Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Plane sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

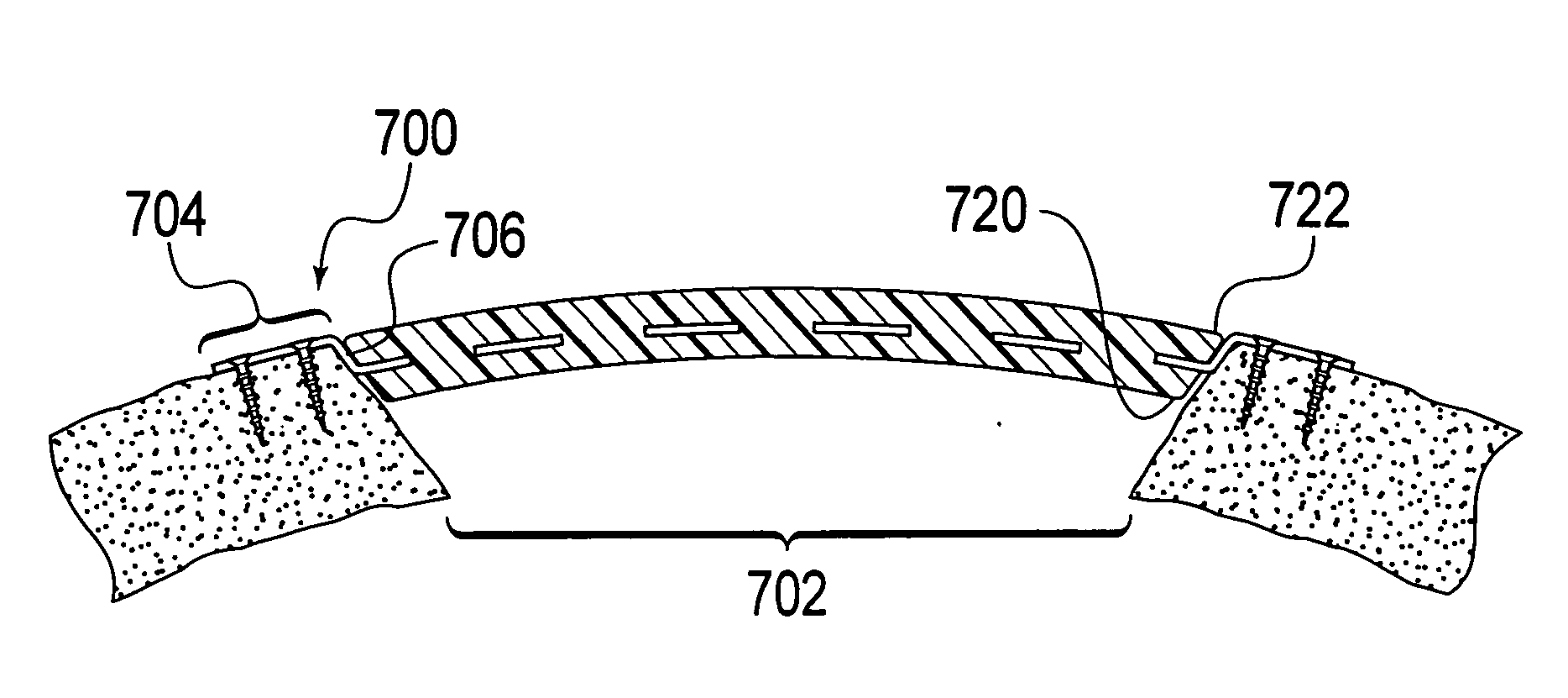

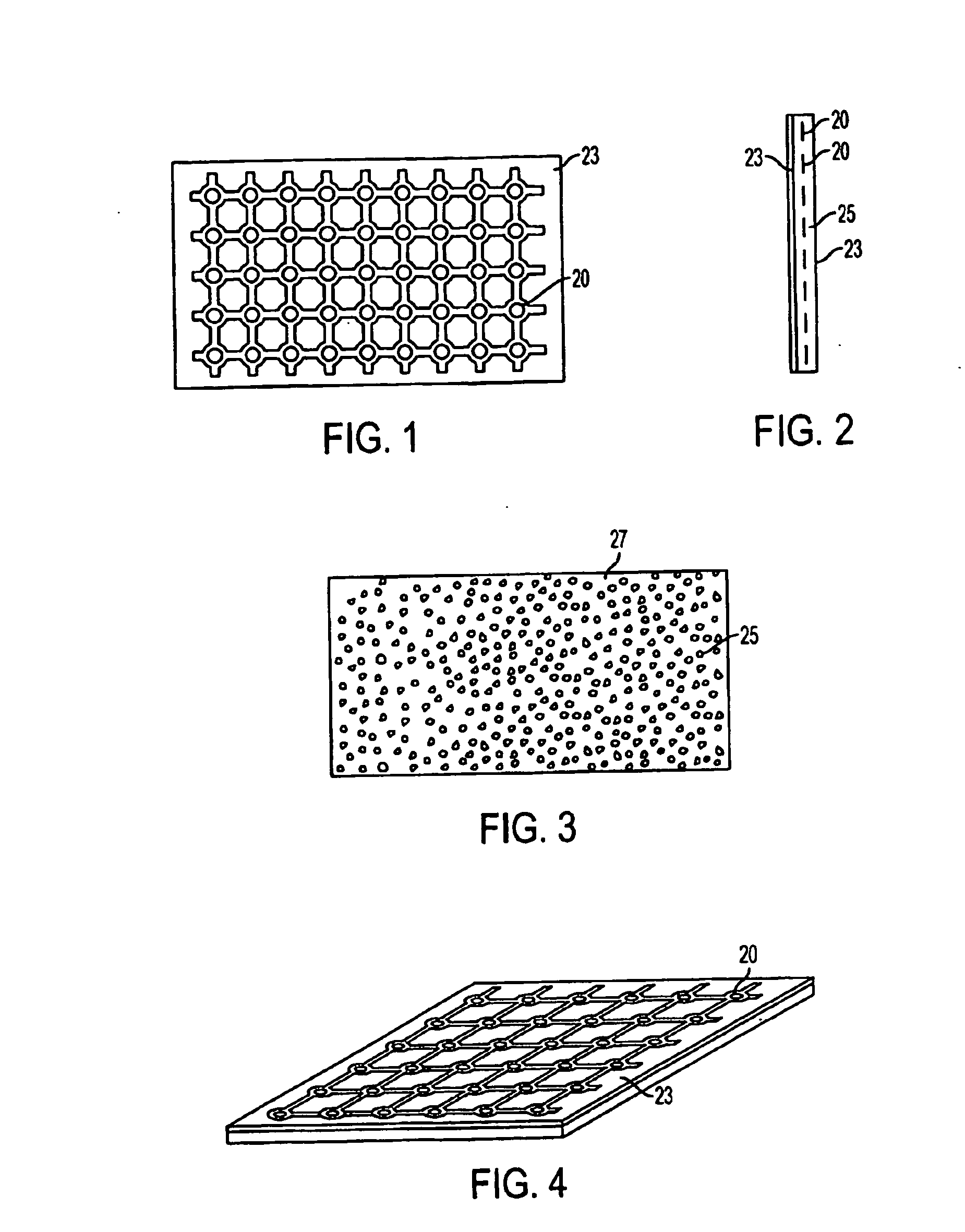

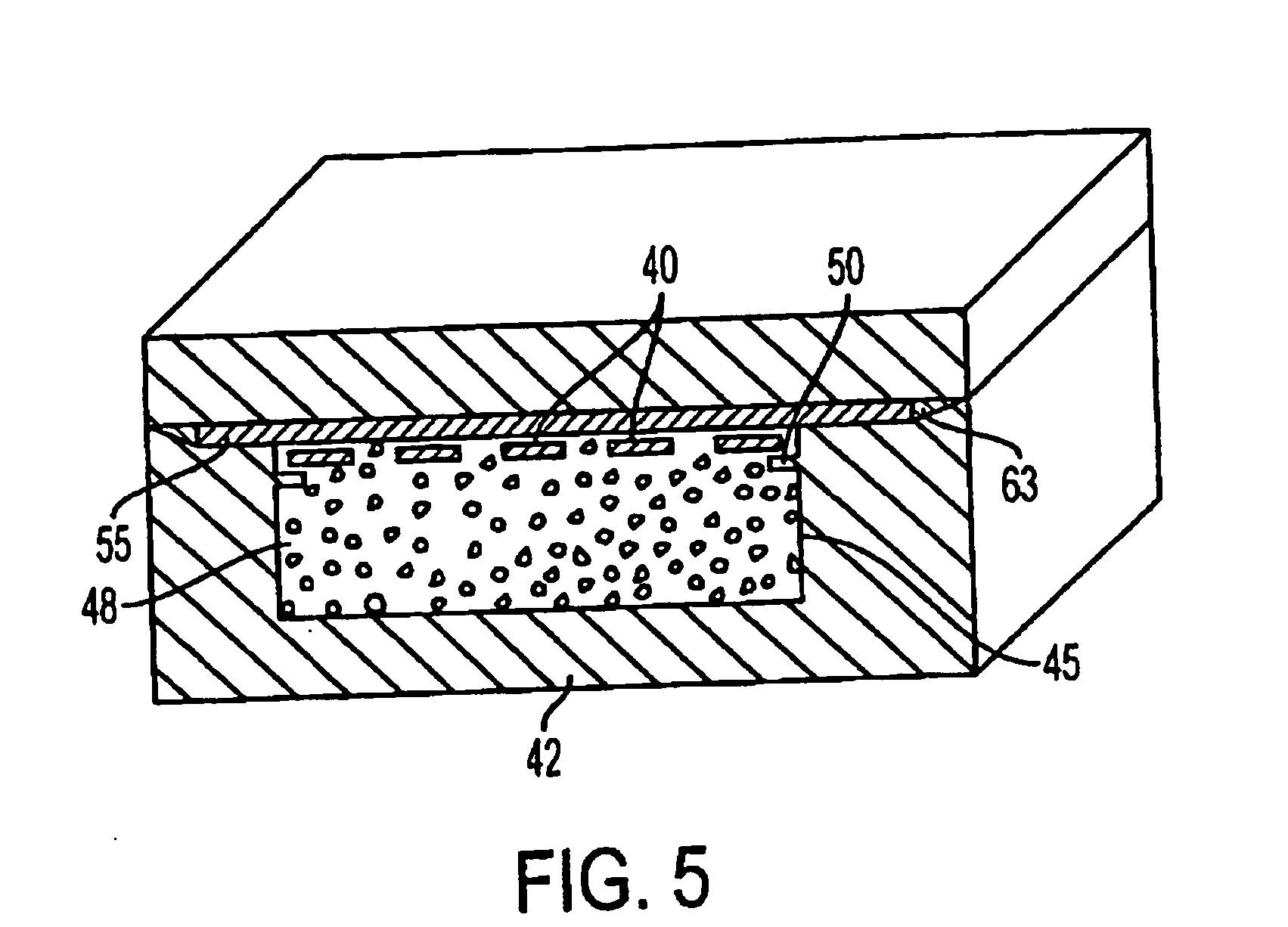

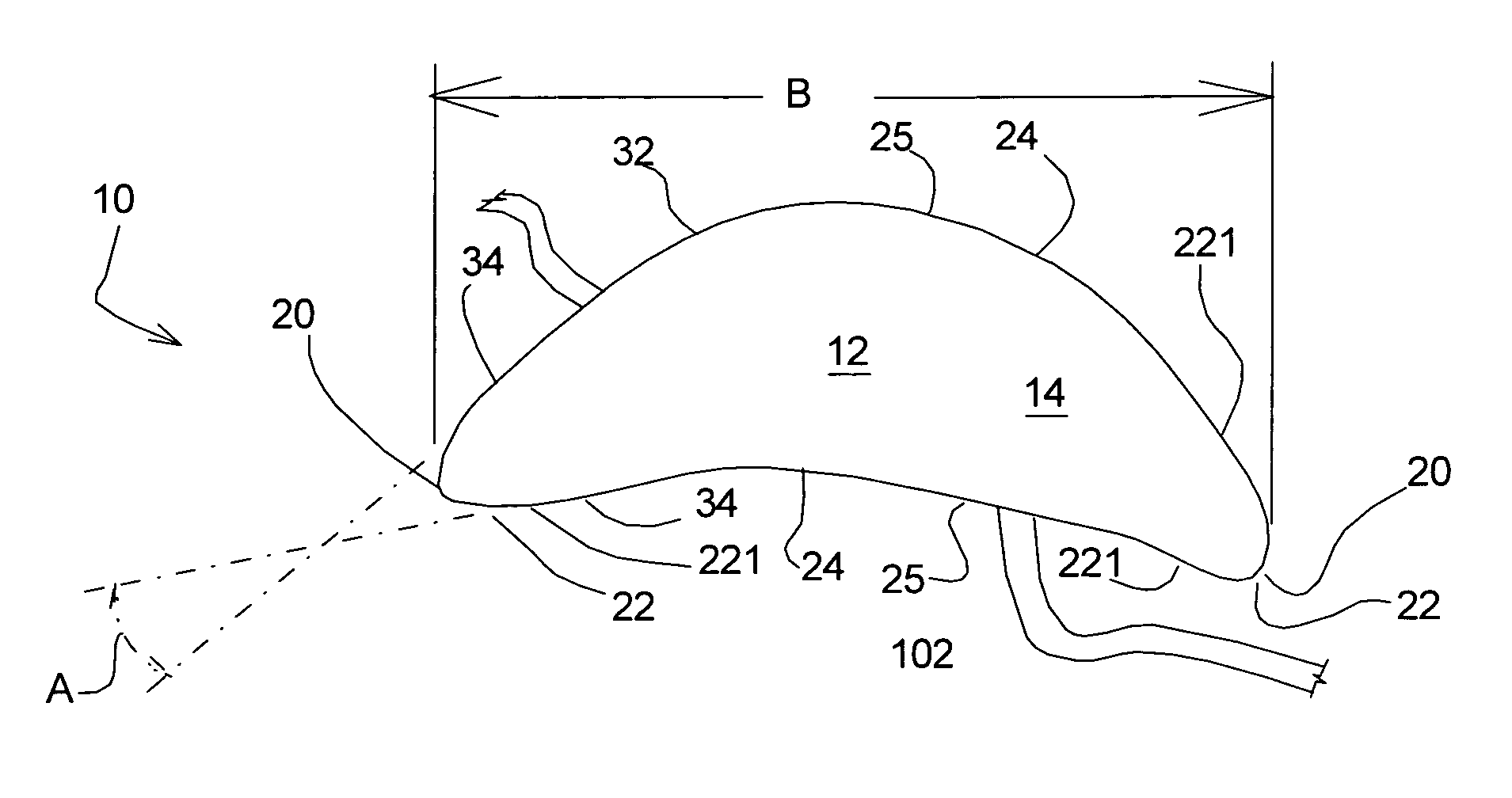

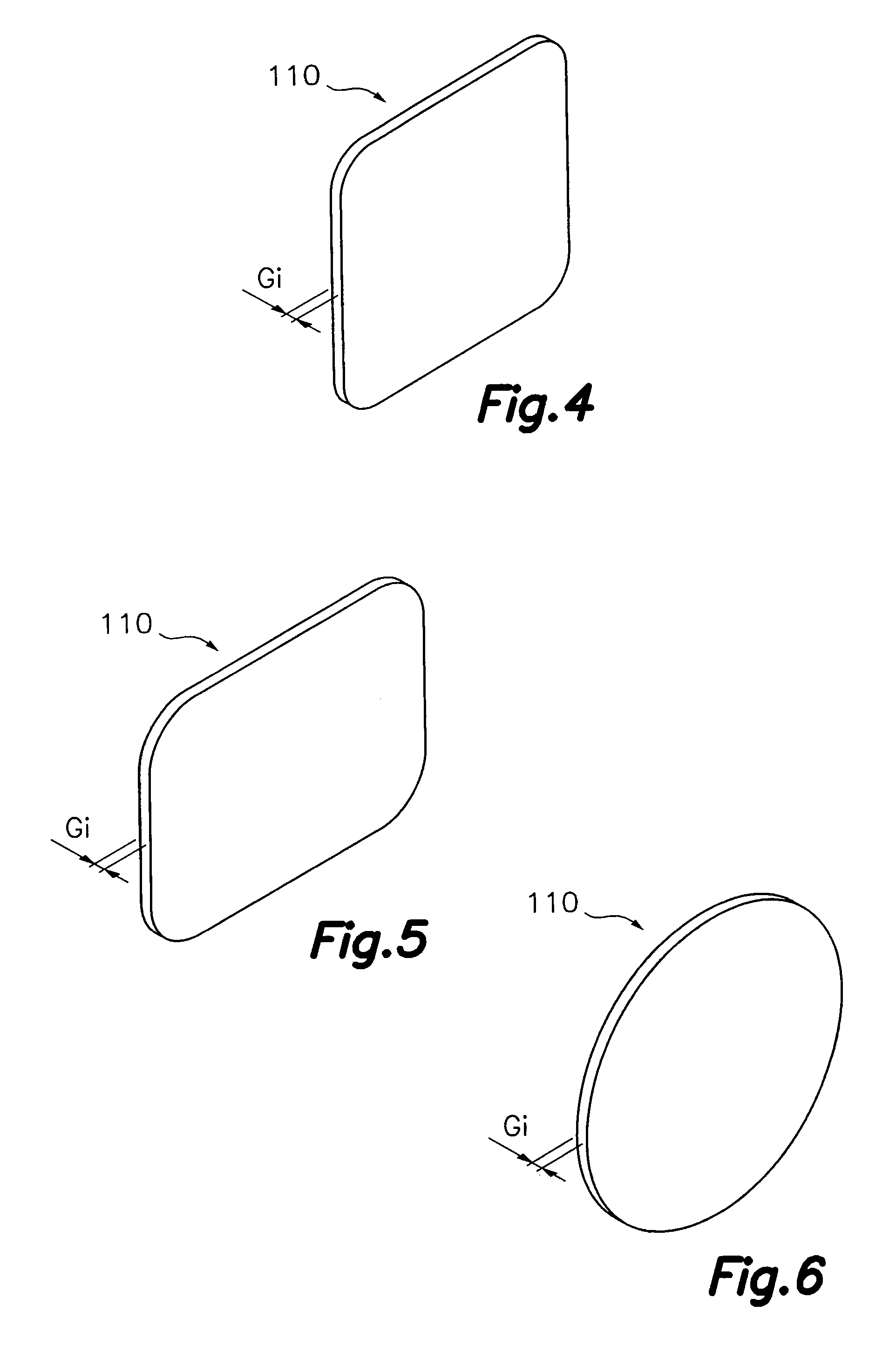

Craniofacial implant

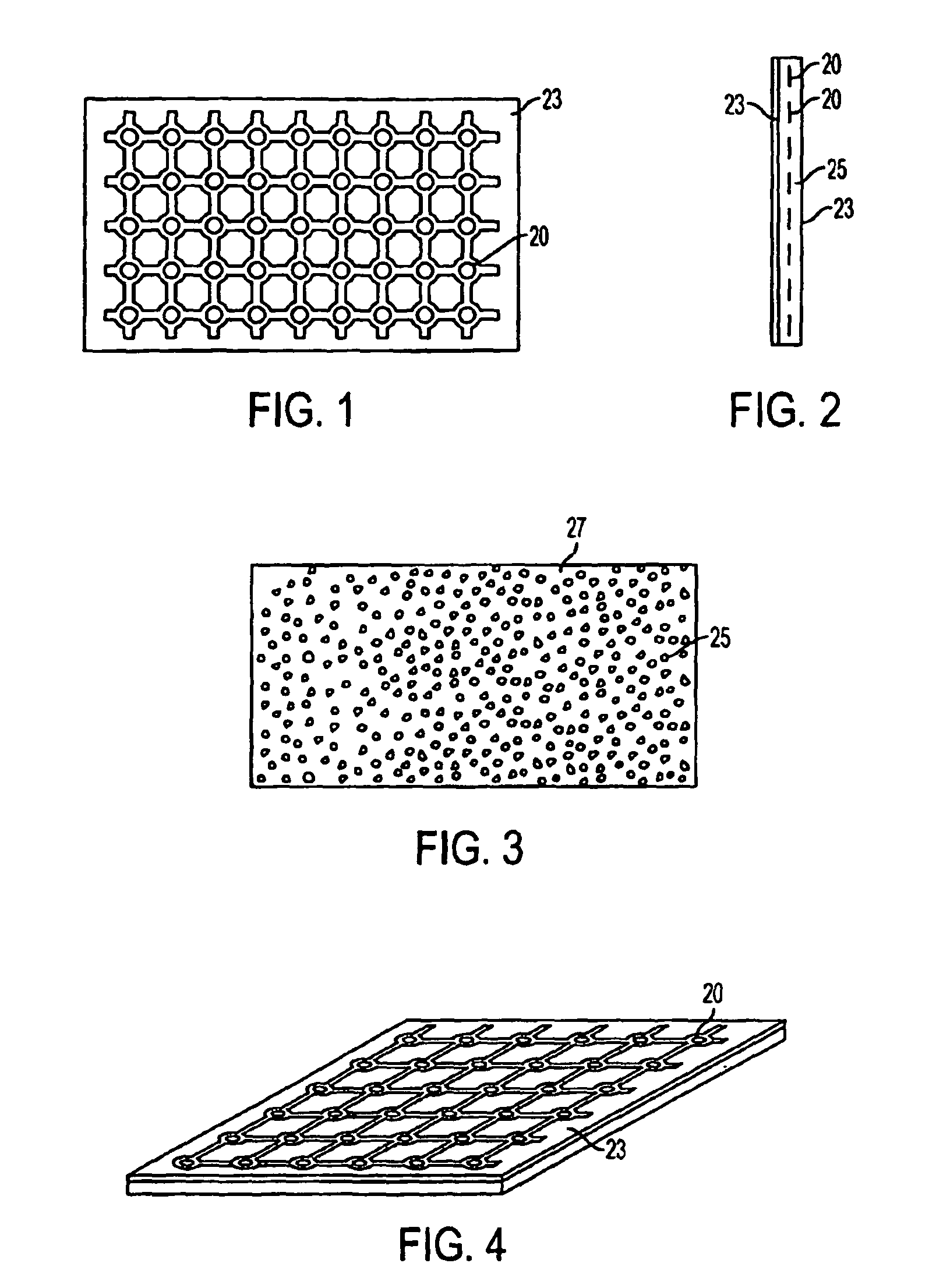

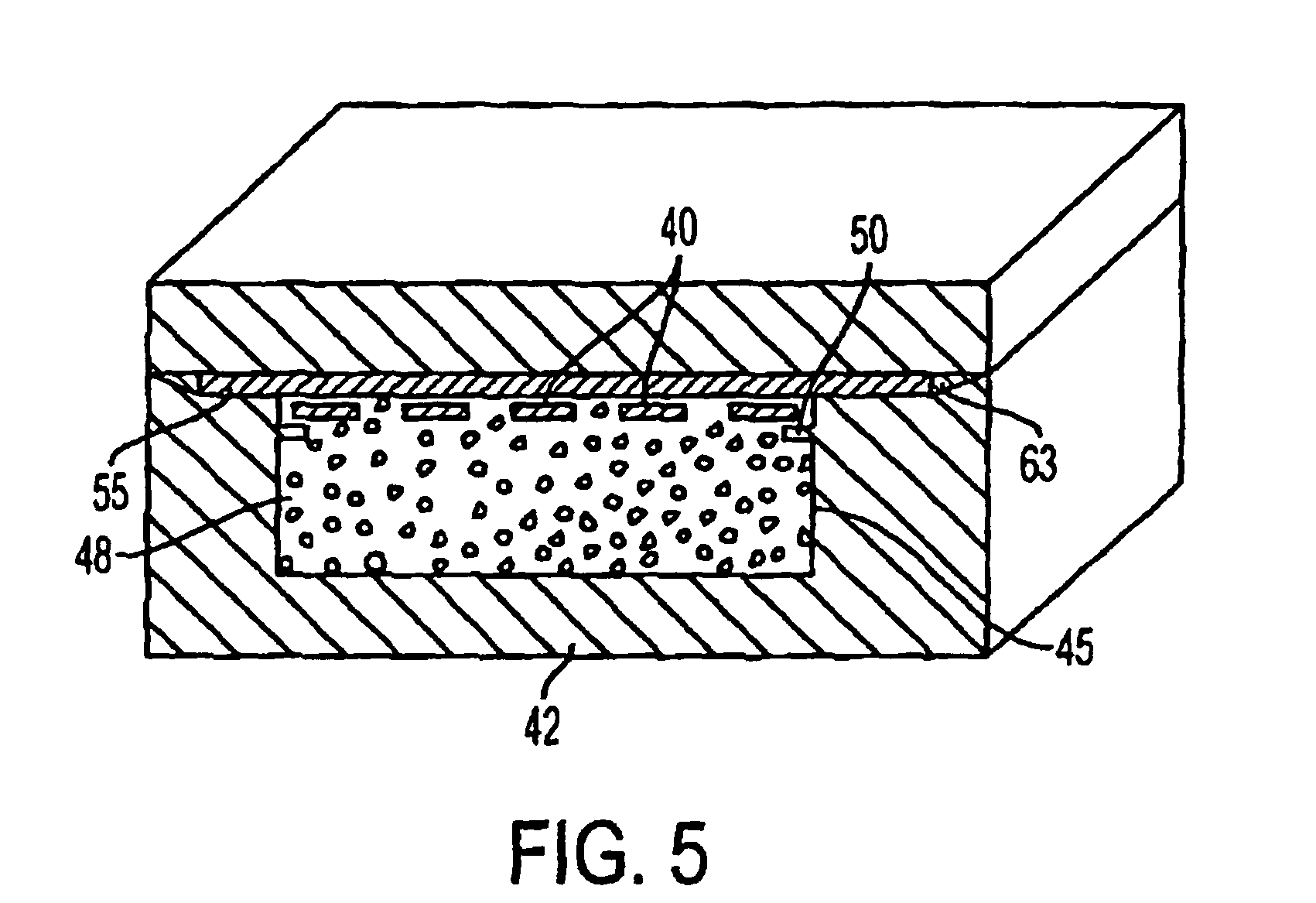

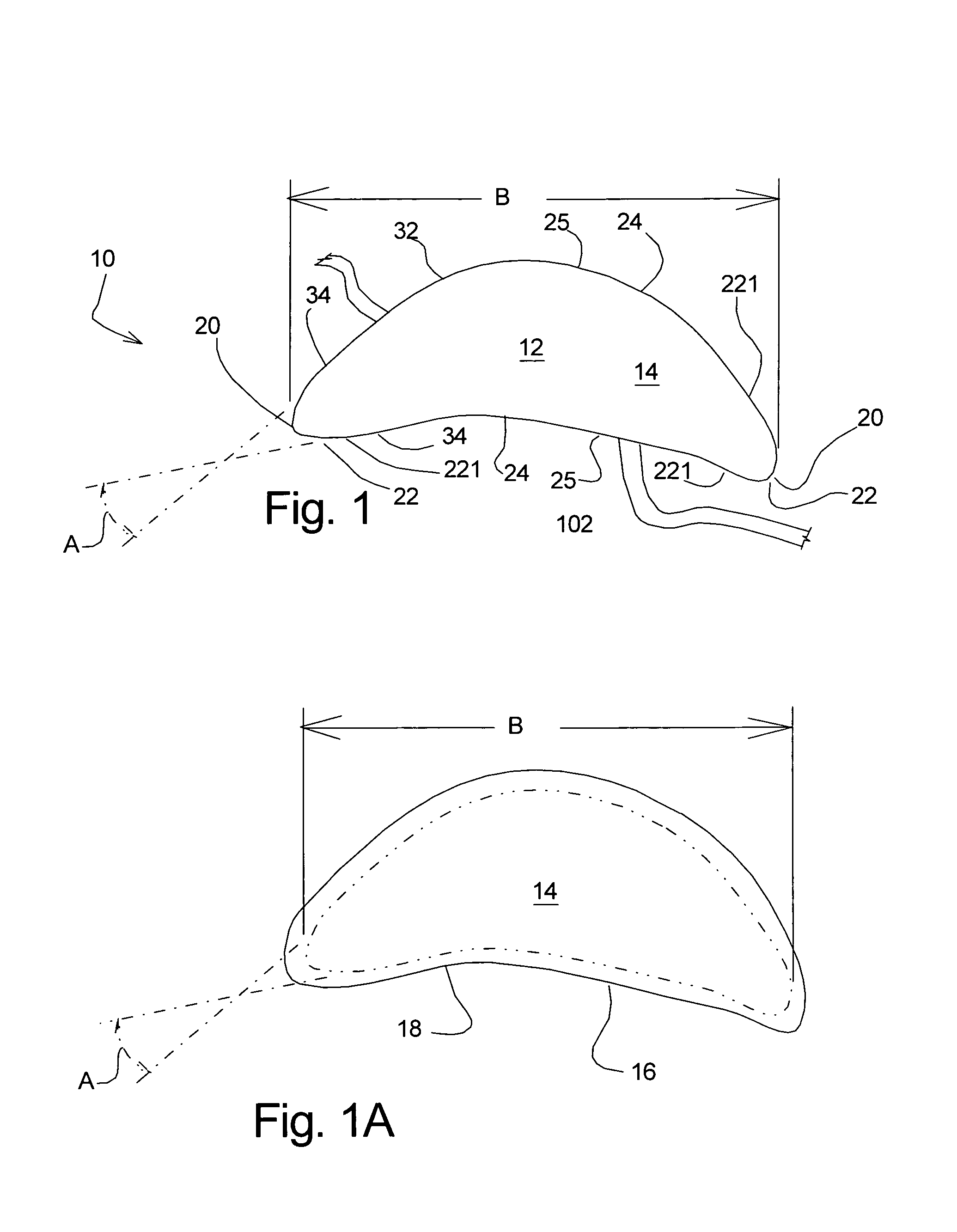

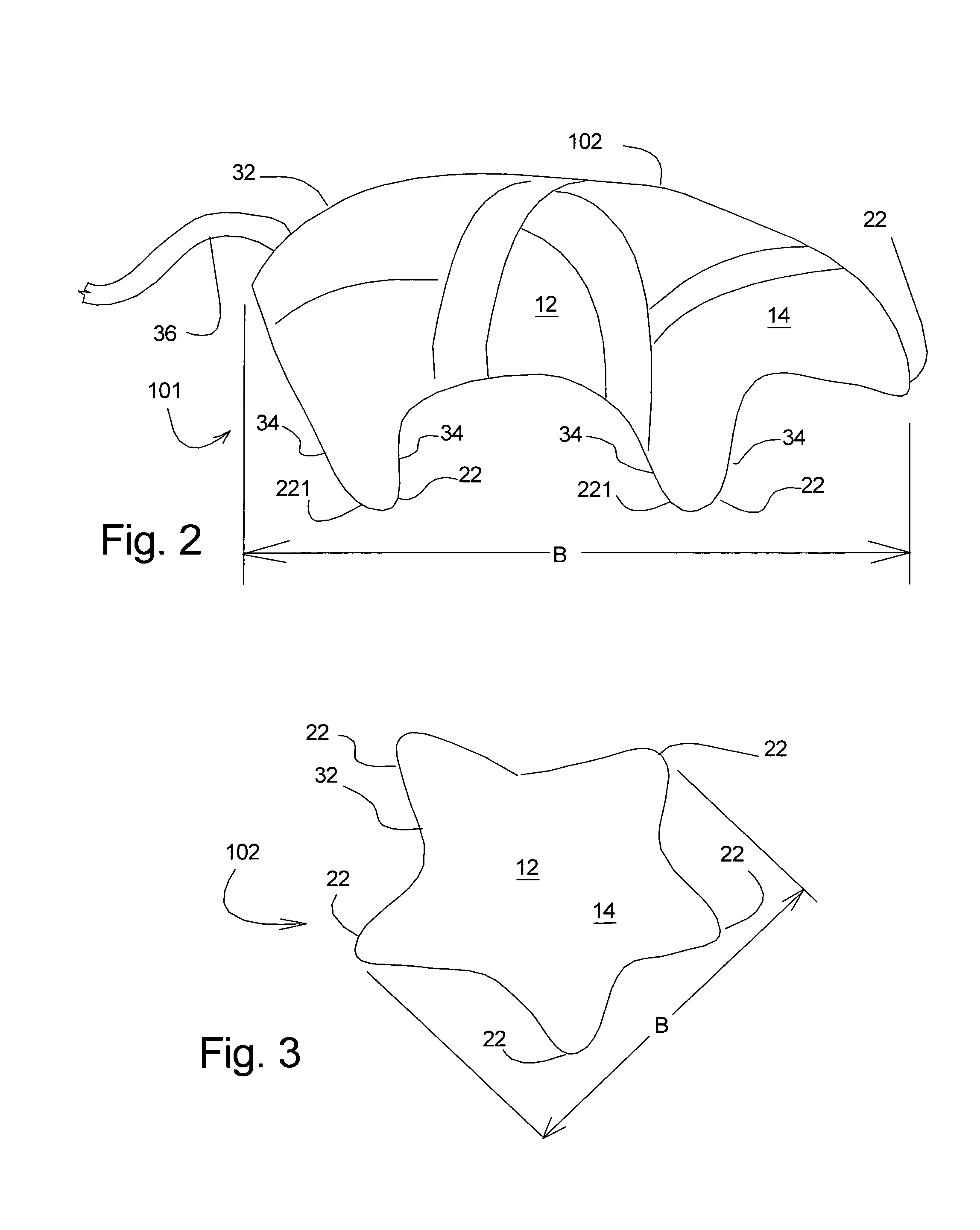

ActiveUS20060224242A1Readily cut and reshaped and bentCoatingsSkullCraniofacialBiomedical engineering

