Insulating structure for rotor coil for high-voltage wound rotor motor

A technology of wound rotor motor and rotor coil, applied in the shape/style/structure of winding insulation, winding insulation material, asynchronous induction motor, etc. problems, to achieve the effect of saving effective material consumption, reducing groove area, and long-term safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

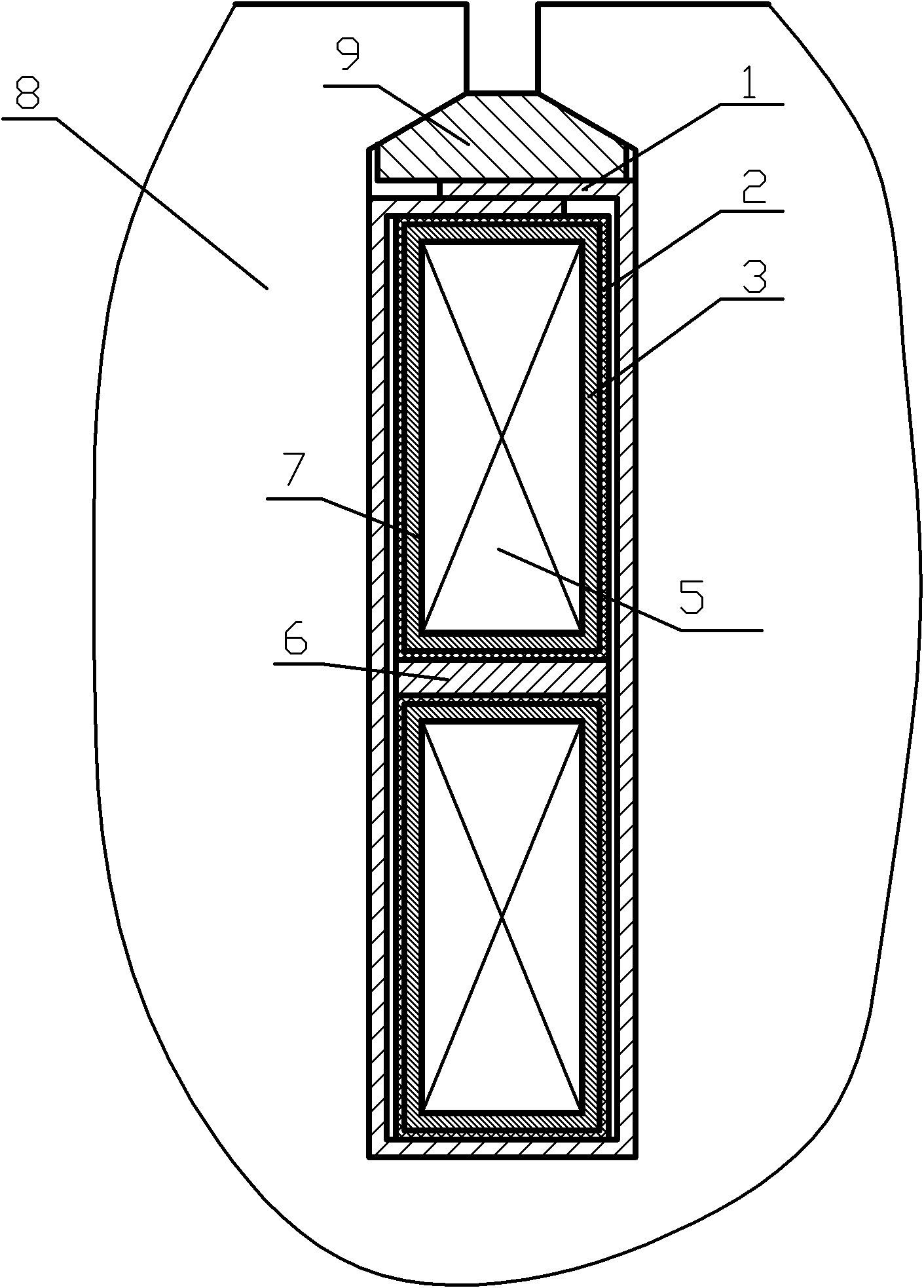

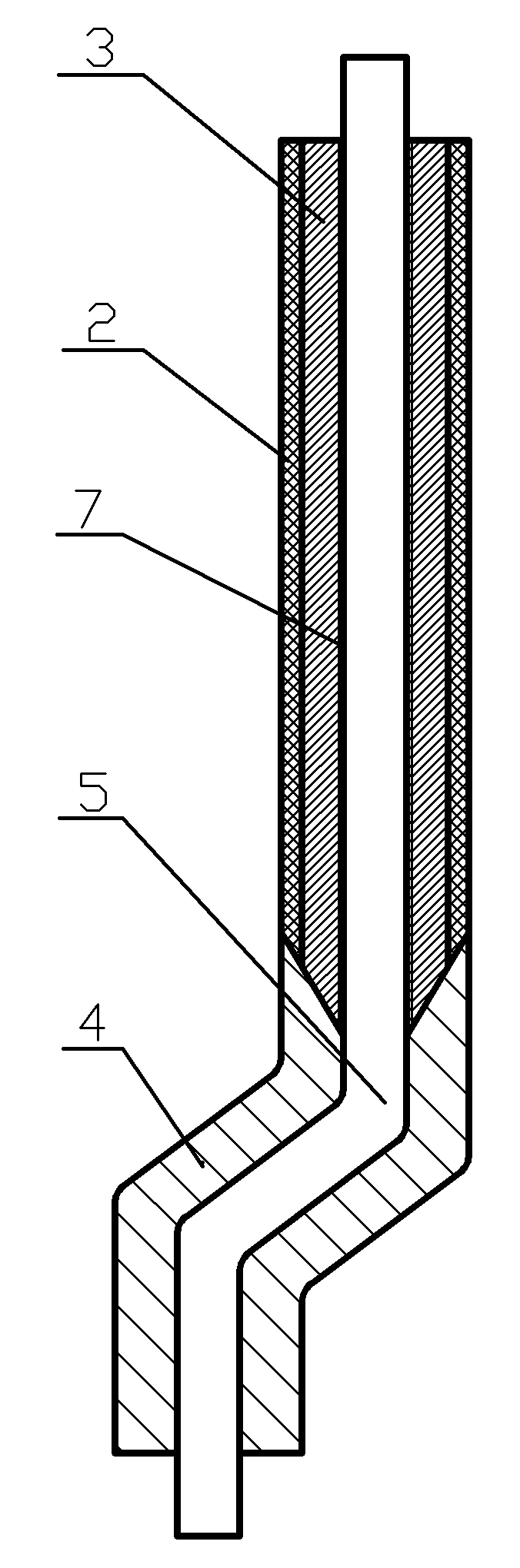

[0010] As shown in the figure, the present invention mainly consists of polyamide film polyaramid fiber paper composite material layer 1, polyimide film tape 2, glass powder mica platinum 3, glass powder mica tape 4, copper coil 5, epoxy phenolic glass The layout plate 6, the modified insulating paint 7, the rotor core 8 and the slot wedge 9 are composed of components.

[0011] The insulation structure of the rotor coil of the high-voltage wound rotor motor includes polyamide film polyaramid fiber paper composite material layer 1, polyimide film tape 2, glass powder mica platinum 3, glass powder mica tape 4, copper coil 5, Epoxy phenolic glass cloth plate 6, modified insulating paint 7, rotor core 8 and slot wedge 9, copper coil 5 installed in rotor core 8, each copper coil 5 is coated with glass powder mica platinum 3, poly Imide film belt 2 and polyamide fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com