Iron-based amorphous composite magnetic powder core and preparation method

An iron-based amorphous and magnetic powder core technology, which is applied in the field of iron-based amorphous composite magnetic powder cores and its preparation, can solve the problems of inability to meet high magnetic permeability, reduce losses, single non-wafer-shaped powder, etc. The effect of production and promotion, saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

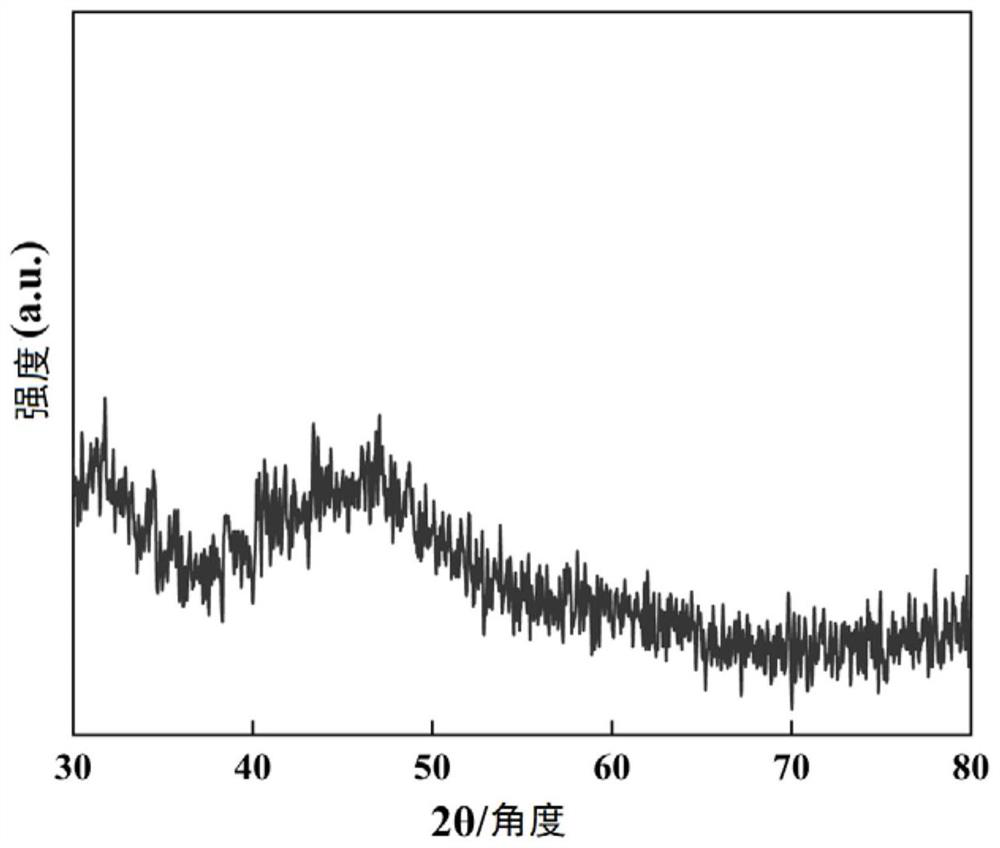

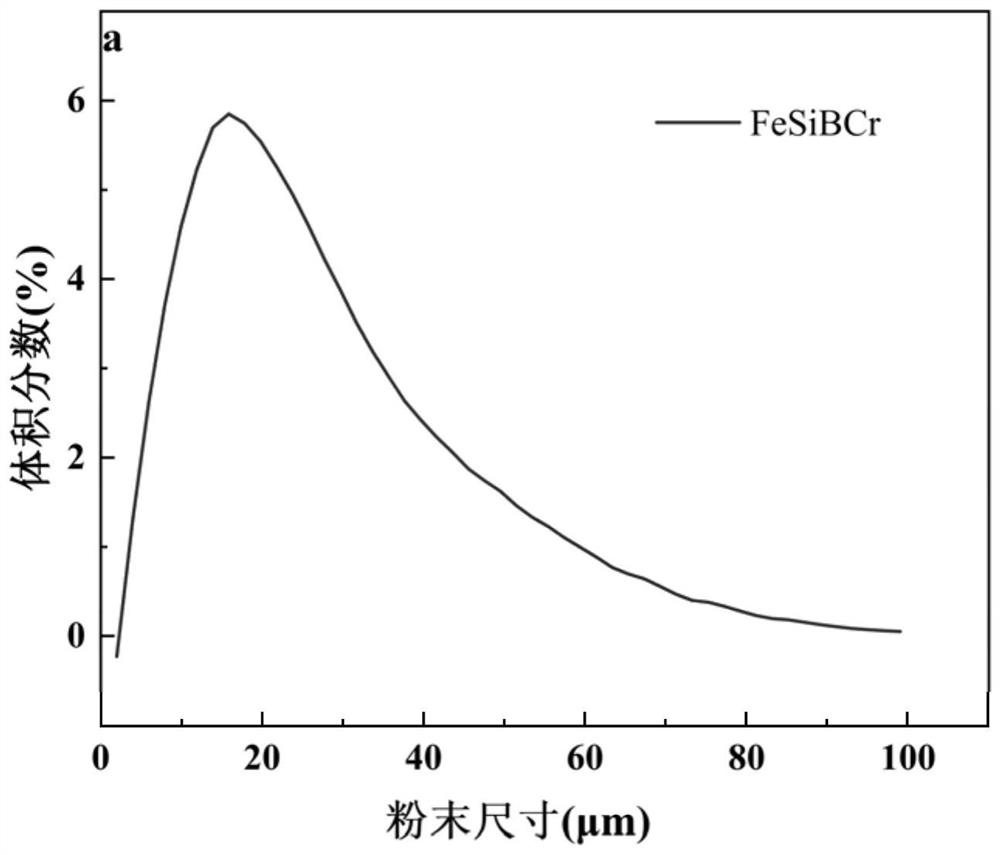

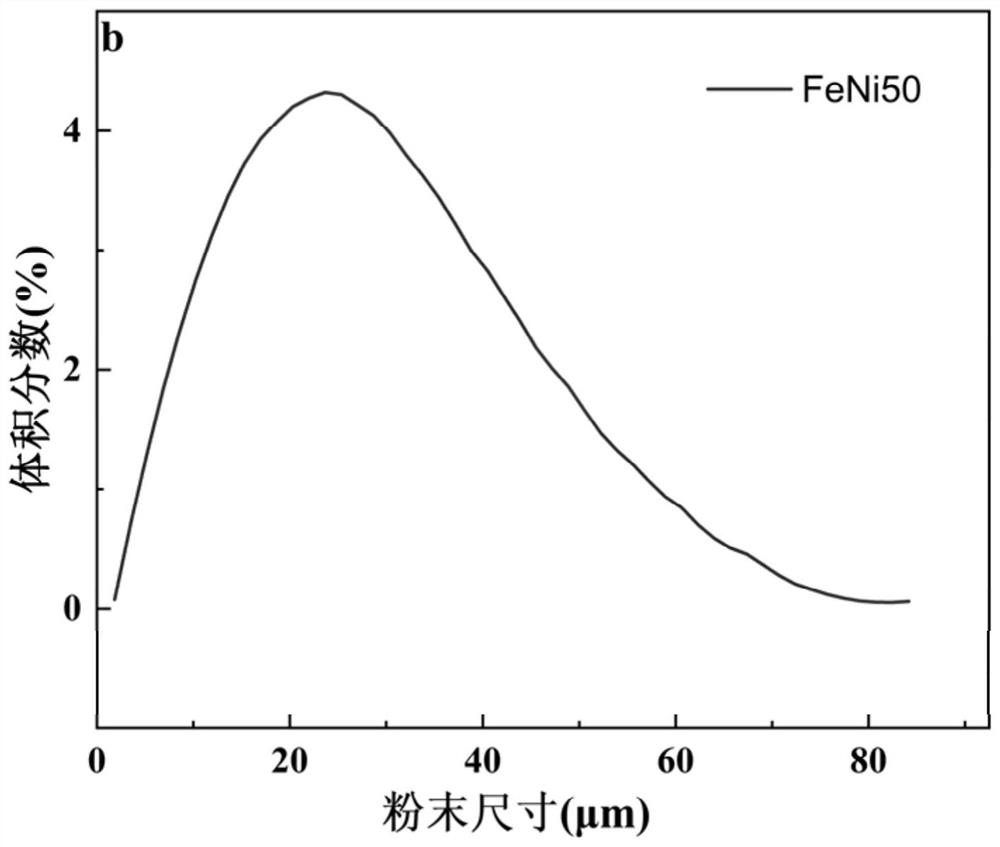

[0043] An iron-based amorphous composite magnetic powder core, the iron-based amorphous composite magnetic powder core is composed of mixed powder coated with insulating material, the mixed powder is composed of FeSiBCr amorphous spherical powder and FeNi50 spherical powder, in the mixed powder The proportion of FeSiBCr amorphous spherical powder is 90wt.%, and the insulating material is Macklin E44.

[0044] Wherein: the particle size of the FeSiBCr amorphous spherical powder is 15-43 μm, and the median diameter is 24.6 μm; the particle size of the FeNi50 spherical powder is 11-43 μm, and the median diameter is 27 μm.

