Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Avoid oily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

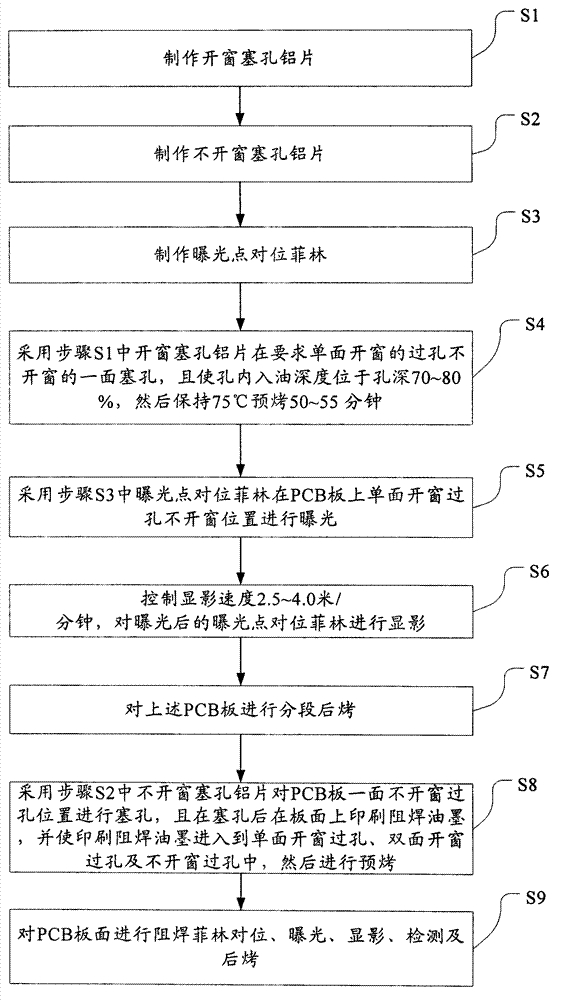

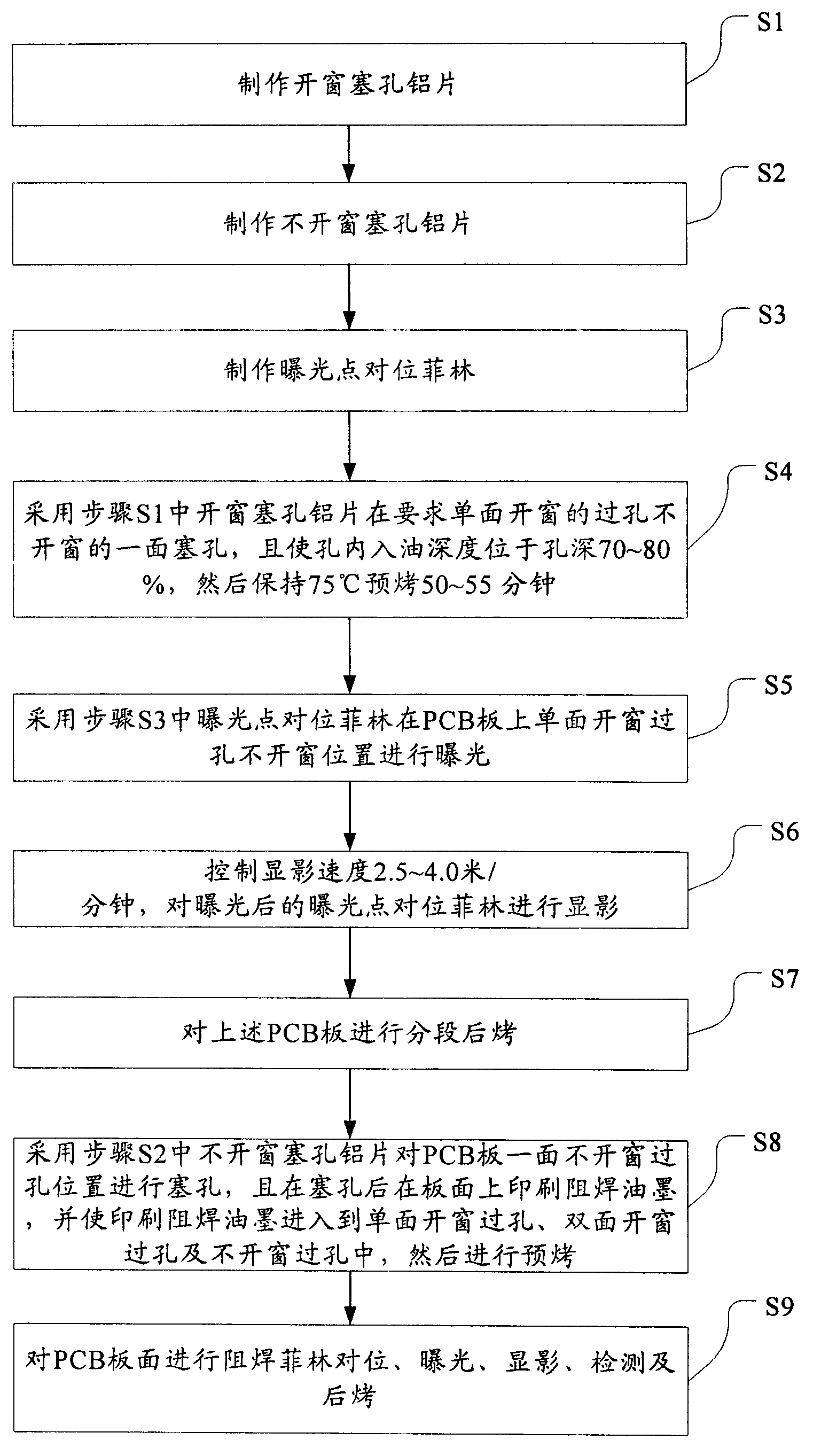

Method for preventing oil from bleeding from solder resist ink plug hole

ActiveCN103079362AAvoid oilyImprove qualityNon-metallic protective coating applicationPrinted element electric connection formationResistExposed point

The invention discloses a method for preventing oil from bleeding from a solder resist ink plug hole. The method comprises the following steps of: manufacturing single-surface and double-side windowing via hole plugging aluminum sheets and non-windowing plug hole aluminum sheets; plugging single-surface and double-side windowing via holes of a PCB (Printed Circuit Board); when the single-surface windowing via hole is plugged, displaying exposed point films on one surface where the windowing via holes are not windowed; and then plugging non-windowing via holes. According to the method disclosed by the invention, solder resist ink is printed after the plugging is carried out in graded times, so that the problem of oil bleeding in the plugging process of single-side windowing, double-side windowing and non-windowing PCB is effectively solved; and the quality and service performance of products are improved.

