Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "Poly-N-vinylcaprolactam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(N-vinylcaprolactam) (PNVCL) is a temperature-responsive polymer, only second to poly(N-isopropylacrylamide), the most popular temperature-responsive polymer. Its applications include its use in cosmetics, as an anticlogging agent in pipelines and increasingly, in biomedical applications.

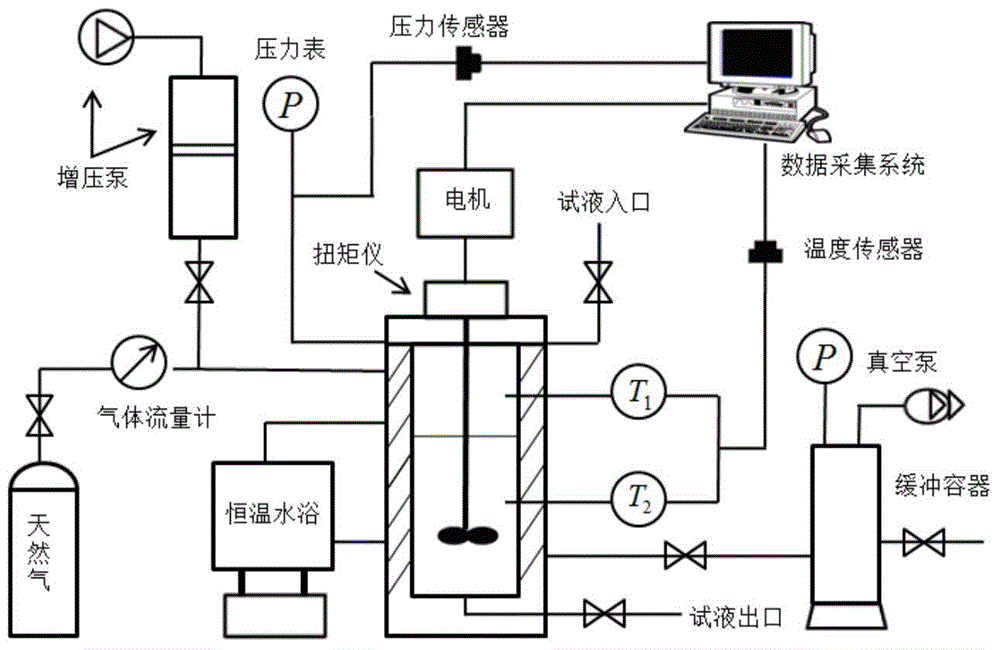

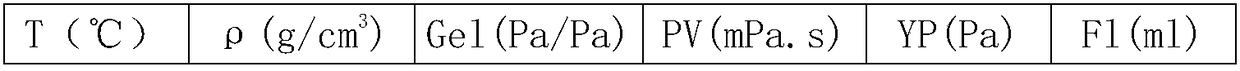

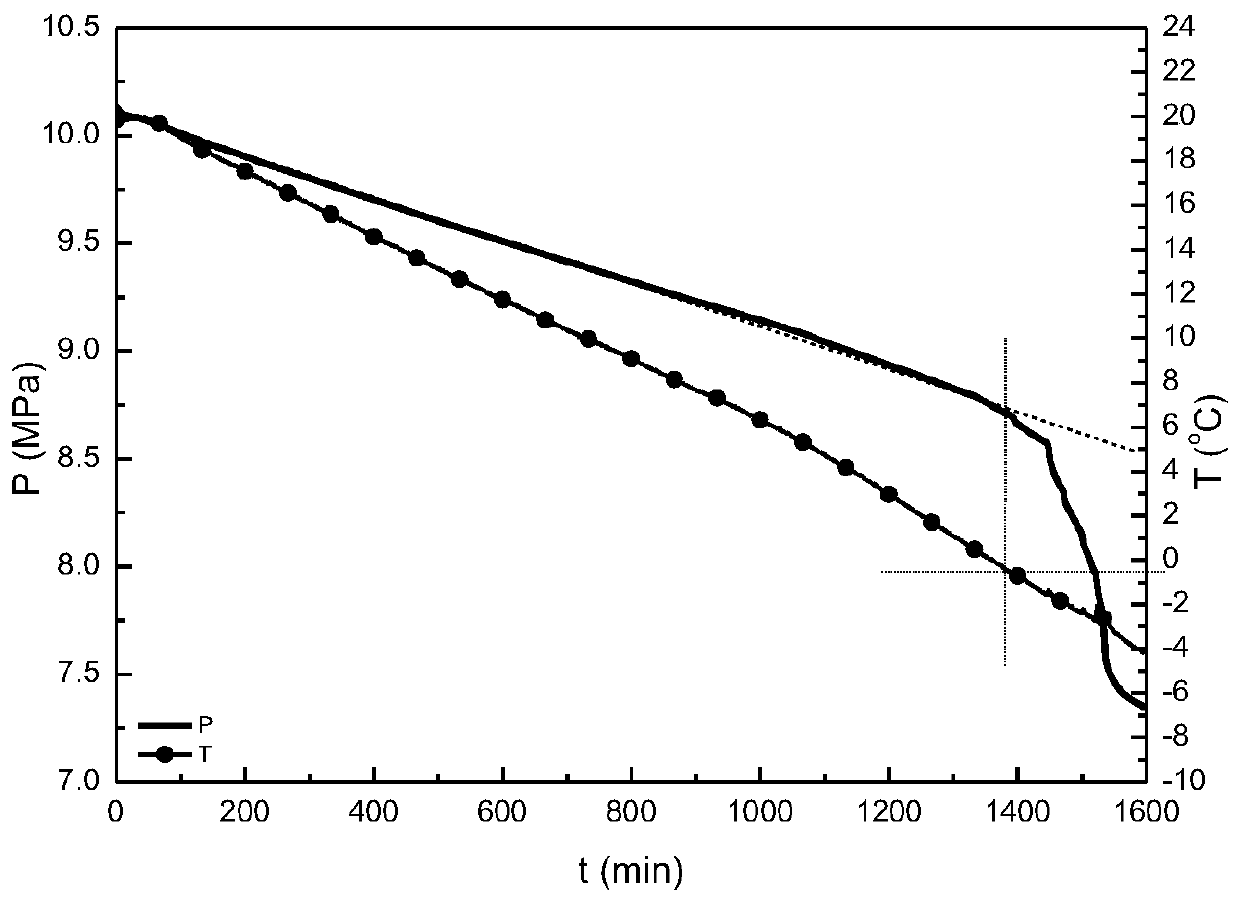

Compound low dosage natural gas hydrate inhibitor

The invention discloses a compound low dosage natural gas hydrate inhibitor. The hydrate inhibitor benchmarked against the mass of water in a deepwater drilling fluid completion fluid comprises, by mass, 0.1-2% of a hydrate kinetic inhibitor, 0.1-2% of a kinetic inhibitor synergist and 0-10% of a hydrate thermodynamic inhibitor. The hydrate kinetic inhibitor is at least one of polyvinyl pyrrolidone, polyvinyl caprolactam, and a copolymer generated through a reaction of vinyl pyrrolidone, vinyl caprolactam, alkenyl sulfonic acid and isopropylmethacrylamide. The kinetic inhibitor synergist is at least one of benzyltributylammonium chloride, tetraheptylammonium bromide, ethylene glycol phenyl ether, propylene glycol phenyl ether, polyoxyethylene and polyoxypropylene. The hydrate inhibitor can effectively inhibit generation of hydrates under a low dosage (0.2-10%), is suitable for deepwater and ultra-deep water drilling and completion, greatly reduces the cost and the logistical support burden, and has small harms to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Inkjet-receptive article

ActiveUS20120027964A1Non-fibrous pulp additionSynthetic resin layered productsPolymer sciencePolymer resin

An inkjet-receptive article comprising a substrate having a coating thereon comprising a vinyl lactam polymer or copolymer and a polymer resin diluent coated from a solvent. A preferred vinyl lactam copolymer is polyvinylcaprolactam (PVCap)—vinyl acetate (VA). Also disclosed are solvent-based compositions for forming an inkjet-receptive coating on a substrate comprising: (i) a vinyl lactam polymer or copolymer; (ii) a solvent; (iii) optionally, a pigment; and (iv) polymer resin diluent.

Owner:ISP INVESTMENTS LLC

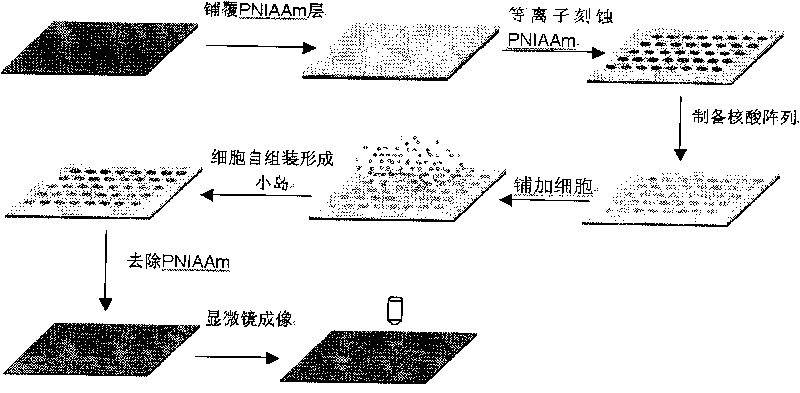

Nucleic acid chip, preparation method and application thereof

ActiveCN101696449ASolve the real problemLow costSequential/parallel process reactionsMicrobiological testing/measurementPoly(N-isopropylacrylamide)Apoptosis

The invention relates to a nucleic acid chip and a preparation method and application thereof, belonging to the detection field of enzymes, microorganisms or nucleic acid molecules. The nucleic acid chip comprises a substrate, nucleic acid molecules are attached to a part of the surface of the substrate; a region of the substrate without the nucleic acid molecules is covered with a material capable of inhibiting cell growth; the material can be a non-biocompatible material, such as poly-N-isopropylacrylamide, polyvinyl caprolactam, polyacrylic acid, chitosan, sodium alginate, and the like or be DNA, siRNA, esiRNA, plasmid, and the like. The nucleic acid chip is particularly suitable for researching functional gene screening aspects, such as cell proliferation, cell differentiation, apoptosis, cell migration, and the like.

