Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Tomato products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

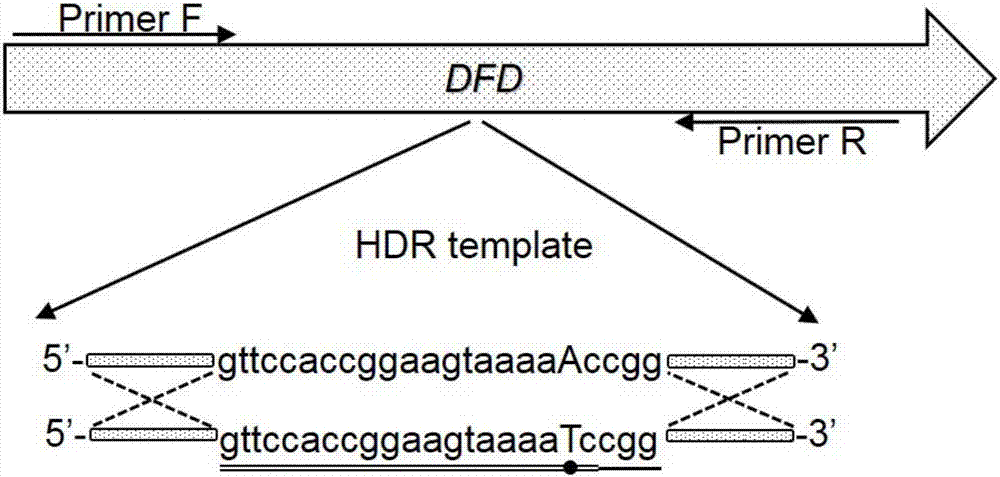

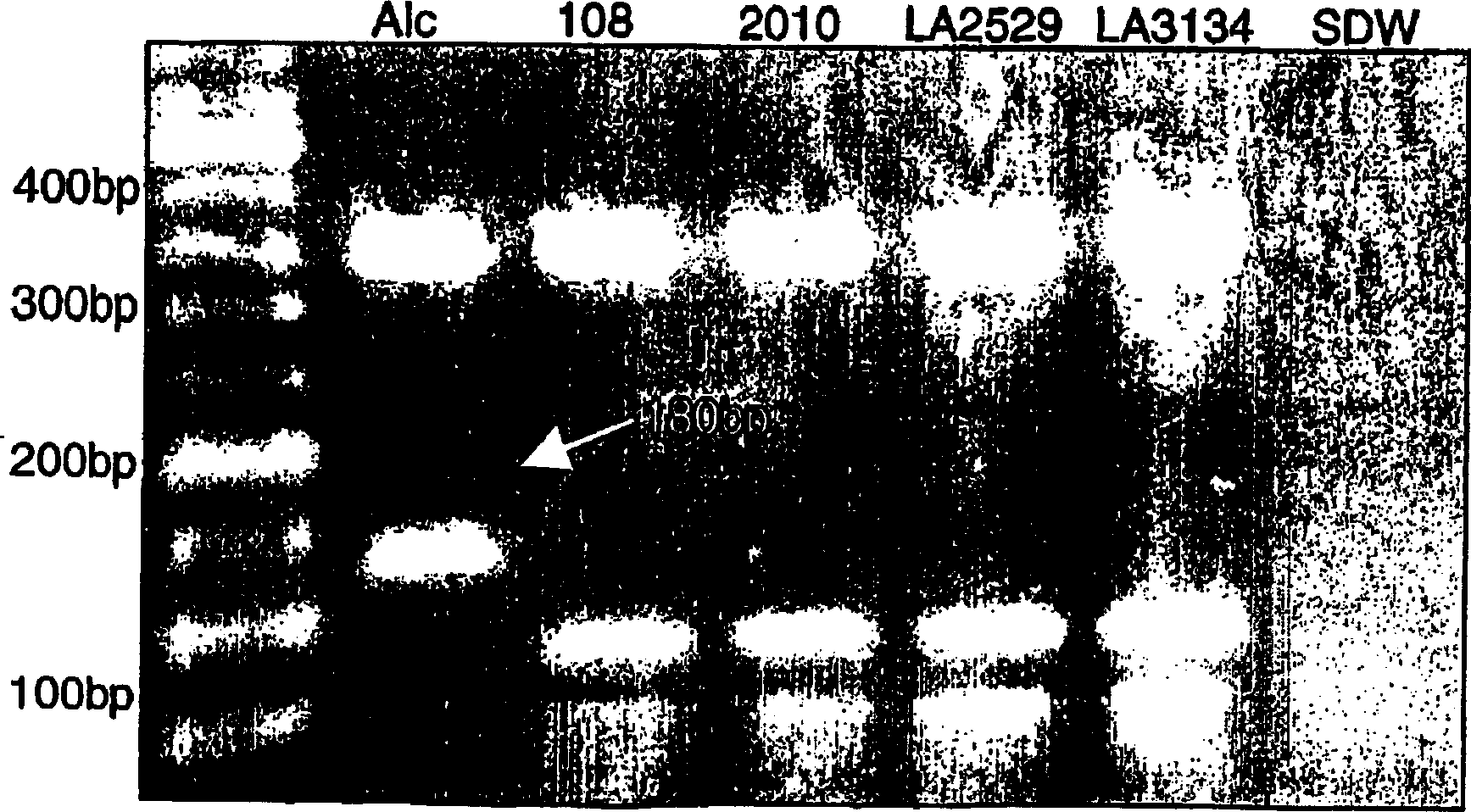

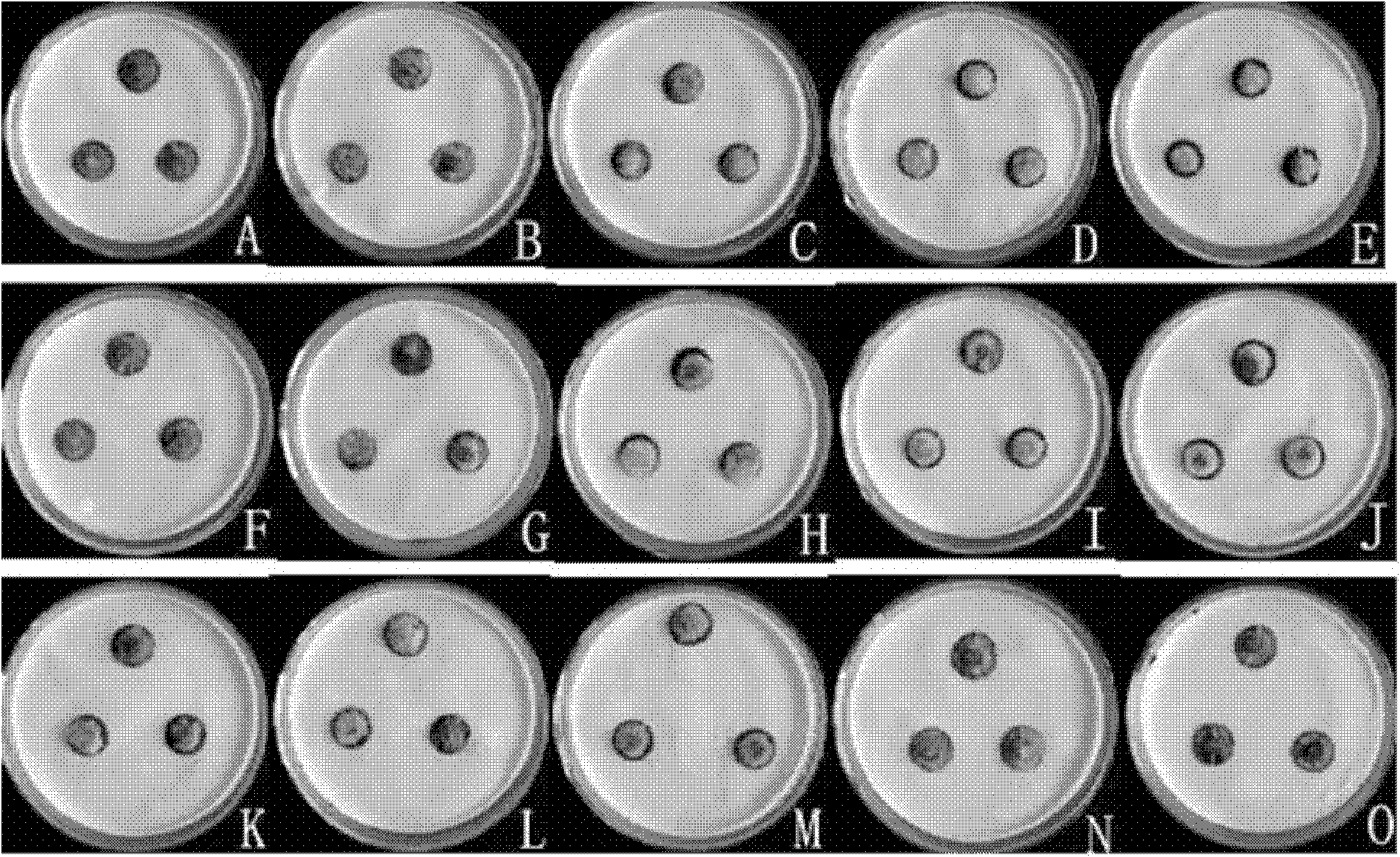

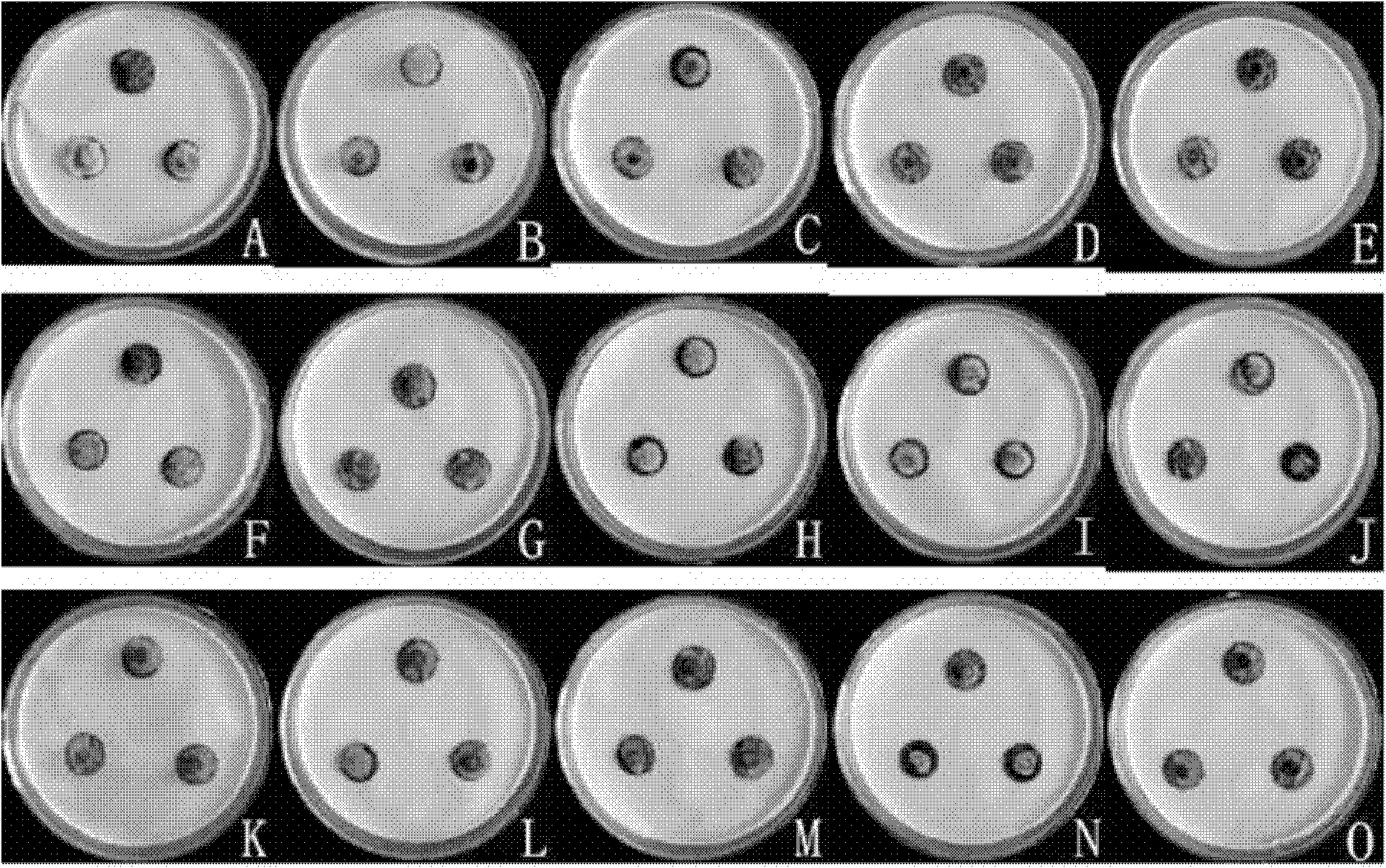

Cas9-mediated tomato gene editing vector and application thereof

InactiveCN107312793AExtended shelf lifeDoes not affect growthHydrolasesVector-based foreign material introductionGenetic engineeringBiology

The invention belongs to the field of genetic engineering technology, and specifically discloses a Cas9-mediated tomato gene editing vector and application thereof. A Cas9 gene is introduced into a tomato M82 by constructing a CRISPR / Cas9 tomato plant expression vector, and gene editing is carried out on the DFD gene of the tomato. The invention provides a method for constructing a storage-endurance transgenic tomato, the new storage-endurance tomato product is obtained, so that the storage endurance of the tomato fruit is improved, and besides, the growth and other qualities of plant are not influenced, and the method can compensate for shortcomings of former research programs.

Owner:HORTICULTURE INST OF XINJIANG ACAD OF AGRI SCI

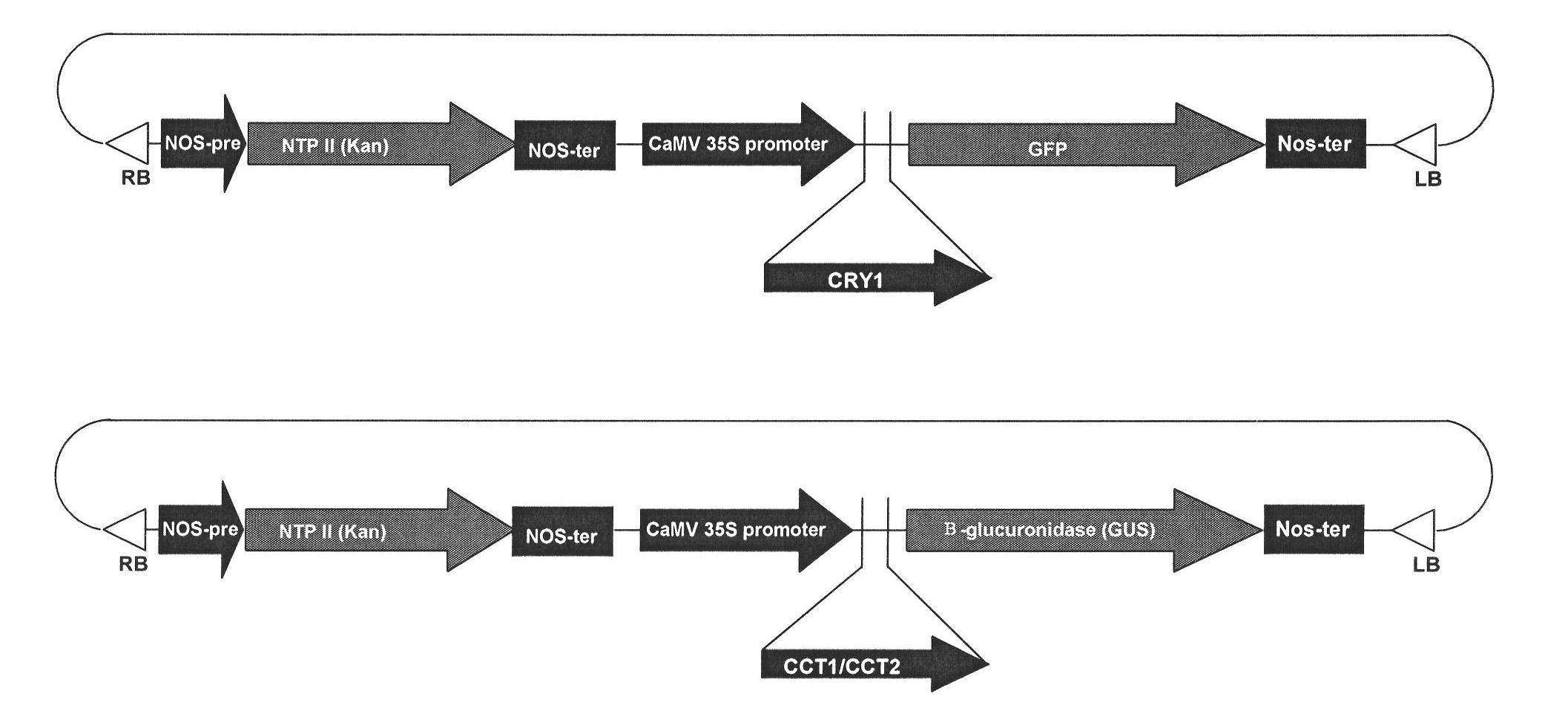

Method for improving carotenoid content of tomato

InactiveCN101979601AIncrease contentEfficient extractionComponent separationMicrobiological testing/measurementAgricultural scienceAdditional values

The invention discloses a method for improving carotenoid content of a tomato. Overexpression vectors of cryptochrome gene 1, the c-terminus of the cryptochrome gene 1 and the c-terminus of cryptochrome gene 2 are constructed by a gene engineering means to transform the tomato so as to obtain the transgenic tomato. By the method, the lycopene content and total carotenoid content in the transgenic tomato fruit are greatly improved by 3.6 times and 3.4 times respectively, so that the extraction of the natural lycopene from the tomato is more efficient, and the additional value of the tomato product is greatly improved.

