Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Mixer-settler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixer settlers are a class of mineral process equipment used in the solvent extraction process. A mixer settler consists of a first stage that mixes the phases together followed by a quiescent settling stage that allows the phases to separate by gravity.

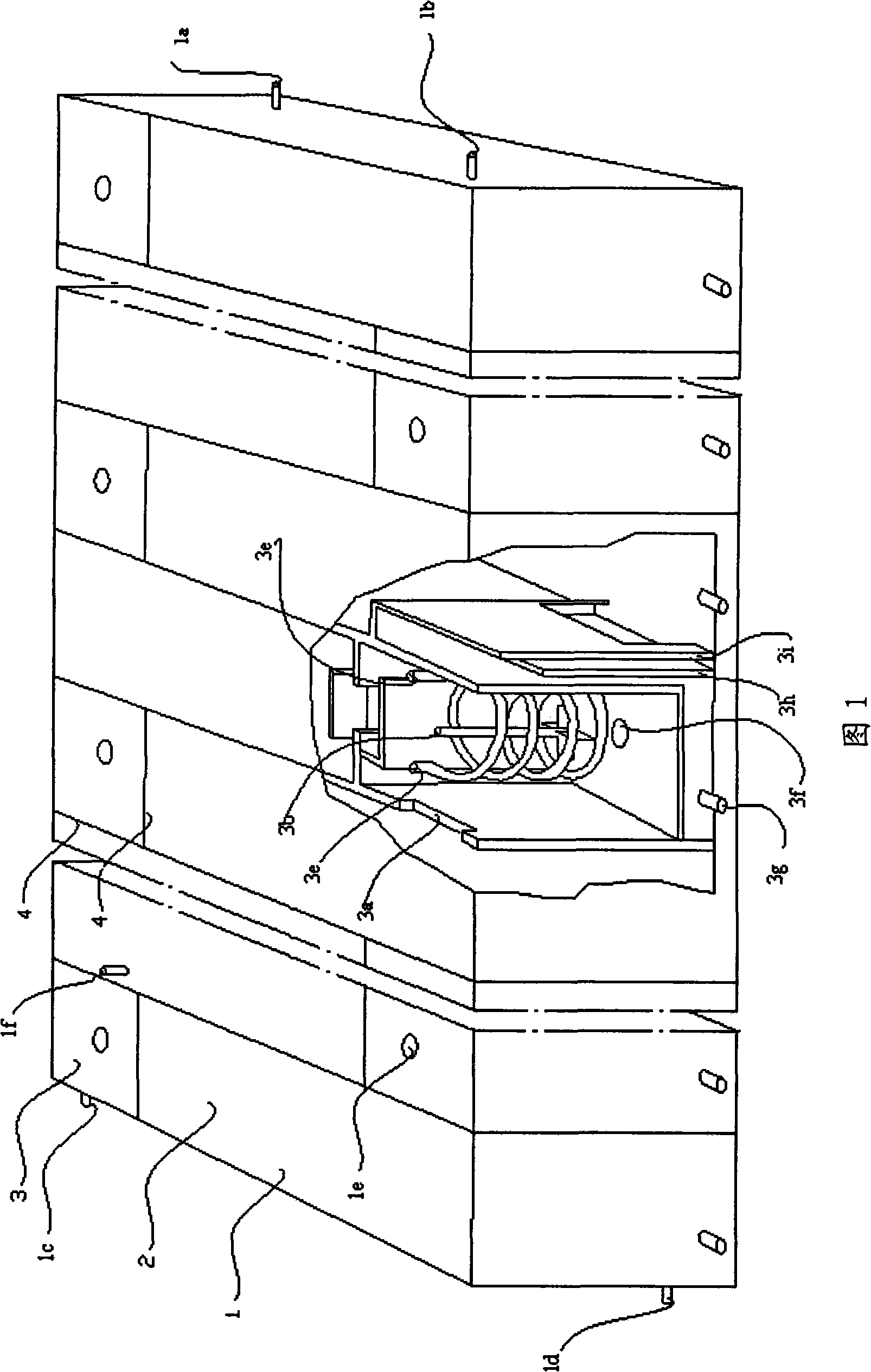

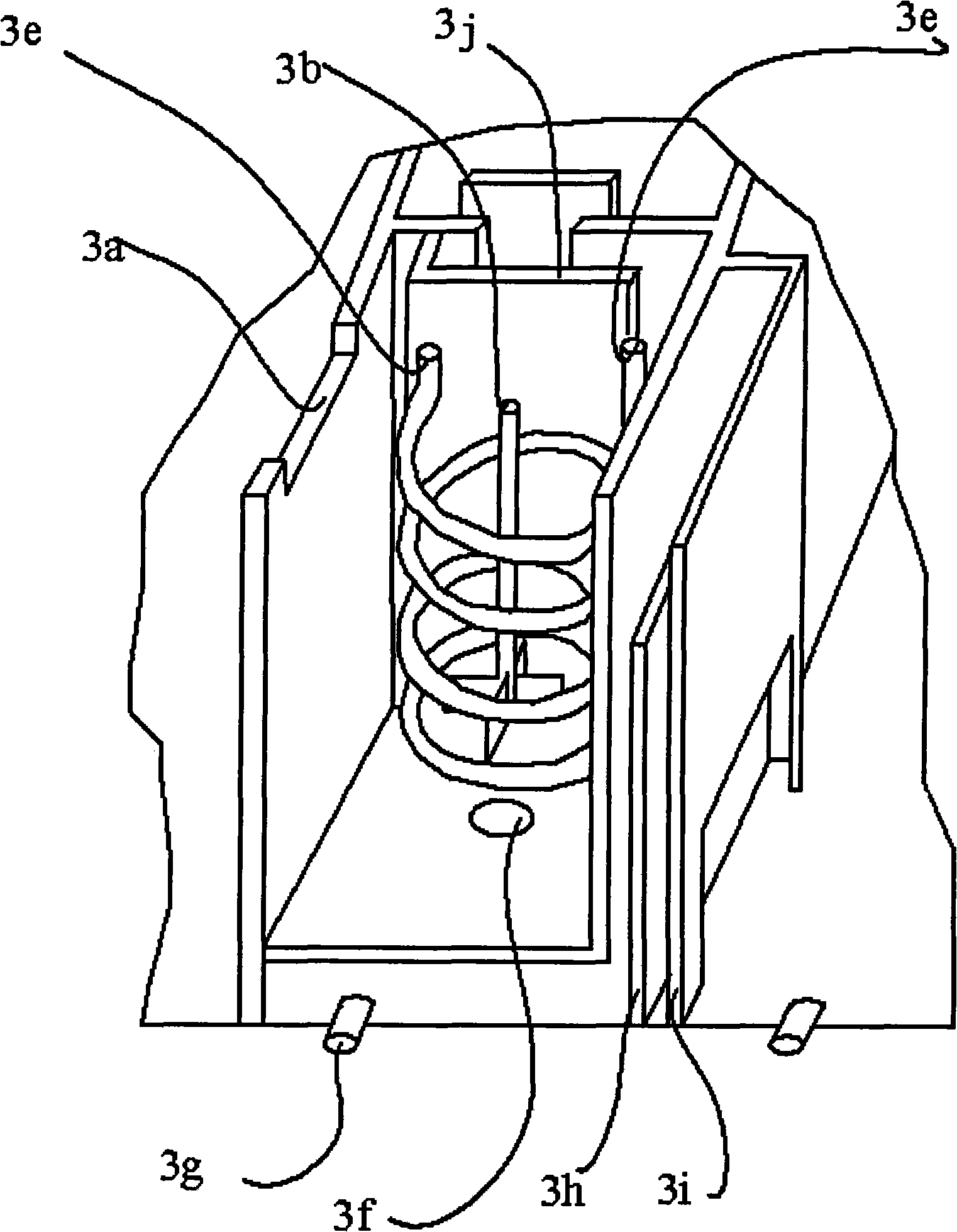

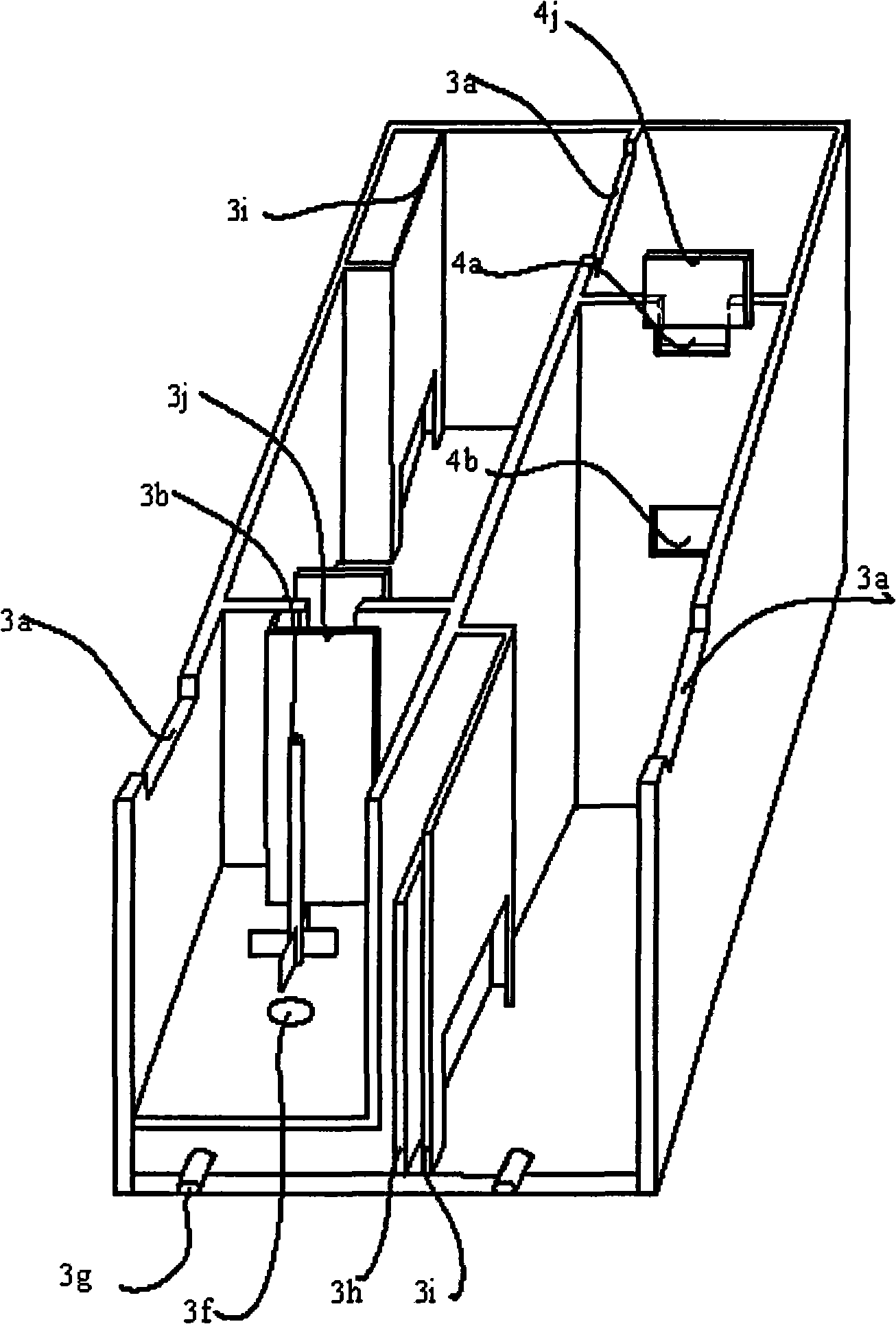

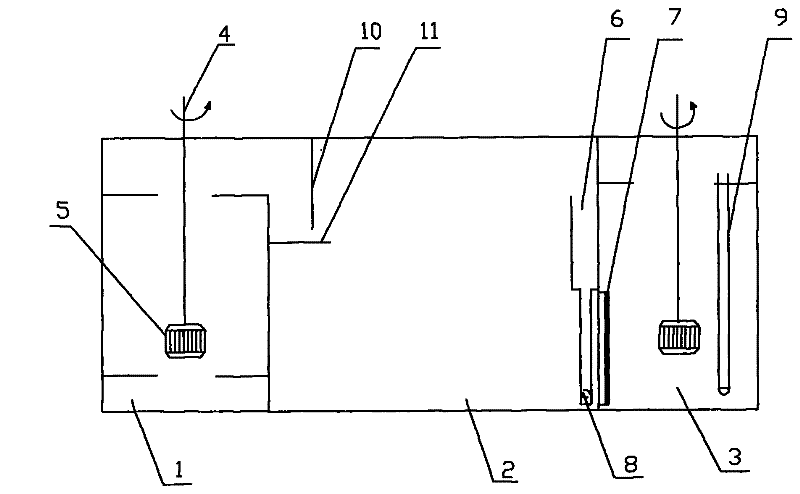

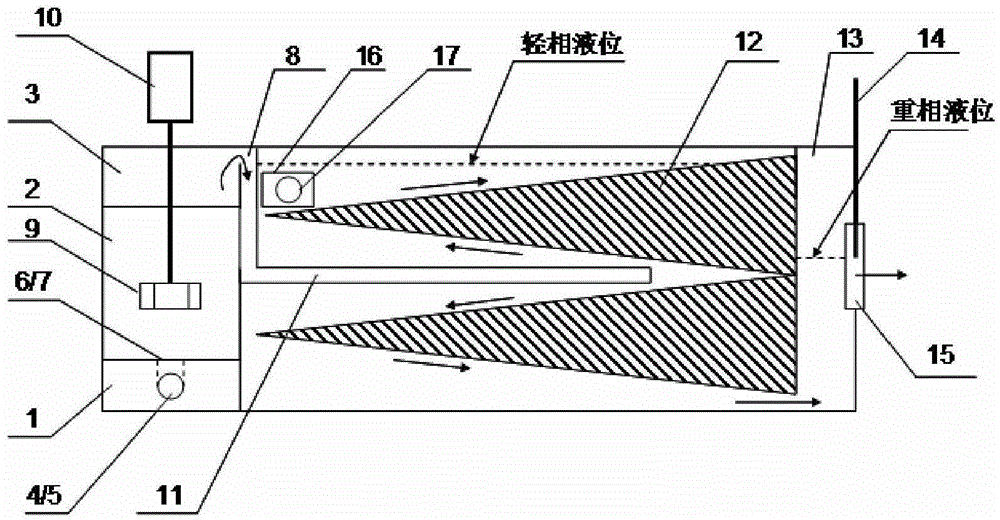

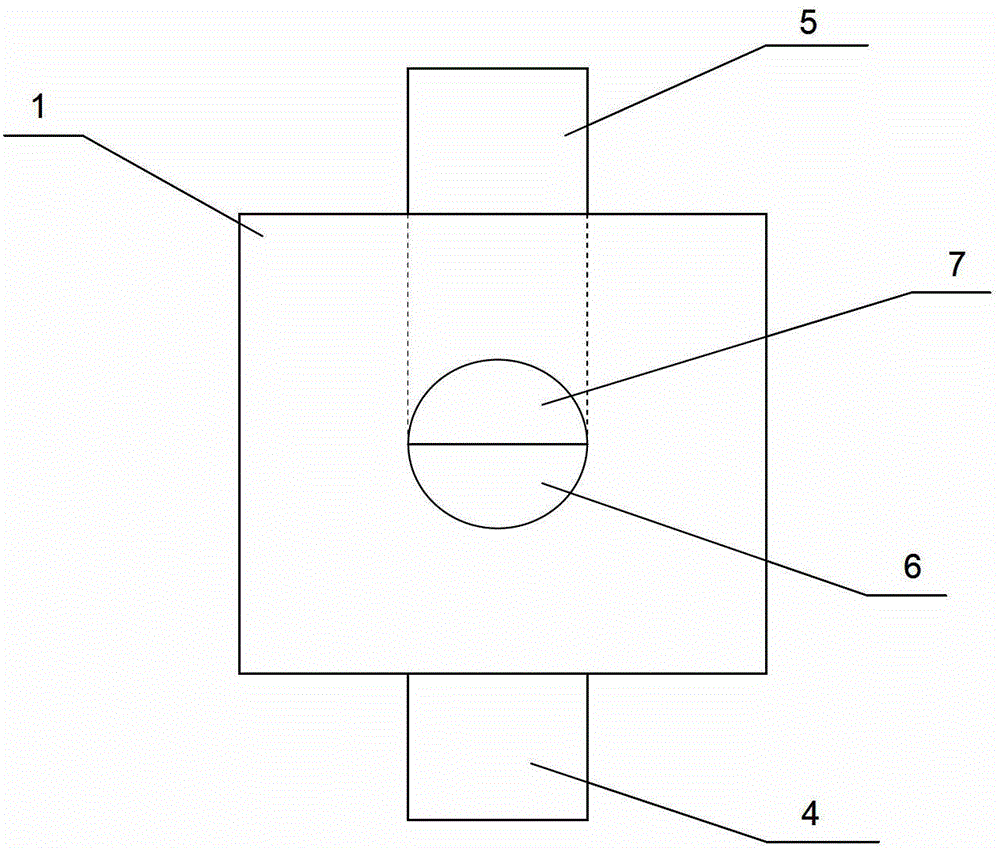

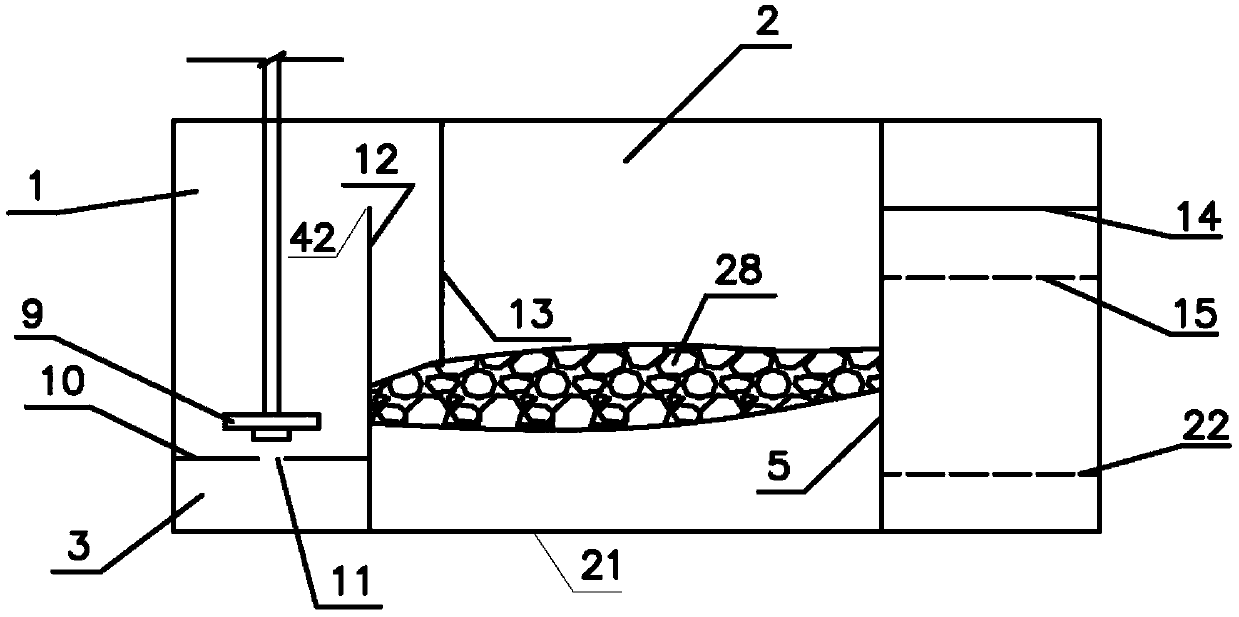

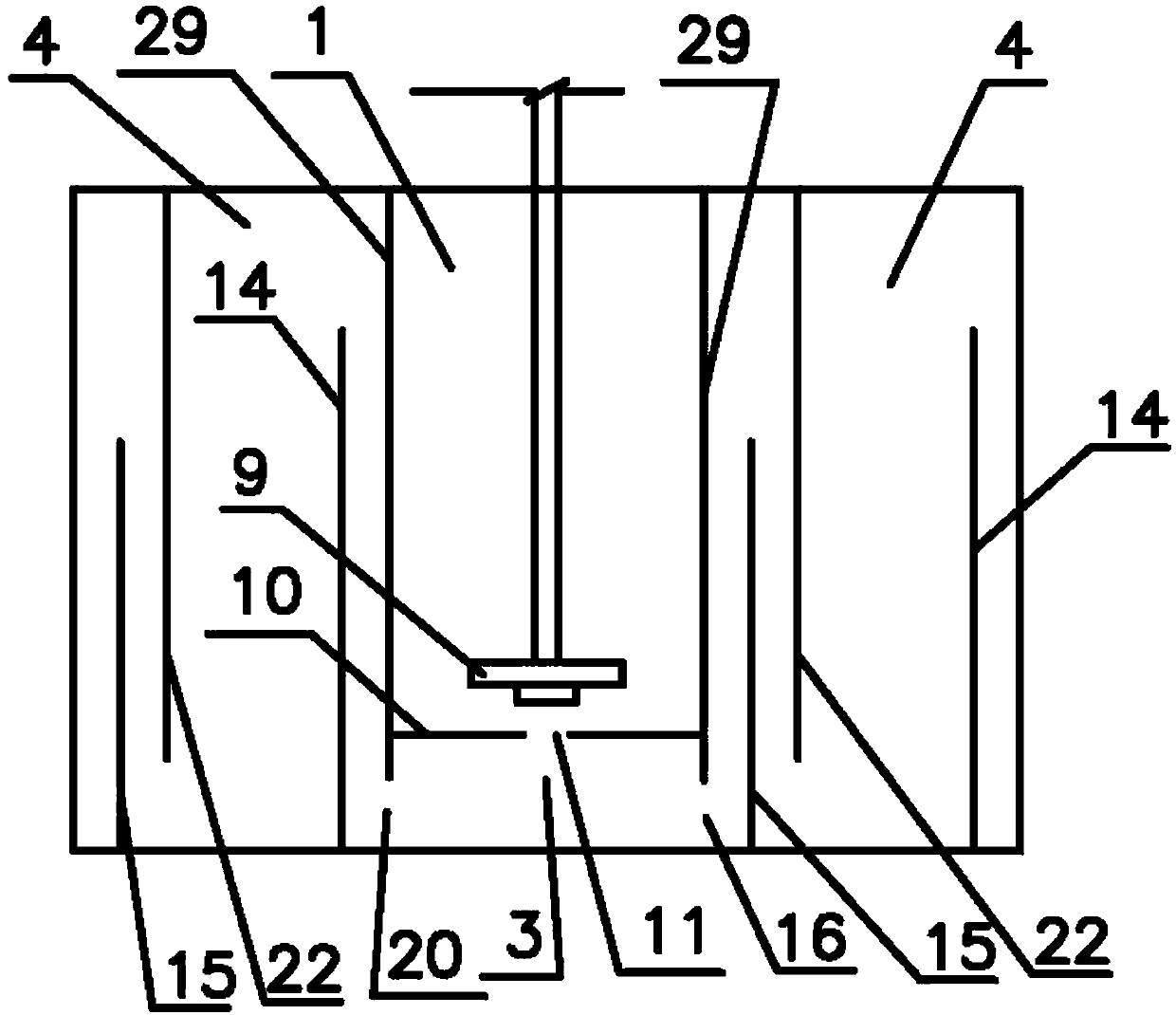

Mixer settler for three-phase extraction

InactiveCN101991971AAchieve separationSolving Three-Phase Flow ProblemsLiquid solutions solvent extractionPhase mixingThree stage

The invention belongs to a liquid-liquid-liquid three-phase multi-stage continuous extraction device, and particularly relates to a mixer settler for three-phase extraction, which can extract the target component in one step and realizes high-level separation in a multi-component complex system. The mixer settler for three-phase extraction comprises a first-level mixer settler, a second-level mixer settler and a third-level mixer settler which have the same structure; and every mixer settler comprises a three-phase mixing chamber, a clarifying chamber, an intermediate-low phase mixing chamber, and the like. As an aqueous two-phase system, an intermediate phase and a salt-rich low phase rich in polymer are used as one phase under the condition of stirring to transfer mass during counterflow with the organic phase so that the problem of three-phase flow in the three-phase extraction process is solved and the multi-stage continuous extraction can be carried out. Under the circumference that the one-stage extraction separating effect is unsatisfactory in the multi-component complex system, the mixer settler for three-phase extraction can realize three-stage reverse flow continuous extraction and high-level multi-component separation according to the components. The invention successfully solves the problem of three-phase flow in the three-phase extraction process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