[0045] The preparation method of the iron-based amorphous composite magnetic powder core, the preparation method comprises the following steps:

[0046] S1, FeSiBCr amorphous spherical powder and FeNi50 spherical powder are mixed according to the required ratio to obtain mixed powder A;

[0047] S2, epoxy resin is dissolved in acetone solvent to obtain mixed ...

Embodiment 2

[0051] An iron-based amorphous composite magnetic powder core, the iron-based amorphous composite magnetic powder core is composed of mixed powder coated with insulating material, the mixed powder is composed of FeSiBCr amorphous spherical powder and FeNi50 spherical powder, in the mixed powder The proportion of FeSiBCr amorphous spherical powder is 80wt.%, and the insulating material is Macklin E44.

[0052] Wherein: the particle size of the FeSiBCr amorphous spherical powder is 23-45 μm, and the median diameter is 25.1 μm; the particle size of the FeNi50 spherical powder is 14-40 μm, and the median diameter is 27.3 μm.

[0053] The preparation method of the iron-based amorphous composite magnetic powder core, the preparation method comprises the following steps:

[0054] S1, FeSiBCr amorphous spherical powder and FeNi50 spherical powder are mixed according to the required ratio to obtain mixed powder A;

[0055] S2, epoxy resin is dissolved in acetone solvent to obtain mixe...

Embodiment 3

[0059] An iron-based amorphous composite magnetic powder core, the iron-based amorphous composite magnetic powder core is composed of mixed powder coated with insulating material, the mixed powder is composed of FeSiBCr amorphous spherical powder and FeNi50 spherical powder, in the mixed powder The proportion of FeSiBCr amorphous spherical powder is 70wt.%, and the insulating material is Macklin E44.

[0060] Wherein: the particle size of the FeSiBCr amorphous spherical powder is 12-33 μm, and the median diameter is 25.3 μm; the particle size of the FeNi50 spherical powder is 20-41 μm, and the median diameter is 28.1 μm.

[0061] The preparation method of the iron-based amorphous composite magnetic powder core, the preparation method comprises the following steps:

[0062] S1, FeSiBCr amorphous spherical powder and FeNi50 spherical powder are mixed according to the required ratio to obtain mixed powder A;

[0063] S2, epoxy resin is dissolved in acetone solvent to obtain mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com