Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99 results about "Threading (manufacturing)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods (many kinds of thread cutting and grinding, as detailed below); deformative or transformative methods (rolling and forming; molding and casting); additive methods (such as 3D printing); or combinations thereof.

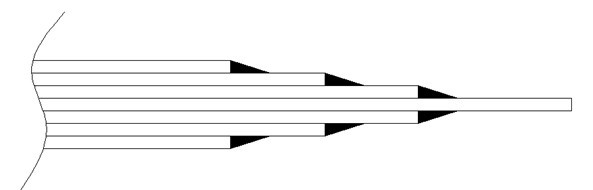

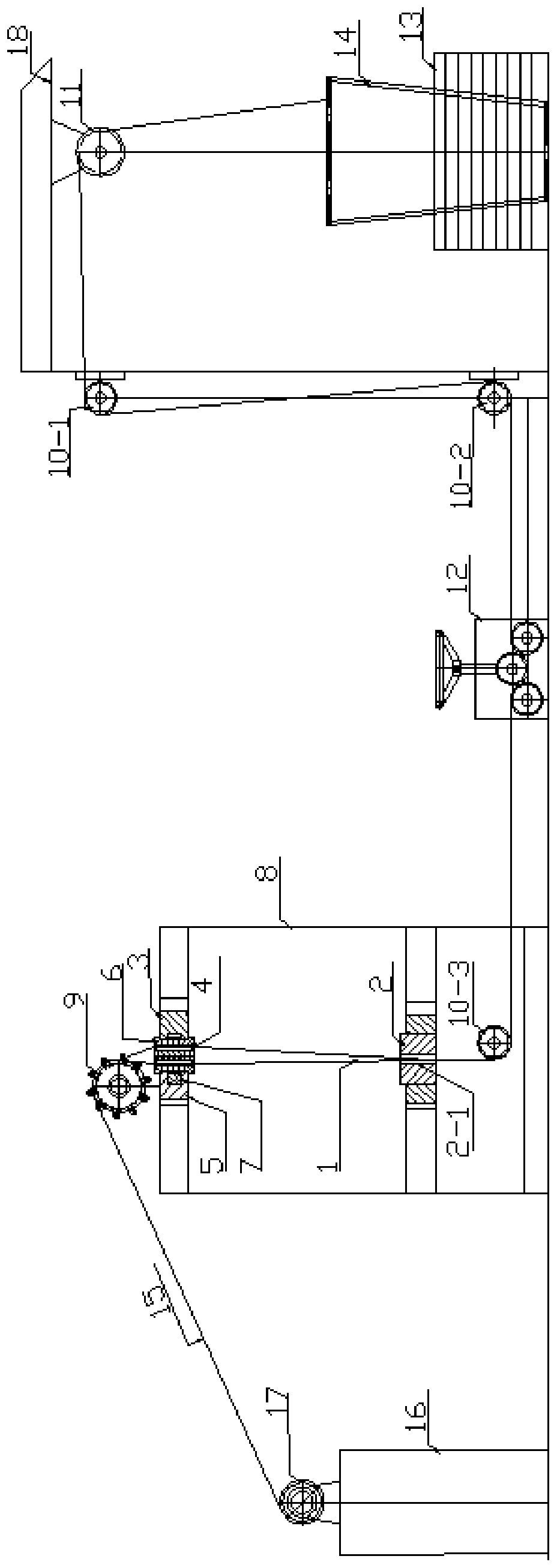

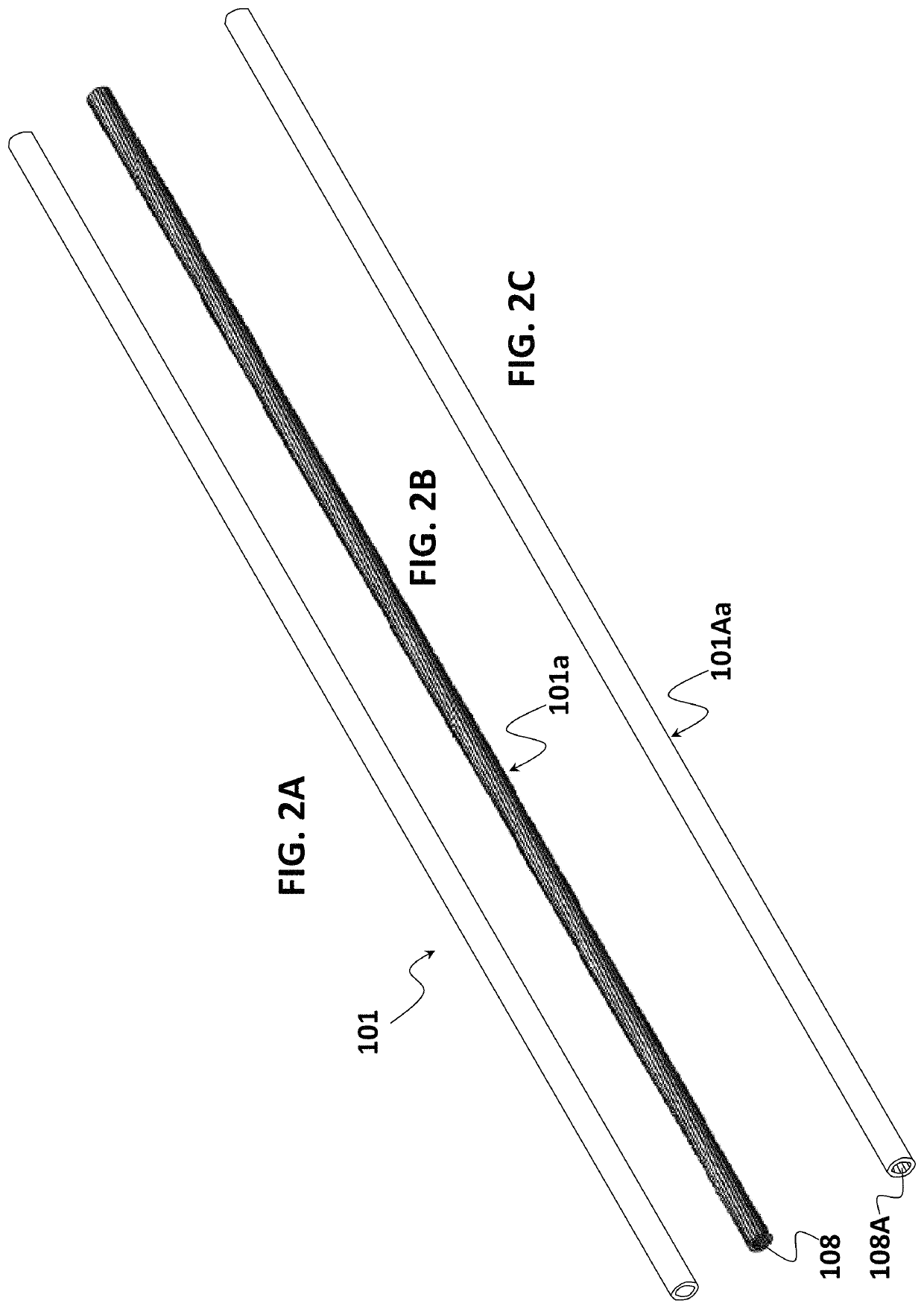

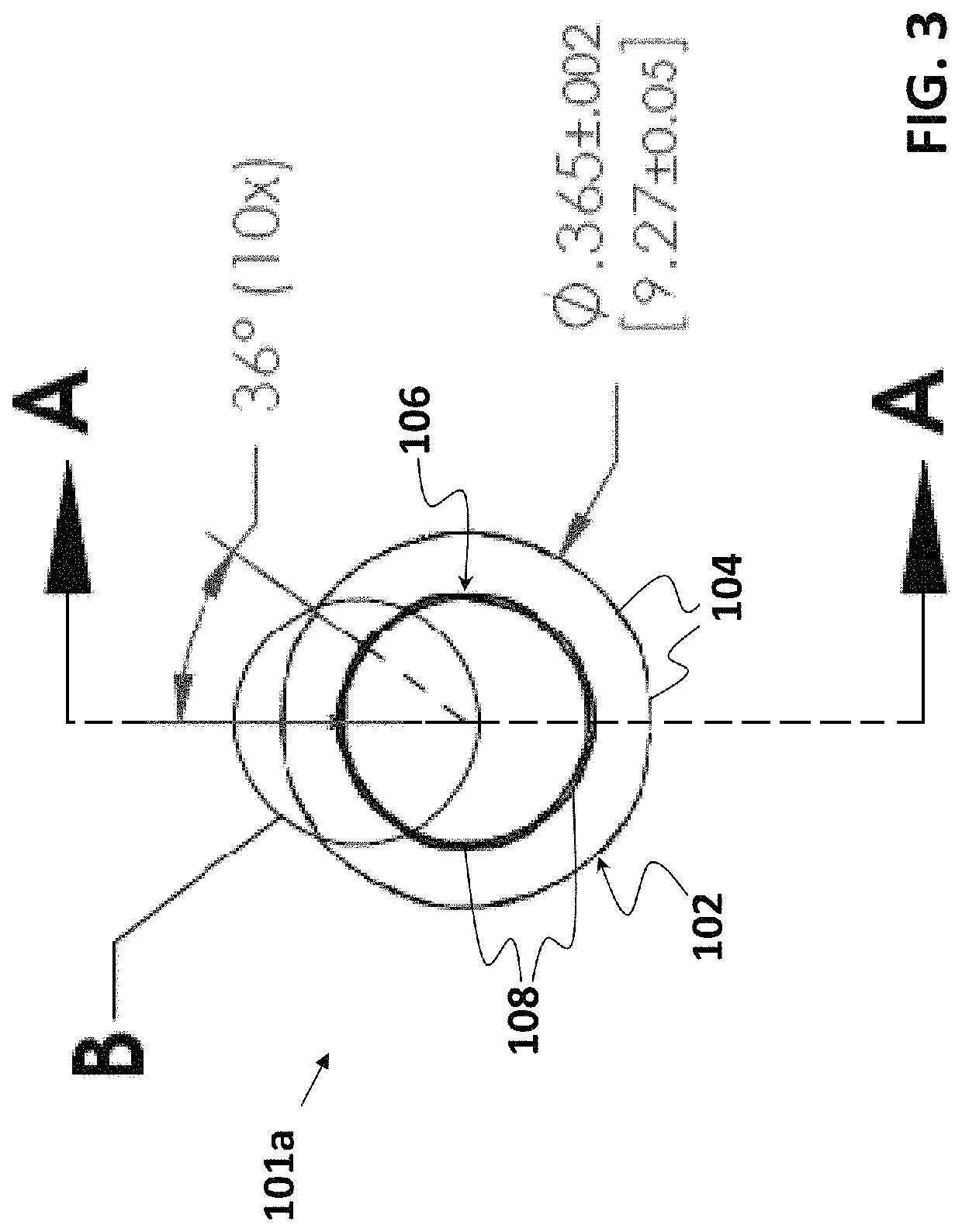

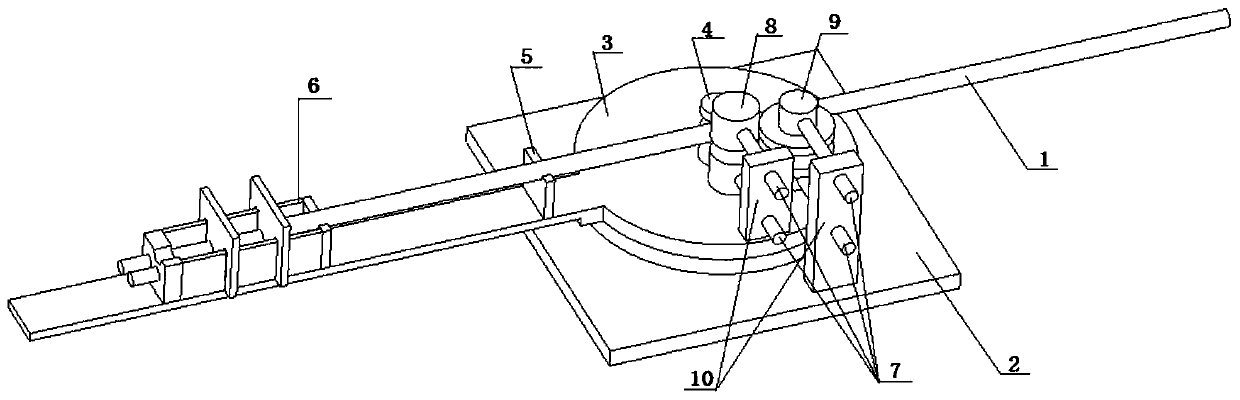

Constructing method for threading pre-stress structure steel strands

InactiveCN102003073ANo thermal stressWon't scratchBridge erection/assemblyBuilding reinforcementsPre stressThreading (manufacturing)

The invention discloses a constructing method for threading pre-stress structure steel strands in a corrugated pipe. In the procedure of manufacturing each bundle of the steel strands, a dragging end of each steel strand is processed; a steel wire is exposed into a certain length relative to the other steel wires; all steel strands are bound to form a bundle; the steel wire exposed out of each steel strand is fixed with a threading anchor fastener; the front end of the threading anchor fastener is connected with a dragging steel wire rope of a dragging device; the back end of the threading anchor fastener is connected with the steel wire exposed out of the steel strand; the dragging steel wire rope drives the steel strand bundle to move in the corrugated pipe so as to pass through the pipe through the threading anchor fastener. The constructing method does not use an end head welding method; the steel strand bundle does not have the thermal stress action; and the end head is not cut again. In addition, the steel strand is good in flexibility and suitable for the linear changing of the pipeline; and the constructing speed is improved by threading the whole steel bundle, and the threading anchor fastener can be reused, therefore, the construction cost is reduced, and the quality and the building construction period are ensured.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

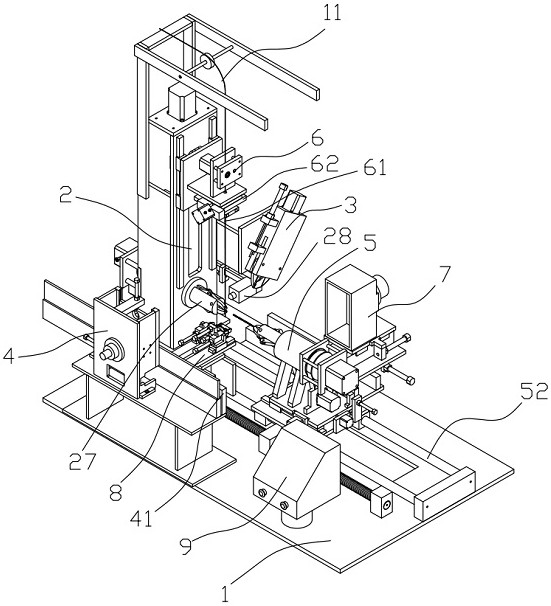

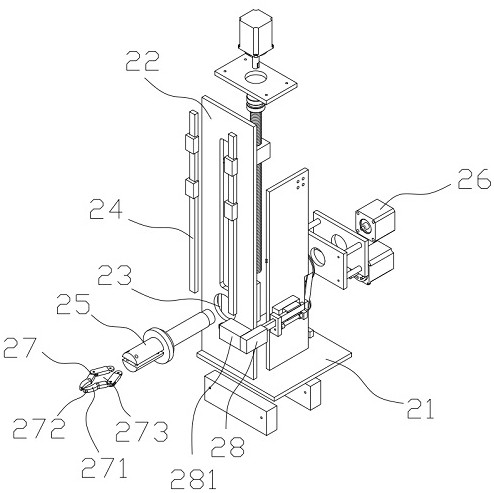

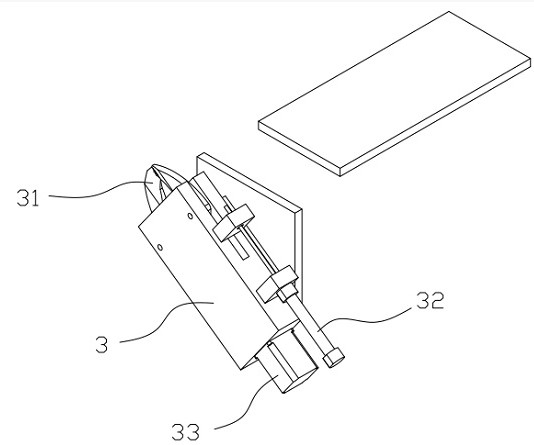

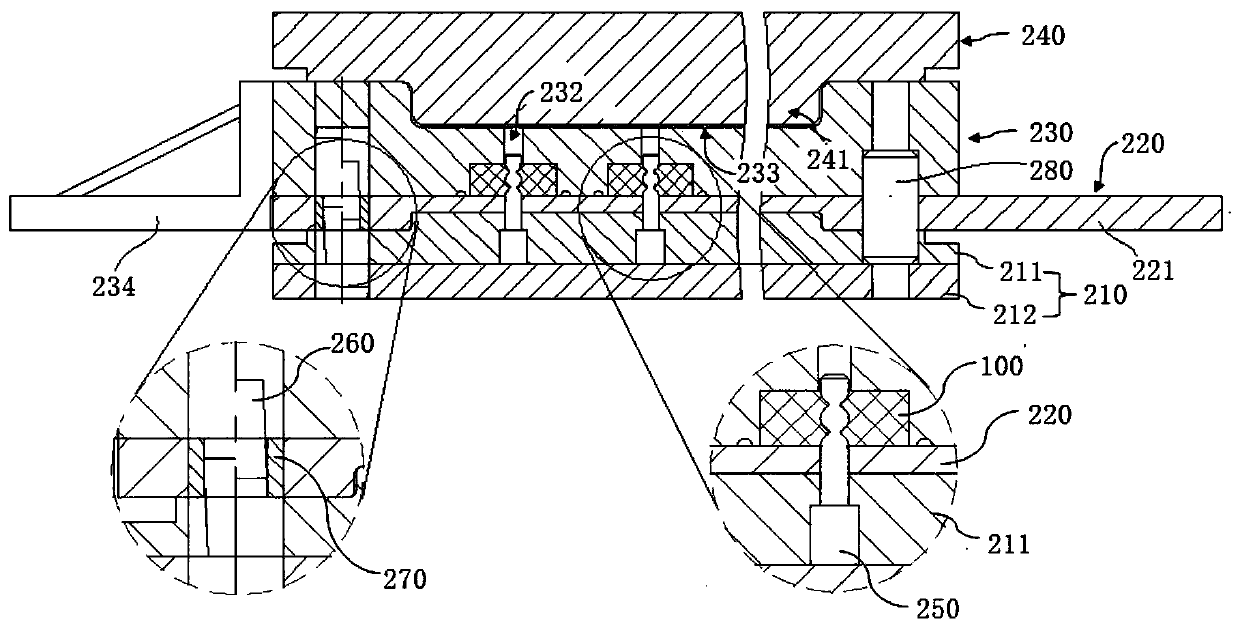

Perforating and threading integrated machine and method for bracelets

InactiveCN107443466ASave human effortShorten the timeJewelleryMetal working apparatusEngineeringRaw material

The invention discloses a perforating and threading integrated machine and method for bracelets. By adoption of the perforating and threading integrated machine and method for the bracelets, the problem that in the prior art, perforating and threading integrated manufacturing cannot be achieved is solved; and the effects of automatic feeding, perforating and threading are achieved, and bracelet perforating and threading tasks can be completed with few manpower resources in a short time. According to the scheme, a feeding mechanism of a bracelet perforating machine comprises a circular ring which is arranged obliquely, a separation disc which can rotate around the central axis of the circular ring is arranged in the circular ring, and a separation blocking piece is arranged on the outer side of the circular ring; a separation plate is arranged on the surface of the separation disc and intersects with the diameter of the separation disc; a discharging hopper is arranged on one side of the separation plate and located below the lateral portion of the circular ring, and a transverse pipe with an opening is arranged at the bottom of the discharging hopper; and a sliding block is arranged in the transverse pipe and connected with a crank, and the crank rotates to drive the sliding block, so that bracelet raw materials in the transverse pipe are pushed to advance and fall down from the opening.

