A dual-mode muffler valve automatic pre-twist welding detection equipment

A welding detection and muffler technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult determination of spring pre-torsion loading force, low manual operation efficiency, and low degree of automation, so as to improve production efficiency and assembly Accuracy, prevention of adverse effects, guaranteed automation and high efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

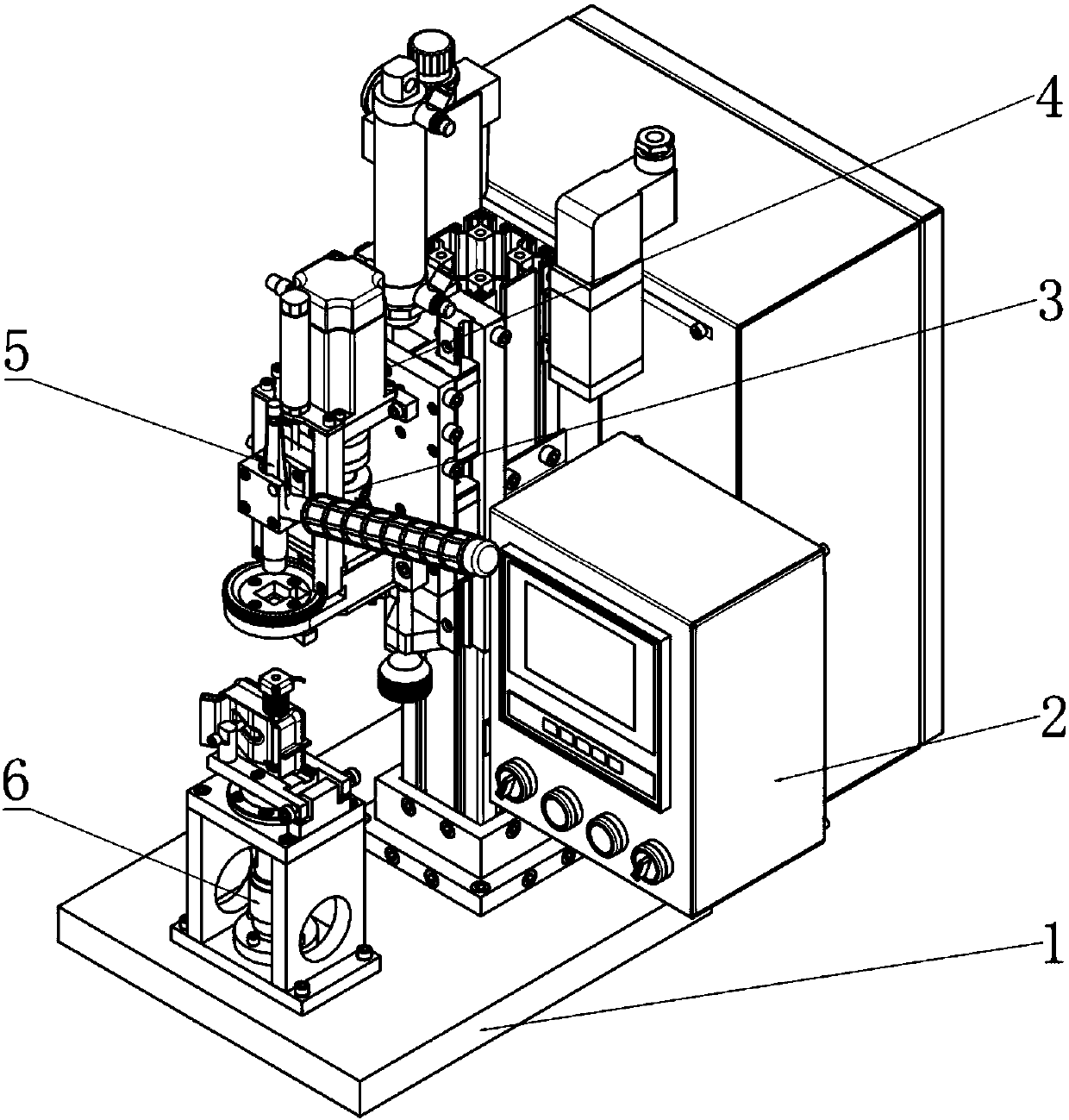

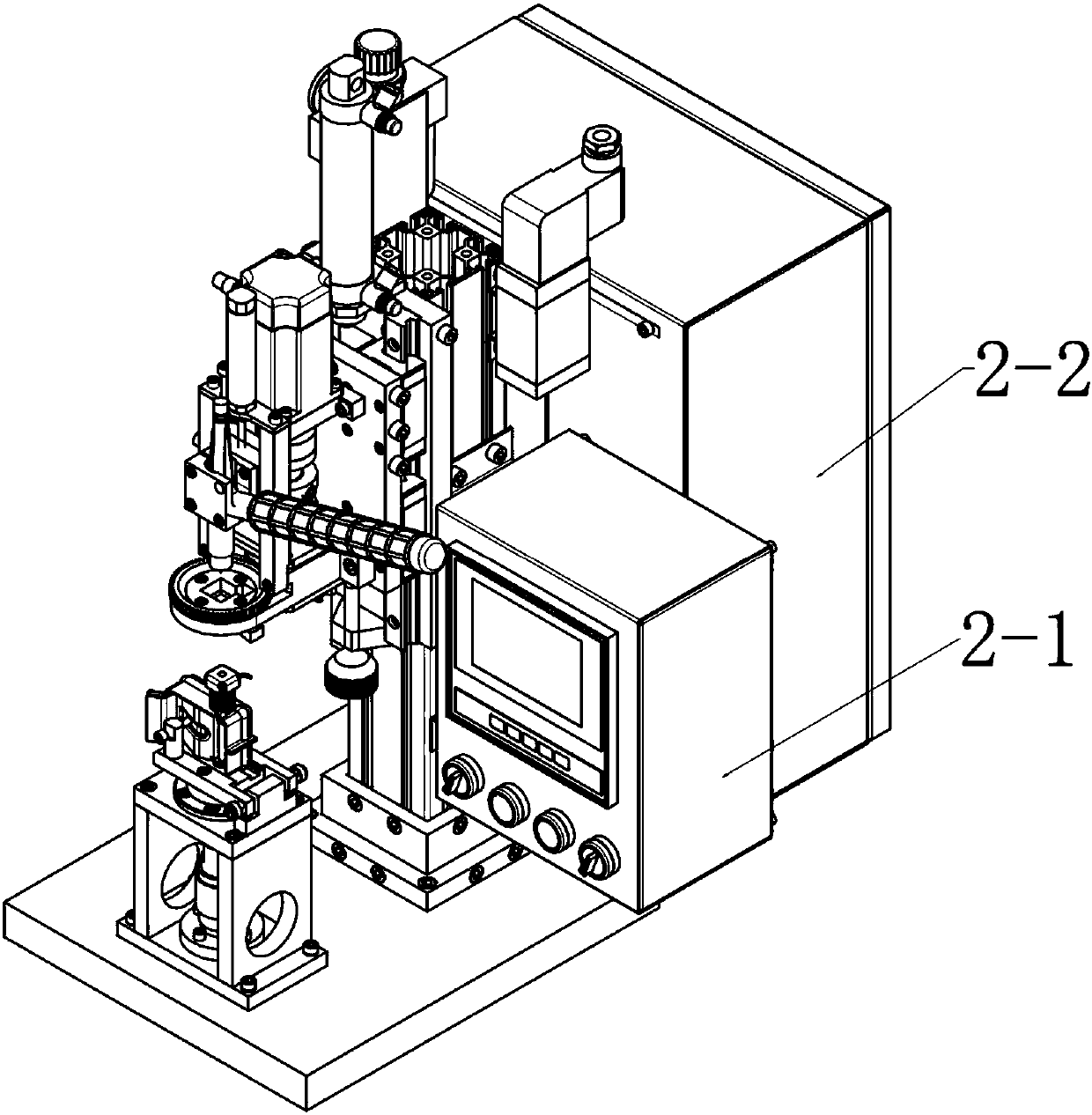

[0034] as attached figure 1 As shown, the present invention is mainly composed of six parts: support 1, control system 2, limit system 3, drive system 4, welding system 5, and torque measurement system 6, wherein support 1 is mainly used to support the other five systems.

