Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156 results about "Micro fuel cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A micro fuel cell is a power source for electronic devices that converts chemical energy into electrical energy. Fuel cells operate by oxidizing combustible fuel, such as hydrogen or alcohol.

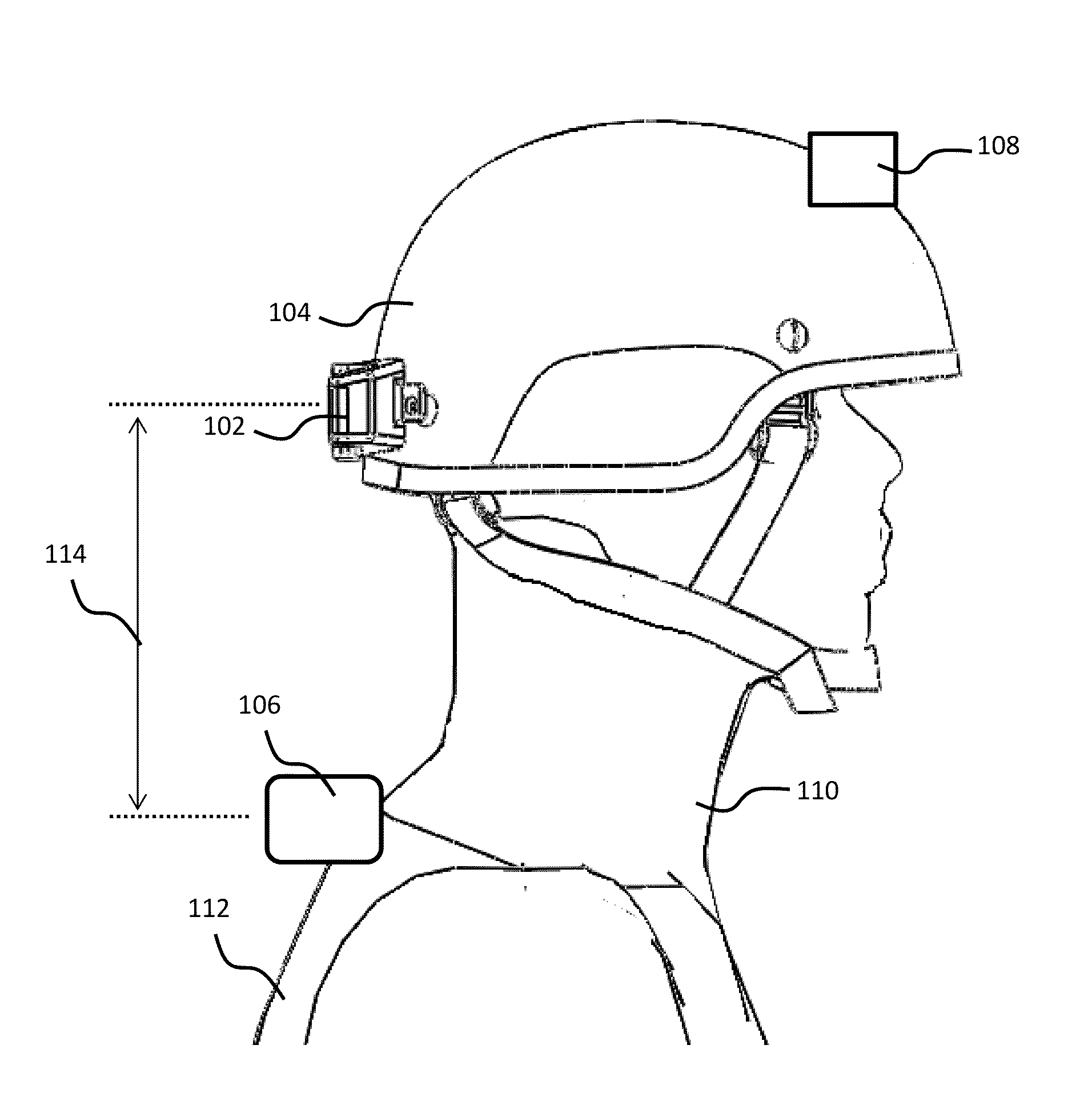

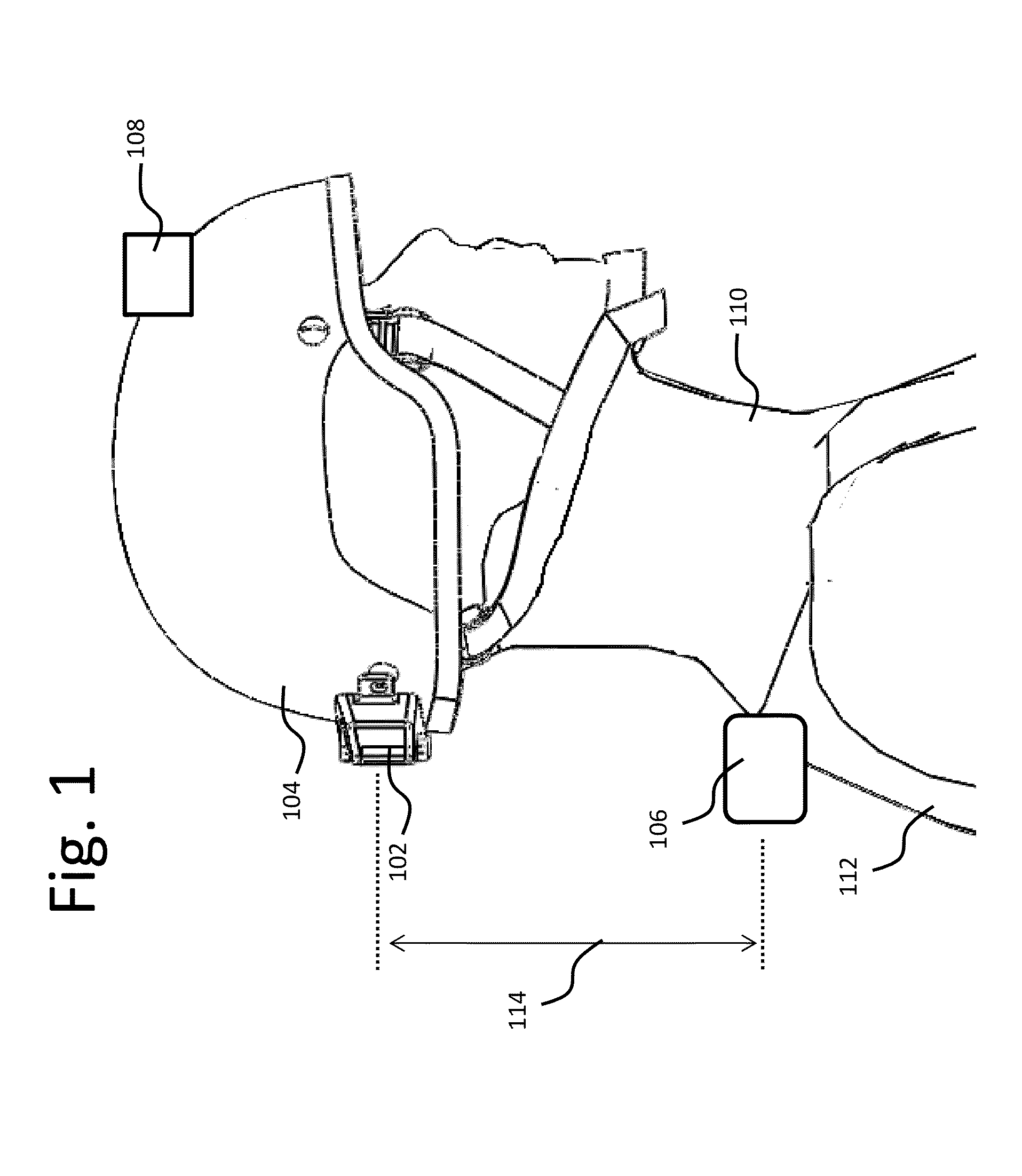

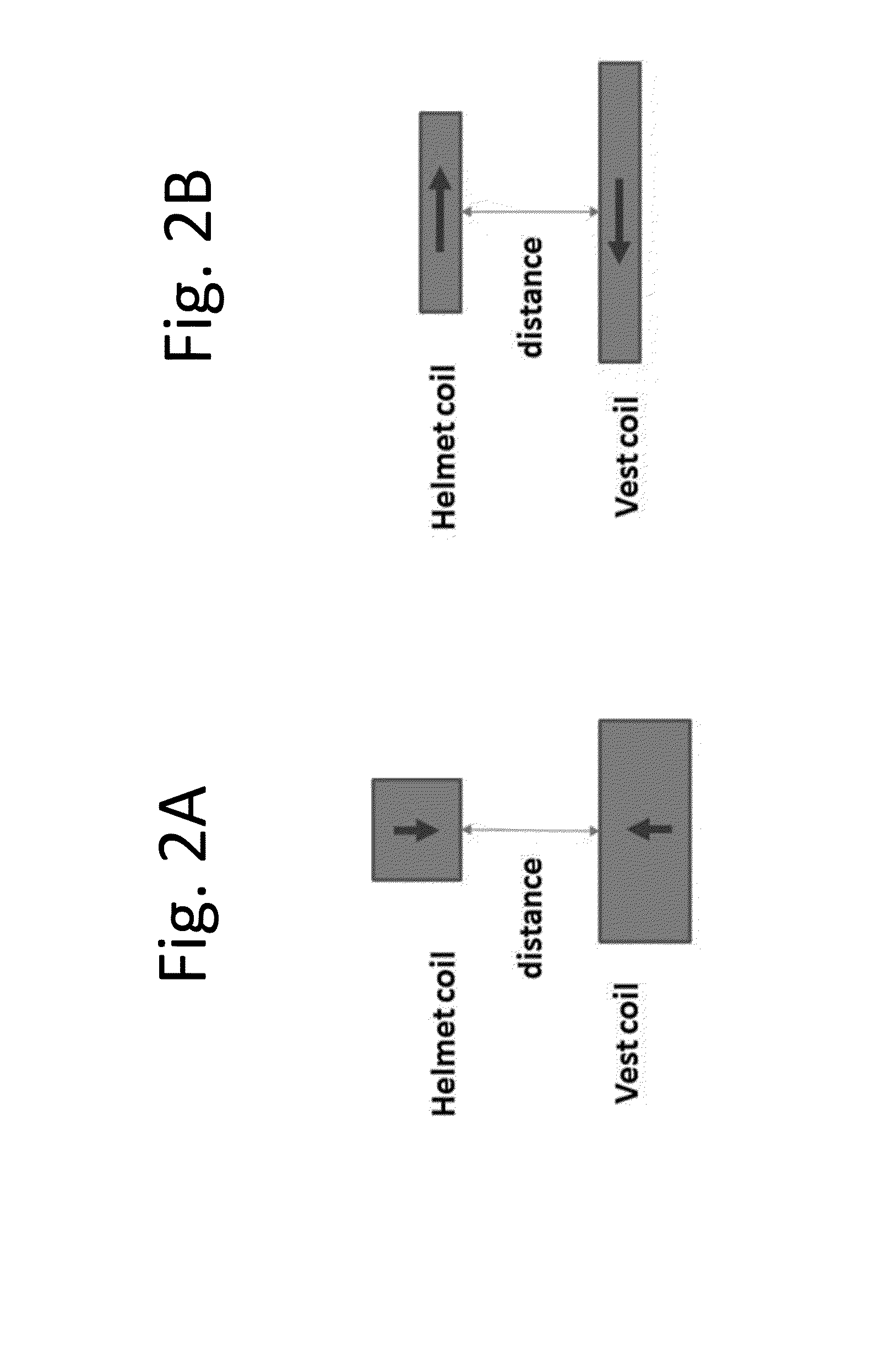

Wireless energy transfer for person worn peripherals

InactiveUS20130007949A1Reduce interactionBatteries circuit arrangementsElectromagnetic wave systemHand heldEngineering

Described is a system for wireless energy transfer for person worn peripherals. The system makes use of a technique referred to as strongly-coupled magnetic resonance to transfer energy across a distance without wires and enables efficient transfer of energy over distances of 10 to 18 cm or more. The system comprises a resonant power source, which could be embedded in a person's equipment vest or backpack receiving power from a central battery pack or micro fuel cell, and a resonant power capture unit which could be integrated with the helmet or hand held weapon, electronic device, and the like that may be carried or handled by a person.

Owner:WITRICITY CORP

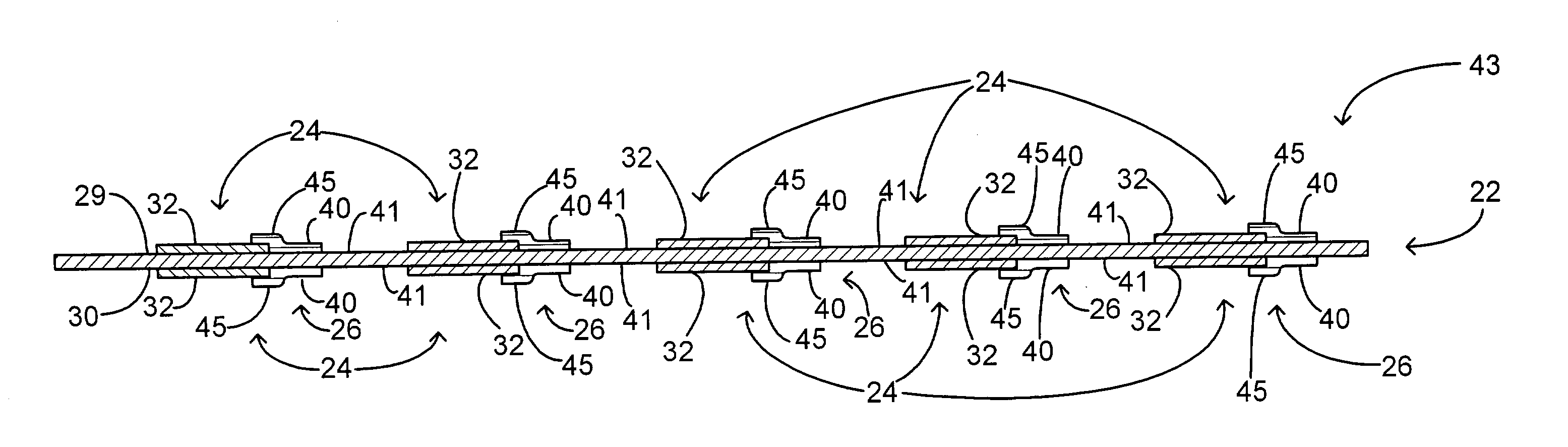

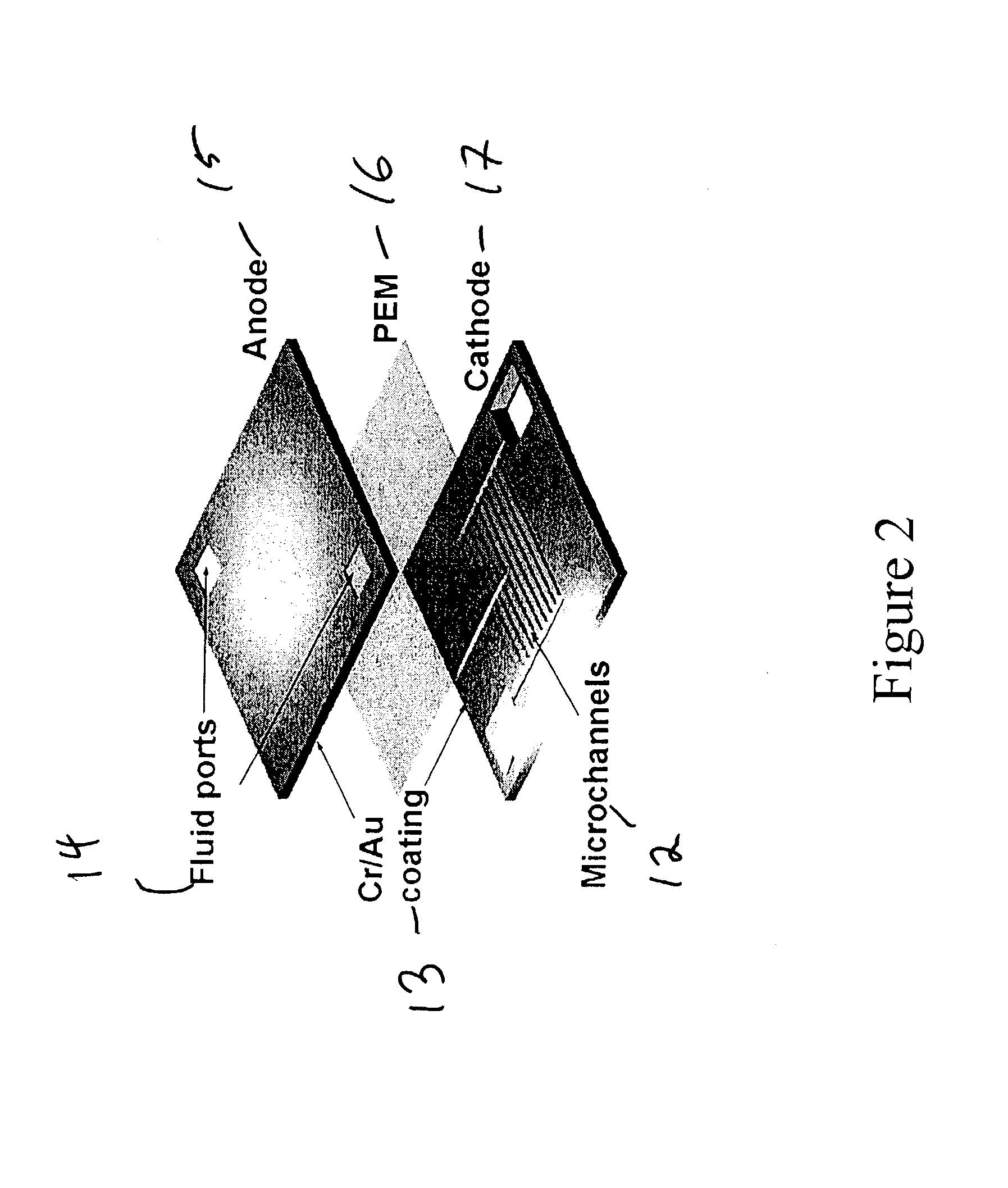

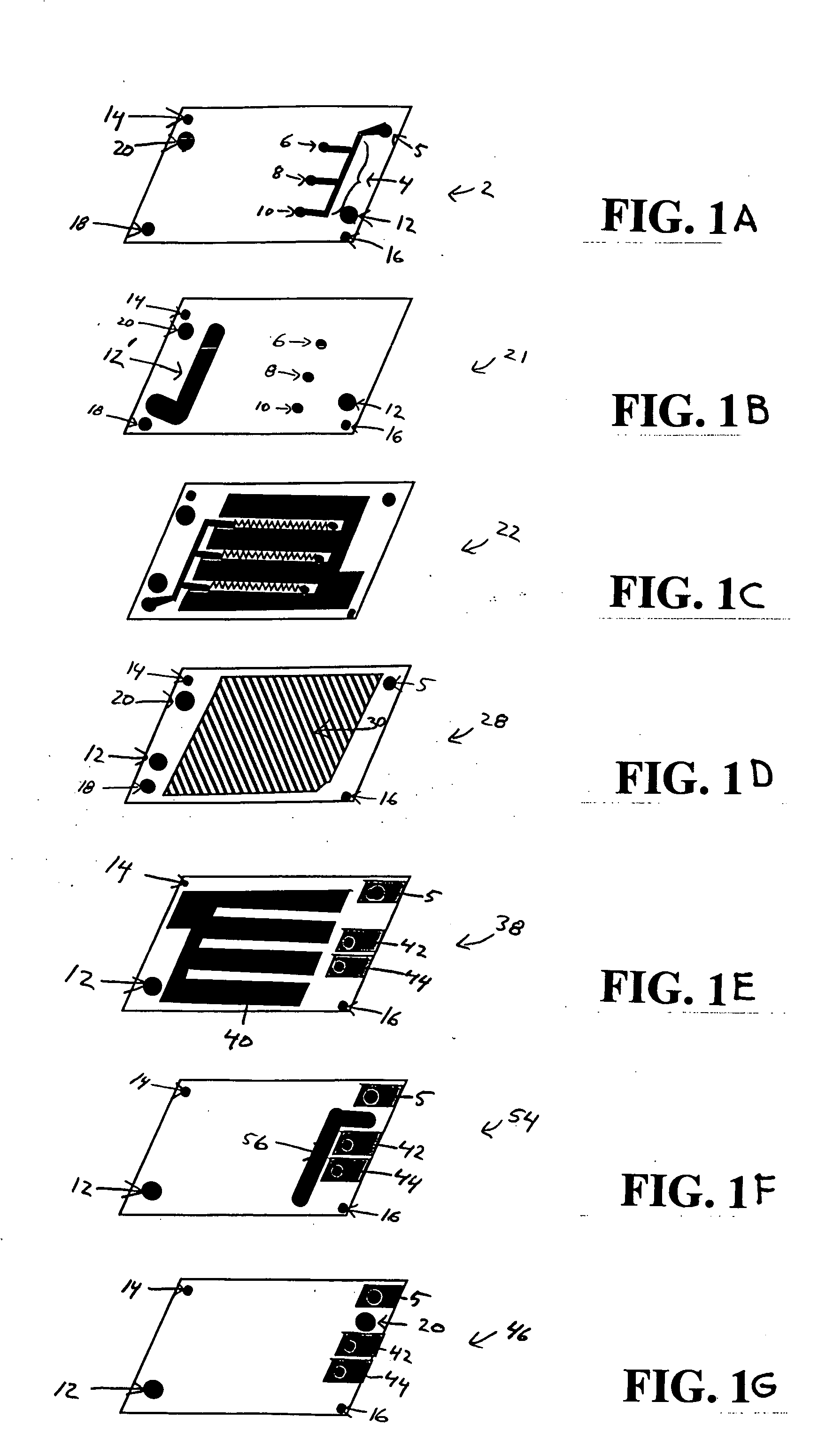

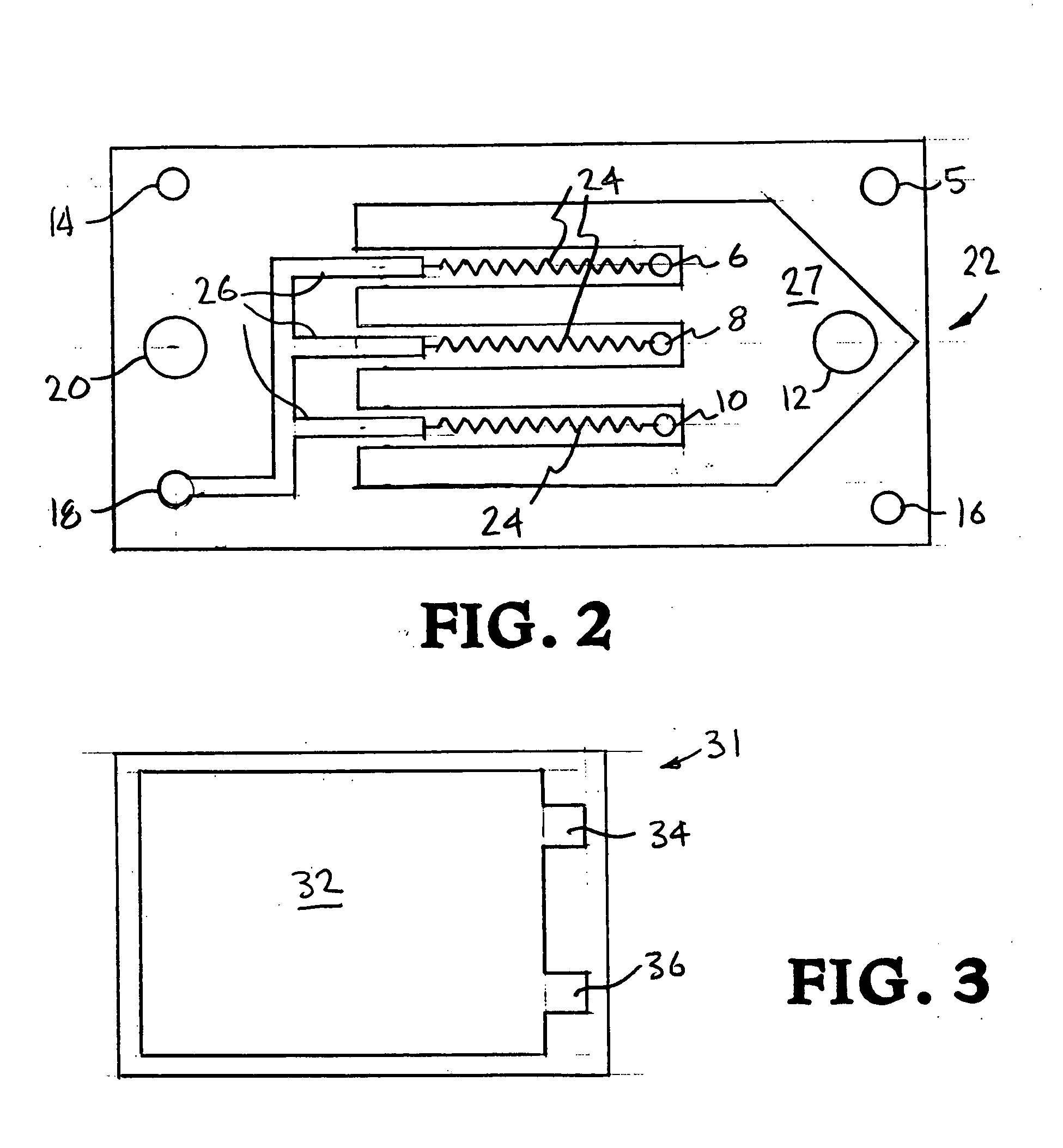

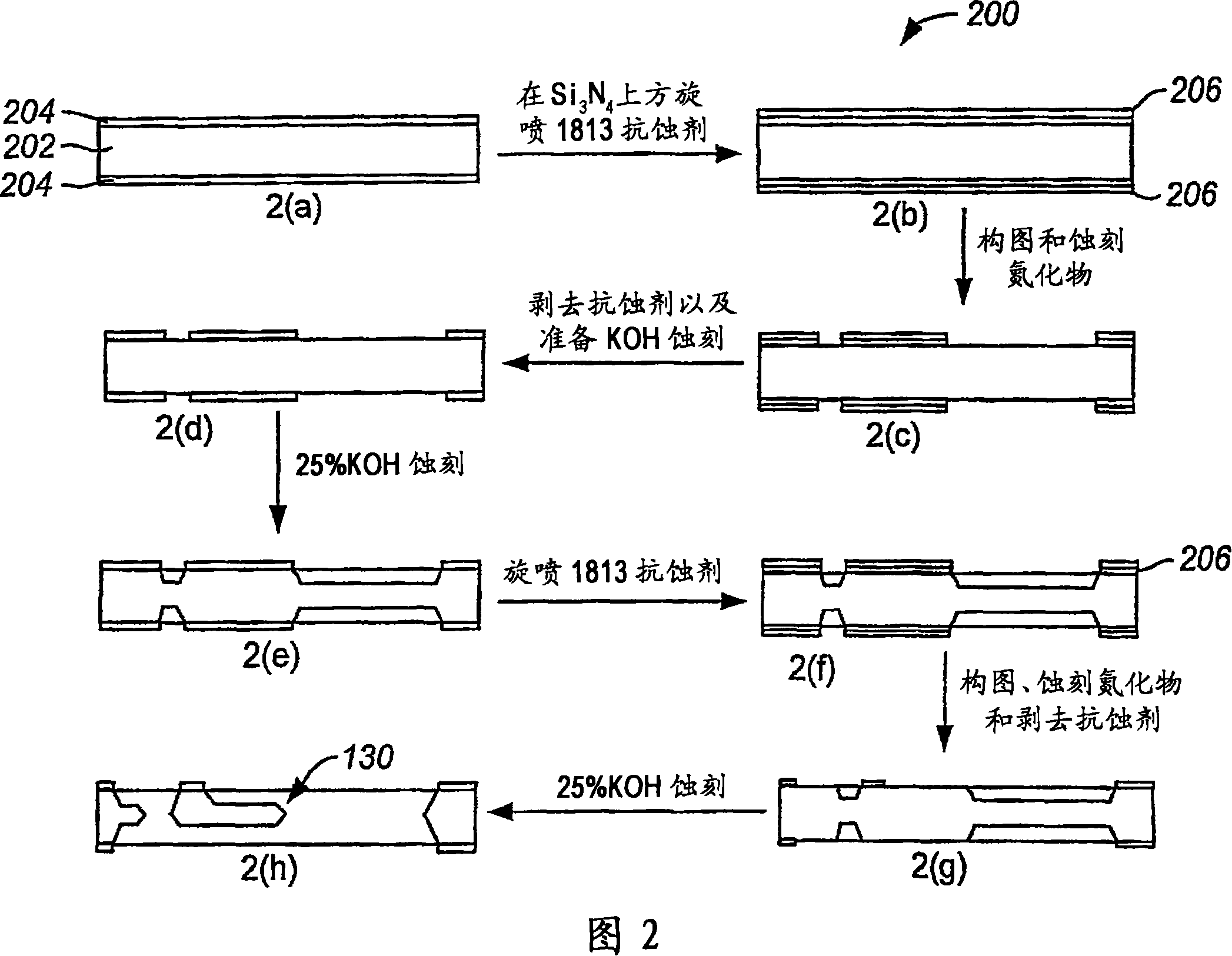

Method of fabricating fuel cells and membrane electrode assemblies

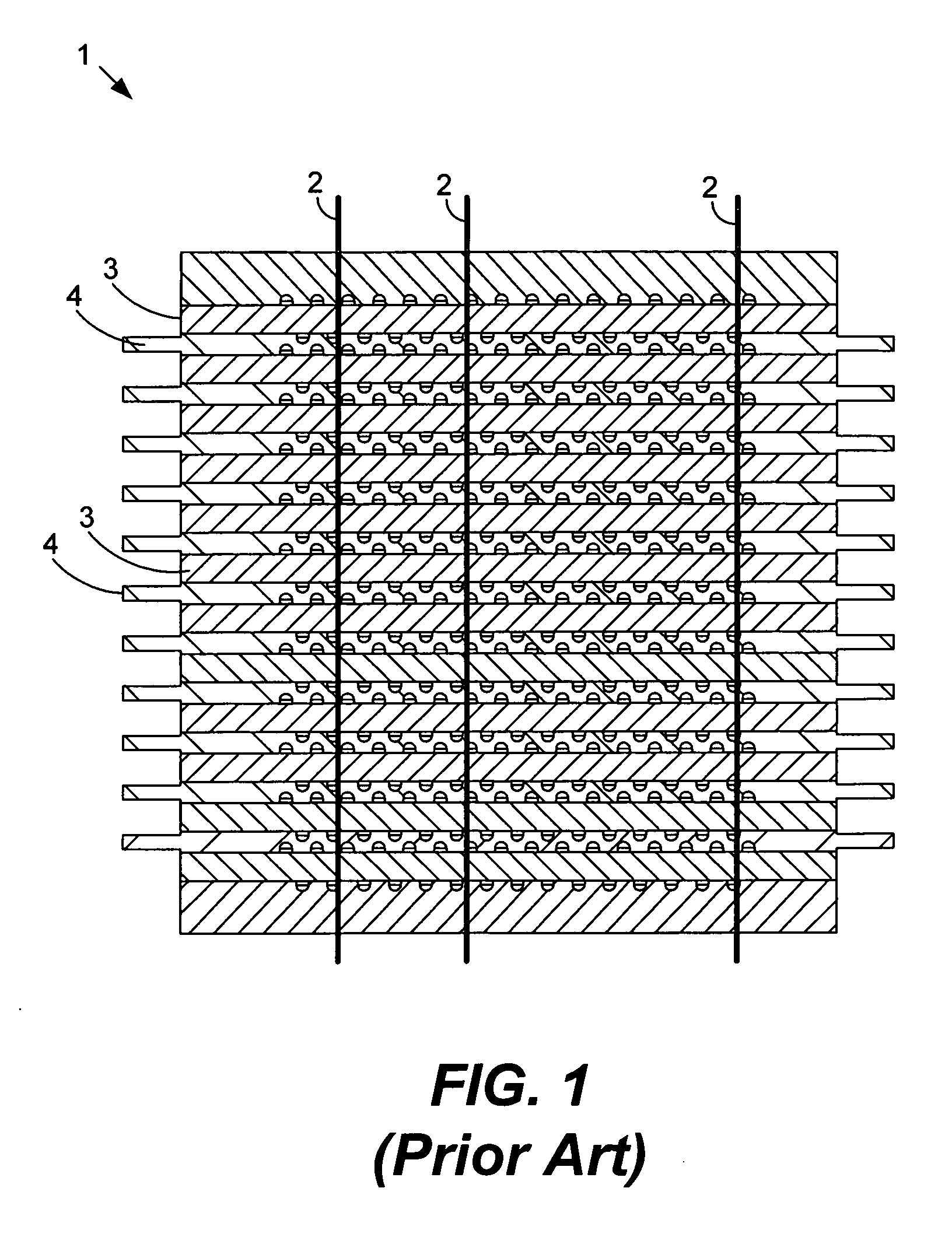

InactiveUS20040053100A1Low production costOvercome limitationsFuel cells groupingCell electrodesElectrical resistance and conductancePower battery