Owner:SUZHOU GENOARRAY

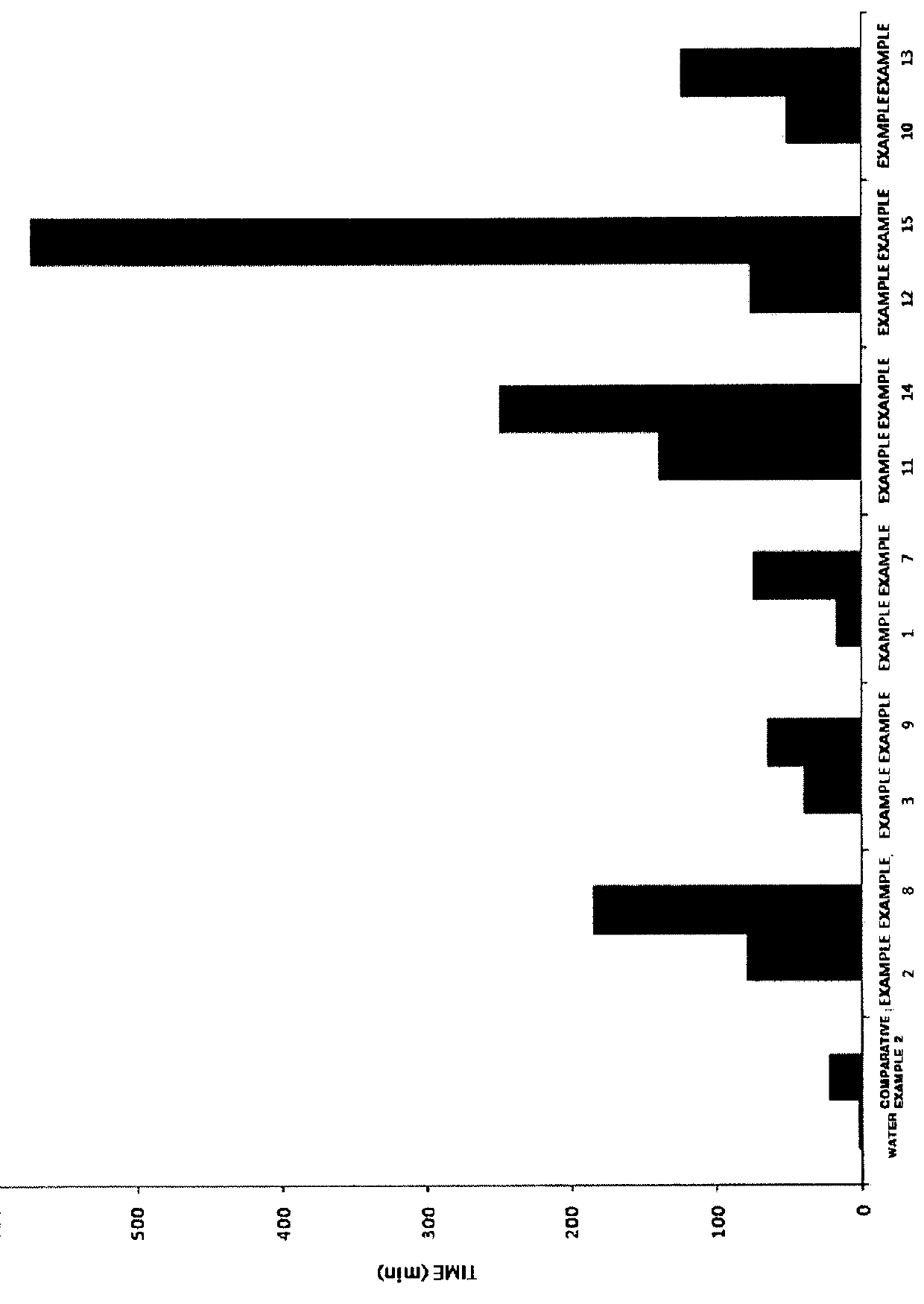

Compound type hydrate inhibitor

InactiveCN103305200AExtend build timeReduce generationPipeline systemsDrilling compositionAlcoholKinetic Inhibitor

The invention belongs to the field of gas storage and transportation, and specifically relates to a compound type gas hydrate inhibitor. The inhibitor consists of the following components in percentage by mass: 0.1-0.5% of polyvinyl caprolactam, 1-5% of alcohol or salt and the balance of water. According to the inhibitor provided by the invention, by adding a certain amount of salt or alcohol into the existing dynamic inhibitor, the generation time of a hydrate can be increased, and the generation amount of the hydrate can be reduced; and moreover, the inhibition effect of the dynamic inhibitor is greatly improved so that the dynamic inhibitor has a better effect and is more stable and wider in range of application.

Owner:CHANGZHOU UNIV

Composite type hydrate inhibitor

InactiveCN103194194AEnhanced inhibitory effectExtend build timePipeline systemsDrilling compositionAlcoholKinetic Inhibitor

The invention discloses a hydrate inhibitor composite which comprises the following components in parts by weight: 1-5 parts of polyvinyl alcohol caprolactam and 1-8 parts of mixed preparations, wherein the mixed preparations are selected from one or more of alcohols, ethers or polymers. The hydrate inhibitor composite disclosed by the invention enhances the inhibition property of an inhibitor by taking the dynamic inhibitor as a main agent and adding certain mixed preparations.

Owner:NORTHWEST UNIV(CN)

Synthesis method of hydrate inhibitor polyvinyl caprolactam

ActiveCN102690391ALow priceEnhanced inhibitory effectPipeline systemsDrilling compositionSynthesis methodsCaprolactam

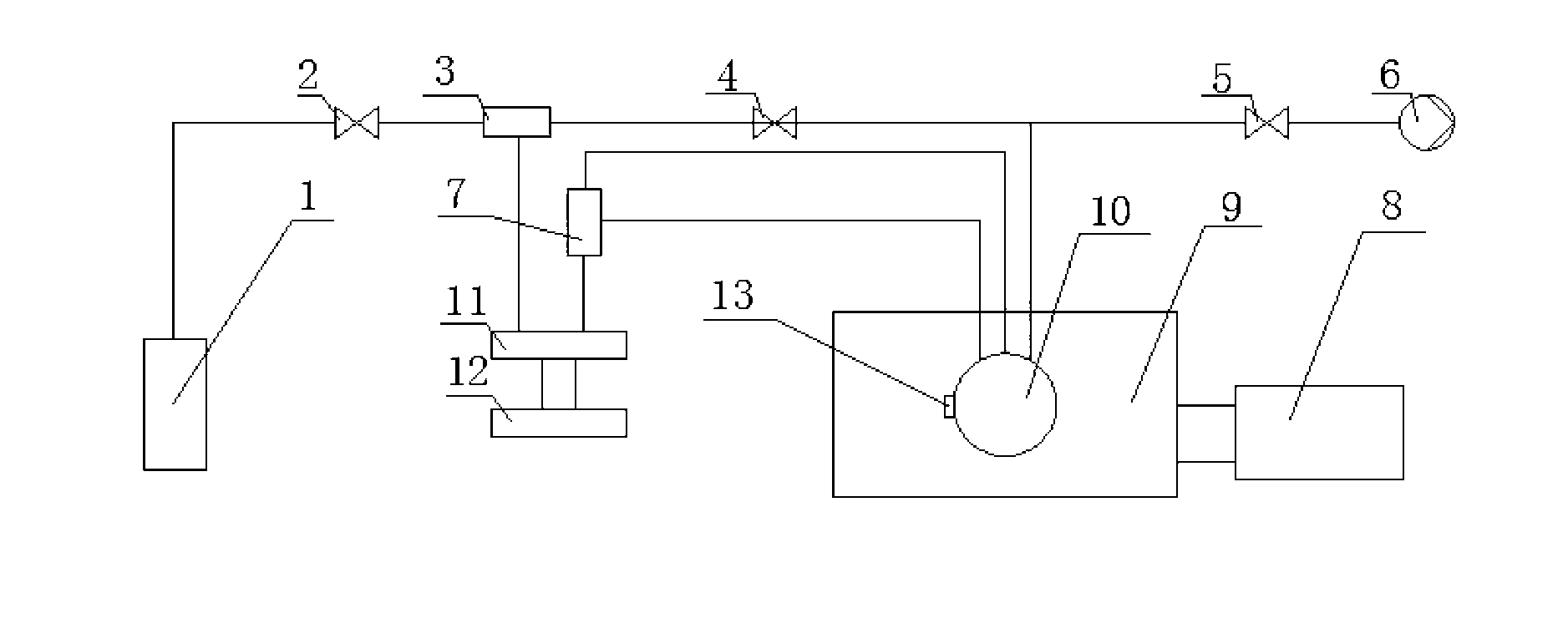

The invention discloses a method for commercial synthesis of hydrate inhibitor polyvinyl caprolactam, which includes the following steps of: A, reaction: distilling vinylcaprolactam and vinylimidazole under reduced pressure to remove the polymerization inhibitor, then putting the mixture into a 3-neck flash together with azo bibutyl imidazoline hydrochloride and absolute ethyl alcohol, introducing nitrogen for protection, stirring until the temperature rises to 65-80 DEG C, making the materials react for 7 hours and then stopping the reaction; and B post-processing: making the reaction solution directly pass through a spray dryer to obtain white solid powder. In a variety of patents of polymer synthesis methods, no spray dryer is mentioned, and compared with other post processing methods, the method of adopting the spray dryer for drying has the advantages that the operation is simplified and a basis for industrial production is achieved. Meanwhile, the inhibition of the hydrate inhibitor polyvinyl caprolactam obtained through the method barely changes, and the hydrate inhibitor polyvinyl caprolactam has good inhibition effect.

Owner:GANSU RES INSTION OF CHEM IND GRICI

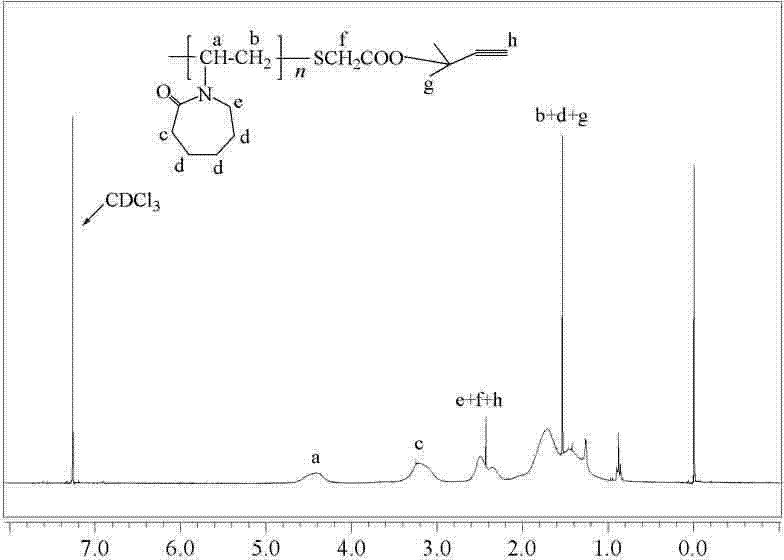

Amphipathic tadpole-shaped block copolymer and preparation method thereof

InactiveCN106750334AEasy to purifyEasy to implementPharmaceutical non-active ingredientsEmulsion deliveryPolyesterBiocompatibility Testing

The invention discloses an amphipathic tadpole-shaped block copolymer and a preparation method thereof, and belongs to the technical field of the preparation of high molecular materials. Aliphatic polyester with alpha,omega-double terminal thiol and poly(N-vinyl caprolactam) with terminal alkynyl are first prepared, and then, through a thiol-yne click reaction between the aliphatic polyester and the poly(N-vinyl caprolactam), an amphipathic single tadpole-shaped block copolymer I is made; four-arm star-shaped polyester with terminal thiol and the poly(N-vinyl caprolactam) with the terminal alkynyl are prepared, and then, through a thiol-yne click reaction between the four-arm star-shaped polyester and the poly(N-vinyl caprolactam), an amphipathic double tadpole-shaped block copolymer II is made. A copper-catalysis-free thiol-yne reaction is applied to the preparation of a tadpole-shaped block copolymer; the pollution problem of a product, which is caused by the use of a copper catalyst, is solved; an obtained product is pure and is easily purified; a reaction condition is easily realized and is safe; the reaction efficiency is high; the amphipathy, the temperature responsiveness, biodegradability and the biocompatibility are integrated on the product; the amphipathic tadpole-shaped block copolymer has a wide application prospect in the field of biological medicines.

