Flue-gas desulphurization system and flue-gas desulphurization method

A desulfurization system and flue gas technology, applied in the field of flue gas purification, can solve the problems of difficult dehydration, secondary pollution, and difficult to produce by-products, etc., and achieve the effects of solving difficult dehydration, saving water, and high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

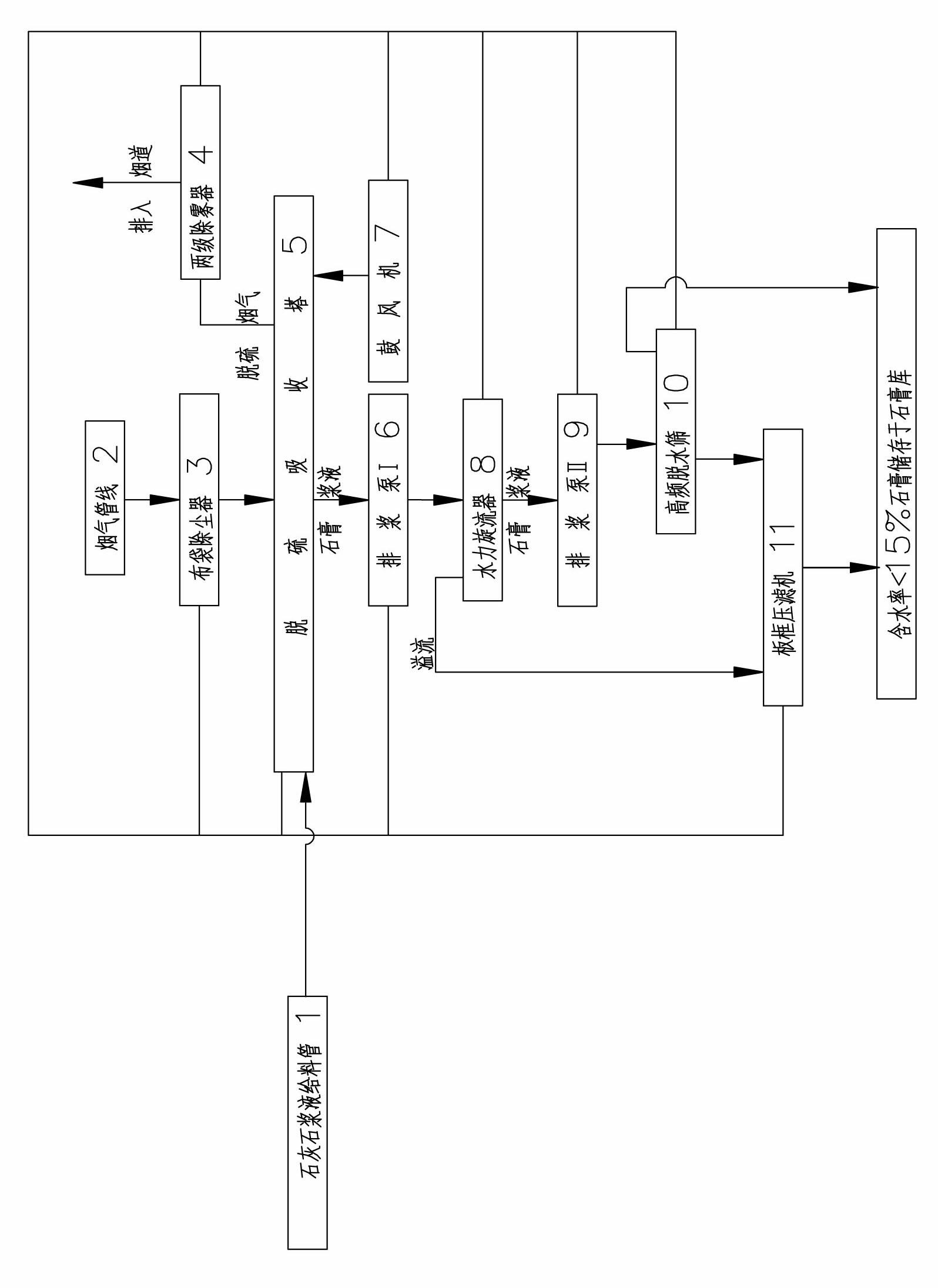

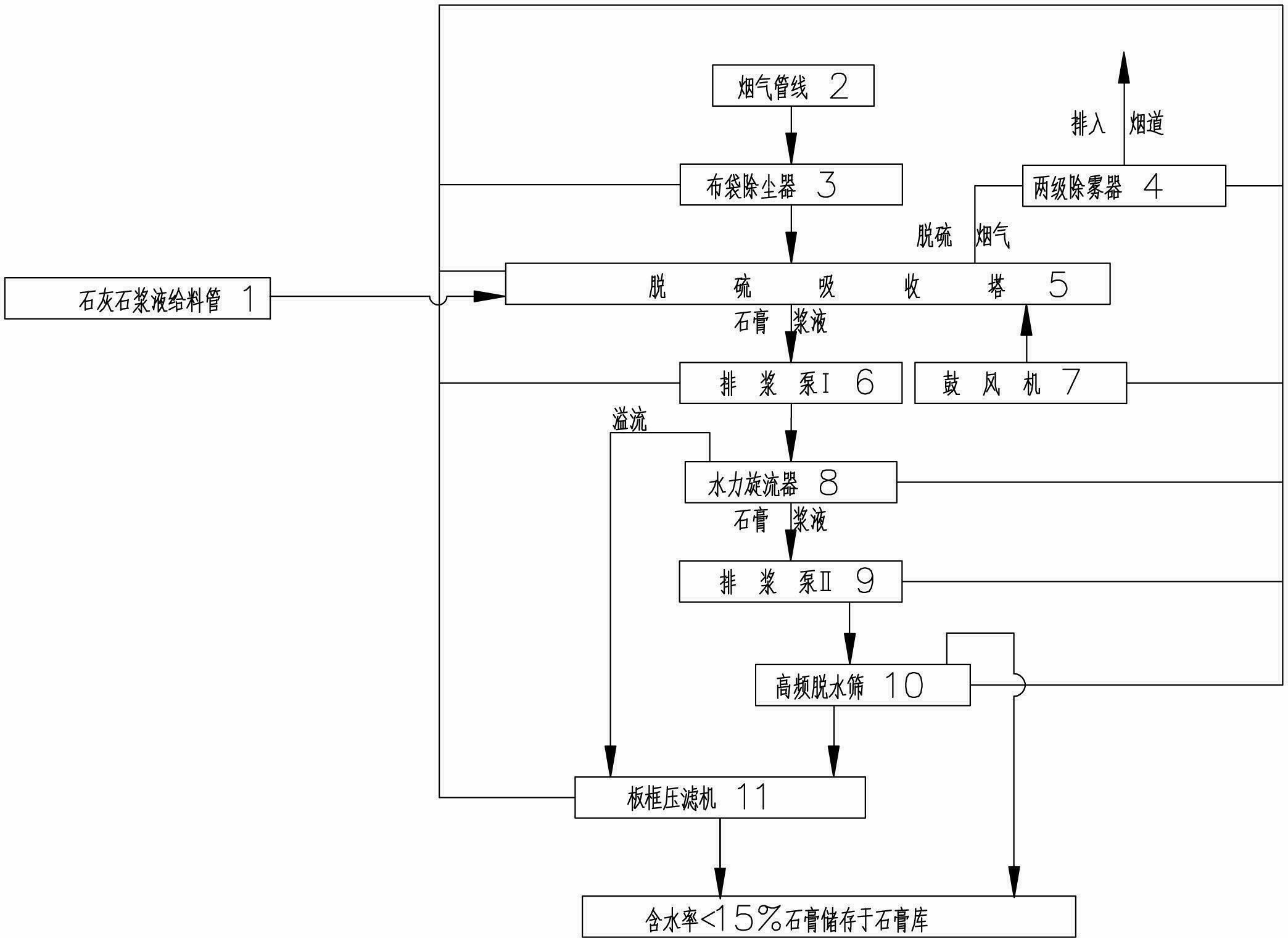

[0014] Such as figure 1 Shown: the flue gas desulfurization system of the present invention includes the desulfurization absorption tower 5 connected with the limestone slurry feed pipe 1, the flue gas pipeline 2 arranged at the upper part of the desulfurization absorption tower 5 system, and the flue gas pipeline 2 connected Bag filter 3, the bag filter 3 is connected to the desulfurization absorption tower 5, the two-stage mist eliminator 4 connected to the desulfurization absorption tower 5, the blower 7, and the slurry discharge pump I6 are connected to the slurry discharge pump I6 The hydrocyclone 8 is characterized in that the hydrocyclone 8 is also connected with the slurry discharge pump II9 and the filter 11, and the filter 11 adopts a plate and frame filter press; the slurry discharge pump II9 is also connected with the dewate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com