Owner:山东省农业科学院高新技术研究中心

Processed tomato products

InactiveUS6924420B2Animal fodder preservationMeat/fish preservation by freezing/coolingHorticultureTomato products

Owner:VOLOAGRI GRP

Polyolefin resin and its use in films, coatings and food containers

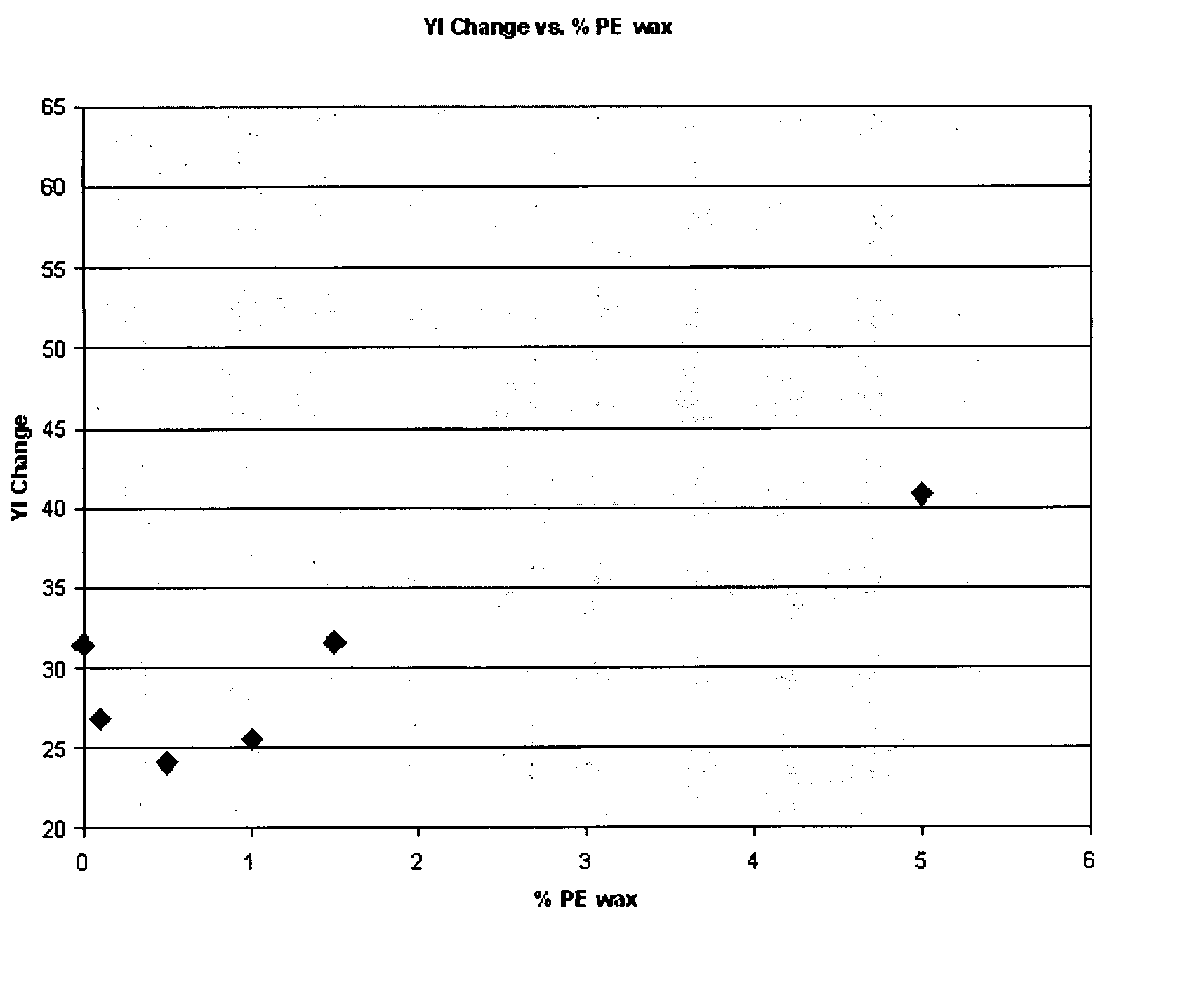

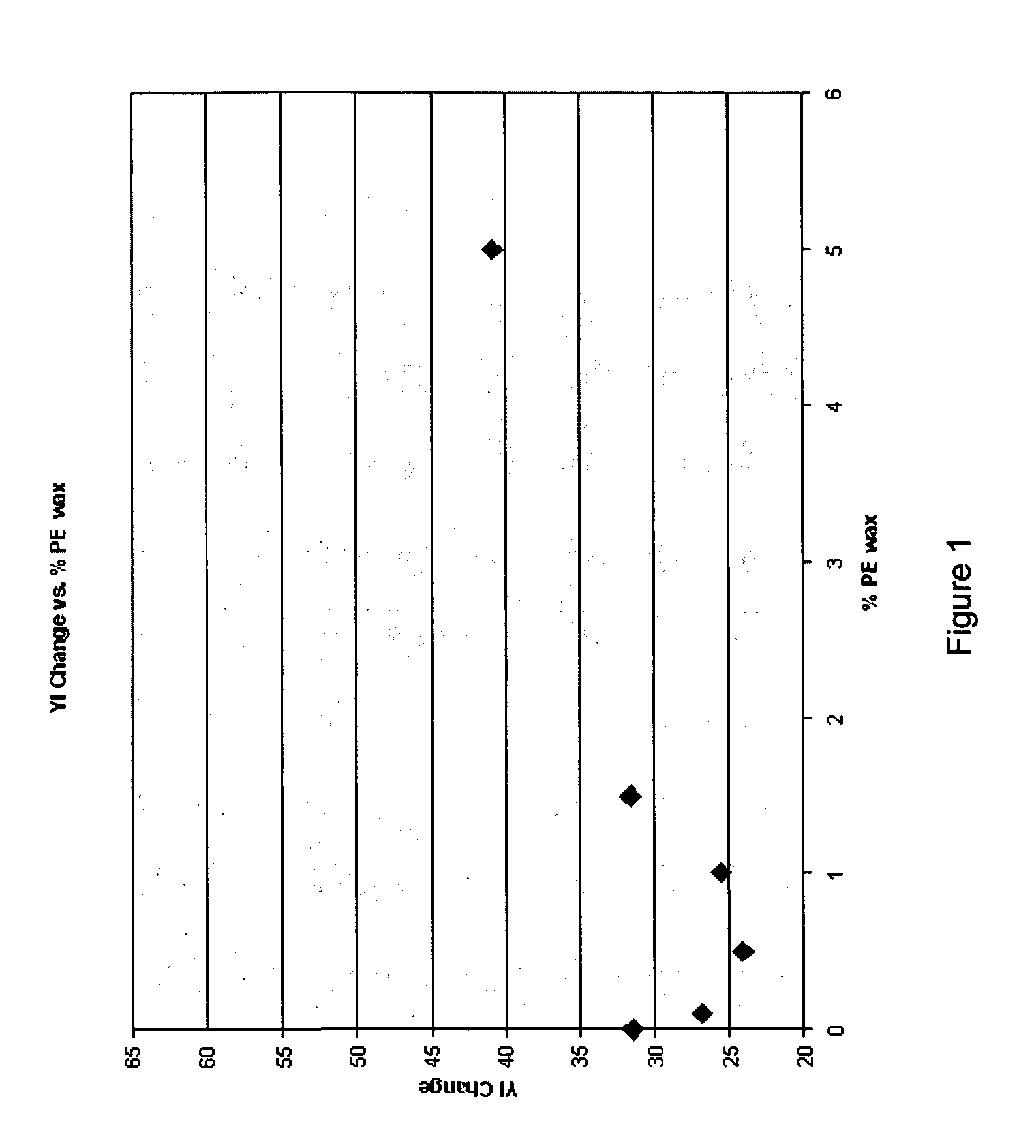

A polyolefin resin, including a high crystalline polyolefin and a crystalline wax, may be used to prepare articles that are resistant to staining. In one embodiment, the resin is an admixture of high crystalline isotactic polypropylene and a polyethylene wax. The articles prepared therewith may be particularly resistant to food staining, including staining from contact with tomato products, and also resistant to scratching, odor adsorption, and distortion during heating.

Owner:FINA TECH

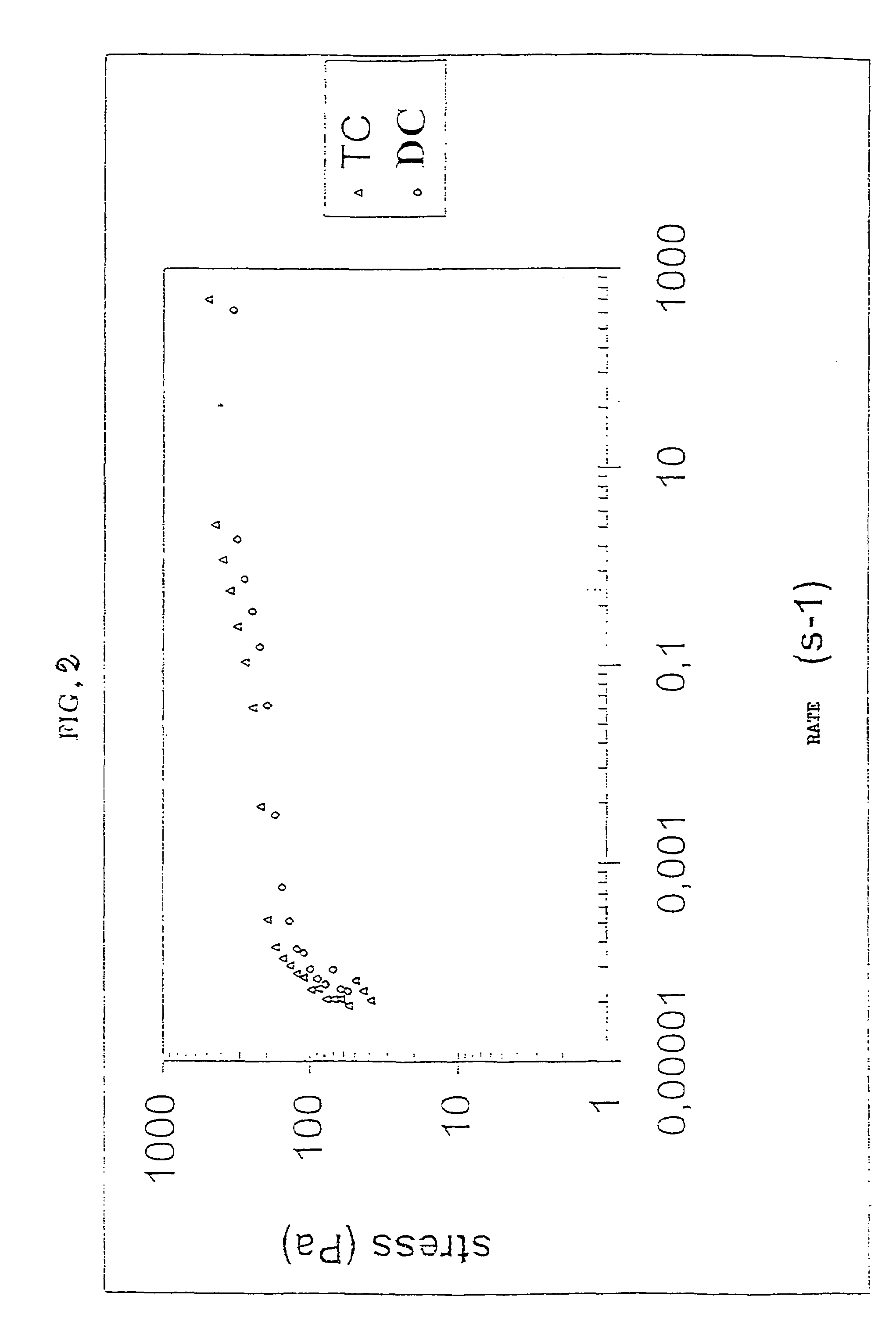

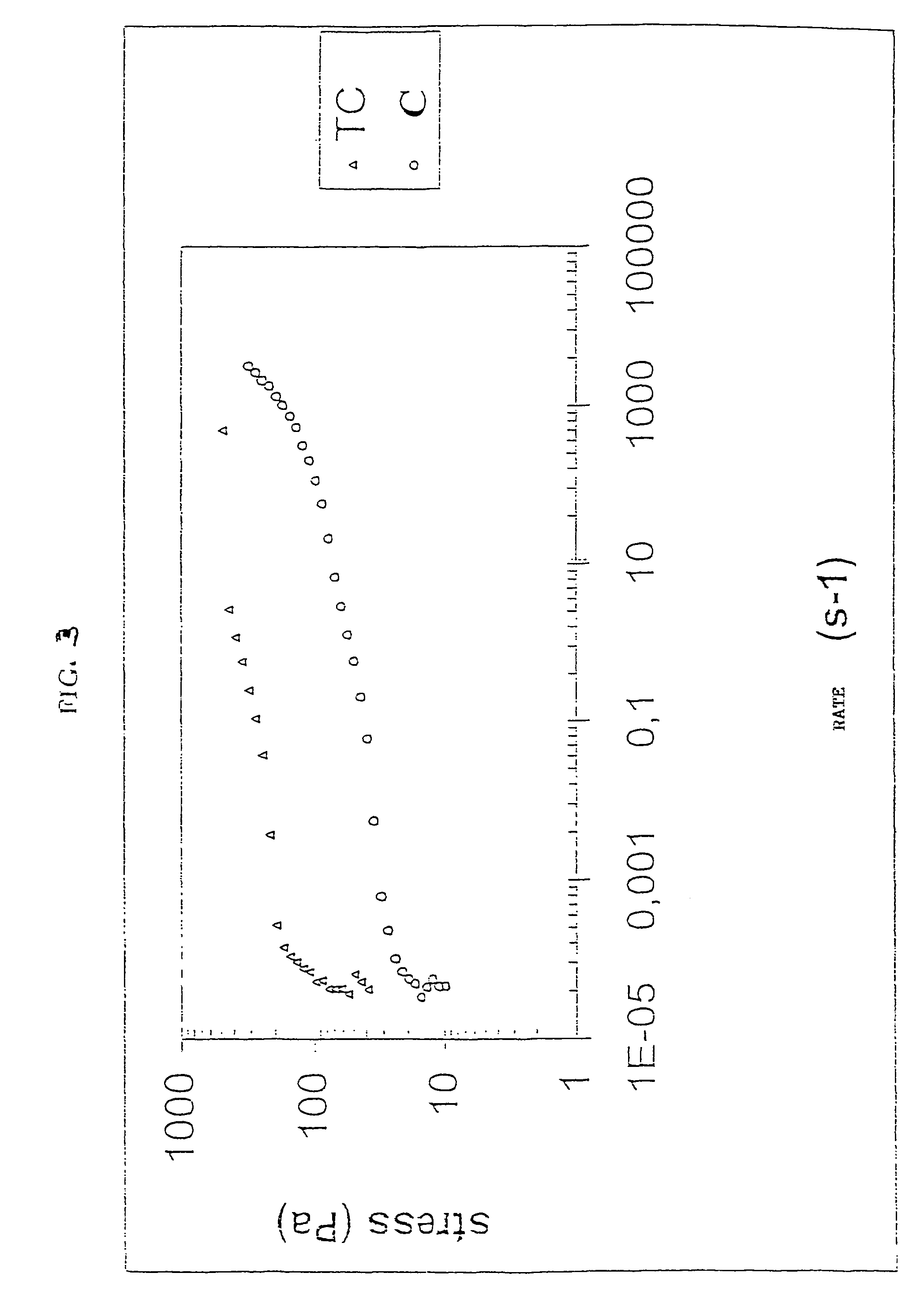

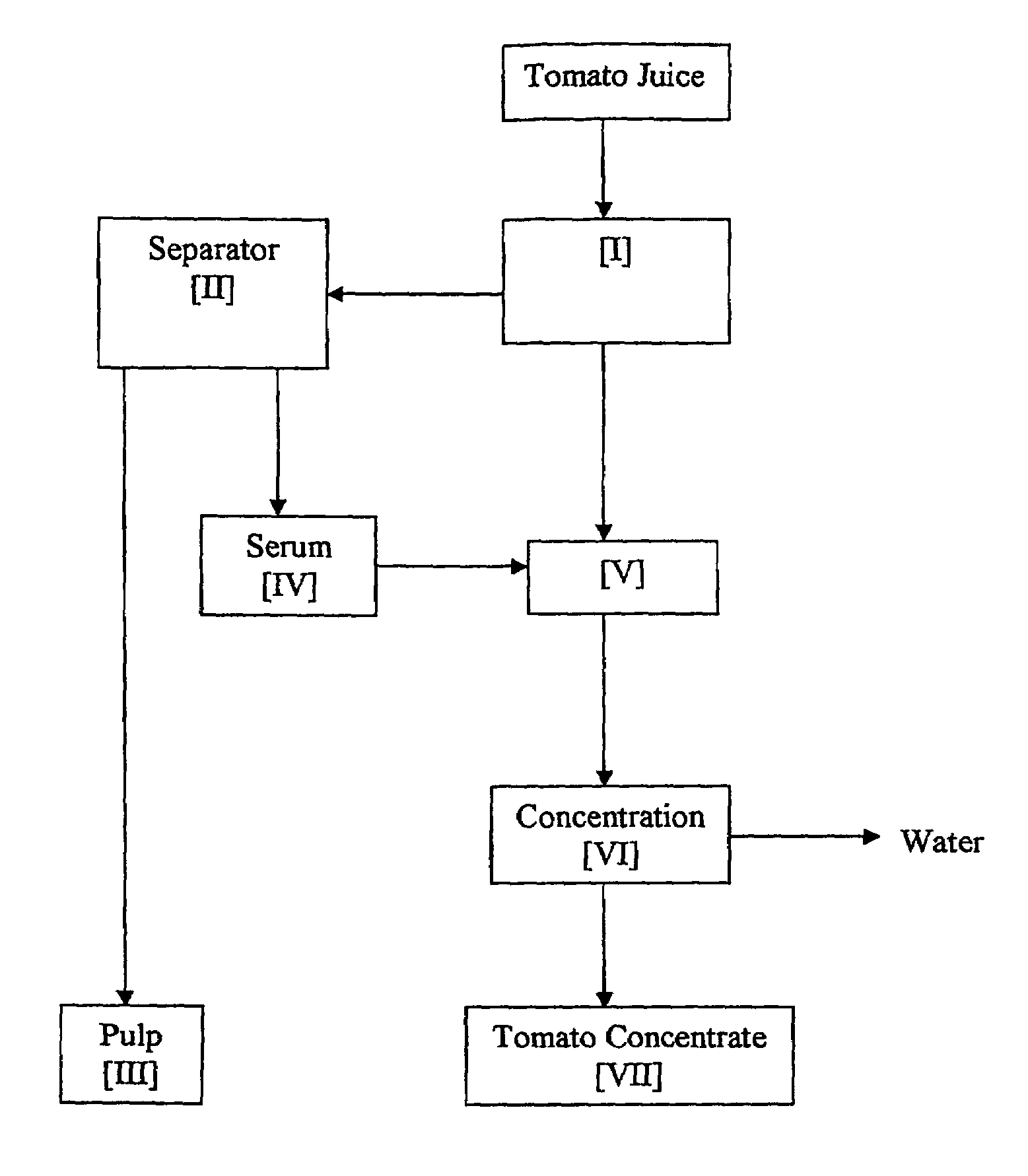

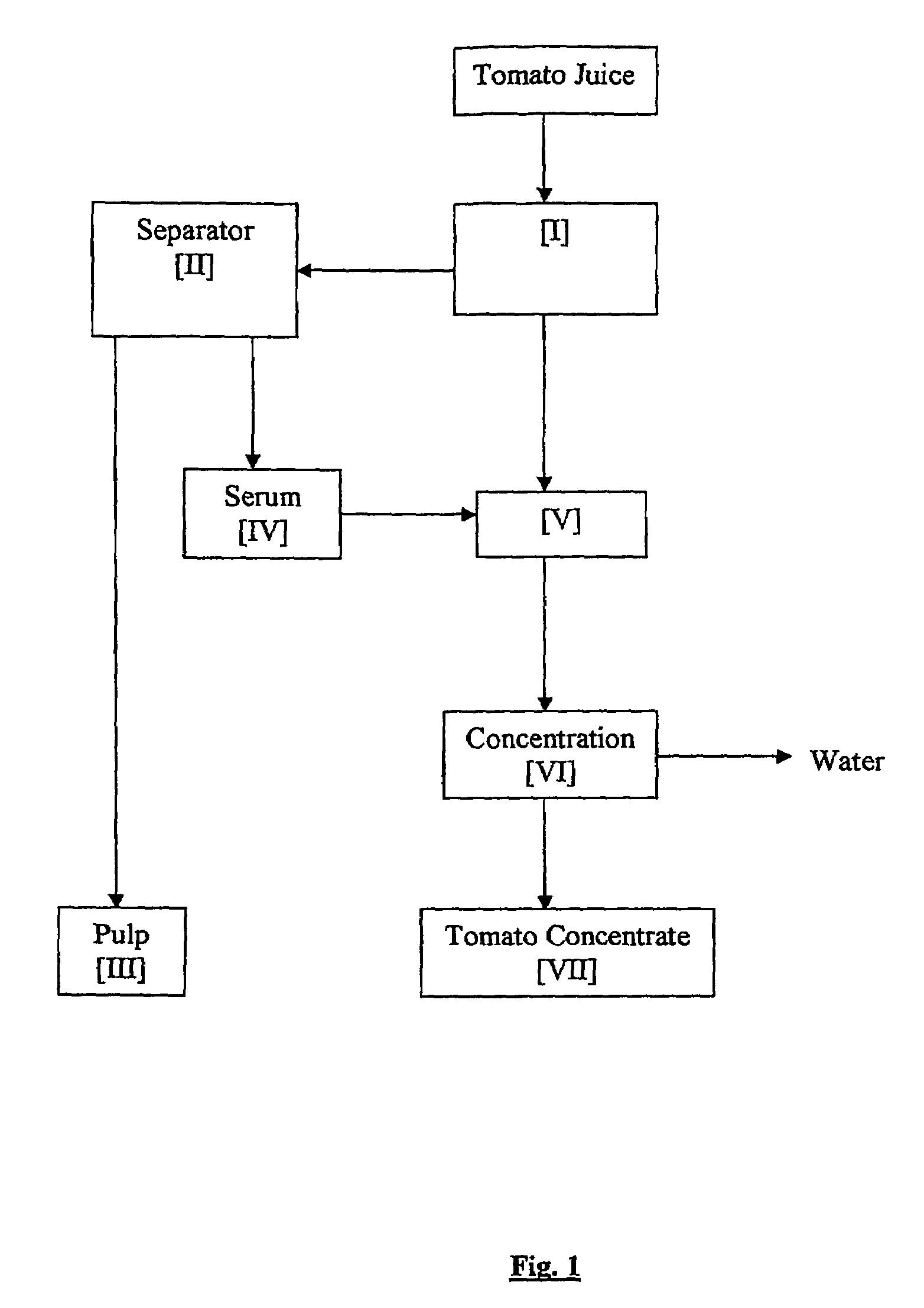

Industrial tomato process and product obtained thereof

ActiveUS20060134306A1Increase capacity ratioEasy to controlFruit and vegetables preservationAnimal feeding stuffLycopersiconAdemetionine