Owner:YUNNAN NORMAL UNIV

Inkjet-receptive article

ActiveUS8808815B2Non-fibrous pulp additionSynthetic resin layered productsPolymer sciencePolymer resin

Owner:ISP INVESTMENTS LLC

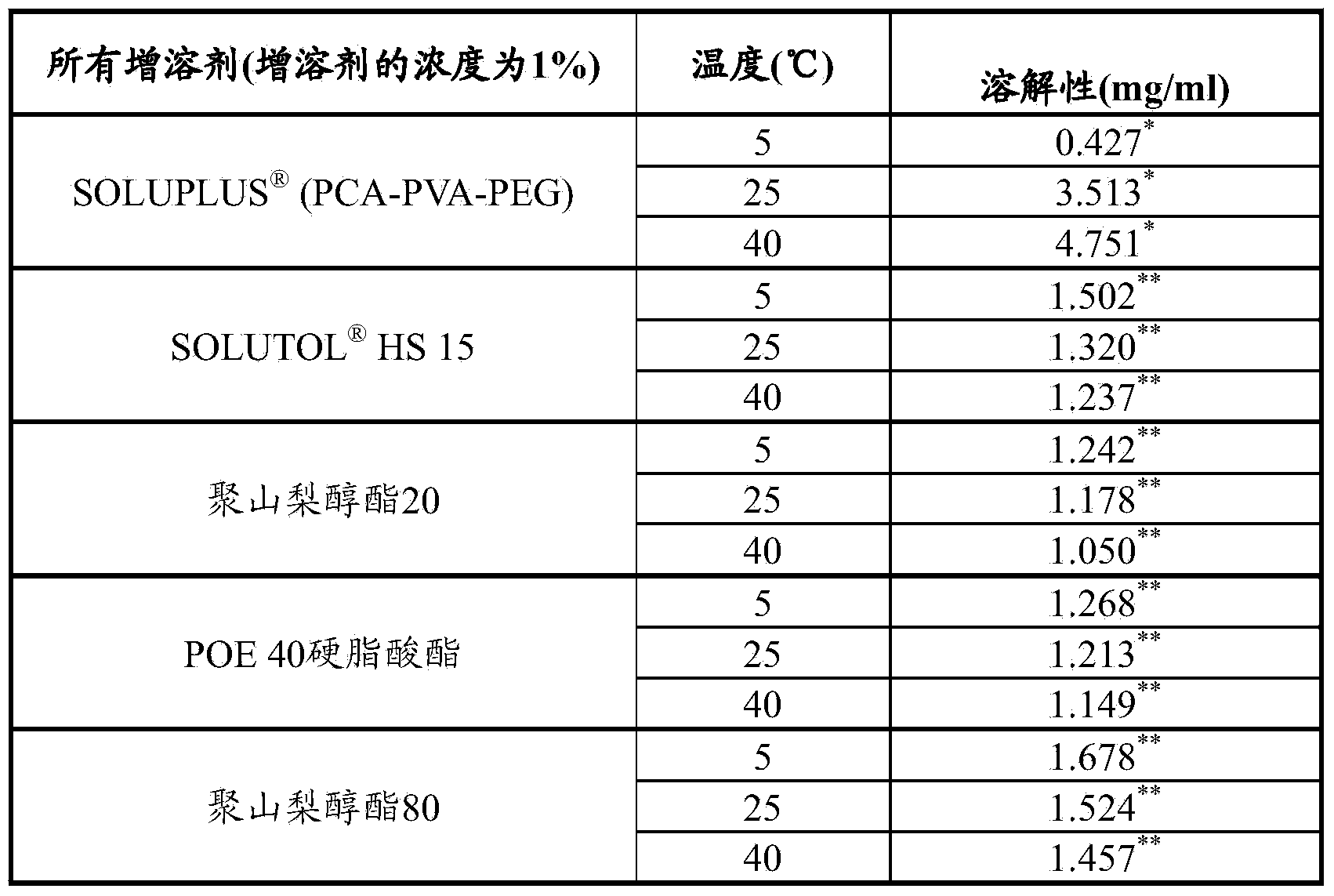

Ophthalmic compositions comprising polyvinyl capralactam-polyvinyl acetate-polyethylene glycol graft copolymers

Compositions and methods related to ophthalmic use of polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymers and therapeutic uses are described herein.

Owner:ALLERGAN INC

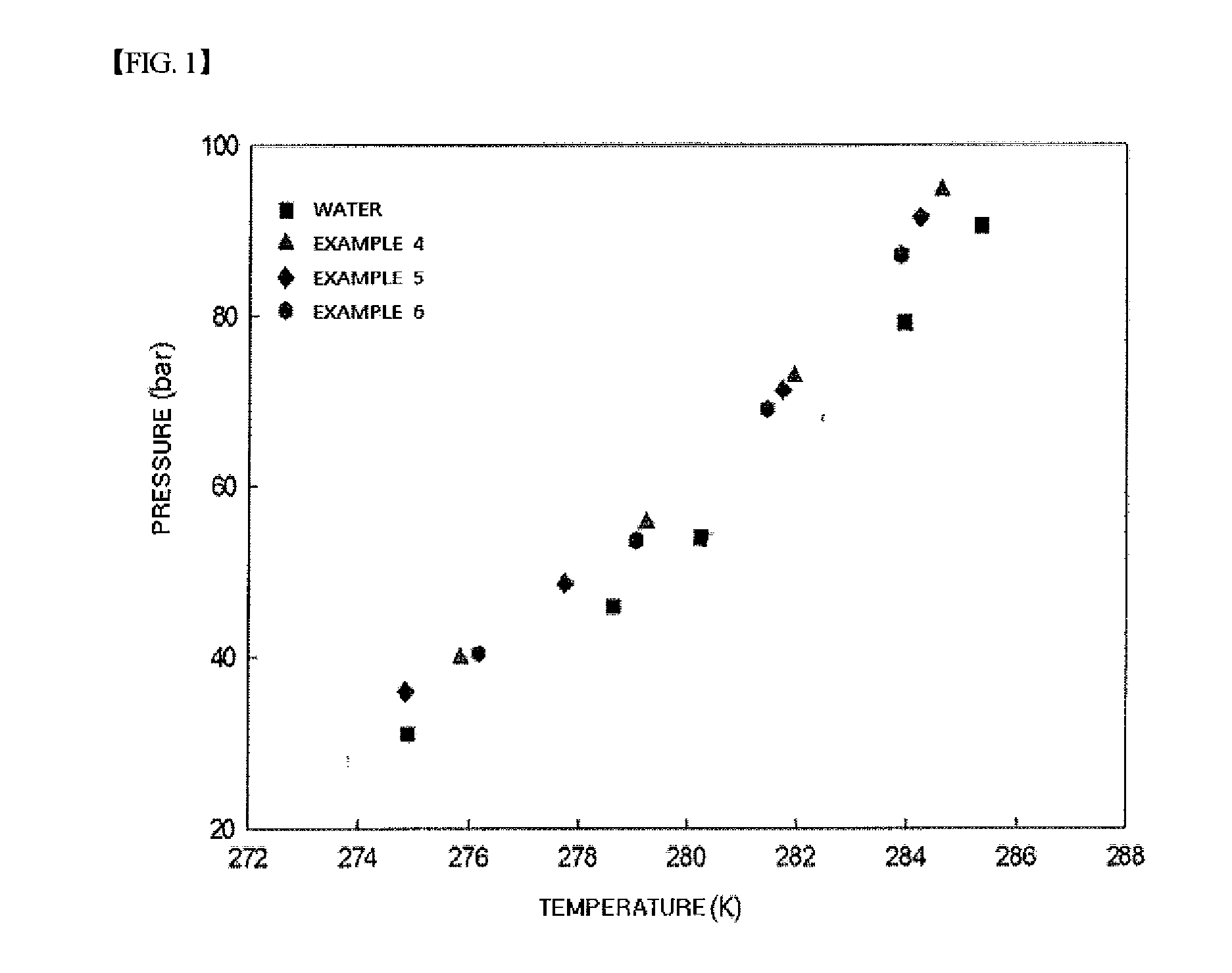

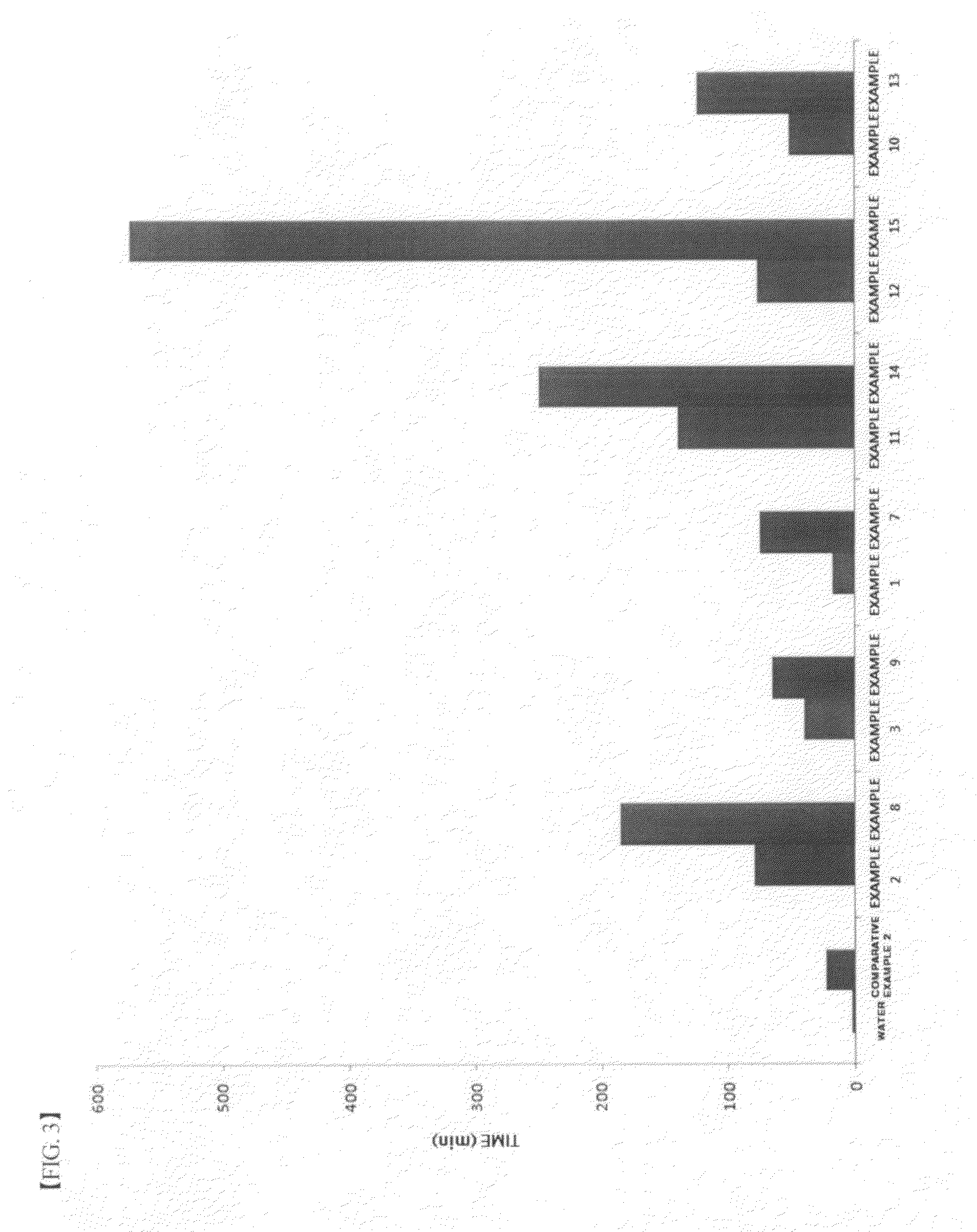

Composition and Method for Inhibiting Gas Hydrate Formation

ActiveUS20130112923A1Inhibit gas hydrate formationInhibit and retard formation of gas hydrateOrganic chemistryOther chemical processesProduct gasPoly-N-vinylcaprolactam

