Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Wound rotor motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wound-rotor motor is a type of induction motor where the rotor windings are connected through slip rings to external resistance. Adjusting the resistance allows control of the speed/torque characteristic of the motor. Wound-rotor motors can be started with low inrush current, by inserting high resistance into the rotor circuit; as the motor accelerates, the resistance can be decreased.

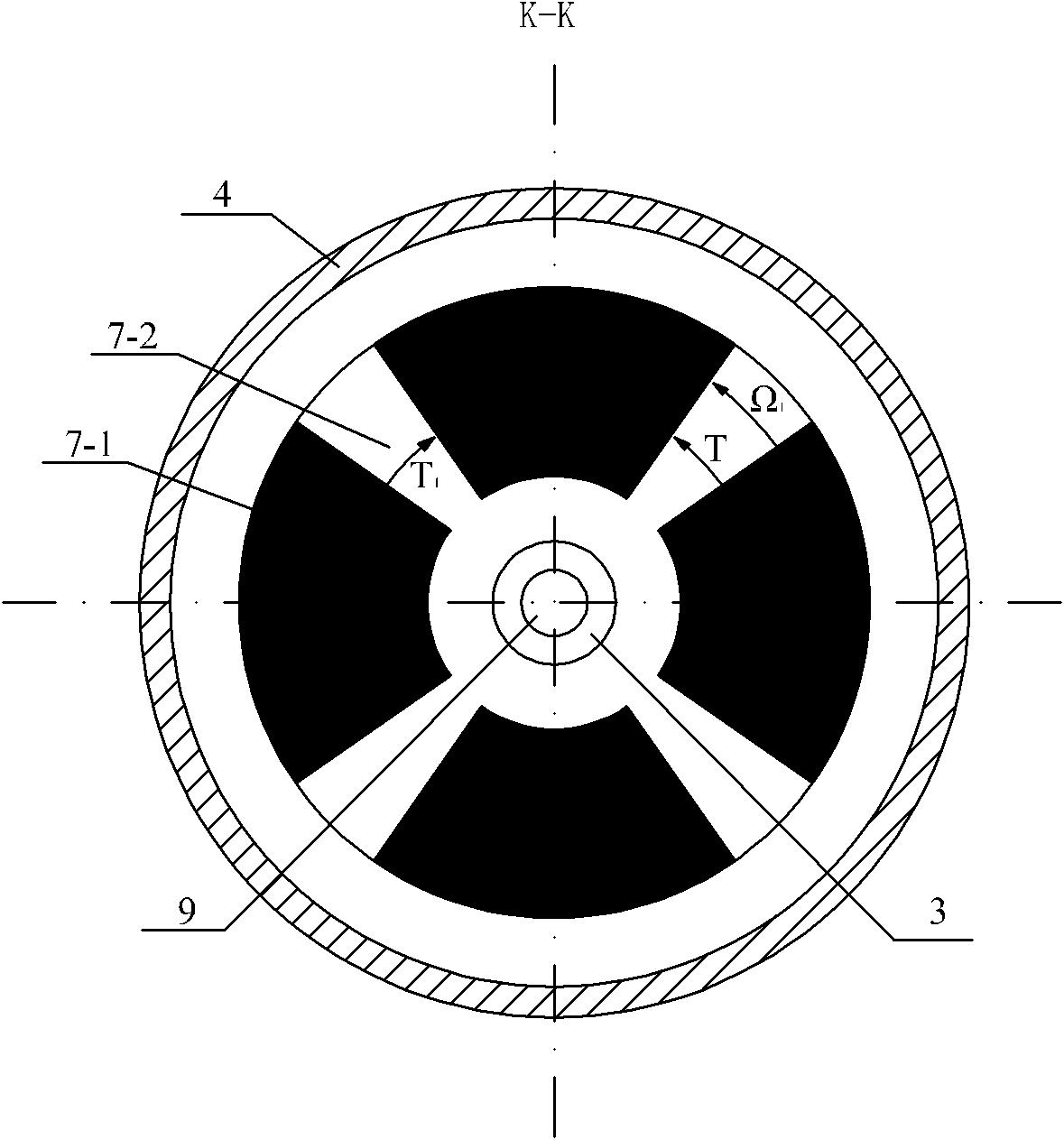

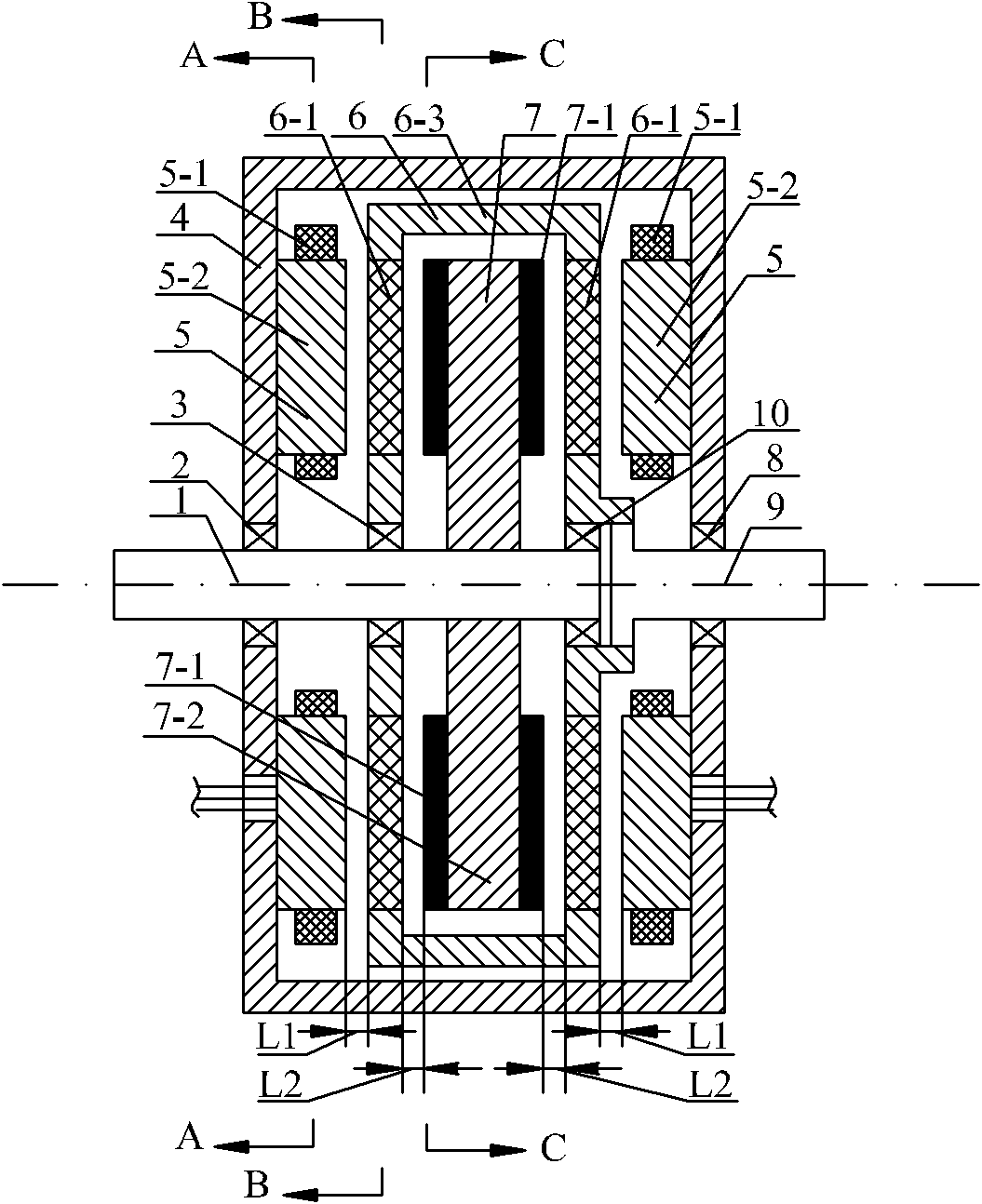

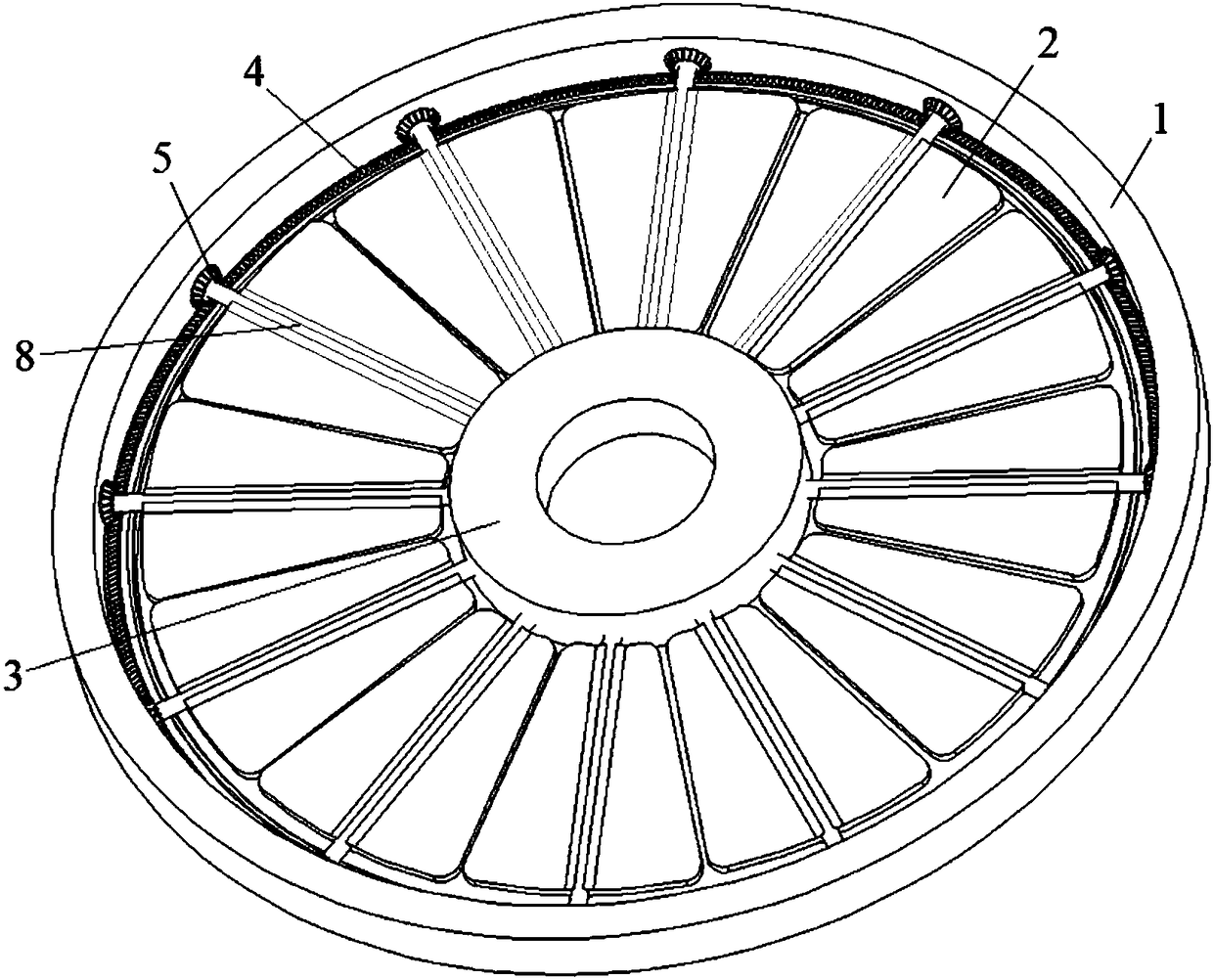

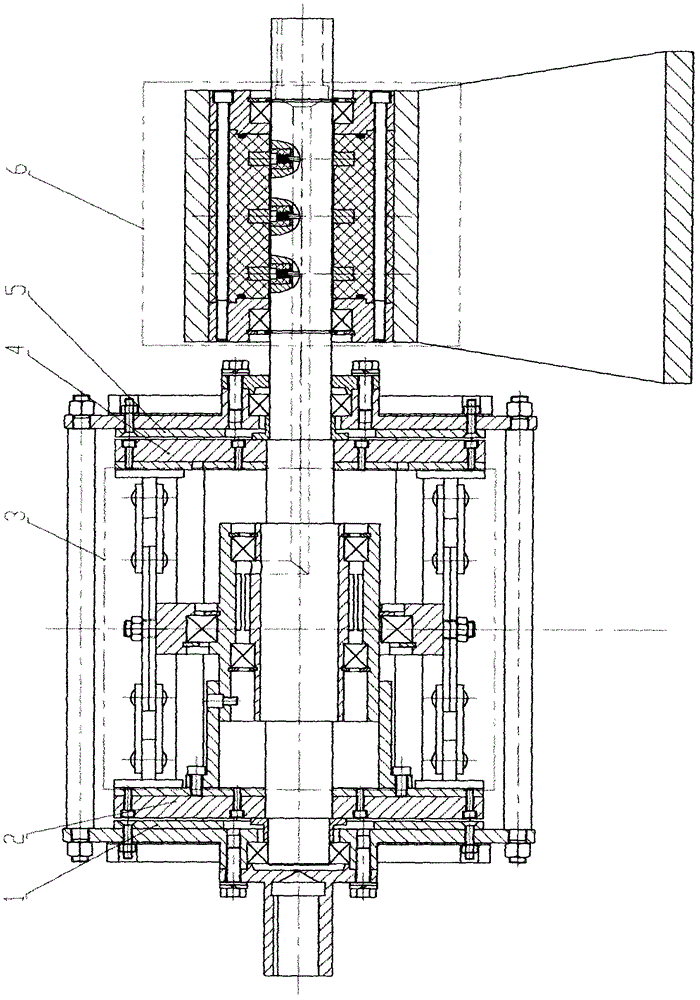

Axial magnetic field modulated brushless double rotor motor

ActiveCN101924436AReduce volumeLow costMagnetic circuit rotating partsElectric machinesPermanent magnet rotorMotor drive

The invention discloses an axial magnetic field modulated brushless double rotor motor, belonging to the motor field and solving the problems that the operating efficiency is lowered and the reliability is reduced because the winding rotation in a double rotor motor introduces the current through an electric brush and a slip ring, and the components, such as electric brushes and the like need to be maintained. The two stators of the invention are fixed the left end and the right end of a shell; a modulated ring rotor is positioned between the two stators and outside a permanent magnet rotor; a prime motor drives the permanent magnet rotor to rotate to form a 2n pole magnetic field; the stator is electrified to form a 2p pole magnetic field; the 2n pole magnetic field and the 2p pole magnetic field are modulated by the modulated ring rotor; q magnetic-conducting pieces and q insulated pieces are arranged on the end surface at the two sides of a stator frame of the modulated ring rotor along the peripheral direction in an interlacing manner; the relational expression that p is equal to the absolute value of the sum of hn and kq is satisfied, which is given to the load by the output shaft of the modulated ring rotor in different rotating speed; and the axial magnetic field modulated brushless double rotor motor of the motor of the invention has two structures, one structure is in axial symmetrical type, and the other structure is in axial unilateral type. The motor of the invention is used for the occasions of electric automobiles, wind power generation and torpedo drive.