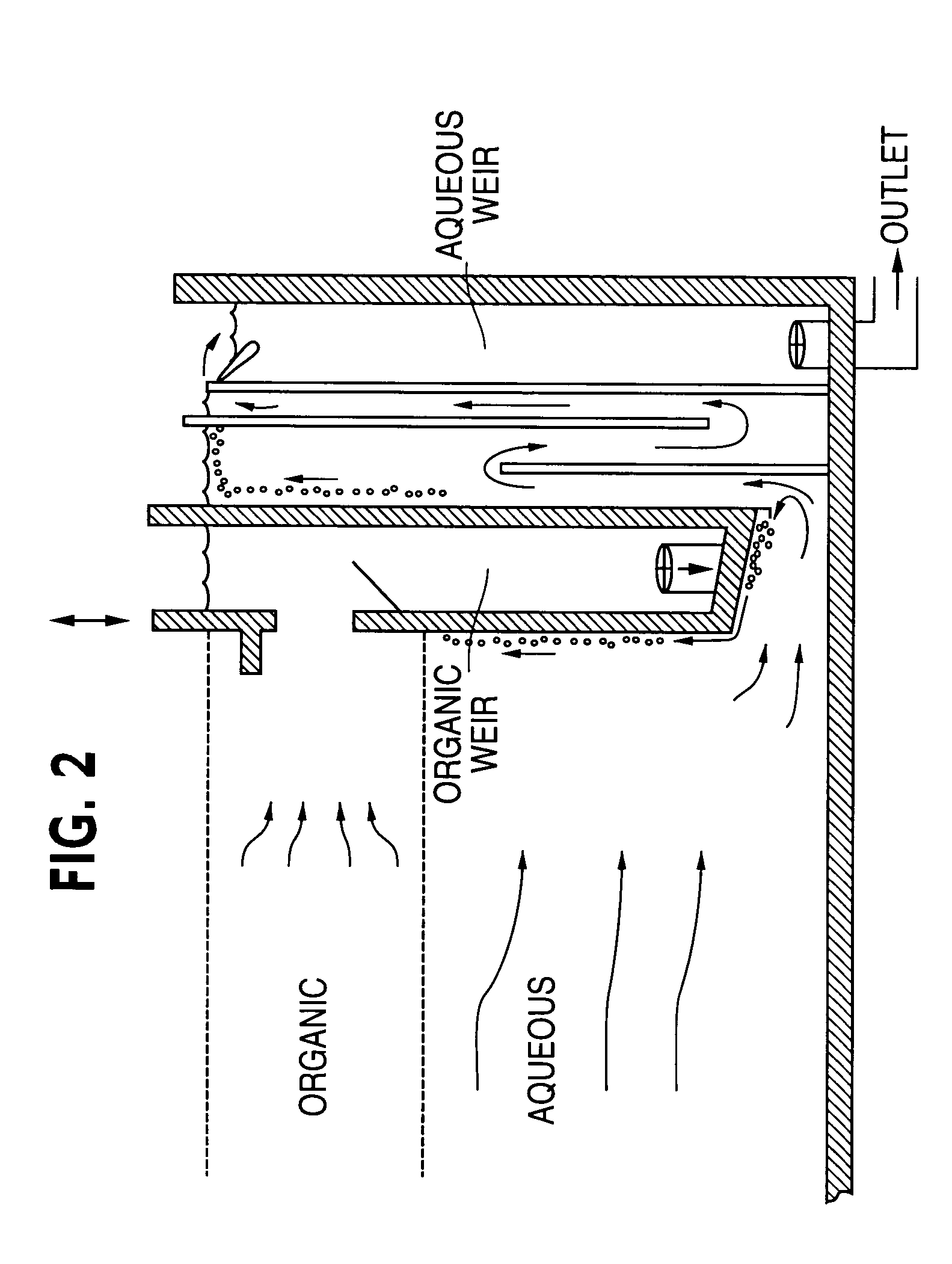

Solvent extraction method and apparatus

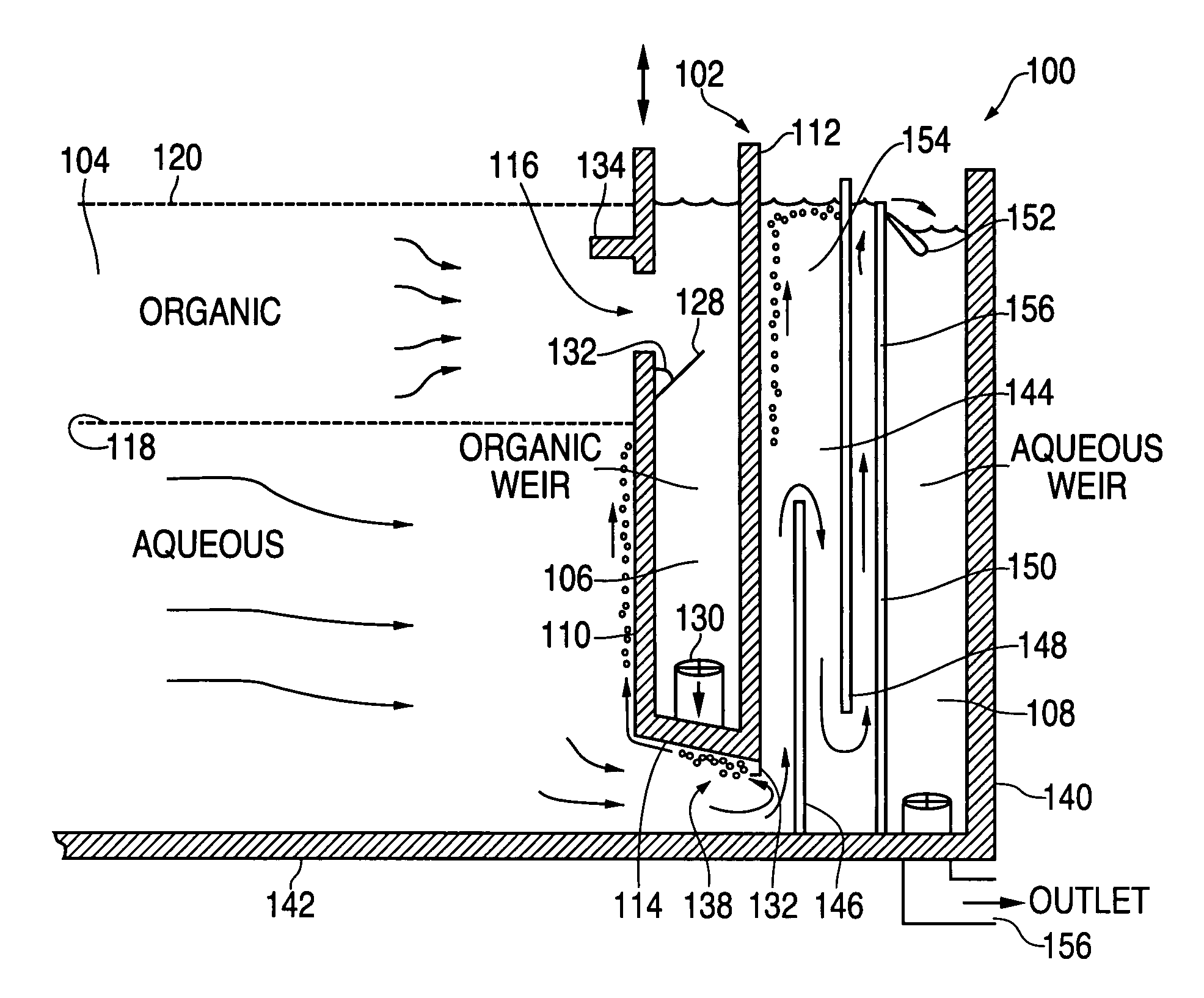

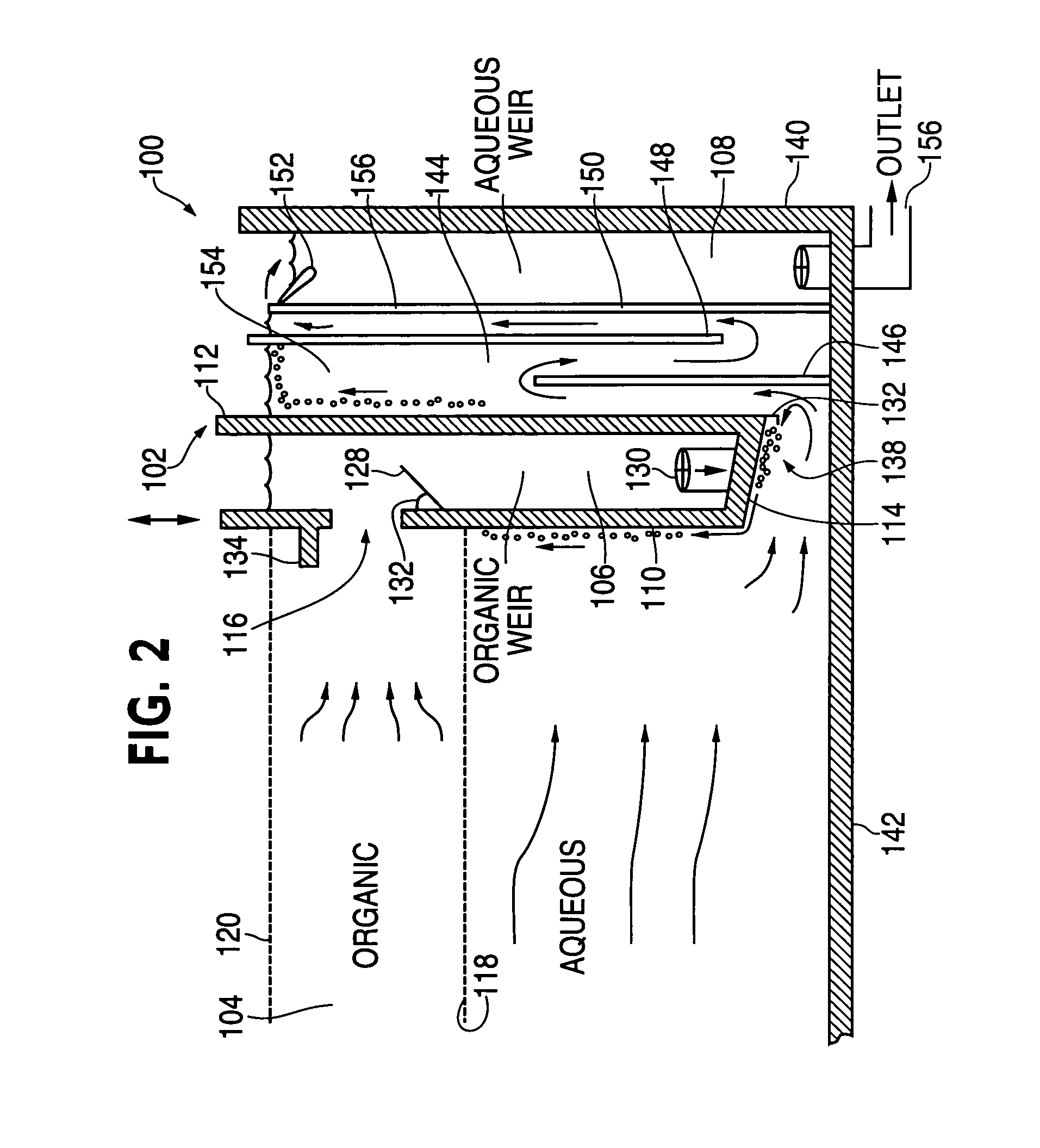

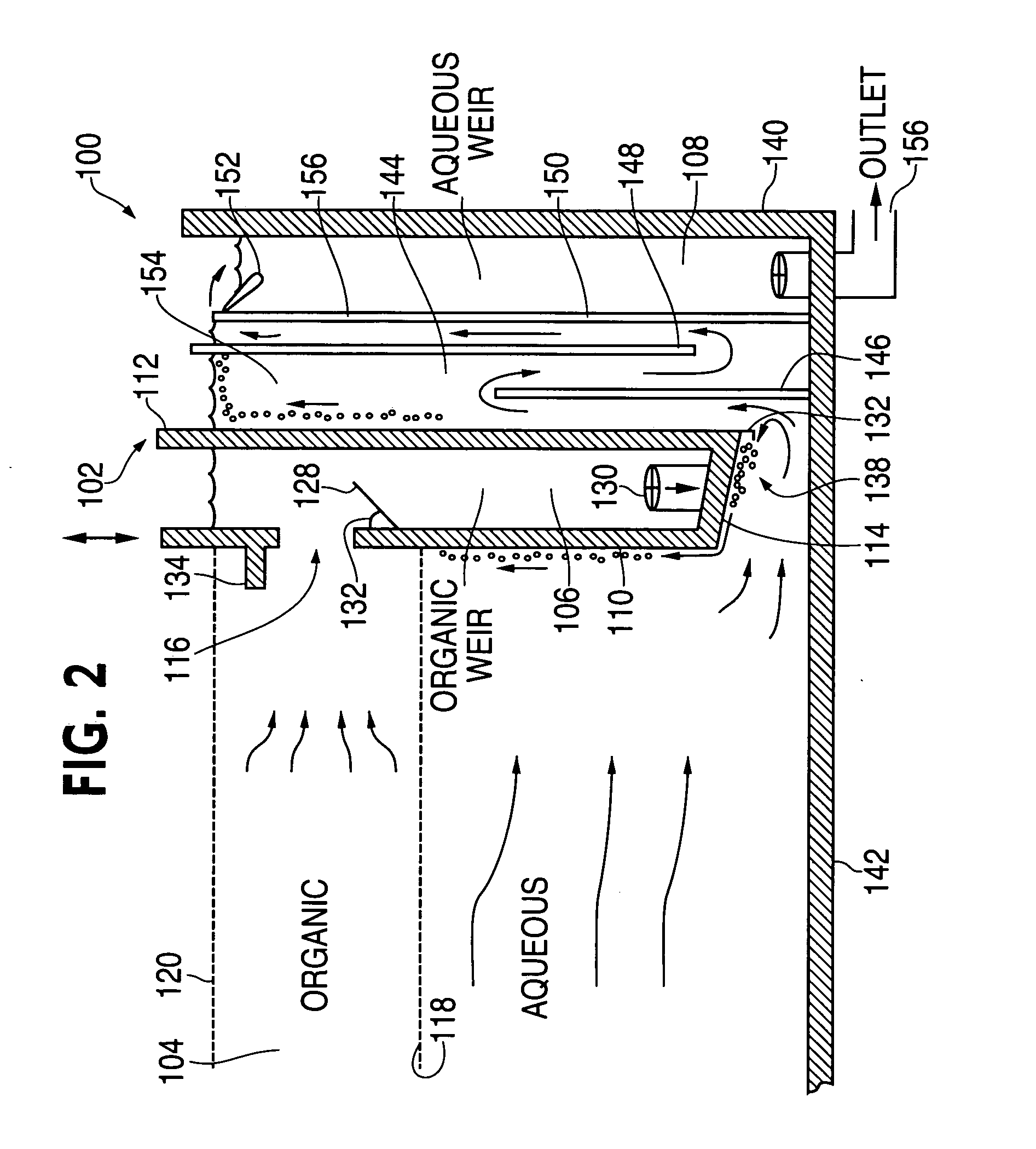

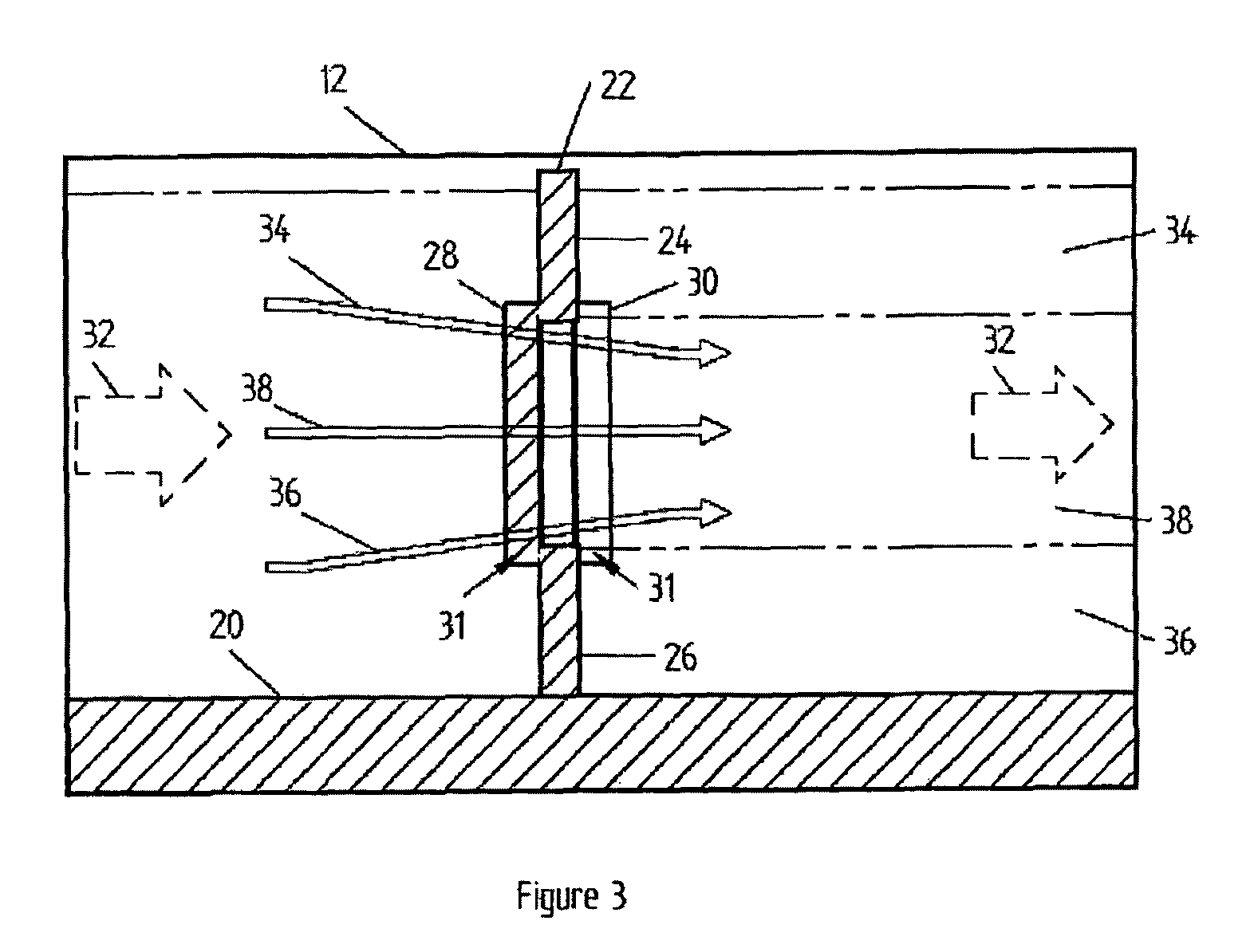

ActiveUS20050040106A1Reduce cross contaminationEasy to separateWater/sewage treatment bu osmosis/dialysisLiquid solutions solvent extractionEngineeringMixer-settler

A weir assembly for use with a mixer-settler for liquid-liquid extraction includes in one embodiment an organic weir having an inlet opening below the free surface of the organic phase liquid and a vertically-adjustable front wall allowing adjustments in the position and / or height of the inlet opening. The organic weir can also feature an angled bottom coupled to a lip segment, an incline plate in the interior of the weir, and a front wall that is angled with respect to incoming fluid flow. In another embodiment the weir assembly can independently or additionally include an aqueous weir with a labyrinth section. The aqueous weir can optionally include an adjustable lip hingedly coupled to the top of the final partition in the labyrinth section.

Owner:SPX FLOW INC

Mixing and settling method and device in solvent extraction processes to recover high-purity products

ActiveUS7507343B2Easy to pourLower Level RequirementsFlow mixersRotary stirring mixersPhase separation processEngineering

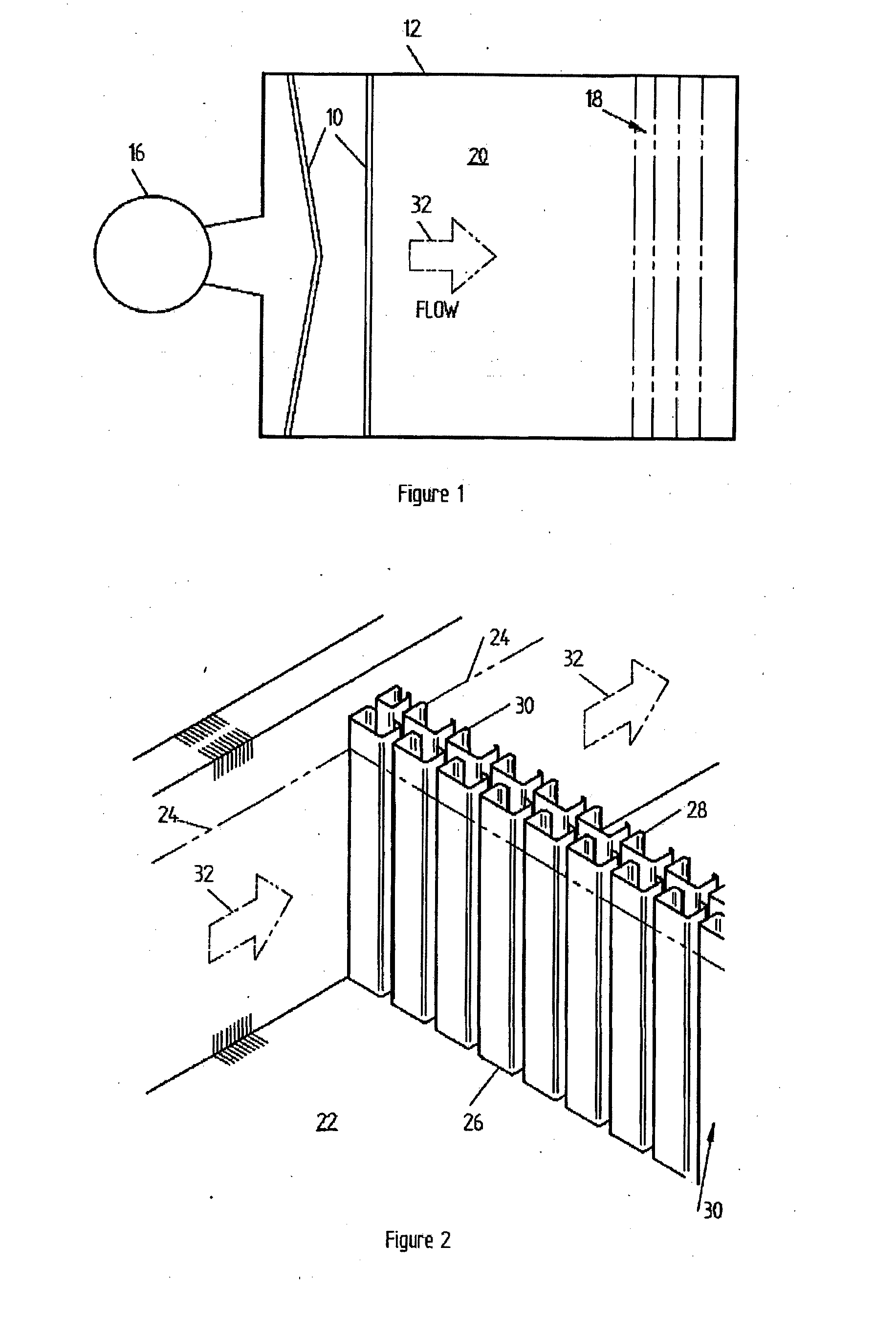

The device of the invention includes the following 5 new elements in each mixer-settler: a) agitators with blunt edged turbines, b) decreasing degree of agitation throughout the series of mixing compartments, c) baffle with a central window in the settler interface, located after the flow buffers, and d) baffle without a window, centered in the settler interface, located after the baffle with a window. These elements allow for an operative method which inhibits secondary dispersion, reducing the formation of micro-droplets, without affecting the mass transfer between the phases. Consequently, this obtains a phase separation process with entrainments so small that it is possible to drastically increase the quality of the product, by obtaining an ultra-pure aqueous extract, simultaneously reducing the settling surface required.

Owner:TECH REUNIDAS SA

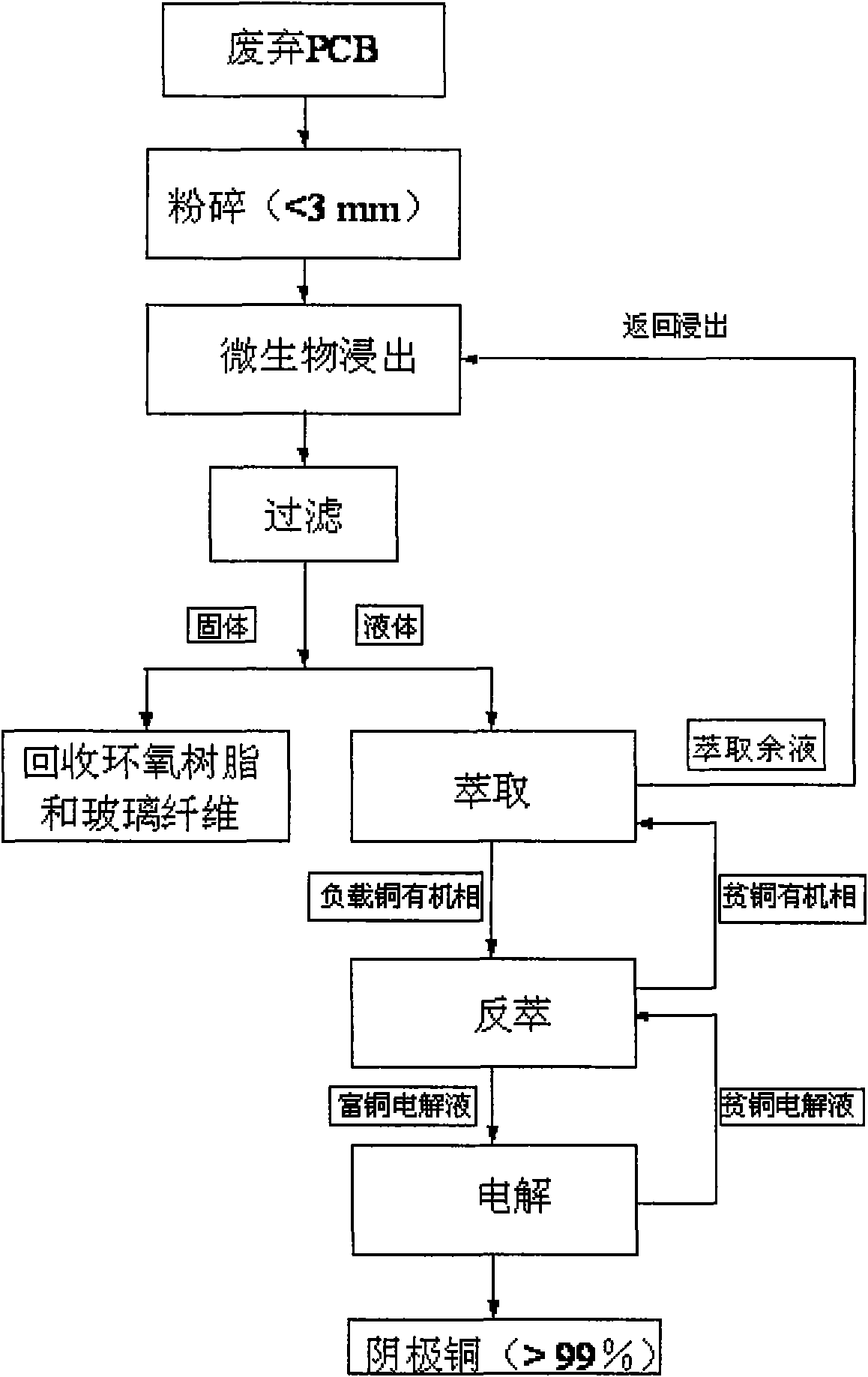

Method for recycling and treating waste circuit board

InactiveCN101935759ACause secondary pollutionImprove recycling efficiencyPhotography auxillary processesProcess efficiency improvementParticulatesReaction temperature

The invention relates to a method for recycling and treating a waste circuit board. The method comprises the following steps of: A, grinding the waste circuit board into particles by using a grinder; B, putting the particles obtained in the step A into a reaction kettle, performing a microbial strain leaching reaction and stirring repeatedly to react uniformly, wherein the reaction temperature is between 25 and 30 DEG C and the concentration of the strain is between 8 and 10 mg / l; C, separating a mixture obtained in the step B by using a filtering machine and allowing filtrate to flow into a mixer settler in an extraction process; D, adding an extracting agent into the mixer settler and shunting a copper-loaded organic phase into a back-extraction groove; E, adding inorganic acid into the back-extraction groove, partitioning copper-loaded solution into lower layer copper-rich electrolyte and upper layer copper-poor electrolyte and shunting the lower layer copper-rich electrolyte into an electrolytic bath; and F, electrolyzing copper electrolyte in the electrolytic bath to obtain elementary copper. The method has the advantages of low treatment cost, good environmental protection and high treatment capability.

Owner:惠州市雄越保环科技有限公司

Solvent extraction method and apparatus

InactiveUS7328809B2Reducing air entrainmentAir entrainment is reducedLiquid displacementLiquid solutions solvent extractionMixer-settlerSolvent

A weir assembly for use with a mixer-settler for liquid-liquid extraction includes in one embodiment an organic weir having an inlet opening below the free surface of the organic phase liquid and a vertically-adjustable front wall allowing adjustments in the position and / or height of the inlet opening. The organic weir can also feature an angled bottom coupled to a lip segment, an incline plate in the interior of the weir, and a front wall that is angled with respect to incoming fluid flow. In another embodiment the weir assembly can independently or additionally include an aqueous weir with a labyrinth section. The aqueous weir can optionally include an adjustable lip hingedly coupled to the top of the final partition in the labyrinth section.

