Sugar-free tomato sparkling wine and preparation method thereof

A technology of sparkling wine and tomato, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, can solve the problems that the research on sparkling wine system has not been reported, and achieve the purpose of improving comprehensive utilization value, acidity, etc. Appropriate sweetness, golden color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

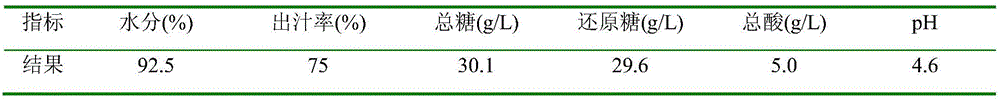

Embodiment 1

[0039] In the present embodiment, tomato original wine and each material composition and ratio are respectively:

[0040] Tomato original wine (9.3% alcohol) 100L

[0041] Honey 2.43kg

[0042] Xylitol 4.0kg

[0043] Prepare as follows:

[0044] 1) After washing and draining the tomato fruit, cut into pieces and beating, and add 0.04g / kg (m / m) of pectinase and 50mg / L (m / v) of SO to the tomatoes respectively. 2 , stand at room temperature for 4 hours in a closed environment to obtain tomato pulp;

[0045] 2) using sucrose to adjust the fermentable sugar content in the tomato pulp to 17.0°Brix;

[0046] 3) Under airtight conditions, 100°C treatment step 2) tomato pulp after adjusting the fermentable sugar content for 15min; then cooled to below 15°C;

[0047] 4) Dissolving and activating commercially available Saccharomyces cerevisiae (adding according to the recommended dosage of Saccharomyces cerevisiae), adding the activated Saccharomyces cerevisiae to the tomato pulp tr...

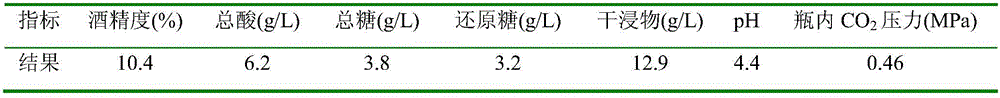

Embodiment 2

[0055] In the present embodiment, tomato original wine and each material composition and ratio are respectively:

[0056] Original tomato wine (9.4% alcohol) 200L

[0057]Honey 4.86kg

[0058] Xylitol 8.0kg

[0059] Prepare as follows:

[0060] 1) After washing and draining the tomato fruit, cut into pieces and beating, and add 0.05g / kg (m / m) of pectinase and 80mg / L (m / v) of SO to the tomatoes respectively. 2 , stand at room temperature for 5h in a closed environment to obtain tomato pulp;

[0061] 2) using sucrose to adjust the fermentable sugar content in the tomato pulp to 17.0°Brix;

[0062] 3) Under airtight conditions, 120°C treatment step 2) tomato pulp after adjusting the fermentable sugar content for 10min; then cooled to below 15°C;

[0063] 4) Dissolving and activating commercially available Saccharomyces cerevisiae (added according to the recommended dosage of Saccharomyces cerevisiae), adding the activated Saccharomyces cerevisiae to the tomato pulp treated i...

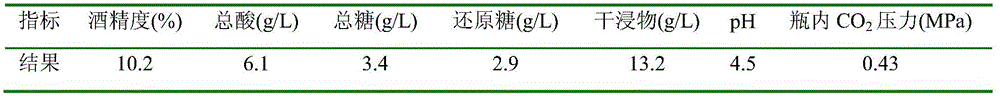

Embodiment 3

[0071] In the present embodiment, tomato original wine and each material composition and ratio are respectively:

[0072] Tomato original wine (9.3% alcohol) 300L

[0073] Honey 7.29kg

[0074] Xylitol 12.0kg

[0075] The preparation steps are the same as those described in Example 1.

[0076] Table 4 Quality of the tomato sparkling wine prepared in this example

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com