System and method for testing and controlling mechanical properties of rocks under complicated condition

A technology of rock mechanics and control methods, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of inability to guarantee rock density data, reduce storage accuracy, inability to match, etc. Improve the measurement accuracy and facilitate the effect of uniform change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

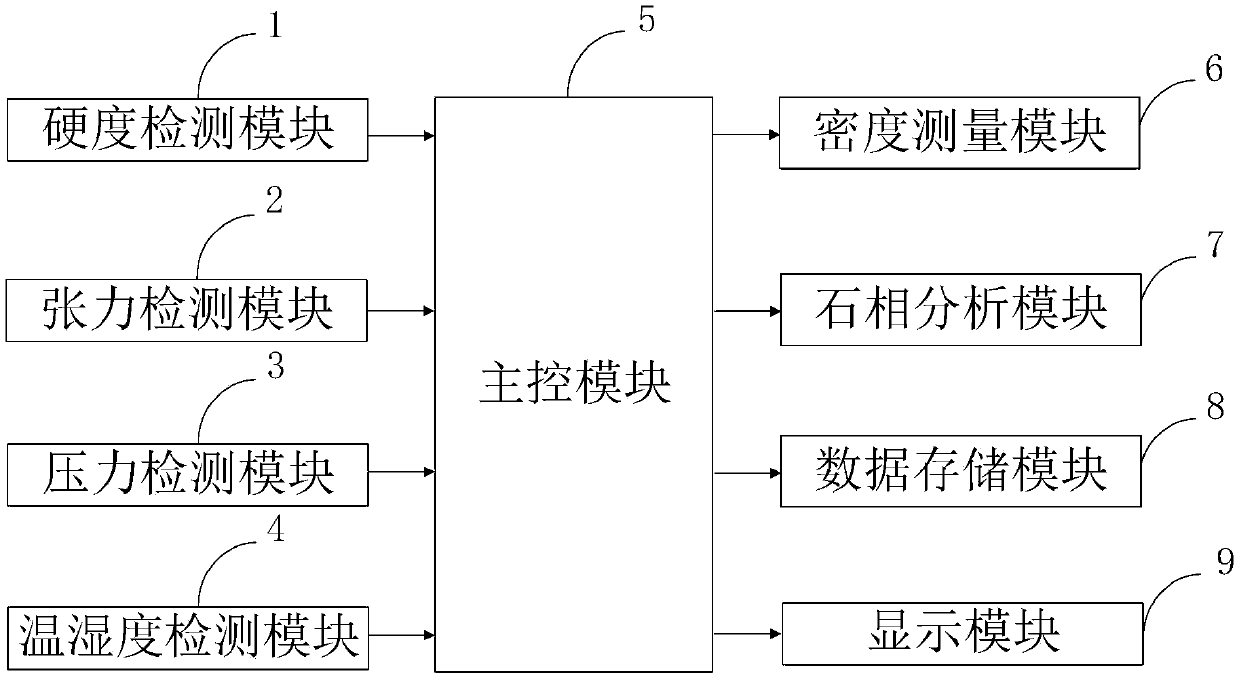

[0040] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0041] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

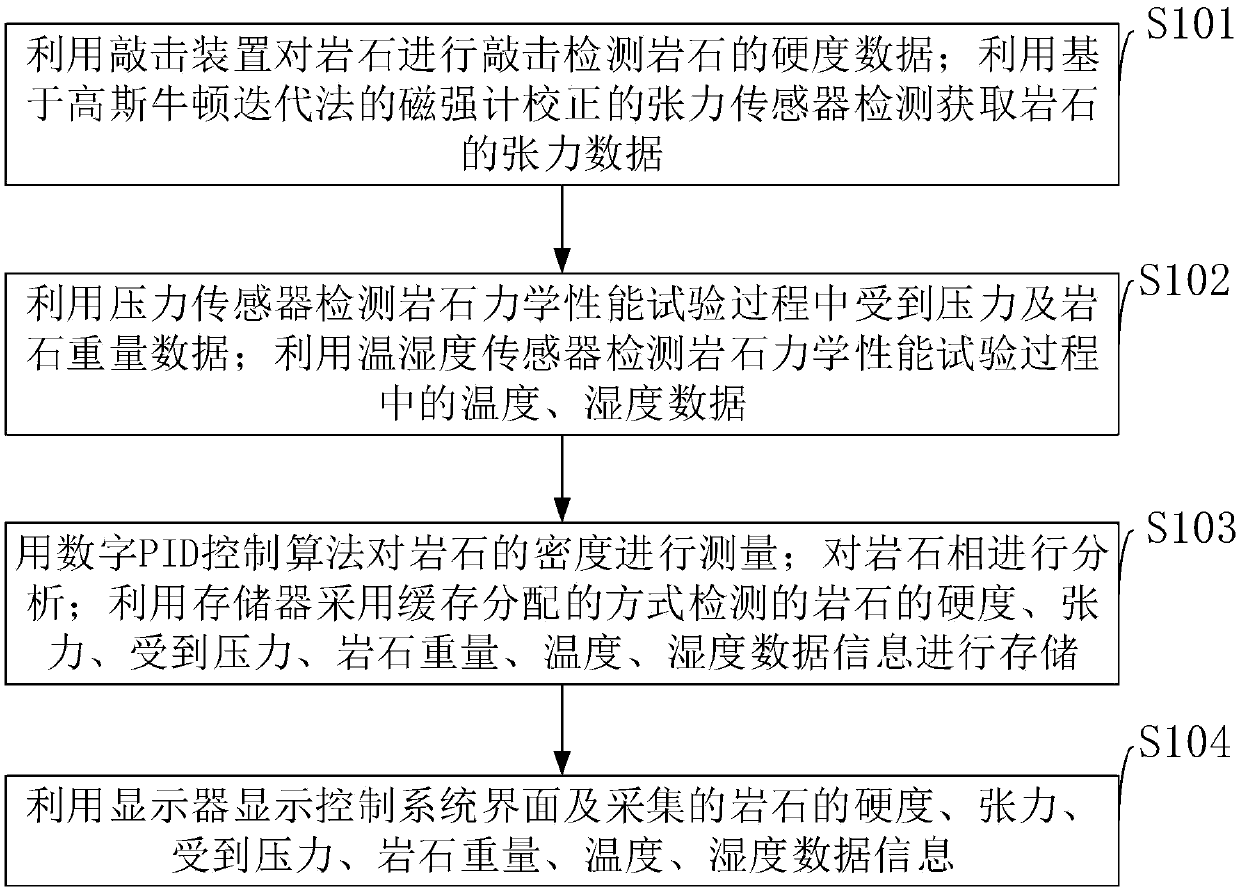

[0042] Such as figure 1 As shown, the rock mechanical performance test control method under complex conditions provided by the embodiments of the present invention specifically includes the following steps:

[0043] S101: Use the tapping device to tap the rock to detect the hardness data of the rock; use the tension sensor calibrated by the magnetometer based on the Gauss-Newton iterative method to detect and obtain the tension data of the rock;

[0044] S102: Use the pressure sensor to detect the pressure and rock weight data during the rock mechanical performance test; use the temperature and humidity sensor to detect the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com