Economical method for desulfurizing and dedusting glue gas produced during smelting of secondary lead

A technology for regenerated lead smelting, desulfurization and dust removal, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of difficult utilization of desulfurization products, increased consumption of desulfurizers, and inability to be discarded everywhere, etc. To avoid waste of resources and pollute the environment, improve operability, and achieve the effect of reprocessing and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

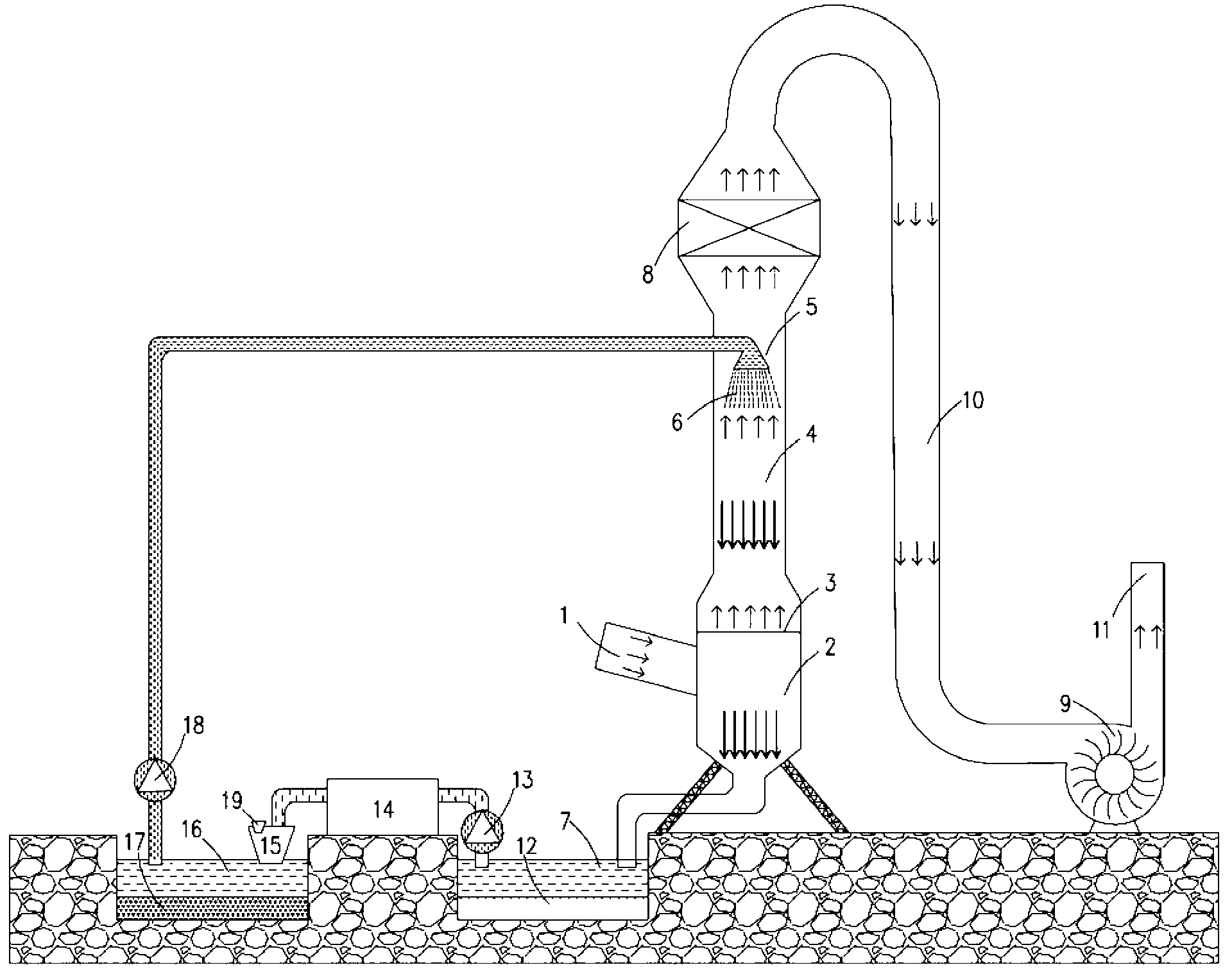

[0020] 1. Lead the secondary lead smelting flue gas from the flue gas inlet 1 to the desulfurization and dust removal tower 2 from bottom to top, the secondary lead smelting flue gas is dispersed and rises evenly through the porous dispersing screen 3, and the eluent with a pH value of 6.5 is discharged from the water mist nozzle 5 Atomized and sprayed, the atomized sprayed eluent and the uniformly rising secondary lead smelting flue gas are fully contacted at 4 places in the spray absorption chamber, and the spray volume of the eluent and the flow ratio of the secondary lead smelting flue gas are 1: 9. The lead dust in the flue gas of secondary lead smelting precipitates downward due to its own gravity and the leaching of the eluent, SO 2 and SO 3 Absorbed by the eluent, the water-gas separation is realized in the flue gas-water-gas separation chamber 8 after the leaching, and the CO 2 Because the solubility in the eluent (slightly acidic aqueous solution) is extremely small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com