Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Joint injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In medicine, a joint injection (intra-articular injection) is a procedure used in the treatment of inflammatory joint conditions, such as rheumatoid arthritis, psoriatic arthritis, gout, tendinitis, bursitis, Carpal Tunnel Syndrome, and occasionally osteoarthritis. A hypodermic needle is injected into the affected joint where it delivers a dose of any one of many anti-inflammatory agents, the most common of which are corticosteroids. Hyaluronic acid, because of its high viscosity, is sometimes used to replace bursa fluids. The technique may be used to also withdraw excess fluid from the joint.

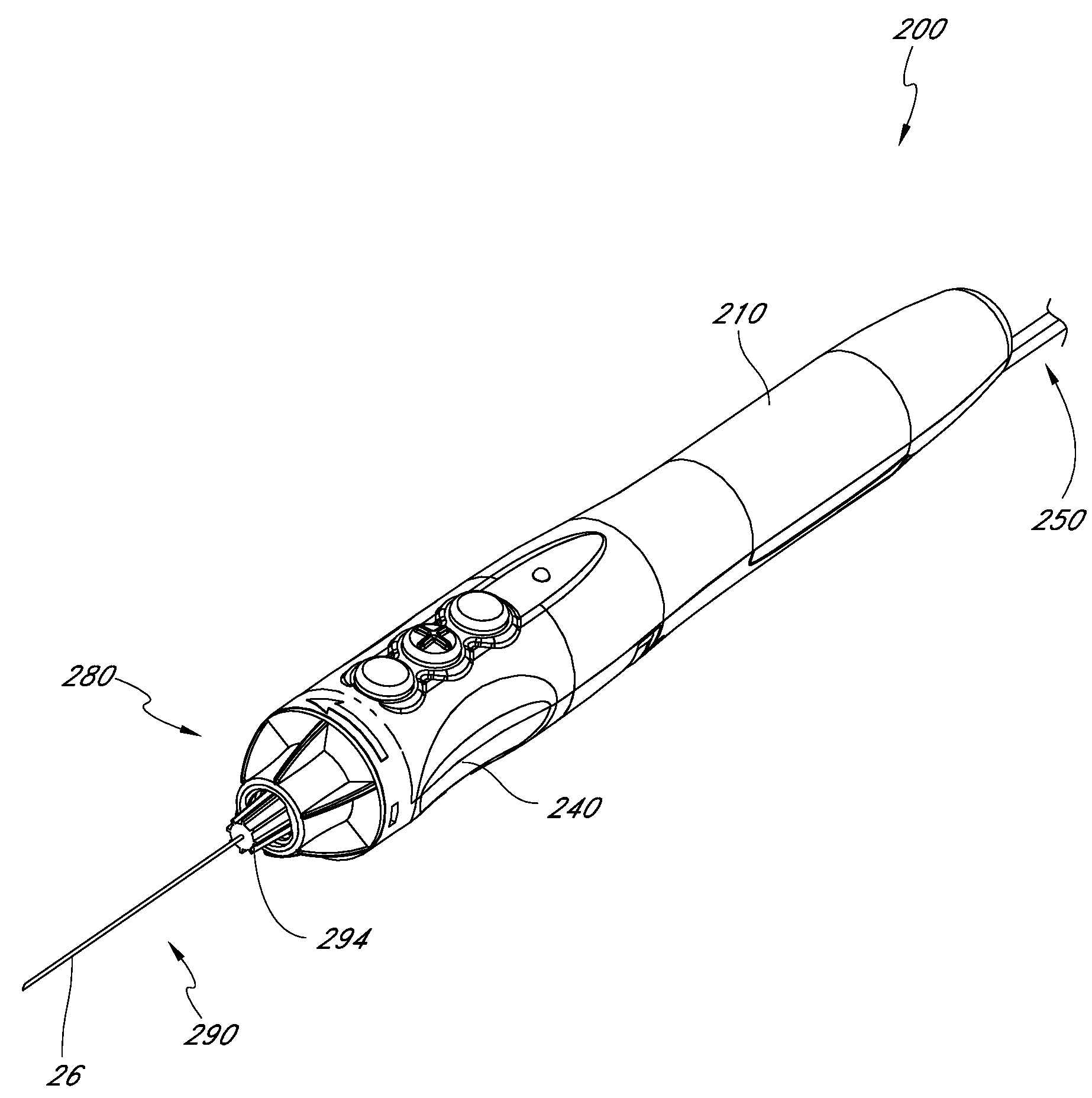

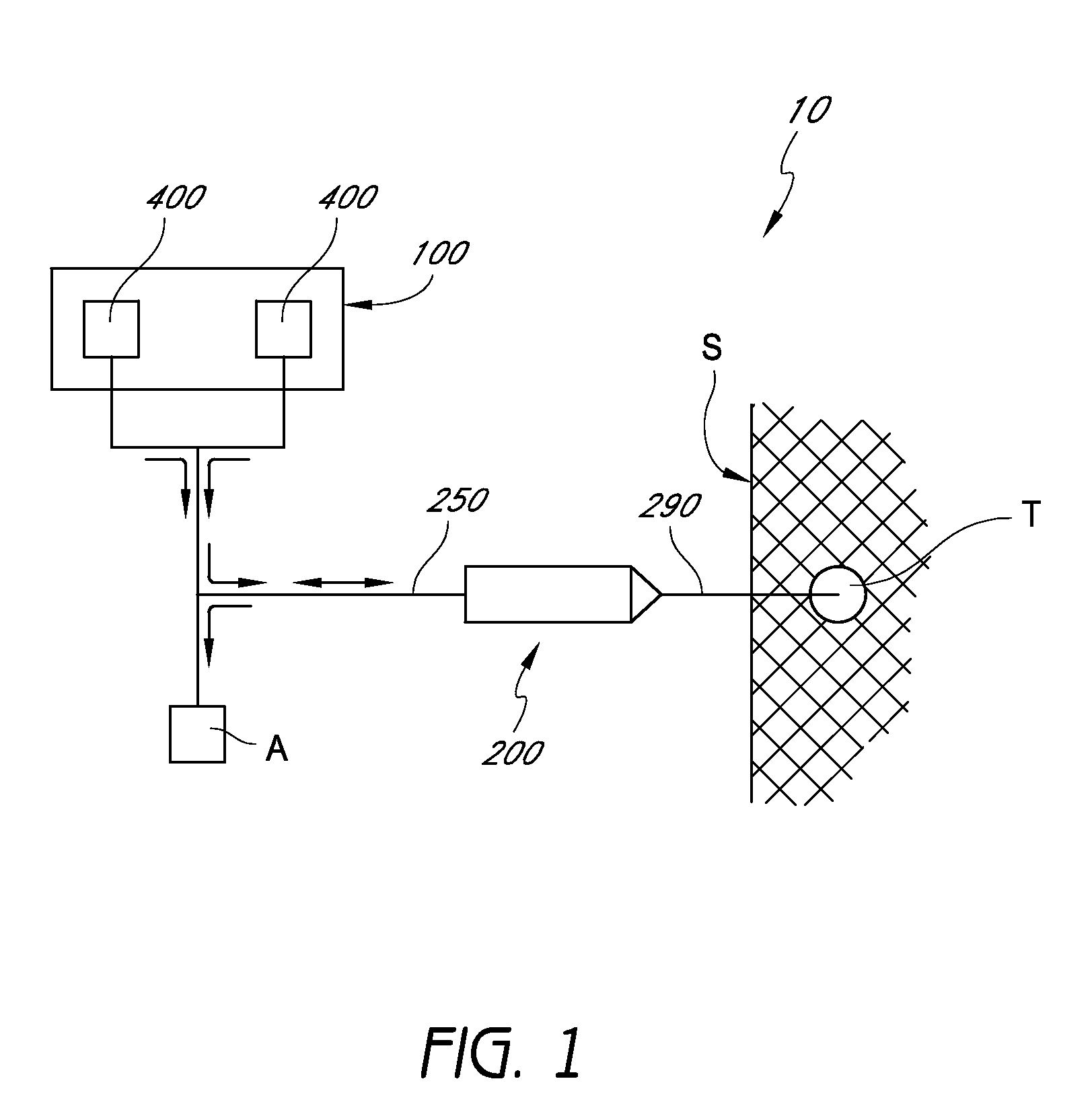

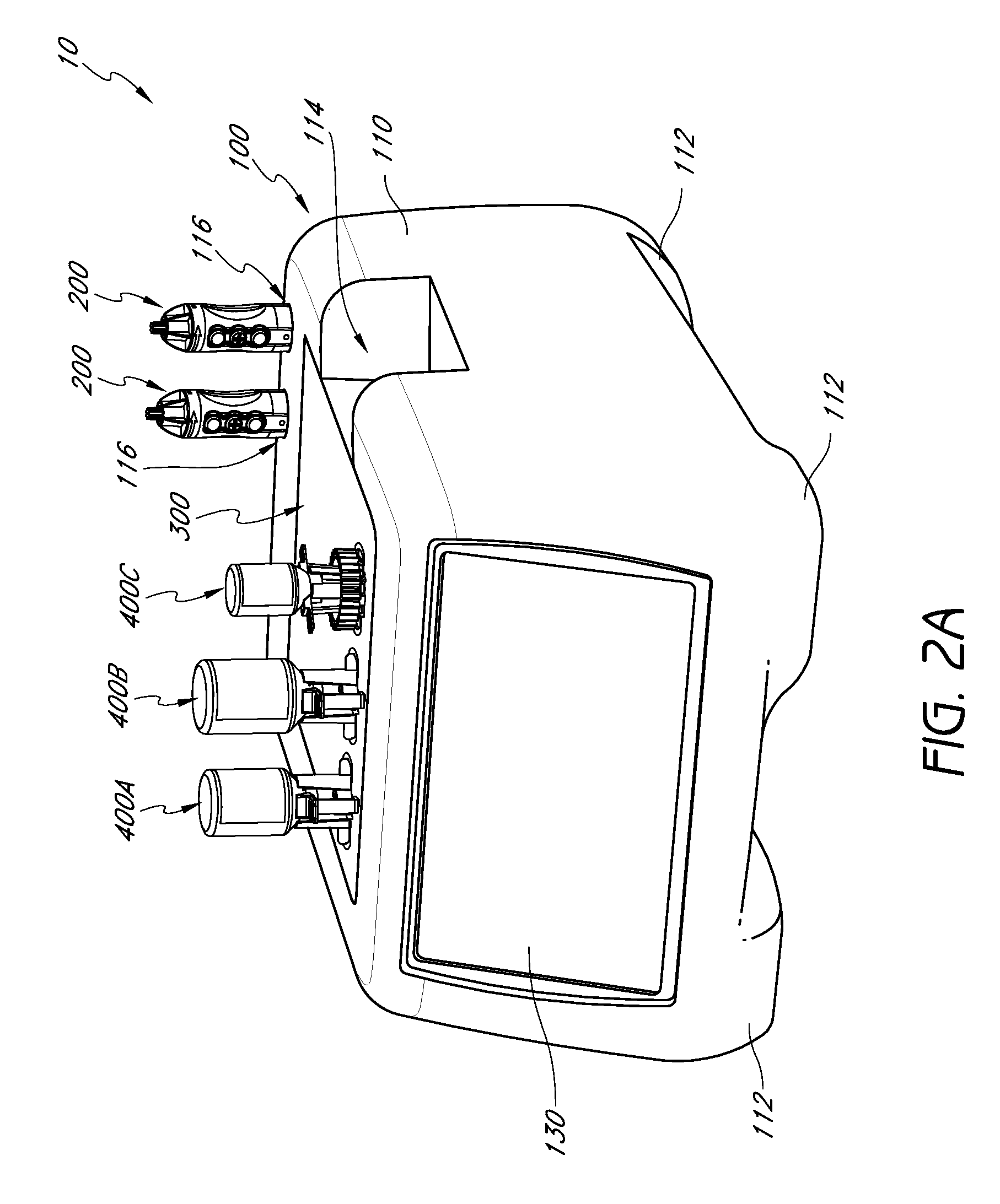

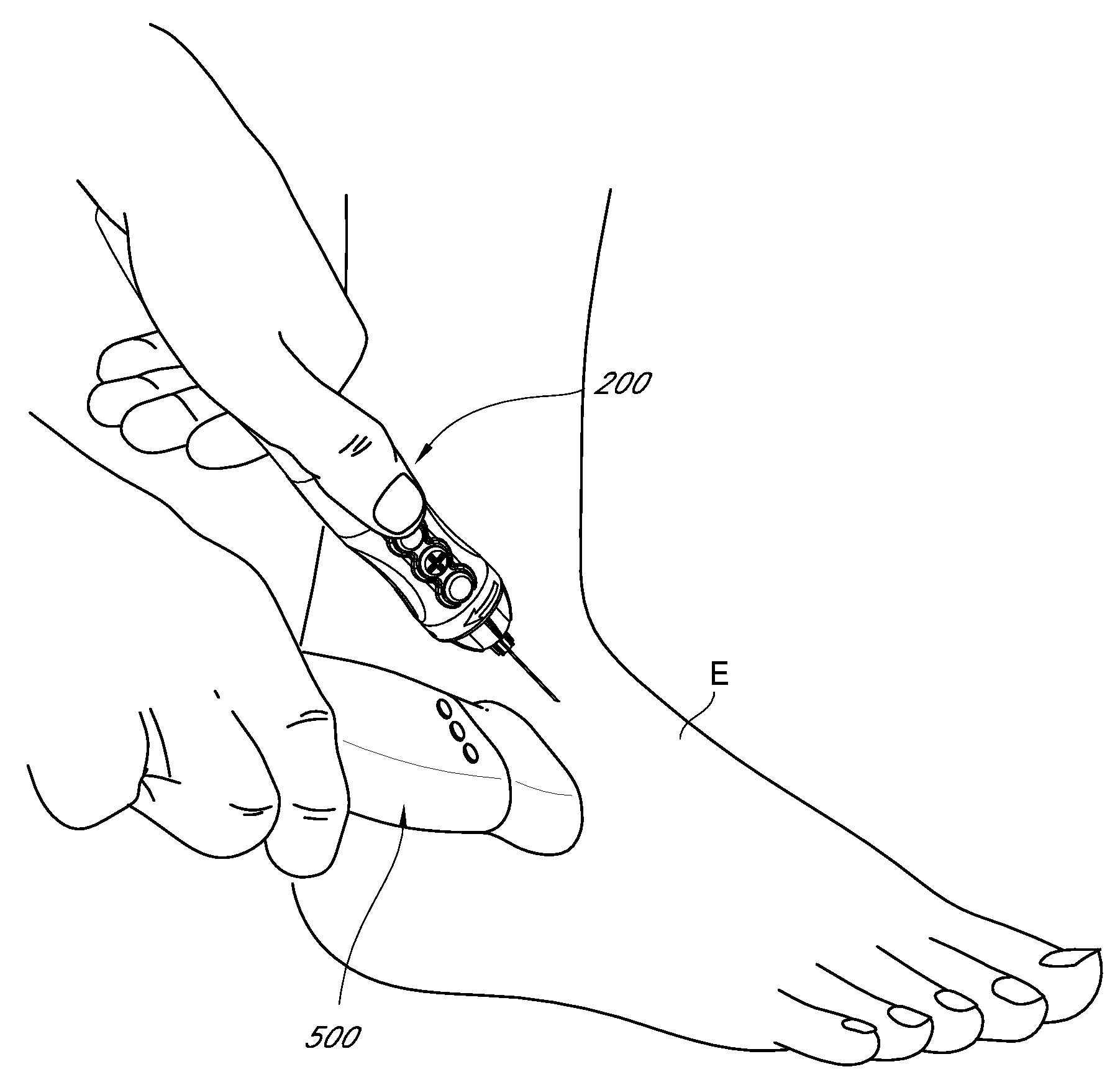

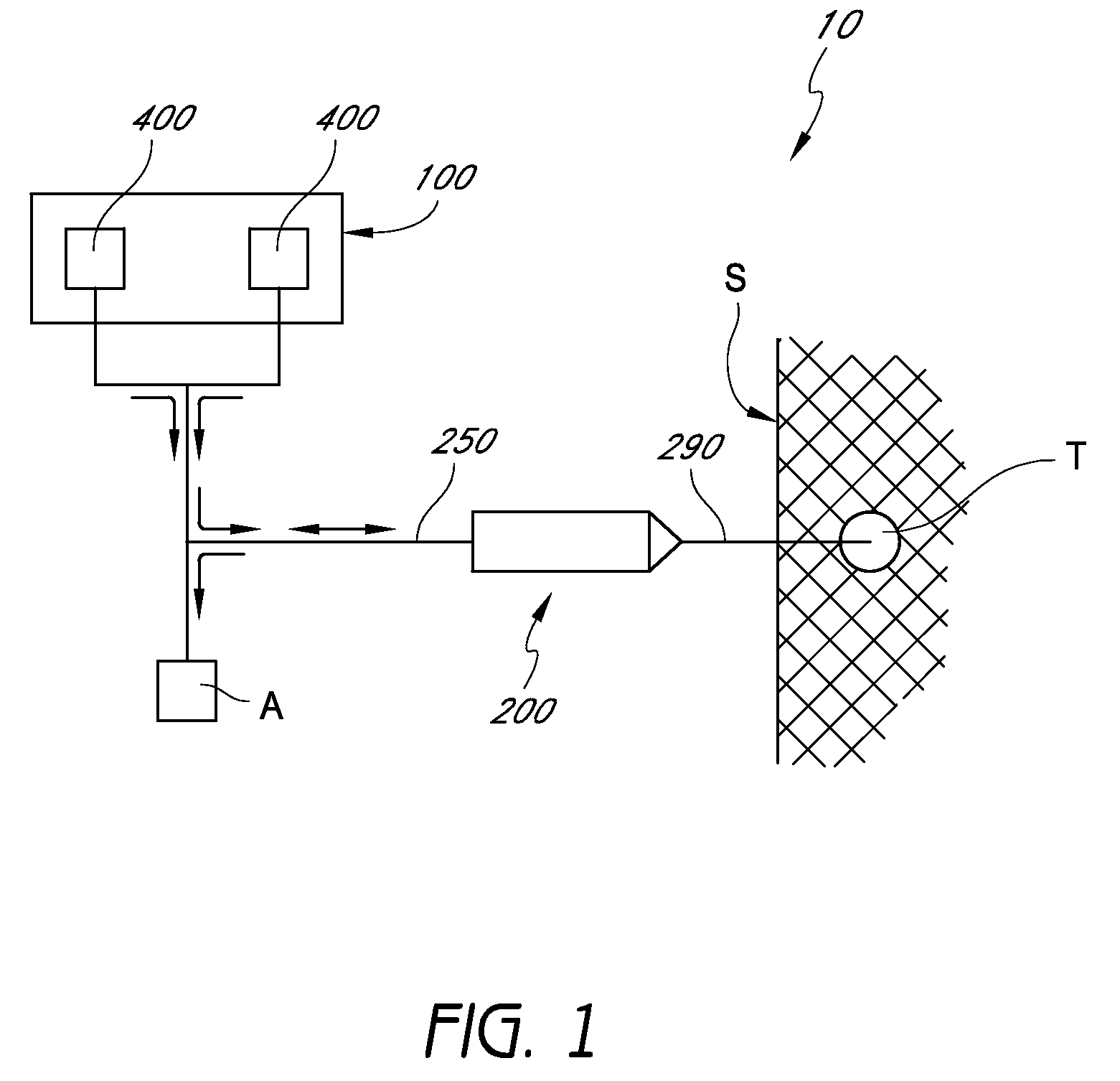

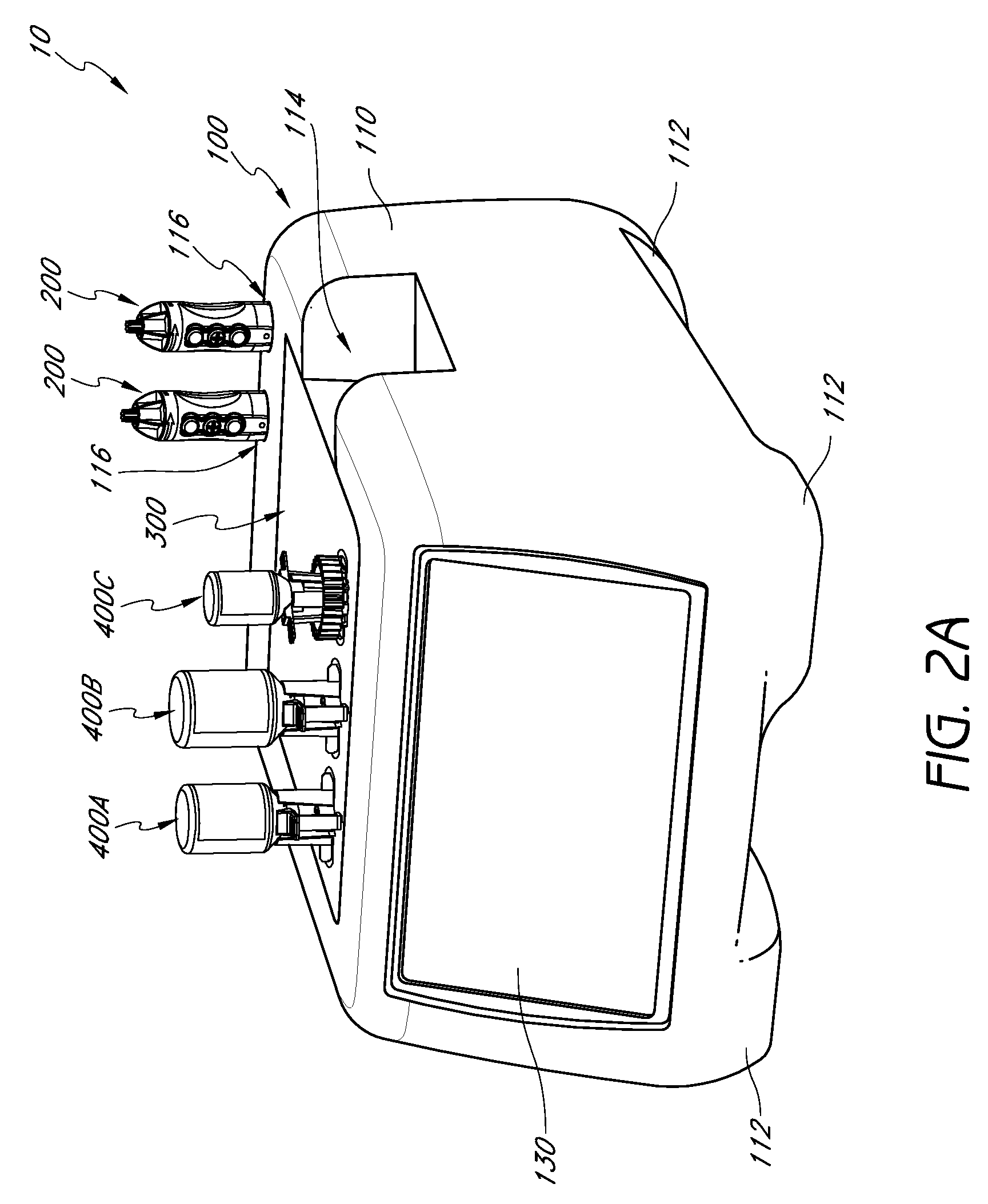

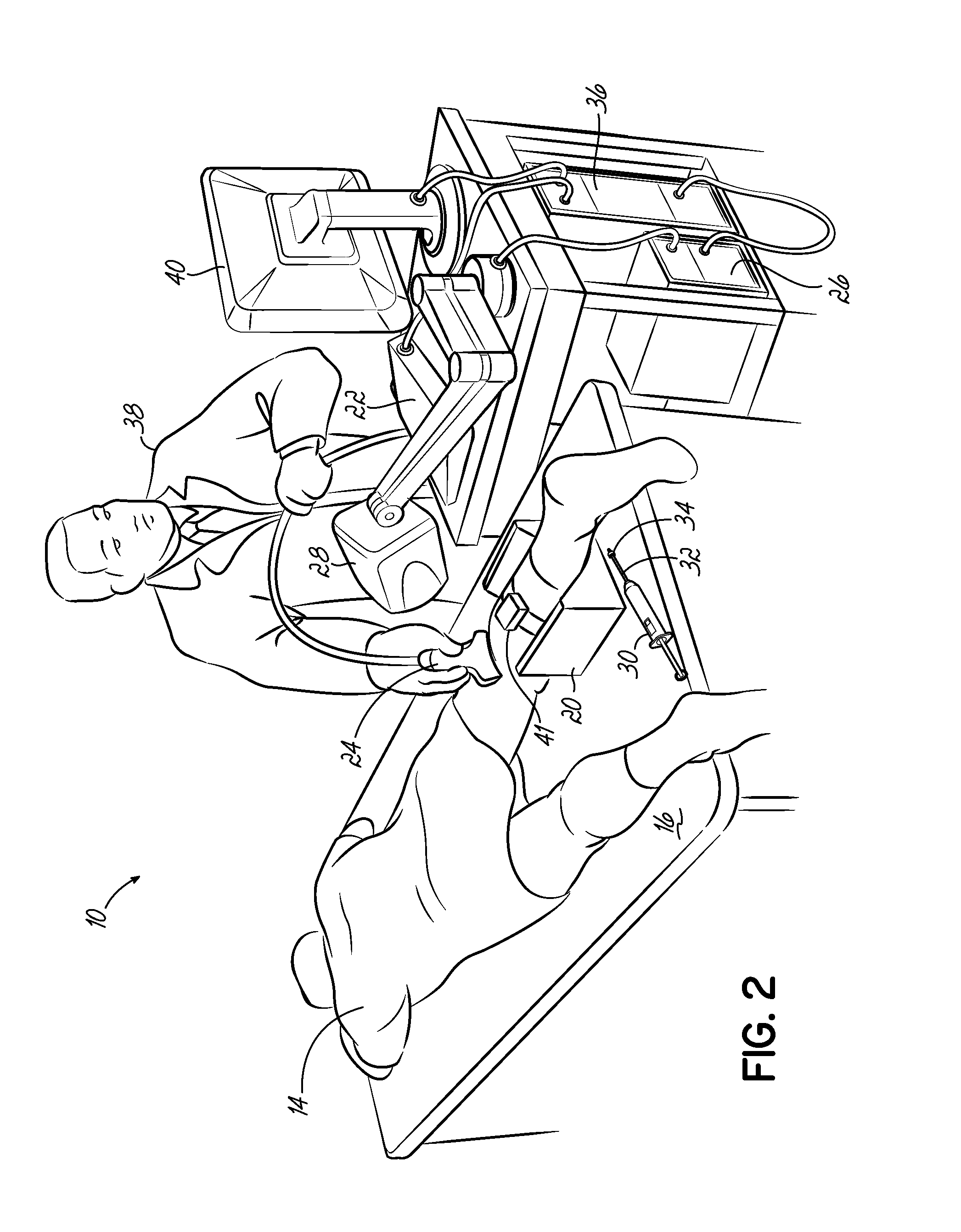

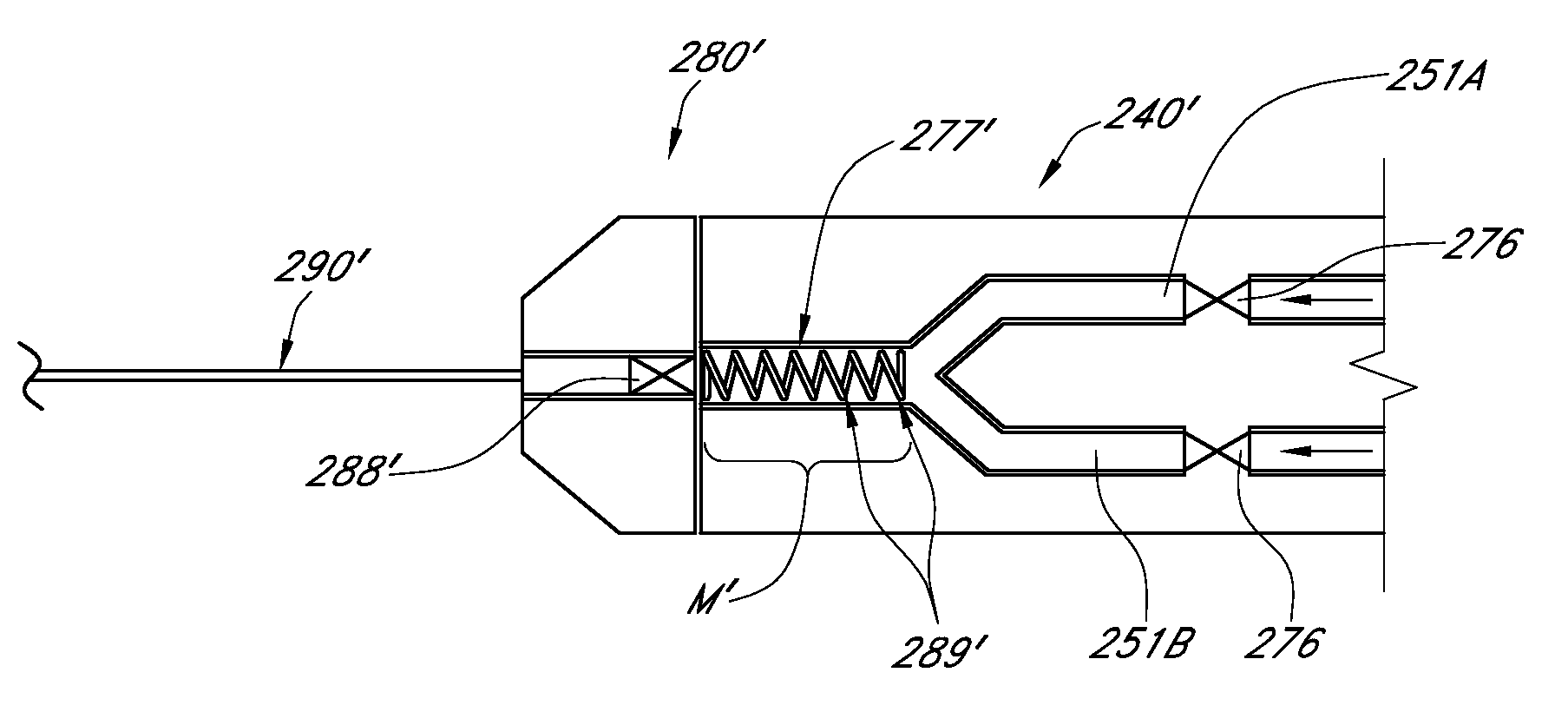

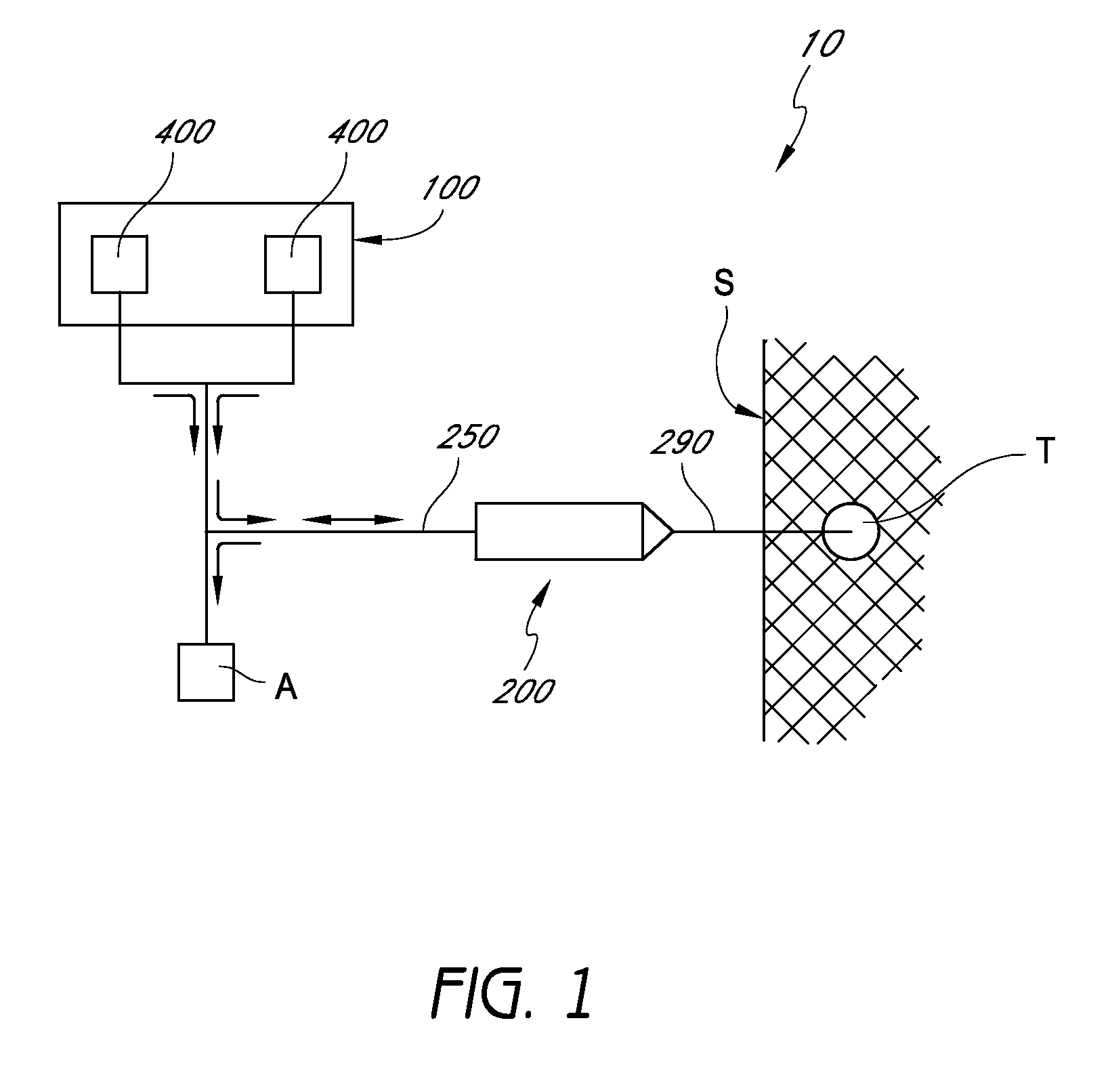

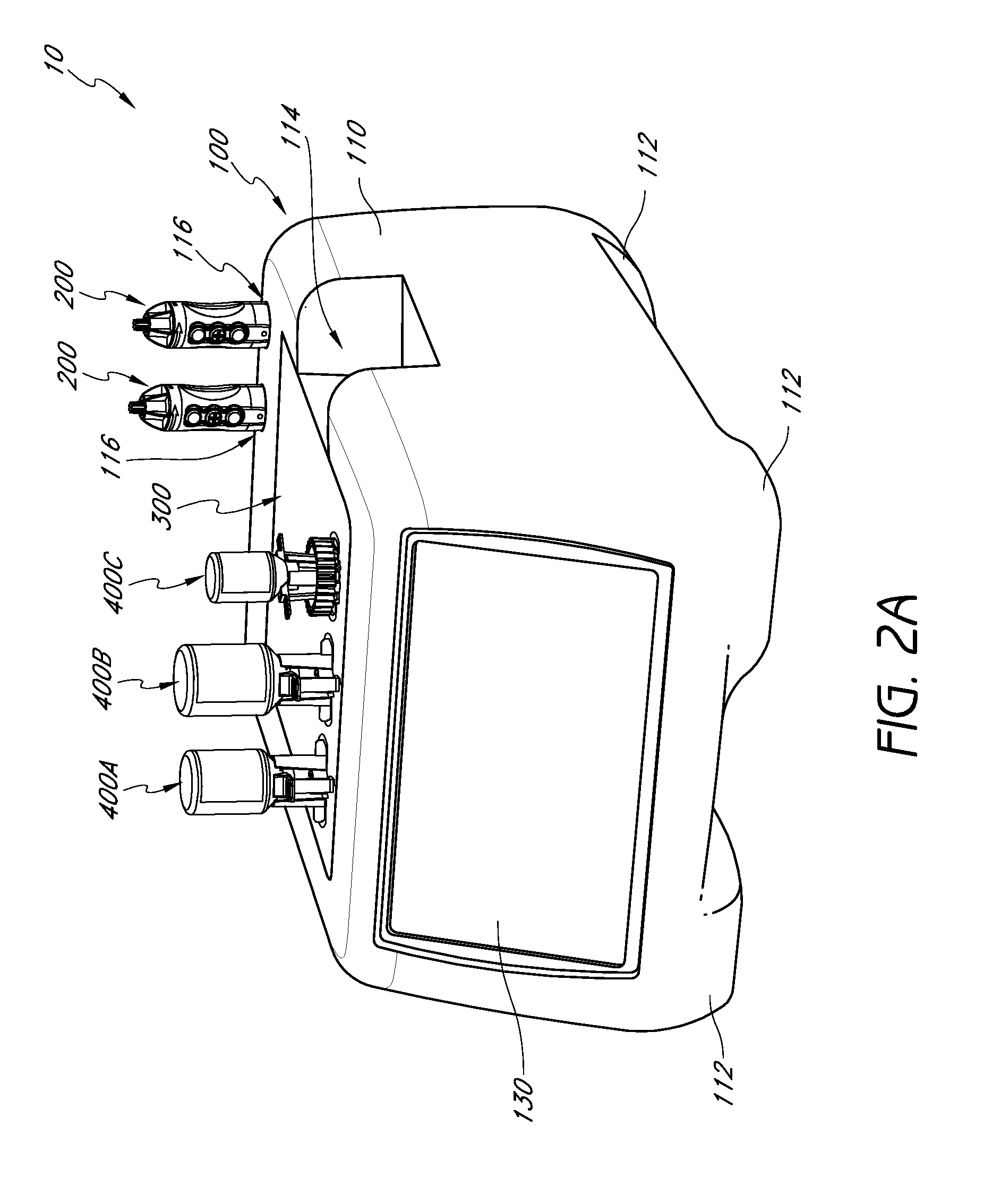

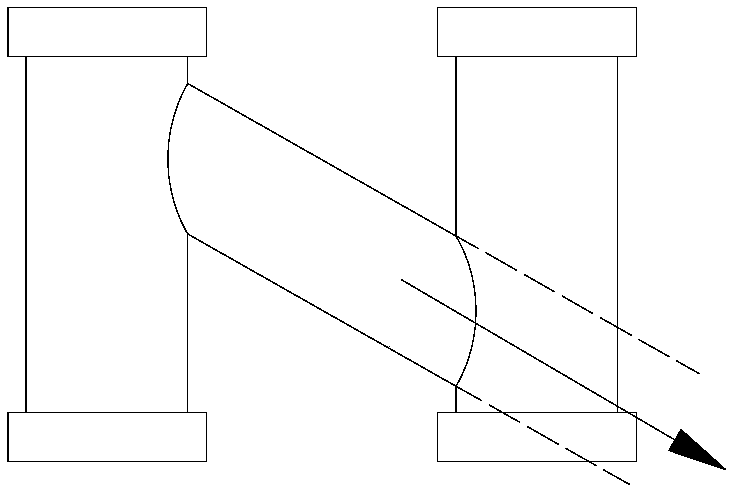

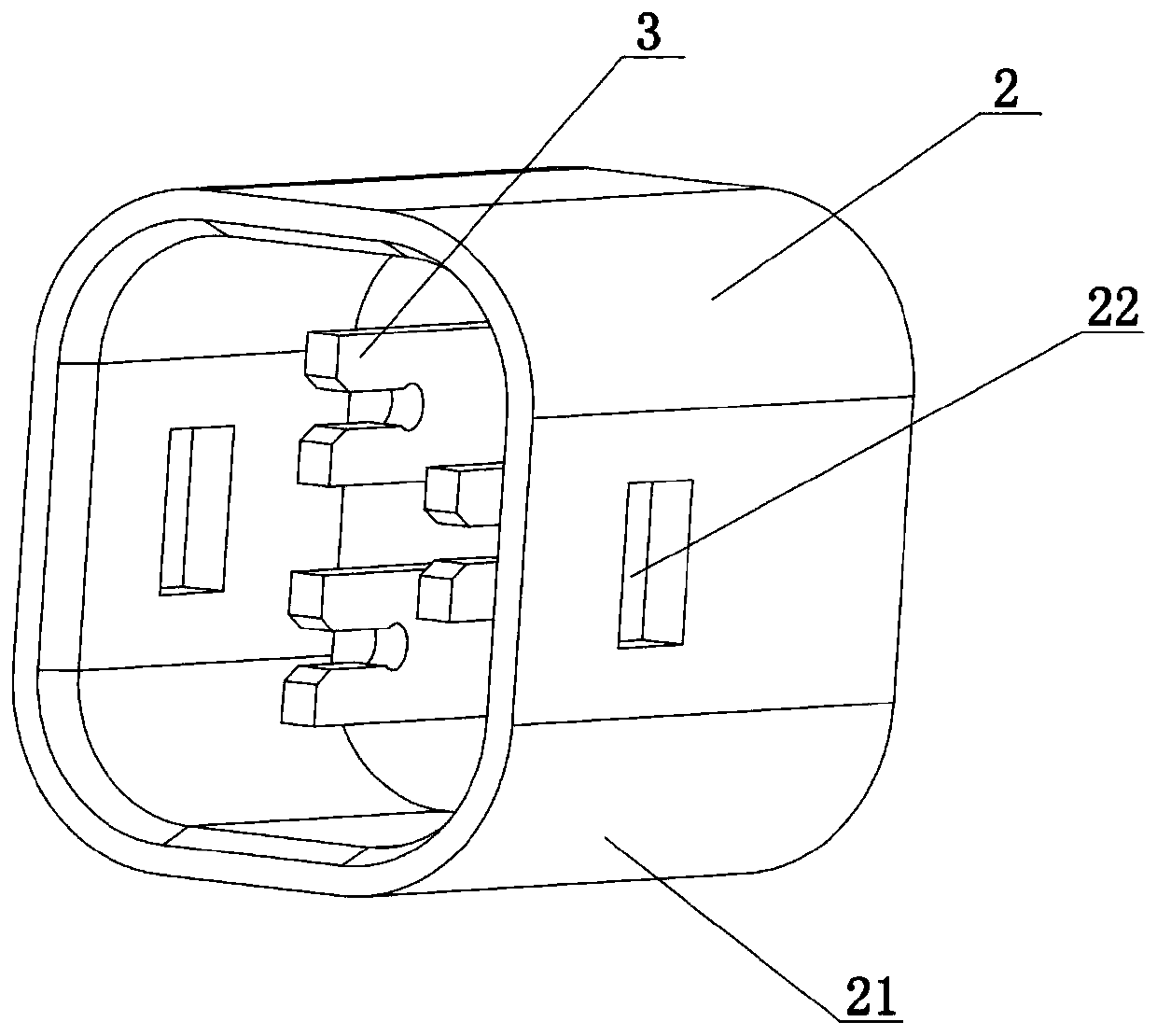

Handpiece assembly for articular injection systems

InactiveUS20090163860A1Precise deliveryPatient benefitUltrasonic/sonic/infrasonic diagnosticsDrug and medicationsJoint injectionSacroiliac joint

