Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Mass velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

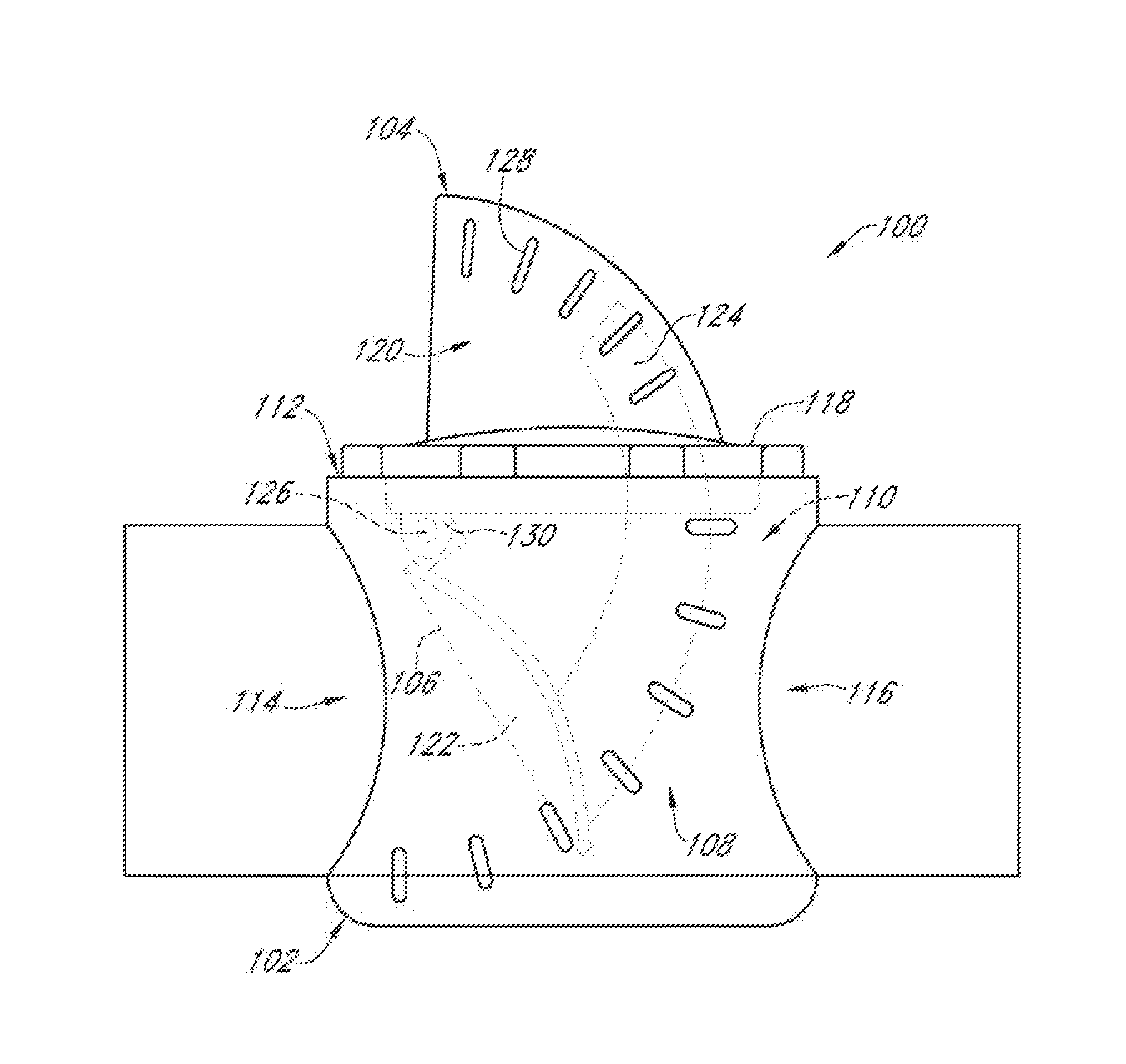

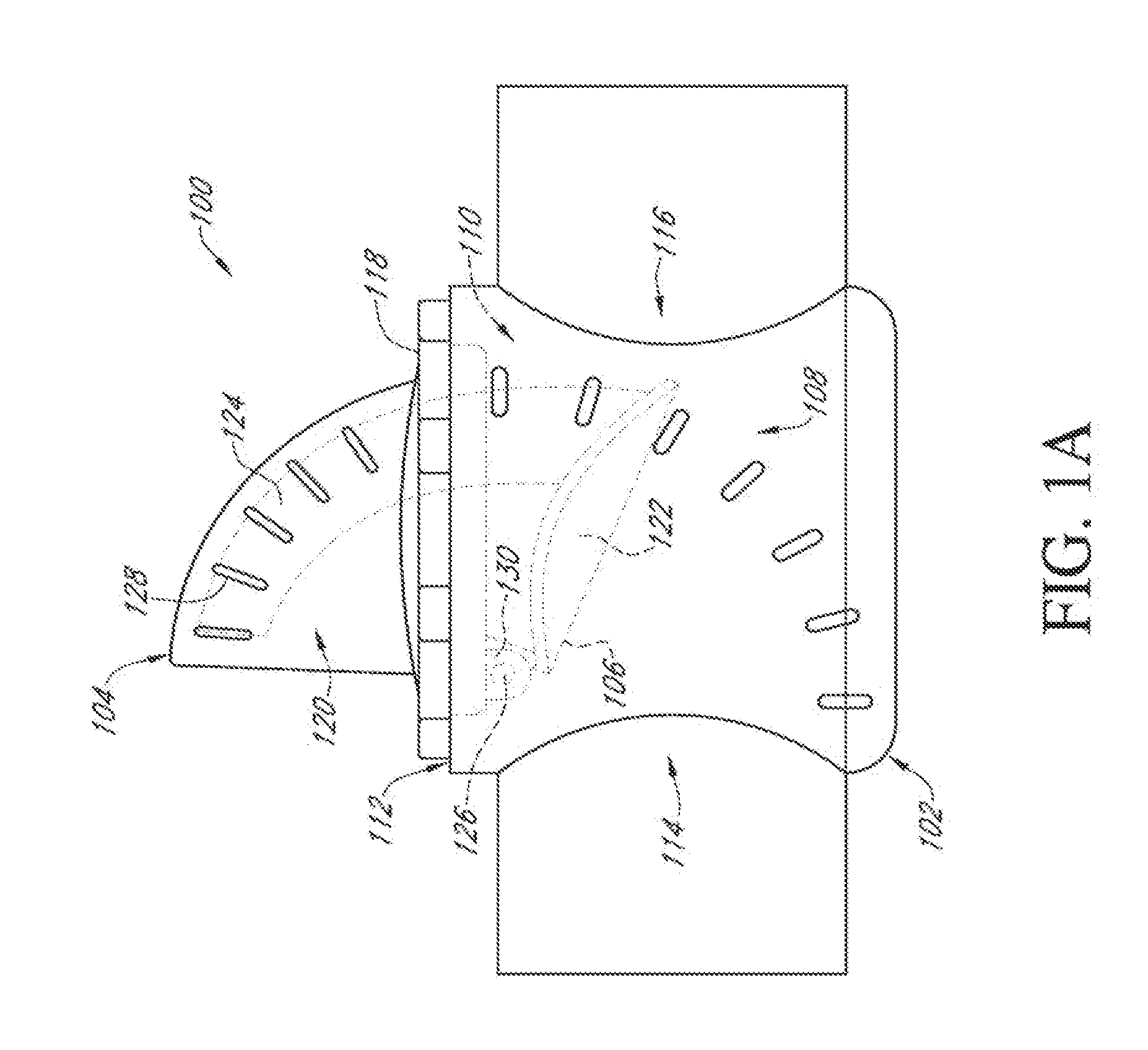

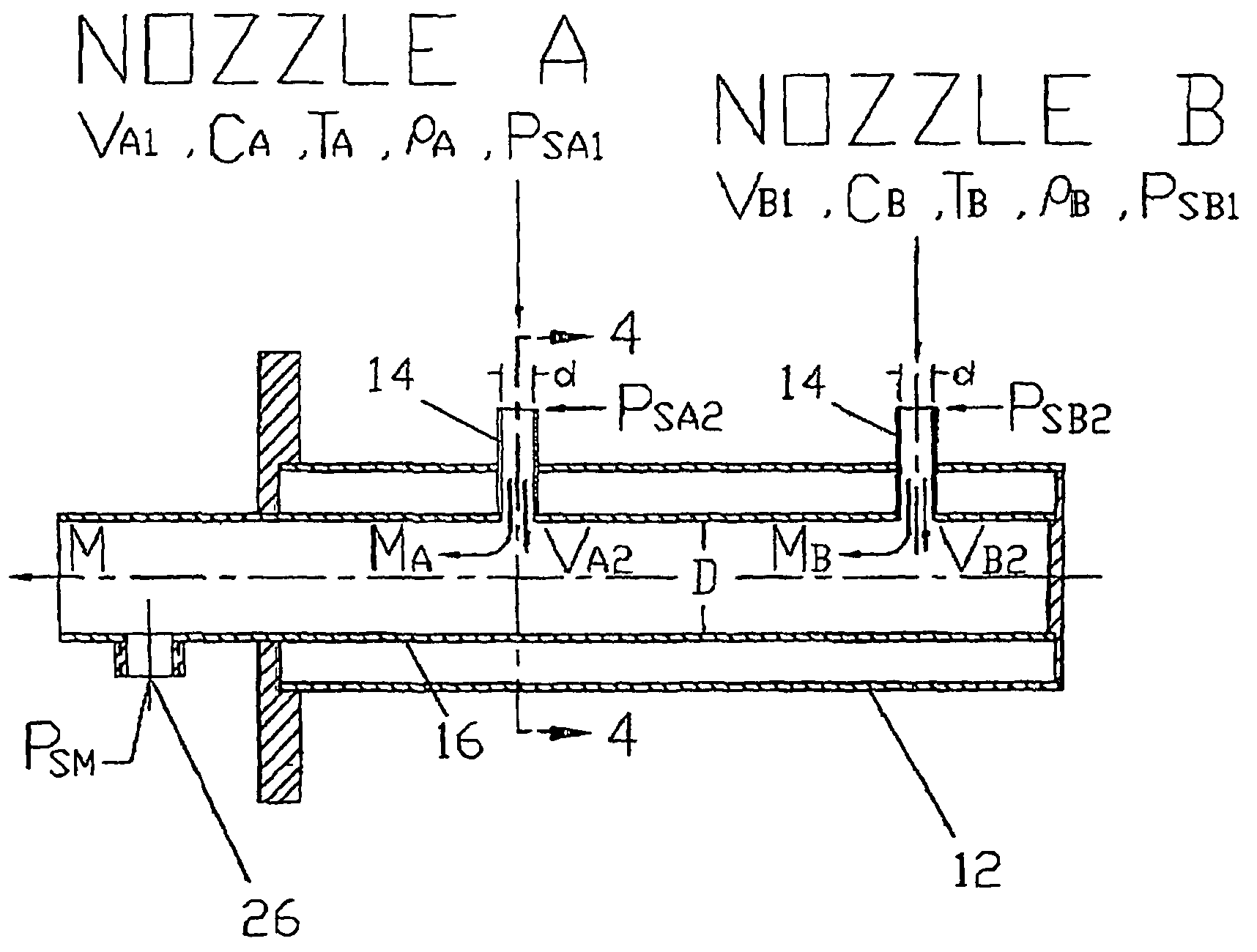

Impact excavation system and method

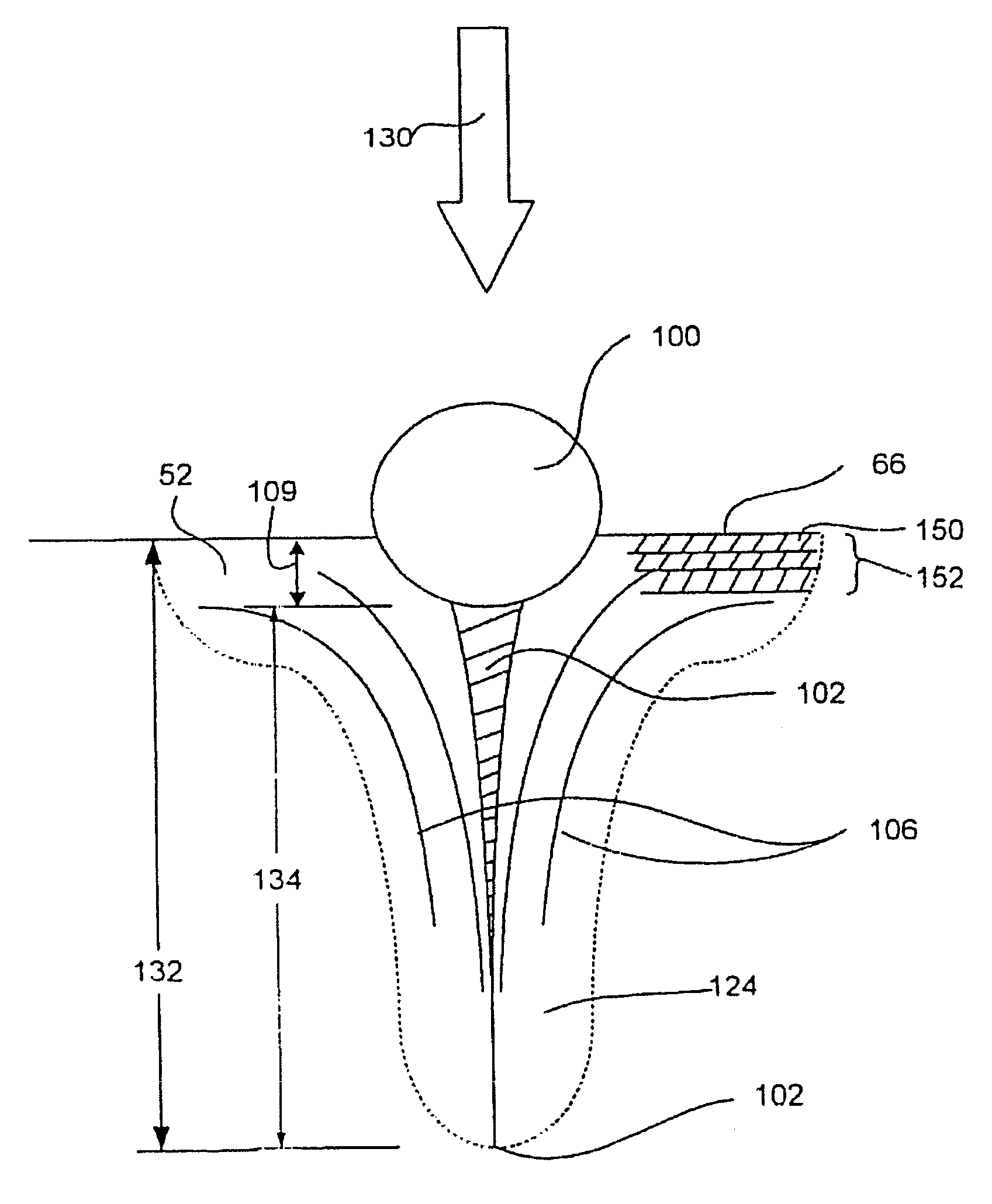

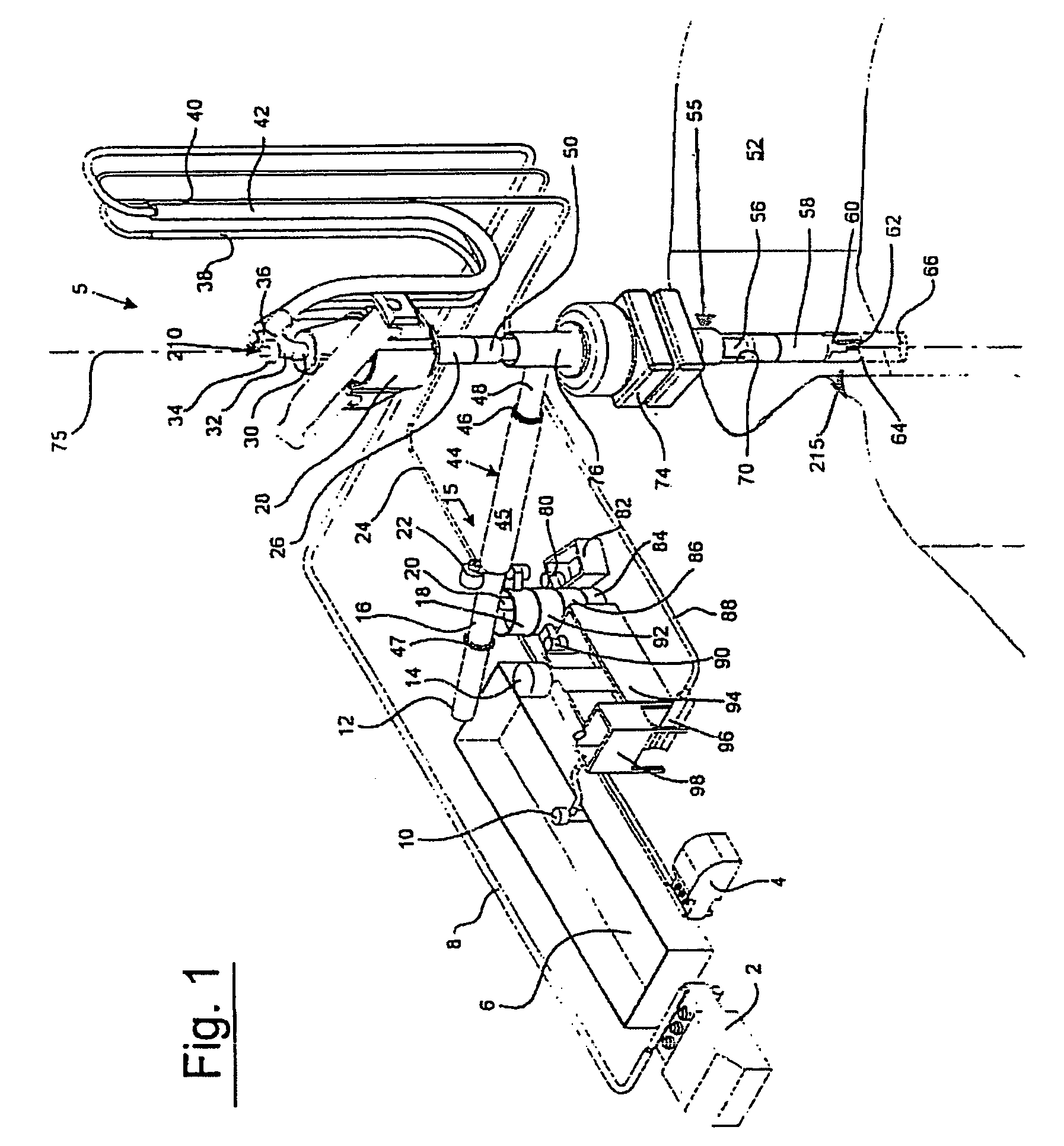

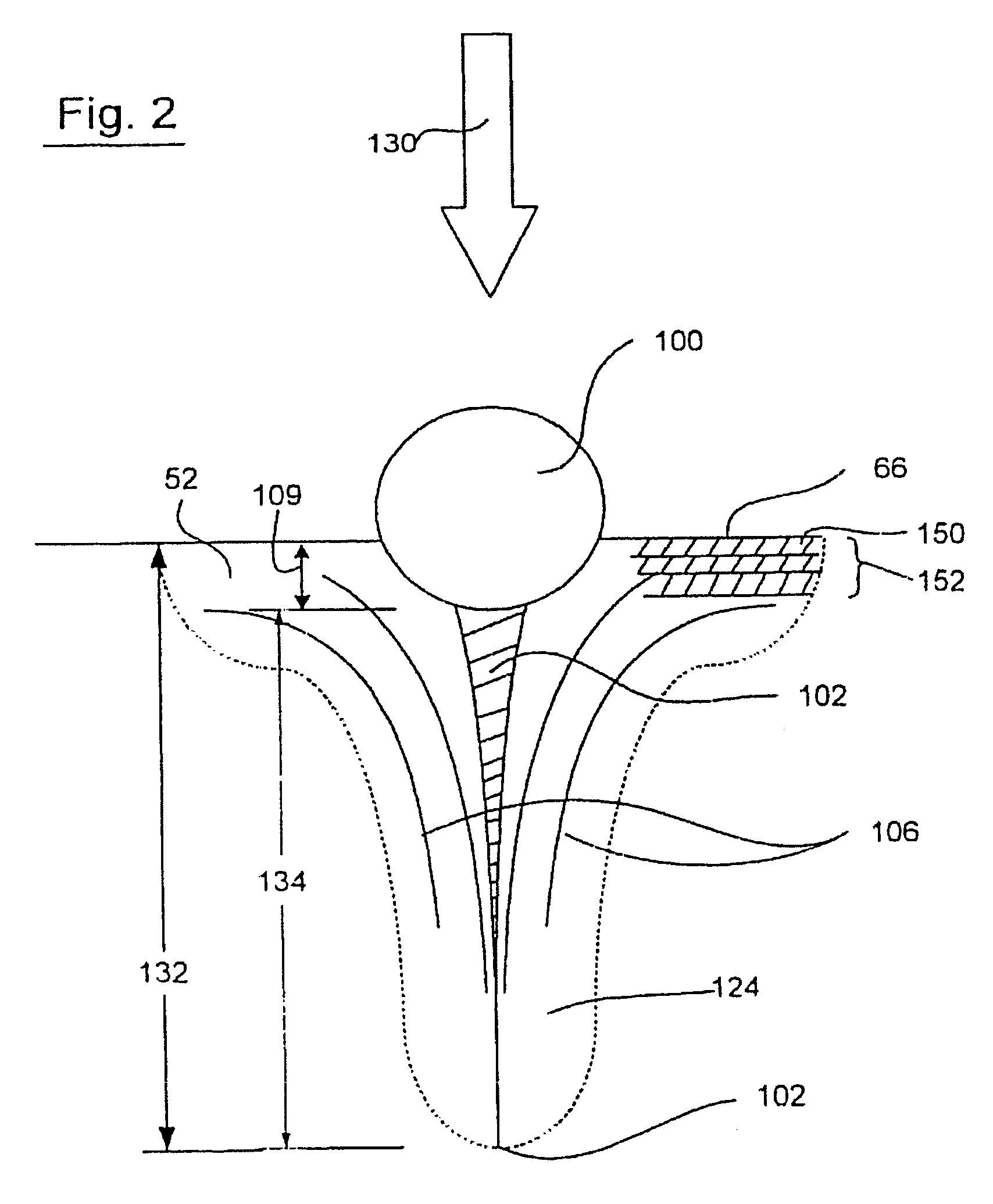

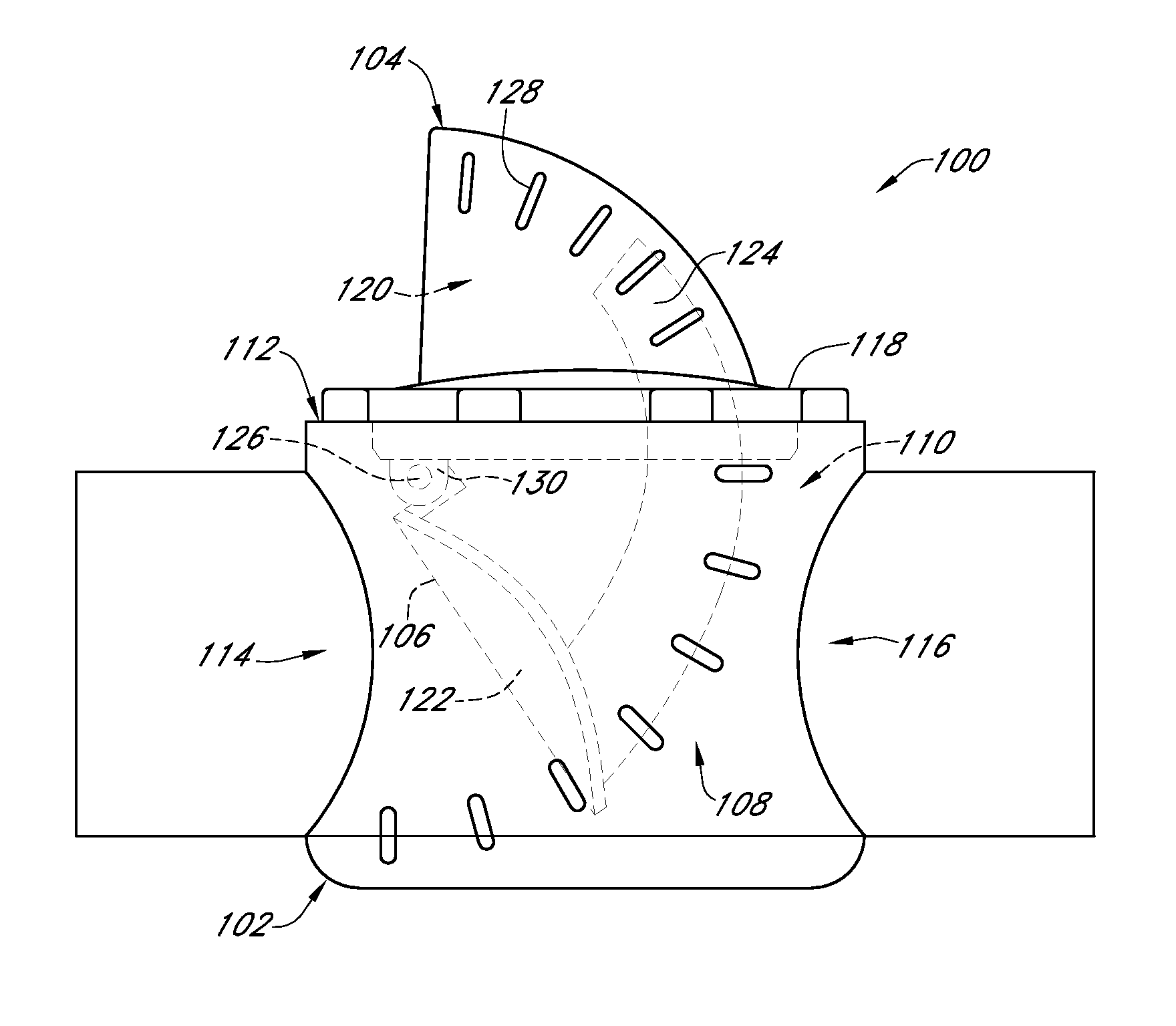

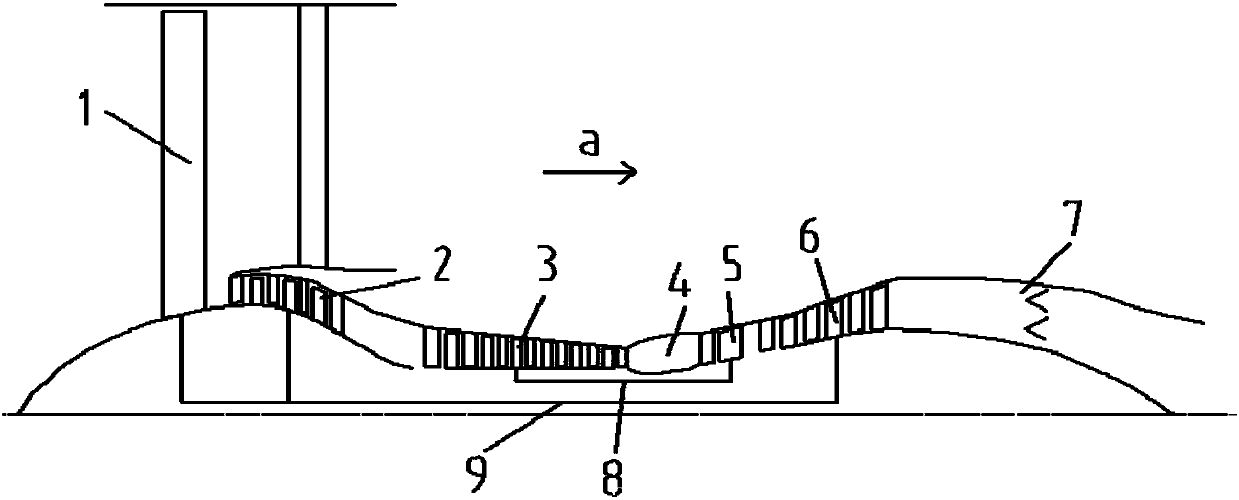

A method and system for excavating a subterranean formation using a fluid comprising pumping the fluid through at least one nozzle such that a velocity of the fluid when exiting the nozzle is greater than a velocity of the fluid entering the nozzle. A plurality of solid material impactors are introduced into the fluid and circulated with the fluid through the nozzle. A substantial portion by weight of the solid material impactors has a mean diameter of equal to or less than approximately 0.100 inches. The fluid is pumped at a pressure level and a flow rate level sufficient to satisfy an impactor mass-velocity relationship wherein a substantial portion by weight of the solid material impactors has a minimum kinetic energy of approximately 0.075 Ft Lbs when exiting the nozzle. The substantial portion by weight of solid material impactors exit the nozzle and contact the formation.

