Open-type heavy hydraulic motor

A hydraulic motor, an open technology, applied in the field of hydraulic motors, can solve the problems of inconvenient installation, maintenance, large energy loss, high cost of use, etc., to achieve the effect of easy installation and maintenance, uniform torque and speed, and super torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

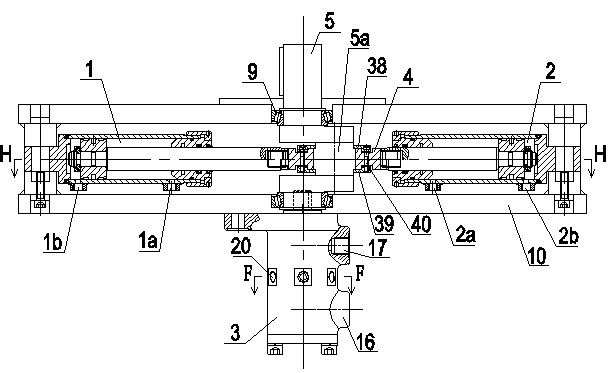

[0035] Such as Figure 1 to Figure 12As shown, the open heavy-duty hydraulic motor includes a fixed bracket 10, a rotary valve 3 fixed on the bracket 10 by bolts, a crankshaft 5 installed in the center of the bracket through bearings 9 at both ends, and an eccentric section 5a around the crankshaft 5. Six double-acting oil cylinders 1, 2, 7, 8, 47, 48 are evenly distributed, the bottom of each double-acting oil cylinder is hinged with the bracket 10 through a pin, and the piston rod of each double-acting oil cylinder is fixedly connected with a fastener 4. The front end of each fastener 4 is provided with an arc surface matching the eccentric section 5a of the crankshaft, and two shoulders are provided on the eccentric section 5a of the crankshaft, and two sets of plates 38, 39 are respectively slidably mounted on both sides of the two shoulders , all the fasteners 4 are connected to the two sets of plates 38, 39 through connecting bolts 40, and the fasteners 4 and the two set...

Embodiment 2

[0042] Such as Figure 13 As shown, the difference between the present embodiment and the first embodiment is only that the respective piston rods of the double-acting oil cylinders 1, 2, 7, 8, 47 and 48 are fixedly connected with the respective combined cylindrical sliding sleeves 49, and all the sliding sleeves 49 The rotatable connection is realized by being fitted in the eccentric section 5a of the crankshaft in the axial direction, and the double-acting oil cylinders are also arranged in the axial direction at the same time. advantage.

Embodiment 3

[0044] Such as Figure 14 and 15 As shown, the difference between this embodiment and Embodiment 1 is that five double-acting oil cylinders 51, 52, 53, 54, 55 are evenly distributed around the eccentric section 5a of the crankshaft 5, and the bottom of each double-acting oil cylinder is connected to the The bracket is hinged by a pin shaft, and the piston rod of each double-acting cylinder is fixedly connected with a fastener 4, and the front end of each fastener 4 is provided with an arc surface matched with the eccentric section 5a of the crankshaft; on the valve body 12 of the rotary valve Ten working oil ports 60 to 69 are evenly distributed, and the five spaced working oil ports 60, 62, 64, 66, 68 are connected with the rodless chambers of the respective double-acting oil cylinders 51, 52, 53, 54, 55 respectively in sequence. The oil ports 51a, 52a, 53a, 54a, and 55a are connected through pipelines, and the working oil port 65 located on the same line as the working oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com