Systems for injecting fluids and / or other materials into a targeted anatomical location, in particular, an intra-articular space, include a handpiece assembly having a proximal end and a distal end, a needle extending from the distal end of the handpiece assembly, a fluid delivery module comprising a cassette and a fluid transfer device. A conduit is generally configured to place the fluid delivery module in fluid communication with the handpiece assembly. Medications, formulations and / or other fluids or materials contained within vials that are secured to the fluid delivery module can be selectively delivered into an anatomy through a needle located at the distal end of the handpiece assembly. In some embodiments, ultrasound or other imaging technologies can be used to locate a joint or other targeted anatomical location.

Owner:CARTICEPT MEDICAL

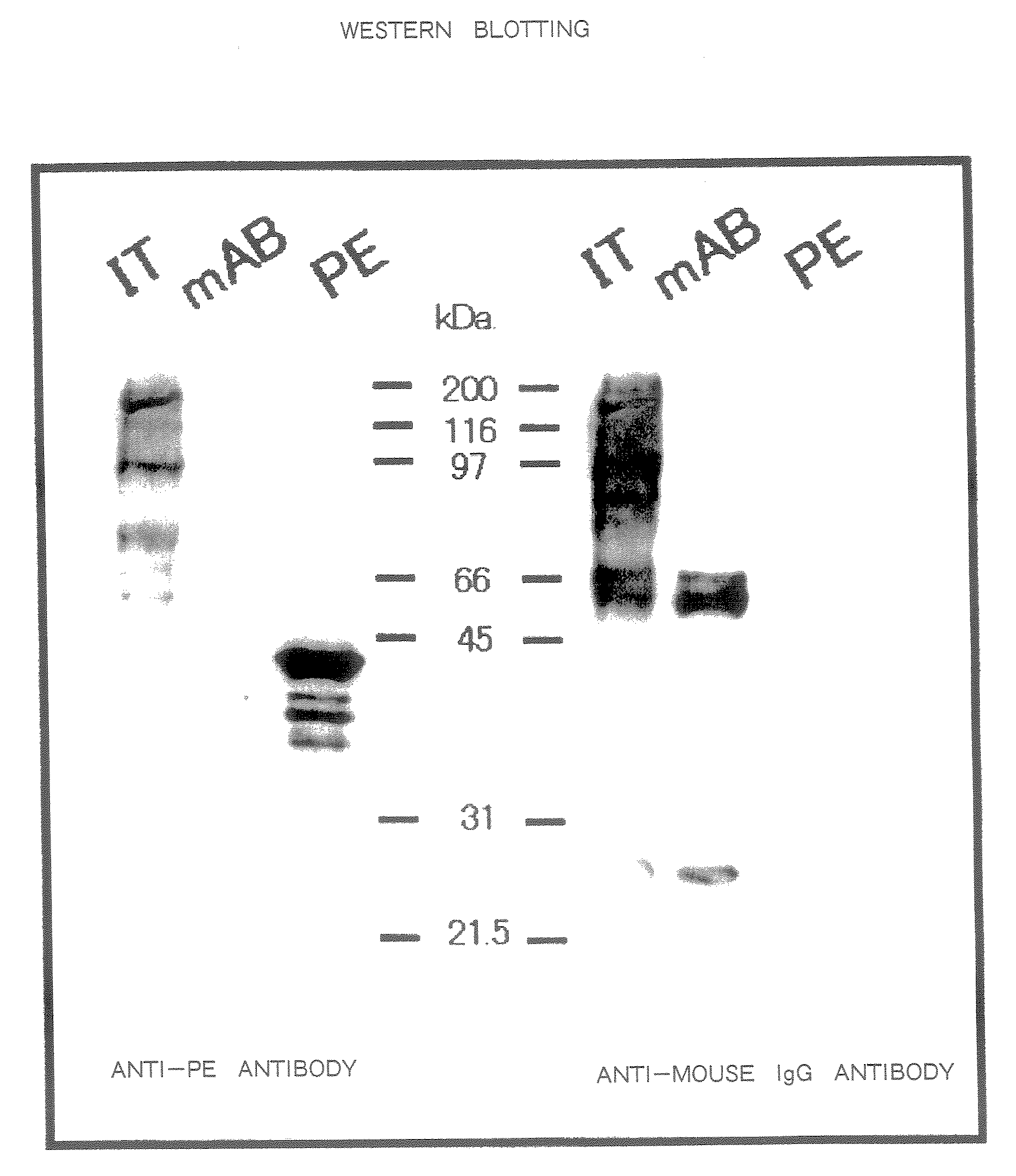

Therapeutic Medicine Containing Monoclonal Antibody Against Folate Receptor Beta (Fr-Beta)

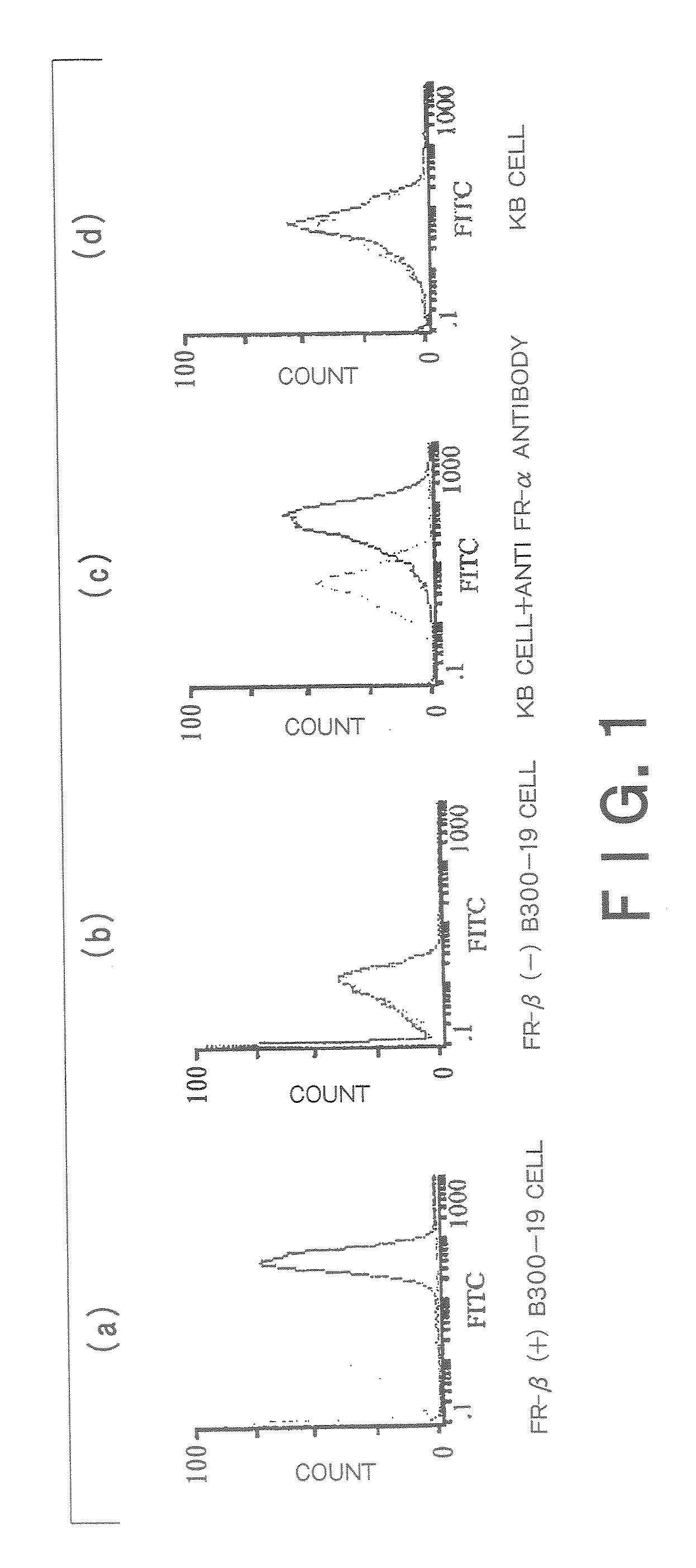

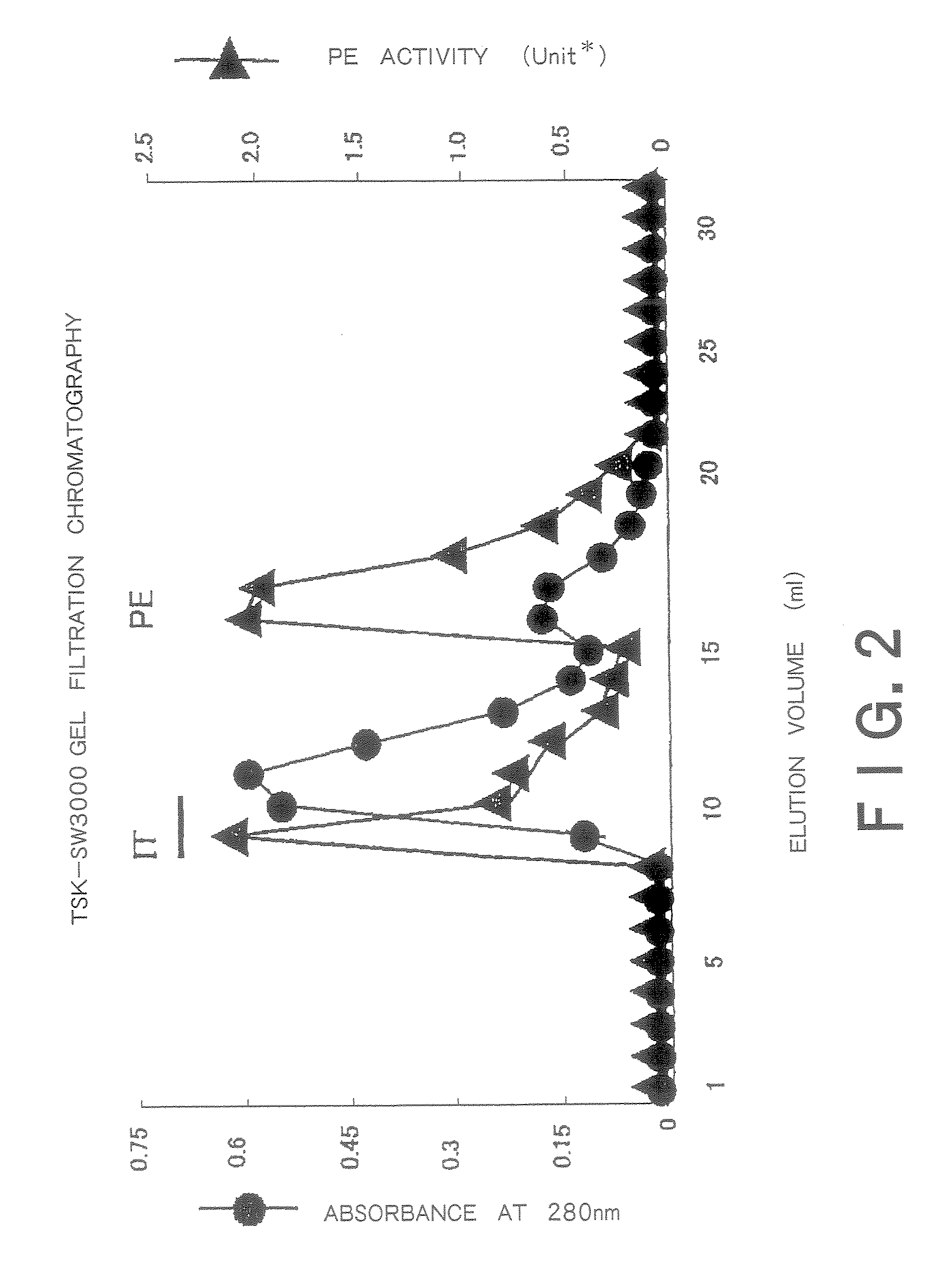

InactiveUS20080260812A1Good chemical stabilitySufficient amountPeptide/protein ingredientsAntipyreticMacrophage activation syndromeArthritis therapy

An objective of the present invention is to provide a therapeutic agent for treating rheumatoid arthritis, juvenile rheumatoid arthritis, macrophage activation syndrome, septicemia, and FR-β expressing leukemia, which induces apoptosis in activated macrophages and folate receptor beta (FR-β) expressing leukemia cells to specifically destroy these cells. An FR-β monoclonal antibody of the present invention is preferably an IgG-type monoclonal antibody which specifically reacts with a human-type FR-β antigen and is produced from a clone resulting from immunization with an FR-β expressing B300-19 cell. The FR-β monoclonal antibody of the present invention specifically reacts with the FR-β antigen of activated macrophages and FR-β expressing leukemia cells and a therapeutic agent of the present invention contains an FR-β antibody immunotoxin which causes apoptosis in activated macrophages and FR-β expressing leukemia cells, as an active ingredient. Further, suitable administration form for the therapeutic agent of the present invention includes intravenous injection as well as joint injection in the case of therapeutic agents for rheumatoid arthritis and juvenile arthritis.

Owner:TAKAMI MATSUYAMA KAGOSHIMA UNIV +1

Joint therapy

InactiveUS20060045904A1Reduce riskPromote resultsOrganic active ingredientsPeptide/protein ingredientsCushioningRegimen

A method for synergistically treating a joint of an animal, including introducing a cushioning agent into a joint; and introducing an enzyme or hormone adapted to stimulate cartilage production into the joint. The joint may be subjected to a compression regimen following injection of the cushioning agent and enzyme / hormone. Alternatively, the invention may include a composition for synergistically treating a joint of an animal, comprising a viscous cushioning material adapted to be introduced within a joint space to provide cushioning for the joint, and hormones dispersed through the cushioning material, the hormones operable to increase cartilage production.

Owner:ARONSON BARRY

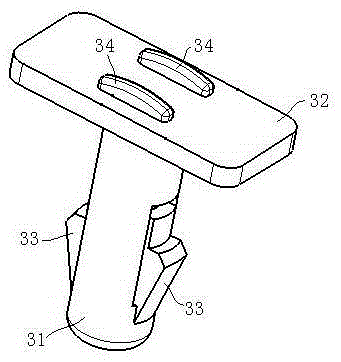

Articular injection system

InactiveUS20090171191A1Precise deliveryPatient benefitUltrasonic/sonic/infrasonic diagnosticsDrug and medicationsJoint injectionSacroiliac joint

Systems for injecting fluids and / or other materials into a targeted anatomical location, in particular, an intra-articular space, include a handpiece assembly having a proximal end and a distal end, a needle extending from the distal end of the handpiece assembly, a fluid delivery module comprising a cassette and a fluid transfer device. A conduit is generally configured to place the fluid delivery module in fluid communication with the handpiece assembly. Medications, formulations and / or other fluids or materials contained within vials that are secured to the fluid delivery module can be selectively delivered into an anatomy through a needle located at the distal end of the handpiece assembly. In some embodiments, ultrasound or other imaging technologies can be used to locate a joint or other targeted anatomical location.

Owner:CARTICEPT MEDICAL

Real-Time 3-D Ultrasound Reconstruction of Knee and Its Implications For Patient Specific Implants and 3-D Joint Injections

Methods and apparatus for treating a patient. The method includes acquiring a plurality of radio frequency (RF) signals with an ultrasound transducer, each RF signal representing one or more return echoes from a scan line of a pulse-mode echo ultrasound scan. A position of the ultrasound transducer corresponding to each of the acquired RF signals is determined, and a plurality of contour lines generated from the plurality of RF signals. The method estimates a 3-D shape and position of an anatomical feature, such as a joint of patient based on the generated contour lines and corresponding ultrasound transducer positions. An apparatus, or computer includes a processor and a memory with instructions that, when executed by the processor, perform the aforementioned method.

Owner:JOINTVUE

Method of treating a joint using an articular injection system

InactiveUS20090171316A1Precise deliveryPatient benefitUltrasonic/sonic/infrasonic diagnosticsDrug and medicationsJoint injectionSacroiliac joint

Systems for injecting fluids and / or other materials into a targeted anatomical location, in particular, an intra-articular space, include a handpiece assembly having a proximal end and a distal end, a needle extending from the distal end of the handpiece assembly, a fluid delivery module comprising a cassette and a fluid transfer device. A conduit is generally configured to place the fluid delivery module in fluid communication with the handpiece assembly. Medications, formulations and / or other fluids or materials contained within vials that are secured to the fluid delivery module can be selectively delivered into an anatomy through a needle located at the distal end of the handpiece assembly. In some embodiments, ultrasound or other imaging technologies can be used to locate a joint or other targeted anatomical location.

