Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Motion boundary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

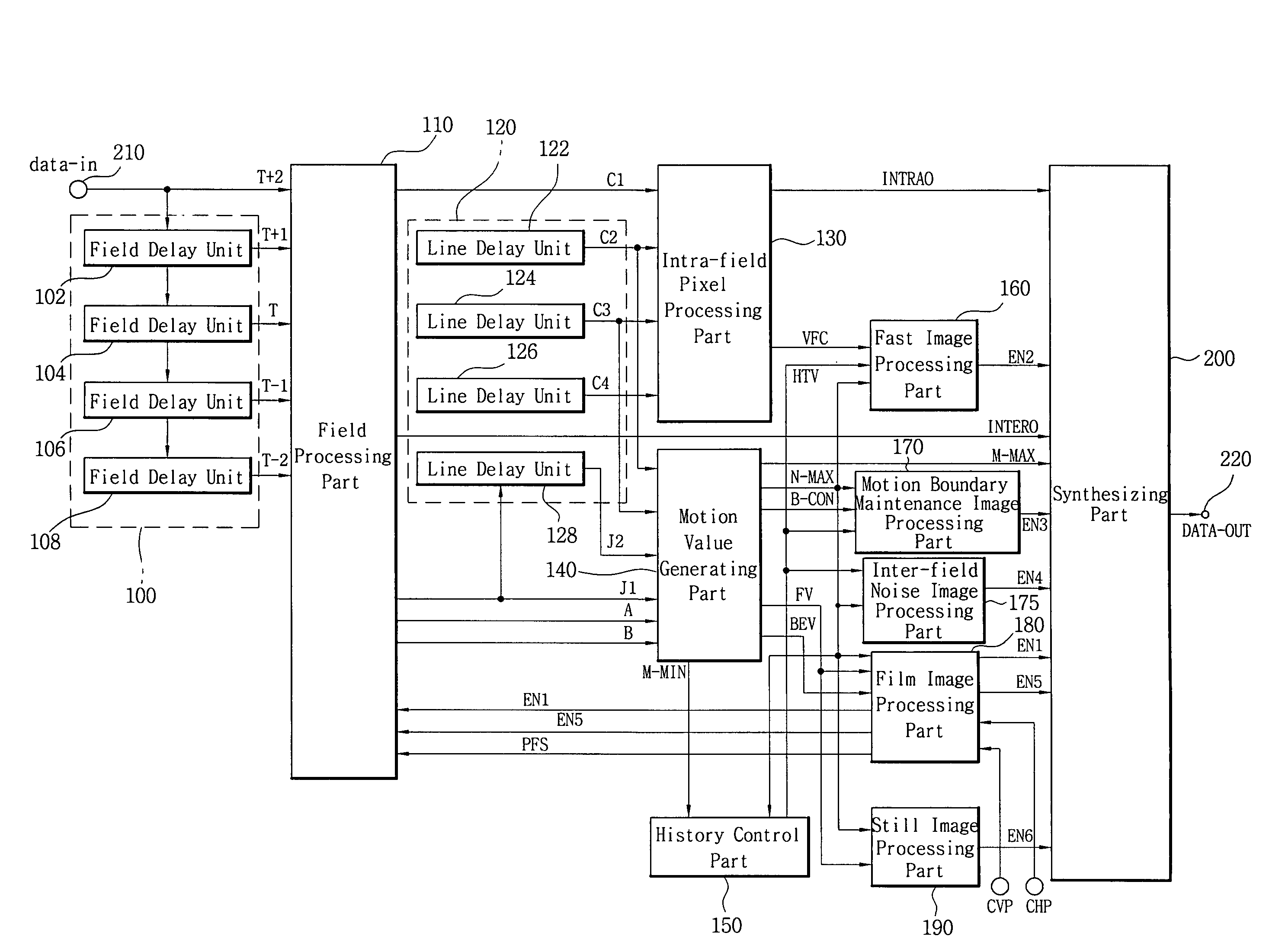

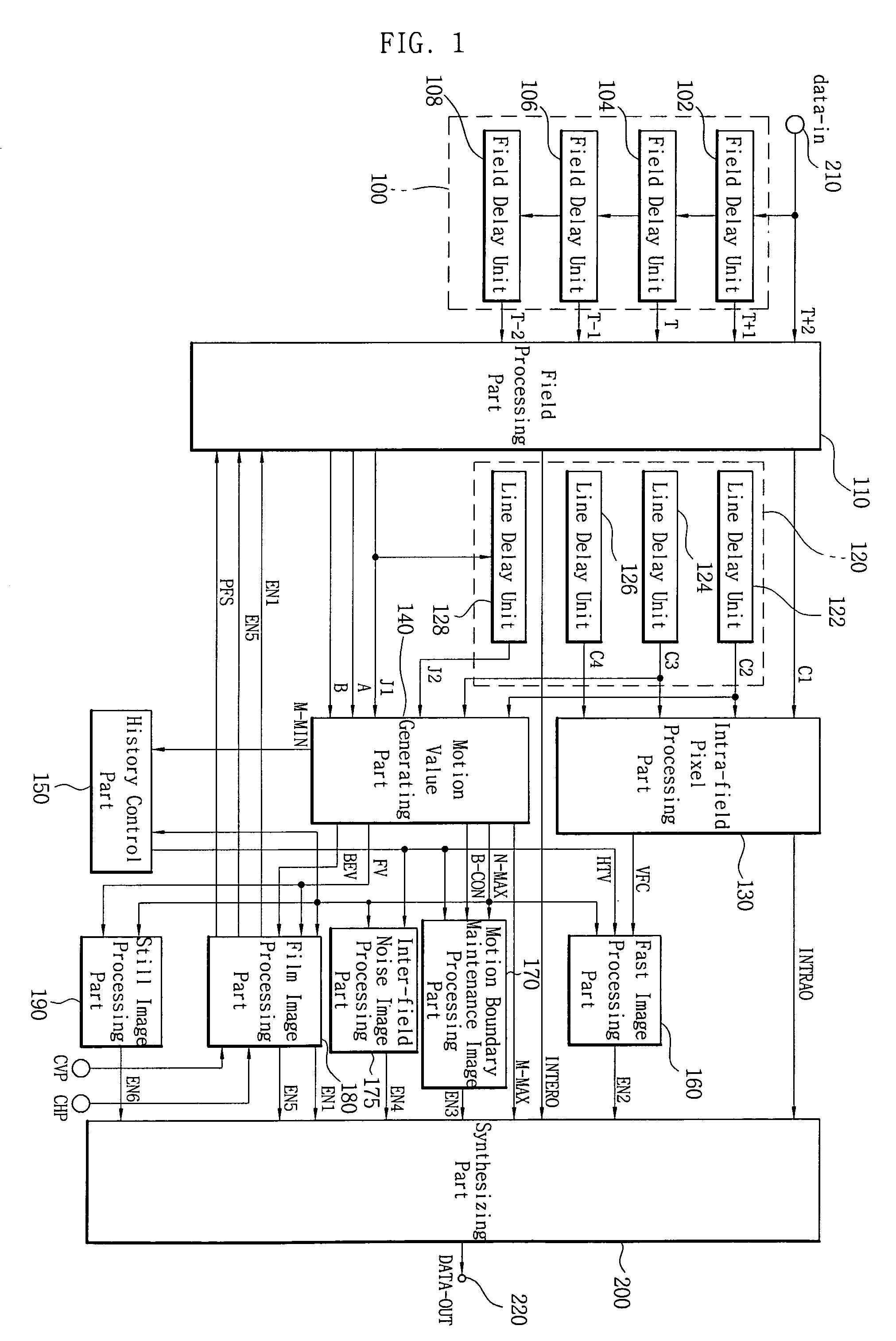

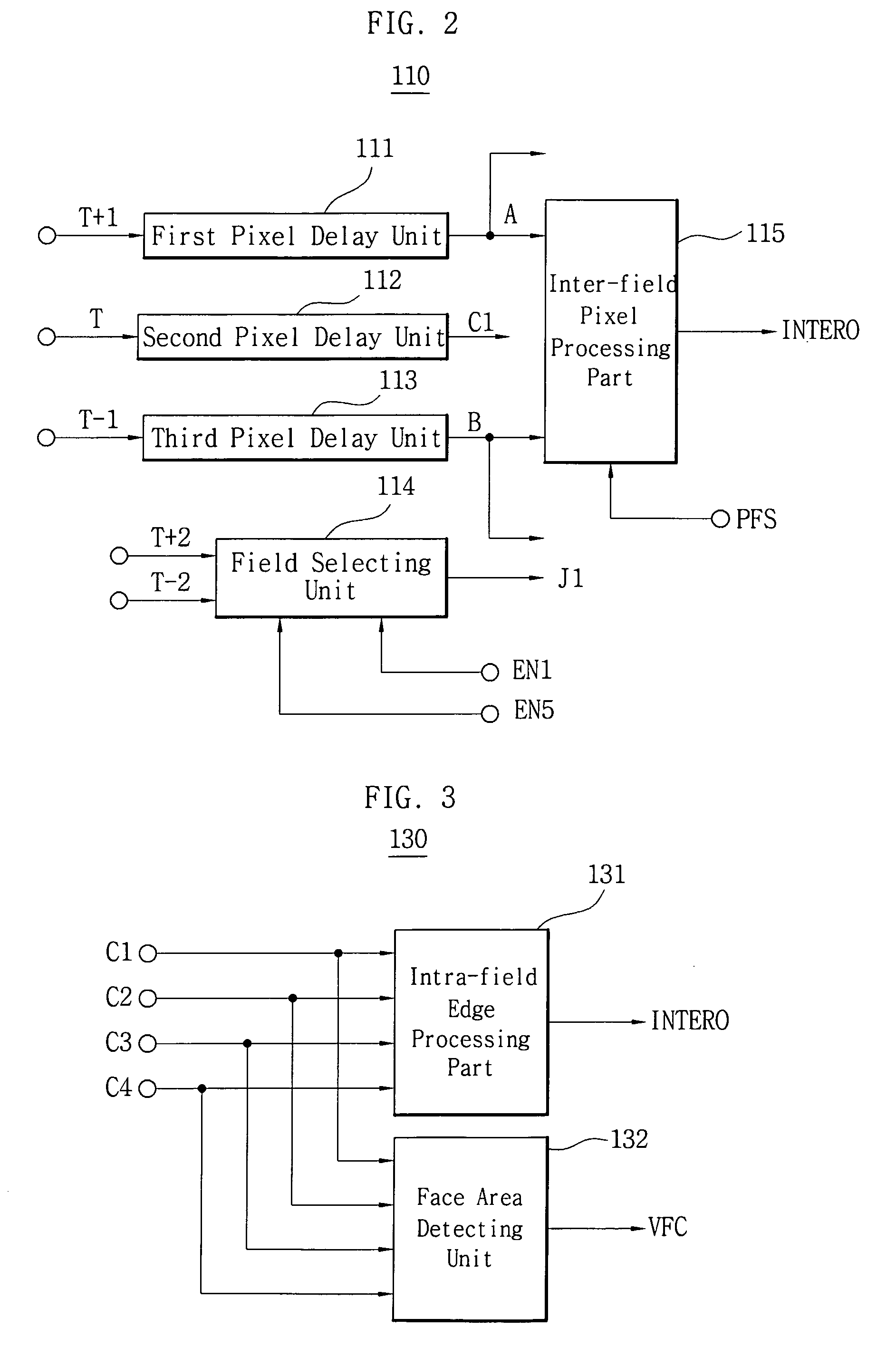

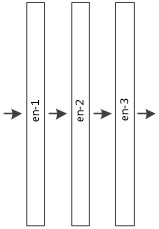

Apparatus and method for deinterlace video signal

InactiveUS7170562B2Improve picture qualityPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningInterlaced videoImaging processing

There is provided an image signal deinterlacing apparatus for converting an interlaced scanning image into a progressive scanning image. The deinterlacing apparatus includes: an intra-field pixel processing unit for detecting a face area and a to-be-interpolated data within a field by using pixels of a field disposed before two field from a current field; a motion value generating unit for detecting first to third motion values and first and second motion degree values; a history control unit for detecting a history value; a fast image processing unit for detecting a fast motion image; a film image processing unit for detecting a film image and a caption area and determining a to-be-interpolated field data; a still image processing unit for accumulating the first motion value and the second motion degree value to detect a still image; an inter-field noise image processing unit for detecting an adjacent inter-field noise image; a motion boundary maintenance image processing unit for detecting a motion boundary maintenance image; and a synthesizing unit for selectively interpolating the intra-field to-be-interpolated data, the before-one-field inter-field data and the before-three-field inter-field data according to the detection result.

Owner:MACRO IMAGE TECH

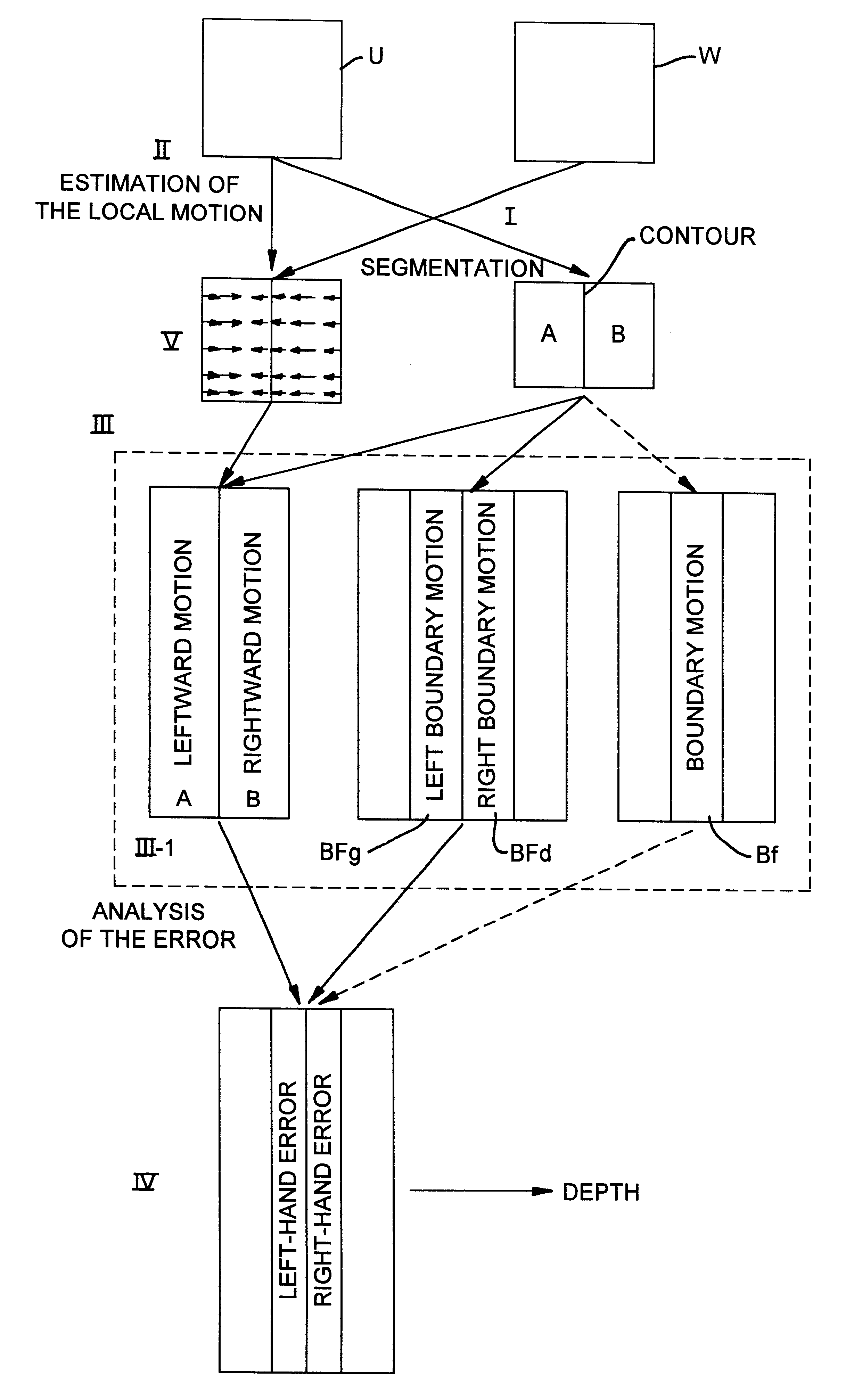

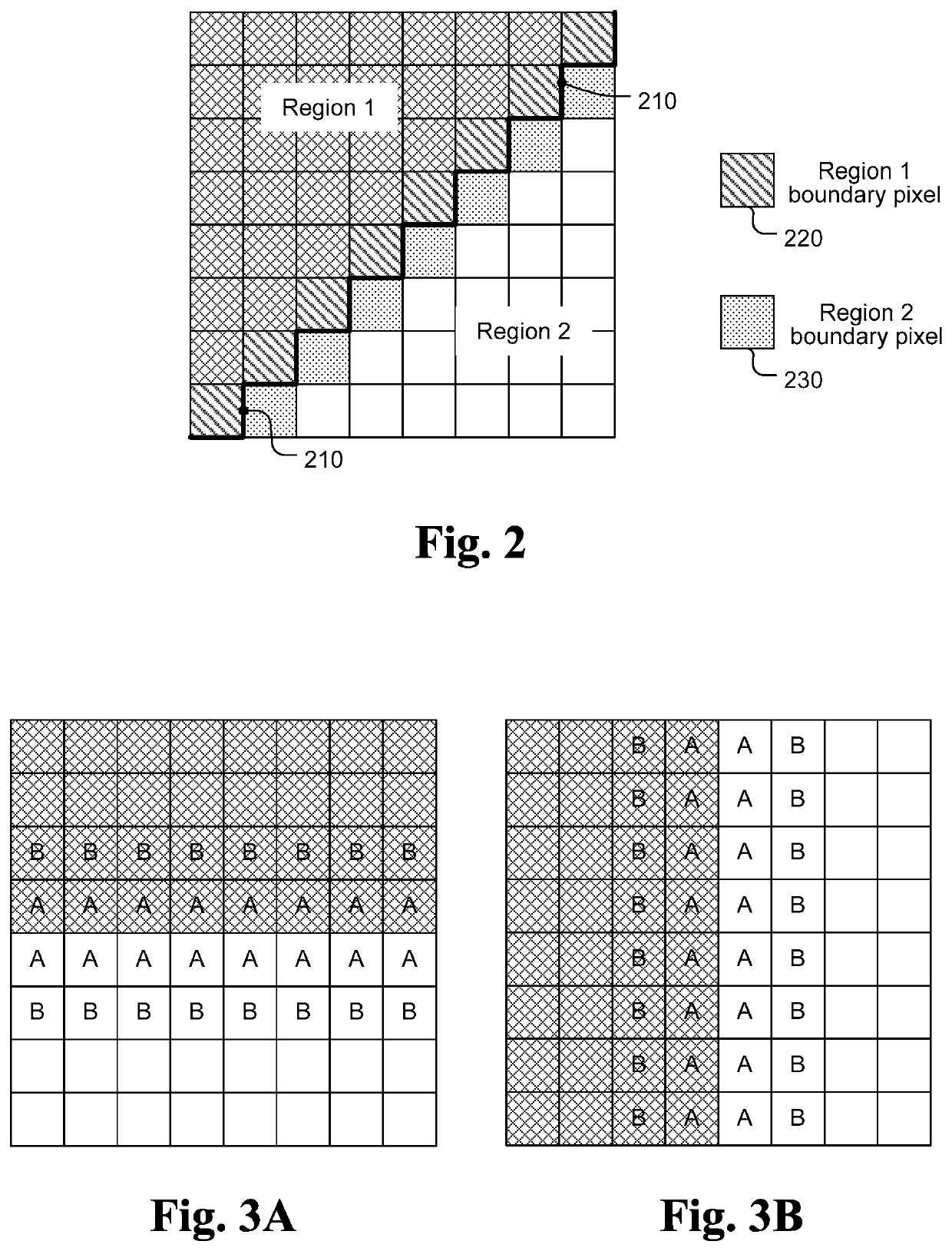

Method for the detection of the relative depth of objects in an image from a pair of images

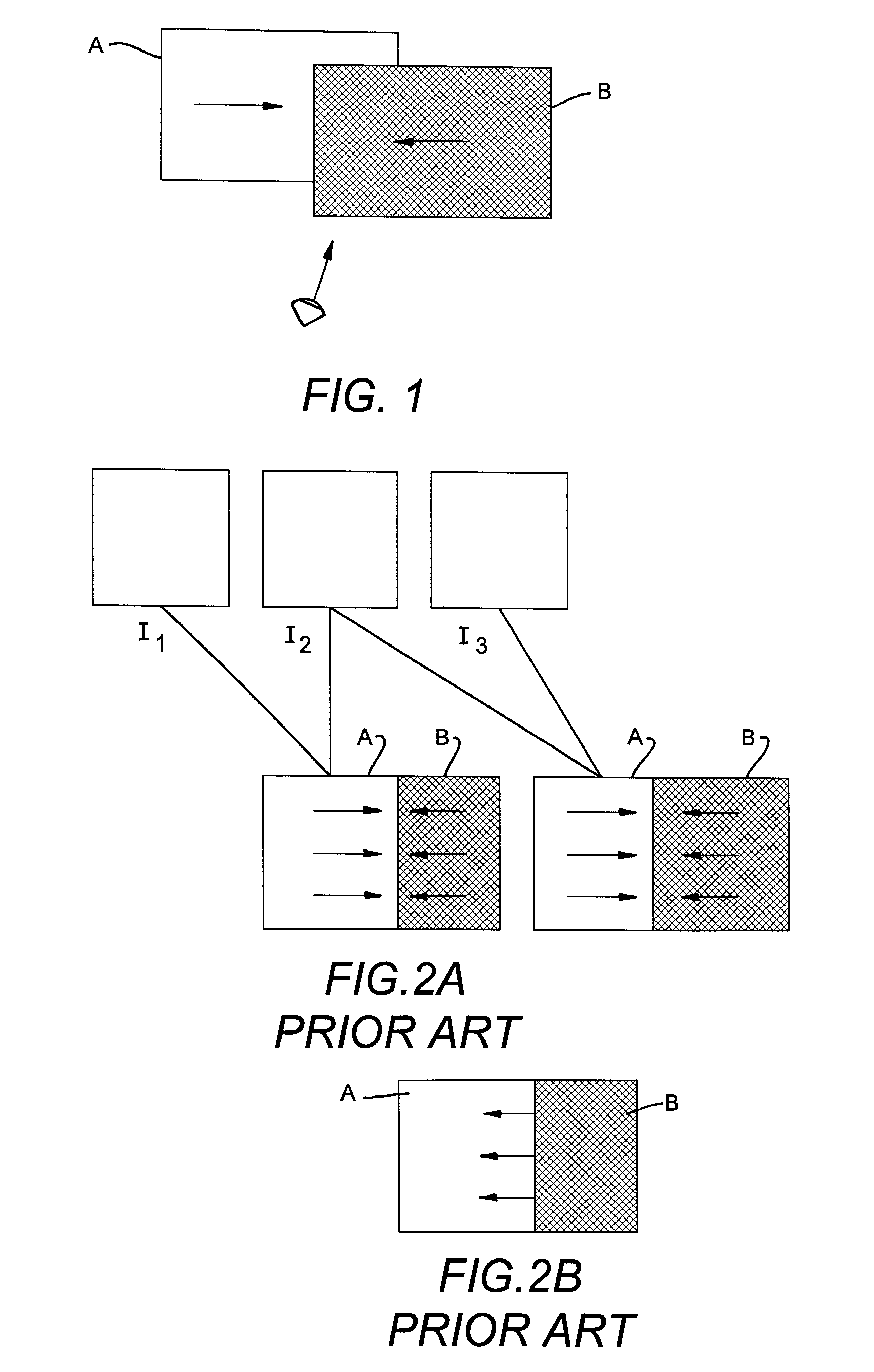

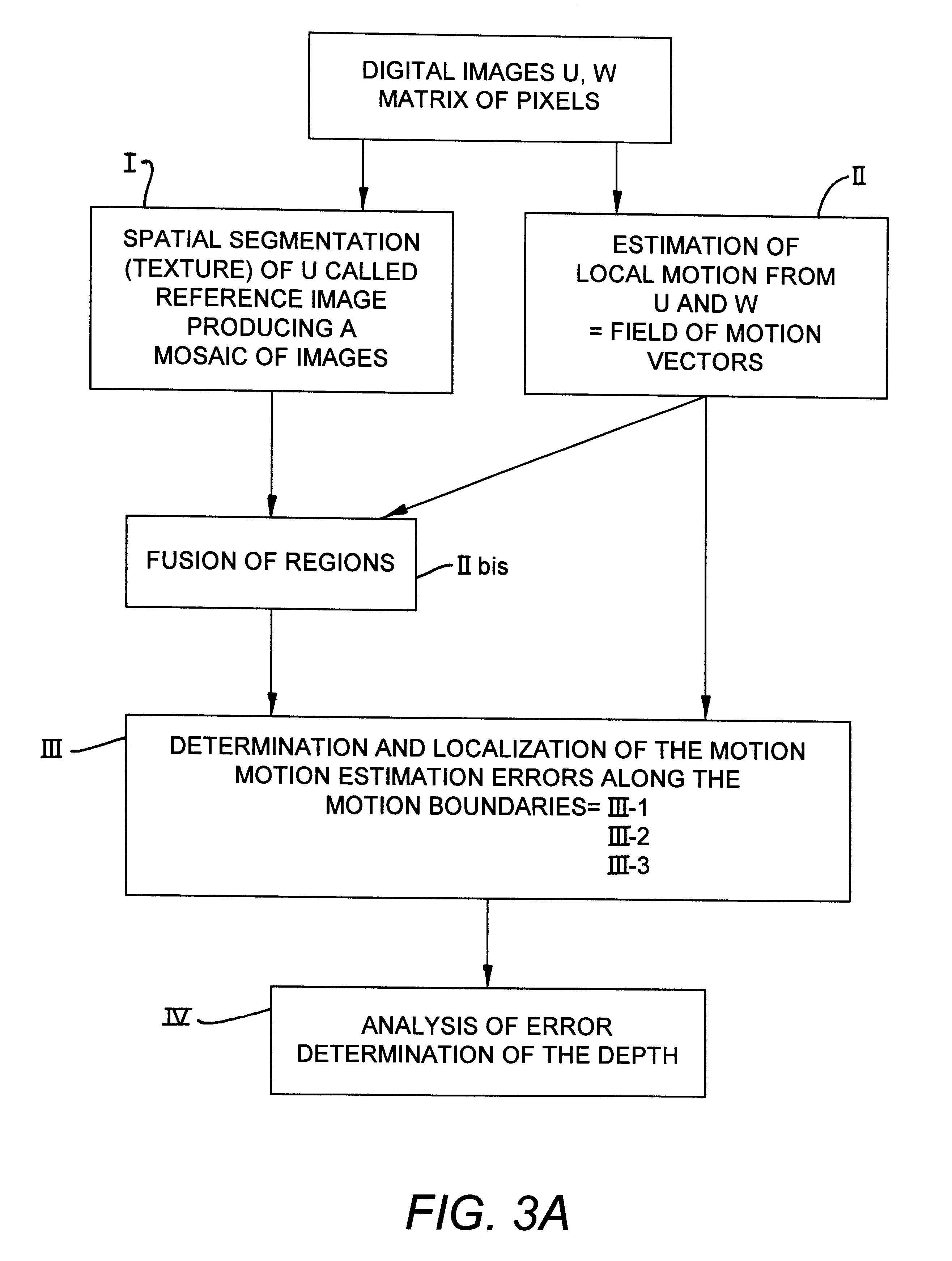

Disclosed is a method for the detection of the relative depth of two neighboring regions in relative motion with respect to each other in two images obtained from different shots of a scene, in order to know the composition of the scene. The method consists in carrying out a spatial segmentation of one of the images, called a reference image; a local estimation of the motion between the two images, the resultant vector field of which is called local motion; a determining of the motion estimation errors along the motion boundaries; and an analysis of the localization of the motion estimation errors along the motion boundaries to conclude that a region A is in front of a region B when the motion estimation error along the boundary is chiefly localized on the side B of this boundary.