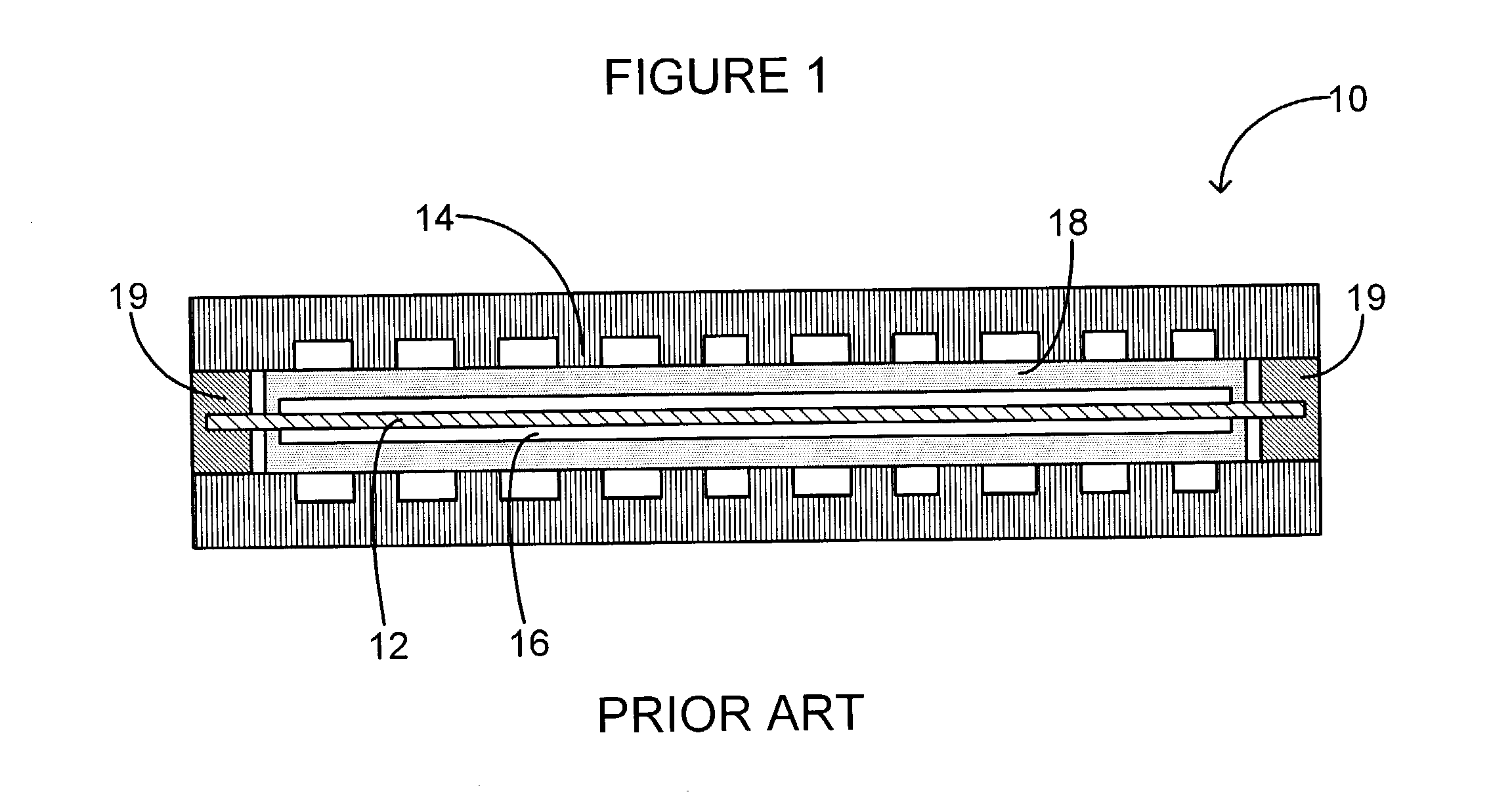

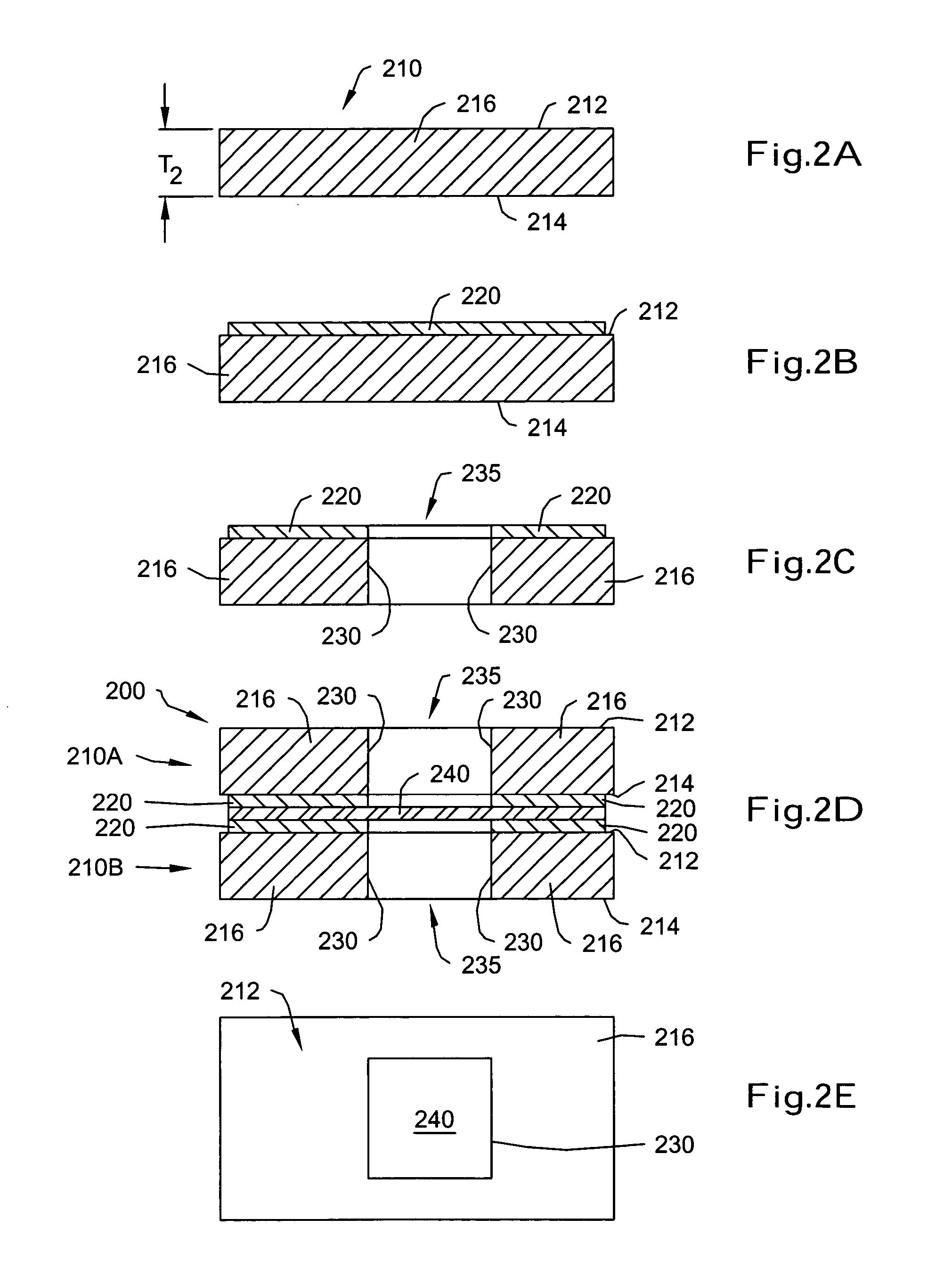

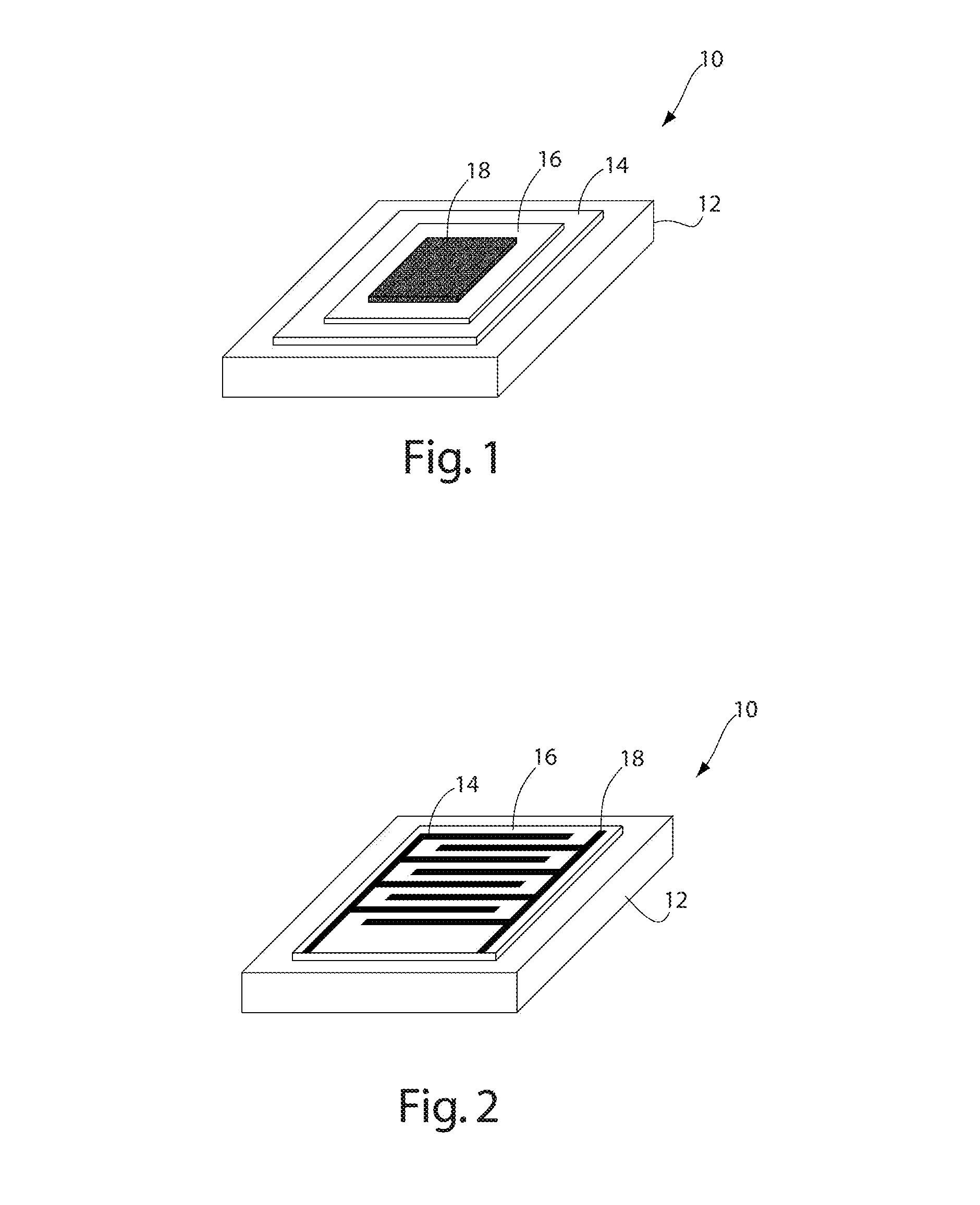

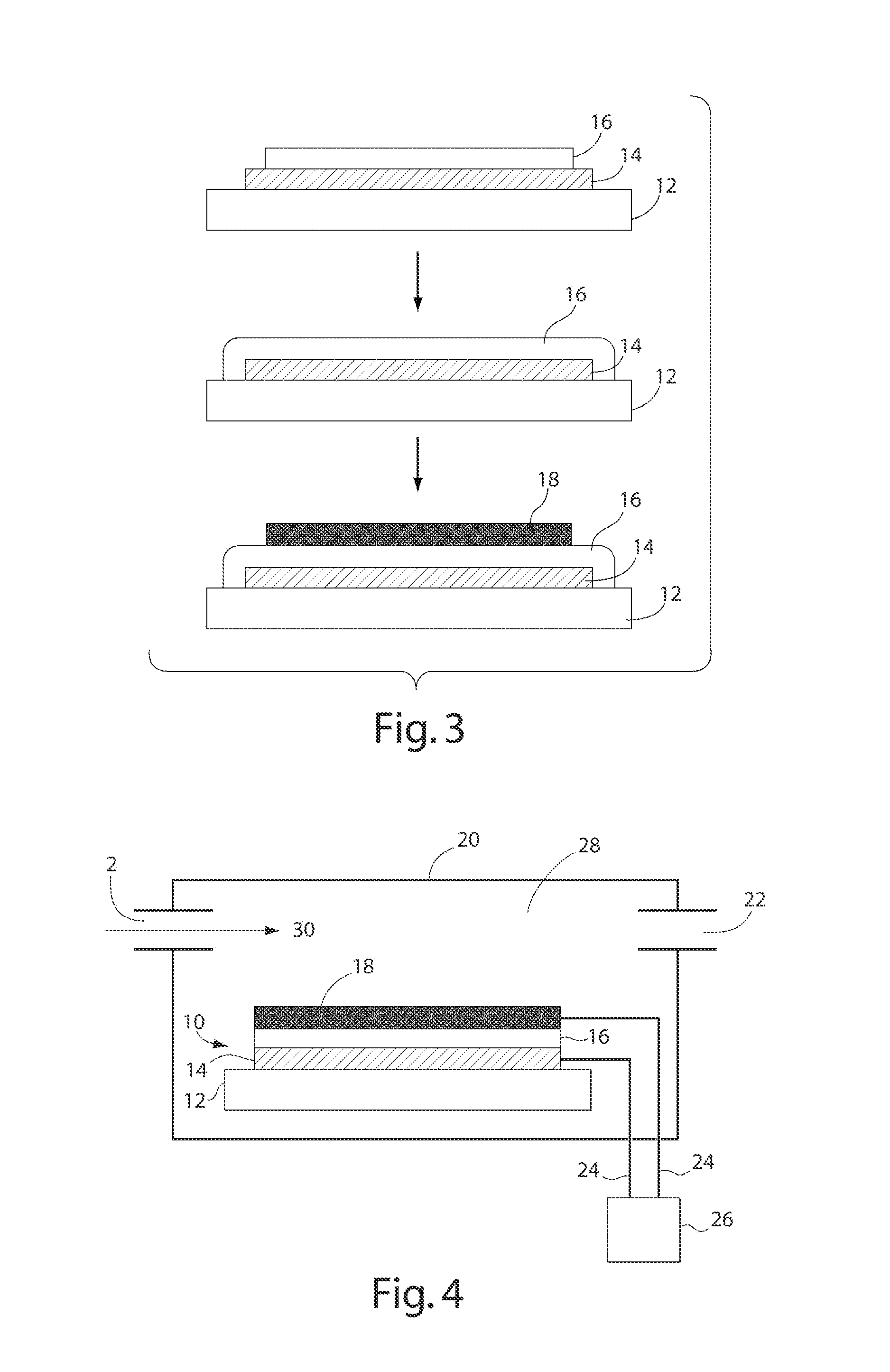

The application relates to a method of fabricating micro fuel cells and membrane electrode assemblies by thin film deposition techniques using a dimensionally stable proton exchange membrane as a substrate. The application also relates to membrane electrode assemblies and fuel cells fabricated in accordance with the method. The method includes the steps of successively depositing catalyst, current collector and flow management layers on the membrane substrate in predetermined patterns. Since the fuel cell is formed layer by layer, the need for assembly and sealing of discrete components is avoided. The method improves the contact resistance between the current collectors and catalyst layers and reduce ohmic losses, thereby avoiding the need for end plates or other compressive elements. This in turn reduces the overall thickness of the manufactured fuel cell. Since the fuel cell layers are optionally flexible, the devices may be fabricated using a continuous roller process or other automated means. The method minimizes production costs and costs of non-essential materials and is particularly suitable for low power battery replacement applications.

Owner:NAT RES COUNCIL OF CANADA

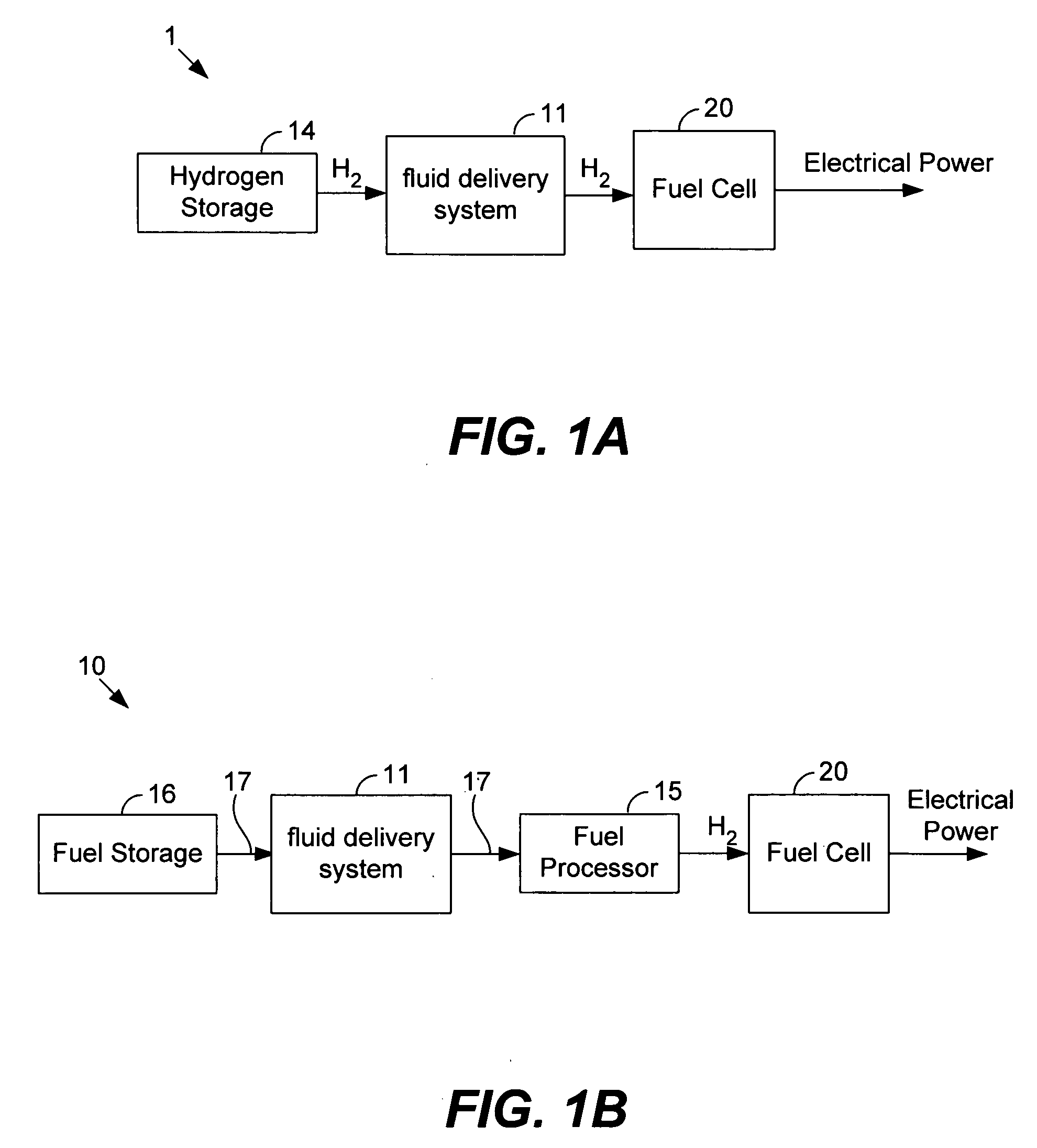

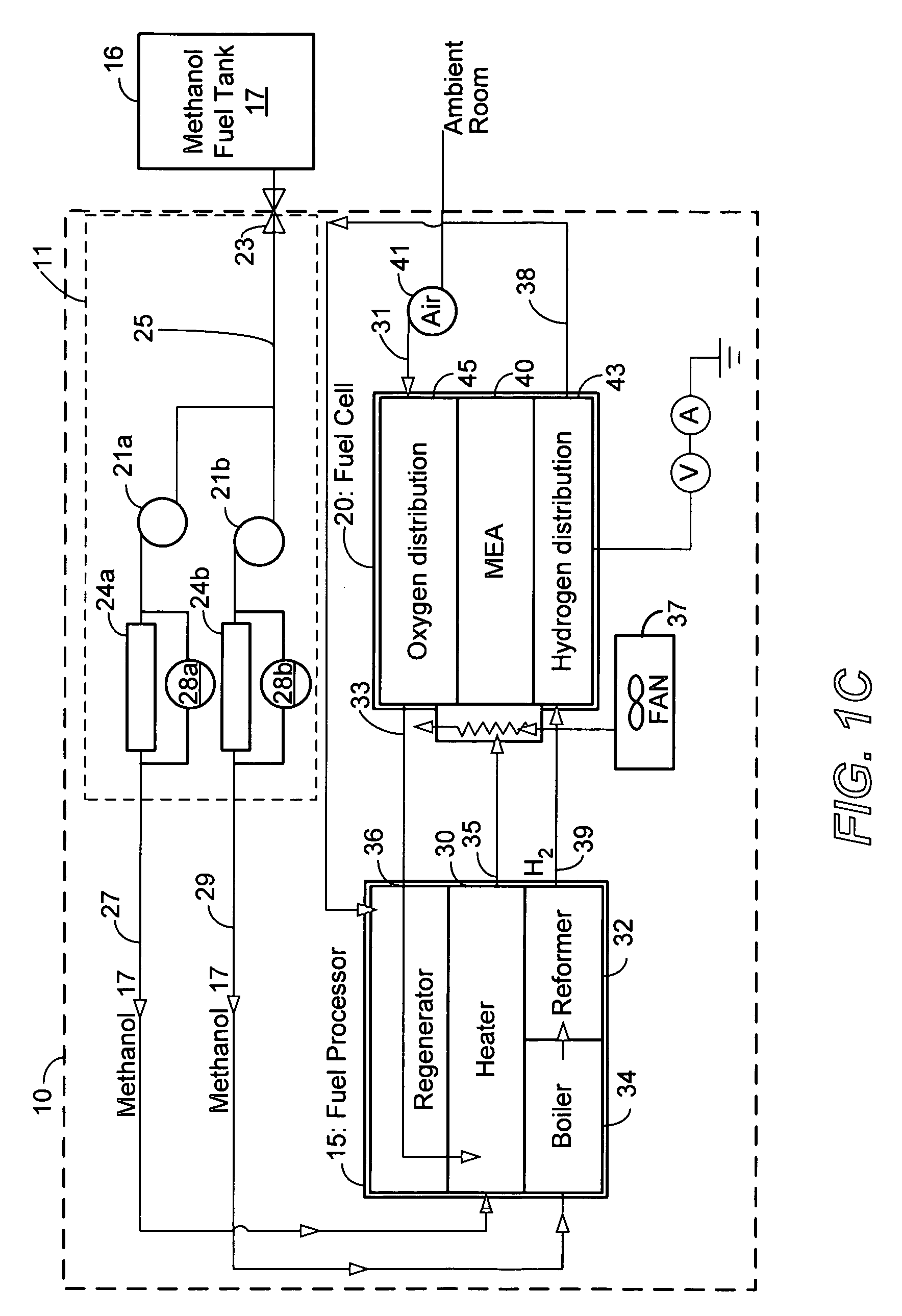

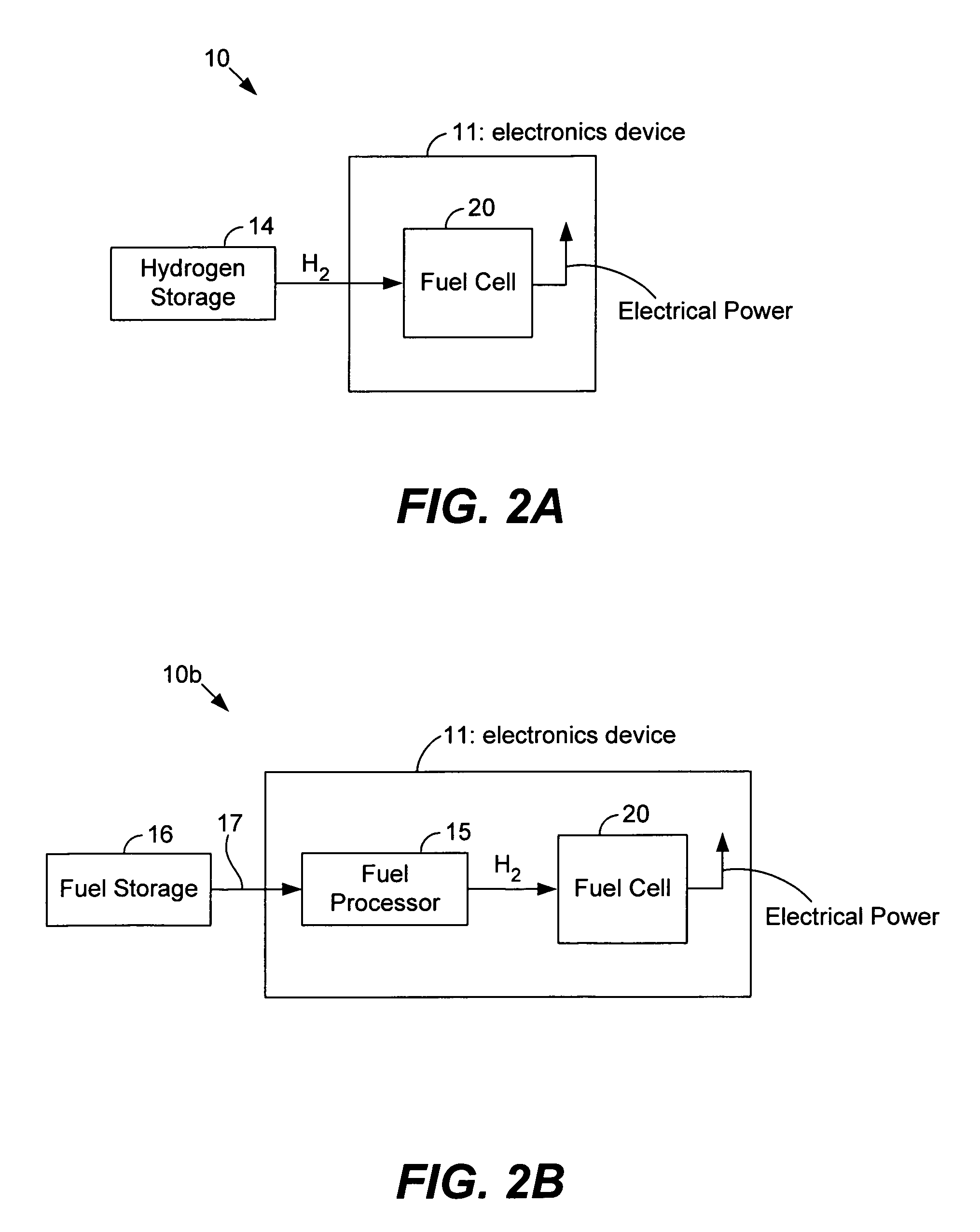

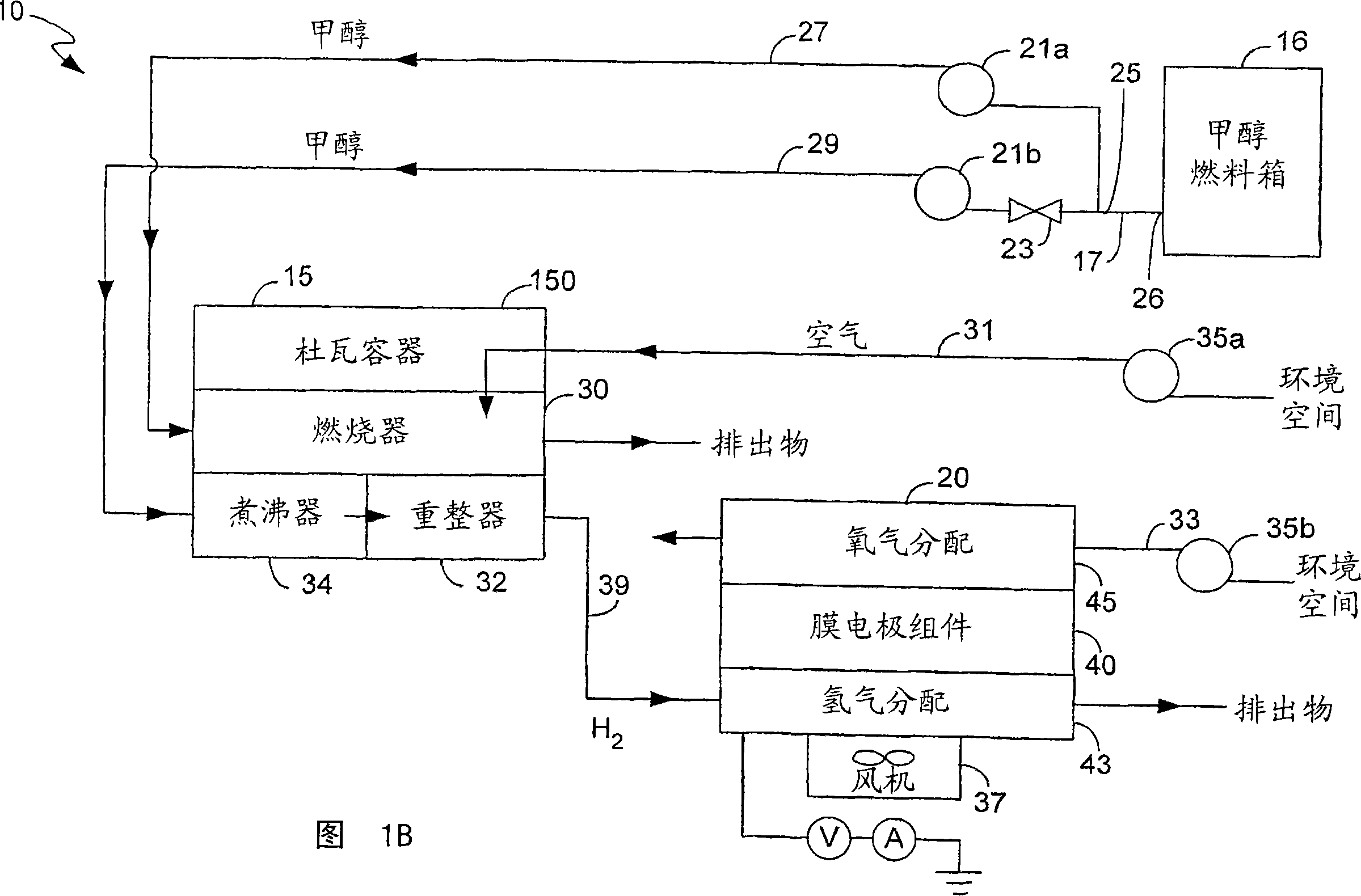

Efficient micro fuel cell systems and methods

ActiveUS20050008909A1Reduce the amount requiredFacilitates production of heatHydrogenFuel cell heat exchangeCombustorHydrogen