Owner:PDTI HLDG

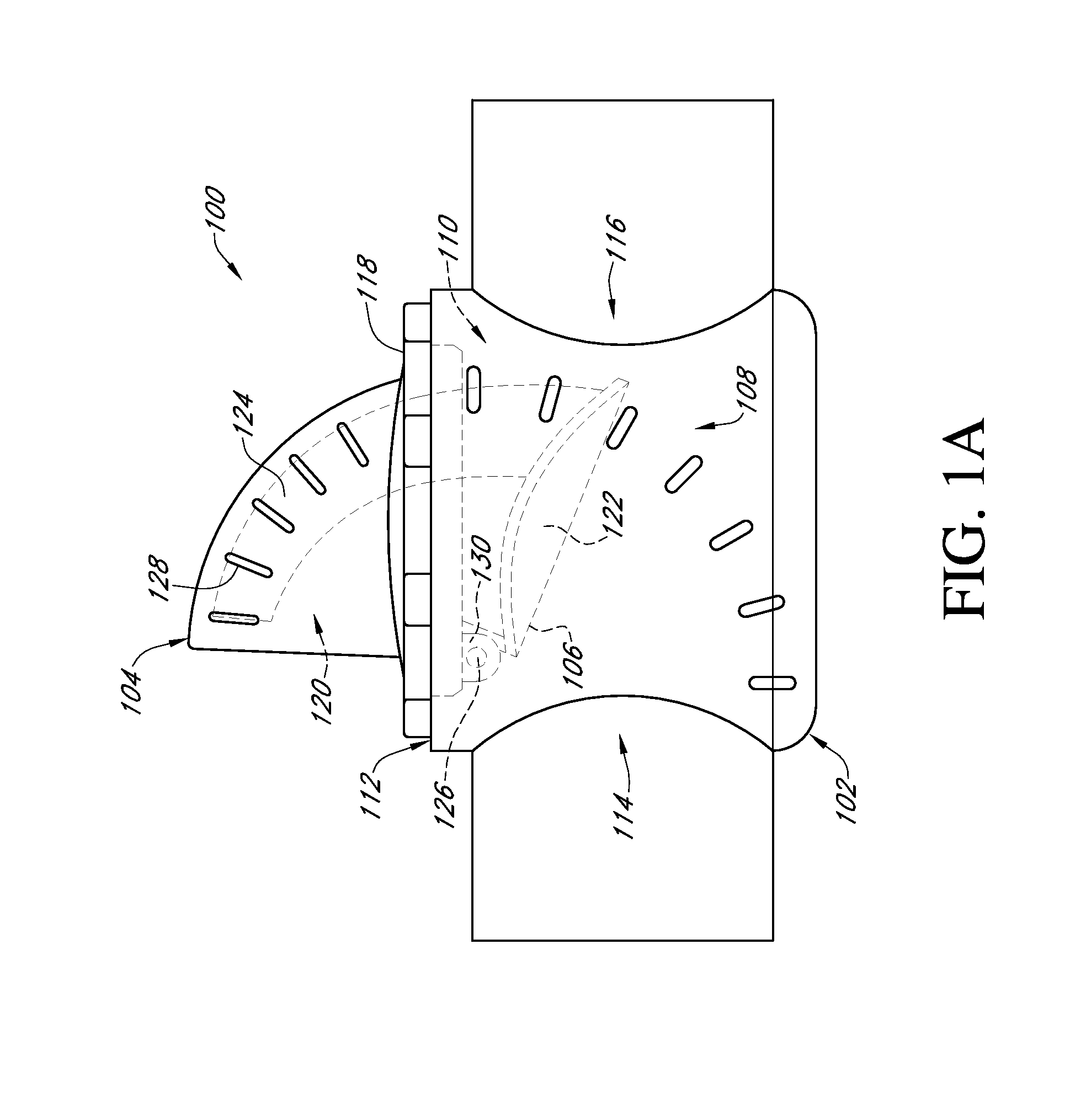

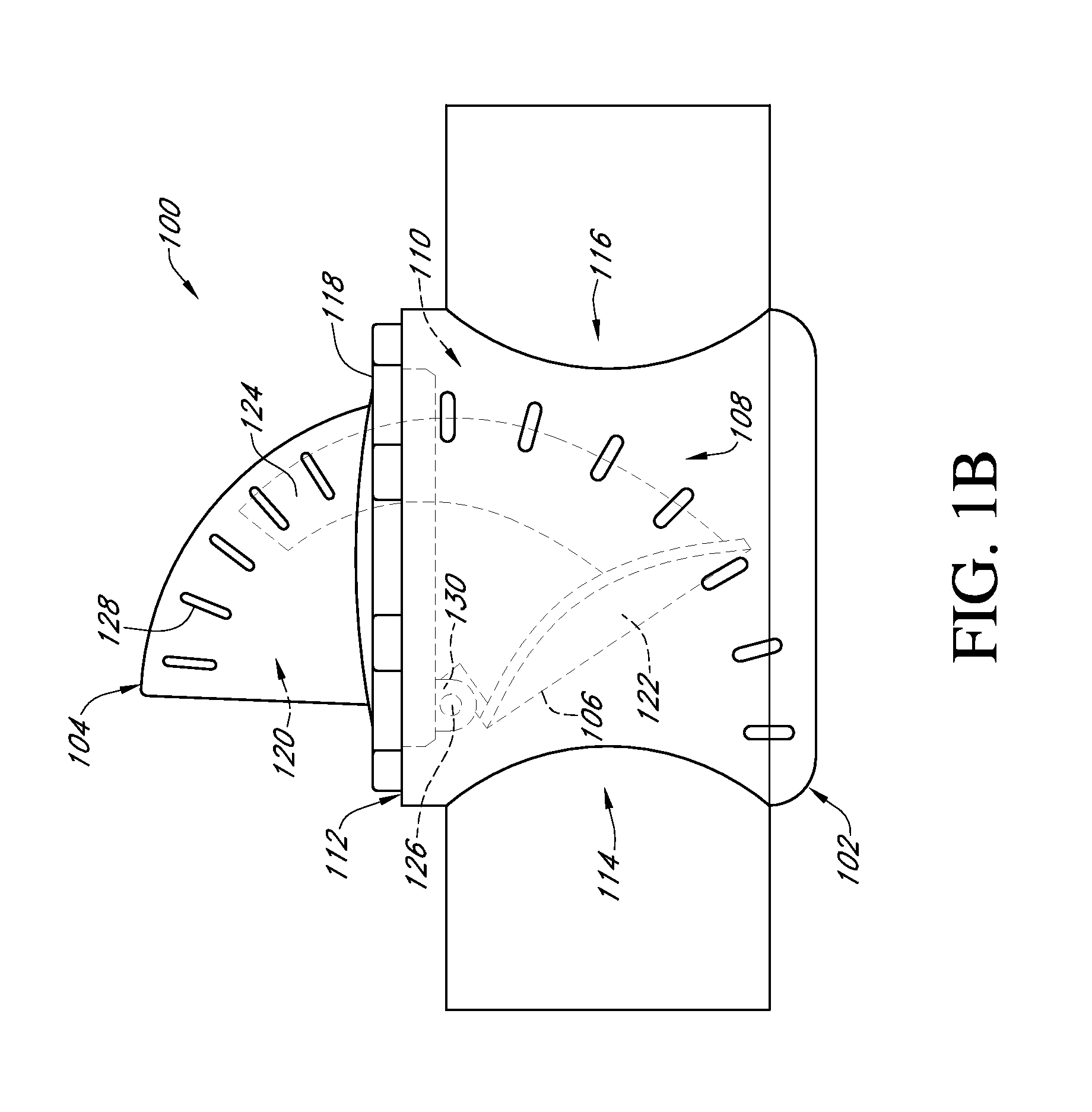

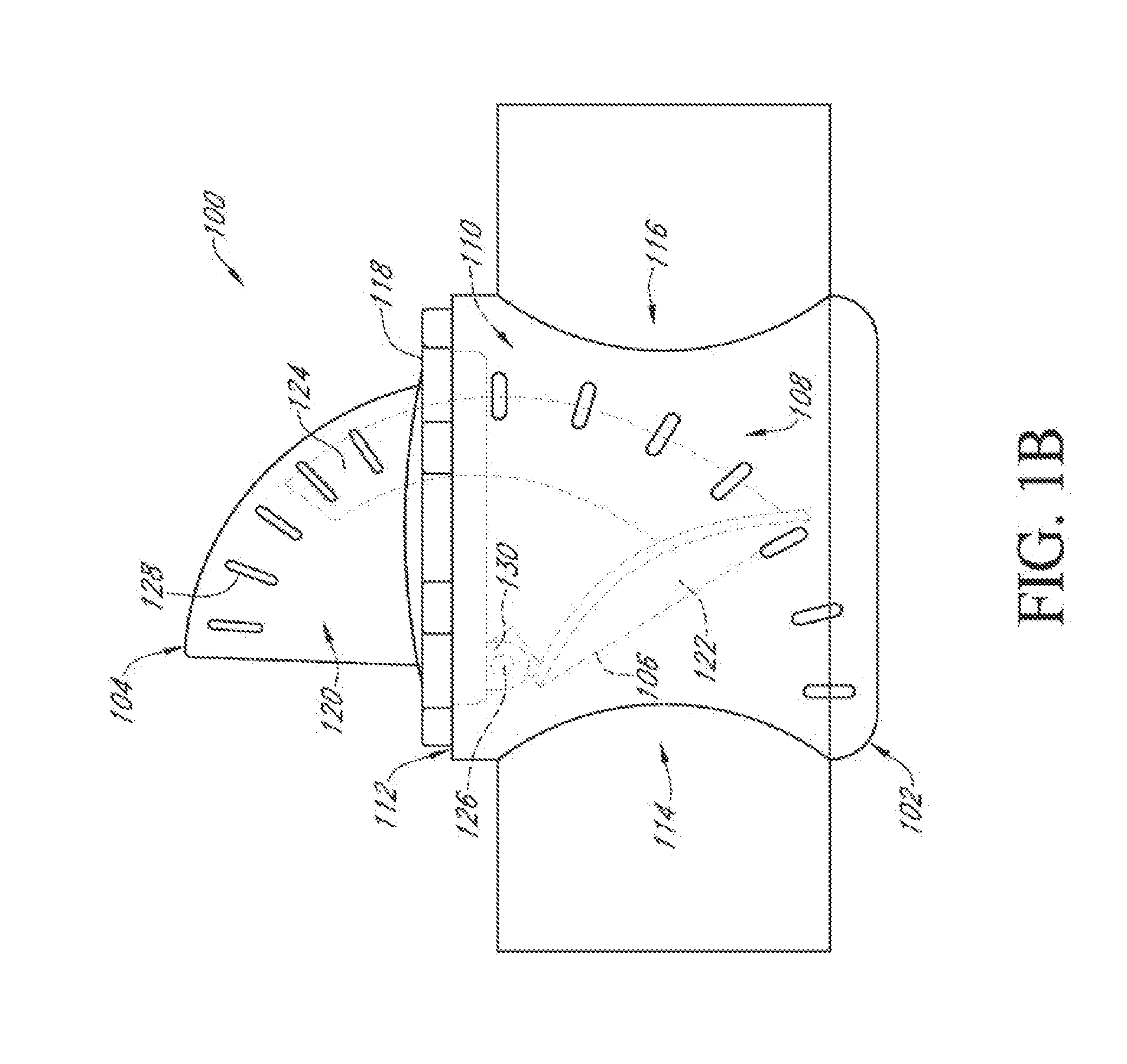

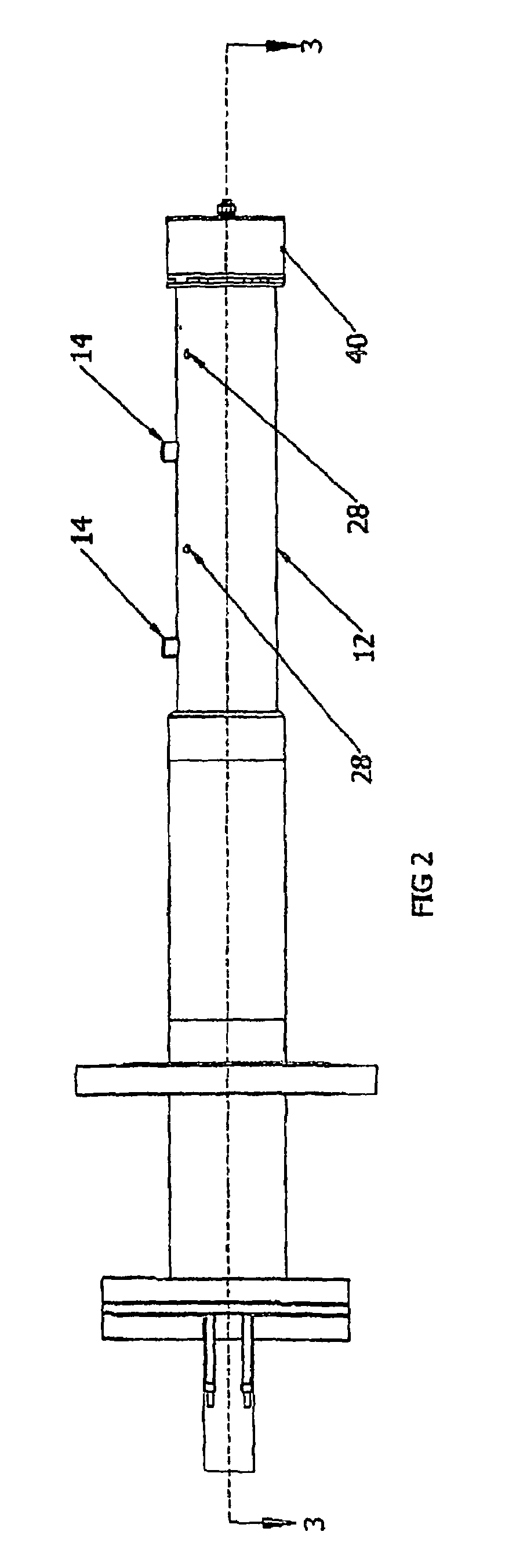

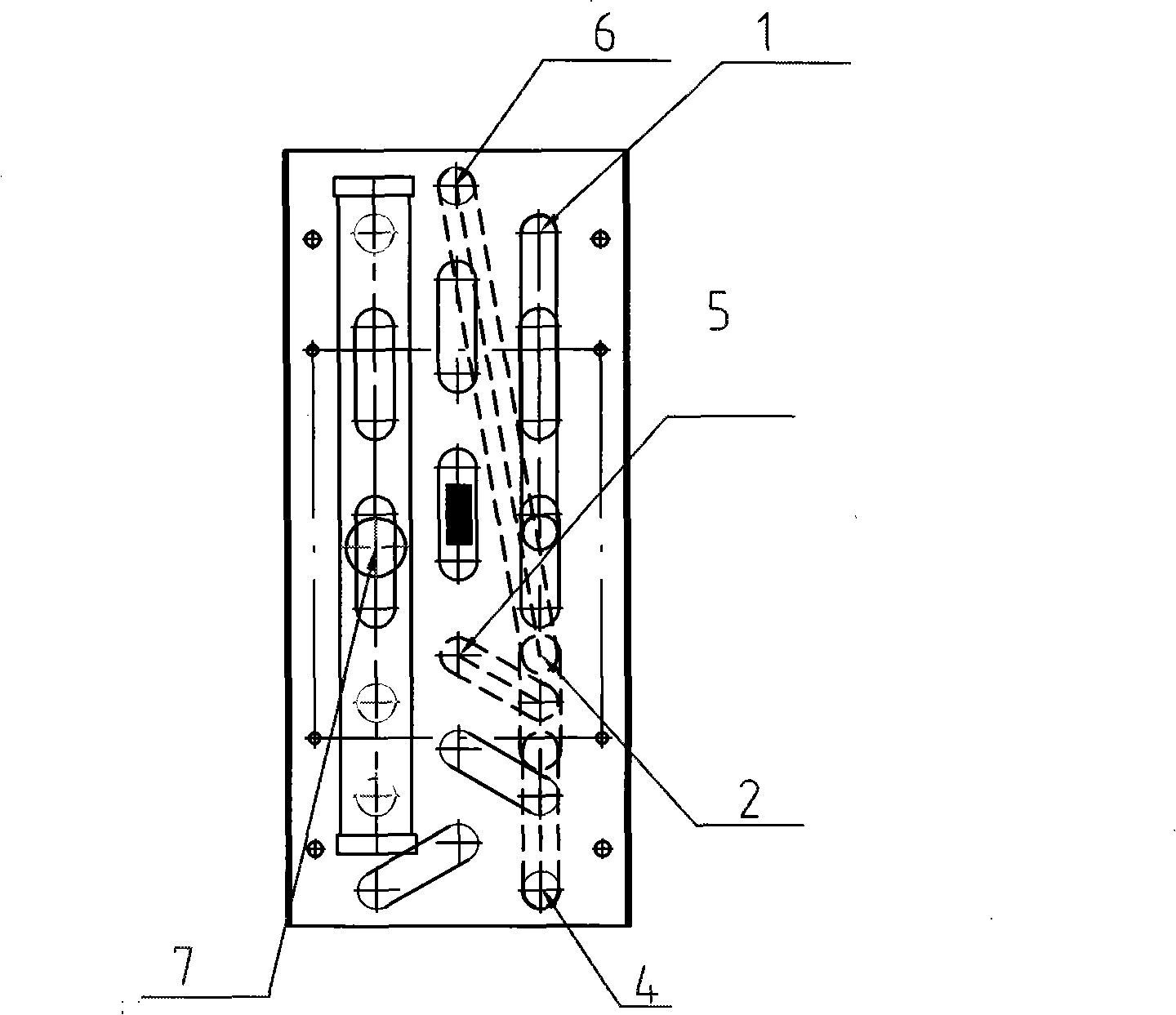

Mass velocity sensor device and method for remote monitoring and visual verification of fluid velocity

ActiveUS8800473B1Easy to adjustEasy maintenanceIndication/recording movementSpeed/acceleration/shock instrument detailsMass velocityEngineering

A wireless multi-range, mass velocity sensor assembly for remote monitoring with direct on-site visual validation of mass velocity is provided. In certain implementations, the sensor assembly comprises a channel body fixture, an obstruction mounted within an aperture formed in the inlet or outlet of the channel body fixture, and an arcuate indicator that protrudes above the fluid flow path and provides clear visual readout of the flow velocity. In some implementations, the sensor assembly can be easily adapted for existing back check valve and other back flow prevention devices.

Owner:DEVERSE RICHARD +1

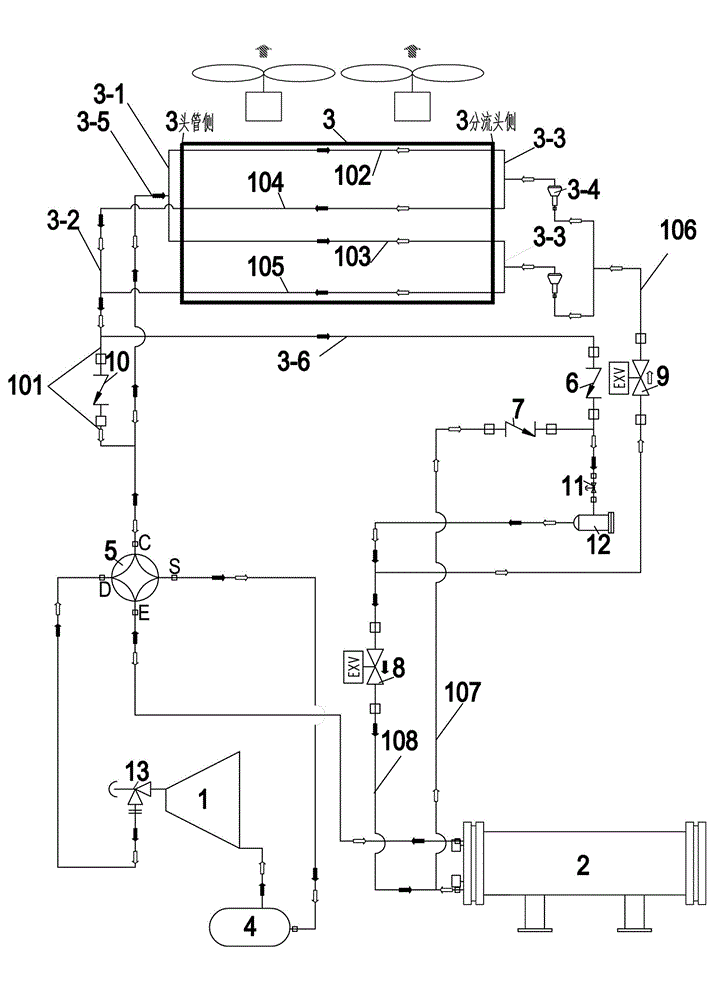

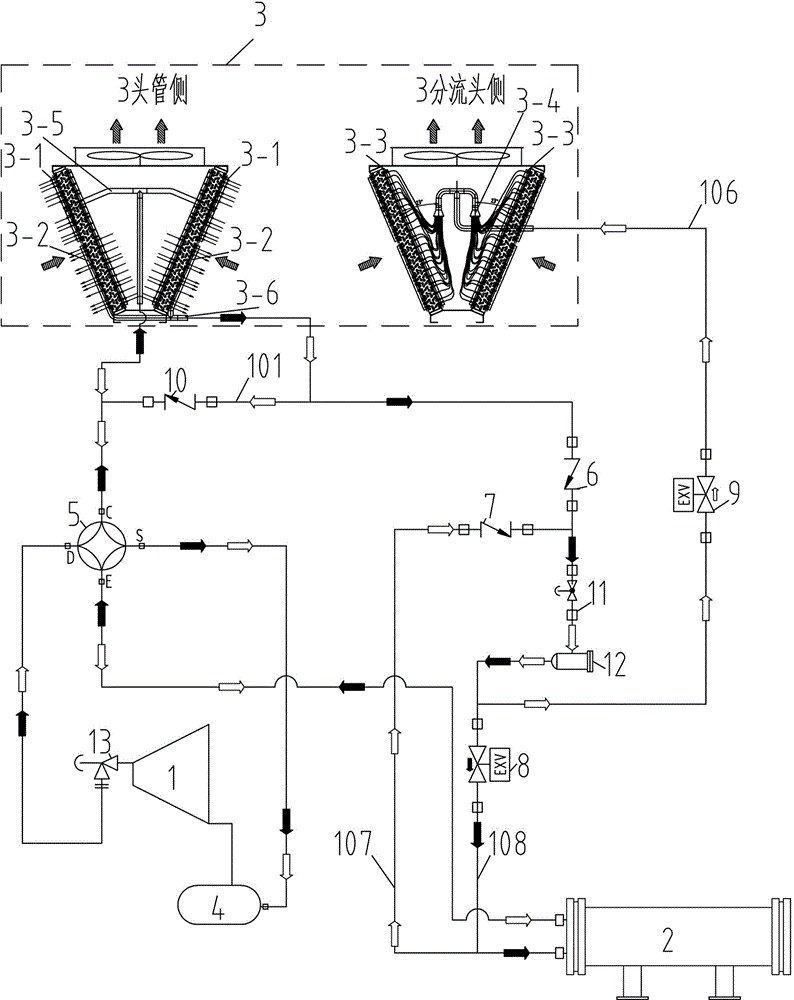

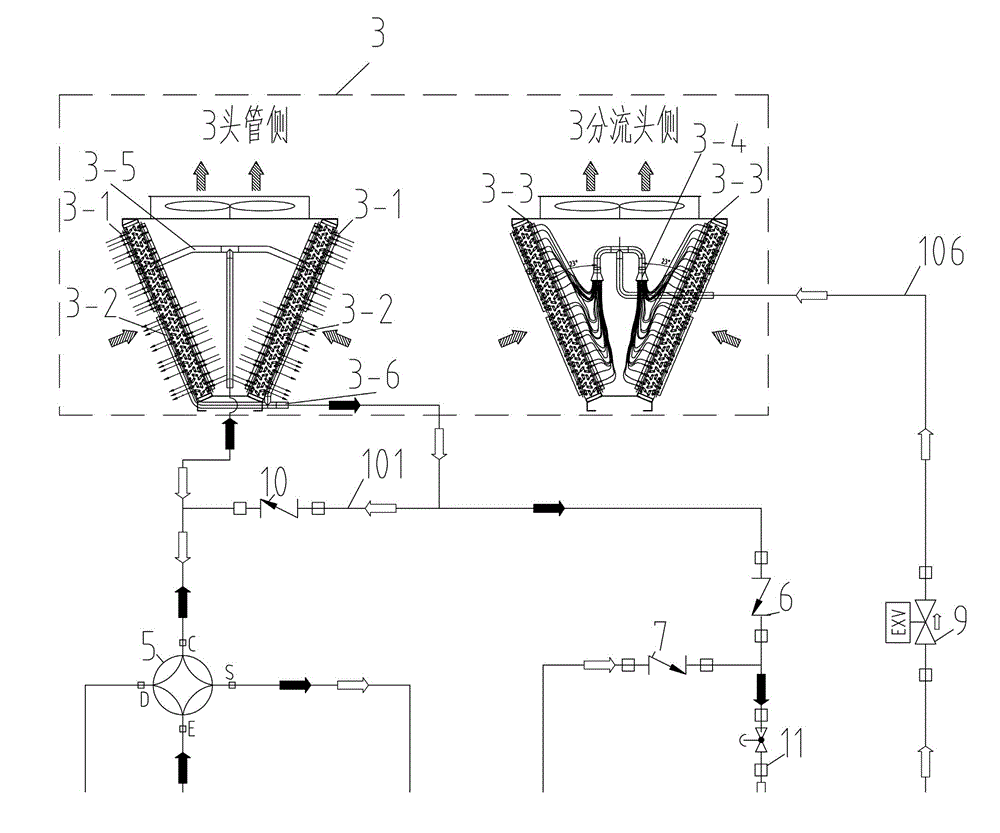

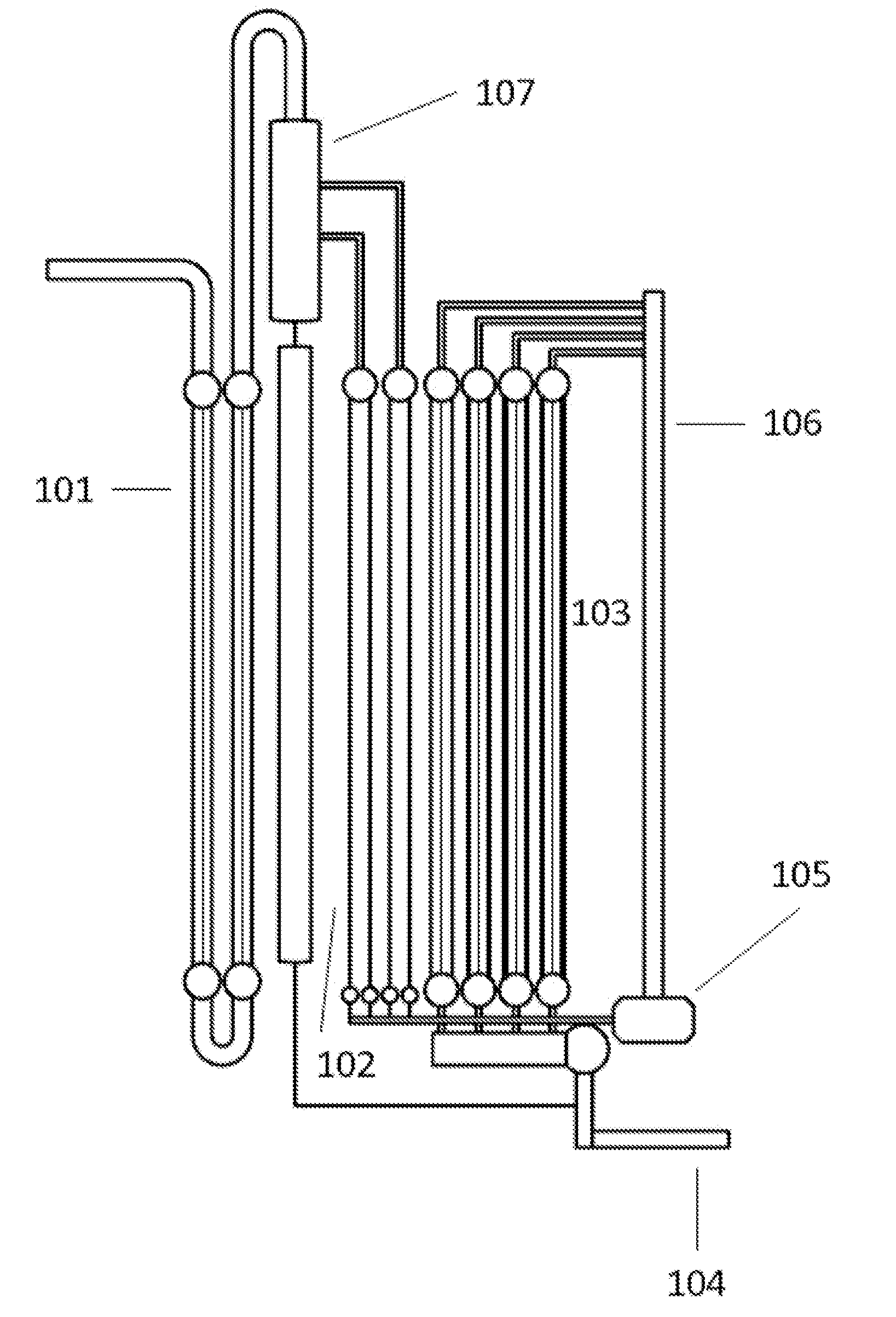

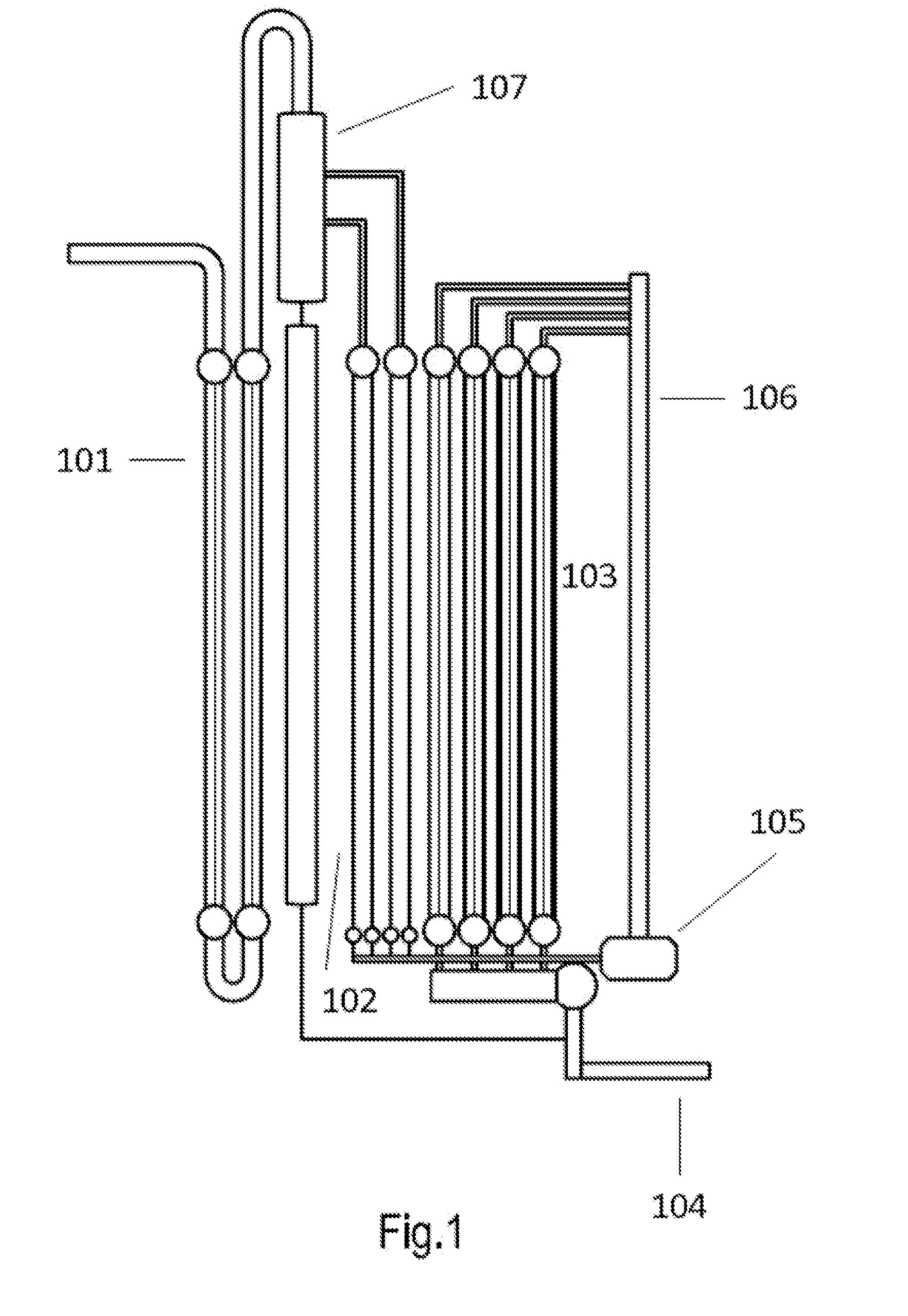

Air-cooled heat pump circulating system and heating and refrigerating methods thereof

InactiveCN102914077ACountercurrent design holdImprove performanceEvaporators/condensersFluid circulation arrangementVapor–liquid separatorShell and tube heat exchanger

The invention provides an air-cooled heat pump circulating system and relates to heat exchangers of refrigeration systems. Air-cooled finned tube heat exchangers serve as the air-cooled heat pump circulating systems of both a condenser and an evaporator. The air-cooled heat pump circulating system comprises a shell-and-tube heat exchanger, an air-cooled finned tube heat exchanger, a compressor, a gas-liquid separator, a four-way reversing valve, a refrigeration non-return valve, a heating non-return valve, a refrigeration expansion valve, a heating expansion valve, a heating inspiration non-return valve, an exhaust corner valve, a liquid path stop valve and a liquid path drying filter, wherein the air-cooled finned tube heat exchanger is provided with a condenser gas header / evaporator gas return header, a condenser collector tube / evaporator gas return header, a condenser secondary distribution collector tube / evaporator liquid distribution header, a shunt head and shunt tube, a condenser exhaust head tube / evaporator gas return head tube and a condenser liquid phase tube. The air-cooled heat pump circulating system comprises two circulation processes of heating and refrigeration. In the two processes, the air-cooled finned tube heat exchanger has different single-circuit heat exchange tube lengths, circuit quantities and in-tube refrigerant mass velocities, and meanwhile, the heat transmission efficiency is optimized.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

