Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174results about "Boiler cleaning control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

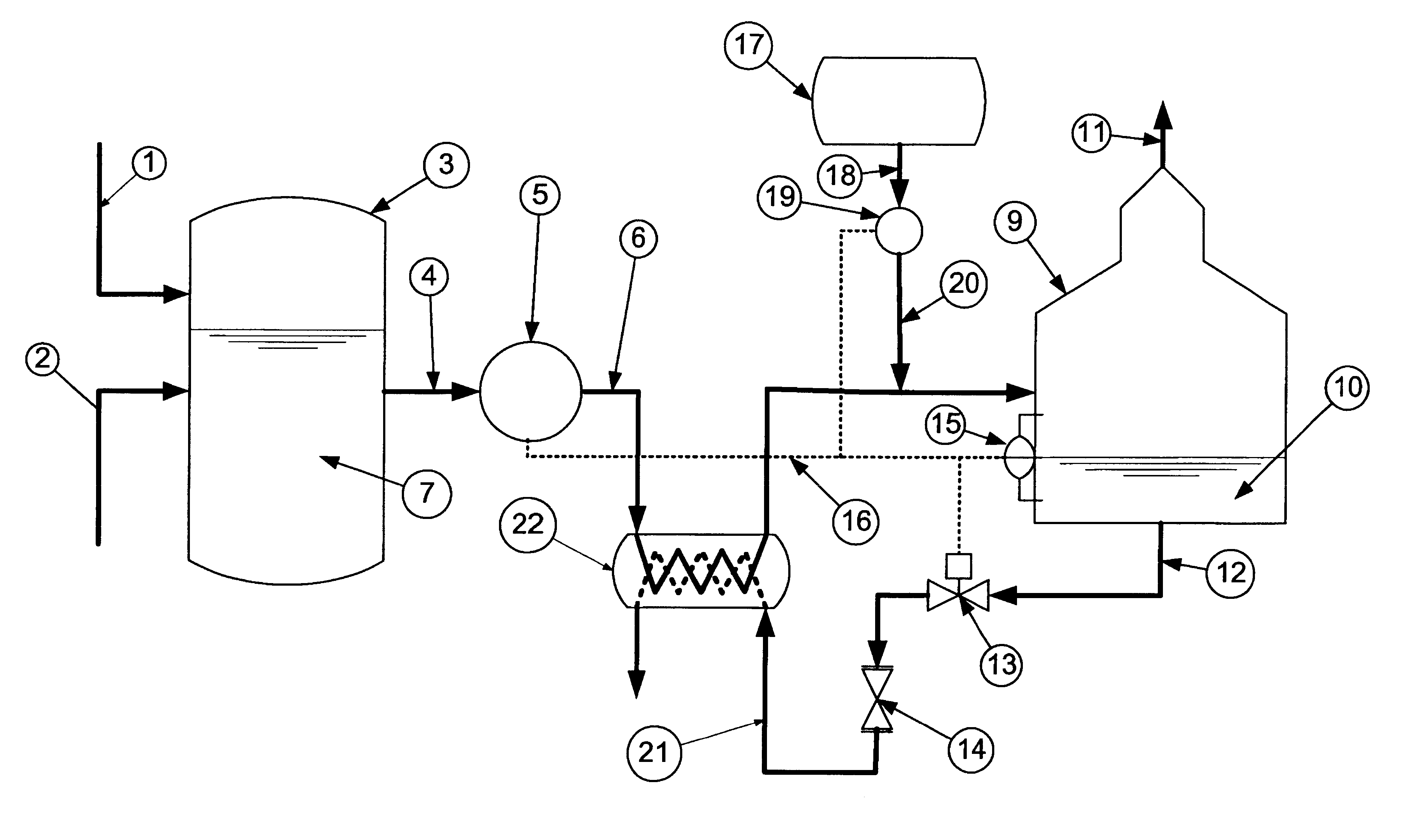

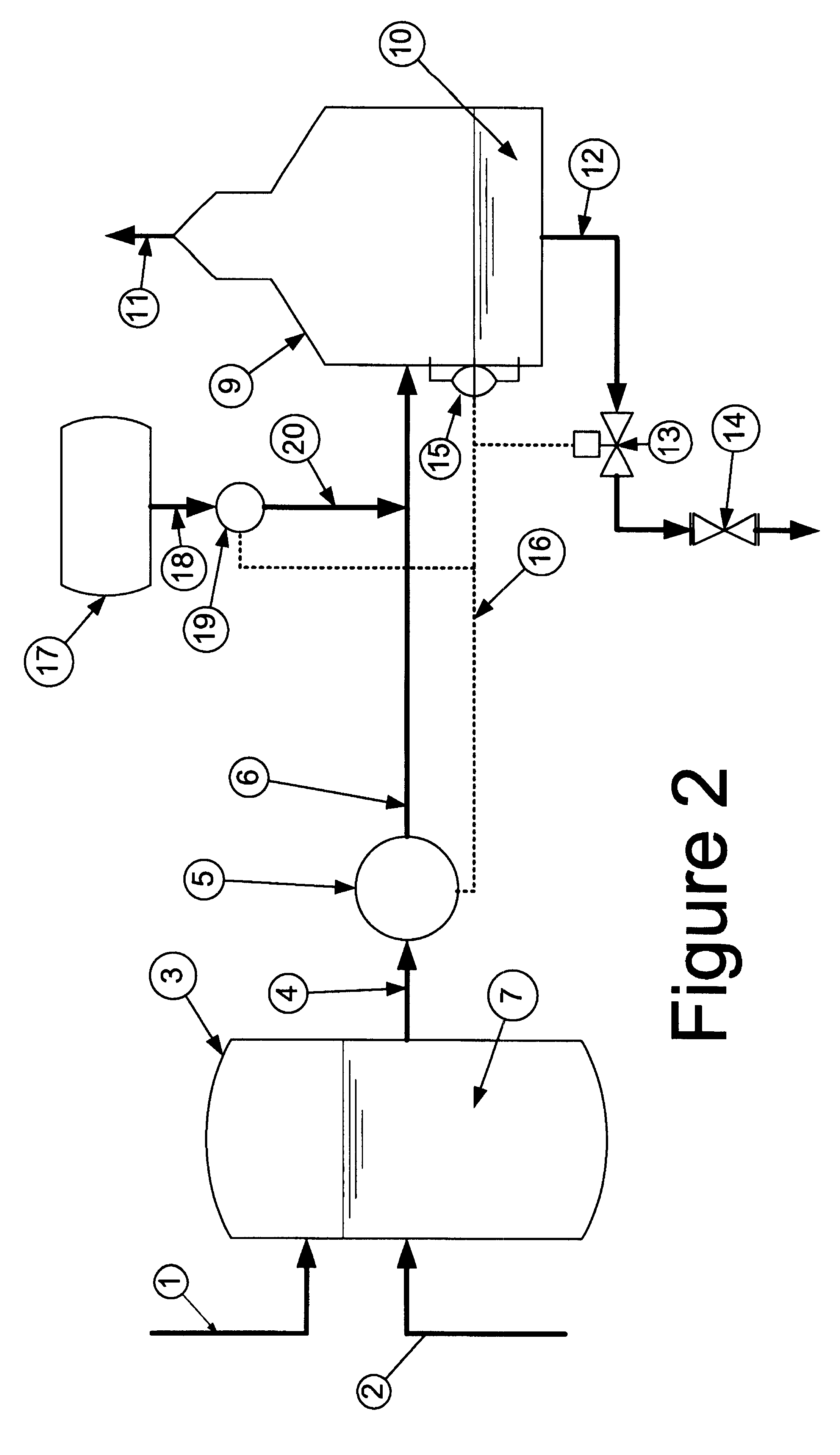

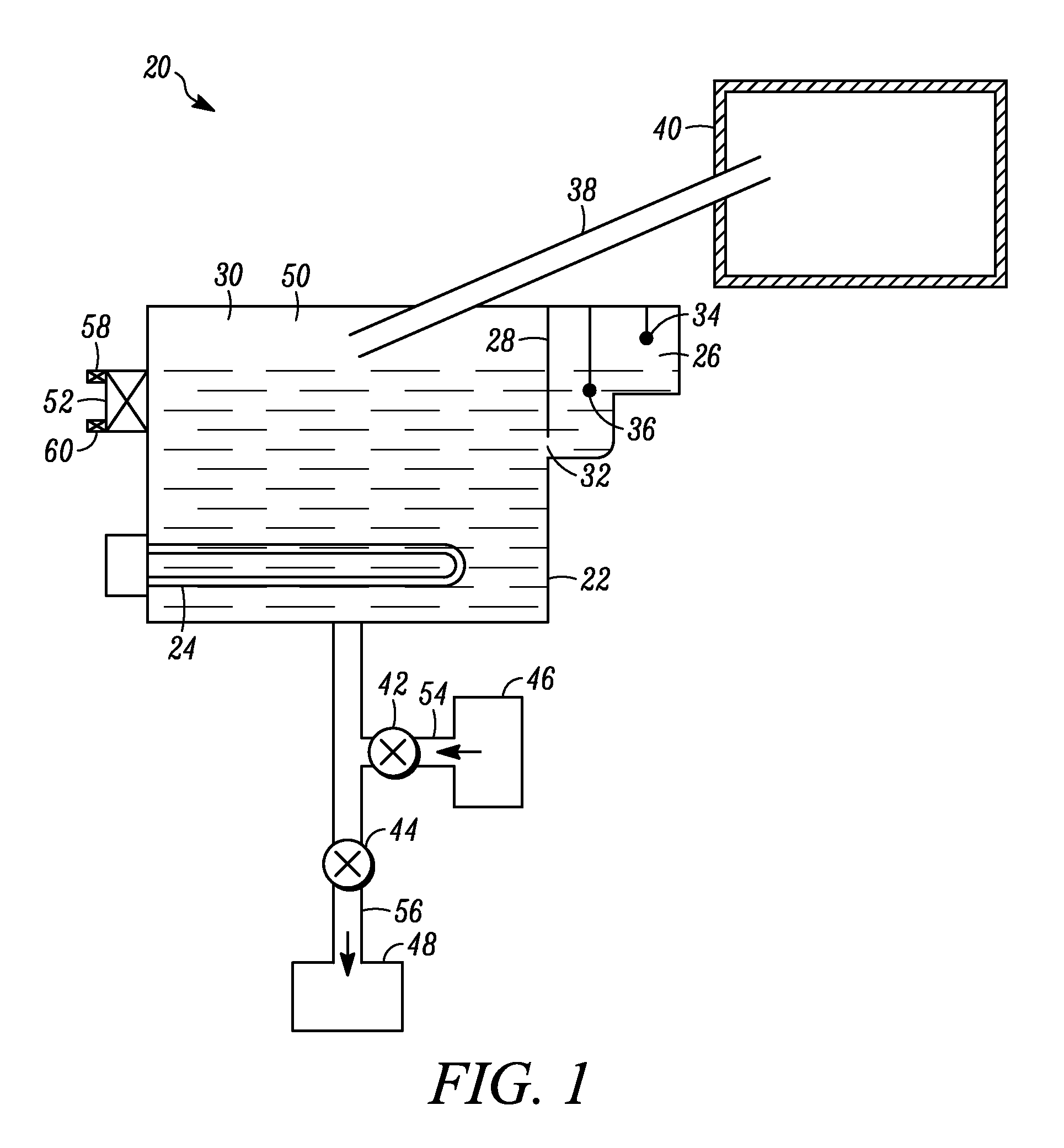

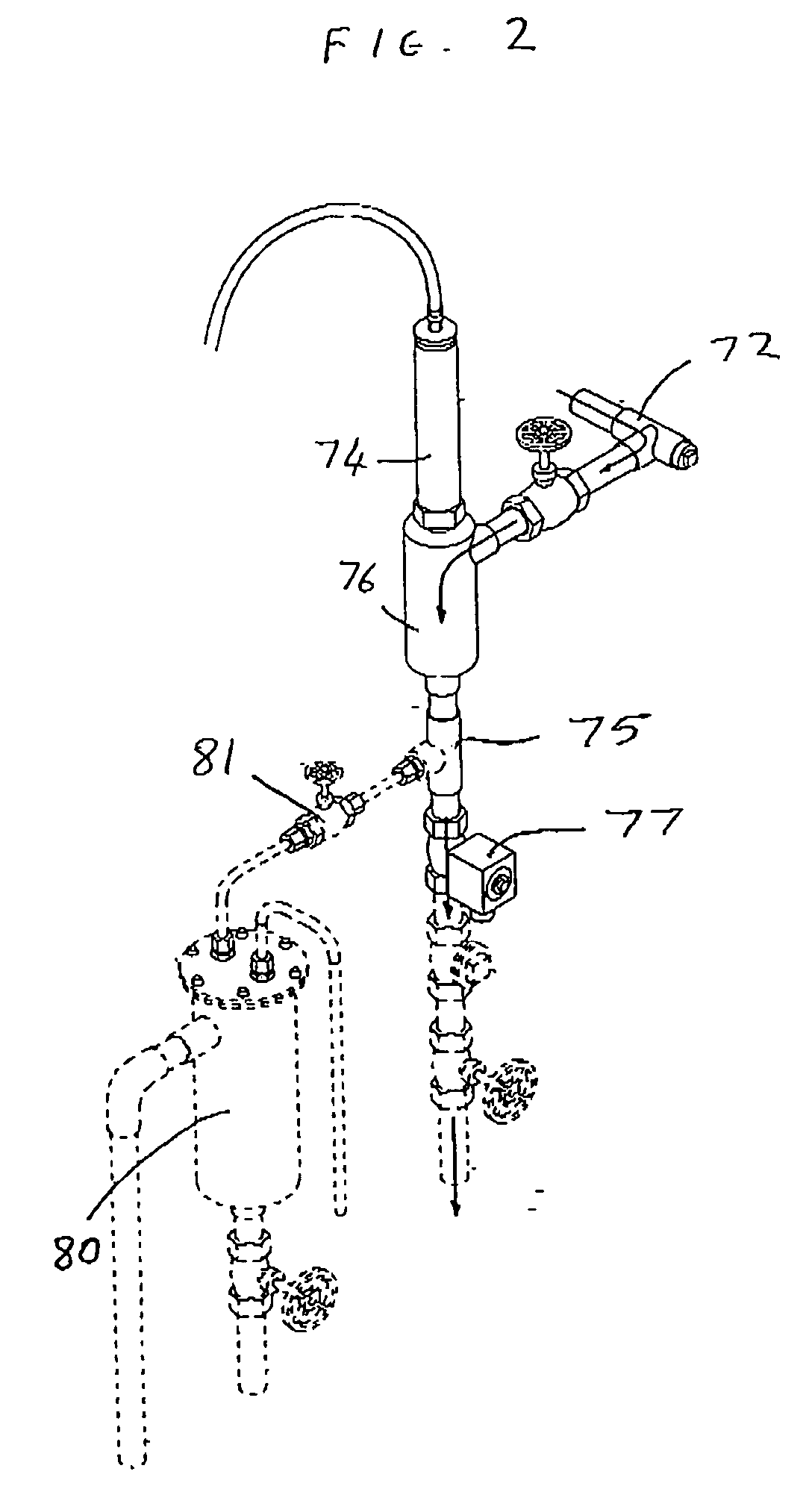

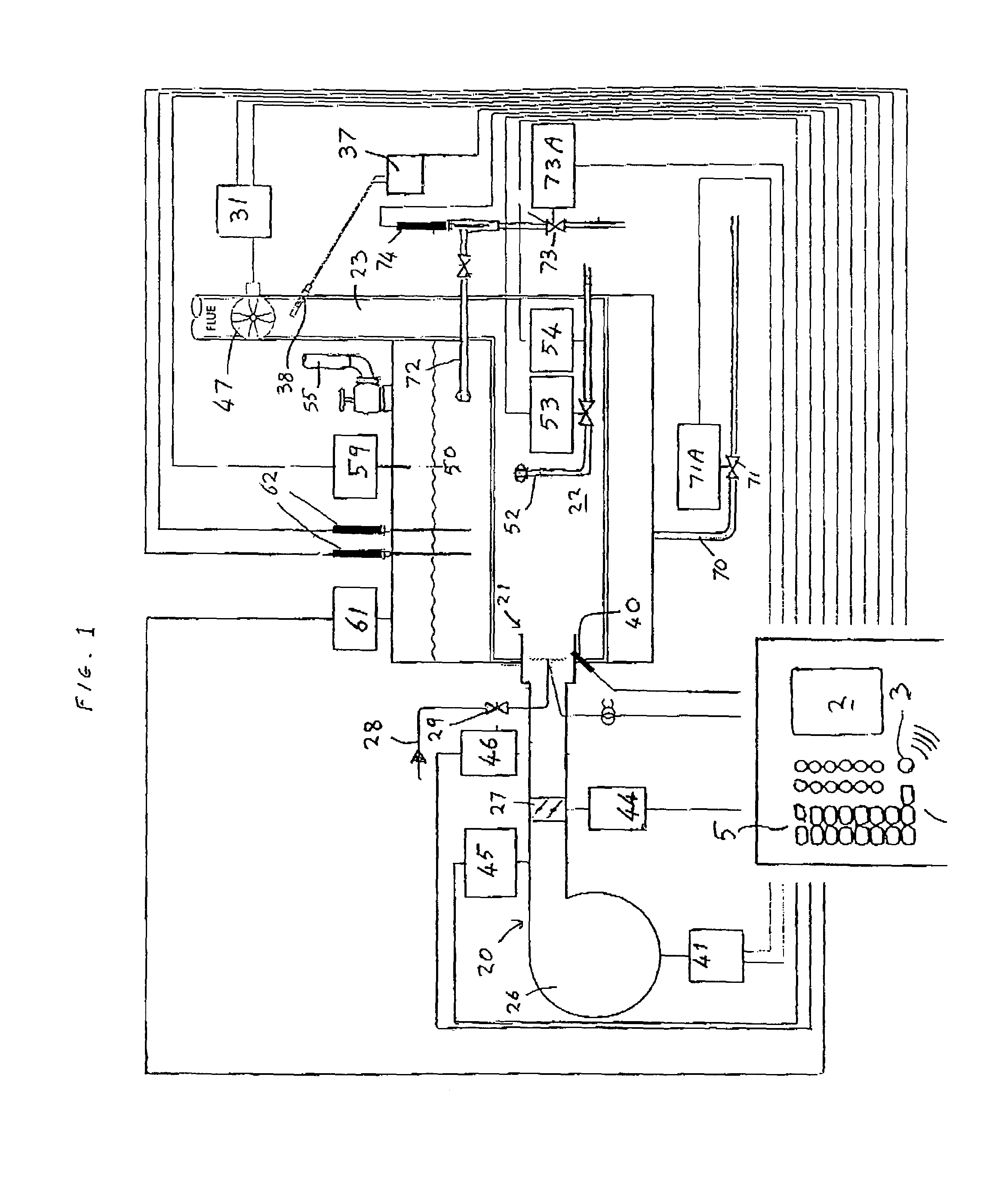

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

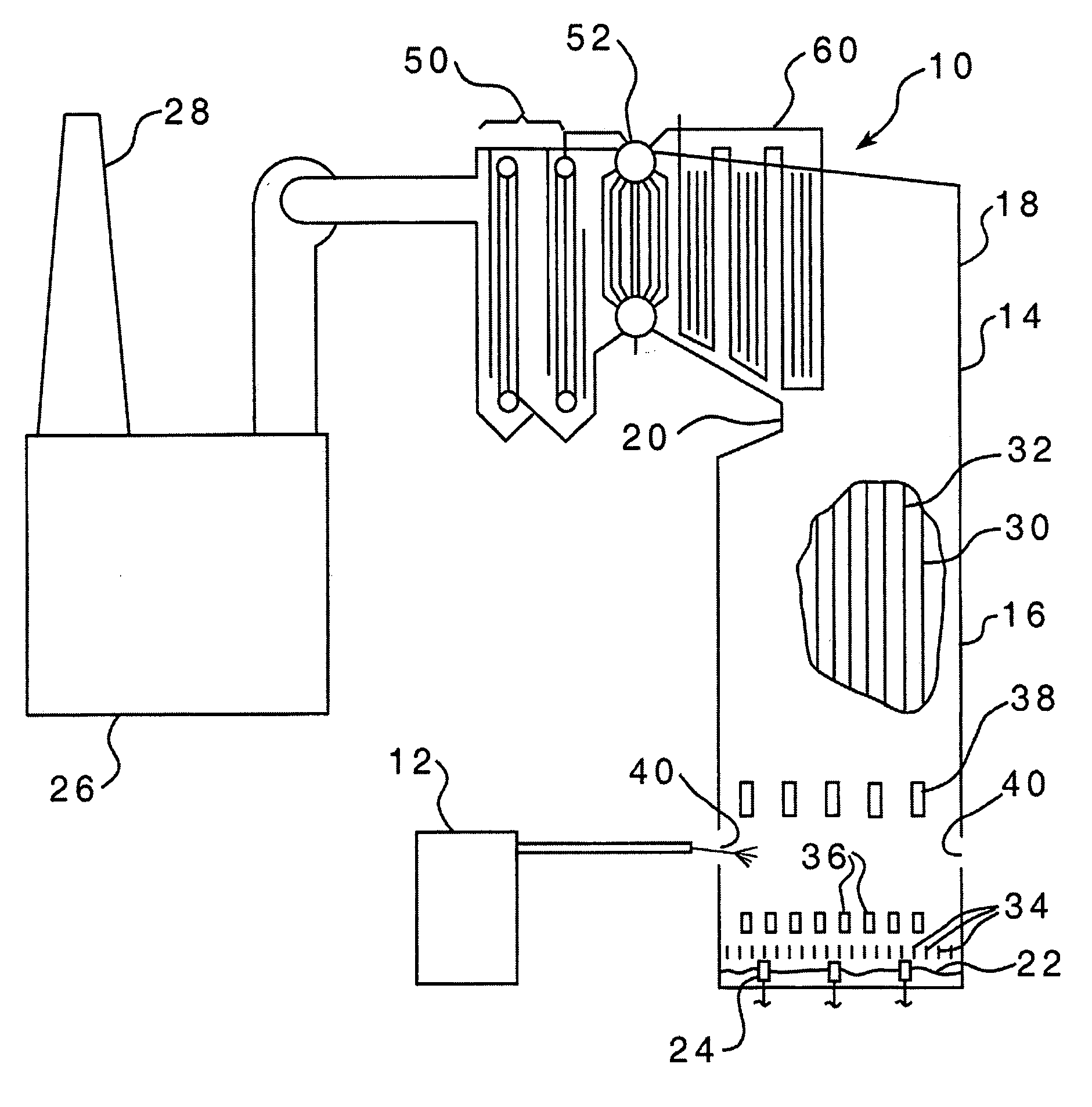

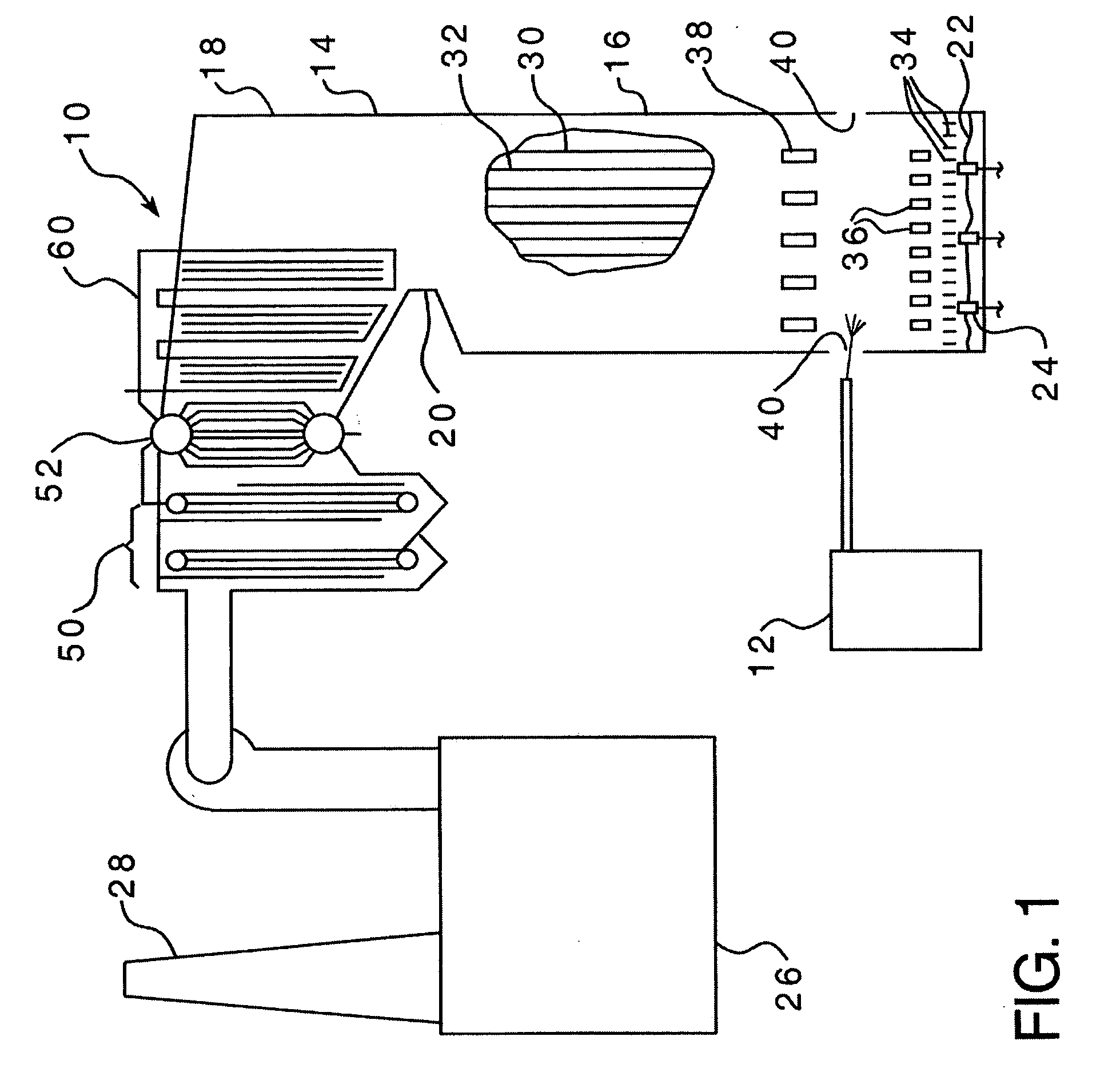

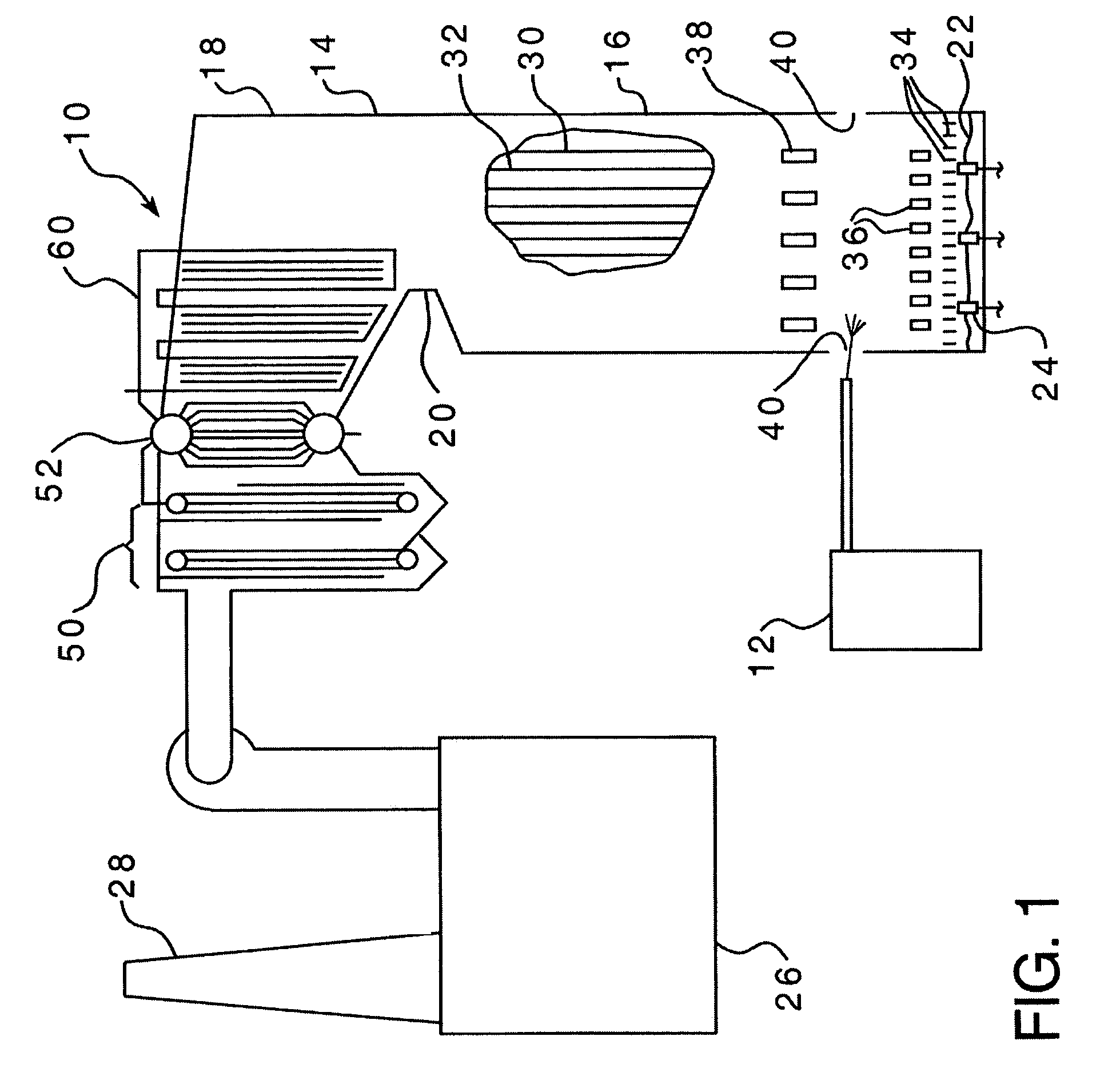

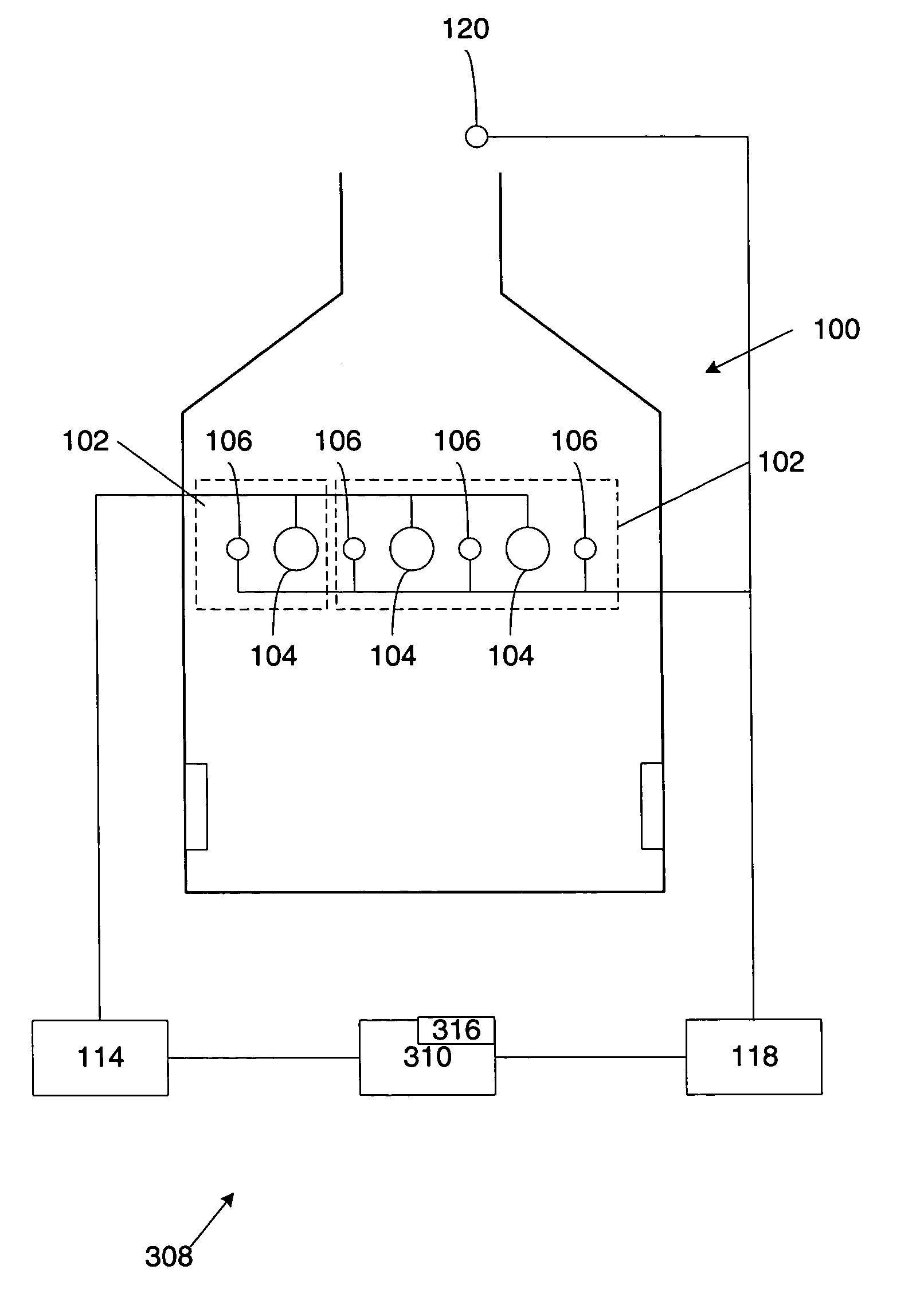

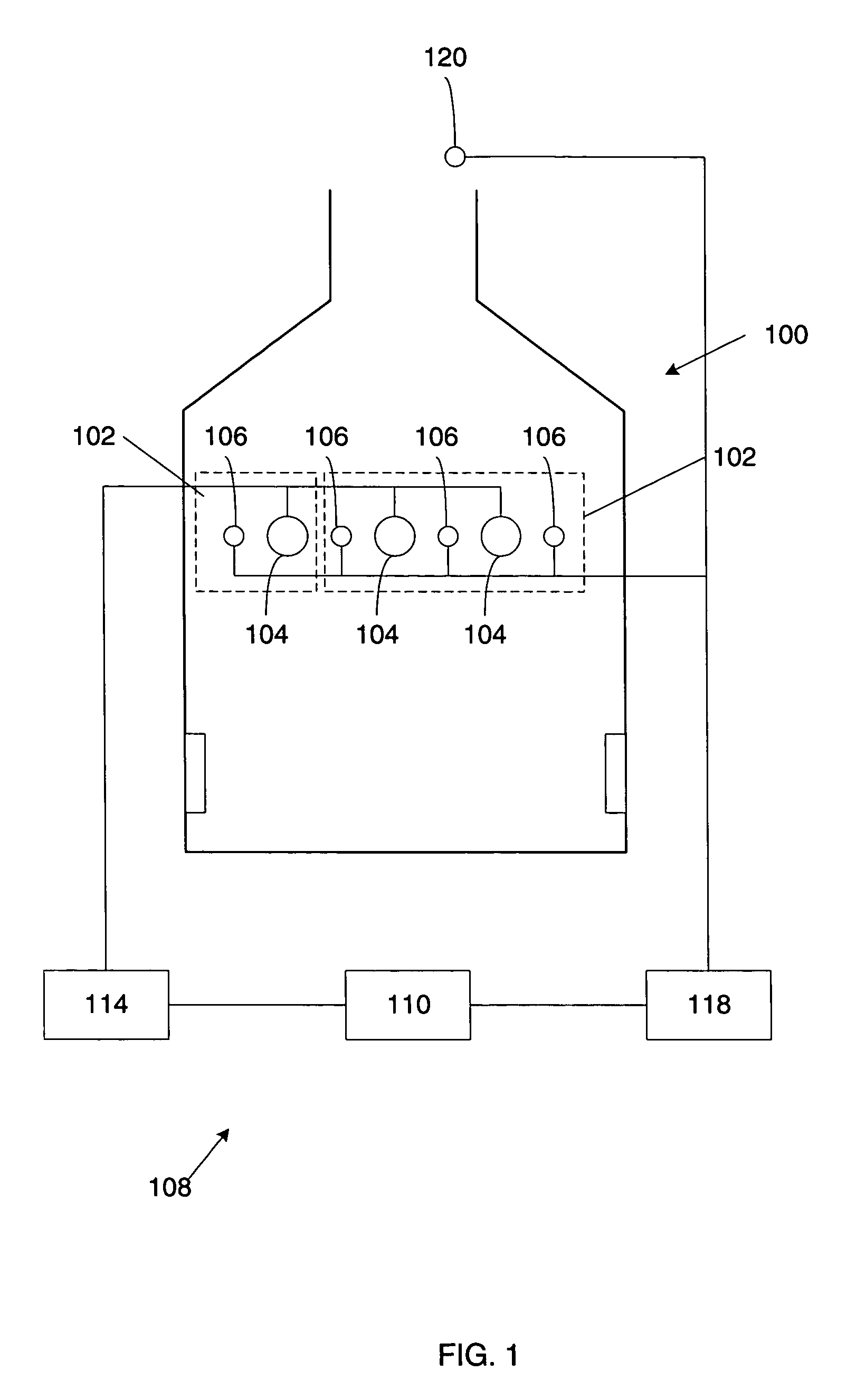

Method of determining individual sootblower effectiveness

ActiveUS20060065291A1Hollow article cleaningBoiler cleaning apparatusBoiler furnaceProcess engineering

