Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Streptomyces avermitilis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Streptomyces avermitilis is a bacterium species in the genus Streptomyces. The first complete genome sequence of S. avermitilis was completed in 2003. This genome forms a chromosome with a linear structure, unlike most bacterial genomes, which exist in the form of circular chromosomes.

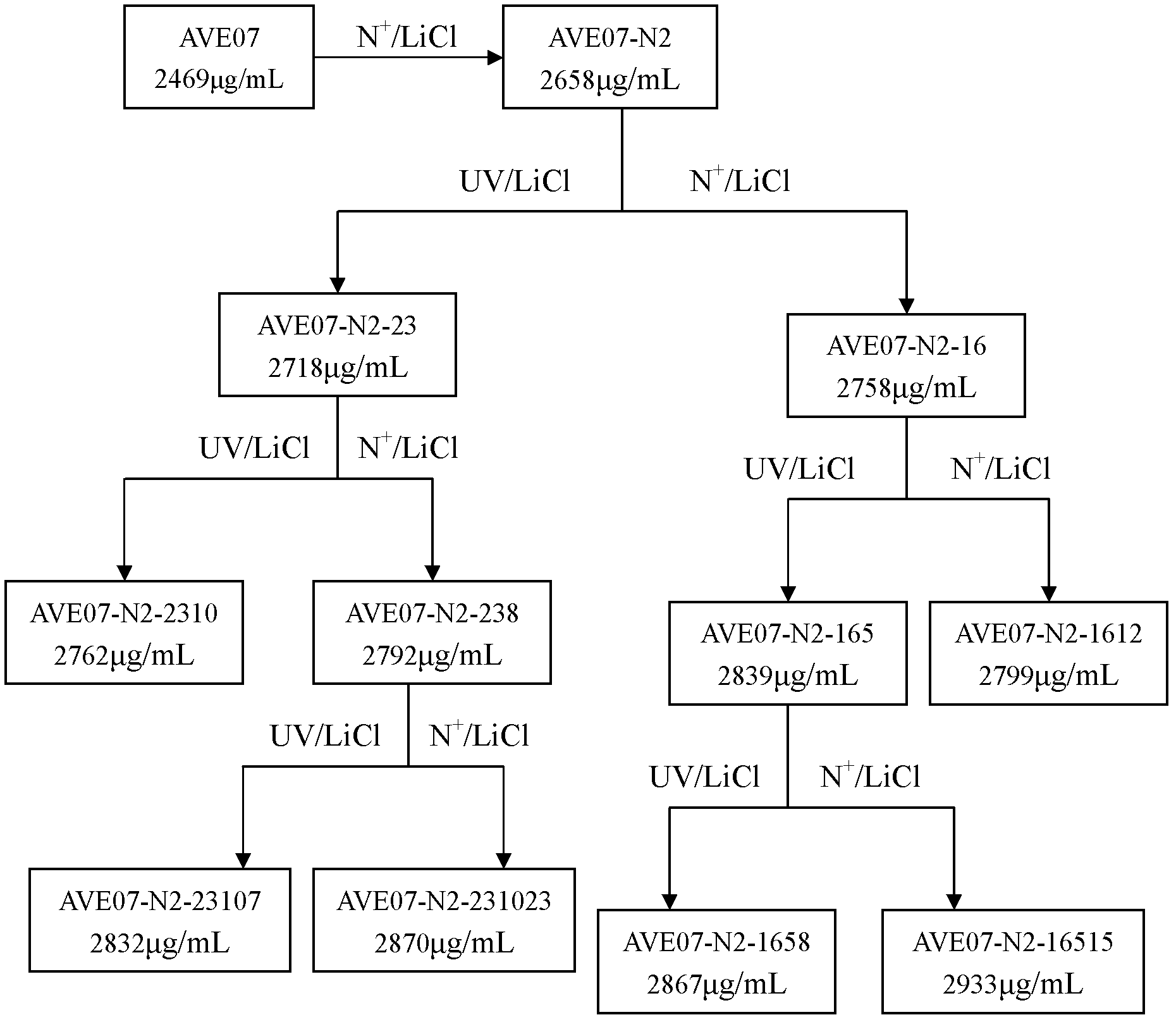

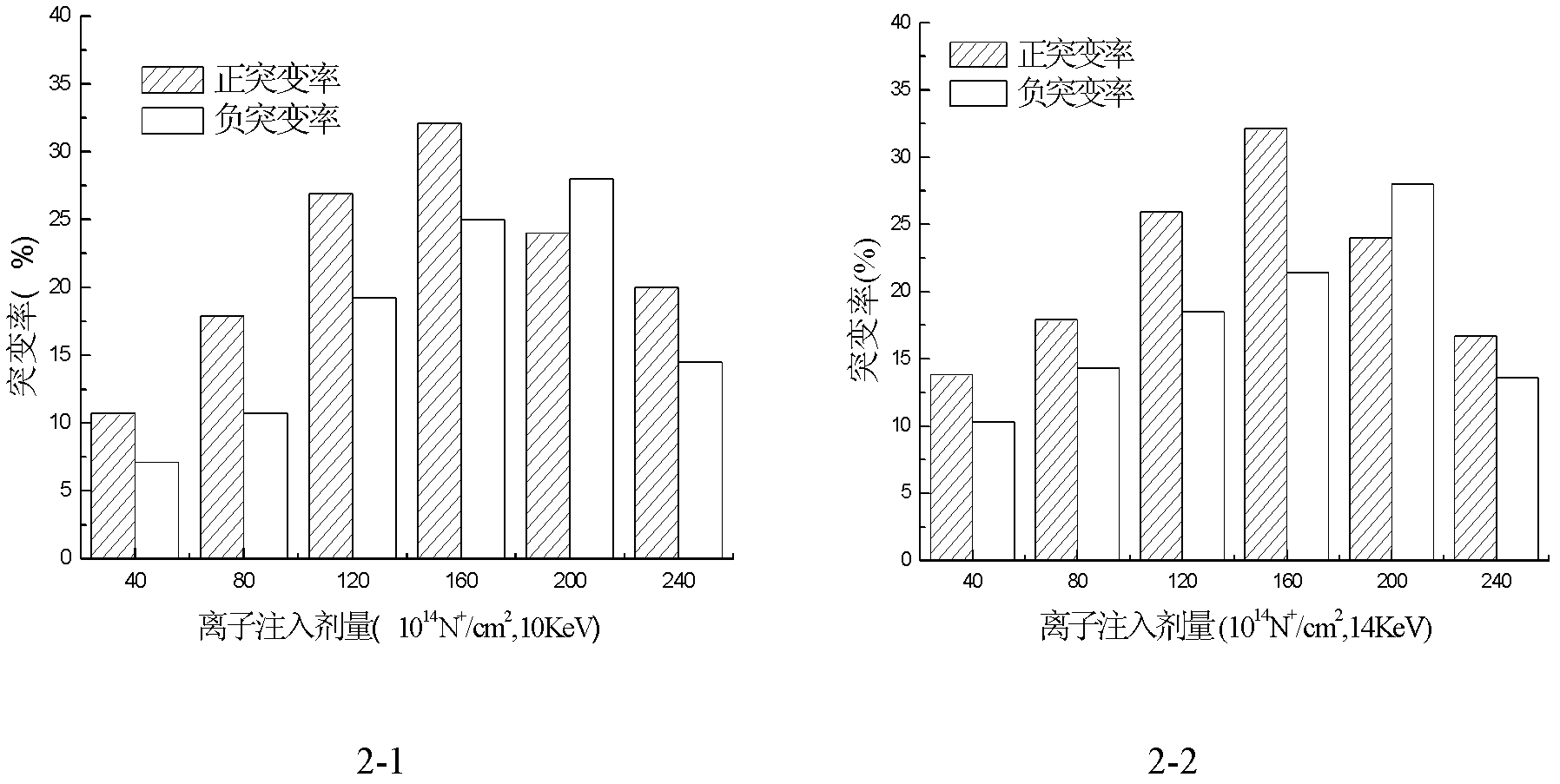

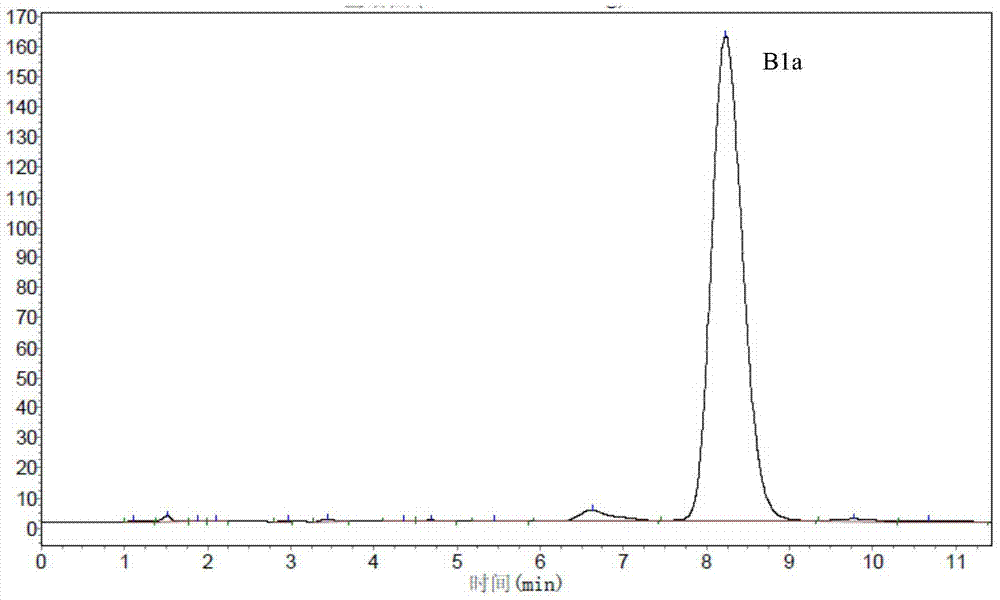

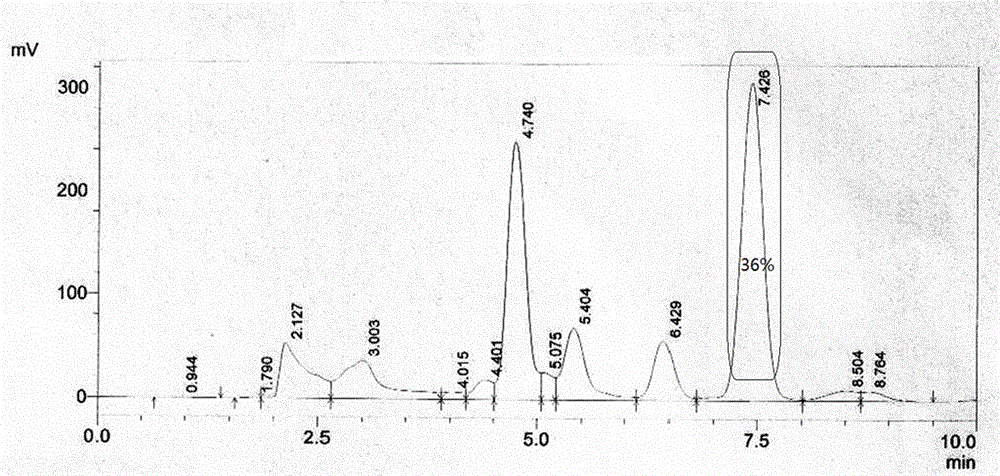

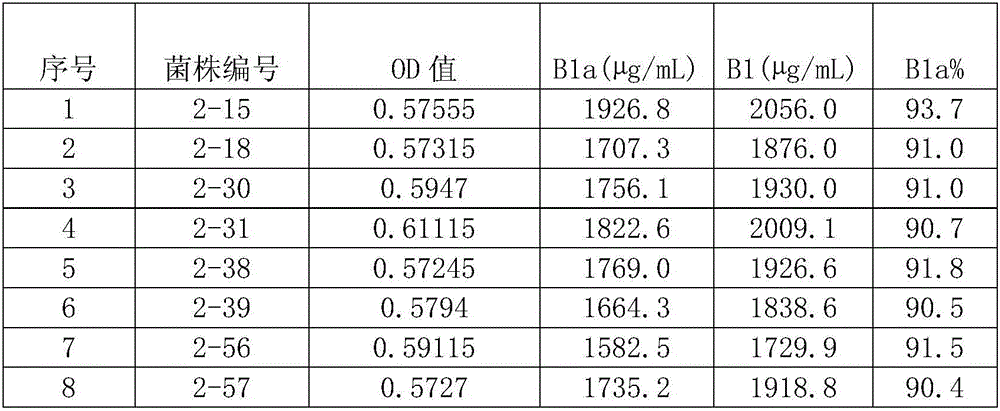

Avermectin B1a high-yielding strain and application thereof

InactiveCN102634471AHigh compositionReduce other componentsBacteriaMicroorganism based processesLithium chlorideUltraviolet

The invention discloses an avermectin B1a high-yielding strain, which is classified and named streptomyces avermitilis AVE 07-N2-16515, and is preserved in a China type culture preservation centre (CCTCC) with the preservation number of CCTCC NO: M2012094. The avermectin B1a high-yielding strain disclosed by the invention is obtained by combining low-energy nitrogen ion implantation-lithium chloride (N<+>-LiCl) compound mutation with ultraviolet ray-lithium chloride (UV-LiCl) compound mutation, primarily screening, and performing shake-flask fermentation secondary screening, and is used as a starting strain for next mutation, so that the target strain AVE07-N2-16515 is finally screened. The obtained strain can greatly increase the avermectin B1a component and reduce other components in fermentation products, and is good in hereditary stability. The strain is fermented in a 5L fermentation tank to produce avermectin B1a by utilizing glucose as a quick-acting carbon source and cornstarch as a delayed-action carbon source, the titer can achieve 3048 mu g / m, which is improved by 23.4% as compared with the original starting strain AVE07; and the strain can be applied on industrial production, greatly improves a fermenting unit, and has great economic application value.

Owner:NANJING UNIV OF TECH

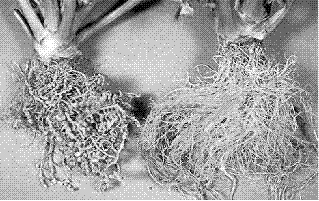

Microbial preparation for inhibiting root-knot nematode and preparation method and application thereof

ActiveCN103039534AImprove securityFew cropping diseasesBiocidePlant growth regulatorsBiotechnologyMetabolite

The invention belongs to the field of biological prevention and control on crop insect damage and provides a microbial preparation for inhibiting root-knot nematode. The preparation is formed by mixing bacterial liquids of streptomyces avermitilis, paecilomyces lilacinus, verticillium chlamydosporium and Bacillus sphaericus and glycerol. The invention also provides a production method and an application effect of the microbial preparation for inhibiting the root-knot nematode. The microbial preparation comprises viable bacteria of which the number is greater than 2,500 millions per milliliter, wherein the viable bacteria comprise the streptomyces avermitilis, the paecilomyces lilacinus, the verticillium chlamydosporium and the Bacillus sphaericus. After the microbial preparation is prepared into soil, eggs of the root-knot nematode are killed by metabolites generated in the continuous growth and reproduction activity process of the viable bacteria, so that a granular structure of the soil is improved, the utilization rate of a fertilizer is improved and an effect of increasing both production and income is achieved.