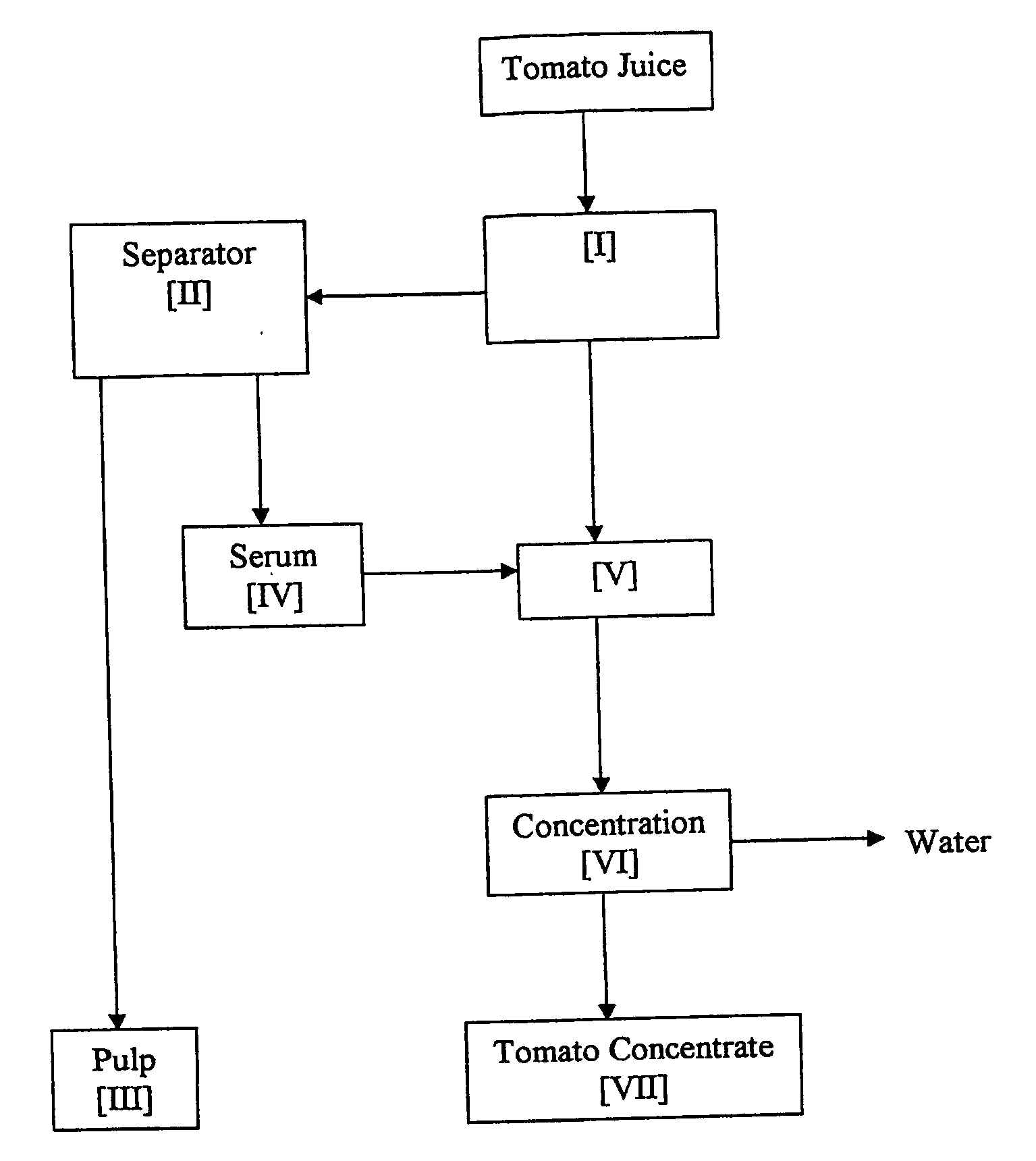

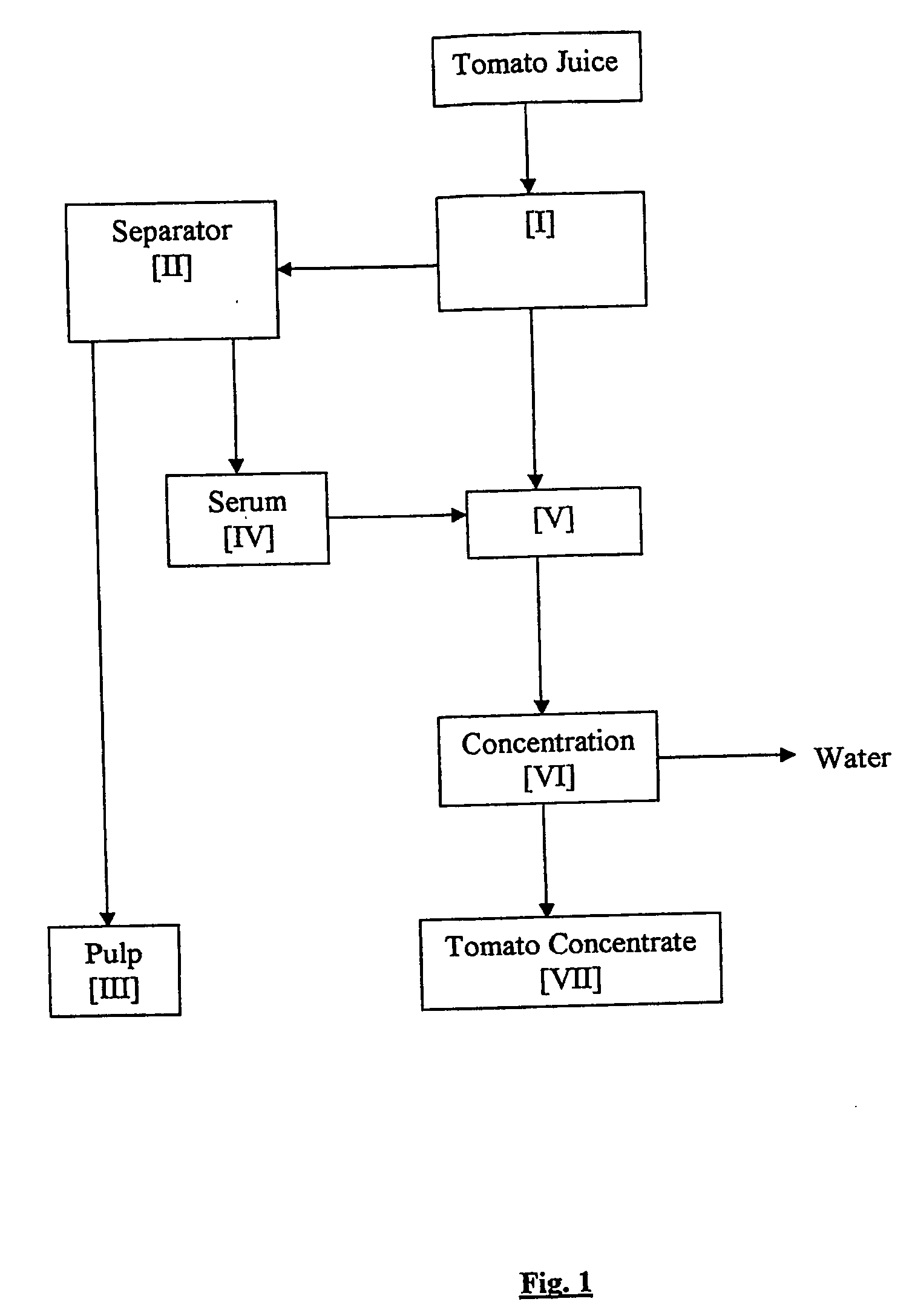

The invention relates to a tomato pulp composition wherein the particle size is not greater than 2.5 which does not contain seeds or peels from the tomato and has a lycopene concentration which is 5 to 15 folds higher than the lycopene concentration in the tomatoes from which said pulp is obtained. The invention further provides an industrial process for obtaining tomato pulp and tomato concentrate from tomato juice. The invention further provides a method for controlling the viscosity and lycopene concentration of tomato products, tomato concentrate or modified tomato juice, by separating a part of the pulp from the tomato juice from which said tomato products are obtained.

Owner:LYCORED NATURAL PRODS INDS

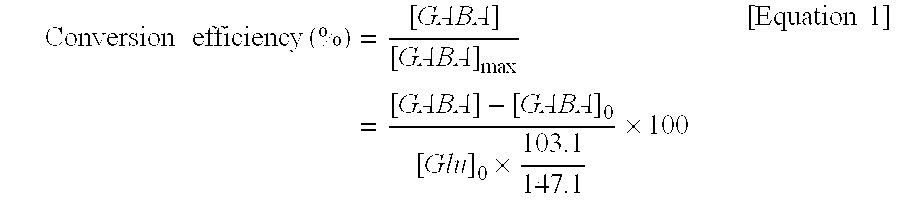

Production Method of Food and Beverage Products with High Content of gamma-Aminobutyric Acid and Food and Beverage Products with High Content of gamma-Aminobutyric Acid

InactiveUS20070048353A1Improve conversion efficiencySimple and easyBiocideMicroorganismsGamma-Aminobutyric acidSugar

A method for producing food and beverage products with a high content of γ-aminobutyric acid, wherein processed tomato products whose filtrate has a coloring degree between 0.02 and 0.2 when sugar content is adjusted to 3% are fermented with lactic acid bacteria, and food and beverage products with a high content of γ-aminobutyric acid obtained by such a method.

Owner:KAGOME

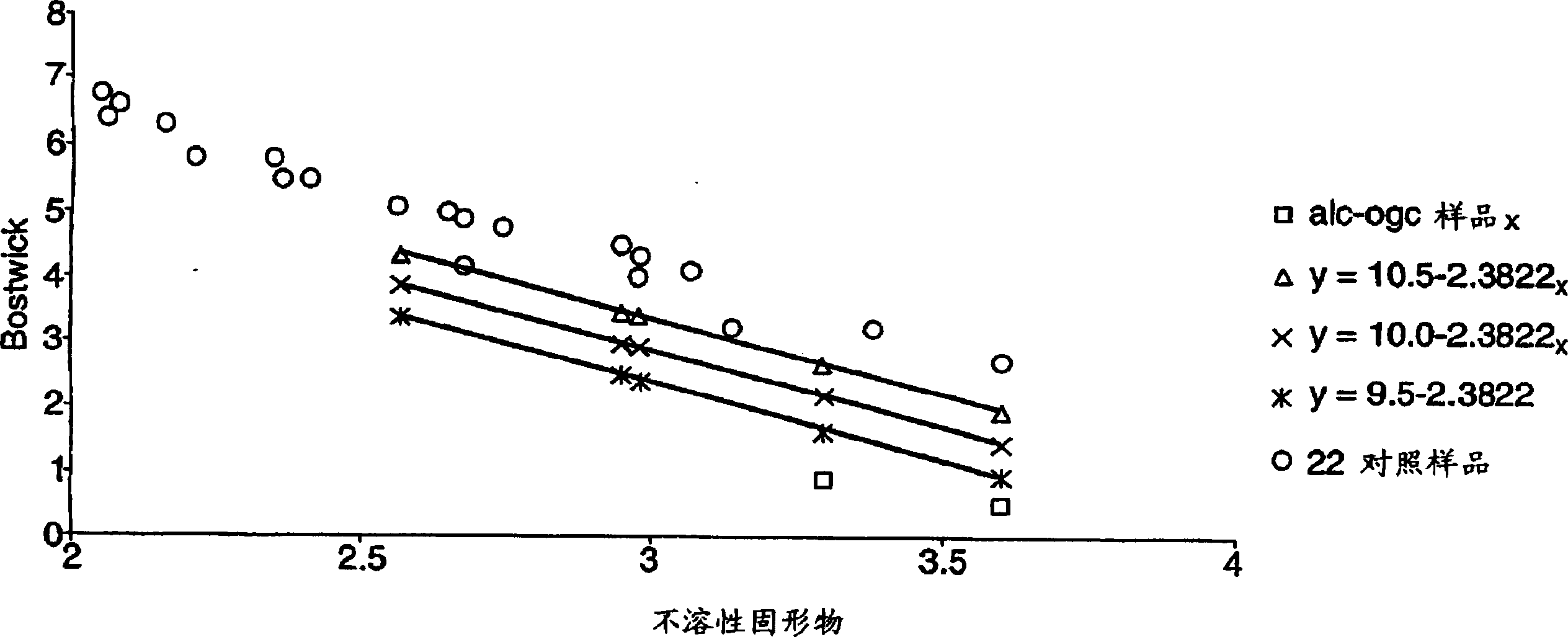

Processed tomato products and process for preparing the same

InactiveCN1674792AImprove the immunityFood preparationAngiosperms/flowering plantsBiotechnologyAnimal science

Processed tomato products which have an increased consistency as expressed by reduced Bostwick at certain insoluble solids level and Brix value.

Owner:UNILEVER NV

Tomato product and method for obtaining same

A tomato product with Brix similar to the Brix of a raw tomato; lycopene content in the range of 600% to 1200% of that of a raw tomato, and viscosity of 3 to 14 cm according to the Bostwick analysis method.

Owner:LYCORED NATURAL PRODS INDS

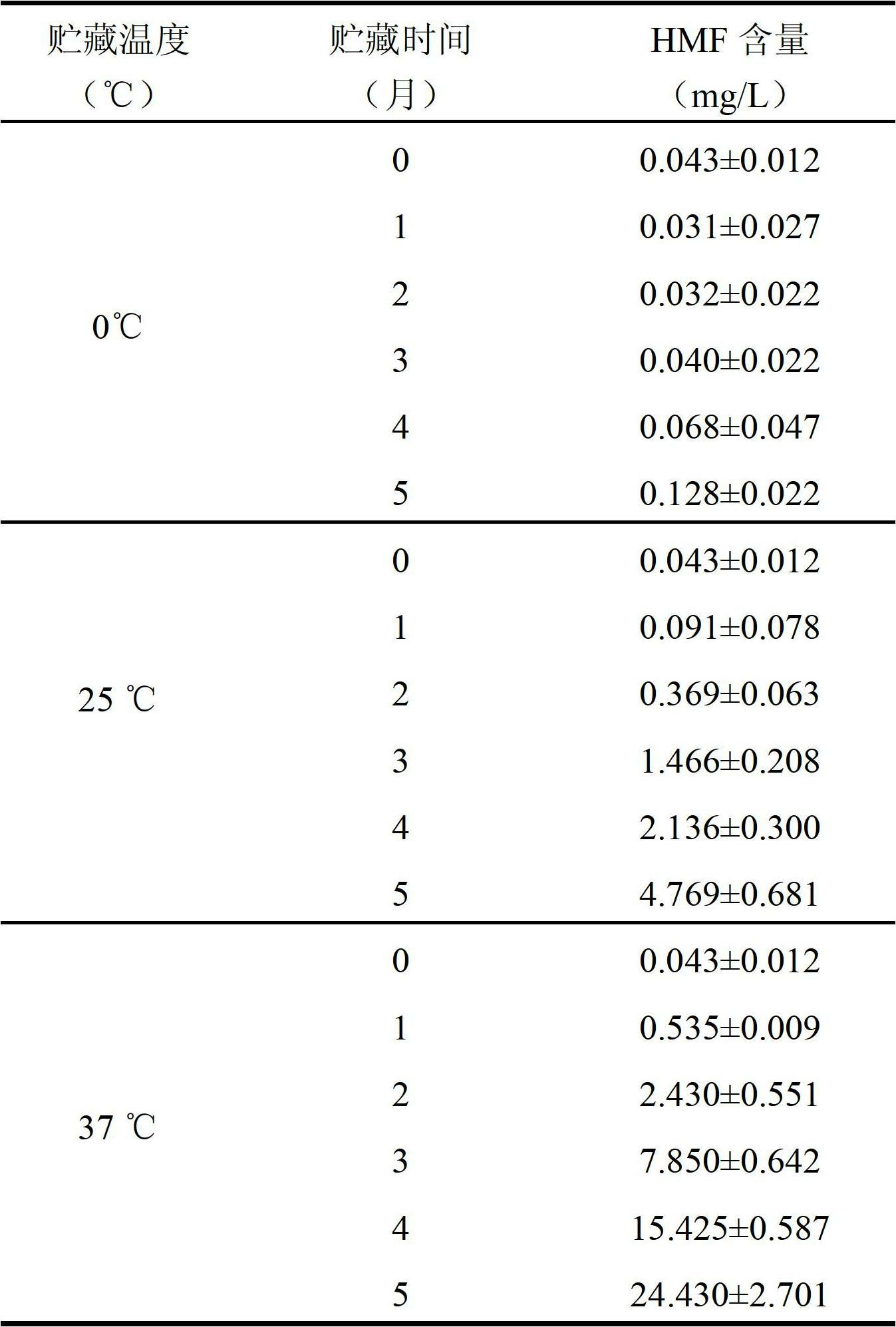

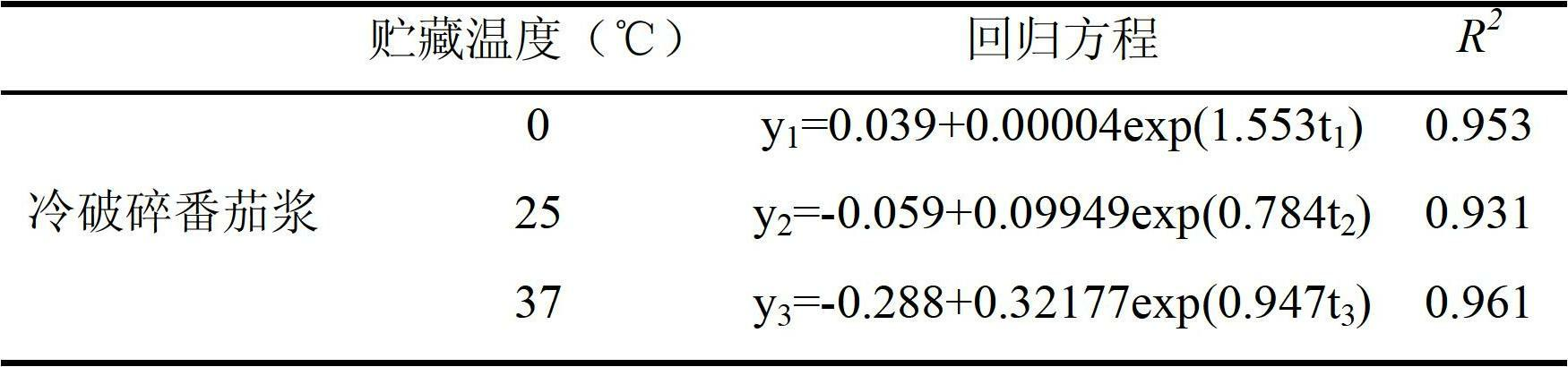

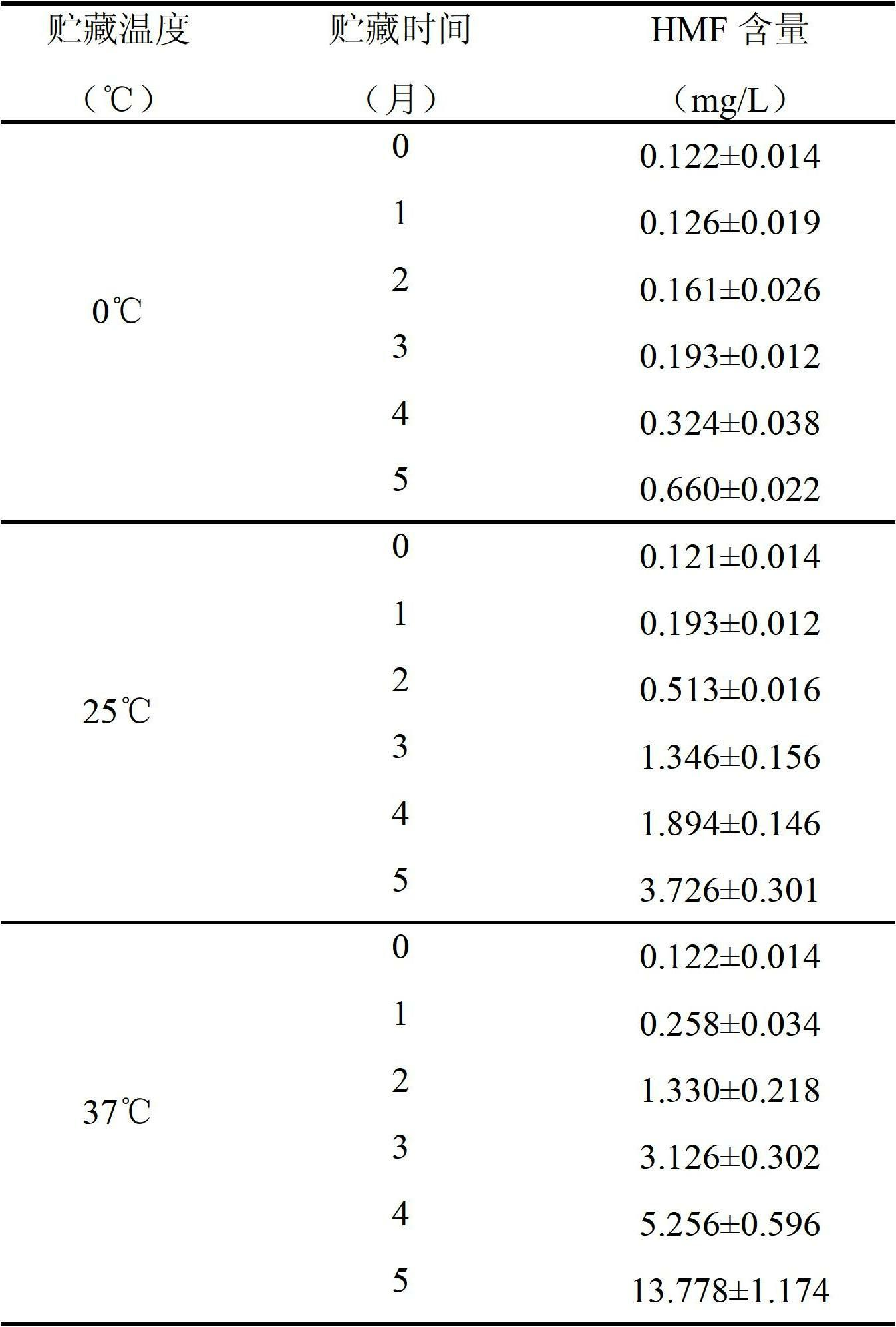

Method for predicting shelf life of tomato product

The invention discloses a method for predicting the shelf life of a tomato product. The method comprises the following steps of: storing the tomato product in a sealing manner; during the storage time, regularly sampling and measuring contents of 5-hydroxymethylfurfural (HMF) in the tomato product for at least three times so as to obtain contents of 5-HMF in the tomato product at different storage times; substituting different storage times and content values of 5-HMF in the tomato product corresponding to various storage times into a formula (a) so as to obtain exponential functions between k0 and k1, and analyzing the obtained exponential functions to obtain values of k0 and k1; substituting the maximum limit provision value of the 5-HMF in the tomato product into the formula (a); and then predicting the shelf life of the tomato product, wherein C=k0 / k1-(k0 / k1-C0)exp(-k1t)(a). The shelf life of the tomato product can be predicted by calculating the time for increasing the initial value of the content of the HMF in the tomato product to the maximum limit provision value; and the method is beneficial to accurately judging the storage safety of the tomato product.