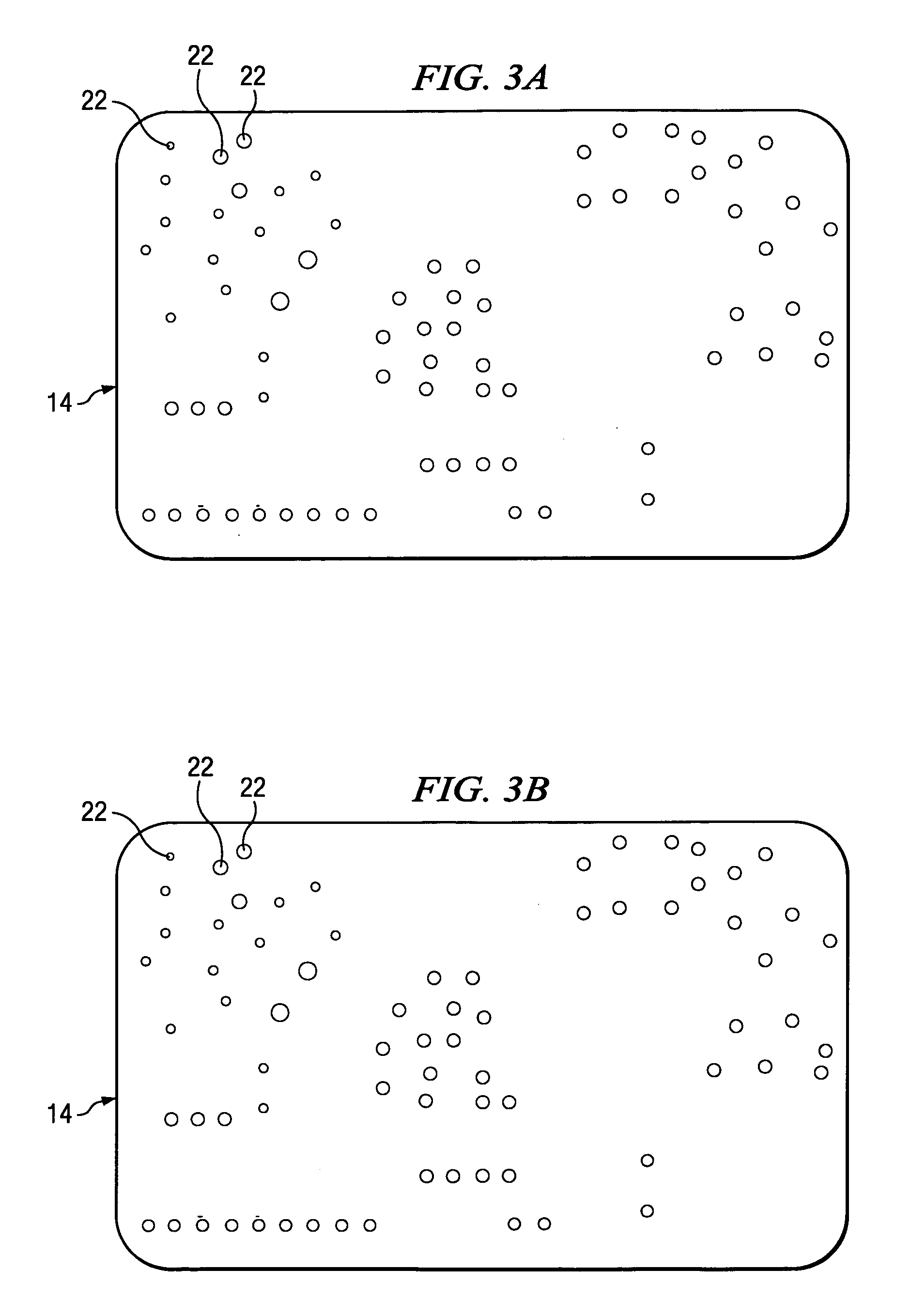

A composite surgical implant that is made of a planar sheet of a thermoplastic resin that includes a top surface, a bottom surface, and a surgical grade metal mesh or metal plates contained therein. The implant may be bent by hand, wherein upon the displacement of the implant, the implant will generally maintain the shape to which it has been displaced.

Owner:ORTHOVITA INC

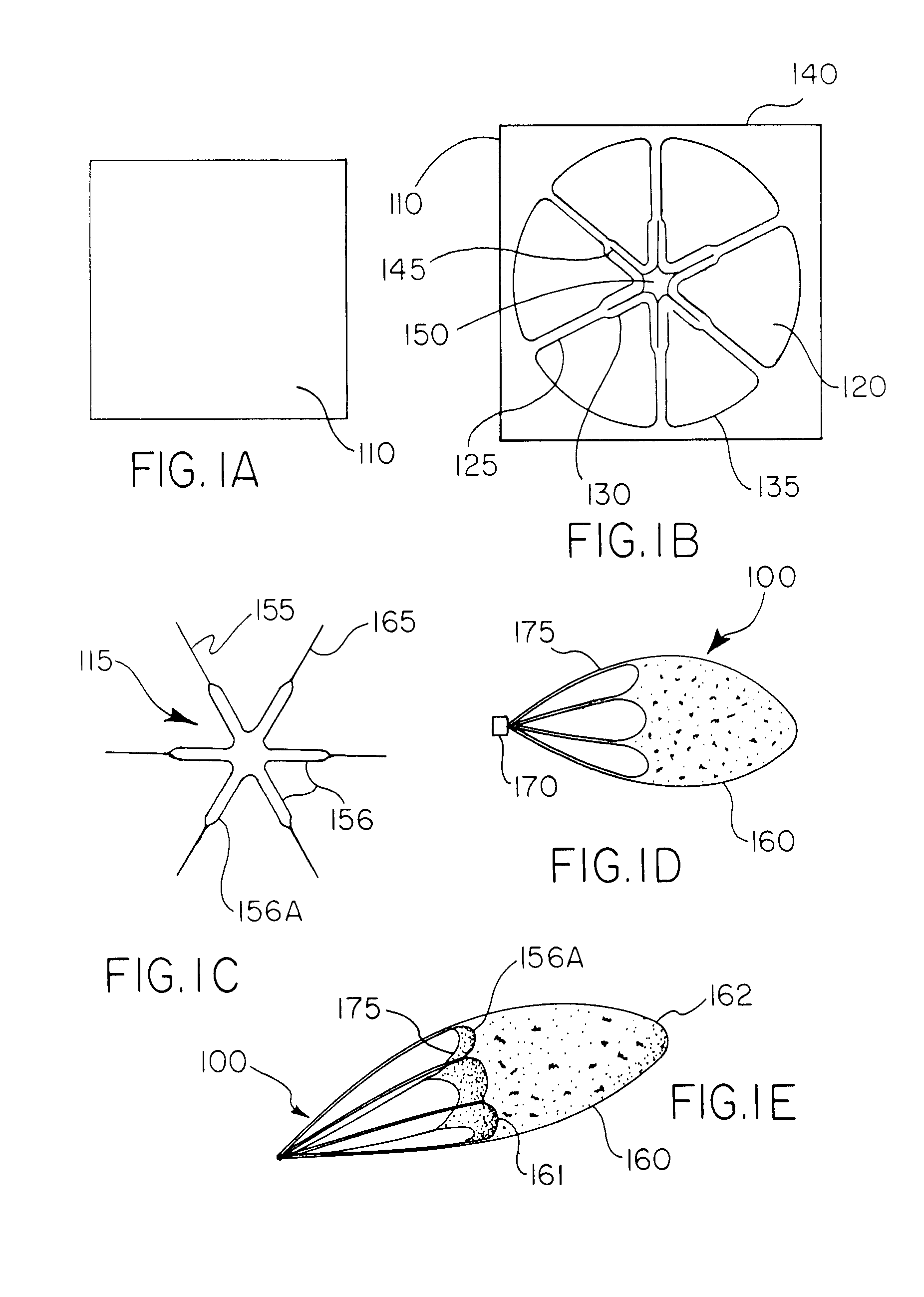

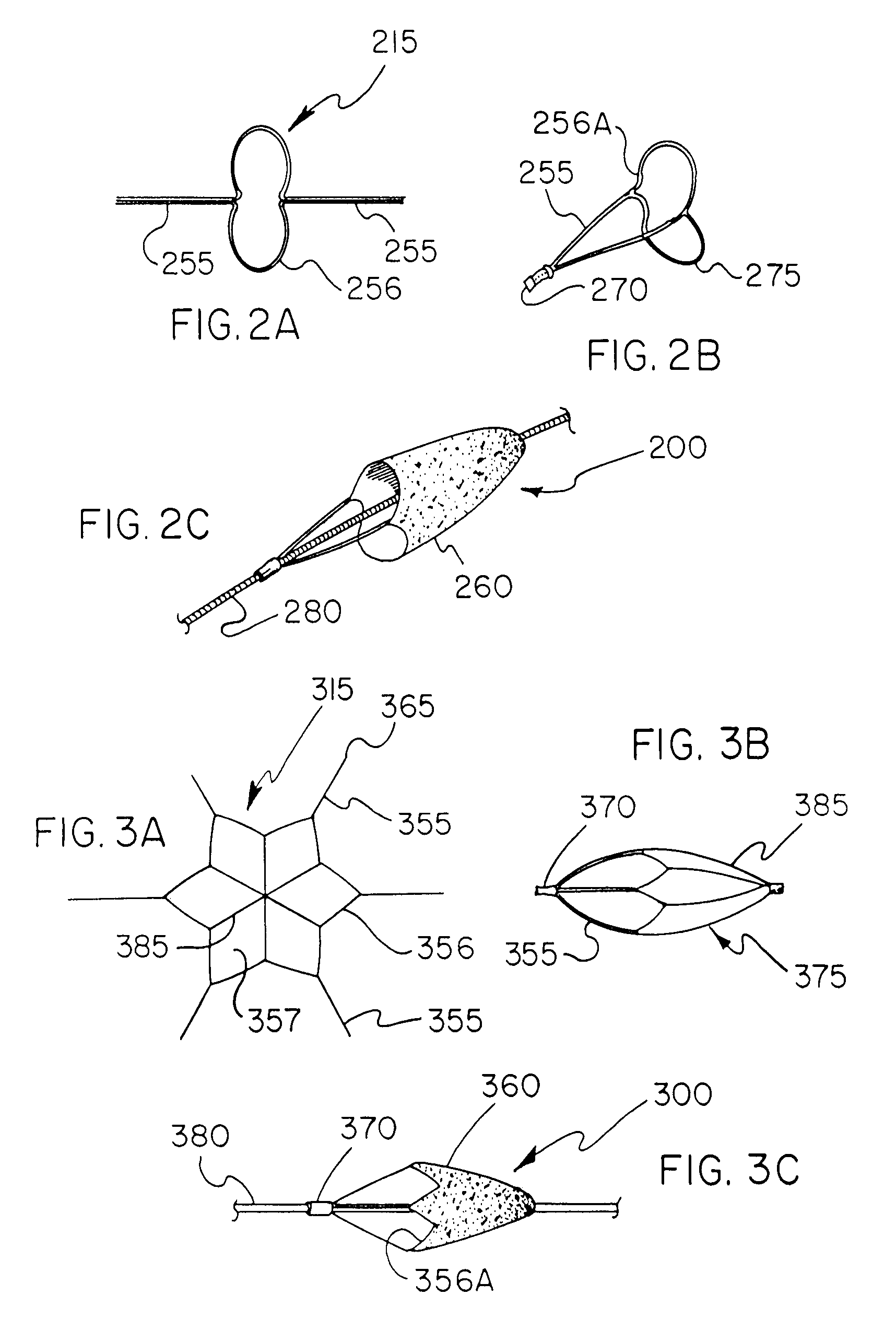

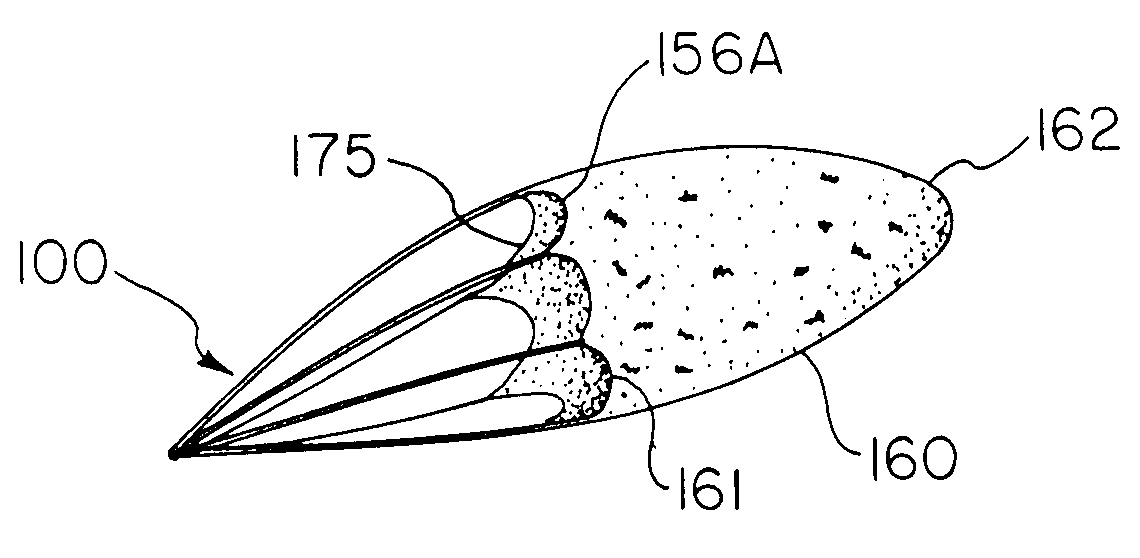

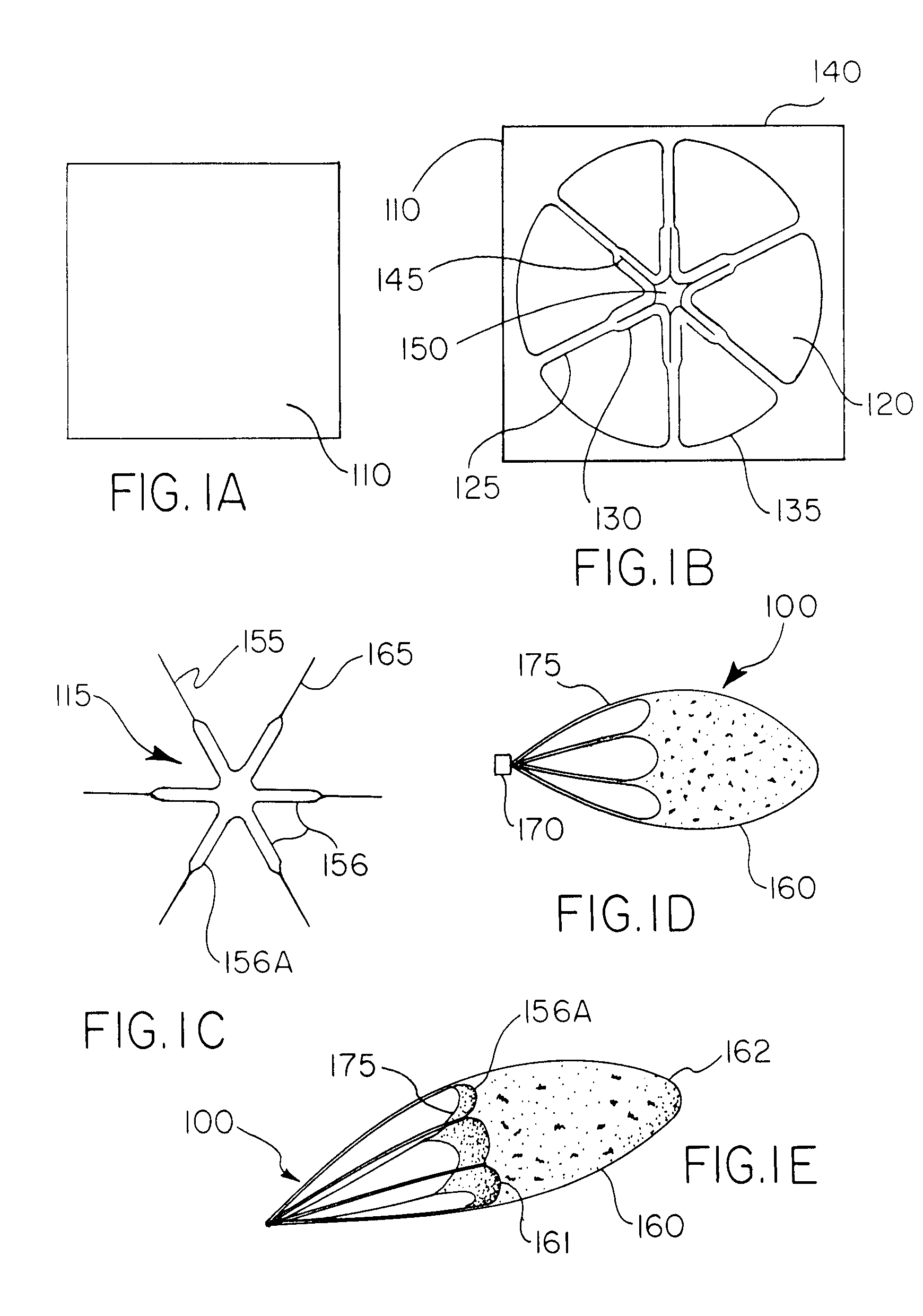

Methods of manufacture and use of endoluminal devices

Owner:WL GORE & ASSOC INC

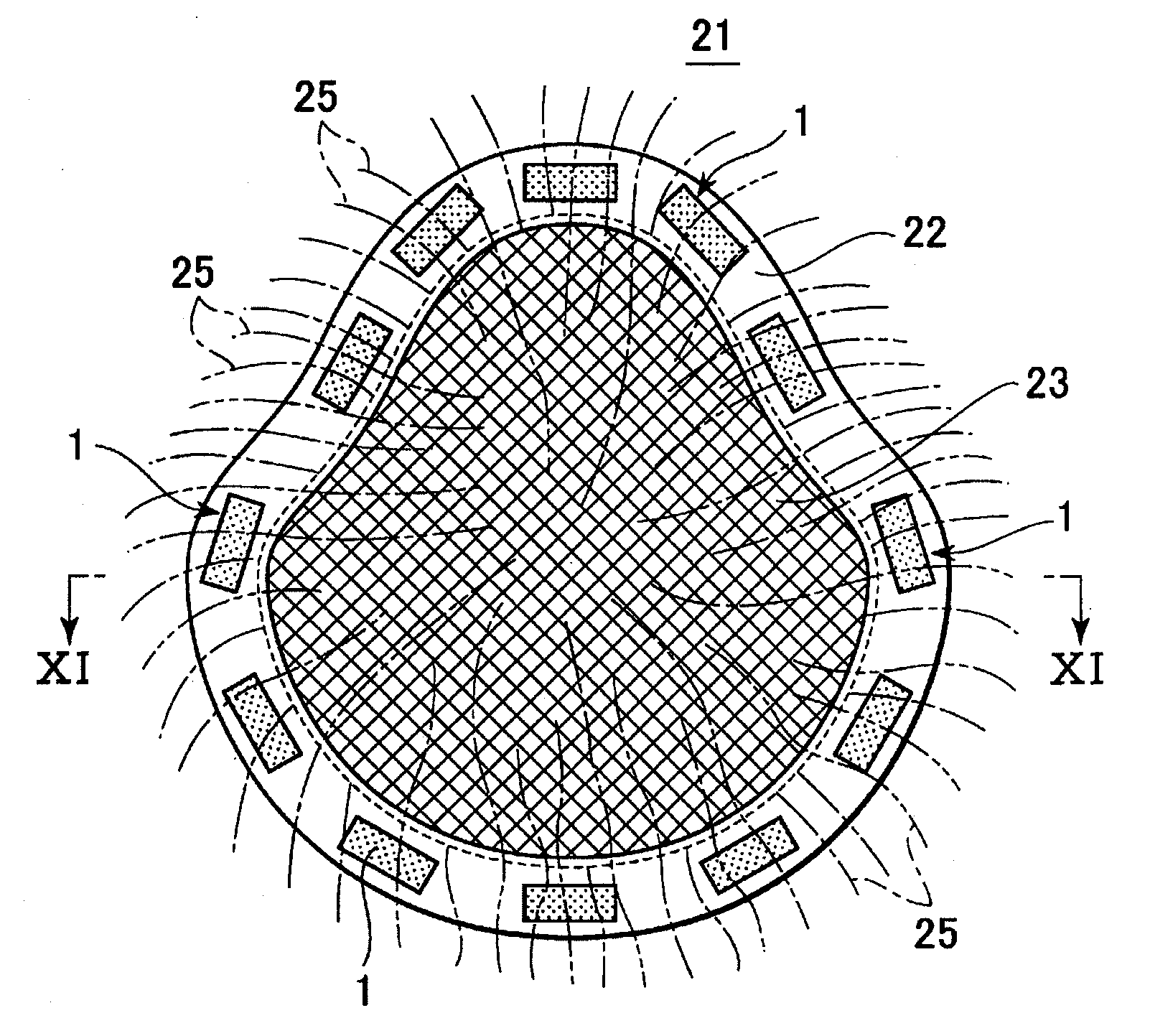

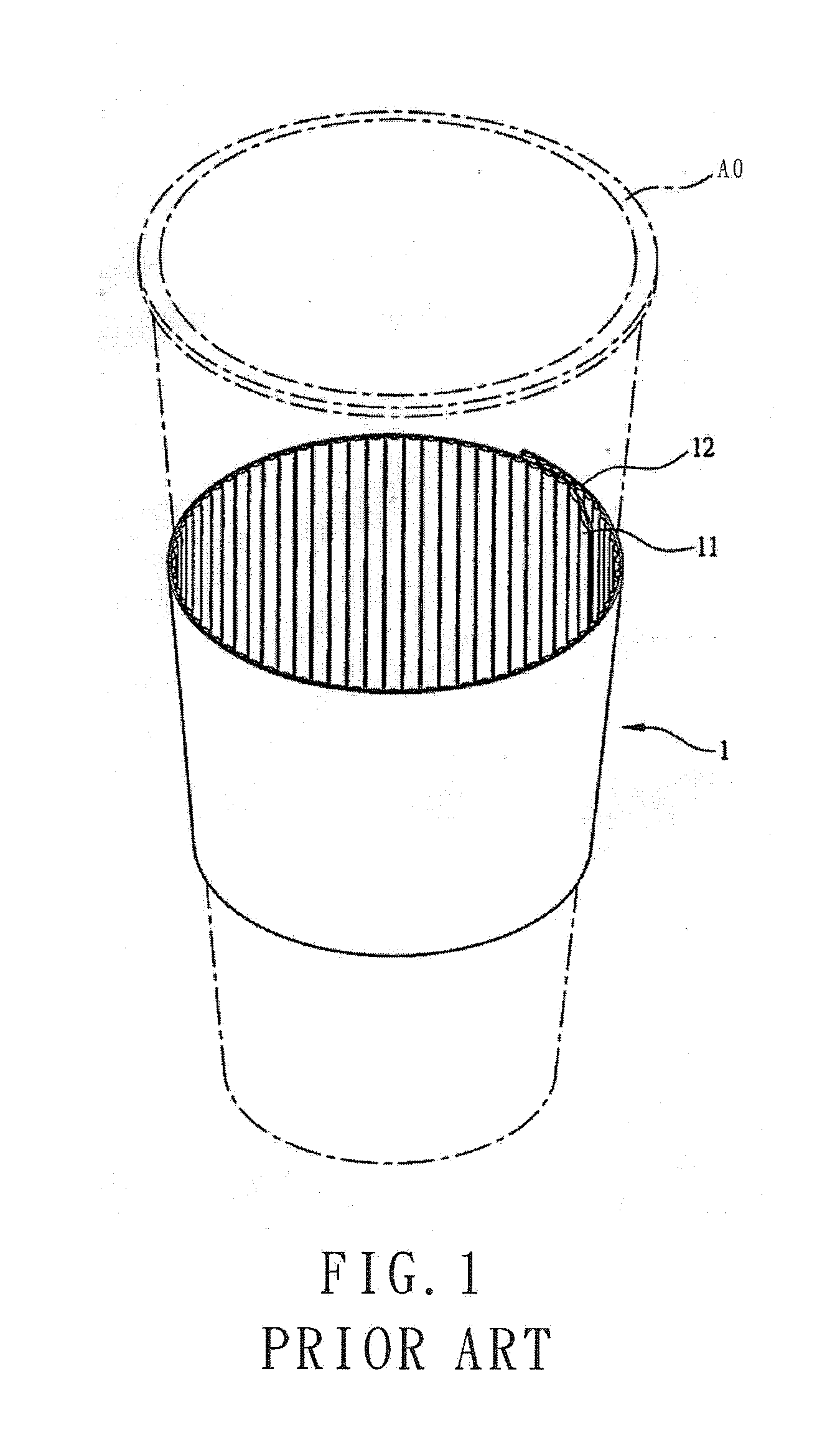

Endoluminal devices

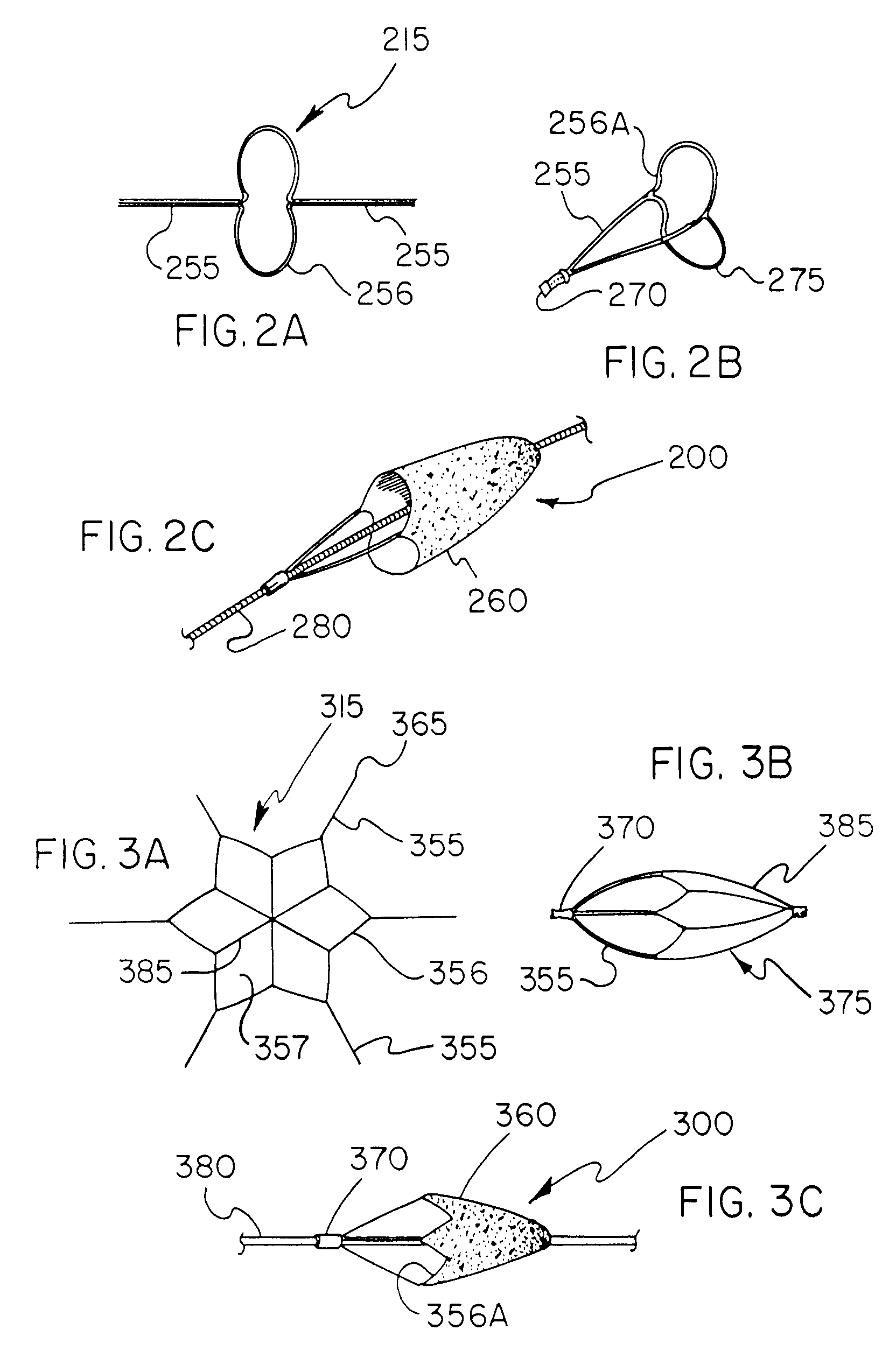

InactiveUS20050177186A1Sufficiently radiopaqueImprove capture efficiencyStentsDilatorsEtchingImplanted device

A seamless, self-expanding implantable device having a low profile is disclosed along with methods of making and using the same. The implantable device includes a frame cut out of a single piece of material that is formed into a three-dimensional shape. The implantable device may comprise an embolic filter, stent, or other implantable structure. The present invention also allows complicated frame structures to be easily formed from planar sheets of starting material, such as through laser cutting, stamping, photo-etching, or other cutting techniques.