Owner:HARBIN INST OF TECH

Permanent magnetism synchronous wheel hub motor for directly driving electric vehicle wheel

InactiveCN101282071AOptimize layoutSimple structureMagnetic circuit rotating partsSynchronous machine detailsInterference fitGear wheel

A permanent magnetism synchronous hub motor for electrically driven vehicle direct drive comprises shafts, a left end cover, rotors, stators, a right end cover, a rotating transformer, bearings are arranged on the shafts, inner rings of the left end cover and the right end cover are connected with the bearings in interference fit, stators are hot sleeved on the support of the shaft, the left end cover, the right end cover and the rotors are jointed together by bolts, the rotors are composed of rare earth magnet steels at interval adhering in the inner wall of the support by the magnet steel glue. The invention can be mounted in the vehicle wheel hub for directly driving the vehicle wheel and save traditional drive devices, thereby simplifying the whole vehicle structure, improving the drive efficiency and using the space effectively; the invention is an outer rotor motor without reduction gear mechanism, has small volume, large power, large starting moment, good control performance and low energy consumption, can reduce the whole vehicle weight and the maintenance cost and improve continued mileage and battery life.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

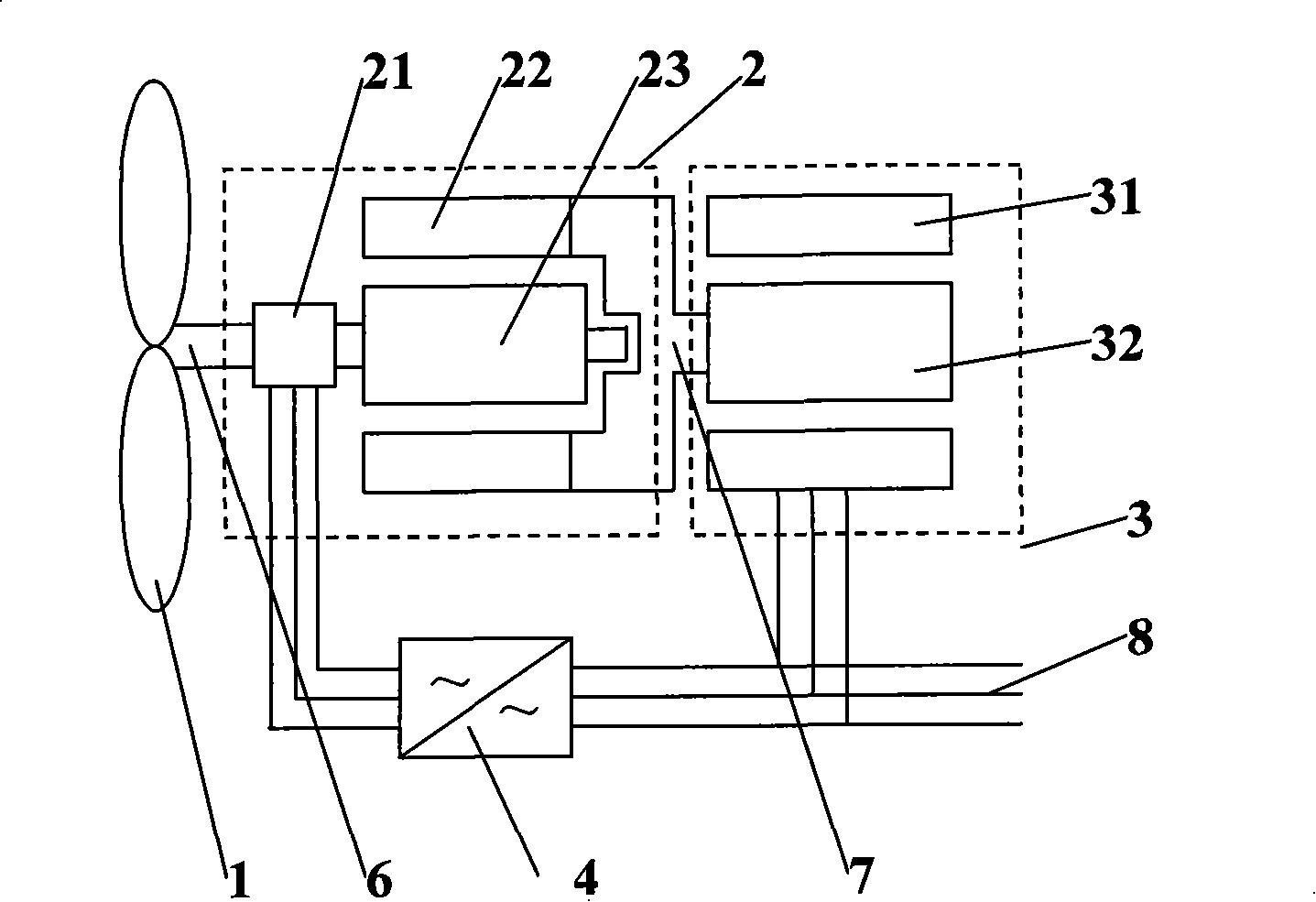

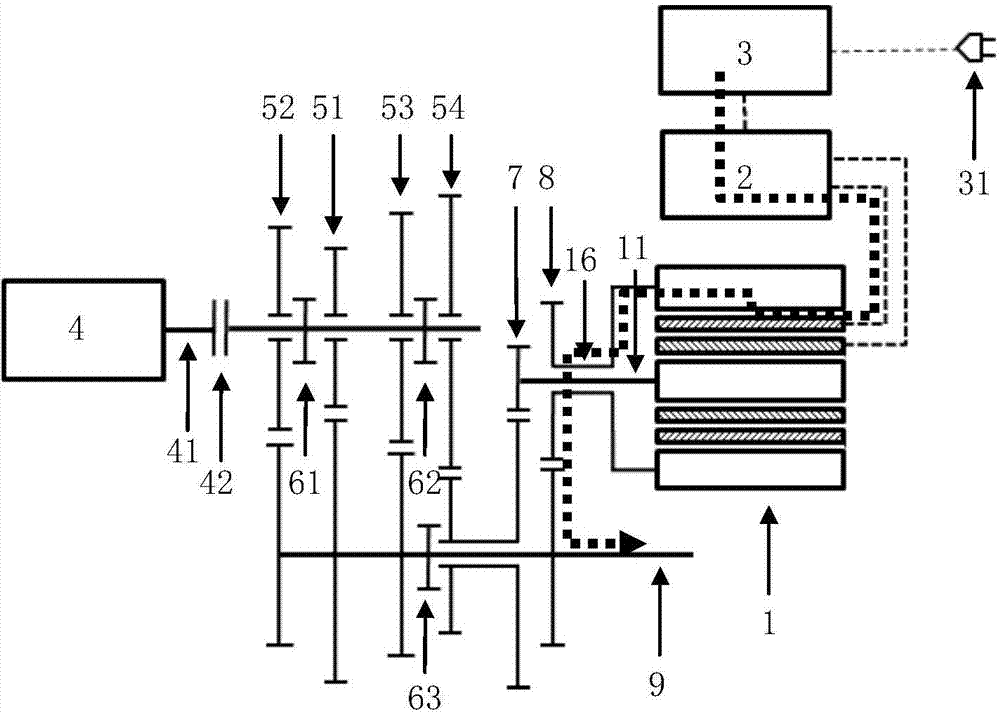

A cascaded speed shift frequency constant wind power generation system

InactiveCN101242157AFirmly connectedQuality improvementDynamo-electric machinesElectric generator controlFailure rateFrequency changer

The invention discloses a cascading variable speed constant frequency wind power system, comprising a winder machine, a double rotor motor, a generator and a transducer; wherein, the double rotor motor comprises a slip ring, a outer rotor, and an inner rotor; the generator comprise a stator and a rotor; the wind machine is cascaded with the inner rotor through a shaft one; the inner rotor is equipped with a three-phase winding, and connected with the transducer; the outer rotor is cascaded with the generator through a shaft two; the stator of the generator has the three-phase winding connected with grid inside. With cascading electric transmission structure, the invention accomplishes function of variable speed constant frequency electricity generation by forming collection of power associated with variable frequency magnetism speed adjustment. The invention also removes the step of speed raising gear case transmission, and reduces failure rate of system. The generator is connected with grid. The power rating capacity of power electronic component can be reduces obviously. The invention is appropriate for the field of wind power generation, steamer generator set, water wheel generator set, internal combustion engine generator, etc.

Owner:SOUTH CHINA UNIV OF TECH

Permanent magnet synchronous motor for extended range electric automobile

InactiveCN102386734ACompact structureReduce volumeMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor for an extended range electric automobile. The permanent magnet synchronous motor comprises a casing and an end cover connected at one end of the casing. The permanent magnet synchronous motor is characterized in that a stator, an inner rotor and an outer rotor are arranged in the casing, wherein the inner rotor is arranged in an inner cavity of the stator and the outer rotor is sleeved outside the stator to form an inner rotor motor and an outer rotor motor; and the inner rotor motor and the outer rotor motor share a stator and are respectively radial magnetic flux motors. According to the permanent magnet synchronous motor disclosed by the invention, the inner rotor motor and the outer rotor motor share one stator and one set of motor casing, the inner rotor motor is connected with an engine and the outer rotor motor is connected with a transmission, so that the permanent magnet synchronous motor has the advantages of compact structure, smaller size and low cost. Under the condition that SOC (State of Charge) of a battery is enough, a motor controller HCU (Hybrid Control Unit) is used for controlling the battery to supply power to an outer layer winding and the outer rotor motor is used for driving an entire automobile to electrically run. When the SOC of the battery is not enough, an ECU (Electric Control Unit) is used for controlling the engine to operate and drive the inner rotor motor to generate power and extend range.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

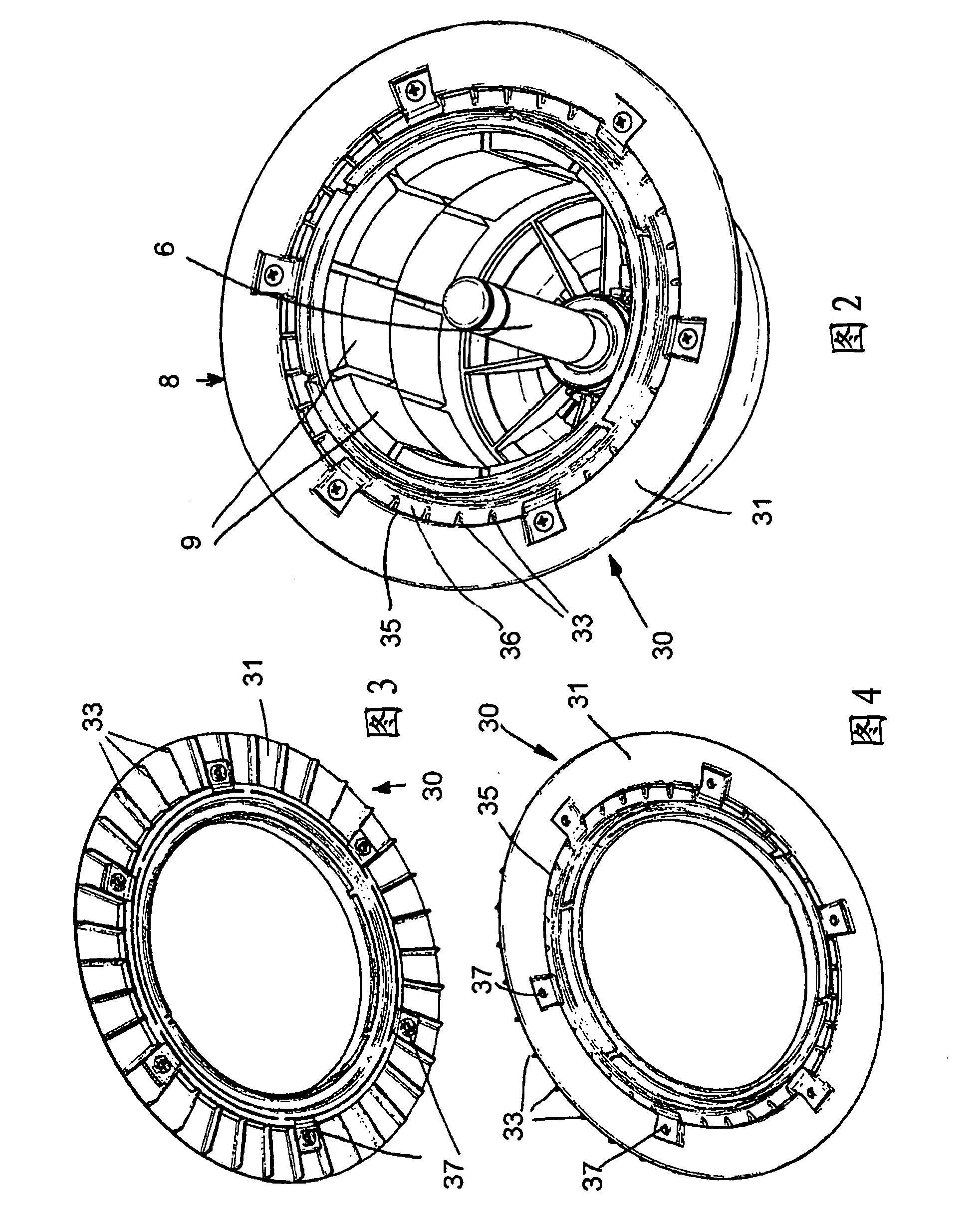

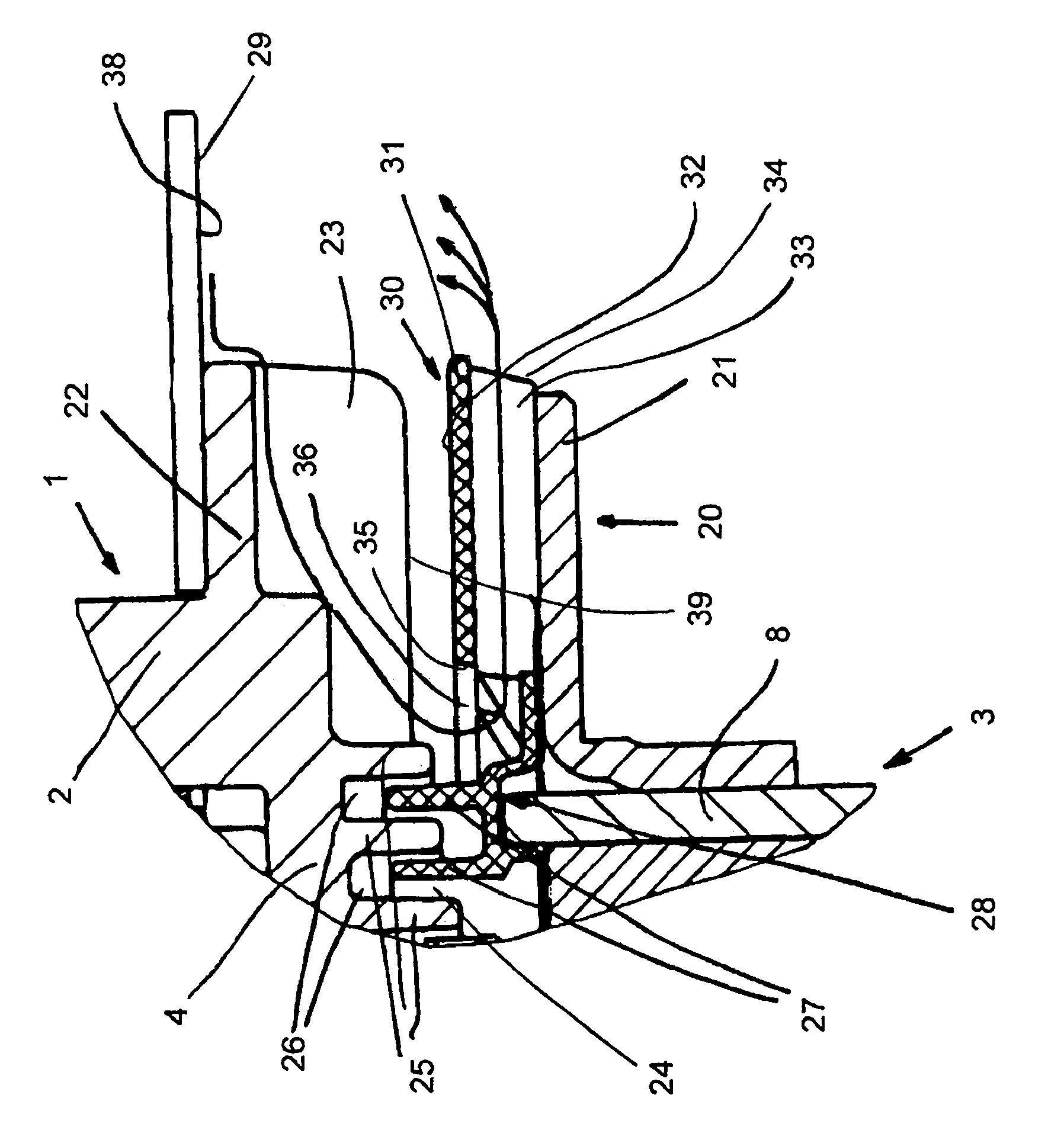

Electric motor, particularly outer rotor motor

ActiveCN102104309ASpeed up the flowImprove cooling effectMagnetic circuit rotating partsCooling/ventillation arrangementLow noiseOptimal control

An electric motor has a stator bushing (1) in which components that generate heat are disposed; a rotor housing (8) which has a conveying element disposed therein. The air conveying element has a top side (32) that is facing the stator bushing and that is at least basically smooth. In-taken air flow can be turned and guided reliably by the top side (32). The uniform air flow through the top side (32) can cause optimal cooling. In addition, because the top side (32) is basically smooth, the motor operation causes only lowest noise even in high rotation speed.

Owner:施乐百股份公司

Alternating current synchronous motor based on three-phase rotary transformer technology, alternating current wound rotor motor and arrangements for speed regulation

This invention relates to alternating synchronous motor, alternating coil rotor motor and its adjusting device based on three phase rotation transducer in machine process and power electrical technique field, which comprises the following parts: three phase rotation transducer fixed on the motor socket inner axis or motor shell outer axis between static three phase alternating power and motor rotation rotor to send power to take place of original slide ring and brush. This invention alternating synchronous motor and its adjusting device realizes transducer speed adjusting.