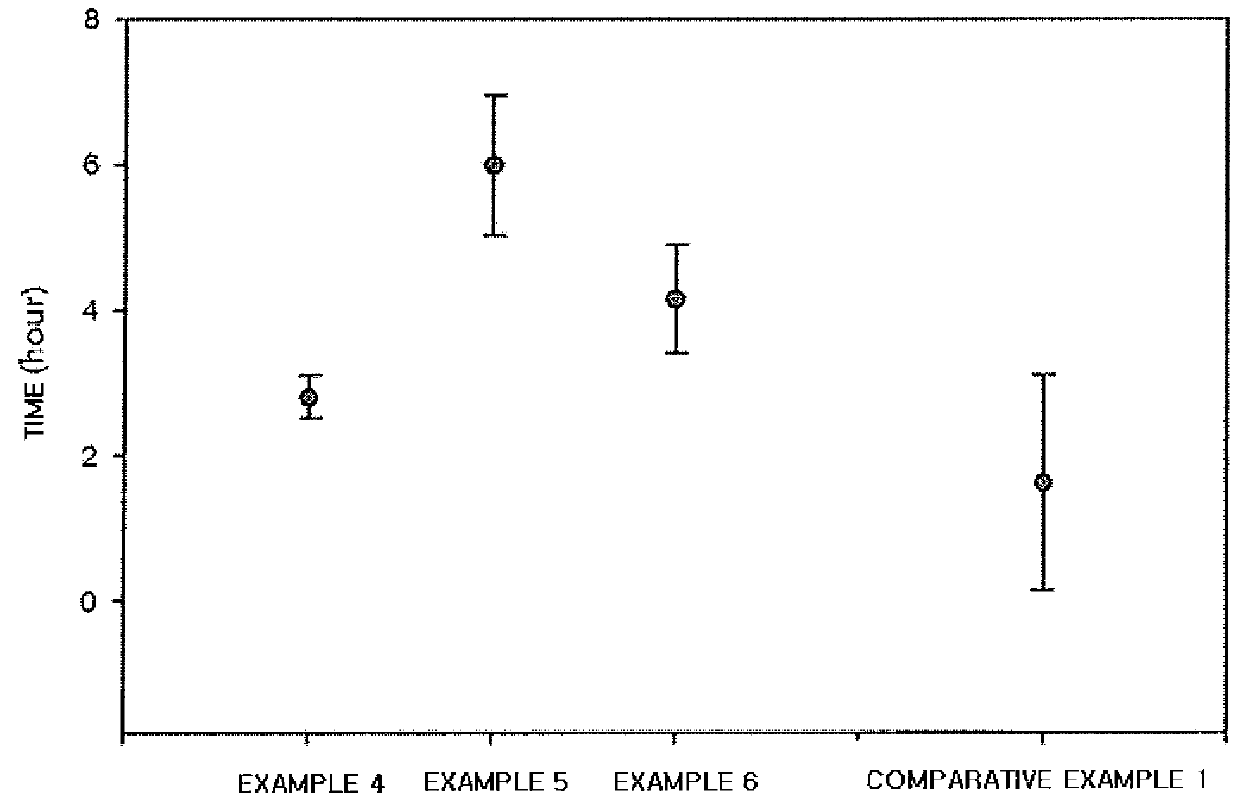

Disclosed herein is a composition for inhibiting a gas hydrate formation, the composition including an ionic liquid compound and polyvinylcaprolactam. The composition can reduce the formation rate of a gas hydrate under the same environment in small quantity, thus remarkably extending the induction time of a gas hydrate formation.

Owner:KOREA INST OF ENERGY RES

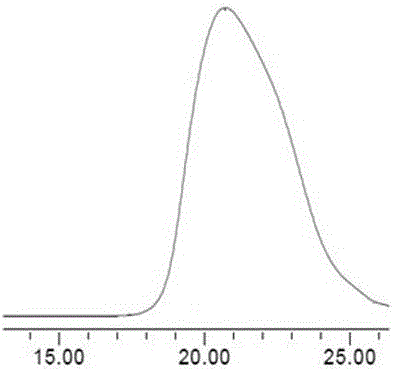

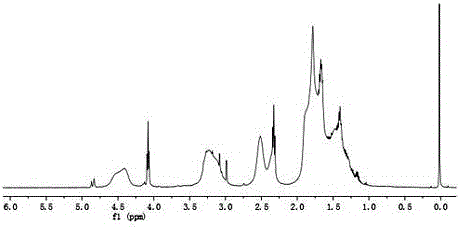

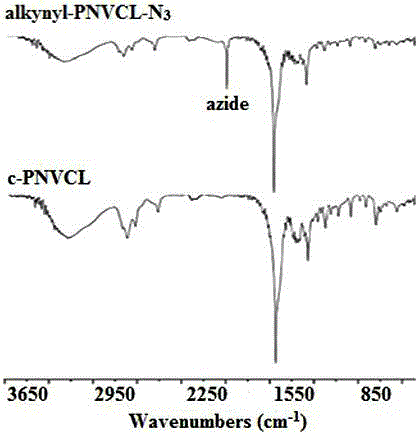

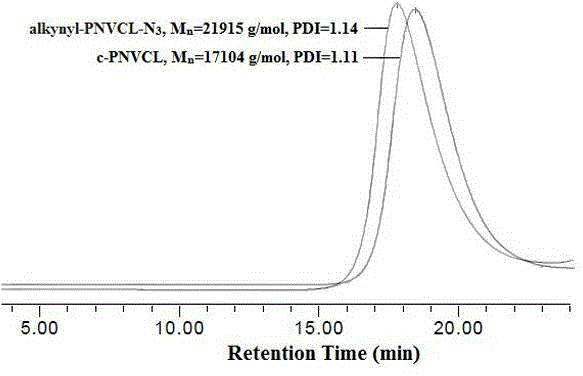

Method for synthesizing poly(N-vinylcaprolactam)/polycaprolactone segmented copolymer

The invention relates to a method for synthesizing a poly(N-vinylcaprolactam) / polycaprolactone segmented copolymer. The employed technical scheme comprises that: moderate alkyne-terminated poly(N-vinylcaprolactam) and azido-terminated polycaprolactone, under the catalysis of sodium ascorbate and blue vitriod, in the mixed solvent of tetrahydrofuran and water, are stirred and reacted for 40-60 h at the temperature of 25 DEG C; rotary evaporation is carried out on the reaction mixture to remove the solvent; anhydrous dichloromethane is used to dissolve the reaction mixture; the dissolved reaction mixture is slowly added dropwise to normal hexane for precipitation; the precipitant is filtered out; and vacuum drying at 30 DEG C is carried out on the precipitant to produce a target product. With the method of the invention, the copolymerization of PNVCL and PCL is realized, and the amphipathic PNVCL-b-PCL segmented copolymer is obtained. The amphipathic PNVCL-b-PCL segmented copolymer can form micelles with kernals and shell structures through self-assembly in water, and has a good application prospect in the fields of controlled drug release, targeted drug delivery, etc.

Owner:LIAONING UNIVERSITY

Synthesis method for poly-N-vinylcaprolactam

The invention is aimed at providing a synthesis method for poly-N-vinylcaprolactam, so as to solve the problems of long time and toxic solvent in the present polymerization process. The method comprises the following steps of: A, reaction: performing reduced pressure distillation on N-vinylcaprolactam, then adding the N-vinylcaprolactam, an initiator azodiisobutyl imidazoline hydrochloride and a solvent in a three-neck flask, charging nitrogen to protect and starting to stir, and heating to 65-80 DEG C, wherein the solvent is one of absolute ethyl alcohol and water, and the usage amount of the initiator is 0.1-0.5 folds of the mass of the N-vinylcaprolactam; and B, post-treatment: steaming away the solvent at 50 DEG C and under a reduced pressure of 0.08 MPa to obtain a colourless sticky liquid, adding tetrahydrofuran to dissolve, and separating out by n-hexane, standing, removing the supernatant, adding ethyl ether to precipitate, filtering, and drying at 30 DEG C to obtain the product poly-N-vinylcaprolactam. The synthesis method provided by the invention eliminates the harm on environment by the utilization of toxic solvent; and the average molecular weight detected by GPC (gel permeation chromatography) is greater than 10000-30000.

Owner:GANSU RES INSTION OF CHEM IND GRICI +1

Negative working light sensitive planographic printing plate material and planographic printing plate manufacturing process

InactiveUS20060210918A1Improve accuracyEfficiently employedPhotomechanical apparatusPhotosensitive material auxillary/base layersVinyl etherPolymer science

Disclosed is a negative working light sensitive planographic printing plate material comprising a support and provieded thereon, a light sensitive layer containing a spectral sensitizing agent, a polymerization initiator, a polymerizable compound, and a polymer as a polymeric binder, wherein the polymer has in the molecule a monomer unit with a polymerizable group and at least one of a polyvinyl ether chain, a polyvinyl pyrrolidone chain and a polyvinyl caprolactam chain.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Composition and method for inhibiting gas hydrate formation

ActiveUS9228075B2Inhibit and retard formation of gas hydrateInhibiting and retarding formation of gas hydrateOrganic chemistryOther chemical processesProduct gasPoly-N-vinylcaprolactam

Disclosed herein is a composition for inhibiting a gas hydrate formation, the composition including an ionic liquid compound and polyvinylcaprolactam. The composition can reduce the formation rate of a gas hydrate under the same environment in small quantity, thus remarkably extending the induction time of a gas hydrate formation.

Owner:KOREA INST OF ENERGY RES

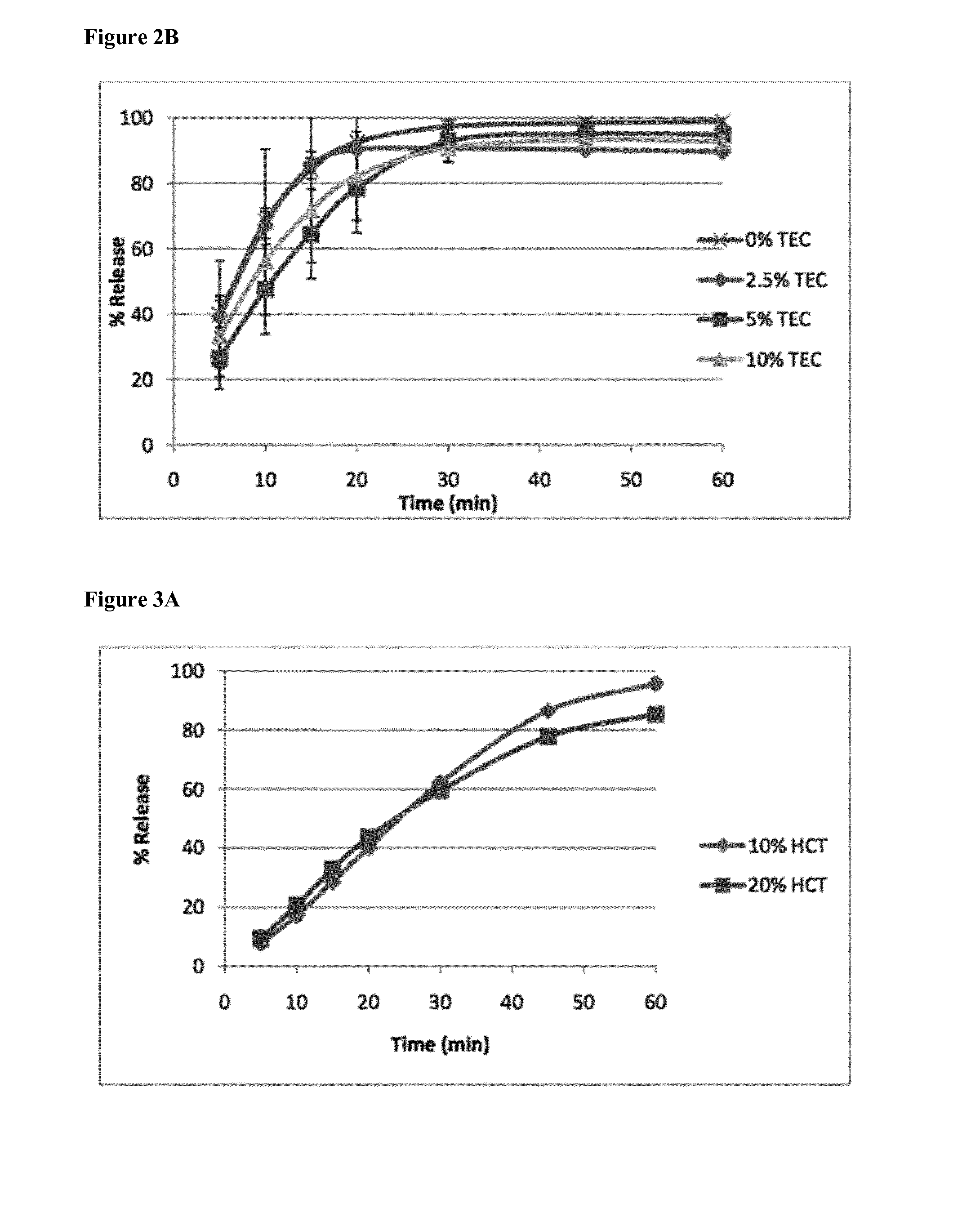

Multi-layered release formulation

The present invention in general relates to a pharmaceutical dosage form comprising a multi-layered release formulation formed by co-extrusion. Said formulation in particular comprises a core layer comprising at least one polymer selected from polycaprolactone, ethylcellulose, or combinations thereof; and a coat layer comprising at least one (co)polymer selected from the list comprising: polyethylene oxide; polyethylene glycol; Basic Butylated Methacrylate (co)polymer; a (co)polymer of polyvinylcaprolactam, PEG and polyvinylacetate; or combinations thereof.

