Waste rubber powder dry micro-surfacing mixed material and preparation method thereof

A technology of micro-surfacing mixed materials and waste rubber powder, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of improving force bearing mode, improving particle gradation, and preventing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

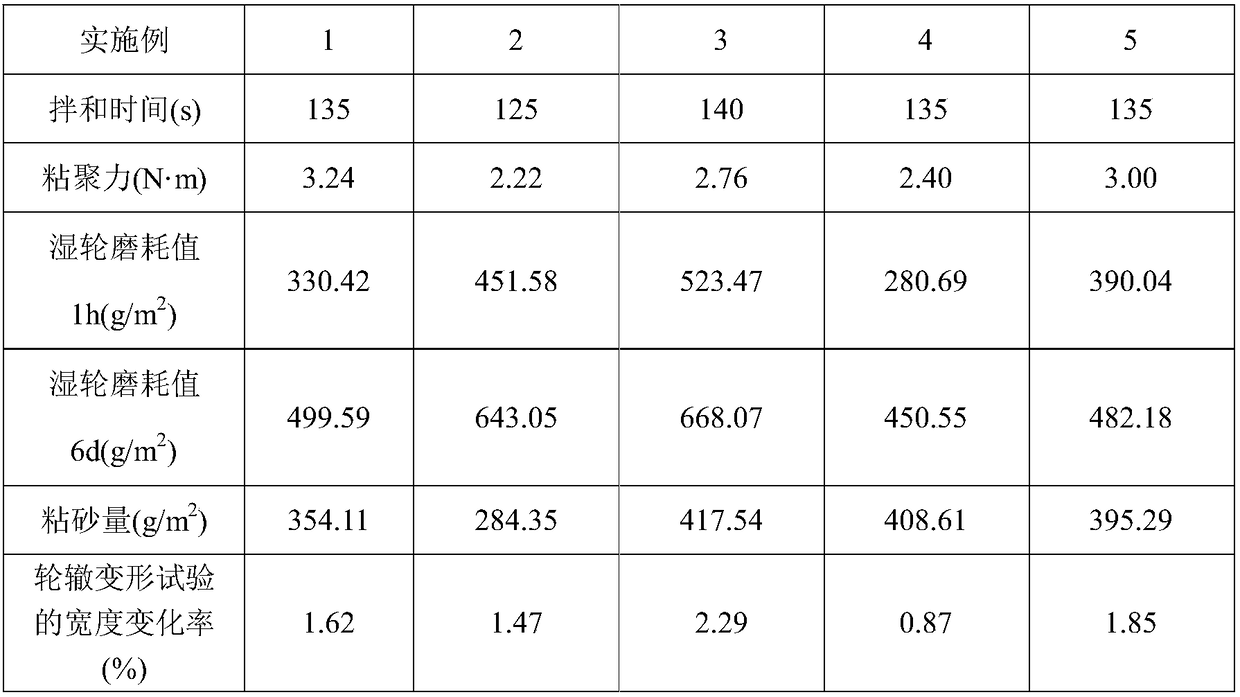

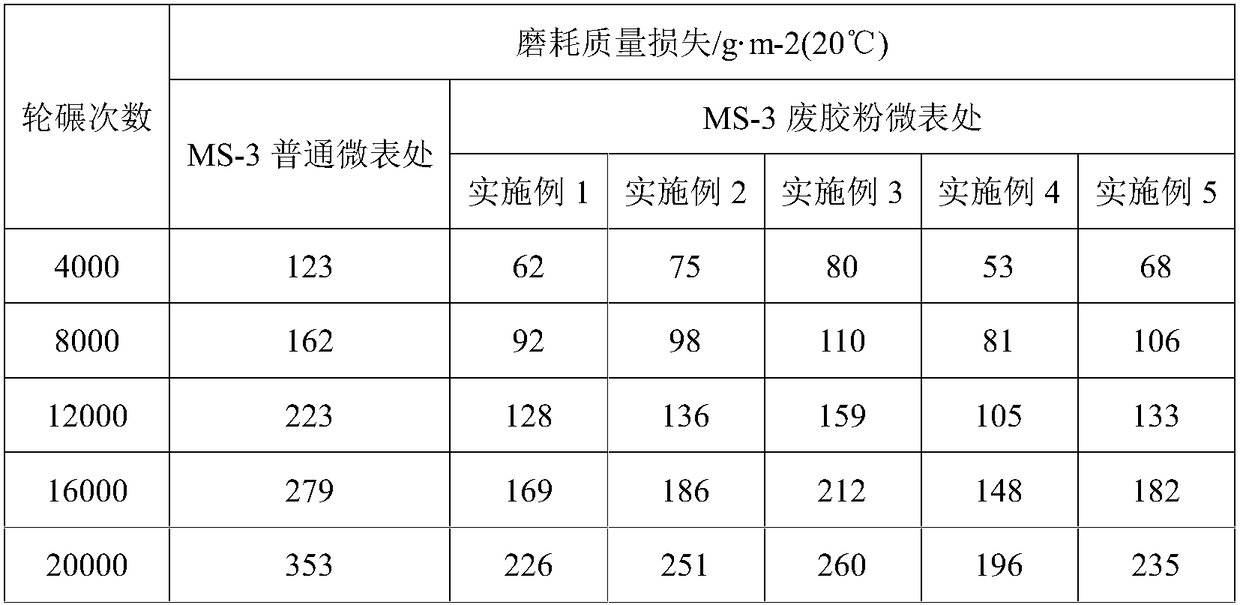

Examples

preparation example Construction

[0020] The preparation method of waste rubber powder dry method micro-surfacing compound comprises the following steps:

[0021] S1: Inspect the raw materials according to the technical requirements of the "Technical Guidelines for Microsurfacing and Slurry Sealing", weigh qualified basalt aggregates, cement and waste rubber powder at room temperature according to the mixing ratio, and use the above materials in the mixing pot Manually mix well with a mixing shovel to obtain the waste rubber powder mixture in a dry state;

[0022] S2: Pour water of specified quality into the mixing pot, and then artificially stir evenly for about 15 seconds to obtain the waste rubber powder mixture in a wet state;

[0023] S3: Pour the specified quality of SBR modified emulsified asphalt into the mixing pot, and continue to manually stir evenly for 15 seconds to obtain the waste rubber powder dry micro-surfacing mixture.

Embodiment 1

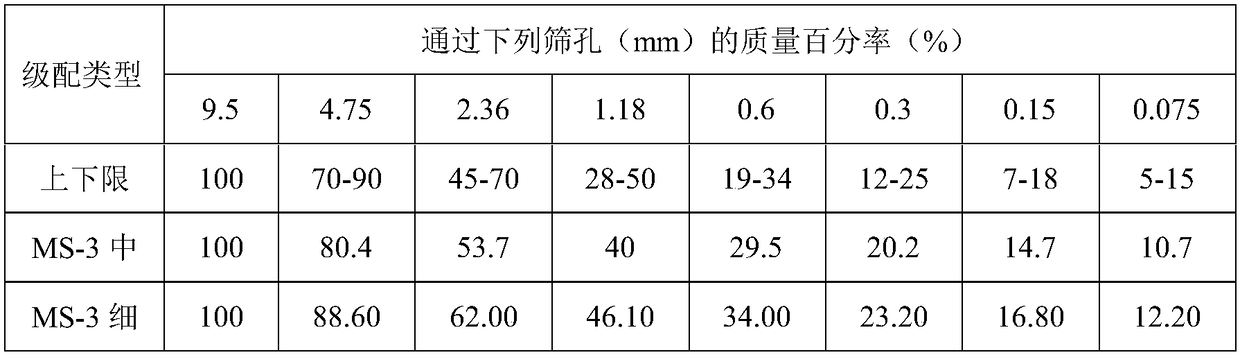

[0025] The waste rubber powder dry micro-surfacing mixture is made of the following raw materials in mass percentage: in the basalt aggregate, the basalt aggregate with a particle size of 5-10mm accounts for 21% of the total mass of the aggregate, and the basalt aggregate with a particle size of 3-5mm Basalt aggregates with a particle size of 0-3 mm accounted for 68% of the total mass of aggregates; SBR modified emulsified asphalt was 12.8%, and cement (P O42.5) was 1.5%. 40 mesh rubber powder is 2%, and water is 7%. The gradation type of the mixed material in the micro-surfacing of waste rubber powder in this embodiment is MS-3 medium gradation, and the specific gradation composition is shown in Table 1.

[0026] Table 1 MS-3 type microsurfacing mixture gradation

[0027]

[0028] In this example, the nominal maximum particle size of the basalt aggregate is ≤9.5mm, and the apparent density is 2.91g / m 3 ; The particle size of waste rubber powder is 40 mesh (0.45mm), and t...

Embodiment 2

[0034]The waste rubber powder dry micro-surfacing mixture is made of the following raw materials in mass percentage: in the basalt aggregate, the basalt aggregate with a particle size of 5-10mm accounts for 21% of the total mass of the aggregate, and the basalt aggregate with a particle size of 3-5mm Basalt aggregates with a particle size of 0-3mm accounted for 68% of the total mass of aggregates; SBR modified emulsified asphalt was 11.2%, and cement (P O42.5) was 1.5%. 40 mesh rubber powder is 1%, water is 6%. The gradation type of the mixed material in the micro-surfacing of waste rubber powder in this embodiment is MS-3 type medium gradation, and the specific gradation composition is shown in Table 1.

[0035] In this example, the nominal maximum particle size of the basalt aggregate is ≤9.5mm, and the apparent density is 2.91g / m 3 ; The particle size of waste rubber powder is 40 mesh (0.45mm), and the relative density is 1.15g / m 3 , the moisture content is 0.68%, the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com