Owner:丁振荣

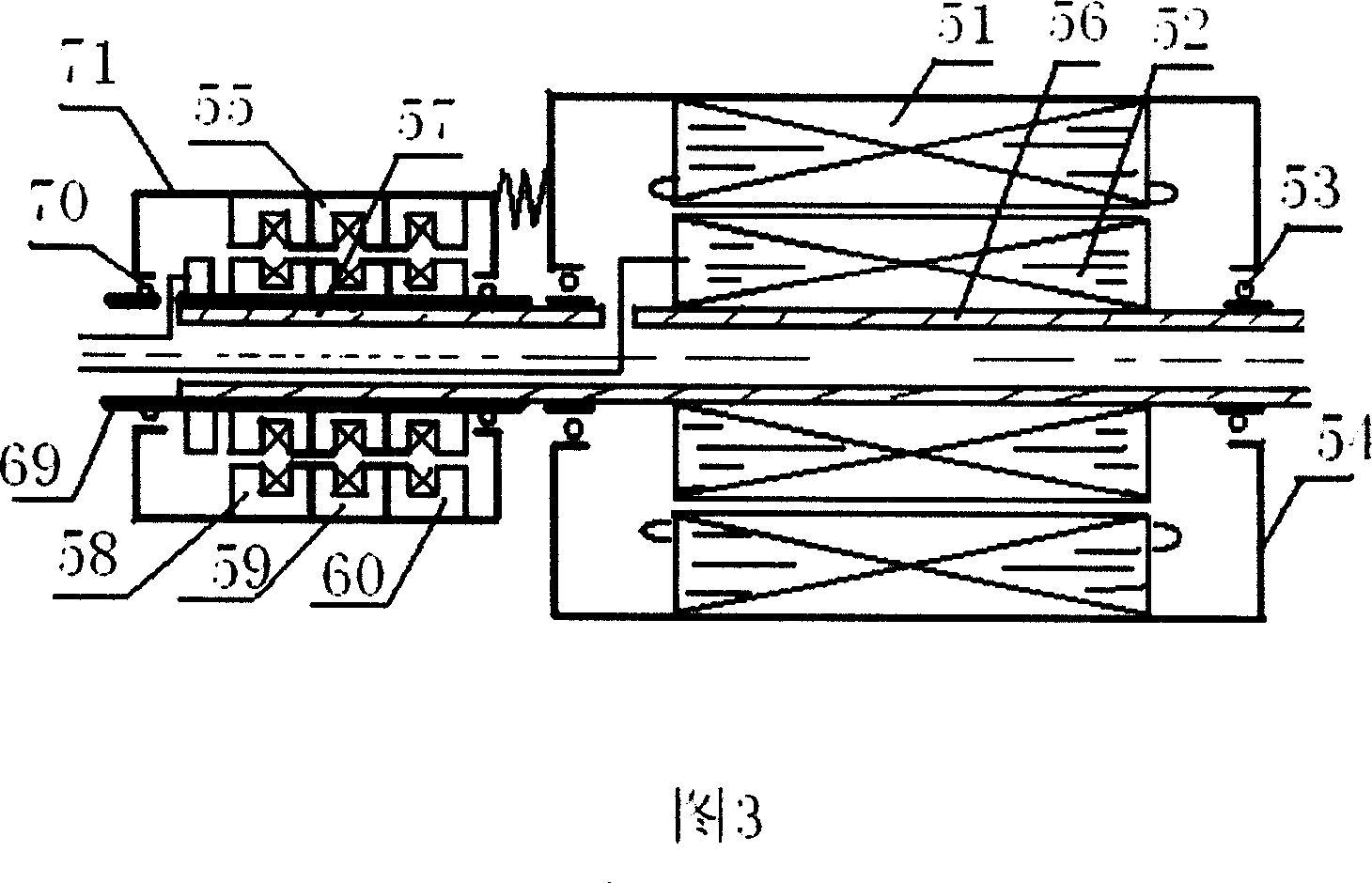

Hybrid electric system adopting double-rotor motor and implementation method of hybrid electric system adopting double-rotor motor

ActiveCN104742717AImprove work efficiencySmooth start at low temperatureHybrid vehiclesGas pressure propulsion mountingPower batteryLow speed

The invention discloses a hybrid electric system adopting a double-rotor motor. The hybrid electric system comprises the double-rotor motor, a double-motor controller and an engine, wherein the double-rotor motor comprises an inner rotor motor and an outer rotor motor; the inner rotor motor is engaged with a power output shaft or a four-speed gear bank through an inner rotor motor reduction gear bank; the outer rotor motor is connected with the power output shaft through an outer rotor motor reduction gear bank; the double-motor controller is used for independently controlling the inner rotor motor and the outer rotor motor, and is connected with a power battery; an output shaft of the engine is engaged with one of a one-speed gear bank, a two-speed gear bank, a three-speed gear bank and the four-speed gear bank through a clutch, or not engaged with the one-speed gear bank, the two-speed gear bank, the three-speed gear bank and the four-speed gear bank; the one-speed gear bank, the two-speed gear bank and the three-speed gear bank are connected with the power output shaft; the four-speed gear bank is engaged with the power output shaft or the inner rotor motor reduction gear bank. The hybrid electric system adopting the double-rotor motor and an implementation method of the hybrid electric system adopting the double-rotor motor have the characteristics of compact structure, high integration of the system, high efficiency of the vehicle, good fuel economy, smoothness in low-temperature coldstart of the engine and good grade ability at a low speed.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Outer rotor motor and method of manufacturing the same

ActiveUS20100314954A1Reduce leakage fluxPrevent intrusionMagnetic circuit rotating partsMagnetic bodiesRotor magnetsMagnetic poles

An outer rotor motor comprises a rotor rotating about an axis, and a fixed stator. Provided over the inner peripheral surface of a cylindrical part of a fan connecting resin member are a ring-shaped yoke, a ring-shaped rotor magnet fixed to a fixing slot defined in the radially inner surface of the yoke, and yokes fixed to fixing slots defined in a radially inner surface of the rotor magnet. The rotor magnet is so magnetized that magnetic poles alternately change in a circumferential direction. The yoke covers a radially outer surface of the rotor magnet, and parts on a radially outer side of an axially upper surface and an axially lower surface of the rotor magnet.

Owner:DAIKIN IND LTD

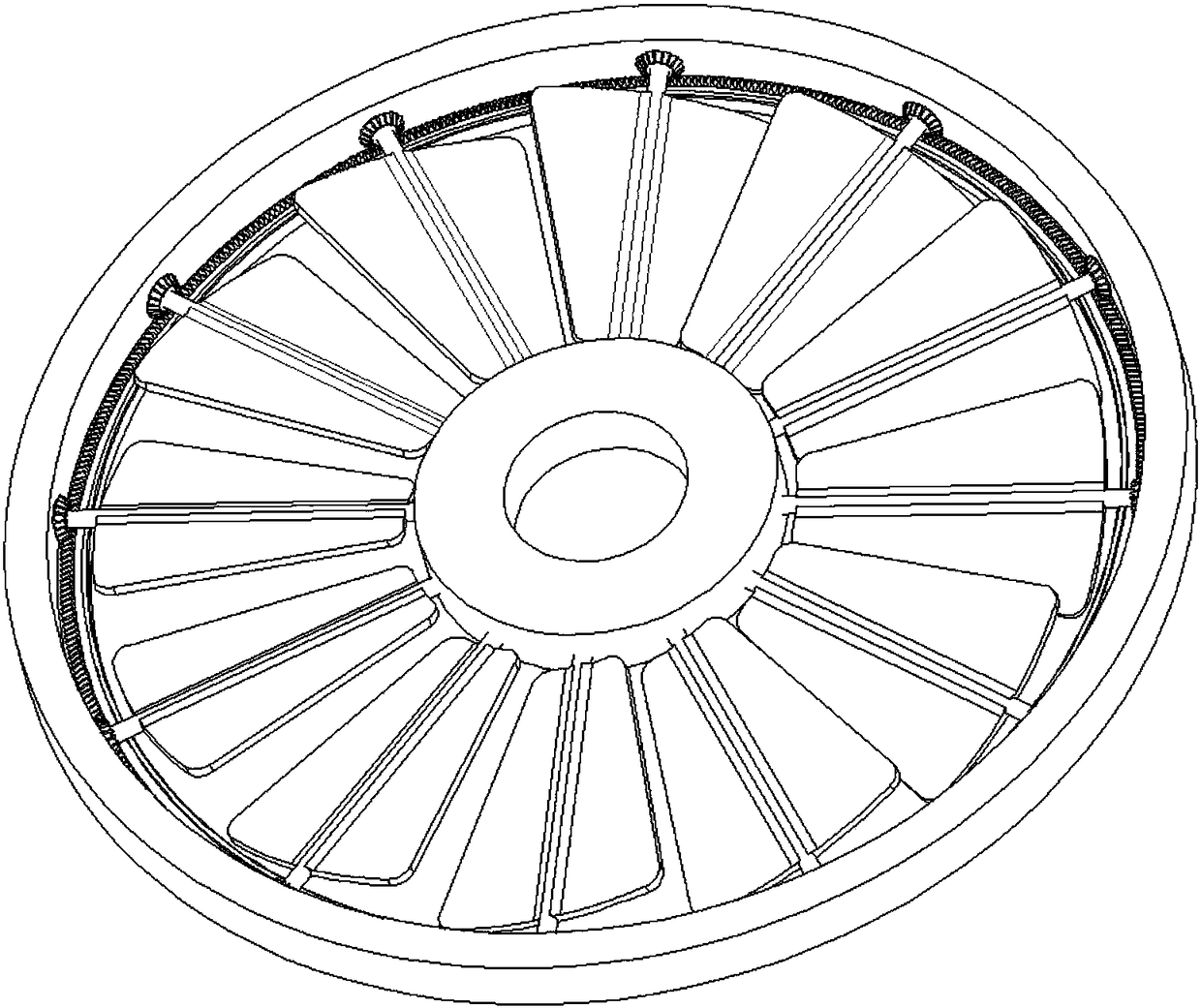

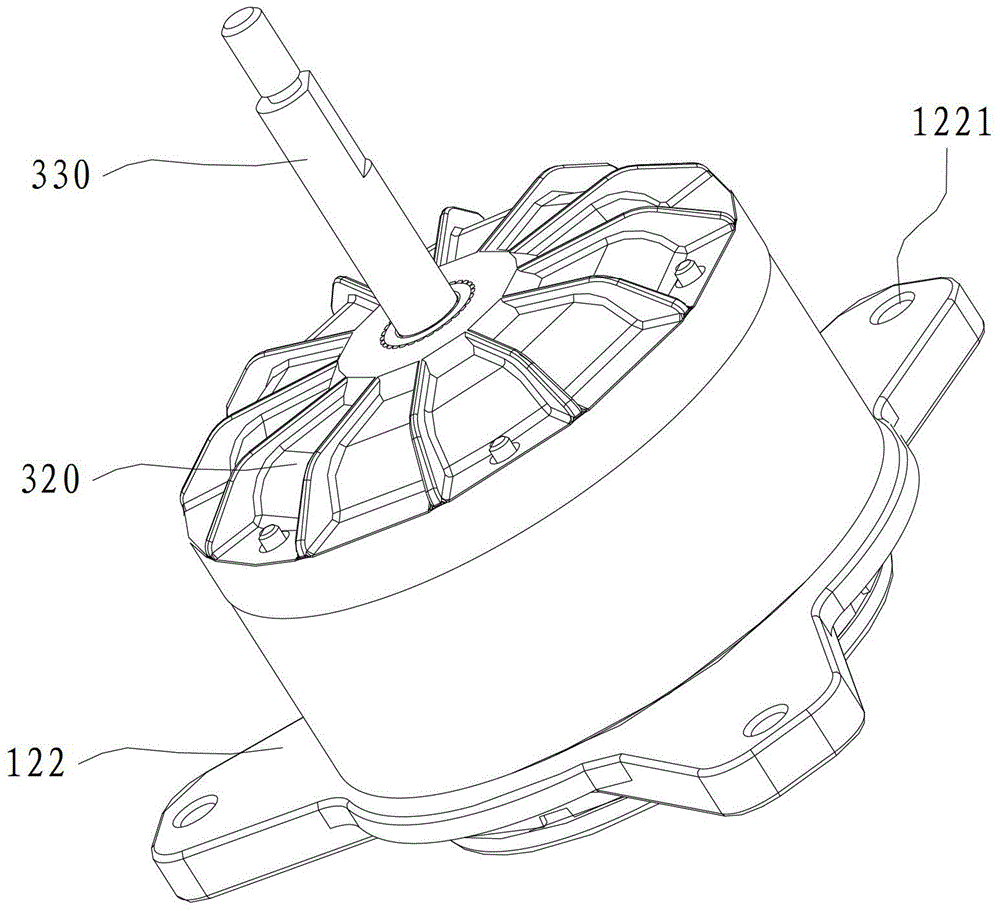

Outer rotor motor

ActiveCN108448763AImprove cooling effectSpeed up the flowMagnetic circuit rotating partsElectric machinesElectric machineCooling effect

The invention discloses an outer rotor motor which comprises a motor rotor, cooling blades positioned in the motor rotor and arranged in a rotatable manner, and a blade adjustment device for adjustingthe angle of attack of the cooling blades; multiple cooling blades are provided and are all distributed circumferentially in the motor rotor. According to the outer rotor motor disclosed by the invention, the cooling blades are arranged in the motor rotor to accelerate the flow of a flow field around the motor to cool the motor body; thus, an effect of forcing ventilation and cooling is realizedwithout increasing the structural complexity and obvious weight, and the cooling effect of the motor is improved.

Owner:芜湖钻石航空发动机有限公司

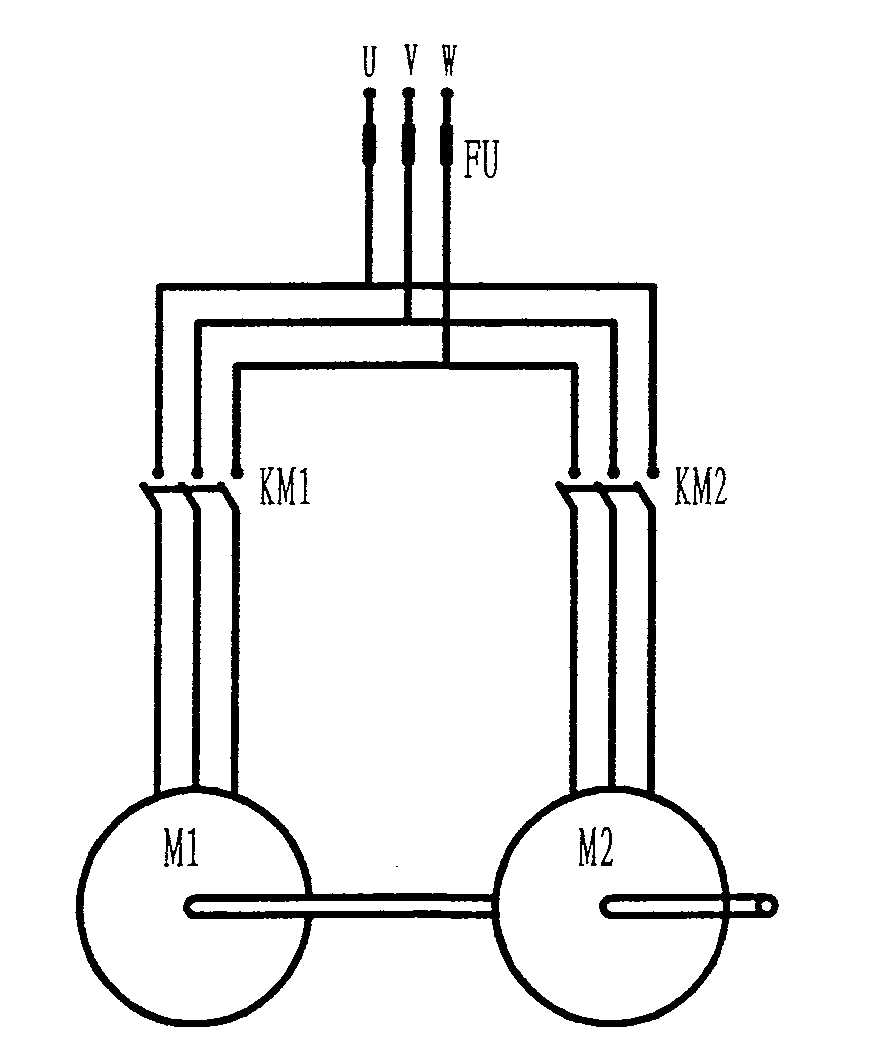

Drive system for unit parallel shunting at side of wound rotor motor operating in two quadrants

The invention relates to a drive system for unit parallel shunting at the side of a wound rotor motor operating in two quadrants, and particularly to a frequency conversion control device for double regulation of the excitation of a stator and a rotor which operate in two quadrants and are connected in parallel by a unit at a wound motor rotor side. The frequency conversion control device is connected to a lead-out end line of the wound rotor motor, and is directly supplied with power by the power grid voltage or other three-phase power. The frequency conversion control system comprises: a rectifier circuit used for rectifying an AC power of a power grid or other voltage sources into a DC power; an inverter circuit used for outputting a PWM AC power; a reactor circuit smoothly outputting a waveform; a PWM modulation unit used for controlling the inverter circuit; and a brake circuit used for protecting the frequency conversion control system when the motor stops rotating. All the frequency, phase and amplitude can be changed by applying one or more phase sequences to the rotor winding. In addition, a three-phase voltage source generated by a frequency transformer forms a rotating magnetic field on the rotor, changes the frequency of the rotating magnetic field, and regulates excitation of the stator and the rotor, thereby changing the rotating speed of the rotor. The invention has the characteristics of high efficiency, easy shifting, small volume, low power consumption, and the like., and can compensate the nearby reactive hysteresis load at the stator side, to achieve local motion compensation.