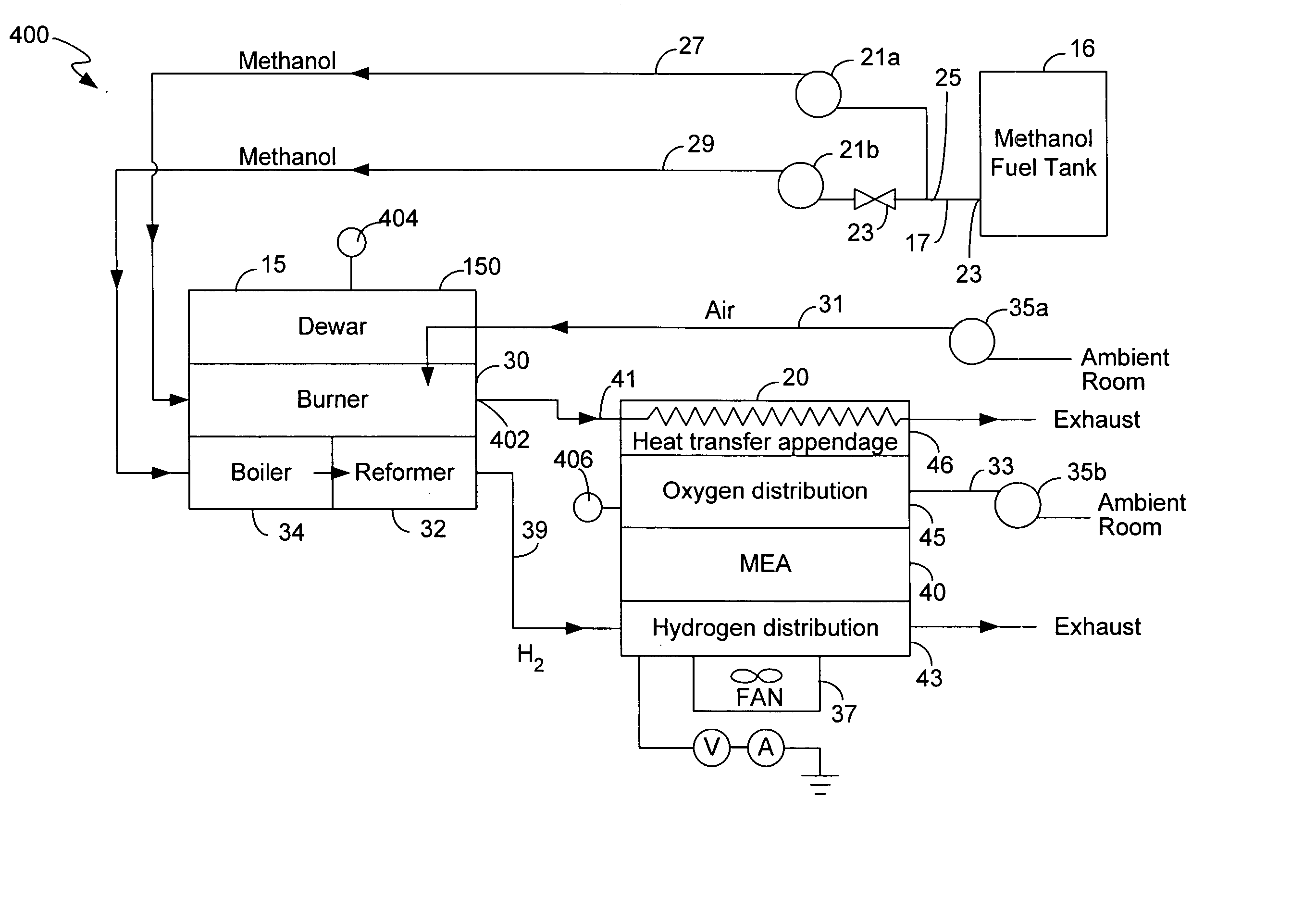

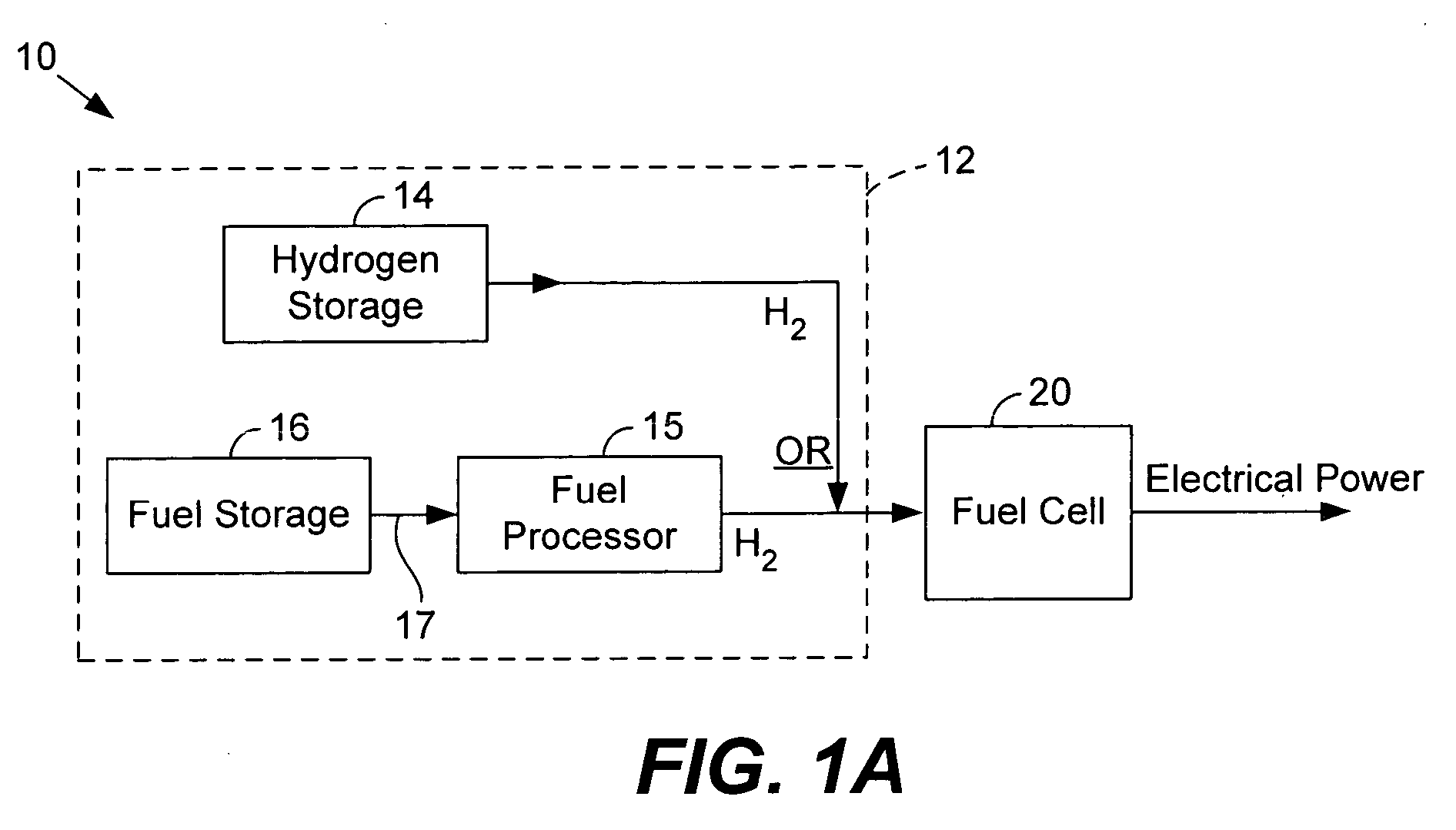

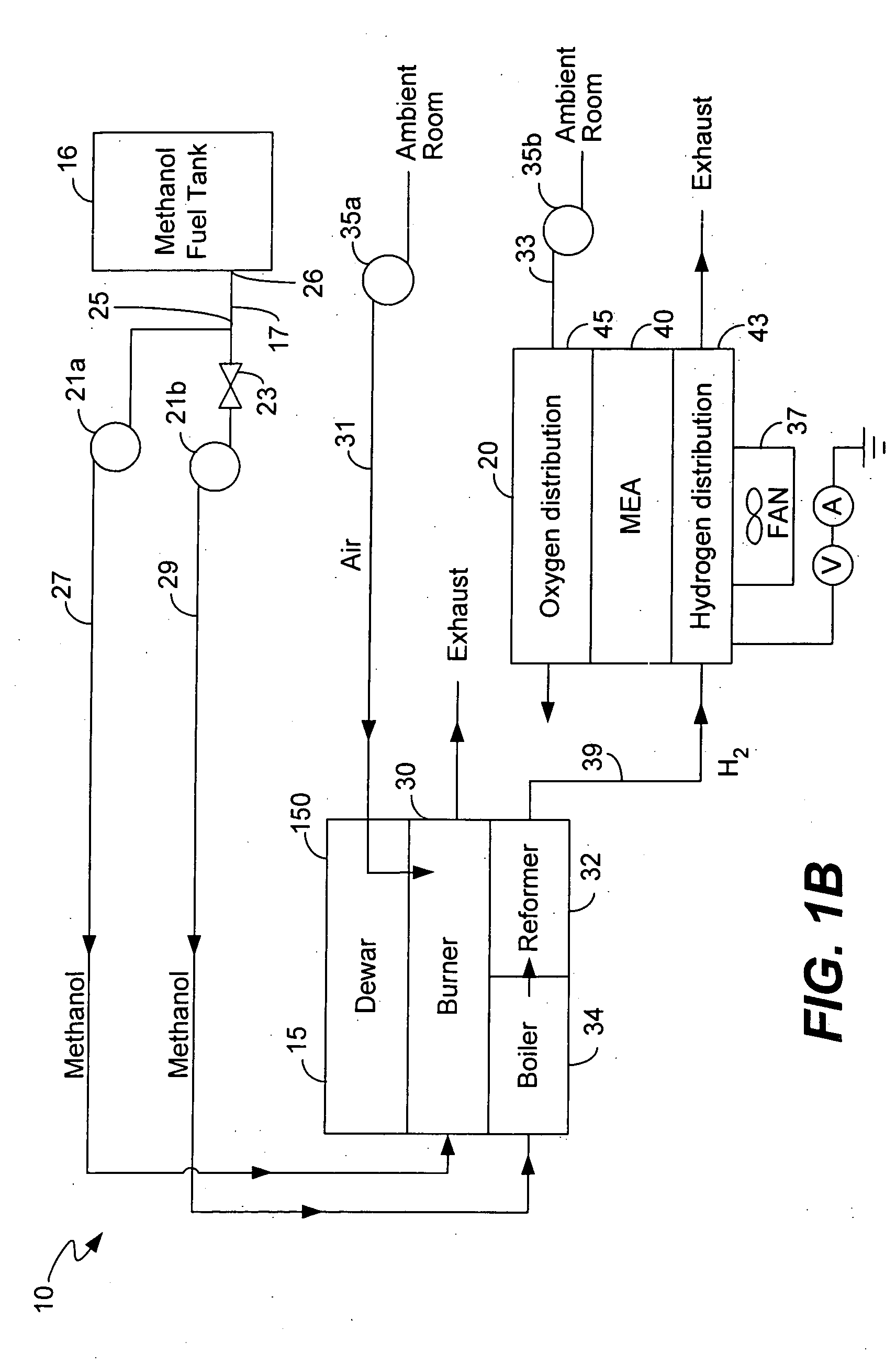

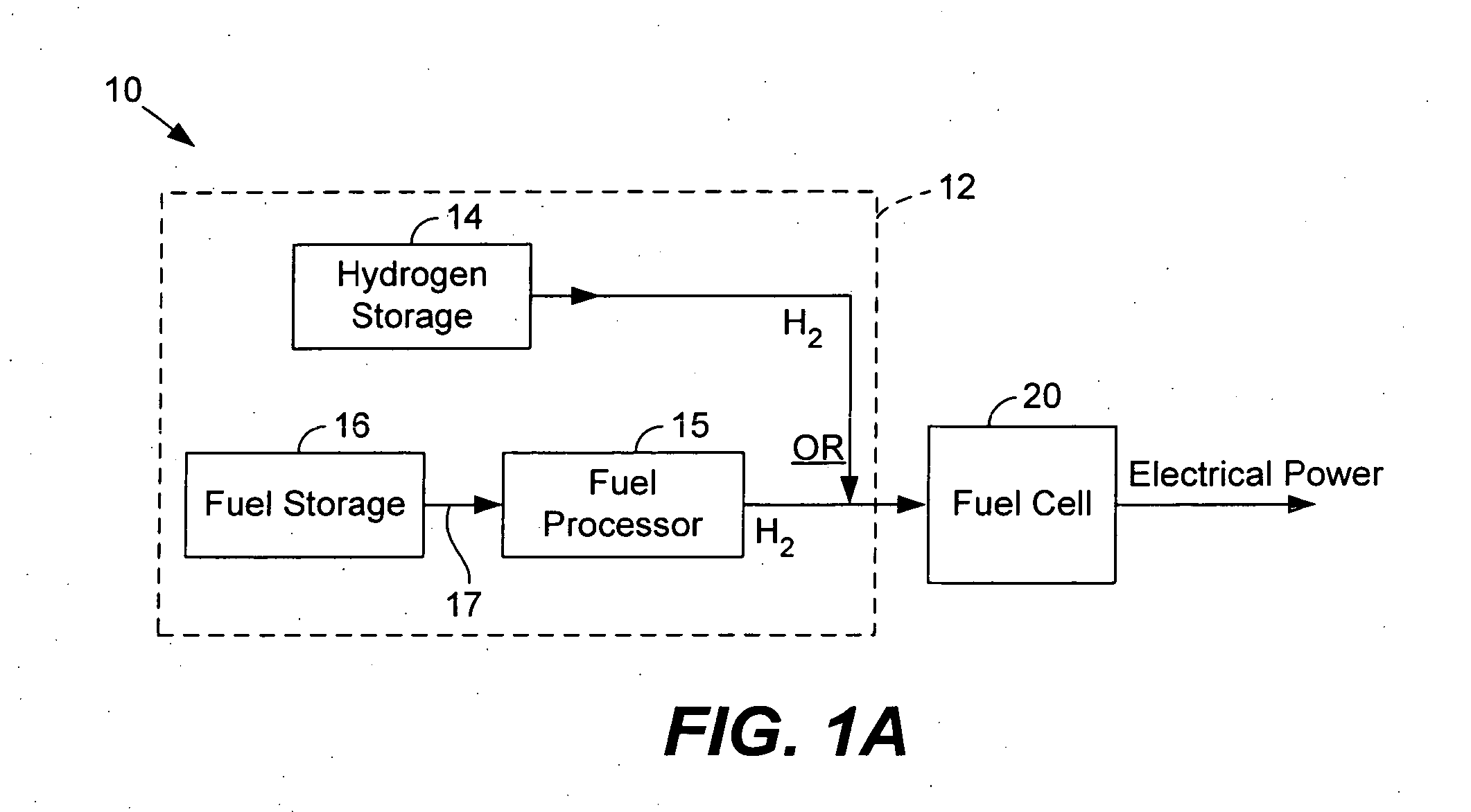

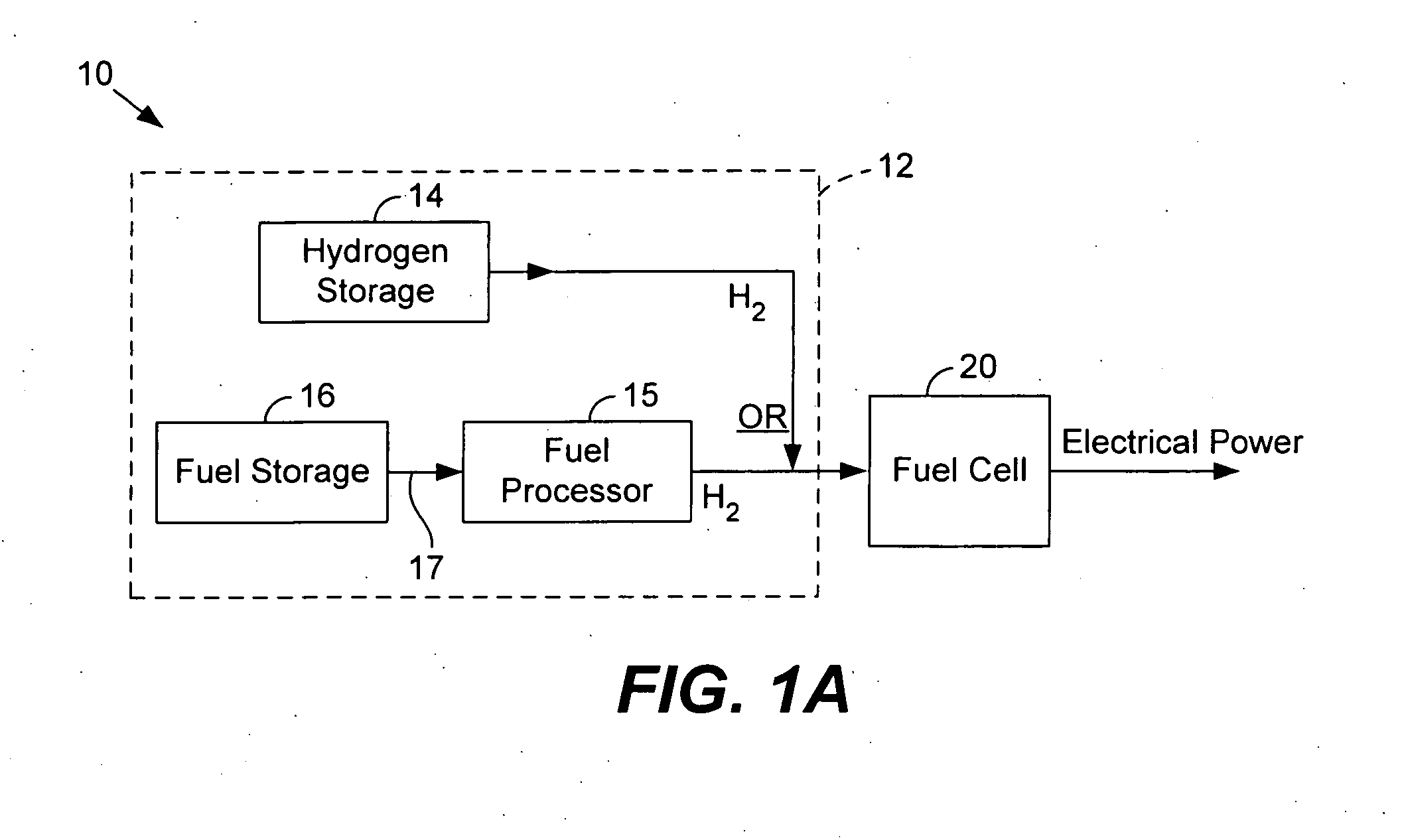

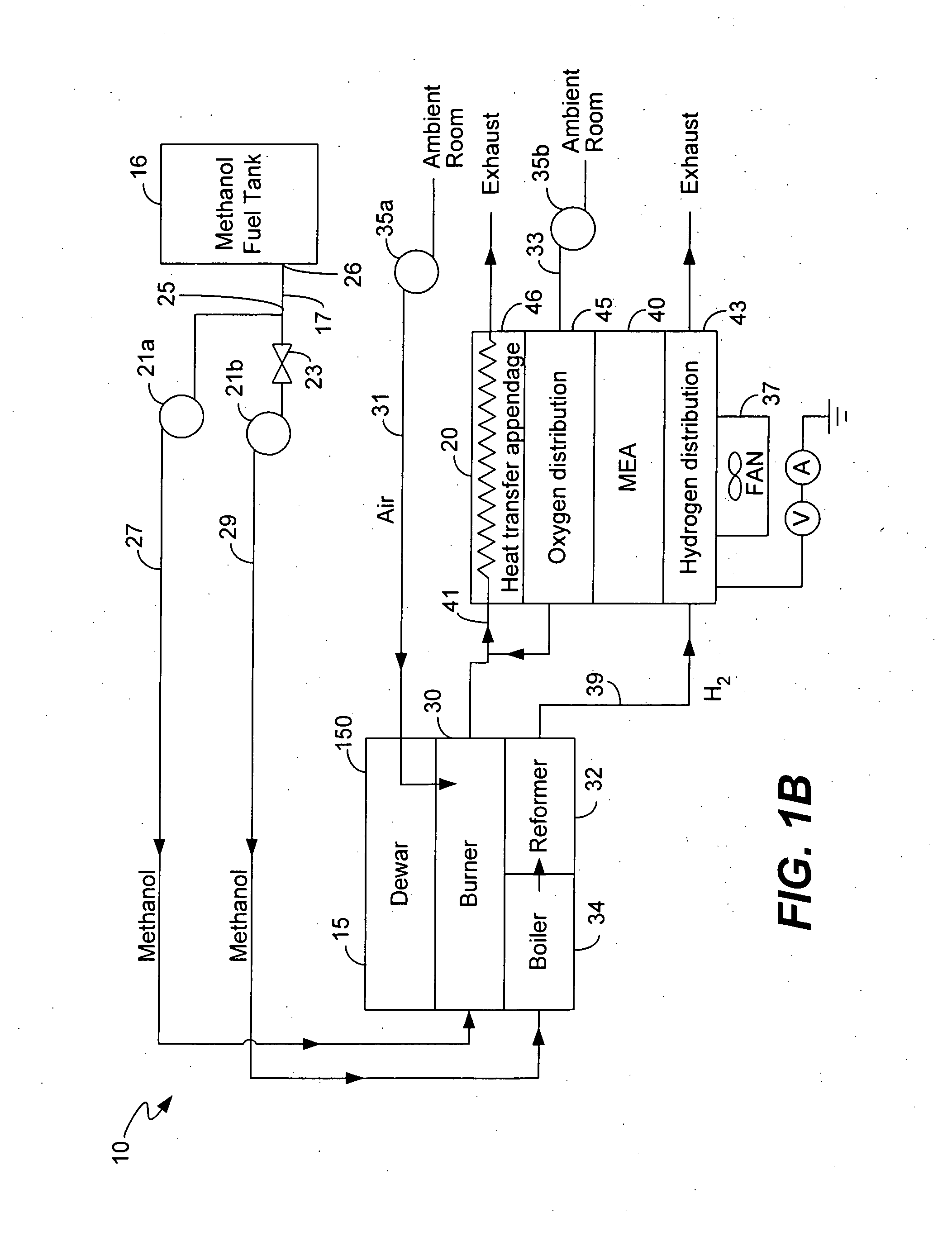

Described herein are fuel cell systems and methods of using fuel cell systems. The systems include a fuel cell that generates electrical energy using hydrogen and a fuel processor that produces hydrogen from a fuel source. The fuel processor includes a reformer and a burner that heats the reformer. One heat efficient fuel cell system described herein heats internal portions of a fuel cell using a heating medium from a fuel processor. The heating medium may comprise gases exhausted at high temperatures from the fuel processor, which are then transported to the fuel cell. The heating medium may also include a gas that reacts catalytically in the fuel cell to produce heat. Systems and methods for expediting fuel cell system start up are provided. Methods for shutting down a fuel cell system are also described that reduce the amount of moisture and gases in the reformer and in one or more fuel cell components. One hydrogen efficient fuel cell system described herein transports hydrogen to an inlet of a burner. The hydrogen may comprise unused hydrogen from a fuel cell and / or hydrogen produced in a reformer. The burner comprises a catalyst that facilitates production of heat in the presence of the hydrogen.

