Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Neck surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

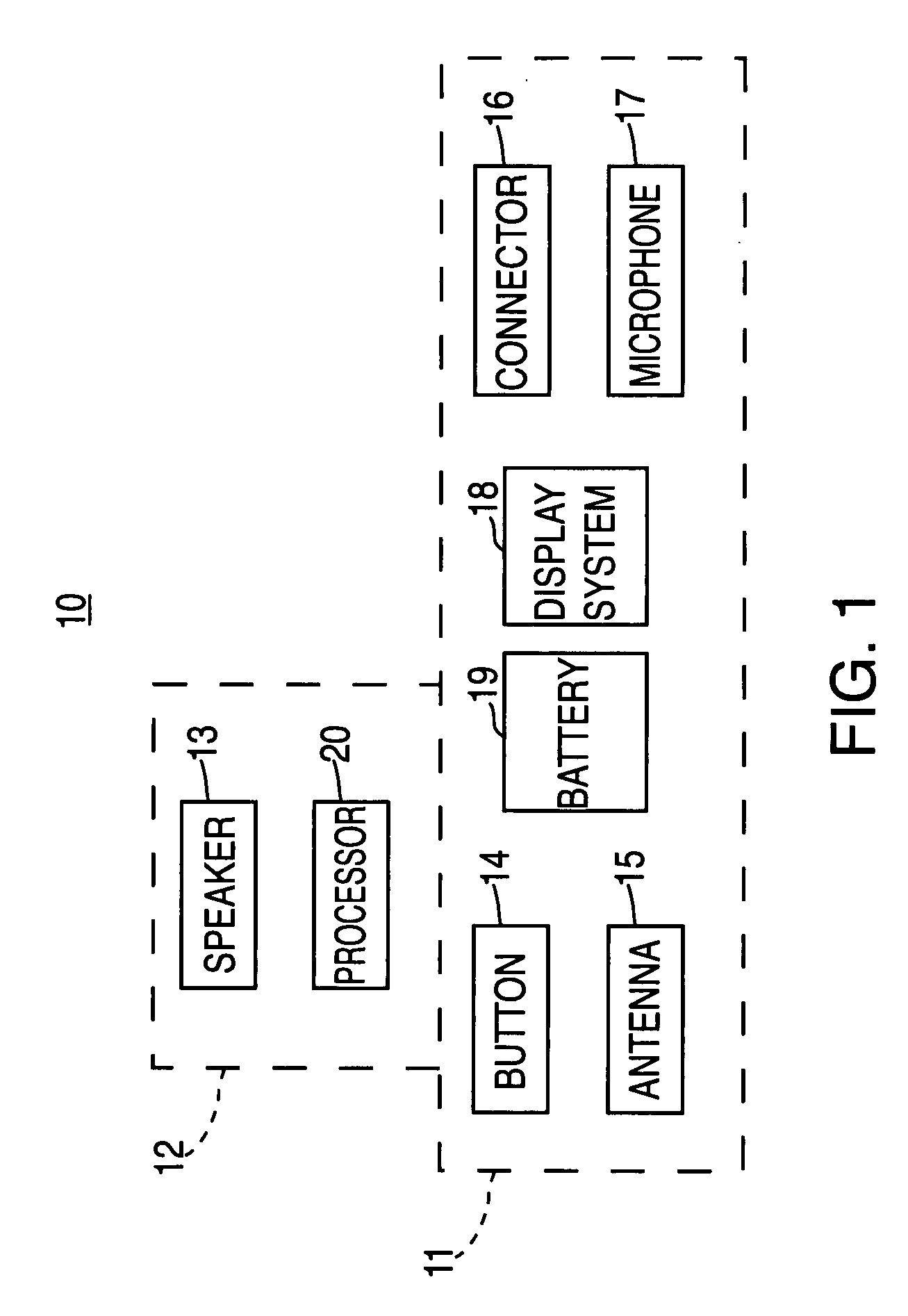

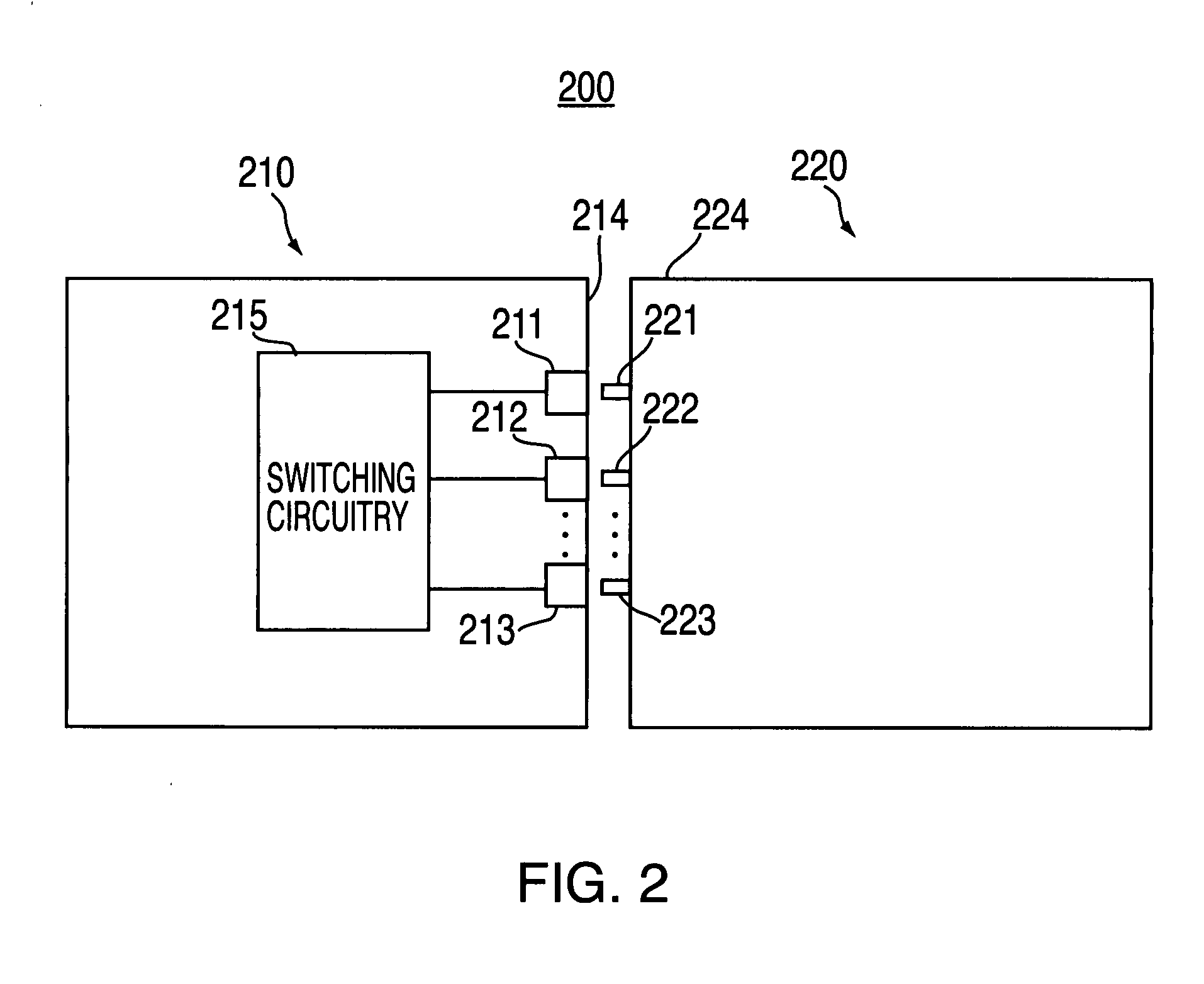

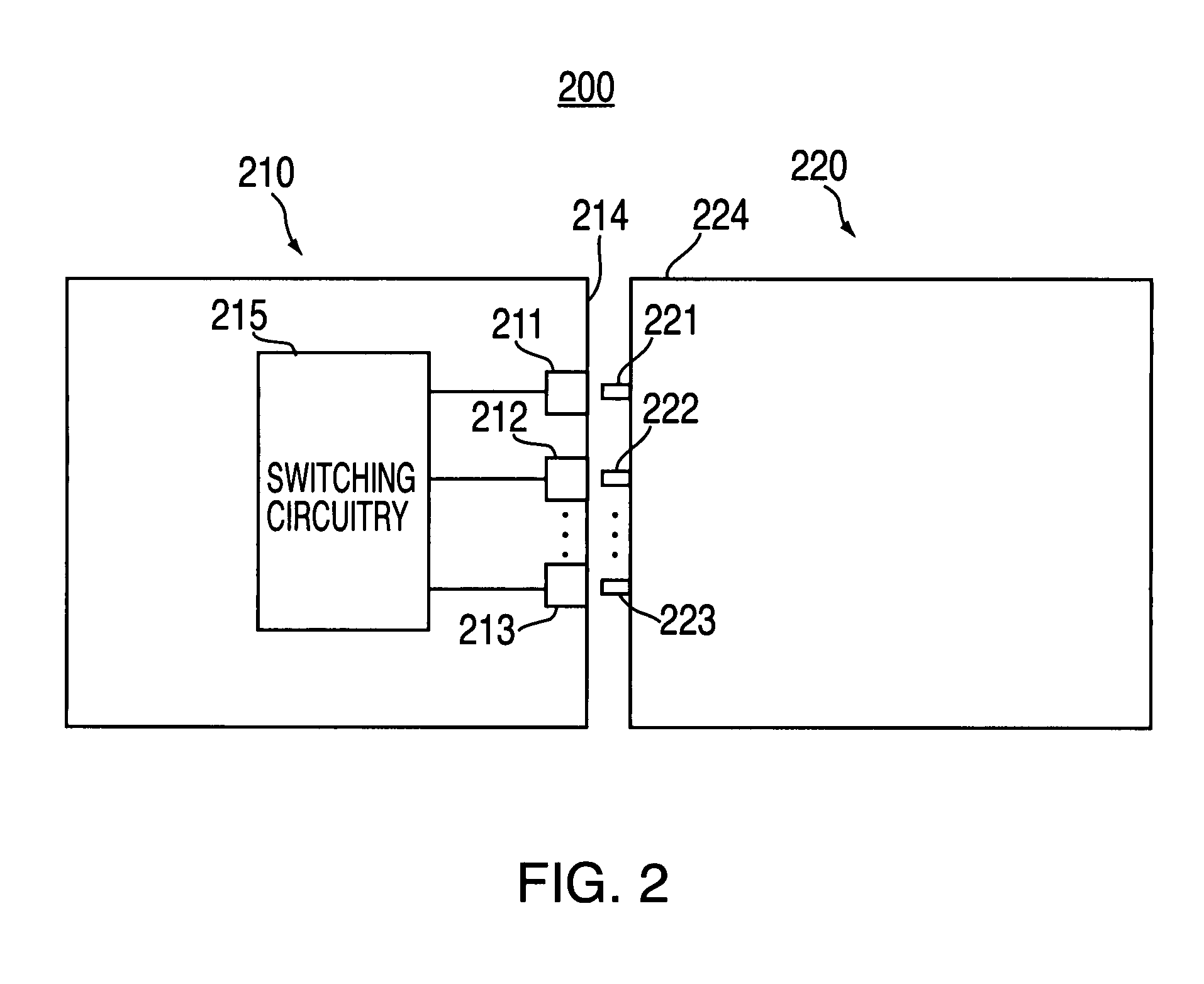

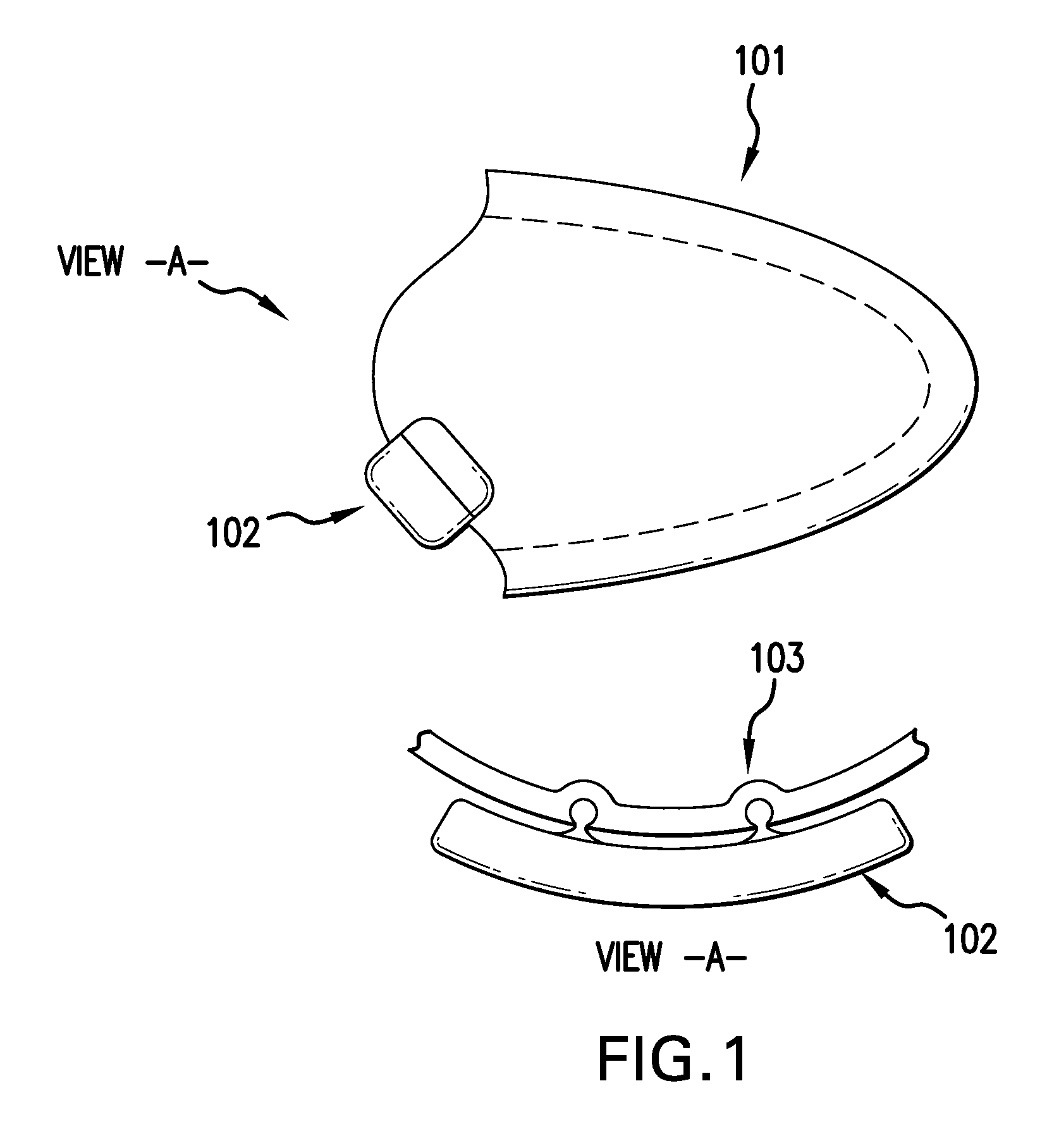

Assembly for coupling the housings of an electronic device

A headset device that includes an earbud housing, a primary housing, a threaded neck, an earbud screw, and a primary housing screw is provided. The earbud housing can include an earbud through-hole and a first neck engaging surface. The primary housing can include a housing through-hole and a second neck engaging surface. The threaded neck can include first and second neck surfaces that can mate, respectively to the first and second neck engaging surface. The earbud screw can fit through the earbud through-hole and can interlock with the threaded neck to fix the earbud housing to the threaded neck. The primary housing screw can fit through the housing through-hole and can interlock with the threaded neck to fix the primary housing to the threaded neck. The threaded neck can include a through-hole for enabling circuitry disposed in the earbud housing to electrically couple to circuitry disposed in the primary housing.

Owner:APPLE INC

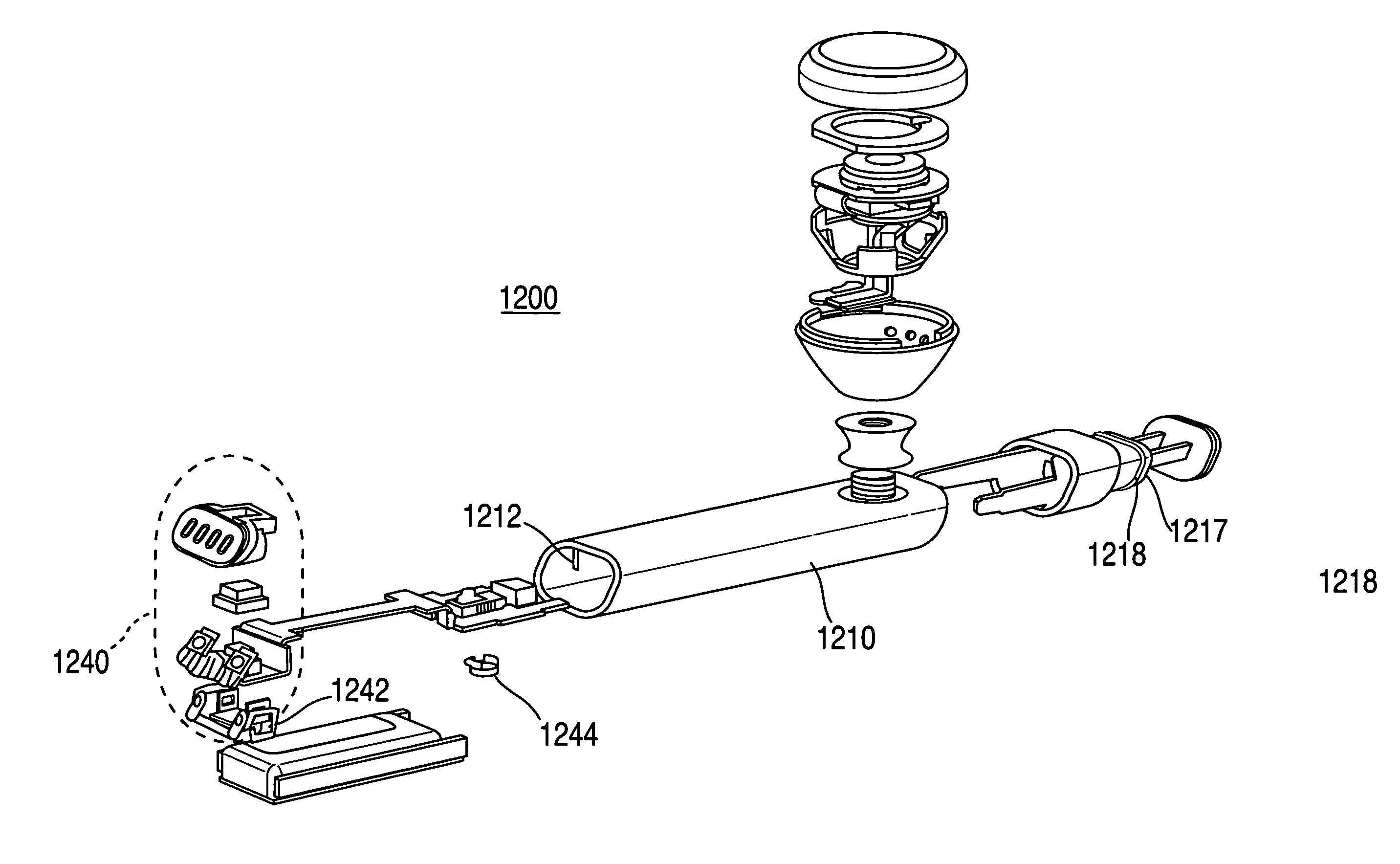

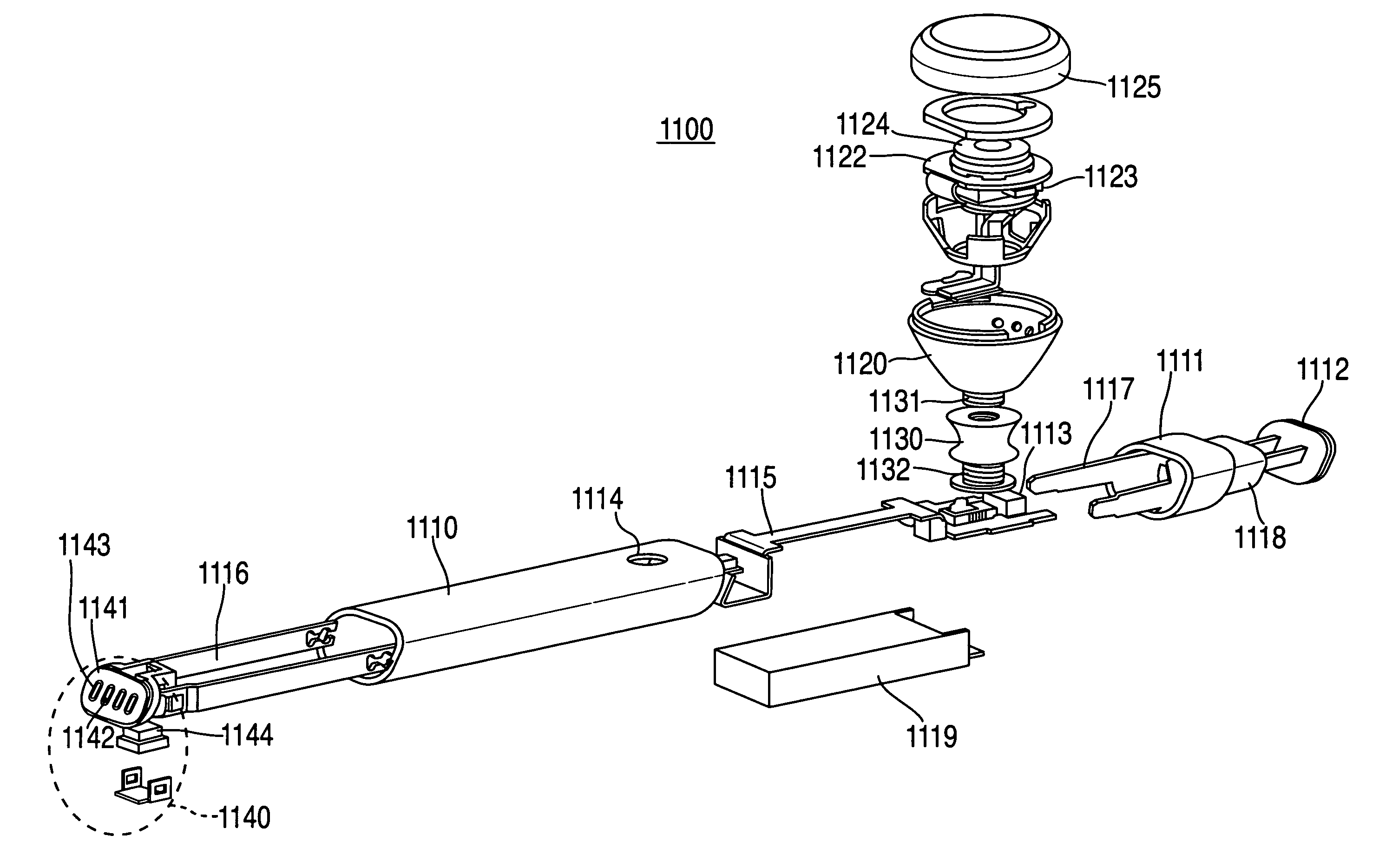

Assembly for coupling the housings of an electronic device

A headset device that includes an earbud housing, a primary housing, a threaded neck, an earbud screw, and a primary housing screw is provided. The earbud housing can include an earbud through-hole and a first neck engaging surface. The primary housing can include a housing through-hole and a second neck engaging surface. The threaded neck can include first and second neck surfaces that can mate, respectively to the first and second neck engaging surface. The earbud screw can fit through the earbud through-hole and can interlock with the threaded neck to fix the earbud housing to the threaded neck. The primary housing screw can fit through the housing through-hole and can interlock with the threaded neck to fix the primary housing to the threaded neck. The threaded neck can include a through-hole for enabling circuitry disposed in the earbud housing to electrically couple to circuitry disposed in the primary housing.

Owner:APPLE INC

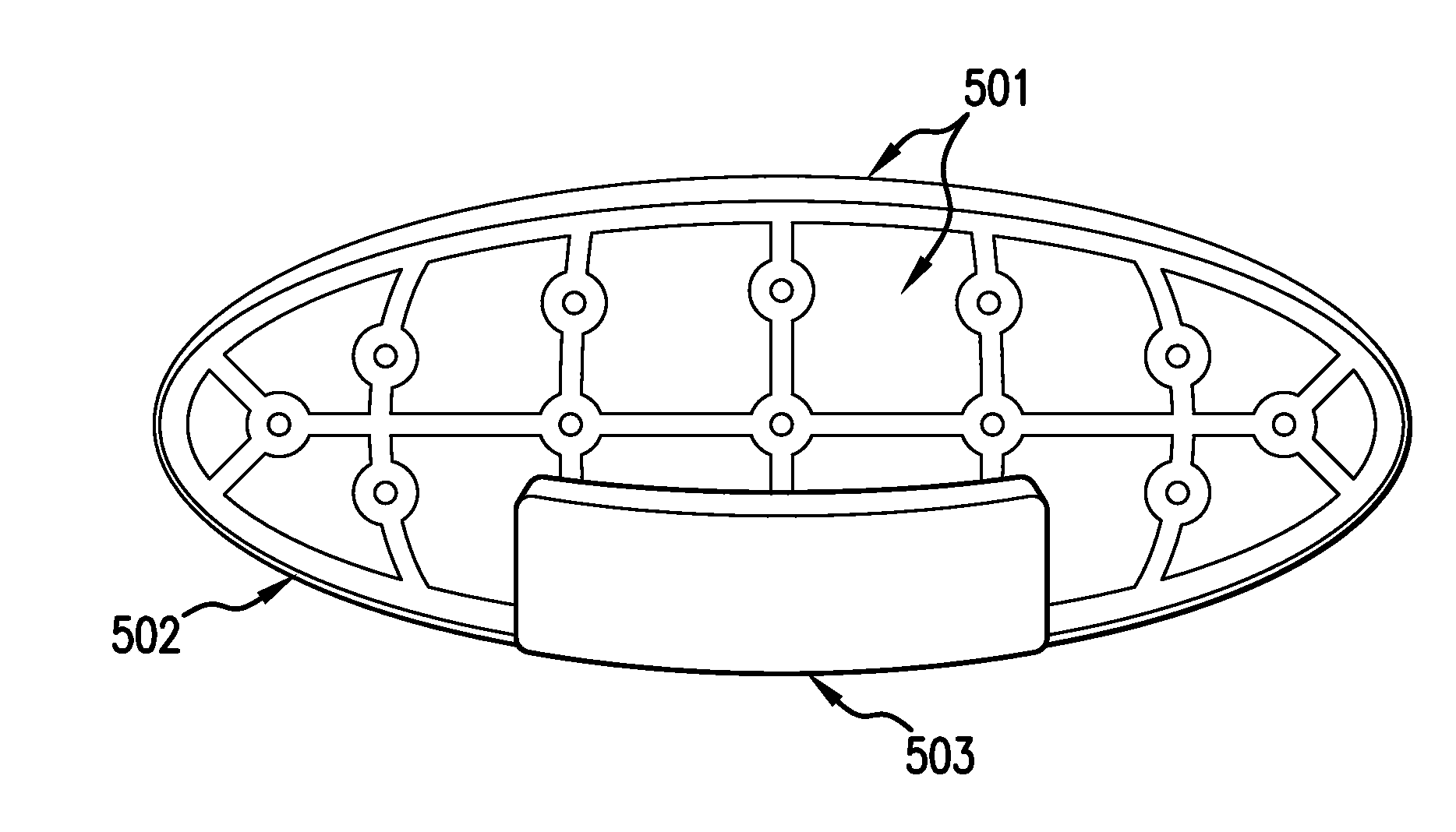

Device and method for opening an airway

ActiveUS20110066086A1Convenient and smoothEasy to replaceSnoring preventionSuction-kneading massageChinAnterior triangle

A device and a method for creating and / or maintaining an obstruction free upper respiratory passages. The device is configured to fit under the chin of a subject adjacent to the subject's neck at an external location corresponding approximately with the subject's internal soft tissue associated with the neck's anterior triangle. The device is capable of exerting negative pressure on the surface of a subject's neck, displacing the soft tissue forward and enlarging the airway.