Owner:河北衡晓生物科技有限公司

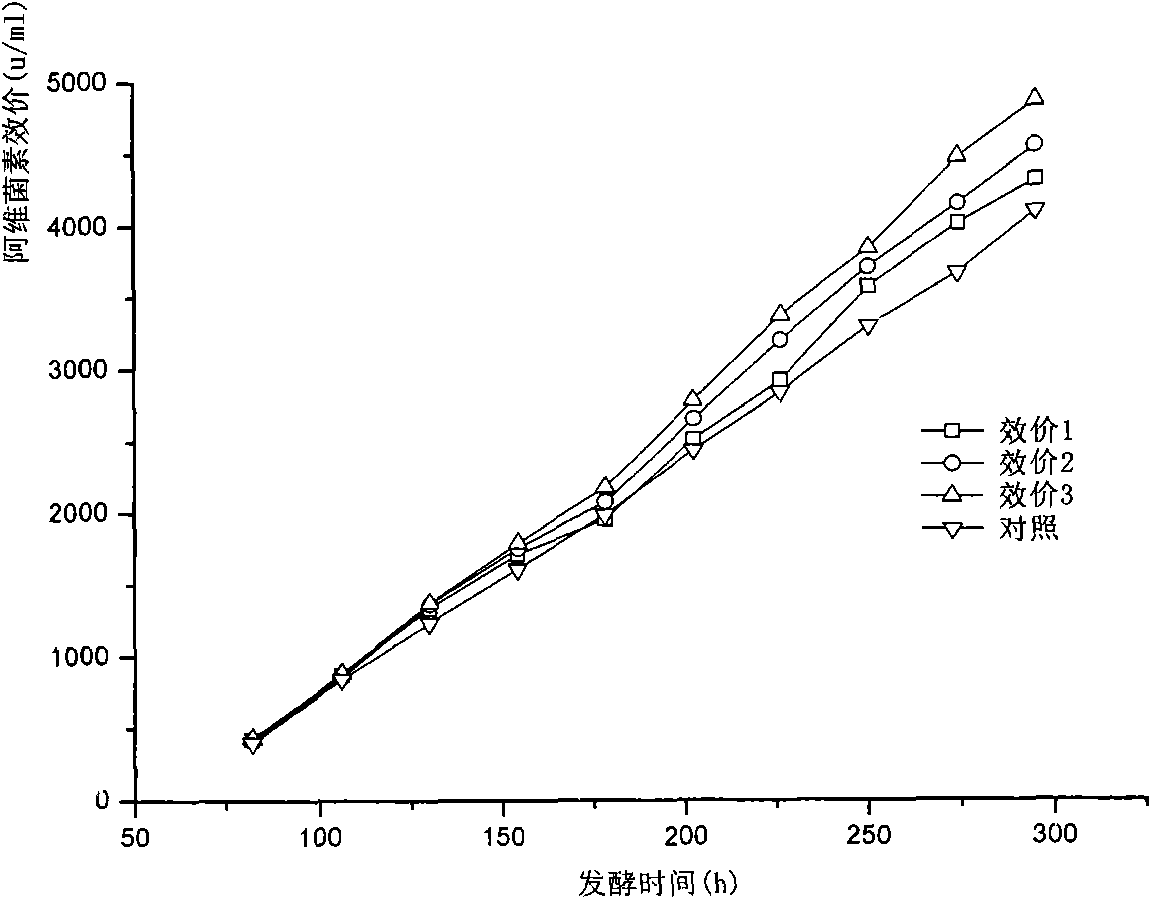

Culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and material supplement method

ActiveCN104561180ALow market priceIncrease productionMicroorganism based processesFermentationBiotechnologyPolystyrene

The invention relates to culture mediums for producing doramectin through fermentation of mutant streptomyces avermitilis and a material supplement method. The culture mediums comprise a seed culture medium and a fermentation culture medium, and are characterized in that the seed culture medium comprises corn lees and low-temperature pressing soya bean cake powder; the fermentation culture medium comprises corn lees, low-temperature pressing soya bean cake powder, polystyrene non-polar adsorbent resins and nonionic surfactants. The cost problem of raw materials and auxiliary materials are solved, the environment influence on sources of the raw materials and the auxiliary materials is reduced to the hilt, the supplying of the raw materials and the auxiliary materials is sufficient, the stable and efficient production of the doramectin is realized, and at the same time, the fermentation unit can be improved by using the culture mediums and the material supplement method.

Owner:宁夏泰瑞制药股份有限公司

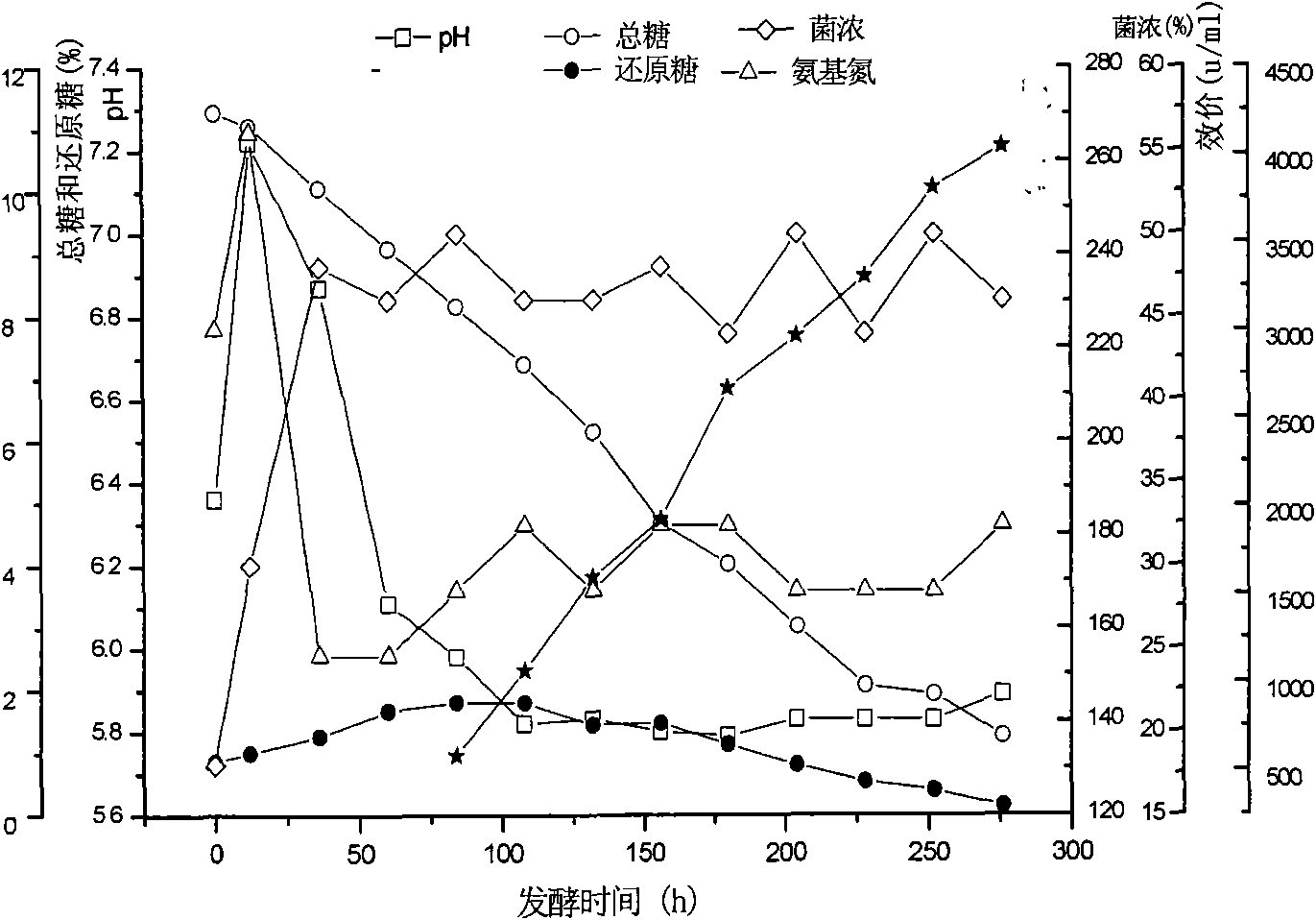

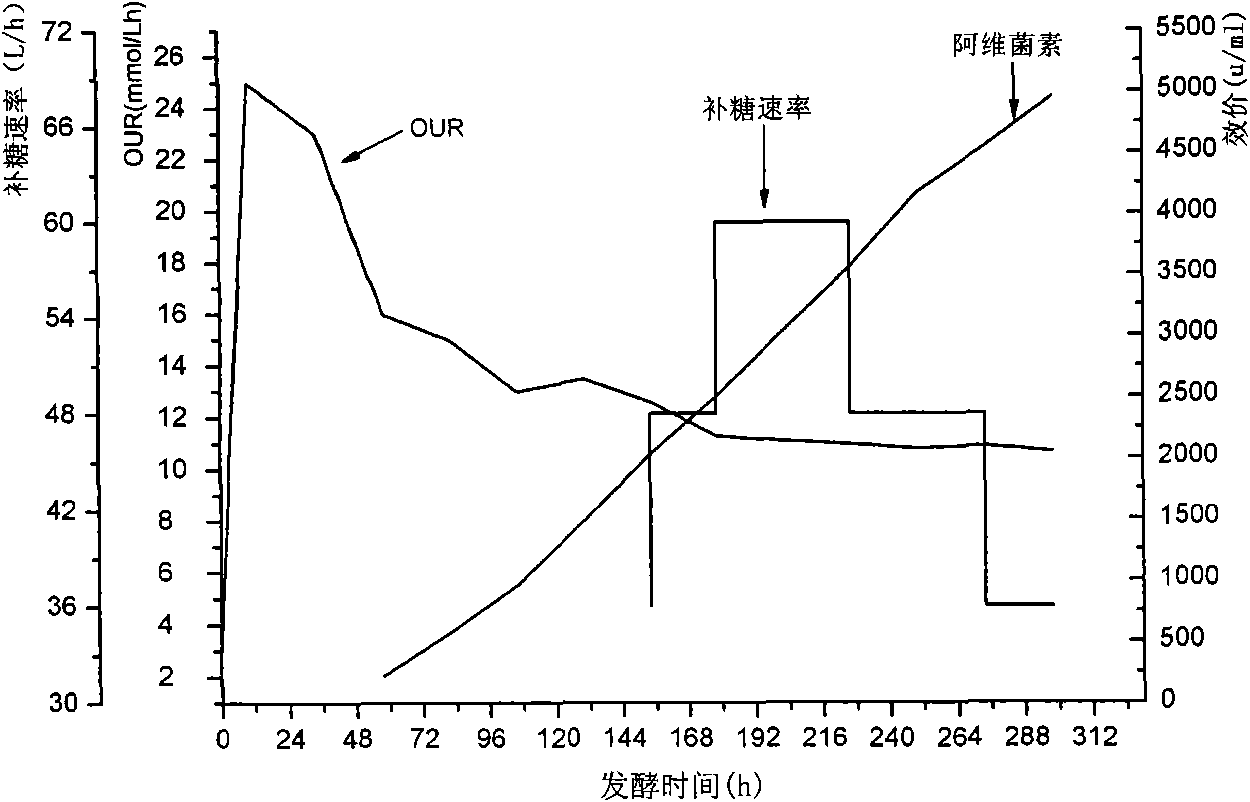

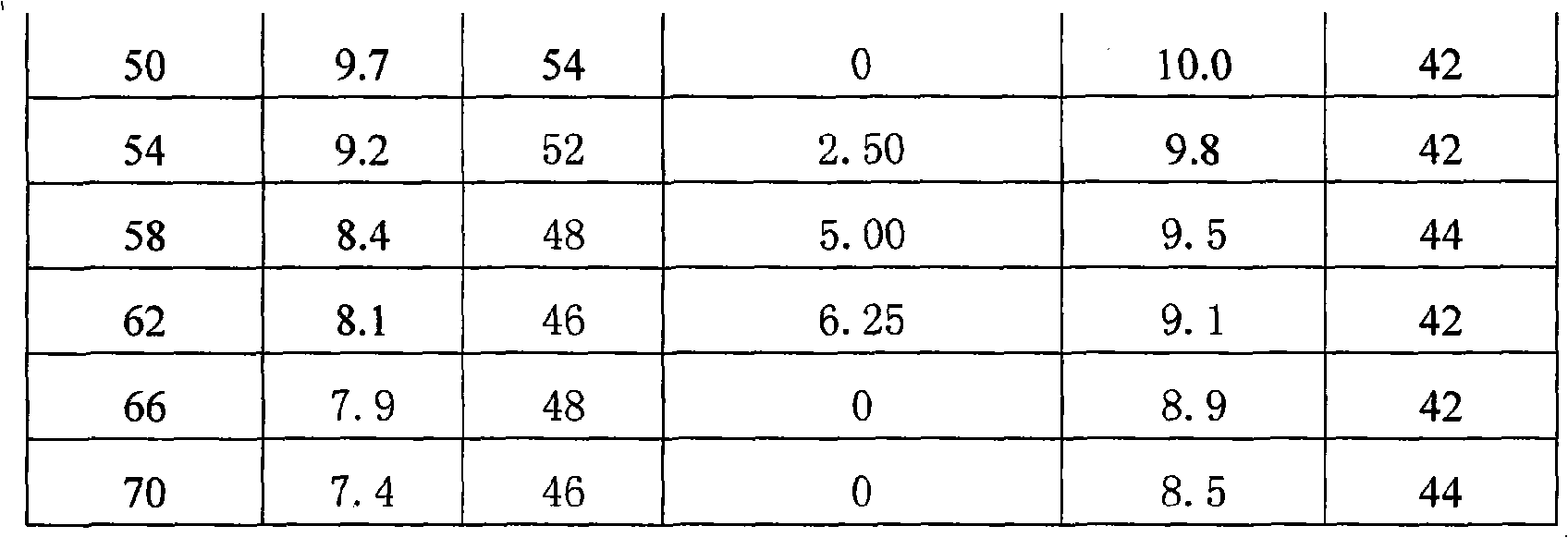

Process for producing abamectin by feeding glucose fermentation based on metabolizing parameters OUR

InactiveCN101560535AHigh potencyAnti agingMicroorganism based processesFermentationBiotechnologyAbamectin

The invention relates to a process for producing abamectin by feeding glucose fermentation based on metabolizing parameters OUR, belonging to the technical field of bio-fermentation. The method is characterized by comprising the following processing steps of: (1) sub-culturing streptomyces avermitilis into a 250ml shake flask for primary seed cultivation; (2) sub-culturing seeds obtained from step (1) into a 15L seed tank for secondary seed cultivation; and (3) sub-culturing the seeds obtained from step (2) into a 50L fermentation tank for fermentation cultivation, measuring OUR value of exhaust gas in the fermentation process in real time and conducting glucose feeding according to the OUR value. As the process is reasonably designed, the cost is reduced, the thalli senescence in the fermentation process is effectively delayed, and the titer of abamectin is improved by about 20 percent, thereby obtaining high yield by effectively utilizing raw materials.

