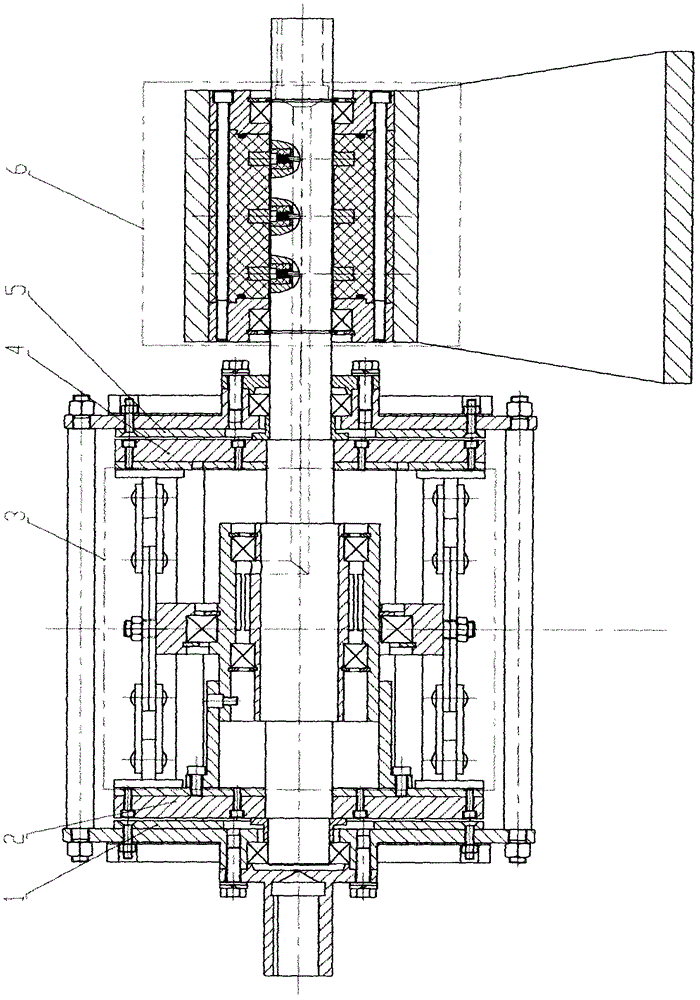

536-model groove cam electric speed regulation disc magnetic coupler

A technology of magnetic coupler and grooved cam, which is applied in the direction of electric components, electromechanical transmission devices, electrical components, etc., can solve the problems of low safety and reliability, poor magnetic coupling of the cylinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] All components of the 536-type grooved cam electric speed regulating disc magnetic coupler can be processed and manufactured by modern industrial manufacturing technology. Motors, magnetic blocks, and bearings can be produced by professional manufacturers, and other parts can be machined, molded, and welded.

[0022] As a dynamic device, the 536-type grooved cam electric speed regulating disc magnetic coupler must meet the following two conditions in order to be successfully applied: (1) Power calibration - establish a complete test bench (each power torque interval), to complete the calibration of serialized products. (2) Dynamic balance detection - rotating equipment must meet the dynamic balance requirements stipulated in relevant standards to achieve the necessary safety and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com