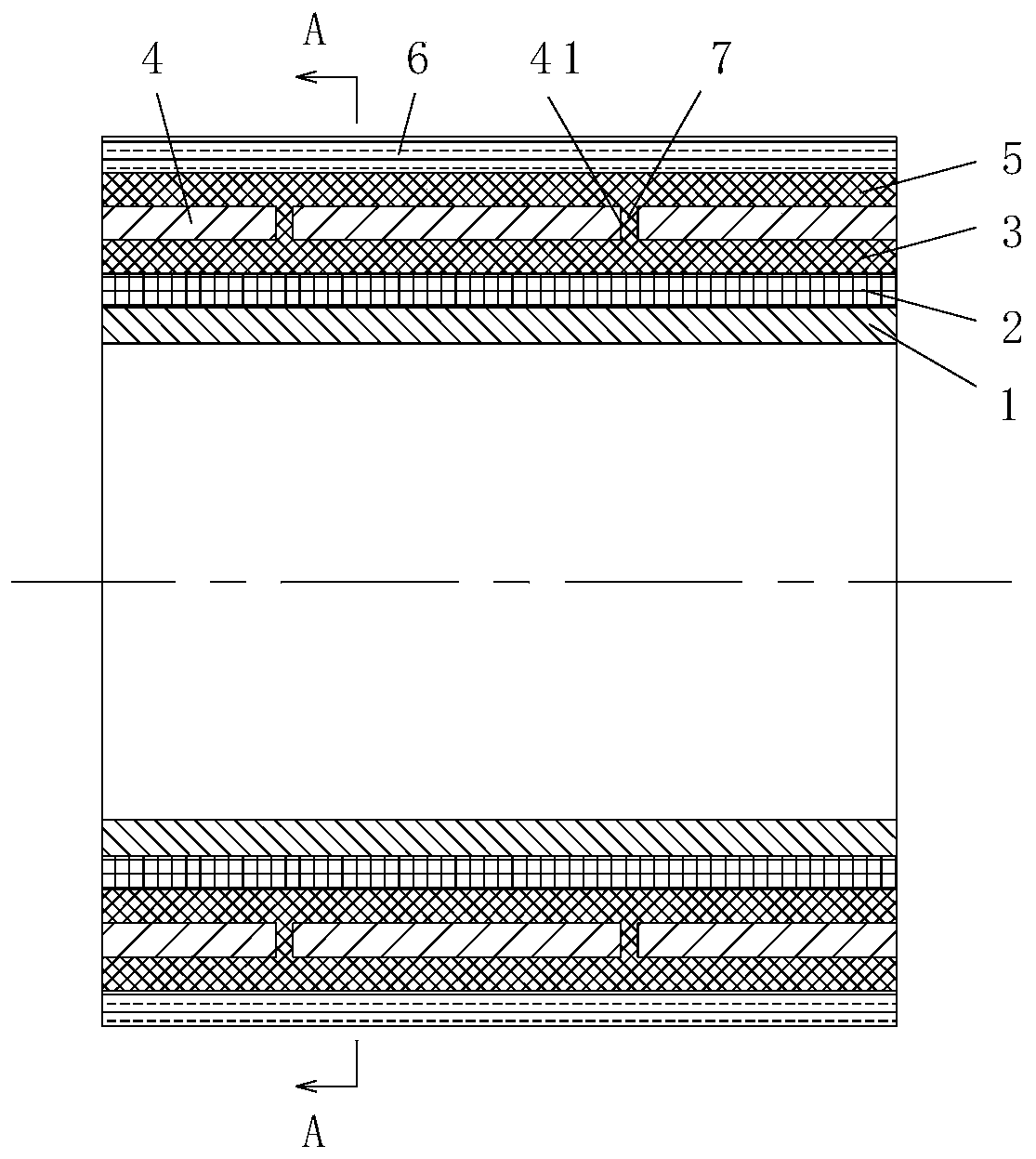

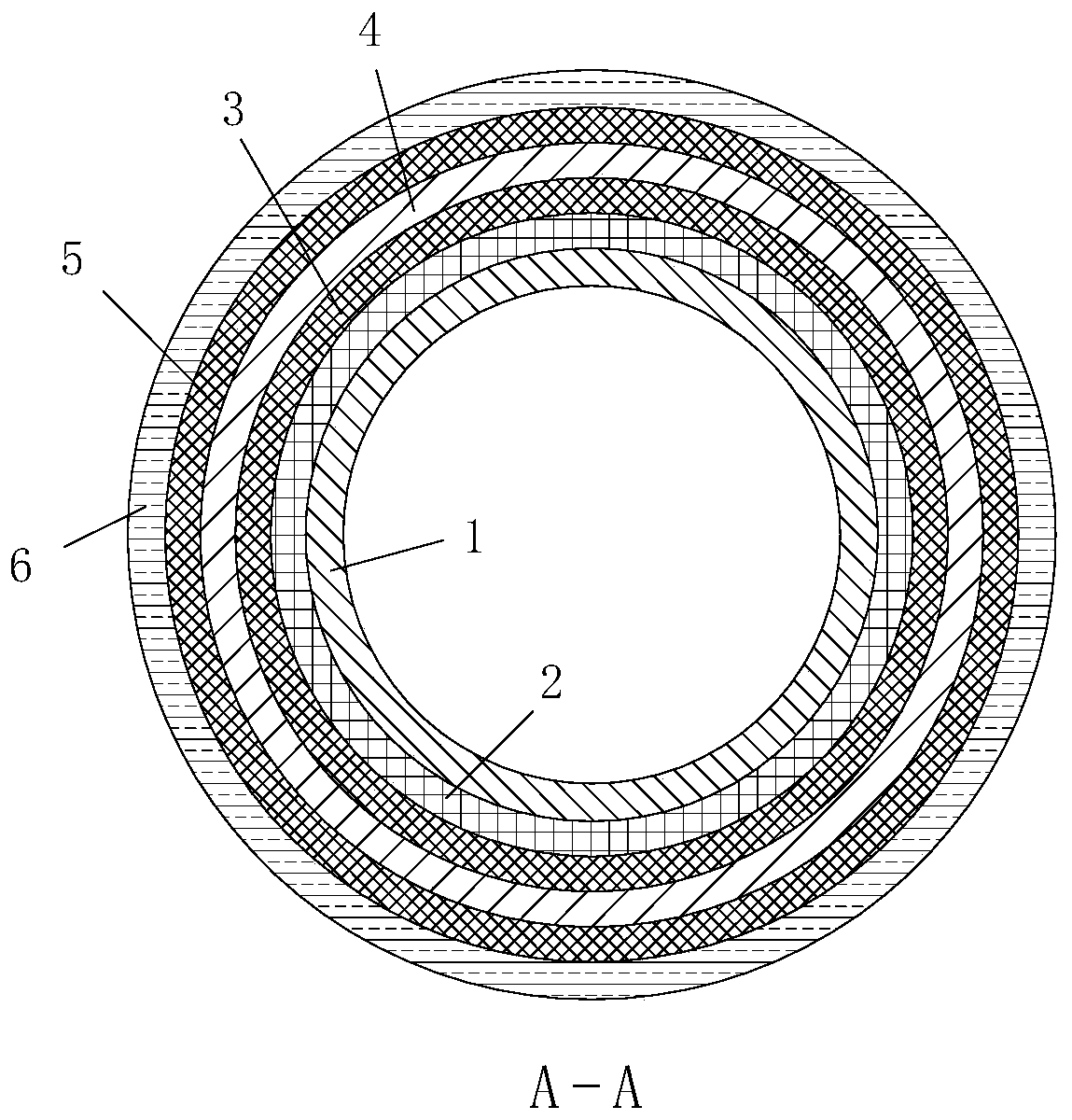

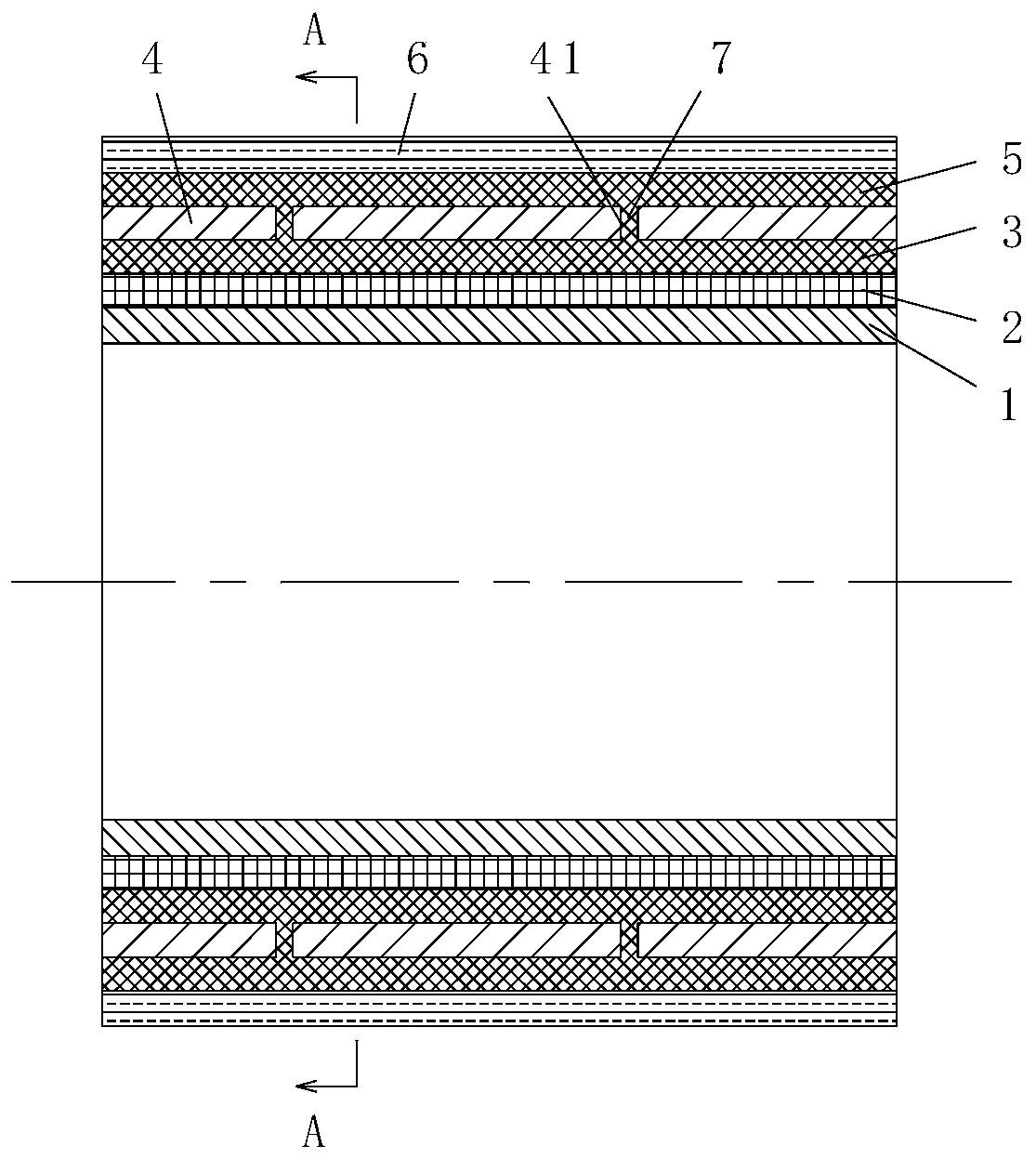

Novel thermal insulation and heat preservation hose and production method thereof

A technology of thermal insulation and production method, which is applied in the direction of protecting pipes, hoses, and thermal insulation through thermal insulation, which can solve the problems of increased heat loss, poor thermal insulation performance, and moisture in the thermal insulation layer, and achieves enhanced service life and thermal insulation effect. Excellent, uniform thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] Embodiment 2: A new type of heat-insulating and heat-preserving hose. The difference from Embodiment 1 is that the wear-resistant