Owner:CARTICEPT MEDICAL

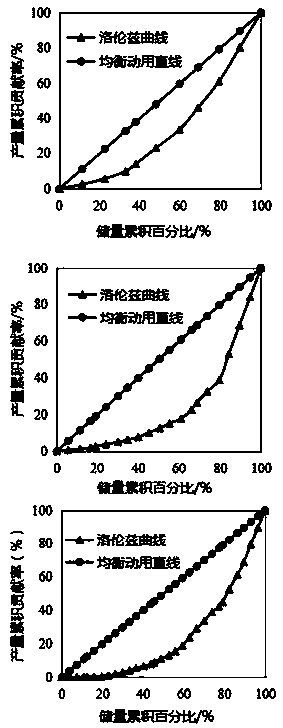

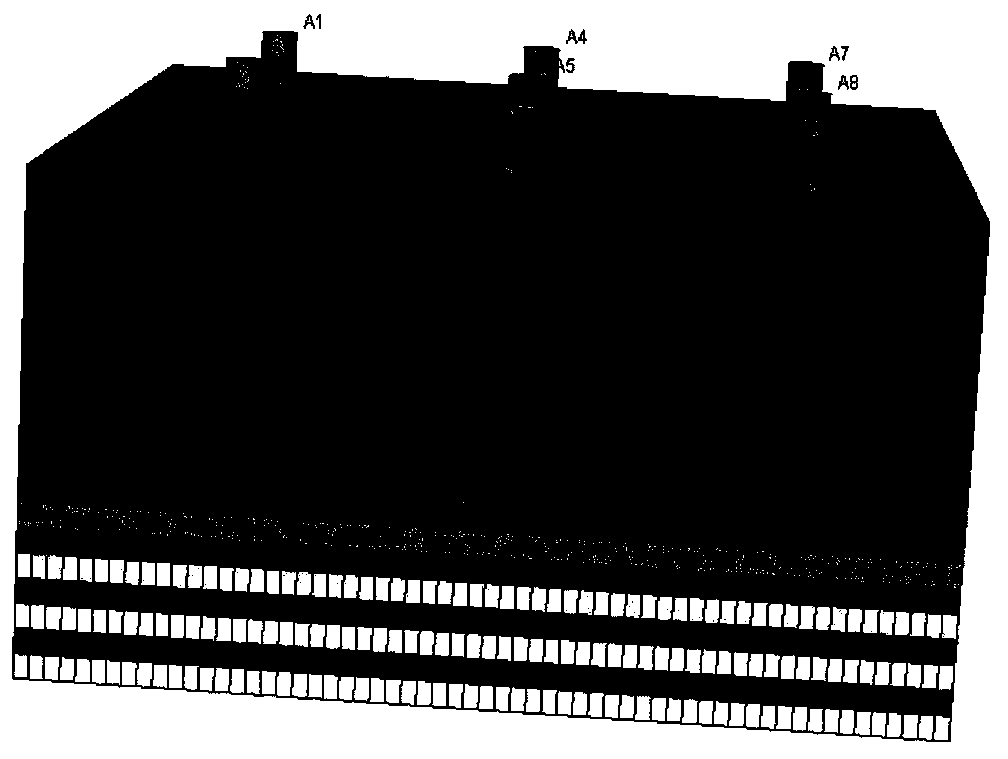

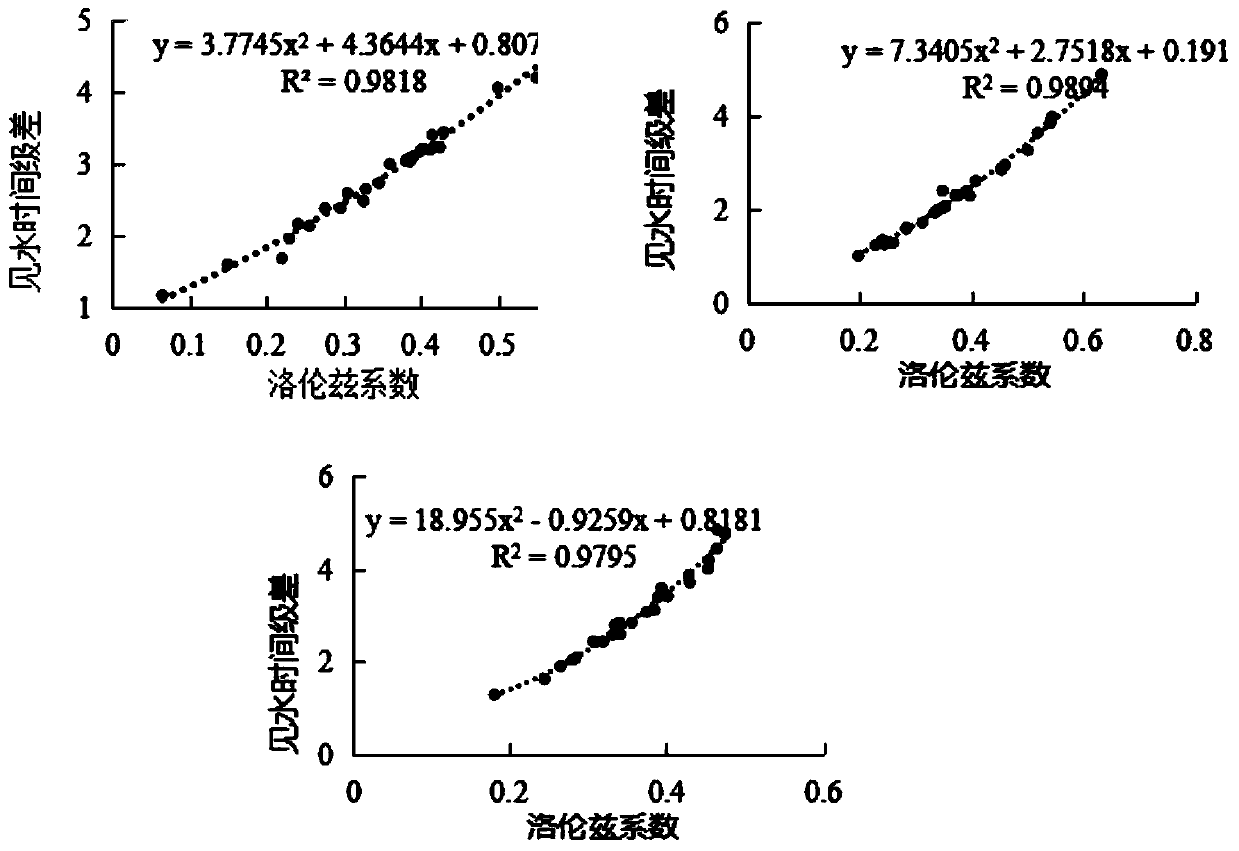

Separate zone waterflooding technology policy limitation before reservoir water breakthrough

The invention discloses a separate zone waterflooding technology policy limitation before reservoir water breakthrough. The separate zone waterflooding technology policy limitation comprises the following steps of firstly, considering multiple factors comprehensively, establishing a series of injection-production well group typical models, then carrying out numerical simulation research of multi-layer joint injection on the models, taking the water breakthrough time level difference as the longitudinal equilibrium displacement criterion, and evaluating the longitudinal dynamic non-equilibrium degree before reservoir water breakthrough through the Lorentz coefficient; and finally, determining the separate zone waterflooding technology policy limitations before reservoir water breakthrough with different rhythmicity and different well pattern forms according to a Lorentz coefficient warning value. The separate zone waterflooding technology policy limitation before reservoir water breakthrough is more accurate, simpler and easier to operate, can provide the guidance for the division of the oil field on-site separate zone waterflooding technology policy limitations, so that the oil reservoir development effect is improved, and the oil reservoir recovery rate is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

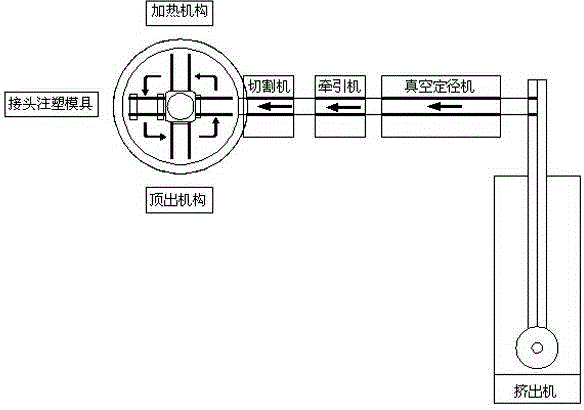

Molding process of PE-RT pipeline

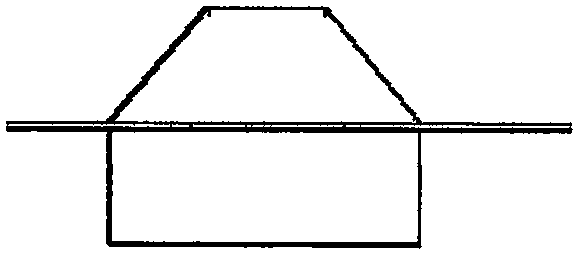

InactiveCN104441674AHigh strengthImprove bindingTubular articlesJoint injectionInjection molding machine

The invention relates to a molding process of a PE-RT pipeline. The process comprises a PE-RT pipe extrusion molding process and a joint injection molding process on the PE-RT pipe, wherein the PE-RT pipe extrusion molding process comprises the following steps of: preparing materials; performing extrusion molding on the PE-RT pipeline by using an extrusion machine; sizing in vacuum; performing traction and conveying; cutting the PE-RT pipeline into a predetermined size and entering a location area. The joint injection molding process on the PE-RT pipeline comprises the steps: locating, namely, enabling a core of a rotating mechanism positioned on a rotary disc to penetrate through the PE-RT pipeline; pre-heating of a joint area, namely, driving the PE-RT pipeline to rotate to a hot air mechanism by virtue of a rotating mechanism, and melting the PE-RT pipeline joint area to a high-elastic state by virtue of the hot air mechanism; injection molding of the joint, namely, driving the PE-RT pipeline to rotate to an injection mould by virtue of the rotating mechanism, closing the injection mould, and performing injection molding of the joint in the PE-RT pipeline joint area; ejection, namely opening the injection mould, driving the PE-RT pipeline to rotate to an ejection mechanism by virtue of the rotating mechanism, and ejecting the PE-RT pipeline by virtue of the ejection mechanism. According to the molding process of the PE-RT pipeline, the integration production of pipe molding and plastic connection molding is realized, the binding force of plastic pieces is increased, and the production efficiency is effectively improved.

Owner:XIAMEN RUNNER IND CORP

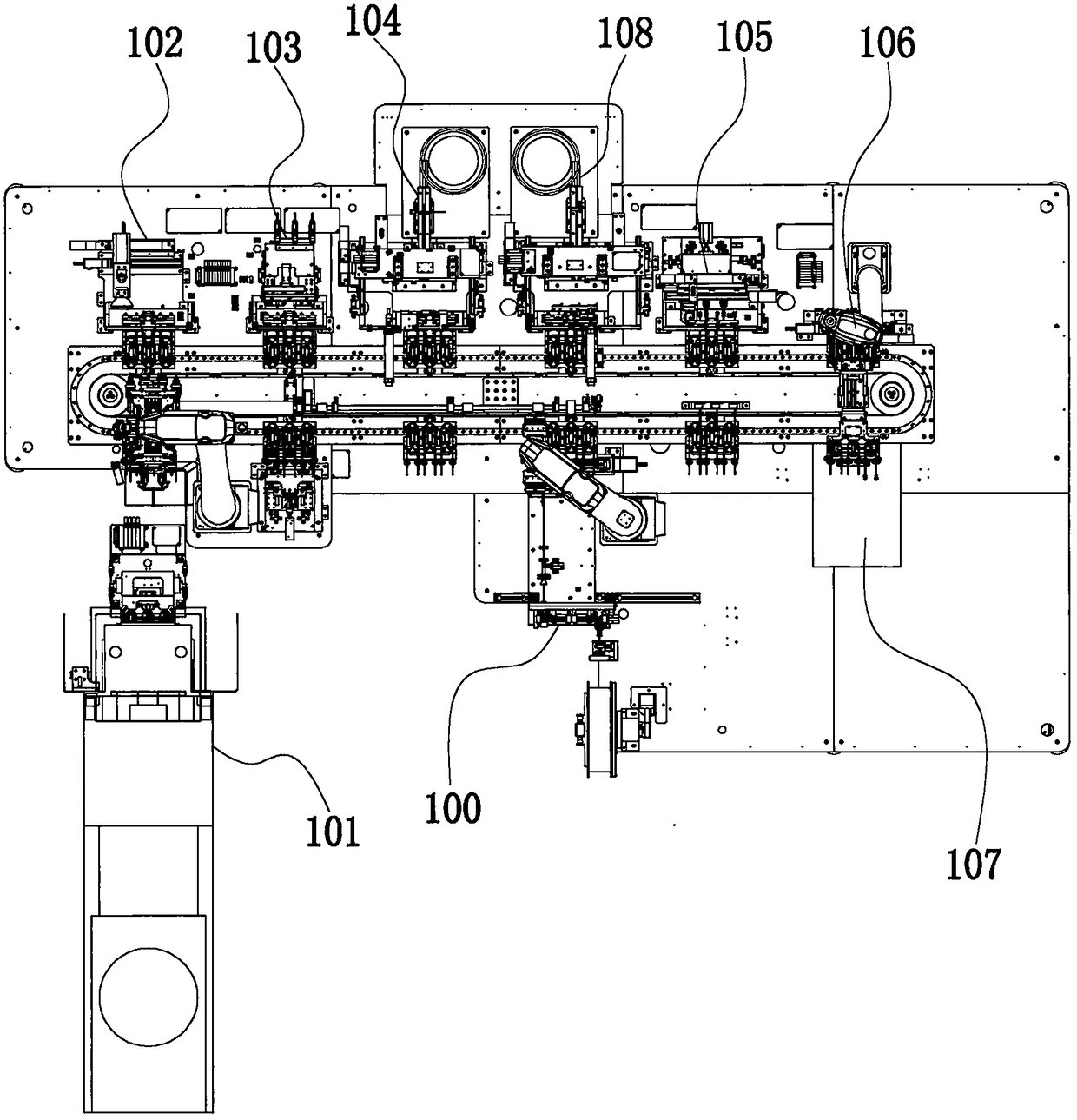

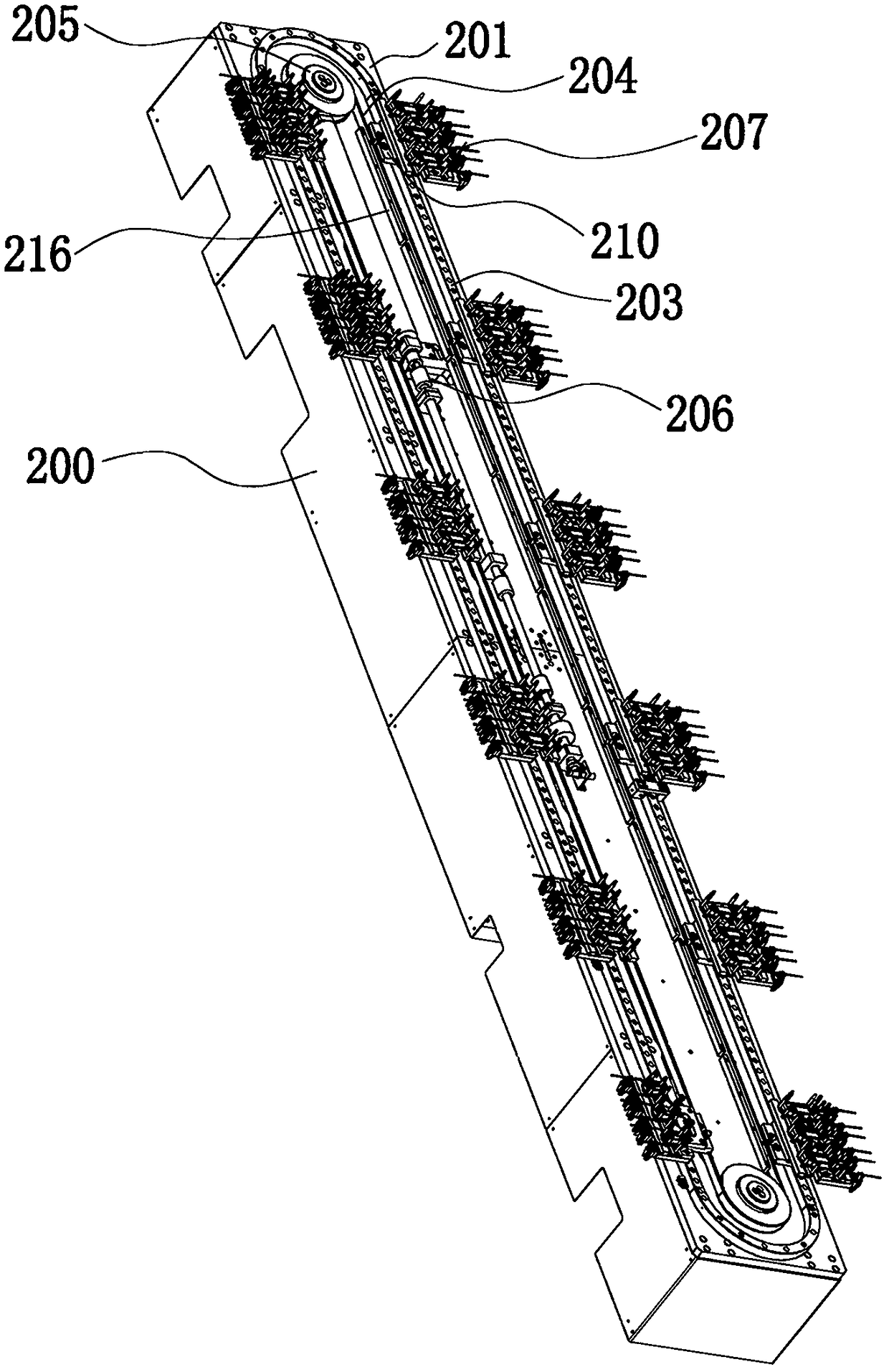

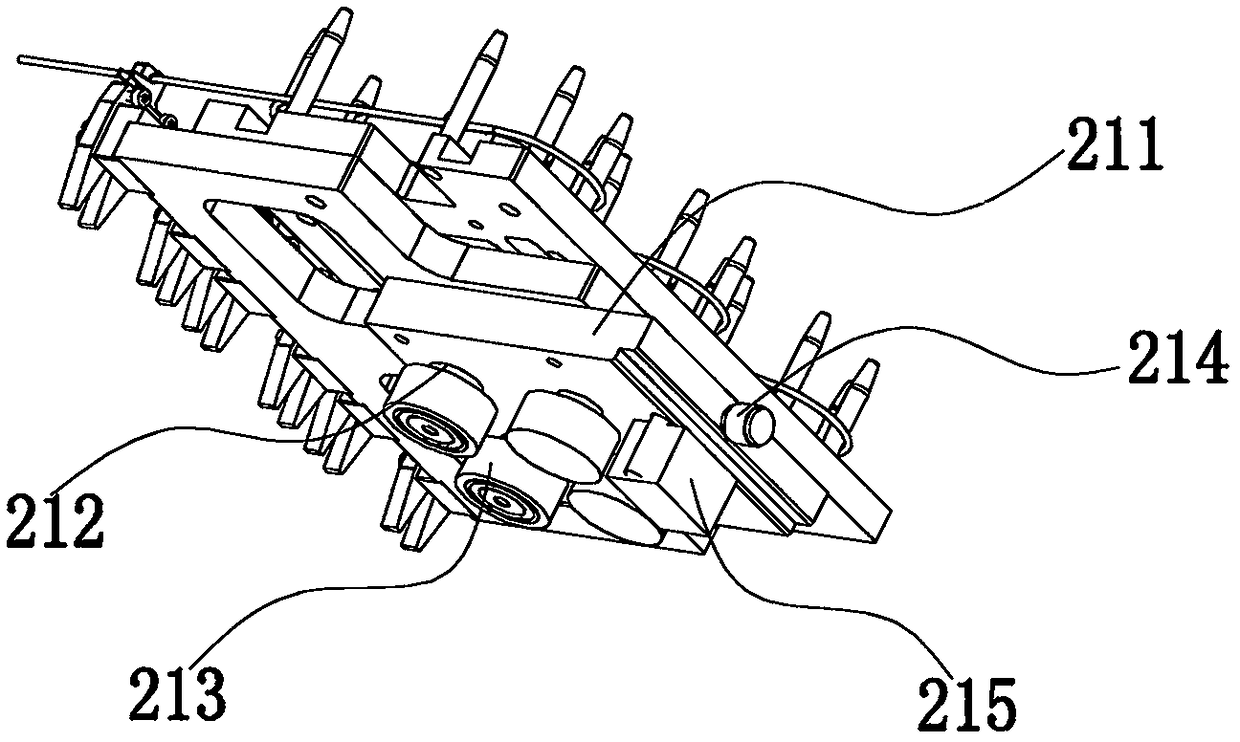

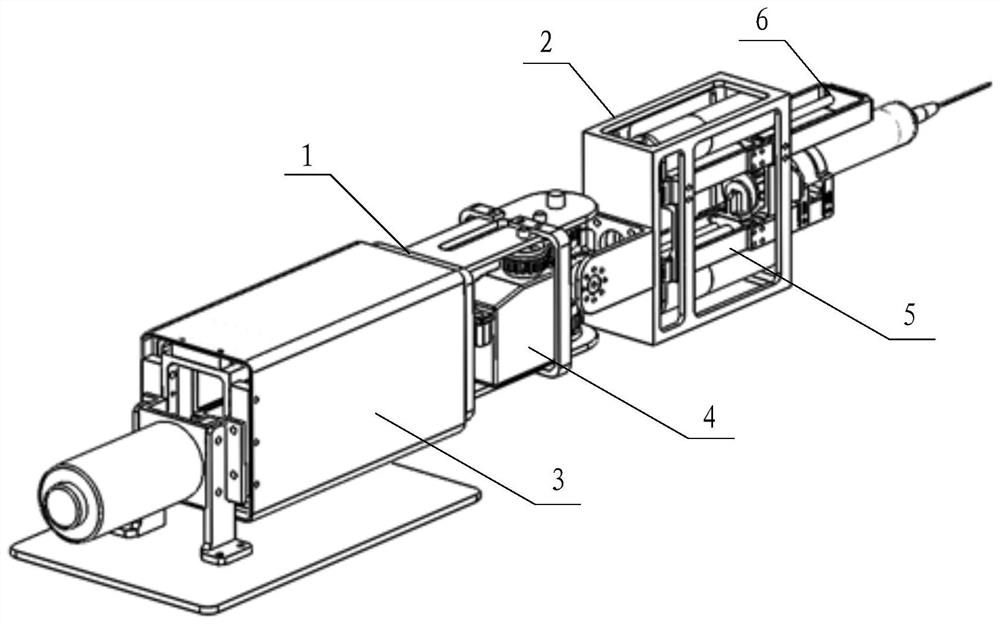

Catheter winding assembly machine

PendingCN108146746ANot easy to attachHigh degree of automationPackaging automatic controlIndividual articlesJoint injectionEngineering

The invention relates to a catheter winding assembly machine which comprises a circulation bracket and a circulation locating plate fixedly arranged on the circulation bracket; a conveying rail and aconveying belt which are annular are fixedly arranged on the circulation locating plate; a pipe conveying device, a catheter joint injection molding device, a CCD burr detection device, a gas measurement and detection mechanism, a transparent shield charging mechanism, a Lure shield charging mechanism, a CCD abscission ring detection device, a catheter shaping mechanism and a catheter winding andsleeving mechanism are sequentially arranged on the circulation bracket along the conveying rail; and carriers for catheter winding are arranged on the conveying rail in the conveying direction. The probability that catheters are contaminated with germs in the winding process is low, and the safety is high; in addition, the automation degree is high, the assembly efficiency is improved substantially, and mass production is facilitated; and the catheter winding assembly machine is reasonable in integrated design, simple in structure and high in practicability.

