Method for preparing oligomycin A and special for bacterial strain thereof

A technology for producing oligomycin and oligomycin, which is applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve problems such as low yield of oligomycin A, and achieve convenient industrial production, fast growth, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

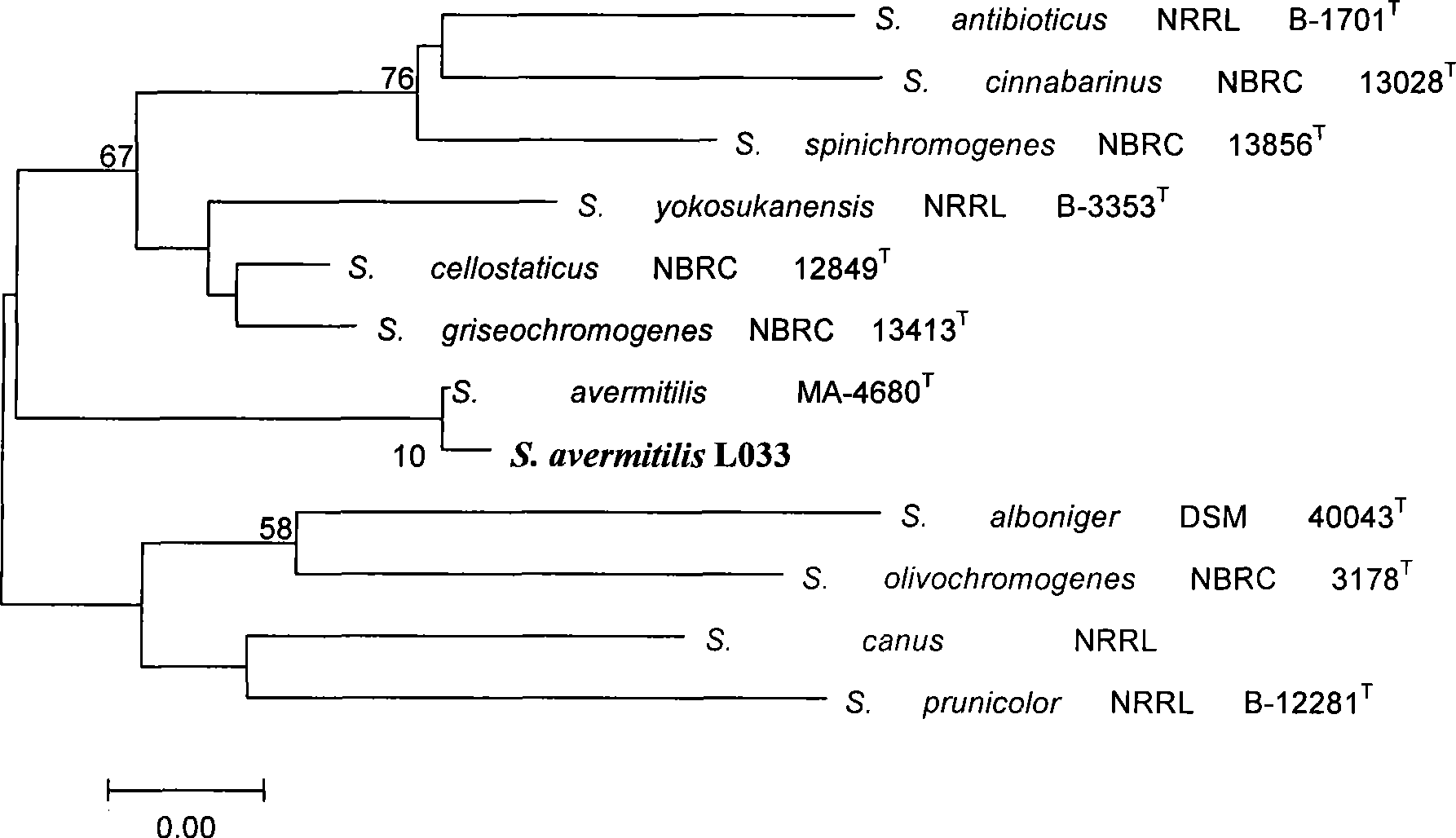

[0025] Example 1 Isolation and screening of Streptomyces avermitilis L033 bacterial strain

[0026] 1. Sample collection

[0027] Soil samples were taken from Huadu District, Guangzhou City, Guangdong Province.

[0028] 2. Isolation and screening of strains

[0029] Prepare Bennett's medium (yeast extract 1.0g, beef extract 1.0g, hydrolyzed casein 2.0g, glucose 10.0g, agar 20g, distilled water 1000ml, pH 7.3), sterilize at 115°C for 20min by high-pressure steam, and pour plate.

[0030] The soil samples were serially diluted by conventional methods and then isolated on plates. After culturing at 28°C for 4, 7, 14, and 21 days, colonies of actinomycetes were picked, and one strain was named L033, which was purified and preserved.

Embodiment 2

[0031] The cultivation of embodiment 2 bacterial strains

[0032] Preparation of plate medium: yeast extract 4g, soluble starch 4g, malt extract 10g, agar 20g, distilled water 1000ml, pH 7.2. Sterilize the plate medium at 121°C for 20 minutes, pour the plate, inoculate the L033 strain after cooling, and culture at 28°C for 7 days.

[0033] Preparation of liquid medium: 70g soluble starch, 16g dry yeast, 0.5g MgSO4 7H2O, 0.5g K2HPO4 3H2O, 4g KCl, 2g CaCO3, 1000ml distilled water, pH 7.2, put 100ml medium into a 500ml culture bottle for sterilization. A piece of bacteria was cut from the plate culture, inoculated in a sterile liquid medium, and cultured on a shaking table at 28° C. with a rotation speed of 170 rpm. The production of oligomycin A began after 24 hours of cultivation, and the production of oligomycin A continued to increase as time went on thereafter. After 216 hours of cultivation, the production of oligomycin A entered a stagnation period, and the fermentation c...

Embodiment 3

[0034] Example 3 Extraction of oligomycin A crude product

[0035] The fermentation broth was centrifuged at 3000rpm for 10min, the supernatant was discarded, and the mycelium was collected. Add acetone to the mycelium (the volume ratio of acetone to mycelium is 2:1), stir evenly with a stirrer, let stand for 24 hours, filter with suction, recover the filtrate, and obtain an acetone solution of oligomycin A. If oligomycin A still remains in the cell residue, repeat the above steps until oligomycin A can no longer be extracted.

[0036] The obtained acetone solution was distilled under reduced pressure to recover the water phase residue. The residue of the aqueous phase was extracted with ethyl acetate, and then subjected to vacuum distillation to recover the residue to obtain the crude extract of oligomycin A, with a yield of 3.6 g crude product of oligomycin A / L fermentation broth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com