Owner:SOMMETRICS INC

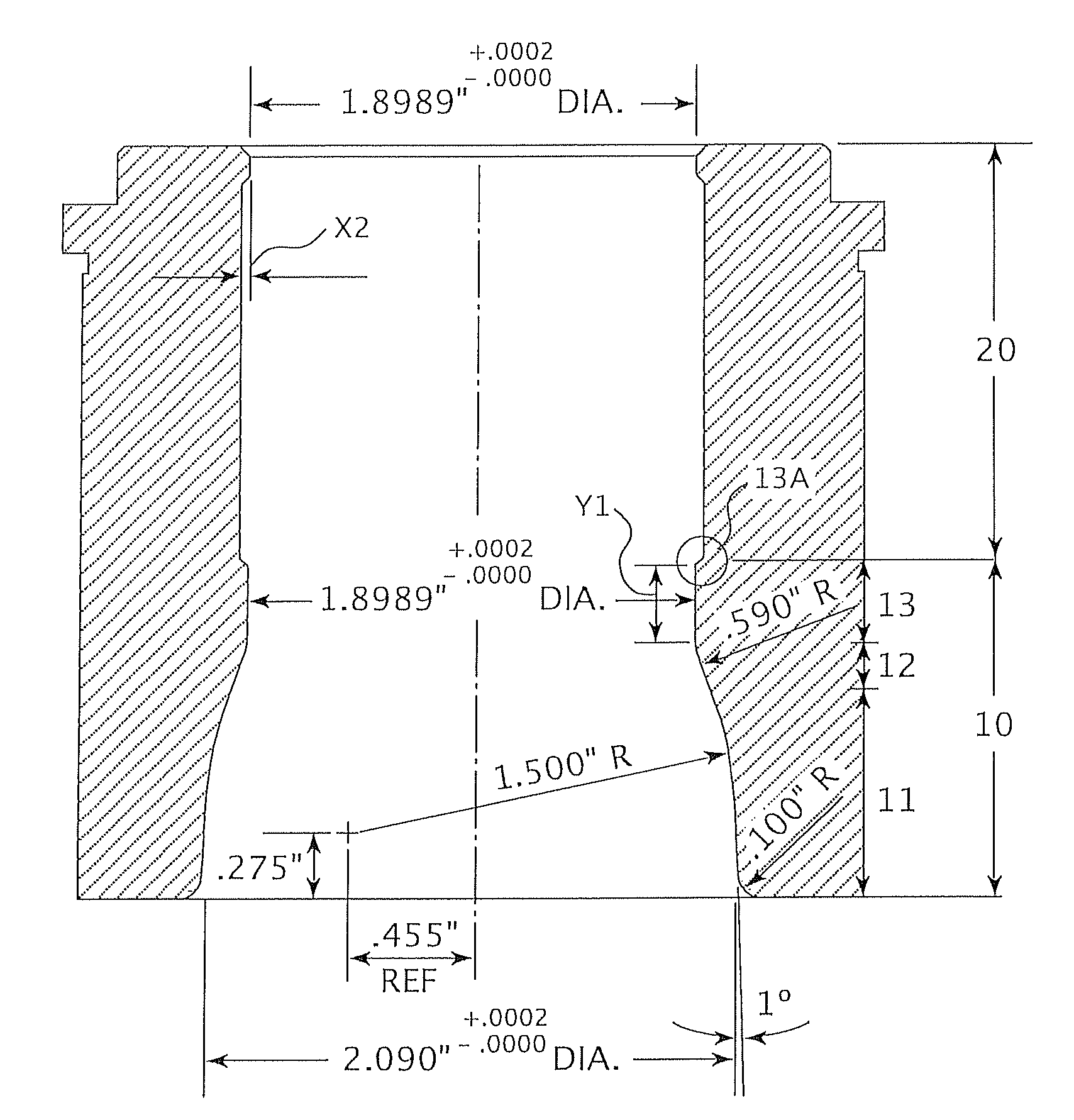

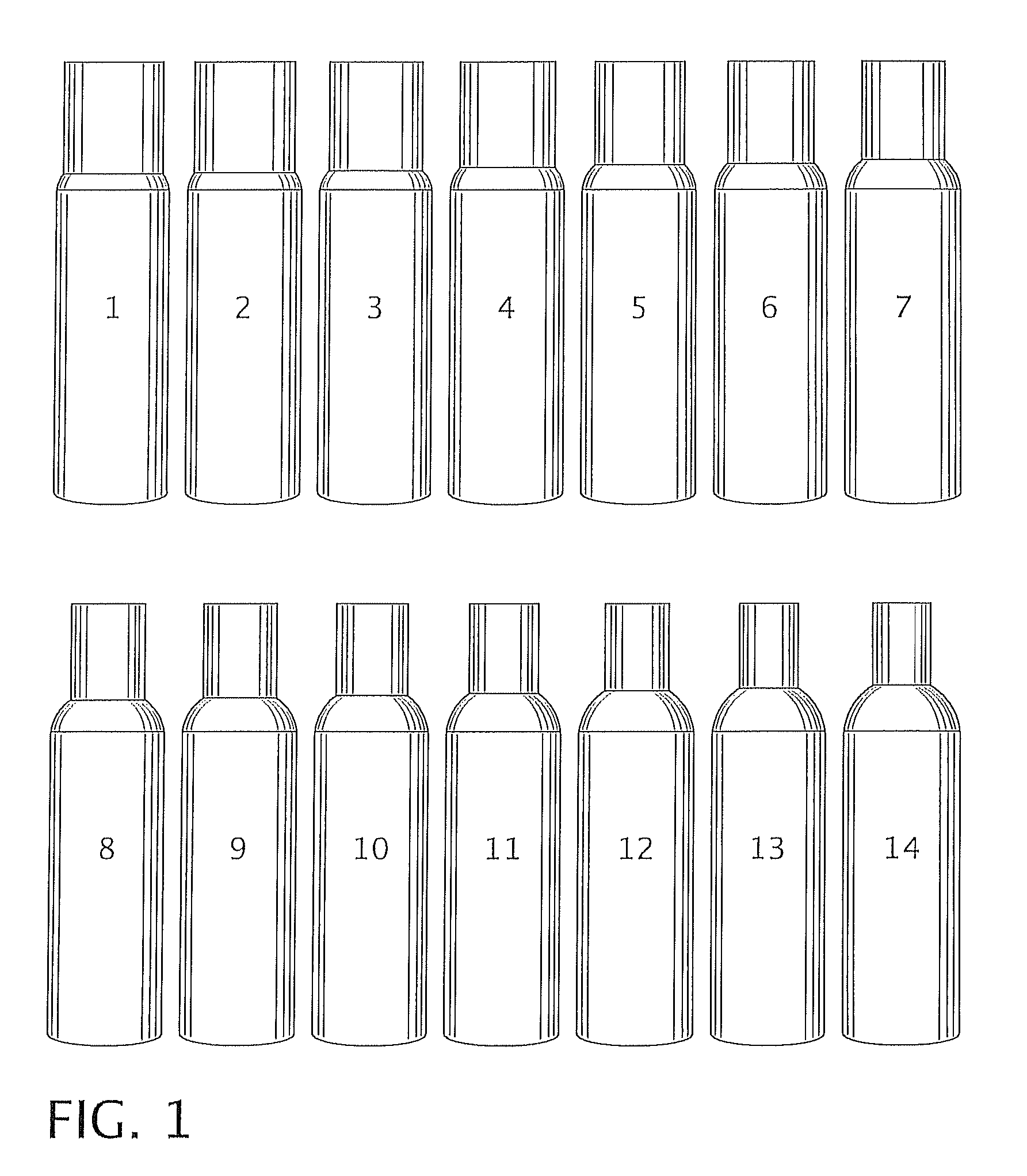

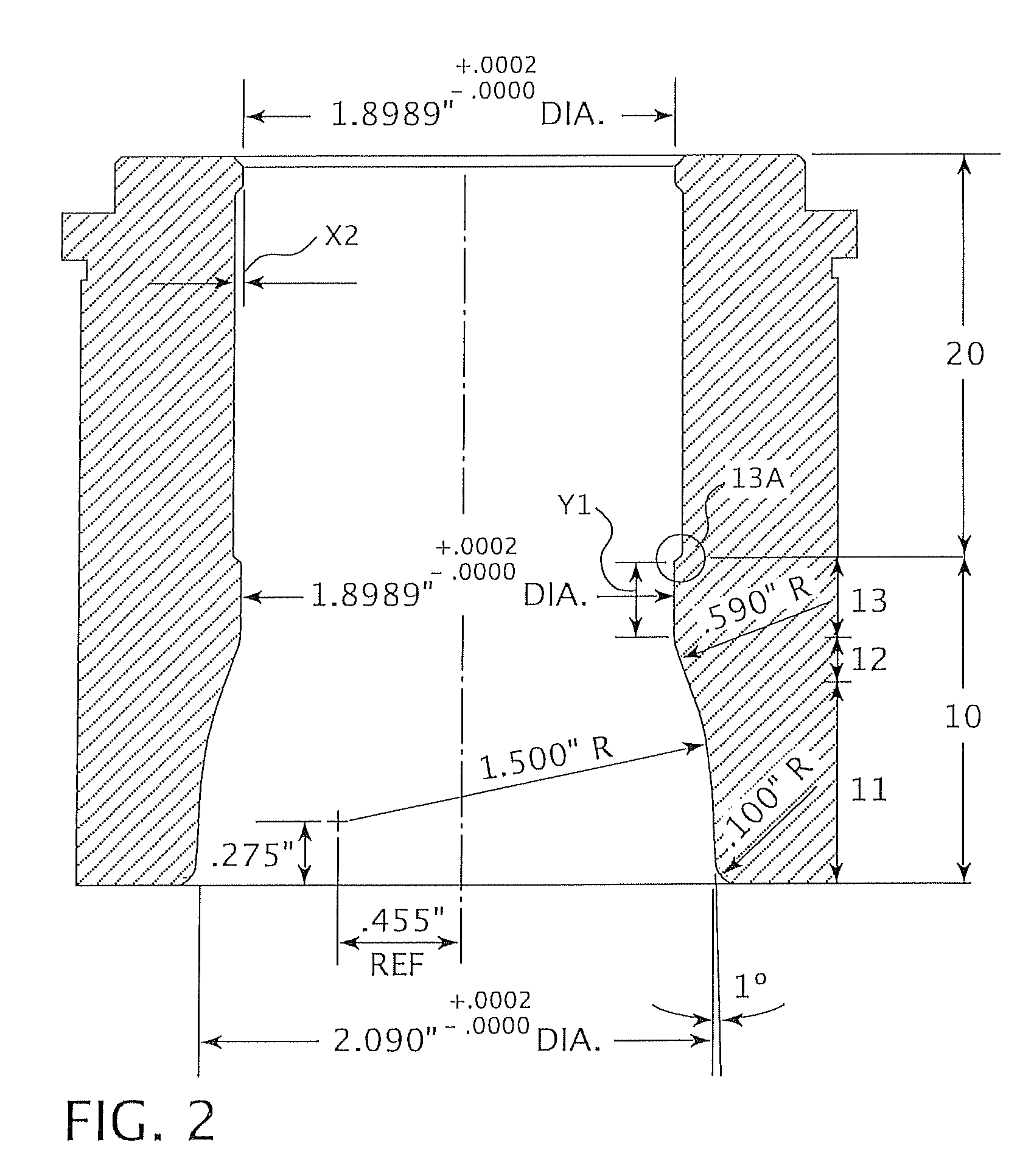

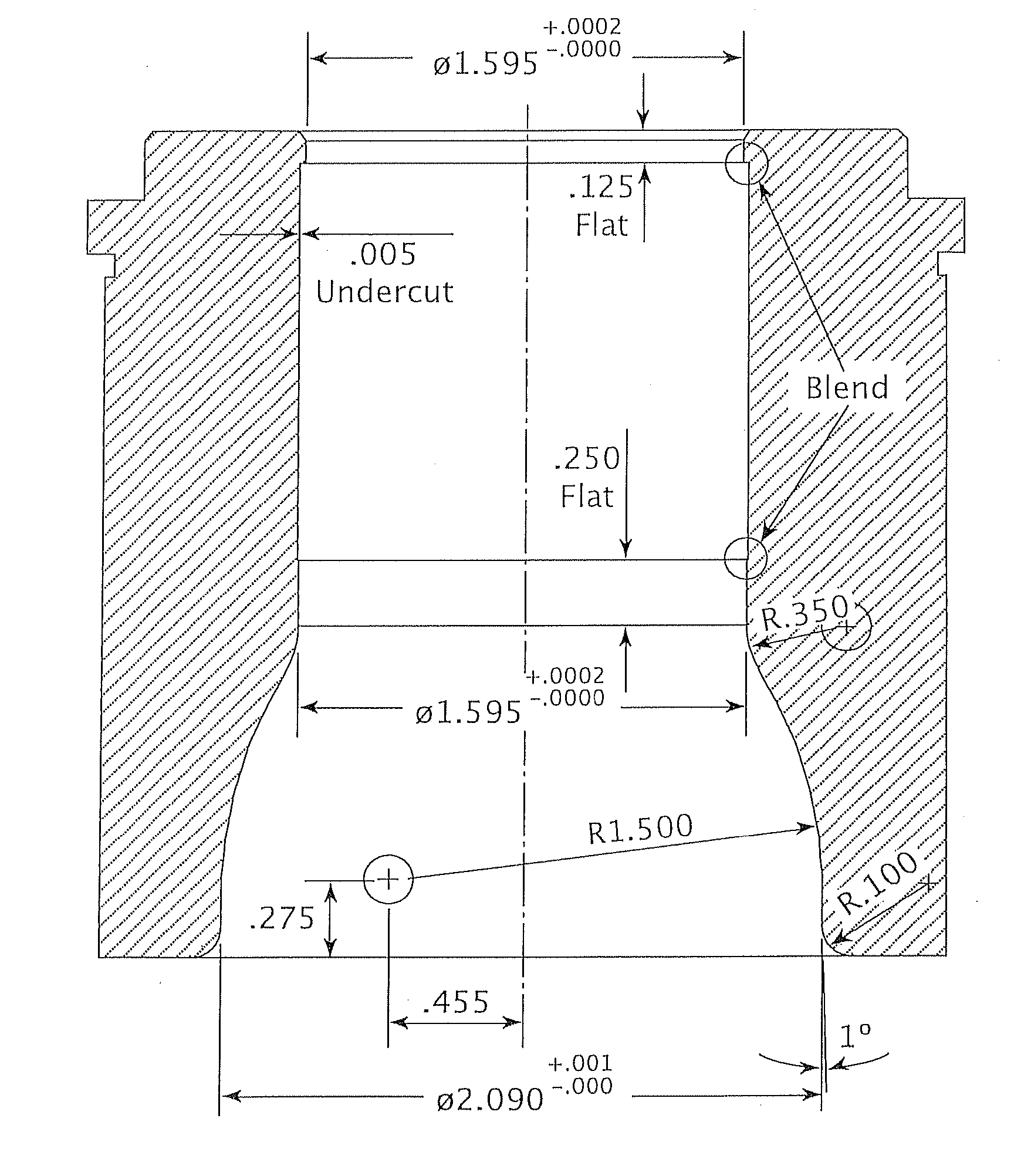

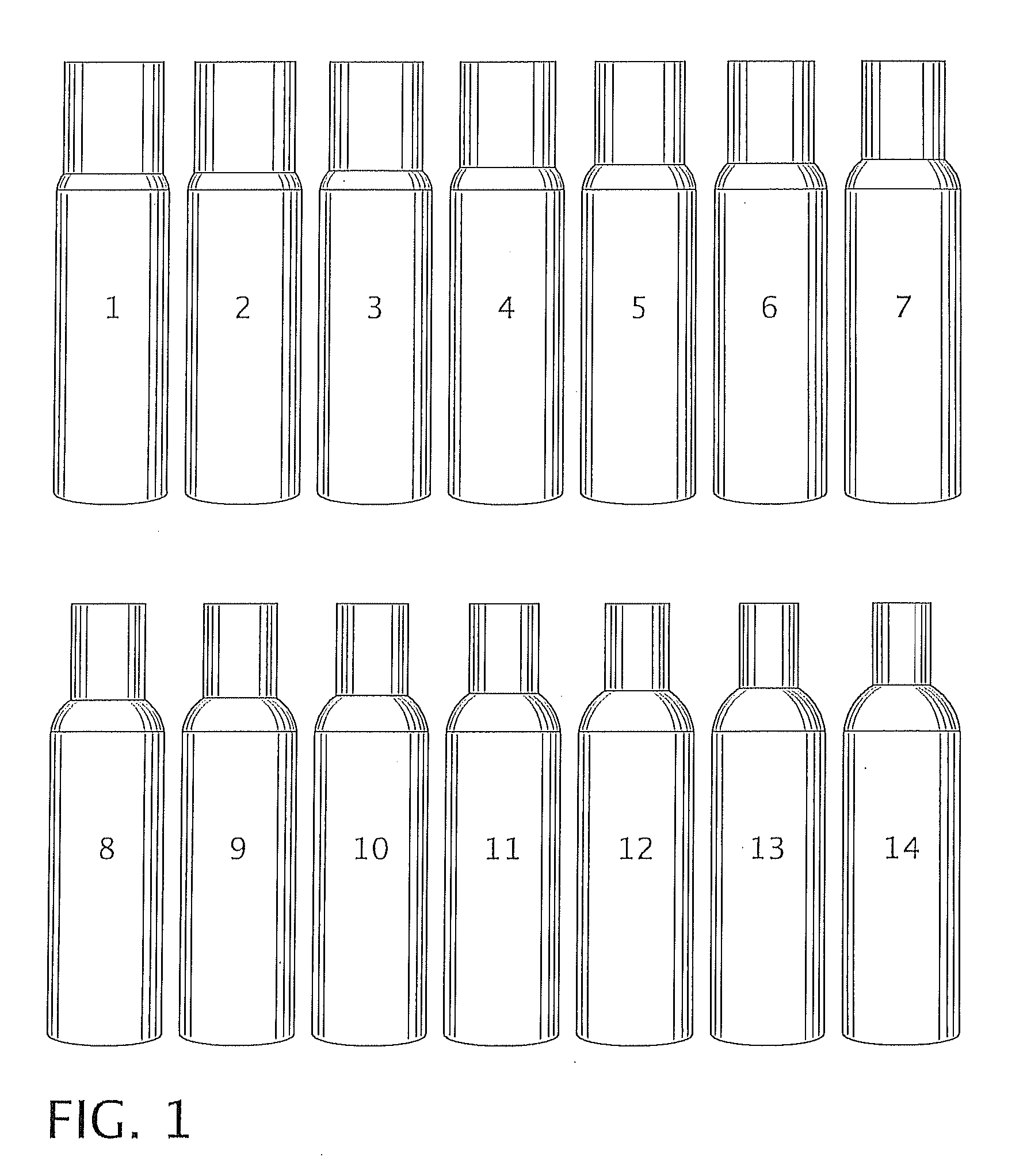

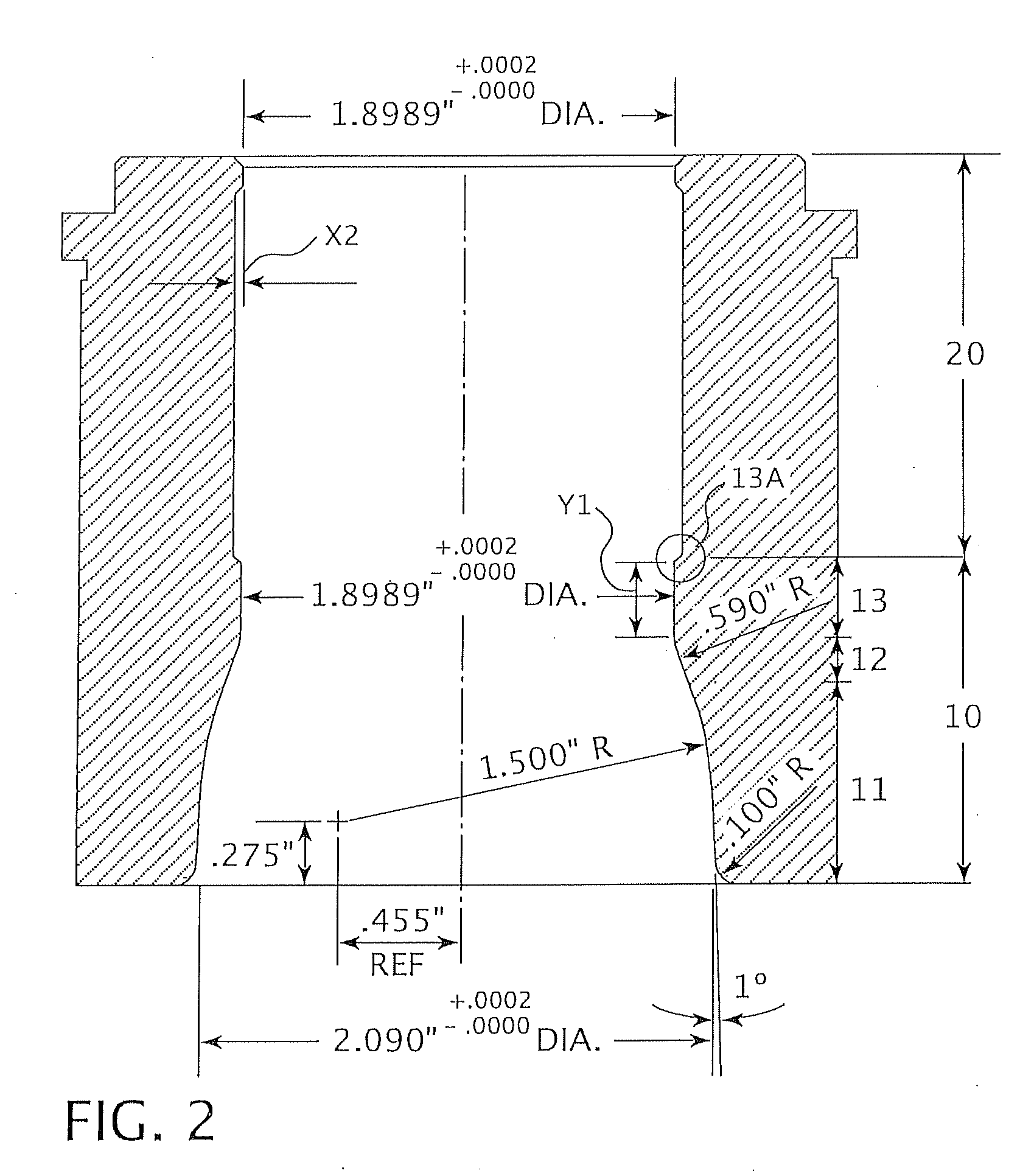

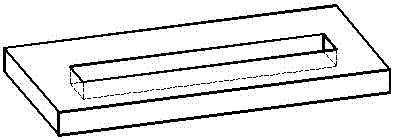

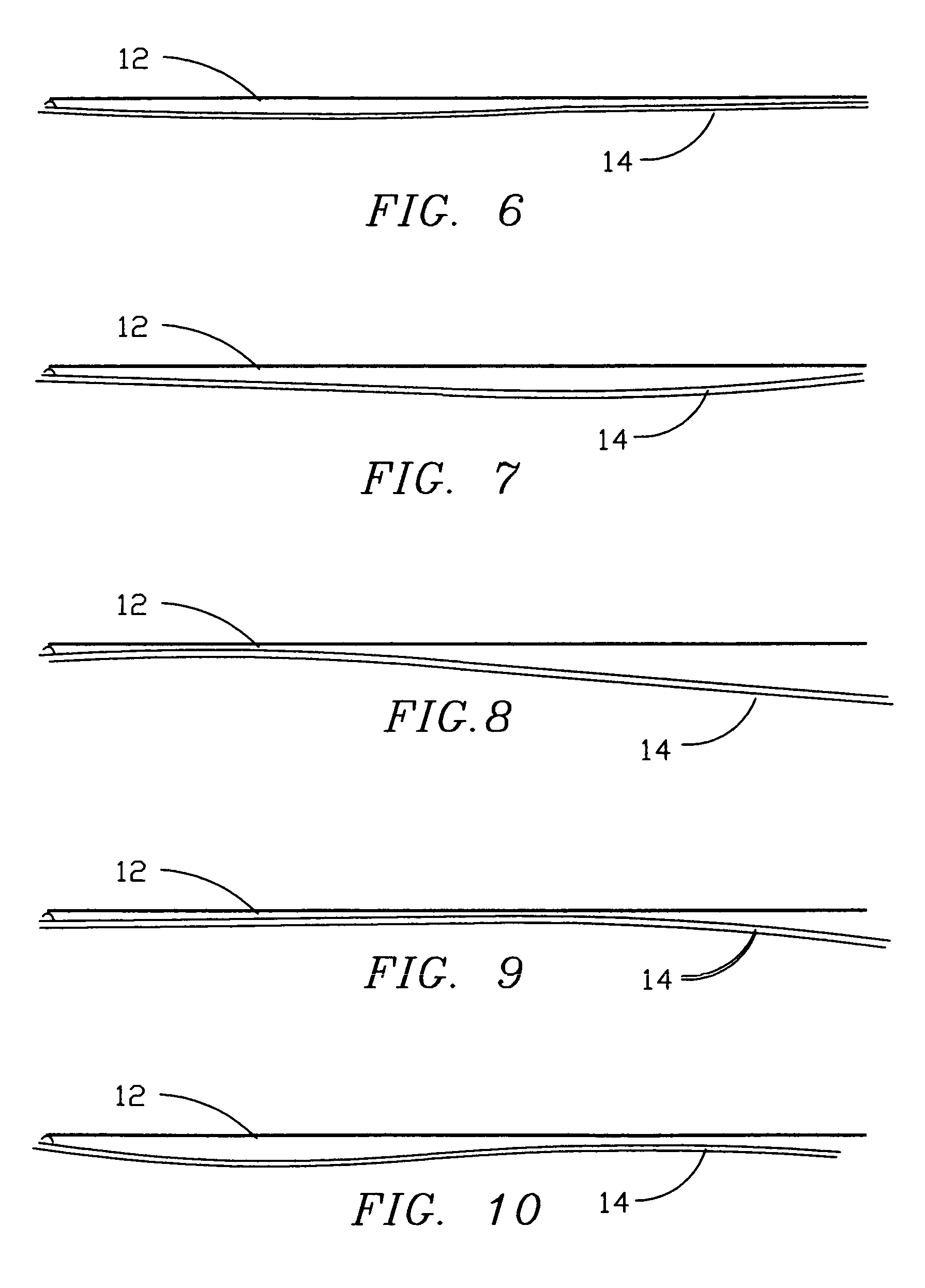

Manufacturing process to produce a necked container

ActiveUS7726165B2Aggressive reduction per necking dieSpeed up the restore processDrawing profiling toolsHollow articlesNeck surfaceBottle

The present invention provides a necking system including a plurality of necking dies each necking dies having an at least partially non-polished necking surface and a non-polished relief following the necking surface. The present invention further provides a method of necking an metal container including providing an metal blank; shaping the blank into a bottle stock; and necking the metal bottle stock, wherein necking includes at least one necking die having an at least partially non-polished necking surface.

Owner:KAISER ALUMINUM WARRICK LLC

Manufacturing Process to Produce a Necked Container

ActiveUS20070266758A1Aggressive reduction per necking dieSpeed up the restore processDrawing profiling toolsHollow articlesManufacturing technologyNeck surface

The present invention provides a necking system including a plurality of necking dies each necking dies having an at least partially non-polished necking surface and a non-polished relief following the necking surface. The present invention further provides a method of necking an metal container including providing an metal blank; shaping the blank into a bottle stock; and necking the metal bottle stock, wherein necking includes at least one necking die having an at least partially non-polished necking surface.