Owner:SPX FLOW INC

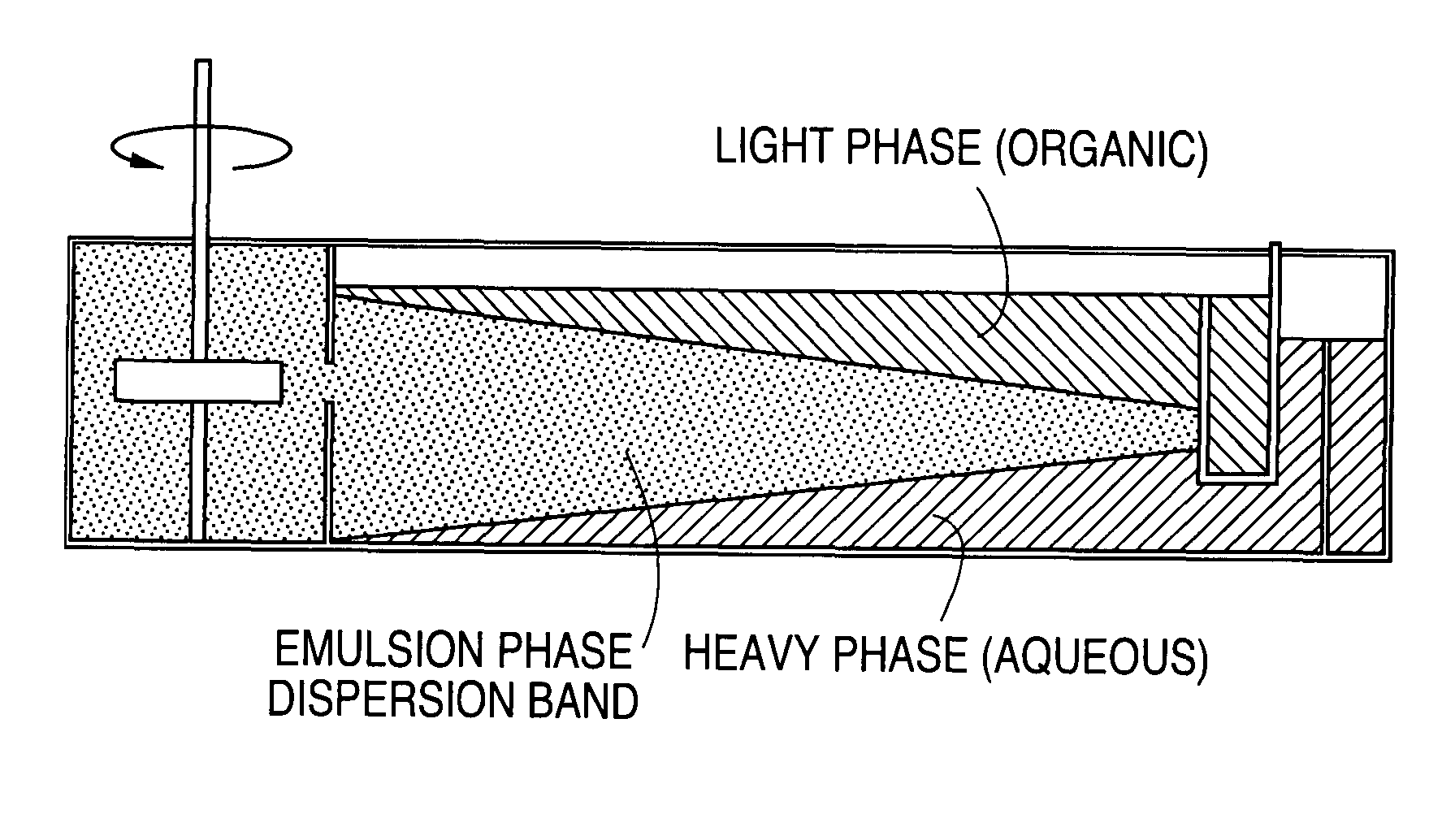

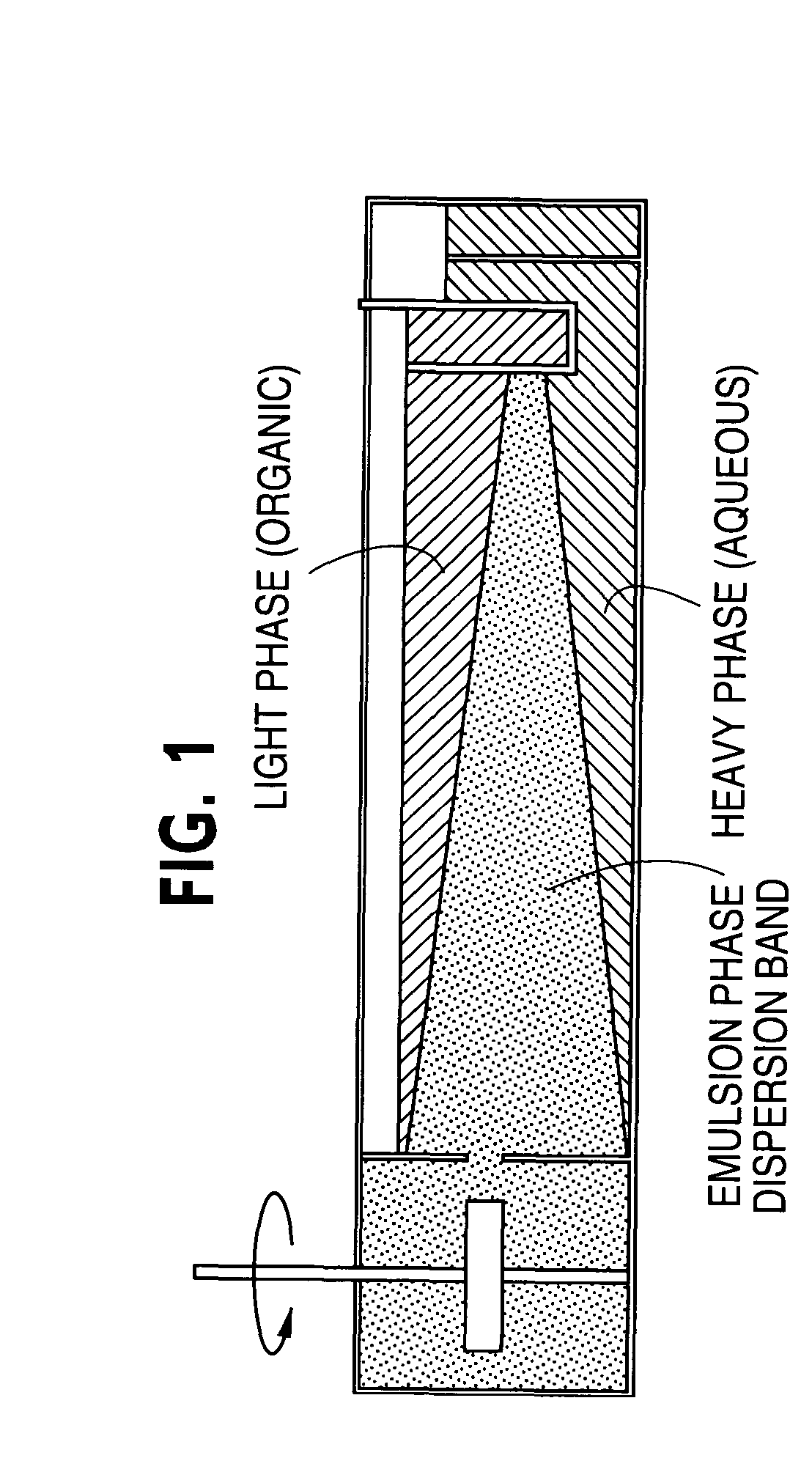

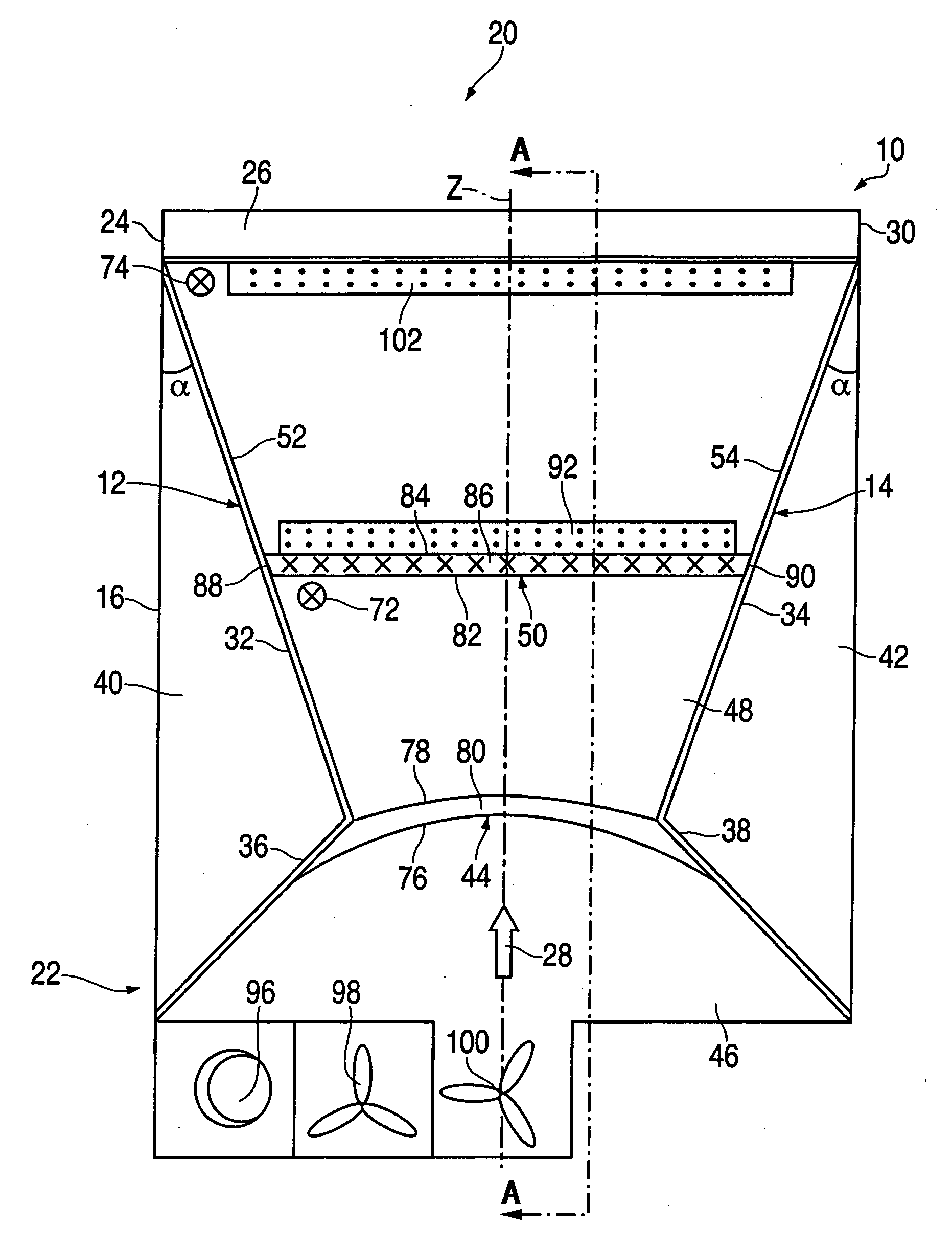

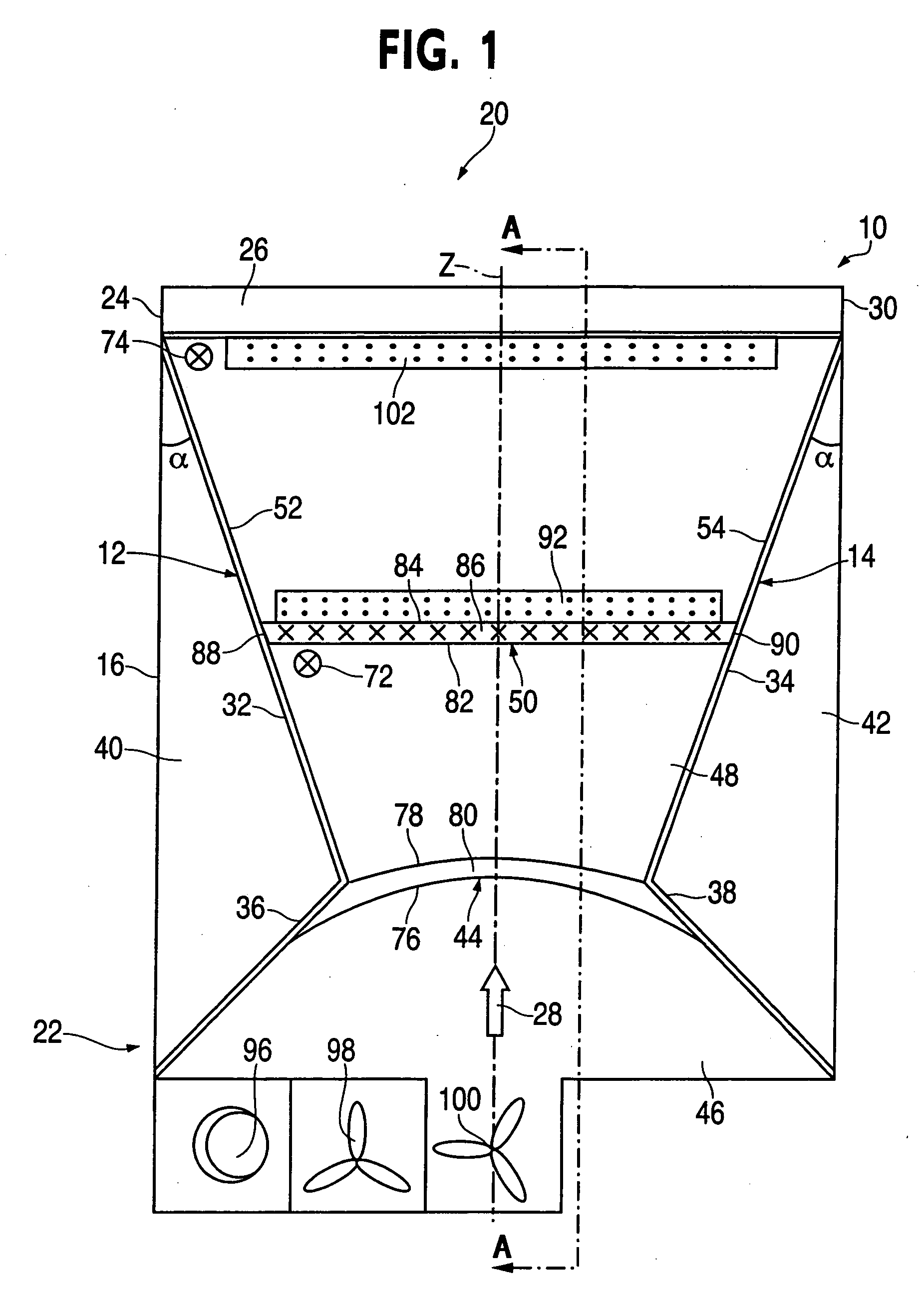

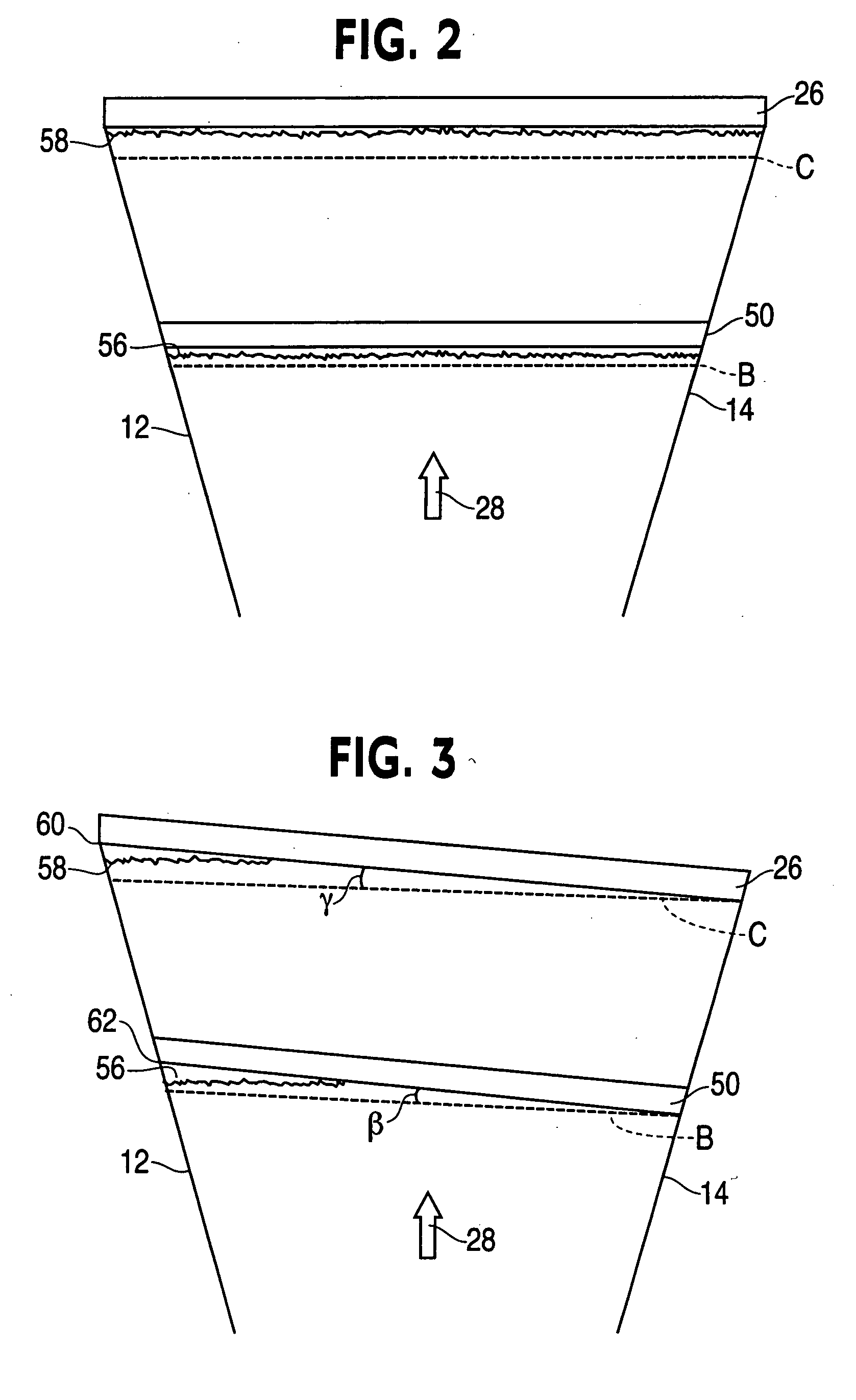

Cylindrical mixer-settler apparatus and method

ActiveUS20060165569A1Effective operational volumeLittle recirculationSolvent extractionLiquid displacementEngineeringMixer-settler

Owner:SPX FLOW INC

Solvent extraction method and apparatus

ActiveUS20060131233A1Reducing air entrainmentAir entrainment is reducedLiquid displacementWater/sewage treatment bu osmosis/dialysisEngineeringMixer-settler

A weir assembly for use with a mixer-settler for liquid-liquid extraction includes in one embodiment an organic weir having an inlet opening below the free surface of the organic phase liquid and a vertically-adjustable front wall allowing adjustments in the position and / or height of the inlet opening. The organic weir can also feature an angled bottom coupled to a lip segment, an incline plate in the interior of the weir, and a front wall that is angled with respect to incoming fluid flow. In another embodiment the weir assembly can independently or additionally include an aqueous weir with a labyrinth section. The aqueous weir can optionally include an adjustable lip hingedly coupled to the top of the final partition in the labyrinth section.

Owner:SPX FLOW INC

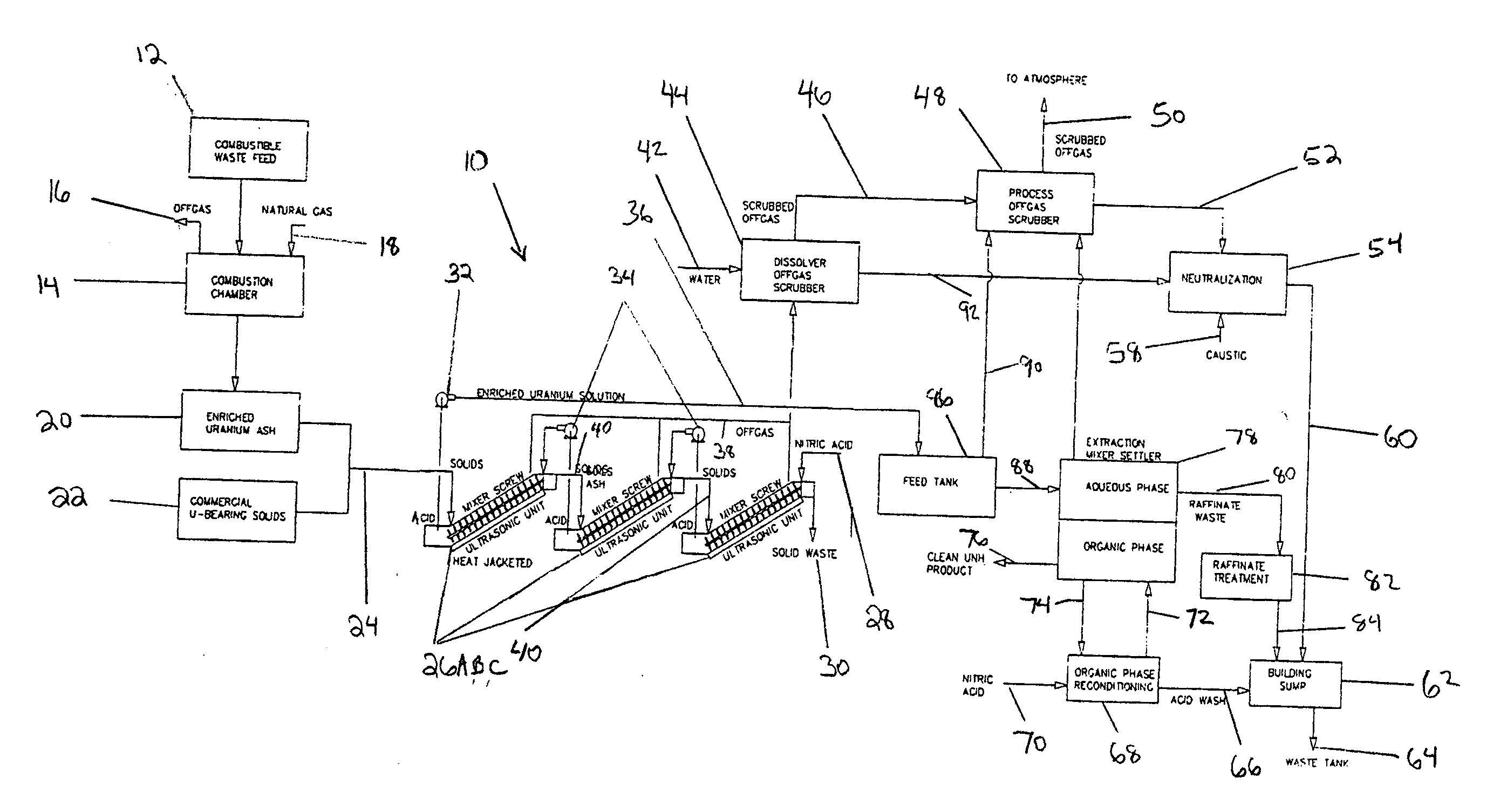

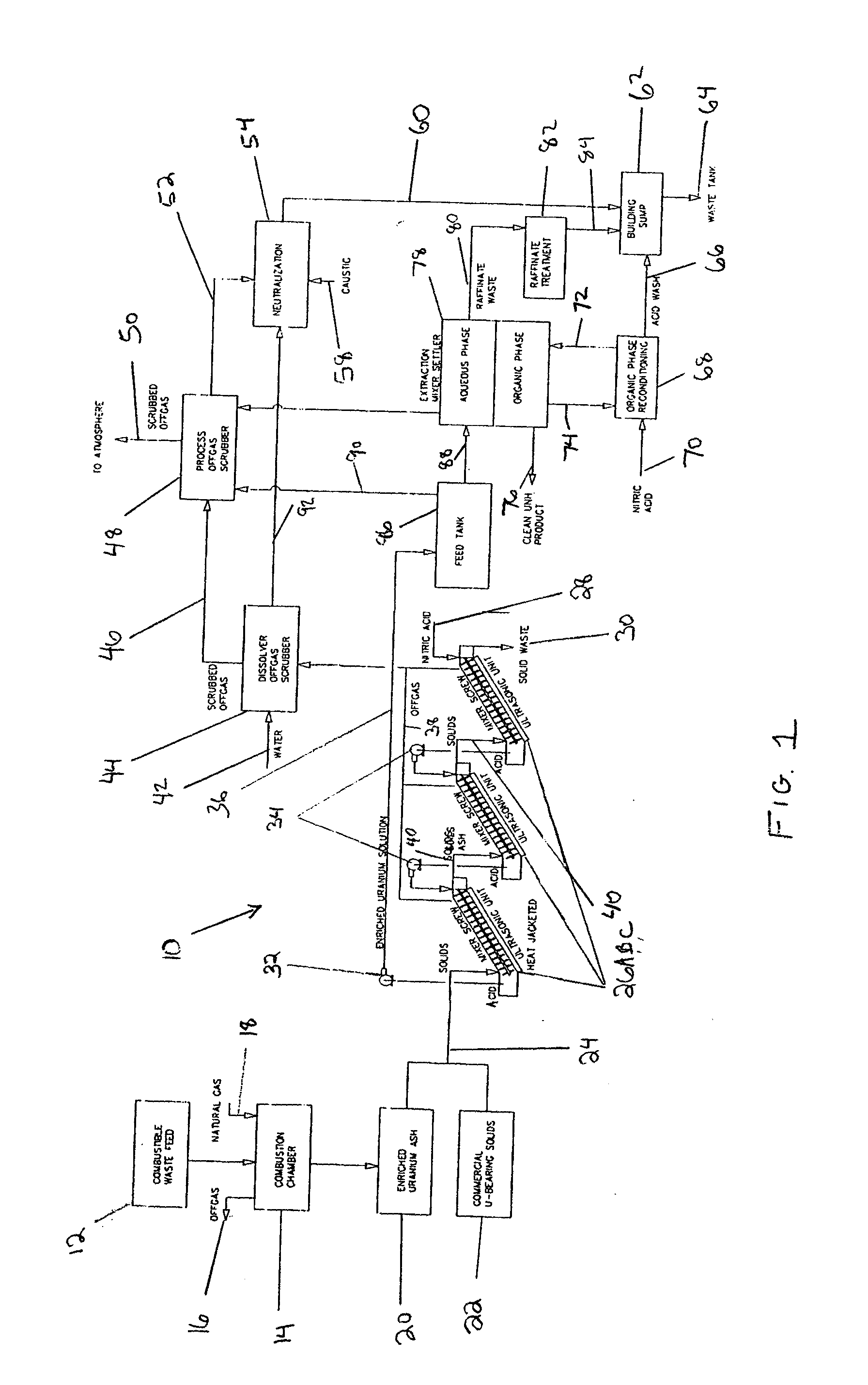

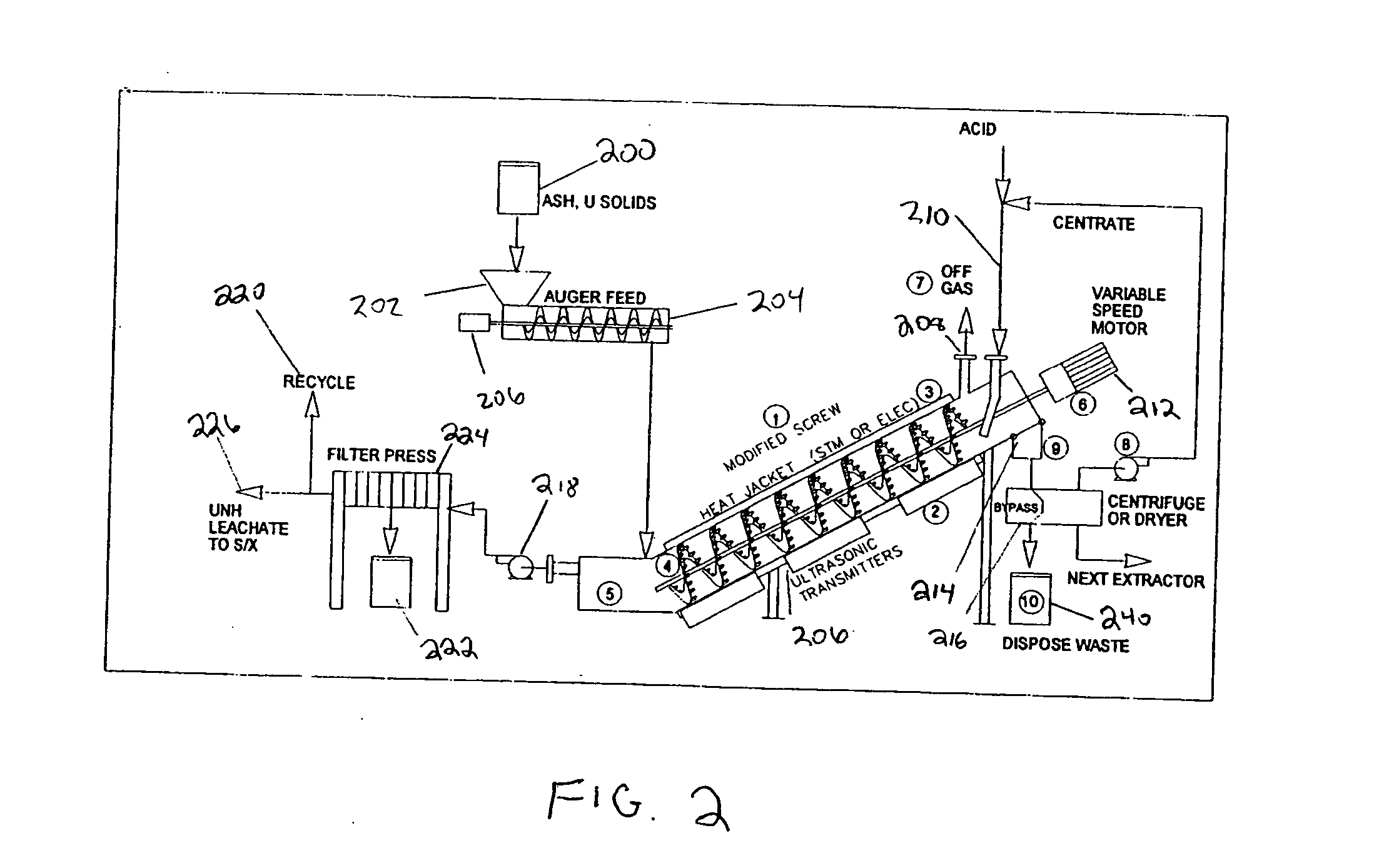

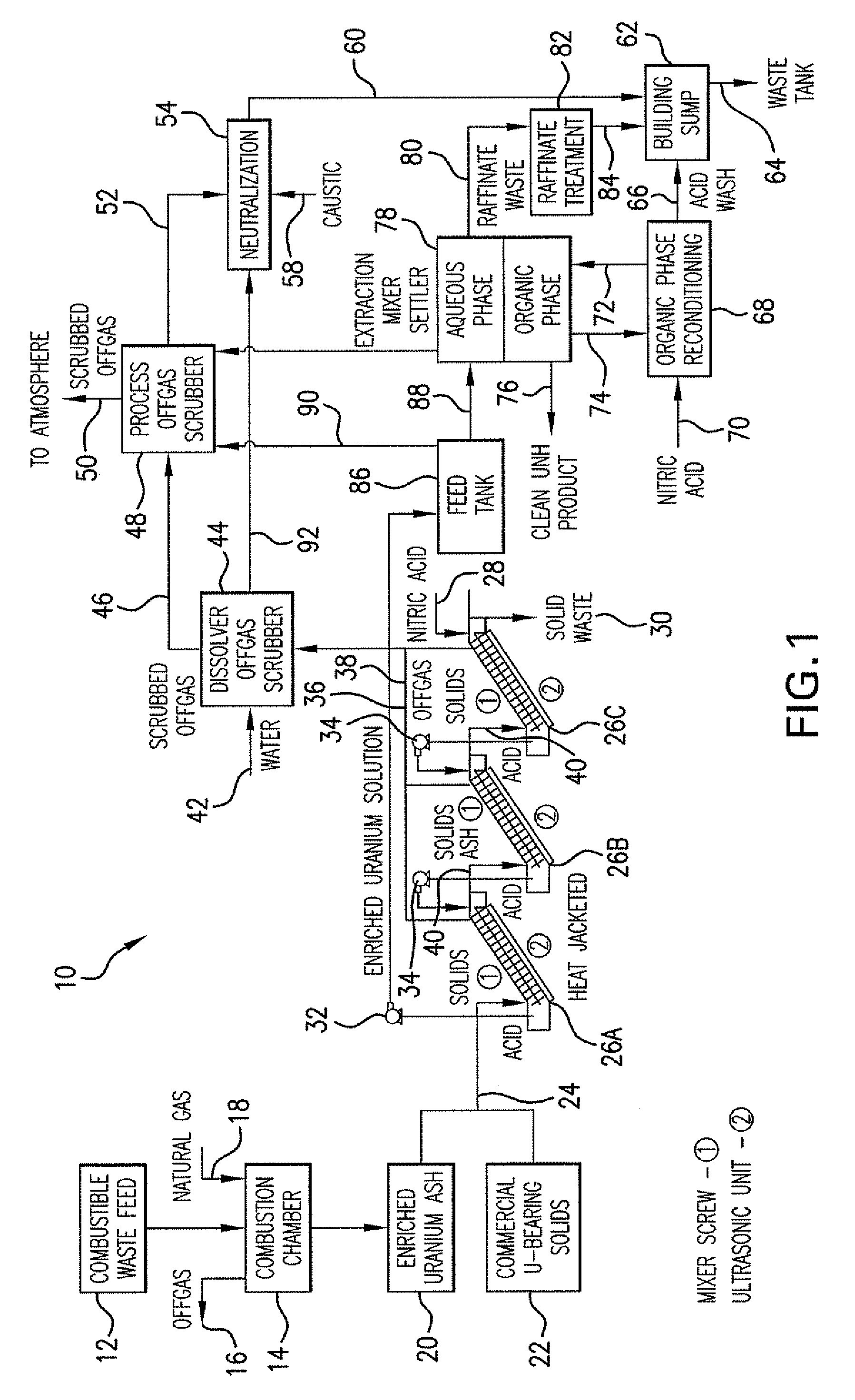

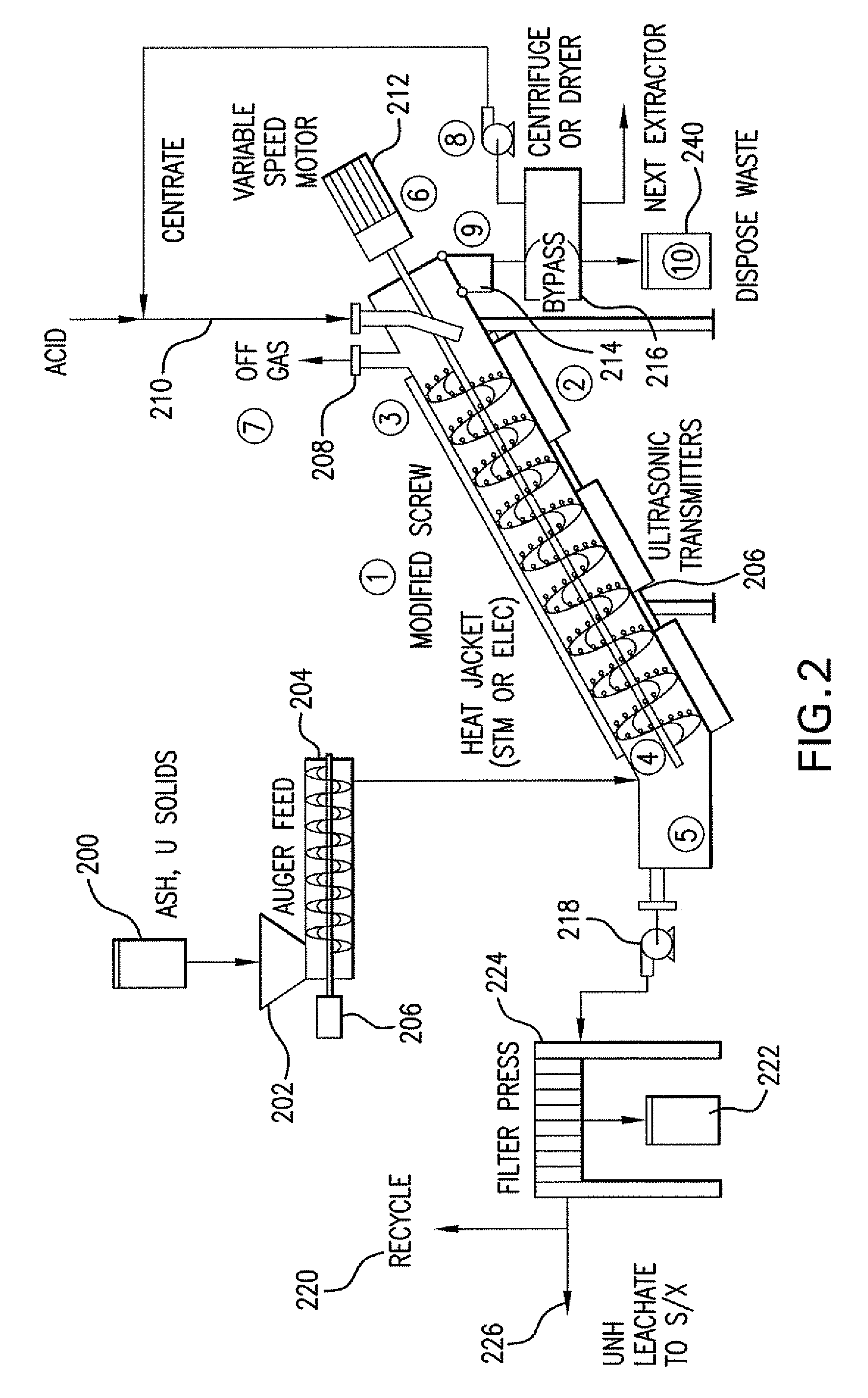

Ultrasonic counter-current screw extractor for uranium recovery

ActiveUS20060088457A1Improve efficiencySeparated economicallyShaking/oscillating/vibrating mixersTransuranic element compoundsScrew extractorMixer-settler

An apparatus and method to remove uranium from a body of material wherein the method includes the steps of depositing the body of solid material in an ultrasonic extractor and depositing an amount of acid in the ultrasonic extractor. The method also provides for the steps of heating a jacket of the ultrasonic extractor, transporting the body of solid material in the ultrasonic extractor and the amount of acid such that the body of solid material and the acid contact each other inside the heated ultrasonic extractor while the ultrasonic extractor provides ultrasonic energy to both the body of solid material and the amount of acid, wherein the amount of acid strips uranium from the body of solid material. The method further provides for collecting the amount of acid and the body of solid material in the ultrasonic extractor in different positions, transporting the amount of acid with the stripped uranium to an extraction mixer settler, and settling uranium product from the extraction mixer settler.

Owner:AREVA NP INC

Device for wet phosphoric acid refining and high-purity ammonium molybdate preparation

ActiveCN101274755AAchieving Continuity SmoothlySmooth realization of productivityMolybdeum compoundsPhosphorus compoundsPhosphoric acidMixer-settler

The invention relates to a device for preparing phosphoric acid and ammonium molybdate, in particular to a device used for refining phosphoric acid by a wet process and preparing high purity ammonium molybdate, and pertains to the field of chemical equipment. The device of the invention comprises an extraction tank, a washing tank and an anti-extraction tank which are all tank-typed mixer-settler extractor. By adopting a structure with a steel framework and made from organic materials, the device can not only effectively prevent corrosion by extraction agent, phosphoric acid, fluoride and sulfuric acid, but also can ensure the stability and durability of the structures of the tanks.