Owner:星河电路(福建)有限公司 +1

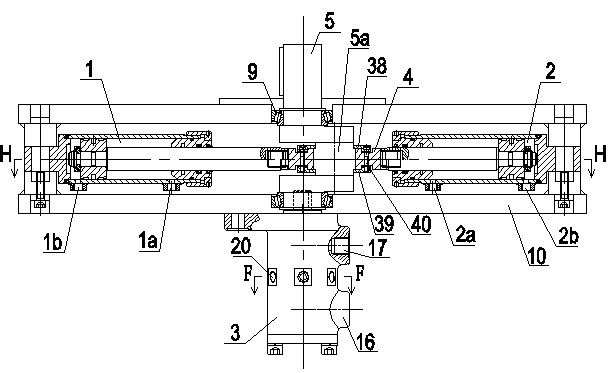

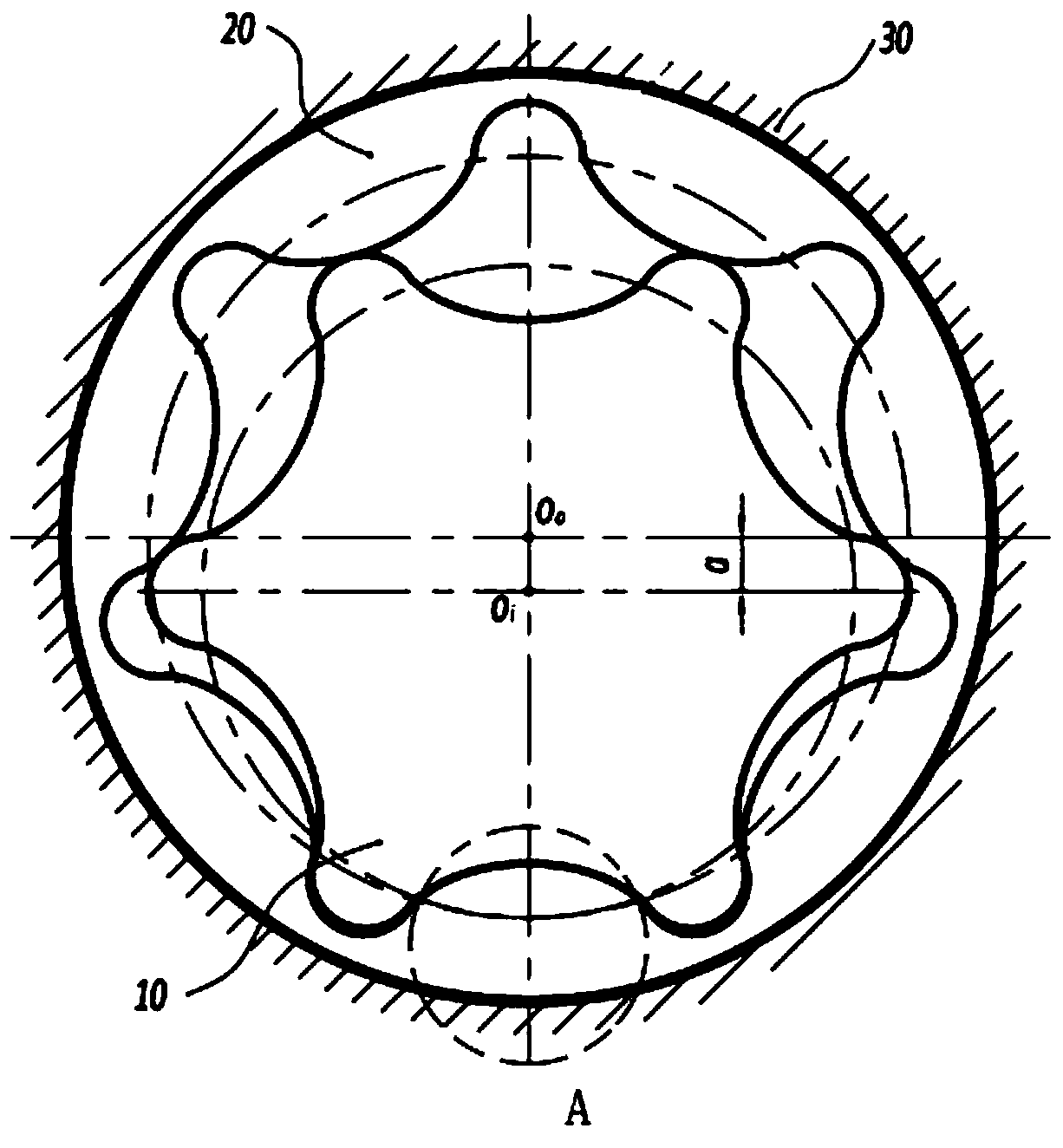

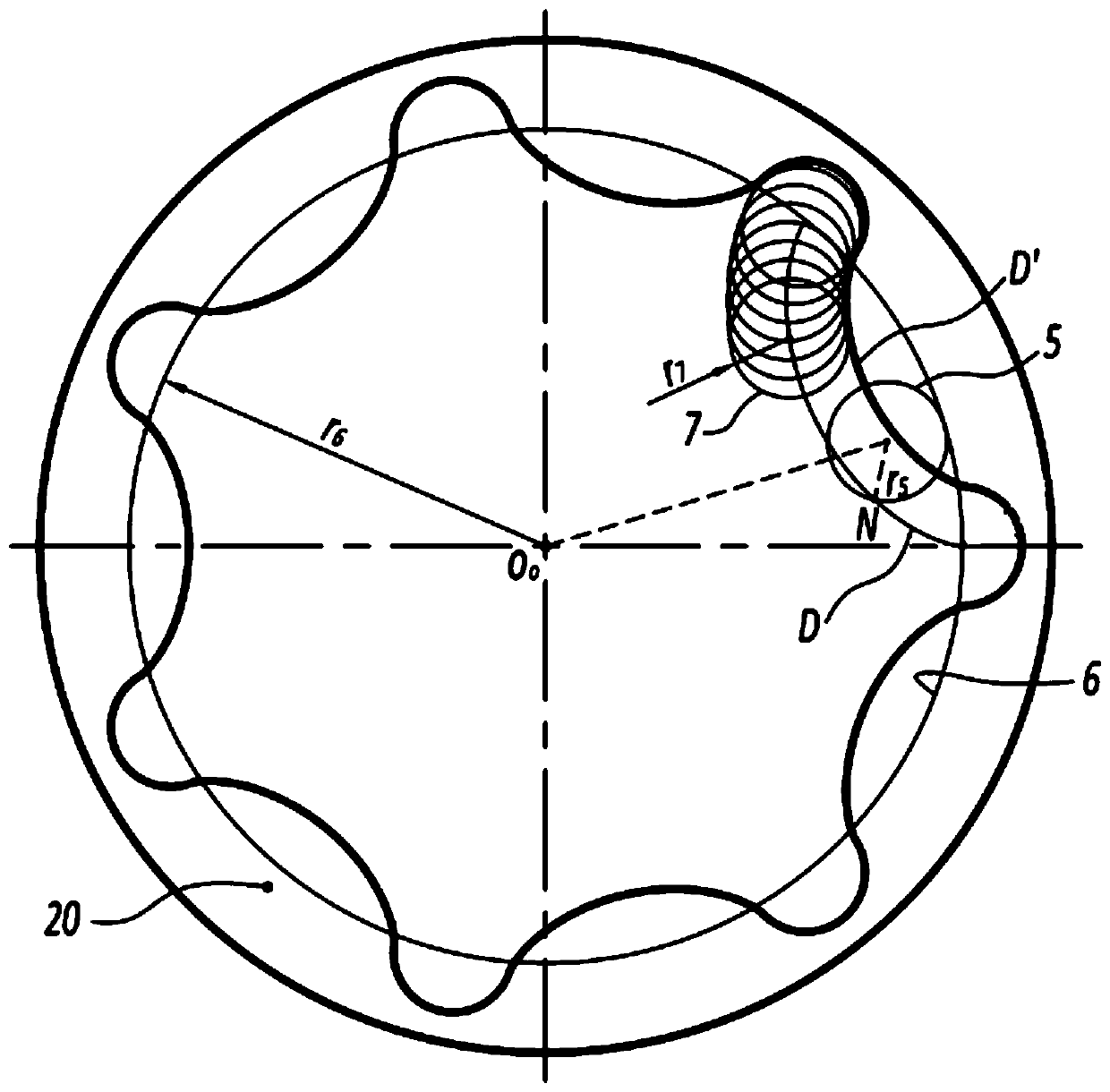

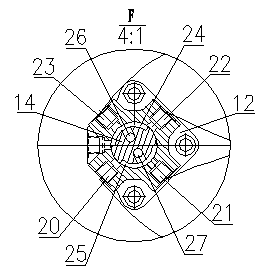

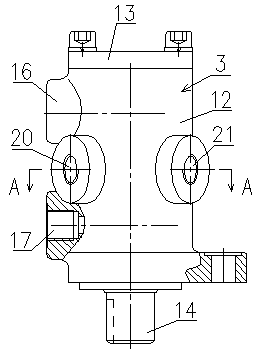

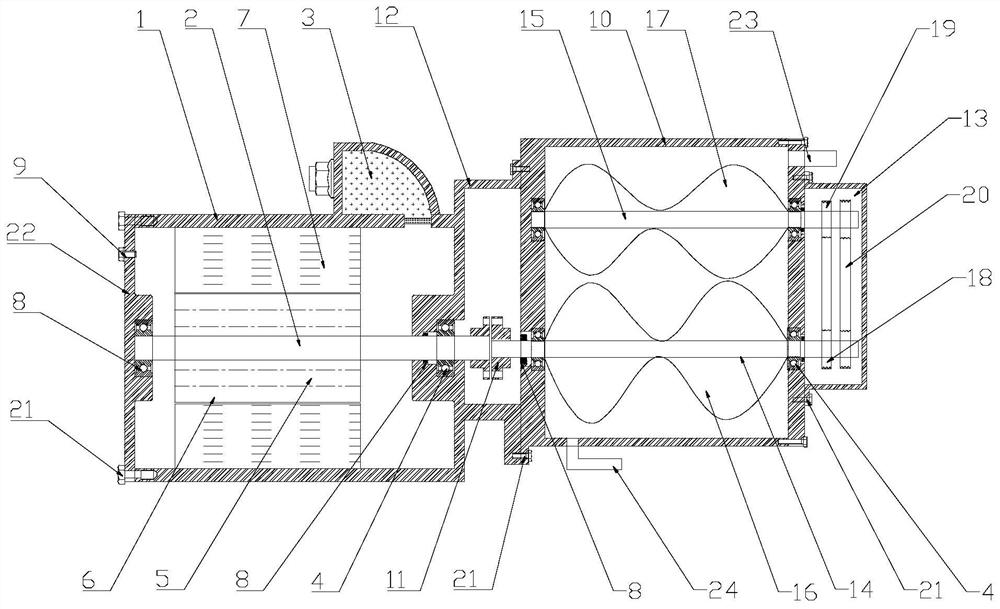

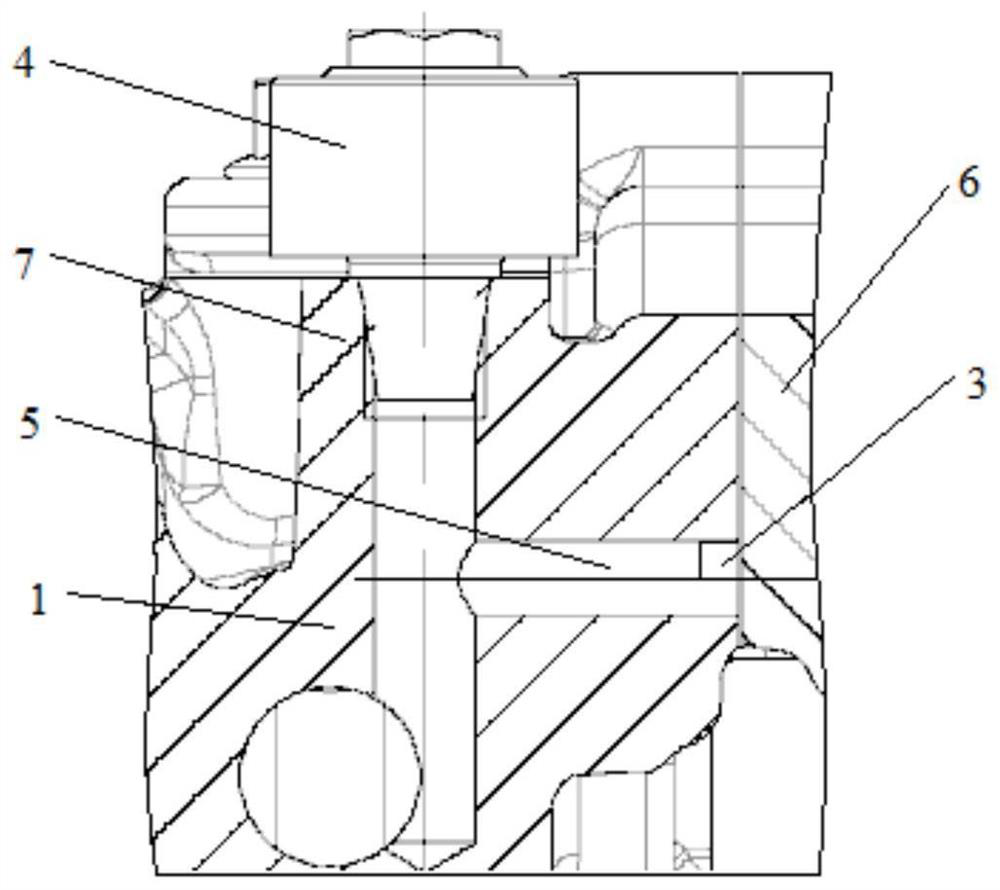

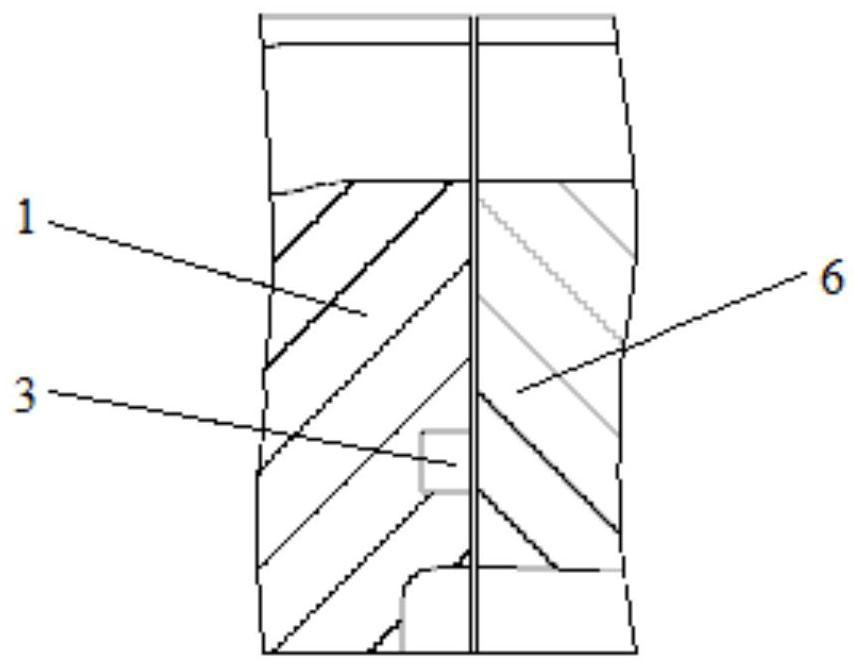

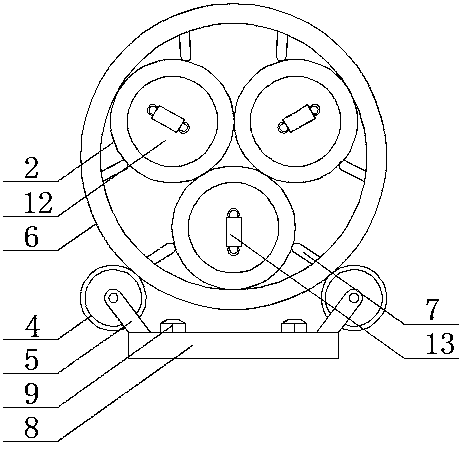

Open-type heavy hydraulic motor

The invention discloses an open-type heavy hydraulic motor which comprises a bracket, a spin valve and a crank shaft arranged at the center of the bracket, wherein one end of the crank shaft is connected with the outer end part of a valve core; more than four uniformly distributed double-acting oil cylinders are arranged around the eccentric section of the crank shaft; the bottom of each double-acting oil cylinder is hinged with the bracket, and the piston rod of each double-acting oil cylinder is connected with the eccentric section of the crank shaft through a rotatable connection structure; a valve body is provided with an oil inlet, an oil outlet and working oil ports of which the number is corresponding to that of the oil cylinders; all the working oil ports are uniformly distributed on the circumference of the valve body; the circumference of the valve core is provided with two annular grooves and two sectorial oil grooves; the corresponding central angles of the two sectorial oil grooves are greater than 90 degrees and less than 180 degrees; the two sectorial oil grooves are respectively connected with the corresponding annular grooves through connecting oil ways; and each working oil port is connected with the rod cavity oil port and rodless cavity oil port of each double-acting oil cylinder according to the corresponding relations. According to the invention, an extra-large torque can be easily realized, and the output torque and rotation speed are more uniform; and the open-type heavy hydraulic motor is convenient to install and maintain and has a wider application range.

Owner:南通艾德森机电设备有限公司

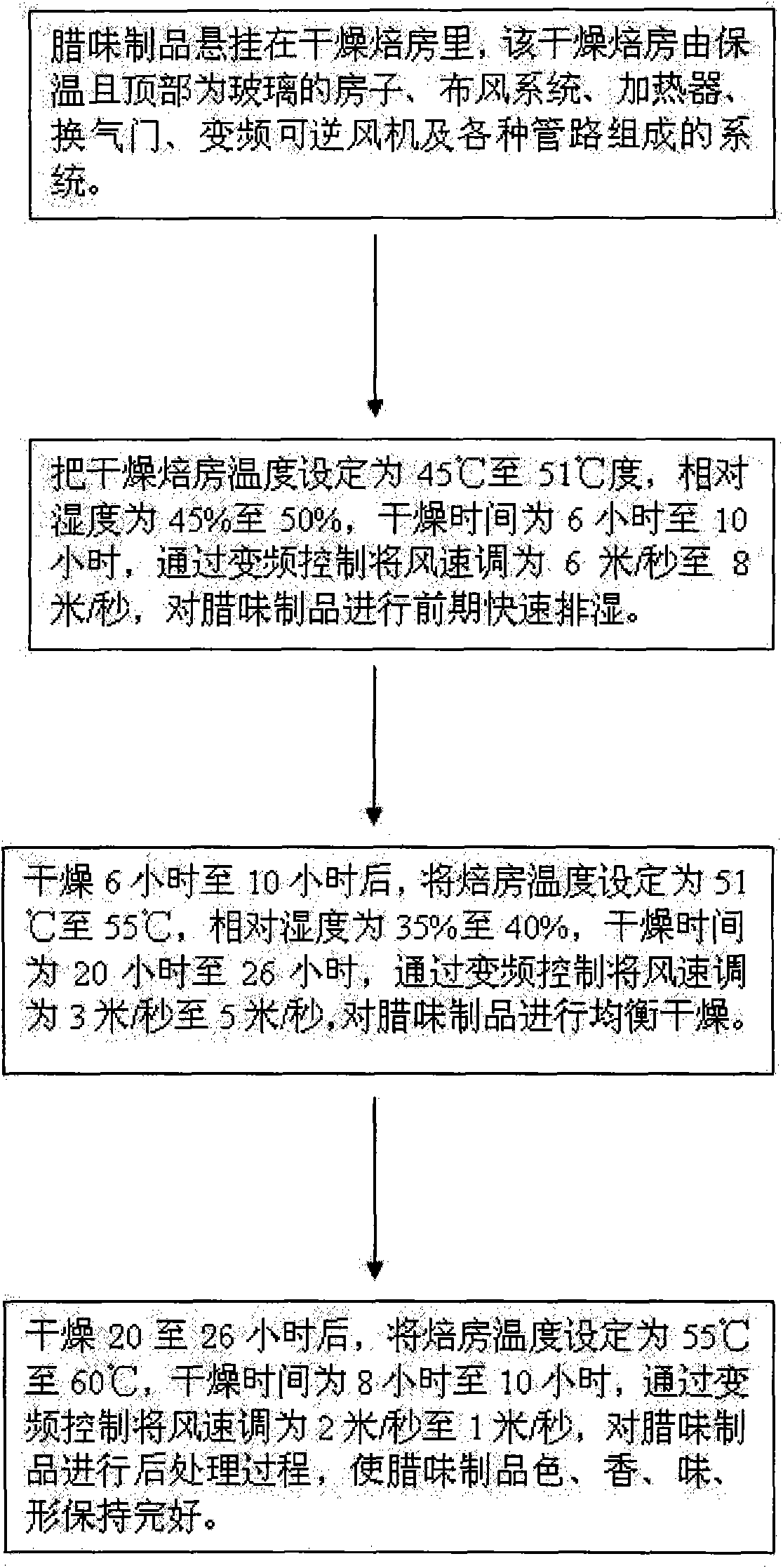

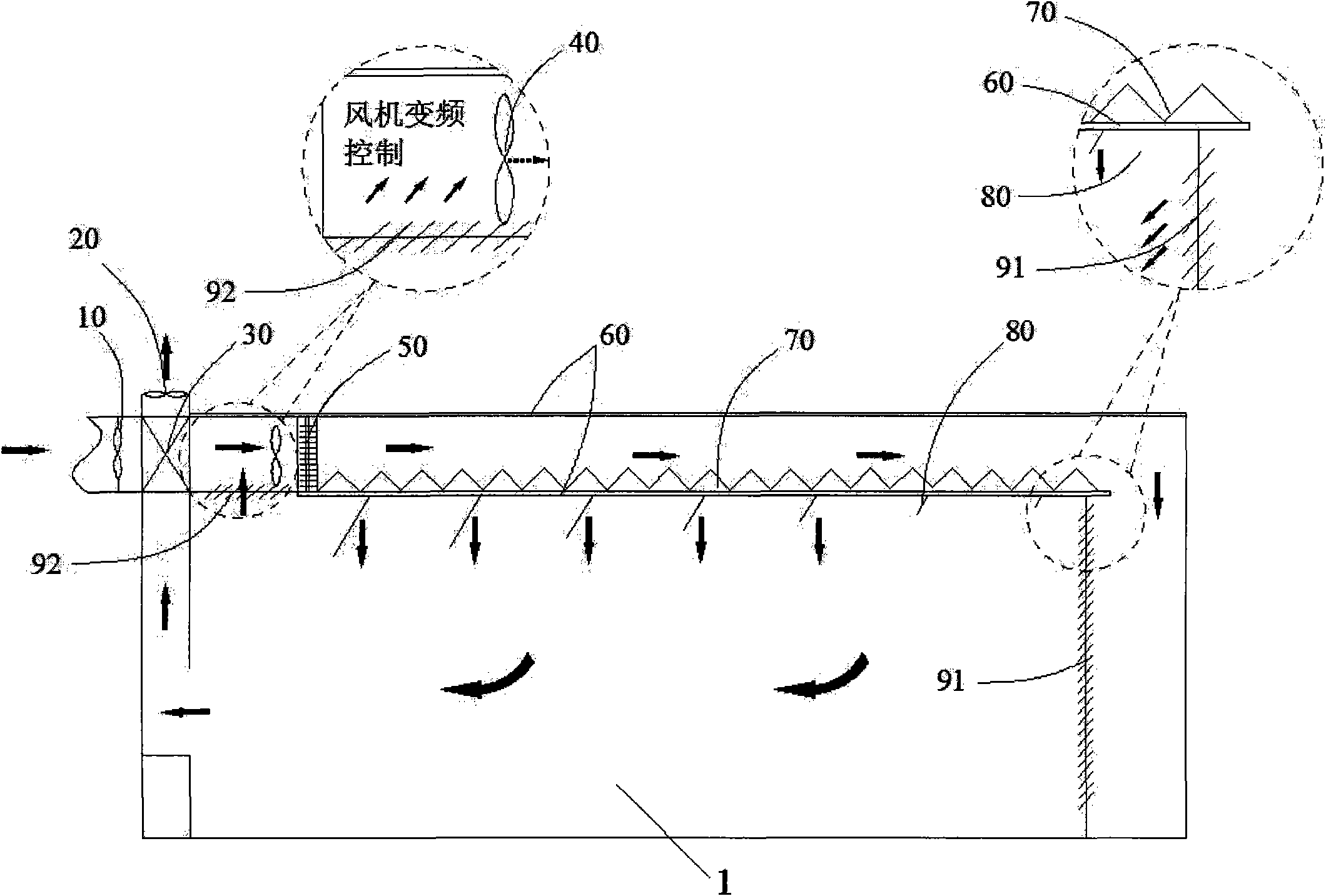

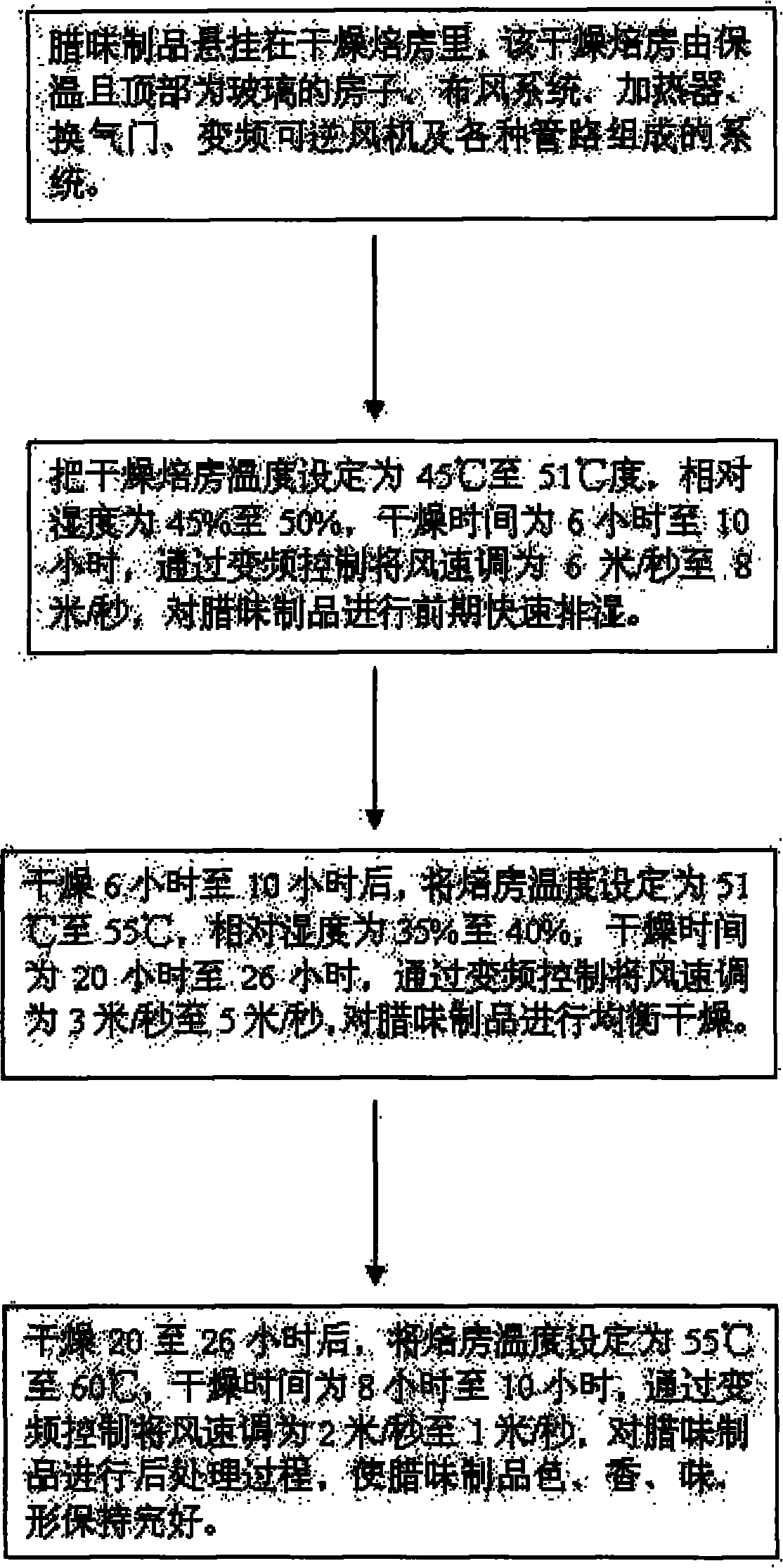

Energy-saving drying method for cured meat product

InactiveCN101878804ASolve consumptionTo overcome the large consumption,Food processingMeat/fish preservation by dryingAir volumeAgricultural engineering

The invention discloses an energy-saving drying method for cured meat products, which comprises a drying and baking main body. The drying method comprises the following steps that: (1) cured meat products required to be dried are hung in the drying and baking room with first preset air flow and first preset temperature, a ventilation door is opened, and the cured meat products exchange heat with hot air in the drying and baking room through convection to rapidly drain moisture out of the drying and baking room along with air; (2) after the moisture is rapidly drained in first preset drying time, the temperature of the drying and baking room is adjusted to second preset temperature, and the drying air flow in the baking room is adjusted to second preset air flow according to the change of humidity in the baking room to keep the drying rate of the cured meat products at certain gradient; and (3) after the balanced drying of the cured meat products in the second preset drying time, the ventilation door is opened, the temperature of the drying and baking room is reduced to third preset temperature, and hot air with third preset air flow is kept to flow in third preset drying time to enable the cured meat product to be well shrunk.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

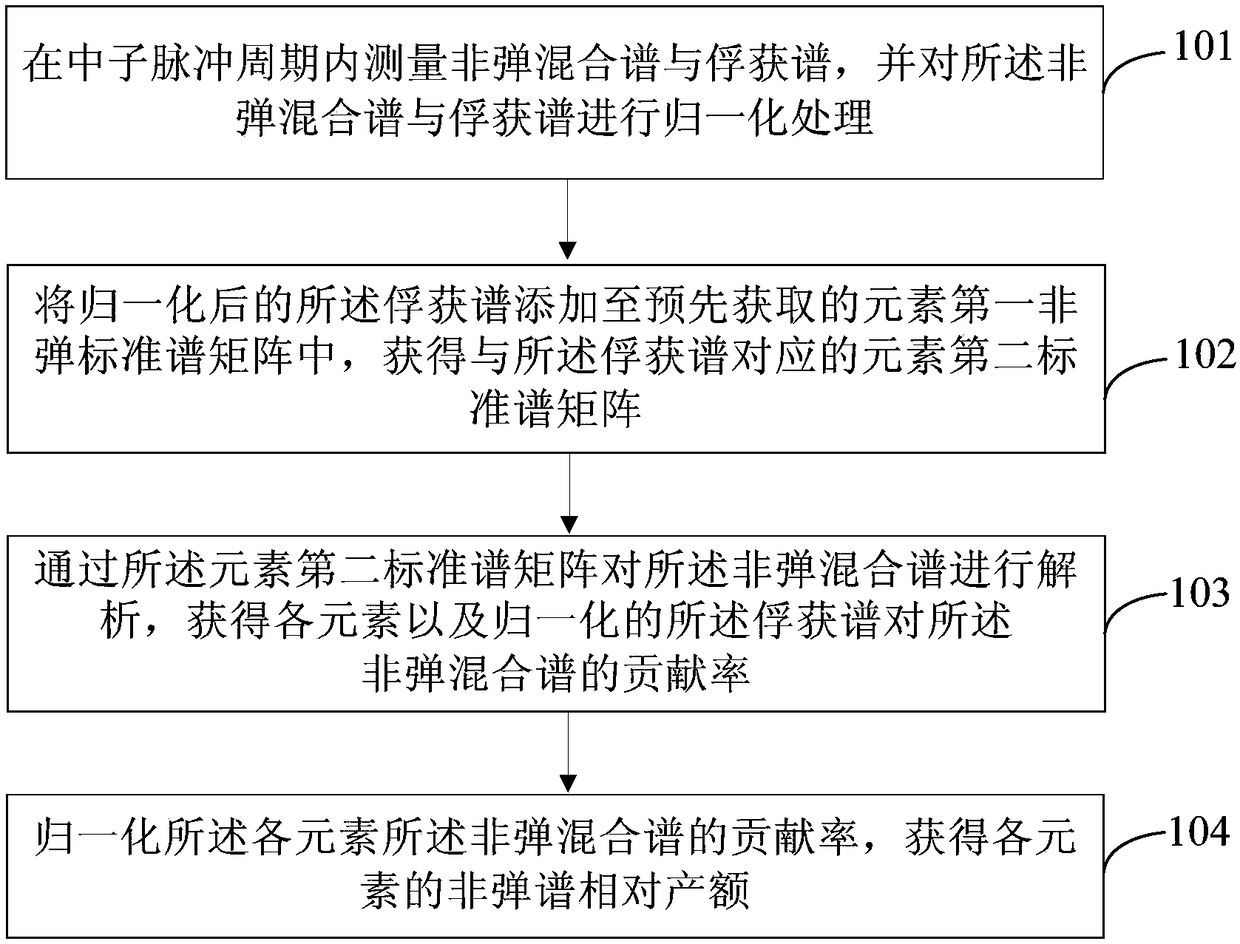

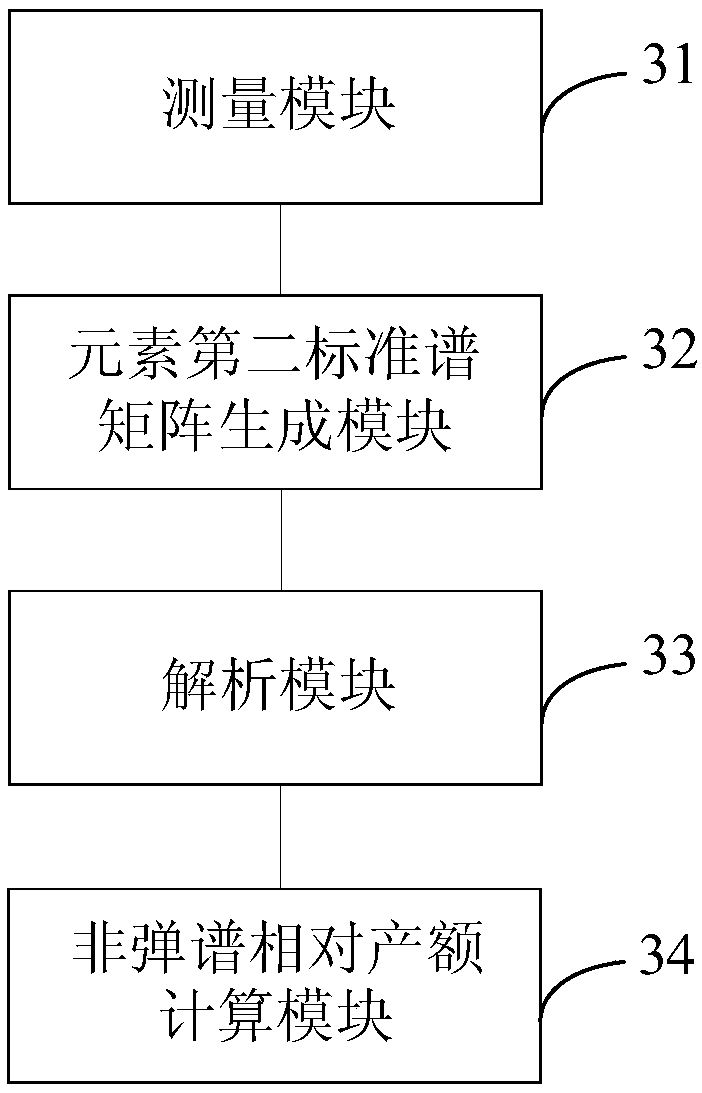

Inelastic scattering gamma-ray spectrometry analysis method and device

ActiveCN108535786AAvoid oilyAvoid accuracyNuclear radiation detectionInelastic scatteringMixed spectrum

