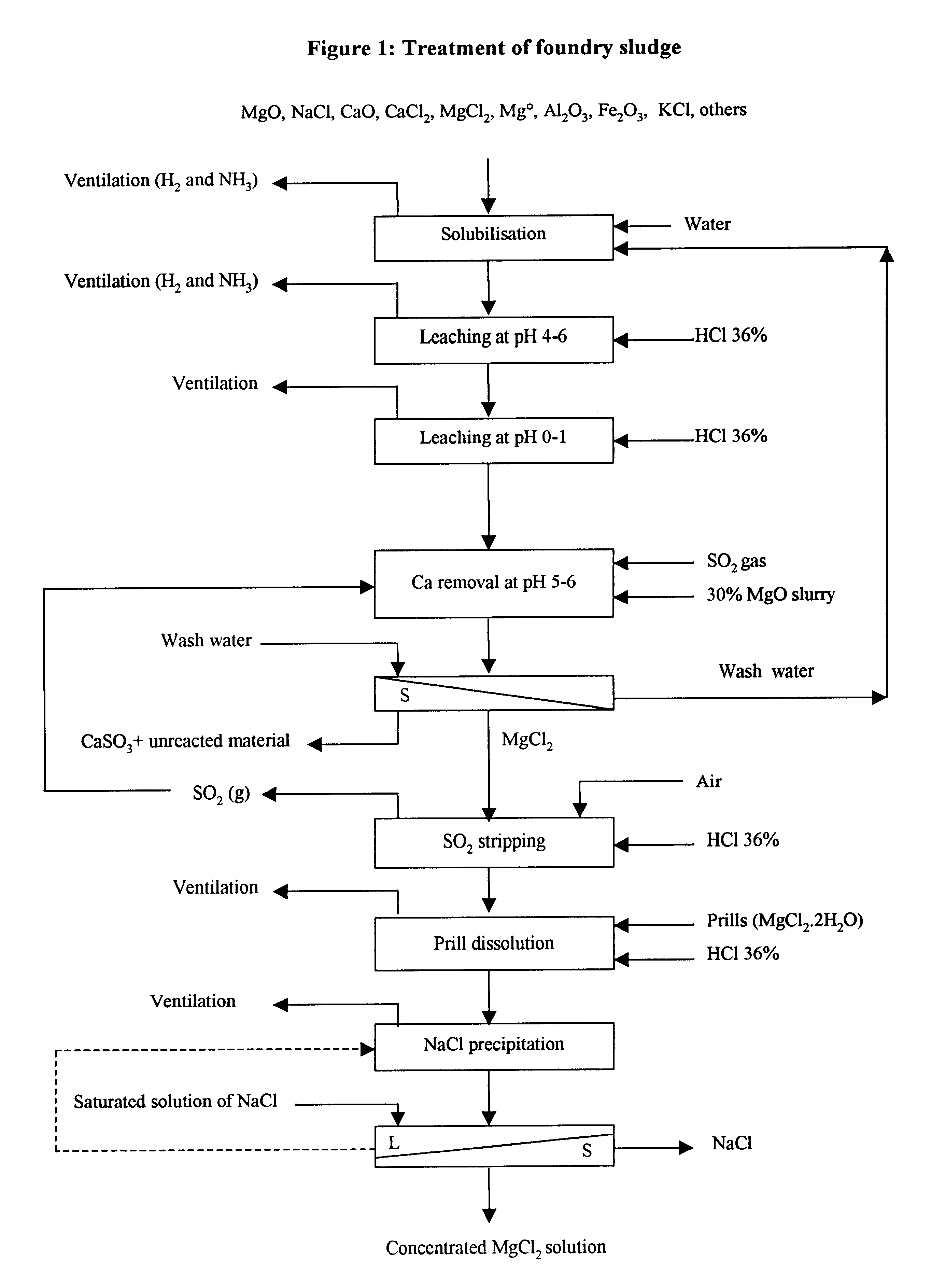

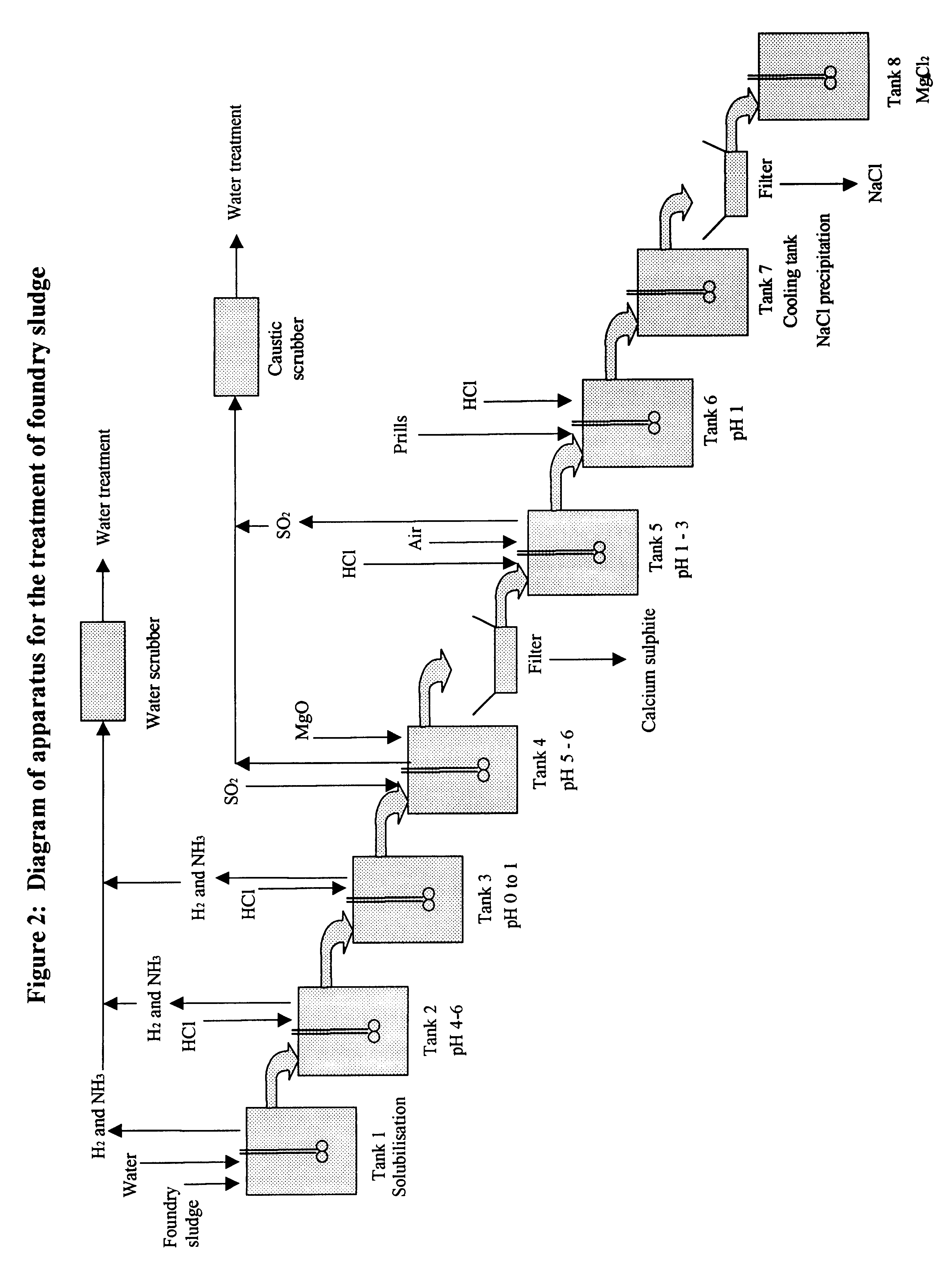

Process and apparatus for treating foundry sludge to recover magnesium

Process and apparatus for recovering magnesium from foundry sludge and cell bleed electrolytes includes structure and / or steps for: (i) dissolving, in a water slurry, soluble chloride compounds in the magnesium-containing material; (ii) acidifying the water slurry to between substantially pH 4 and substantially pH 6; (iii) further acidifying the water slurry to between substantially pH 1 and substantially pH 0, and providing a magnesium chloride solution; (iv) precipitating calcium from the magnesium chloride solution; (v) separating solids from the magnesium chloride solution; (vi) stripping SO2 from the magnesium chloride solution; and (vii) precipitating NaCl from the magnesium chloride solution to provide a concentrated magnesium chloride solution.