Owner:侯炎学 +2

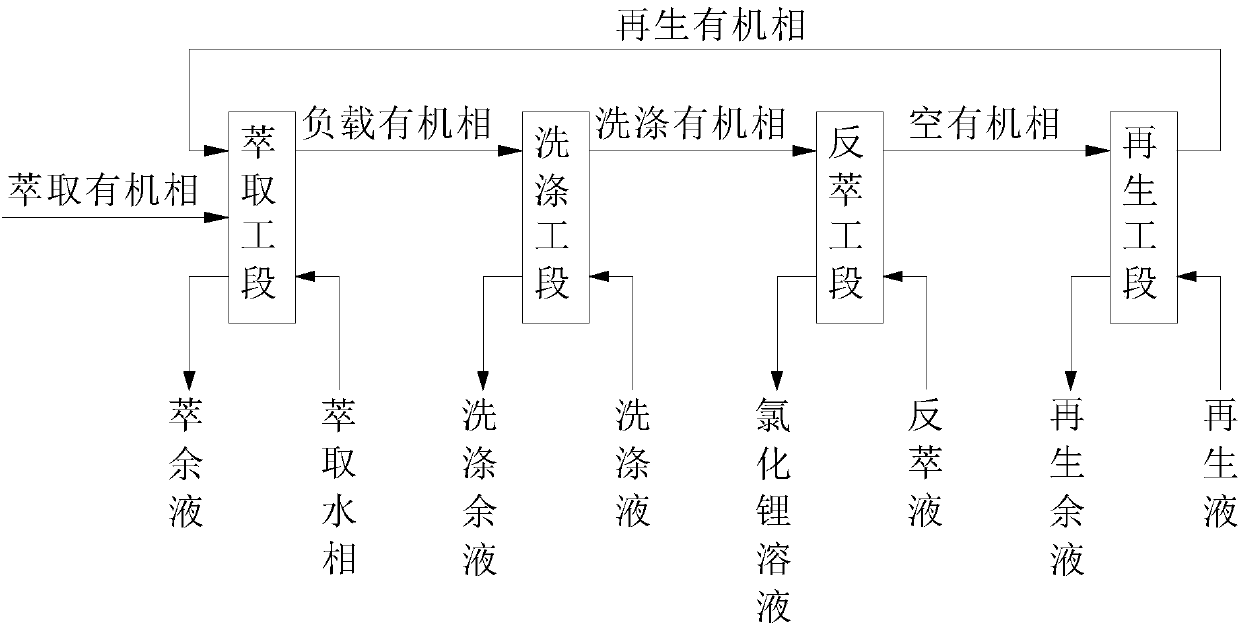

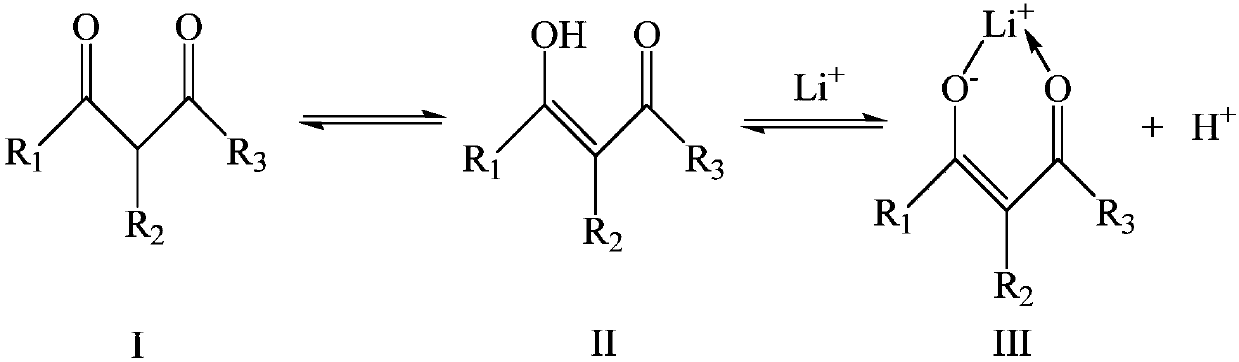

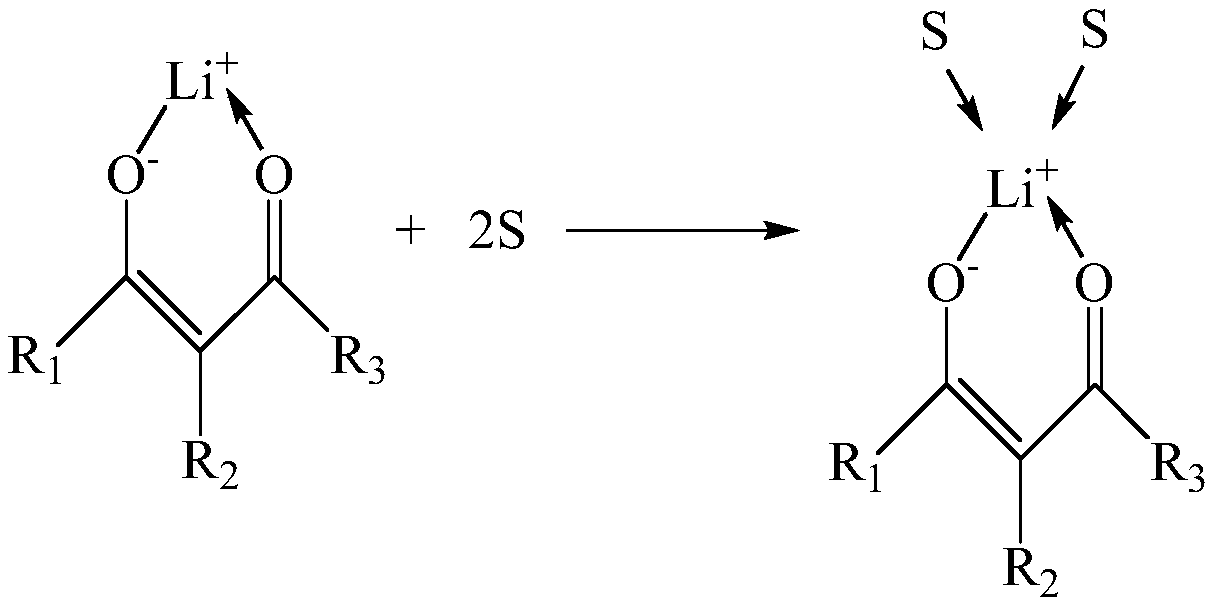

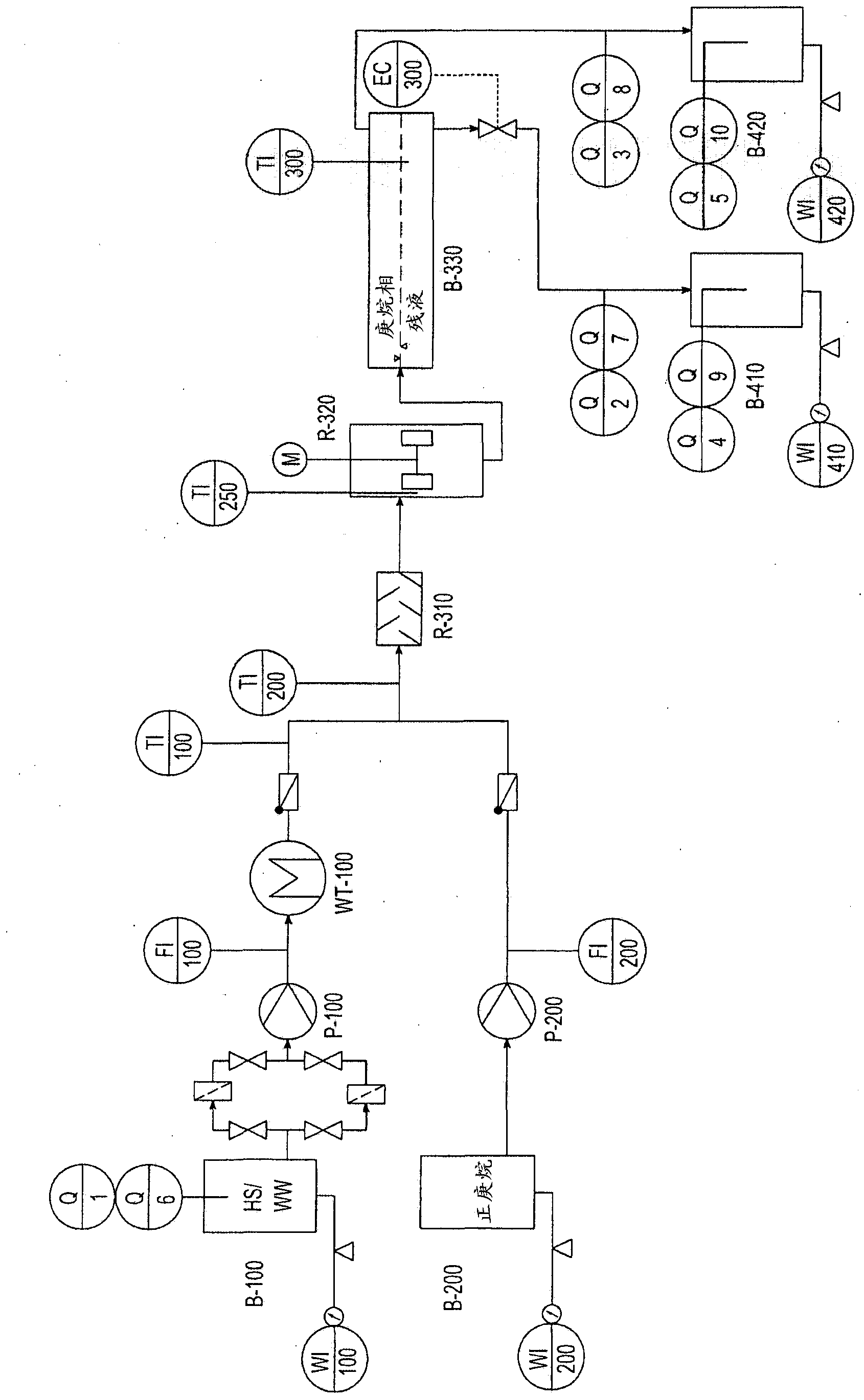

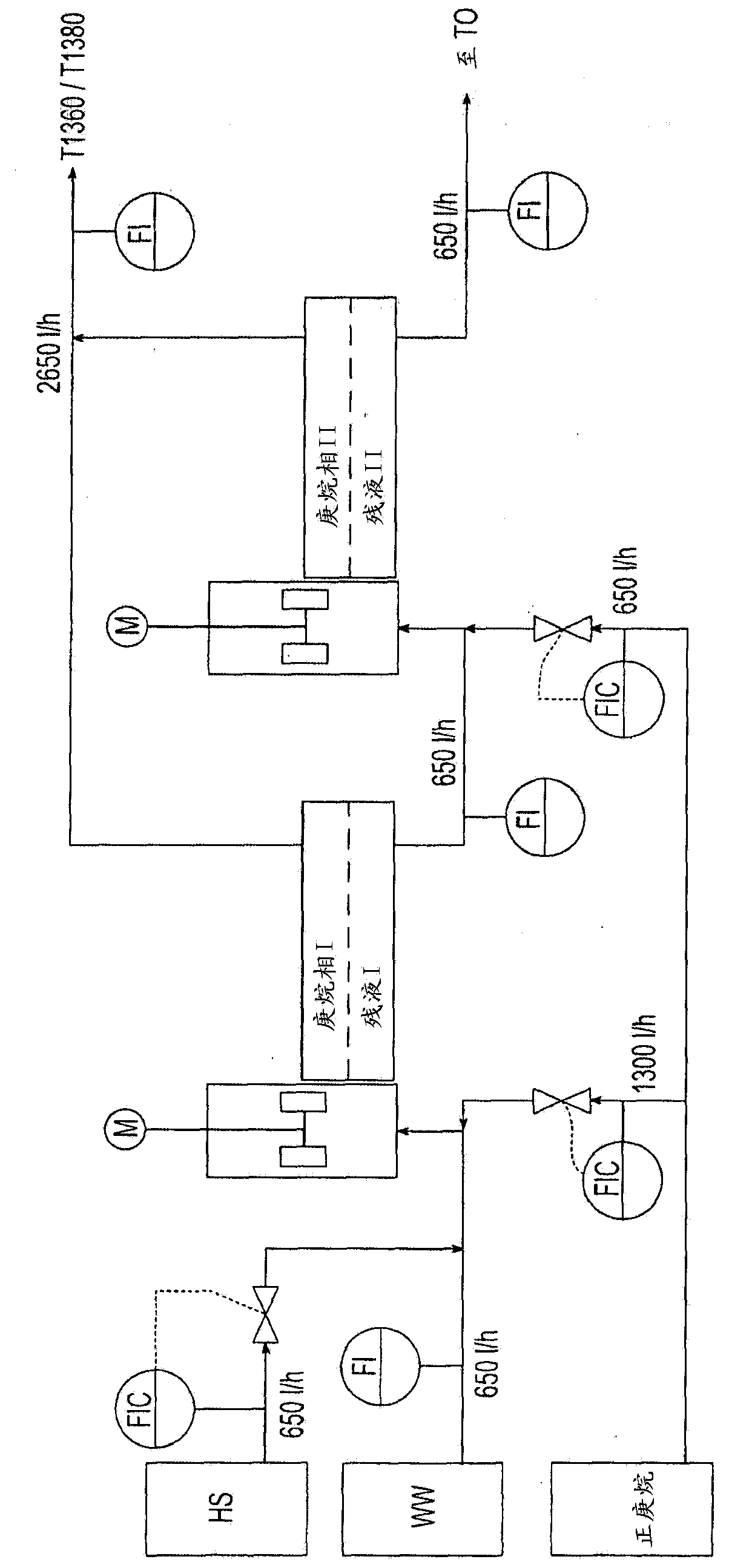

Technology for extracting lithium from lithium-containing alkaline brine based on mixer settlers

ActiveCN107937734AReduce usageAvoid densityProcess efficiency improvementLithium chlorideLithium carbonate

The invention discloses a technology for extracting lithium from lithium-containing alkaline brine based on mixer settlers. The technology includes the following steps that an extraction water phase is provided; an extraction organic phase is provided; extraction is conducted; washing is conducted; back extraction is conducted; and regeneration is conducted. According to the technology, a brand new extraction system is adopted, the lithium is extracted from a lithium-containing alkaline brine system, in addition, an extraction-washing-back extraction-regeneration total-process technology basedon the mixer settlers is determined for the first time, people not only rest on the fundamental research of an extraction section, finally, technological parameters matched with the extraction systemare determined, and an industrial production technological path based on the mixer settlers is provided, wherein the technological parameters include the stage number of each section, the flow ratioand the concentration of all reagents. The technology for extracting the lithium from the lithium-containing alkaline brine is particularly suitable for a filter liquid system generated in the processthat a lithium chloride solution is used for preparing a lithium carbonate product, so that the lithium is further extracted from the filter liquid system, true comprehensive recycling of salt lake brine is achieved, and the practical significance is achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

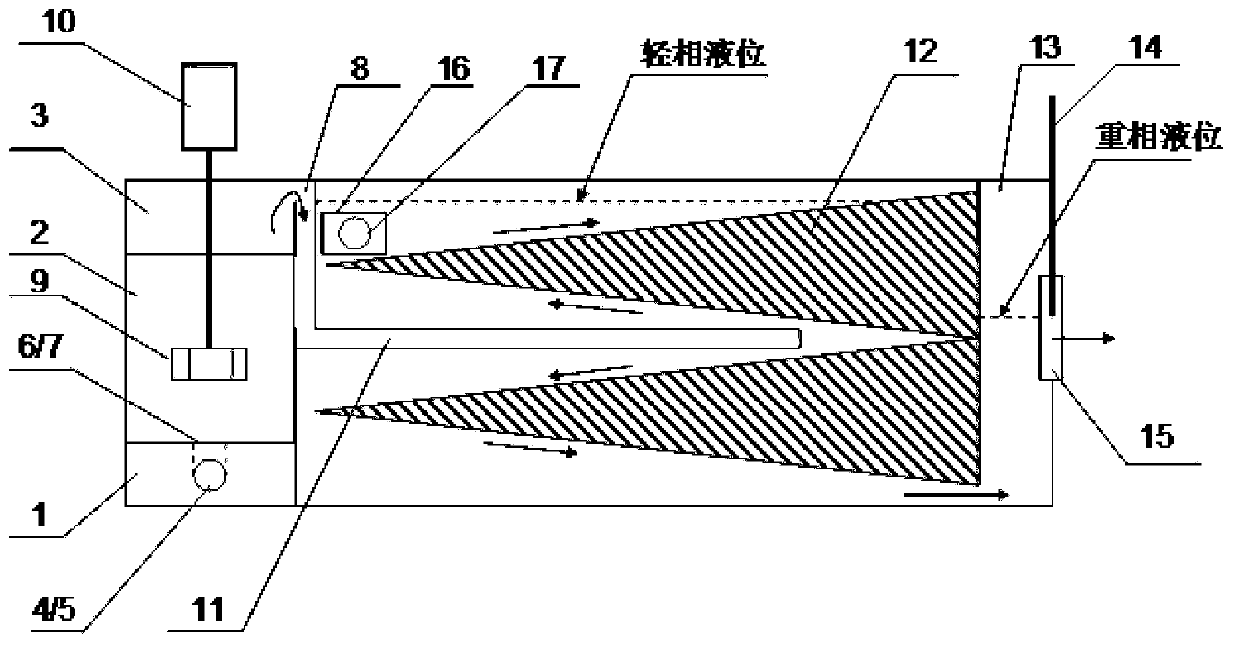

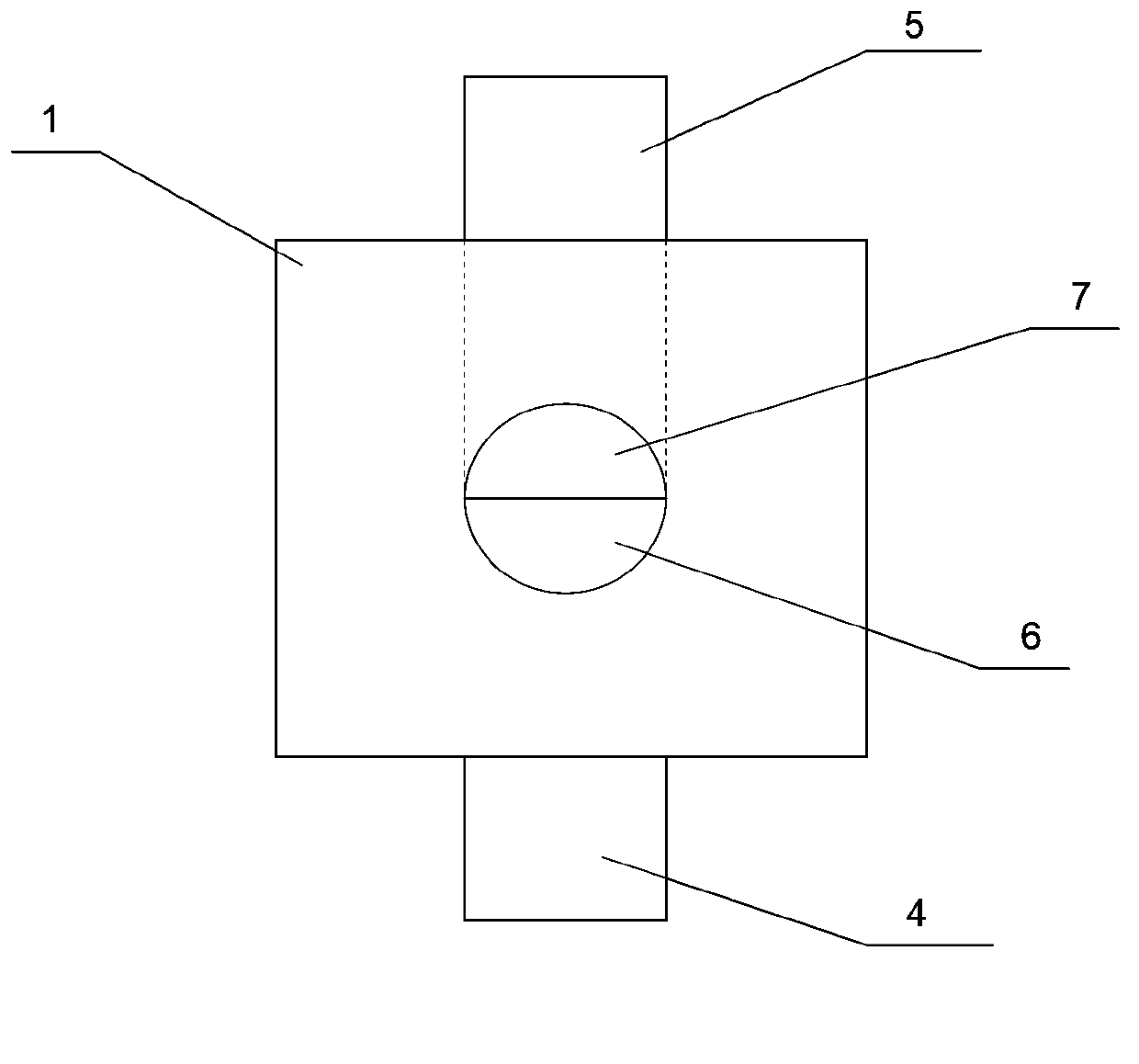

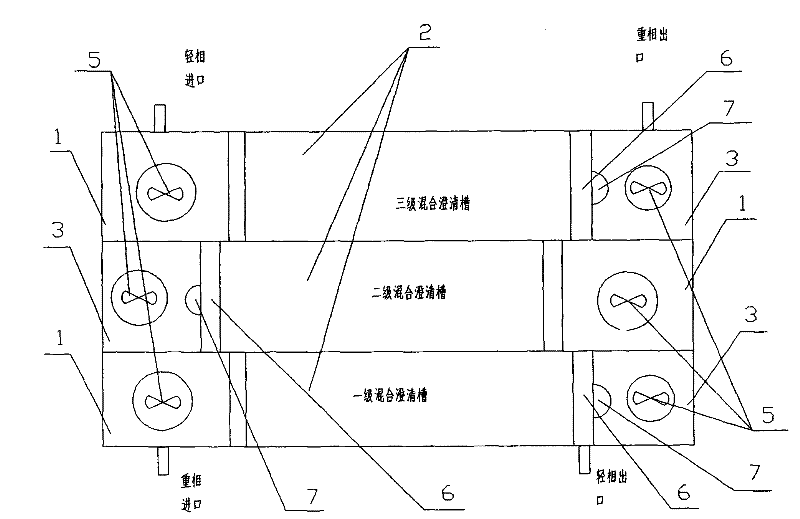

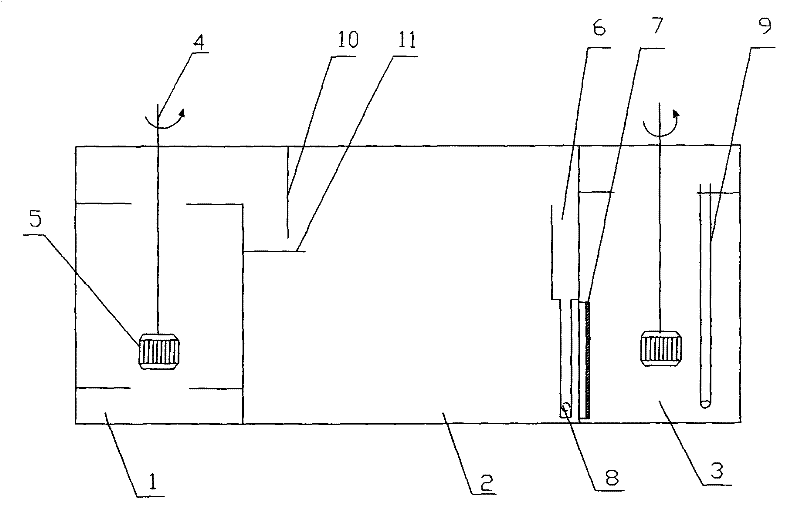

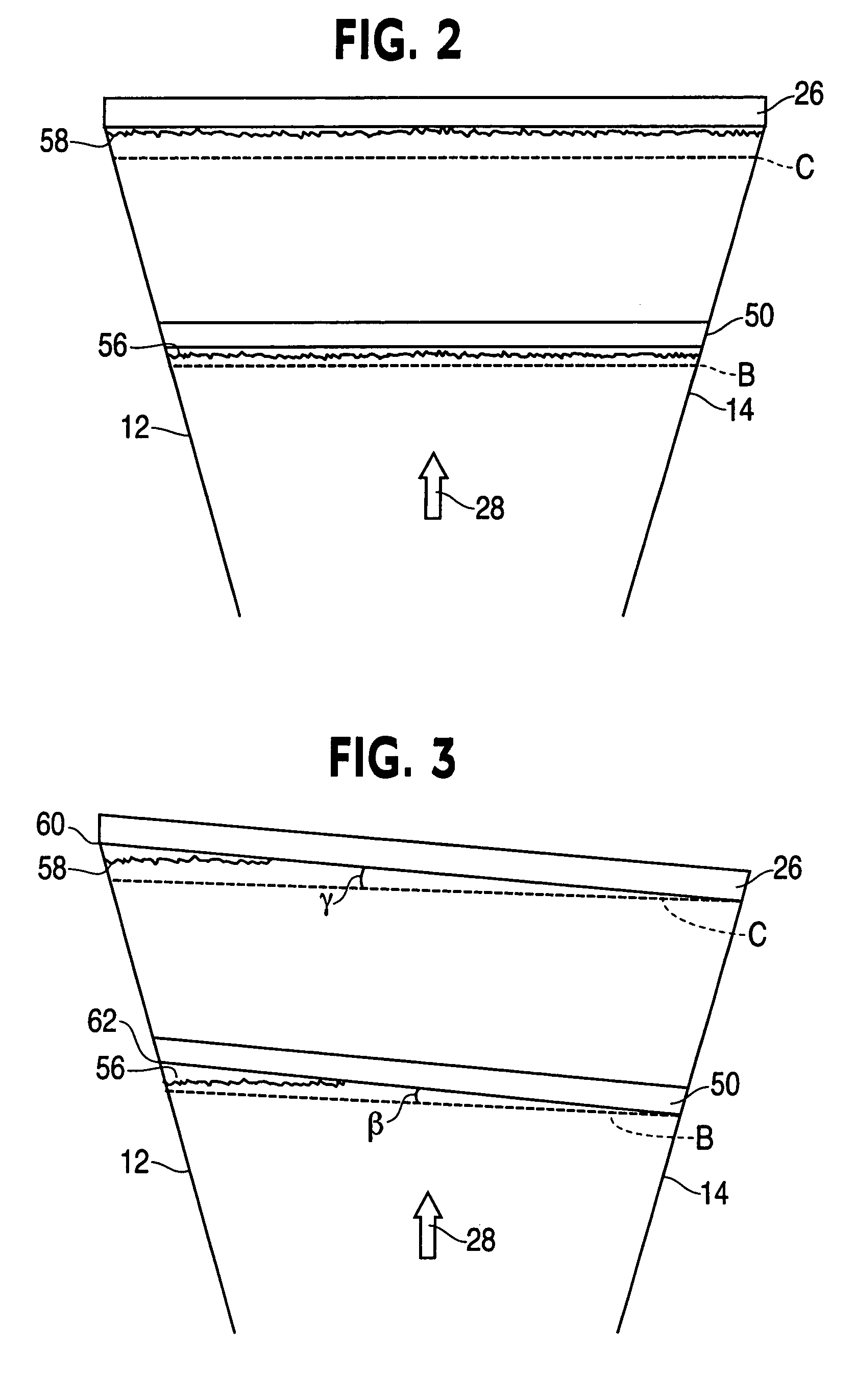

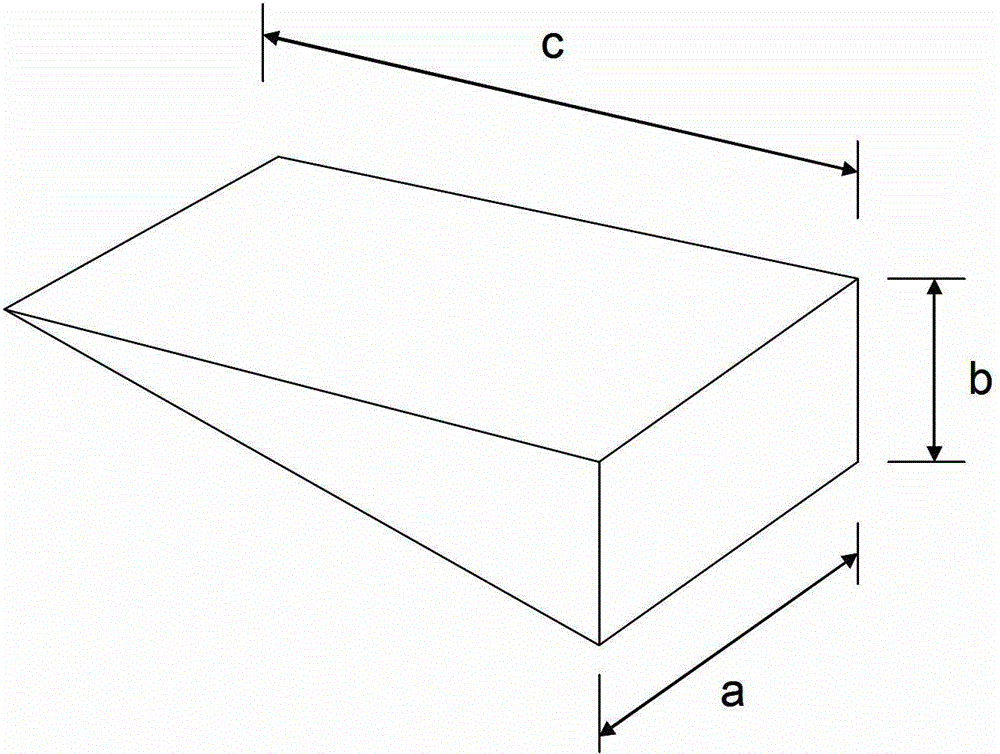

Liquid-liquid extraction mixer-settler and extraction method and application thereof

InactiveCN103120863AIncrease the settlement areaReduce holdupLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