Owner:KAISER ALUMINUM WARRICK LLC

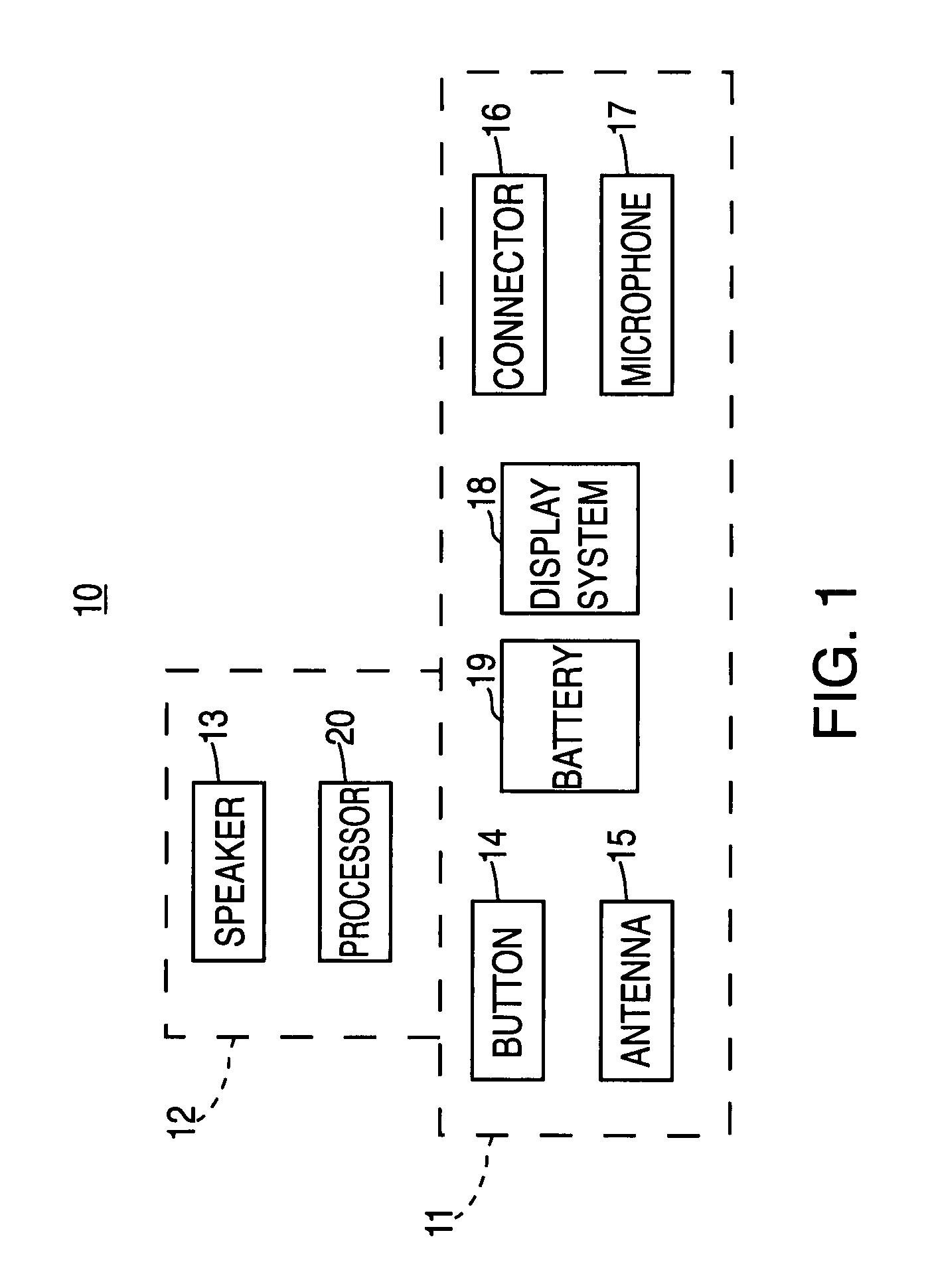

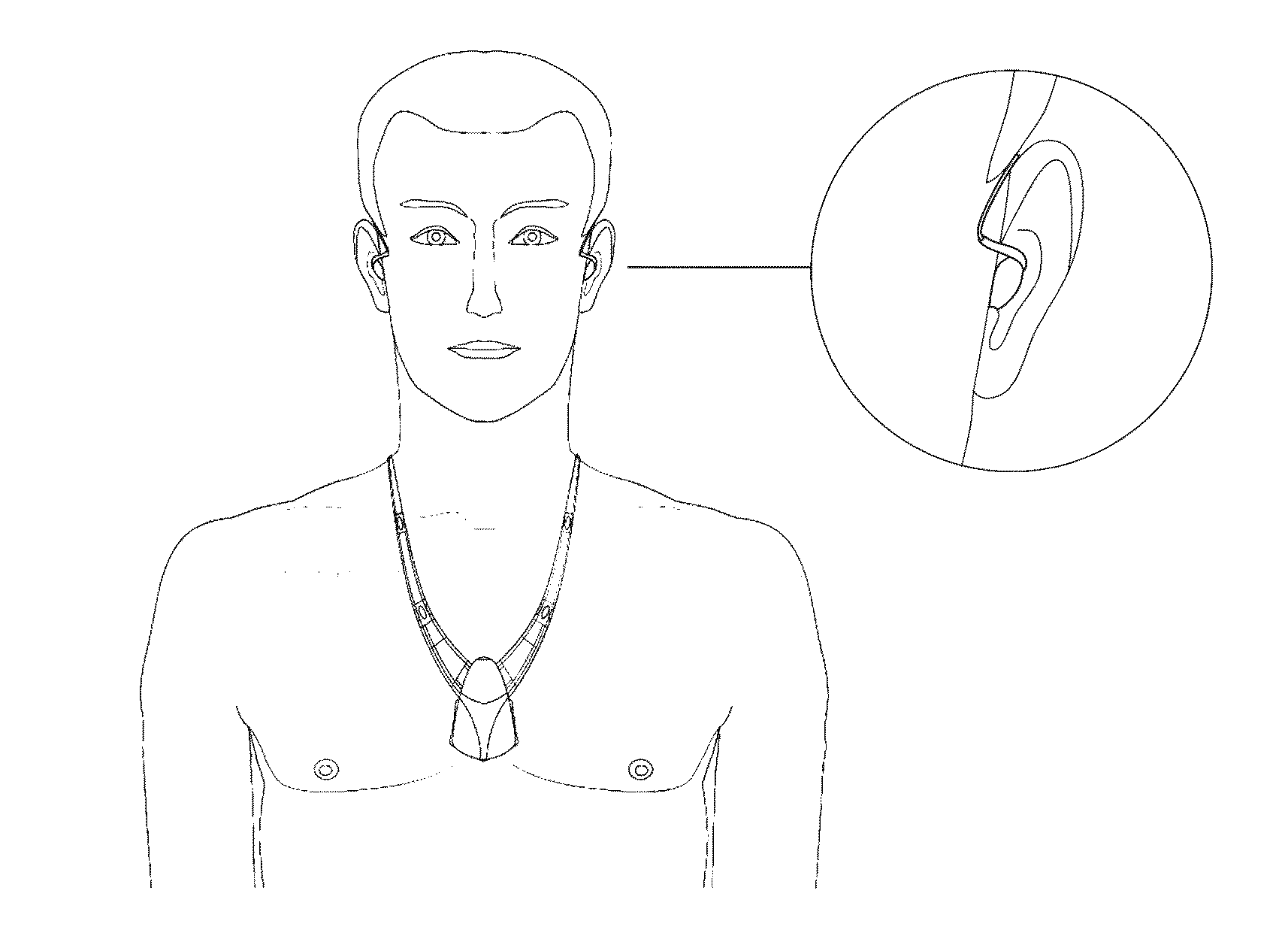

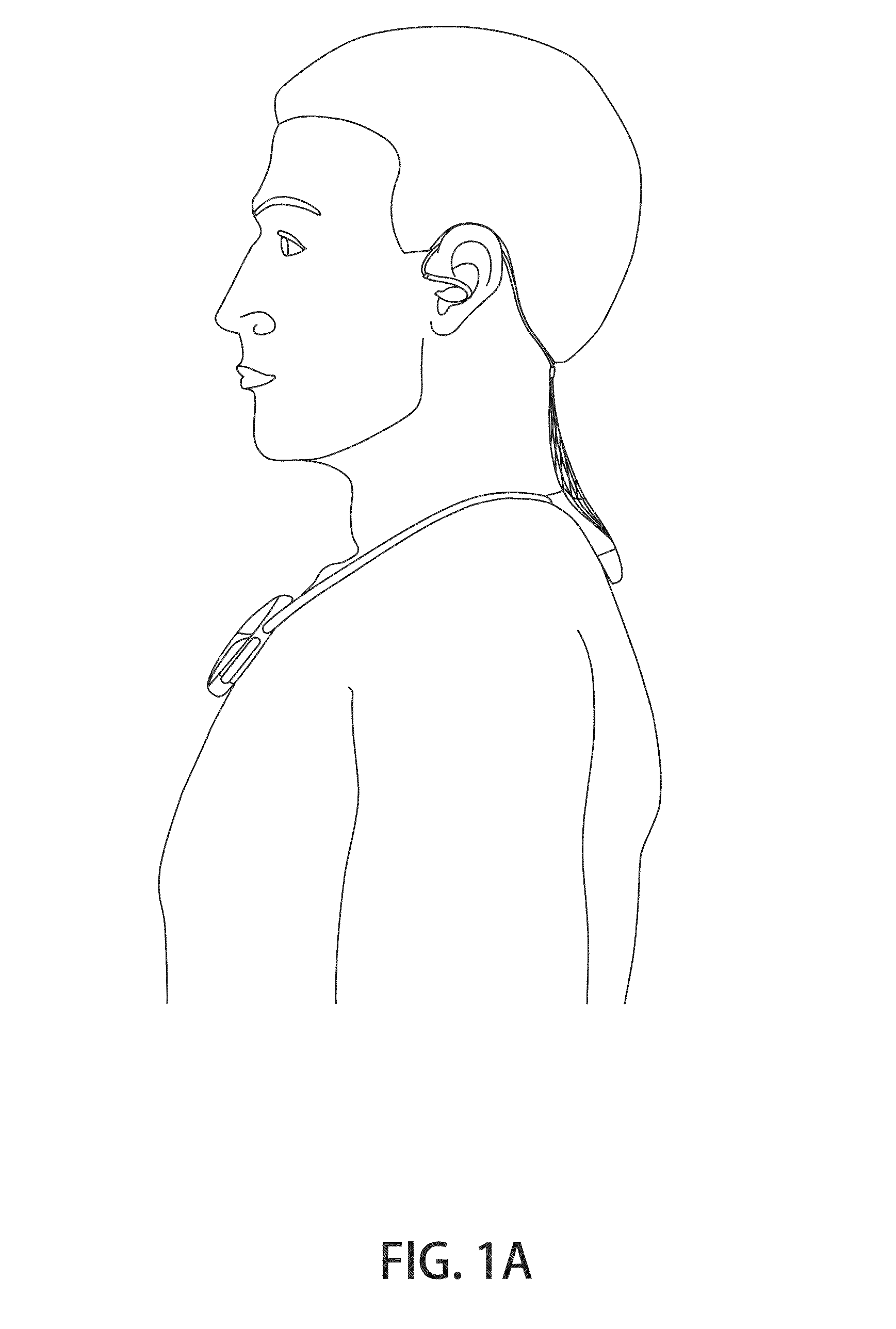

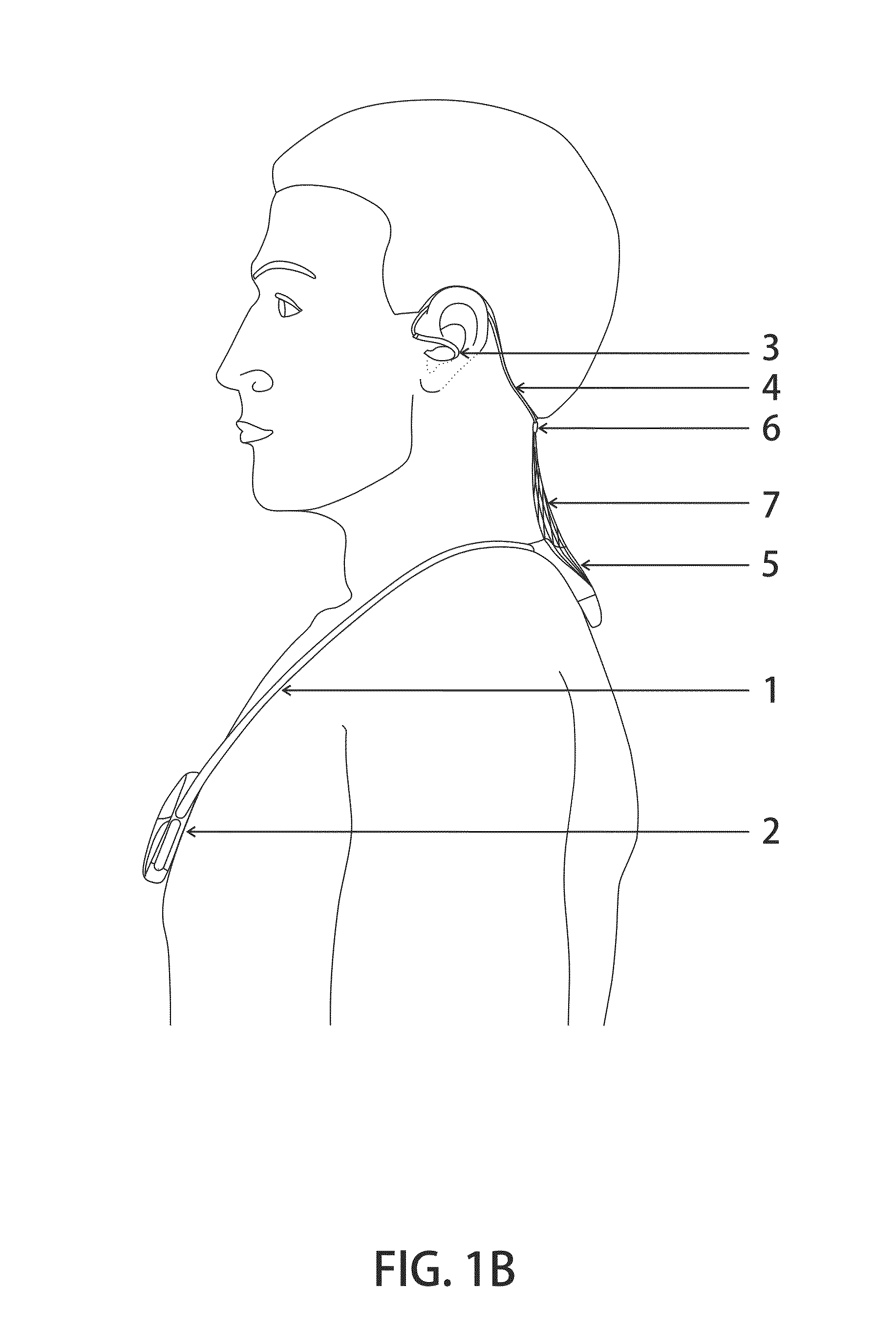

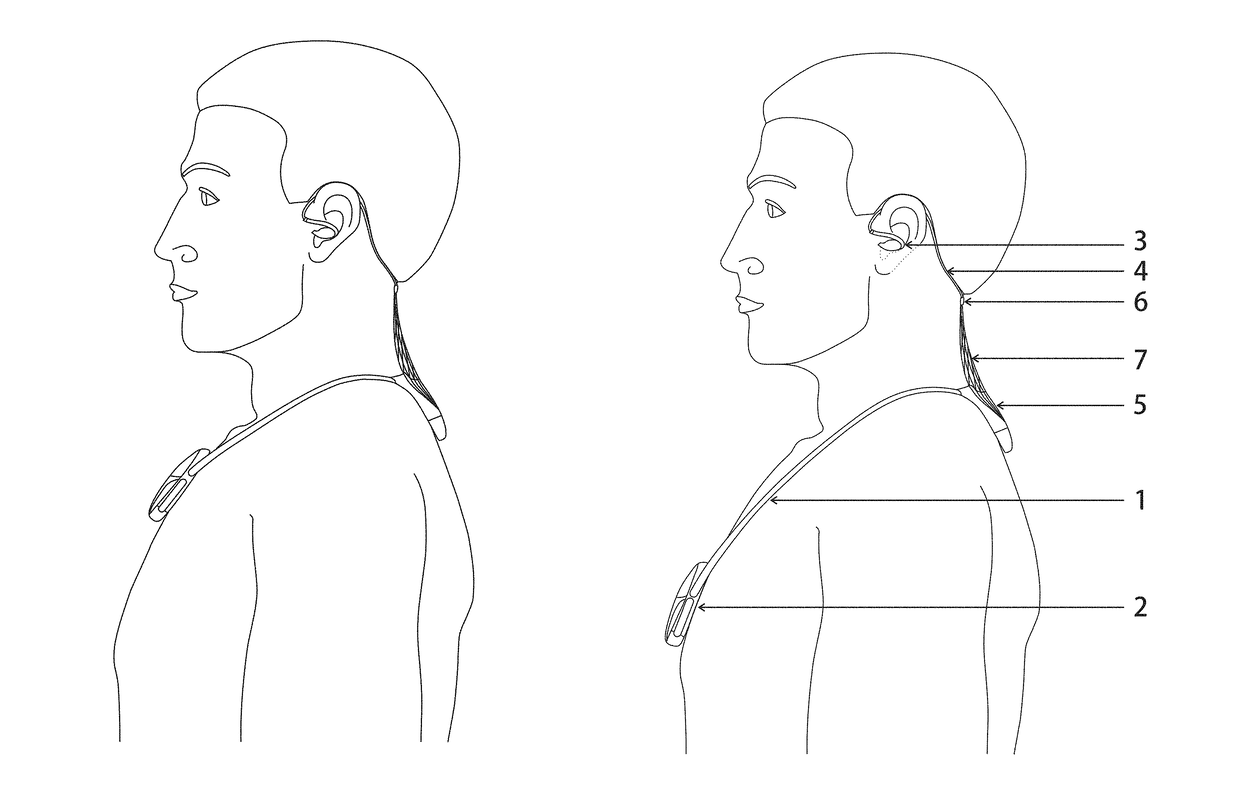

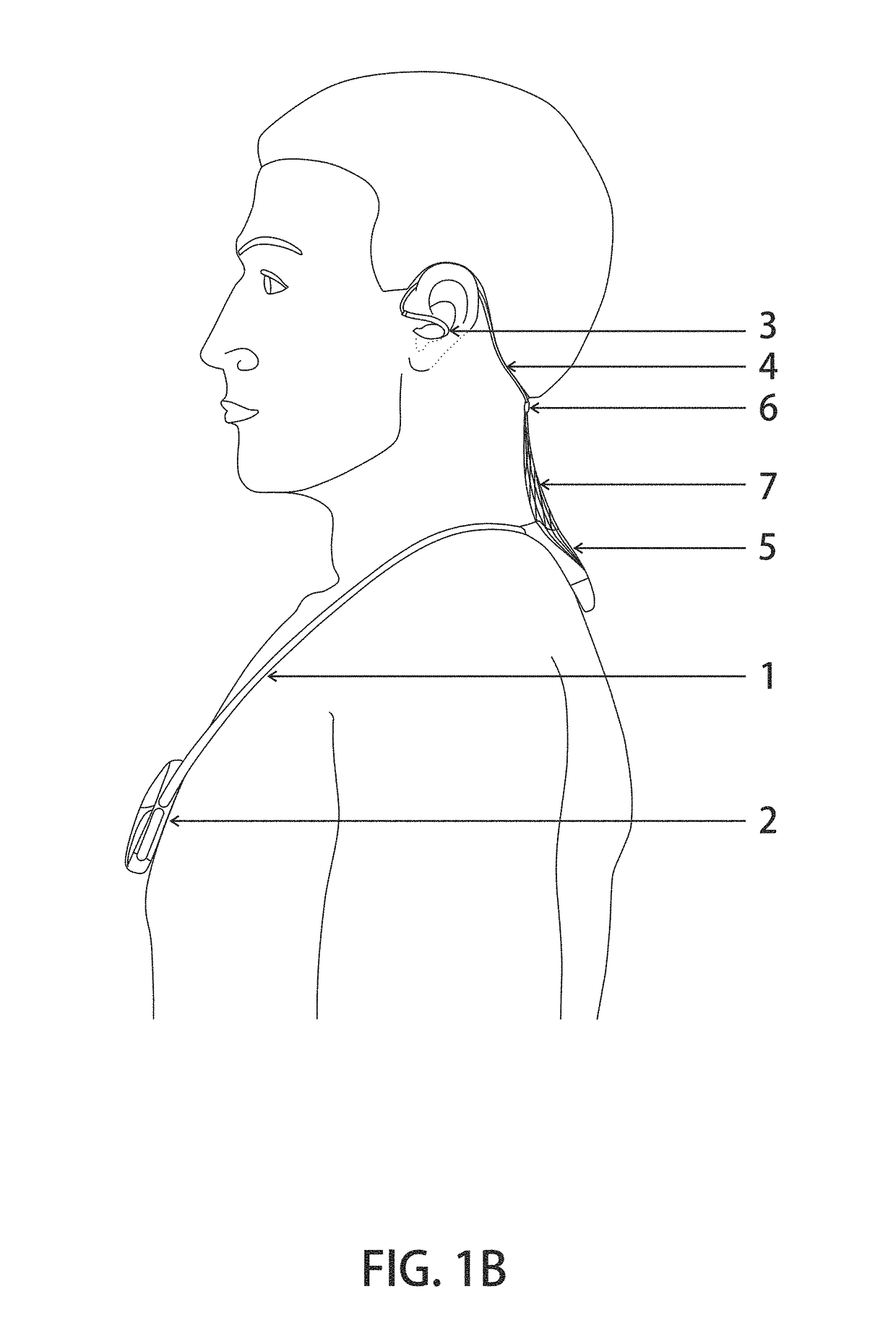

Wearable telecommunication device in a form of a necklace

A wearable telecommunication device configured as an electronic necklace in a form of an open or closed neck loop comprising electronic components and connected to two in-ear earphones. The point of connection of the proximal end of the earphone cords to the neck loop is on the dorsal neck surface. An additional cord connection node positioned under the user's occiput, which allows the earphones and the cords to be secured when the earphones are operational, and reduces excursion of the loose portions of the cords, thus providing the device to be non-changing appearance of the user. Ferromagnetic inserts allow the earphones and the cords to be secured when non-operational, for the device to be hidden. The device may be embodied as a wireless headset for a mobile telecommunication device, a telecommunication device itself, an audio player, a CB radio station, a part of a personal health or security system, etc.

Owner:USHAKOV ALEXEY

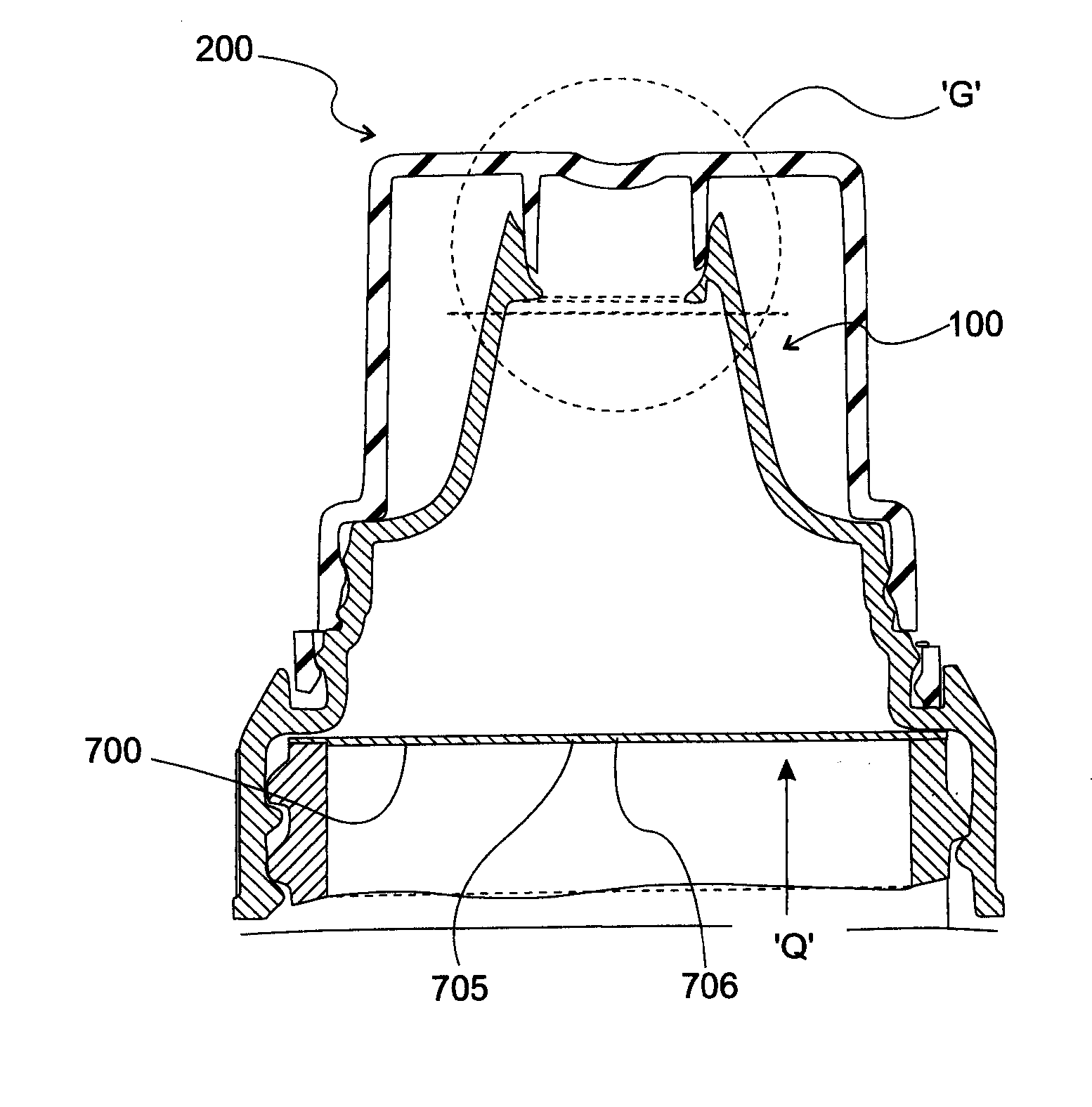

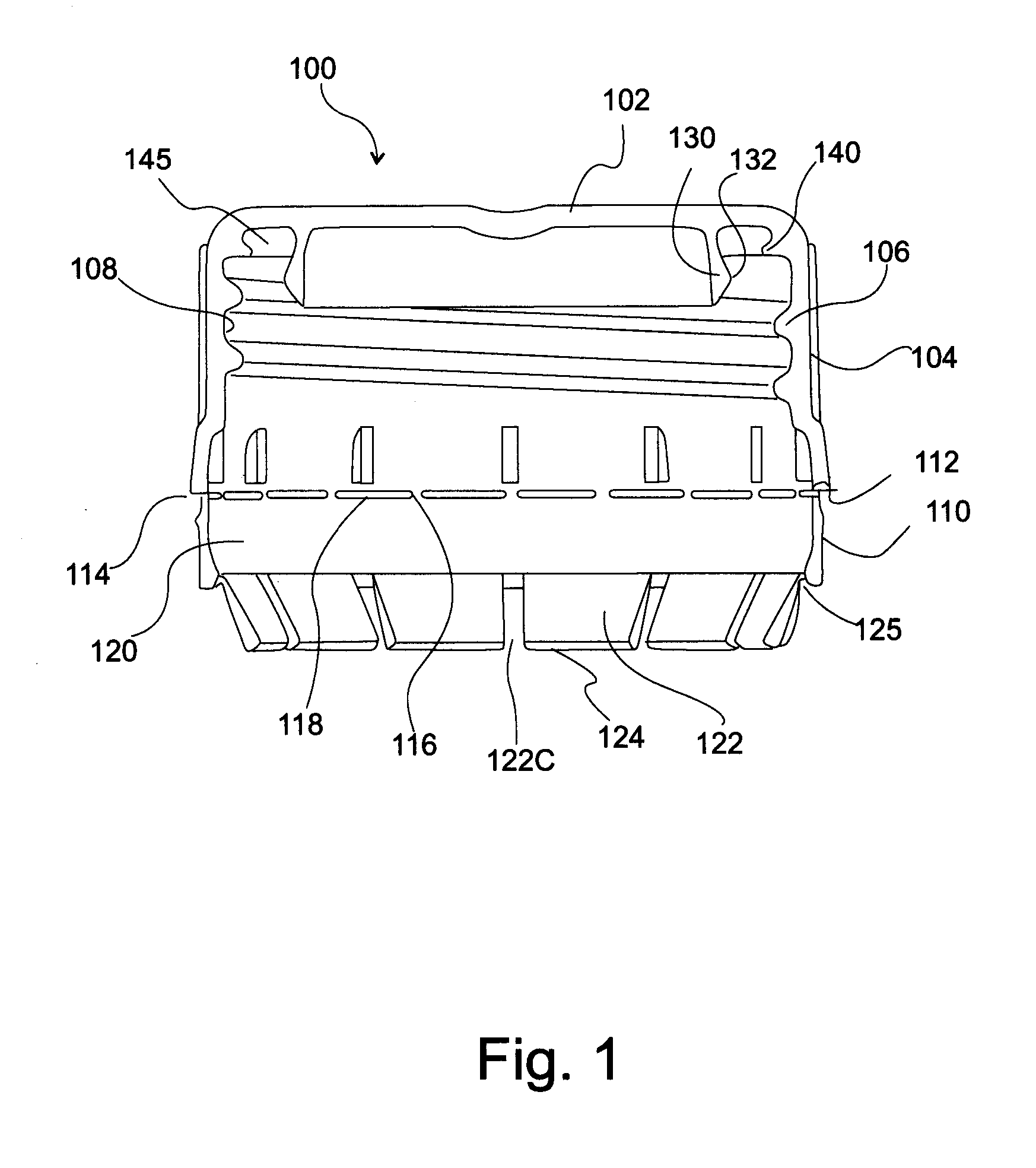

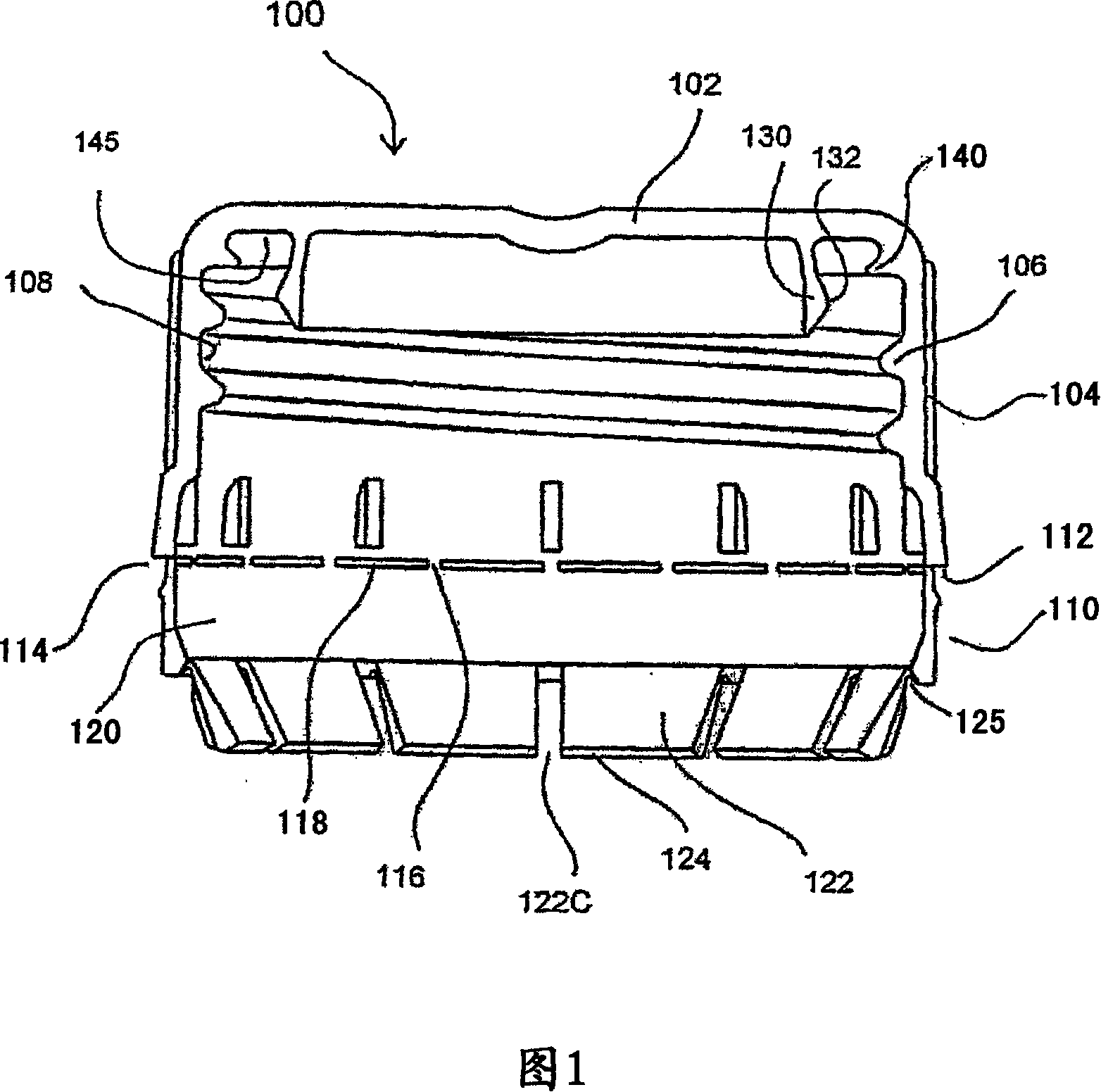

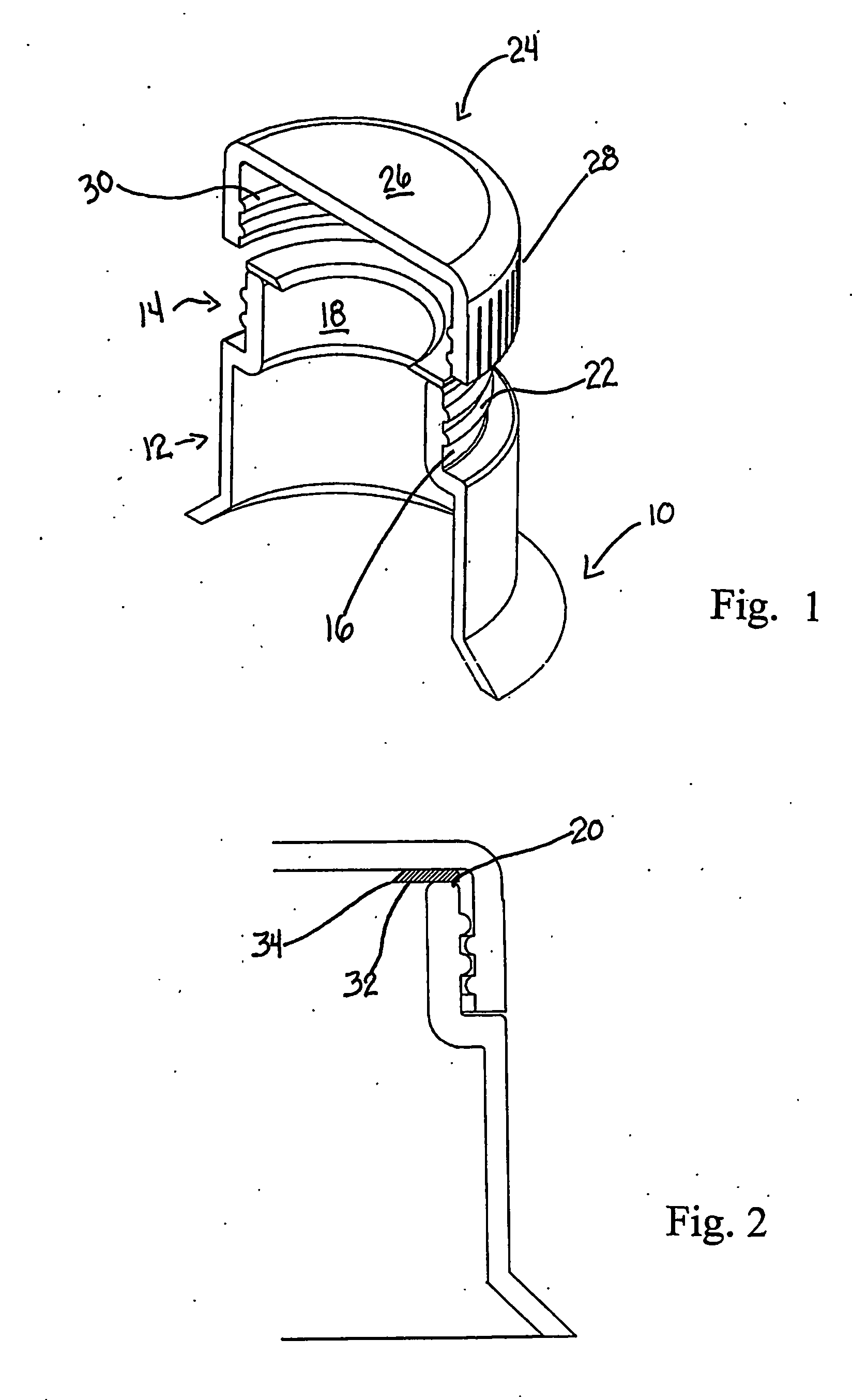

Closure and container neck

InactiveUS20080073382A1The relationship is accurateClosure capsDischarging meansNeck surfaceEngineering

This invention relates to closures for containers, and more particularly to tamper-evident closures for containers. One aspect of the invention provides a container and a closure for connection to said container, said closure including: an upper wall (102); a skirt (104) formed integrally with and extending downwardly from said upper wall, said skirt adapted to engage with a neck portion of the container to secure the closure to the container; a tamper-evident band (110) frangibly connected to said skirt; the neck of a container including a tamper bead adapted to engage with tabs (122) on said tamper-evident band to facilitate separation of the band (110) from the skirt of the closure and an inwardly and downwardly sloping container neck surface beneath said tamper bead, said inwardly and downwardly sloping surface urging said separated tamper-evident band downwards away from said skirt.