The invention provides an inelastic scattering gamma-ray spectrometry analysis method and device. The method comprises the steps as follows: inelastic mixed spectrum and capture spectrum are measuredin a neutron pulse cycle and subjected to normalization processing; the normalized capture spectrum is added to an element first inelastic standard spectrum matrix obtained in advance, and an elementsecond standard spectrum matrix corresponding to the capture spectrum is obtained; the inelastic mixed spectrum is analyzed through the element second standard spectrum matrix, and contribution ratesof elements and the normalized capture spectrum for the inelastic mixed spectrum are obtained; the contribution rates of all the elements for the inelastic mixed spectrum are normalized, and inelasticspectrum relative yields of all the elements are obtained. Pure inelastic spectrum is not required to be obtained firstly during measurement of inelastic spectrum relative yields of all the elements,so that the defect of inaccurate underground stratum oil saturation due to defects of a fixed pure spectrum coefficient method which is mainly adopted at present can be overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

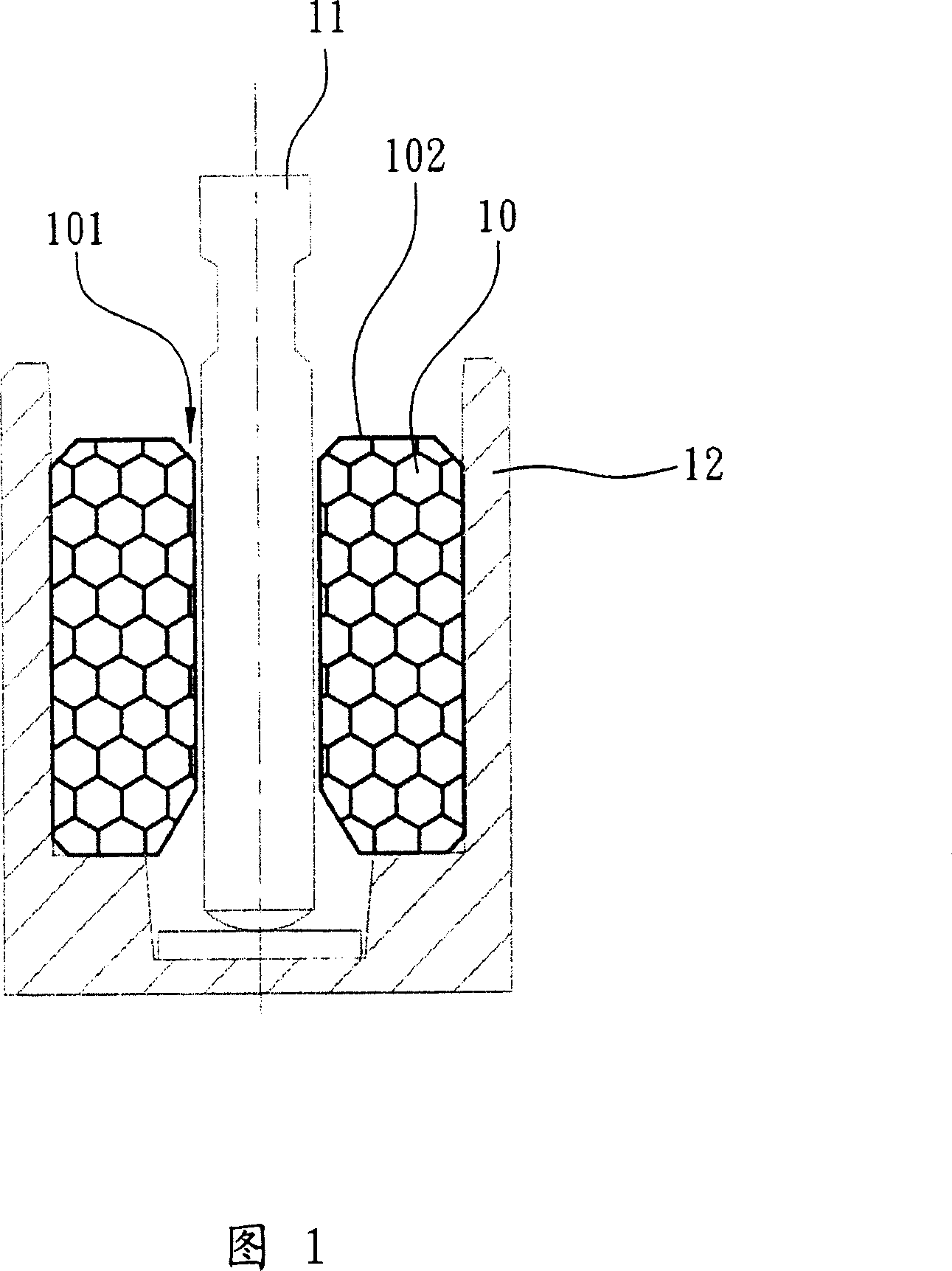

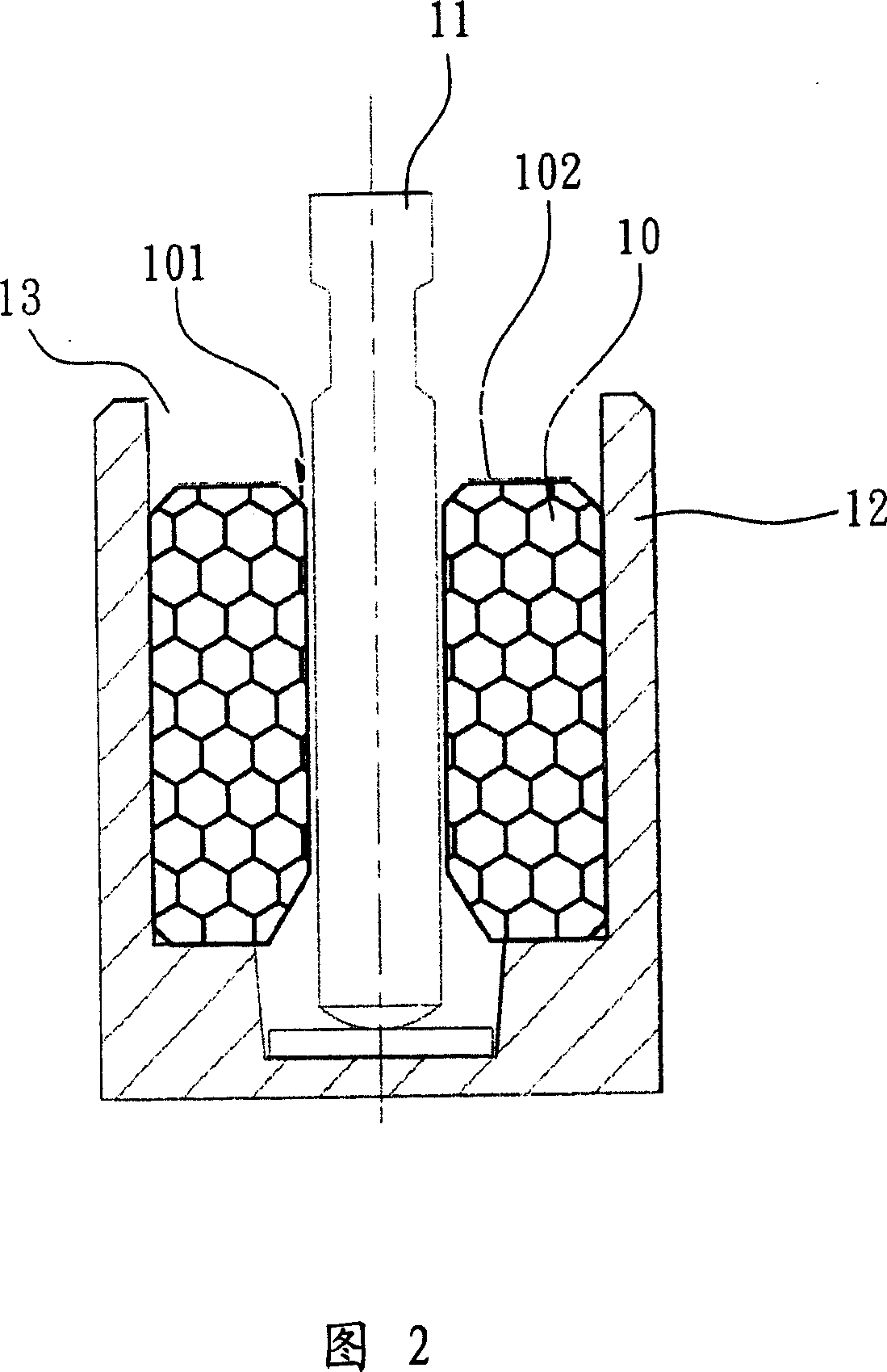

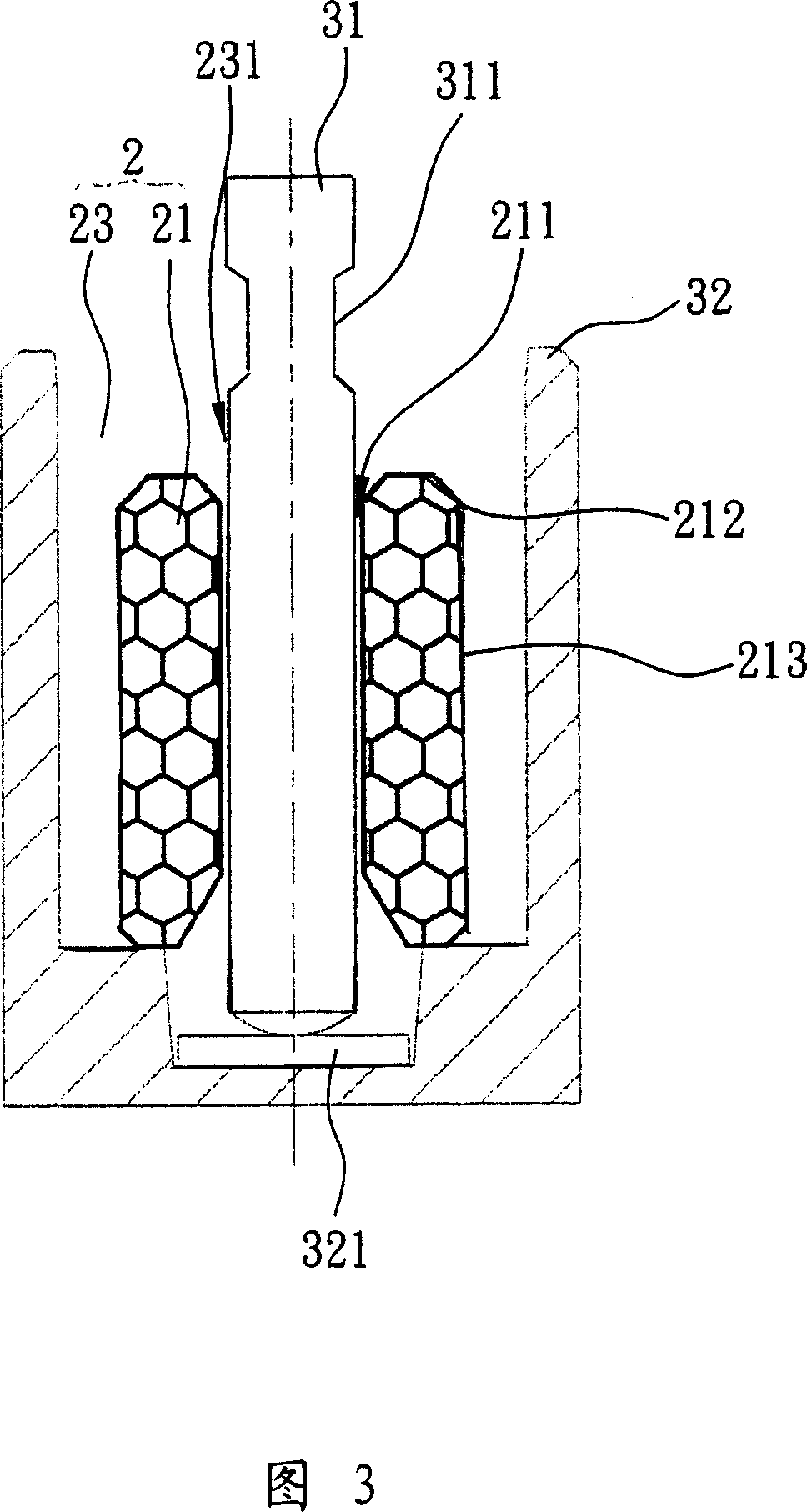

Fan, motor and their bearing structure

InactiveCN101046227AExtended service lifeWays to Stop LeakagePump componentsBearing componentsEngineeringMechanical engineering

The present invention discloses one kind of bearing structure matching with a rotation shaft and set inside a shaft tube. The bearing structure includes one self-oiling bearing and one cylindrical sealing structure, the self-oiling bearing has one shaft hole for the rotation shaft to be set inside, and the cylindrical sealing structure covers the top and at least one part of the side wall of the self-oiling bearing and has one central through hole for holding the rotation shaft. The bearing structure has no leakage of lubricant oil, and the motor and the fan with the bearing structure has long service life.

Owner:DELTA ELECTRONICS INC

Warm mix asphalt mixture and preparation method thereof

ActiveCN108658510AFunction increaseImprove mechanical propertiesClimate change adaptationFiberRoad surface

The invention belongs to the technical field of petroleum asphalt, and particularly relates to a warm mix asphalt mixture and a preparation method thereof. The warm mix asphalt mixture is prepared from the following raw materials in parts by mass: 95 parts of a mineral material, 5 parts of warm mix asphalt, 0.5-2 parts of a viscosity reducing lubricant and 0.05-1 part of fibers. According to the warm mix asphalt mixture disclosed by the invention, the added fibers and the viscosity reducing lubricant are swollen into the asphalt during wet mixing and transportation to form a gel layer, so thatan elastic recovery function and mechanical properties of an asphalt pavement are improved; the fibers exists in the asphalt mixture in the form of a three-dimensional dispersed phase, as reinforcingsteel in concrete has a reinforcement effect; and because a thickness of an oil film is improved, pavement bleeding and rutting can be effectively avoided. The preparation method disclosed by the invention is simple and easy to implement and realize.