Owner:WL GORE & ASSOC INC

Imaging devices and methods

Owner:INT TECH CENT

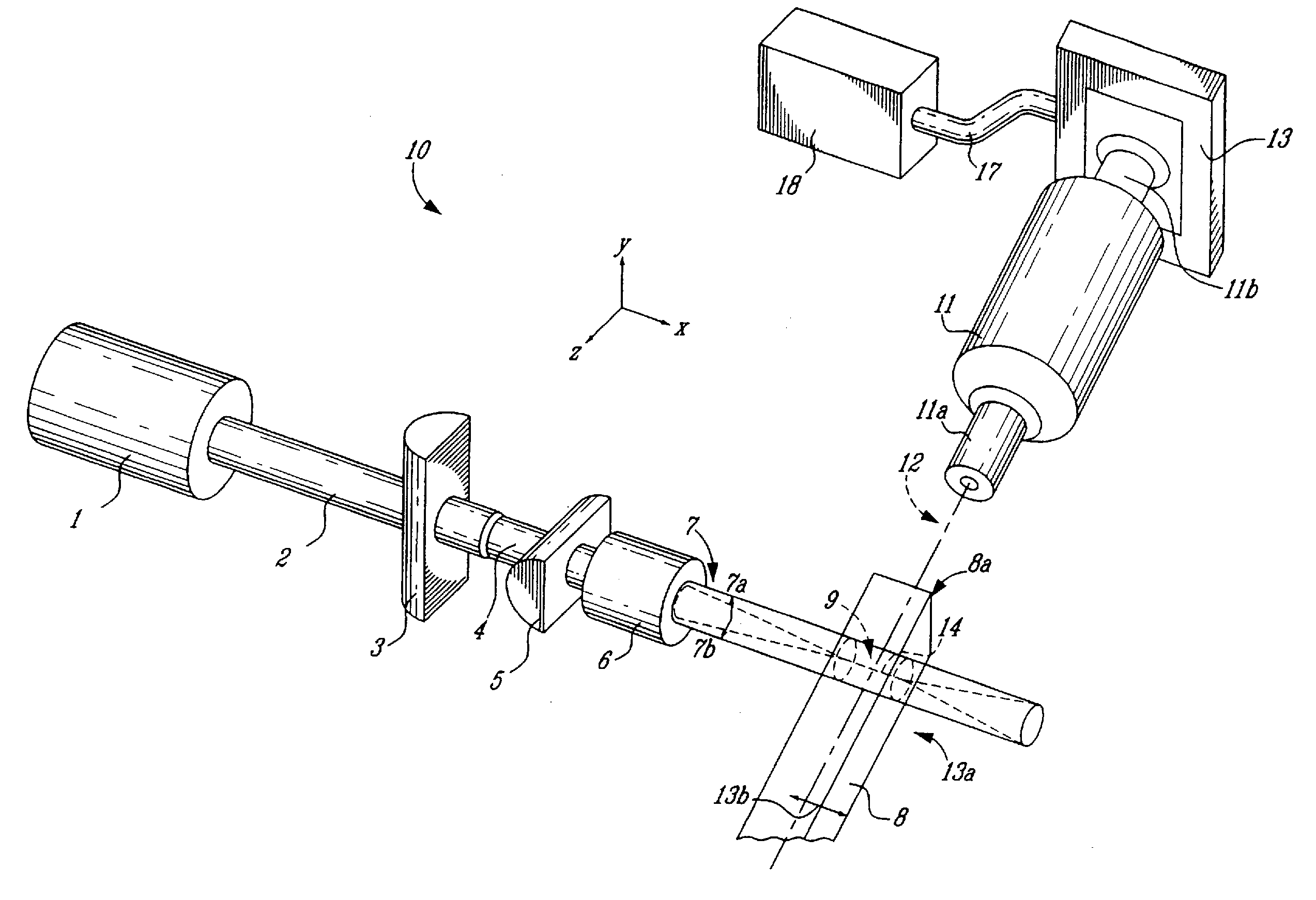

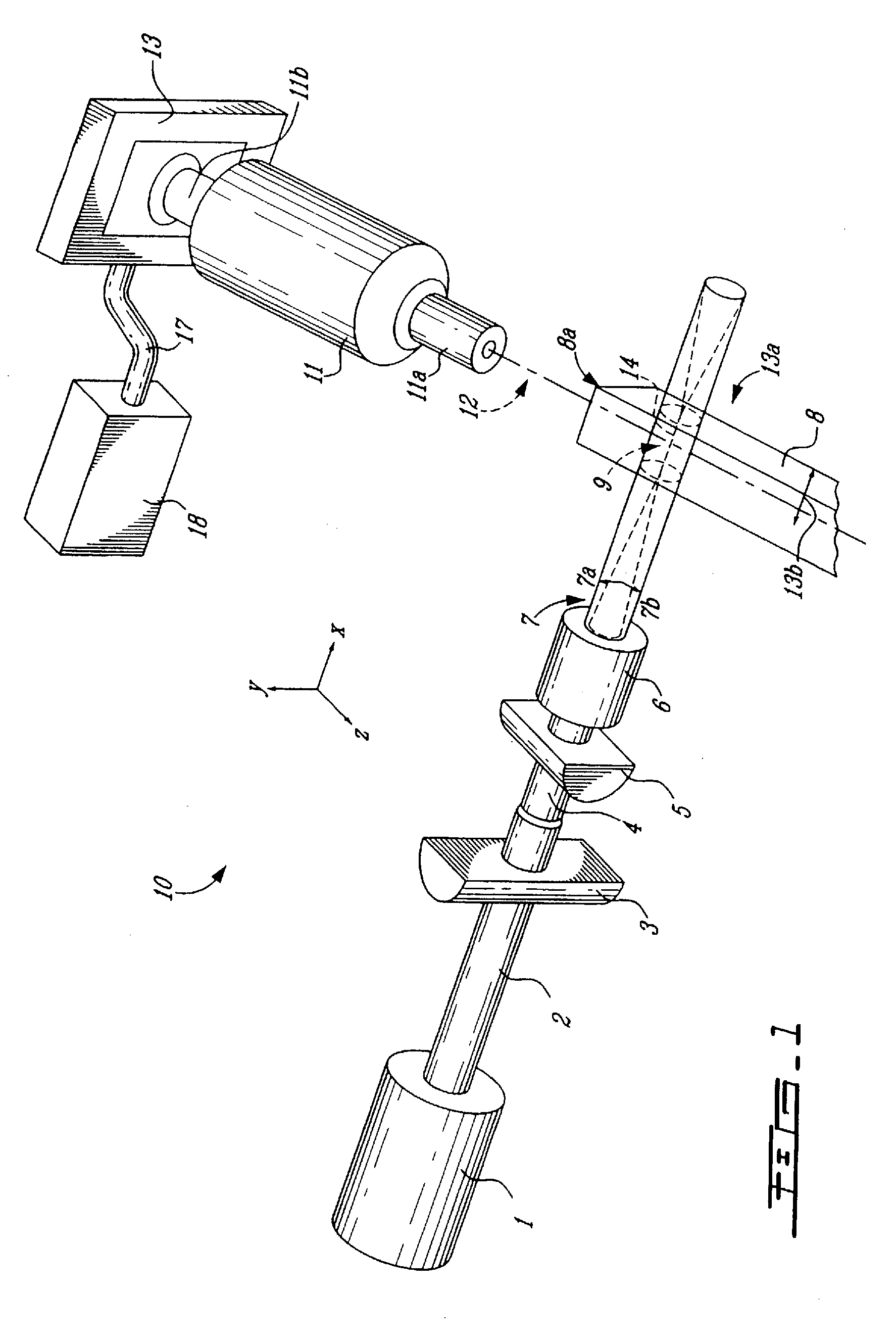

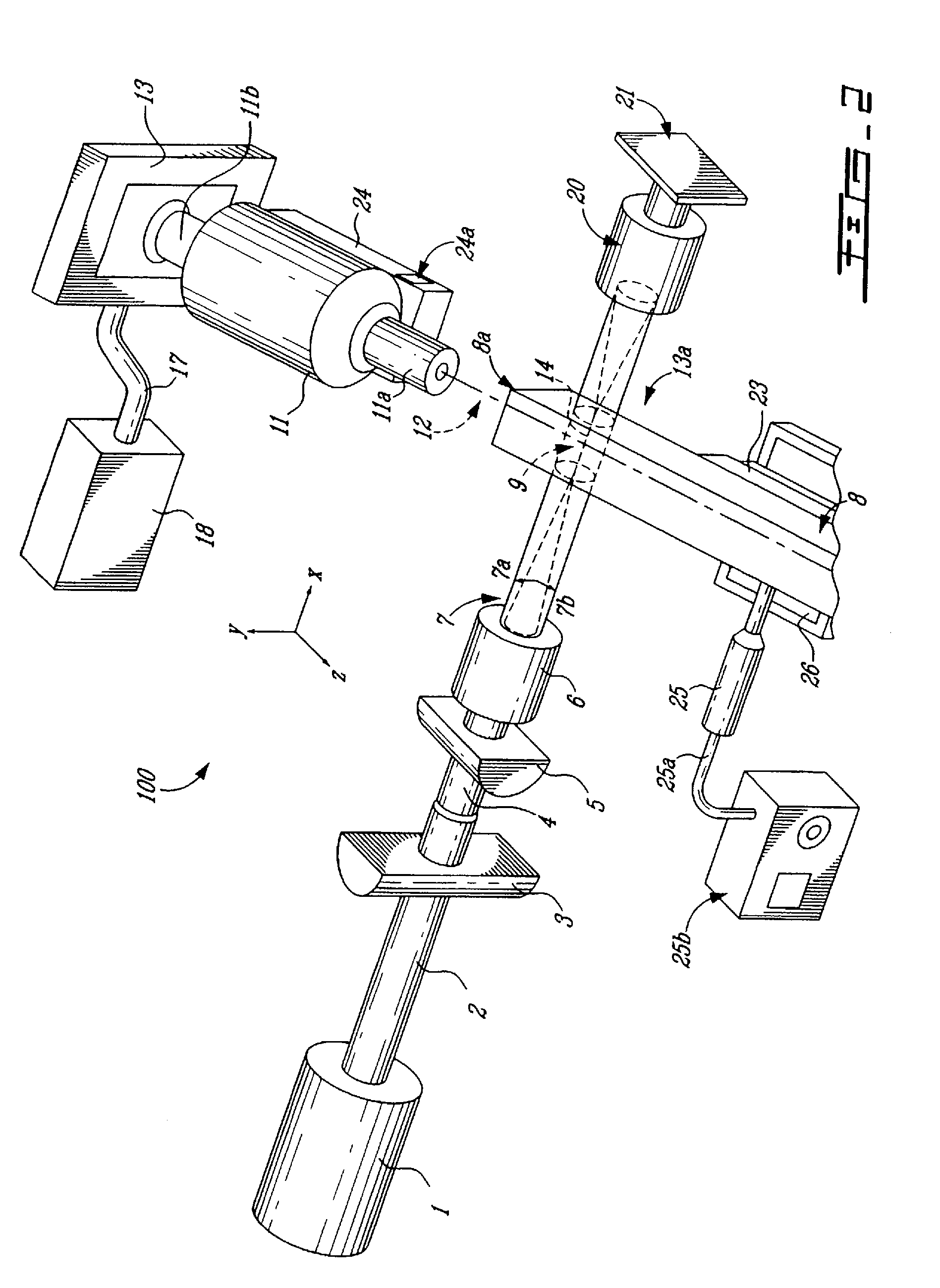

Light Profile Microscopy Apparatus and Method

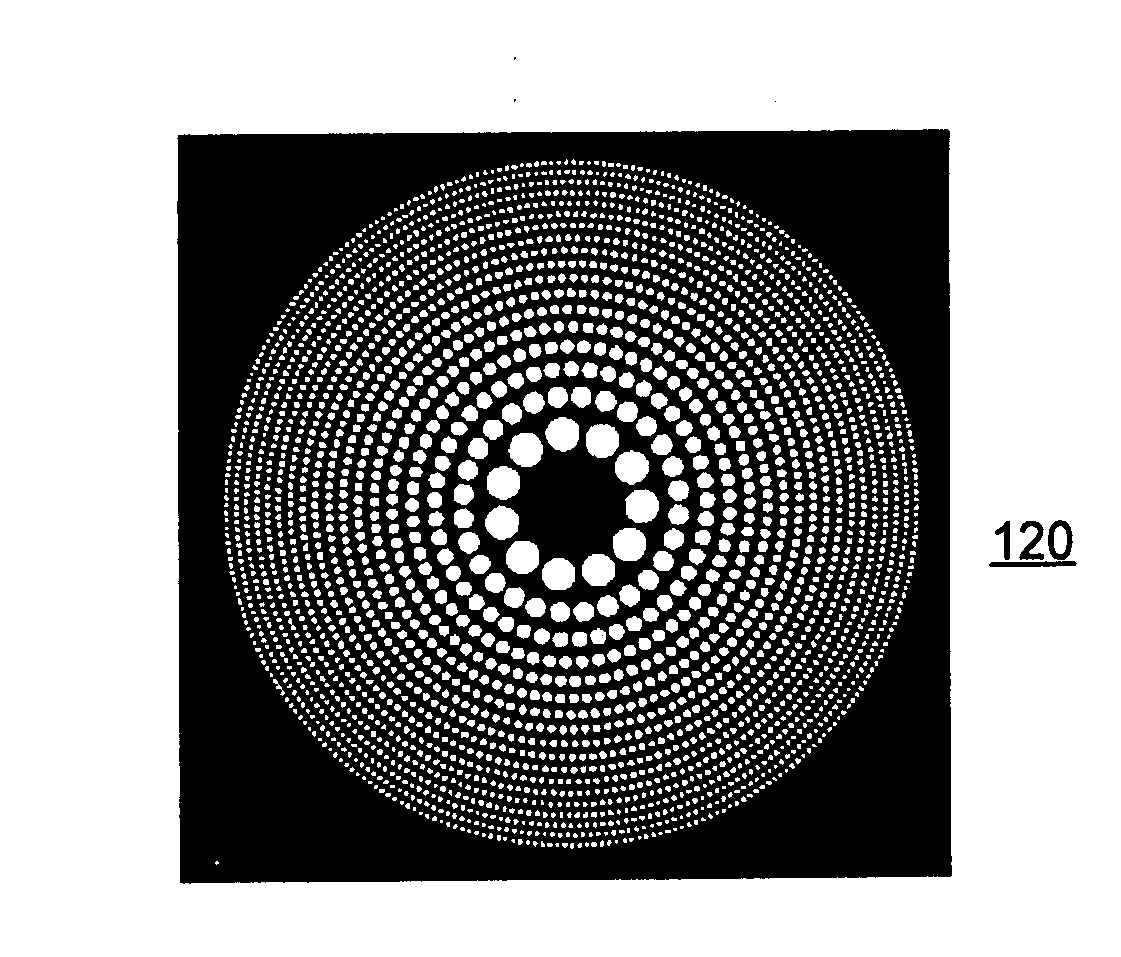

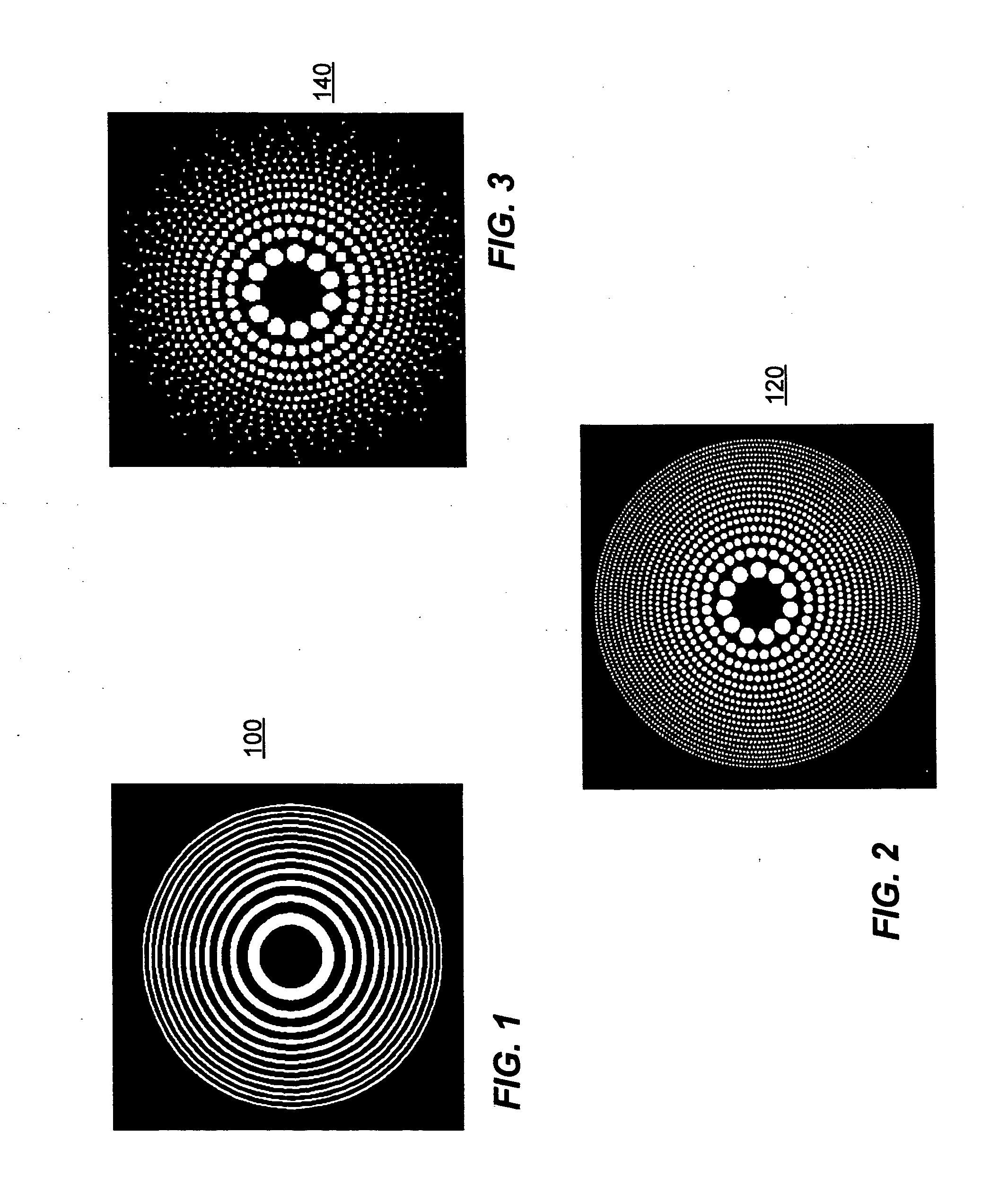

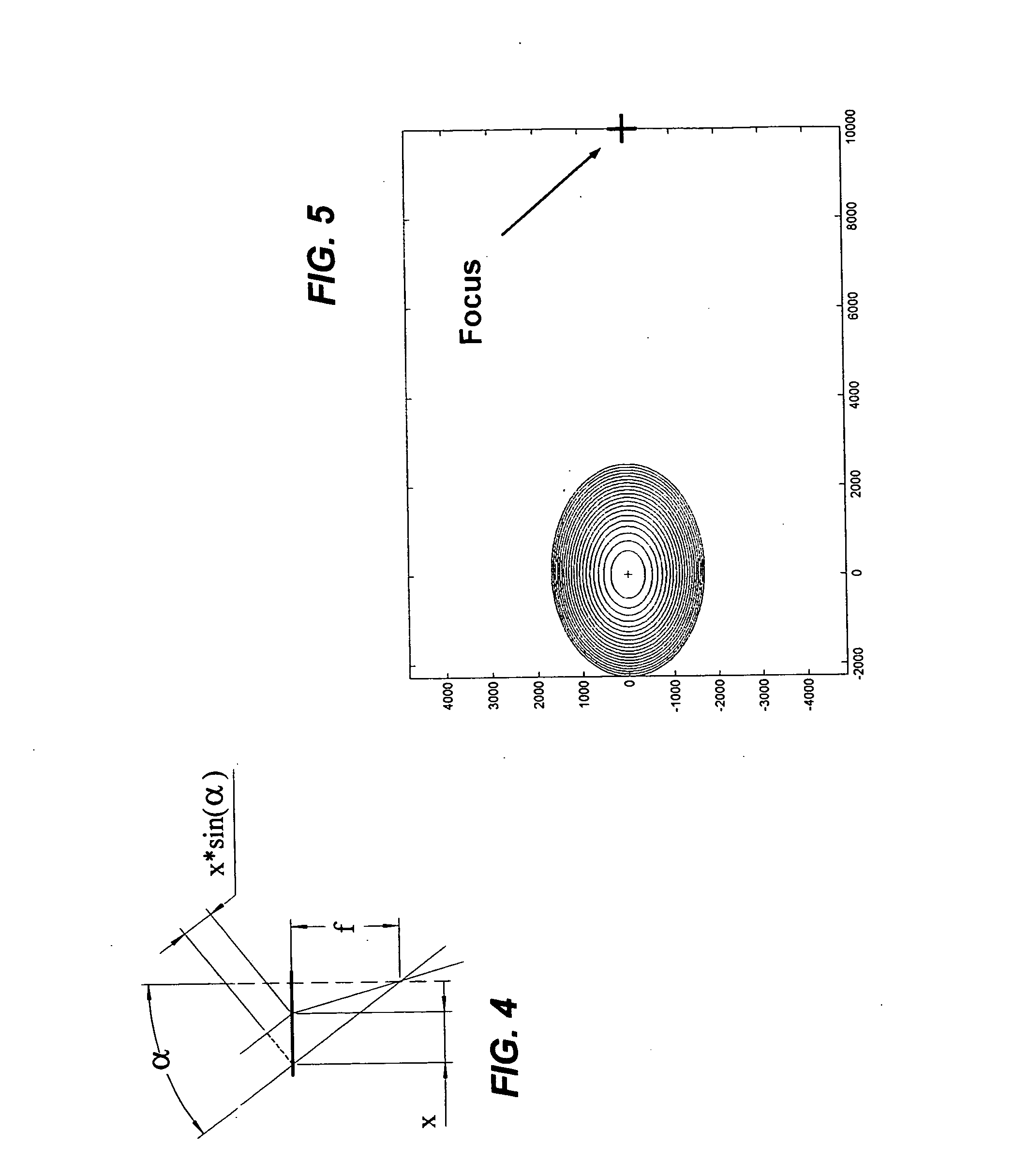

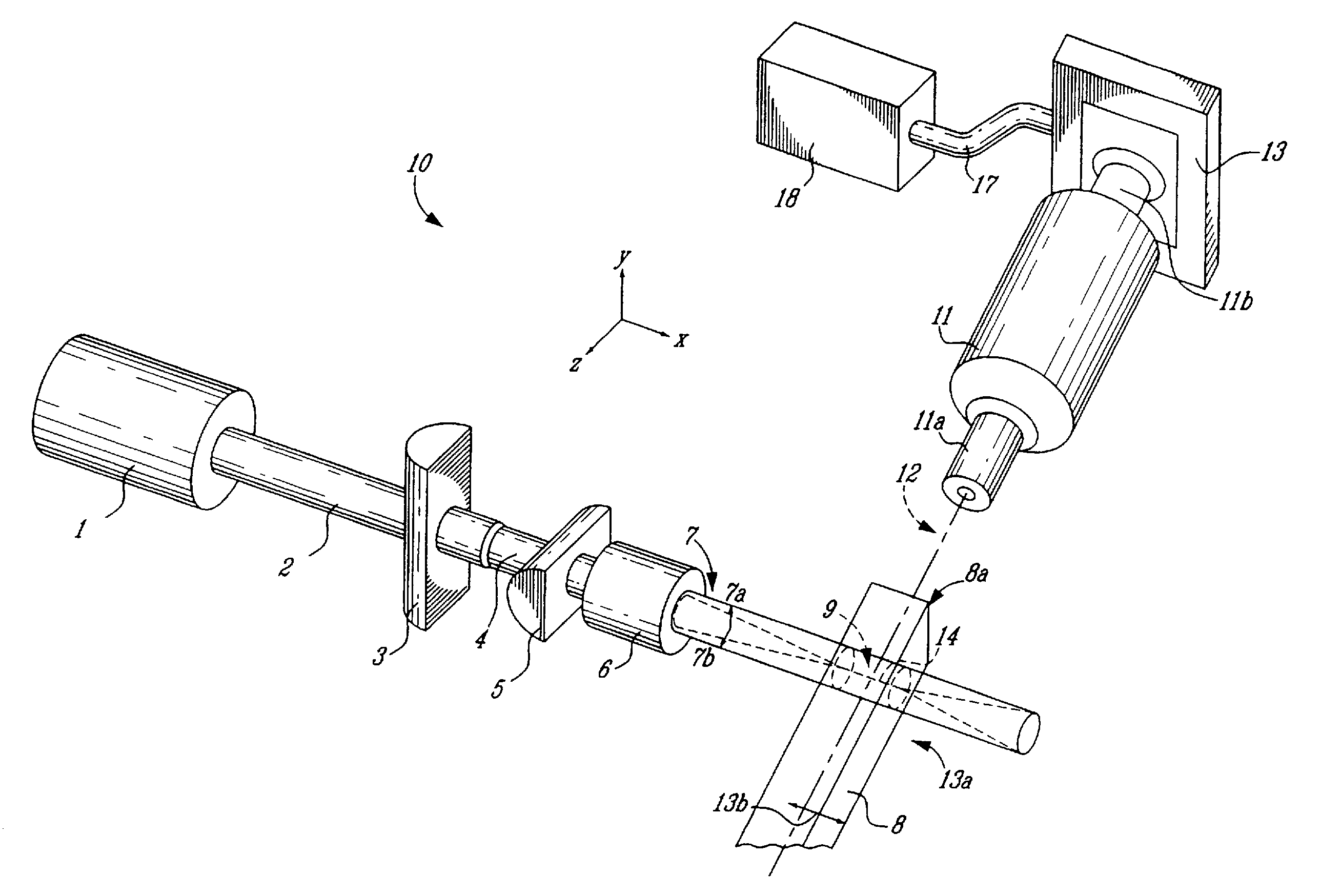

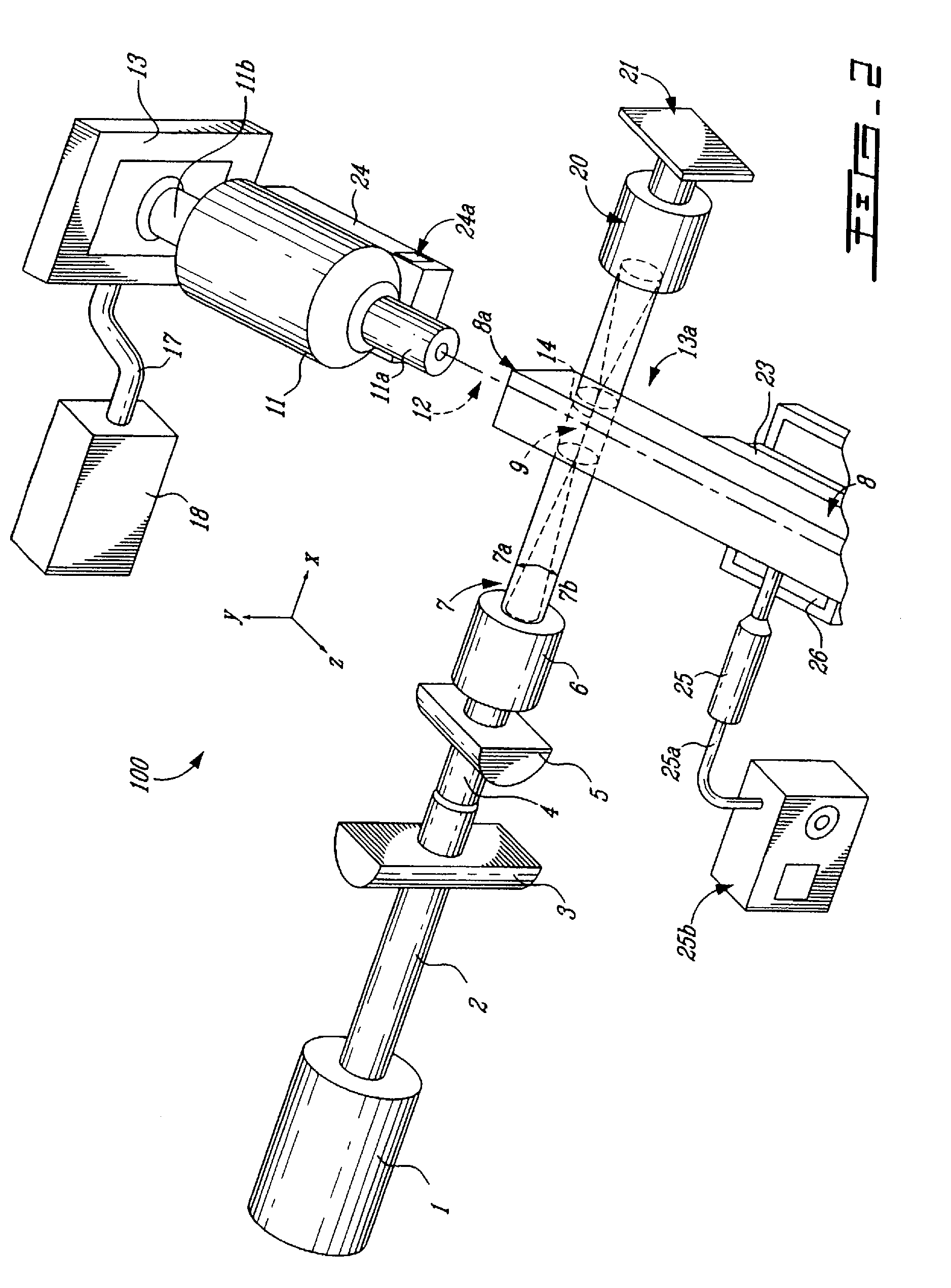

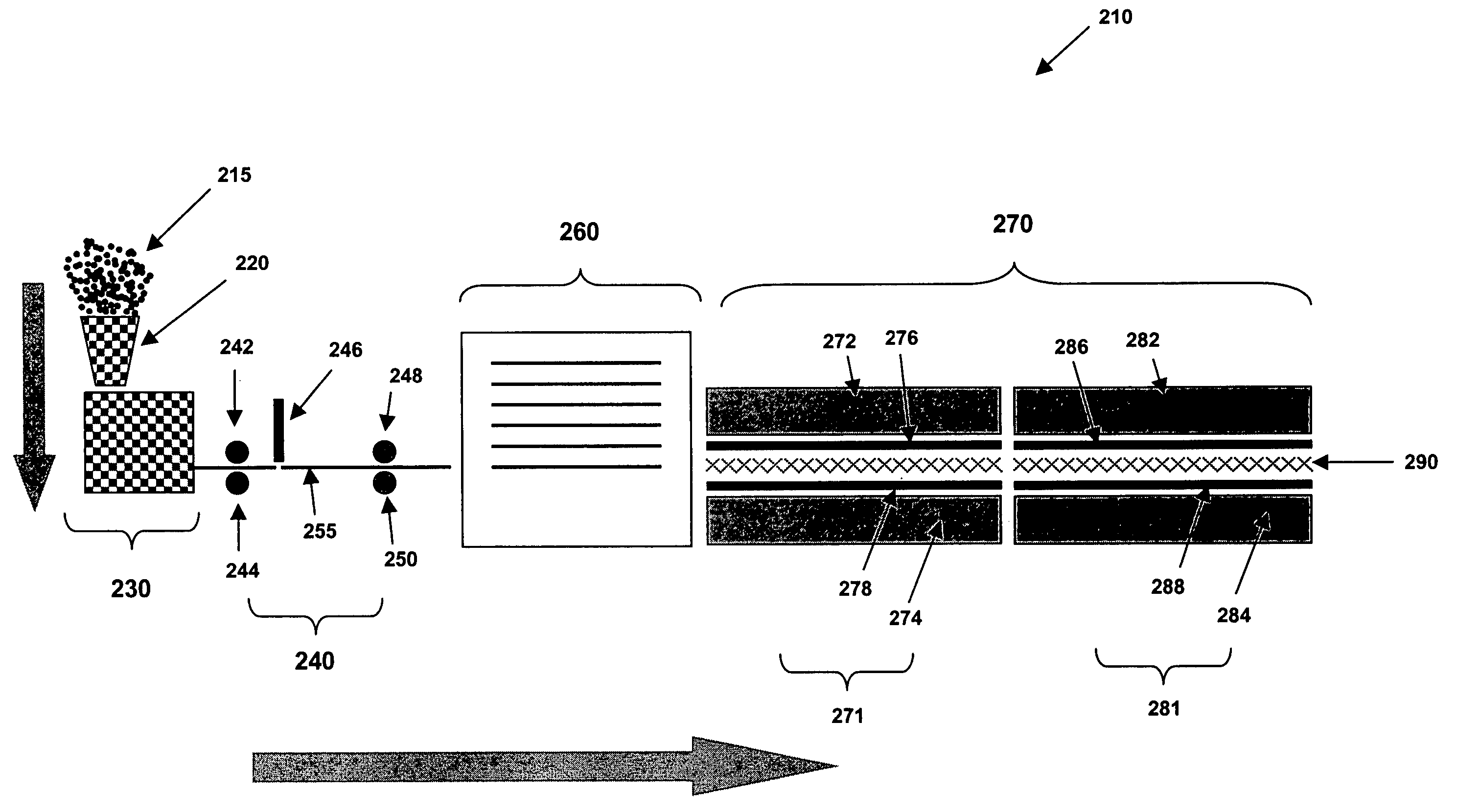

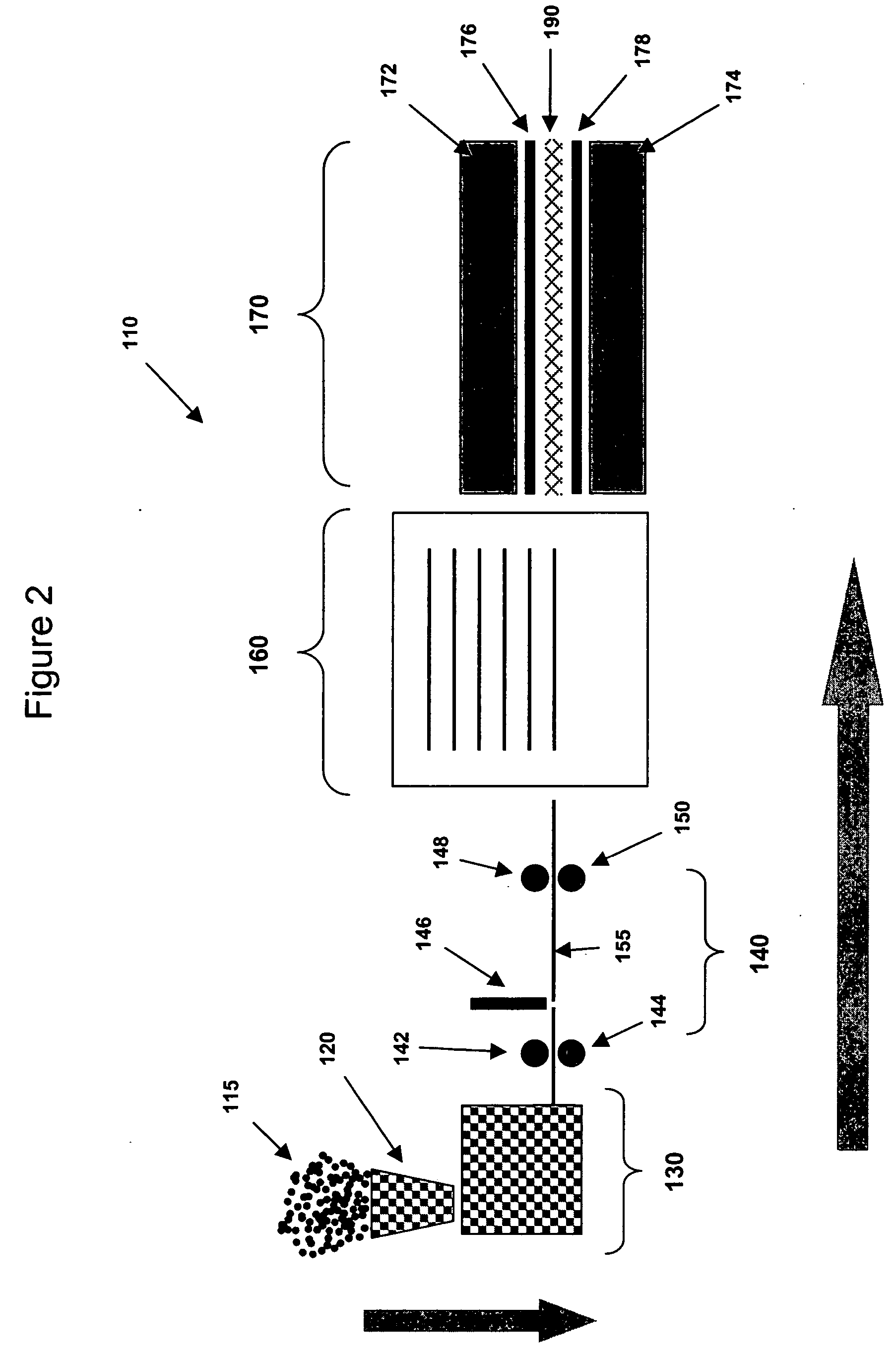

InactiveUS20080218850A1High image resolutionWide image fieldMaterial analysis by optical meansMicroscopesImage resolutionEllipse

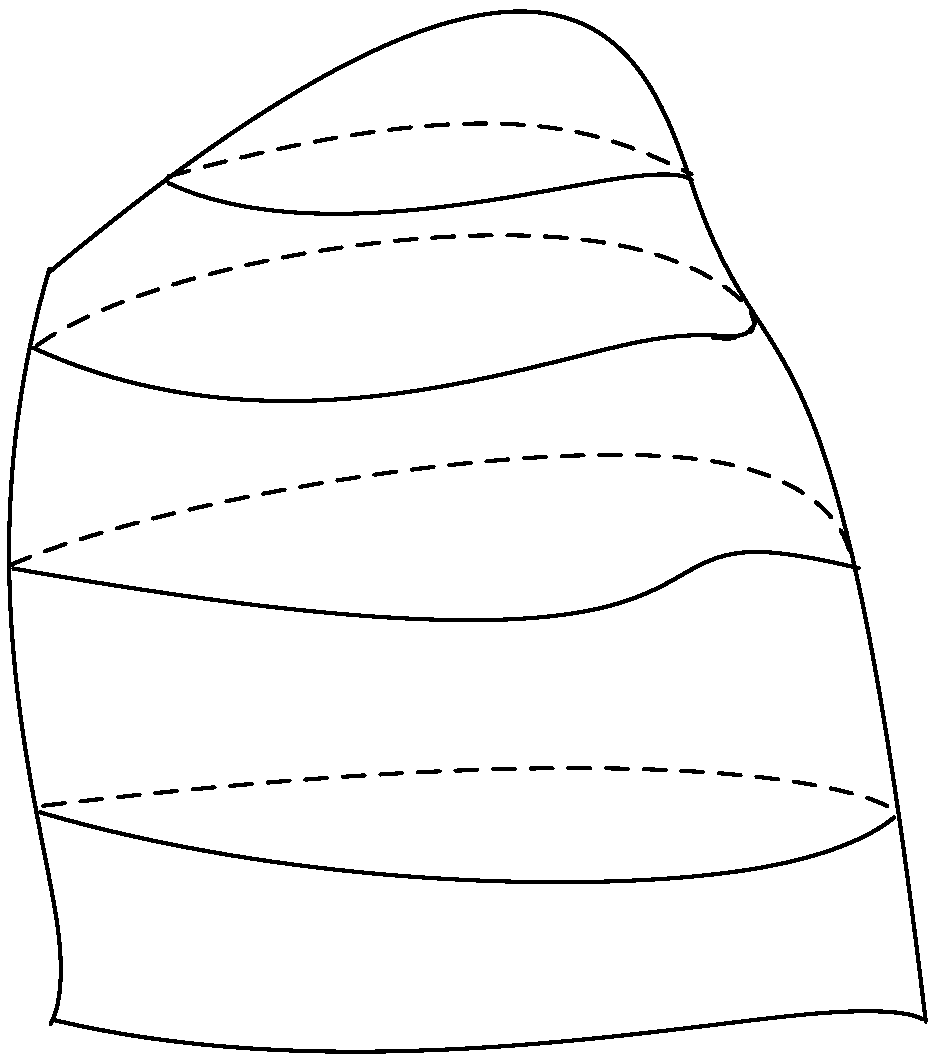

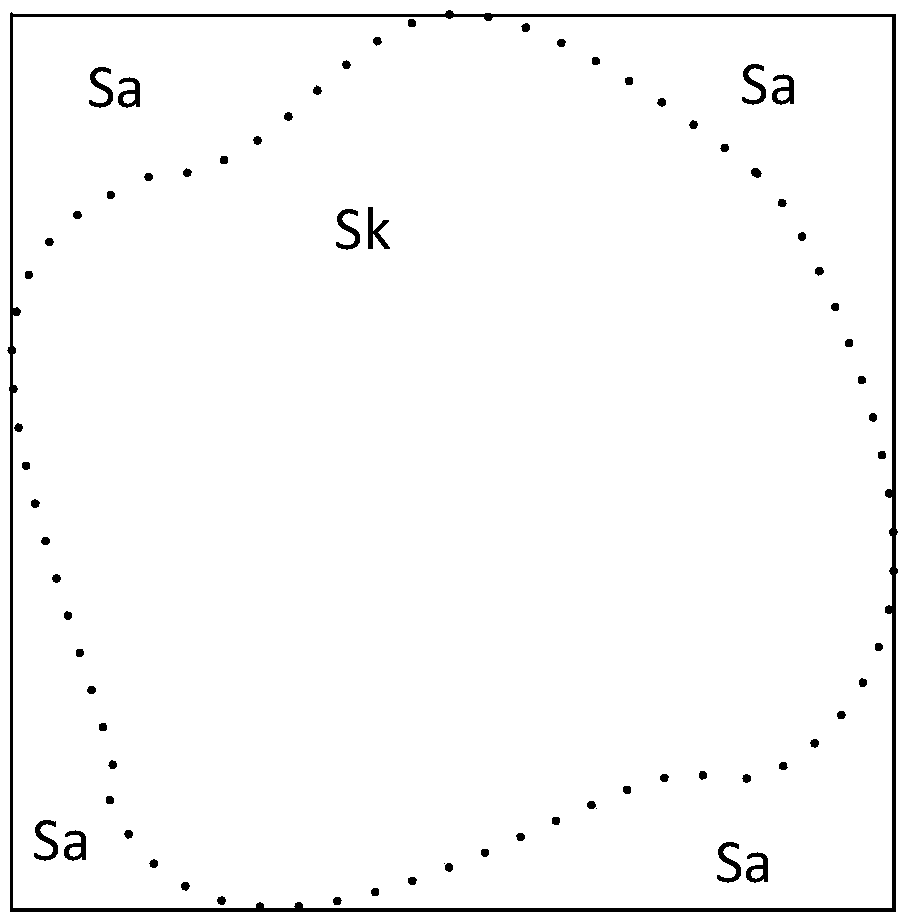

An apparatus and method allowing an optimized illumination in a light profile microscope by excitation of a sample with an elliptically collimated beam. The beam, which is typically supplied by a laser is collimated with unequal beam waist radii (and Rayleigh ranges) along major and minor axes orthogonal to a propagation direction, and approximates a plane sheet of illumination. The plane sheet of illumination is aligned with a thinnest width dimension thereof along the optic axis of the microscope objective, and with a center thereof at the object plane of the objective. Excitation light in a test sample is thereby confined to within a narrow thickness of the object plane of the objective lens, which minimizes out-of focus light in the image. The major axis width of the plane illumination sheet is typically a factor of ten or more greater than the minimum width, allowing a large