Desulfurization wastewater treatment process and transfer device for same

A technology for desulfurization wastewater and treatment process, applied in the field of flue gas treatment, can solve the problems of inability to utilize wastewater, difficult storage and treatment, etc., and achieve the effect of convenient recycling operation, convenient collection and storage of precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The invention discloses a desulfurization wastewater treatment process, which is characterized in that it comprises the following steps:

[0055] S1. Collect, collect desulfurization wastewater. The desulfurization wastewater can be collected stably at the outlet of the desulfurization tower.

[0056] S1.1, neutralization, add a certain amount of 5% milk of lime solution as a neutralizing agent, and adjust the pH value of the desulfurization wastewater to above 9. Alkaline environment can cause most heavy metal ions to form insoluble hydroxide precipitates in alkaline environment. When the pH is 9.0~9.5, most of the heavy metal ions form insoluble hydroxides; at the same time, Ca2+ in milk of lime can also react with part of F- in wastewater to form insoluble CaF2 to achieve the effect of defluoridation effect.

[0057] S1.2. Settling, add organic sulfides such as mercaptan and thiophenol, and wait for insoluble substances to settle.

[0058] The content of Cd2+ and...

Embodiment 2

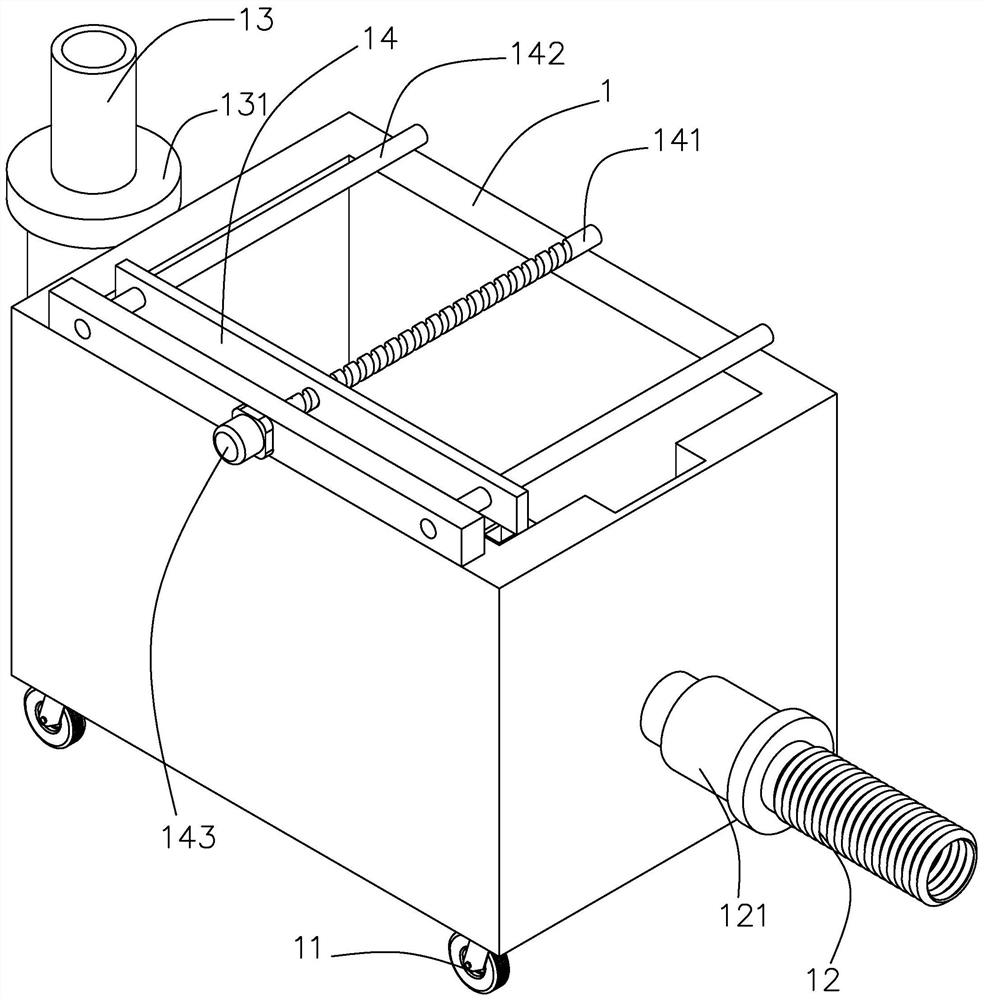

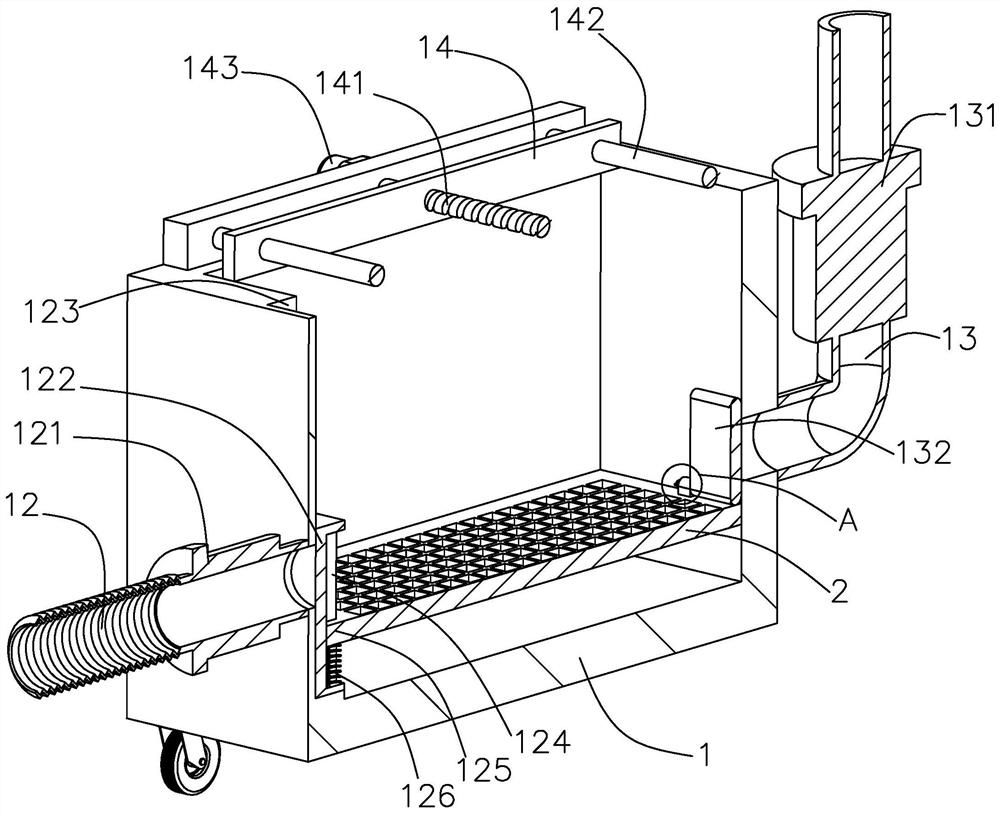

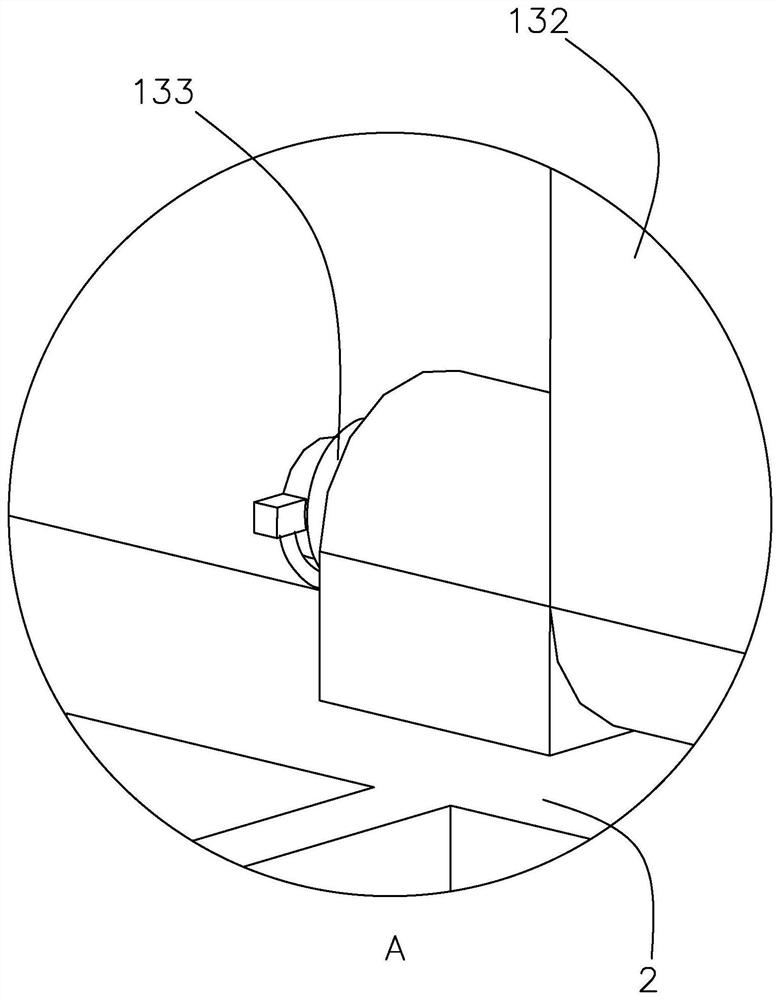

[0075] refer to figure 1 , on the basis of Example 1, the present invention discloses a transfer device for desulfurization wastewater treatment process, comprising a box 1, the top surface of the box 1 is provided with a feeding port, and the bottom surface of the box 1 is provided with a plurality of Directional wheels 11 and universal wheels 11 are respectively located at the four corners of the bottom of the box body 1. The bottom of the side wall of the box body 1 is fixedly connected with a discharge pipe 12. The discharge pipe 12 communicates with the inner space of the box body 1. There is a drainage pump 121 , and a discharge end cover 122 capable of covering the discharge pipe 12 is slidably connected to the inner wall of the box body 1 . After the desulfurization wastewater is obtained, the desulfurization wastewater is introduced into the box body 1, and the desulfurization wastewater can be oxygenated in the box body 1, and after a sufficient reaction, the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com