Owner:宋崇辉 +1

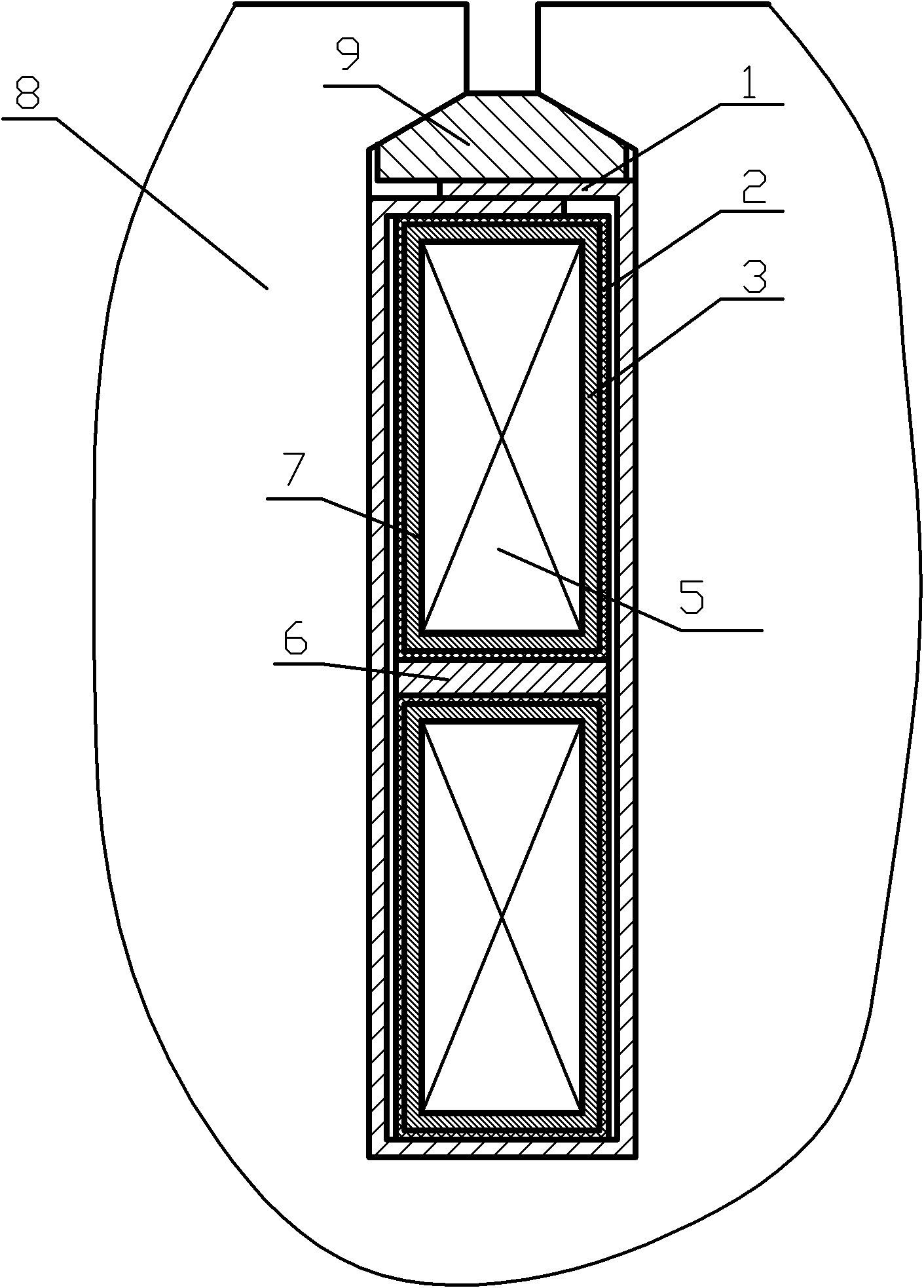

Insulating structure for rotor coil for high-voltage wound rotor motor

InactiveCN101958594AUniform insulationEven thickness of insulationWindings insulation materialWindings insulation shape/form/constructionFiberEngineering

The invention relates to an insulating structure for a rotor coil for a high-voltage wound rotor motor. Copper coils are arranged in a rotor core; glass powder mica platinum, a polyimide thin film tape and a polyimide film polyaryl amide fiber paper composite material layer are coated on each copper coil; a slot wedge is formed on the polyimide film polyaryl amide fiber paper composite material layer; an epoxy novolac glass cloth plate is arranged between two copper coils; the glass powder mica platinum is coated on a linear segment of each copper coil; improved insulating varnish is coated on an inner surface of the glass powder mica platinum; the polyimide thin film tape is coated on the glass powder mica platinum; and an outer surface of the glass powder mica platinum and an outer surface of the polyimide thin film tape are arranged in parallel. The insulating structure for the rotor coil for the high-voltage wound rotor motor has the advantages of uniform insulating thickness of the linear segment of the rotor coil, smooth surface, convenient penetration of the rotor coil in the rotor core, and capacities of reducing groove shape area, saving the usage of effective materials, reducing manufacturing labor hour and guaranteeing safe and reliable operation of the motor.

Owner:WUXI ZHONGDA MOTORS

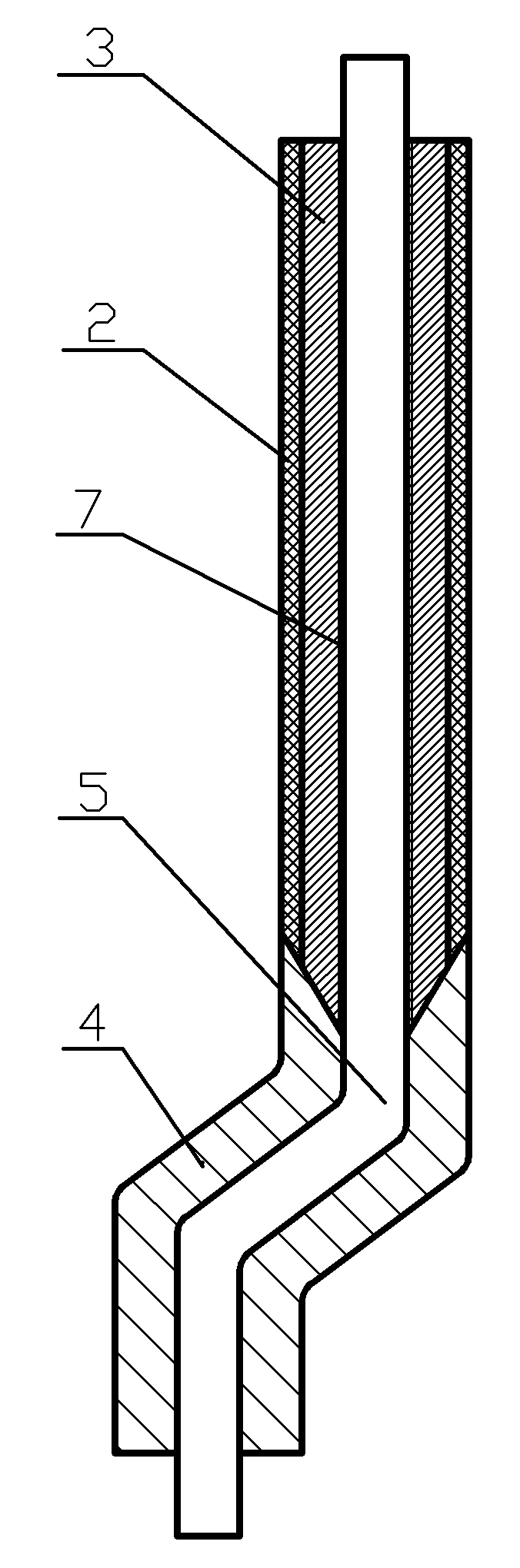

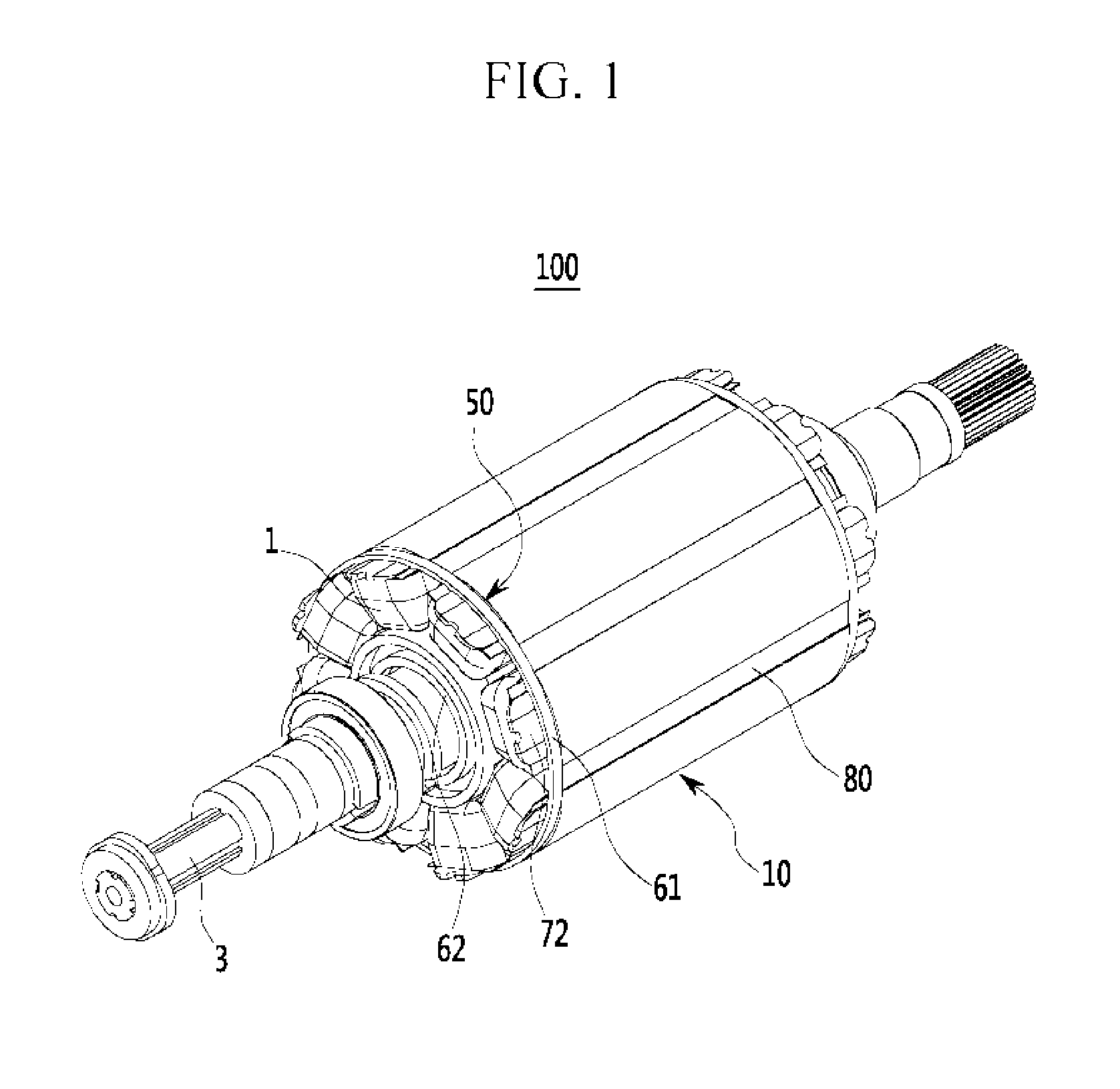

Rotor structure of wound rotor driving motor

ActiveUS20160164357A1Efficient dischargeLoss of resistanceWindings insulation shape/form/constructionMagnetic circuit rotating partsBobbinAir movement

A rotor of a wound rotor driving motor is provided. The rotor includes a rotor body that is rotatably installed with a predetermined air gap within a stator and in which a rotor coil is wound in a plurality of rotor teeth. A bobbin is fixed to the rotor body by the rotor coil disposed at opposing sides of an axial direction of the rotor body and supports the rotor coil. The rotor body forms a plurality of air movement passages that are opened to the exterior in an axial direction therein, and the bobbin forms a plurality of connection passage that are coupled to the air movement passages.

Owner:HYUNDAI MOTOR CO LTD

End-part cooling structure for rotor winding of bipolar wound rotor motor

The invention provides an end-part cooling structure for a rotor winding of a bipolar wound rotor motor. Rotor pressing rings are arranged at both ends of a rotor punching plate; the rotor pressing ring at one end is positioned by a shaft shoulder; the rotor pressing ring at the other end is positioned by an arc key; the arc key is placed in a shaft groove; a rotor coil is placed inside the rotor punching plate; a rotor bracket heating sleeve is arranged on a shaft; the end parts of the rotor coil are bound by weftless tapes; the thickness of each weftless tape is calculated by a centrifugal force; and the end parts of the rotor coil need to be sectionally bound in the axial direction. According to the invention, under the premise that a motor power, a power factor, the vibration and the like meet the requirements, a rotor pressing ring and rotor bracket separated structure is adopted, so that more wind energy can pass through the rotor coil, the weftless tapes are reasonably arranged, a part installation fixing and manufacturing method is also optimized and the heat dissipation condition at the end parts of the rotor winding is greatly improved.

Owner:SEC ELECTRIC MACHINERY

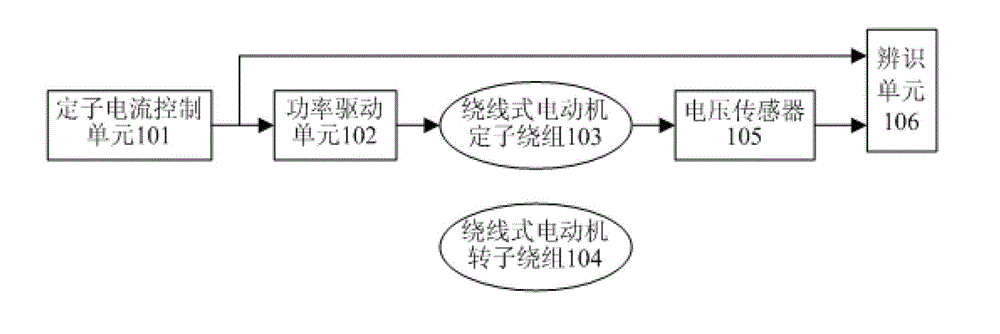

Method for identifying resistor parameter of stator of wound rotor type motor

ActiveCN103338001AReduce tedious workReduce mistakesElectronic commutation motor controlVector control systemsDriving currentControl signal

The invention discloses a method for identifying the resistor parameter of the stator of a wound rotor type motor. The method comprises the following steps: opening the circuit of the rotor winding of the wound rotor type electric motor; adopting a stator current control unit to output a control signal that the current of the q axis of the stator is 0 and the current of the d axis of the stator is a constant; adopting a power drive unit to receive the control signal and output a drive current; adopting the stator winding of the wound rotor type motor to receive the drive current; adopting a voltage sensor to measure the stator winding of the wound rotor type motor to obtain a voltage signal of the d axis of the stator; adopting an identification unit to receive the control signal and the voltage signal of the d axis of the stator, and using the voltage of the d axis of the stator to be divided by the current of the d axis of the stator to obtain the resistor parameter of the stator. According to the method, cumbersome work and errors, caused by manual identification, can be eliminated; the method is simple in computation and spends less time in identification.

