Electric motor, particularly outer rotor motor

A technology of electric motors and external rotors, applied in the field of electric motors, can solve problems such as interference, and achieve the effect of small noise formation and good cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

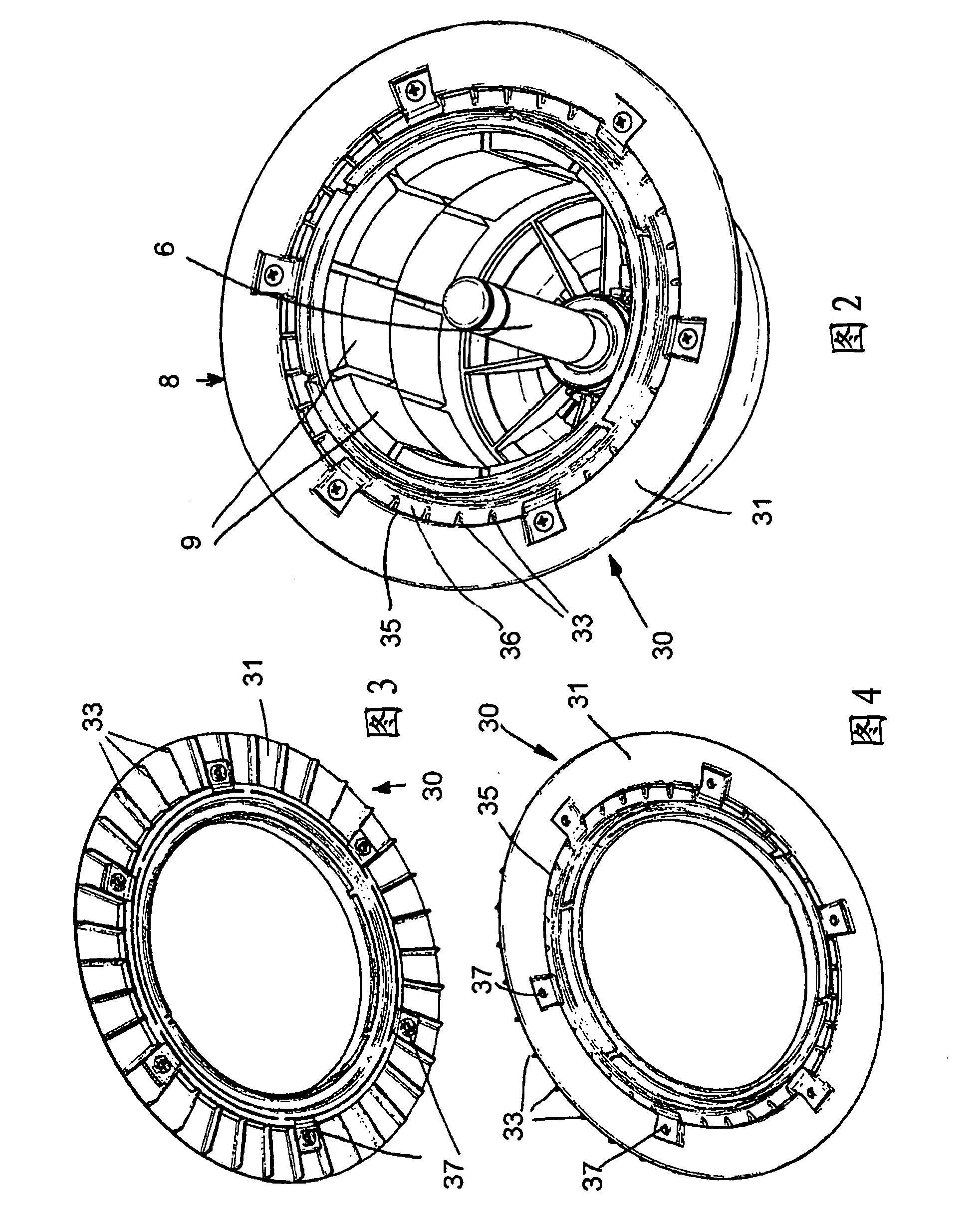

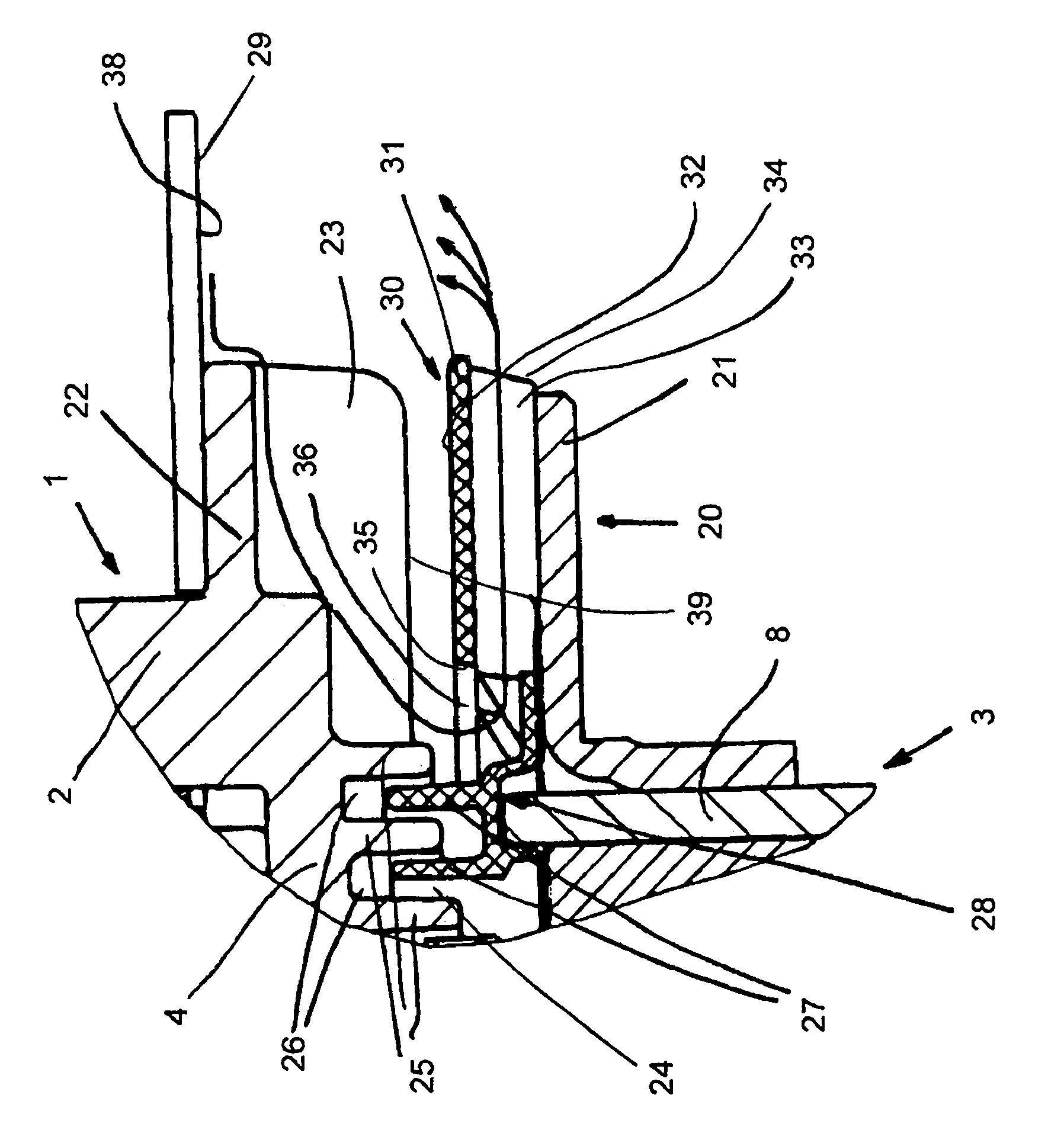

[0025] In the exemplary embodiment, the electric motor is an external rotor motor, which can be, for example, an electronically commutated DC motor. The electric motor has a stator sleeve 1 with a housing 2, which is preferably designed cylindrically. At its end facing the rotor 3 , the stator sleeve 1 has a base 4 , from the center of which protrudes a sleeve-shaped bushing 5 , which protrudes into the rotor 3 . The bushing 5 is advantageously formed in one piece with the base 4 . The rotor shaft 6 is rotatably supported in the bushing 5 with two bearings 7 near the upper end and the lower end. The bearing 7 is in the embodiment a ball bearing, but can be any other suitable bearing.

[0026] The rotor 3 has a rotor housing 8 , on the inside of which permanent magnets 9 are fastened. The permanent magnets surround a rotor lamination 11 (Rotor lamination), which is provided with rotor coils in a known manner, while forming an annular air gap 10 .

[0027] The bushing 5 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com