Owner:ULTRACELL LLC

Micro fuel cell thermal management

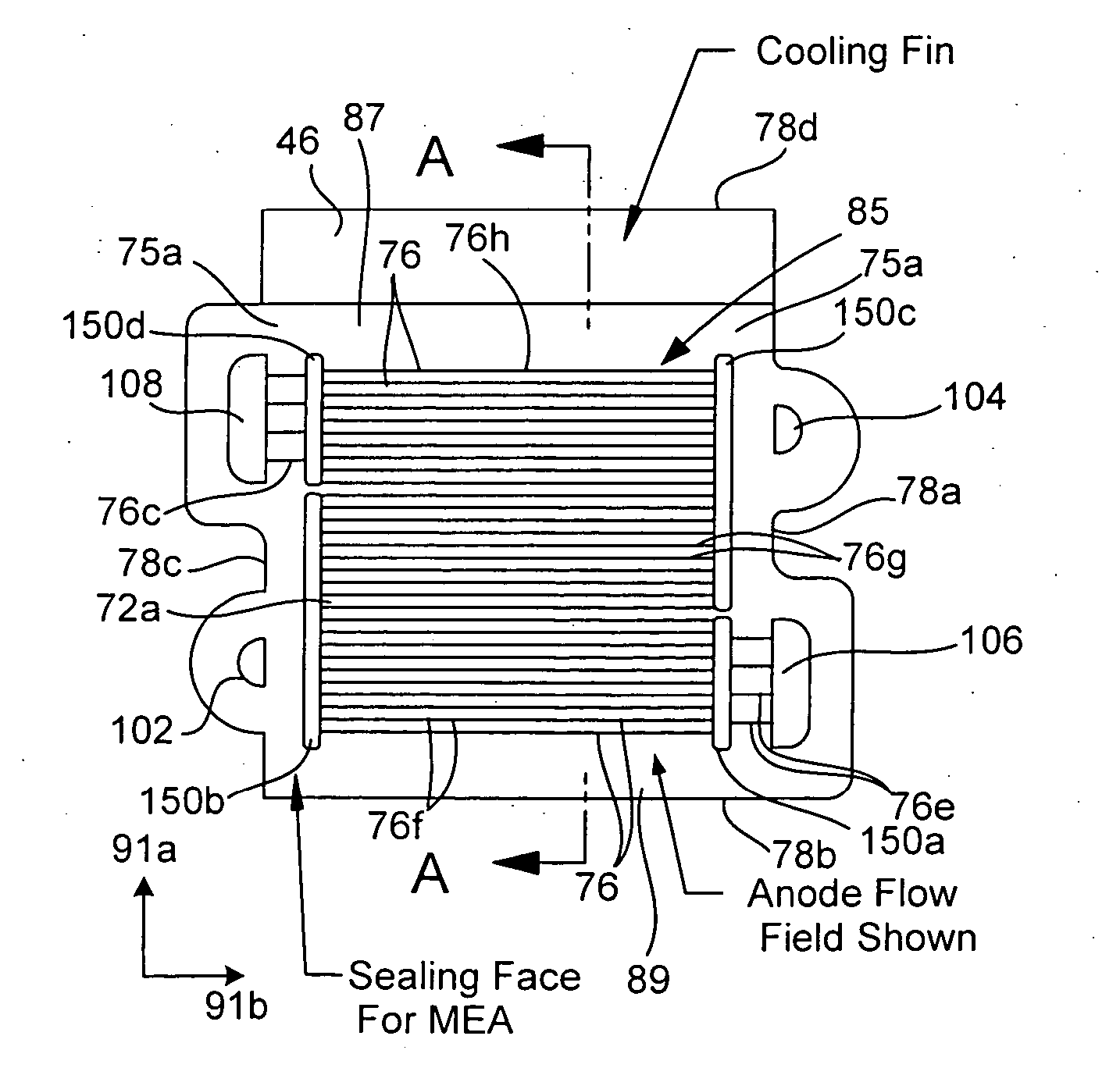

ActiveUS20050008911A1Improves fuel cell thermal managementFacilitates thermal communicationFuel cell heat exchangeFuel cells groupingSingle plateEngineering

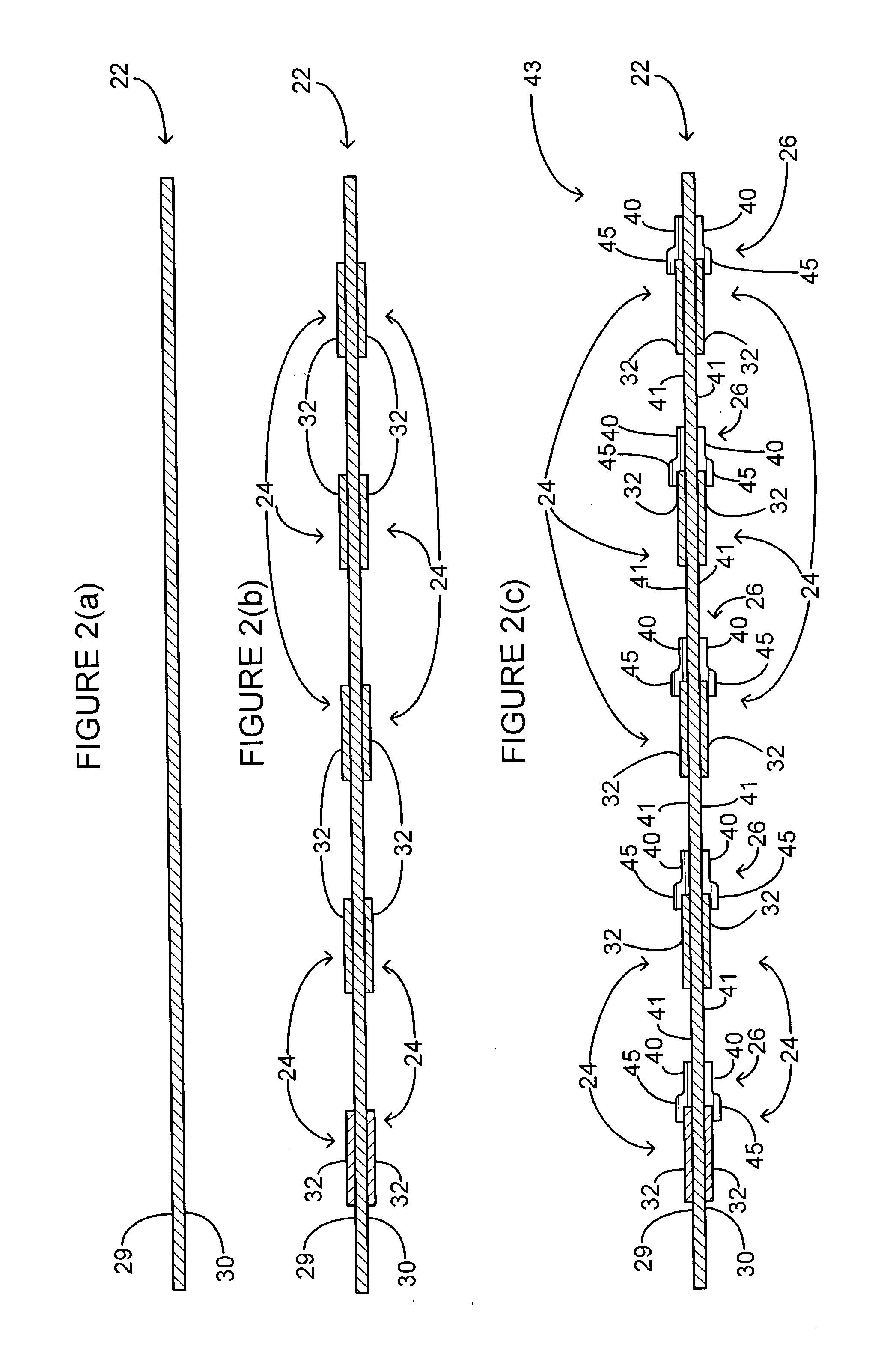

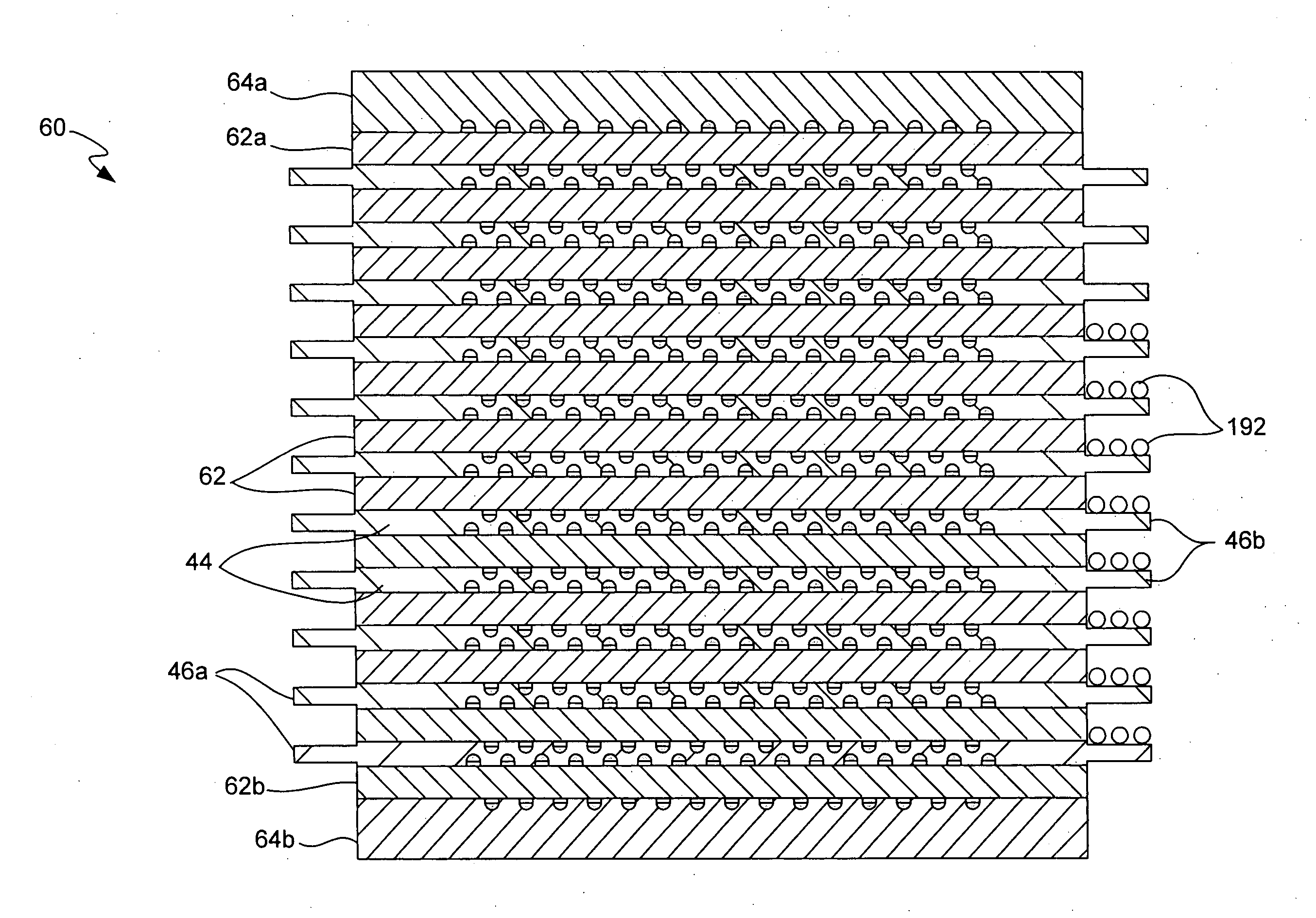

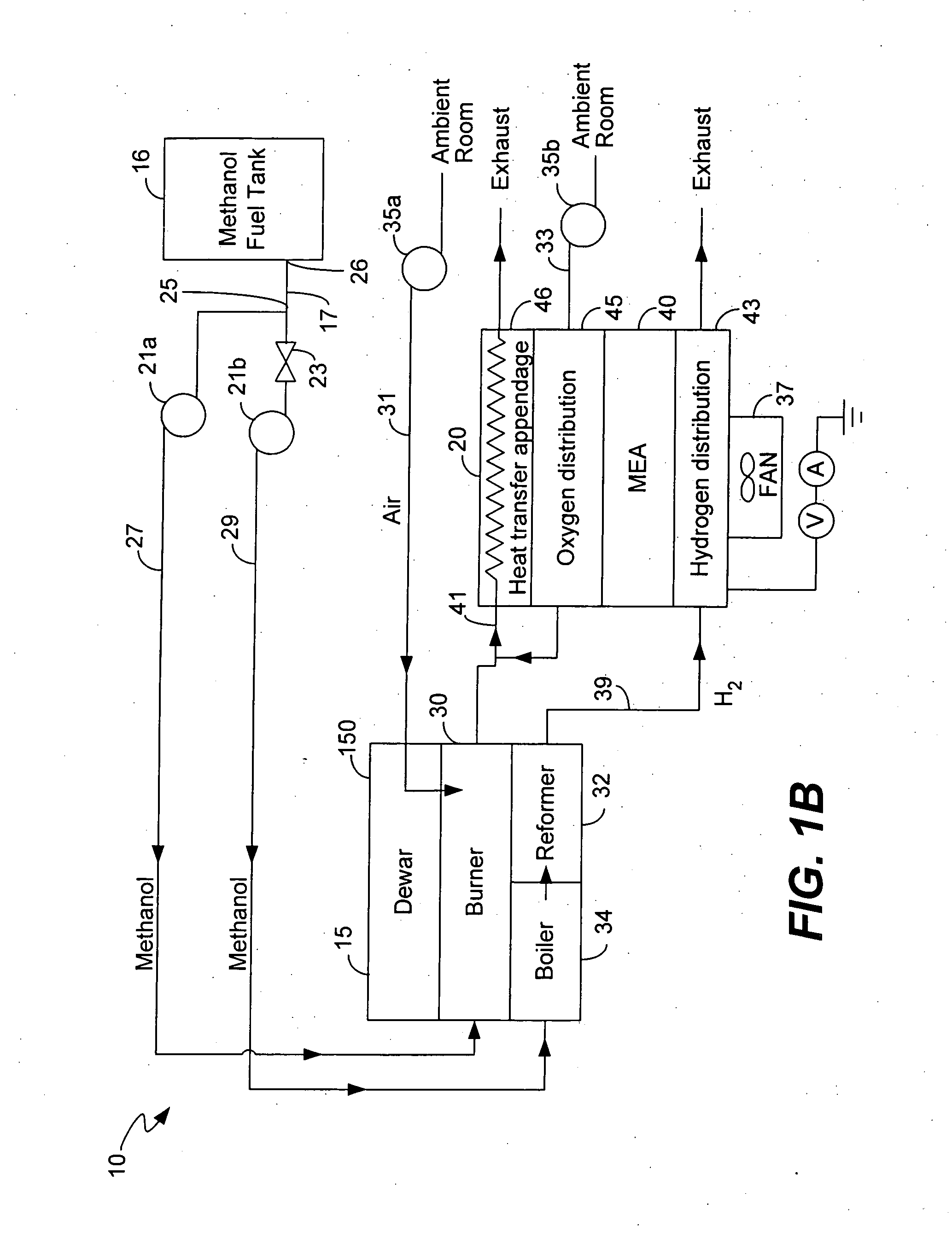

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

Micro fuel cell architecture

InactiveUS20050014059A1Improved thermal managementFacilitate communicationFuel cell heat exchangeLayered productsSingle plateEngineering

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

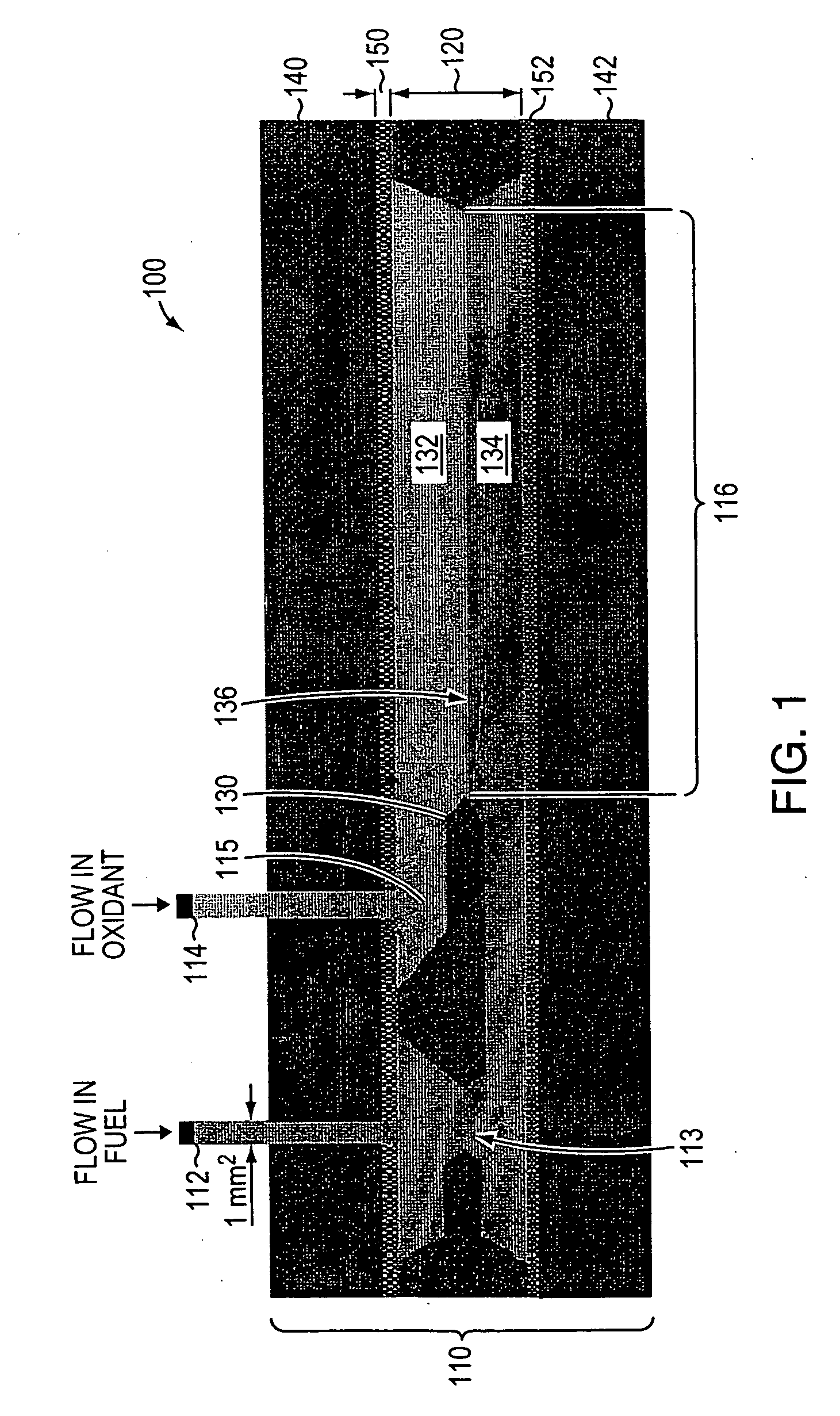

Dual electrolyte membraneless microchannel fuel cells

InactiveUS20060228622A1Maintain structural integrityHigh power deviceElectrolyte holding meansCell electrodesFlow cellEngineering

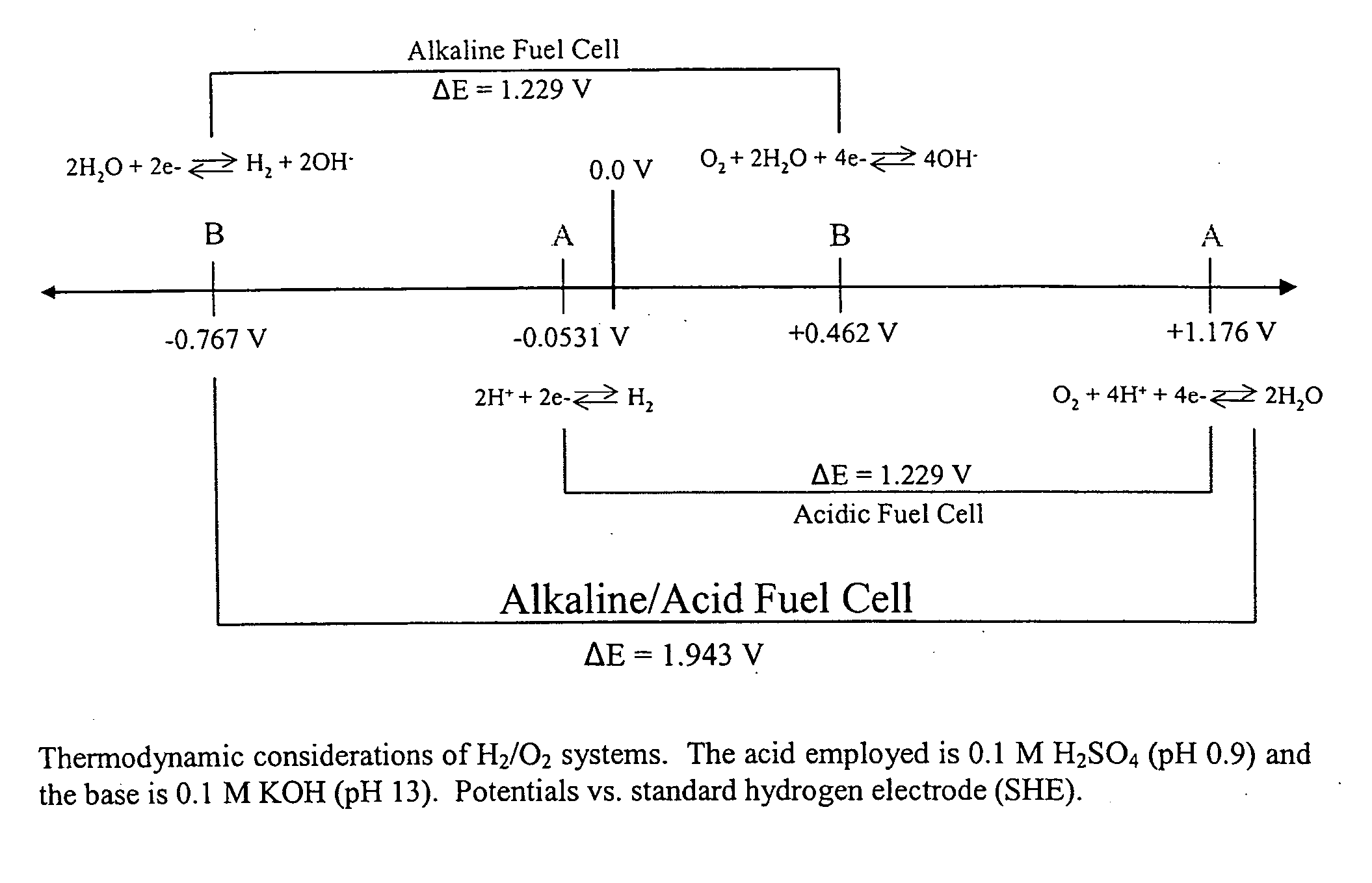

A microfluidic membraneless flow cell formed with multiple acidic / alkaline electrolyte solutions. The flow cell can be adapted to provide a dual electrolyte H2 / O2 fuel cell that generates thermodynamic potentials of up to 1.943 V or possibly greater. The selected fuel can be hydrogen dissolved in 0.1 M KOH, and the selected oxidant can be oxygen dissolved in 0.1 M H2SO4. Individual fuel cells can be combined to form fuel cell stacks to generate increased power output. Furthermore, microchannels of varying dimensions may be selected, including thickness variations, and different flow rates of acid / base electrolyte solutions can be applied to satisfy predetermined power generation needs. Some (micro-) fuel cell embodiments can be formed with silicon microchannels of fixed length and variable width and height, and can be used with hydrogen or formic acid as a fuel and oxygen as an oxidant, each dissolved in different acid / base electrolyte solutions. Micro-fuel cells are also provided which can be designed to generate different power levels for various applications including portable electronic devices such as wireless communication handsets and cellular telephones.

Owner:CORNELL RES FOUNDATION INC

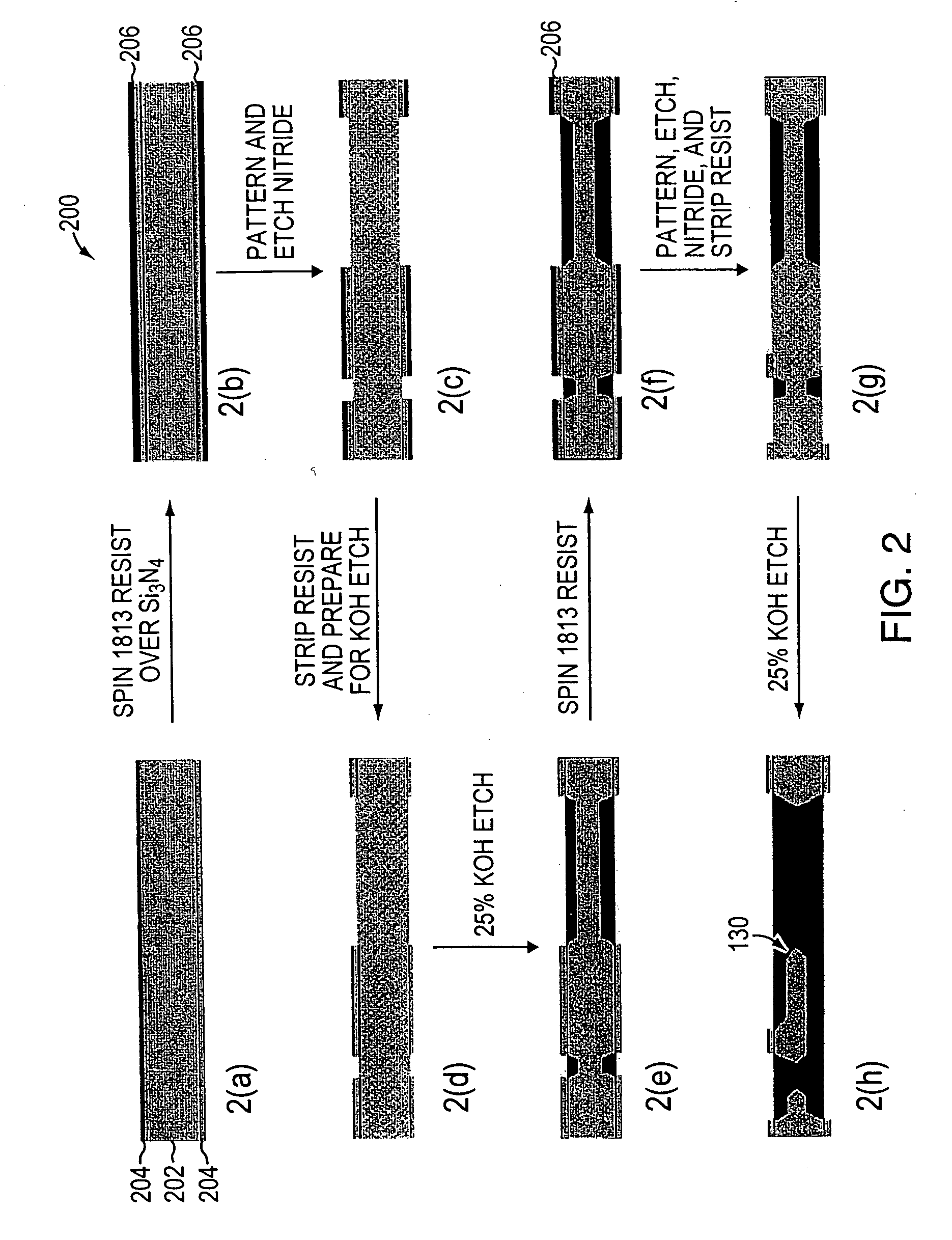

Implantable, miniaturized microbial fuel cell

InactiveUS7160637B2Low costSmall sizeCell electrodesBiochemical fuel cellsMetaboliteNuclear engineering

A miniaturized microbial fuel cell is described deriving electrical power from the biological activity of microbes, typically the metabolism of glucose by baker's yeast. Microfabrication techniques are used to miniaturize the components as well as the overall fuel cell and are capable of integration with other biomedical and implantable devices. Substantial reductions in both the size and the cost of implantable systems are thereby achievable. Electrode structures are used that facilitate electron transfer and power production giving favorable power densities in a miniature fuel cell. In addition, the microbial fuel cell of the present invention extracts glucose or other metabolite(s) from the ambient body fluids as its fuel, thus achieving a renewable, long-term power source for implantable biomedical devices.

Owner:RGT UNIV OF CALIFORNIA

Method and system for controlling fluid delivery in a fuel cell

ActiveUS20060029848A1Increase supplyImprove performanceReactant parameters controlVolume/mass flow by differential pressureChemical treatmentDifferential pressure

The invention relates to micro fuel cell systems whose performance is enhanced by an accurate fluid delivery system. The fluid delivery system improves reactant fluid provision to meet electrical output, while maintaining correct stoichiometries for chemical processing in a downstream reactor. The fluid delivery system includes a pressure source and a differential flow meter. The differential flow meter uses a flow restrictor and a sensor. The pressure source moves a fluid through the flow restrictor; the sensor detects differential pressure in the flow restrictor and outputs a signal that permits dynamic control of fluid flow, e.g., by controlling a pump.

Owner:ADVENT TECH LLC

Laminated membranes for diffusion limited gas sensors resistant to pressure variations

ActiveUS20060032742A1Small sizeWeather/light/corrosion resistanceVolume/mass flow measurementDiffusionAcid electrolyte

A micro fuel cell sensor having laminated gas permeable membrane. The sensor comprises a housing, first and second gas diffusing electrodes spaced from one another, a fuel-cell spacer having an acidic electrolyte disposed between said first and second electrodes, and two gas permeable membranes. The first gas permeable membrane comprises a polymer laminated on a metal substrate, wherein the substrate comprises pores that have dimensions at least less than one-half the thickness of the polymer film.

Owner:GENERAL ELECTRIC CO

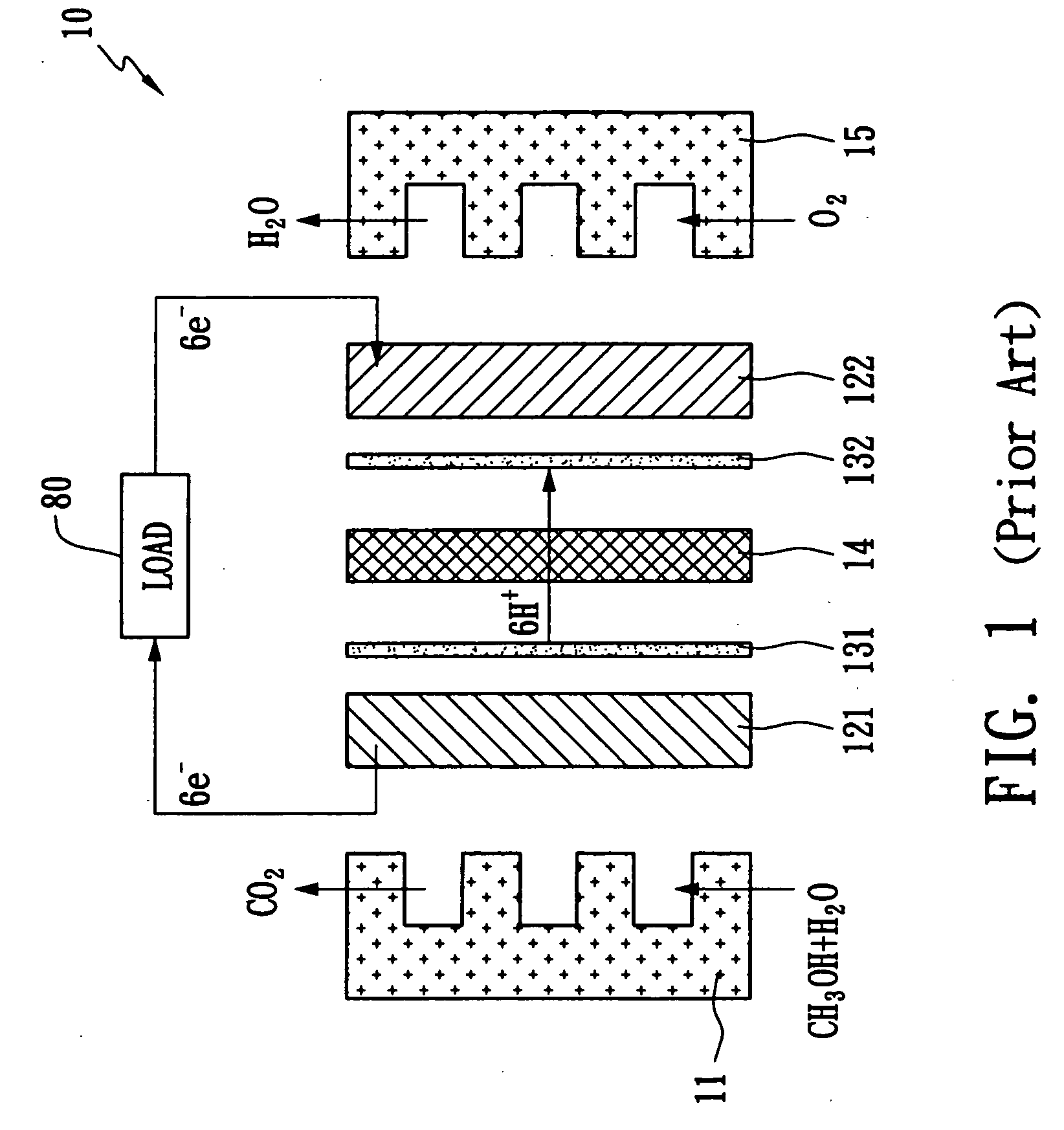

Micro fuel cell

A fuel cell, fuel cell array and methods of forming the same are disclosed. The fuel cell can be made by forming a first aperture defined by a first aperture surface through a first electrode layer and forming a second aperture defined by a second aperture surface through a second electrode layer. A proton exchange membrane is laminated between the first electrode layer and the second electrode layer. At least a portion of the first aperture is at least partially aligned with the second aperture.