Owner:CHINA AGRI UNIV

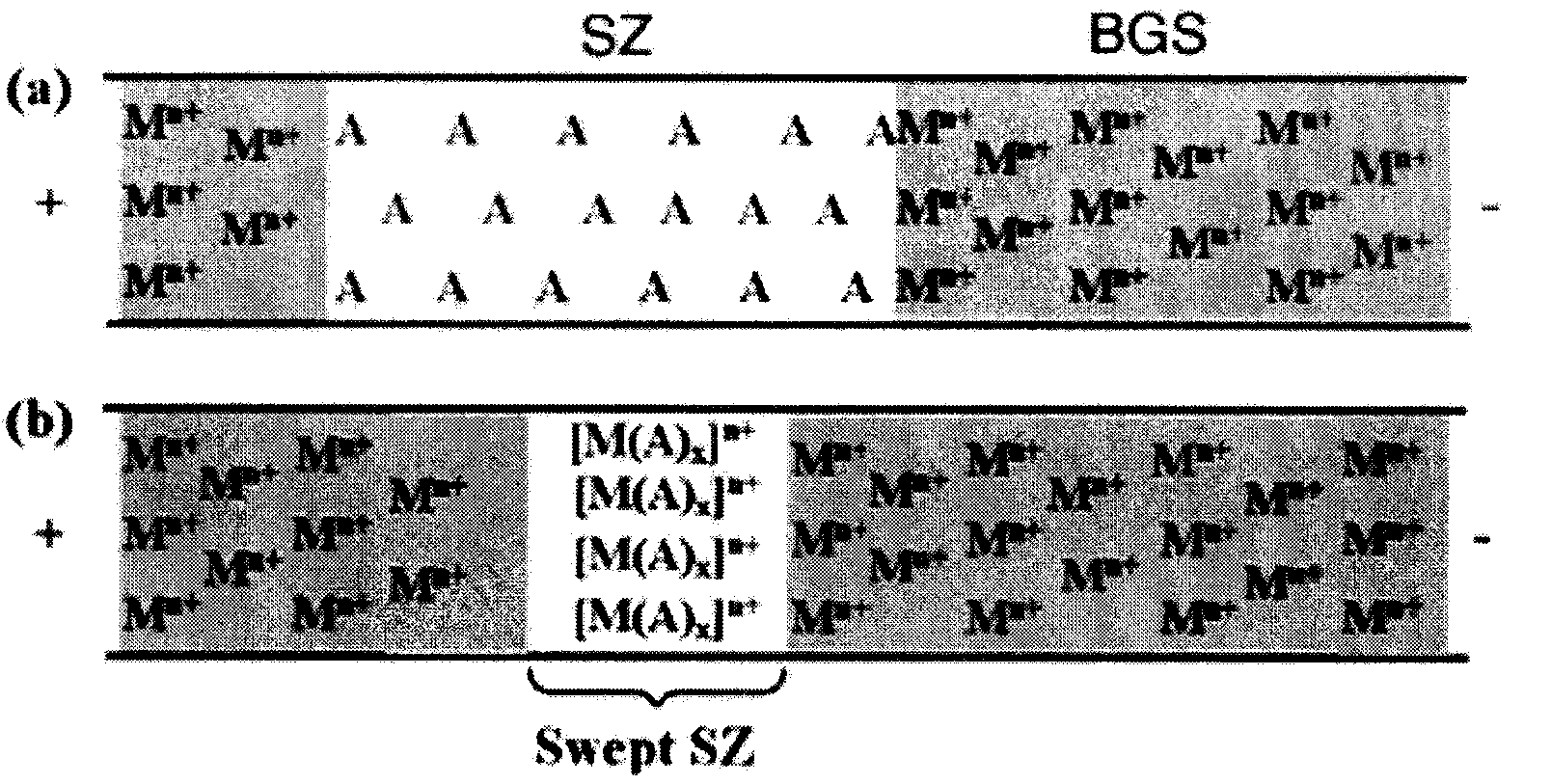

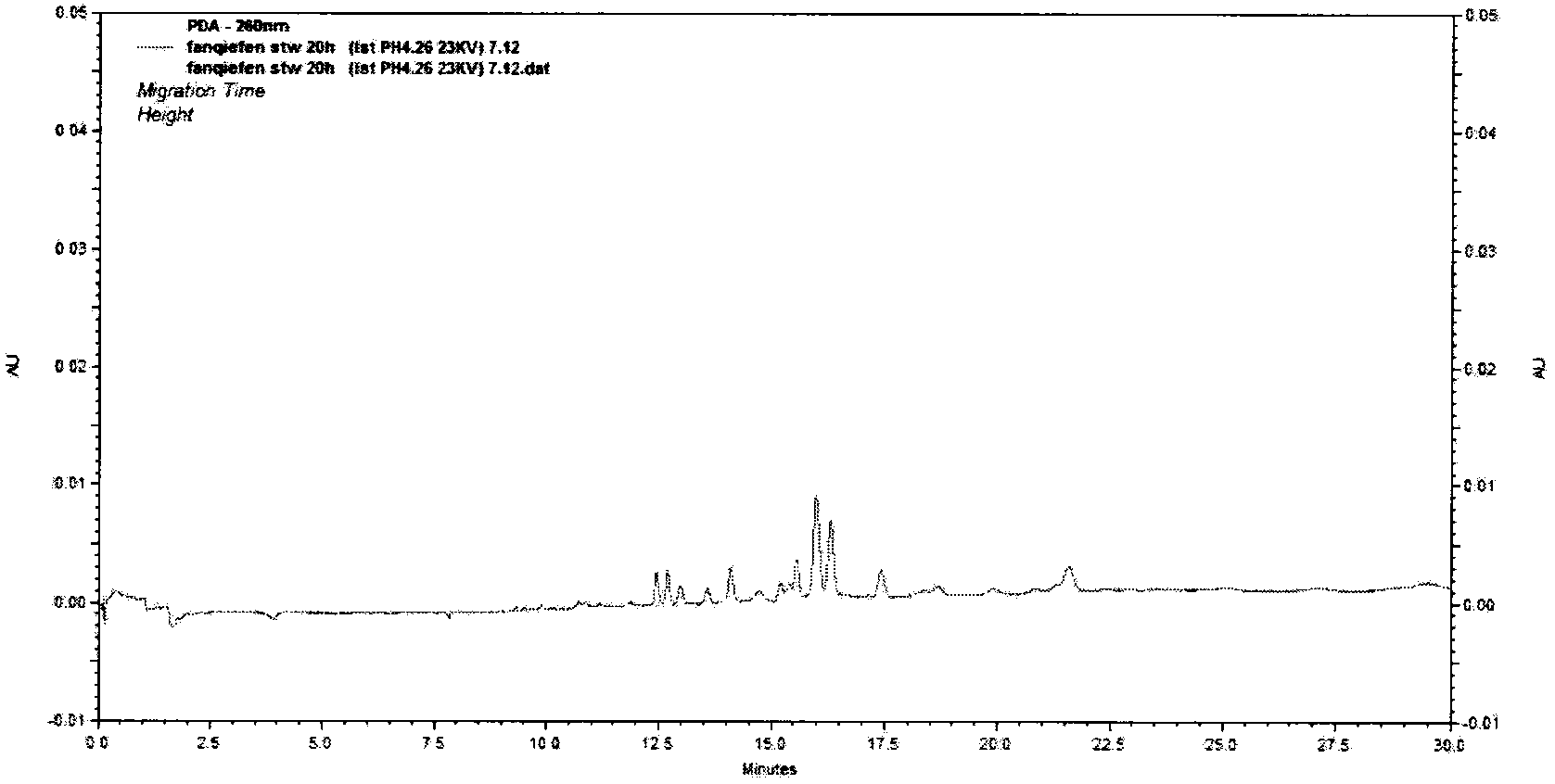

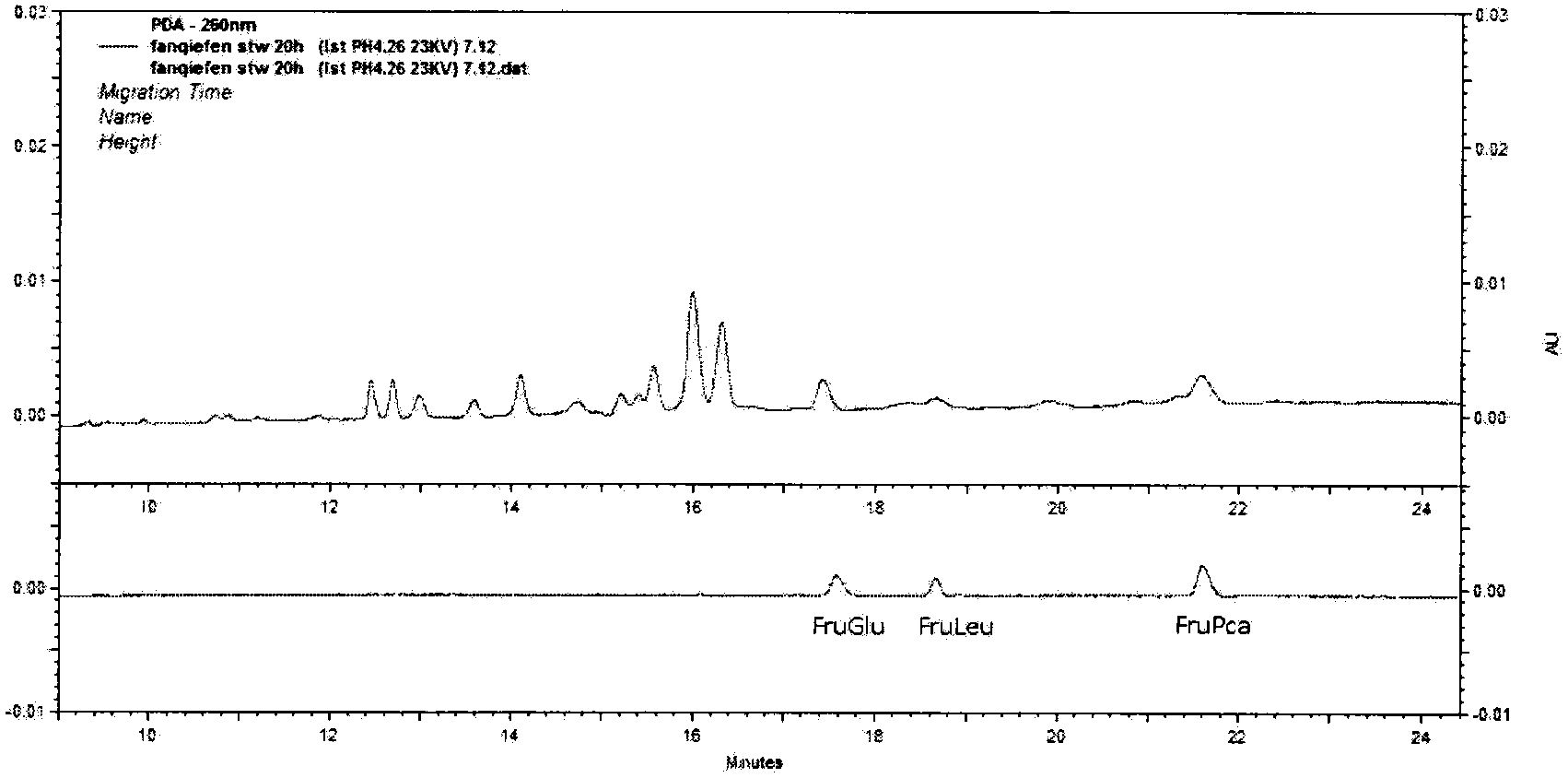

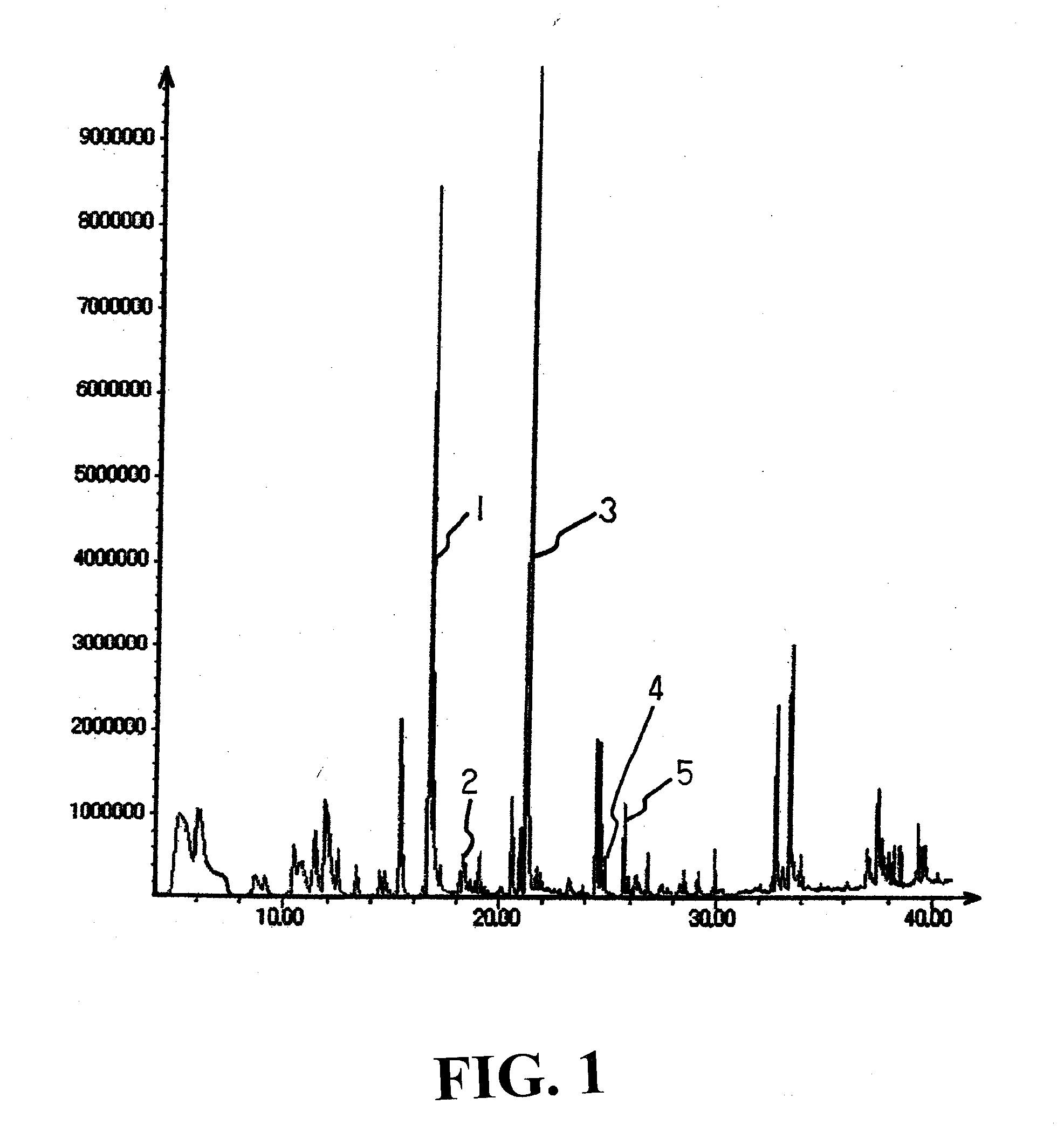

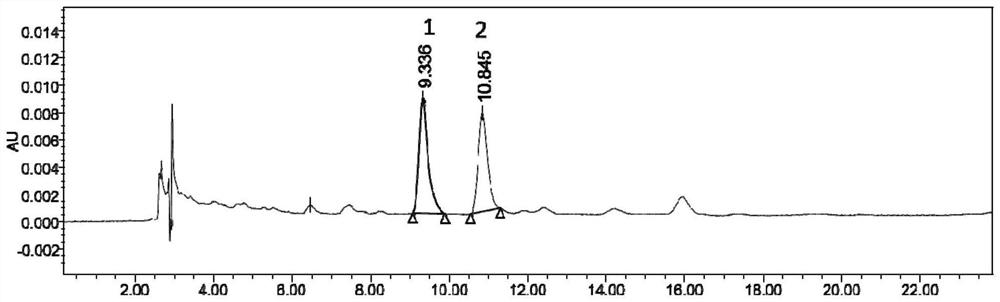

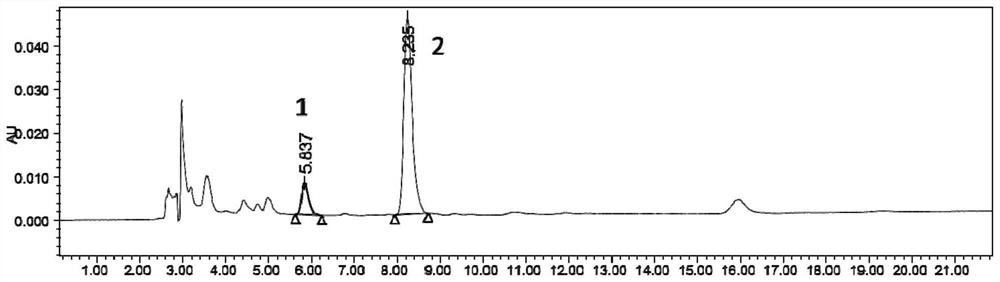

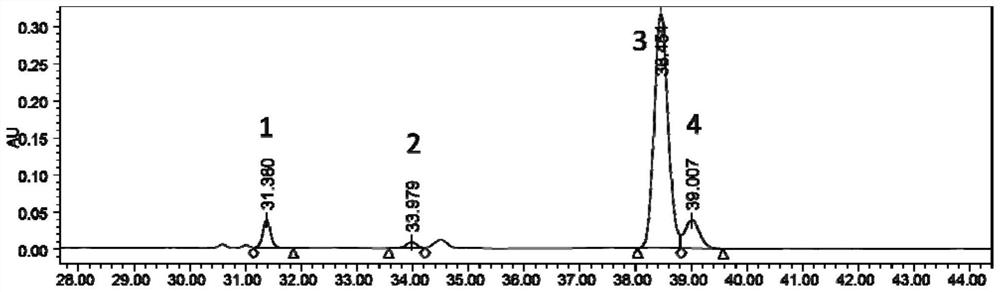

Capillary electrophoresis direct ultraviolet method for rapidly detecting Amadori compound based on complexation and online sweeping technique

InactiveCN104297326AEfficient separationEfficient determinationMaterial analysis by electric/magnetic meansCapillary electrophoresisElectrophoresis

The invention discloses a capillary electrophoresis direct ultraviolet method for rapidly detecting an Amadori compound based on complexation and an online sweeping technique, and relates to the detection of an Amadori compound in foods such as tomato products, dried fruits and tobaccos so as to further guide food processing. An Amadori compound and Cu<2+> are utilized by the method so as to form a stable complex, and the complex has characteristics of ultraviolet absorption and wavelength red shift which are higher than those of the Amadori compound, the capillary electrophoresis separation power is provided by combining the complexing capability of Amadori compound and Cu<2+> and different charge-to-mass ratios; the detection sensitivity and the detection limit are improved further by utilizing the capillary electrophoresis online sweeping technique, and the capillary electrophoresis online sweeping technique can be used for detecting the Amadori compound in tomato powder, and dried fruits such as raisin, and tobaccos. The capillary electrophoresis direct ultraviolet method has the prominent advantages that the Amadori compound in the samples is not required to be subjected to derivatization treatment, the operation is convenient, the Amadori compound can be effectively separated and determined within a short time of 30 minutes, sensitiveness and detection limit are relatively high, efficiency and convenience are realized, and the reliability is high.