Owner:HANGER SOLUTIONS LLC

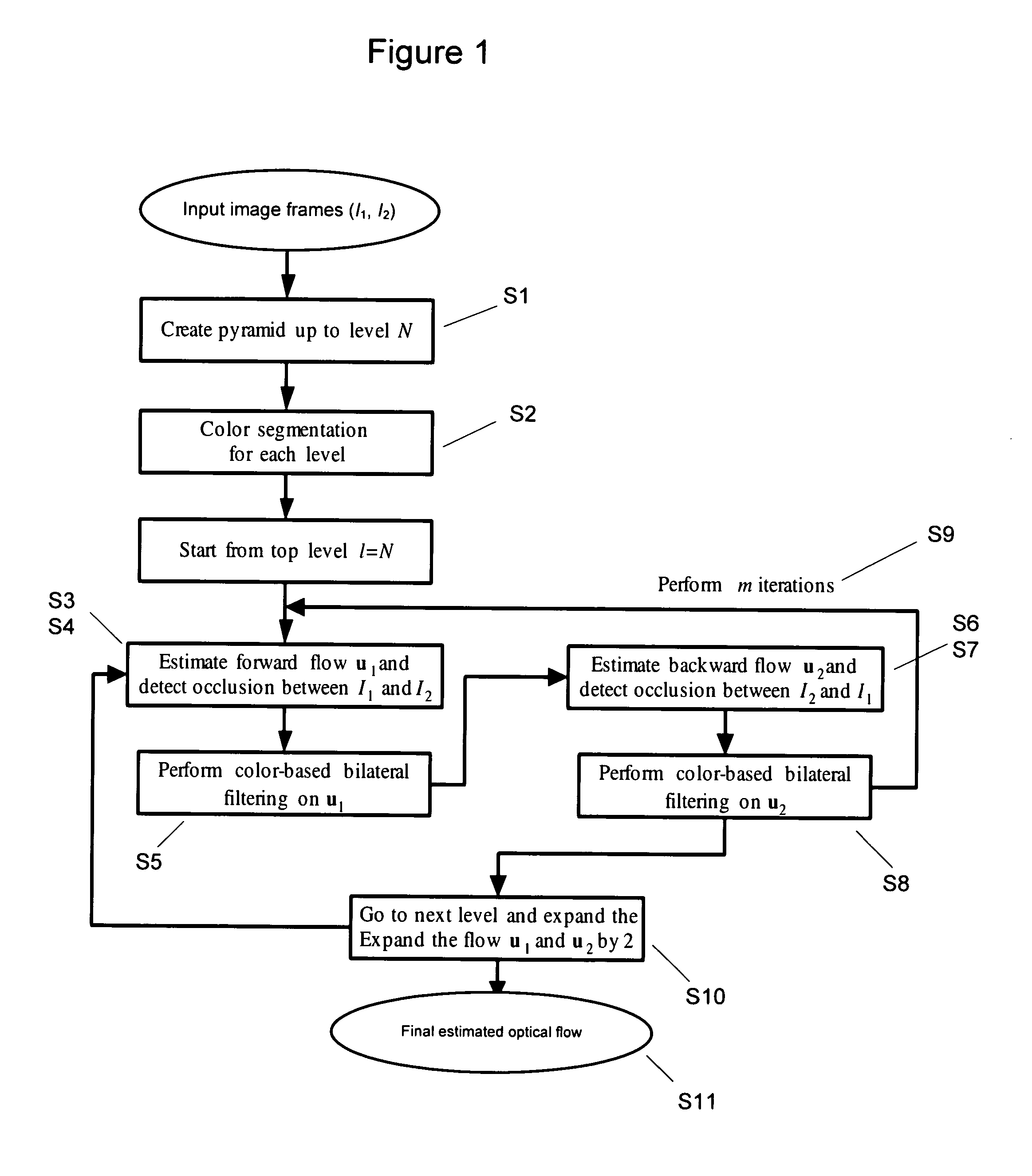

Method and system for segment-based optical flow estimation

InactiveUS20070092122A1Reduce transmissionEfficiently breaks the spatial coherence over the motion boundariesTelevision system detailsImage analysisOcclusion detectionPyramid

The methods and systems of the present invention enable the estimation of optical flow by performing color segmentation and adaptive bilateral filtering to regularize the flow field to achieve a more accurate flow field estimation. After creating pyramid models for two input image frames, color segmentation is performed. Next, starting from a top level of the pyramid, additive flow vectors are iteratively estimated between the reference frames by a process including occlusion detection, wherein the symmetric property of backward and forward flow is enforced for the non-occluded regions. Next, a final estimated optical flow field is generated by expanding the current pyramid level to the next lower level and the repeating the process until the lowest level is reached. This approach not only generates efficient spatial-coherent flow fields, but also accurately locates flow discontinuities along the motion boundaries.