Owner:ZHEJIANG SHENGHUA BIOK BIOLOGY +1

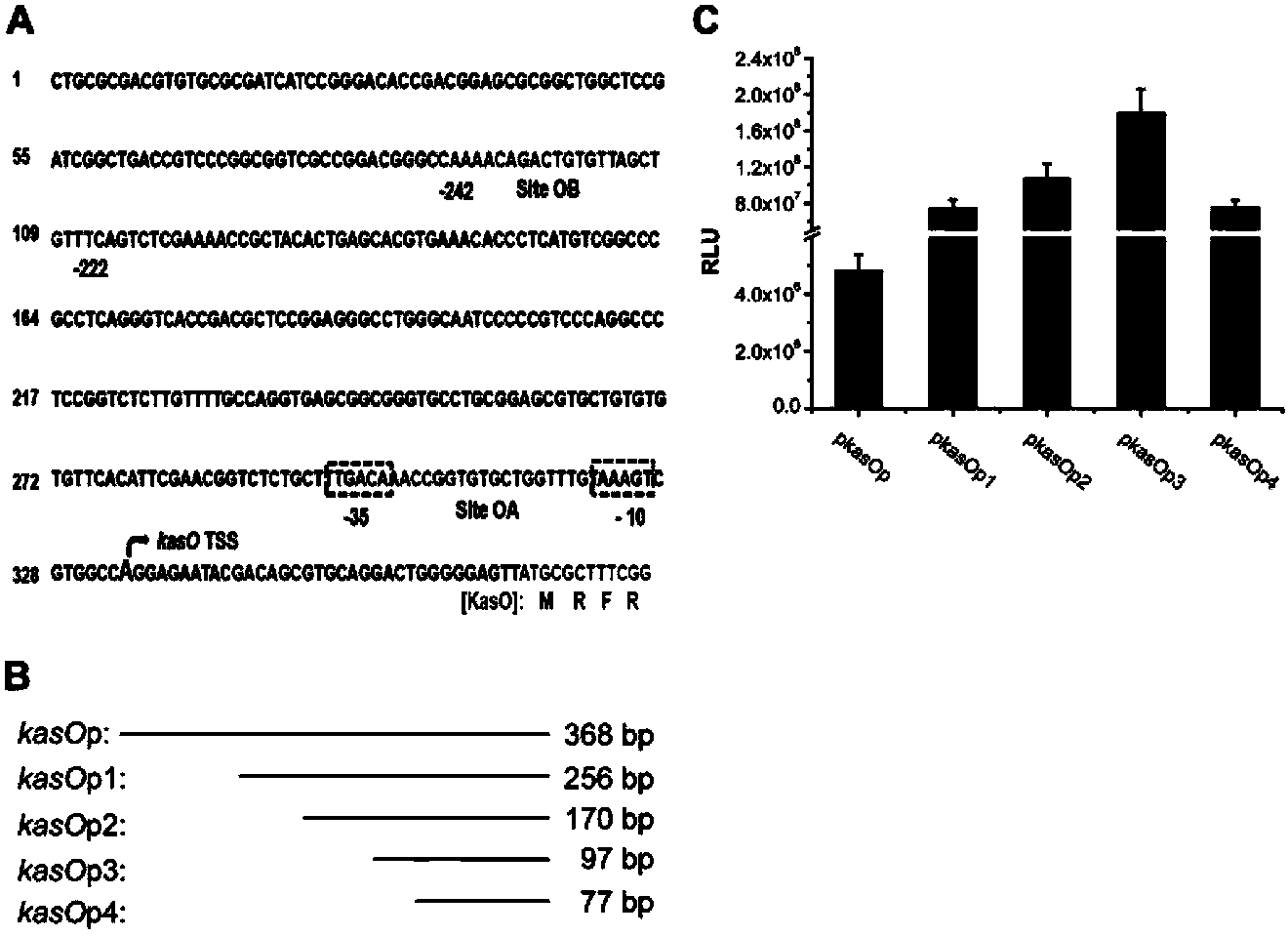

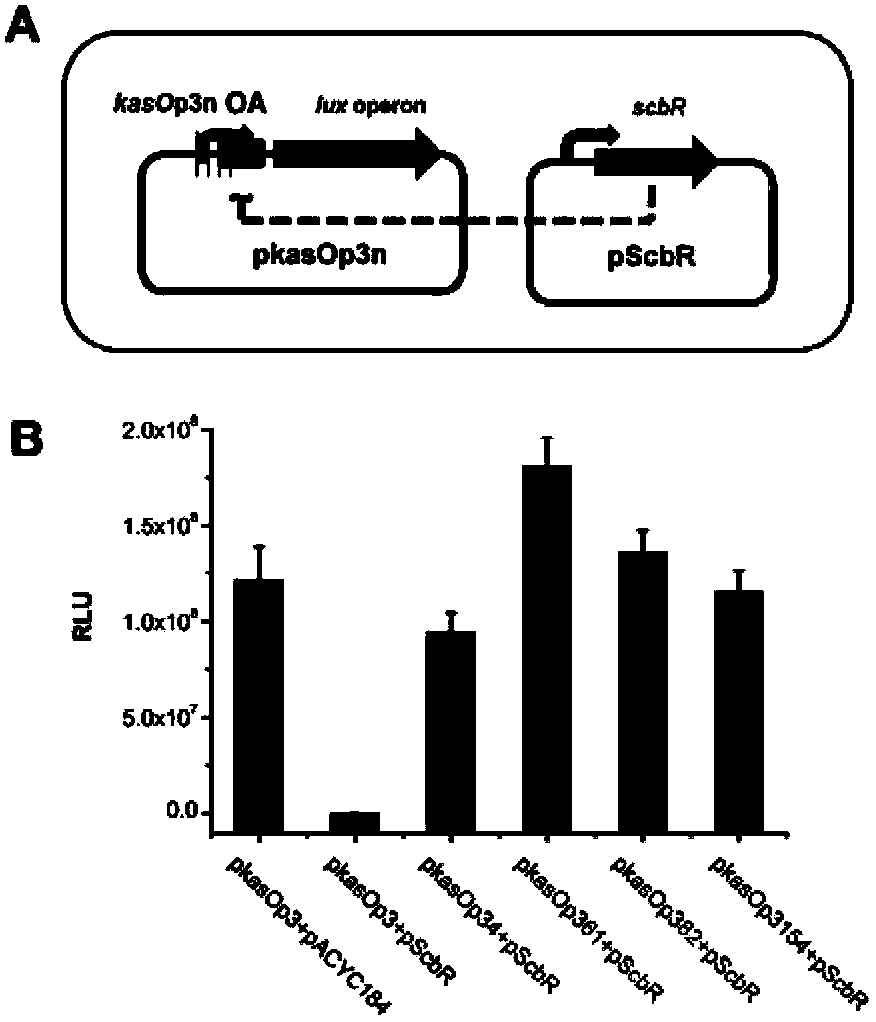

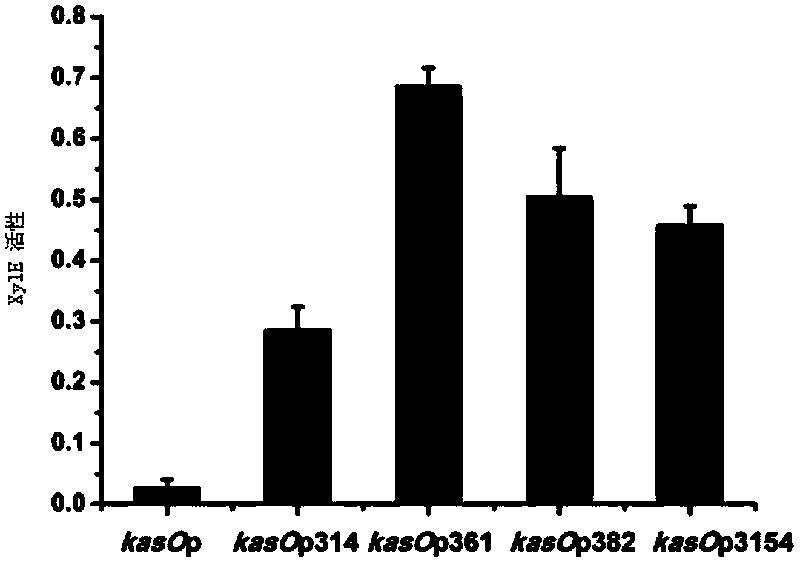

Streptomycete constitutive promoter and applications thereof

InactiveCN103421778AIncrease productionIncreased transcript levelsBacteriaMicroorganism based processesAgricultural scienceStreptomyces venezuelae

The invention discloses a streptomycete constitutive promoter and applications thereof, and provides an DNA fragment. The DNA fragment is any one selected from the following DNA molecules in 1)-3): 1) an DNA molecule represented by the sequence 1 in a sequence table; 2) an DNA molecule with promoter functions and hybrid with the DNA molecule shown in 1) under strict conditions; 3) an DNA molecule with more than 90% of homology with the DNA molecule shown in 1) and with promoter functions. The experiments shows that a strong constitutive promoter kasO*p is screened out, and the promoter and the erythromycin promoter ermE*p are compared in representation of transcriptional level and expression level in streptomyces coelicolor, streptomyces avermitilis and streptomyces venezuelae, and the results show that the modified promoter kasO*p is better than the the erythromycin promoter ermE*p.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

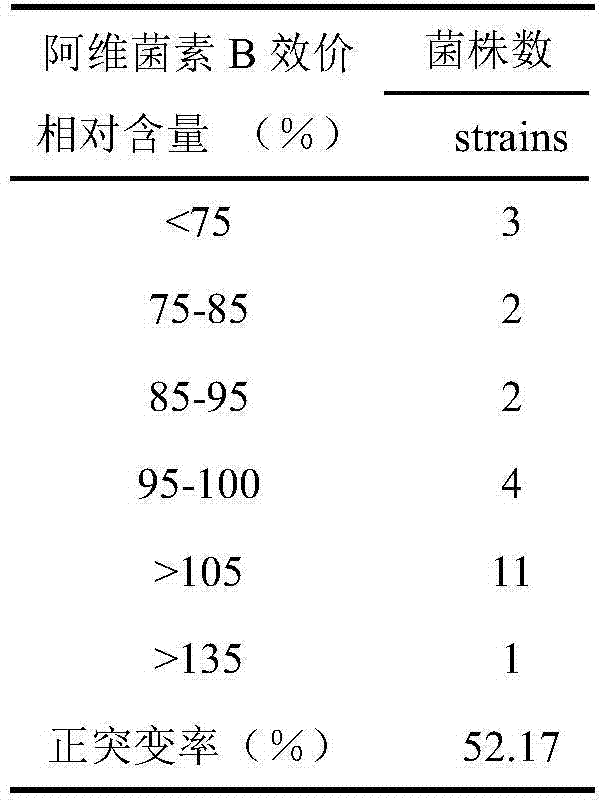

Mutant strain of high-yield abamectin B component and screening method thereof

InactiveCN104498400AA simple mutagenesis method for high-yielding bacteriaSimple bacterial mutagenesis methodBacteriaMutant preparationMicroorganismAbamectin

The invention discloses a mutant strain of a high-yield abamectin B component, which is classified and named as streptomyces avermitilis. The strain is collected in China General Microbiological Culture Collection Center (CGMCC) on November 6, 2014, and the collection number is CGMCC No.9950. The invention also discloses a screening method of the mutant strain of the high-yield abamectin B component. The invention also discloses a production method of the abamectin B component. The invention is designed for solving the technical problem of providing a simple, efficient and safe mutation method of a high-yield strain of an abamectin B component, a strain of the abamectin B component is also obtained according to the invention, the positive mutation rate of a high-yield abamectin strain is over 40%, and the fermentation yield of the abamectin B component is over 8000mu g / ml.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

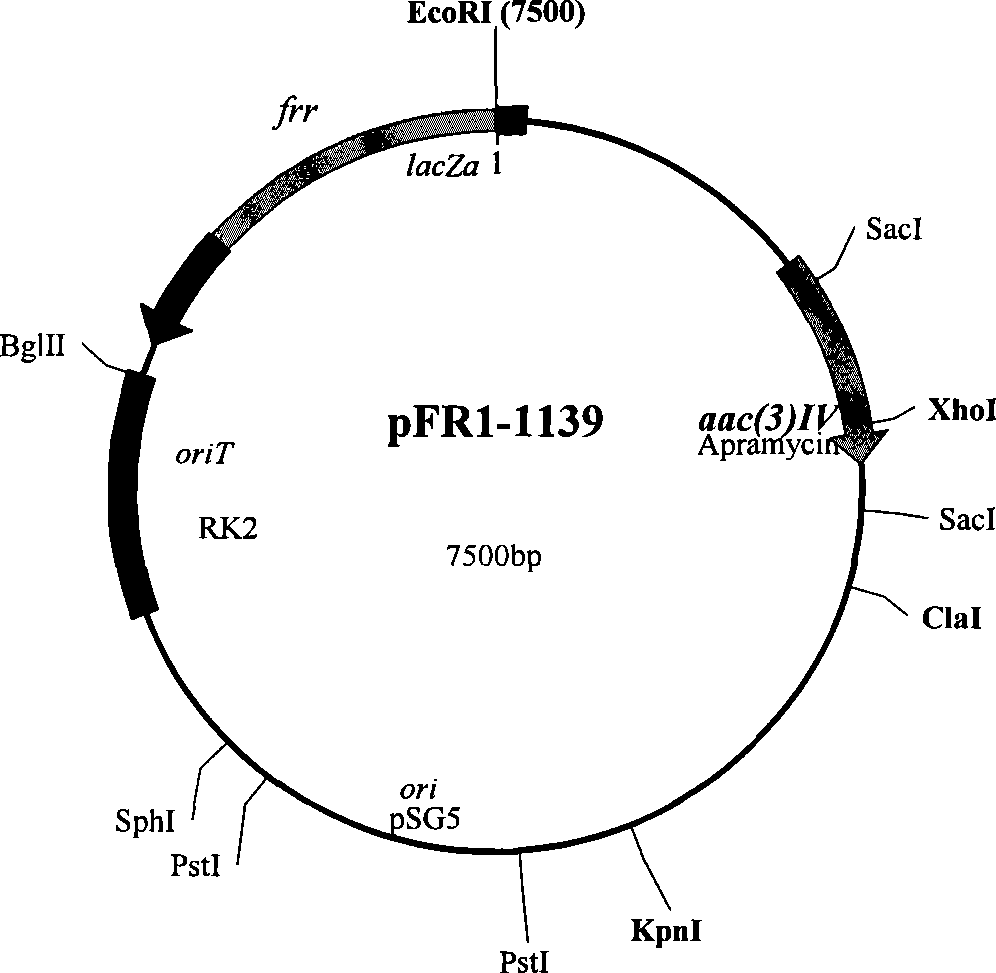

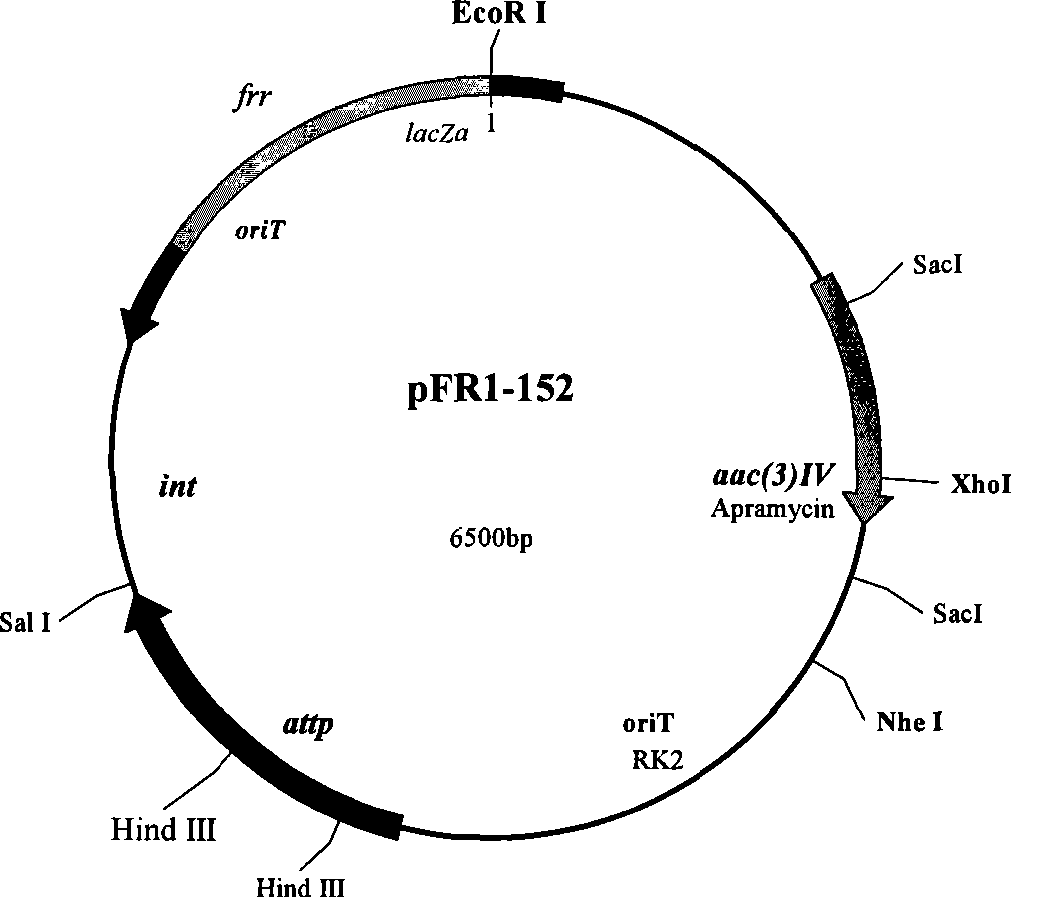

Avid kyowamycin genetic engineering bacterium and use thereof

InactiveCN101386829AIncrease productionReduce manufacturing costBacteriaMicroorganism based processesBiotechnologyAvermectin

The invention provides a genetic engineering bacterium capable of improving the yield of abamectin, which is a recombinant bacterium over-expressed by ribosome circular factors obtained by the introduction of frr genes of the encoded ribosome circular factors in acitretin streptomycete into the acitretin streptomycete through an expression vector. The genetic engineering bacterium can be directly used for fermentation production of the abamectin and for improving the fermentation unit of the abamectin and reducing the production cost.