Owner:CHINA PETROLEUM & CHEM CORP

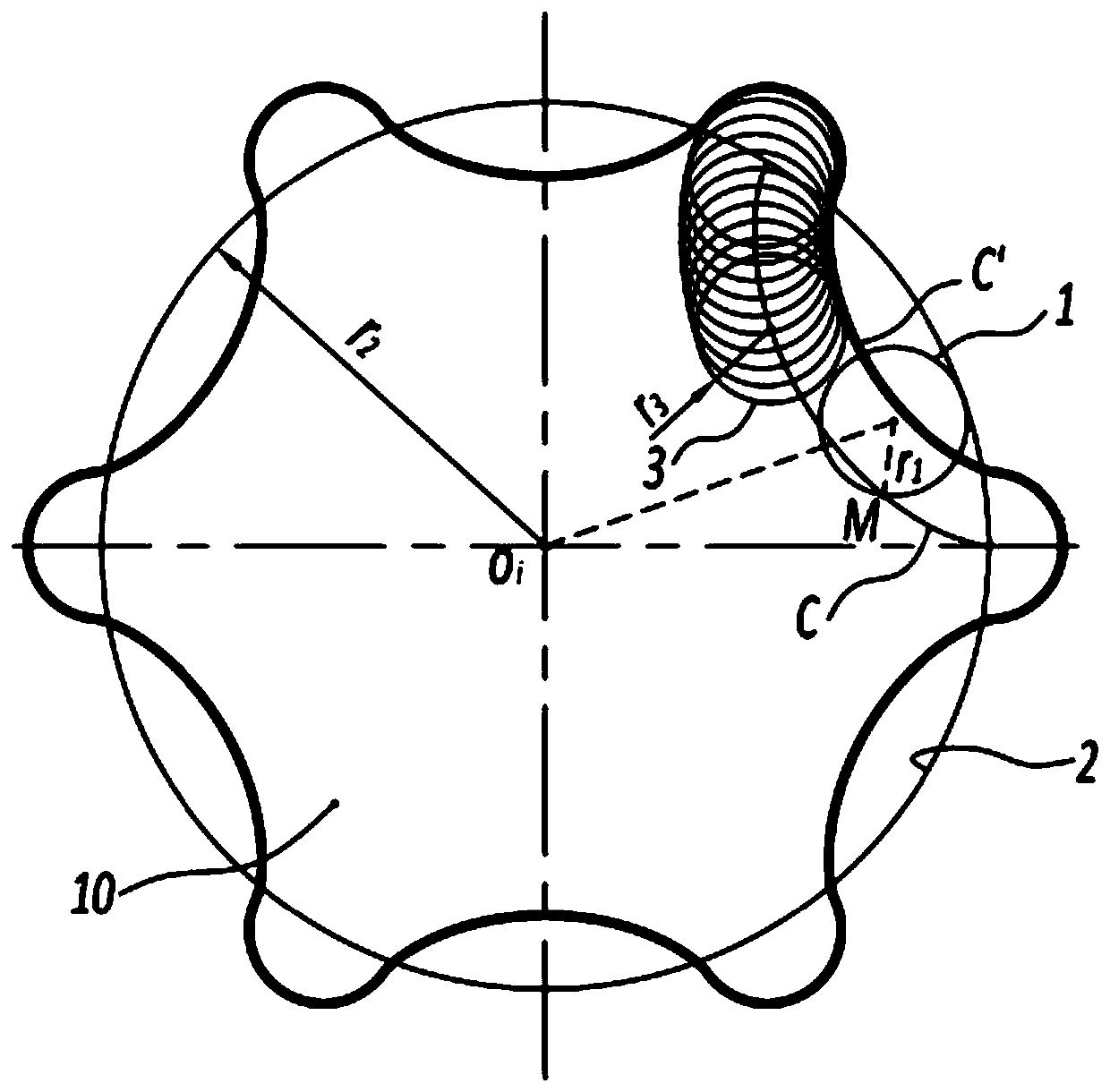

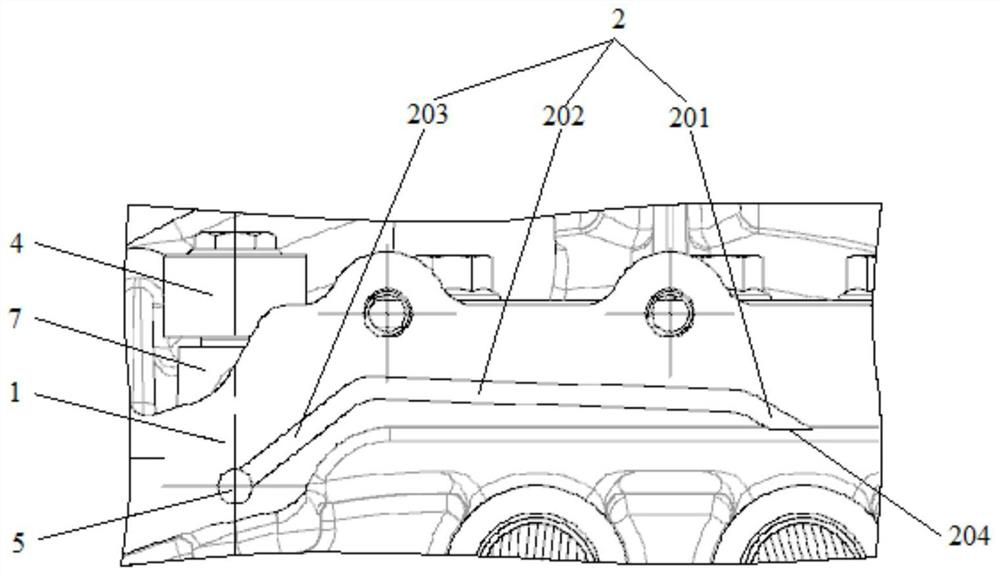

Oil pump rotor assembly

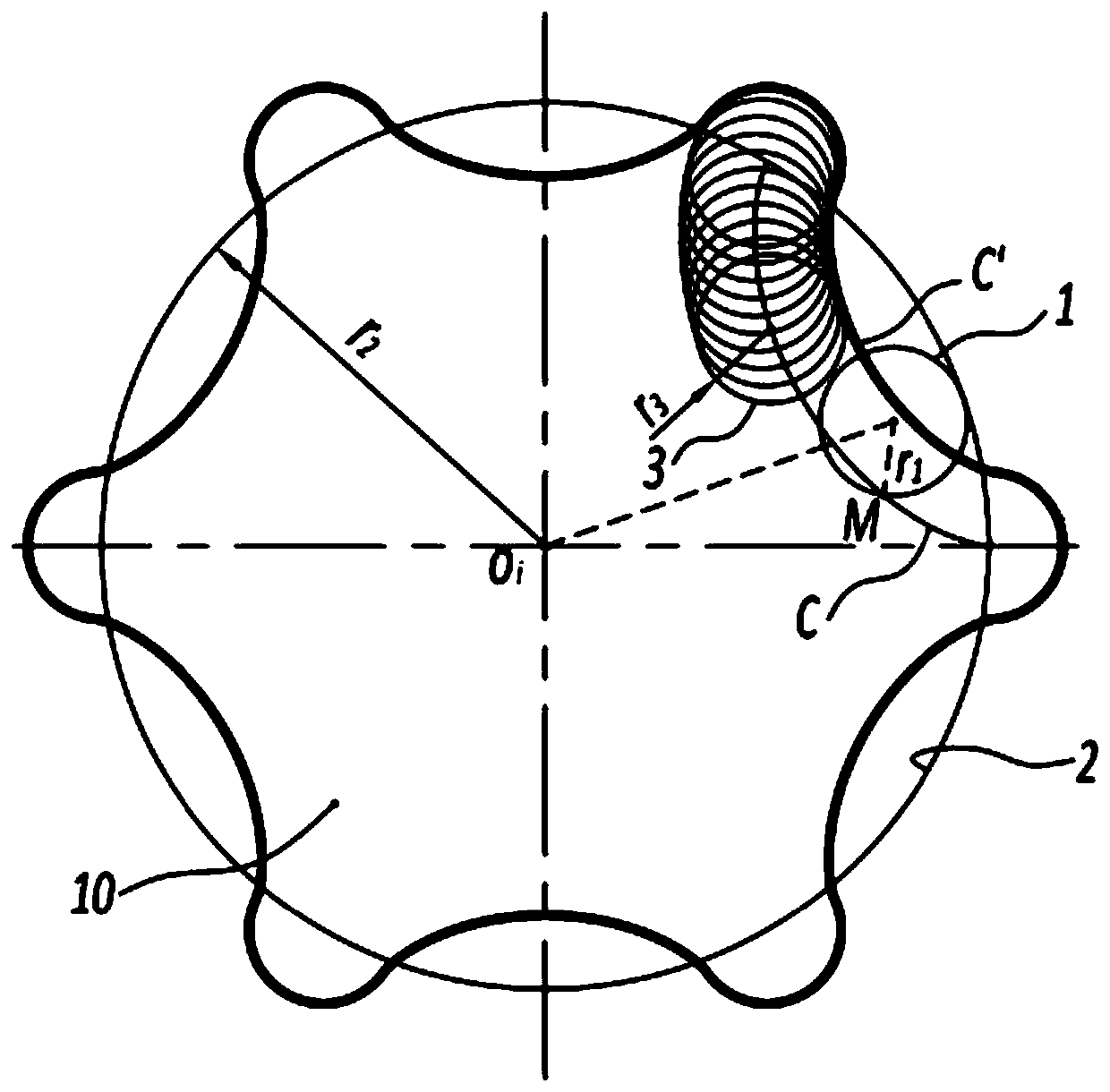

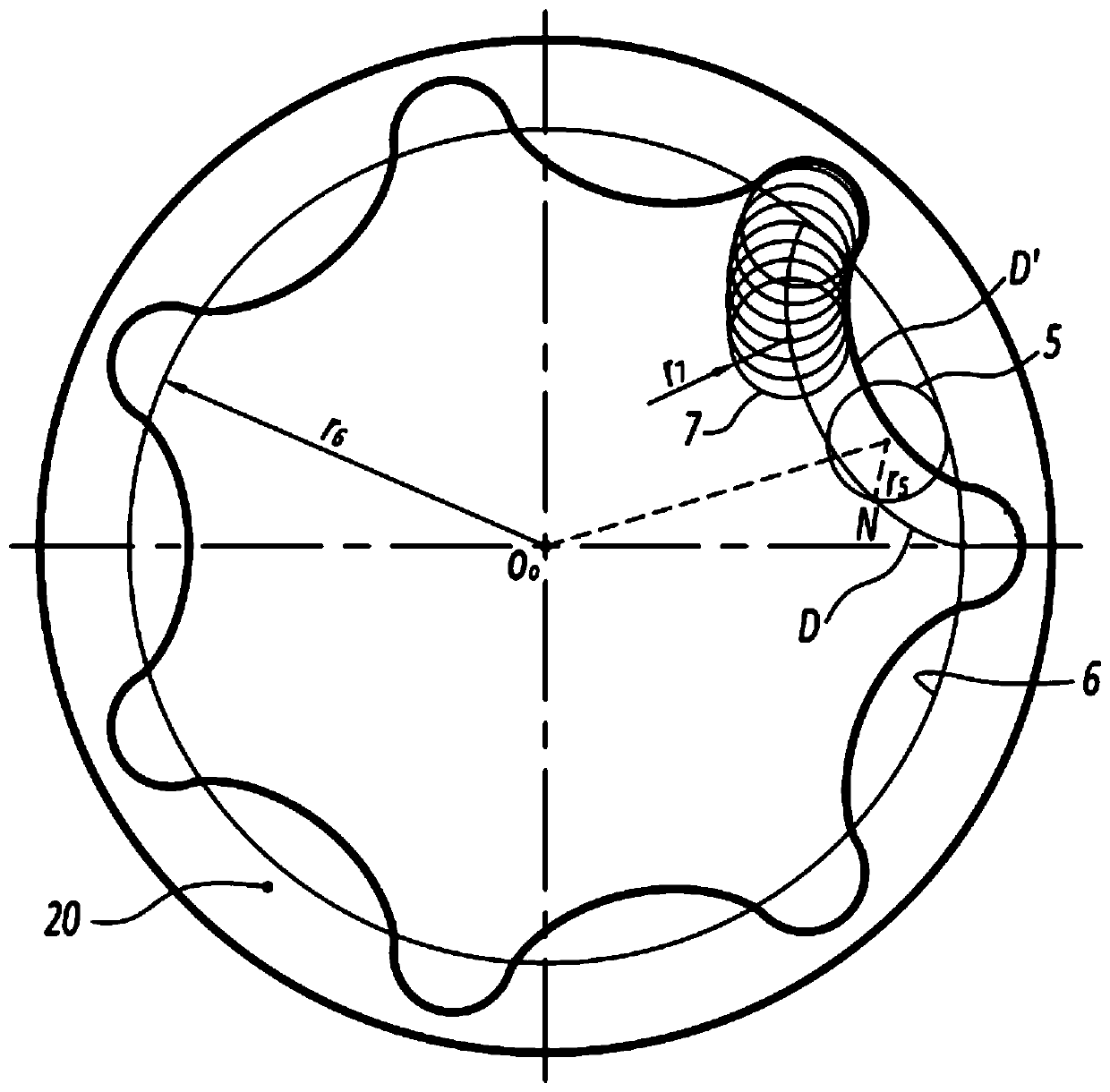

ActiveCN109737055AAvoid bulgingAvoid top cutRotary piston pumpsLubricating pumpsEngineeringHypocycloid

The invention provides an oil pump rotor assembly. The tooth shapes of an inner rotor and an outer rotor in the oil pump rotor assembly are composed of envelope curves of a hypocycloid formed by a fixed connection point on a rolling circle and circular arcs through the mode that the rolling circle purely rolls along a fixed base circle. According to the oil pump rotor assembly, the tooth shapes ofthe inner rotor and the outer rotor are set through appropriate parameters, the appropriate meshing clearance is set, edge bulging and crest cutting of tooth crests of rotors in a traditional rotor pump are avoided, the problems of tooth crest meshing abrasion, vibration, noise, meshing oil-trapping during working of the traditional rotor pump are effectively solved, meanwhile, the displacement of an oil pump is increased, and the efficiency is improved.

Owner:重庆红宇精密工业集团有限公司

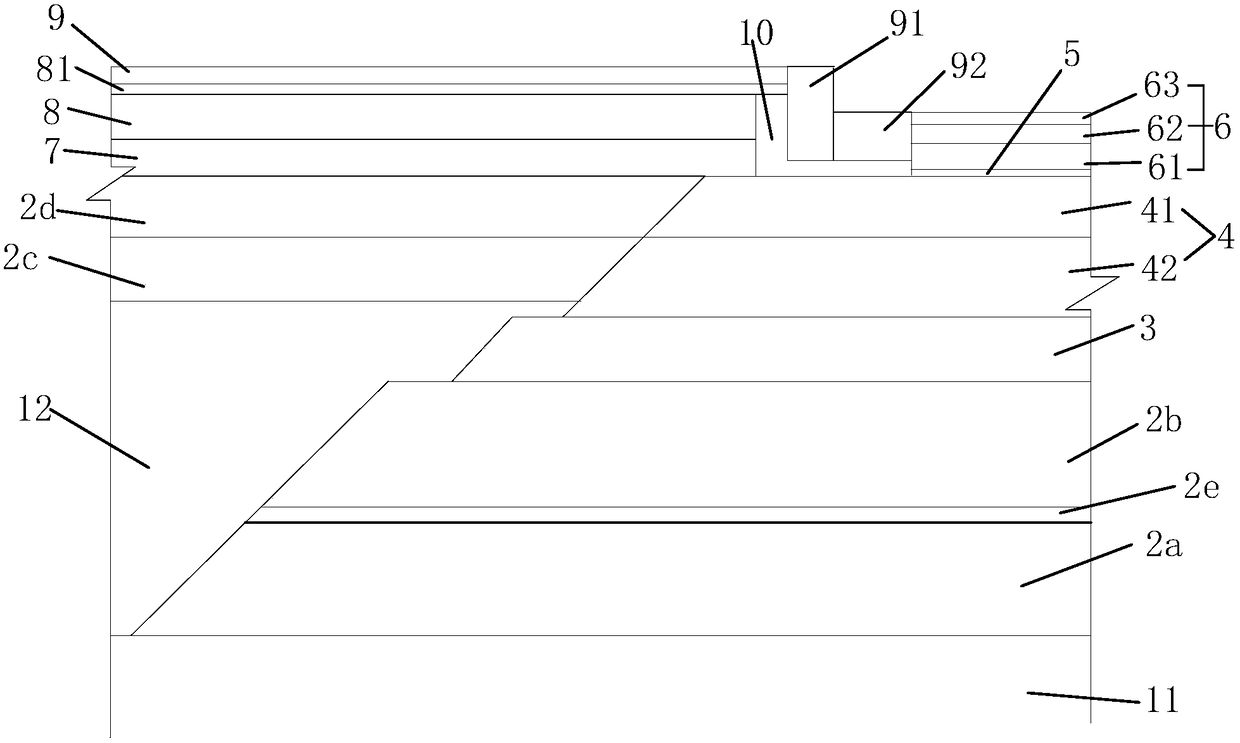

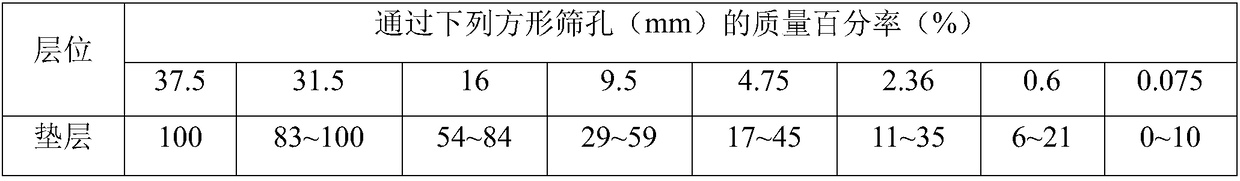

Road construction method

ActiveCN106120524AImprove waterproof performanceQuality improvementIn situ pavingsRoads maintainenceCrushed stoneRoad surface

The invention discloses a road construction method, and solves the problems that asphalt road surfaces are frequent in cracking, low in intensity and poor in stability because of non-standard construction of many regions. The road construction method is characterized by adopting the technical scheme comprising the following steps of (a), cleaning and levelling a road surface of a road requiring paving, and forming a roadbed for pond residues to fill and pave; (b), sequentially paving a first pond residue processing layer and a second pond residue processing layer; (c), grinding macadam materials to form a macadam cushion layer of which the crushing value is 30%, and paving the macadam cushion layer on the second pond residue processing layer; (d), paving a cement stabilizing crushed stone layer of which the cement content is 3-6%; (e), uniformly sprinkling petroleum asphalt of which the consumption is 1.2 Kg / m<2>, then sprinkling aggregates, and immediately grinding the aggregates by a road roller to form a lower sealing layer; and (f), paving an asphalt mixed material layer of which the void percentage is 3-6%. The road construction method disclosed by the invention has the advantages of being high in strength, not liable to crack and strong in durability.

Owner:天鸿建设集团有限公司

Test method for evaluating asphalt consumption of asphalt mixture

InactiveCN110646598AAffects durabilityPrevent leakageWeighing by removing componentPreparing sample for investigationFiberYarn

A test method for evaluating asphalt consumption of the asphalt mixture is provided. The method comprises the following steps: S1, preparing a leak tester, a leak test cylinder, a glass plate, a smallasphalt mixture mixer, a hand shovel, a balance, and a cotton yarn test tool; S2, according to an asphalt viscosity temperature test, determining a mixing temperature to conduct a leak test; S3, in the leak test cylinder that is washed and dried, weighing the leak test cylinder m0 accurate to 0.01g, and putting the leak test cylinder m0 in a test box for a constant temperature, wherein the constant temperature time is not less than 2 hours; and S4, according to the mix ratio of the asphalt mixture that is actually used, mixing the mixture of the aggregate, the ore powder, the asphalt, the fiber stabilizer and the like by using the small asphalt mixture mixer according to the method of T7022, and during the mixing, adding a fiber stabilizer after the coarse and fine aggregates are added. According to the test method provided by the present invention, the amount of asphalt consumption in the asphalt mixture can be accurately and quantitatively evaluated, the influence of too little asphalt on the durability of the pavement can be avoided, and leakage and oil flooding caused by too much asphalt can be avoided.

Owner:CHINA FIRST HIGHWAY ENG

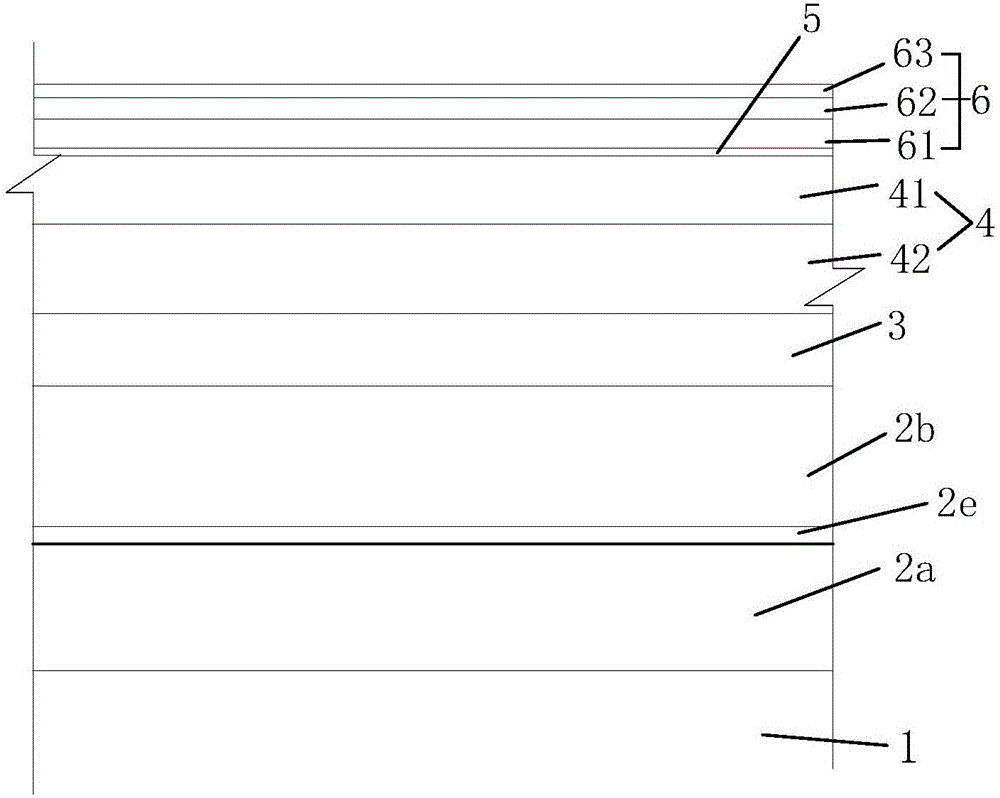

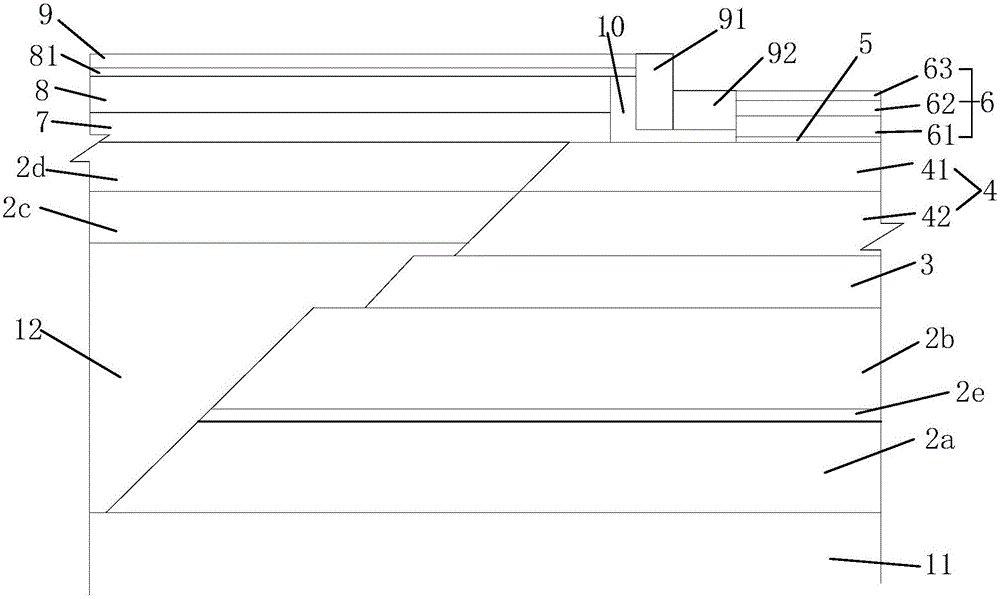

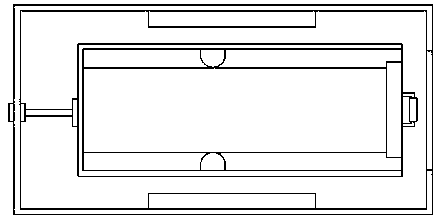

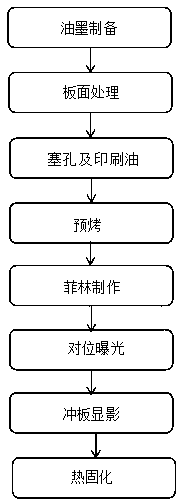

Method for improving solder resist oil leakage of PCB

PendingCN111385979AImprove cleanlinessLow costNon-metallic protective coating applicationPhysical chemistryEngineering

The invention relates to a method for improving solder resist oil leakage of a PCB, which comprises the steps of ink preparation, PCB processing, hole plugging and oil printing, pre-baking, film manufacturing, alignment exposure and thermocuring. The method solves the problem of solder resist oil leakage of the PCB by controlling various parameters.