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

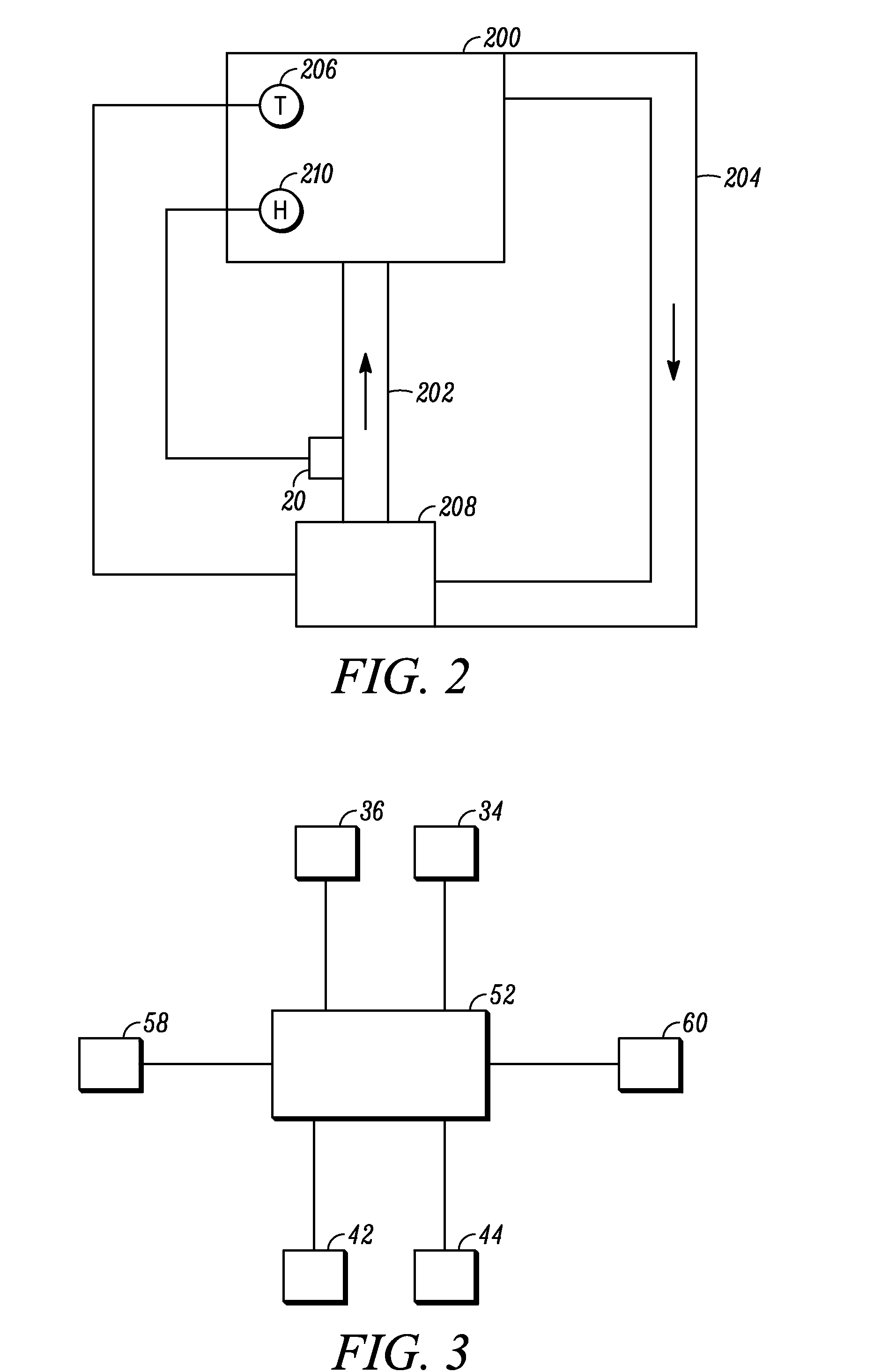

Detection of deposits in steam humidifiers

A humidifier configured to determine when the humidifier requires cleaning. The humidifier includes a tank for containing water, a heater for heating the water in the tank to generate steam, and one or more water level sensors for detecting the level of water in the tank, including detecting water at first level and a second level, where the first level is lower than the second level. The humidifier further includes a drain valve for draining water from the tank and a controller. The controller is configured to open the drain valve to drain water from the tank, measure a time interval required for the water to drain from the second level to the first level, and compare the time interval against a threshold value. If the time interval exceeds the threshold value, then the controller is configured to provide an indication to clean the humidifier. Methods are also disclosed.

Owner:ADEMCO INC

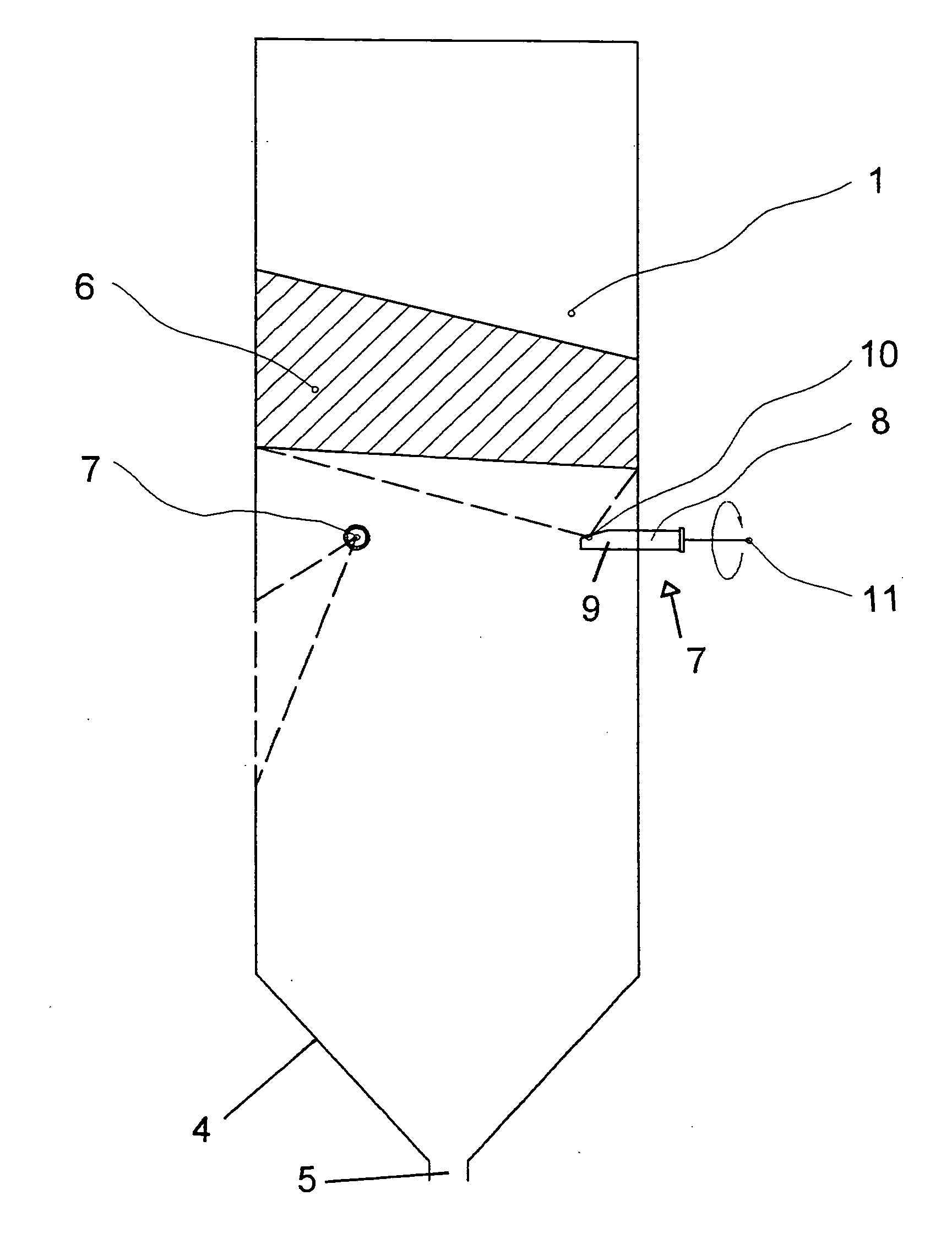

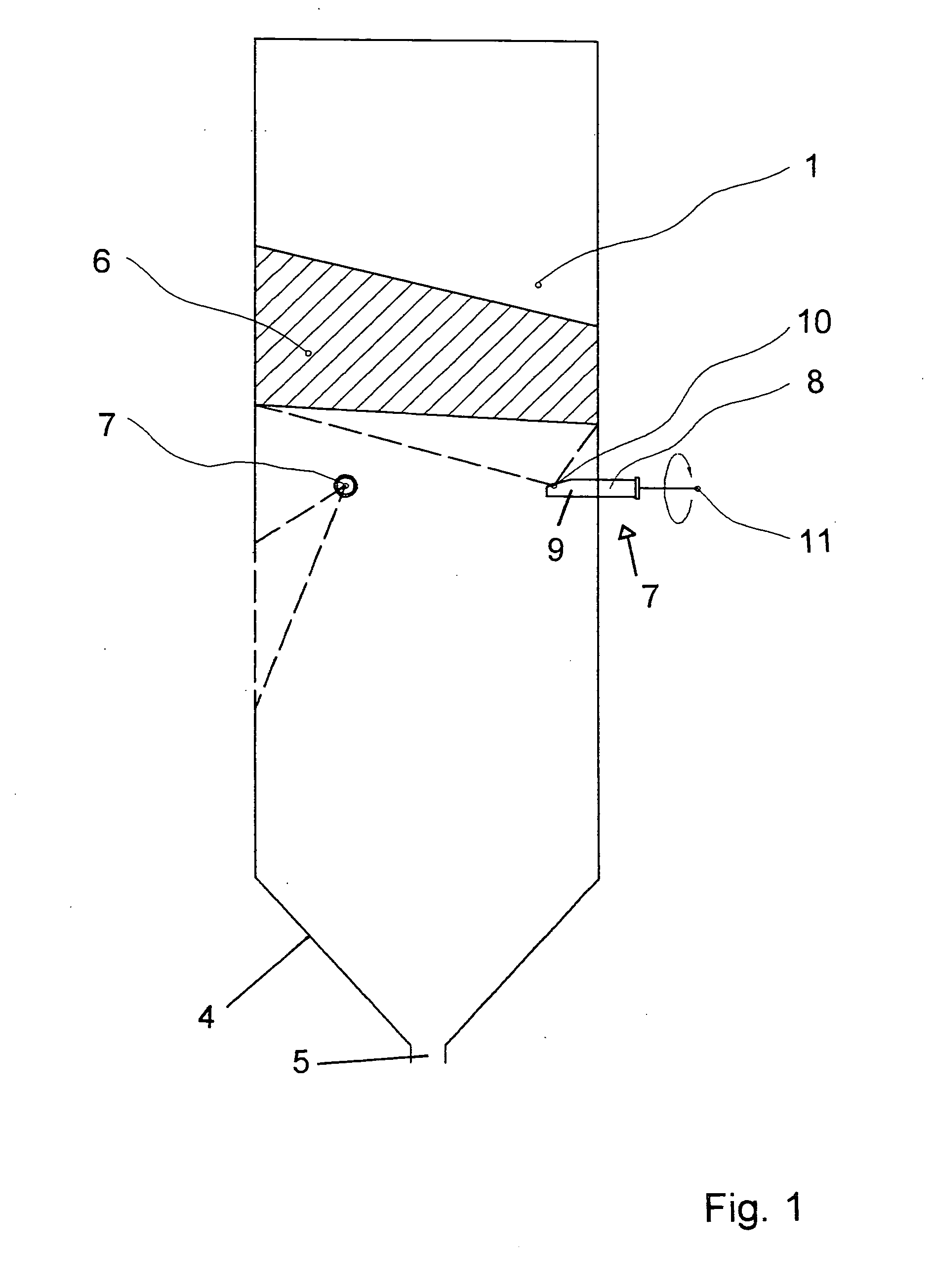

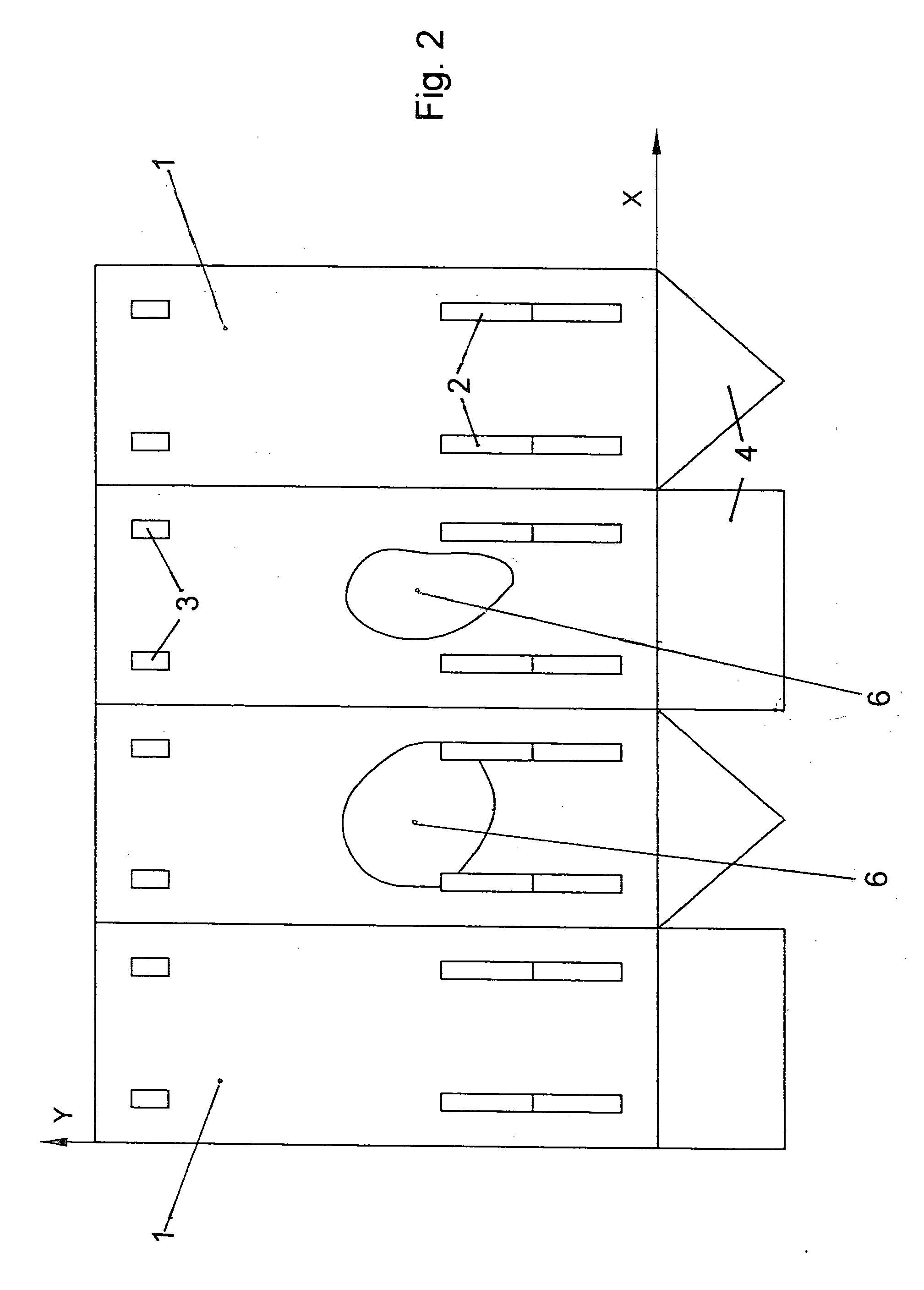

Method and apparatus for monitoring the formation of deposits in furnaces

InactiveUS20080298426A1Simpler and universally usableIncrease temperatureThermometer detailsRadiation pyrometryFlue gasSolid particle

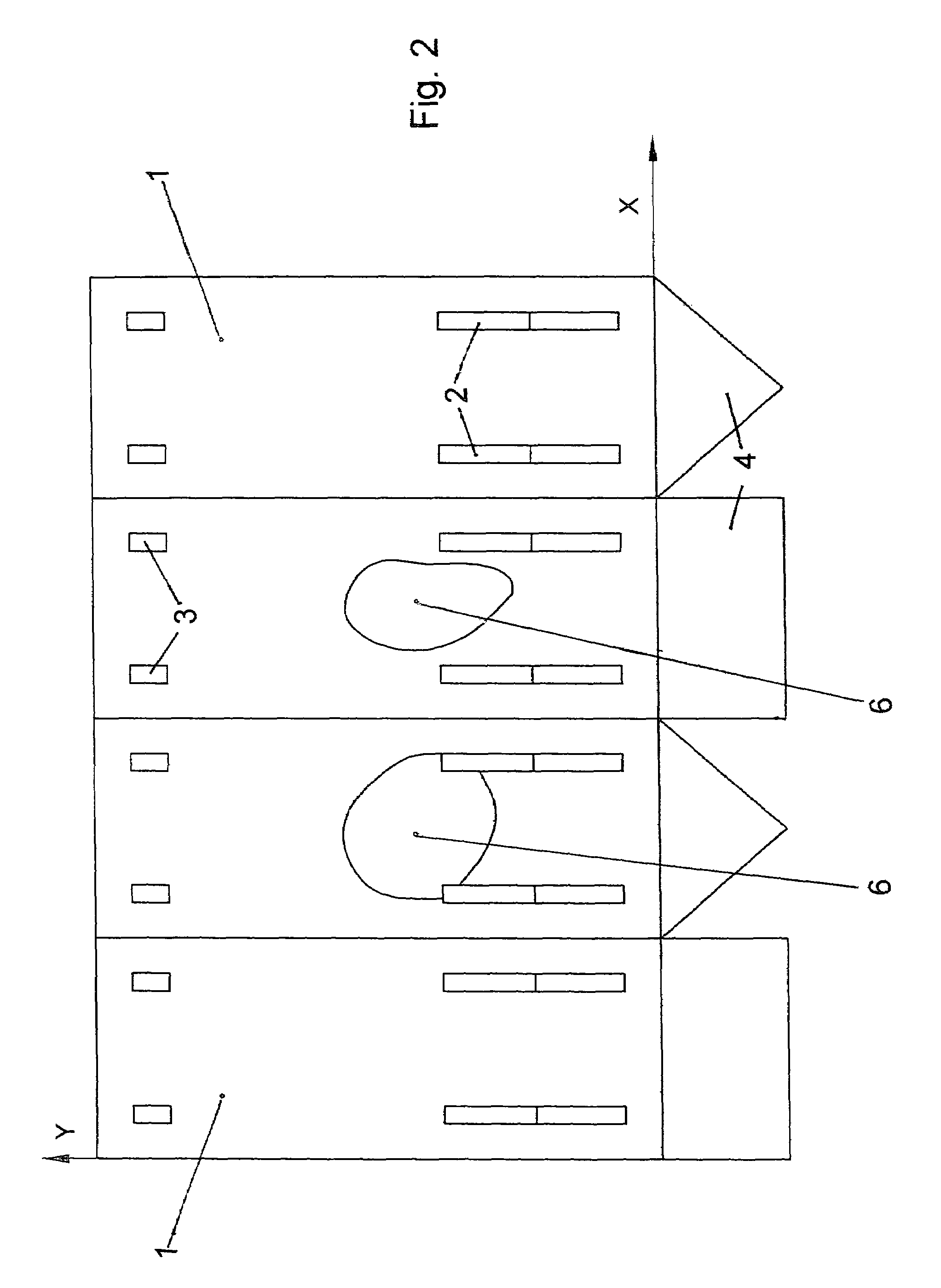

Method and apparatus for monitoring formation of deposits of solid particles from flue gas onto furnace walls formed of welded-together tubes through which cooling medium flows. For the entire surface of the walls, the exact surface temperature is detected with infrared cameras, offset by 90° relative to one another, via a thermal image obtained of a surface development of the furnace. This exact surface temperature is compared with the temperature of the cooling medium from measurement locations. Individual images from the cameras are composed to form an overall development of the inner surface of the furnace walls. The coordinates of the deposits on the walls are determined from the overall development, and the thickness of the deposits is determined from the temperature comparison.