Owner:CHINA AGRI UNIV

Effective method for preparing avermectin

InactiveCN103882080AStrong ability to produce abamectinIncrease productionMicroorganism based processesFermentationBiotechnologyMicroorganism

The invention belongs to the technical field of microorganisms, and particularly relates to a method for preparing avermectin (Avermectins). The method comprises the following steps: cultivating a streptomyces avermitilis strain capable of generating avermectin and genetic improved bacteria thereof in a first stage of fluid nutrient medium, and then inoculating into a second stage of fluid nutrient medium as a seed solution; fermenting and cultivating after inoculating the seed solution into the second stage of fluid nutrient medium, and feeding a sodium propionate precursor to carry out feeding cultivation; collecting the avermectin B1a from fermentation broth after fermentation is finished. The effective method has the characteristics of being high in production efficiency and the like.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

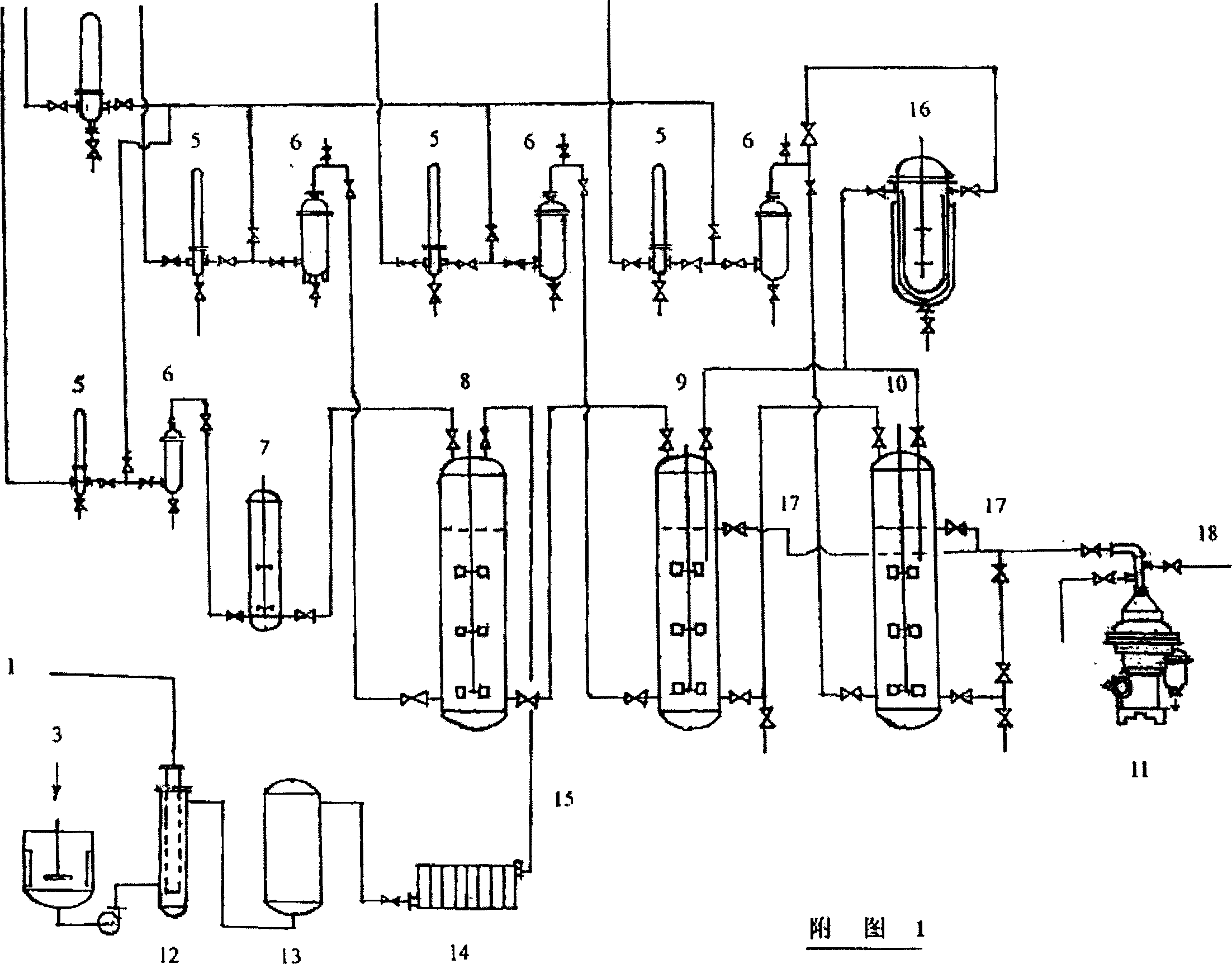

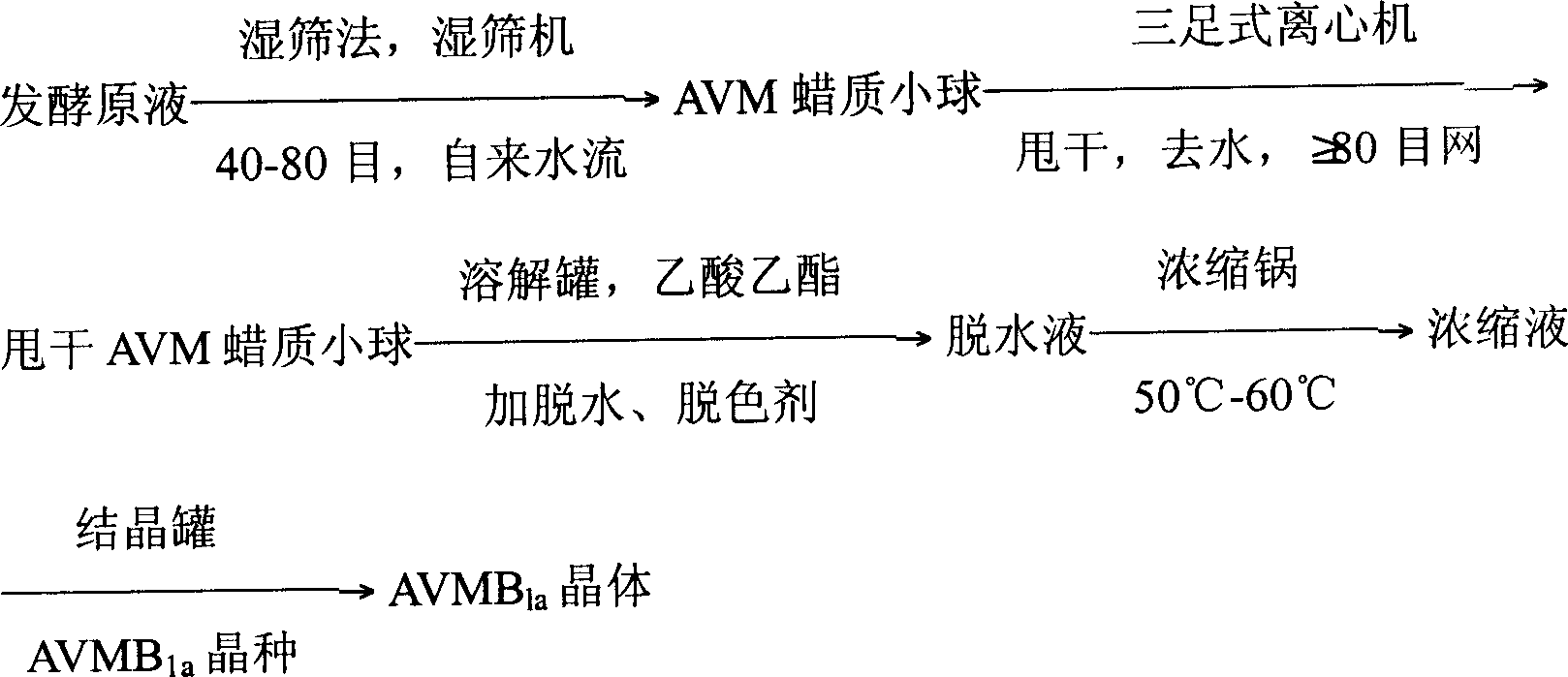

Production bacterial strain of abamectin with high yield and high secreation rate and new method of extracting AVM

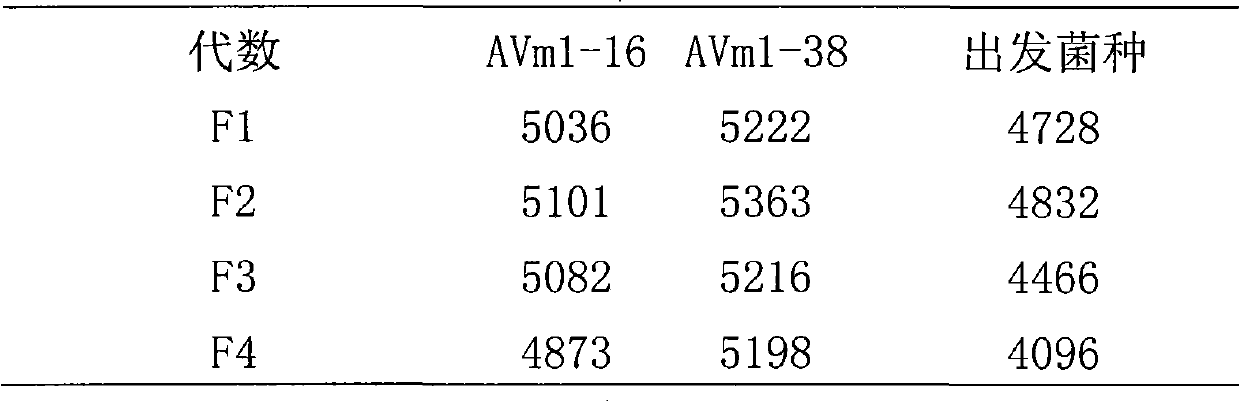

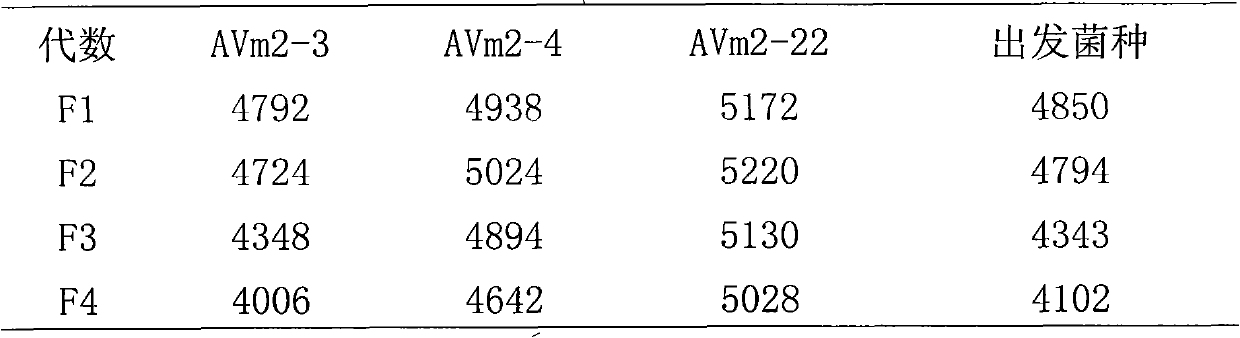

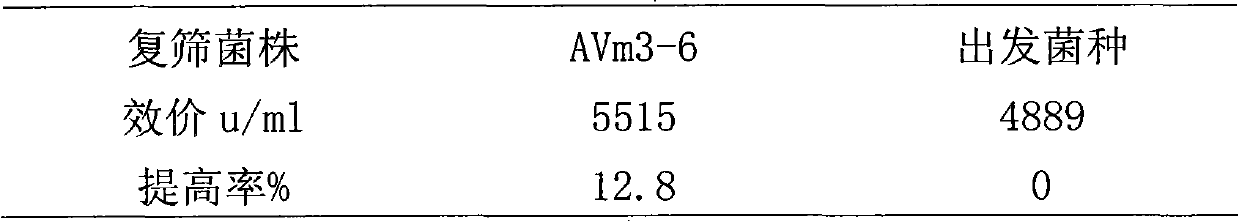

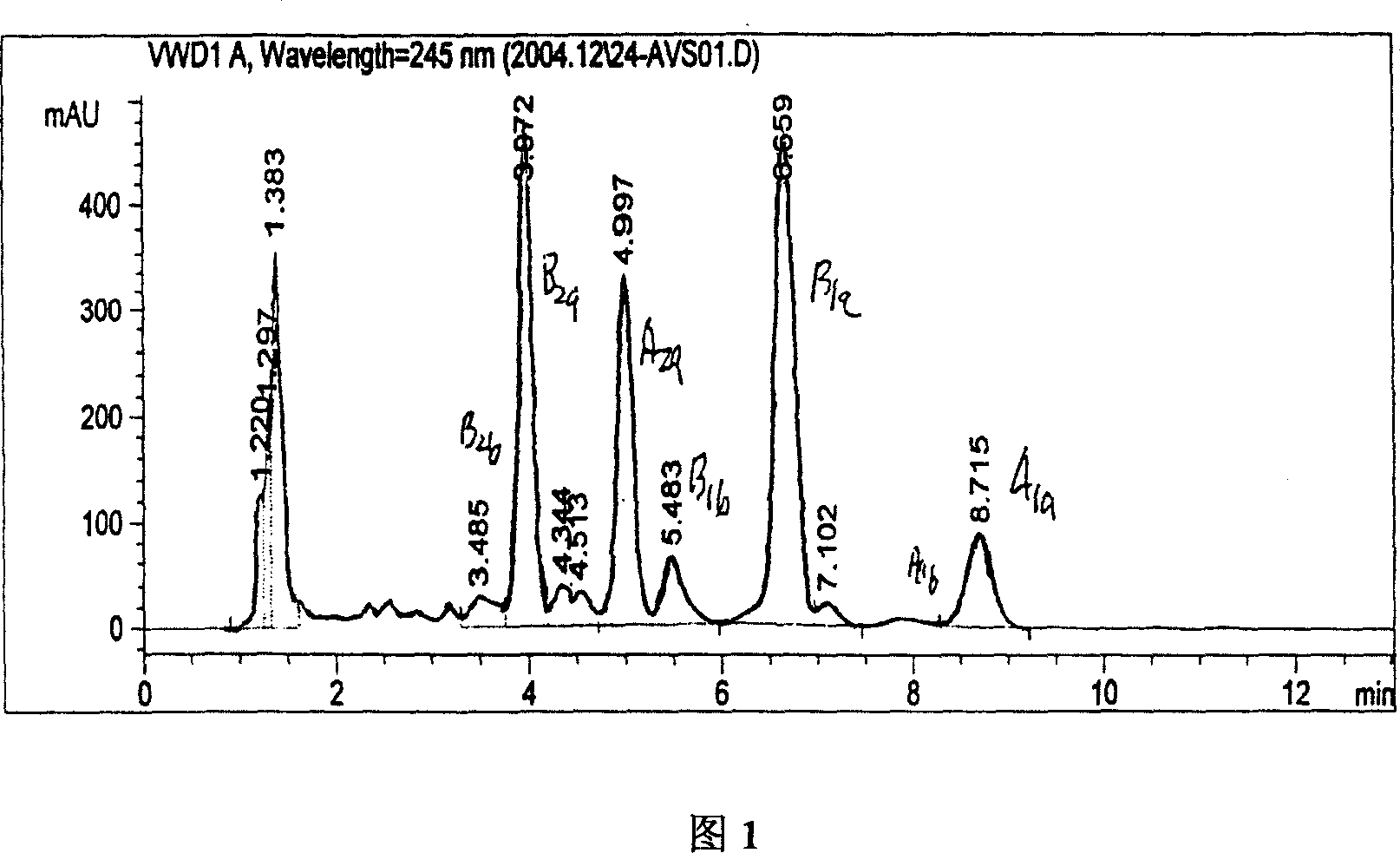

A process for preparing abamectin (AVM) by use of the bacterium with high AVM secreting power includes such steps as mutagenizing the initial streptomyces avermitilis (CCTCC No.M200028), choosing the bacteria (CCTCC No.M204069 and CCTCC No.M204070) with high potency and high secretion rate, fermenting to obtain wax ball suspension of AVM, and extracting AVM by five-step method.

Owner:武汉天惠生物工程有限公司

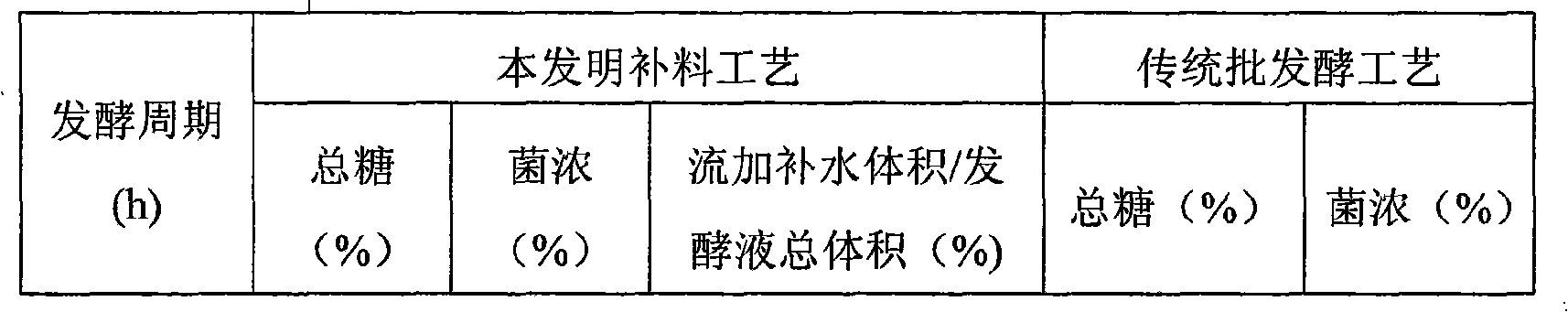

Method for producing enramycin by fermentation

ActiveCN102174624ARaise the level of fermentationMicroorganism based processesFermentationEnramycinOxygen

The invention discloses a method for producing enramycin by fermentation. Cabicidin streptomyces avermitilis is used as a fermentation strain in the method; and water is supplied to the fermentation solution in the fermentation process of constant temperature culture in a fermentation medium, so that the dissolved oxygen quantity of the fermentation solution is improved, and the fermentation level of the enramycin is improved. The method is simple and feasible; and after a proper amount of water is supplied at proper time in the fermentation culture process, the fermentation level of the enramycin can be improved by about 130 percent.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Medium for producing ivermectin by fermenting streptomyces avermitilis and fermenting method

ActiveCN103642865AStable productionEfficient productionMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention relates to a medium for producing ivermectin by fermenting streptomyces avermitilis and a fermenting method. By adding substances such as formula molasses, formula earthworm powder and the like into the medium for optimizing the medium formula, and corresponding optimizing the fermenting technology, the medium and the cultivation method for enabling ivermectin fermentation unit to be stable are provided, the average fermentation unit of ivermectin is 6000 mu g / mL or more and is improved by 20% or more compared with domestic conventional fermentation level. The fermentation period of ivermectin is averagely shortened by 10 h or more, so that the problem is effectively solved that conventional fermentation technology is high in cost; and the environmental influence on sources of raw materials and auxiliary materials is furthest reduced, and the raw materials and the auxiliary materials are guaranteed to be sufficiently supplied, so that the stable efficient production of ivermectin is realized.