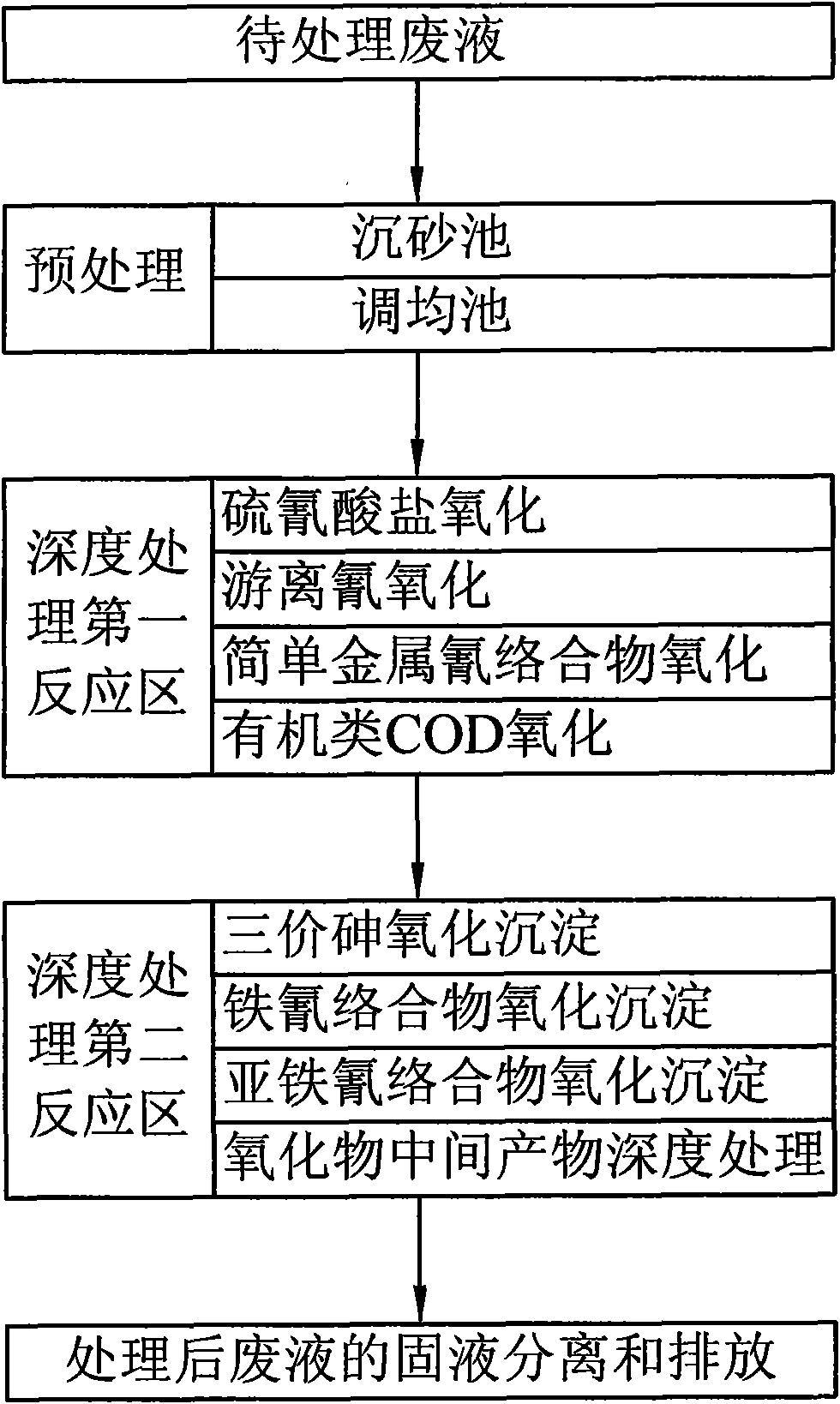

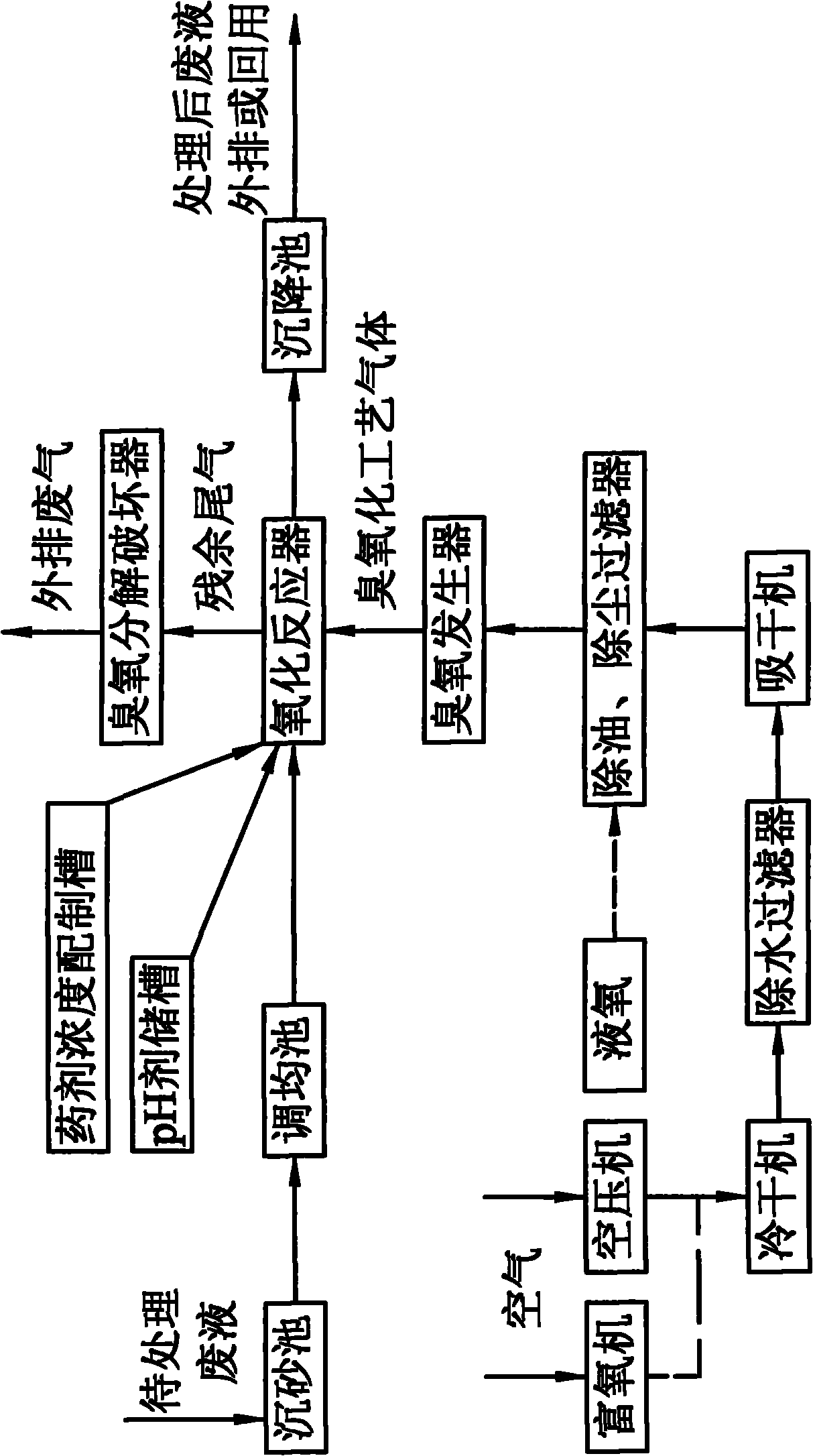

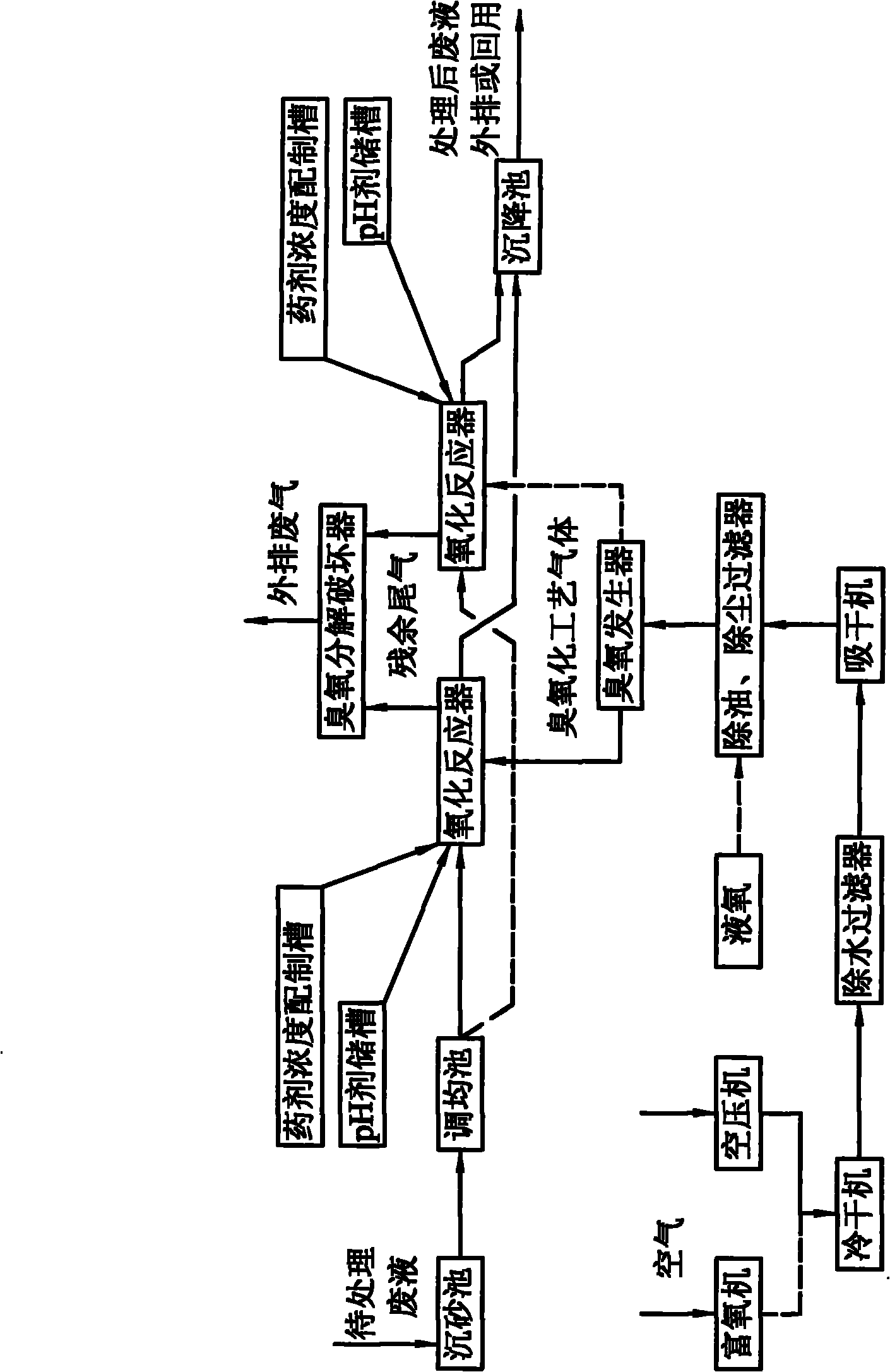

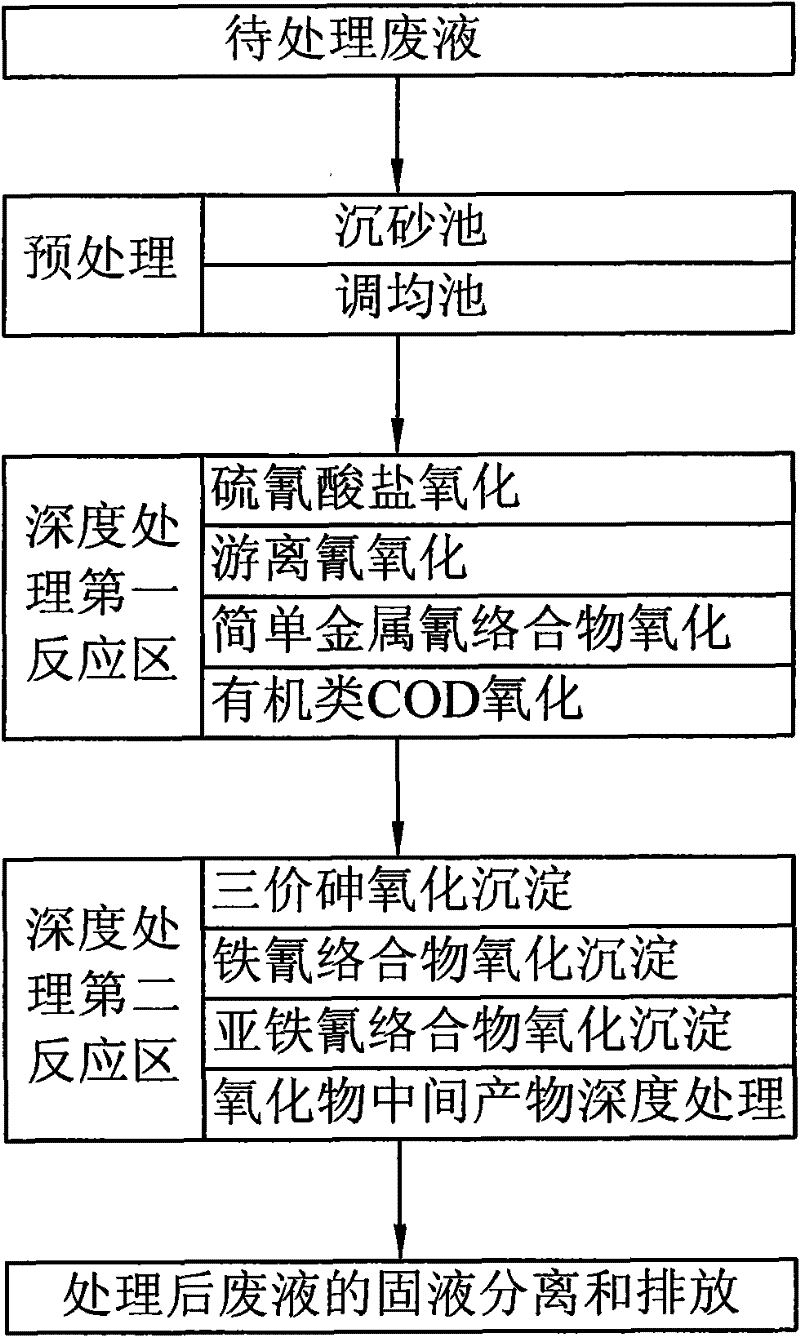

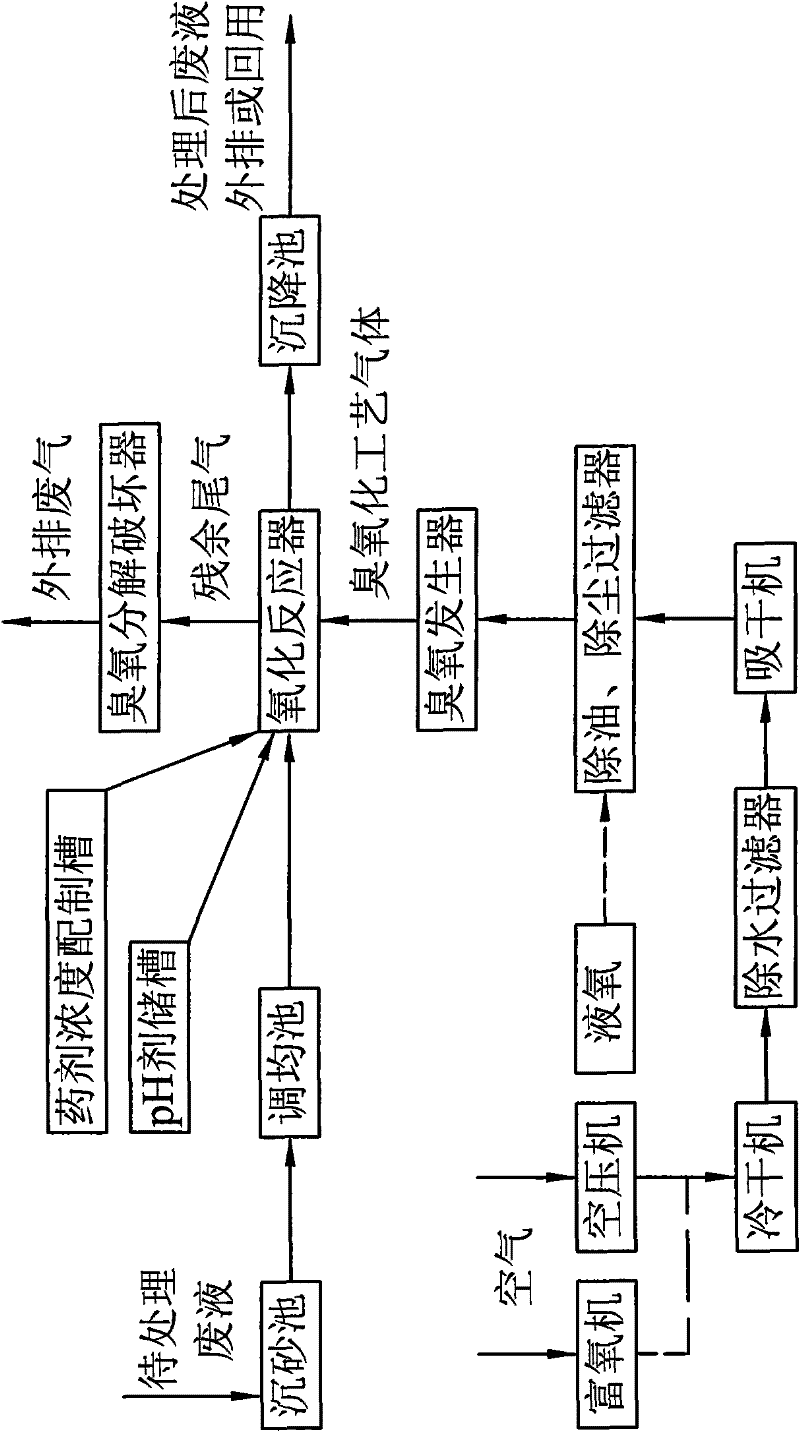

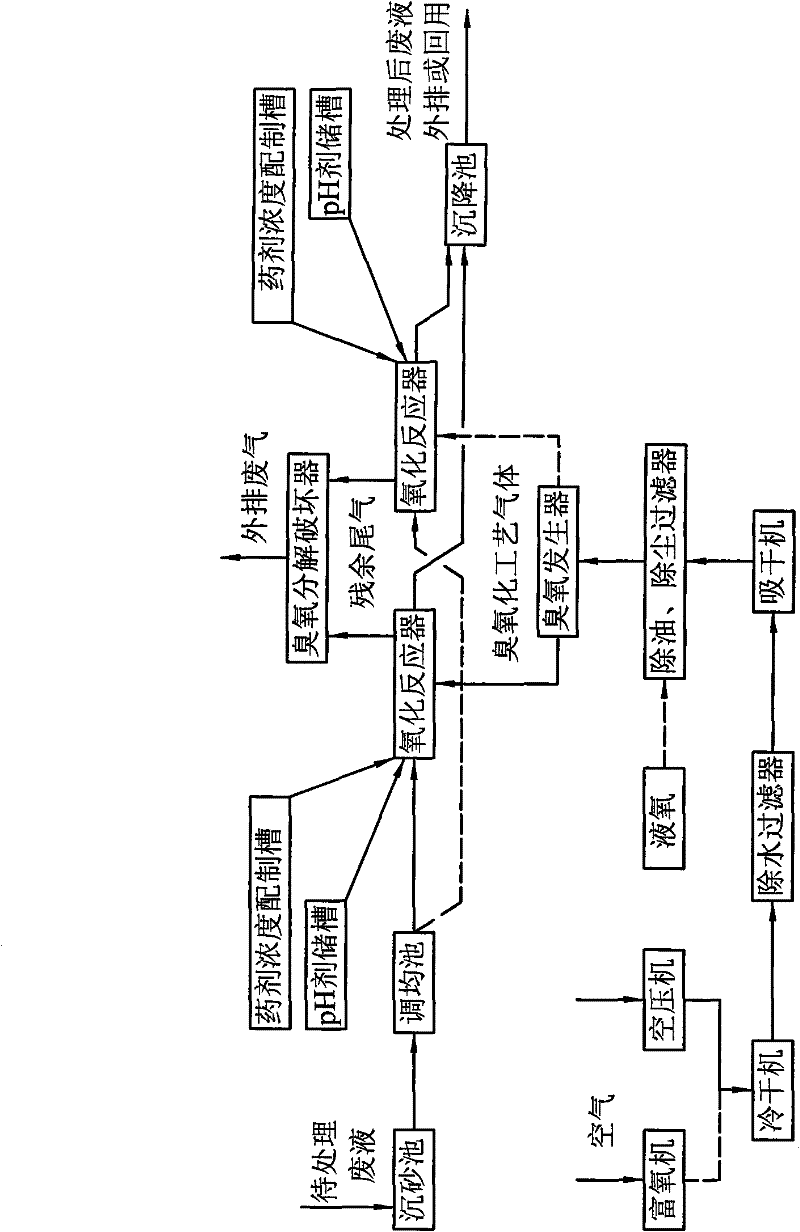

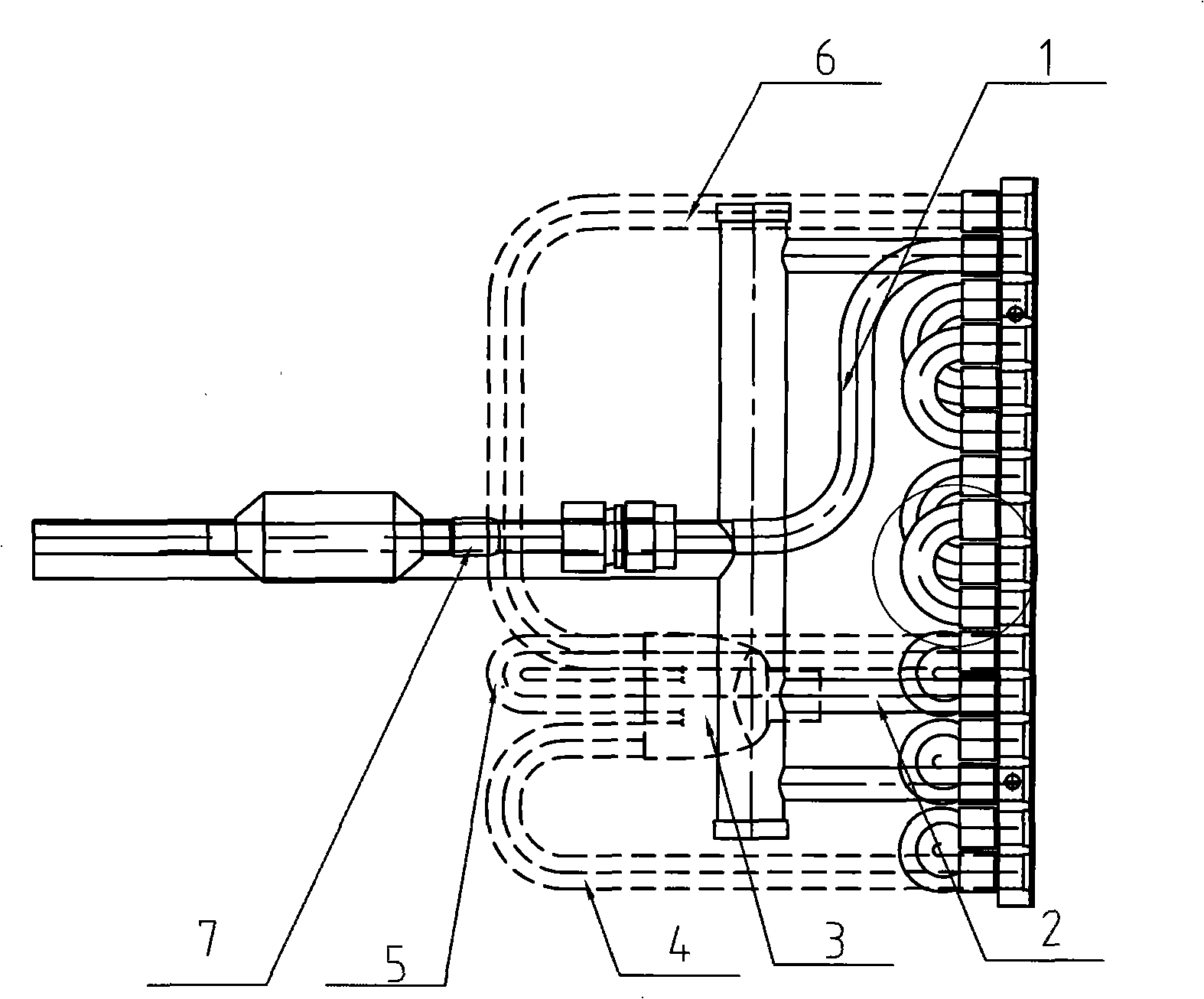

Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

ActiveCN102070264ALow costReduce complexityWater contaminantsMultistage water/sewage treatmentLiquid wasteThiocyanate

The invention discloses a method for removing cyanide, thiocyanate, COD and arsenic in waste liquid, comprising the following steps: the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid are deeply treated by utilizing ozonized gas, a mode with continuous treatment and direct discharge can be adopted, also a mode with batch treatment and intermittent discharge can be adopted, and the implementation process of the method is easy to control; in the range of the pH value with sectioned control, the generation concentration and mass velocity of ozone do not need to be required strictly, the problem that single technology can not treat the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid deeply can be solved, the cost and the operation complexity of technological equipment are reduced, and the environmental pollution is reduced; solid suspensions (SS) in the treated waste liquid is removed by settlement, and clear liquor is directly discharged outwards or returned to the upstream technology for repeated use; the contents of pollutants in the treated waste liquid are stable, the total content of the cyanide is less than 0.2mg / L(waste water); the content of the thiocyanate is less than 5mg / L(waste water); the total content of the COD is less than 30mg / L; the total content of the arsenic is less than 0.5mg / L(waste water), and no secondary pollutants are generated in the reaction process.

Owner:CHANGCHUN GOLD RES INST +1

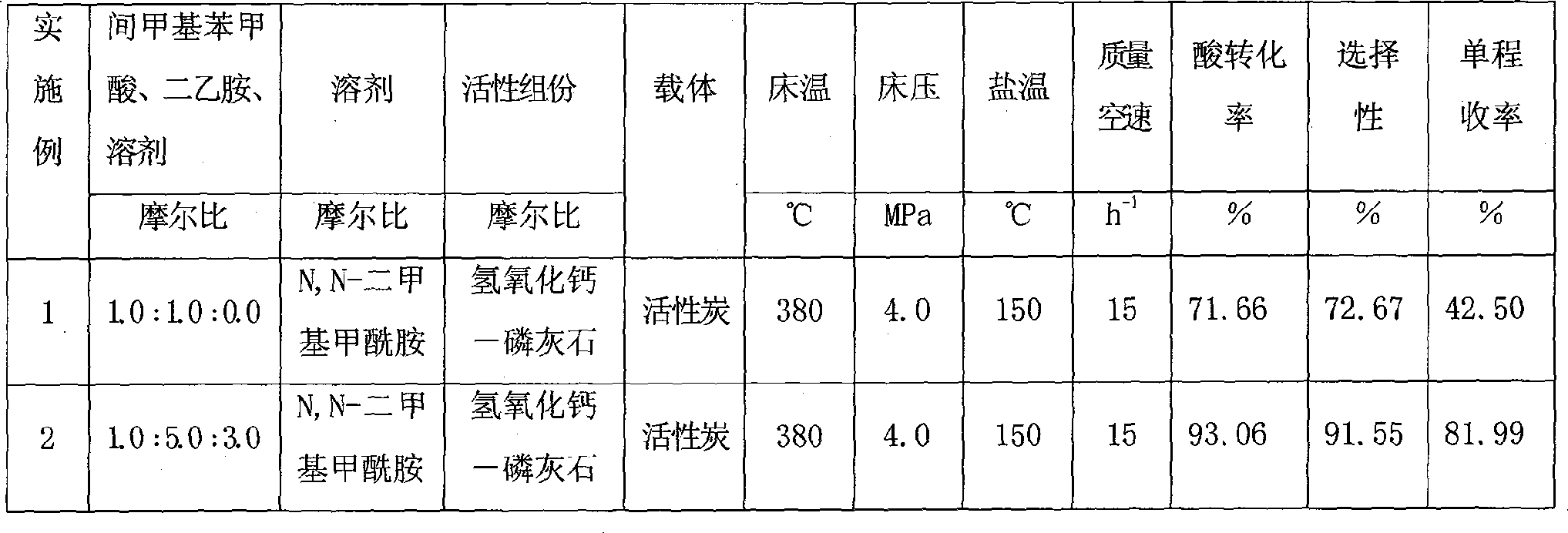

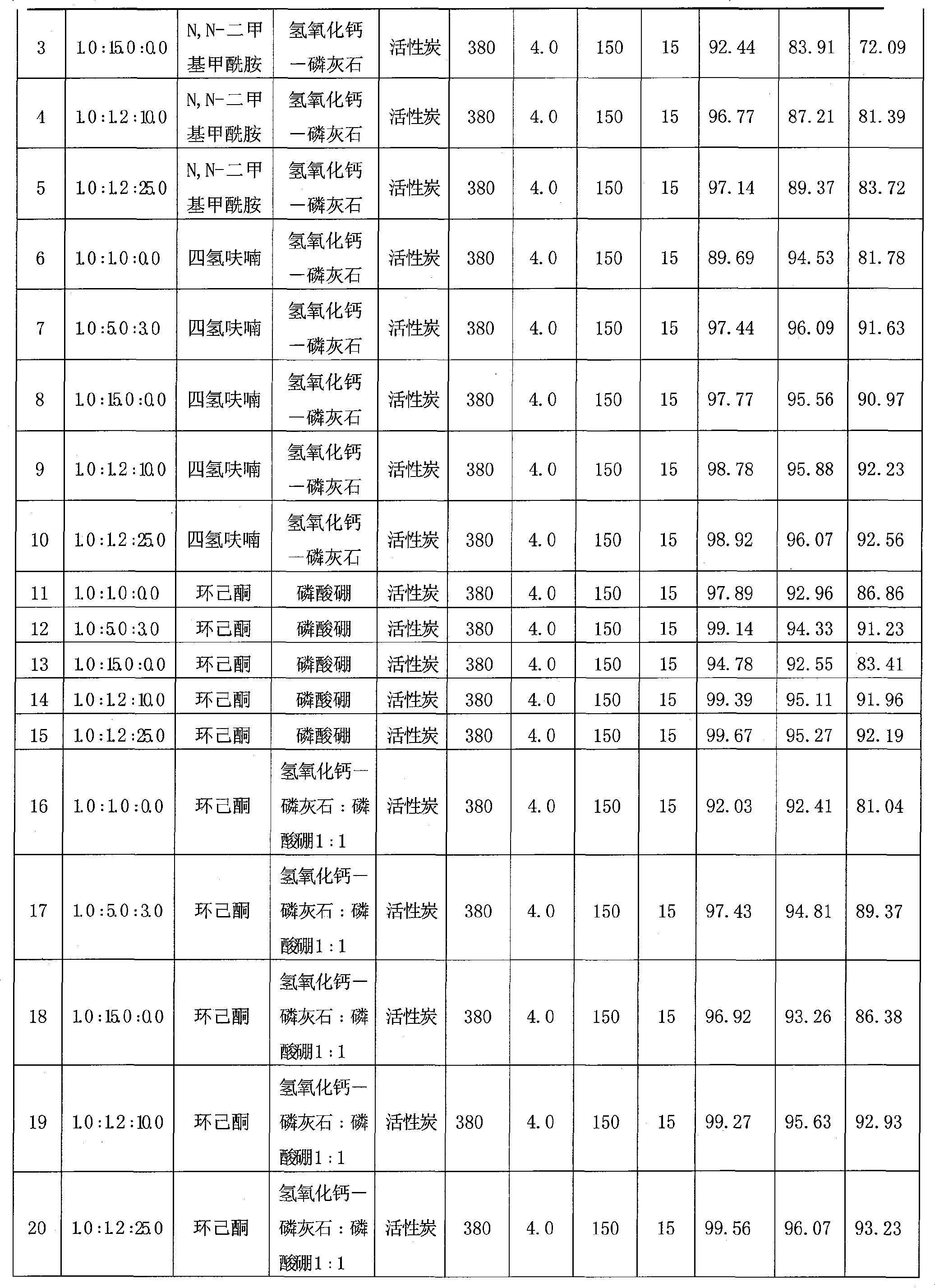

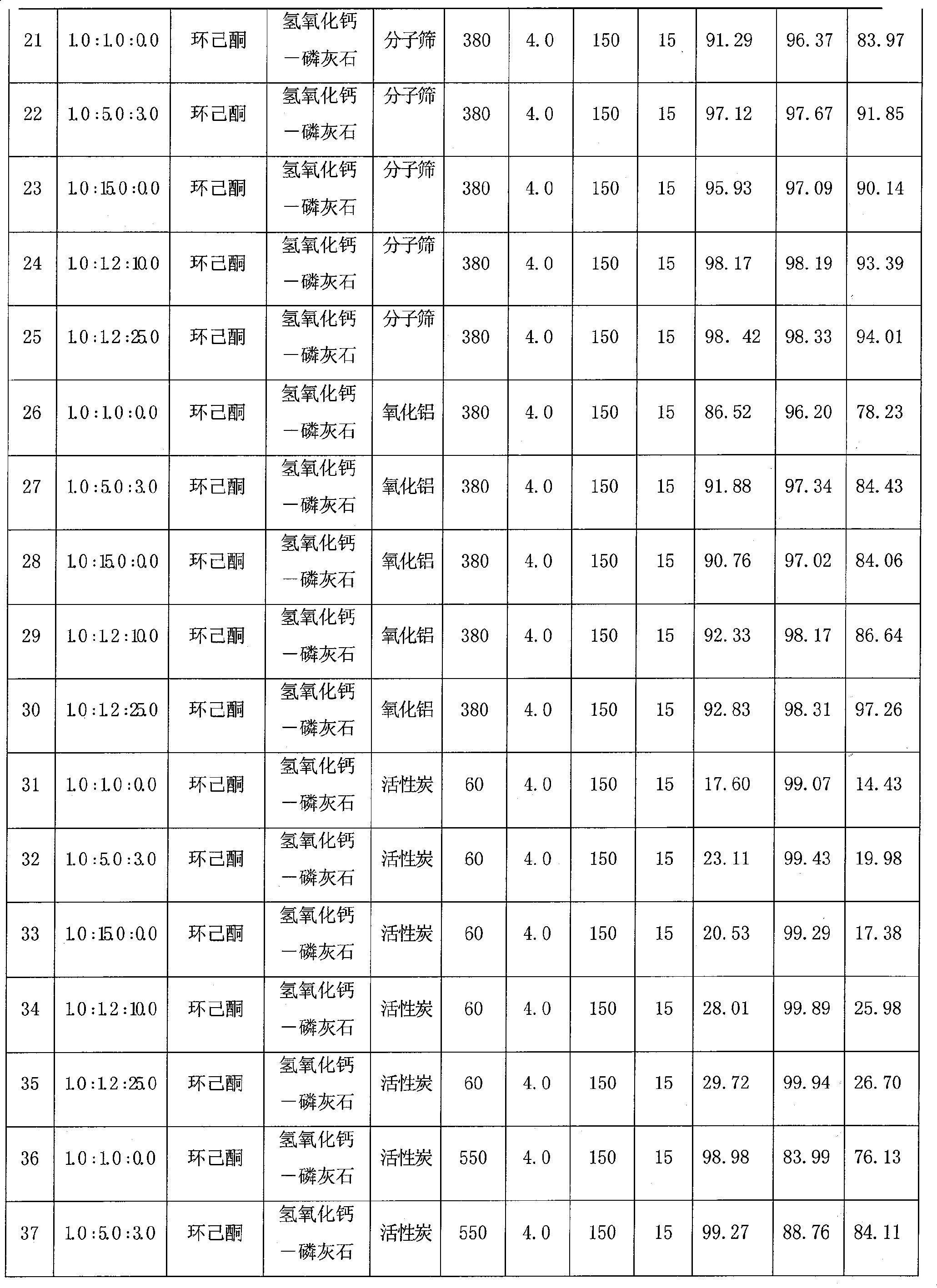

Method for one-step synthesizing N,N-diethyl-m-methyl benzamide in fixed bed

InactiveCN101362707ALow costIncrease profitOrganic compound preparationCarboxylic acid amides preparationRecyclable catalystBenzoic acid

The invention discloses a one-step synthesis method of N, N-diethyl-3-methyl-benzamide with a fixed bed, which comprises the steps that: 3-methyl benzoic acid and diethylamine are stirred under a solvent system for reaction to generate a complex salt compound of the 3-methyl benzoic acid and diethylamine, and then materials are fed to the catalyzing fixed bed continuously under constant temperature and constant pressure, then dehydrated continuously to obtain a crude product; the solvent is recovered by distillation under ordinary pressure; finally the pure product of the N, N-diethyl-3-methyl-benzamide is obtained after rectification under vacuum. The molar ratio of the 3-methyl benzoic acid to the diethylamine to the solvent is 1.0: (1.0-15.0): (0-25.0), the mass velocity is 0.1 h<-1> to 20.0 h<-1>, the reaction temperature of the fixed bed is 60 DEG C to 550 DEG C and the reaction pressure of the fixed bed is 0.1 MPa to 5.0 MPa. The synthesis technology has the advantages of short technological process, high conversion ratio, good selectivity, high yield rate, small amount of waste gas, waste water and waste residues, reproducible and recyclable catalyst and low cost.