Owner:DIPL ING INGO RADUNZ

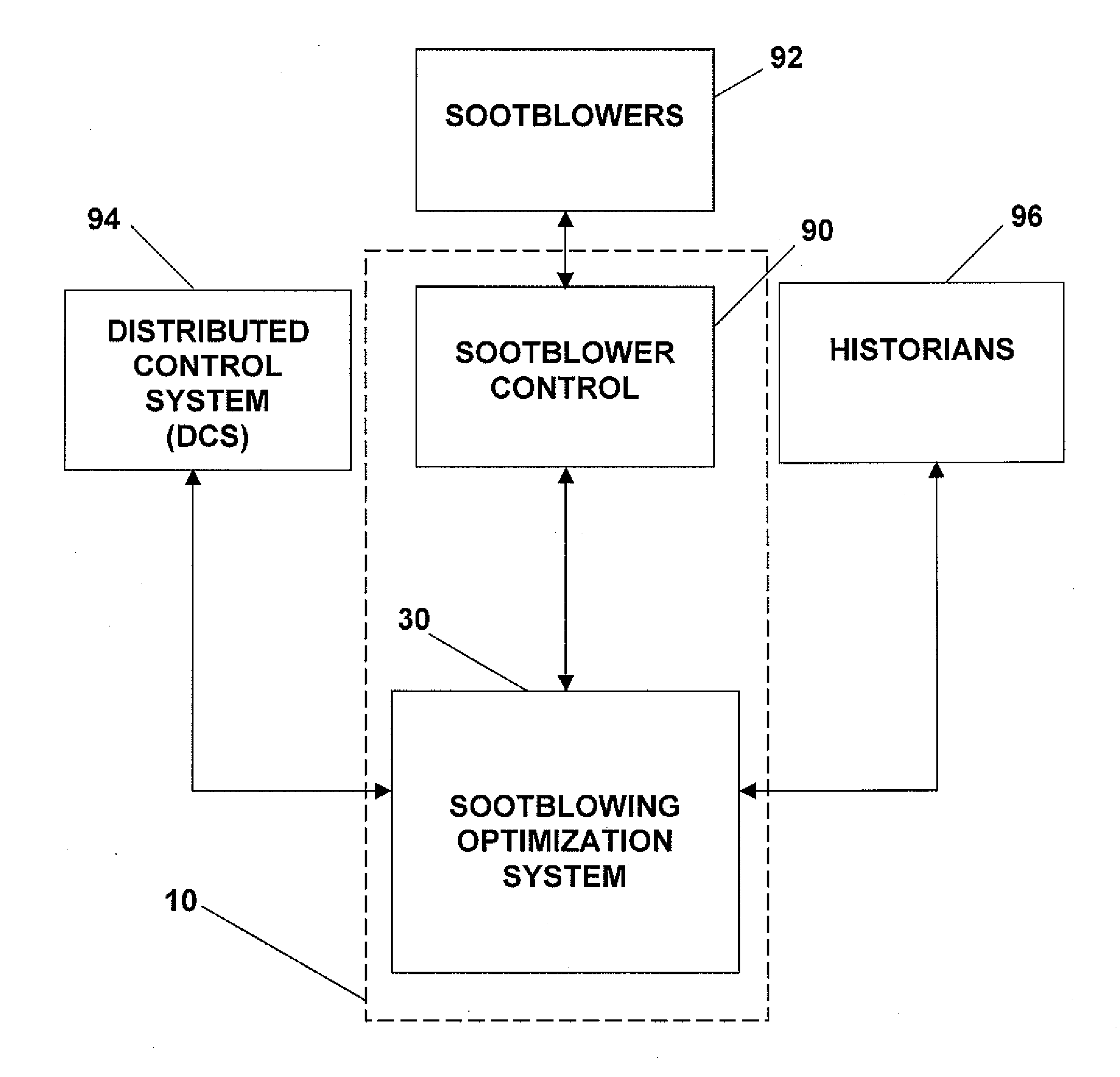

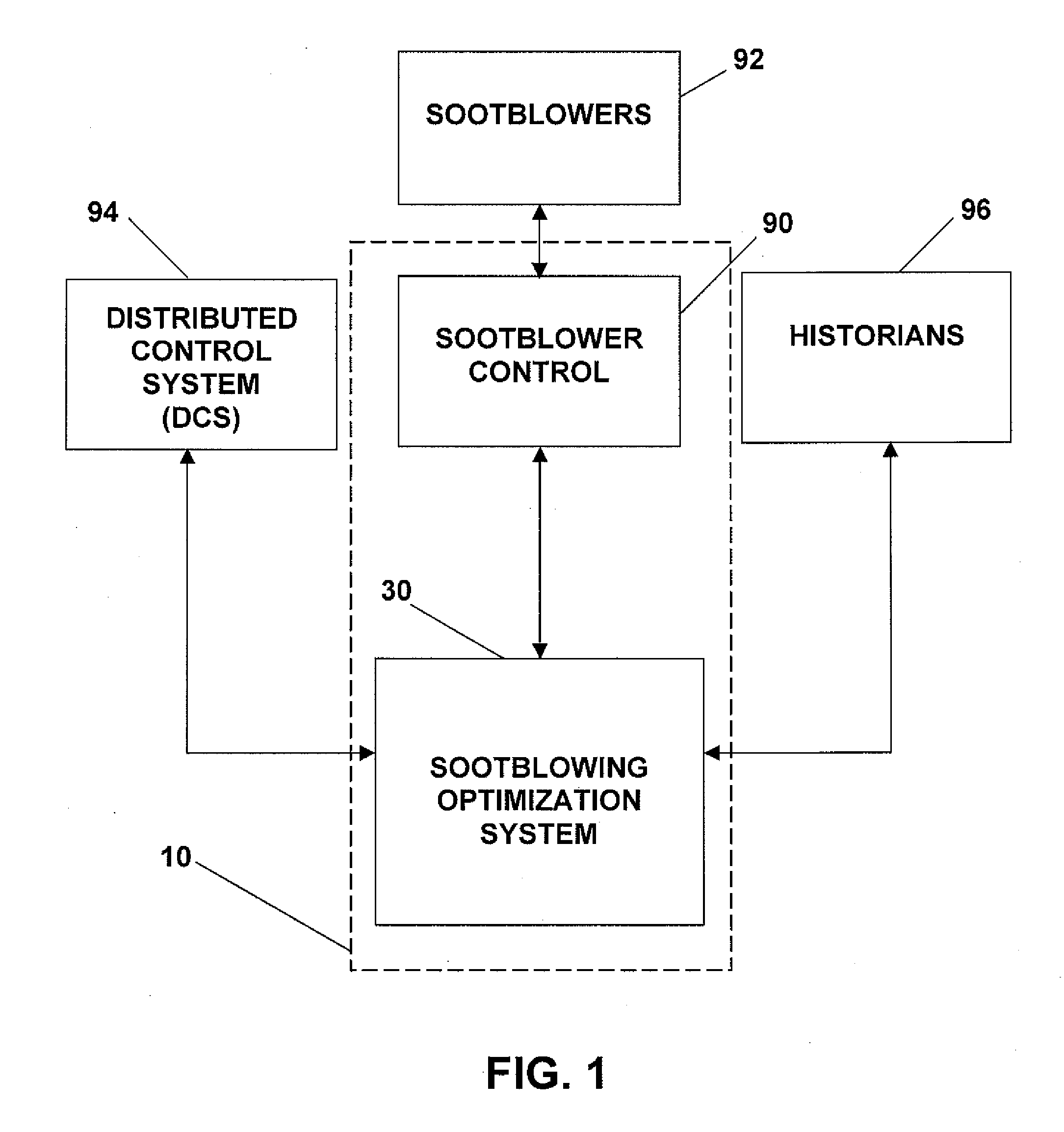

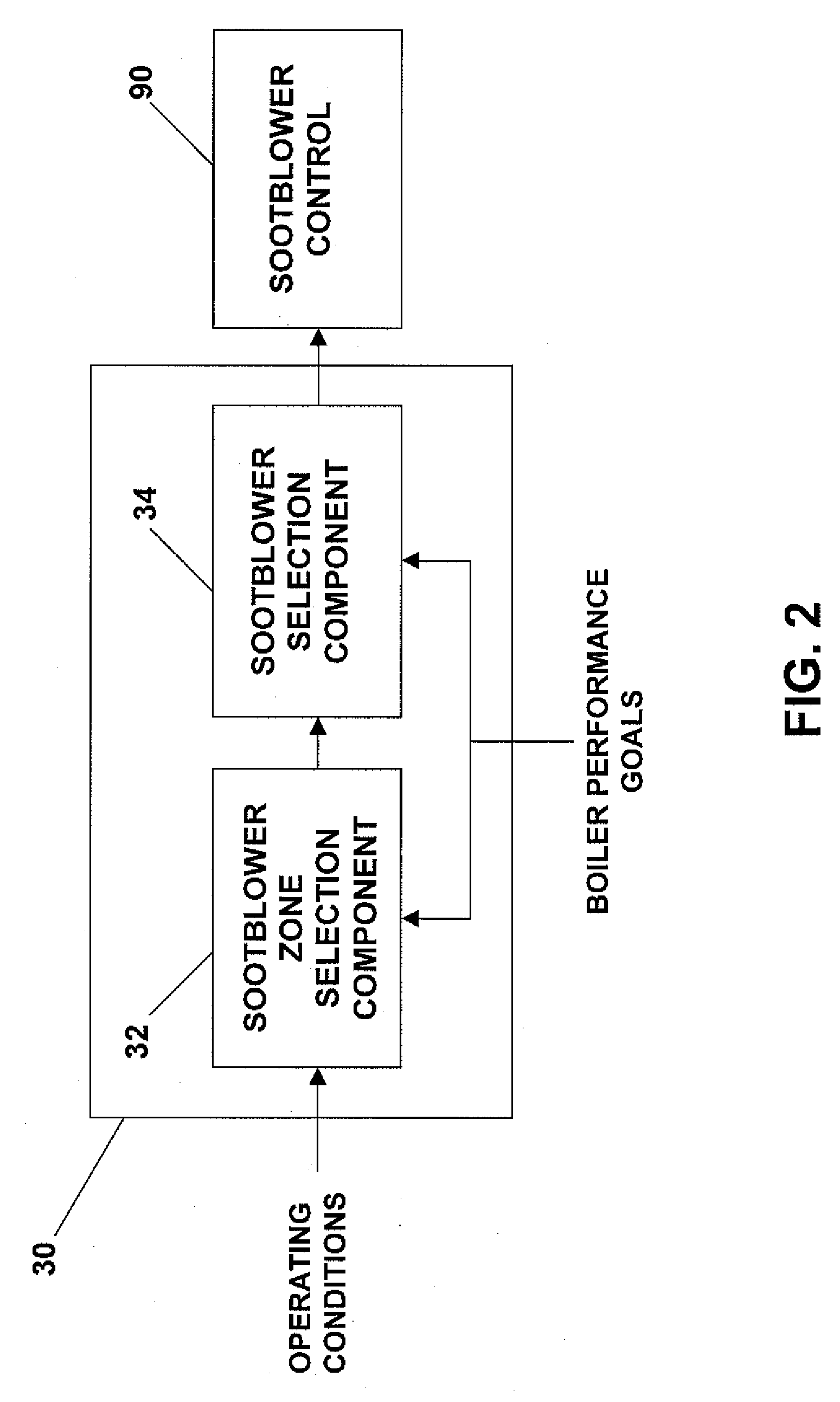

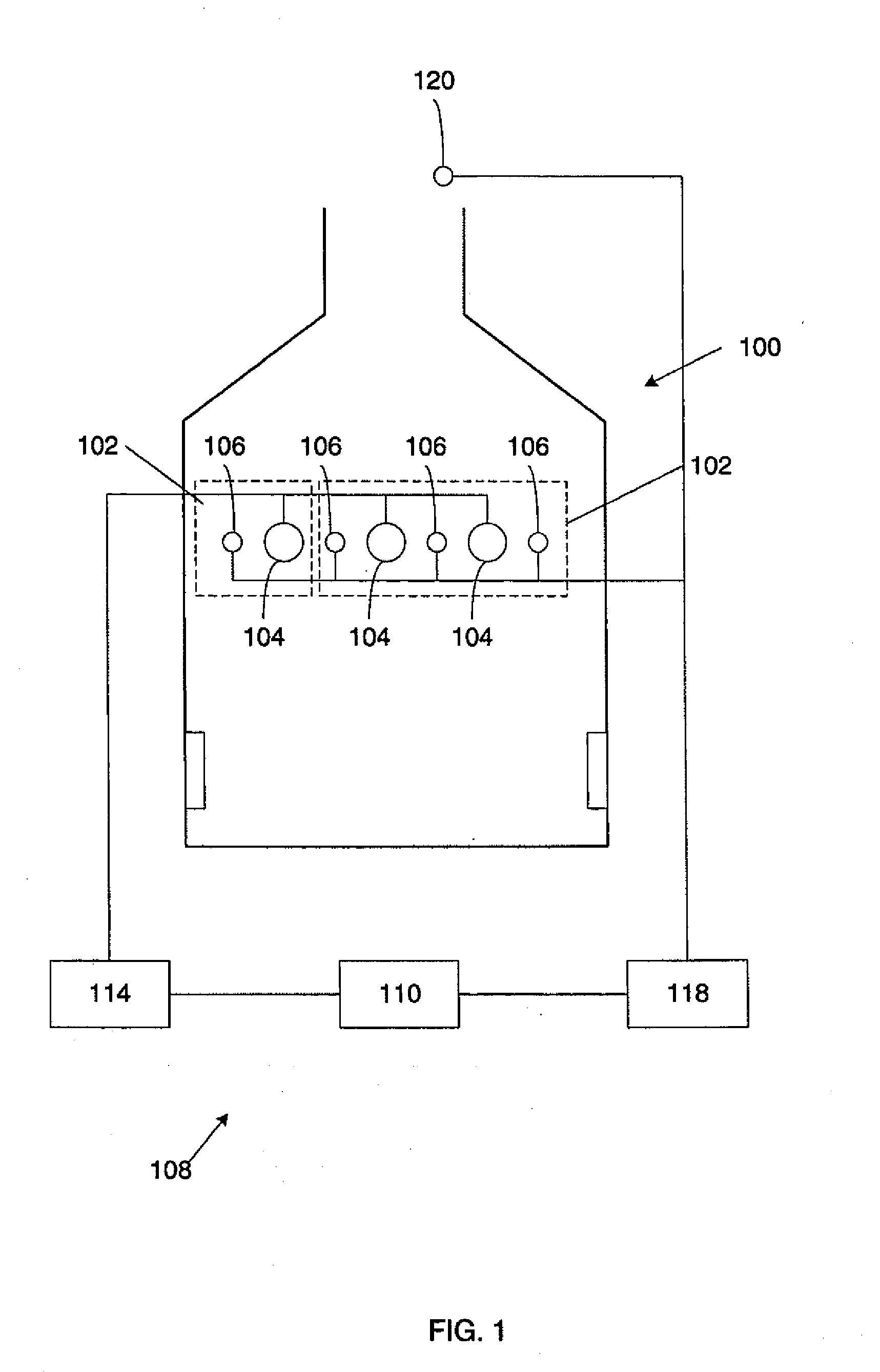

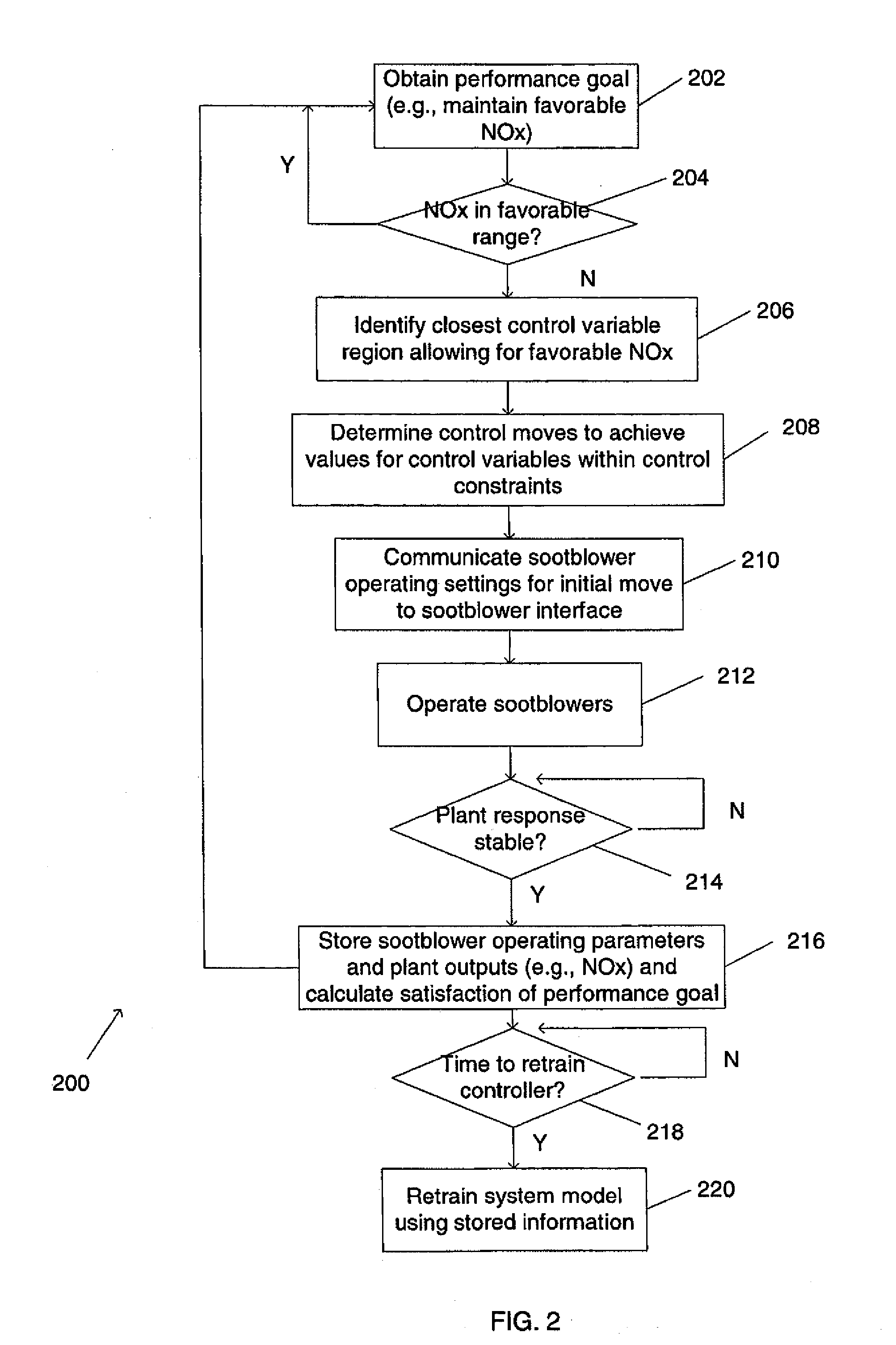

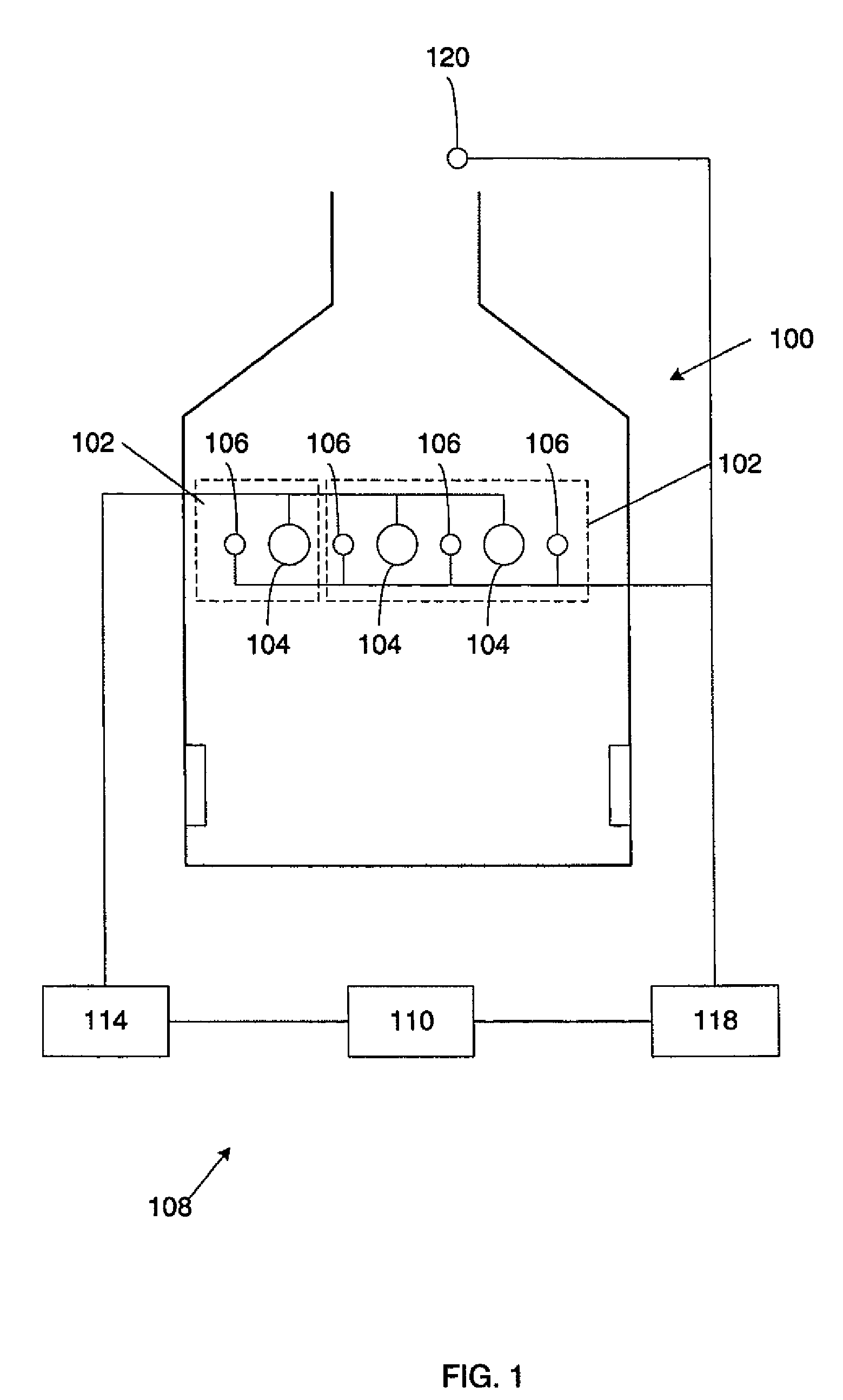

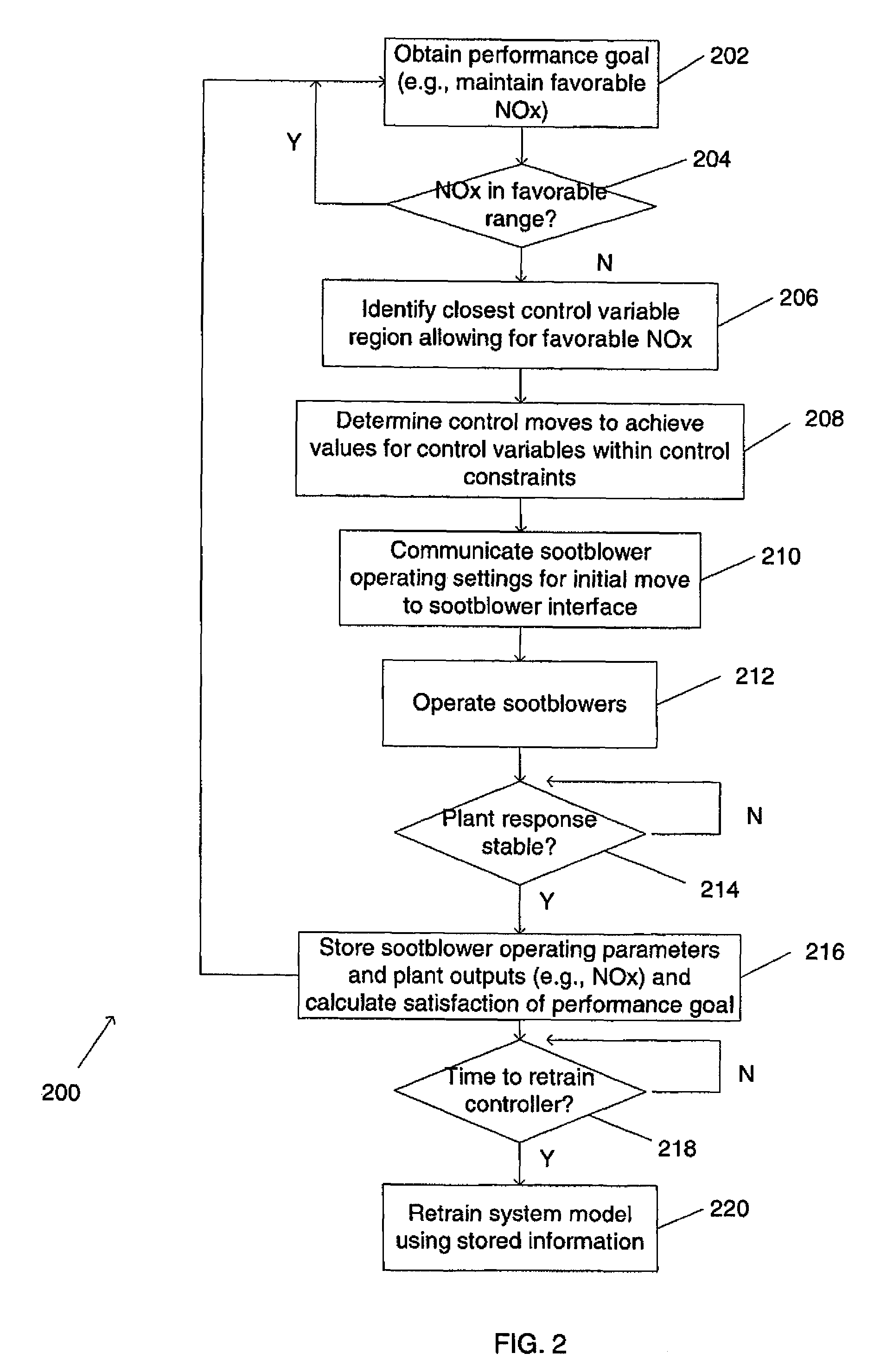

Sootblowing optimization for improved boiler performance

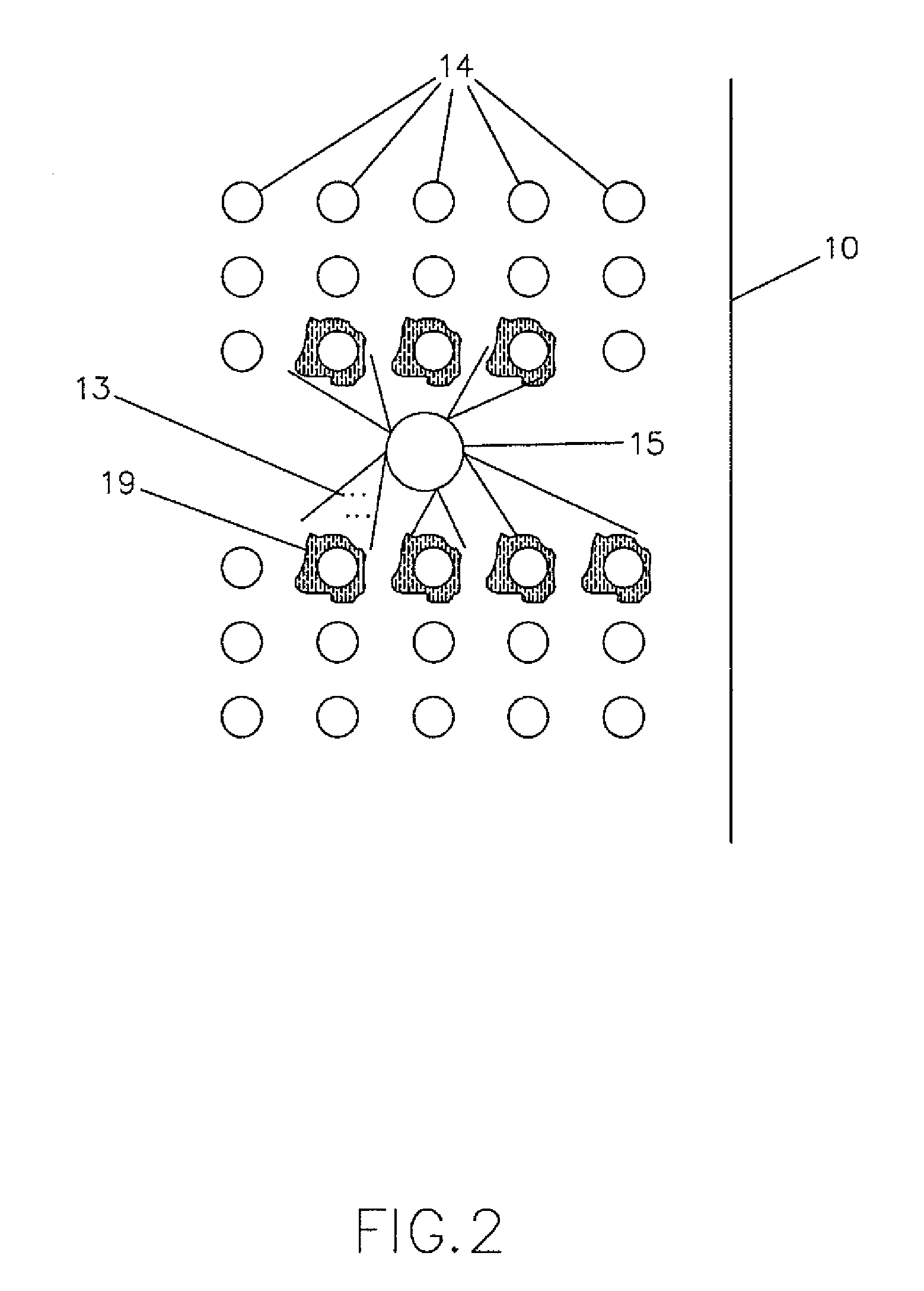

A sootblowing control system that uses predictive models to bridge the gap between sootblower operation and boiler performance goals. The system uses predictive modeling and heuristics (rules) associated with different zones in a boiler to determine an optimal sequence of sootblower operations and achieve boiler performance targets. The system performs the sootblower optimization while observing any operational constraints placed on the sootblowers.

Owner:GENERAL ELECTRIC CO

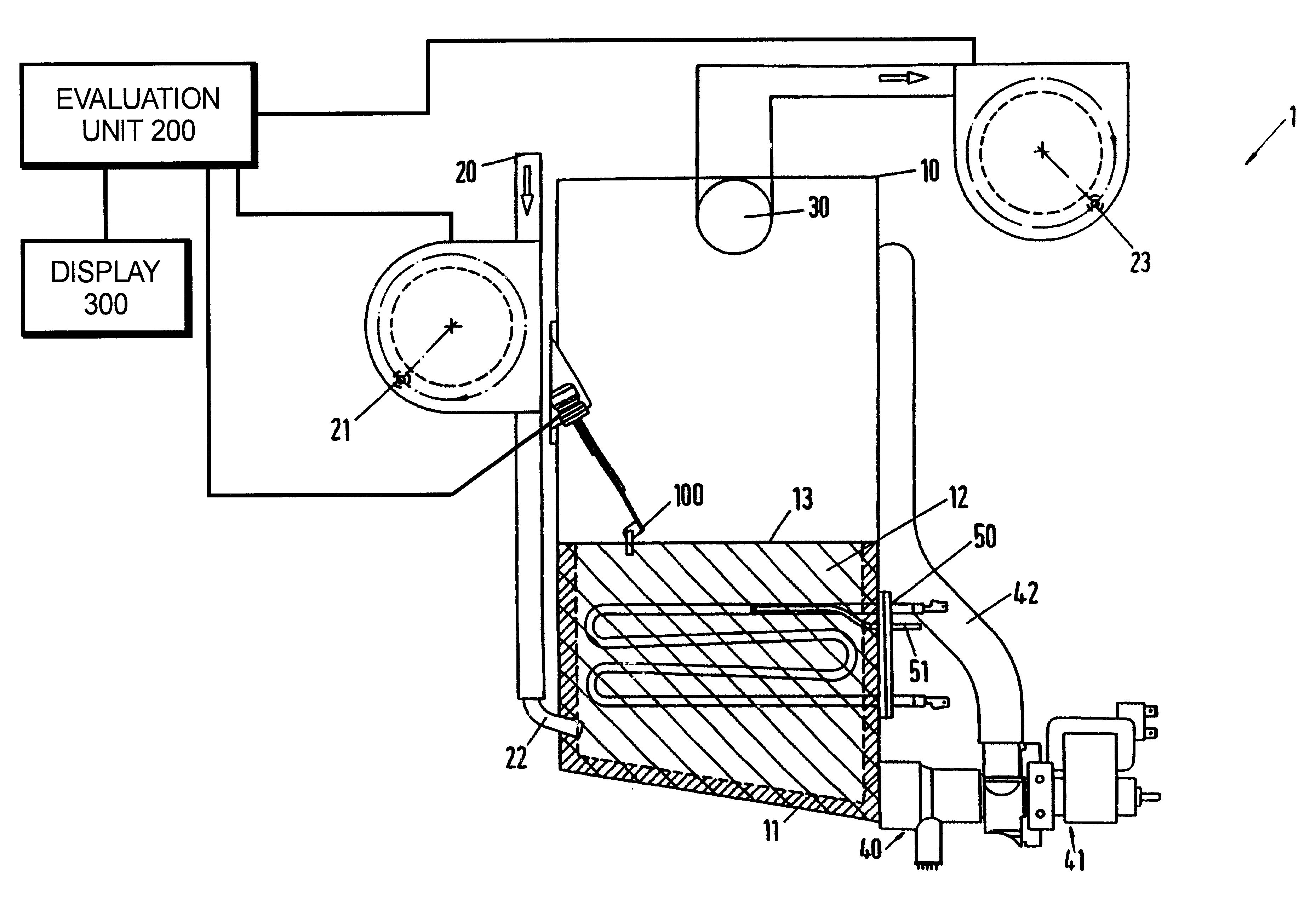

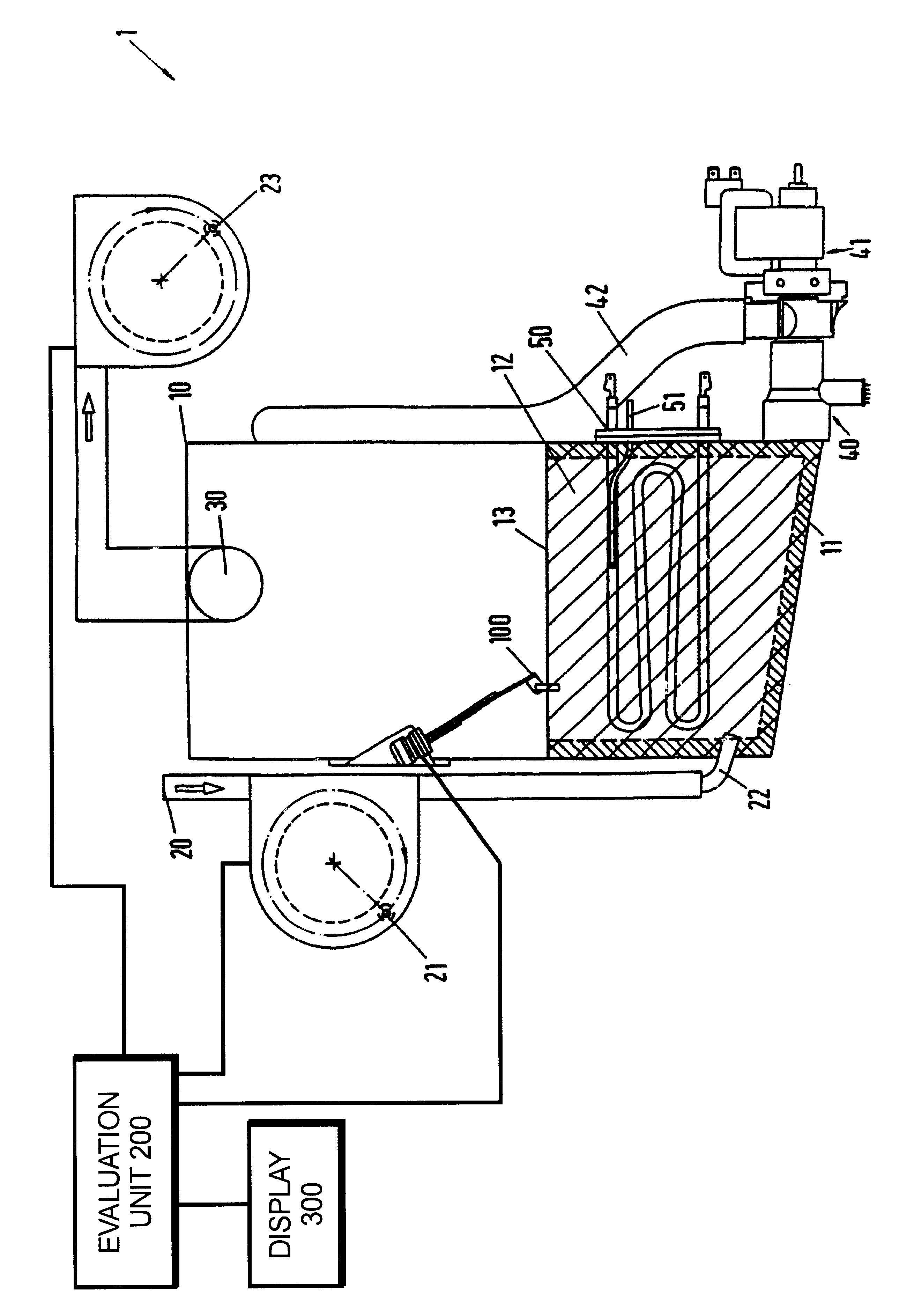

System for electronically monitoring scaling in an apparatus for heating and/or evaporating a liquid

InactiveUS6510782B1Easy to monitorSteam generation heating methodsBoiler indication operationsLevel sensorEngineering

A system for electronically monitoring scaling in an apparatus for heating and / or evaporating a liquid, comprising a container for at least temporarily receiving the liquid. The container comprises a liquid inlet, a liquid outlet and / or a vapor outlet and a heating element for evaporating liquid from the container. An evaluation unit is connected to at least one liquid level indicator and at least one flowmeter. A value relating to a desired filling volume of the container can be inputted into the evaluation unit and / or can be stored therein. The desired filling volume can be compared to a nominal liquid level in the evaluation system when water is constantly added by the flow meter, whereby the nominal liquid level is detected by the liquid level indicator, or to a nominal filled-in quantity detected by the flowmeter when the liquid flow indicator regulates the level of the filled-in liquid. A signal can be sent by the evaluation unit, wherein the signal is a measure of the absolute nominal liquid level, the absolute nominal filled-in quantity, the nominal liquid level relative to the desired liquid level, and / or the nominal filled-in quantity relative to the desired filled-in quantity.

Owner:RATIONAL AG

Method of managing the cleaning of heat transfer elements of a boiler within a furnace

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

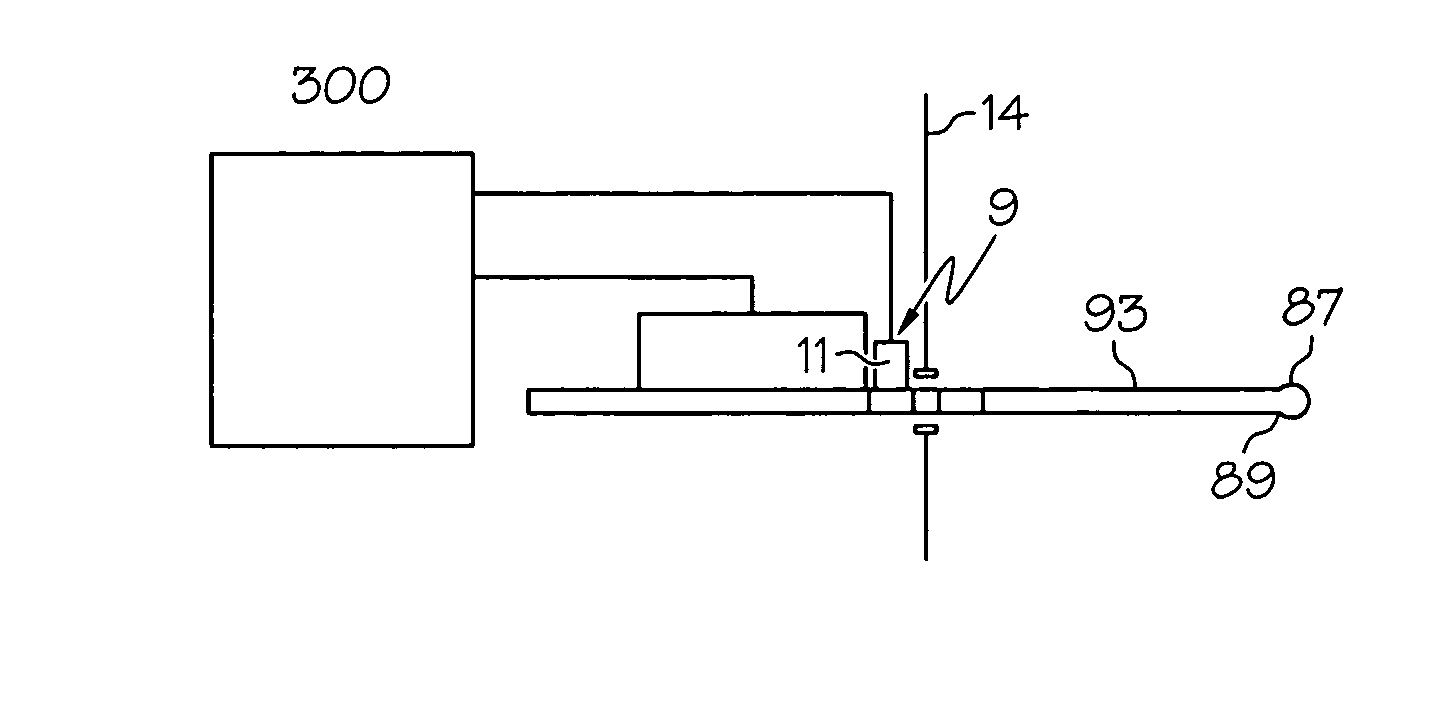

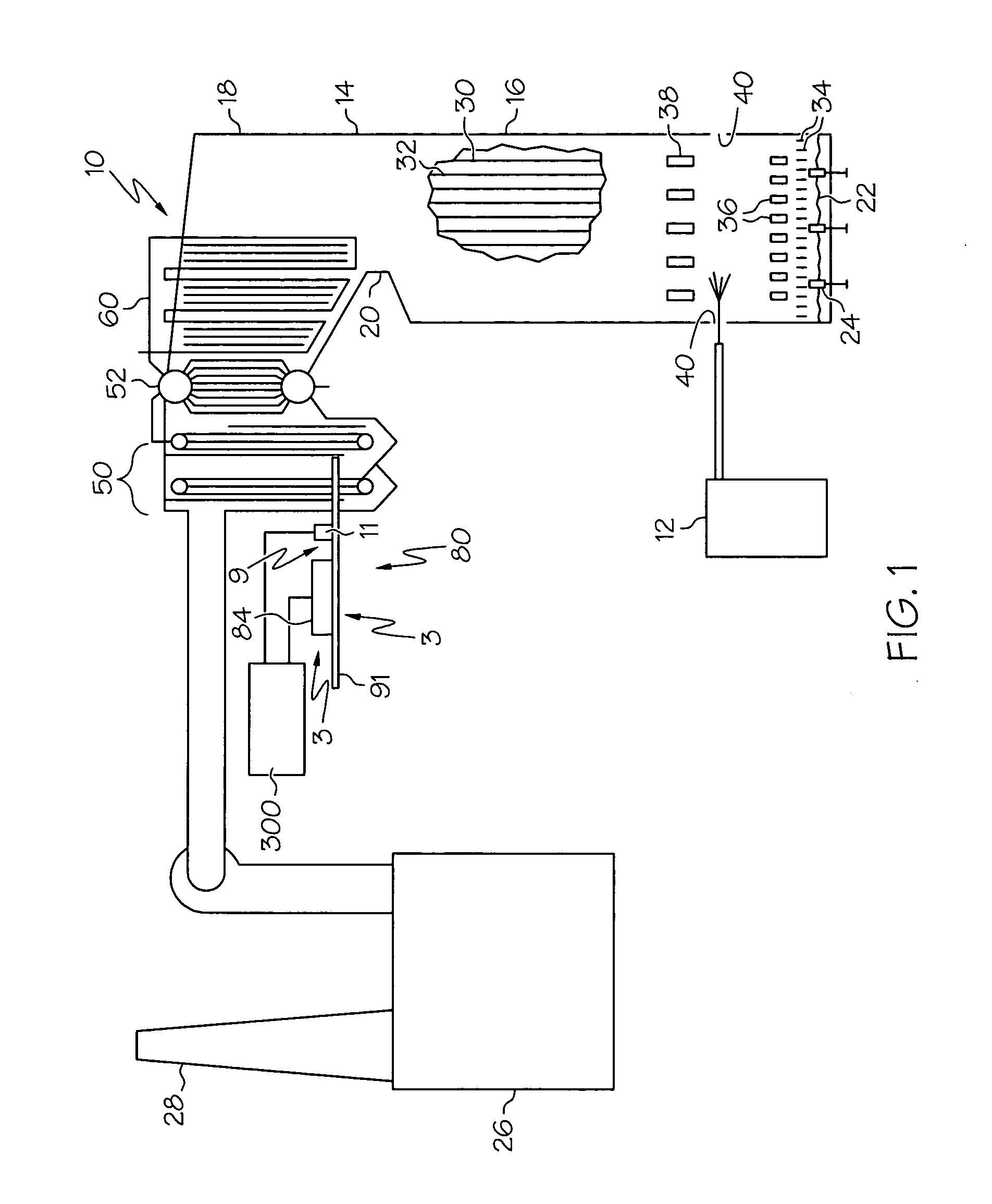

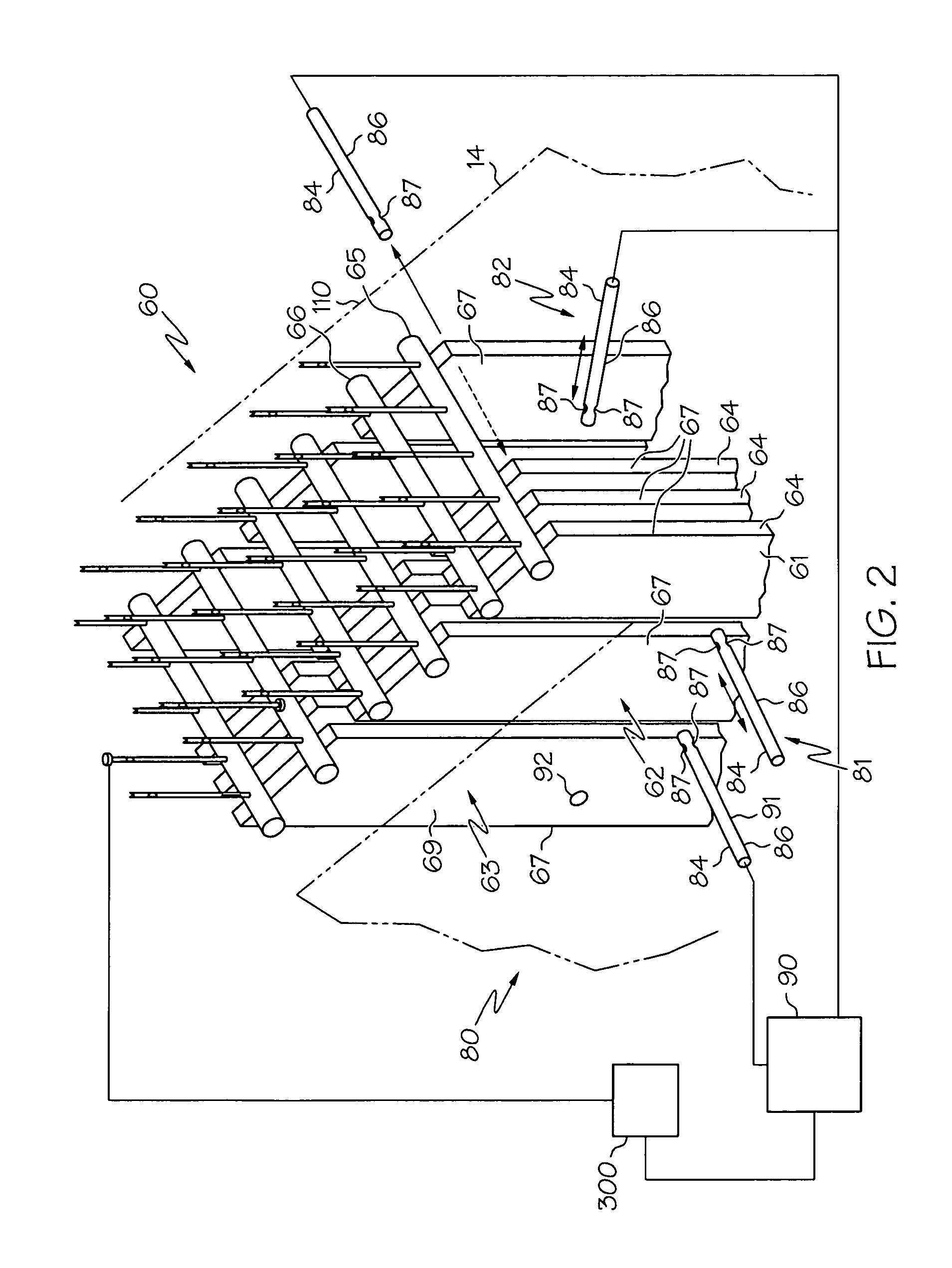

Controlling cooling flow in a sootblower based on lance tube temperature

A cleaning system and method for cleaning heat transfer surfaces in a boiler using a temperature measuring system for measuring and monitoring wall temperature of an annular wall of the tube of a lance of one or more sootblowers. Controlling a flow of steam or other fluid through the tube during the cooling portions of the strokes based on wall temperature measurements from the temperature measuring system. Infrared or thermocouple temperature measuring systems may be used. The steam or other fluid may be flowed at a default flowrate that may be substantially zero until the temperature measuring system indicates the wall temperature of the annular wall begins to exceed a predetermined temperature limit which may be the softening point of the annular wall. Then the steam or other fluid is flowed at a rate greater than the default flowrate.