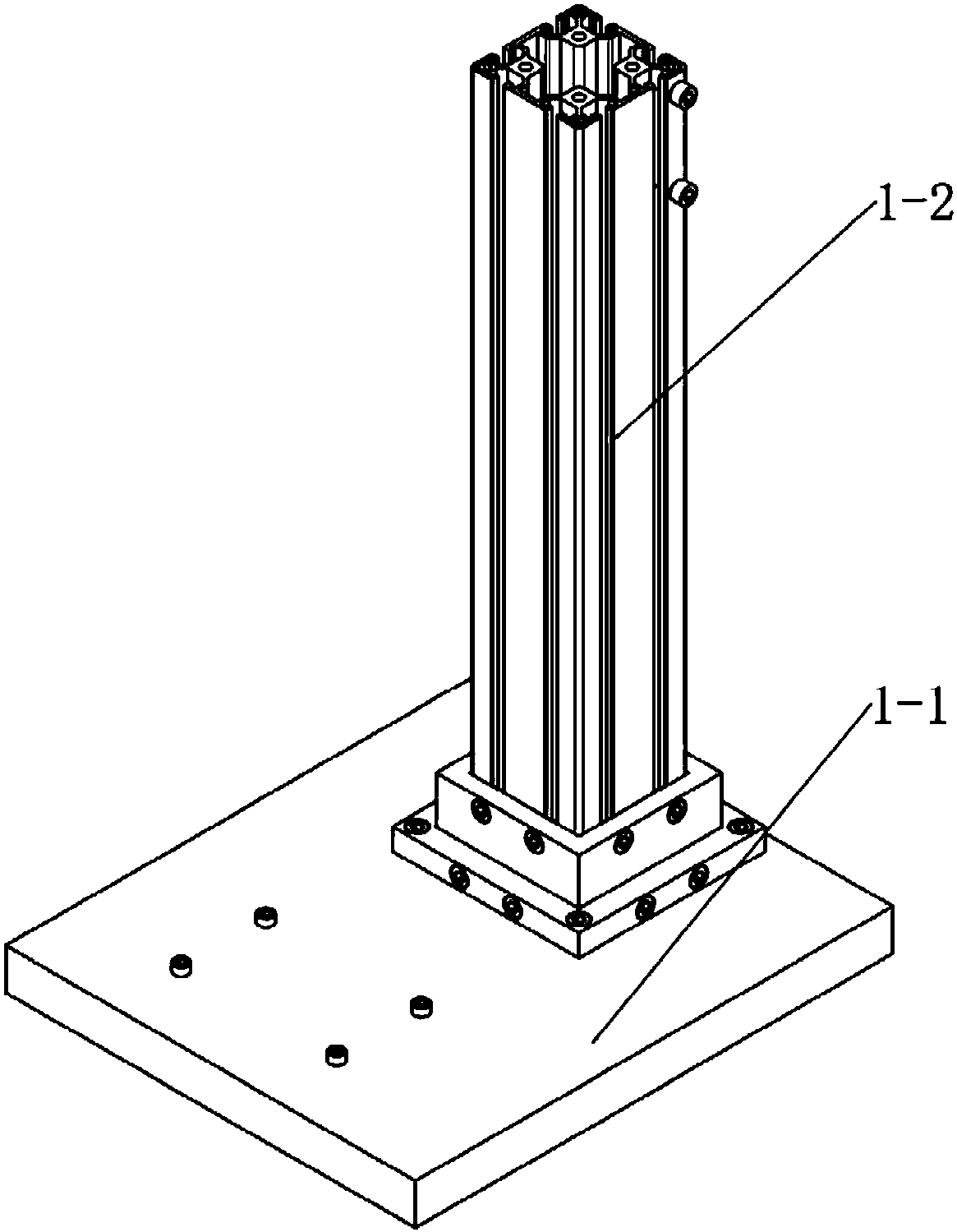

[0035] as attached figure 2 As shown, the bracket 1 is mainly composed of two parts: the base 1-1 and the column 1-2: the base 1-1 is made of thick steel plate, which is convenient for lowering the overall center of mass and reducing vibration, and there are multiple bolt holes processed on the base for easy installation The torsion measurement system 6; the column 1-2 is made of aluminum alloy profiles, and there are multiple grooves on the outer surface, which is convenient for fixing other systems by bolts.

[0036] as attached image 3 Shown is the hardware syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com