Owner:扬州市泰康动力科技有限公司

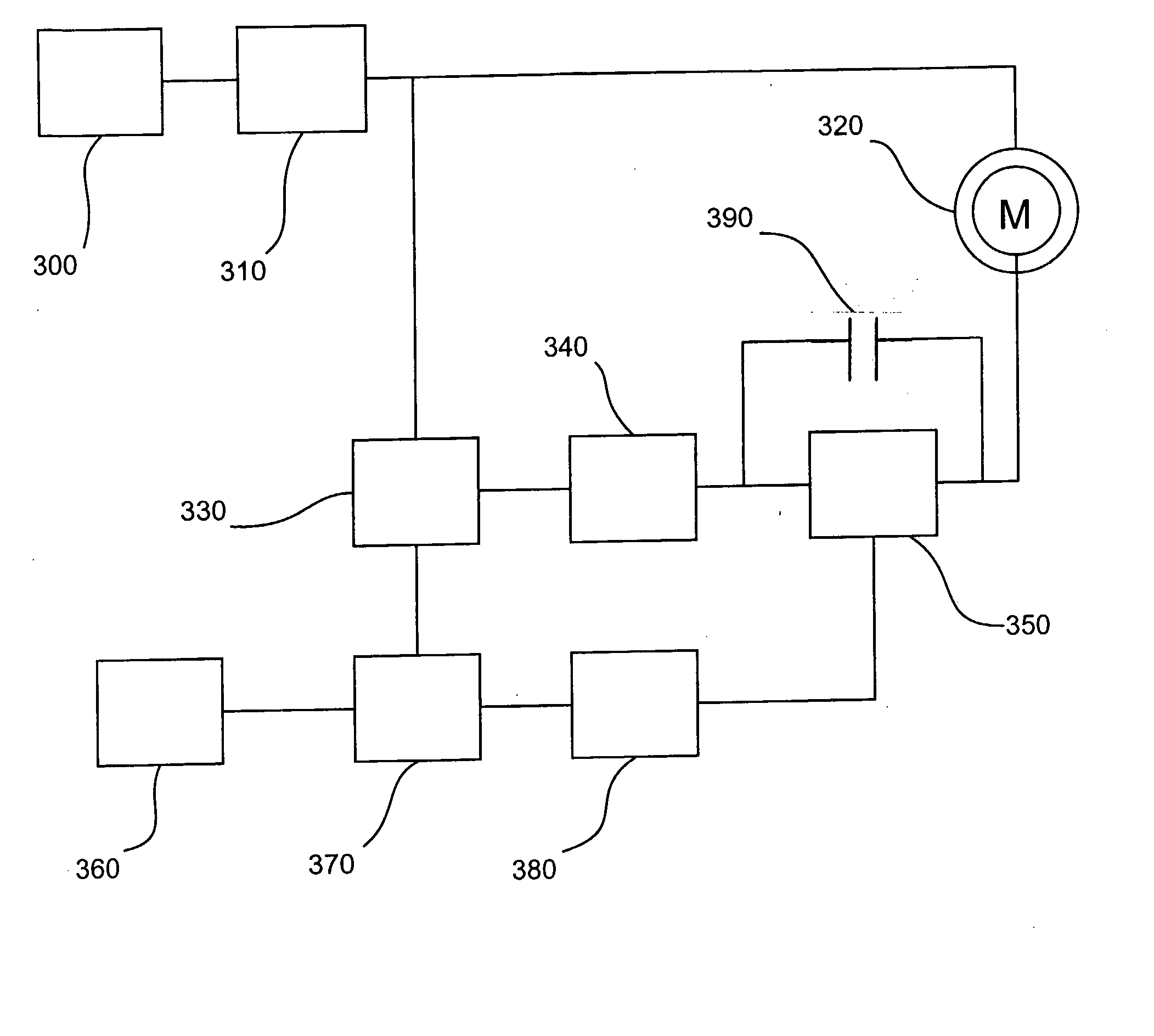

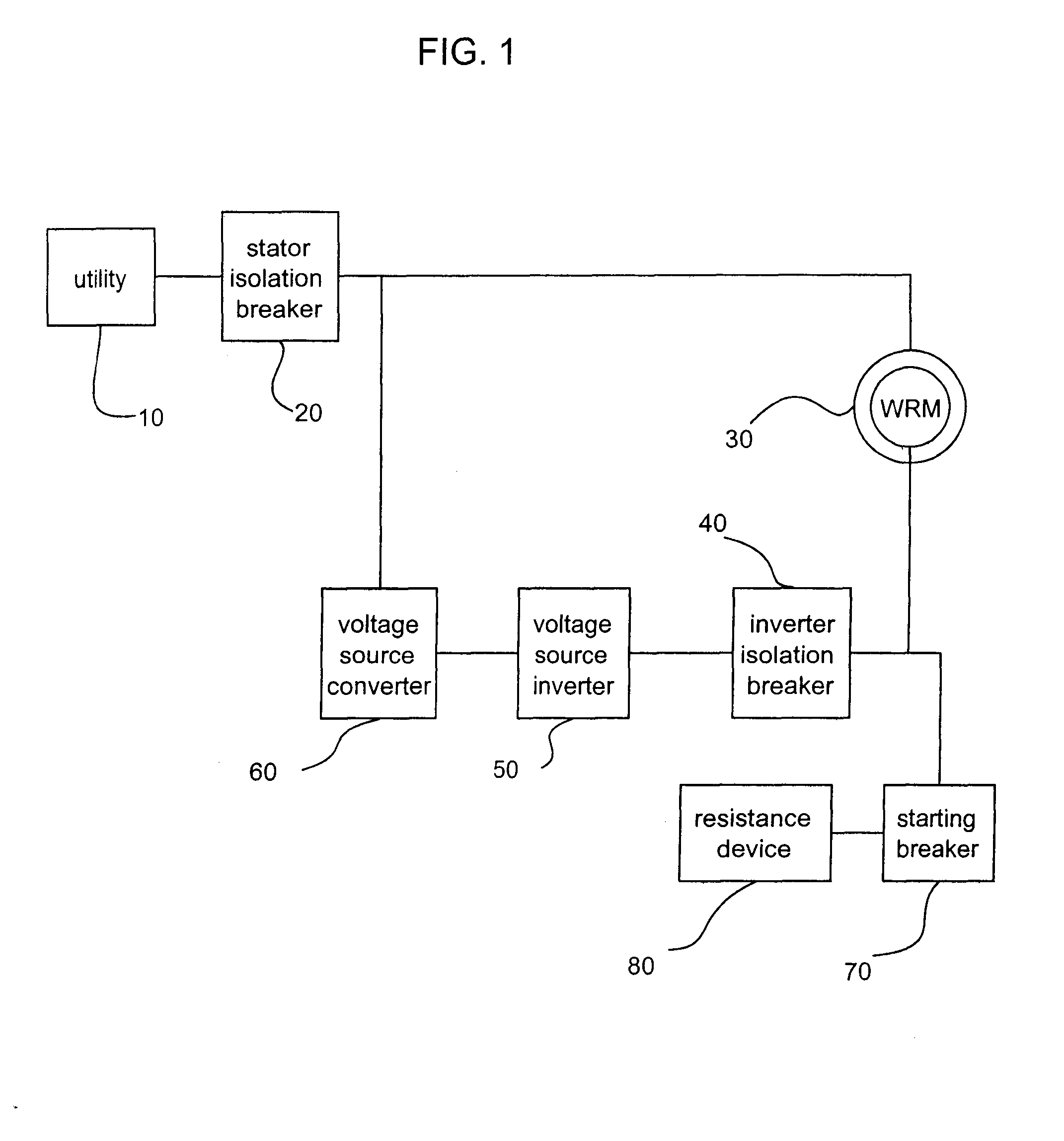

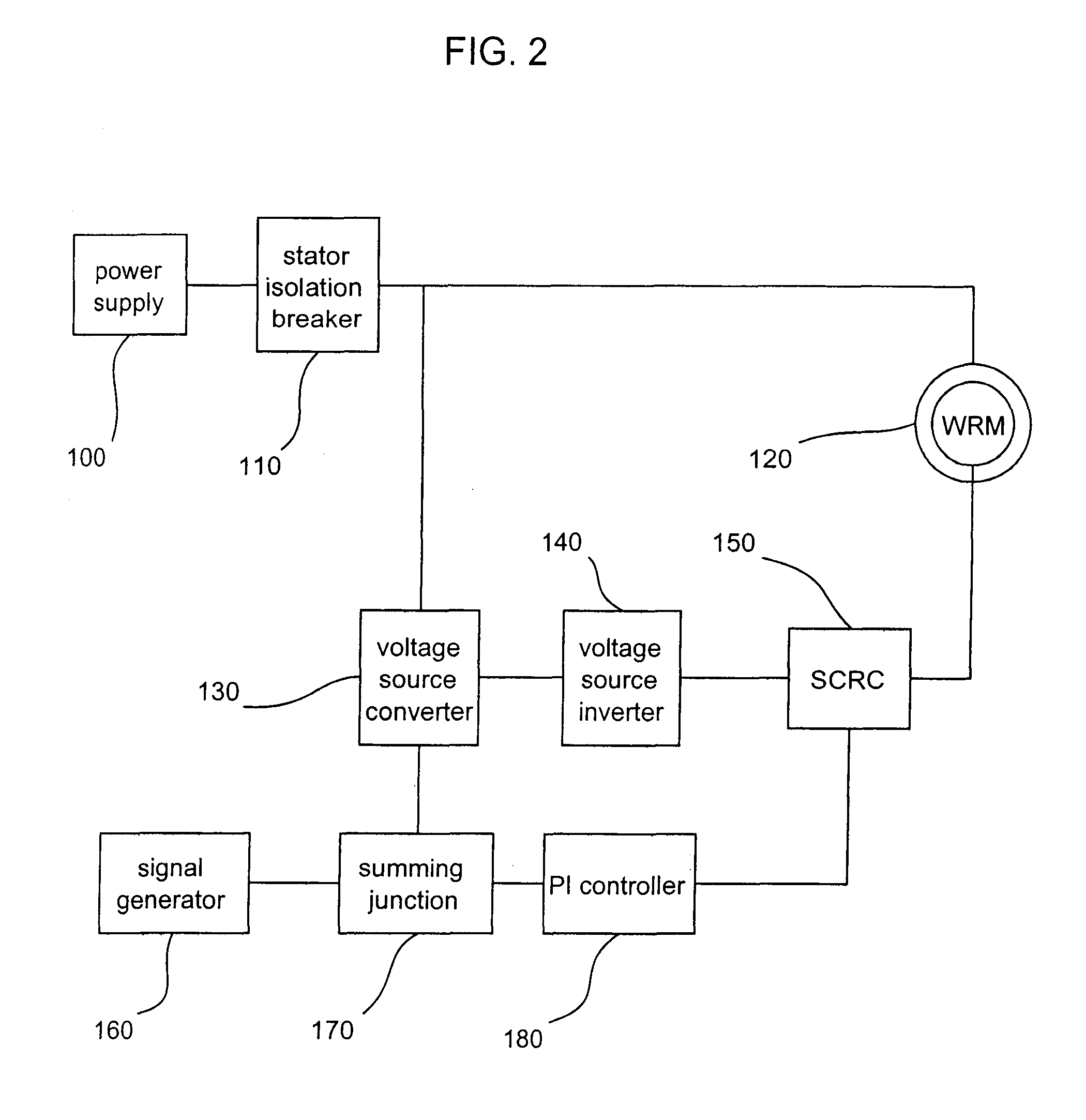

System And Method For Starting A Wound Rotor Motor

ActiveUS20070278985A1Single-phase induction motor startersMotor/generator/converter stoppersEngineeringPhase control

A system and method for starting and regulating a wound rotor motor (320) including a phase-controlled SCR converter (350) and a drive circuit (330, 340) having a voltage source inverter (340) and a voltage source converter (330). The SCR converter (350) regulates power transmitted to the drive circuit from the rotor of the motor so that the ratings of the drive circuit are not exceeded. A shorting contactor (390) is employed in various embodiments to increase the efficiency of the circuit.

Owner:TMEIC

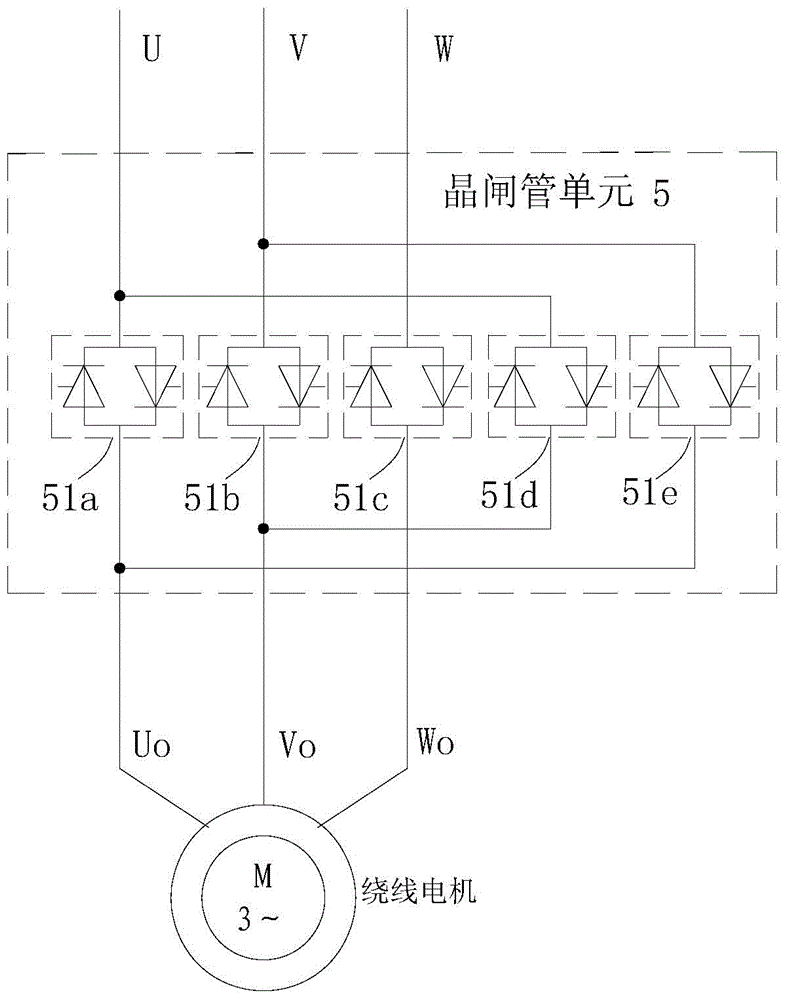

Method of realizing wound-rotor motor redundant rotation speed feedback and device

ActiveCN104868819AImprove the protective effectAccurate feedbackAC motor controlSquare waveformSignal processing circuits

The invention discloses a method of realizing wound-rotor motor redundant rotation speed feedback and a device. The method comprises steps: according to the quantity of rotary shaft square wave signals within a unit time and the cycle of the rotary shaft square wave signals, a first real-time rotation speed is calculated; according to the cycle of rotor square wave signals, a second real-time rotation speed is calculated; whether the difference value between the first real-time rotation speed and the second real-time rotation speed is in a set range is judged; if not, whether the difference value duration time exceeds the set time is further judged; and if not, abnormal protection signals are sent. The device comprises an encoder, a differential signal processing circuit, a rotor frequency signal processing circuit, a main control module and a thyristor unit. The real-time rotation speed of the wound-rotor motor whether in a high-speed operation condition or in a low-speed operation condition can be timely and accurately fed back, the speed regulation mechanism of the wound-rotor motor can be safely protected, and a reliable guarantee is provided for safety operation of the wound-rotor motor.

Owner:SHANGHAI EECTRL ELECTRIC

System and method for starting a wound rotor motor

ActiveUS7511446B2Single-phase induction motor startersMotor/generator/converter stoppersEngineeringPhase control

Owner:TMEIC

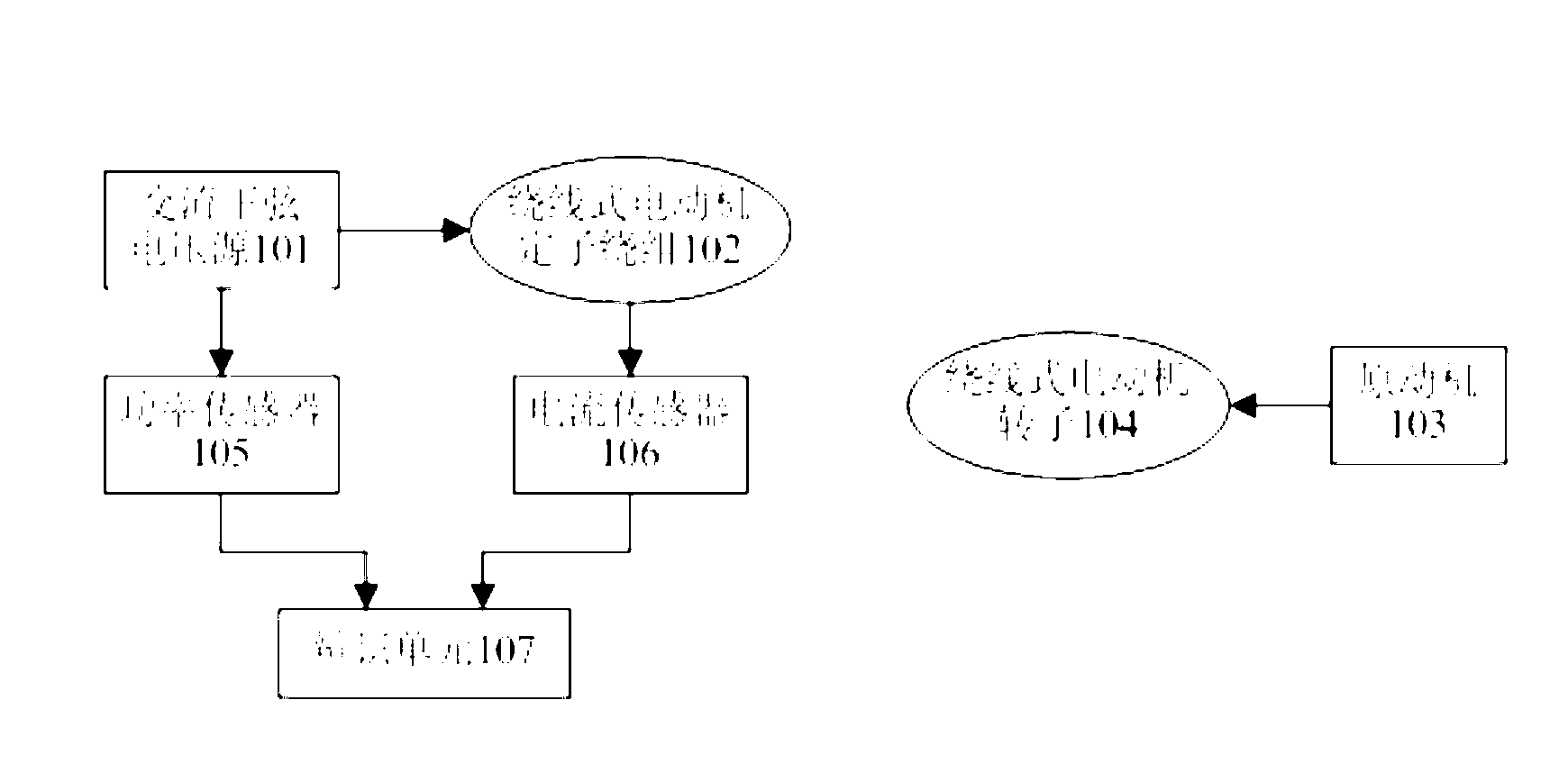

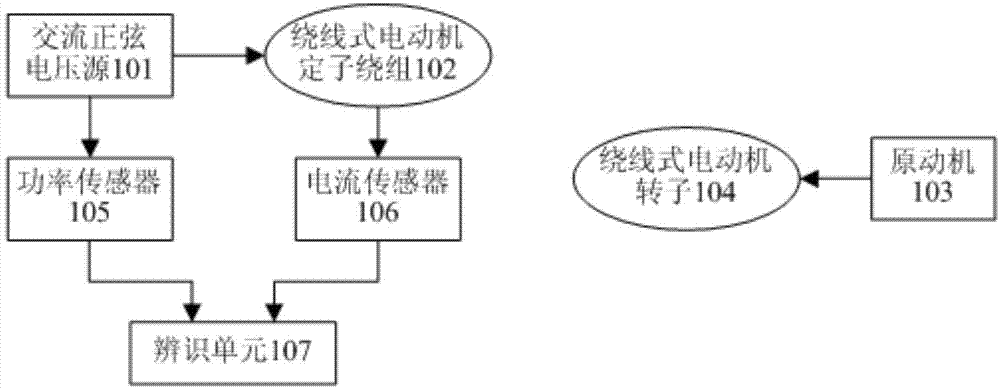

Method for measuring wound rotor type motor rated condition rated condition iron loss

ActiveCN103323679AEasy to measureAccurate measurementResistance/reactance/impedencePower sensorPower flow

The invention discloses a method for measuring wound rotor type motor rated condition rated condition iron loss, and belongs to methods for measuring wound rotor type motor parameters. A prime motor is adopted to drag a wound rotor type motor rotor to rotate at the rated speed of a wound rotor type motor. A wound rotor type motor stator winding is conducted to an alternate current sinusoidal voltage source. A power sensor is adopted to measure the alternate current sinusoidal voltage source to obtain power output power. A current sensor is adopted to measure the wound rotor type motor stator winding to obtain a stator current effective value. The stator current effective value and the square of wound rotor type motor stator equivalent resistance are multiplied, and then the copper loss of a wound rotor type motor rated condition rated condition is obtained. The copper loss of the wound rotor type motor rated condition rated condition is subtracted from the output power of the alternate current sinusoidal voltage source, and then the iron loss of the wound rotor type motor rated condition rated condition is obtained. According to the method for measuring the wound rotor type motor rated condition rated condition iron loss, a complex iron loss computer model of the wound rotor type motor does not need to be set, and measuring is easy and accurate.