Owner:NORANDA MINES

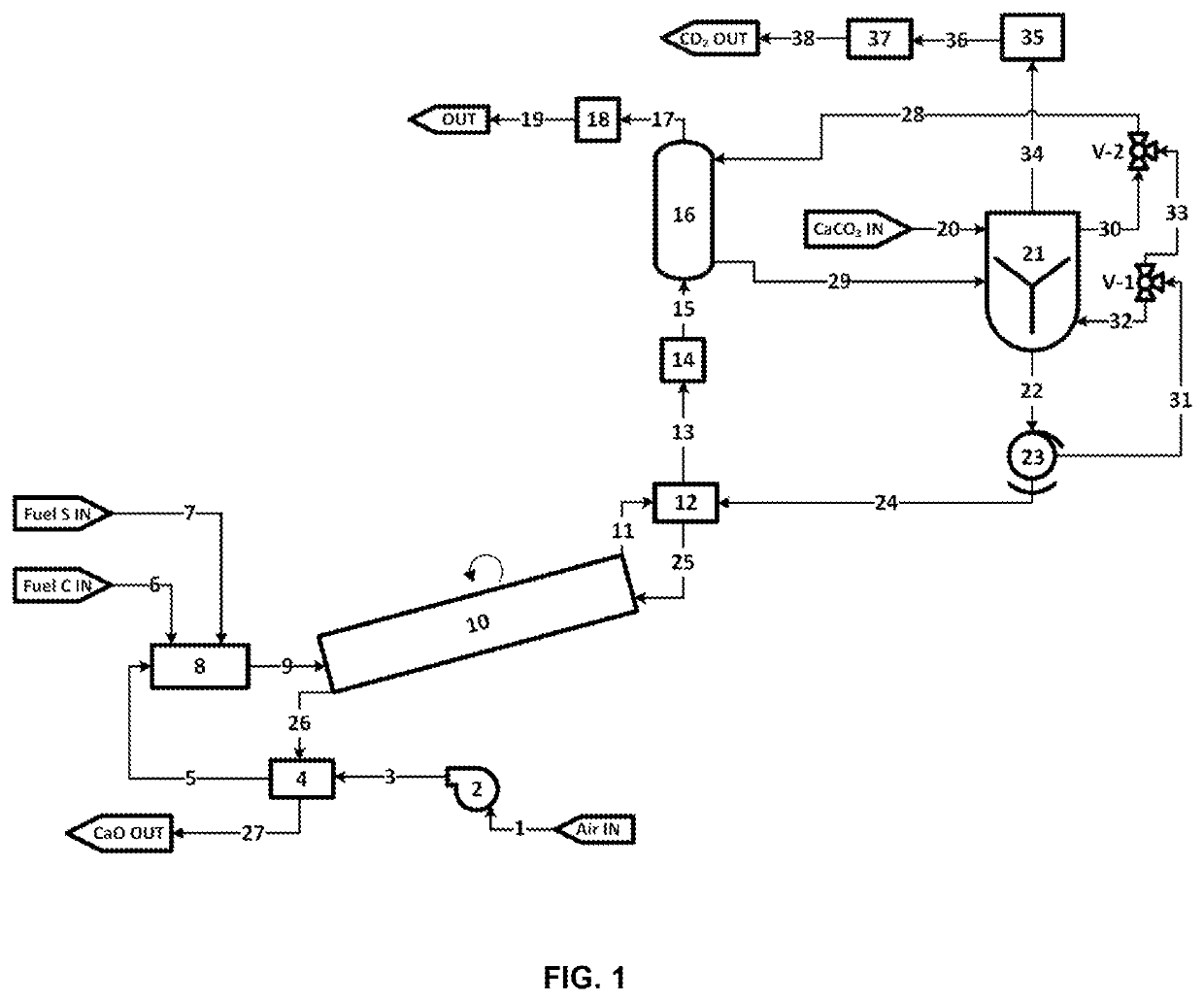

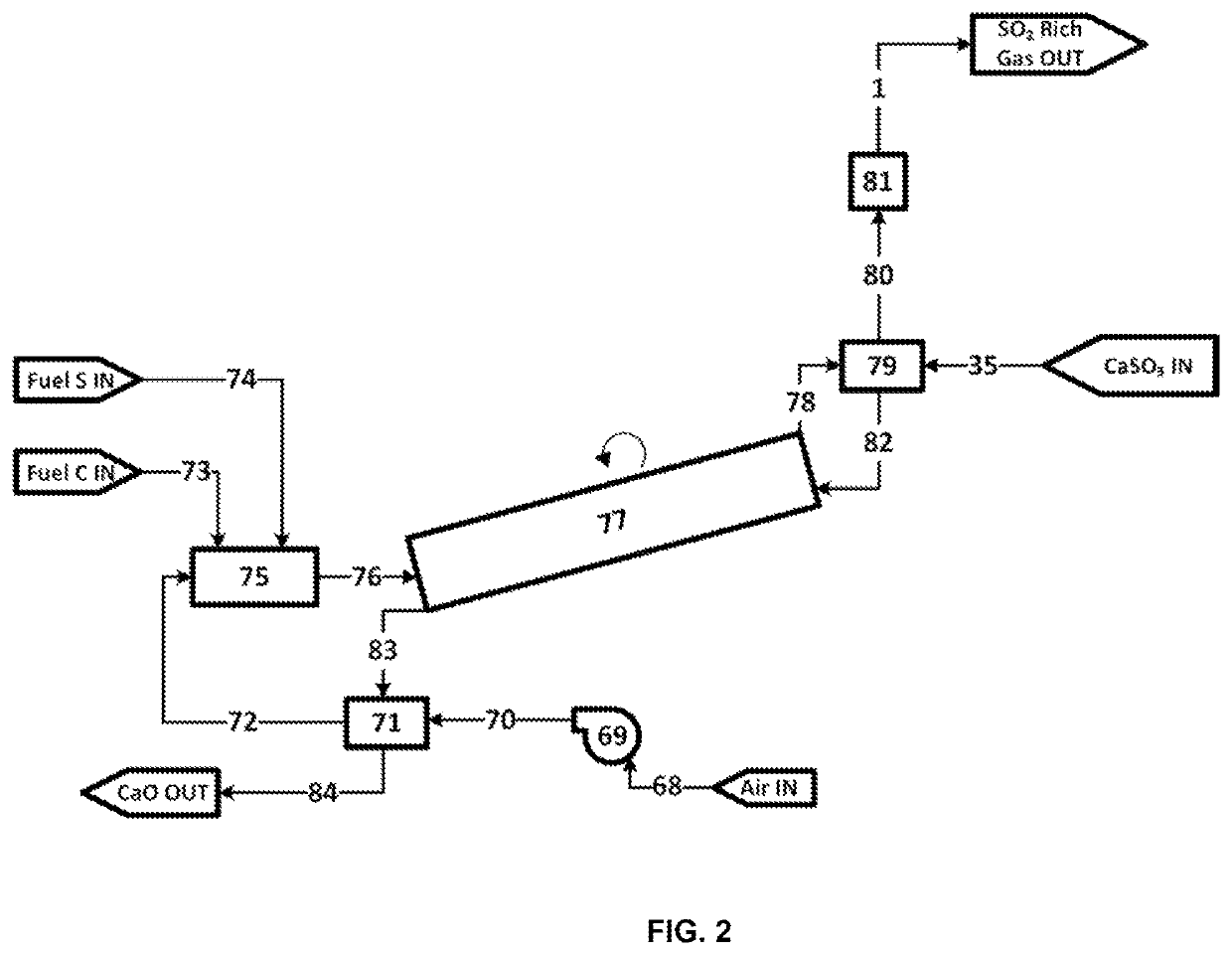

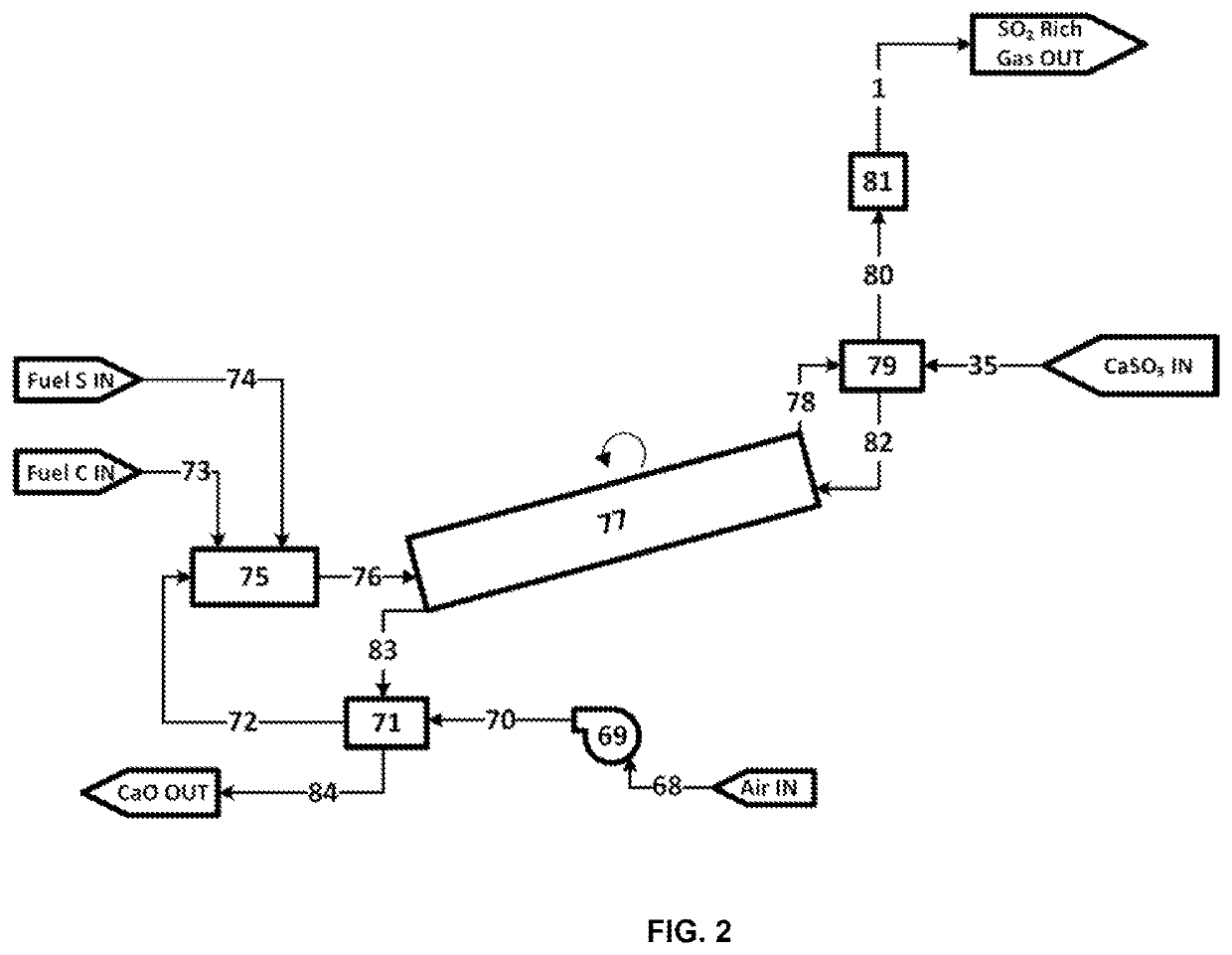

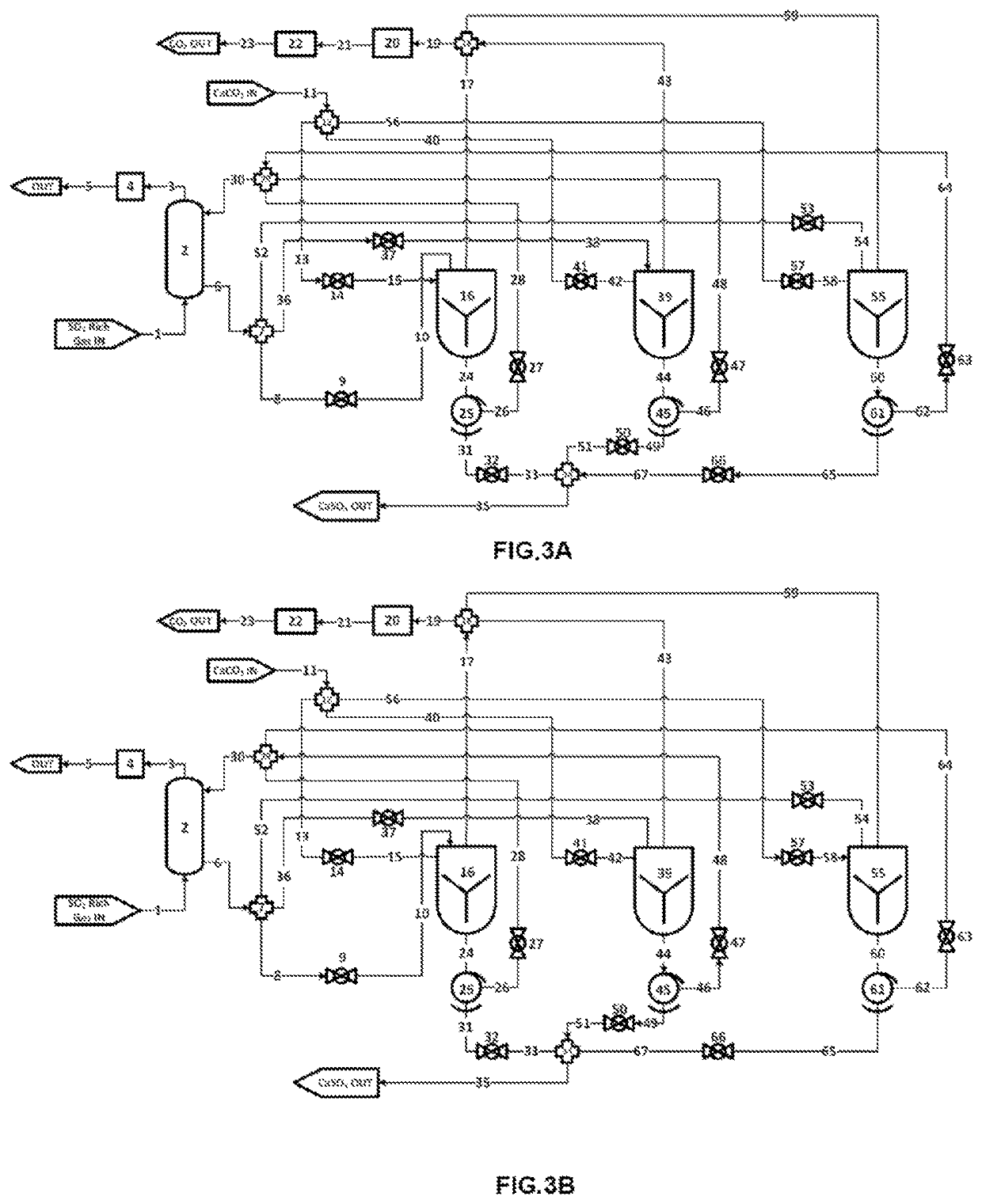

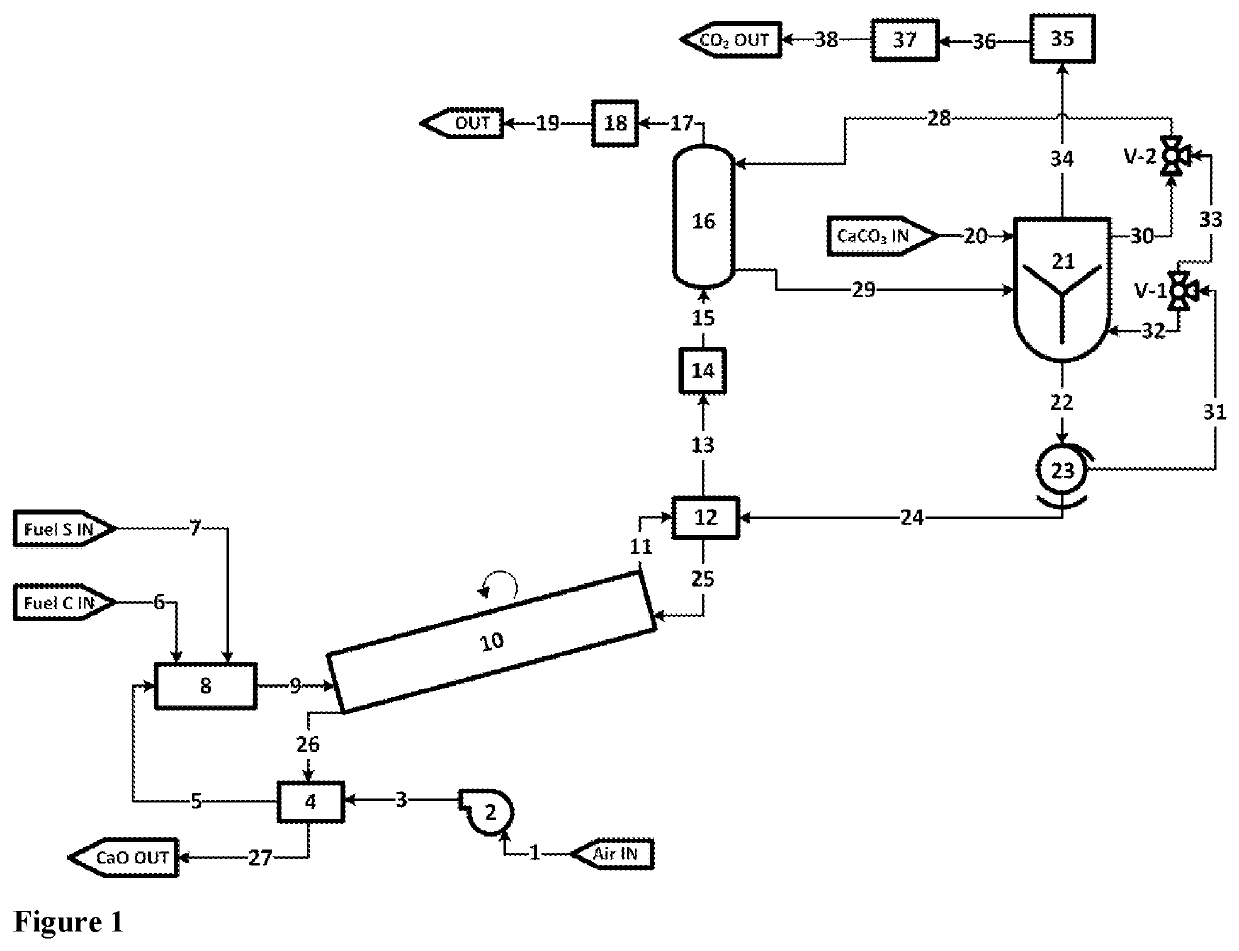

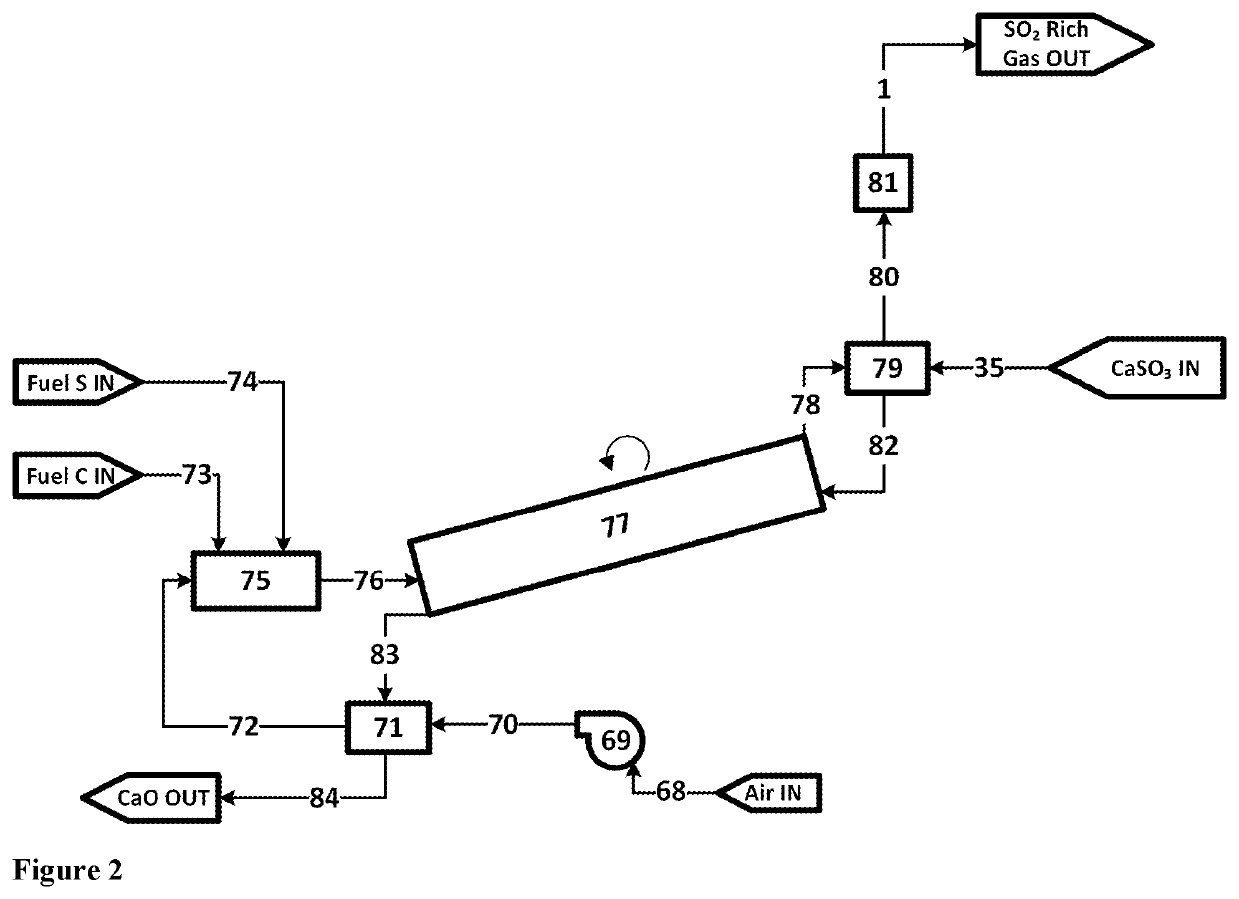

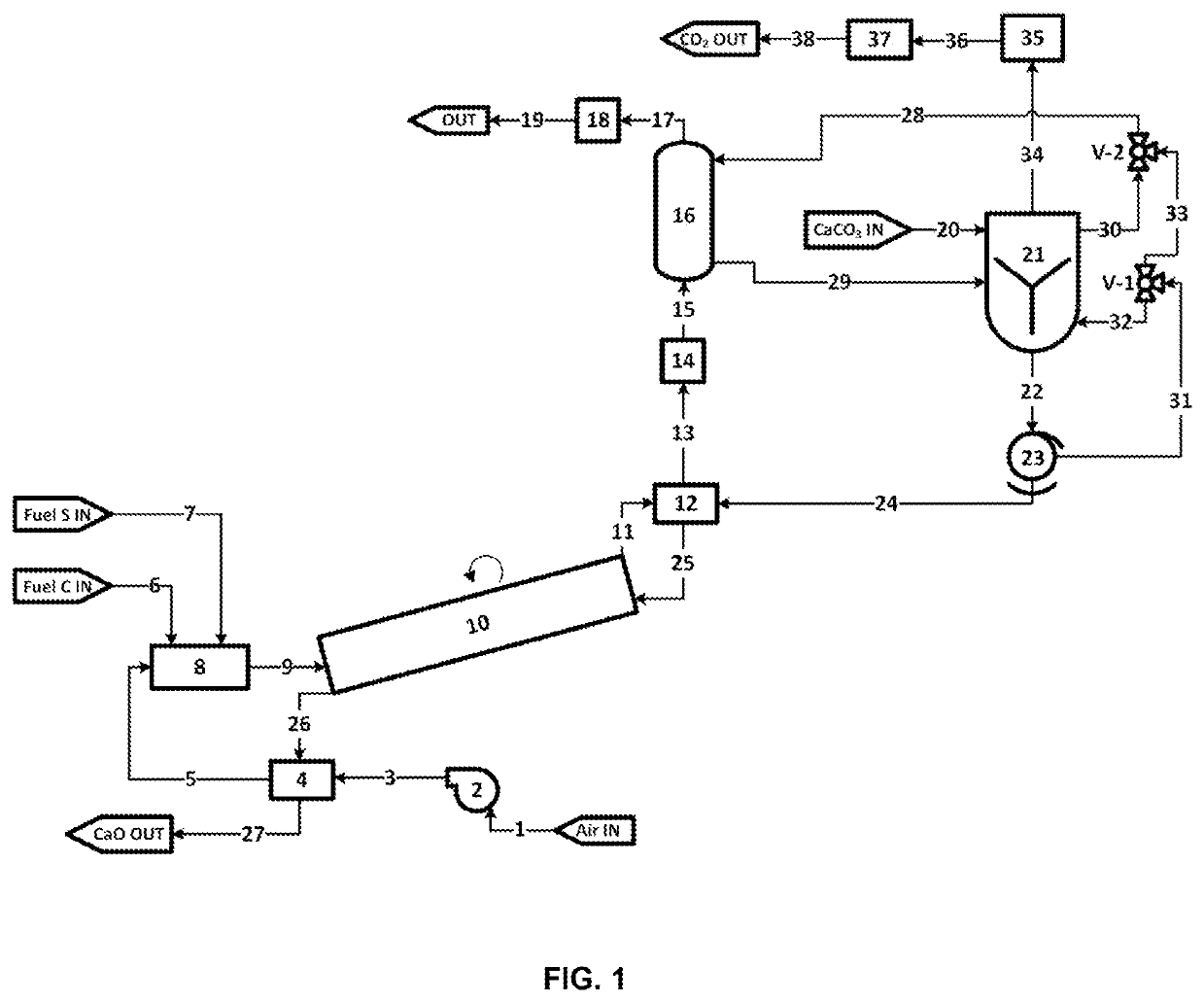

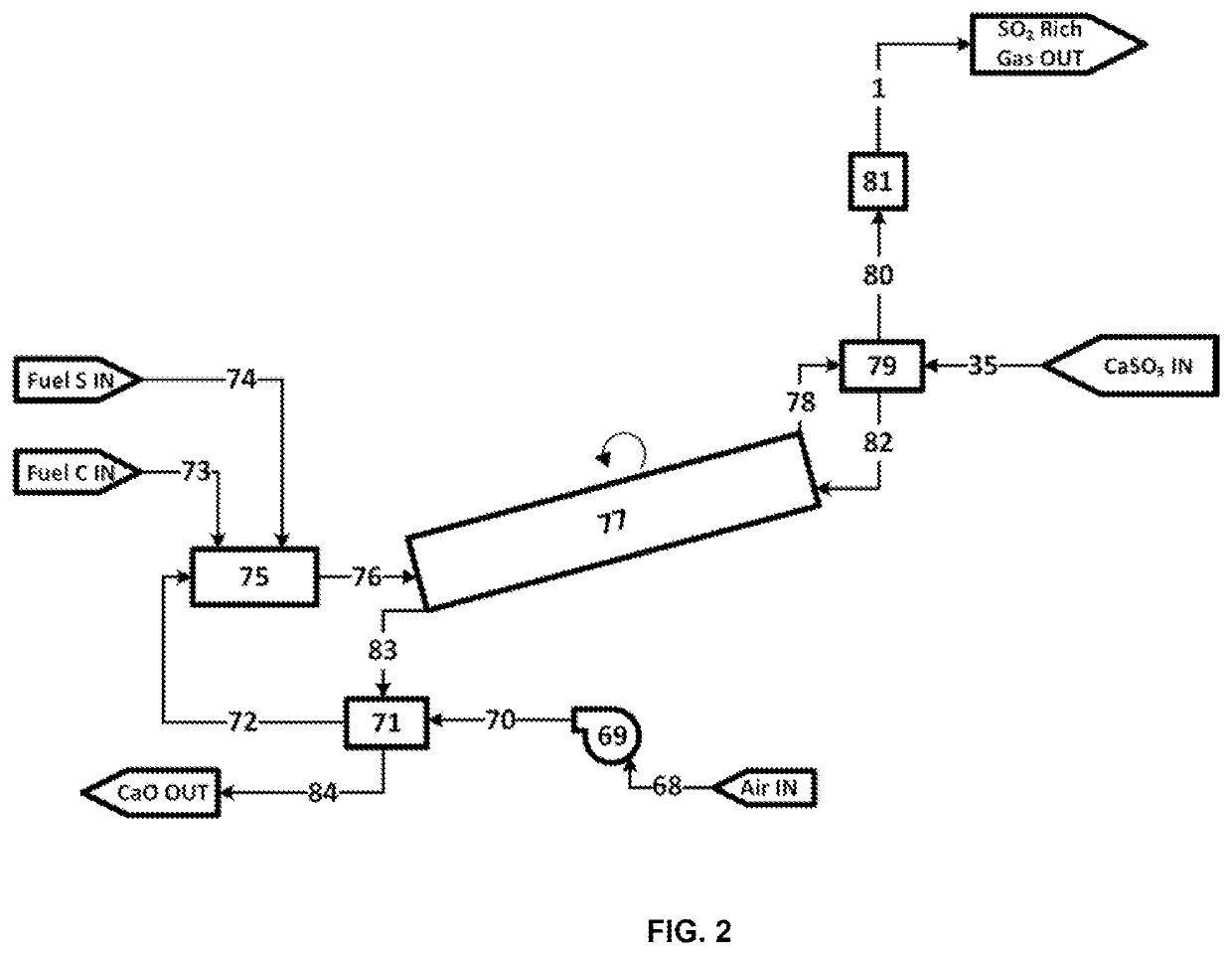

Sour gas combustion using in-situ oxygen production and chemical looping combustion

InactiveCN106029559AAchieve conversionAvoid direct contactFluidized bed combustionCalcium/strontium/barium sulfatesSorbentSulfur

Owner:SAUDI ARABIAN OIL CO

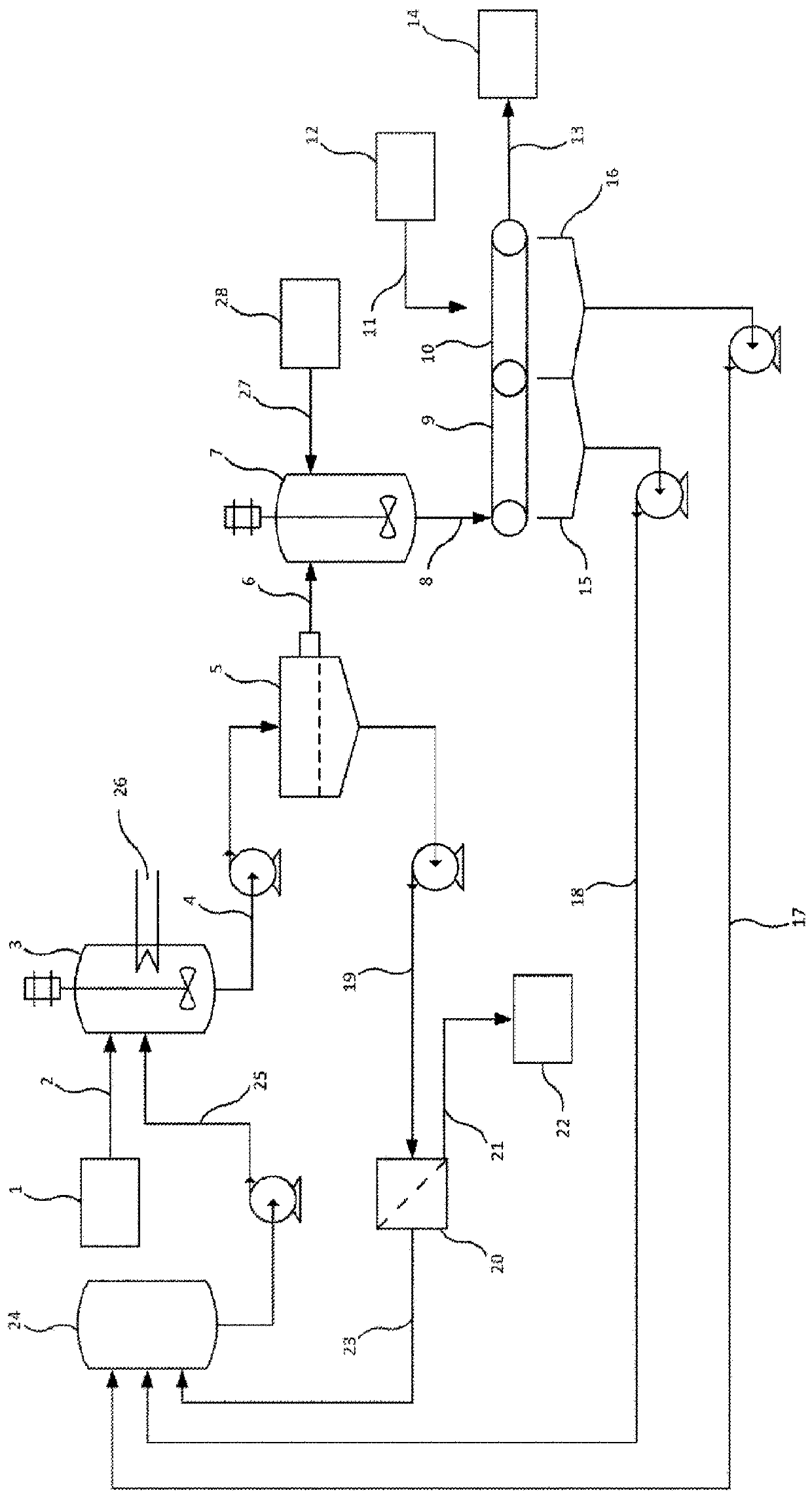

Desulfurization and denitrification system and method by adopting ozone oxidation in cooperation with ammonia method

PendingCN111495160AExtended stayReduce the temperatureAmmonium nitratesGas treatmentFlue gasEnvironmental engineering

The invention provides a desulfurization and denitrification system and method by adopting ozone oxidation in cooperation with an ammonia method. The desulfurization and denitrification system comprises a first absorption device and a second absorption device which are sequentially communicated in the flue gas flow direction. An ozone generation device is connected into an inlet flue of the firstabsorption device; the interior of the second absorption device is sequentially divided into a circulating spraying area and at least two layers of multi-effect spraying areas from bottom to top in the flue gas flowing direction, the circulating spraying area is externally connected with at least two absorbent storage tanks, the absorbent storage tanks are independently connected into the multi-effect spraying areas respectively, and the absorbent storage tanks supply absorbents to the circulating spraying area and the multi-effect spraying areas respectively; and the circulating spraying areais externally connected with a recovery unit. By adopting a double-tower structure for absorption, the retention time of the absorbent in the tower is prolonged, the contact time with flue gas is prolonged, and the desulfurization and denitrification efficiency is improved. A mixed absorbent of ammonia water and a calcium-based absorbent is adopted, and NOx in the flue gas is converted into chemical fertilizer and gypsum with higher additional value.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