area of the test sample to be illuminated and imaged. This excitation arrangement optically emulates the operation of micro-toming a thin cross section of a material for analysis, and provides optimum resolution and field in a light profile microscope.

Owner:POWER JOAN F

Craniofacial implant

Owner:HOWMEDICA OSTEONICS CORP

Light profile microscopy apparatus and method

InactiveUS7538879B2High image resolutionWide image fieldMaterial analysis by optical meansMicroscopesImage resolutionEllipse

An apparatus and method allowing an optimized illumination in a light profile microscope by excitation of a sample with an elliptically collimated beam. The beam, which is typically supplied by a laser is collimated with unequal beam waist radii (and Rayleigh ranges) along major and minor axes orthogonal to a propagation direction, and approximates a plane sheet of illumination. The plane sheet of illumination is aligned with a thinnest width dimension thereof along the optic axis of the microscope objective, and with a center thereof at the object plane of the objective. Excitation light in a test sample is thereby confined to within a narrow thickness of the object plane of the objective lens, which minimizes out-of focus light in the image. The major axis width of the plane illumination sheet is typically a factor of ten or more greater than the minimum width, allowing a large area of the test sample to be illuminated and imaged. This excitation arrangement optically emulates the operation of micro-toming a thin cross section of a material for analysis, and provides optimum resolution and field in a light profile microscope.