Owner:QINGDAO UNIV

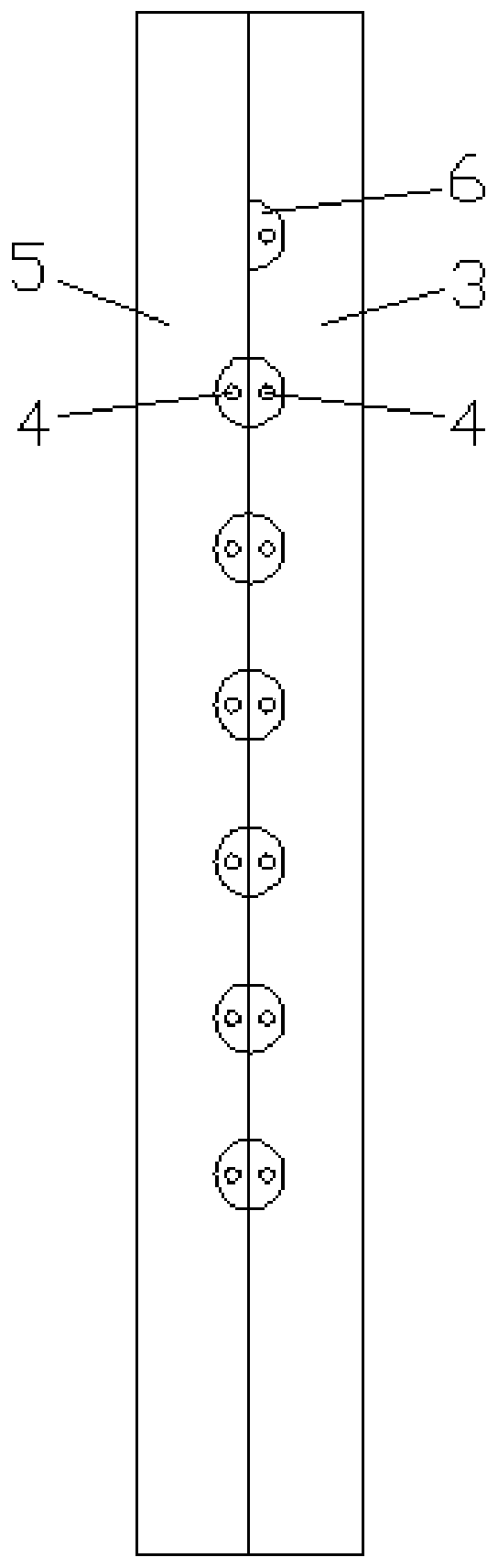

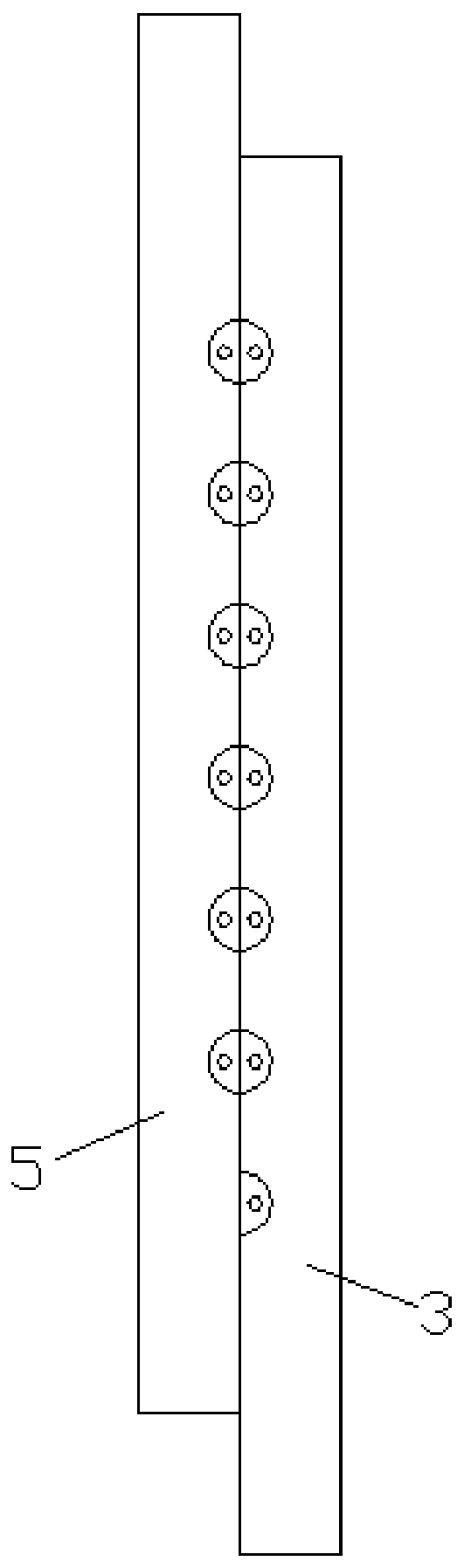

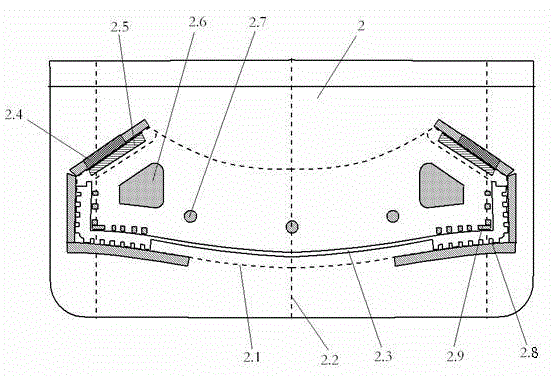

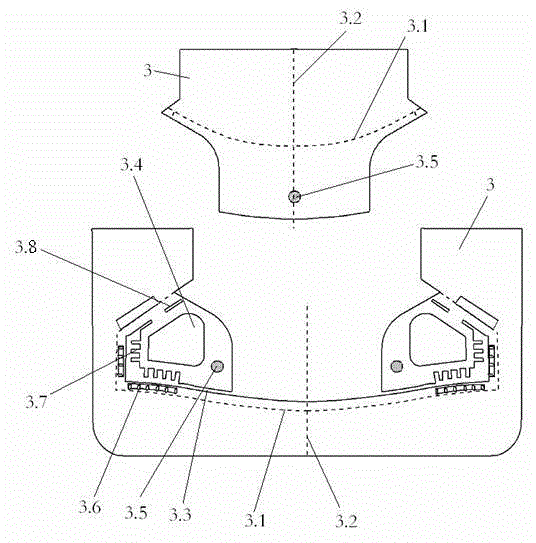

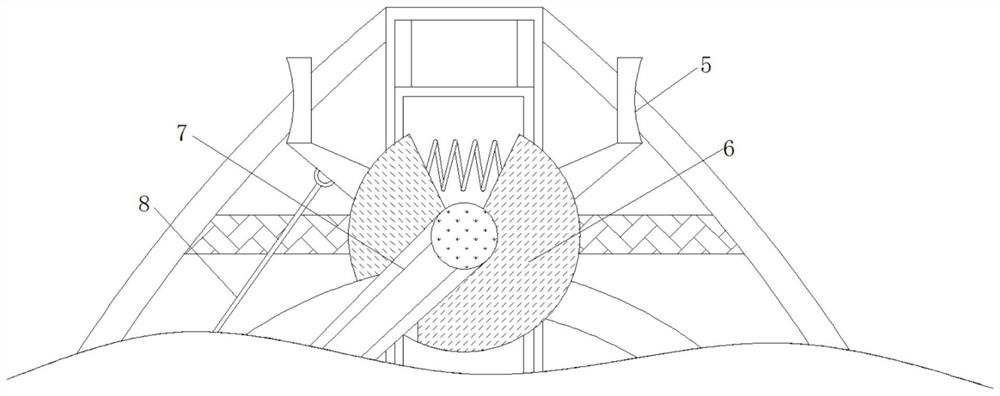

Twisting net structure and twisting net method of simple and efficient gabion box machine

ActiveCN110788257AReduce overall heightImprove securityWire networkGear wheelThreading (manufacturing)

The invention relates to the technical field of gabion box manufacturing equipment, and discloses a twisting net structure and a twisting net method of a simple and efficient gabion box machine. The twisting net structure comprises a threading guide plate and a dragging plate assembly which are arranged in sequence according to the advancing direction of a wire during the twisting net operation, aplurality of through wire holes which are arranged at intervals are formed in the threading guide plate, the dragging plate assembly comprises a pair of dragging plates, half gears and threading twisting holes, the dragging plates are mutually aligned on the side face of the dragging plate assembly and can reciprocate in the opposite-closing plane, the multiple half gears are arranged at equal intervals on each dragging plate at equal intervals and are located on the corresponding plane are rotationally arranged at the center of the rotating center, each threading twisting hole is formed in each half gear, and the half gears on the pair of dragging plates in corresponding positions on the pair of dragging plates are correspondingly spliced into whole gears when the pair of dragging platesare twisted to the twisting net operation position. According to the twisting net structure, the equipment cost can be reduced, the working efficiency and the reliability are improved, and the quality of netting is improved.

Owner:江阴市金利达轻工机械有限公司

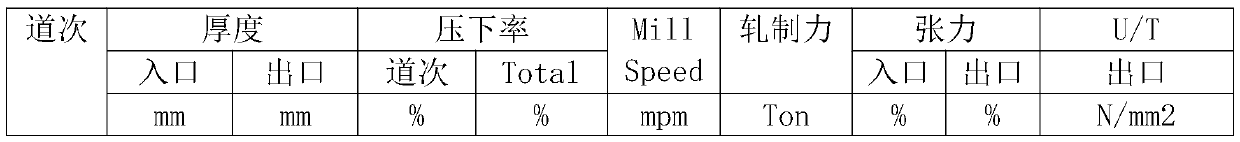

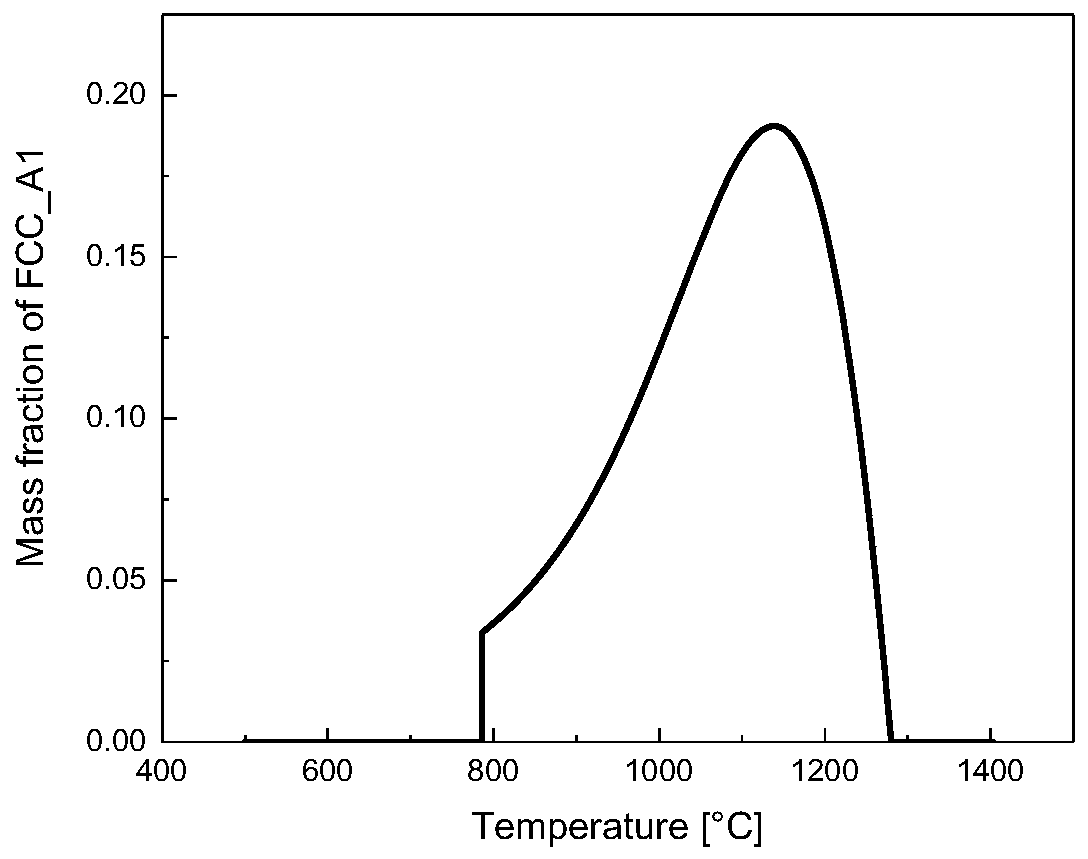

Method for producing nickel-based alloy through twenty-roller reversible rolling mill

InactiveCN110756585AHigh speedIncrease productionRoll force/gap control deviceMetal rolling arrangementsThreading (manufacturing)Alloy

The invention discloses a method for producing nickel-based alloy through a twenty-roller reversible rolling mill. The method is characterized in that the twenty-roller reversible rolling mill is utilized for manufacturing a cold-rolled nickel-based alloy product through coiling-threading-cold rolling and calendaring-annealing-finishing trimming productization, wherein in the cold rolling and calendaring step, the twenty-roller reversible rolling mill is adopted for conducting seven-pass rolling on industrial nickel-based alloy; the reduction rate of each pass is controlled to range from 6% to11%, the rolling force is controlled to range from 200 Ton to 250 Ton, the rolling speed is controlled to range from 100 mpm to 300 mpm, and the tension of each pass is kept constant in the rolling process; and the target thickness is achieved through one rolling process. The method has the beneficial effects that the thickness of a finished product can be obtained through rolling of the single rolling process of the twenty-roller reversible rolling mill, the material model is controlled, the production procedure is shortened, and the production cost of the nickel-based alloy is reduced; andthe production technology condition requirement can be met without modifying single-rack twenty-roller reversible rolling mill equipment, and the equipment utilization rate is increased.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Carburizing and manufacturing technology for split down-the-hole drill bit

ActiveCN104120431AImprove reuse efficiencyHigh strengthDrill bitsFurnace temperatureManufacturing technology

The invention relates to a carburizing and manufacturing technology for a split down-the-hole drill bit. The carburizing and manufacturing technology comprises the following steps: thread cutting: carrying out threading cutting on the top of a drill rod and inside a drill bit, wherein the drill rod and the drill bit are split; preheating: heating the separated drill rod and the drill bit to 600-650 DEG C; carburizing: heating to 880-900DEG C and keeping the constant temperature for 1-1.5 hours, and heating to 920-930DEG C and keeping the temperature for 12-14 hours; precooling: cooling furnace temperature to 850-870DEG C and keeping for 0.9-1.1 hours; quenching: quenching the drill rod and the drill bit for 25-35 minutes; tempering: tempering the cooled drill rod and the drill bit, then heating to 170-190 DEG C and keeping for 5.8-6.2 hours, and then naturally cooling; and milling of a carburized layer of the drill bit: rubbing off the carburized part of the drill bit and guaranteeing the rubbed-off part of the drill bit to range from 2.5mm to 3mm. According to the technology, the down-the-hole drill bit which is split from the drill rod can be produced, the reuse efficiency of the drill rod can be greatly improved, the cost can be saved, and the efficiency can be improved.

Owner:武穴市长江工具股份有限公司

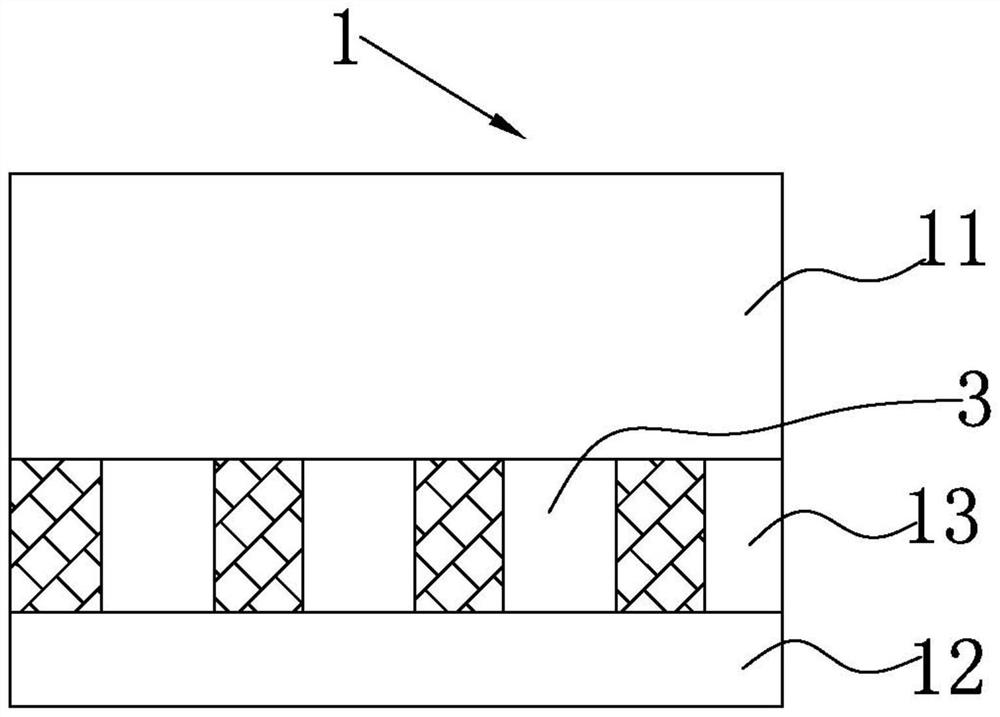

Filled jacquard mesh fabric and manufacturing method thereof

PendingCN111172668AImprove breathabilitySoft touchFlat warp knitting machinesFiberThreading (manufacturing)

The invention relates to the technical field of mesh fabric weaving, and especially relates to a filled jacquard mesh fabric. The filled jacquard mesh fabric comprises a mesh fabric body formed by integrally weaving a double needle bed sheet / double jacquard creel warp knitting machine; the mesh fabric body comprises a surface layer, a bottom layer and a bonding layer for connecting the surface layer and the bottom layer; the bonding layer comprises a jacquard layer; and the jacquard layer is formed by interweaving 100 to 300D CD bright low stretch yarns and 100D to 300D CD bright low stretch yarns. According to the filled jacquard mesh fabric provided by the invention, a two-needle bar jacquard creel warp knitting machine is applied, various guide bars are designed through a reasonable process, a jacquard comb connecting 2 to 4 guide bars has a special change pattern design, that is, the unique advantages of the double needle bed sheet / double jacquard creel warp knitting machine is fully used, in combination with the guide bar non-threading threading changes, and the use of precision design pattern designs and chemical fiber yarns, the filled jacquard mesh fabric with high performance, good chemical structure stability and unique appearance pattern is produced.

Owner:SINCETECH FUJIAN TECH CO LTD

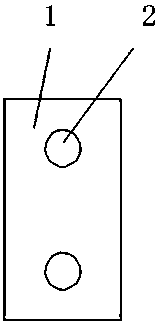

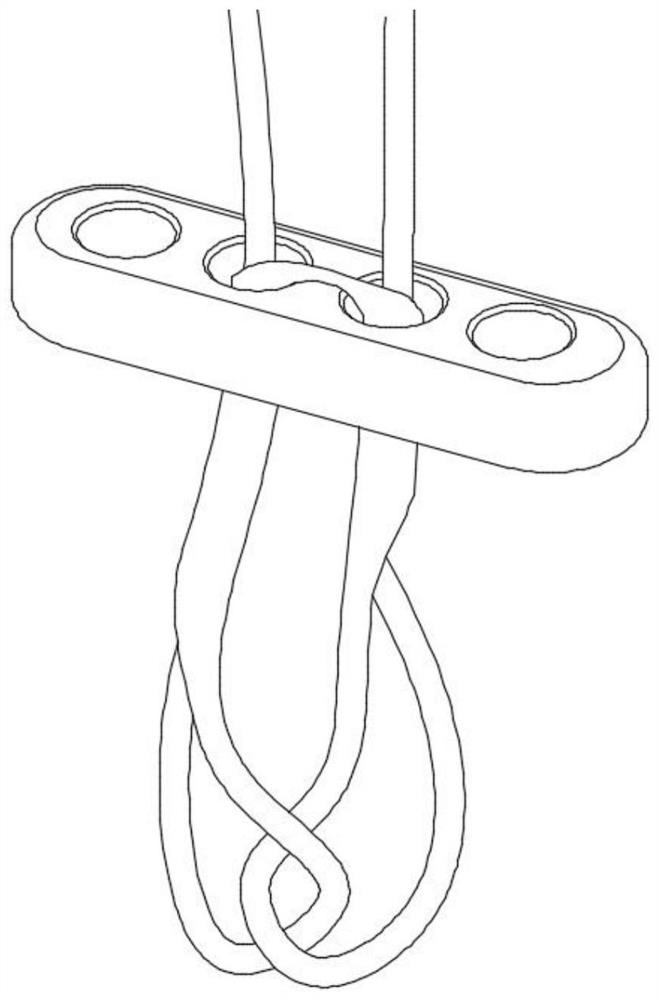

Multi-hole wire locking device

InactiveCN110848328AImprove stabilityThere will be no delaminationRopes and cables for vehicles/pulleyTextile cablesThreading (manufacturing)Engineering

The invention discloses a multi-hole wire locking device. The multi-hole wire locking device comprises a longitudinal wire locking device and a transverse wire locking device, wherein a fixing hole Iis formed in the longitudinal wire locking device in the transverse direction; a fixing wire I is arranged in the fixing hole I; a threading hole I is formed in the longitudinal wire locking device inthe longitudinal direction; a fixing hole II is formed in the transverse wire locking device in the transverse direction; a fixing wire II is arranged in the fixing hole II; a threading hole II is formed in the transverse wire locking device in the longitudinal direction; the threading hole II communicates with the fixing hole II; the threading hole I corresponds to the threading hole II; and thetop surface of the longitudinal wire locking device is connected with the bottom surface of the transverse wire locking device. According to the multi-hole wire locking device, the stability of fixing a steel wire rope is good, when a bearing object is large, the wire locking device cannot generate a wire falling phenomenon, so that the safety during use is improved, and wide popularization is facilitated; the multi-hole wire locking device is simple to use, convenient to mount and better in practicability; and the multi-hole wire locking device is simple in structure, low in manufacturing cost and capable of being widely popularized.

Owner:徐州道亨钢绳索具有限公司

Process wire winding device

ActiveCN111118687AImprove work efficiencyQuality is easy to controlSevering textilesAdhesivesWinding machineThreading (manufacturing)

The invention relates to the technical field of process line production equipment, and provides a process line winding device, which comprises a box body, wherein a workbench is arranged on the box body, a first supporting plate is arranged on the workbench, a fixed winding mechanism is arranged on one side of the first supporting plate, and a threading mechanism and a welding bonding mechanism are arranged on the other side of the first supporting plate; a movable winding mechanism arranged opposite to the fixed winding mechanism is movably arranged on the box body, and a traction mechanism is arranged on one side, away from the fixed winding mechanism, of the movable winding mechanism; a process line horizontally passes through the fixed winding mechanism, the movable winding mechanism and the traction mechanism, the process line penetrates through the side surface of the threading mechanism, is bonded through the welding bonding mechanism, and is wound through the fixed winding mechanism and the movable winding mechanism; and a rack is further arranged on the box body and a cutting mechanism is arranged on the rack. The device solves the problems that a current process line is lack of corresponding winding processing equipment, manual winding and manufacturing are needed, the working efficiency is low, the quality is uncontrollable, and the cost is high.