Owner:JIANGNAN UNIV

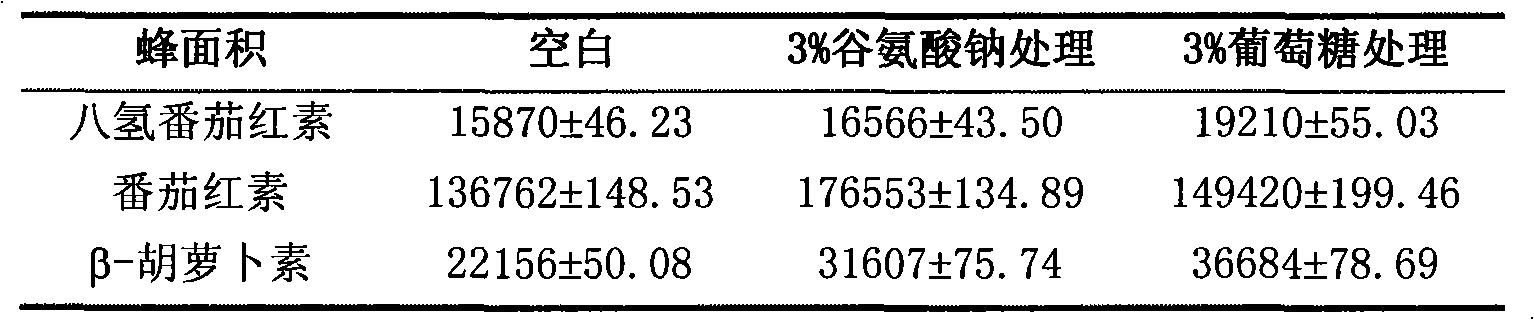

Processing technology for improving lycopene content in tomato product

The invention relates to a processing technology for improving the lycopene content in a tomato product, which comprises the following steps that: the synthesized quantity of lycopene in tomato homogenate is improved; at the atmospheric temperature, the cherry tomato fruit at the firm ripe stage is capped, washed and juiced, the juice is collected, and citrus peels inside a juicer filter is mixed with the juice after being minced so as to obtain the tomato homogenate. 3.0 percent of glucose and 2.5 percent of sodium glutamate are added into the tomato homogenate to be processed for 60 minutes at a constant temperature of 25 DEG C. Different tomato products with high lycopene content can be prepared by adopting the processed tomato homogenate as raw material. (1) The lycopene content in tomato ketchup which is prepared by the processed tomato homogenate is improved by 39.8 percent, and the production process of the tomato ketchup is: 0.25 percent of carrageenan and 2.0 percent of sucrose are added into the processed tomato homogenate to be heated and concentrated until the content of the solid substances reaches 35 percent, the tomato ketchup is covered and sealed after being canned in a glass bottle to be sterilized in the hot water with the temperature of 95 DEG C for 15 minutes. (2) The lycopene content of the tomato haw sheet prepared by the processed tomato homogenate is improved by 21.4 percent, and the production process of the tomato haw sheet is that: 40 percent of white granulated sugar, 0.1 percent of lemon acid and 4 percent of starch are added into the processed tomato homogenate, the thickness of the sheet is 2 mm, and the haw sheet is baked for 11 hours at the temperature of 60 DEG C.

Owner:杜为民

Tomato products

InactiveUS7635496B2Increase powerImprove propertiesAnimal feeding stuffFood preparationWater insolubleWater soluble

Tomato products obtained from tomato juice or tomato passata having the following composition in percentage by weight:dry residue 5.5-20%,water 94.5-80%,100% being the sum of the two components,wherein the amount of water-insoluble and water-soluble solids in the dry residue ranges in percentage by weight:Water-insoluble solids from 18% to 70%Water-soluble solids from 82% to 30%,the sum of the two components being 100% of the dry residue.

Owner:ZANICHELLI RICERCHE

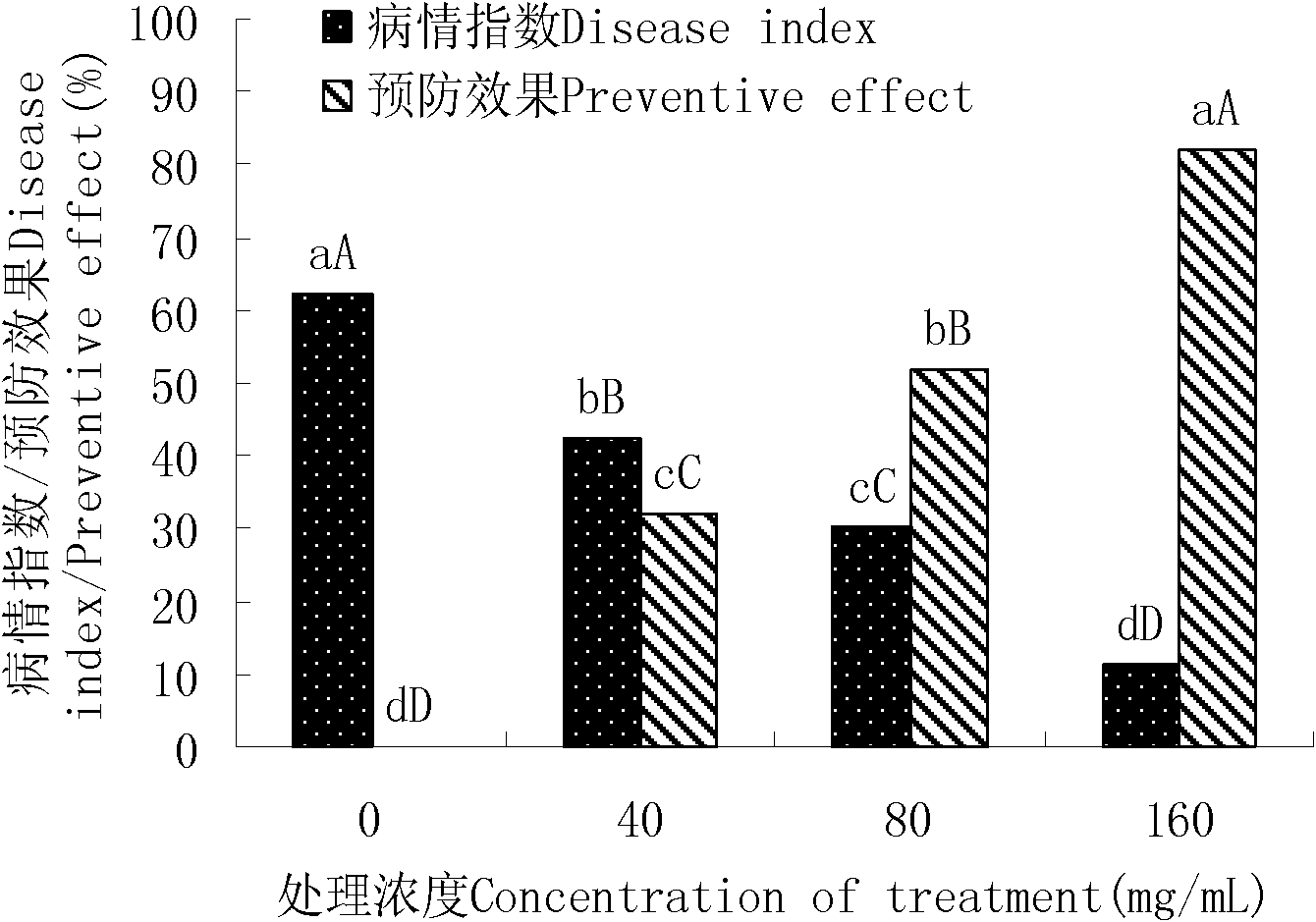

Method for biologically preventing and controlling leaf mold of tomatoes

The invention discloses a method for biologically preventing and controlling leaf mold of tomatoes. The method comprises the following steps of: grinding peeled garlic bulbs; adding water into the ground product in a ratio of 60 to 200 grams of the ground product to 1 L of water to prepare garlic control liquid; and uniformly spraying the garlic control liquid onto tomato plants once every 7 to 10 days. When the mass concentration of the garlic control liquid is 80 mg / mL, the growth of hyphae of leaf mold is fully suppressed and a suppression ratio is up to 100 percent. High-concentration garlic control liquid can fully suppress the growth of the hyphae of leaf mold of tomatoes and spore germination and does not affect the growth of tomatoes. The method sprays the garlic bulb water control liquid onto disease plants, can remarkably prevent and cure the leaf mold of tomatoes, is safe and nontoxic to tomato products and the growth of plants and is simple to operate and easy to popularize.

Owner:NORTHWEST A & F UNIV

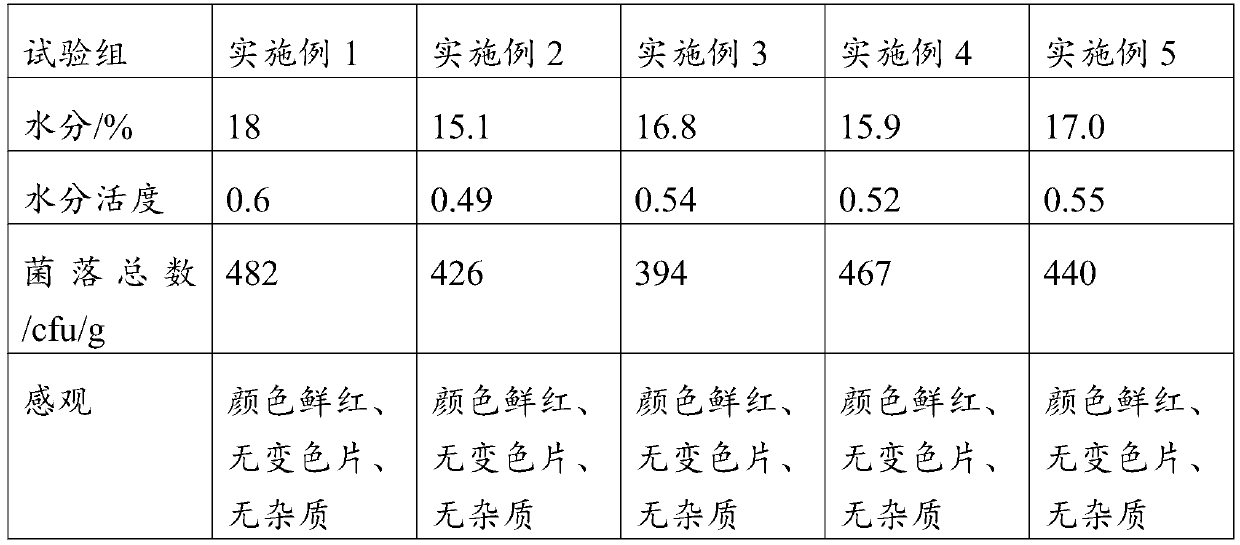

Production method of nutritional preserved tomato

InactiveCN104366335AHas a sweet and sour flavorEnhance immune functionClimate change adaptationFood ingredient functionsThirstSweet flavor

The invention discloses a production method of nutritional preserved tomato and belongs to the field of food processing. The production method is characterized by the processing steps of selecting materials, cleaning, blanching for peeling, shaping and dicing, hardening, boiling with low sugar, dipping, cooking with high sugar, dipping, drying, shaping and packaging. The production method of the nutritional preserved tomato has the beneficial effects that the nutritional preserved tomato product is crystal clear, chewy and thick in pulp, has the peculiar sour and sweet flavors of the tomato, and is sour and sweet, and delicious, and the nutritional preserved tomato product is rich in nutrient substances such as vitamins and mineral materials, easily absorbed by a human body, capable of helping produce saliva and slake thirst, and invigorating stomach and helping digestion, and helpful for boosting the immunity of an organism, has the effects of softening blood vessels, reducing pressure and protecting heart, maintaining beauty and keeping young, and preventing and resisting cancer, and is naturally pure, nutritional and healthy green food.

Owner:张金宝

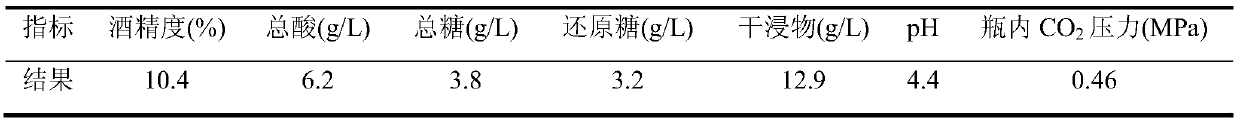

Sugar-free tomato sparkling wine and preparation method thereof

ActiveCN106520490AGolden colorPure tomato flavorAlcoholic beverage preparationMicroorganism based processesLarge CalorieHigh triglycerides

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Tomato Products

InactiveUS20100136193A1Increase powerImprove propertiesFood shapingFood preparationWater insolubleWater soluble

Tomato products obtained from tomato juice or tomato passata having the following composition in percentage by weight:dry residue 5.5-20%,water94.5-80%,100% being the sum of the two components,wherein the amount of water insoluble and water soluble solids in the dry residue ranges in percentage by weight:Water insoluble solids from 18% to 70%,Water soluble solids from 82% to 30%,the sum of the two components being 100% of the dry residue.