Owner:惠东县建祥电子科技有限公司

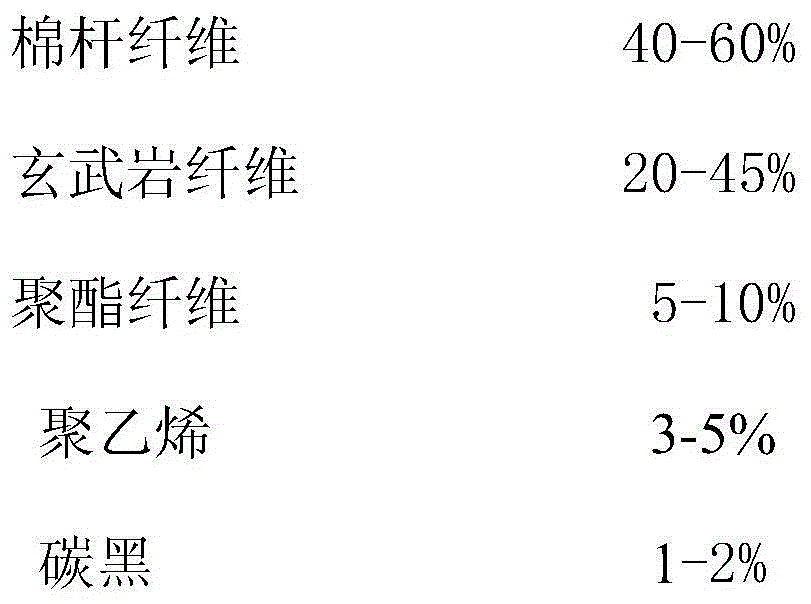

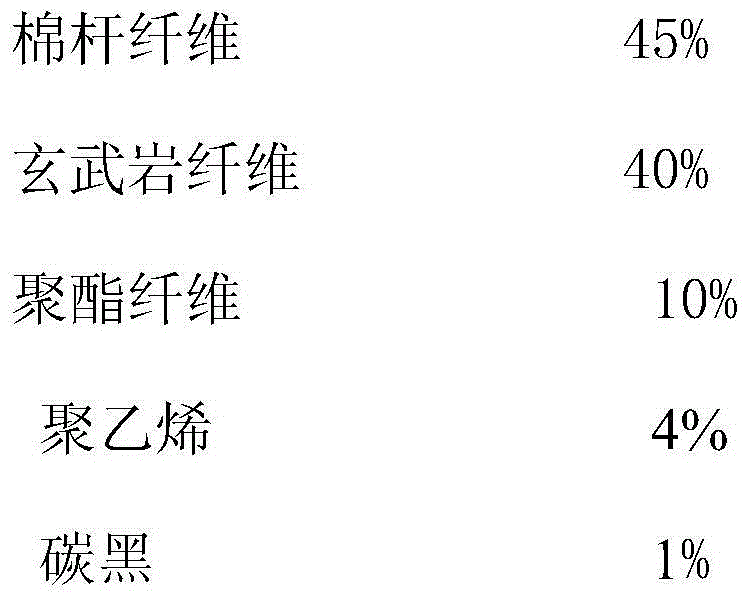

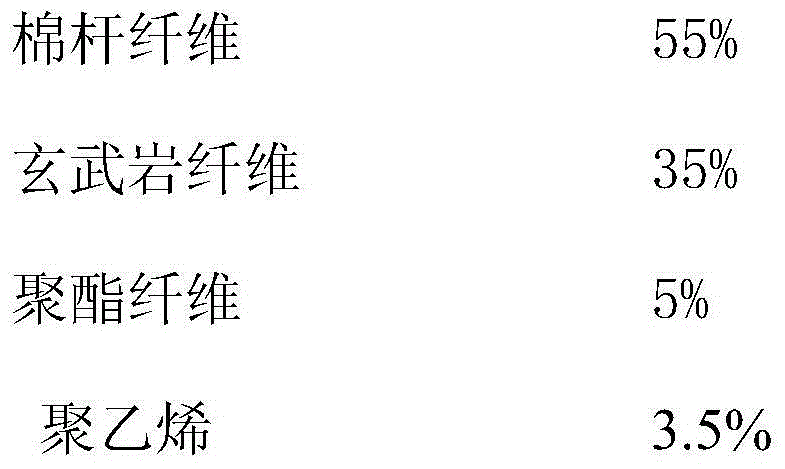

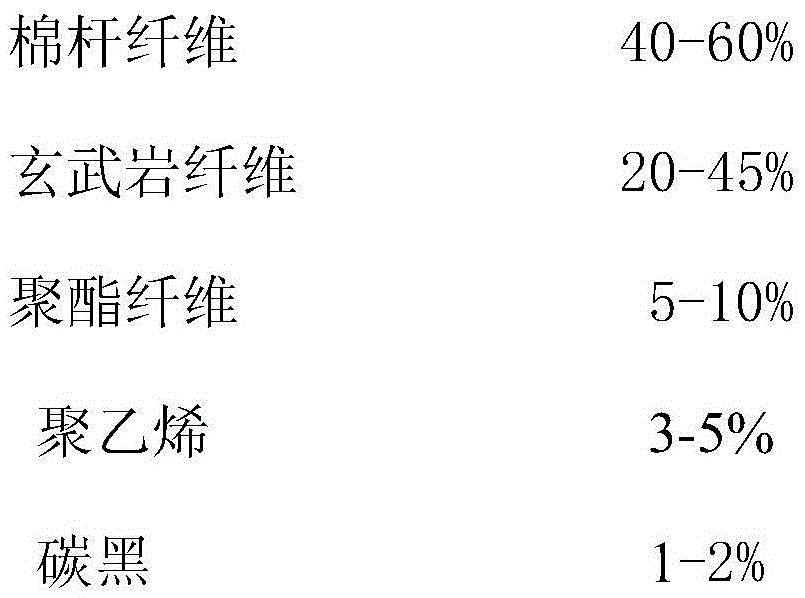

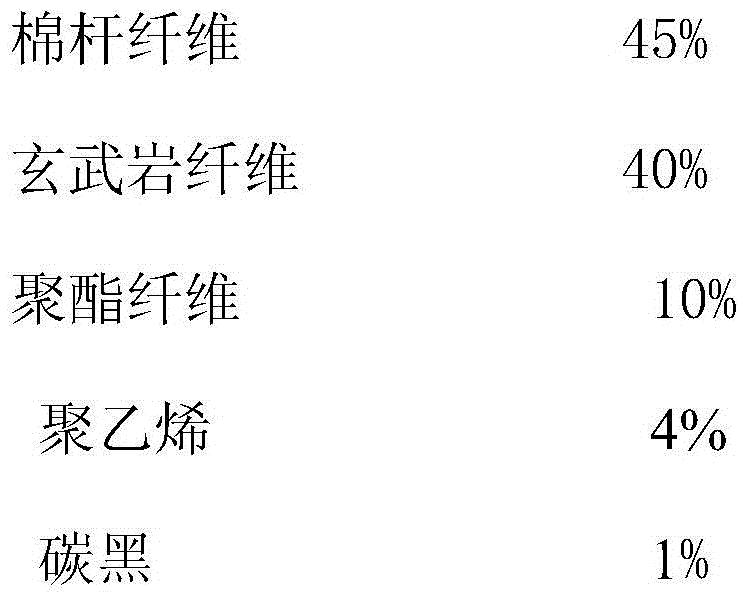

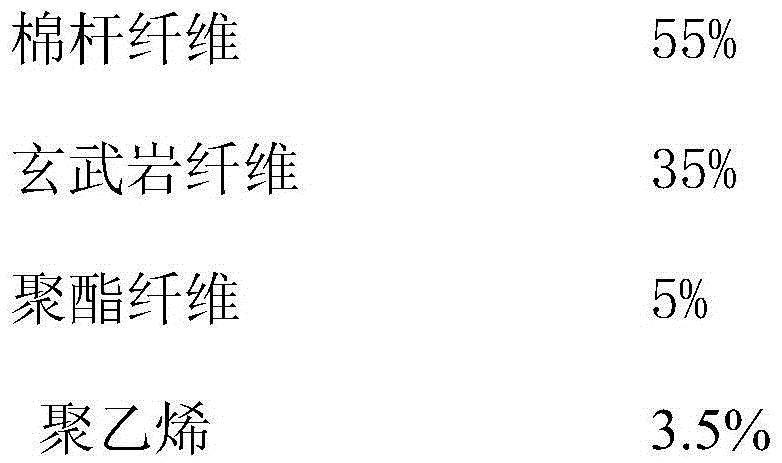

Bituminous pavement reinforcing material

The invention discloses a bituminous pavement reinforcing material. The bituminous pavement reinforcing material is prepared from the following raw material components in percentage by weight: 40-60% of cotton stalk cellulose, 20-45% of basalt fiber, 5-10% of polyester fiber, 3-5% of polyethylene and 1-2% of carbon black. The bituminous pavement reinforcing material has the advantages that strength of a pavement can be improved, the pavement can be prevented from cracking at a low temperature, and temperature shrinkage cracks are reduced; at a high temperature, partial bitumen expanded after being heated is absorbed, so that oil bleeding and high temperature loss of the bitumen, which are caused under a high temperature, are prevented; high temperature stability is improved, and the service life of the pavement is prolonged; pavement oil spot caused by formation of a micelle-shaped substance is prevented; leak and isolation of the bitumen are prevented; raw materials are available, a preparation process is simple, and cost for laying a bituminous pavement is greatly reduced.

Owner:中部华科建设集团有限公司

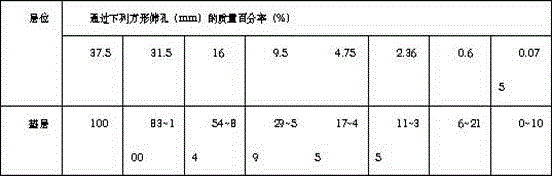

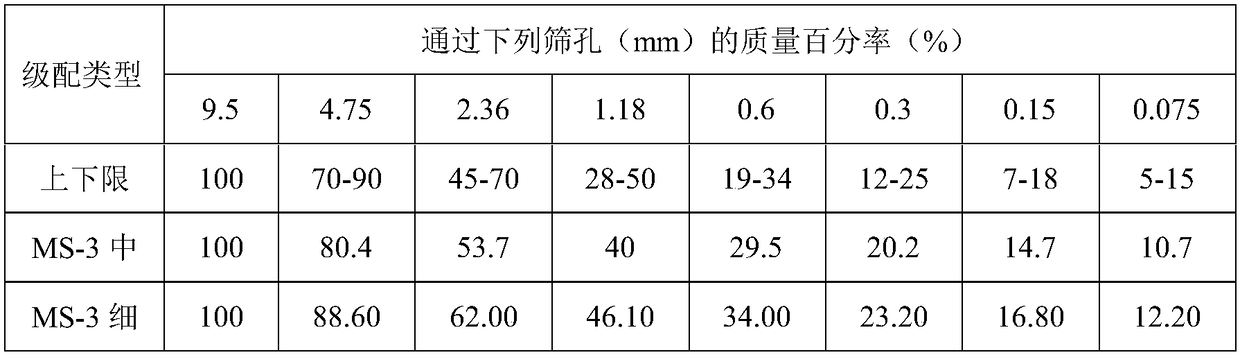

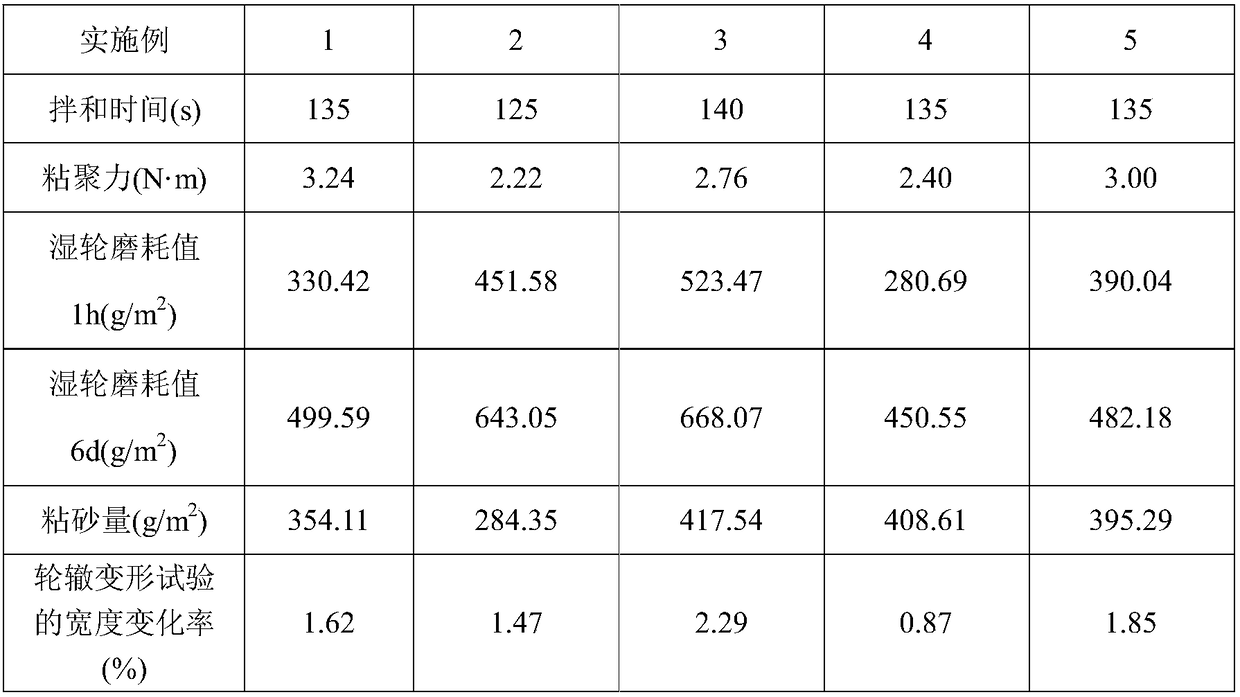

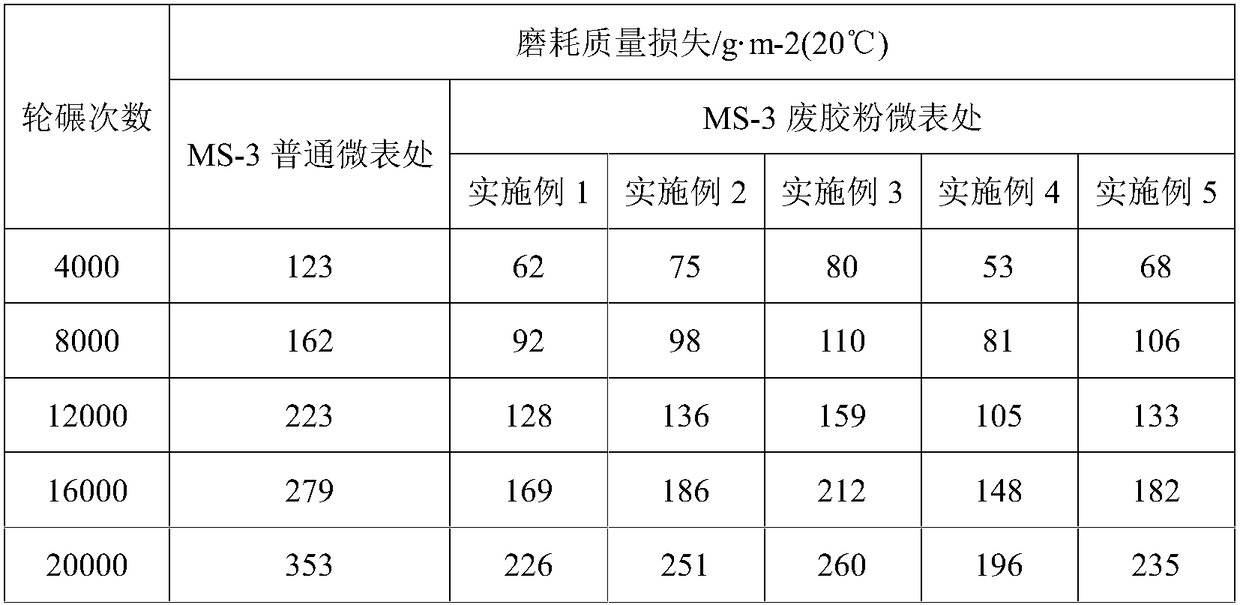

Waste rubber powder dry micro-surfacing mixed material and preparation method thereof

InactiveCN108147744AImprove the way of forceImproved particle gradation and particle size distributionSolid waste managementPortland cementWaste rubber

The invention discloses a waste rubber powder dry micro-surfacing mixed material and a preparation method thereof. The waste rubber powder dry micro-surfacing mixed material is prepared from, by masspercent, 100% of basalt aggregate, 12%-13% of SBR (styrene butadiene rubber) modified emulsified asphalt, 1%-2% of ordinary Portland cement, 1%-3% of waste rubber powder and water in a weight ratio of5%-7% to the aggregate; the waste rubber powder dry micro-surfacing mixed material is in an MS-3 medium grading; the ordinary Portland cement is P.O42.5 ordinary Portland cement. The preparation method of the waste rubber powder dry micro-surfacing mixed material includes steps of detecting raw materials according to the technical requirements in Micro-surfacing and Slurry Seal Technical Manual,according to the proportional ratio, weighing out the basalt aggregate, the cement and the waste rubber power which are qualified, and manually uniformly mixing the raw materials inside a mixing pot;pouring water of the specified weight into the mixing pot, uniformly mixing for about 15 seconds; then pouring the SBR modified emulsified asphalt of the specified weight into the mixing pot, and continuing to manually uniformly mixing for 15 seconds to obtain the waste rubber powder dry micro-surfacing mixed material.