Owner:潍坊极尚智能科技有限公司

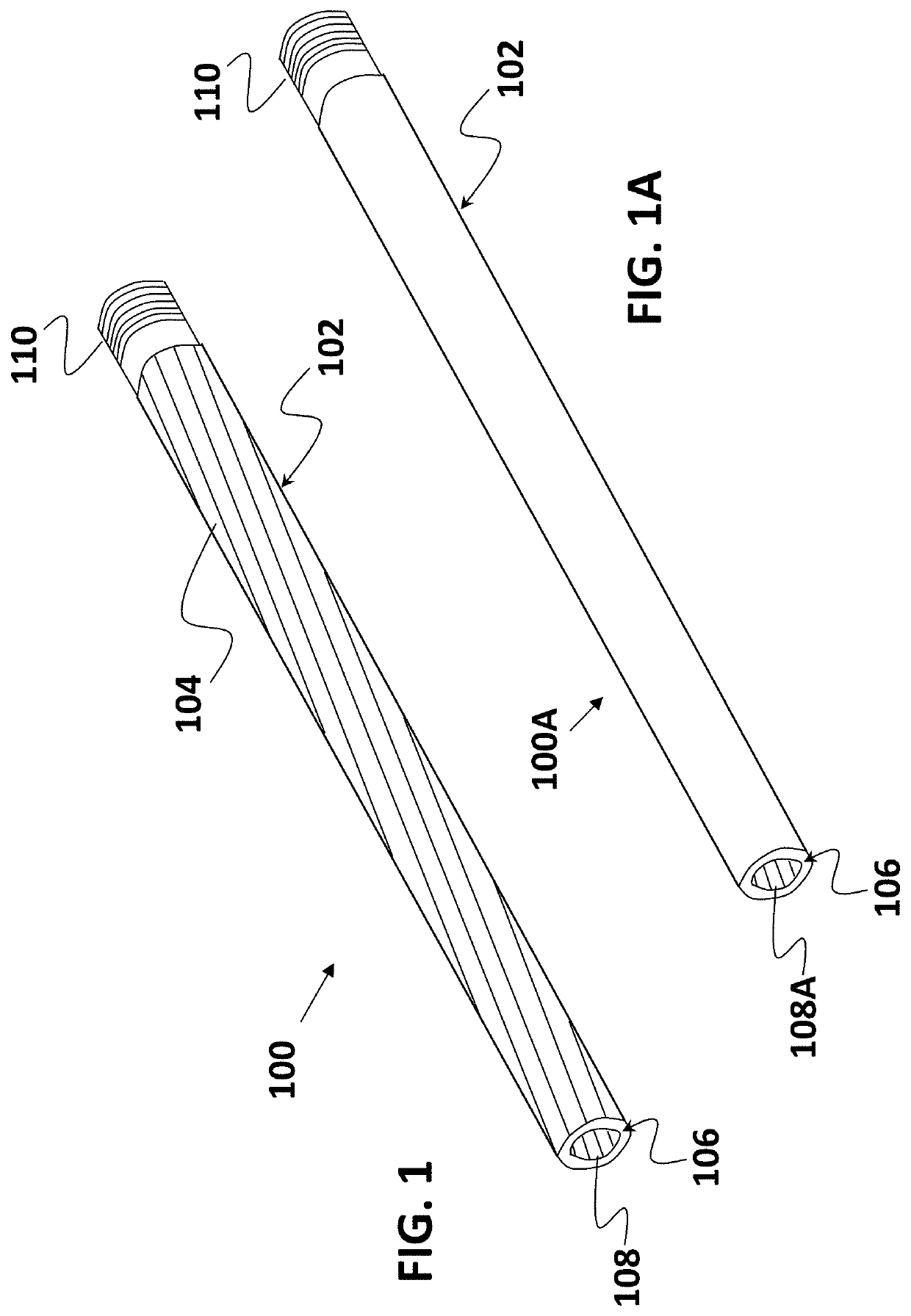

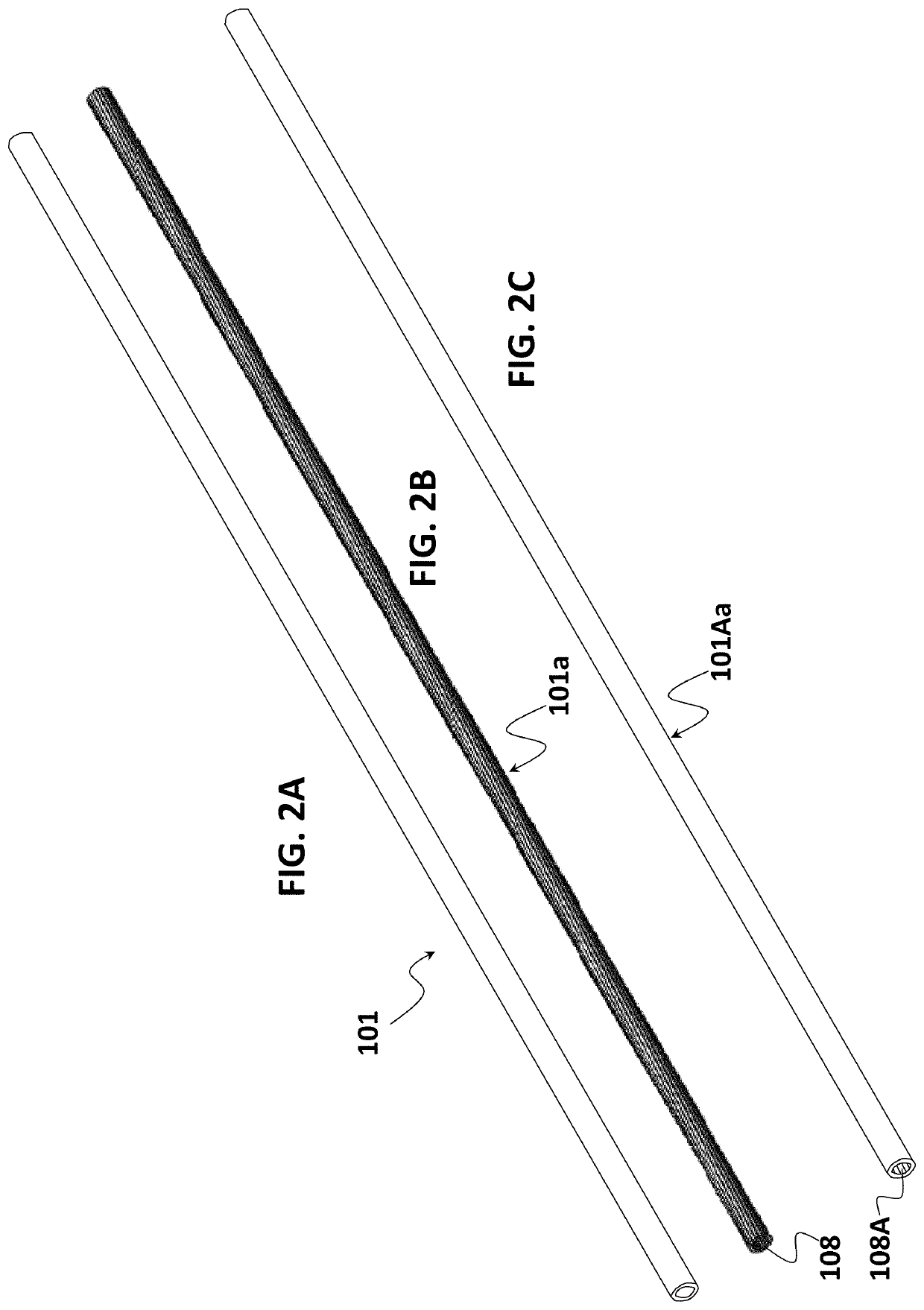

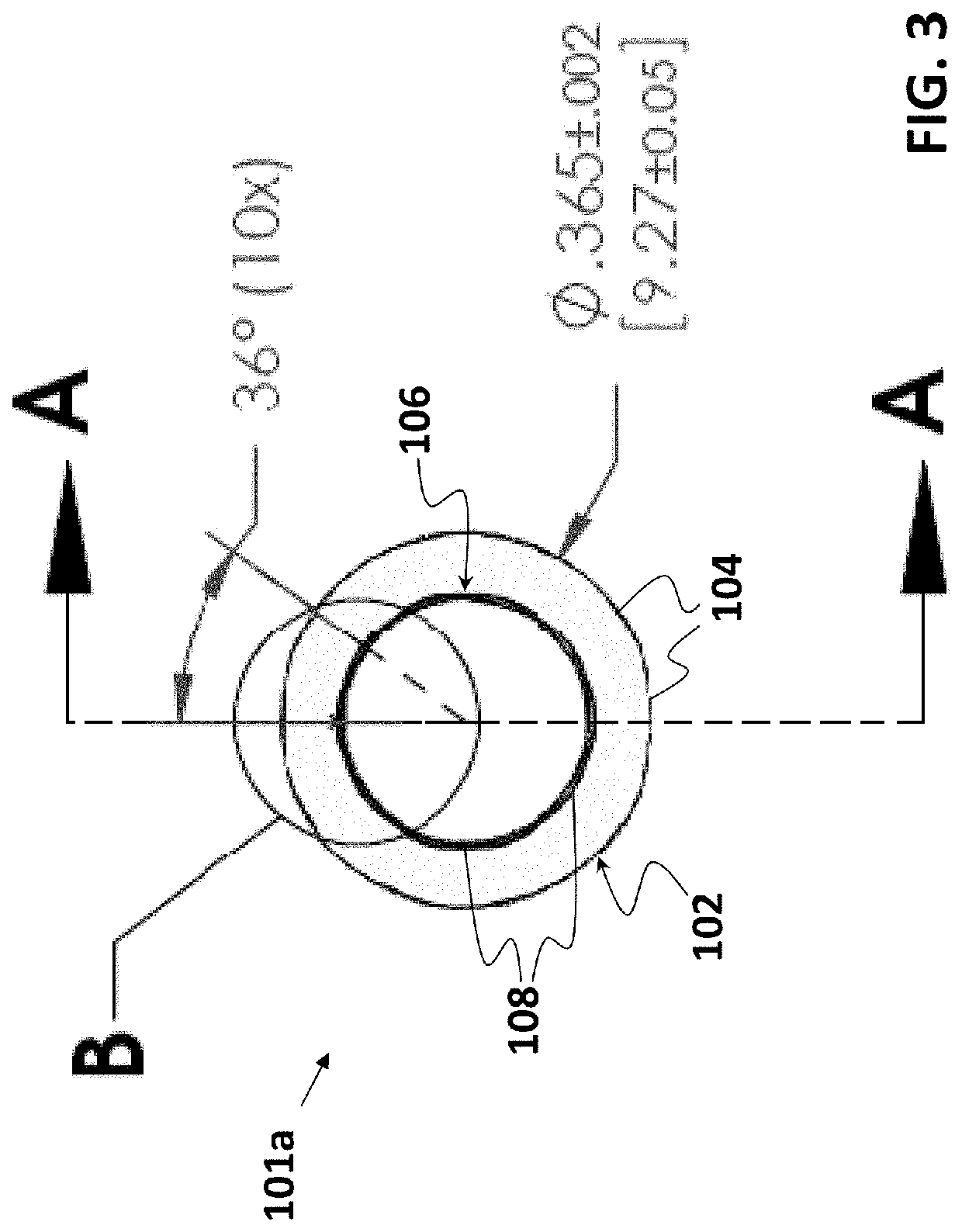

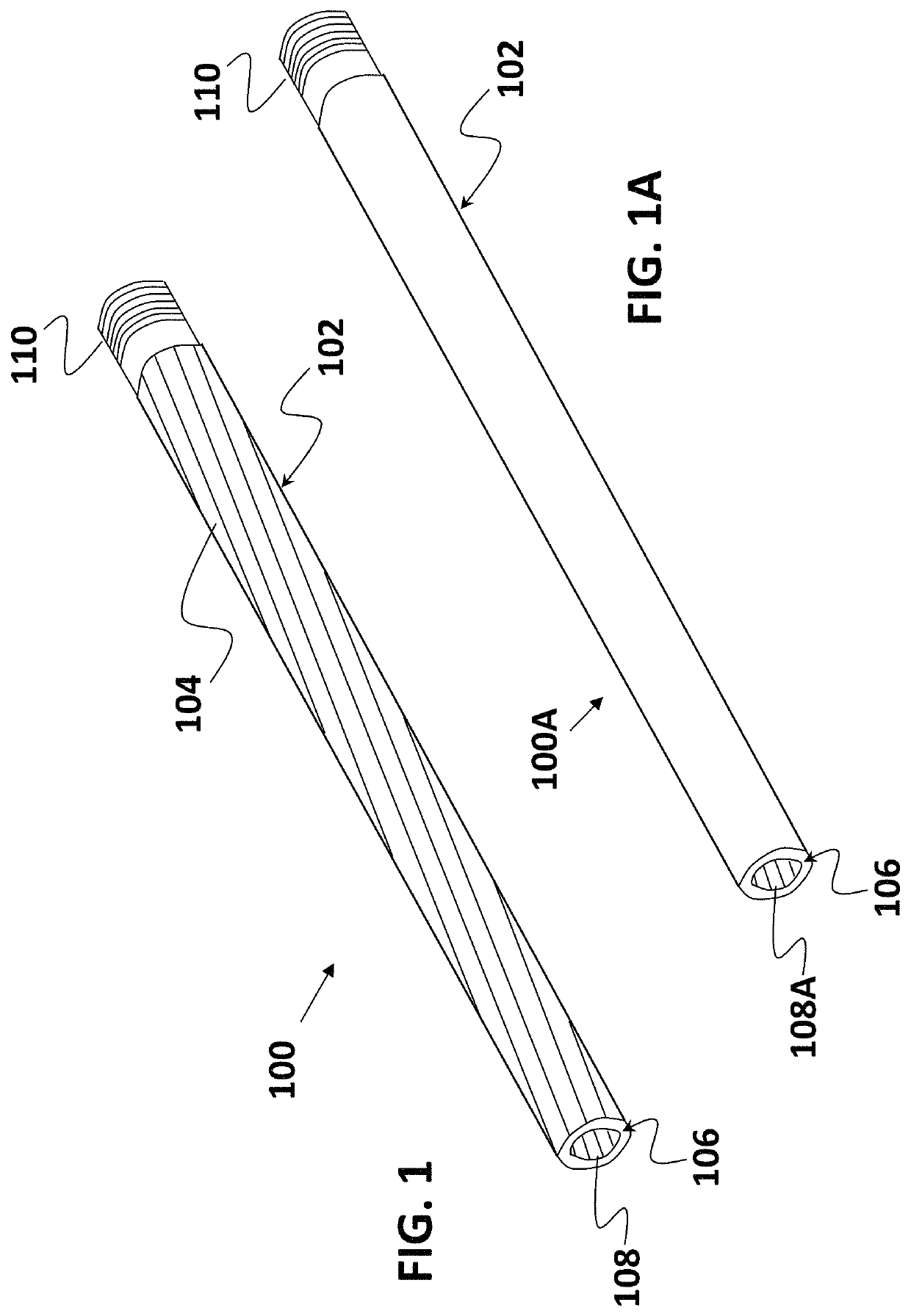

Barrel with rifling and method for forming

A rifled barrel may have a rifling pattern formed along an internal surface of the barrel by forming a corresponding pattern on the external surface of the barrel. The rifling pattern includes one or more indentations or protrusions formed in a spiral pattern along a length of the barrel. The corresponding pattern includes indentations formed into the external surface. A method of manufacturing includes moving a length of tubing past a die or other tool having one or more protrusions configured to indent the external surface. Alternatively, the rifled pattern may be formed by drawing a tool through tubing before it is cut into individual barrel lengths. The tool or tubing is rotated to create one or more spiral indentations and / or protrusions in a rifling pattern along the internal diameter of the tubing. The tubing is then cut and provided with threading to form a rifled barrel.

Owner:GARDNER & GARDNER REALTY CO INC

Lead screw nut and manufacturing method for same

A lead screw nut comprises a circular table top, a side lug and a conical threaded barrel which are of an integral structure, and the lead screw nut is formed by stamping a waste iron plate. The lead screw nut is manufactured according to the steps: cutting a large waste iron plate into an iron plate of a proper size for standby application; punching outline blanks of the circular table top and the side lug of the lead screw nut on the iron plate by using an outline mould; heating the outline blanks at the temperature of 700-800 DEG C; placing the heated outline blanks on a punch and punchingthe circular table top and the conical barrel by using an inner barrel mould; and machining an internal thread on the inner wall of a conical tube by using a threading machine to complete manufacturing. The lead screw nut made of the waste iron plate is low in manufacturing cost and convenient in operation, the manufacturing method is simple and easily understood, and on the basis of ensuring theuse effect and the use strength of the nut, the bearing capacity of the nut is improved, and the service life of the lead screw nut is prolonged.

Owner:唐山市丰润区宏辉建筑器材制造有限公司

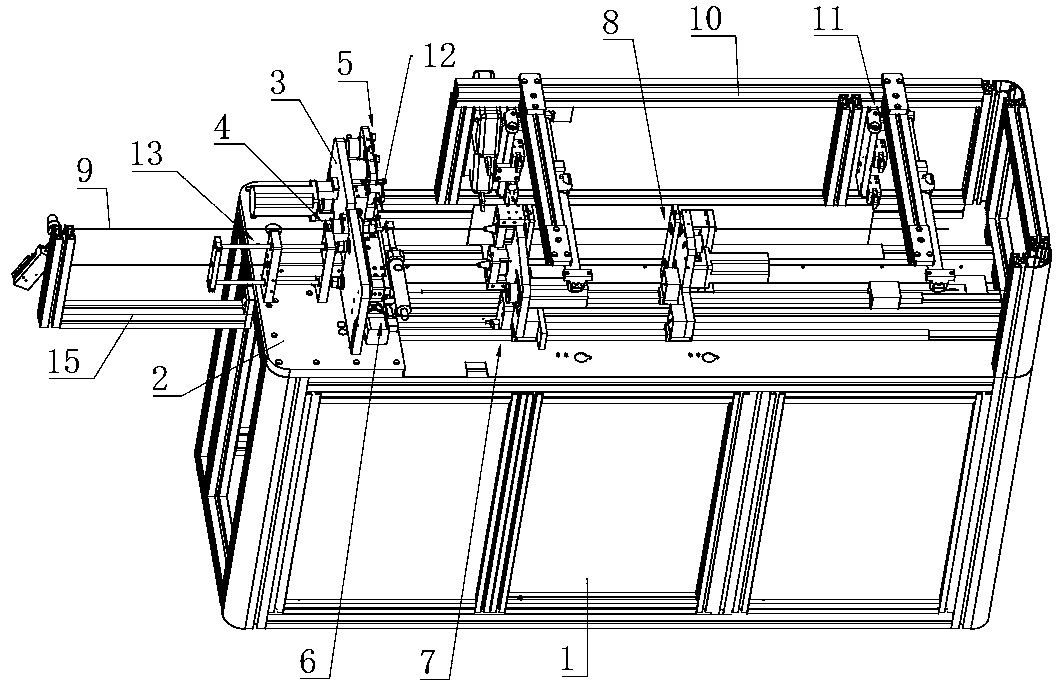

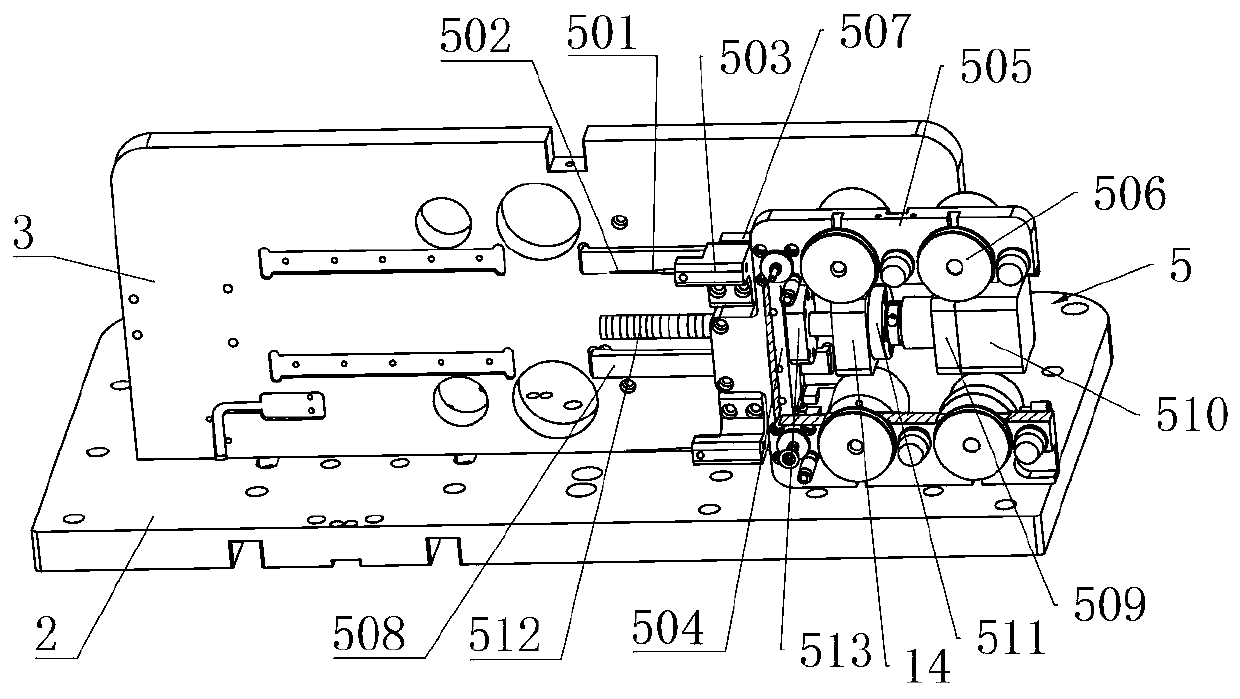

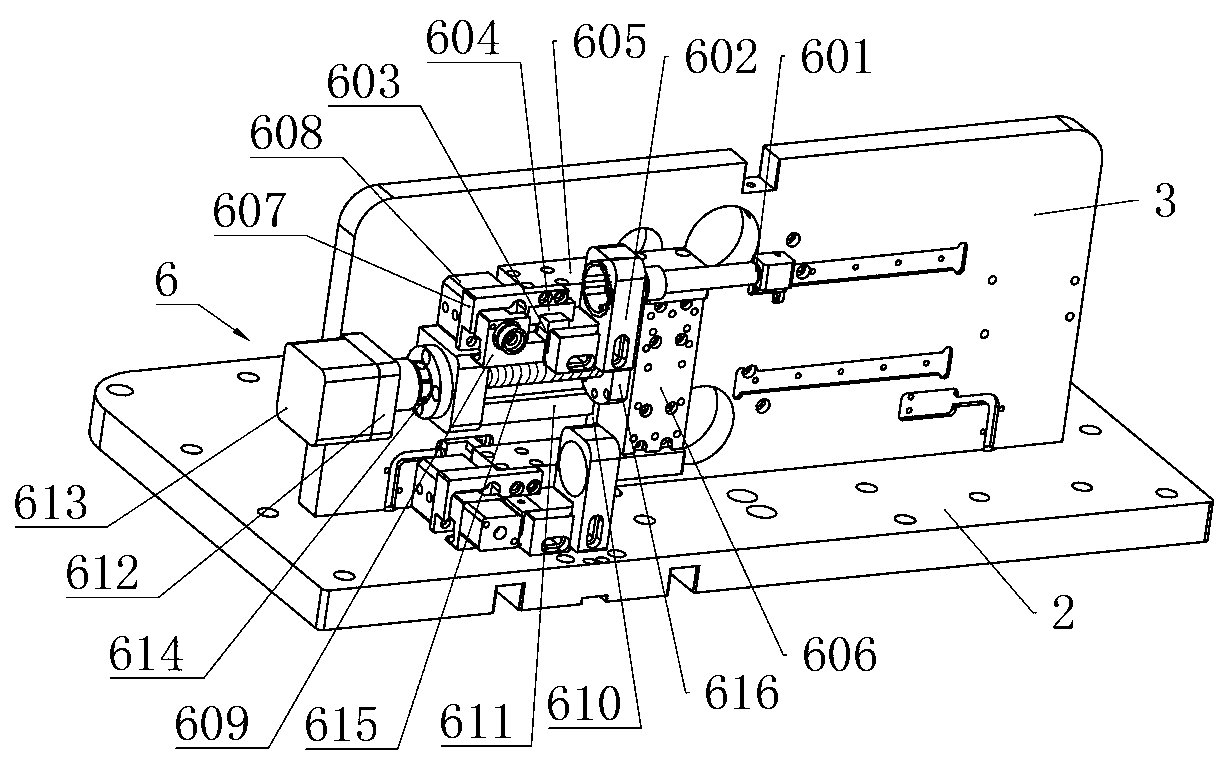

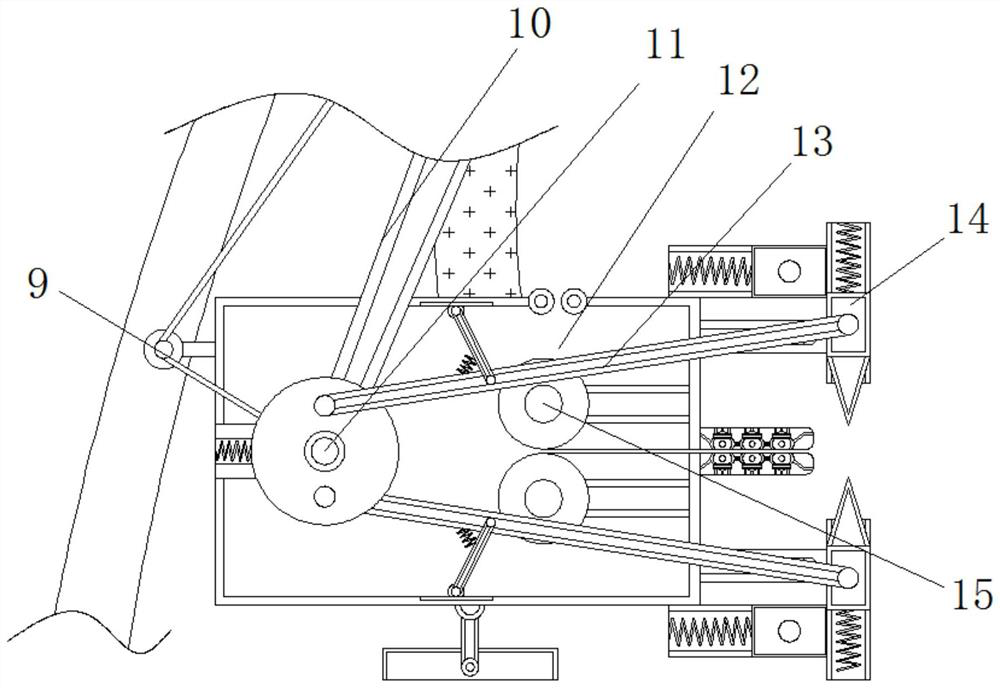

Full-automatic spiral brush making machine

The invention relates to a full-automatic spiral brush making machine which comprises a machine table, a wire penetrating set is arranged on the machine table, a first mechanical chuck is arranged on the wire penetrating set, and a metal wire penetrates through the first mechanical chuck; the threading group is used for threading a metal wire for manufacturing the spiral brush on the first mechanical chuck; a wire group is arranged on the threading group, and a metal wire is guided to penetrate into the first mechanical chuck by the wire group; a scissors group is arranged on the threading group and is used for cutting off a metal wire; a sliding winding group is arranged on one side opposite to the first mechanical chuck and is used for twisting a metal wire into a folded wire; a bristle clamping set and a bristle box set connected with the bristle clamping set are arranged beside the first mechanical chuck, the bristle box set provides bristles for the bristle clamping set, and the bristle clamping set provides bristles for metal wires. A bristle flying cutter set is arranged on the opposite side of the bristle clamping set and used for repairing the bristles. The full-automatic spiral brush making machine is simple in structure and small in occupied space, all procedures are continuously distributed, manual operation is not needed, the production quality is stable, and the production efficiency is high.

