Parabolic reflector lamp assembly capable of reduced lamp seal temp.

A technology of reflector and reflective layer, applied in the field of reflector lamps and electric lamps enclosed in reflectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

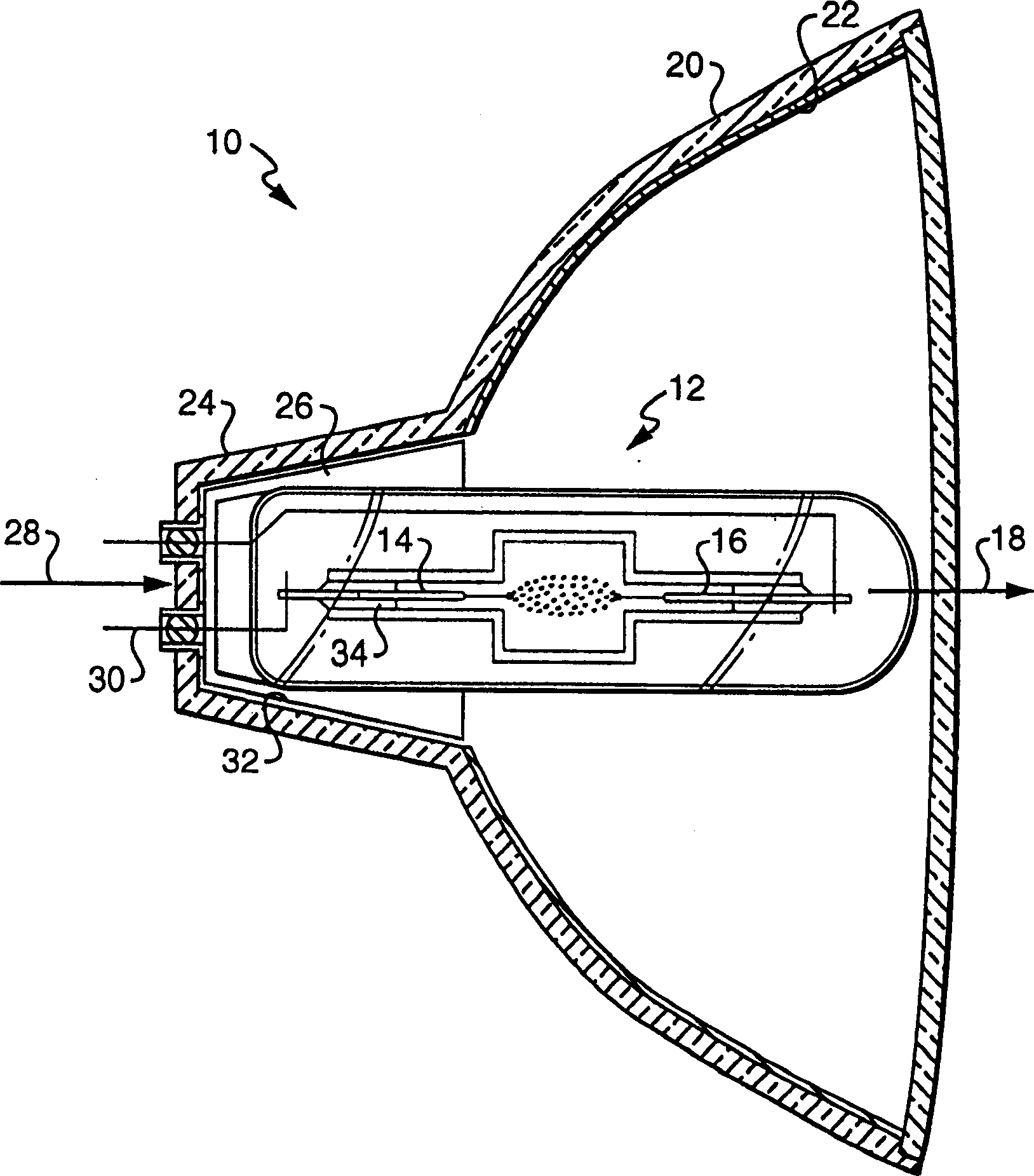

[0011] figure 1 A schematic cross-sectional view of a preferred embodiment of a lamp assembly with an internal light absorbing coating is shown. A preferred PAR lamp assembly 10 includes a light source 12 having two sealed electrodes 14 , 16 defining a lamp axis 18 ; a concave ceramic envelope 20 having an internal reflective surface 22 . The housing 20 also has a neck 24 defining a neck cavity 26 and a reflector axis 28 . The neck 24 is provided with electrical connections 30 and mechanical support for the light source 12 . Housing 20 surrounds light source 12 to reflect light from light source 12 to the area to be illuminated during operation of the lamp. Preferably the light source 12 and reflector 20 are oriented such that the lamp axis 18 is substantially coaxial with the reflector axis 28, and at least a portion of at least one of the electrodes 14, 16 extends in the neck cavity 26, and an area With a substantially non-transmissive light-absorbing layer 32 .

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com