Owner:梁启明

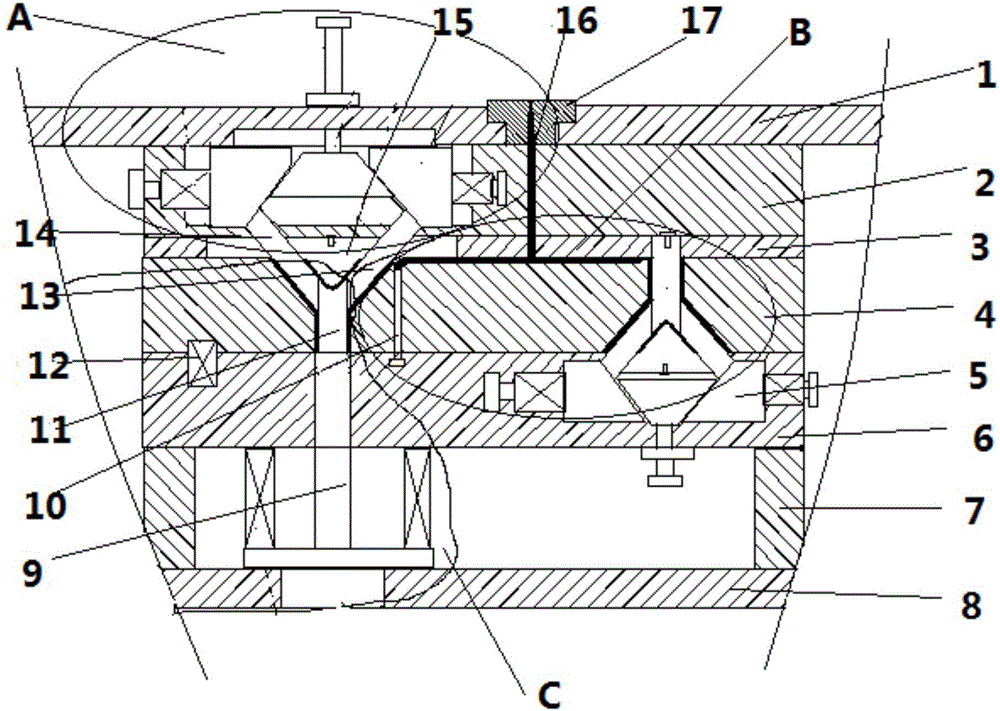

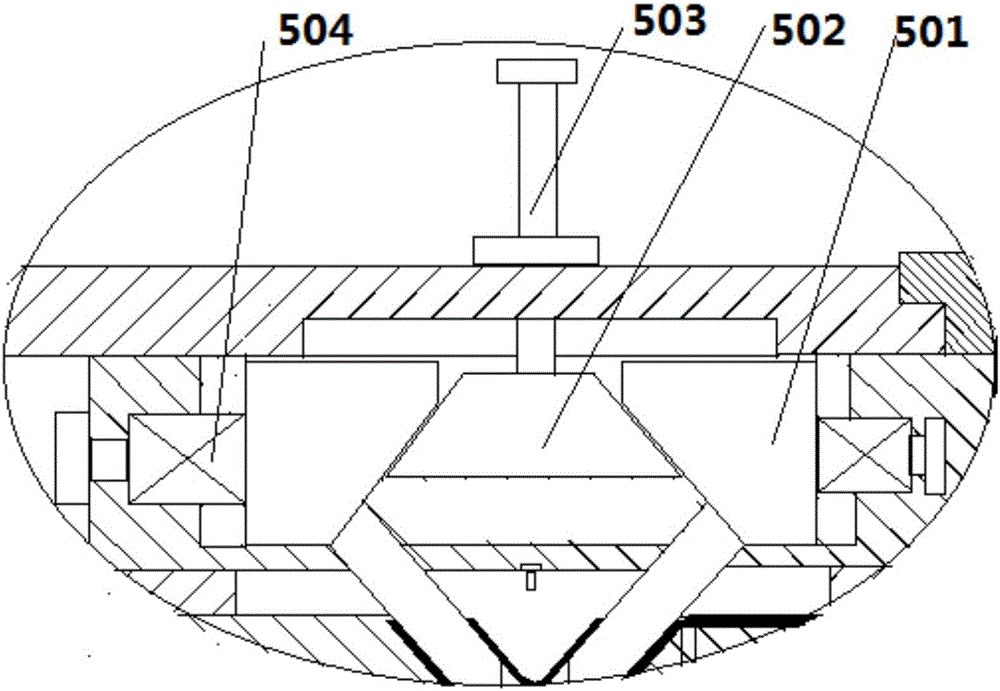

Y-shaped tee joint injection mold with easy-molding function

The invention provides an easy-to-form Y-shaped three-way injection mold, which includes a lower mold base and feet, a fixed template fixed plate, a fixed template, a movable template, a movable template fixed plate and an upper mold base. There is a flow channel in the center of the sprue sleeve and the sprue sleeve. The flow channel includes the main channel and the branch channel. There are multiple groups of Y-shaped cavities on the fixed platen. The third core is set on the movable platen and the fixed platen. The first core and the second core are respectively arranged on the fixed plate and the movable mold, the first spring is fixed between the fixed plate and the fixed plate, and the lower mold base is provided with a straight ejection mechanism, which includes The ejector rod, the runner and the positive Y-shaped cavity are equipped with a pull rod. The easy-to-form Y-shaped tee injection mold of the present invention has a simple structure and is easy to process and manufacture. The cavity arrangement is reasonable and the structure is compact, which saves mold materials and reduces the production cost of the mold, and is suitable for large workpieces. Mass production.

Owner:TIANJIN WANJIA PLASTICS

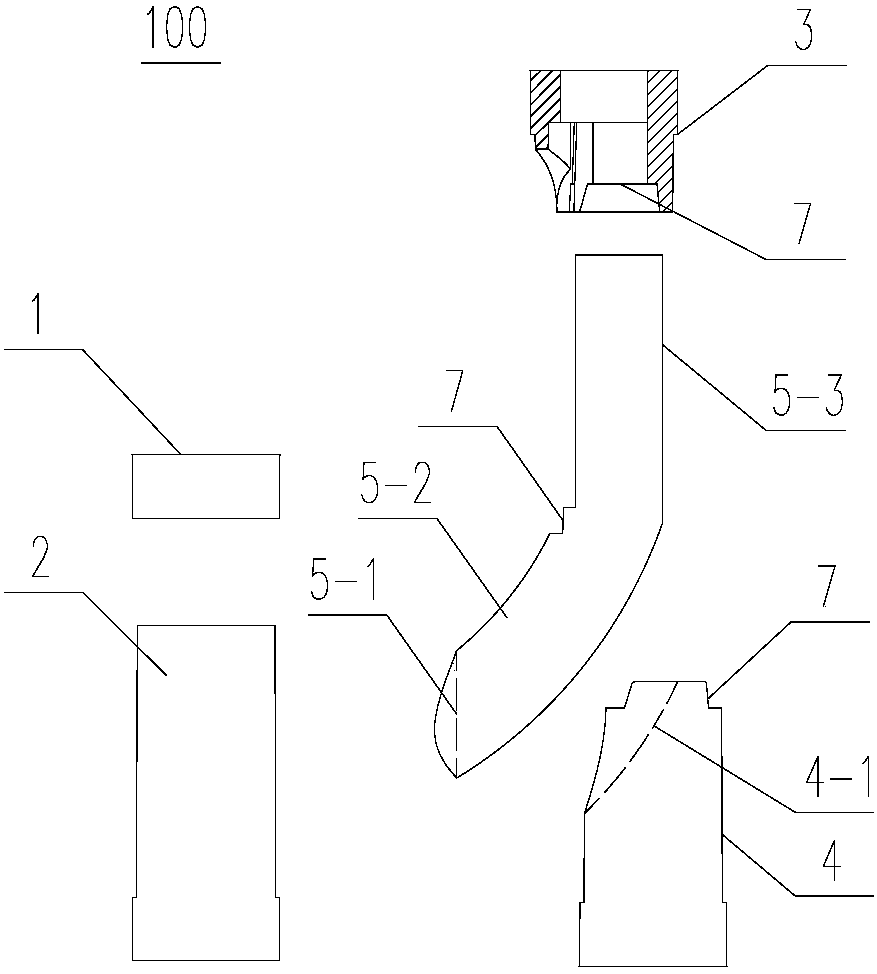

Robot injection device

PendingCN112604085AWide range of injection anglesInject evenlyAutomatic syringesIntravenous devicesPhysical medicine and rehabilitationJoint injection

The invention relates to ruin rescue equipment, in particular to a robot injection device. The device comprises a pose adjusting mechanism and an injection mechanism; the pose adjusting mechanism comprises a telescopic joint and a coupling joint, and the injection mechanism comprises a pushing joint for controlling the depth of a needle inserted into a body and a dosing joint for controlling the injection amount of liquid medicine in the body. One end of the telescopic joint is installed on the robot, the other end of the telescopic joint is a telescopic end, one end of the coupling joint is connected with the telescopic end of the telescopic joint and driven by the telescopic joint to stretch out and draw back, and the other end of the coupling joint has pitching freedom degree or deflection freedom degree; the pushing joint is installed at the other end of the coupling joint, the output end of the pushing joint is connected with a medicine feeding joint, and the pushing joint and the medicine feeding joint are driven by the telescopic joint and the coupling joint to reach the set position and angle. The device has the characteristics of light weight and modularization of the structure, high injection precision, easiness in installation and replacement and accuracy in operation and control.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