Owner:广州智研数控科技有限公司

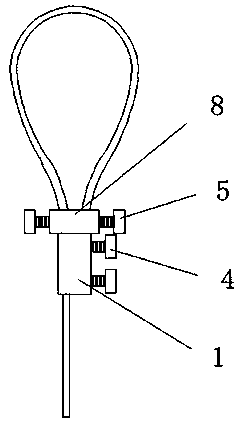

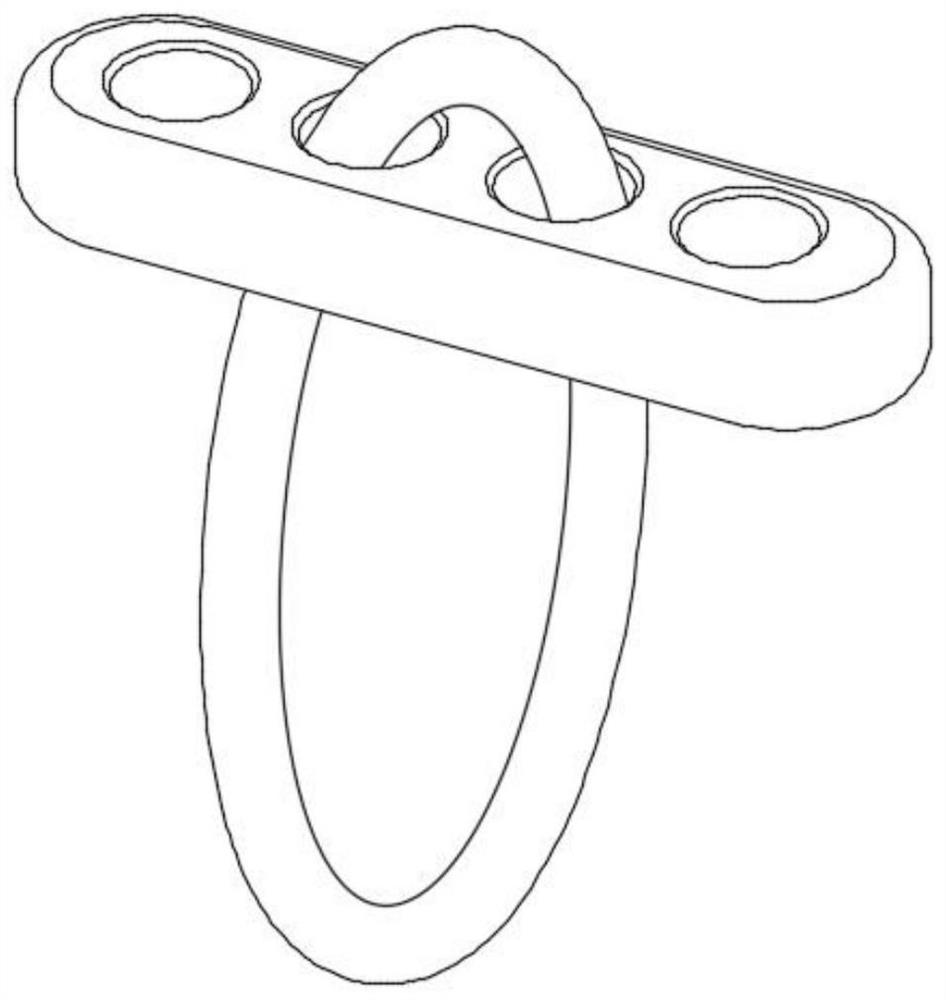

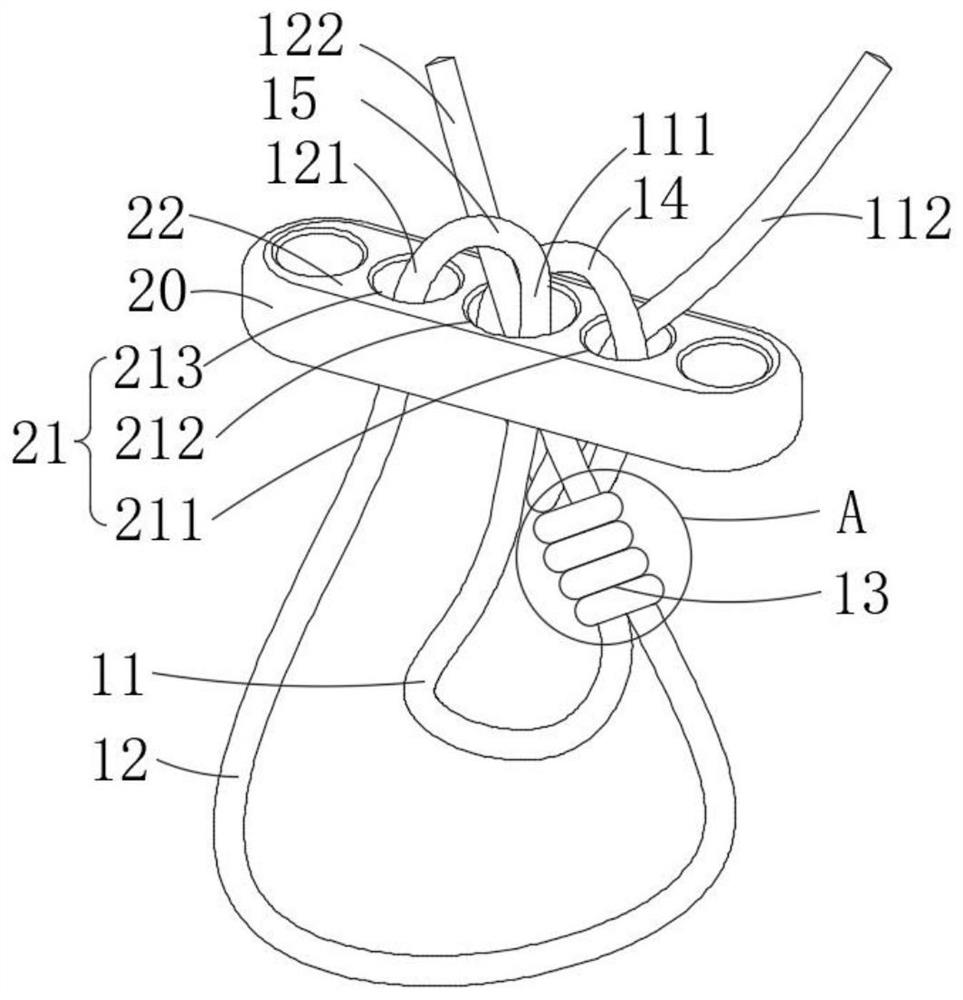

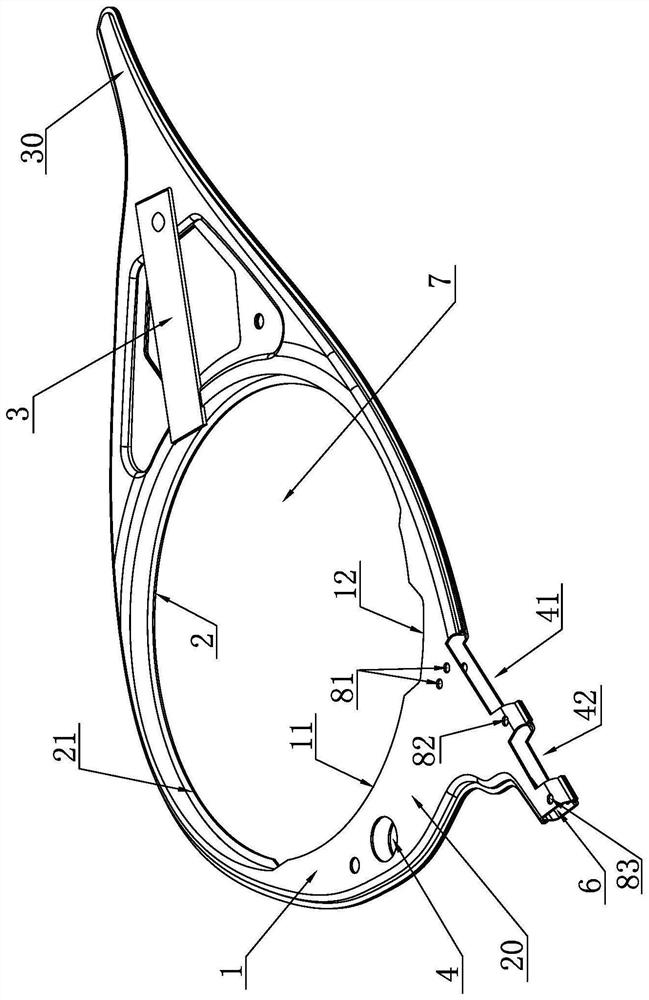

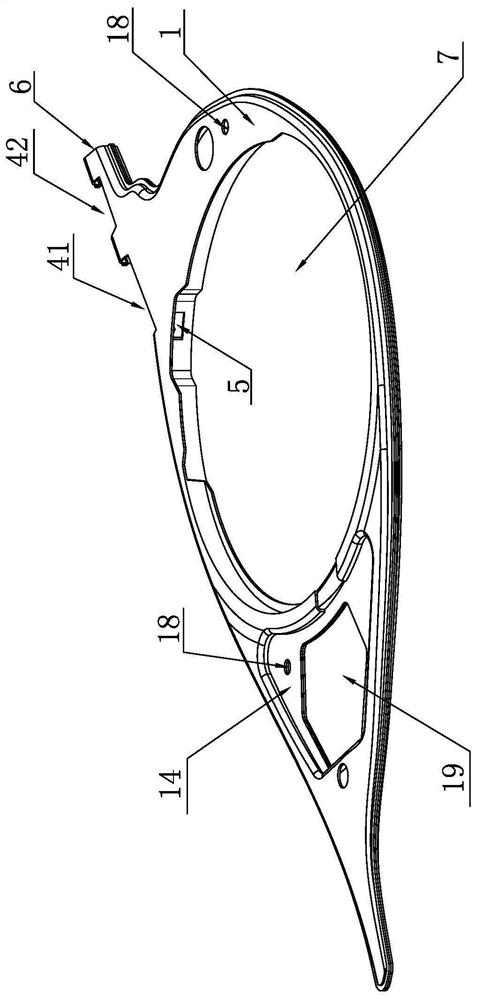

Loop and manufacturing method thereof

ActiveCN112790894AImprove the strength of forceShare the pullSuture equipmentsLigamentsPull forceThreading (manufacturing)

Owner:SHANGHAI ORTHOPAIR MEDICAL CO LTD

Manufacturing method of suit collar

ActiveCN104921361AImprove processing efficiencyReduce labor intensityGarmentsClothes making applicancesEngineeringUltimate tensile strength

The invention relates to a manufacturing method of a suit collar. By the adoption of the method, a collar lining and a collar surface are positioned and sewn through a suit collar manufacturing template. The method includes the following technological steps that firstly, the clipped collar lining is placed on the upper surface of a bottom plate; secondly, an intermediate plate covers the upper surface of the bottom plate; thirdly, the clipped collar surface is placed on the upper surface of the intermediate plate; fourthly, a panel covers the upper surface of the intermediate plate; fifthly, the collar lining and the collar surface are sewn along a threading channel. The manufacturing method of the suit collar has the advantages of being high in machining efficiency, low in labor intensity and good in product quality.

Owner:HEILAN HOME

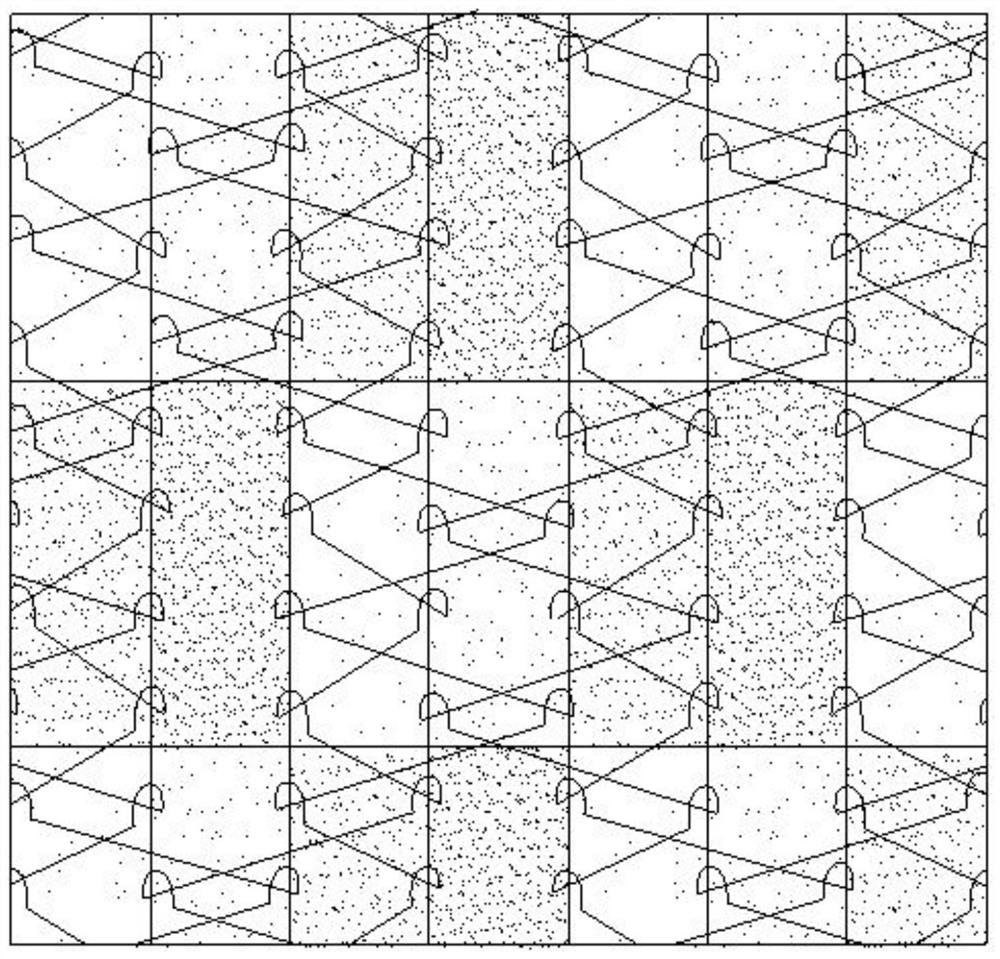

Fabric with segmentation effect, vamp and manufacturing method of fabric

PendingCN113957598AHighlight the segmented effect of weavingRich multi-segment weaving effectWarp knittingSynthetic resin layered productsRegular patternThreading (manufacturing)

The invention relates to the technical field of fabrics, in particular to a fabric with a segmentation effect. The fabric comprises a first knitting area and a second knitting area; the second knitting area comprises a second surface layer, a second middle layer and a second bottom layer; the second surface layer is provided with a segmented knitting layer and a basic knitting layer; and the segmented knitting layer is knitted in a certain area of the fabric on a same guide bar in a local segmented threading and empty threading mode. The single characteristic that only mesh holes, plain cloth and jacquard can be made on sandwich screen cloth in the traditional market is broken through, namely the limitation that the whole face is provided with regular patterns is broken through; a segmented weft insertion knitting mode, a segmented looping knitting mode, a segmented jacquard knitting mode, a segmented opposite-pulling knitting mode and a segmented jacquard hidden knitting mode are achieved; and the segmented change is used as a breakthrough point of research and development for knitting the unique effect of the segmented area of the fabric, different material colors and mesh holes can be knitted in a segmented mode, and the fabric knitting segmentation effect is highlighted.

Owner:SINCETECH FUJIAN TECH CO LTD

Barrel with rifling and method for forming

ActiveUS10890399B2Well formedSimple manufacturing processBarrelsThreading (manufacturing)Engineering

Owner:GARDNER & GARDNER REALTY CO INC

Manufacturing process for high-strength square U-shaped bolts

The invention relates to a manufacturing process for high-strength square U-shaped bolts, and belongs to the technical field of mechanical processing. The manufacturing process comprises the steps ofthread lathing and heating bending forming and non-oxidizing heat treatment processes. In the heating bending forming process, the scopes of the two sides of the center of a bending corner of a part are heated, wherein R is the bending inner corner radius, d is the bolt diameter, and A is the elongation of a material of the part; the heating temperature of the part is controlled to be within the range from (Ac3+30 DEG C) to (Ac3+100 DEG C), wherein Ac3 is the austenite phase change temperature of the material of the part; the bending forming time is controlled to be within the range of K*d seconds under the condition that it is ensured that the bending corner does not deform, wherein K is equal to 1 to 1.3; and the cooling rate is controlled to be 80 DEG C / h-120 DEG C / h. Compared with theprior art, the manufacturing process for the high-strength square U-shaped bolts is optimized, the processing efficiency of the high-strength square U-shaped bolts is improved, the labor intensity ofan operator is reduced, use of a special hard alloy manual threading die is not needed, and cost is saved.

Owner:SHANXI NORTH MACHINE BUILDING

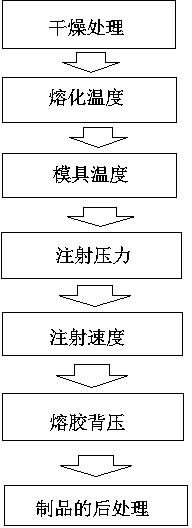

Manufacturing technology of threading box

InactiveCN104309052AImprove heat resistanceInsulation effectCoatingsThermodynamicsManufacturing technology

The invention discloses a manufacturing technology of a threading box. The manufacturing technology comprises the following steps of dry treatment, melting temperature, mold temperature, injection pressure, injection speed, melt backpressure and aftertreatment of a product. An edge-shaped gate length is 0.5-0.7 mm; a depth is half of wall thickness; and a width is twice of the wall thickness. The mold has good exhaust property; and an exhaust vent has a depth of 0.025 mm-0.038 mm and thickness of 1.0 mm-1.5 mm. The threading box is made of polypropylene. The manufacturing technology provided by the invention is precise, is relatively little in time consumption, and saves labor source and time. The threading box is made of polypropylene. Polypropylene has good heat resistance and excellent high-frequency insulating properties, and polypropylene does not absorb water, so that the insulating properties are not influenced by humidity.