Owner:INT PAPER CO

Detection of deposits in steam humidifiers

A humidifier configured to determine when the humidifier requires cleaning. The humidifier includes a tank for containing water, a heater for heating the water in the tank to generate steam, and one or more water level sensors for detecting the level of water in the tank, including detecting water at first level and a second level, where the first level is lower than the second level. The humidifier further includes a drain valve for draining water from the tank and a controller. The controller is configured to open the drain valve to drain water from the tank, measure a time interval required for the water to drain from the second level to the first level, and compare the time interval against a threshold value. If the time interval exceeds the threshold value, then the controller is configured to provide an indication to clean the humidifier. Methods are also disclosed.

Owner:ADEMCO INC

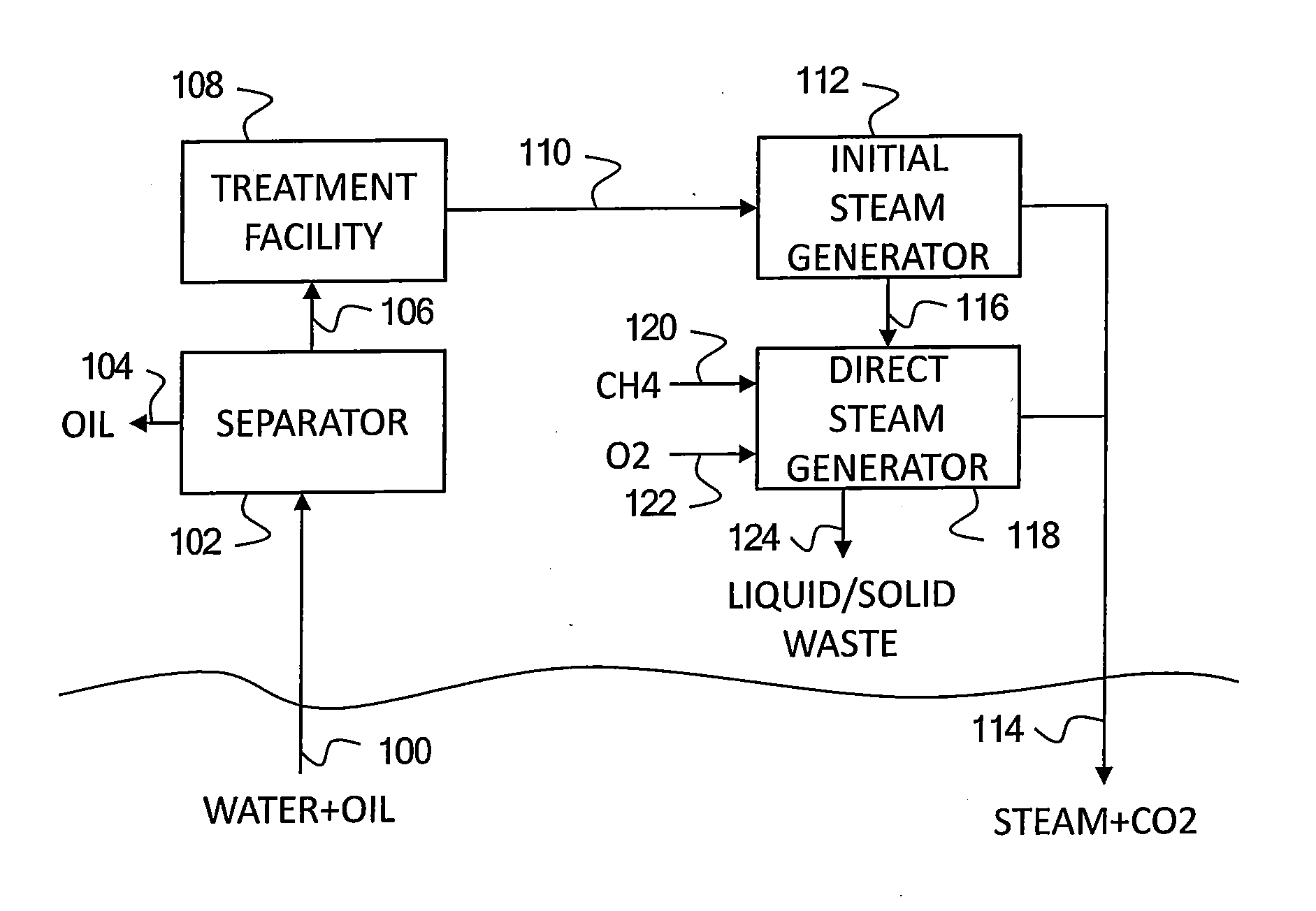

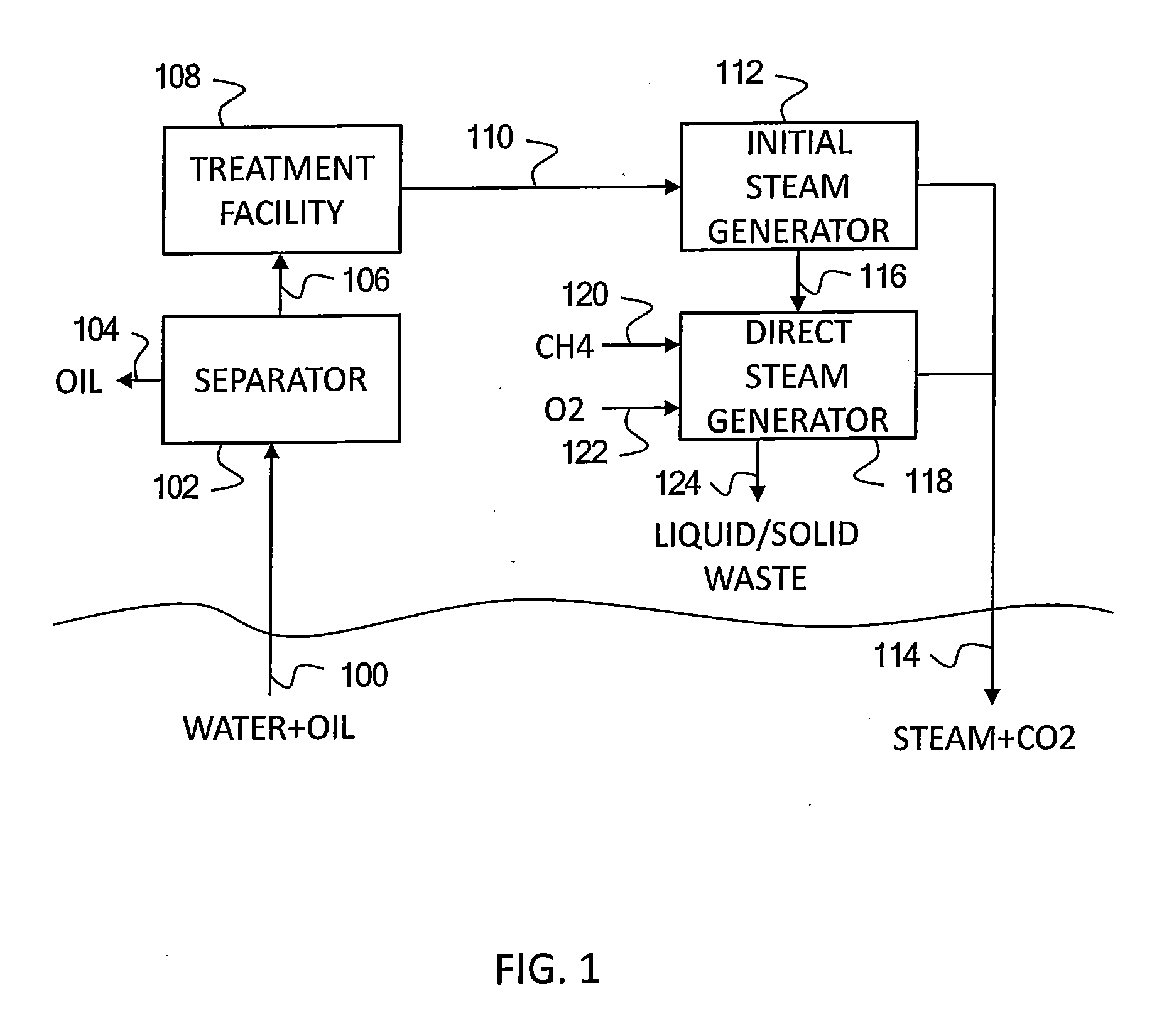

Direct steam generation of boiler blowdown

Systems and methods generate steam from produced water by passing the produced water through first and second steam generators coupled together. The first steam generator produces wet steam in which a liquid effluent with impurities of the produced water passes to the second steam generator. The second steam generator combusts fuel and oxidant in direct contact with the liquid effluent. The first and second steam generators limit fouling and waste while providing a combined steam output that may include combustion products from only the second steam generator.

Owner:CONOCOPHILLIPS CO

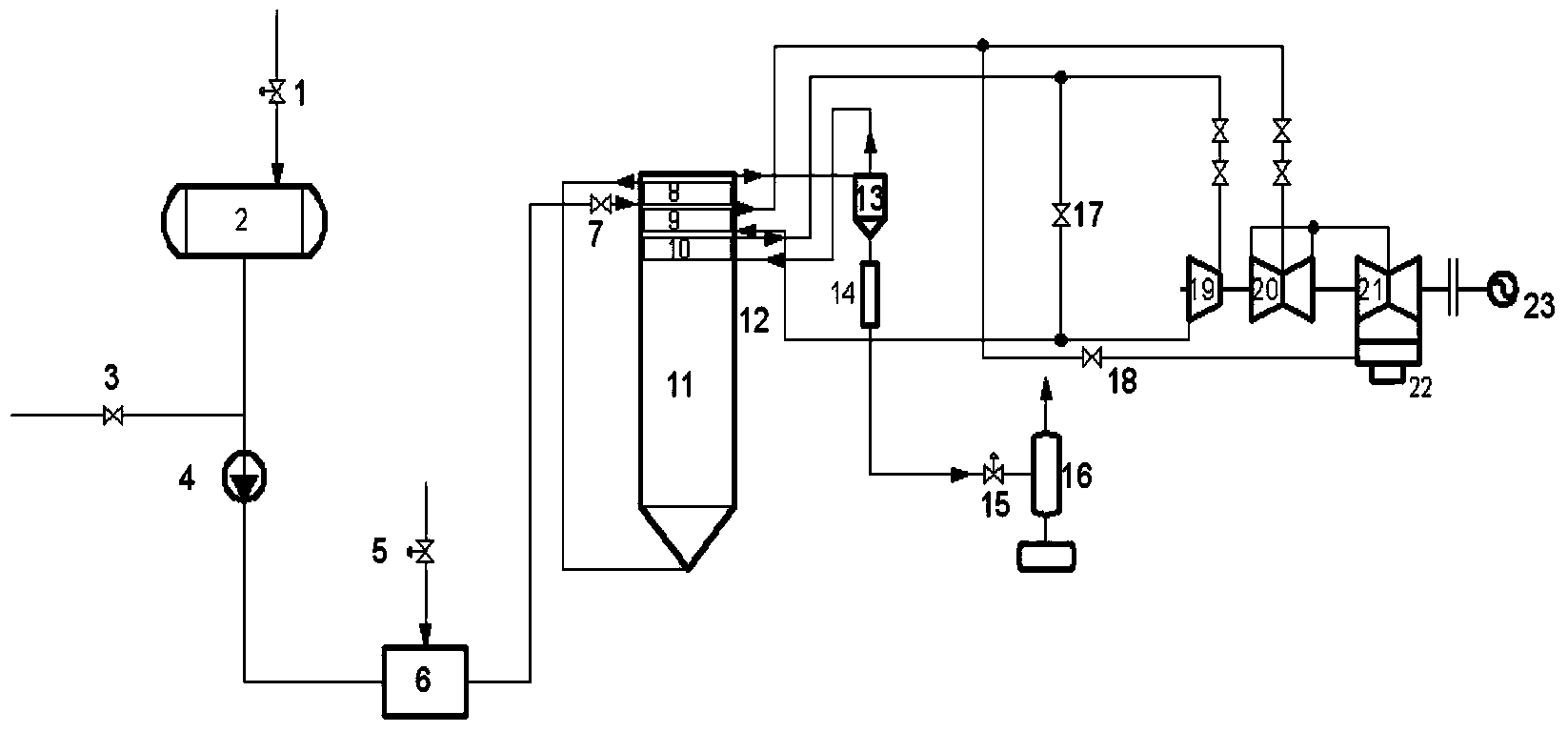

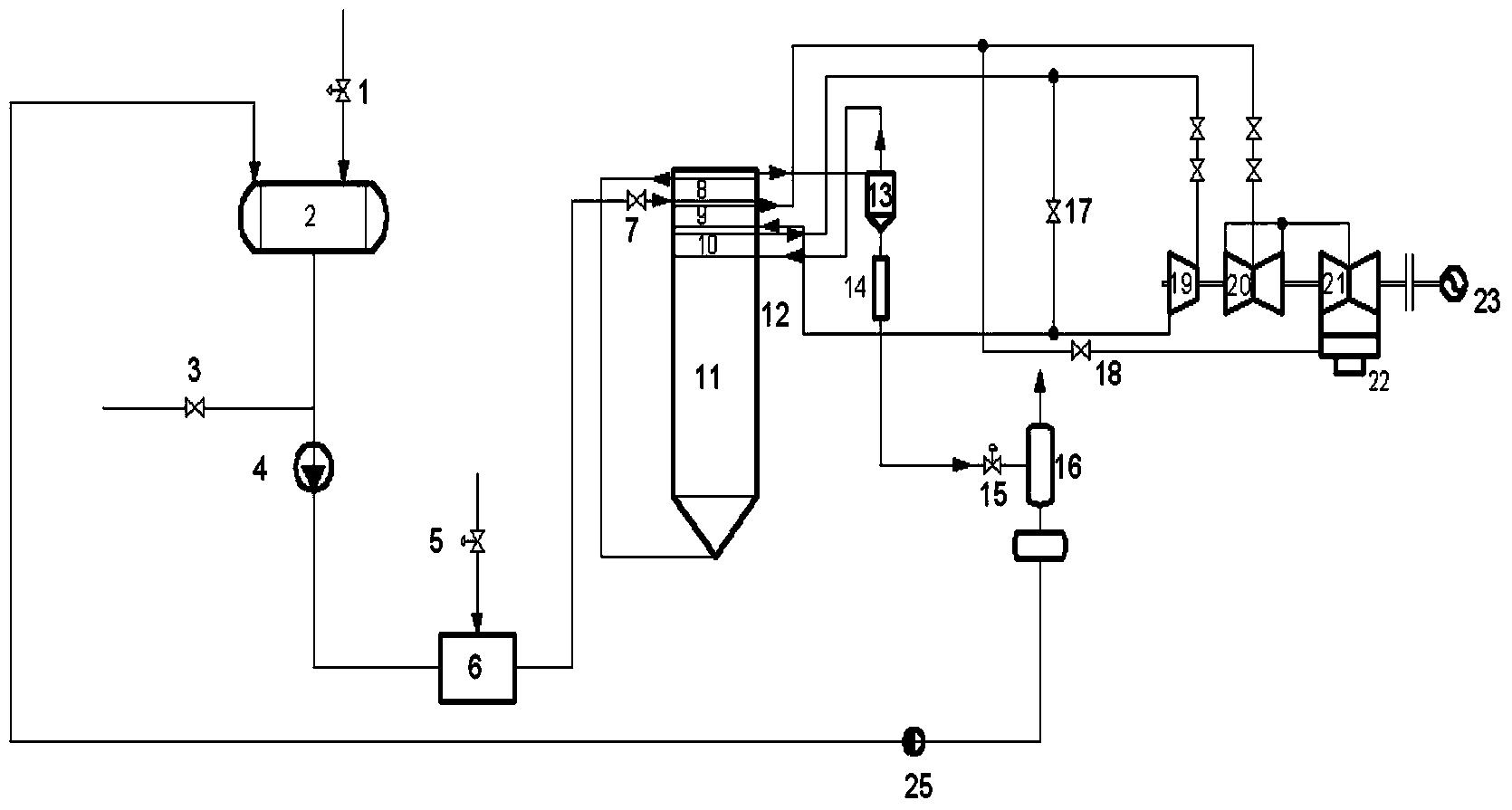

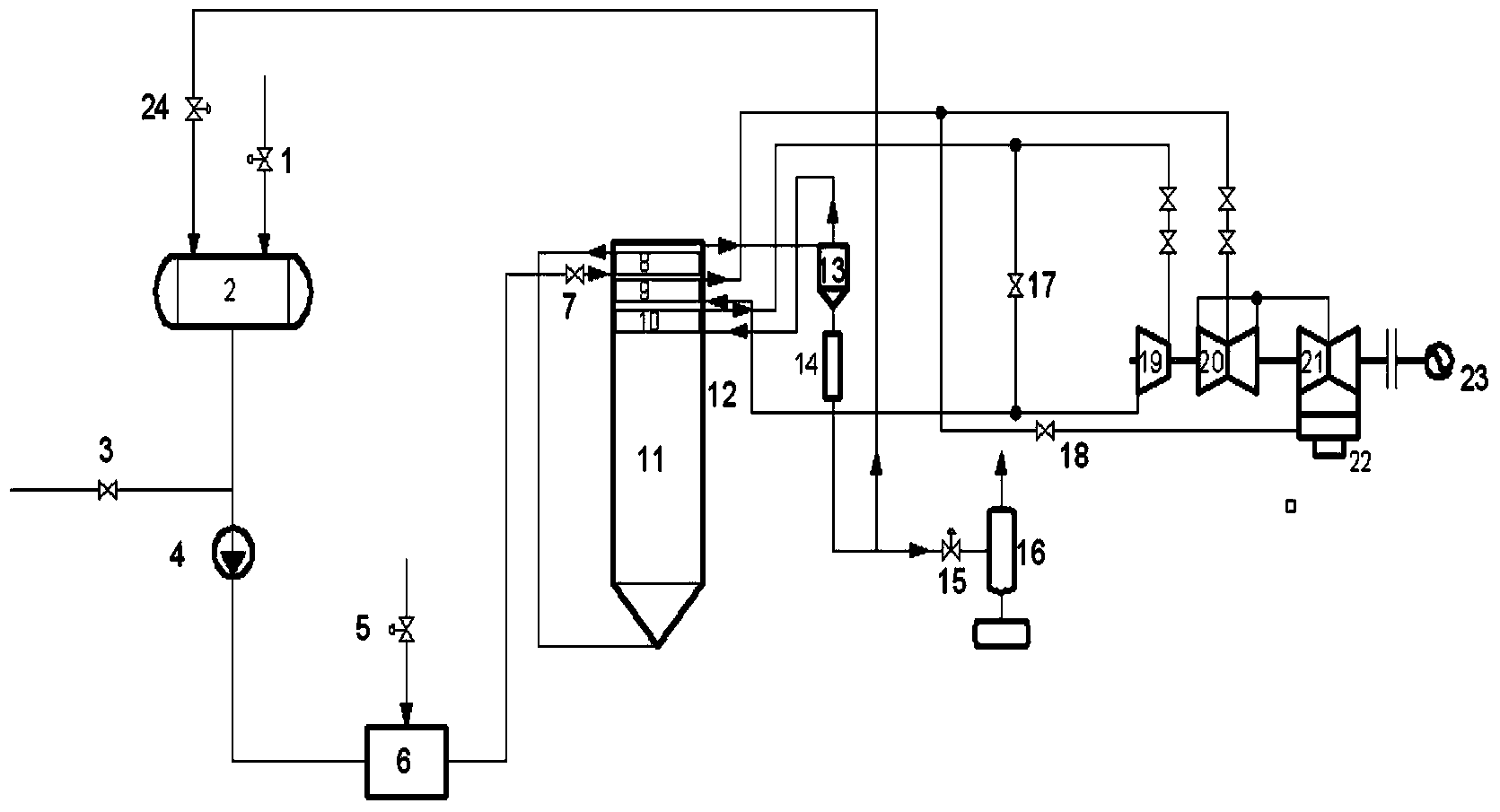

Energy-saving type quick start method for supercritical unit or ultra-supercritical unit

ActiveCN103712197AReduce startup timeIncrease temperature rise rateLiquid degasificationBoiler controlPressure riseThermal state

The invention discloses an energy-saving type quick start method for a supercritical unit or an ultra-supercritical unit. According to the method, steam from another resource is used for heating supplied water so that a boiler can be indirectly heated, and the thermal stress of a heated surface is reduced when the boiler is started so that the heating rate of the boiler can be improved; meanwhile, the heated high-temperature supplied water is converted into steam-liquid two-phase flow through throttling and pressure reduction, the flowing scouring action of the steam-liquid two-phase flow is far superior to the effect of thermal-state washing, and in other words, the boiler can complete thermal-state washing under the non-ignition condition, and can preheat the whole heated surface before ignition till certain pressure is reached. After ignition of the boiler, due to the fact that enthalpy of subcooling on an inlet of a water wall is eliminated, the problem of water power can be readily solved and the input speed of fuel can be increased. Meanwhile, by adjusting the open degree of a turbine bypass valve, the flow, the temperature rising speed and the pressure rising speed of main stream and reheat steam are controlled, and the temperature rising speed of the heated surface of the boiler is increased; when the temperature of the main steam and the temperature of the reheat steam are larger than the temperature of a turbine heating valve, valve heating is started, and a main machine can early satisfy the impulse starting condition.

Owner:冯伟忠

Method and apparatus for monitoring the formation of deposits in furnaces

InactiveUS7607825B2Increase temperatureThickness can be qualitatively valuedThermometer detailsRadiation pyrometryFlue gasEngineering

Owner:DIPL ING INGO RADUNZ

Method and System for Sootblower Flow Analyzer

InactiveUS20110203535A1Improve availabilityImprove efficiencyBoiler cleaning apparatusMachines/enginesTraffic flow analysisMonitoring system

The present invention relates to a method and a system for optimizing steam or other cleaning medium used during soot removal in a boiler in which energy is generated by fuel combustion, with accompanying production of soot, and heat energy is transferred from the product gases to a heated medium via heat exchanger tubes on which the soot collects, by; monitoring the mass flow rate of the cleaning medium, determining which set of sootblowers are in operation, calculating appropriate high flow alarm set point and low flow set point for each particular sootblower, notifying an operator whether the sootblowers are operating within the setpoints so that appropriate action can be taken to the set of sootblowers. In addition, the invention performs leak detection by monitoring for a system bottled up situation and notifies the operator when a steam leak is detected.

Owner:NRG ENERGY

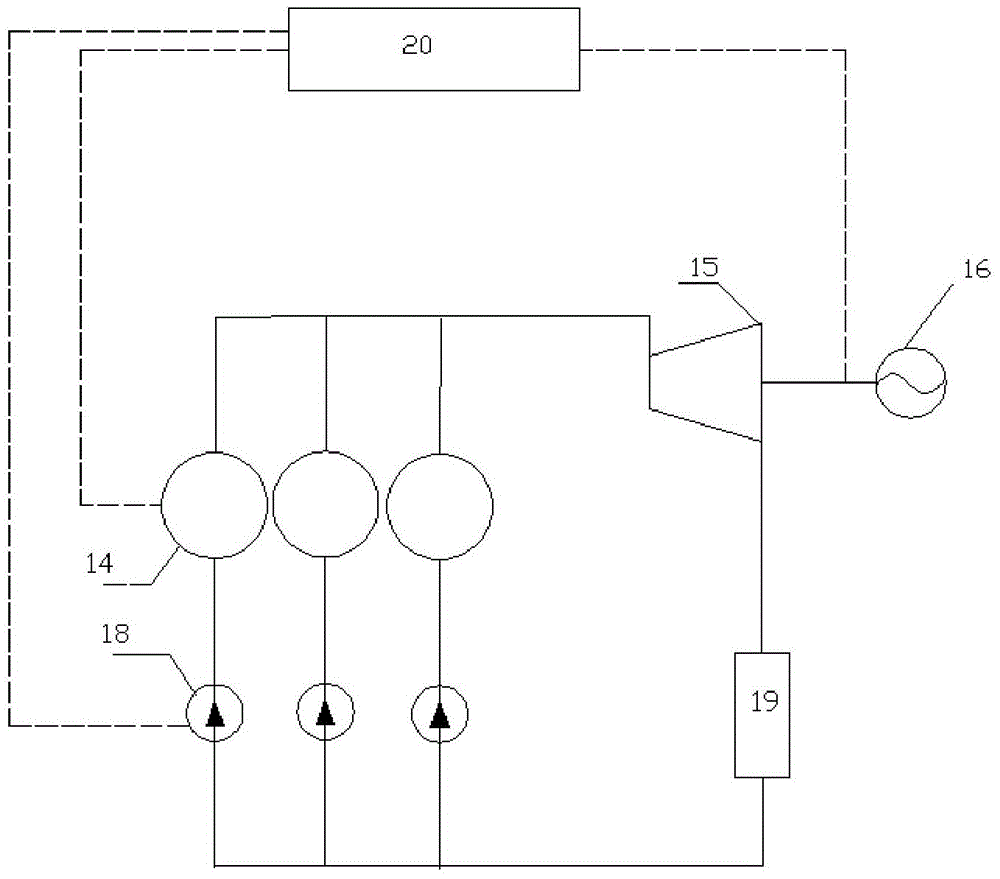

Intelligent blowdown boiler

InactiveCN104949098AAvoid wastingRealize automatic online monitoringBoiler cleaning apparatusEnergy industryThermal energyAutomatic control

The invention provides an intelligent blowdown boiler which comprises an automatic control blowdown system. The automatic control blowdown system is automatically controlled according to the amount of steam generated by the boiler and the amount of water input into the boiler. The water supply amount and the generated steam amount of each boiler are monitored in real time, so that the dynamic relation of the water supply amount and the generated steam amount is obtained, whether the blowdown system of the boiler works normally or not is judged, and waste of a large amount of heat energy waste caused by faults of the blowdown system of the boiler is avoided.