Owner:RBC TRUSTEES CI

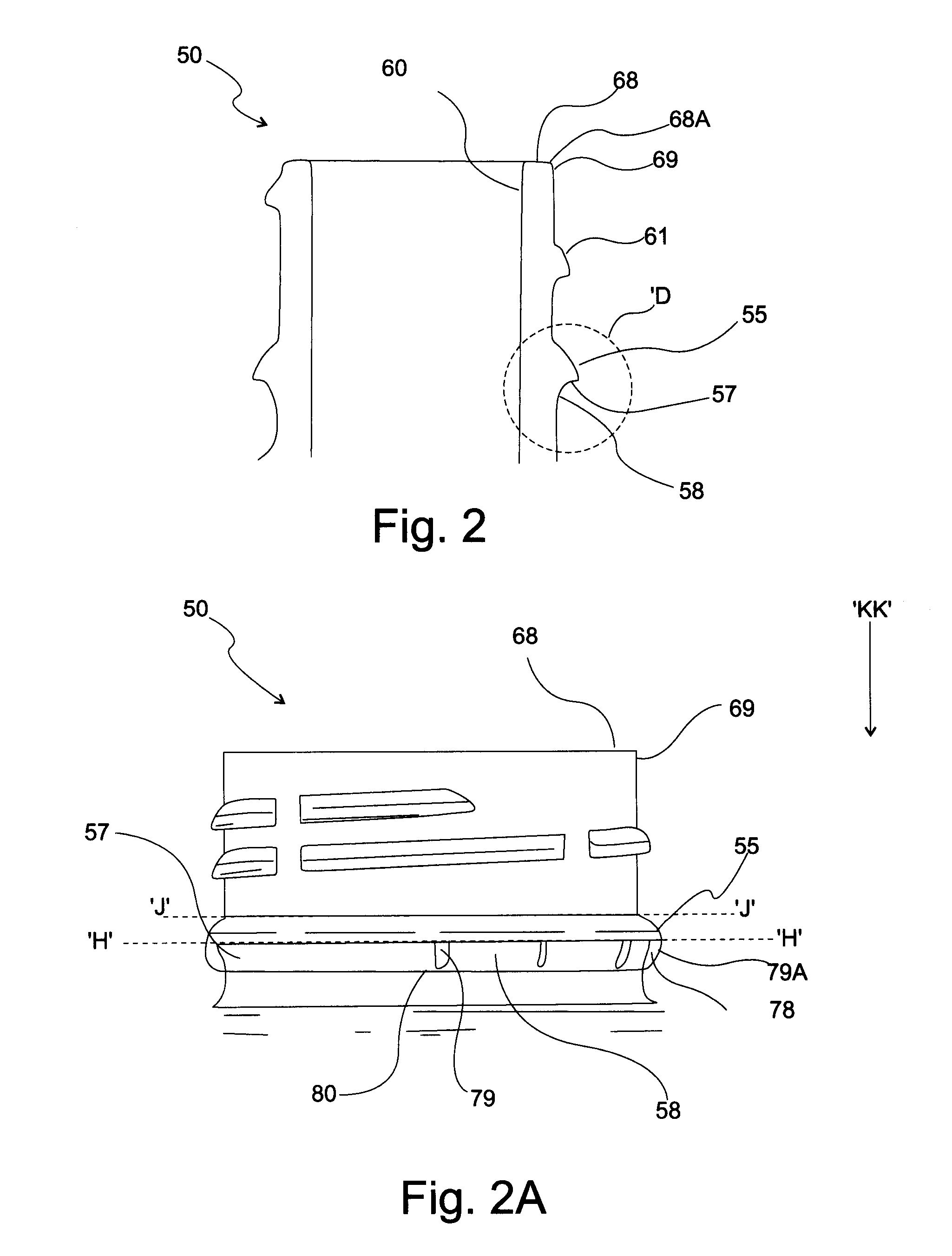

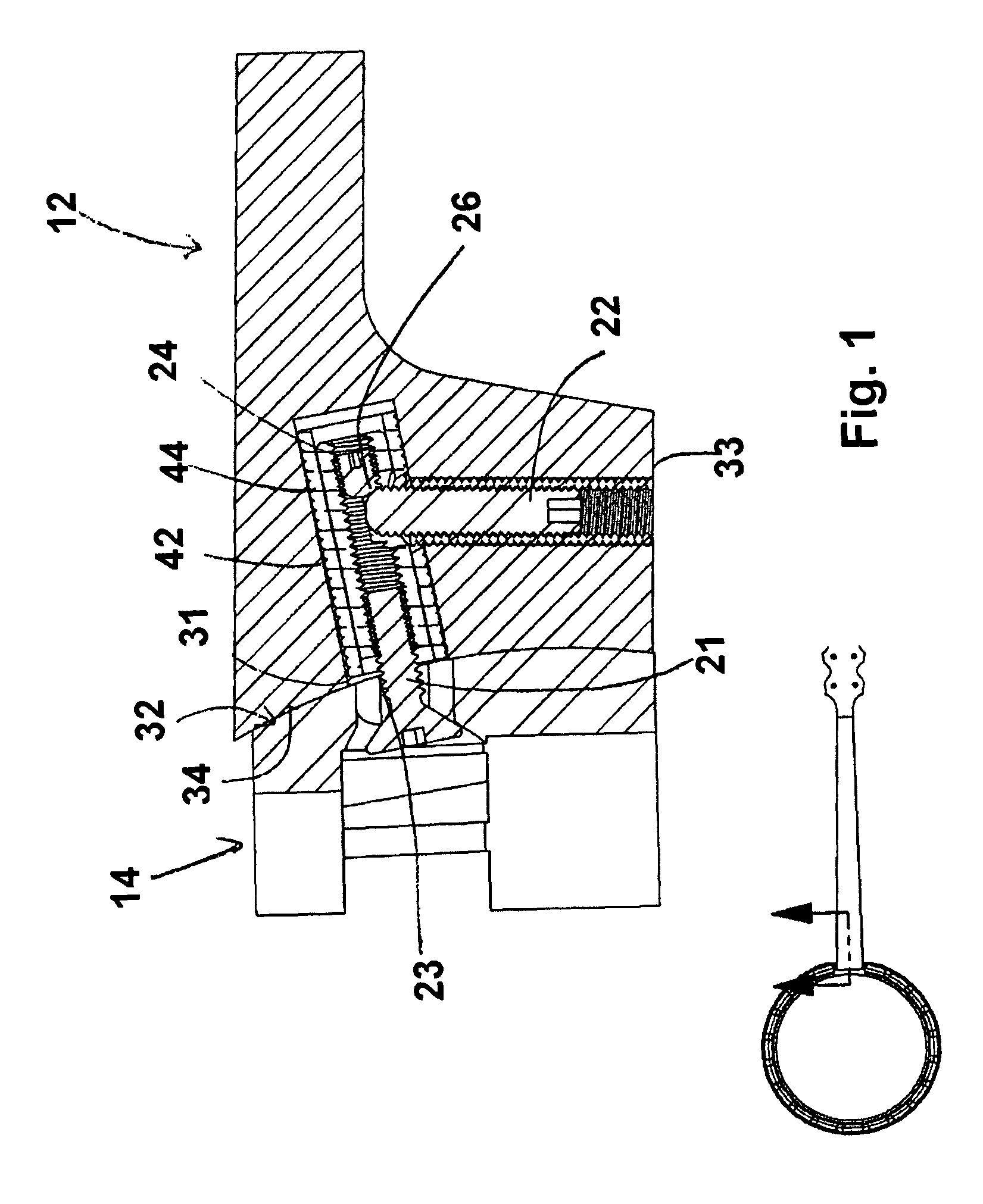

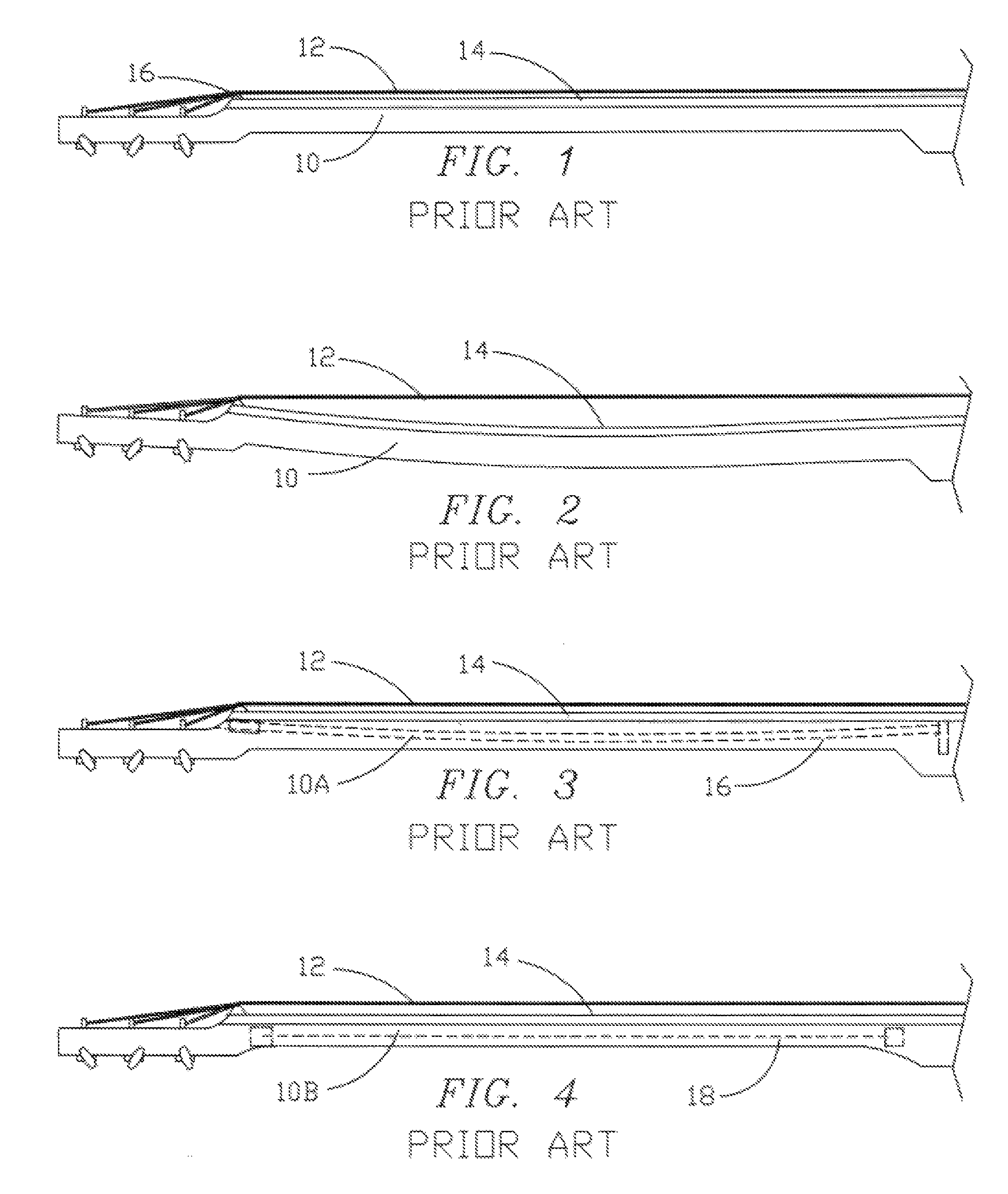

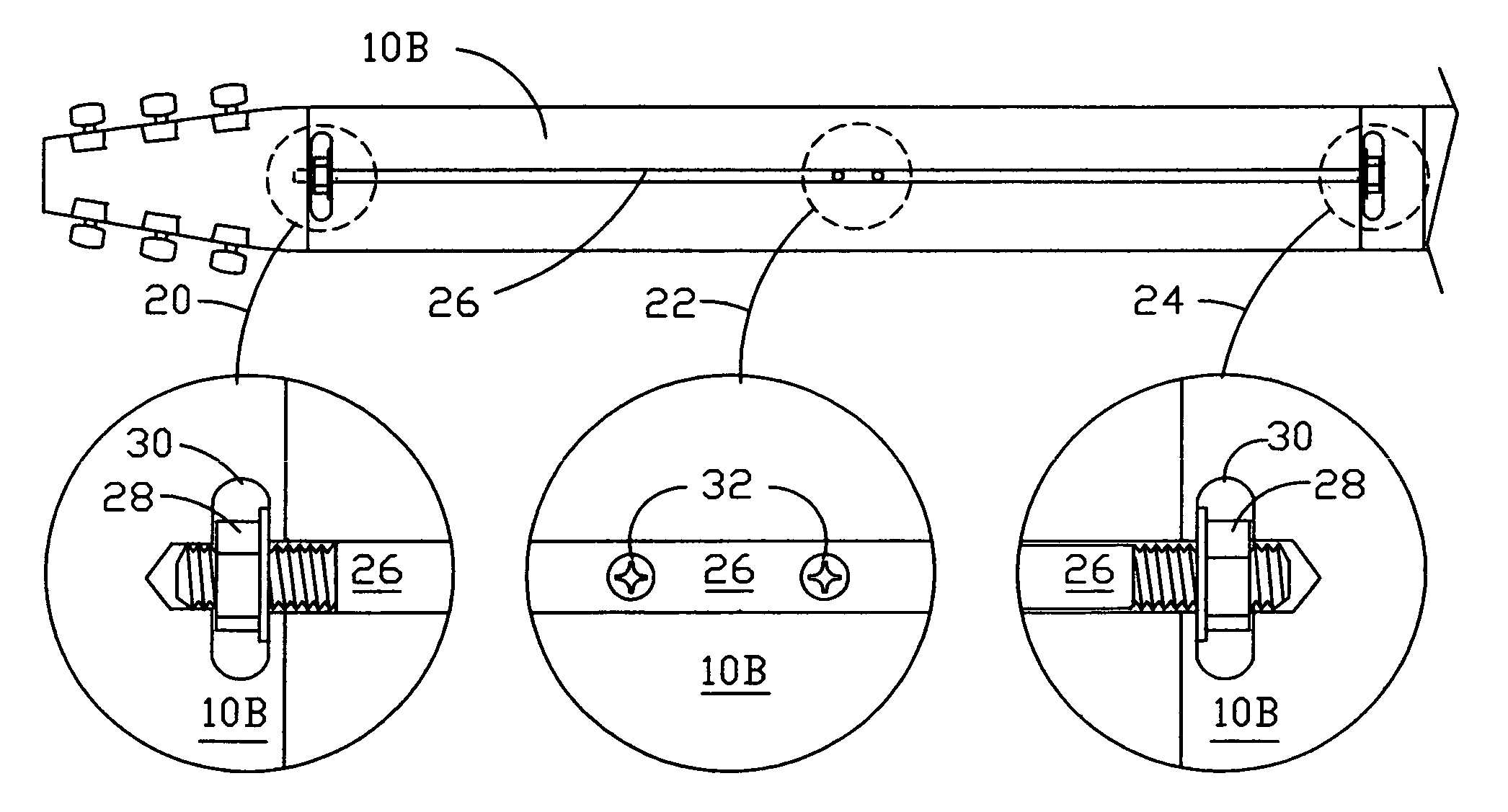

Adjustable and removable neck for a stringed instrument

A musical instrument includes a neck, a body, a playing surface covering the body, a plurality of strings, and a connective element. The connective element varies the distance of the plurality of strings from the playing surface of the instrument. The connective element includes a set screw and a receiving unit having an inclined surface. The set screw contacts the inclined surface on the receiving unit and adjustably fastens the receiving unit to the body and the neck. along a radiused neck surface and a radiused body surface. The connective element may be attached to a removable interface between the neck and the body. The musical instrument may be completely disassembled for transport.

Owner:NECHVILLE THOMAS

Coating material for preventing engine crankshaft from being locked, and preparation method and application method of coating material

InactiveCN103710116AGood synergyImprove flame retardant performanceBase-materialsCarbon monofluorideEpoxy

The invention discloses a coating material for preventing an engine crankshaft from being locked, and a preparation method and an application method of the coating material. The coating material comprises the following raw materials in parts by weight: PAG (Polyalkylene Glycol ethers) polyether base oil, modified plant-based synthetic ester oxide sunflower oil, epoxy resin, organic molybdenum, tungsten disulfide powder, tungsten diselenide powder, carbon monofluoride powder, polyphenyl, a fire retardant, an antiwear agent and an antioxidant. The coating material is coated on a crankshaft neck surface and / or bearing bush surface between a crankshaft neck and a bearing bush (tile), so that a protective coating which is lubricant enough, and not easy to wash off or damage, and can bearing extremely high temperature is provided under the condition that the engine oil cannot provide effective lubricating due to poor quality, or cannot provide an enough lubricating effect between the crankshaft and a connecting rod due to reduction of the engine oil, the coating material has excellent waterproof properties, anti-rust characteristics, anti-corrosion property, and micro-grinding resistance on metal parts, can form solid dry film lubrication under the environment above 200 DEG C, and can play the roles in lubricating and preventing metal from being locked by sintering at the temperature which can be up to 1400 DEG C, and the locking phenomenon between the crankshaft and the connecting rod caused by dry friction between the tile and the crankshaft is effectively avoided.

Owner:杨毅

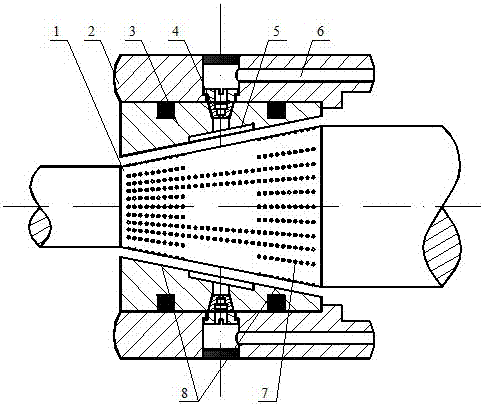

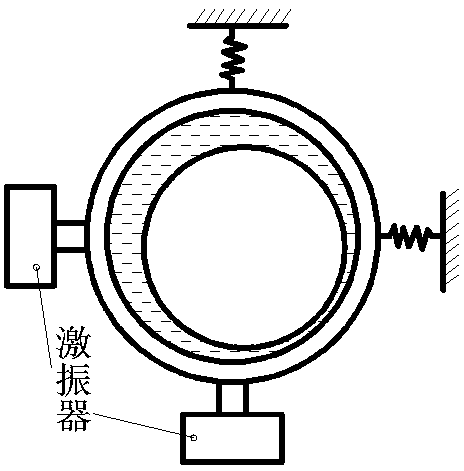

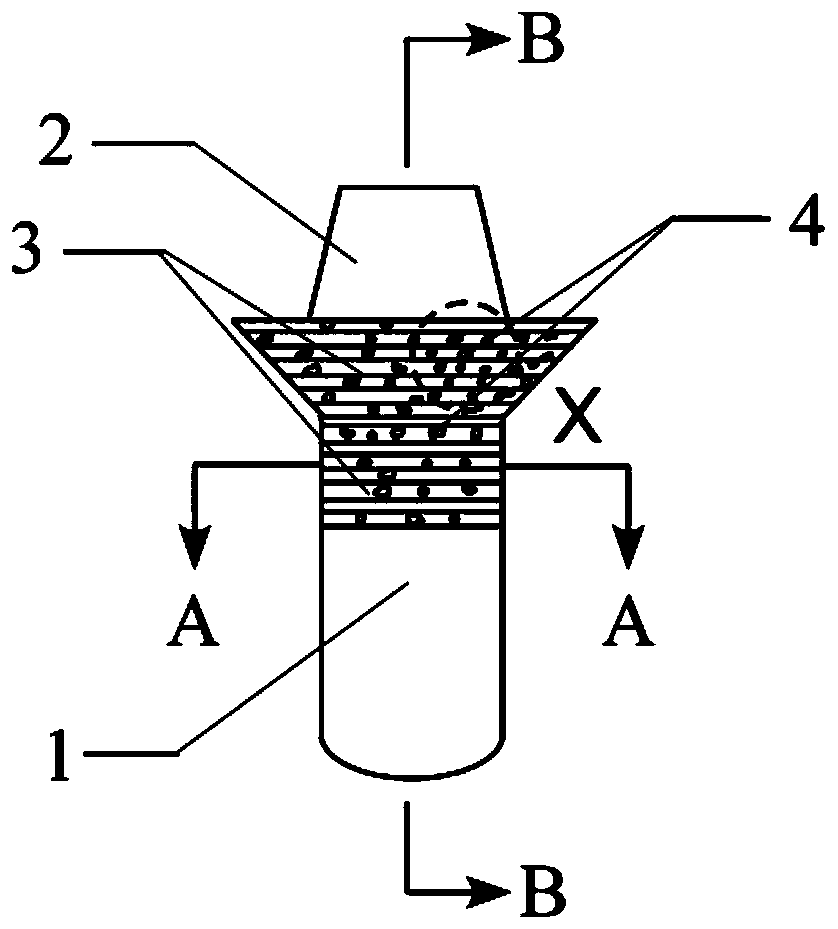

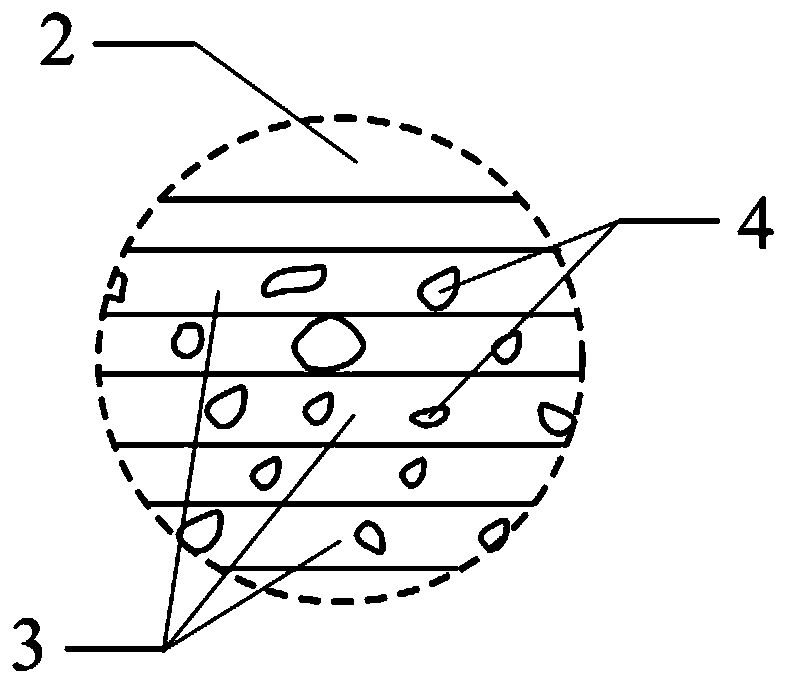

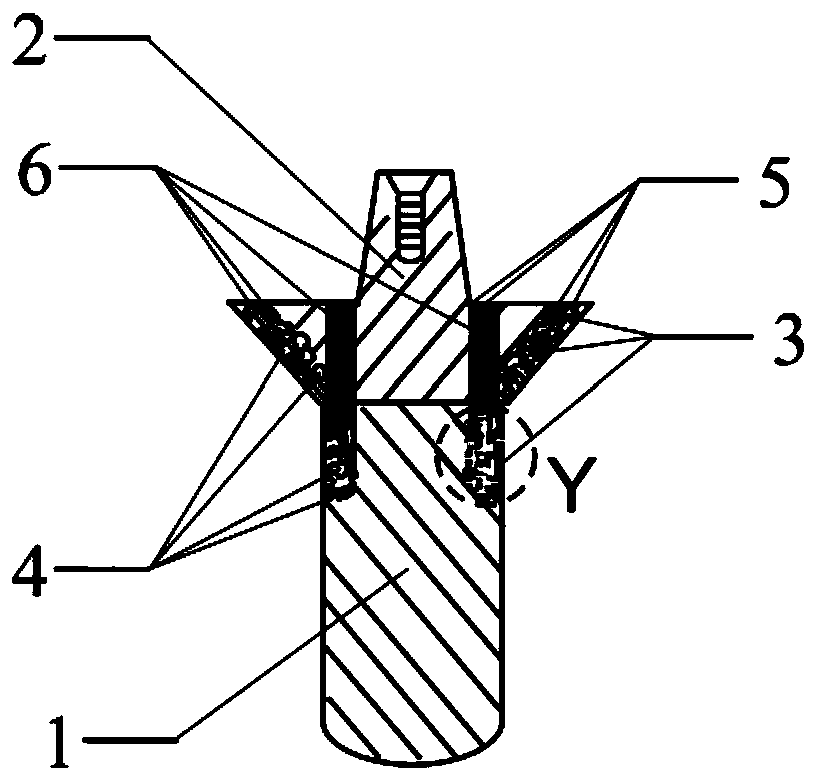

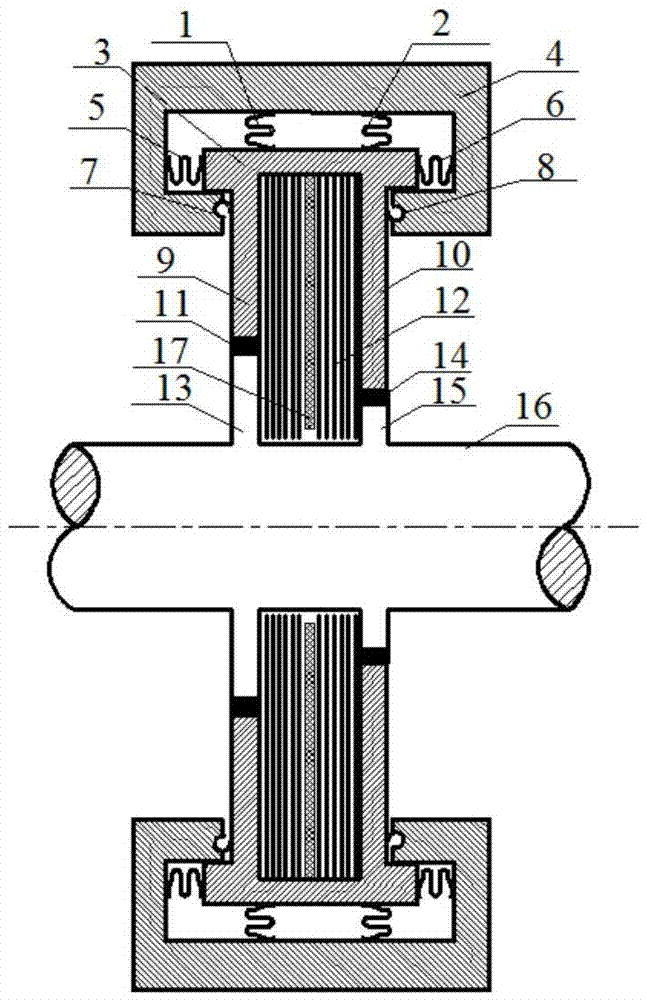

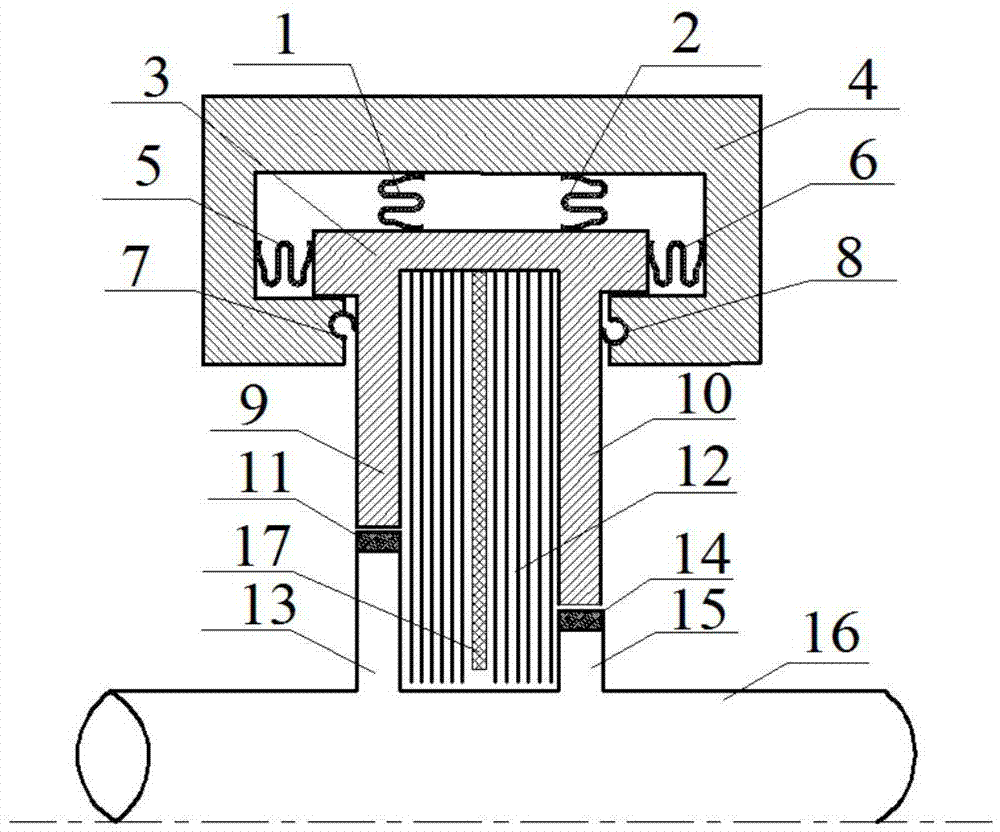

Tapered hybrid bearing assembly part with textured shaft neck surface

ActiveCN106870562AImprove carrying capacityReduce high-speed temperature riseBearingsInlet channelNeck surface

The invention relates to a tapered hybrid bearing assembly part with a textured shaft neck surface. The tapered hybrid bearing assembly part comprises a bearing and a shaft neck, wherein the bearing comprises housings and bearing pads; oil inlet channels are arranged on the housings; an oil cavity and an oil sealing surface are arranged on the inner surface of each bearing pad; a small-hole restrictor is arranged between each oil inlet channel and the corresponding oil cavity; inner holes of each bearing pad are tapered holes; the shaft neck is of a tapered structure matched with the bearing pads; a surface texture is arranged on the shaft neck surface; the surface texture is one or more of a bump, a pit and a groove; the bump, the pit or the groove is distributed in the surface, matched with the oil sealing surface of each bearing pad, of the shaft neck in the bus direction of the tapered shaft neck; and a lubricating medium enters the oil cavities after being restricted through the small-hole restrictors, flows through the oil sealing surfaces and is discharged from the end surface of the bearing, wherein the lubricating medium is pressure water or low-viscosity pressure oil. The tapered hybrid bearing assembly part with the textured shaft neck surface can improve bearing capacity of the bearing while reducing the high-speed temperature rise of the bearing, and increasing the limited working rotation speed.