Owner:SHANDONG JIAOTONG UNIV

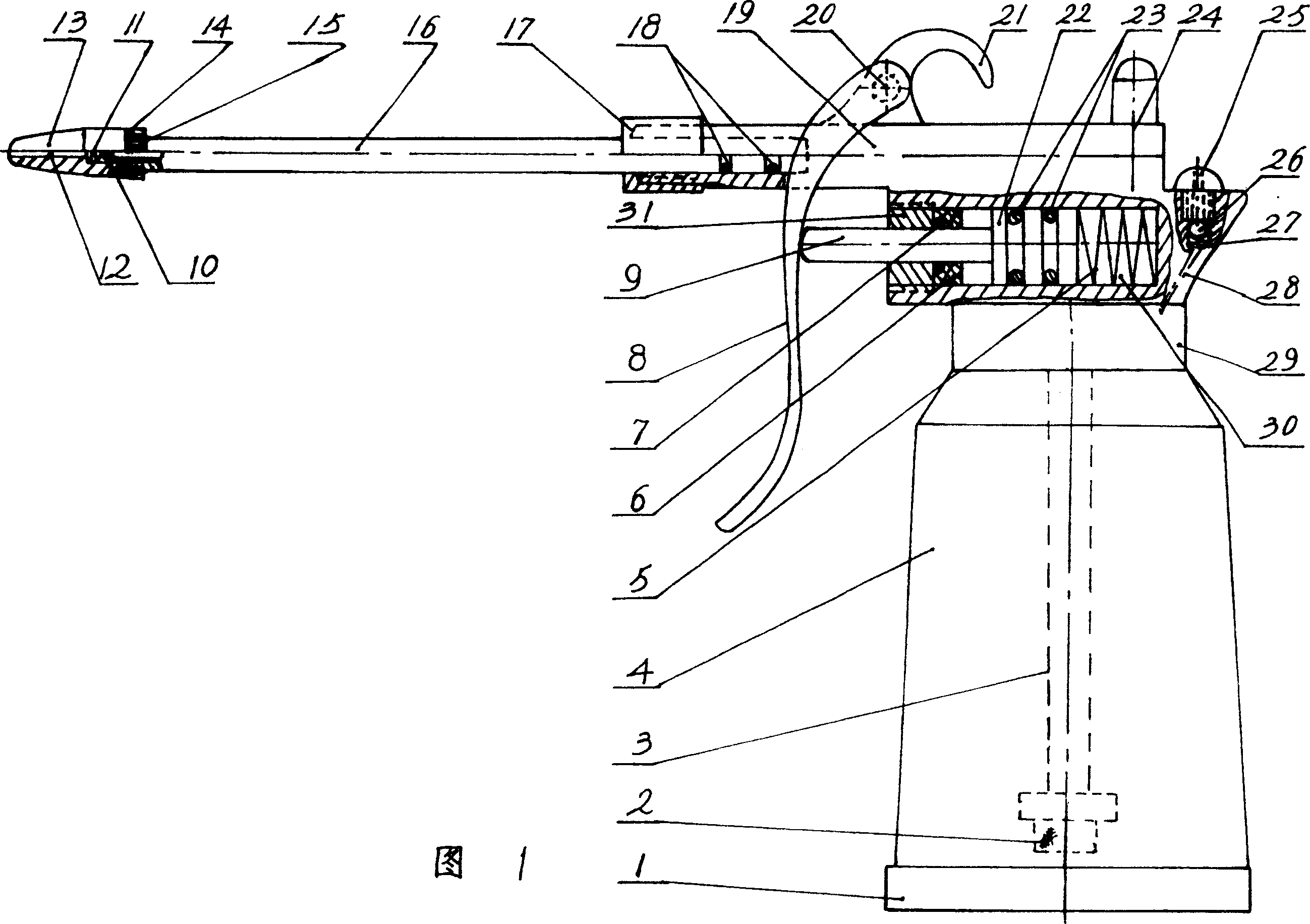

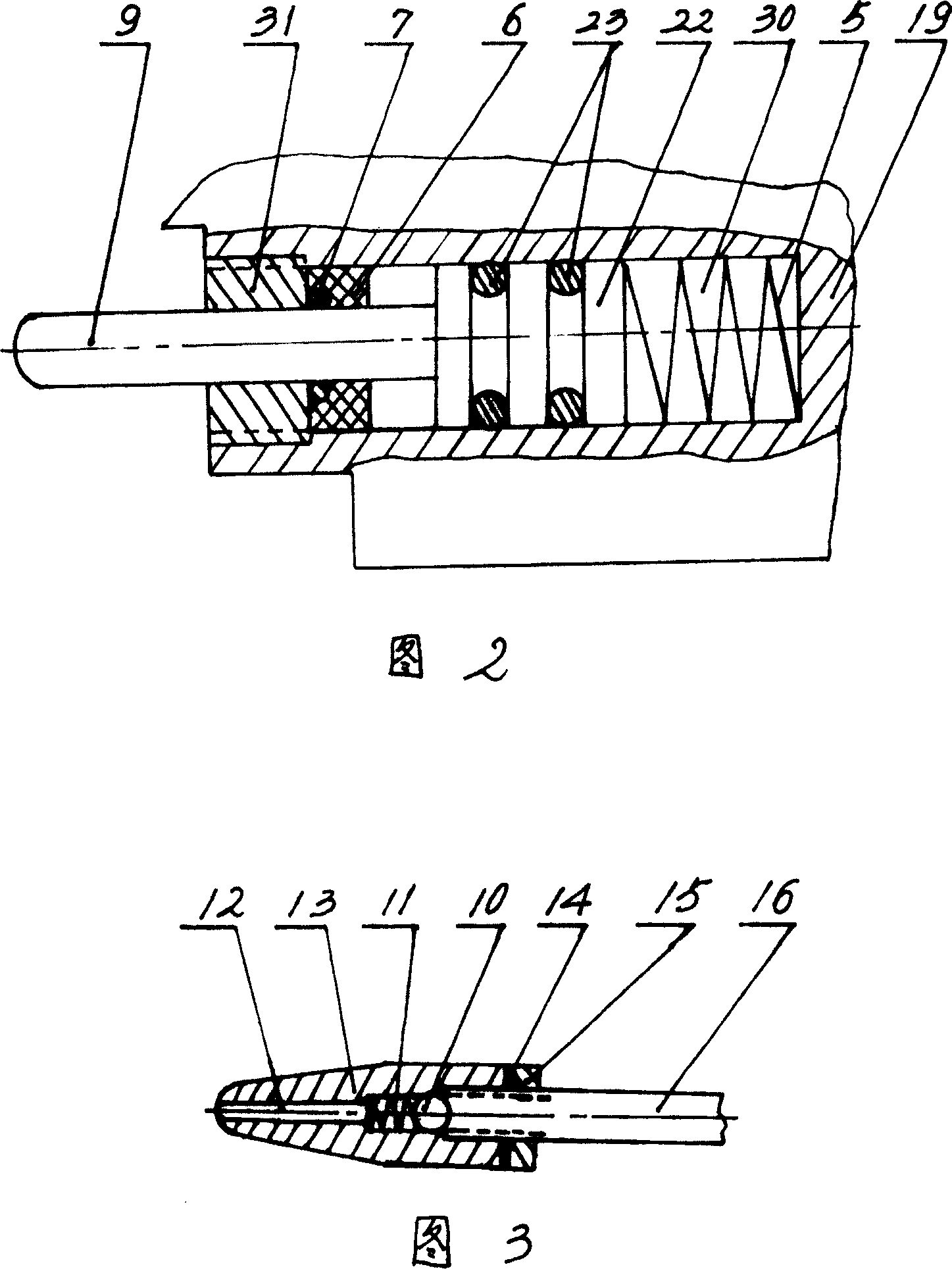

Oil gun

An oil gun, which contains gun body including upper and lower section, the upper is the joint injection rod with nozzle in head, oil filled piston cylinder in middle section with piston and reset spring, the lower section is connection cover connected with oil tank having suction pipe, screw plug set in open of oil filled cylinder, stop ring, seal ring for preventing the oil from leakage when the manual wrench turns to press the piston making oil to bottom of piston cylinder.

Owner:ZHEJIANG REFINE WUFU AIR TOOLS

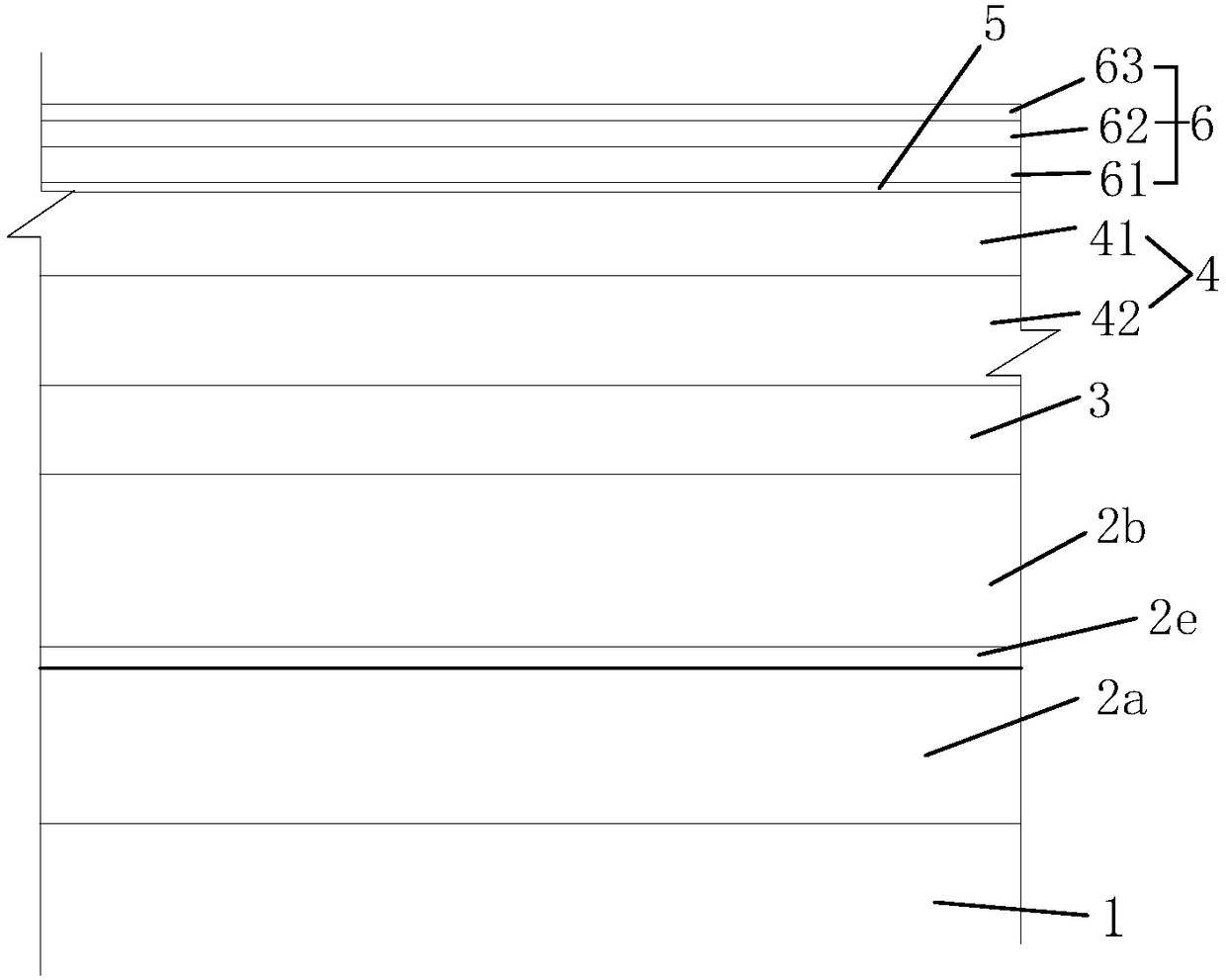

A road construction method at the junction of sidewalks and non-motor vehicle lanes

ActiveCN106120524BStrong resistance to deformationGood anti-rutting ability at high temperatureIn situ pavingsRoads maintainenceVoid ratioCrushed stone

The invention discloses a road construction method, and solves the problems that asphalt road surfaces are frequent in cracking, low in intensity and poor in stability because of non-standard construction of many regions. The road construction method is characterized by adopting the technical scheme comprising the following steps of (a), cleaning and levelling a road surface of a road requiring paving, and forming a roadbed for pond residues to fill and pave; (b), sequentially paving a first pond residue processing layer and a second pond residue processing layer; (c), grinding macadam materials to form a macadam cushion layer of which the crushing value is 30%, and paving the macadam cushion layer on the second pond residue processing layer; (d), paving a cement stabilizing crushed stone layer of which the cement content is 3-6%; (e), uniformly sprinkling petroleum asphalt of which the consumption is 1.2 Kg / m<2>, then sprinkling aggregates, and immediately grinding the aggregates by a road roller to form a lower sealing layer; and (f), paving an asphalt mixed material layer of which the void percentage is 3-6%. The road construction method disclosed by the invention has the advantages of being high in strength, not liable to crack and strong in durability.

Owner:天鸿建设集团有限公司

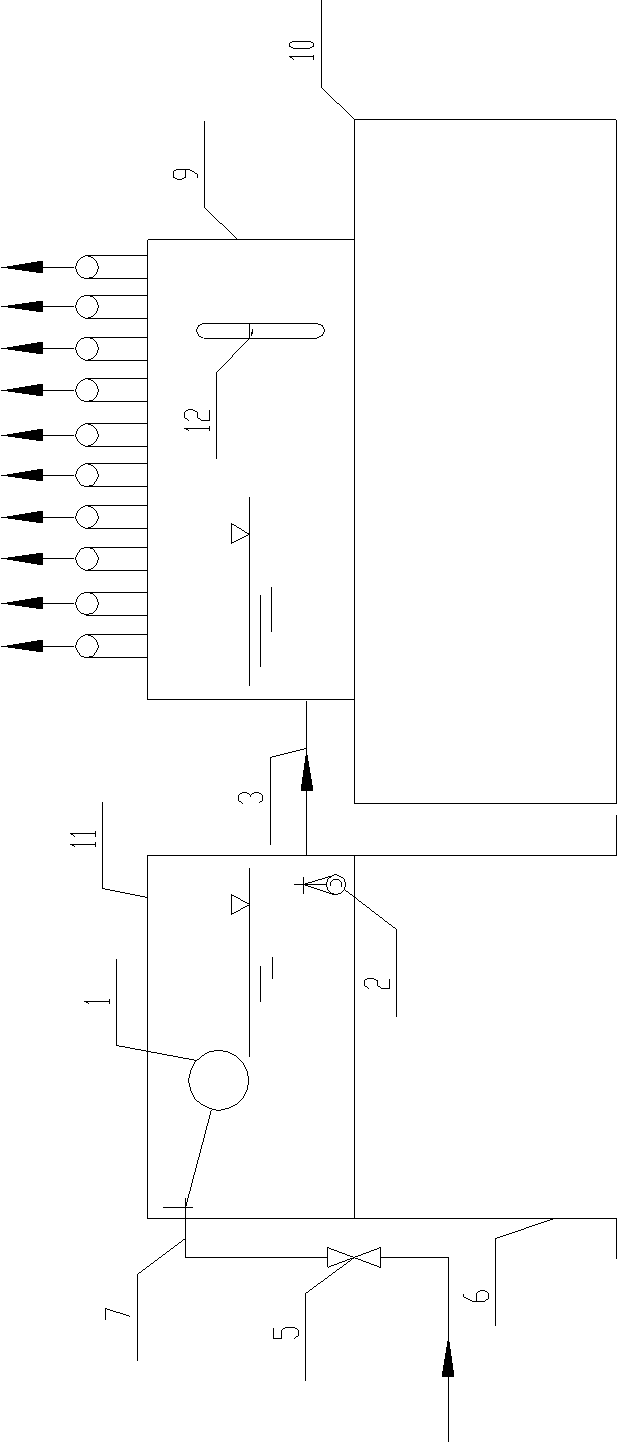

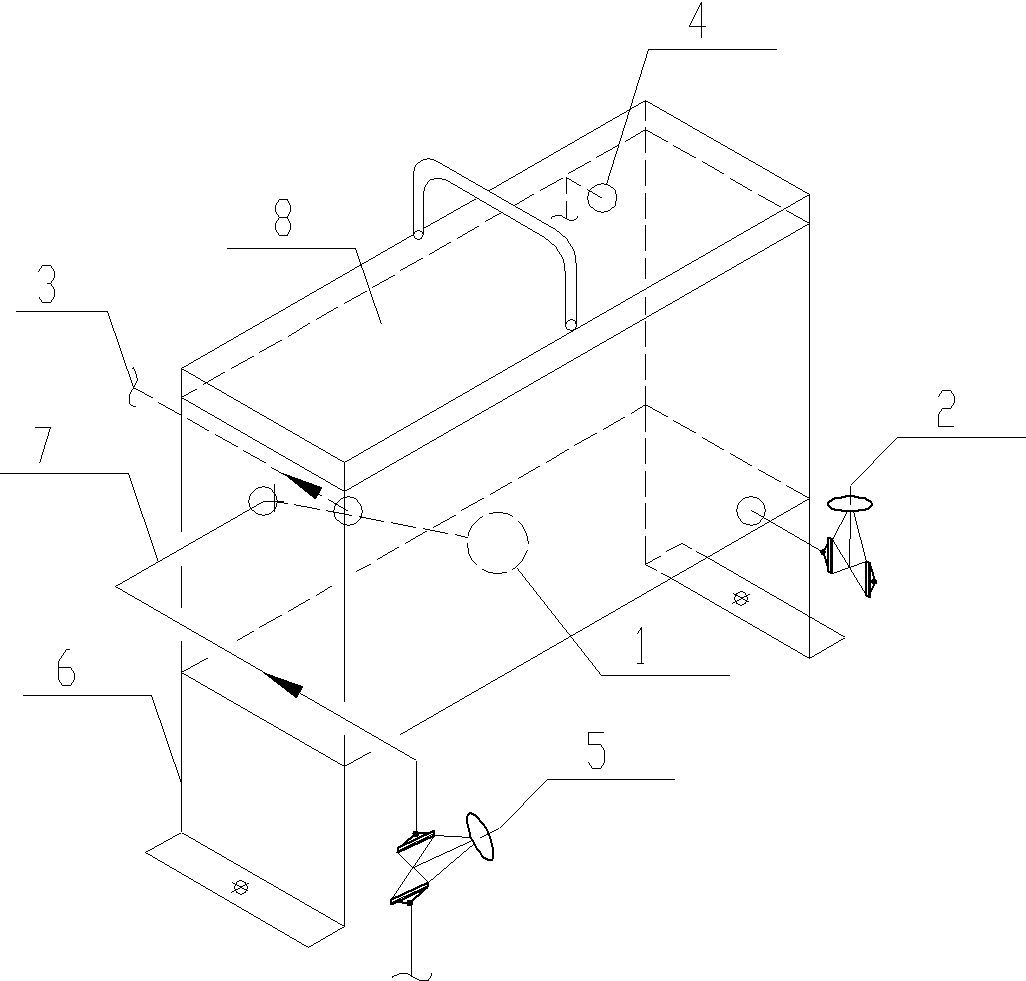

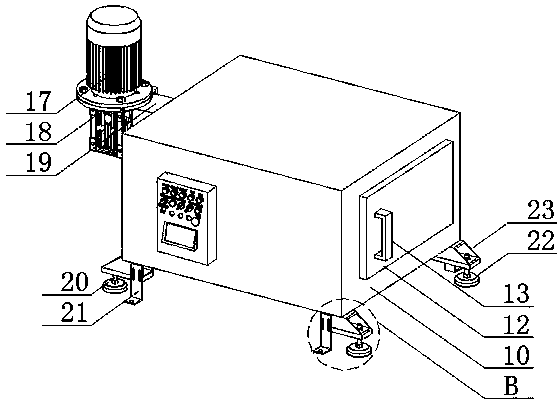

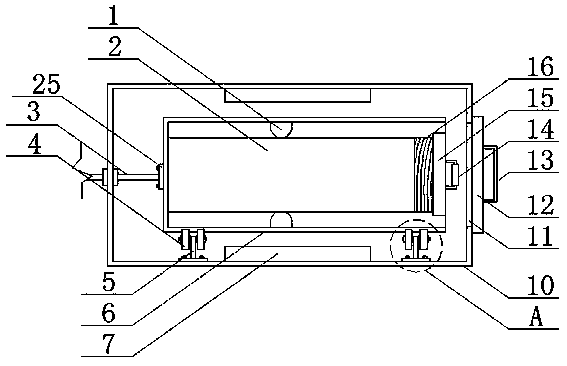

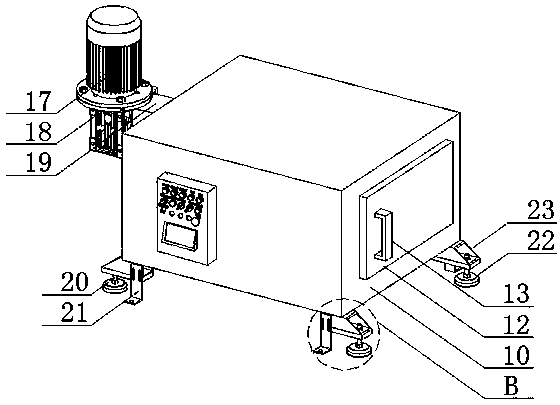

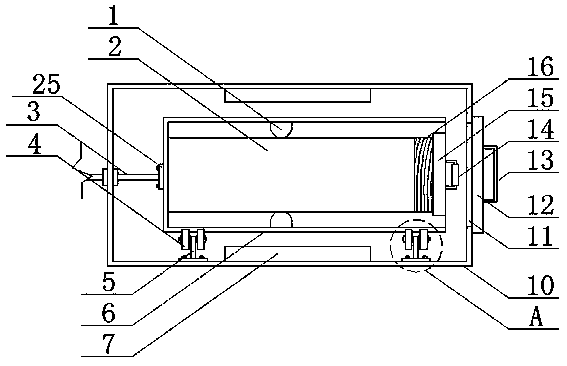

Oil injection device of ketone-benzene drum filter and automatic oil replenishing machine of oil injection device

The invention relates to an oil injection device of a ketone-benzene drum filter and an automatic oil replenishing machine of the oil injection device. The oil injection device of the ketone-benzene drum filter comprises an oil injector. The automatic oil replenishing machine is arranged on the outer portion of the oil injector and comprises an oil tank and a liquid level control device. The oil tank is used for injecting oil into the oil injector and is communicated with the oil injector by a communicating pipe, the communicating pipe is lower than a set oil level, an oil inlet is formed in the oil tank, and the liquid level control device is used for controlling opening and closing of the oil inlet, so that an internal liquid level of the oil tank is positioned at the set oil level. The oil injection device and the automatic oil replenishing machine have the advantages that the internal oil level of the oil injector can be automatically controlled, so that oil in the oil injector can be positioned at the set liquid level, labor can be saved, and oil overflow or oil starvation phenomena can be prevented.