Owner:张雪原

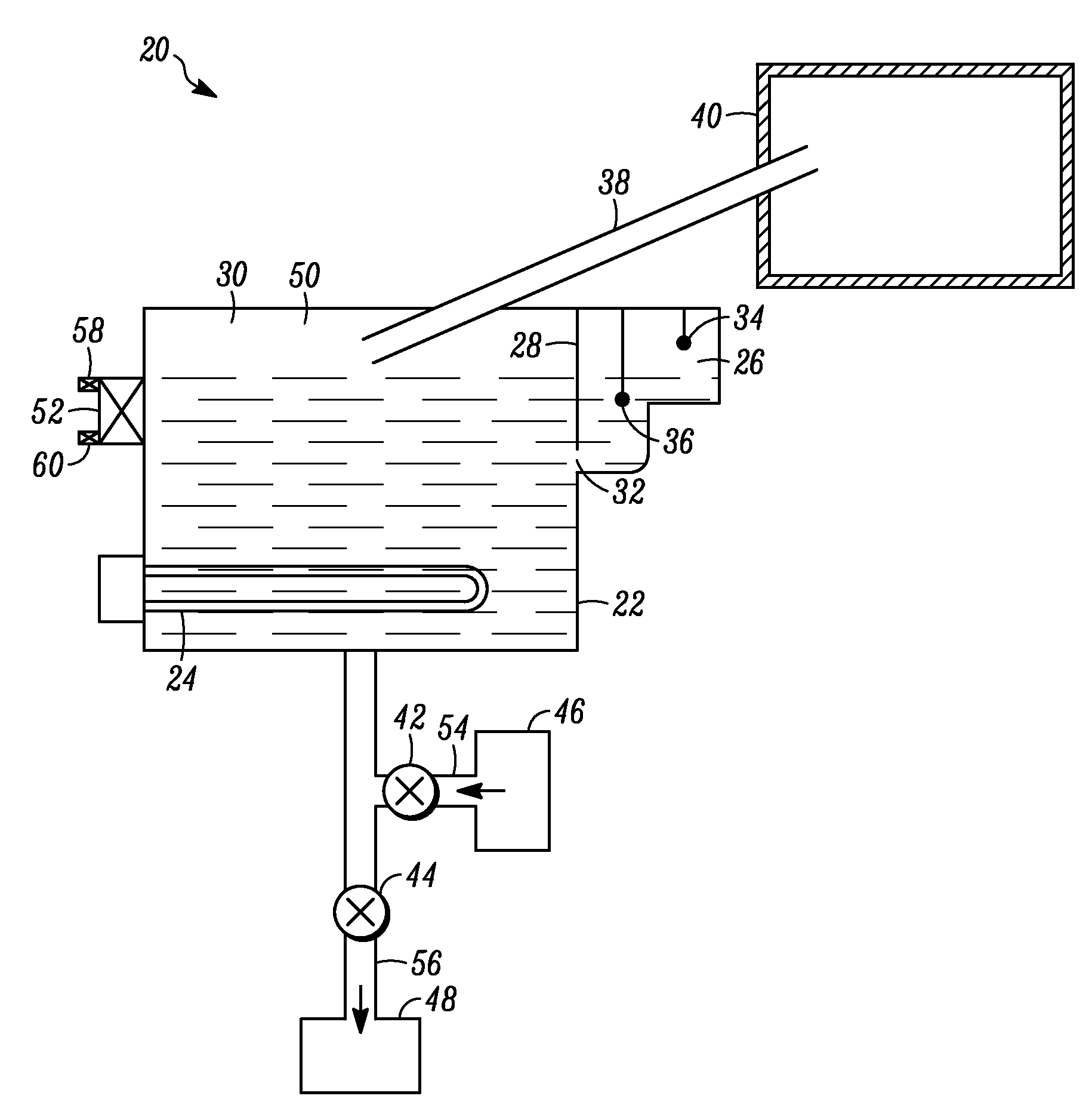

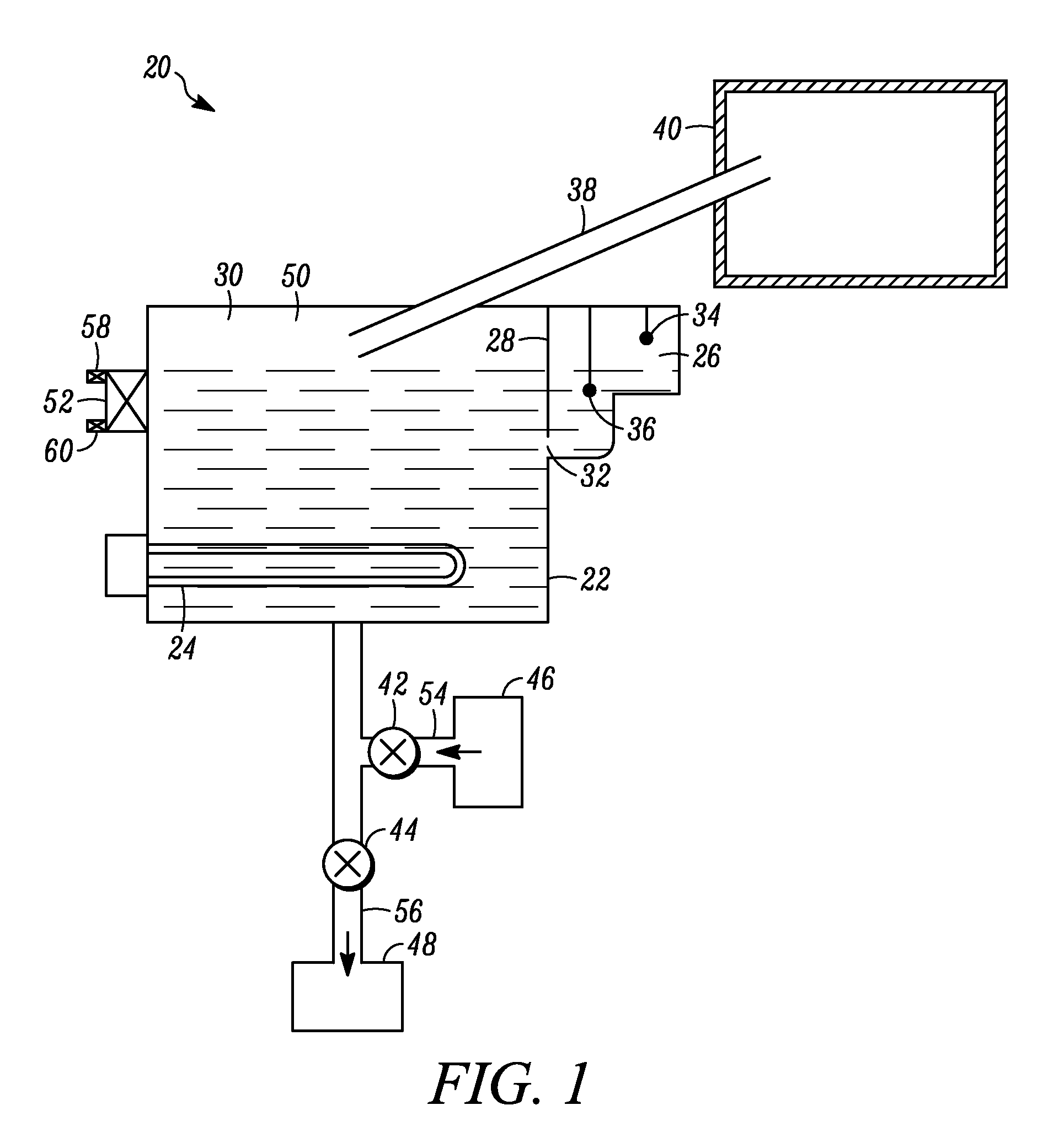

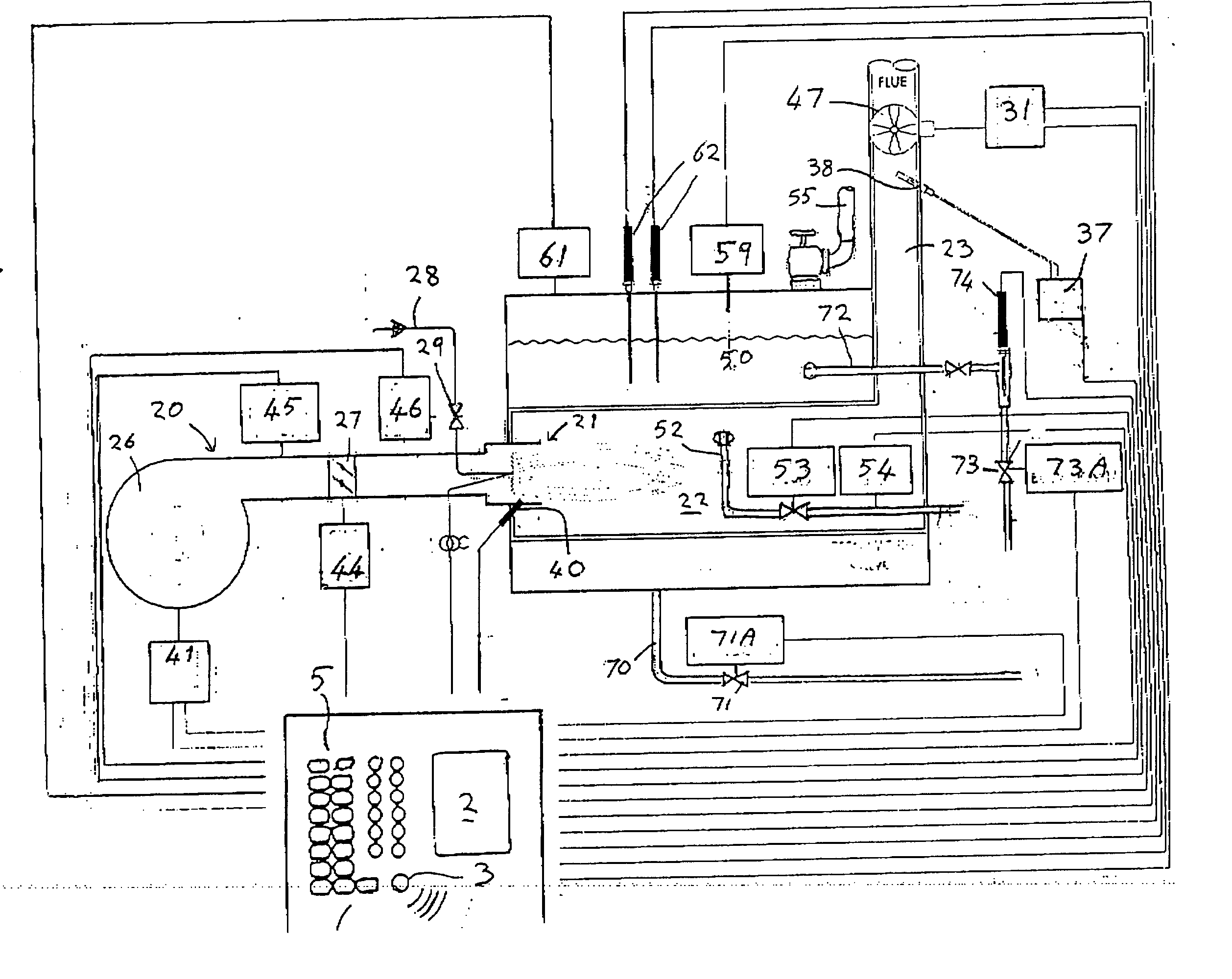

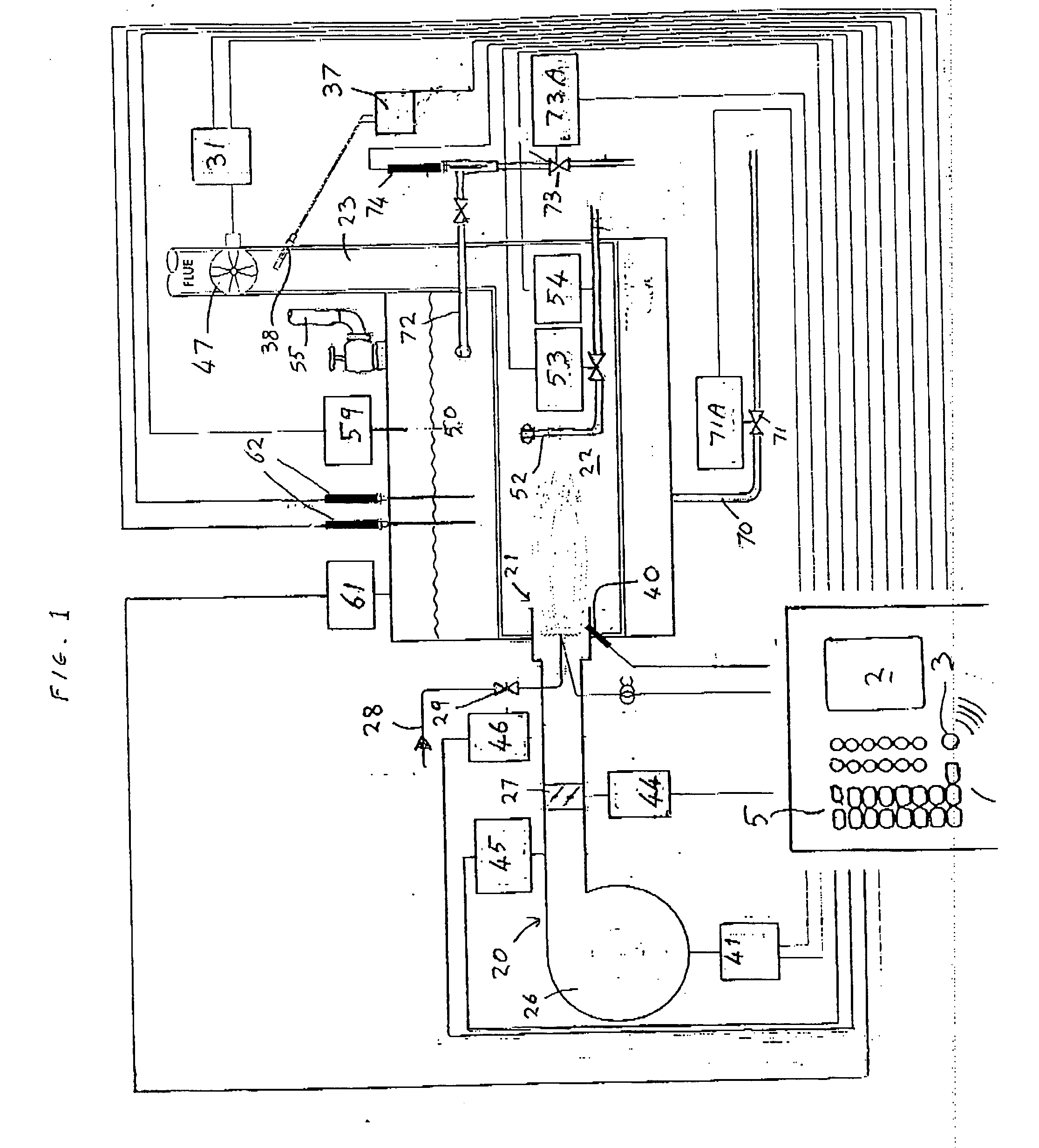

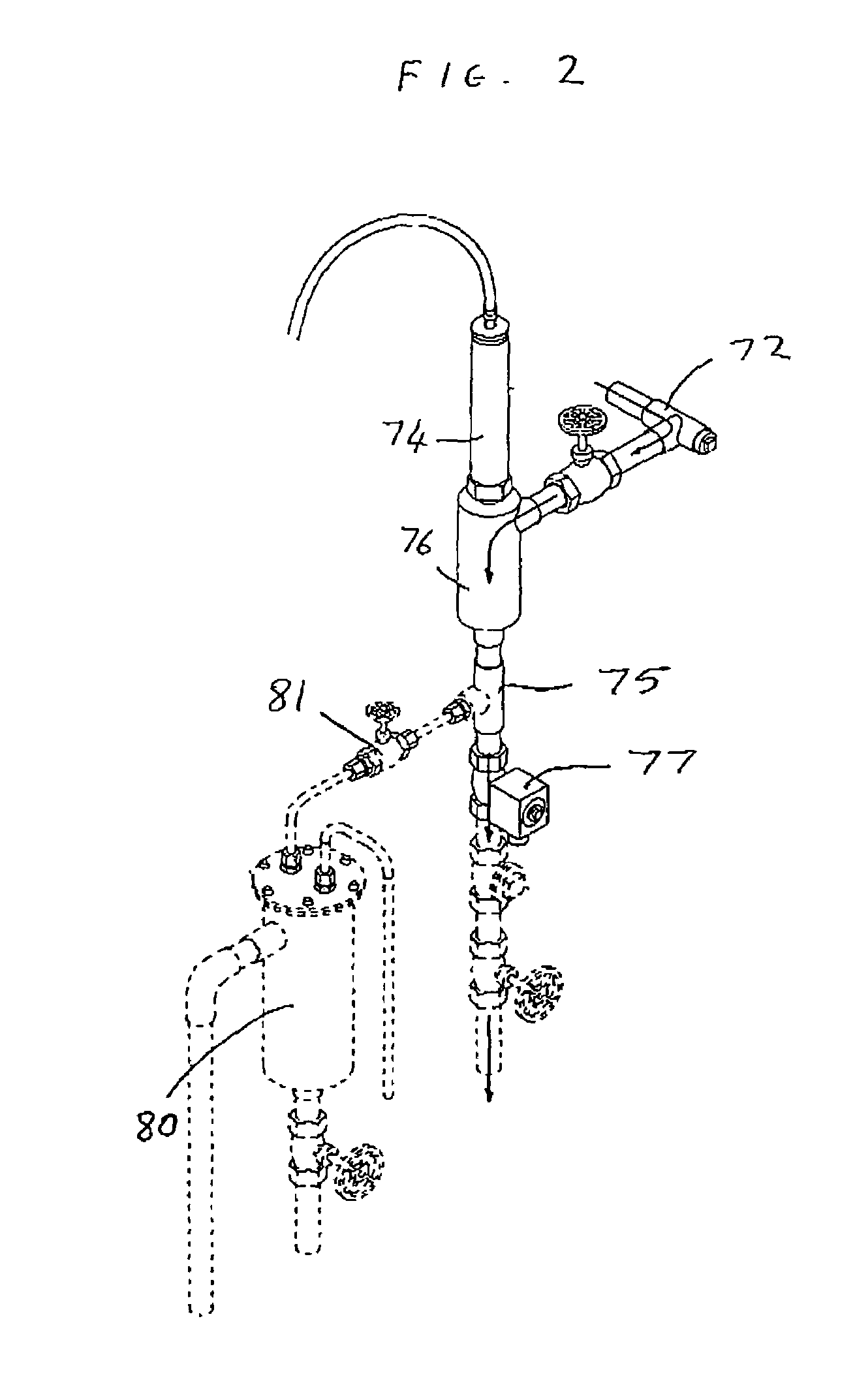

Apparatus and method for measuring total dissolved solids in a steam boiler

ActiveUS20050224016A1Reducing and avoiding any unnecessary blow downEffective controlFluid heatersGas pressure propulsion mountingCombustorTotal dissolved solids

A method and apparatus for controlling the operation of a pressurised steam boiler heated by a burner. The method includes the steps of monitoring the level of total dissolved solids in water contained in the boiler, monitoring the level of water in the boiler, monitoring the pressure of steam in the boiler, monitoring the firing rate of the burner; controlling the blow down of the boiler having regard to the level of total dissolved solids in water contained in the boiler, and controlling the flow rate of water into the boiler and the firing rate of the burner. All input signals relating to the monitoring steps are passed to a common control unit and all output signals relating to the controlling steps are transmitted from the common control unit.

Owner:AUTOFLAME ENG

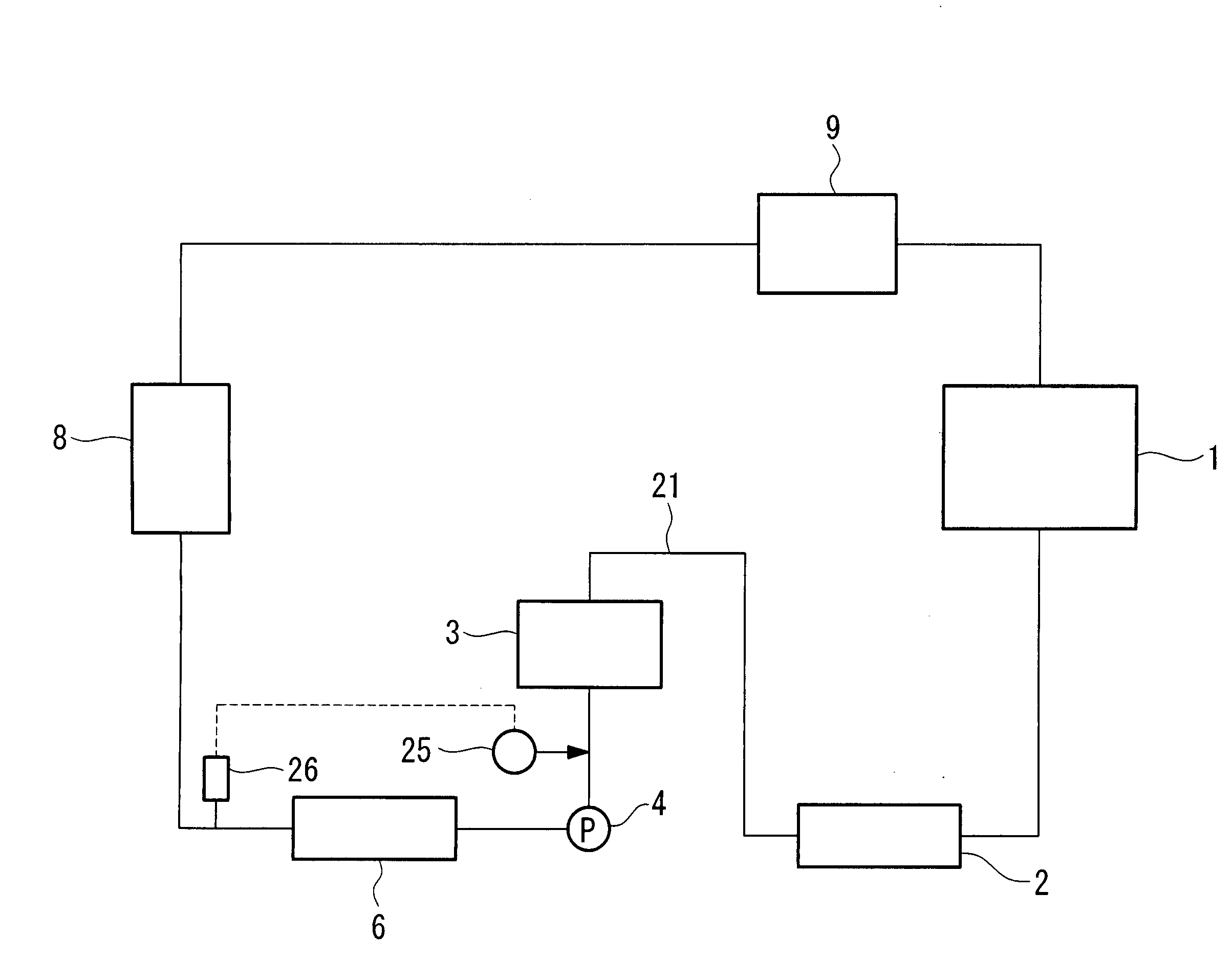

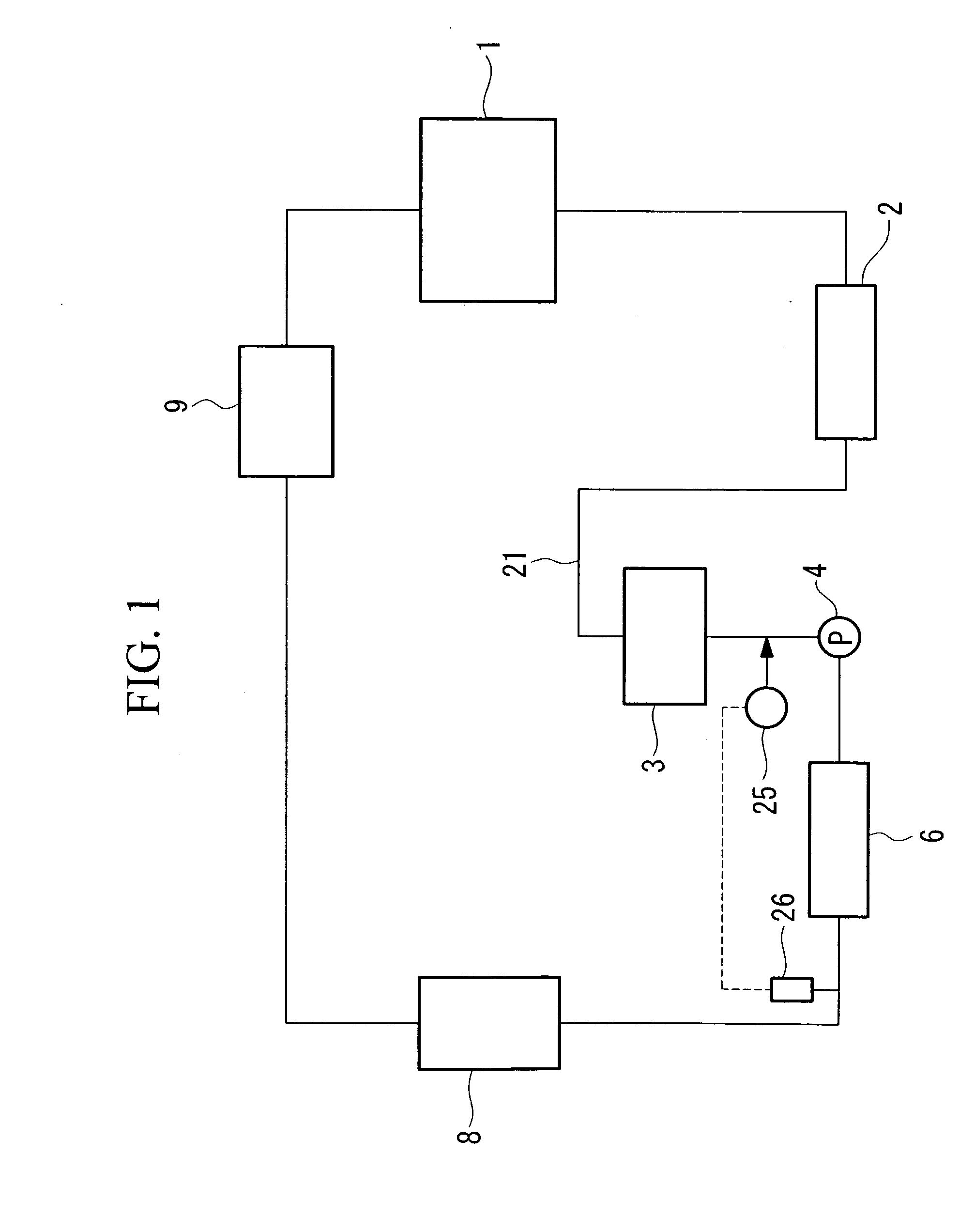

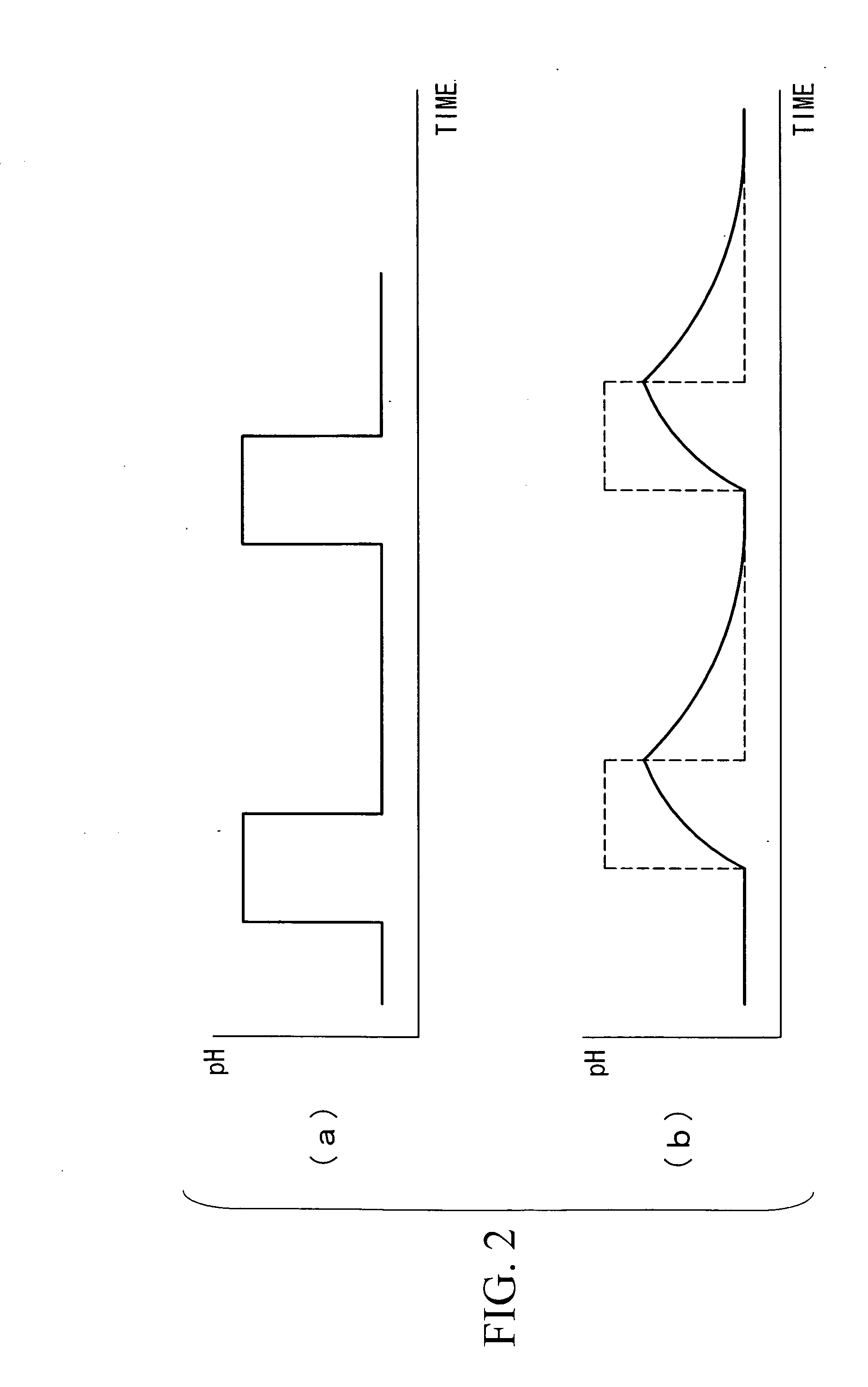

Water Treatment Process for Steam Plant

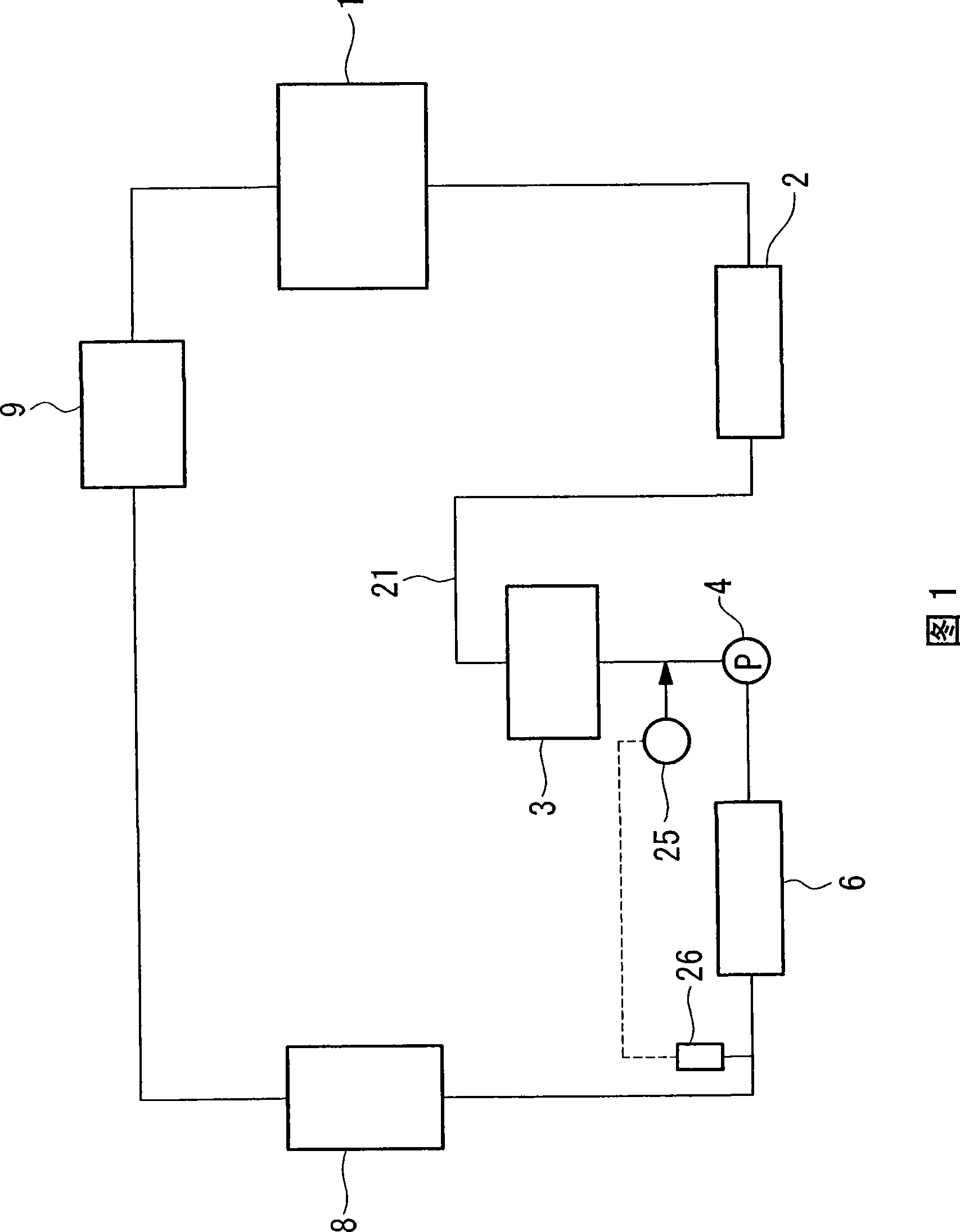

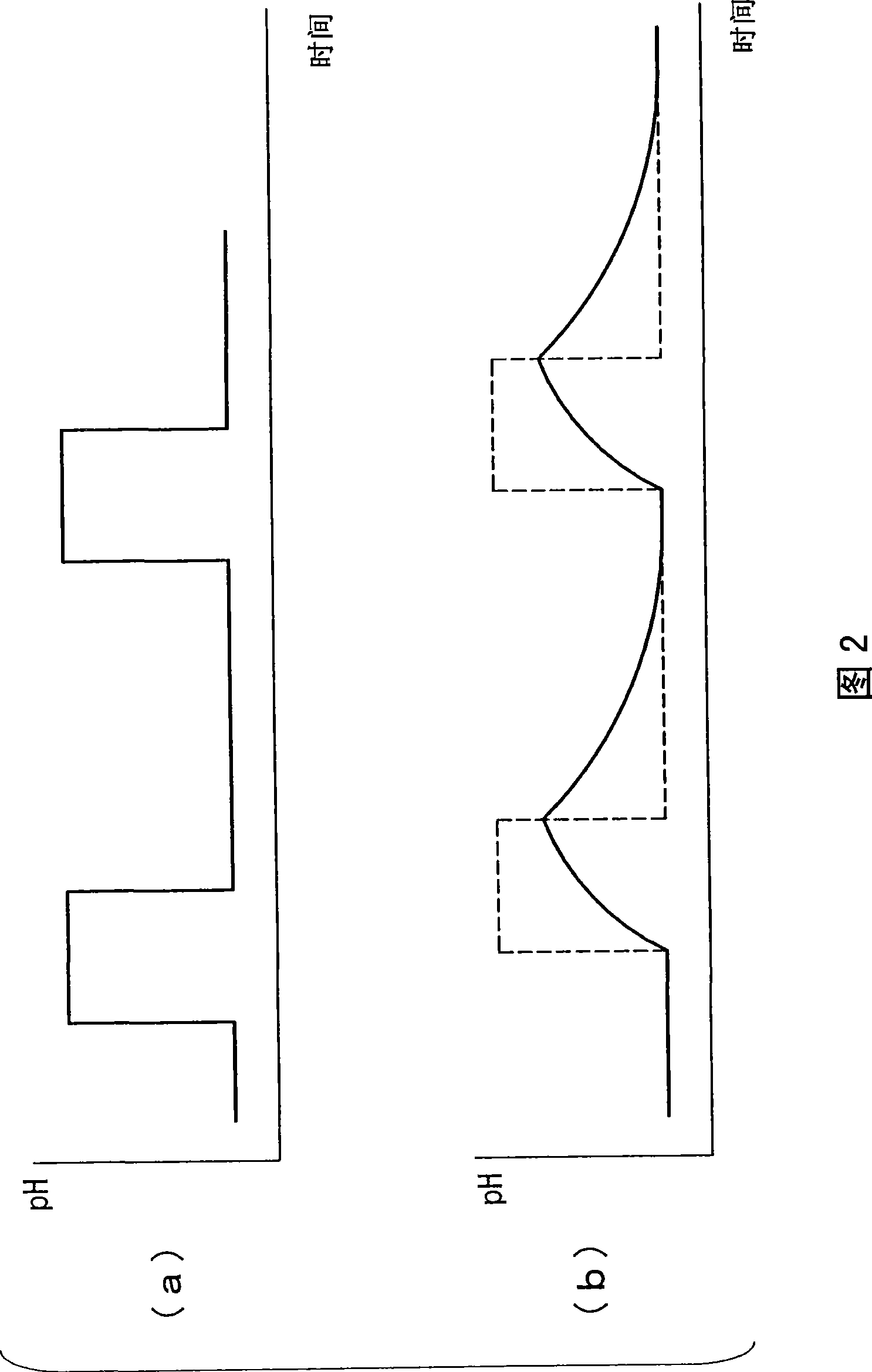

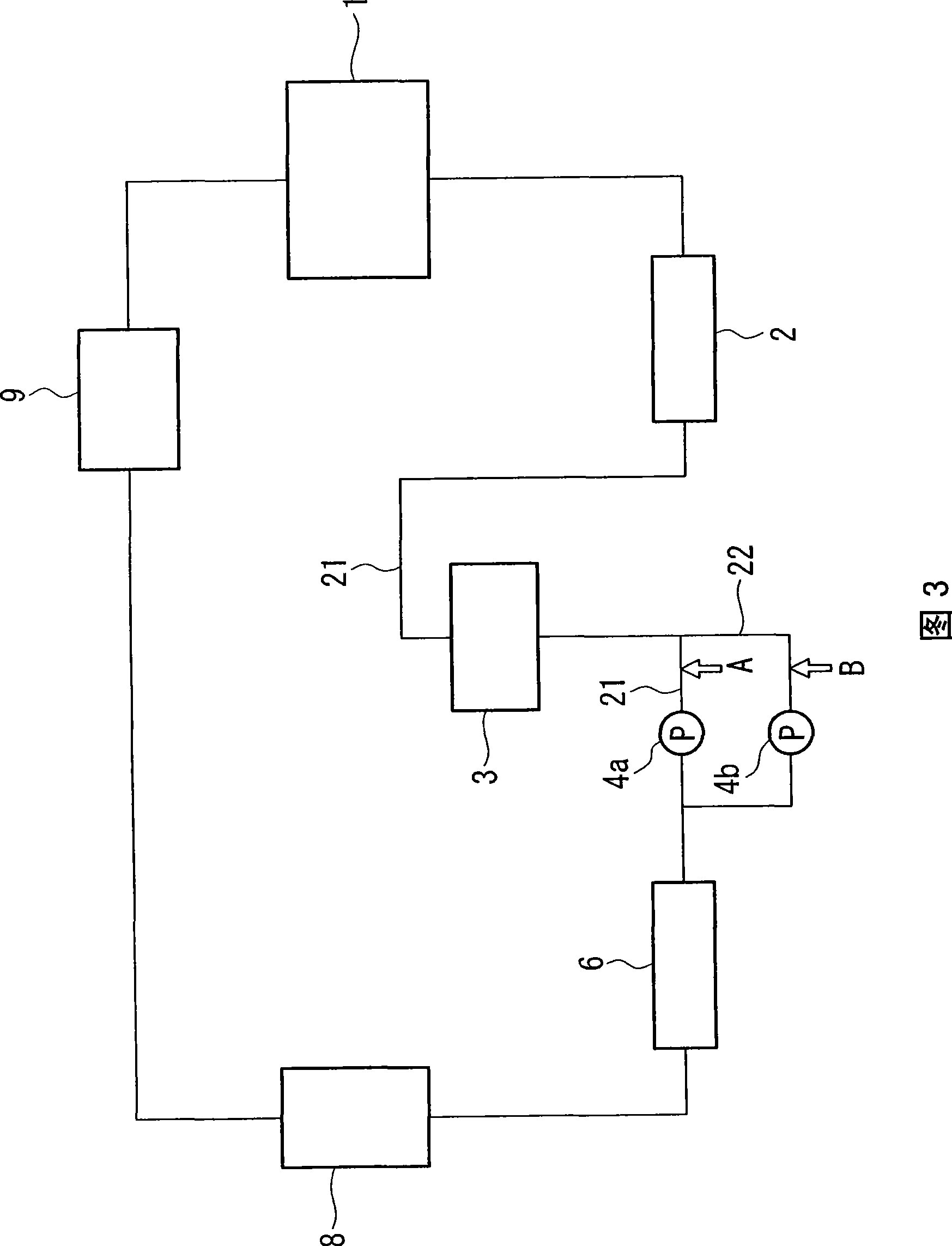

InactiveUS20100163399A1Scale adhesion can be preventedPreventing scale adhesionWater treatment parameter controlSpecific water treatment objectivesProcess engineeringWater treatment

In a steam plant, scale adhesion to the inside of a specific device is prevented, while reducing the amount of an agent such as hydrazine to the lowest possible level. A temporary change in the chemical environment or an approximately periodic variation in the chemical environment is brought about in a channel (21) inside the prescribed device, during operation of the steam plant.