Owner:宁夏泰瑞制药股份有限公司

Fermentation medium for producing doramectin, and preparation method and application thereof

ActiveCN108018324ARaise the level of fermentationPromote productionMicroorganism based processesFermentationGranularityNitrogen source

The invention relates to the field of fermentation engineering, and concretely discloses a fermentation medium for producing doramectin, and a preparation method and an application thereof. The fermentation medium adopts cottonseed cake powder preheated at 40-60 DEG C and having a granularity of 10-40 meshes and corn protein powder as a combined nitrogen source, and is better than fermentation media using single nitrogen sources in Streptonmyces avermitilis metabolism, so the production of doramectin is benefited. The control of granularity of the cottonseed cake powder and the corn protein powder is combined with the preheating treatment, so the paste formation phenomenon of a feed liquid in fermentation process (especially the middle and late fermentation stage) is effectively avoided, and the fermentation level of doramectin is significantly improved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

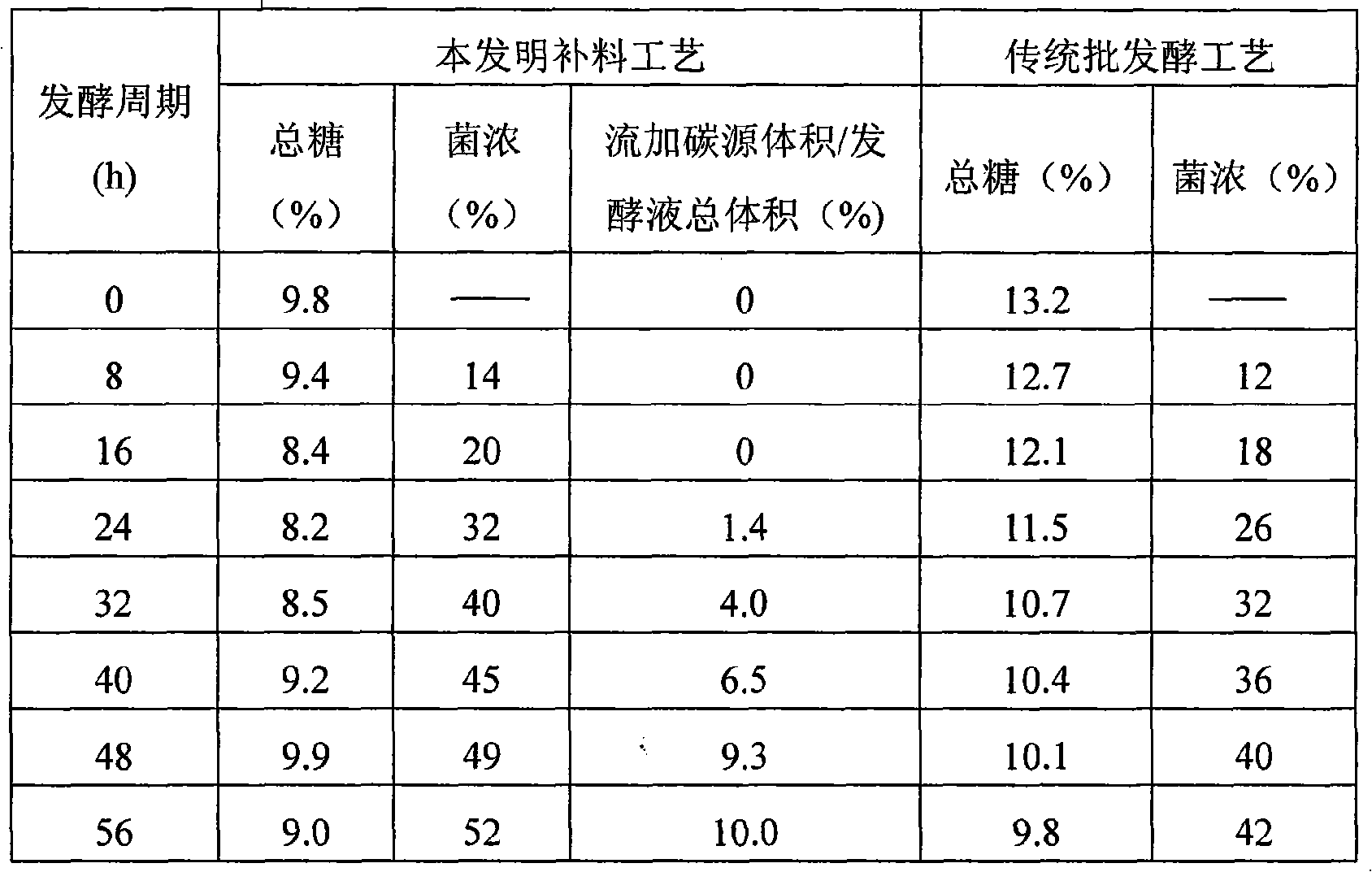

Abamectin batch fermentation optimizing process

InactiveCN101586133AIncrease the total amount of fermentationIncrease profitMicroorganism based processesFermentationAbamectinSterile water

The present invention provides an abamectin batch fermentation optimizing process, which is improved on the basis of the process for producing the abamectin by the streptomyces avermitilis batch fermentation, wherein, the carbon source proportion in the fermentation solution is 8-11 % during fermentation initial stages, when the fermentation is performed for 20-30 hours, the mixed solution containing glucose and starch is added, so that the carbon source proportion in the fermentation solution keeps 8-11 %; after fermenting 50-60 hours, the adding of the mixed solution containing glucose and starch is stopped, the sterile water is added, the added volume of the sterile water is 2-10 % of the total volume of the added primary fermentation solution; after fermenting 175-185 hours, 15%-20% fermentation solution is added, the residual fermentation solution is added with nutrient solution, the carbon source proportion in the fermentation solution keeps 1-4 %, the fermentation period is completed. The abamectin batch fermentation optimizing process provided by the invention improves the utilization ratios of the fermentation process, the fermentation equipment and the raw materials mainly by the optimization of the material compensating process.

Owner:张福志

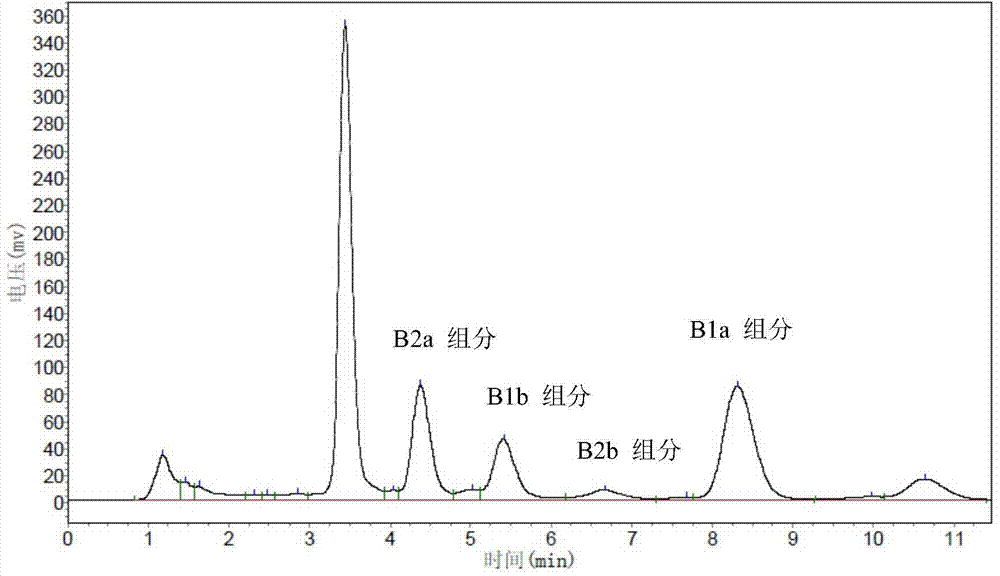

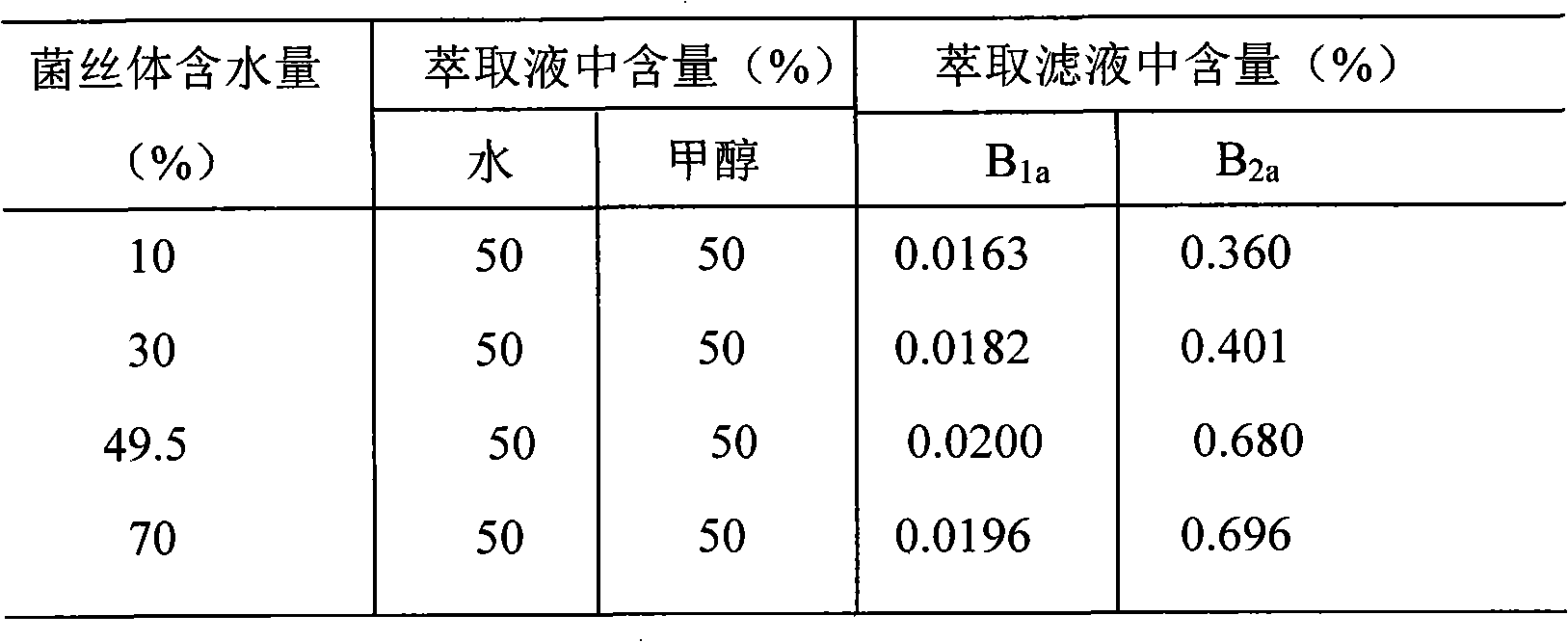

Method for step by step extracting avermectin B1a and B2a from mycelium

The invention discloses a method for selectively extracting avermectin B1a and B2a from streptomyces avermitilis mycelium, and the method is prominently characterized in that the avermectin B1a and B2a are extracted from the mycelium in two steps, first water / methanol or water / ethanol cosolvent is used for selective extraction of the B2a from the mycelium, and then an organic dissolvent such as methanol or ethanol and the like is used for extraction of the B1a from the mycelium. The method can effectively separate the B1a and the B2a, facilitates subsequent separation and purification of the B1a and the B2a, and can enhance the crystallization yield of the B1a and the B2a.

Owner:王玉万 +2

Novel insecticidal and antibacterial biofertilizer and preparation method thereof

The invention relates to a biofertilizer, particularly a novel insecticidal and antibacterial biofertilizer and a preparation method thereof. The invention enhances the bactericidal and insecticidal effects and fertilizer efficiency of the microbial fertilizer. The novel insecticidal and antibacterial biofertilizer is prepared from 30-50 parts of 550 million / ml Bacillus megaterium, 10-30 parts of 400 million / ml Rhodopseudomonas palustris, 1-3 parts of 562mg / mL Streptomyces avermitilis drug effect component B1a, 200-300 parts of molasses, 0.02-0.04 part of sodium dodecyl benzene sulfonate, 0.03-0.05 part of Tween-80 and 600-800 parts of water. The insecticide / fertilizer compound biological agent and the production technique thereof establish technical parameters of fermentation of Bacillus megaterium, Rhodopseudomonas palustris and Streptomyces avermitilis, and all the indexes satisfy the quality standard of microbial fertilizers of Department of Agriculture. The insecticide / fertilizer compound biological agent provided by the invention has insecticidal and antibacterial effects, and has wide application prospects.

Owner:山西神宇惠农科技有限公司 +2

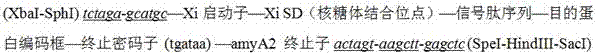

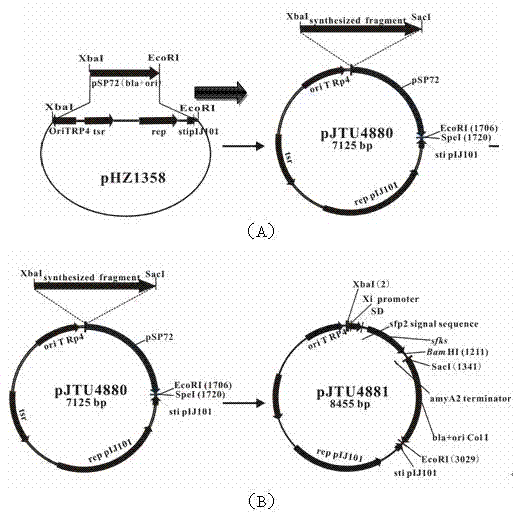

Construction method for streptomycete expression plasmids and production method for keratinase

InactiveCN102533833AIncrease productionHydrolasesVector-based foreign material introductionAmylaseSrc family kinase

The invention relates to a construction method for streptomycete expression plasmids and a production method for keratinase. The construction method for streptomycete expression plasmids includes the following steps: a promoter Xi of actinoplanes missouriensis xylose isomerase and a terminator of streptomycete avermitilis amylase are sleeved, and the promoter-shine-dalgarno (SD) sequence comes from 90 to 269bp of an actinoplanes missouriensis xylose isomerase gene; a cloned src family kinases (sfks) gene is inserted in a construction expression frame structure of a synthetic Xi promoter-SD-amyA2 terminator fragment, and then a conventional method is used for constructing the streptomycete expression plasmids. The production method for keratinase includes: leading the streptomycete expression plasmids into an expression host of streptomycete lividans TK24 through conjugal transfer, performing recombinant expression and generating the keratinase. Specific activity of a crude enzyme solution is 1700 U / mg after expression of the expression plasmids in the streptomycete lividans TK24 and is improved by 50 times compared with specific activity of starting strain streptomycete fradiae varieties S-221, and yield of the keratinase is much higher than starting strains after the expression.

Owner:SHANGHAI JIAO TONG UNIV

Method for screening methionine resistant deinsectization streptomyces avermitilis strain

ActiveCN101948826AImprove efficiencySimple and fast operationMutant preparationElectrical/wave energy microorganism treatmentSporeMicroorganism

The invention discloses a method for screening a methionine resistant deinsectization streptomyces avermitilis strain, which belongs to the field of the screening of microbial strains. The method comprises the following steps of: performing ultraviolet mutagenesis on deinsectization streptomyces avermitilis spore suspension; performing enrichment on tolerant strains by using a methionine-containing liquid culture medium; screening methionine solid-plate tolerant strains; and screening strains of which the shake flask capacity is improved compared with that of parent strains through preliminary screening, secondary screening and genetic stability research so as to provide a feasible method for screening the deinsectization streptomyces avermitilis strain. The shake flask production capacity of the deinsectization streptomyces avermitilis strain screened by the method is greatly improved, and the genetic stability is high.