Owner:JIANGSU PANOXI CHEM

Mass velocity sensor device and method for remote monitoring and visual verification of fluid velocity

InactiveUS20140345516A1Reduce resolutionEasy to adjustSpeed/acceleration/shock instrument detailsVolume/mass flow by dynamic fluid flow effectBackflow prevention deviceEngineering

Owner:FLUIDICS HAWAII

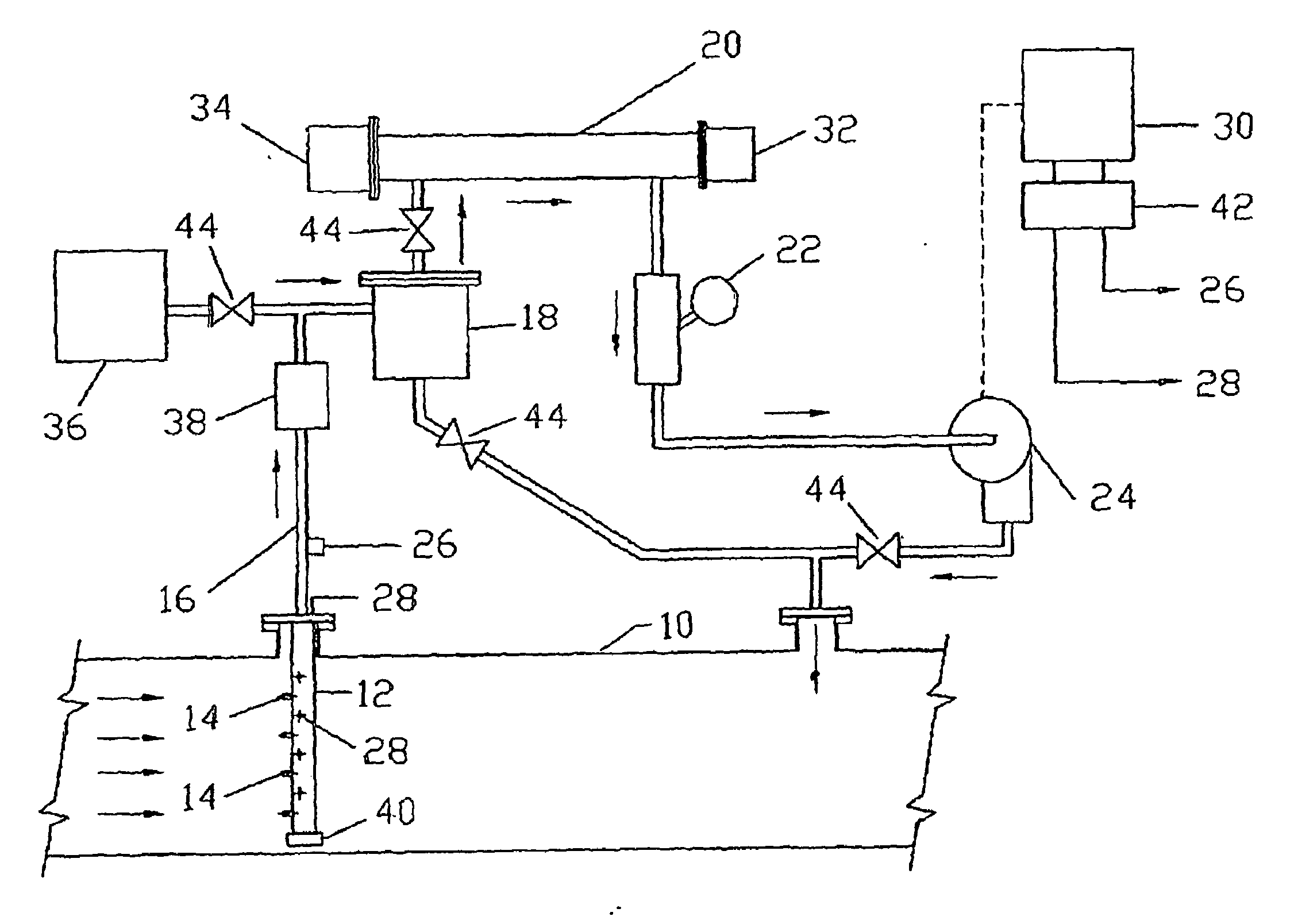

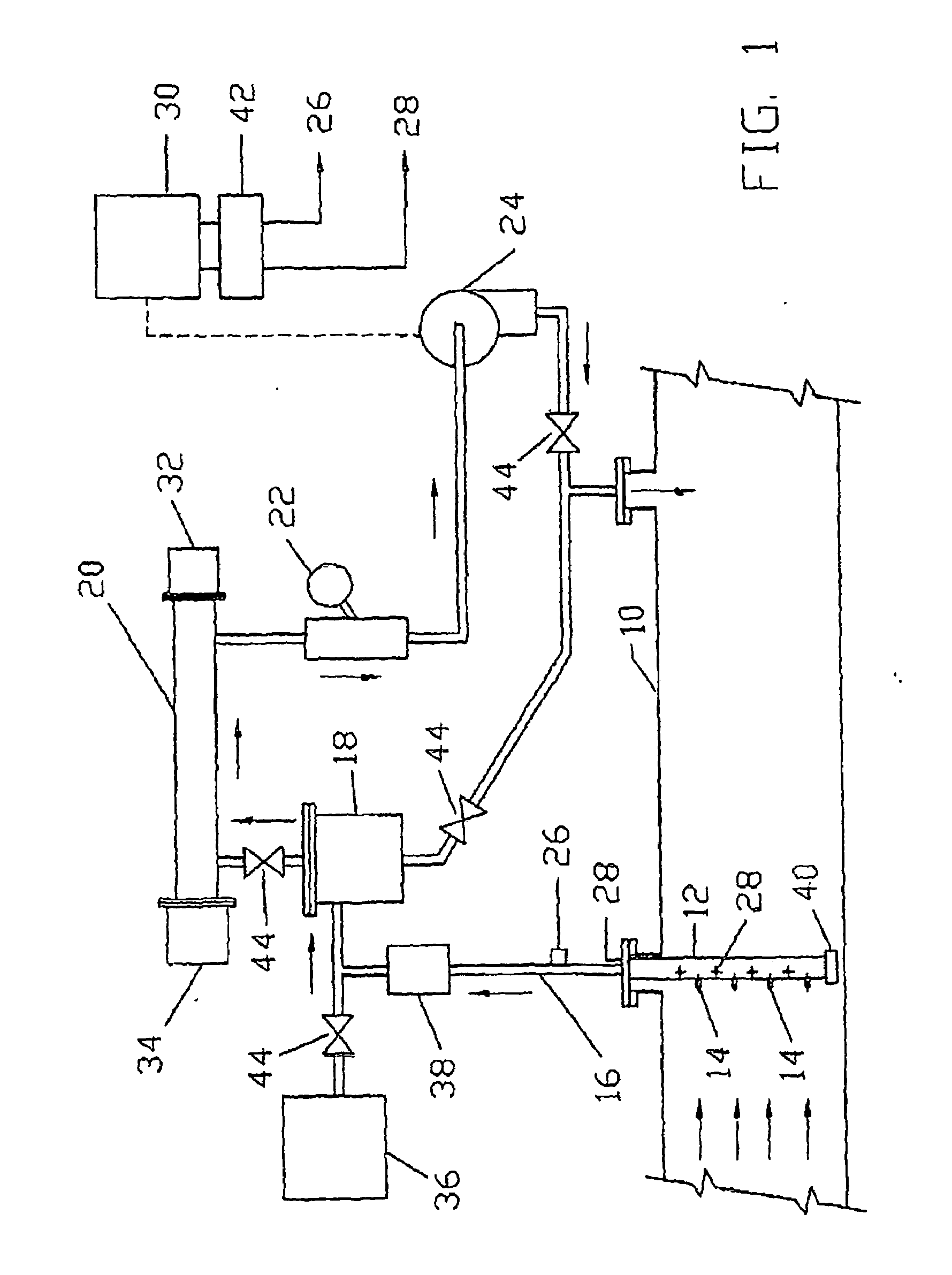

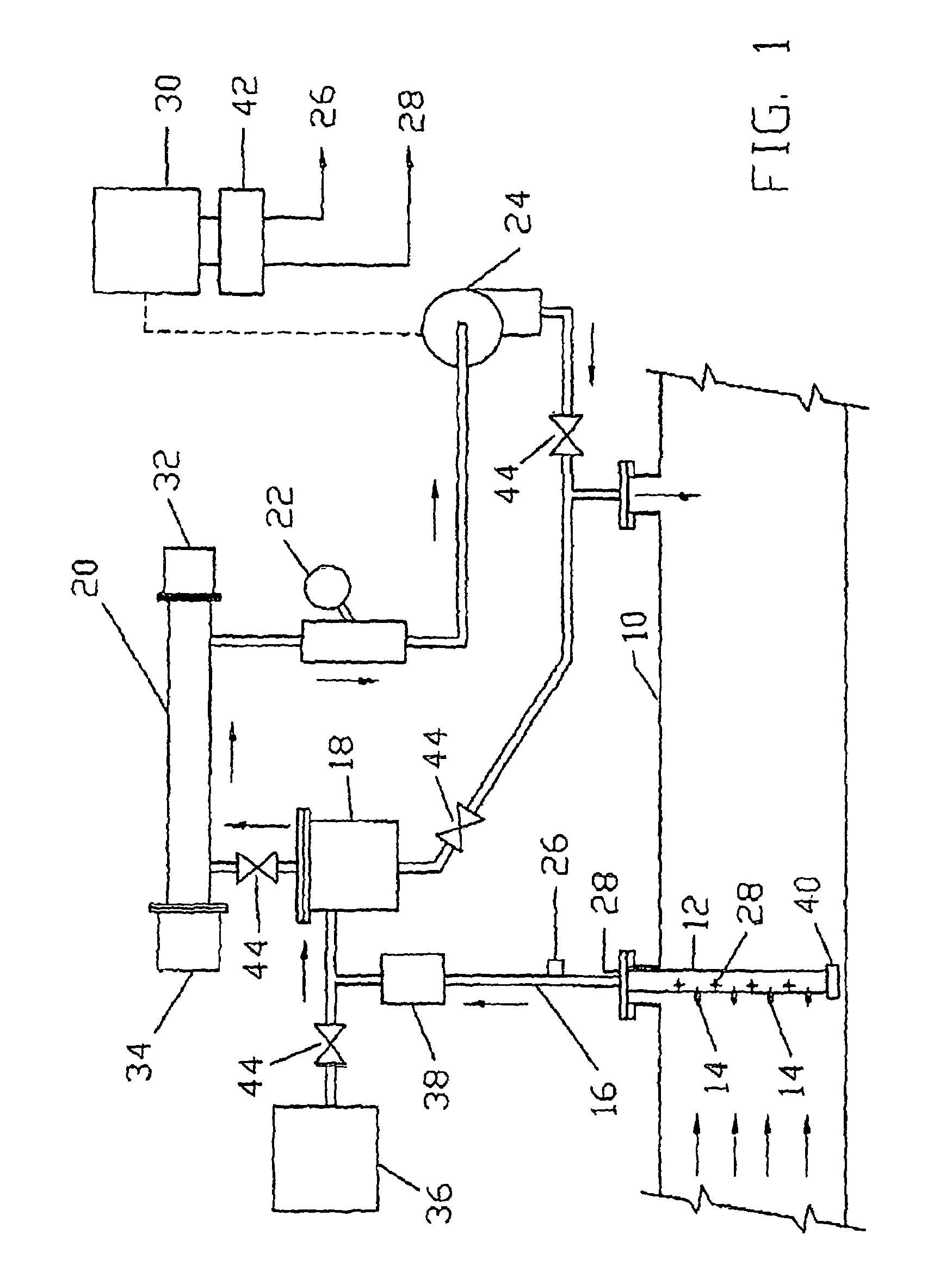

Mass Velocity and Area Weighted Averaging Fluid Compositions Sampler and Mass Flow Meter

A sampling device and method for use with a conduit for fluid which has at least one sampling nozzle or sample hole. The sample collected is directed to a manifold where an analysis is conducted and flow rates are measured. The sampled fluid is returned to the conduit. The Static Pressure Control System uses a vacuum pump or other device to equalize the static pressures of the sample nozzle collection manifold and the Static Pressure of the Conduit to achieve the mass-velocity and area-weighted average fluid composition and mass flow rate.

Owner:LOS ROBLES ADVERTISING

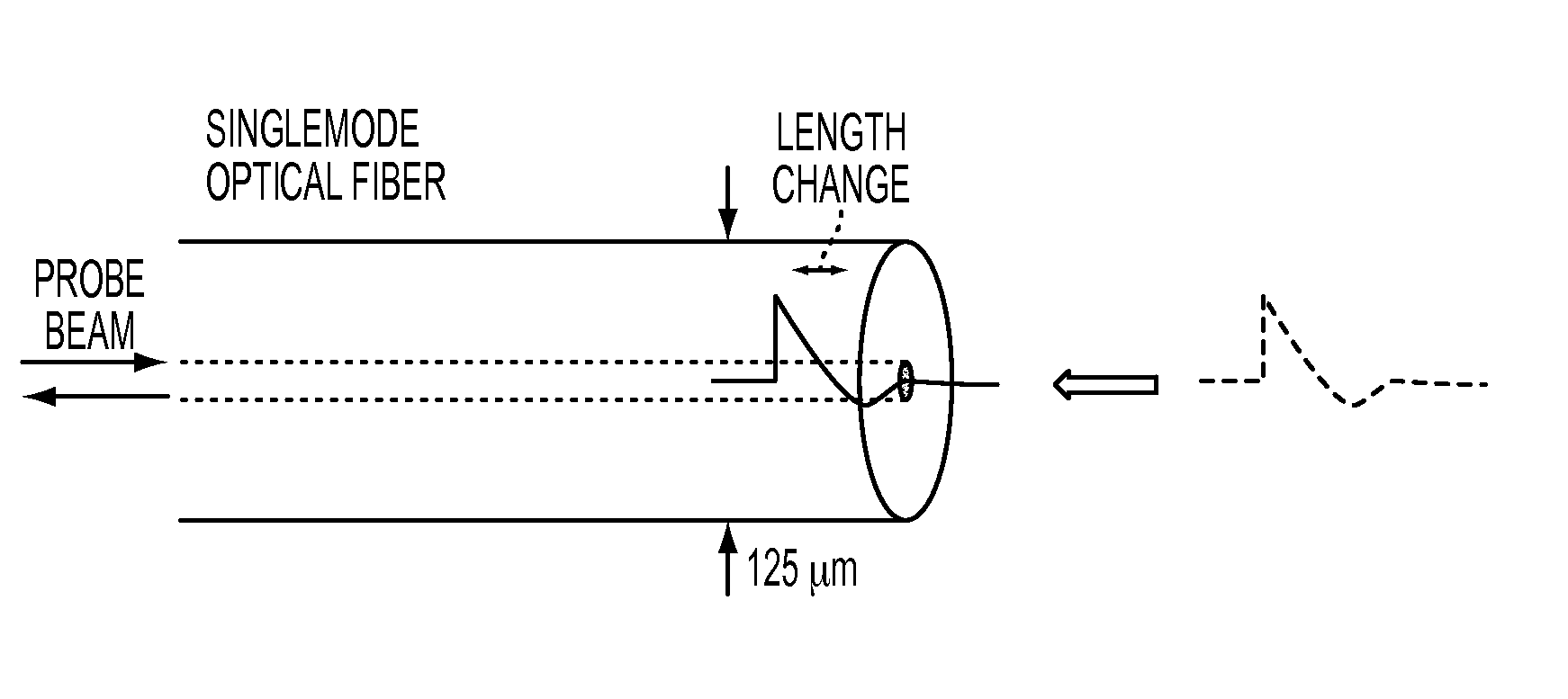

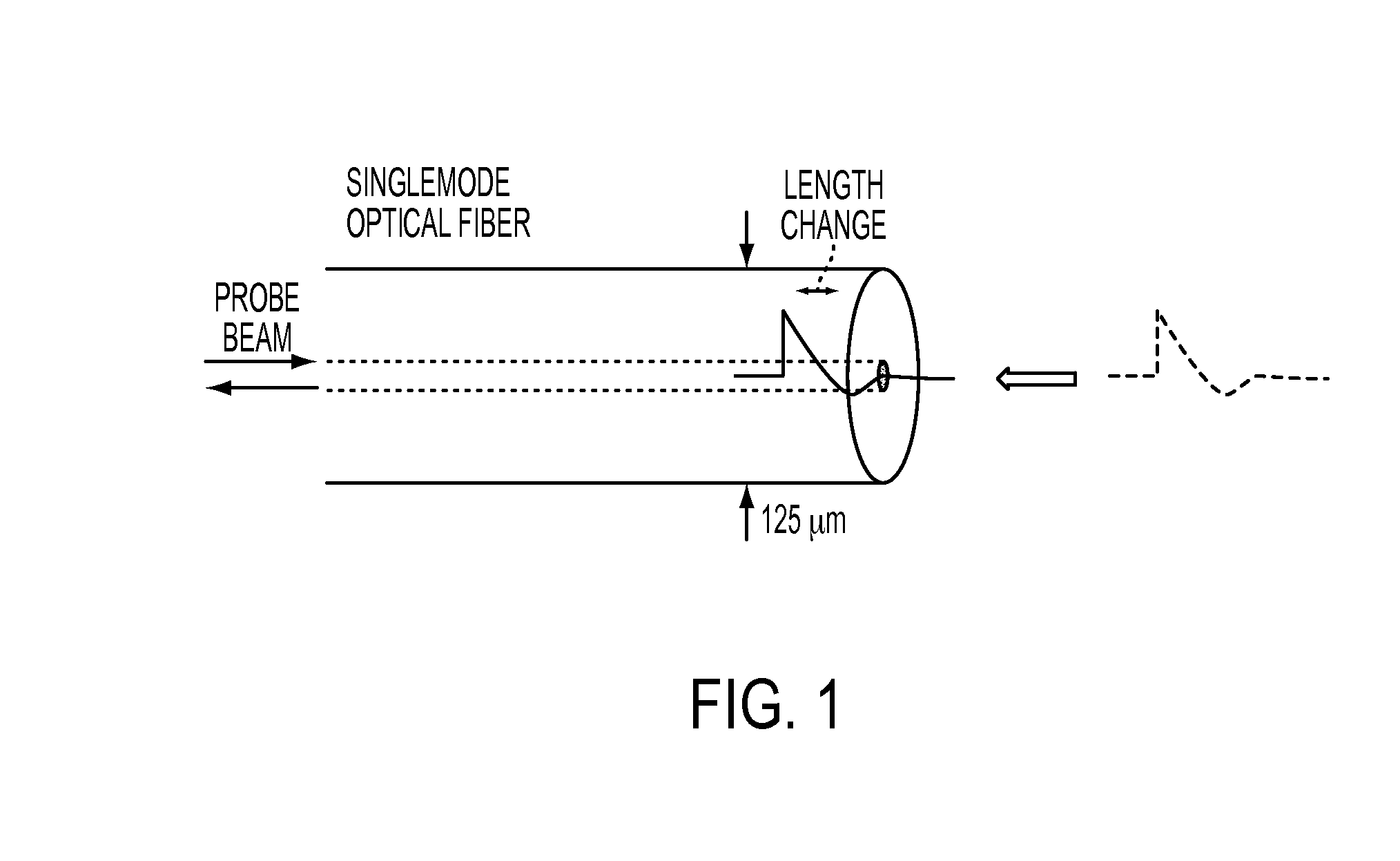

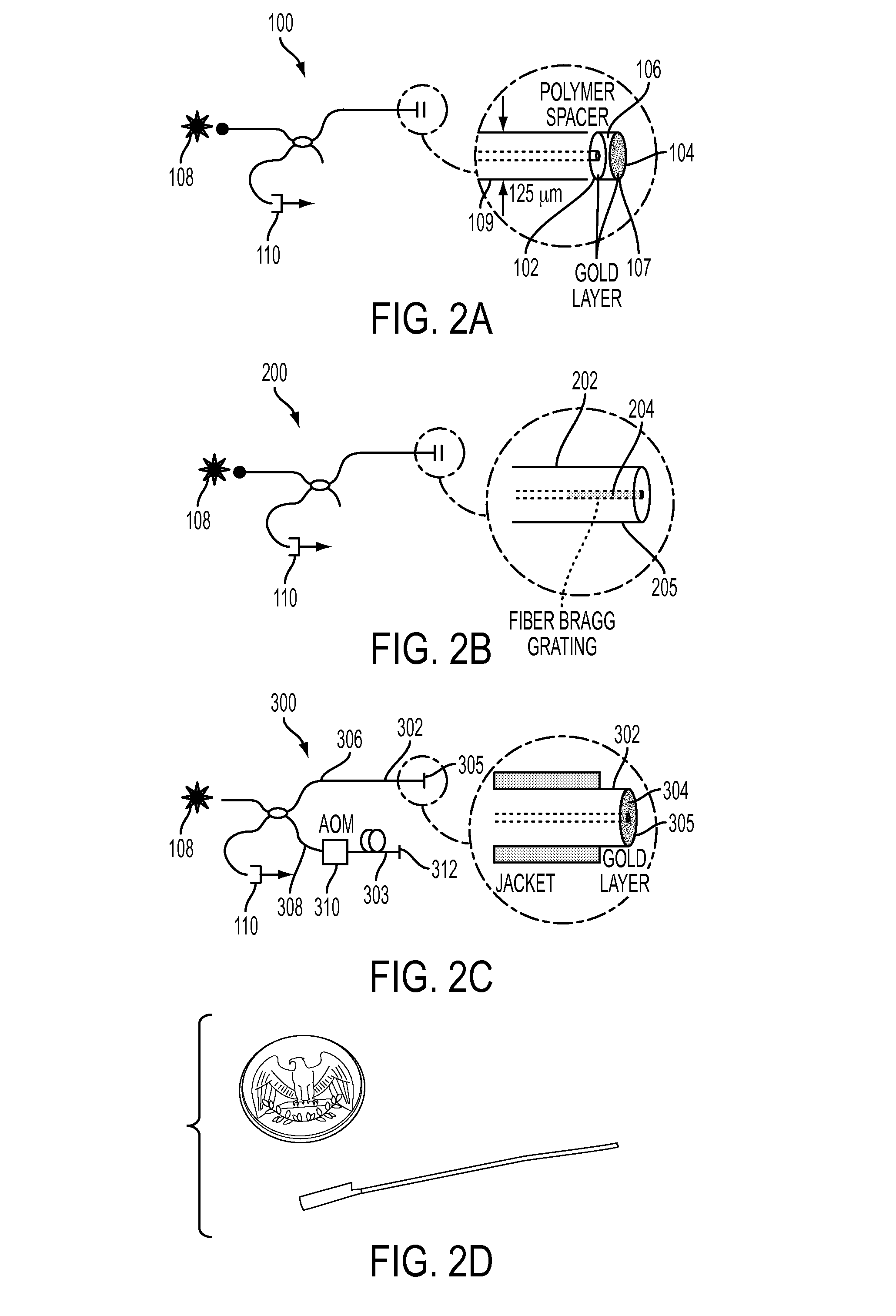

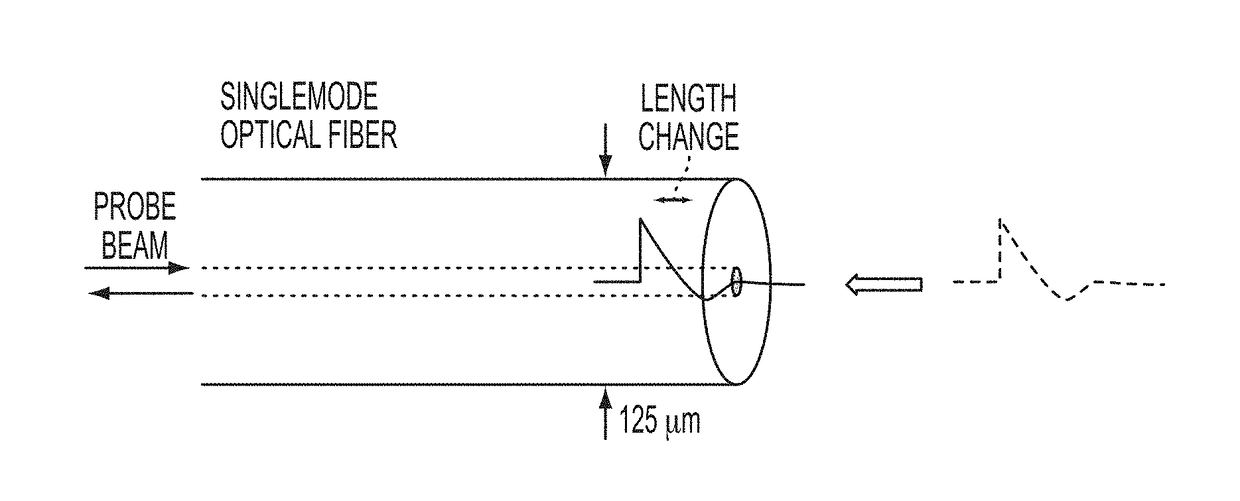

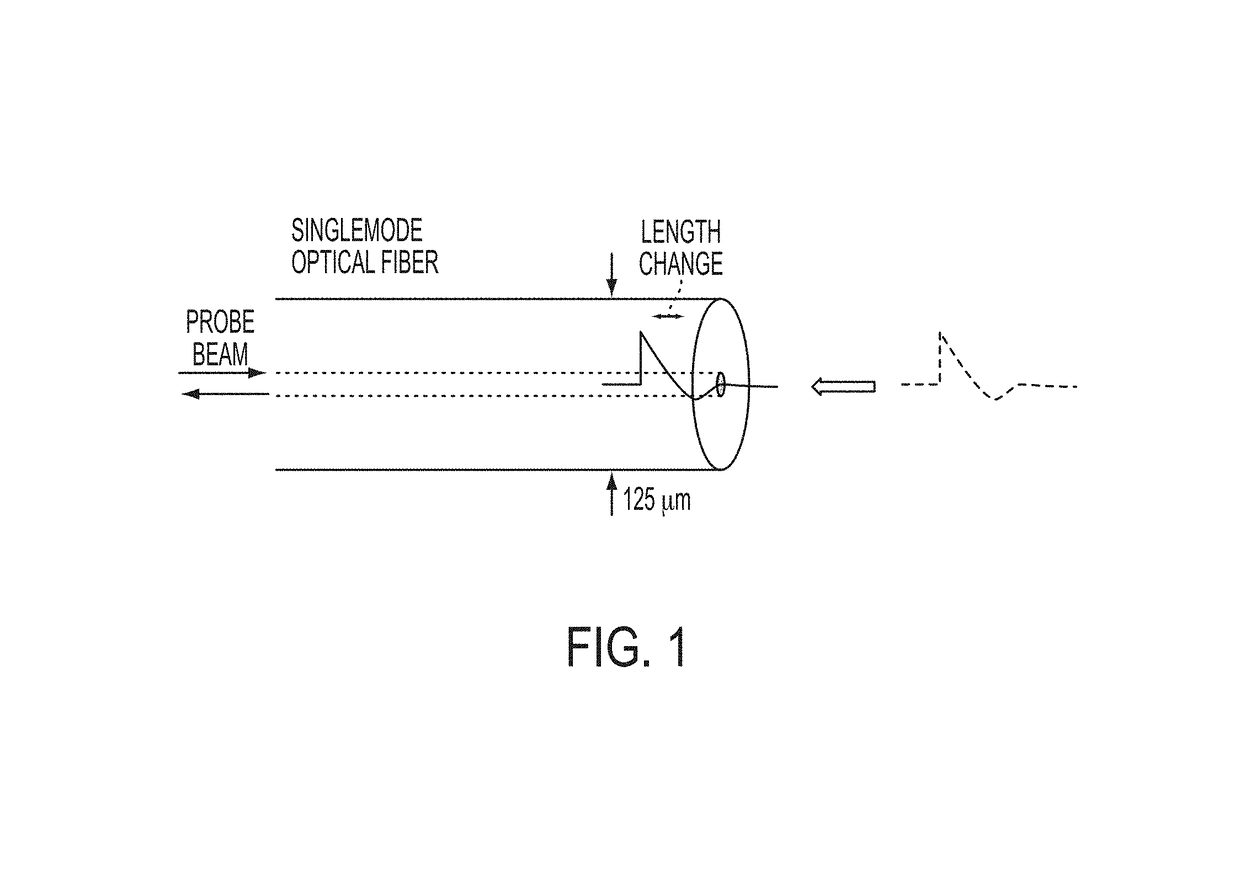

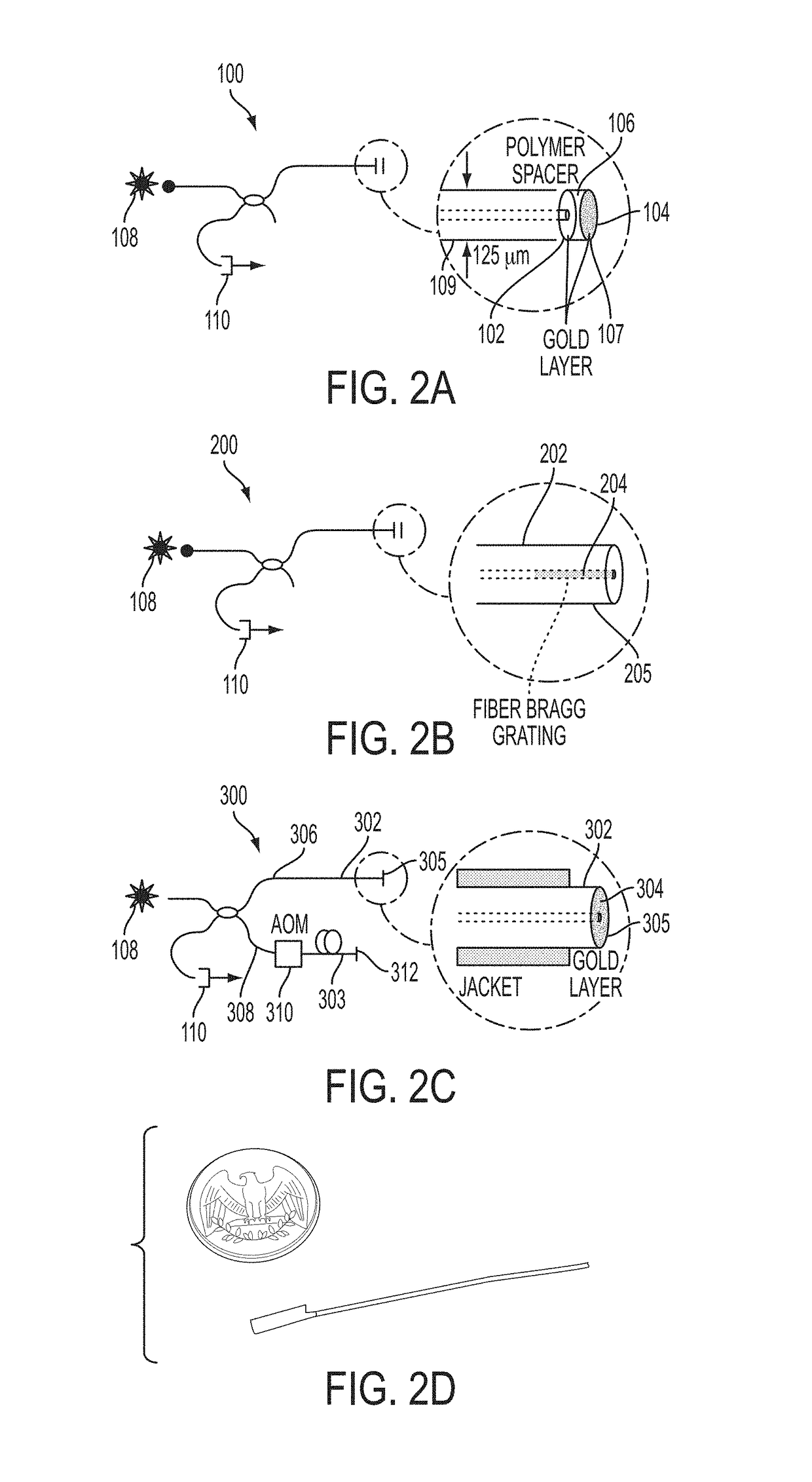

Fiber optic sensor and method for detecting shock wave pressure and mass velocity in solid media

ActiveUS20150323558A1Increased operating bandwidthRigid enoughForce measurementFluid pressure measurementShock waveClassical mechanics

A fiber optic pressure and mass velocity sensor for measuring a shock wave pressure in a solid media includes an optical fiber having a means for measuring a change in an optical path length (OPL) of the fiber when positioned in the solid media caused by the shock wave altering the physical length of the fiber and the refractive index of the fiber. The means for measuring the change in the OPL is coupled at one end to a laser and at its second end to a means for detecting the change in OPL. The sensor has a high operating bandwidth (>>10 MHz), is sufficiently rigid to withstand the force of the shock wave, has a sensitivity that can also be tailored for the application, and is immune to electromagnetic interference. Measurement can be made on materials under extreme strain conditions, and the sensor can also provide characterization of protective materials such as bullet / blast proof materials.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

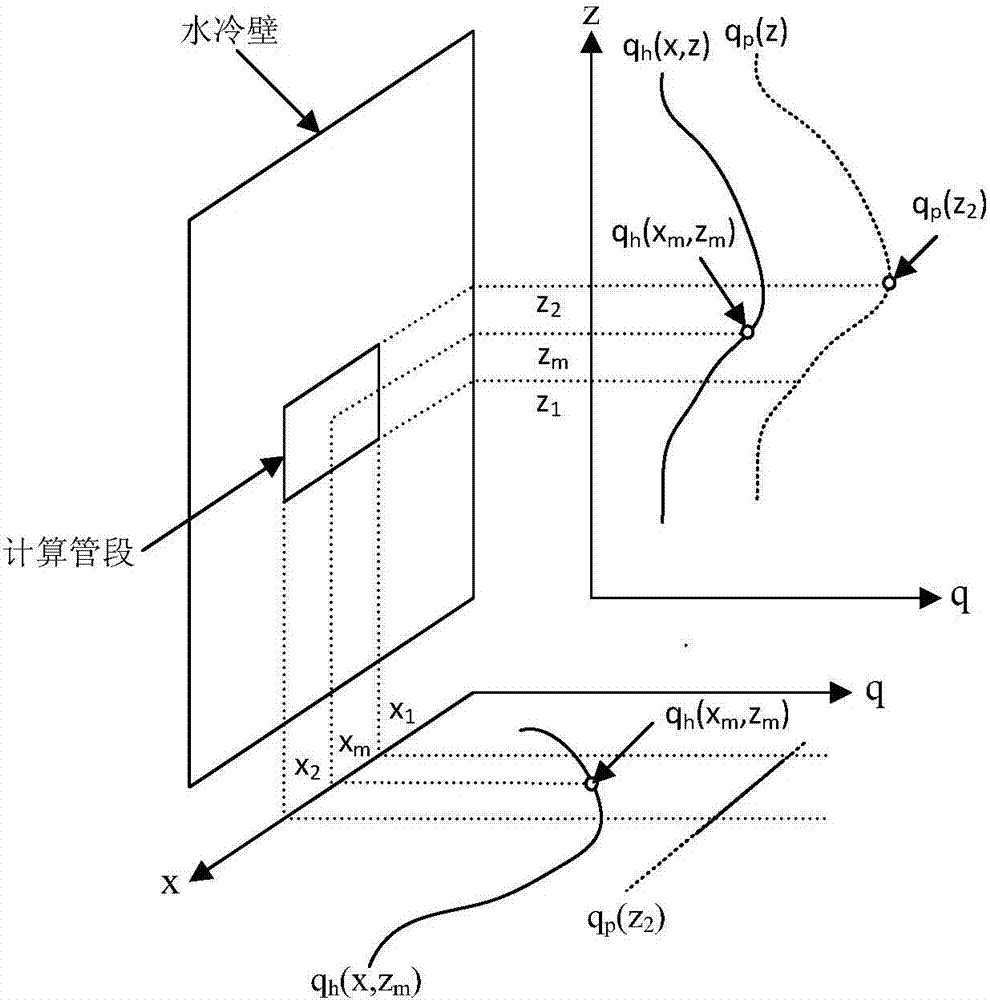

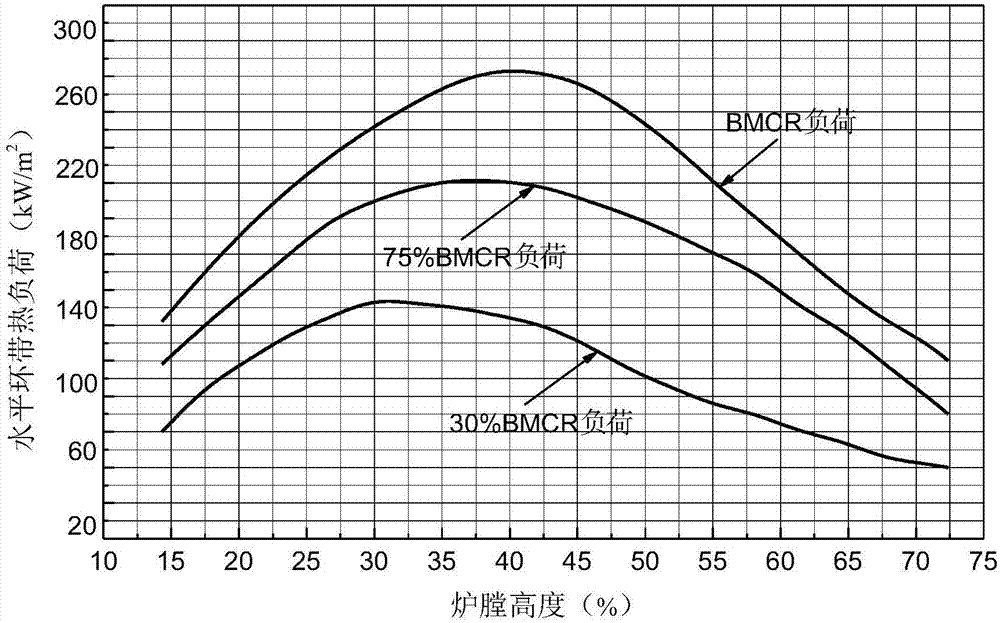

General hydrodynamic calculation method for ultra-supercritical boiler

ActiveCN106897547AFit closelyInformaticsSpecial data processing applicationsSupercritical steam generatorCombustion

The invention discloses a general hydrodynamic calculation method for an ultra-supercritical boiler, and provides a flow network system method consisting of a nonlinear model applied to a computer. The calculation method is suitable for hydrodynamic calculation and wall temperature safety analysis of the ultra-supercritical once-through boiler under various boiler overall arrangement forms, various pipe coil forms, various combustion technologies and various mass velocity combinations. The method comprises the steps of simplifying a water wall into a flow network system consisting of elements such as a connecting pipe loop, a heated loop, a pressure node and the like according to structure characteristics of the water wall and heat load distribution of a furnace chamber; and building the nonlinear calculation model of flow distribution according to a mass conservation equation, a momentum conservation equation and an energy conservation equation. Through direct solving of a nonlinear equation set, flow distribution and node pressure distribution in the heated loop and a connecting pipe are determined, and based on this, boiler water wall flow and metal wall temperature are subjected to safety check, so that guidance calculation can be performed for design and safety check of the boiler.