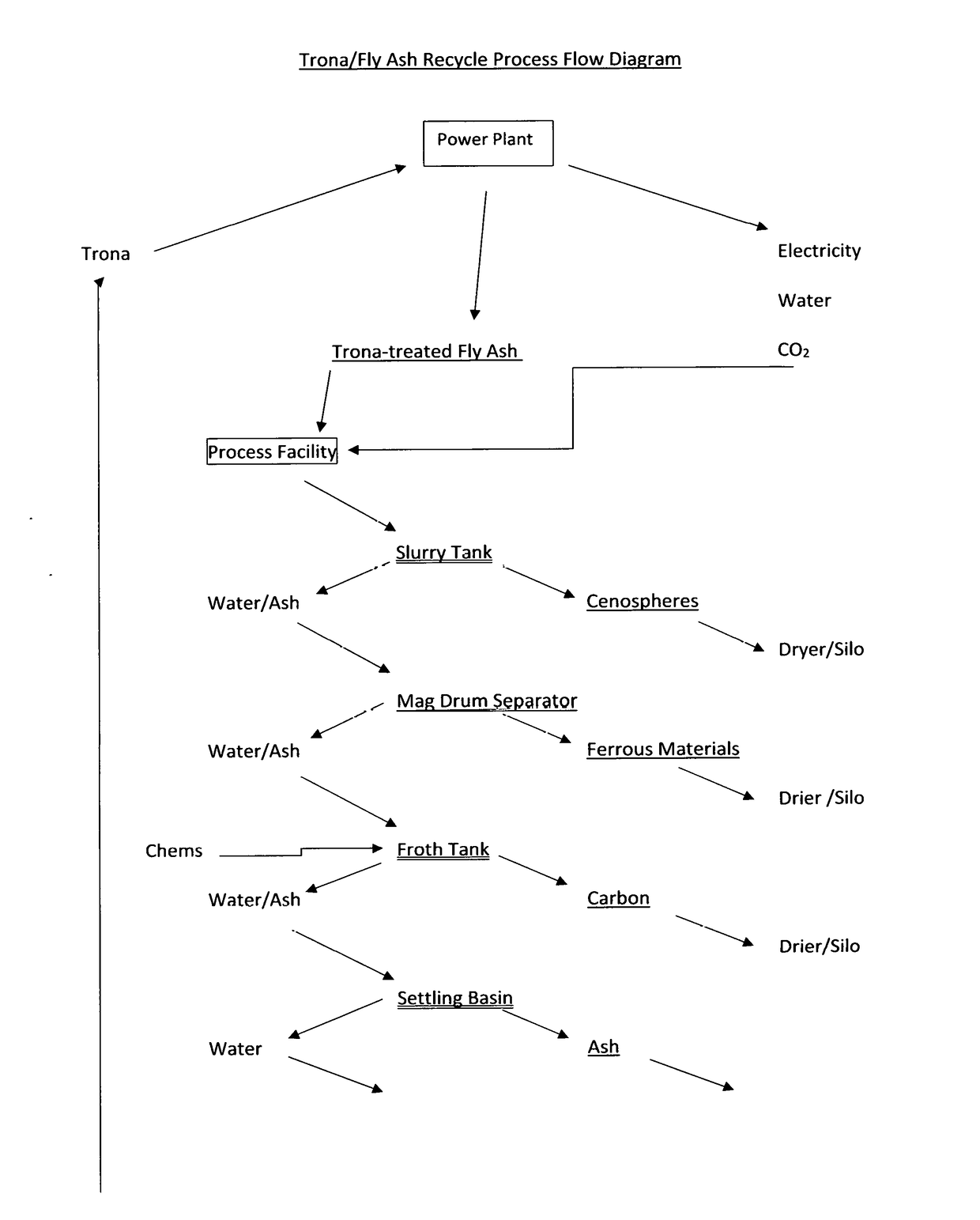

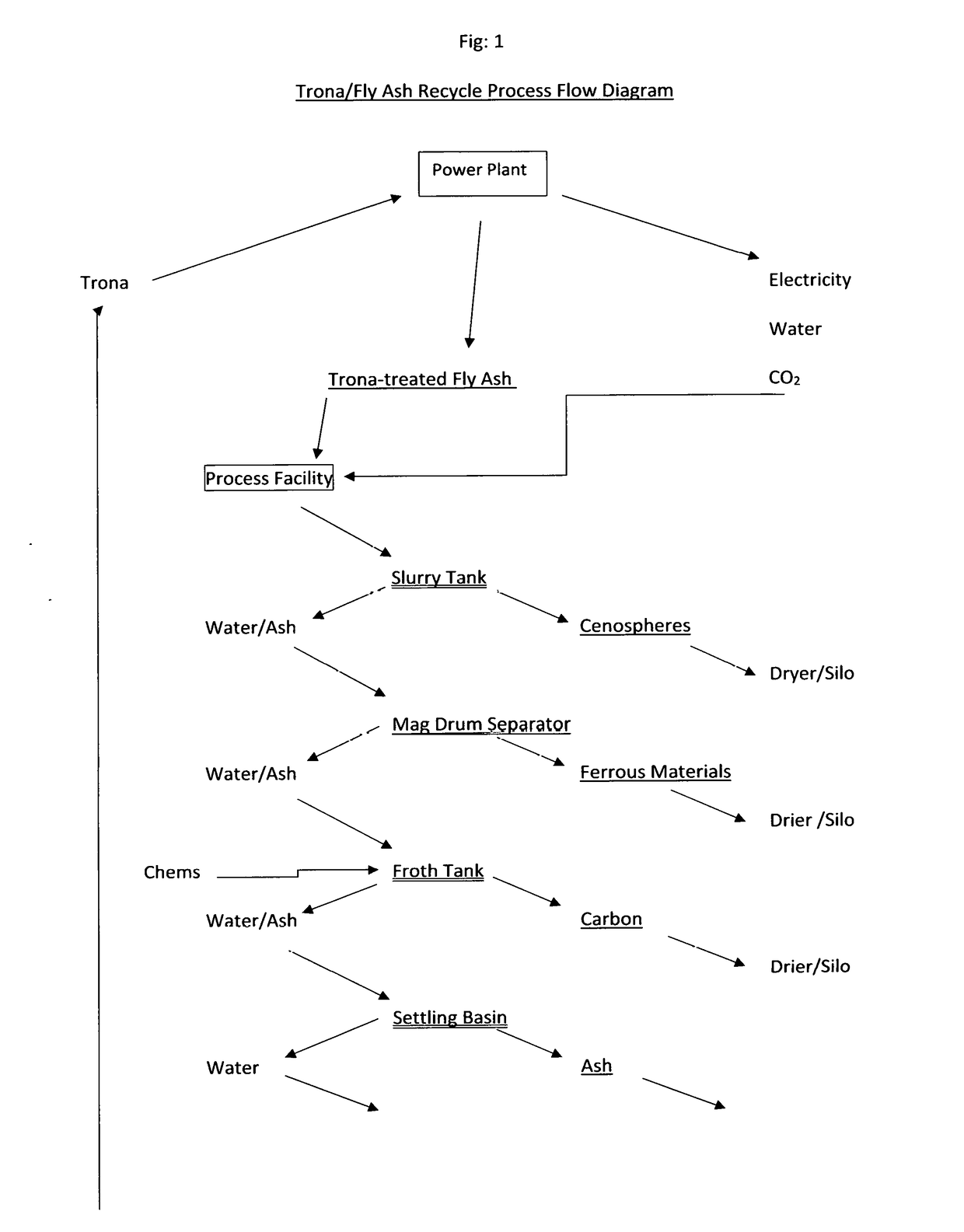

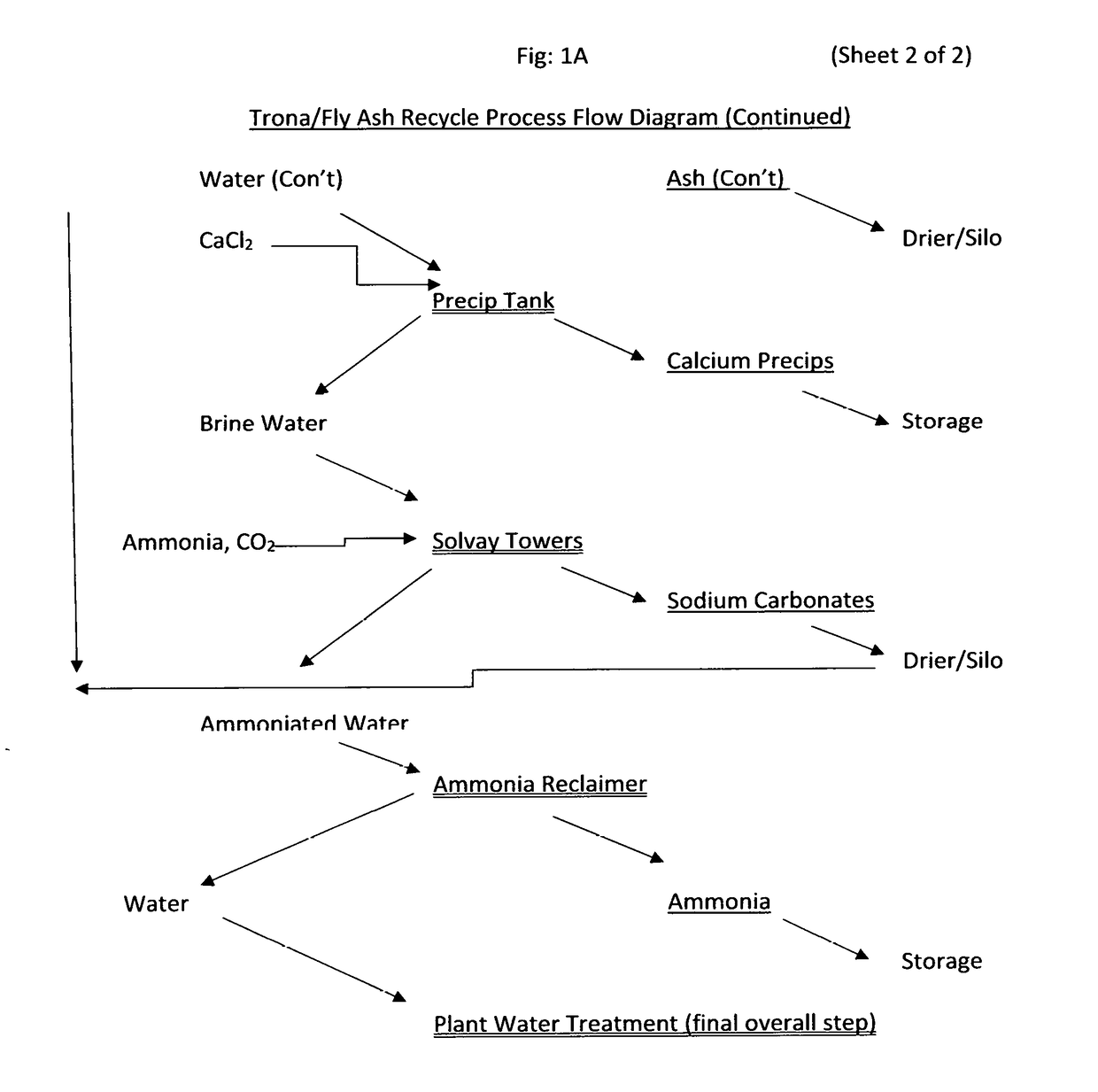

Process to Recycle and Reuse Trona and Coal Combustion Byproducts in a Coal-Fired Power Plant

InactiveUS20180044193A1Reduce disposal costsReduce formationCalcium/strontium/barium carbonatesSolid waste managementWaste streamVolcano

A process is developed wherein sodium carbonate is reclaimed from Trona-treated fly ash waste stream, and the fly ash rendered suitable for use as a Pozzolan. The process is a closed system wherein all separated aspects of the waste stream are reused by the generating power plant or offered as a commercial product.

Owner:ASH RECOVERY SYST INC

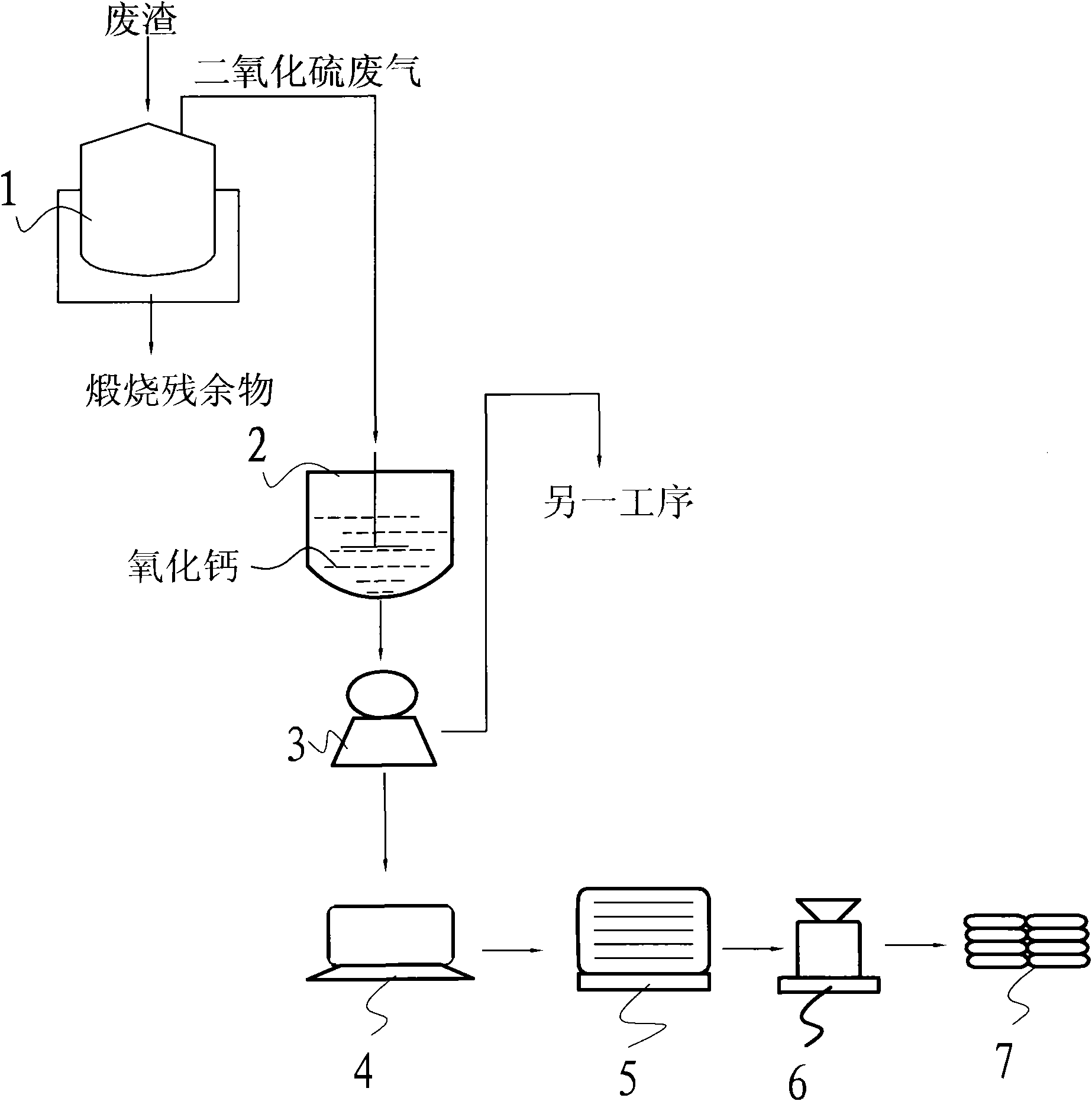

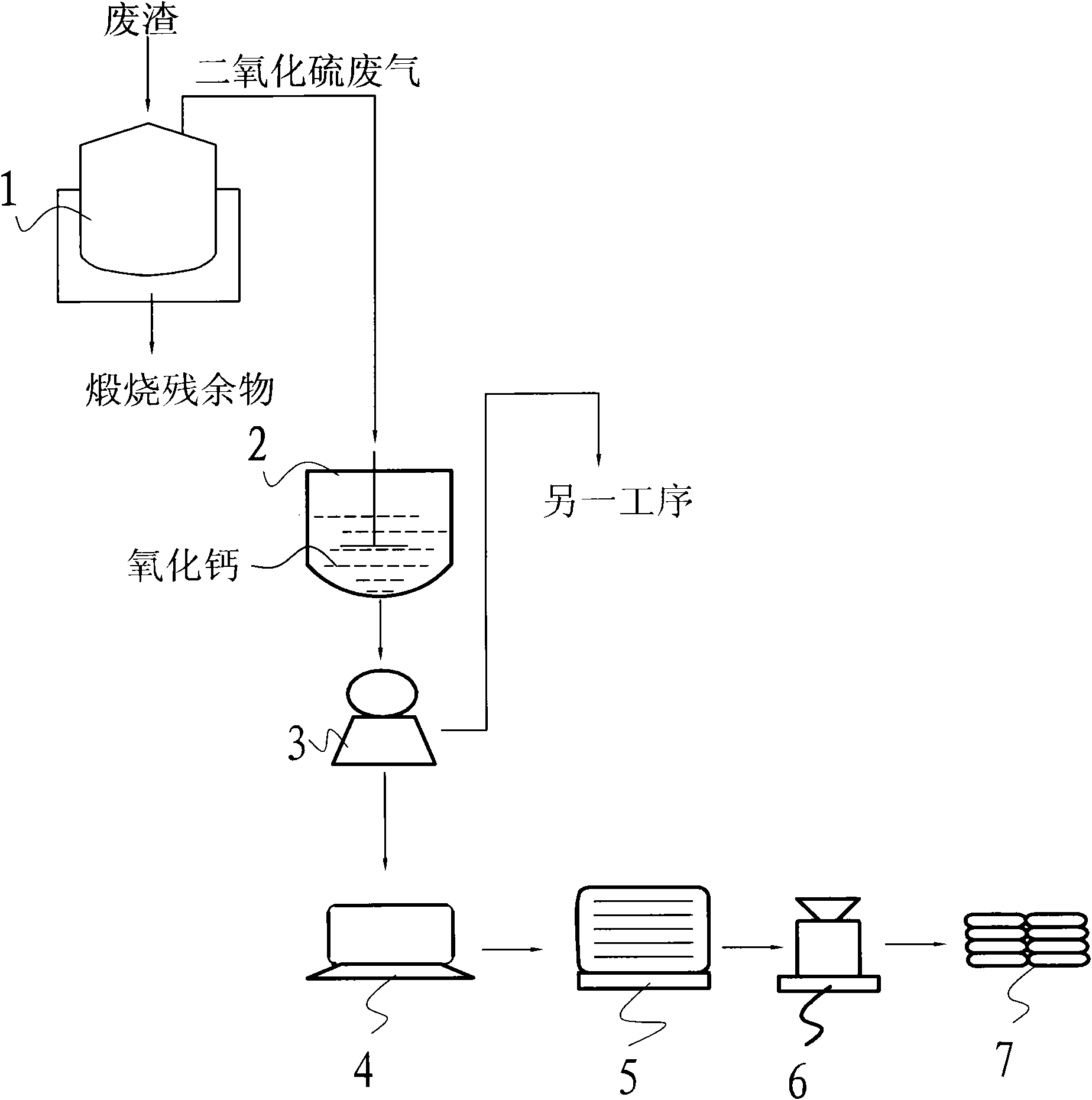

Method for preparing calcium sulfite by utilizing sulfur dioxide waste gas

InactiveCN101972597AEliminate effectiveReduce pollutionSolid waste disposalDispersed particle separationSocial benefitsInorganic Chemical

The invention relates to the technical field of comprehensive utilization of inorganic chemical lithopone manufacture waste lead skim, in particular to a method for preparing calcium sulfite by utilizing sulfur dioxide waste gas. In the invention, calcium oxide is mainly utilized to treat released sulfur dioxide gas while lithopone waste residue heavy metals are extracted by utilizing an electric arc furnace technique, and the gas is applied to prepare a calcium sulfite product. The invention not only eliminates the toxic sulfur dioxide gas but also prepares the valuable product, reduces the pollution of the waste gas to the environment and meanwhile prepares the valuable product, thereby having obvious social benefits and economic benefits; and especially, the process and the production equipment are simple, thereby the method is a comparatively practical treatment and utilization method.

Owner:汪晋强

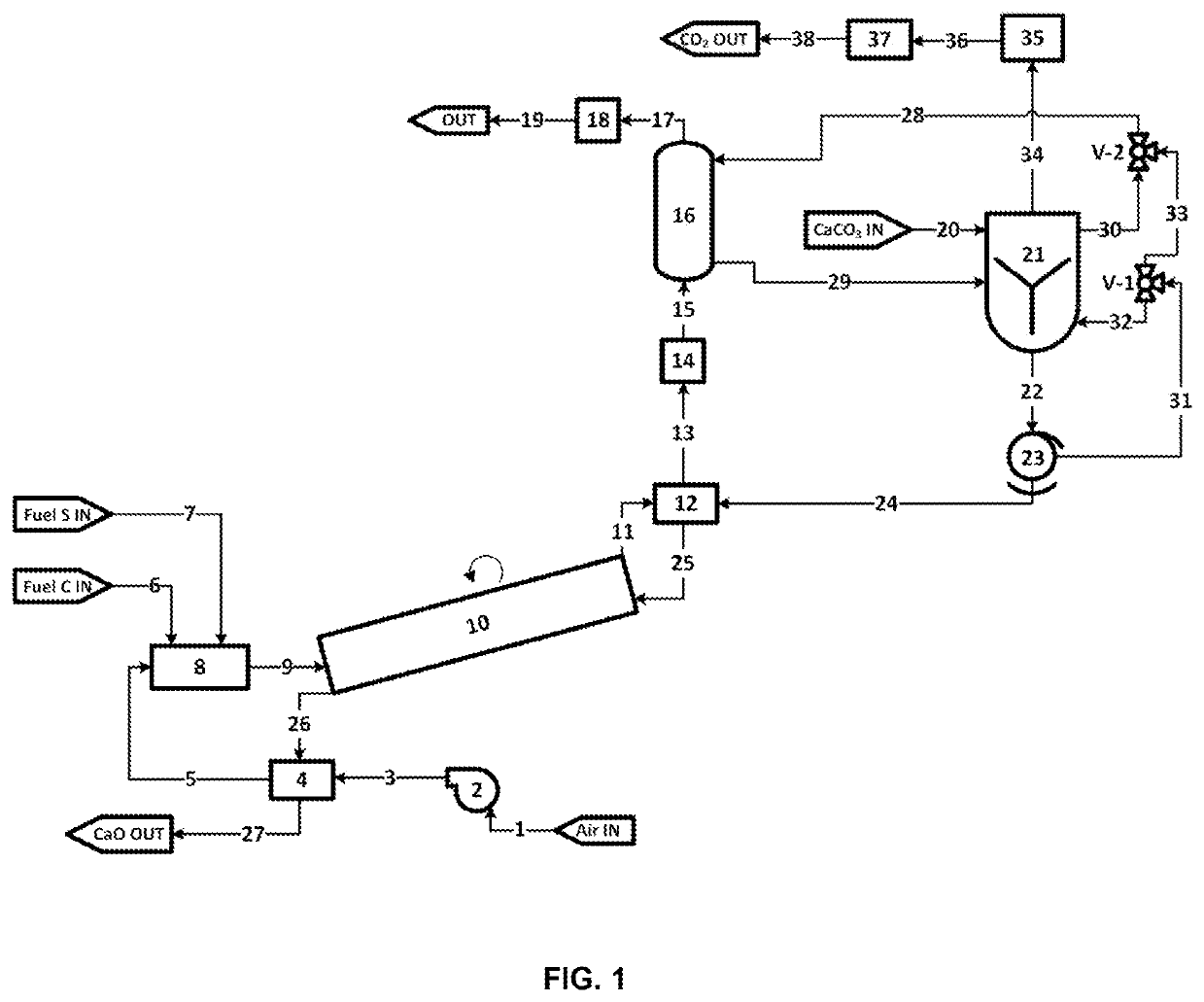

Process for the production of metal oxides

ActiveUS11174169B2High operating temperaturePrevent oxidationCarbon compoundsCarbon captureAlkaline earth metalCarboxylic acid anion

The present application pertains to methods for making metal oxides and / or citric acid. In one embodiment, the application pertains to a process for producing calcium oxide, magnesium oxide, or both from a material comprising calcium and magnesium. The process may include reacting a material comprising calcium carbonate and magnesium carbonate. Separating, concentrating, and calcining may lead to the production of oxides such as calcium oxide or magnesium oxide. In other embodiments the application pertains to methods for producing an alkaline-earth oxide and a carboxylic acid from an alkaline earth cation-carboxylic acid anion salt. Such processes may include, for example, reacting an alkaline-earth cation-carboxylic acid anion salt with aqueous sulfur dioxide to produce aqueous alkaline-earth-bisulfite and aqueous carboxylic acid solution. Other useful steps may include desorbing, separating, and / or calcining.