Owner:HOHAI UNIV CHANGZHOU

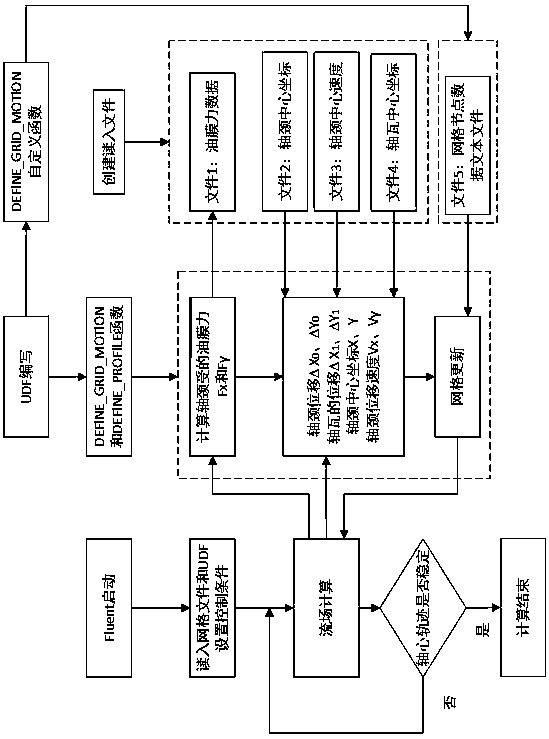

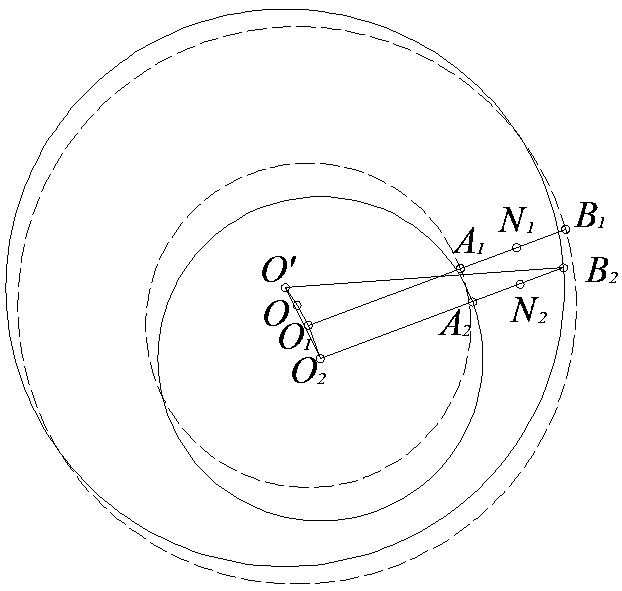

Radial oil film bearing dynamic mesh updating method based on Fluent

InactiveCN107269700AAvoid Cumulative ErrorsCalculation speedLiquid cushion bearingsDesign optimisation/simulationNeck surfaceData file

The invention provides a radial oil film bearing dynamic mesh updating method based on Fluent. The method comprises the following steps that (1), a bearing oil film mesh file is established; (2), a UDF control macroprogram in Fluent software is compiled; (4) a data file obtained in the third step is treated with an Excel tool; (5) fluid calculation software Fluent is started, the mesh file is imported, a UDF program is mounted, and UDF control conditions are set; (6), flow field calculation is controlled through a UDF dynamic mesh program; and (7) whether a bearing neck center track is convergent or not is judged. According to the radial oil film bearing dynamic mesh updating method based on the Fluent, the problem that due to the fact that the length-width ratio of bearing oil film meshes is too large, mesh distortion is prone to occur in the dynamic mesh moving process is solved, and equal-interval distribution, in the circumferential direction, of mesh lines in the radial direction before and after the moving process is guaranteed. When the method is used for calculating node coordinates of dynamic meshes, the mesh lines are always perpendicular to the bearing neck surface, the meshes are not prone to distortion, accumulated errors of mesh calculation are avoided, and the bearing performance calculating speed is increased.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

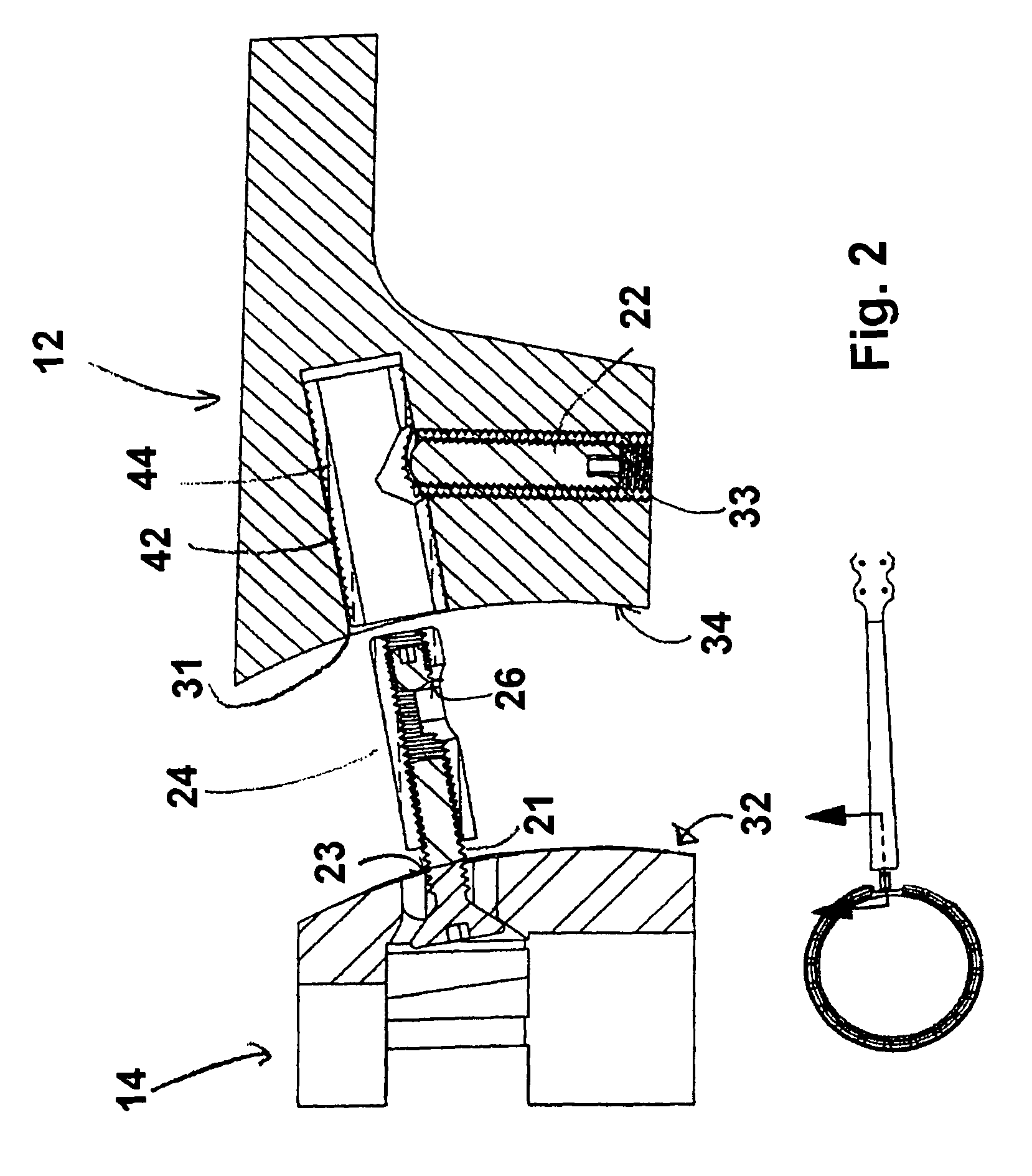

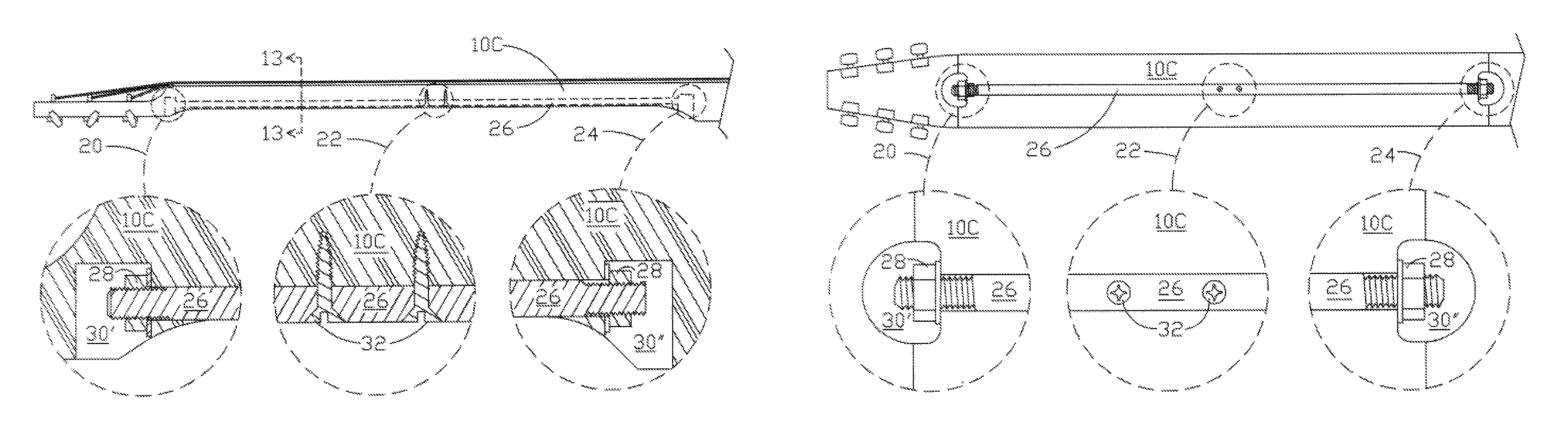

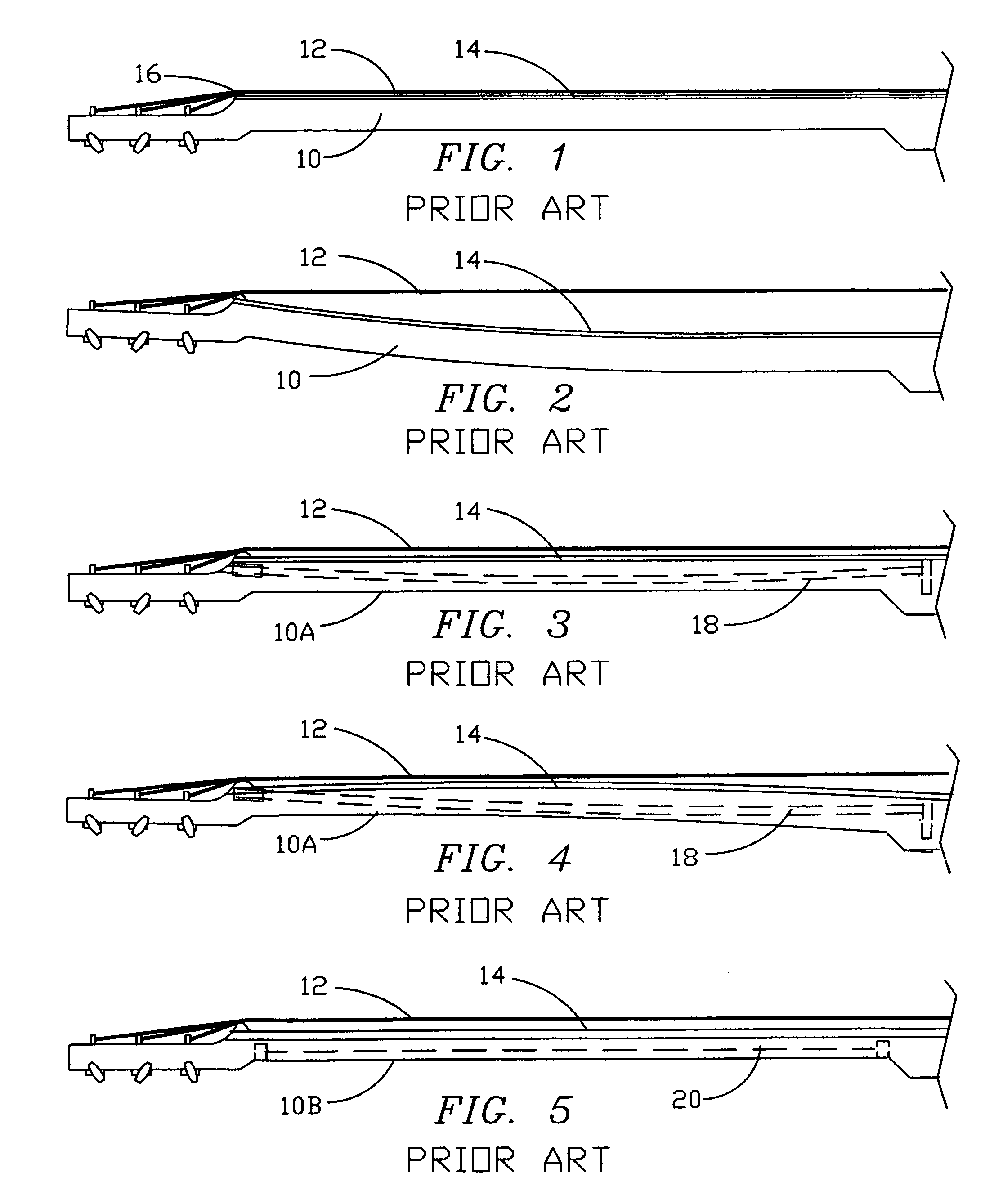

Dual-tensioned neck truss system for stringed musical instruments

A dual-inline neck truss system in a stringed musical instrument is disposed uniformly along the instrument neck, generally toward the rear side, opposite the front side that forms or supports a fingerboard or fret-board. The truss system may be a two-portion single member or two separate in-line members, and is enclosed close to the rear surface of the neck or else with a surface exposed along its full length and made flush with the rear neck surface, smooth to the touch. The truss system is secured to the neck at a designated intermediate location so as to form two substantially co-linear truss portions, either of which can be adjusted for tension independently via manual adjustment hardware for applying pressure against opposite end regions of the neck, thus enabling special desired instrument setup for optimal string-to-fretboard / fingerboard spacing, e.g. providing optimal low “action” with “relief” in the form of special concave curvature contour in a low pitched portion of the neck, particularly advantageous for instruments such as The Stick®, which is designed to be played with two-handed string-tapping technique.

Owner:CHAPMAN EMMETT E

Versatile neck truss system for stringed musical instruments

A versatile four-way adjustable truss system in a stringed musical instrument is disposed uniformly within the instrument neck that provides or supports a fingerboard or fret-board on its top side. The bottom surface of the truss may be exposed along its full length and made flush with the bottom neck surface and smooth to the touch. The truss is made adjustable at both ends in either tension or compression and is securely fastened to the neck at an intermediate fastening point so as to form two substantially co-linear neck sections either of which can be adjusted independent of the other, via an associated adjustment nut constrained in a corresponding thrust cavity configured in the neck, to satisfy a desired section profile requirement in a range that includes both concave and convex curvature.

Owner:CHAPMAN EMMETT H

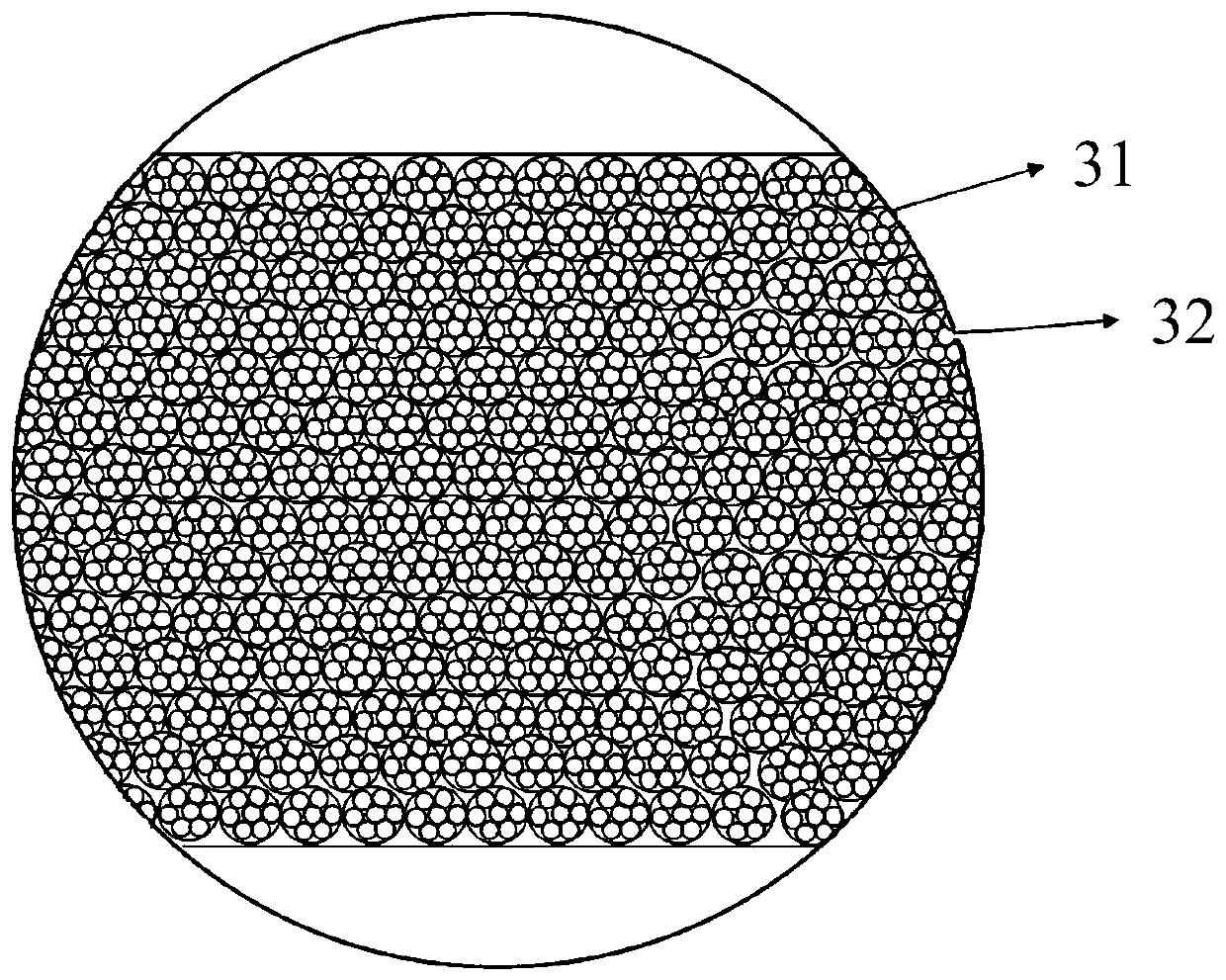

Dental implant

The invention relates to a dental implant. The dental implant comprises an implant body and an abutment connected with the body, wherein an annular groove region is formed in dental implant neck surface layers, which are in contact with soft tissues, of the body and the abutment; a porous layer region is arranged on the inner layer of the annular groove region; a plurality of spherical cavities are formed in the porous layer region and between annular grooves in the annular groove region; the spherical cavities which are in contact with each other communicate with each other; all the sphericalcavities which are in contact with the surfaces of the annular grooves are provided with openings in the surfaces of the annular grooves; and a plurality of axial pipes are arranged in the porous layer region, the lower portions of the axial pipes communicate with the spherical cavities, and the upper portions of the axial pipes are provided with openings in the surface of the abutment. Due to the structure of the porous layer region and a bioactive molecule combination, the soft tissue position of the neck of the implant is promoted to be stable in multiple ways, aesthetic defects caused bydisplacement of the neck of the implant to the root as well as reduction of bone absorption around the implant and shortening of the service life of the implant caused by the low bonding strength areavoided, and therefore, the implanting success rate is further improved.

Owner:STOMATOLOGICAL HOSPITAL TIANJIN MEDICAL UNIV

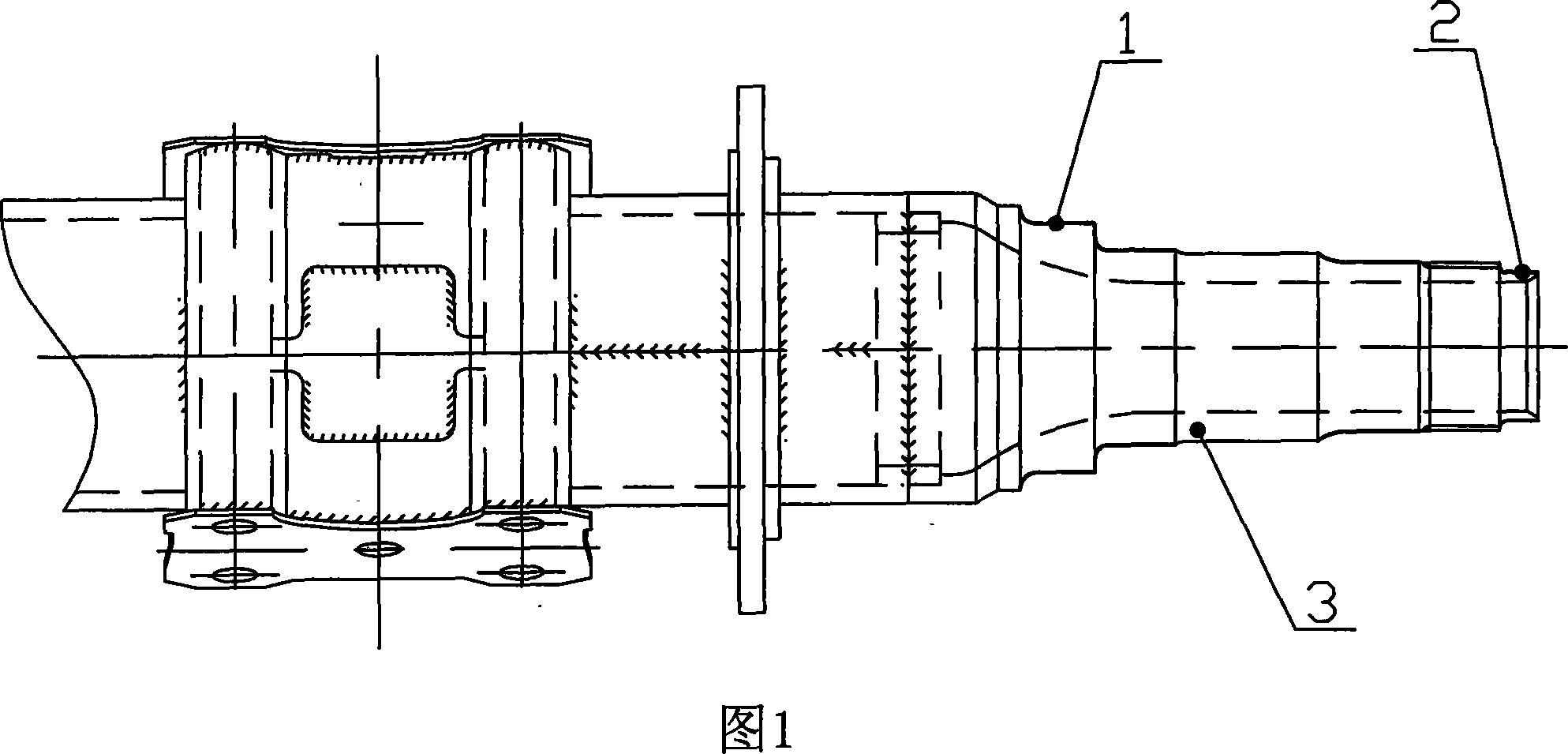

Rear axle housing assembly axle sleeve oil sealed shaft neck surface processing technique

InactiveCN101224535ALow costImprove product qualityOther manufacturing equipments/toolsNumerical controlNeck surface

The invention belongs to the technical field of mechanical processing, which relates to a surface processing technology of a full floating typed rear axle assembly half shaft sleeve oil seal shaft neck. The tool holder of a numerical control lathe is respectively provided with a nipping and turning tool of a numerical control machine and an external round rolling tool; the surface of the external round of all sections of the half shaft sleeve 3 is precisely turned by the nipping and turning tool of the numerical control machine; wherein, a rolling processing allowance is preserved along the diameter direction of the external round of an internal oil seal shaft neck and an external oil seal shaft neck; after the surface roughness is less than Ra3.2, the tool holder is rotated; the rolling process is achieved for the external round surfaces 1, 2 which are matched with the internal oil seal and the external oil seal by the external round rolling tool, so as to lead the surface roughness to be less than Ra0.8; after that, a polisher abrasive belt which is arranged on the lathe is used for polishing, so as to eliminate fine spiral line patterns which are generated on the rolling surface. The invention has lower cost compared with the method that polishing is achieved after directly precise turning and the grinding is replaced by the turning, furthermore, the oil leakage ratio of the oil seal of the rear axle rear hub is reduced from 4-6 millesimal before the method is improved to 1.8 millesimal, the quality of the products is obviously improved, and the requirements of the users are satisfied.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

Tamper-evident closure and bead on container neck

This invention relates to closures for containers, and more particularly to tamper-evident closures for containers. One aspect of the invention provides a container and a closure for connection to said container, said closure including: an upper wall (102); a skirt (104) formed integrally with and extending downwardly from said upper wall, said skirt adapted to engage with a neck portion of the container to secure the closure to the container; a tamper-evident band (110) frangibly connected to said skirt; the neck of a container including a tamper bead adapted to engage with tabs (122) on said tamper-evident band to facilitate separation of the band (110) from the skirt of the closure and an inwardly and downwardly sloping container neck surface beneath said tamper bead , said inwardly and downwardly sloping surface urging said separated tamper-evident band downwards away from said skirt.

Owner:爱博克斯(C.I.)有限公司(湾景信托公司托管人)

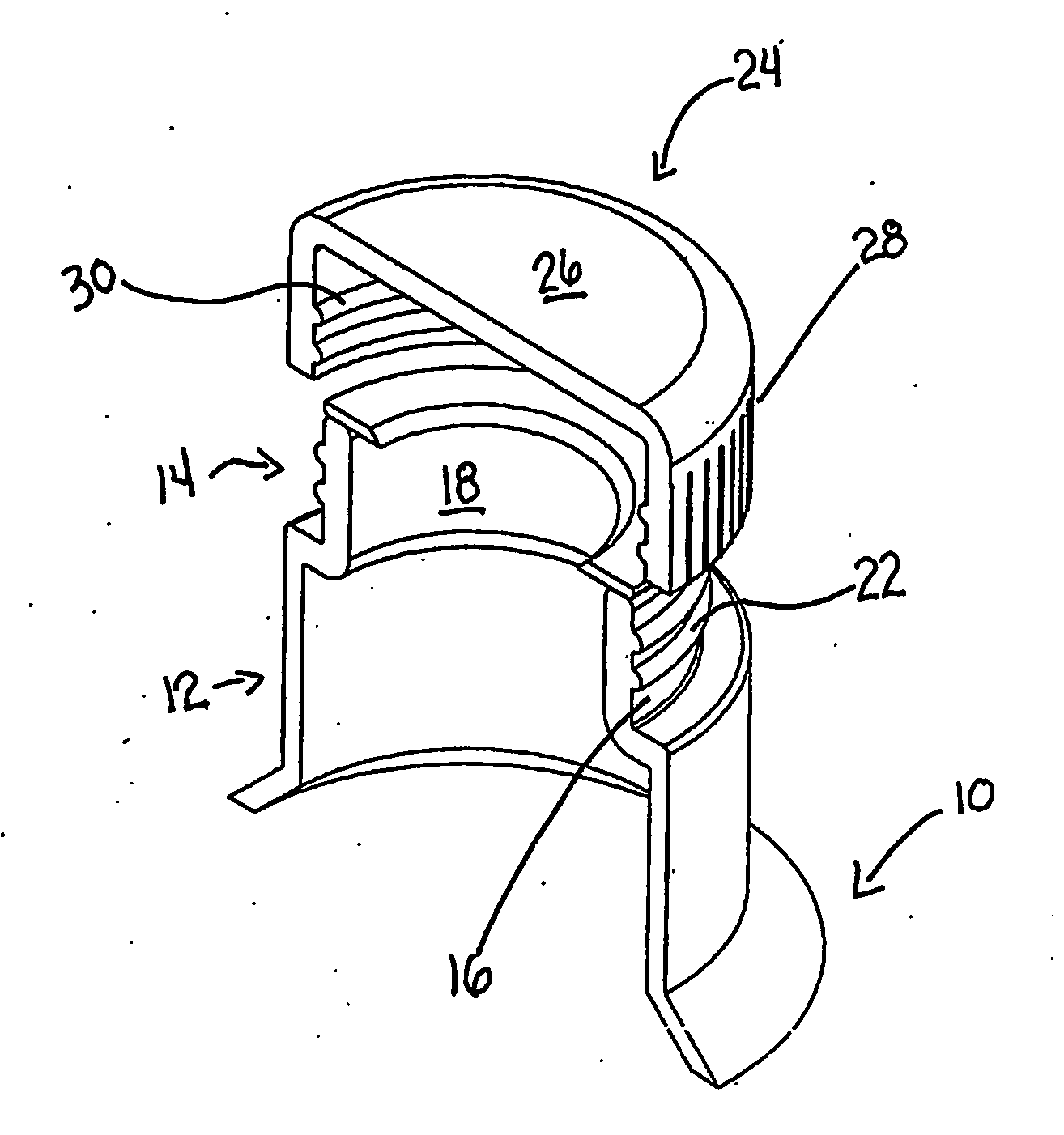

Container with a non-drip pouring lip

A container having a body portion (10) and a dispensing opening, a neck (14) surrounding said dispensing opening, the neck having a rim (20), an inner neck surface (18) and an outer neck surface (16), and a drip minimizing member (32, 68) extending inwardly over a portion of the dispensing outlet, the member being located proximate the rim (20), the member terminating in a sharp edge (34, 70) to minimize dripping when pouring from the container.

Owner:MORIN

Self-concentric brush seal structure with rotor provided with discs

ActiveCN105443161ASimple structureEasy to processBlade accessoriesLeakage preventionNeck surfaceWear resistant

A self-concentric brush seal structure with a rotor provided with discs comprises a brush seal part composed of a fusion welding area, a front baffle, a rear baffle and a brush wire bundle, a stator box, C-shaped seal rings, W-shaped seal rings, wear-resistant coatings, a bearing plate, the front disc, the rear disc and the rotor. The C-shaped seal rings are embedded into the neck surfaces of the front baffle and the rear baffle and are matched with the stator box. The W-shaped seal rings are clamped in the axial direction and the radial direction through the brush seal part and the stator box. The front disc is located at the lower end of the front baffle and is vertically fixed to the surface of the rotor, and the rear disc is located at the lower end of the rear baffle and is vertically fixed to the surface of the rotor. The self-concentric brush seal structure is simple; compared with traditional fixed brush seals, the self-concentric brush seal structure has the advantages that the brush seal part can move freely in the radial direction by being clamped in the stator box through the C-shaped seal rings and the W-shaped seal rings and can move along with the rotor for keeping self-concentric when the rotor moves in the radial direction, and continuous damage caused by direct rubbing between the rotor and the brush seal part can be avoided.