Owner:XINYU PHARM CO LTD

Strain capable of generating avermectin B component and utilization thereof

The present invention relates to one kind of Streptomyces avermitilis generating abamectin B1a and abamectin B2a only. The Streptomyces avermitilis has the strain numbered as X-28 and has the preservation number of CGMCC No. 1765. The present invention also relates to the application of the Streptomyces avermitilis in producing abamectin.

Owner:郭正 +3

Method for producing avermectins by fermentation by using air-lift loop reactor

InactiveCN109517865AImprove fermentation titerReduce consumptionBacteriaMicroorganism based processesMicroorganismSpore

The invention belongs to the technical field of microbial fermentation, and particularly relates to a method for producing avermectins by fed-batch fermentation by using an air-lift loop reactor. Themethod comprises the following steps that streptomyces avermitilis is inoculated to a slant culture medium for culture, and a spore slant is taken to prepare into a spore suspension; the spore suspension is inoculated to a seed culture medium and cultured to a logarithmic growth phase; and the streptomyces avermitilis spore suspension cultured to the logarithmic growth phase is transplanted into the air-lift loop reactor provided with a fermentation culture medium for fermentation culture, and a supplementary medium is added in batches in the middle and later periods of fermentation. The method adopts the air-lift loop reactor as a fermentation vessel, optimizes the fed-batch process and the composition of the supplementary medium, effectively reduces the bacterial infection rate in the fermentation culture process, and significantly increases the titer of the avermectins in fermentation liquid.

Owner:内蒙古新威远生物化工有限公司

Method for preparing doramectin sterile solution

ActiveCN105232457AOrganic active ingredientsPharmaceutical delivery mechanismBiotechnologyOrganic solvent

The invention relates to a method for preparing a doramectin sterile solution. The method comprises the following steps: firstly, pre-treating a doramectin fermentation broth prepared by fermenting mutational streptomyces avermitilis which serves as a strain; performing flash drying to obtain dried strain slag, and extracting with an organic solvent a; cooling and adding purified water to separate; filtering to obtain a doramectin crude product, and dissolving the crude product with an organic solvent; performing ultrafiltration and crystallization; and dissolving a solid doramectin obtained by one more filtration with an organic solvent B; and performing microfiltration to obtain the doramectin sterile solution. The method can be used for realizing effective separation and purification on the doramectin in the fermentation broth, the total extraction yield is over 85 percent, the product quality accords with the requirement, the production cost is reduced, and the international market competition of doramectin can be improved.

Owner:宁夏泰瑞制药股份有限公司

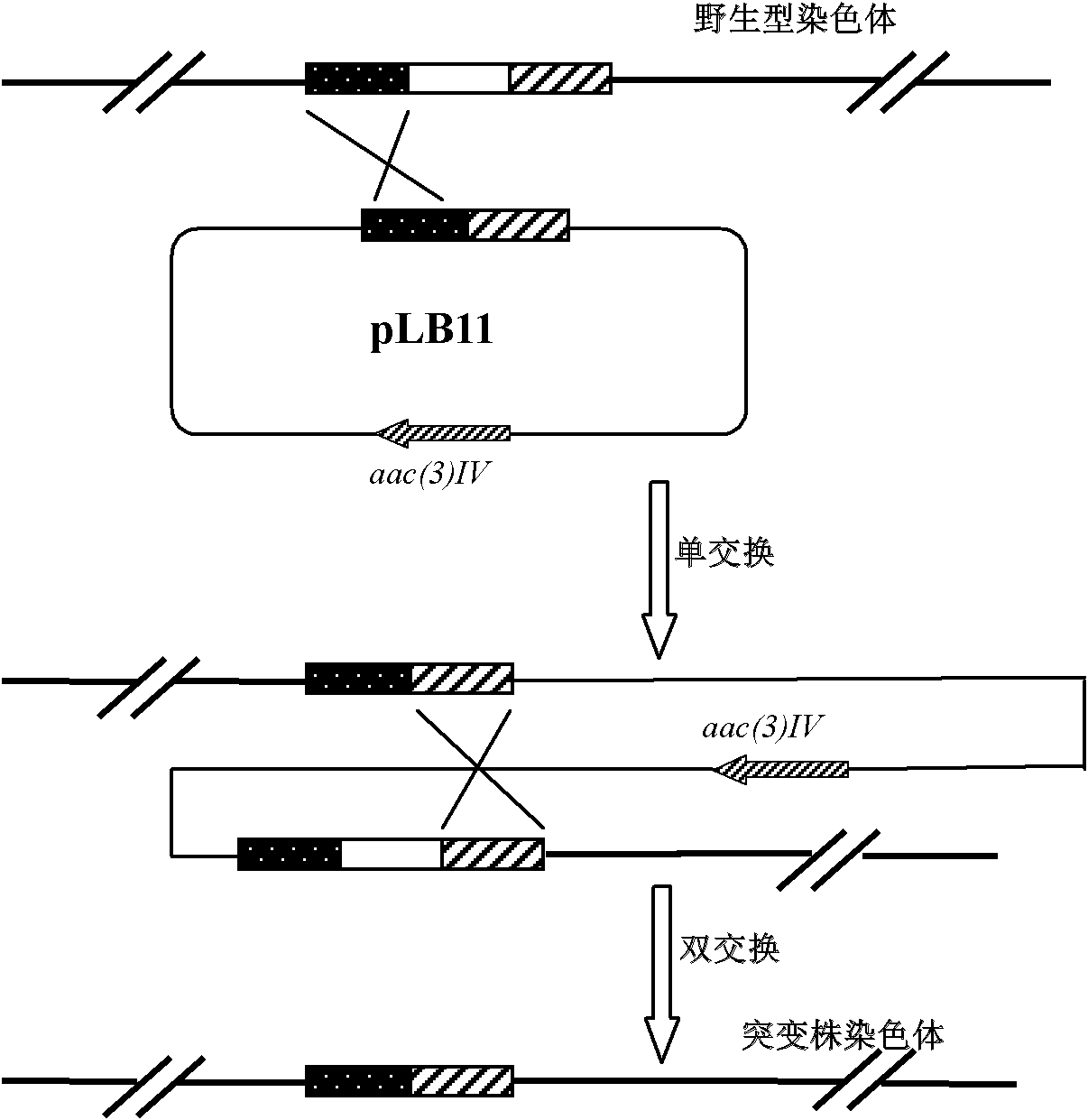

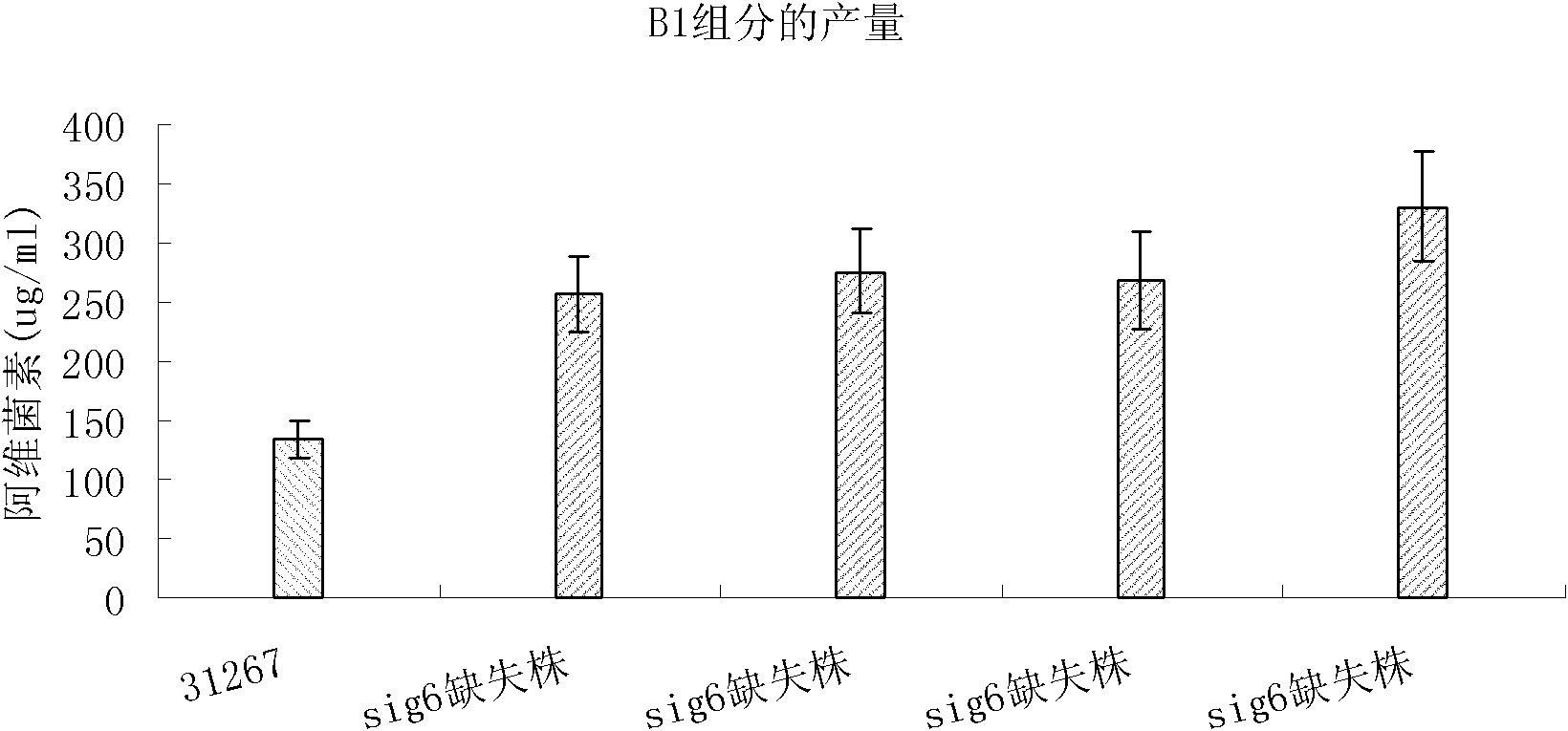

Method for improving yield of avermectins and producing strain thereof

InactiveCN102162003AIncrease productionRaise the fermentation unitBacteriaMicroorganism based processesAvermectinPolymerase L

The invention provides a method for improving the yield of avermectins and a producing strain thereof. A deletion vector of a sig6 gene, which is used for encoding an extracytoplasmic function (ECF) subfamily ribonucleic acid (RNA) polymerase sigma factor, in Streptomyces avermitilis is introduced into the Streptomyces avermitilis to obtain a recombinant strain in which the sig6 gene is lacked toensure that the recombinant strain cannot synthesize sig6 any more, so that the yield of the avermectins is improved. The genetic engineering strain can be directly used for fermentation production of the avermectins, improves the fermentation unit of the avermectins, and reduces production cost.

Owner:CHINA AGRI UNIV

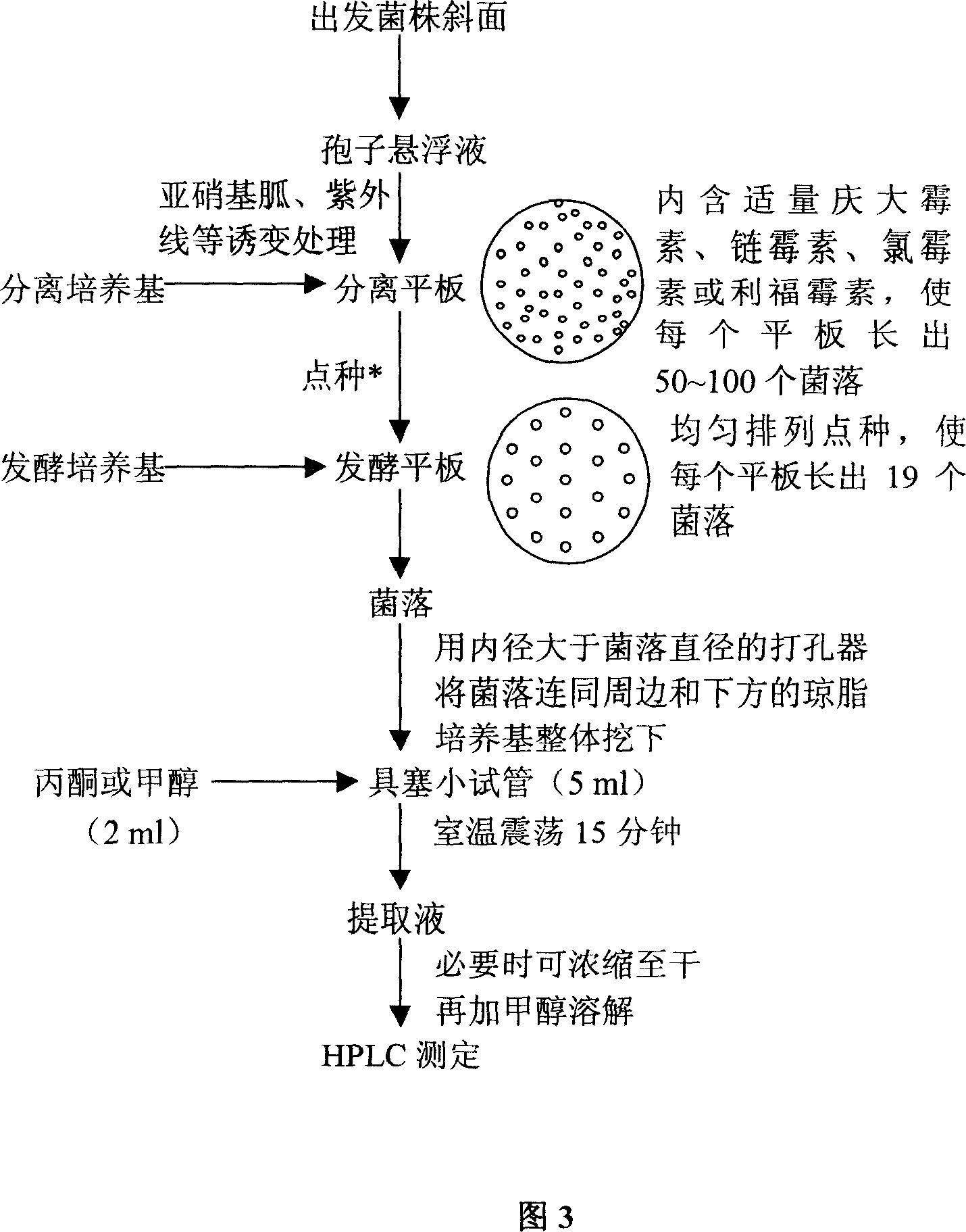

Efficient screening method for abamectin high-producing strain

InactiveCN106222120AFast growthSimplify the screening processBacteriaMutant preparationAbamectinScreening method

The invention discloses an efficient screening method for an abamectin high-producing strain and belongs to the technical field of metabolic engineering. The method includes the steps that firstly, several different abamectin inclined mediums are compared, a proper inclined medium is selected for abamectin, and goodness of an original strain is guaranteed. ARTP mutation and other similar mutation treatment means are carried out on the original strain abamectin, a porous plate culture method and a microplate reader high-throughput test method are combined for use, the whole screening process is simplified, and screening efficiency is improved. A microplate reader preliminary screening method is verified, the pore plate OD value measured by a microplate reader and a pore plate tier obtained after efficient liquid detection are compared, it is found that good relevance is achieved, and therefore the preliminary screening feasibility and accuracy of the microplate reader are proved. The high-producing mutant strain of abamectin is screened out, and compared with original bacteria, the yield of abamectin of the mutant strain is increased by 10% or above on a shake flask and increased by 10% or above on a 30L fermentation tank.