Owner:JIANGSU HAIWEI GROUP

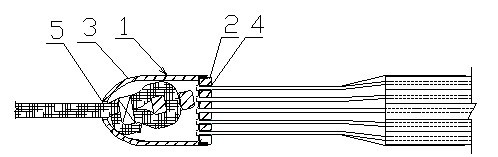

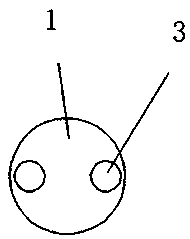

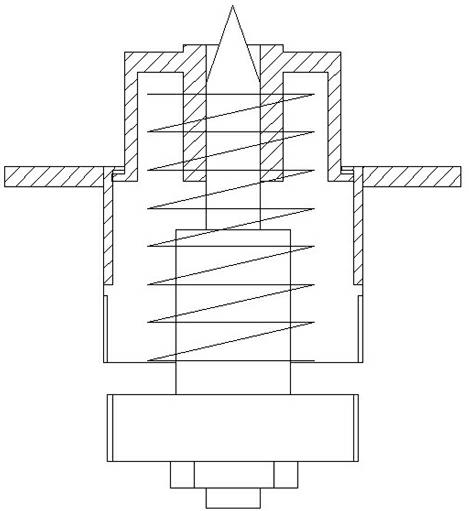

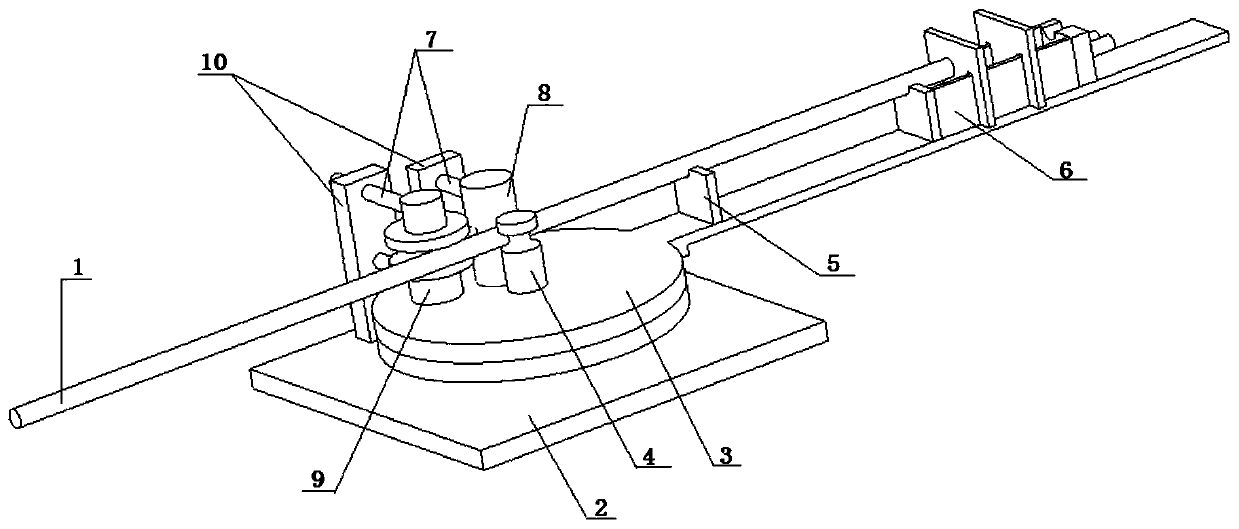

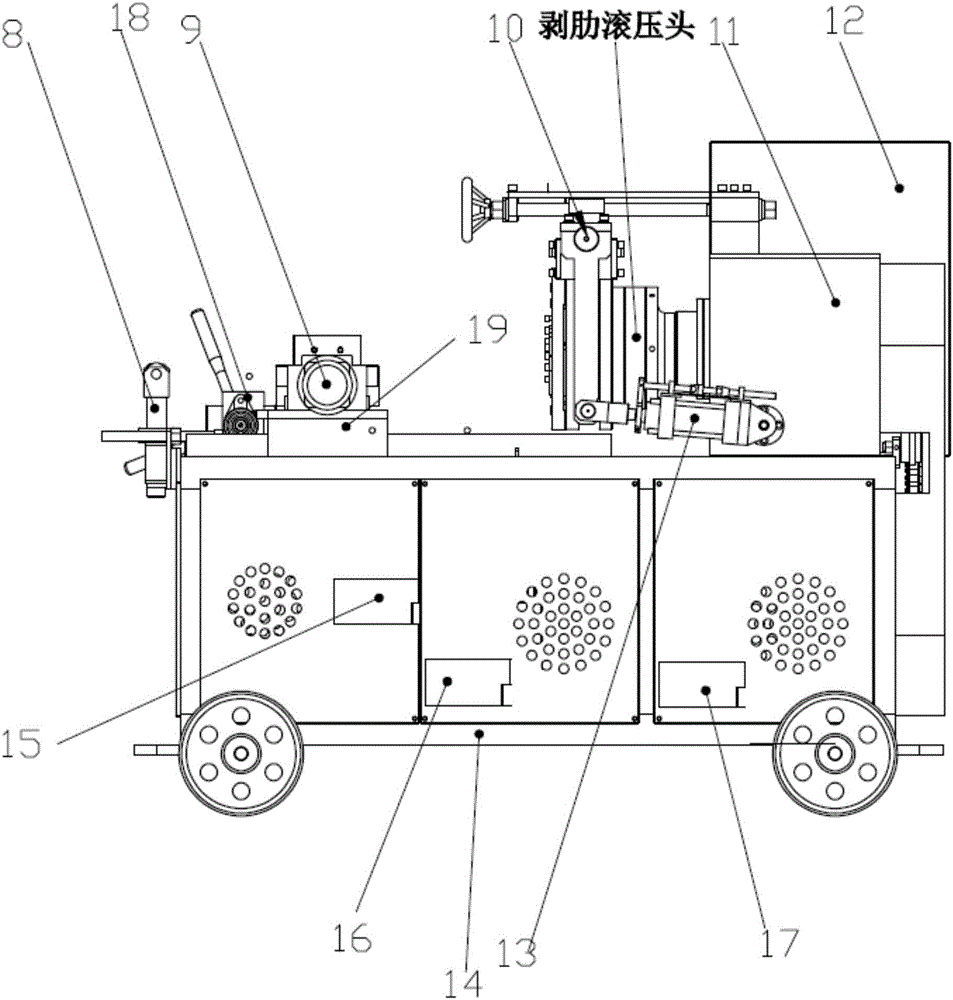

Stripping rib rolling head and steel bar thread machine tool

InactiveCN106391953ALow costImprove structural rigidityScrew-threads articlesThreading (manufacturing)Machine building

The invention relates to a stripping rib rolling head and a thread machine tool for the steel bar connecting industry, and belongs to the technical field of manufacturing of steel bar connecting machines. The stripping rib rolling head comprises a stripping rib cutterhead, a stripping rib cutter holder, a stripping rib cutter, a cutter pressing block, a cutter holder fixing block, a rotary shaft, an adjustment gear ring and the like. For achieving automatic threading of steel bars, the stripping rib rolling head and other components are matched to form the steel bar thread machine tool. According to the stripping rib rolling head and the steel bar thread machine tool, the defects that a structure in the prior art is poor in overall rigidity, simplex in function and high in labor intensity, and the precision of machined threads is low are overcome; and the stripping rib rolling head and the steel bar thread machine tool have the advantages that the structural rigidity is high, the labor intensity is low, various purposes are achieved, the machining dimension can be adjusted, and the accessory cost is reduced, and have extremely high practicability.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

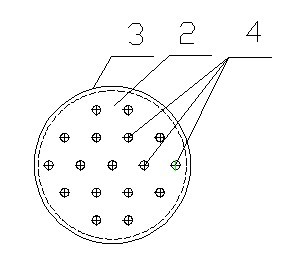

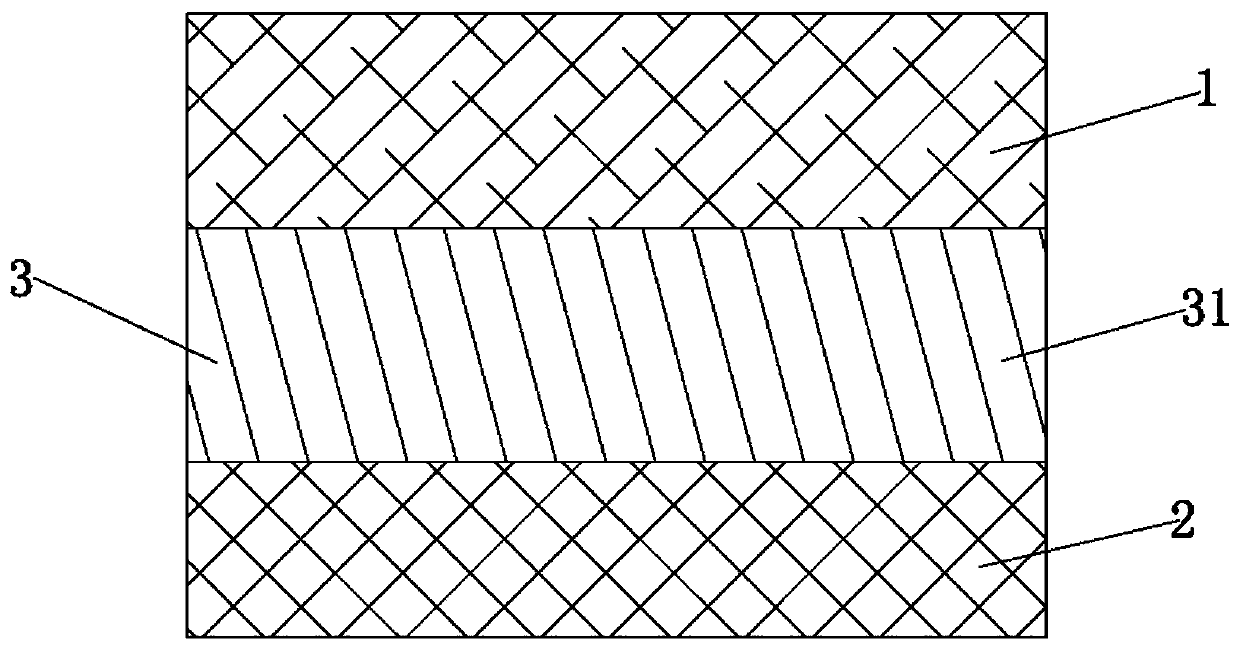

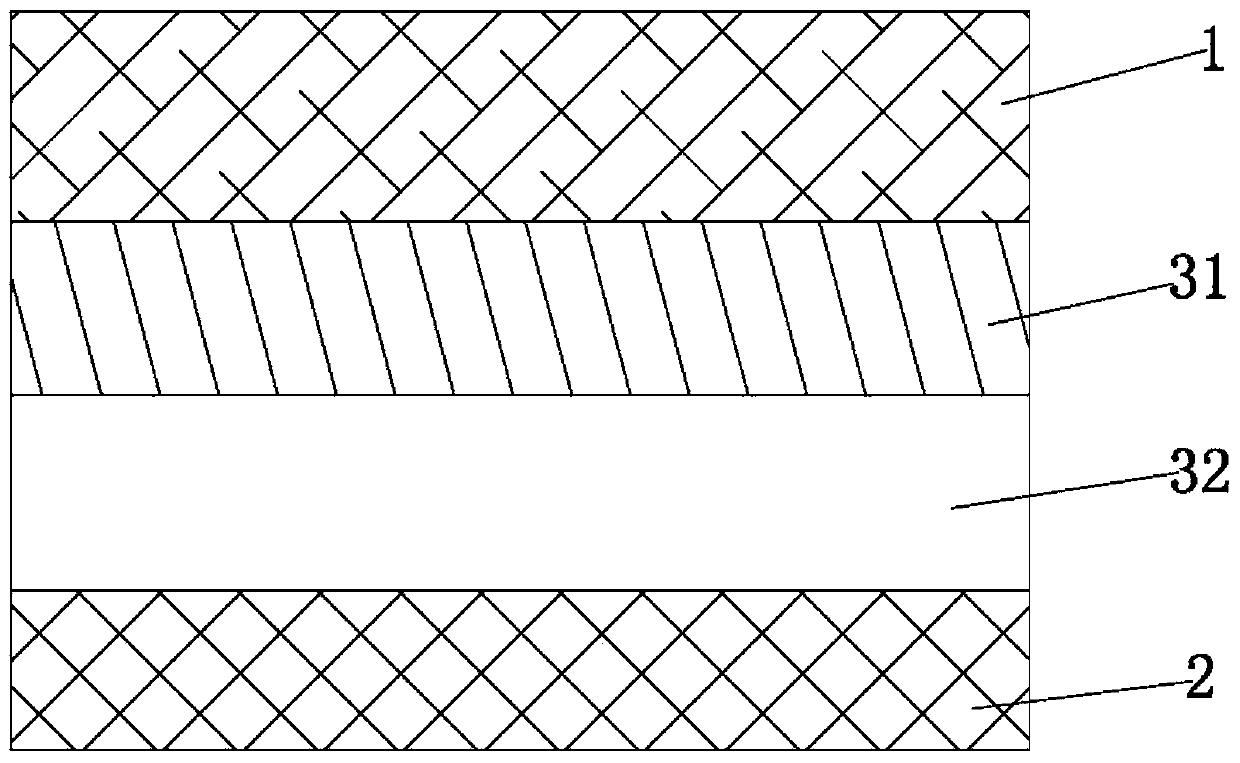

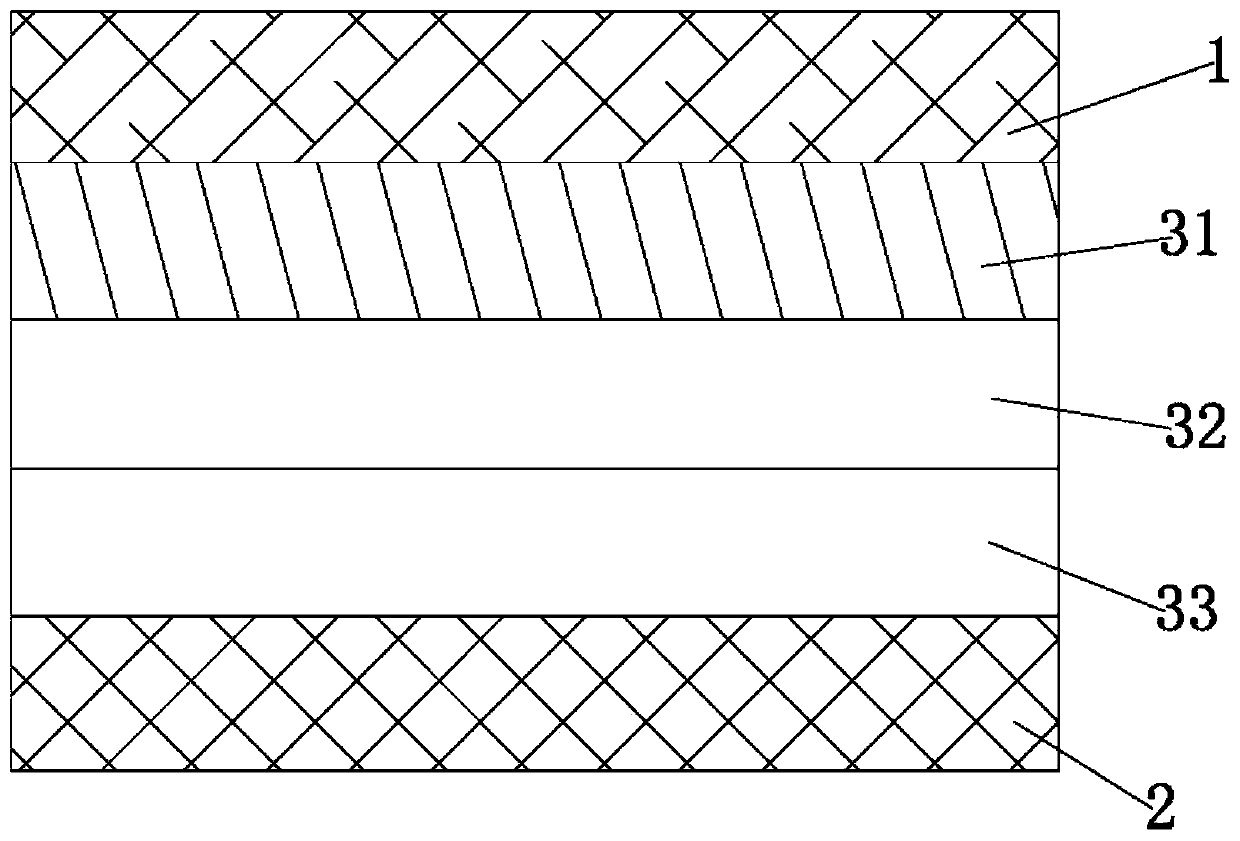

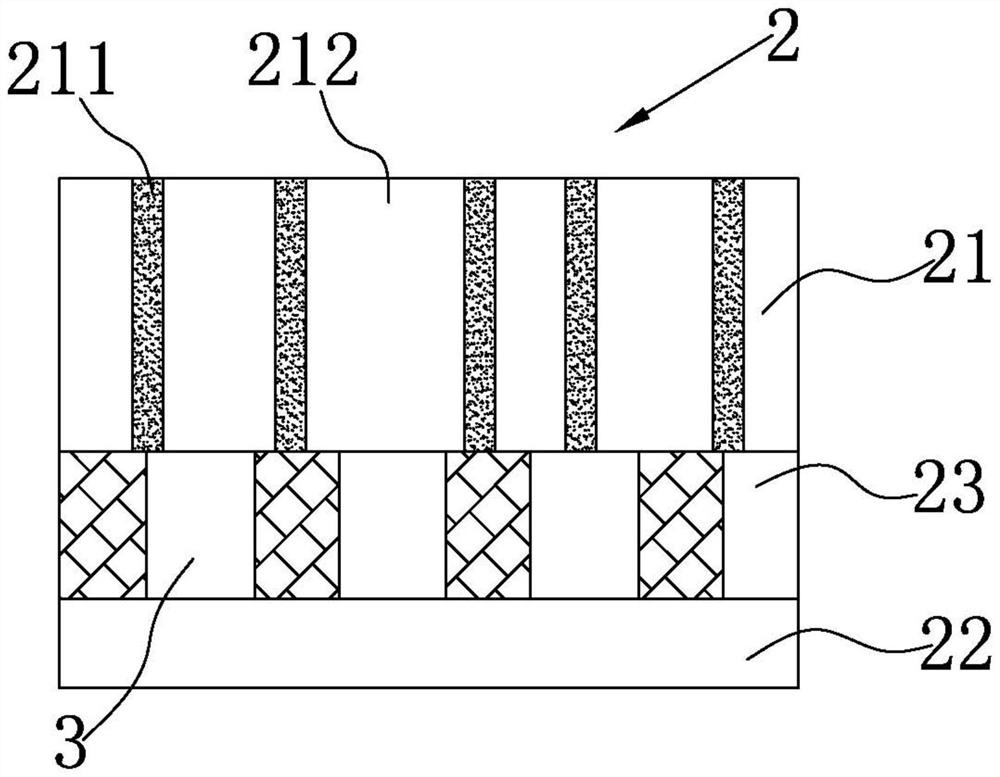

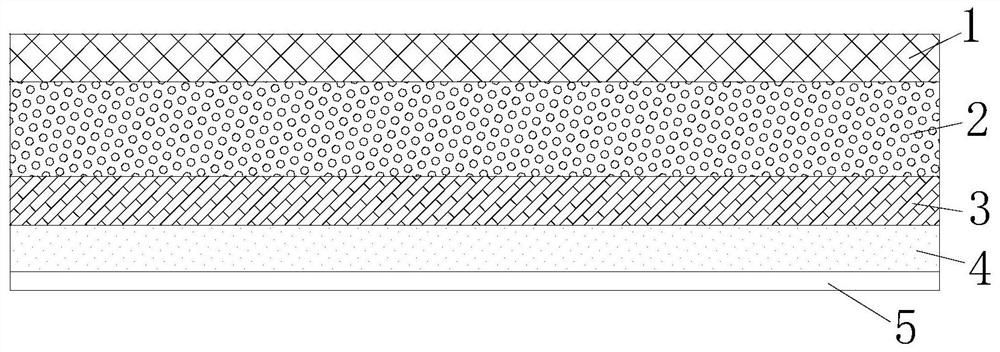

Punching needle, threading needle, system and method for manufacturing foam sandwich preform

ActiveCN113246585AReduce squeeze frictionReduce fillingLamination ancillary operationsSynthetic resin layered productsYarnFiber

The invention belongs to the technical field of a preparation process of a foam sandwich preform for a composite material structural member, and particularly relates to a punching needle, a threading needle, a system and a method for manufacturing a foam sandwich preform. The punching needle for manufacturing a foam sandwich preform is of a solid columnar structure and comprises a clamping part on the upper section and a punching part on the lower section. The clamping part is of a columnar structure with a polygonal section so that clamping can be facilitated. The punching part is of a cone structure with the diameter gradually decreased from top to bottom, and the section of the punching part is in a polygonal star shape or a gear shape. The punching needle is utilized, punching and sewing are completed in two steps, the phenomena of fuzzing, yarn breaking and the like caused by friction between fibers and solid foam in the sewing process can be effectively avoided, and therefore the purpose of improving the production efficiency is achieved. And the problem that the resin content of the through hole part is too high when the resin is introduced in a vacuum manner can be avoided.

Owner:WUHAN TEXTILE UNIV

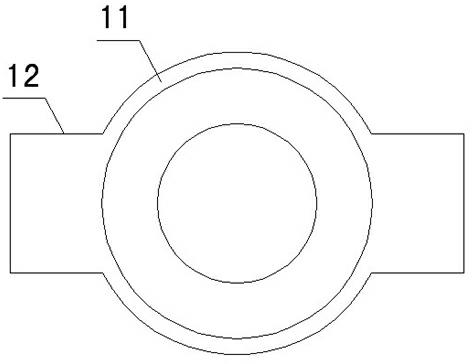

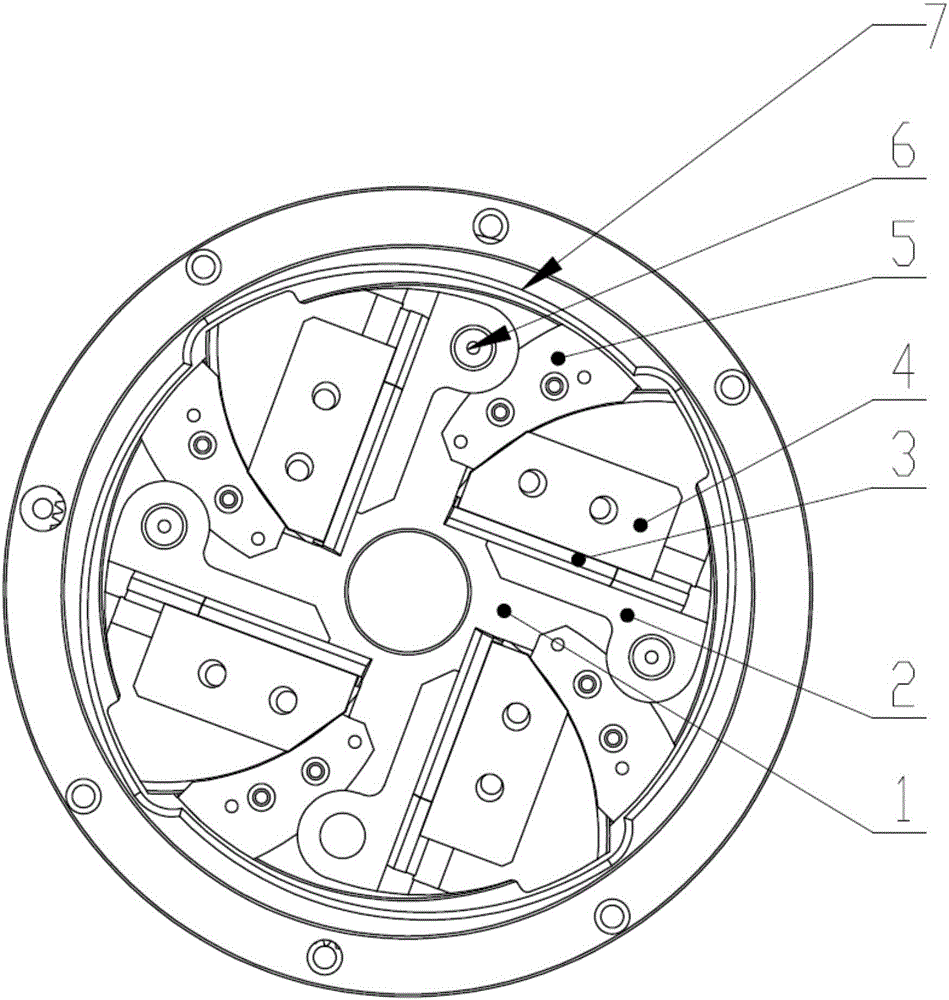

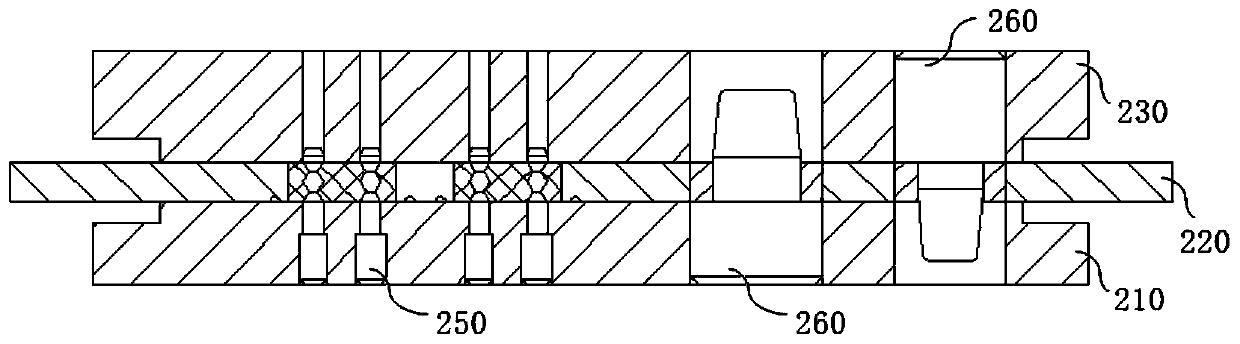

Automatic demoulding vulcanization molding die and manufacturing method for wire harness sealing ring with sugarcoated haws structure

PendingCN111086130AWill not cause ruptureQuality improvementDomestic articlesVulcanizationThreading (manufacturing)

The invention discloses an automatic demoulding vulcanization molding die and a manufacturing method for a wire harness sealing ring with a sugarcoated haws structure, and belongs to the technical field of rubber product production. The vulcanization molding die comprises a lower die, a middle die, an upper die, a top die and a die core, wherein the lower die, the middle die, the upper die and thetop die are sequentially arranged from bottom to top, the die core is arranged on the lower die, the lower side of the upper die is provided with a die cavity, the upper side of the upper die is provided with an injection cavity, the die cavity communicates with the injection cavity through an injection hole, and the lower side of the top die is provided with an injection plug; after the lower die, the middle die, the upper die and the top die are matched, the die core can penetrate through the middle die and enter the die cavity, the top of the die core is inserted into the injection hole, and the injection plug is embedded into the injection cavity. According to the method, the wire harness sealing ring with the sugarcoated haws structure can be manufactured by adopting the vulcanization molding die. The wire harness sealing ring can be automatically demoulded after the wire harness sealing ring is vulcanized, a threading hole cannot be broken, the die core cannot be damaged, the product qualification rate is high, and the production efficiency is high.