Owner:JIANGSU WELM TECH

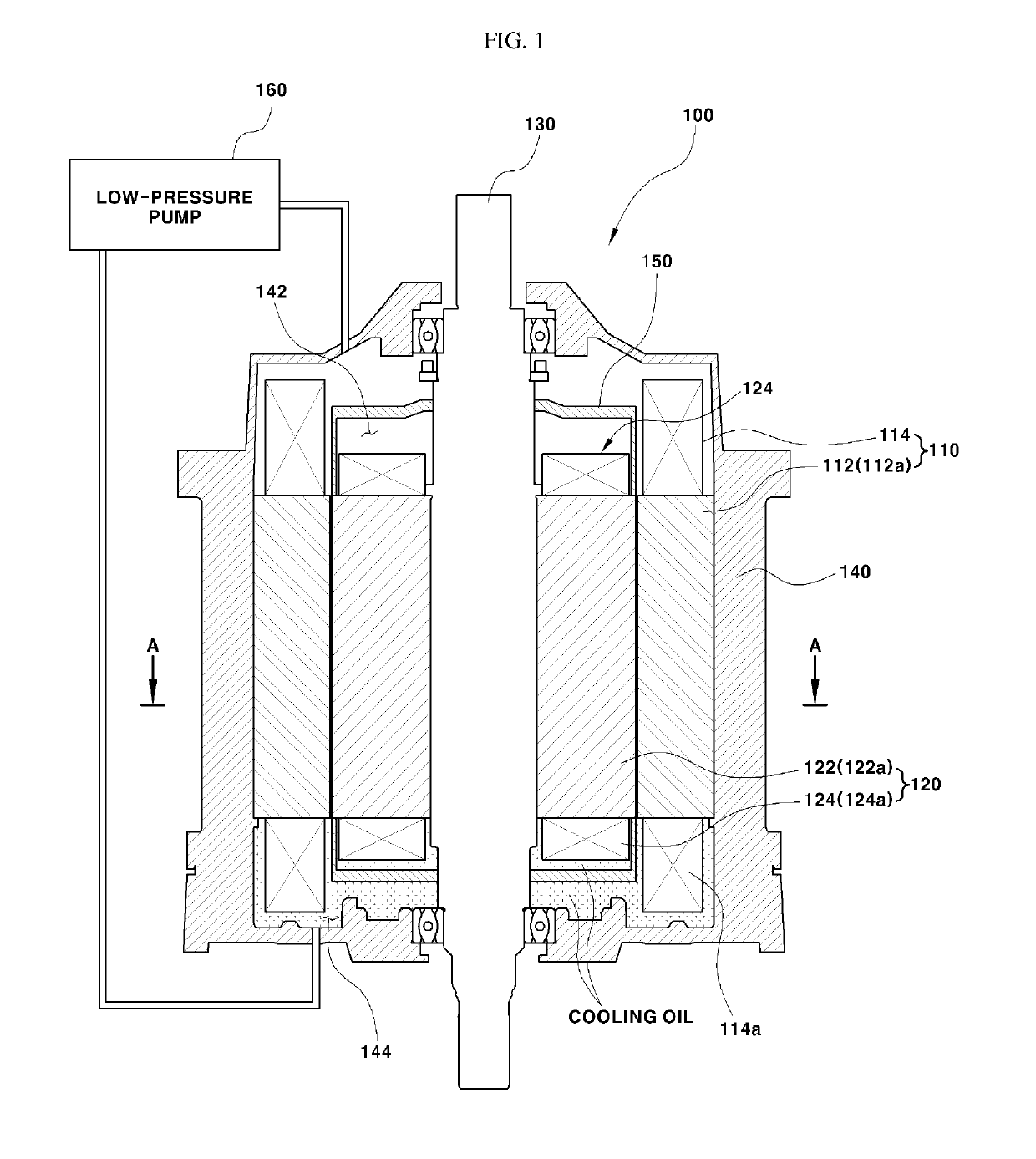

Wound rotor motor for vehicle

ActiveUS20190115805A1Improve cooling effectReduce capacityPropulsion by batteries/cellsVehicular energy storageCooling effectCentrifugal force

A wound rotor motor is provided, in which a rotary shaft is arranged in the vertical direction, to immerse lower coil portions of a stator and a rotor in cooling oil, thereby improving the cooling effect beyond that of a conventional configuration, in which lower coil portions are partially immersed, and consequently decreasing the capacity of an oil pump. A wound rotor motor is provided, in which a rotary shaft is arranged in the vertical direction and has therein a flow passage, through which cooling oil moves up from the region below the rotor and is sprayed to the region above the rotor by centrifugal force generated by rotation of the rotor, thereby enhancing the motor-cooling effect, decreasing the frictional loss of the rotor due to the cooling oil, and consequently improving the operational efficiency of the motor.

Owner:HYUNDAI MOTOR CO LTD +1

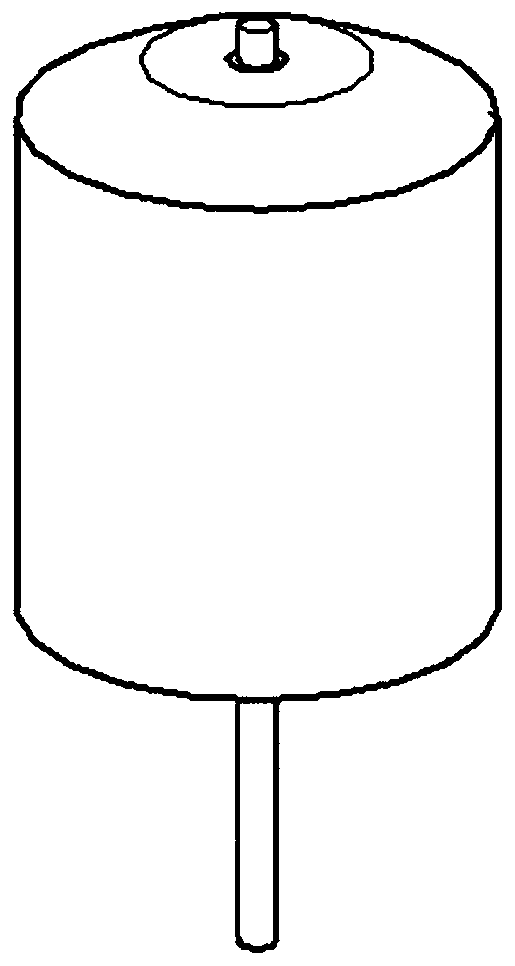

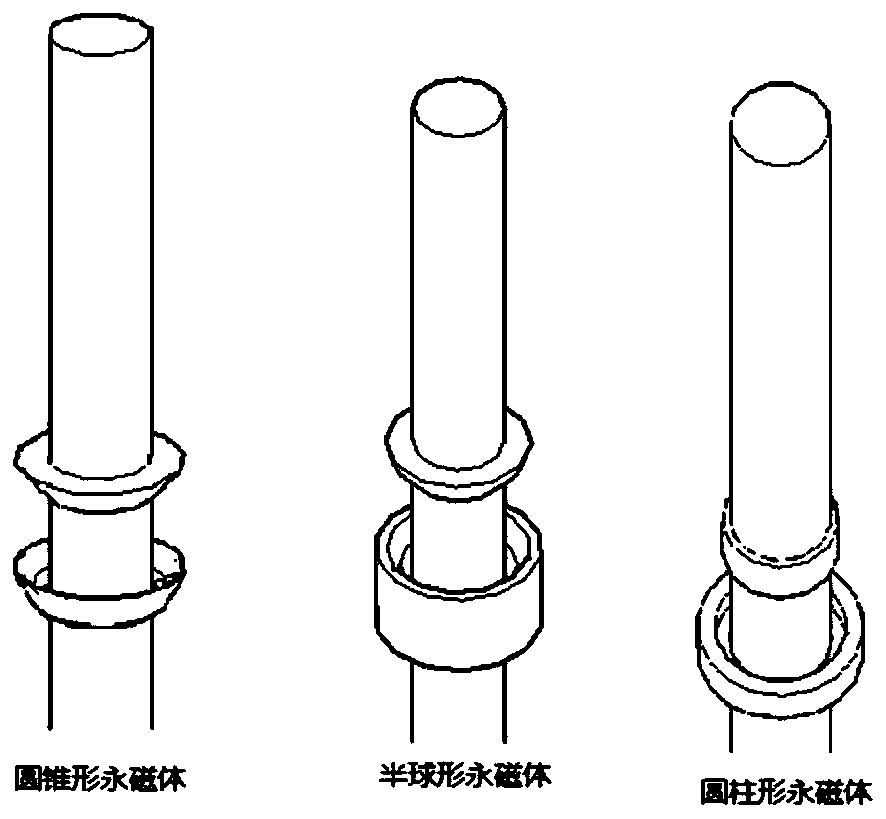

Novel brushless ringless starter for wound rotor motor

InactiveCN101951210AHuge starting powerGreat starting powerPolyphase induction motor starterEngineeringCentrifugal force

The invention relates to a novel brushless ringless starter for a wound rotor motor. The brushless ringless starter is composed of a motor mounting shaft sleeve, a key slot, a starting component mounting nut, a positioning bolt and a starting component, wherein the inside of the starting component is provided with a sliding bar, an insulating sleeve and a spring; the insulating sleeve, a centrifugal pole plate, a contact head, a wire sliding module, the spring, a wire slideway and a binding post are connected by screws; a resistor slideway module, the spring, a resistor slideway and a resistor are connected by wires; both the wire slideway and the resistor slideway are installed on the inner wall of the cylindrical iron core in a uniform insulation mode; the insulating layer on the outer wall of the iron core winds around the resistor wire, and is insulated with the shell of the starting component; one end of the resistor is connected with the shell; the inner wall of the shell is provided with the contact head; the top of the starting component mounting bolt is provided with a vacuum valve; the inside of the starting component is vacuumized to form a vacuum chamber; the centrifugal pole plate slides in the vacuum chamber under the action of the centrifugal force of the motor; the spring is reset; and when in use, the shaft sleeve is installed on the motor shaft, the sleeve nut is arranged on the starting component, the motor lead is correspondingly connected to the screw at the binding post of the starting component, and the starter can be started after confirming to be errorless.

Owner:刘辉

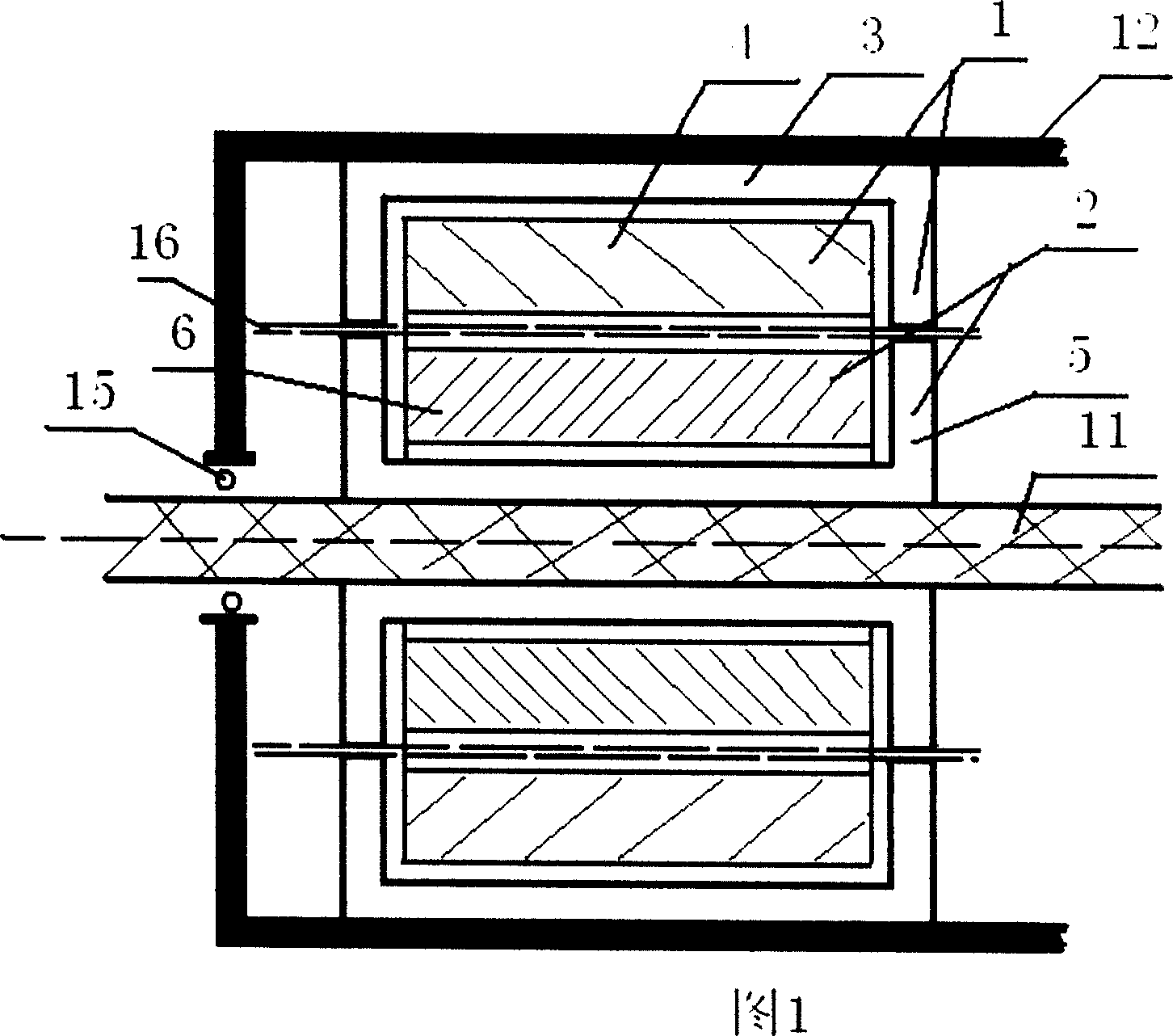

Double stator double rotor motor of solid rotor start-up and squirrel-cage rotor operation, and the start-up and operation method

InactiveCN100566086CHigh starting figure of meritImprove reliabilityDynamo-electric motors/converters startersDynamo-electric machinesPower switchingDrive shaft

The solid rotor starts the double-stator double-rotor motor running on the squirrel-cage rotor, including the stator, rotor, end cover, transmission shaft, and bearing system. Its main technical feature is that there are two rotors, namely the squirrel-cage rotor and the solid rotor. Coaxially installed on the same transmission shaft, there are two stators, namely the main stator and the removable stator. The main stator and the squirrel-cage rotor correspond to form an independently running squirrel-cage rotor asynchronous motor, and the removable stator corresponds to the solid rotor. It constitutes a solid rotor asynchronous motor that operates independently, and a fan is installed on the transmission shaft. The present invention cleverly combines solid rotor and squirrel-cage rotor motors, which have different starting and running characteristics, into a coaxial double-stator double-rotor motor, which gives full play to their advantages respectively, and proposes and uses uninterrupted power switching technology, which truly solves the problem of The problem of "starting", "running" and "reliability" that has plagued the motor industry for a long time can not be achieved at the same time. The implementation method is simple and easy to promote.

