Lead screw nut and manufacturing method for same

A technology for screw nuts and manufacturing methods, applied to nuts, threaded fasteners, connecting components, etc., can solve the problems of high brittleness, time-consuming and labor-consuming, low strength, etc., and achieve prolonging service life, improving bearing capacity, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

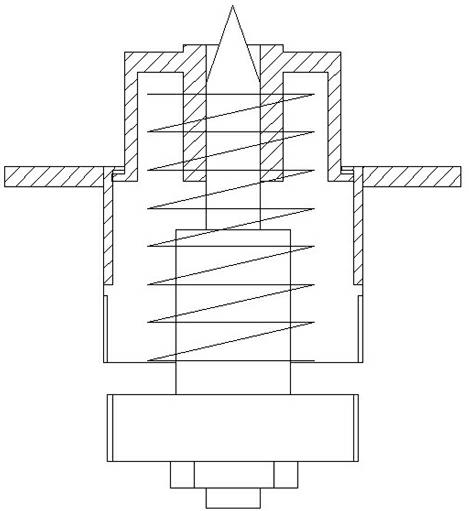

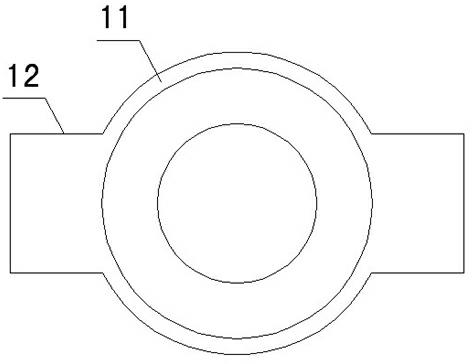

[0024] See attached Figure 1-4 , The lead screw nut disclosed in the present invention is used for adjusting and connecting building lead screws, and includes a circular platform 11 , side ears 12 and a tapered threaded barrel 13 in an integral structure. The screw nut is stamped from waste iron plate. And the circular platform 11 of the nut, the side ear 12 and the tapered threaded cylinder 13 are integrally structured, wherein a concave circular concave surface is arranged on the circular platform.

[0025] The lead screw nut is made according to the following steps:

[0026] a. Cut large pieces of waste iron plates into iron plates of appropriate size for later use;

[0027] b. Use a shape mold to punch out the circular table top and the outer contour blank of the side ear of the screw nut on the iron plate, that is, the structure of the plate-shaped circular ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com