Owner:UNIV GENT

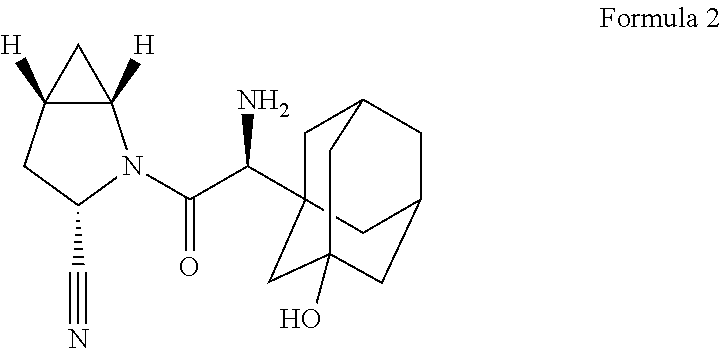

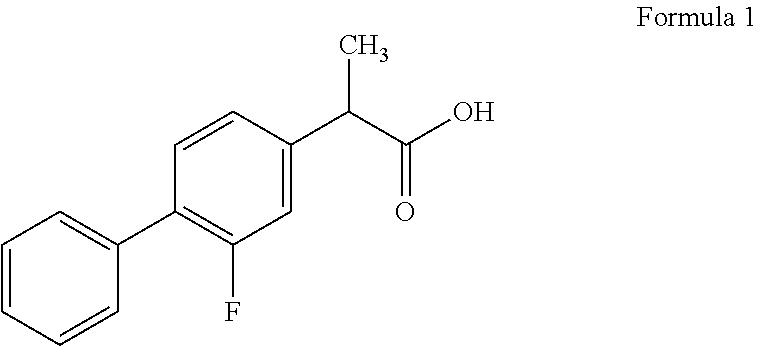

Flurbiprofen formulations

InactiveUS20140322338A1Lower glass transition temperatureImprove stabilityBiocidePowder deliveryPolyvinyl acetateMedicine

This invention relates to a pharmaceutical formulation, characterized by comprising flurbiprofen and polyvinylcaprolactam-polyvinyl acetate-polyethylene glycol graft copolymer.

Owner:SANOVEL ILAC SANAYI & TICARET ANONIM SIRKETI

Preparation method of nanofiltration membrane with adjustable desalination rate

ActiveCN112870980AChange soak timeEase of industrial productionSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention relates to a preparation method of a nanofiltration membrane with an adjustable desalination rate. The preparation method is characterized by comprising the following steps: (1) preparing a membrane casting solution; (2) preparing a hollow fiber base membrane, namely metering the membrane casting solution and a core solution, pumping the membrane casting solution and the core solution into a spinning nozzle, extruding feed liquid from the spinning nozzle, enabling the extruded feed liquid to pass through an air gap and enter a coagulating bath, forming hollow membrane filaments through phase inversion in the coagulating bath, and winding the hollow membrane filaments for later use; and (3) preparing a hollow fiber nanofiltration composite membrane, namely soaking the wound membrane filaments with pure water, then soaking the membrane filaments in a water phase solution of polyamine, and carrying out polymerization reaction on an oil phase containing a polyacyl chloride monomer and a water phase monomer on the surface of the membrane on a coating machine to form a compact separation skin layer so as to finally obtain the nanofiltration membrane. Poly(N-vinylcaprolactam) gel is introduced in the preparation of the base membrane, so that the pore structure of the ultrafiltration base membrane can be adjusted through temperature, and the surface pore diameter of the base membrane and the interfacial polymerization reaction rate in the preparation process of the composite nanofiltration membrane can be adjusted and controlled while the water-phase temperature is realized.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Dpp-iv inhibitor formulations

The present invention relates to a pharmaceutical formulation, characterized by comprising a DPP-IV inhibitor and polyvinylcaprolactam-polyvinyl acetate-polyethylene glycol graft copolymer.

Owner:SANOVEL ILAC SANAYI & TICARET ANONIM SIRKETI

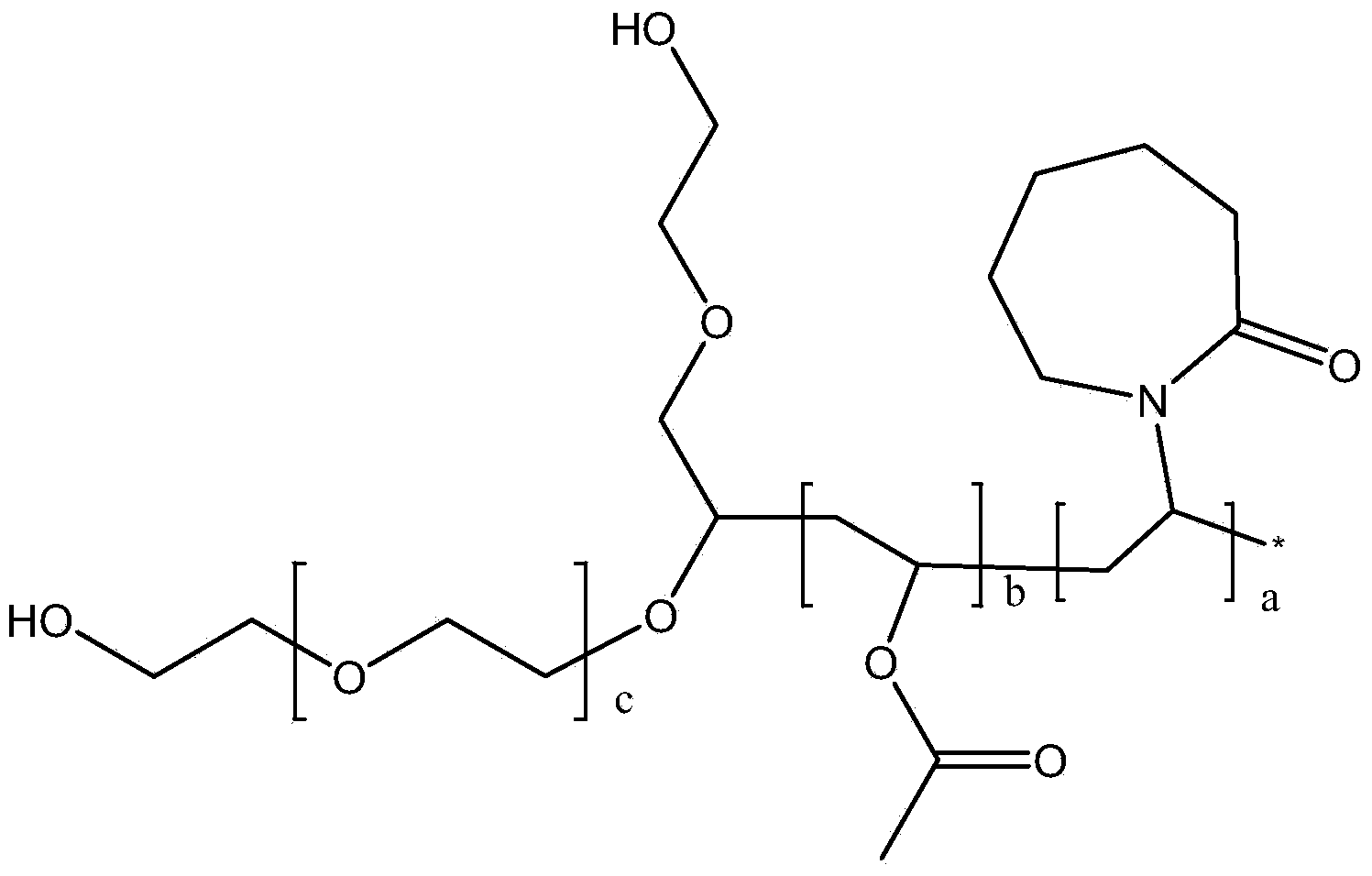

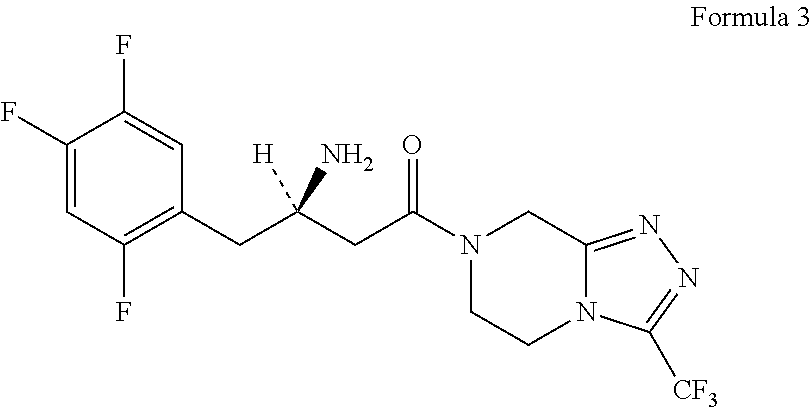

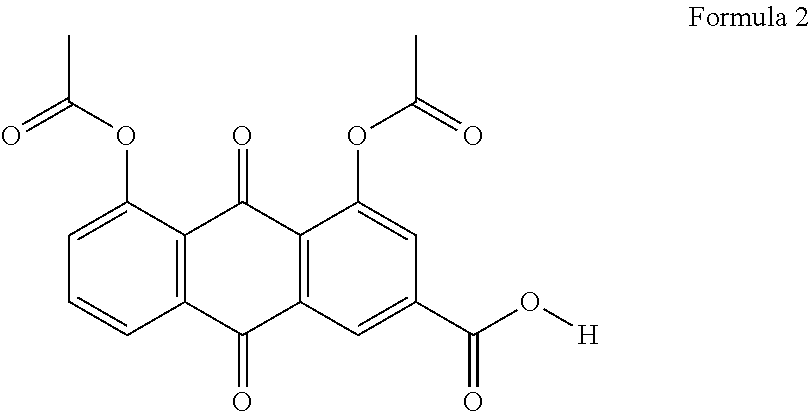

A hydrate kinetic inhibitor

ActiveCN109705246BHigh cloud pointIncrease subcoolingDrilling compositionKinetic InhibitorCombinatorial chemistry

