Solid-state starting and speed regulation device with closed loop control function for wound-rotor motor

A technology of closed-loop control and speed regulating device, applied in the direction of control/regulation system, program control, comprehensive factory control, etc., which can solve the problems of not meeting the real-time requirements of the process and reducing the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

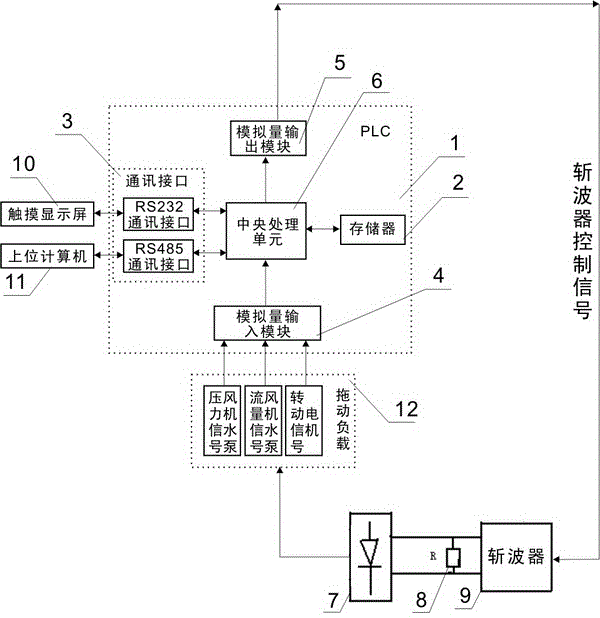

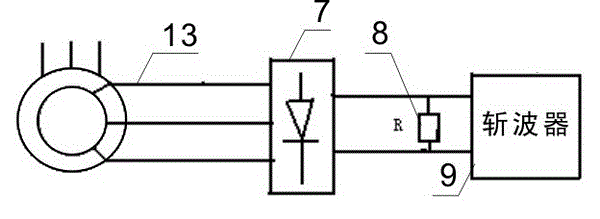

[0014] figure 1 Among them, the PLC programmable controller 1 is connected to the external touch screen 2 through the RS232 communication port, and the keyboard adopts membrane buttons to set the controlled object: closed-loop control function winding motor solid-state start-up speed control device and dragging load fan water pump Relevant parameters, display equipment running status and parameters. The PLC programmable controller 1 is connected with the upper computer 3 through the RS485 interface to realize data communication, real-time data exchange and accept commands from it. The PLC programmable controller 1 collects the relevant parameters of the controlled object liquid soft starter and the load fan and water pump driven by it through the analog input module 4, converts the 4-20mA analog signal into a digital signal, and saves the set parameters in the PLC The memory area (memory) 2 is compared and calculated by the central processing unit 6 with the set parameters, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com