Owner:HONEYWELL INT INC

Pattern molding of polymeric flow channels for micro fuel cells

The invention relates to a method for large scale manufacturing of polymeric micro fuel cells using a metallic mold. The method includes creating a Gaussian-shaped channel on a first substrate using a laser; sputtering a metallic seed layer over the first substrate using a first metal; electroplating a second metal over the seed layer to create a negative mold; releasing the negative mold from the first substrate; fabricating a plurality of second substrates, each having a Gaussian-shaped channel, and using the negative mold to fabricate multiple fuel cells. The method provides lower cost and greater flexibility as compared with conventional ablation and etching processes of manufacturing of polymeric micro fuel cells.

Owner:NANYANG TECH UNIV

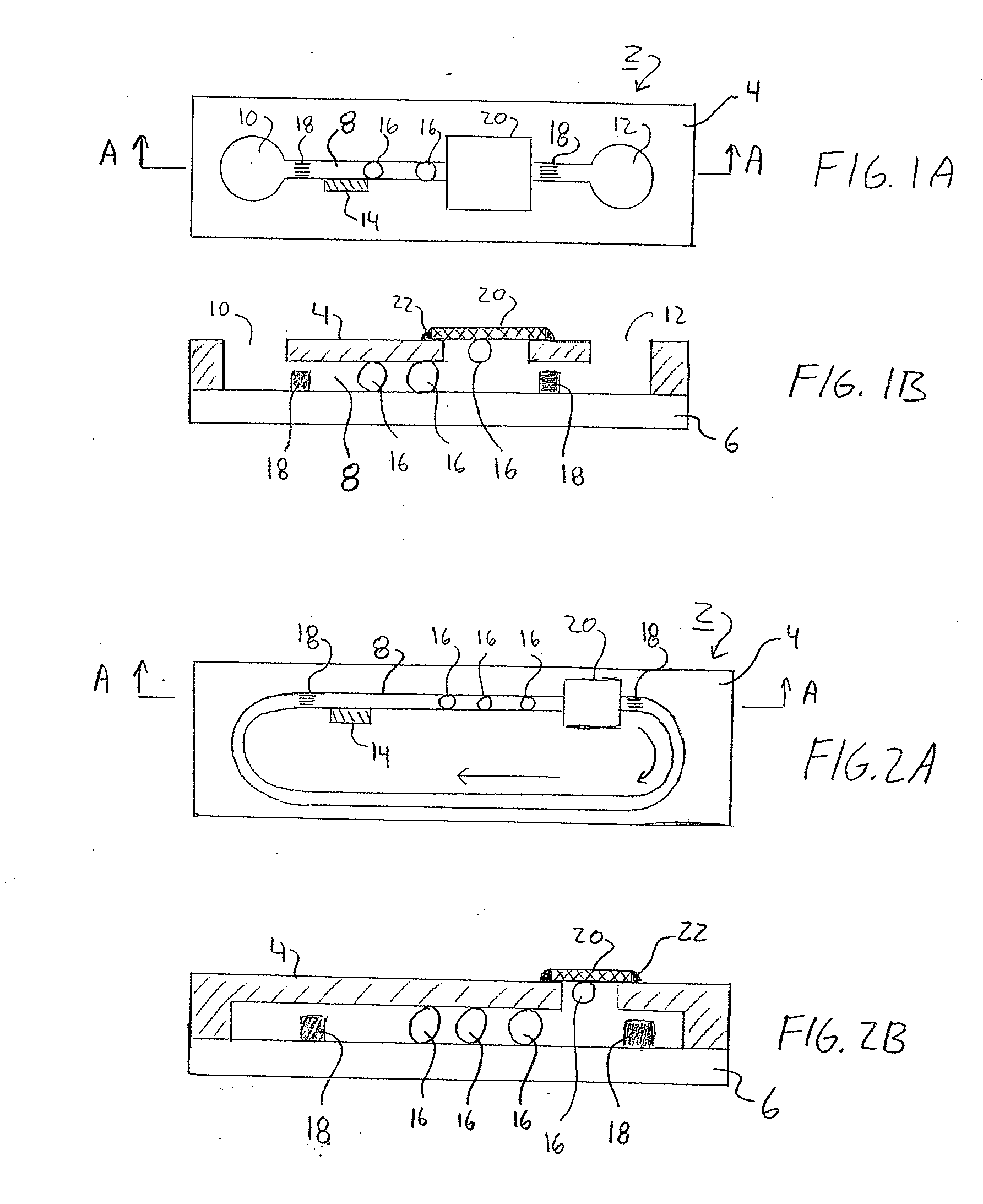

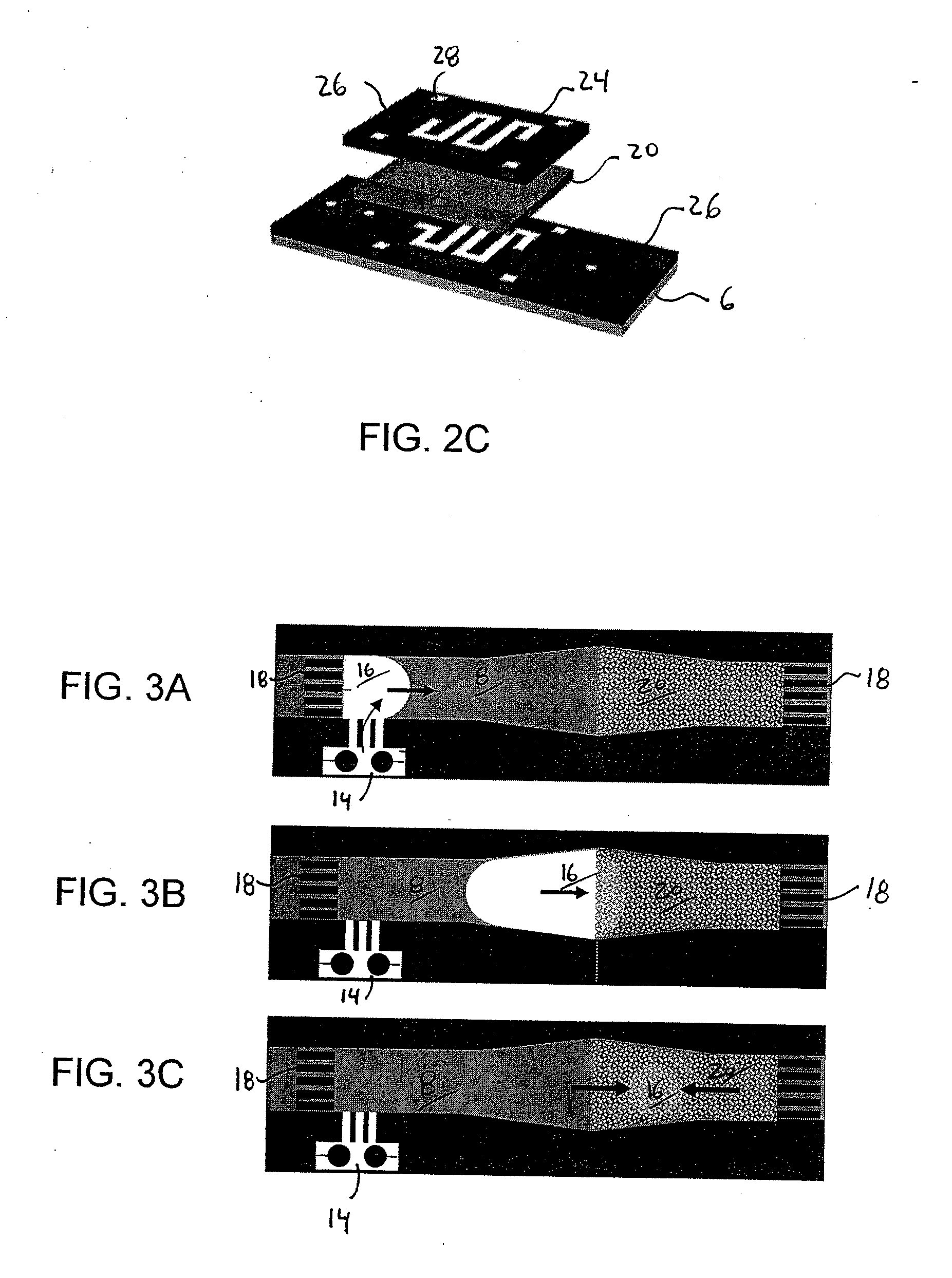

Method and Apparatus for Pumping Liquids Using Directional Growth and Elimination Bubbles

ActiveUS20080118790A1Particular applicabilitySufficient pressure toleranceReactant parameters controlPressure pumpsOrganic fluidEngineering

A method and device for the pumping of liquids utilizes the directional growth and elimination of gaseous vesicles or bubbles to provide the motive or pumping force. In one embodiment, the pumping device is a microfluidic pumping mechanism having a channel, a bubble generator for generating a plurality of bubbles within the channel, and a venting membrane disposed over a portion of the channel downstream of the bubble generator. A one-way valve or directional resistance feature is positioned upstream of the bubble generator to introduce directional transport of bubbles within the channel. The method and device may be integrated into micro fuel cells with organic liquid fuel such that liberated gaseous bubbles may be utilized to deliver fresh fuel or circulate reusable fuel without any power-consuming components.

Owner:RGT UNIV OF CALIFORNIA

Micro fuel cell

InactiveUS20050260461A1Improve adhesionLamination ancillary operationsFuel cells groupingProtonEngineering

A fuel cell, fuel cell array and methods of forming the same are disclosed. The fuel cell can be made by forming a first aperture defined by a first aperture surface through a first electrode layer and forming a second aperture defined by a second aperture surface through a second electrode layer. A proton exchange membrane is laminated between the first electrode layer and the second electrode layer. At least a portion of the first aperture is at least partially aligned with the second aperture.

Owner:HONEYWELL INT INC

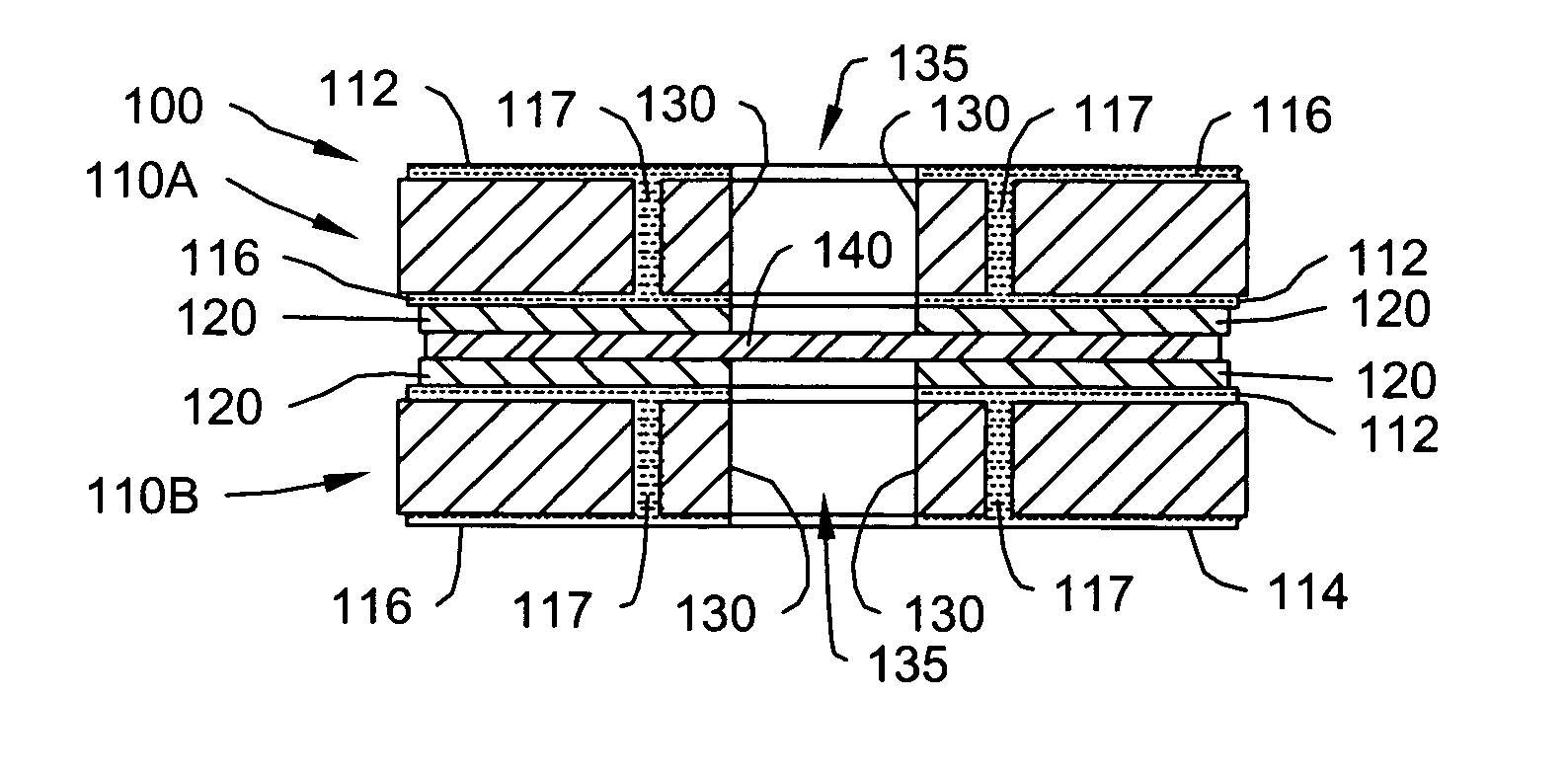

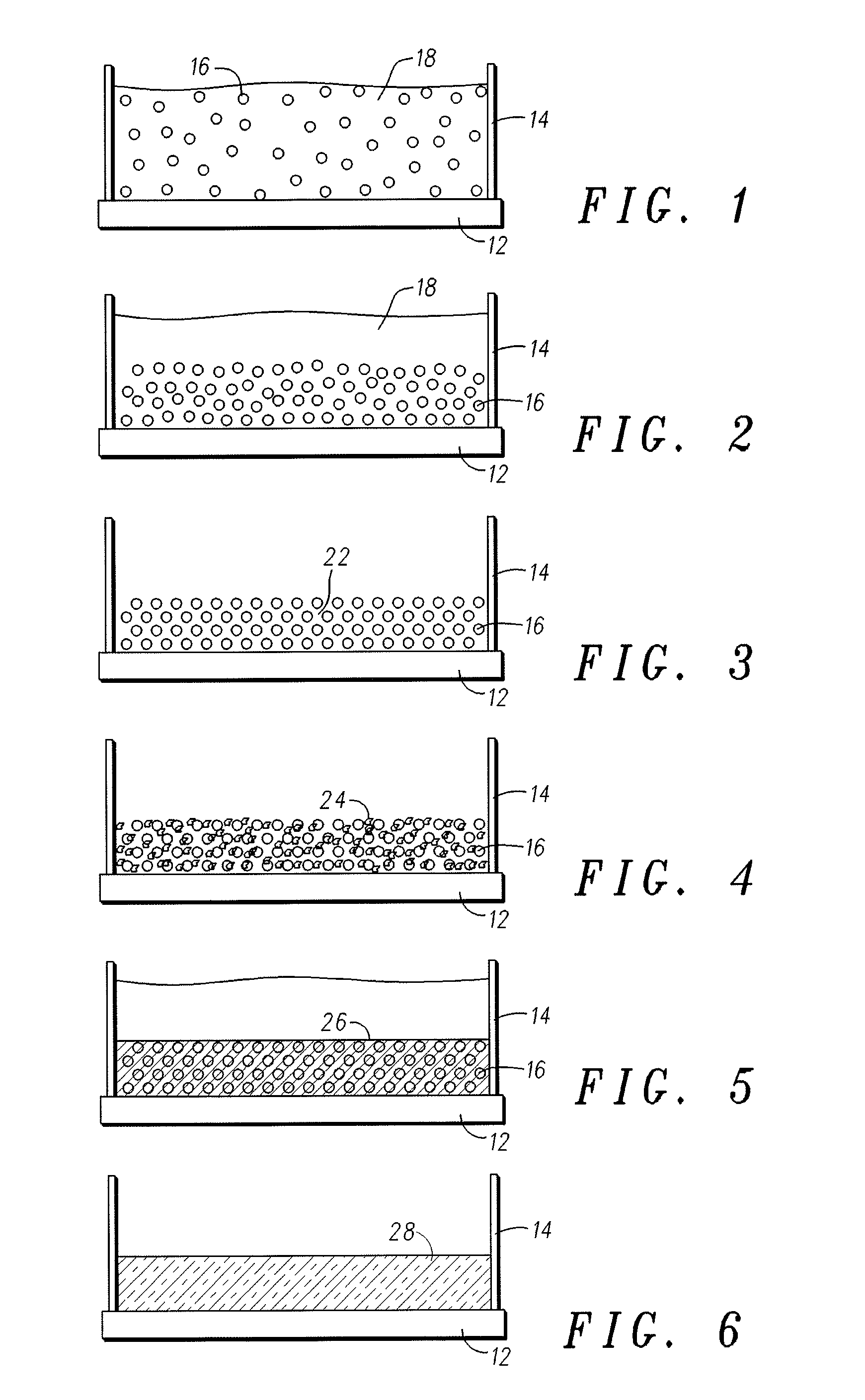

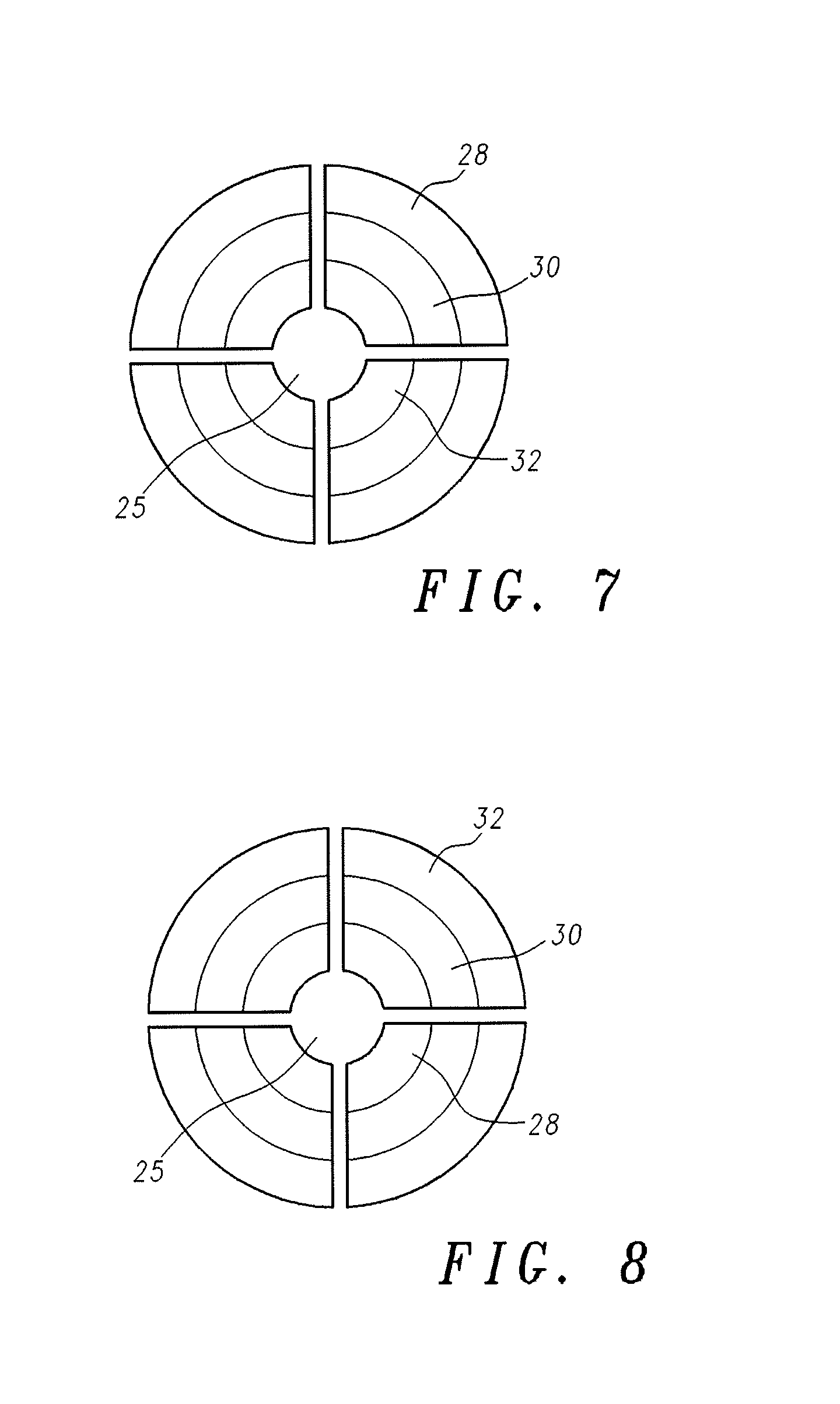

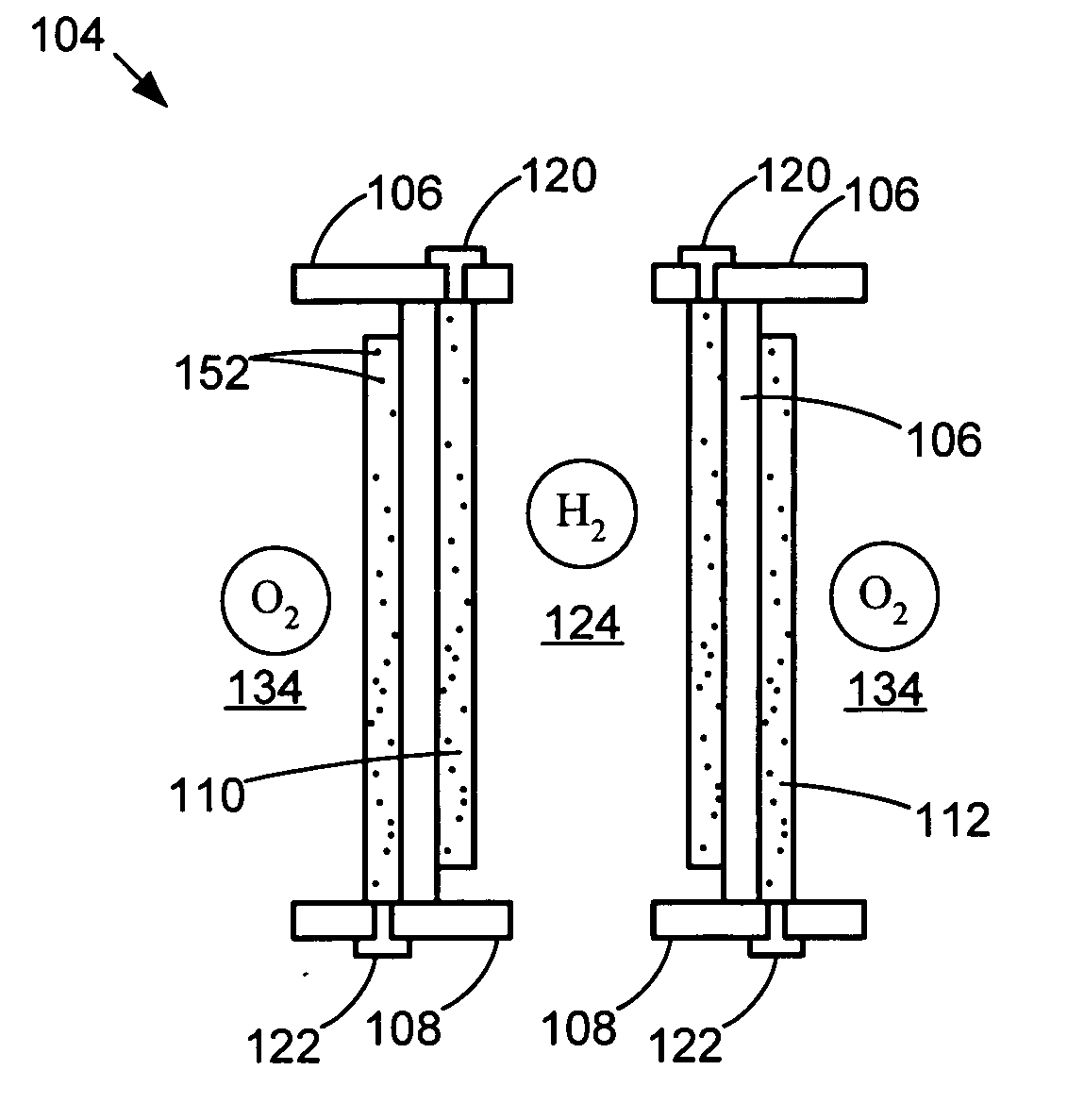

Micro fuel cell having macroporous metal current collectors

A method is provided for fabricating a hybrid gas diffusion layer / current collector / electrocatalyst structure (28) suitable for 3D microfuel cell devices (180). The method comprises forming a macroporous electrically conductive structure (28) on a substrate (12, 112) positioned such that a plurality of cathode current collector / GDL (168) and anode current collector / GDL (166) are formed. An electrocatalyst material (158) is deposited in contact with these structures, completing the formation of cathode (168) and anode (166) hybrid current collector / GDL / electrocatalyst structures. When electrolyte (158) is positioned between the electrocatalyst material (158) contacting the cathode collector (168) and the electrocatalyst material (158) contacting each of the plurality of anode collectors (166), the resulting MEA is suitable for use in a micro fuel cell device.