Owner:MITSUBISHI HEAVY IND LTD

Articles and methods for enhanced boiling heat transfer

ActiveUS20140314947A1Improve heat transfer performanceEnhanced boiling heat transferBoiler water tubesVolume/mass flow measurementBoiling heat transferMaterials science

The present disclosure provides, among other things, scale-coated surfaces, vessels with controlled deposits of scale, and associated methods for enhanced boiling heat transfer. It is presently found that creating and / or maintaining a scale deposit at a controlled thickness actually enhances a type of boiling called nucleate boiling, which improves heat transfer.

Owner:MASSACHUSETTS INST OF TECH

Apparatus and method for measuring total dissolved solids in a steam boiler

ActiveUS6978741B2Reducing and avoiding any unnecessary blow downEffective controlFluid heatersFeed water supplyCombustorTotal dissolved solids

A method and apparatus for controlling the operation of a pressurized steam boiler heated by a burner. The method includes the steps of monitoring the level of total dissolved solids in water contained in the boiler, monitoring the level of water in the boiler, monitoring the pressure of steam in the boiler, monitoring the firing rate of the burner; controlling the blow down of the boiler having regard to the level of total dissolved solids in water contained in the boiler, and controlling the flow rate of water into the boiler and the firing rate of the burner. All input signals relating to the monitoring steps are passed to a common control unit and all output signals relating to the controlling steps are transmitted from the common control unit.

Owner:AUTOFLAME ENG

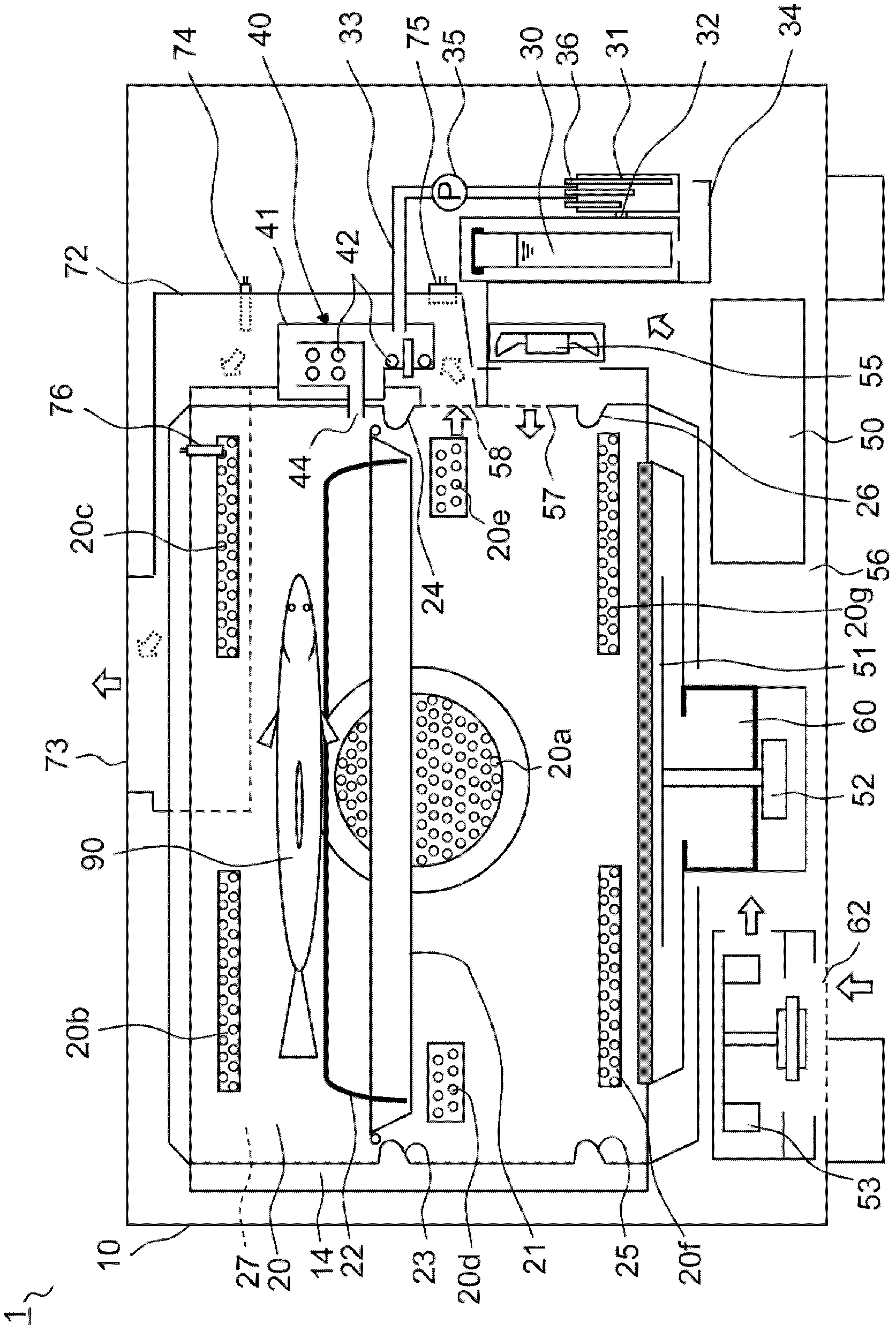

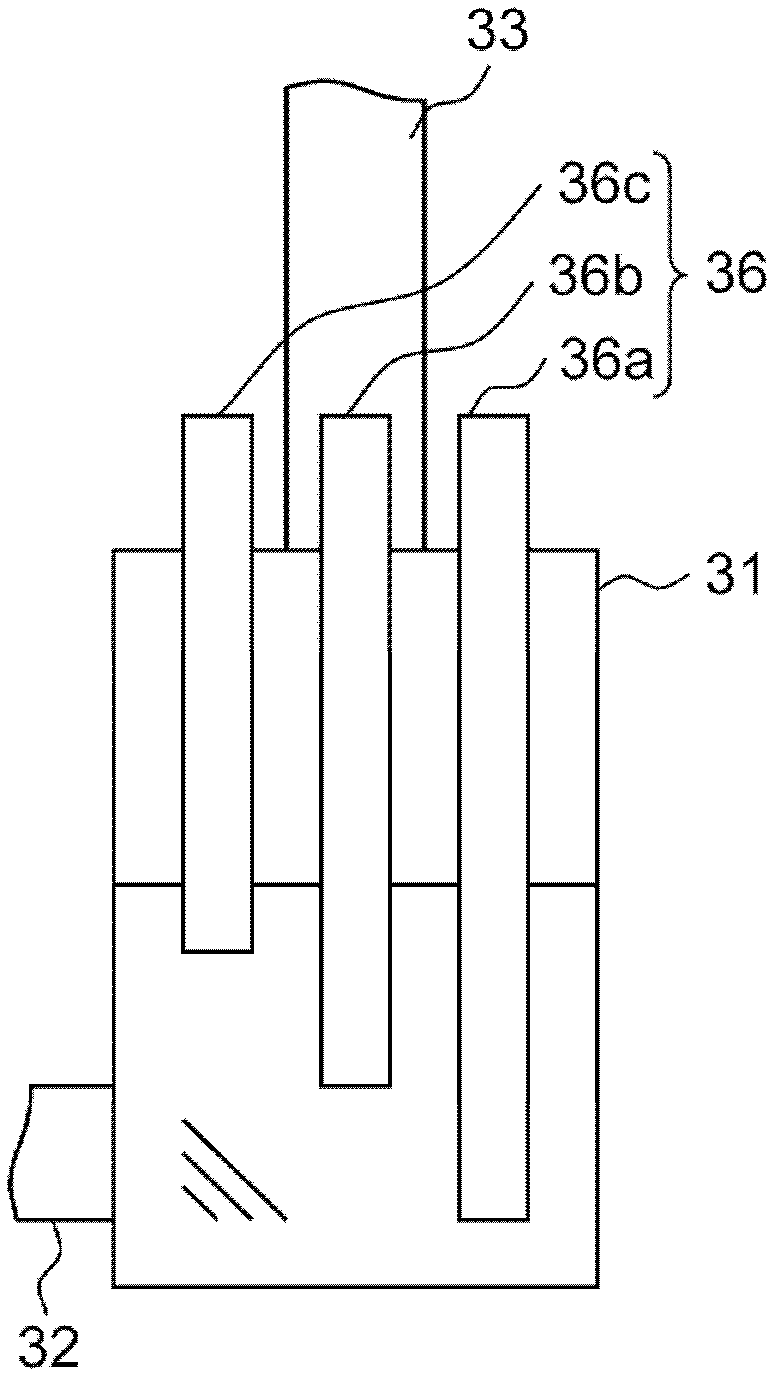

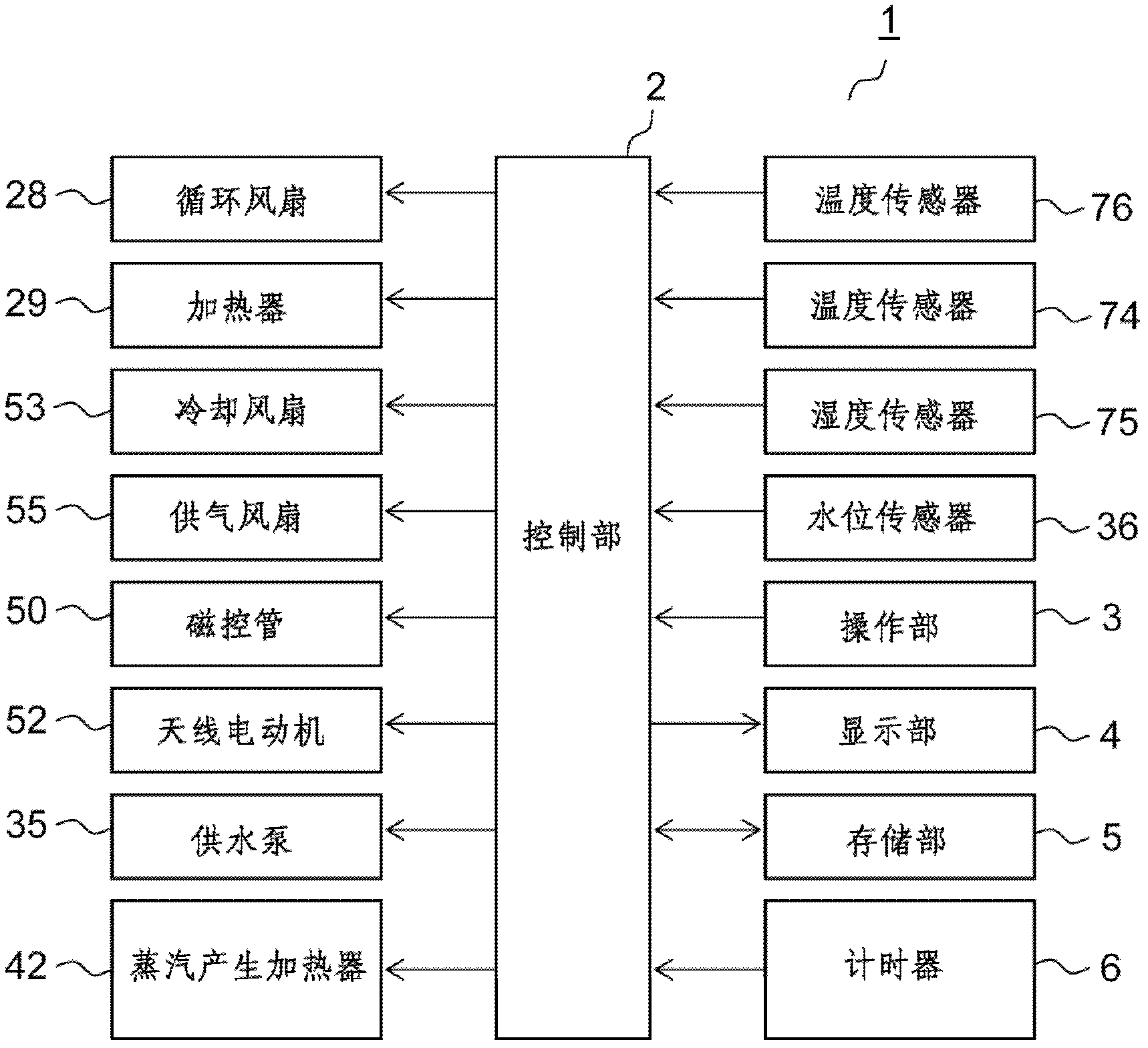

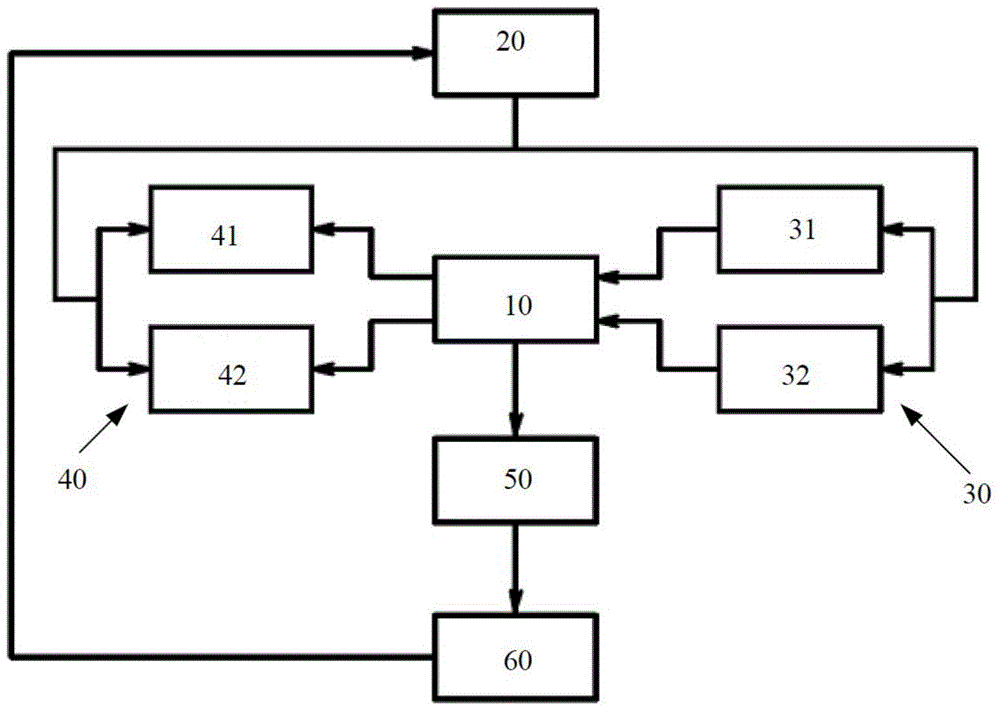

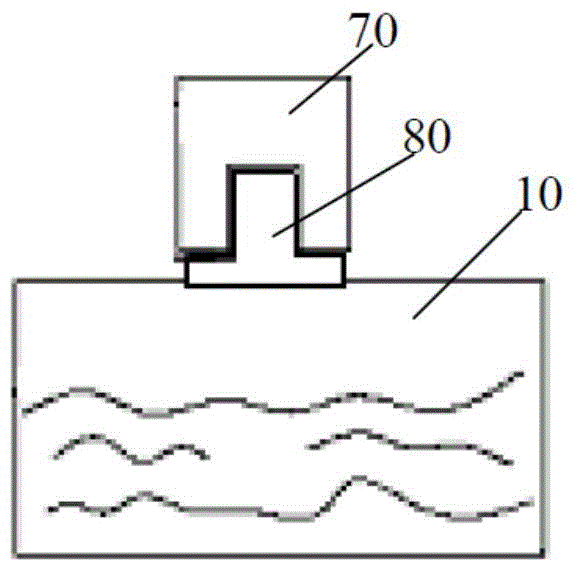

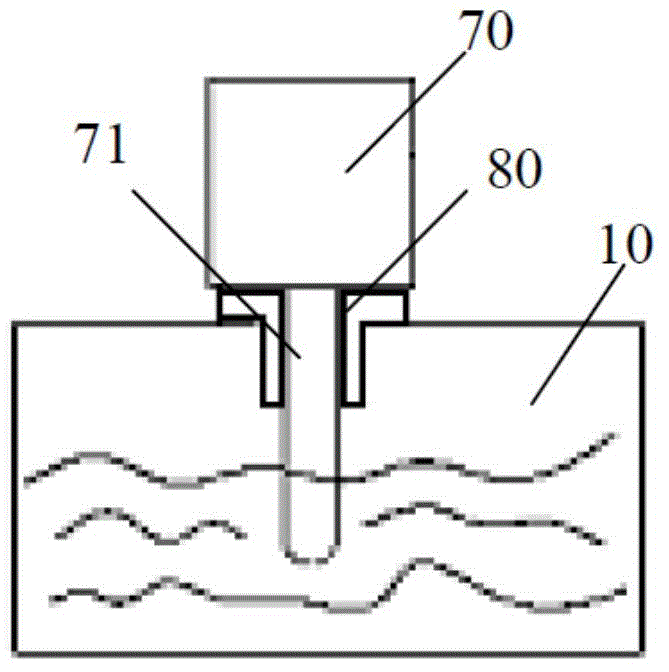

Vapor cooker

InactiveCN102460011AShorten the cleaning cycleImprove ease of useDomestic stoves or rangesSteam generation heating methodsWater reservoirCooker

A vapor cooker comprising: a heating chamber (20) for containing an object (90) to be cooked; a removable water tank (30); a vapor generating device (40) having a housing (41) to which water is supplied from the water tank (30) and supplying vapor to the heating chamber (20) by heating the water within the housing (41) by means of a vapor generating heater (42); a hardness detecting section (36) having electrodes (30a-30c) which are immersed in the water tank (30) or in a water reservoir section (31), to which the water tank (30) is connected, and detecting the hardness of the water within the water tank (30) from the resistance values between the electrodes (30a-30c); and a notification section (4) for notifying the timing of cleaning of the vapor generating device (40). When the hardness of the water within the water tank (30) detected by the hardness detection section (36) is high, the frequency of the cleaning of the vapor generating device (40) is set to be lower than that when the hardness of the water within the water tank (30) is low.

Owner:SHARP KK

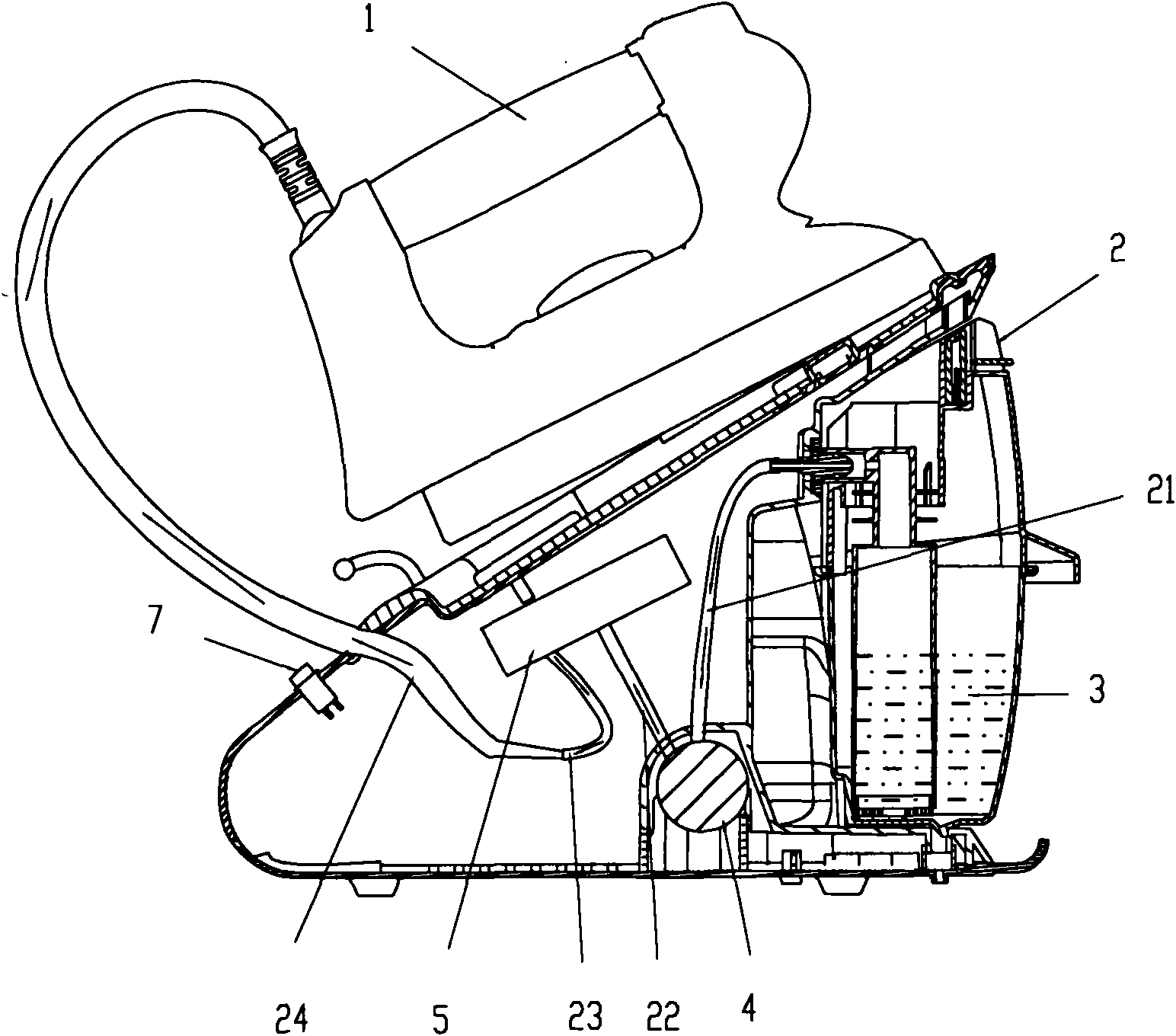

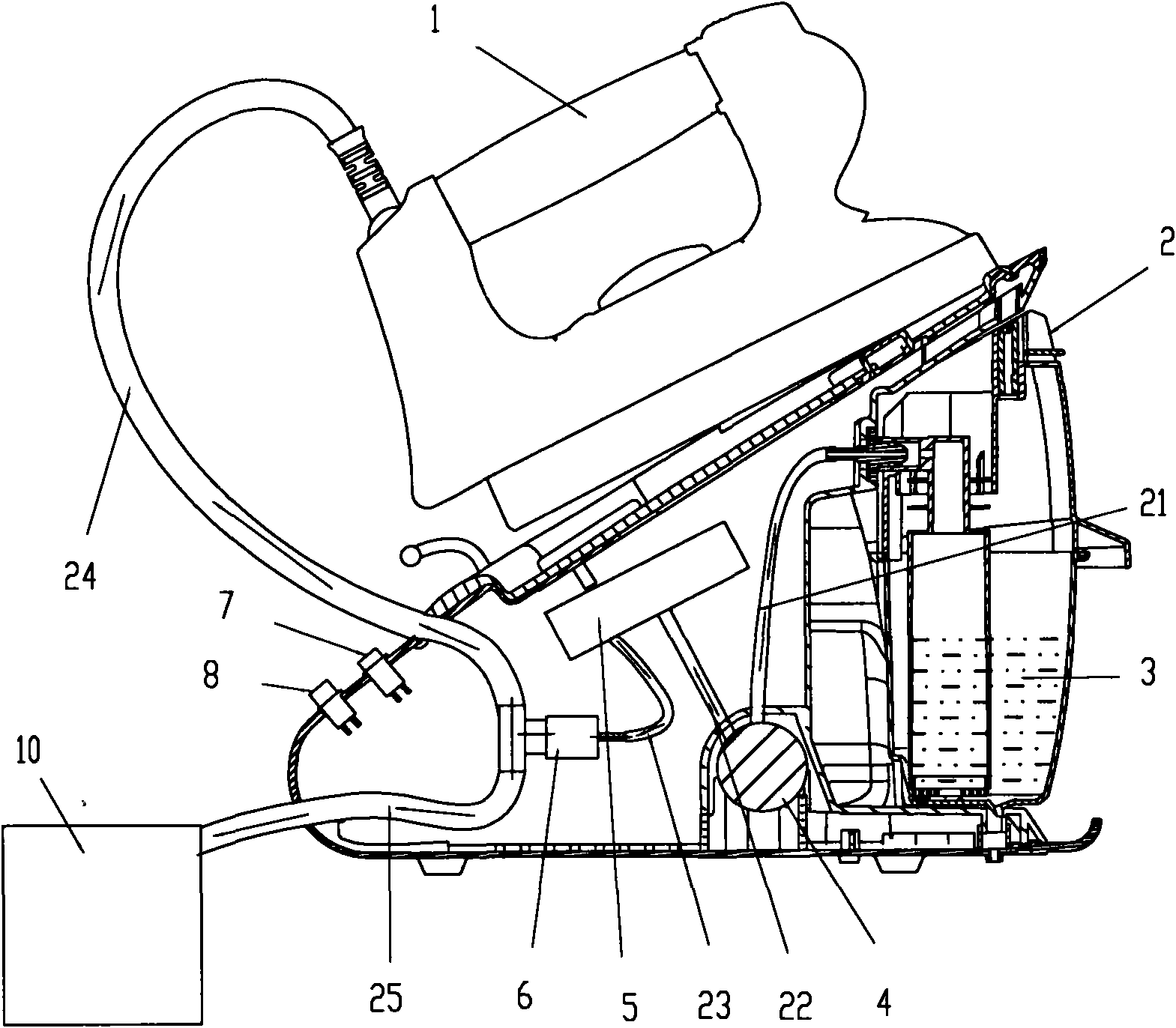

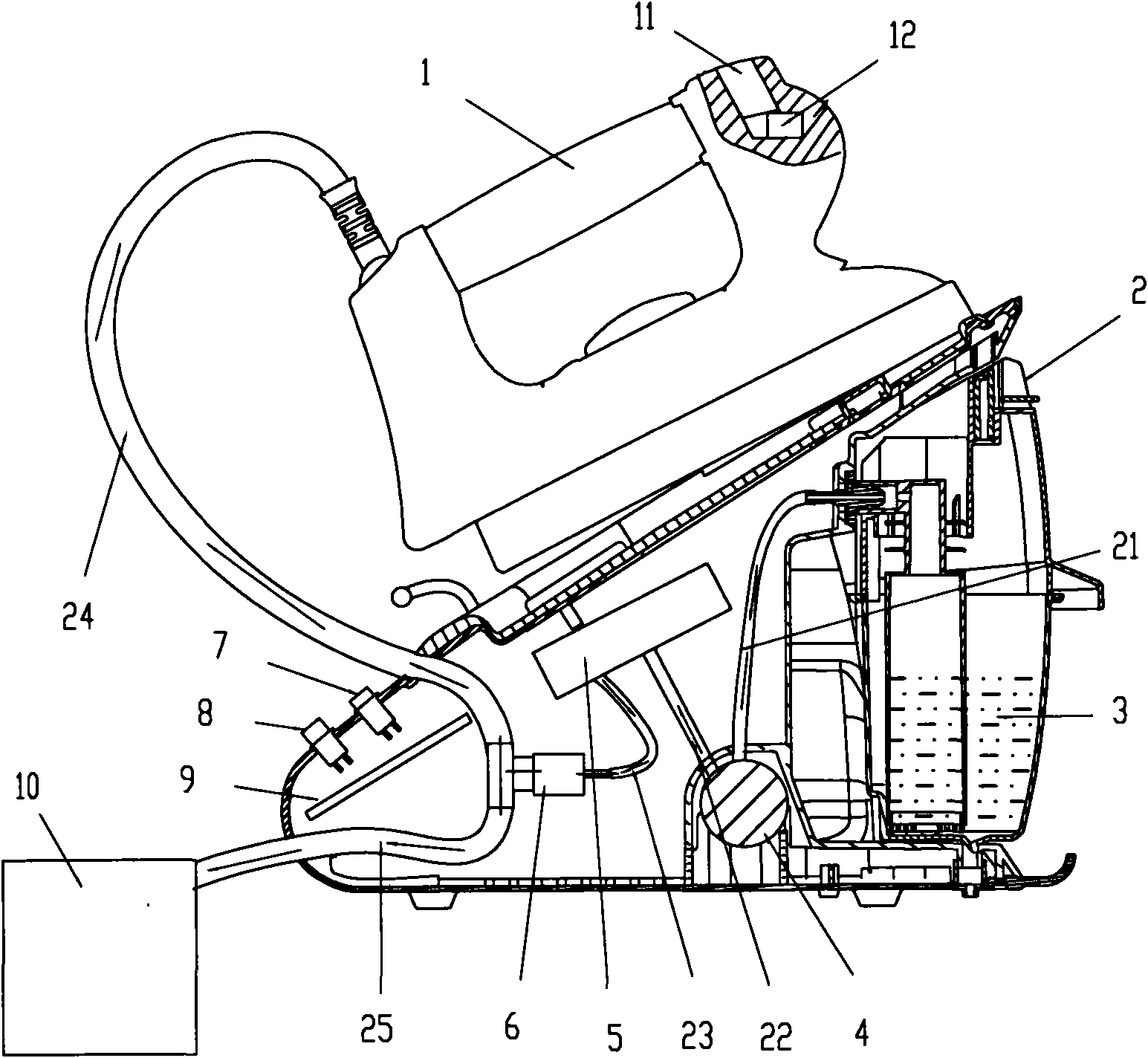

Descaling system for vapor generator in ironing and cleaning equipment

The invention provides a descaling system for a steam generator in ironing and cleaning equipment. The descaling system is connected with the steam generator. The descaling system includes: a control unit for controlling the operation of the descaling system; The detection device is used to detect the TDS value of each water used in the steam generator and the accumulated water volume entering the steam generator; the descaling device is used to shatter the dirt in the steam generator through ultrasonic vibration; the sewage unit is connected to the control Between the unit and the steam generator, the dirt in the steam generator is discharged through the control of the control unit. The descaling system for the steam generator in ironing and cleaning equipment of the present invention uses TDS detection technology and water volume records to calculate the accumulation of dirt and utilizes the principle of ultrasonic vibration, which can remove the dirt accumulated on the inner wall of the steam generator from the steam The inner wall of the steam generator is completely peeled off and shattered, and then the dirty sewage is discharged out of the steam generator by the pressure inside the steam generator.

Owner:CUORI ELECTRICAL APPLIANCES GRP

Steam station capable of removing calcium scale

InactiveCN101839468AExtended service lifeSimple homeworkSteam generation heating methodsBoiler cleaning apparatusSolenoid valveEngineering

The invention provides a steam station capable of removing calcium scale, relating to a device supplying steam to electric iron. The invention solves the problem that normal operation of boiler is influenced by calcium scale. The case of the steam station is internally provided with a water tank, a water pump, a boiler and a power switch; wherein the water outlet of the water tank is communicated with the water inlet of the water pump, the water outlet of the water pump is communicated with the water inlet of the boiler; the power switch controls the power supply for the electric hot tray of the boiler and the water pump; the case is also internally provided with a three-way solenoid valve and a calcium removing switch; the steam outlet of the boiler is communicated with the inlet of the three-way solenoid valve, a first outlet of the three-way solenoid valve is communicated with a steam pipe, a second outlet of the three-way solenoid valve is communicated with a drain pipe; and the calcium removing switch controls the three-way solenoid valve to be switched between a first state of the inlet communicated with the first outlet and a second state of the inlet communicated with the second outlet. The invention adopts the three-way solenoid valve to switch discharge of the boiler, thus realizing the function that wet steam is produced to supply an external electric iron, besides, the boiler can be utilized to heat calcium removing solution, so as to dissolve and remove calcium scale.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

