Method for producing nickel-based alloy through twenty-roller reversible rolling mill

A nickel-based alloy and twenty-roll technology, applied in the field of metallurgy, can solve the problems of shortening the production cost of nickel-based alloys, low output, and rolling defects in the production process, so as to improve the production speed and output of the operation, shorten the preparation time, and improve the production process. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The twenty-high reversing cold rolling mill used in this embodiment is a single-stand Sendzimir twenty-high rolling mill.

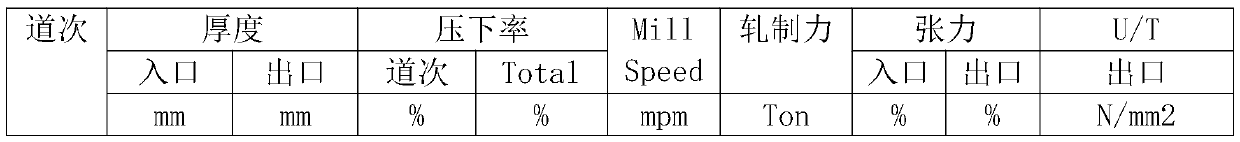

[0015] The purpose of this embodiment is to use a single-stand 20-high reversing cold rolling mill to roll an industrial nickel-based alloy with a thickness of 5.5 mm and a width of 1250 mm and a brand name of N08825 through the first rolling process to obtain a target thickness specification of 3.000mm nickel-based alloy finished product, the first rolling process includes the following steps:

[0016] Coiling: The industrial nickel-based alloy coil with a thickness of 5.5mm and a width of 1250mm is transported to the uncoiler by a feeding trolley. The industrial nickel-based alloy coil and the left and right coiling mandrels of the rolling mill are kept on the same horizontal line, and the mandrel expands. Rollup completed;

[0017] Strip threading: The strip head of the industrial nickel-based alloy coil passes through the five-roller straighte...

Embodiment 2

[0023] The twenty-high reversing cold rolling mill used in this embodiment is a single-stand Sendzimir twenty-high rolling mill.

[0024] The purpose of this embodiment is to use the single-stand twenty-high reversing cold rolling mill to carry out the rolling of the industrial nickel-based alloy with a thickness of 3.000 mm and a width of 1250 mm obtained in embodiment 1 in the second rolling process to obtain the target thickness specification 1.200mm nickel base alloy finished product; the first rolling process includes the following steps:

[0025] Coiling: The industrial nickel-based alloy coil with a thickness of 3.000mm and a width of 1250mm is transported to the uncoiler by a feeding trolley. The industrial nickel-based alloy coil and the left and right coiling mandrels of the rolling mill are kept on the same horizontal line, and the mandrel expands. Rollup completed;

[0026] Strip threading: The strip head of the industrial nickel-based alloy coil passes through th...

Embodiment 3

[0033] Three batches of 1.200mm thick nickel-based alloys obtained in the above-mentioned embodiment 2 are annealed and pickled, and the numbers of the three batches of nickel-based alloys are successively nickel-based alloy 1, nickel-based alloy 2, nickel-based alloy 3.

[0034] The annealing parameters are set as follows according to the nickel-based alloy:

[0035]

[0036] After the annealing furnace temperature is set, it runs smoothly at an online speed of 15mpm.

[0037] Pickling parameters are set as follows:

[0038]

[0039] After annealing and pickling, the surface quality of the 1.200mm thick nickel-based alloy is good.

[0040] Finishing products: Through the finishing shearing unit, the titanium coils are cut to the corresponding specifications to reach the product specifications required by customers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com