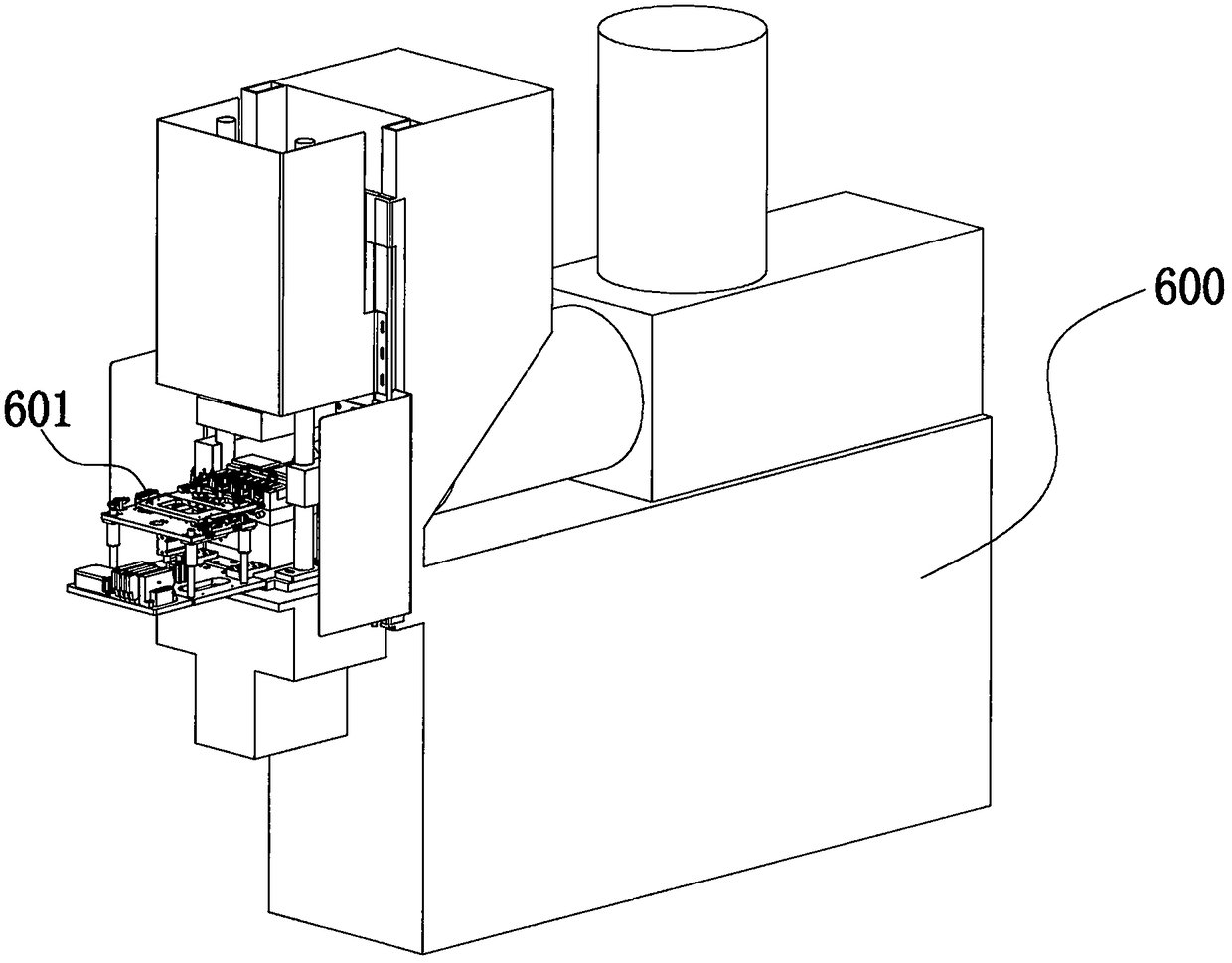

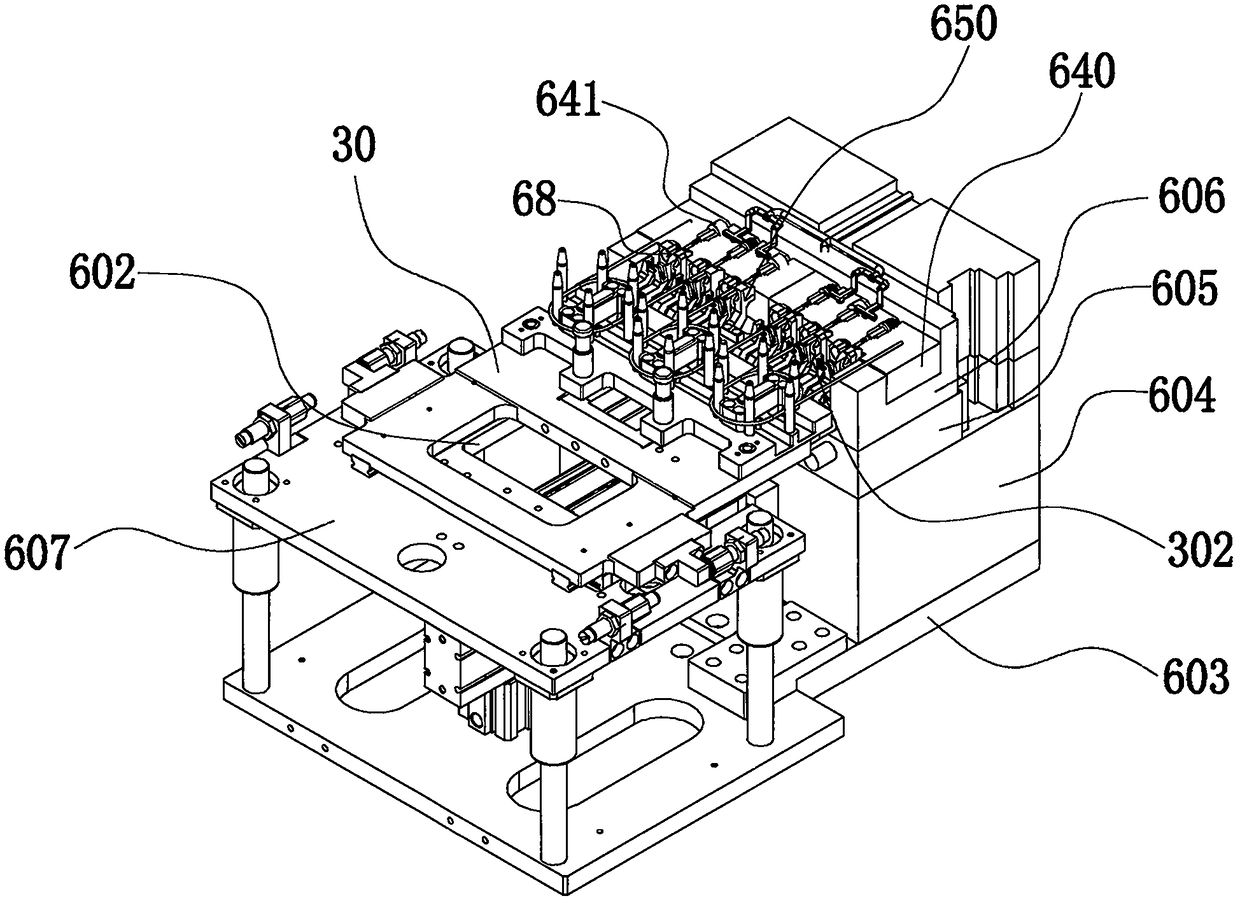

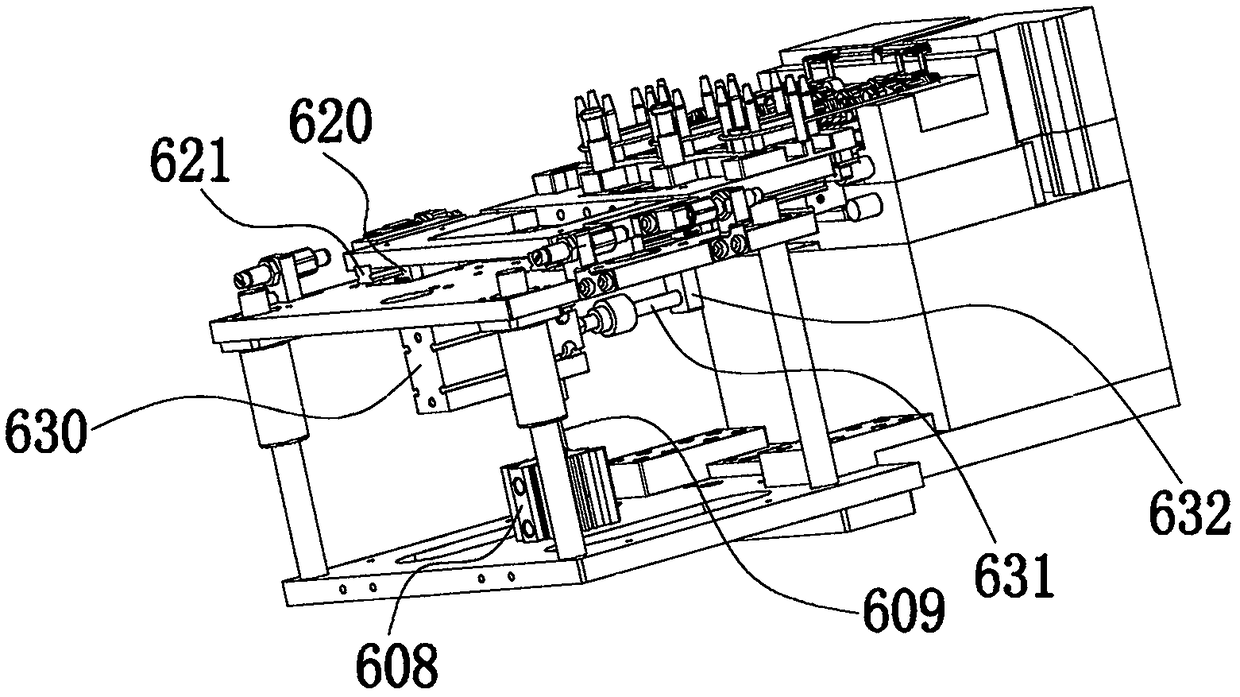

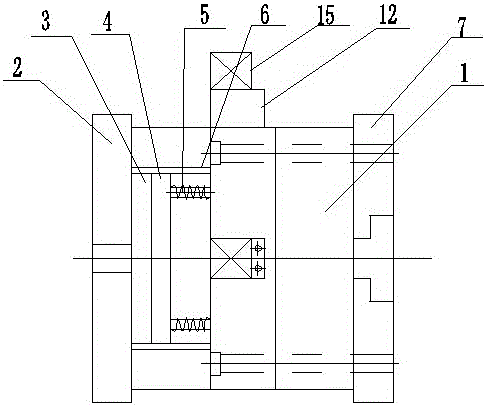

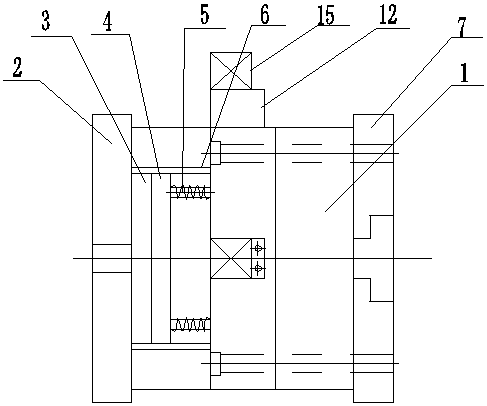

Servo drive laminating device

ActiveCN110216182APressing to achieveMeet different location requirementsMetal working apparatusControl systemBall screw

The invention provides a servo drive laminating device, which solves the problem of the power source of a special laminating machine during the laminating process; the device comprises an installationbase, a servo motor, a bidirectional ball screw nut pair, two cam sliding blocks driven by the bidirectional ball screw nut pair, a sliding block, a weighing sensor, an external reference limiting block, an internal reference limiting block, a joint injection oil cup, a longitudinal guide mechanism composed of a V-shaped convex guide rod and a V-shaped concave guide plate, a collision block, a stroke switch, a shaft, a support type roller, a straight-through injection oil cup, etc., the device can realize the different position requirements of the upward movement of a concave mold according to the product laminating process requirement, so multiple flanging can be finished and the laminating is realized; the weighing sensor feeds back the condition of the laminating force at different positions of the control system in real time.

Owner:CHINA FIRST AUTOMOBILE +1

Injection mold for pipe joints

ActiveCN106217770BReduce manufacturing costImprove sealingTubular articlesJoint injectionEngineering

The present invention provides a pipe joint injection mold, which comprises an upper die, a lower die and a mandrel assembly. A cavity matched with the shape of the joint is formed between the upper die and the lower die; the mandrel assembly includes a first mould jacket, a first lower core, a second mould jacket, a second lower core and a bending mandrel; the first mould jacket, the first lower core, the second lower core, and bending mandrel are spliced into a shape matched with an inner hole of the pipe joint; the bending mandrel has a arc structure; and the bending mandrel passes through a mouthing of a pipe joint formed by the second mould jacket along the virtual extension of an arc direction of the arc structure. According to the pipe joint injection mold provided by the invention, the arrangement of bending mandrel and a rotating mode mandrel removal make the injection molding production of pipe joint possible, thereby reducing pipe joint production cost, and improving production efficiency; and in addition, the seal performance of the pipe joint is improved by using the injection mold.

Owner:JIANGSU HIPPO PLASTICS

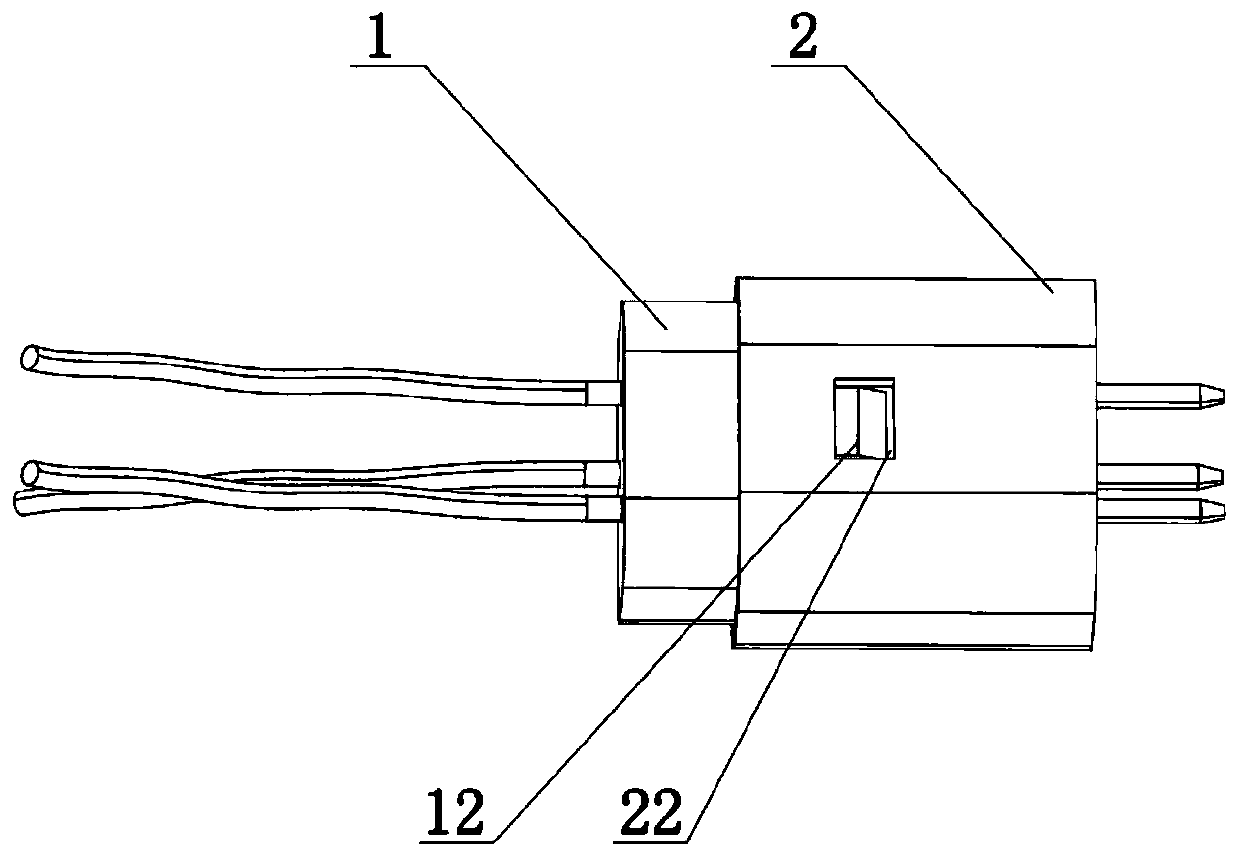

Injection molded cable joint

PendingCN109742574AGuaranteed continuitySimple structureCoupling contact membersCouplings bases/casesMating connectionJoint injection

The invention relates to an injection molded cable joint. The cable joint comprises a male joint and a female joint; the male joint comprises a plurality of male joint conductive sheets; the outer sides of the male joint conductive sheets are in injection molding connection with male joint injection molded shells; the female joint comprises a plurality of female joint conductive sheets; the outersides of the female joint conductive sheets are in injection molding connection with female joint injection molded shells; the male joint and the female joint are in matched connection through the male joint injection molded shells and the female joint injection molded shells; one ends of the male joint conductive sheets and the female joint conductive sheets are in contact connection when the male joint and the female joint are in assembly connection; and the other ends of the male joint conductive sheets and the female joint conductive sheets are connected with a cable. The injection moldedcable joint is simple in structure; injection molding production can be directly carried out, so that the production is convenient; and the connection between the male joint and the female joint can be ensured.

Owner:ADVANCED PLATINUM TECH

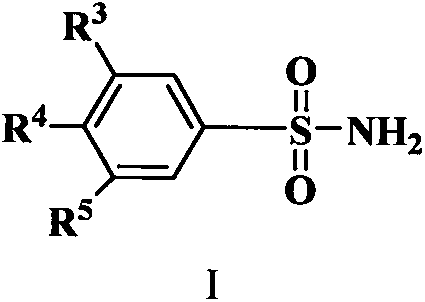

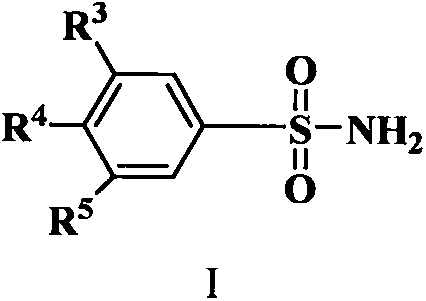

Injection medicine composition with synergistic action of vitamin C and benzsulfamide compounds

InactiveCN106822099AImprove the effect of chemotherapySynergisticAmide active ingredientsAntineoplastic agentsSide effectAdditive ingredient

The invention relates to a medicine composition for treating malignant tumors by injection administration. The medicine composition is characterized in that vitamin C is used as an anti-tumor component, and is compounded with one or multiple benzsulfamide compounds so as to prepare a pharmaceutically acceptable injection preparation for administration, or is compounded with one or multiple of benzsulfamide compounds for joint injection administration, especially for the tumor internal injection and interventional administration or vein, artery, muscle and subcutaneous administration. The vitamin C composition preparation has the advantages that the vitamin C composition preparation is directly injected into multiple malignant tumors of liver cancers, pancreatic cancers, brain tumors, esophagus cancers and the like, the medicine concentration in the tumor is increased, the medicine concentration in other tissues is decreased, the therapy effect is improved, and the toxic or side effect of a whole body is reduced; an effective method for overcoming the barriers of blood brain barriers, blood tumor barriers and the like is provided; an ideal therapy selection is provided for a patient of which the tumor cannot be cut off by surgery.

Owner:王子厚

Oil extraction method based on joint injection of hydrogen and carbon monoxide

The invention relates to an oil extraction method based on the joint injection of hydrogen and carbon monoxide. The method comprises the following steps: injecting hydrogen or carbon monoxide; heating injected gas; heating rock in an immediate vicinity of wellbore to 100-400DEG C; injecting hydrogen and carbon monoxide into a gas injection well, wherein hydrogen injection amount is 1000-100000 cubic meters / atmosphere every day, and carbon monoxide injection amount is 1000-100000 cubic meters / atmosphere every day; detecting hydrogen output of production wells; when the hydrogen output of one of the surrounding production wells is above 500 cubic meters everyday, closing the production well; when more than 50% of the production wells are closed, finishing the oil extraction mode of hydrogen and carbon monoxide injection. By the adoption of the oil extraction method, the wettability of rock can be changed so that the rock is changed into rock with strong hydrophily, strong capillary force oil expelling effect is formed so as to improve recovery ratio; fluid in sealed pore spaces in a low-osmosis oil deposit is heated and expanded to spall the sealed spaces so as to form a channel so that crude oil in the sealed pore spaces flows out.

Owner:PETROCHINA CO LTD

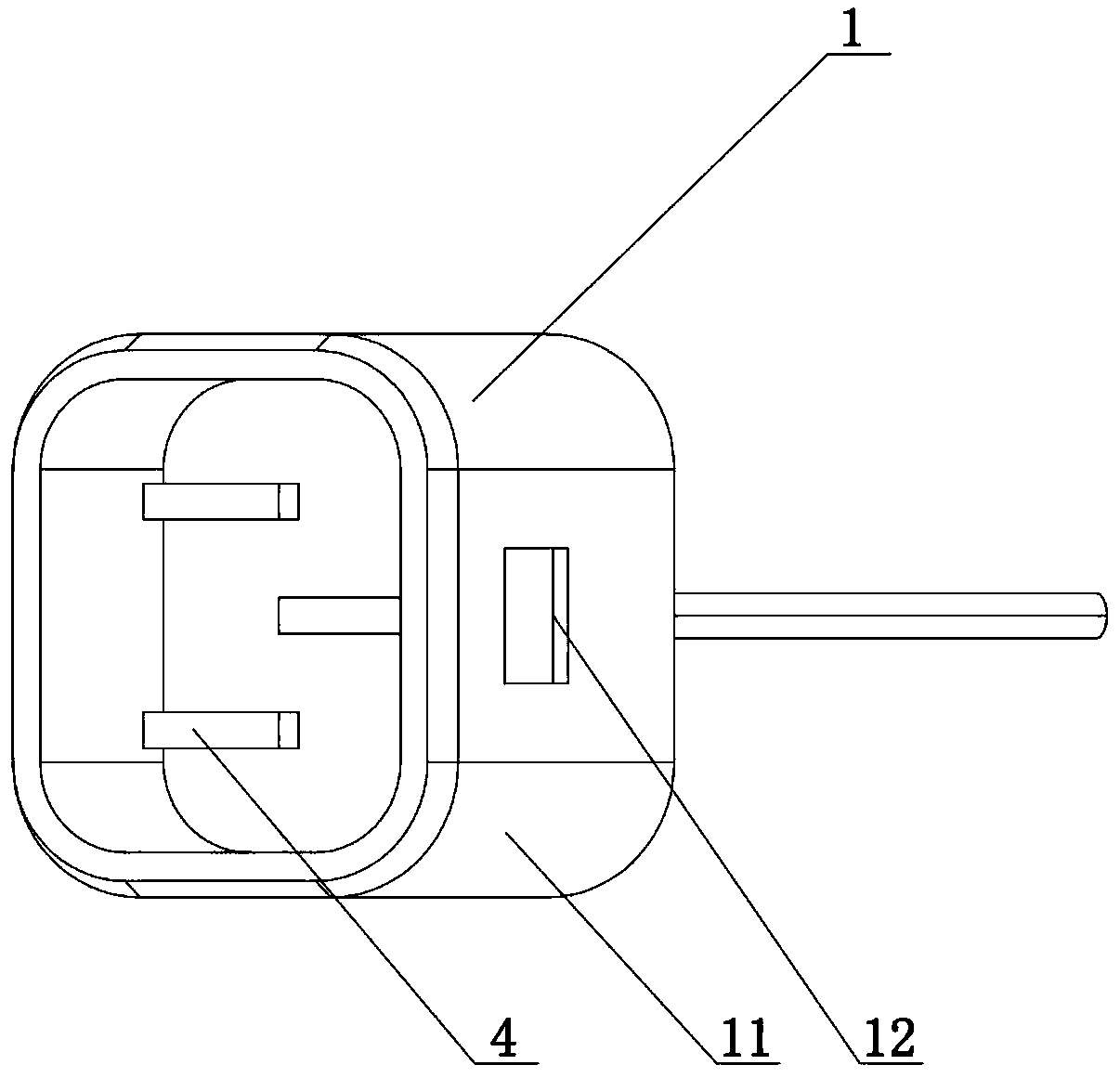

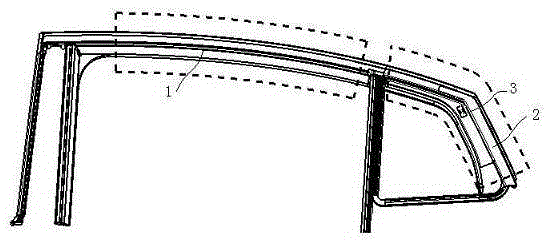

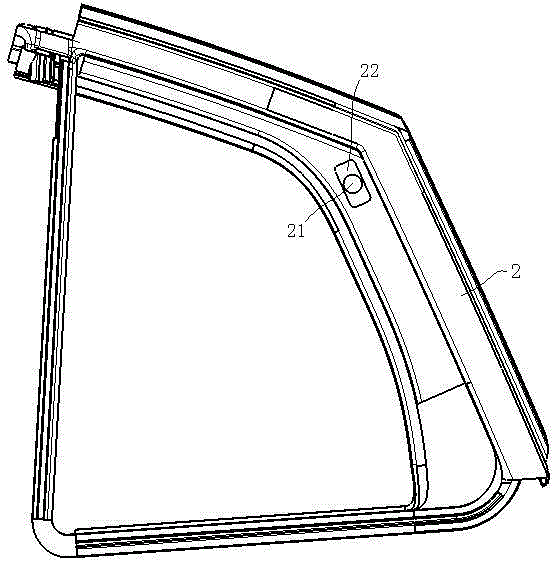

Glass guide rail structure for automobile rear door

ActiveCN105346364ASolve warpingSolve the gapEngine sealsVehicle sealing arrangementsMetal frameworkJoint injection

The invention relates to a glass guide rail structure for an automobile rear door. The guide rail structure is characterized by comprising a uniform section part (1), a variable section part (2) and a buckle (3); the uniform section part (1) is formed in an extrusion manner, and the variable section part (2) is formed in an injection manner; during injection molding, the uniform section part (1) is placed in a mold for joint injection molding, and therefore the uniform section part (1) and the variable section part (2) are combined; and the glass guide rail structure is fixed to an automobile door metal plate through the buckle (3). The uniform section part (1) is formed by dense rubber and a metal framework (13) in a composite extrusion manner. The variable section part (2) is formed by dense rubber and a metal insert (24) in a secondary injection molding manner.

Owner:CHERY AUTOMOBILE CO LTD

Mold opening method for pipe joint injection mold

The invention provides a mold opening method for a pipe joint injection mold. The mold opening method includes the step of mandrel assembly drawing and specifically includes the following steps that a first sleeve and a second sleeve are drawn down from the upper portion of an injection molding pipe joint; a first lower core and a second lower core are drawn out of the lower portion of the injection molding pipe joint; and a bent core rod is rotated out of an inner hole of a pipe joint formed by the second sleeve. According to the mold opening method for the pipe joint injection mold, the bent core rod is adopted for a mandrel assembly, the manner of rotating the bent core rod out of a connection pipe subjected to injection molding is adopted during drawing, and therefore the H-shaped connection pipe is obtained through the injection molding integral-forming processing technology, and a new thought is provided for injection mold opening.