Owner:POWER JOAN F

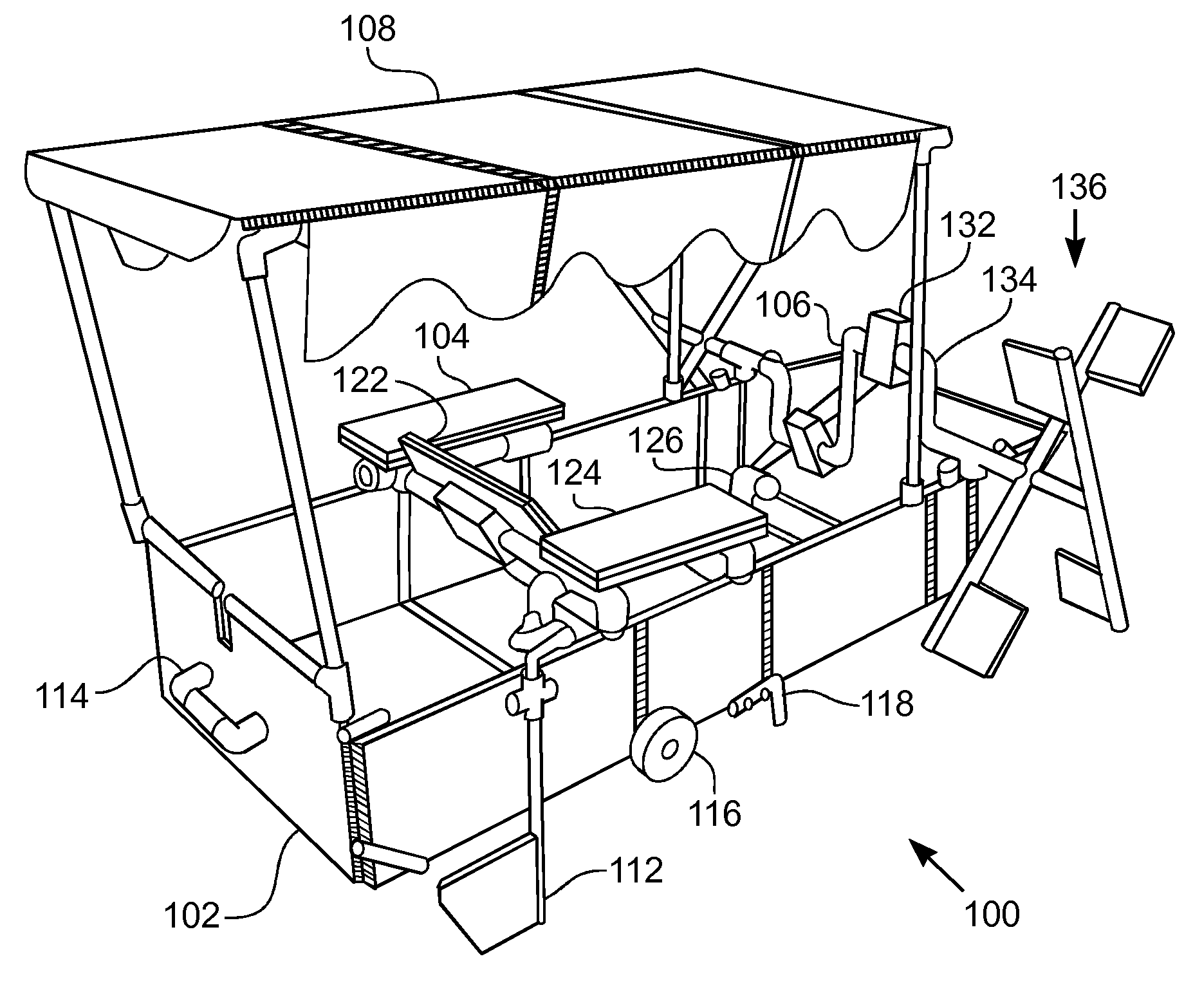

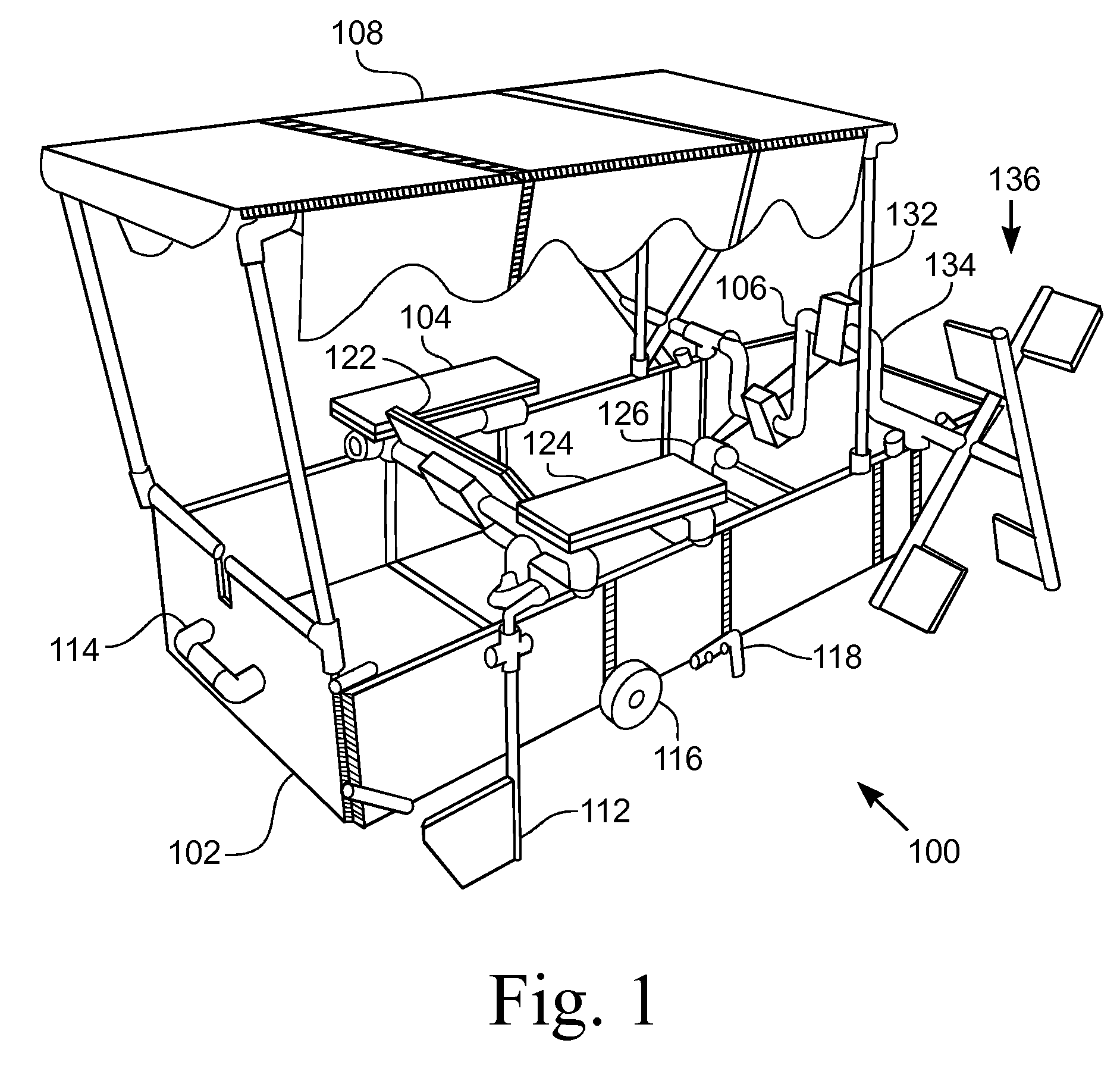

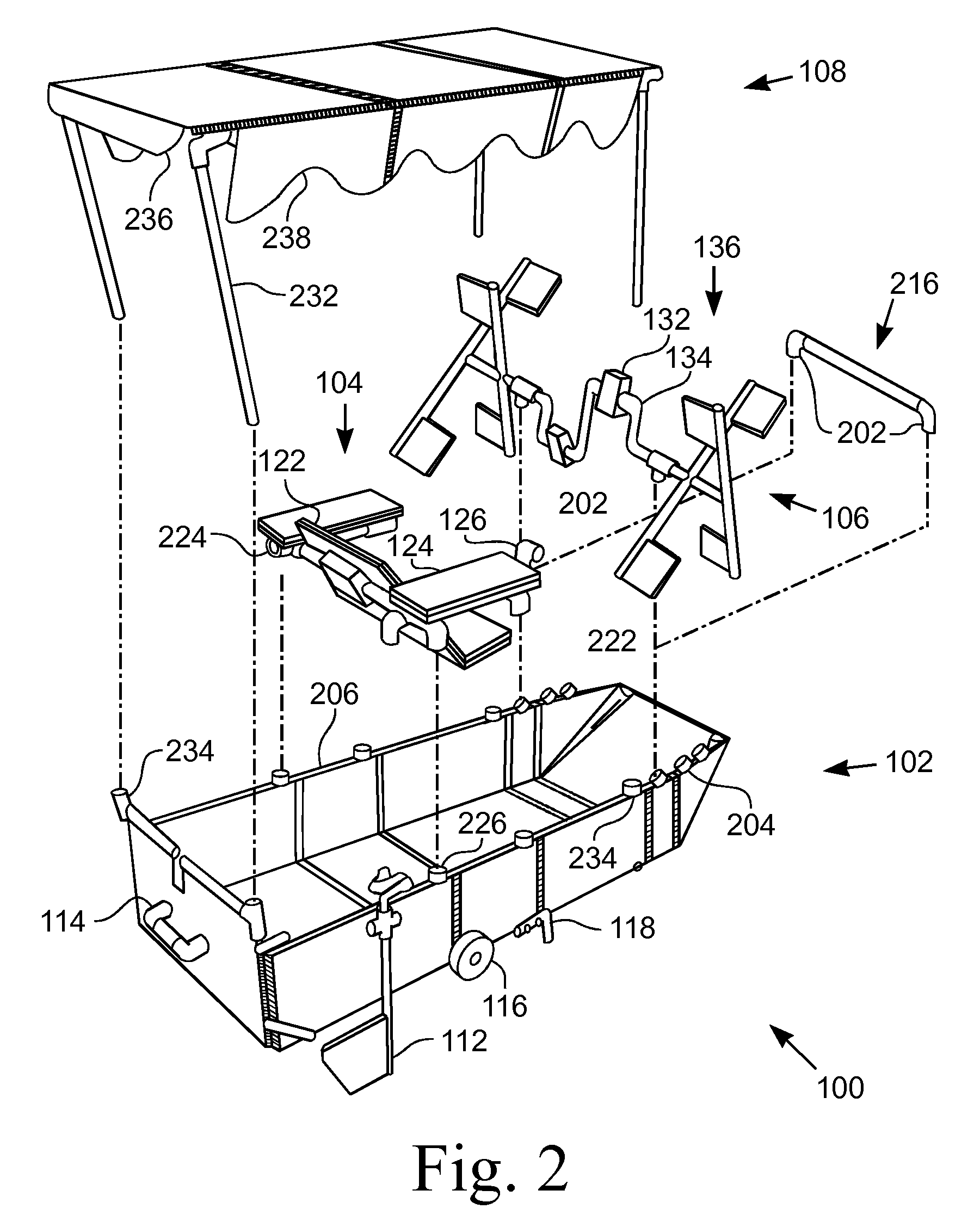

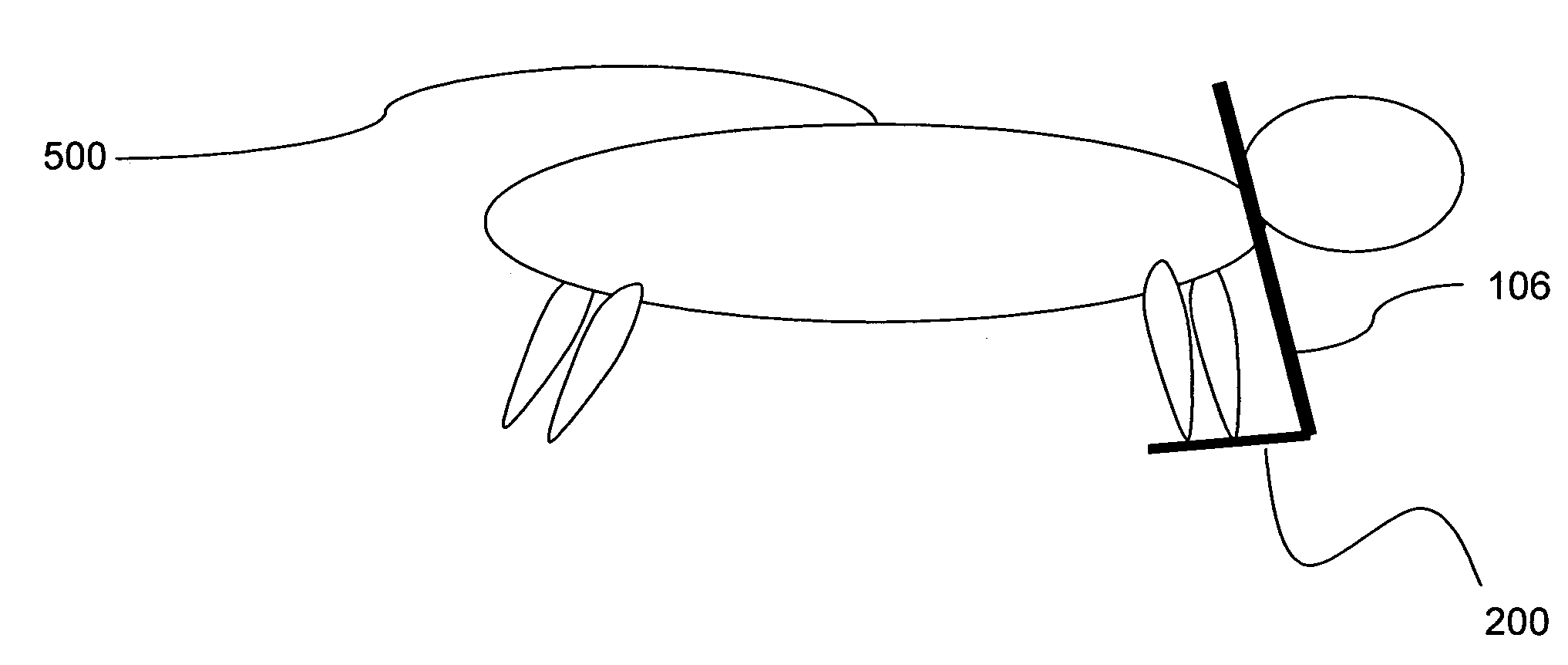

Boat foldable into a compact self-contained shape

InactiveUS7530322B2Comfortable postureImprove rigidityPropulsive elements of rotary typeMuscle power acting propulsive elementsEngineeringWatercraft

An apparatus with two configurations: a deployed configuration forming a watercraft that floats in water and a folded configuration that allows for transport of the apparatus. The apparatus includes multiple modules. One module is a planar sheet of corrugated material with a plurality of joints that allow the sheet to assume the shape of a hull when in the deployed configuration and to assume a box-shape when in the folded configuration. Another module is a paddle assembly that is releaseably connected to a pair of sidewalls when the sheet is in the deployed configuration. The paddle assembly is foldable such that it fits within the box-shape when the sheet is in the folded configuration. The planar sheet is foldable around a plurality of joints or hinges that are configured to fold two ways, thereby allowing the sheet to assume the two configurations.

Owner:ANGELINI JOSEPH A

Method for manufacturing shape memory anti-counterfeiting label

The invention relates to a method for manufacturing a shape memory anti-counterfeiting label, which is characterized by comprising the following steps of: performing cross-linking, extrusion or injection molding on a high polymer material with a shape memory function in a charging barrel of an extruder or an injection molding machine by a peroxide cross-linking process or one-step silane cross-linking process to make a product directly have the memory function, wherein an extruded sheet can be a plane sheet and can also be a sheet with concave-convex patterns and characters on the surface; and heating the cross-linked sheet to over the deformation temperature thereof, pressing the patterns or characters on the plane sheet, or pressing the sheet with the concave-convex patterns or characters into a plane or other patterns and characters, and cutting the sheet into slices, wherein each slice contains one pattern or a group of characters. Sheet molding (or injection molding) and chemical cross-linking are performed simultaneously, so a manufacturing process is simplified and cost is saved.

Owner:GUANGZHOU MANBORUI MATERIAL TECH

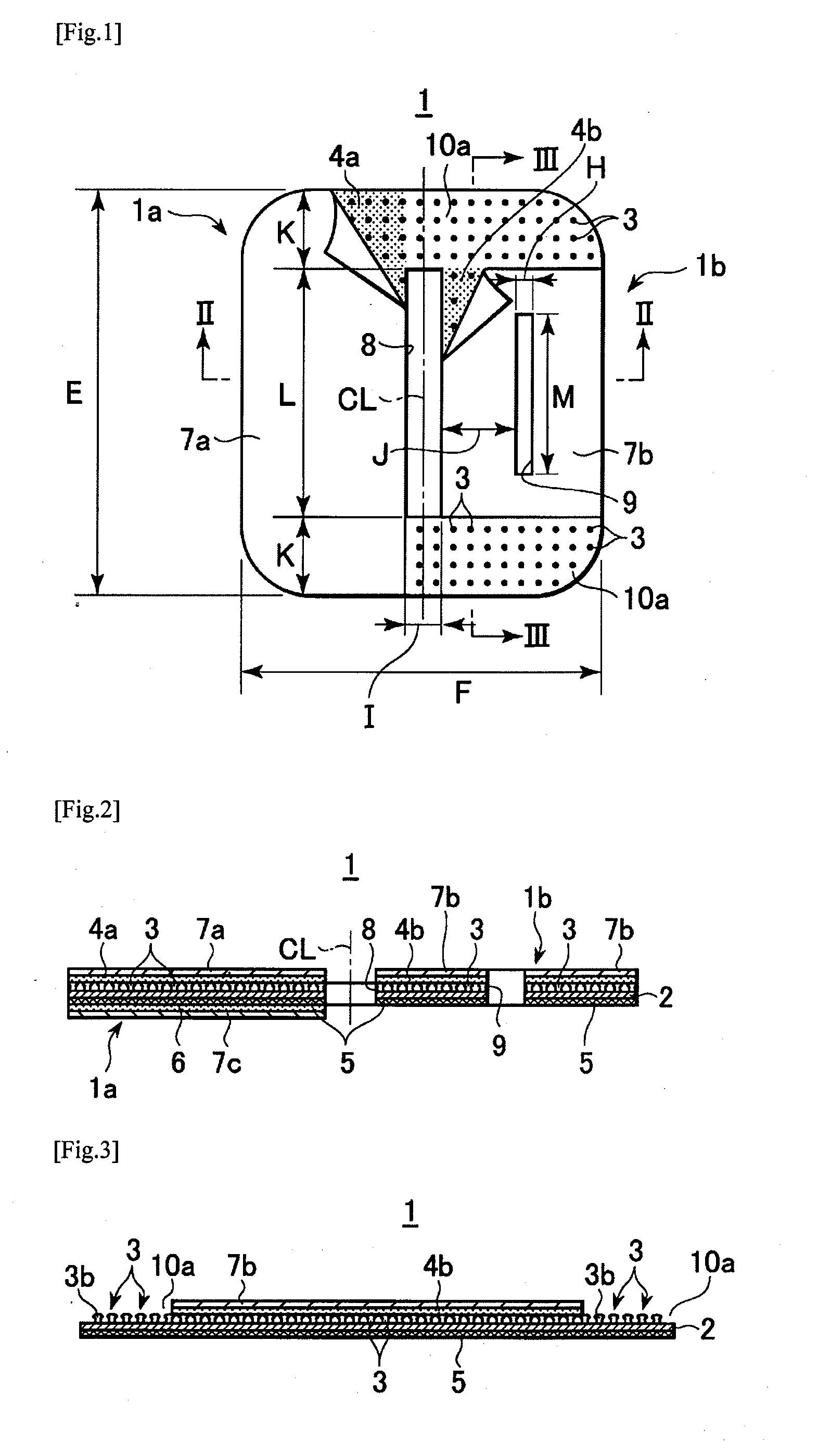

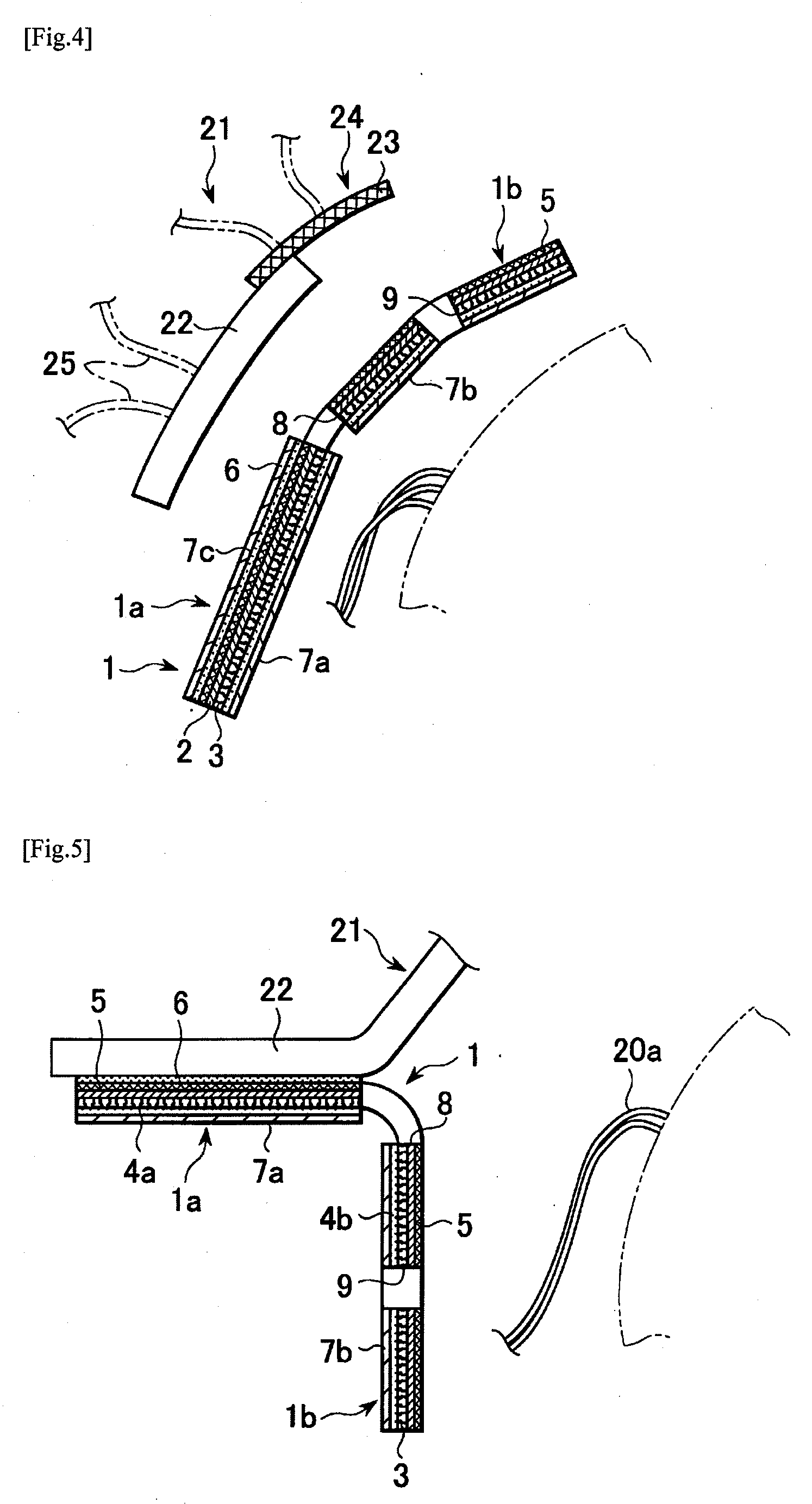

Apparatus for fixing a wig and method for fixing a wig using the apparatus

ActiveUS20100170527A1Keeping tangling stateGood conditionSnap fastenersHair accessoriesEngineeringMechanical engineering

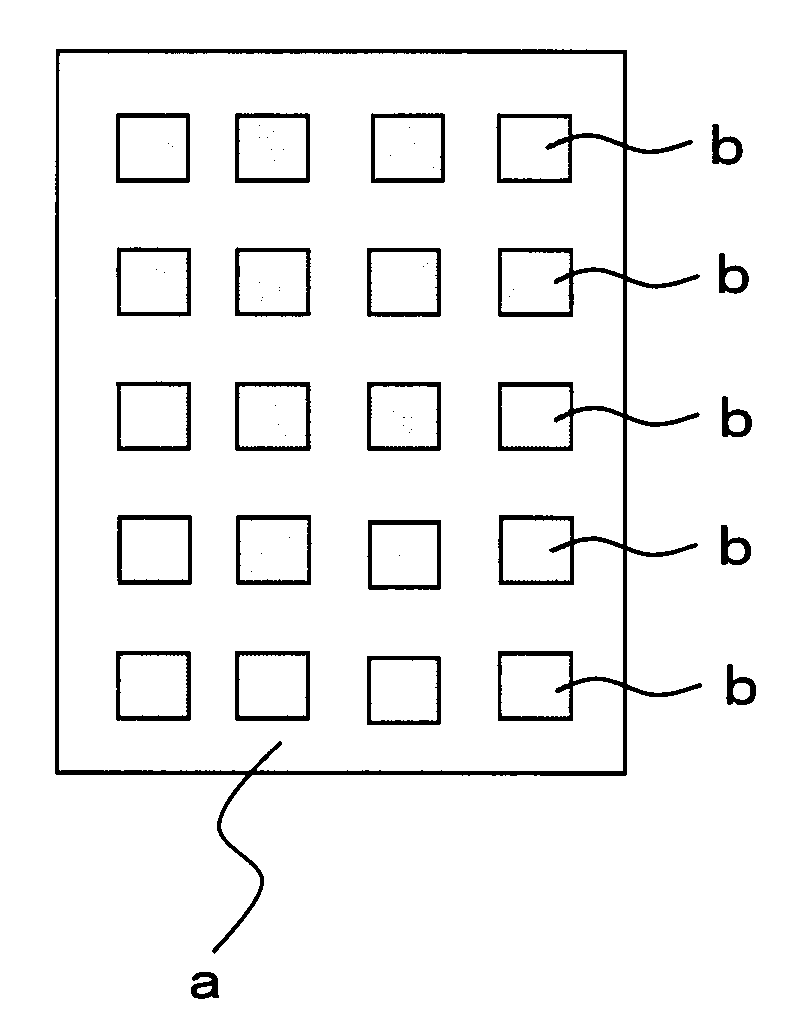

An apparatus for fixing a wig to head of a user, including a flexible plane sheet including a first opening and a second opening, a plurality of monofilaments each including a swollen head and protrusively provided on a first side of the flexible plane sheet, a first adhesive layer provided so as to cover the monofilaments, a net member provided on a second side of the flexible plane sheet, and a second adhesive layer provided on the net member of a first half area, the flexible plane sheet being divided into the first half area and a second half area by a line bisecting the flexible plane sheet is provided. The first opening is provided on the line bisecting the flexible plane sheet while having a thin and long shape so that a part of natural hair of the user passes through the first opening, and the second opening is provided at a predetermined position on the second half area so that other part of the natural hair of the user passes through the second opening.

Owner:ADERANS HLDG CO LTD

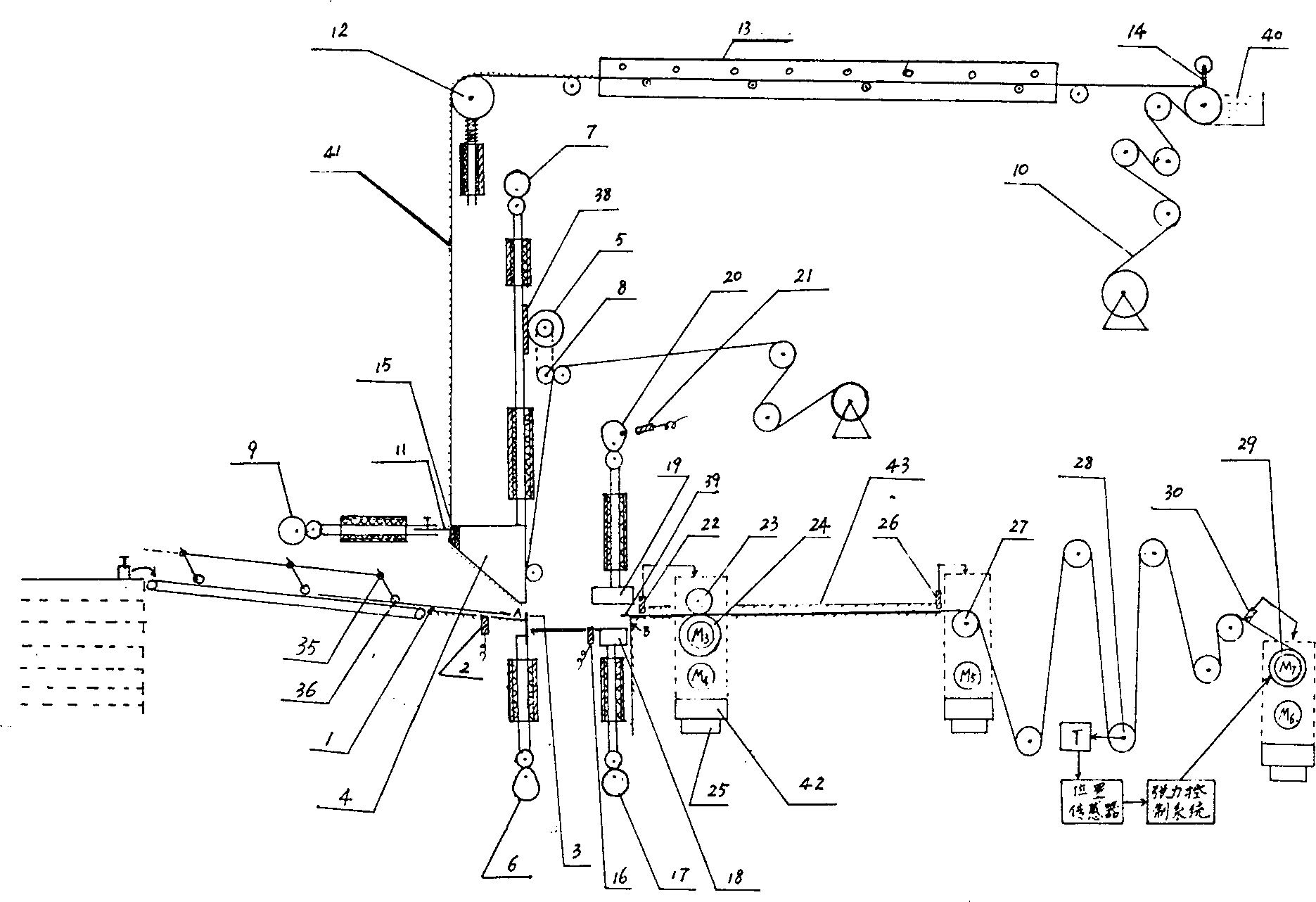

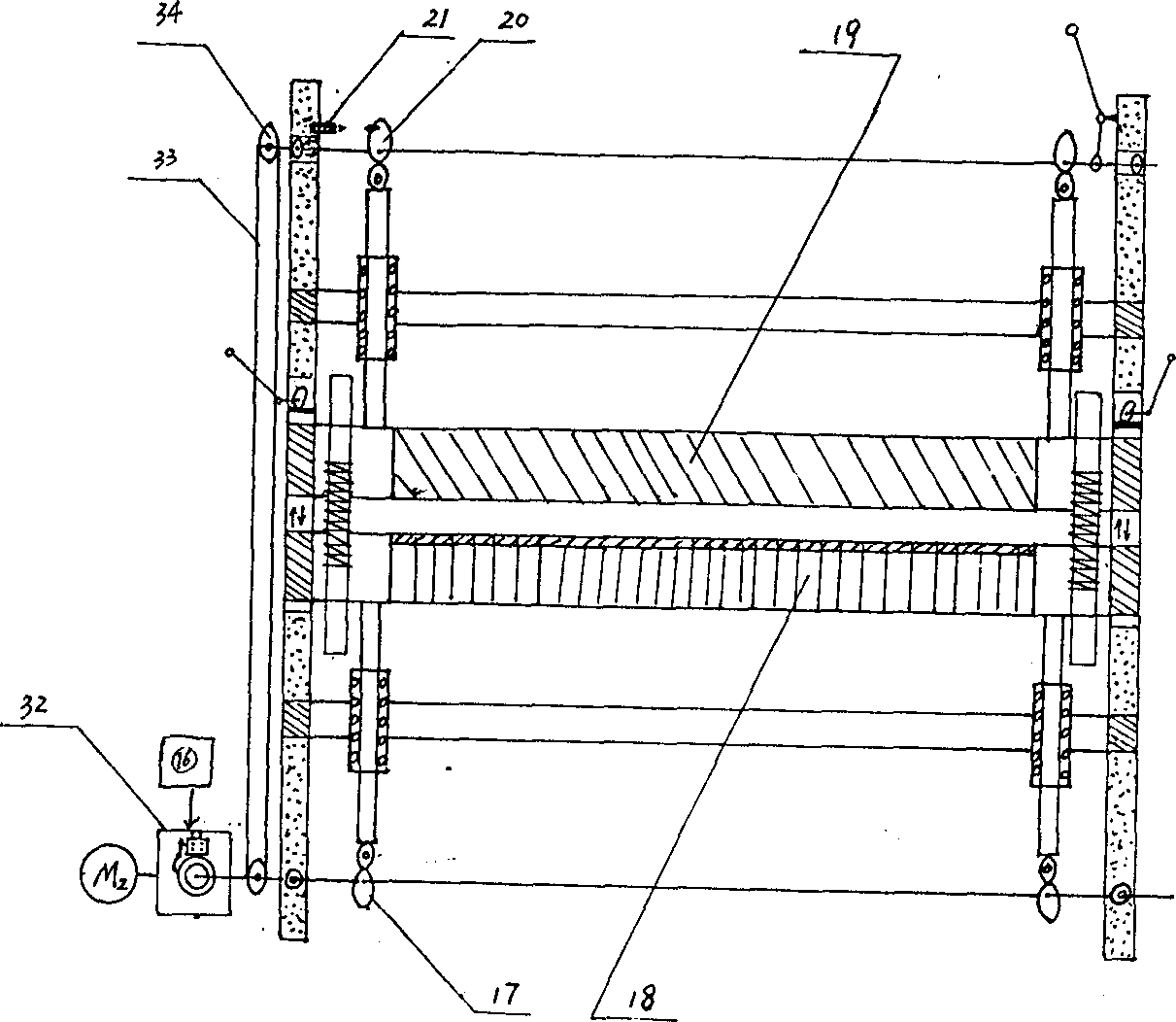

Production process of flat offset printing roll color-printing pressure-sensitive adhesive trade mark

The production process of plane sheet offset rolled colour-printed pressure-sensitive adhesive label includes the following steps: 1. face paper plane sheet PS plate printing; 2. edging; 3. automatically-adhering single-sheet printed face paper and coiling; 4. finely-coating pressure-sensitive adhesive and lamination; 5. cutting roll and die-cutting. The single-sheet printed face paper automatically adhering and coiling process includes the following steps: positioning face paper to the glue-applying place, at the same time transferring and pressing pressure-sensitive adhesive onto the face paper form parting paper; adhering head and tail of face paper, digital-control taking up by servo-motor, rectifying deviation, using position sensor and tension control system to regulate and control brake and constant tension rolling up.