Owner:XI AN JIAOTONG UNIV +2

Mass velocity and area weighted averaging fluid compositions sampler and mass flow meter

ActiveUS7752929B2Accurate measurementWithdrawing sample devicesVolume flow proportion measurementControl systemEngineering

Owner:LOS ROBLES ADVERTISING

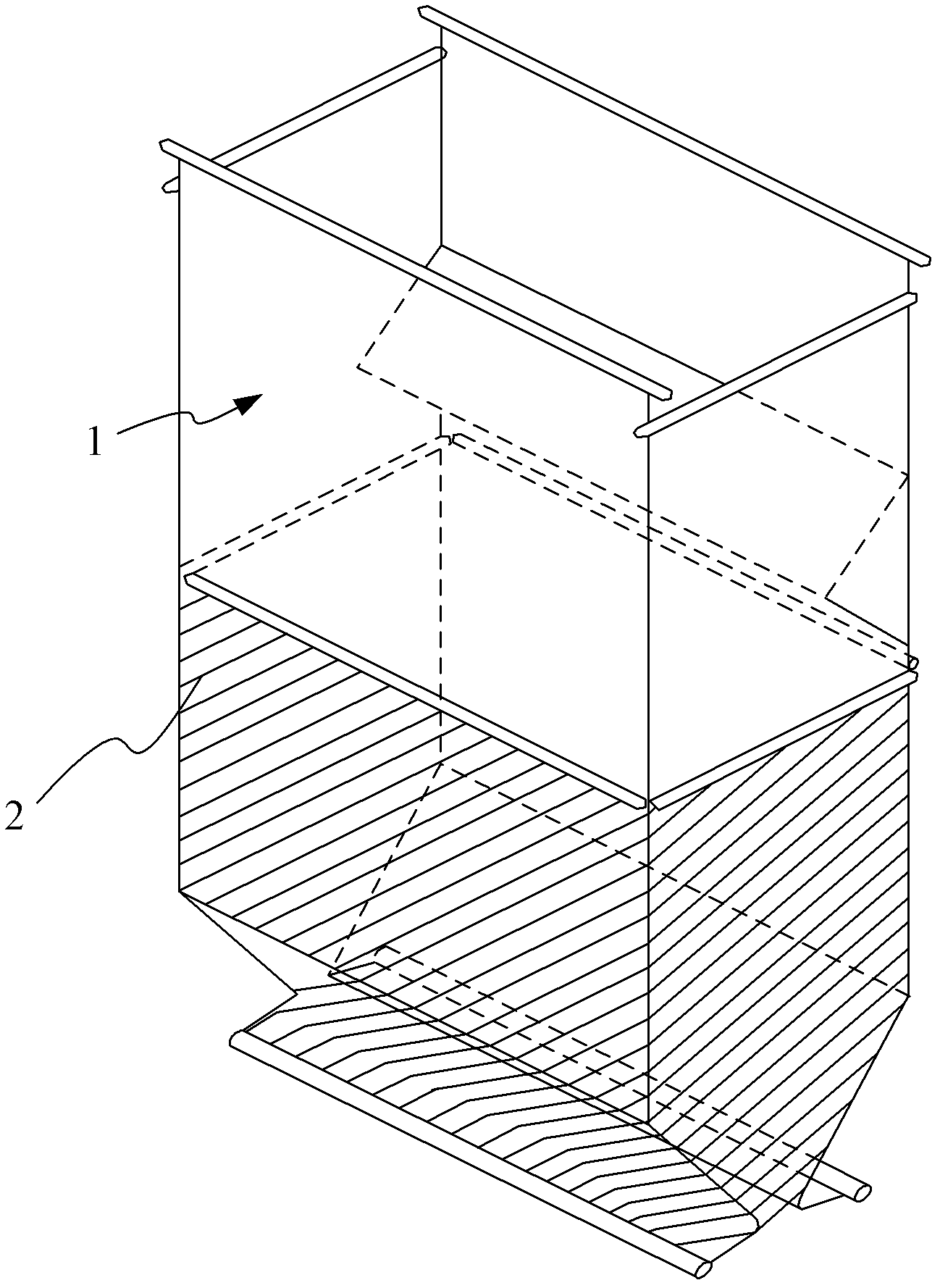

Vertical multiple passage drainable heated surfaces with headers-equalizers and forced circulation

InactiveUS20160102926A1Improve stabilityQuality improvementRecuperative heat exchangersBoiler water tubesStraight tubeEngineering

The present invention discloses improved heated surfaces (HS) with vertical multiple passage panels or vertical serpentine coils from straight tubes with connections between them by top and bottom bends. In HS with tube bends there is not any mixing headers—each circuit has a single tube from inlet header to outlet header. This increases mass velocity of flow and improves stability and temperature regulation of tubes. The bottom bends have holes. The bottom bend holes of the adjacent passes are connected with drain header by drain stubs. Each header serves to drain the adjacent tube passes and as equalizing header of pressure / flow. It will help to decrease multivaluedness and maldistribution of flow between parallel tubes of the module. Such design of HS noticeably decreases the corrosion of tubes.

