Twisting net structure and twisting net method of simple and efficient gabion box machine

A technology of gabion net and net structure, applied to online nets, other household appliances, household appliances, etc., can solve the problems of high equipment cost, low reliability, frequent shutdown, etc., to reduce investment costs, improve production efficiency, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

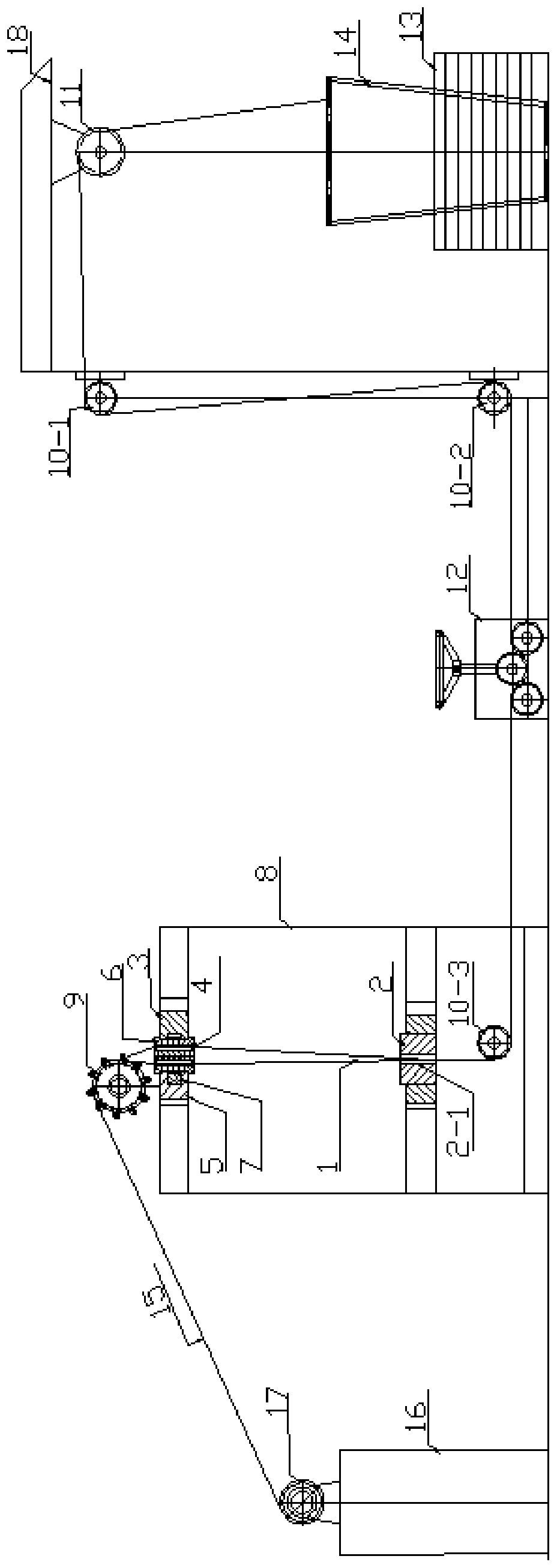

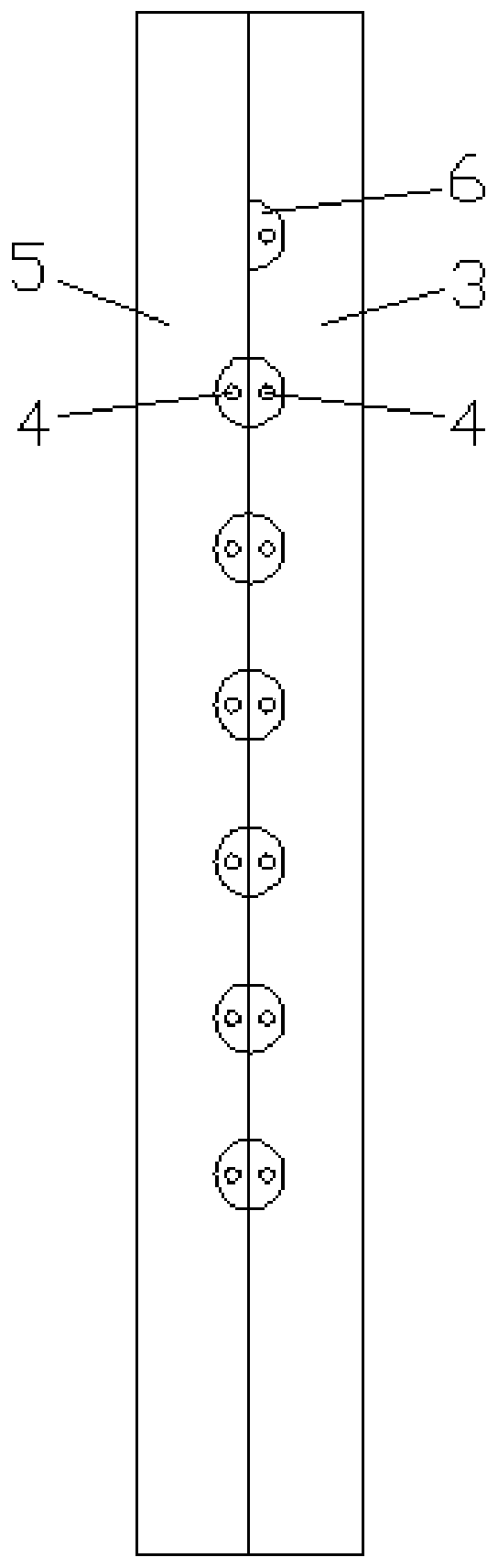

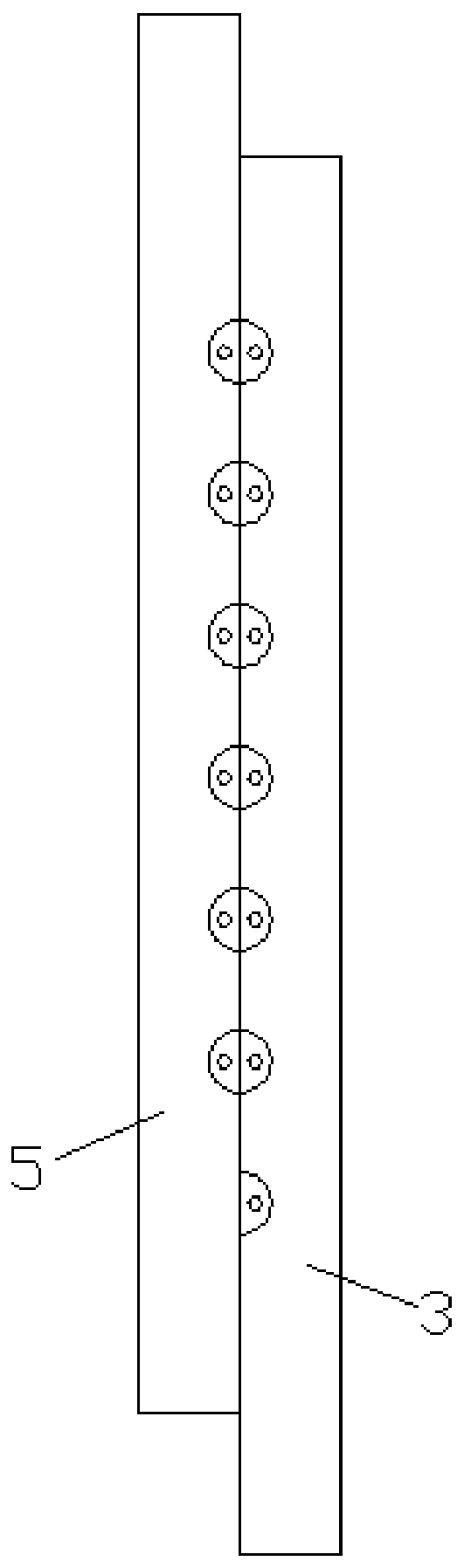

[0053] Such as Figures 1 to 4 Shown is an embodiment of the twisting structure and the twisting method of a simple and efficient gabion netting machine of the present invention, including threading guide plates 2 and carriage assemblies arranged in sequence according to the advancing direction of the metal wire 1 during the twisting operation, The threading guide plate 2 is provided with a number of threading holes 2-1 arranged at intervals, and the carriage assembly includes a pair of carriages 3 whose sides are aligned with each other and can rub back and forth along the alignment plane. 5. Rotate the half gears 6 arranged at equal intervals on each of the carriages 3 and 5 and whose center of rotation is located on the mating plane, the threading twisters arranged on each of the half gears 6 Silk hole 4, the semi-gear 6 of mutually corresponding position on its described pair of dragging boards 3,5 when described a pair of dragging boards 3,5 rubs to twist net operation po...

Embodiment 2

[0072] A twisting method adopting the twisting net structure of the simple and efficient gabion netting machine of Embodiment 1, including passing the metal wire 1 through the threading guide plate 2 and the carriage assembly in sequence before the twisting operation starts, and then fixing it to the The threading step on the drawing roller 9; wherein, the threading is to adopt the reverse pre-twisting threading method, and the reverse pre-twisting threading method refers to the first twisting of two adjacent metal wires 1 when the twisting operation starts. In the wire direction, after two adjacent metal wires 1 pass through the corresponding two threading holes 2-1 on the threading guide plate 2, they are pre-twisted in a direction opposite to the first twisting direction, and then threaded. Pass through the threading twist hole 4 provided on the half gear 6 of the carriage assembly.

[0073] Wherein, the step of described twist net operation is as follows:

[0074] (1) Car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com