Owner:SRI INTERNATIONAL

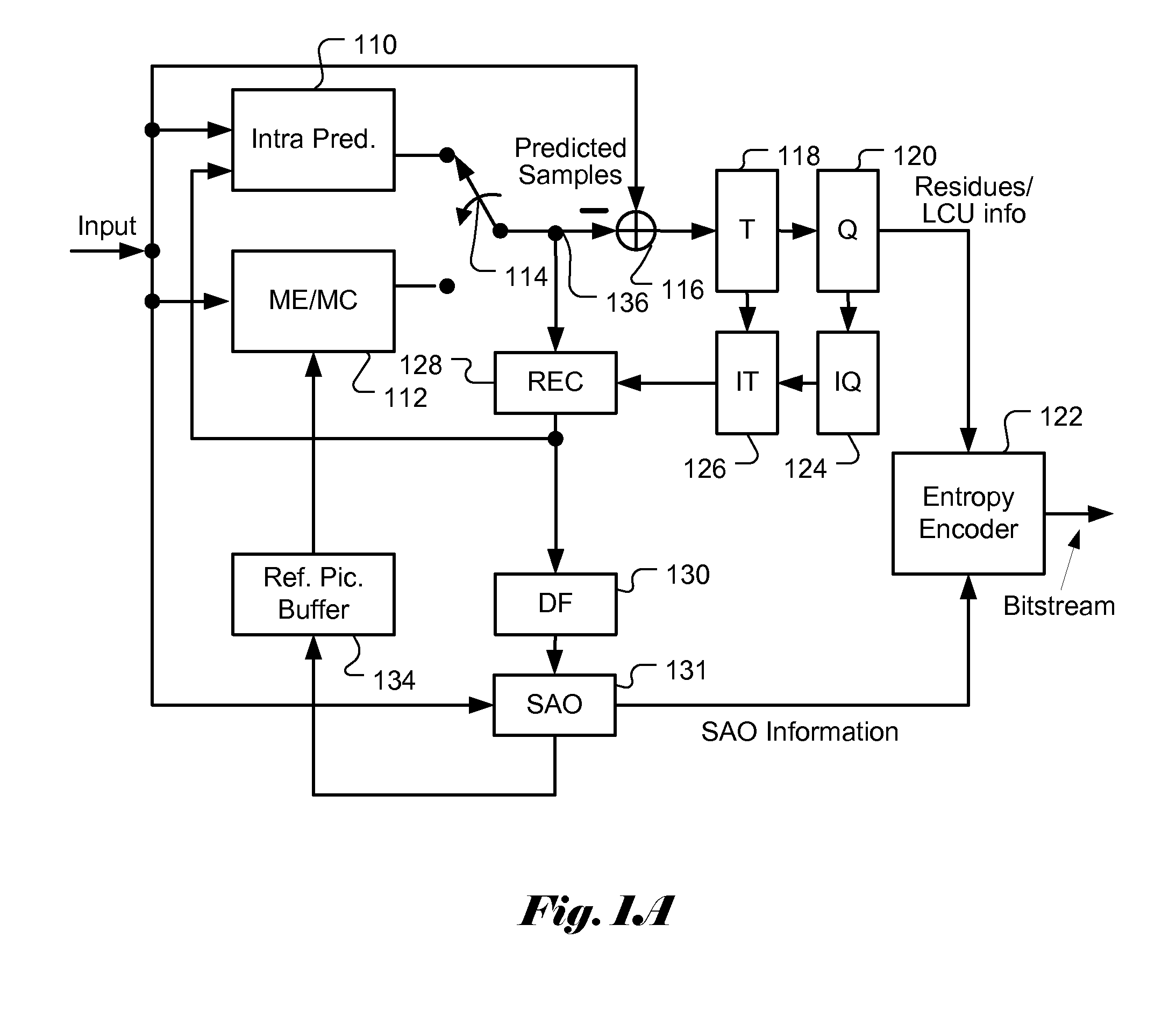

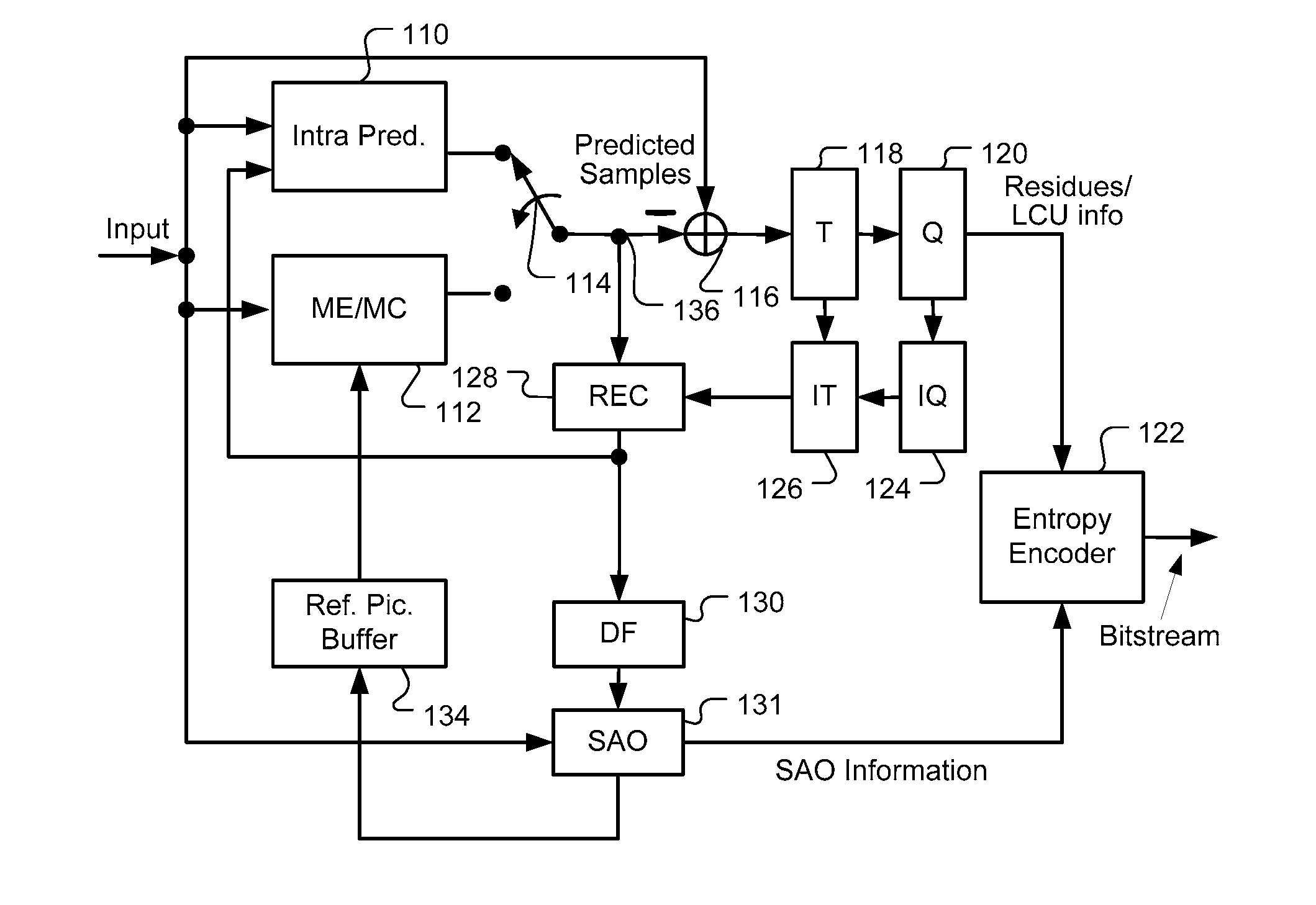

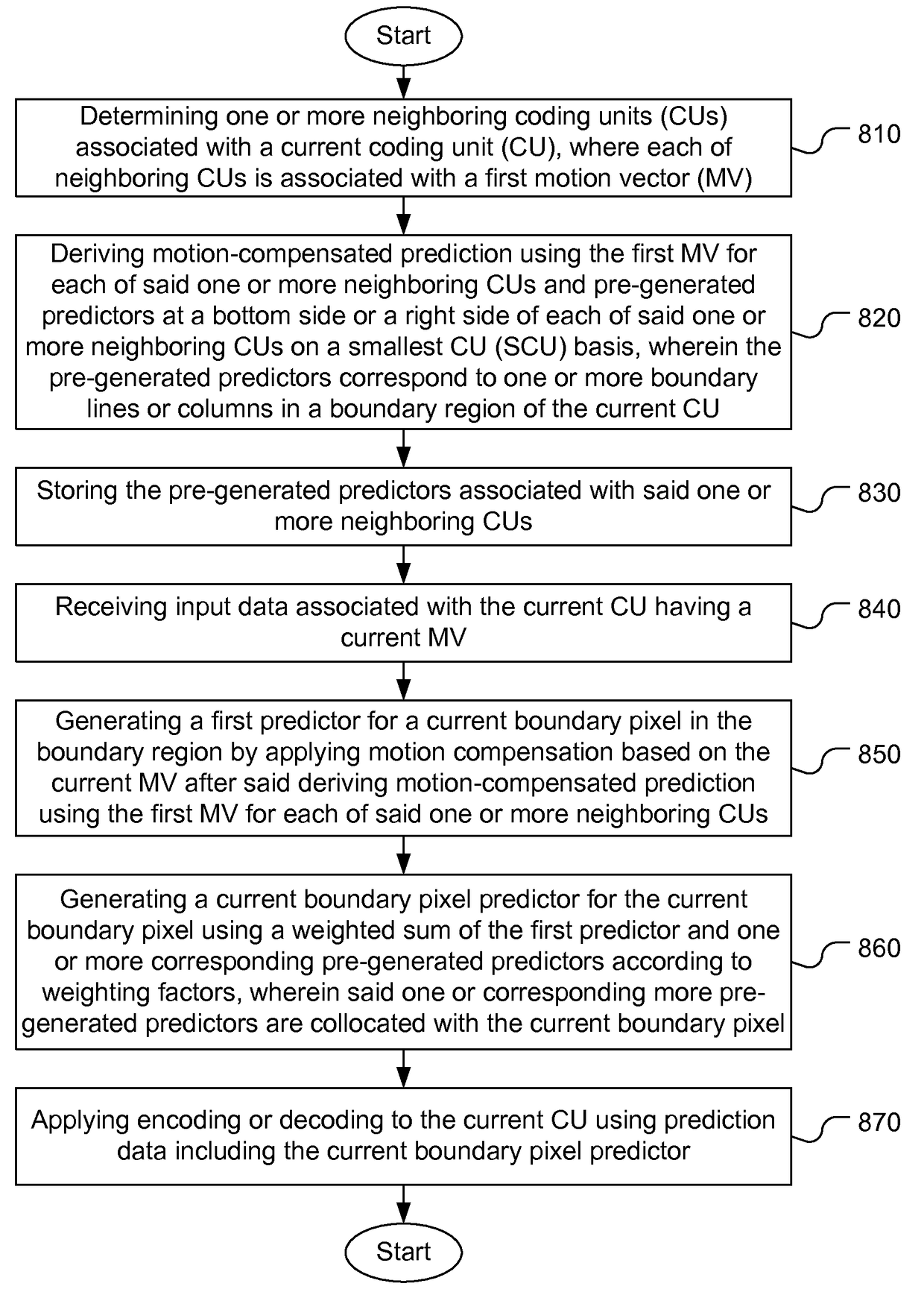

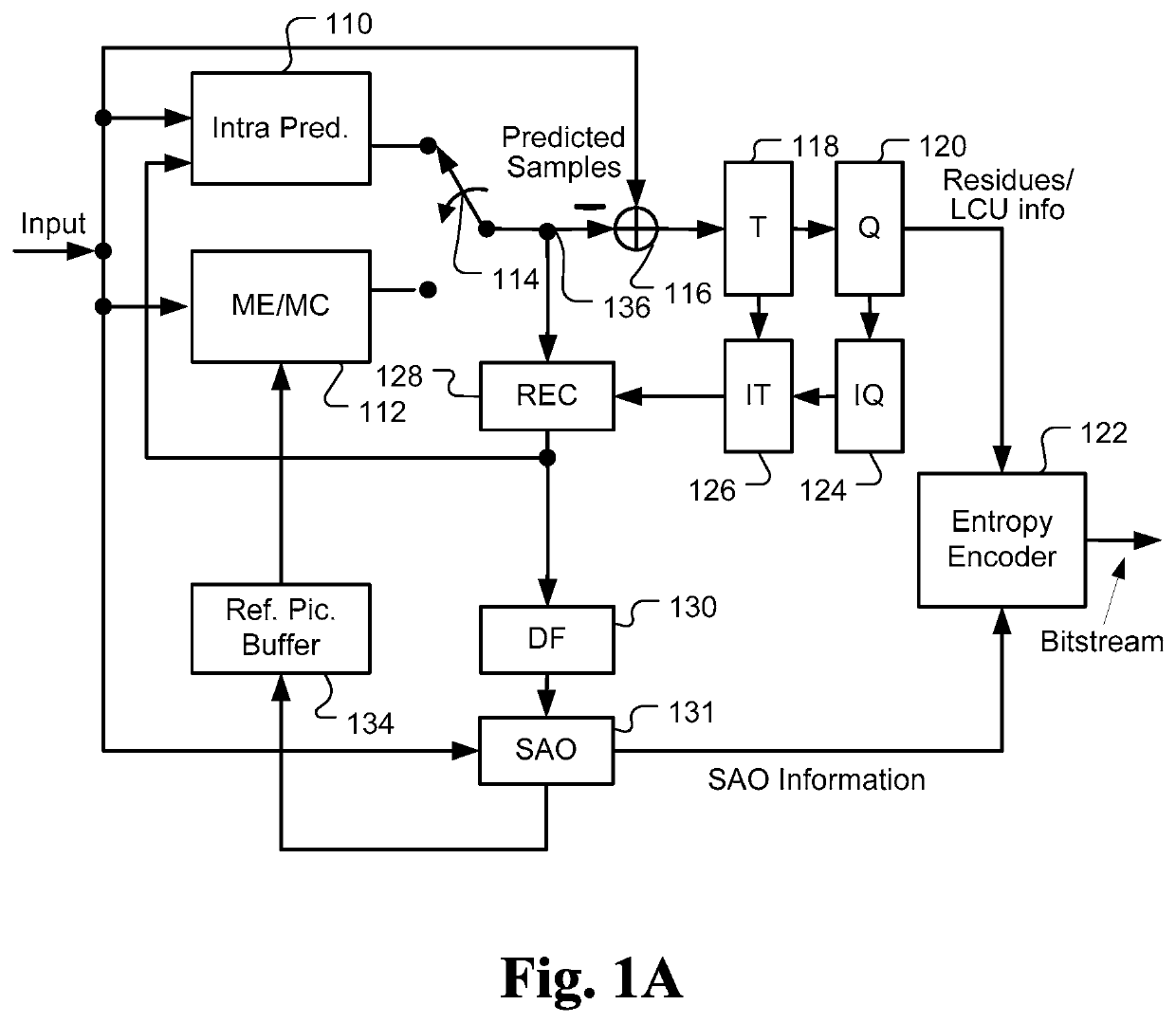

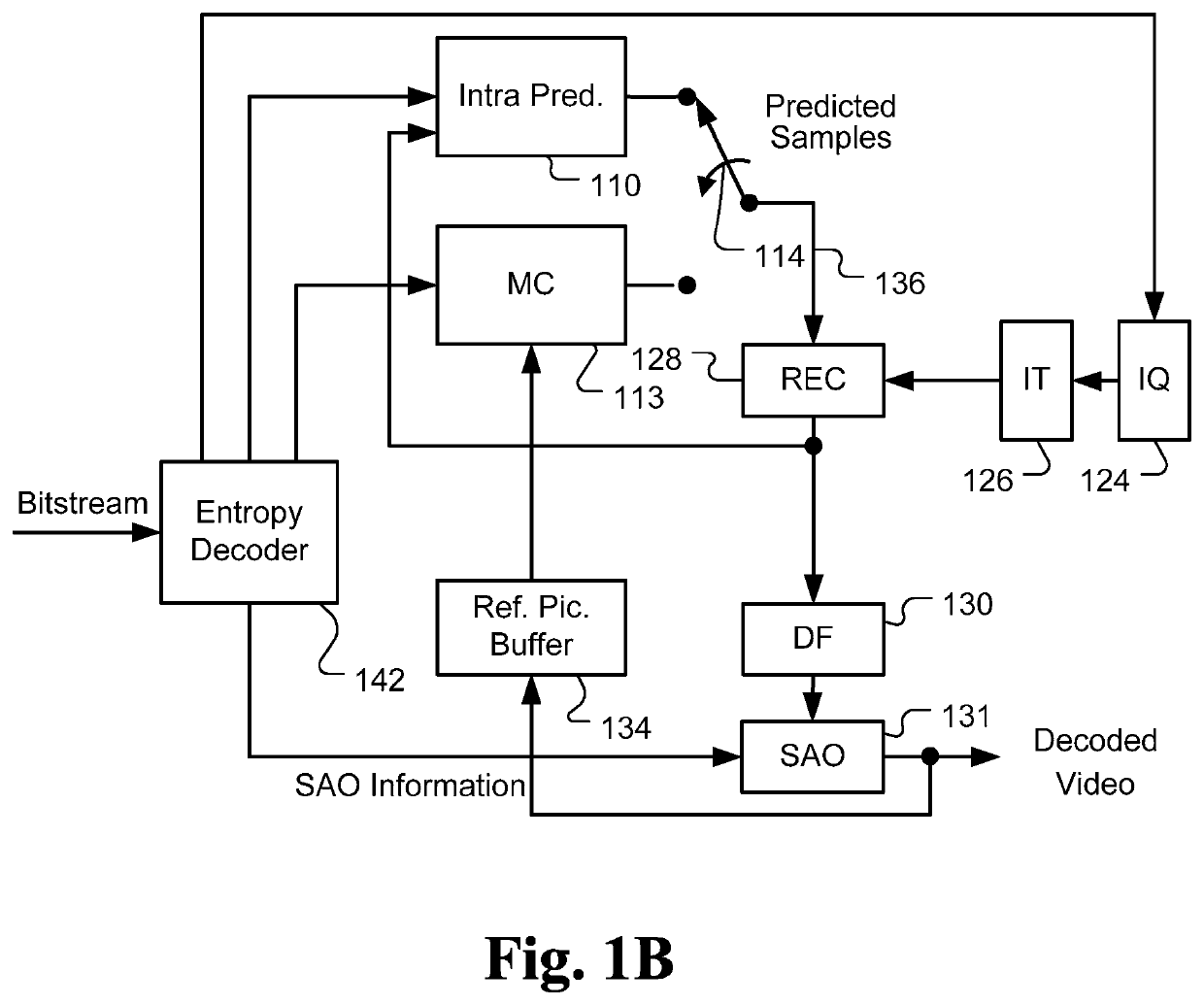

Method and Apparatus for Fine-grained Motion Boundary Processing

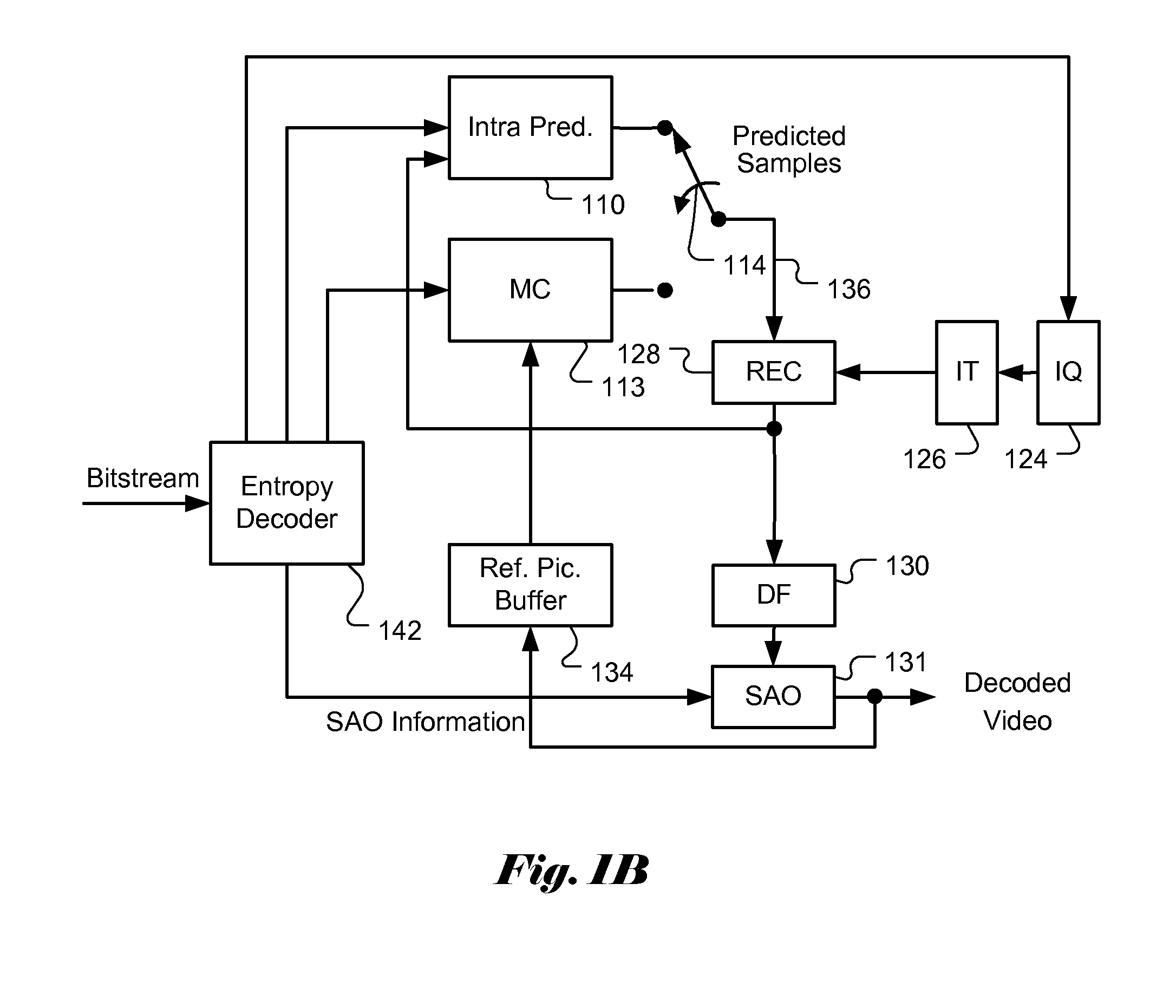

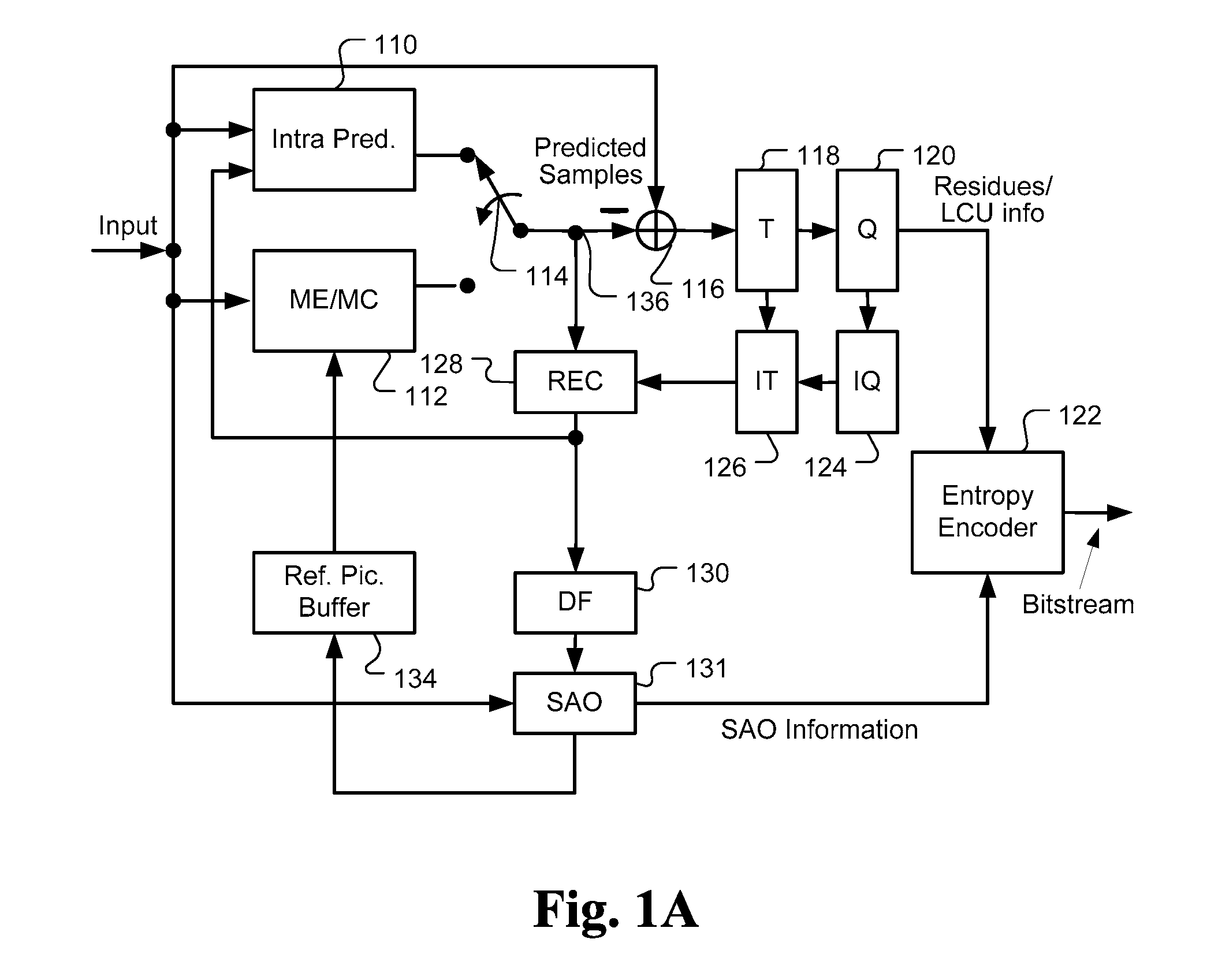

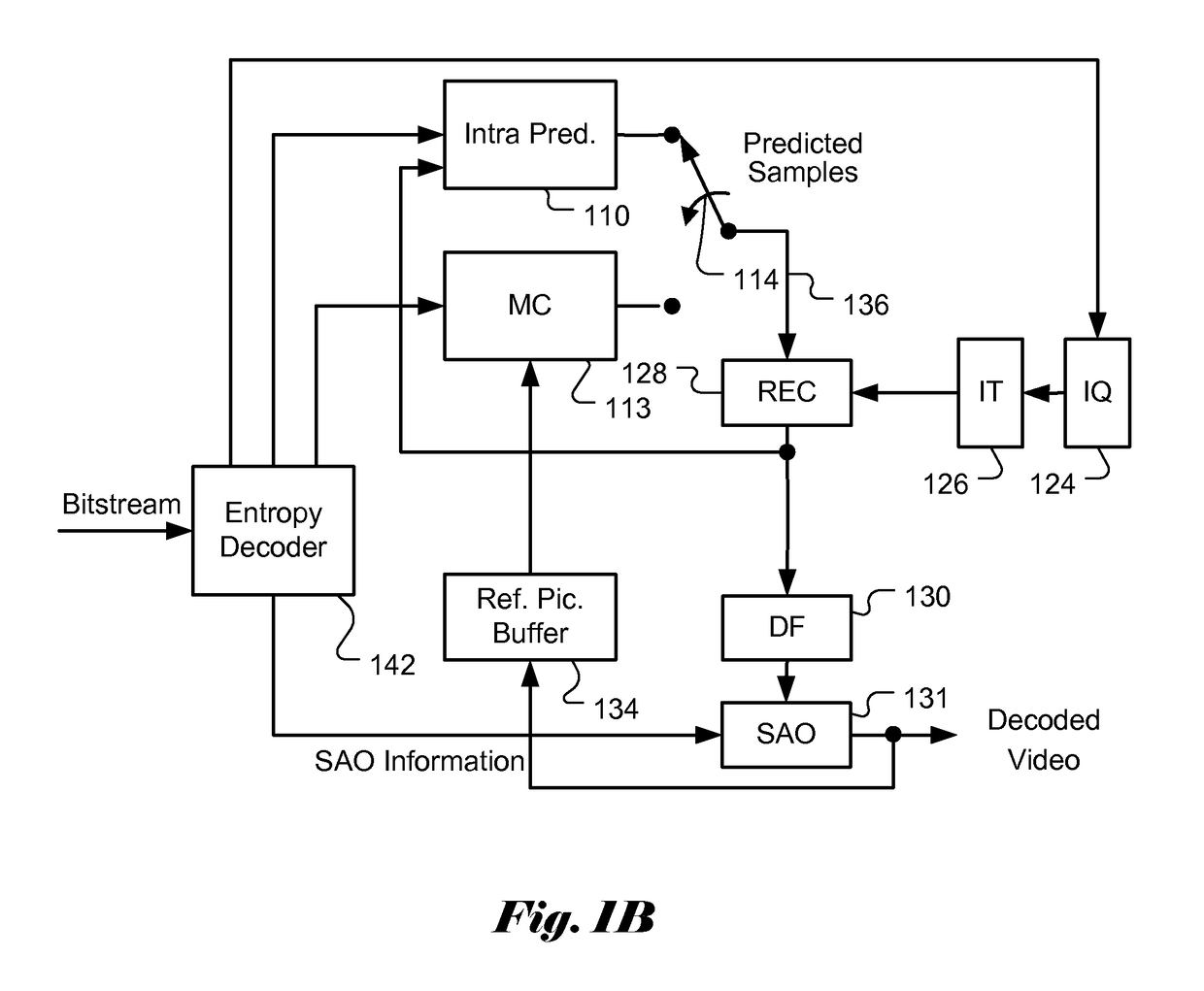

ActiveUS20150163509A1Color television with pulse code modulationColor television with bandwidth reductionCombined useComputer science

A method and apparatus for deriving fine-grained motion compensated prediction of boundary pixels in a video coding system are disclosed. Embodiments of the present invention determine one or more neighboring coding units (CUs) adjacent to a current coding unit (CU). For each neighboring CU, motion-compensated prediction is derived for each neighboring CU using the MV of the neighboring CU. The pre-generated predictors at a bottom side or a right side of each neighboring CUs are derived and stored on a smallest CU (SCU) basis. The pre-generated predictors and the motion compensated predictor for a current boundary pixel are combined using weighting factors to form a final predictor for the current pixel.

Owner:XUESHAN TECH INC

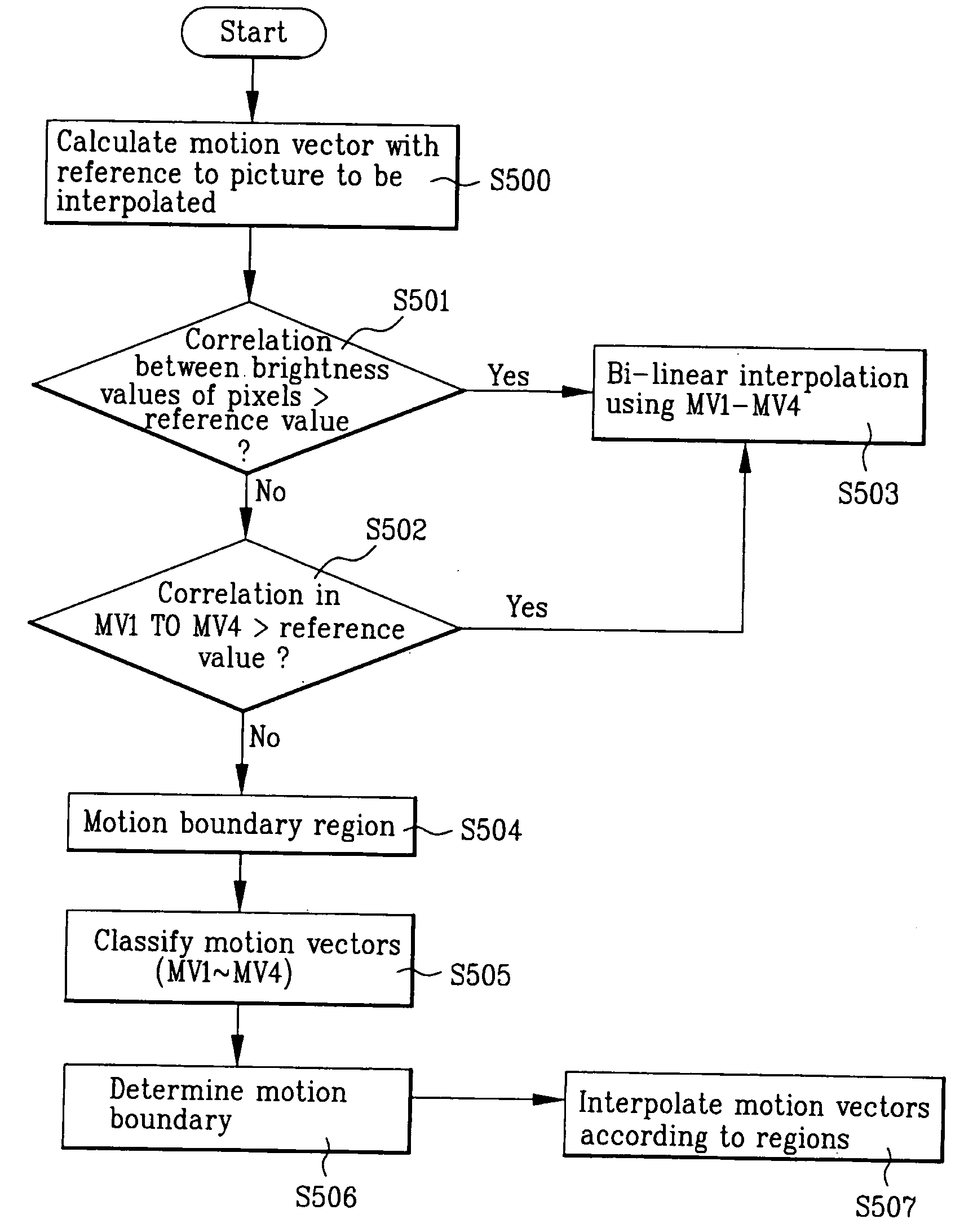

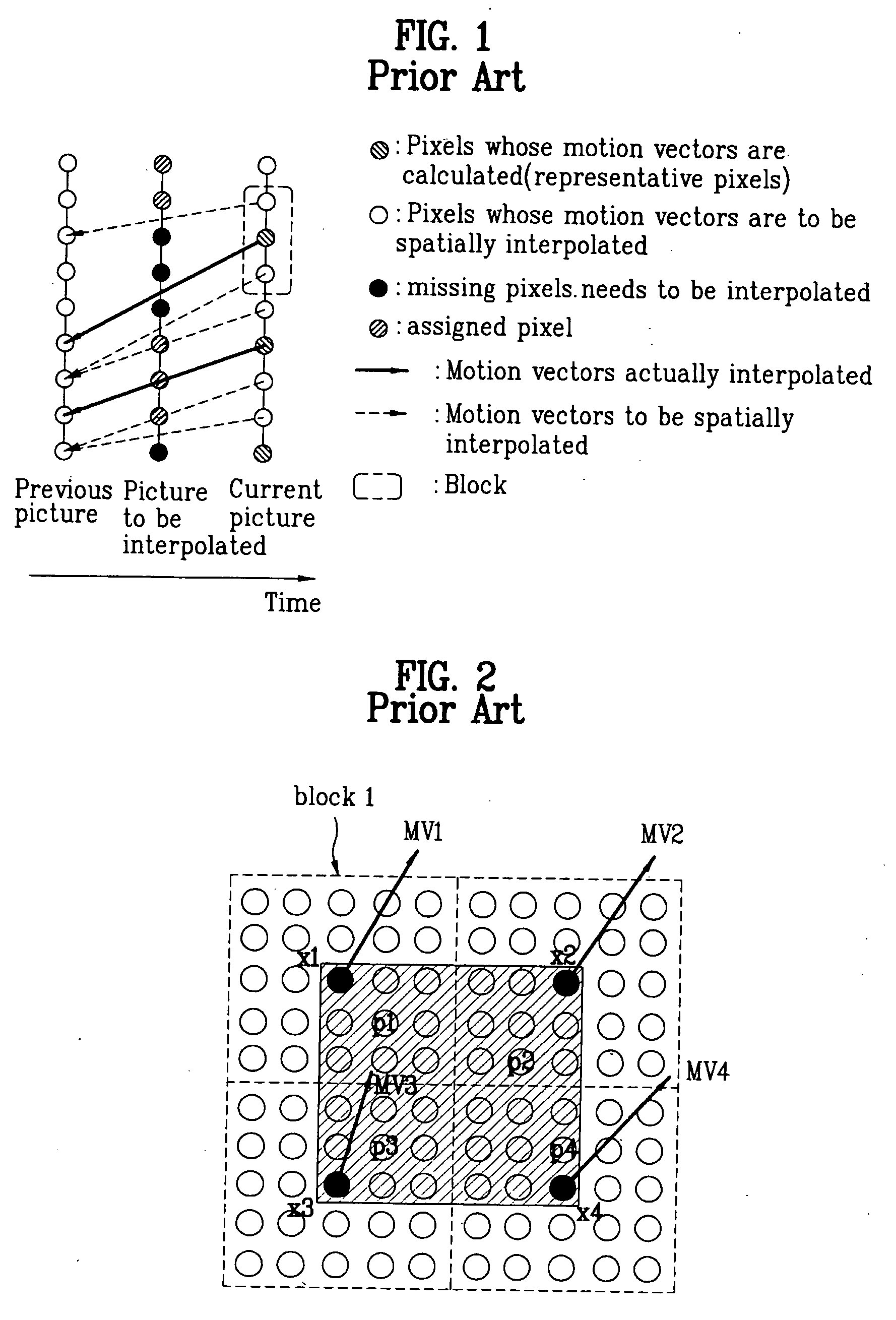

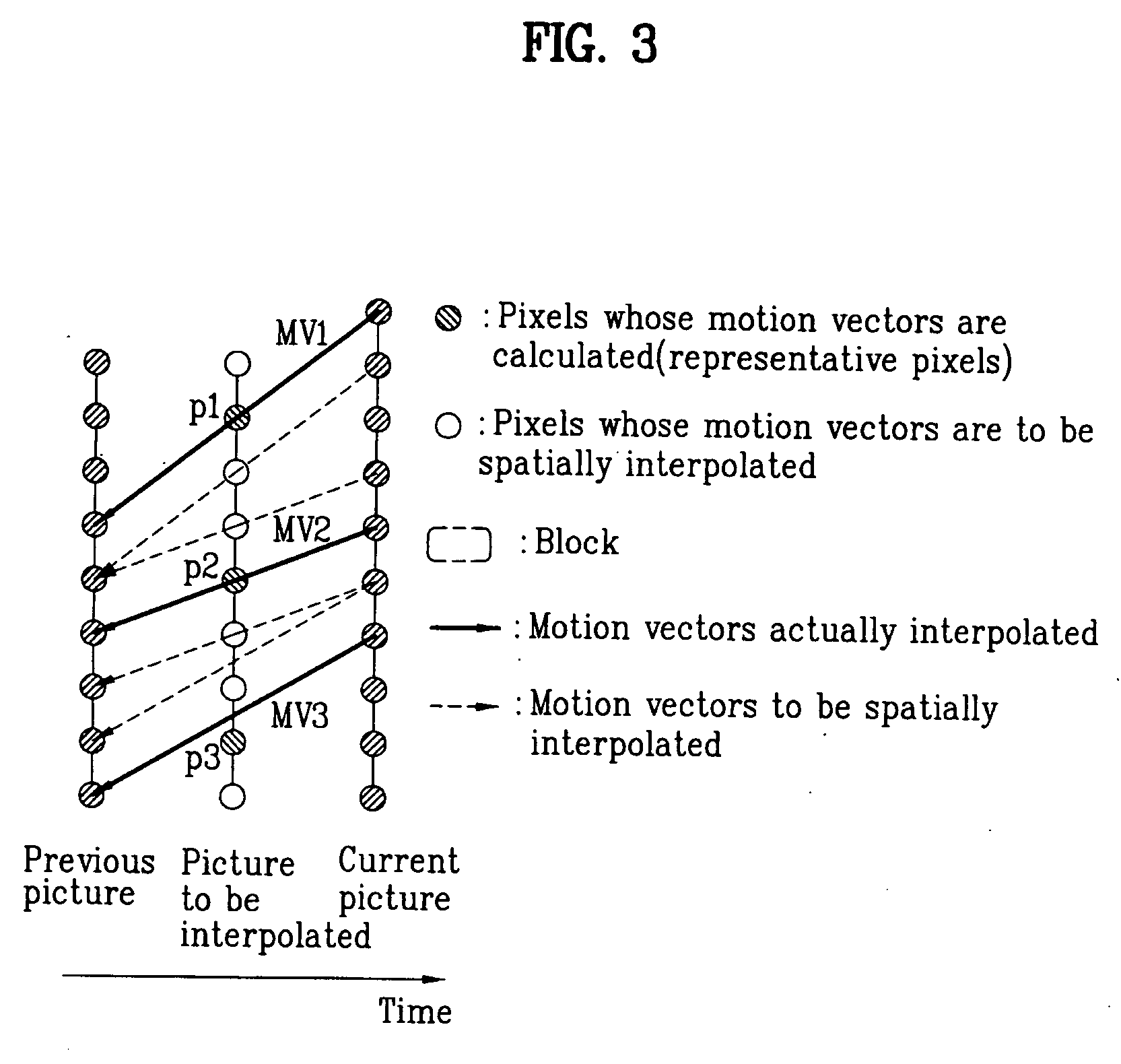

Method of converting frame rate of video signal based on motion compensation

InactiveUS20050195324A1Eliminate the problemPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningHigh frame rateMotion vector

There is provided a method of converting frame rate of video signal based on motion estimation, which is adapted to convert an arbitrary video signal into a video signal having higher frame rate than the arbitrary video signal. The method includes the steps of: estimating a plurality of motion vectors based on block unit with reference to a picture to be interpolated; and if a current pixel exists in a motion boundary according to a correlation between brightness values of pixels with respect to motion vectors based on pixel unit, classifying and interpolating the plurality of estimated motion vectors based on the block unit according to motion boundary region's.

Owner:LG ELECTRONICS INC

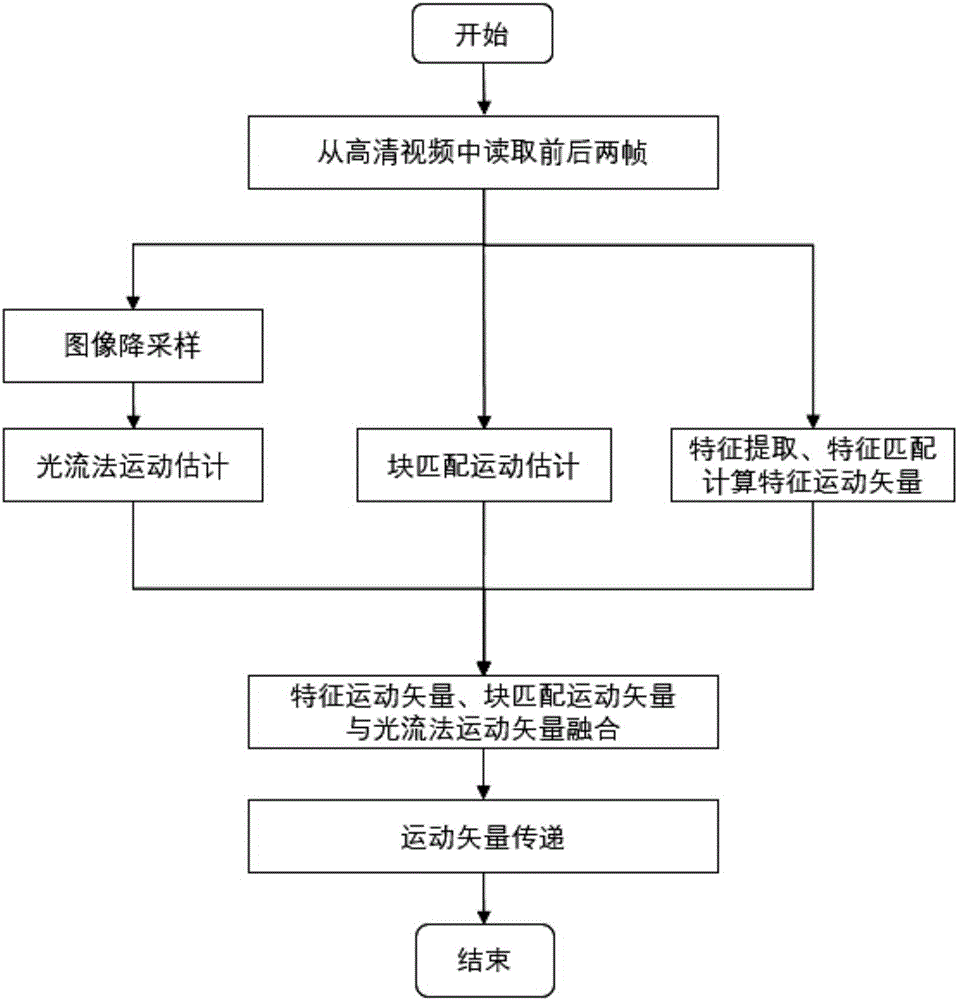

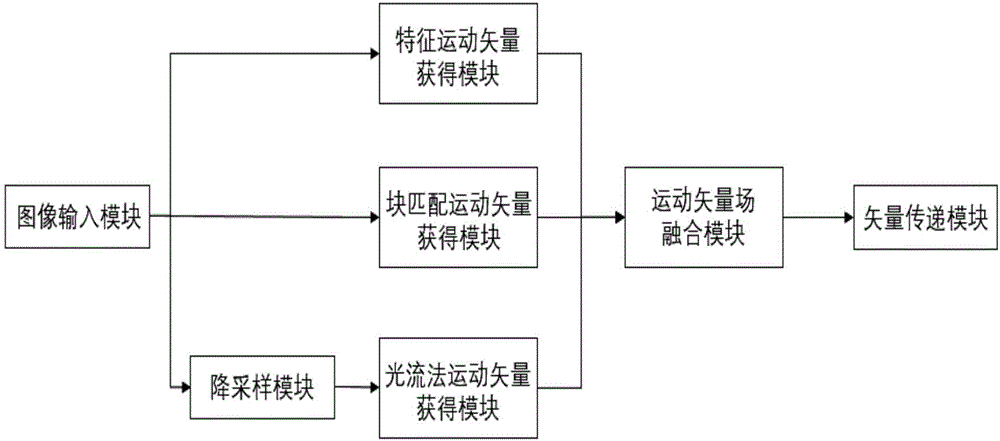

Multi-information integration-based frame rate up-conversion motion estimation method and system

ActiveCN106210449AThe motion vector field is basically smoothMotion vector field smoothTelevision system detailsColor television detailsObject motionMotion vector

The present invention discloses a multi-information integration-based frame rate up-conversion motion estimation method and system. The method comprises the steps of reading a previous frame image and a next frame image; performing down-sampling on the previous frame image and the next frame image; performing optical flow method-based motion estimation on the images experienced down-sampling; performing block match motion estimation on an original image; extracting SIFT characteristics of the previous and the next frame images; calculating a characteristic vector and performing characteristic match, so as to obtain a motion vector of characteristic match; and integrating the block match motion vector, the motion vector of characteristic match, and the motion vector of the optical flow method, and performing motion vector transmission. Compared with traditional block match-based motion estimation algorithm, the method greatly improves the accuracy. Compared with common optical flow estimation algorithm, the method can better maintain the motion vector of a small object and a motion boundary vector.

