Hybrid electric system adopting double-rotor motor and implementation method of hybrid electric system adopting double-rotor motor

A technology of hybrid power system and dual-rotor motor, which is applied in the field of power system, can solve the problems of poor power output of lithium battery and poor engine smoothness, and achieve the effects of good low-speed climbing ability, smooth start at low temperature, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

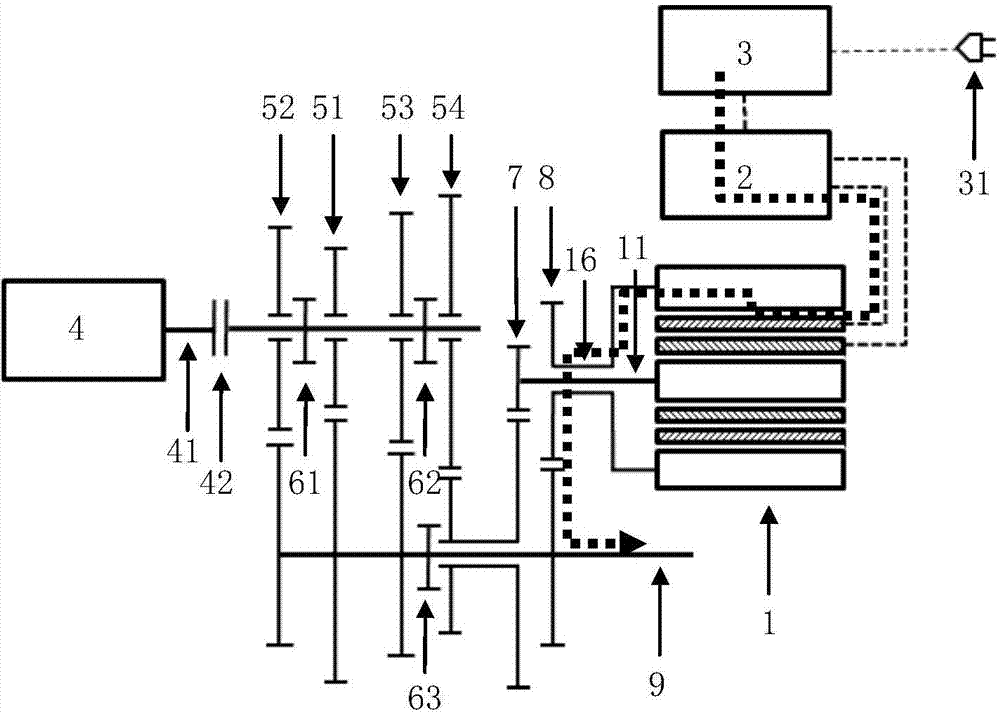

[0031] see figure 1 , the dual-rotor motor used in this application includes:

[0032] ——The housing 10 surrounds the remaining components, wherein the output shaft 11 of the inner rotor motor and the output shaft 16 of the outer rotor motor extend out of the housing 10 .

[0033] ——The output shaft 11 of the inner rotor motor is sealed with the casing 10 by bearing one 101 .

[0034] ——The inner rotor 12 surrounds and is fixed on the inner rotor motor shaft 11, and the two keep rotating synchronously.

[0035] - The inner stator 13 surrounds the inner rotor 12 with a gap in between.

[0036] - the outer stator 14 surrounding the inner stator 13 . The inner stator 13 and the outer stator 14 share a stator bracket and are fixed to the casing 10 by fixing bolts 135 . There is a cooling water channel 145 between the inner stator 13 and the outer stator 14 .

[0037] - The outer rotor 15 surrounds the outer stator 14 with a gap in between. An outer rotor position sensor 155,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com