Permanent magnetism synchronous wheel hub motor for directly driving electric vehicle wheel

An electric vehicle, permanent magnet synchronous technology, applied in electric vehicles, synchronous machine parts, motors, etc., can solve the problems of increasing the design difficulty of the whole vehicle, complicated structure space layout, and increased maintenance workload, etc. The effect of good control performance and efficient use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described.

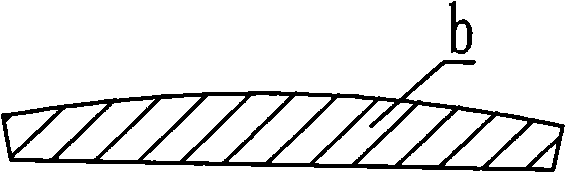

[0014] Refer to attached figure 1 , this embodiment includes a shaft 1, a left end cover 3, a rotor 4, a stator 5, a right end cover 6, and a rotary transformer 7, the shaft 1 is equipped with a bearing 2, and the inner rings of the left end cover 3 and the right end cover 6 are in interference fit with the bearing 2, The stator 5 is shrunk onto the bracket a of the shaft 1, and the silicon steel sheets in the stator 5 are connected by high temperature resistant glue; the left end cover 3, the right end cover 6 and the rotor 4 are connected by bolts; the rotor 4 is made of rare earth magnetic steel b The polarity is alternately pasted with magnetic steel glue on the inner wall of the bracket a, which can rotate around the axis 1. The iron core is punched with equally distributed grooves, and coils are wound in the grooves;

[0015] The shaft 1 is a hollow shaft, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com