Owner:南京云起共振电力科技有限公司

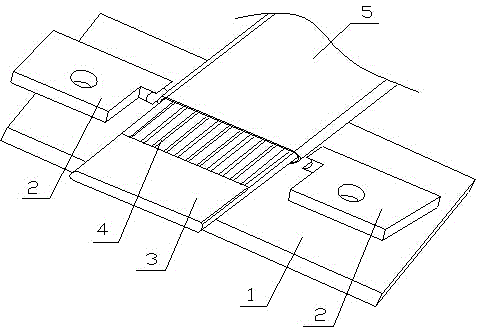

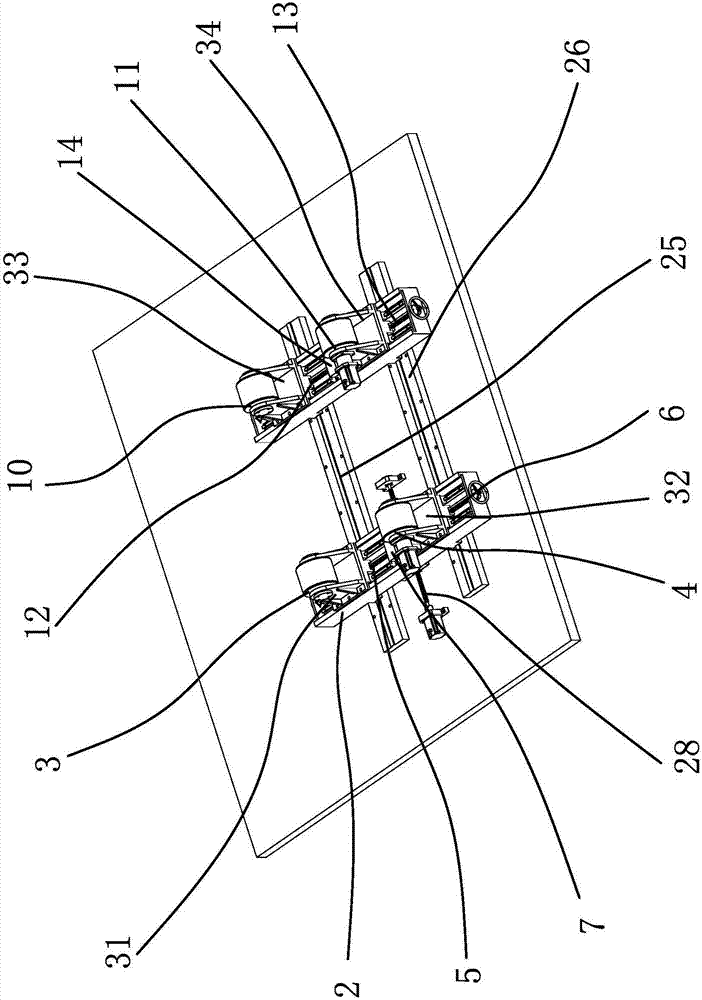

Flat tube necking machine

The invention discloses a flat tube necking machine. The flat tube necking machine comprises a machine table and necking puncher pins arranged on the machine table. The machine table is further provided with a steel supporting needle. One end, provided with supporting needles, of the steel supporting needle is arranged between the necking puncher pins. The structure is simple, a flat tube which is cut in the fixed length is placed on the necking machine, the supporting needles of the steel supporting needle are inserted into micro holes of the flat tube, and width necking is carried out. In this way, in the punching necking process, due to the limitation on the pipe wall of the supporting needles, inward collapse cannot be carried out, the outer side is a cold punching forming mold, and only heading can be carried out. The flat necking surface is obtained, and the flatness requirement for brazing can be met.

Owner:ANHUI JINSANHUAN METAL SCI & TECH

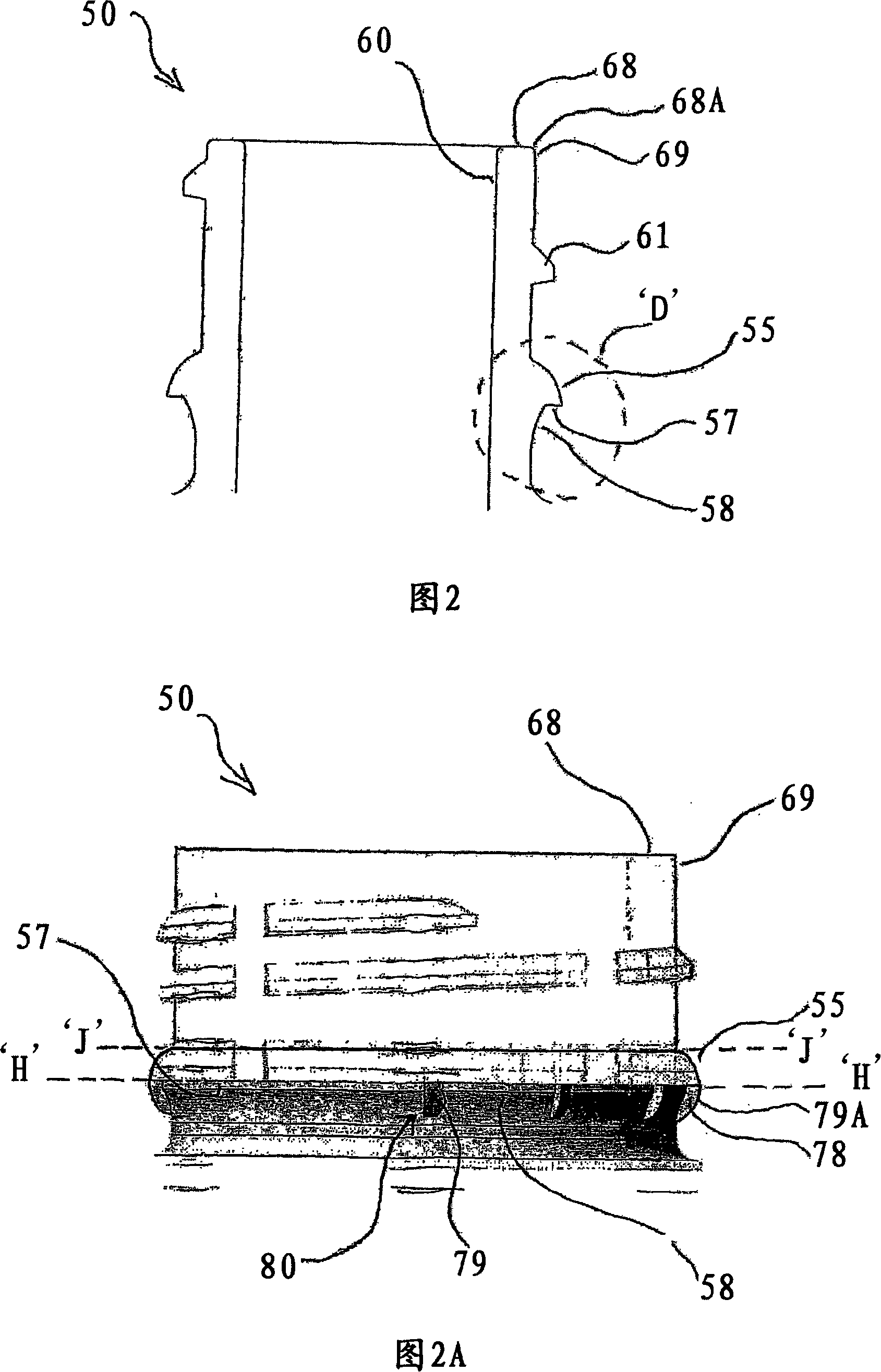

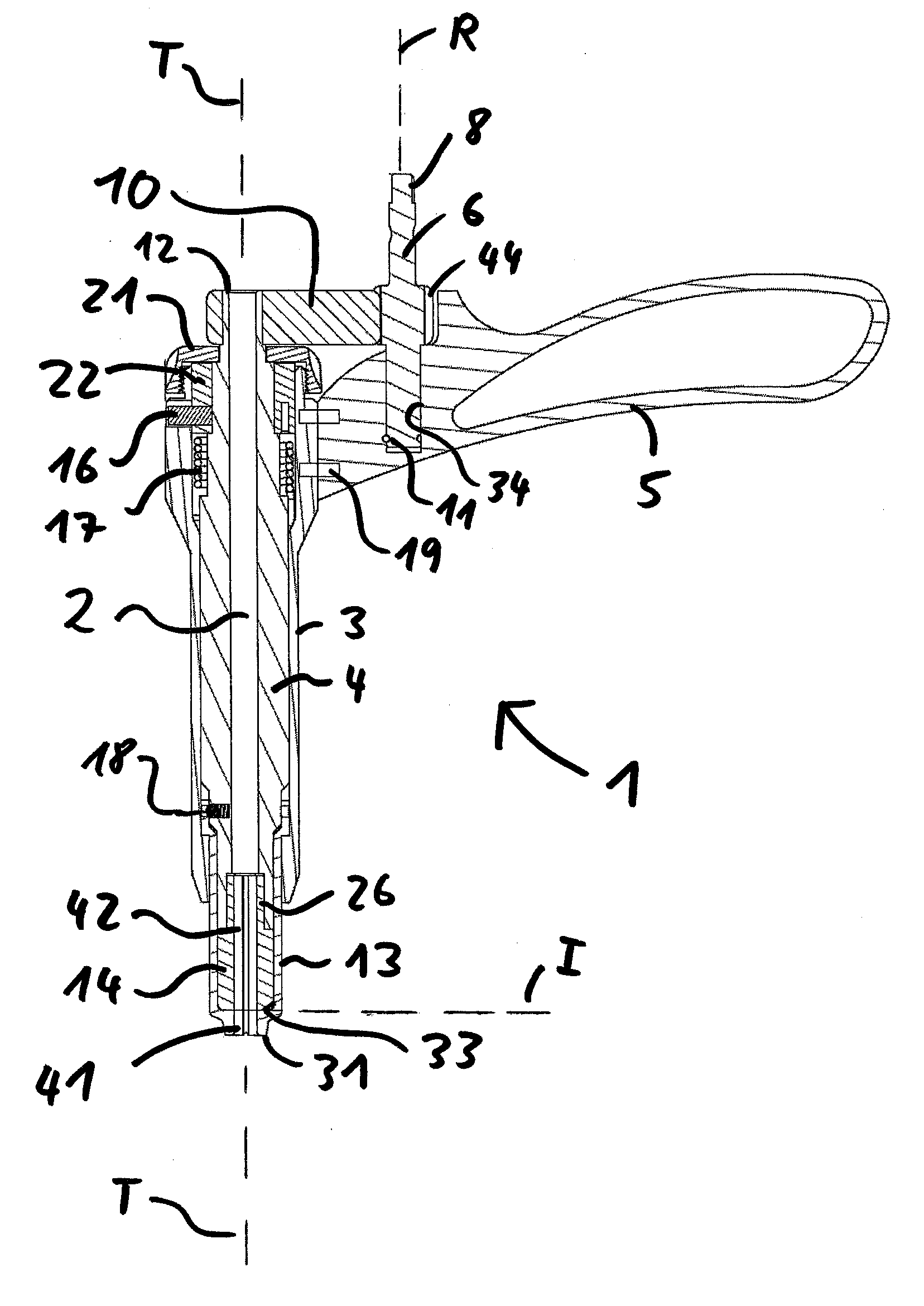

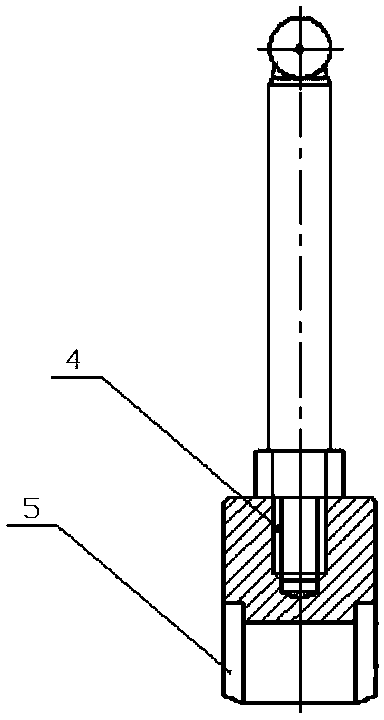

Pin cutting tool

ActiveUS20110062204A1Portable handheld shearing machinesMetal working apparatusNeck surfaceEngineering

A tool for breaking a shaft has a first and a second tubular element, both provided with inner through bores adapted to receive a first and second portion of a shaft in a first position of the tool. A first handle is fixedly connected with the first tubular element and the second tubular element is connected to a second handle. A bottom surface of the second tubular element is in contact with a neck surface of the first tubular element forming a shearing plane perpendicular to the main axis of the tool. A rotation between the two tubular elements around this axis creates a twisting movement of the two shaft portions received within the two tubular elements, and shears the shaft portions at the shearing plane. The second handle turns the first tubular element around an axis and has a gear engaging the second tubular element for transmitting the rotation of the second handle into a rotation of the second tubular element for producing the twisting movement.

