Bituminous pavement reinforcing material

A technology for asphalt pavement and reinforcing materials, applied in the field of additives to improve the performance of asphalt pavement, can solve the problems of expensive chemical fibers, difficult to achieve reinforcement and toughening, and limited source of raw materials, so as to increase the consistency and facilitate construction Sexuality, improve anti-aging ability, and the effect of easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

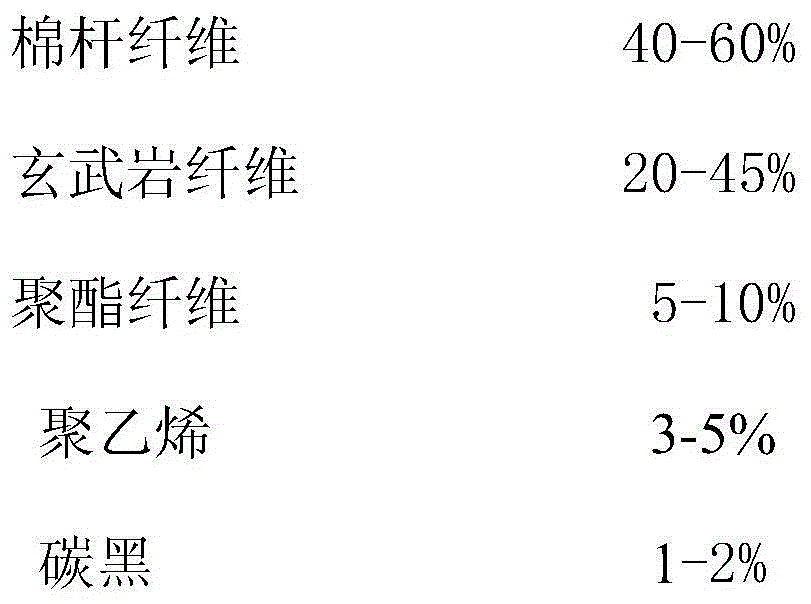

[0015] A kind of asphalt pavement reinforcing material, its raw material components include by weight percentage:

[0016]

[0017] The waxy material on the surface layer of the above-mentioned cotton stalk fiber is removed through separation.

[0018] A kind of preparation method of asphalt pavement reinforcing material: add polyester fiber, cotton stalk fiber, basalt fiber, polyethylene, carbon black respectively in the mixer according to the above-mentioned ratio, stir for 3 minutes and obtain this asphalt pavement reinforcing material; First add asphalt pavement reinforcement materials and aggregates into the asphalt mixer, mix for 2 minutes, then add asphalt and wet mix for 1 minute, and it is ready.

Embodiment 2

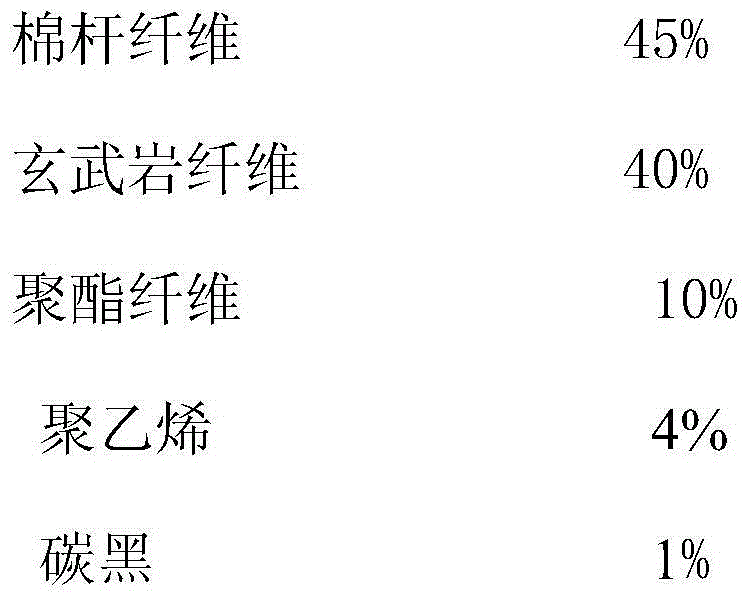

[0020] A kind of asphalt pavement reinforcing material, its raw material components include by weight percentage:

[0021]

[0022]

[0023] The waxy material on the surface layer of the above-mentioned cotton stalk fiber is removed through separation.

[0024] A kind of preparation method of asphalt pavement reinforcing material: respectively add polyester fiber, cotton stalk fiber, basalt fiber, polyethylene, carbon black in the mixer according to the above-mentioned ratio, stir for 5 minutes and obtain this asphalt pavement reinforcing material; First add asphalt pavement reinforcement materials and aggregates into the asphalt mixer, mix for 2 minutes, then add asphalt and wet mix for 1 minute, and it is ready.

Embodiment 3

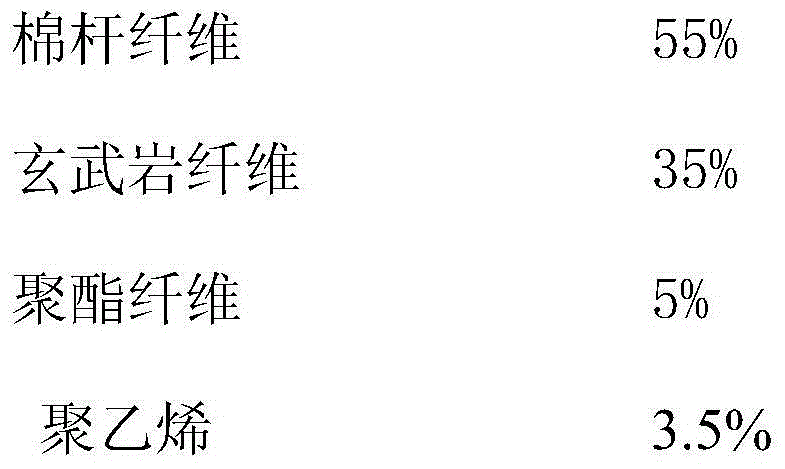

[0026] A kind of asphalt pavement reinforcing material, its raw material components include by weight percentage:

[0027]

[0028] The waxy material on the surface layer of the above-mentioned cotton stalk fiber is removed through separation.

[0029] A kind of preparation method of asphalt pavement reinforcing material: respectively add polyester fiber, cotton stalk fiber, basalt fiber, polyethylene, carbon black in the mixer according to the above-mentioned ratio, stir for 5 minutes and obtain this asphalt pavement reinforcing material; First add asphalt pavement reinforcement materials and aggregates into the asphalt mixer, mix for 2 minutes, then add asphalt and wet mix for 1 minute, and it is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com