Owner:ROMEO AURELIO

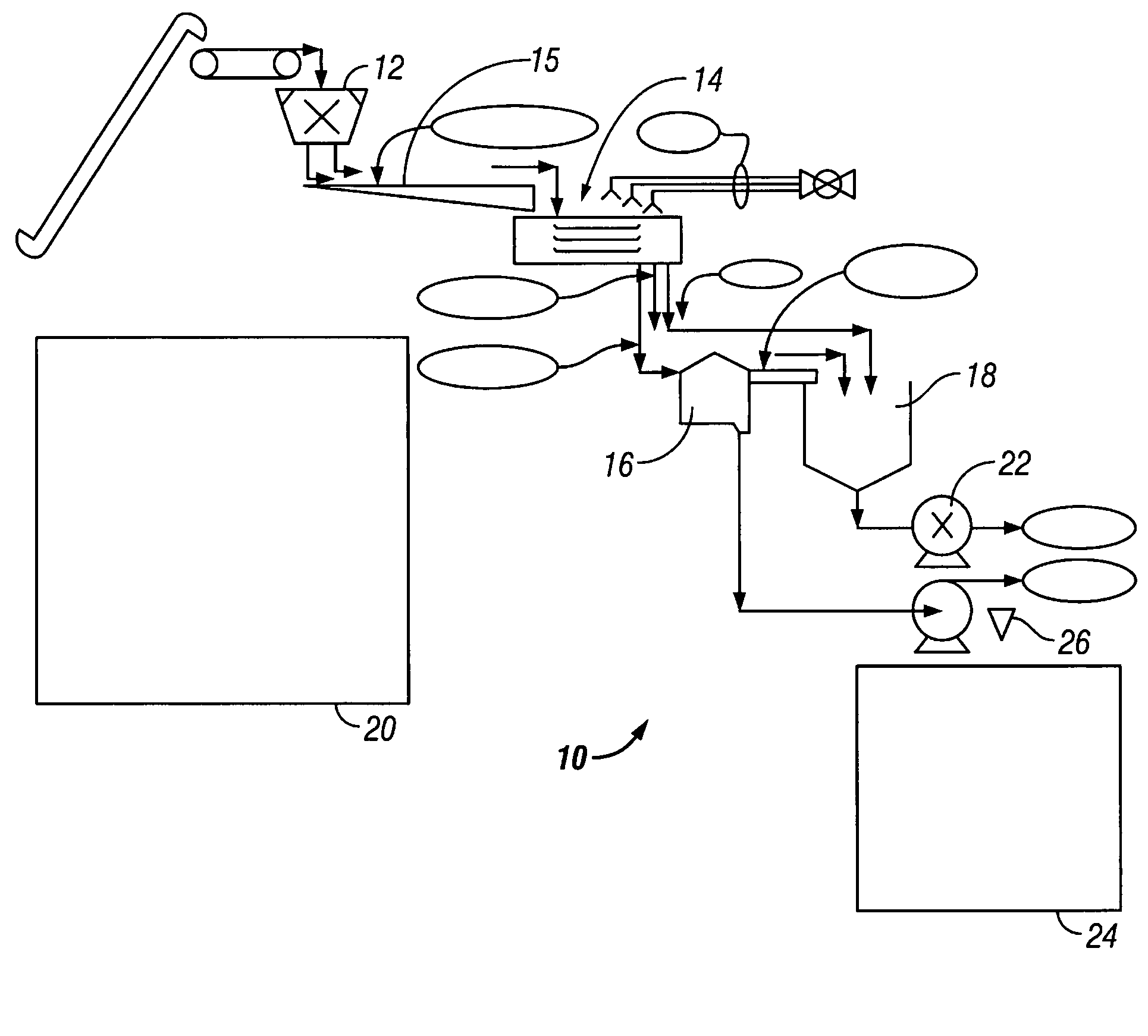

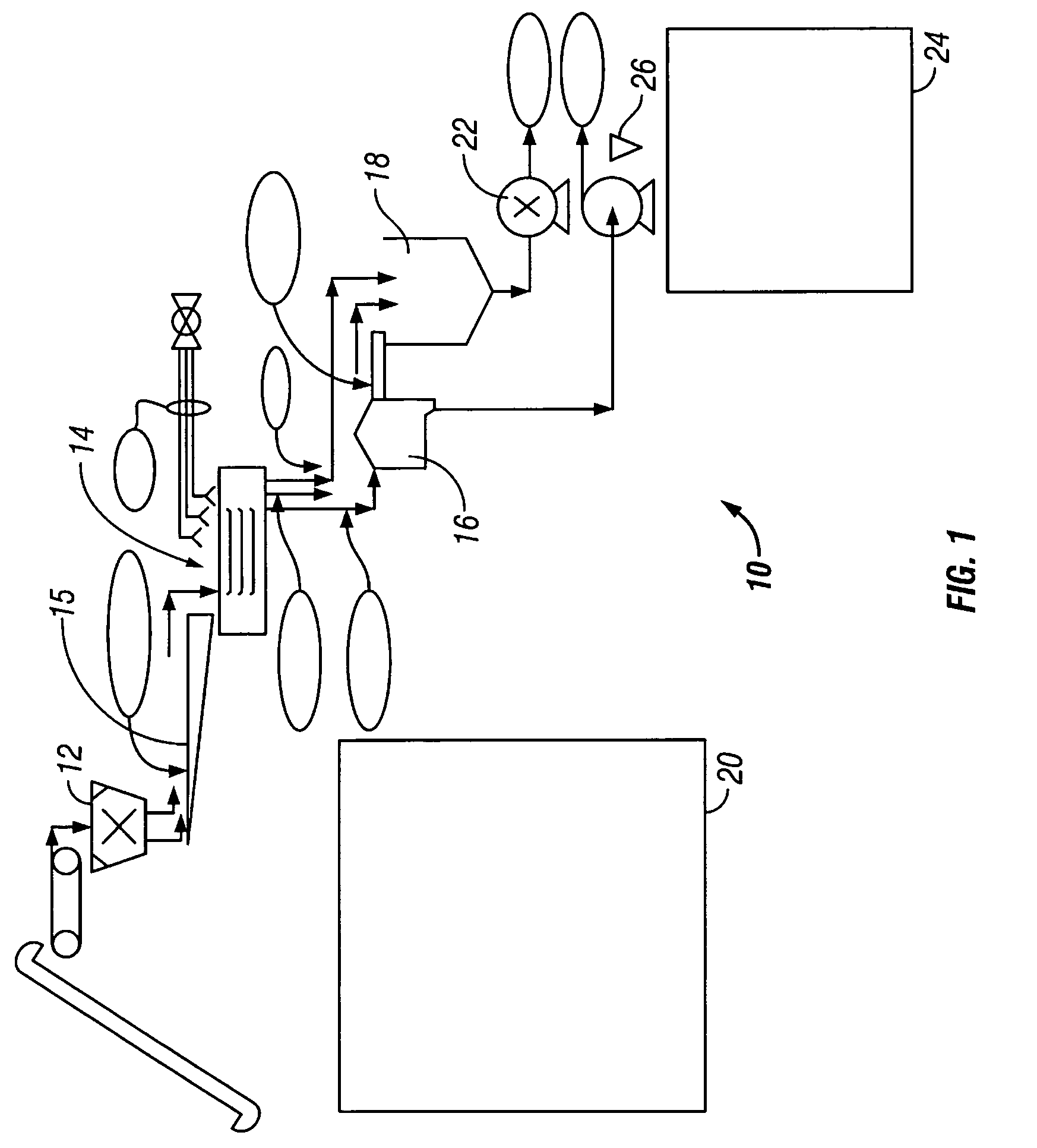

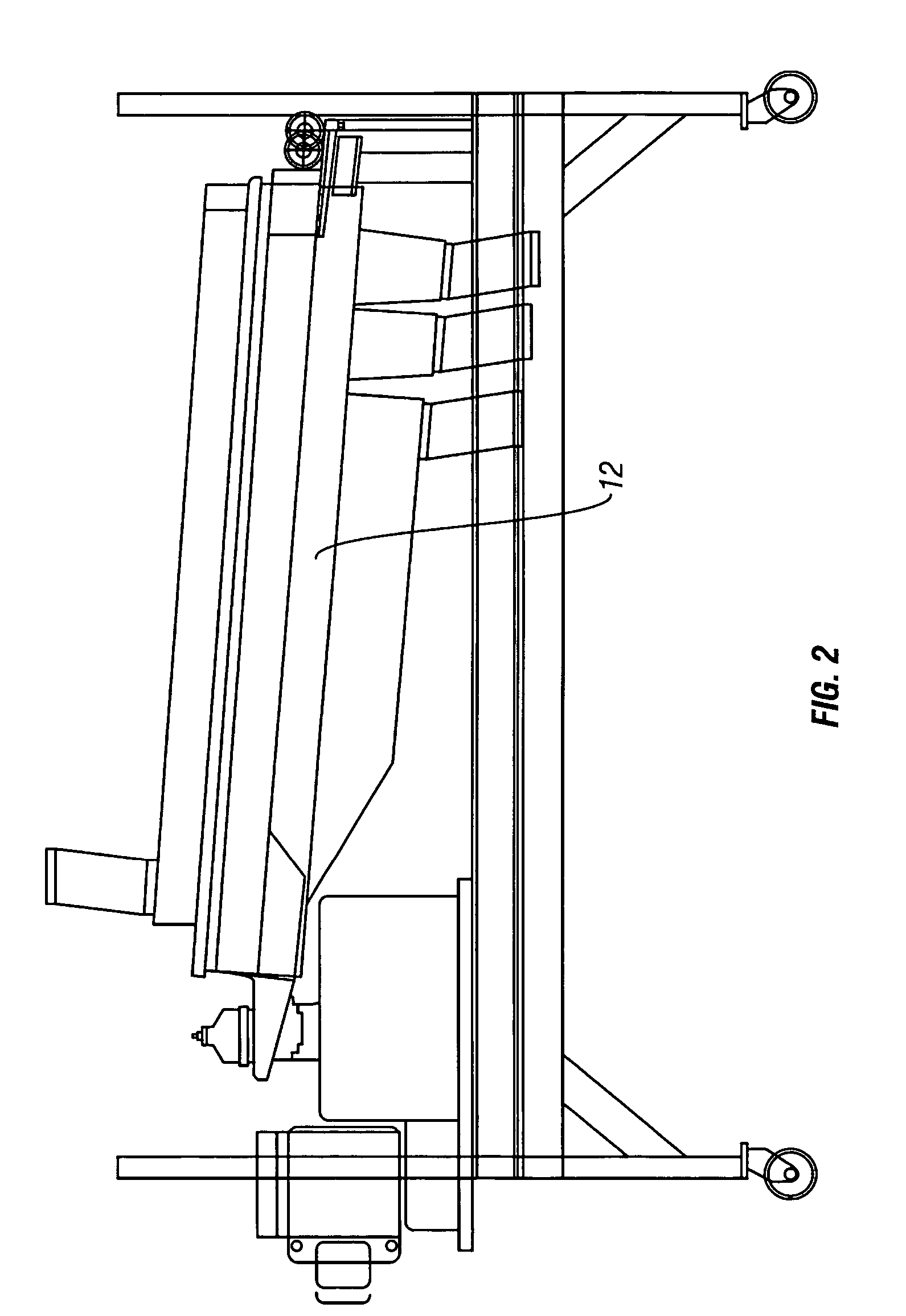

Method for processing tomatoes for the production of chunk tomato products

A method of making chunk tomato pieces from tomatoes. The tomatoes are introduced into a tomato preparation system where they are cleaned, de-stemmed, peeled and chopped. This creates a mixture of tomato chucks, seeds and juice. The tomato chunks are separated from the seeds and juice. The juice is separated from the seeds and subsequently added back to the chunks in proper proportions.

Owner:STANISLAUS FOOD PRODS

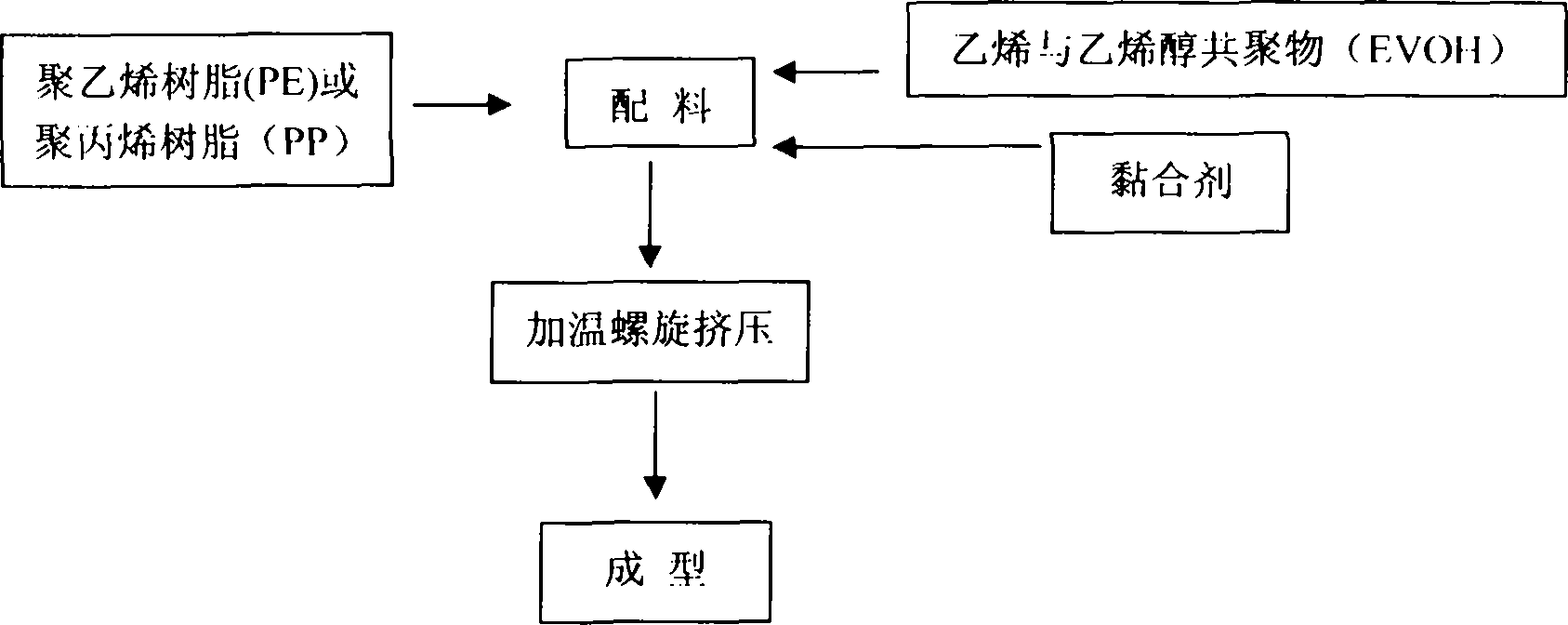

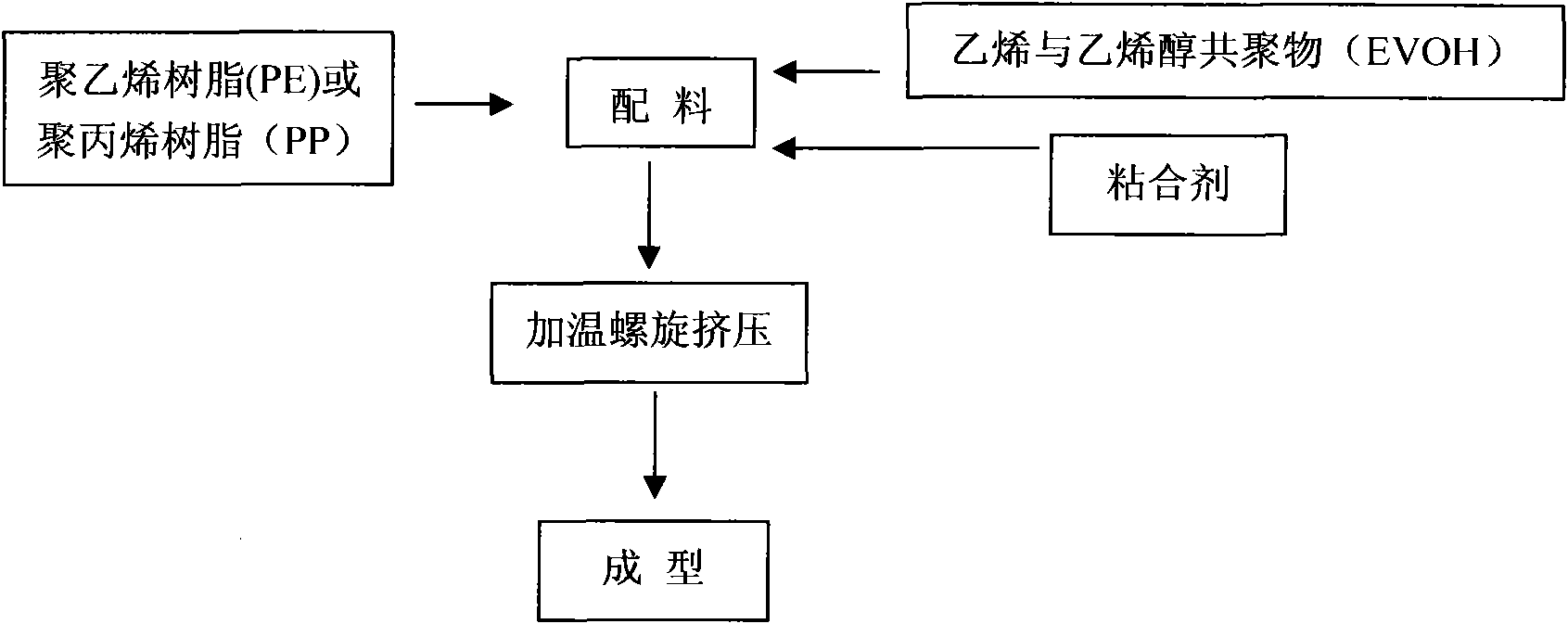

Ethylene-vinyl alcohol (EVOH) copolymer packaging material for tomato products

InactiveCN102336299AGive full play to isolationGive full play to the good barrier properties of ethylene and vinyl alcohol copolymerFlexible coversWrappersAdhesivePolypropylene

The invention relates to an ethylene-vinyl alcohol (EVOH) copolymer packaging material for tomato products, which is prepared by a method comprising the steps of: respectively evenly stirring 83%-89% of polyvinyl resin or polypropylene resin and 3%-7% of EVOH copolymer which are metered in part by weight, and maintaining the stirred material to be dry; after homogenizing, respectively adding the stirred material and 8%-10% of adhesive into a molding mechanical material groove, and heating up at the temperature of 170-200 DEG C; and finally, taking the EVOH copolymer as intermediate materials, and respectively compounding the polyvinyl resin or the polypropylene resin by the adhesive at the two sides of the EVOH copolymer for five-layer compounding. After the inside and outside five-layer compounding structure is adopted, the good insulation performance of the EVOH copolymer is fully exerted, and both the manufacturing cost and the shelf-life performance of the food are considered; furthermore, the EVOH copolymer packaging material for the tomato products is molded in a way of co-extrusion, so that the packaging material is convenient, practical and low in manufacturing cost, the quality of the tomato food is effectively guaranteed within the quality guarantee period, and the requirement of secure storage can be reached.

Owner:陈其钢

Combined dehydration method for preparing dried tomatoes

ActiveCN110012931AReduce drynessReduce intensityClimate change adaptationFruits/vegetable preservation by dehydrationDried cherrySaline water

The invention discloses a combined dehydration method for preparing dried tomatoes. The method comprises the following steps: selection and cleaning: selecting and cleaning ripe tomatoes, and performing peeling and needling treatment by using a steam blanching way; salting pre-dehydration: adding a certain amount of salt into the needled tomatoes, performing uniform mixing and standing salting fora period of time, and separating the tomatoes from saline water; hot air drying: sending the salted tomatoes into a dryer to be dried; rolling kneading and sugar penetration: loading the dried tomatoes into a rolling kneading machine, adding a penetrating liquid, starting vacuum rolling kneading until the penetrating liquid is completely absorbed, stopping rolling kneading, and taking out the tomatoes; and performing drying and packaging to obtain the finished product. The invention provides a dehydration method of instant dried cherry tomato product. The method takes high fidelity as a primary purpose, takes the soft product structure and the meeting of the instant requirement of consumers as a secondary purpose, and prolongs the quality guarantee period of the product as much as possible on the premise of no corrosion prevention.