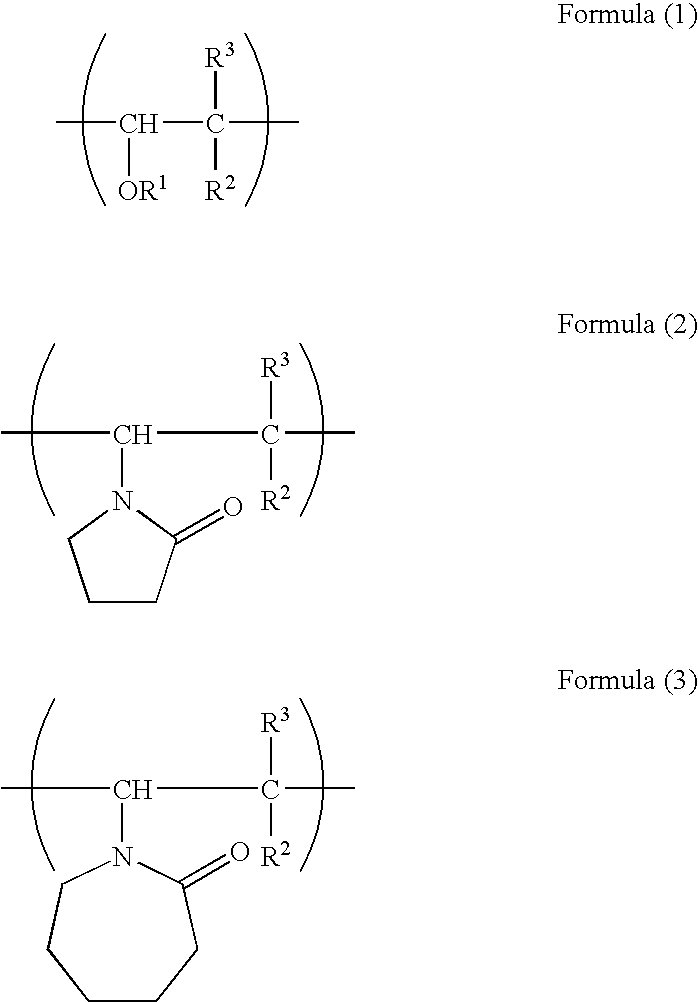

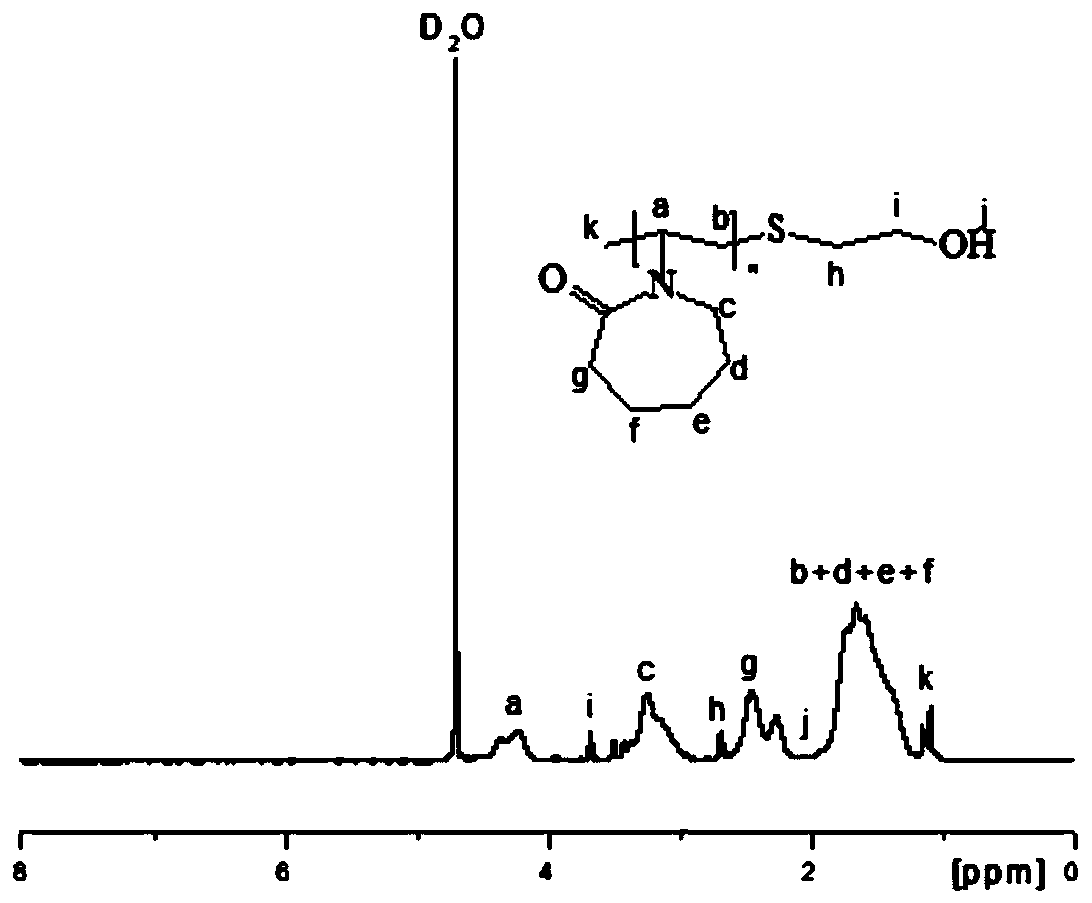

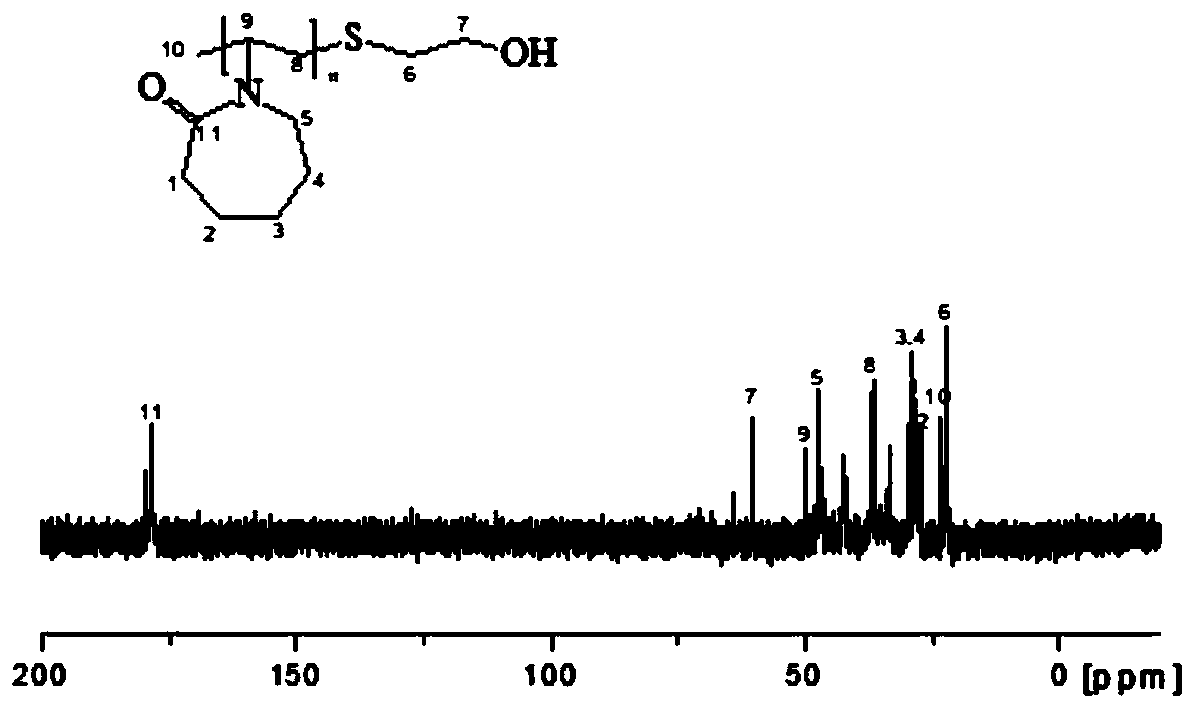

The invention provides a hydrate kinetic inhibitor. The hydrate kinetics inhibitor is formulated from vinylimidazole copolymer and auxiliary agent; the hydrate kinetics inhibitor is poly N-vinyl caprolactam modified by terminal hydroxyl, and its structure is shown in formula I , wherein n=10~1000. The hydrate kinetic inhibitor is a hydroxyl-modified amide type hydrate kinetic inhibitor, and is a new type of high-efficiency hydrate inhibitor with low dosage, high cloud point and ability to withstand a large degree of supercooling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Compound drilling fluid for natural gas hydrate (NGH) reservoir in frozen soil area

InactiveCN108611077AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumCaprolactam

The invention discloses a compound drilling fluid for natural gas hydrate (NGH) reservoir in a frozen soil area, and relates to the field of NGH exploitation. The drilling fluid comprises following components: sodium formate, sodium chloride, glycol, low viscosity carboxymethyl cellulose (LV-CMC), potassium polyacrylate, xanthan gum, polyvinyl caprolactam, polyvinyl methyl ether, tetra-n-butyl ammonium phosphate, and make-up water. The drilling fluid is suitable for NGH drill wells in a frozen soil layer, does not contain any solid phase, and is resistant to low temperature. The drilling fluidis compounded with a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluid has the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