Owner:高国明

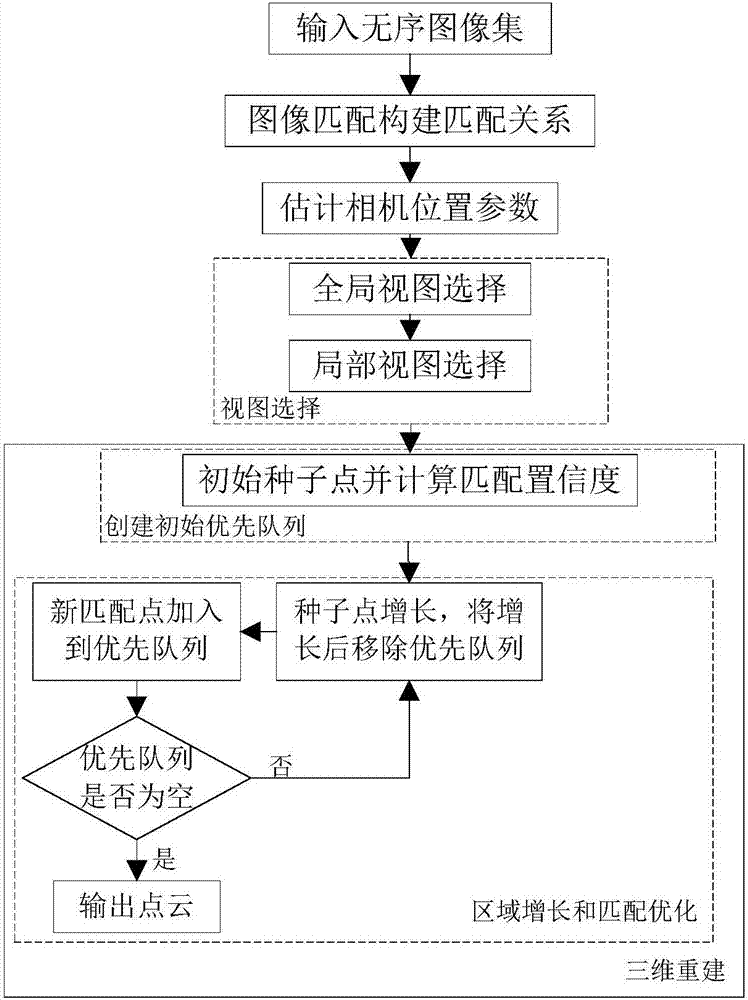

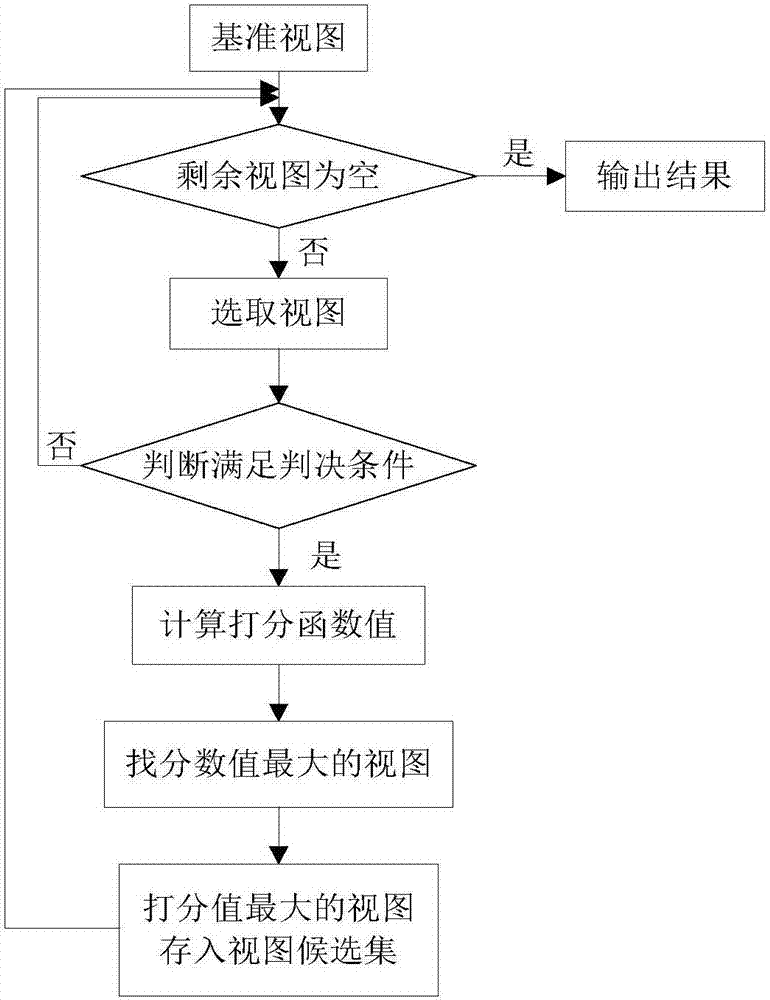

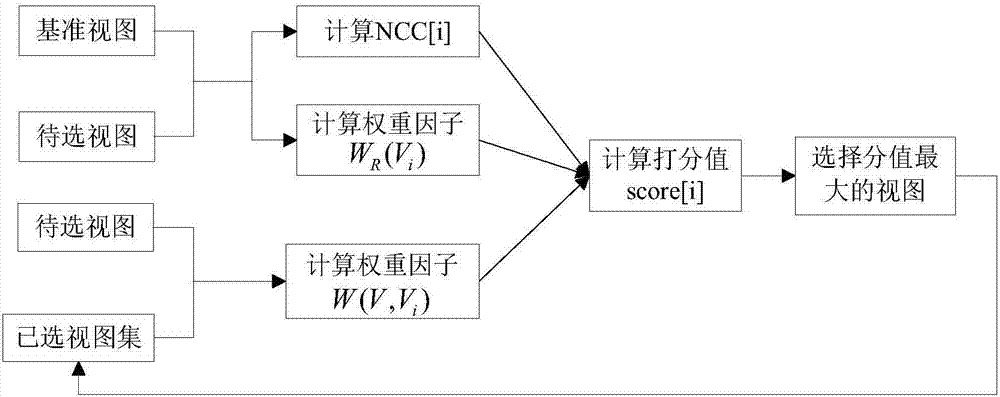

Multi-view stereo matching three-dimensional reconstruction method of disordered image

InactiveCN107170042AShorten the timeBroken matching result is goodImage analysis3D modellingStereo matchingData set

The invention belongs to the field of three-dimensional reconstruction technology, and relates to a multi-view stereo matching three-dimensional reconstruction method of a disordered image. According to the method of the invention, at a view selection algorithm part, 1), for aiming at a global view selection process, firstly a decision condition is introduced; and furthermore the number of views in a candidate view set is fixed adaptively instead of the view set with fixed number of views. No scoring is performed on the views which do not satisfy a condition in an algorithm. Along with continuous expansion of an application range, the number of views in an experiment data set gradually increases, and reduction of view selection time is very important. 2), For a local view algorithm, the method improves a weight influence factor of a polar plane included angle between a neighbor view and a reference view, so that the selected neighbor view is more accurate and more representative. 3), In a view matching area increasing process, the invention provides an adaptive shape space plane sheet algorithm, an adaptive shape can adaptively adapt boundary information, thereby better matching a result.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Implementing and applying method of paper folding structure

InactiveCN104376132ASpecial data processing applications3D modellingAlgorithmThree-dimensional space

Disclosed is an implementing and applying method of a paper folding structure in the technical field of computer image processing. The implementing and applying method includes connecting all adjacent vertexes by straight lines after determining coordinates of m points in an x-z plane and of n+2 points in a y-z plane in a three-dimensional coordinate system, wherein every three connecting line segments connected end to end form a plane, and all connecting line segments form a three-dimensional paper folding structure; mapping the coordinates of the vertexes of the three-dimensional paper folding structure into the coordinates of the vertexes in a two-dimensional plane, connecting the adjacent vertexes in the two-dimensional plane to obtain a planar fold line pattern of the three-dimensional paper folding structure, projecting the line segments and the vertexes of the planar fold line pattern into a plane sheet and processing to obtain a required three-dimensional paper folding structure. The implementing and applying method is easy to realize by programming in a computer and can directly design to obtain various geometric shapes of accurate paper folding structures in the three-dimensional space.

Owner:SHANGHAI JIAO TONG UNIV

Production of offset thermal transfer paper and transfer method thereof

InactiveCN101590751AStrong color fastnessVariety of colorsTransfer printingThermographyPulp and paper industryMetal sheet

The invention discloses production of offset thermal transfer paper and a transfer method thereof. The method for producing the offset thermal transfer paper comprises the following steps: designing a transfer pattern; separating colors of the pattern by a computer so as to produce each color separating film after color separation; exposing and printing down by each color separating film; producing a color separating printed backplane; and assembling the printed backplane on an offset printer, and separately overprinting the pattern on thermal transfer paper for printing by transfer ink to produce the offset thermal transfer paper. The method for transferring a metal plane sheet comprises the following steps: removing impurities on the metal surface to be transferred, and coating paint on the surface; attaching the surface of the offset thermal transfer paper printed with the transfer ink to the metal surface with a paint film; heating the metal surface to a temperature of between 190 and 200 DEG C by a flat-bed press; pressing the offset thermal transfer paper and the paint film to ensure that the offset thermal transfer paper and the surface of the paint film are attached closely; and peeling off the transfer paper to complete transfer of the pattern after heating and pressing for 33 to 40 seconds. The method for transferring on fabrics is similar to that of on the metal sheet, but paint is not painted.

Owner:周福根

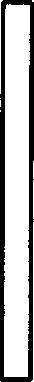

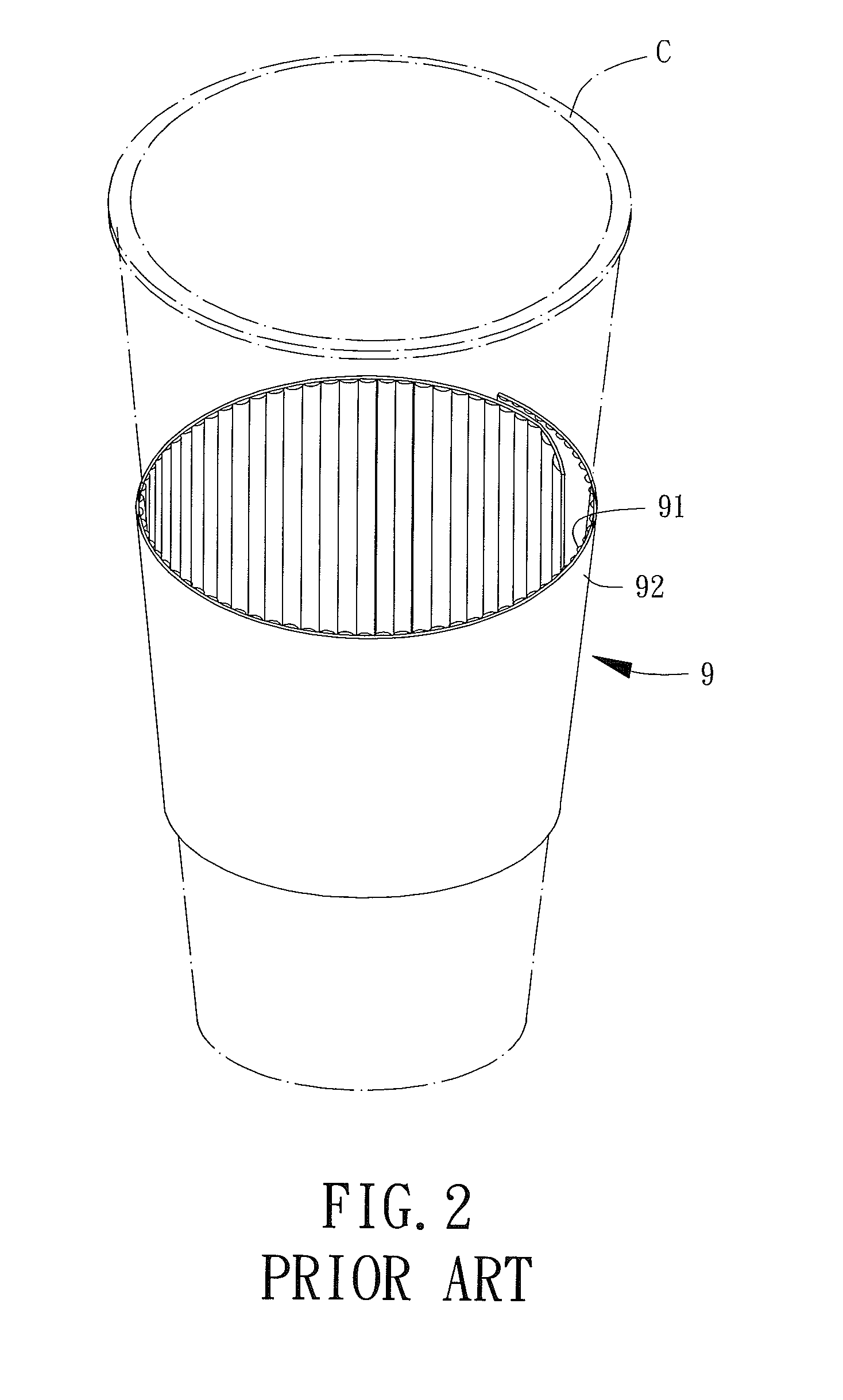

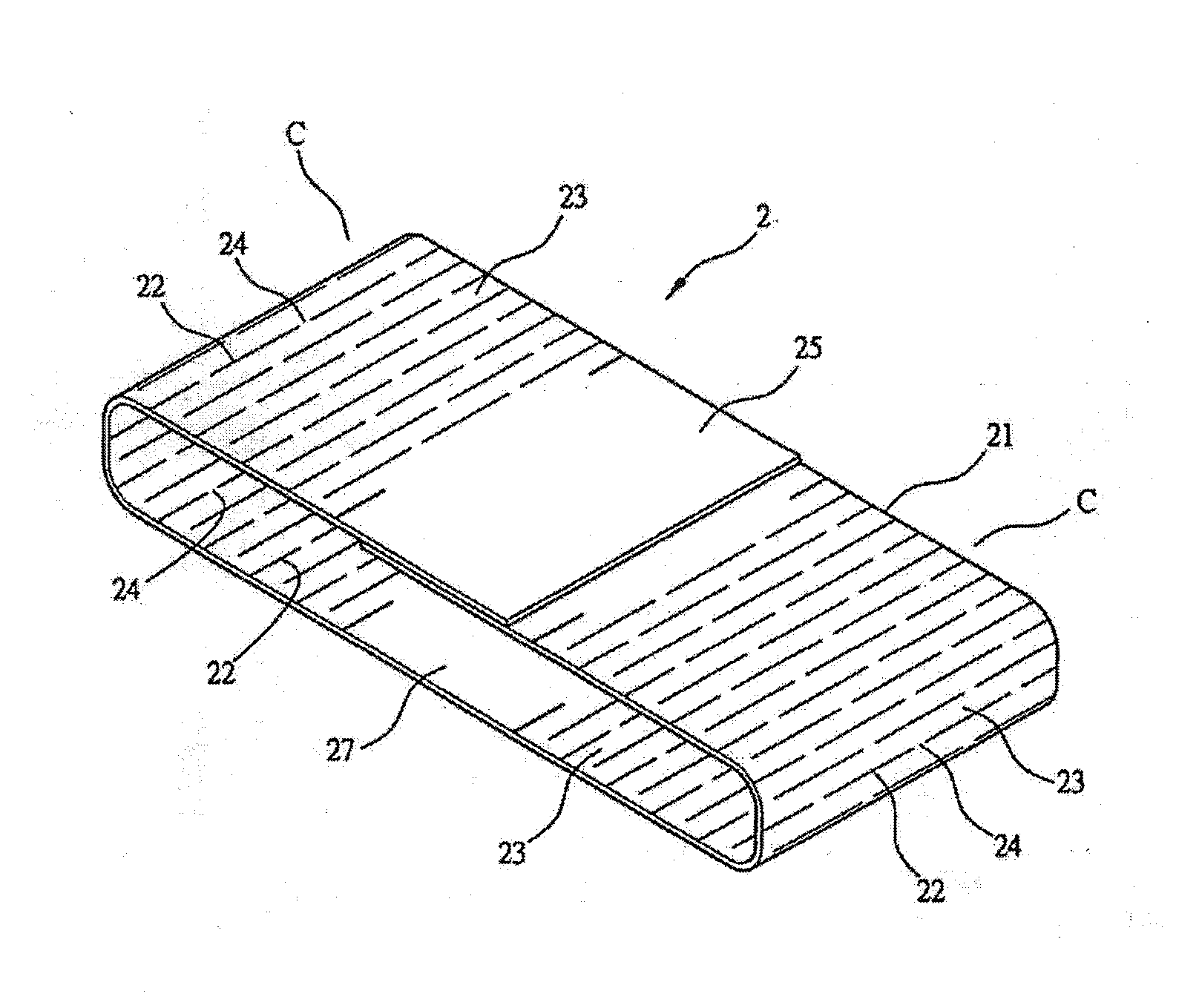

Thermally insulating member

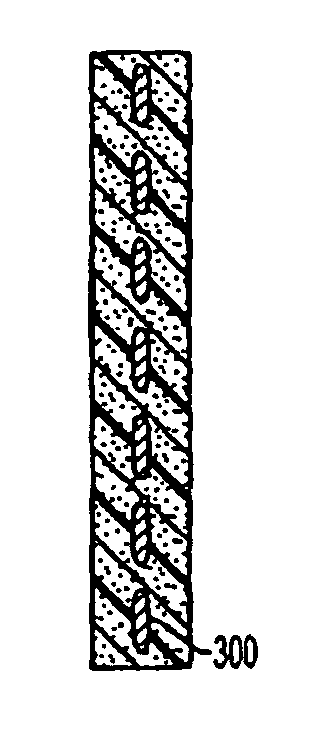

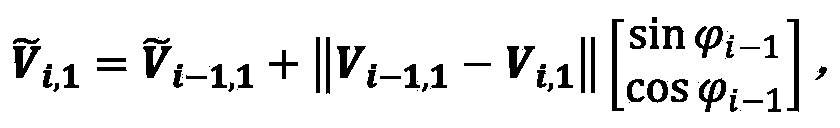

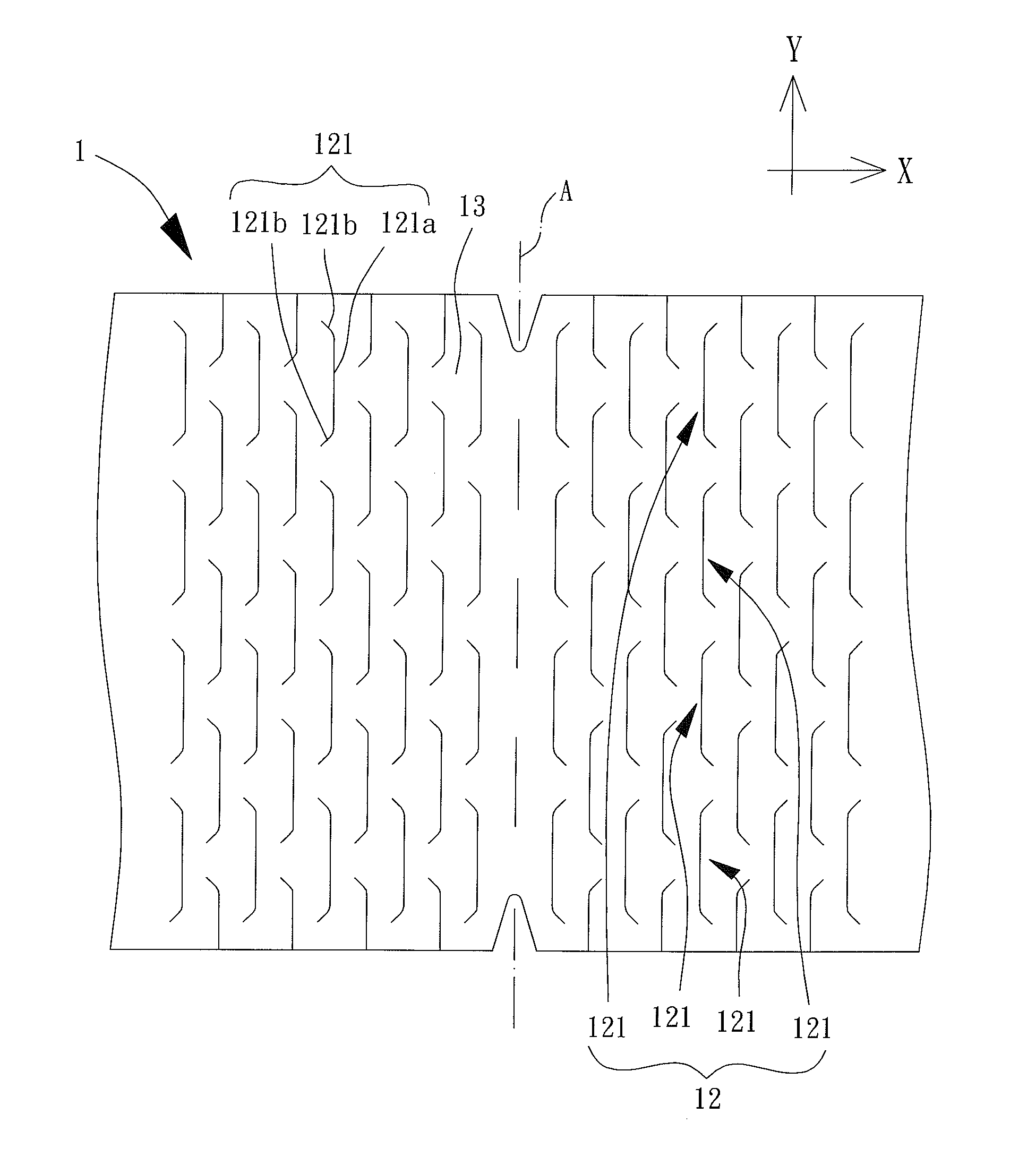

ActiveUS9586747B2Good effectLower the volumeDomestic cooling apparatusLighting and heating apparatusEngineeringPlane sheet

A thermally insulating member includes a plane sheet having two ends spaced in a length direction and two sides spaced in a thickness direction perpendicular to the length direction. The plane sheet includes a plurality of rows of slits between the ends of the plane sheet. Each row of slits extends from one of the sides through the other side of the plane sheet. A first spacing between two adjacent rows of slits in the length direction is larger than a spacing between two adjacent slits in the same row of slits in a width direction perpendicular to the length and width directions by a second spacing. A thermally insulating strip is defined between two adjacent rows of slits. A stretchable rib is formed between two adjacent slits in the same row of slits. Each end of the plane sheet is a coupling portion free of the slits.

Owner:BETTER ALLYING DESIGN

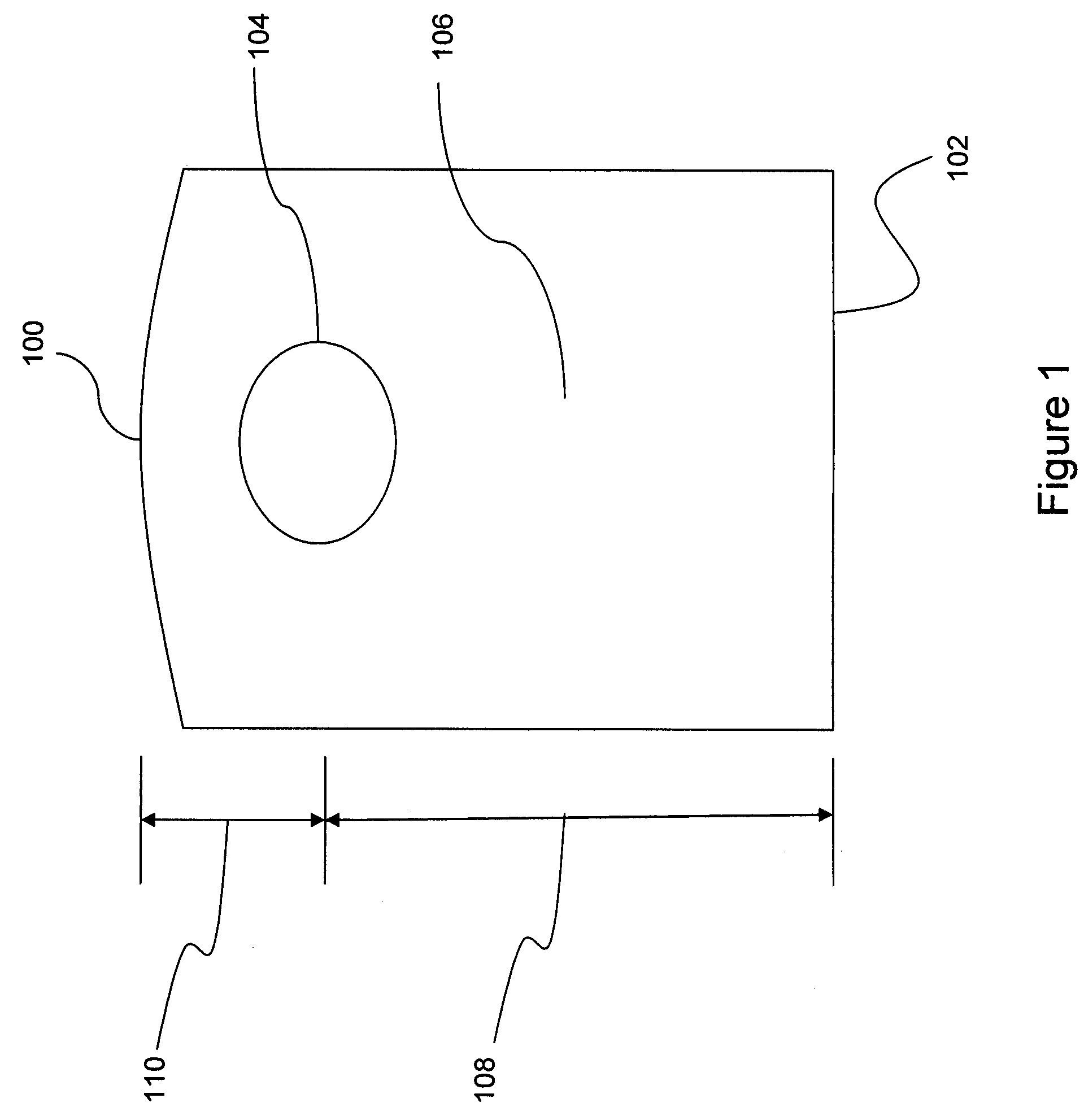

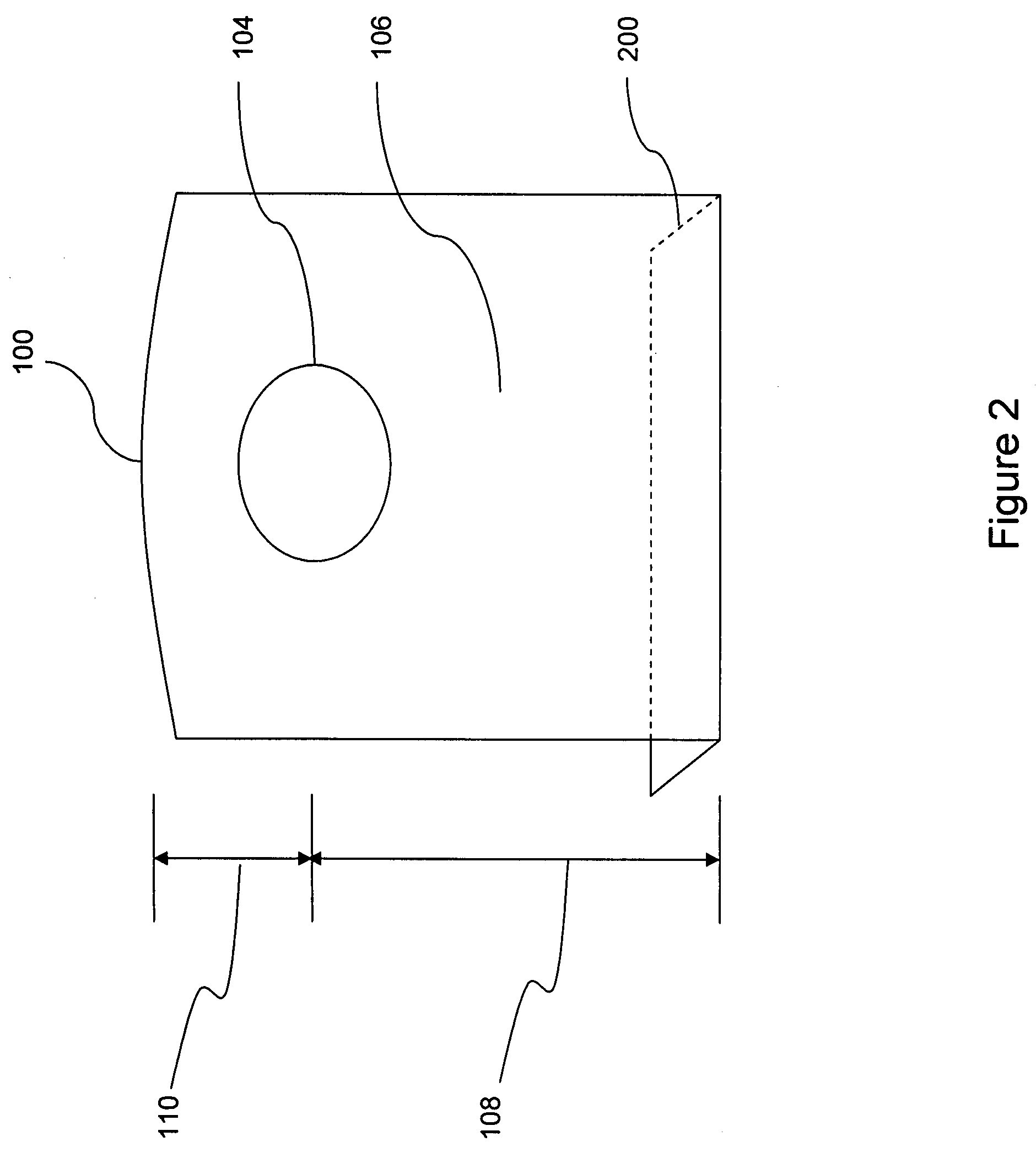

Animal restraining apparatus and protective device

An animal restraining shield comprising a planar sheet having a vertical edge and a horizontal edge and an aperture in the planar sheet sized to permit a head of an animal to pass through the aperture, wherein the animal restraining shield is adapted to limit motion of one or more limbs of the animal and wherein the vertical edge extends a downward distance from the aperture comprising at least a full length of a forelimb of the animal as measured from the head of the animal to a foot of the animal.