Owner:POLONSKY VLADIMIR S +1

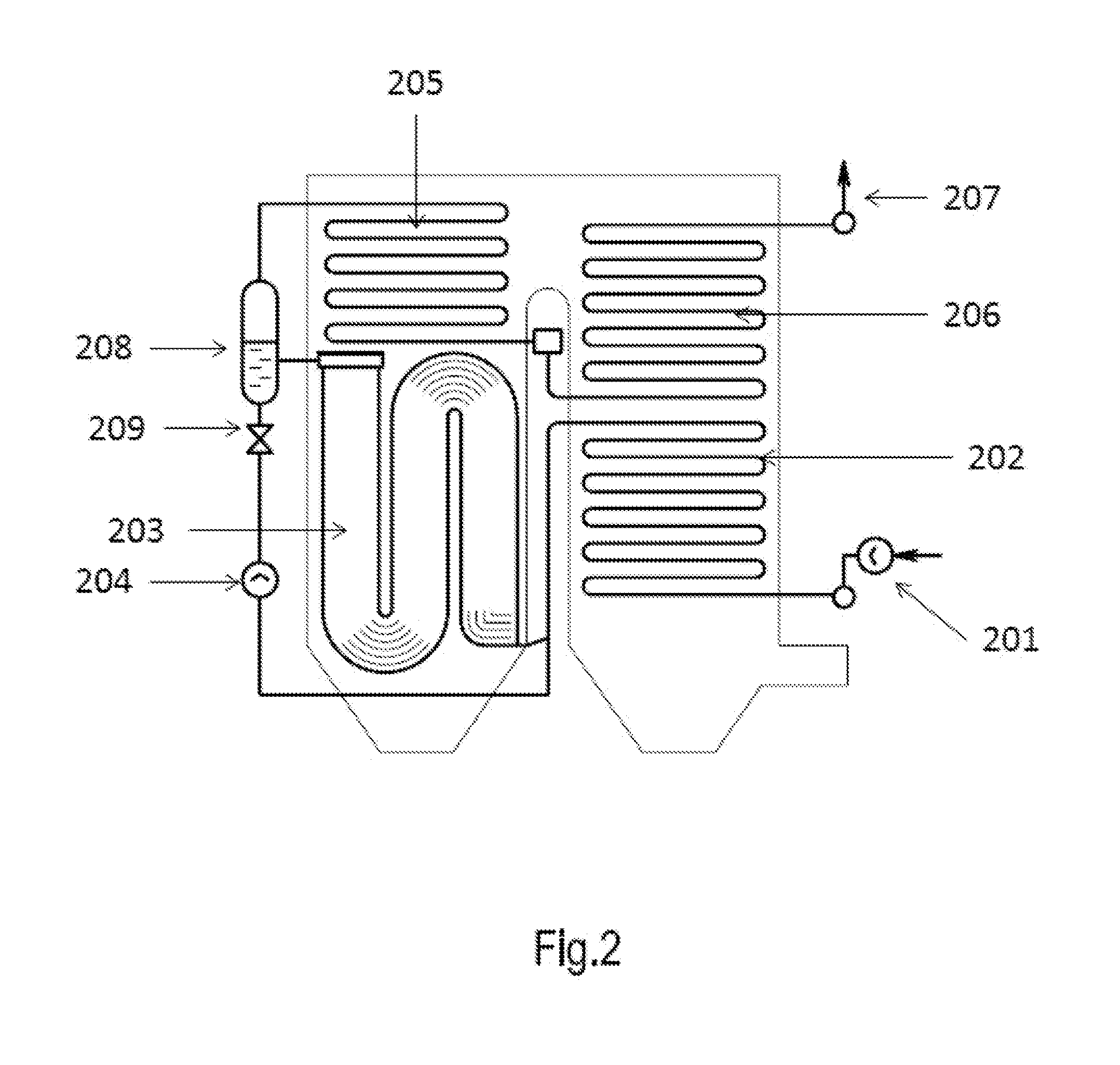

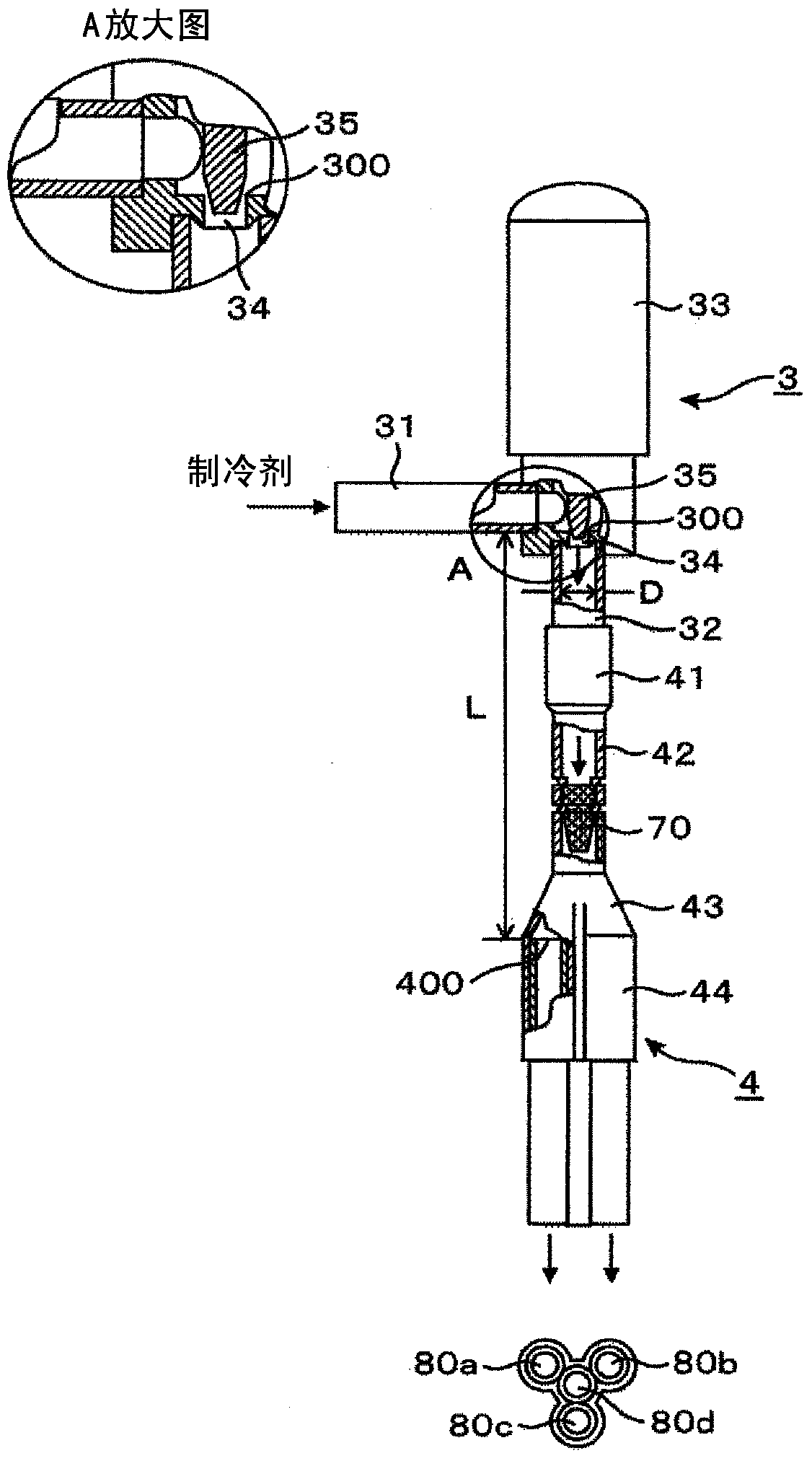

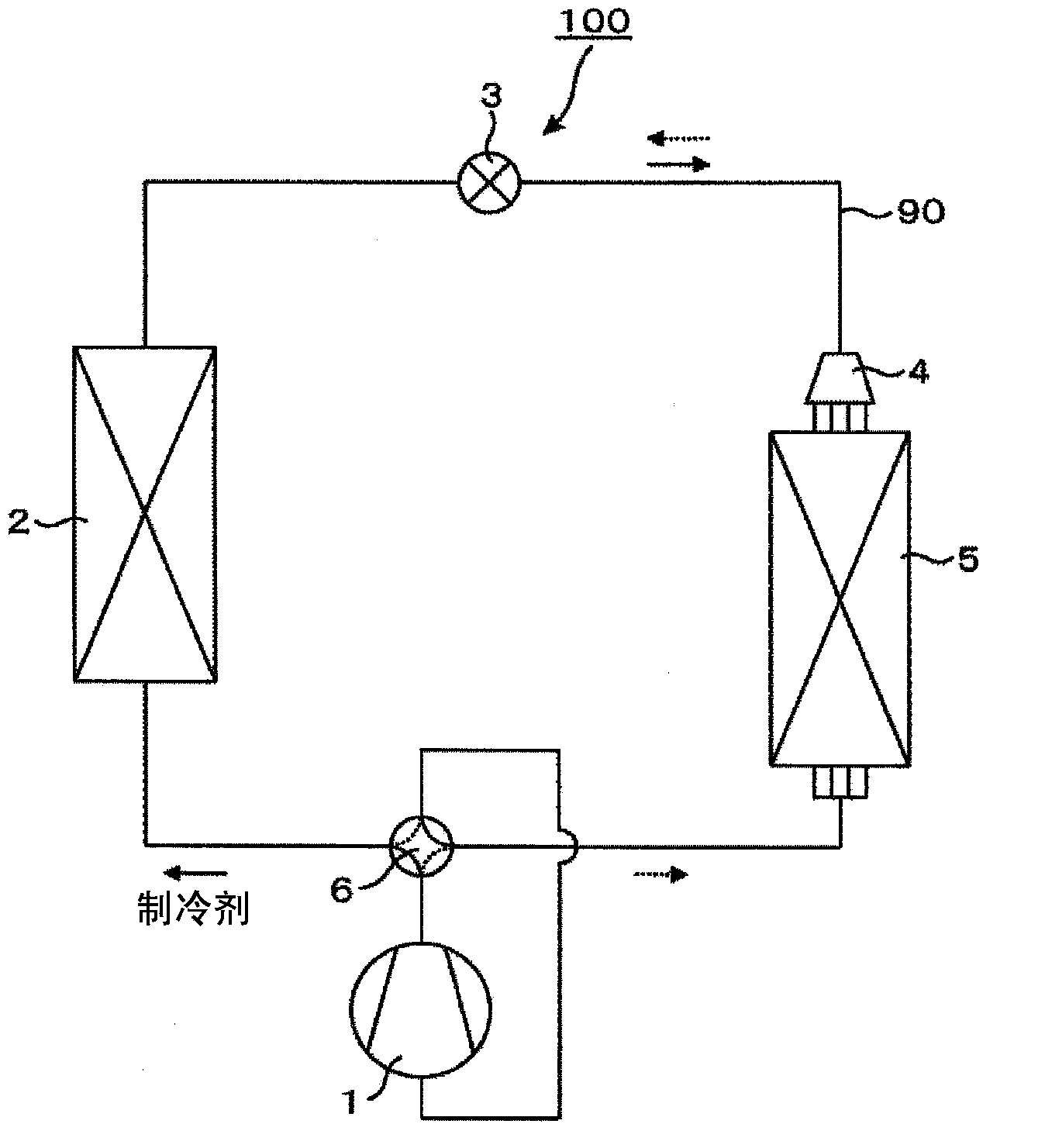

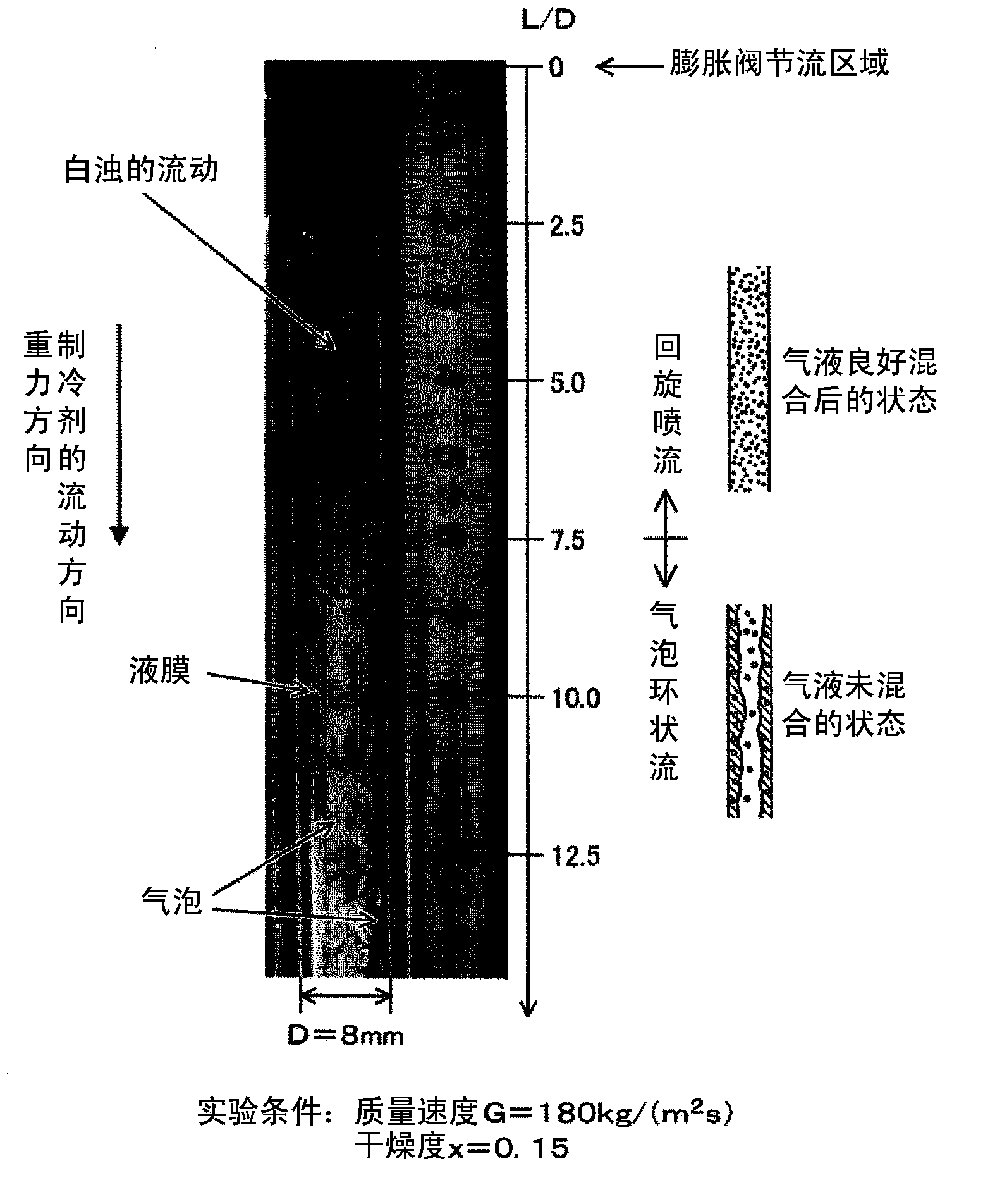

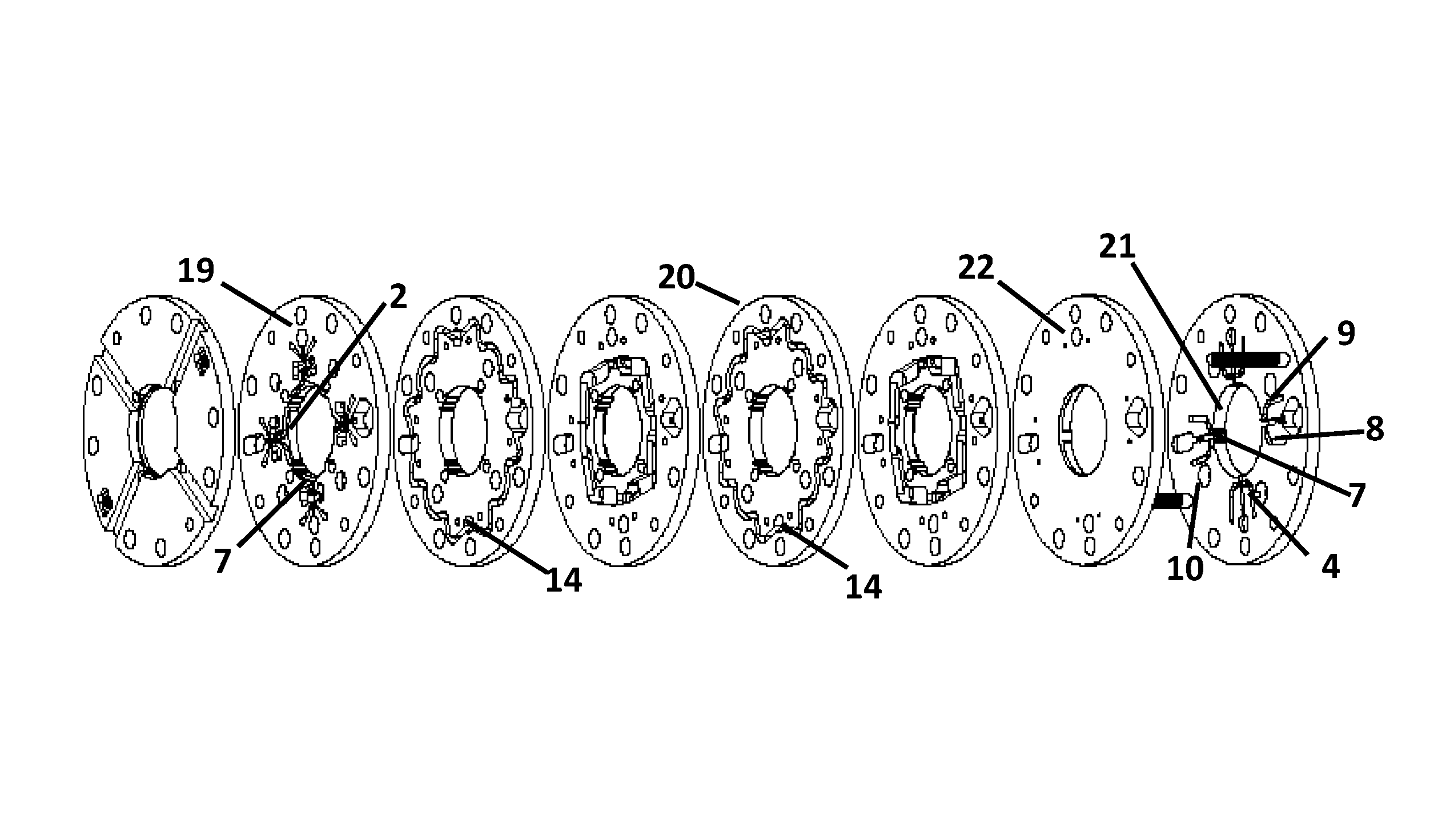

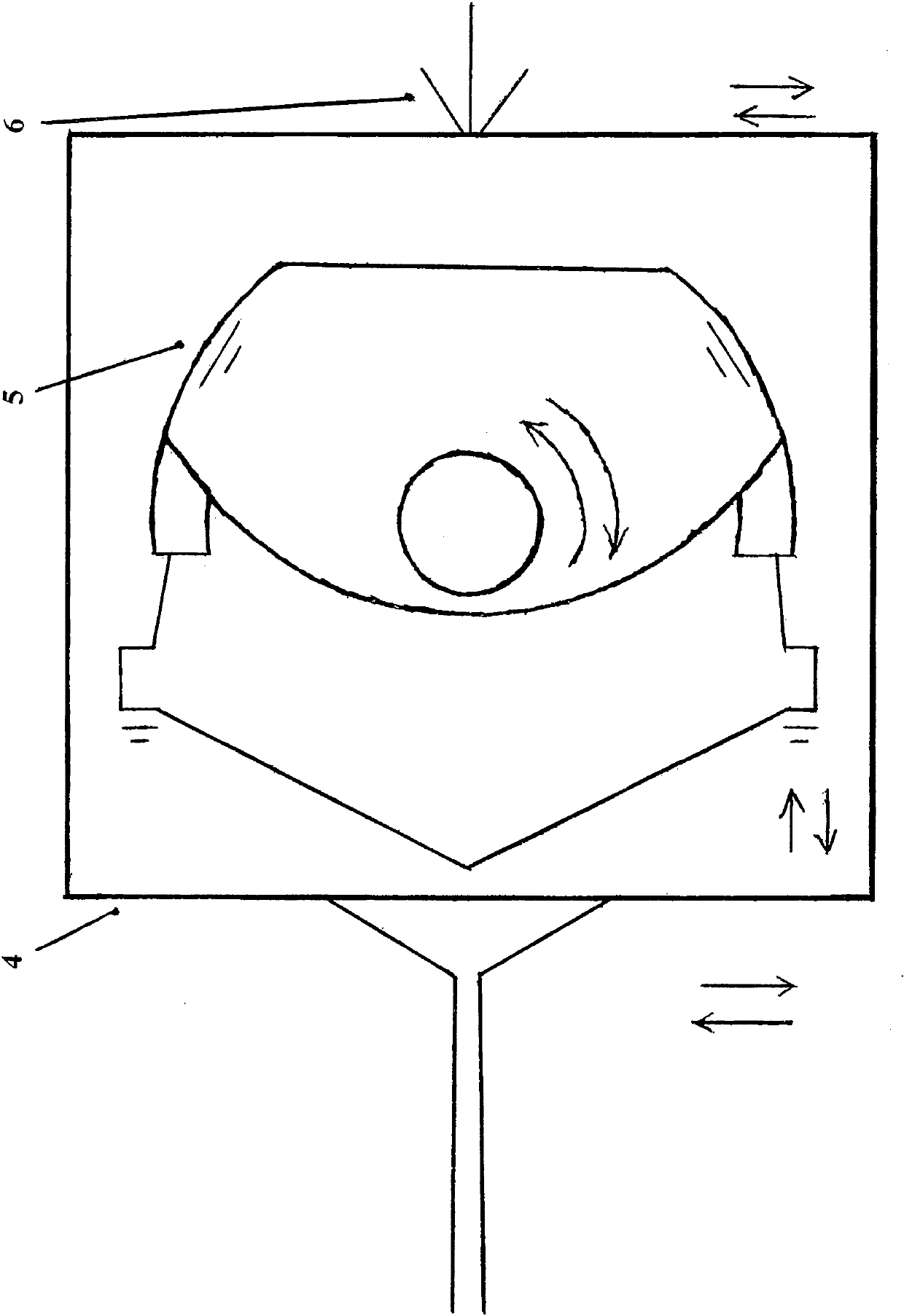

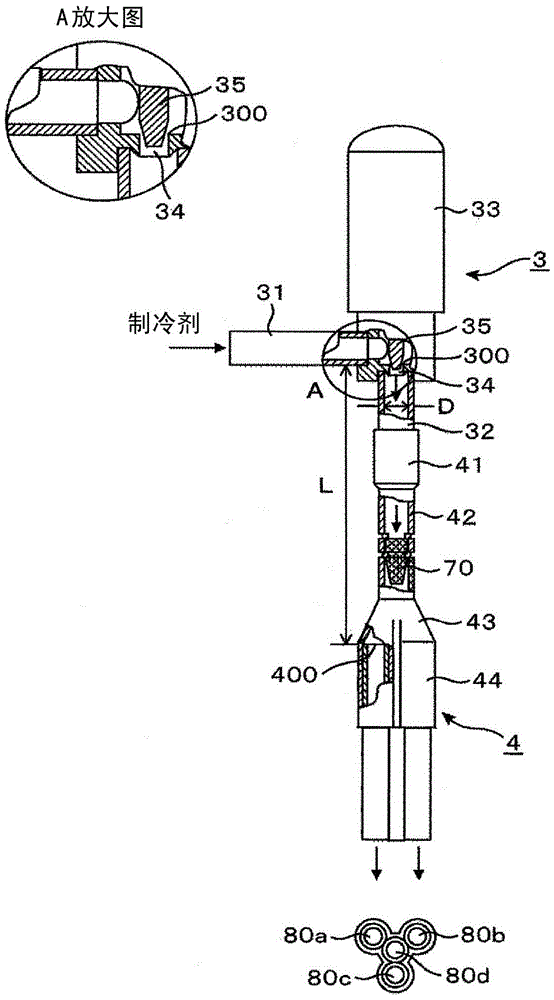

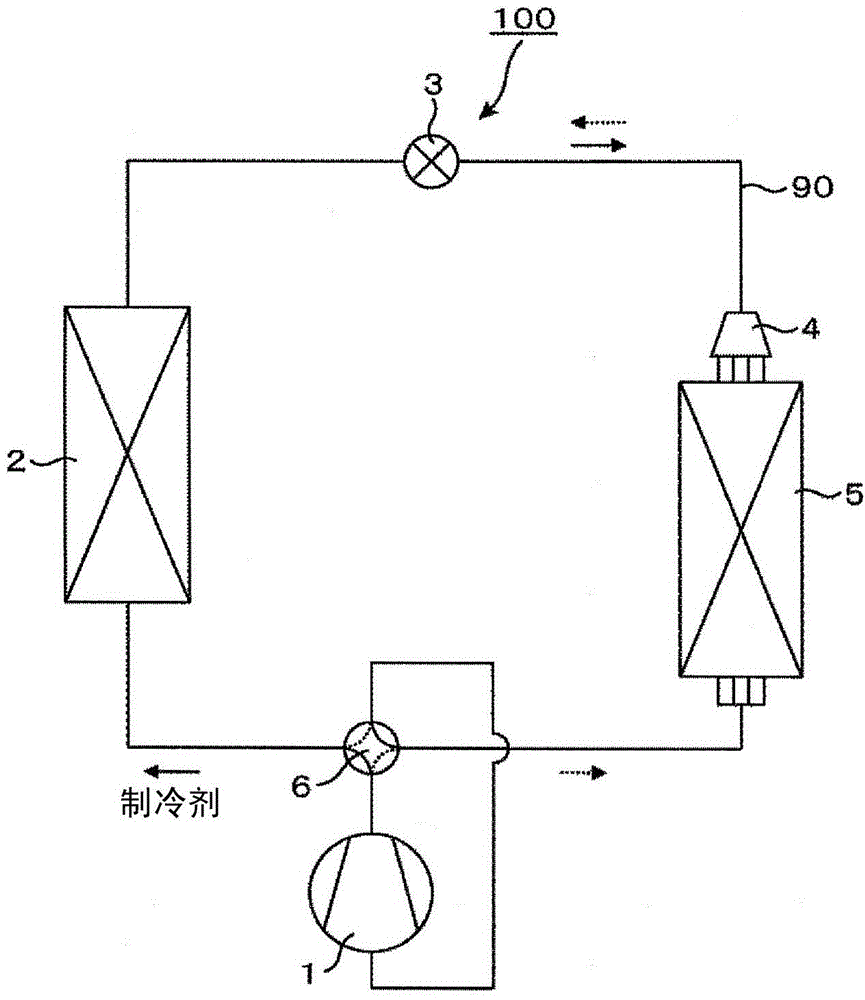

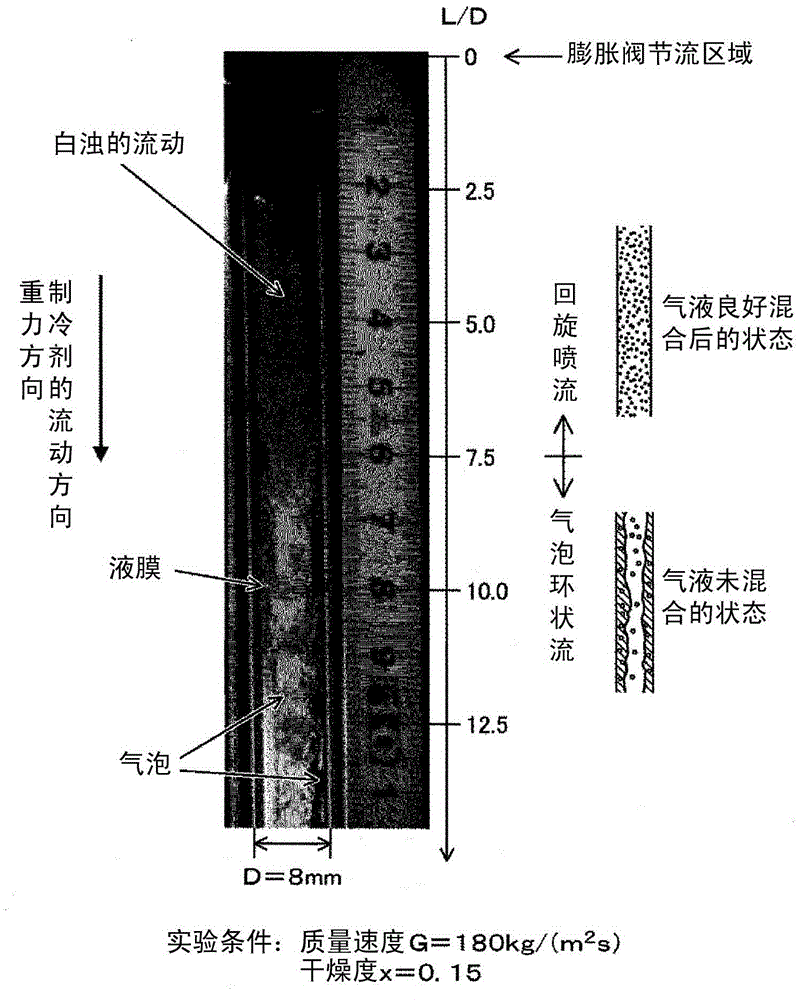

Refrigeration cycle device

ActiveCN104126099AGood shunt characteristicsMechanical apparatusEvaporators/condensersEngineeringManufacturing variation

The objective of the present invention is to achieve an excellent flow division characteristic under a wide range of usage conditions, without being influenced by the installation position of a refrigerant flow divider, or by manufacturing variations, or the like. This refrigeration cycle device is equipped with: a compressor that compresses a refrigerant; a condenser that condenses the refrigerant compressed by the compressor; an expansion valve (3) that decompresses the refrigerant condensed by the condenser; a flow divider (4) that is constructed separately from the expansion valve (3), and that divides the flow of the refrigerant decompressed by the expansion valve (3) into multiple flow paths formed in the interior of the flow divider; and an evaporator that vaporizes the refrigerant that has been divided by the flow divider (4). The expansion valve (3) and the flow divider (4) are arranged so as to satisfy the equations L / D <= 1.2 G0.36 and L / D >= 1.5, where L [m] is the distance from the throttle region (300) of the expansion valve (3) to the branching region (400) of the flow divider (4), D [m] is the inner diameter of a second connecting tube (32) of the expansion valve (3), and G [kg / (m2s)] is the mass velocity of the refrigerant flowing in the second connecting tube (32) of the expansion valve.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

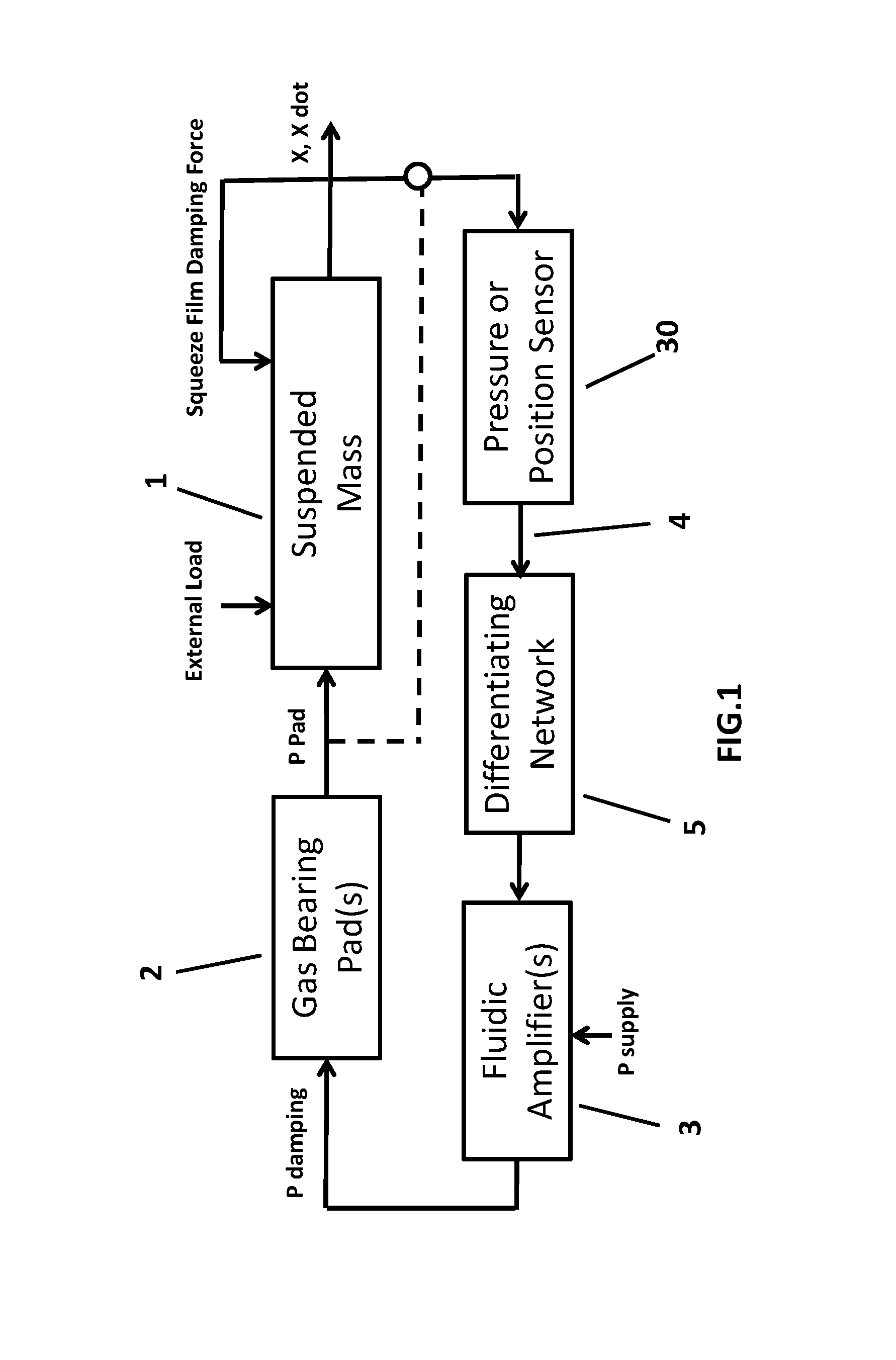

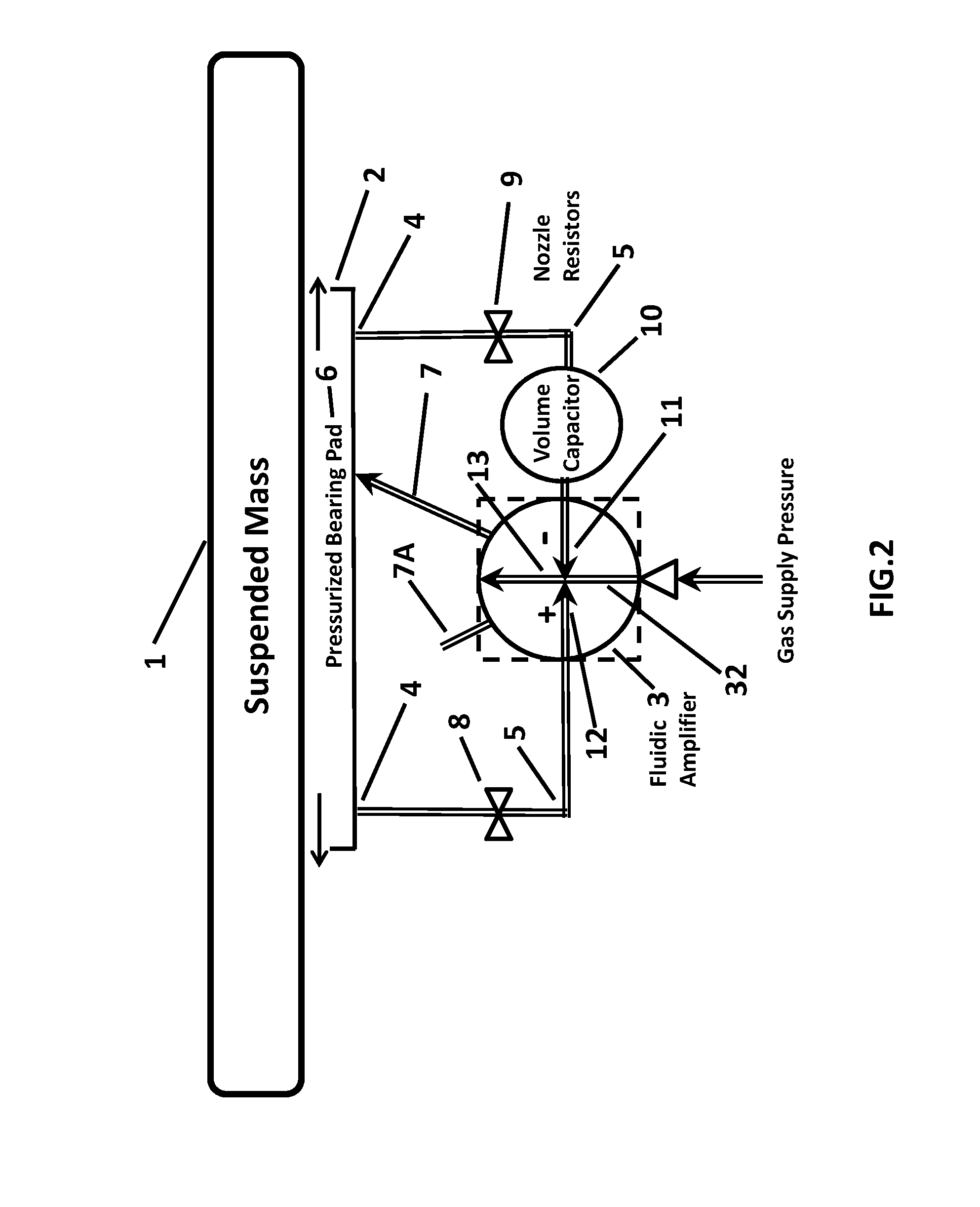

Damped air bearing

ActiveUS8662754B1Improvement in air bearing stiffnessImprovement in positioning system accuracyCrankshaftsLinear bearingsAir bearingEngineering

An air or gas bearing supports a moving mass on a thin column of gas which is partially constrained in a pressurized cavity. The gas to the cavity is supplied through a fluidic amplifier. Pressure in the thin supporting column above the bearing pad, or the position of the mass surface relative to the open end of the pressurized cavity, is sensed. The resulting feedback pressure signal is dynamically compensated to produce a pressure signal to the input ports of the fluidic amplifier which is a function of the velocity of the mass. The compensation network consists of orifices, or flow resistors, and volume cavities, or compressible fluid capacitors. The compensated feedback pressure is amplified by the fluidic amplifier to provide an output pressure to the bearing cavity which is indicative of and nearly proportional to the mass velocity perpendicular to the bearing pad and achieve a high degree of damping without use of extremely small orifices or complicated electromechanical damping means.

Owner:FLUIDIC MICROCONTROLS

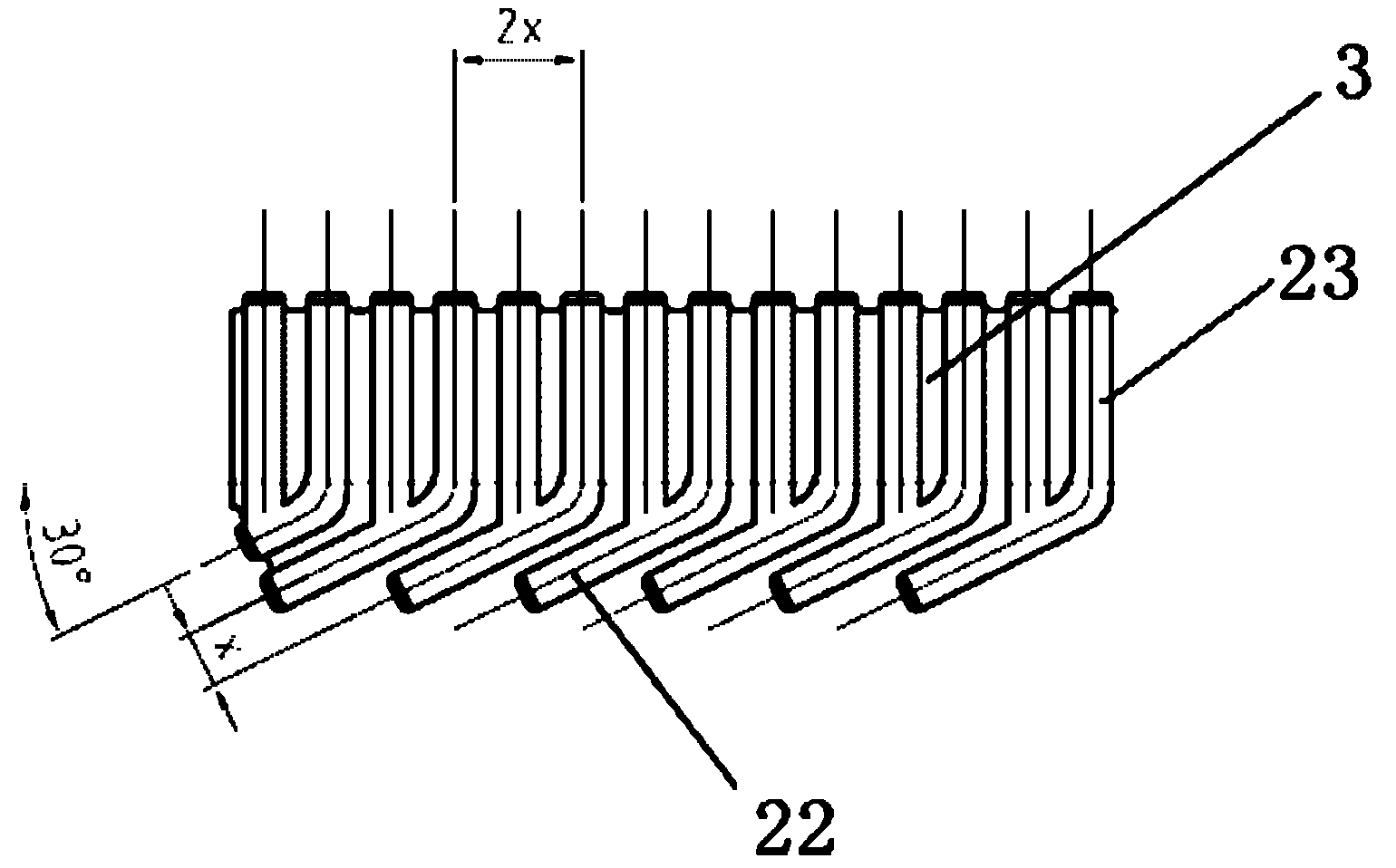

Manufacturing method of heat product

InactiveCN101152775AAvoid wrinklesPrevent peelingSynthetic resin layered productsTectorial membraneUltimate tensile strength

The present invention provides a method for manufacturing thermal forming product. The method includes thermal forming the thermoplastic resin plate laminated with protection film. The protection film is made of resin material. The resin material has a fondant mass velocity less than 1g / 10 minute at 190 DEG C under the load of 2.16kg, and the peeling strength of the protection film relative to the thermoplastic resin plate is not less than 04.N / 25mm after heated to 200 DEG C.

Owner:SUMITOMO CHEM CO LTD

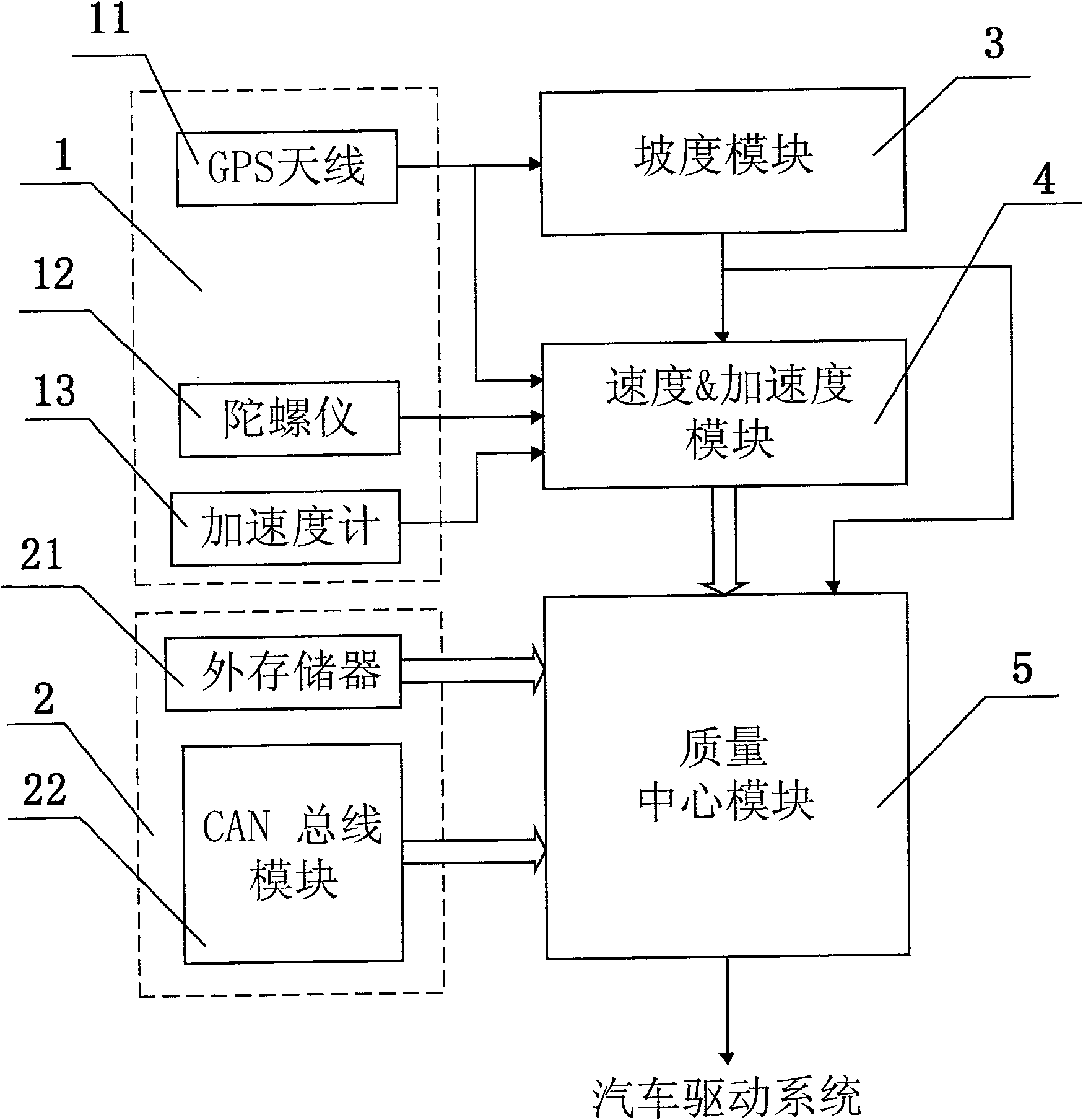

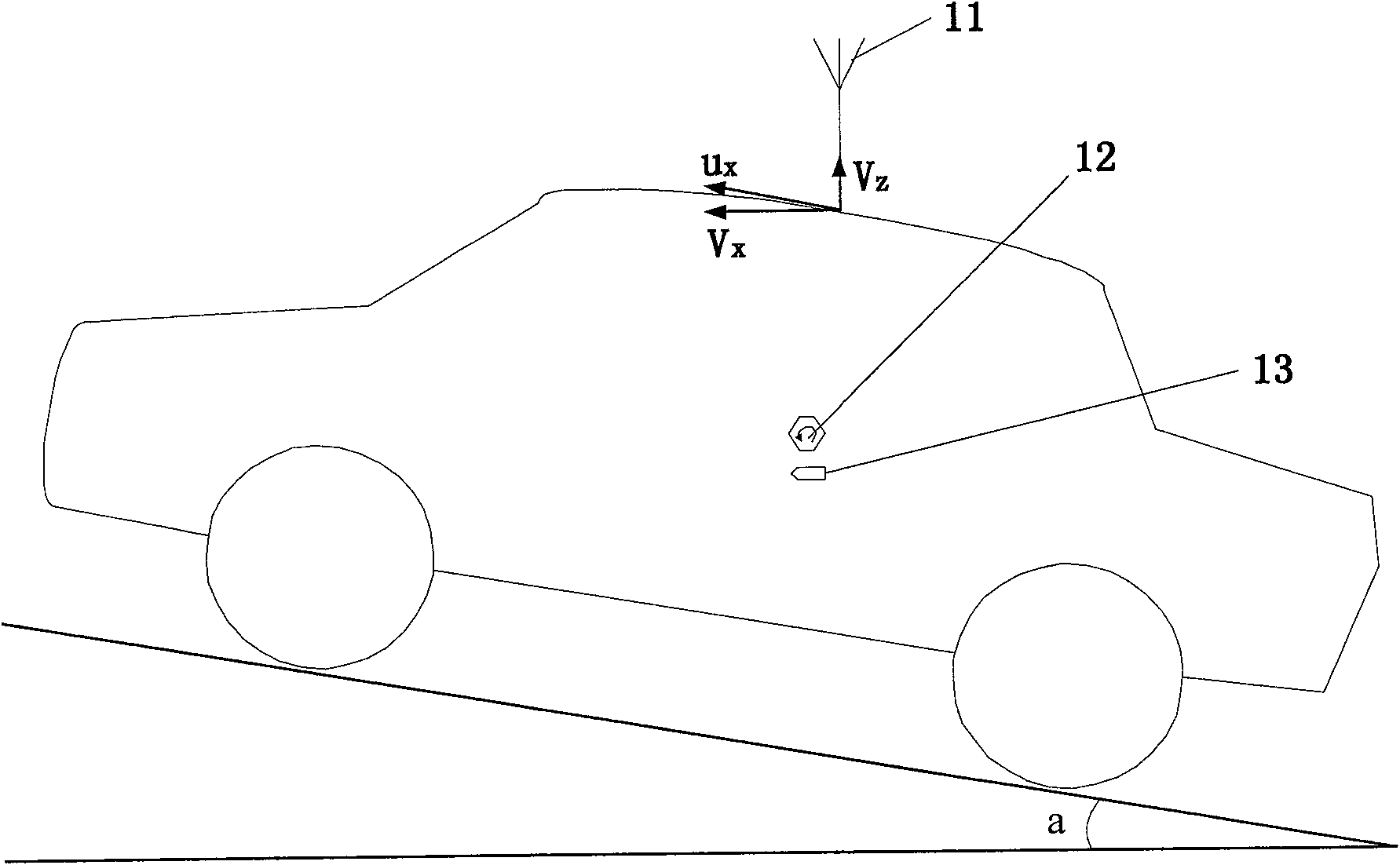

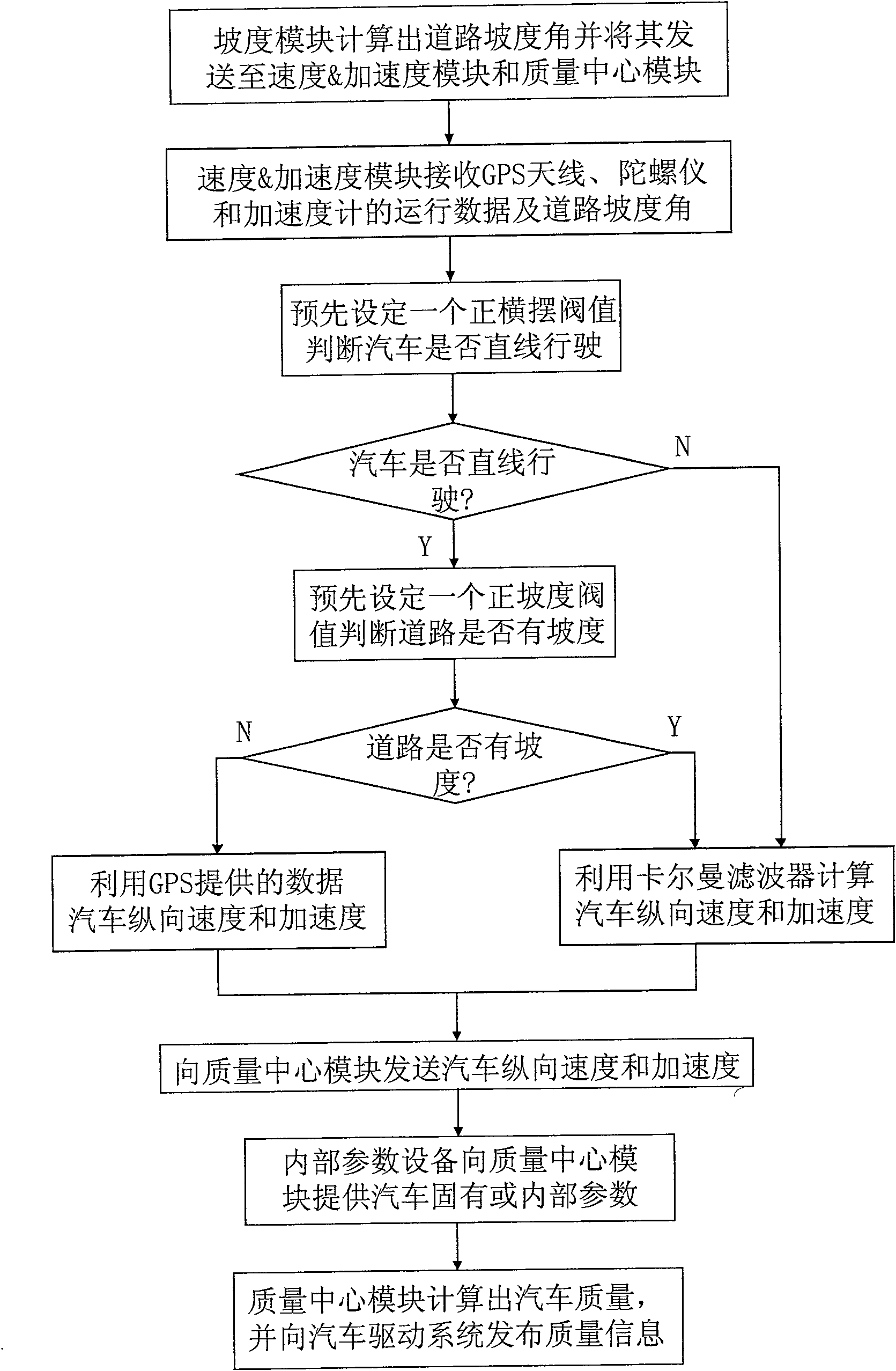

Automotive quality estimation system and method

InactiveCN100545595CReduce the amount of runningTaking into account real-timeVehicle testingSpecial purpose weighing apparatusReal-time dataExternal data

A car quality estimation system and method related to cars, including external data equipment, internal parameter equipment, slope module, speed & acceleration module and mass center module, the external data equipment receives real-time data of automobile operation and provides it to the slope module and speed &acceleration module; the internal parameter device receives the inherent or internal parameters of the vehicle and provides them to the center of mass module; the slope module calculates the slope angle of the vehicle based on the data provided by the external data device and transmits the relevant parameters or data to the speed&acceleration module and the center of mass module; the speed & acceleration module calculates the speed and acceleration of the car according to the data provided by the external data device and the slope module, and transmits the relevant parameters or data to the center of mass module; the center of mass module According to the parameters or data provided by the speed & acceleration module, the vehicle quality is calculated, and the quality information is released to the vehicle driving system. The quality estimation accuracy of the present invention is high, the real-time performance is good, and the practicability is strong.