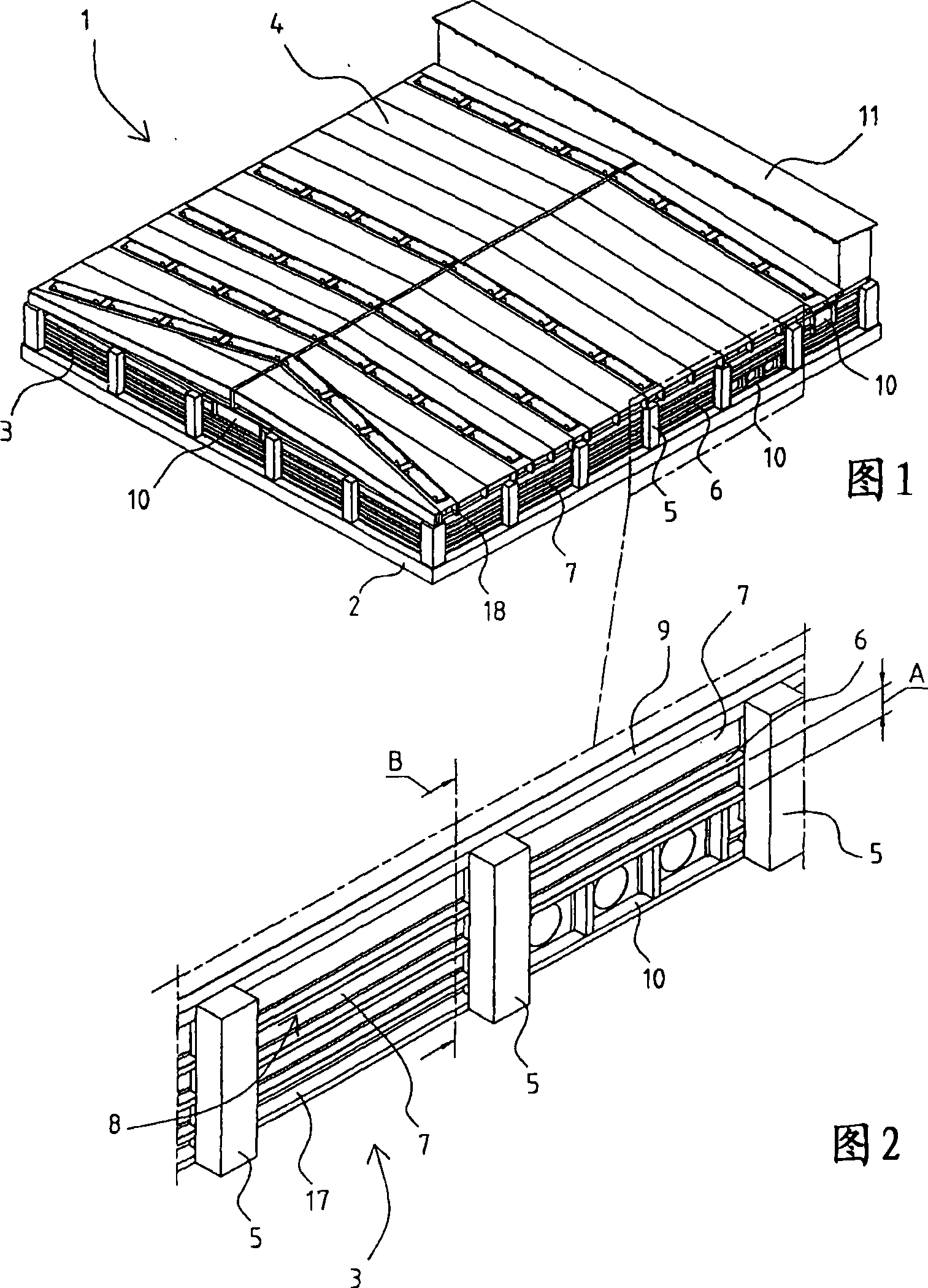

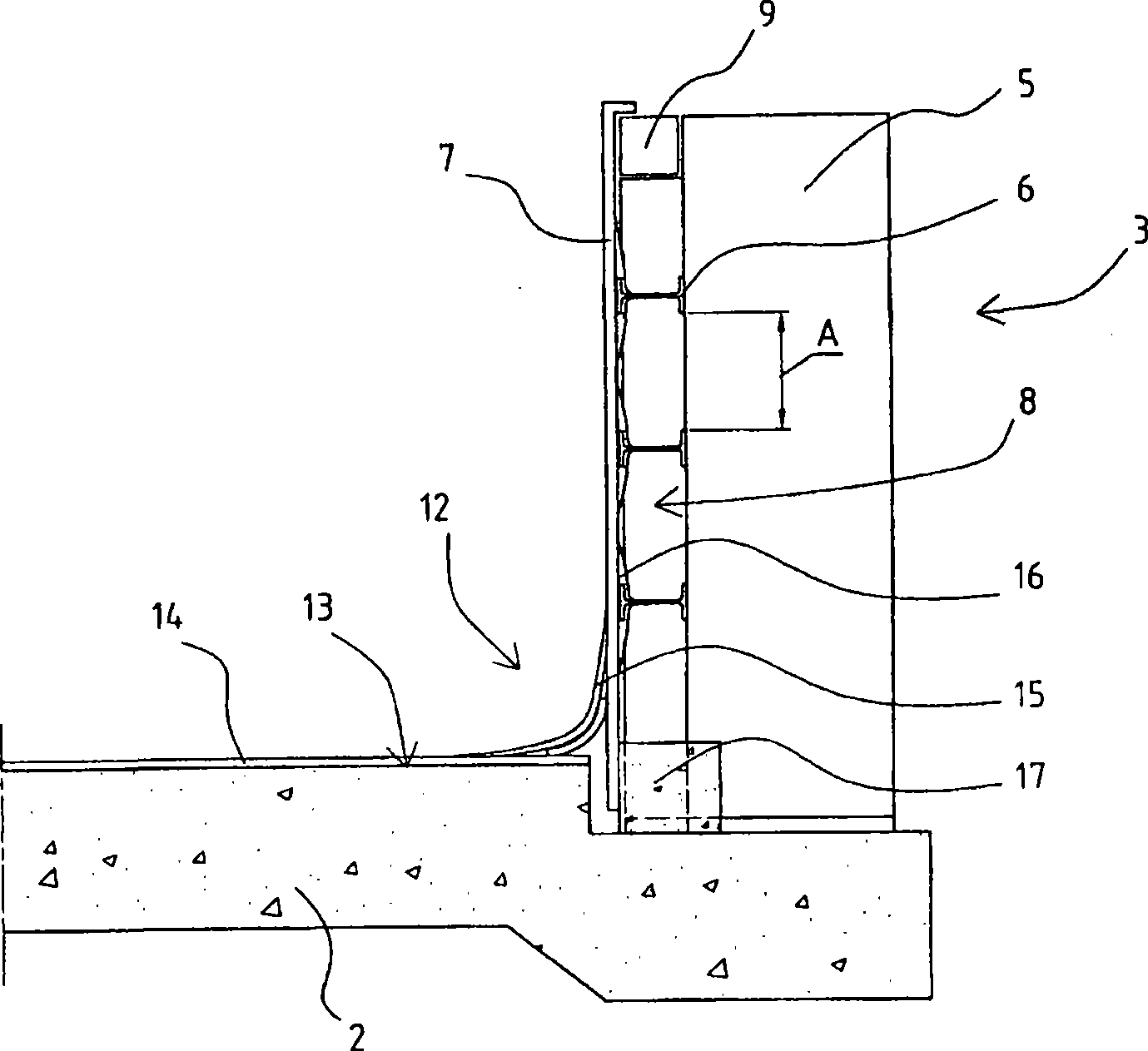

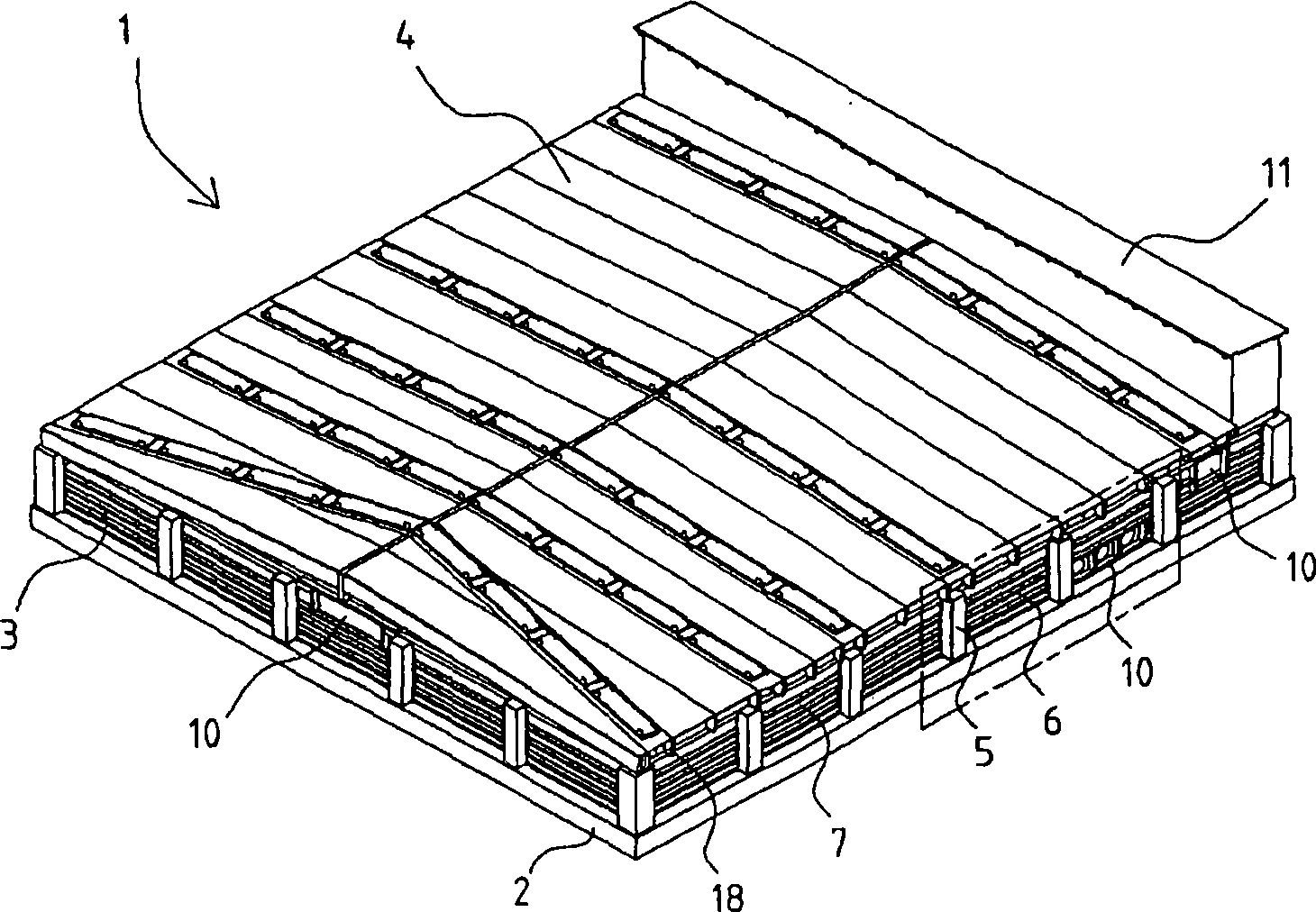

Method for manufacturing a mixer-settler and a mixer-settler

InactiveCN101449012BFavorable and sturdy constructionEasy to installSolvent extractionAdhesivesMetallurgyMixer-settler

The invention relates to a method for manufacturing a mixer-settler (1) used in hydrometallurgical metal processes, such as liquid-liquid extraction, and to a mixer-settler structure where there is used chemically resistant material, such as plate-like wall elements made of reinforced plastic.

Owner:OUTOTEC OYJ

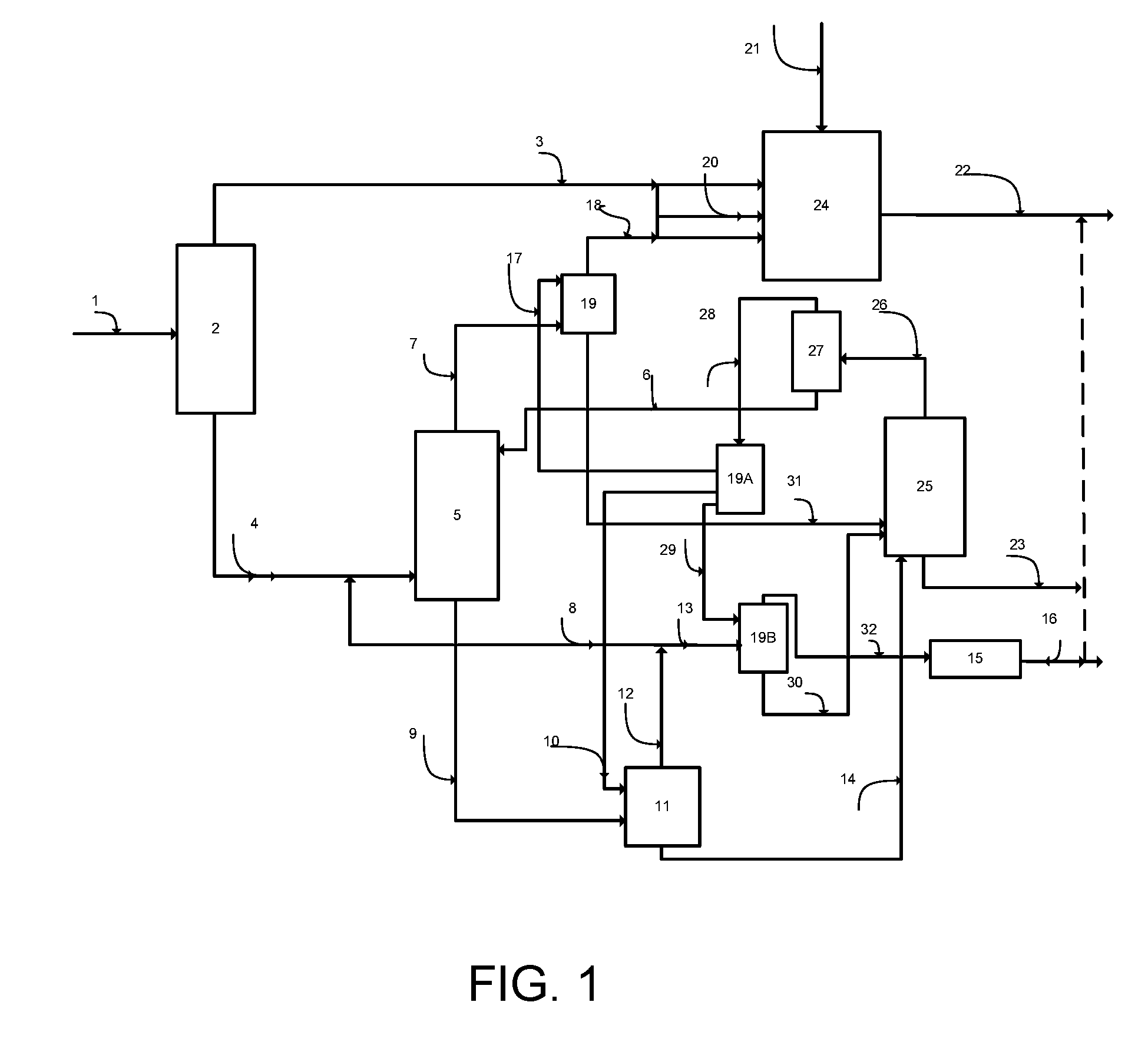

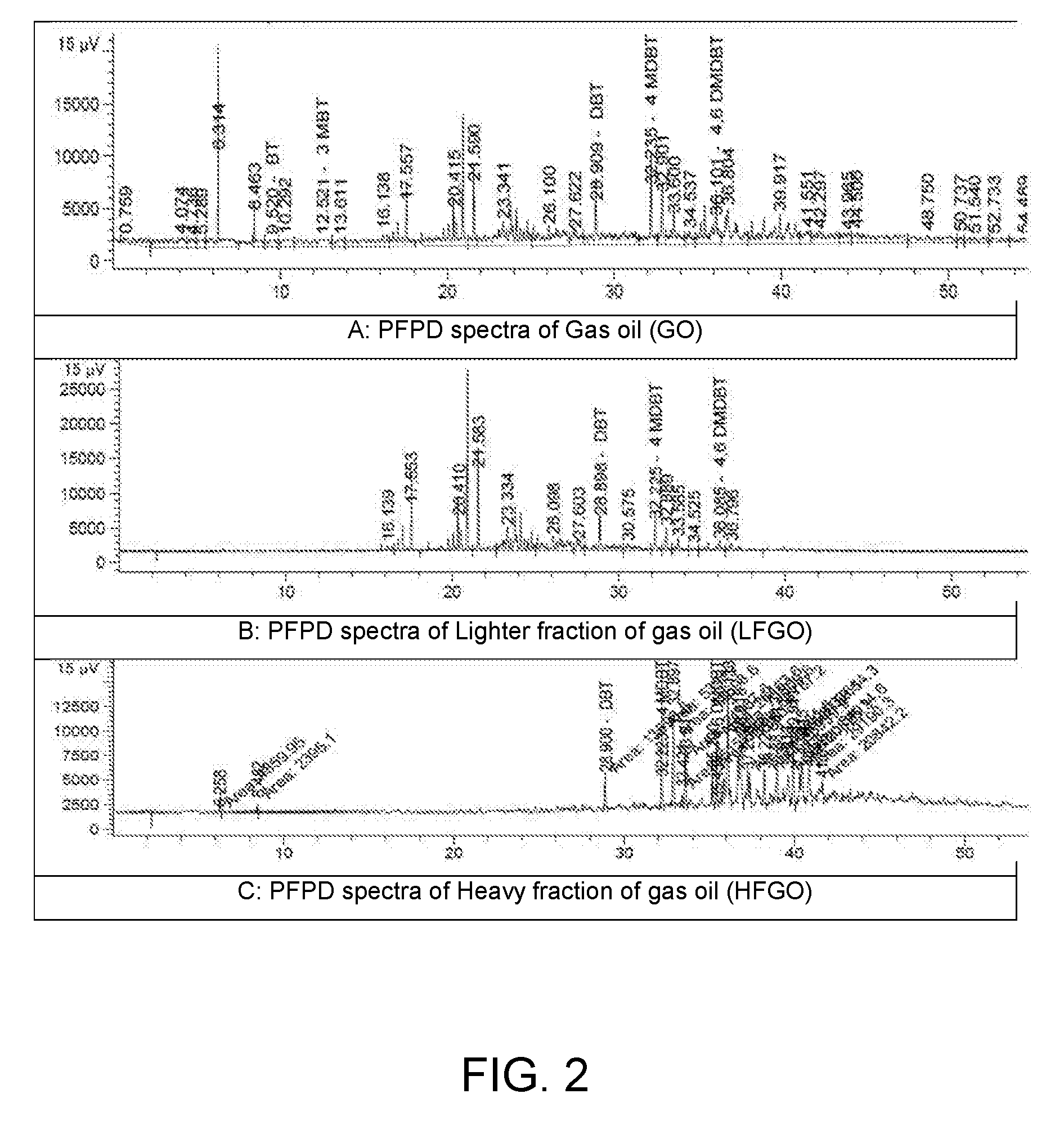

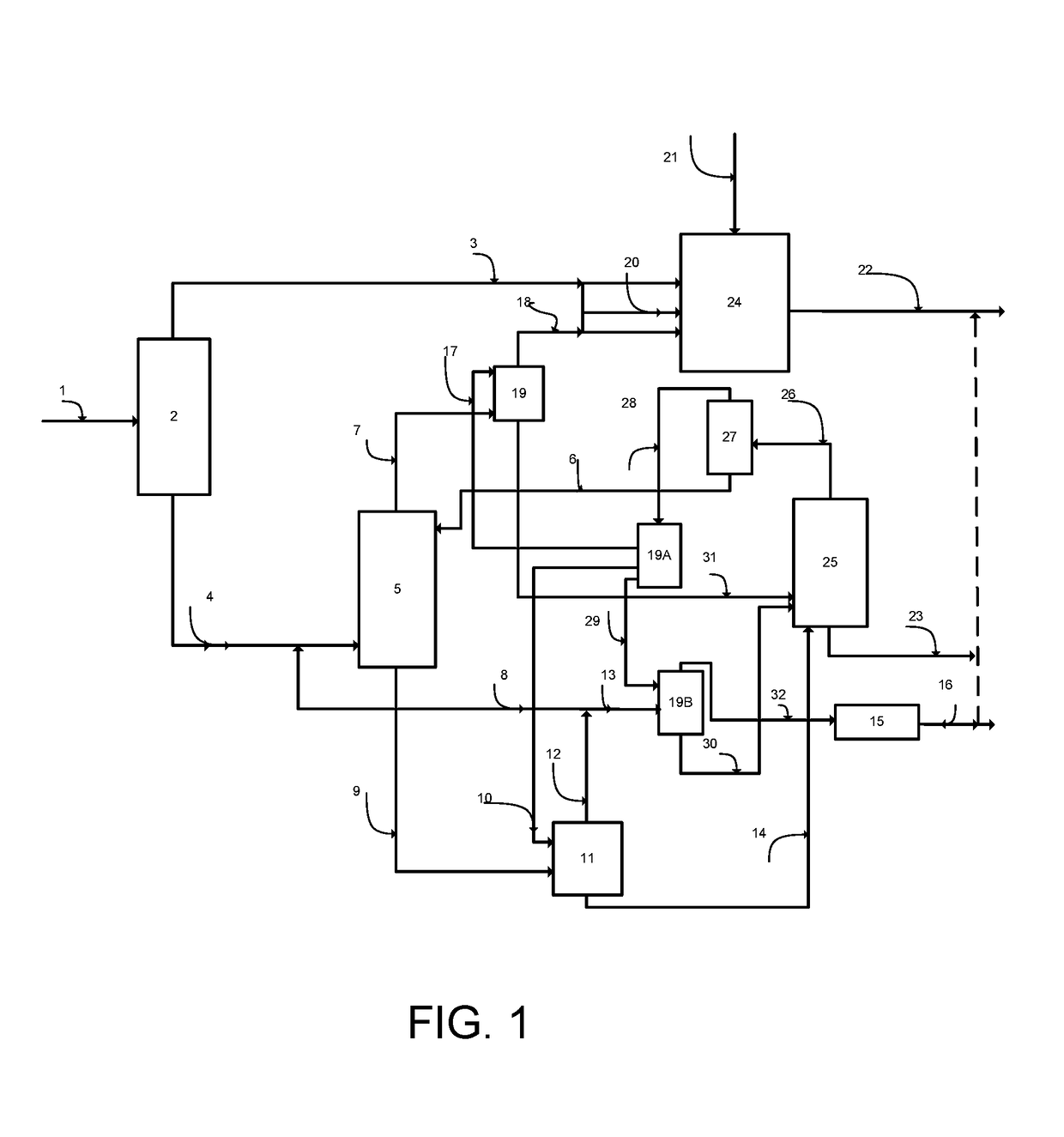

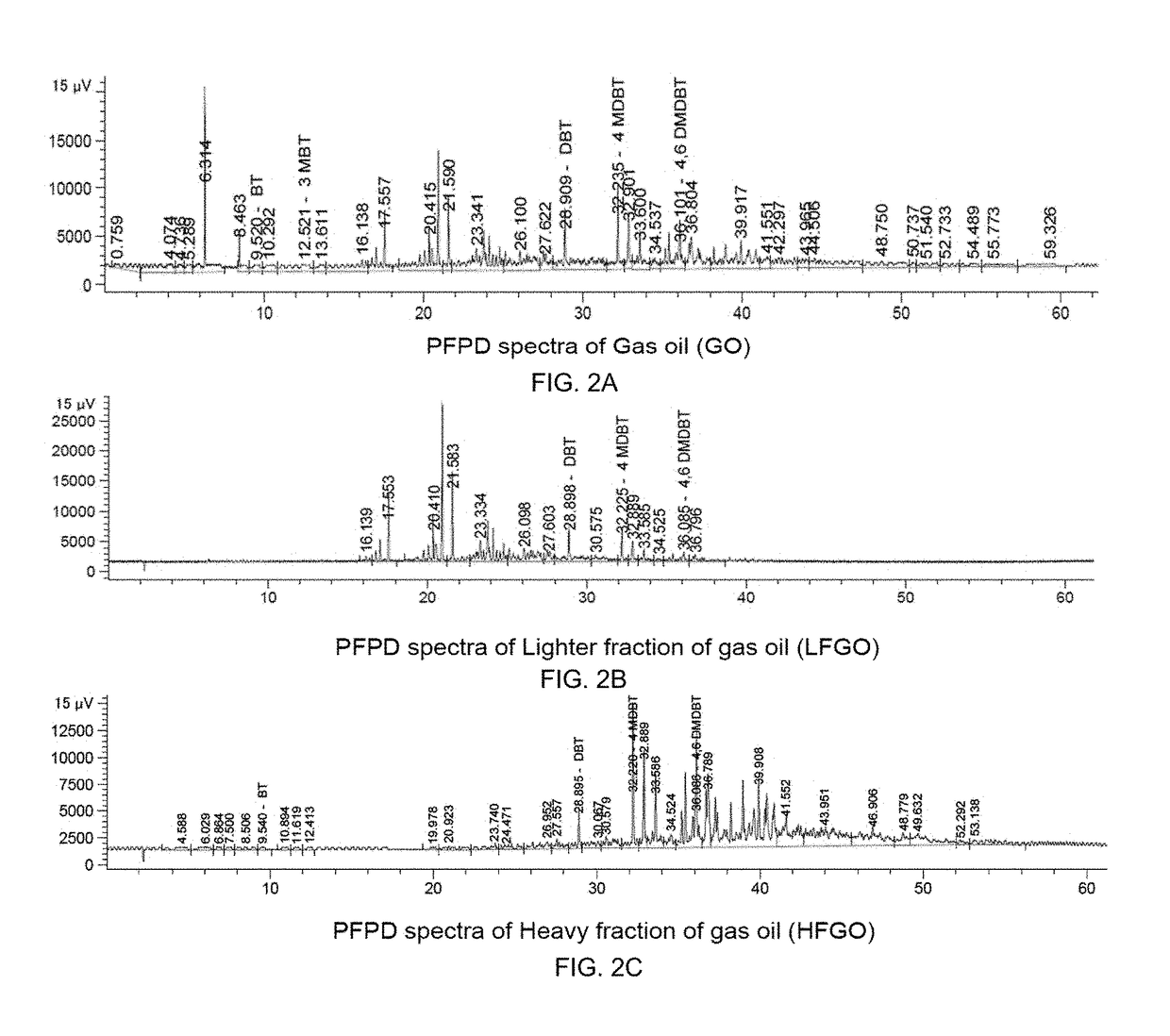

Integrated process for simultaneous removal and value addition to the sulfur and aromatics compounds of gas oil

ActiveUS20160281008A1Improve performanceEasy to separateTreatment with hydrotreatment processesHydrocarbon oils refiningDistillationSulfur

An integrated process for simultaneous removal and value addition to sulfur and aromatics compounds of gas oil is disclosed. Refractive sulfur and aromatics compounds of gas oil are segregated in heavy fraction of gas oil using distillation. The refractive sulfur and aromatic compounds rich heavy fraction of gas oil is subjected to continuous solvent extraction zone. The lighter fraction of gas oil and raffinate of heavy fraction of gas oil are subjected to hydrotreating reaction zone operating under mild conditions of temperature and pressure for producing the gas oil with reduced sulfur and aromatic compounds to deep level. The pseudo raffinate from the extract phase of continuous extraction is generated using the water in mixer settler for improving the yield of raffinate by generating the pseudo raffinate which can be used as suitable feed to hydrocracker to generate sulfur free gas oil.

Owner:COUNCIL OF SCI & IND RES

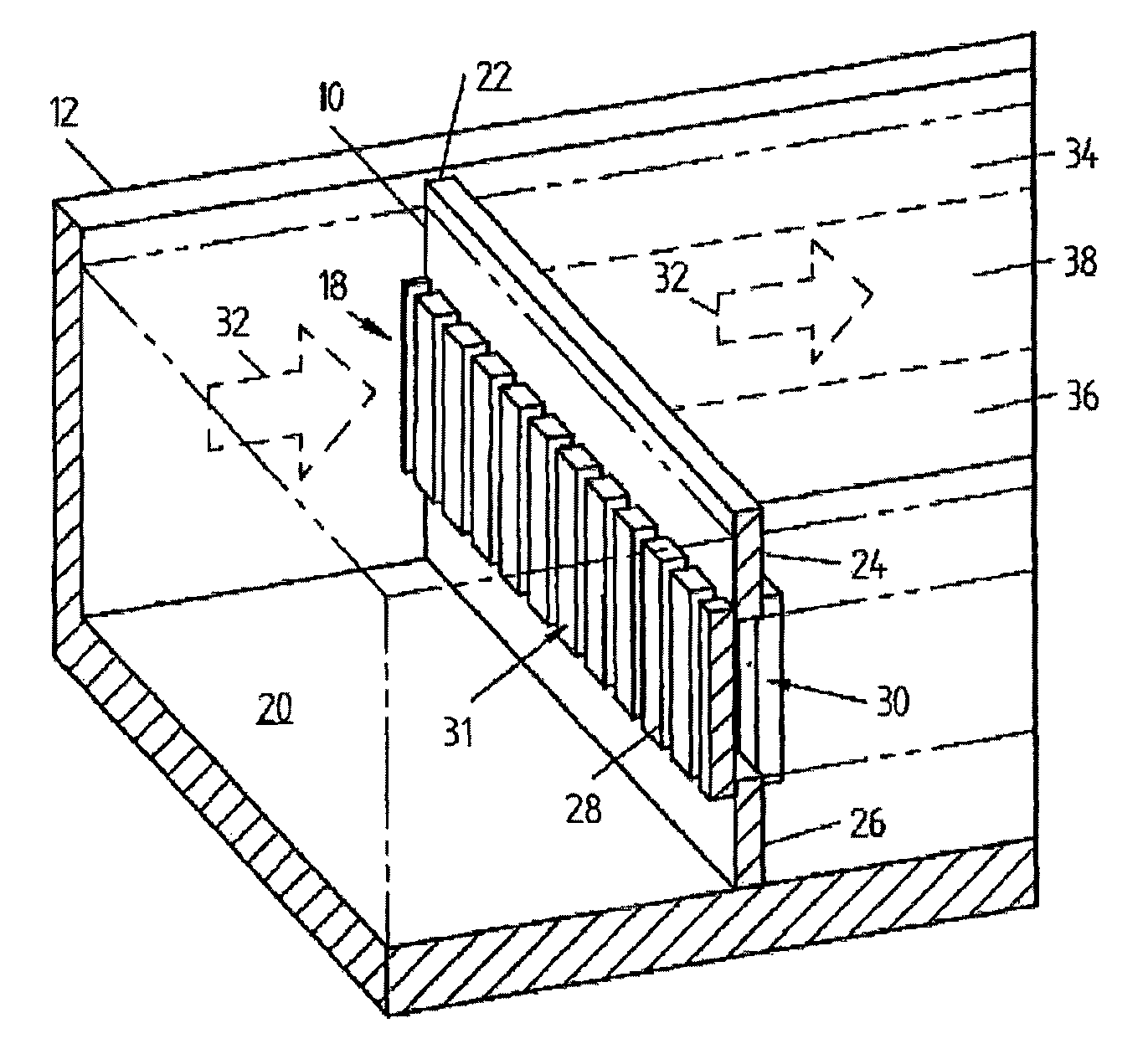

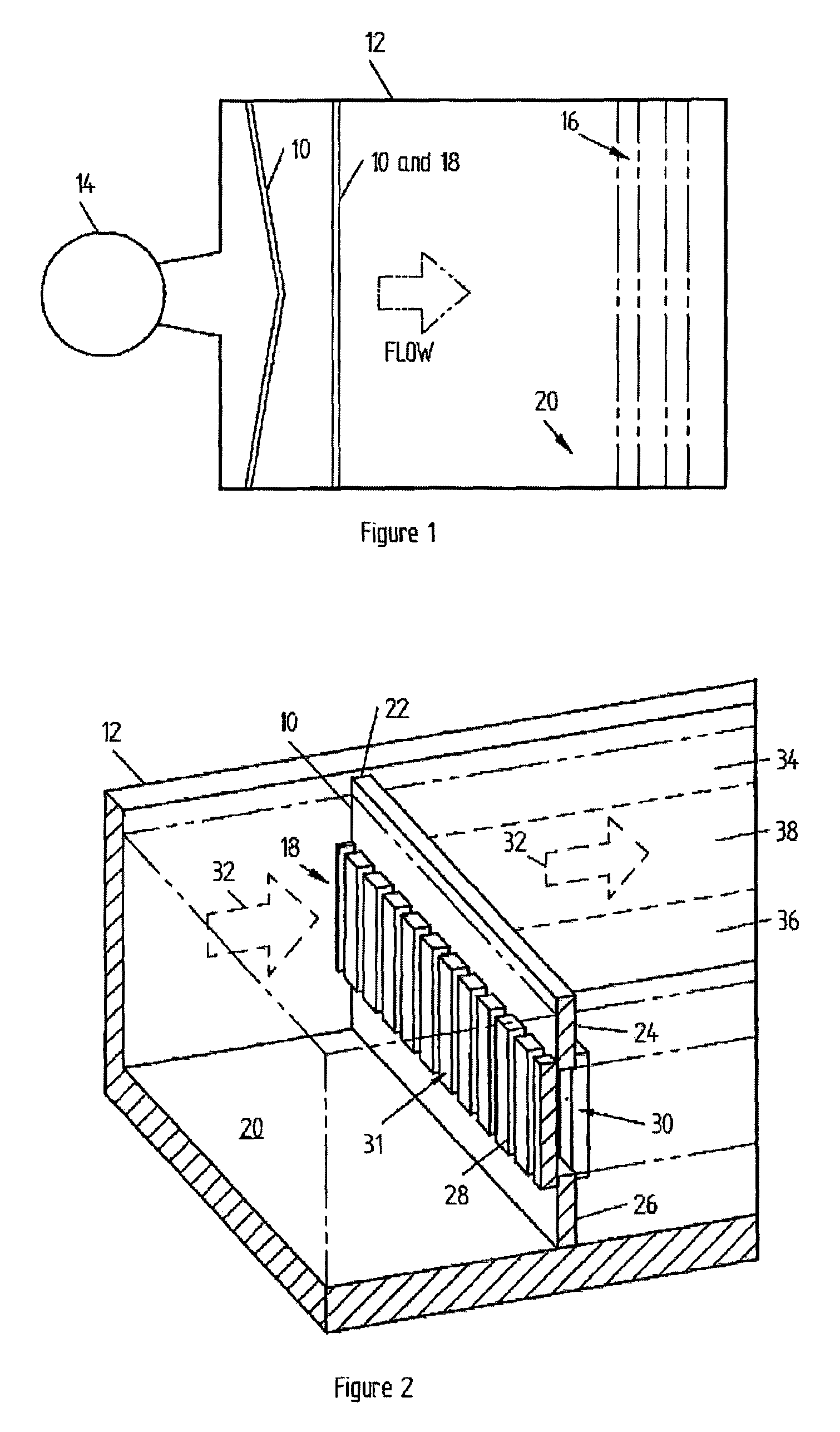

Re-entrainment prevention apparatus

ActiveUS9308471B2Preventing and limiting vertical componentSettling tanks feed/dischargeRecovering materialsEngineeringMixer-settler

