Tapered hybrid bearing assembly part with textured shaft neck surface

A dynamic and static pressure bearing, surface texture technology, applied in the direction of shaft and bearing, bearing, mechanical equipment, etc., can solve the problems of assembly difficulty, sealing difficulty, material deformation, etc., to improve bearing capacity, reduce high-speed temperature rise, and improve bearing capacity force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be explained in further detail below in conjunction with the accompanying drawings and specific embodiments.

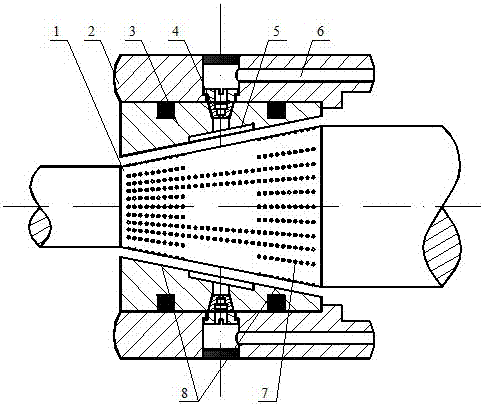

[0020] Such as figure 1 As shown, the tapered dynamic and static pressure bearing assembly with the journal surface textured includes the bearing and the journal 1, and the bearing includes the bearing shell 2, the bearing bush 3, the small hole restrictor 4, the oil chamber 5, the oil inlet passage 6, the seal The oil surface 8 is provided with a surface texture 7 on the shaft diameter 1 .

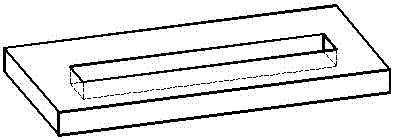

[0021] The bearing bush 3 is installed in the bearing shell 2, and the oil inlet passage 6 is opened in the bearing shell 2, and the small hole restrictor 4 on the outer cone surface is screwed into the passage or the plate type small hole restrictor 4 structure is adopted, and the small hole restrictor 4 The oil chamber 5 communicates with the oil chamber 5, and the oil chamber 5 can be one of a rectangular structure, a fan-shaped structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com