Owner:高明真

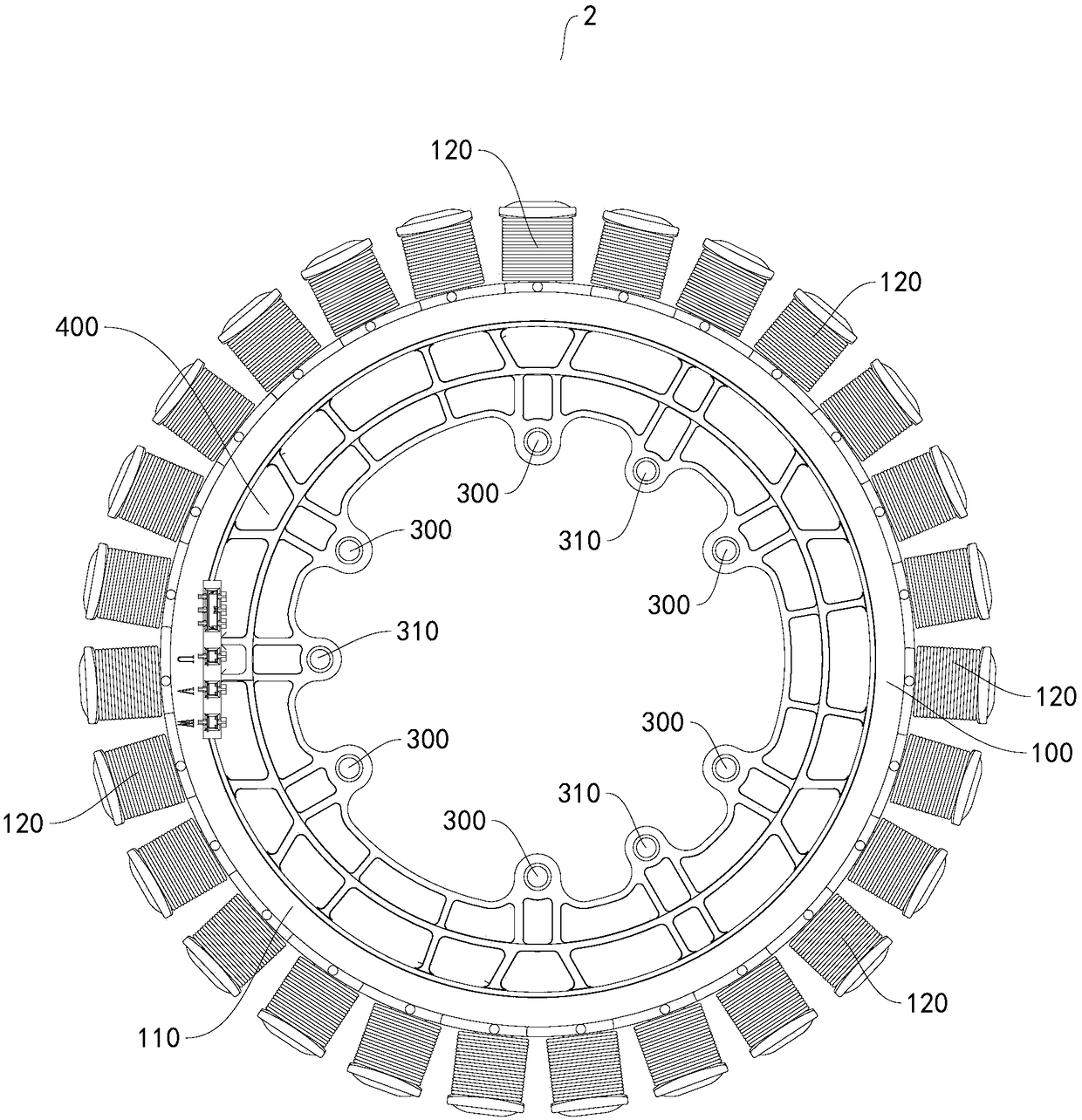

Outer rotor motor and washing machine having with same

ActiveCN109274237ASmall torqueReduce vibrationMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsLow speedMagnetic poles

The invention discloses an outer rotor motor and a washing machine having the same. The outer rotor motor comprises a stator, wherein the stator comprises a core body, wherein the core body comprisesan annular portion and 27 magnetic poles, and the 27 magnetic poles are arranged on the outer peripheral surface of the annular portion at a circumferential interval around the annular portion; A three-phase winding comprising a plurality of coils wound around the 27 magnetic poles; An insulator for insulating the three-phase winding from the 27 magnetic poles; A rotor, the rotor comprising: a magnetically conductive hub frame; A magnetic permeable re is provided on that magnetic permeable hub frame and together with at least a part of the magnetic permeable hub frame form a yoke portion. 32 magnet provided at that yoke portion. The outer rotor motor implemented according to the invention can reduce the tooth groove torque, reduce the speed fluctuation at low speed, and reduce vibration and noise while ensuring the opposite electromotive force, torque constant and load capacity.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

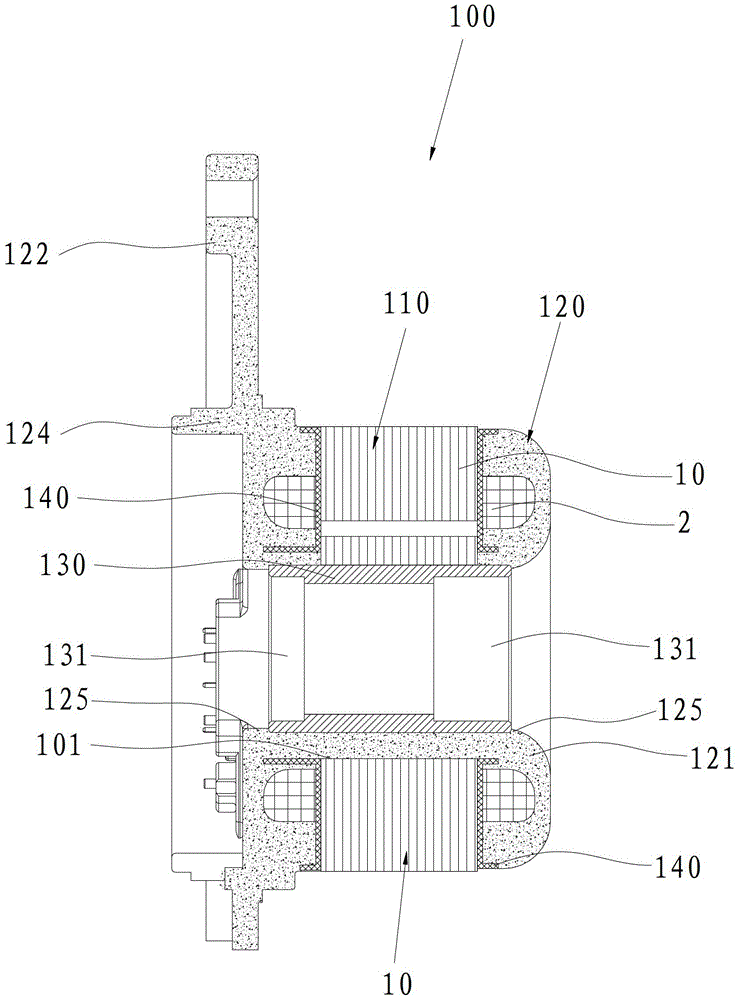

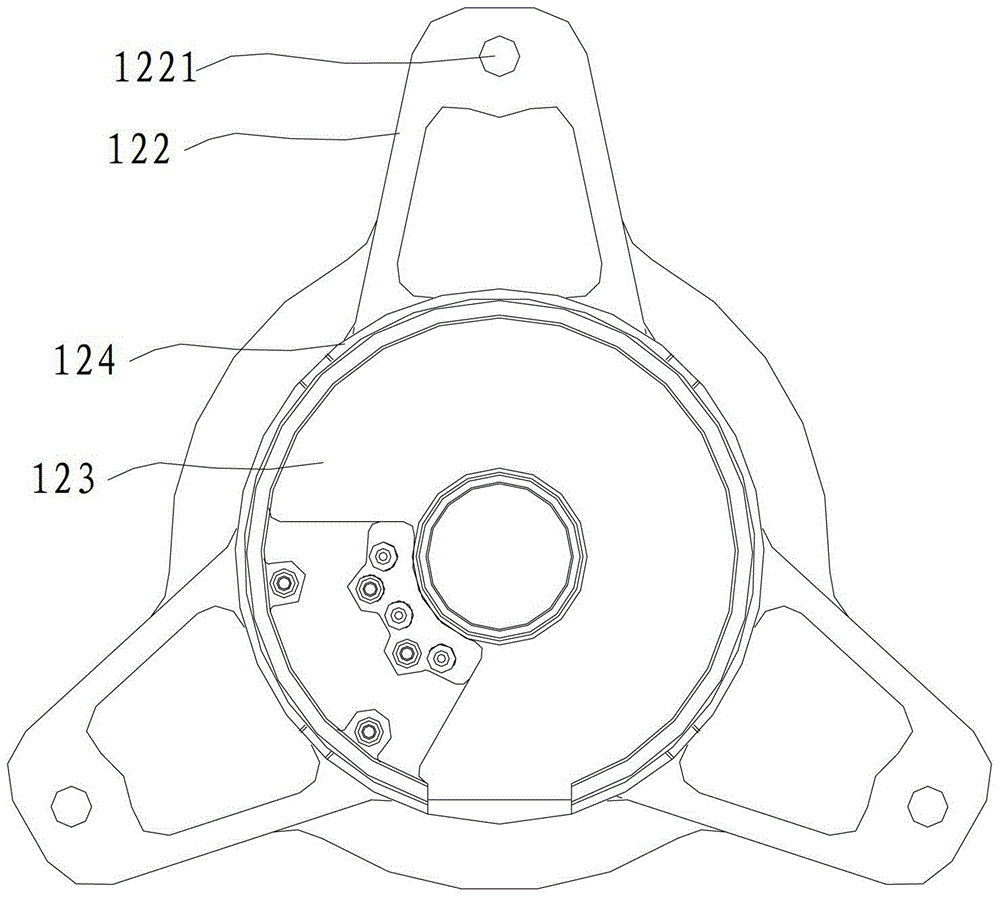

Motor stator and outer rotor motor having the same

ActiveCN103227519BReduce vibrationReduce noiseMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringConductor Coil

The invention is appropriate for the technical field of motors, and discloses a motor stator and an external rotor motor with the motor stator. The motor stator comprises a stator assembly which comprises a stator iron core with a through hole and a winding winded on the stator iron core. The motor stator further comprises a plastic package body wrapping the stator assembly and a bearing sleeve which is positioned in the through hole and used for mounting of a bearing. The plastic package body comprises a body plastic package part which covers the stator iron core and the winding. The plastic package body limits the bearing sleeve by means of arranging a limiting part integrated with the body plastic package part. The external rotor motor comprises the motor stator arranged in the rotor. The motor stator and the external rotor motor with the motor stator provided by the invention are convenient to assemble, less in production vibration and noise and high in reliability.