Owner:MOTOROLA INC

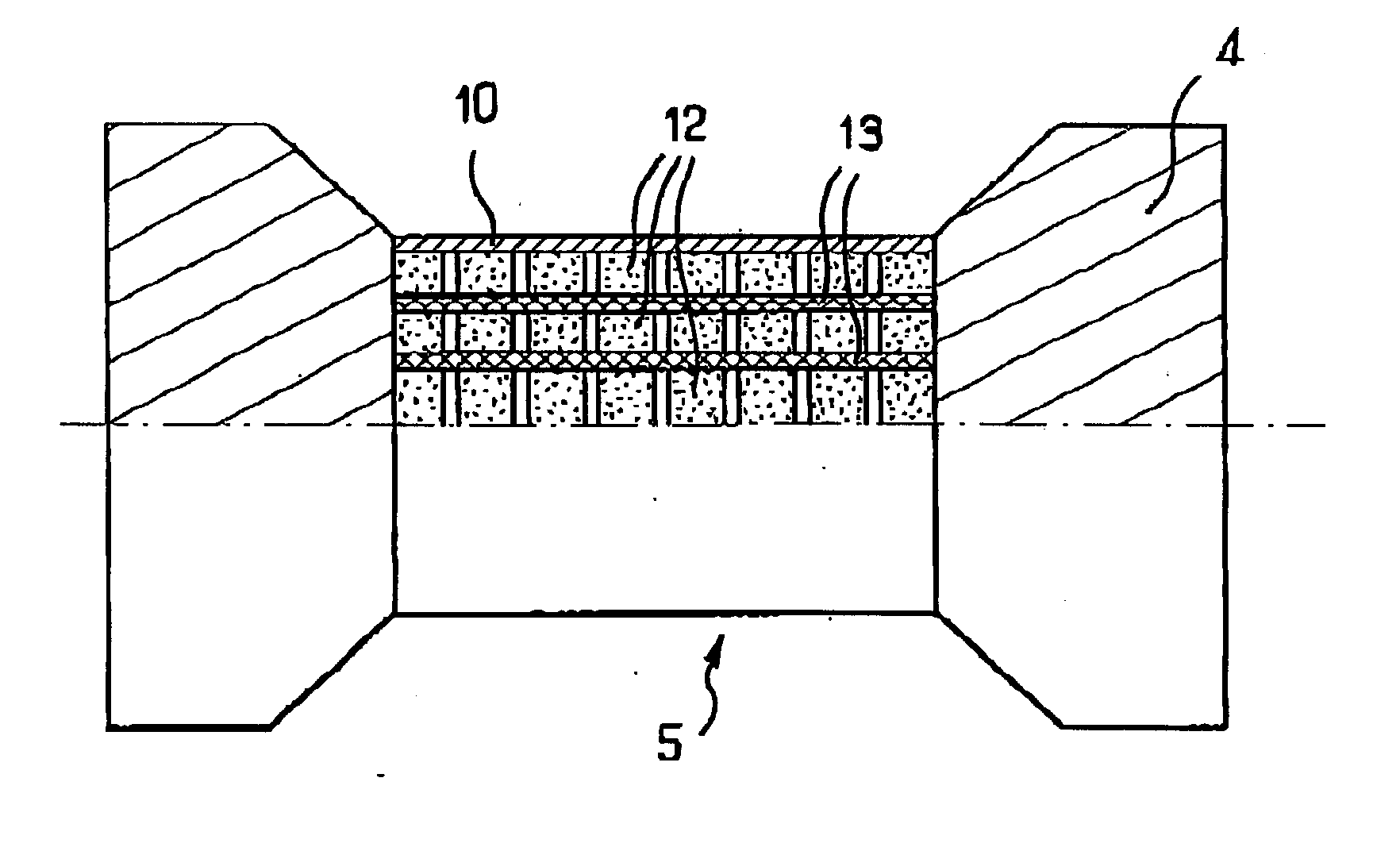

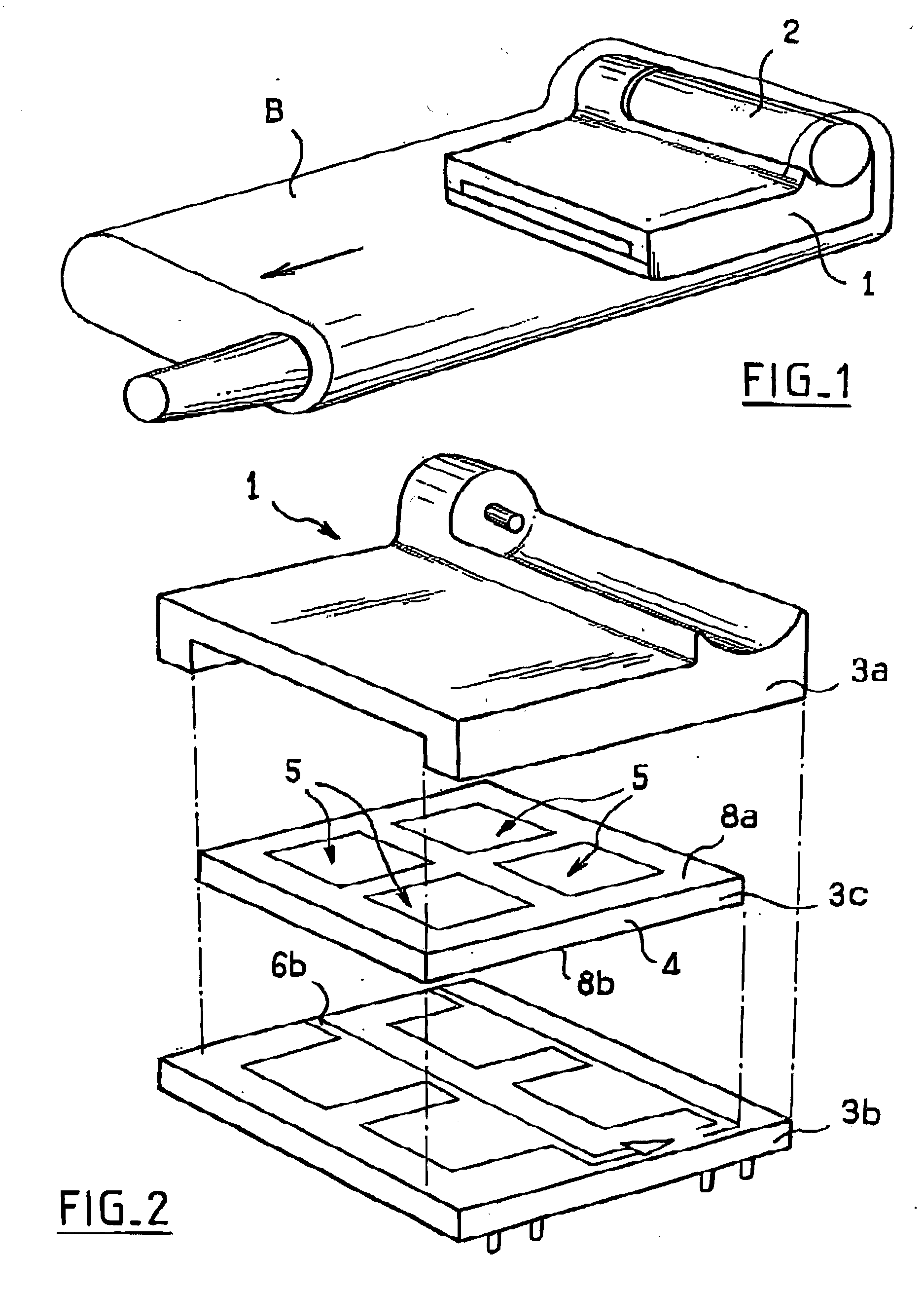

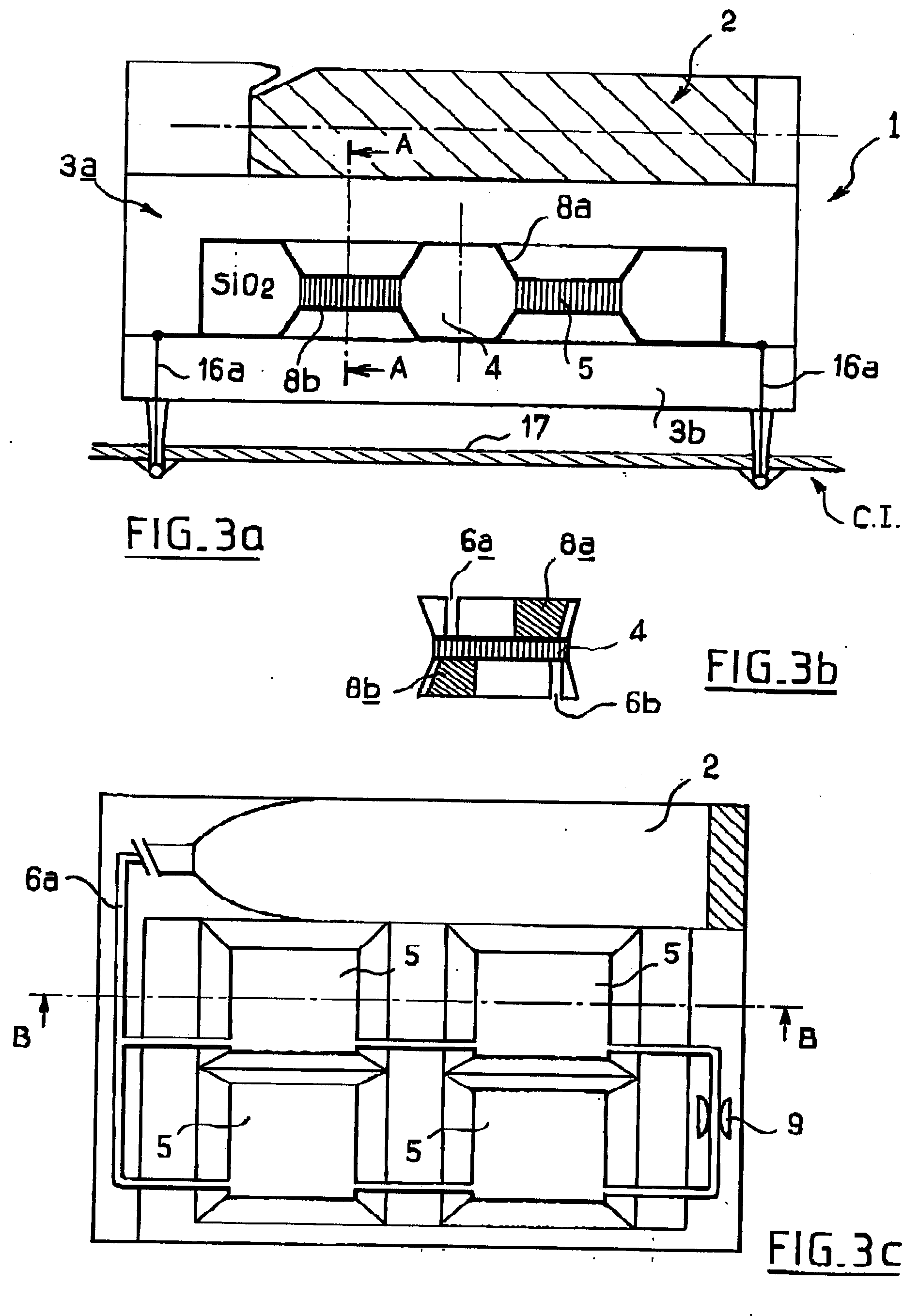

Microfuel cells for use particularly in portable electronic devices and telecommunications devices

InactiveUS20040197613A1MiniaturisationControl DimensionsFinal product manufactureFuel cell auxillariesState of artProton

The invention relates to a miniature fuel cell powered by a hydrocarbon fuel making heavy use of micro-technologies in making and assembling the sub-assemblies of the cell. Relative to the prior art, the main innovation consists in using a semiconductor oxidised and made porous in predetermined areas, to receive an electrolytic polymer allowing the composition of the proton exchange membrane necessary for the fuel cell to operate.

Owner:SAGEM SA +1

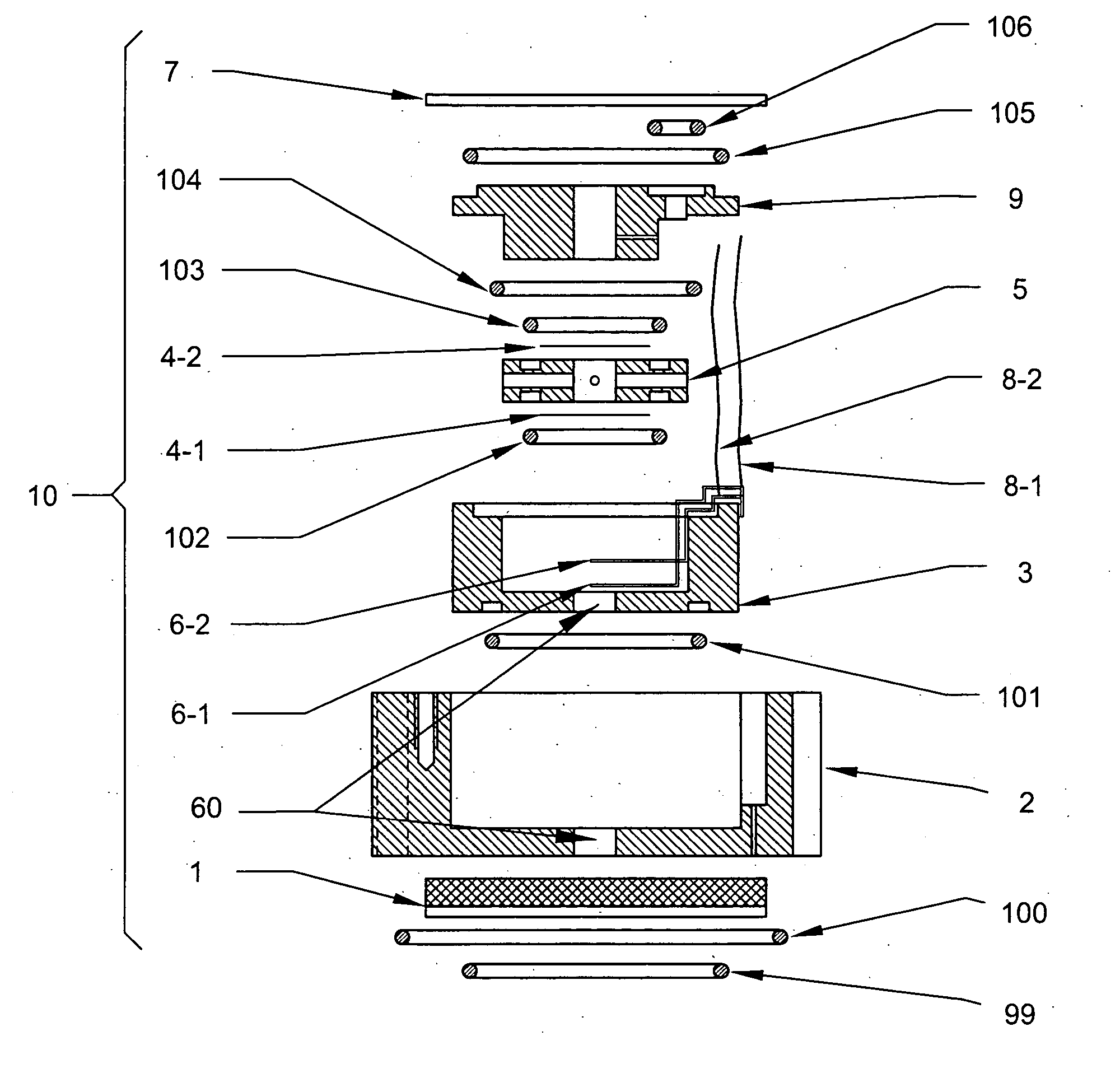

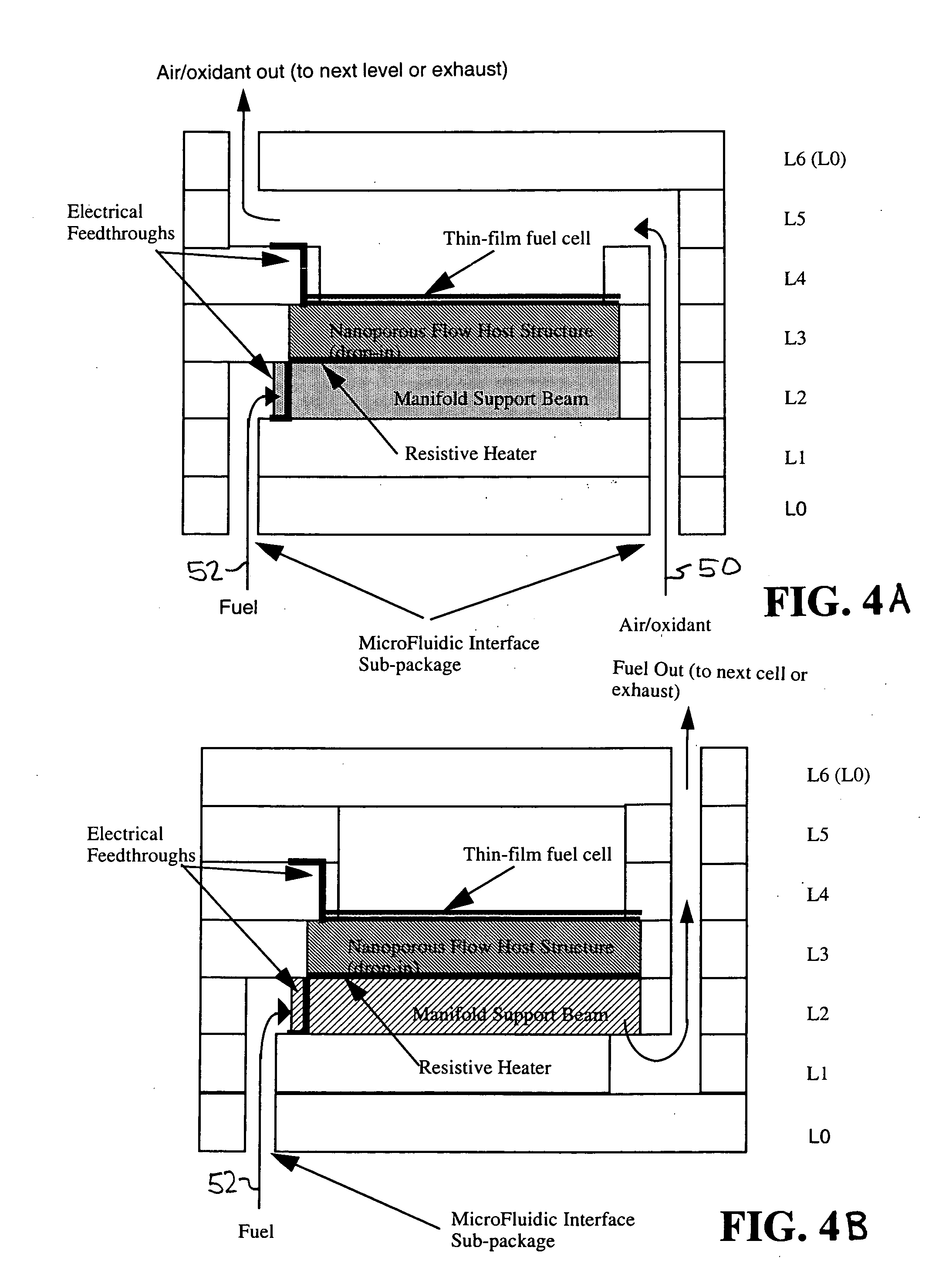

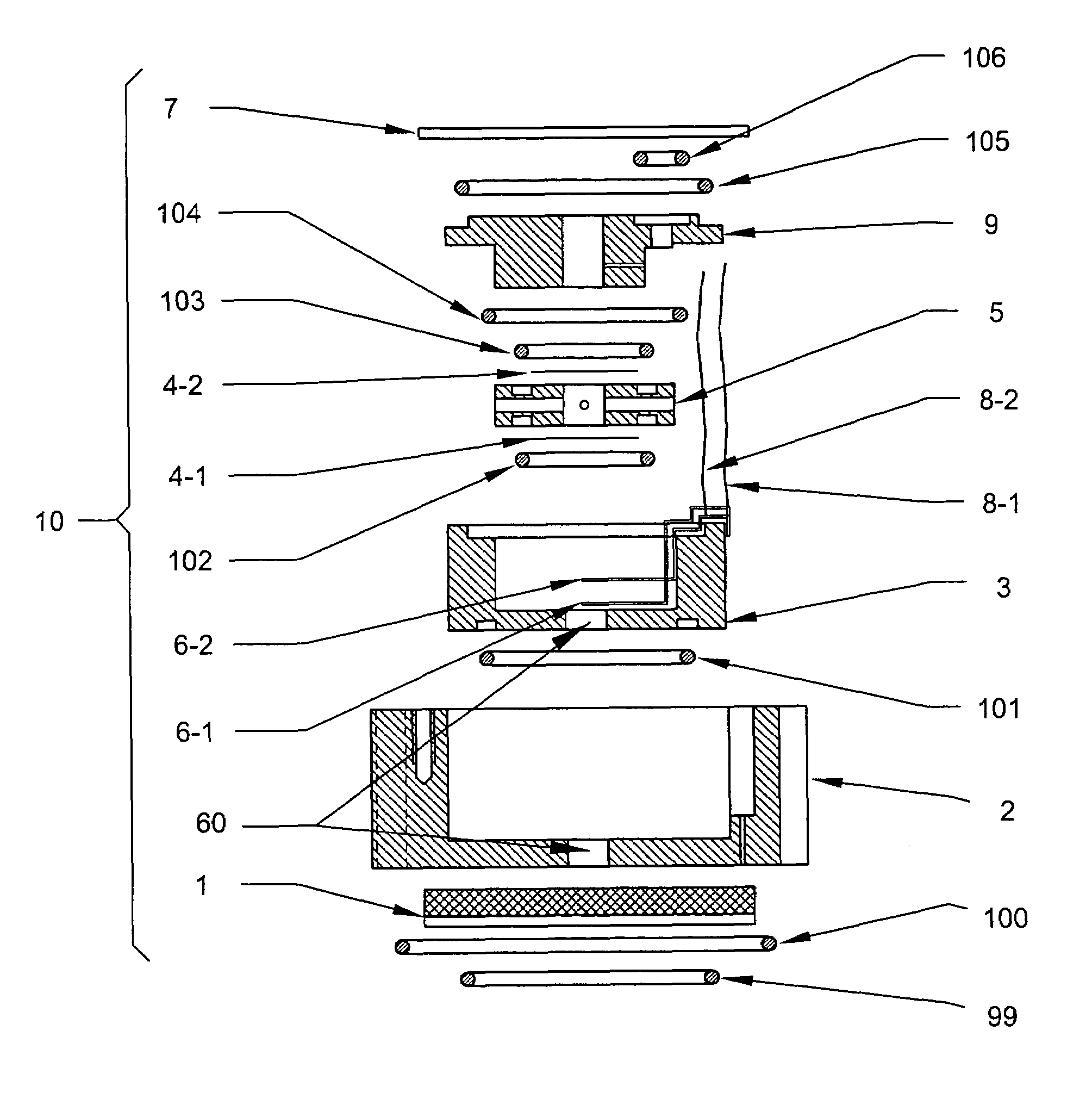

Method of forming a package for MEMS-Based fuel cell

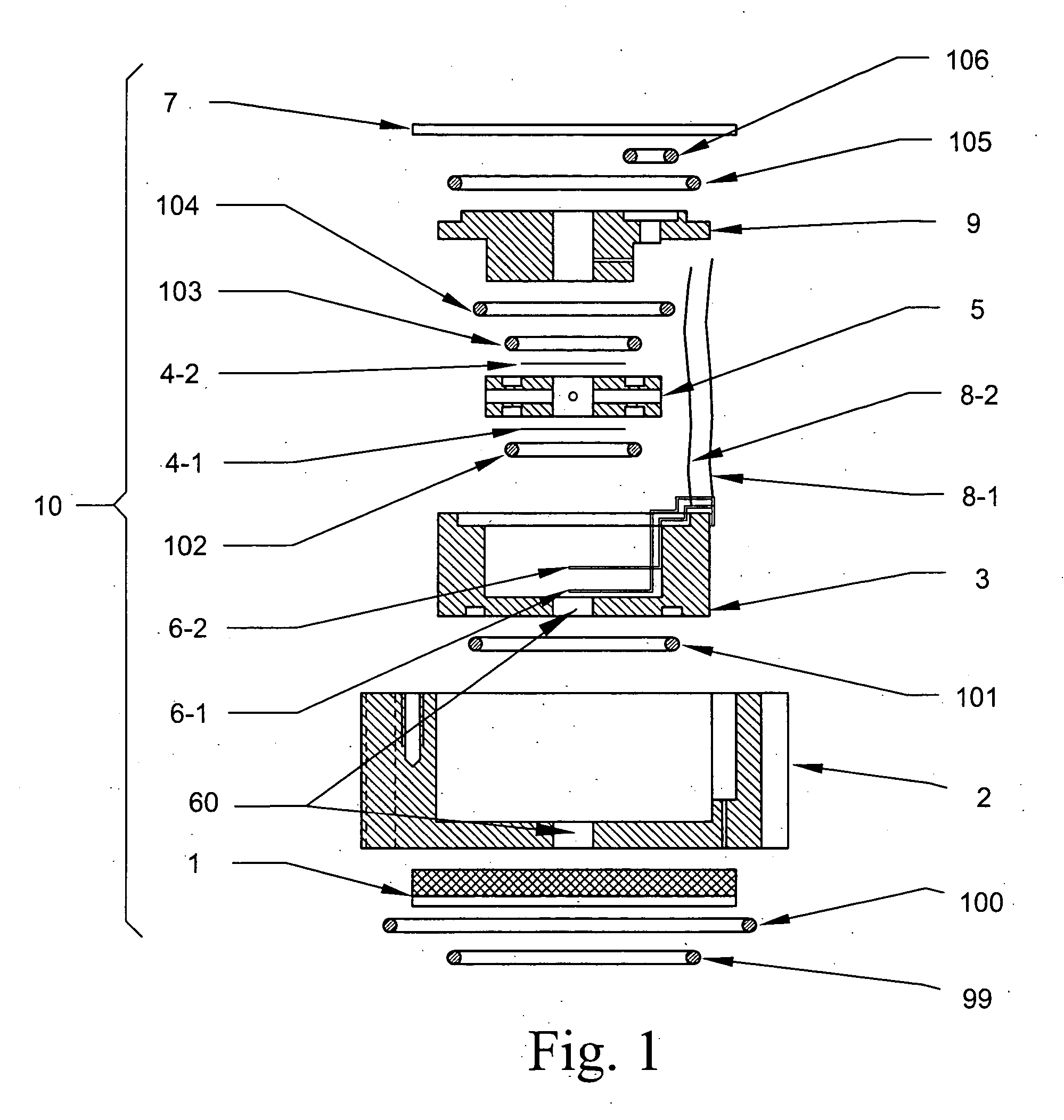

A MEMS-based fuel cell package and method thereof is disclosed. The fuel cell package comprises seven layers: (1) a sub-package fuel reservoir interface layer, (2) an anode manifold support layer, (3) a fuel / anode manifold and resistive heater layer, (4) a Thick Film Microporous Flow Host Structure layer containing a fuel cell, (5) an air manifold layer, (6) a cathode manifold support structure layer, and (7) a cap. Fuel cell packages with more than one fuel cell are formed by positioning stacks of these layers in series and / or parallel. The fuel cell package materials such as a molded plastic or a ceramic green tape material can be patterned, aligned and stacked to form three dimensional microfluidic channels that provide electrical feedthroughs from various layers which are bonded together and mechanically support a MEMS-based miniature fuel cell. The package incorporates resistive heating elements to control the temperature of the fuel cell stack. The package is fired to form a bond between the layers and one or more microporous flow host structures containing fuel cells are inserted within the Thick Film Microporous Flow Host Structure layer of the package.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