Owner:BYD CO LTD

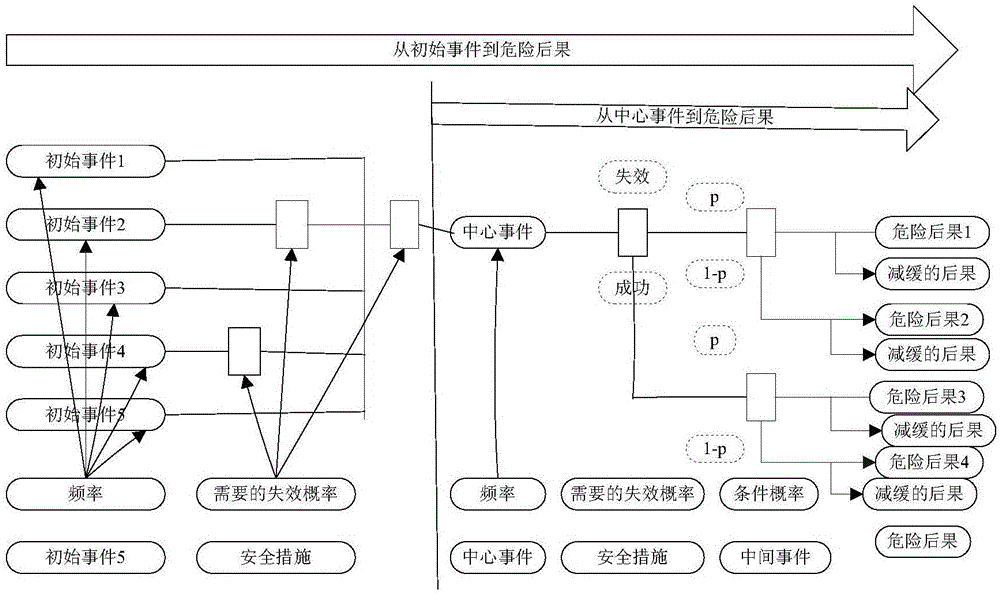

Method for determining safety distance of compressed natural gas (CNG) gas station

InactiveCN105868156AThe result is reasonableResourcesComplex mathematical operationsCombustionCompressed natural gas

The invention relates to a method for determining a safety distance of a compressed natural gas (CNG) gas station. The method comprises a first step of measuring combustion heat and mass velocity of jet fire; a second step of obtaining a flame length L of the jet fire, calculating flux of thermal radiation, and obtaining a thermal radiation flux received which is X (m) away from a flame point source; a fourth step of utilizing the thermal radiation flux received which is X (m) away from the flame point source to make a comparison with a set thermal radiation flux, and obtaining the safety distance of the CNG gas station. According to the method, against the problems that only a concrete safety distance of an internal process device in the CNG gas station away from an external building is given in the current standard specification, no concrete determination method is given, determination methods are different and external safety distances differ much, the external safety distance of the CNG gas station is determined, initial events and safety measure failure frequency are determined, so that the determined external safety distance of the CNG gas station is close to actual conditions, and the result is also more reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +1

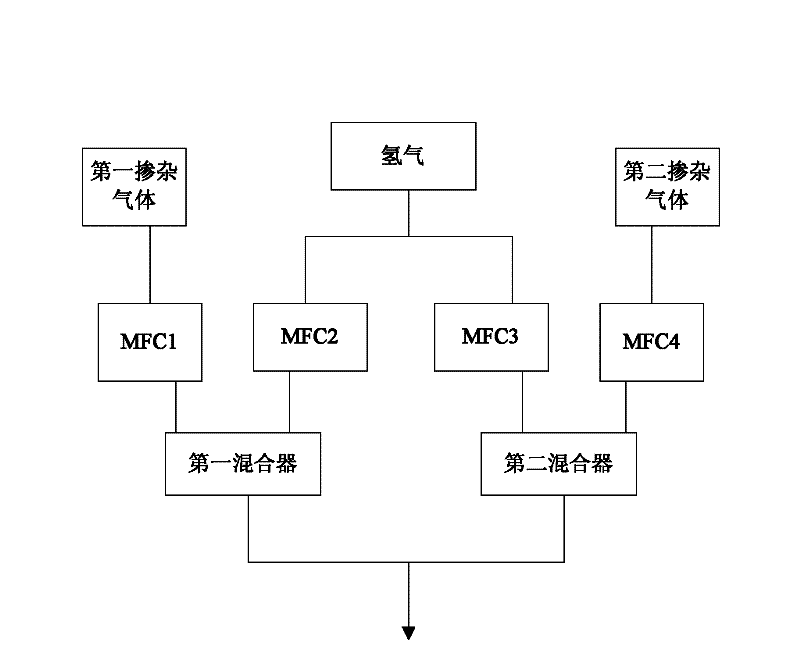

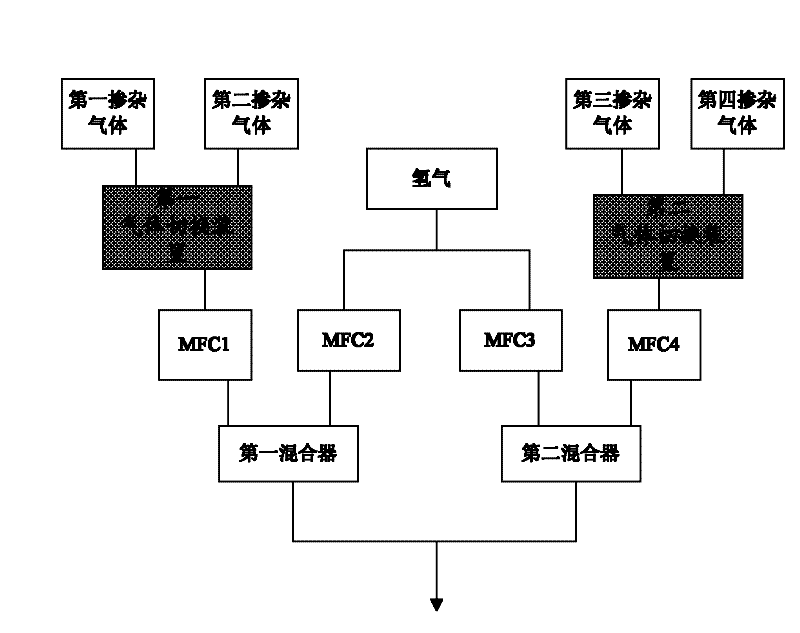

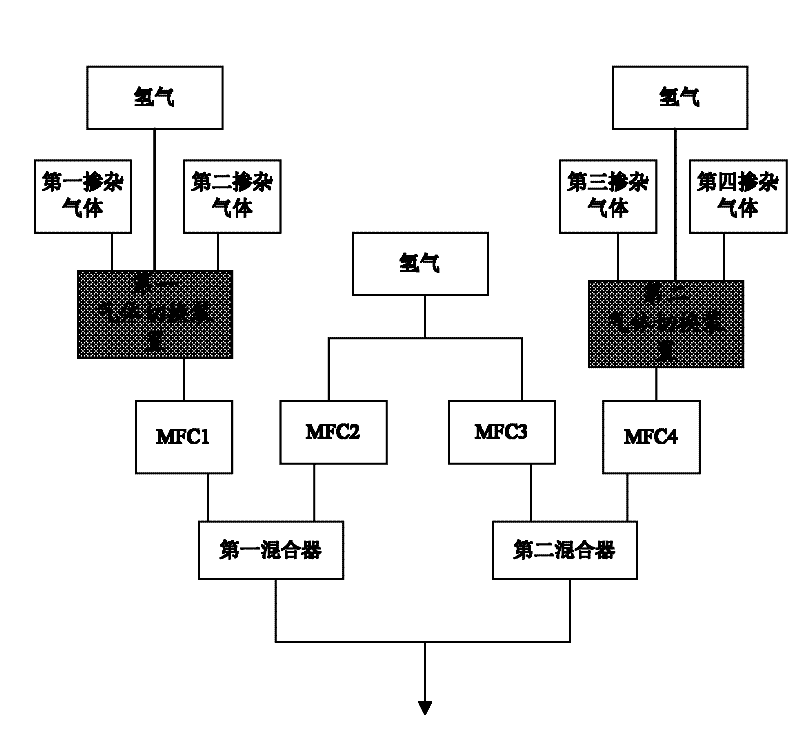

Doped gas supply equipment and doped gas supply method

InactiveCN102162138AAchieving Concentration VariationsDiffusion/dopingProcess engineeringGas supply equipment

The invention provides doped gas supply equipment and a doped gas supply method. The doped gas supply equipment comprises a first doped gas source, a second doped gas source, a first gas switching device and a first gas mass velocity controller, wherein the input end of the first gas switching device is connected to the first doped gas source and the second doped gas source so as to connect the first doped gas source and / or the second doped gas source; and the first gas mass velocity controller is connected to the output end of the first gas switching device. The doped gas supply equipment and the doped gas supply method can obtain epitaxial film resistivity adjusting capacity of wide range.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

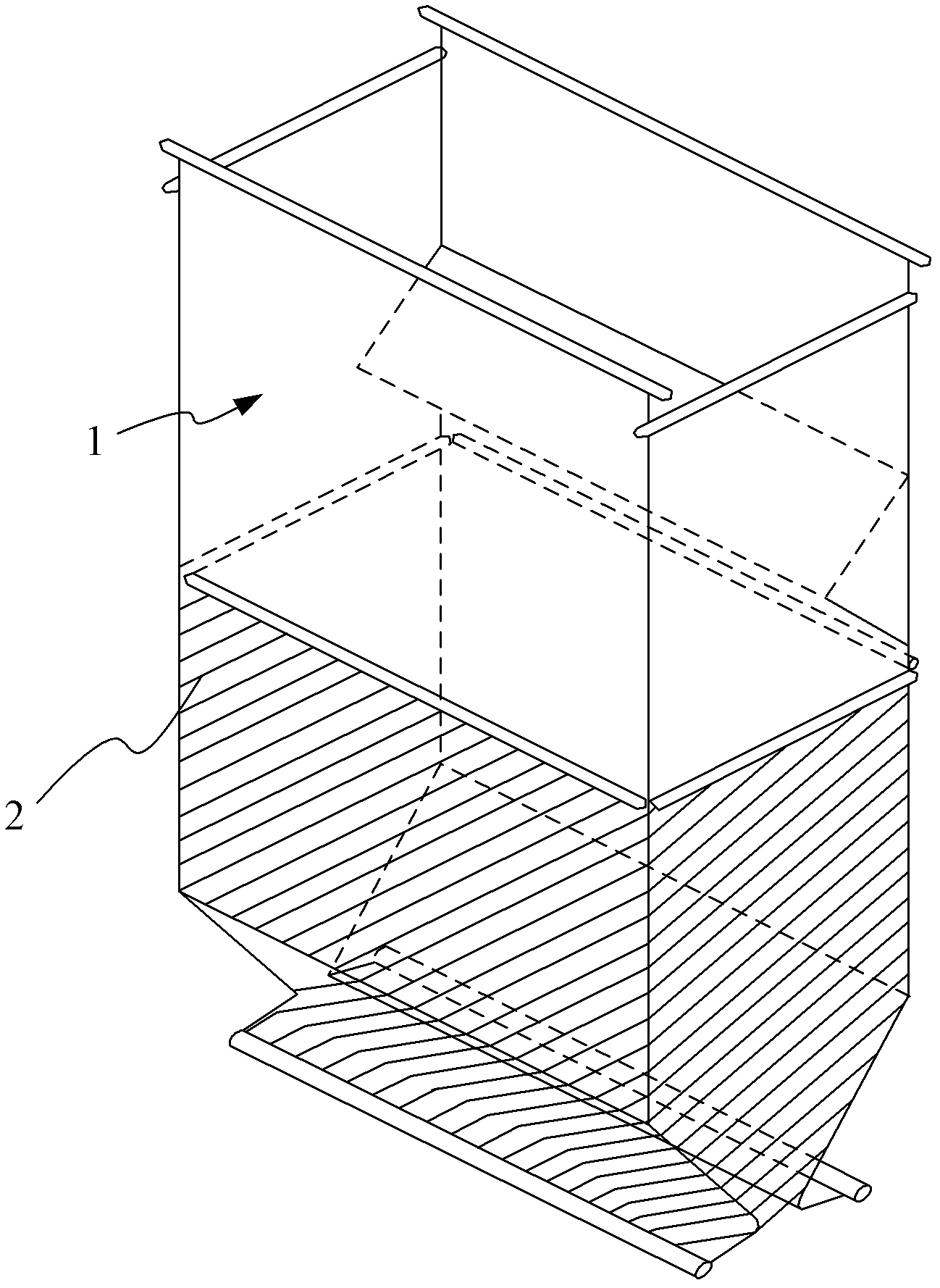

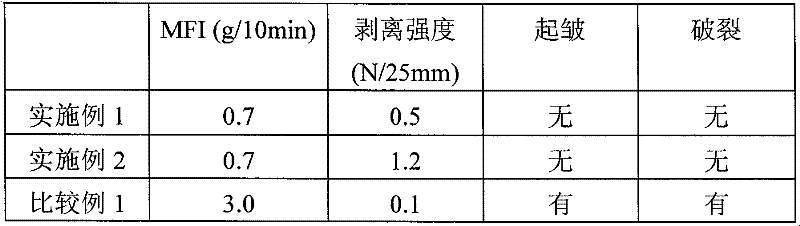

Boiler comprising water cooling system for variable-section hearth

The invention discloses a boiler comprising a water cooling system for a variable-section hearth. The boiler comprises a lower hearth and an upper hearth, the lower hearth is divided into a transitional area, a lower hearth body and an ash hopper from top to bottom, lower front and back walls, side walls and upper front and back walls are film walls, pipes and flat steel are combined to form the film walls, the water cooling system consists of spiral tubes and vertical tubes corresponding to the spiral tubes one by one, and the film walls of the lower hearth completely or partially consist of spiral tubes. The water cooling system in the boiler is simple in structure, flow rate of working media in the tubes is constant, and the problem that original flow in one tube is distributed into two or more tubes, mass velocity in each tube is reduced, and accordingly a cooling effect of the spiral tubes and corresponding vertical tubes is affected is avoided.

Owner:SHANGHAI BOILER WORKS

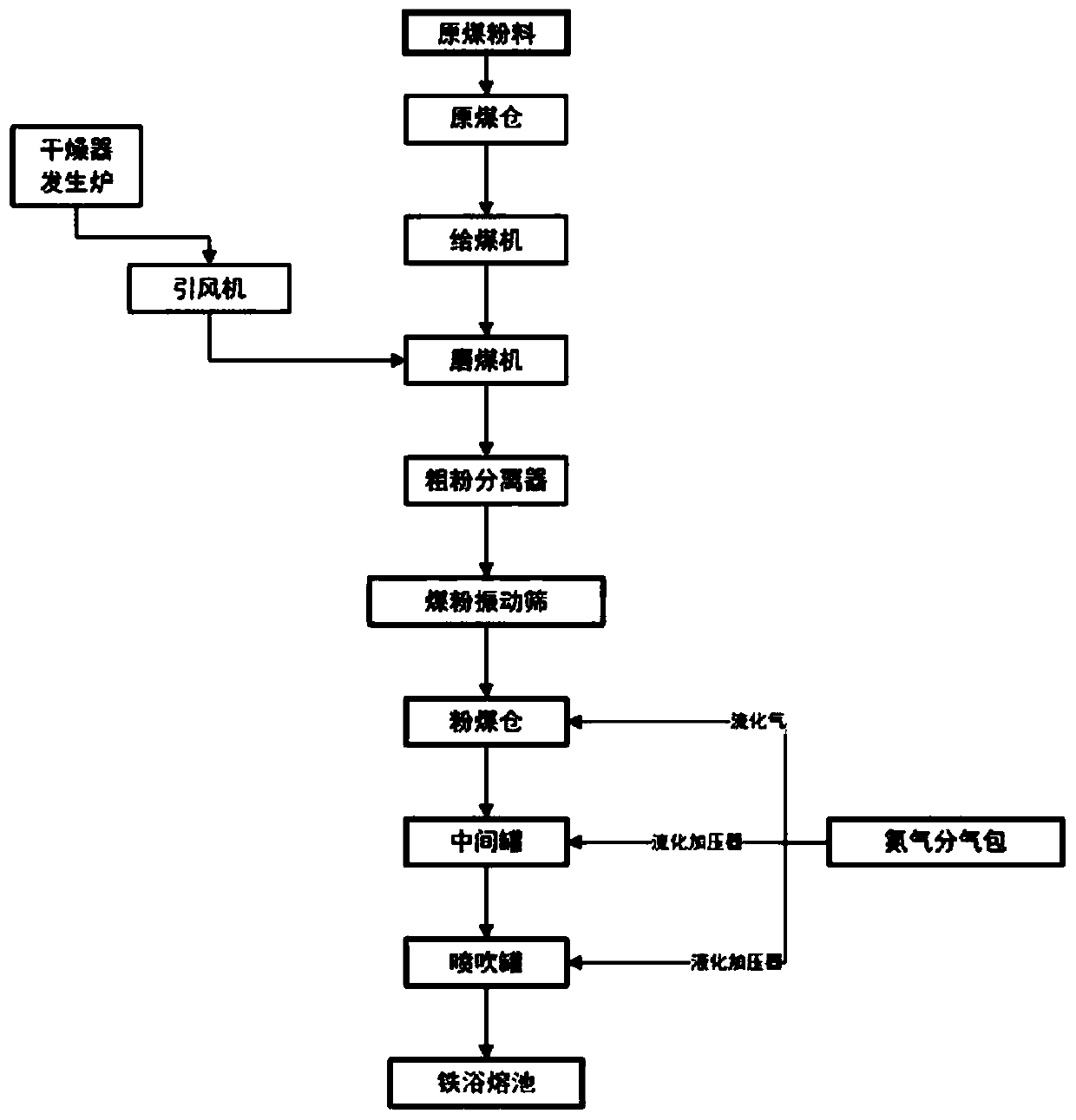

Low-concentration nitrogen pulverized coal conveying method for smelting reduction furnace

InactiveCN110055364AImproved Pneumatic Conveying DesignOptimization parametersHigh concentrationMicrometer

The invention belongs to the field of ironmaking processes, and particularly relates to a low-concentration nitrogen pulverized coal conveying method for a smelting reduction furnace. According to thetechnical scheme, the low-concentration nitrogen pulverized coal conveying method for the smelting reduction furnace includes the following steps that firstly, pulverized coal enters a coal mill through a coal feeder to be coarsely ground, and the grain diameter of the pulverized coal ranges from 53 micrometers to 178 micrometers; the coarsely-ground pulverized coal is fed into a dryer generatorfrom the coal mill, and the pulverized coal is dried at the temperature of 110-130 DEG C for 2-4 hours; the dried pulverized coal is finely ground before being jet and fed into a coarse powder separator to be treated, and then passes through a pulverized coal vibrating screen, and the grain diameter of the pulverized coal ranges from 53 micrometers to 74 micrometers; and the finely-ground pulverized coal is jet to a coal spraying pipeline through a double-tank single pipeline under distribution of nitrogen, pulverized coal high-concentration and nitrogen low-concentration jetting is kept, andthe mass velocity of the pulverized coal ranges from 0.138 kg / s to 0.55 kg / s. By means of the method, the purpose of efficiently conveying the high-concentration pulverized coal in the low-concentration nitrogen environment can be achieved.

Owner:NORTHEASTERN UNIV

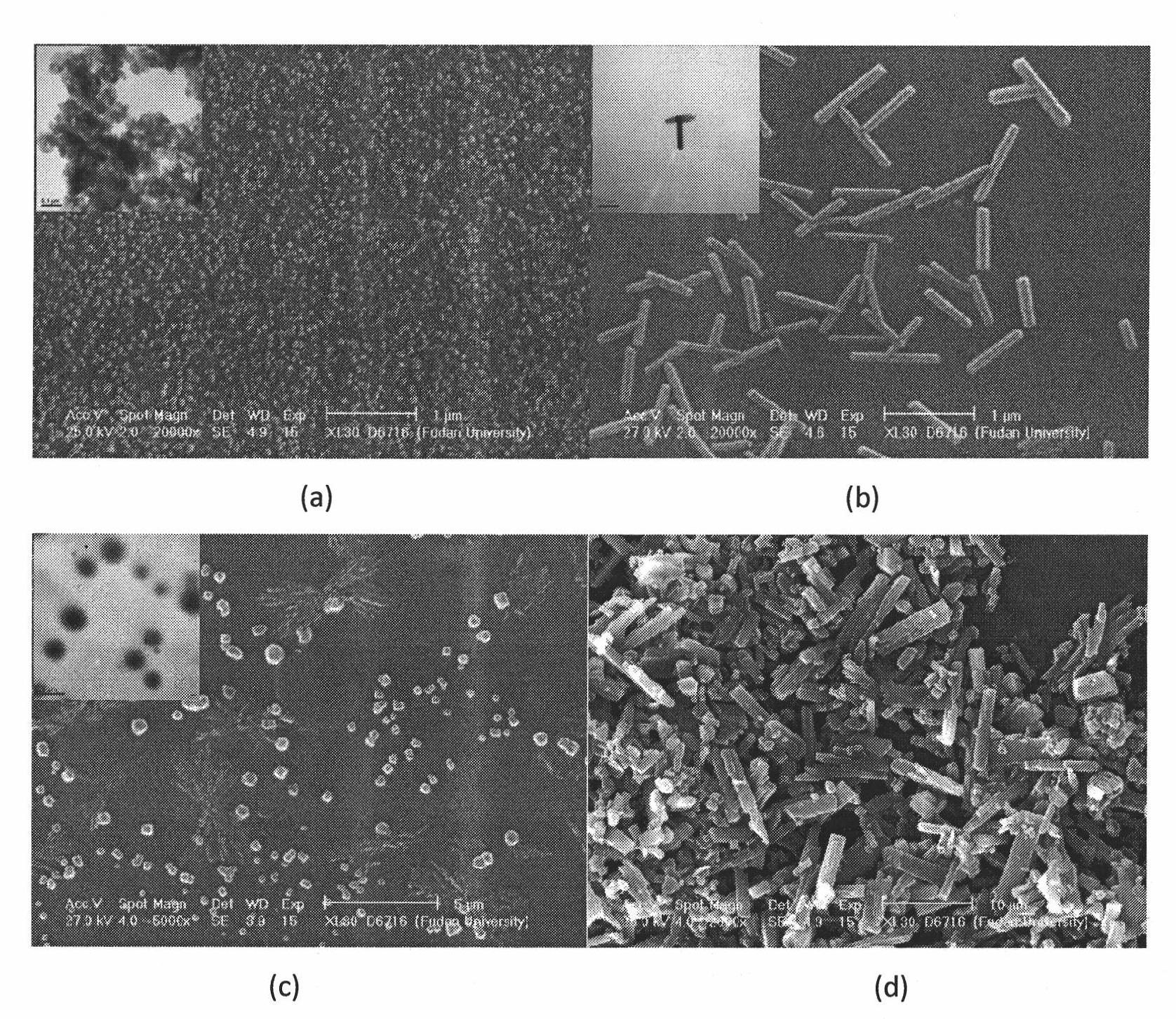

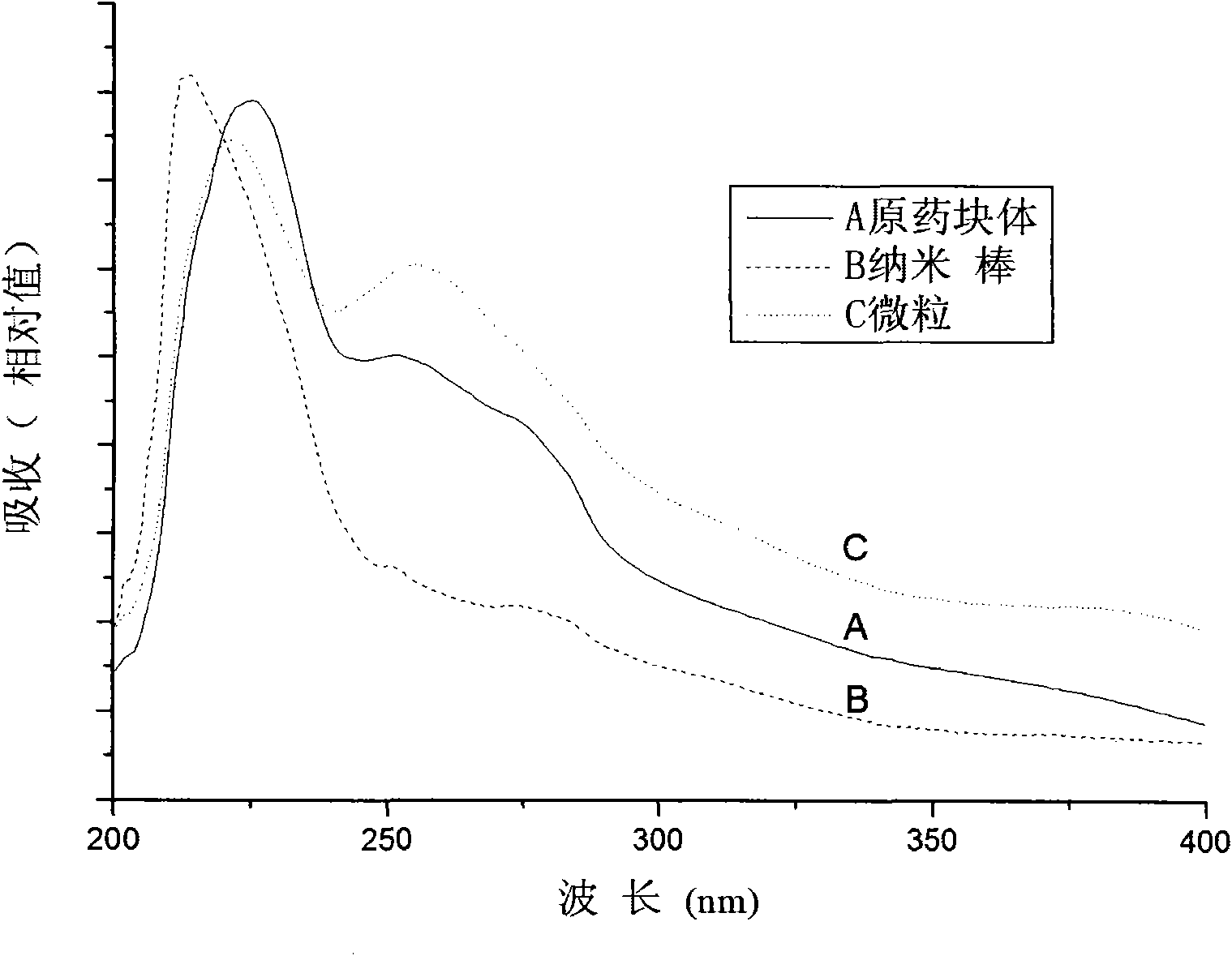

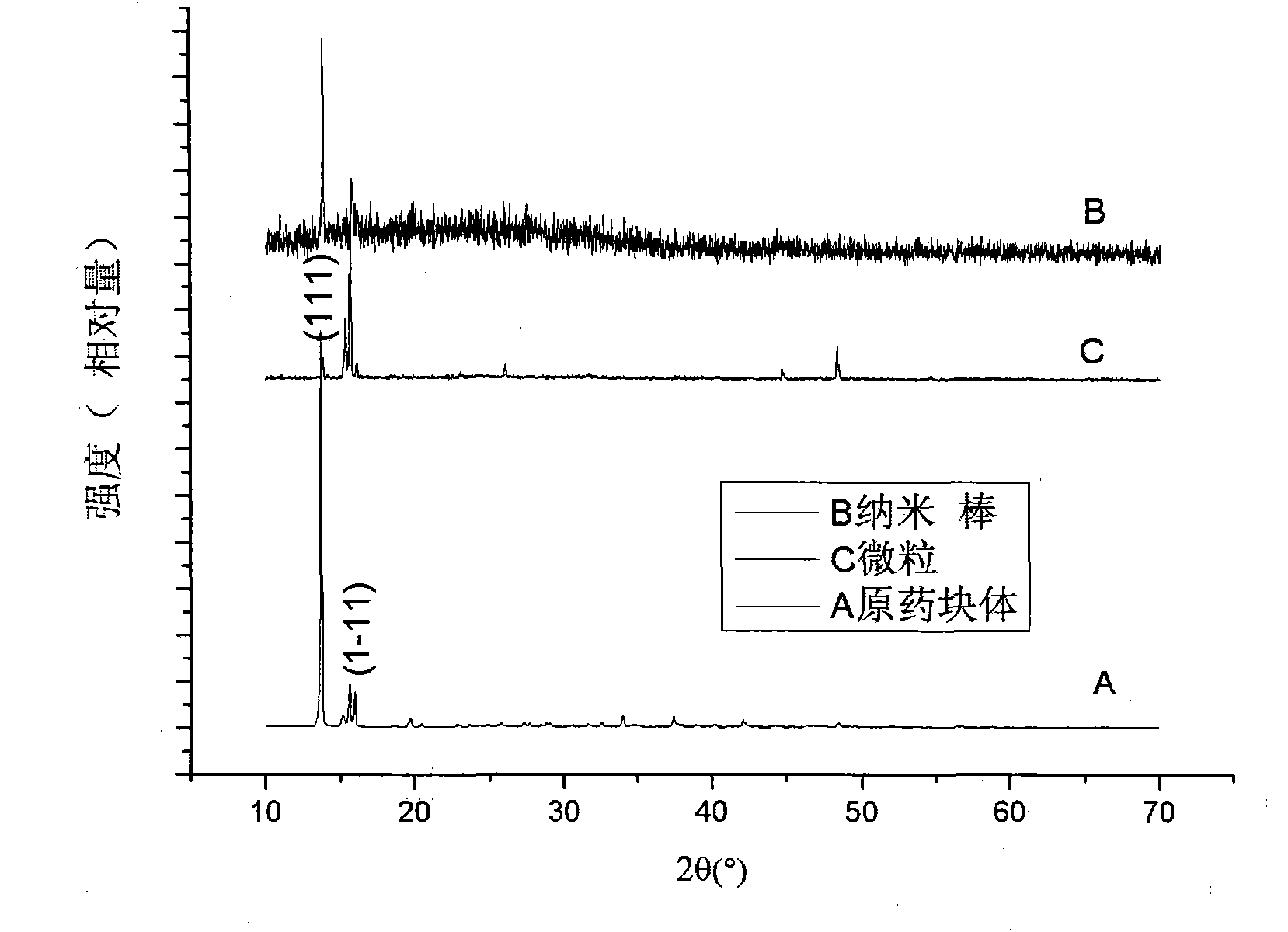

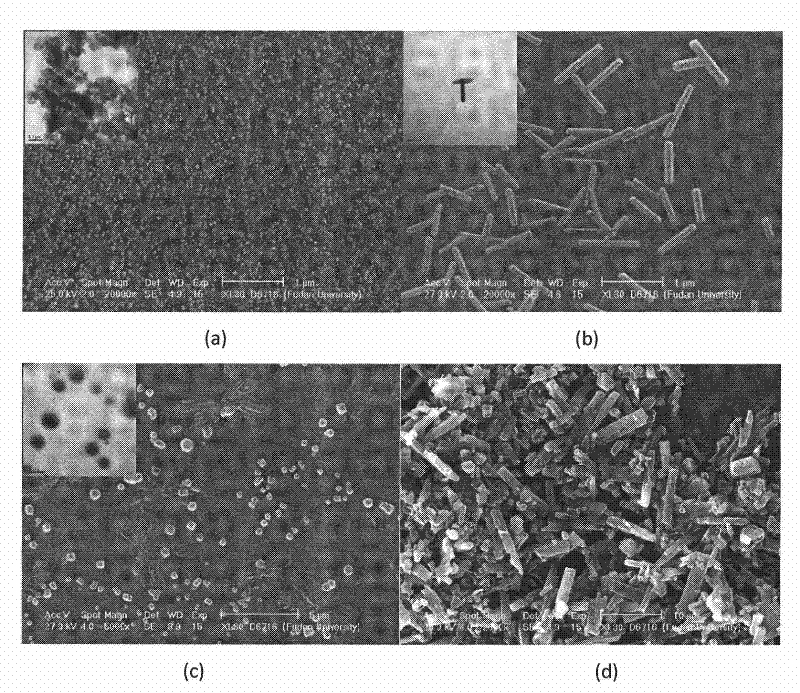

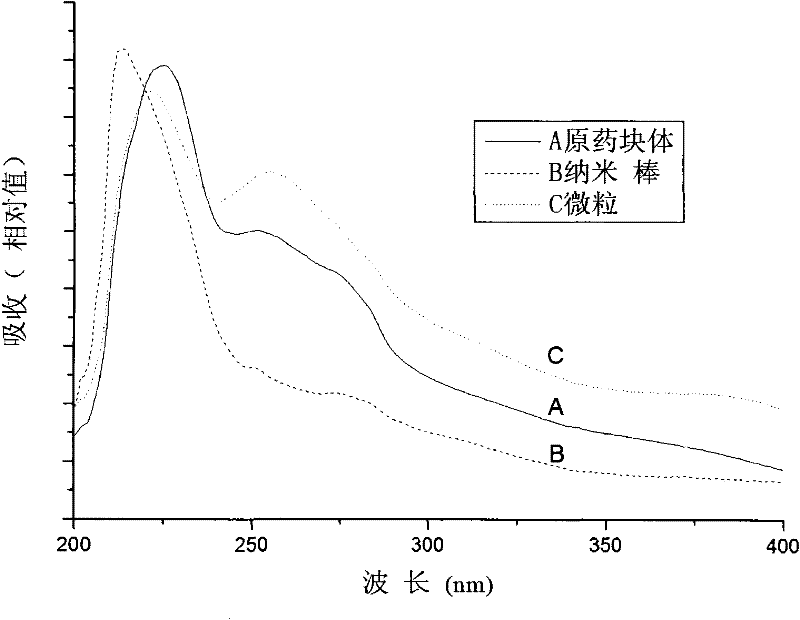

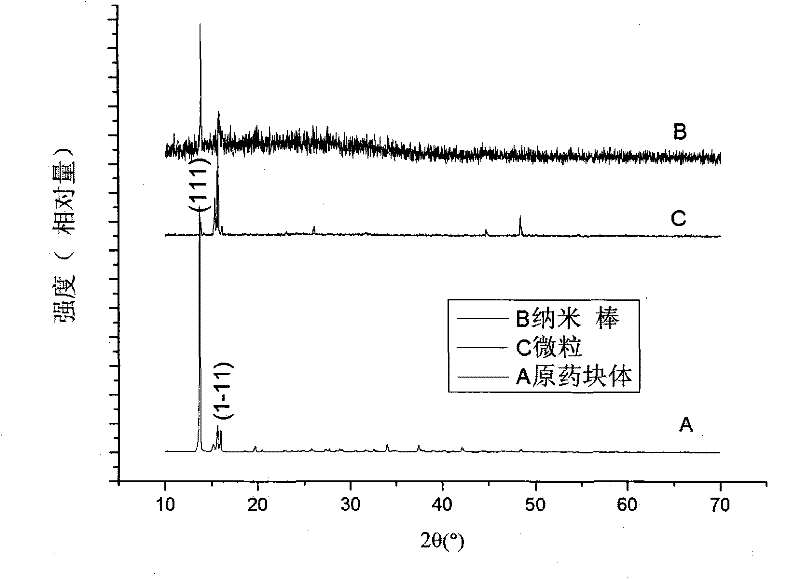

Method for preparing dichloro dicyclopentadienyl titanium and cis-platinum nano-particles by atomization ultrasound polarity difference technology

InactiveCN101773803AEasy to prepareReduce manufacturing costRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPharmaceutical product form changeMicroparticleSolvent

Belonging to the field of nano biomedicine and material, the invention in particular relates to the atomization ultrasound polarity difference technology for preparing organic metal anti-cancer drug-dichloro dicyclopentadienyl titanium and cis-platinum nano-particles. The method comprises the following steps: preparing solution A with an appropriate concentration; placing the solution A into a squeezing type sprayer and spraying the solution A into solution B; controlling environment temperature to range from 15 DEG C to 25 DEG C, environment humidity to range from 45% to 50%, ultrasound intensity to be 100w and jet mass velocity to range from 0.4mL / min to 0.5mL / min; wherein the whole reaction system is in an ultrasound environment. The method of the invention features simple equipment, convenient preparation process and low production cost. Medicine size and shape of the product can be controlled by controlling conditions such as medicine concentration in the solution A, reaction time and the like; therefore controlled production of the medicine is expected to be realized by further studies, thus providing more choices for multi-drug administration of the medicine. The method of the invention has the advantages of simple and convenient operation, short production cycle, controlled production, freedom from addition agent and easy realization of industrialization, thus being of great value for industrialized application and expected to be promoted to achieve large-scale application. In addition, the product features even distribution, difficult agglomeration, high purity and easy realization of industrialized production.