Owner:CHINA PETROLEUM & CHEM CORP +1

Full-sealed leakage-free magnetic drive hydrogen circulating pump

InactiveCN113757140APrevent leakageAvoid oilyPump componentsPump controlPermanent magnet rotorImpeller

The invention relates to a full-sealed leakage-free magnetic drive hydrogen circulating pump. The hydrogen circulating pump comprises a motor cavity and a pump shell; a sealing partition plate is arranged between the motor cavity and the pump shell; a stator winding is fixedly installed in the motor cavity; an impeller is rotationally installed in the pump shell; a permanent magnet rotor is fixedly inlaid in the surface of the impeller; an iron core and a coil of the stator winding are designed in a plane mode; the magnetic field plane of the stator winding faces the permanent magnet rotor on the plane of the impeller; the stator winding generates a magnetic field to drive the permanent magnet rotor to drive the impeller to rotate; and the pump shell is provided with a gas inlet and a gas outlet. The hydrogen circulating pump can effectively prevent a medium from containing oil, a motor stator and the motor permanent magnet rotor are sealed and isolated, the permanent magnet rotor and the impeller are integrated, the medium is completely sealed, medium leakage is completely avoided, and potential safety hazards are avoided.

Owner:山东凯格瑞森能源科技有限公司

Test method for evaluating asphalt consumption of asphalt mixture

InactiveCN111398572AAffects durabilityPrevent leakageWeighing by removing componentPreparing sample for investigationFiberSoil science

The invention discloses a test method for evaluating asphalt consumption of an asphalt mixture. The test method comprises the following steps: S1, preparing a precipitation and leakage tester, a precipitation and leakage test cylinder, a glass plate, a small asphalt mixture mixer, a hand shovel, a balance and a cotton yarn test tool; S2, determining a mixing temperature according to an asphalt equiviscous temperature test, and carrying out a precipitation and leakage test; S3, in a cleaned and dried precipitation and leakage test cylinder, weighing the precipitation and leakage test cylinder m0 accurately to 0.01 g, putting the precipitation and leakage test cylinder m0 into a test box, and keeping a constant temperature for not less than 2 hours; and S4, mixing aggregate, a mineral powder, asphalt, a fiber stabilizer and the like by using the small asphalt mixture mixer according to a T0702 method according to a mixing ratio of the actually used asphalt mixture, and adding the fiber stabilizer after a coarse aggregate and a fine aggregate are added during mixing. According to the test method, the asphalt consumption of the asphalt mixture can be accurately and quantitatively evaluated, durability of a pavement is prevented from being influenced by too small asphalt mixture consumption, and precipitation, leakage and bleeding caused by too large asphalt consumption are also avoided.

Owner:CHINA FIRST HIGHWAY ENG

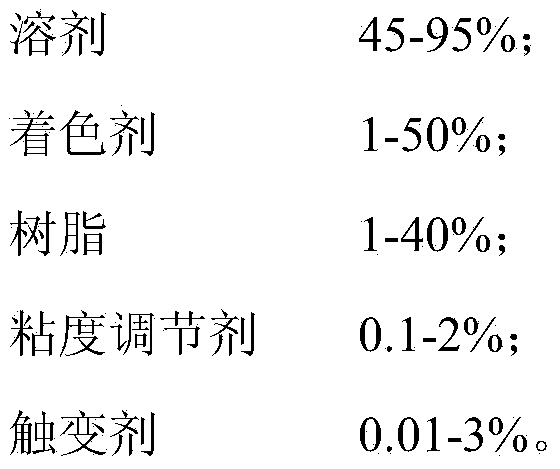

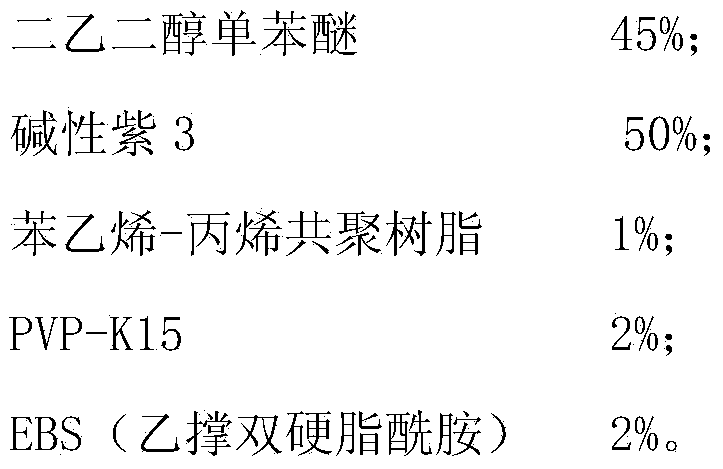

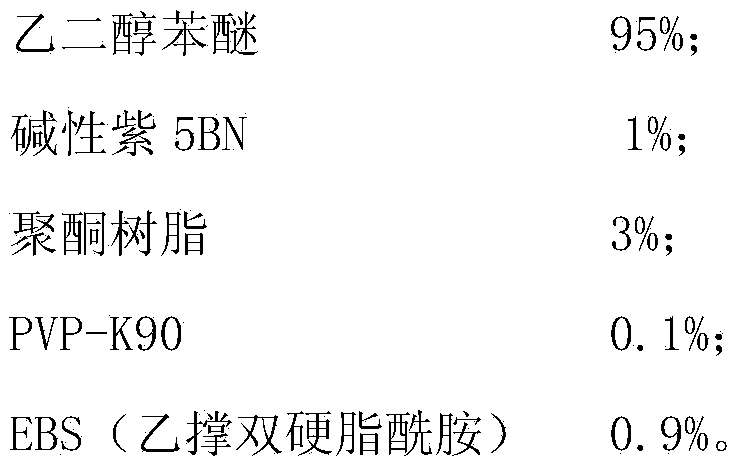

Low-temperature-resistant oil-base ink

The invention relates to a low-temperature-resistant oil-base ink, belonging to the technical field of writing inks. The ink is prepared from the following raw materials in percentage by mass: 45-95% of solvent, 1-50% of colorant, 1-40% of resin, 0.1-2% of viscosity modifier and 0.01-3% of thixotropic agent. The viscosity of the ink is 500-3000 mpa.s when the temperature is 25 DEG C and the shear rate is 500 S<-1>, and the viscosity is 1000-5000 mpa.s when the shear rate is 5 S<-1>; and thus, the ink can improve the writing lubricating property in a low-temperature environment, reduce the writing pressure and prevent the penpoint from bleeding, and can not have the phenomenon of broken lines.

Owner:常熟市协新冶金材料有限公司

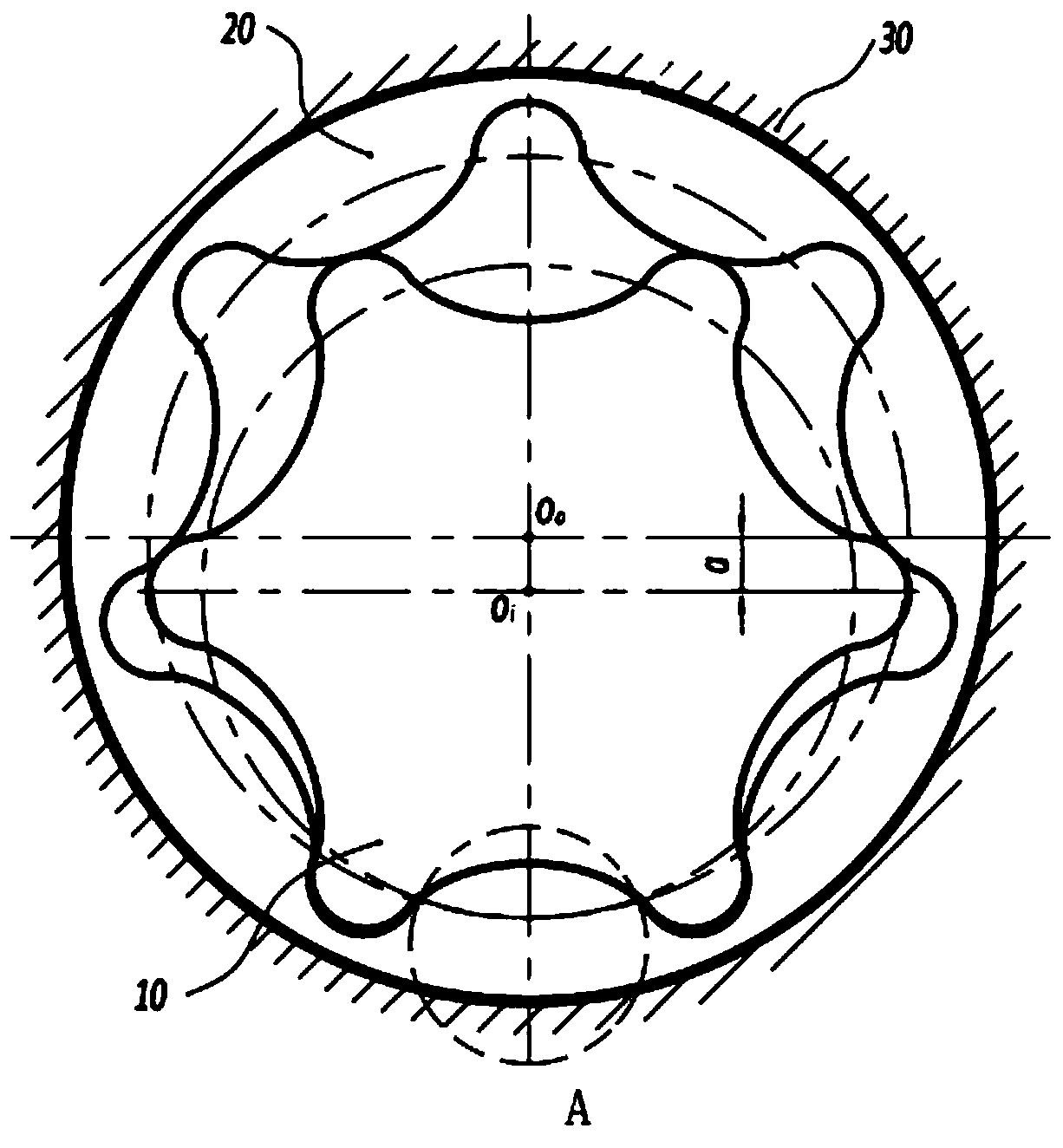

An oil pump rotor assembly

ActiveCN109737055BLarge displacementAvoid oilyRotary piston pumpsLubricating pumpsClassical mechanicsEngineering

The invention provides an oil pump rotor assembly. The tooth shapes of an inner rotor and an outer rotor in the oil pump rotor assembly are composed of envelope curves of a hypocycloid formed by a fixed connection point on a rolling circle and circular arcs through the mode that the rolling circle purely rolls along a fixed base circle. According to the oil pump rotor assembly, the tooth shapes ofthe inner rotor and the outer rotor are set through appropriate parameters, the appropriate meshing clearance is set, edge bulging and crest cutting of tooth crests of rotors in a traditional rotor pump are avoided, the problems of tooth crest meshing abrasion, vibration, noise, meshing oil-trapping during working of the traditional rotor pump are effectively solved, meanwhile, the displacement of an oil pump is increased, and the efficiency is improved.

Owner:重庆红宇精密工业集团有限公司

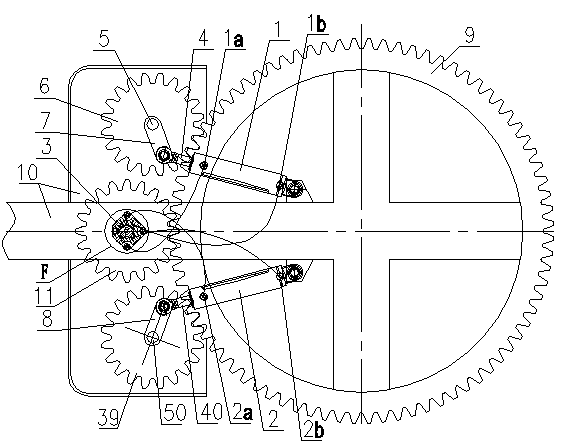

Hydraulic follow-up rotating mechanism

The invention discloses a hydraulic follow-up rotating mechanism, which comprises a machine frame, two central shafts arranged on the machine frame, small gears on all the central shafts, two double-acting oil cylinders hinged with the machine frame, and a rotating valve, wherein a piston rod of each double-acting oil cylinder is hinged with one end of a respectively corresponding connecting rod; the other end of each connecting rod is connected with a respectively corresponding central shaft; the two small gears are engaged with a large gear; the large gear is engaged with a follow-up gear; the rotating valve comprises a valve body, a valve cover, a valve core and a sealing ring which is arranged on the valve core; an oil inlet, an oil outlet and four working oil ports are formed in the valve body; and two working oil ports which are formed at the periphery of the valve body at intervals are connected with a rod-containing cavity oil port or a rod-free cavity oil port of a respective double-acting oil cylinder through pipelines respectively. The sequences of oil supply or oil discharge at the rod-containing cavity oil ports or the rod-free cavity oil ports of the two double-acting oil cylinders are adjusted through the rotating valve, so that the rotating mechanism can be continuously rotated in the positive and reverse directions at the angle of 360 DEG and output high torque, and has the advantages of simple structure and wide using range.

Owner:泸州天府液压件有限公司

Full-sealed leakage-proof oil-free compressor system

PendingCN112253456AFully enclosedPrevent leakageRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectric machineCoupling

The invention relates to a full-sealed leakage-proof oil-free compressor system. The system comprises a motor assembly and a compressor assembly. The motor assembly comprises a motor shell and a motorshaft, the upper end of the motor shell is fixedly connected with a potting junction box, the motor shaft is connected with the motor shell through a bearing, the middle of the motor shaft is fixedlyconnected with a potting motor rotor, a permanent magnet is fixed in the potting motor rotor, a potting motor stator is fixed in the motor shell, and a shaft seal is arranged between the motor shaftand the motor shell. The compressor assembly comprises a compressor shell and a compressor shaft, a shaft seal is arranged between the compressor shaft and the compressor shell, the motor shaft is connected with the compressor shaft through a coupling, and the outer portion of the coupling is covered with a sealing cover. The full-sealed leakage-proof oil-free compressor system is composed of theleakage-proof and explosion-proof stator and rotor, a junction box potting motor and a full-enclosed oil-free compression mechanism, so that oil is effectively prevented from being contained in a medium, the medium is prevented from leaking, and explosion prevention of the motor is realized.

Owner:山东凯格瑞森能源科技有限公司

Method for preventing oil from bleeding from solder resist ink plug hole

ActiveCN103079362BAvoid oilyImprove qualityNon-metallic protective coating applicationPrinted element electric connection formationResistExposed point

The invention discloses a method for preventing oil from bleeding from a solder resist ink plug hole. The method comprises the following steps of: manufacturing single-surface and double-side windowing via hole plugging aluminum sheets and non-windowing plug hole aluminum sheets; plugging single-surface and double-side windowing via holes of a PCB (Printed Circuit Board); when the single-surface windowing via hole is plugged, displaying exposed point films on one surface where the windowing via holes are not windowed; and then plugging non-windowing via holes. According to the method disclosed by the invention, solder resist ink is printed after the plugging is carried out in graded times, so that the problem of oil bleeding in the plugging process of single-side windowing, double-side windowing and non-windowing PCB is effectively solved; and the quality and service performance of products are improved.