Owner:SHANGHAI JIAO TONG UNIV

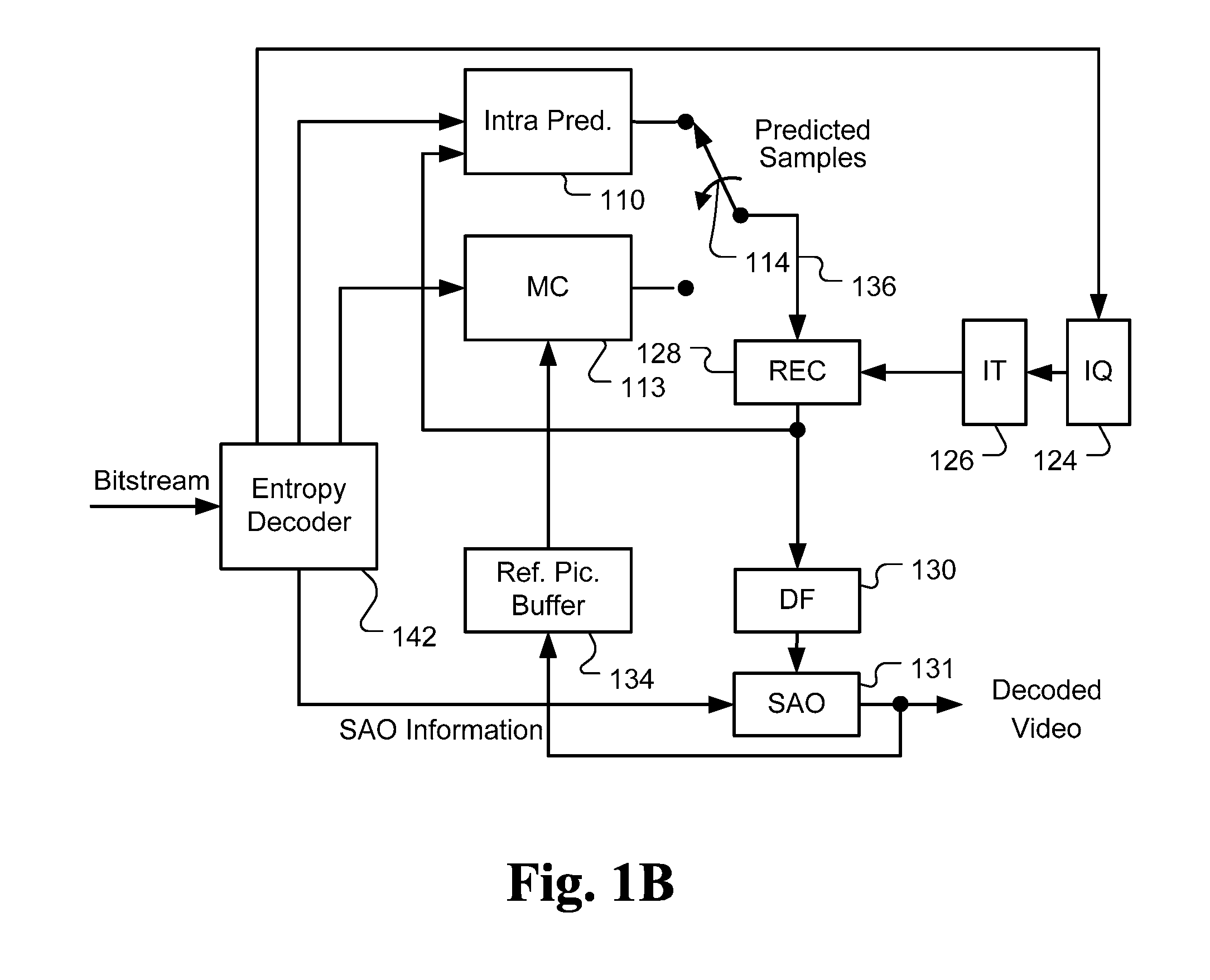

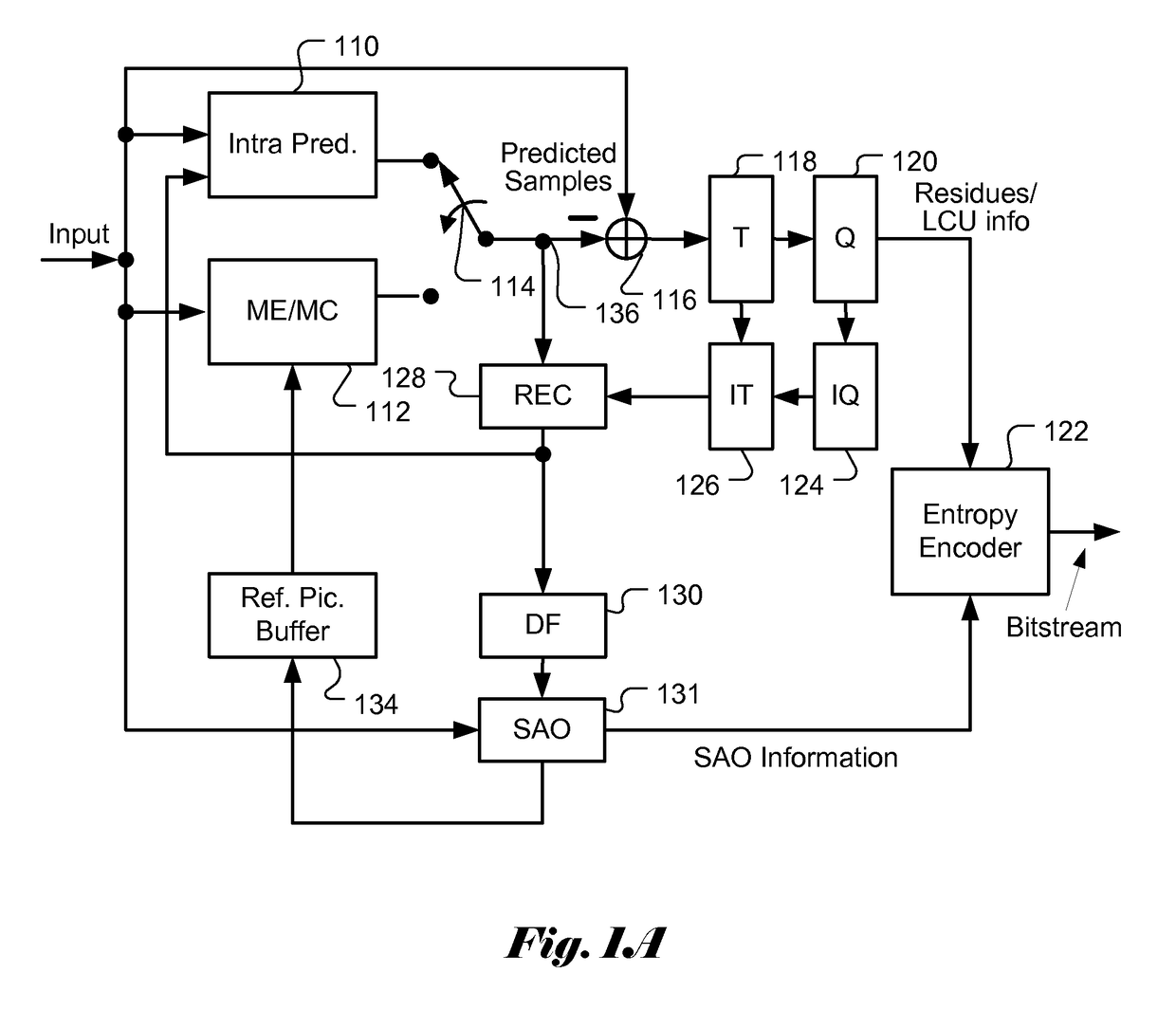

Method and Apparatus for Motion Boundary Processing

A method and apparatus for deriving motion compensated prediction for boundary pixels in a video coding system are disclosed. Embodiments of the present invention determine a current motion vector (MV) and one or more neighboring MVs corresponding to an above MV, a left MV, or both the above MV and the left MV. A first predictor for a current boundary pixel in a boundary region of the current CU is generated by applying motion compensation based on the current MV and a first reference picture pointed by the current MV. One or more second predictors for the current boundary pixel are generated by applying the motion compensation based on the neighboring MVs and reference pictures pointed by the neighboring MVs. A current boundary pixel predictor for the current boundary pixel is then generated using a weighted sum of the first predictor and the second predictors according to weighting factors.

Owner:MEDIATEK INC

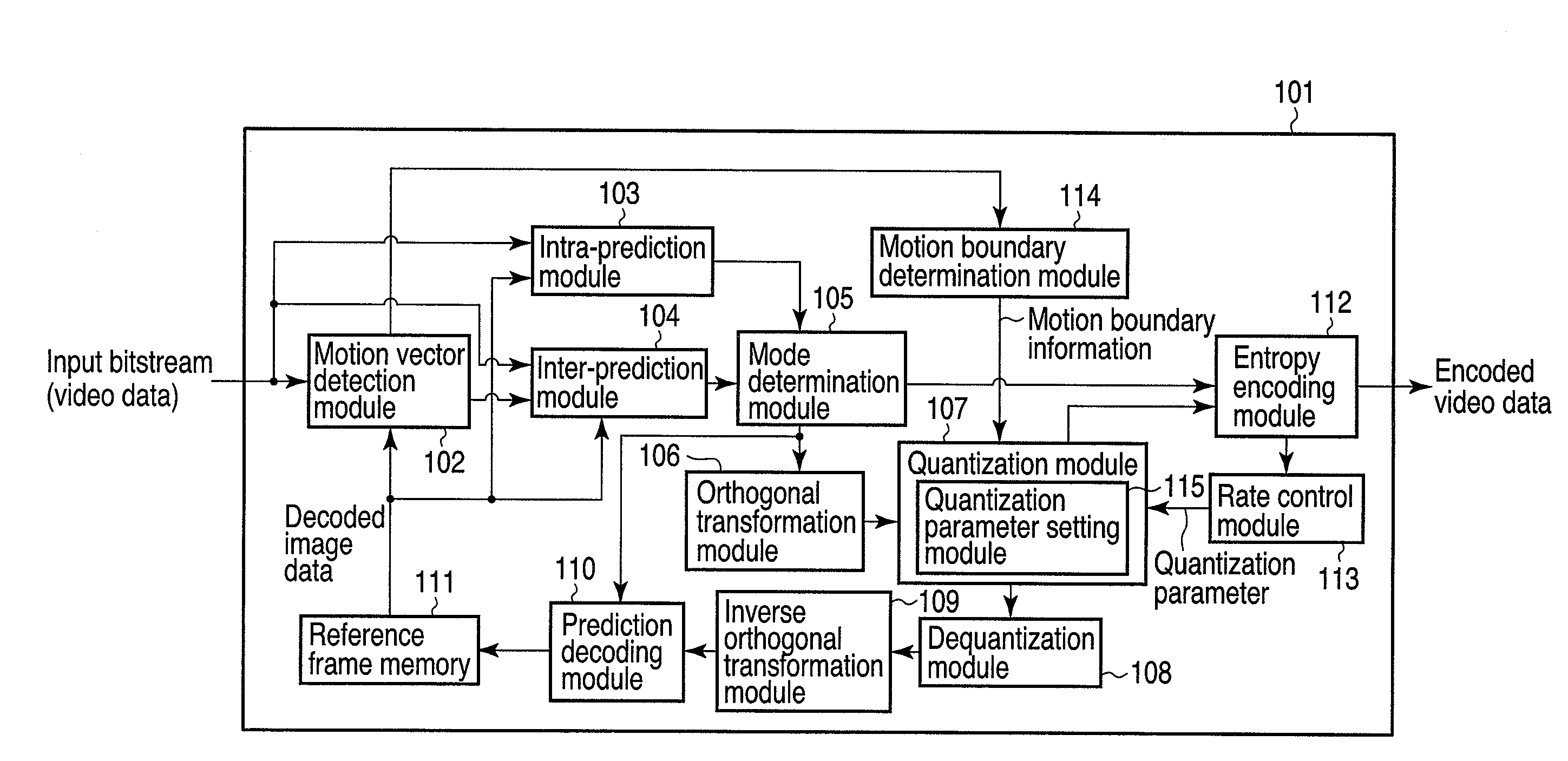

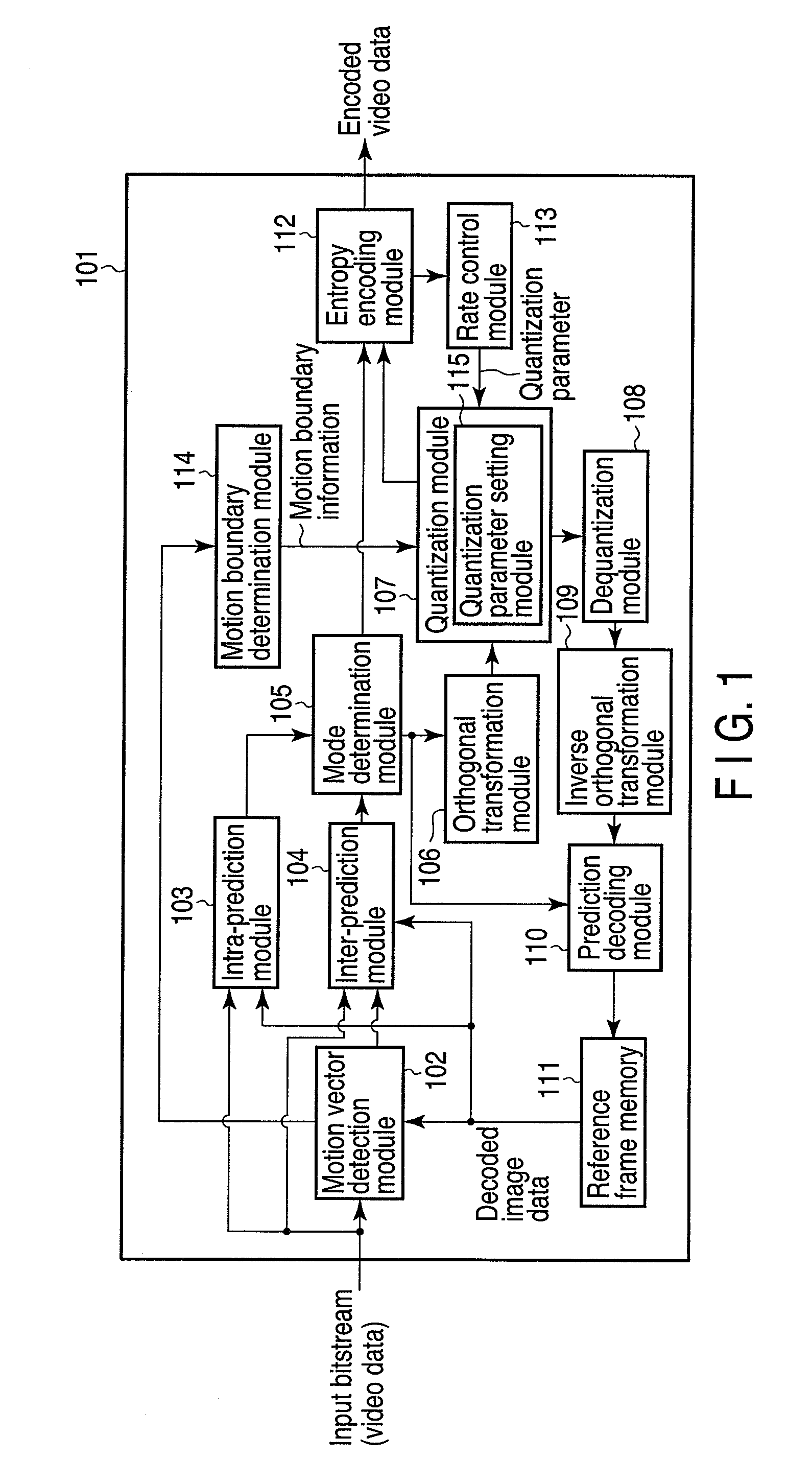

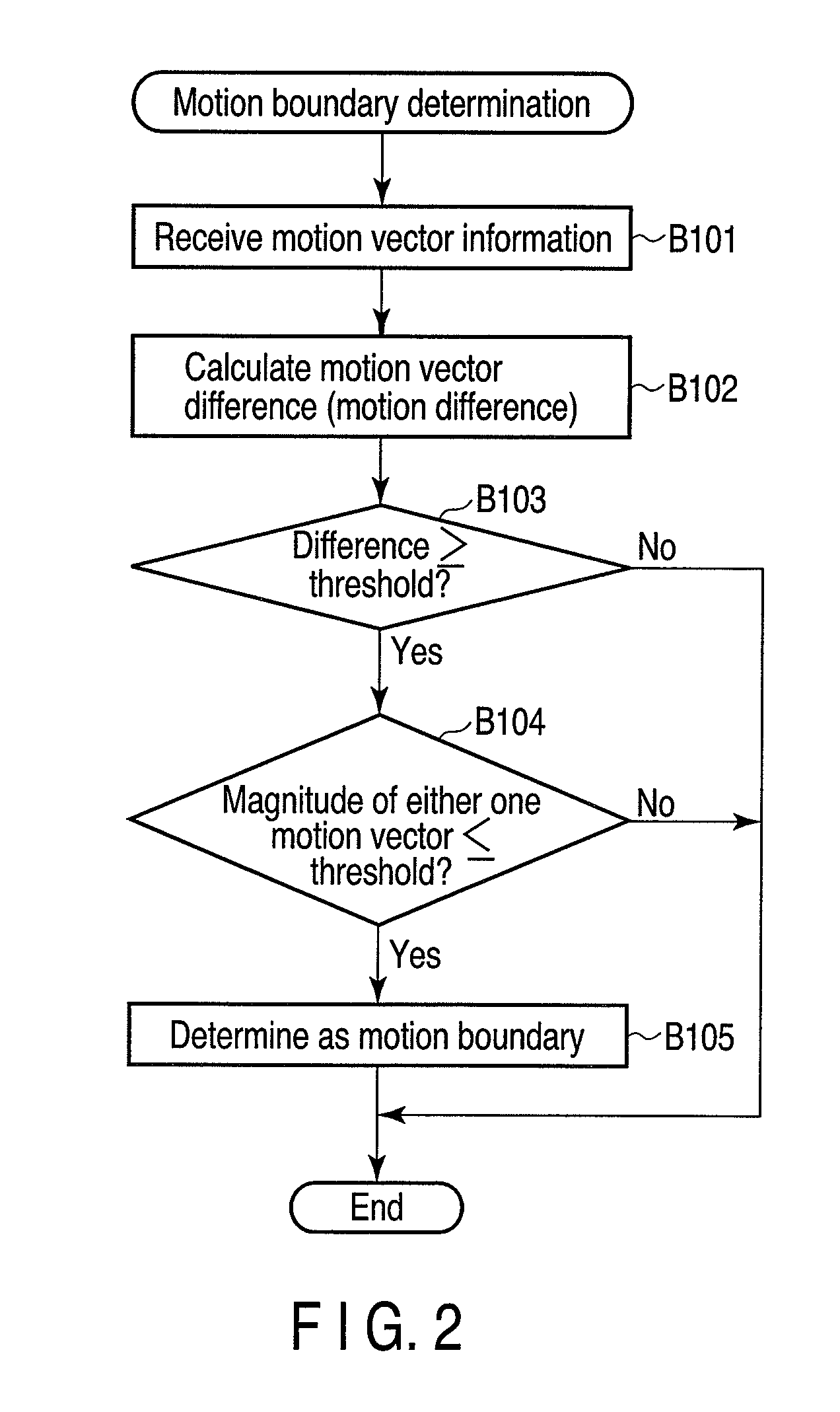

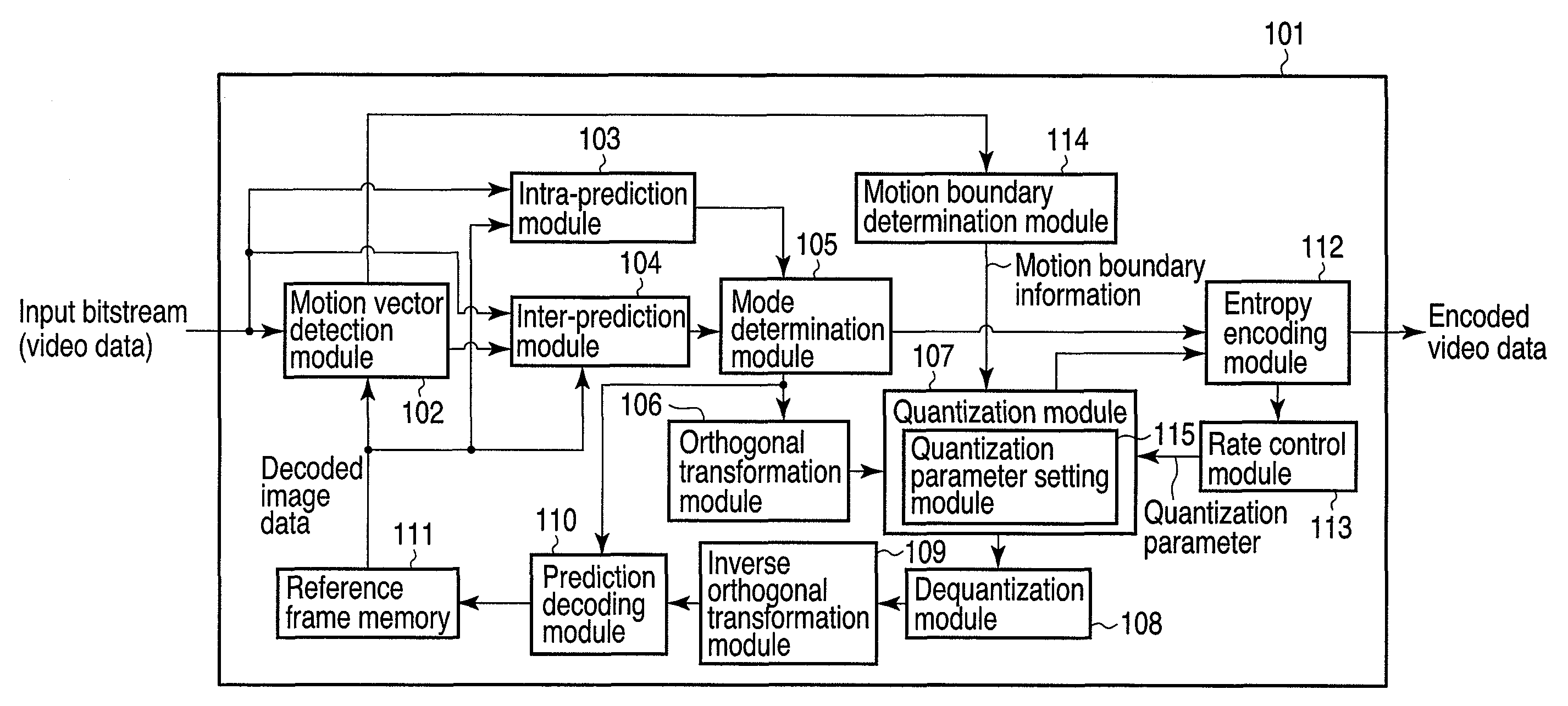

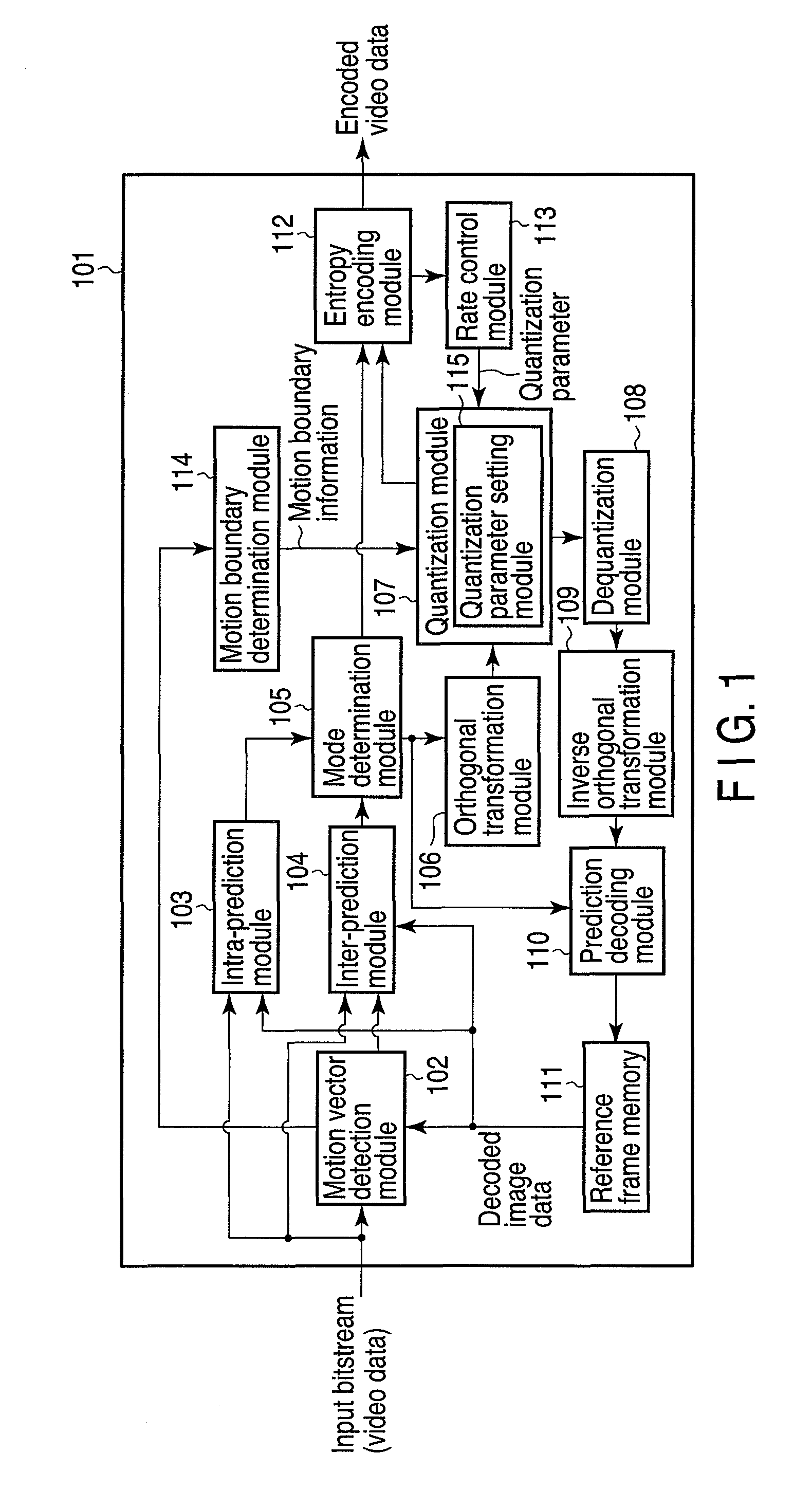

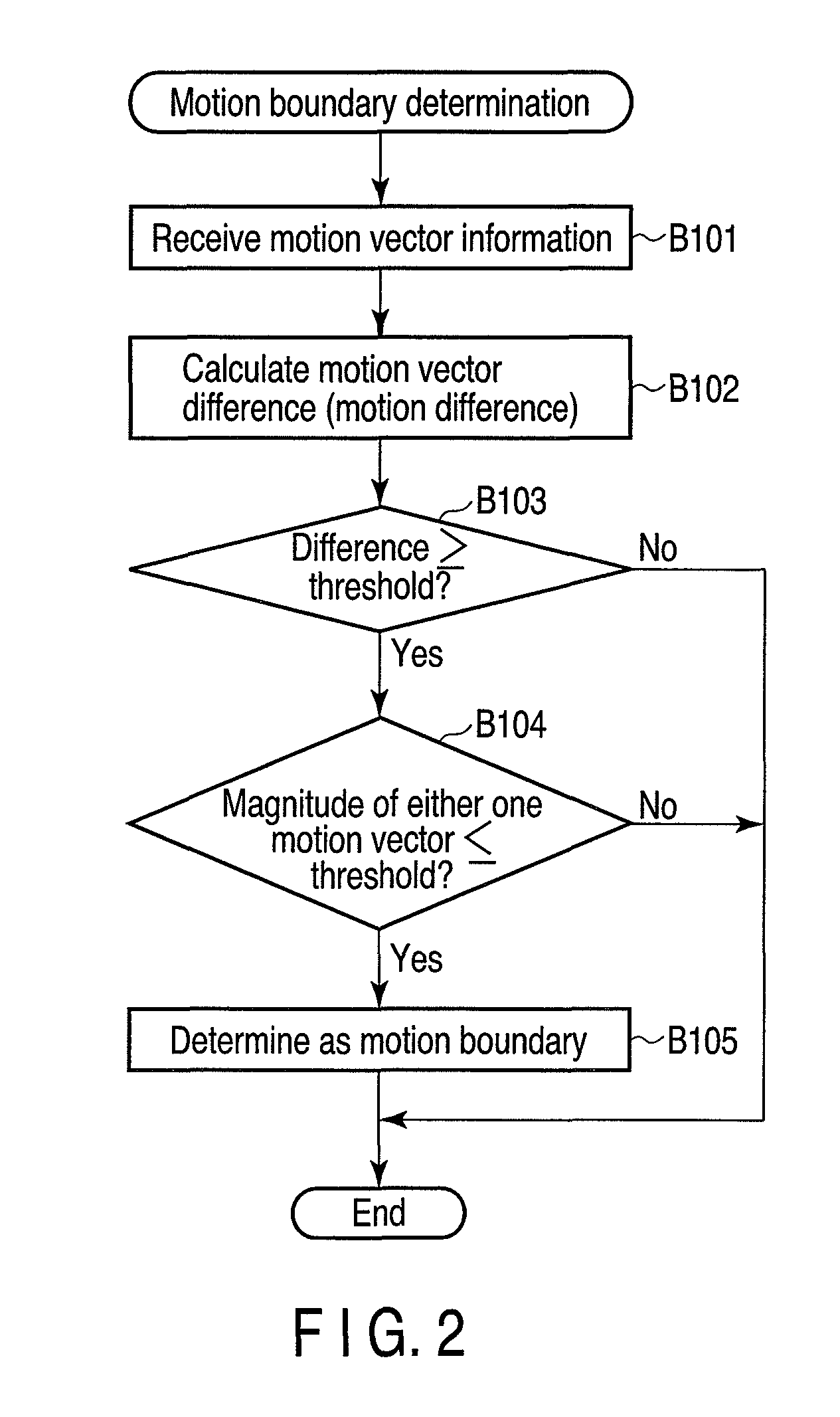

Video encoding apparatus and video encoding method

InactiveUS20100135397A1Color television with pulse code modulationColor television with bandwidth reductionVideo encodingMotion vector

According to one embodiment, a video encoding apparatus includes a motion vector calculation module, a motion boundary detection module, and a quantization parameter setting module. The motion vector calculation module calculates motion vectors for respective blocks in an input image. The motion boundary detection module detects a motion boundary between a motion region and a still region in the input image based on the motion vectors of the respective blocks. The quantization parameter setting module sets a value of a quantization parameter used to quantize a block that borders the detected motion boundary to a value smaller than a value which is set when the block does not border the motion boundary in accordance with a detection result of the motion boundary.