Owner:TONGJI UNIV

Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

ActiveCN102070264BLow costReduce complexityWater contaminantsMultistage water/sewage treatmentLiquid wasteThiocyanate

The invention discloses a method for removing cyanide, thiocyanate, COD and arsenic in waste liquid, comprising the following steps: the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid are deeply treated by utilizing ozonized gas, a mode with continuous treatment and direct discharge can be adopted, also a mode with batch treatment and intermittent discharge can be adopted, and the implementation process of the method is easy to control; in the range of the pH value with sectioned control, the generation concentration and mass velocity of ozone do not need to be requiredstrictly, the problem that single technology can not treat the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid deeply can be solved, the cost and the operation complexity of technological equipment are reduced, and the environmental pollution is reduced; solid suspensions (SS) in the treated waste liquid is removed by settlement, and clear liquor is directly discharged outwards or returned to the upstream technology for repeated use; the contents of pollutants in the treated waste liquid are stable, the total content of the cyanide is less than 0.2mg / L(waste water); the content of the thiocyanate is less than 5mg / L(waste water); the total content of the COD is less than 30mg / L; the total content of the arsenic is less than 0.5mg / L(waste water), and no secondary pollutants are generated in the reaction process.

Owner:CHANGCHUN GOLD RES INST +1

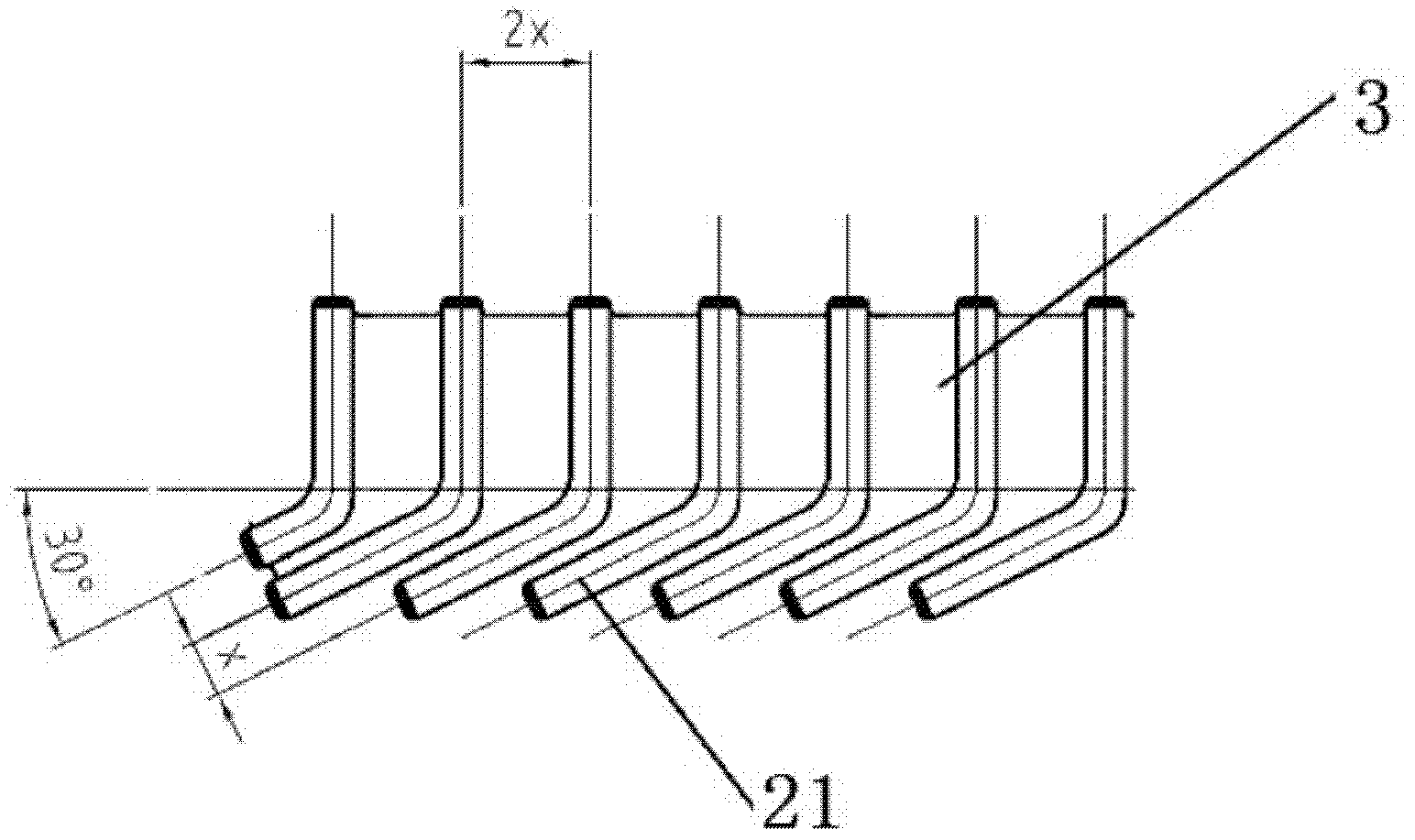

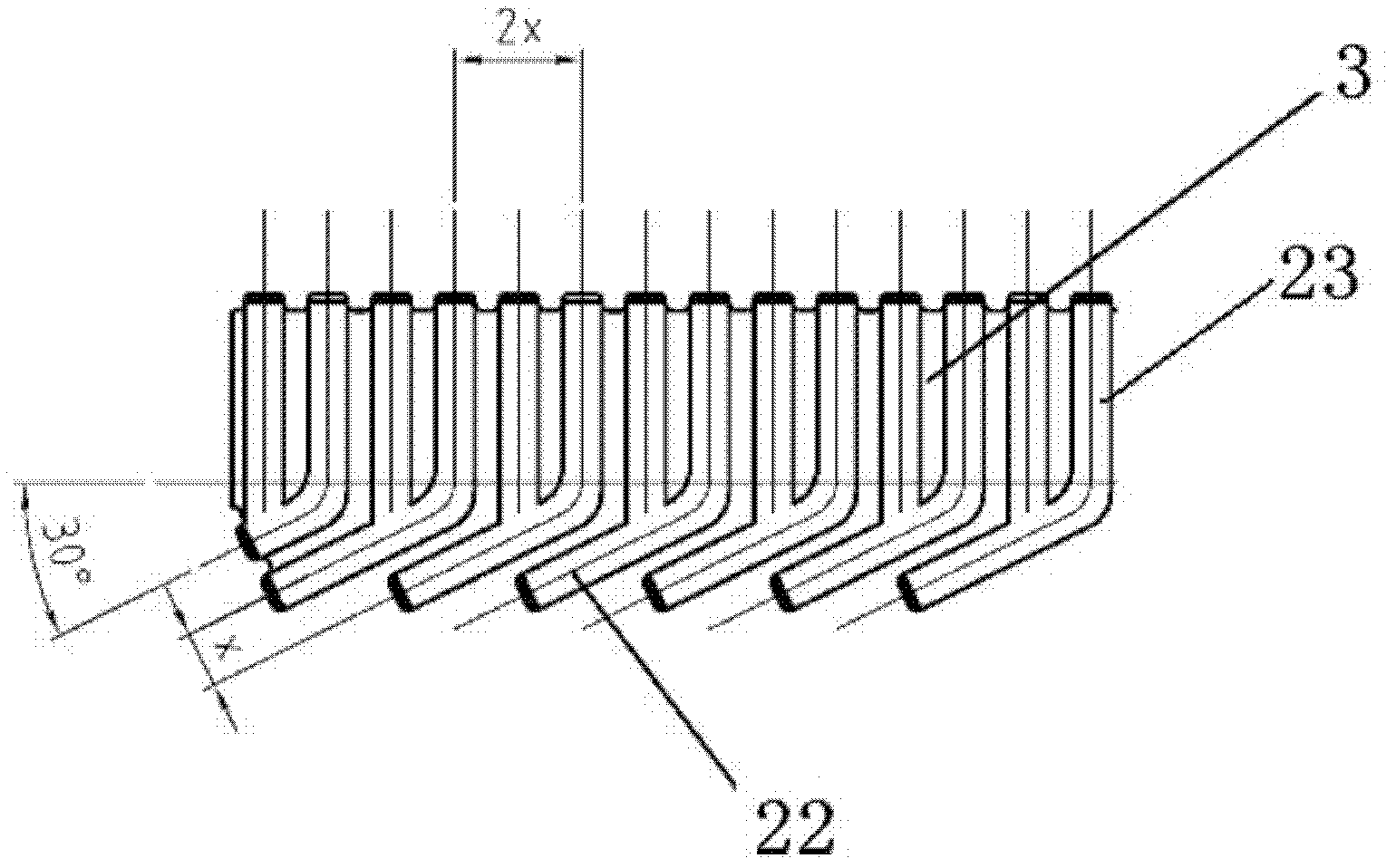

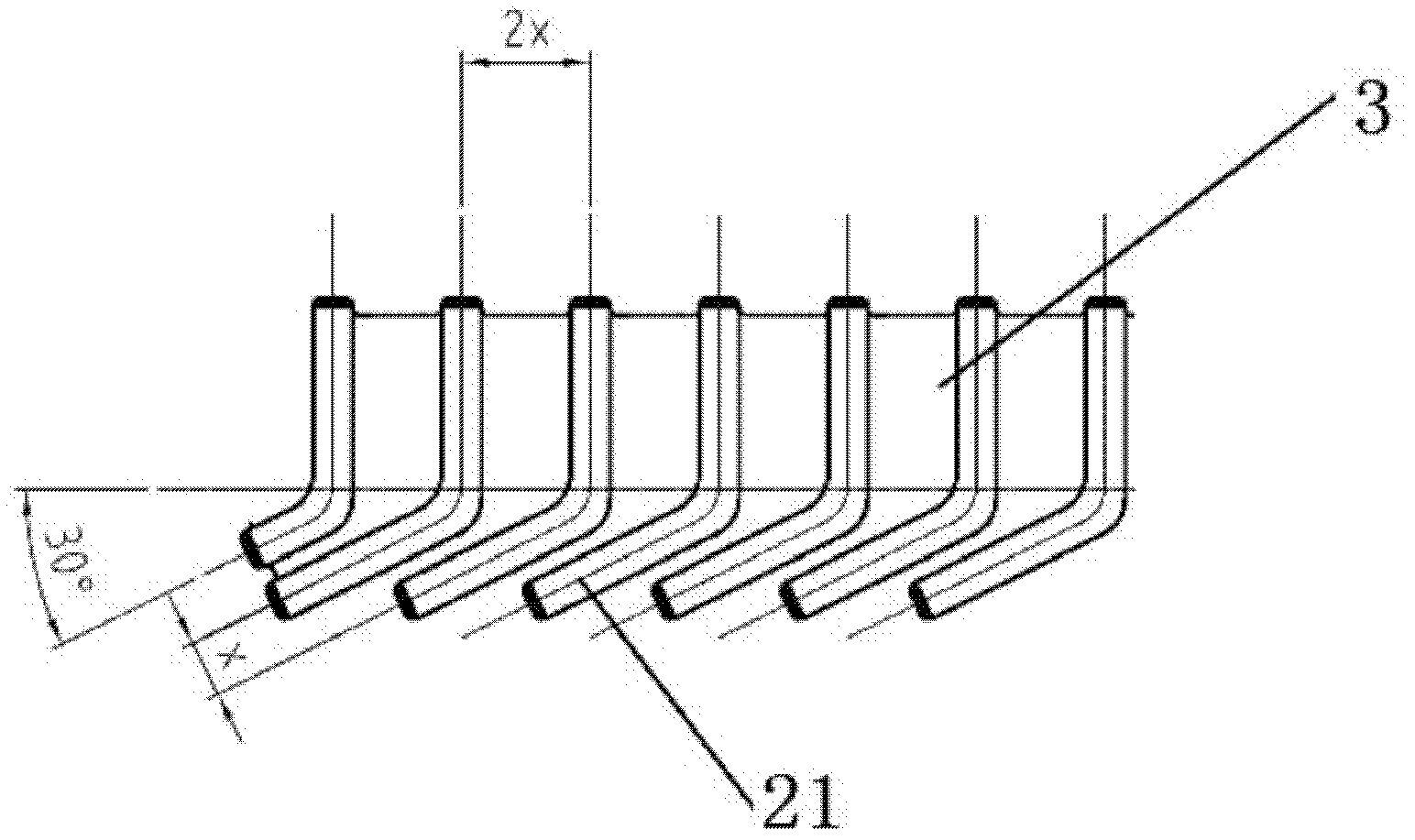

High-efficiency evaporation type fin heat exchanger

InactiveCN101408361AImprove heat transfer coefficientReduce manufacturing costEvaporators/condensersHeat transmissionEvaporation

The invention discloses a high-efficiency evaporative fin heat exchanger, comprising a gas-collecting pipe, a collecting pipe and a gas outlet pipe. One end of the collecting pipe is formed by integrating the gas-collecting pipe through a plurality of loops and a plurality of branches derive from the other end of the collecting pipe and each branch is communicated with the plurality of loops to be integrated into the vent pipe. For the high-efficiency evaporative fin heat exchanger provided by the invention, the liquid refrigerant is converted into gaseous refrigerant in the fin heat exchanger; the mass velocity of the refrigerant is maintained but the volume velocity changes along with the changing of the refrigerant density during the process; the liquid refrigerant is converted into gaseous refrigerant under heat-absorbing in the evaporative fin heat exchanger; as the enlarging of the specific gravity of the gaseous refrigerant, the volume velocity of refrigerant rises gradually; when the specific gravity of the gaseous refrigerant occupies three loops, the conversion is finished through a pant-type three-way; and the heat transmission coefficient is enhanced and the increase of one loop occupied by refrigerant reduces the manufacturing cost of the unit while the specific gravity of the gaseous refrigerant rises.

Owner:山东奇威特人工环境有限公司

Fiber optic sensor and method for detecting shock wave pressure and mass velocity in solid media

A fiber optic pressure and mass velocity sensor for measuring a shock wave pressure in a solid media includes an optical fiber having a means for measuring a change in an optical path length (OPL) of the fiber when positioned in the solid media caused by the shock wave altering the physical length of the fiber and the refractive index of the fiber. The means for measuring the change in the OPL is coupled at one end to a laser and at its second end to a means for detecting the change in OPL. The sensor has a high operating bandwidth (>>10 MHz), is sufficiently rigid to withstand the force of the shock wave, has a sensitivity that can also be tailored for the application, and is immune to electromagnetic interference. Measurement can be made on materials under extreme strain conditions, and the sensor can also provide characterization of protective materials such as bullet / blast proof materials.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

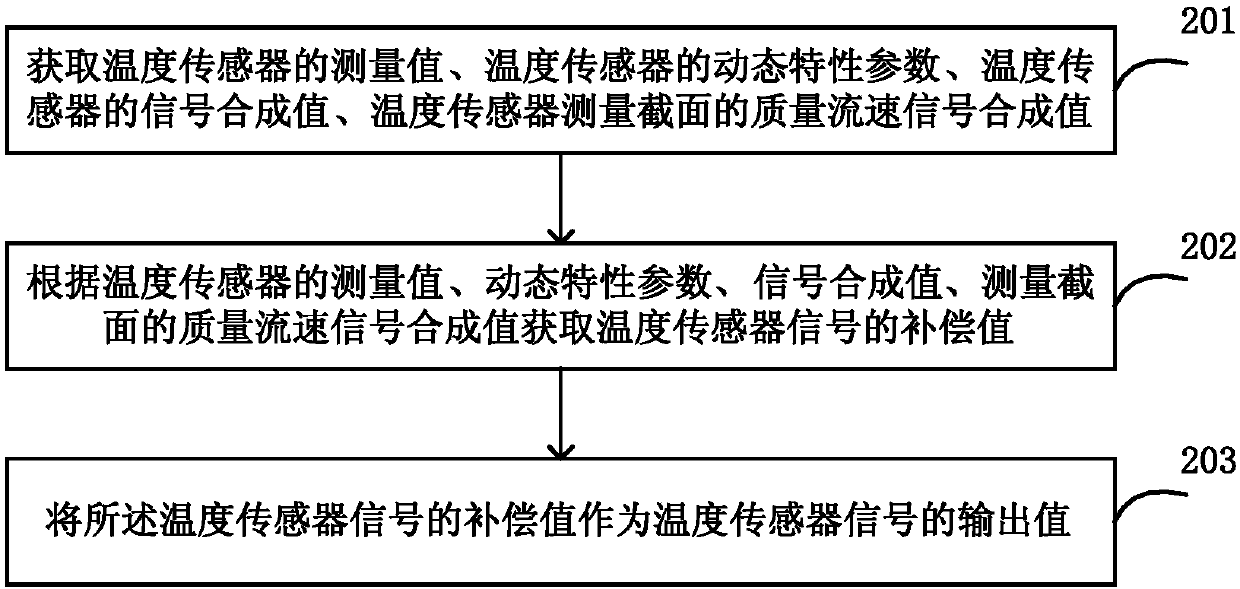

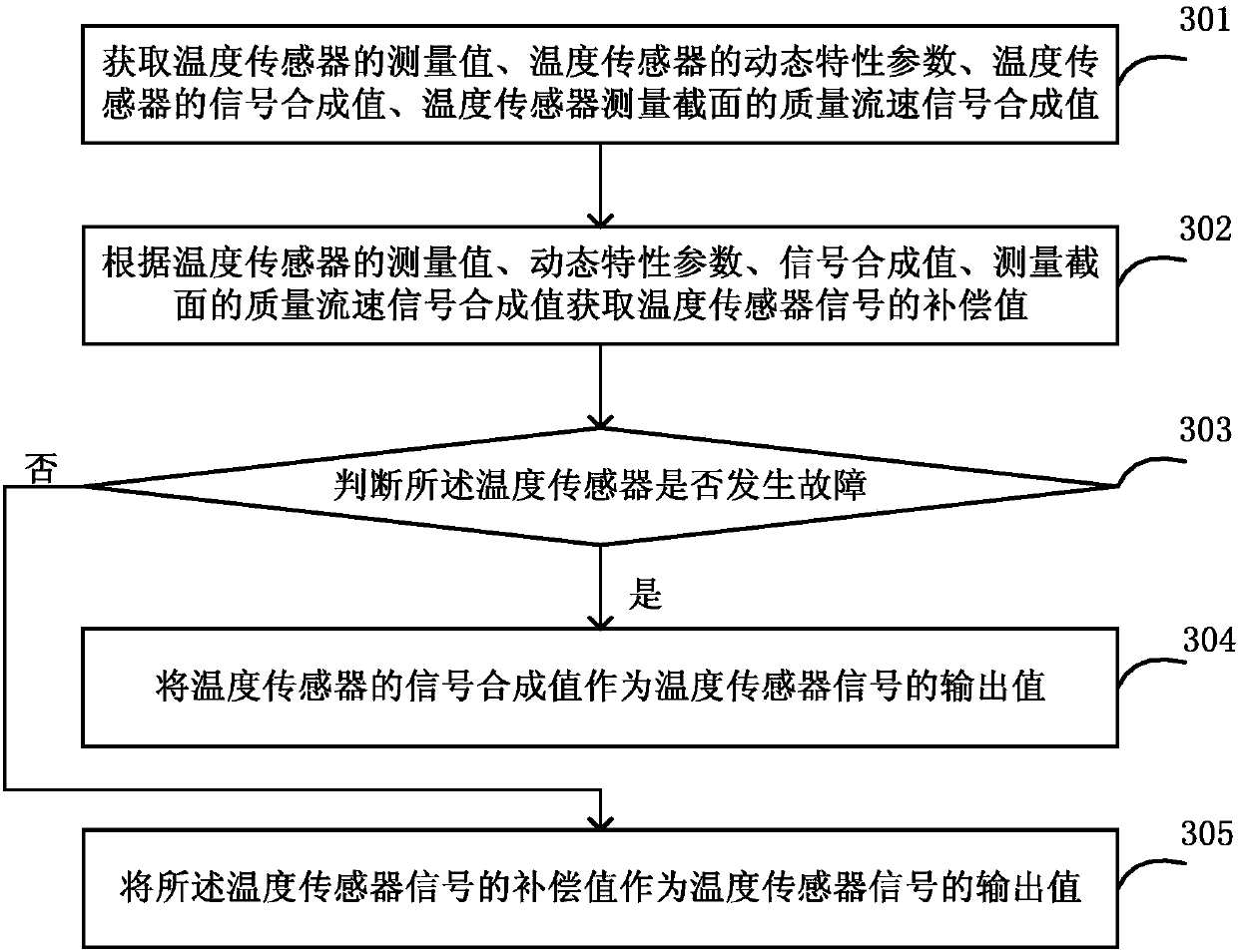

Temperature sensor signal compensation methods and devices and computer readable memory medium

ActiveCN110006548AAchieve high precision compensationThermometers using electric/magnetic elementsUsing electrical meansCompensation methodsMass velocity

The invention discloses temperature sensor signal compensation methods and devices and a computer readable memory medium. A method comprises the steps of obtaining a measured value of a temperature sensor, a dynamic characteristic parameter of the temperature sensor, a signal synthesized value of the temperature sensor and a mass velocity signal synthesized value of a temperature sensor measured section; obtaining a compensation value of a temperature sensor signal according to the measured value of the temperature sensor, the dynamic characteristic parameter of the temperature sensor, the signal synthesized value of the temperature sensor and the mass velocity signal synthesized value of the temperature sensor measured section; and taking the compensation value of the temperature sensor signal as an output value of the temperature sensor signal. According to the methods, the devices and the computer readable memory medium, influence of gas flow temperature itself on a sensor characteristic is taken into consideration, influence of various factors on a measured error of the temperature sensor is taken into consideration relatively comprehensively, and high precision compensation ofthe measured signal of the temperature sensor is realized.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Method for preparing dichloro dicyclopentadienyl titanium and cis-platinum nano-particles by atomization ultrasound polarity difference technology

InactiveCN101773803BEasy to prepareReduce manufacturing costRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPharmaceutical product form changeMicroparticleDrug administration

Belonging to the field of nano biomedicine and material, the invention in particular relates to the atomization ultrasound polarity difference technology for preparing organic metal anti-cancer drug-dichloro dicyclopentadienyl titanium and cis-platinum nano-particles. The method comprises the following steps: preparing solution A with an appropriate concentration; placing the solution A into a squeezing type sprayer and spraying the solution A into solution B; controlling environment temperature to range from 15 DEG C to 25 DEG C, environment humidity to range from 45% to 50%, ultrasound intensity to be 100w and jet mass velocity to range from 0.4mL / min to 0.5ml / min; wherein the whole reaction system is in an ultrasound environment. The method of the invention features simple equipment, convenient preparation process and low production cost. Medicine size and shape of the product can be controlled by controlling conditions such as medicine concentration in the solution A, reaction time and the like; therefore controlled production of the medicine is expected to be realized by further studies, thus providing more choices for multi-drug administration of the medicine. The method of the invention has the advantages of simple and convenient operation, short production cycle, controlled production, freedom from addition agent and easy realization of industrialization, thus being of great value for industrialized application and expected to be promoted to achieve large-scale application. In addition, the product features even distribution, difficult agglomeration, high purity and easy realization of industrialized production.

Owner:TONGJI UNIV

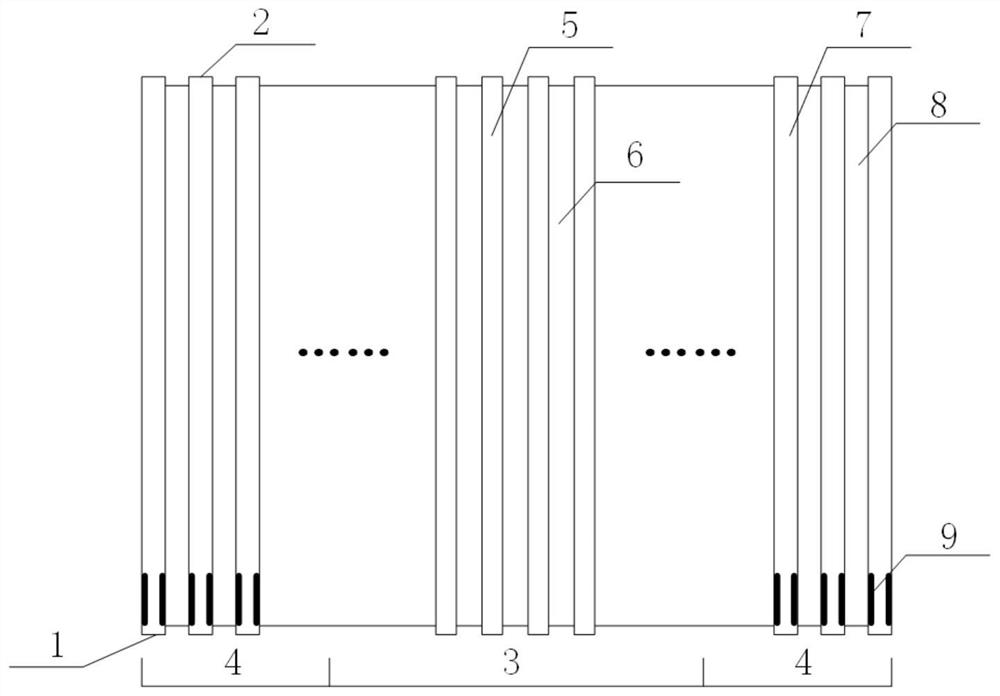

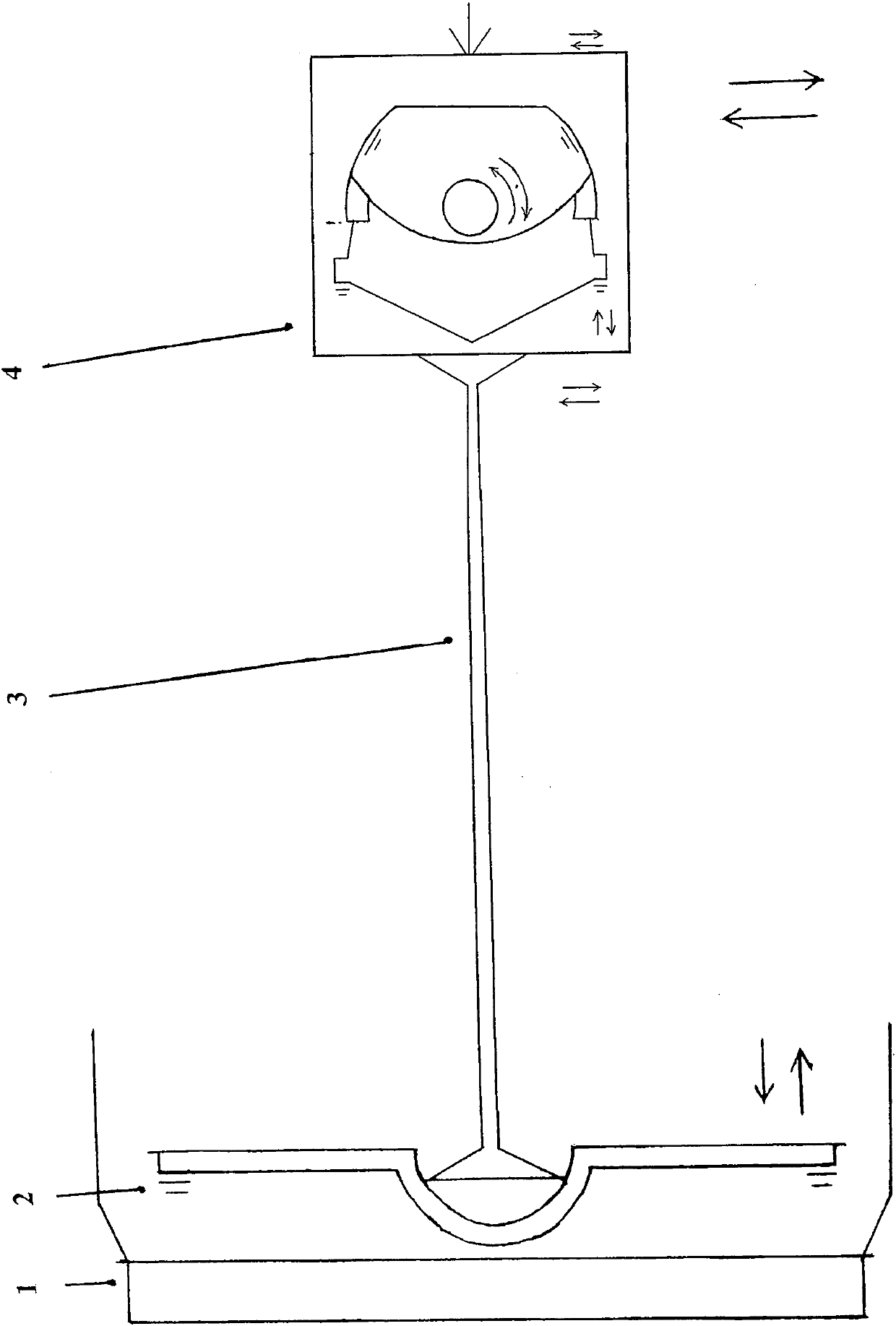

700-DEG-C boiler water wall arrangement structure capable of inhibiting negative flow response characteristics

PendingCN111780080AReduced negative flow response characteristicsIncrease resistanceBoiler water tubesWater-tube boilersSupercritical steam generatorThermodynamics

The invention discloses a 700-DEG-C boiler water wall arrangement structure capable of inhibiting negative flow response characteristics. The 700-DEG-C boiler water wall arrangement structure comprises water wall tube inlets, water wall tube outlets, a high heat load area water wall, low heat load area water walls, high heat load area water wall tubes, high heat load area water wall fins, low heatload area water wall tubes, low heat load area water wall fins and low heat load area water wall tube inlet throttle rings. Through the comprehensive consideration of the negative flow response characteristics of an ultra-supercritical boiler water wall and the strict restrictions of a 700-DEG-C boiler to the wall temperature deviation, the tubes of relatively small tube diameters are arranged ina high heat load area, and meanwhile, the tubes of relatively large tube diameters are arranged in low heat load areas and equipped with the inlet throttle rings; and through the structural arrangement and the design of resistance characteristics, the mass velocity of the high heat load area water wall tubes is relatively high, the mass velocity of the low heat load area water wall tubes is relatively low, the wall temperature deviation caused by the negative flow response characteristics is effectively inhibited, and the water wall local overtemperature risk of the 700-DEG-C boiler is remarkably reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Boiler comprising water cooling system for variable-section hearth

The invention discloses a boiler comprising a water cooling system for a variable-section hearth. The boiler comprises a lower hearth and an upper hearth, the lower hearth is divided into a transitional area, a lower hearth body and an ash hopper from top to bottom, lower front and back walls, side walls and upper front and back walls are film walls, pipes and flat steel are combined to form the film walls, the water cooling system consists of spiral tubes and vertical tubes corresponding to the spiral tubes one by one, and the film walls of the lower hearth completely or partially consist of spiral tubes. The water cooling system in the boiler is simple in structure, flow rate of working media in the tubes is constant, and the problem that original flow in one tube is distributed into two or more tubes, mass velocity in each tube is reduced, and accordingly a cooling effect of the spiral tubes and corresponding vertical tubes is affected is avoided.

Owner:SHANGHAI BOILER WORKS

Manufacturing method of heat product

InactiveCN101152775BAvoid wrinklesPrevent peelingSynthetic resin layered productsTectorial membraneUltimate tensile strength

The present invention provides a method for manufacturing thermal forming product. The method includes thermal forming the thermoplastic resin plate laminated with protection film. The protection film is made of resin material. The resin material has a fondant mass velocity less than 1g / 10 minute at 190 DEG C under the load of 2.16kg, and the peeling strength of the protection film relative to the thermoplastic resin plate is not less than 04.N / 25mm after heated to 200 DEG C.

Owner:SUMITOMO CHEM CO LTD

Gravity machine main body master piece device capable of spontaneous rolling under action of practical overhead overweight inertia mass

InactiveCN107664101ASimple structureImprove performanceMachines/enginesMotorsEngineeringGravity center

A kind of device for the main part of the gravity machine with super-heavy inertial mass spontaneously rolling in the sky, after being bent and deformed in the unilateral load-bearing rolling of the ultra-firm special board, the spring on the outer edge of the load-bearing support on the vertical point, and the super-long elastic steel sheet Dedicated upright oscillating body that must bounce back quickly moves in the sky. In the upright type, above the super high position of the center of gravity, on the support rod, the support rod must rebound rapidly after the rod is bent and deformed; The huge shape on the top is dedicated to the extremely heavy roller on the huge arc-shaped raceway on the very long elastic steel sheet with a small standing point and the spring on the very long path on the rebounding cyclical shaking motion layer after being tilted. Under the high-speed impact of huge mass and huge inertia, the springs are connected to each other on the extremely heavy wheel-speed rolling motion box that can bounce back quickly after being compressed and must roll back to the neutral position for a long time and can spontaneously circulate for a long time. Move in the sky.

Owner:陈明 +1

Refrigeration cycle device

ActiveCN104126099BGood shunt characteristicsMechanical apparatusEvaporators/condensersEngineeringRefrigeration

An object of the present invention is to provide a refrigeration cycle device capable of realizing good flow distribution characteristics under a wide range of usage conditions without being affected by installation postures of refrigerant flow dividers, manufacturing differences, and the like. The refrigeration cycle device includes: a compressor for compressing the refrigerant; a condenser for condensing the refrigerant compressed by the compressor; and an expansion valve (3) for decompressing the refrigerant condensed by the condenser; A splitter (4) that is separate from the expansion valve (3) and diverts the refrigerant decompressed by the expansion valve (3) to a plurality of flow paths formed inside; and the splitter ( 4) An evaporator for evaporating the divided refrigerant, wherein the expansion valve (3) and the flow divider (4) are configured in such a way that L / D≤1.2G0.36 and L / D≥1.5. Where, L[m] is the distance from the throttling area (300) of the expansion valve (3) to the branching area (400) of the flow divider (4), D[m] is the second connecting pipe of the expansion valve (3) The inner diameter of (32), G[kg / (m2s)] is the mass velocity of refrigerant flowing in the second connecting pipe (32) of the expansion valve.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com