Owner:HATCH PTY LTD

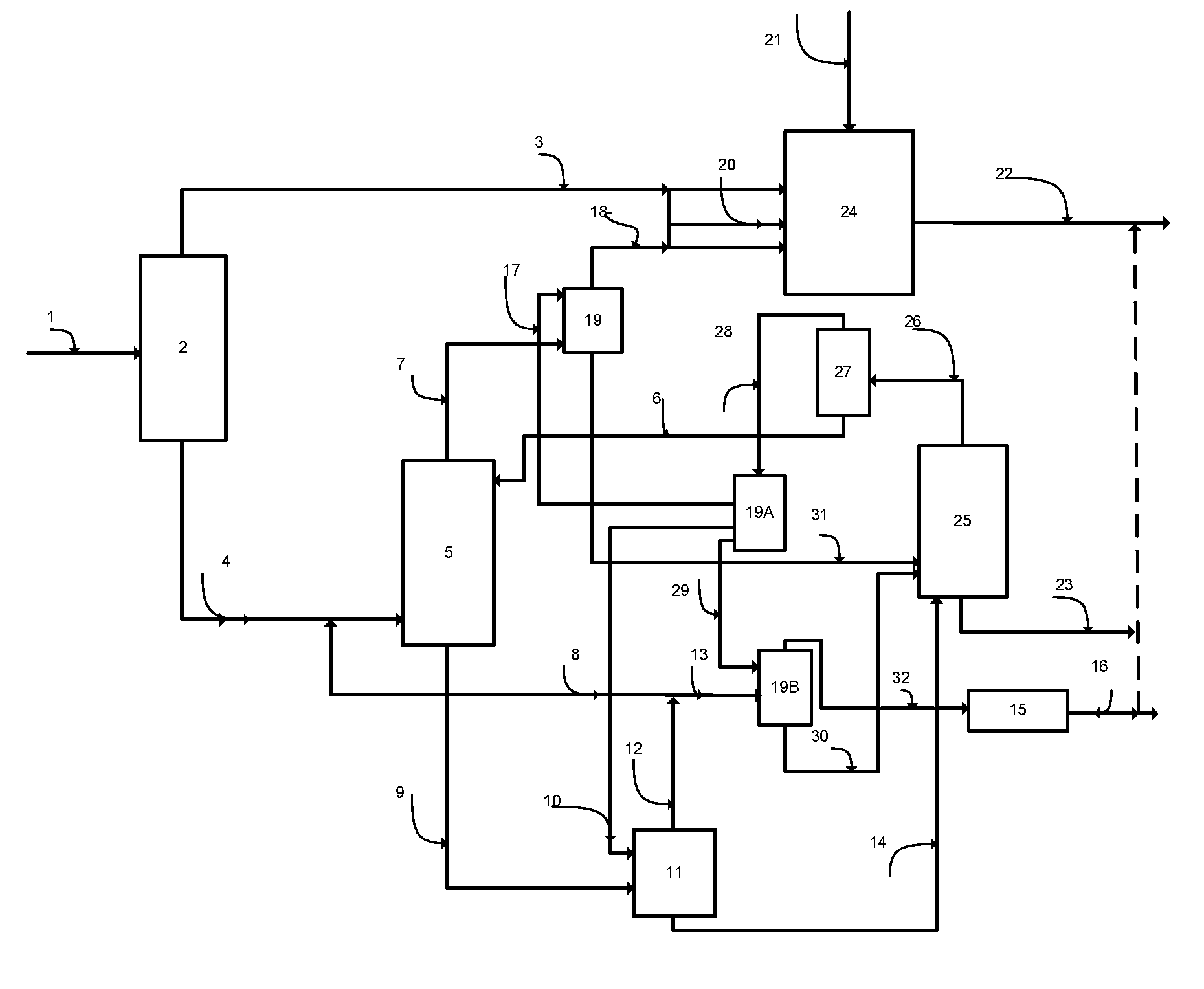

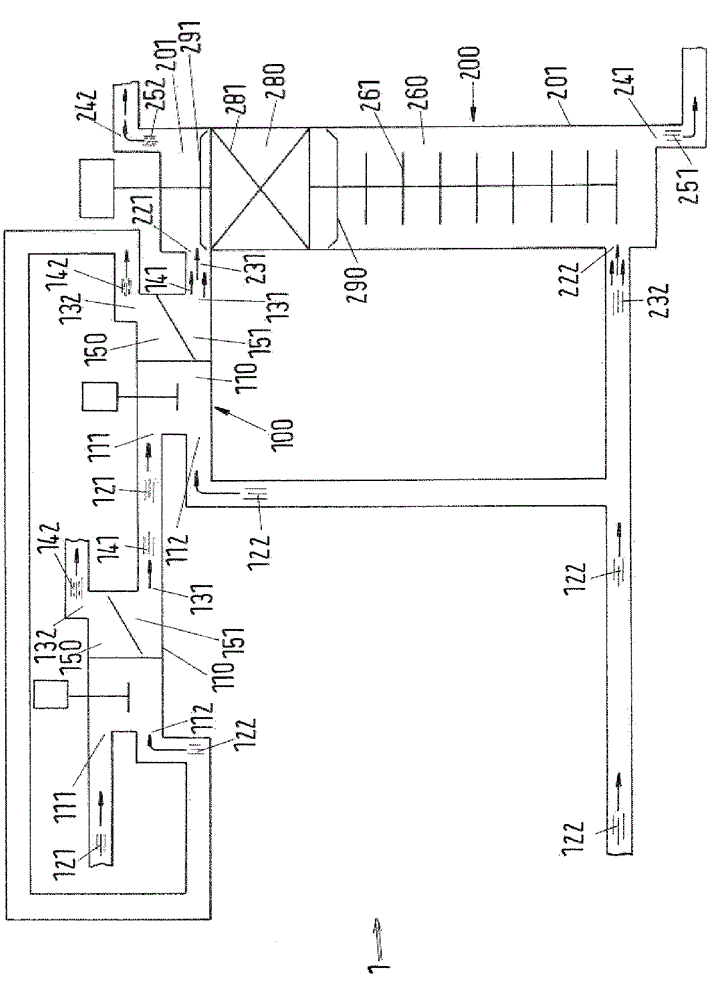

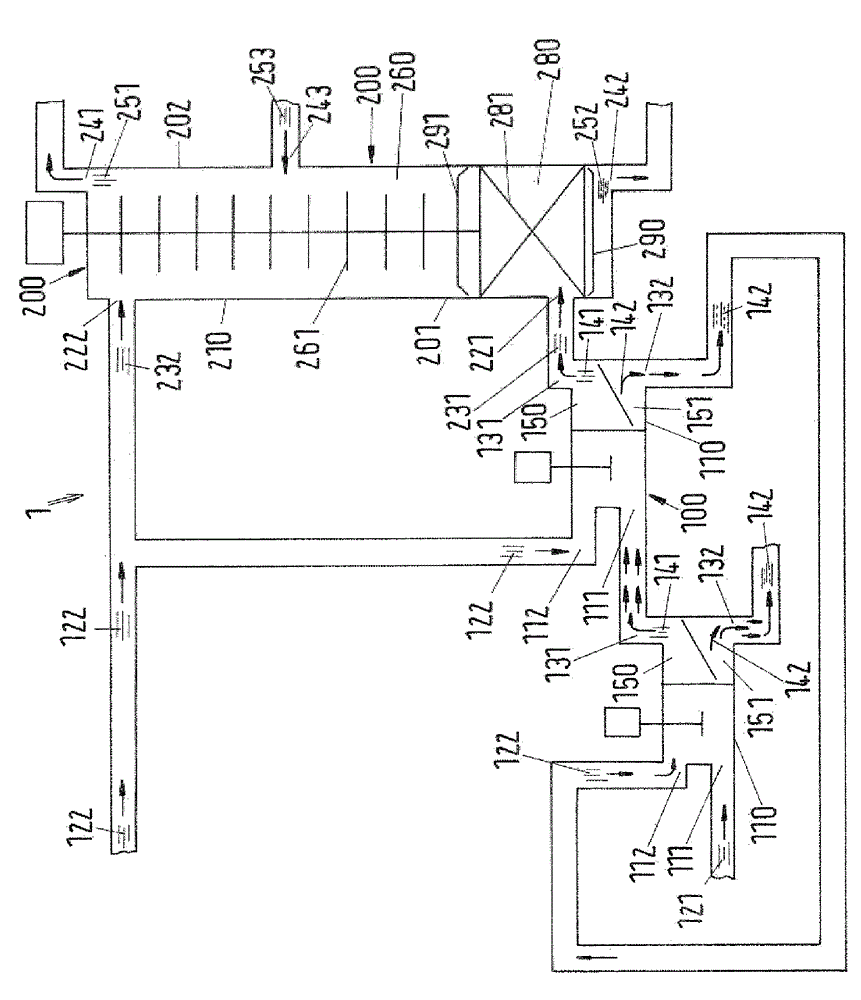

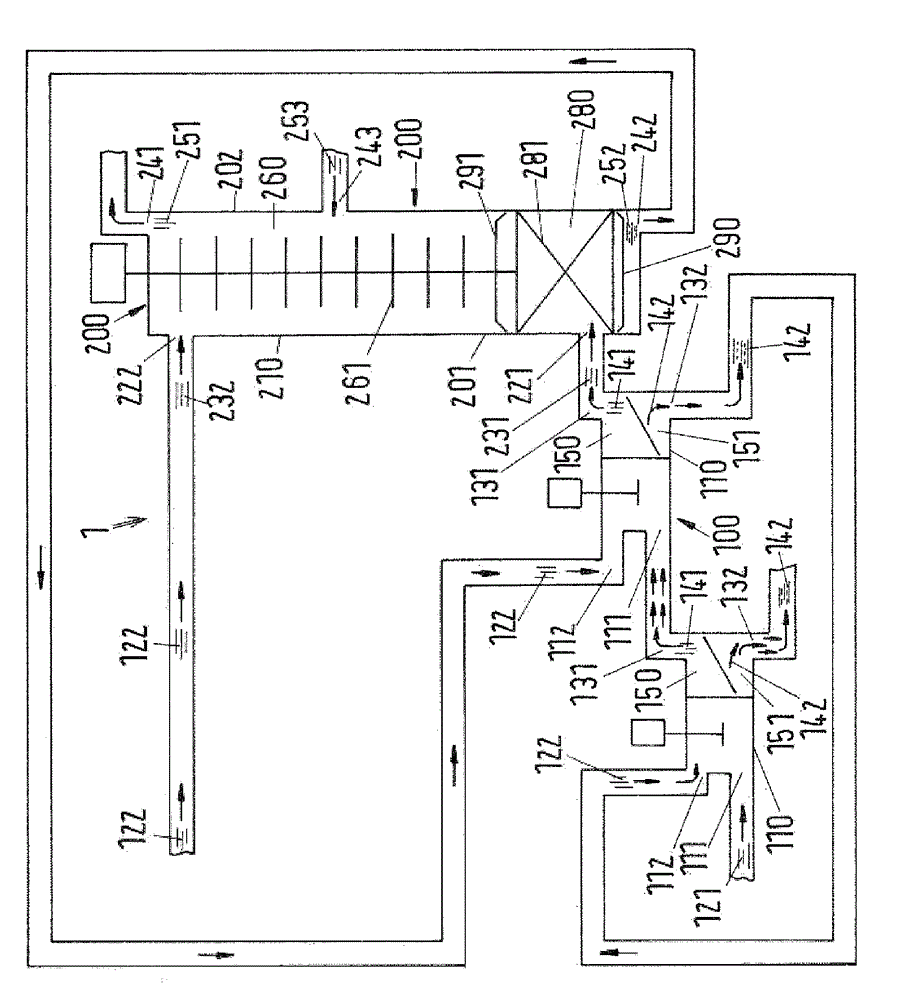

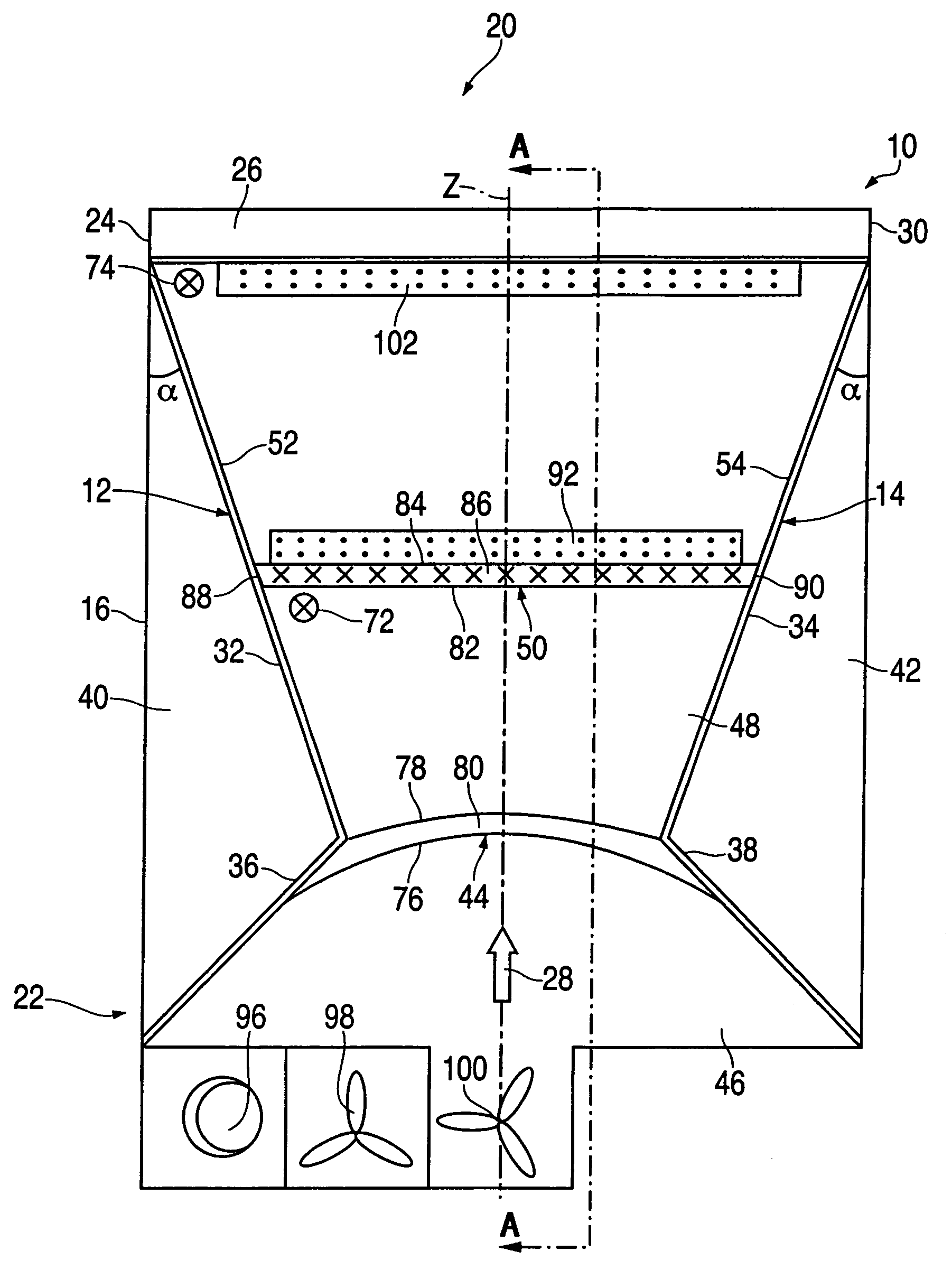

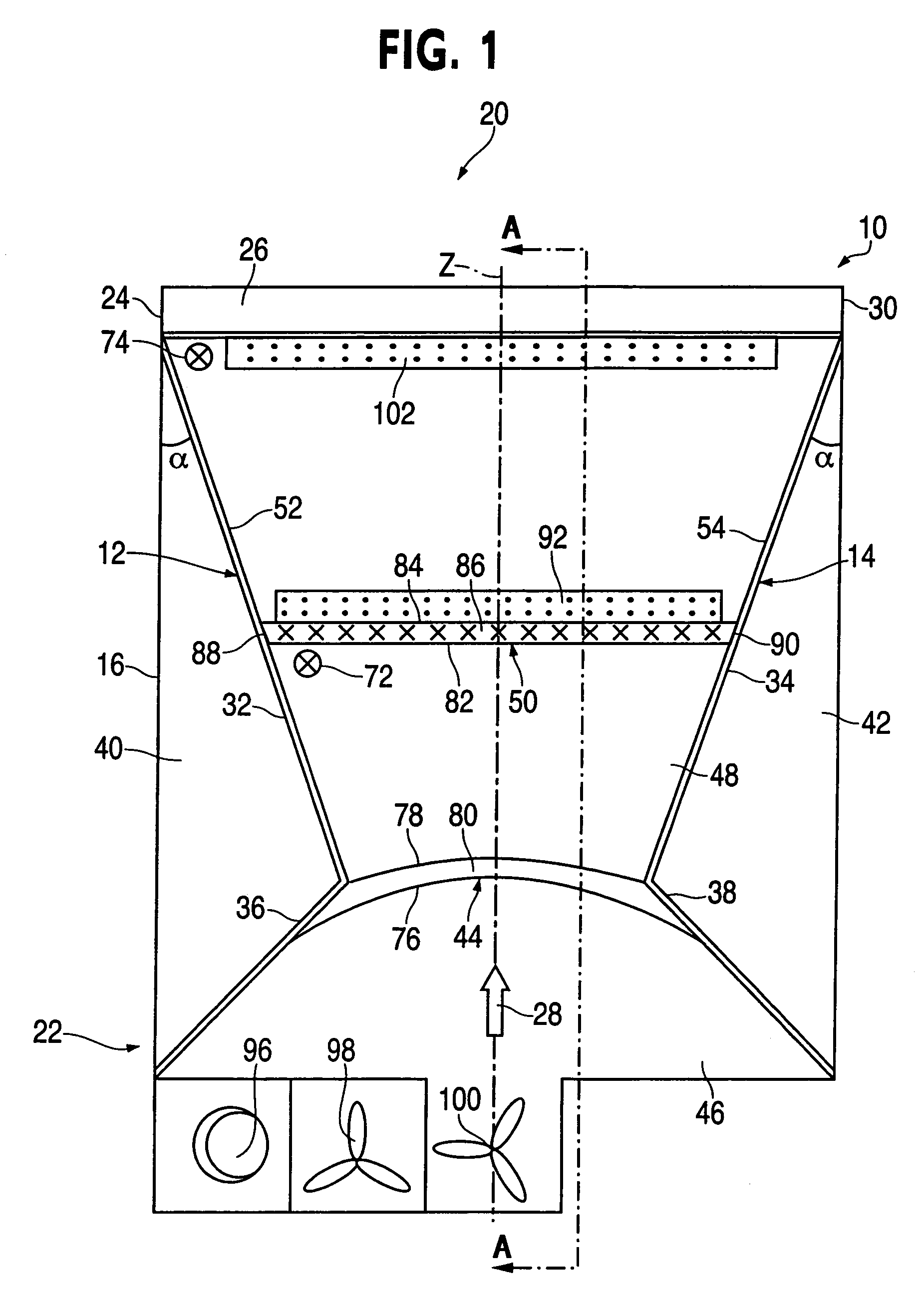

A liquid-liquid extraction system and process for use thereof

A liquid-liquid extraction system (1) adapted for the flow of two or more liquids therein is disclosed. The system comprises a mixer settler sub-system (100) and a counter-current liquid-liquid extraction column (200). The sub-system (100) comprises one or more mixer settlers (110) connected in series, and the column (200) comprises either a mixing section (260) comprising an agitation means (261) and / or a static section (280) comprising an internal (281). The first outlet (131) of the mixer settler sub-system (100) is in fluid communication with the first inlet (221) of the column (200) and the second inlet (112) of the mixer settler sub-system (100) is in fluid communication with the second inlet (222) of the counter-current liquid-liquid extraction column (200). The invention further relates to a counter-current liquid-liquid extraction process for using said system 1. The present invention further relates also to the use of the system (5) or process in removing aromatic compounds from organic streams, in treating an oil stream of a refinery, or in a liquid-liquid extraction process having at least two feed streams of different viscosity, similar density, or low interfacial tension.

Owner:SULZER MANAGEMENT AG

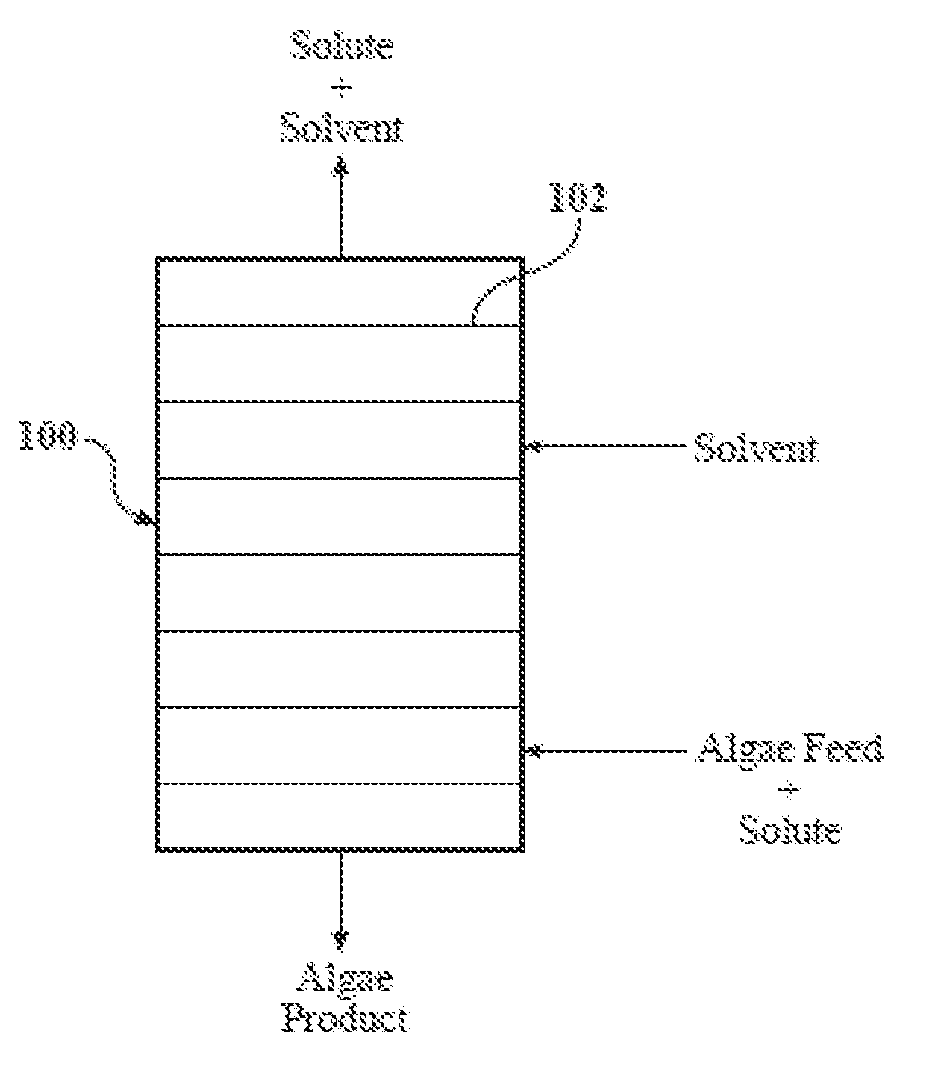

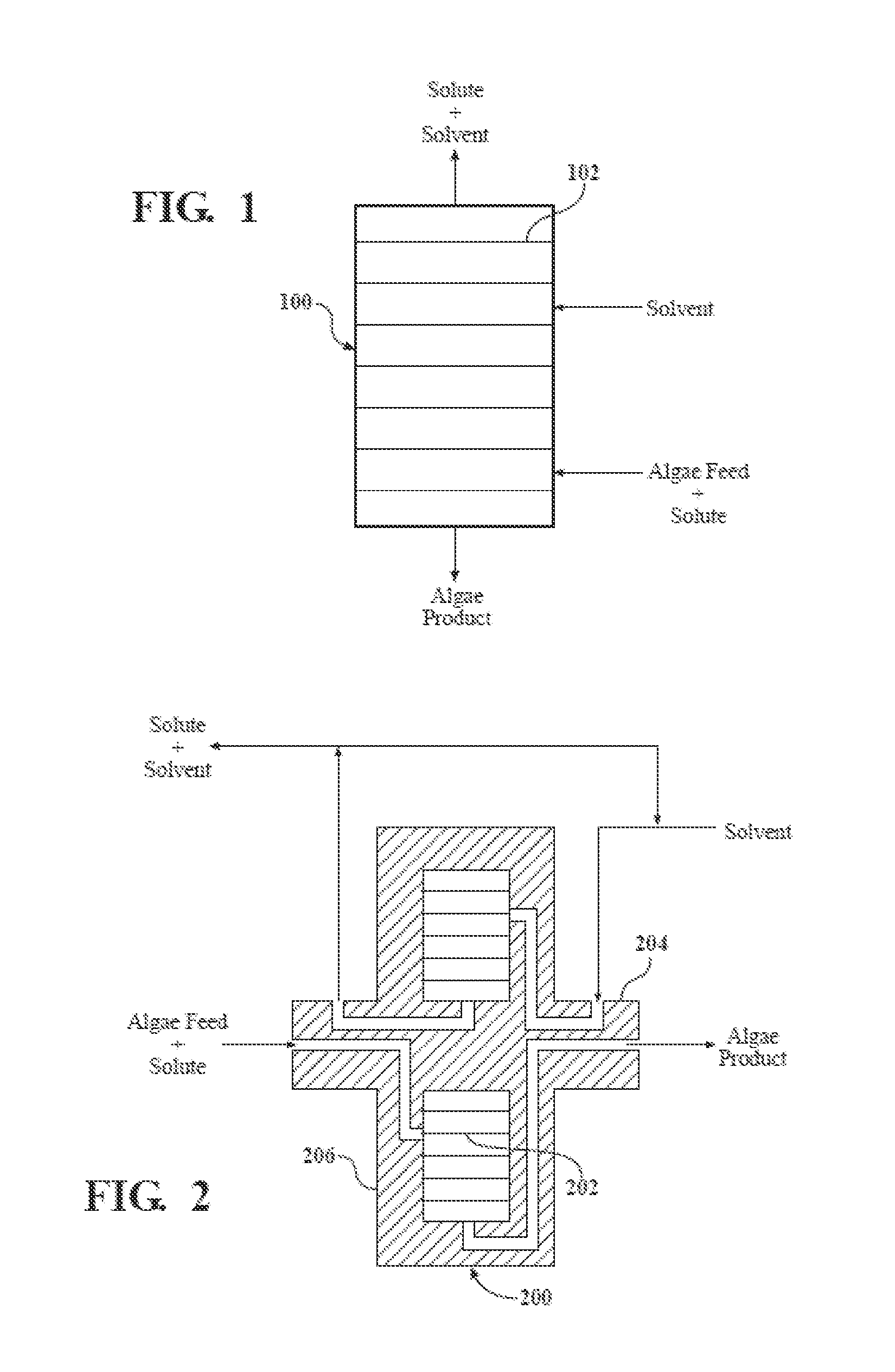

Process for separating solute material from an algal cell feed sream

ActiveUS20120065415A1A large amountImprove efficiencyFatty-oils/fats productionAsymmetric synthesesMixer-settlerSolvent

This invention provides a process for separating solute material from an algal cell feed stream. The algal cell feed stream, which contains the solute material, can be introduced into on portion of a mixer-settler vessel, and a solvent feed stream can be introduced into another portion of the vessel to mix with the algal cell feed stream, with a goal of separating at least a portion of the solute material from the algal feed stream.