Owner:GUANGXI UNIV

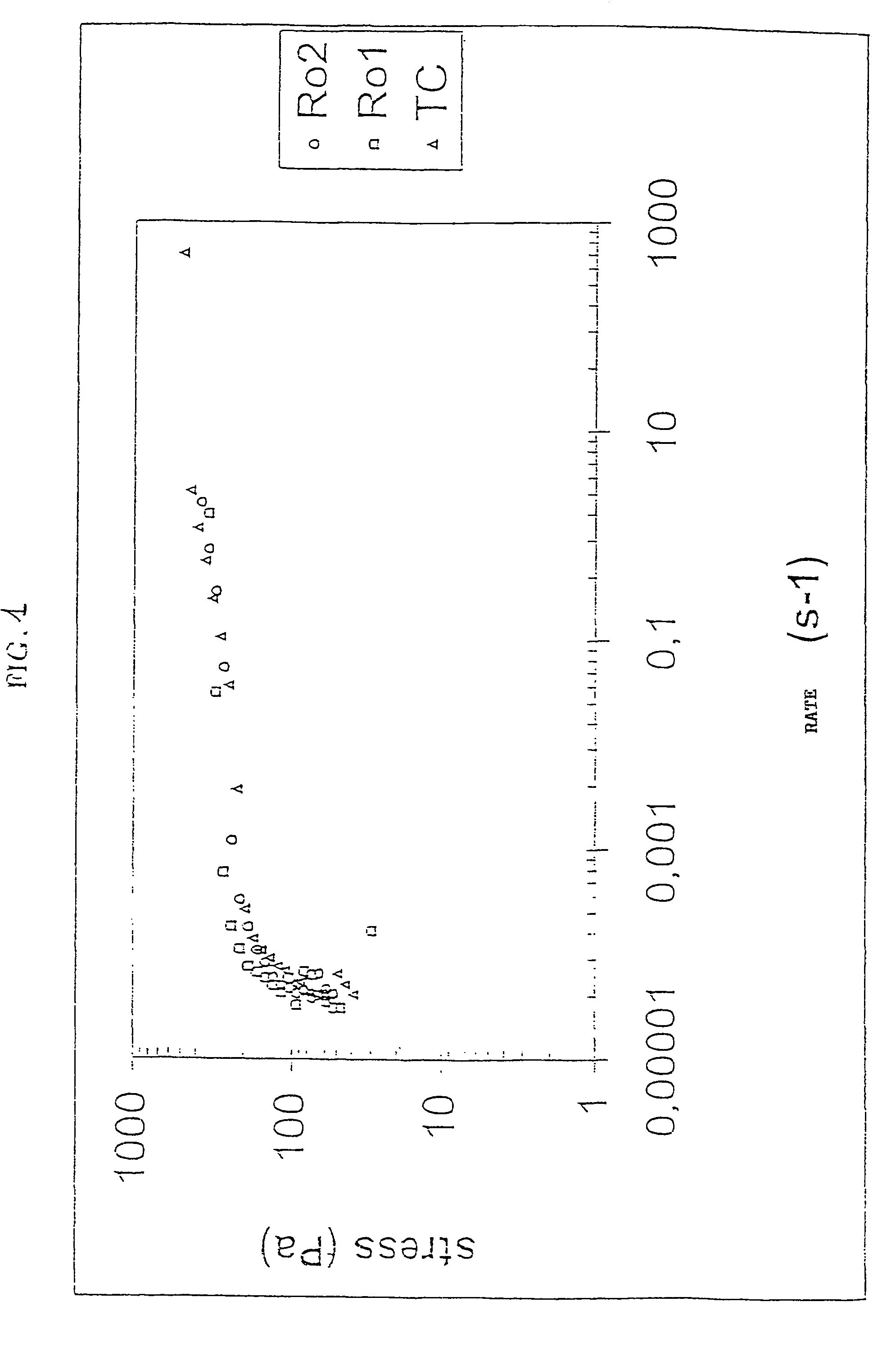

Industrial tomato process and product obtained thereof

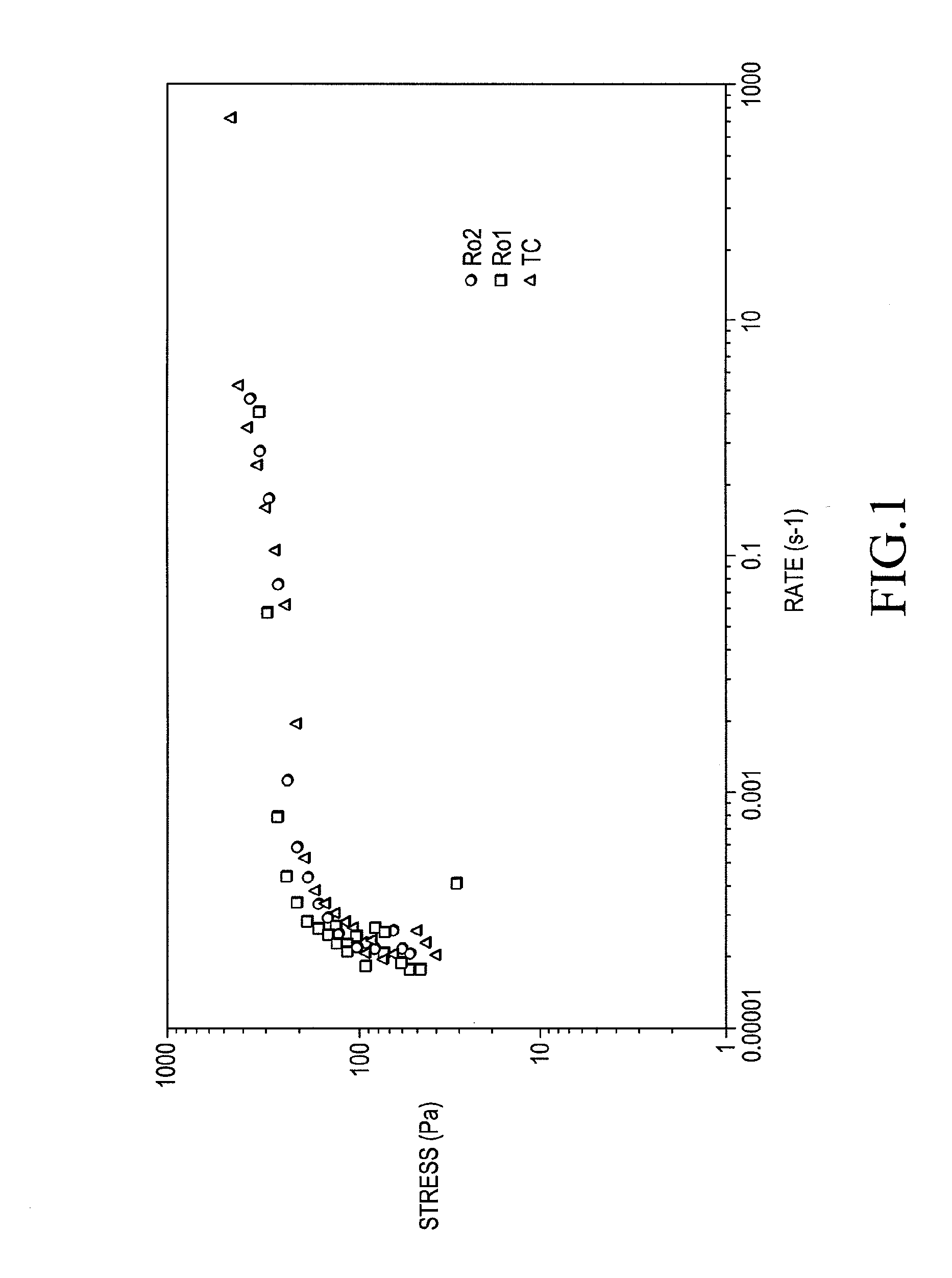

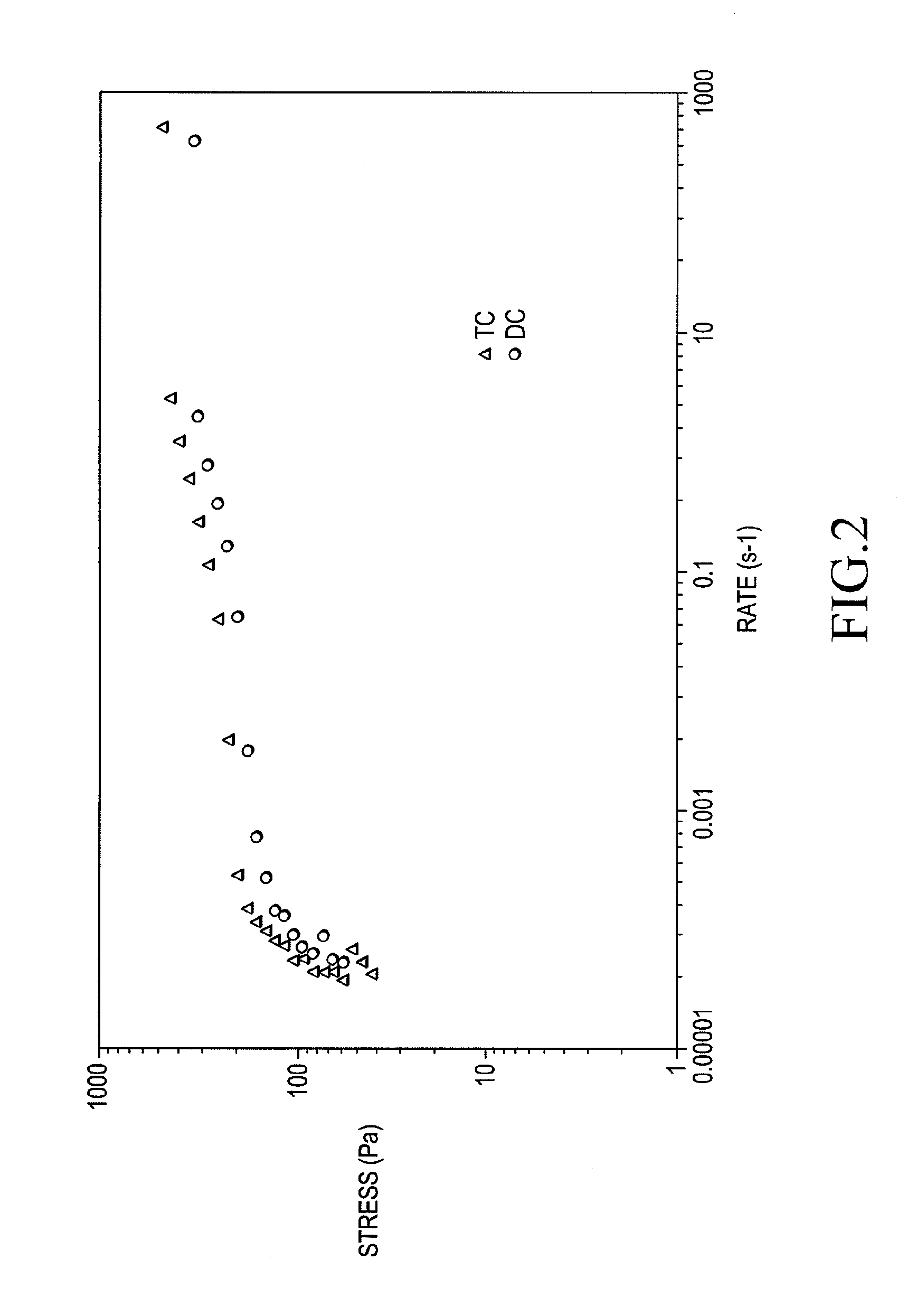

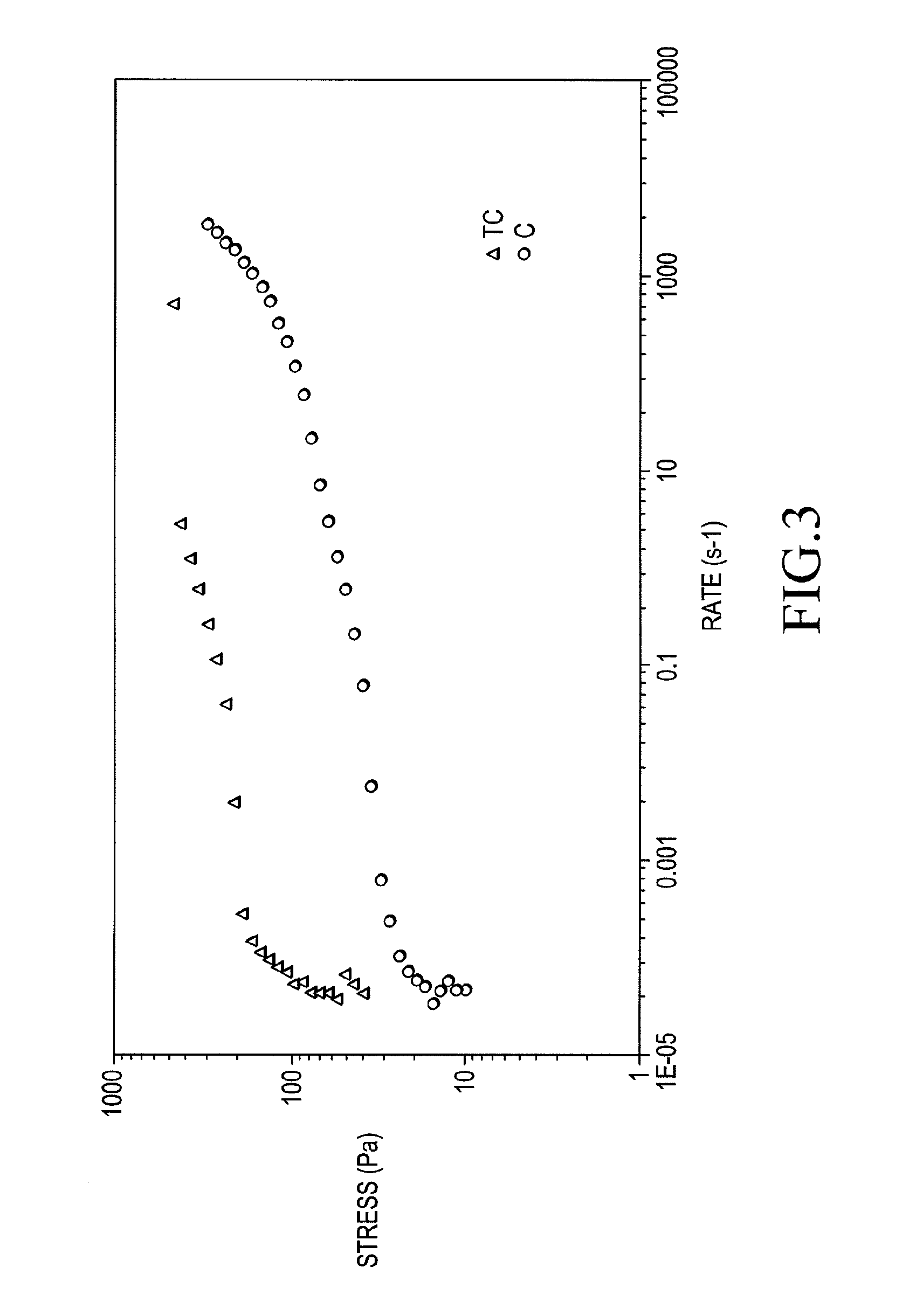

ActiveUS7641931B2Easy to controlCheap sourceFruit and vegetables preservationAnimal feeding stuffViscosityChemistry

The invention relates to a tomato pulp composition wherein the particle size is not greater than 2.5 which does not contain seeds or peels from the tomato and has a lycopene concentration which is 5 to 15 folds higher than the lycopene concentration in the tomatoes from which said pulp is obtained. The invention further provides an industrial process for obtaining tomato pulp and tomato concentrate from tomato juice. The invention further provides a method for controlling the viscosity and lycopene concentration of tomato products, tomato concentrate or modified tomato juice, by separating a part of the pulp from the tomato juice from which said tomato products are obtained.

Owner:LYCORED NATURAL PRODS INDS

Tomato solid drink and preparation method thereof

InactiveCN103598656AUnique preparation methodSimple processFood scienceAdditive ingredientFood products

The invention relates to a tomato solid drink and a preparation method thereof. The method concretely comprises the following steps: with fresh tomatoes as a main raw material, processing the tomato raw material, and adding isomaltooligosacharide and resistant starch into the raw material; and finally, carrying out spray drying to prepare a powder product and filling water into the powder product to obtain the tomato solid drink. According to the tomato solid drink and the preparation method thereof, pigment, essence and preservative are not added into the tomato solid drink in the product preparation process, so that the tomato solid drink and the preparation method thereof are completely in accordance with the development tendency that the modern food is safe, nutrient and convenient. Furthermore, the technology of the method is high in efficiency, good in effect, high in raw material utilization rate, free from waste and little in nutritional ingredient loss. The produced product is long in shelf life, and the problems that the tomatoes are excessive in supply in the peak season as well as rotted and inferior in the slack season, and the like can be solved. The current situation that fewer processed tomato products are available on the market is changed, the produced tomatoes are well sold, the development of industries related to the tomatoes is driven, and a new economic growth point can be formed, so that the tomato solid drink and the preparation method thereof have great economic benefit and social benefit.

Owner:黄秀英

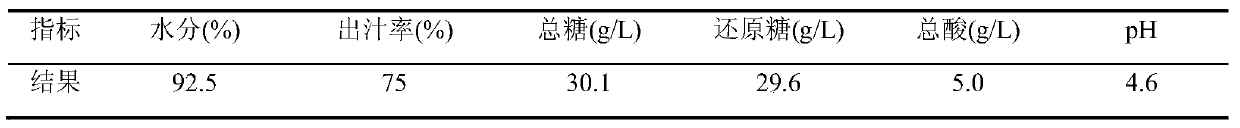

Preparation method of sugar-free tomato juice drink

InactiveCN109393263AImprove stabilityImprove the environmentFood ingredient functionsOligosaccharide food ingredientsAcute hyperglycaemiaCentrifugation

The invention belongs to the technical field of food drink processing and particularly relates to a processing technology and a production method of a sugar-free tomato juice drink. A double-channel pulping and horizontal screw centrifugation process is adopted, the good stability of tomato juice can still be kept under the condition that no stabilizer or thickener is added, functional sugar whichcannot be absorbed and used by the human body is added in a blending process to replace white granulated sugar and sweetening agents, the sugar content of the tomato juice is reduced, the functionality is strengthened, the nutrient value is increased, the demand of vast consumers is met, gospel is brought to people suffering from obesity, hyperglycemia and diabetes, the method has great significance in improving added value, market competitiveness and economic benefits of tomato products, and the foundation is laid for development of high-end products of tomato series.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

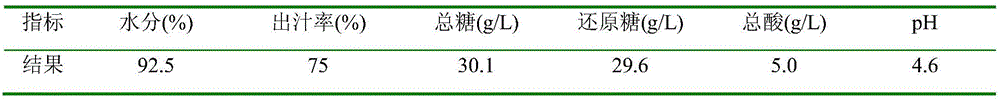

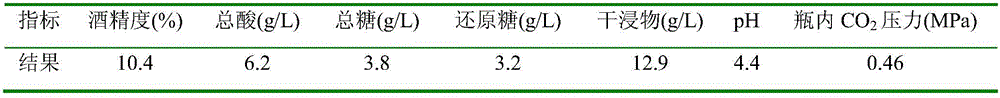

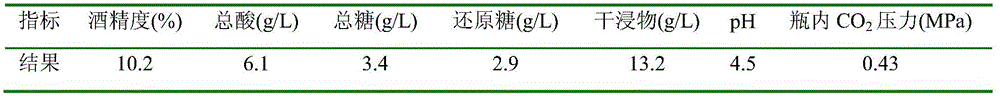

A kind of sugar-free tomato sparkling wine and preparation method thereof

ActiveCN106520490BIncrease incomeGuaranteed NutrientsMicroorganism based processesAlcoholic beverage preparationBiotechnologyHigh triglycerides

The invention relates to sugar-free tomato sparkling wine and a preparation method thereof. The sugar-free tomato sparkling wine is prepared by the following operations: conducting primary fermentation on sterilized tomato pulp so as to obtain fermented tomato original wine; then, adding xylose and honey to the fermented tomato original wine, conducting stirring until the xylose and the honey are completely dissolved; conducting filtering by virtue of a microporous filter membrane which is 0.22-0.45 [mu]m; and conducting secondary fermentation, so that the sugar-free tomato sparkling wine is obtained. According to the sugar-free tomato sparkling wine and the preparation method thereof provided by the invention, the variety of tomato products is enriched, a new way for deep processing of tomato foods is created, the comprehensive utilization value of tomatoes is improved, and the development of such industry chains as tomato planting, processing and the like is promoted. The sugar-free tomato sparkling wine is low in calorie, low in alcoholic strength, proper in sweetness and sourness, harmonious in fruit fragrance and honey fragrance, fresh and delicate in taste, good in stability and long in shelf life; the sugar-free tomato sparkling wine is applicable to people of all ages; and the sugar-free tomato sparkling wine is also an excellent drink for people with 'three high' (high blood pressure, high blood sugar and high triglyceride).

Owner:SHANDONG AGRICULTURAL UNIVERSITY

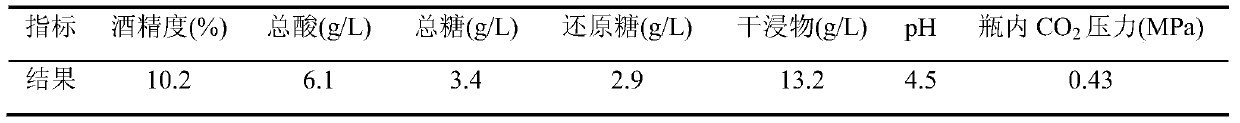

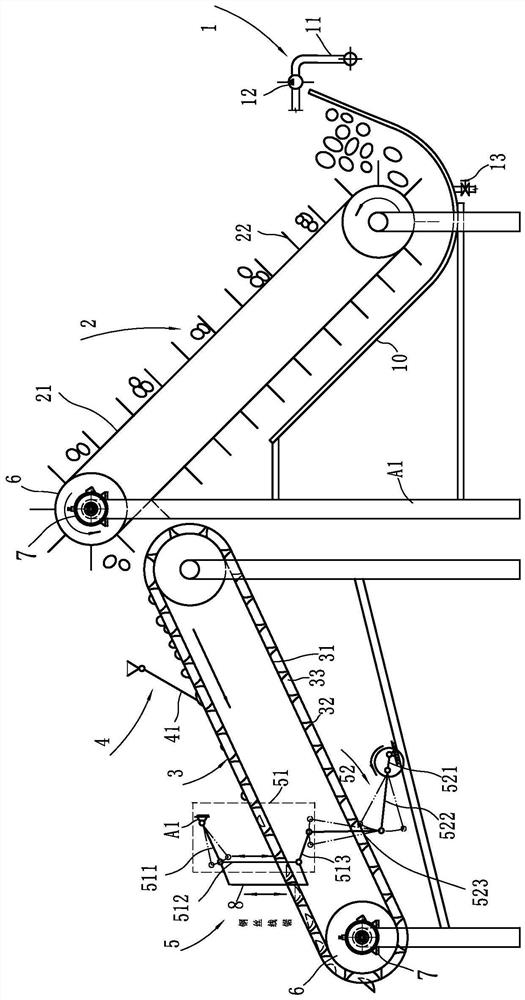

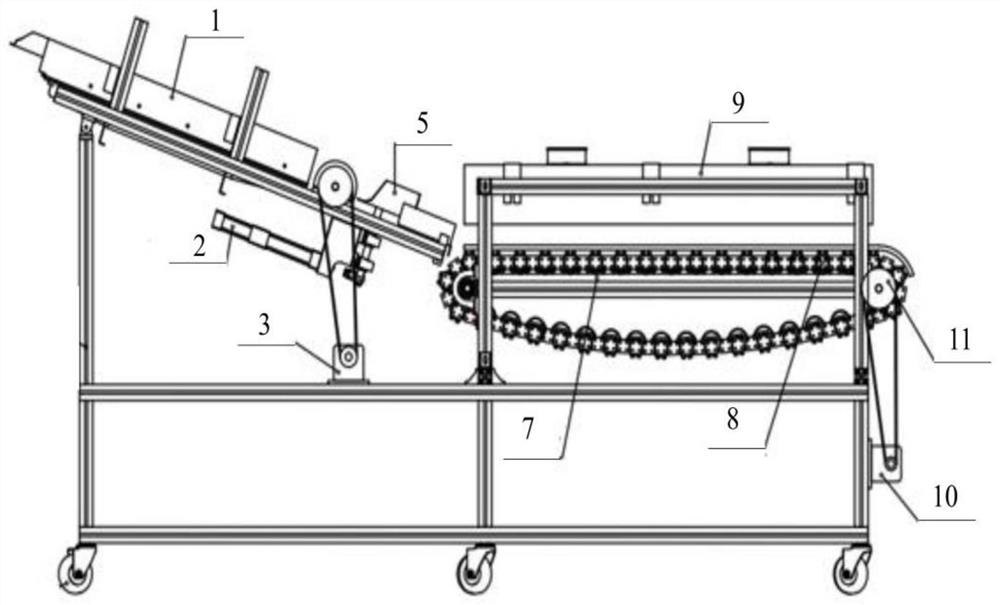

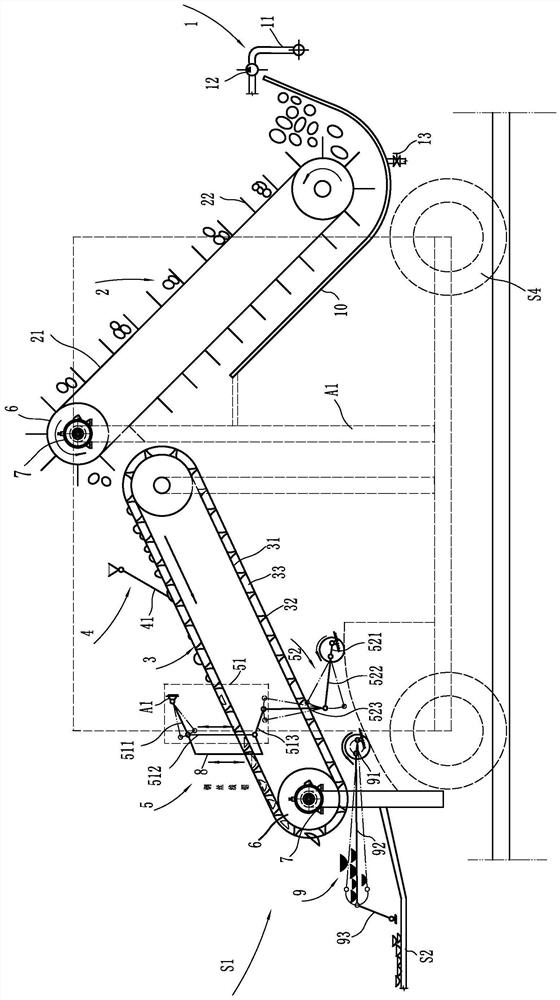

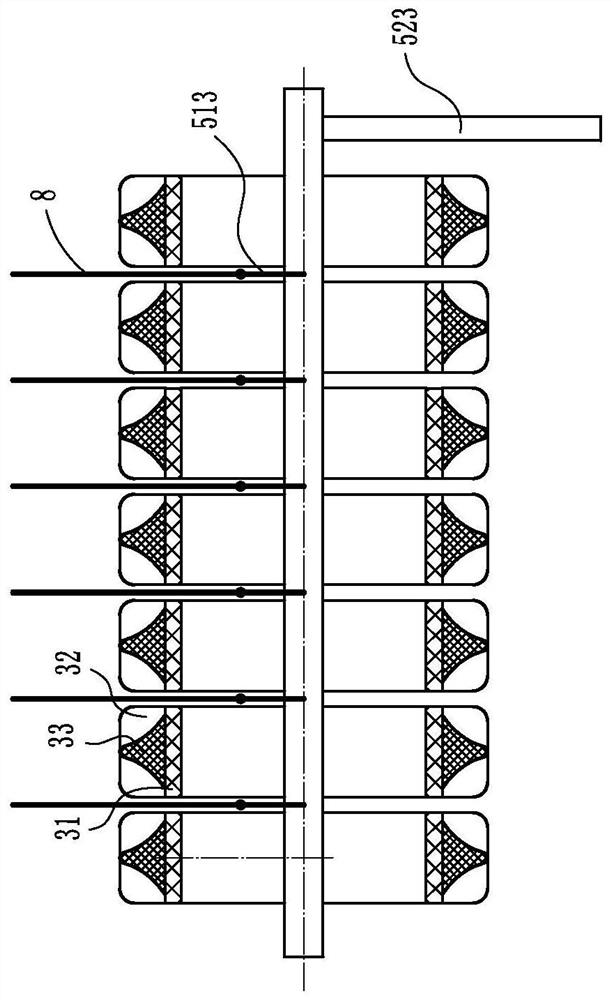

Dried tomato cutting flap laying operation device

ActiveCN110228095BImprove the efficiency of flap cuttingEnsure consistencyMetal working apparatusLoading/unloadingAgricultural engineeringTransfer mechanism

The invention discloses a device for laying dried tomato slices, which includes a frame, a cleaning mechanism, a transfer mechanism, a conveying mechanism and a cutting mechanism, and is used to disperse workshop-cleaning-transportation-cutting-transportation in the traditional tomato processing process. The equipment is integrated into a set of operating devices, thereby avoiding the time-consuming, laborious, high cost and affecting the quality of dried tomato processing caused by the two shipments and turnovers in the traditional processing of dried tomatoes. It has the advantages of saving time, labor, and low production costs. It is characterized by high production efficiency and excellent quality of dried tomato products.