Owner:TRESCOTT SARA LOU

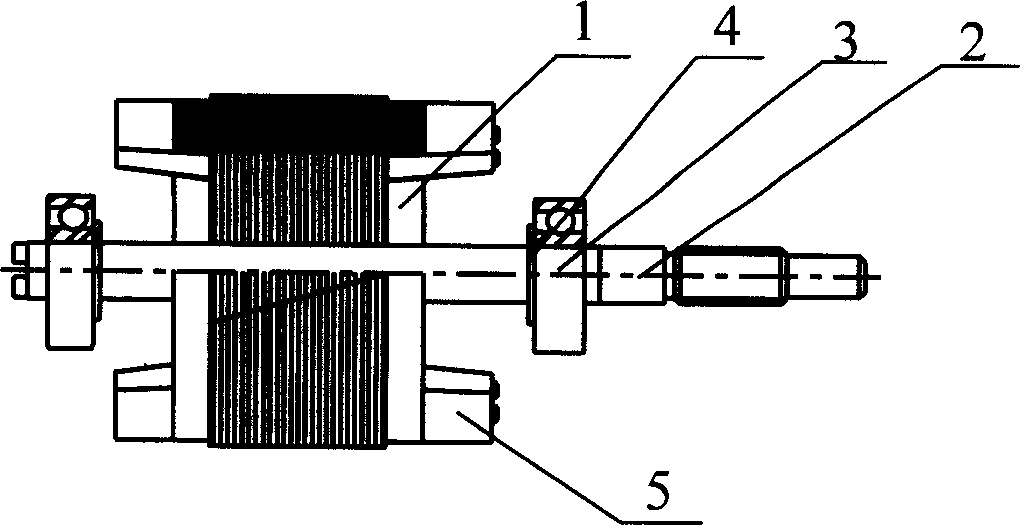

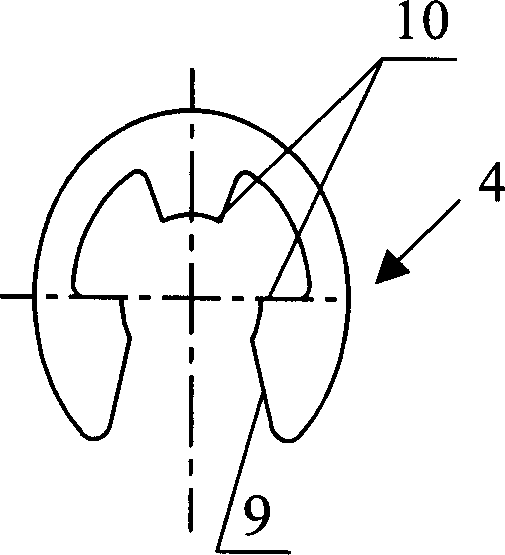

Ring fixing structure of motor bearing of washing machine

This invention discloses a ring fixing structure for a washing machine motor bearing including a motor shaft fixed at the center of a motor rotor, a bearing connected with the shaft, a spacing ring for limiting the bearing, in which, limiting cams are formed at the bearing on the shaft for clamping the spacing ring, which is a round plane sheet one with the shaft passing through, more than two spacing humps are set on the shaft and the ring fixing structure is processed with a broach cutting on the original shaft to heave the edge of the shaft to clamp the spacing ring.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method for manufacturing shape memory anti-counterfeiting label

The invention relates to a method for manufacturing a shape memory anti-counterfeiting label, which is characterized by comprising the following steps of: performing cross-linking, extrusion or injection molding on a high polymer material with a shape memory function in a charging barrel of an extruder or an injection molding machine by a peroxide cross-linking process or one-step silane cross-linking process to make a product directly have the memory function, wherein an extruded sheet can be a plane sheet and can also be a sheet with concave-convex patterns and characters on the surface; and heating the cross-linked sheet to over the deformation temperature thereof, pressing the patterns or characters on the plane sheet, or pressing the sheet with the concave-convex patterns or characters into a plane or other patterns and characters, and cutting the sheet into slices, wherein each slice contains one pattern or a group of characters. Sheet molding (or injection molding) and chemicalcross-linking are performed simultaneously, so a manufacturing process is simplified and cost is saved.

Owner:GUANGZHOU MANBORUI MATERIAL TECH

Thermally Insulating Member

ActiveUS20150151895A1Lower the volumeGood effectDomestic cooling apparatusLighting and heating apparatusCouplingEngineering

A thermally insulating member includes a plane sheet having two ends spaced in a length direction and two sides spaced in a thickness direction perpendicular to the length direction. The plane sheet includes a plurality of rows of slits between the ends of the plane sheet. Each row of slits extends from one of the sides through the other side of the plane sheet. A first spacing between two adjacent rows of slits in the length direction is larger than a spacing between two adjacent slits in the same row of slits in a width direction perpendicular to the length and width directions by a second spacing. A thermally insulating strip is defined between two adjacent rows of slits. A stretchable rib is formed between two adjacent slits in the same row of slits. Each end of the plane sheet is a coupling portion free of the slits.

Owner:BETTER ALLYING DESIGN

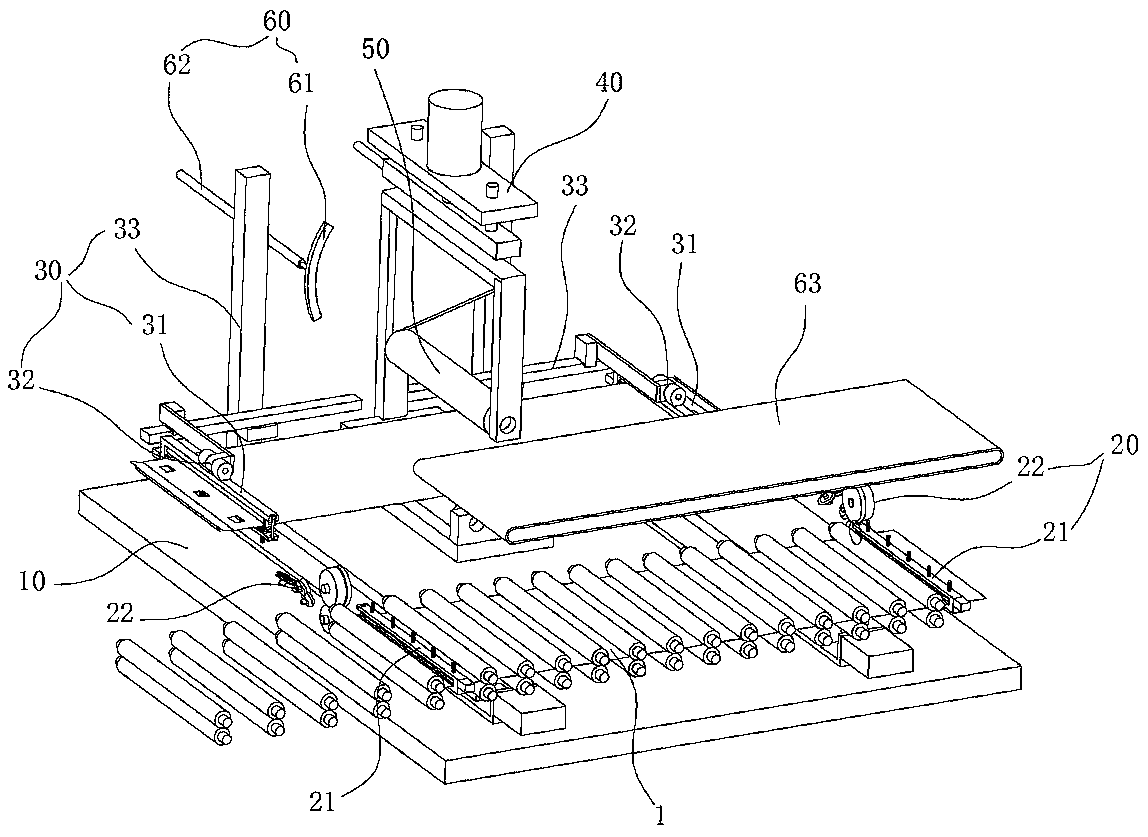

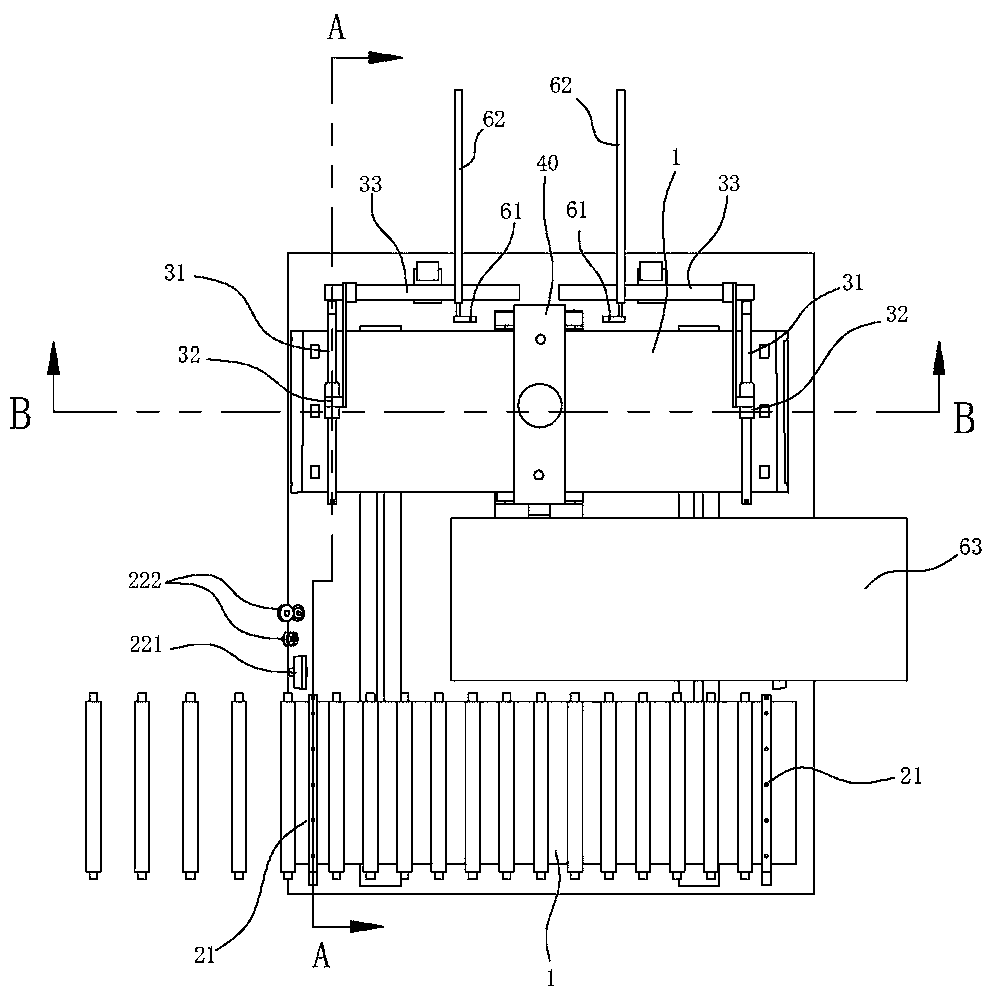

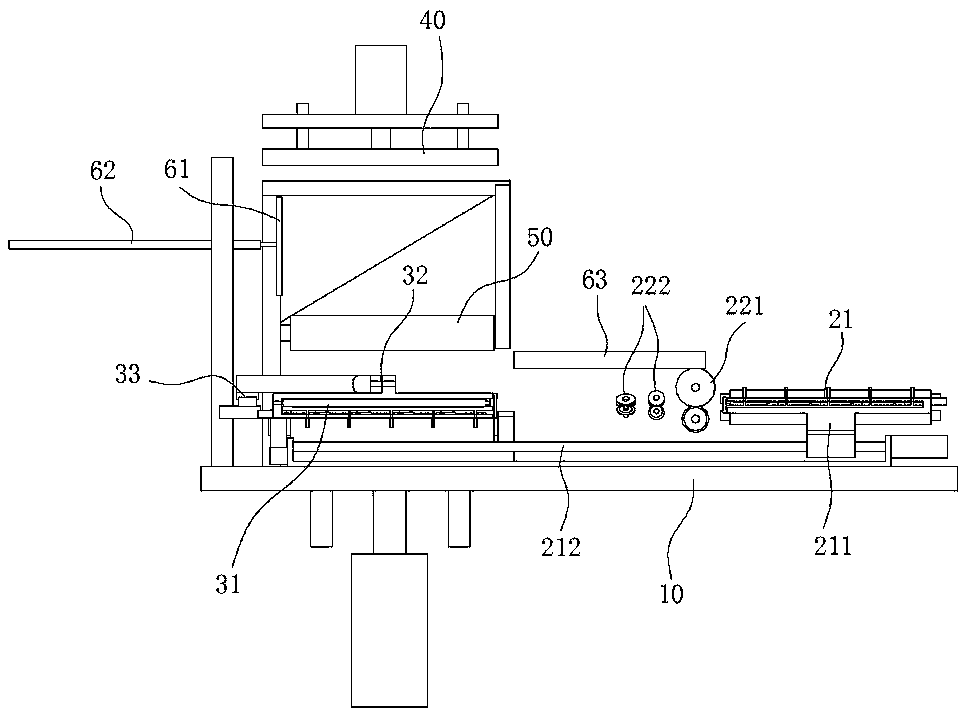

Cylindrical material forming method

ActiveCN110947838ASolve defects that are not suitable for transportationRealize automatic moldingMetal-working feeding devicesOther manufacturing equipments/toolsConvex structureMetal strips

The invention belongs to the technical field of assembly manufacturing, and particularly relates to a cylindrical material forming method. The cylindrical material forming method includes the following steps of blanking, specifically, cutting a metal strip into a rectangular flat sheet; embossing, specifically, stamping the rectangular flat sheet to form a concave-convex structure and an installing hole according to design requirements; edge folding, specifically, using an edge folding mechanism to bend the two ends of the flat sheet to form V-shaped bayonets; turning, specifically, using a turning mechanism to turn the two ends of the flat sheet by 180 degrees, and enabling the V-shaped bayonets at the two ends to be transferred to a seam buckling mechanism for seam buckling; seam buckling, specifically, using the seam buckling mechanism to rivet buckle areas of the V-shaped bayonets; shaping, specifically, driving a shaping roller to rotate to enable the cylindrical material to rotate by at least 360 degrees; and unloading, specifically, transferring the shaped cylindrical material to be moved out from a shaping mechanism, and ending shaping of the cylindrical material. Accordingto the cylindrical material forming method, the machining sequence of the cylindrical material is adjusted, shaping is carried out after seam buckling, the defect of conveying difficulties after rolling of a thin-wall part is solved, automatic forming of the thin-walled cylindrical part is achieved, the processing process is simplified, and the production efficiency is improved.

Owner:长丰吾道智能光电科技有限公司

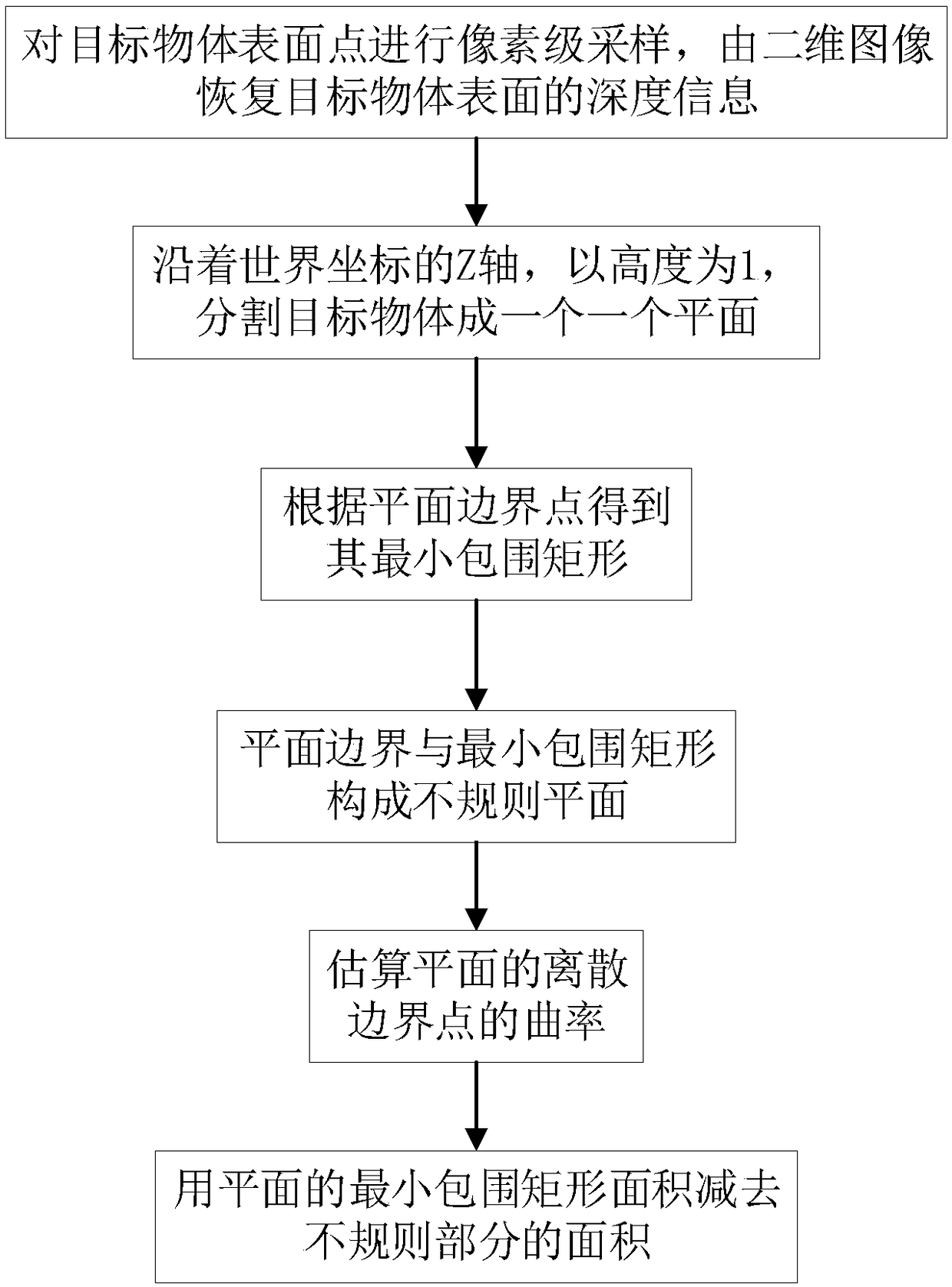

A method for determining the volume of a three-dimensional object

InactiveCN109272542AAvoid fit problemsImprove computing efficiencyImage enhancementImage analysisThree-dimensional spaceDiscrete points

Owner:SOUTH CHINA UNIV OF TECH

Thermally Insulating Member

ActiveUS20140329049A1Low costGood effectDomestic cooling apparatusLighting and heating apparatusEngineeringPlane sheet

A thermally insulating member includes a plane sheet having two ends spaced in a length direction and two sides spaced in a thickness direction perpendicular to the length direction. The plane sheet includes a plurality of rows of slits between the ends of the plane sheet. Each row of slits extends from one of the sides through the other side of the plane sheet. A first spacing between two adjacent rows of slits in the length direction is larger than a spacing between two adjacent slits in the same row of slits in a width direction perpendicular to the length and width directions by a second spacing. A thermally insulating strip is defined between two adjacent rows of slits. A stretchable rib is formed between two adjacent slits in the same row of slits. Each end of the plane sheet is a coupling portion free of the slits.

Owner:BETTER ALLYING DESIGN

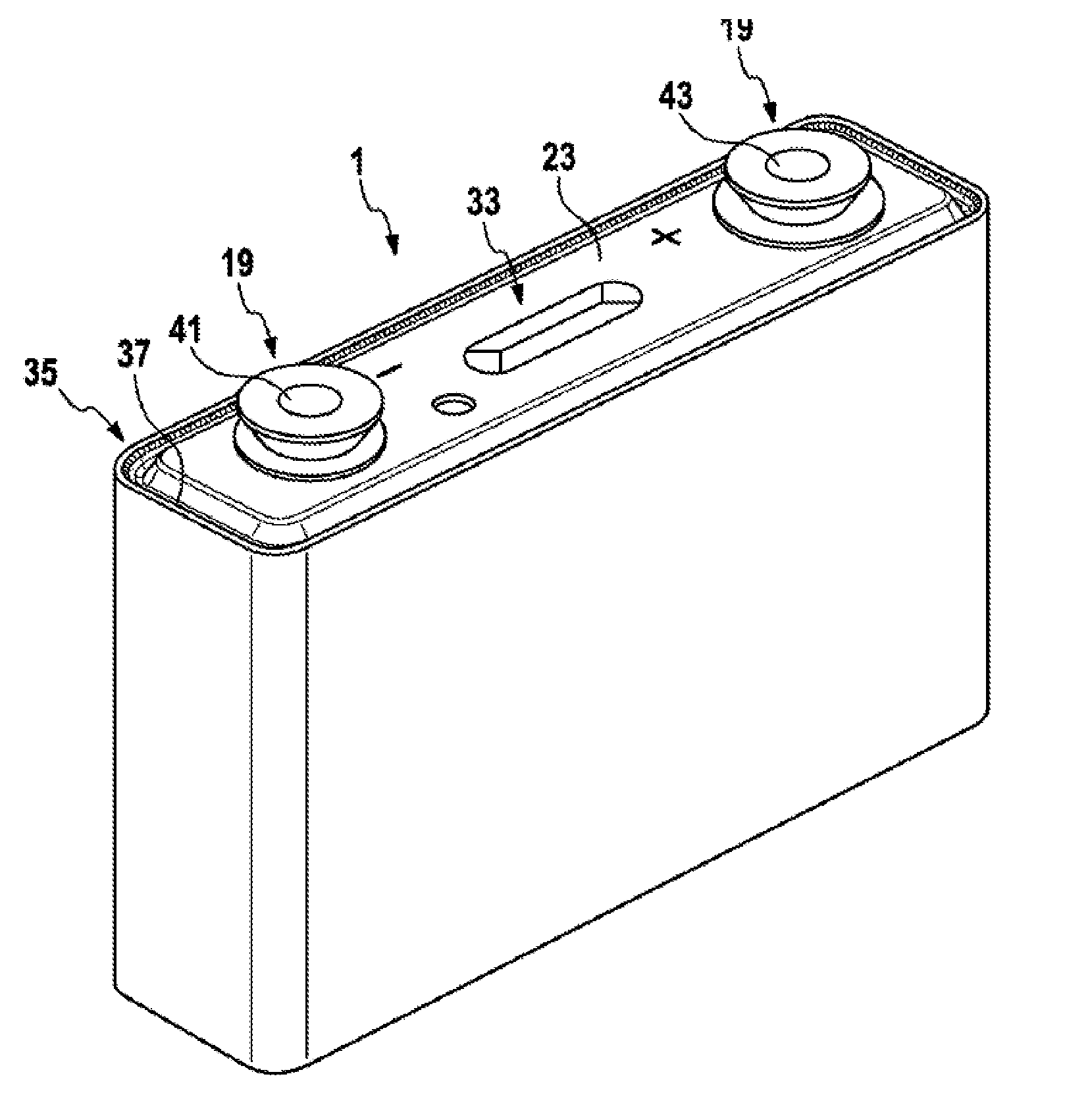

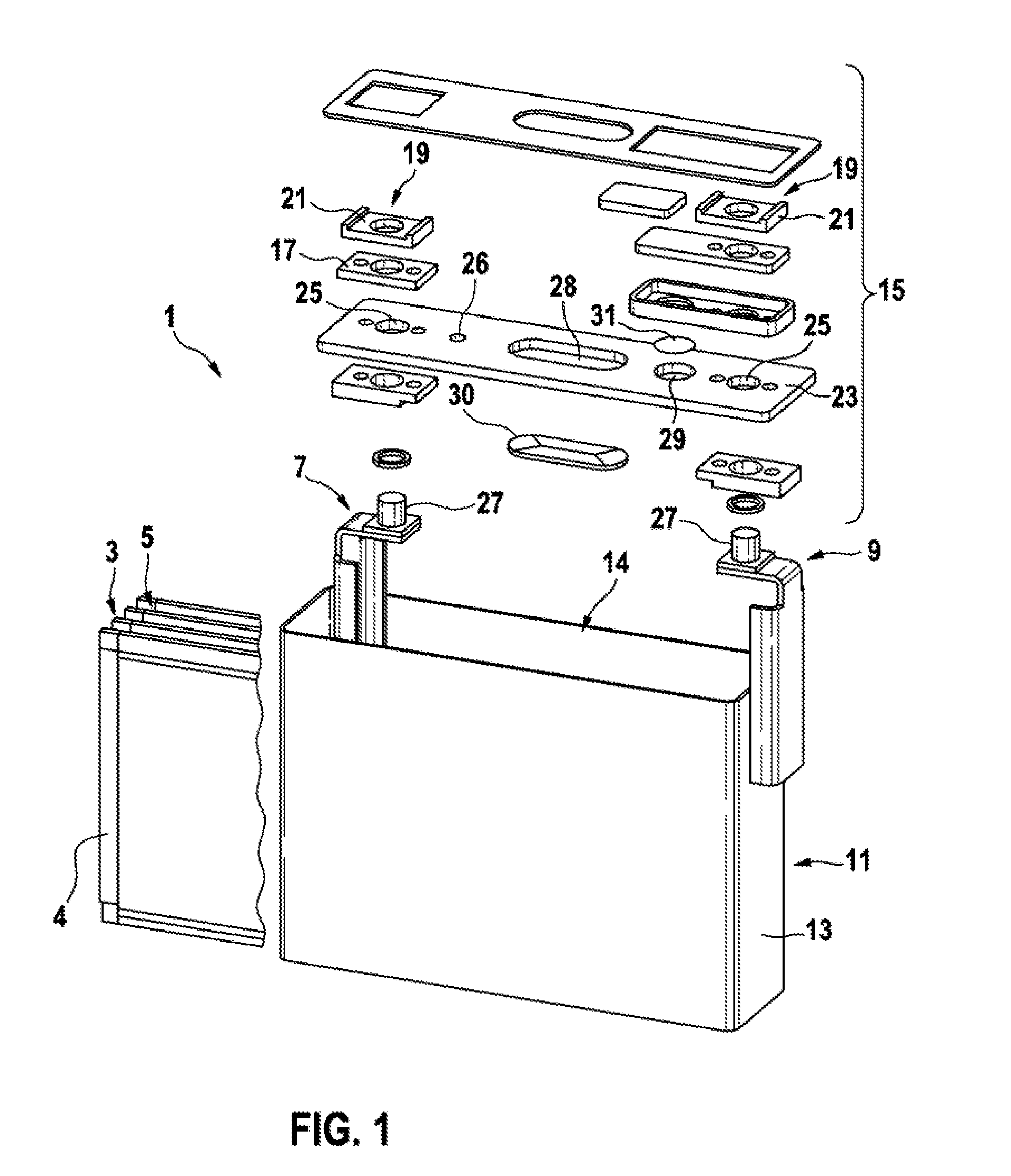

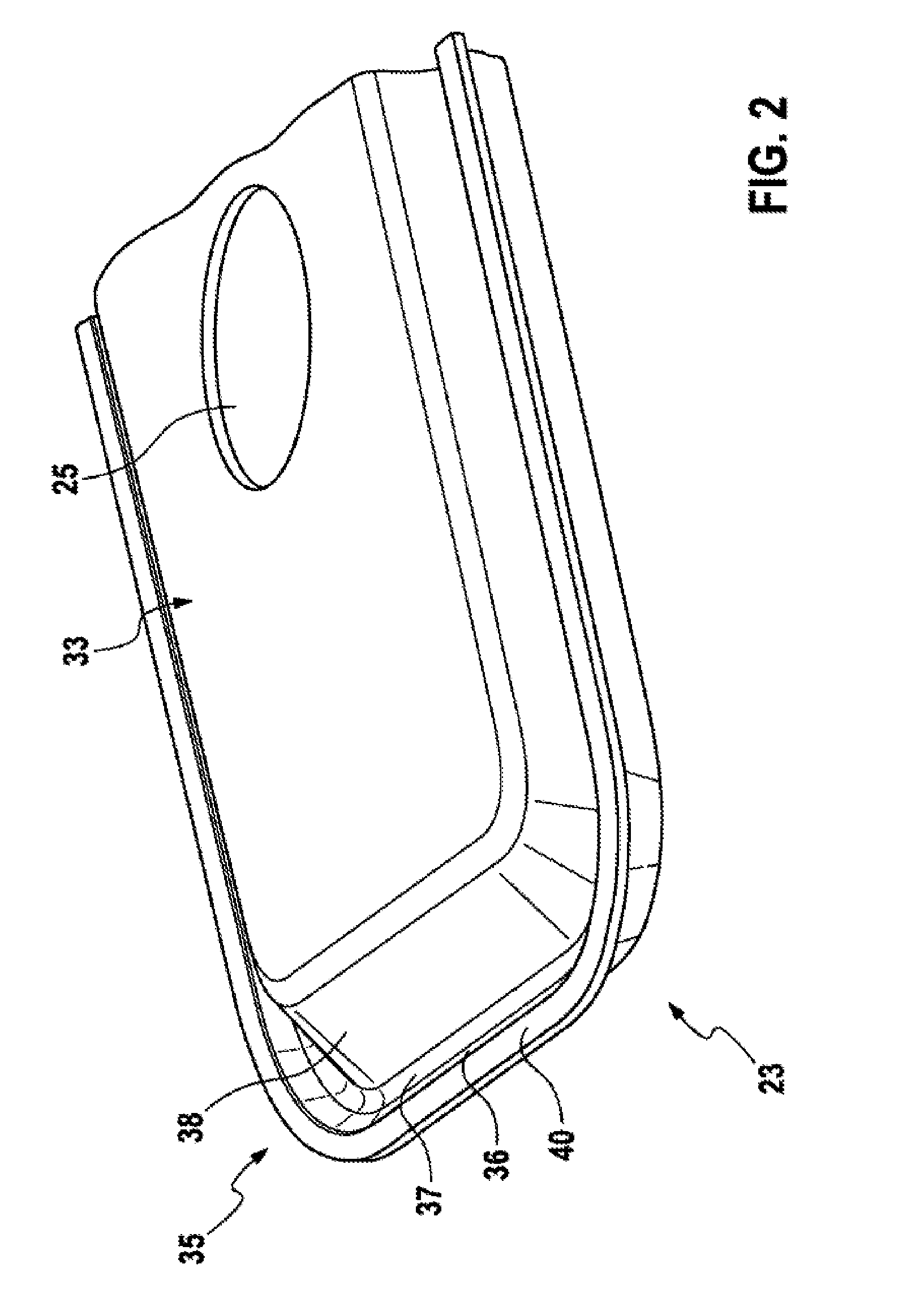

Battery cell comprising a housing covering plate having a raised central region

ActiveUS20150255762A1Reduce riskEasy to weldCell electrodesFinal product manufactureEngineeringLithium-ion battery

The invention relates to a battery cell, in particular a lithium-ion battery cell, wherein a cover plate (23) forming a part of a battery cell housing, which is designed as a plane sheet in a conventional manner, is modified to avoid short circuits between the poles of the battery cell due to moisture, for example. To this end, the cover plate (23) is provided with a central area (33) and an edge area (35) surrounding said central area (33). The central area (33) is located above an opening (14) to be closed off by the cover plate (23) of a container (13) forming a part of the battery cell housing, whereas the edge area (35) extends inside said opening (14). Thus, occurring moisture can drain off the platform-like raised central area (33) sideways toward a channel (37) in the edge area (35), and evaporate from there.