Owner:INNOVATOR ENERGY LLC

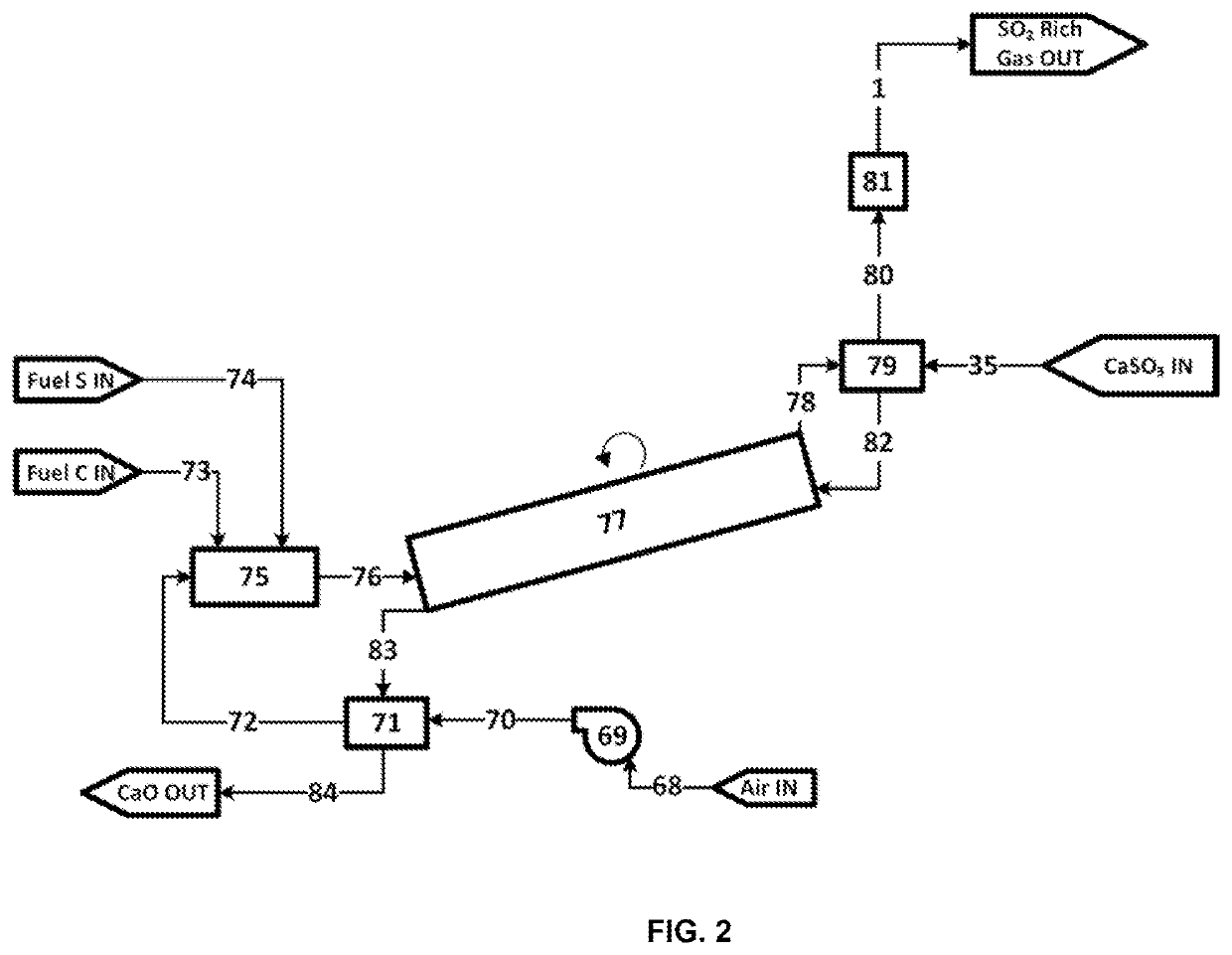

Processes for the Production of Citric Acid

ActiveUS20210261489A1Prevent oxidationAvoid contaminationPreparation from carboxylic acid saltsCarbon compoundsAlkaline waterAqueous solution

The present application pertains to methods for making metal oxides and / or citric acid. In one embodiment, the application pertains to a process for producing calcium oxide, magnesium oxide, or both from a material comprising calcium and magnesium. The process may include reacting a material comprising calcium carbonate and magnesium carbonate. Separating, concentrating, and calcining may lead to the production of oxides such as calcium oxide or magnesium oxide. In other embodiments the application pertains to methods for producing an alkaline-earth oxide and a carboxylic acid from an alkaline earth cation—carboxylic acid anion salt. Such processes may include, for example, reacting an alkaline-earth cation—carboxylic acid anion salt with aqueous sulfur dioxide to produce aqueous alkaline-earth—bisulfite and aqueous carboxylic acid solution. Other useful steps may include desorbing, separating, and / or calcining.

Owner:INNOVATOR ENERGY LLC

Process for the Production of Metal Oxides or Citric Acid

ActiveUS20220267242A1Prevent oxidationAvoid contaminationPreparation from carboxylic acid saltsSulfur compoundsAlkaline earth metalSulfite salt

The present application pertains to methods for making metal oxides and / or citric acid and / or capturing carbon dioxide. In one embodiment, the application pertains to a process for producing calcium oxide, magnesium oxide, or both from a material comprising calcium and magnesium. The process may include reacting a material comprising calcium carbonate and magnesium carbonate. Separating, concentrating, and calcining may lead to the production of oxides such as calcium oxide or magnesium oxide. In other embodiments the application pertains to methods for producing an alkaline-earth oxide and a carboxylic acid from an alkaline earth cation-carboxylic acid anion salt. Such processes may include, for example, reacting an alkaline-earth cation-carboxylic acid anion salt with aqueous sulfur dioxide to produce aqueous alkaline-earth sulfite or bisulfate and an aqueous carboxylic acid solution. Other useful steps may include desorbing, separating, and / or calcining.

Owner:INNOVATOR ENERGY LLC

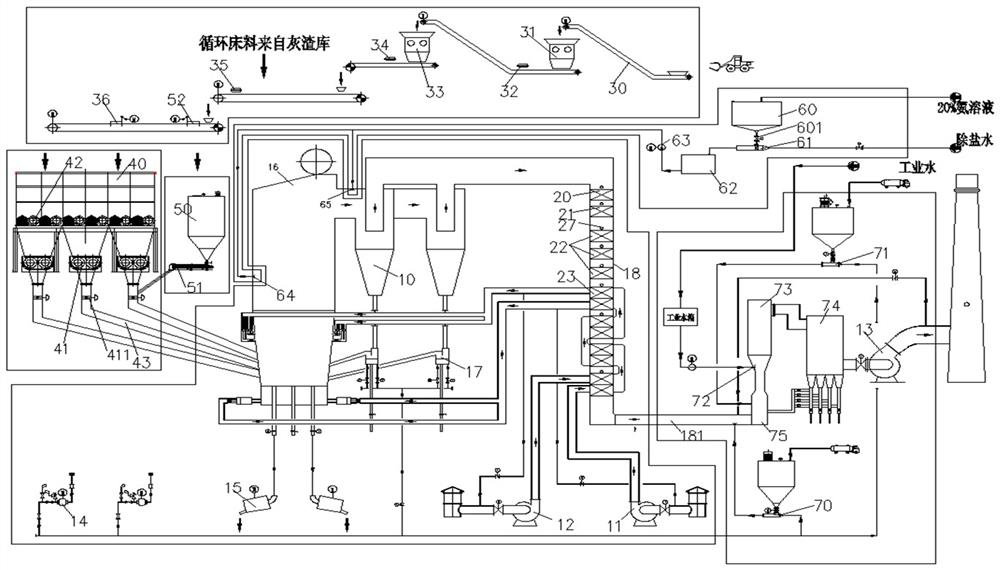

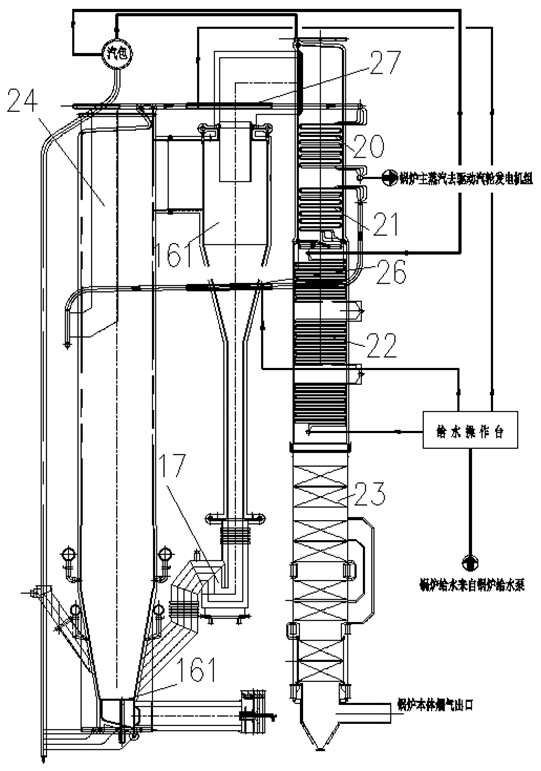

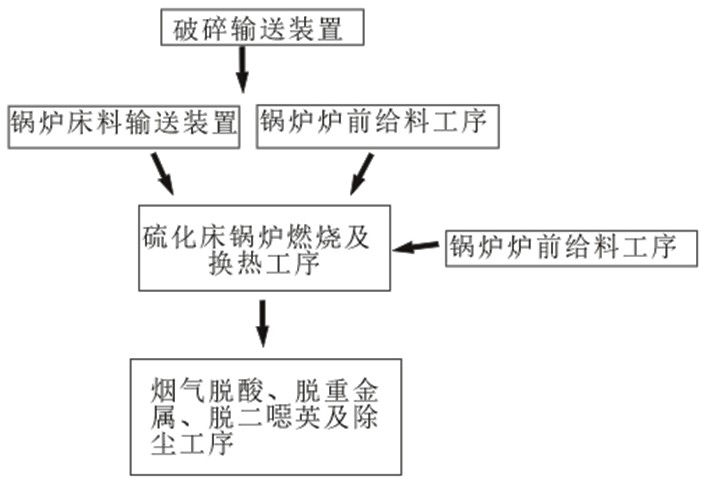

Disposal system and method for combustible industrial solid wastes

ActiveCN111637465AReduce generationGas treatmentDispersed particle filtrationAir preheaterDust control

The invention relates to the technical field of disposal of combustible industrial solid wastes, in particular to a disposal system and a disposal method for combustible industrial solid wastes. The disposal system comprises a circulating fluidized bed boiler, a crushing and conveying device, a furnace feeder, a bed material conveying device, a two-stage SNCR denitrification device and a flue gastreatment subsystem; a gas inlet pipeline of a "J" valve returner of the circulating fluidized bed boiler communicates with a material return fan; flue gas outlets of two cyclones each communicate with a shaft flue at the tail part of the circulating fluidized bed boiler through a pipeline; and a high-temperature superheater, a low-temperature superheater, a coal economizer and a horizontal air preheater from are sequentially arranged from top to bottom at the shaft flue. The disposal system provided by the invention solves the problem of disposal of industrial solid wastes and does not need to burn other fuels such as coal, oil and natural gas in a normal combustion process; the ash and deacidified ash produced in combustion are both general wastes that can be comprehensively utilized; and the deacidified and dust-removed flue gas meets the ultra-clean emission requirements.

Owner:EAST CHINA ENG SCI & TECH

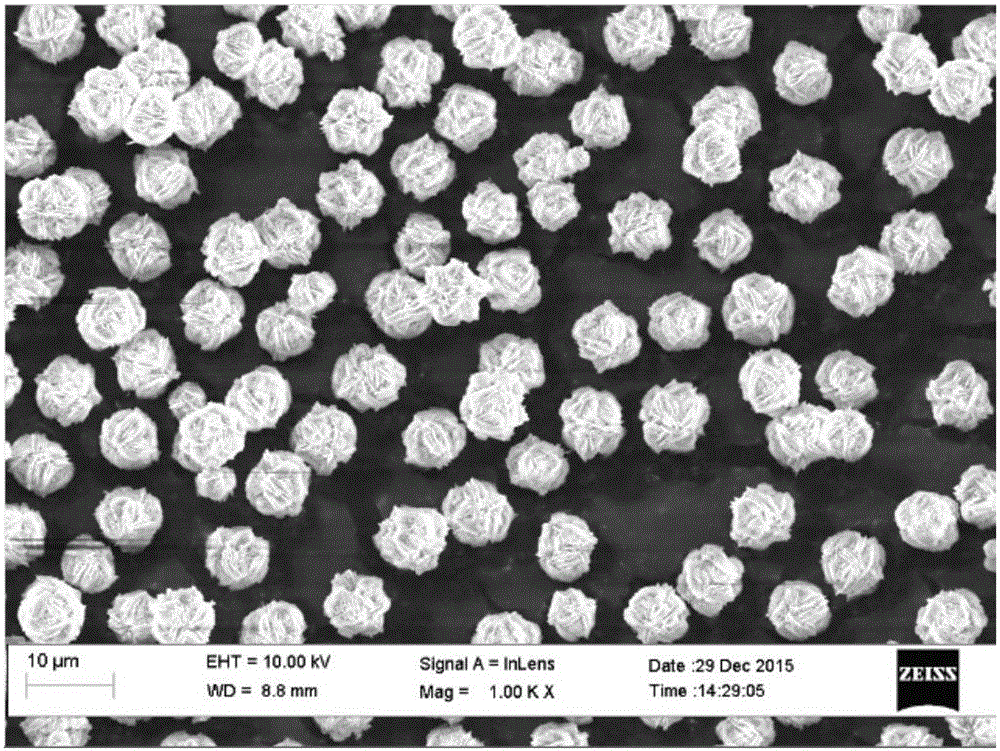

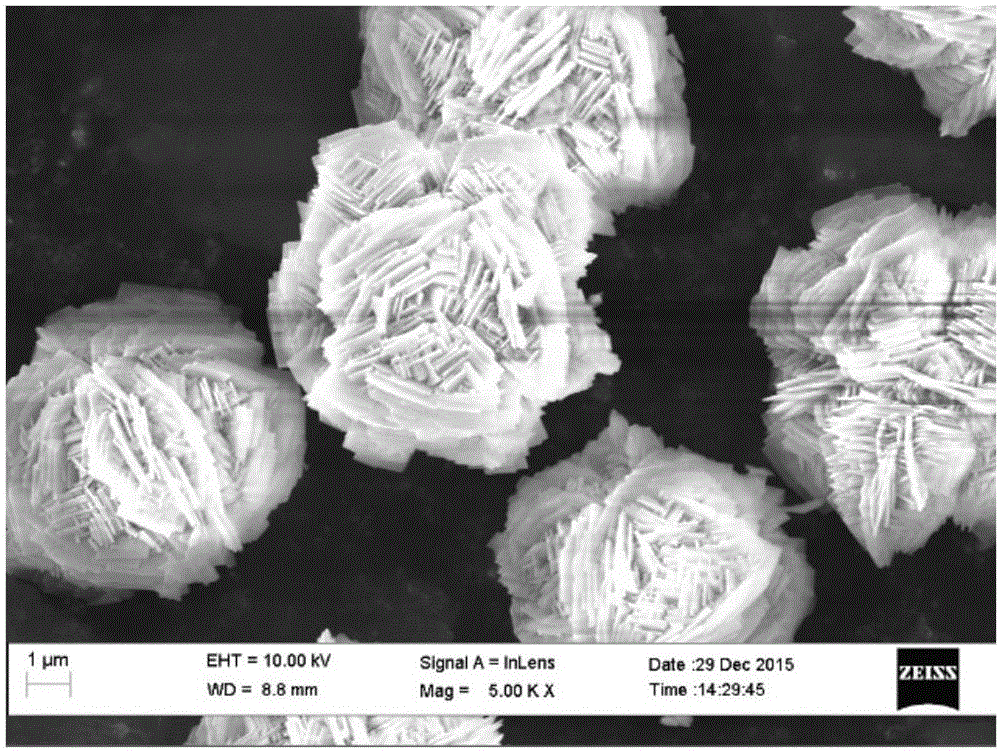

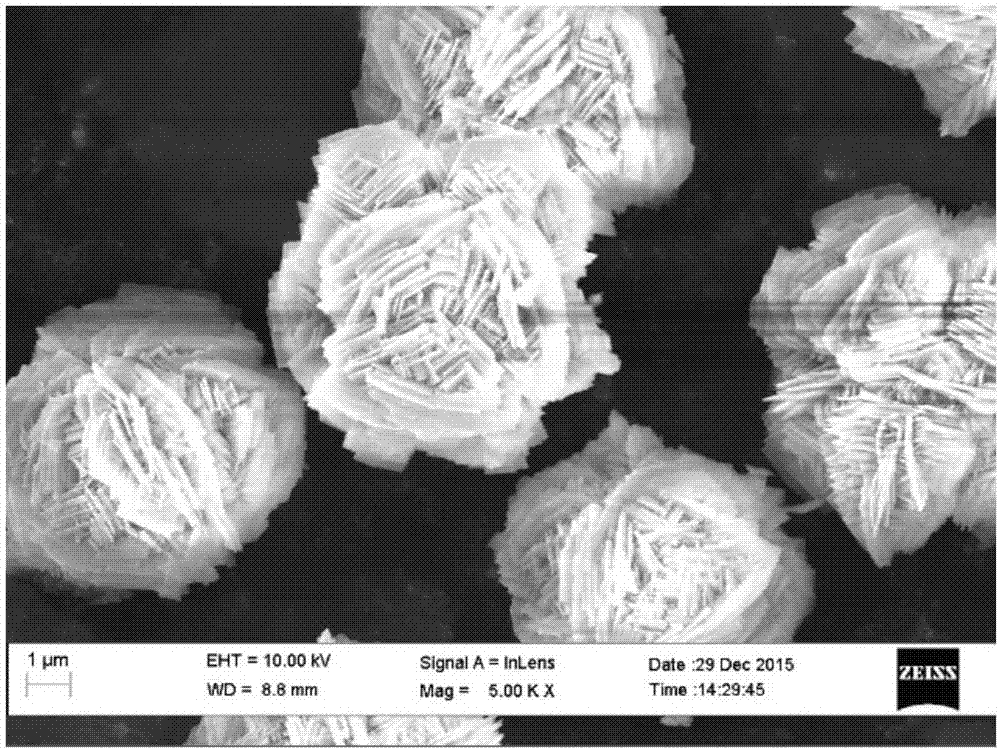

Method for preparing cauliflower-like calcium sulfite microparticles

ActiveCN106115762AEasy to operateRaw material environmental protectionCalcium/strontium/barium sulfitesFiltration membraneSulfite salt

The invention relates to a method for preparing cauliflower-like calcium sulfite microparticles. The method comprises the steps of separately preparing a calcium chloride solution of finite concentration and a sodium sulfite solution of finite concentration from calcium chloride and sodium sulfite which serve as raw materials by using water, carrying out filtrating by using filtration membranes, collecting filtrates, adding a certain volume of citric acid into the calcium chloride solution, adjusting the pH of the calcium chloride solution to 10 by using a sodium hydroxide solution, slowly adding the sodium sulfite solution into the calcium chloride solution while carrying out stirring, finally, filtrating produced calcium sulfite precipitates, carrying out centrifuging, carrying out washing with secondary distilled water and anhydrous ethanol alternately, and carrying out drying at the temperature of 60 DEG C, thereby obtaining cauliflower-like calcium sulfite. According to the method, the morphology of the obtained product is cauliflower-like, the particle size is 5 to 10 microns and is uniform in distribution, the preparation process is simple, the cost is low, and the raw materials are safe and non-toxic, so that the method has a great application value in the field of purification of cane sugar juice.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Process for the Production of Metal Oxides

ActiveUS20210261427A1Prevent oxidationAvoid contaminationCarbon compoundsCarbon captureAlkaline waterProcess engineering

The present application pertains to methods for making metal oxides and / or citric acid. In one embodiment, the application pertains to a process for producing calcium oxide, magnesium oxide, or both from a material comprising calcium and magnesium. The process may include reacting a material comprising calcium carbonate and magnesium carbonate. Separating, concentrating, and calcining may lead to the production of oxides such as calcium oxide or magnesium oxide. In other embodiments the application pertains to methods for producing an alkaline-earth oxide and a carboxylic acid from an alkaline earth cation-carboxylic acid anion salt. Such processes may include, for example, reacting an alkaline-earth cation-carboxylic acid anion salt with aqueous sulfur dioxide to produce aqueous alkaline-earth-bisulfite and aqueous carboxylic acid solution. Other useful steps may include desorbing, separating, and / or calcining.