Owner:南京金三力高分子科技有限公司

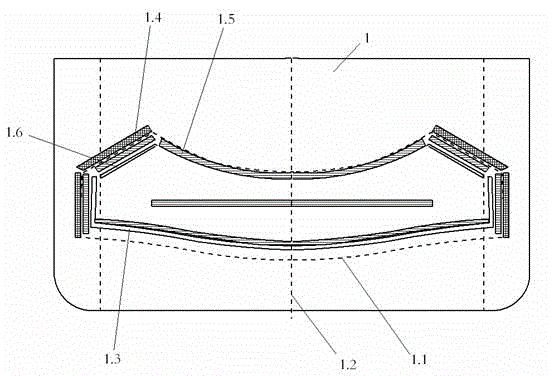

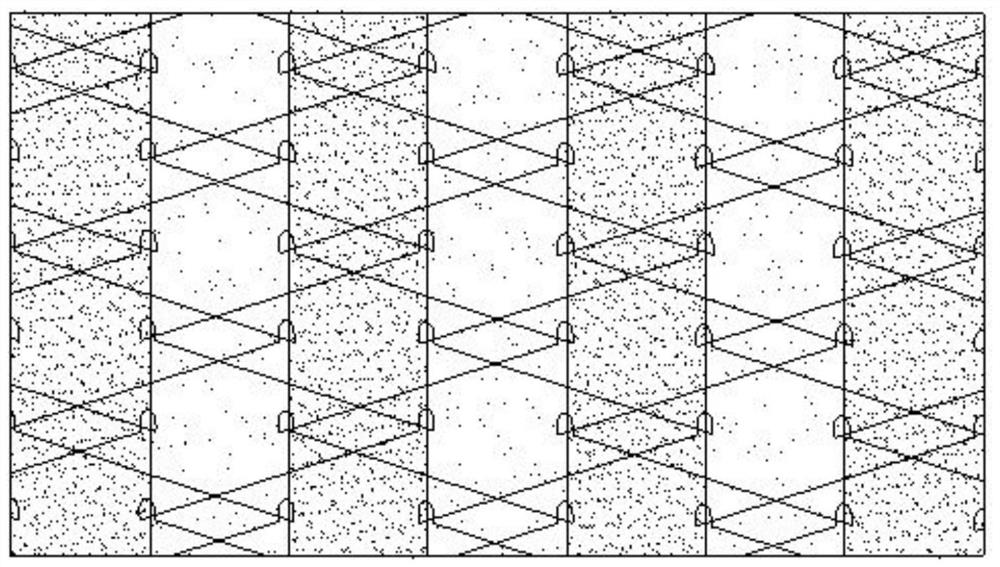

Creel three-jacquard jacquard screen cloth and manufacturing method

The invention relates to creel three-jacquard jacquard screen cloth and a manufacturing method. The screen cloth comprises a screen cloth body formed through integrated warp knitting. The screen clothbody comprises a mesh jacquard face layer, a creel framework layer and a pattern jacquard layer. In the mesh jacquard face layer, two semi-number jacquard guide bars JB1 and JB2 are adopted for jacquard weaving, and various kinds of single jacquard patterns are woven according to design process requirements to achieve the effect of the single jacquard screen cloth. In the creel framework layer, two semi-number jacquard guide bars JB3 and JB4 are adopted for jacquard weaving, and a framework layer structure is formed through free front and back face jacquard weaving. In the pattern jacquard layer, two semi-number jacquard guide bars JB5 and JB6 are adopted for carrying out jacquard weaving on the face portion of the mesh jacquard face layer and / or the bottom of the creel framework layer according to design process requirements. Through the unique advantages of a two-needle bar creel three-jacquard machine and combination with cooperative use of the guide bar empty threading change, precise design patterns and chemical fiber yarn, the jacquard screen cloth with high performance and unique appearance patterns is produced out.

Owner:SINCETECH FUJIAN TECH CO LTD

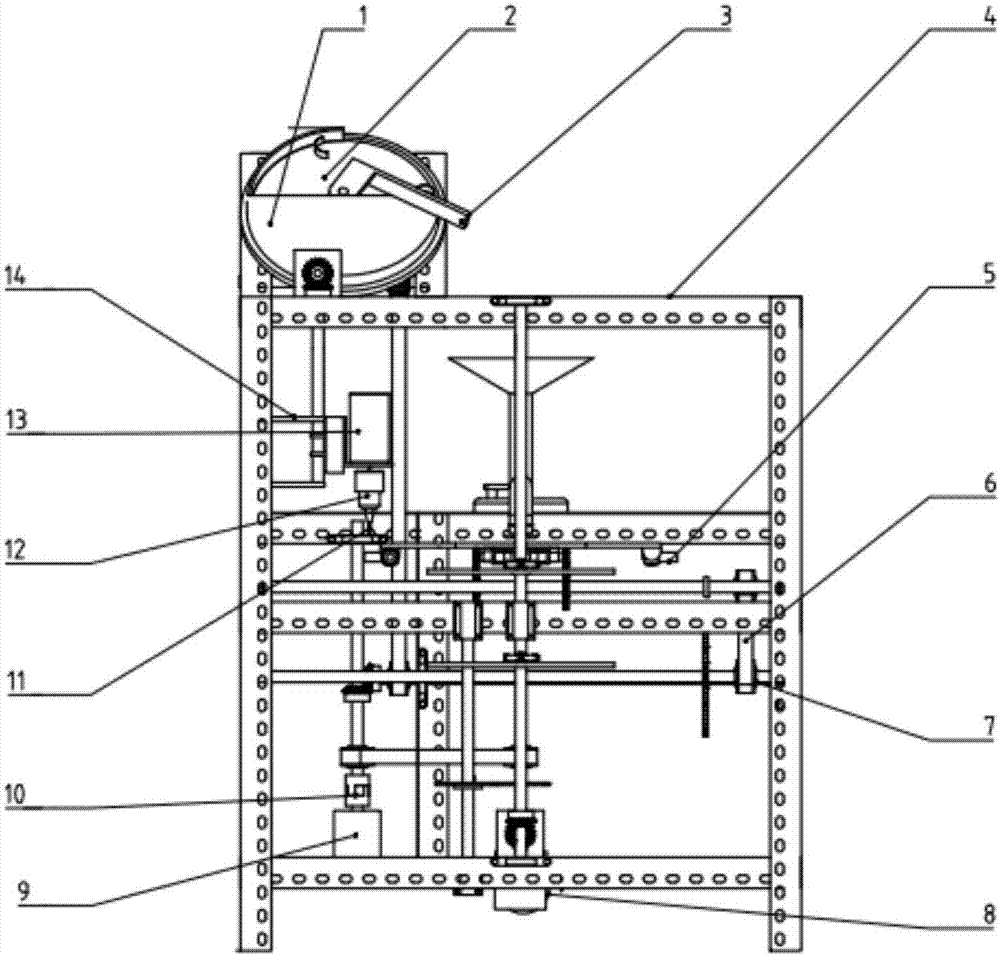

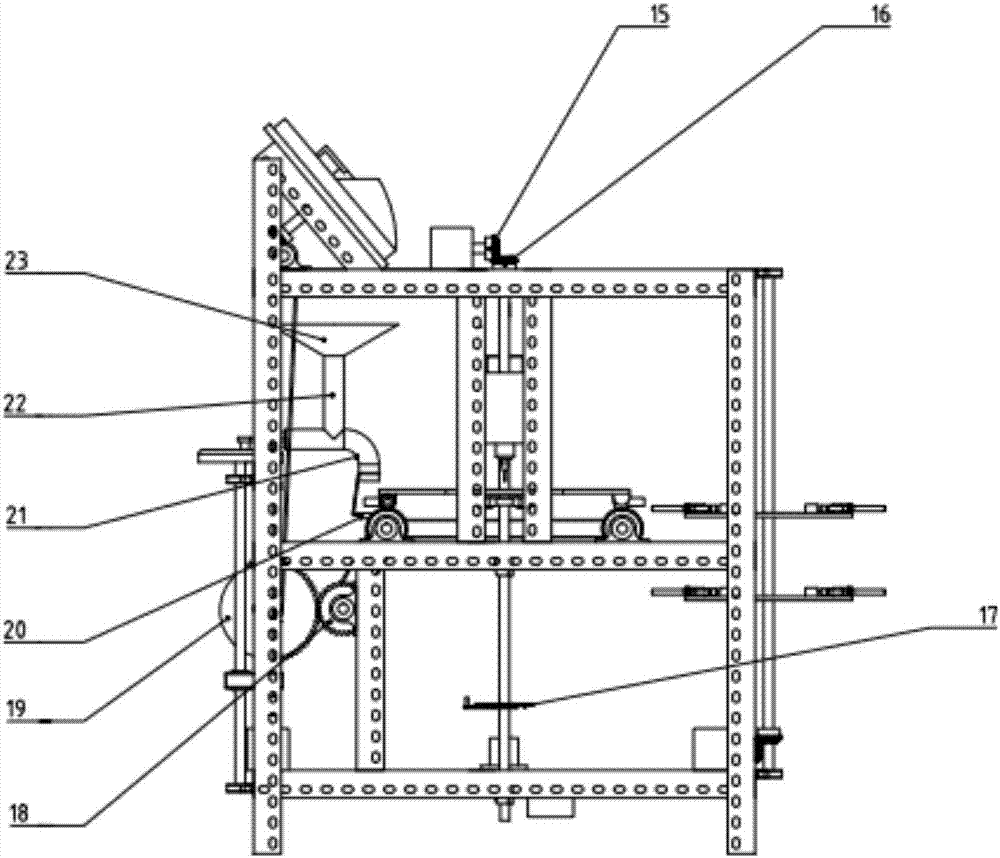

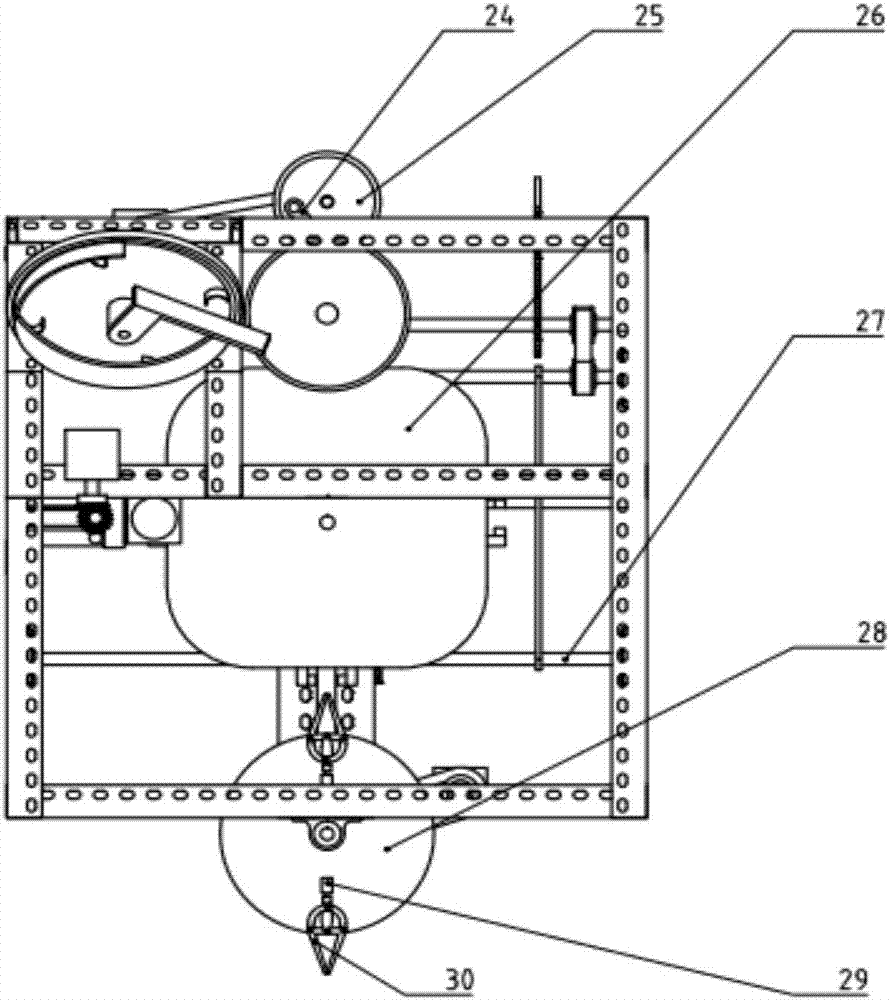

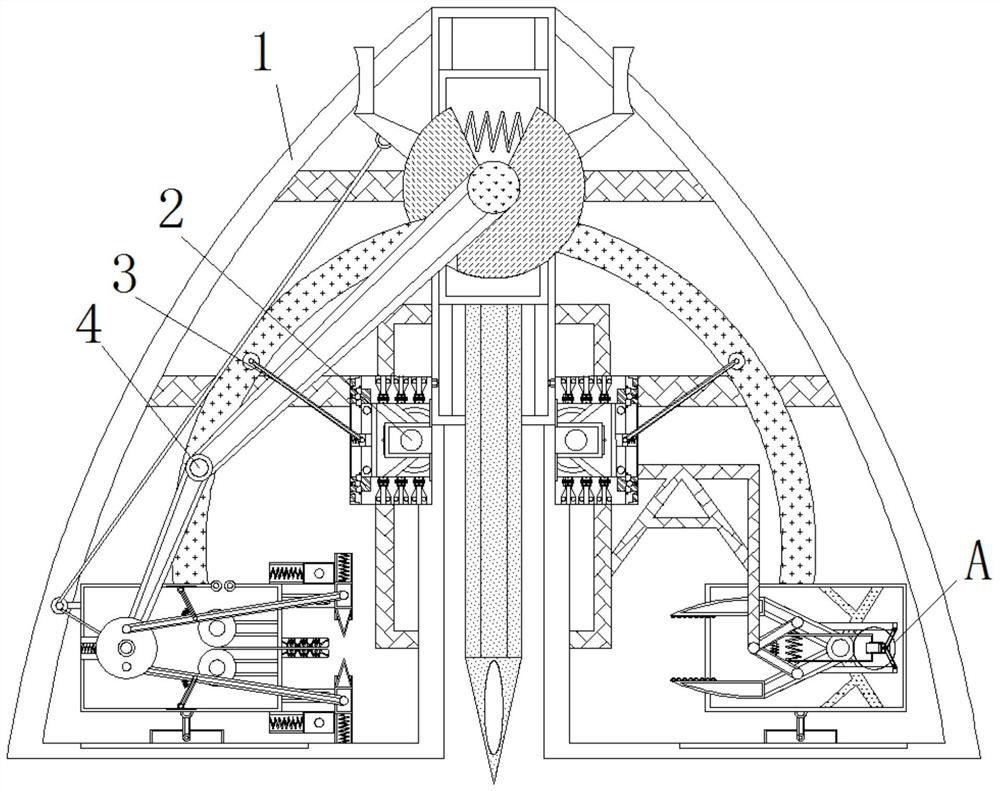

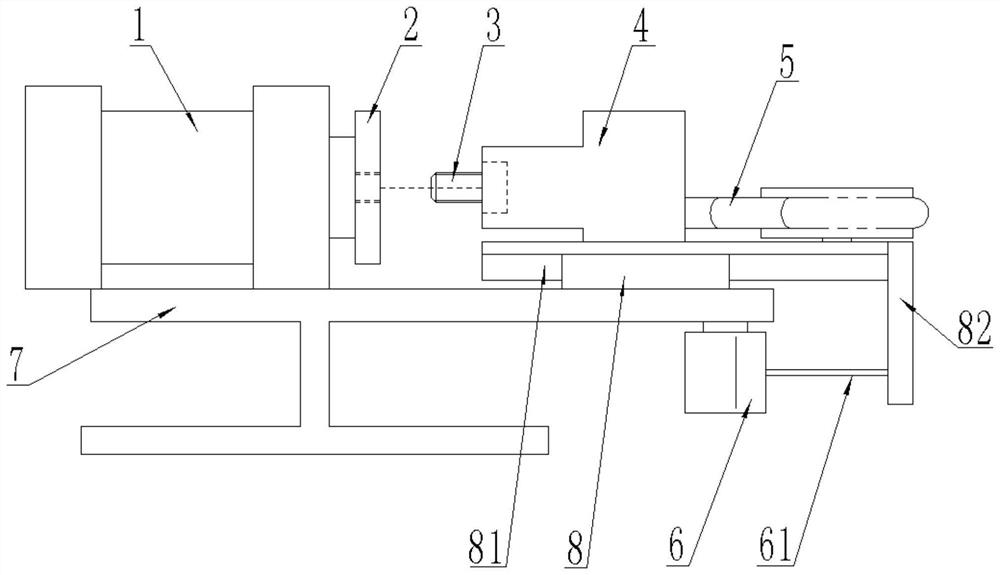

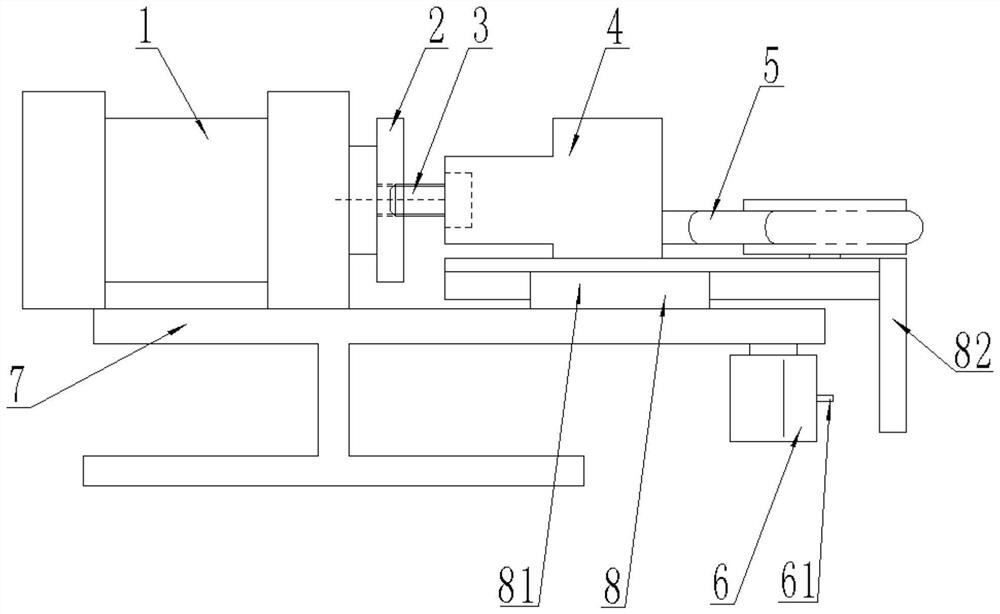

Intelligent manufacturing integrated threading machine for a building

ActiveCN113681093AConvenient threading workRealize automatic operationThread cutting machinesThreading (manufacturing)Pipe fitting

The invention provides an intelligent manufacturing integrated threading machine for building, belongs to the field of building tools, and aims at solving the problem that potential safety hazards exist when pipe fittings are manually taken. The intelligent manufacturing integrated threading machine comprises a pipe fitting hopper; a pipe fitting outlet is formed in the bottom of the outer wall of the right side of the pipe fitting hopper, a pipe fitting fixing assembly is arranged at the top of the pipe fitting outlet, a pipe pushing assembly is connected to the bottom of the right side of the pipe fitting hopper, a fixing base is placed on the ground of the right side of the pipe fitting hopper, and a lead screw motor is mounted on the top end face of the fixing base; and the top of the fixing base is transversely and slidably connected with a sliding platform. Through the arrangement of the pipe pushing assembly and the pipe fitting fixing assembly, a pipe in the pipe fitting hopper extends out of a round hole of the pipe fitting outlet through the pipe pushing assembly, the pipe is fixed through the pipe fitting fixing assembly, automatic operation is achieved, the operation that the pipe fitting is manually taken one by one is not needed, the threading machine can conveniently conduct threading work on the pipe fitting, the threading efficiency is improved, safety is improved, and potential safety hazards are reduced.

