Closure and container neck

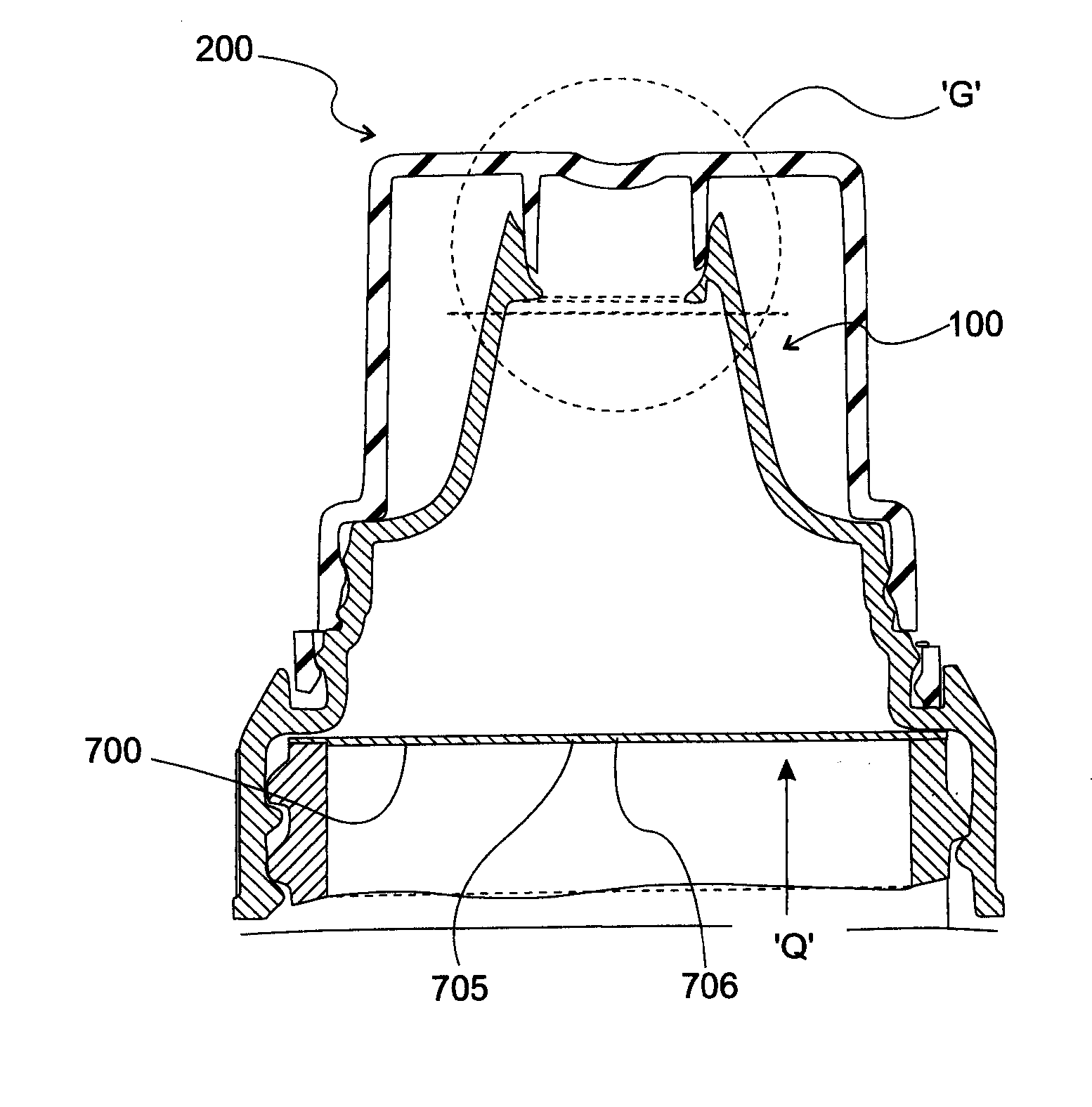

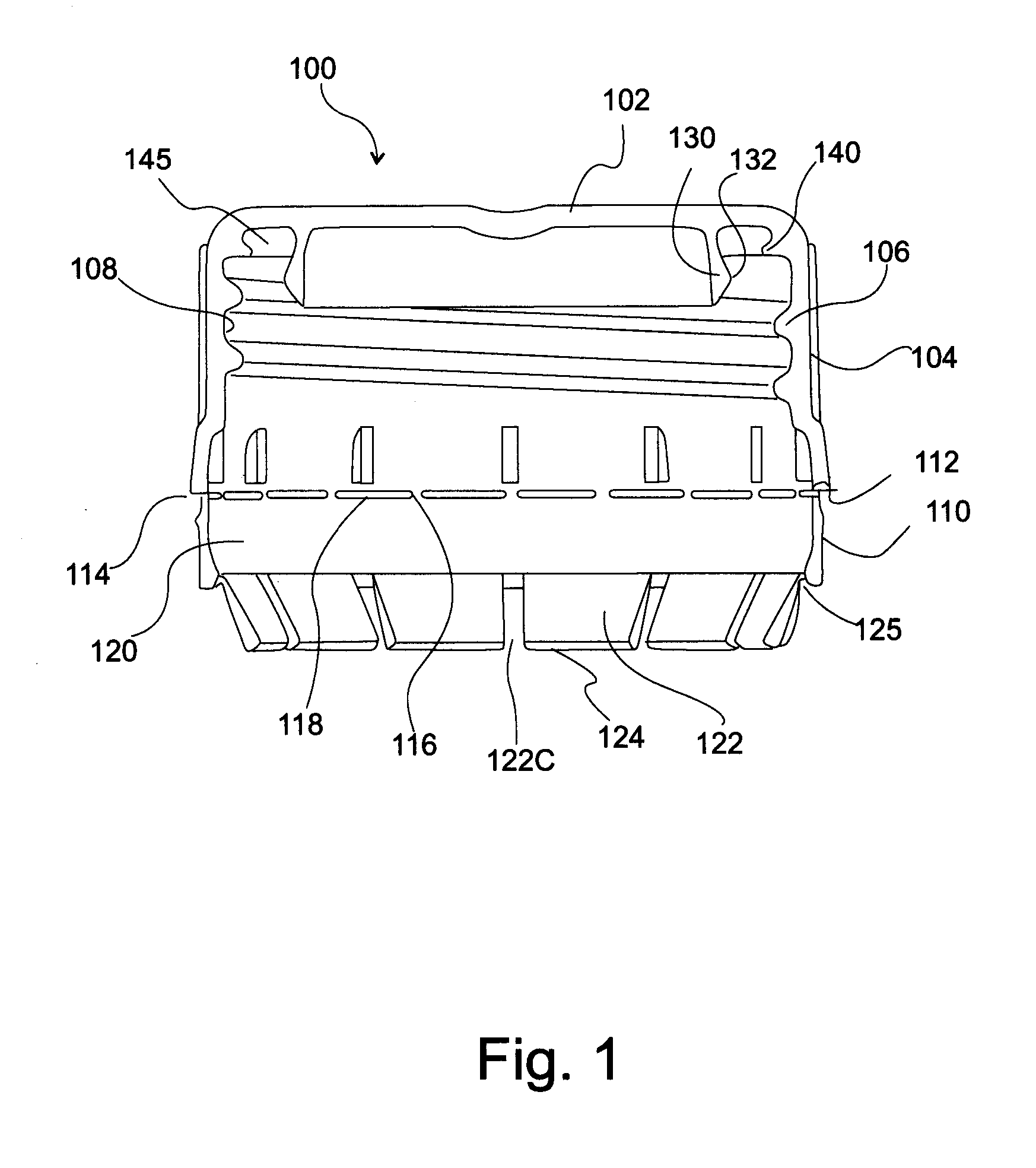

a container and closure technology, applied in the field of container closures, can solve the problems of insufficient visibility of tamper evidence, loss of sealing between the container closure and the container opening, and air in the sealed container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