Owner:INNOVATOR ENERGY LLC

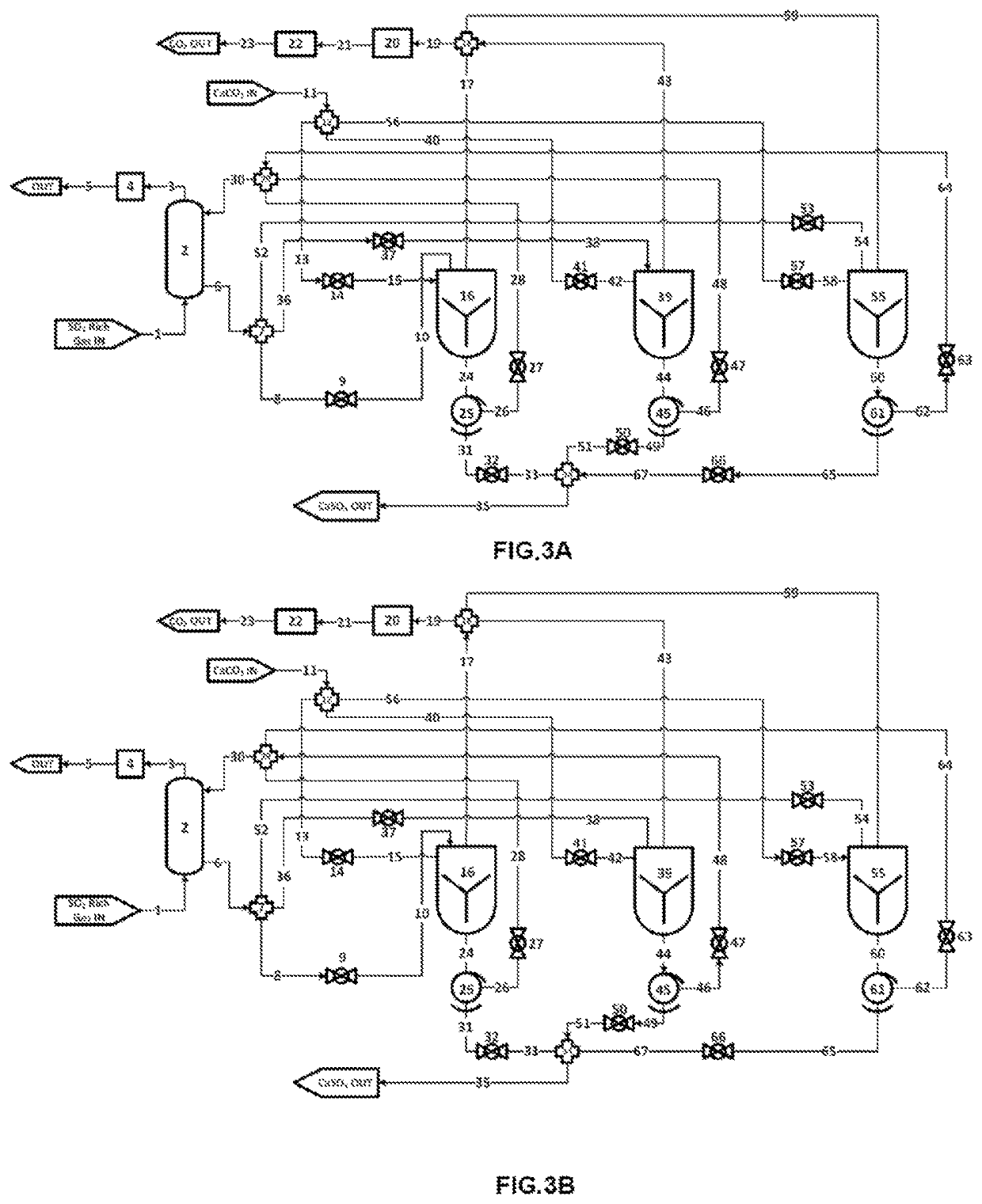

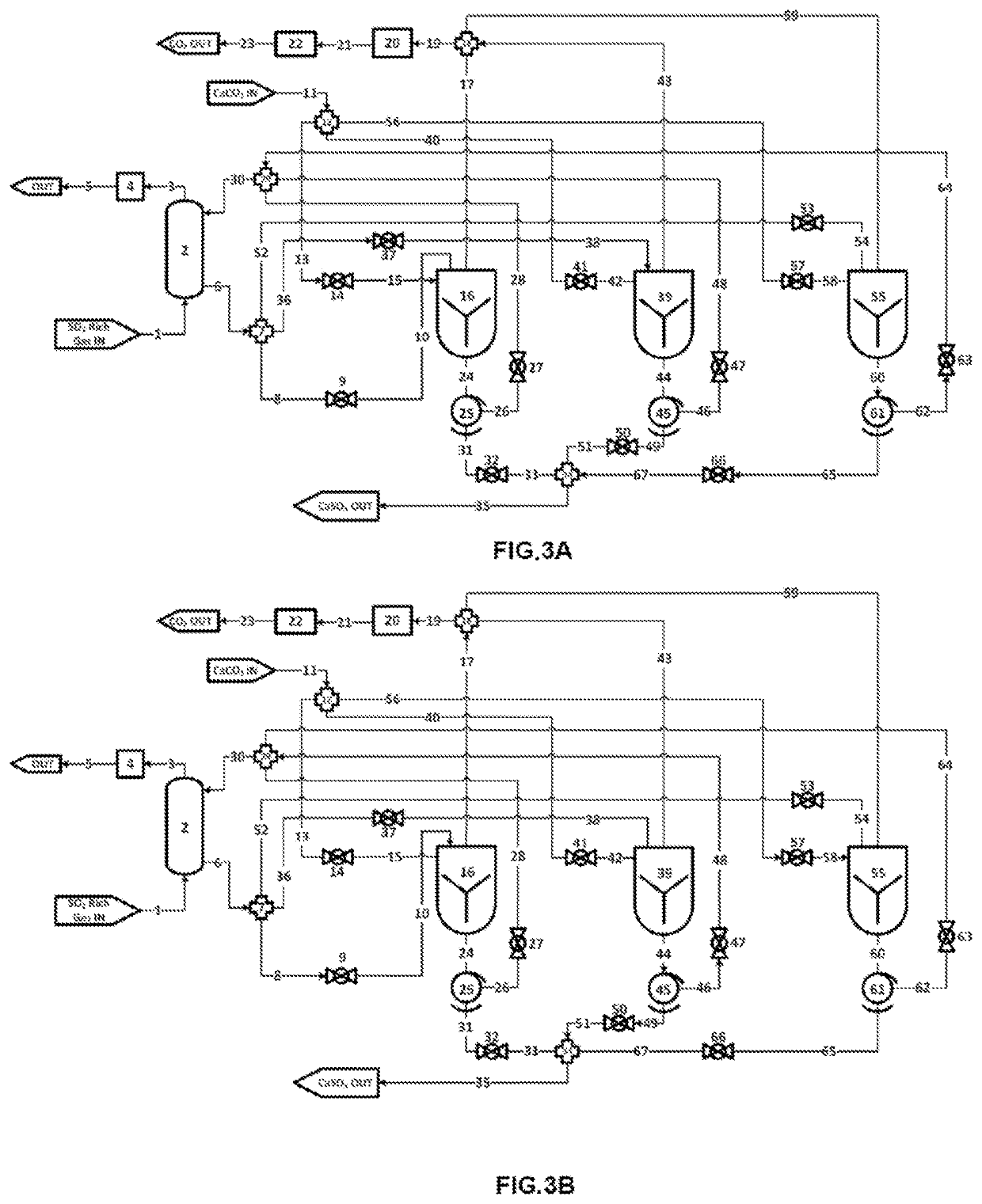

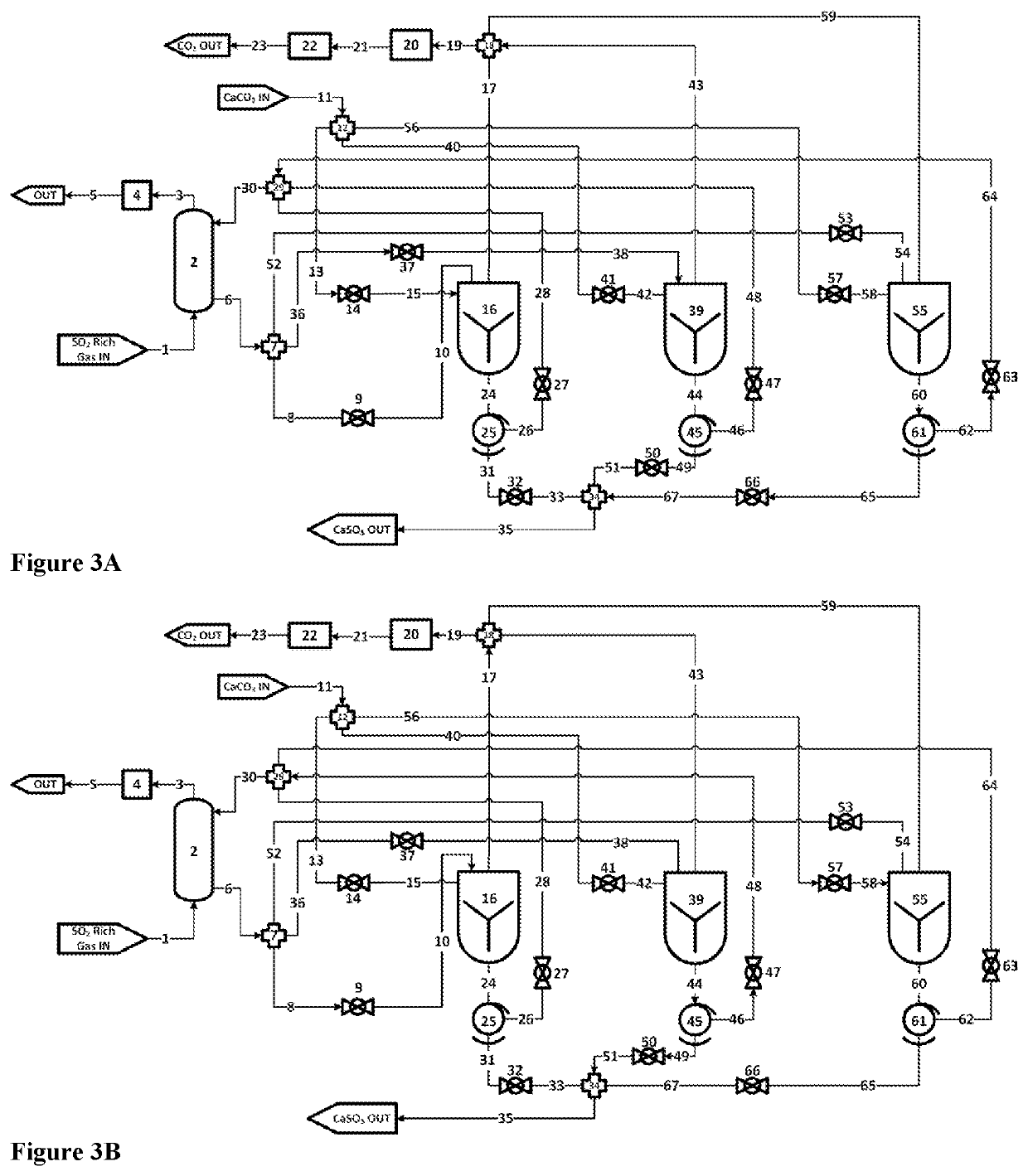

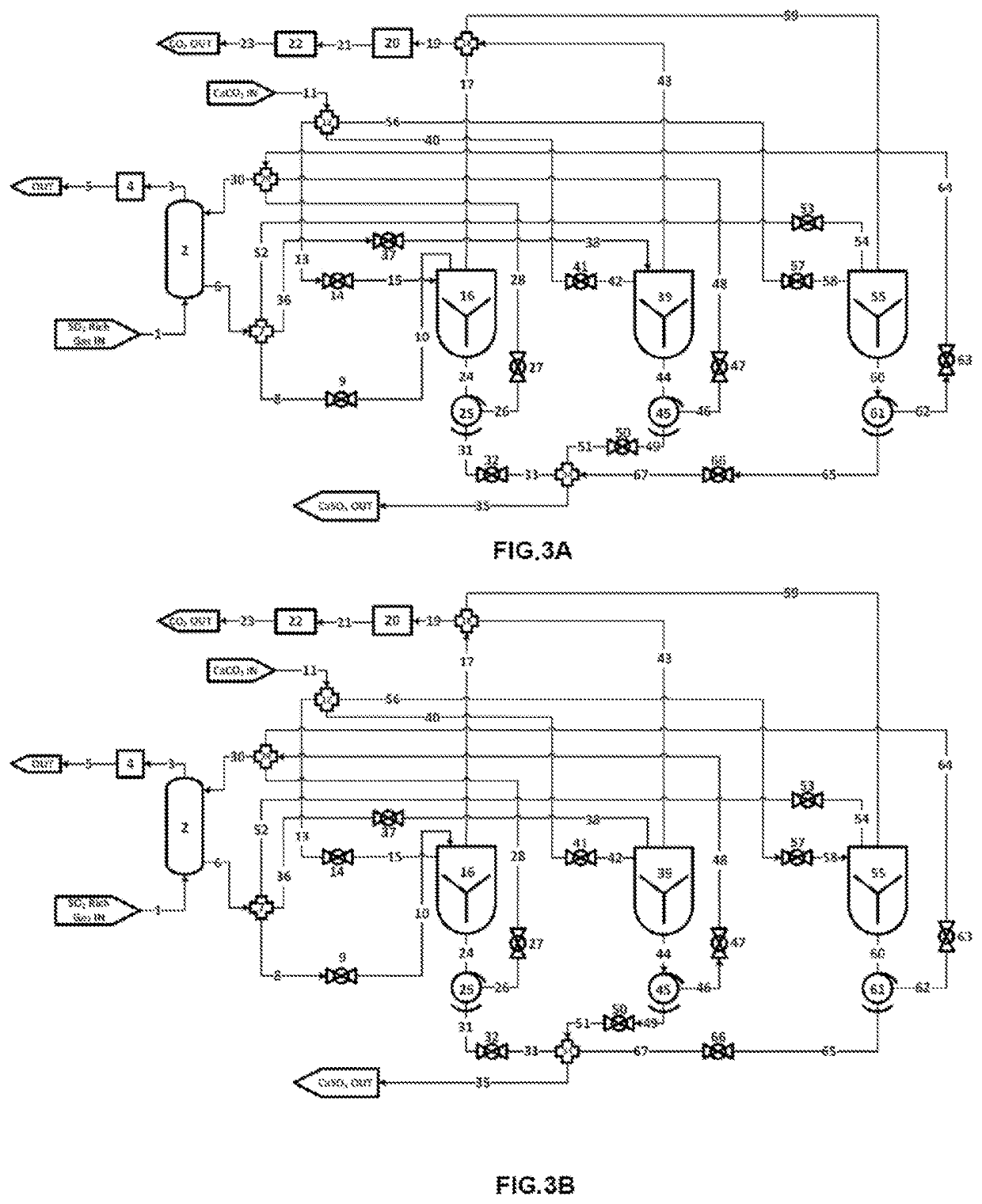

Systems and method for removal of acid gas in a circulating dry scrubber

ActiveUS10668480B1Improve efficiencyLowering of average gas temperaturePigmenting treatmentCalcium/strontium/barium chloridesFlue gasEnvironmental engineering