Owner:EXXON RES & ENG CO

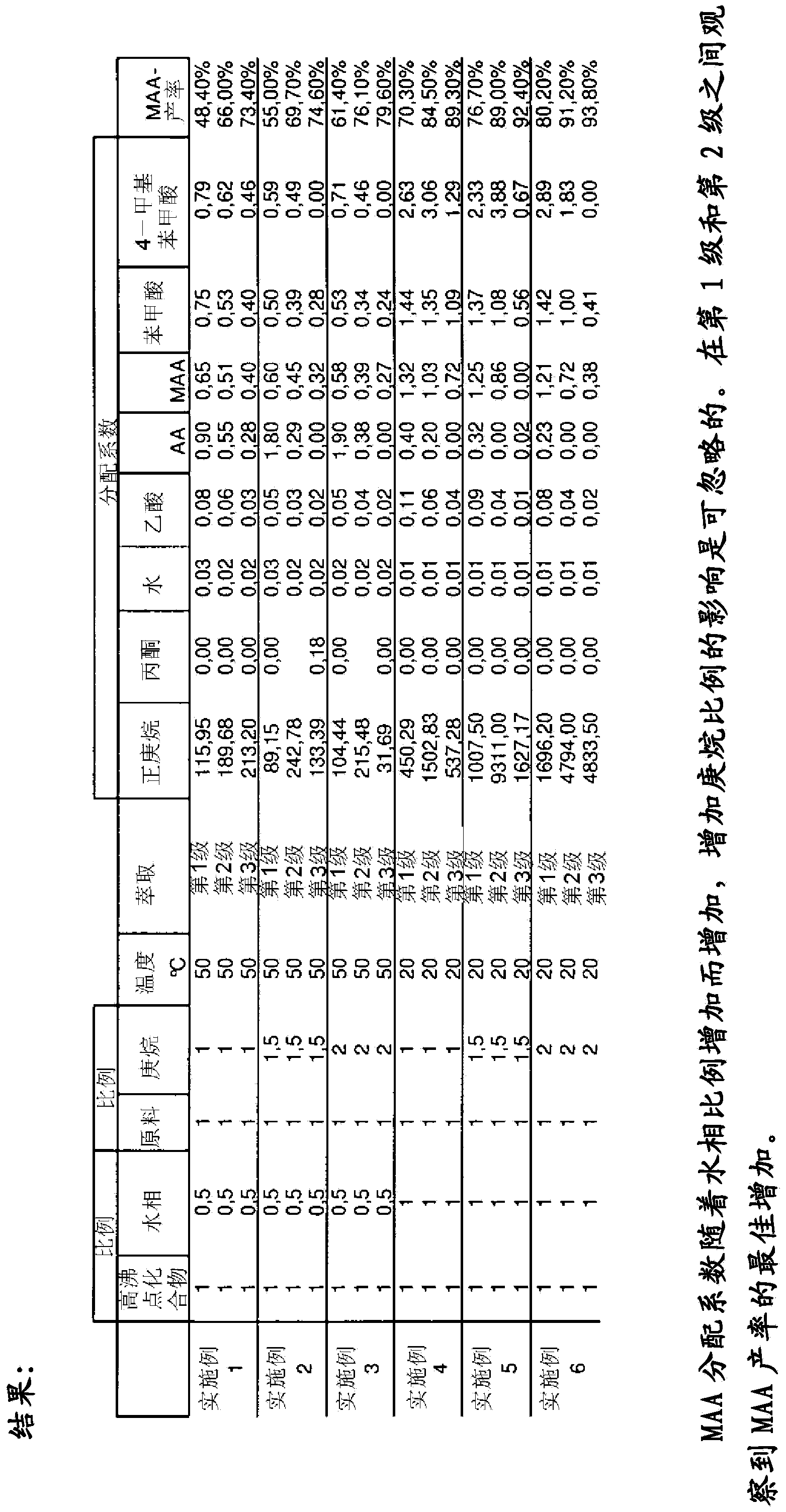

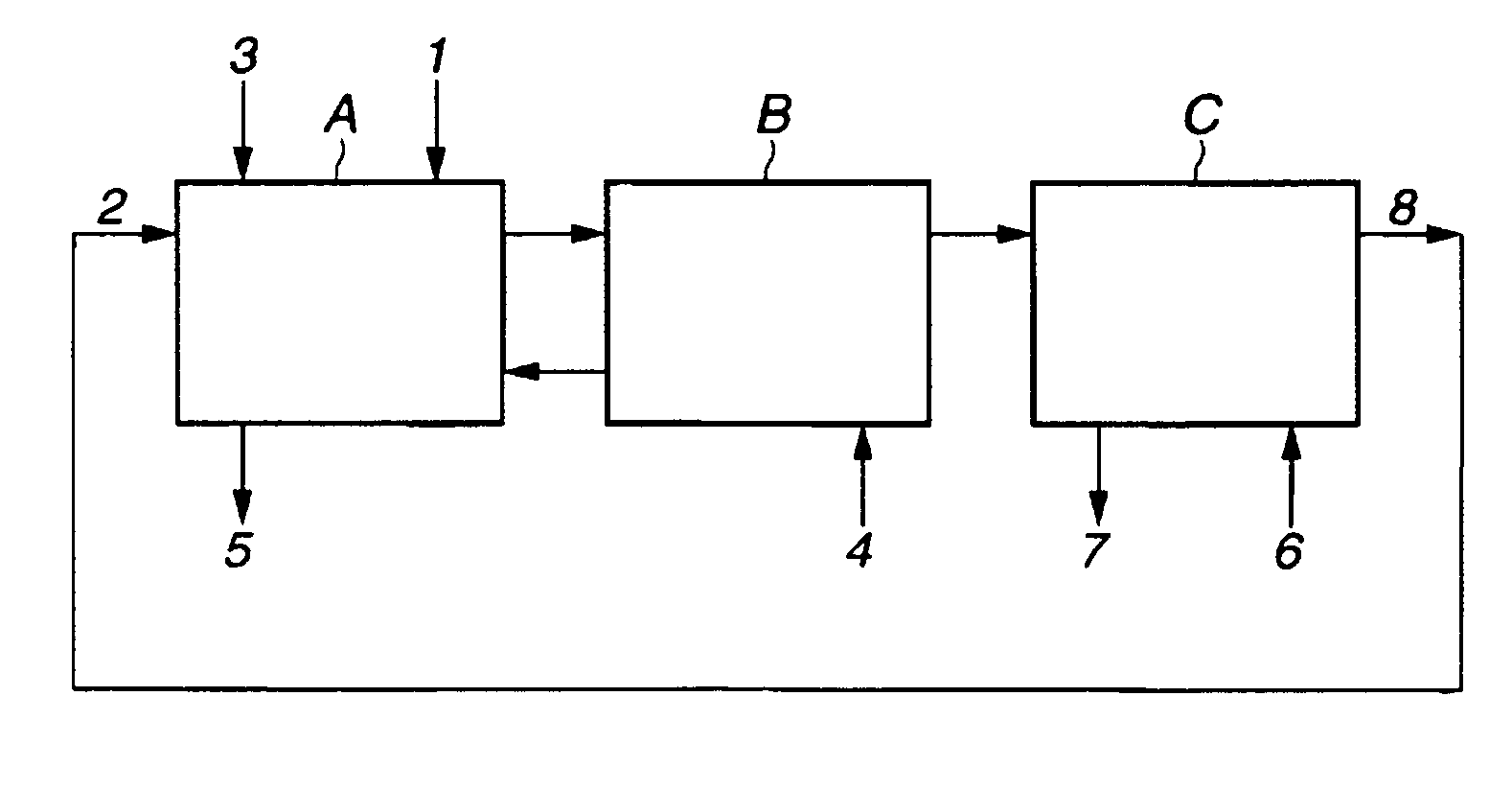

Process for reclaiming methacrylic acid from a high-boiler phase and an aqueous phase

The invention relates to a process for reclaiming methacrylic acid from a high- boiler phase in a heterogeneously catalysed gas phase oxidation of a C4- compound to methacrylic acid comprising the following steps a) Providing a high-boiler phase from a heterogeneously catalysed gas phase oxidation of a C4-compound to methacrylic acid b) Providing an aqueous phase, preferably organically loaded, from a heterogeneously catalysed gas phase oxidation of a C4-compound to methacrylic acid c) Mixing of components a) and b) optionally followed by filtration or centrifugation d) Adding an extraction media to the mixture from c) e) Subjecting the multiple-phase mixture from d) to at least one mixer-settler extraction process f) Recycling the organic phase from the last mixler-settler process back into the C4-process.

Owner:EVONIK ROEHM GMBH

Dephenolizing method for phenol-containing wastewater

InactiveCN106698776AReduction of recycling energy consumptionImprove recycling efficiencyWater contaminantsMultistage water/sewage treatmentRefluxDistillation

The invention provides a dephenolizing method for phenol-containing wastewater. The dephenolizing method for the phenol-containing wastewater comprises the following steps: a, mixing phenol-containing wastewater and an extracting agent which takes methyl terschyl ether as a main body and extracting in an extracting tower or a multi-stage mixer-settler to obtain a solvent phase and a raffinate aqueous phase; b, rectifying the solvent by a rectification process and recycling the solvent and coarse phenol, wherein the rectifying tower theoretical stage is 15 to 25, the reflux ratio is 0.1 to 1, the operating pressure is 0.1 to 0.91 MPa, the tower top operating temperature is 50 to 90 DEG C, and the tower bottom temperature is 150 to 300 DEG C; c, distilling the raffinate aqueous phase by a distillation solvent recovery process and recycling residual extracting solvent, wherein the tower top temperature is 62 to 90 DEG C, the tower bottom temperature is 100 to 130 DEG C, and the amount of a material which is distilled from the top of the tower is 1.5 to 5 percent of that of a fed material; d, recycling the extracting solvent. The dephenolizing method for the phenol-containing wastewater has the beneficial effects that the process flow is simple; the equipment investment is low; the solvent recycling energy consumption is low; the recycling rate of the phenol is high.

Owner:YANCHENG OUHUA CHEM IND

Mixer settler for three-phase extraction

InactiveCN101991971BSolving Three-Phase Flow ProblemsLiquid solutions solvent extractionPhase mixingThree stage

The invention belongs to a liquid-liquid-liquid three-phase multi-stage continuous extraction device, and particularly relates to a mixer settler for three-phase extraction, which can extract the target component in one step and realizes high-level separation in a multi-component complex system. The mixer settler for three-phase extraction comprises a first-level mixer settler, a second-level mixer settler and a third-level mixer settler which have the same structure; and every mixer settler comprises a three-phase mixing chamber, a clarifying chamber, an intermediate-low phase mixing chamber, and the like. As an aqueous two-phase system, an intermediate phase and a salt-rich low phase rich in polymer are used as one phase under the condition of stirring to transfer mass during counterflow with the organic phase so that the problem of three-phase flow in the three-phase extraction process is solved and the multi-stage continuous extraction can be carried out. Under the circumference that the one-stage extraction separating effect is unsatisfactory in the multi-component complex system, the mixer settler for three-phase extraction can realize three-stage reverse flow continuous extraction and high-level multi-component separation according to the components. The invention successfully solves the problem of three-phase flow in the three-phase extraction process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

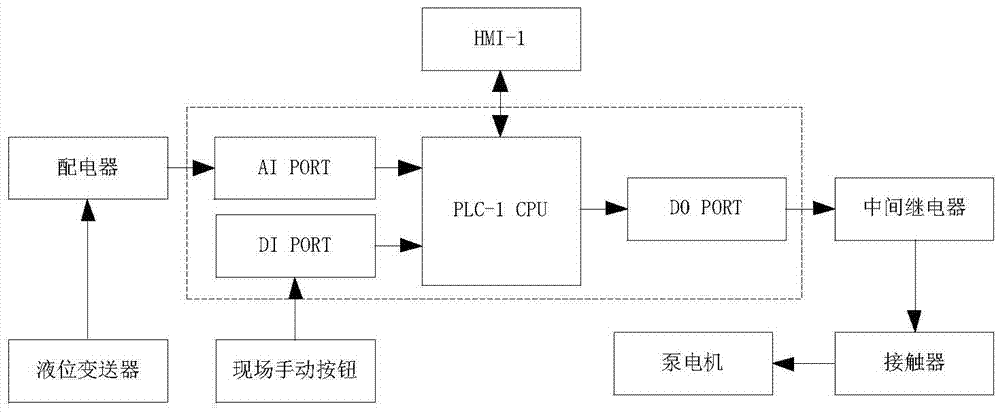

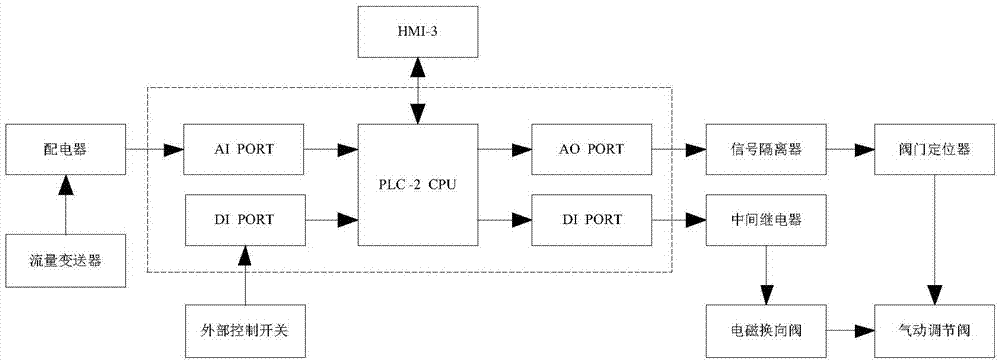

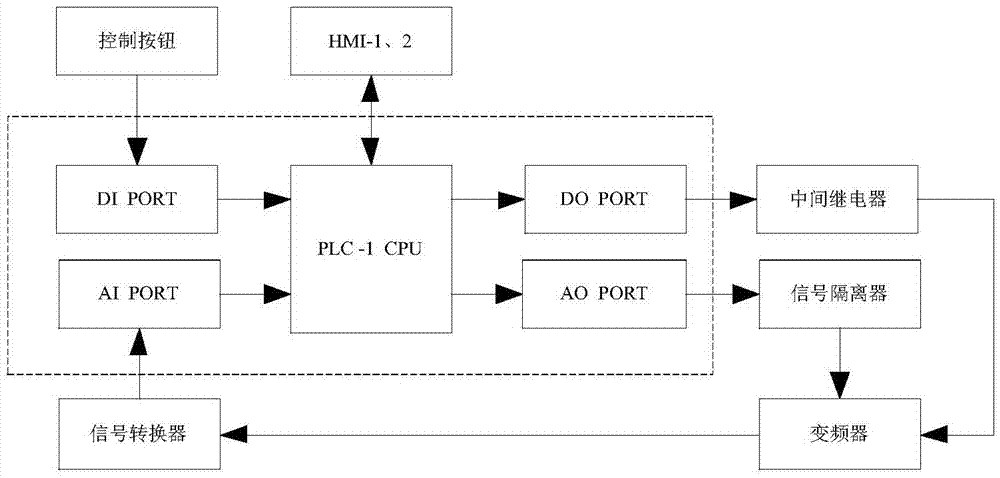

Uranium-containing material extraction process control method

InactiveCN106929674ARealize automatic chain controlRealize automatic adjustmentProgramme control in sequence/logic controllersCapacitanceMixer-settler

The invention relates to the technical field of treatment of uranium-containing waste materials during production of uranium dioxide powder and fuel pellets, in particular to a uranium-containing material extraction process control method. The method includes the steps of liquid level interlocking controlling over a liquid distribution tank and all liquid storing tanks, controlling over flows of all reaction media in the extraction process and the reextraction process, and controlling over the stirring speed of a mixer-settler. An electrical capacitance level meter is adopted for liquid level measurement; a putting-into-type liquid level meter is adopted for tributyl phosphate (TBP) liquid level measurement; a magnetic liquid level meter is adopted for nitric acid liquid level measurement; an electromagnetic flow meter is adopted for flow measurement of a uranyl nitrate solution; a mass flow meter is adopted for measurement of flow and density of a TBP extraction agent; and a metallic rotor flow meter is adopted for flow measurement of non-ionic water. The uranium-containing material extraction process control method is applied to production, the continuity, stability and the like of extraction production are greatly improved, the quality indexes including the uranium concentration, acidity, purity and other indexes of back water output to a precipitation station are stable and controllable, and the uranium content of waste water output to an adsorption station is greatly reduced.

Owner:CNNC JIANZHONG NUCLEAR FUEL

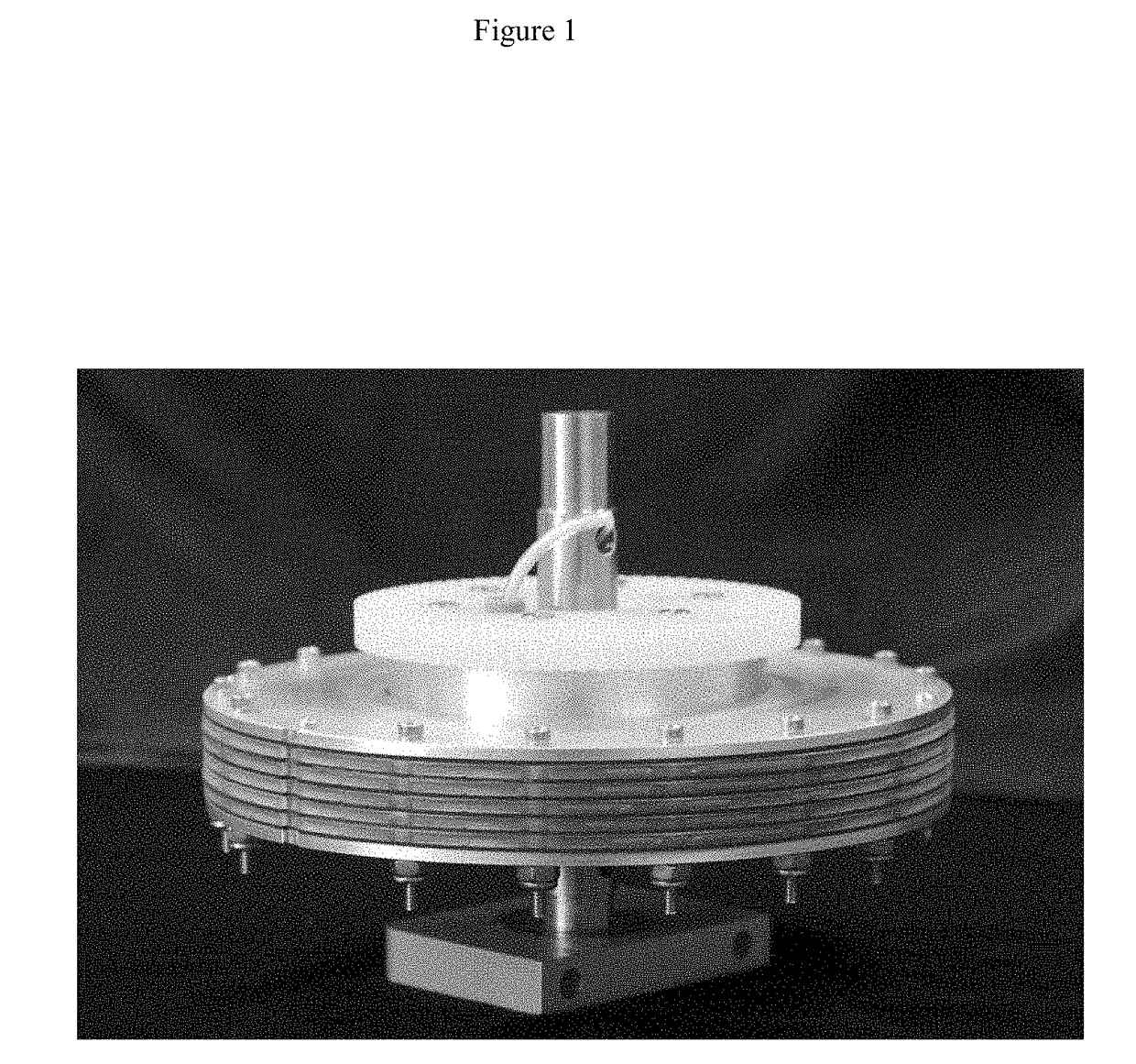

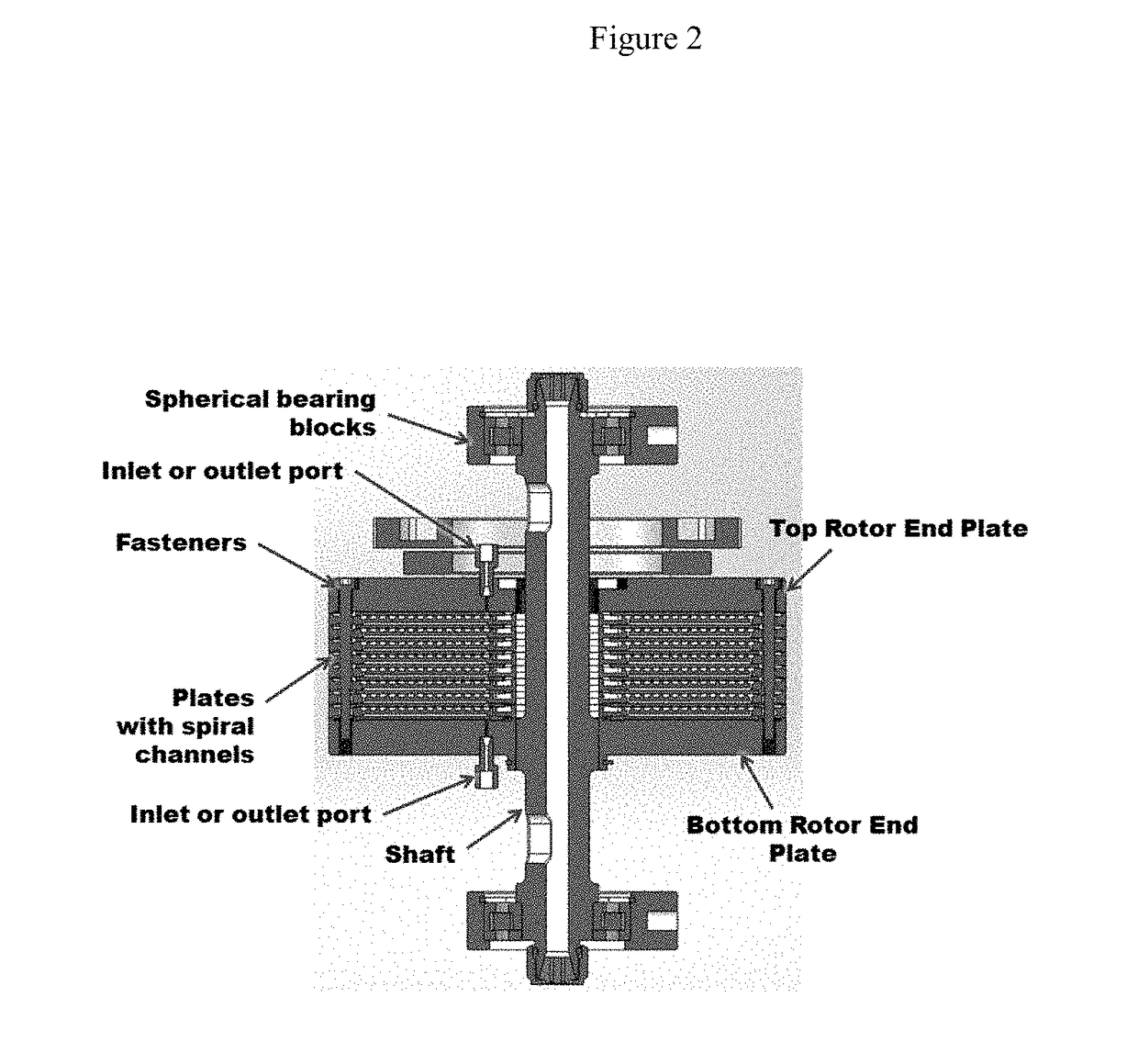

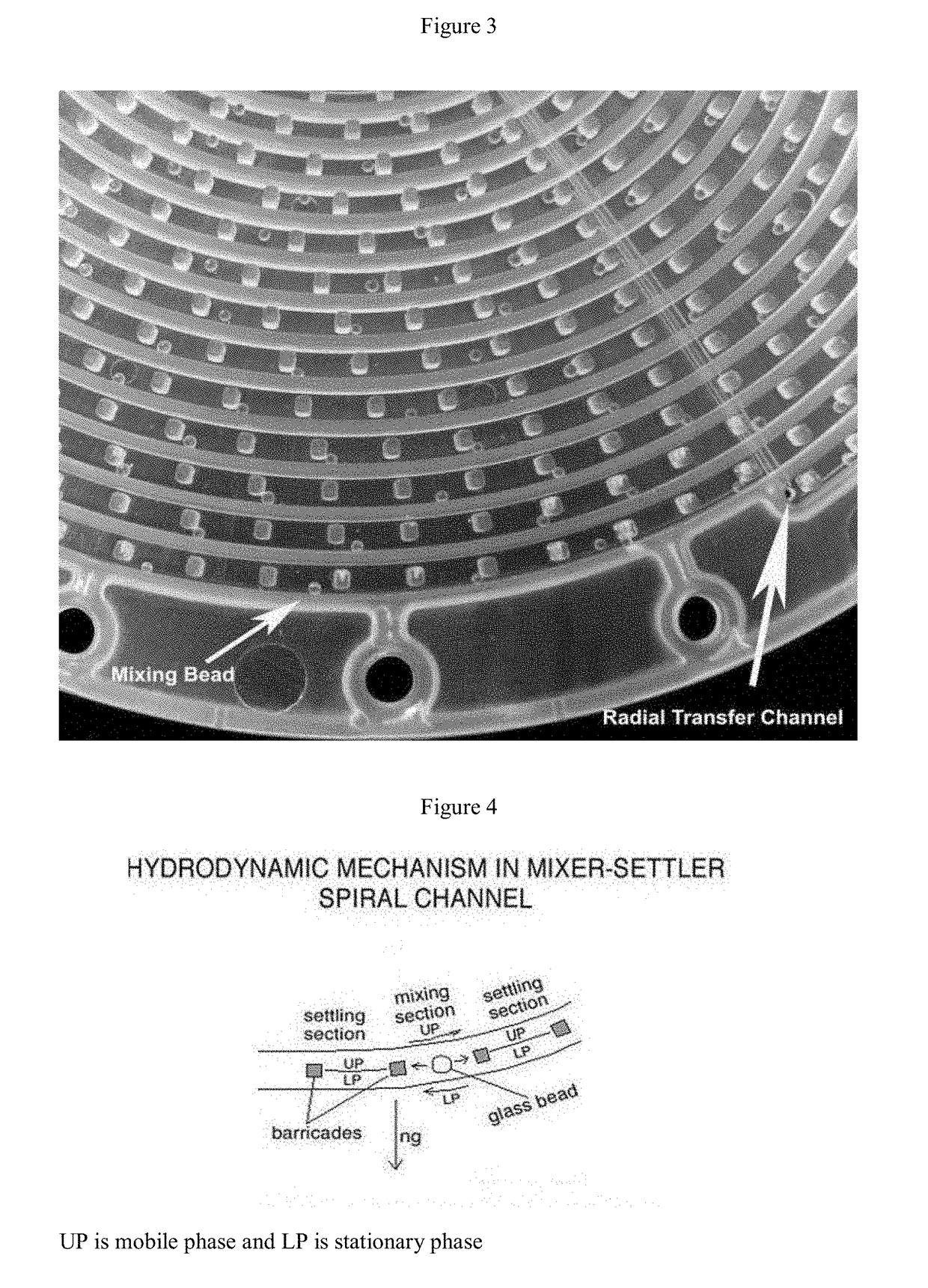

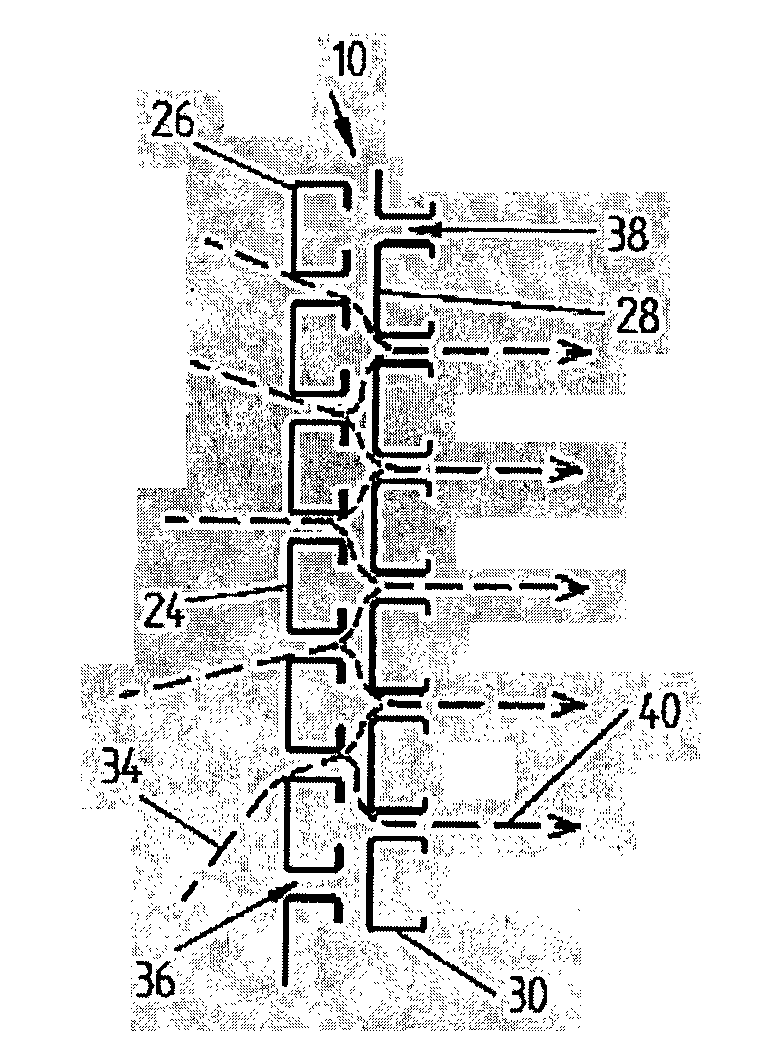

Planetary Countercurrent Chromatography Centrifuge and Mixer-Settler Rotor

InactiveUS20190015761A1Avoid high rotor weightWear minimizationComponent separationSolid sorbent liquid separationCountercurrent chromatographyMixer-settler

A mixer-settler countercurrent chromatography centrifuge and rotor of increased capacity is described.

Owner:CC BIOTECH

Distribution array for use in a settler area of a mixer-settler

ActiveUS20140083956A1Minimal impact dynamicSolvent extractionWater/sewage treatmentEngineeringMixer-settler

Owner:HATCH LTD

Method for extracting and separating light rare earth element

ActiveUS8802040B2Extraction and separation of a target LREESimple stepsRare earth metal chloridesRare earth metal compounds preparation/treatmentRare-earth elementMixer-settler

A target light rare earth element is separated from an aqueous solution containing two or more of La, Ce, Pr and Nd by contacting an organic phase containing an extractant with the aqueous solution in a counter-current flow multistage mixer-settler while adding an alkaline solution thereto, and contacting the organic phase with an acid aqueous solution for back-extracting the target element. The extractant is a dialkyl diglycol amic acid having formula: R1R2NCOCH2OCH2COOH wherein R1 and R2 are alkyl, at least one having at least 6 carbon atoms.

Owner:SHIN ETSU CHEM IND CO LTD

Cylindrical mixer-settler apparatus and method

Owner:SPX FLOW INC

Ultrasonic counter-current screw extractor for uranium recovery and process therefore

ActiveUS7527772B2Improve efficiencySeparated economicallyShaking/oscillating/vibrating mixersSolvent extractionScrew extractorMixer-settler

An apparatus and method to remove uranium from a body of material wherein the method includes the steps of depositing the body of solid material in an ultrasonic extractor and depositing an amount of acid in the ultrasonic extractor. The method also provides for the steps of heating a jacket of the ultrasonic extractor, transporting the body of solid material in the ultrasonic extractor and the amount of acid such that the body of solid material and the acid contact each other inside the heated ultrasonic extractor while the ultrasonic extractor provides ultrasonic energy to both the body of solid material and the amount of acid, wherein the amount of acid strips uranium from the body of solid material. The method further provides for collecting the amount of acid and the body of solid material in the ultrasonic extractor in different positions, transporting the amount of acid with the stripped uranium to an extraction mixer settler, and settling uranium product from the extraction mixer settler.