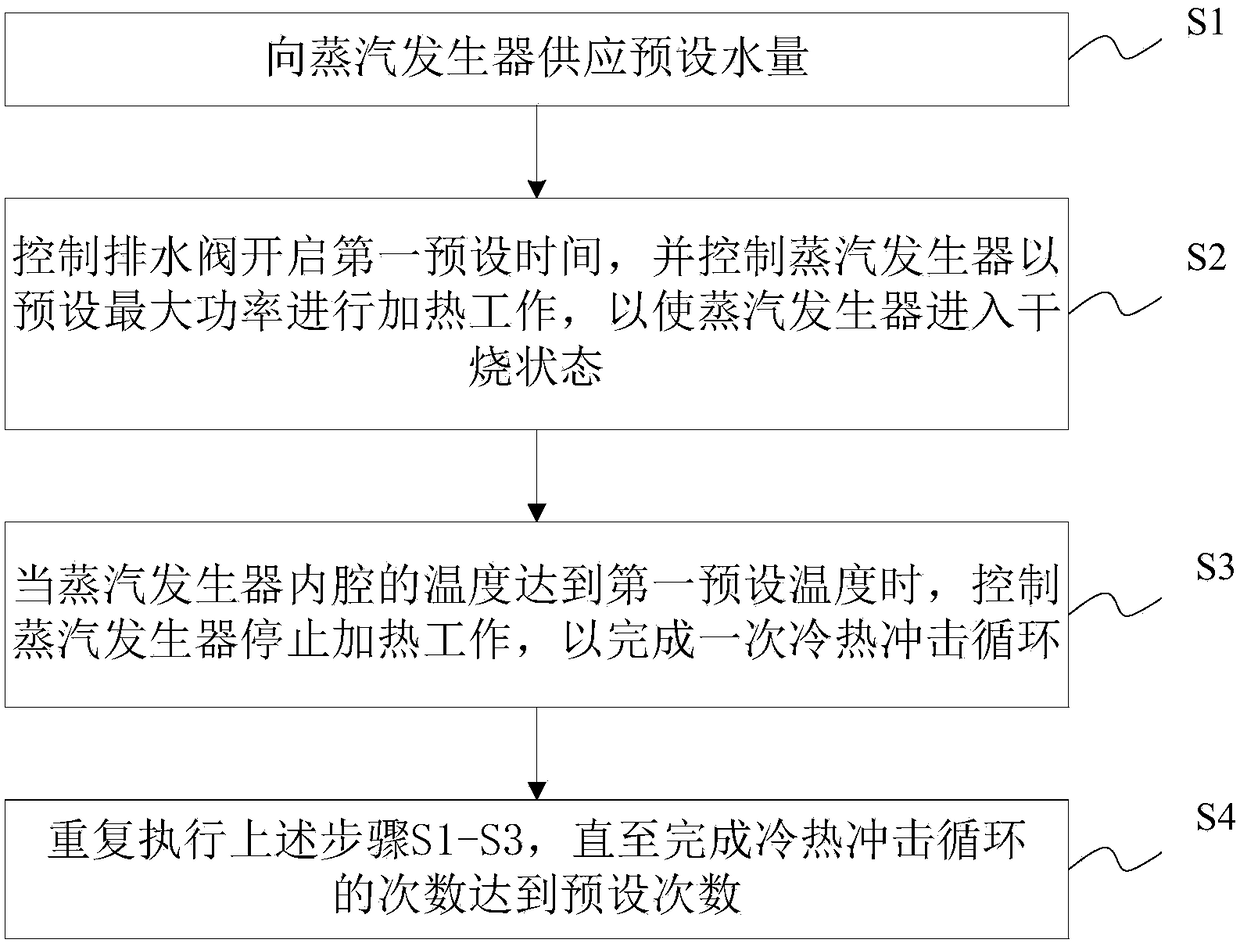

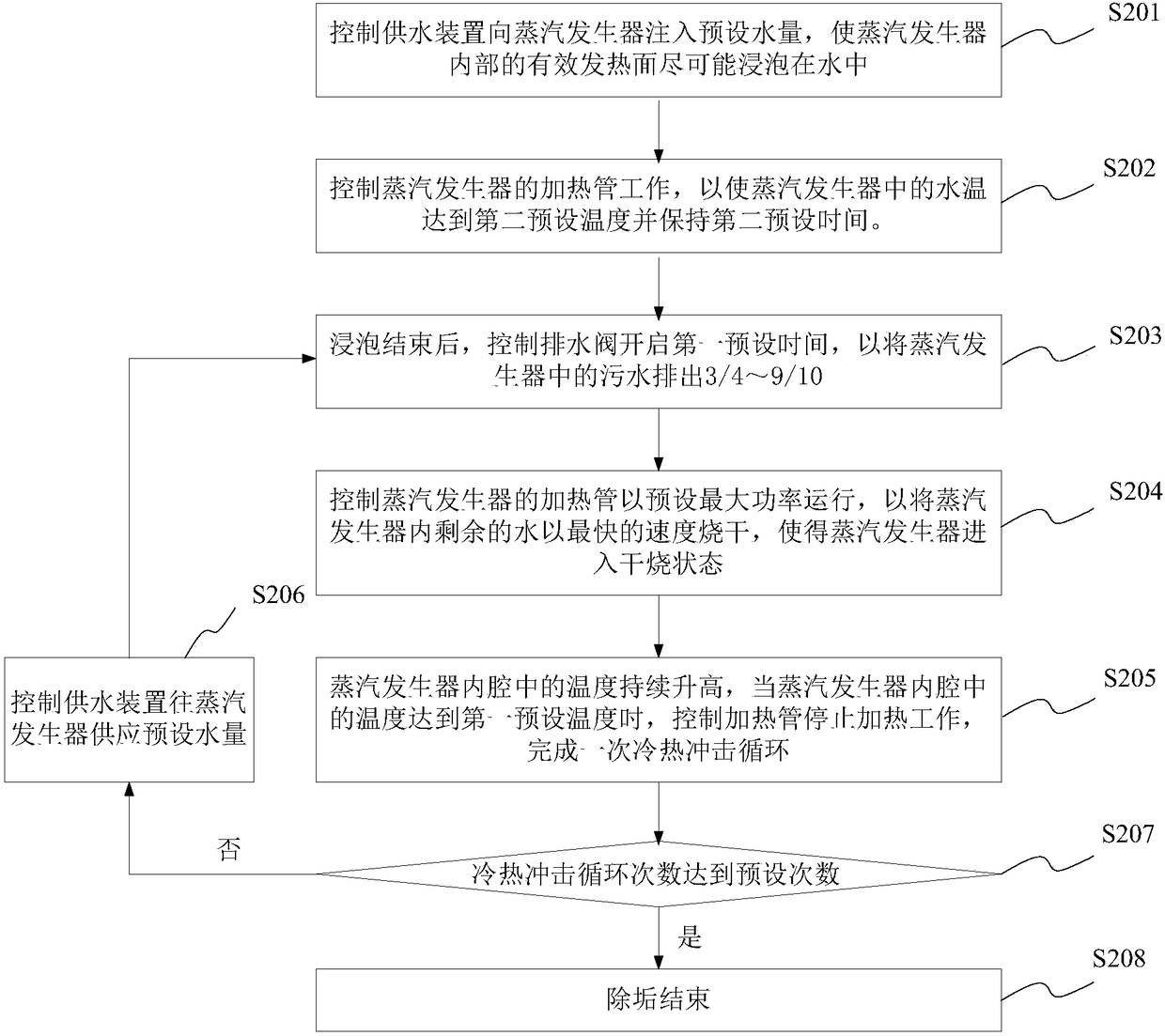

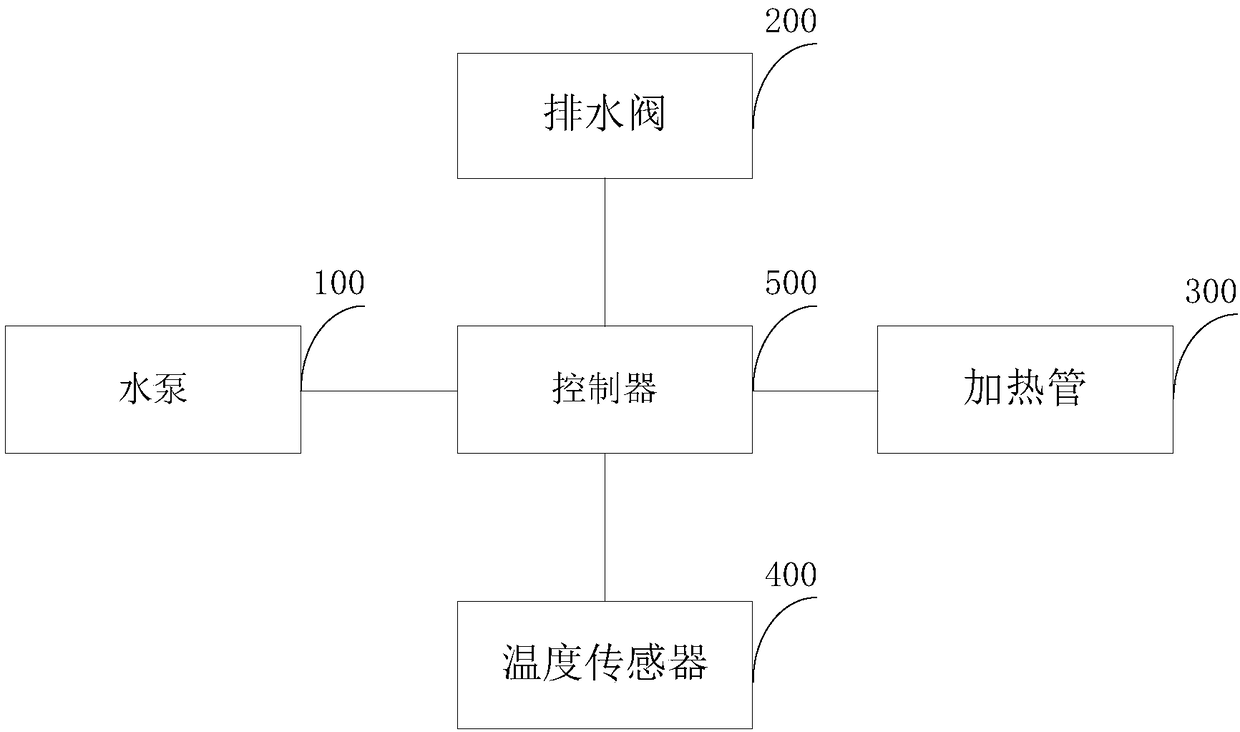

Cooking apparatus, steam generator and descaling control method and device thereof

ActiveCN108592002AShorten the timeImprove convenienceBoiler cleaning apparatusBoiler cleaning control devicesEngineeringElectrical equipment

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

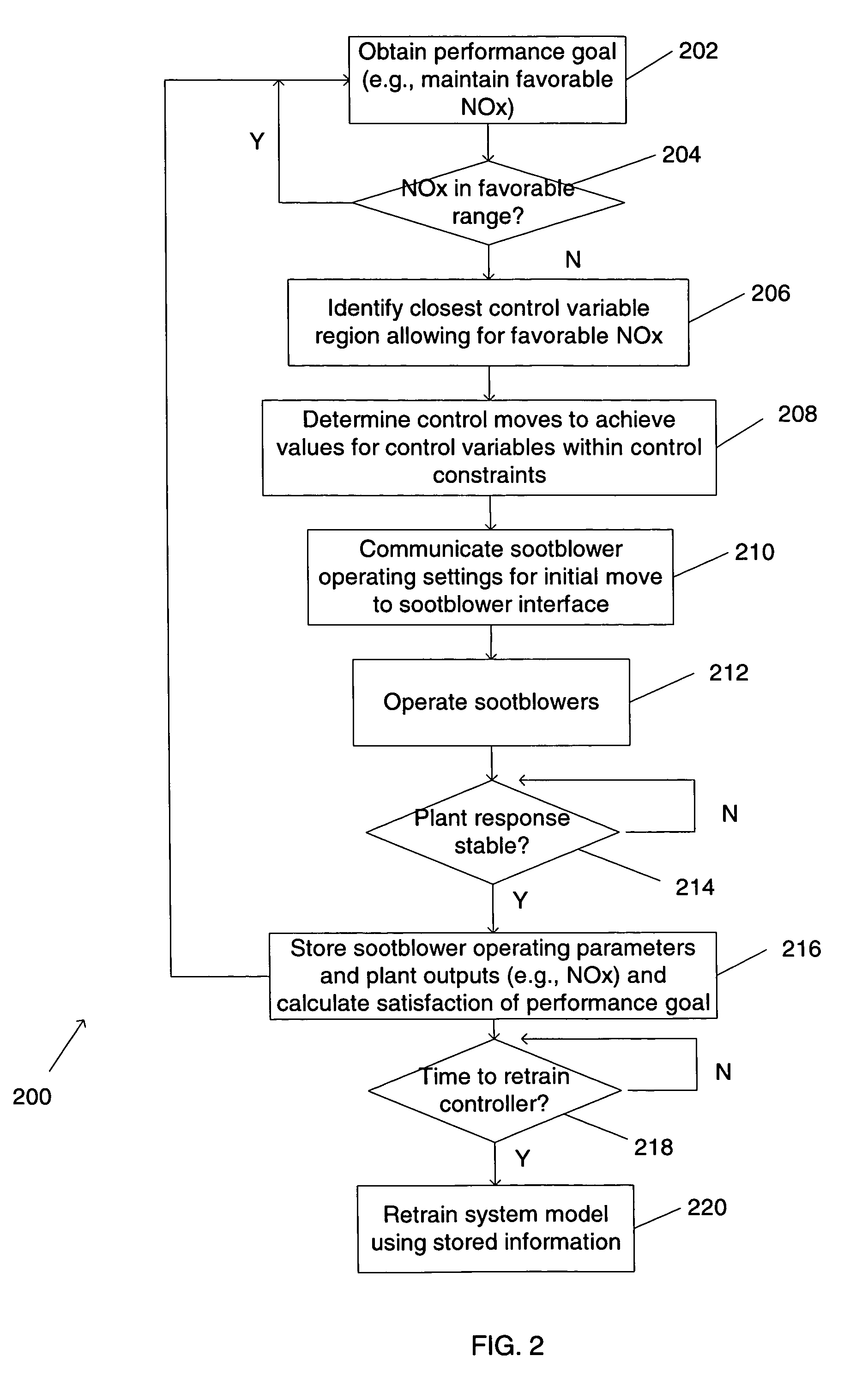

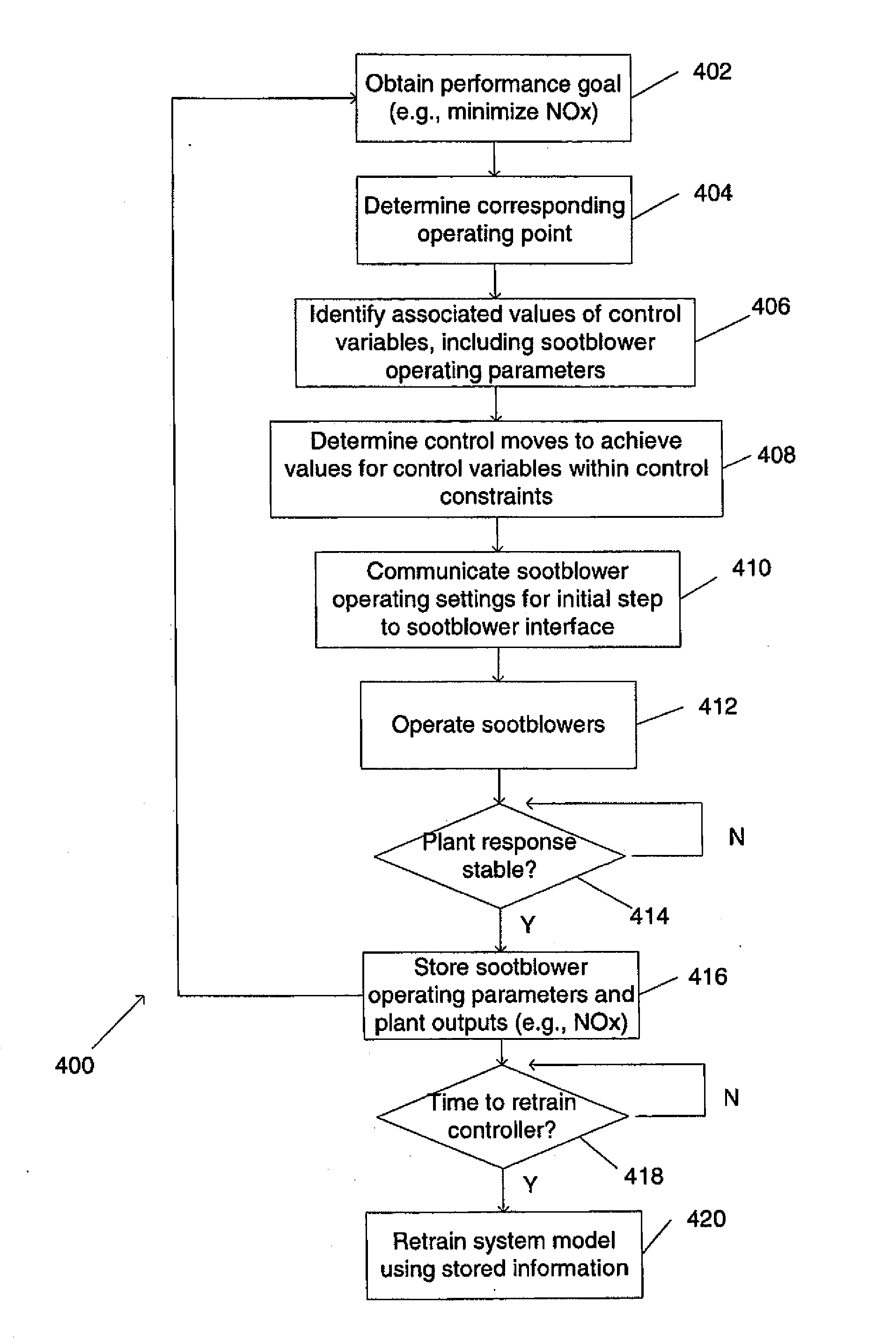

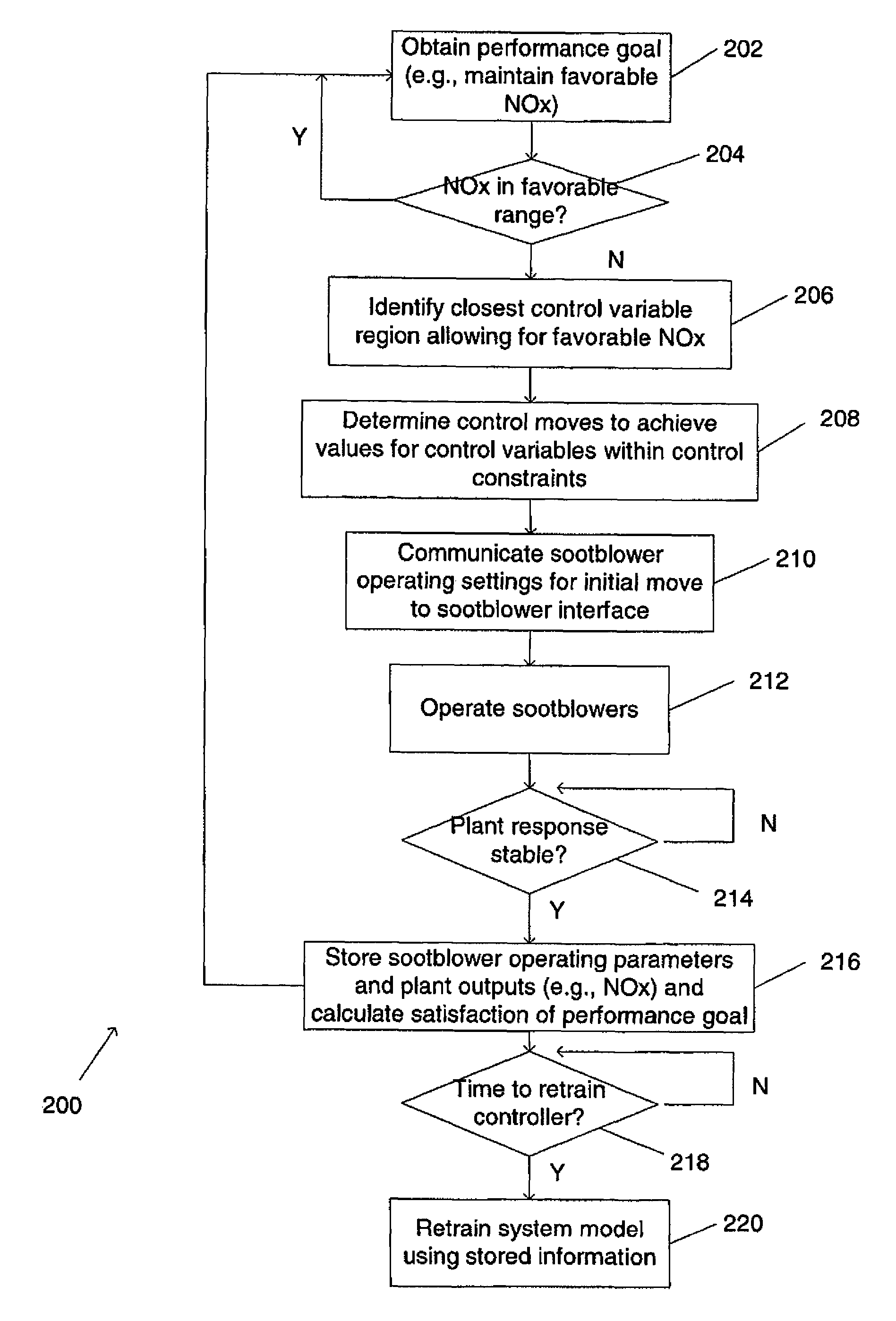

Method and system for sootblowing optimization

InactiveUS7458342B2Cleanliness levelCleanliness levels for different heat zones in the boiler can be determinedMechanical cleaningPressure cleaningSystem parametersProgram model

A controller determines and adjusts system parameters, including cleanliness levels or sootblower operating settings, that are useful for maintaining the cleanliness of a fossil fuel boiler at an efficient level. Some embodiments use a direct controller to determine cleanliness levels and / or sootblower operating settings. Some embodiments use an indirect controller, with a system model, to determine cleanliness levels and / or sootblower settings. The controller may use a model that is, for example, a neural network, or a mass energy balance, or a genetically programmed model. The controller uses input about the actual performance or state of the boiler for adaptation. The controller may operate in conjunction with a sootblower optimization system that controls the actual settings of the sootblowers. The controller may coordinate cleanliness settings for multiple sootblowers and / or across a plurality of heat zones in the boiler.

Owner:GENERAL ELECTRIC CO

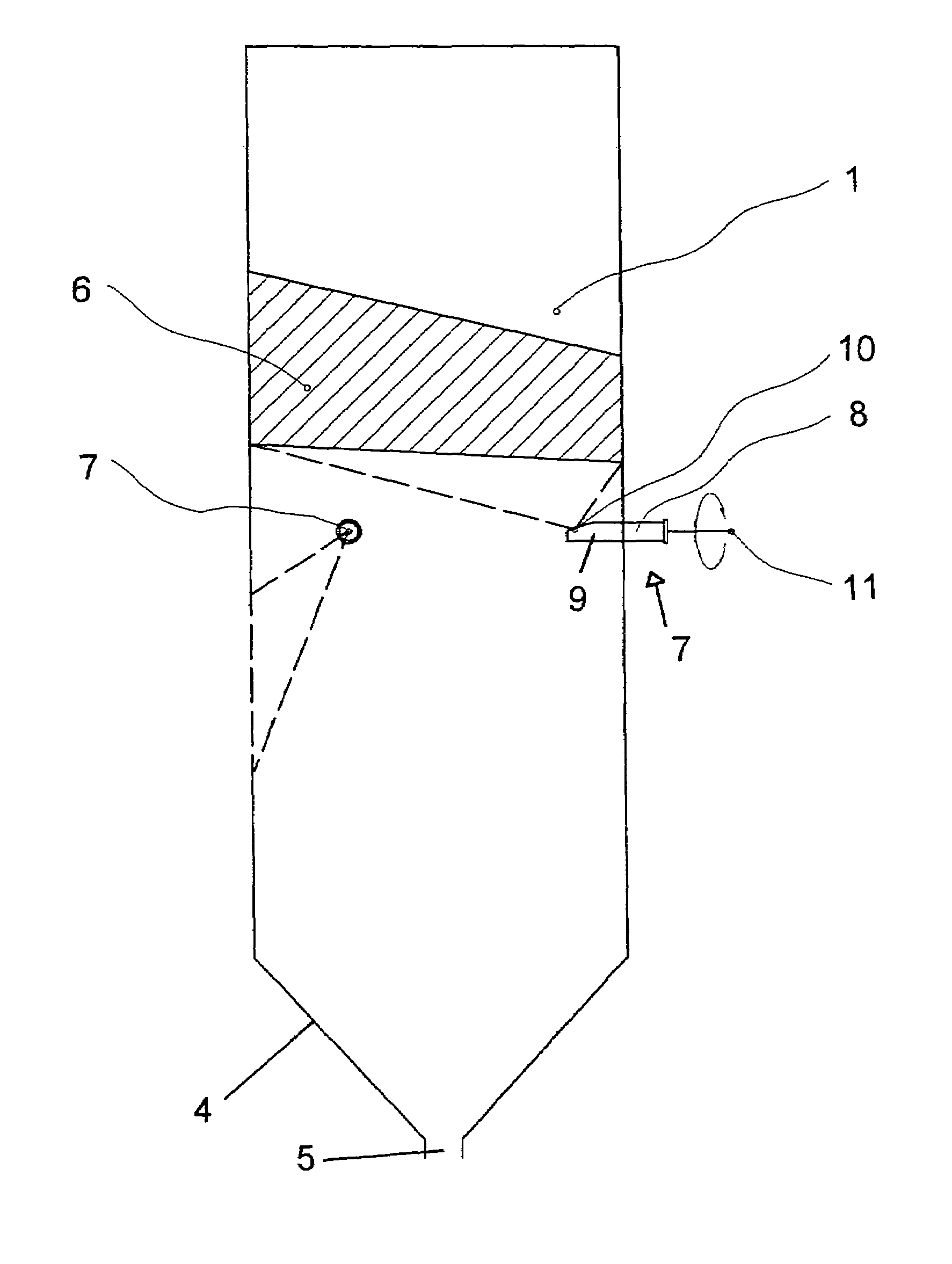

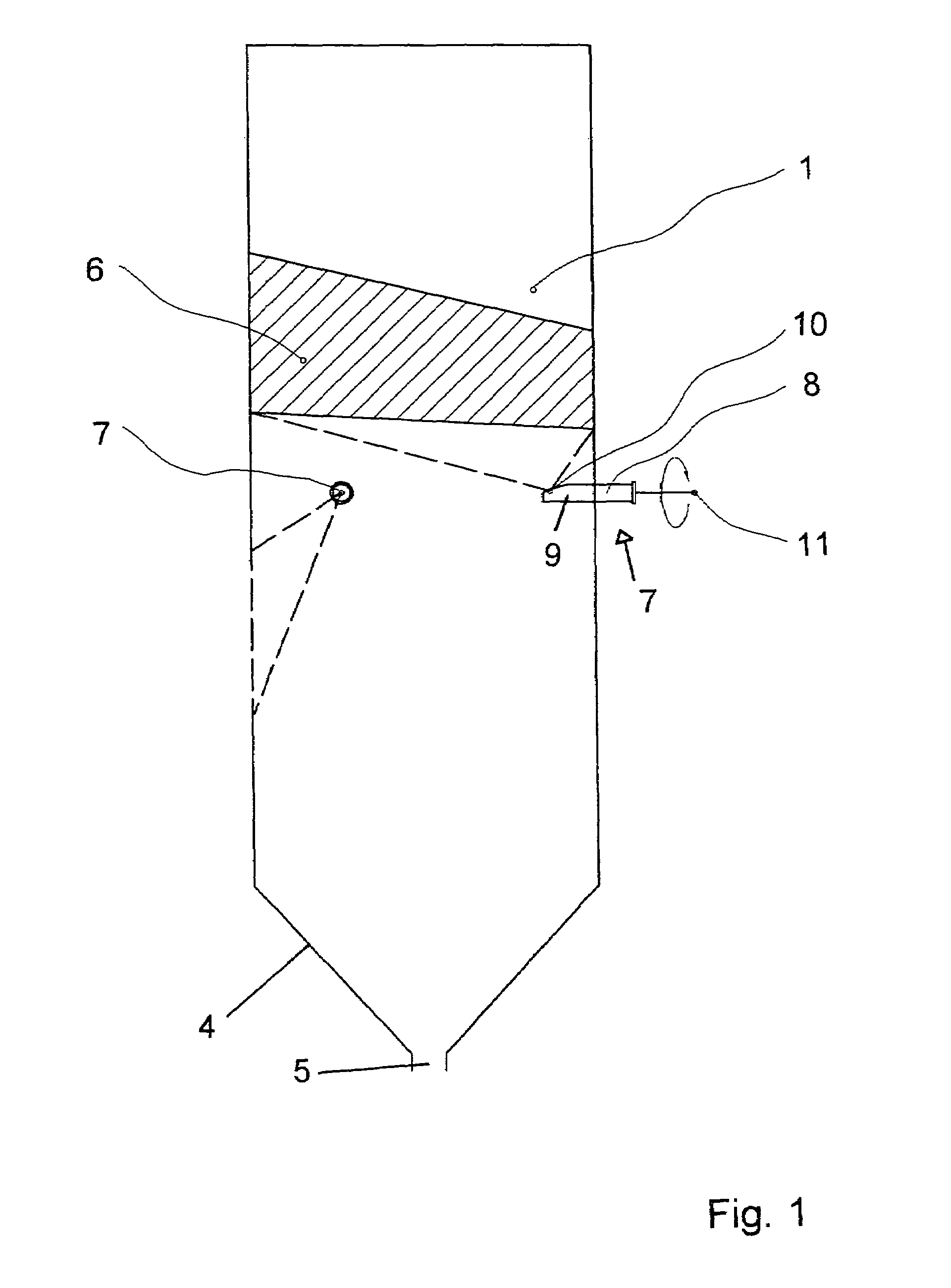

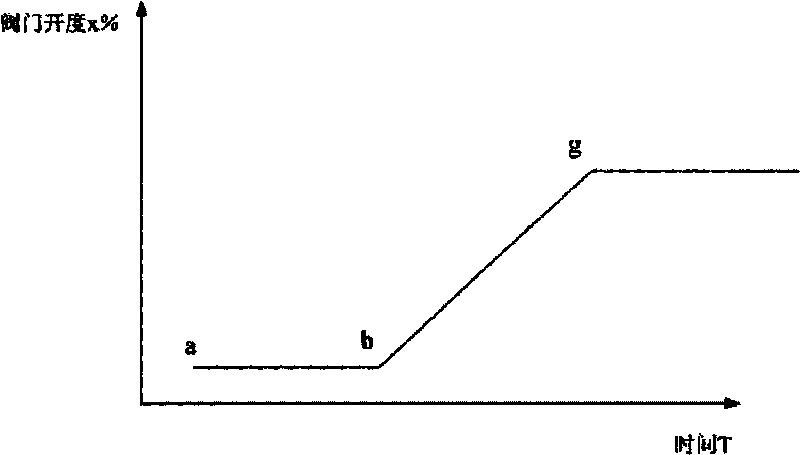

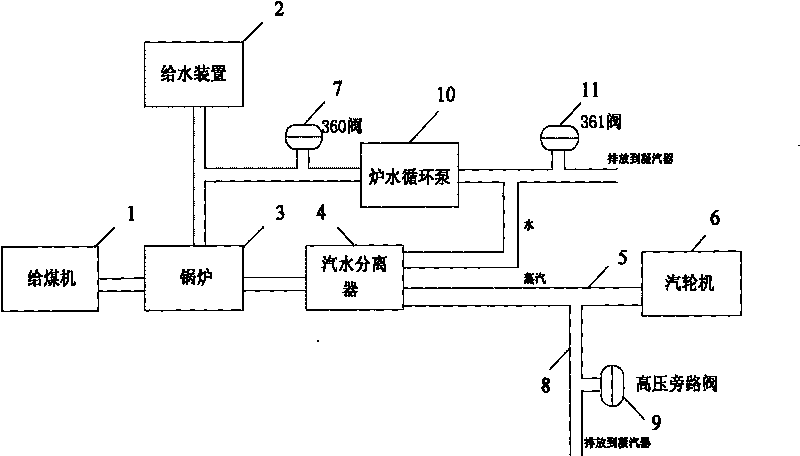

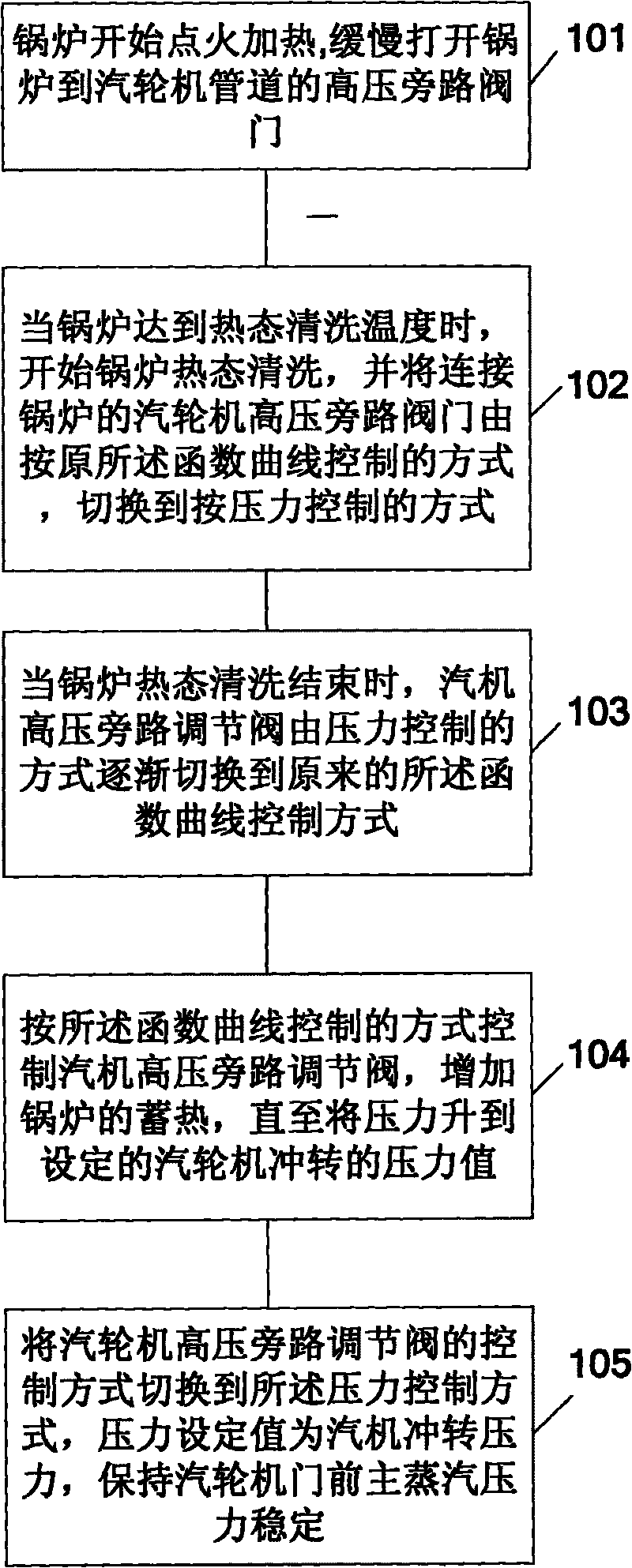

Automatic control method for realizing boiler thermal-state cleaning by supercritical machine set

ActiveCN101696793ASolve the problem of inlet temperature stabilityRealize full controlBoiler cleaning control devicesSteam pressureAutomatic control

The invention discloses an automatic control method for realizing boiler thermal-state cleaning by a supercritical machine set, which comprises the following step: performing matching control on a coal feeder, a recirculation flow regulating valve of a boiler water circulating pump, a high-voltage bypass regulating valve of a steam turbine and a feedwater device respectively according to the changes of correlation parameters of a system, such as fuel quantity, boiler water inlet flow, the recirculation flow of the boiler water circulating pump, steam pressure and temperature of the system and the like, in thermal-state pre-cleaning, in-cleaning and post-cleaning three stages of a boiler of a boiler steam generator set system to realize the stable inlet temperature of a vapour-water separator during cleaning of the boiler of the supercritical machine set in the thermal state. The method can simply and conveniently realize the stable inlet temperature of a vapour-water separator during cleaning of the boiler of the supercritical machine set in the thermal state, and ensure that the boiler thermal-state cleaning process is smooth.