Owner:STRYKER EURO OPERATIONS HLDG LLC

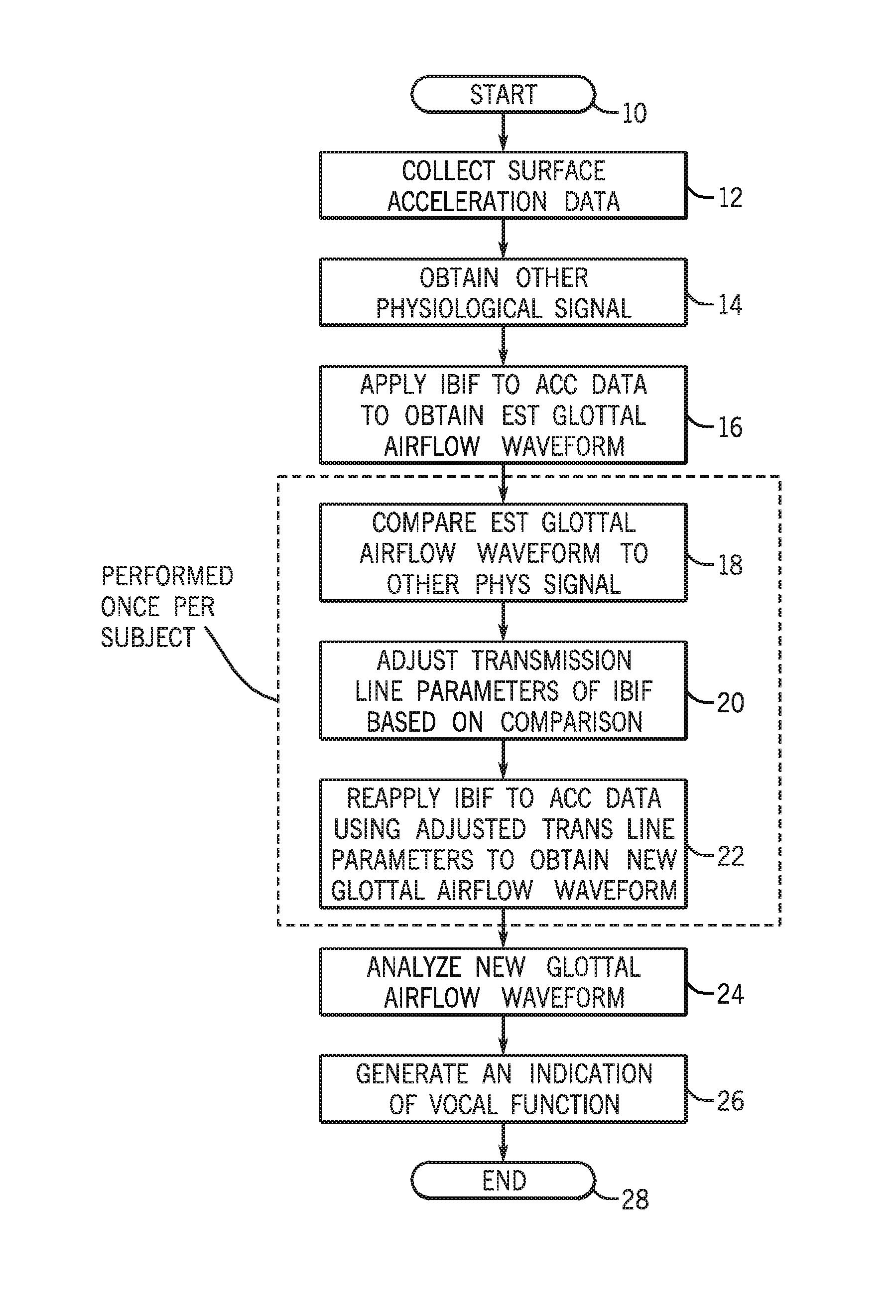

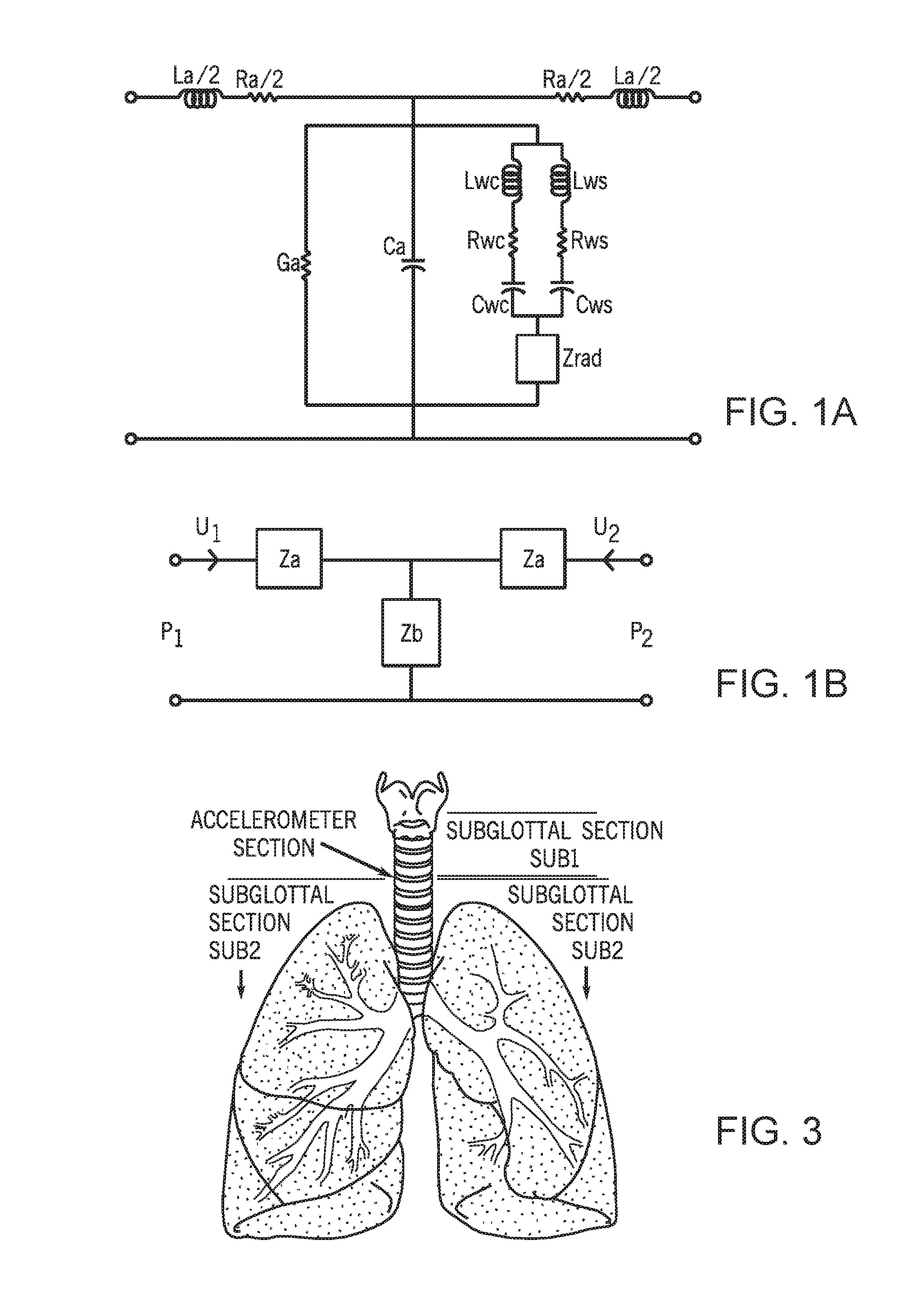

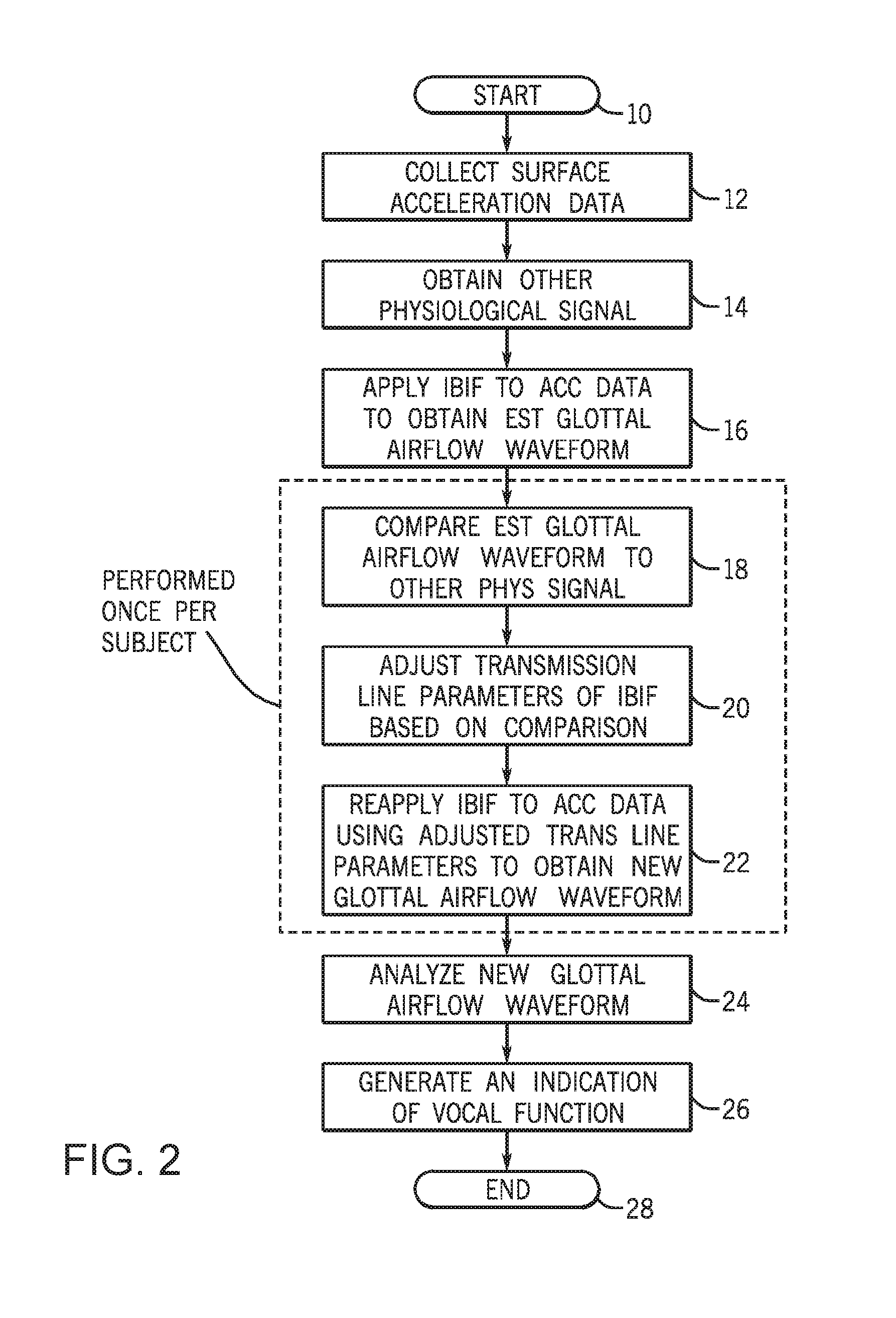

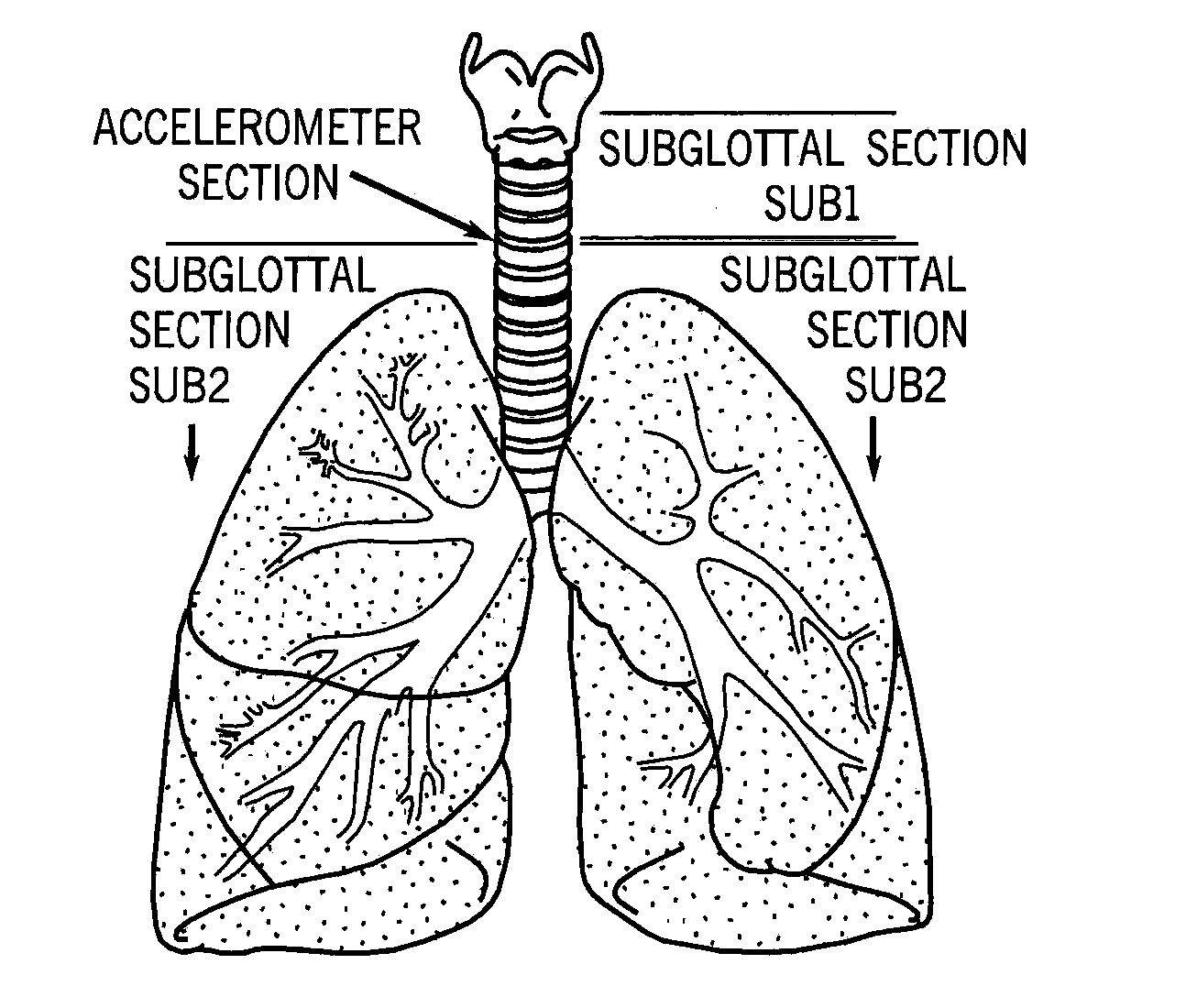

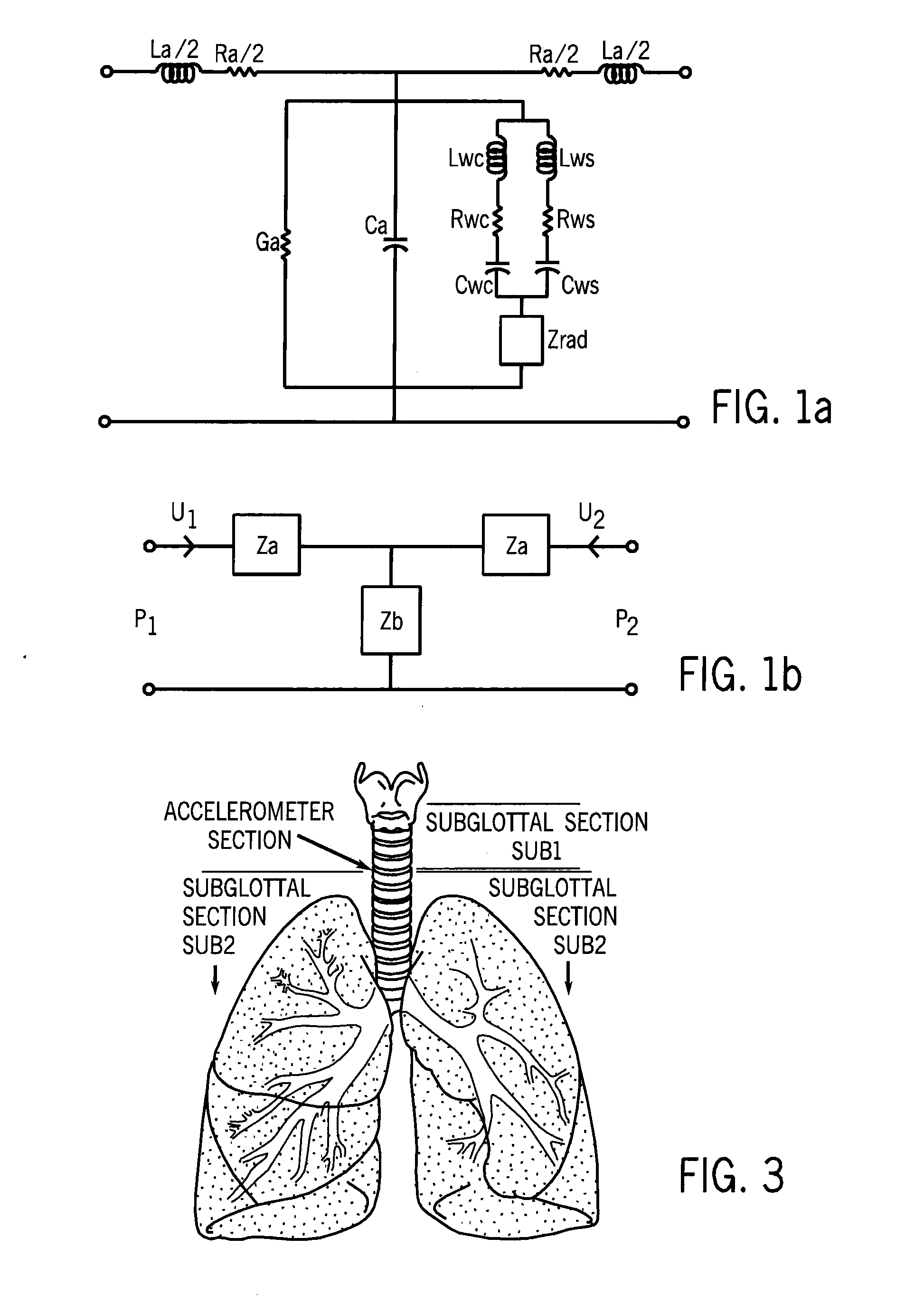

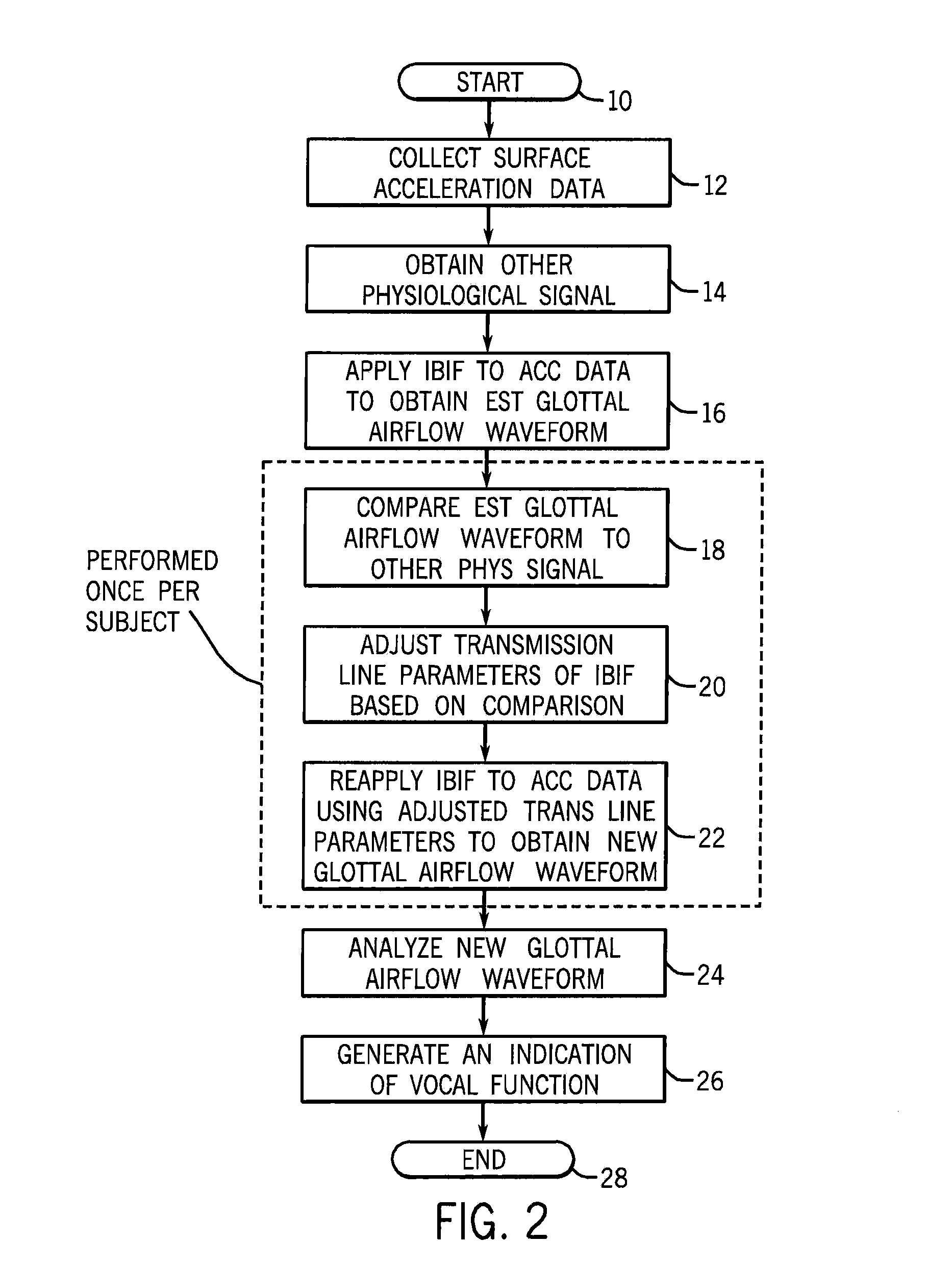

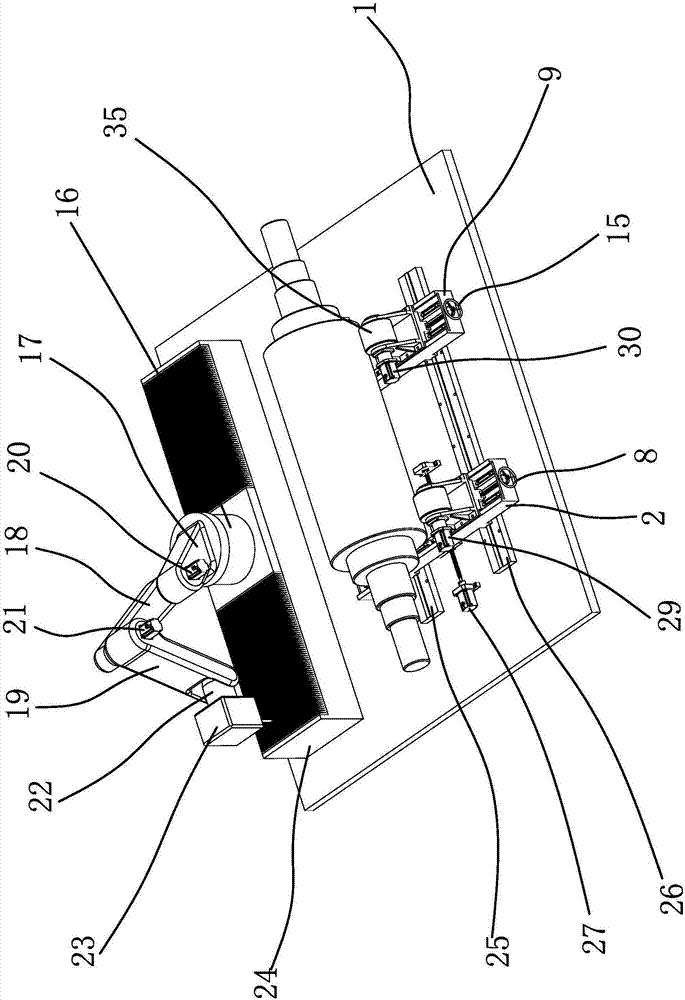

System and Method for Evaluating Vocal Function Using an Impedance-Based Inverse Filtering of Neck Surface Acceleration

A system and method to assess vocal function of a subject. The system includes an accelerometer configured to acquire surface acceleration data associated with vocal functionality of the subject and a computer system configured to analyze the surface acceleration data and to estimate glottal airflow waveforms produced by the subject based on the surface acceleration data. The computer system performs the analysis and estimation by applying an inverse filter to the surface acceleration data based on a calibrated transmission line model and generates an indication of vocal functionality of the subject based on the estimated glottal airflow waveforms.

Owner:THE GENERAL HOSPITAL CORP +1

System and Methods for Evaluating Vocal Function Using an Impedance-Based Inverse Filtering of Neck Surface Acceleration

InactiveUS20140066724A1Accurate and non-invasive estimationPerson identificationInertial sensorsAccelerometerNeck surface

A system and method to assess vocal function of a subject. The system includes an accelerometer configured to acquire surface acceleration data associated with vocal functionality of the subject and a computer system configured to analyze the surface acceleration data and to estimate glottal airflow wave-forms produced by the subject based on the surface acceleration data. The computer system performs the analysis and estimation by applying an inverse filter to the surface acceleration data based on a calibrated transmission line model and generates an indication of vocal functionality of the subject based on the estimated glottal airflow waveforms.

Owner:PURDUE RES FOUND INC

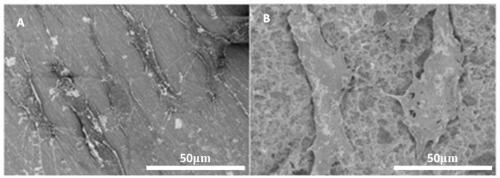

Process for roller shaft neck abrasion repairing and complete equipment for process

ActiveCN107034461AMeet the use requirementsInhibit sheddingMetallic material coating processesNeck surfaceEngineering

The invention provides a process for roller shaft neck abrasion repairing and complete equipment for the process, and belongs to the technical field of machines. The problem that in the prior art, the roller shaft neck abrasion repairing effect is poor is solved. According to the process for roller shaft neck abrasion repairing and the complete equipment for the process, the process comprises the following steps of a, pretreatment, b, placement, c, fusion covering, d, checkout, e, annealing treatment and f, gold machining treatment on a roller shaft is carried out. The complete equipment comprises a base, a first roller, a second roller and a semiconductor laser used for roller shaft neck abrasion repairing. The process and the complete equipment have the beneficial effects that the roller shaft neck surface strength and abrasive resistance are improved, and roller shaft neck abrasion repairing is more convenient and quicker.

Owner:南通德元机械制造有限公司

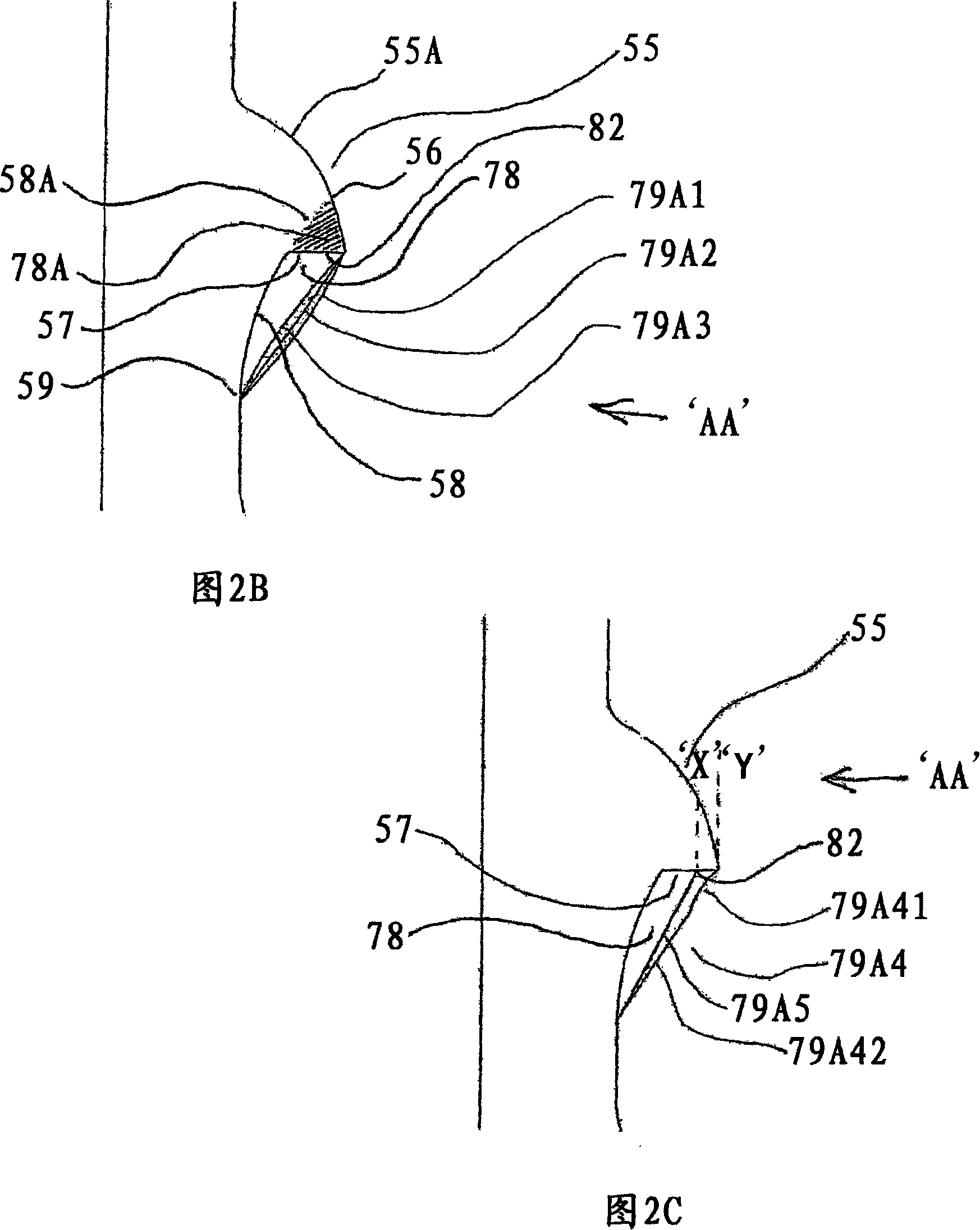

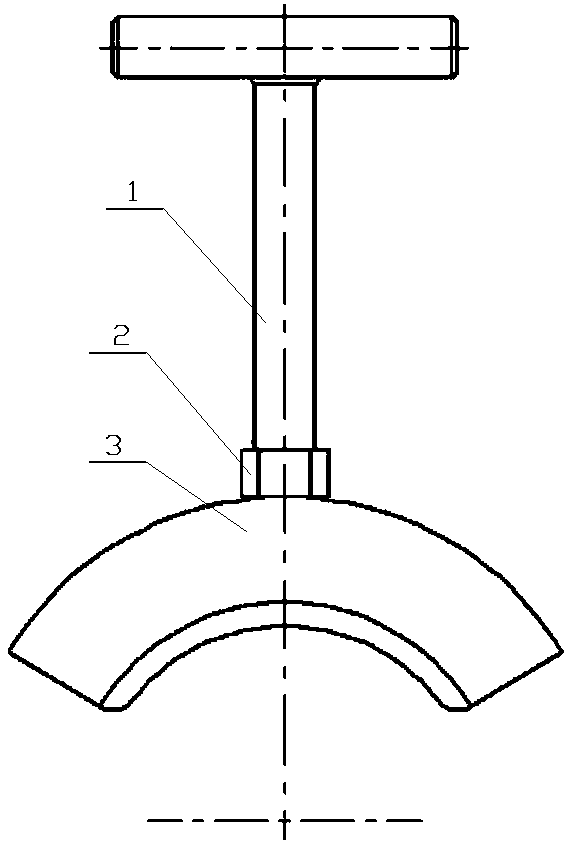

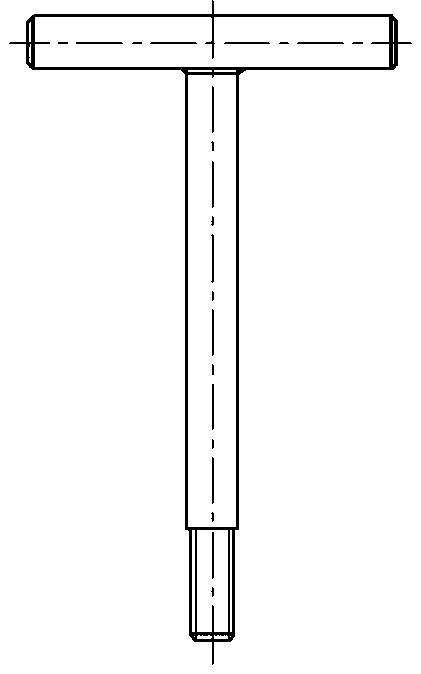

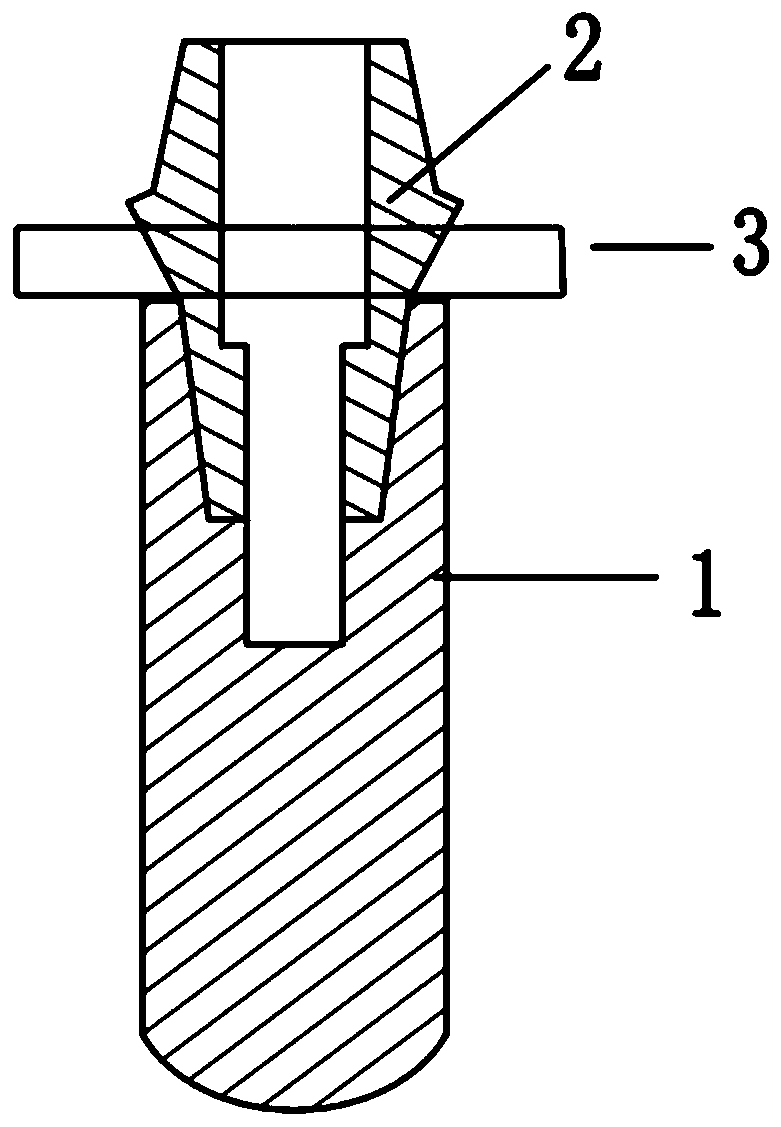

Crankshaft neck surface waviness grinding tool and using method thereof

PendingCN110434696ASimple structureSimple methodRevolution surface grinding machinesNeck surfaceCrankshaft

The invention discloses a crankshaft neck surface waviness grinding tool and a using method thereof. The grinding tool is mainly composed of a handle (1), a locking unit (2) and a grinding body (3). The grinding body (3) is a fan-shaped circular ring of the 1 / 3-1 / 2 arc length, and the width of the fan-shaped circular ring is 0.1 mm smaller than the length of a ground crankshaft neck. A thread hole(4) is formed in the middle position of the top of the grinding body (3). The bottom arc surface of the grinding body (3) is a grinding work surface. Cutter withdrawal grooves (5) are formed in the two sides of the bottom arc surface correspondingly. An outer thread is arranged at the lower end of the handle (1). The specification size of the outer thread is matched with the thread hole (4) of the grinding body (3). The lower end of the handle (1) penetrates through the locking nut (2), and then is fixed together with the thread hole (4) of the grinding body (3) in a thread connecting manner.The tool is simple in structure, high in practicality and high in flexibility, the effect of removing or relieving the circumferential waviness of the crankshaft neck is remarkable, the rework technology is simple, and the cost is low.

Owner:桂林福达曲轴有限公司

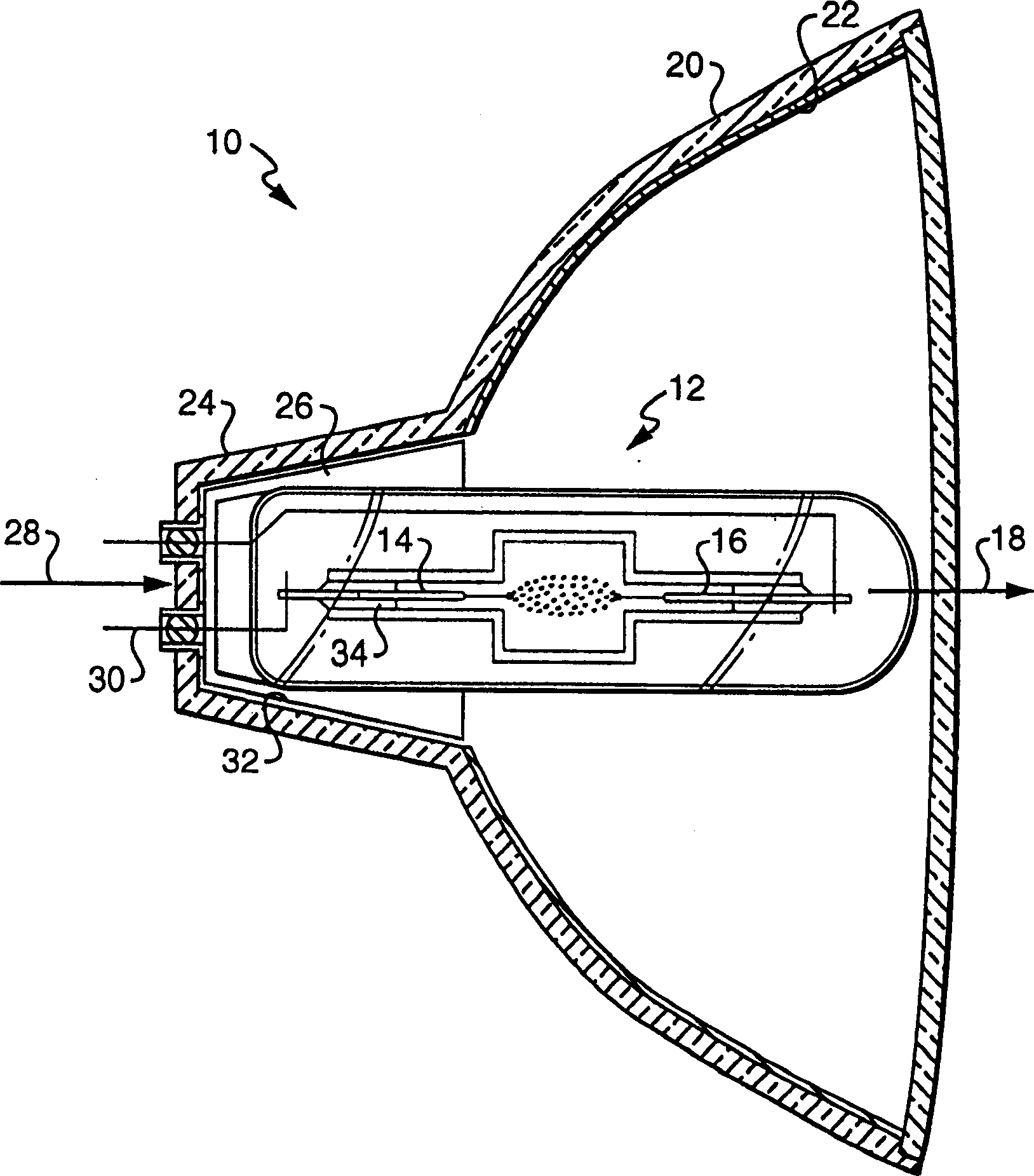

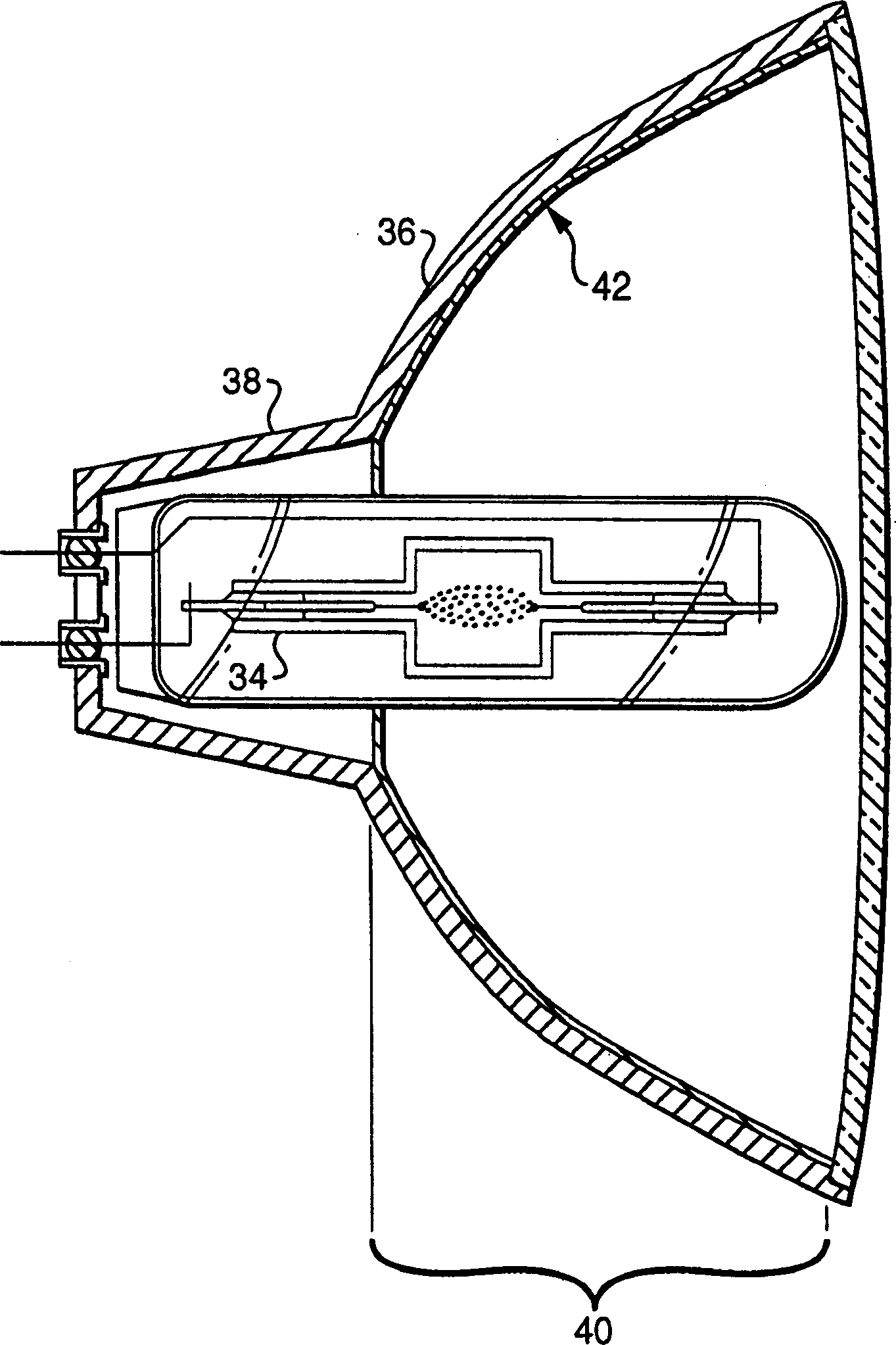

Parabolic reflector lamp assembly capable of reduced lamp seal temp.

InactiveCN1450588AExtend your lifeIncadescent screens/filtersPoint-like light sourceNeck surfaceEngineering

The neck of a typical PAR lamp tends to focus the light issued in the neck or heel of the lamp back onto the lamp seals. The focused lost light then tends to overheat the seal and shorten lamp life. A practical solution is to intercept this lost light with a light absorbing layer. The light is then converted to heat in the layer. The heat is then re-radiated in an unfocused fashion with only a small portion of it redirected to the seal area. The interception layer may be formed as a black top coating on the neck interior or the neck exterior if the reflector is otherwise light transmissive. Alternatively, the neck may be formed from a translucent or opaque material that then converts the light into heat in the body of the reflector wall. The neck is then specifically not metallized so as to reflect light from the internal neck surface back to the lamp seal.