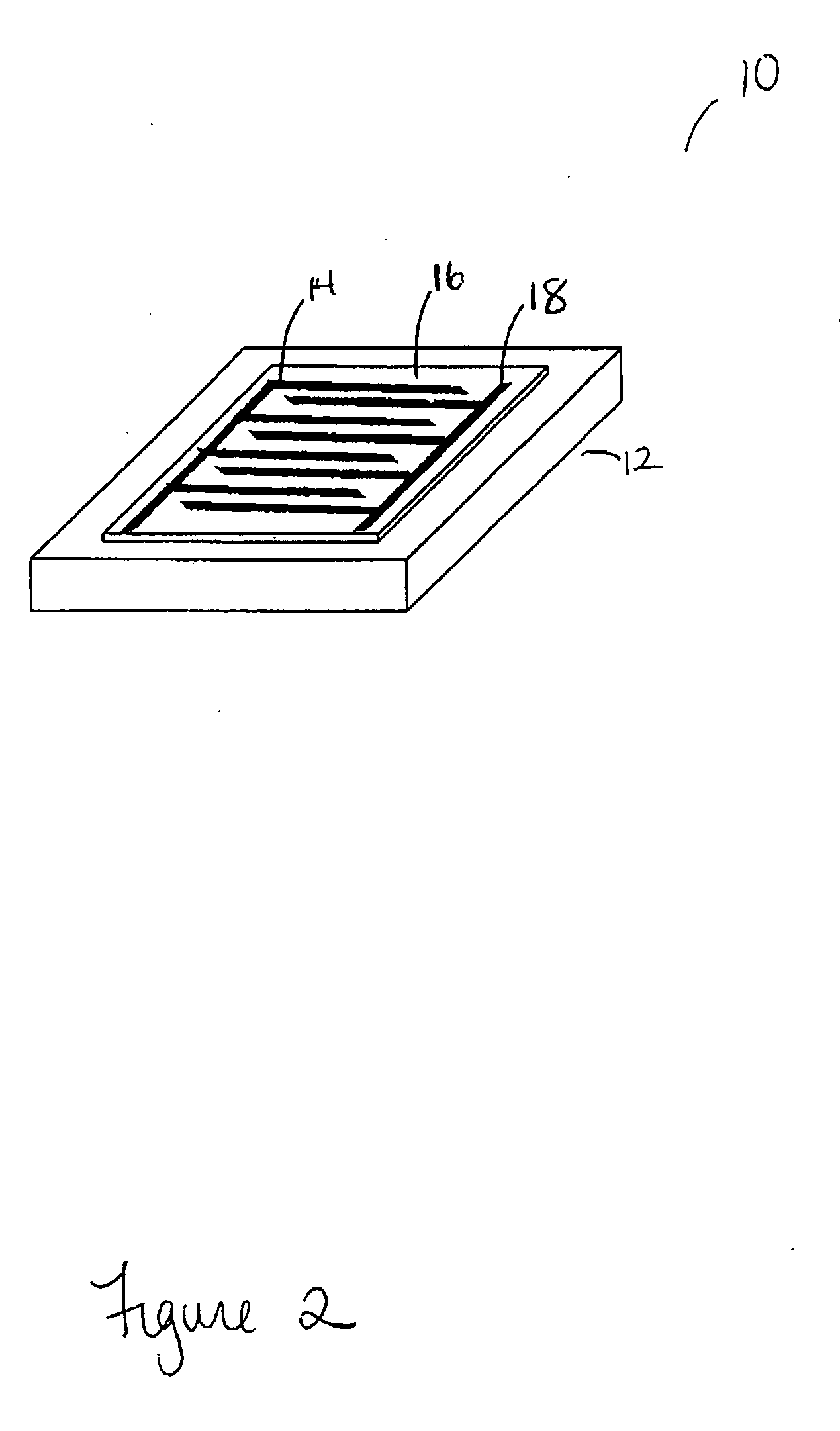

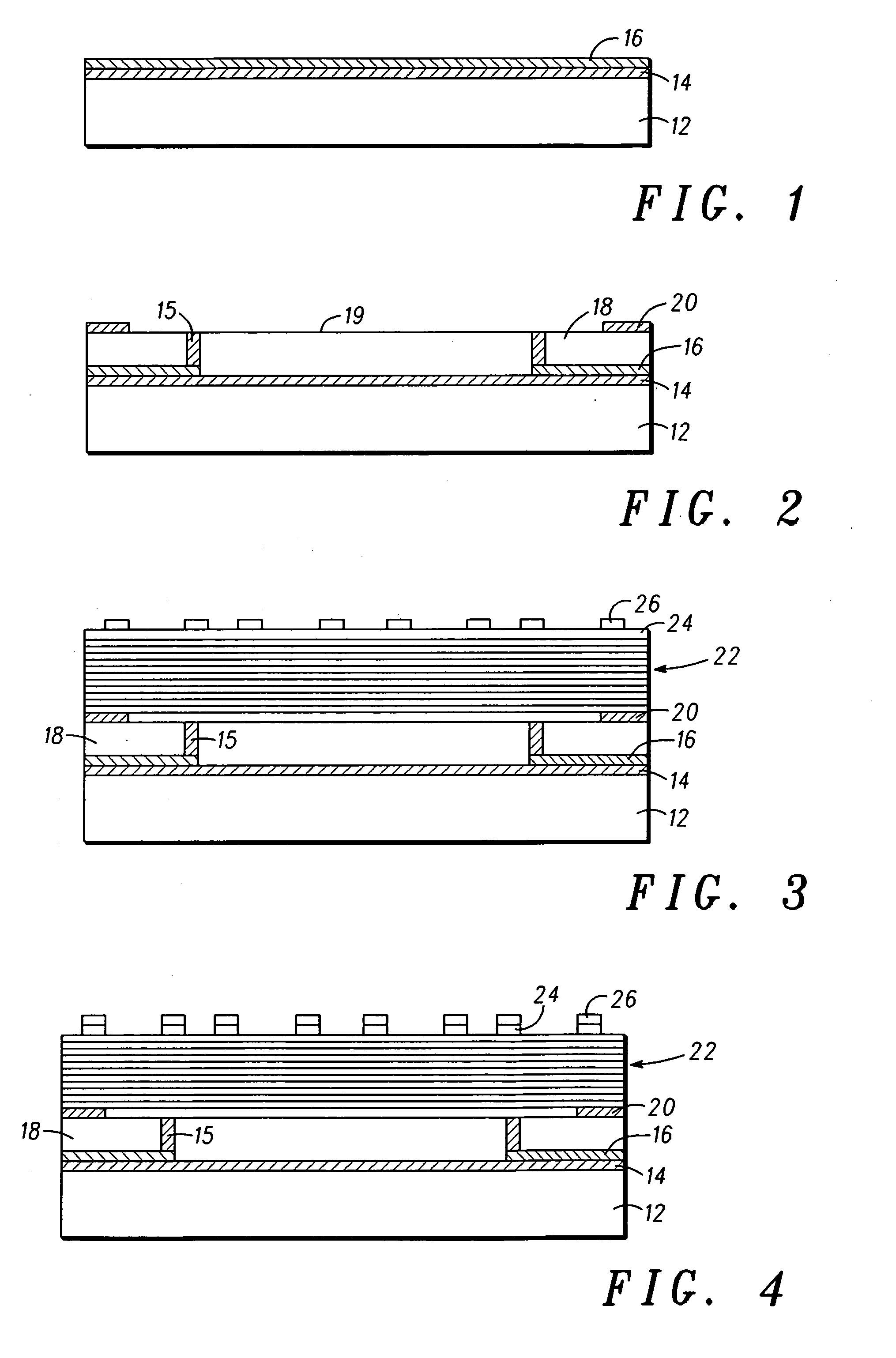

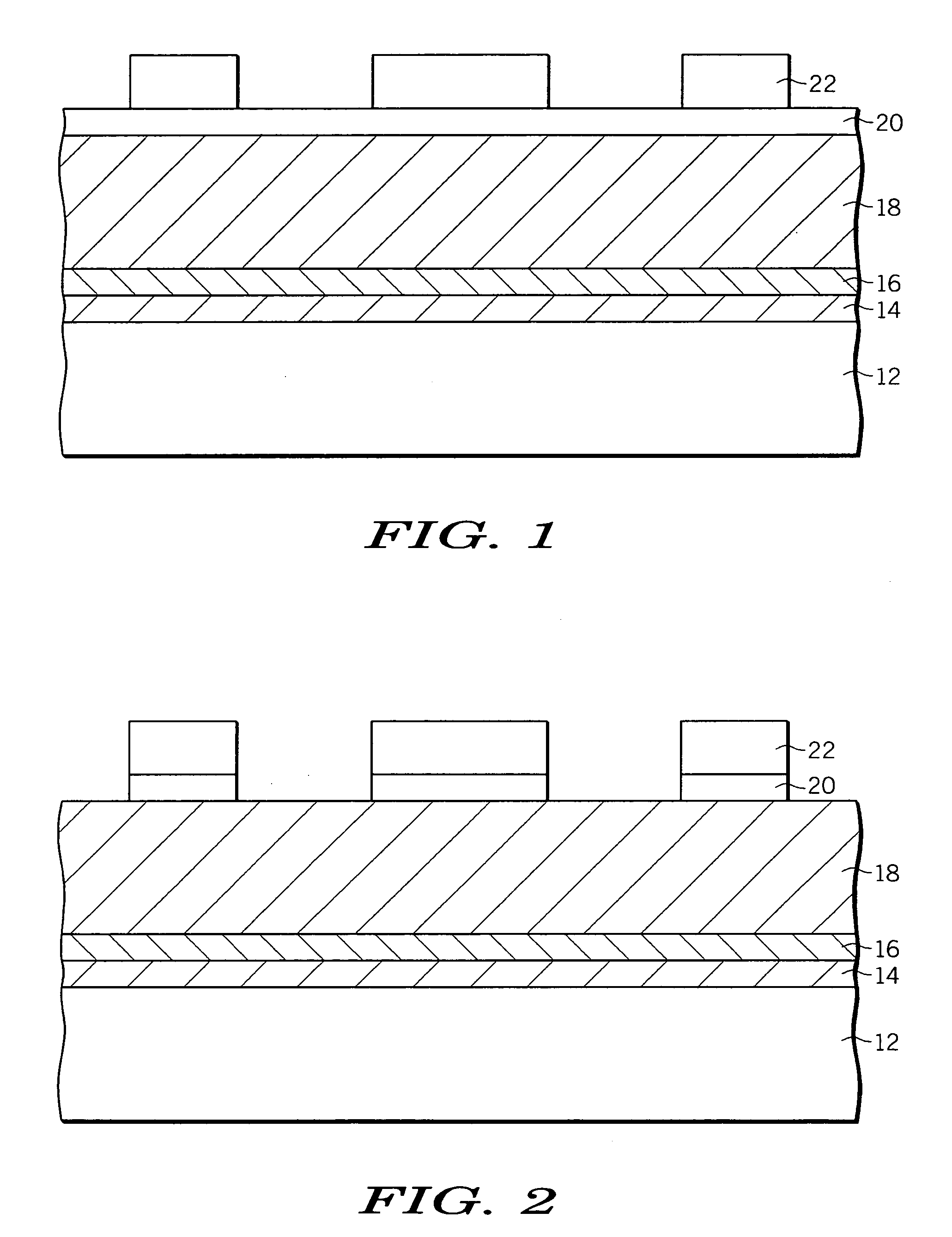

Fuel cell having patterned solid proton conducting electrolytes

InactiveUS20080003485A1Increase surface areaFinal product manufactureActive material electrodesElectrical conductorProton

A method is provided for patterning a solid proton conducting electrolyte (22, 60) for a micro fuel cell. The method comprises patterning a first side (30, 63) of a solid proton conducting electrolyte (22, 60) to increase the surface area, coating the patterned first side (22, 60) with an electrocatalyst (33, 66), providing a first electrical conductor (20) to the first side (22, 60), and providing a second electrical conductor (15, 16) to a second side (19) of the solid proton conducting electrolyte (22, 60) opposed to the first side (22, 60). One exemplary embodiment comprises depositing a solid proton conducting electrolyte (60) over a substrate (12), patterning the solid proton conducting electrolyte (60) to form a plurality of pedestals (28), each pedestal (28) having an anode side adjacent a anode region (42) and a cathode side adjacent a cathode region (43), coating the anode (42) and cathode (43) sides with an electrocatalyst (33), providing a first electrical conductor (15, 16) to the anode side (42); and providing a second electrical conductor (20) to the cathode side (43).

Owner:MOTOROLA INC

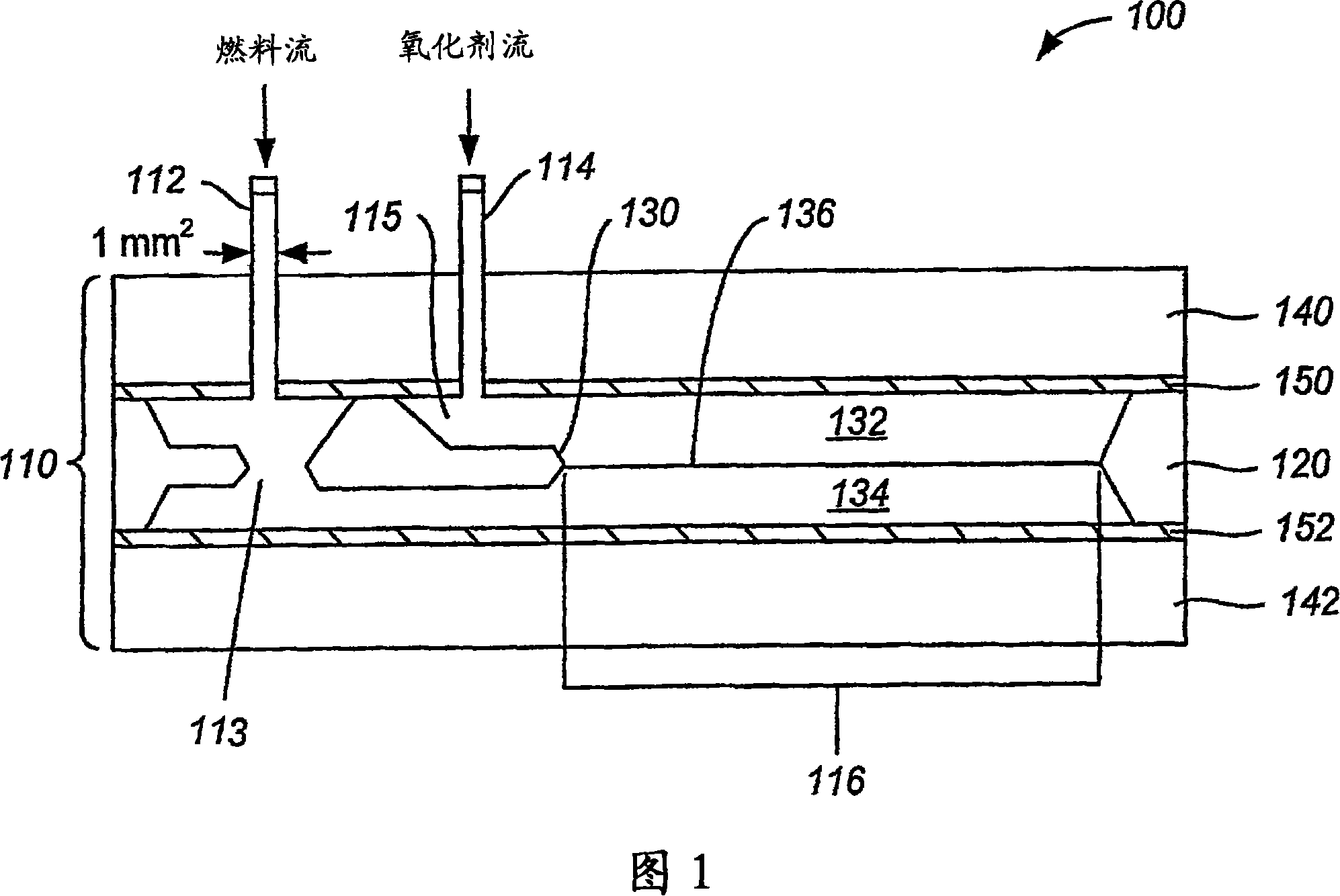

Planar membraneless microchannel fuel cell

InactiveCN101084364AChange thicknessChange flow rateElectrolyte holding meansFuel cell shape/formFlow cellEngineering

A microfluidic membraneless flow cell formed with multiple acidic / alkaline electrolyte solutions. The flow cell can be adapted to provide a dual electrolyte H2 / O2 fuel cell that generates thermodynamic potentials of up to 1.943 V or possibly greater. The selected fuel can be hydrogen dissolved in 0.1 M KOH, and the selected oxidant can be oxygen dissolved in 0.1 M H2SO4. Individual fuel cells can be combined to form fuel cell stacks to generate increased power output. Furthermore, microchannels of varying dimensions may be selected, including thickness variations, and different flow rates of acid / base electrolyte solutions can be applied to satisfy predetermined power generation needs. Some (micro-) fuel cell embodiments can be formed with silicon microchannels or fixed length and variable width and height, and can be used with hydrogen or formic acid as a fuel and oxygen as an oxidant, each dissolved in different acid / base electrolyte solutions. Micro-fuel cells are also provided which can be designed to generate different power levels for various applications including portable electronic devices such as wireless communication handsets and cellular telephones.

Owner:CORNELL RES FOUNDATION INC

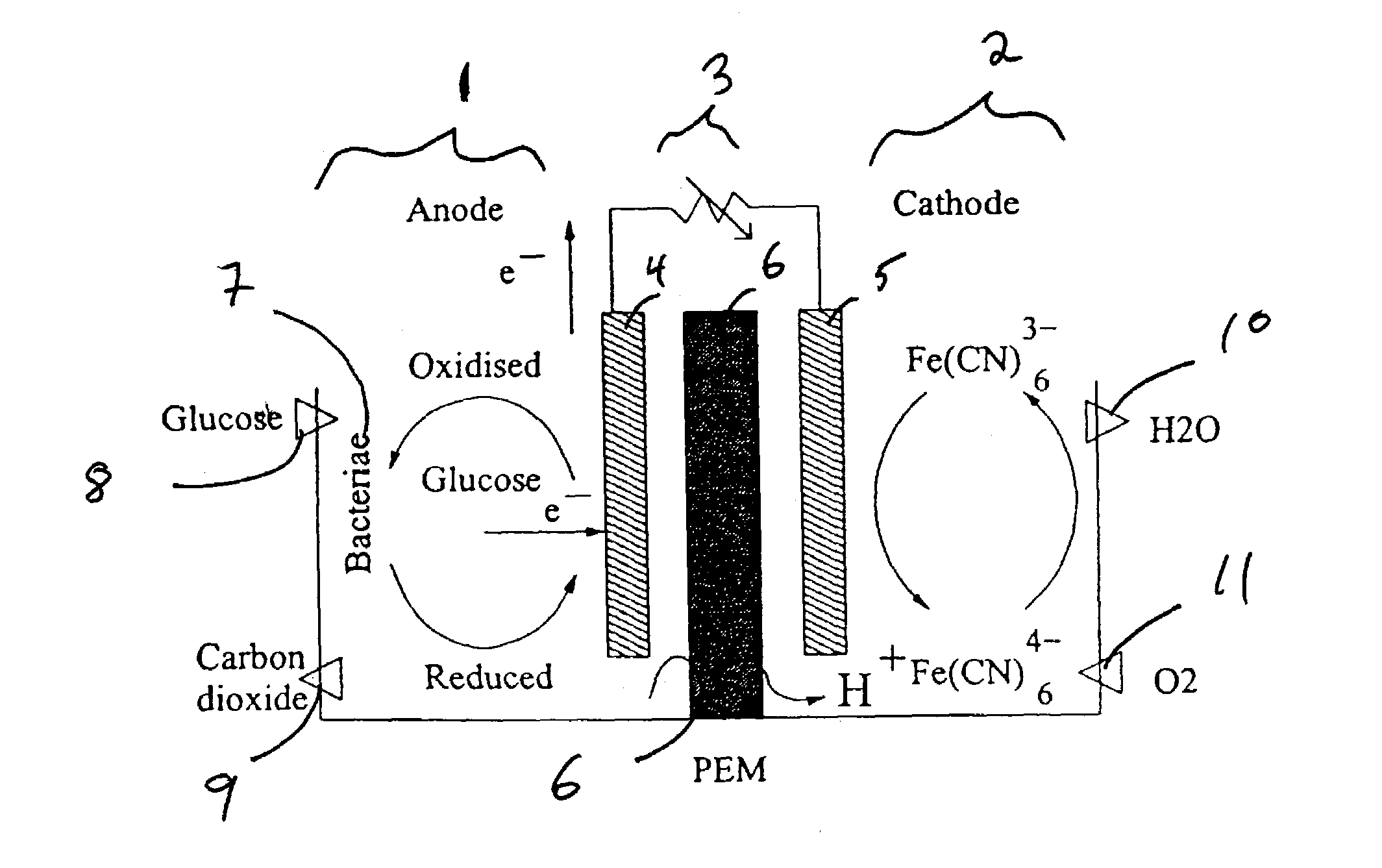

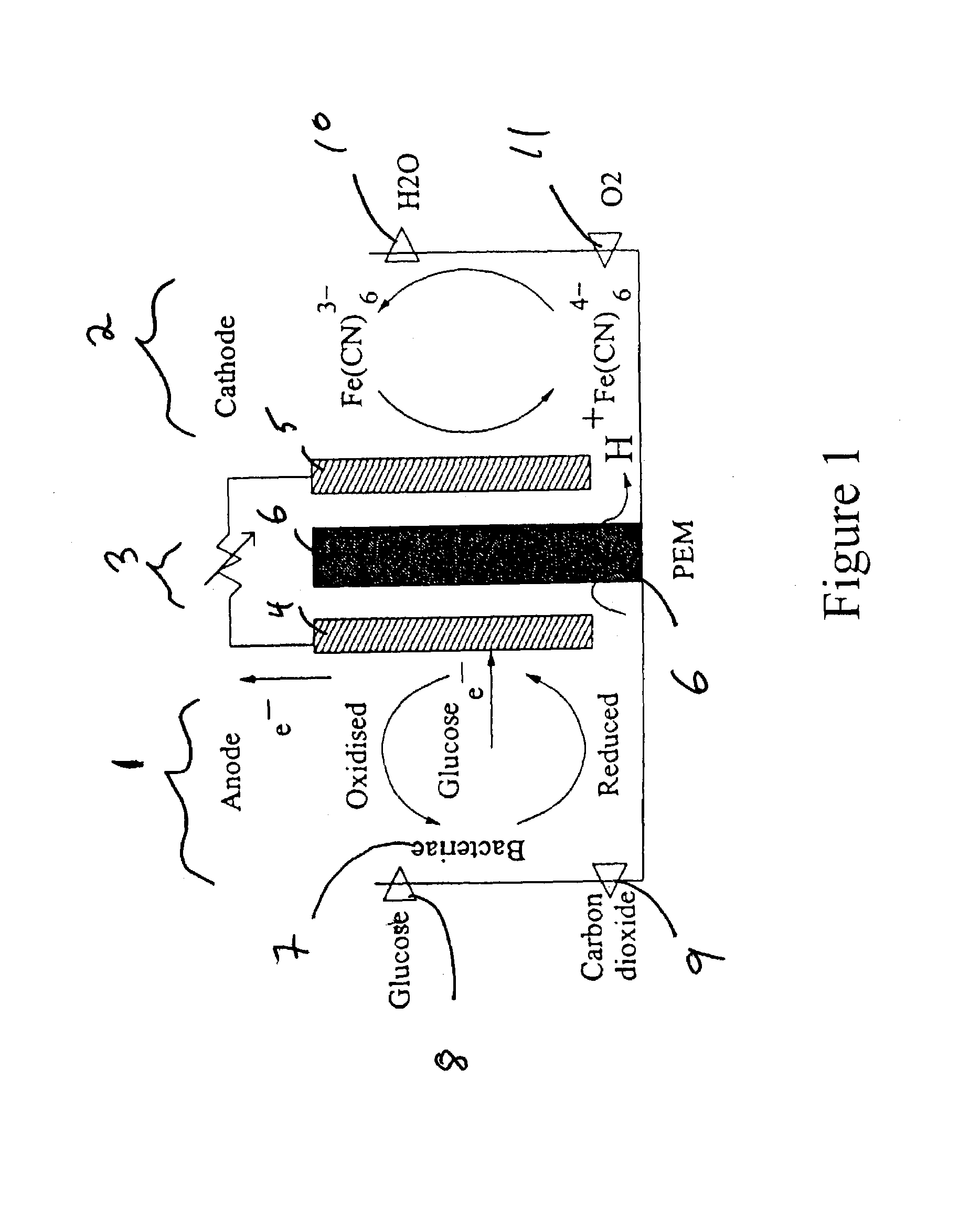

Microbial fuel cell

InactiveCN1588683AGuaranteed survivalNon-pollutingBiochemical fuel cellsPotassium ferricyanideEngineering

The invention microbe fuel cell consists of box, separating plate dividing the box to positive pole cavity and negative pole cavity, there is a hole on the separating plate, hydrogen selecting film is fit on the hole. In positive pole cavity, there is solution compounded by amylaceum, sodium dithydrogen phosphate and methylene blue, a sealine lid is covered on the positive pole cavity, a positive pole graphite rod is fit on the sealing lid, one end of the positive pole grahpite rod with honeycomb small holes rod is soaked in the solution in positive pole cavity, beer saccharomycetes and the substratum are in the honeycomb small holes. In negative pole cavity, there is solution compounded by potassium ferricyanide and fumaric and ferrous, an end lid is covered on the negative pole cavity, a negative pole graphite rod is fit on the end lid, one end of the negative pole graphite rod is soaked in the solution in negative pole cavity.

Owner:ZHEJIANG UNIV

Passive micro fuel cell

ActiveUS20060183015A1Relieve stressStable power generationMaterial nanotechnologyReactant parameters controlFuel tankCarbon nanotube

An efficient and passive micro fuel cell includes an anode plate, a reaction plate, a cathode plate and a condensation plate. The anode plate draws a dilute solution of methanol from a fuel tank to delivery to a series of upper oxidation reaction room through micro-channels by thermal capillarity. The condensation plate separates carbon dioxide and vapor from each other. Meanwhile, the methanol solution is delivered to a plurality of lower oxidation reaction rooms. Protons pass through the inner walls of the reaction holes and a porous membrane layer and arrive in the lower reduction reaction rooms. The lower reduction reaction rooms and the lower oxidation reaction rooms have reaction holes whose inner walls have carbon nanotubes and catalysts. A plurality of upper reduction reaction rooms delivers oxygen for the reduction reaction and drains the reduced water at the same time.

Owner:NATIONAL TSING HUA UNIVERSITY

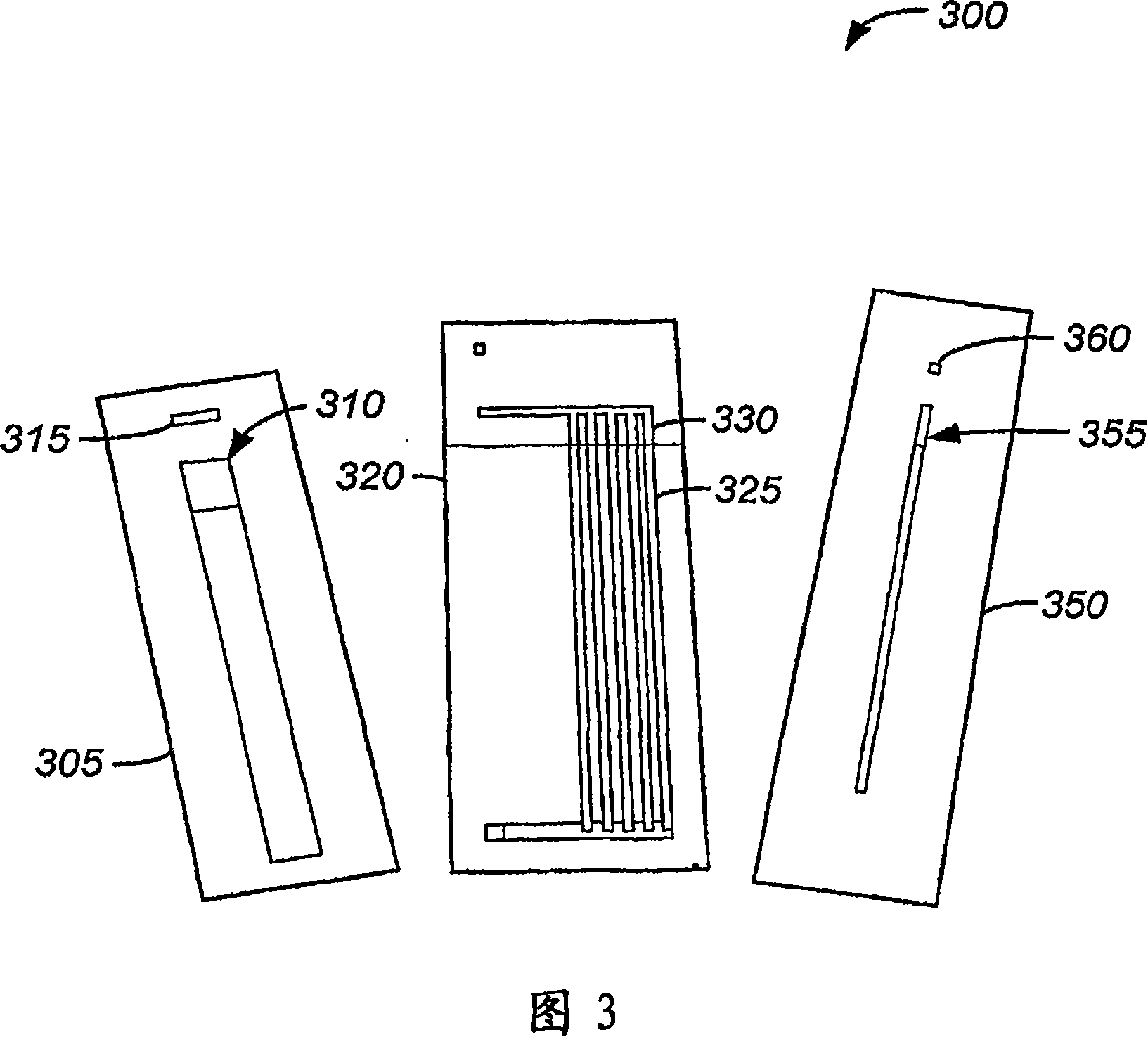

High surface area micro fuel cell architecture

InactiveUS20050255368A1Eliminate dependenciesImprove robust delivery of powerFuel cells groupingFuel cell auxillariesHigh power densityHigh surface area

The present invention relates to compact and high power density fuel cells. The fuel cells generate electrical energy and include a three-dimensional (3-D) architecture. The 3-D architectures include active surfaces whose dimensions may be varied during fuel cell design in three dimensions. Fabrication of the 3-D architectures may use wafer-processing technologies such as etching and deposition on etched surfaces. Fuel cells described herein provide power densities (power per unit volume or mass) at levels not yet seen in the fuel cell industry; some fuel cells are small enough to fit in a cell phone and power the cell phone.