Owner:JIANGSU HIPPO PLASTICS

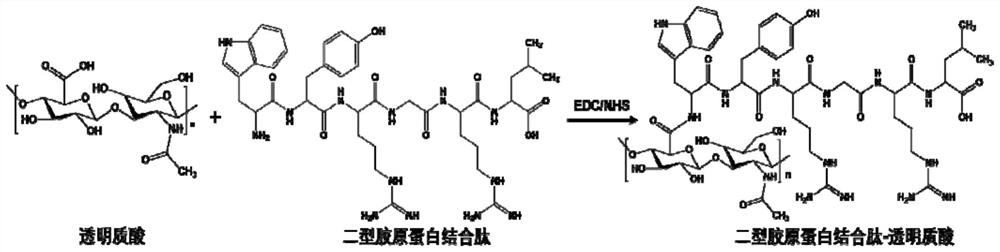

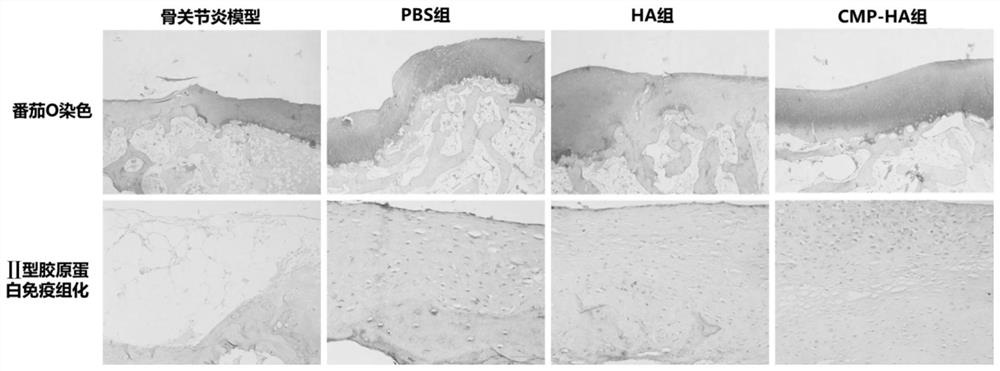

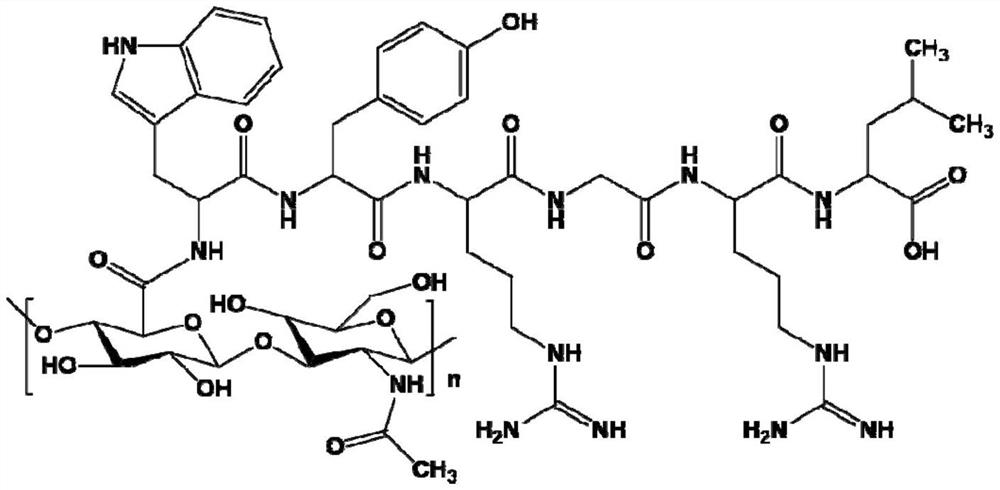

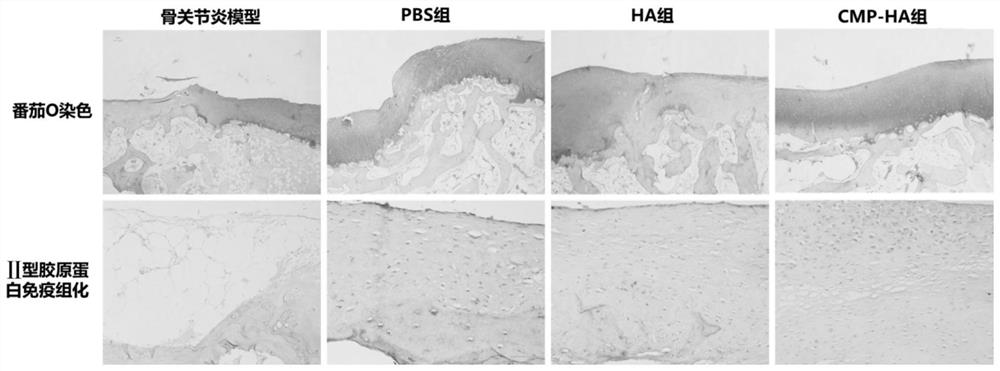

Joint injection preparation based on collagen binding polypeptide-modified hyaluronic acid as well as preparation method and application of joint injection preparation

ActiveCN111701072AGood resistance to non-specific adsorptionOvercome the shortcomings of poor anti-nonspecific adsorption performancePharmaceutical delivery mechanismTissue regenerationInflammatory factorsCartilage repair

The invention discloses a joint injection preparation based on collagen binding polypeptide-modified hyaluronic acid as well as a preparation method and application of the joint injection preparation.The method comprises the following steps: firstly, designing and synthesizing a polypeptide molecule capable of being combined with collagen, then grafting modified hyaluronic acid through amidationreaction, and then embedding the hyaluronic acid to the surface of a cartilage matrix through the specific recognition binding effect of the collagen binding polypeptide and cartilage surface II typecollagen so as to obtain the joint injection preparation based on collagen binding polypeptide-modified hyaluronic acid. The joint injection preparation not only can specifically bind the hyaluronic acid to the surface of damaged cartilage tissue, but also endows the surface of the damaged cartilage with excellent non-specific adsorption resistance and lubricating property, and can be used for preparing cartilage repair materials, treating osteoarthritis and improving anti-inflammatory factors and lubricating property of the surface of the damaged cartilage; and the joint injection preparationcan also be used as a modified material for improving the friction performance of cartilage repair materials.

Owner:TIANJIN UNIV

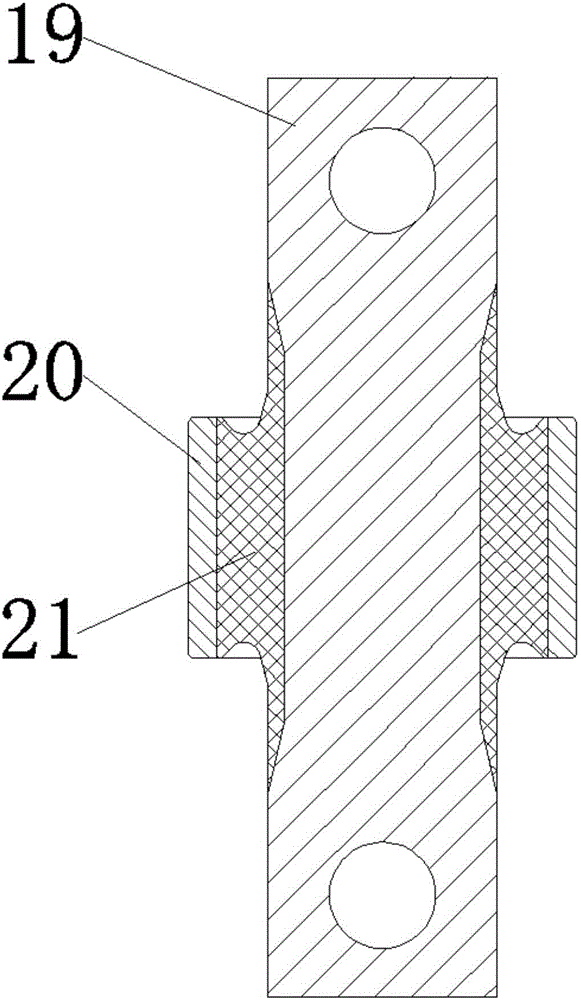

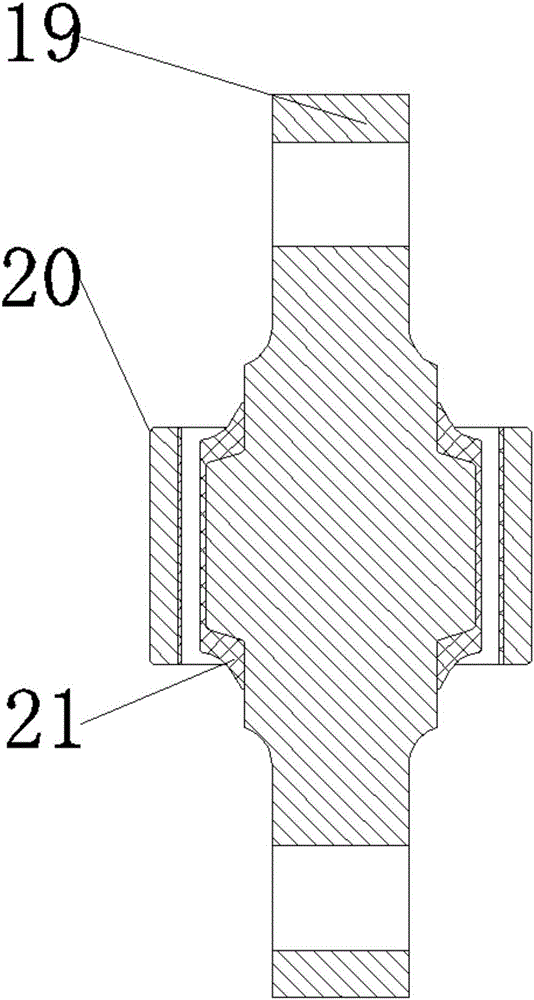

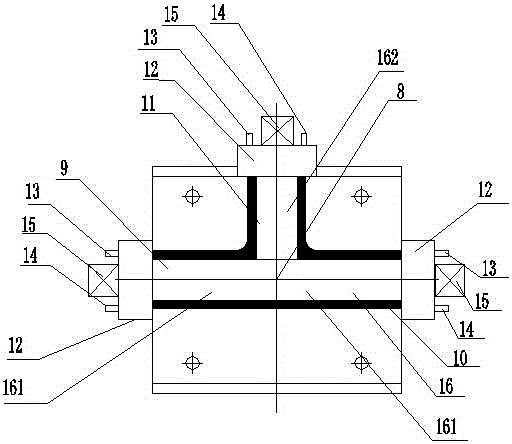

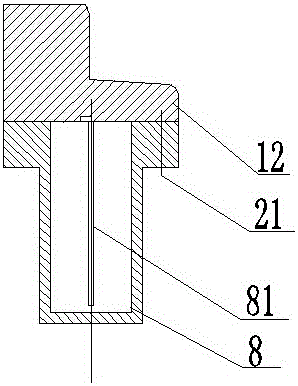

Rubber elastic joint injection mold

ActiveCN106426807AEfficient extractionMeet the requirements of mass productionHigh volume manufacturingJoint injection

The invention provides a rubber elastic joint injection mold which comprises an upper mold body, a lower mold body and a middle mold body. The upper mold body comprises a top plate located at the top of the upper mold body, an upper core mold fixing plate arranged on the lower portion of the top plate, upper core molds fixedly arranged on the upper core mold fixing plate, an upper push plate arranged on the lower portion of the upper core mold fixing plate and a limit piece capable of limiting the upper core mold fixing plate to move vertically. The lower mold body comprises a base plate located at the bottom and lower core molds fixedly arranged on the base plate. The middle mold body comprises a lower push plate arranged above the base plate, clamping blocks which are arranged between the adjacent lower core molds correspondingly and are fixedly arranged at the top of the lower push plate, and slide blocks capable of horizontally sliding along the top of the lower push plate. By adoption of the rubber elastic joint injection mold, vulcanized rubber elastic joints can be effectively taken out of the mold, and meanwhile, requirements of large-batch production of the rubber elastic joints can be met.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

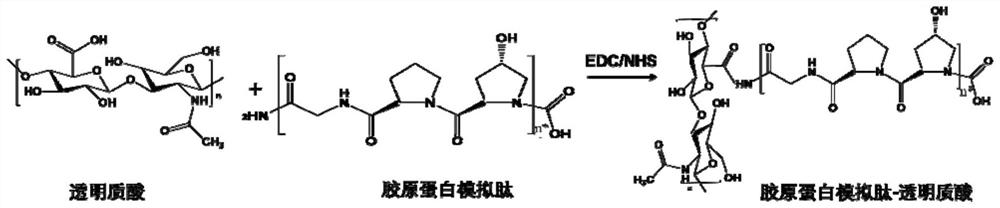

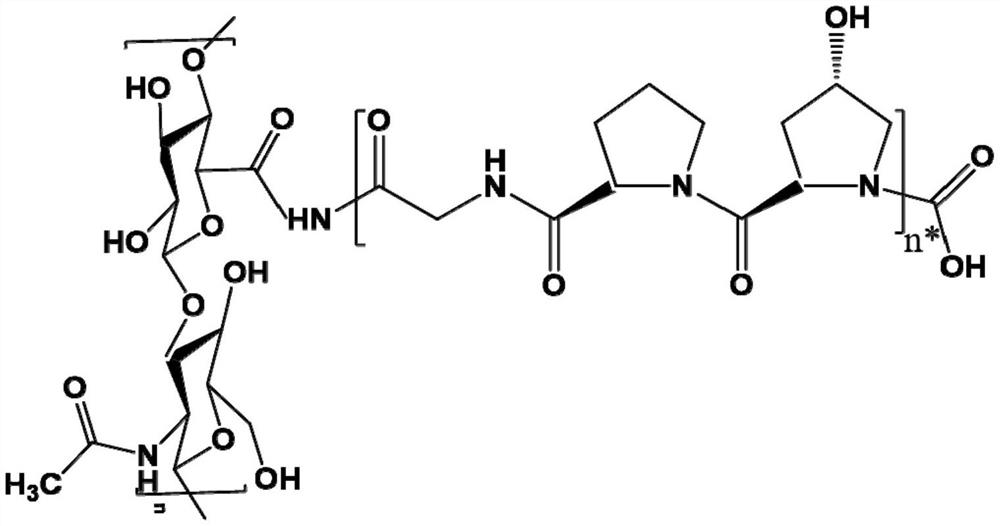

Collagen mimic peptide modified hyaluronic acid-based joint injection preparation and preparation method thereof and application of joint injection preparation

InactiveCN111701073AGood resistance to non-specific adsorptionOvercome the shortcomings of poor anti-nonspecific adsorption performanceOrganic active ingredientsPeptide/protein ingredientsInflammatory factorsCartilage repair

The invention discloses a collagen mimic peptide modified hyaluronic acid-based joint injection preparation and a preparation method thereof and application of the joint injection preparation. Collagen mimic peptide grafted modified hyaluronic acid is synthesized by an amidation reaction; then collagen mimic peptide is intercalated to the surface of a cartilage matrix under the specific recognition and intercalation action of the collagen mimic peptide and type II collagen on the surface of the cartilage, thereby obtaining the collagen mimic peptide modified hyaluronic acid-based joint injection preparation. The joint injection preparation not only can make hyaluronic acid specifically bound to the surface of damaged cartilage tissue, but also gives the damaged cartilage surface excellentanti-nonspecific adsorption property and lubricating property, can be used for preparing cartilage repair materials and treating osteoarthritis, improves anti-inflammatory factors and lubricating property of the surface of the damaged cartilage, and can also be used as a modified material for improving the friction performance of the cartilage repair materials.