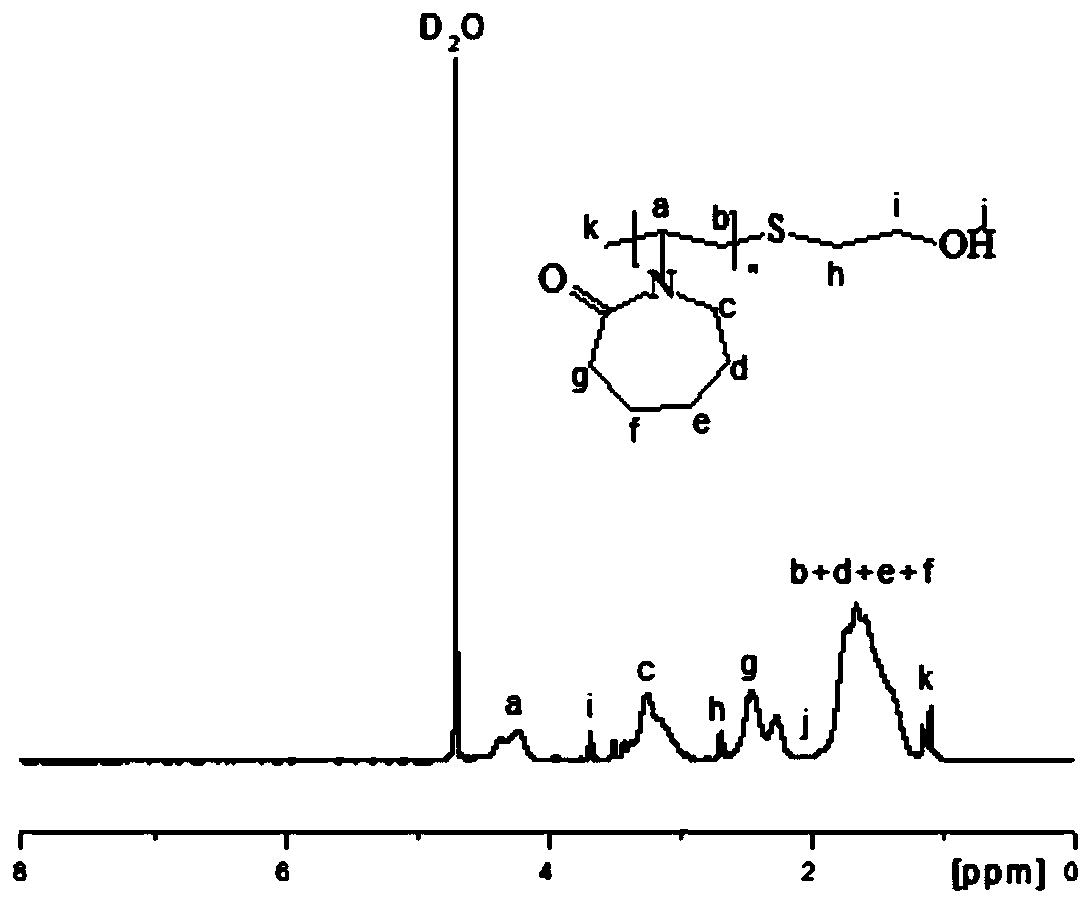

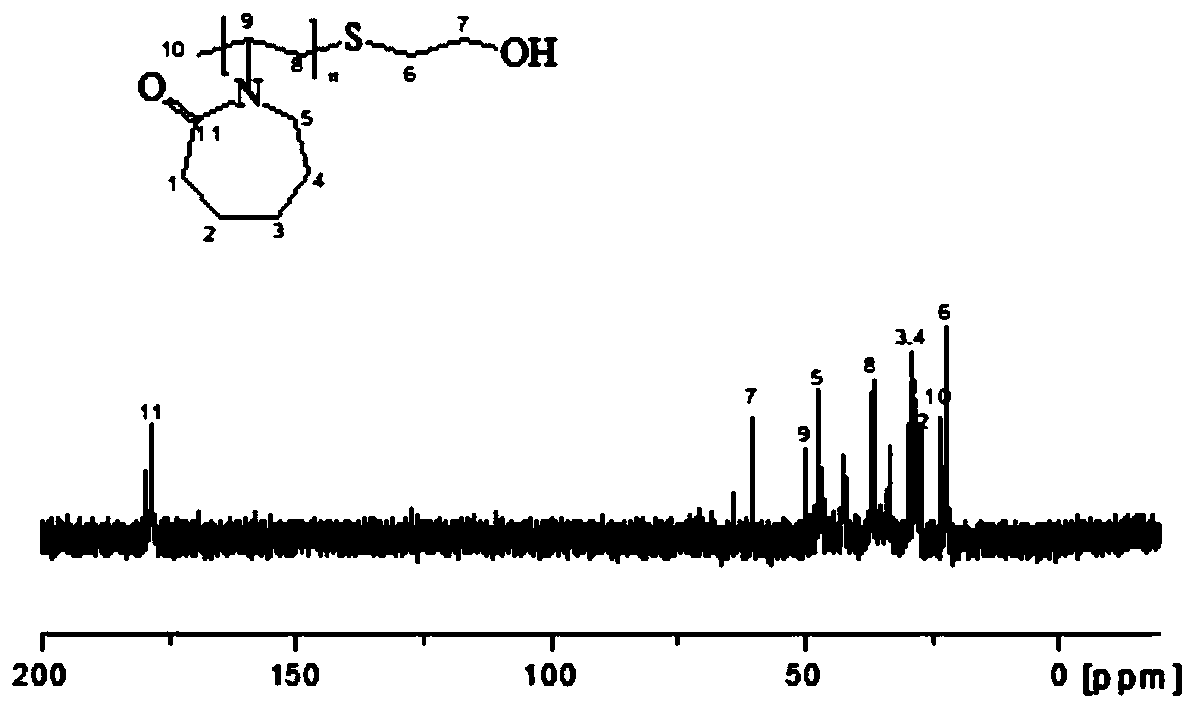

Cyclopoly(N-vinylcaprolactam) as well as preparation method and application thereof

The invention discloses cyclopoly(N-vinylcaprolactam) as well as a preparation method and application thereof, and belongs to the field of functional polymer materials. Two types of cyclopoly(N-vinylcaprolactam) including c-PNVCL and (c-PNVCL)-OH are obtained for the first time. The preparation method comprises the steps of combining with atom transfer radical polymerization, supermolecular self-assembly and click chemistry, and performing a ring closing reaction of a linear precursor at a high concentration, so as to obtain the high-efficiency and high-yield cyclopoly(N-vinylcaprolactam). (C-PNVCL)-OH prepared according to the invention can be used for triggering the ring opening polymerization of any one of glycolide, D-lactide, L-lactide, DL-lactide and epsilon-caprolactone, so as to synthesize and obtain a tadpole-shaped segmented copolymer containing cyclopoly(N-vinylcaprolactam), wherein the tadpole-shaped segmented copolymer has a potential application value in the field of biological medicine. The molecular structures of c-PNVCL and (c-PNVCL)-OH are as shown in the specifications, wherein in the formulae of c-PNVCL and (c-PNVCL)-OH, n is equal to 20-200.

Owner:YUNNAN NORMAL UNIV

Natural gas hydrate storage compound drilling fluid for frozen earth region

The invention discloses a natural gas hydrate storage compound drilling fluid for a frozen earth region and relates to the field of exploration of natural gas hydrate. The drilling fluid comprises thefollowing components: polyethylene glycol, sodium chloride, ethylene glycol, low viscosity carboxymethylcellulose LV-CMC, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, butyl cellosolve,tetracaproyl trimethyl ammonium bromide and prepared water. The drilling fluid can be used for drilling the natural gas hydrate storage drilling of a frozen layer, and plays roles of being free of solid phases and low-temperature resistant. By adding a dynamic inhibitor into the drilling fluid to be compounded with a synergist, the drilling fluid has a relatively high hydrate generation inhibiting effect, and the components of the drilling fluid are small in environmental damage, so that the drilling fluid has the advantages of high efficiency, environmental protection, low cost of raw materials, easily available materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

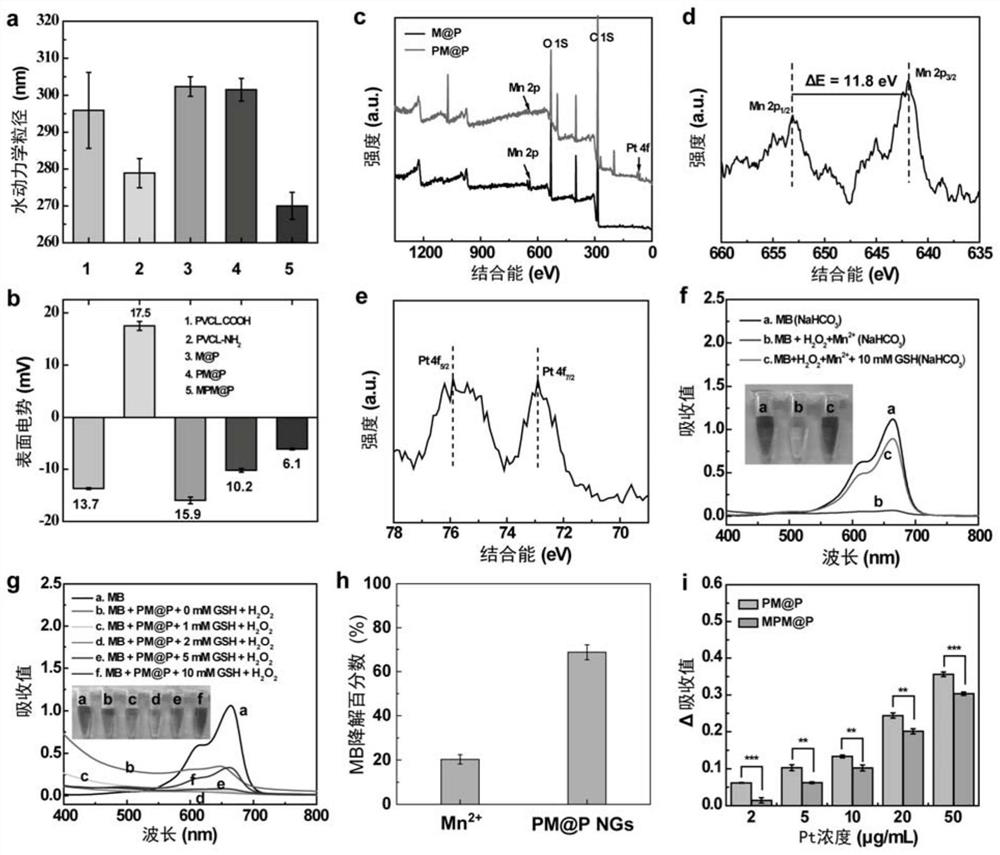

Bionic nano hydrogel coated with a macrophage membrane and loaded with manganese dioxide MnO2 and cis-platinum Pt as well as preparation and application thereof

InactiveCN113577316AEasy to implementEasy to operateInorganic active ingredientsAerosol deliveryCell membraneTumor cell apoptosis

The invention relates to a bionic nano hydrogel coated with a macrophage membrane and loaded with manganese dioxide MnO2 and cis-platinum Pt as well as preparation and application thereof. The bionic nano hydrogel is coated with the macrophage membrane; and the nano hydrogel is poly (N-vinyl caprolactam) (PVCL) nano hydrogel loaded with manganese dioxide (MnO2) and a chemotherapeutic drug cis-platinum. According to the prepared bionic drug-loaded nano hydrogel coated with the macrophage membrane, on one hand, through combined chemotherapy and enhanced chemokinetic therapy (CDT), the half inhibitory concentration (IC50) of the bionic drug-loaded nano hydrogel is remarkably reduced, and the drug safety index (Safety index) and the tumor cell apoptosis rate are increased; and moreover, the integrin [alpha]4 and [beta]1 on the surface of the macrophage membrane can effectively improve the proportion of the integrin [alpha]4 and [beta]1 penetrating through the blood brain barrier (BBB) to target brain glioma, and has a potential application prospect in the aspect of tumor in-situ tumor diagnosis and treatment.

Owner:DONGHUA UNIV

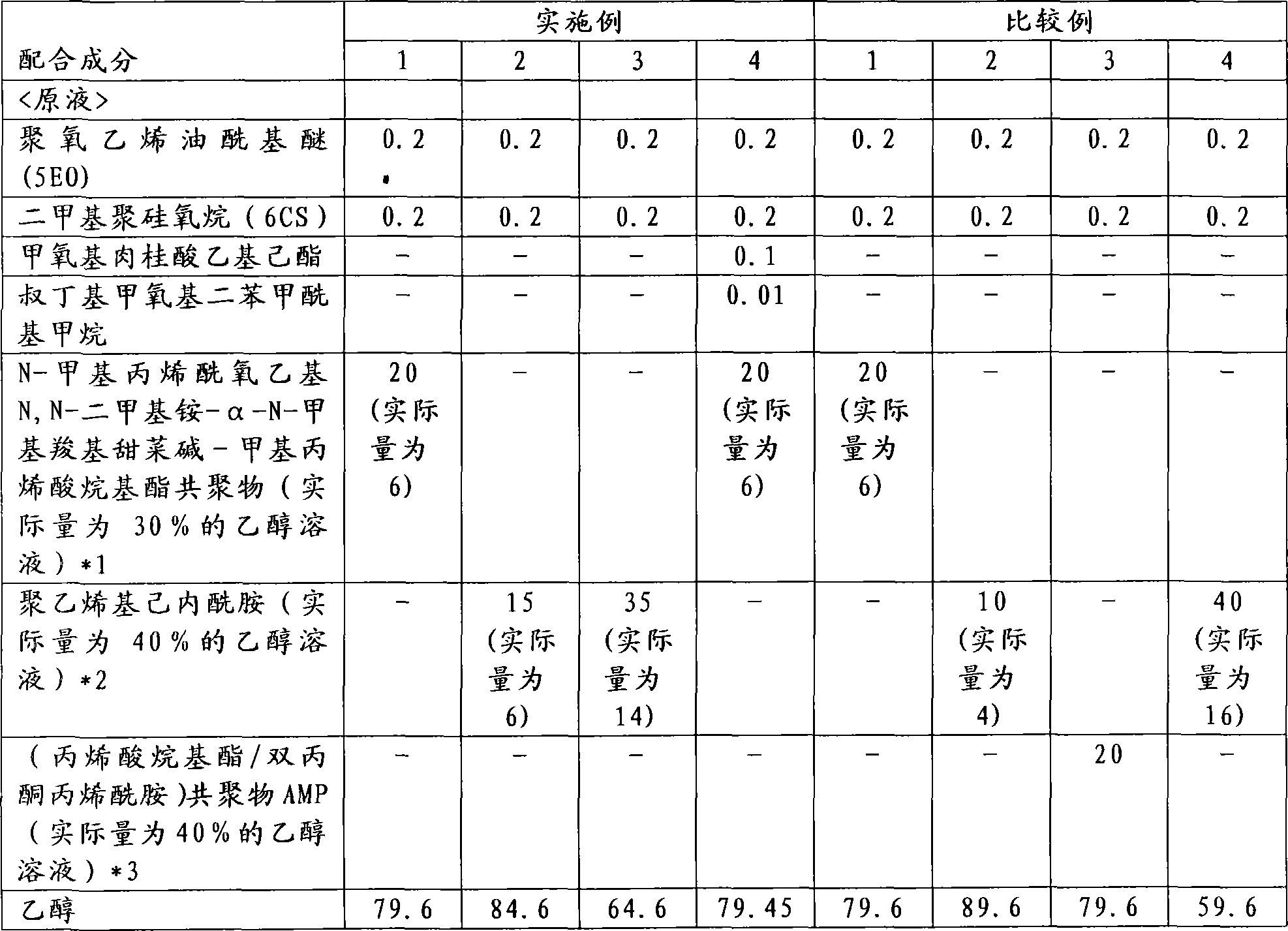

Aerosol type cosmetic hair preparations

InactiveCN101472549AEasy to useNo cloggingCosmetic preparationsHair cosmeticsPolymer chemistryCopolymer

An aerosol type cosmetic hair preparation characterized in that a raw ethanol solution containing 0.1-15 mass% N-methacryloyloxyethyl-N,N-dimethylammonium a-N-methylcarboxybetaine / alkyl methacrylate copolymer and an aerosol propellant comprising a liquefied petroleum gas having an initial internal pressure as measured at 20 DEG C of 0.15-0.2 MPa have been packed in such a mixing proportion that the raw ethanol solution / aerosol propellant ratio by mass is in the range of 40 / 60 to 50 / 50. Also provided is an aerosol type cosmetic hair preparation characterized in that a raw ethanol solution containing 0.1-15 mass% polyvinylcaprolactam and an aerosol propellant comprising a liquefied petroleum gas having an initial internal pressure as measured at 20 DEG C of 0.15- 0.2 MPa have been packed in such a mixing proportion that the raw ethanol solution / aerosol propellant ratio by mass is in the range of 40 / 60 to 50 / 50. Based on the results of a detailed investigation made again on behaviors of hair-spray users, the hair sprays which can be comfortably used are provided.