Owner:KK TOSHIBA

Video encoding apparatus and video encoding method

InactiveUS8000393B2Color television with pulse code modulationColor television with bandwidth reductionMotion vectorVideo encoding

According to one embodiment, a video encoding apparatus includes a motion vector calculation module, a motion boundary detection module, and a quantization parameter setting module. The motion vector calculation module calculates motion vectors for respective blocks in an input image. The motion boundary detection module detects a motion boundary between a motion region and a still region in the input image based on the motion vectors of the respective blocks. The quantization parameter setting module sets a value of a quantization parameter used to quantize a block that borders the detected motion boundary to a value smaller than a value which is set when the block does not border the motion boundary in accordance with a detection result of the motion boundary.

Owner:KK TOSHIBA

Immersion boundary control method used for underwater obstacle avoidance of multi-joint snake-like robot

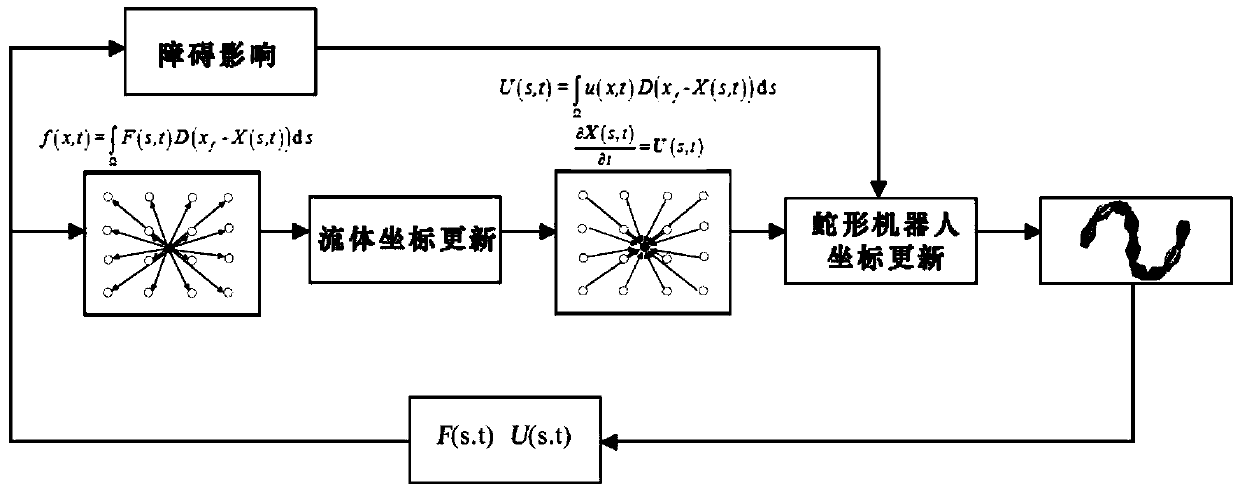

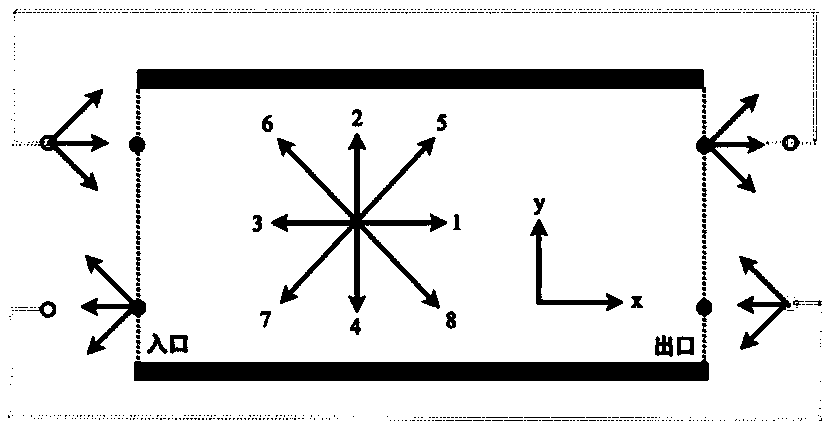

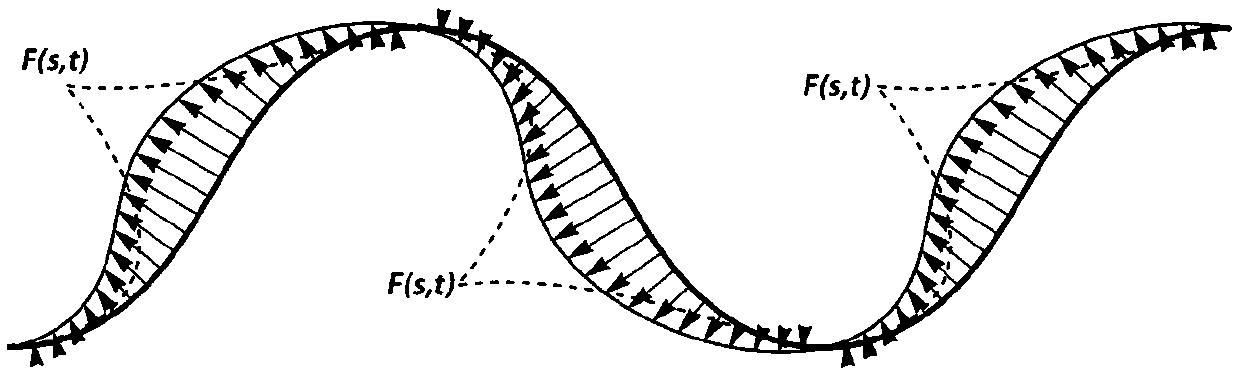

InactiveCN109571450AQuality assuranceGuaranteed conservation of momentumProgramme-controlled manipulatorNODALBoundary knot method

The invention discloses an immersion boundary control method used for underwater obstacle avoidance of a multi-joint snake-like robot, and belongs to the field of robot control. The implementation method comprises the steps that the lattice Boltzmann method is introduced to replace a traditional Navier-Strokes equation for solving fluid and in second order partial differential equation simulation,and starting from the angle of probability statistics, the macroscopic and microcosmic relation and the discrete and continuous relation are solved from different angles. The lattice Boltzmann methodis simple in calculation, and parallel realization is easy. When complex boundary conditions are treated, macroscopic and microcosmic conversion can be achieved, a flexible multi-joint snake-like robot force source model is set up through an immersion boundary method, Euler variables in a fluid field are adopted for controlling the fluid dynamic state, the motion boundary of the multi-joint snake-like robot is controlled through the Lagrange variable of the force source model, a smooth Delta approximate function is used for controlling the interaction of nonlinear fluid field force and the force source boundary through distribution node force and the difference value speed, and nonlinear control of the multi-joint snake-like robot is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

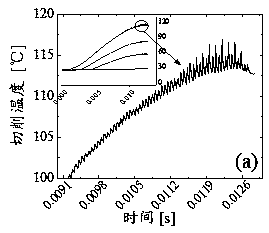

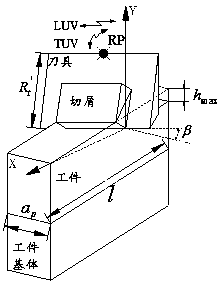

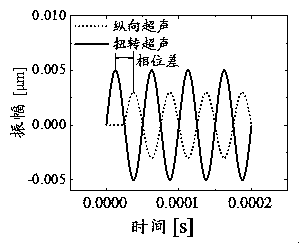

Finite element simulation modeling method suitable for longitudinal torsion ultrasonic milling

ActiveCN110032748AGuaranteed torsional amplitudeAvoid output inaccuraciesGeometric CADDesign optimisation/simulationMilling cutterEngineering

The invention discloses a finite element simulation modeling method suitable for longitudinal and torsional ultrasonic milling. The finite element simulation modeling method comprises the following steps of setting geometric parameters of a milling cutter, material parameters of a workpiece, material parameters of the milling cutter, machining process parameters and ultrasonic vibration parameters; converting the milling model, and establishing a longitudinal-torsional ultrasonic milling three-dimensional equivalent model; establishing a cutter, a workpiece, a workpiece base body and an assembly three-dimensional model; dividing grids for the cutter, the workpiece and the workpiece bse body; realizing longitudinal and torsional ultrasonic vibration of the cutter; setting cutter cutting motion boundary conditions; submitting calculation, and outputting the calculation results of the cutting edge movement track, the cutting force and the cutting temperature. According to the method, themilling model is converted, the milling three-dimensional finite element simulation of the tool serving as a longitudinal-torsional ultrasonic vibration carrier is successfully achieved, the spiral angle and the cutting edge radius of the tool are considered, the model and the actual machining process are more appropriate, and the calculation precision is guaranteed. Meanwhile, by establishing theworkpiece base body model, the output of the cutting force is realized.

Owner:HENAN POLYTECHNIC UNIV

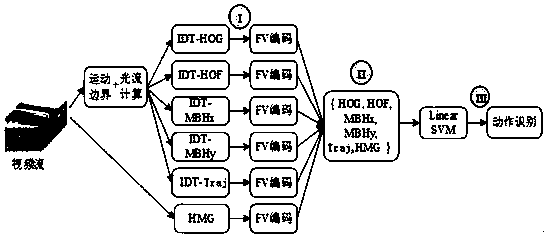

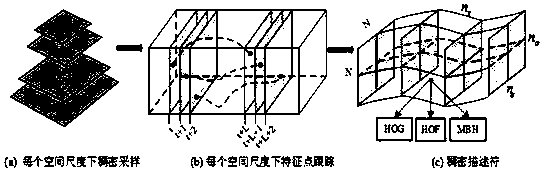

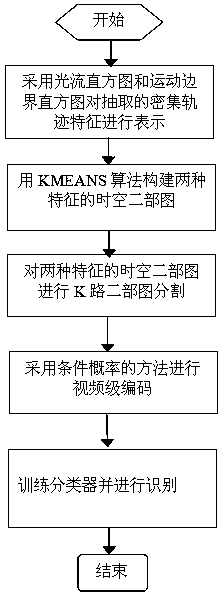

Human motion identification method based on dense sampling of motion boundary and motion gradient histogram

ActiveCN108629301AReduce the number of tracesEnhance feature expressionImage enhancementImage analysisFeature vectorHuman body

The invention discloses a human motion identification method based on dense sampling of the motion boundary and a motion gradient histogram. The method mainly comprises steps that 1), a video stream is inputted; 2), the optical flow field of the inputted video is calculated, feature point sampling is carried out, and dense feature points are extracted; 3), the trajectory of the feature points is calculated; 4), dense descriptors along the feature point trajectory are calculated; 5), two adjacent frames of video images are derived in time to obtain time series motion images, and the spatial gradient of the motion images is calculated to obtain a motion gradient descriptor HMG; 6), feature encoding is performed separately for each descriptor; 7), after regularization of each descriptor, thedense descriptors and the motion gradient descriptor are connected in series to form a feature vector; 8), the feature vector is trained and learned to obtain a human motion identification model; and9), the human body motion is identified through utilizing the human motion identification model. The method is advantaged in that motion identification precision is improved, and calculation cost is further reduced.

Owner:CHONGQING UNIV

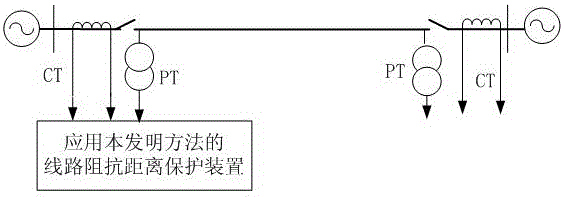

Adaptively-adjusted action boundary based single phase grounding fault relay protection method for power transmission line

InactiveCN105703340ASmall amount of calculationThe principle of the algorithm is simpleEmergency protective circuit arrangementsHigh resistancePhase currents

The invention discloses an adaptively-adjusted action boundary based single phase grounding fault relay protection method for power transmission line. According to the method, a fault phase voltage, a fault phase current, a fault phase negative sequence current and a zero sequence current in the protection installation position of the power transmission line are measured firstly; action boundary adjustment impedance is calculated; the summation of the action boundary adjustment impedance and protection set impedance is calculated to obtain adjusted action boundary impedance; measurement impedance is obtained by dividing the zero sequence compensation current by the fault phase voltage; then whether the measurement impedance amplitude is lower than the adjusted motion boundary impendence amplitude or not is determined; and if the measurement impedance amplitude is lower than the adjusted motion boundary impendence amplitude, a single phase grounding fault occurring in the protection set range of the power transmission line is determined, and a protection apparatus sends out an action tripping signal. The method adopts lumped parameters for modeling, so that simple algorithm principle, easy implementation of the programs, low calculated amount and high protection action speed are realized; the protection set impedance is adjusted in real time by the action boundary impedance, so that the protection action performance is not affected by the transition resistance and the load current; and therefore, the method can carry out correct and reliable action when the power transmission line is in the singe phase high resistance grounding fault.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

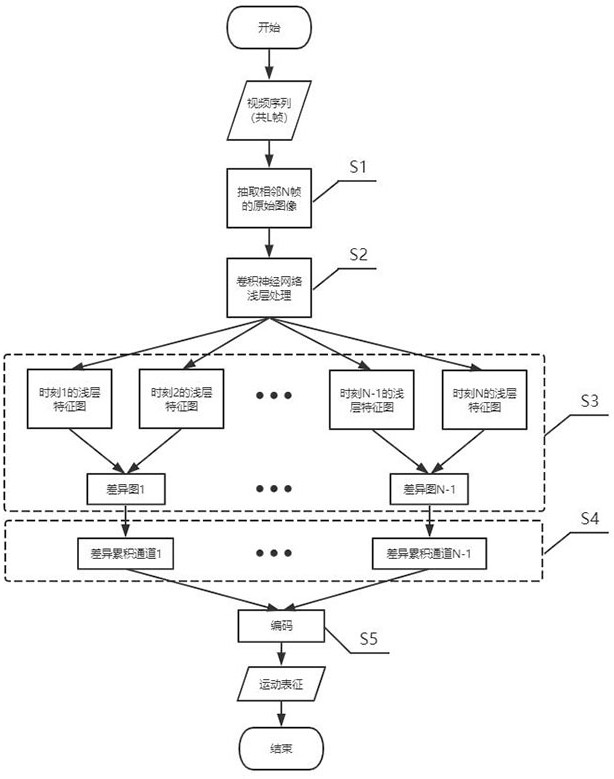

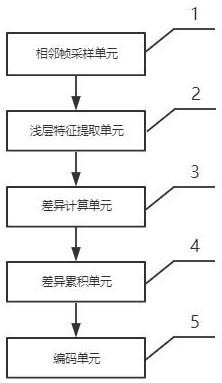

Efficient motion characterization method and device based on motion boundary small displacement

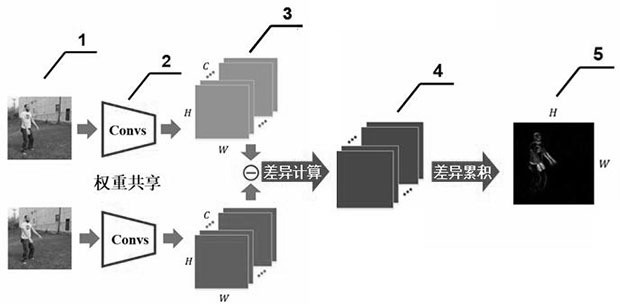

PendingCN112446245AMeet the requirements for understandingGuaranteed real-timeCharacter and pattern recognitionNeural architecturesComputer graphics (images)Difference-map algorithm

The invention relates to an efficient motion characterization method and device based on motion boundary small displacement. The method comprises the following steps: step 1, extracting original images of adjacent N frames in a video sequence; 2, processing adjacent N frames of original images by using a convolutional neural network to obtain a corresponding shallow feature map; 3, performing difference calculation on the shallow feature maps of all the two adjacent frames of the adjacent N frames to obtain a difference map of all the two adjacent frames in the feature space; 4, carrying out difference accumulation on difference graphs of all two adjacent frames in the feature space along the channel dimension; and step 5, encoding the difference accumulation result according to an encoding scheme so as to obtain the efficient motion representation provided by the invention. Compared with some methods depending on optical flow as motion characterization, the method does not need to perform complex optical flow calculation in advance, and can model the small displacement of the motion boundary by calculating the difference on the shallow feature space, thereby greatly reducing the complexity of motion characterization calculation.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Method for detecting occlusion areas

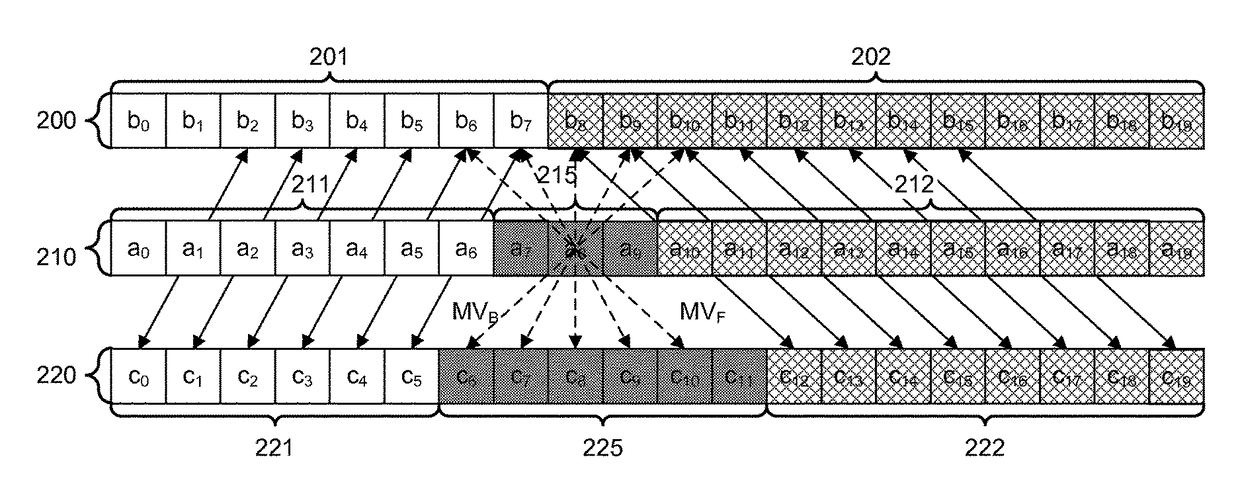

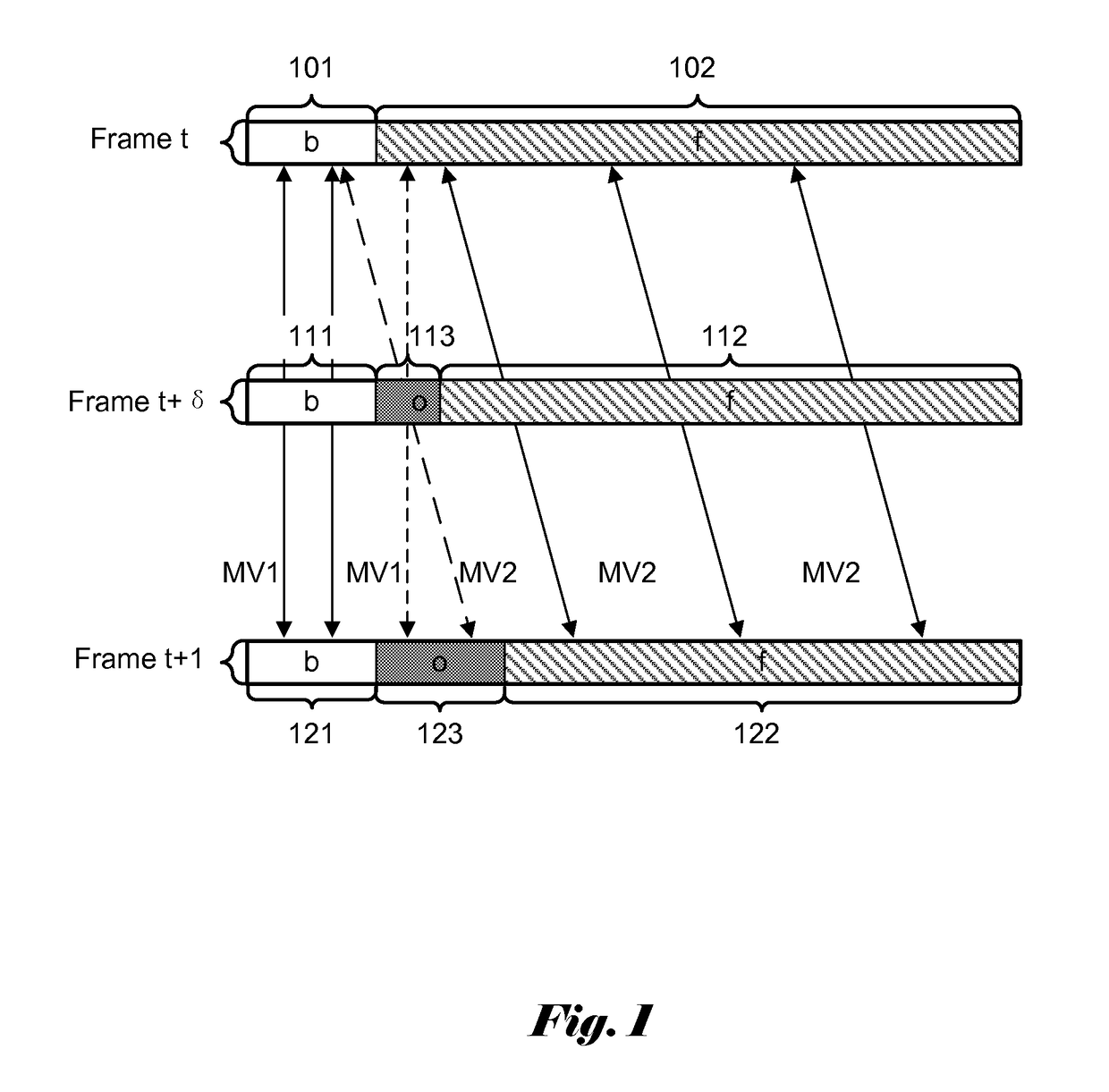

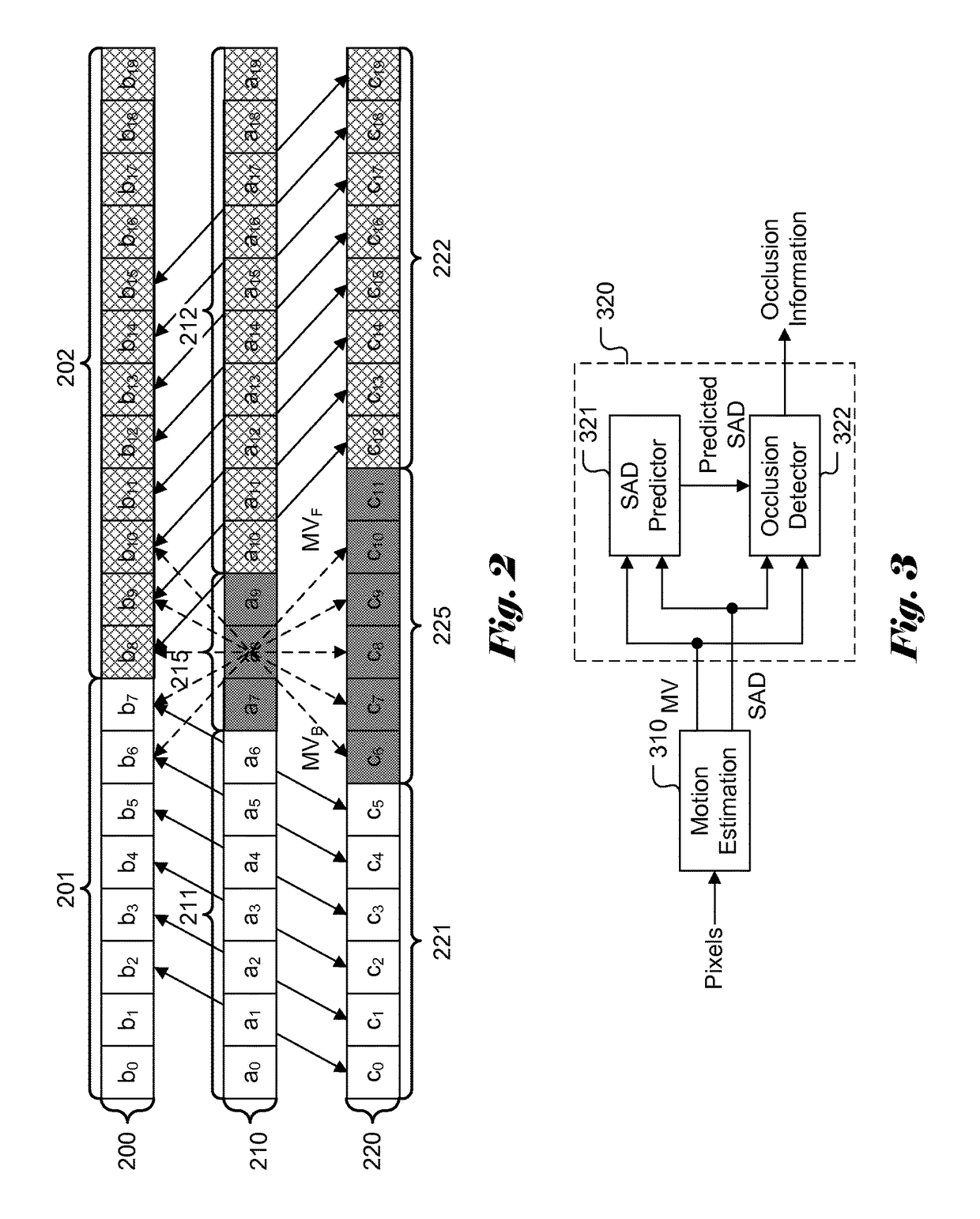

ActiveUS9917988B2Improve efficiencyComputational complexity is reducedTelevision system detailsColor television detailsMotion vectorRegion detection

A method and apparatus for occlusion area detection based on block difference associated with a motion vector and a predicted block difference are disclosed. For each current block of a frame, motion estimation is performed based on a temporally previous frame and a temporally subsequent frame. Based on the motion vector derived, two reference blocks of the current block are located in the temporally neighboring frames. The block difference between these two reference blocks is calculated for the current block. By comparing the block difference with a predicted block difference of the current block, the current block is determined to be an occlusion block or not accordingly. The predicted block difference is updated by averaging the block difference of neighboring blocks in a non-motion boundary area.