Owner:JIANGNAN UNIV

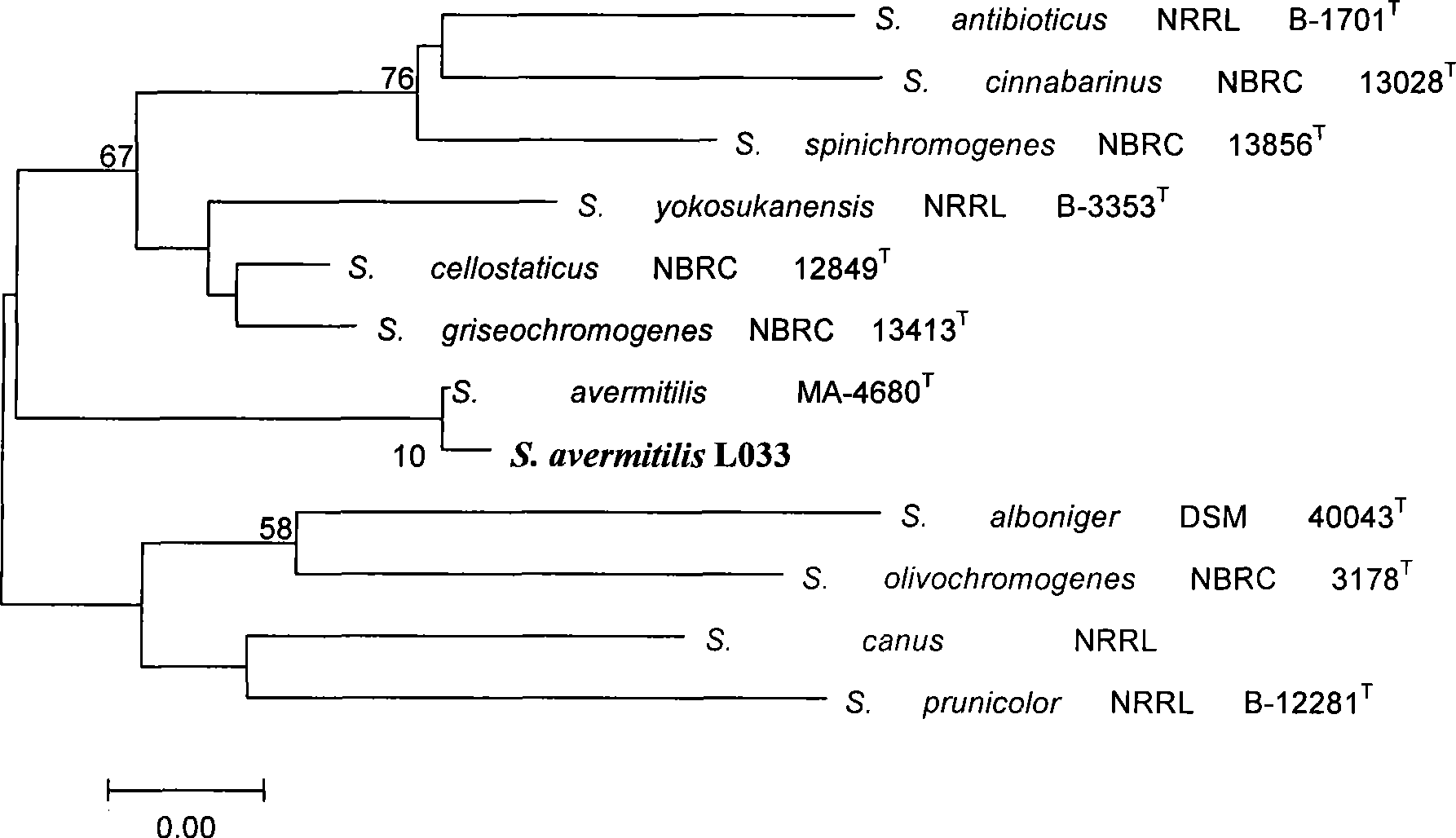

Method for preparing oligomycin A and special for bacterial strain thereof

The invention provides a method for producing oligomycin A and a special bacterial strain thereof. The method includes the following steps: 1), strain culture: the bacterial strain Streptomyces avermitilis L033 CGMCC No.2678 which can produce oligomycin A is cultured by fermentation to obtain mycelium; 2), the mycelium is extracted through organic solvent to obtain oligomycin A. The bacterial strain is S.avermitilis L033 CGMCC No.2678. The bacterial strain of the invention can produce rich sporus, which has fast growth rate and is convenient for industrial production. The bacterial strain of the invention has high yield of oligomycin A and the yield can be up to 1461 Mug / ml of fermentation liquid.

Owner:CHINA AGRI UNIV

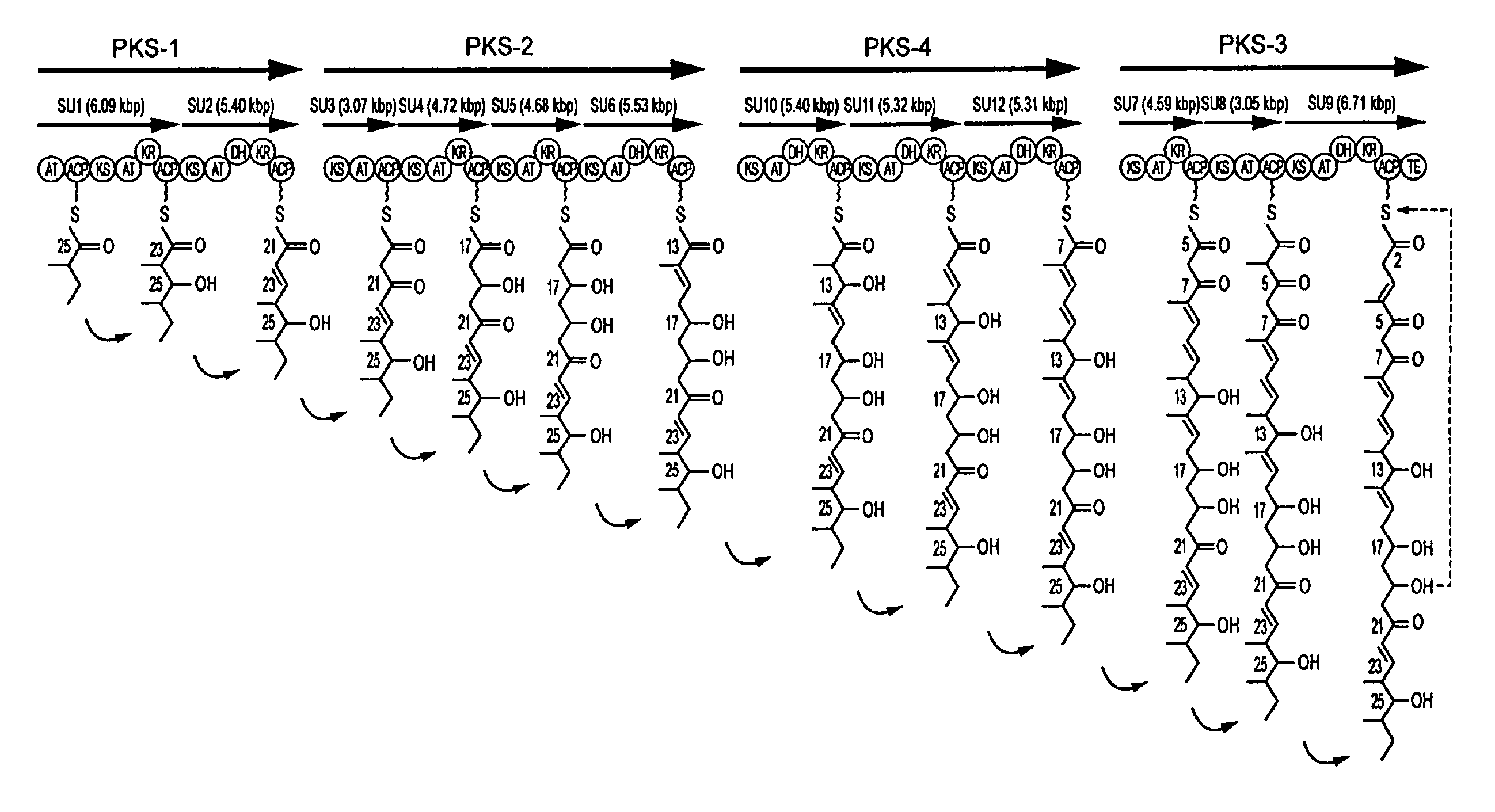

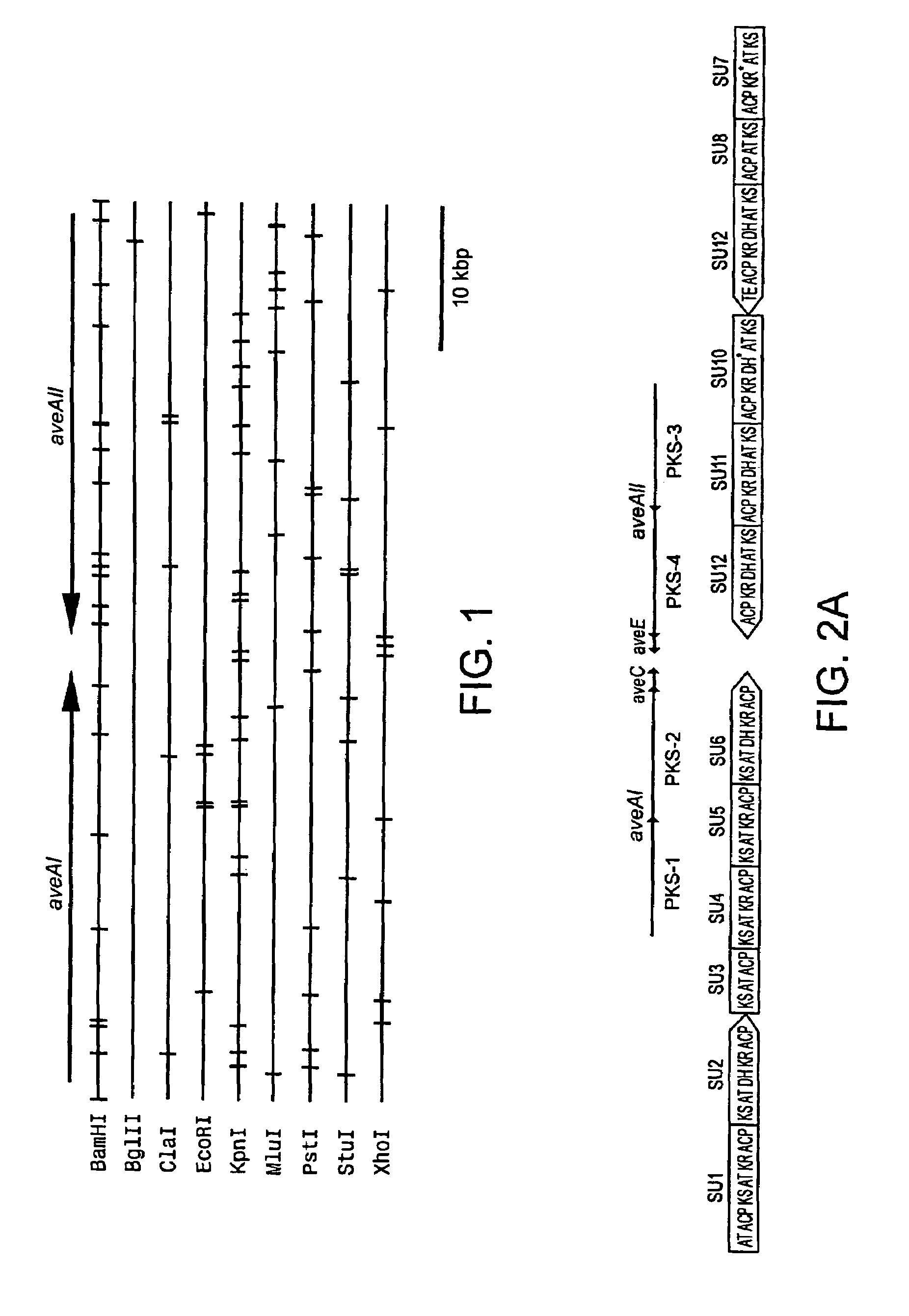

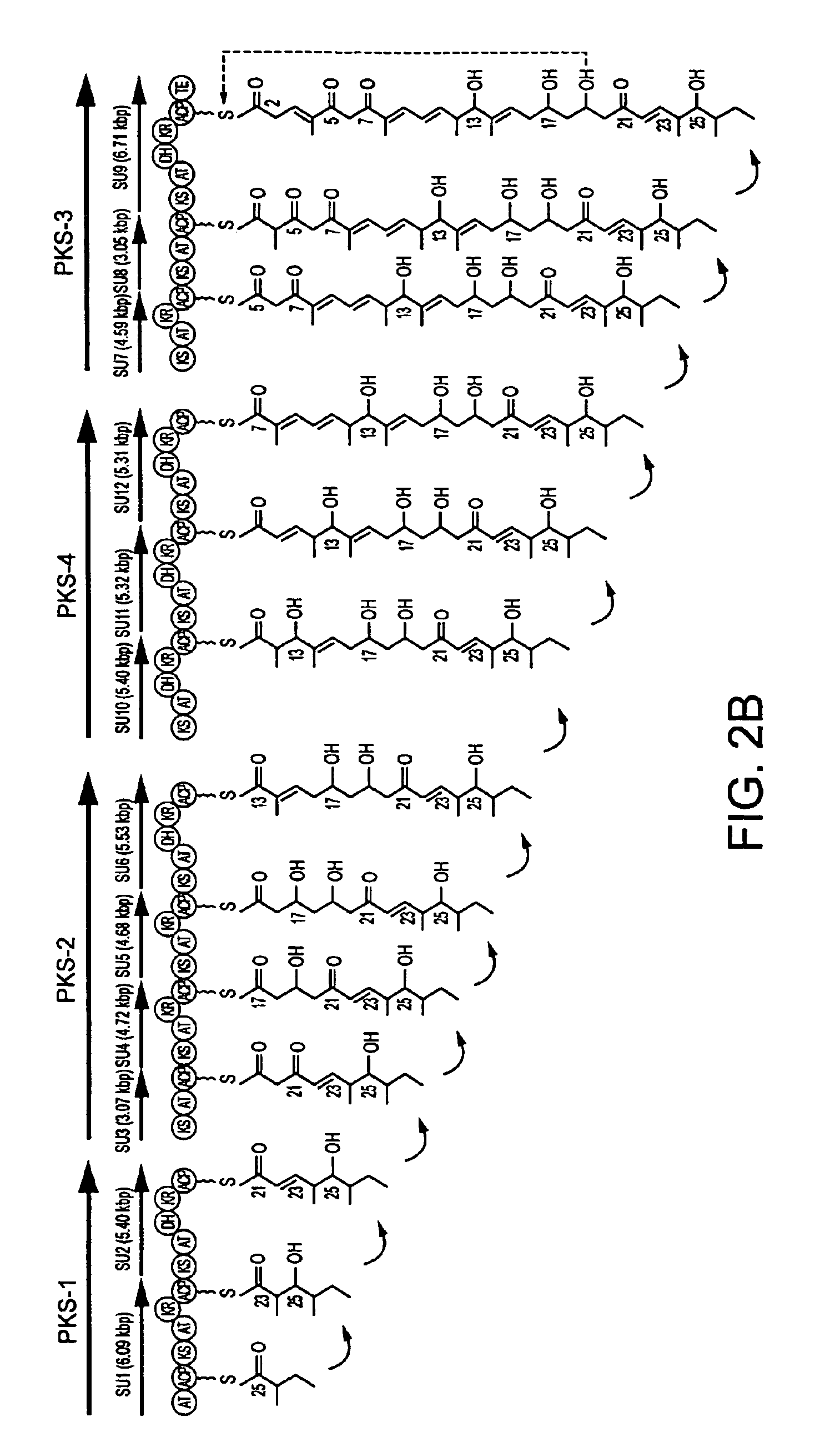

Avermectin aglycon synthase genes

The present invention relates to an isolated DNA which comprises a DNA sequence encoding avermectin aglycon synthase domains that corresponds to multifunctional enzyme proteins involved in the biosynthesis of a polyketide compound, or its mutants having avermectin aglycon synthase activity, particularly functional modules and submodules in the DNA sequence derived from Streptomyces avermitilis, a polypeptide or mutants thereof encoded by the DNA or the mutants, a vector containing the DNA or the mutants, a host cell transformed with the DNA, the mutants thereof, or the vector, and a method for producing avermectin.

Owner:THE KITASATO INST

Method for producing enramycin by fermentation

ActiveCN102174624BRaise the level of fermentationMicroorganism based processesFermentationEnramycinOxygen

The invention discloses a method for producing enramycin by fermentation. Cabicidin streptomyces avermitilis is used as a fermentation strain in the method; and water is supplied to the fermentation solution in the fermentation process of constant temperature culture in a fermentation medium, so that the dissolved oxygen quantity of the fermentation solution is improved, and the fermentation level of the enramycin is improved. The method is simple and feasible; and after a proper amount of water is supplied at proper time in the fermentation culture process, the fermentation level of the enramycin can be improved by about 130 percent.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Microbial preparation for inhibiting root-knot nematode and preparation method and application thereof

ActiveCN103039534BReduce morbidityImprove aggregate structurePlant growth regulatorsBiocideBiotechnologyMetabolite

The invention belongs to the field of biological prevention and control on crop insect damage and provides a microbial preparation for inhibiting root-knot nematode. The preparation is formed by mixing bacterial liquids of streptomyces avermitilis, paecilomyces lilacinus, verticillium chlamydosporium and Bacillus sphaericus and glycerol. The invention also provides a production method and an application effect of the microbial preparation for inhibiting the root-knot nematode. The microbial preparation comprises viable bacteria of which the number is greater than 2,500 millions per milliliter, wherein the viable bacteria comprise the streptomyces avermitilis, the paecilomyces lilacinus, the verticillium chlamydosporium and the Bacillus sphaericus. After the microbial preparation is prepared into soil, eggs of the root-knot nematode are killed by metabolites generated in the continuous growth and reproduction activity process of the viable bacteria, so that a granular structure of the soil is improved, the utilization rate of a fertilizer is improved and an effect of increasing both production and income is achieved.