Owner:AREVA NP INC

Liquid-liquid extraction mixer-settler and extraction method and application thereof

InactiveCN103120863BSimple structureCompact structureLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

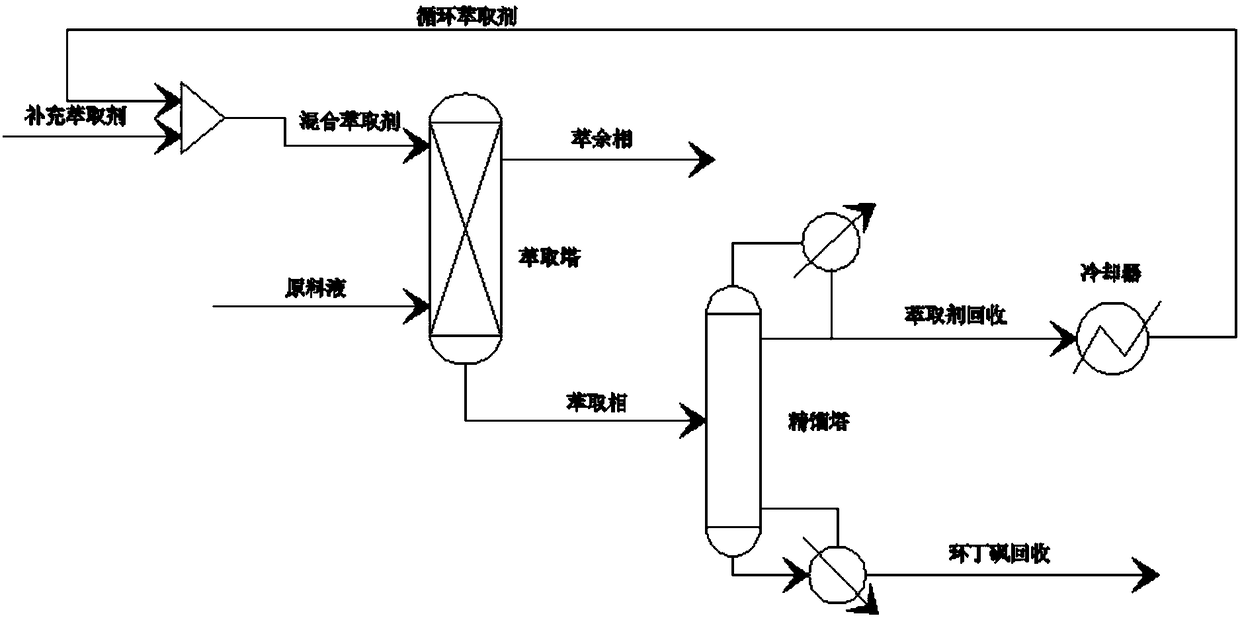

Method for treating sulfolane wastewater

ActiveCN109019740AReduce energy consumptionReduce the reflux ratioOrganic chemistryWater contaminantsSulfolaneChlorobenzene

The invention belongs to the technical field of wastewater treatment and relates to a method for treating sulfolane wastewater. The method comprises the following steps: treating wastewater and an extraction agent in an extraction tower or a mixer-settler to obtain an extract phase and a raffinate phase; recycling the raffinate phase; rectifying the extract phase, recovering the extraction agent at the top of the tower, cooling and recycling, and recovering at the tower bottom to obtain sulfolane, wherein the extraction agent is one or more ingredients selected from a group consisting of halogenated hydrocarbon, aromatic hydrocarbon and an ester compound, preferably one or more ingredients selected from a group consisting of dichloromethane, trichloromethane, dichloroethane, benzene, chlorobenzene, o-dichlorobenzene and ethyl acetate. The method has advantages of simple process, convenient operation, energy conservation and high efficiency. The extraction agent can be recycled; the extraction rate of sulfolane and the purity of the recovered sulfolane are both greater than 99%; the content of sulfolane in the treated wastewater is less than 50 mg / L, and the sulfolane can be recycled to achieve zero discharge of wastewater.

Owner:DALIAN UNIV OF TECH +1

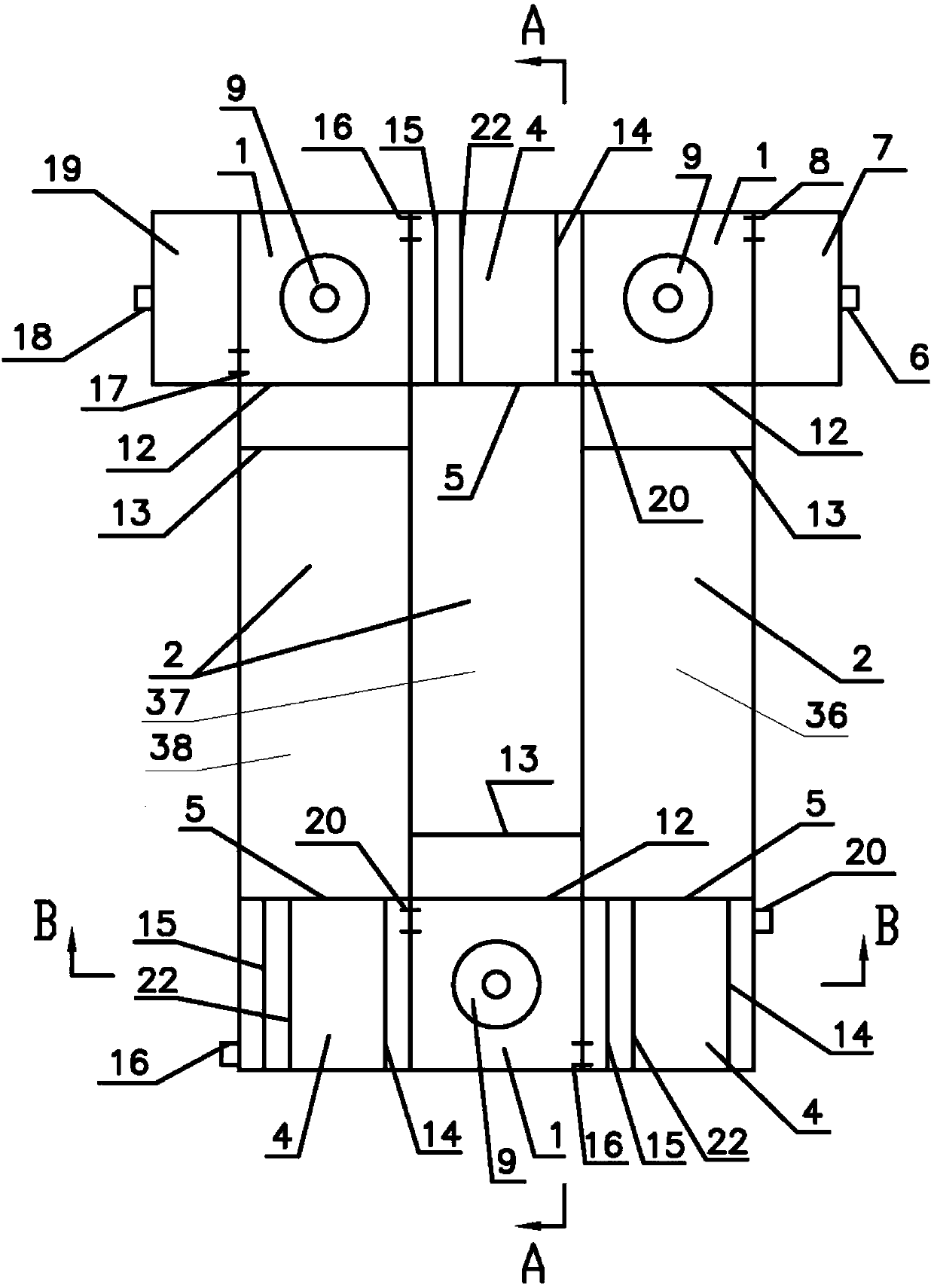

Mixer-settler

ActiveCN109646996AMeet the needs of useGuaranteed contactLiquid solutions solvent extractionRefluxMixer-settler

The invention discloses a mixer-settler which comprises at least one settling tank. The settling tank comprises a mixing chamber, a settling chamber and a separation chamber which are sequentially arranged and communicated. The settling tank also comprises a submersible chamber which is arranged below the mixing chamber and communicated with the mixing chamber. The separation chamber comprises a heavy phase chamber, a light phase chamber, and the separation chamber also comprises a reflux chamber, wherein the heavy phase or the light phase in the separation chamber flows into the reflux chamber. One end of a reflux pipeline is connected with the submersible chamber and the other end of the reflux pipeline is connected with the reflux chamber. The reflux pipeline is used for refluxing the heavy phase or the light phase back to the submersible chamber. Under the condition that the two-phase flow of the heavy phase and the light phase in the mixer-settler is relatively large, a part of one phase with a smaller flow rate can be refluxed into the mixing chamber, so that the contact phase ratio of the two phases in the mixing chamber is close to 1, and the mass transfer efficiency is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Integrated process for simultaneous removal and value addition to the sulfur and aromatics compounds of gas oil

ActiveUS10190064B2Cost effectiveEnvironmentally friendlyLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesDistillationPhysical chemistry

An integrated process for simultaneous removal and value addition to sulfur and aromatics compounds of gas oil is provided. Process includes the segregation of refractive sulfur and aromatics compounds of gas oil in heavy fraction of gas oil using distillation processing of heavy fraction of gas oil in continuous solvent extraction zone, processing of lighter fraction of gas oil and raffinate of heavy fraction of gas oil in hydrotreating reaction zone operating under mild conditions of temperature and pressure for producing the gas oil with reduced sulfur and aromatic compounds and contact of extract phase generated during continuous extraction with water in mixer settler for generating the pseudo raffinate which can be used as suitable feed to hydrocracker to generate sulfur lean gas oil.

Owner:COUNCIL OF SCI & IND RES

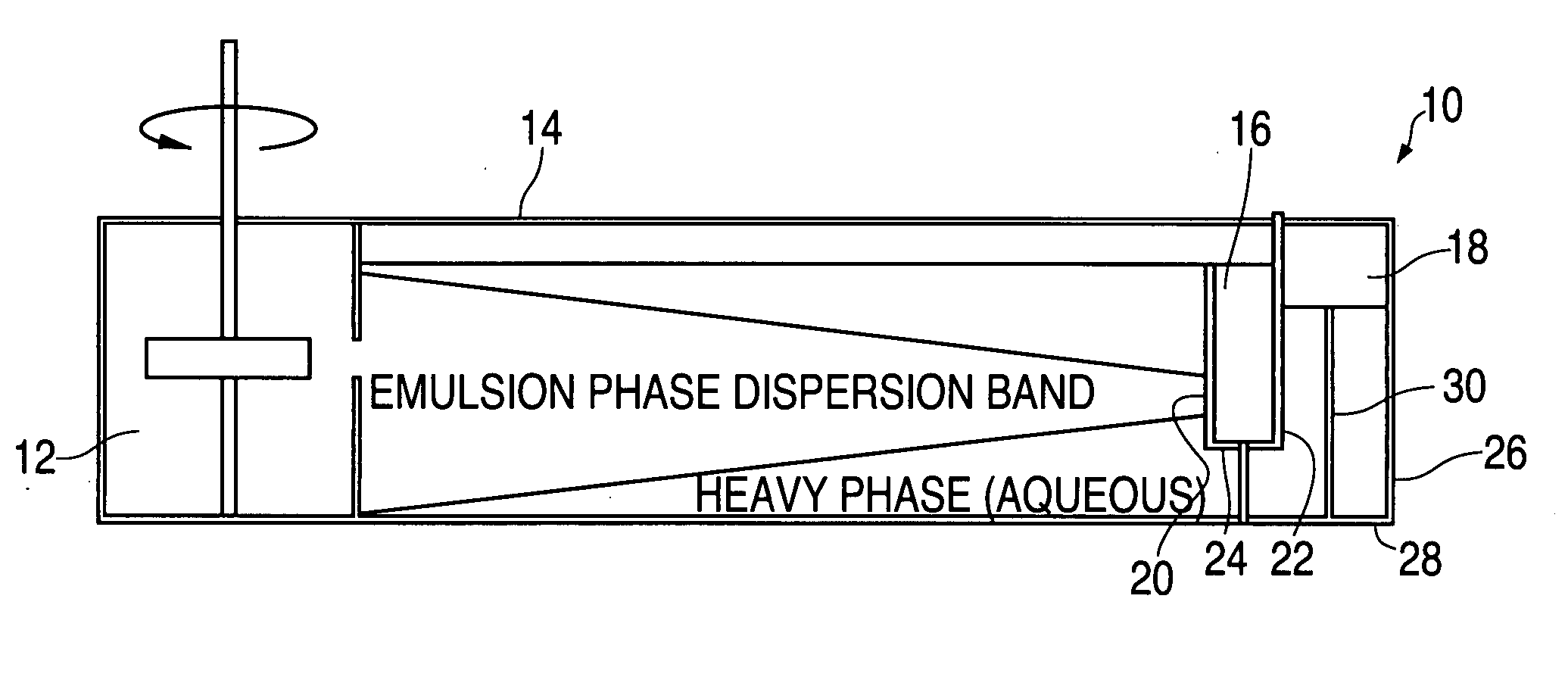

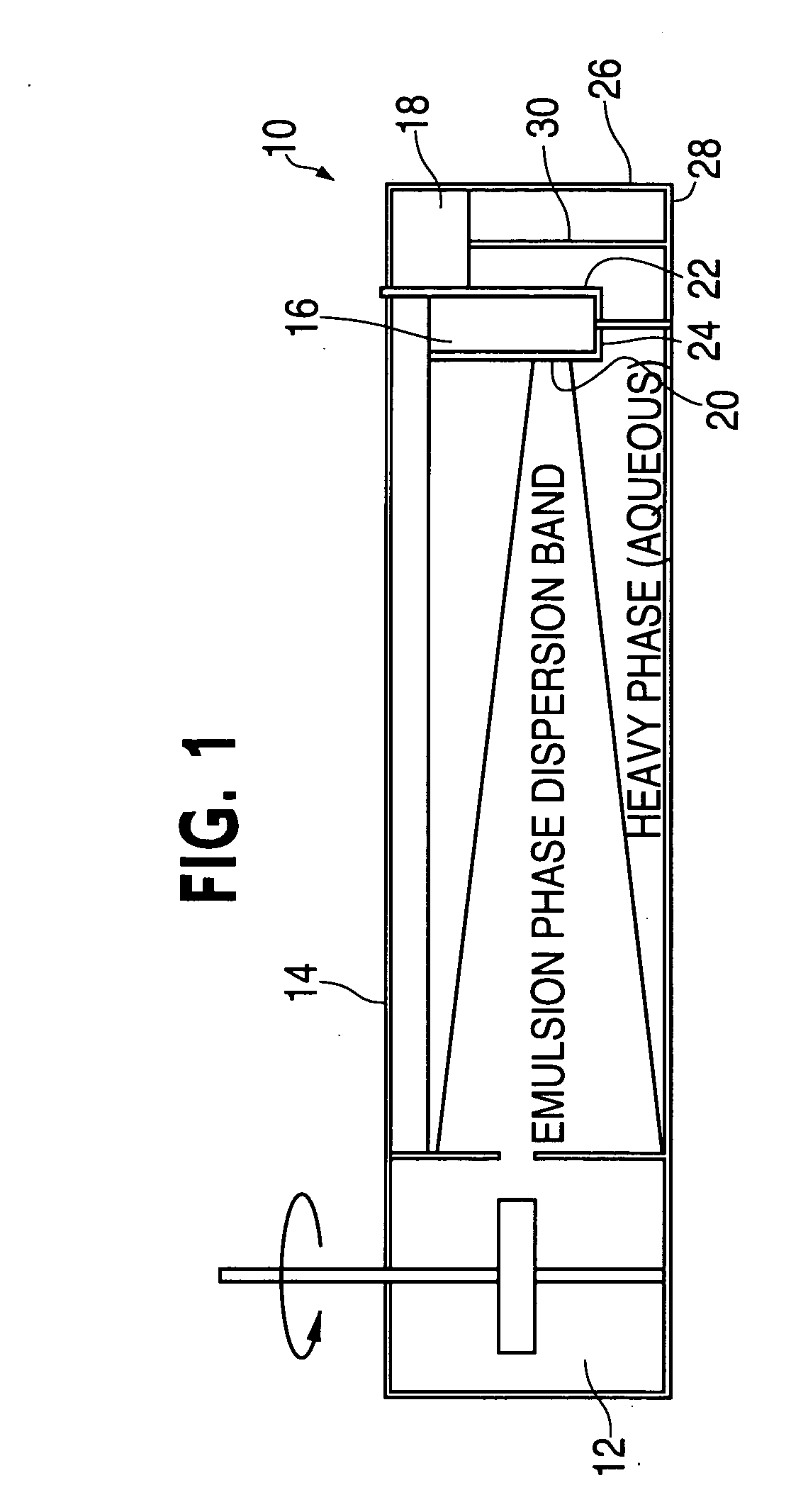

Column settler for high performance liquid/liquid phase separations in hydromellurcial processes and methods thereof

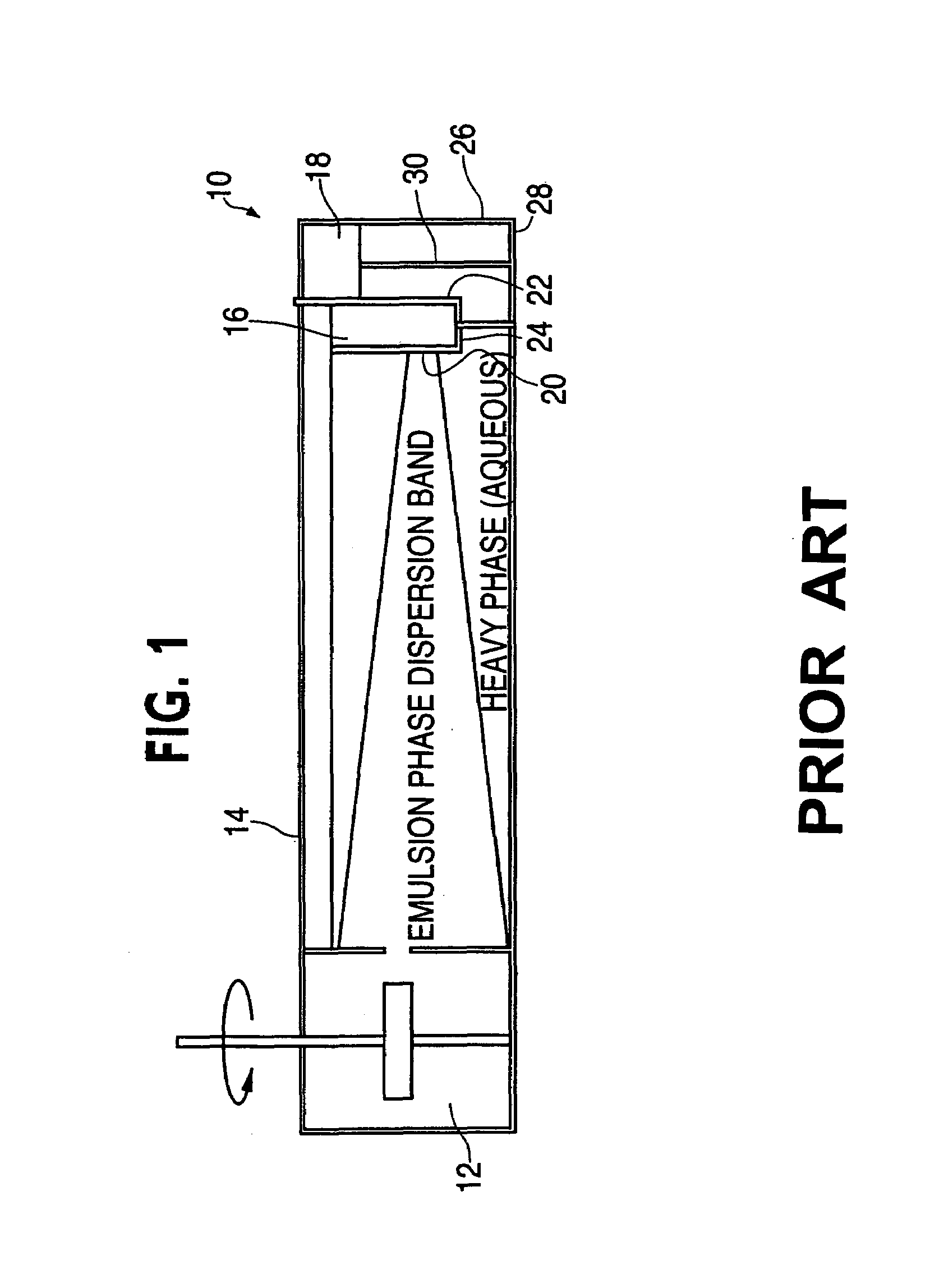

InactiveUS20170080355A1Reduces necessary footprint areaFaster and short residence timeLiquid solutions solvent extractionNon-miscible liquid separationEmulsionMixer-settler

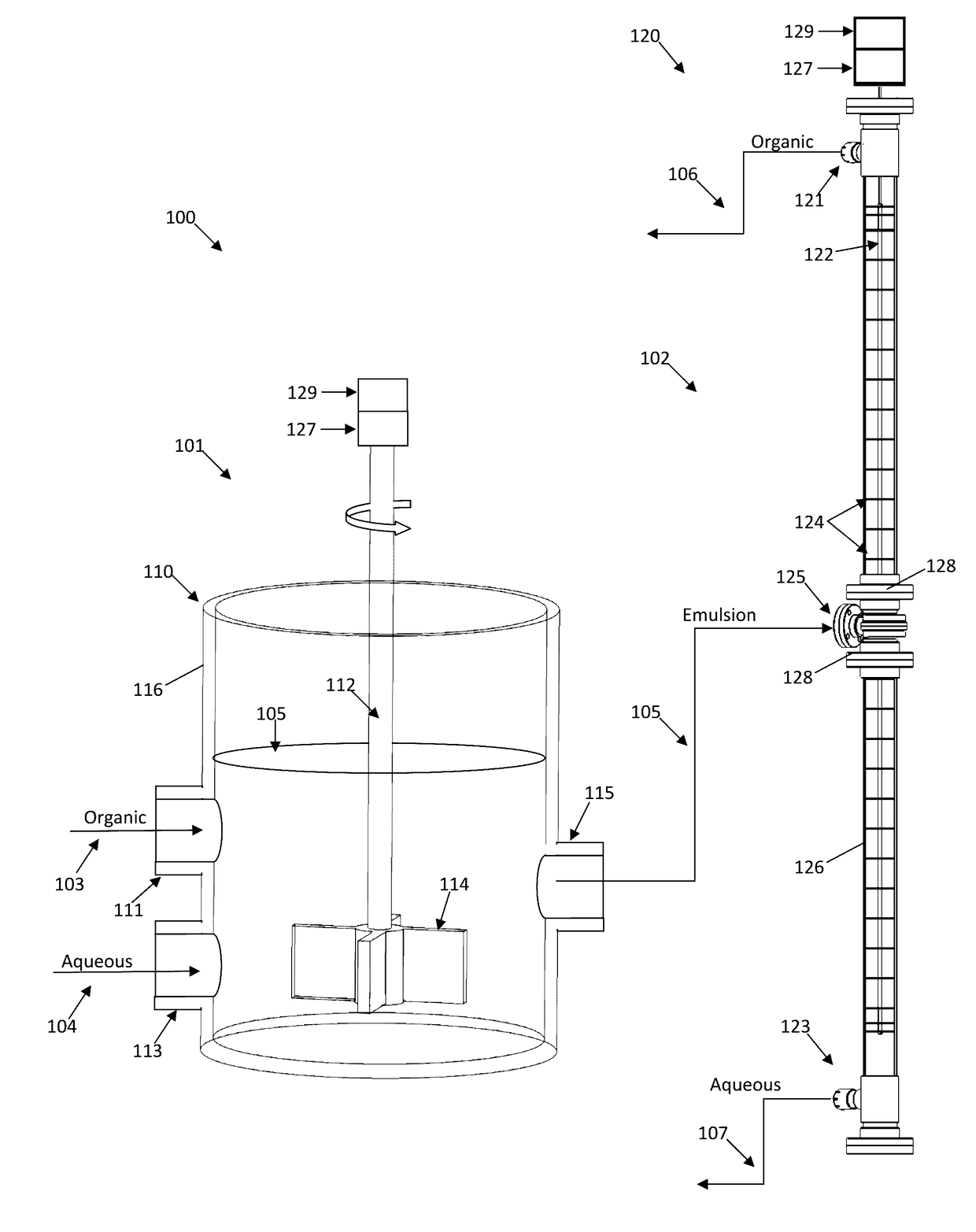

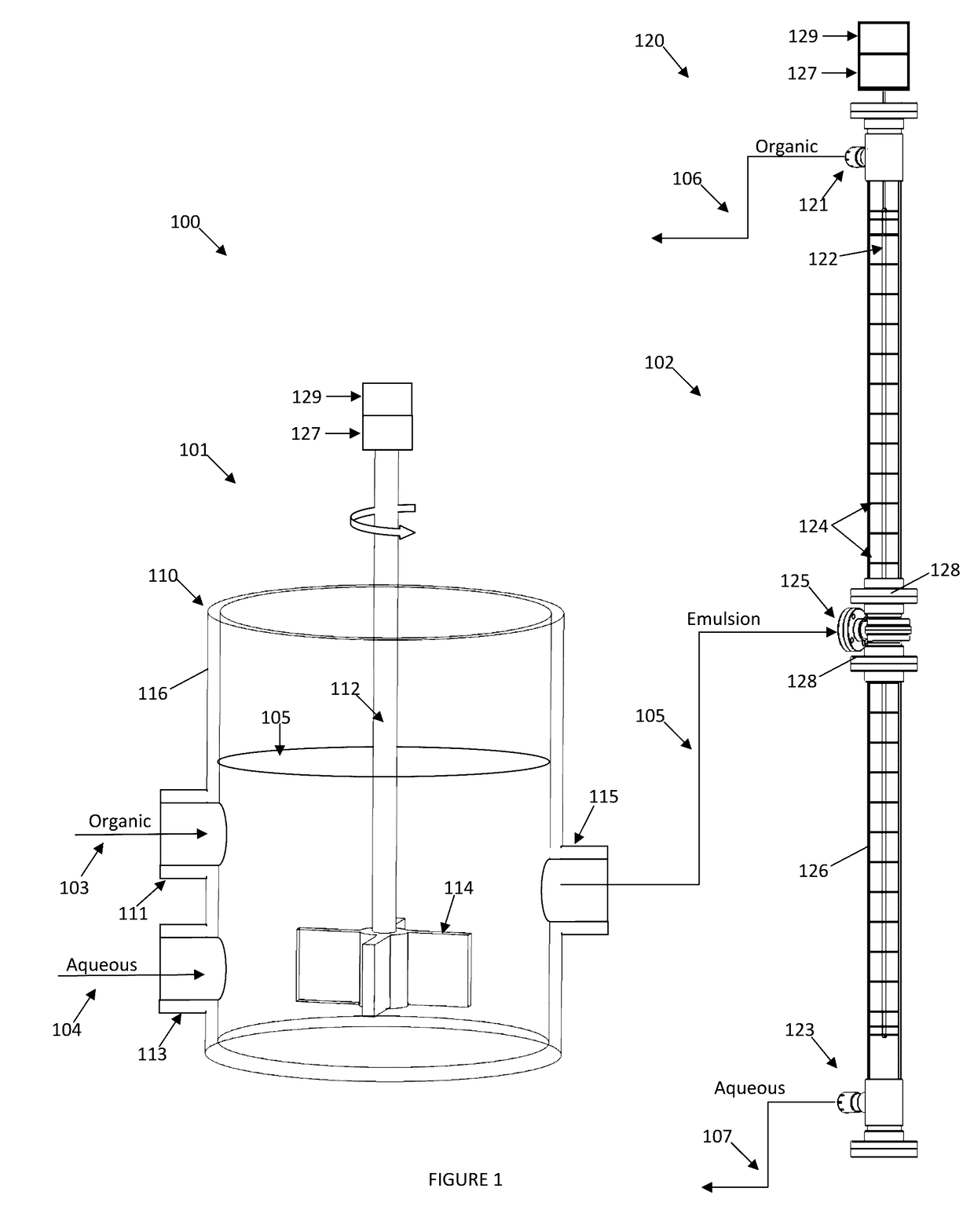

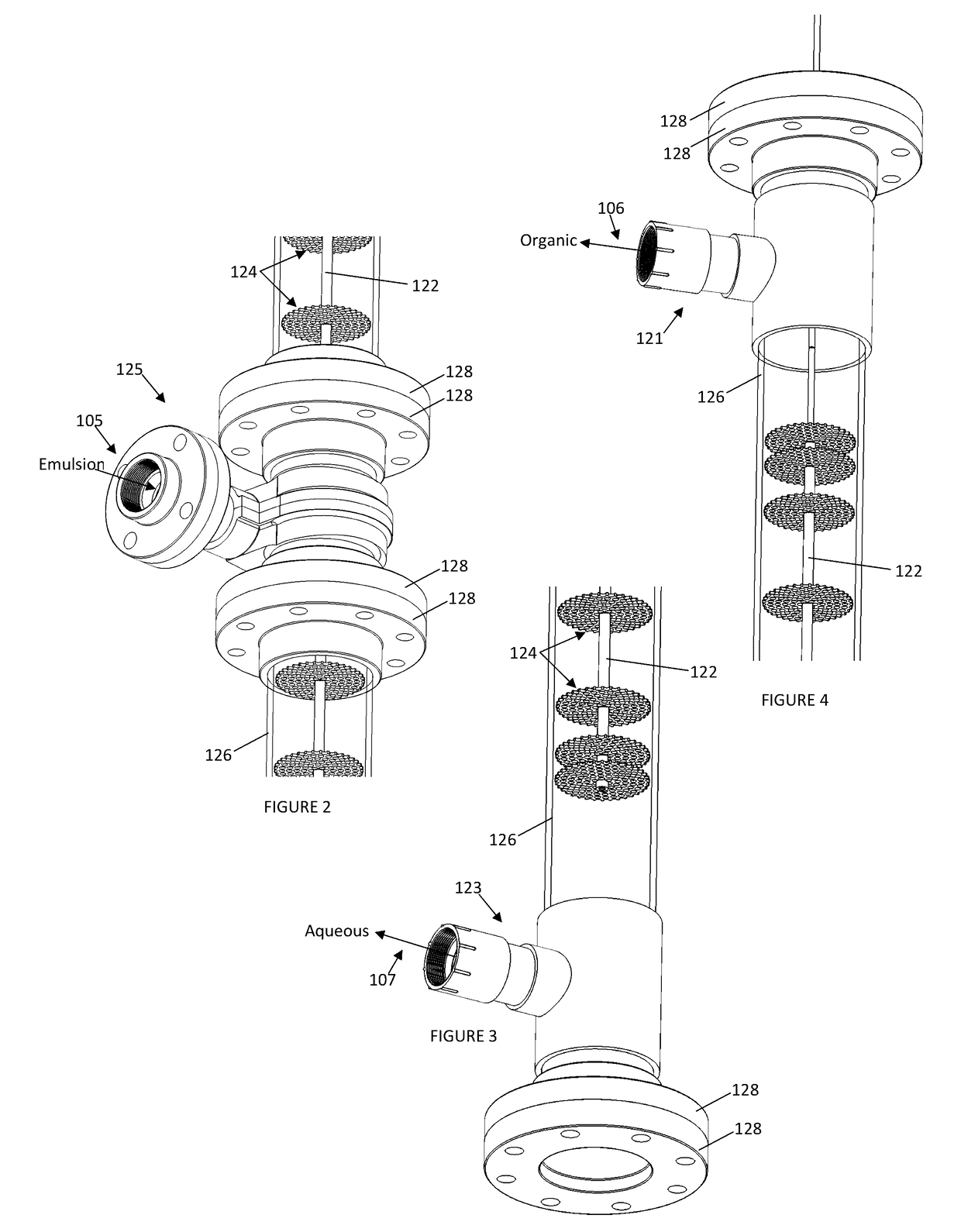

A mixer settler system is disclosed. The system comprises a mixer [110] configured for receiving an organic phase and an aqueous phase, the mixer [110] being further configured to maintain the organic phase and the aqueous phase in a single unstable emulsion phase, wherein mass transfer occurs between said organic phase and said aqueous phase; and, a column settler [120] which is configured to receive a single unstable emulsion phase from the mixer [110] via an emulsion inlet [125] and is also configured to separate the single unstable emulsion phase into a stable organic phase and a stable aqueous phase by virtue of coalescence; the column settler further comprising an organic outlet [121] above the emulsion inlet [125] and an aqueous outlet [123] below the emulsion inlet [125]; the column settler [120] further discouraging mass transfers within the unstable emulsion phase and further promoting coalescence of each of said stable organic phase and stable aqueous phase. A method of settling two immiscible liquids is further disclosed. The method comprises providing a mixer [110] configured for receiving an organic phase and an aqueous phase; maintaining the organic phase and the aqueous phase in a single unstable emulsion phase using the mixer [110], wherein mass transfer occurs between said organic phase and said aqueous phase; providing a column settler [120] which is configured to receive a single unstable emulsion phase from the mixer [110]; sending the single unstable emulsion phase to the column settler [120]; and separating the single unstable emulsion phase into a stable organic phase and a stable aqueous phase within the column settler [120] by virtue of coalescence.

Owner:BACZEK FR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com