layer consists of 130 parts of butyl rubber, 3 parts of heat-resistant aging agent, 3 parts of antioxidant, 13 parts of carbon black, 9 parts of calcium carbonate, 13 parts of chlorosulfonated polyethylene, 7 parts of quartz powder and 16 parts of hydroxypropyl cellulose.

[0045] The DN80 thermal insulation hose is produced and prepared by the above materials and methods, the thermal insulation hose is set on the DN80 lined steel pipe, and the -40°C medium is passed into the lined steel pipe, and the room temperature is 21°C. The outer surface temperature of the thermal insulation hose is 21°C, and the thermal insulation hose has a good thermal insulation effect.

Embodiment 3

[0046] Embodiment 3: A new type of heat-insulating and heat-preserving hose. The difference from Embodiment 1 is that the wear-resistant layer consists of 125 parts of butyl rubber, 2 parts of heat-resistant aging agent, 3 parts of antioxidant, 12 parts of carbon black, 8 parts of calcium carbonate, 13 parts of chlorosulfonated polyethylene, 6 parts of quartz powder and 15 parts of hydroxypropyl cellulose.

[0047]The DN80 thermal insulation hose is produced and prepared by the above materials and methods. The thermal insulation hose is used to transport steam at a temperature of 150°C, the internal pressure is 1.0MPa, and the ambient temperature is 16°C. The outer surface of the thermal insulation hose is detected The surface temperature is 16°C, and the thermal insulation hose has a good thermal insulation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com