Production process of flat offset printing roll color-printing pressure-sensitive adhesive trade mark

A production process and reel technology, applied in the general parts of printing machinery, printing, sealing and other directions, can solve the problems of increasing printing costs, inability to reel printing, and high costs, to improve production efficiency, increase production speed, and eliminate printing. The effect of indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

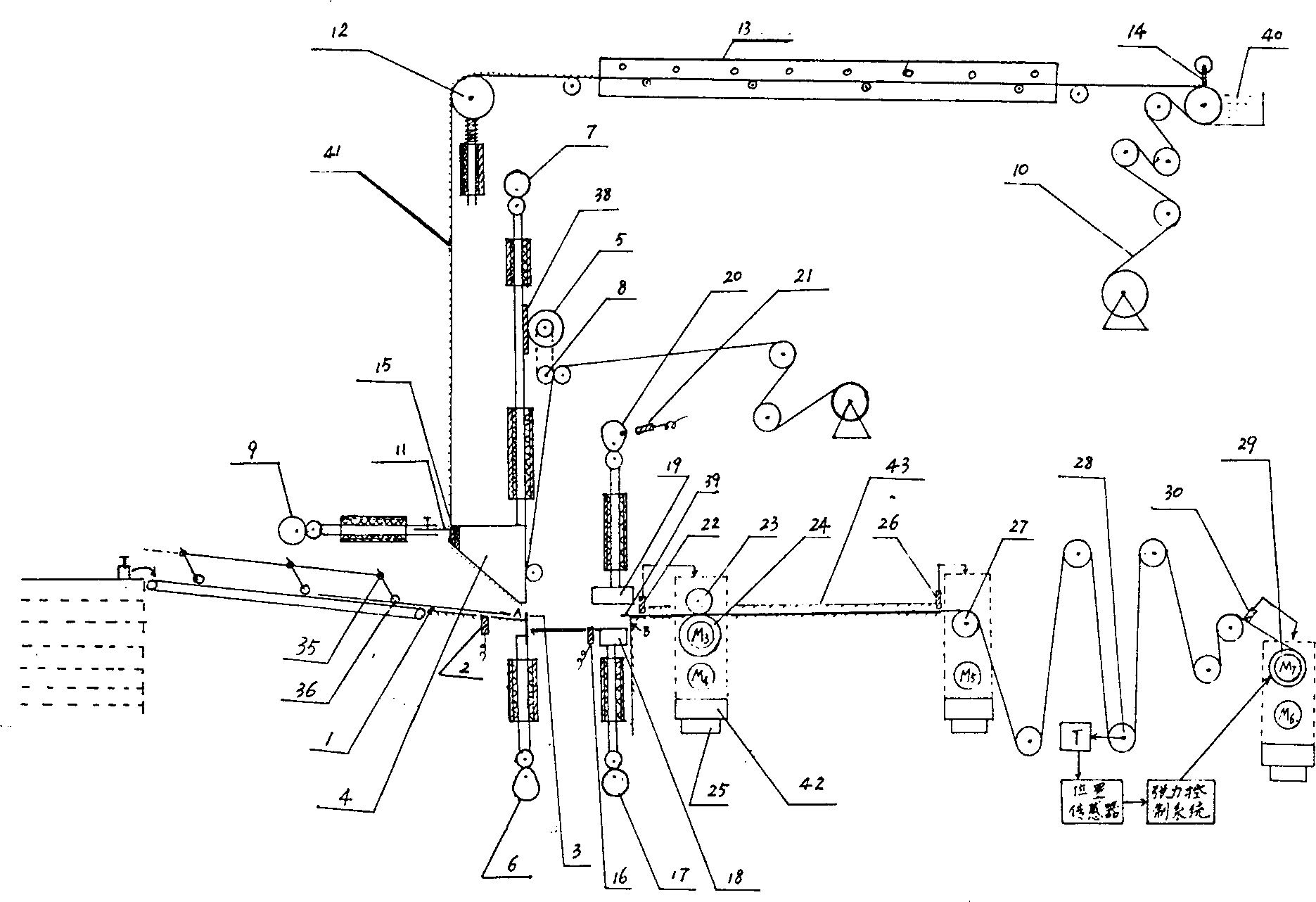

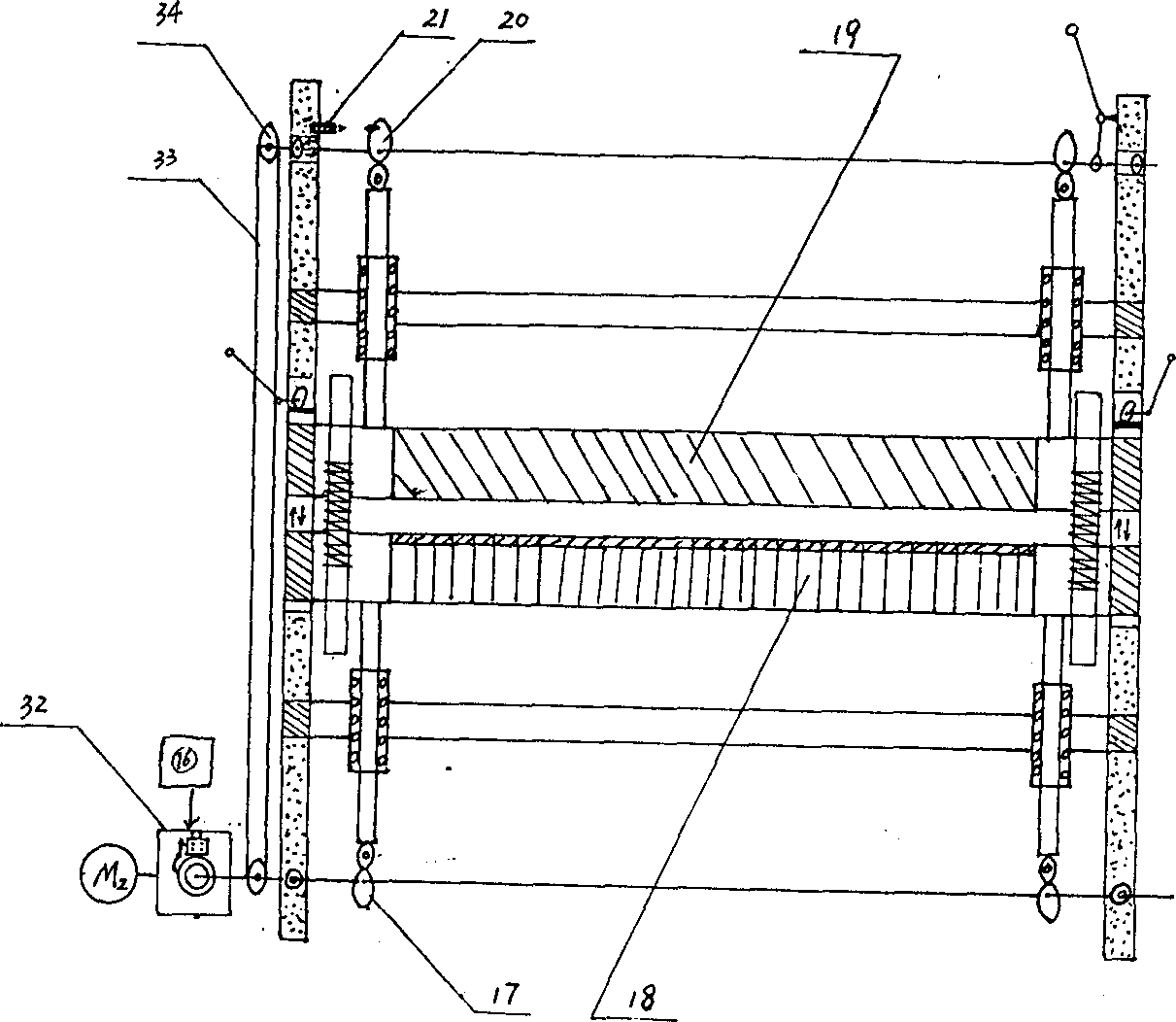

[0041] The present invention will be further described below in conjunction with embodiment. The production process of this kind of sheet-fed offset printing reel color printing self-adhesive trademark mainly includes the following steps: surface paper sheet PS plate printing → edge trimming → sheet-fed printing surface paper is automatically glued into a roll → self-adhesive precision coating compound → Roll Die Slitting

[0042] 1. PS plate printing on surface paper sheet: ① Typesetting: according to the direction of automatic labeling of the roll, the trademarks are arranged equidistantly parallel to the bite edge, and the die-cutting tracking point and tracking line are marked on the edge of the bite edge and both sides of the drag gauge , Mark the trimming line on both sides of the pull gauge and side gauge. ②. The surface paper is treated with static electricity, temperature and humidity before printing to reduce the expansion and contraction of the paper. ③. When prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com