Owner:星河电路(福建)有限公司 +1

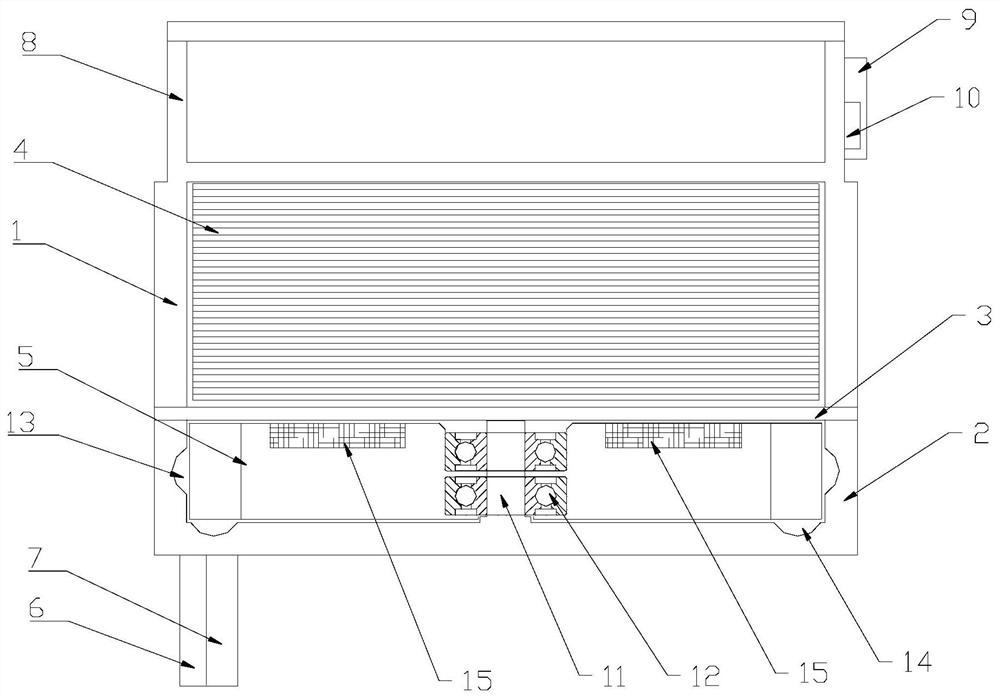

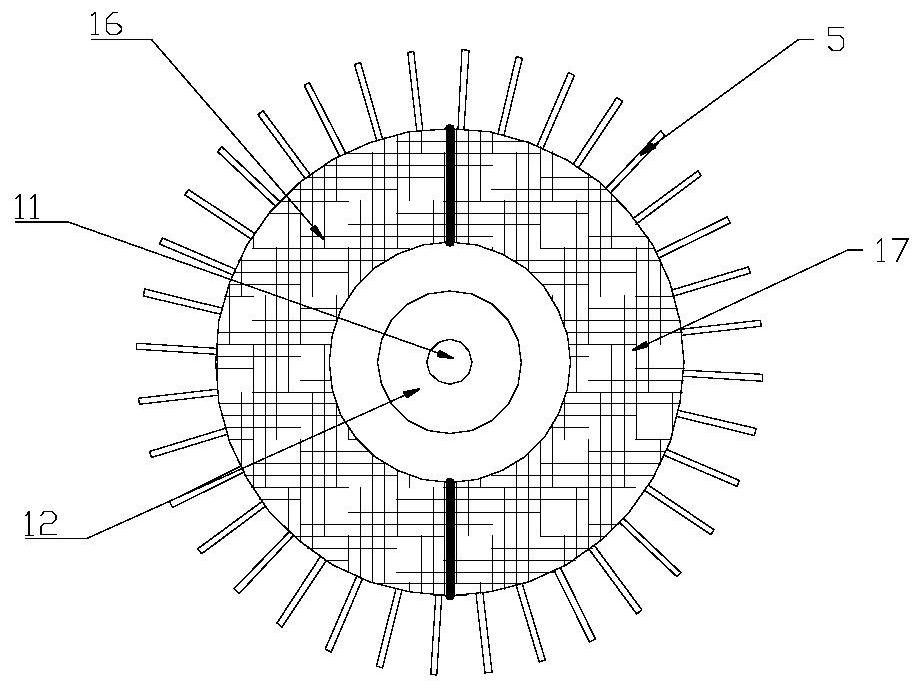

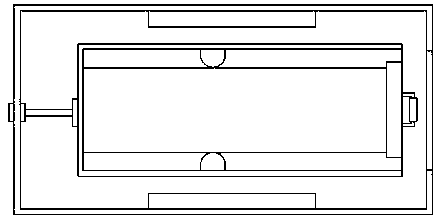

Test device for evaluating asphalt consumption of asphalt mixture

PendingCN111381015ALeakage test results are accurateReduce the influence of factors on manual loading of samplesWeighing by removing componentPreparing sample for investigationRoad surfaceMechanical engineering

The invention discloses a test device for evaluating asphalt consumption of an asphalt mixture, which comprises a drying box, wherein one side of the drying box is provided with a rotating device, therotating device is connected with a rotating rod, one end of the rotating rod penetrates through the side wall of the drying box and extends into the drying box, and one end of the rotating rod is detachably connected with a roller. By means of the test device, redundant asphalt binders, fine aggregates, mastic and the like in the asphalt mixture sample can continuously rotate in the rotating process and fully contact with the inner wall of a stirring barrel, so that the factor influence of manual sample loading is reduced, the asphalt drain-down test result is more accurate, the asphalt consumption of the asphalt mixture can be evaluated more accurately and quantitatively, the influence of too small asphalt mixture consumption on the durability of the pavement is avoided, and drain-downand oil flooding caused by too large asphalt consumption are also avoided. Compared with traditional asphalt drain-down test equipment, the test result is more accurate, and the effect is more obvious.

Owner:CHINA FIRST HIGHWAY ENG CO LTD

A kind of asphalt pavement reinforcement material

The invention discloses a bituminous pavement reinforcing material. The bituminous pavement reinforcing material is prepared from the following raw material components in percentage by weight: 40-60% of cotton stalk cellulose, 20-45% of basalt fiber, 5-10% of polyester fiber, 3-5% of polyethylene and 1-2% of carbon black. The bituminous pavement reinforcing material has the advantages that strength of a pavement can be improved, the pavement can be prevented from cracking at a low temperature, and temperature shrinkage cracks are reduced; at a high temperature, partial bitumen expanded after being heated is absorbed, so that oil bleeding and high temperature loss of the bitumen, which are caused under a high temperature, are prevented; high temperature stability is improved, and the service life of the pavement is prolonged; pavement oil spot caused by formation of a micelle-shaped substance is prevented; leak and isolation of the bitumen are prevented; raw materials are available, a preparation process is simple, and cost for laying a bituminous pavement is greatly reduced.

Owner:中部华科建设集团有限公司

Ventilation structure and transmission system

PendingCN114458749ASimple ventilation structureReduce manufacturing costGearing detailsInterior spaceEngineering

The invention relates to the related technical field, and aims to provide a ventilation structure and a transmission system, the ventilation structure is simple, the manufacturing cost is low, the internal space is not occupied, and ventilation and oil-gas separation can be effectively carried out. The ventilation structure comprises a transmission shell and an adaptive device shell assembled with the transmission shell, a ventilation channel is only formed in the outer surface of the transmission shell, the ventilation channel is recessed inwards from the outer surface of the transmission shell, and the extension direction of the ventilation channel is in the outer surface of the transmission shell. A ventilation cavity is formed by the ventilation channel and the outer surface of the adapter device shell, one end of the ventilation channel is communicated with the interior of the transmission shell, and the other end of the ventilation channel is communicated with a ventilation plug. The problems that an existing transmission ventilation structure is complex, the manufacturing cost is high, and the occupied internal space is large are solved.

Owner:SUOTE TRANSMISSION EQUIP

A method for preventing small white spots on the surface of fermented bean curd during post-fermentation and shelf life

ActiveCN105875863BGrowth inhibitionImprove solubilityCheese manufactureFood scienceBiotechnologyActivated carbon

The invention discloses a method for preventing small white spots on the surface of fermented bean curd during the post-fermentation period and shelf life. The post-fermentation process is carried out under the technological conditions of maintaining a sufficient pre-fermentation time of 15-20 days and maintaining the original unique fresh flavor of fermented bean curd. When packing hot pepper, Chinese prickly ash, salt and other ingredients into barrels or bottles, place 3-5 grams of dried ginger granules and a 2-5 grams of activated carbon pouch for every 500 grams of wet bean curd, and add cooking wine according to the original process formula after packing The post-fermented fermented bean curd soup composed of , salt and cooking oil, control the amount of salt and white wine in the fermented bean curd soup and wrapping materials, and adjust the pH value of the fermented bean curd after adding the soup to 4.2‑6.1 with glacial acetic acid. After adding the soup Cover and seal, and store in a cool and clean environment. The invention realizes the best effect of preventing small white spots on the surface of the fermented bean curd during post-fermentation and shelf life, maintains the taste and flavor of the fermented bean curd to the greatest extent, is beneficial to the preservation of the fermented bean curd, and has good economic significance and commercial value.

Owner:龙山县刘大姐土家特色食品有限公司

Warm mix asphalt mixture and preparation method thereof

ActiveCN108658510BFunction increaseImprove mechanical propertiesClimate change adaptationFiberRoad surface

The invention belongs to the technical field of petroleum asphalt, and in particular relates to a warm asphalt mixture and a preparation method thereof. The warm-mix asphalt mixture of the present invention is made of the following raw materials in parts by mass: 95 parts of mineral material, 5 parts of warm-mix asphalt, 0.5-2 parts of viscosity-reducing lubricant and 0.05-1 part of fiber. The fiber and the viscosity-reducing lubricant added in the invention swell in the asphalt during wet mixing and transportation to form a gel layer, thereby improving the elastic recovery function and mechanical properties of the asphalt pavement. Fiber exists in three-dimensional dispersed phase in asphalt mixture, just like the steel bar in concrete plays a reinforcing role, and because the oil film thickness is increased, it can effectively avoid oil flooding and rutting on the road surface. The preparation method of the invention is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

Testing device for evaluating asphalt amount of asphalt mixture

InactiveCN110646597ALeakage test results are accurateReduce the influence of factors on manual loading of samplesWeighing by removing componentPreparing sample for investigationRoad surfaceAsphalt

The invention discloses a testing device for evaluating the asphalt amount of an asphalt mixture. The testing device comprises a drying box, wherein a rotating device is arranged on one side of the drying box; a rotating rod is connected to the rotating device; one end of the rotating rod penetrates through the side wall of the drying box and extends into the drying box; and one end of the rotating rod is detachably connected to a roller. Through the testing device, during a rotating process, excess asphalt binders, fine aggregates, mastic and the like in asphalt mixture samples can be in contact with the inner wall of a stirring barrel fully through continuous rotation, so that the influence of factors of manual loading of the samples is reduced, an asphalt drain-down test result is moreaccurate, and thus the size of the asphalt amount of the asphalt mixture is reduced more accurately, the influence of the too small amount of the asphalt mixture on the durability of the road surfaceis avoided, the drain-down and flooding caused by the too large asphalt amount are also avoided, and compared with traditional asphalt drain-down test equipment, the test result is more accurate, andthe effect is more obvious.

Owner:CHINA FIRST HIGHWAY ENG

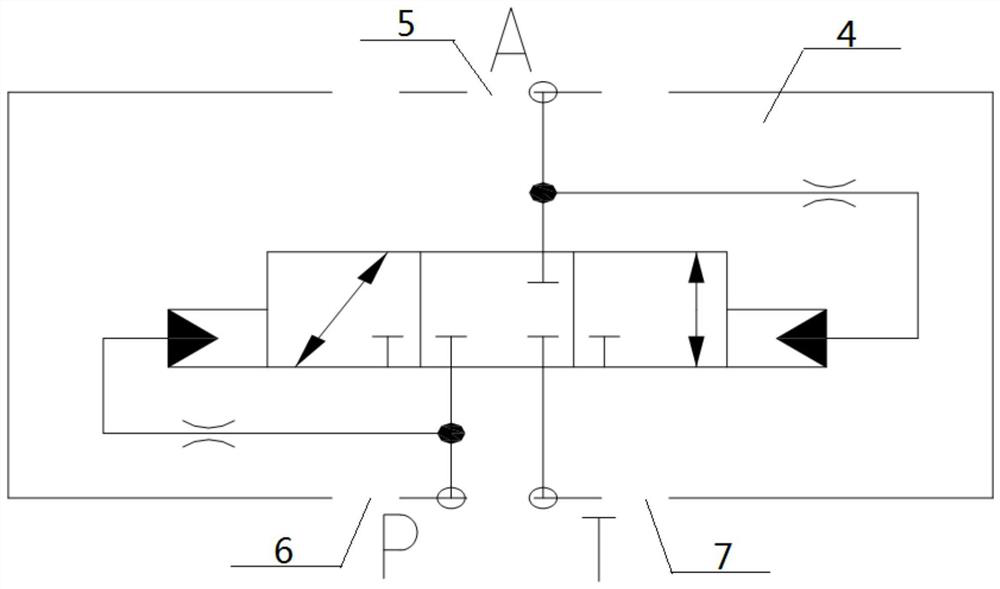

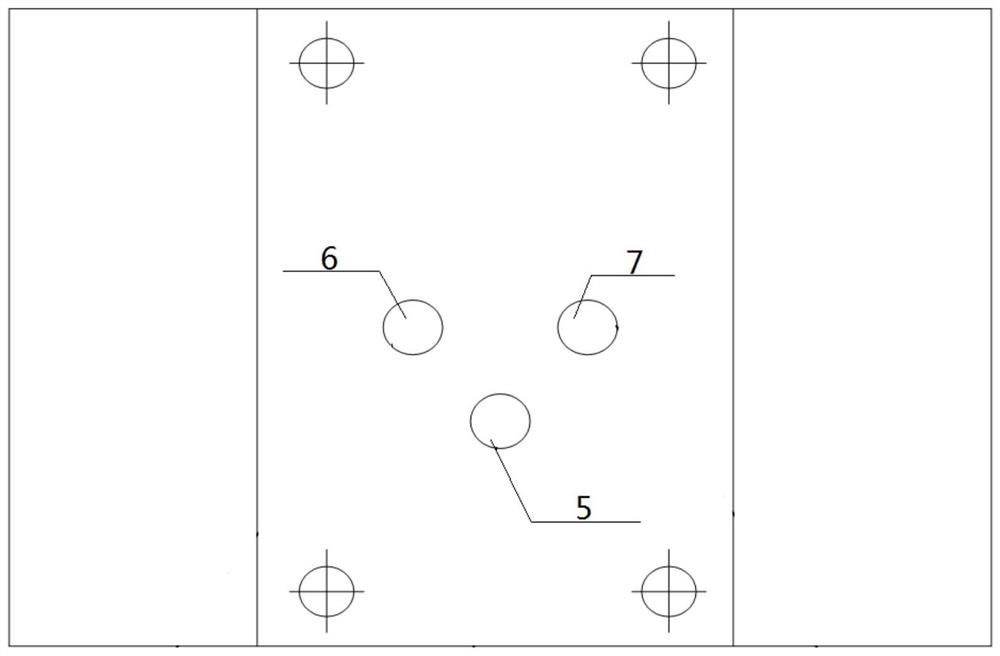

Rotary motor control system with same pressure difference

PendingCN112343879AConsistent output powerAvoid damageServomotor componentsServomotorsControl systemControl engineering

The invention discloses a rotary motor control system with the same pressure difference. The rotary motor control system comprises a first motor, a follow-up motor and a pressure regulating valve, wherein the first motor is provided with a first output end, a first oil inlet and a first oil outlet, the follow-up motor is provided with a rear output end, a rear oil inlet and a rear oil outlet, thefirst output end and the rear output end are connected with the same load, the first oil inlet communicates with a first oil tank, and the first oil outlet communicates with a rear oil tank after sequentially passing through the rear oil inlet and the rear oil outlet; the pressure regulating valve is provided with a port A, a port P and a port T, and the communication structure of the port A comprises any one of a structure communicating with the opening P, a structure communicating with the opening T and a structure not communicating with the opening P and the opening T; and the port P communicates with the first oil inlet, the port A communicates with the first oil outlet and the rear oil inlet, and the port T communicates with the rear oil outlet. According to the design, the motors connected in series are free of oil trapping, and equipment is not prone to damage.

Owner:WUHAN MARINE MACHINERY PLANT

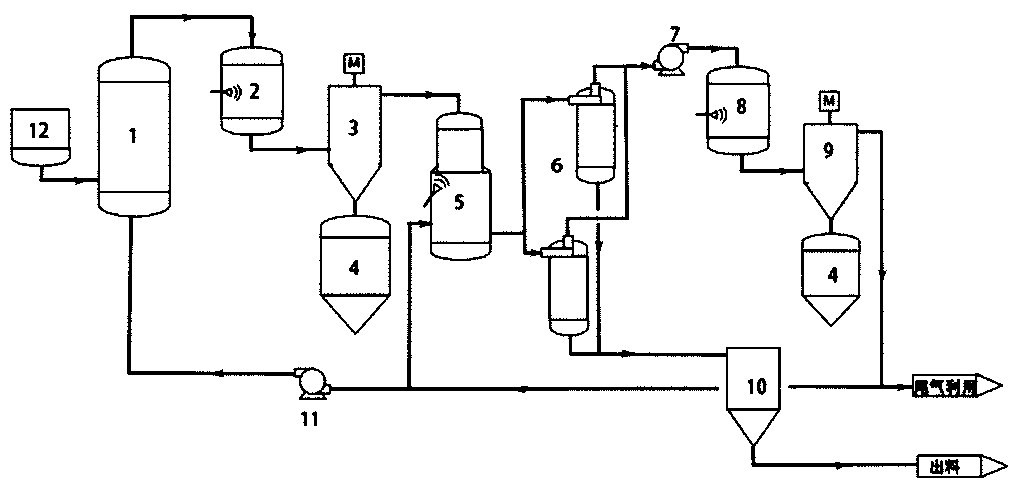

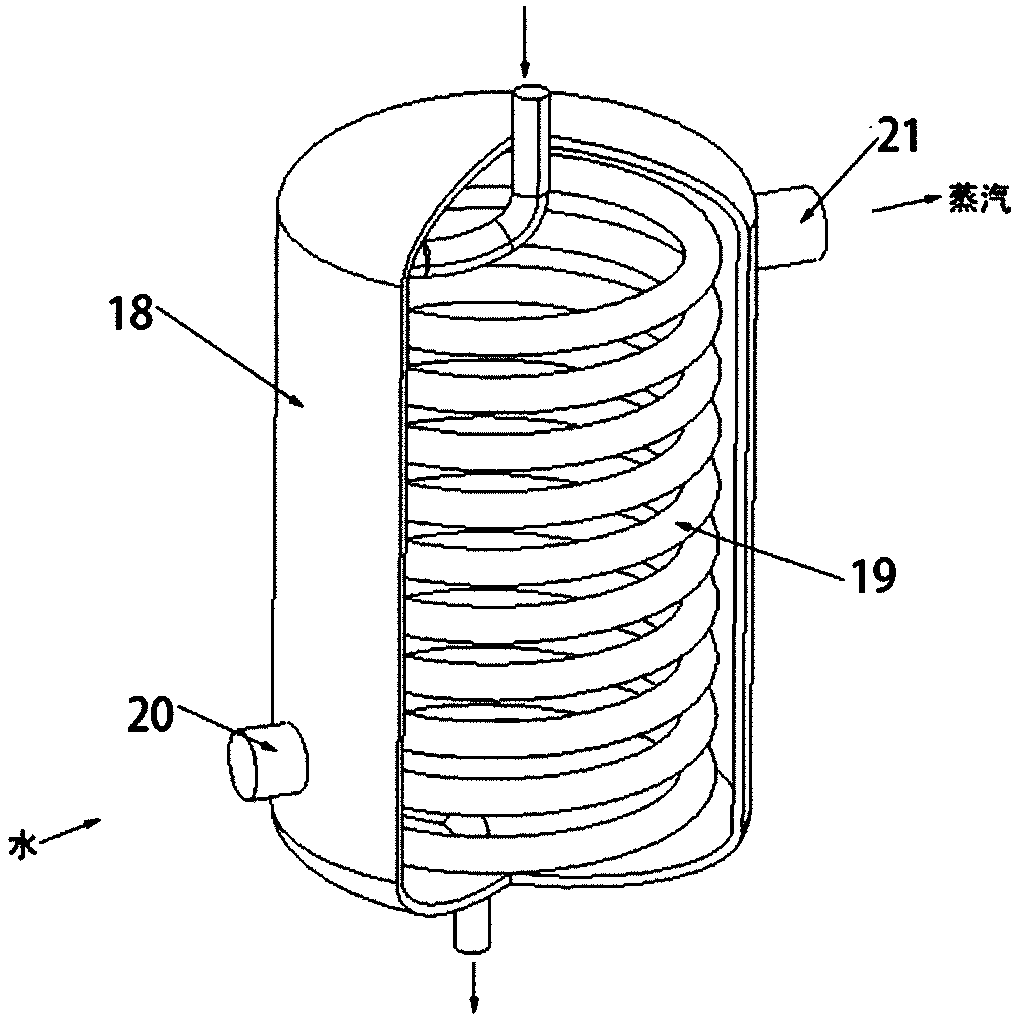

Long-period energy-saving melamine production system

InactiveCN109369551AGuaranteed cleanlinessGuaranteed uptimeOrganic chemistryChemical industrySlagGas cooler

The invention belongs to the technical field of melamine production and in particular relates to a long-period energy-saving melamine production system. The melamine production system comprises a reactor, a hot gas exchanger, a hot gas separator, a crystallizer, a finished cyclone separator, a tail gas exchanger and a tail gas separator connected in sequence, wherein the reactor is connected witha quick melting kettle; and the hot gas separator and the tail gas separator are respectively connected with slag pots. Compared with other processes, the melamine production system disclosed by the invention has the advantages that a liquid urine washing system is removed, standby equipment of a hot gas cooler and a filter is reduced, and investment is less; long-period stable operation is realized, and the period can reach one year or longer; a liquid urine pump, an air-cooling fan and other equipment are reduced, and due to simplified process procedures and an optimized energy conversion scheme, the process energy consumption is low; the energy consumption of ammonia back-flushing is greatly reduced, and the production cost is reduced; the tail gas is clean, equipment corrosion and wallscales can be reduced, and the influence of entrainments on later sections during tail gas utilization can be reduced; and diphenyl ether is not used in the hot gas cooling system, and production ofsolid wastes such as filter bags and the like is reduced.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com