Owner:MISSISSIPPI LIME CO

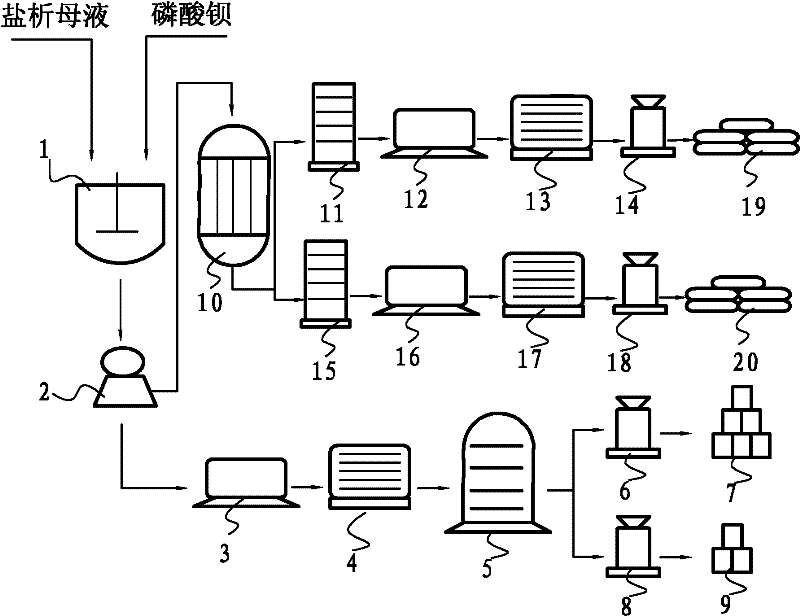

Method for reusing desulfurization and denitration by-products

InactiveCN105540611AHigh purityHigh market demandSulfur-dioxide/sulfurous-acidCalcium/strontium/barium sulfitesCatalytic oxidationNitrogen gas

The invention relates to a method for reusing desulfurization and denitration by-products. The invention comprises the following steps: (1) in an ammonia process of desulfurization and denitration, stopping adding oxygen (or air) to enable the most by-products to be converted into sulfite and nitrite; (2) continuously adding concentrated sulfuric acid into sulfite and nitrite produced in the reaction above to generate sulfur dioxide, nitrogen, ammonium sulfate, and the like; (3) absorbing the mixed gas generated above through water, sodium hydroxide, sodium carbonate, and the like to product sulfurous acid or sulfite, or adding a catalytic oxidation process for producing sulfurous acid or sulfite; and (4) performing centrifugal separation and drying on ammonium sulfate containing a certain ash content, wherein ammonium sulfate is the main component in the reaction substrate left in the step (2), to obtain an ammonium sulfate product with extremely high purity. The produced products, such as sulfurous acid, sulfite, and ammonium sulfate, have high purity, less impurity contents, and remarkable economic and social benefit.

Owner:SHAOXING UNIV YUANPEI COLLEGE

Economical method for desulfurizing and dedusting glue gas produced during smelting of secondary lead

ActiveCN103239979AAvoid secondary pollutionRealize reprocessing and utilizationProductsReagentsSulfurDissolution

The invention discloses an economical method for desulfurizing and dedusting glue gas produced during smelting of secondary lead. The economical method comprises the following steps of: adsorbing lead dust, SO2 and SO3 first by using slightly acidic water to separate from the CO2 by using the characteristic that the dissolution and adsorption capacity of the CO2 in a slightly acidic water solution is remarkably lower than that of the lead dust, the SO2 and the SO3; then removing the lead dust by using a precipitation or centrifugal mode; and finally adding lime to carry out sulfur fixation and desulfuration. According to the method disclosed by the invention, the consumption of a desulfurizer and the desulfurization cost are reduced, and a desulfurized product cannot be subjected to secondary pollution by the lead dust and can be recycled.

Owner:安徽华创环保设备科技有限公司

Method for preparing roasted sulfate residues into sulfites by using chemical method

InactiveCN102092765AHigh purityQuality assuranceSolid waste disposalCalcium/strontium/barium sulfitesAluminium chlorideMagnesium sulfite

The invention relates to a method for preparing roasted sulfate residues into sulfites by using a chemical method. The method comprises the following steps: putting roasted sulfate residues and hydrochloric acid in a pure mass ratio of 1: (1.95-2.35) in a first corrosion-resistant reactor, and starting an agitator to stir for 20 minutes; then reacting to generate chlorides such as aluminium chloride, ferric chloride, calcium chloride, magnesium chloride and the like; filtering to obtain silicides and black filter cakes of elementary sulfur as well as a clear chloride liquid at the same time; feeding the obtained chloride liquid and sulphurous acid in a pure mass ratio of 1: (0.54-0.94) to a second corrosion-resistant reactor, starting the agitator to stir, reacting to generate a mixed liquid of calcium sulfite, magnesium sulfate and hydrochloric acid, and then filtering to obtain white filter cakes; and carrying out washing and drying, winnowing classification and smashing package on the white filter cakes so as to respectively obtain calcium sulfite and magnesium sulfate products, and simultaneously, returning the obtained clear diluted hydrochloric acid back to the former process for cycle utilization. In the invention, the sulfites are prepared by using the roasted sulfate residues as raw materials.

Owner:何侠

White carbon black prepared from industrial waste slag and production technology thereof

InactiveCN109809418ANo emissionsReduced production cost recoveryAlkaline-earth metal silicatesAlkali metal silicatesCalcium silicateSlag

The invention relates to white carbon black prepared from industrial waste slag and a production technology thereof. The production technology is characterized by comprising the following steps of adding quartz sand, calcium sulfate and charcoal into a kiln furnace, reacting, and treating generated solid and sulfur dioxide by the following steps so as to generate calcium silicate, calcium sulfiteand calcium bisulfite: (1) generation of calcium silicate: dissolving the generated solid, precipitating and filtering, adding sulfuric acid, washing, pulping and drying, so as to obtain the calcium silicate; (2) generation of calcium sulfite: adding sodium carbonate into a calcium bisulfite solution, generating a calcium sulfite solution, and concentrating and drying one part to obtain the calcium sulfite; enabling the other part and the generated sulfur dioxide to react, generating a calcium bisulfite solution, and recycling to obtain the calcium sulfite; (3) generation of calcium bisulfite:adding sodium carbonate into the calcium bisulfite solution, generating the calcium sulfite solution, reacting with the generated sulfur dioxide, crystallizing, and drying, so as to obtain the calcium bisulfite. The production technology provided by the invention has the advantages that the process is simple, multiple types of products are jointly produced, the production cost is low, and the application and popularization value is higher.

Owner:王娟

Releasing impurities from calcium-based mineral

Owner:CARBON CYCLE

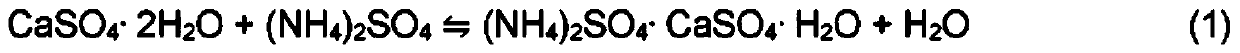

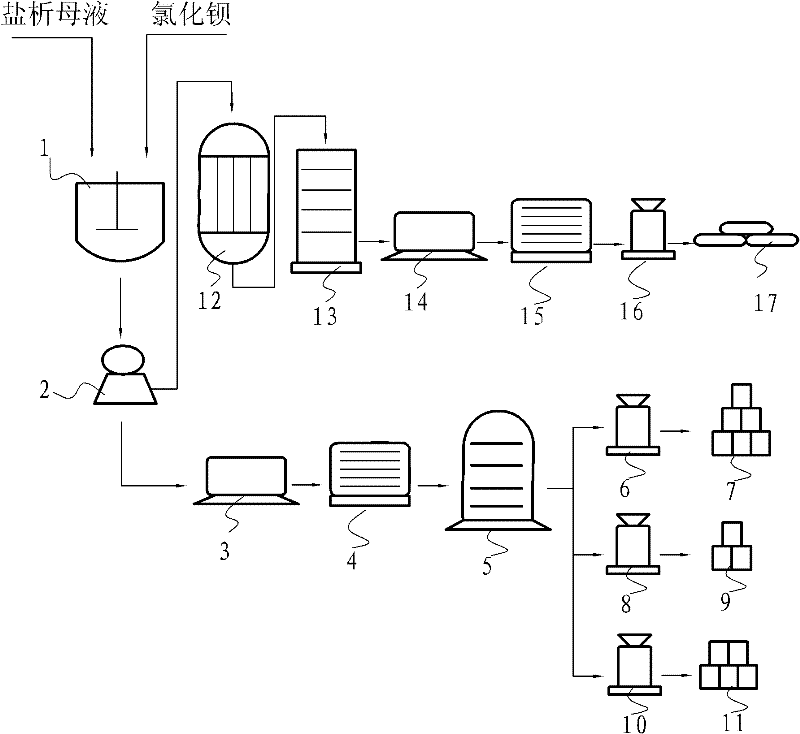

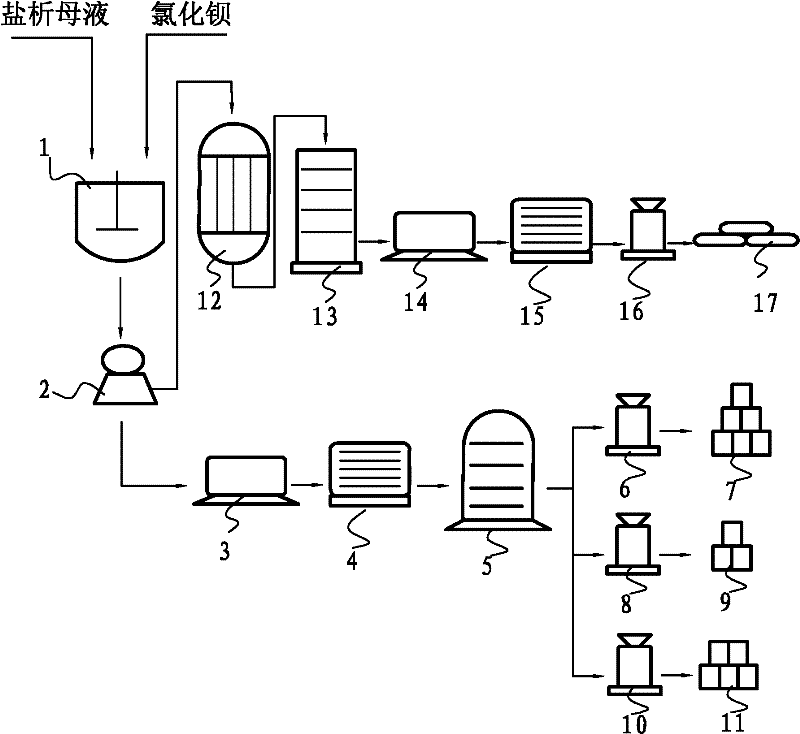

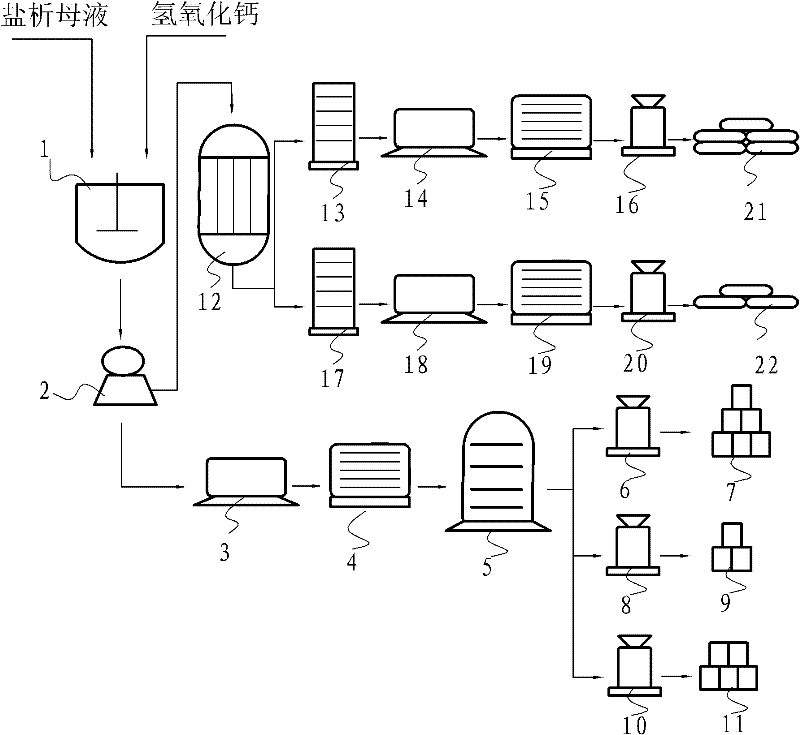

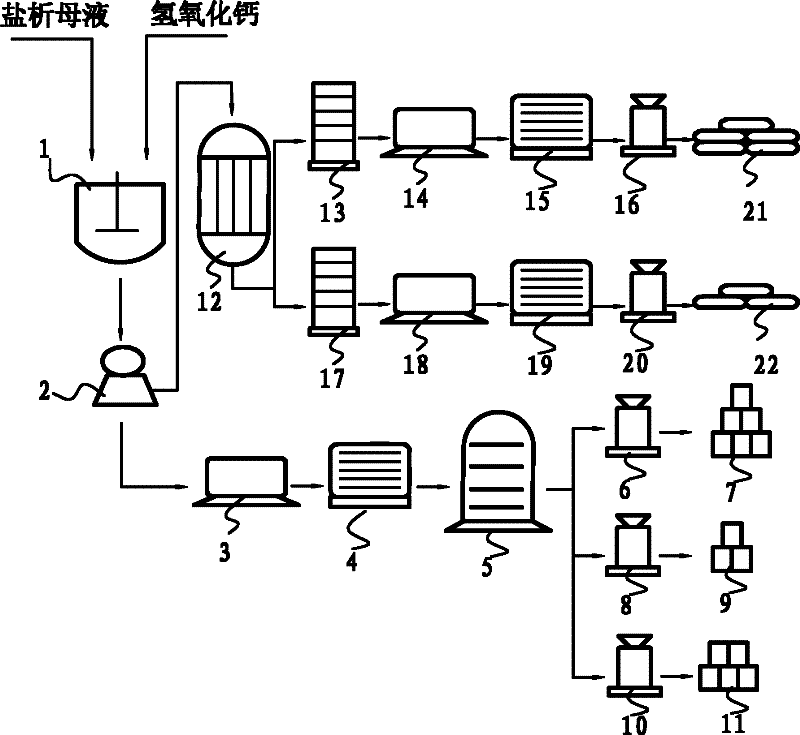

Method for preparing sodium phosphate and barium chloride with cogeneration of powdery barium salt by using salting-out master liquid generated in zinc powder method

InactiveCN102328921AEffective Pollution ControlPollution controlCalcium/strontium/barium chloridesThiosulfates/dithionites/polythionitesChemical industryBarium salt

The invention belongs to the technical field of treatment and utilization of three wastes (waste gas, waste water and waste residues) in the chemical industry, and particularly relates to a method for preparing sodium phosphate and barium chloride with cogeneration of a powdery barium salt by using salting-out master liquid generated in a zinc powder method. In the invention, by mainly utilizing the salting-out master liquid, which is generated in a process of preparing sodium hydrosulfite by using the zinc powder method, for treating barium phosphate, not only can sodium phosphate, barium chloride and powdery barium salt products with economic values and better purity be produced, but also the three wastes are hardly discharged to cause pollution, and a semi-finished product of detergent can even be recycled for dissolving raw materials. The method disclosed by the invention not only has the advantage of simple production process and equipment and low cost, but also can be used for effectively treating the environment pollution caused by the salting-out master liquid generated when the zinc powder method is used for preparing the sodium hydrosulfite, and is beneficial to creation of considerable economic benefits at the same time.