Owner:浙江瑞利工程有限公司

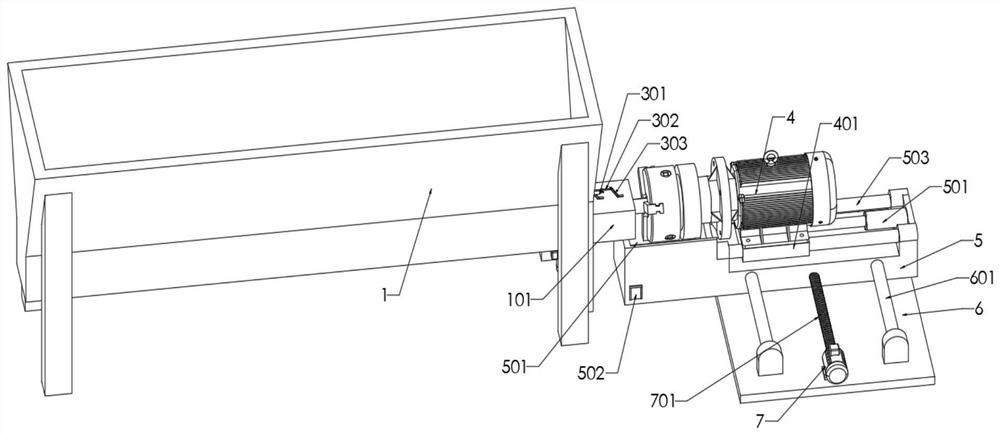

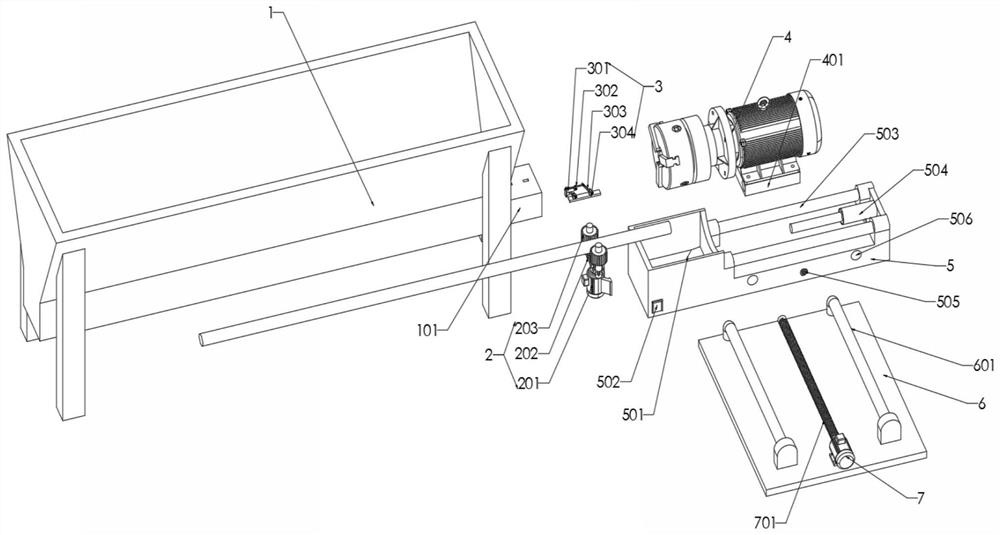

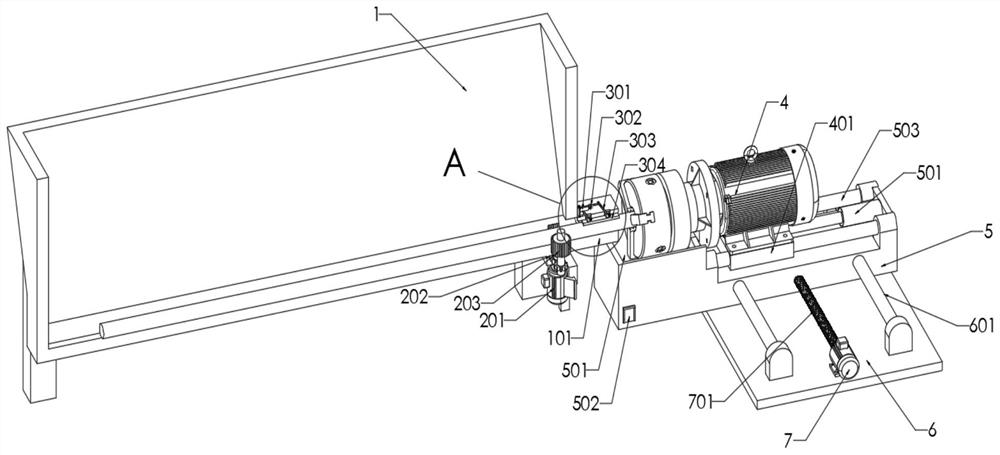

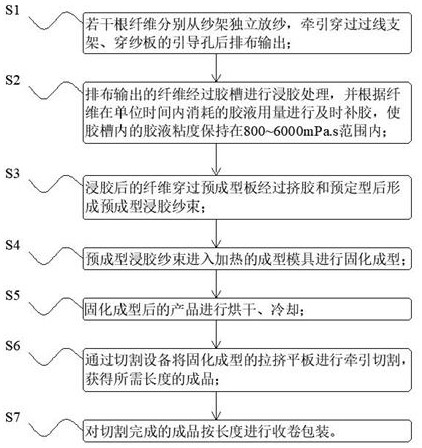

Preparation method for stably producing pultrusion flat plate at high speed

ActiveCN114770979AQuality improvementReduce manufacturing costDomestic articlesYarnThreading (manufacturing)

The invention relates to the technical field of composite material pultrusion processes, in particular to a preparation method for high-speed stable production of a pultrusion flat plate, which comprises the following steps: a plurality of fibers are independently unwound from a creel, are pulled to pass through guide holes of a thread passing bracket and a threading plate, and then are distributed and output; glue dipping treatment is conducted through a glue tank, glue is supplemented in time according to the consumption of glue liquid consumed by fibers, and the viscosity of the glue liquid in the glue tank is kept within the range of 800 mPa.s to 6000 mPa.s; the impregnated fibers penetrate through a pre-forming plate to form impregnated yarn bundles; the impregnated yarn bundles enter a heated forming mold to be subjected to curing forming; drying and cooling the product; and drawing and cutting the product to obtain a finished product with the required length. Compared with a traditional pultrusion preparation process, the preparation method of the pultrusion flat plate has the advantages that the pultrusion speed of the composite pultrusion flat plate is increased, the continuous and stable production time is greatly prolonged to about 30 days, the plate manufacturing cost is reduced, the material waste in the production process is reduced, and the stable and reliable quality of the pultrusion flat plate is guaranteed.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

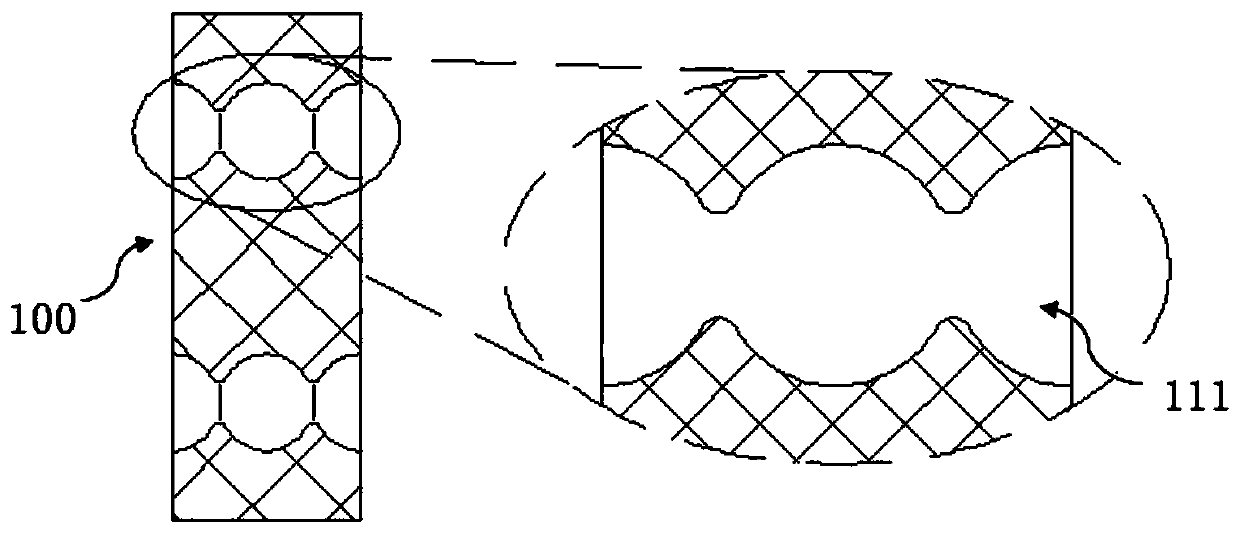

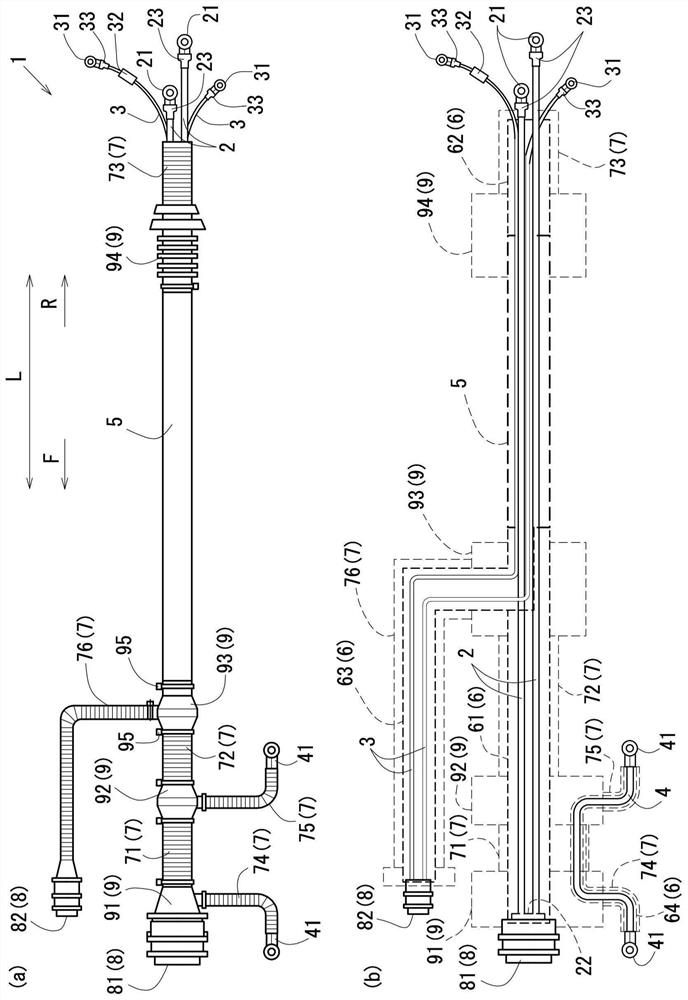

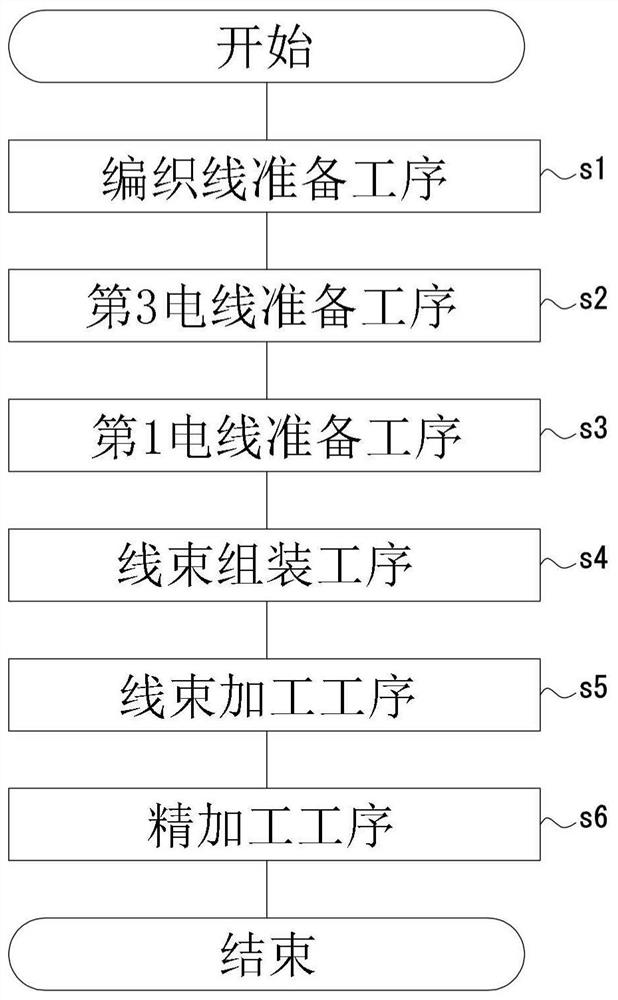

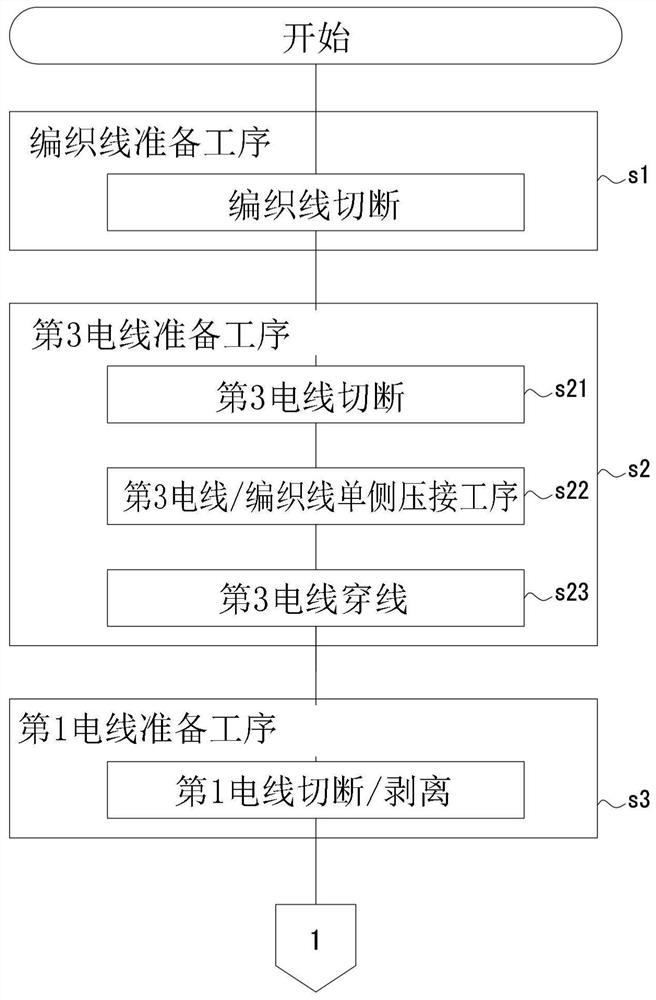

Method for manufacturing shielded wire harness

PendingCN113450972AEasy to handleImprove workabilityCable/conductor manufactureThreading (manufacturing)Electrical connection

The object of the present invention is to provide a method for manufacturing a shielded wire harness capable of efficiently manufacturing the shielded wire harness of a cable so that at least a part of theshielded wire harness is inserted into theelectromagnetic shielded multilayer tube and the rest is covered by abraided wire which is electrically connected with theelectromagnetic shielded multilayer tube. In a first wire threading / combining process (step s41), a first wire (2) is inserted into the braided wire (6). The method also comprises a handle installation process (step s51) and a wire harness processing process (step s5). In the step of pressing the braided wire of the electromagnetic shielding multilayer tube (step s52) in the wire harness processing step (step s5), The position of a handle (10) attached to a fixed part (110) of a braided thread pressing work table (100) is restricted for processing.

Owner:FURUKAWA ELECTRIC CO LTD +1

Sewing machine broken thread quick threading device for intelligently manufacturing leather products

InactiveCN112342703AAchieve the function of automatic spraying lubricating oilLubrication/cooling devicesNeedle severing devicesThreading (manufacturing)Industrial engineering

The invention relates to the technical field of leather products, and discloses a sewing machine broken thread quick threading device for intelligently manufacturing leather products. The sewing machine broken thread quick threading device comprises a shell, a rotating block is movably connected into the shell, and the rotating block is connected with an automatic threading mechanism and an automatic lubricating oil spraying mechanism. After a sewing thread is broken in the operation process of a worker using a sewing machine, the worker presses a finger pressing block to contract towards themiddle, the contraction of the finger pressing block drives the rotating block to rotate, the rotation of the rotating block drives a clamping block to move leftwards in a clamping block groove, the clamping block is clamped in the clamping block groove due to the elastic force of a clamping block spring, at the moment, a thread residue is clamped, after the worker loosens the finger pressing block, the clamping block is extruded under the action of a fixed sliding groove rod, so that the clamping block resets from the clamping block groove and compresses the clamping block spring, a thread pulling clamping jaw is opened again to release the thread of the sewing machine, and the function of automatic threading after the thread of the sewing machine is broken is achieved.

Owner:广州篮海贸易有限公司

Split stamping and splicing type weaving shuttle of fishing net weaving machine and assembling method of split stamping and splicing type weaving shuttle

PendingCN113026181AReduce weightImprove wear resistanceAuxillary apparatusShuttlesStampingMarine engineering

The invention discloses a split stamping and splicing type weaving shuttle of a fishing net weaving machine. The weaving shuttle comprises a steel shuttle cover shell, a shuttle shell seat and a pressing piece, wherein the shuttle cover shell and the shuttle shell seat are fixedly connected along the periphery; a thread outlet is formed in the shuttle head of the weaving shuttle; a thread inlet is formed in the inner side face of a reel hole; one end of the pressing piece is installed on the shuttle cover shell, and the other end of the pressing piece can press a reel; and a thread guide column is arranged between the thread inlet and the thread outlet. Through the improvement of the structure and the material, on the premise that the use function of the fishing net weaving shuttle is guaranteed, a splicing structure of two steel plate stamping parts is adopted, the thread inlet, the thread outlet and the like of the weaving shuttle are naturally formed through a butt joint structure, additional machining is not needed, machining and assembling of a shuttle body are simplified, the overall strength of the shuttle body is improved, internal threading, winding and unwinding of the fishing net weaving shuttle are more convenient, the application range of the net thread diameter of the weaving shuttle is widened, and the weaving shuttle is good in abrasion resistance, light in weight, high in production efficiency, short in production period, long in service life, low in manufacturing cost and low in thread breakage rate.