Owner:ULTRACELL ACQUISITION

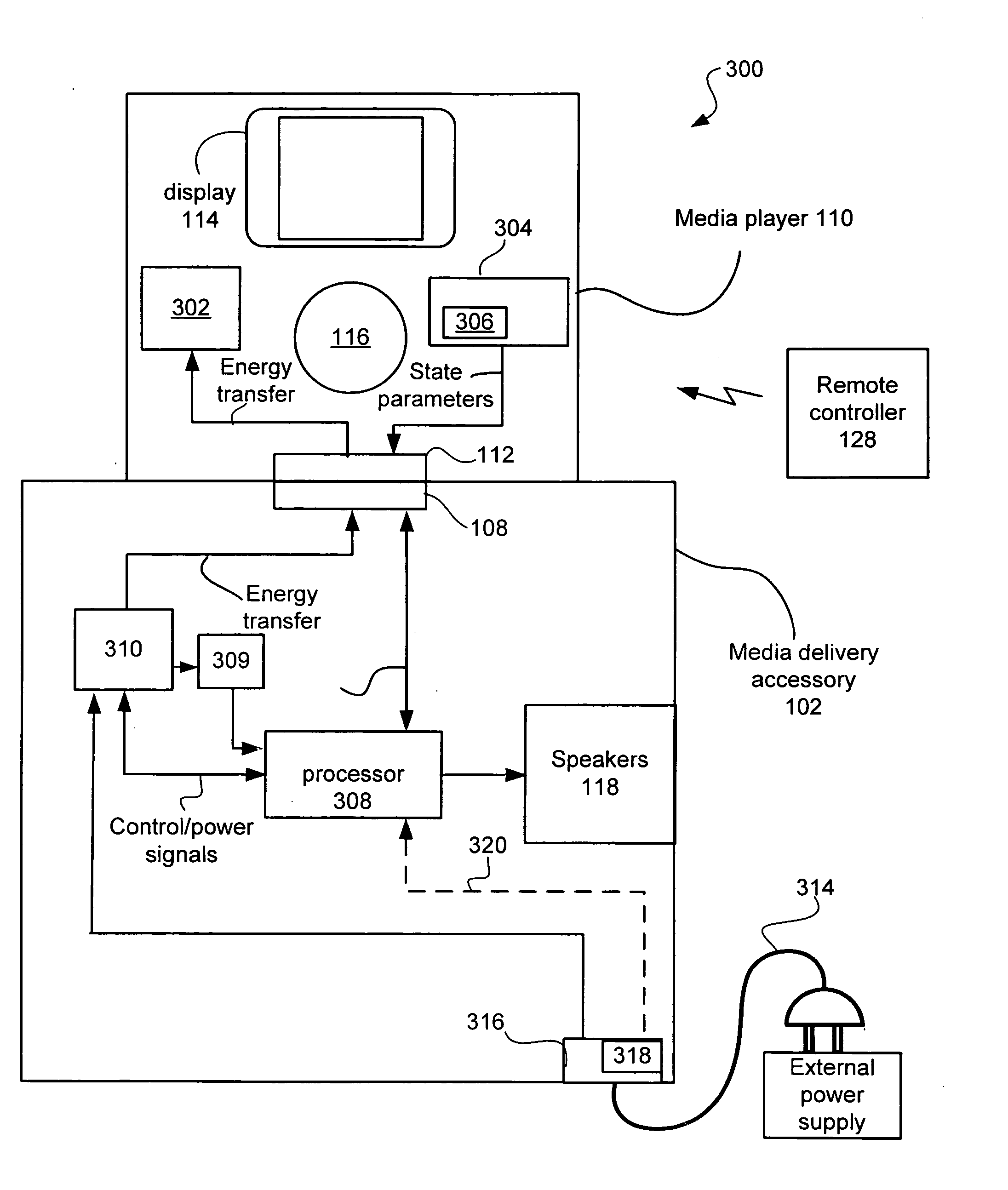

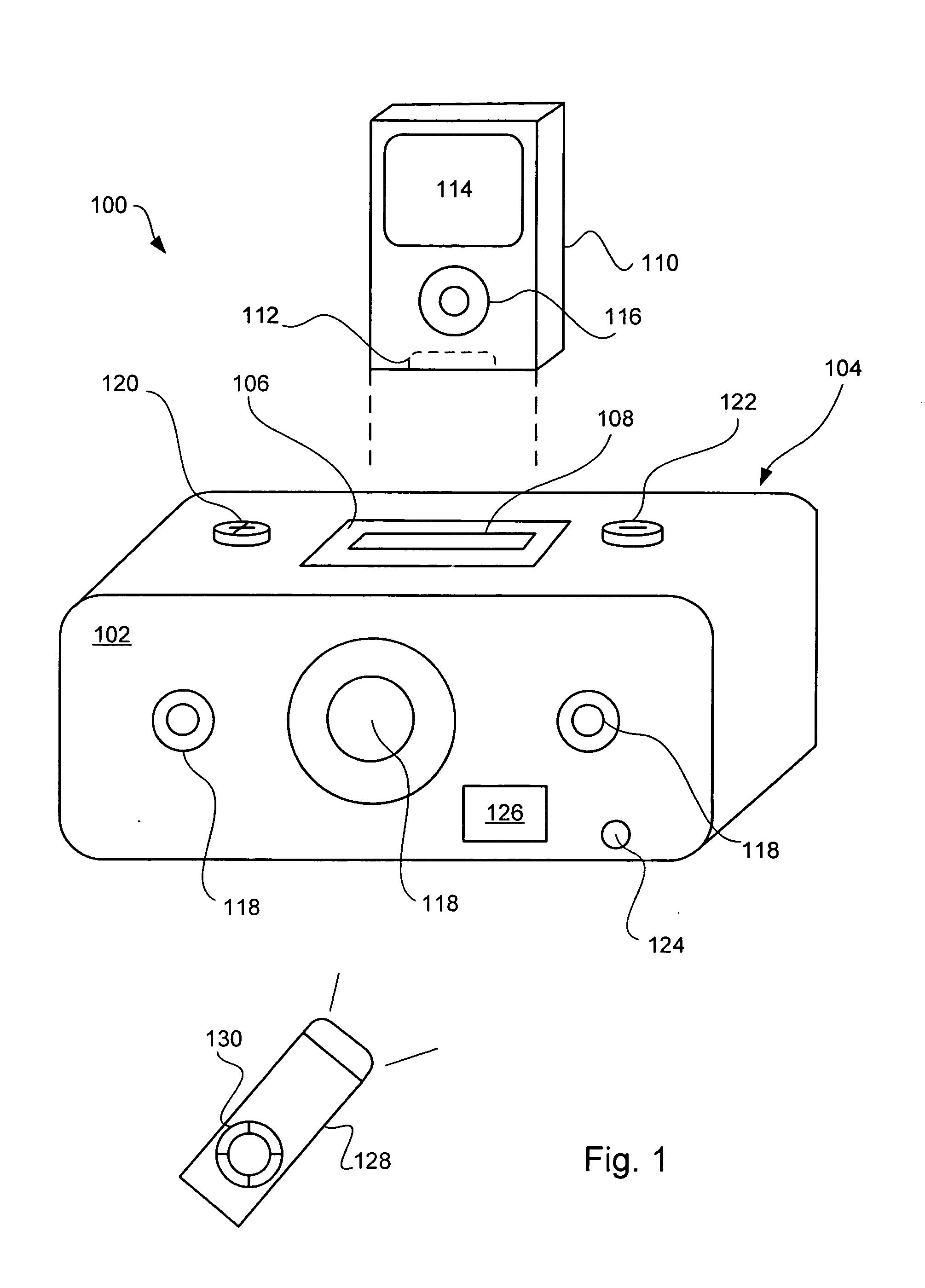

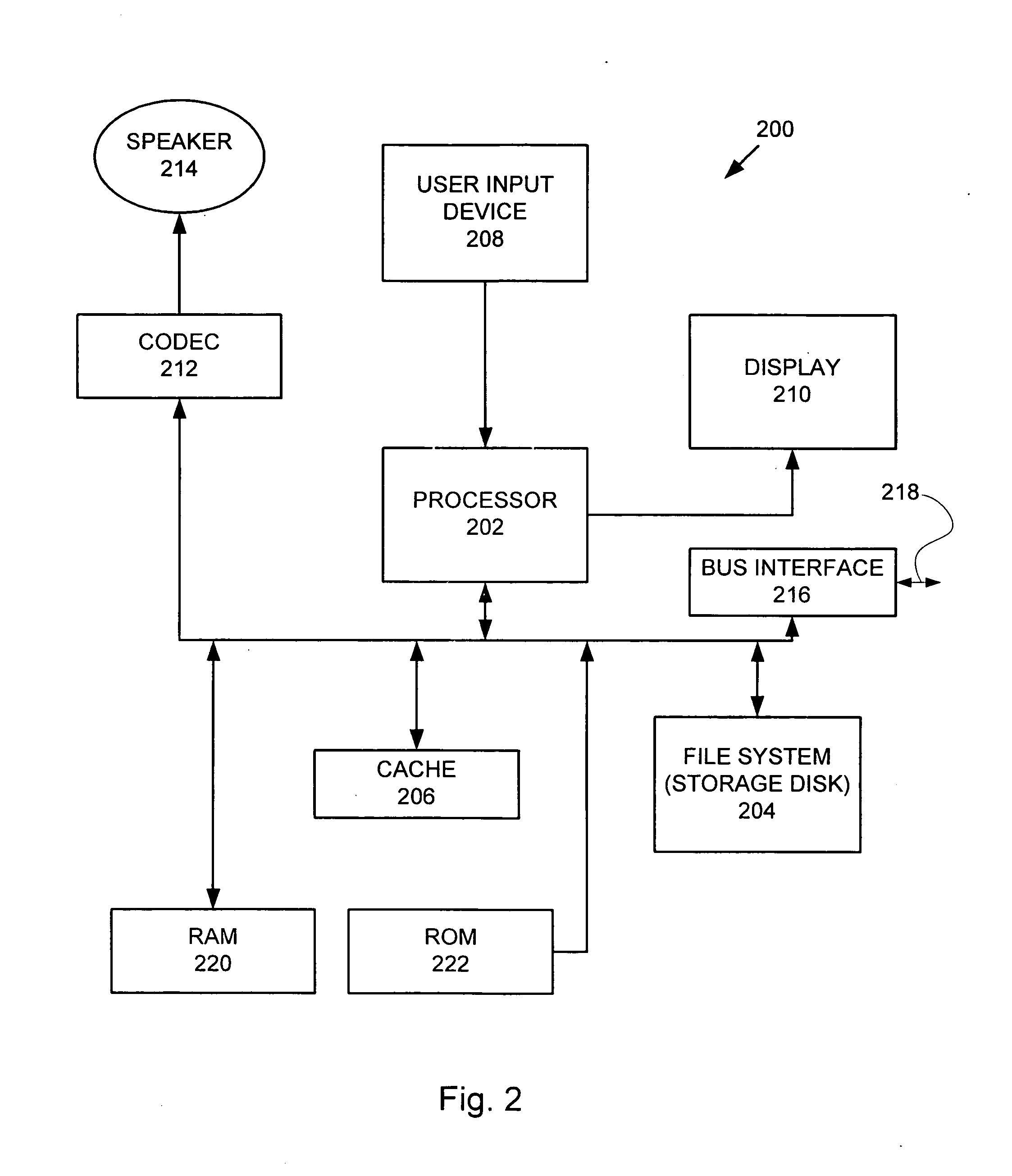

Dynamic power management in a portable media delivery system

ActiveUS20070201703A1AdvertisingPower supply for data processingStored energyDynamic power management

A consumer electronic product (e.g., a portable media player ported to a media delivery accessory) is powered by a limited capacity DC power source (such as a battery or mini-fuel cell). The consumer electronic product limits the maximum allowable sound pressure level (SPL) that can be produced by the speakers. In one embodiment, the maximum allowable SPL is based upon an amount of stored energy available in the limited capacity DC power source.

Owner:APPLE INC

Laminated membranes for diffusion limited gas sensors resistant to pressure variations

ActiveUS7582196B2Weather/light/corrosion resistanceVolume/mass flow measurementDiffusionAcid electrolyte

A micro fuel cell sensor having laminated gas permeable membrane. The sensor comprises a housing, first and second gas diffusing electrodes spaced from one another, a fuel-cell spacer having an acidic electrolyte disposed between said first and second electrodes, and two gas permeable membranes. The first gas permeable membrane comprises a polymer laminated on a metal substrate, wherein the substrate comprises pores that have dimensions at least less than one-half the thickness of the polymer film.

Owner:GENERAL ELECTRIC CO

Micro fuel cell

The present invention discloses a solid oxide fuel cell and method for fabricating solid oxide fuel cells using thin film processing techniques. The fuel cell comprises a cathode layer, an electrolyte layer, and an anode layer arranged in various configurations to optimize fuel cell performance.

Owner:MASSACHUSETTS INST OF TECH

Micro fuel cell

The present invention discloses a solid oxide fuel cell and method for fabricating solid oxide fuel cells using thin film processing techniques. The fuel cell comprises a cathode layer, an electrolyte layer, and an anode layer arranged in various configurations to optimize fuel cell performance.

Owner:MASSACHUSETTS INST OF TECH

Micro fuel cell, fabrication method thereof, and micro fuel cell stack using the same

InactiveUS20090181278A1Keep the structure stablePrevent coagulationAnodisationMaterial nanotechnologyAnodizingMicro cell

Owner:KOREA INST OF SCI & TECH

Integrated micro fuel cell apparatus

Owner:MOTOROLA INC

Efficient micro fuel cell systems and methods

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:超电池公司

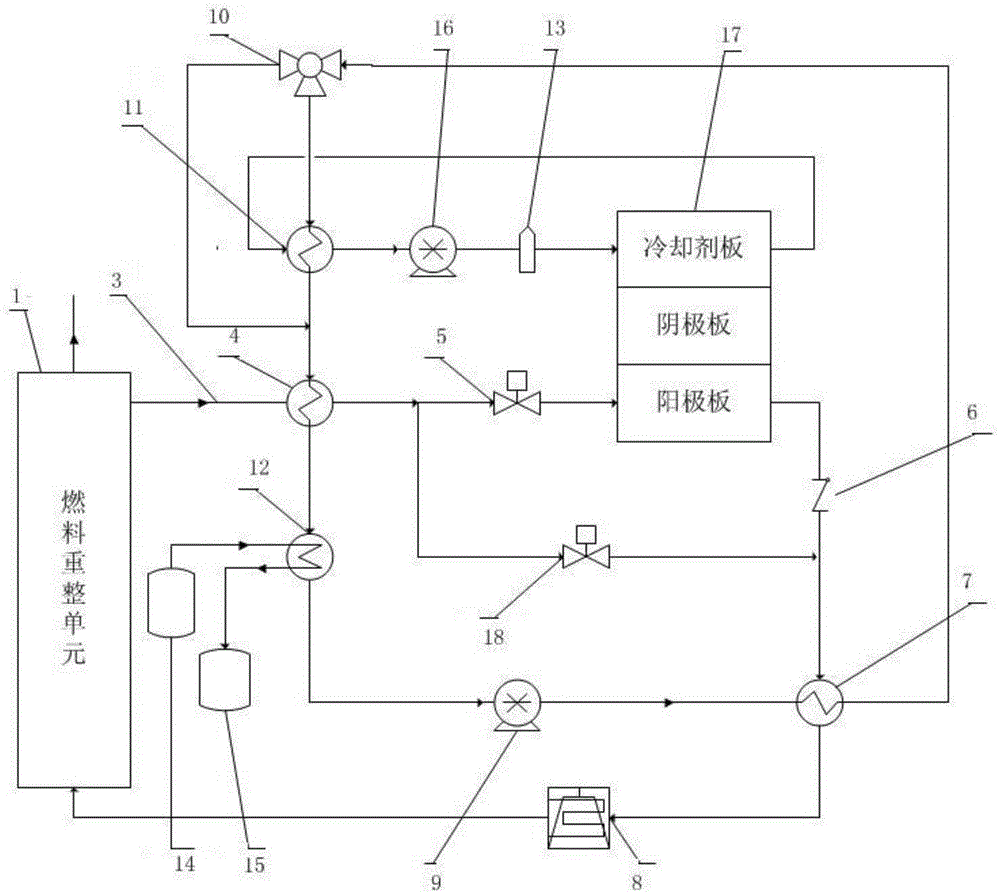

Thermal control system of fixed mini-type fuel cell cogeneration device

ActiveCN105576269AReduce the temperatureShorten the timeFuel cell heat exchangeSolenoid valveCogeneration

The invention relates to a thermal control system of a fixed mini-type fuel cell cogeneration device. A gas path entering a fuel cell galvanic pile is a normal working gas path; high-temperature hydrogen-enriching mixed gas flow generated by a fuel reforming unit enters a No.1 heat exchanger through a pipeline, passes through an outlet of the No.1 heat exchanger and then enters a positive electrode plate through a No.1 solenoid valve for power generation; high-temperature tail gas discharged from the positive electrode plate enters a No.2 heat exchanger through a one-way valve, then enters a condenser to be subjected to water-steam separation and then flows back to the reforming unit for cyclic utilization respectively; a cooling water pump is communicated with a No.4 heat exchanger and is used for pumping cold water; the cold water is subjected to heat exchange through the No.2 heat exchanger and the high-temperature tail gas discharged from the positive electrode plate; after the cold water passes through a three-way valve, the cold water is divided into two paths to be controlled according to high and low temperatures of cooling liquid, measured by a thermocouple temperature measuring device; and a cooling liquid circulating loop is communicated with a cooling water circulating loop through a No.3 heat exchanger. A cooling circulating unit provided by the invention is simple in structure and simple in design; and a lot of parts are omitted, so that the size of the cogeneration device is greatly reduced and the cost is reduced at the same time.

Owner:JINCHENG ABOUND ENERGY CO LTD

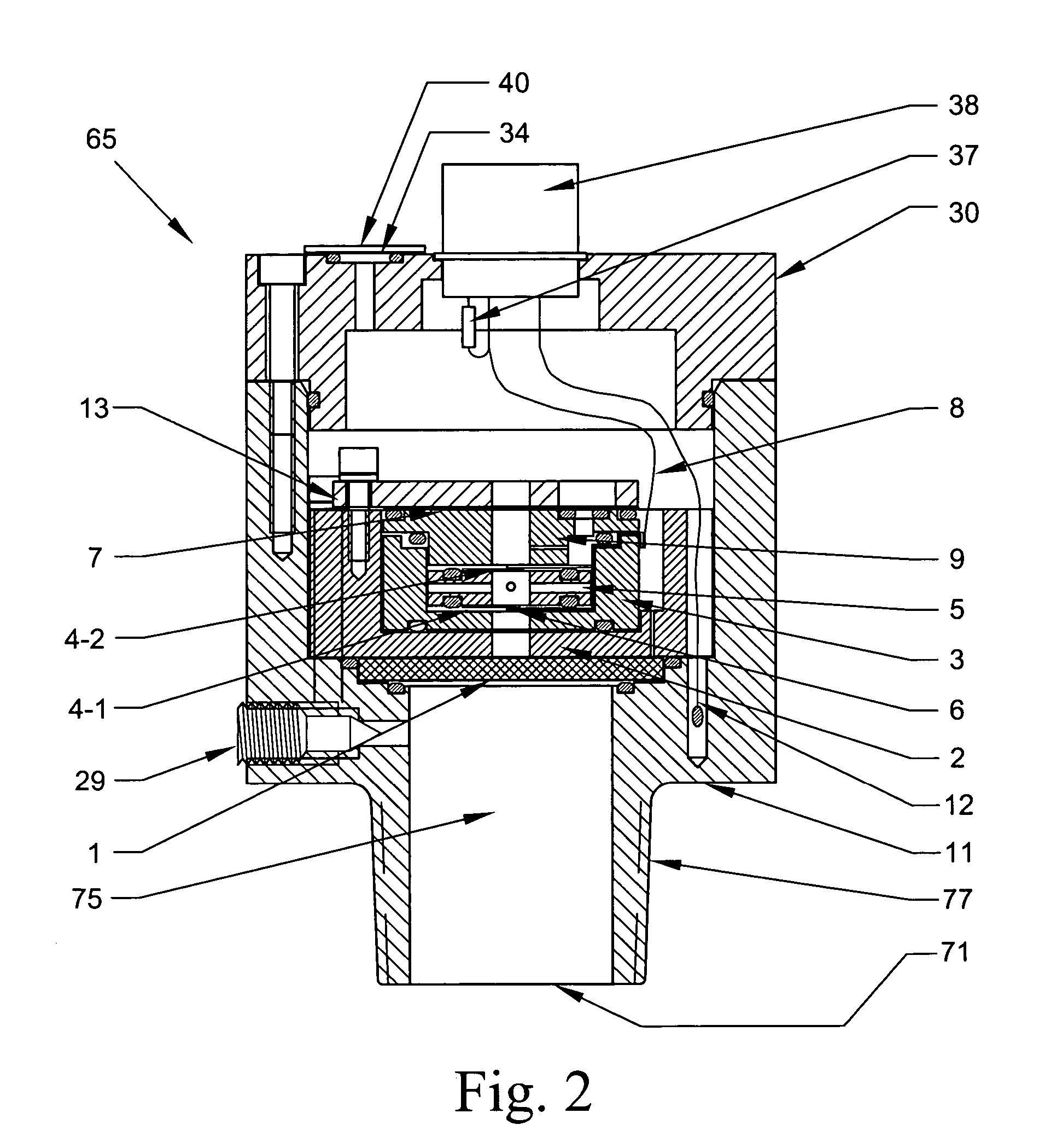

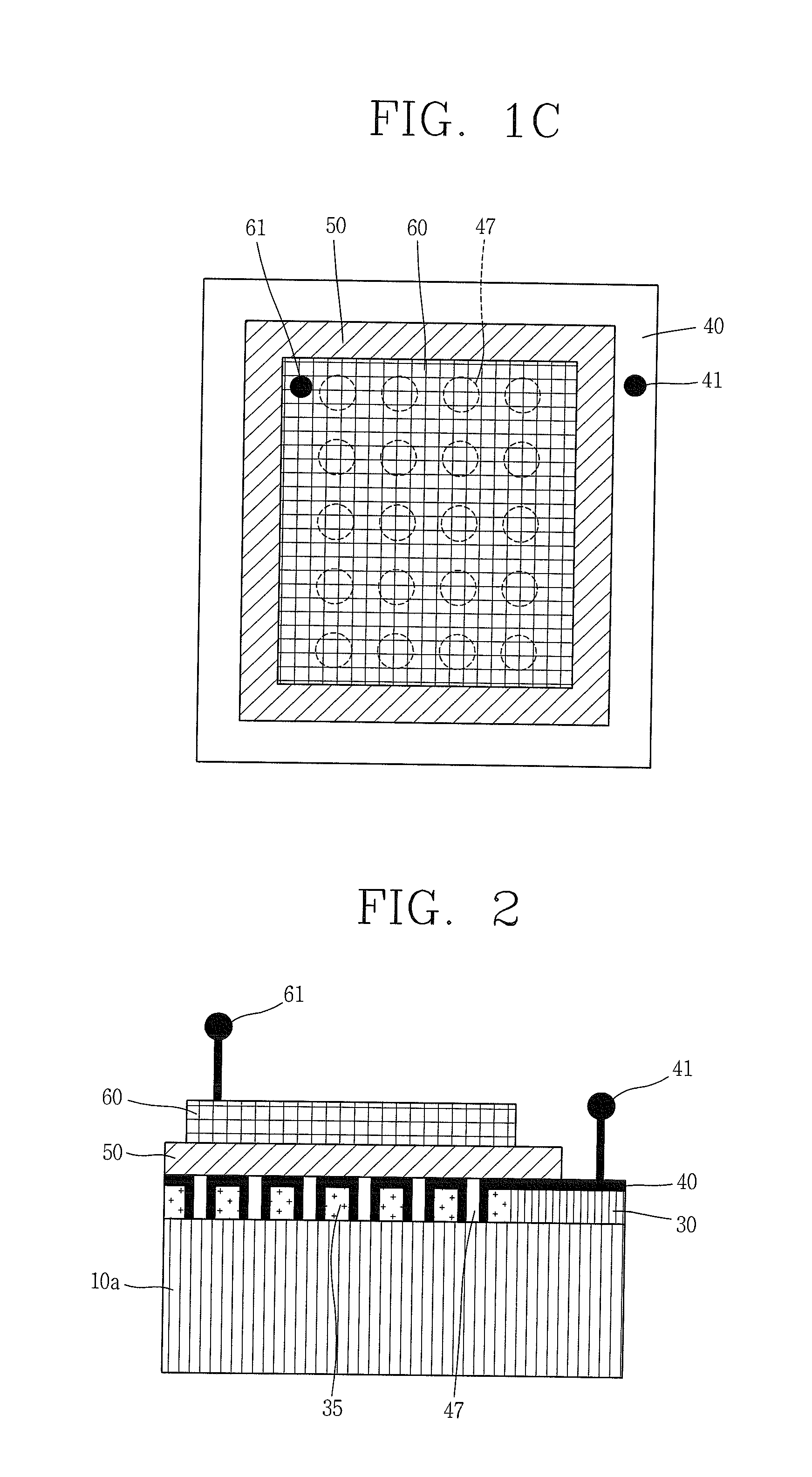

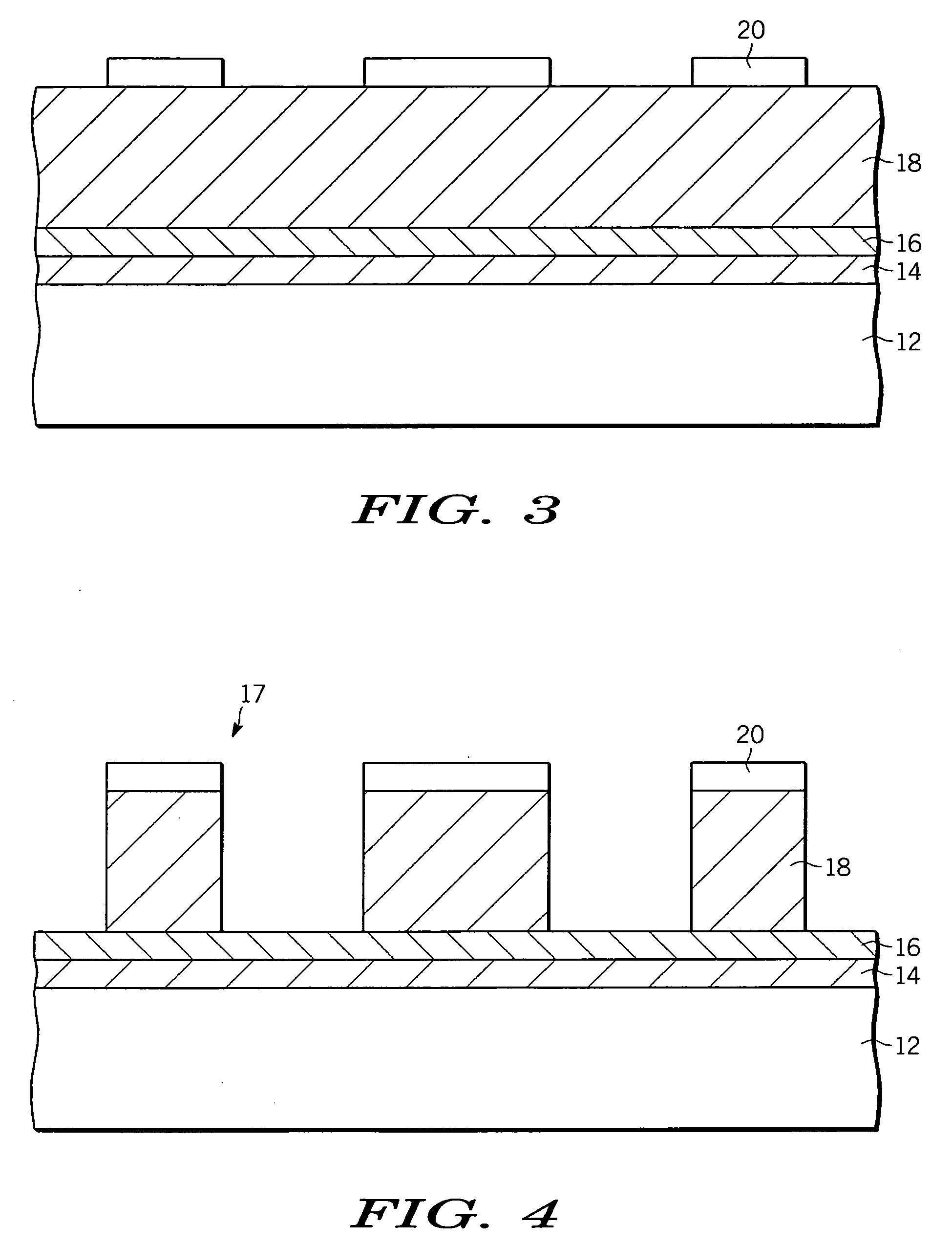

Integrated micro fuel cell apparatus

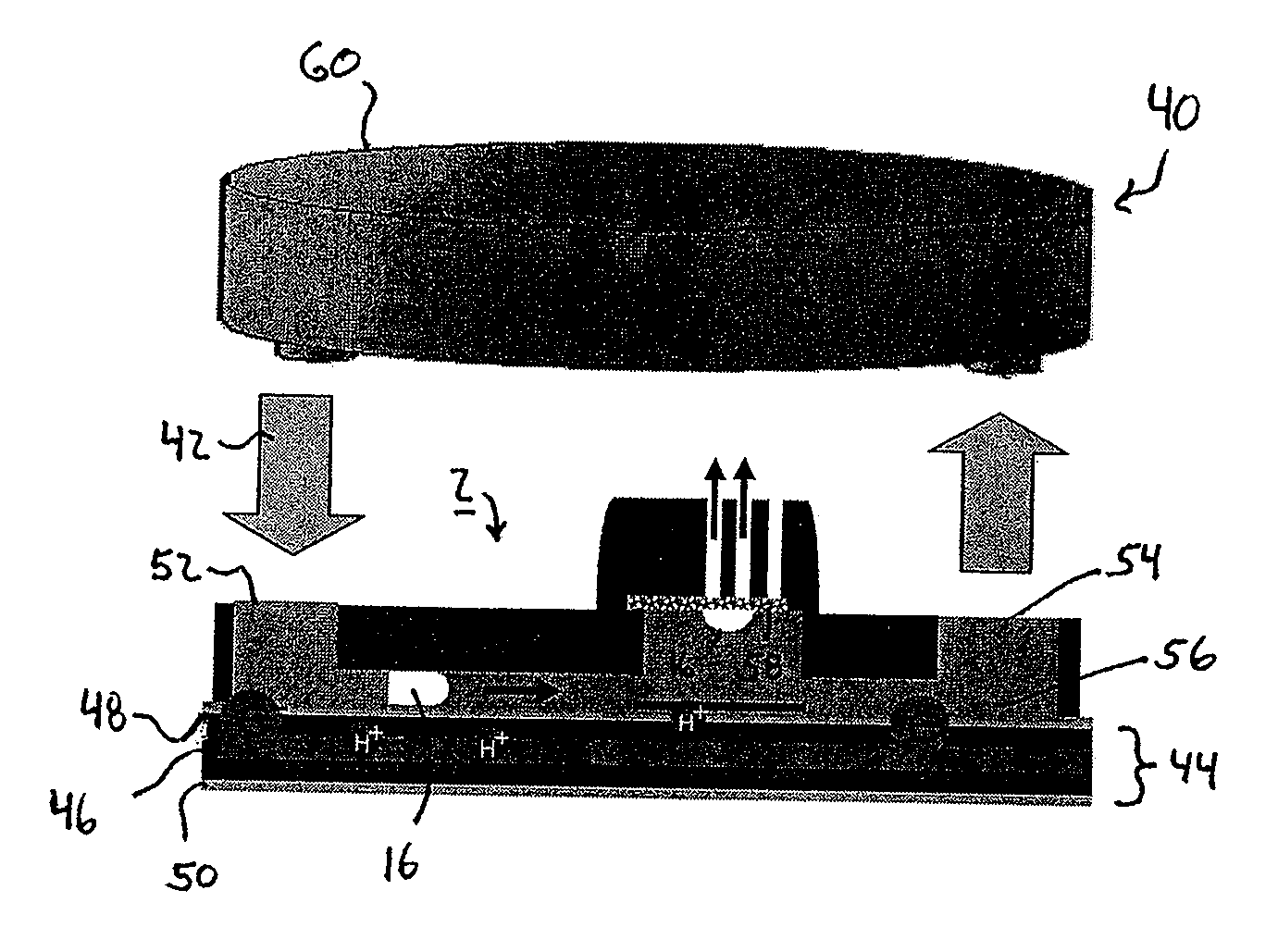

A micro fuel cell and method of forming such on a substrate (12) is provided that derive power from a three dimensional fuel / oxidant interchange. The fuel cell includes a plurality of porous pedestals (17) formed on the substrate (12), each porous pedestal (17) including an anode (68), a cathode (70) surrounding the anode (68); and an electrolyte (60) filling a cavity between the anode (68) and the cathode (70). The cathode (70) is accessible to ambient air, and the anode (68) has a passageway (30) thereto for receiving a fuel. The anode (68) and cathode (70) may be formed by etching a cavity for the electrolyte (60) or by forming trenches (58, 66) to form each anode (68) and cathode (70), wherein each trench (66) between an anode and cathode is filled with electrolyte.

Owner:MOTOROLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com