Owner:SHIHEZI UNIVERSITY

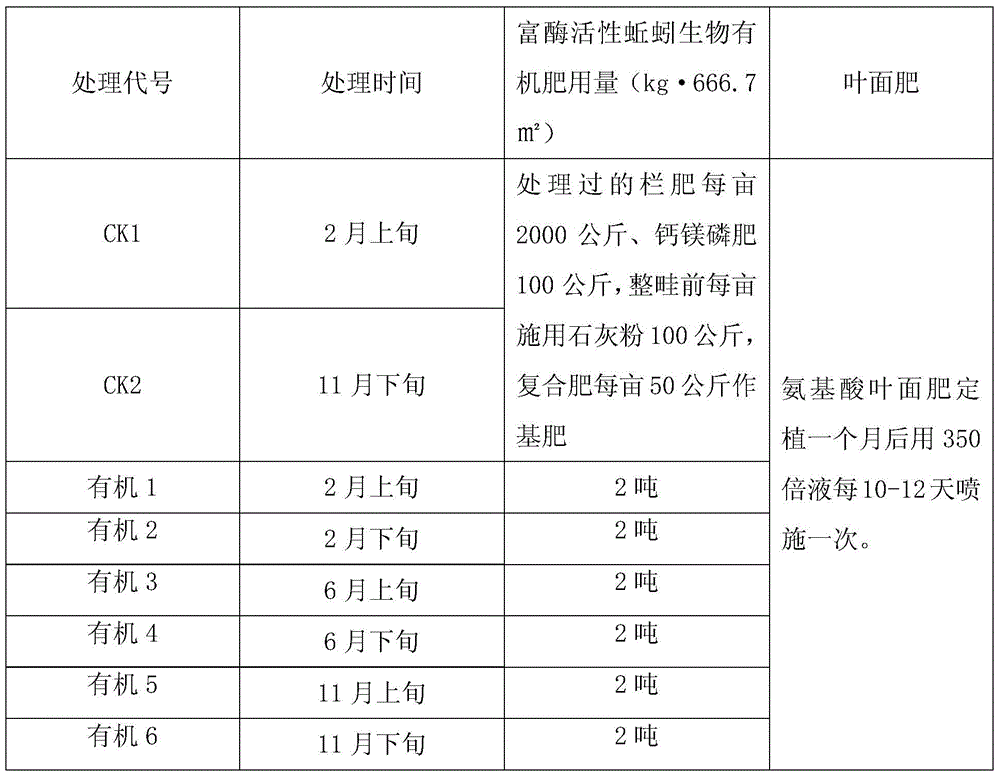

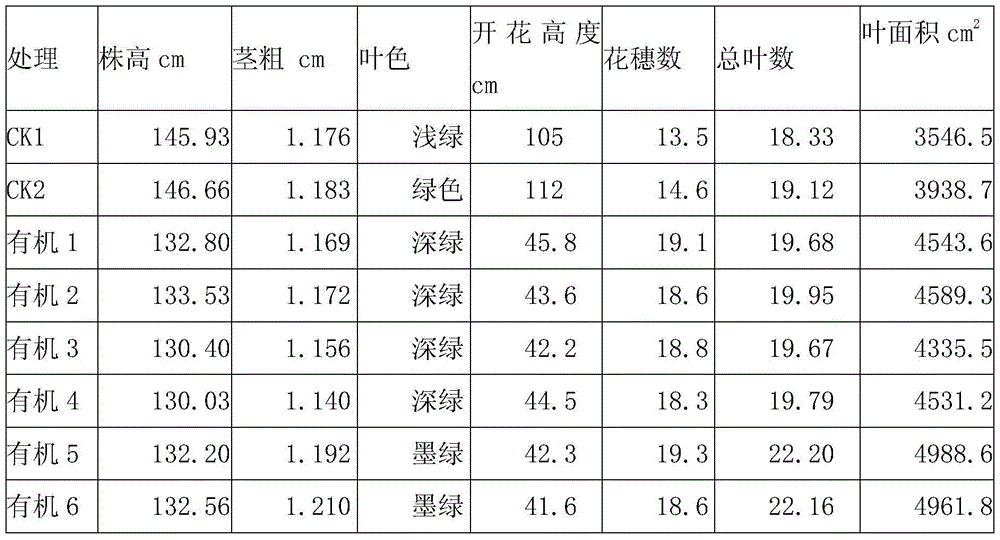

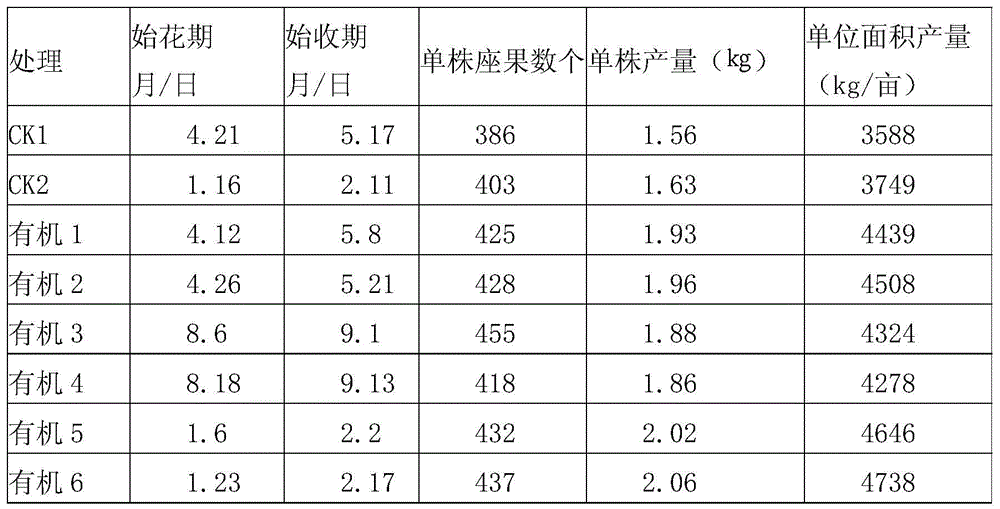

A kind of organic tomato healthy cultivation method

InactiveCN104429581BIncrease cationic fertilizer sourceMaintain regulationFertilising methodsPlant cultivationPesticide pollutionNutrition quality

Owner:GUANGXI POLYTECHNIC

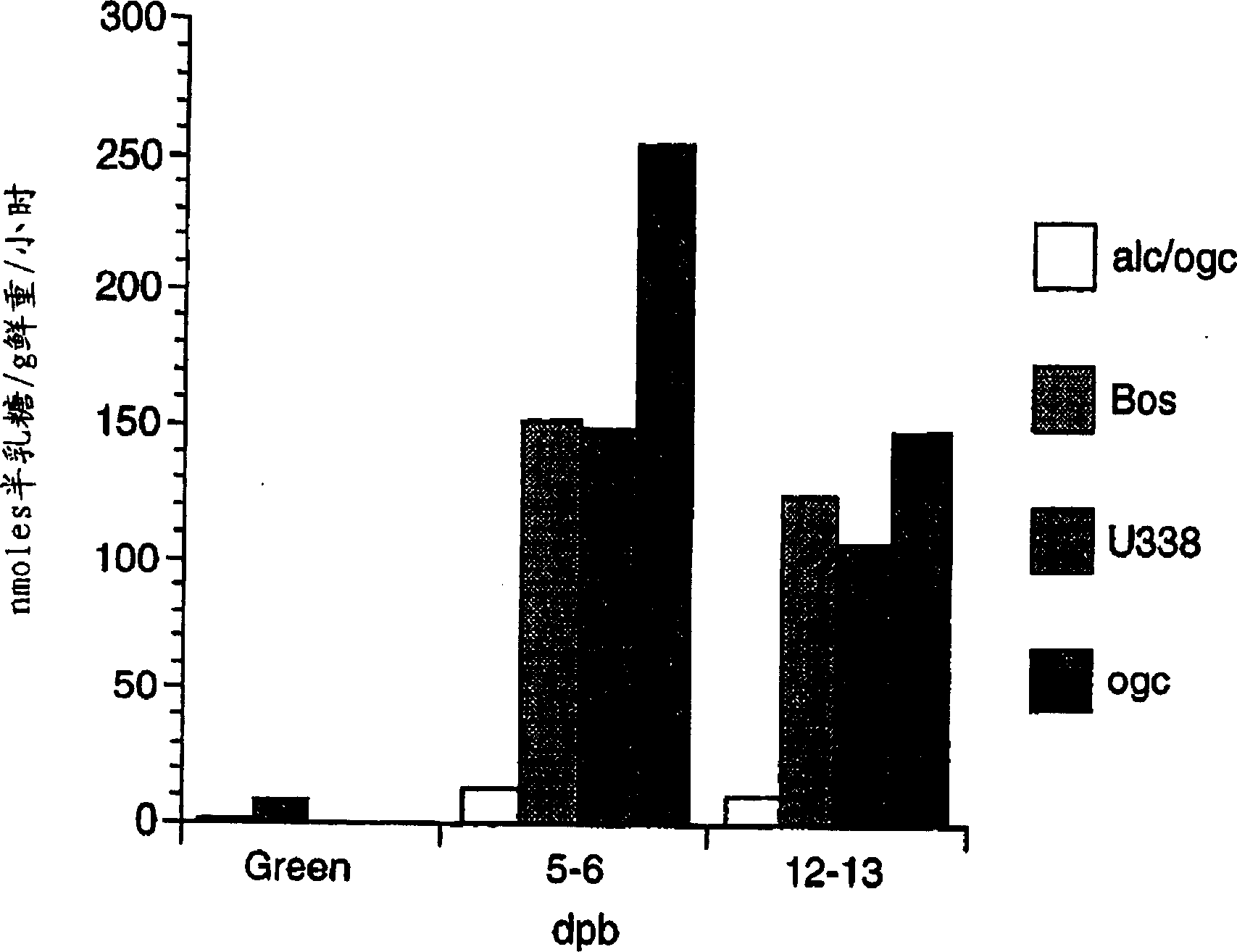

Method of producing processed tomato product

Owner:KAGOME

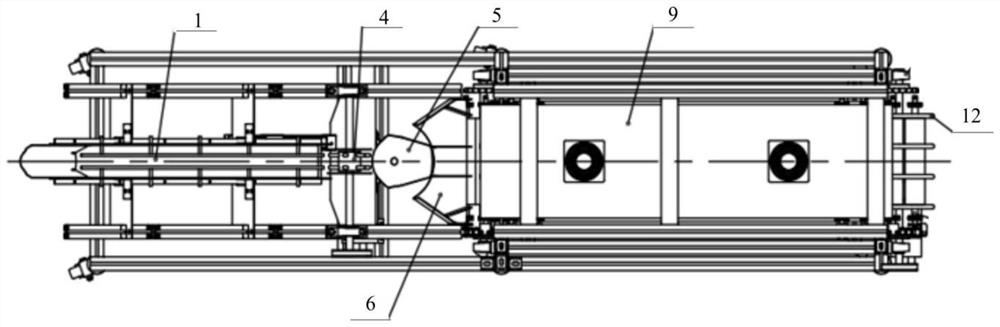

Gas-roller conveying-type catalytic infrared heating peeling method for tomatoes

InactiveCN112535302AIncreased lycopene contentHigh hardnessVegetable peelingPhysical chemistryThermal water

The invention discloses a gas-roller conveying-type catalytic infrared heating peeling method for tomatoes, and relates to the technical field of processing of agricultural products and food. The method comprises the following steps of turning on a front-section gas generator, and heating the tomatoes for 10 seconds by combustion flame; and then feeding the tomatoes sequentially enter a conveyingroller chain to rollably advance by 360 degrees, breaking the skins of the tomatoes after the tomatoes are heated for 4 min at the catalytic infrared temperature of 350 DEG C, and then obtaining peeled tomato products after the tomatoes are peeled. Compared with existing common methods of peeling with hot water and alkali liquor, the dry peeling method has the advantages that no waste water is generated, the method is more environmentally friendly, and the content of lycopene is increased by 133% and 454% respectively; and compared with a static catalytic infrared peeling method, the method provided by the invention has the advantages that the heating is more uniform, the processing time is shortened by 17%, and the lycopene content is improved by 77%. Therefore, the method is more energy-saving and environmentally friendly, the product quality is better, the efficiency of continuous production is higher, and the industrial popularization value is higher.

Owner:JIANGSU UNIV

Production method of tomato food

The invention relates to a production method of a tomato food, which overcomes the defect in the prior art, namely, the production method of the tomato food provided by the invention does not exist in the prior art. The tomato sauce is characterized in that the tomato is divided into three parts, namely sour soup, dish frying and tomato sauce processing. The temperature in the bottle for fumigating the tomatoes in the bottle is 90 DEG C or above. The taste is good, the mouthfeel is good, and eating is convenient. The shelf life can reach two years, and the eating, preservation and storage problems of a large number of tomatoes are solved. Importantly, as the tomato peel is removed, residual pesticide on the tomato peel is removed, so that the tomato food processed by the processing method is green and environment-friendly, is free of any additive, is safe to eat, benefits common people and society, and has a good market prospect. And a plurality of varieties of tomato products are provided for the masses of people. In addition, the peeled tomato peel can be used as a raw material of a compound fertilizer. The method is used for processing tomato food.

Owner:余星达

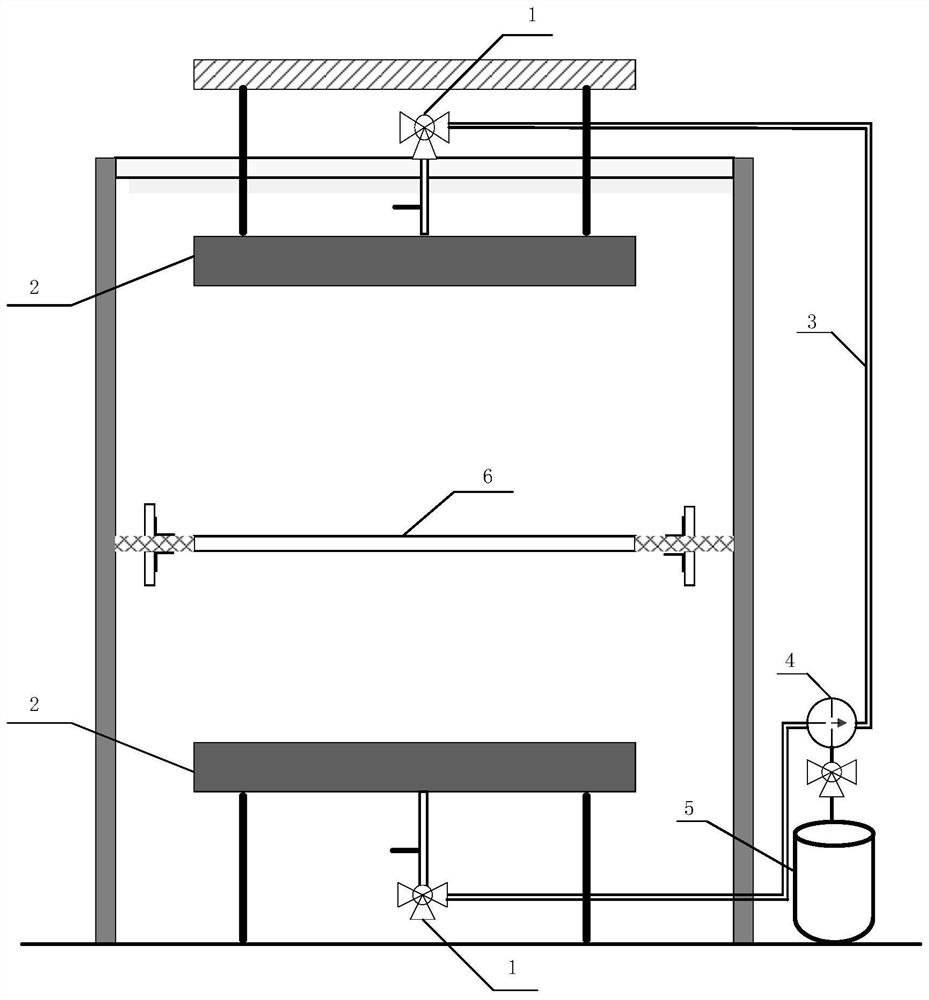

Dried tomato cut petals drying laying platform

ActiveCN110142818BHigh degree of automationIncrease productivityMetal working apparatusLoading/unloadingAgricultural engineeringHorticulture

The invention discloses a drying and laying platform for dried tomato petals, which includes a tomato petal cutting device and a platform, and integrates workshop-cleaning-transportation-petal cutting-transportation-laying and dispersing equipment in the traditional tomato processing operation process into a complete set of operating devices The tomato cutting device and the paving platform can be moved or fixed. Using this operation system can achieve the effect of tomato feeding to tomato cutting evenly laid on the platform. It provides a variety of operation modes, making tomato dry cutting Petal processing has the characteristics of high automation, time saving, labor saving, low cost, high production efficiency and excellent quality of dried tomato products.

Owner:SHIHEZI UNIVERSITY

Resource utilization method of incompletely ripe tomatoes

ActiveCN112120225AIncrease profitExtraction conditions are simpleFood dryingFood ingredient functionsLycoperseneAlcohol ethyl

The invention discloses a resource utilization method of incompletely ripe tomatoes, and belongs to the technical field of food ingredient production. According to the method, tomatoes which are not completely ripe or tomato products which are not completely ripe are used as raw materials, moisture content of the tomatoes is controlled to be 20%-40%, then ethyl alcohol is used as an extracting agent for separation and extraction, and an extract containing phytofluene and phytoene and an extract containing lycopene are obtained respectively. According to the method, the moisture content is adjusted to be 20%-40%, alkaloid contained in the raw materials is removed to the maximum extent, meanwhile, content of lycopene, phytofluene and phytoene is not affected, graded extraction is conducted through solubility difference, and a product with a content of phytofluene and phytoene being 0.9-1.1% is obtained; meanwhile, subsequent extraction of lycopene with strong hydrophobicity is also facilitated, and extraction rate is as high as 85%.

Owner:JIANGNAN UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com