Owner:XUESHAN TECH INC

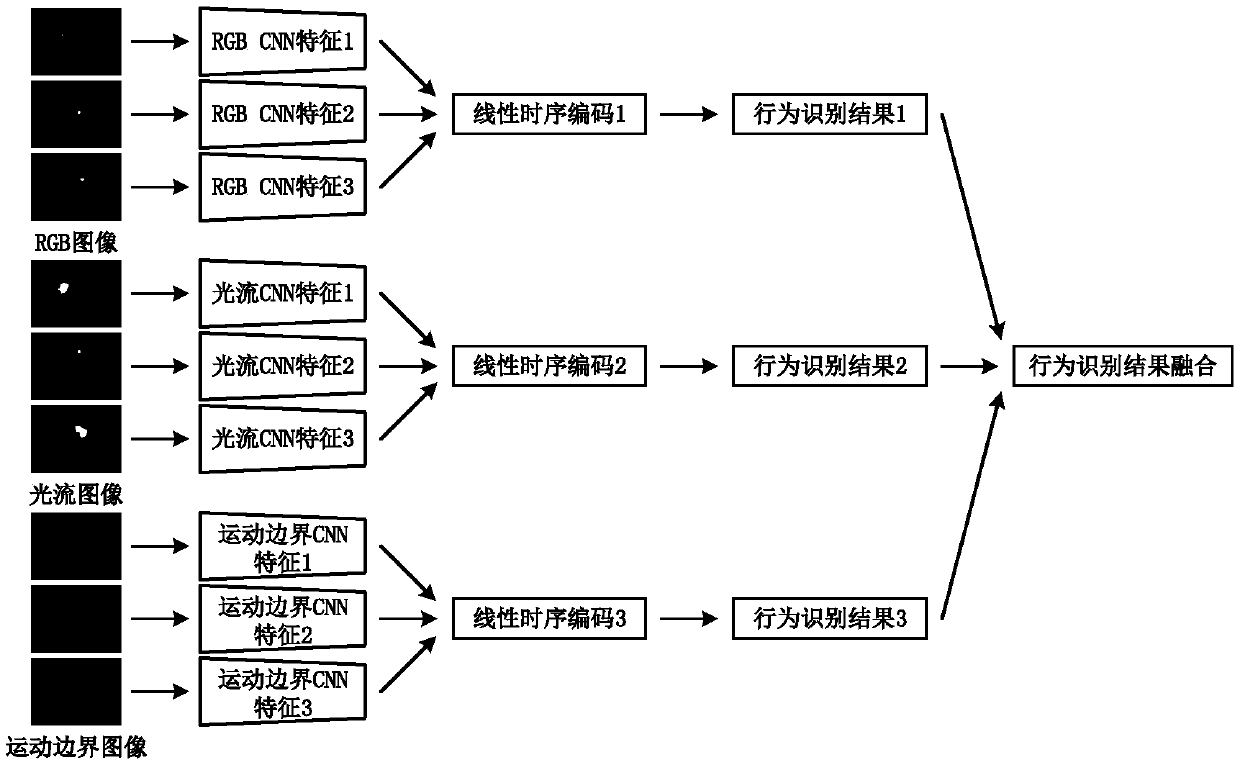

A human body behavior identification method and system based on multi-feature linear time sequence coding

PendingCN109635764AImprove the accuracy of behavior recognitionCharacter and pattern recognitionHuman bodyDiagnostic Radiology Modality

The invention discloses a human body behavior identification method and system based on multi-feature linear time sequence coding, and the method comprises the steps: firstly, uniformly dividing an original video into a plurality of sub-segments, constructing a continuous frame set in each sub-segment, and respectively calculating the optical flow between two adjacent image frames in each sub-segment continuous frame set, and obtaining an optical flow image set; Calculating a motion boundary value to obtain a motion boundary image set; Taking a representative frame, an optical flow image set and a motion boundary image set of the original video as input, and obtaining CNN characteristics of each sub-segment of the original video by adopting a CNN network; Performing linear time sequence coding according to the CNN features of different modalities; Respectively carrying out action recognition by adopting an action classification algorithm according to the linear time sequence coding characteristics; And carrying out weighted fusion on the plurality of behavior recognition results to obtain a final behavior recognition result. According to the method, the important behavior representation information of the motion boundary graph is fused, and the integrated learning process of the behavior convolution features and the time sequence features is fused through the linear time sequence coding method, so that the human body behavior recognition accuracy is improved.

Owner:JINGCHU UNIV OF TECH

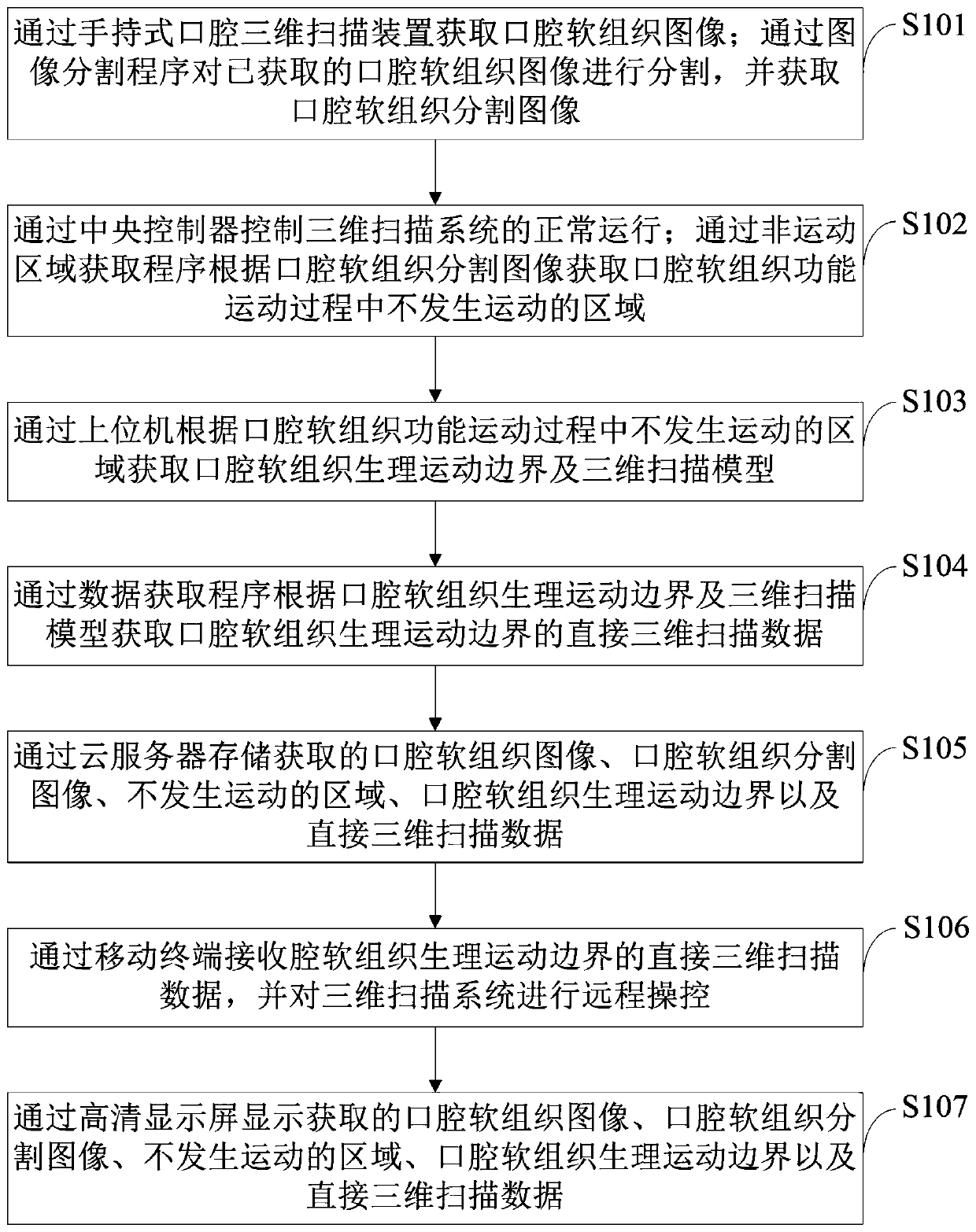

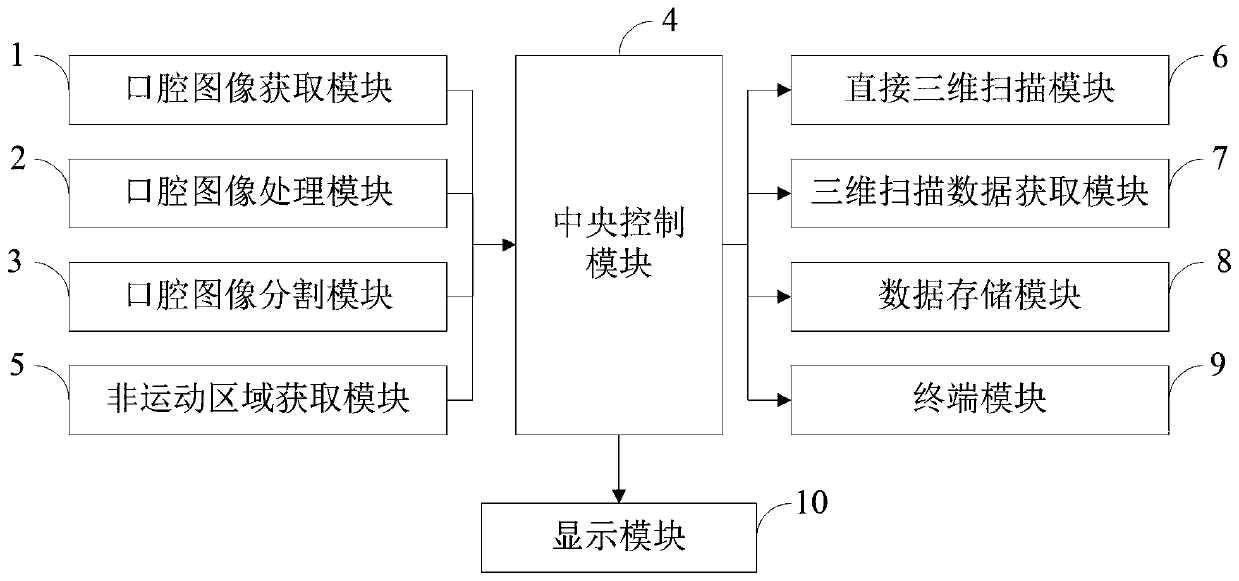

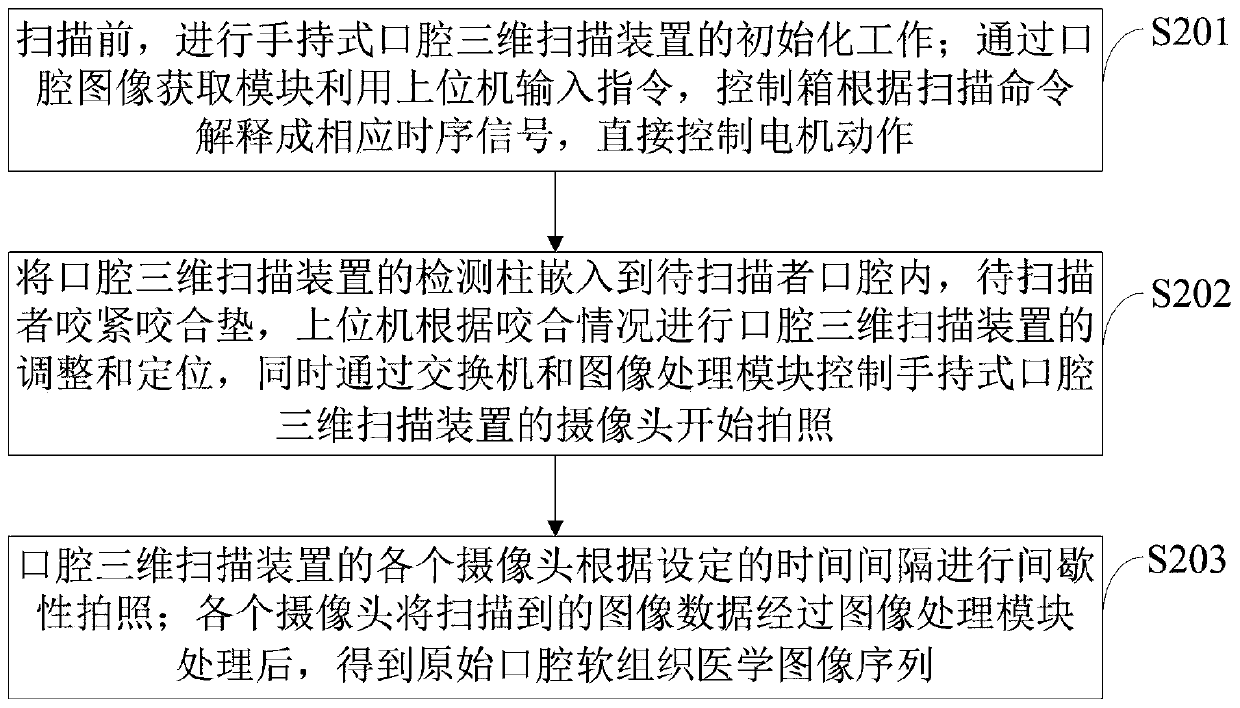

Direct three-dimensional scanning method and system for physiological motion boundary of oral soft tissue

PendingCN111568376AFast scanningHigh precisionDiagnostic recording/measuringSensorsOral medicineImaging processing

The invention belongs to the technical field of oral scanning, and discloses a direct three-dimensional scanning method and system for a physiological motion boundary of oral soft tissue. The direct three-dimensional scanning system for the physiological motion boundary of the oral soft tissue comprises an oral image acquisition module, an oral image processing module, an oral image segmentation module, a central control module, a non-motion area acquisition module, a direct three-dimensional scanning module, a three-dimensional scanning data acquisition module, a data storage module, a terminal module and a display module. The scanning system provided by the invention is high in scanning speed, high in precision and simple to operate; an active contour method is used for semi-automatically carrying out labeling segmentation on an oral medical image serving as a training set, and the semi-automatic method improves the accuracy and timeliness of labeling segmentation; and a confrontation generation network is used for automatically generating a segmentation result of the oral medical image, so that the complete and effective expression of the healthy oral physiological structure isbalanced in key indexes such as segmentation precision, efficiency, stability and robustness.