Owner:OSRAM SYLVANIA INC

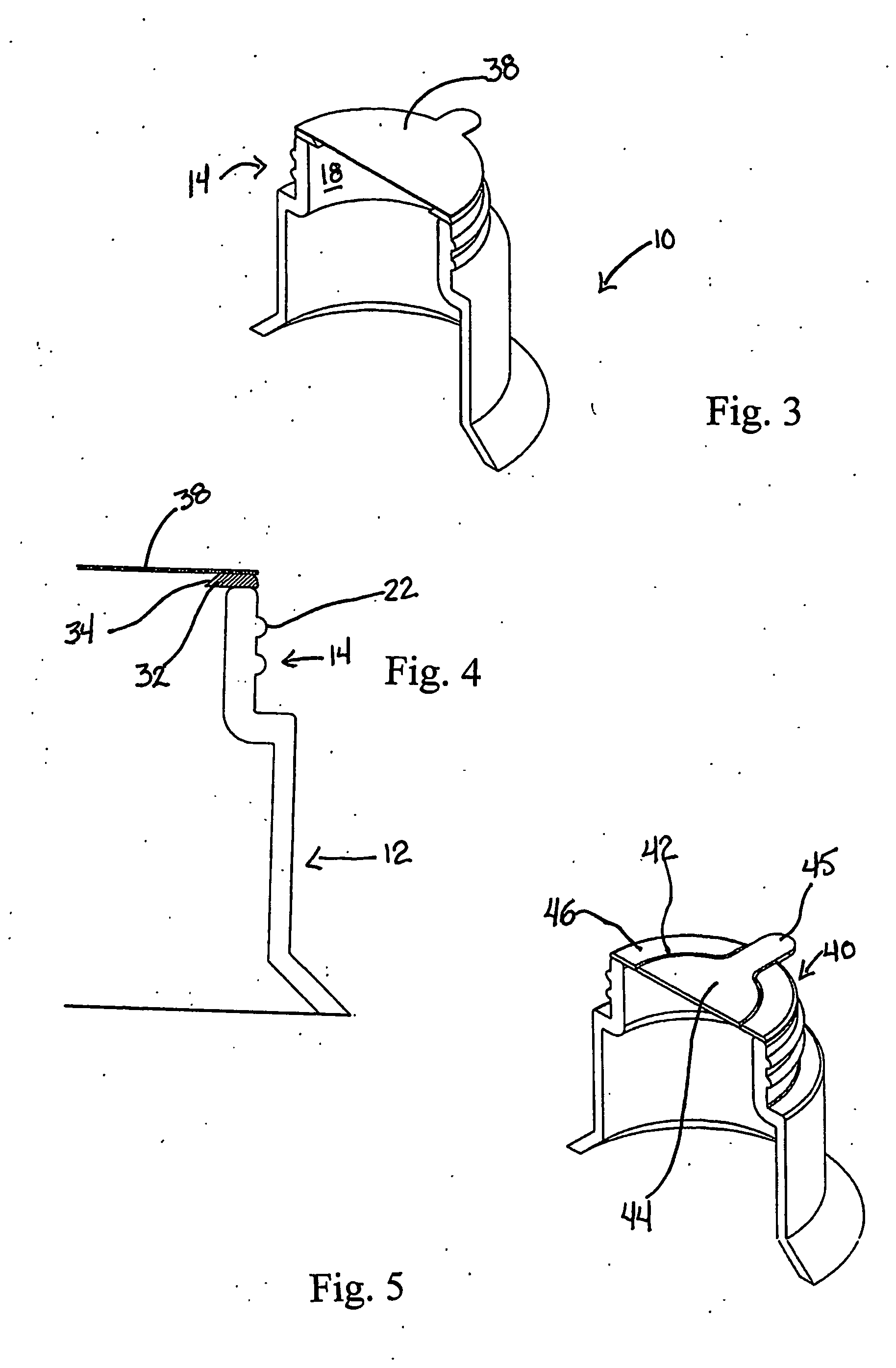

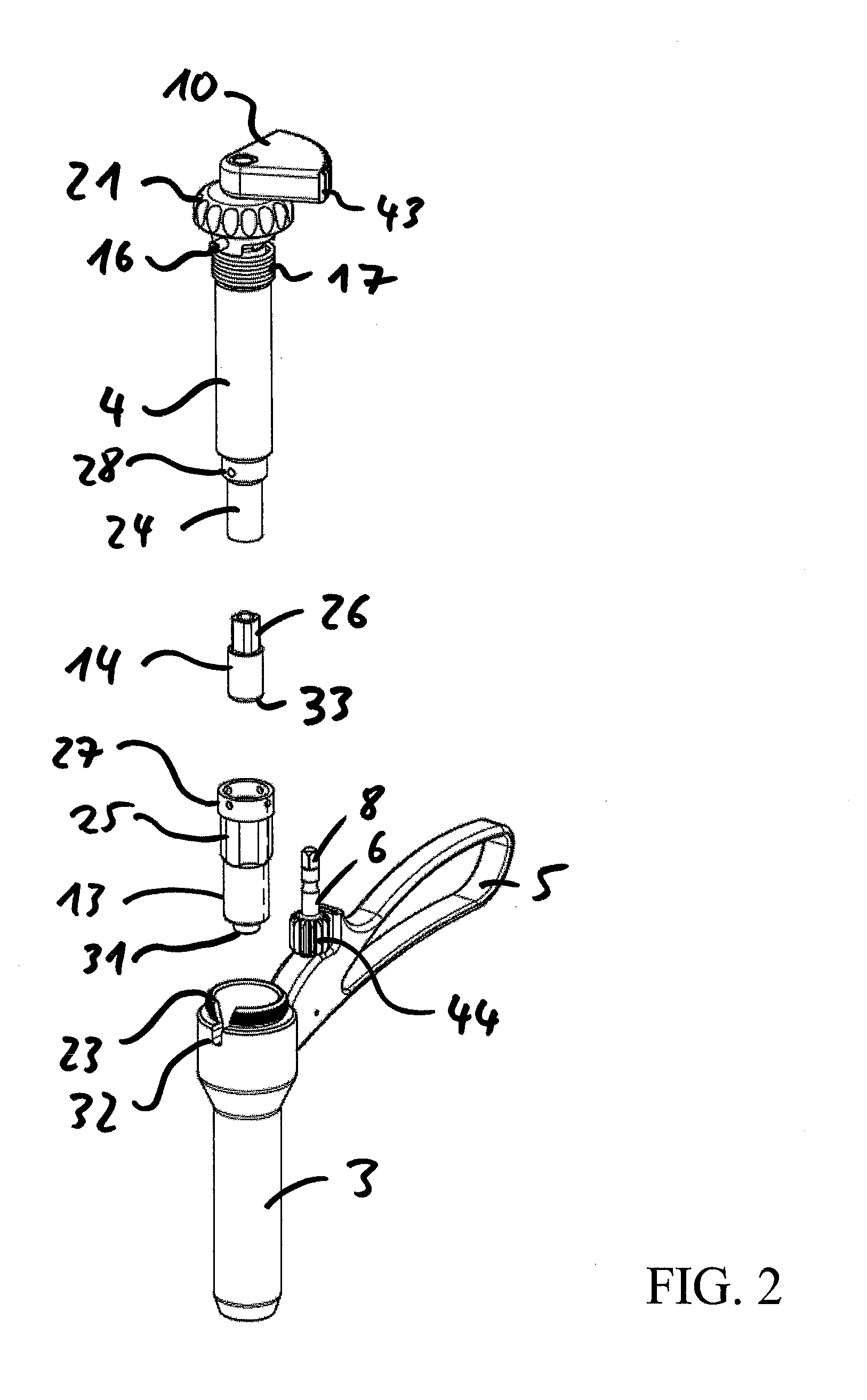

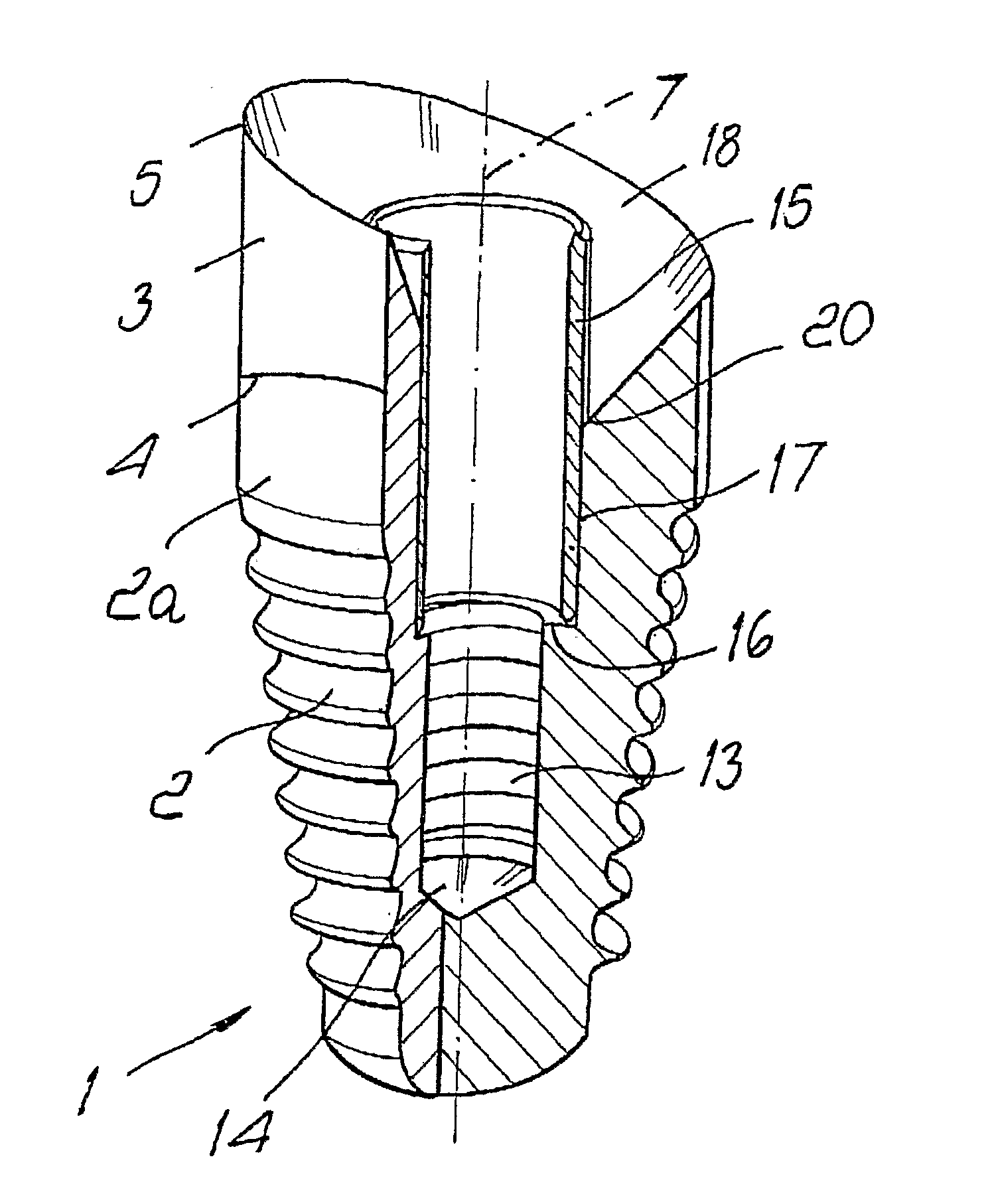

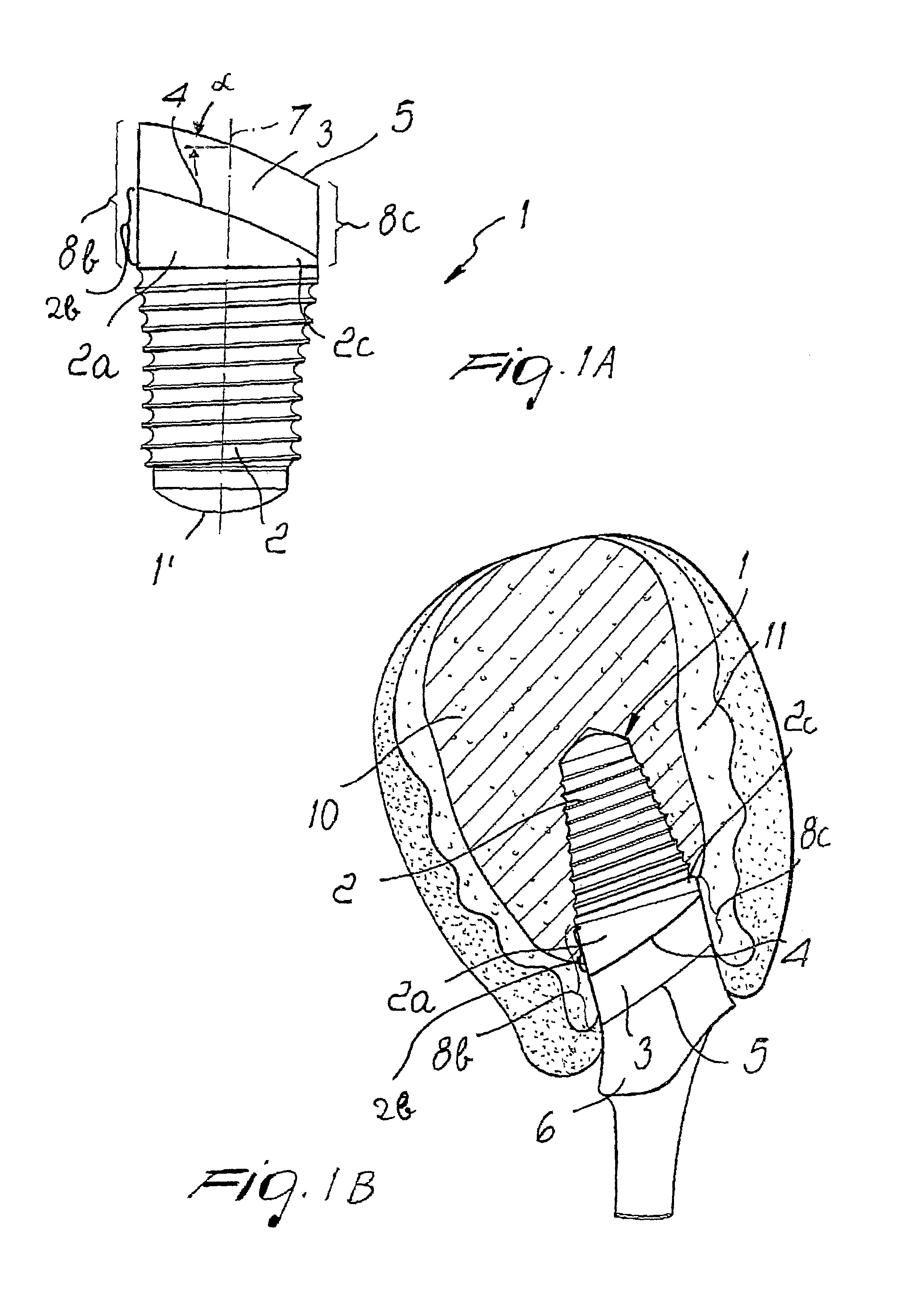

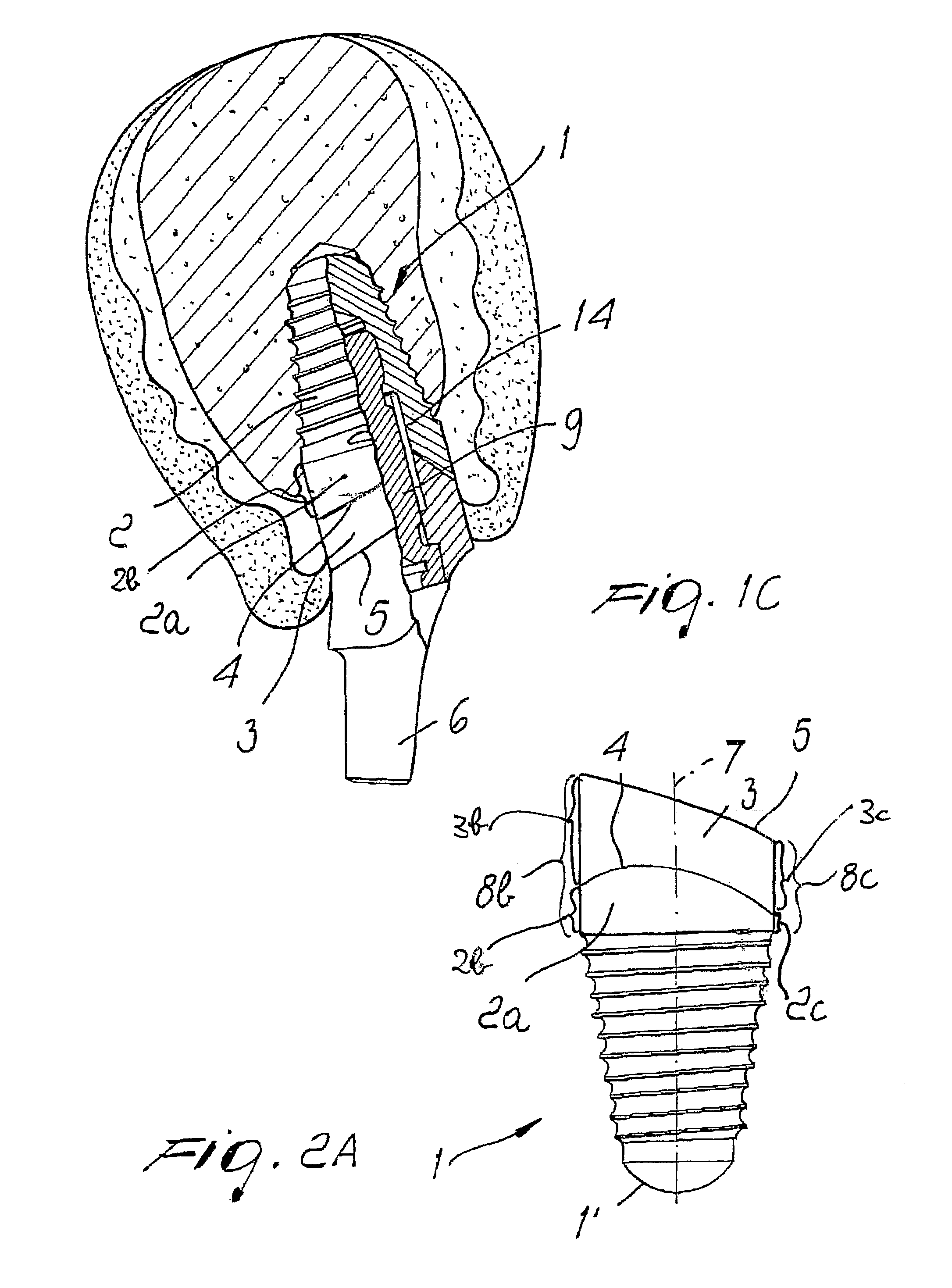

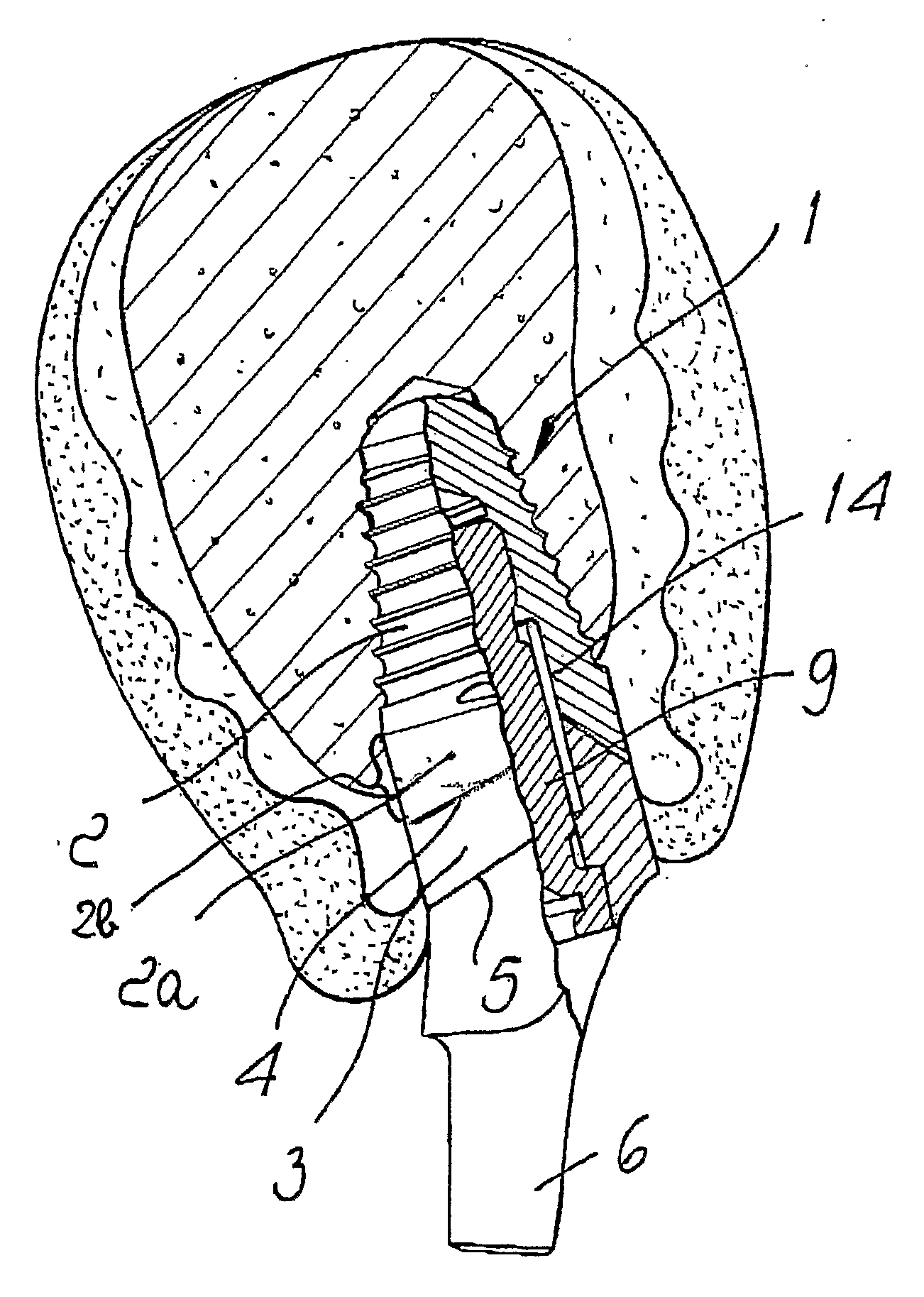

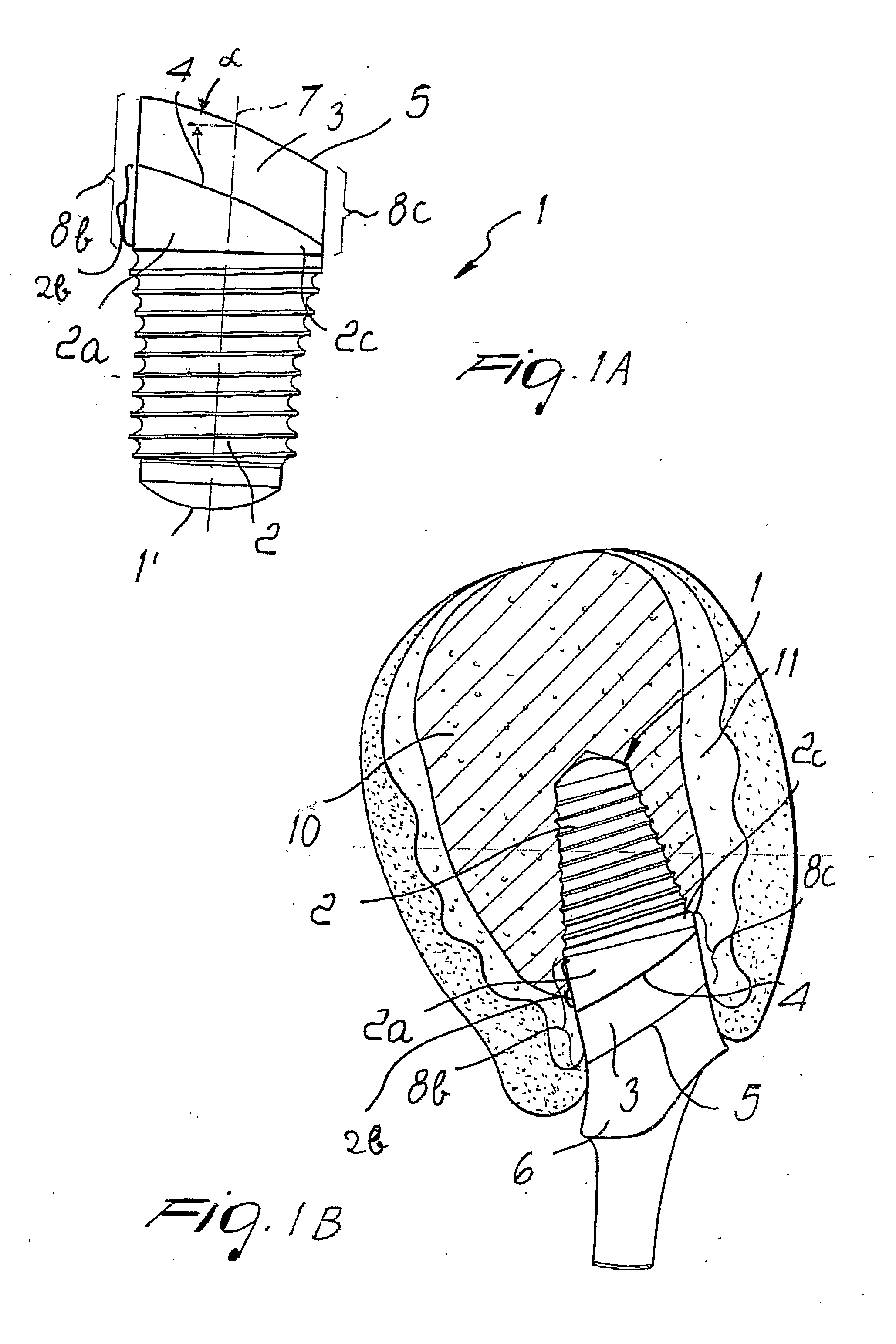

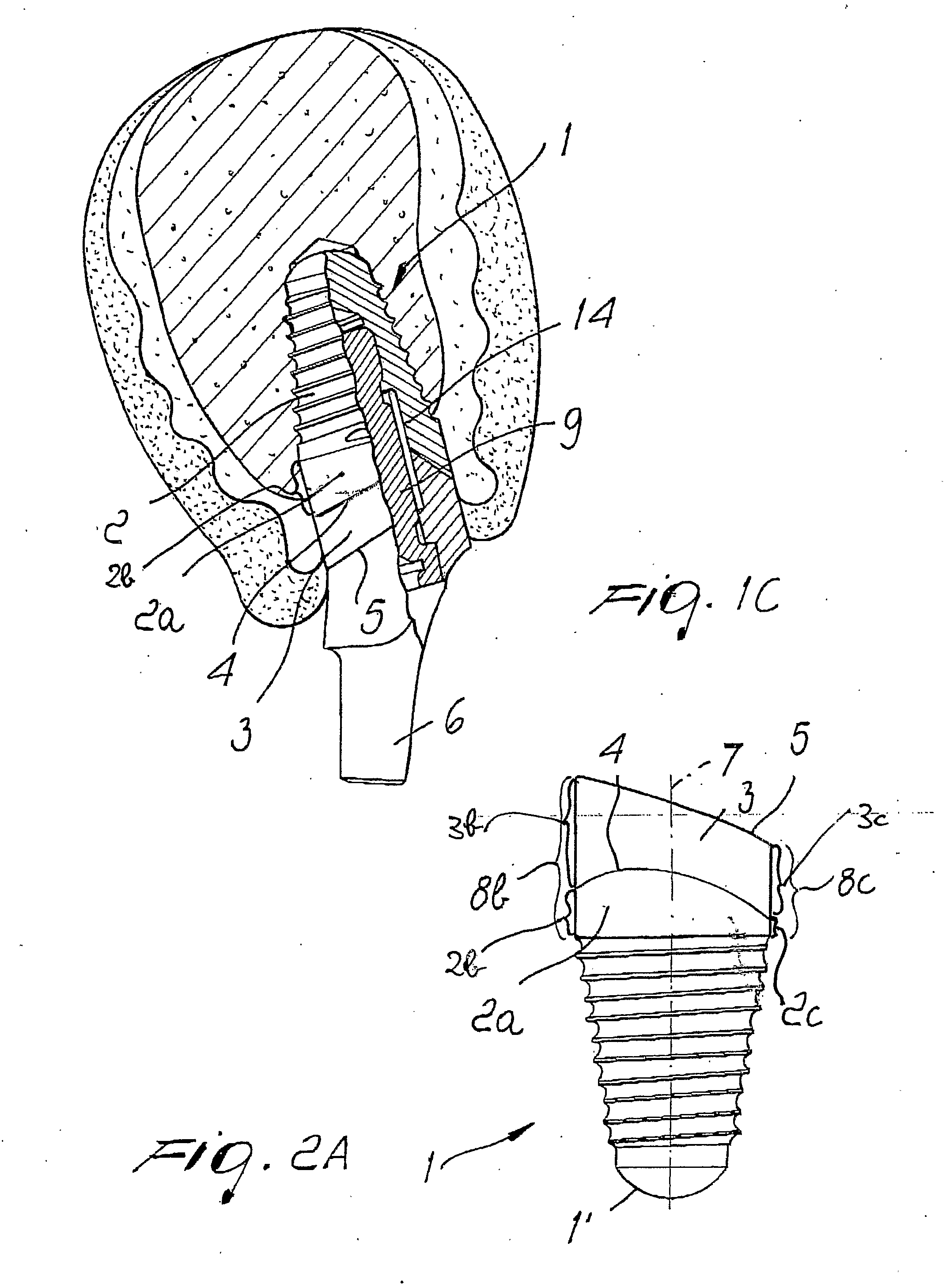

Dental implant with positioning means

InactiveUS7665990B2Simple and reliable positioningAvoid disadvantagesDental implantsNeck surfaceAbutment

The present invention relates to an intraosteal dental implant (1) including a bore (14) in the form a blind hole, the bore (14) being shaped and devised such as to rotationally secure an abutment (6) receivable in the dental implant (1), wherein the bore (14) is provided with a substantially cylindrical sleeve (15) extending coaxially to the dental implant (1), wherein the dental implant (1) includes an inner neck surface (18), and wherein an intersection curve (20) between the inner neck surface (18) of the dental implant (1) and the sleeve (15) does not lay in a plane perpendicular to the axis (7) of the dental implant (1) or wherein the inner neck surface (18) of the dental implant (1) has a substantially conical shape with an imaginary tip (19) offset from the axis (7) of the dental implant (1).

Owner:STRAUMANN HLDG AG

Dental implant with positioning means

InactiveUS20070196786A1Simple and reliable positioningAvoid disadvantagesDental implantsNeck surfaceAbutment

The present invention relates to an intraosteal dental implant (1) including a bore (14) in the form a blind hole, the bore (14) being shaped and devised such as to rotationally secure an abutment (6) receivable in the dental implant (1), wherein the bore (14) is provided with a substantially cylindrical sleeve (15) extending coaxially to the dental implant (1), wherein the dental implant (1) includes an inner neck surface (18), and wherein an intersection curve (20) between the inner neck surface (18) of the dental implant-(1) and the sleeve (15) does not lay in a plane perpendicular to the axis (7) of the dental implant (1) or wherein the inner neck surface (18) of the dental implant (1) has a substantially conical shape with an imaginary tip (19) offset from the axis (7) of the dental implant (1).

Owner:STRAUMANN HLDG AG

Wearable telecommunication device in a form of a necklace

A wearable telecommunication device configured as an electronic necklace in a form of an open or closed neck loop comprising electronic components and connected to two in-ear earphones. The point of connection of the proximal end of the earphone cords to the neck loop is on the dorsal neck surface. An additional cord connection node positioned under the user's occiput, which allows the earphones and the cords to be secured when the earphones are operational, and reduces excursion of the loose portions of the cords, thus providing the device to be non-changing appearance of the user. Ferromagnetic inserts allow the earphones and the cords to be secured when non-operational, for the device to be hidden. The device may be embodied as a wireless headset for a mobile telecommunication device, a telecommunication device itself, an audio player, a CB radio station, a part of a personal health or security system, etc.

Owner:USHAKOV ALEXEY

Treatment method of roller neck surface

InactiveCN105344715AImprove tensile propertiesFirmly connectedRolling safety devicesMetal rolling arrangementsNeck surfacePhosphoric acid

The invention discloses a treatment method of a roller neck surface. The method includes the specific steps that the center portion of a roller neck is heated at the temperature ranging from 600 DEG C to 700 DEG C, after the center portion is heated, the temperature is kept for 2 to 3 hours, and the outer edge portion of the roller neck is treated through a surface treating agent; and the outer edge portion of the roller neck is treated in the process that firstly, the outer edge of the roller neck is evenly coated with the surface treating agent, the roller neck and a roller body are assembled and placed in a vibrator to be fixed and then shake for 3 minutes to 5 minutes at 700 r / m, and finally the end, close to the roller neck, of the surface of the roller body is heated at the temperature ranging from 550 DEG C to 650 DEG C, wherein the surface treating agent comprises 5 g / L to 30 g / L of polyethylene glycol, 1 g / L to 5 g / L of titanium sulfate, 2 g / L to 8 g / L of phosphoric acid, 1 g / L to 20 g / L of sodium metavanadate, 2 g / L to 8 g / L of tartaric acid, 4 g / L to 11 g / L of malic acid, 4 g / L to 15 g / L of ammonium fluoride, 1 g / L to 6 g / L tungstic acid and 7 g / L to 13 g / L of lactic acid zirconium. By the adoption of the method, a roller is resistant to abrasion and corrosion and is provided with the surface with the good tensile property, it is guaranteed that the connection performance of the roller neck and the roller body is stable, shake is reduced, the noise is low in the rolling process, the rolled product quality is guaranteed, and the safety of the production process is guaranteed as well.

Owner:TONGLING MINGCHENG FOUNDRY

Implant for improving sealing performance of soft tissue around implant

The invention discloses an implant for improving the sealing performance of soft tissue around the implant. The implant comprises a body part and a base foundation or a neck part, wherein the base foundation is connected with the body part through a screw; the neck part is integrally connected with the body part; the upper part of the body part matches with the bottom of the base foundation to form a shoulder foundation of 0.2-0.7mm wide; a first micro pore zone of 3-5mm wide is arranged on the implant; first micro pores which are uniformly distributed are formed in the first micro pore zone;the size of the first micro pores is 1-3 micrometers; the surface of an area above the first micro pore zone is a smooth surface; and the first micro pore zone is positioned on the surface of the basefoundation or the neck part above the top of the body part. The implant emphasizes on creativeness of the sealing performance of a gum threading part of the implant, the adhesiveness of soft tissue to the implant is improved, mucosal inflammation around the implant and peri-implantitis can be reduced, and the long-term success rate of implanting can be increased.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com