Owner:常州德飞机械有限公司

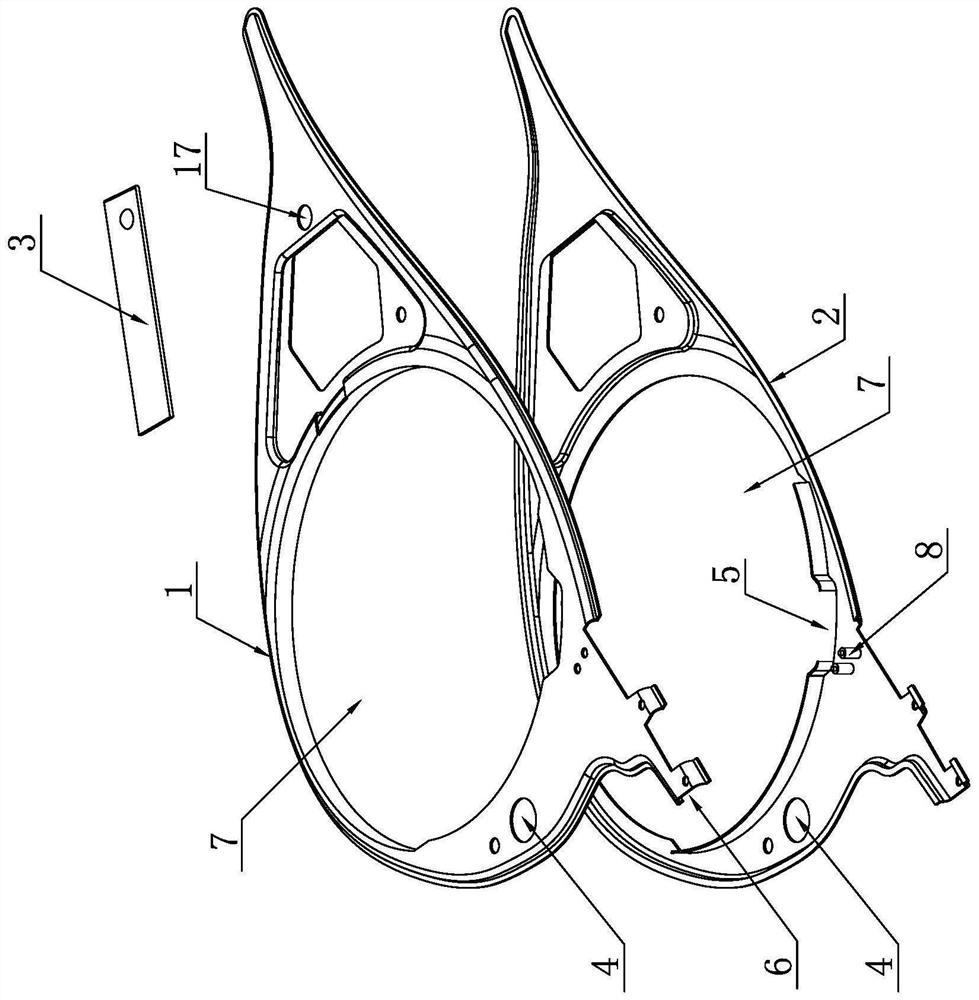

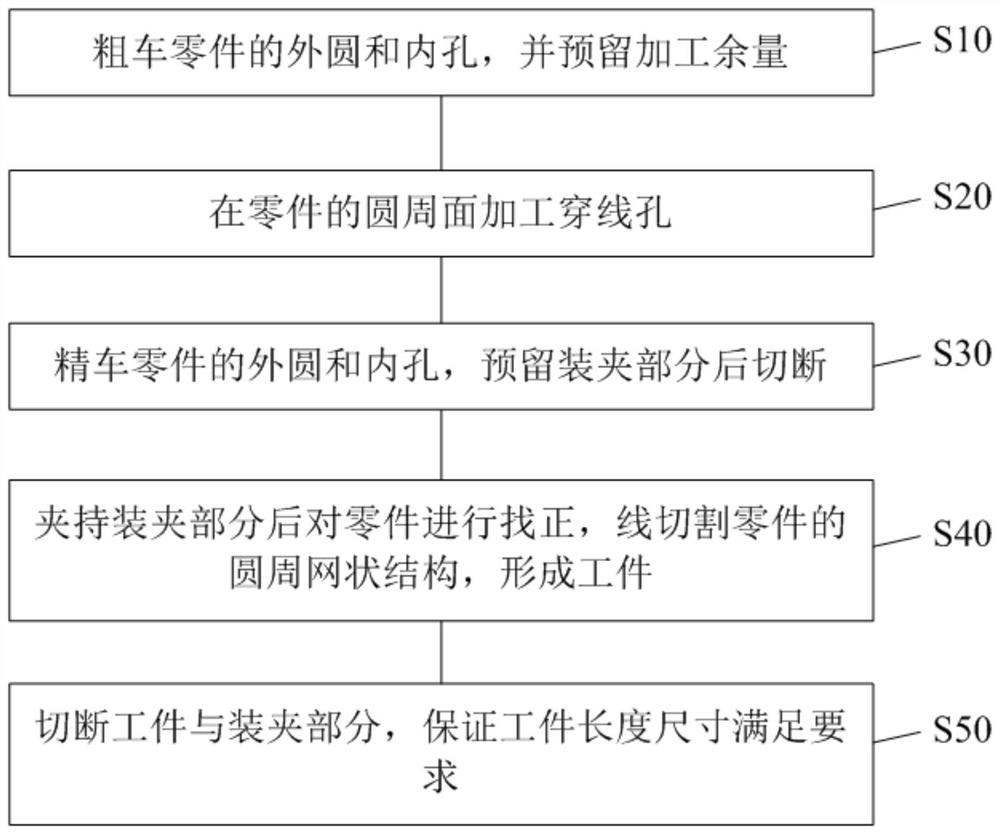

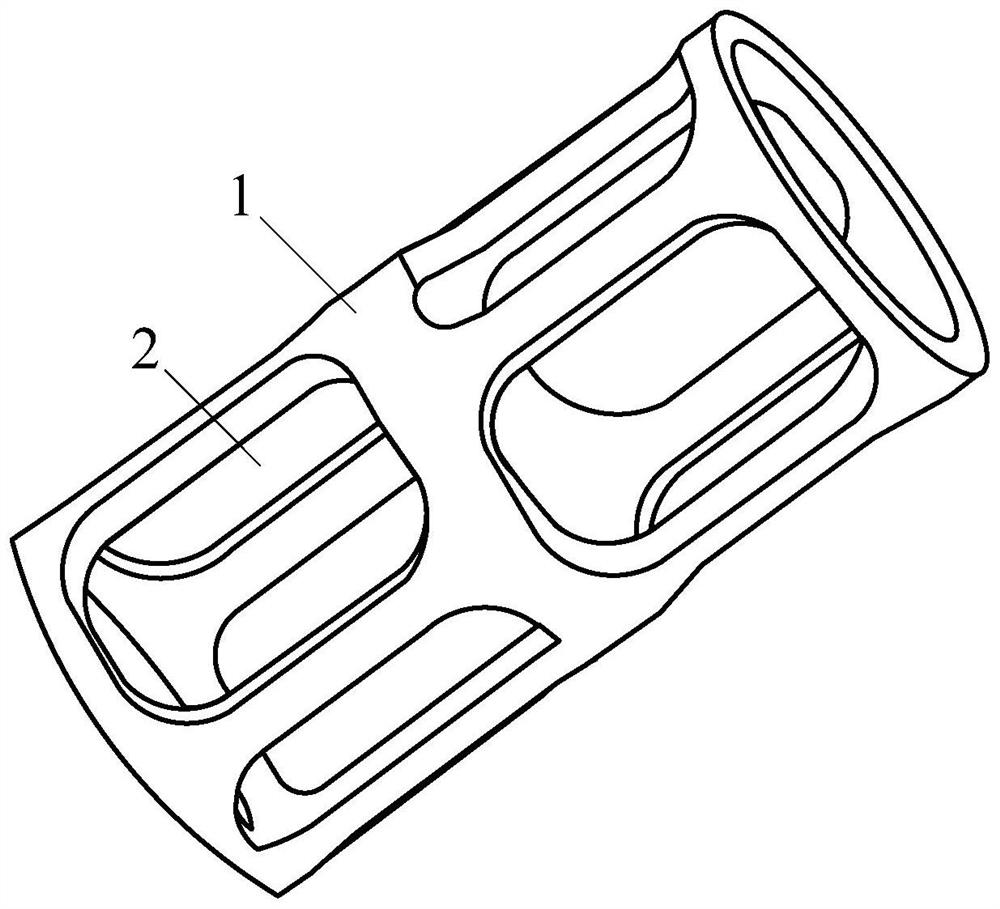

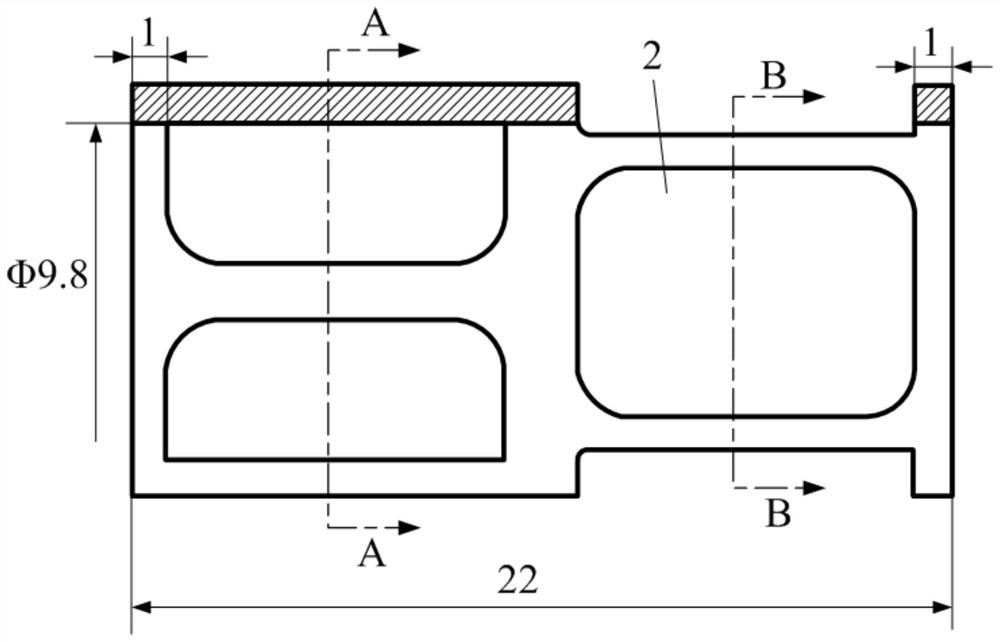

Machining method for frame parts

PendingCN114193091AEasy clampingEasy to convertPositioning apparatusMetal-working holdersMachining deformationThreading (manufacturing)

The invention discloses a machining method of a frame part, which comprises the following steps of: roughly turning an outer circle and an inner hole of the part, and reserving machining allowance; threading holes are formed in the circumferential surface of the part; the outer circle and the inner hole of the part are subjected to finish turning, stress deformation generated during threading hole manufacturing is repaired while burrs are removed, it is guaranteed that the part meets the requirements for design size precision and form and location tolerance, and cutting is conducted after a clamping part is reserved; after the clamping part is clamped, the part is aligned, the circumferential net structure of the part is linearly cut, and a workpiece is formed; and the workpiece and the clamping part are cut off to ensure that the length size of the workpiece meets requirements. According to the machining method, the problem of machining deformation of the frame parts is solved, the product quality is stable, the requirements of design drawings are met, and the product percent of pass and the machining efficiency are improved.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

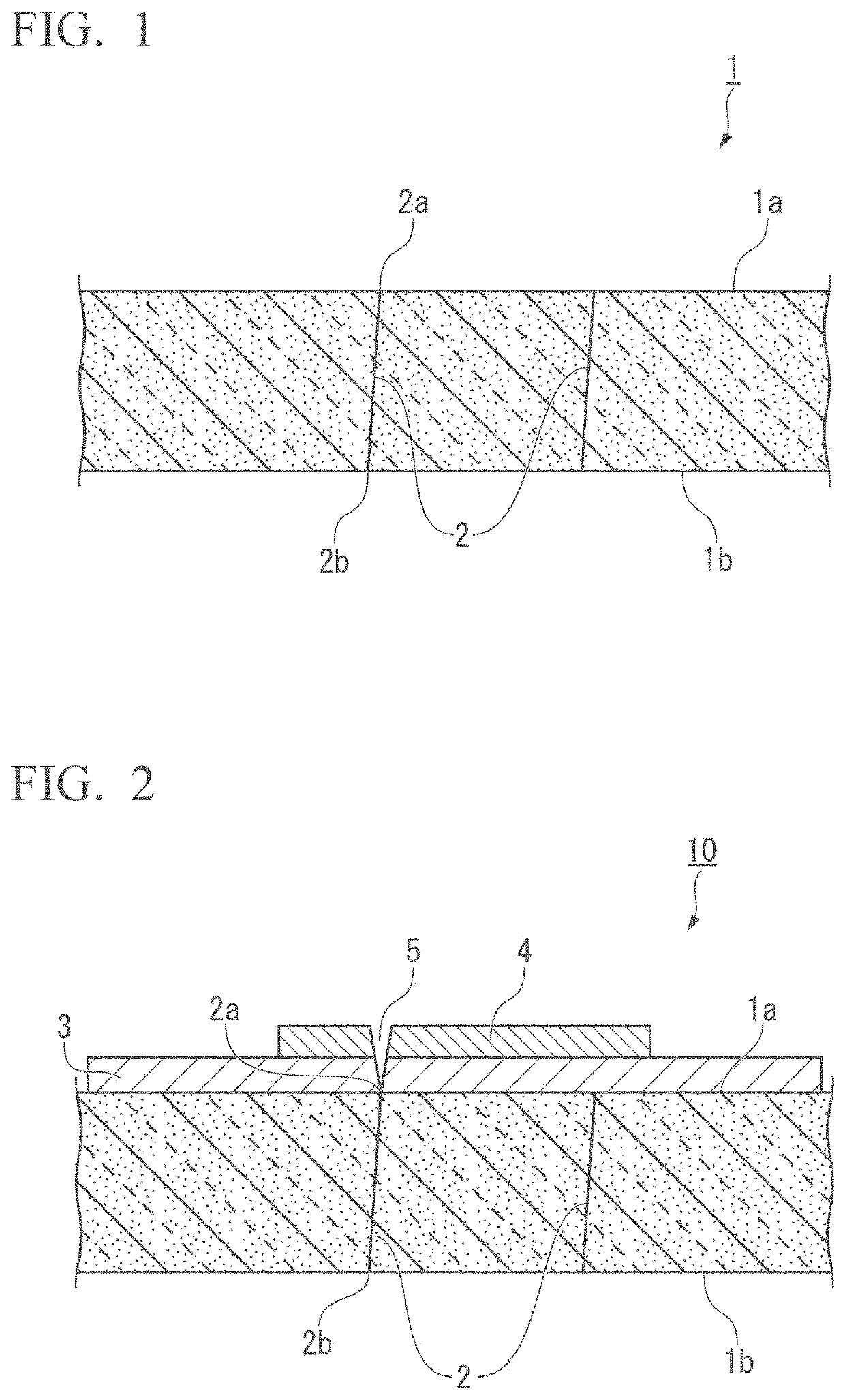

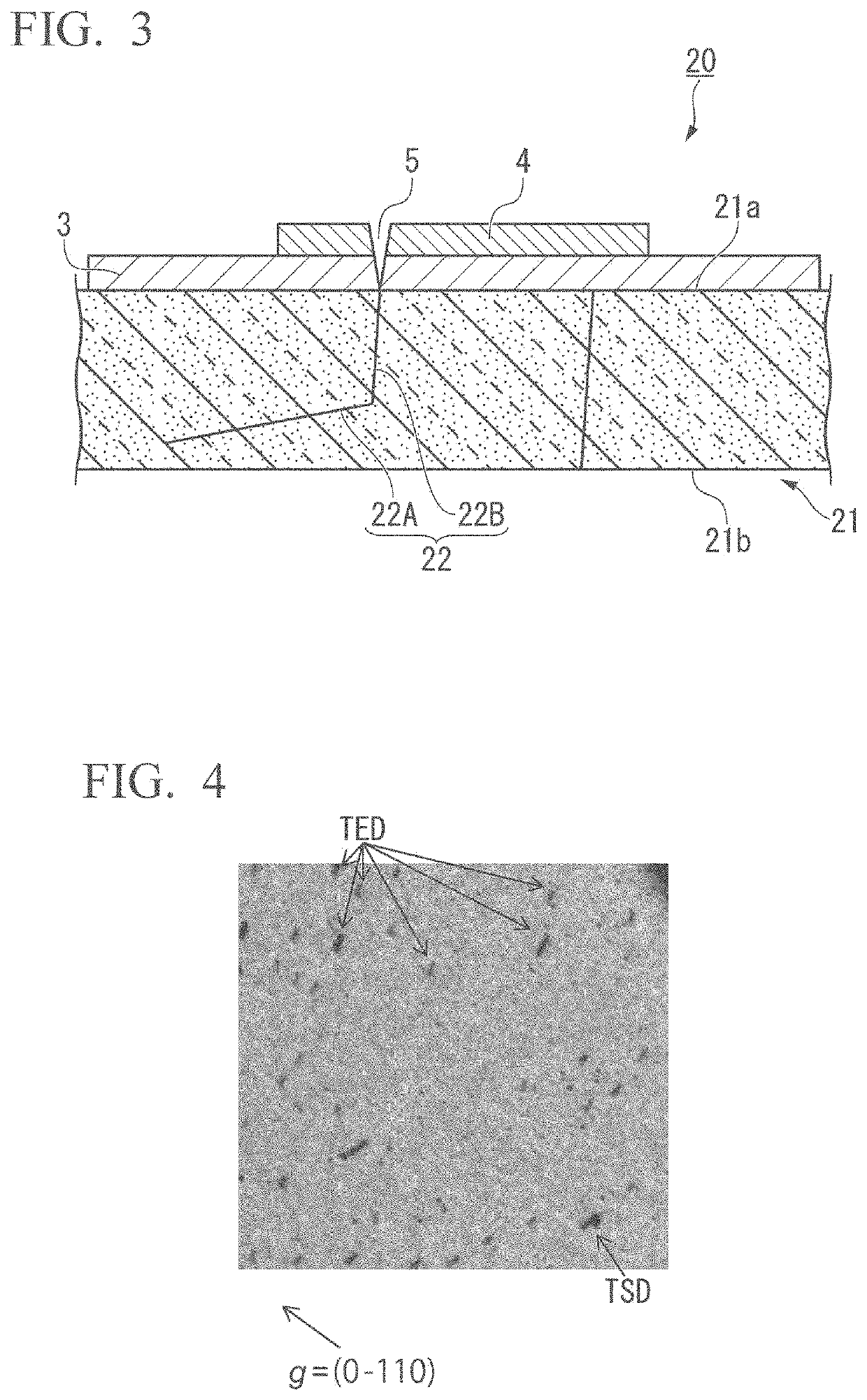

SiC WAFER AND MANUFACTURING METHOD OF SiC WAFER

PendingUS20200020777A1Polycrystalline material growthFrom condensed vaporsCrystallographyThreading dislocations

In a SiC wafer, a difference between a threading dislocation density of threading dislocations exposed on a first surface and a threading dislocation density of threading dislocations exposed on a second surface is 10% or less of the threading dislocation density of the surface with a higher threading dislocation density among the first surface and the second surface, and 90% or more of the threading dislocations exposed on the surface with a higher threading dislocation density among the first surface and the second surface extend to the surface with a lower threading dislocation density.

Owner:DENSO CORP +1

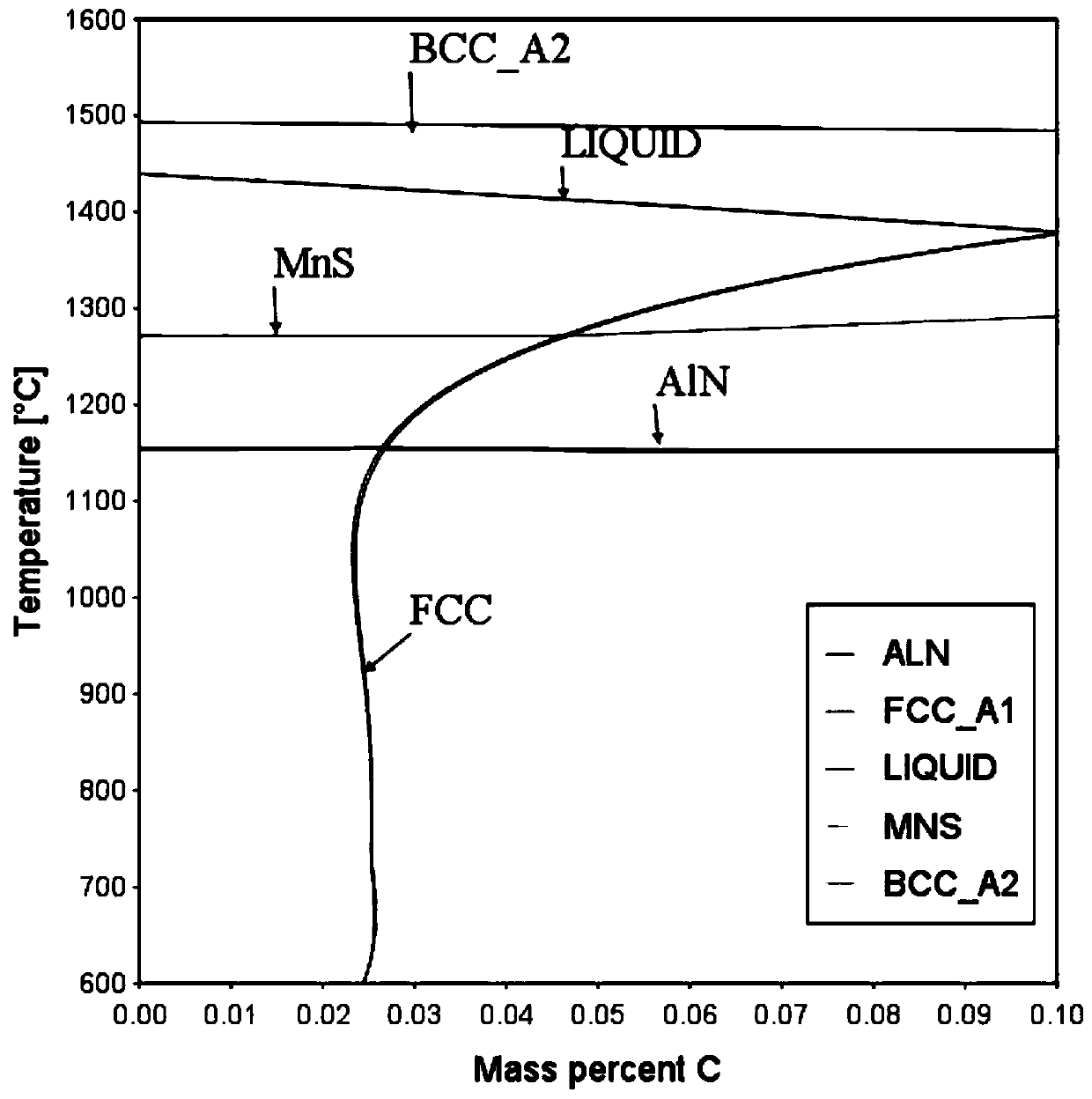

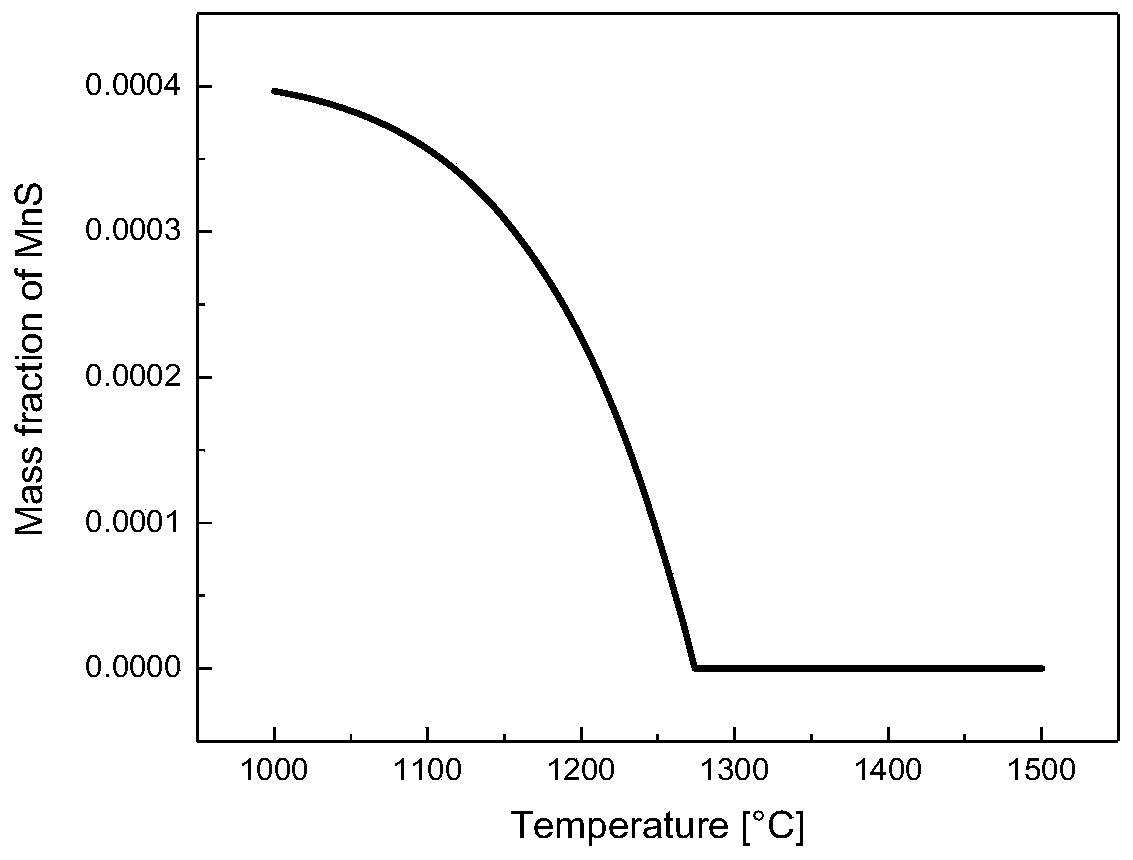

A method for producing high magnetic induction grain-oriented silicon steel based on ESP endless rolling technology

ActiveCN108546814BSmall footprintSave investment in infrastructure constructionManufacturing technologyThin slab

The invention discloses a method for producing high magnetic induction orientated silicon steel based on an ESP endless rolling technology. The method particularly comprises the following steps: thinslab continuous casting, rough rolling, induction furnace heating, finish rolling, laminar flow cooling, cold rolling, decarbonization treatment and high temperature annealing. The method is characterized in that a brand-new short process method is used for producing orientated silicon steel, and compared with a traditional orientated silicon steel high temperature heating manufacturing process, the heating process is simplified; compared with a current popular low temperature heating process, the nitriding process is omitted. An ESP production line is used for producing a hot rolled plate, continuous casting and rolling can be directly connected in series, the production efficiency is improved, head and tail cutting can be significantly reduced, and the production cost can be greatly reduced. At the same time, the full endless thin slab continuous casting and rolling process (ESP) avoids the process fluctuation caused by threading and tail flick stages of a classical process, and thephysical and mechanical property stability of strip coils are ensured.

Owner:UNIV OF SCI & TECH BEIJING

Automatic threading machine

PendingCN111715950AReduce the burden onImprove work efficiencyThread cutting feeding devicesThread cutting machinesThreading (manufacturing)Electric machinery

The invention relates to an automatic threading machine, and belongs to the technical field of automatic threading machines. The automatic threading machine comprises a fixing frame, wherein a motor and a sliding block are fixedly connected with the fixing frame, an air cylinder is fixedly connected with the lower end face of the fixing frame, a sliding rail is slidably connected with the slidingblock, a connecting piece is fixedly and vertically connected to one end of the sliding rail, a clamping member is fixedly connected above the sliding rail, a spring is arranged between the clamping member and the sliding rail, one end of the spring is fixed to the rear side of the clamping member, the other end of the spring is fixed to the right side of the upper portion of the sliding rail, a detachably connected threading die is arranged on the motor, the fixed end of the air cylinder is fixedly connected with the fixing frame, and the other end of the air cylinder is movably connected with the connecting piece. By means of the automatic threading machine, automatic threading can be directly carried out on workpieces needing threading, such as an external-thread connector, the workingefficiency is high, the effect is good, the threading effect is guaranteed, manual threading in a traditional mode is replaced, operation is easy and fast, the manufacturing cost is low, and the burden of enterprises is reduced.

Owner:龙口市通达油管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com