Owner:冯若愚

A kind of preparation method of cauliflower-shaped calcium sulfite particles

ActiveCN106115762BEasy to operateRaw material environmental protectionCalcium/strontium/barium sulfitesFiltration membraneSulfite salt

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

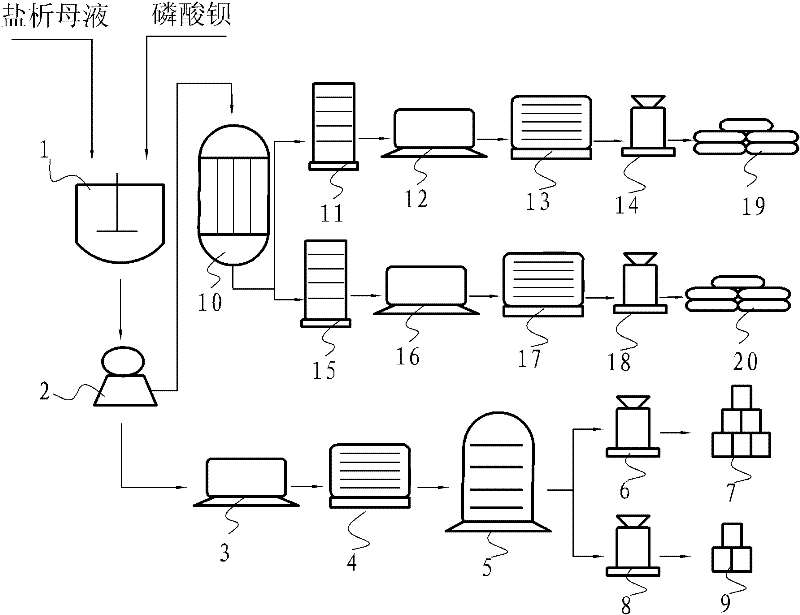

Method for preparing sodium chloride and powdery barium salt by using salting-out mother liquor generated in zinc powder method

InactiveCN102328937APollution controlSimple production processThiosulfates/dithionites/polythionitesCalcium/strontium/barium sulfatesChemical industryBarium salt

The invention belongs to the technical field of treatment and utilization of the three wastes in the chemical industry, and in particular relates to a method for preparing sodium chloride and powdery barium salt by using salting-out mother liquor generated in a zinc powder method. According to the invention, barium chloride is mainly adopted to treat the salting-out mother liquor which is generated in the preparation of sodium hydrosulfite by using the zinc powder method, thus not only can sodium chloride and powdery barium salt products which have economic values and are pure be produced, but also almost no pollution is caused by the emission of the three wastes, and even a semi-finished product cleaning solution can also be recovered and utilized to dissolve raw materials. The method has the advantages of simple production process, simple equipment and low cost; and by using the method, the environmental pollution caused by the salting-out mother liquor, which is generated in the preparation of sodium hydrosulfite by using the zinc powder method, can be effectively controlled, and considerable economic benefits are created at the same time.

Owner:冯若愚

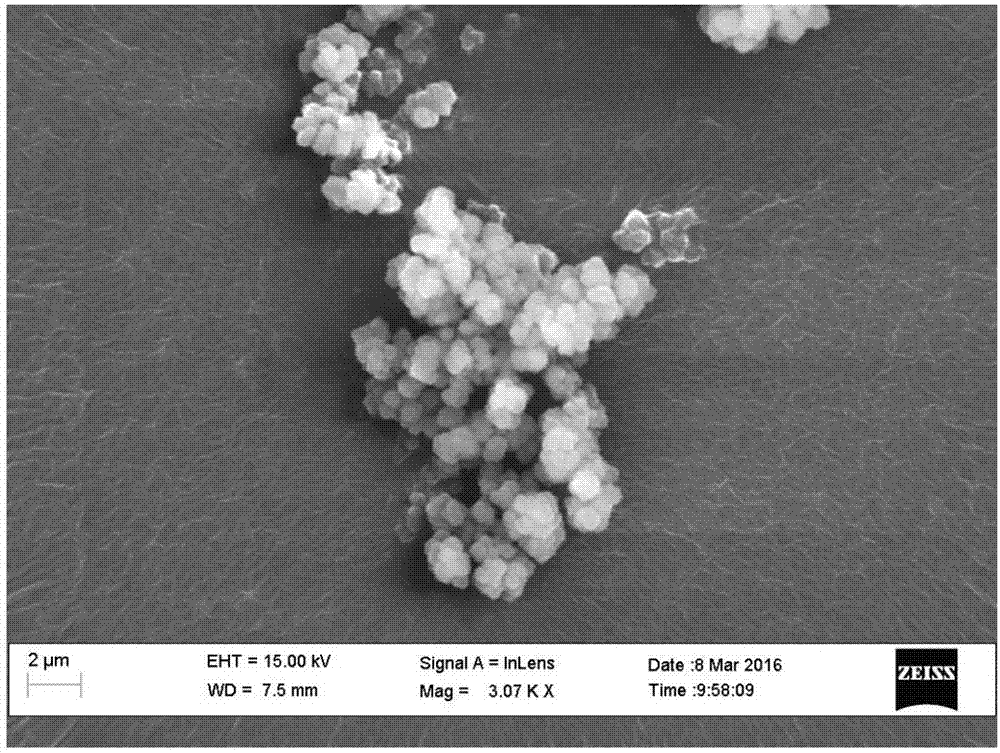

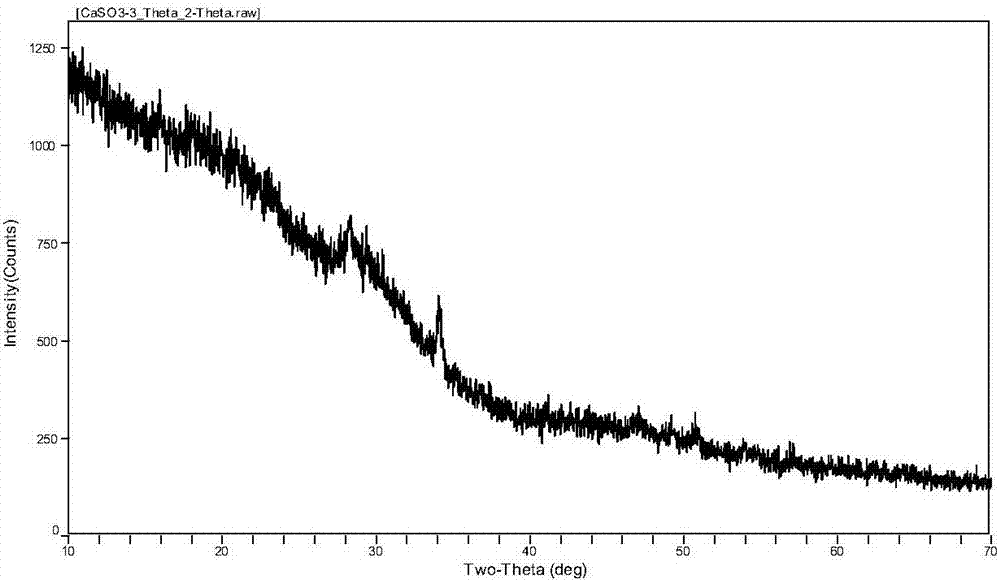

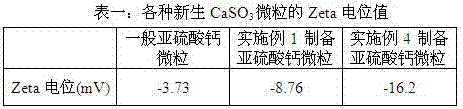

Preparation method of calcium sulfite particles having amorphous structure

ActiveCN107188213AGood effect of removing turbidityImprove adsorption capacityCalcium/strontium/barium sulfitesFiltrationTurbidity

The invention relates to a preparation method of calcium sulfite particles having an amorphous structure. The method comprises: preparing certain concentrations of lime milk and a sodium hexametaphosphate solution with water, respectively, performing filtration with a filter membrane to remove undissolved impurities, adding a certain amount of the sodium hexametaphosphate solution to lime milk, performing continuous stirring for uniform mixing, adding calcium sulfite to adjust pH of the obtained solution to 6.8-7.2, and performing slow stirring to generate calcium sulfite. The generated calcium sulfite precipitation is filtered and centrifuged and is subjected to alternative washing with secondary distilled water and absolute ethanol, and the obtained product is subjected to full drying at 60 DEG C. Crystal structure detection by XRD (X-ray diffraction) and morphology observation by SEM (scanning electron microscope) are carried out to obtain the amorphous calcium sulfite particles. The obtained calcium sulfite particles have an amorphous crystal structure, have the particle size of 600-800 nm, and are uniform in preparation process. The calcium sulfite particles are simple in preparation process and low in cost, are safe and non-toxic in raw materials, and have a good turbidity removal effect on sugarcane juice.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

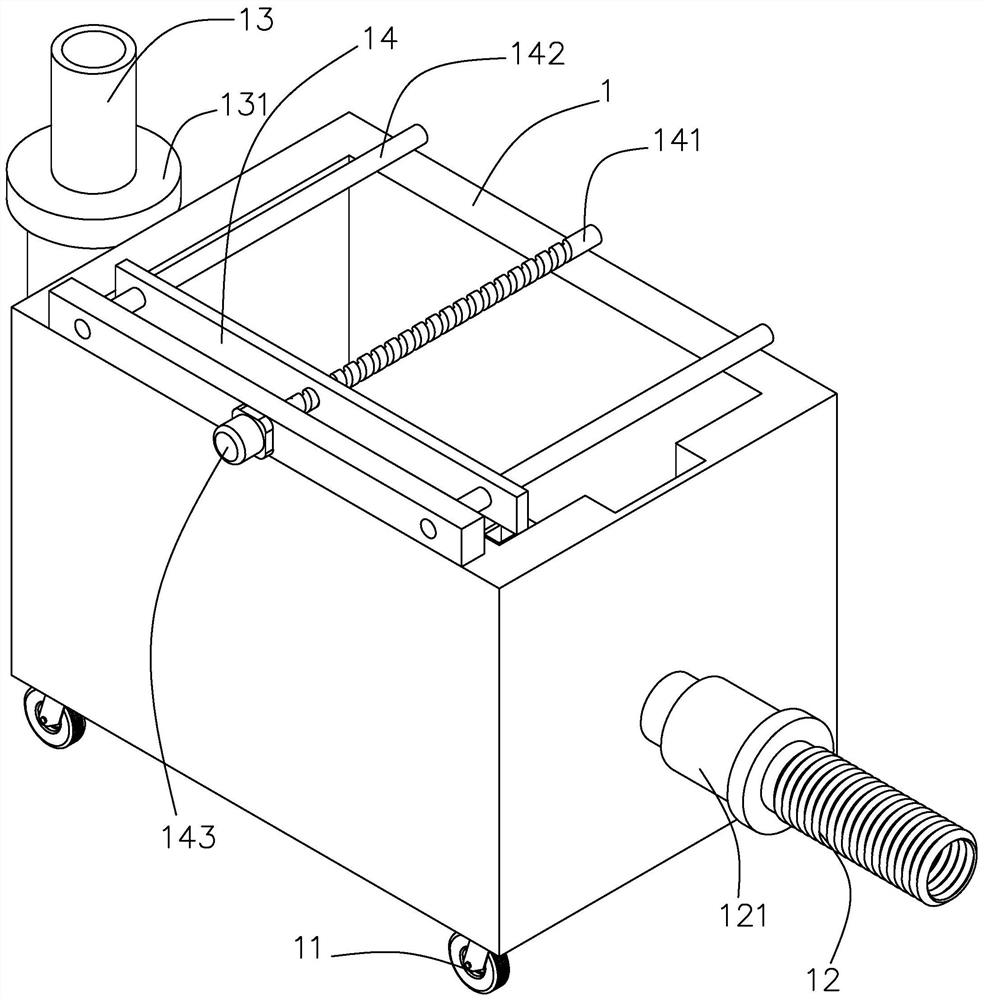

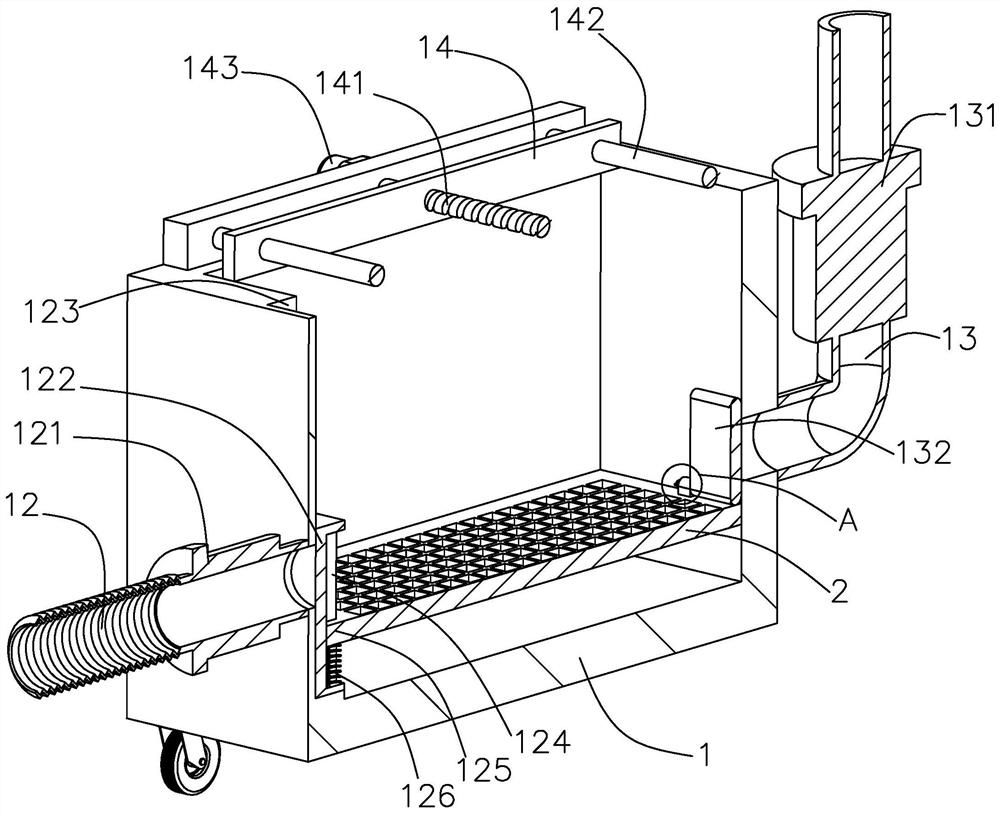

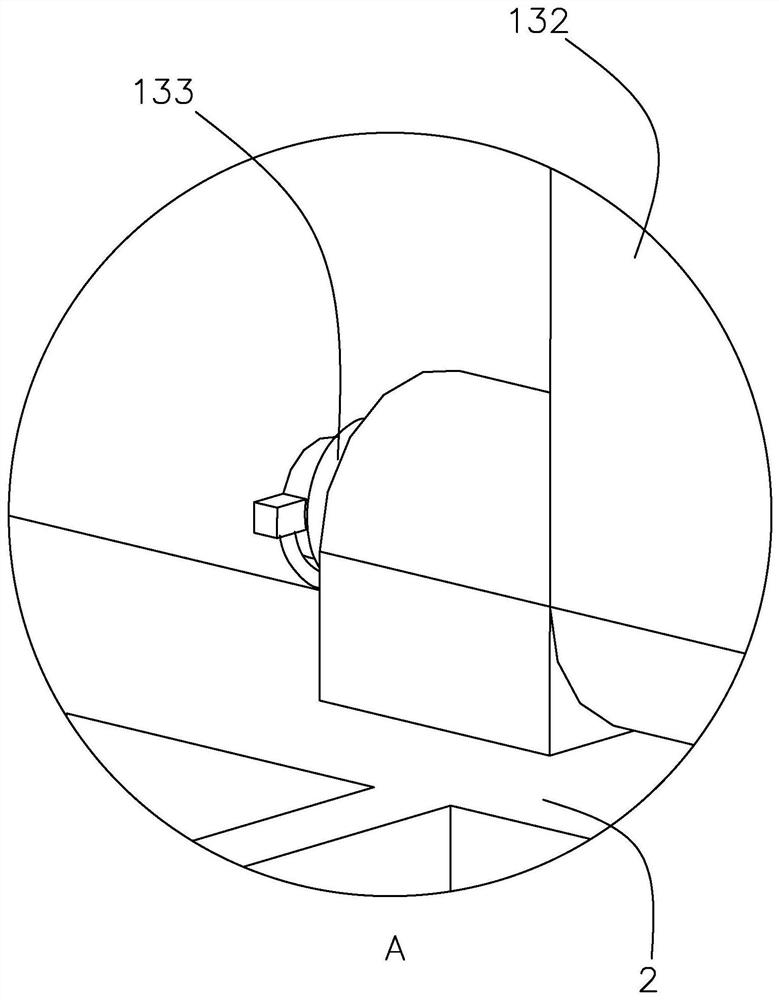

Desulfurization wastewater treatment process and transfer device for this process

ActiveCN111635056BConvenient recycling operationEfficient collectionCalcium/strontium/barium sulfatesTreatment involving filtrationWater treatmentWastewater disposal

The invention relates to a desulfurization wastewater treatment process, which comprises the following steps: S1, collecting, collecting desulfurization wastewater; S2, forced reaction, passing a sufficient amount of oxygen into the desulfurization wastewater; S3, evaporating and separating, evaporating the desulfurization wastewater to obtain Sulfur-containing solids; S4, storage, collecting and storing sulfur-containing solids. The invention has the effect of efficiently treating and reusing desulfurization wastewater.

Owner:杭州临江环保热电有限公司

Method for preparing caustic soda and calcium chloride with cogeneration of powdery calcium salt by using salting-out master liquid in zinc powder method

InactiveCN102328946APollution controlSimple production processCalcium/strontium/barium chloridesThiosulfates/dithionites/polythionitesChemical industryCogeneration

The invention belongs to the technical field of treatment and utilization of three wastes (waste gas, waste water and waste residues) in the chemical industry, and particularly relates to a method for preparing caustic soda and calcium chloride with cogeneration of a powdery calcium salt by using salting-out master liquid generated in a zinc powder method. In the invention, by mainly utilizing the salting-out master liquid, which is generated in a process of preparing sodium hydrosulfite by using the zinc powder method, for treating calcium hydroxide, not only can caustic soda, calcium chloride and powdery calcium salt products with economic values and better purity be produced, but also the three wastes are hardly discharged to cause pollution, and a semi-finished product of detergent can even be recycled for dissolving raw materials. The method disclosed by the invention not only has the advantage of simple production process and equipment and low cost, but also can be used for effectively treating the environment pollution caused by the salting-out master liquid generated when the zinc powder method is used for preparing the sodium hydrosulfite, and is beneficial to creation of considerable economic benefits at the same time.

Owner:冯若愚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com