Owner:TIANJIN UNIV

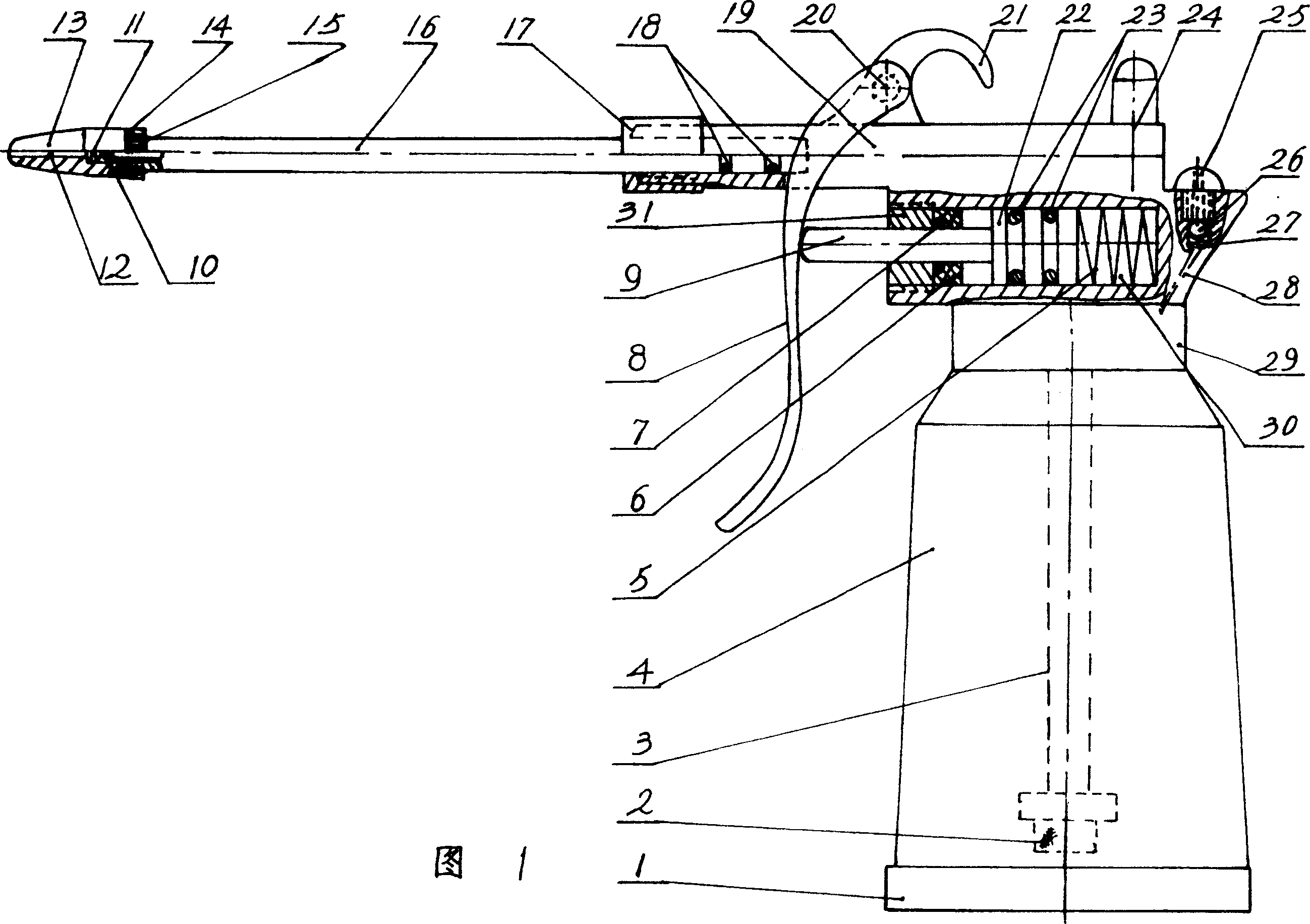

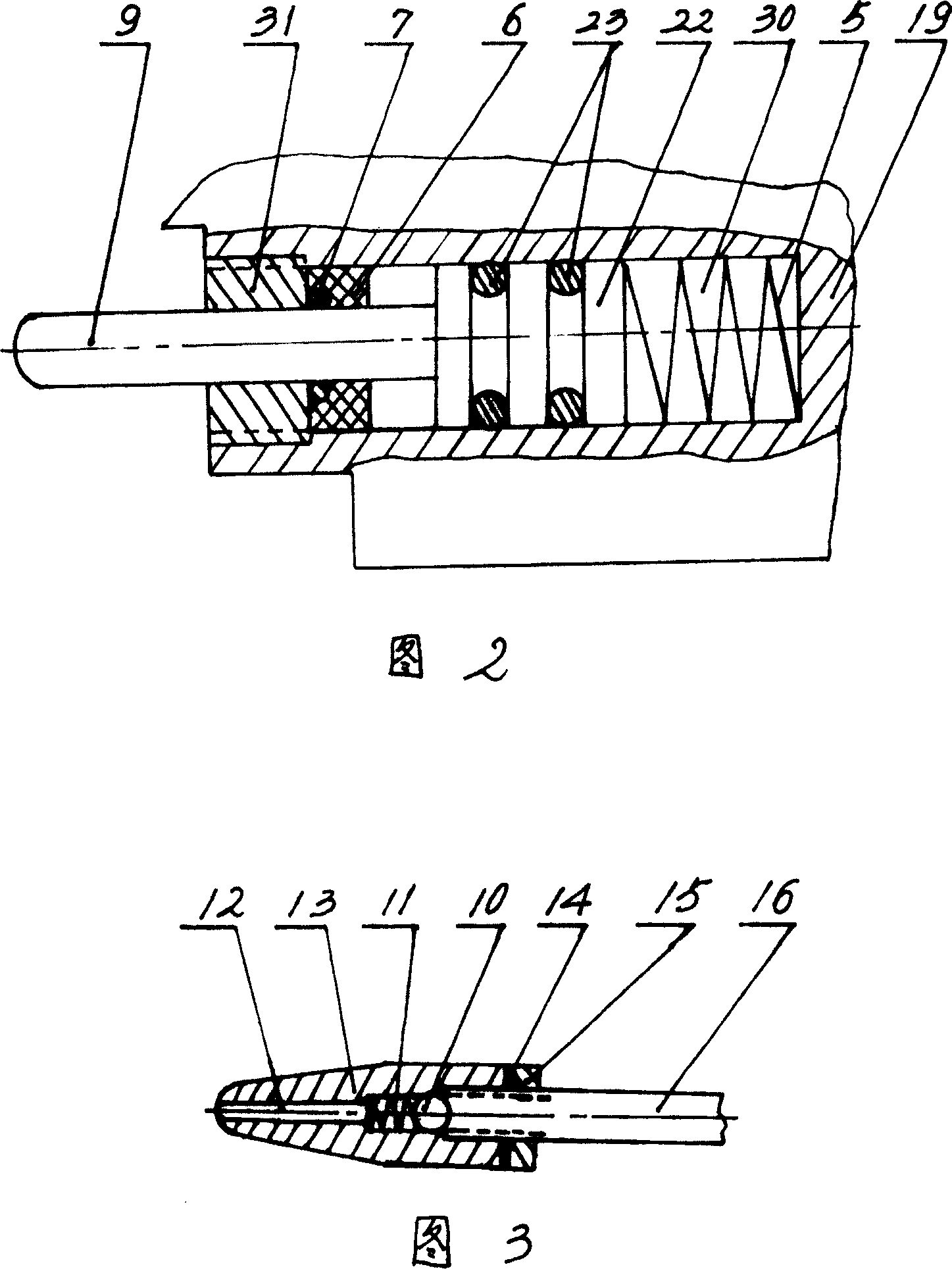

Oil gun

An oil gun, which contains gun body including upper and lower section, the upper is the joint injection rod with nozzle in head, oil filled piston cylinder in middle section with piston and reset spring, the lower section is connection cover connected with oil tank having suction pipe, screw plug set in open of oil filled cylinder, stop ring, seal ring for preventing the oil from leakage when the manual wrench turns to press the piston making oil to bottom of piston cylinder.

Owner:ZHEJIANG REFINE WUFU AIR TOOLS

Cantilever beam vertical pipeline grouting double-pipe joint injection construction method

InactiveCN109252449AImprove crack resistanceShorten the timeBridge erection/assemblyBridge materialsCrack resistanceDouble tube

The invention relates to the technical field of bridge construction, in particular to a cantilever beam vertical pipeline grouting double-pipe joint injection construction method. The construction method comprises the following steps: firstly, blanking the vertical prestressed tendon and the vertical prestressed casing; next, the vertical prestressed casing after blanking is processed into holes;next, the vertical prestressed tendon is assembled; next, the assembled vertical prestressed tendons are positioned and installed at the same time of the web reinforcement binding; next, the bottom oftwo adjacent vertical prestressed casing pipes are communicated; next, the vertical prestressed steel bar is tensioned; finally, the grout is pressed into the vertical prestressed casing. By adoptingthe construction method, the grouting in the vertical prestressed tendons can be made more dense and full, so that the bonding effect of the grouting concrete on the prestressed tendons is more prominent, the stress loss of the vertical prestressed tendons is avoided to a greater extent, and the cantilever beam concrete has better crack resistance.

Owner:CHINA RAILWAY SIXTH GROUP +1

Catheter joint injection molding device

PendingCN108162303ASimple connection processReduce manufacturing costCoatingsTubular articlesJoint injectionEngineering

The invention relates to a catheter joint injection molding device. The catheter joint injection molding device comprises an injection molding machine, a mold base plate, and a support block, a firstcushion plate and a second cushion plate fixedly arranged on the mold base plate in sequence; an upper mold plate is fixedly arranged on the second cushion plate; multiple catheter joint molds corresponding to medical catheters are fixedly arranged on the upper mold plate; clamping and positioning devices for positioning the medical catheters are fixedly arranged on the first cushion plates, and are opposite to the catheter joint molds; a sliding mechanism is arranged between a support base and a catheter winding carrier; and annular injecting pipes corresponding to the catheter joint molds are arranged on the second cushion plate, and are connected with the injection molding machine. Through cooperation among the injection molding machine, the annular injecting pipes and the catheter joint molds, catheters are used as inserts for injection molding with catheter joints, so that connection between the catheters and the molds in the catheter joints is realized, and the manufacturing costof intervention catheters is reduced.

Owner:梁启明

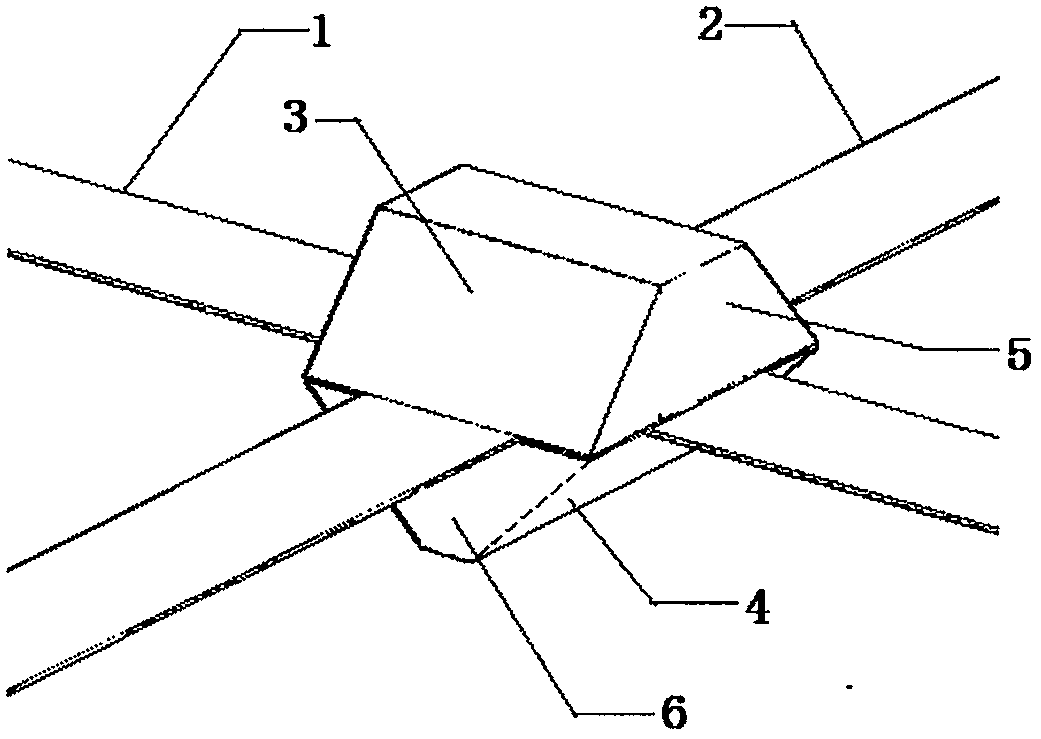

A joint injection molding type polypropylene geogrid and a preparation method thereof

PendingCN109594551AHigh tensile strengthImprove corrosion resistanceDomestic netsSoil preservationJoint injectionEngineering

The invention discloses a joint injection molding type polypropylene geogrid and a preparation method thereof. The geogrid comprises transverse strips and longitudinal strips. The transverse strips and the longitudinal strips are polypropylene strips, wherein the transverse strips and the longitudinal strips intersect to form a grid shape, joints are formed at the intersecting positions of the transverse strips and the longitudinal strips, polyethylene reinforcing blocks which are integrally formed in an injection molding mode are arranged at the joints, the joints are located in the centers of the reinforcing blocks; and the left sides and the right sides of the portions, located at the top ends of the joints, of the reinforcing blocks are provided with upslopes of 30-50 degrees and the front sides and the rear sides are planes, and the front sides and the rear sides of the portions, located at the bottom ends of the joints, of the reinforcing blocks are provided with downslopes of 30-50 degrees, and the left sides and the right sides are planes. The geogrid has the advantages that the tensile strength of a body is high, the stripping force at the joints is large, and the corrosion resistance is good.

Owner:武向晖

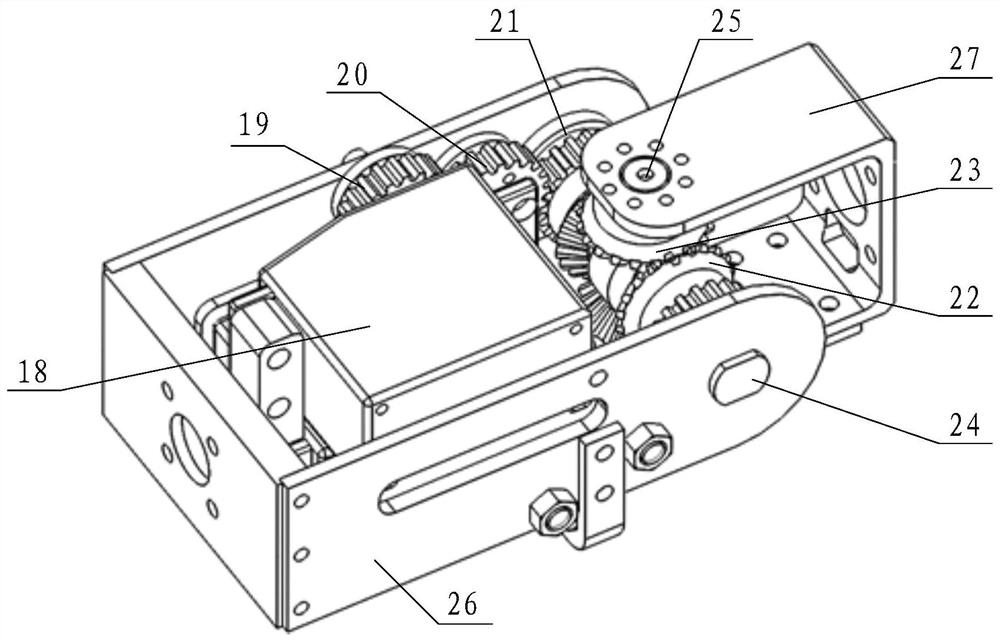

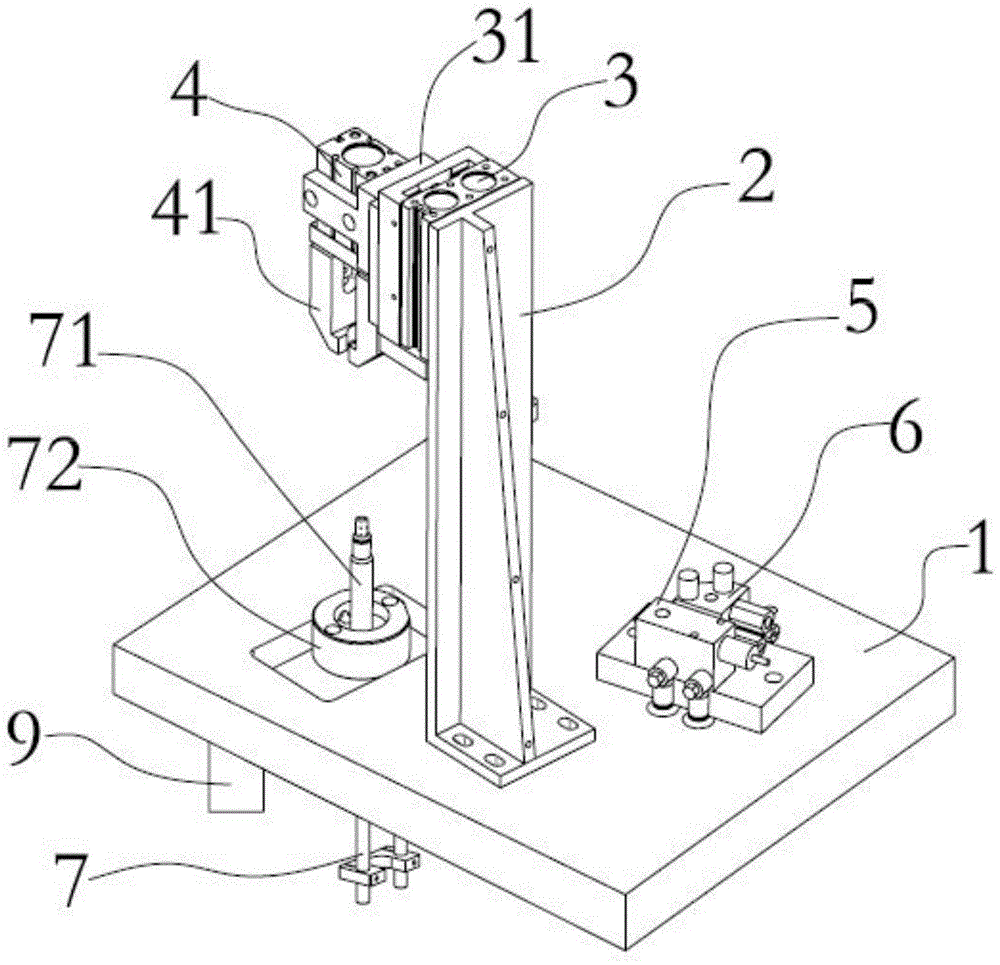

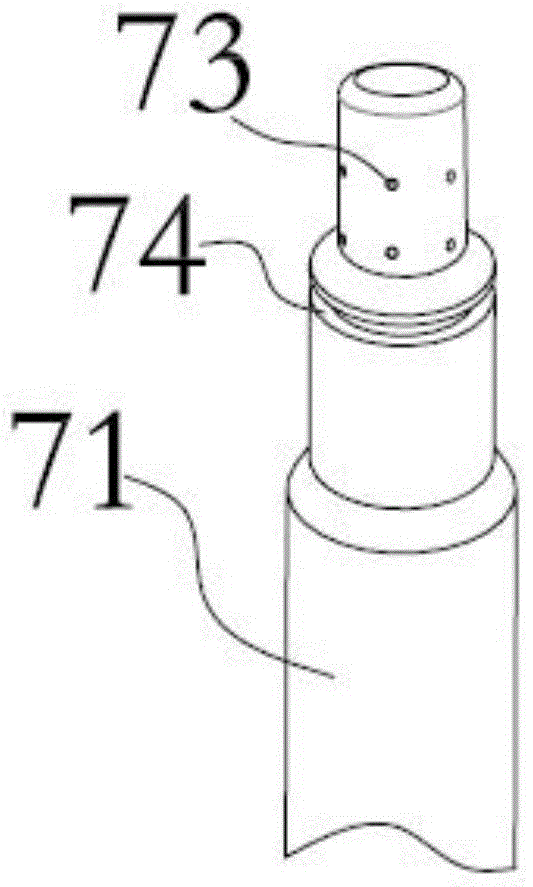

Joint injector

ActiveCN104848023BHigh degree of automationEven spraying effectEngine lubricationJoint injectionEngineering

Owner:CHONGQING SULIAN AUTO PARTS

A polyester fiber joint injection molding type geogrid and a processing method thereof

PendingCN109594550ANot easy to peel offHigh tensile strengthRoadwaysCoastlines protectionFiberPolyester

The invention discloses a polyester fiber joint injection molding type geogrid and a processing method thereof. The polyester fiber joint injection molding type geogrid comprises transverse strips andlongitudinal strips; each of the transverse strips and the longitudinal strips consists of a polyester fiber core arranged inside and a polypropylene or polyethylene coating arranged outside; the transverse strips and the longitudinal strips intersect to form a grid shape; joints are formed at the intersecting positions of the transverse strips and the longitudinal strips; a reinforced block which is integrally injection-molded and is made of a polyethylene material is arranged at each joint, the joint is positioned in the center of the reinforced block, and the reinforced block is of a square structure with a slope at each edge. The geogrid has the advantages that the tensile strength is high, the joints are not liable to peeling-off and corrosion, the interlocking with a soil body is strong, and the cost is saved.

Owner:武向晖

Prepn process of combined delayed releasing agent for preventing and treating animal's tinea pedis and mite disease

InactiveCN1210040CHigh inclusion rateGood control effectPowder deliveryOrganic active ingredientsDiseaseSolvent

The invention discloses a preparation method of a combined slow-release agent for preventing and treating animal skin ringworm and mite disease, which significantly improves the inclusion rate of the drug in β-cyclodextrin, thereby successfully preparing an efficient and stable drug for preventing and treating animal skin diseases. new drug dosage forms. The main point of its technical plan is to use griseofulvin and abamectin or ivermectin and beta cyclodextrin as main raw materials, carry out reasonable optimization ratio and supplement with certain process conditions, first griseofulvin Dissolve in a solvent, grind the β-cyclodextrin with distilled water to form a paste, mix the two together for a period of time, then add the abamectin solution or ivermectin solution dissolved in a solvent, stir, mix and include After being dried and pulverized, it can be prepared as joint sustained-release powder or formulated as joint sustained-release injection, and then packaged. It is mainly used in the prevention and treatment of psoriasis and mites in rabbits, pigs, sheep, dogs, cats, cattle and other animals.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

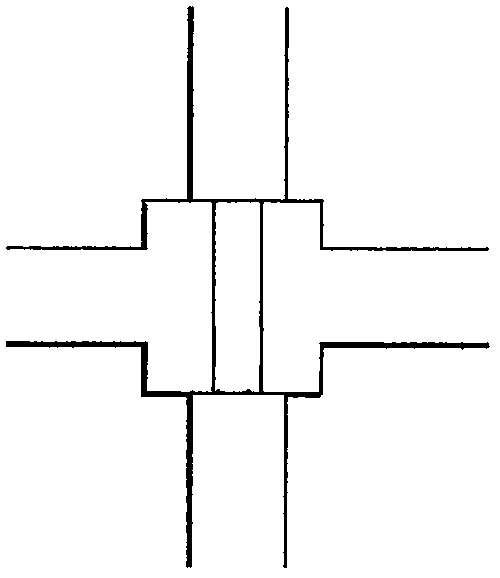

Tee joint injection mold

ActiveCN106273254ADimensionally stableImprove product qualityDomestic articlesJoint injectionEngineering

Owner:BAODING TIANYIN MACHINERY

A three-way injection mold

ActiveCN106273254BDimensionally stableImprove product qualityDomestic articlesJoint injectionEngineering

The invention provides a tee joint injection mold which comprises a stationary mold main body and a mold core, wherein a bottom plate main body is arranged on the left side of the stationary mold main body; a propping bottom plate is arranged on the right side of the bottom plate main body; a propping plate is arranged on the right side of the propping bottom plate; a return spring is fixed on the right side of the propping plate; propping rods are arranged on the upper sides and the lower sides of the propping bottom plate and the propping plate; a fixing plate is arranged on the right side of the stationary mold main body; the mold core comprises a tee joint mold core I, a tee joint mold core II and a tee joint mold core III; the tee joint mold core I is arranged on the right side inside the stationary mold main body; the tee joint mold core II is arranged on the left side inside the stationary mold main body; the tee joint mold core III is arranged on the upper side inside the stationary mold main body; a partitioning plate is arranged inside the mold core. By adopting the tee joint injection mold, machine tool cooling circulation molding can be achieved, a product is already cooled and molded after being taken out from an injection molding machine tool and is stable in size, the product quality is improved, the production cost is reduced, the production efficiency is improved, the operation is simple, the labor is saved, and a very good use effect can be achieved.

Owner:BAODING TIANYIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com