Owner:SICHUAN UNIV

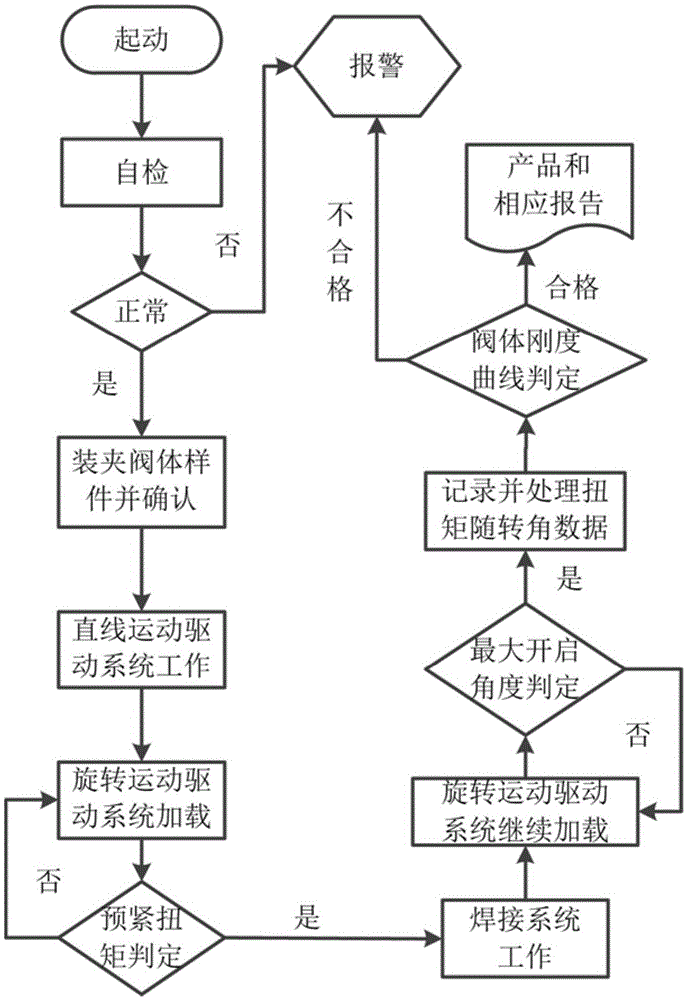

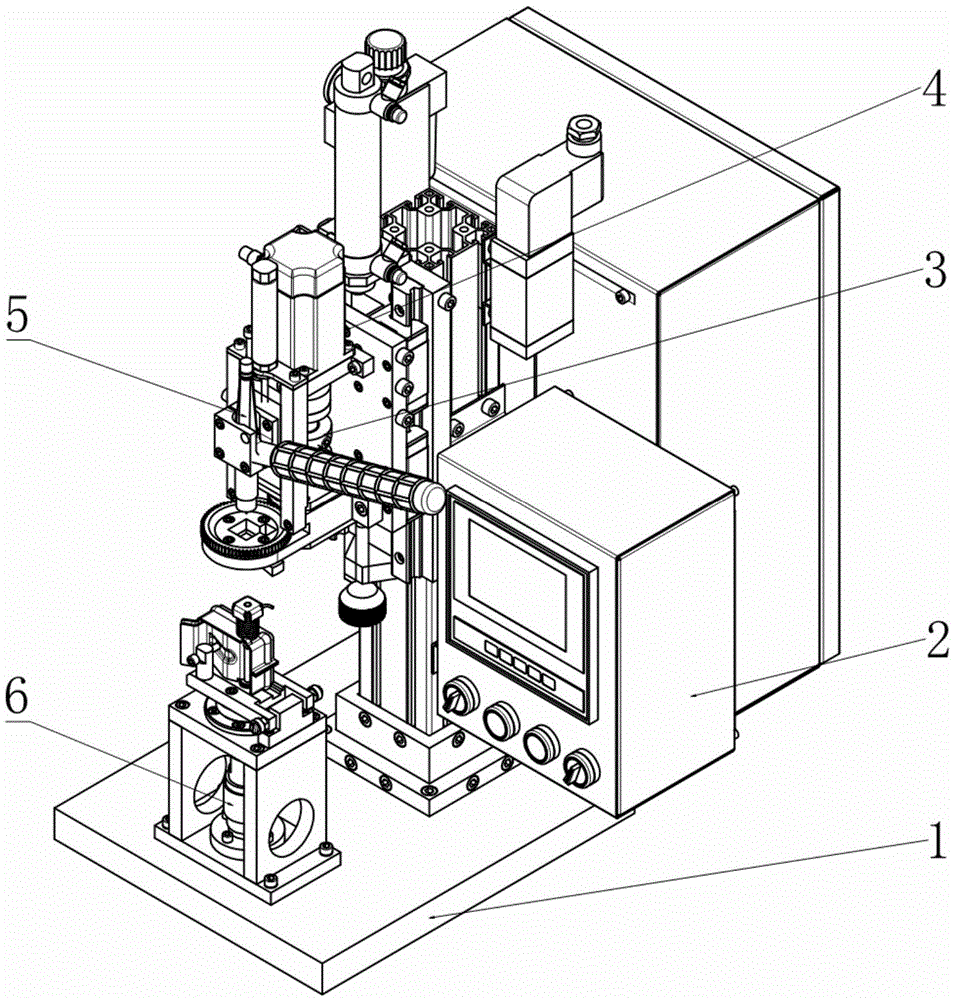

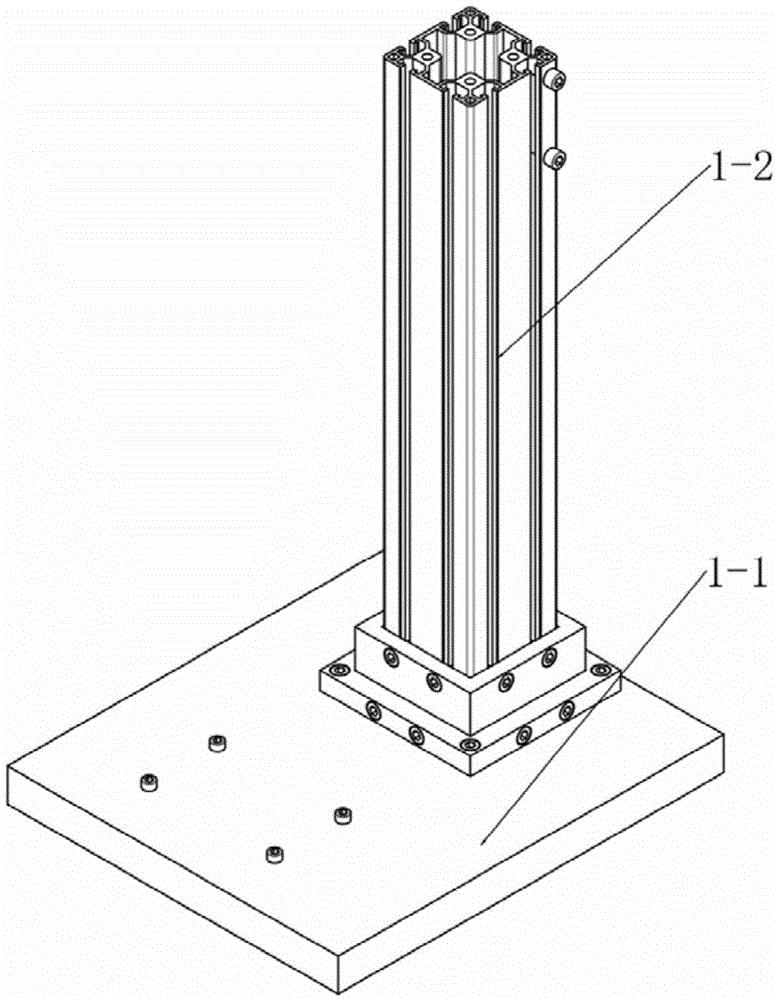

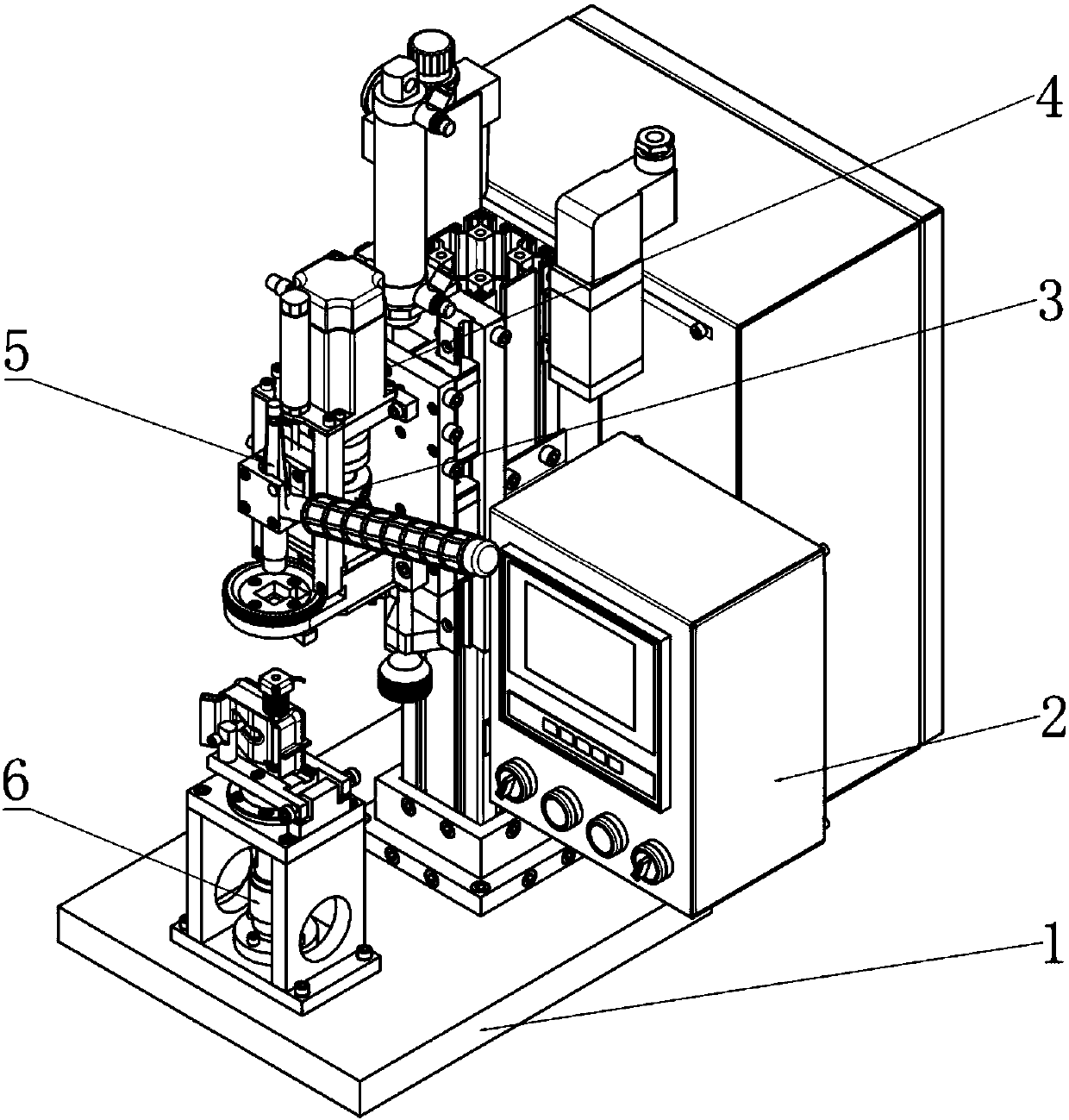

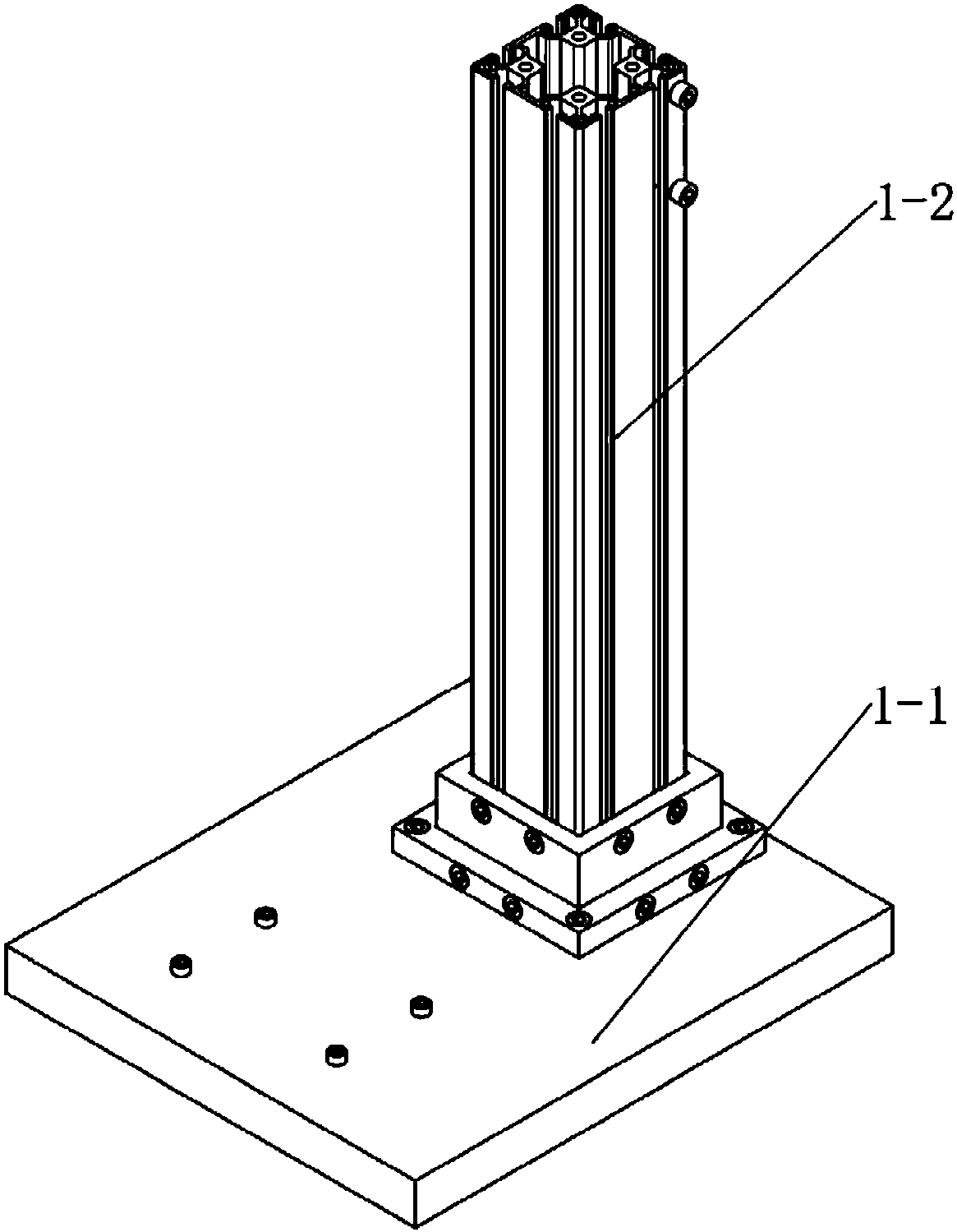

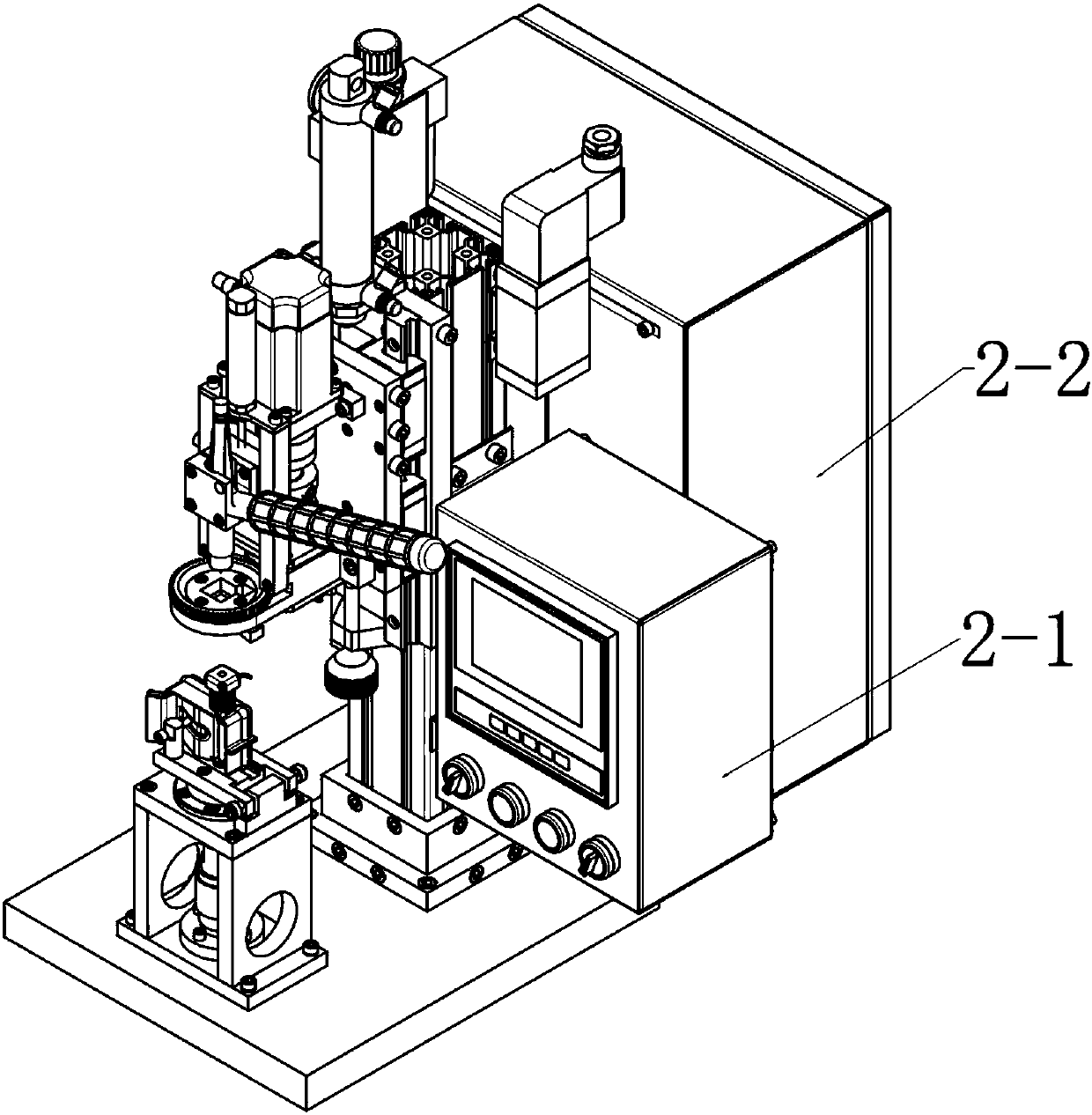

Automatic pre-twisting, welding and detecting equipment for dual-mode silencer valve

ActiveCN105618950AIncrease productivityReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesDual modeSlide plate

Automatic pre-twisting, welding and detecting equipment for a dual-mode silencer valve is composed of a support, a twisting force measuring system, a driving system, a limiting system, a welding system and a control system, wherein the twisting force measuring system, the driving system and the control system are fixed to the support, and the limiting system and the welding system are installed on the driving system. The twisting force measuring system transmits the moment of force to a static torque sensor for measuring the moment of force through an asbestos plastic connector, and impact of heat and currents generated by welding to the sensor is isolated; the driving system realizes automatic clamping and pre-twisting of the valve through the combination of linear motion and rotational motion; the limiting system controls the motion boundary position of the driving system through linear motion limitation and rotational motion limitation; the welding system automatically welds a valve torsion spring fixing base through the combination of an air cylinder and a sliding plate; the control system controls orderly motion of the other systems through programs, and pre-twisting, welding and detecting of the dual-mode silencer valve can be automatically completed.

Owner:EAST CHINA JIAOTONG UNIVERSITY

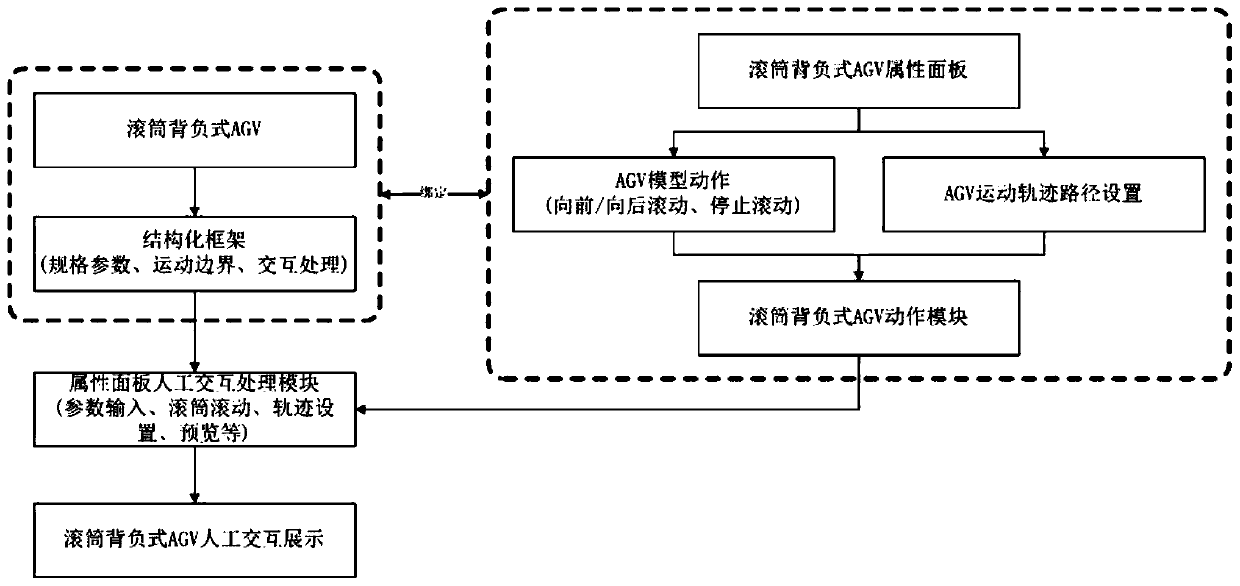

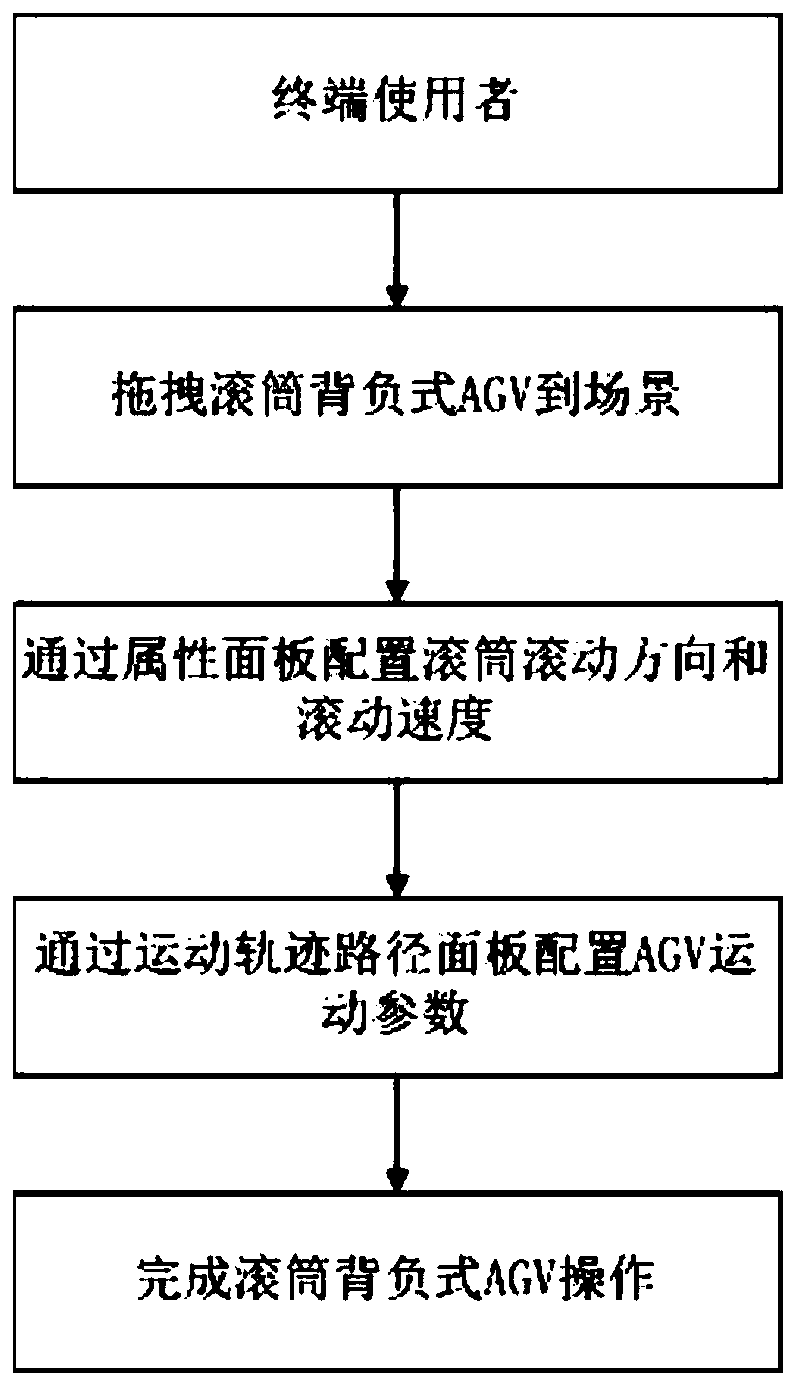

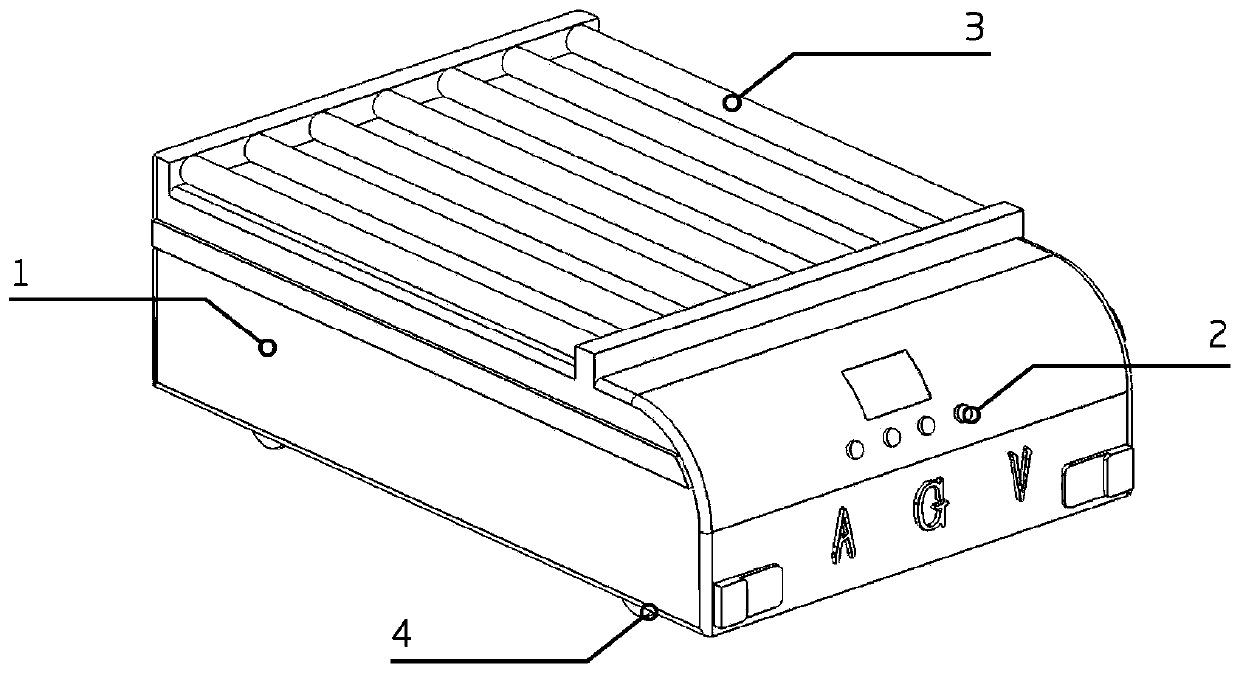

Roller backpack type AGV three-dimensional model for teaching, building method and simulation system

InactiveCN110718113AImprove reusabilityIncrease flexibilityTeaching apparatus3D modellingControl engineeringIndustrial engineering

The invention discloses a roller backpack type three-dimensional model for teaching, a building method and a simulation system. The roller backpack type AGV three-dimensional model comprises a body and an attribute panel, wherein attribute information of enabling a roller to roll forwards, enabling the roller to roll backwards, enabling the roller to stop rolling and the like is set by the attribute panel, and a user sets a path editing interface of an AGV through the attribute panel. The building method comprises the following steps of firstly, binding specification parameter information of the roller backpack type AGV through a unified structured framework, and then limiting a motion boundary of the model according to the specification parameter information of the roller backpack type AGV; and finally, setting use methods of a motion path and the like for the AGV according to the attribute panel of the roller backpack type AVG three-dimensional model. According to the roller backpacktype three-dimensional model, a unified structured mode is adopted, the user sets a motion track of the AGV through a path setting panel in the attribute panel, the modes that what you see is what you get and adjustment is flexible are achieved, and the goal of improving the flexibility is achieved.

Owner:上海明材数字科技有限公司

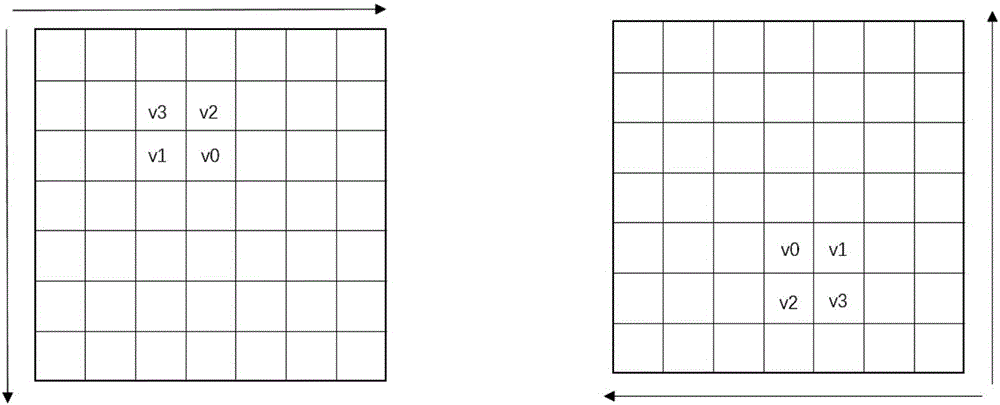

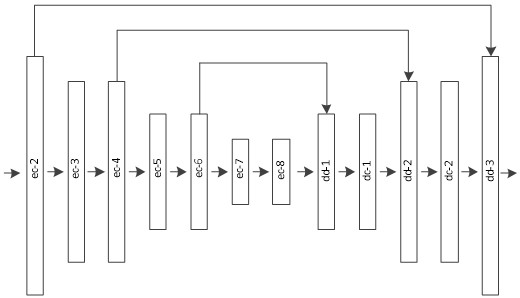

Method and apparatus for fine-grained motion boundary processing

A method and apparatus for deriving fine-grained motion compensated prediction of boundary pixels in a video coding system are disclosed. Embodiments of the present invention determine one or more neighboring coding units (CUs) adjacent to a current coding unit (CU). For each neighboring CU, motion-compensated prediction is derived for each neighboring CU using the MV of the neighboring CU. The pre-generated predictors at a bottom side or a right side of each neighboring CUs are derived and stored on a smallest CU (SCU) basis. The pre-generated predictors and the motion compensated predictor for a current boundary pixel are combined using weighting factors to form a final predictor for the current pixel.

Owner:XUESHAN TECH INC

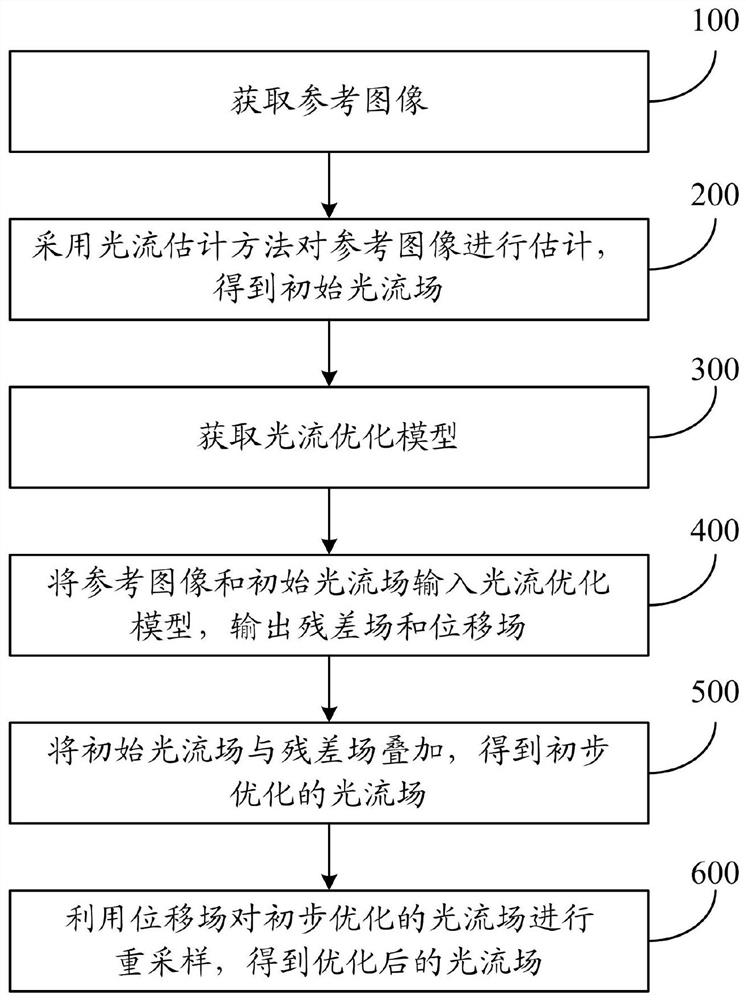

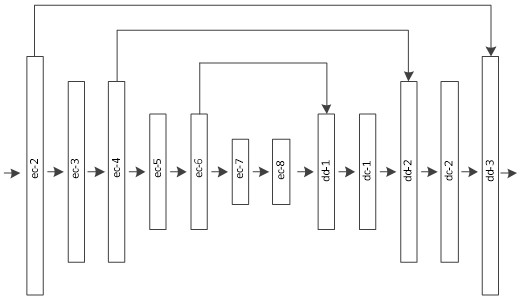

Image optical flow optimization method and system based on residual field and displacement field

ActiveCN112767441AImprove calculation accuracyImproved accuracy of optical flow fieldImage enhancementImage analysisReference imageComputer science

The invention relates to an image optical flow optimization method and system based on a residual field and a displacement field. The method comprises the following steps: acquiring a reference image; estimating the reference image by adopting an optical flow estimation method to obtain an initial optical flow field; obtaining an optical flow optimization model, wherein the optical flow optimization model comprises an image encoder, an optical flow encoder, a first decoder and a sub-decoder; inputting the reference image and the initial optical flow field into the optical flow optimization model, and outputting a residual field and a displacement field; superposing the initial optical flow field and the residual field to obtain a preliminarily optimized optical flow field; and resampling the preliminarily optimized optical flow field by using the displacement field to obtain an optimized optical flow field. According to the invention, the precision and robustness of the image sequence optical flow estimation in the motion boundary region can be improved.

Owner:NANCHANG HANGKONG UNIVERSITY

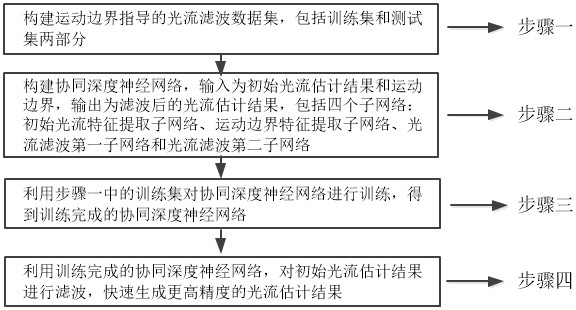

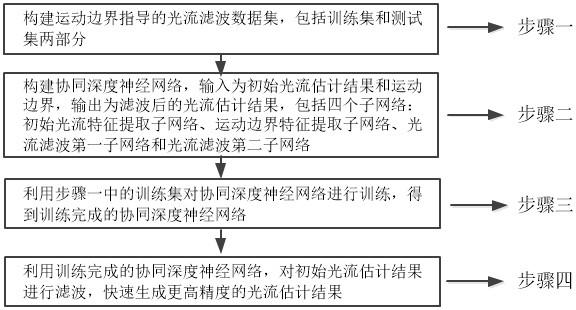

Moving boundary guided optical flow filtering method based on collaborative deep neural network

ActiveCN112991398AImprove efficiencyImprove accuracyImage enhancementImage analysisData setFeature extraction

The invention discloses a moving boundary guided optical flow filtering method based on a collaborative deep neural network, and the method comprises the steps: constructing a moving boundary guided optical flow filtering data set and the collaborative deep neural network, inputting an initial optical flow estimation result and a moving boundary, and outputting a filtered optical flow estimation result, comprising an initial optical flow feature extraction sub-network, a moving boundary feature extraction sub-network, a first optical flow filtering sub-network and a second optical flow filtering sub-network, training the collaborative deep neural network by using the training set, and filtering an initial optical flow estimation result by using the trained collaborative deep neural network, and quickly generating an optical flow estimation result with higher precision. According to the method, the collaborative deep neural network is used for automatically learning the optical flow filtering process guided by the moving boundary, the complex function relation from variable input to optical flow filtering result output is accurately simulated, new errors are prevented from being introduced into irrelevant edge information except the moving boundary, and the efficiency and accuracy of optical flow filtering are improved.