Owner:广州粤能电力科技开发有限公司

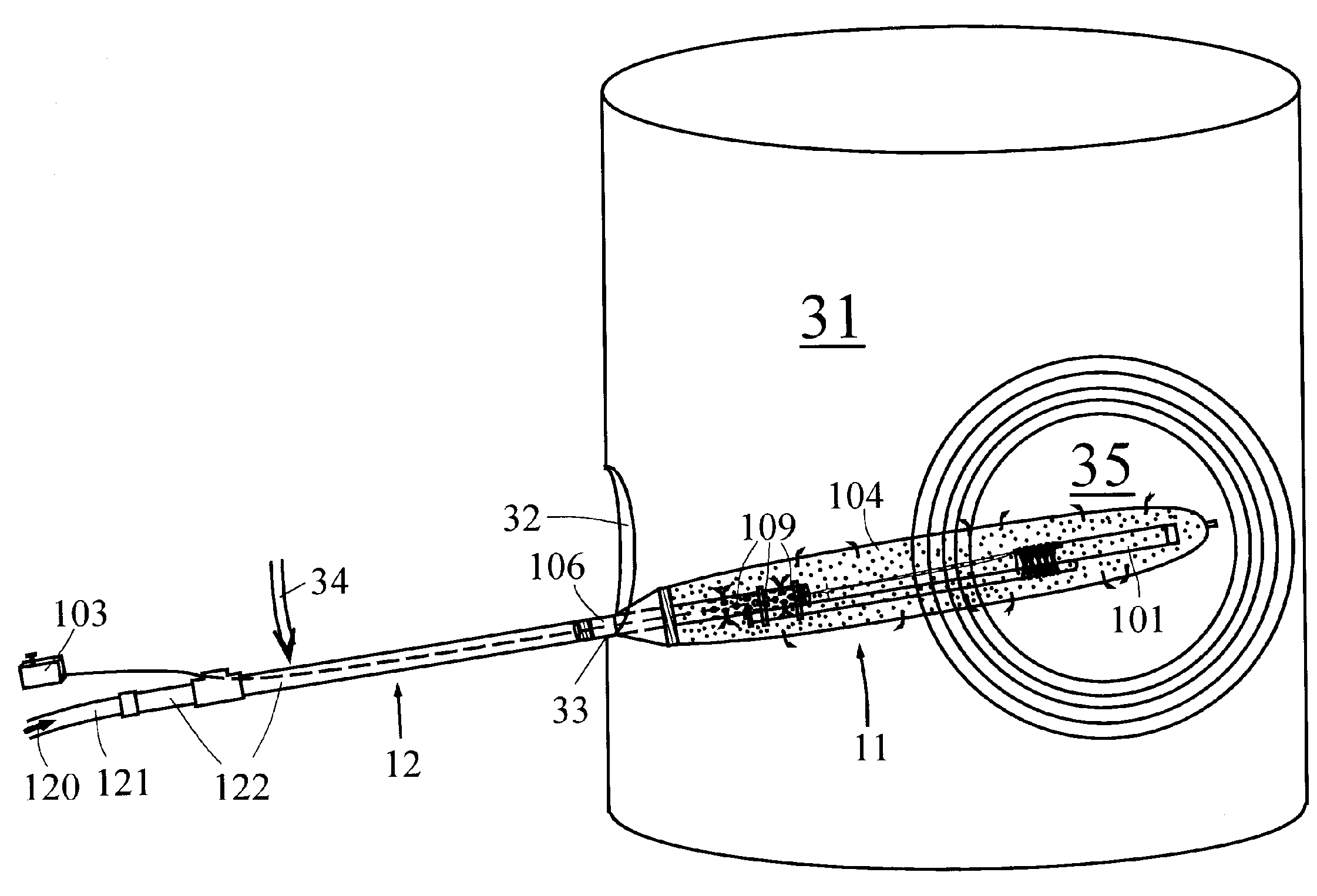

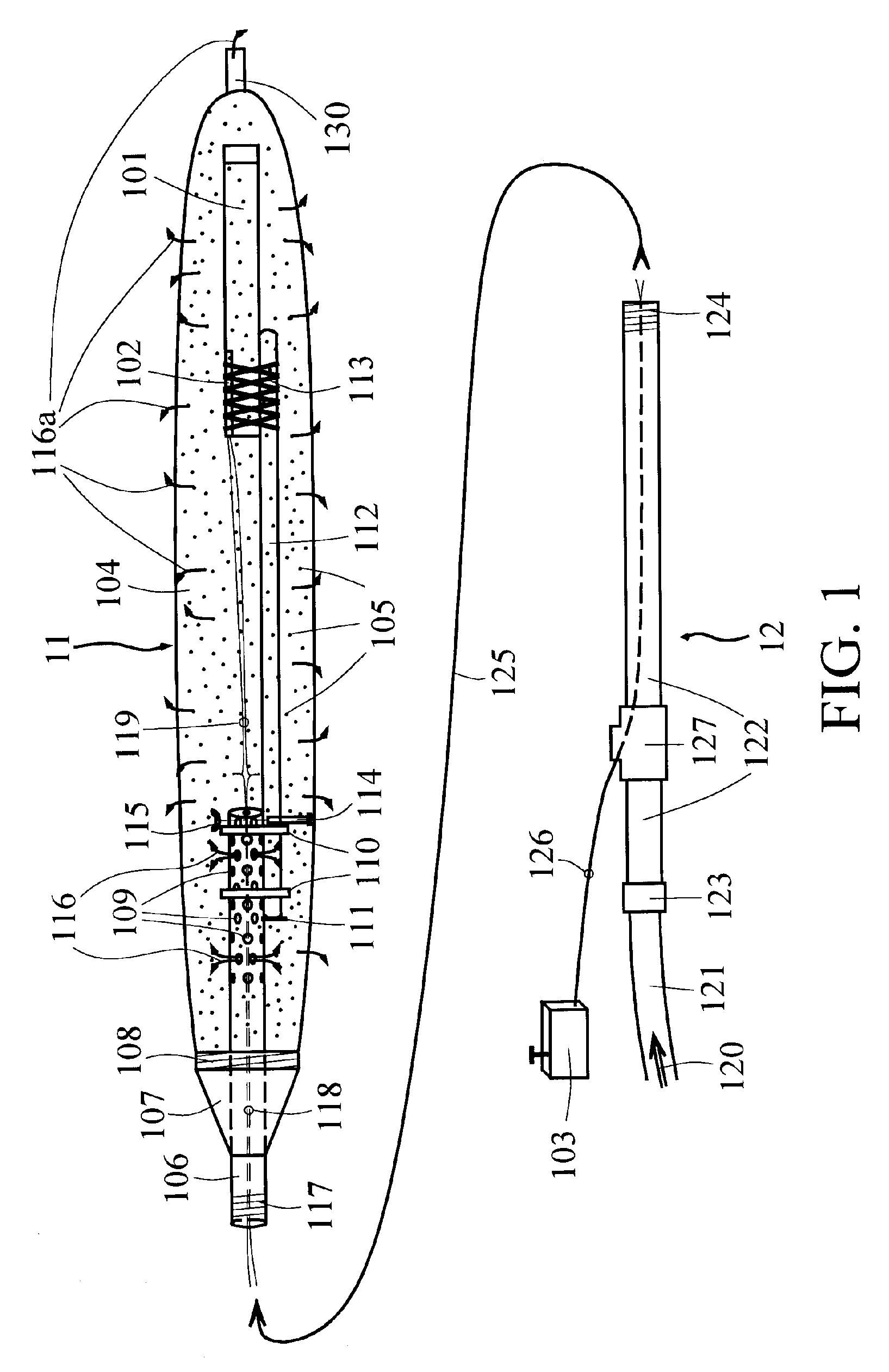

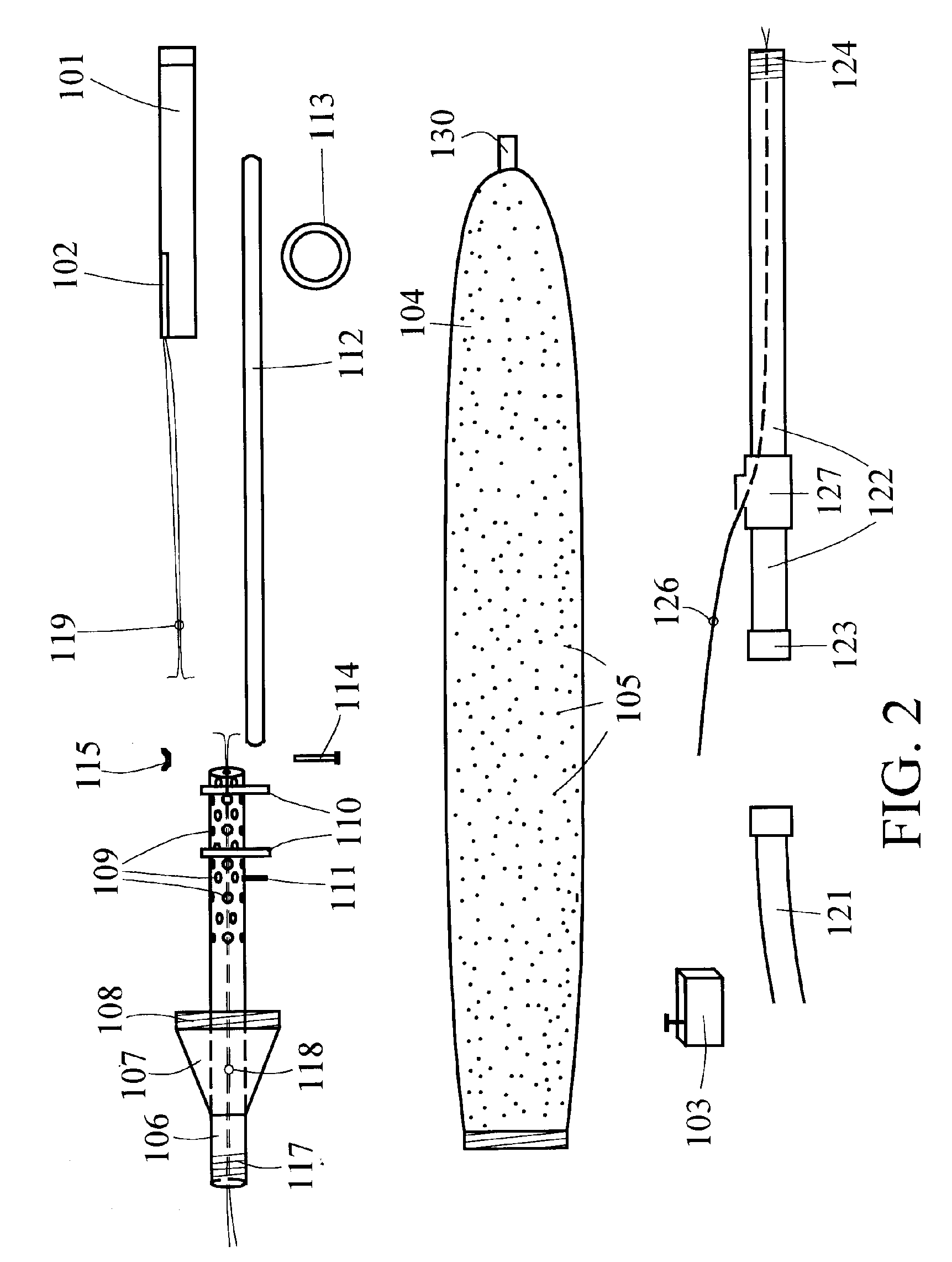

Device, system and method for on-line explosive deslagging

A device, system and method permitting on-line explosives-based cleaning and deslagging of a fuel burning facility (31) such as a boiler, furnace, incinerator, or scrubber. A coolant, such as ordinary water, is delivered to the explosives (101) to prevent them from detonating due to the heat of the on-line facility. Thus, controlled, appropriately-timed detonation can be initiated as desired, and boiler scale and slag is removed without the need to shut down or cool down the facility.

Owner:NORTHAMERICAN IND SERVICES INC NAIS

Method for sootblowing optimization

InactiveUS20090062961A1Cleanliness levelCleanliness levels for different heat zones in the boiler can be determinedExhaust apparatusElement comparisonSystem parametersFossil fuel

A controller determines and adjusts system parameters, including cleanliness levels or sootblower operating settings, that are useful for maintaining the cleanliness of a fossil fuel boiler at an efficient level, Some embodiments use a direct controller to determine cleanliness levels and / or sootblower operating settings. Some embodiments use an indirect controller, with a system model, to determine cleanliness levels and / or sootblower settings. The controller may use a model that is, for example, a neural network, or a mass energy balance, or a genetically programmed model. The controller uses input about the actual performance or state of the boiler for adaptation. The controller may operate in conjunction with a sootblower optimization system that controls the actual settings of the sootblowers. The controller may coordinate cleanliness settings for multiple sootblowers and / or across a plurality of heat zones in the boiler.

Owner:GE DIGITAL HLDG LLC

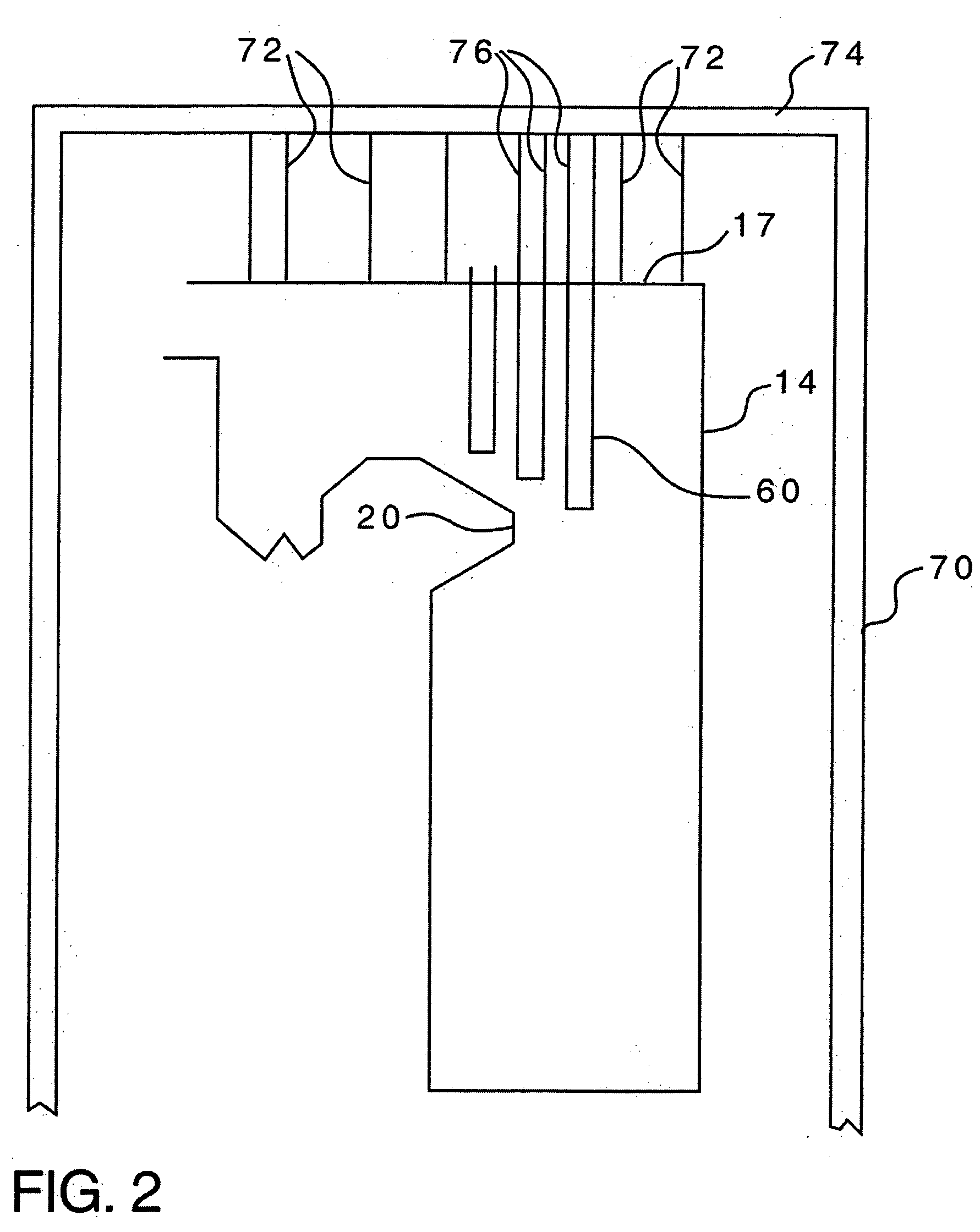

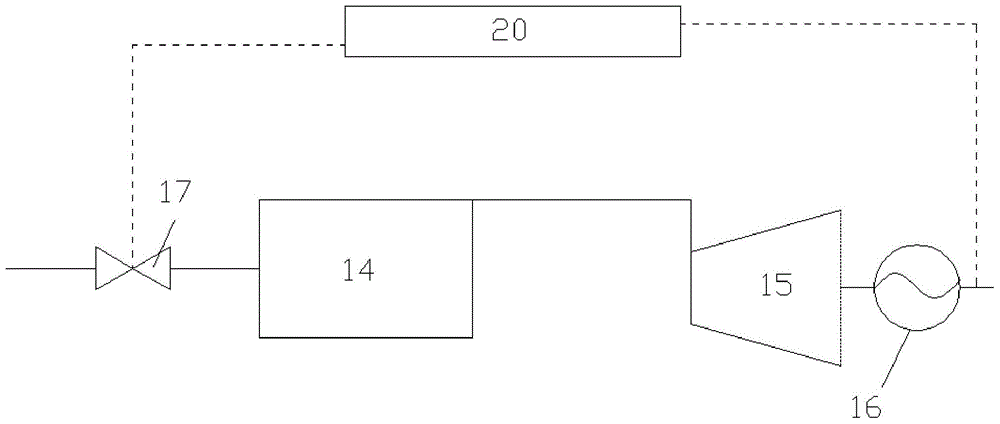

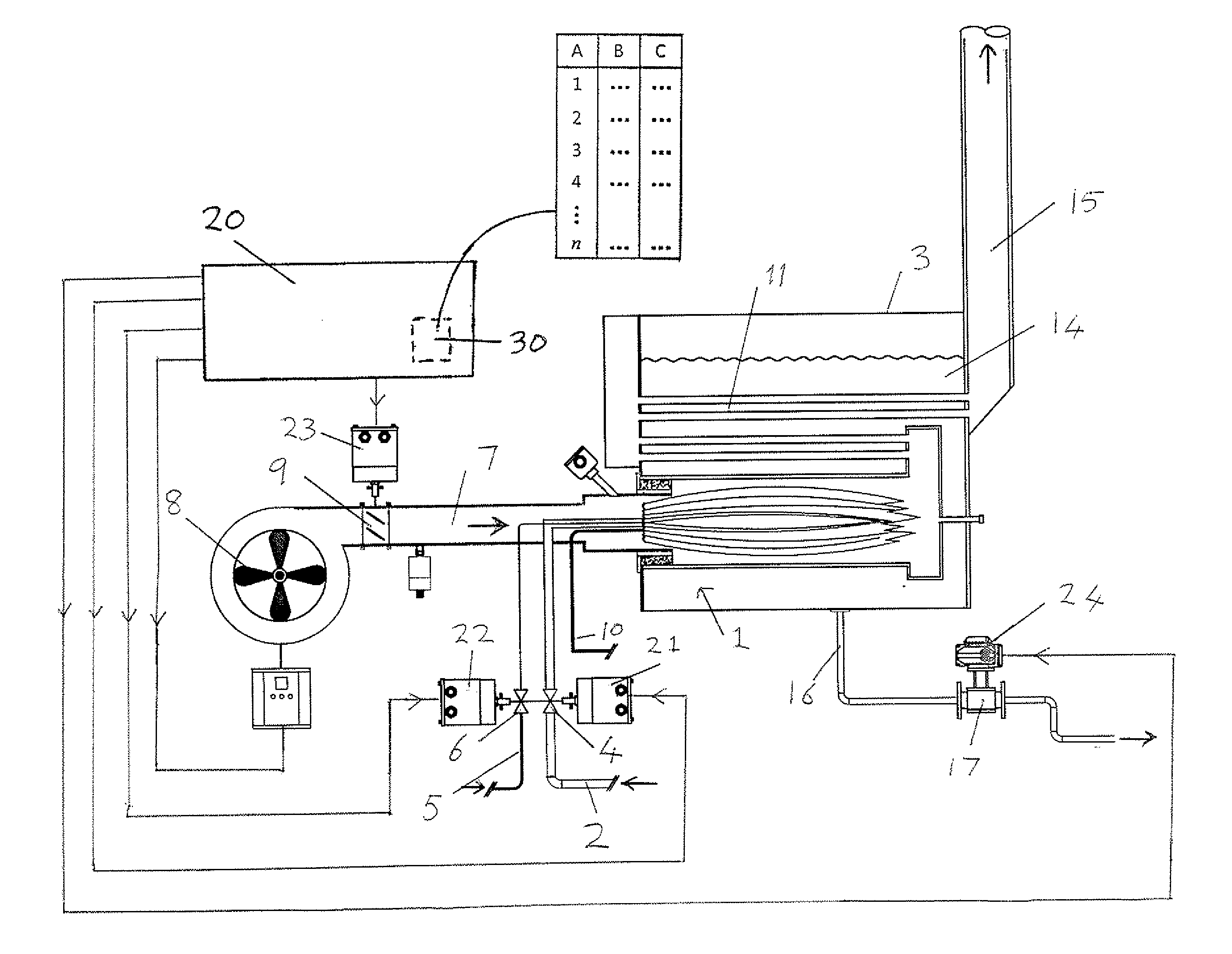

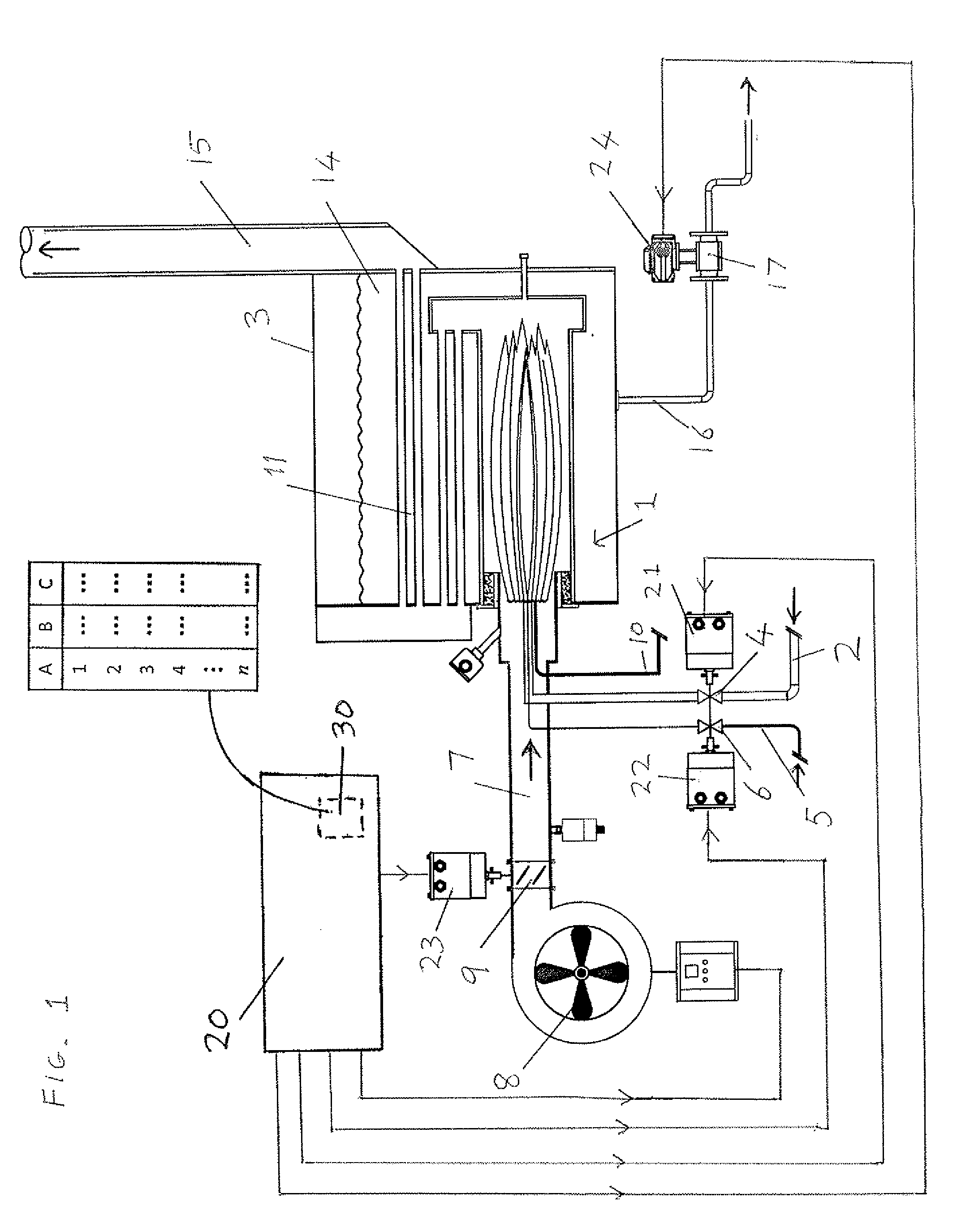

Control of blowdown in steam boilers

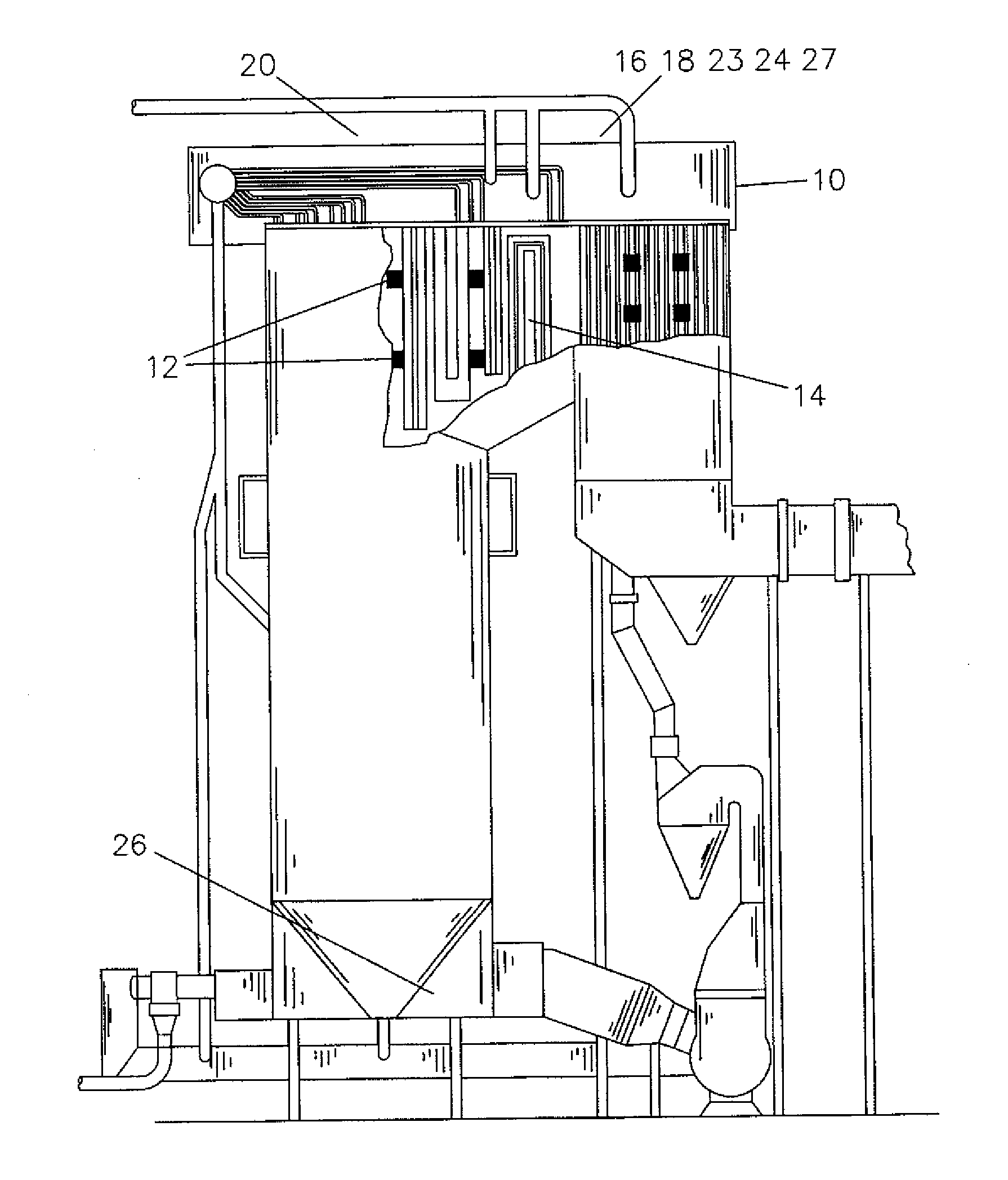

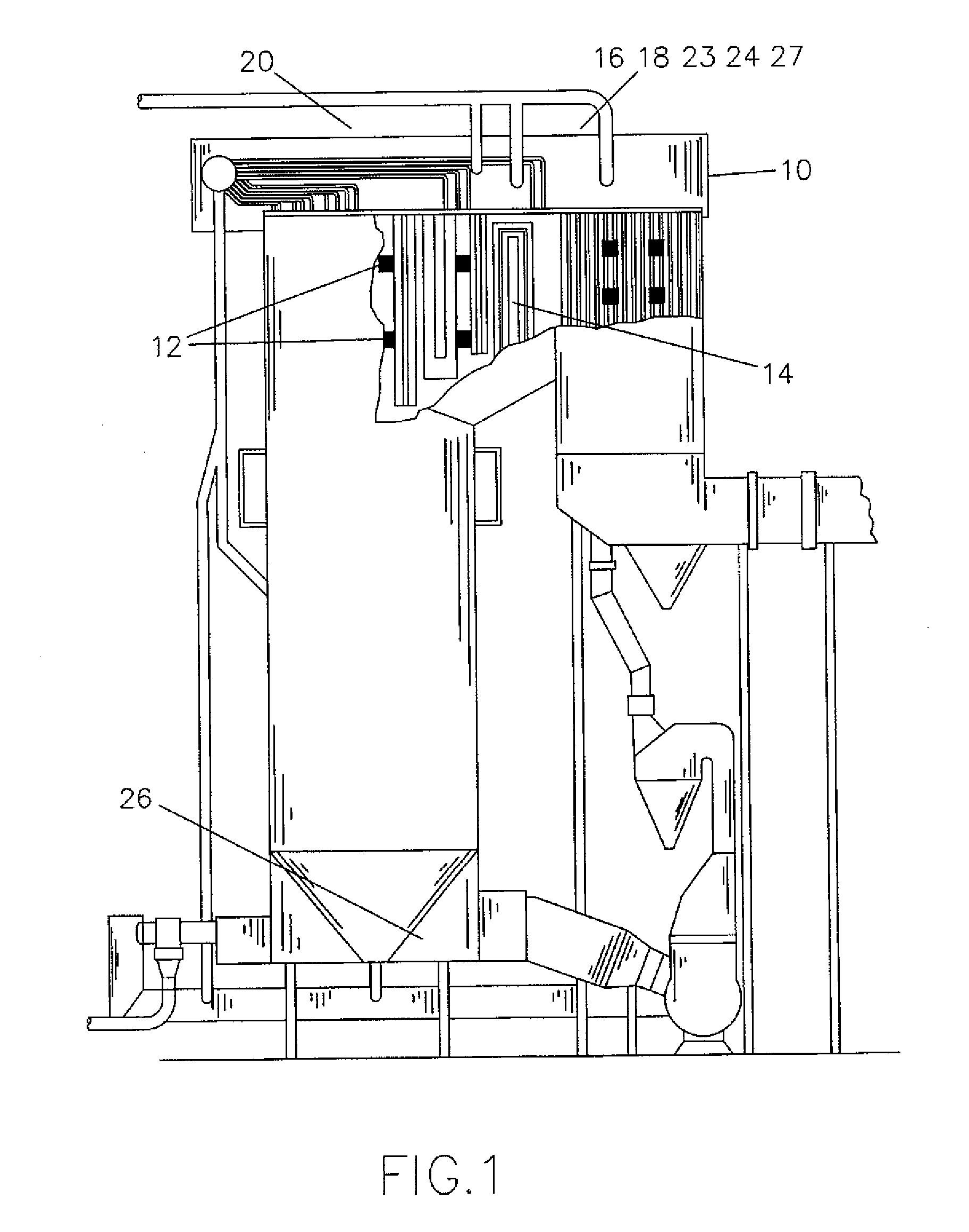

InactiveUS20140102382A1Reduce heat lossReduce wasteBoiler cleaning apparatusMachines/enginesProduction rateBoiler blowdown

Blowdown of a pressurised steam boiler heated by a burner 1 and including a blowdown flow control valve 17 is controlled by opening the control valve in response to receiving a control signal from a control unit 20 to allow water to leave the boiler. The control unit receives one or more signals indicative of the steam production rate of the boiler and adjusts the amount of blowdown in dependence upon the aggregate steam production.

Owner:AUTOFLAME ENG

Method of water treatment in steam plant

InactiveCN101395426APrevent adhesionWater treatment parameter controlFeed water supplyHydrazine compoundEngineering

In a steam plant, the amount of chemicals, such as hydrazine, used is minimized so as to prevent any sticking of scale in specified equipment. During the operation of the steam plant, temporary chemical environmental change or approximately periodic chemical environmental variation is applied to flow channel (21) within given equipment.

Owner:MITSUBISHI HEAVY IND LTD

Method for sootblowing optimization

InactiveUS8447431B2Cleanliness levelCleanliness levels for different heat zones in the boiler can be determinedExhaust apparatusBoiler cleaning apparatusNerve networkControl engineering

A controller determines and adjusts system parameters, including cleanliness levels or sootblower operating settings, that are useful for maintaining the cleanliness of a fossil fuel boiler at an efficient level. Some embodiments use a direct controller to determine cleanliness levels and / or sootblower operating settings. Some embodiments use an indirect controller, with a system model, to determine cleanliness levels and / or sootblower settings. The controller may use a model that is, for example, a neural network, or a mass energy balance, or a genetically programmed model. The controller uses input about the actual performance or state of the boiler for adaptation. The controller may operate in conjunction with a sootblower optimization system that controls the actual settings of the sootblowers. The controller may coordinate cleanliness settings for multiple sootblowers and / or across a plurality of heat zones in the boiler.

Owner:GE DIGITAL HLDG LLC

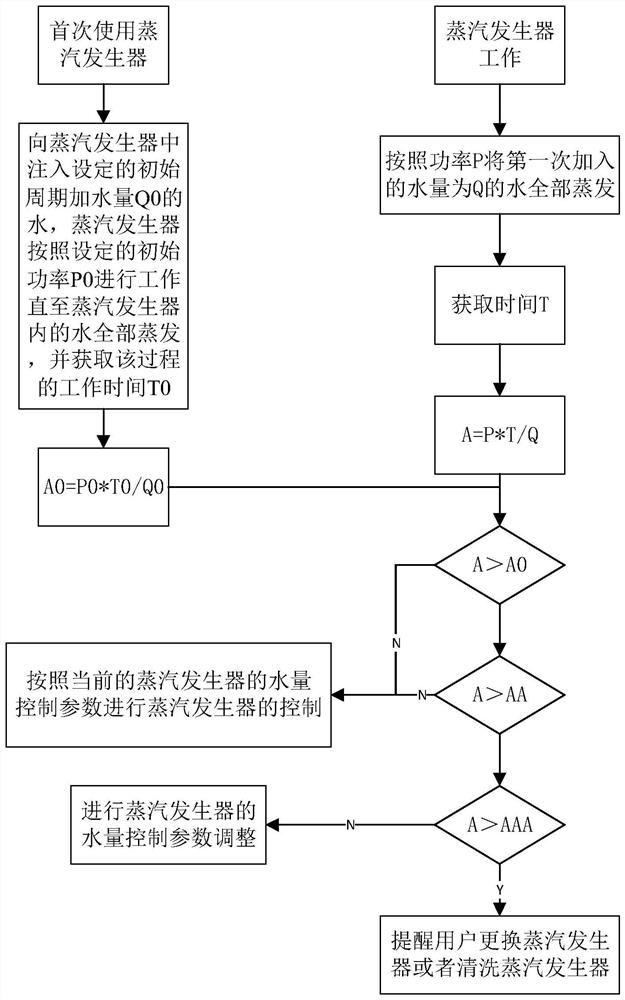

Steam generator self-adaptive control method and steam generation system

ActiveCN112050179AExtended service lifeImprove experienceSteam generation heating methodsBoiler cleaning apparatusThermodynamicsProcess engineering

The invention relates to a steam generator self-adaptive control method. The method comprises the following steps of calculating an initial steam conversion parameter A0 of a steam generator when thesteam generator is used for the first time; and during later work, calculating a current steam conversion parameter A of the steam generator, comparing A with A0, judging that the steam generator hasincrustation, and adjusting a water volume control parameter of the steam generator. The invention further relates to a steam generation system. The steam generation system comprises a control circuitboard, a water tank, a steam generator, a micro-flow pump, an electromagnetic valve and a temperature controller, wherein the steam generator, the micro-flow pump, the electromagnetic valve and the temperature controller are electrically connected with the control circuit board. According to the steam generation system, the steam generator self-adaptive control method is utilized, the incrustation condition in the steam generator can be predicted in a normalized mode according to the water quality conditions of regions with different water qualities, then the steam generator is adjusted and controlled to work according to the specific incrustation condition, risks of excessive residual water in the steam generator and dry burning of the steam generator are avoided, the service life of thesteam generator is prolonged, and the user experience performance of a whole machine product is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com