Owner:FOSHAN WEILING WASHER MOTOR MFG

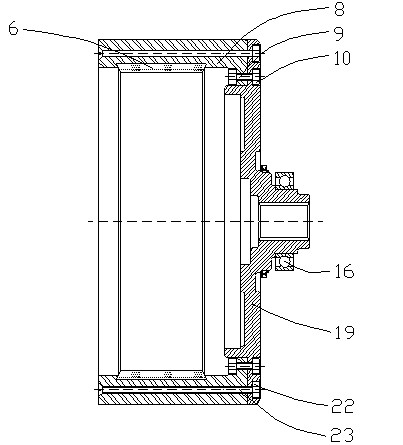

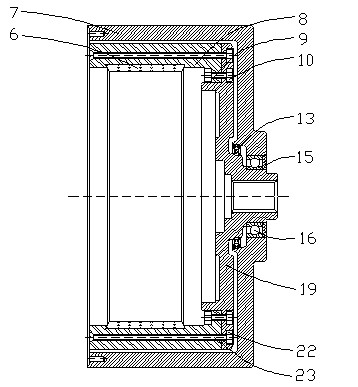

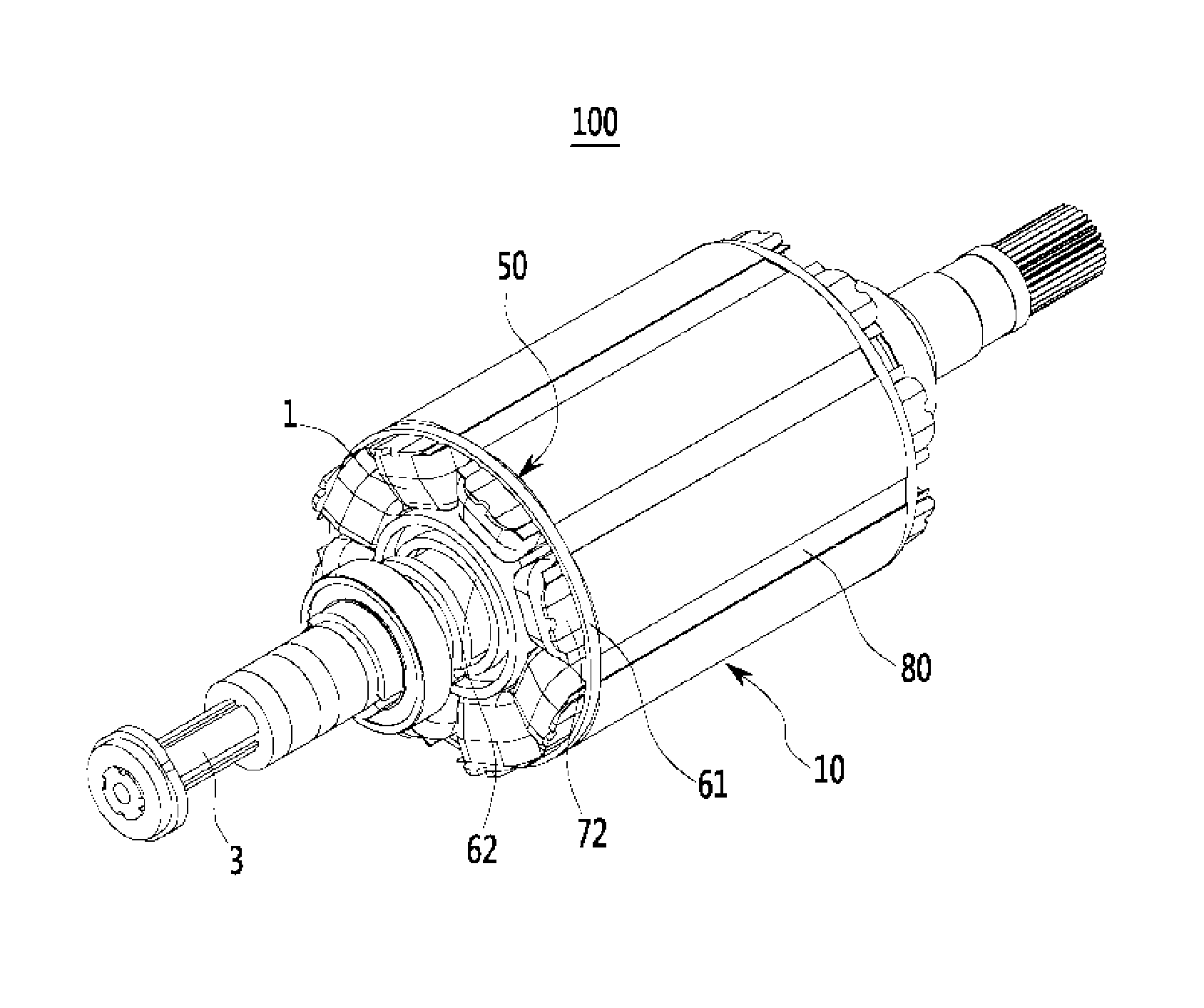

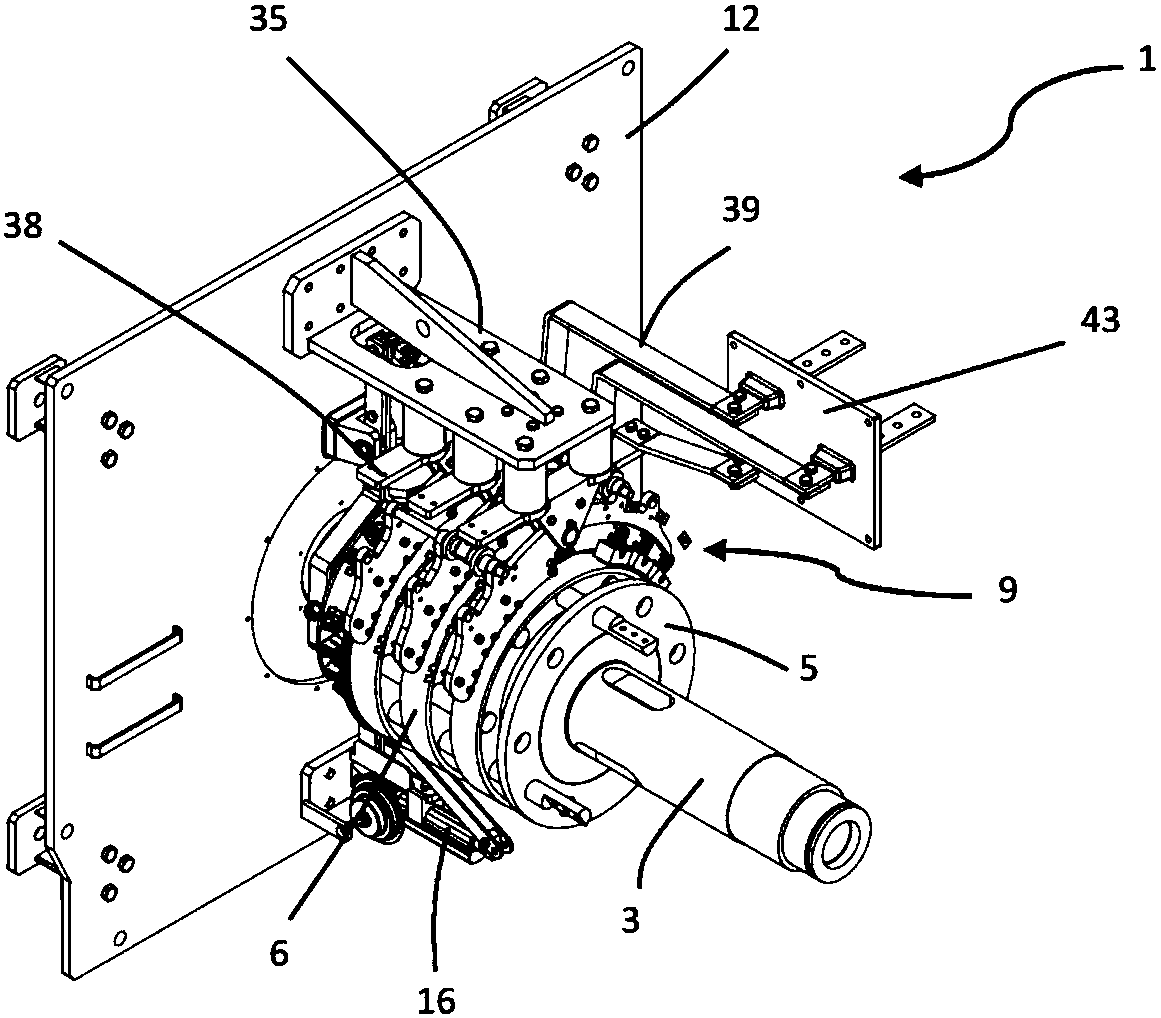

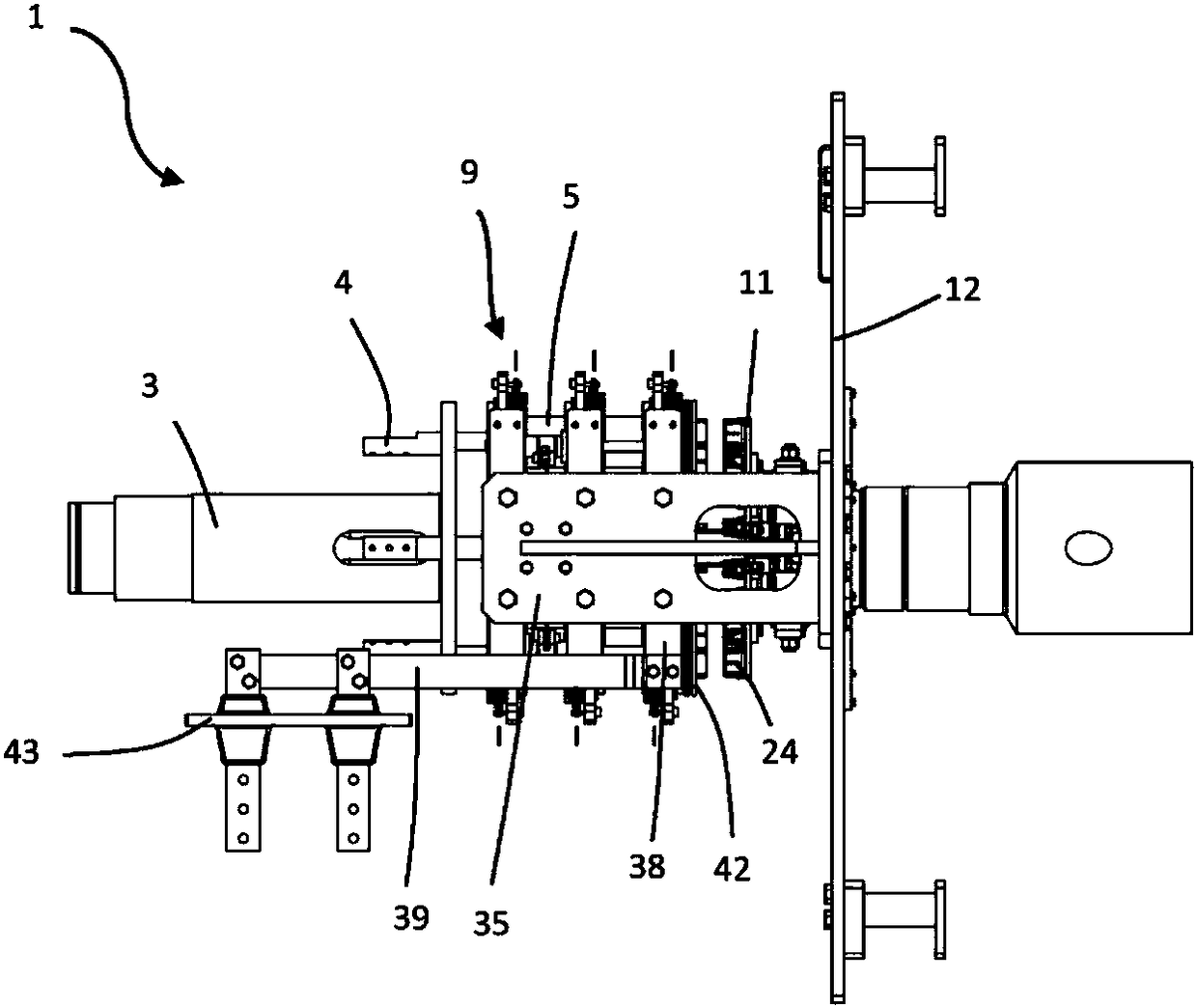

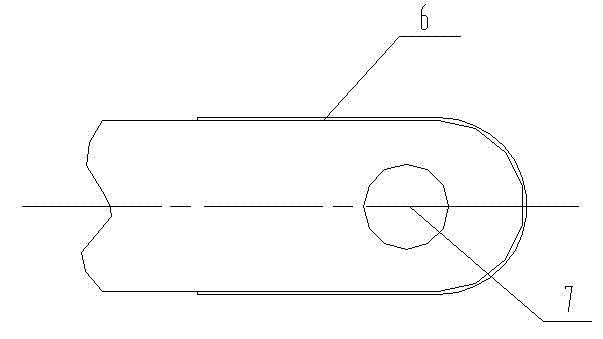

Slipring unit for a wound rotor motor

ActiveCN108880128ALow costEasy to set upRotary current collectorAsynchronous induction motorsEngineeringWound rotor motor

A slipring unit (1) for a wound rotor motor comprises: - a support plate (12); - a stator; - a rotatable shaft (3); - a ring bushing (5); - one or more brushes assemblies (9), each comprising one or more brushes (10), and a brushes lifting mechanism (21) for moving said one or more brushes (10) between a lowered position; - a short-circuiting bushing (11) integrally rotatable with and slidingly movable relative to the shaft (3) between a short-circuiting position; - at least a main lever (14) hinged to the support plate (12), so to be rotatable relative to the support plate (12) between a first position and a second position.

Owner:ABB (SCHWEIZ) AG

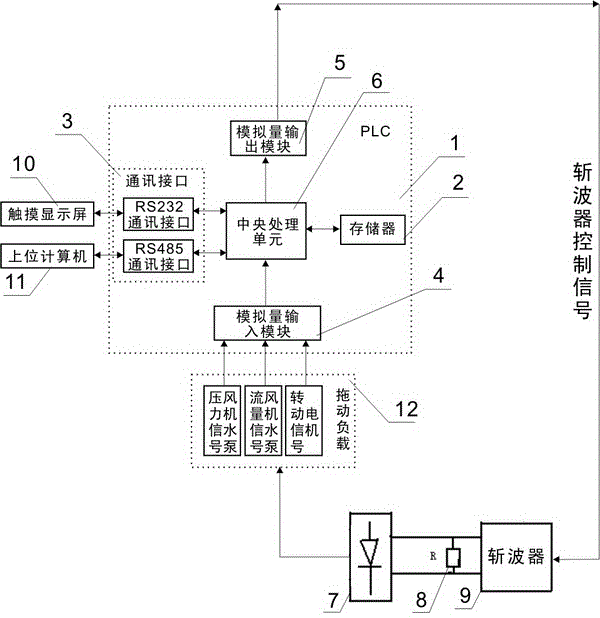

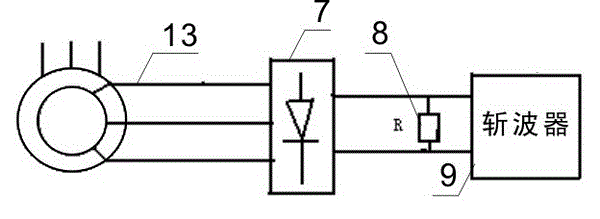

Solid-state starting and speed regulation device with closed loop control function for wound-rotor motor

InactiveCN104656603AHigh efficiency and energy saving effectTotal factory controlProgramme total factory controlLoop controlControl manner

The invention relates to a solid-state starting and speed regulation device with a closed loop control function for a wound-rotor motor. The solid-state starting and speed regulation device comprises a PLC (programmable logic controller), an upper computer, a touch display screen, and an adjusting module connected with the PLC and used for receiving a control command to adjust a dragged load; the adjusting module comprises a chopper and a rectifier bridge circuit; the chopper is connected with the input end of the rectifier circuit through a resistor, and the output end of the rectifier bridge circuit is connected with the dragged load; the PLC comprises a first communication interface, a second communication interface, an analog quantity input module, a central processing unit, and an analog quantity output module. The solid-state starting and speed regulation device provided by the invention overcomes the defects that since a conventional speed regulation device of a load fan or a water pump carried by the wound-rotor motor is controlled manually, process requirements of mining cannot be met, and the real-time property in speed regulation is insufficient, the purpose of closed loop control over the flow rate and pressure of a dragged object, namely the fan or the water pump is achieved by automatically regulating the rotational speed of the controlled motor is achieved, and the effects of high efficiency and energy conservation are further achieved.

Owner:HUBEI XINBAITE AUTOMATION EQUIP

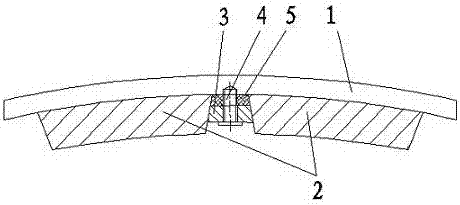

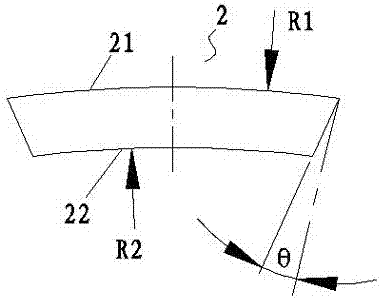

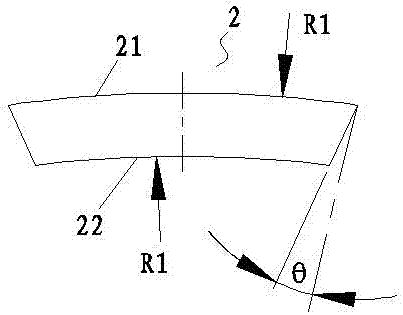

Permanent magnet installation structure of outer rotor motor

ActiveCN104158325BQuality assuranceImprove electromagnetic performanceMagnetic circuit rotating partsTemperature controlLow speed

The invention relates to a permanent magnet installation structure of an outer rotor motor, comprising a cylindrical rotor shell and several permanent magnets installed on the inner wall of the rotor shell, the several permanent magnets adopt the same tile-shaped hexahedron structure and The inside of the rotor housing is regularly arranged along the circumferential direction and the axial direction. The two circumferential sides and the two axial sides of the permanent magnets are all in the shape of an inclined plane with chamfered inner sides. The circumferential direction and the axial direction An axially extending longitudinal bar and a circumferentially extending transverse bar are respectively arranged between upward adjacent permanent magnets, and the longitudinal bar and the transverse bar are fastened to the rotor housing by screws and The permanent magnet is compressed and fixed. The permanent magnet of the present invention has simple installation process, good firmness and reliability, and low processing cost, which is beneficial to optimize the rotor magnetic field, reduce vibration, reduce noise, reduce heat loss and control temperature rise, and is especially suitable for low-speed and high-torque external rotor motors And according to the reel direct drive crane hoisting mechanism of this motor, etc.

Owner:JIANGXI GONGBU MACHINERY

Large current pin structure of coil wound rotor motor

InactiveCN103035327ASolve the problem of large current carrying and agingSolve the problem of longevityInsulated cablesDynamo-electric machinesLacquerEngineering

A large current pin structure of a coil wound rotor motor comprises a plurality of layers of red copper sheets which are in a flexible state, a imine film, a silicon rubber self-adhesive tape and a fiber glass tape, half block of crossed flexible red copper sheets wrap the imine film and the silicon rubber self-adhesive tape, and the fiber glass tape is wrapped in an upper block of the flexible red copper sheets, and a layer of epoxy self- dried lacquer is coated on the fiber glass tape. The large current pin structure of the coil wound rotor motor replaces utilization of the prior copper core rubber insulating leading and connecting wires in a parallel connection mode, and the problems that the current-carrying is big, and insulating rubber of the wire is prone to aging and short in insulating service life are effectively solved. The large current pin structure of the coil wound rotor motor has the advantages of being low in cost, high in reliability, convenient to operate and the like.

Owner:JIANGSU AEROSPACE POWER ELECTRIC

Magnetic levitation bearing servo motor for underwater robot

InactiveCN110098687AAvoid wear and tearExtended service lifeMechanical energy handlingSupports/enclosures/casingsMagnetic polesWound rotor motor

The invention relates to a magnetic levitation bearing servo motor for an underwater robot, which comprises an outer rotor motor and an inner rotor motor, wherein the outer rotor motor includes an inner stator bearing, an inner rotor bearing, a set of permanent magnets A arranged at two ends of the inner stator bearing in the axial direction, the permanent magnets are made of rubidium iron boron,the magnetizing direction is along the axial direction of the inner rotor bearing , and the magnetic pole of the inner rotor bearing adopts the same polarity as the permanent magnet A at the magneticpole of the inner stator bearing; and the inner rotor motor includes an external stator bearing and a set of permanent magnets B arranged at two ends of the external stator bearing in the axial direction, the permanent magnets B are made of rubidium iron boron, the magnetizing direction is along the axial direction of the external rotor bearing, and the magnetic pole of the external rotor bearingadopts the same polarity as the permanent magnet B at the magnetic pole of the external stator bearing.

Owner:蚁人(苏州)智能科技有限公司

536-model groove cam electric speed regulation disc magnetic coupler

The invention provides a 536-model groove cam electric speed regulation disc magnetic coupler belonging to the field of power transmission, energy saving and emission reduction, moving equipment, and magnetic drive. A speed regulation system formed by an outer rotor motor, a groove cam component, a lever synchronous mechanism, and a high-speed rotary conductive joint (or electric speed regulation special high-speed rotary joint) is utilized. The 536-model groove cam electric speed regulation disc magnetic coupler has four series which are an air-cooled 536-model groove cam electric speed regulation disc magnetic coupler (FT536), a liquid-cooled 536-model groove cam electric speed regulation disc magnetic coupler (YT536), a series connection air-cooled 536-model groove cam electric speed regulation disc magnetic coupler (CFT536), and a series connection liquid-cooled 536-model groove cam electric speed regulation disc magnetic coupler (CYT536). The present invention provides an economic and feasible method for the speed regulation and energy saving of the moving equipment.

Owner:李启飞

Method for measuring wound rotor type motor rated condition rated condition iron loss

ActiveCN103323679BEasy to measureAccurate measurementResistance/reactance/impedencePower sensorPower flow

The invention discloses a method for measuring wound rotor type motor rated condition rated condition iron loss, and belongs to methods for measuring wound rotor type motor parameters. A prime motor is adopted to drag a wound rotor type motor rotor to rotate at the rated speed of a wound rotor type motor. A wound rotor type motor stator winding is conducted to an alternate current sinusoidal voltage source. A power sensor is adopted to measure the alternate current sinusoidal voltage source to obtain power output power. A current sensor is adopted to measure the wound rotor type motor stator winding to obtain a stator current effective value. The stator current effective value and the square of wound rotor type motor stator equivalent resistance are multiplied, and then the copper loss of a wound rotor type motor rated condition rated condition is obtained. The copper loss of the wound rotor type motor rated condition rated condition is subtracted from the output power of the alternate current sinusoidal voltage source, and then the iron loss of the wound rotor type motor rated condition rated condition is obtained. According to the method for measuring the wound rotor type motor rated condition rated condition iron loss, a complex iron loss computer model of the wound rotor type motor does not need to be set, and measuring is easy and accurate.

Owner:JIANGSU WELM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com