Owner:NAT UNIV OF DEFENSE TECH

Method and apparatus for motion boundary processing

A method and apparatus for deriving motion compensated prediction for boundary pixels in a video coding system are disclosed. Embodiments of the present invention determine a current motion vector (MV) and one or more neighboring MVs corresponding to an above MV, a left MV, or both the above MV and the left MV. A first predictor for a current boundary pixel in a boundary region of the current CU is generated by applying motion compensation based on the current MV and a first reference picture pointed by the current MV. One or more second predictors for the current boundary pixel are generated by applying the motion compensation based on the neighboring MVs and reference pictures pointed by the neighboring MVs. A current boundary pixel predictor for the current boundary pixel is then generated using a weighted sum of the first predictor and the second predictors according to weighting factors.

Owner:MEDIATEK INC

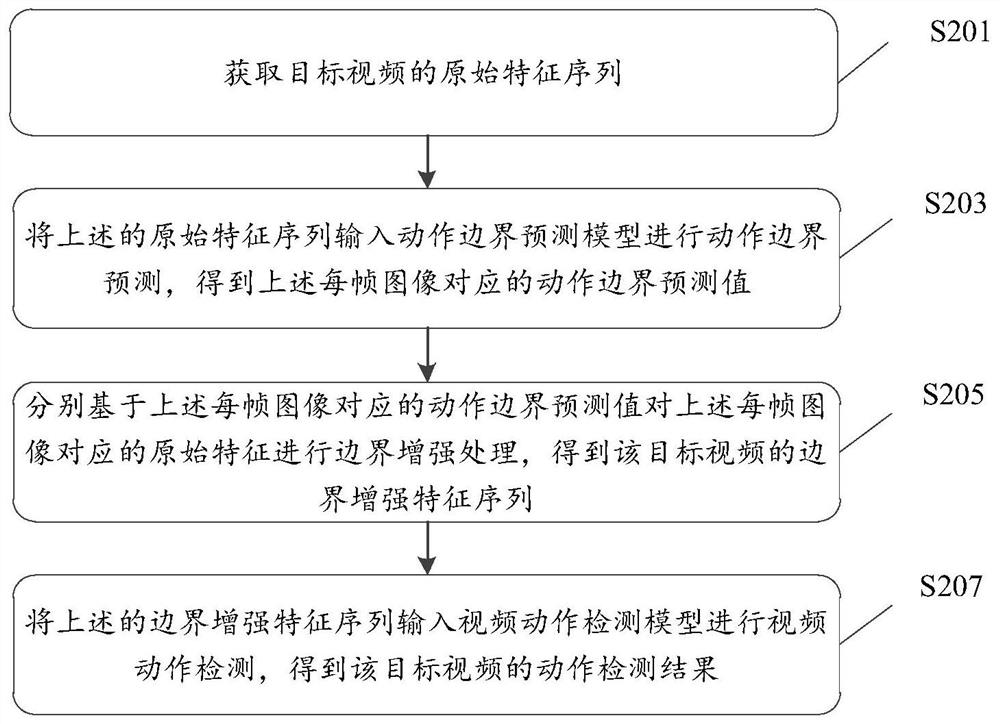

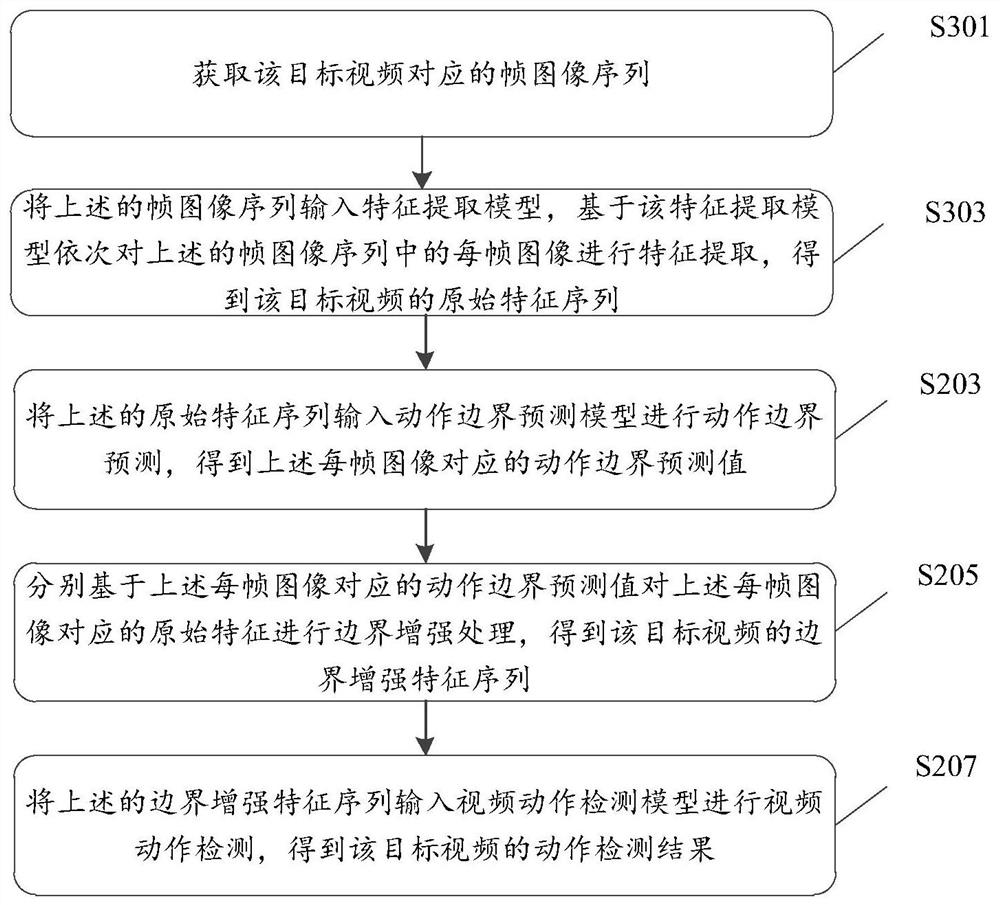

Video action detection method and device, electronic equipment and storage medium

PendingCN113705303AHigh precisionImprove reliabilityCharacter and pattern recognitionNeural architecturesComputer graphics (images)Video processing

The invention discloses a video action detection method and device, electronic equipment and a storage medium, and relates to the technical field of video processing, the method comprises the steps: acquiring an original feature sequence of a target video, wherein the original feature sequence comprises original features corresponding to each frame of image in the target video; inputting the original feature sequence into an action boundary prediction model for action boundary prediction to obtain an action boundary prediction value corresponding to each frame of image; performing boundary enhancement processing on the original features corresponding to each frame of image based on the motion boundary predicted value corresponding to each frame of image to obtain a boundary enhancement feature sequence of the target video; and inputting the boundary enhancement feature sequence into a video action detection model for video action detection to obtain an action detection result of the target video, the action detection result comprising start-stop position information of an action in the target video. By using the technical scheme provided by the invention, the precision and reliability of video action detection can be improved.

Owner:深圳市雅阅科技有限公司

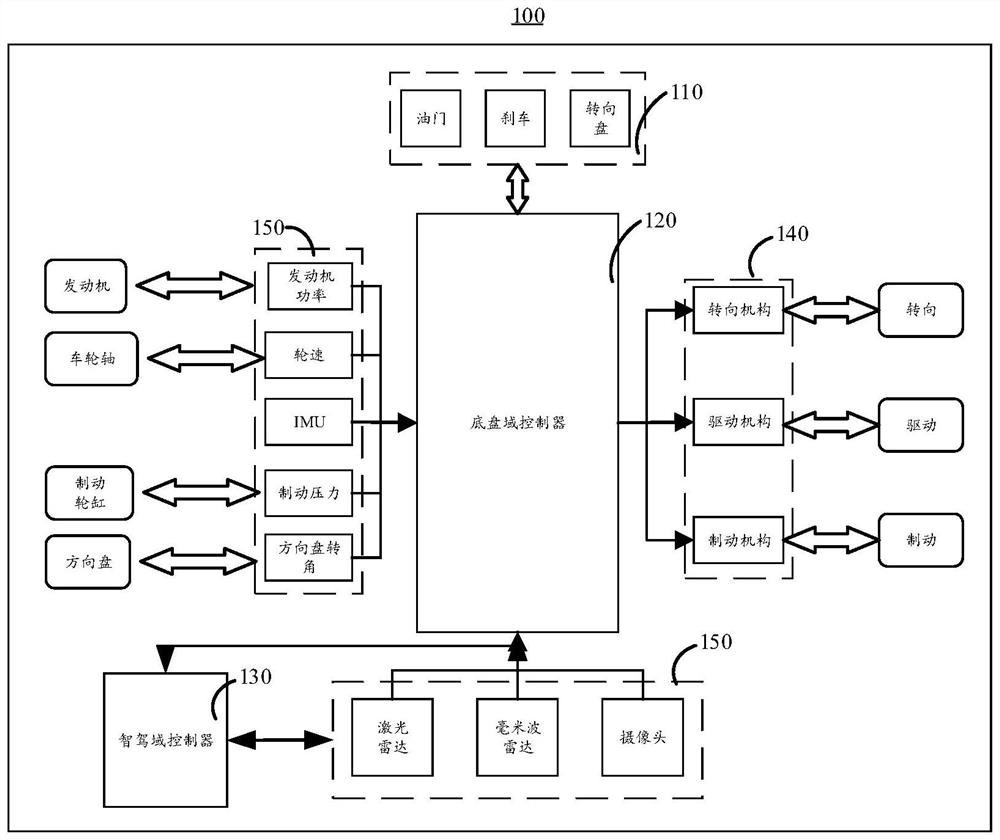

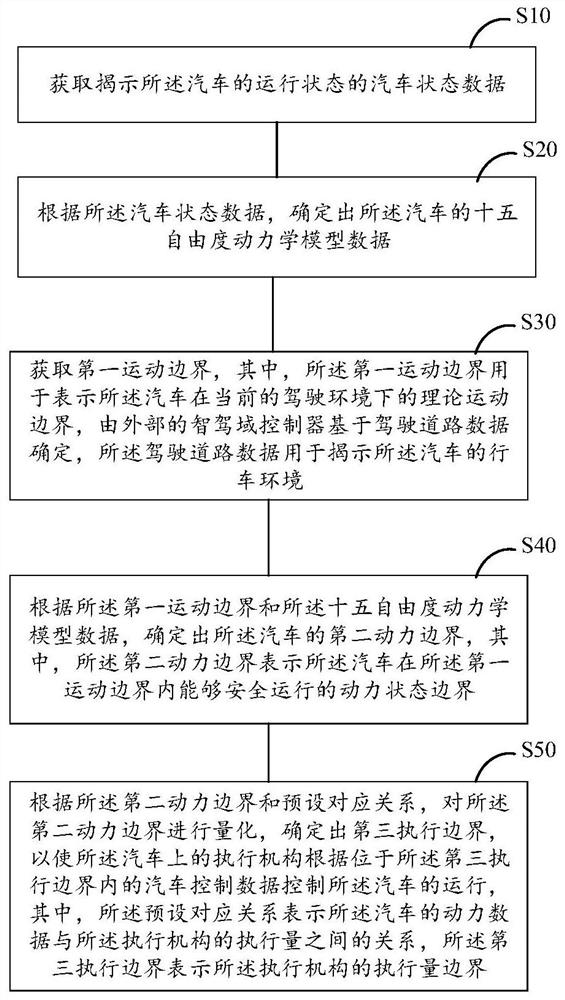

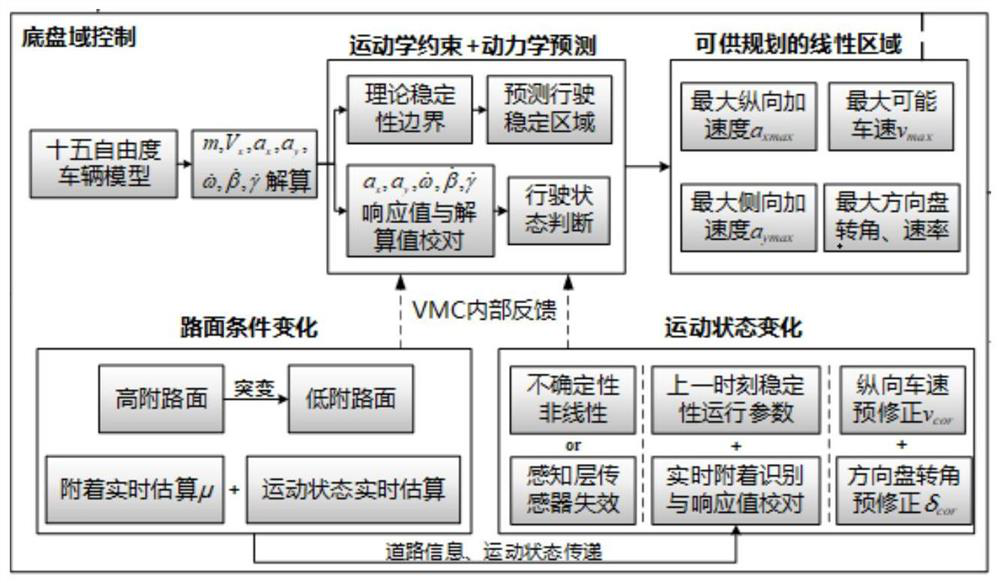

Vehicle control method, chassis domain controller and intelligent driving vehicle

Owner:TSINGHUA UNIV

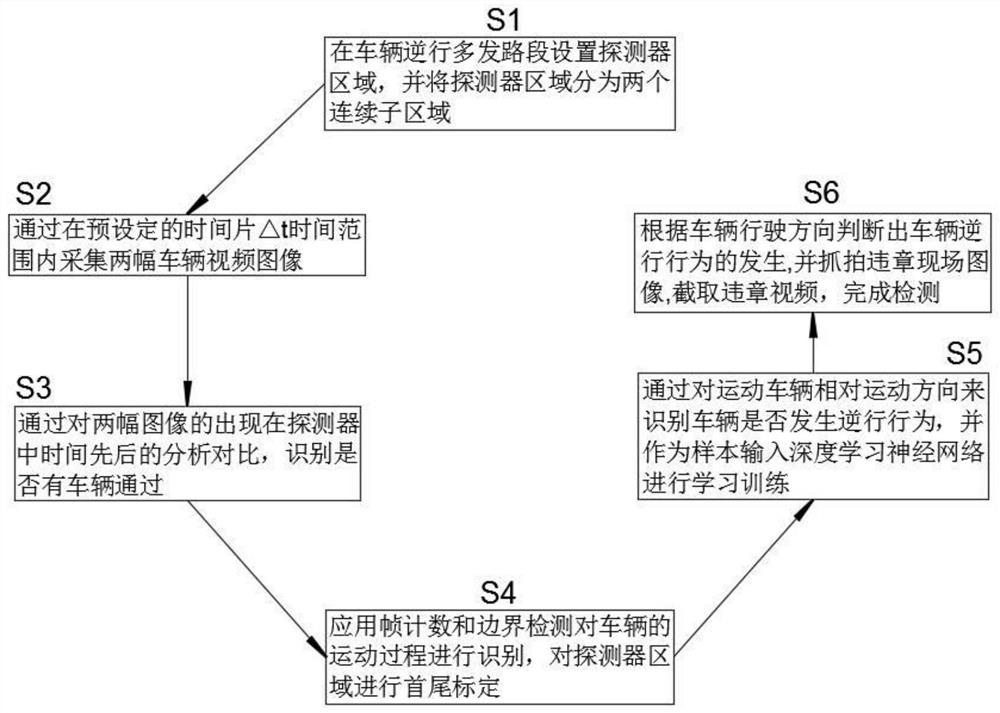

Deep learning retrograde motion detection method based on embedded terminal

PendingCN112364794ARealize real-time judgmentAccurate automatic identificationRoad vehicles traffic controlCharacter and pattern recognitionComputer graphics (images)Engineering

The invention relates to the technical field of intelligent transportation, in particular to a deep learning retrograde motion detection method based on an embedded terminal, which comprises the following steps: setting a detector area in a vehicle retrograde motion multi-occurrence road section, and dividing the detector area into two continuous sub-areas; identifying whether a vehicle passes ornot is by analyzing and comparing the appearing time sequence of the two images in the detector; recognizing whether the vehicle has a retrograde motion behavior or not according to the relative motion direction of the moving vehicle, and inputting the vehicle as a sample into a deep learning neural network for learning training; and judging the occurrence of a vehicle retrograde motion behavior according to the vehicle driving direction, capturing a violation scene image, intercepting a violation video, and completing detection. According to the invention, by means of deep learning, boundarydetection is carried out by using a sobel operator, and a motion boundary formed in a background when a vehicle passes through a detector is identified, so that comprehensive judgment is enhanced, thejudgment accuracy is improved, real-time judgment of vehicle retrograde motion is realized, and a retrograde motion behavior of a traffic vehicle is relatively accurately and automatically identified.

Owner:合肥湛达智能科技有限公司

Motion Boundary-Guided Optical Flow Filtering Method Based on Collaborative Deep Neural Networks

ActiveCN112991398BImprove efficiencyImprove accuracyImage enhancementImage analysisData setFeature extraction

Owner:NAT UNIV OF DEFENSE TECH

A dual-mode muffler valve automatic pre-twist welding detection equipment

ActiveCN105618950BIncrease productivityImprove assembly accuracyWelding/cutting auxillary devicesAuxillary welding devicesDual modeEngineering

A dual-mode muffler valve automatic pre-twisting welding detection equipment is composed of a bracket, a torque measurement system, a drive system, a limit system, a welding system and a control system. The torque measuring system, driving system and control system are respectively fixed on the bracket, and the limit system and welding system are installed on the driving system. The torque measurement system transmits the torque to the static torque sensor through the asbestos plastic joint to realize the measurement of the torque, and at the same time isolates the impact of the heat and current generated by welding on the sensor; the drive system realizes the automatic clamping of the valve through the combination of linear motion and rotary motion and pre-twist; the limit system controls the motion boundary position of the drive system through linear motion limit and rotary motion limit; the welding system realizes the automatic welding of the torsion spring seat of the valve through the combination of cylinder and slide plate; the control system controls each The orderly movement of the system makes the three processes of pre-twisting, welding and testing of the dual-mode muffler valve automatically completed.

Owner:EAST CHINA JIAOTONG UNIVERSITY

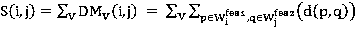

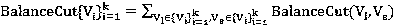

A Human Behavior Recognition Method Based on the Fusion of Multi-feature Spatial-Temporal Relationships

InactiveCN104881655BEasy to digImprove recognition accuracyCharacter and pattern recognitionHuman behaviorShortest distance

The invention discloses a human behavior recognition method based on the fusion of multi-feature spatio-temporal relations. The specific steps include: expressing the dense track features extracted from the video through the optical flow histogram and the motion boundary histogram, and then using the KMEANS algorithm to construct the two features Corresponding to the spatio-temporal bipartite graph between the centroids, the K-way bipartite graph segmentation technology is used to segment the spatio-temporal bipartite graph, and the representation method based on conditional probability is used to obtain the video-level code after the fusion of the two features, and finally the classifier is trained and recognized , through the above method, the present invention is a human behavior recognition method based on multi-feature spatio-temporal relationship fusion, the method calculates the spatio-temporal distance between the features in each video, thereby constructing the spatio-temporal bipartite graph between the centroids corresponding to the two features , the K-way bipartite graph segmentation technology is used to segment the spatio-temporal bipartite graph, and the centroid with strong spatio-temporal relationship is fused, which better excavates the effective information of different features and improves the recognition accuracy.

Owner:SOUTHEAST UNIV

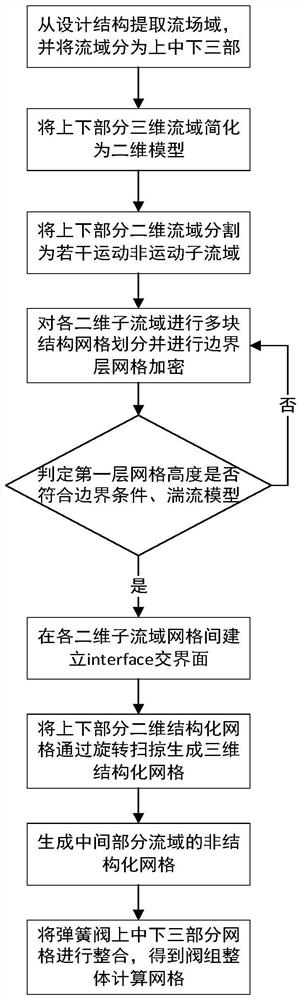

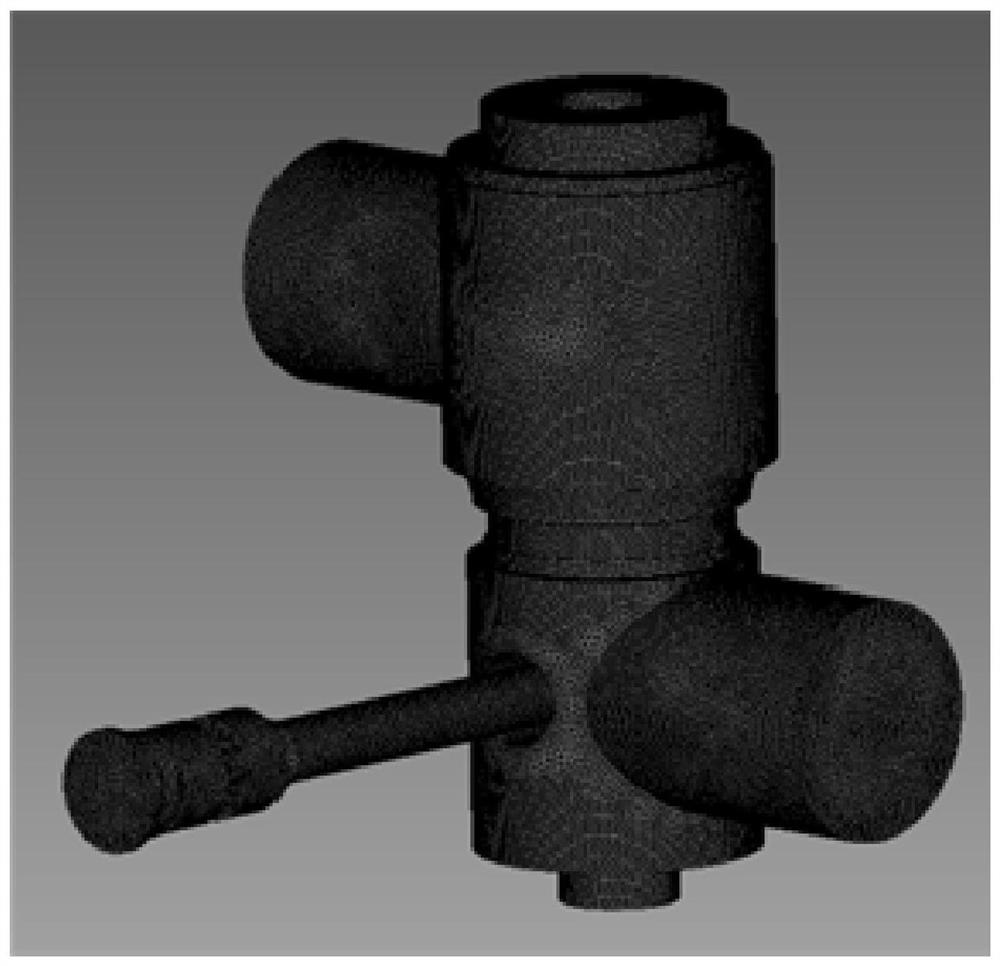

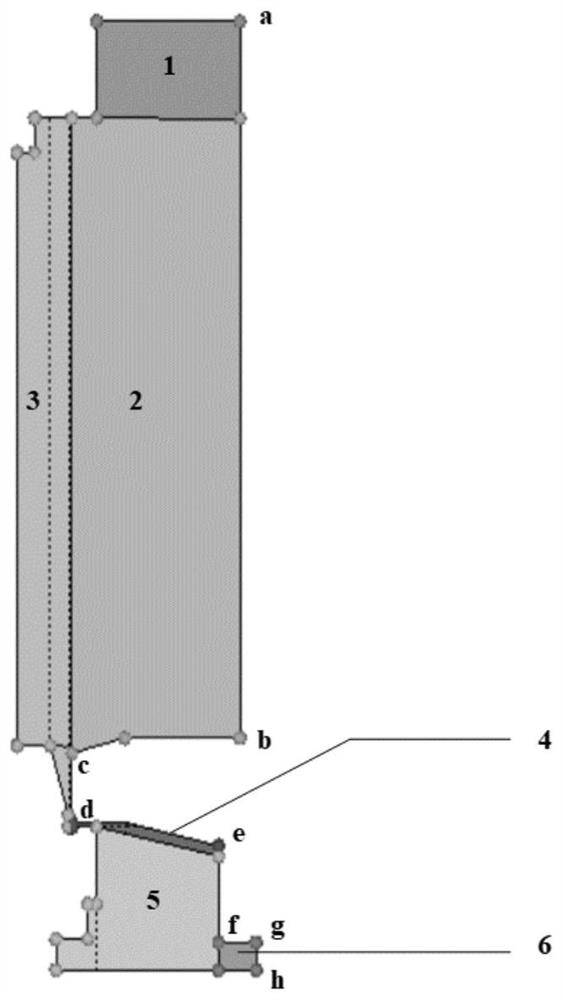

A multi-block structure meshing method for unsteady flow field of spring valve with complex structure

ActiveCN112287615BQuality improvementReduce in quantityDesign optimisation/simulationSpecial data processing applicationsEngineeringBlock structure

The purpose of the present invention is to provide a multi-block structure grid division method for the unsteady flow field of a complex structure spring valve, which includes the following steps: extracting a flow field model from a design model of a spring check valve; The simplified two-dimensional watershed of the model is divided into moving and non-moving sub-basins; the height of the first layer grid is calculated, and each two-dimensional sub-basin is divided into structural grids; the upper and lower parts of the two-dimensional structured grid are generated into three-dimensional At the same time, the three-dimensional unstructured mesh of the middle part of the watershed is generated; the three-dimensional flow field meshes of the upper, middle and lower parts of the spring valve are integrated to obtain the overall flow field mesh of the valve group. The invention can provide a grid that conforms to the actual motion law of the model and facilitates the setting of dynamic grids for the numerical simulation of the dynamic flow field of the spring valve. The motion and static sub-regions in the watershed do not affect each other, and the block-structure grid is easy to generate dense motion. Boundary layer mesh, the accuracy of numerical simulation is greatly improved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com