Owner:河北衡晓生物科技有限公司

High-producing strain containing abamectin and screening method thereof

ActiveCN106190928AHigh potencyEnables high-throughput screeningBacteriaMutant preparationLithium chlorideLiquid medium

The invention discloses a high-producing strain containing abamectin, and also provides a screening method of the high-producing strain containing abamectin. The high-producing strain containing abamectin is (Streptomyces avermitilis) AV-185S, the preservation unit of the high-producing strain is the China general microbiological culture collection center, the preservation date of the high-producing strain is March 15, 2016. The screening method mainly comprises the steps of a, preparing a spore suspension; b, conducting ultraviolet-lithium chloride compound mutation treatment; c, preparing a streptomyces avermitilis liquid medium; d, screening the high-producing strain through liquid culture in a deep well plate; and e, detecting the strain fermentation potency. The average fermentation potency of the (Streptomyces avermitilis) AV-185S screened according to the screening method can be up to 6842.8 ug / mL.

Owner:NORTH CHINA PHARMA GROUP AINO

Method for screeningabamectin high-yield strain in high throughput based on flow cytometry

InactiveCN106222162AIncrease growth rateTrouble growingBacteriaMutant preparationSporeHigh-Throughput Screening Methods

The invention discloses a method for screening abamectin high-yield strain in high throughput based on a flow cytometry, belonging to the technical field of high-troughput screening. The method comprises the following steps: performing PI dyeing method on mutated spores with different activities, correctly distinguishing a spore area with activity by regulating and optimizing various parameters such as FSC, SSC and voltage threshold, and excluding the interference mixed with the background in flow cytometry detection due to oversmall volume of spores. The screened live spores are subjected to a solid-liquid combined high-throughput culturing scheme to effectively improve the growth rate of an abamectinpore plate. According to the invention, the abamectin with activity can be screened based on the flow cytometry, and a novel and effective manner is provided for the high-throughput screening of abamectin.

Owner:JIANGNAN UNIV

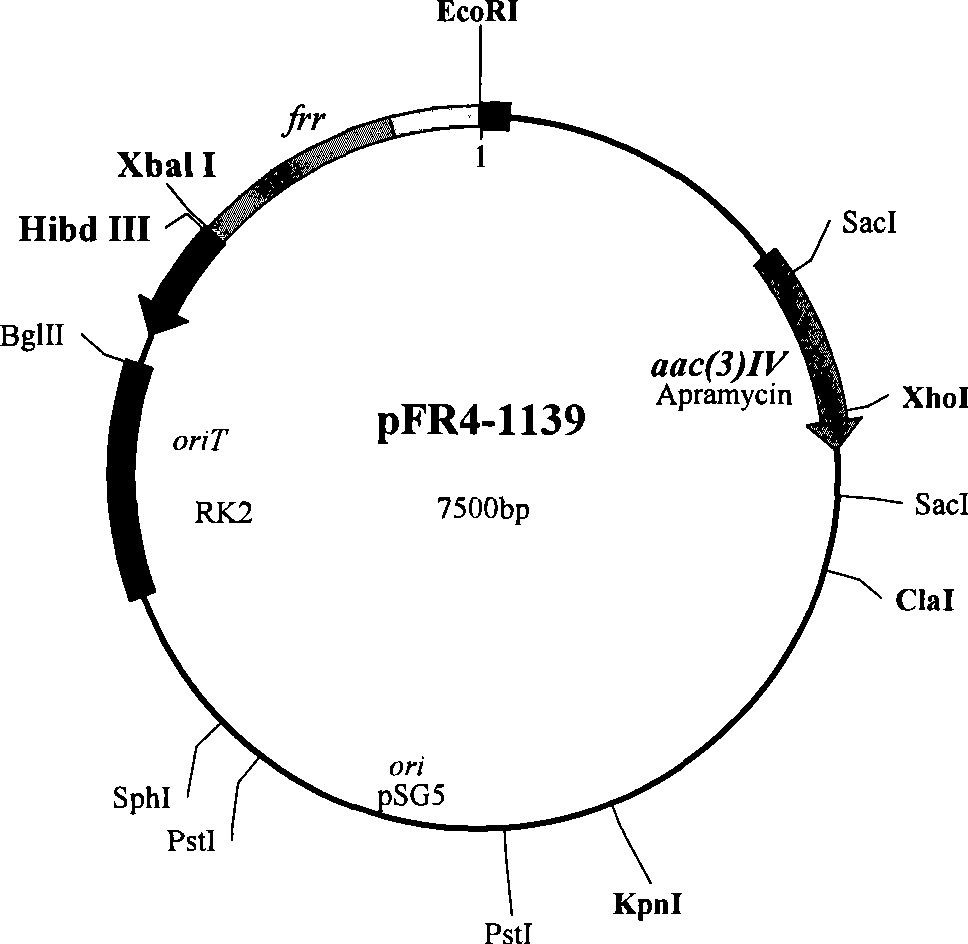

Optimized production method of abamectin

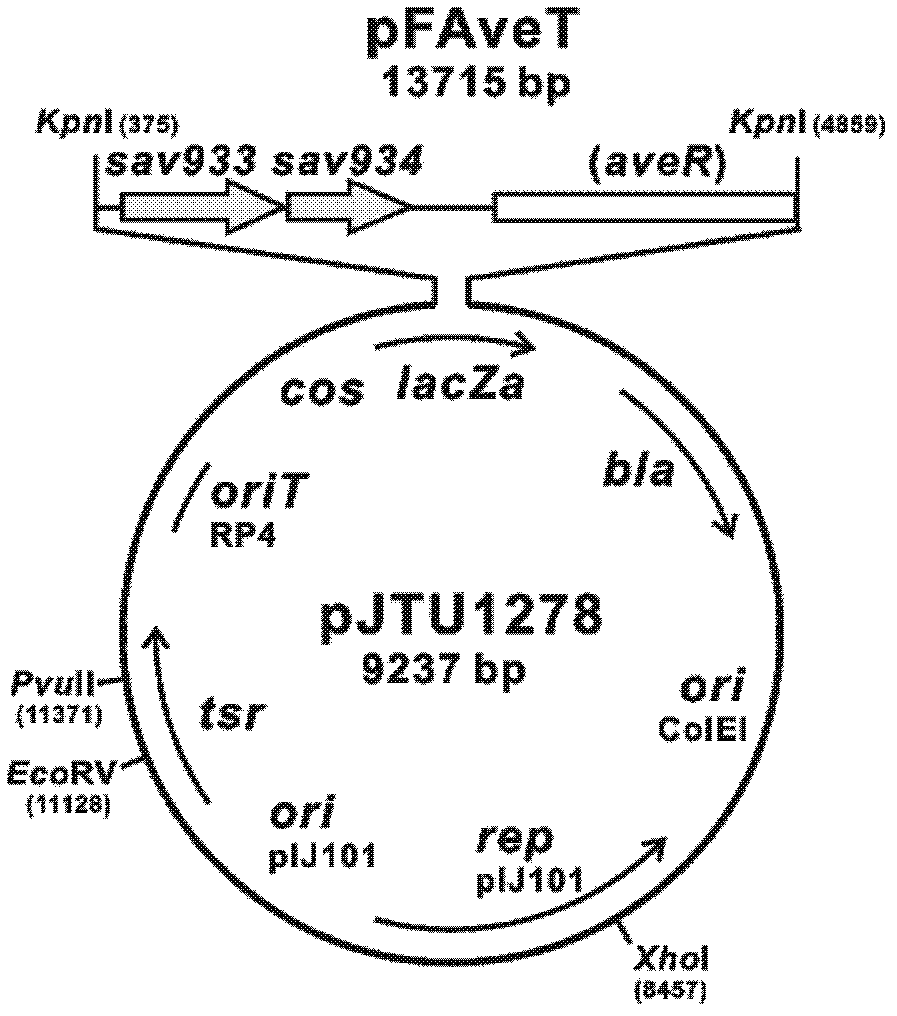

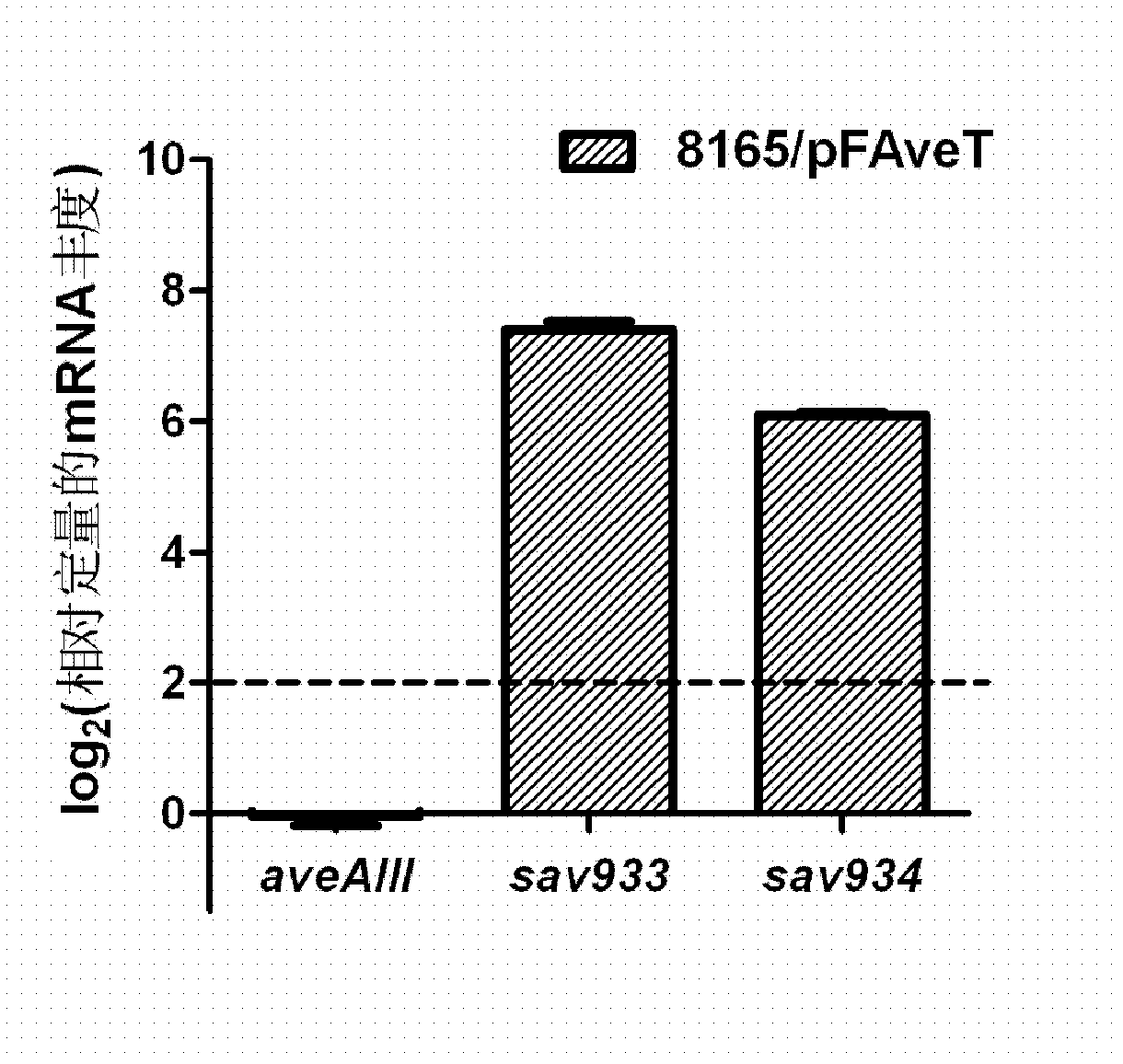

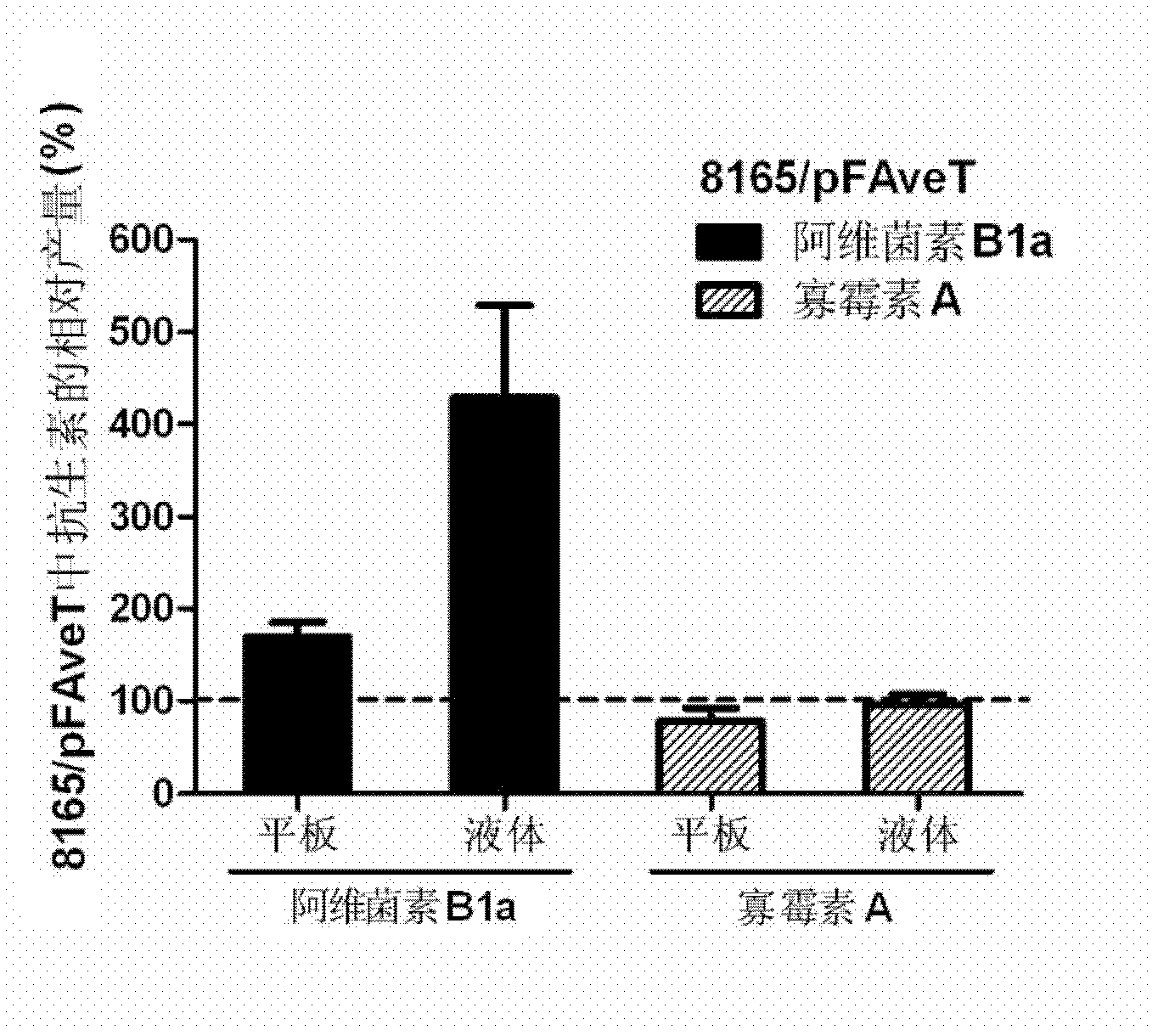

An optimized production method of abamectin belongs to the technical field of biomedicine, and includes of constructing over-expression plasmid pFAveT containing gene sav933 and gene sav934, transferring the expression plasmid into streptomyces avermitilis 3-115, and finally realizing yield increase. The yield of specific antibiotics is increased by means of over expression of efflux gene in strains for industrial production of antibiotics.

Owner:SHANGHAI JIAO TONG UNIV

Abamectin strain and screening method thereof

ActiveCN109868239ADoes not affect potencyEmission reductionBacteriaMutant preparationLithium chlorideAbamectin

The invention discloses an abamectin strain and a screening method thereof. The strain has the Latin name Streptomyces avermitilis in classification nomenclature, is preserved in China General Microbiological Culture Collection Center; and the preservation number is CGMCC No.17157, and the preservation date is January 10, 2019. The screening method comprises the following steps: preparing spore suspension; carrying out compound mutation on the spore suspension in a lithium chloride solution, then carrying out ultraviolet lamp irradiation mutation, then adding NTG into a bacterium solution treated by ultraviolet light-lithium chloride, and terminating the reaction; carrying out plate and slant culture; carrying out shaking culture and screening; and finally obtaining the strain. The strainis applicable, utilizes residual nutrient substances and organic acids in wastewater, without influencing a tank discharge titer of a fermentation tank, and can reduce the discharge amount of tap water for fermentation and plate frame wastewater.

Owner:内蒙古新威远生物化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com