Owner:SHISEIDO CO LTD

Compound drilling fluid applied to stratums with natural gas hydrates in seafloor

The invention provides compound drilling fluid applied to stratums with natural gas hydrates in the seafloor and relates to the field of exploitation of natural gas hydrates. The drilling fluid comprises the following components: polyethylene glycol, sodium chloride, ethylene glycol, low-viscosity carboxymethyl cellulose LV-CMC, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, propyleneglycol phenyl ether, tetranbutylammonium phosphate and prepared water. The compound drilling fluid is capable of being applied to drilling with storage of the natural gas hydrates in the seafloor, isfree of solid phase and has resistance to low temperature; kinetic inhibitors and synergists are added into the drilling fluid and are compounded with each other; the drilling fluid has a relativelystrong effect of inhibiting generation of the hydrates; meanwhile, the components of the drilling fluid are low in harm to environment; and the drilling fluid has the advantages of high efficiency, environment friendliness and cheap and easily available raw materials.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Formulations of flurbiprofen and diacerein

InactiveUS20140377343A1Eliminate needPrevent and minimize burning sensationBiocidePowder deliveryPolyvinyl acetatePolyvinyl alcohol

The present invention relates to a pharmaceutical formulation, characterized by comprising flurbiprofen or a pharmaceutically acceptable salt of flurbiprofen, diacerein or a pharmaceutically acceptable salt of diacerein, as well as at least one or a properly-proportioned mixture of polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer or polyvinyl alcohol-polyethylene glycol copolymer.

Owner:SANOVEL ILAC SANAYI & TICARET ANONIM SIRKETI

Compound drilling fluid for natural gas hydrate (NGH) reservoir in siltstone

InactiveCN108611073AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumCaprolactam

The invention discloses a compound drilling fluid for natural gas hydrate (NGH) reservoir in siltstone, and relates to the field of NGH exploitation. The drilling fluid comprises following components:sodium formate, sodium chloride, glycol, potassium chloride, potassium humate, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, ethylene glycol butyl ether, tetra-n-butyl ammonium phosphate, and make-up water. The drilling fluid is suitable for NGH drill wells in siltstone reservoir, is resistant to low temperature, and can inhibit and reduce the solid phase. The drilling fluid is compounded with a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluidhas the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

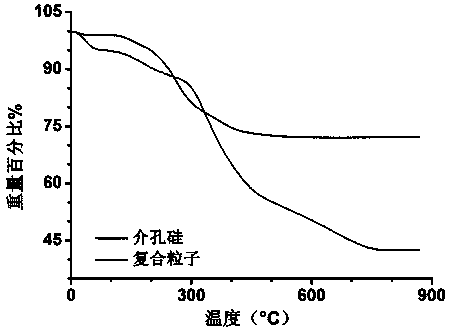

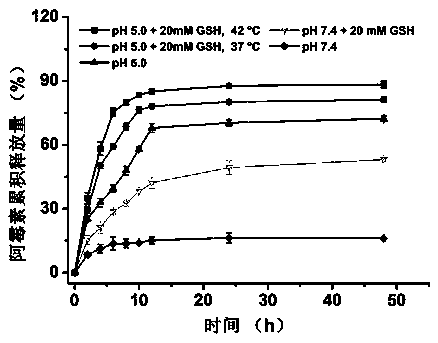

Preparation method of multi-response targeting mesoporous silicon-based intelligent carrier

InactiveCN109223730AAdvantages of preparation processExcellent Smart Drug Release BehaviorOrganic active ingredientsPharmaceutical non-active ingredientsPotassium persulfateMulti response

The invention relates to a preparation method of a multi-response targeting mesoporous silicon-based intelligent carrier. The preparation method of the intelligent carrier comprises the following steps: preparing mesoporous silicon nanoparticles, a silane coupling agent is used to modify it so as to form an active double bond on the surface, Disulfide bonded crosslinked gel shell was prepared on mesoporous silicon by emulsion polymerization in aqueous solution using potassium persulfate as initiator, bis (acryloyl) cystamine as crosslinking agent, polyvinylcaprolactam and methacryloylated hyaluronic acid as monomers. The composite carrier can simultaneously respond to three kinds of stimuli of temperature, high reducibility and enzyme, realize degradation of organic layer, open pore channel to release drug, synthesize zero leakage, multi-response and hyaluronic acid targeting, the intelligent carrier is expected to greatly improve the anti-tumor effect, and has good application prospect in the field of drug release.

Owner:嘉兴德扬生物科技有限公司

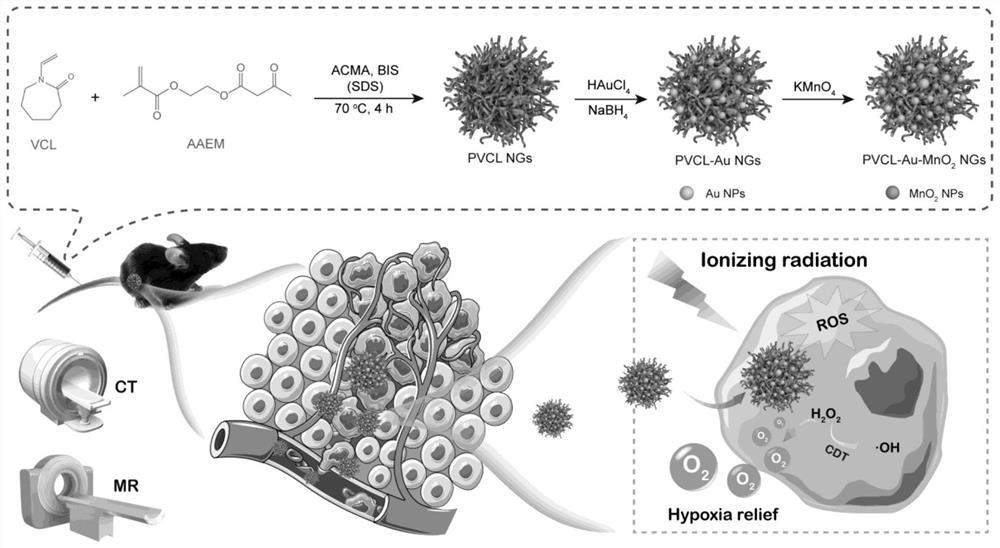

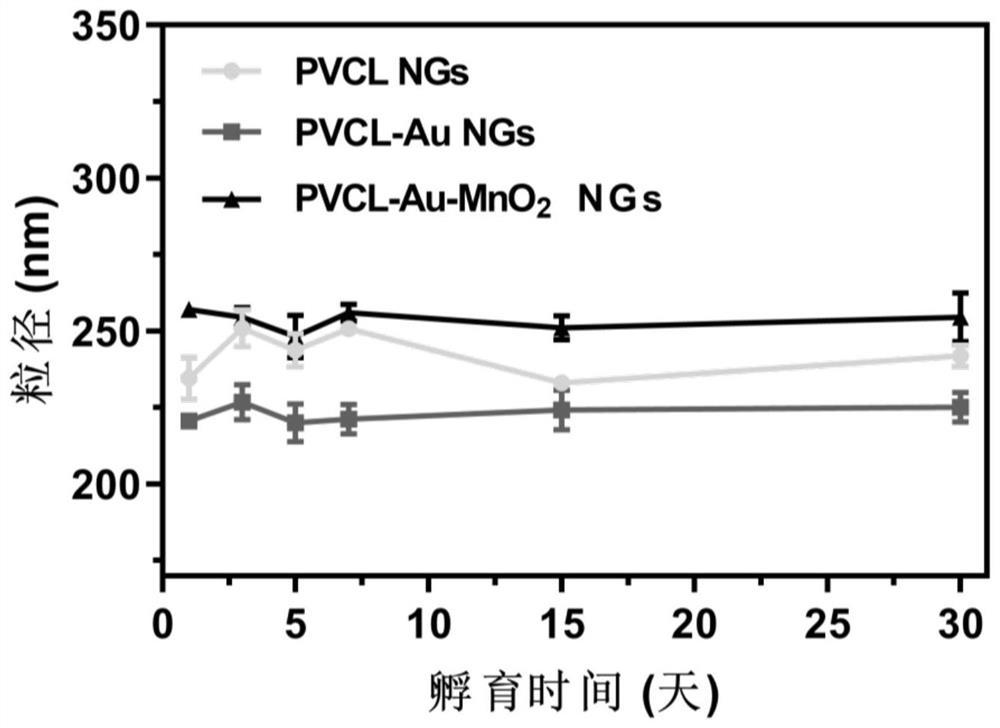

Poly (N-vinylcaprolactam) nanogel loaded with gold and manganese dioxide nanoparticles as well as preparation and application of poly (N-vinylcaprolactam) nanogel

ActiveCN113499452AGrowth inhibitionSmall tumor massPhotodynamic therapyAerosol deliveryManganese oxideEthylene Glycol Methacrylate

The invention relates to poly (N-vinylcaprolactam) nanogel loaded with gold and manganese dioxide nanoparticles as well as a preparation method and application of the poly (N-vinylcaprolactam) nanogel. The nanogel is prepared from gold nanoparticles, manganese dioxide nanoparticles, acetoacetic acid ethylene glycol methacrylate and poly (N-vinyl caprolactam) nanogel. The method comprises the following steps: preparing poly (N-vinylcaprolactam) nanogel, preparing poly (N-vinylcaprolactam) nanogel loaded with gold nanoparticles, and preparing poly (N-vinylcaprolactam) nanogel loaded with gold and manganese dioxide nanoparticles. The method is simple in process, easy to operate and separate, wide in raw material source and good in development and application prospect; the prepared nanogel has the advantages of good colloidal stability, cell compatibility, good X-ray attenuation, high r1 relaxation rate and good'whole process' radiotherapy sensitization.

Owner:DONGHUA UNIV +1

Hydrate kinetic inhibitor

ActiveCN109705246AHigh cloud pointIncrease subcoolingDrilling compositionKinetic InhibitorPoly-N-vinylcaprolactam

A hydrate kinetic inhibitor is provided. The hydrate kinetic inhibitor is prepared from vinyl imidazole copolymer and auxiliary agent. The hydrate kinetic inhibitor is a hydroxyl-terminated modified poly N-vinylcaprolactam having a structure represented by formula I, wherein n=10 to 1000. The hydrate kinetic inhibitor is a hydroxyl modified amide type hydrate kinetic inhibitor. It is a new type ofhighly effective hydrate inhibitor with low dosage and high cloud point and can bear high undercooling capacity.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com