Permanent magnet installation structure of outer rotor motor

An external rotor motor and installation structure technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts and other directions, can solve the problems of large installation workload of permanent magnets, poor machinability of permanent magnets, and difficulty in ensuring quality, etc. Achieve the effect of improving electromagnetic performance, reducing processing difficulty, and facilitating installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

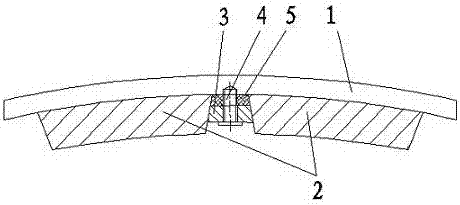

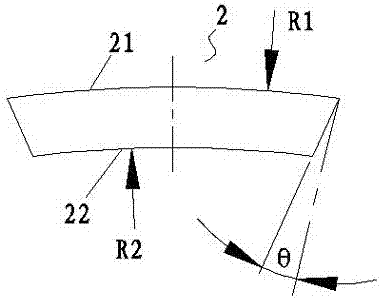

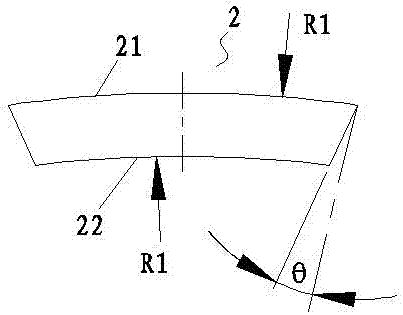

[0008] see figure 1 and 2, the permanent magnet installation structure of the outer rotor motor provided by the present invention includes a cylindrical rotor housing 1 and a number of permanent magnets 2 installed on the inner wall of the rotor housing, and the number of permanent magnets adopts the same tile-shaped hexahedron structure and are regularly arranged in the rotor housing along the circumferential direction (direction along the circumference) and the axial direction (direction parallel to the axis of the stator main shaft), and the two circumferential sides of the permanent magnets are chamfered inside In the shape of an inclined plane, axially extending longitudinal pressure strips 3 are arranged between adjacent permanent magnets in the circumferential direction, and the longitudinal pressure strips are fastened to the rotor housing by screws 4. The circumferential direction of the longitudinal pressure strips The two sides are respectively pressed against the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com