Owner:ROBERT BOSCH GMBH

Hot extrusion technological process for elbow from X80 grade steel plate

The invention discloses a technical process of an X80 steel plate hot extrusion elbow. The technical process comprises the following steps: (1) designing chemical compositions of raw materials, selecting proper X80 steel plates, controlling the grain size of the X80 steel plates at above 11 grade to basically comply with requirements of API SPEC 5L standard; (2) blanking; (3) hot press moulding, controlling the heating temperature within 930 DEG C and the temperature of workblank in a furnace lower than 600 DEG C; (4) planing sheets; (5) spot welding and welding, selecting suitable current and voltage, controlling the interlayer temperature within 200 DEG C, the current between 160A and 190A and the voltage at 30V; (6) planing ends, trimming and detection; (7) hot treatment, putting welding seams at the same heated layer when a plurality of parts are simultaneously treated in a furnace; and (8) surface cleaning, end part processing and finished product detection. The technical process selects the raw materials with agreeable chemical compositions, reduces the current and the voltage, improves the welding speed and reduces the heat quantity during processing procedures, thus preventing the augmentation of grains and meeting the requirements of the X80 steel plate hot extrusion elbow.

Owner:河北恒通管件集团有限公司

Toy and pacifying device for infants

InactiveUS7244166B1Increase attractivenessPromote activationMusical toysDollsEngineeringFull Term Infant

A soft toy that incorporates pacifiers into the shape of the toy. The toy includes a body made from a pair of planar sheets of a flexible material, the planar sheets having a perimeter that extends along an edge, and a soft, flexible filling. the filling being generally in the shape of the perimeter of the planar sheets. The sheets are connected to one another by way of a seam along a plane to form an enclosed space that covers the filling and results in the edges of the planar sheets are contained within the enclosed space. The connected sheets will create at least one area where a pair of sections of the seam converge towards one another at an angle of from 20 to 40 degrees, but preferably at an angle of about 25 to about 35 degrees. This connection will create an integral pacifier from the material of the toy. The pacifier portion will be nearly conical in shape.

Owner:SHERMAN KRISSA +1

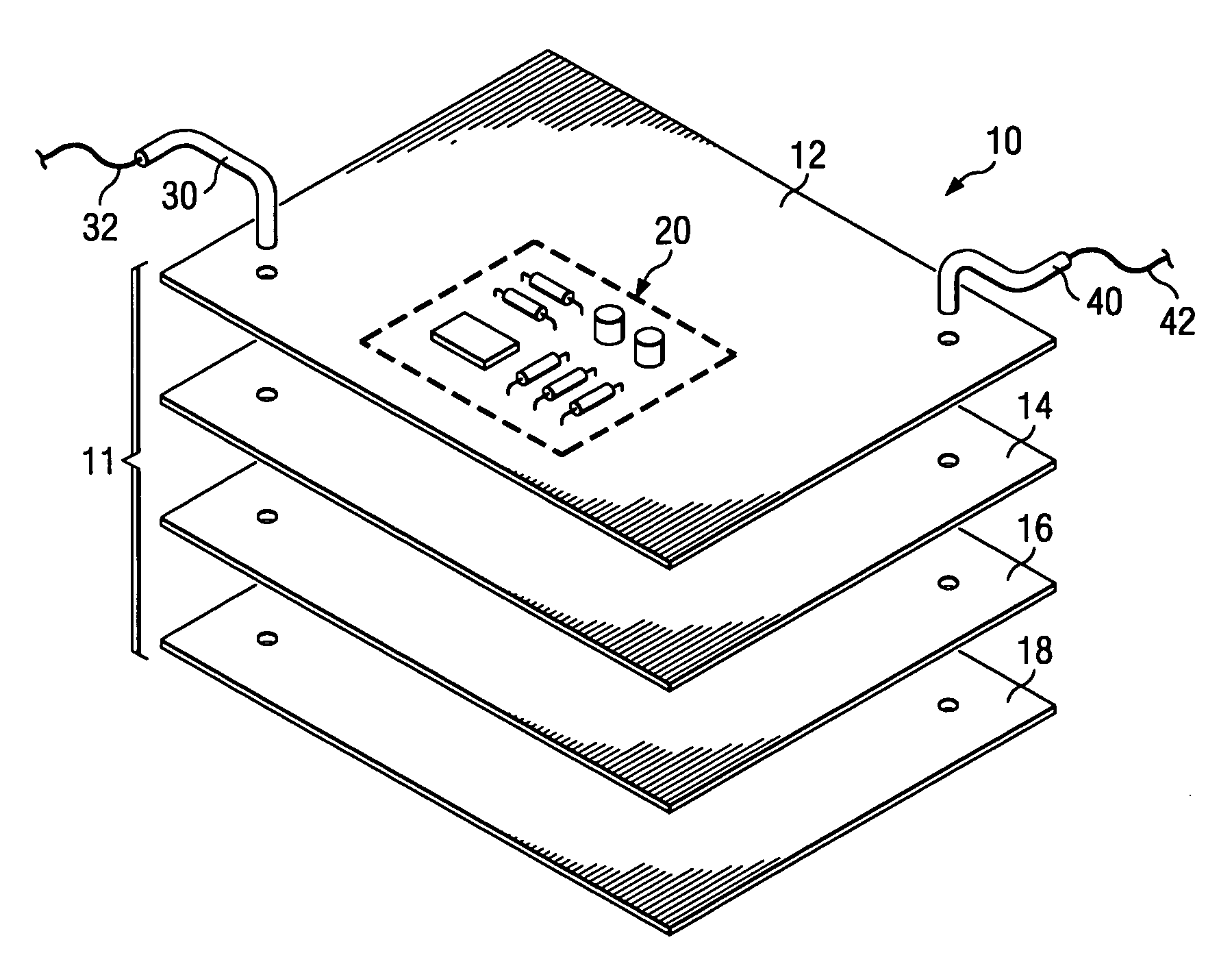

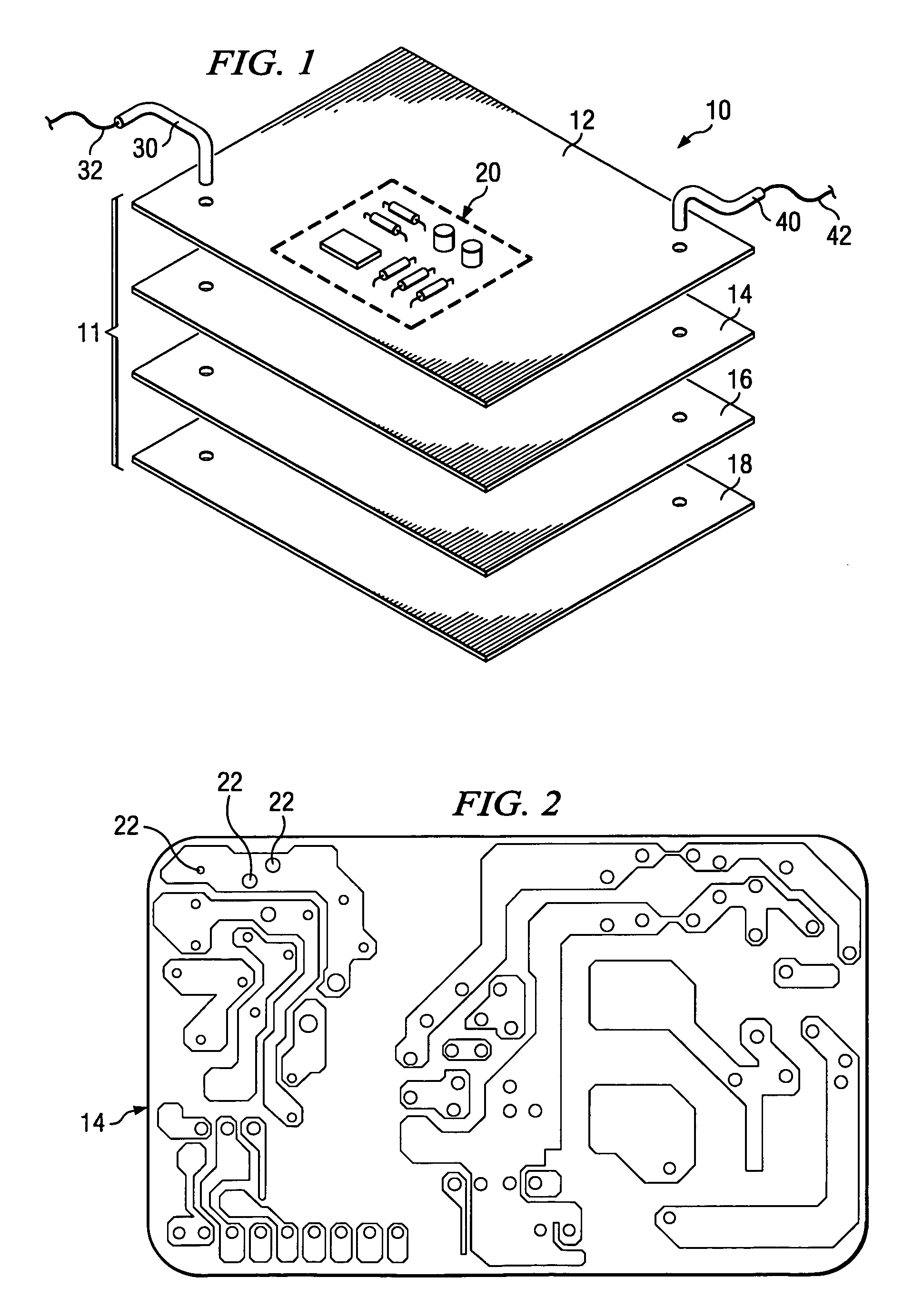

Power converter having multiple layer heat sinks

InactiveUS20070175655A1Compact power converterHigh power outputSemiconductor/solid-state device detailsPrinted electric component incorporationEngineeringConductive materials

A power converter including a printed circuit board (PCB) having a plurality of heat conductive layers configured to sink heat generated by the power converter electronics. Each of these heat conductive layers are comprised of thermally conductive material configured as planar sheets, each of these heat conductive layers being coupled to at least one wire to sink heat therefrom, such as via a wire of an input cable and / or output cable. Advantageously, a more compact power converter is realized having improved power output while operating within safety guidelines.

Owner:IGO INC

Method and apparatus for continuously producing discrete expanded thermoformable materials

InactiveUS20060157886A1Reduce viscoelasticityMaterial nanotechnologyArtifical filament manufactureContinuous productionMetallurgy

A method and apparatus for continuously and cost-effectively producing expanded thermoformable materials encompassing the steps of: providing raw thermoformable material into an extruder or mold; heating the material in the extruder or mold; extruding or co-extruding molding planar sheet material of suitable engineering performance parameters to a gauge and width; cutting or shearing the extruded or molded material while it is still hot to suitable lengths for expansion in a coreformer; conveying the hot thermoformable sheet material in between forming platens; heating the thermoformable material to a temperature at which the material adhesively bonds to the platens; expanding the cross-section of the thermoformable material; and then cooling the expanded thermoformable material by changing the temperature of the forming platens such that the thermoformable material can maintain its structural integrity and be released from the platens.

Owner:PANTERRA ENGINEERED PLASTICS

Luminescent sheet having see-through property, luminescent decorative material, and method of producing luminescent sheet

According to this invention, a luminescent decorative material, which is visible even at night, of which different decorative properties are obtained in the daytime or under lighting due to the presence or absence of luminescence is provided. A luminescent sheet (plane sheet) having see-through property and comprising a transparent part, through which it is possible to see the area behind the plane sheet, and a luminescent part is provided.

Owner:LINTEC CORP

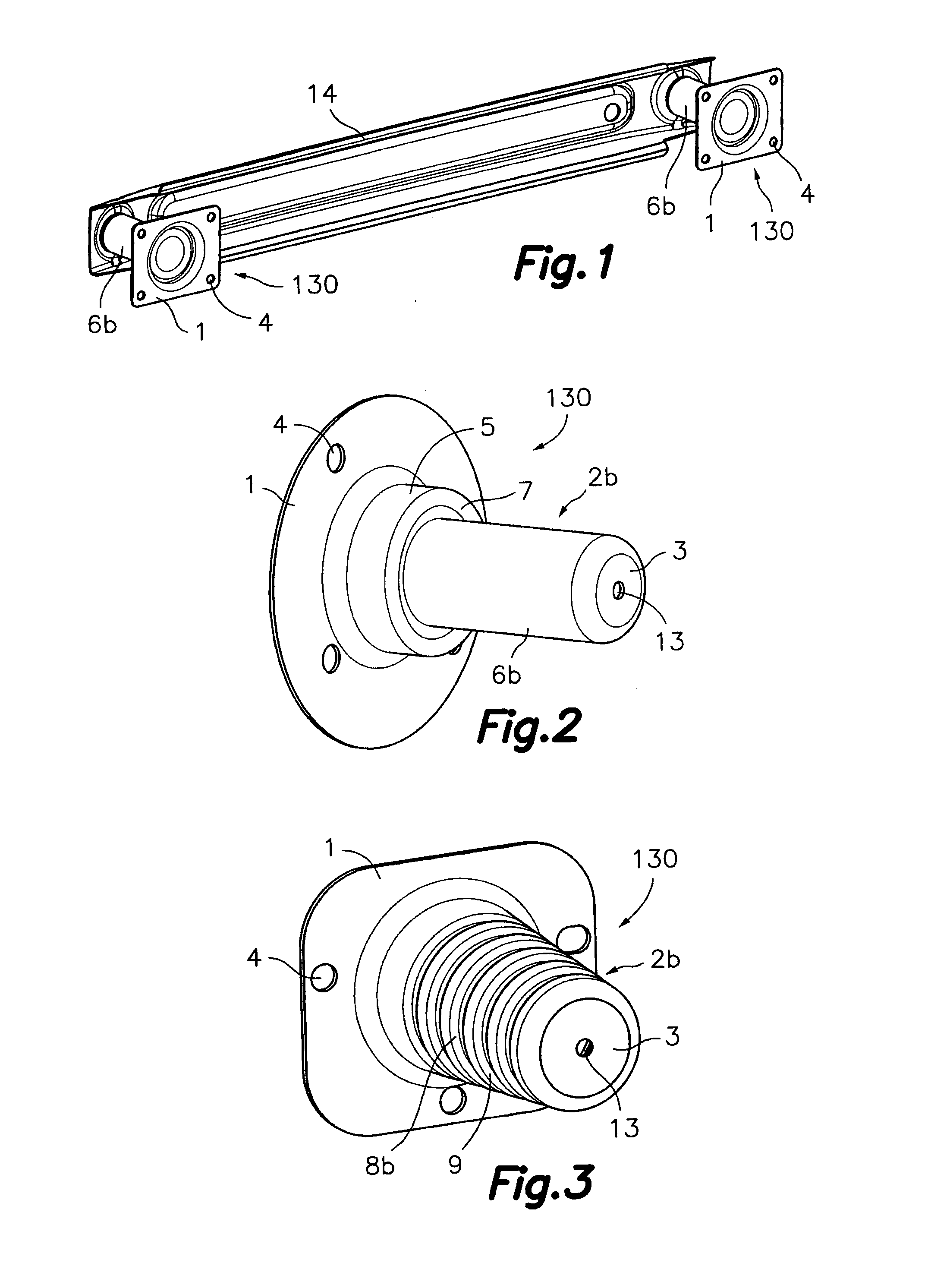

Method for producing a shock absorber and shock absorber thus obtained

ActiveUS8359893B2Relative resistance of the material of the wall of the elongated section is increasedExcellent mechanical propertiesElastic dampersBumpersEngineeringShock absorber

The method includes providing a planar sheet part; forming the planar sheet part by drawing or conical spinning to the shape of a partially formed part made up of a plate and a provisional hollow portion extending from the plate with a revolution shape with respect to an axis perpendicular to the plate, and an end wall closing an end of the provisional hollow portion opposite to the plate; and elongating a section of the provisional hollow portion by cylindrical or conical spinning. The shock absorber is integral with a plate and an elongated hollow portion extending from the plate with a revolution shape. A section of the elongated hollow portion has a thickness that is thinner than the thickness of the plate.

Owner:AUTOTECH ENG SL

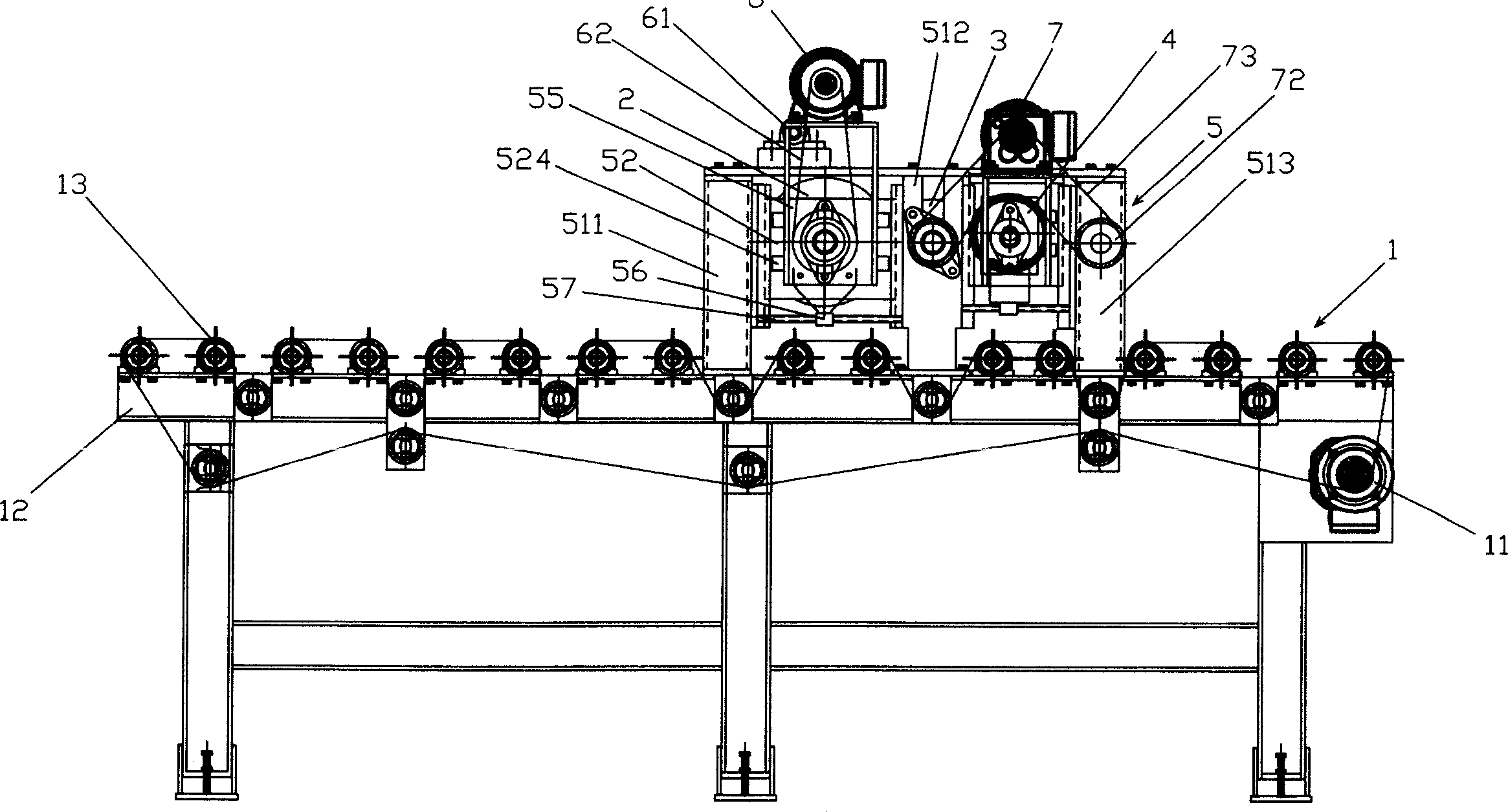

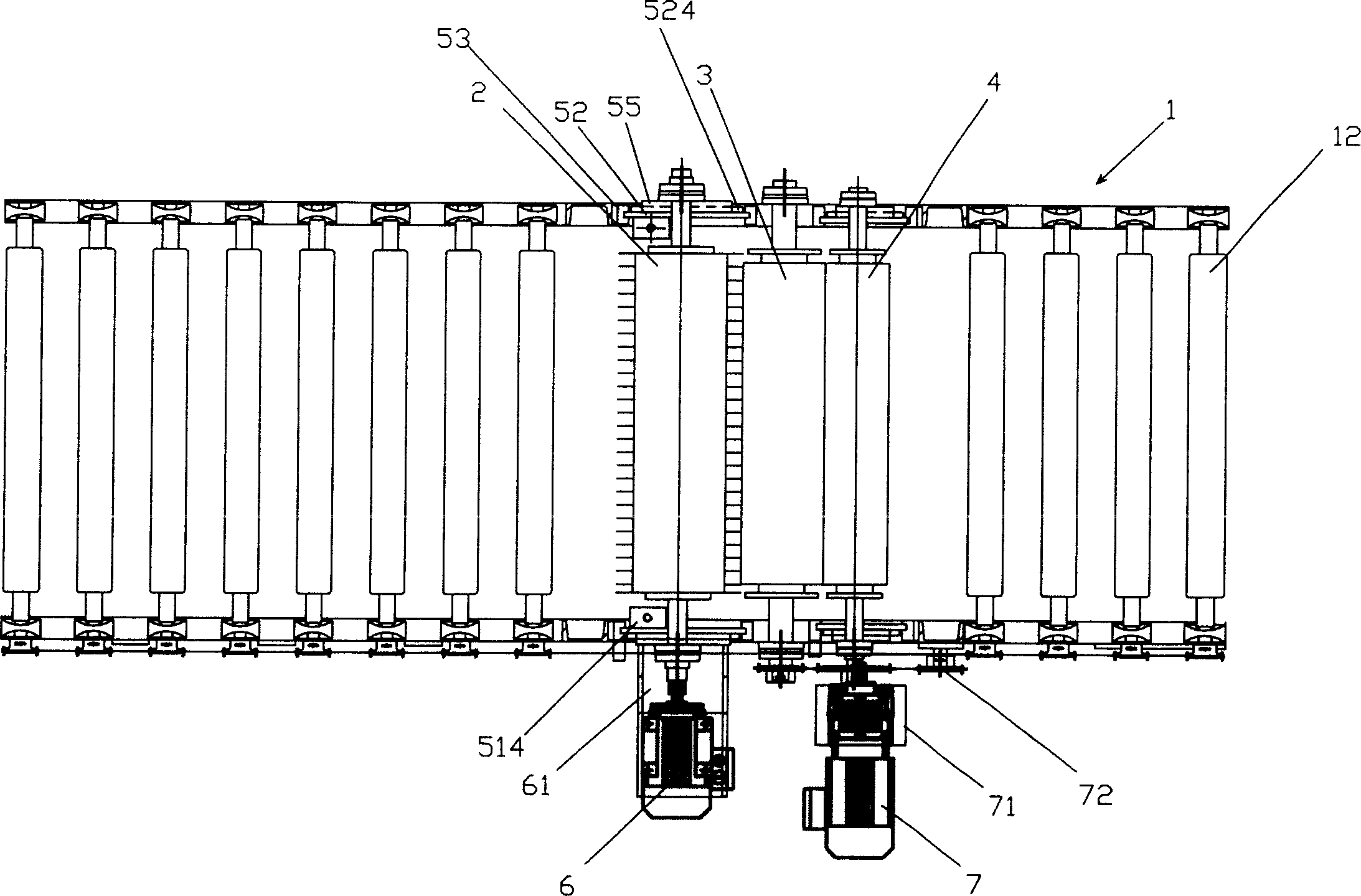

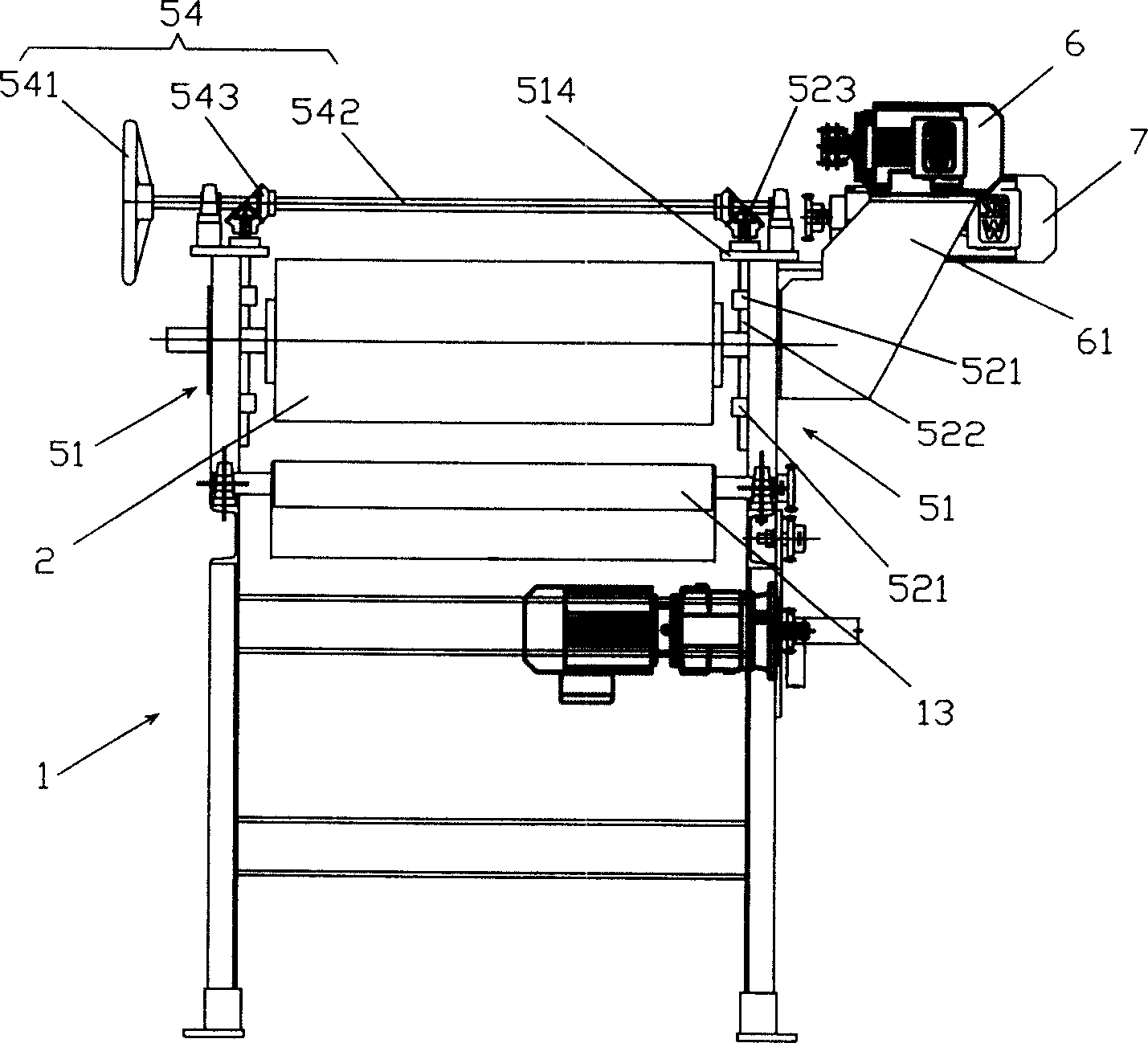

Salient point type plane sheet material surface treating method and equipment thereof

The process of forming raised dots on planar plate includes setting brush roller, gluing roller and homogenizing roller in parallel, making the distance between the brush roller and the gluing roller smaller than the length of brush on the brush roller, forming axial interval between the homogenizing roller and the gluing roller, adding emulsion paint through the interval, rotating the brush roller and the gluing roller in the same direction, rotating the homogenizing roller and the gluing roller oppositely, and conveying sound absorbing mineral wool board to below the brush roller. The corresponding apparatus includes conveyer, brush roller, gluing roller, homogenizing roller, installing frame and driver, and may have brush roller and homogenizing roller level regulating mechanism. The present invention forms raised dots on planar plate with the brush to spin off paint and has no damage to the plate.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com