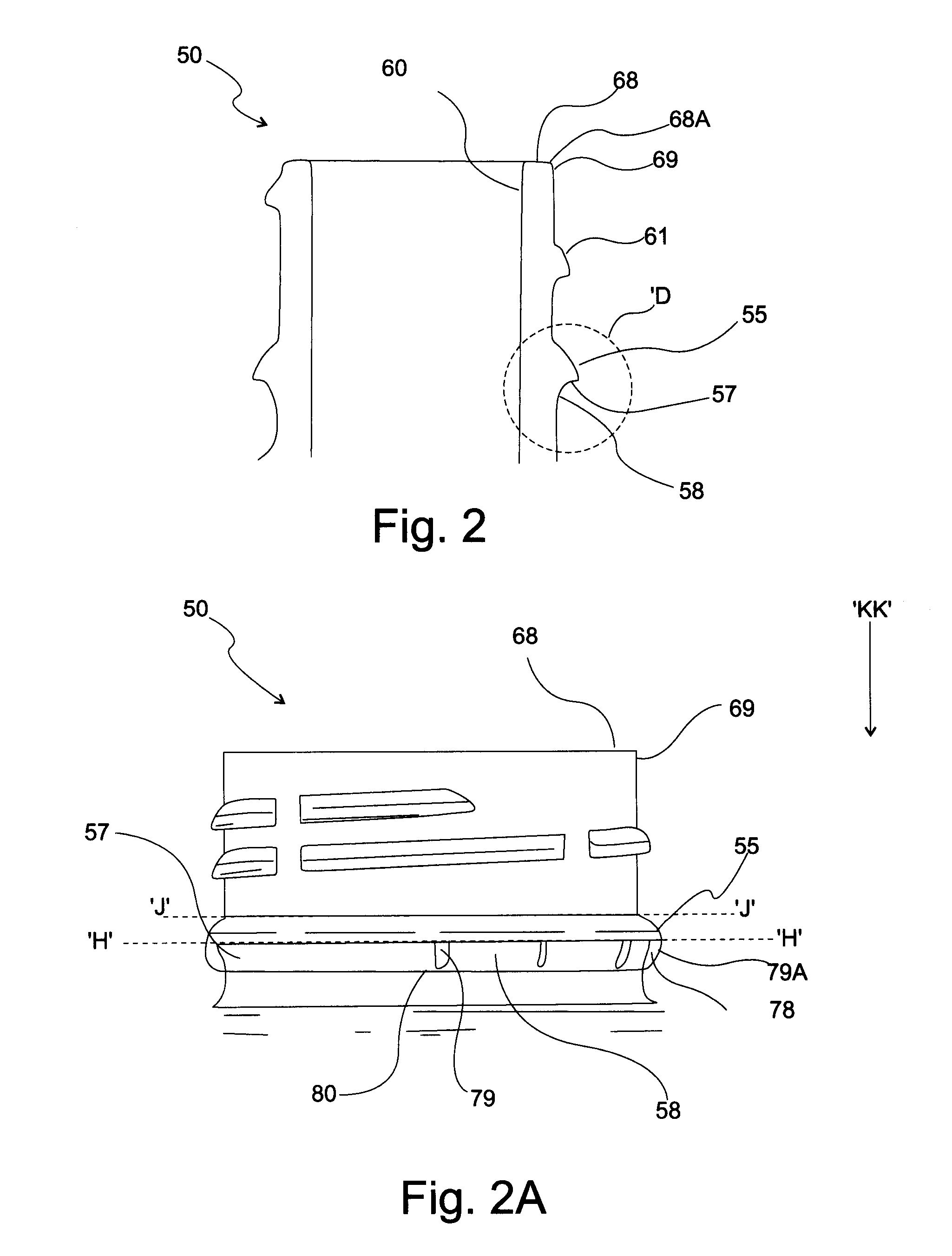

[0072] Embodiment 1 has joining edge 79A1 as a sloped curved shape with a convex curve viewed from ‘AA’ and

embodiment 2

[0073] Embodiment 2 has joining edge 79A2 as a linear sloped surface and

embodiment 3

[0074] Embodiment 3 has joining edge 79A3 as a sloped curved shape with a concave curve viewed from ‘AA’ and

[0075] In yet another embodiment 4 curved wall 58 between each engagement means 80 continues as indicated by dotted line 58A intersecting the upper surface of tamper bead 55 at edge 56 and creating an extension to engagement face 78 represented by hatched area 78A. Said curved wall 58 may have a compound curve having a varying radius at various points.

[0076] In yet another embodiment said wall 58 may be a linear surface not curved.

[0077] In yet another embodiment 5 the upper outer edge of engagement faces 78 may abut the lower surface 57 of said tamper bead 55 at a point radially inwards towards the axis of the said container neck for example at joining point 82 and leaving at least adjacent to engagement means 80 a portion of tamper bead lower surface 57 adjoining tamper bead upper surface 55A to engage at least with closures relying on contact between closure tamper eviden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com